Shrouded impeller finish machining tool path planning method

A closed impeller and tool path technology, applied in electrical program control, digital control and other directions, can solve the problems of low machining accuracy, reduced product performance, low machining efficiency, etc., to improve product work efficiency, reduce tool deformation, and improve machining. The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0033] The invention provides a finishing tool track planning method for a closed impeller, comprising the following steps:

[0034] Step 1. Build a model

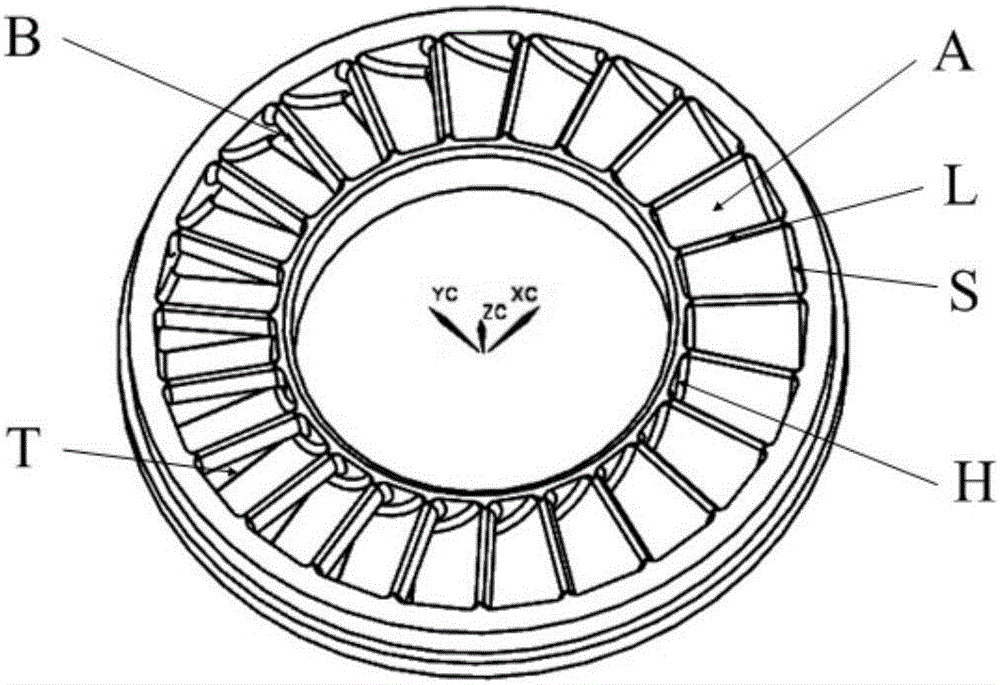

[0035] Obtain the three-dimensional digital model of the closed impeller, and define the blade pot surface as A, the blade back surface as B, the inner hub surface as H, the outer hub surface as S, and the leading edge surface as L with double 3 tensor product B-spline surfaces , the trailing edge surface is T, and the above characteristic surface constitutes a basic channel unit such as figure 1 Shown:

[0036] Define the direction from the leading edge to the trailing edge (streamline direction) of the above surface as the u-direction, and the direction from the inner hub to the outer hub as the v-direction, then take the vane surface A as an example, and use the double 3 tensor product B-spline su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com