Numerical machine tool machining state multi-parameter online active monitoring system and implement method thereof

A CNC machine tool and processing state technology, applied in the field of CNC machine tools, can solve the problem of inability to fully realize the comprehensive index detection of the state of the CNC machining process, the accuracy and stability are difficult to meet the application requirements of harsh working conditions on the processing site, and it is difficult to realize high-speed command coding Millisecond-level strong real-time requirements and other issues, to achieve comprehensive index detection and maintenance early warning, processing accuracy and processing efficiency improvement effect, cost-effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

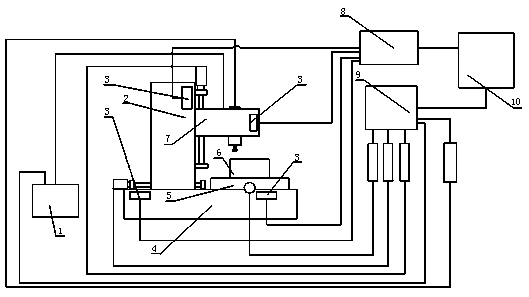

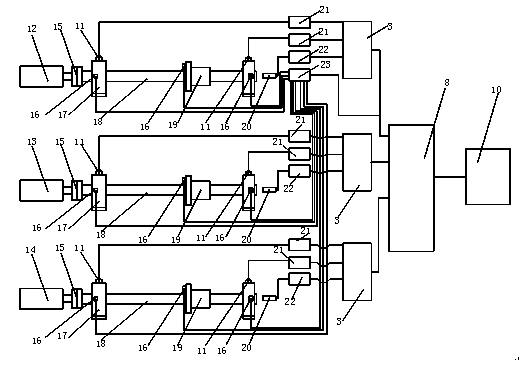

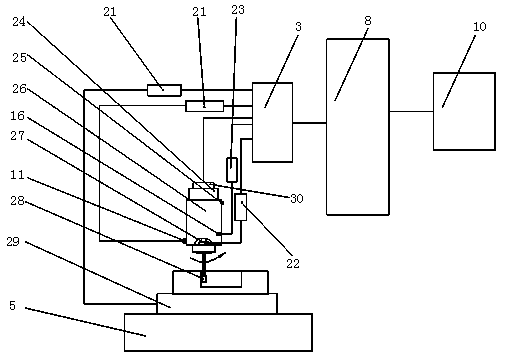

[0053] Such as figure 1 As shown, this embodiment provides a multi-parameter online active monitoring system for the machining status of CNC machine tools that can completely realize the comprehensive index detection of the status of the CNC machining process. Parameters are detected and controlled, which mainly includes various sensors installed on the relevant parts of the servo feed axes and spindles of CNC machine tools (including various CNC lathes, milling and grinding machines) to completely detect the processing status, and are used to receive sensor signals. The multi-channel synchronous data acquisition PXI box 8 and the data used for analysis and acquisition, and compare the value of the collected data with the set value to judge the monitoring computer 10 for comprehensively judging whether the CNC machine tool is in an abnormal state, if the monitoring computer judges When the CNC machine tool is in an abnormal working state, corresponding active control commands ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com