Patents

Literature

955 results about "Industrial Ethernet" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Industrial Ethernet (IE) is the use of Ethernet in an industrial environment with protocols that provide determinism and real-time control. Protocols for Industrial Ethernet include EtherCAT, EtherNet/IP, PROFINET, POWERLINK, SERCOS III, CC-Link IE, and Modbus TCP. Many Industrial Ethernet protocols use a modified Media Access Control (MAC) layer to provide low latency and determinism. Some microcontrollers such as Sitara provide Industrial Ethernet support.

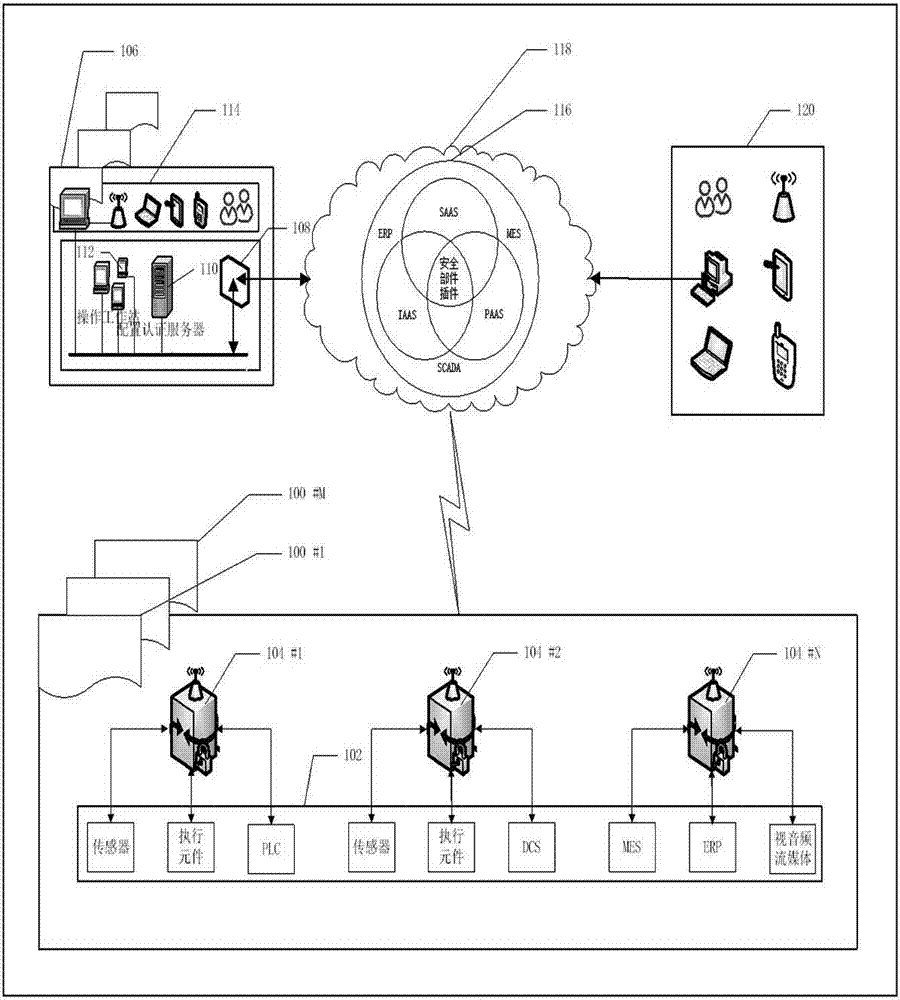

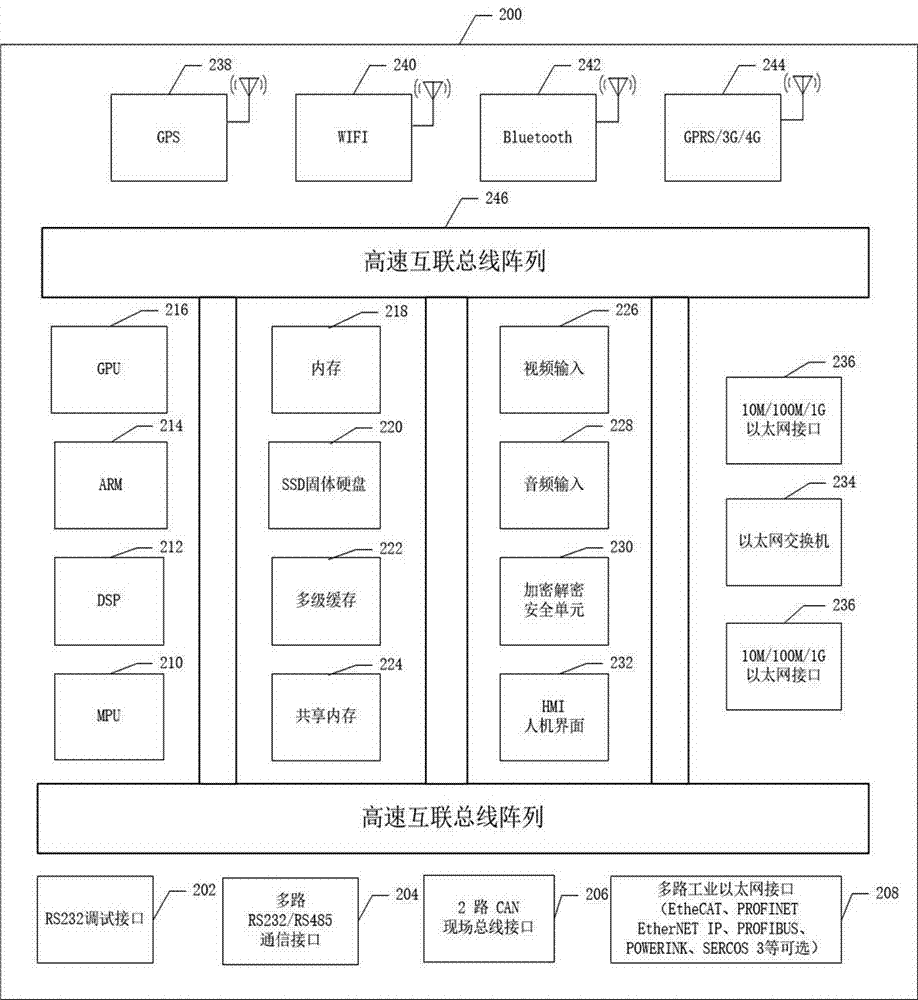

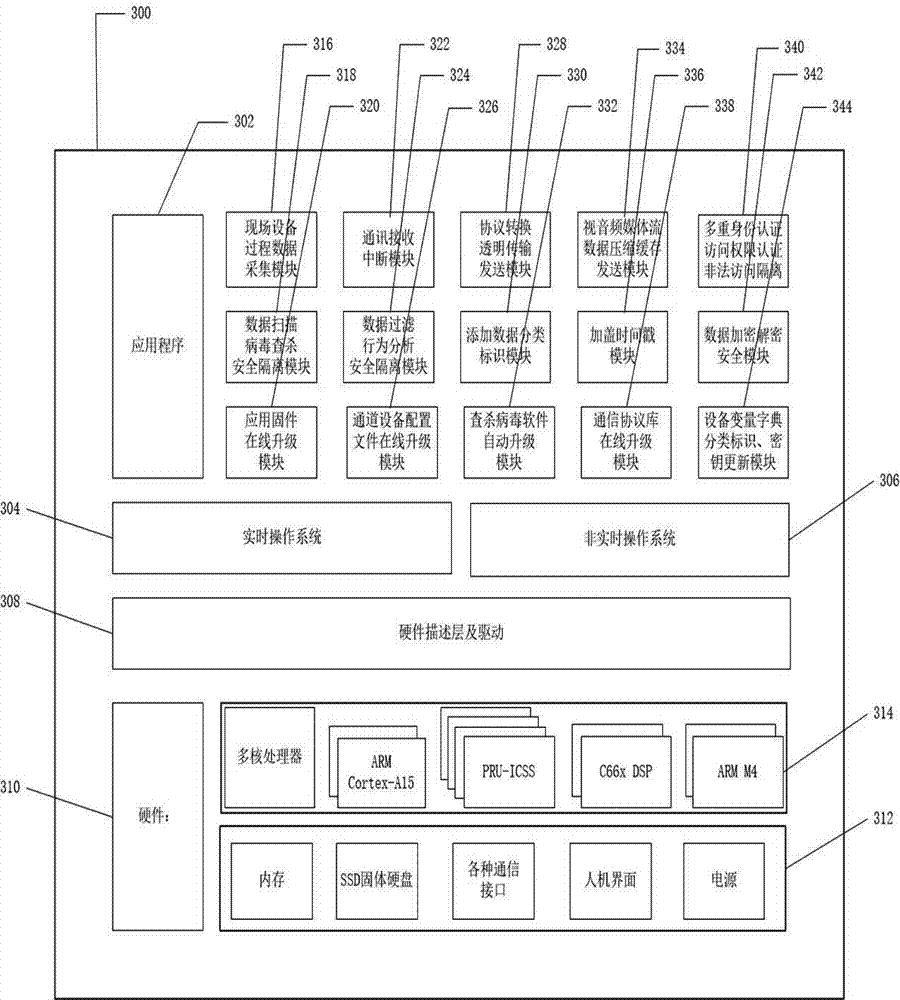

Intelligent industrial security cloud gateway equipment system and method

InactiveCN107040459AUser identity/authority verificationNetwork connectionsData centerSecurity authentication

The invention discloses an intelligent industrial security cloud gateway equipment system and method. The industrial cloud security gateway equipment and method is characterized in that upper cloud data is encrypted and added with data classification identifiers and time stamps, and decryption, security scanning and multiple security authentication access control are carried out on data on downlink intelligent equipment, so that interconnection, protocol conversion, and multi-directional transparent and real-time transmission among cloud equipment, enterprise datacenter equipment and various intelligent equipment on an industrial field can be achieved. An intelligent industrial cloud security gateway is embedded intelligent equipment comprising various serial ports, communication interfaces for a field bus and field intelligent equipment such as the industrial Ethernet, communication interfaces for wireless mobile communication and wired Internet cloud equipment, wireless or wired local area network interfaces for Bluetooth, broadband and the like, an Ethernet switch, a GPS module, and embedded software. The intelligent industrial cloud security gateway can systematically prevent user data leakage and network virus attacks, is core equipment of a secure and reliable intelligent industrial cloud service system, and can serve intelligent industrial manufacturing.

Owner:高岩

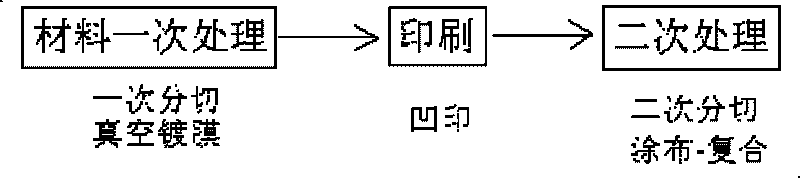

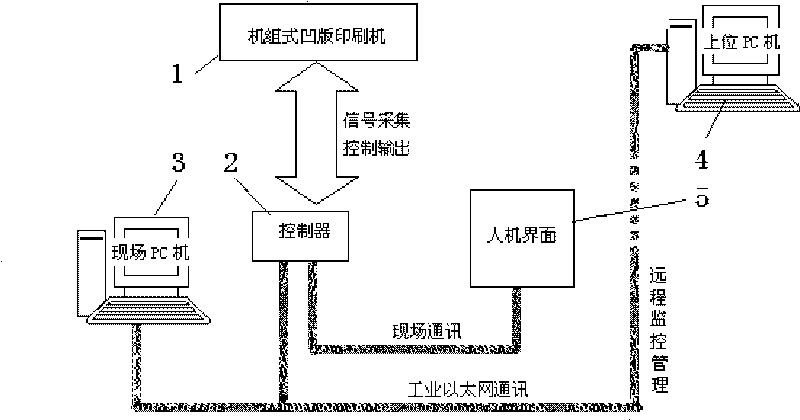

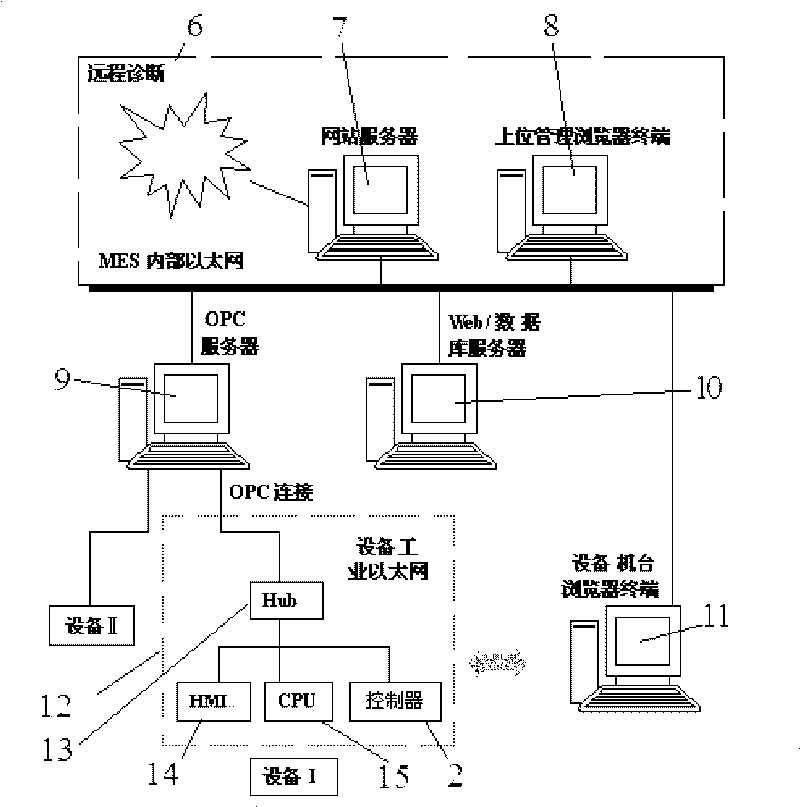

Information management system for on-line production of printing machine and method thereof

ActiveCN101713994AImprove efficiencyChange efficiencyData switching by path configurationTotal factory controlEmbedded systemReal time networks

The invention discloses an information management system for on-line production of a printing machine, which is characterized in that a web server and an upper management browser terminal which are mutually connected are arranged in an MES internal Ethernet to be used for realizing on-line remote diagnosis and maintenance; the MES internal Ethernet is respectively connected with an OPC server and an equipment station browser terminal, and the MES internal Ethernet is also connected with an equipment industrial Ethernet of a plurality of printing machine units through the OPC server; an Hub, an HMI, a CPU and a controller are arranged in the equipment industrial Ethernet; the Hub is externally connected with the OPC server; the Hub is respectively connected with the HMI, the CPU and the controller; and the controller is connected with a PLC control system in the printing machine equipment. The invention also discloses a method of on-line control and real-time data acquisition of the control system. The invention realizes the real-time network monitoring, parameter reporting, production management and analytic statistics under the B / S structure in an Ethernet communication mode, and realizes multi-browser and multi-user operation.

Owner:SHAANXI BEIREN PRINTING MACHINERY

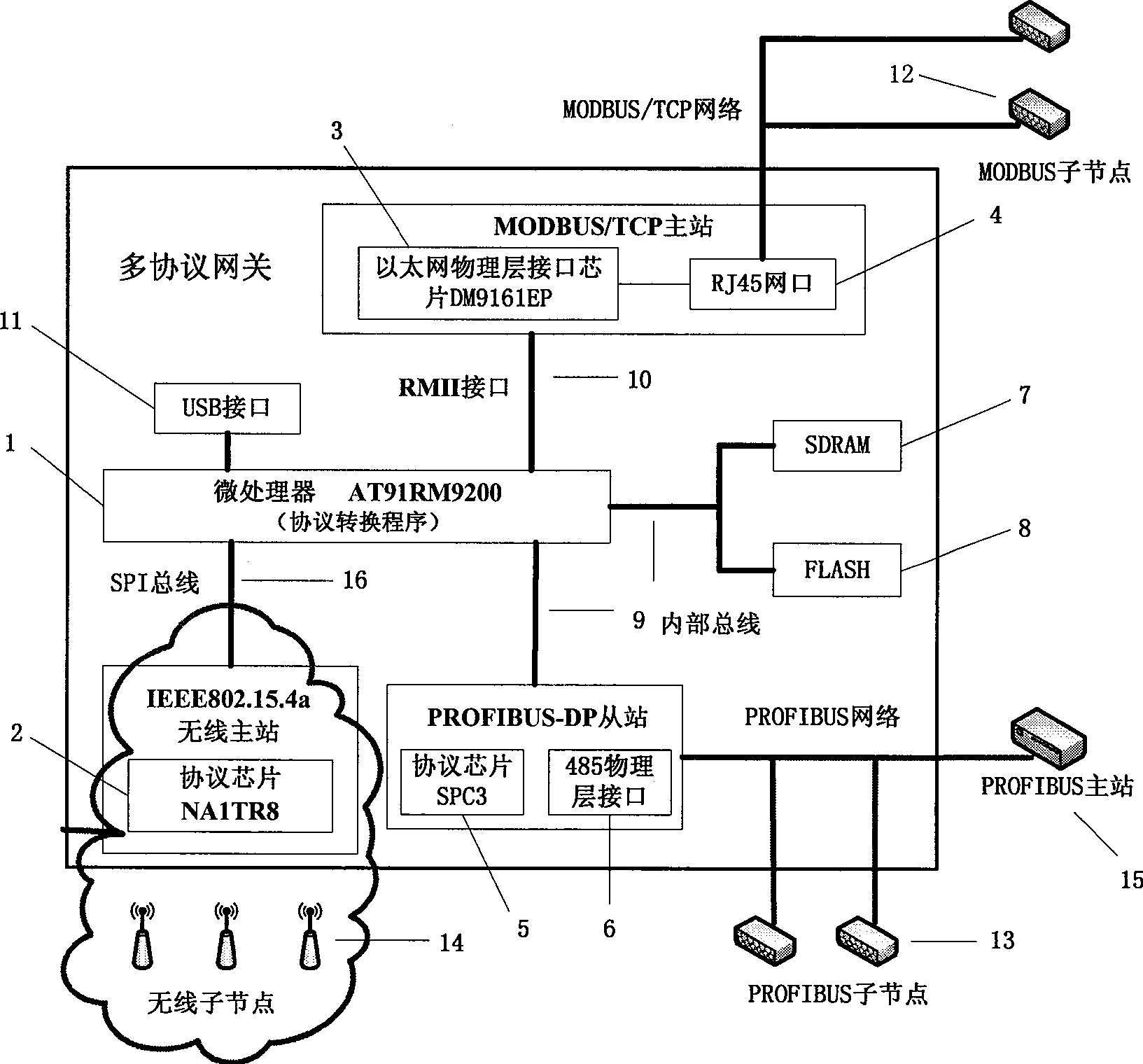

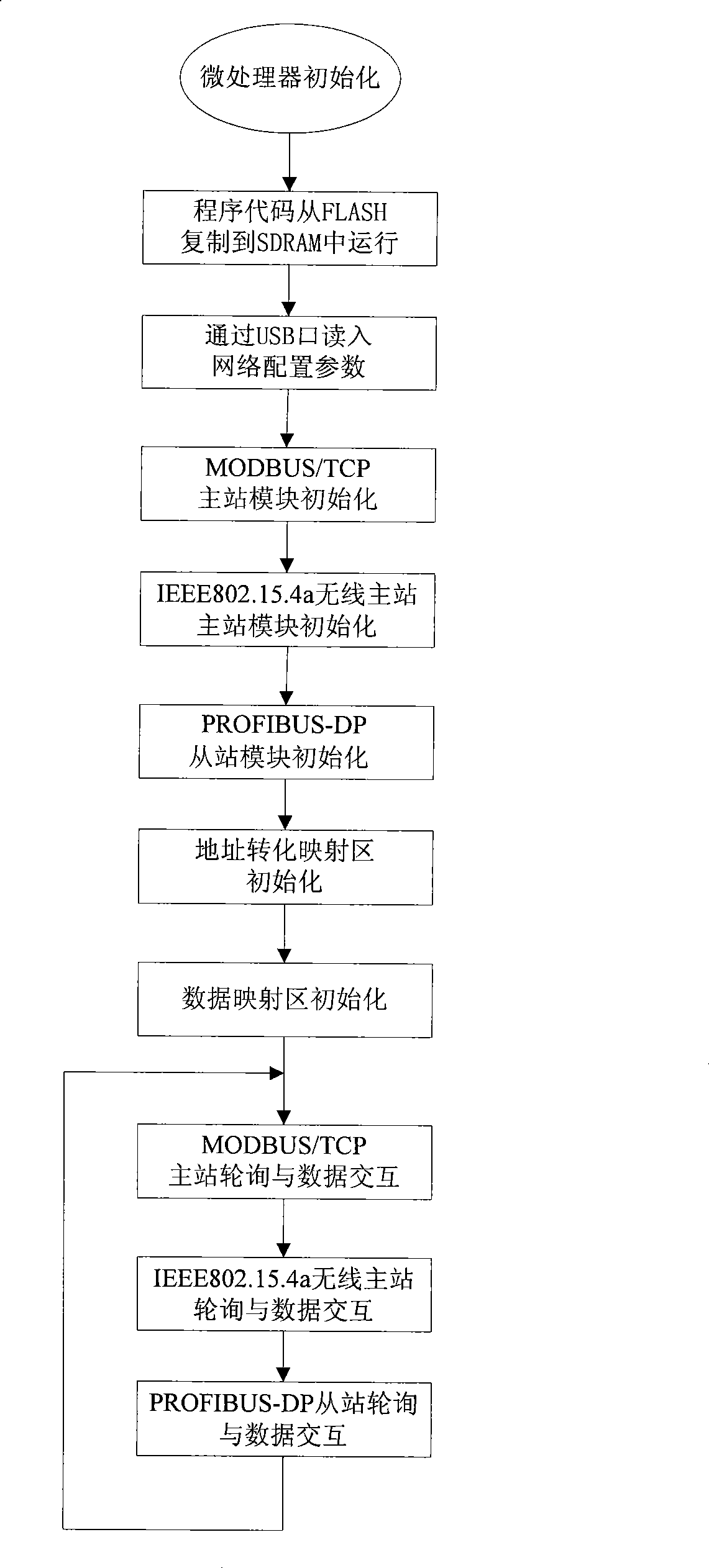

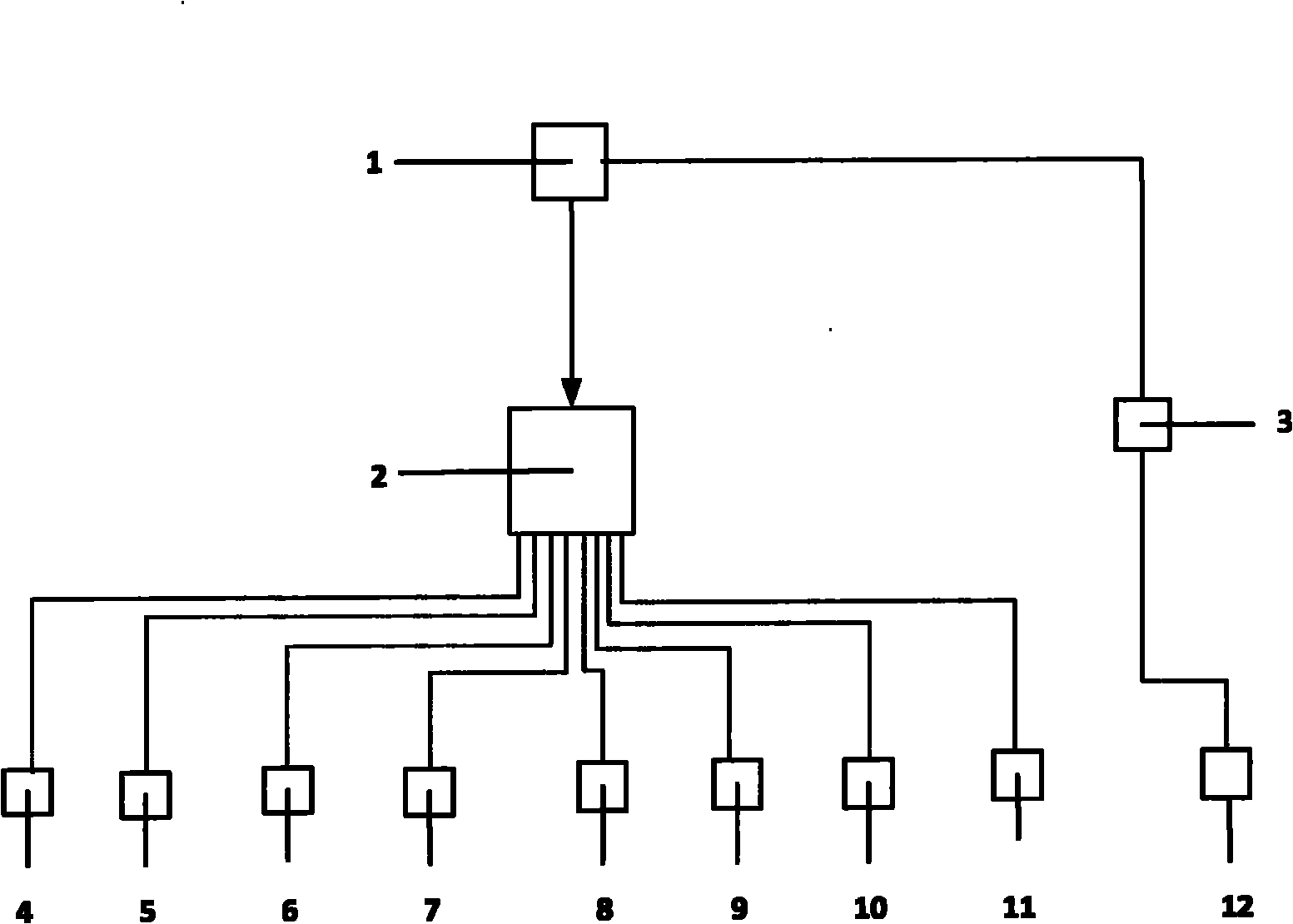

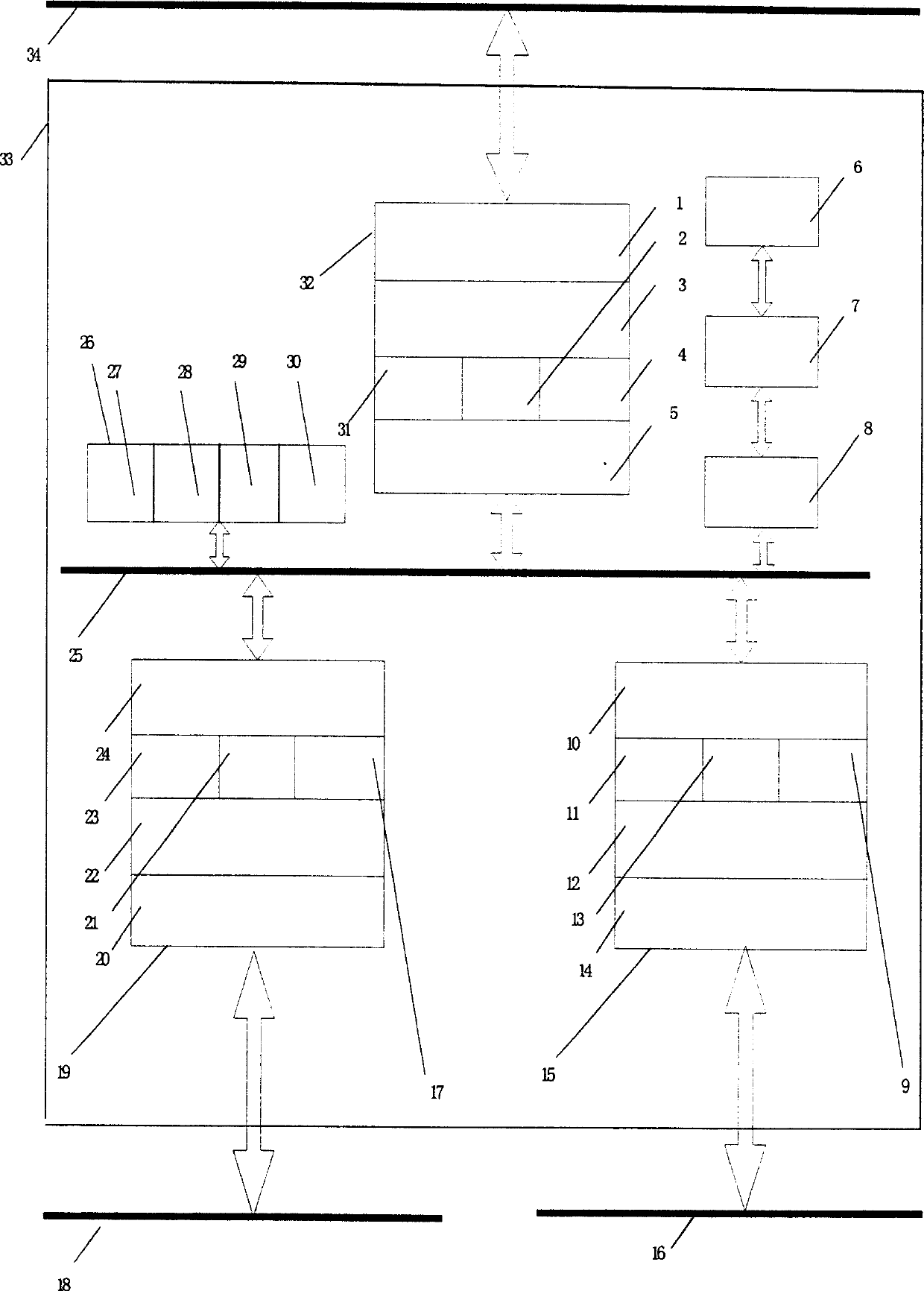

Industrial wireless network access industrial Ethernet, multi-protocol gateway of field bus and protocol conversion method

The invention relates to a multi-protocol gateway and protocol conversion method accessing industrial radio network into MODBUS / TCP industrial Ethernet and PROFIBUS-DP field bus based on IEEE802.15.4a. The multi-protocol gateway comprises microprocessor, MODBUS / TCP main station, IEEE802.15.4a radio main station, PROFIBUS-DP slave station, extent SDRAM memory and FLASH memory, RJ45 network port, 486 physical layer interface, USB interface. The circuit connection style is that the microprocessor is positioned at center; the DM9161EP Ethernet physical layer interface chip extends via MDIO interface; the PROFIBUS-DP protocol chip SPC3 connects via internal bus, the NA1TR8 radio protocol chip connects the circuit via SPI bus; the USB interface extends from the circuit. The protocol conversion method of multi-protocol gateway is controlled by microprocessor for implementing protocol conversion among three networks. The invention implements wired / wireless Heterogenous control network gateway fitting the demand for industrial real-time and open data communication considering the status of wired spot bus / industrial Ethernet for the present and combining the wireless network frontier technology.

Owner:SHANGHAI UNIV

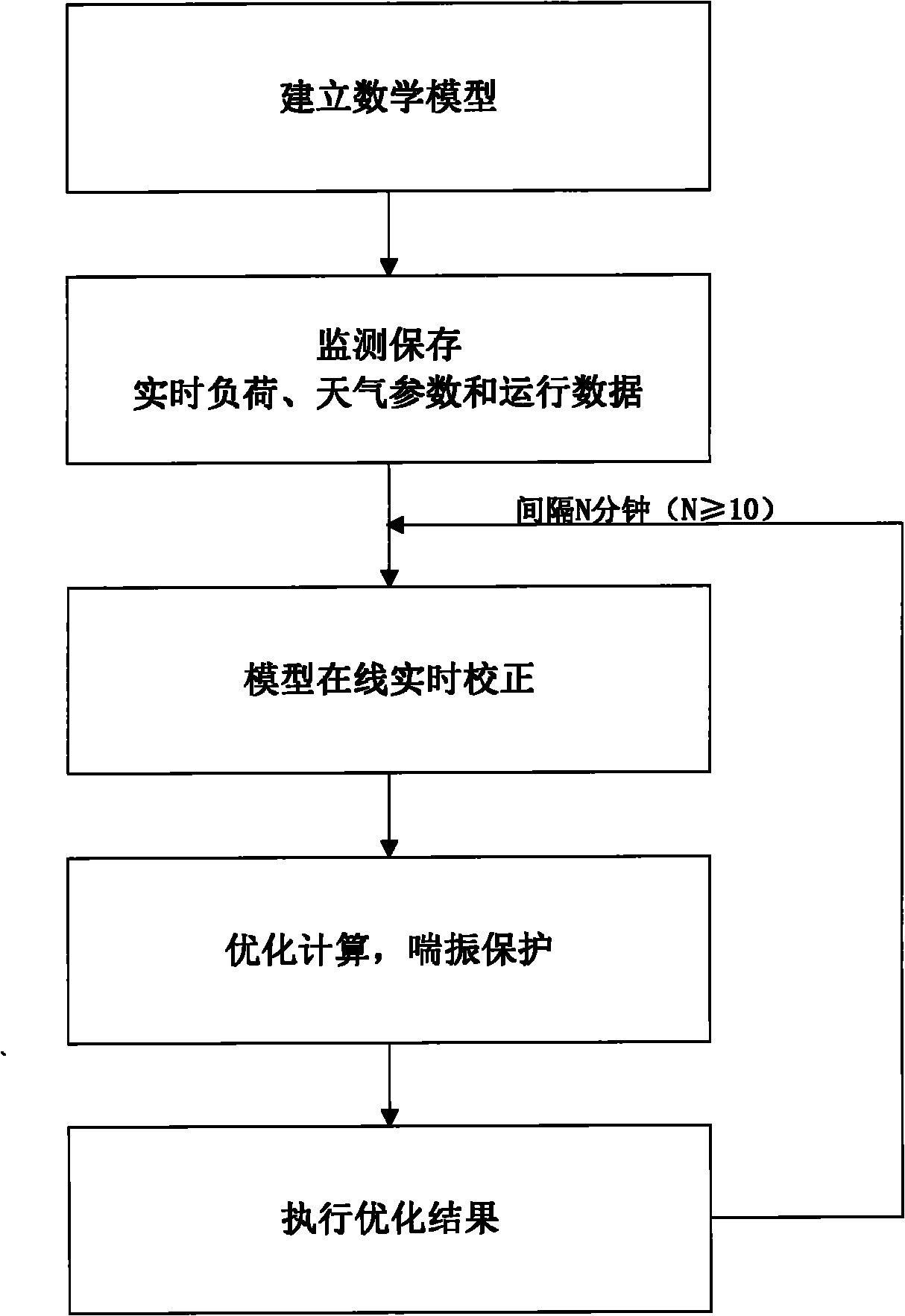

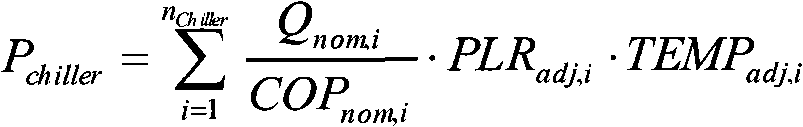

Energy-saving optimized control system and method for refrigerator room

ActiveCN101968250ASpace heating and ventilation safety systemsLighting and heating apparatusFrequency changerRefrigerator car

The invention relates to an energy-saving optimized control system and an energy-saving optimized control method for a refrigerator room. The energy-saving optimized control system comprises an industrial control computer, a flow sensor, a temperature sensor, an outdoor temperature and humidity sensor, a three-phase active power transmitter, a water pump frequency converter and a cooling tower fan frequency converter which are connected with a programmable logic controller respectively, wherein the programmable logic controller communicates with the industrial control computer through an industrial Ethernet; and an RS485 communication interface module is connected with a water cooling unit and communicates with the industrial control computer through a ModBus protocol. A mathematical model of relationships between the energy consumption and running parameters of each equipment in the refrigerator room is established to regulate the running state of each equipment in combination with real-time refrigeration loads and weather parameters, thereby fulfilling the aim of making the lowest running energy consumption of the whole refrigerator room at the premise of meeting the refrigeration loads.

Owner:WELDTECH TECH SHANGHAI

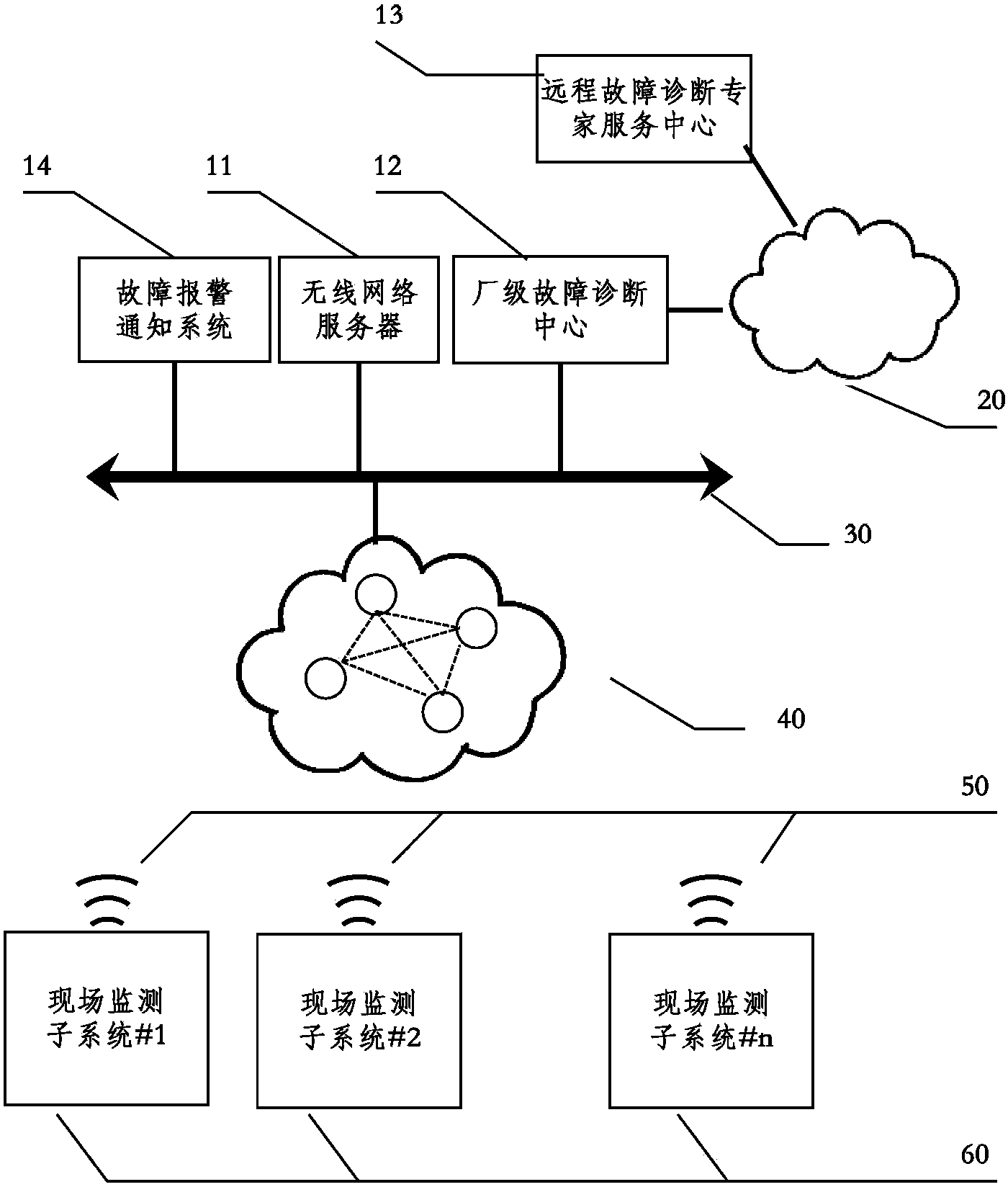

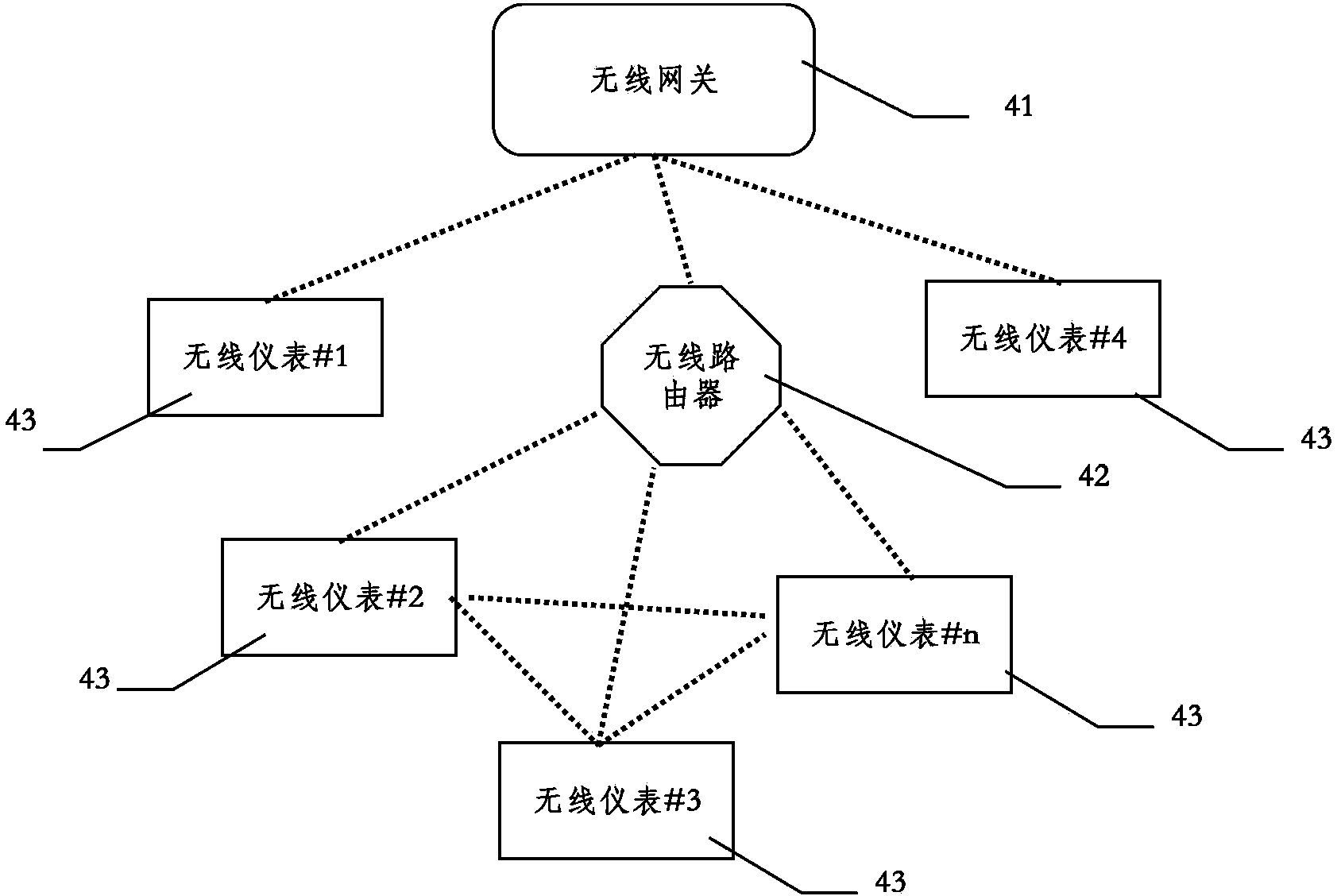

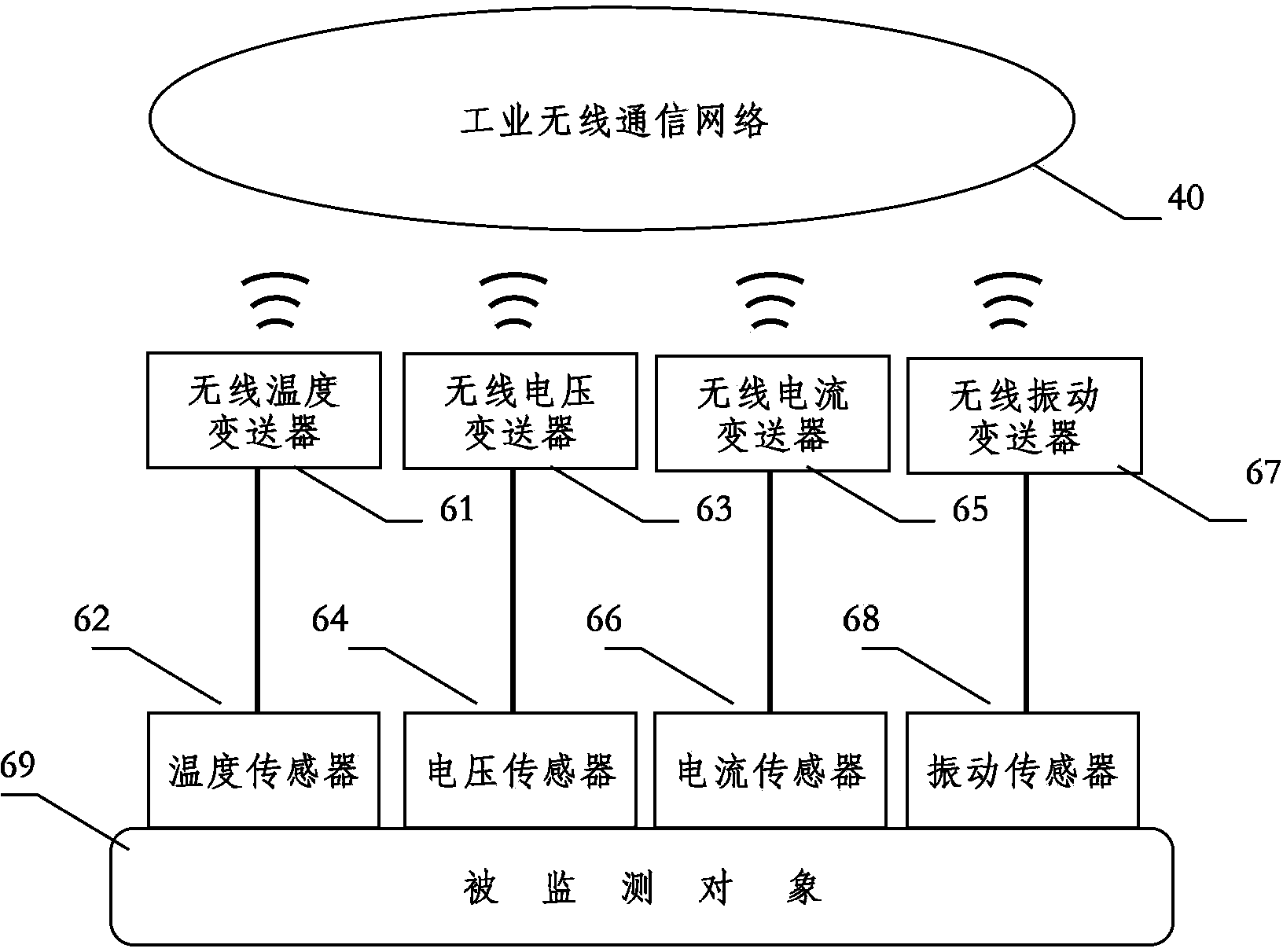

Device fault pre-maintenance method based on industrial wireless technology

InactiveCN103913193AEliminate dead endsIncrease flexibilityMeasurement devicesTransmission systemsIndustrial EthernetMonitor equipment

The invention relates to a device fault pre-maintenance method based on an industrial wireless technology. In the method, through data communication of an industrial wireless network and an industrial Ethernet, real-time monitoring and fault pre-maintenance are performed on an on-site device. The method includes the following steps: an upper computer performs parameter configuration on on-site instruments, which are used for monitoring the device, through the industrial Ethernet and the industrial wireless network; the instruments acquire sensor information of the on-site device according to the parameter configuration and upload result data, which is obtained after local processing of the sensor information, to the upper computer through the industrial wireless network and the industrial Ethernet; the upper computer performs fault diagnosis according to the result data and judges the operation state of the device; and if the fault diagnosis result is obtained, on-site maintenance personnel are notified through a fault alarm so as to maintain the device.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

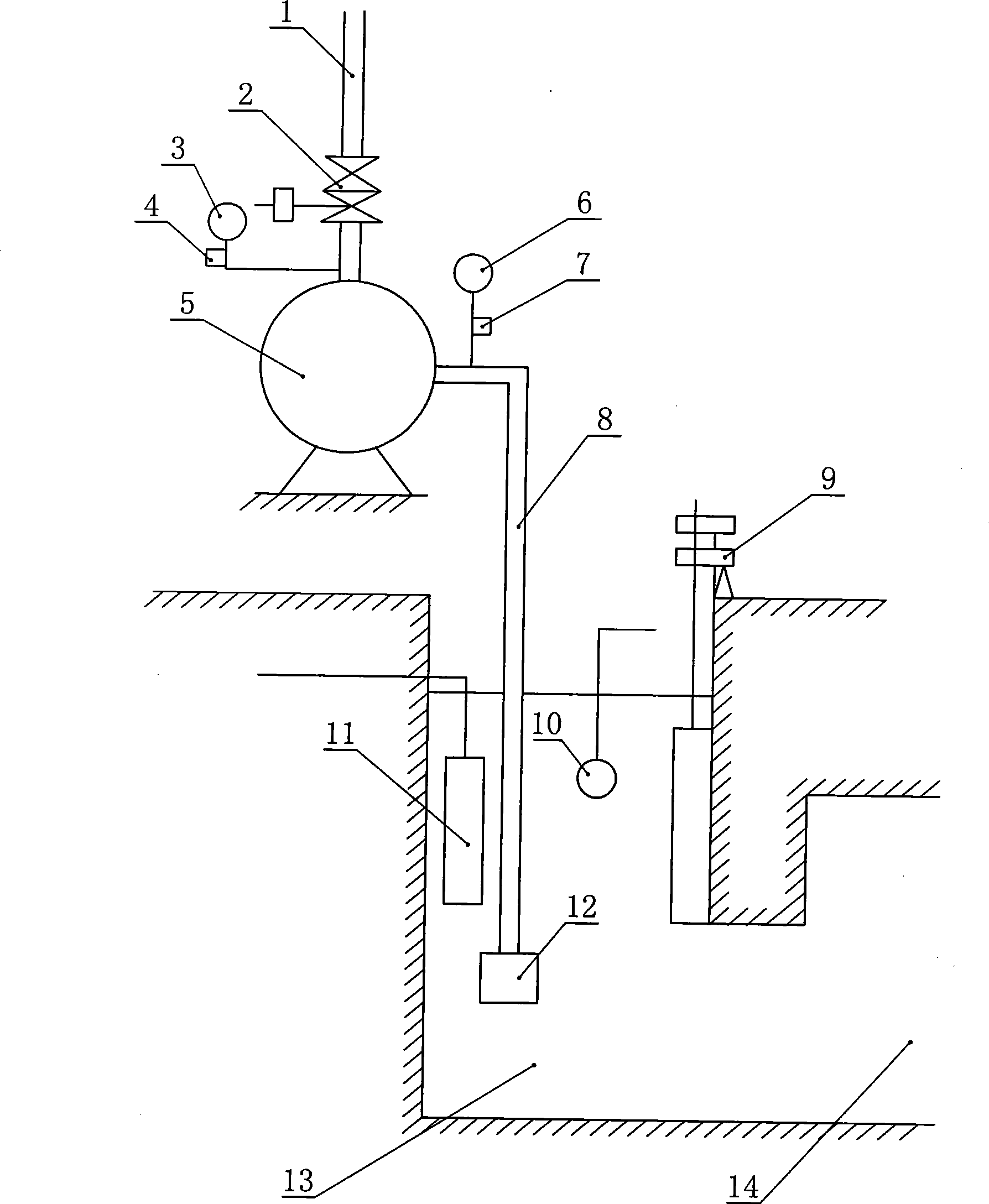

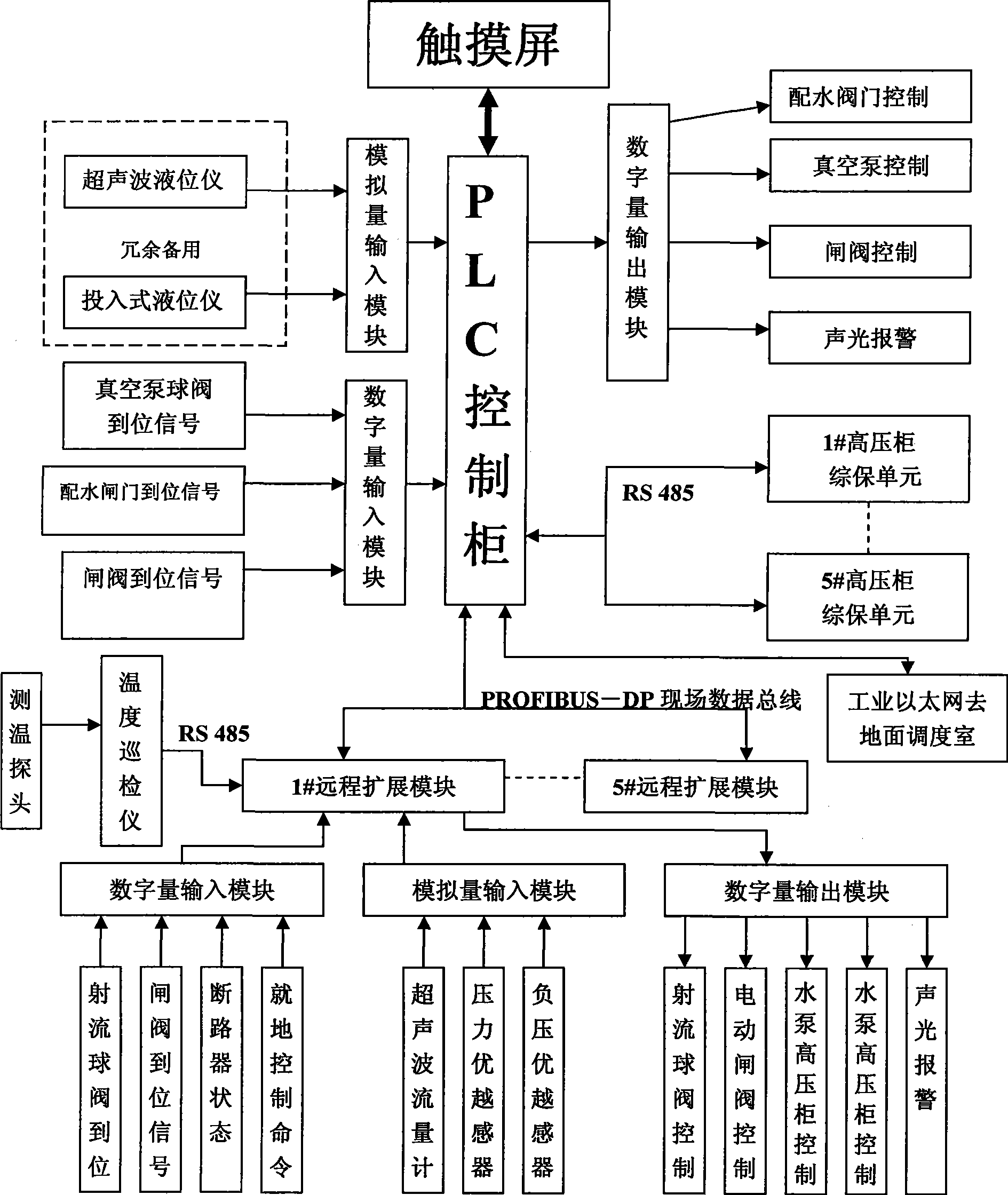

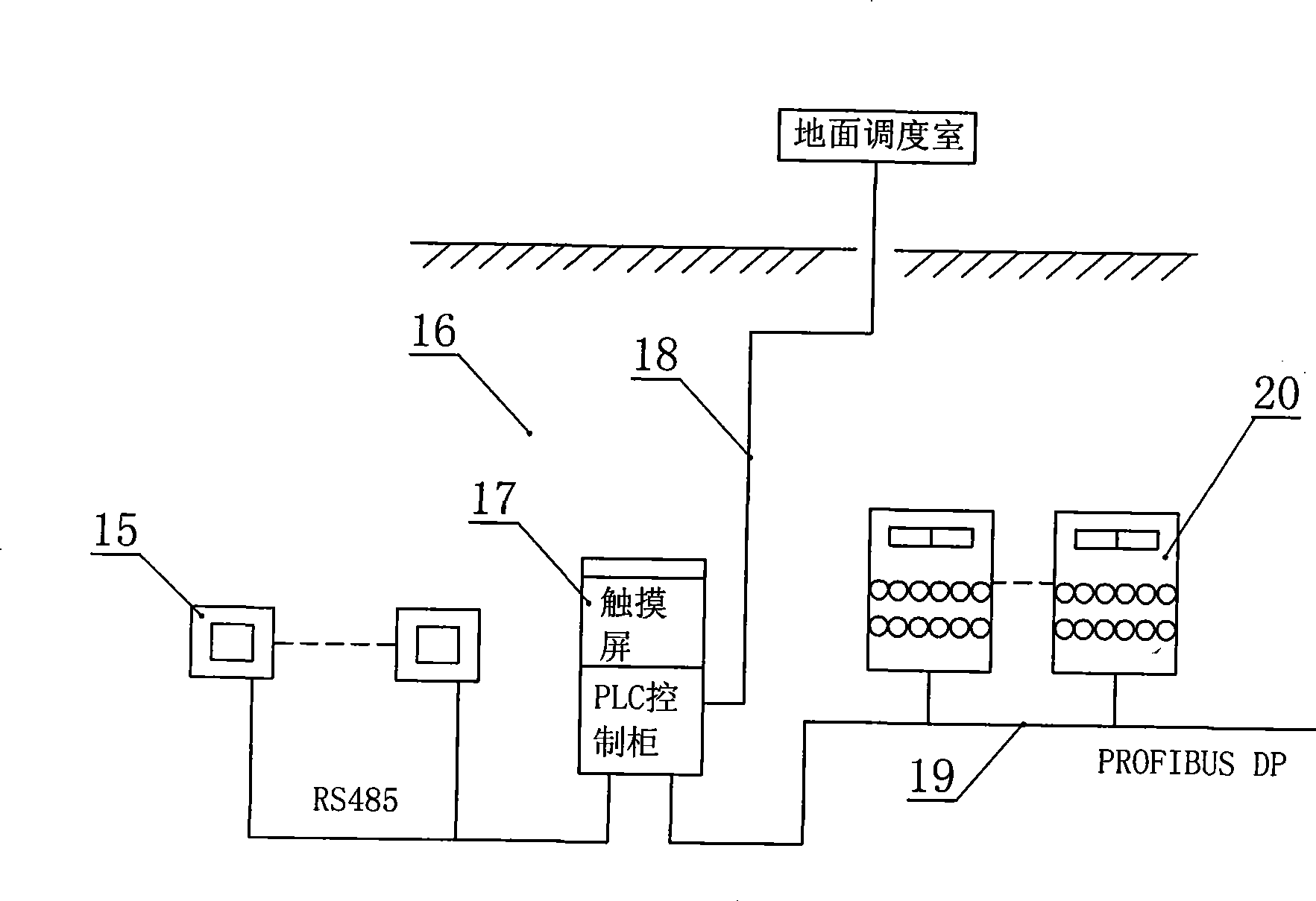

Automatic monitoring system for down-hole central pumping room drainage

The invention relates to an underground central pump room draining automatic monitoring system, which comprises a PLC control cabinet, a remote expanding module, a site data bus, a contact screen, an analog quantity and switching value input module, various monitoring probes, a travel switch, a level instrument and an executable section. A monitoring net adopts a form of combining a PROFIBUS DP site data bus and an industrial ethernet. A monitoring method for the system comprises: (1) monitoring the absorbing well water level; (2) monitoring the state for starting a high pressure switching cabinet by a water pump; (3) judging the valve levels of a gate valve, a ball valve of a water jet pumping device and a water distribution gate; (4) judging the valve levels of a vacuum pump ball valve; (5) measuring each equipment temperature measuring point; (6) measuring signals of a pressure sensor and a negative pressure sensor; (7) judging system faults; (8) automatically controlling the start-stop and operation numbers of the water pumps according to the absorbing well water level conditions; and (9) setting power supply peak avoiding time periods, and automatically selecting starting time and numbers of a pump. The system improves the system working reliability, reduces the equipment fault rate, and adopts a three-stage monitoring structure for a draining system.

Owner:BINHU COAL MINE ZAOZHUANG MINING GRP

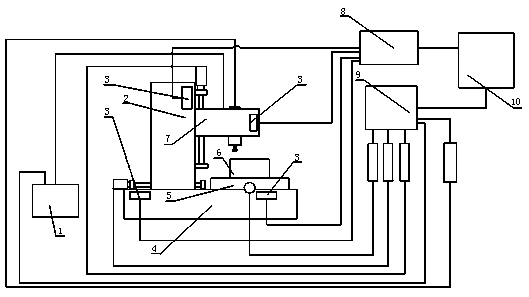

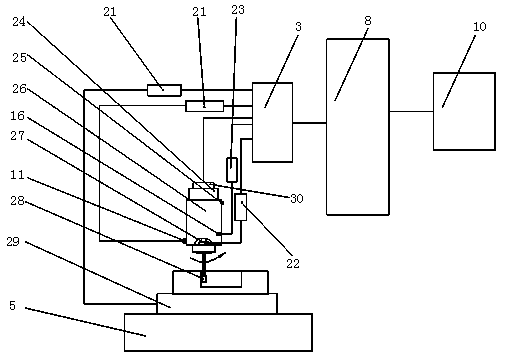

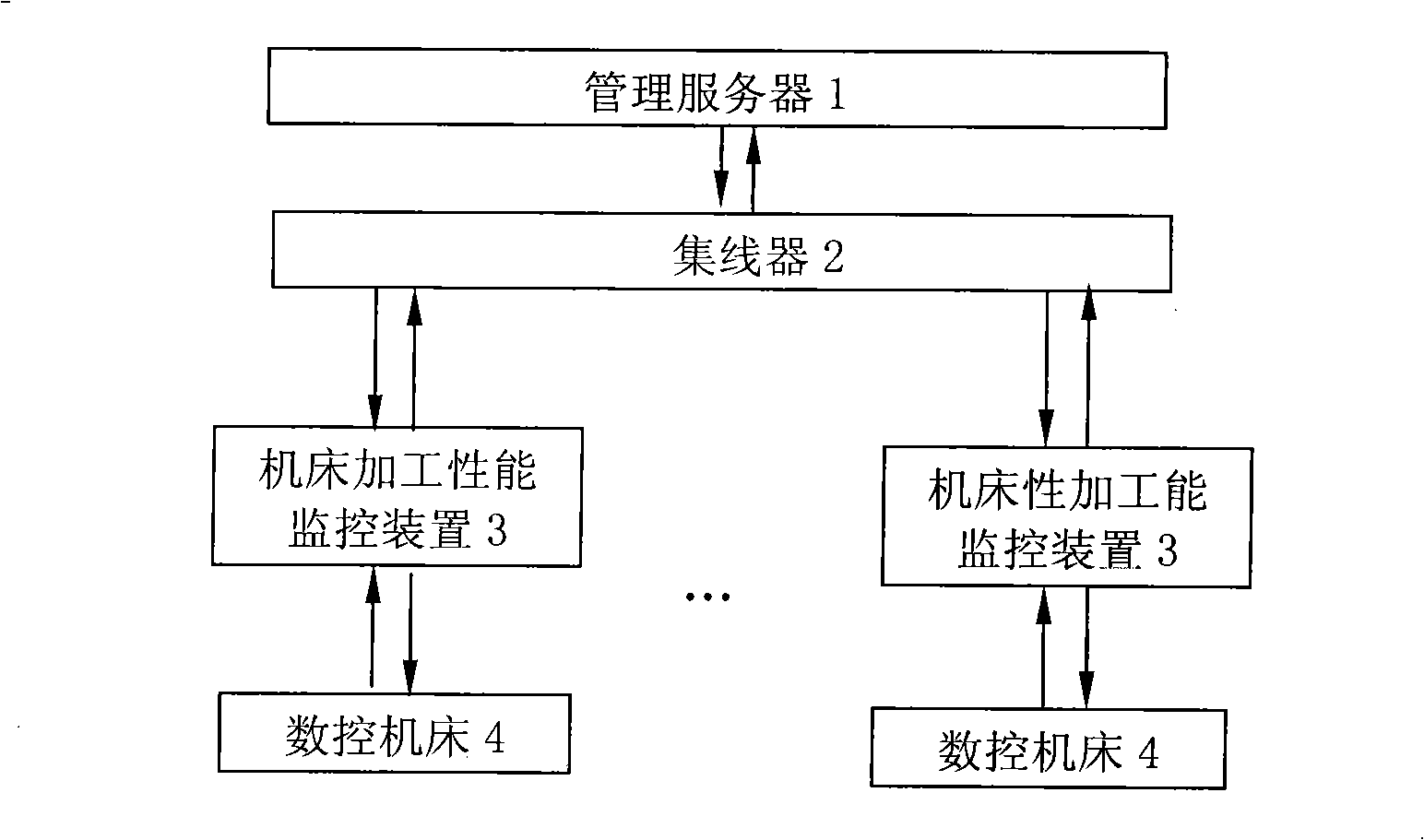

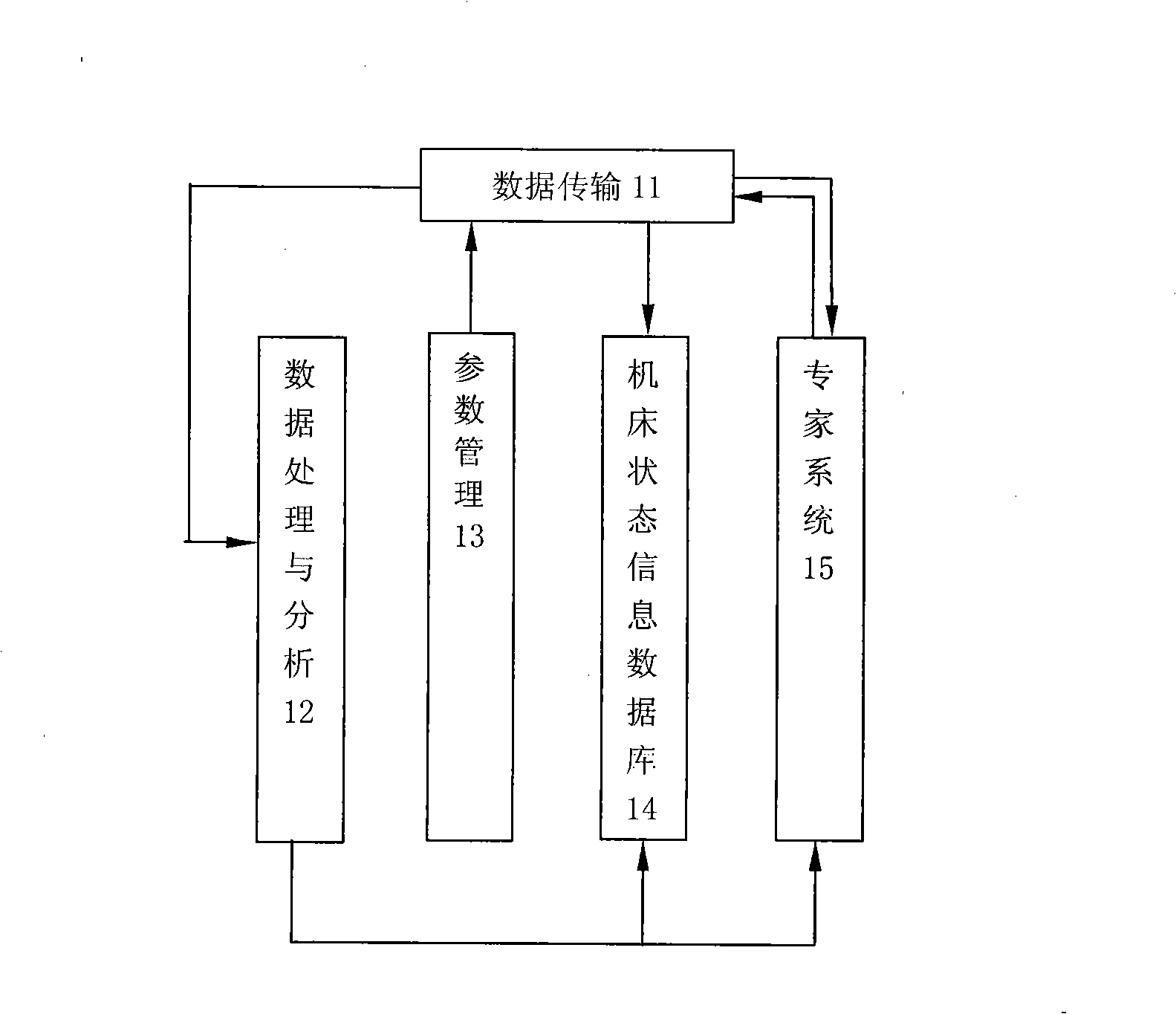

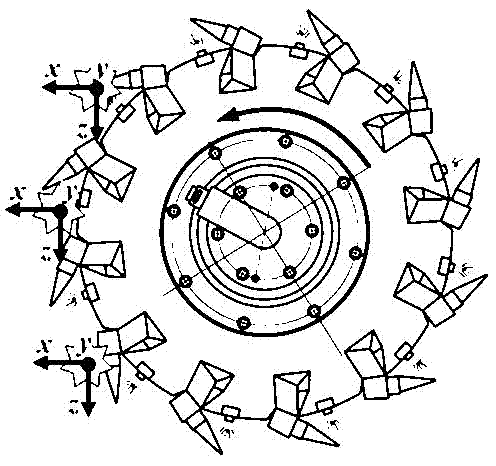

Numerical machine tool machining state multi-parameter online active monitoring system and implement method thereof

ActiveCN103823409AImprove processing qualityImprove processing efficiencyProgramme controlComputer controlActive monitoringState parameter

The invention discloses a numerical machine tool machining state multi-parameter online active monitoring system and an implement method thereof. The system and the method mainly solve the problems that state detection performance indexes of an existing numerical control machine tool are not comprehensive, and closed-loop control during the machining process can not be achieved. The numerical machine tool machining state multi-parameter online active monitoring system comprises a first sensor assembly arranged on a numerical control machine tool servo feeding unit, a second sensor assembly arranged on a main shaft unit, a third sensor assembly disposed on a cooling liquid circulating unit and a multi-channel synchronous data collecting PXI box used for receiving information of collected data. The multi-channel synchronous data collecting PXI box sends related collected state signals to a monitoring computer in real time for analysis, calculation, display and storage, the monitoring computer generates related control instructions according to abnormal or optimized machining state parameters, transmits the related control instructions to a numerical control system of the numerical control machine tool through an Ethernet bus and executes related active control instruments, and accordingly real-time adjustment and control of numerical control machining process states are finished.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

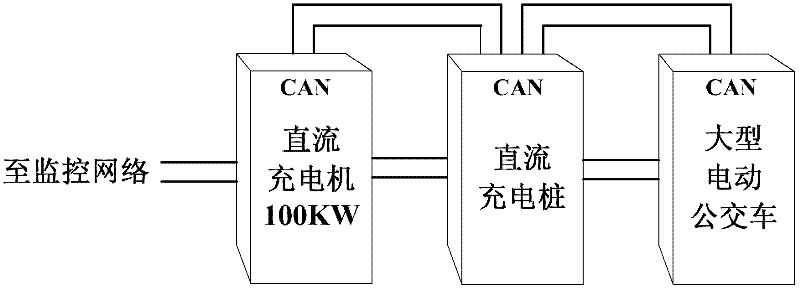

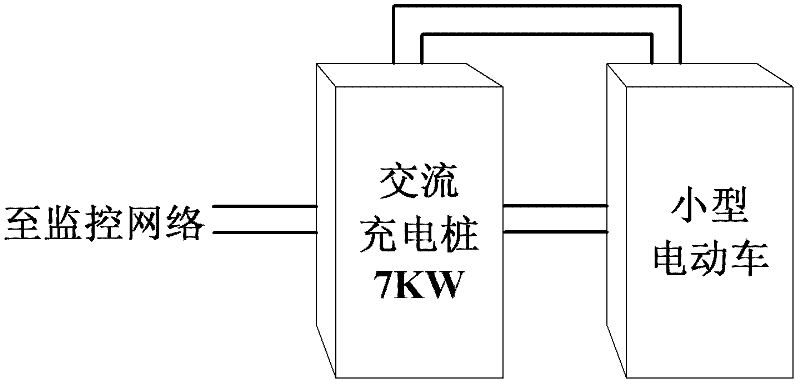

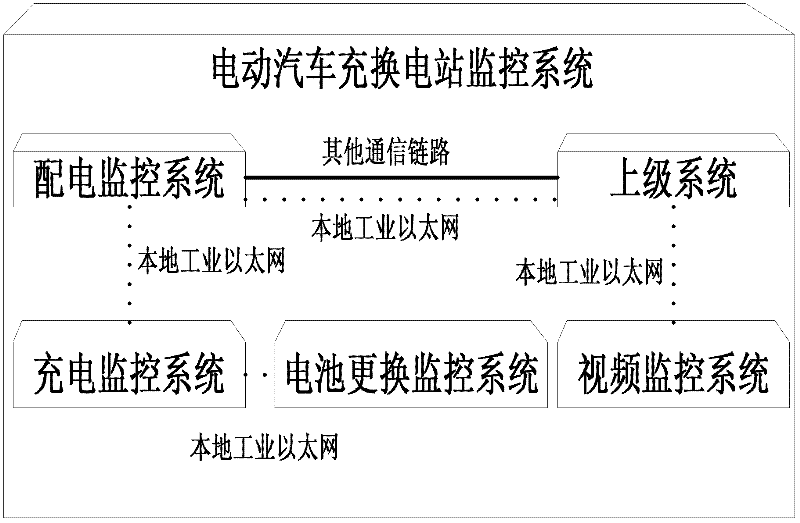

Monitoring system for electric automobile battery charging and replacing station

InactiveCN102315677ASolve the monitoring problem of compatible charging and swapping of large and small carsMeet the requirementsBatteries circuit arrangementsClosed circuit television systemsVideo monitoringDistribution power system

The invention relates to a monitoring system for an electric automobile battery charging and replacing station. The system comprises a superior system, an electricity distribution monitoring system, a charging monitoring system, a battery replacement monitoring system and a video monitoring system; a monitoring work station, a server, a printer, an electricity distribution system communication management machine and an electricity utilization information collecting terminal are connected with a network exchanger of the charging monitoring system through a local industrial Ethernet; a network exchanger of the electricity distribution monitoring system is connected with a communication gateway of the superior system through the local industrial Ethernet; an intelligent communication terminal of the battery replacement monitoring system is connected with the network exchanger of the charging monitoring system through the local industrial Ethernet; and a video server of the video monitoring system is connected with the communication gateway of the superior system through the local industrial Ethernet. The system can meet the requirement of electric energy complement of large commercial vehicles and small passenger vehicles and can realize omnibearing, effective and real-time monitoring on the battery charging and replacing of electric automobiles.

Owner:CHINA ELECTRIC POWER RES INST +1

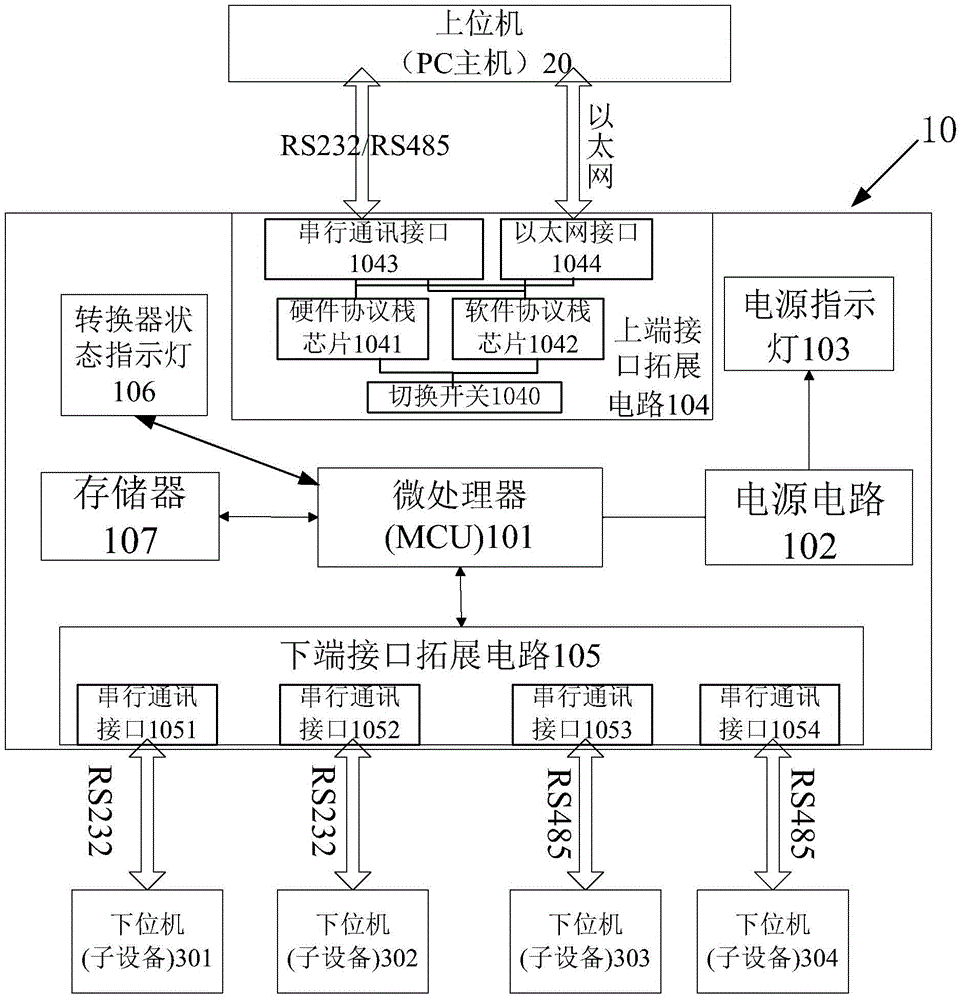

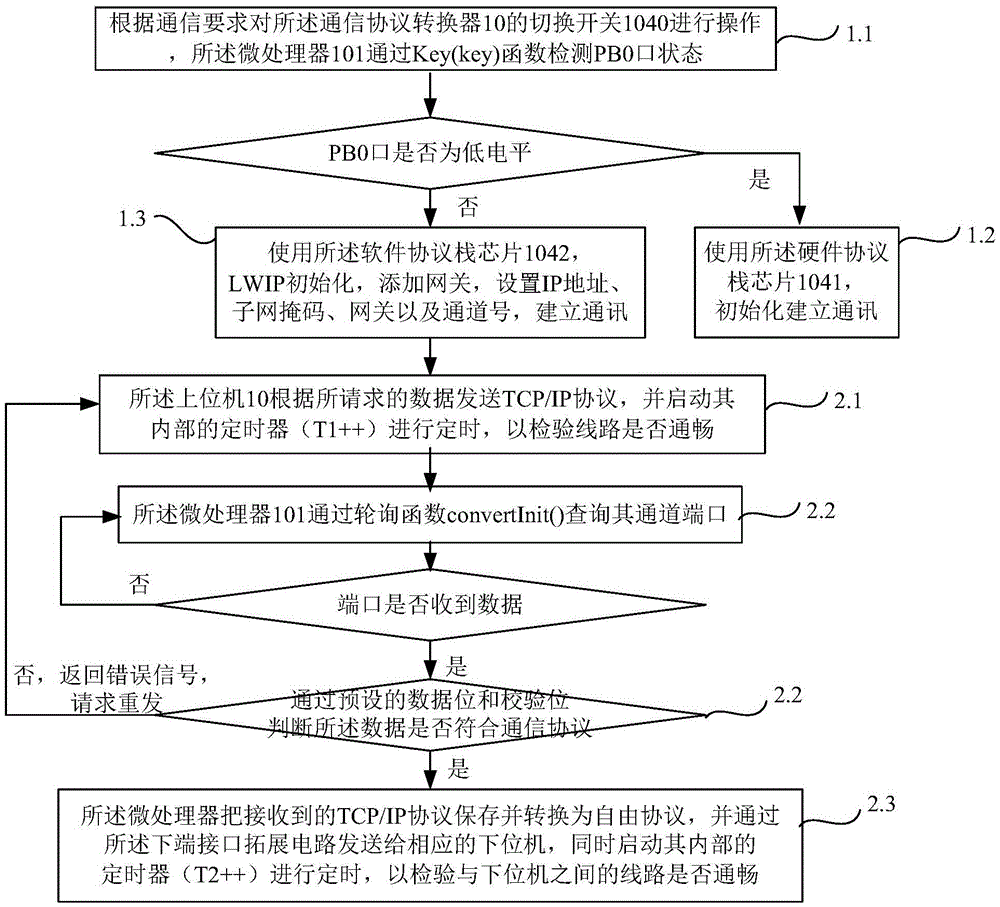

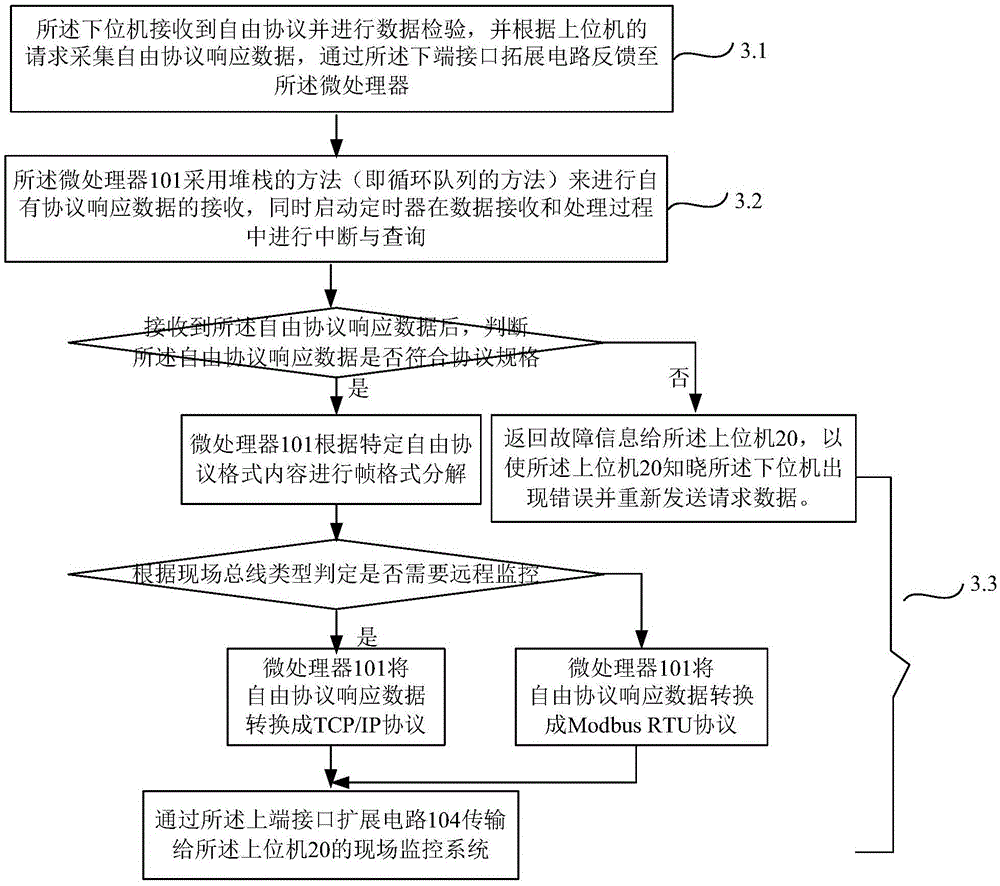

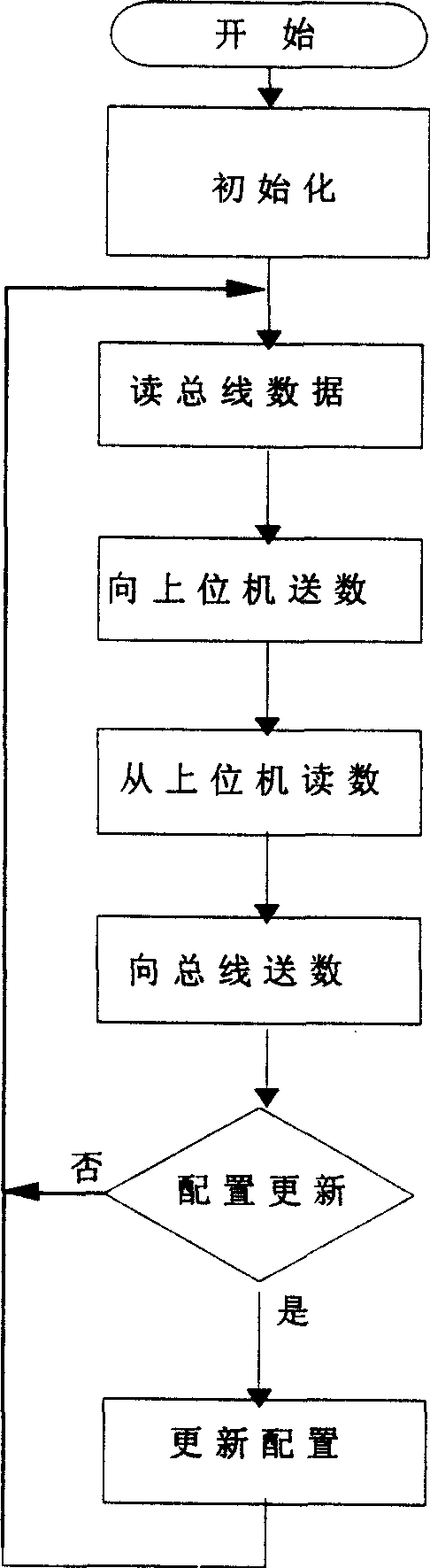

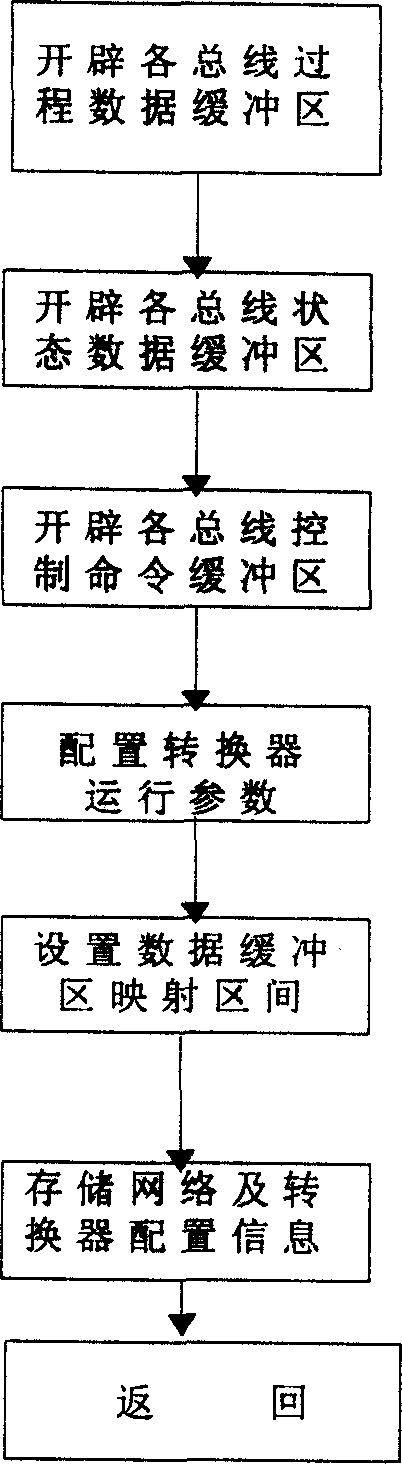

Industrial control type automatic network communication protocol converter and communication protocol conversion method

ActiveCN105610876AIncrease flexibilityFast transferTransmissionNetwork Communication ProtocolsMicroprocessor

The invention discloses an industrial control type automatic network communication protocol converter and a communication protocol conversion method. The network communication protocol converter comprises a microprocessor, an upper end connector expanding circuit, a lower end connector expanding circuit, a memory and a power supply circuit, wherein the upper end connector expanding circuit comprises a serial communication interface, an Ethernet interface, a hardware protocol stack chip, a software protocol stack chip and a switching switch for switching communication of the hardware protocol stack chip and the hardware protocol stack chip, and an upper computer; the serial communication interface is used for realizing connection of the microprocessor and a Modbus network; the Ethernet interface is used for realizing connection of the microprocessor and industrial Ethernet; and the lower end connector expanding circuit comprises a plurality of serial communication interfaces which are in communication connection with a plurality of lower computers one by one. With the adoption of the industrial control type automatic network communication protocol converter, the mutual conversion of free protocols and Modbus RTU (Remote Terminal Unit) protocols or TCP / IP (Transmission Control Protocol / Internet Protocol) can be realized, and the requirements of field-grade control and remote control are met.

Owner:江苏航天龙梦信息技术有限公司

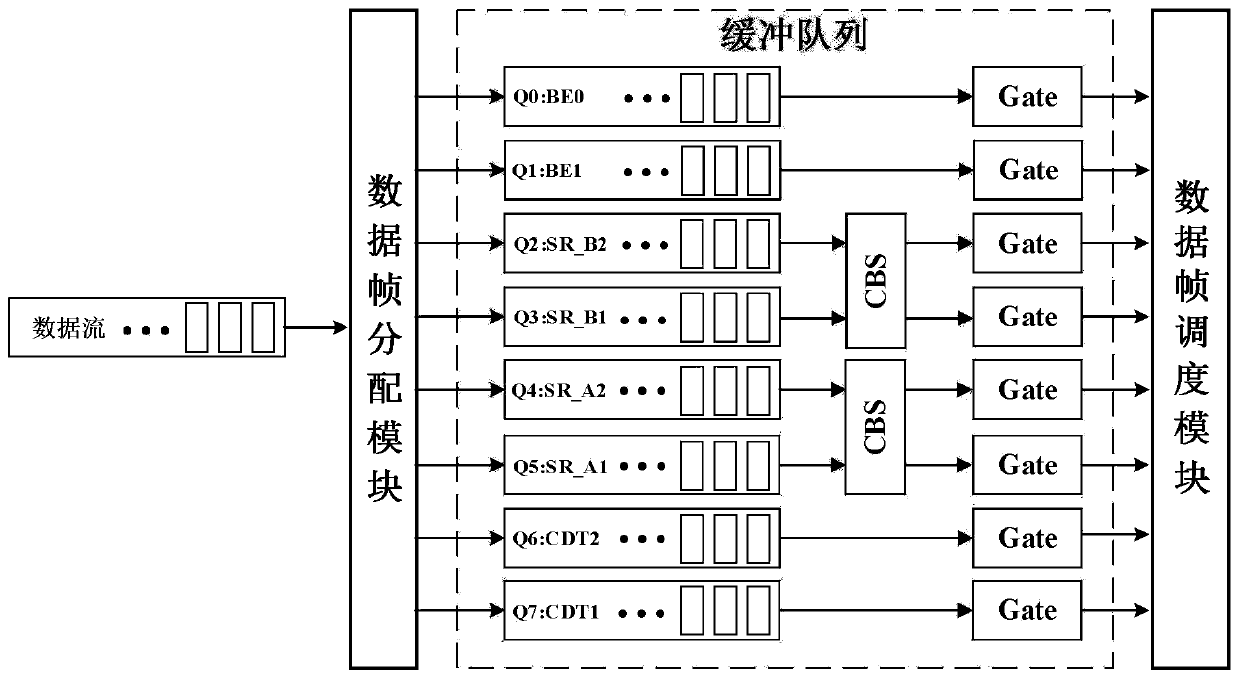

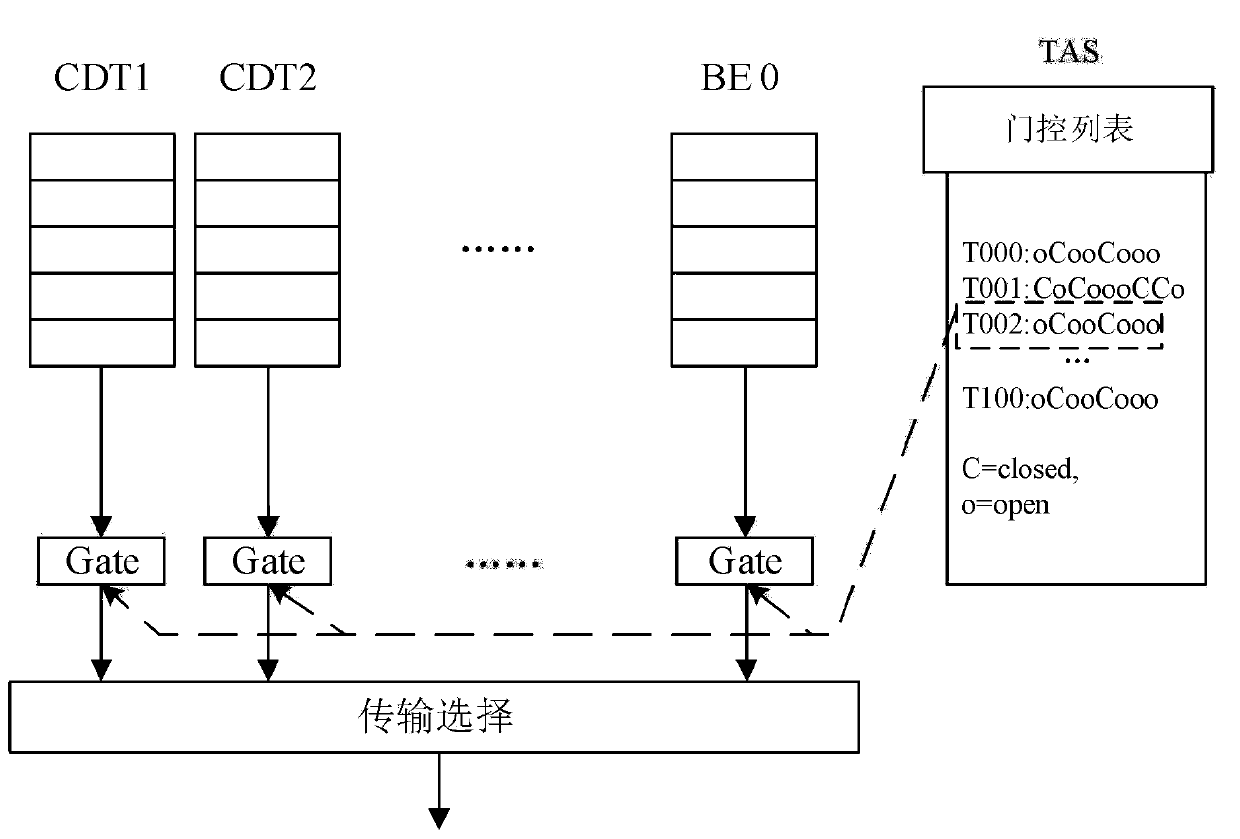

Industrial time-sensitive network data deterministic scheduling method

PendingCN111327540AGuaranteed normal transmissionImprove connectivityData switching networksIndustrial EthernetNetwork data

The invention relates to an industrial time-sensitive network data deterministic scheduling method, which belongs to the technical field of industrial networks and comprises the following steps that:S1: a TSN management network allocates priorities to data frames sent by industrial Ethernet equipment; S2, defining industrial data characteristics according to the data frame characteristic parameters; S3, establishing a data scheduling model at an output port of the industrial TSN switch, wherein the data scheduling model is composed of a data frame distribution module, a buffer queue and a data frame scheduling module; the data frame distribution module divides the buffer queue into eight scheduling queues according to the frame characteristic parameters; S4, distributing the data frames into different scheduling queues; S5, different shaping mechanisms are adopted for all the scheduling queues according to different determinacy and real-time requirements of the data frames; and S6, the data frame scheduling module performs output scheduling on the data frames. According to the method, the determinacy and the real-time performance of industrial CDT type data transmission are ensured, the jitter of SR type data can be effectively reduced, and meanwhile, the transmission of BE type data is allowed.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

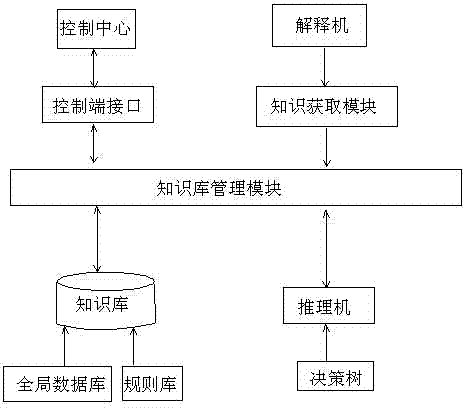

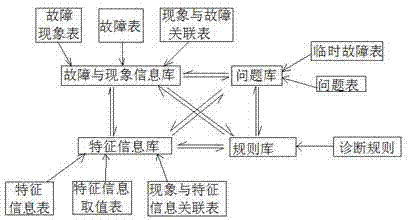

Fault diagnosis expert system based on decision tree for industrial Ethernet network

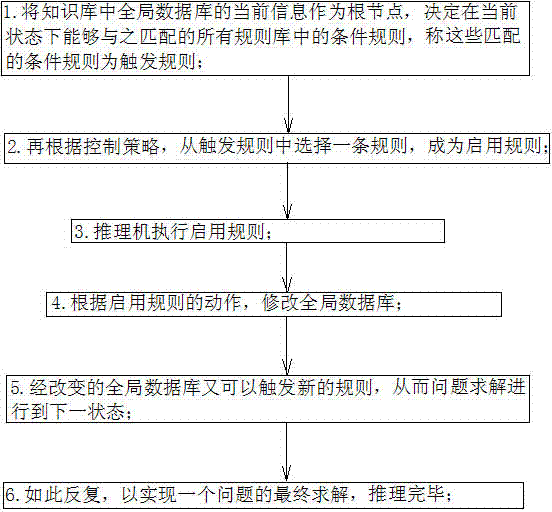

The invention discloses a fault diagnosis expert system based on a decision tree for an industrial Ethernet network. Firstly, an expert system comprising a knowledge base, an inference engine, a knowledge base management module, a knowledge acquisition module, an explanation facility and a control center is established; secondly, the knowledge base is utilized to contact the inference engine and the control center to obtain data required by the modules for storing a diagnosis rule, various pieces of data of the system and an intermediate result generated during the system diagnosis period; thirdly, comparison, commonly called as matching, is carried out between a condition part of a rule base and a content of a global data base through the inference engine, if matching is successful, a conclusion part is displayed, the global data base is modified according to an action part of an enable rule, the changed global data base can trigger a new rule, so that problem solving proceeds to the next state, and so forth, one problem is finally solved; and lastly, post processing is carried out through the inference engine, a new knowledge base is updated by the control center, so that the expert system is gradually improved.

Owner:CHINA TOBACCO HENAN IND

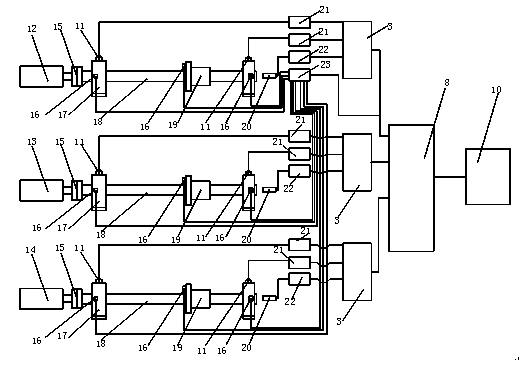

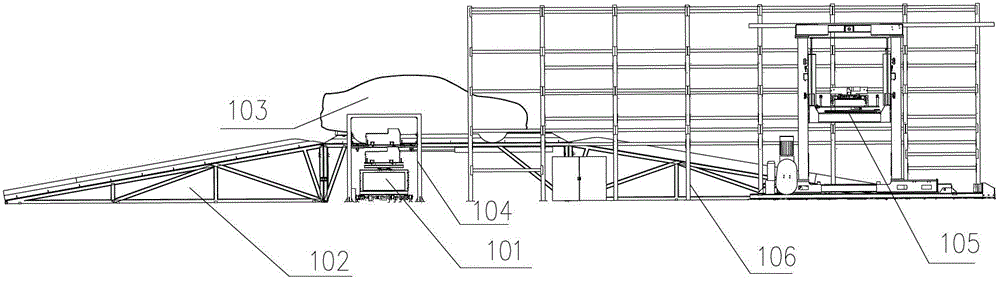

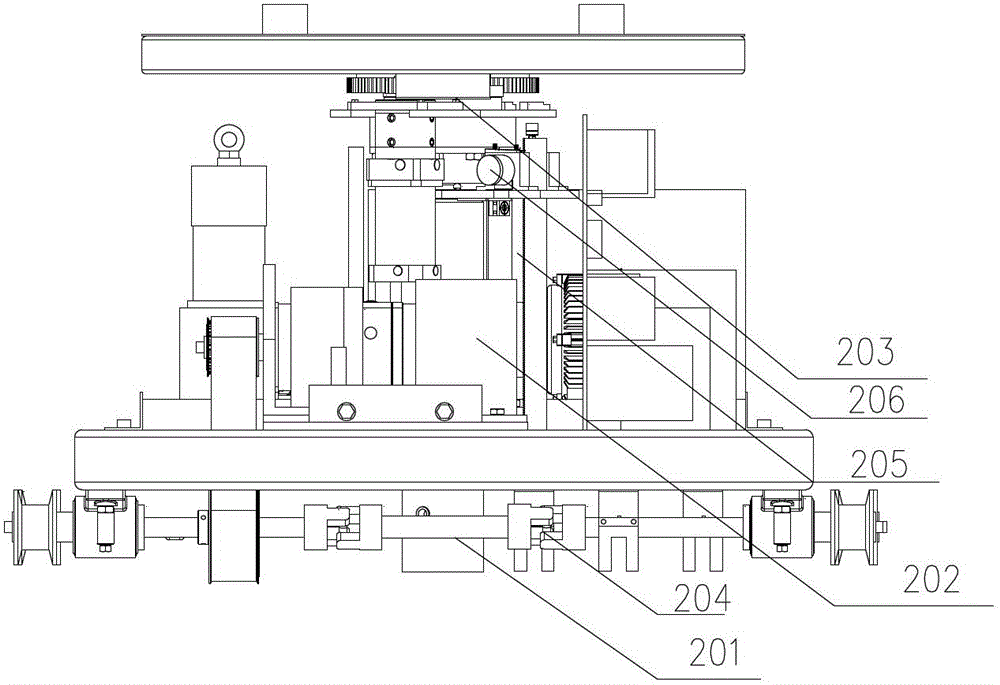

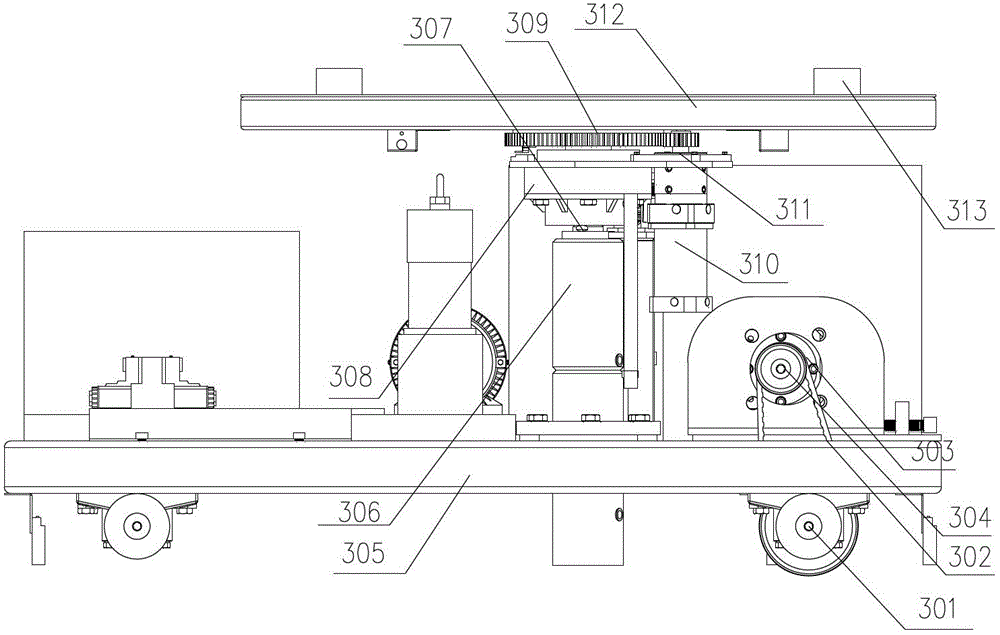

Chassis battery change system for electric passenger cars and method of the system

ActiveCN102717778APrecise positioningLow costProgramme-controlled manipulatorElectric propulsion mountingElectricityIndustrial Ethernet

The invention discloses a chassis battery change system for electric passenger cars. The chassis battery change system comprises a rapid change robot, a battery change platform, a transfer platform, a background monitoring system, a stacking machine and a charging frame, wherein the transfer platform, the stacking machine and the charging frame are arranged on one side of the battery change platform; the rapid change robot is arranged between the battery change platform and the transfer platform; an electric passenger car is capable of passing through the battery change platform; a locking mechanism which corresponds to a battery box supported by the rapid change robot is arranged on the electric passenger car; and the background monitoring system is connected with the rapid change robot and the stacking machine respectively through an industrial Ethernet. At the same time, the invention also discloses a using method of the system. A mechanical positioning mechanism of the battery change platform is simple, correct in positioning and low in manufacturing cost; a hydraulic lifting mechanism is used in the rapid change robot, so that the whole change process is reliable and stable, the size of the change equipment is decreased effectively and the actual occupied area of the change system is saved; and the transfer platform is used as a battery change interaction link between the rapid change robot and the stacking machine, so that the time spent by the battery change is further shortened.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

Multi protocol conversion method and device between MODBUS/TCP industry Ethernet and field bus device network as well as field bus of PRofibus DP

InactiveCN1697448ARealize the interface functionRealize the master node functionNetwork connectionsBus networksInformation layerHigh rate

Software in MPU builds united message model to realize protocol conversion in application layer among MODBUS / TCP industrial Ethernet, DeviceNet field bus and Profibus DP field bus. Corresponding interface module and communication adapter modules at main nodes realize their relevant protocols. Through an internal bus, protocol conversion device built from a MPU is connected to industrial Ethernet interface module, DeviceNet communication adapter module at main node, Profibus DP communication adapter module at main node and a SRAM. Through a serial peripheral interface, MPU is connected to an electrically erasable memory. The invention solves converting protocols based on different standards. One communication frame is compatible to multiple industrial communication networks so as to meet requirements of network real-time at low-layered devices as well as high rate and large capacity of network on information layer.

Owner:SHANGHAI UNIV

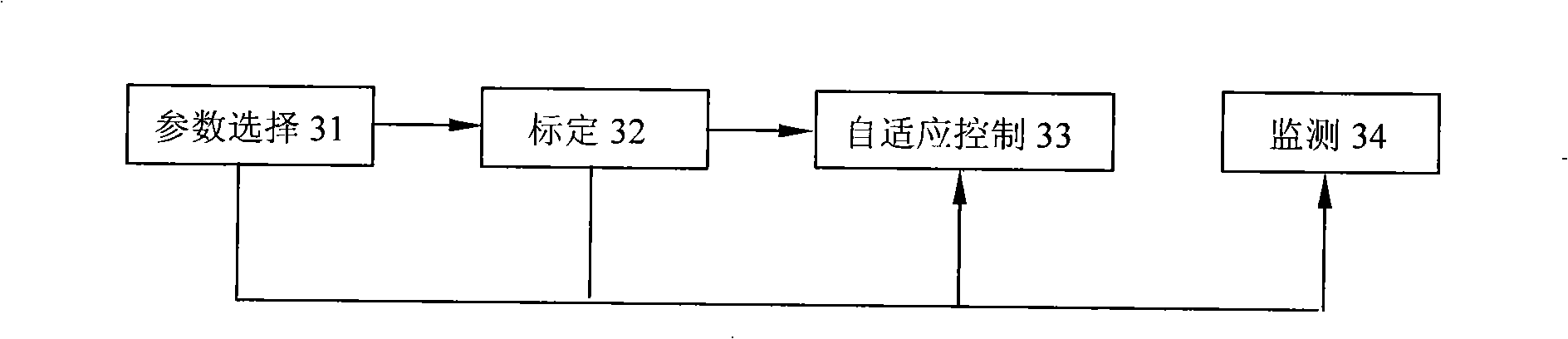

Numerical control machine processability monitoring system

InactiveCN101334656AFocus on statusFocus on processabilityProgramme controlComputer controlIndustrial EthernetNumerical control

The invention provides a numerical control machine tool processing performance monitoring system which is characterized in that monitoring devices on a plurality of machine tools are connected with each other by Ethernet network by a management server; the monitoring device receives the data of the self-state of the machine tool, collects the current of a mainshaft motor and a feeding motor and the vibration quantity of a mainshaft, processes the collected data, compares the processing result with the judgment standard of the machine tool processing performance, emits control instructions to control the processing process according to the given control strategy, and feeds back all relevant information to the management server; the management server analyses the processing performance state and the development trend of the machine tool. The system carries out monitoring to the self-parameters and the in-situ processing state of a plurality of the machine tools, analyses the current processing performance the development trend of the machine tool, and self-adaptively controls the complex processing process, thus effectively ensuring the processing safety and quality.

Owner:HUAZHONG UNIV OF SCI & TECH +1

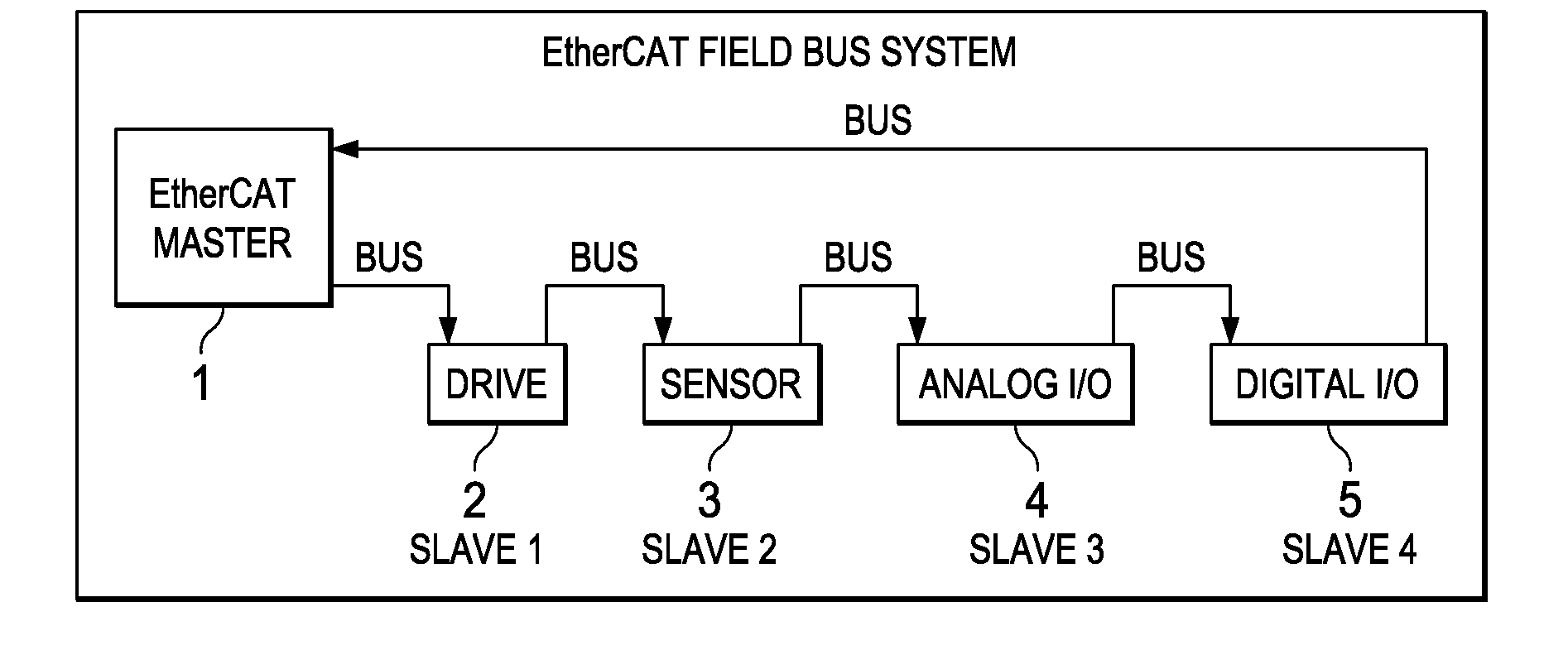

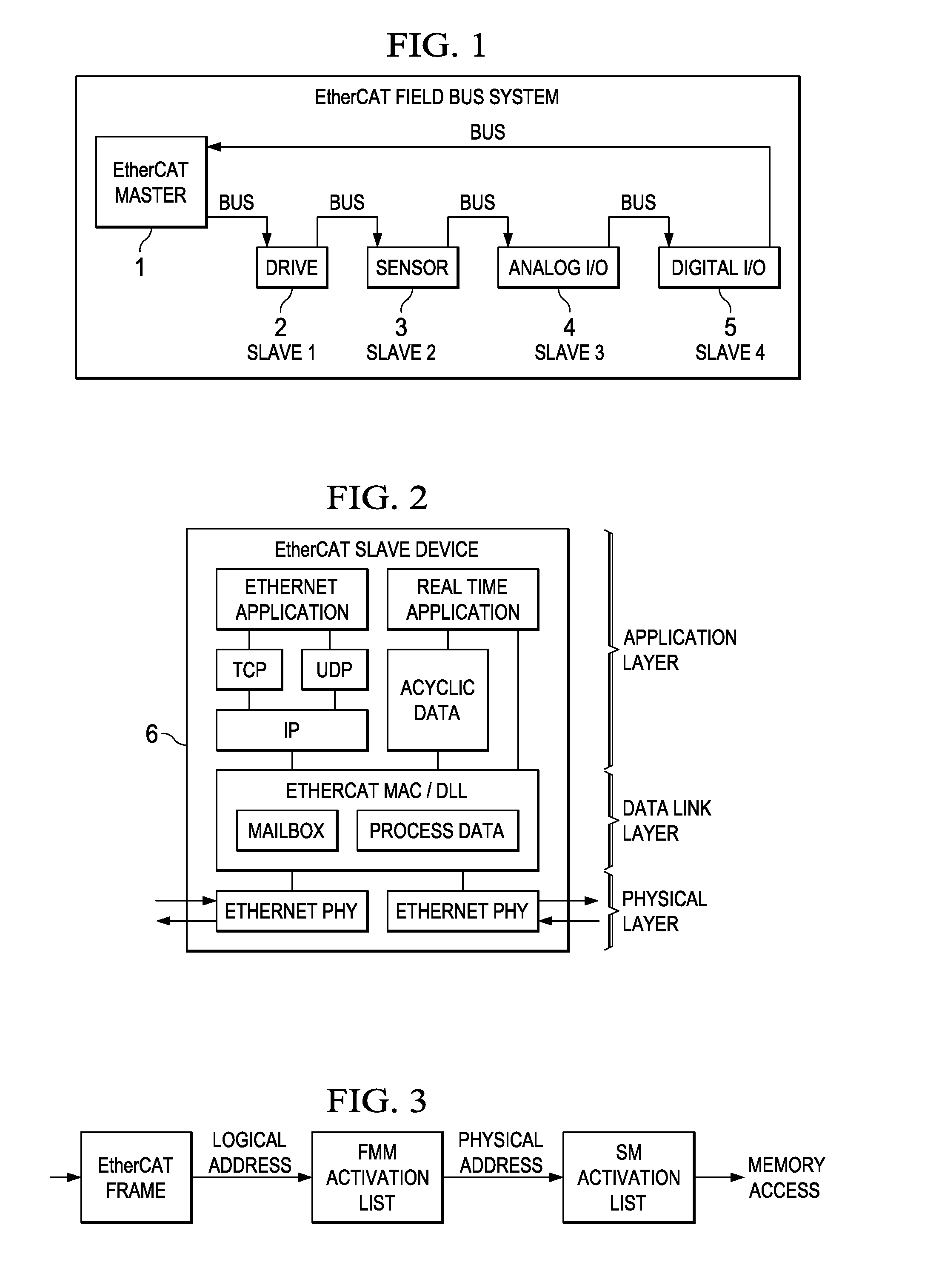

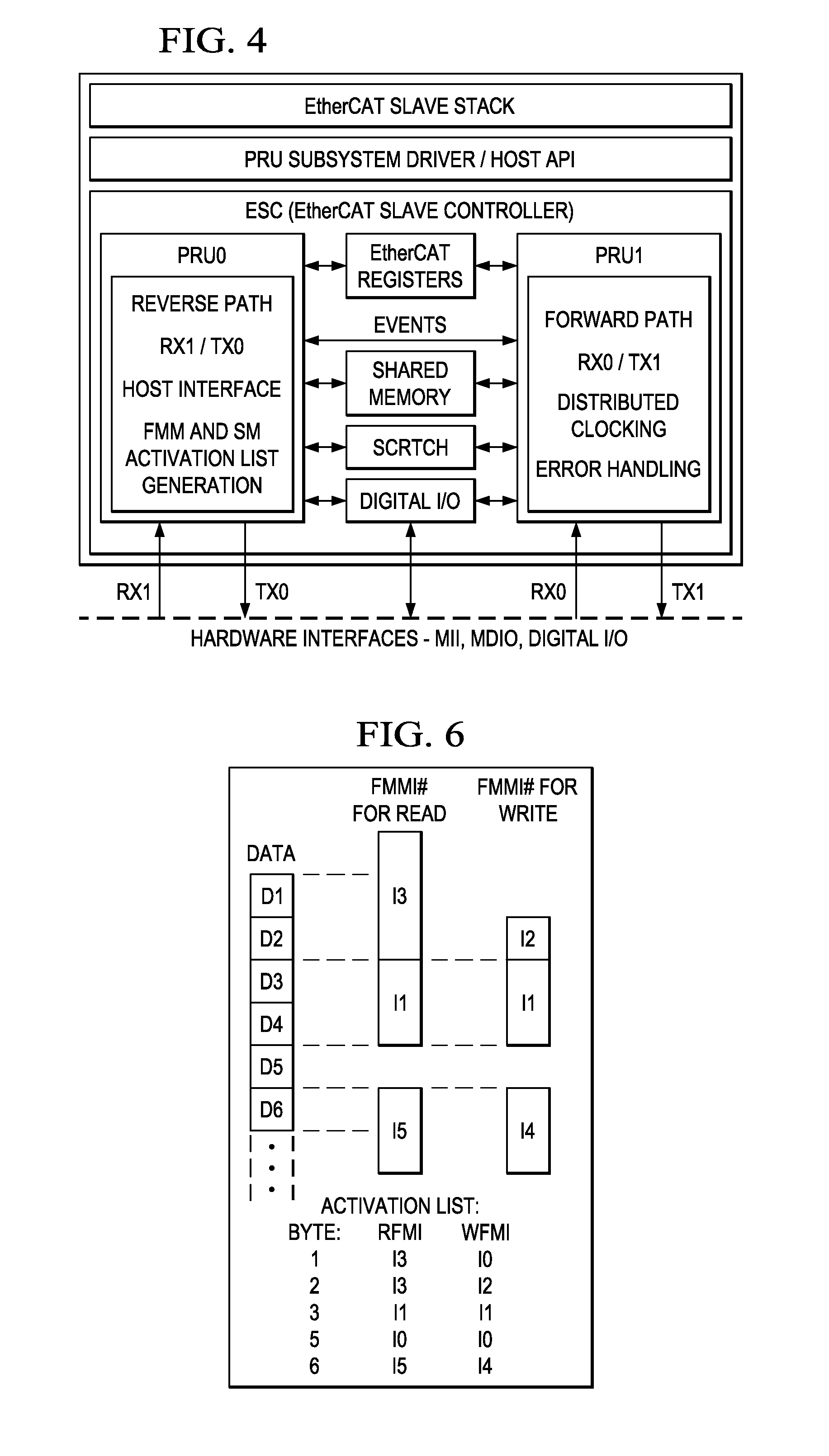

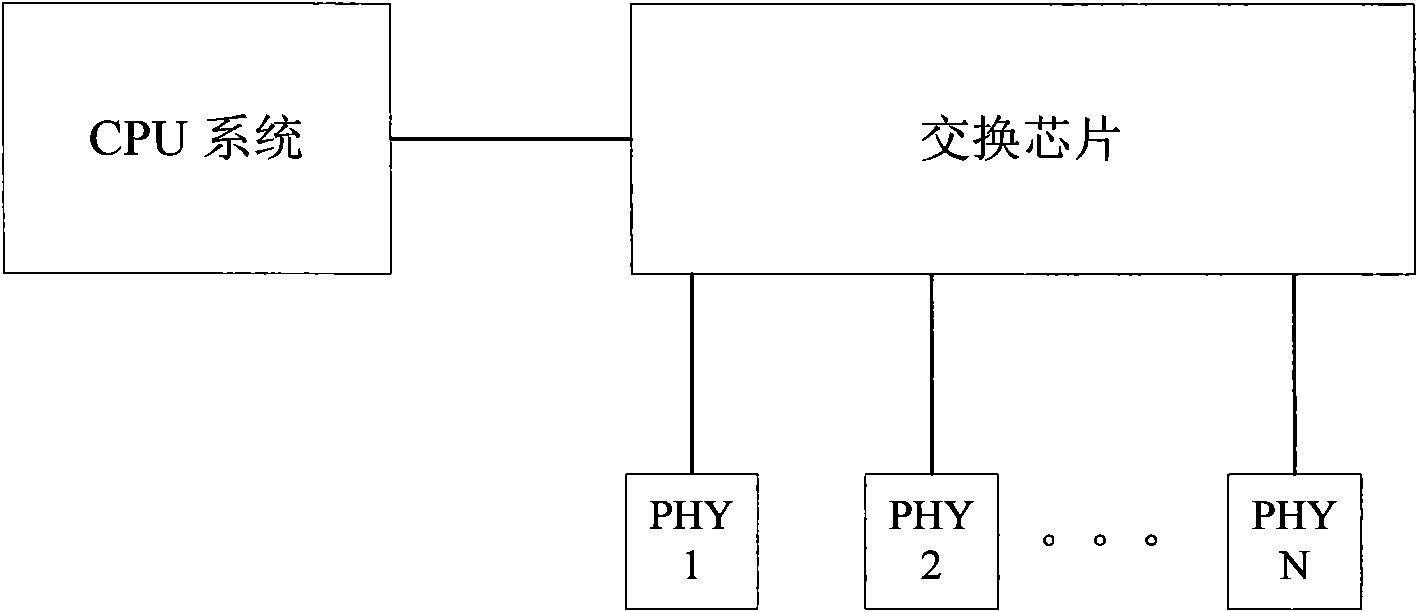

Generation of Activation List for Memory Translation and Memory Access Protection in Industrial Ethernet Standard

InactiveUS20130173868A1Reduce areaShorten the lengthUnauthorized memory use protectionData switching networksIndustrial EthernetEtherCAT

The invention relates to an EtherCAT fieldbus system, a master and a slave for the system and a method. The slave is configured to be coupled to the EtherCAT fieldbus. A first configurable memory of the slave stores a first activation list indicating for consecutive bytes of data of an EtherCAT datagram a corresponding fieldbus memory management information or synchronization management information.

Owner:TEXAS INSTR INC

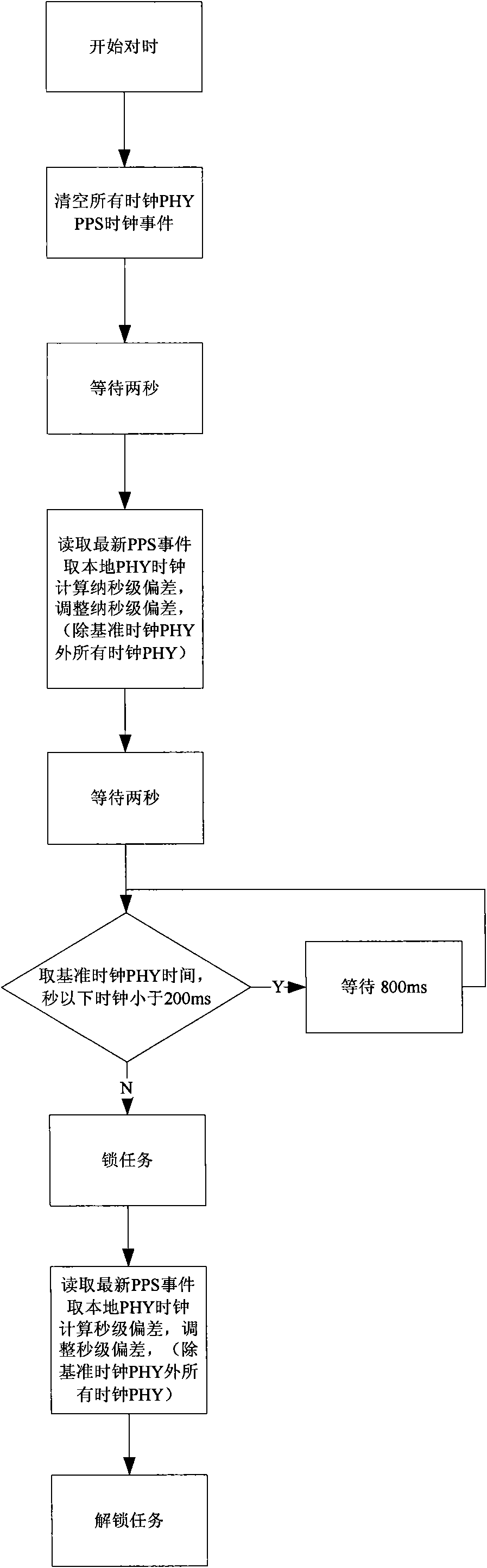

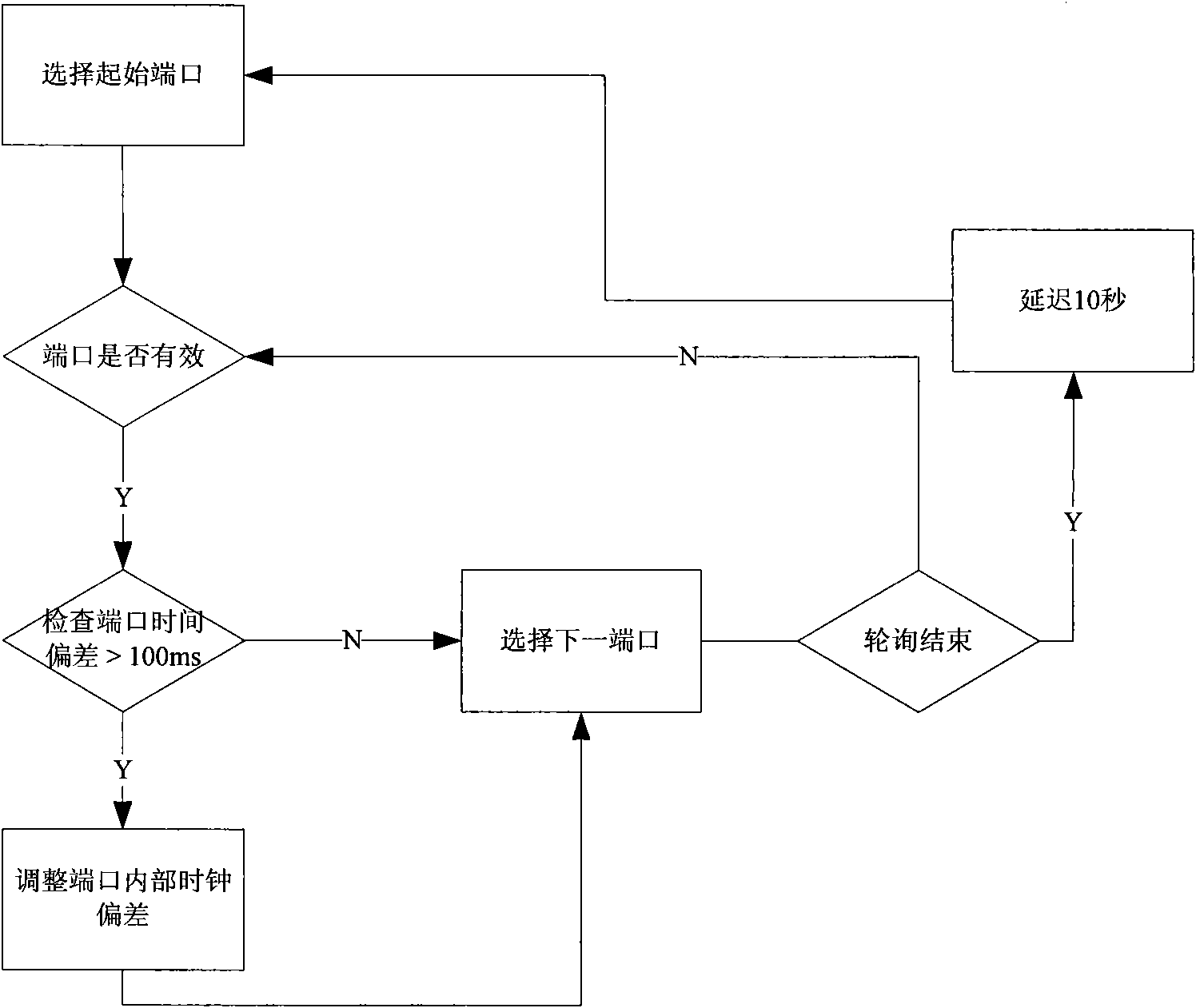

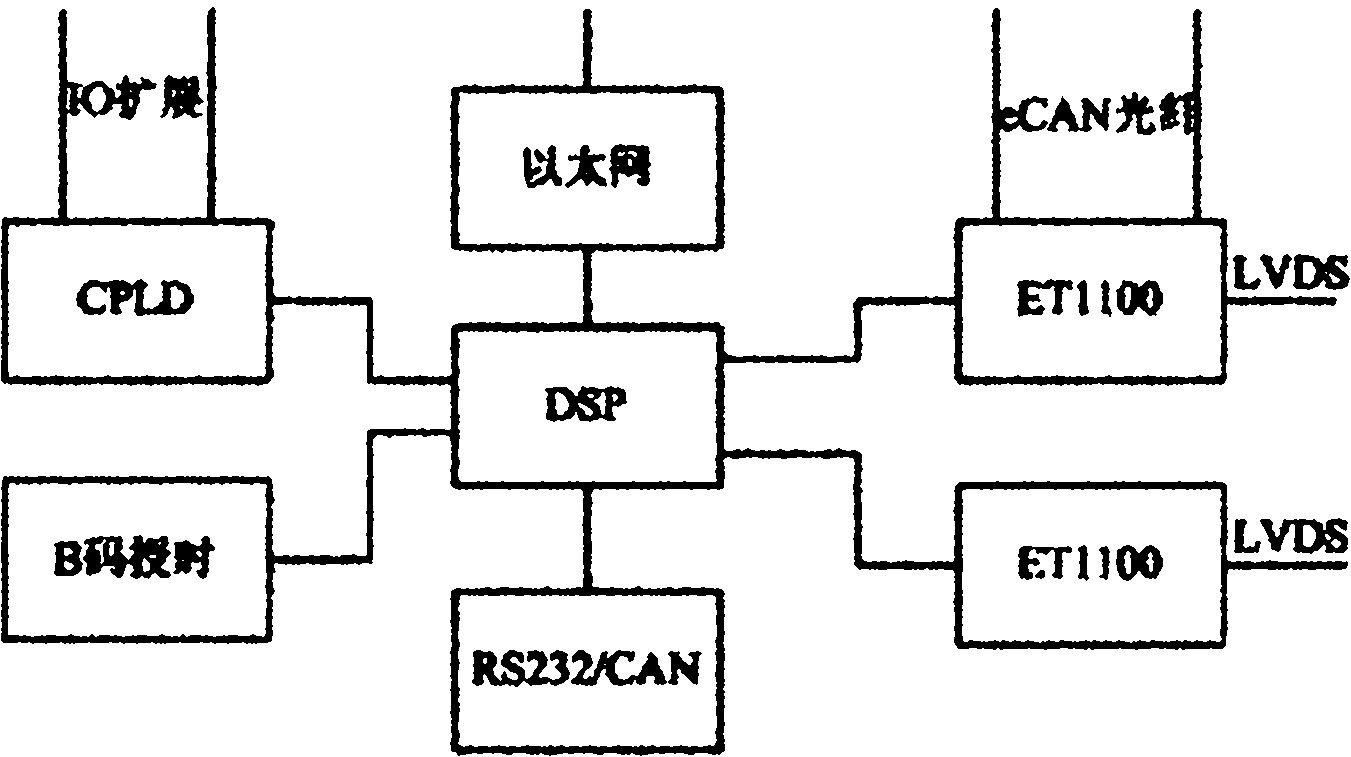

Realization method of precision synchronous clock

ActiveCN101867469AQuick switchDegraded Clock HOLDOVER FunctionTime-division multiplexSynchronising arrangementSoftwareFast switching

The invention discloses a realization method of a precision synchronous clock and aims at providing a transmission method of a precision synchronous clock in a measuring and automatic system based on an industrial Ethernet. The essential points of the technical scheme of the invention are that the realizing method comprises a frequency and deviation adjusting algorithm based on a fuzzy PID (Proportion Integration Differentiation), a quick internal clock synchronous algorithm, a real-time synchronous check method and a real-time clock frequency and time deviation adjusting algorithm. The invention has the following applications that the method can be used for realizing quick switch of the clock, can be applied to a high-reliability redundant clock source system and can finish the switch of the clock in ten seconds; the transmission precision of a single-stage clock can reach 50ns level; and since the algorithm can be used for realizing the quick switch of the clock, the algorithm is also applied to a high-reliability clock synchronous system under a redundant loop net and the clock HOLDOVER function on terminal equipment is degraded. The invention achieves the functions of software for receiving and transmitting a precision synchronous clock protocol message and adjusting and calibrating a system clock.

Owner:KYLAND TECH CO LTD

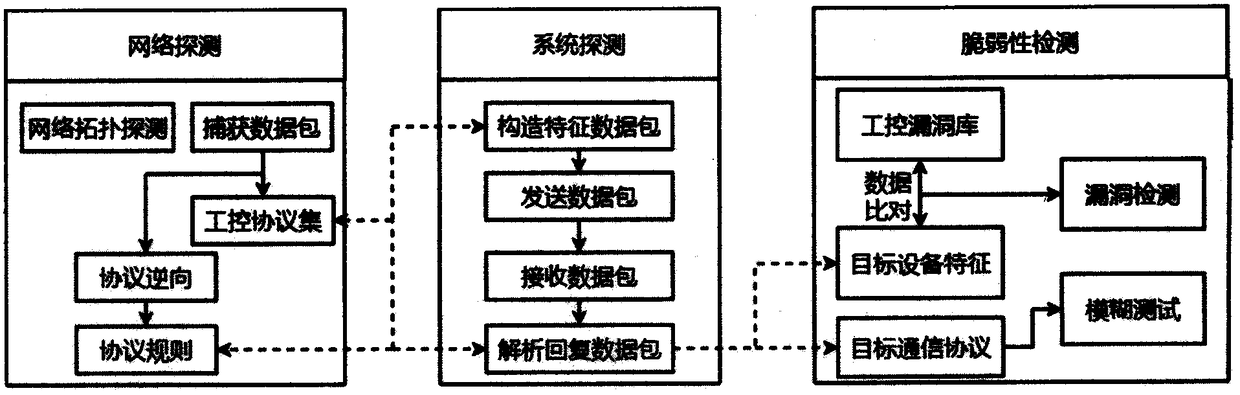

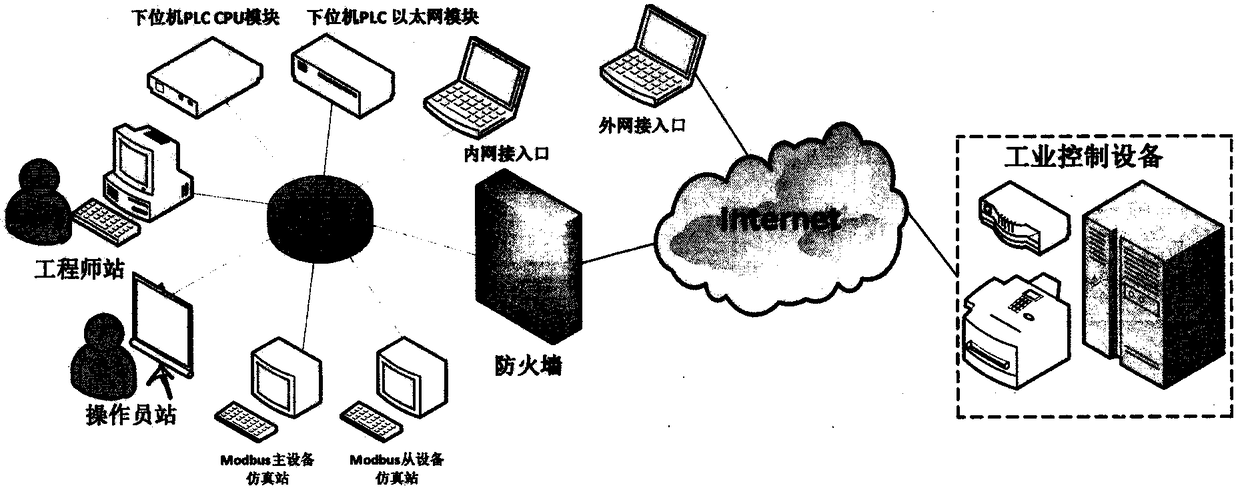

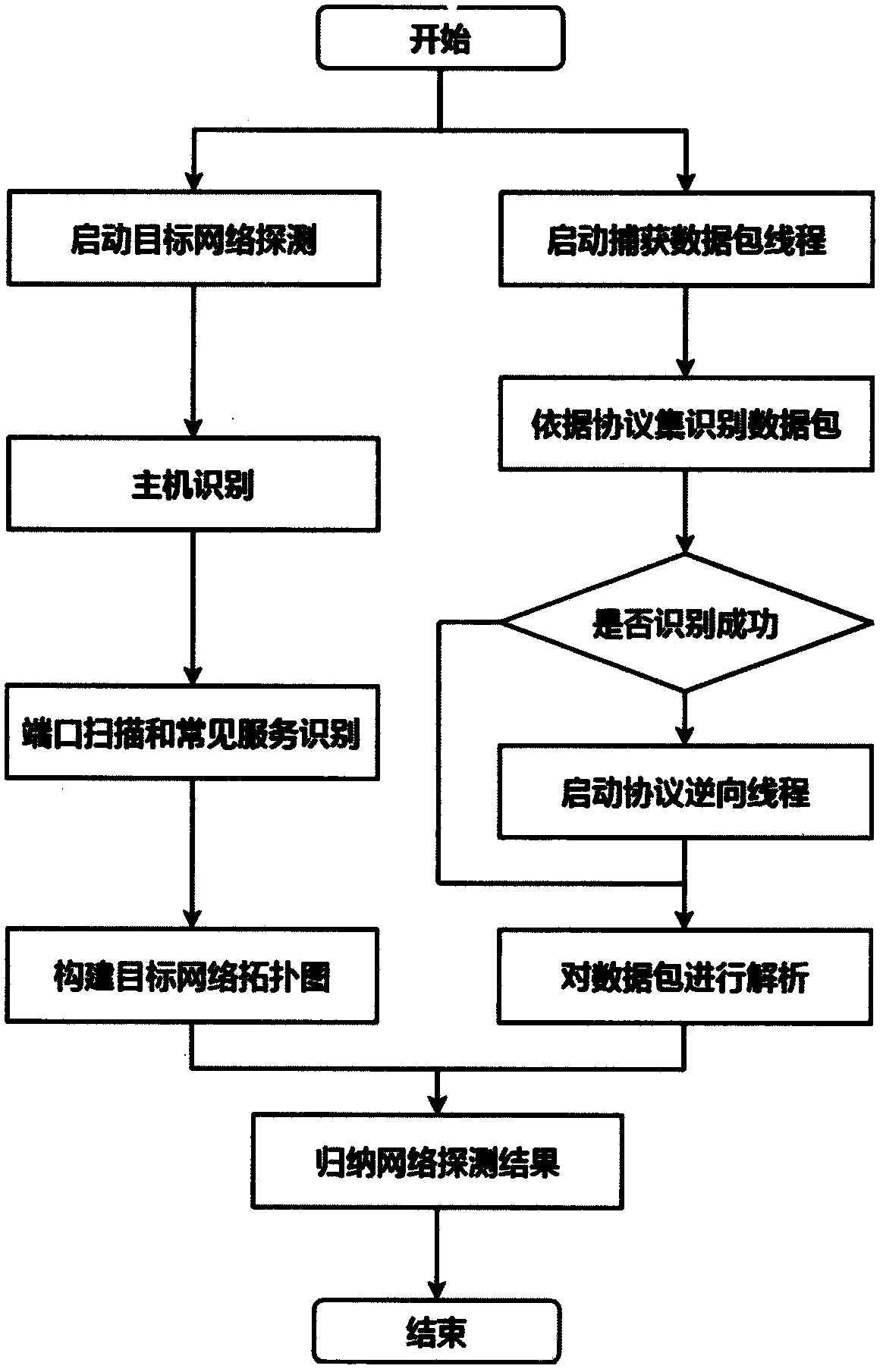

Vulnerability detection method for industrial control system

InactiveCN108737417AGain advantageImprove applicabilityTransmissionIndustrial EthernetNetwork packet

The invention provides a vulnerability detection method for an industrial control system. The method comprises the following steps: performing network detection on a target environment based on industrial Ethernet features, identifying an industrial control device, and capturing a session data packet; parsing the data packet according to the industrial control protocol specification and the private protocol reverse technology, and constructing a feature code data packet to perform further system detection to obtain specific fingerprint information; comparing the vulnerability information of amatching target based on the features of an industrial control dedicated vulnerability database, and performing related vulnerability detection based on strategy drive; and performing a fuzzy test based on the industrial control protocol vulnerability, and mining the security vulnerabilities of the industrial control system network, and detecting the security vulnerability. According to the vulnerability detection method provided by the invention, the vulnerability detection is performed on the industrial control target to detect the security vulnerabilities before the network attackers so asto improve the security and reliability of the industrial control system.

Owner:NANJING UNIV +3

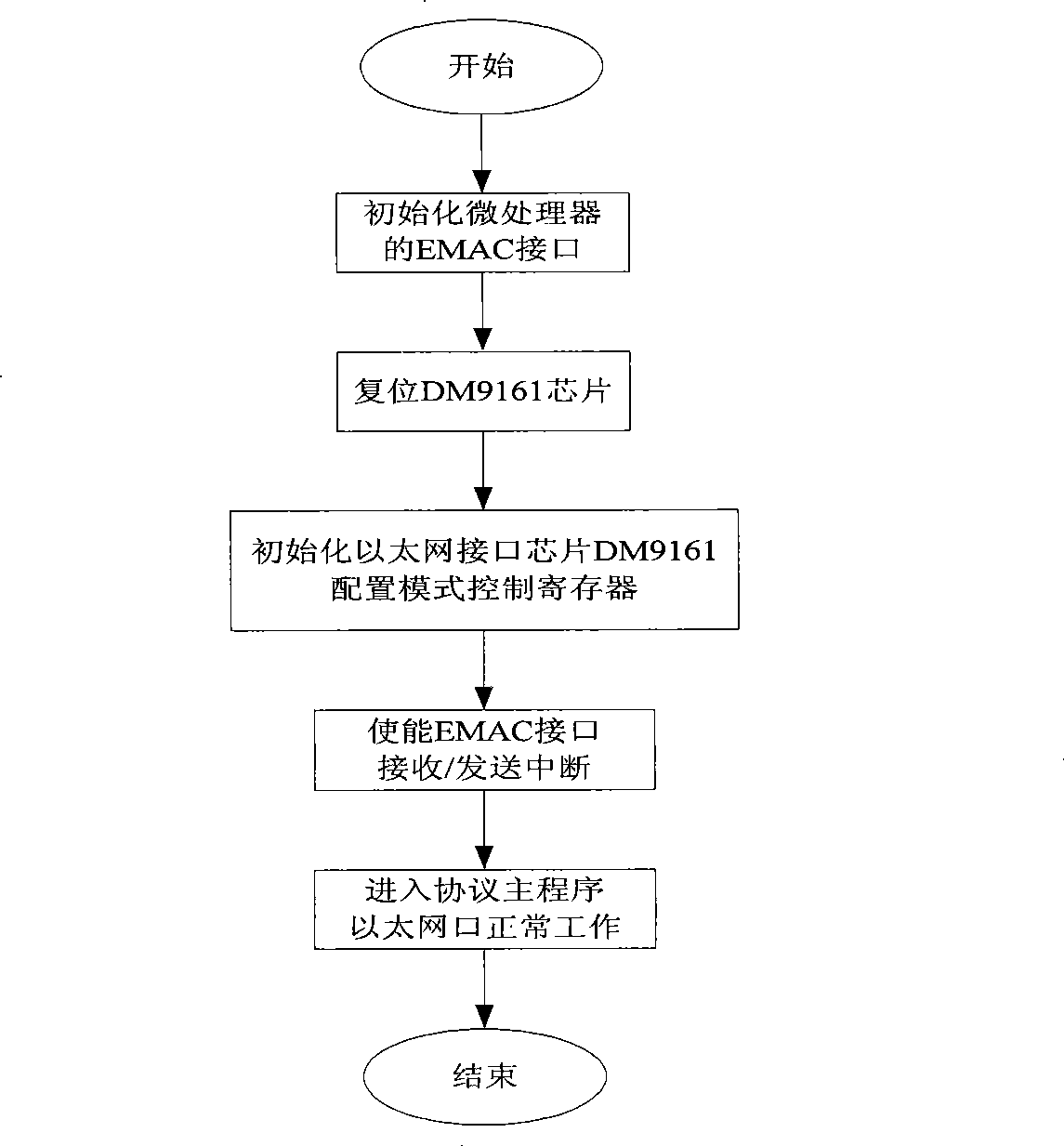

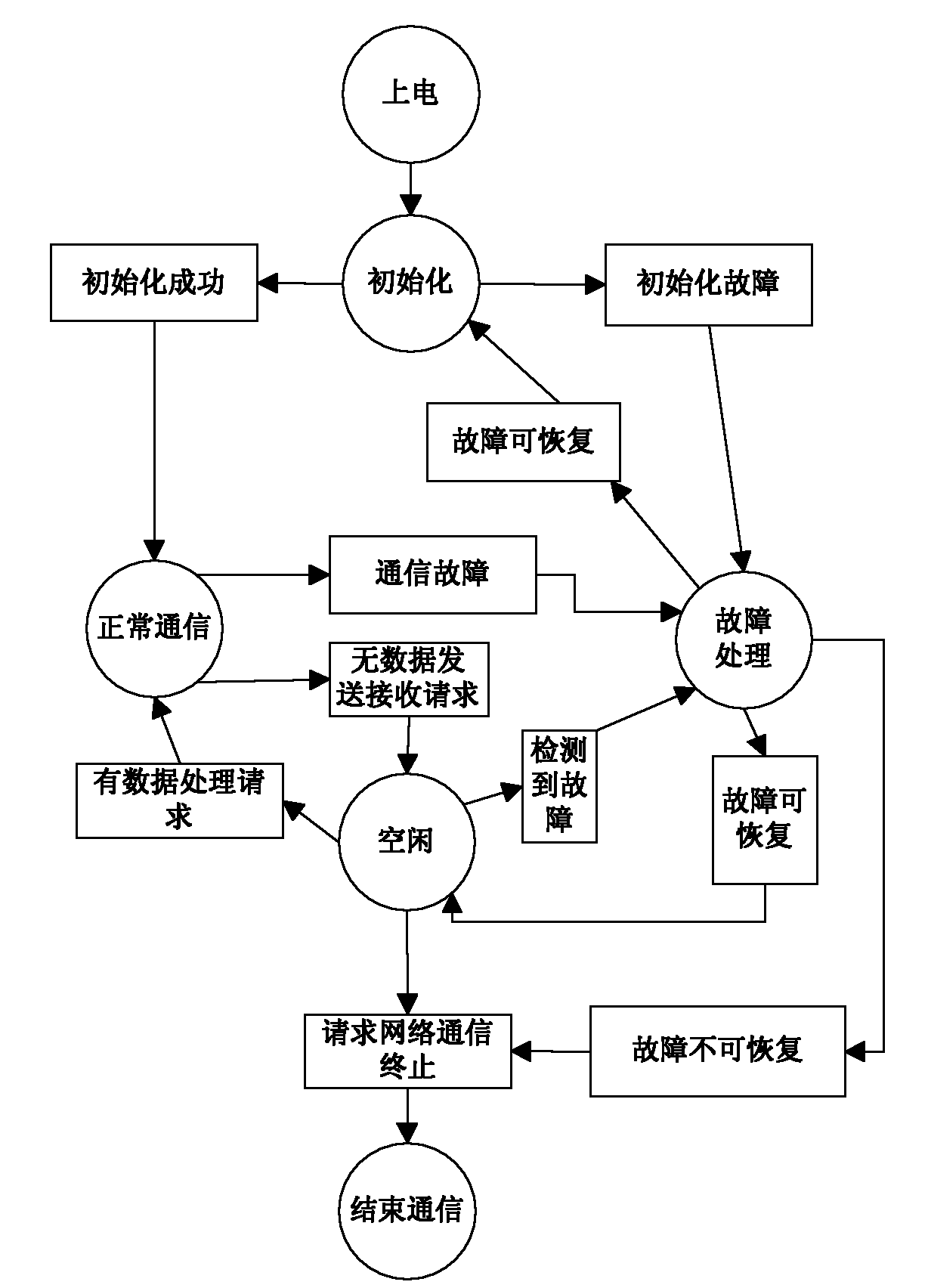

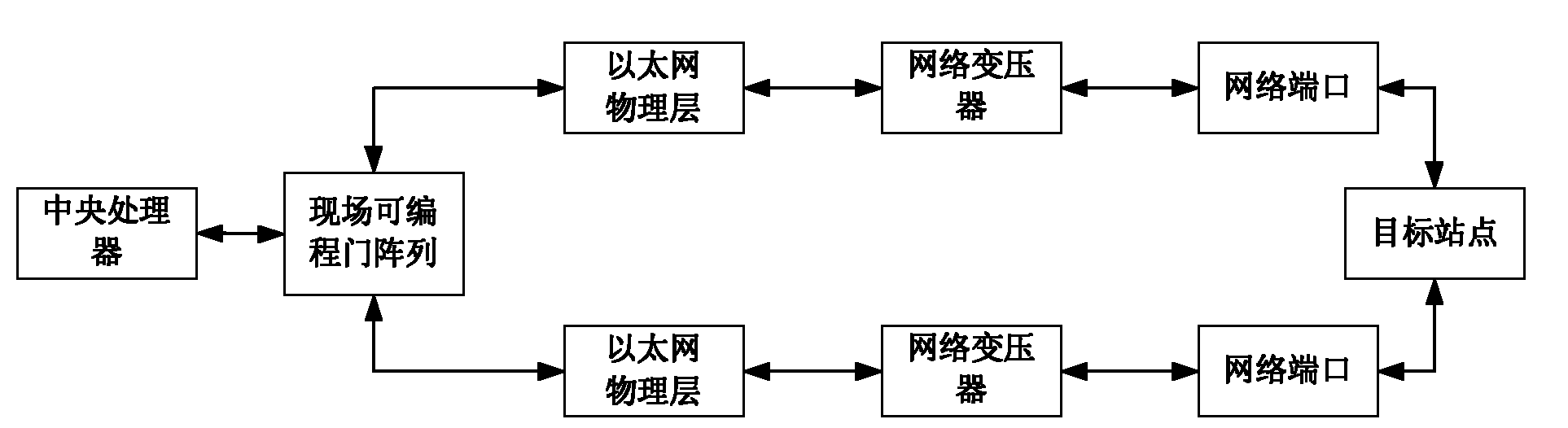

Implementation method of high-speed fieldbus based on industrial Ethernet

ActiveCN101950175AData transfer speed is fastImprove data transfer efficiencyTotal factory controlProgramme total factory controlComplete dataElectricity

The invention provides an implementation method of a high-speed fieldbus based on industrial Ethernet, which comprises the following steps: (1) electrifying a fieldbus system, and carrying out initialization setting; carrying out the step (3) if the initialization setting is successful, otherwise, carrying out fault treatment of the step (2); (2) carrying out the fault treatment; (3) carrying out data communication, and returning to the step (2) for carrying out the fault treatment if a fault emerges; entering into the idle state if the cycle further has remaining time after completing data transmission of all station points, waiting for the next data sending or receiving request, returning to the step (2) for carrying out the fault treatment if the fault emerges during the waiting process, otherwise, carrying out the step (4); and (4) finishing the communication. The invention further provides the high-speed fieldbus system based on the industrial Ethernet for implementing the method, that is a GSK-Link high-speed fieldbus system. Slave stations can mutually carry out the data communication, thereby greatly improving the data transmission speed and the efficiency.

Owner:GSK CNC EQUIP

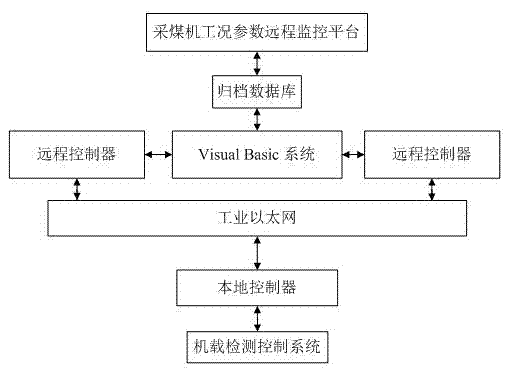

Work state virtual simulation system for electric haulage shearer based on different geological conditions

InactiveCN102759909AReal-time display of working statusIncrease authenticityTotal factory controlProgramme total factory controlVisual BasicAutomatic control

A work state virtual simulation system for an electric haulage shearer based on different geological conditions belongs to automatic control and system simulation of shearers. The work state virtual simulation system comprises devices and a method, wherein the devices consist of a shearer work condition remote monitoring platform, a database, a remote controller, a visual basic system, an industrial Ethernet, a local controller and a machine-mounted detection control system. The method comprises the following steps of: acquiring shearer work condition parameters for the machine-mounted detection control system; carrying out data analysis on the shearer work condition parameters; finally, transmitting the shearer work condition parameters to the shearer monitoring platform for detecting and achieving through the local controller and the industrial Ethernet; on the basis of accessing an achieving database in real time, drawing fully mechanized coal faces under different geological conditions by applying a virtual real technology; and driving a shearer virtual sample machine to realize real reappearance of the work state of the shearer. A shearer virtual sample machine model is driven by using real-time work condition parameters provided by the machine-mounted detection control system, so that a shearer virtual simulation system has the field feeling entering the fully mechanized coal faces and favorable interaction.

Owner:CHINA UNIV OF MINING & TECH

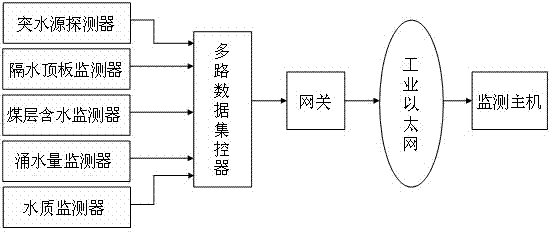

Method and system for monitoring water burst of mine in real time

InactiveCN102866434AAvoid disasterAvoid major disastersMining devicesWater resource assessmentIndustrial EthernetWater source

The invention relates to a method and a system for monitoring water burst of a mine in real time and belongs to methods and systems for monitoring water burst of mines. The system comprises a water burst source detector, a top water baffle plate monitor, a coal layer water content monitor, a water inflow monitor, a water quality monitor, a central multi-channel data controller, a gateway, an industrial Ethernet and a monitoring host, wherein the water burst source detector, the top water baffle plate monitor, the coal layer water content monitor, the water inflow monitor and the water quality monitor are connected with an input end of the central multi-channel data controller, and an output end of the central multi-channel data controller is in communication with the monitoring host via the gateway and the industrial Ethernet. The method includes that five kinds of monitoring signals from the water brust source detector, the top water baffle plate monitor, the coal layer water content monitor, the water inflow monitor and the water quality monitor are input to the monitoring host via the central multi-channel data controller, the gateway and the industrial Ethernet, the monitoring host analyzes the received signals, completely monitors danger source and forewarning information of water burst of the mine and early warns for real-time water burst monitoring of the mine.

Owner:CHINA UNIV OF MINING & TECH

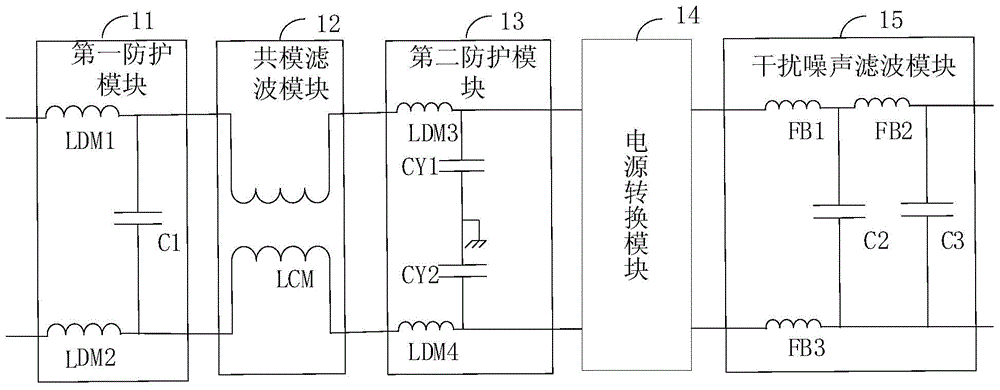

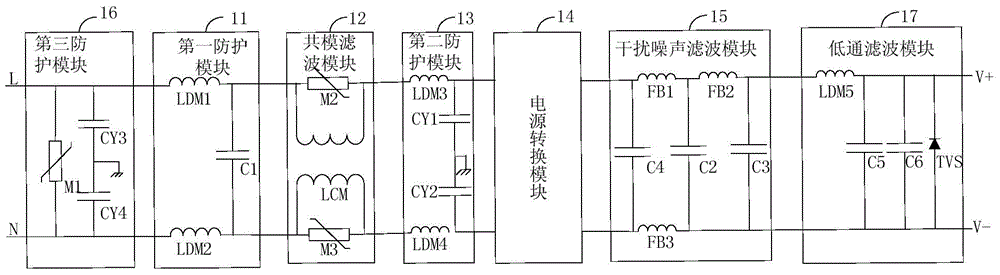

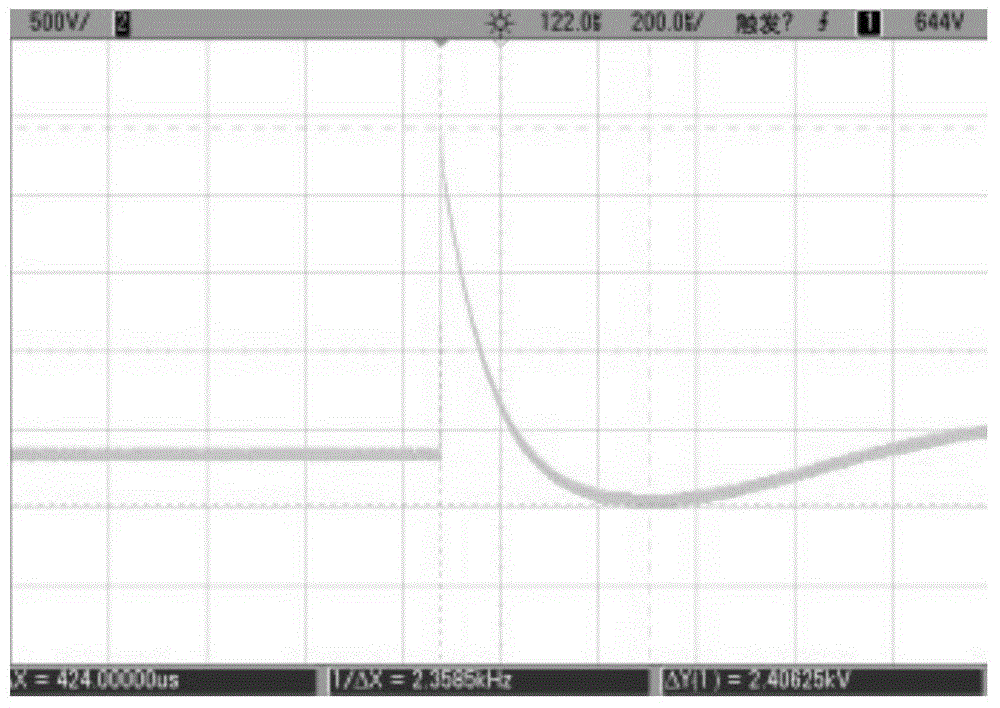

EMC protection and filtering device and method of high voltage power supply

ActiveCN105099165AIncrease damping factorReduce high frequency noisePower conversion systemsIndustrial EthernetPacket loss

The invention discloses an EMC protection and filtering device and method of a high voltage power supply, and solves the problem that Data packet loss of an industrial Ethernet switch is caused when existing equipment is subjected to EMC interference. The device includes a first protection module, a common-mode filter module, a second protection module, a power supply conversion module and an interference noise filter module; and a power input end is connected with the first protection module, the common-mode filter module, the second protection module, the power supply conversion module and the interference noise filter module in sequence. Elements in the first protection module and the second protection module equivalently form a double-T-shaped filter before and behind the common-mode filter module, thereby improving input damping of the common-mode filter module, elements in the interference noise filter module form a T-shaped filter and a pi-shaped filter, thereby reducing high frequency noise and peak interference of direct current output, realizing zero packet loss in data receiving and transmitting of equipment when high-level EMC interference exists in an alternating current power supply inlet of an industrial Ethernet switch, and effectively improving reliability of the equipment.

Owner:东土科技(宜昌)有限公司

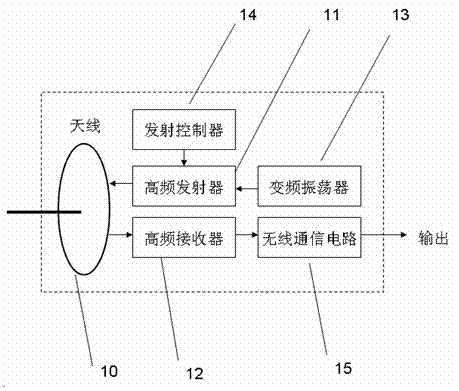

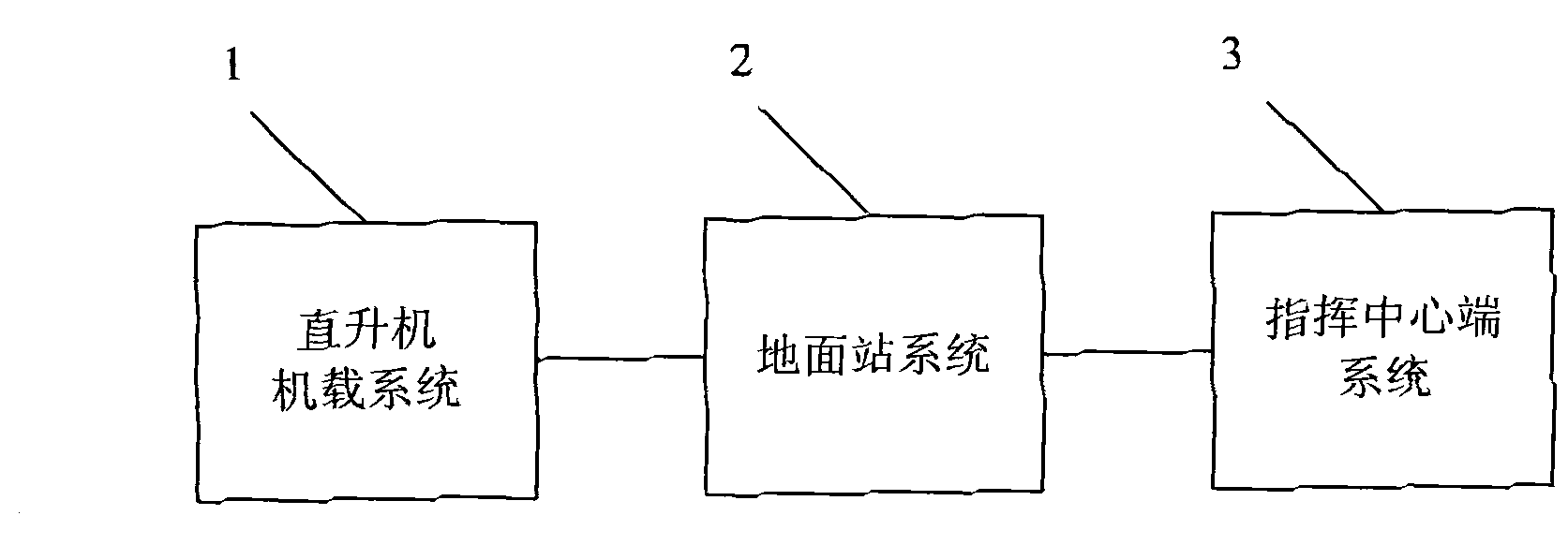

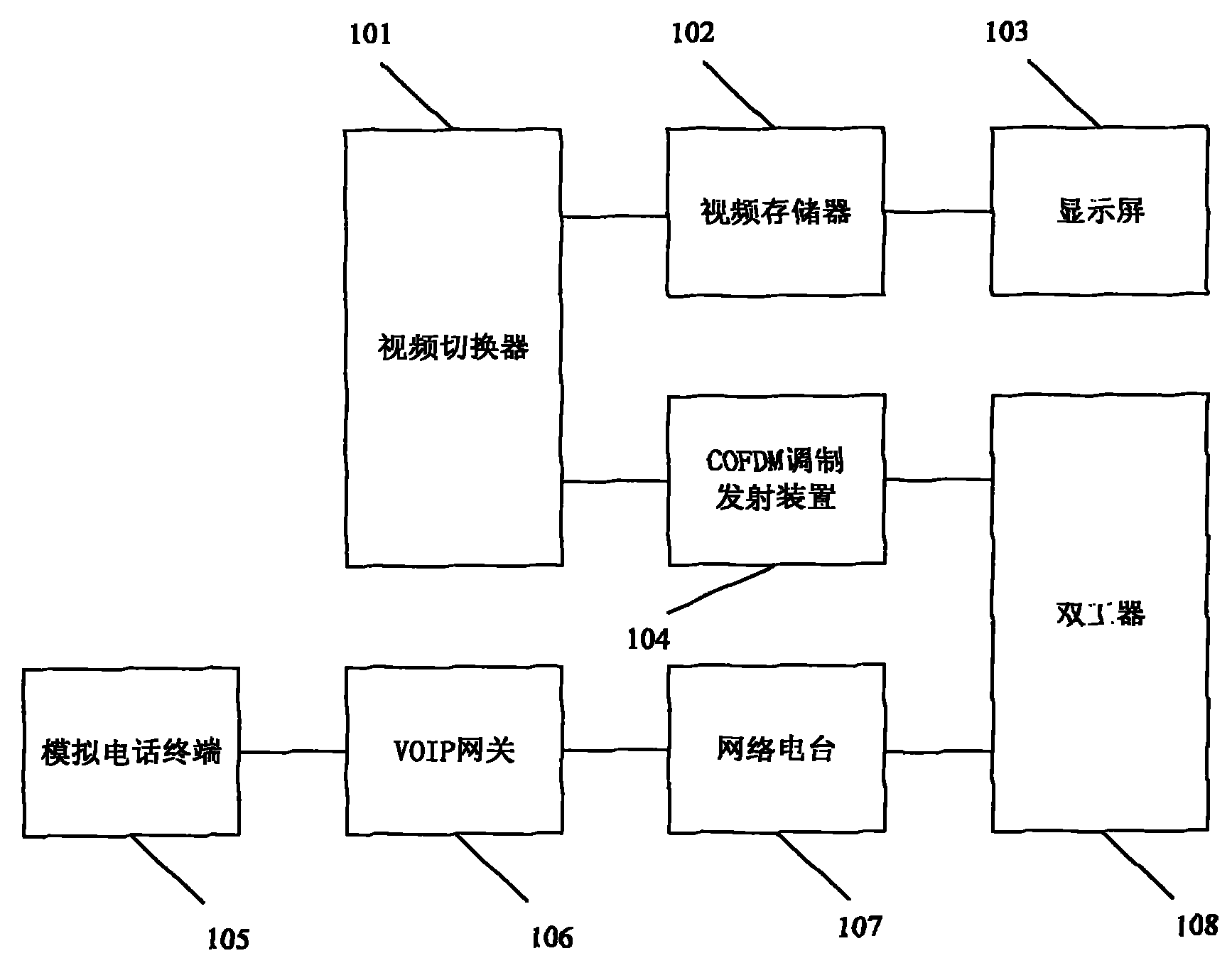

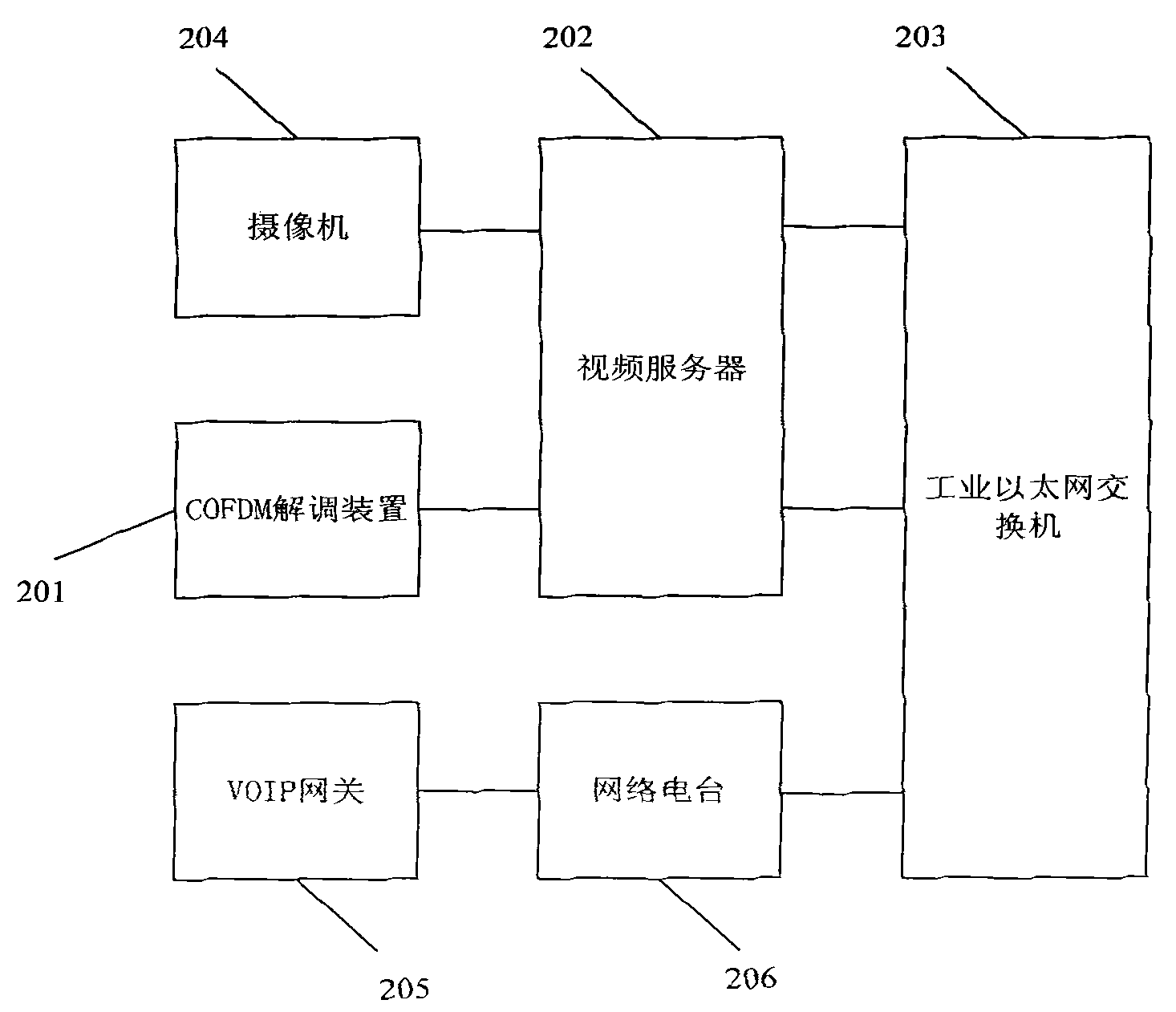

Wireless audio and video transmission system for transmission line helicopter routing inspection

InactiveCN101945188ALarge operating radiusSolve collectionInterconnection arrangementsData switching by path configurationVideo monitoringVideo transmission

The invention discloses a wireless audio and video transmission system for transmission line helicopter routing inspection. The system comprises a helicopter airborne system, a ground station system and a command center end system, wherein the helicopter airborne system is connected with the ground station system in a wireless communication way; the ground station system is connected with the command center end system in an industrial Ethernet way; the helicopter airborne system further comprises a front end video acquisition and storage system, a video transmission system and a voice intercom system; the ground station system further comprises an audio and video receiving system, a local video monitoring system, a VOIP telephone system and an optical fiber transmission system; and the command center end system further comprises a video playing system, a picture recording system and a VOIP telephone system. Due to the adoption of the technical scheme, the system not only can change and improve the conventional line walking mode and work efficiency, but also can achieve real-time multi-channel video transmission, storage and voice intercom.

Owner:北京有恒斯康通信技术有限公司

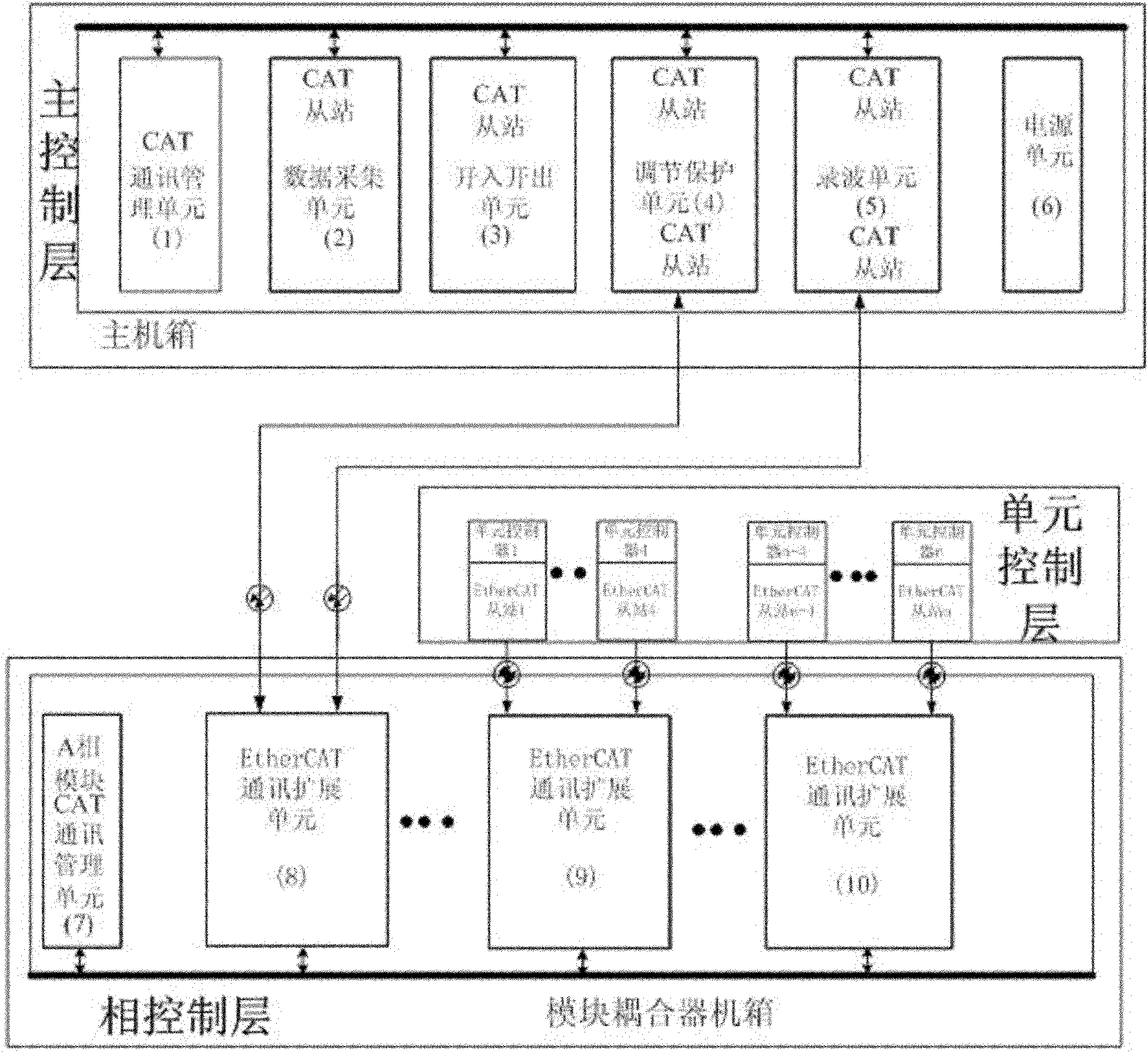

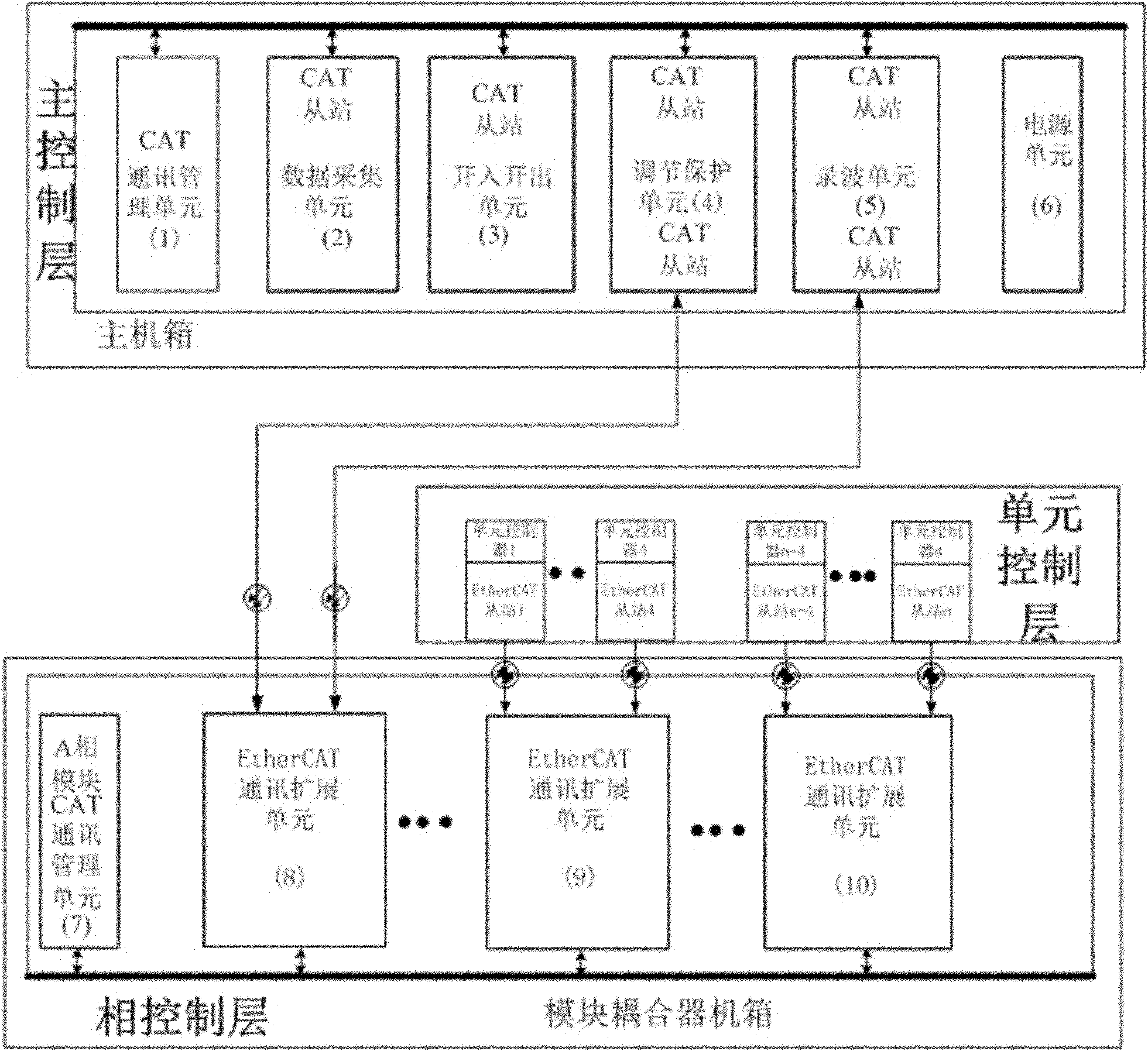

Chain type STATCOM control system based on EtherCA technology

ActiveCN102096407AData transfer speed is fastGuaranteed reliabilityFlexible AC transmissionReactive power adjustment/elimination/compensationIndustrial EthernetControl layer

The invention provides a chain type STATCOM (Static Synchronous Compensator) control system based on EtherCA technology, wherein the chain type STATCOM control system uses real-time industrial Ethernet EtherCA as a channel of data transferring, and the control system uses a layered distribution topology structure. The layered distribution topology structure of the STATCOM control system comprises a main control layer, a phase control layer and a unit control layer. The main control layer comprises a main control case and the like functional cases, the phase control layer is composed of a phase coupler case, and the unit control unit is composed of a unit controller. The communication between the main case and the phase coupler case is carried out by means of firewire connected EtherCA. The chain type STATCOM control system based on EtherCA technology provided by the invention has the advantages that the data transferring speed is high, the number of the cable is less, the exchange speed is fast, the expansion is convenient, the accurate synchronism and the diagnosis ability are strong and the configuration is flexible.

Owner:CHINA EPRI SCIENCE & TECHNOLOGY CO LTD +2

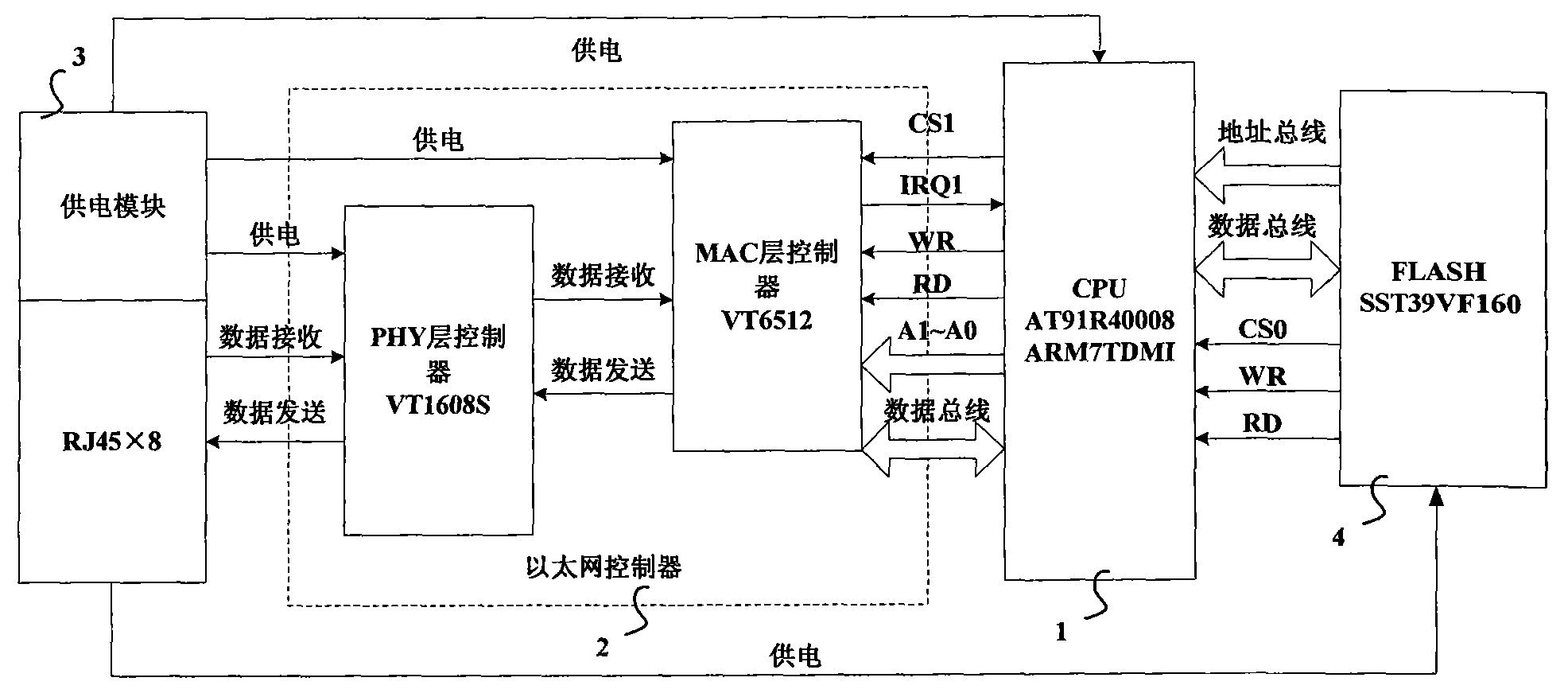

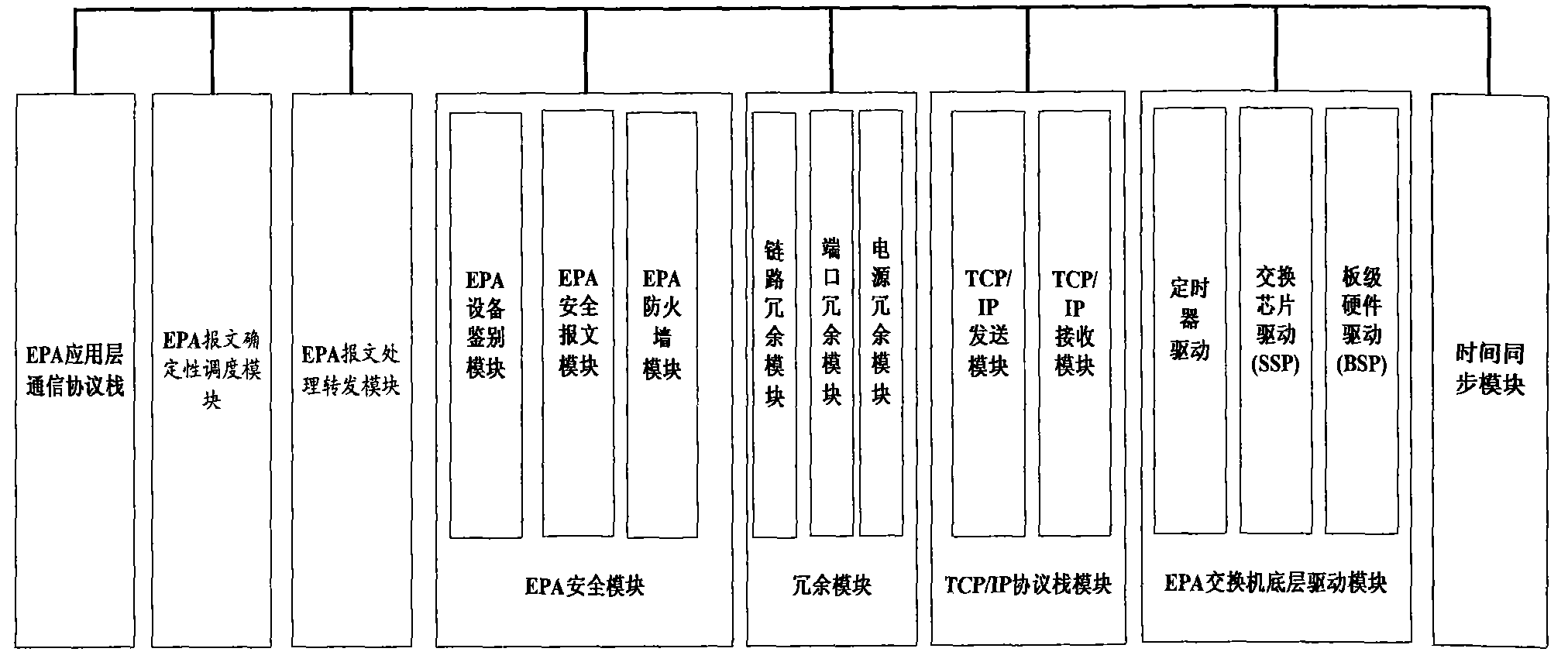

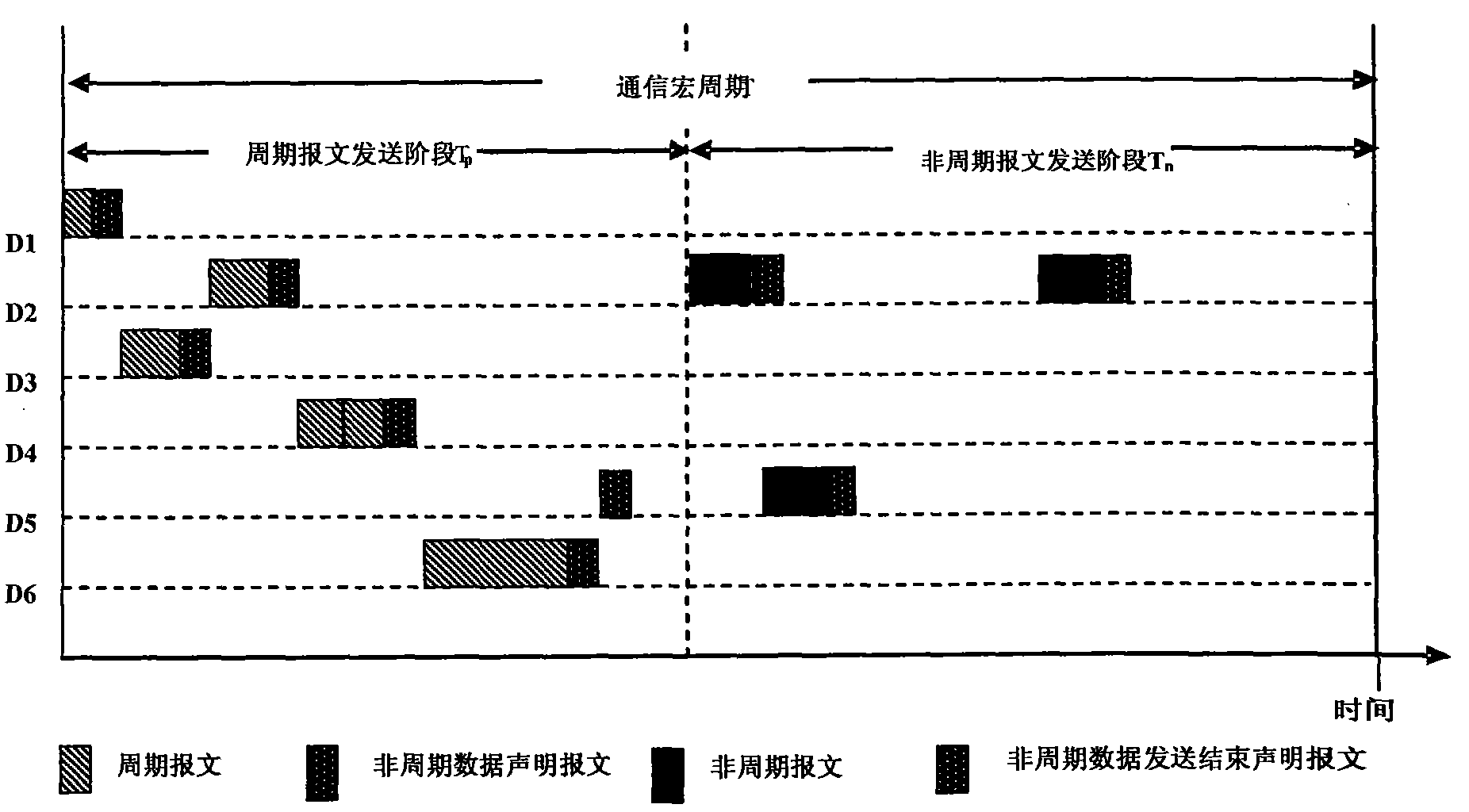

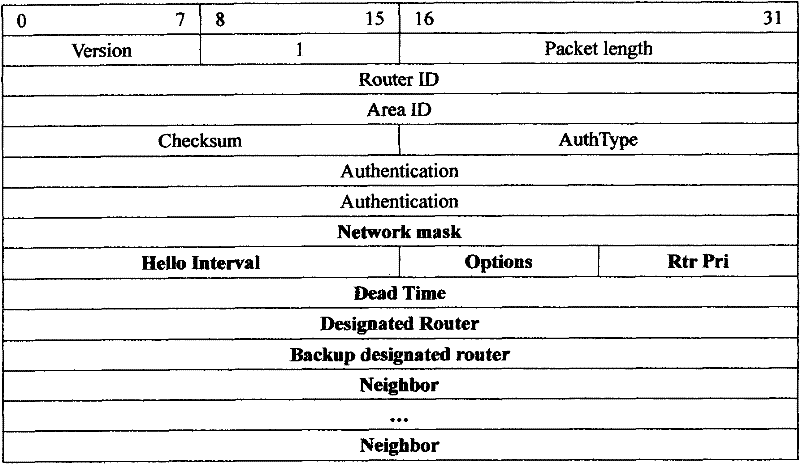

Industrial Ethernet exchanger and message forwarding method based on EPA protocol

ActiveCN101631080AEnsure safetyGuaranteed real-timeData switching networksSynchronising arrangementIndustrial EthernetMessage processing

The invention provides an industrial Ethernet exchanger based on an EPA protocol, comprising an EPA message processing and forwarding module and an EPA message deterministic scheduling module, wherein the EPA message processing and forwarding module directly forwards the EPA network data messages of communication between EPA site equipment in the same subfield; the EPA message deterministic scheduling module divides the EPA network data messages of the communication between the EPA site equipment in different subfields into periodic EPA network data messages and nonperiodic EPA network data messages; and in one macro period, the periodic EPA network data messages and the nonperiodic EPA network data messages are respectively scheduled and forwarded, wherein the periodic EPA network data messages are transmitted in a fixed time slice, and the nonperiodic EPA network data messages are sequentially transmitted according to the priority in a nonperiodic time section. The invention also provides a message forwarding method of an industrial Ethernet based on an EPA protocol.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

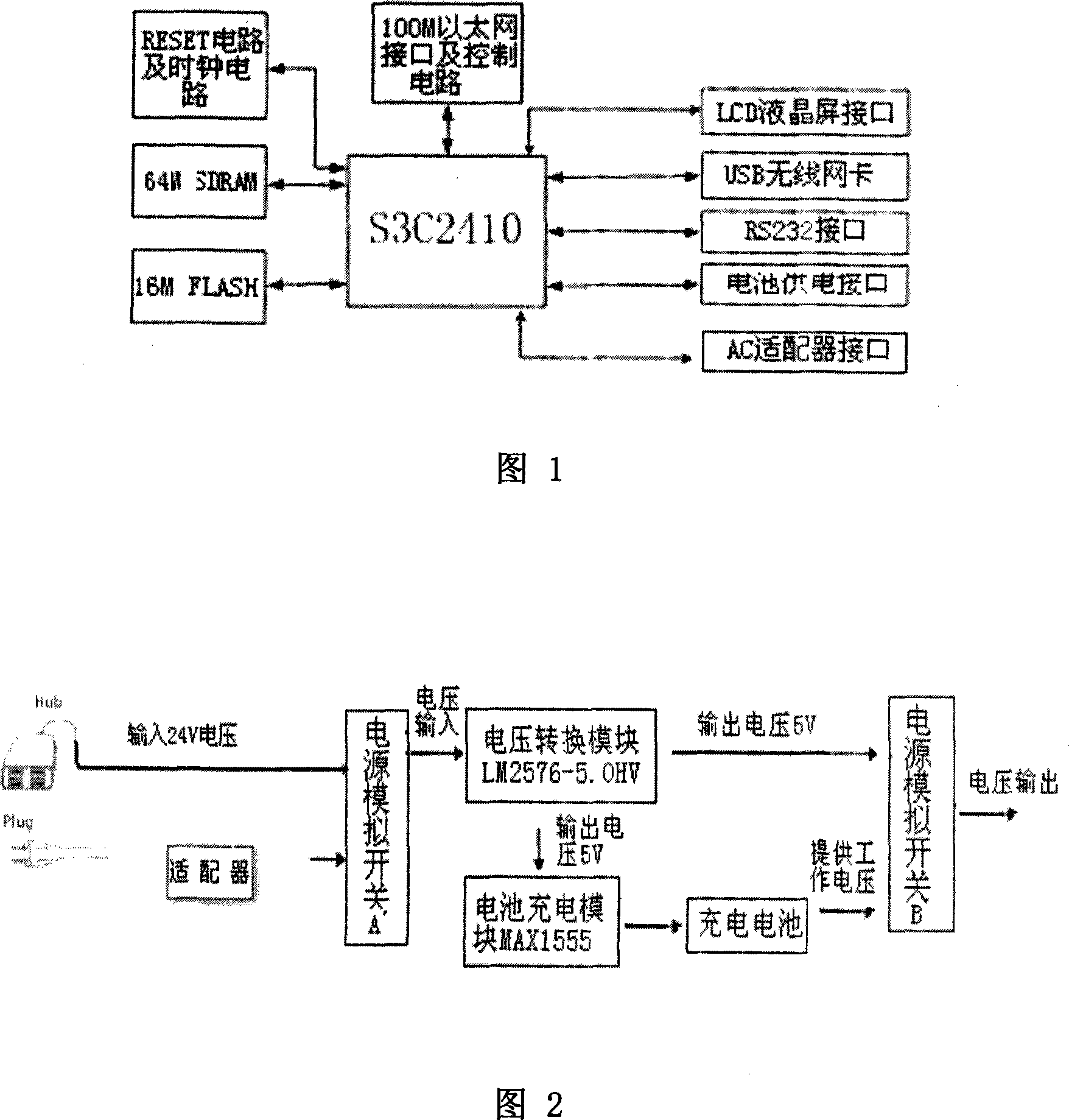

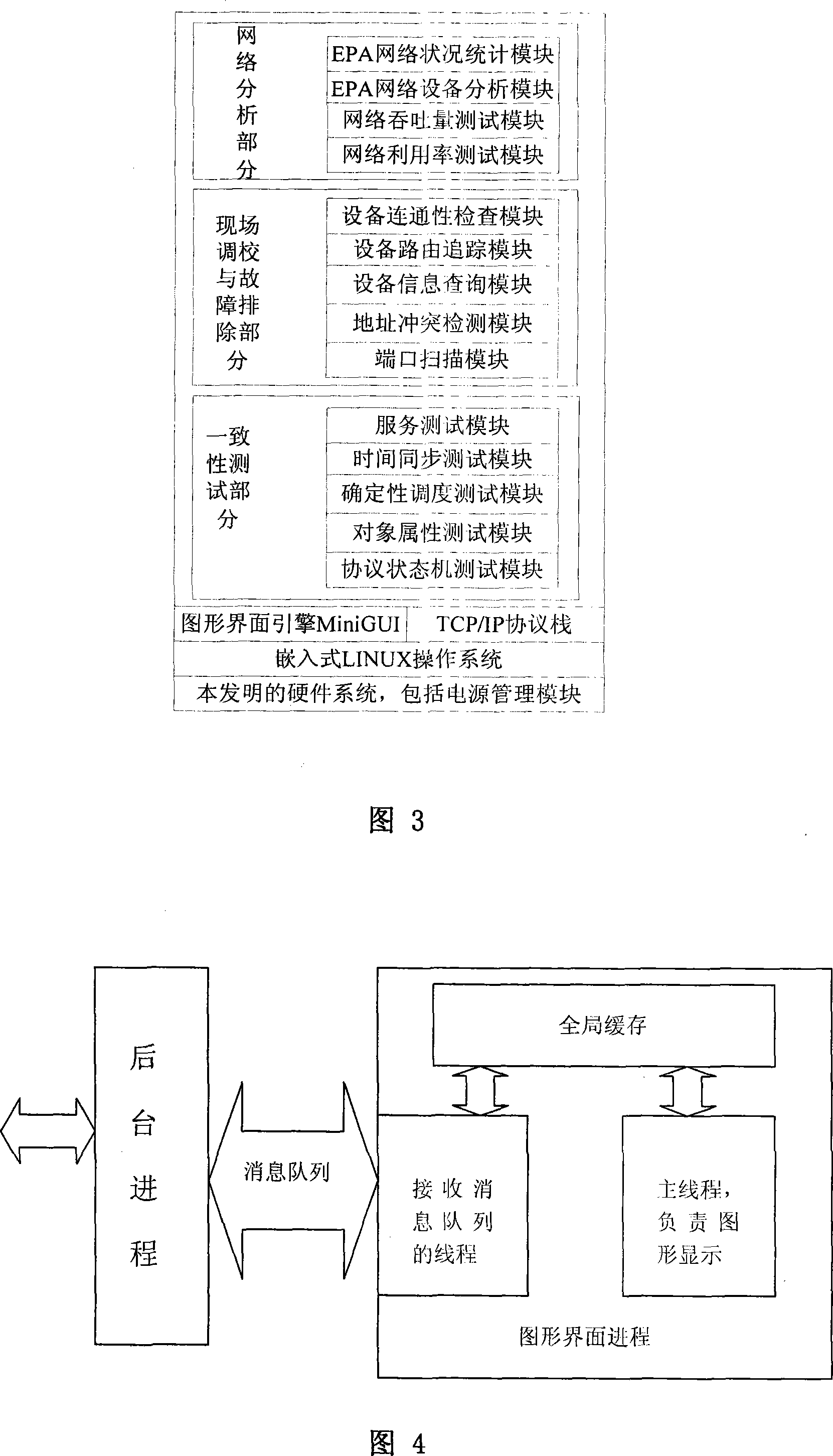

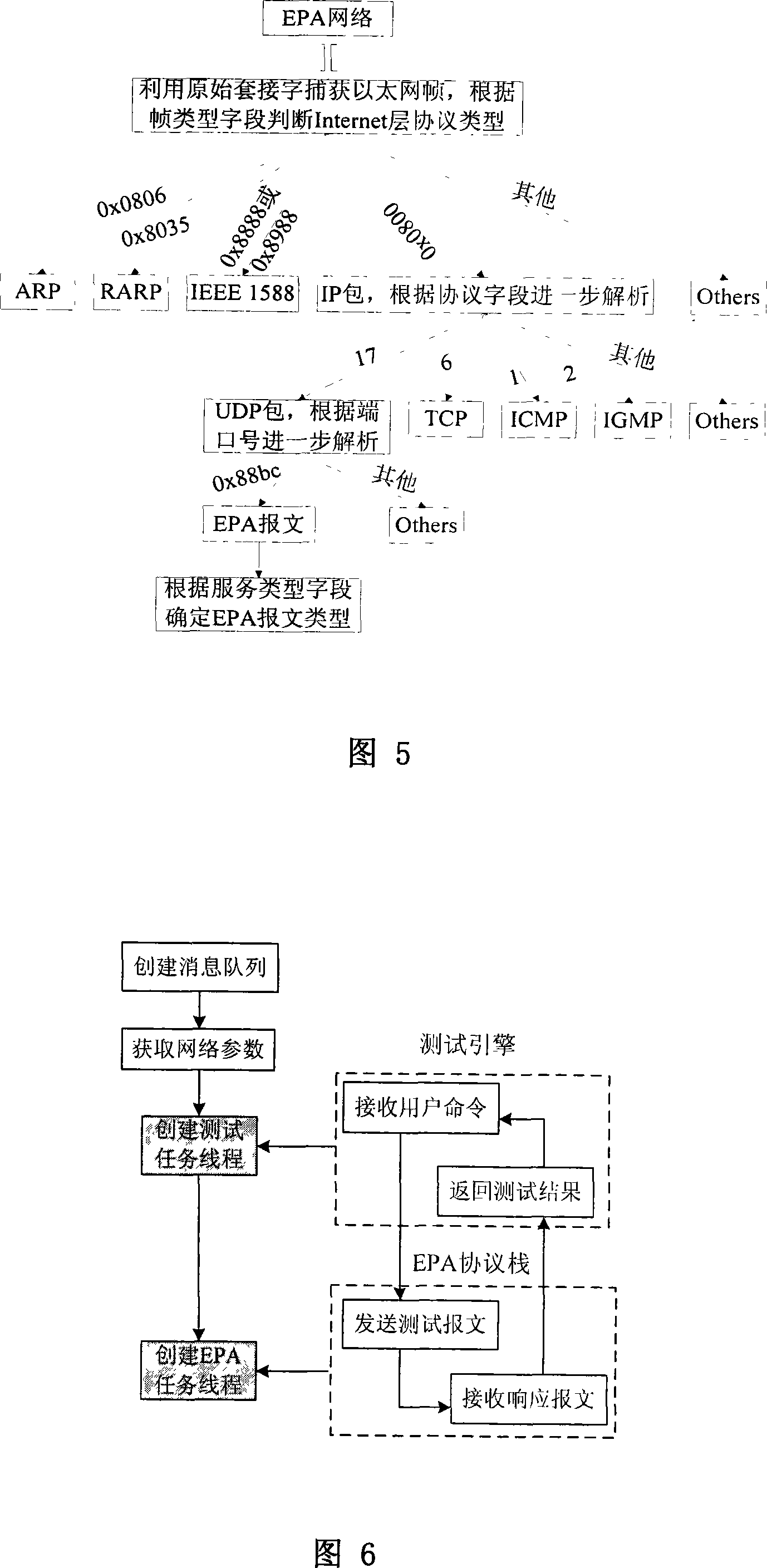

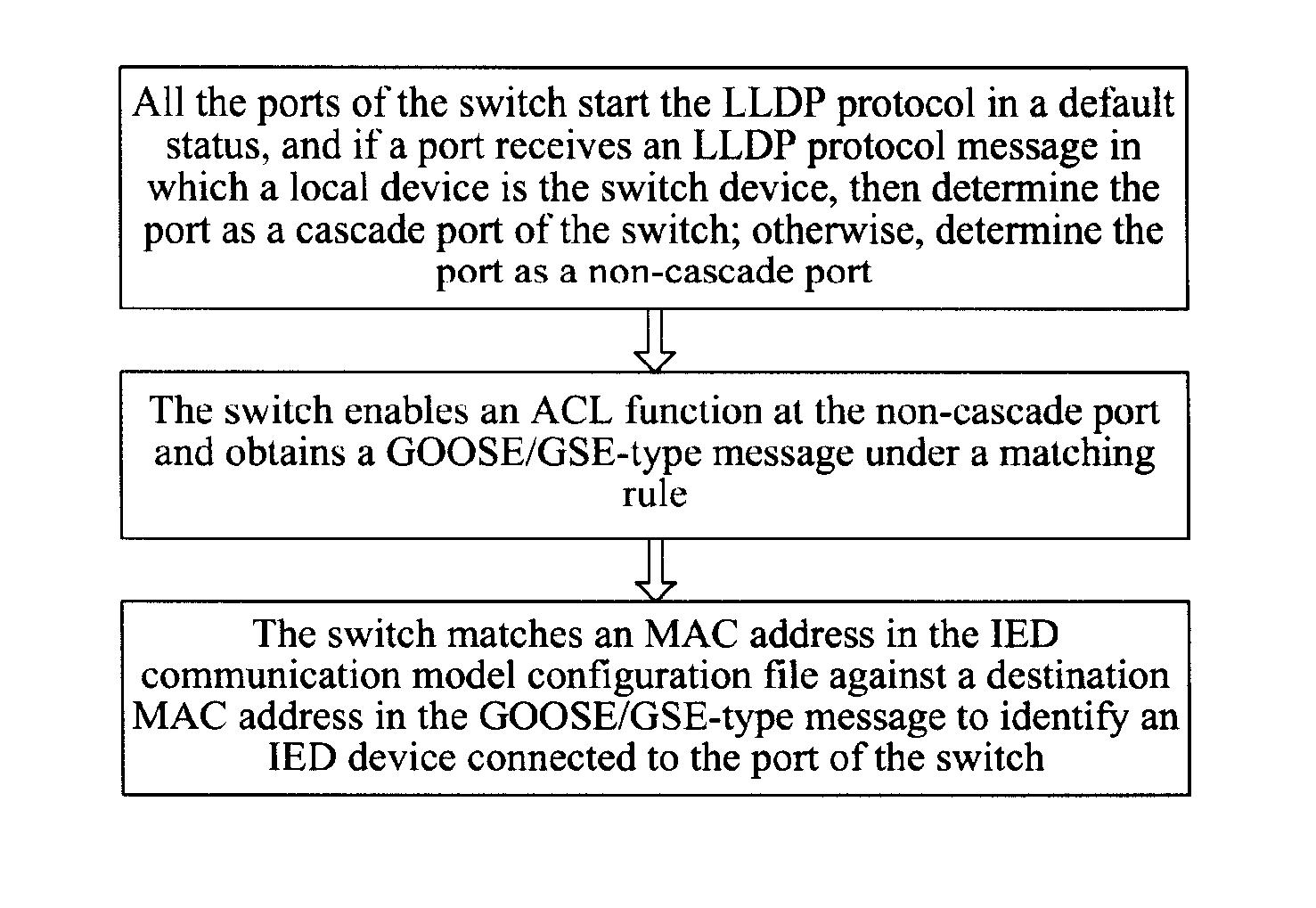

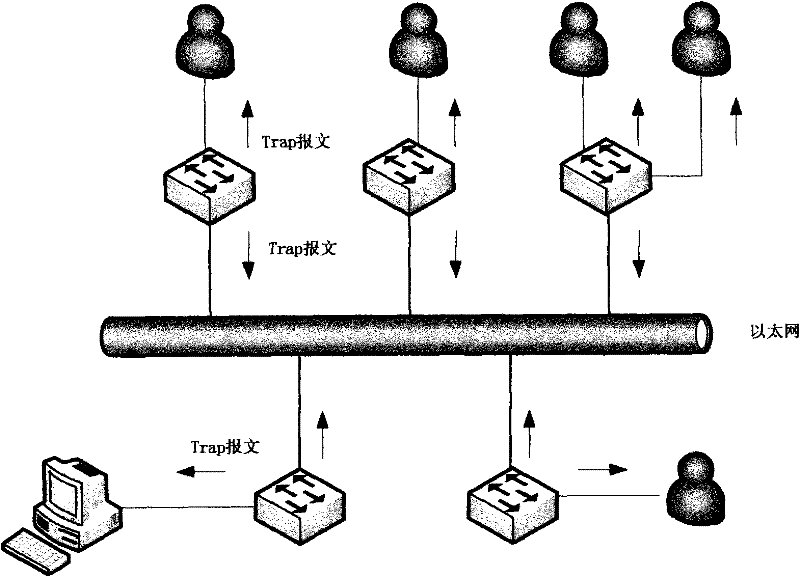

Industrial Ethernet protocol analysisand field tester

InactiveCN101072147AImprove continuous working abilityData switching by path configurationIndustrial EthernetManagement information base

Aiming at disadvantages of current on site testing instrument for industrial control network, the invention designs portable instrument of analyzing and on site testing industrial Ethernet protocol (IEP). The designed instrument possesses features: monitoring state of EPA network in real time; carrying out performance analysis based on message of equipment declaration on network; detecting whether network connection and equipment are connected to network correctly; determining route of target equipment (TE), querying information of TE, detecting port state of TE; testing whether the tested object realizes service declared by the object according to EPA standard; testing time Synch precision between tested equipment and main clock; based on EPA standard to carry out deterministic scheduling analysis for message captured from network; carrying out attribute test for objects in management information database etc. The invention can widely be applicable to analyze and on site testing IEP.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

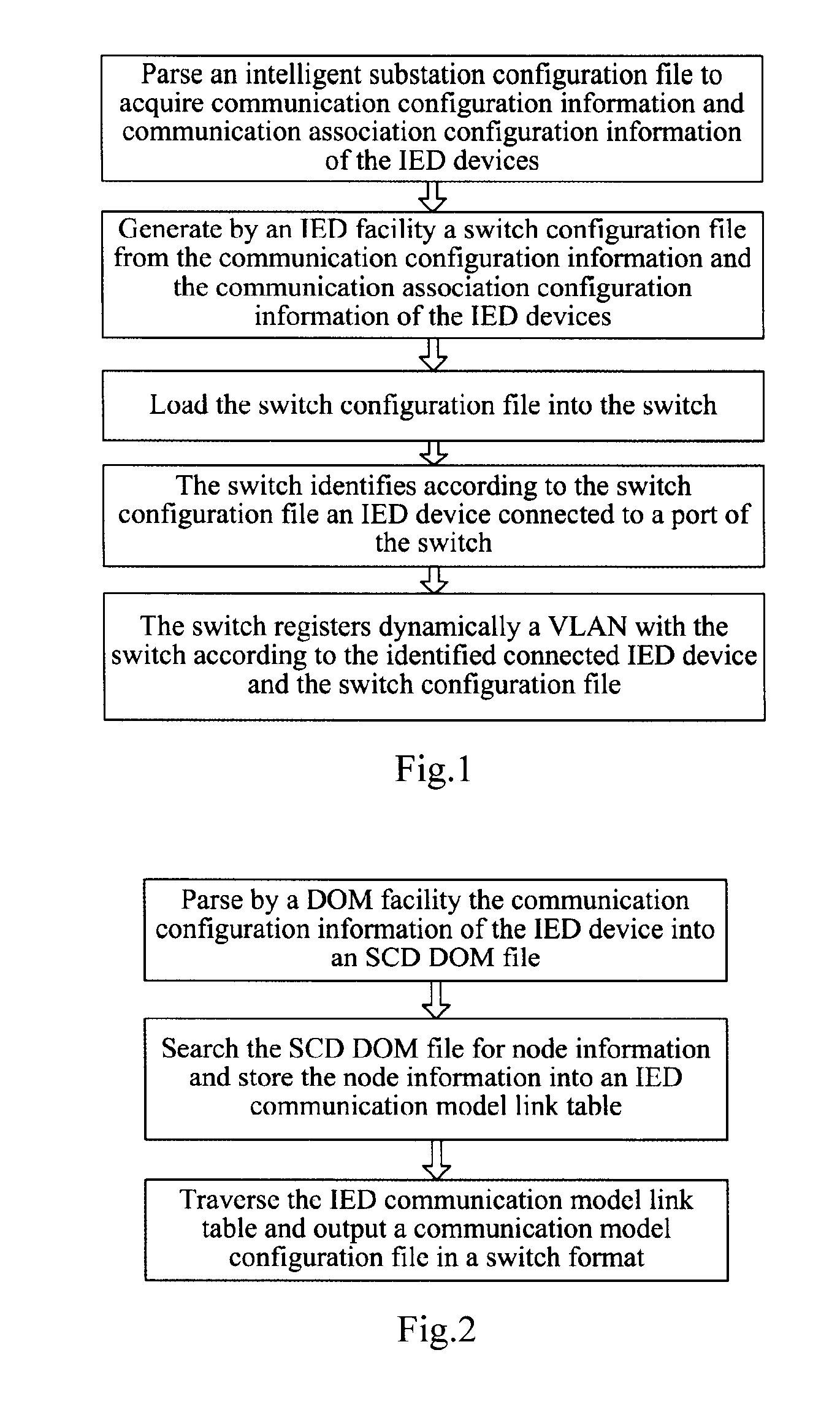

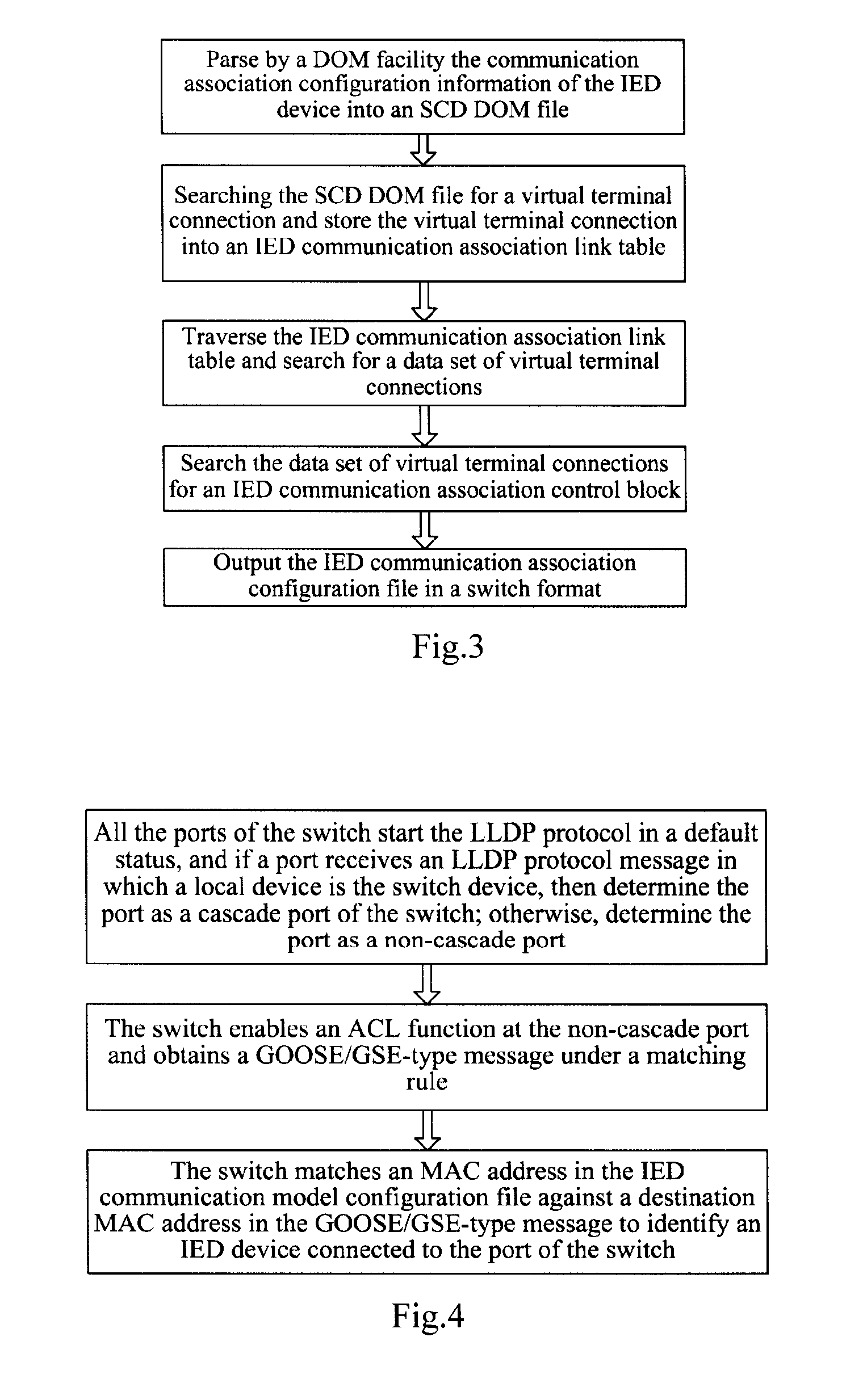

Configuration information auto-management method based on intelligent substation

ActiveUS20150341207A1Easy maintenanceOperation configuration informationDigital computer detailsData switching networksIndustrial EthernetSmart substation

The invention discloses a method of automatic management on configuration information based upon an intelligent substation, the intelligent substation applying the IEC-61850 standard including IED devices and a switch, wherein the method includes the following steps: parsing an intelligent substation configuration file to acquire communication configuration information and communication association configuration information of the IED devices; and generating a switch configuration file from the communication configuration information and the communication association configuration information of the IED devices. The invention can parse the intelligent substation configuration file, generate the switch configuration file and perform automatic configuration of the industrial Ethernet switch in the intelligent substation using the switch configuration

Owner:KYLAND TECH CO LTD

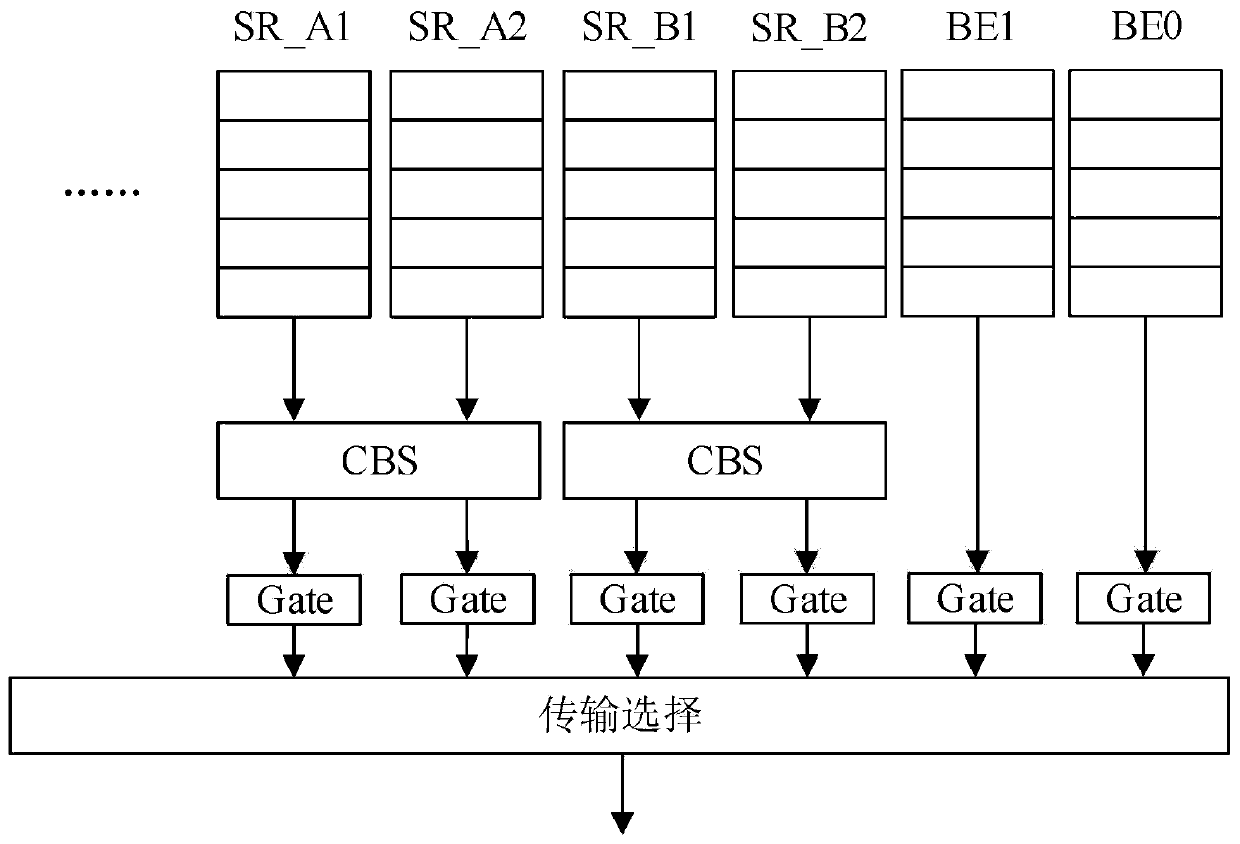

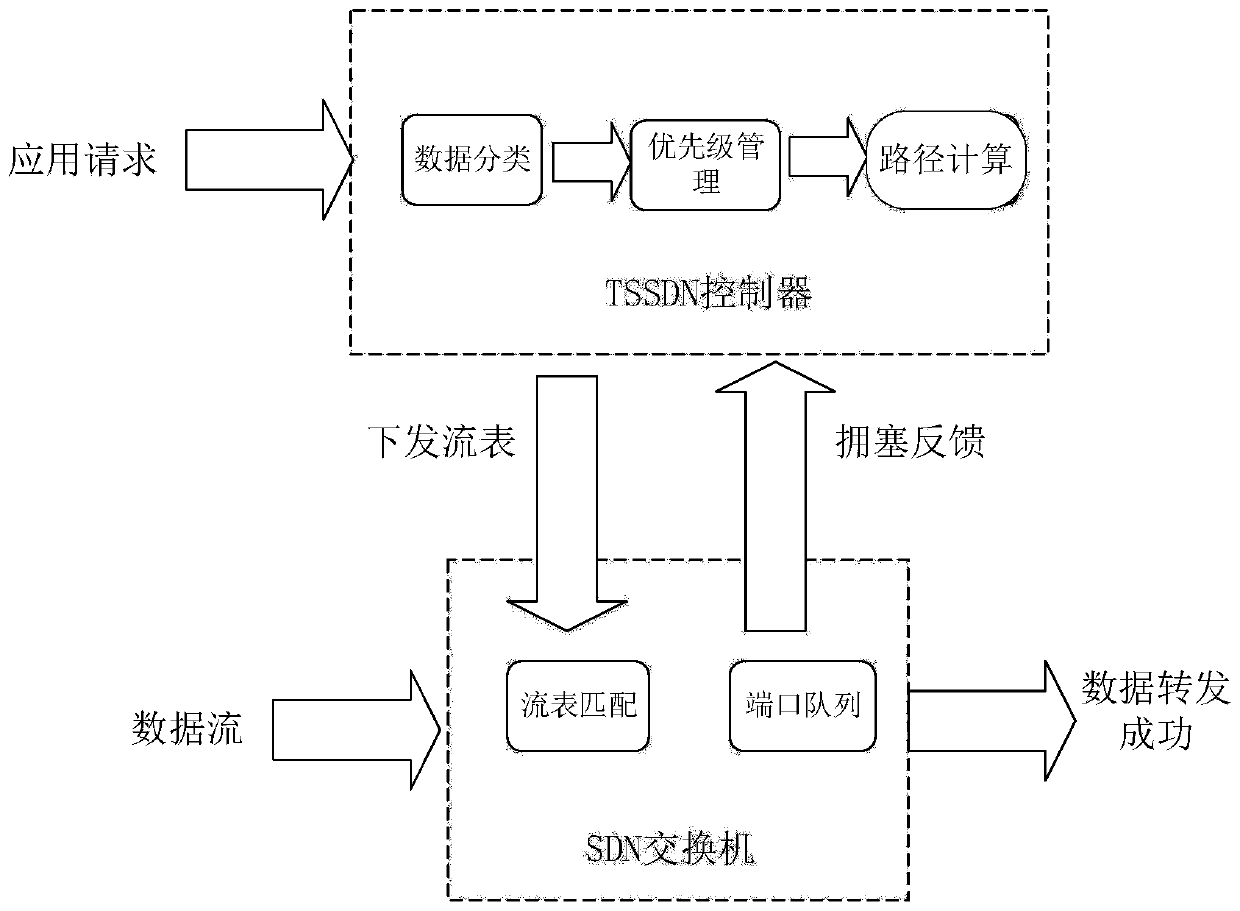

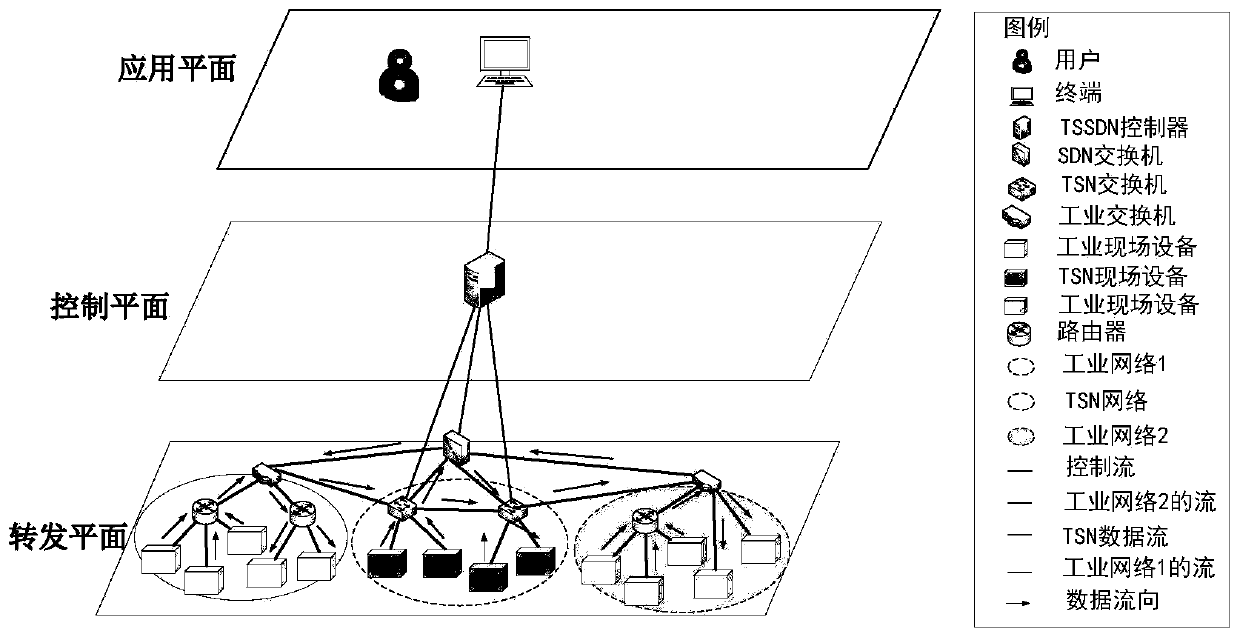

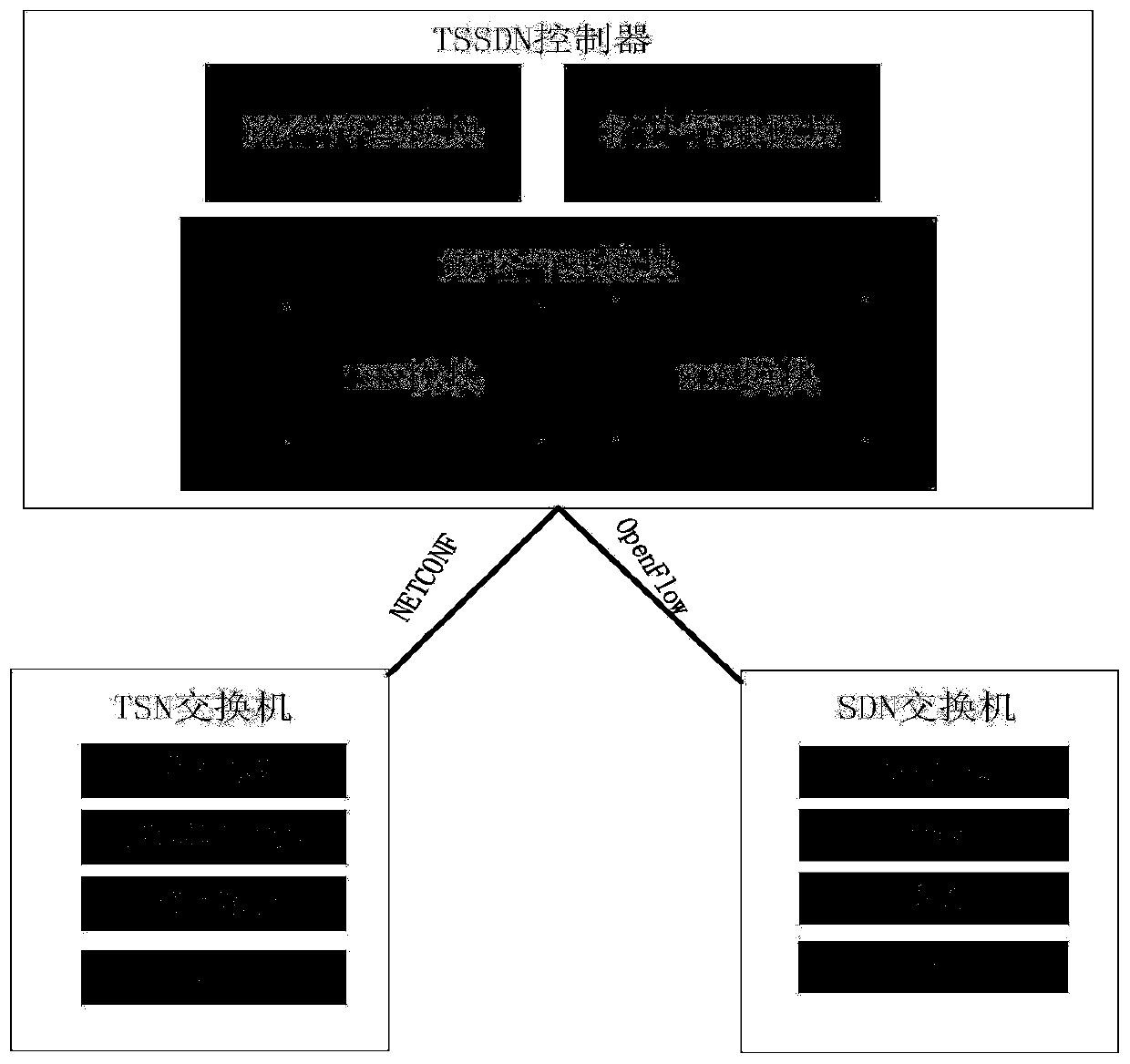

Industrial heterogeneous network scheduling method oriented to TSN and non-TSN interconnection

The invention relates to a TSN and non-TSN interconnection oriented industrial heterogeneous network scheduling method, which belongs to the field of industrial Ethernet and comprises the following steps that: in a network deployment stage, a user performs configuration management on a TSSDN controller according to application requirements through a terminal application program; the TSSDN controller performs data classification according to a delay demand; the TSSDN controller carries out scheduling priority management on the data; the TSSDN controller calculates the shortest path and schedules the priorities; the SDN switch performs flow table matching,and judges the congestion condition of the queue; and the feedback adjustment to queue congestion is carried out. According to the method,high-efficiency and high-quality scheduling is carried out in the industrial heterogeneous network with the TSN and the non-TSN interconnected, and low-delay and deterministic transmission of different types of data in the network is guaranteed.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

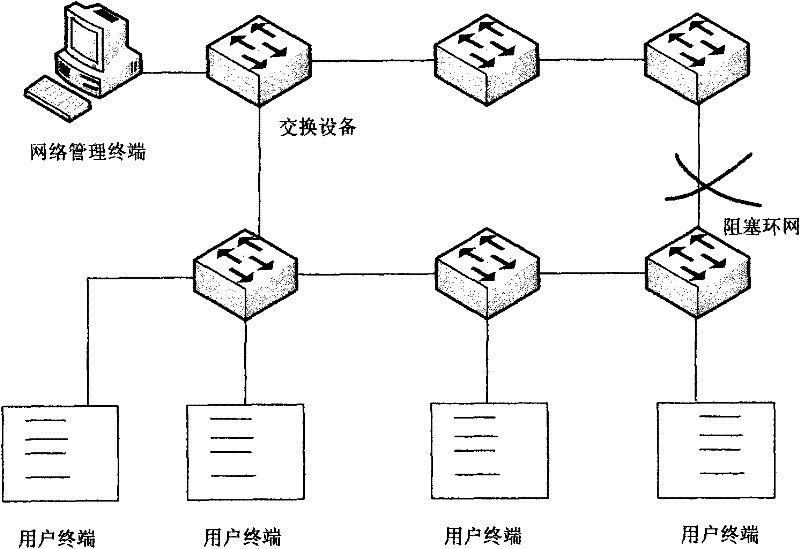

Network topology structure and node information gathering method

InactiveCN102195857AReal-time acquisitionReal-time performanceData switching networksIndustrial EthernetNeighbor finding

The invention relates to a network topology structure and a node information gathering method, which are applied to a network topology structure in industrial Ethernet equipment and accurate search of network information. The method mainly comprises the following steps of: presetting interface information and an interface index of neighboring node state information in an exchange equipment host computer; receiving a neighbor finding report by using a network management terminal; determining the linking relation between ports according to the port linking state of the neighbor finding report and neighboring node information by using a network equipment node; and establishing a network topological diagram according to the port linking relation by using the network management terminal to perform corresponding network management.

Owner:WUHAN MAIWE OPTOELECTRONICS TECH

Intelligent automated control method for traditional Chinese medicine production

InactiveCN102109846ASolve complex MIMO problems with severe couplingSolving Complex MIMO ProblemsProgramme total factory controlBiotechnologyBiology

The invention relates to a control method for a traditional Chinese medicine production process, in particular to an intelligent automated control method for the extraction and production process of a traditional Chinese medicine by adopting a water-extraction and alcohol-precipitation technique as well as a water-decoction and alcohol-extraction technique. In the method, the whole production process is respectively controlled by a plurality of control stations; industrial Ethernet is connected with an upper operator station; non-PROFIBUS (process field bus) instruments are utilized as the field instruments of which an analog input / output signal is 4-20mA and an on-off input / output signal is plus +24VDC; and all the instruments are provided with field indicators and are connected with actuating mechanisms such as a valve, a pump, a motor, various transmitters and the like so as to realize control and data management for the whole extraction and production process of the traditional Chinese medicine from feeding, extraction, concentration, removal of impurities, extract collection, ethanol recovery to dreg draining. Compared with the existing traditional Chinese medicine extraction and production technologies, the method provided by the invention has the advantages that extraction ratio of liquid medicine is improved by 13%, extraction ratio of volatile oil is improved by 30%, total energy consumption is reduced by 28%, and recovery rate of ethanol and the liquid medicine are increased by 35% and 25% respectively.

Owner:HONGYI SCI & TECH CO LTD NANCHANG

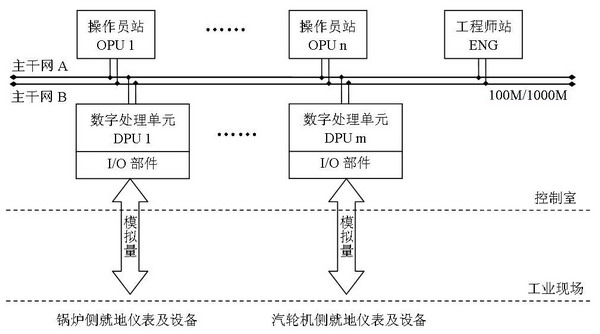

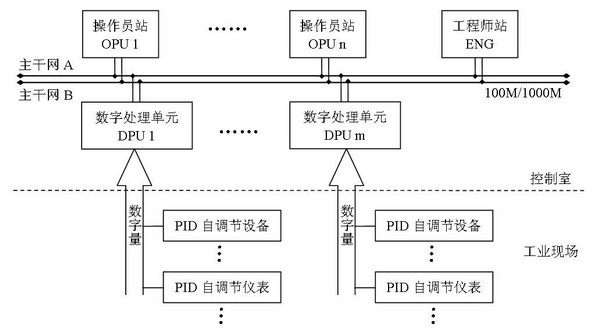

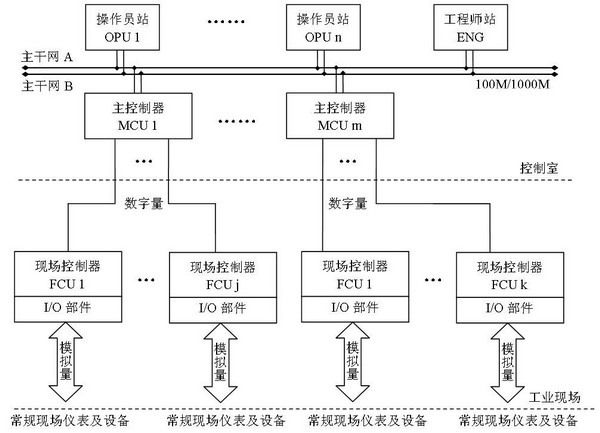

Decentralized control system for layering controller

InactiveCN101957619ATo achieve cooperative workReduce load rateTotal factory controlProgramme total factory controlIndustrial EthernetProportion integration differentiation

The invention relates to a decentralized control system for layering a controller. The traditional controller arranged in a plane layout manner is divided into a plurality of layers to ensure that a plurality of tasks completed by one control unit set in an original DSC (Decentralized Control System) are respectively executed by a plurality of FCUs after the function is subdivided and coordinatedby using an MCU (Microprogrammed Control Unit), thus the correspondence of the control unit and equipment is more clear, the load factor of data transmission on a backbone network is effectively reduced, the control risk is dispersed and the response speed is increased. Because the FCUs controlled in device level are placed at a site of an equipment side, the length of a cable connecting the siteequipment is reduced, and the function of realizing PID (Proportion Integration Differentiation) regulation is realized in stead of the traditional intelligent apparatus; and the site equipment is always measured by adopting conventional apparatuses. According to the invention, industrial Ethernet transmission is adopted in longer distance between the site FCUs and the MCU in a control chamber, compared with the original DCS with same control scale and distance, the control cable cost can be saved by above 60 percent, the investment cost of the site equipment is lowered, the area of the control chamber is effectively reduced, and the cost is greatly decreased.

Owner:JING YI HUA WEN AUTOMATION SYST ENG SHANGHAI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com