Patents

Literature

282 results about "Industrial communication" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

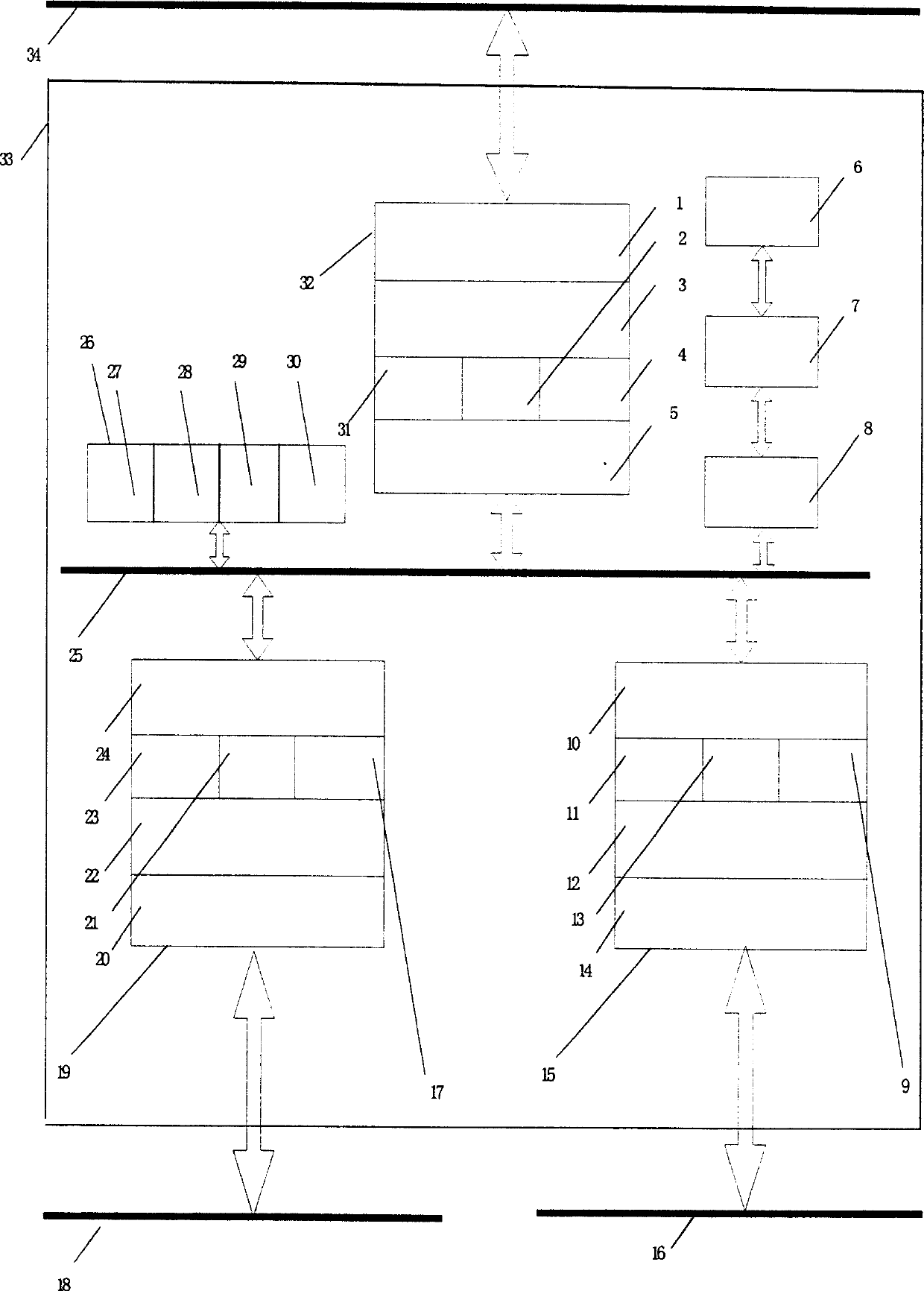

Multi protocol conversion method and device between MODBUS/TCP industry Ethernet and field bus device network as well as field bus of PRofibus DP

InactiveCN1697448ARealize the interface functionRealize the master node functionNetwork connectionsBus networksInformation layerHigh rate

Software in MPU builds united message model to realize protocol conversion in application layer among MODBUS / TCP industrial Ethernet, DeviceNet field bus and Profibus DP field bus. Corresponding interface module and communication adapter modules at main nodes realize their relevant protocols. Through an internal bus, protocol conversion device built from a MPU is connected to industrial Ethernet interface module, DeviceNet communication adapter module at main node, Profibus DP communication adapter module at main node and a SRAM. Through a serial peripheral interface, MPU is connected to an electrically erasable memory. The invention solves converting protocols based on different standards. One communication frame is compatible to multiple industrial communication networks so as to meet requirements of network real-time at low-layered devices as well as high rate and large capacity of network on information layer.

Owner:SHANGHAI UNIV

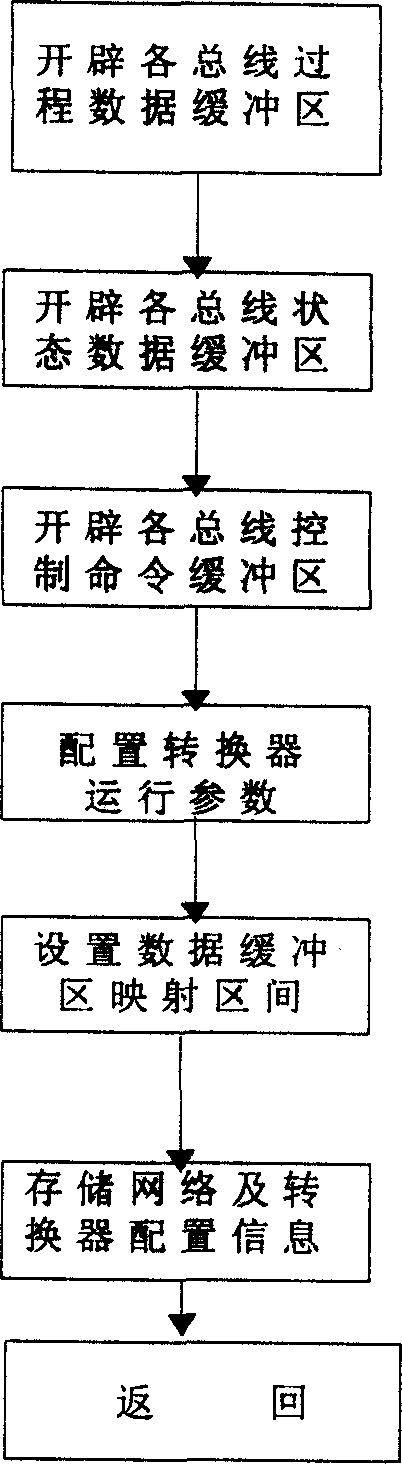

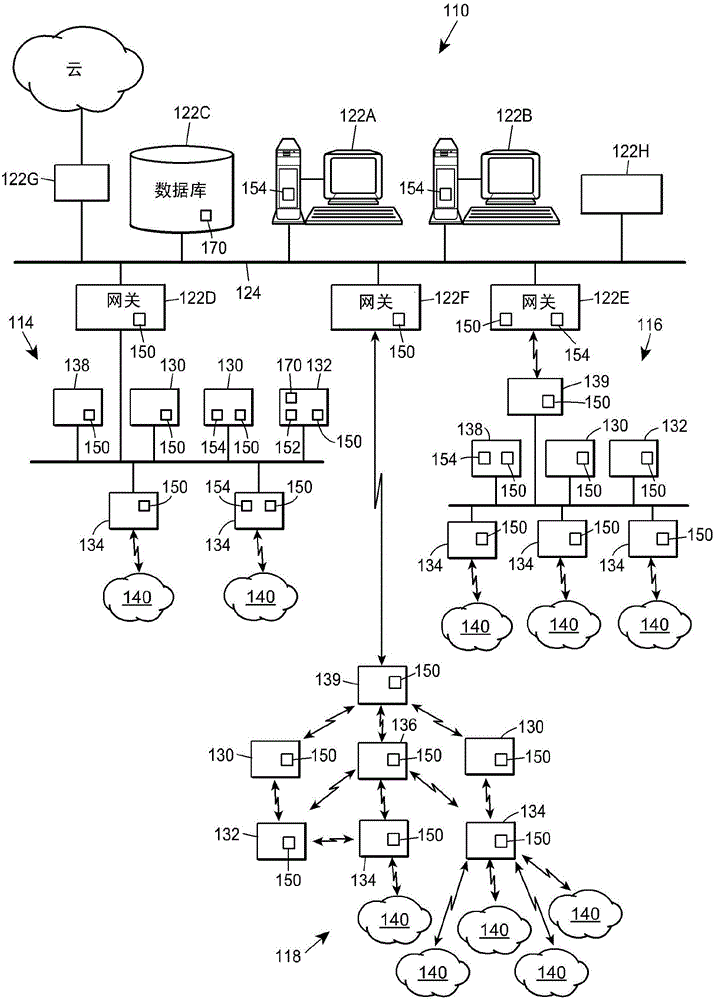

Anomaly detection in industrial communications networks

ActiveCN105939334AReduce false positive rateReduce loadElectric testing/monitoringElement comparisonBaseline dataAnomaly detection

The anomaly detection system detects unexpected changes or anomalies in traffic patterns, to detect potentially infected nodes. The detection system generally consists of distributed data collection modules at each node of a network, and a centralised or separate anomaly analysis engine. The collection modules view the message traffic into and out of the node to generate metadata pertaining to the message traffic. This metadata is sent to the analysis engine which processes the metadata using a rules engine, analysis it with a set of logic rules, it can also use traffic pattern baseline data, to determine if the traffic patterns at the nodes are anomalous. If it does determine an anomalous pattern, it will generate a message, it also may perform some corrective action. An example is disconnecting the node from the network.

Owner:FISHER-ROSEMOUNT SYST INC

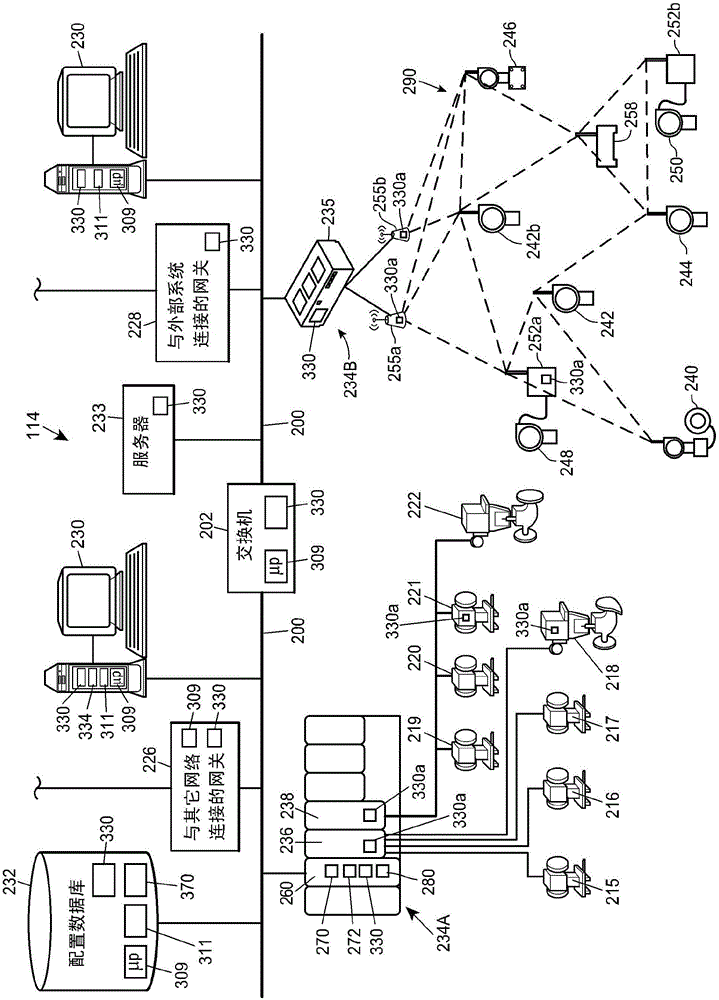

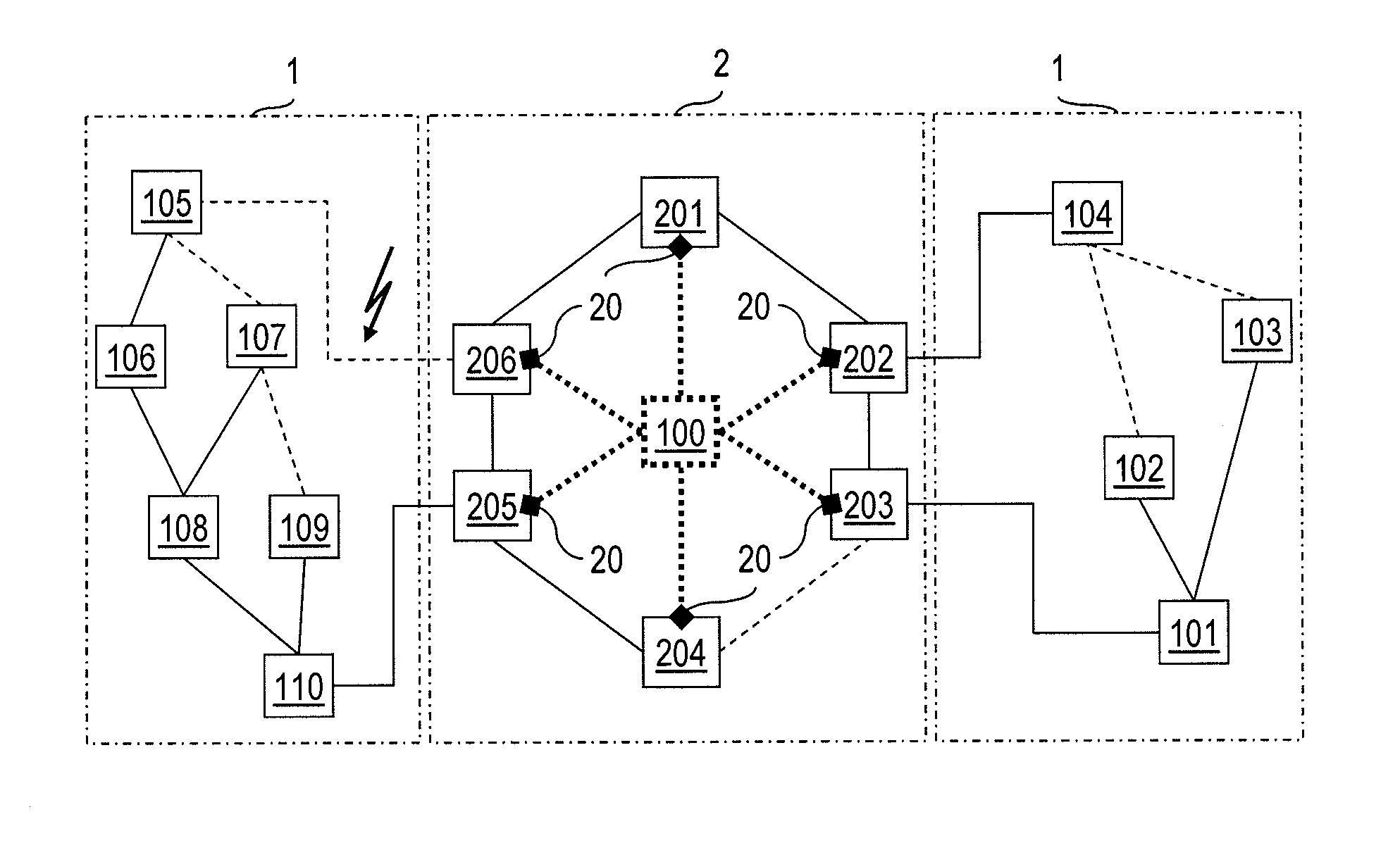

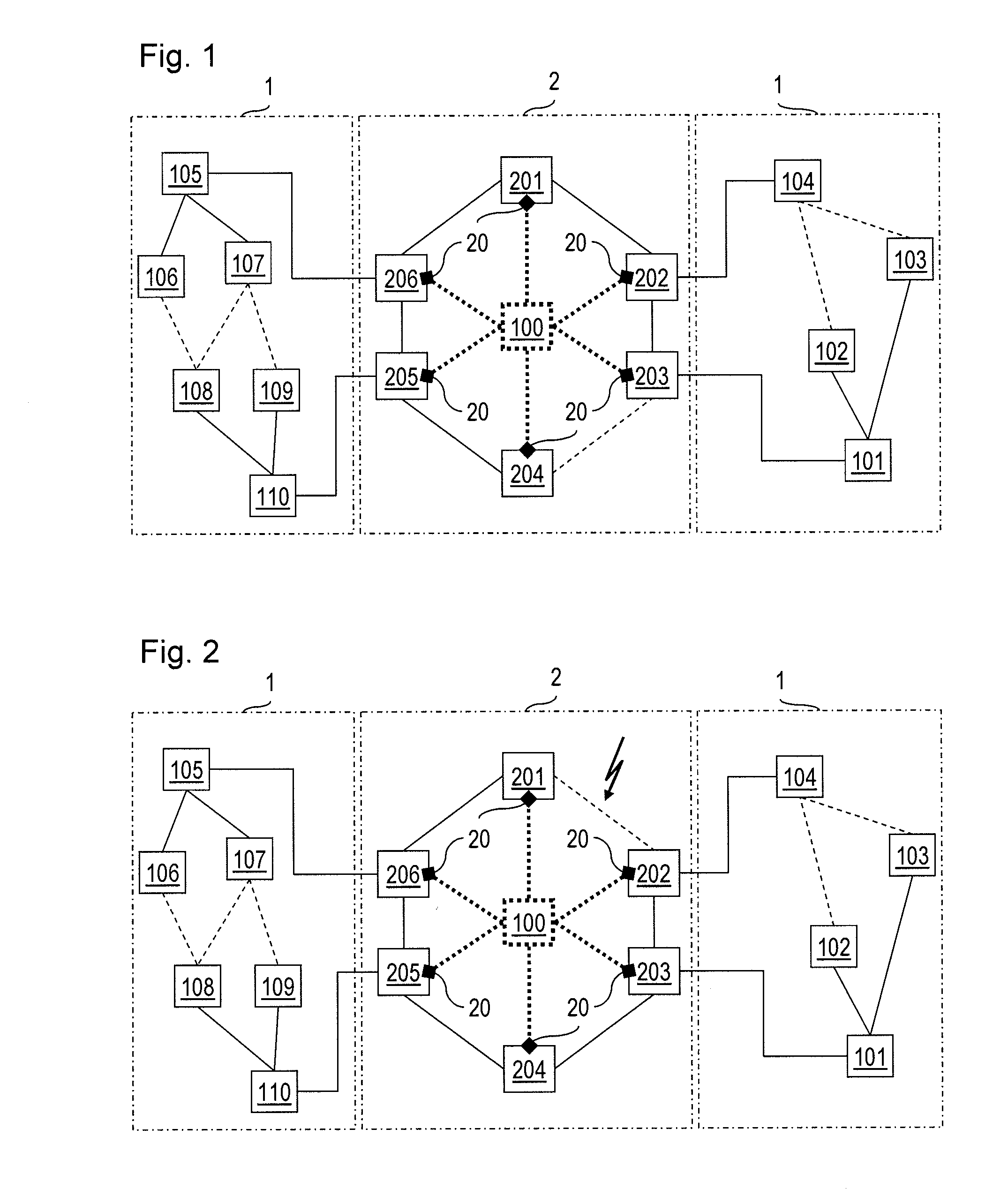

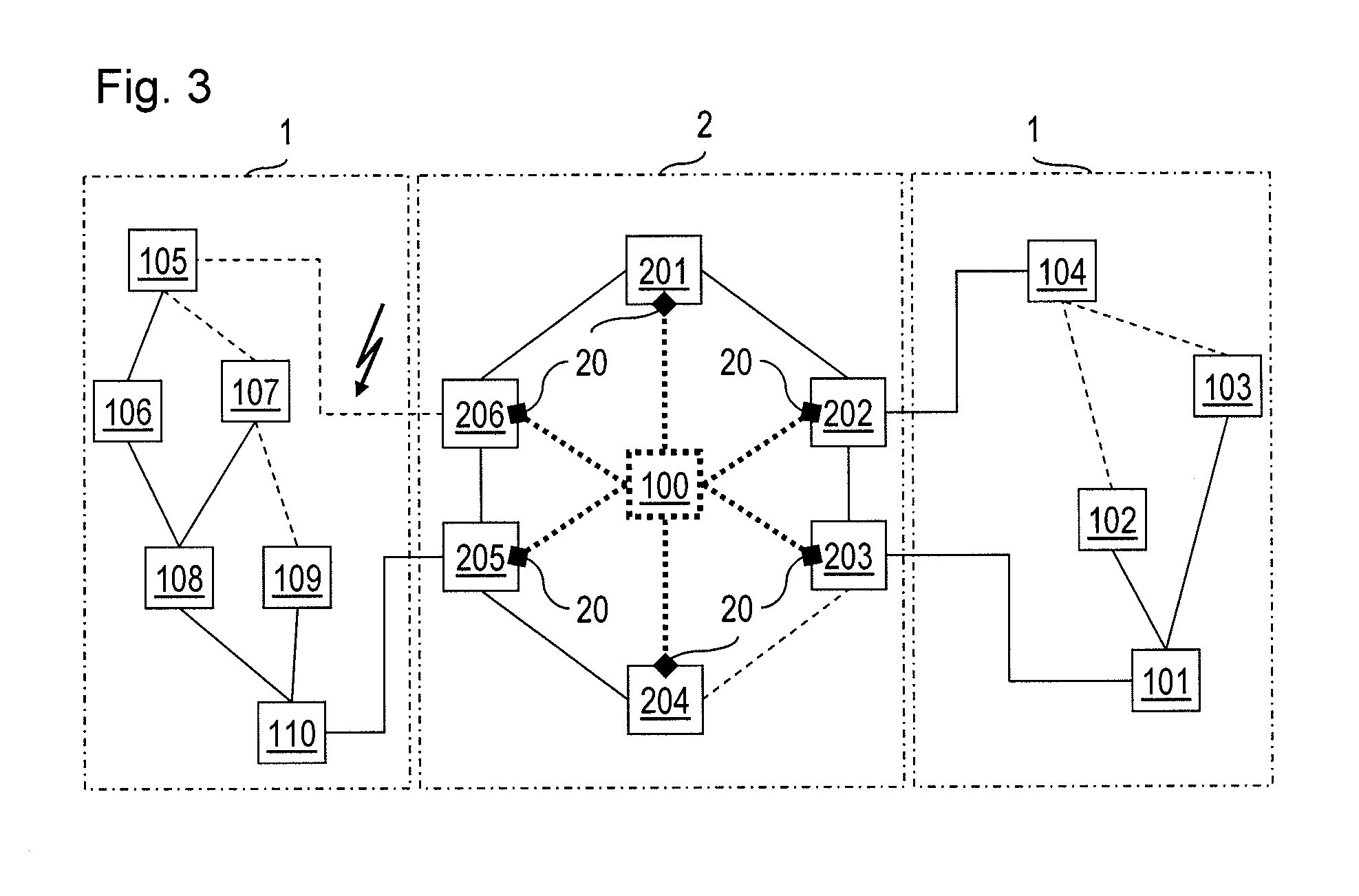

Monitoring an industrial communication network

The present invention is concerned with the identification of a failed communication network component of an industrial communication network and of a substation automation system in particular. This is achieved by supervising communication paths of a communication network having components. A failure status or operating status of each communication path is determined and reported. Any network component that is part of an operating path is regarded as operating, i.e. failure-free, whereas all other network components are considered as non-operating or potentially failed. If there is more than one non-operating component, additional suitable communication paths are evaluated, until one single failed network component is identified and subsequently reported as requiring repair or replacement. The invention is particularly applicable in cases where some of the network components, i.e. the lines or some nodes of the communication paths, are passive components or non-intelligent devices that are unable to report an operating status themselves.

Owner:ABB TECH AG

Machine condition indication system

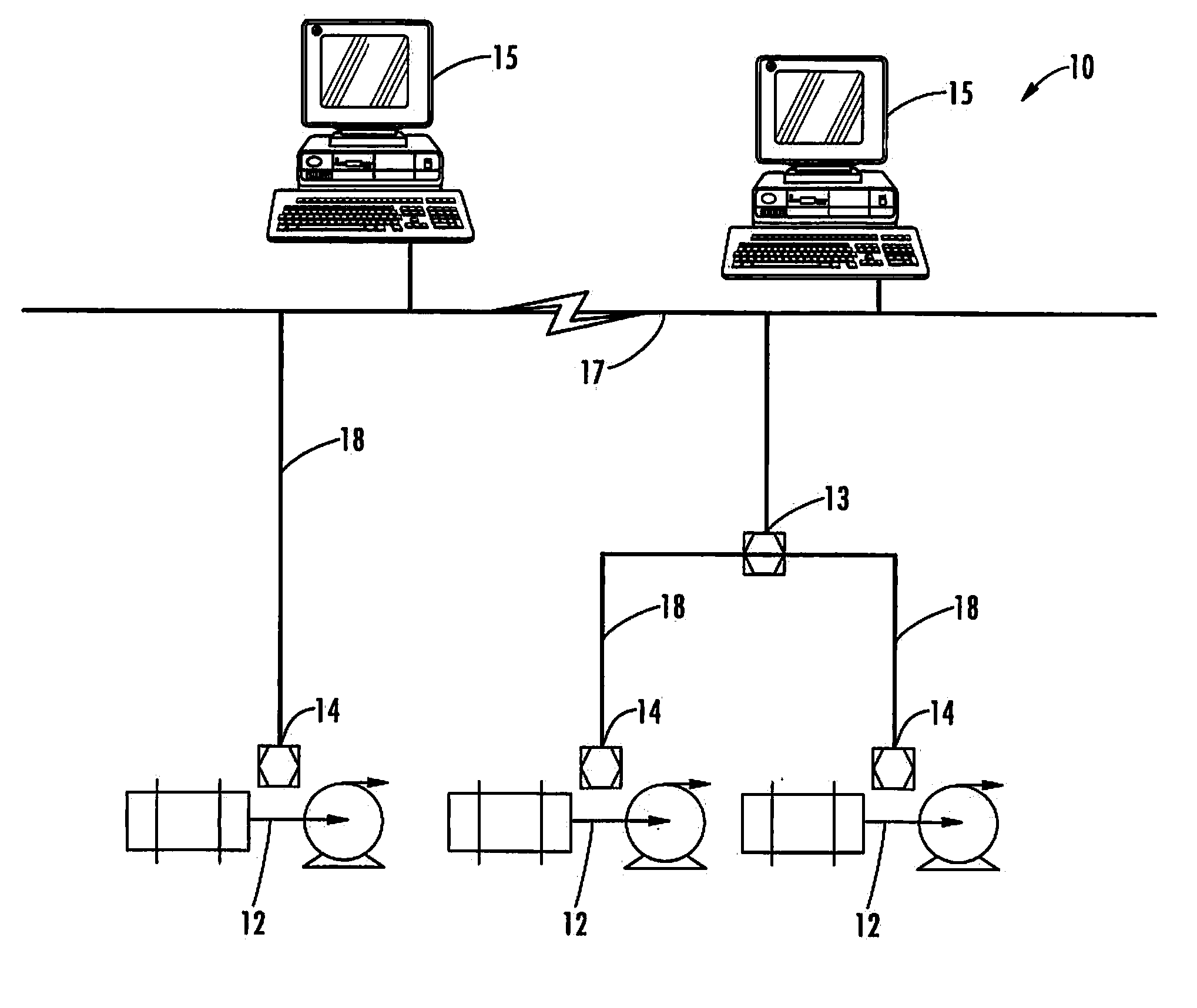

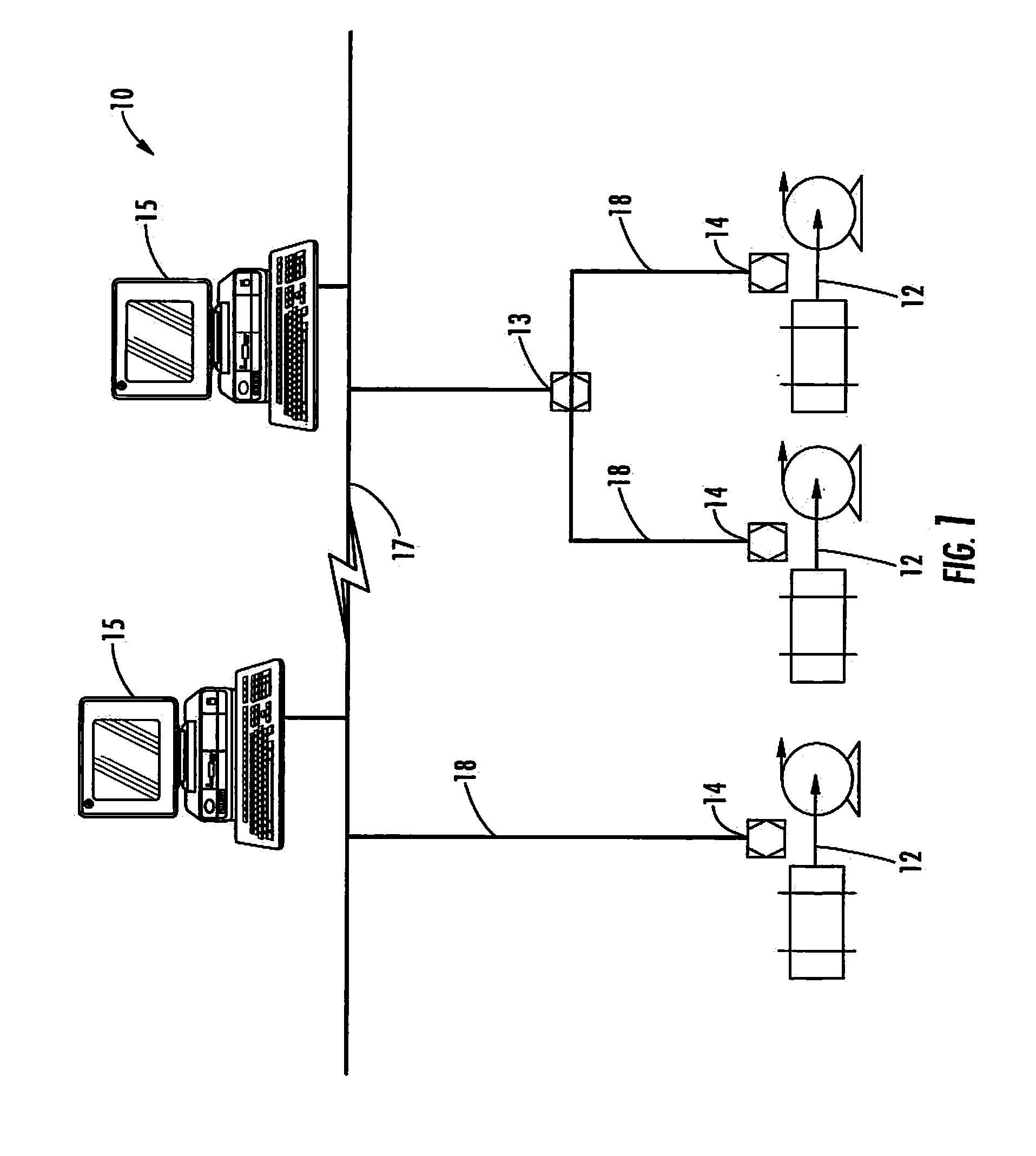

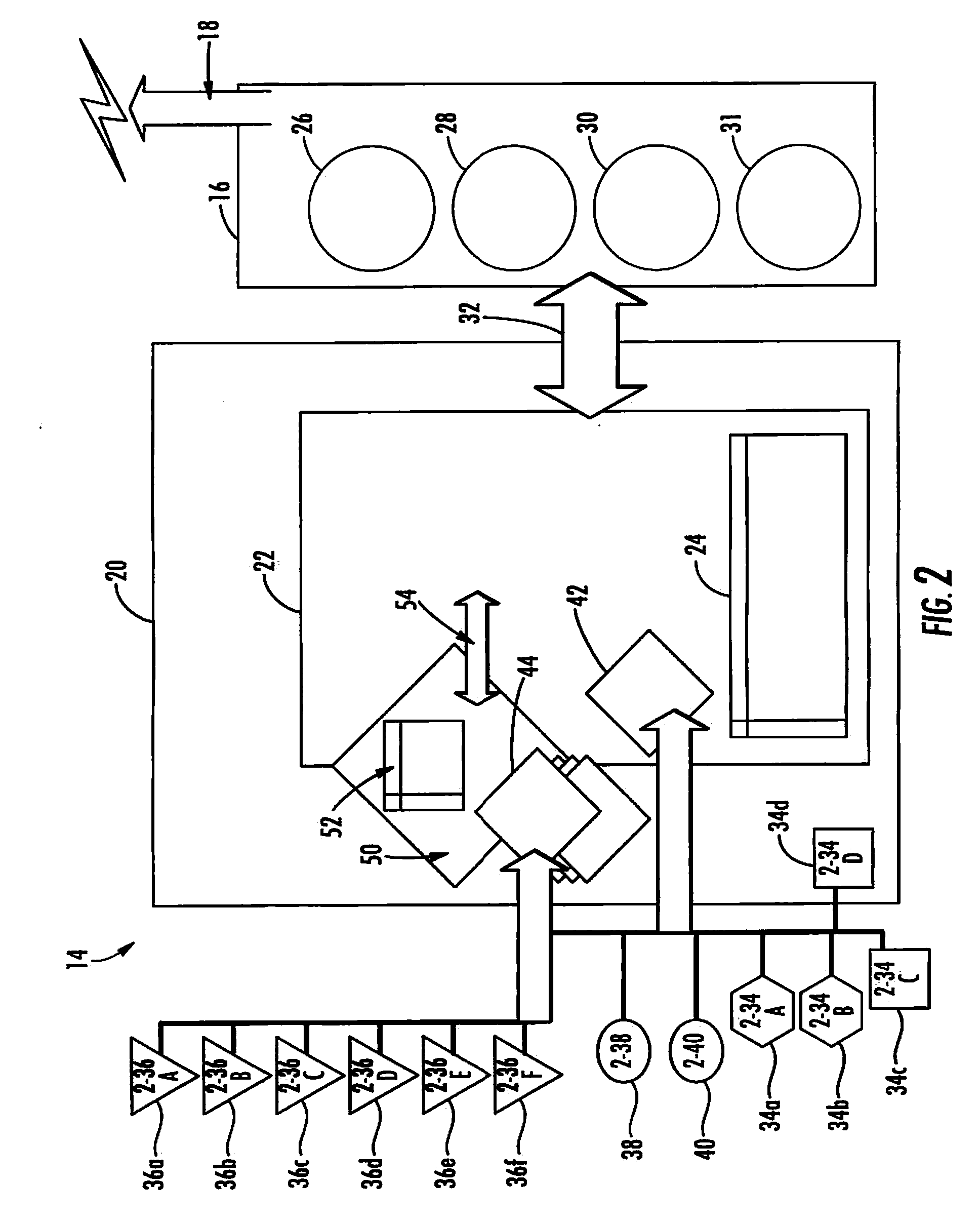

ActiveUS20080106424A1Programme controlTesting/monitoring control systemsState parameterIndustrial communication

A machine condition monitor resides in close proximity to a machine train, such as an AC inductive electric motor coupled to a driven unit such as a centrifugal pump or fan. A plurality of sensing devices are connected to the machine and the machine condition monitor. Machine state and condition parameters sensed by these devices are utilized by the machine condition monitor to derive machine condition values for each component and for the machine train as a whole. These derived condition values are transmitted via an industrial communications network to a control center where they can be trended and monitored. With no particular knowledge of machine analysis techniques or severity of specific machine faults, and no special training, Operators and Production Planners can use the condition values to plan production schedules, adjust process parameters, and request appropriate maintenance action.

Owner:COMPUTATIONAL SYST

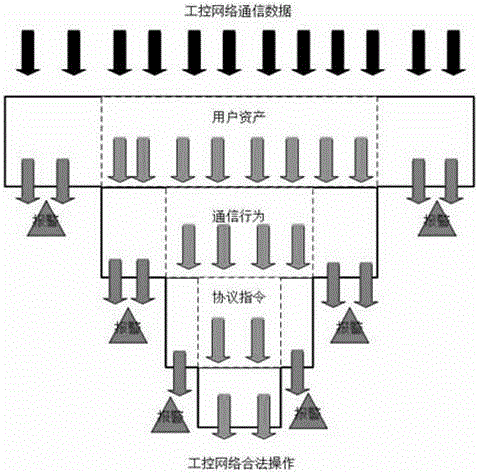

Industrial control network information security monitoring method based on funnel type white list

ActiveCN105208018AResolve identifiabilityResolve analysisTransmissionMonitoring systemPattern perception

The invention relates to an industrial control network information security monitoring method based on a funnel type white list. The industrial control network information security monitoring method comprises the following steps that (1) industrial communication data are deeply parsed; (2) a credible framework is established for legal operation in an industrial control network; and (3) a white list funnel is established based on the credible framework. The beneficial effects of the industrial control network information security monitoring method are that reductive analysis is performed on multiple industrial communication protocols so that abnormal monitoring of the production control behavior can be realized; and the credible framework is established through combination of the industrial control network environment so that the white list funnel with the industrial characteristics is generated, filtering precision is high and the communication behavior in the industrial control network is monitored in real time, early warning time for perception of the unknown threat is enhanced, and thus the industrial control information system environment is stabilized as the core guiding thought and a monitoring system is constructed.

Owner:上海三零卫士信息安全有限公司

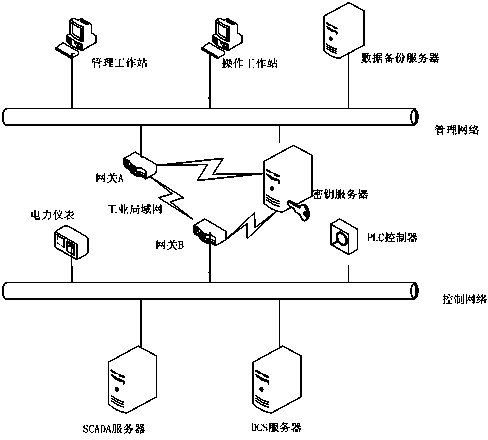

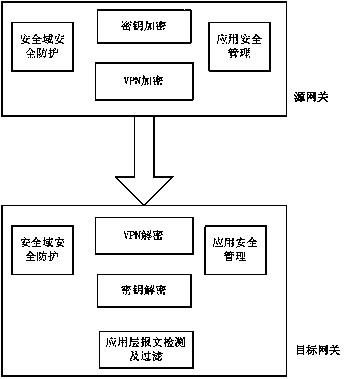

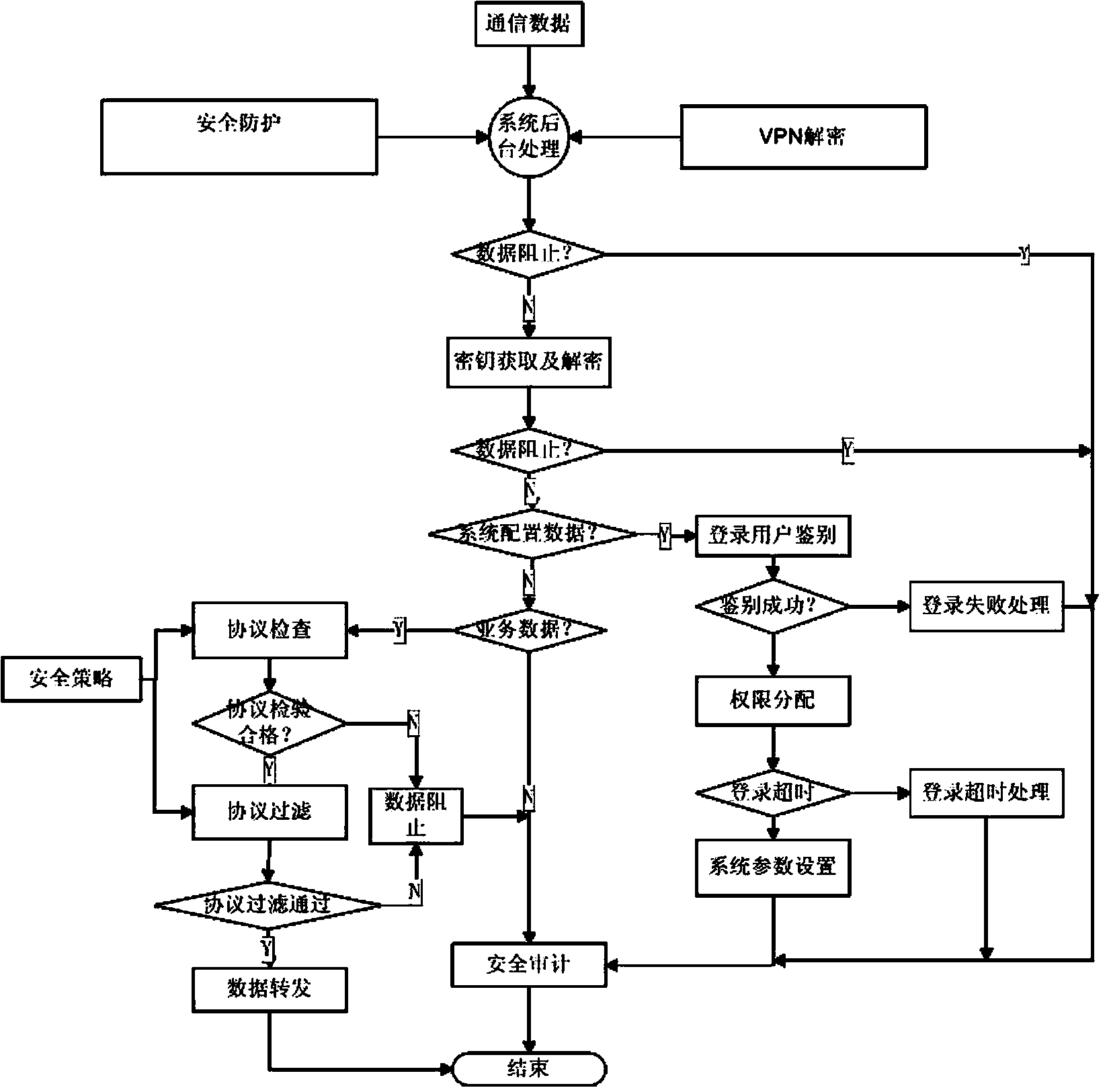

Multi-protocol industrial communication safety gateway and communication method with gateway applied

InactiveCN104320332AEnsure safetyImprove forwarding speedNetworks interconnectionNetwork connectionsCommunications securityMulti protocol

The invention relates to a multi-protocol industrial communication safety gateway and a communication method with the gateway applied. In the data communication process, a source gateway encrypts data through a secret key management mechanism module and a VPN encryption and decryption module and then sends the data to a target gateway. The target gateway decrypts the data through the VPN encryption and decryption module, and provides safe detection and control service for data communication through a safety domain safety protection module; if the data are safe, secret key decryption is carried out on application layer data, the types of the application layer data are judged, an application management safety module is used for management if the application layer data are application management data, and an application layer message detecting and filtering module is called for detecting and filtering messages if the application layer data are application layer messages. The mode of combination of the VPN encryption and decryption, the secret key encryption and decryption, and the application layer message detecting and filtering is adopted for communication safety assurance; the safety domain safety protection and the application safety management are adopted for gateway application safety assurance.

Owner:山东华汉电子有限公司

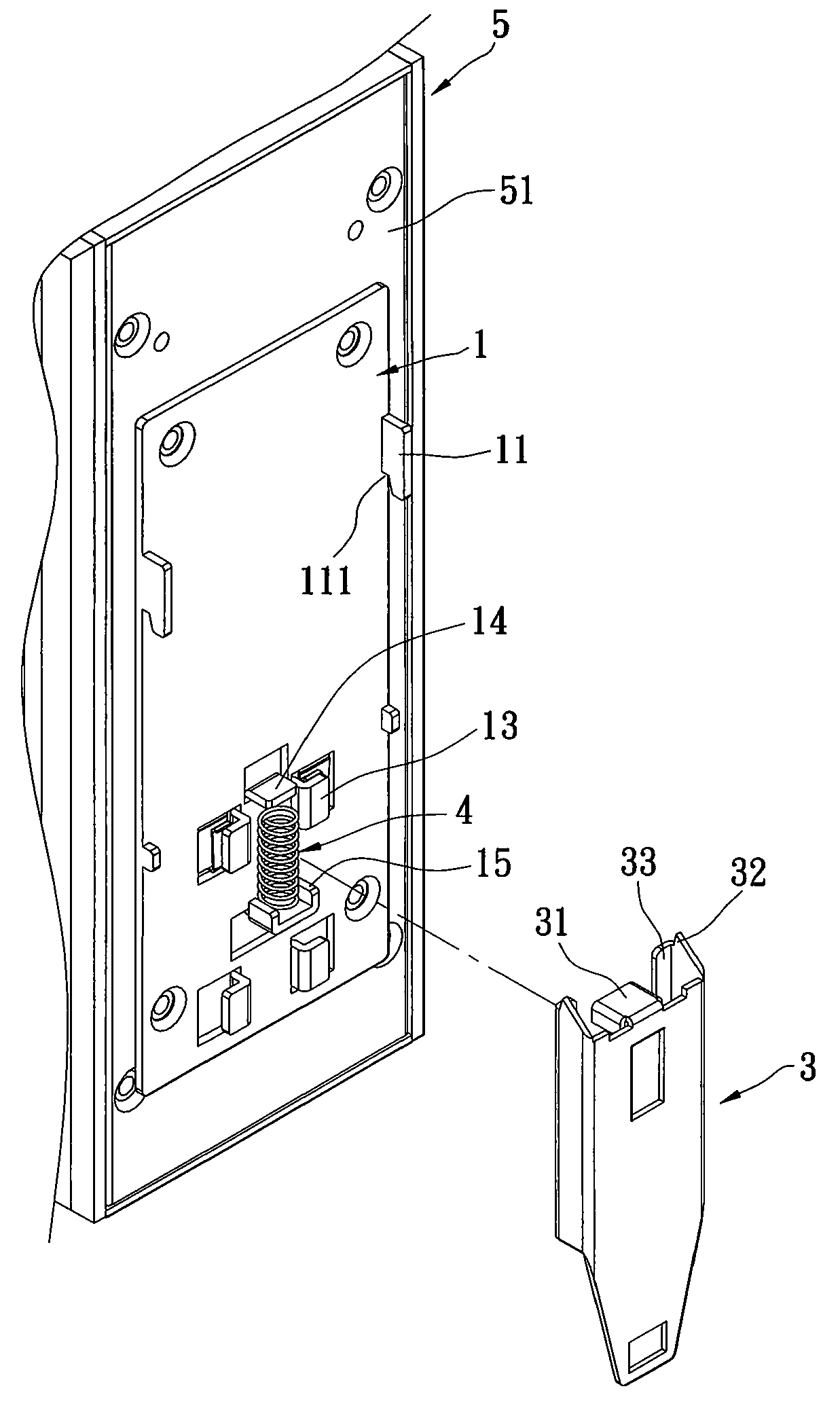

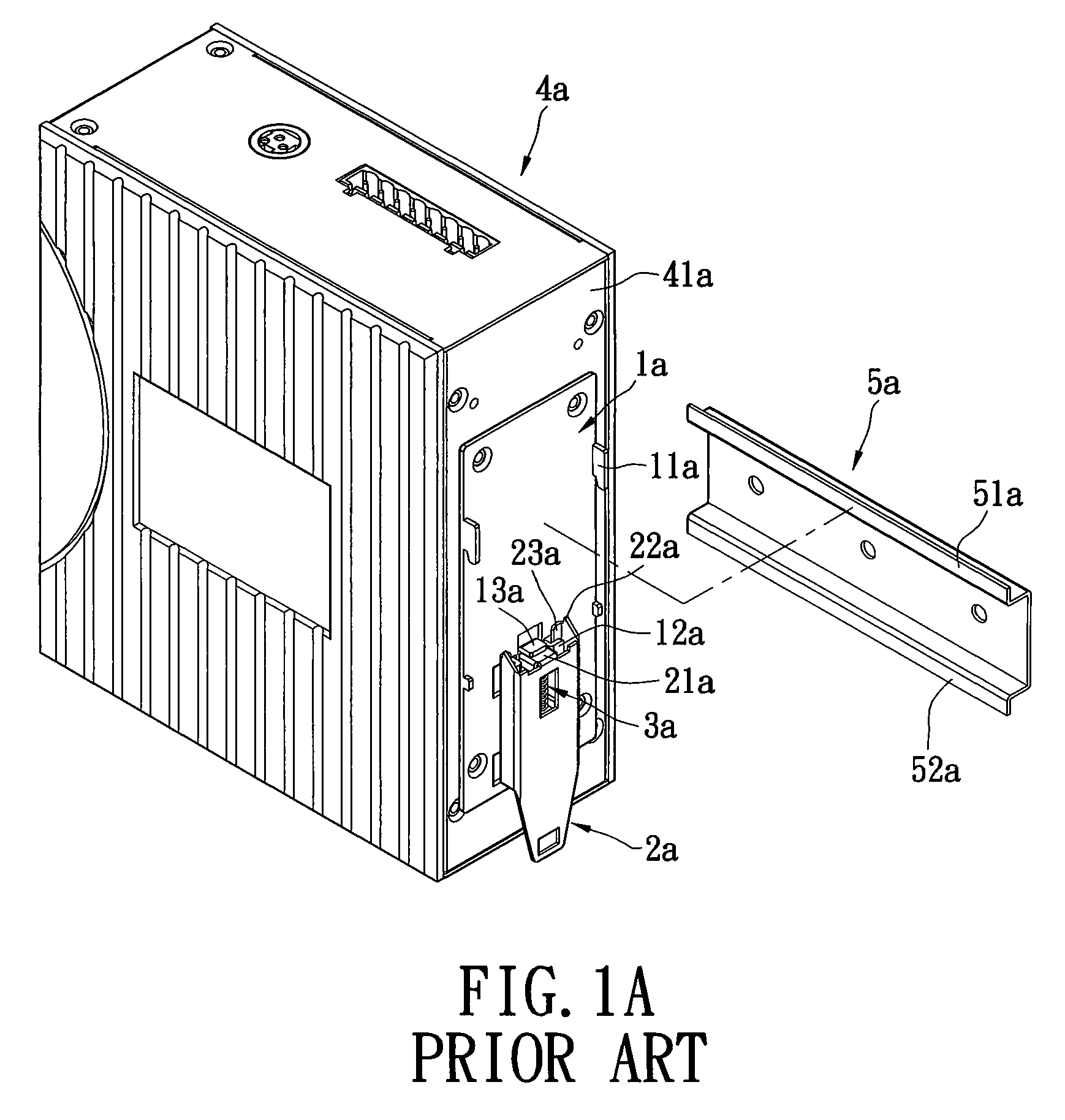

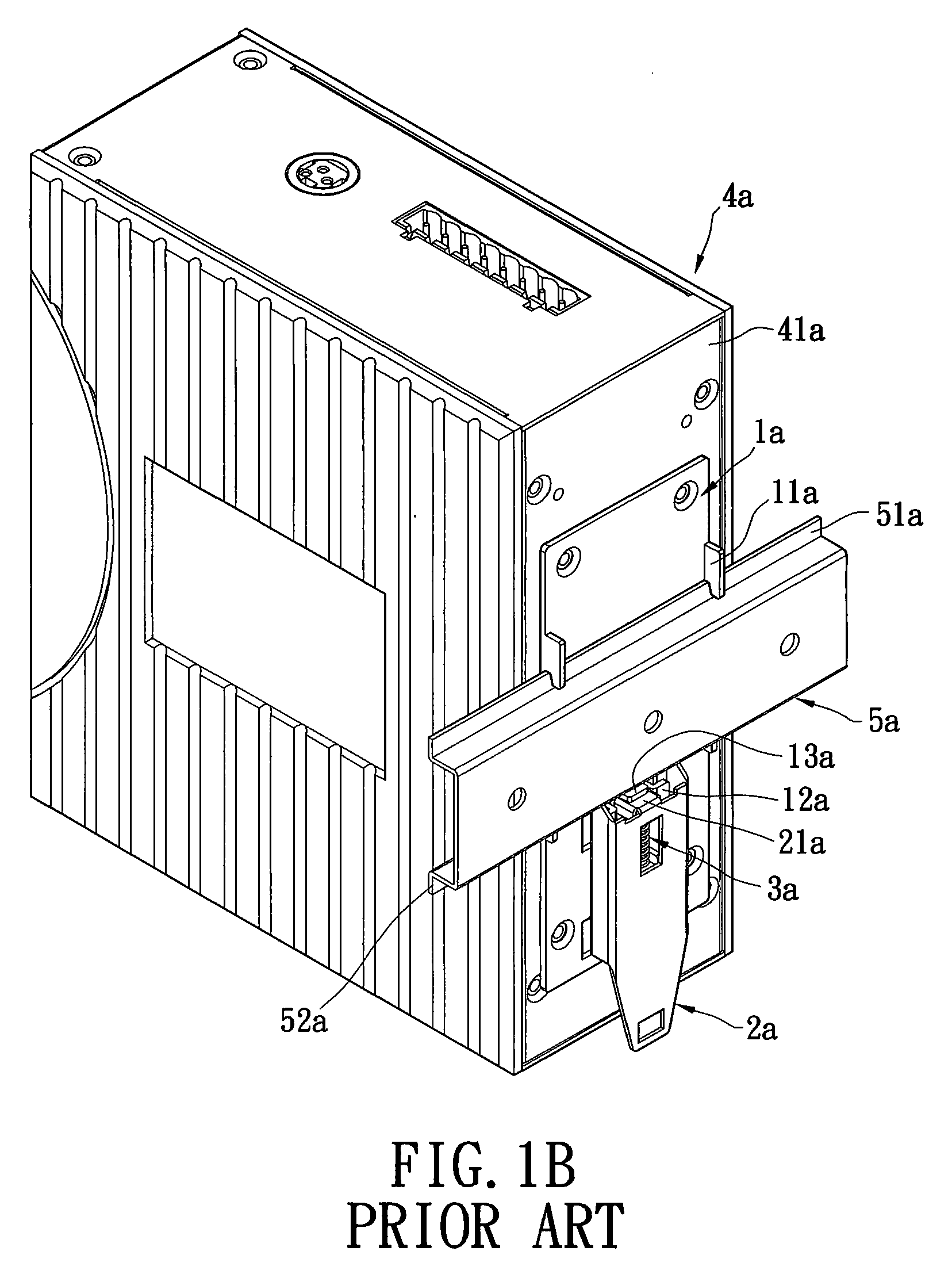

Fixing device for industrial communication product

ActiveUS20100255713A1Easy to separateFree from injurySubstation/switching arrangement detailsDigital data processing detailsEngineeringIndustrial communication

A fixing device is provided on a casing of an industrial communication product, which includes a fixing plate, at least one elastic piece with an end, a pulling element, and an elastic element. The fixing plate is provided with at least two first connecting portions. The elastic piece is disposed corresponding to the first connecting portions. The pulling element is provided with two stoppers and at least two second connecting portions. The two second connecting portions are slidingly connected to the two first connecting portions. The pulling element is movable between a first position and a second position; wherein when at the first position, the end of the elastic piece abuts the second connecting portion; when at the second position, the end of the elastic piece is stopped by the second connecting portion, and thereby unlocking the industrial communication product, thus making the product accessible for repair and testing.

Owner:ETHERWAN SYST

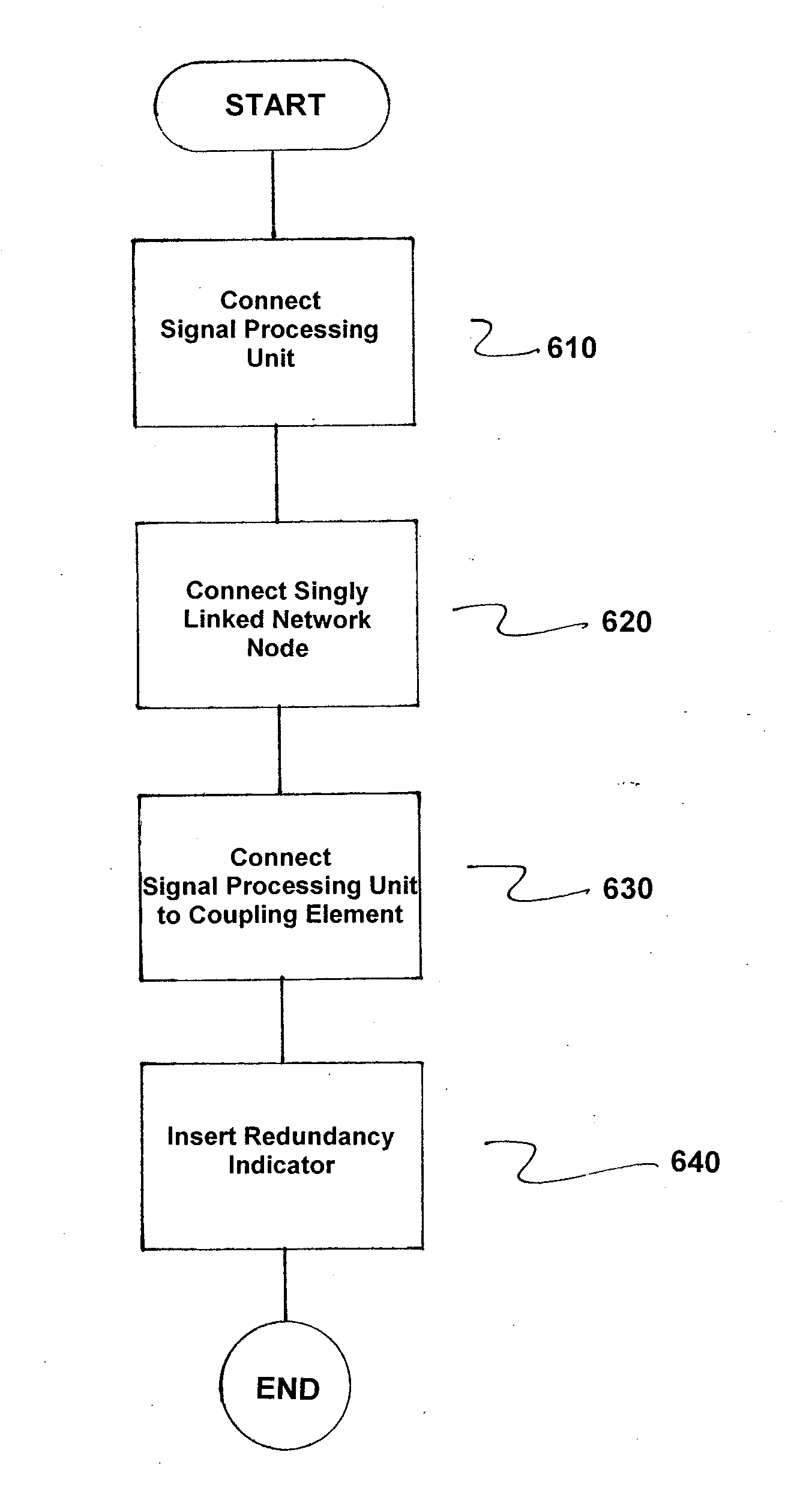

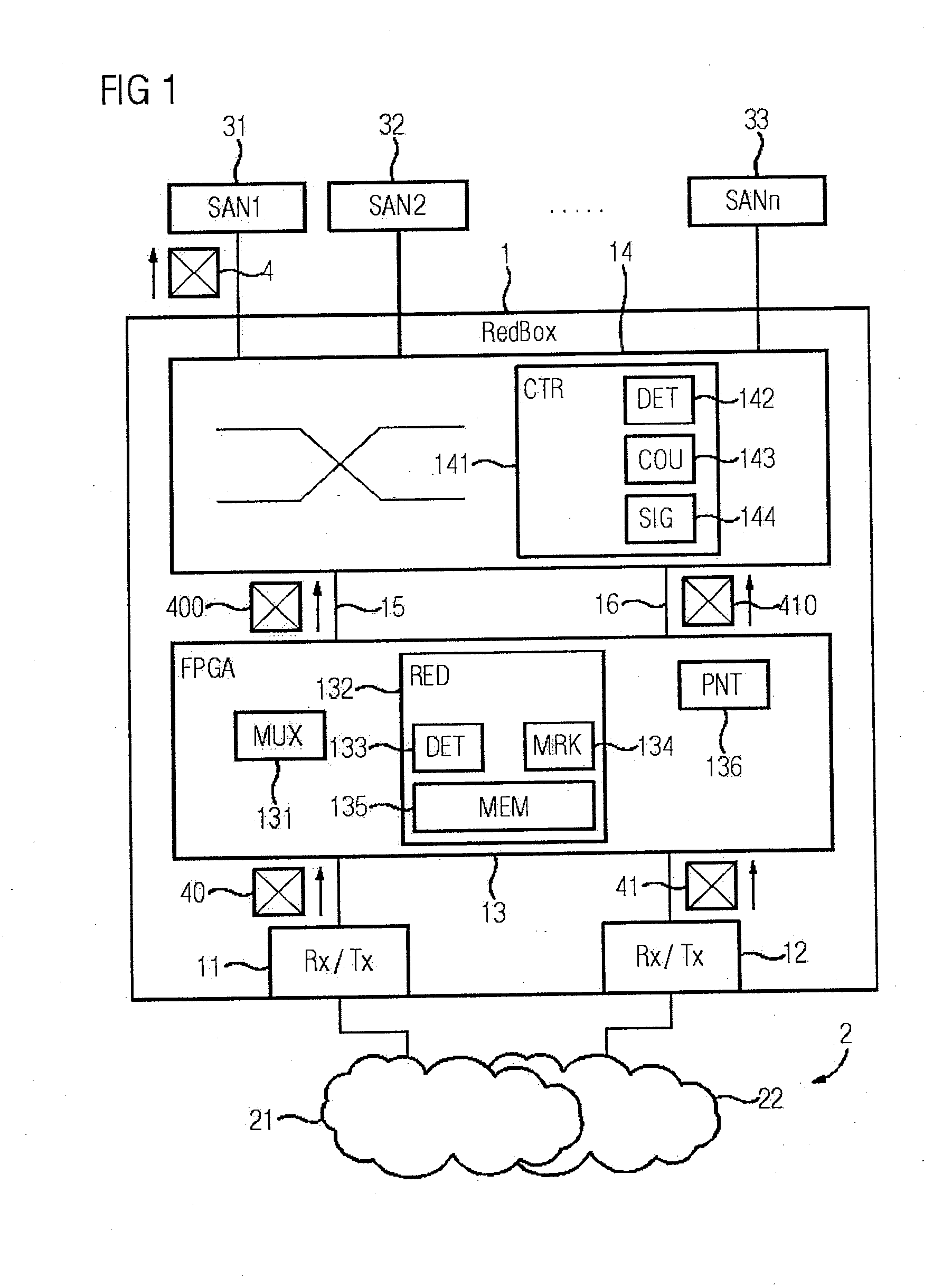

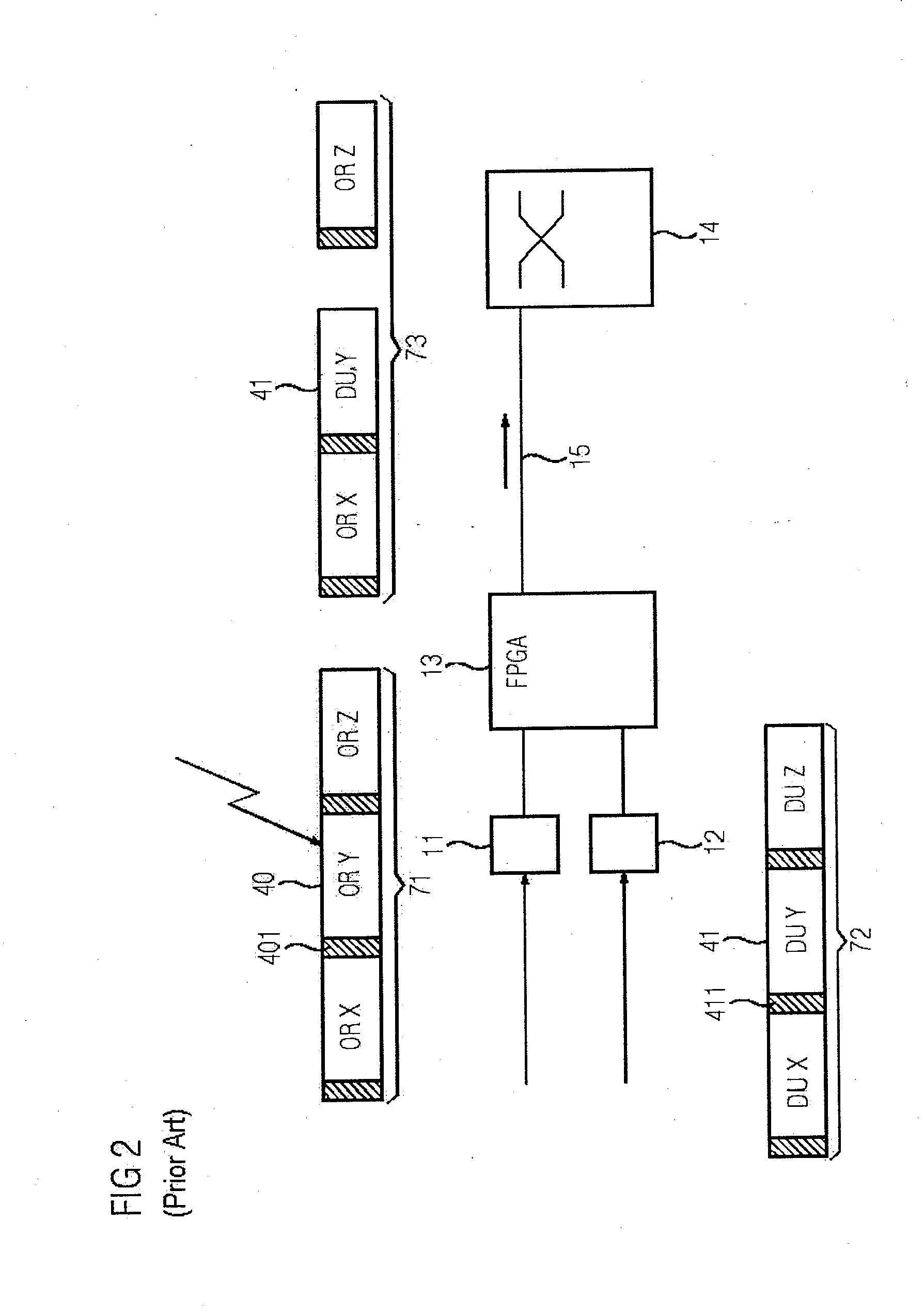

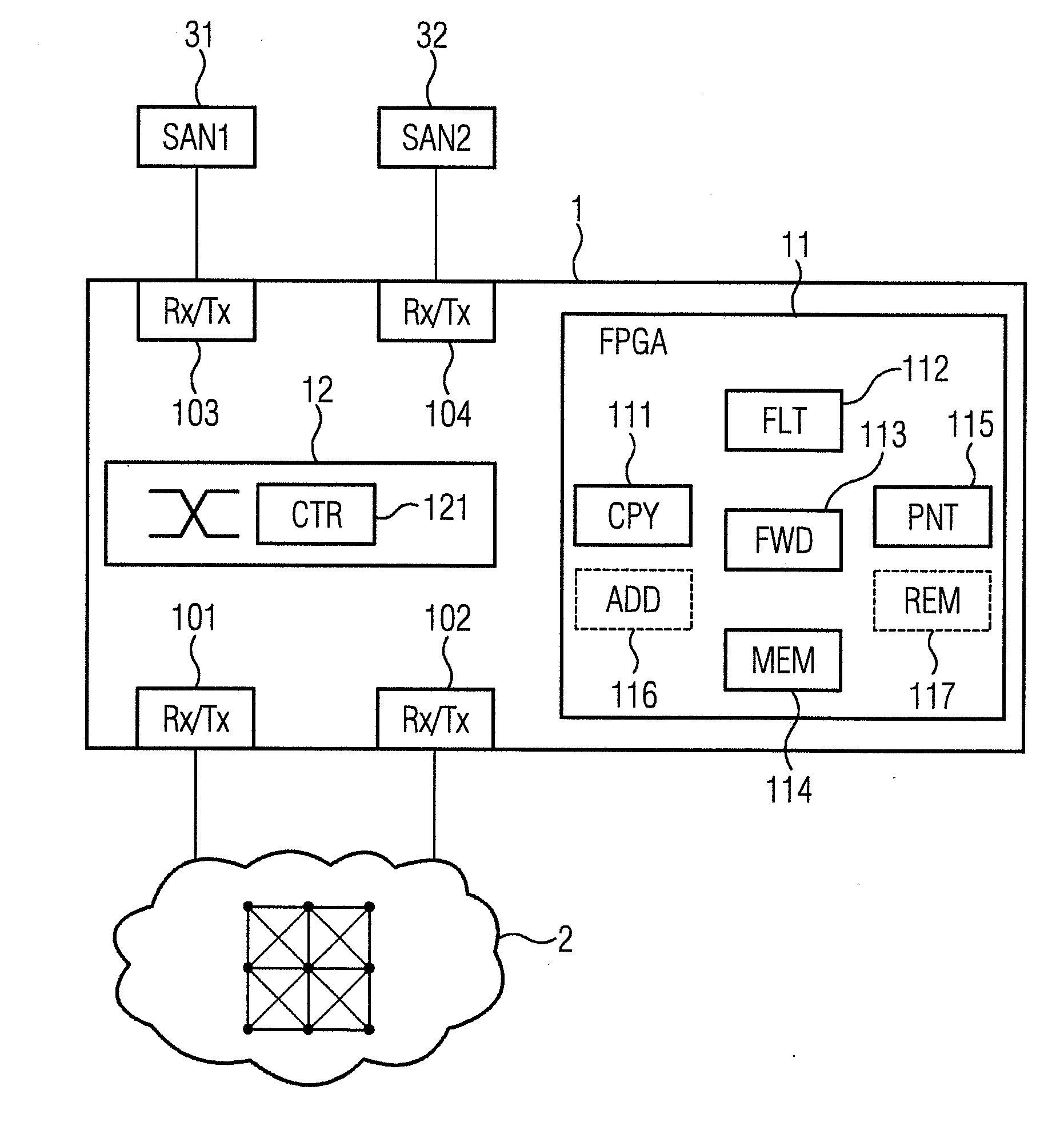

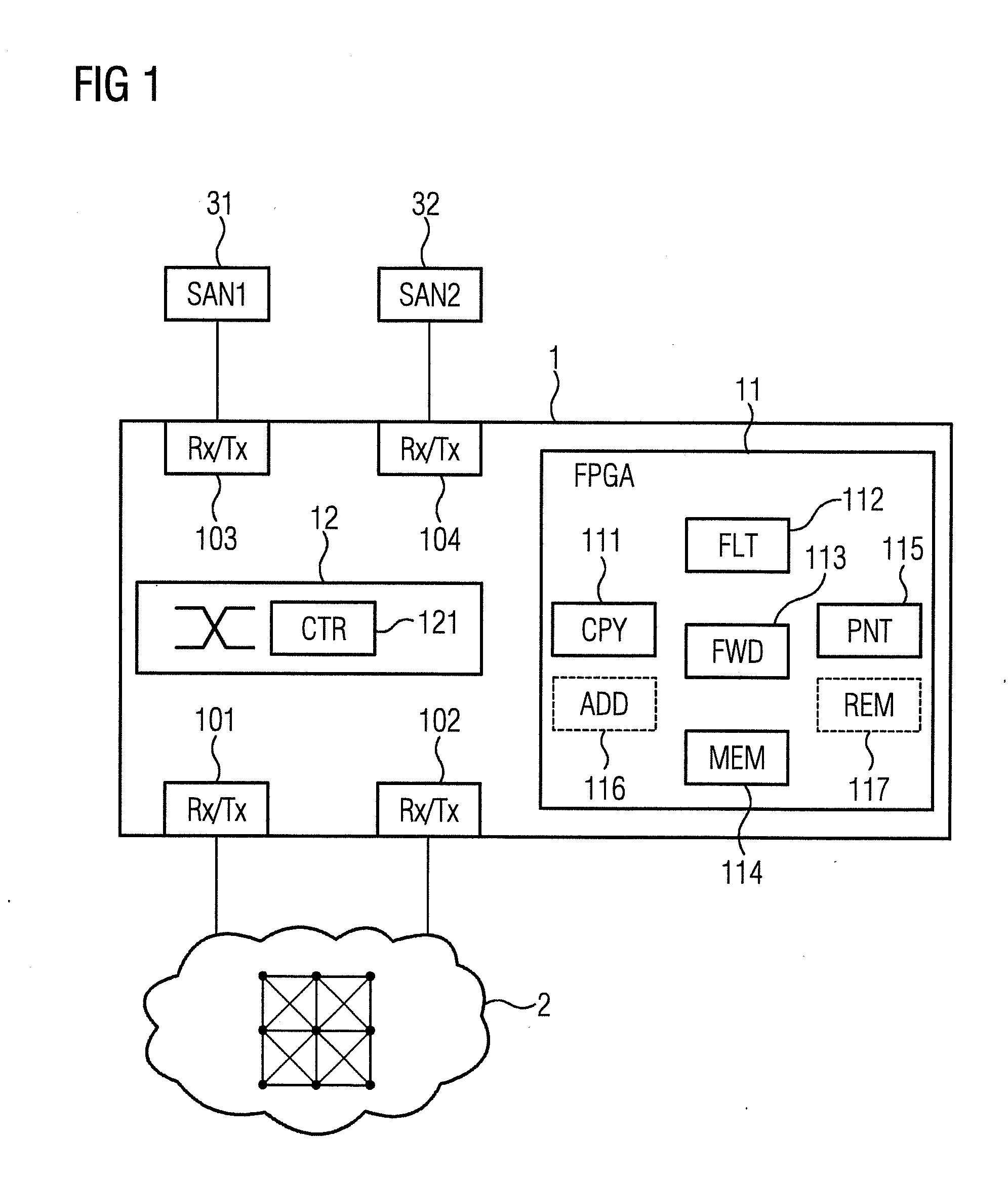

Communication Device for a Redundantly Operable Industrial Communication Network and Method for Operating the Communication Device

ActiveUS20130223204A1Cost-effectiveError preventionFrequency-division multiplex detailsNetwork connectionCoupling

A communication device for a redundantly operable industrial communication network comprises at least one first and one second transmitting and receiving unit each having an interface for a network connection of the industrial communication network. A signal processing unit is connected to the first and second transmitting and receiving units. A singly linked network node is connected to the signal processing unit via a coupling element. The signal processing unit is connected to the coupling element via a first and second interface. In this case, the first interface is provided exclusively for communicating data packets received by the first receiving unit, while the second interface is provided exclusively for communicating data packets received by the second receiving unit.

Owner:SIEMENS AG

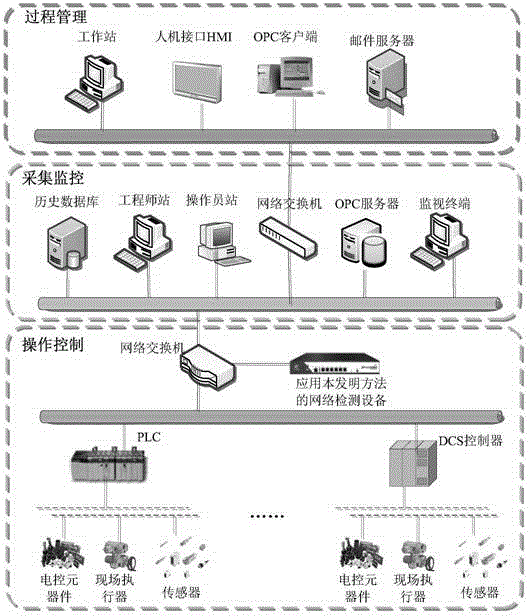

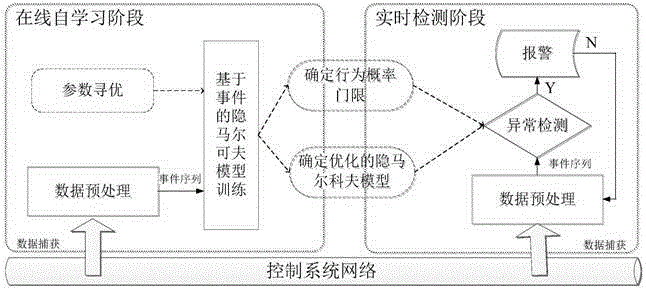

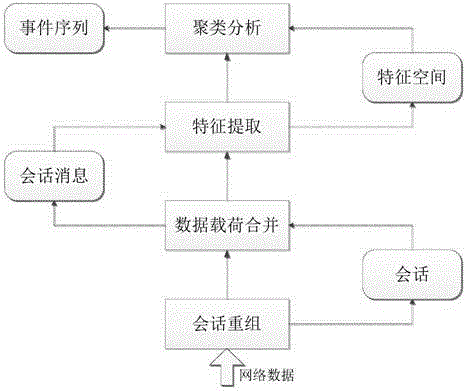

Abnormal behavior detection method for unknown industrial communication protocol specification

The invention discloses an abnormal behavior detection method for an unknown industrial communication protocol specification. The abnormal behavior detection method is divided into an online self-learning stage and a real-time detection stage, wherein the online self-learning stage mainly completes the analysis and feature extraction of network original network communication data, forms an event sequence, takes the event sequence as the input of a hidden Markov model to train the model, and finally obtains the optimized hidden Markov model and a behavior probability threshold through iteration; and the real-time detection stage uses the optimized hidden Markov model to perform behavior probability calculation on the event sequence which is processed in real time, and completes the abnormal detection of an industrial communication behavior by comparing the behavior probability with the behavior probability threshold. The abnormal behavior detection method for the unknown industrial communication protocol specification provided by the invention can detect the legitimacy of an industrial communication data stream using the unknown industrial communication protocol specification, and detect the abnormal industrial communication behavior and give an alarm in real time, so as to guarantee the network communication security of an industrial control system.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

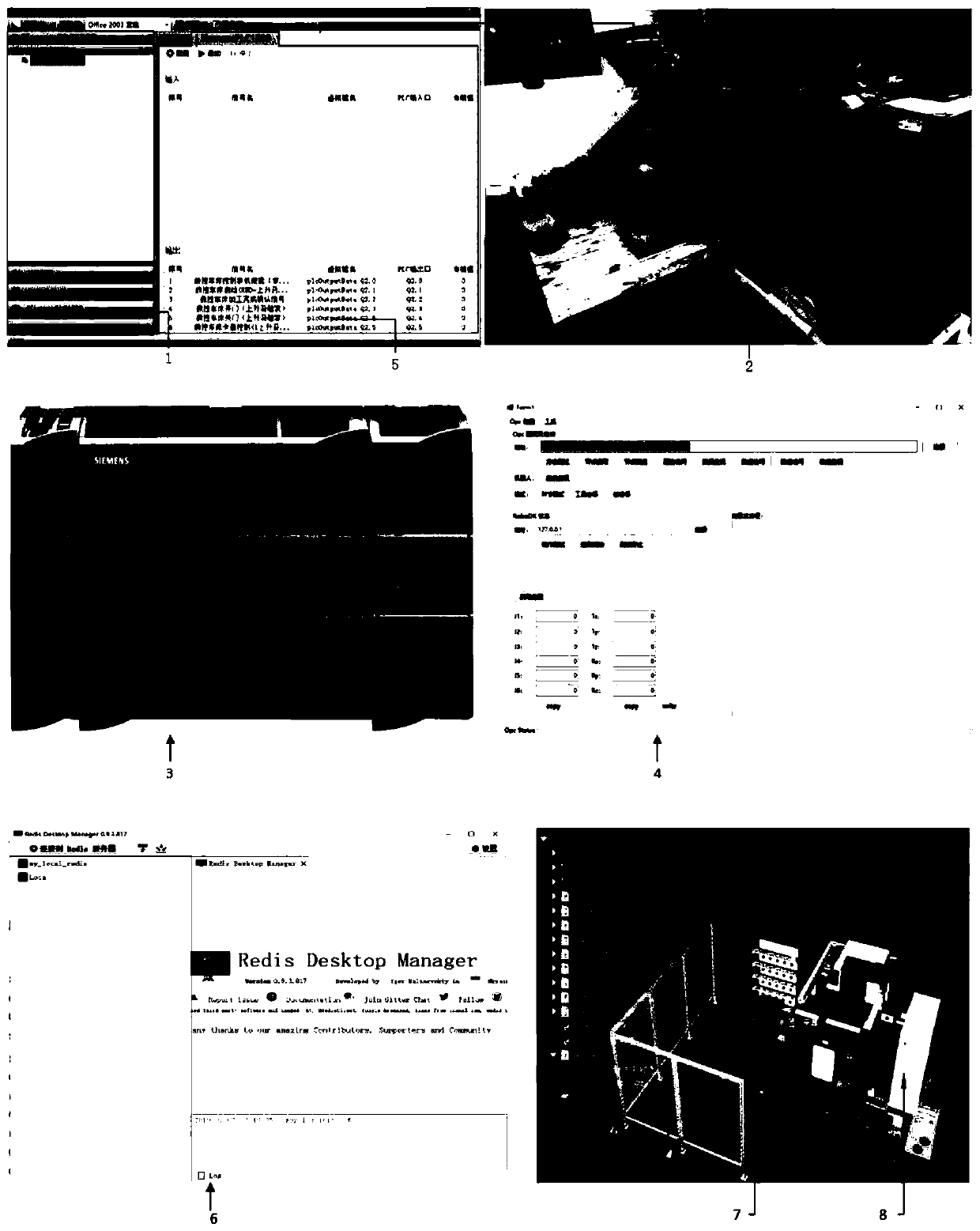

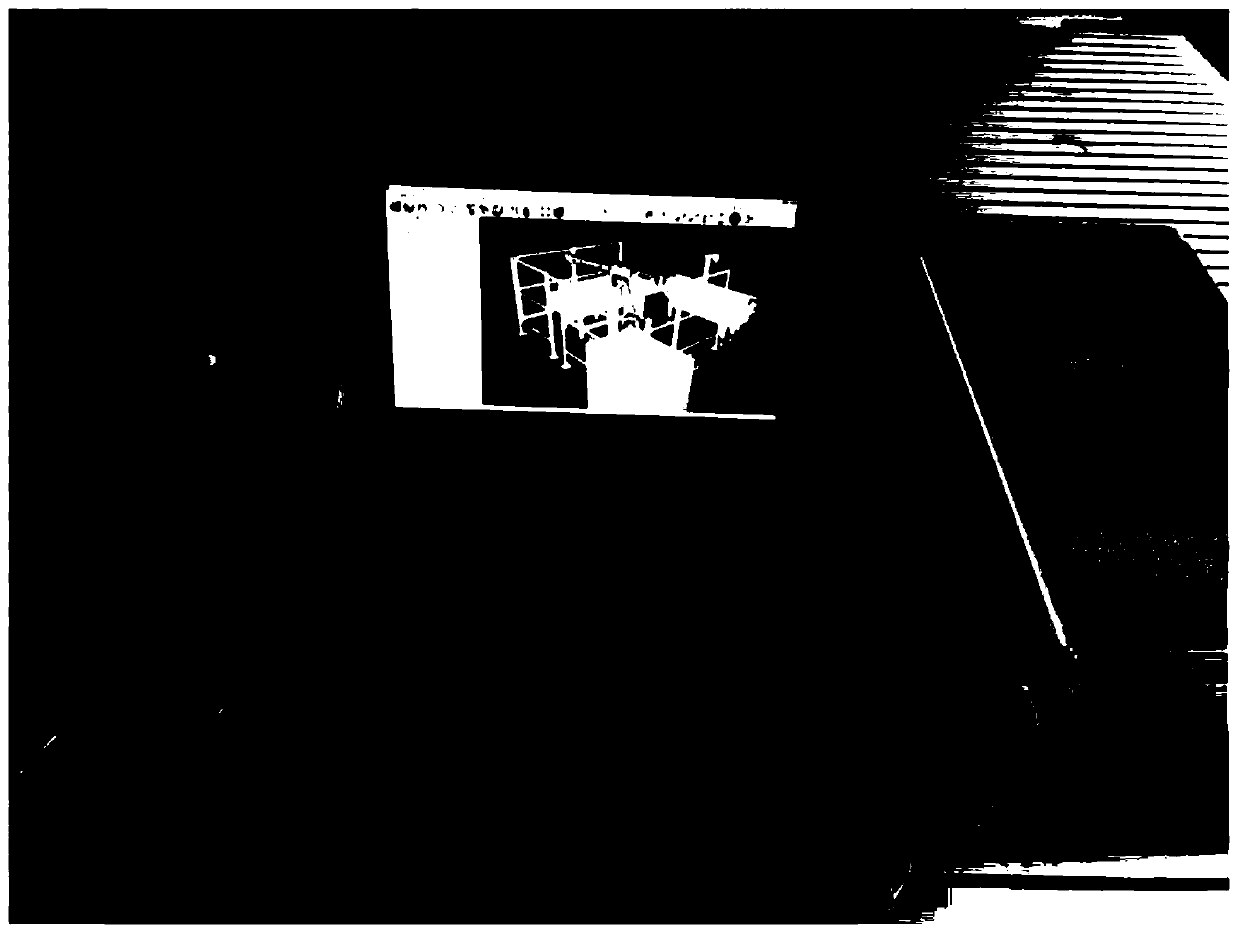

A virtual debugging system based on an OPC UA industrial communication protocol

ActiveCN109831354AOvercome the problem of not being able to connect multiple types of devicesSolve the problem of obtaining specified data in real timeProgramme-controlled manipulatorData switching networksInteraction layerSimulation

The invention discloses a virtual debugging system based on an OPC UA industrial communication protocol. Modules of the virtual debugging system are mainly divided into a data acquisition layer, a data interaction layer and a simulation equipment layer. The data acquisition layer comprises an industrial robot, a PLC and an OPC UA acquisition module; the data interaction layer comprises a data processing module, a Redis database module and an interaction interface module; the simulation equipment layer comprises a RoboDK simulation robot and a RoboDK simulation machining center; the data acquisition layer acquires output data of the PLC and the industrial robot through an OPC UA protocol, transmits the data as input to the data interaction layer, and writes the data transmitted by the datainteraction layer into equipment; the data interaction layer transmits data into the simulation equipment layer according to a data address configured by the interaction interface module and transmitsthe data of the simulation equipment layer to the data acquisition layer; the simulation equipment layer transmits data of the data interaction layer to the simulation model through an API, and transmits a signal of simulation equipment to the data interaction layer; and the system completes a virtual debugging function by controlling input and output of the simulation equipment.

Owner:ZHEJIANG UNIV OF TECH

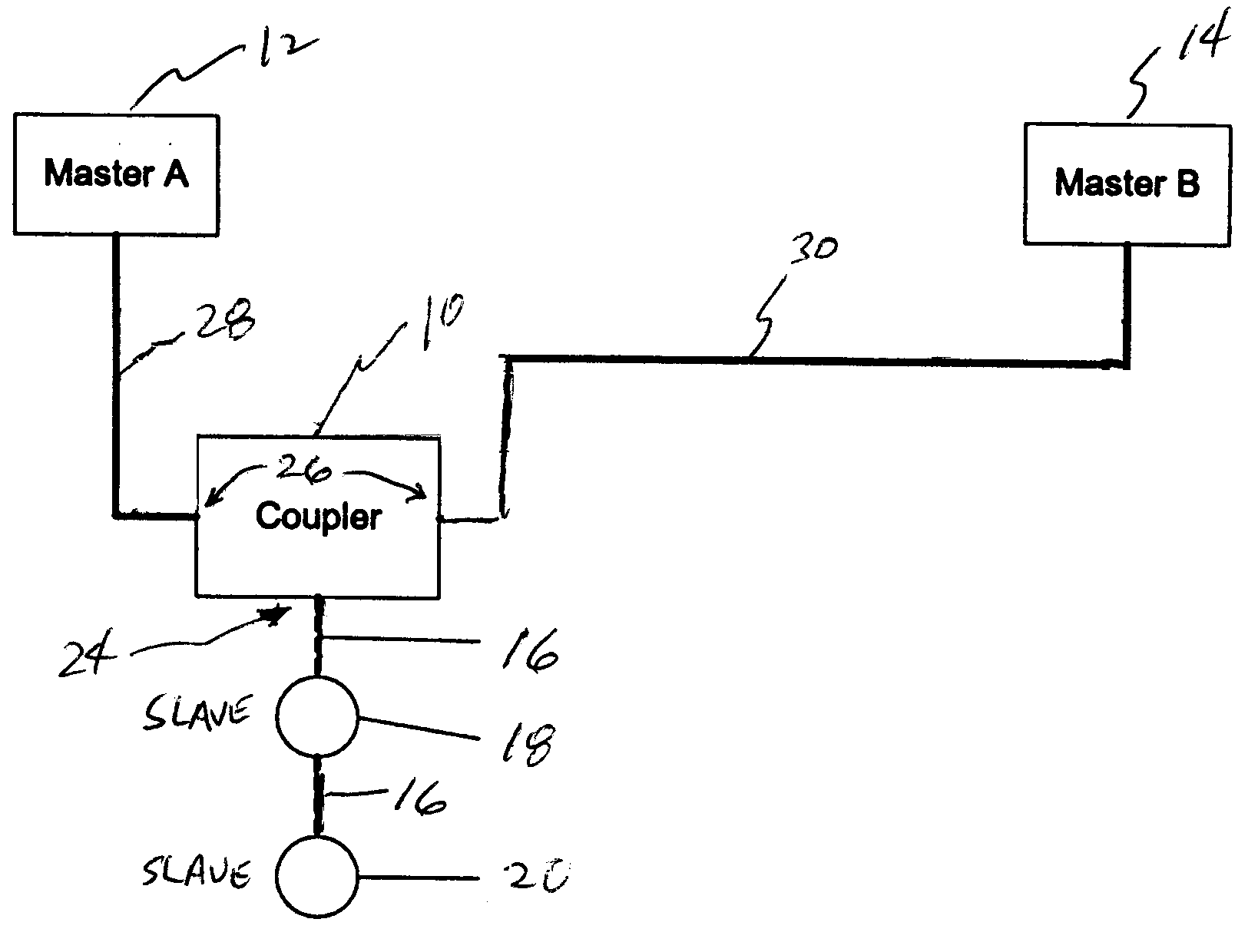

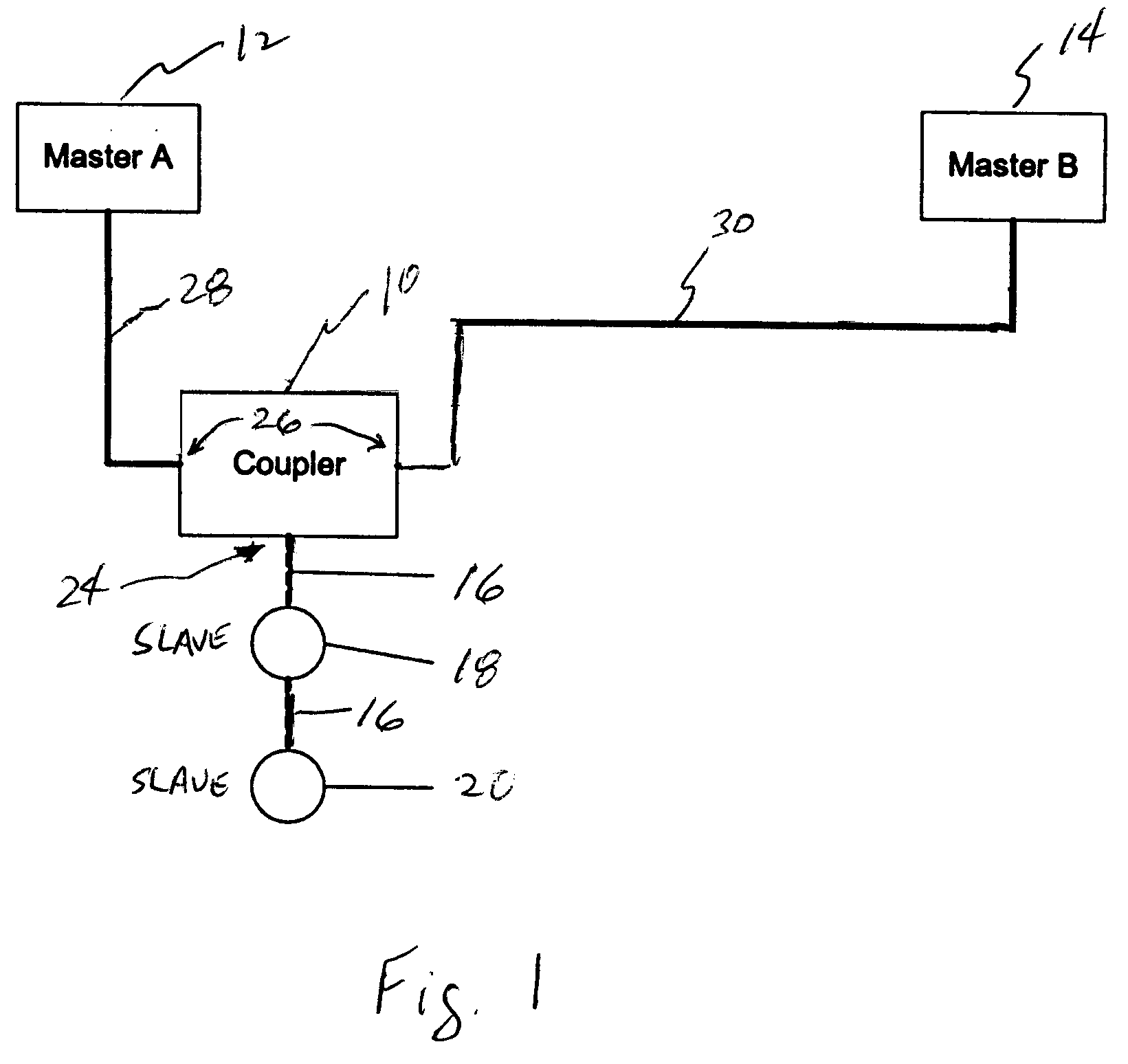

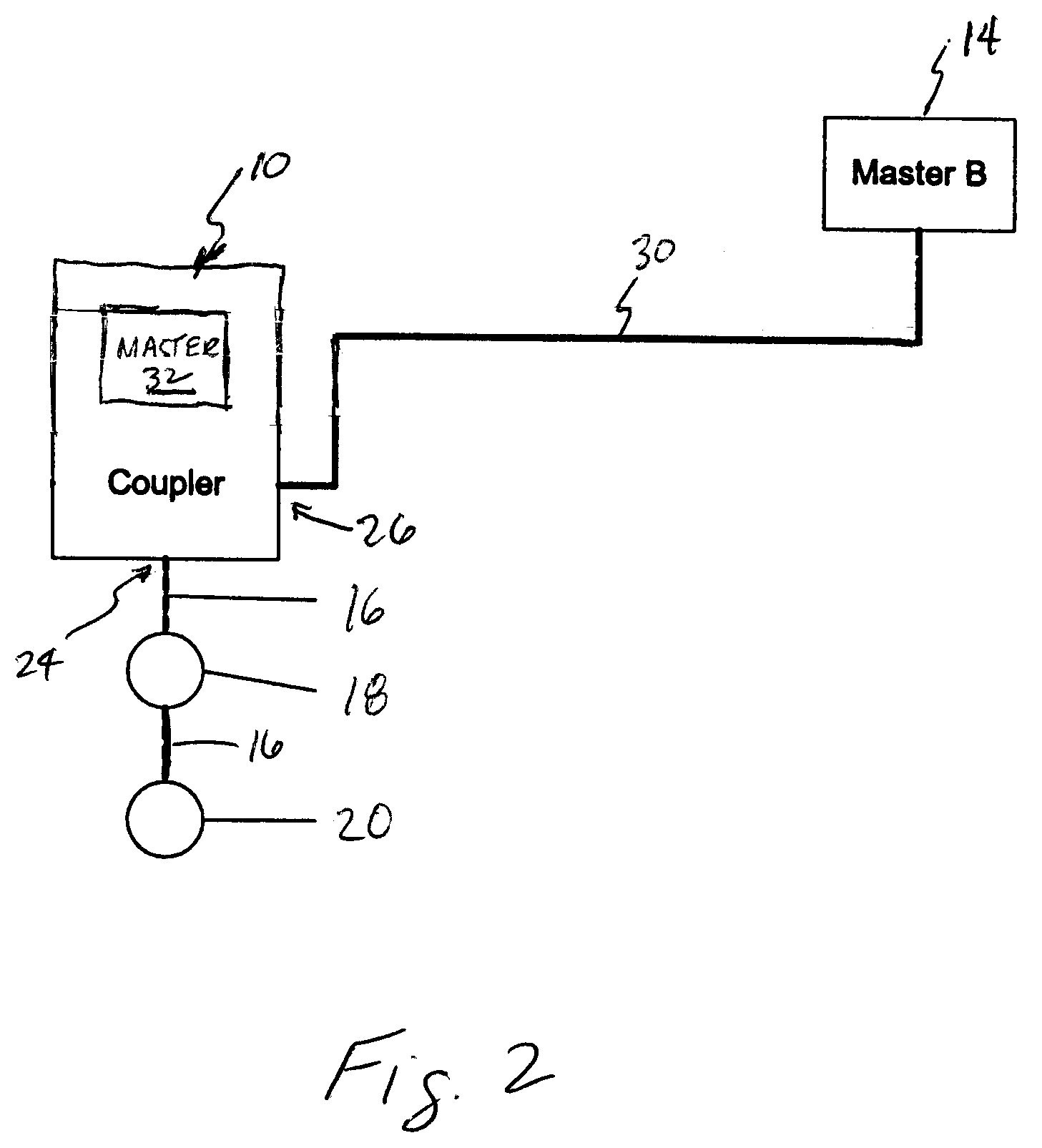

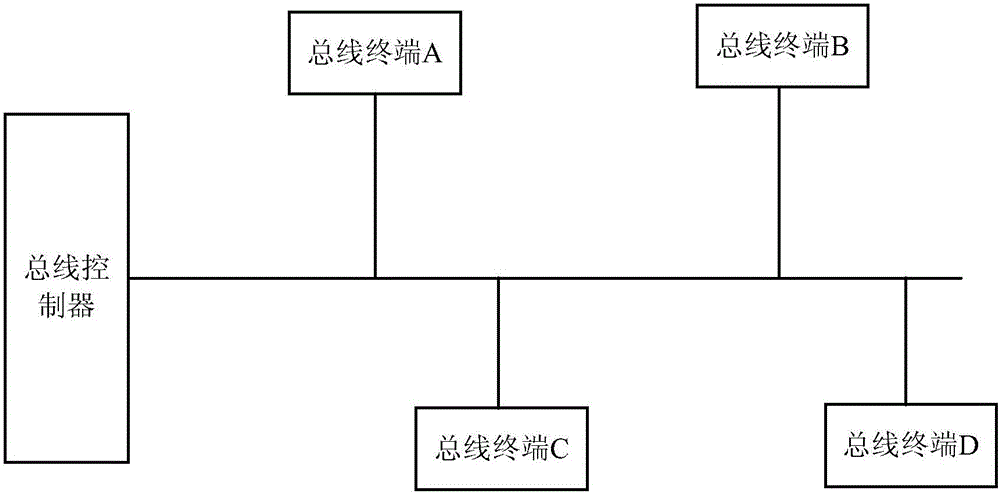

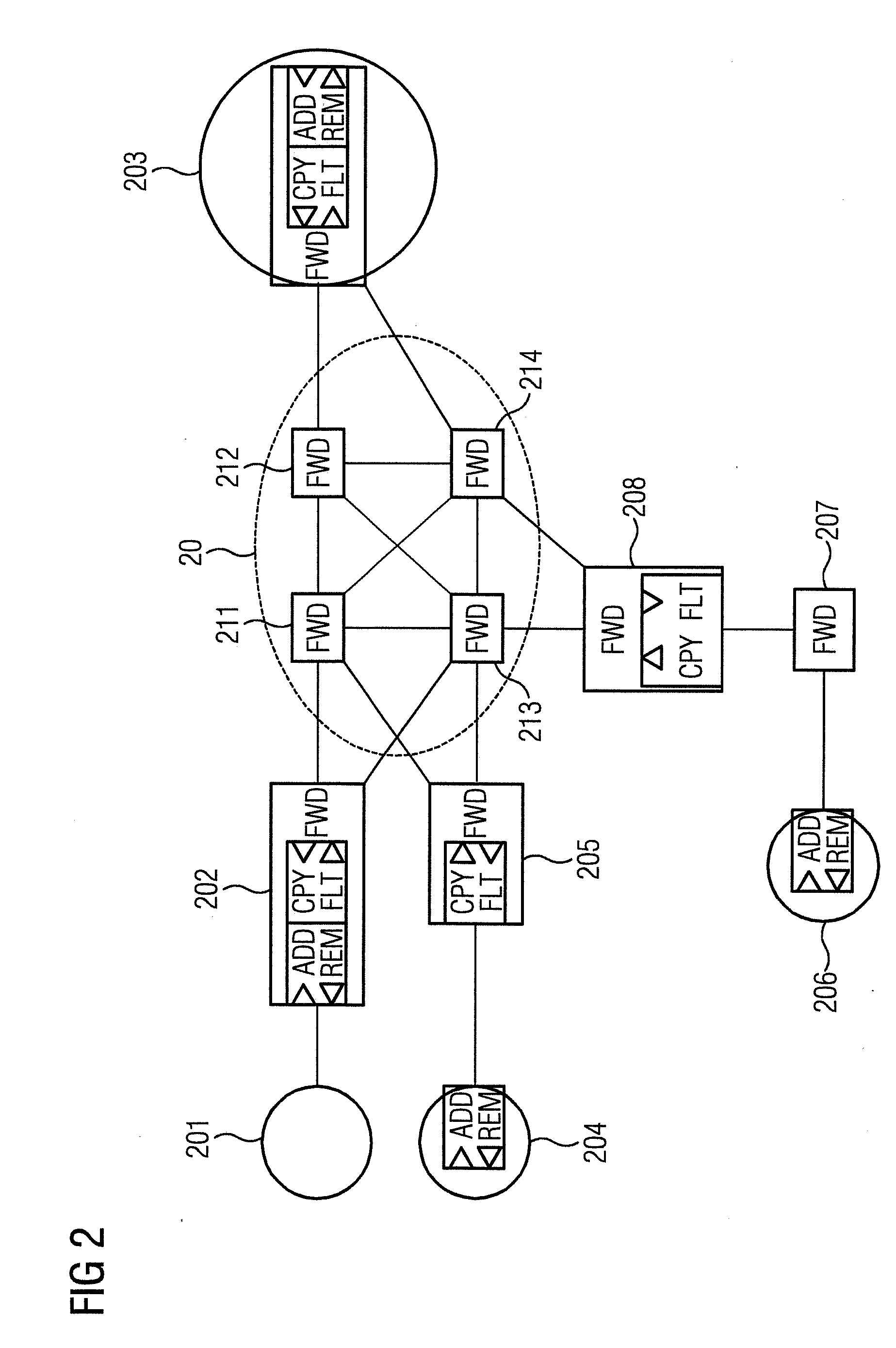

Redundancy coupler for industrial communications networks

InactiveUS20080123522A1Error preventionFrequency-division multiplex detailsIndustrial communicationMaster controller

A method for providing a hot standby master on a fieldbus includes communicatively coupling a redundancy coupler to a fieldbus having at least one slave device communicatively coupled thereto. The method further includes communicatively coupling a plurality of redundant fieldbus master controllers (MCs) to the coupler and utilizing the coupler to determine which of the plurality of redundant MCs is active. Also included in the method is using the coupler to receive communications from the active MC and to forward the received communications from the active MC to the one or more slave devices via the fieldbus. In addition, the coupler is used to receive communications from the other redundant MCs and to prevent the received communications from the redundant MCs from being forwarded to the one or more slave devices.

Owner:GE FANUC AUTOMATION NORTH AMERICA INC

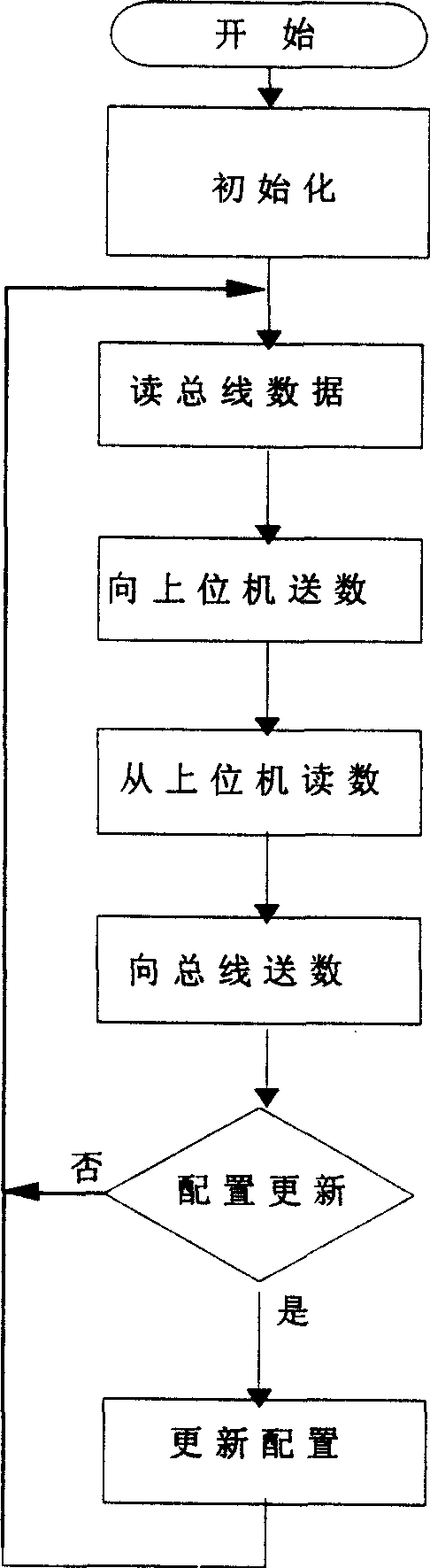

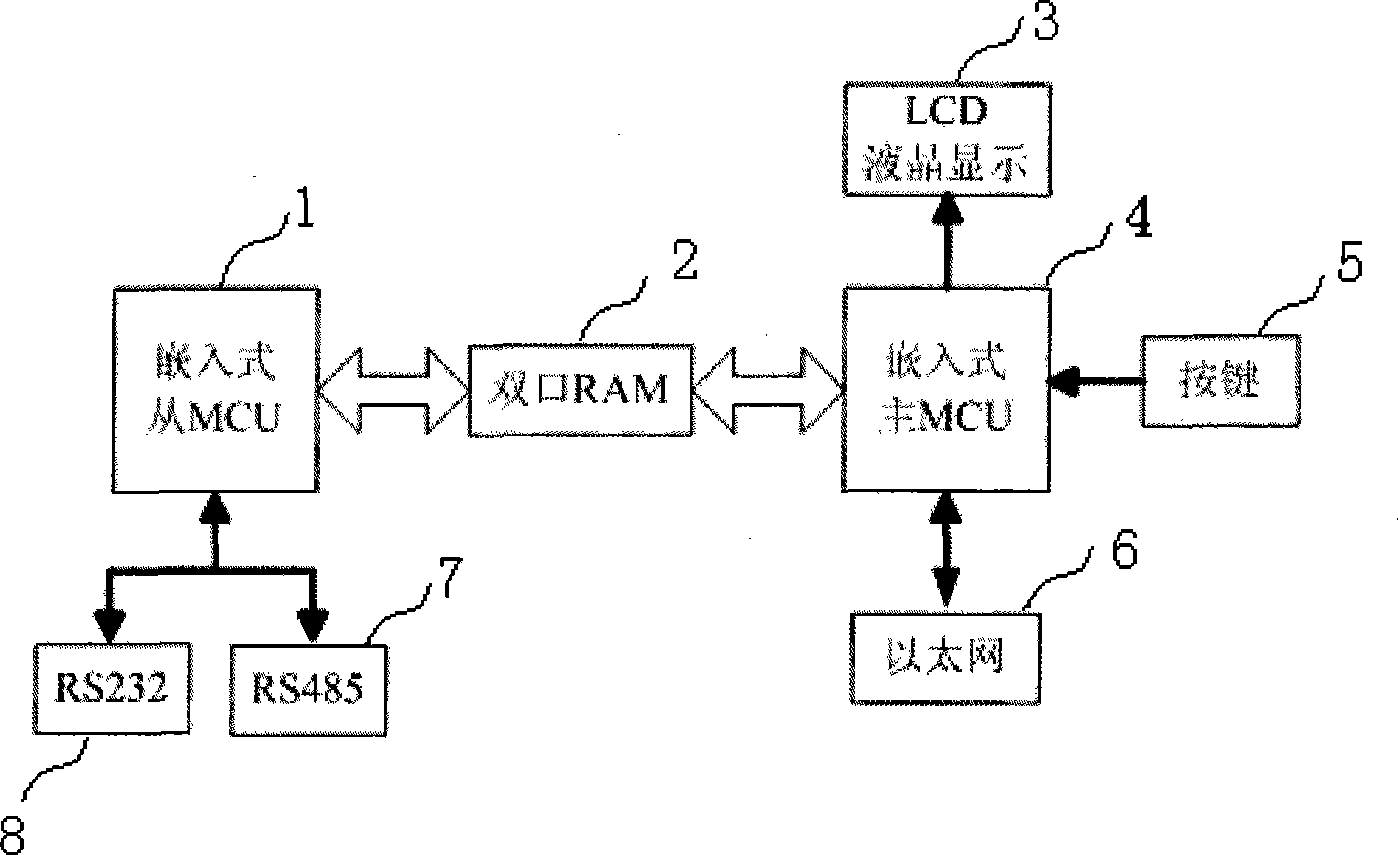

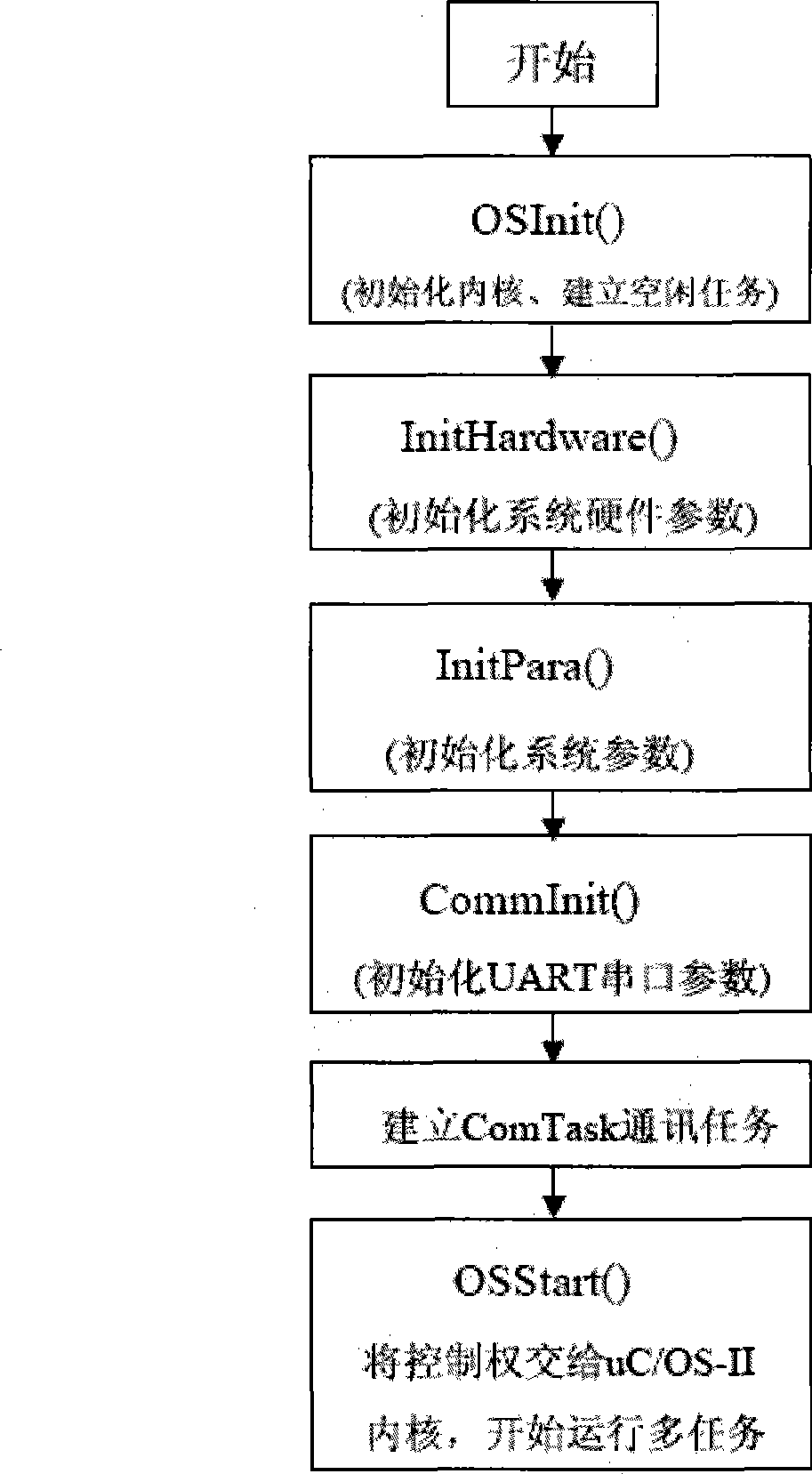

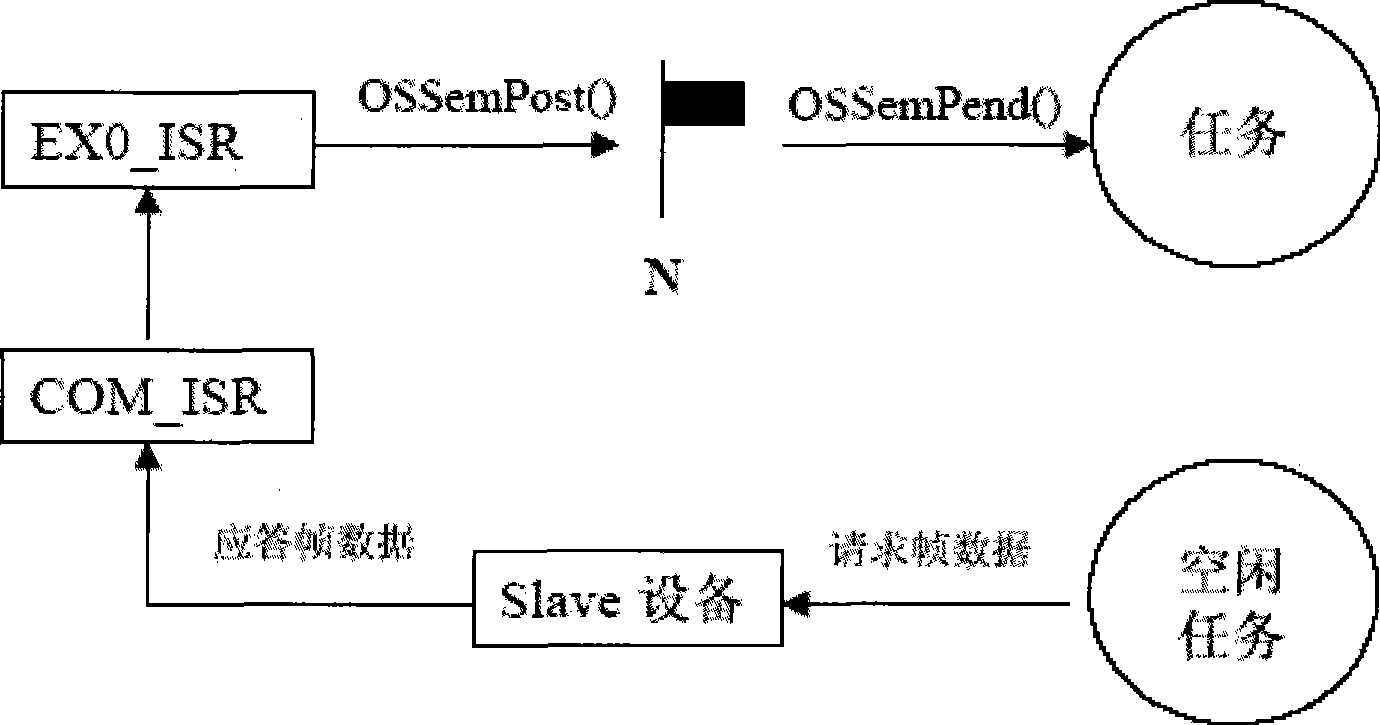

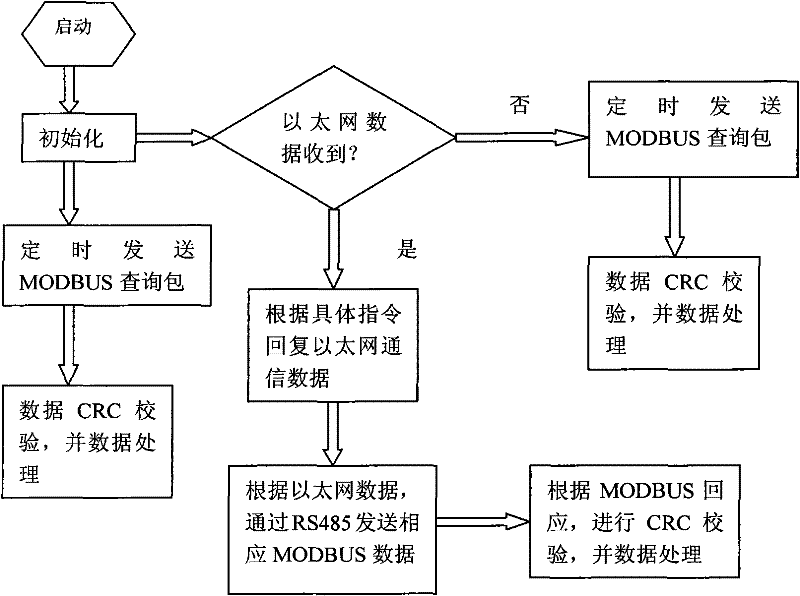

Communication protocol conversion device and method based on embedded multiple MCU

ActiveCN101420435AEliminate cumulative errorsImplement relayNetwork connectionsInformation processingOperational system

The present invention relates to a communication protocol converter based on embedded type multi-MCU and a method thereof, wherein the communication protocol converter adopts an embedded type multi-MCU and a real-time multiple task operating system Uc / OS-II. The communication protocol converter realizes the communication to the data collecting I / O module of a device layer through protocols of Nodbus / RTU or ASCII, etc. The measuring data of industrial field is obtained, and then the data is transmitted to remote monitoring systems of upper DAS, DCS, etc. through the protocols of Modbus / TCP, TCP / IP, etc. with an Ethernet communication interface. The functions of relaying and protocol converting in industrial communication network are realized. The serial interface device of the device layer can be easily connected to a monitoring layer network. The embedded type multi-MCU and high-speed RAM data sharing technology are adopted for simplifying circuit design, increasing the reliability and real-time property of system, and facilitating the data exchange, data sharing and information processing between the embedded type MCUs.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER +1

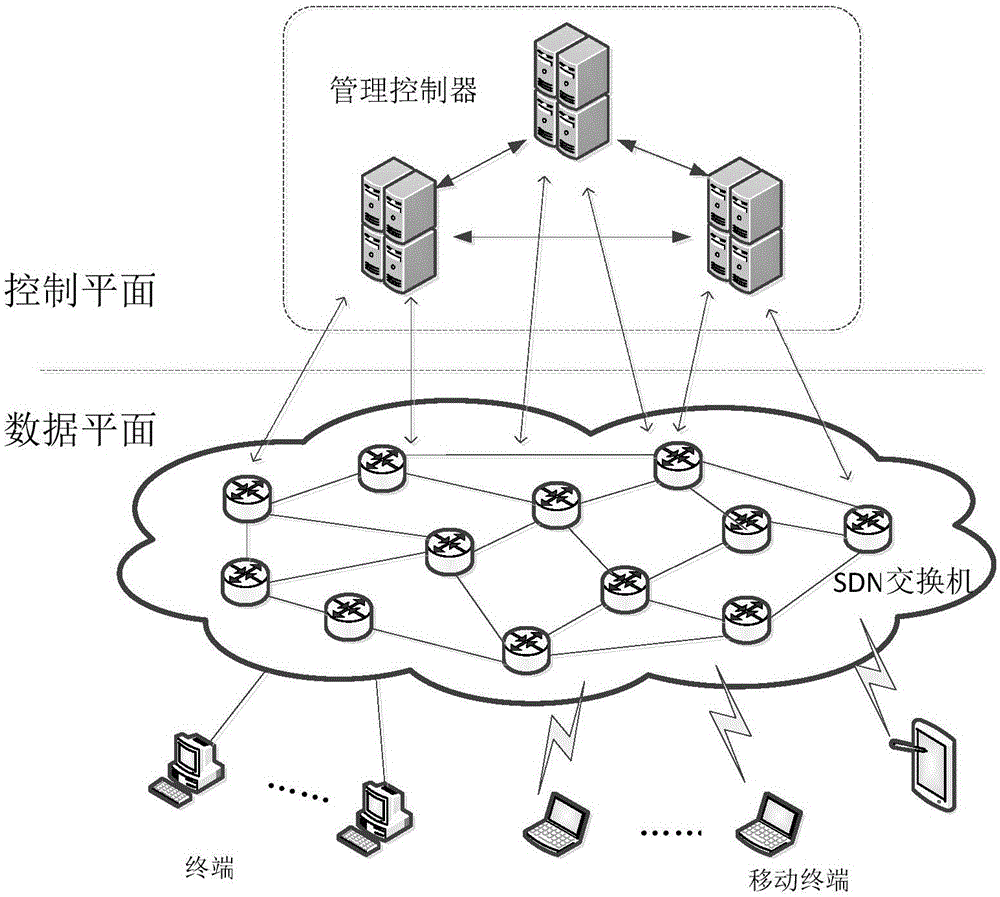

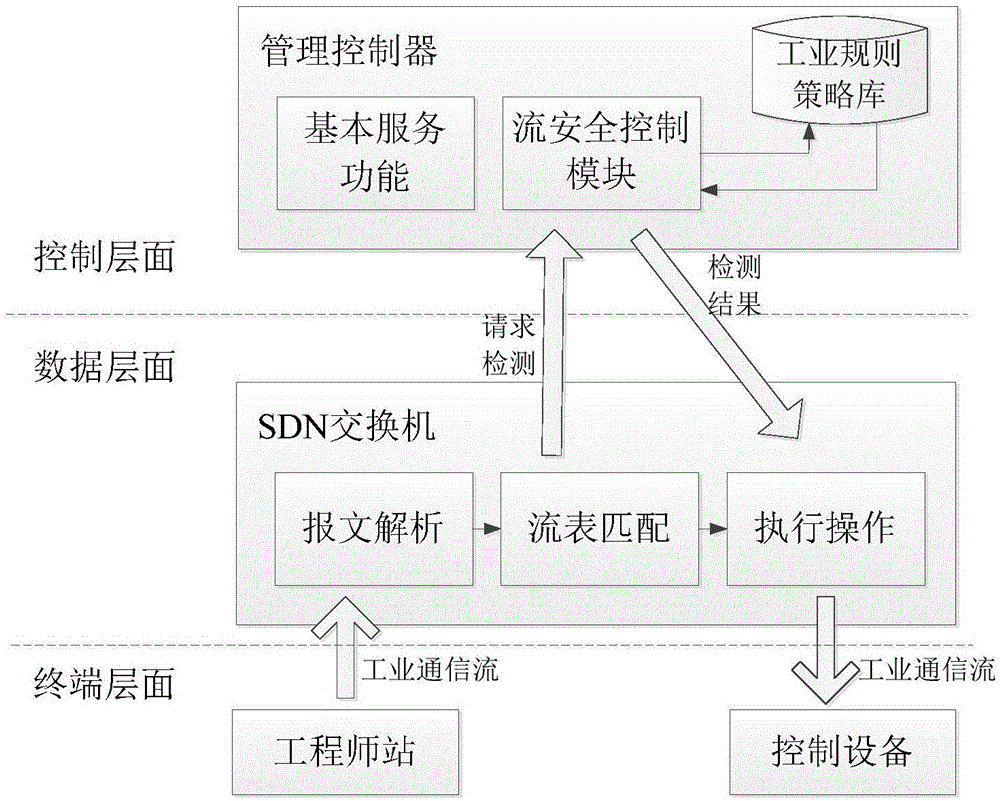

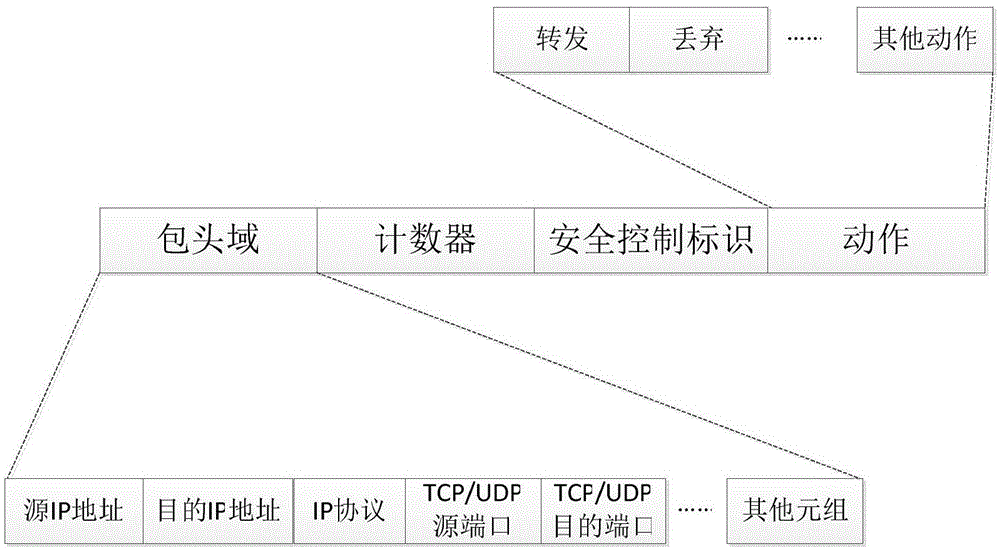

Industrial communication flow transmission safety control method based on SDN architecture

ActiveCN106411820ARaise checkAdd control mechanismSecuring communicationProgramme total factory controlData streamSecure transmission

The invention discloses an industrial communication flow transmission safety control method based on an SDN architecture. According to the method, a flow safety control module is designed in a management controller, deep analysis of industrial communication flow data is conducted, matching is performed with a preset industrial rule strategy, control processing operation in the industrial rule strategy is performed, and transmission control of the industrial communication flow is realized. The management controller comprises an industrial rule strategy database used for storing all industrial rule strategies set by users and an SDN switch maintenance flow table structure, the industrial communication flow is forwarded according to a flow table, and the flow table comprises a safety control identifier used for indicating whether the communication flow needs safety transmission control. According to the method, the legitimacy of the industrial communication data flow can be detected, access control for industrial communication which is not in accordance with the industrial rule strategy is realized, and the security and the reliability of an industrial control system based on the SDN architecture is guaranteed.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

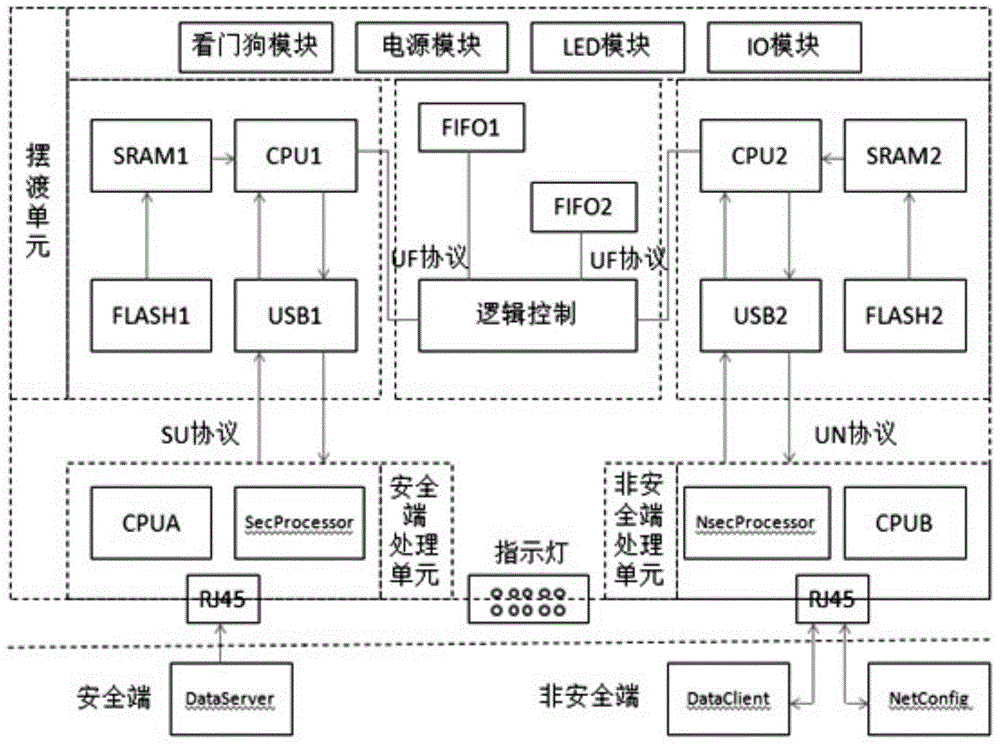

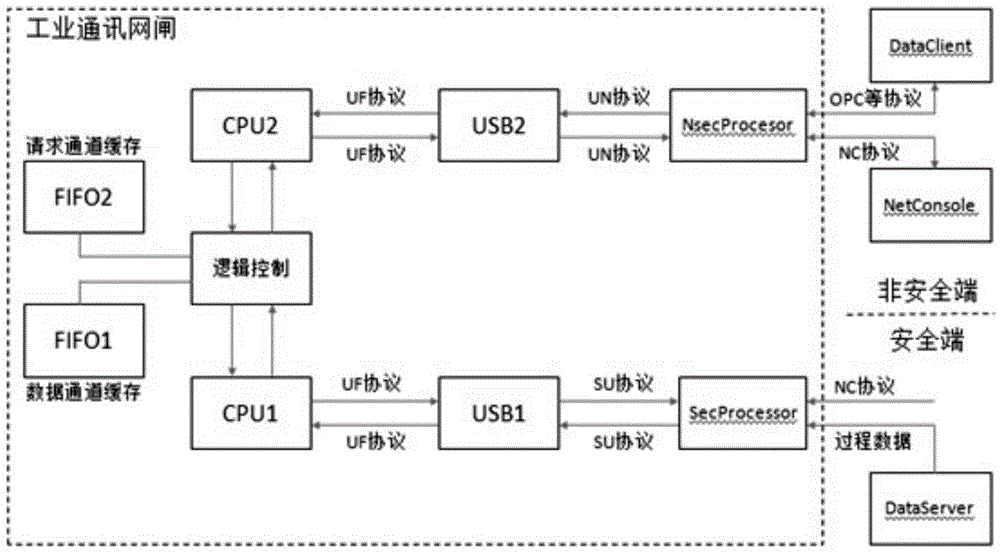

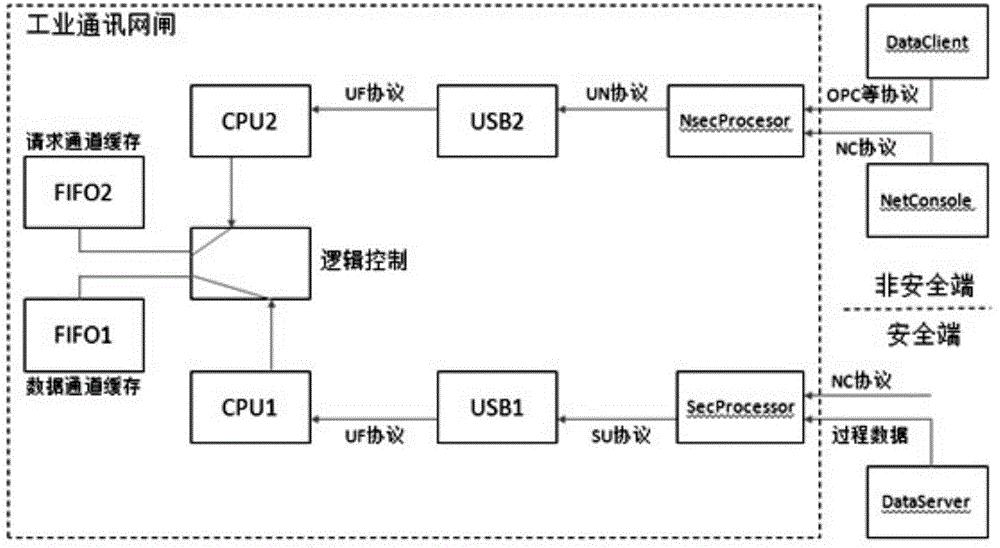

Industrial communication isolation gap with double-channel ferrying function

ActiveCN104683352AEasy data collectionEasy for daily maintenanceTransmissionData acquisitionInformation networks

The invention discloses an industrial communication isolation gap with a double-channel ferrying function. The industrial communication isolation gap comprises a safety end processing unit, a non-safety-end processing unit and a ferrying unit. The circuit of the safety end processing unit, that of the non-safety-end processing unit and that of the ferrying unit are all independent of one another and three units are communicated by USBs (Universal Serial Bus); the ferrying unit adopts a double-channel ferrying form; double channels are two independent one-way channels; one channel is a request channel, takes charge of carrying out one-way requesting from a non-safety end to a safety end and is used for configuration requesting and label requesting; the other channel is a data channel, takes charge of carrying out one-way transmission from the safety end to the non-safety end and is used for process data transmission and state data transmission. The isolation gap is used for an industrial control network and an upper layer information network to realize one-way transmission of process data under the condition of physical isolation, can perform functions of no maintenance of a tag and remote configuration, maintenance and management and brings great convenience to normal data acquisition and daily maintenance.

Owner:NINGBO KEAN WANGXIN COMM TECH CO LTD

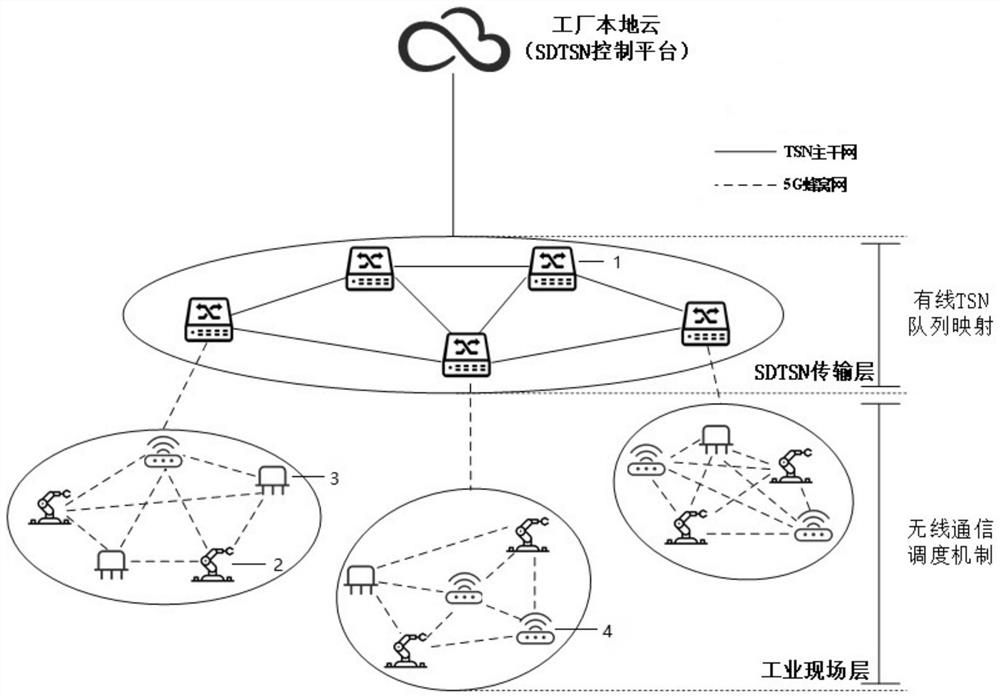

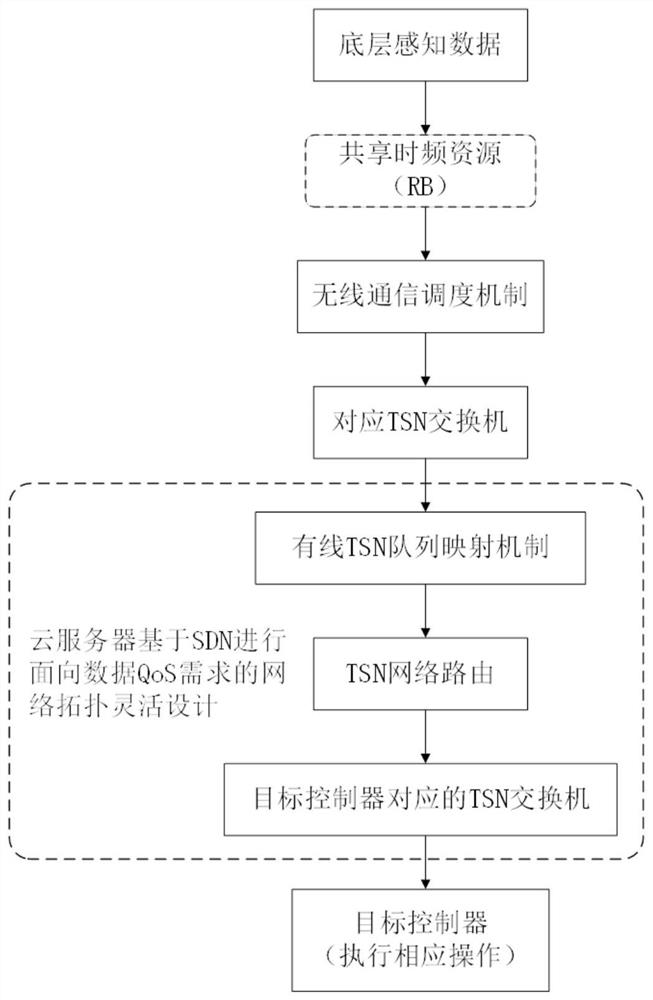

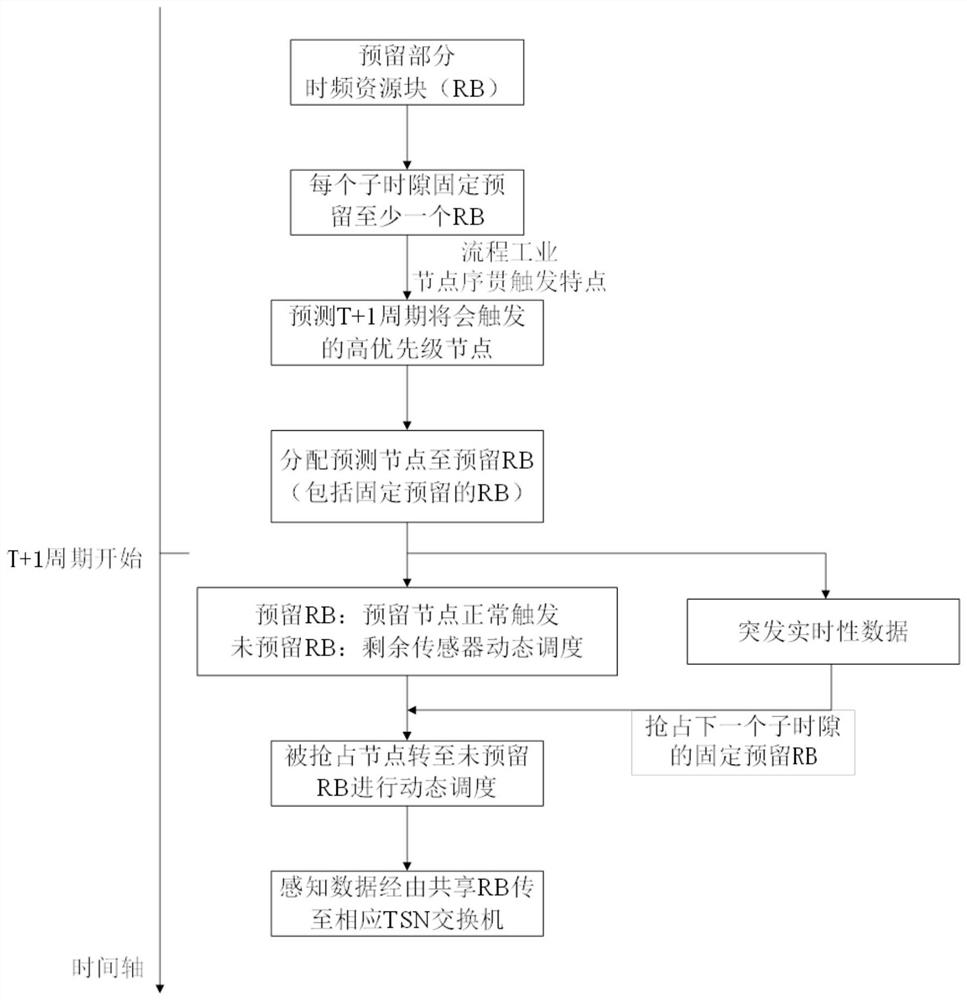

Software-defined industrial heterogeneous time-sensitive network system and resource scheduling method

ActiveCN112511462AConducive to intelligent manufacturingMeet transmission needsNetwork traffic/resource managementData switching networksData streamNetwork architecture

The invention discloses a software-defined industrial time-sensitive heterogeneous network system and a resource scheduling method, and relates to the field of industrial communication. The inventiondiscloses a software-defined industrial heterogeneous time-sensitive network architecture. The software-defined industrial heterogeneous time-sensitive network architecture comprises an industrial field layer, an SDTSN (Software Defined Network) transmission layer and an industrial cloud platform, the invention discloses a software-defined industrial heterogeneous time-sensitive network resource hierarchical scheduling method. The method comprises a 5G technology-based multi-priority wireless scheduling mechanism considering burst data and a wired TSN multi-priority queue mapping and scheduling mechanism. The problems that an existing industrial communication mode is single, and the QoS requirements of industrial field mass data are different are solved, data streams with different QoS requirements can be dispatched in a centralized mode based on global information of a network, on-demand deterministic delivery of industrial heterogeneous data is achieved, full-process time-sensitive communication of a wireless and wired industrial heterogeneous network is achieved, and the time determinacy and the resource utilization rate of the TSN are greatly improved.

Owner:SHANGHAI JIAO TONG UNIV

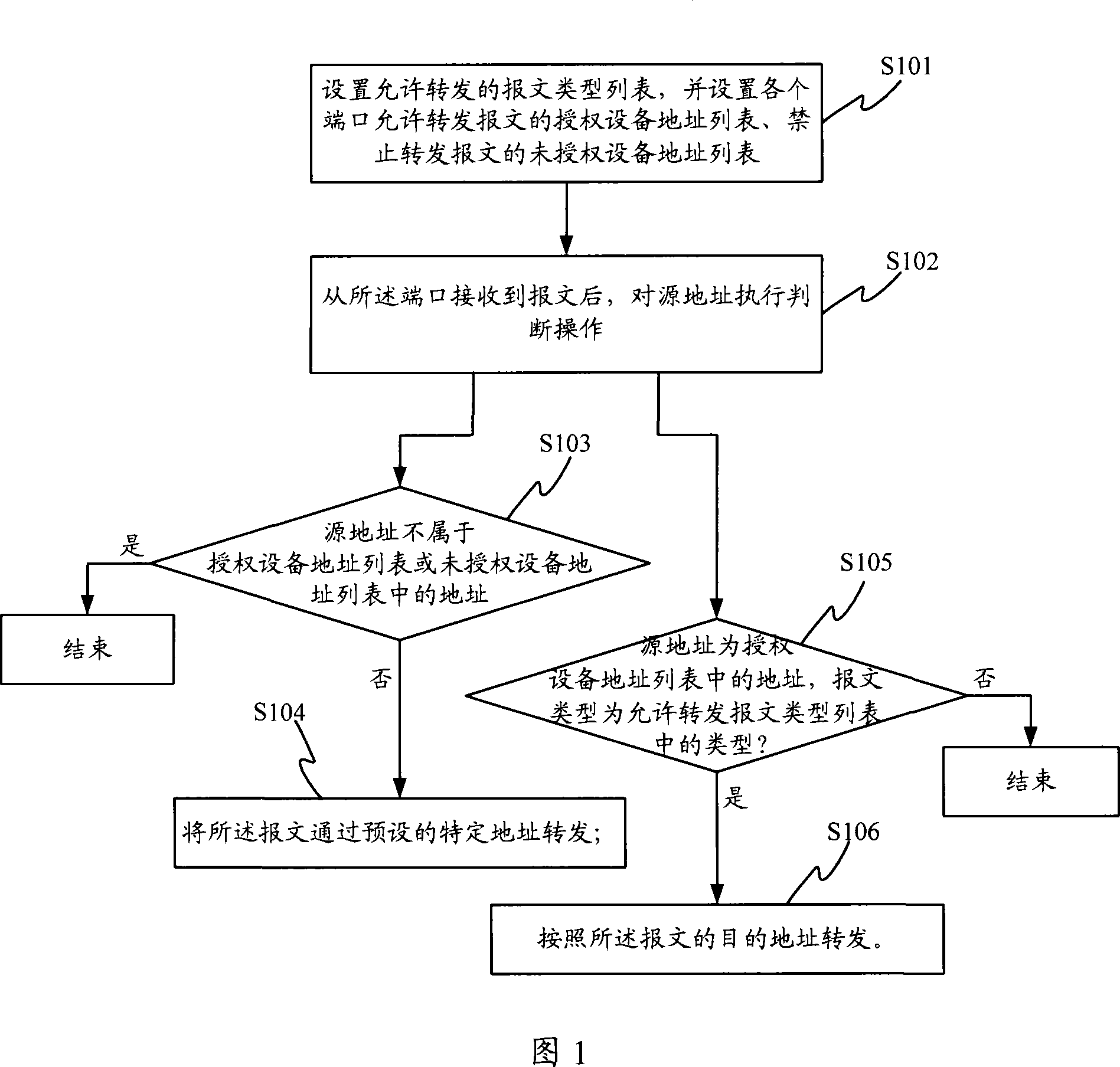

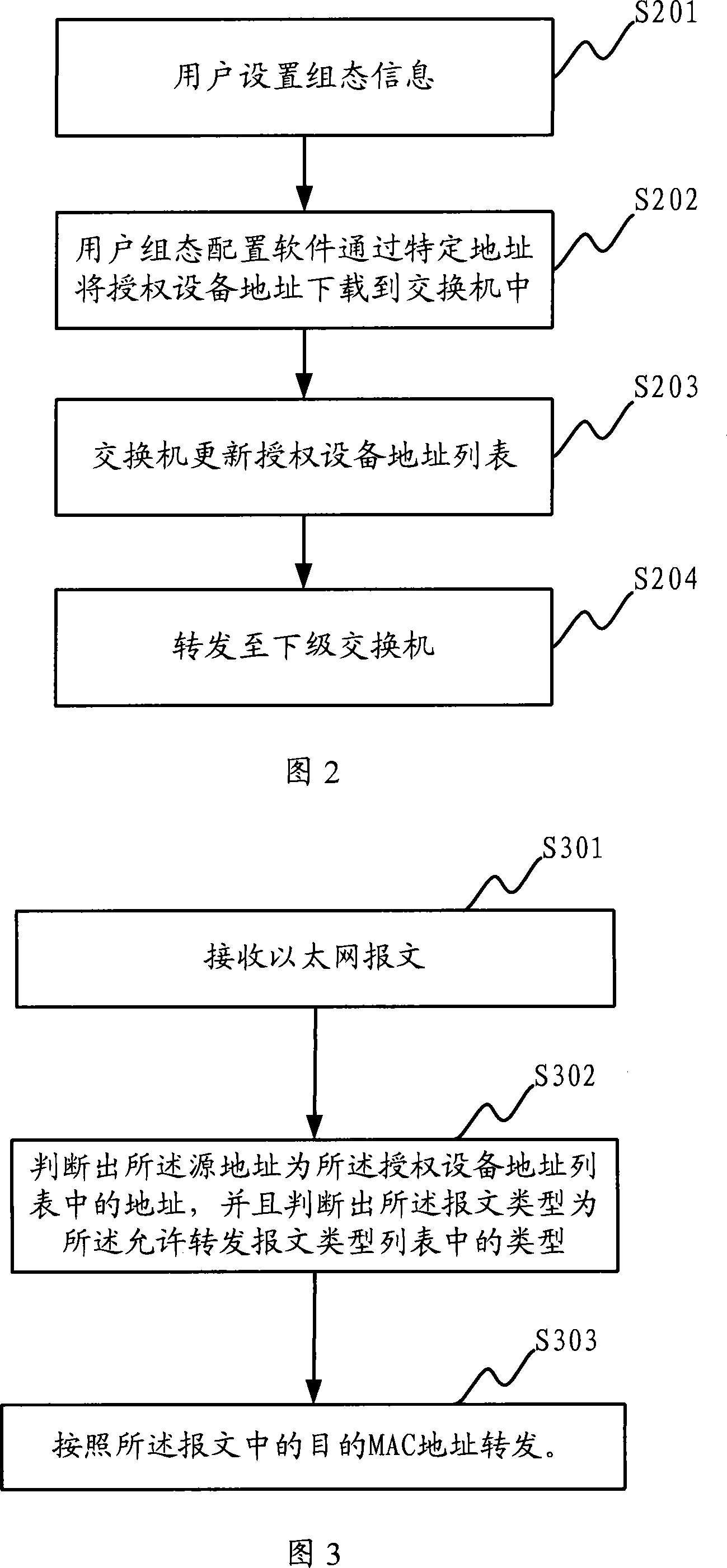

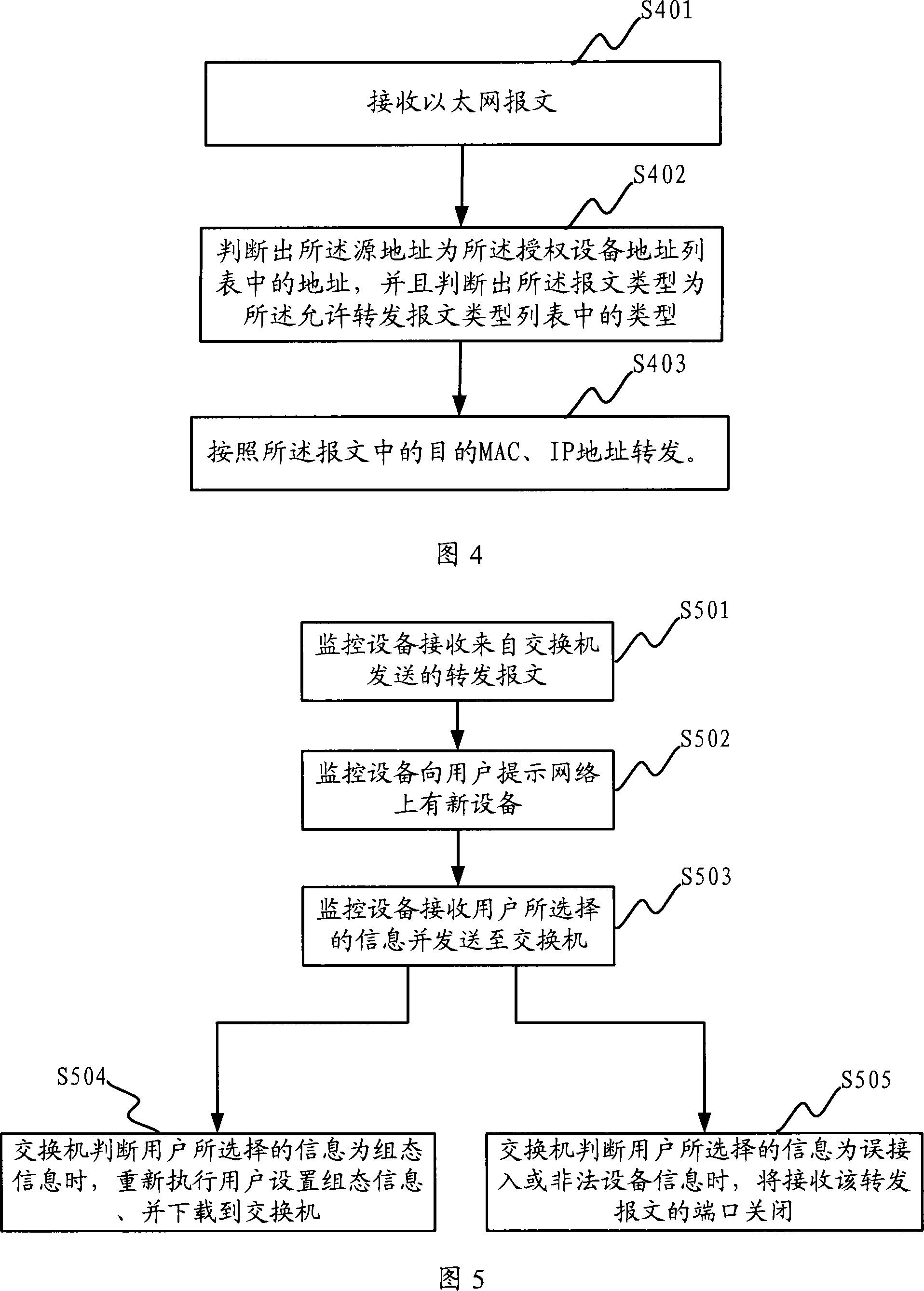

A packet forward method and switch

The utility model discloses a packet forwarding method, relating to the technical field of industrial communication. The utility model comprises: a preset list enabling message transmission, a preset authorized equipment address list enabling message transmission in each port and an unauthorized equipment address list disabling message transmission; the source address of the message is judged after the message is received from the port, and then if the source address is judged not to belong to the authorized equipment address list or the address in the unauthorized equipment address list, the message is transmitted via preset special address; if the source address belongs to the address in the authorized equipment address list, and the message belongs to the type in the message type list enabling transmission, then the transmission is performed as the message destination address. The utility model also discloses an exchanger. The utility model has the advantage that when message and illegal message are sent by unauthorized equipment, the normal equipment is not affected with the method and the exchanger.

Owner:SUPCON GRP +1

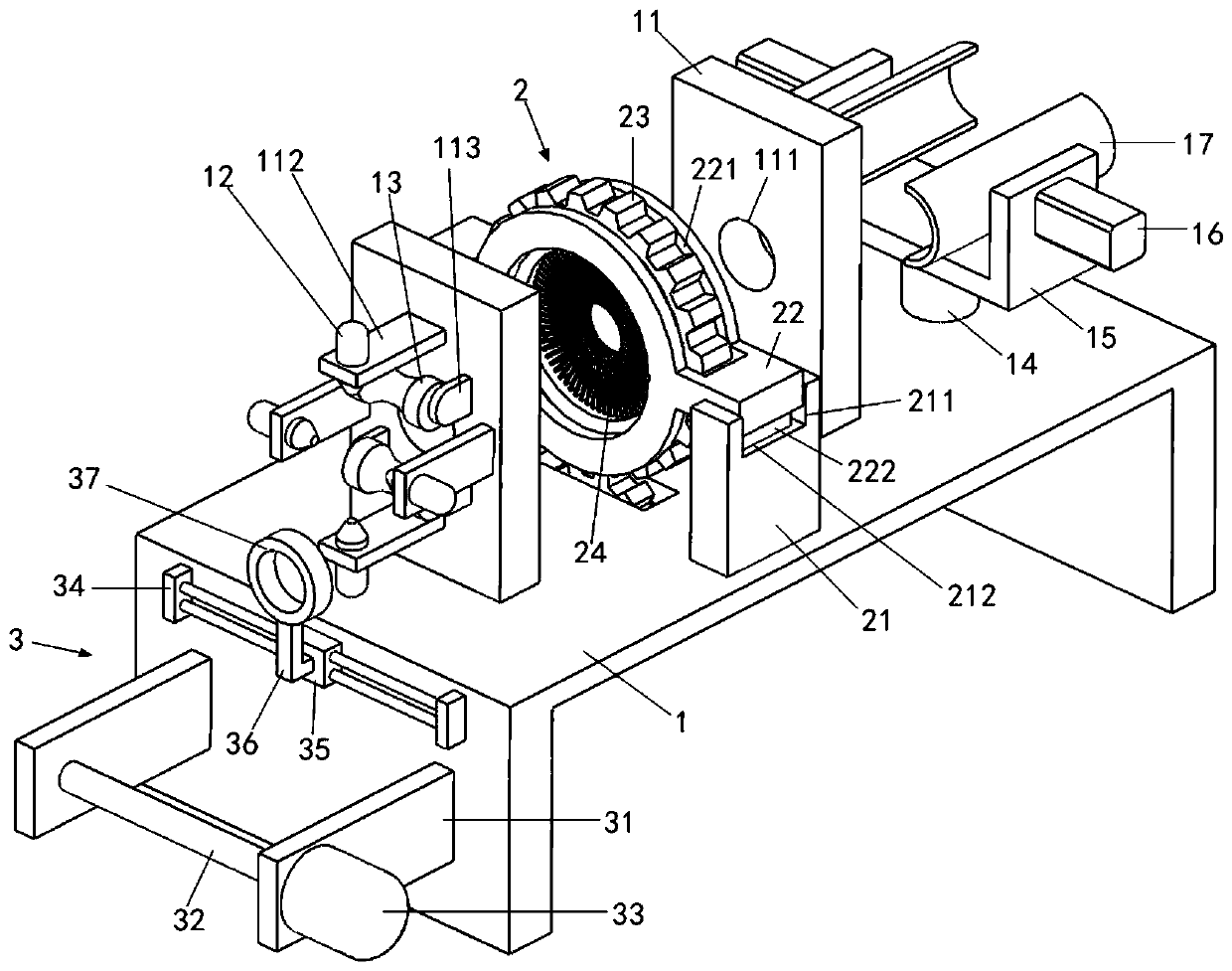

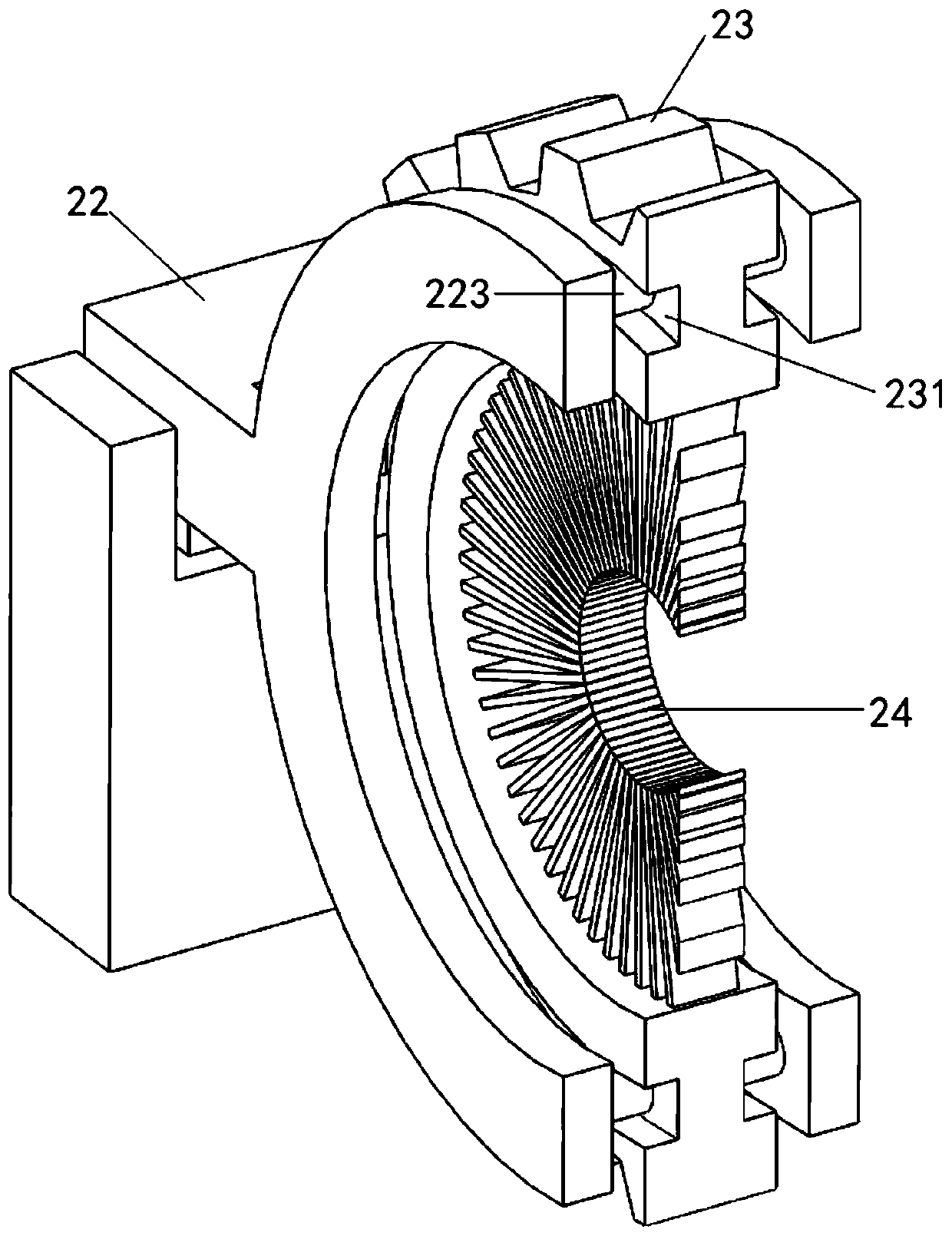

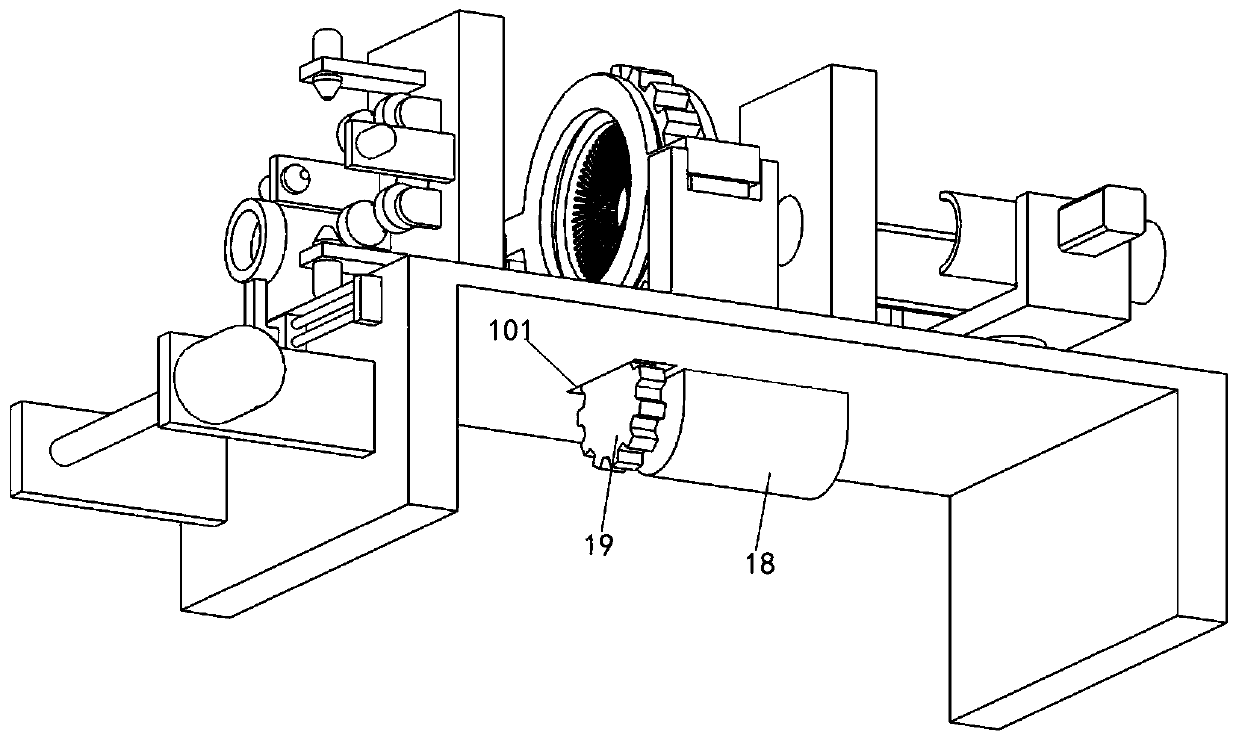

Industrial communication cable dedusting device

ActiveCN110496805AThorough dust removal effectGood effectCleaning using toolsCleaning using gasesIndustrial communicationAutomation

The invention discloses an industrial communication cable dedusting device. The device comprises a work frame. A pair of guide penetration plates are arranged on the top surface of a top plate of thework frame. Concentric penetration holes are formed in the two guide penetration plates correspondingly. A contact dedusting device is arranged between the two guide penetration plates. A winding roller is arranged on the outer surface wall of a front side plate of the work frame. The contact dedusting device comprises a pair of fixed supporting blocks. The two ends of a gear mounting frame are movably arranged on the fixed supporting blocks. A gear mounting groove is formed in the center of the gear mounting frame. An annular gear is rotationally arranged in the gear mounting groove. A ring-shaped dedusting bristlebrush is arranged on the inner circular wall of the annular gear. The industrial communication cable dedusting device has the advantages that two procedures of cleaning treatment is performed on the surface of a cable, the dedusting effect is thorough, the cleaned cable can be automatically wound and collected while dedusting is performed, the automation degree is good, andthe effect is good.

Owner:SUZHOU YUANLIAN SCI & TECH PIONEER PARK MANAGEMENT CO LTD

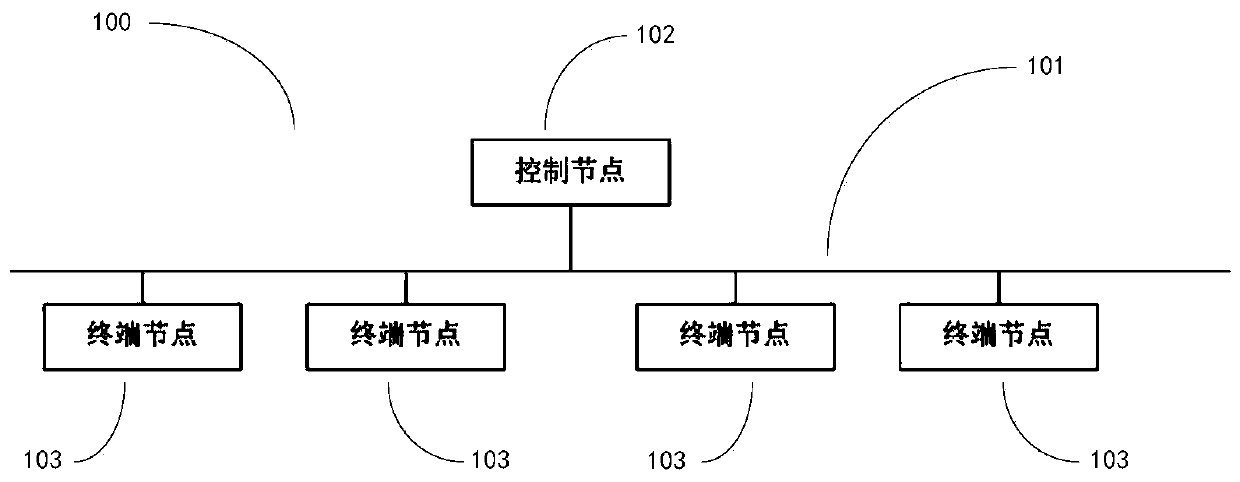

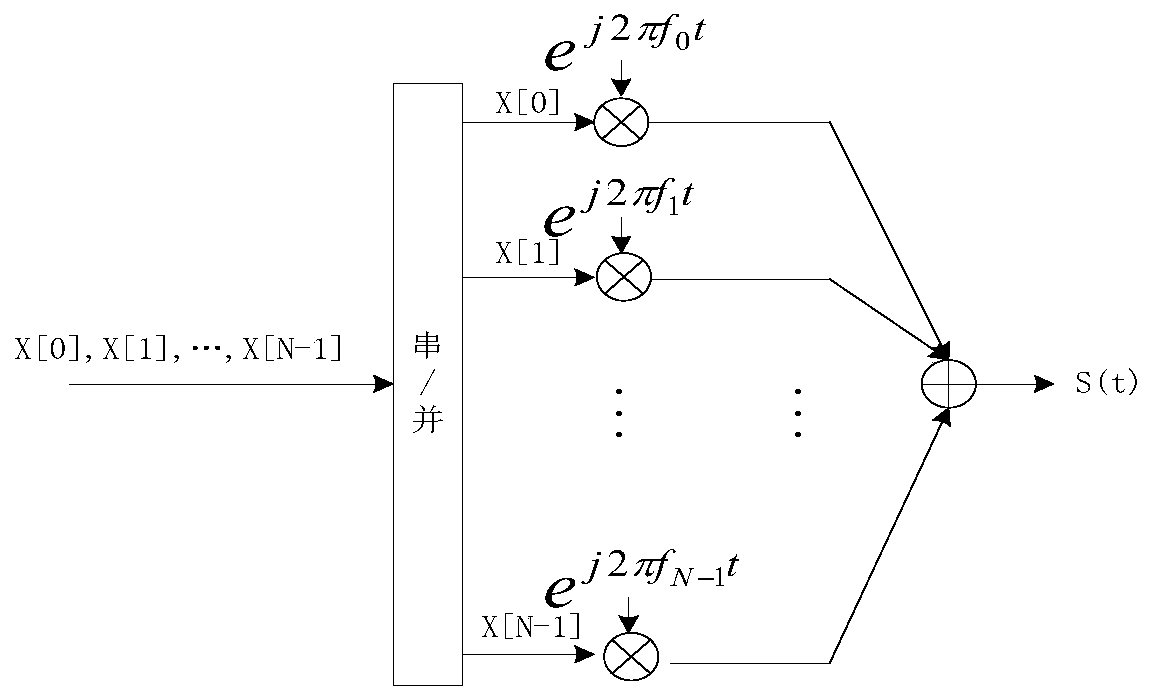

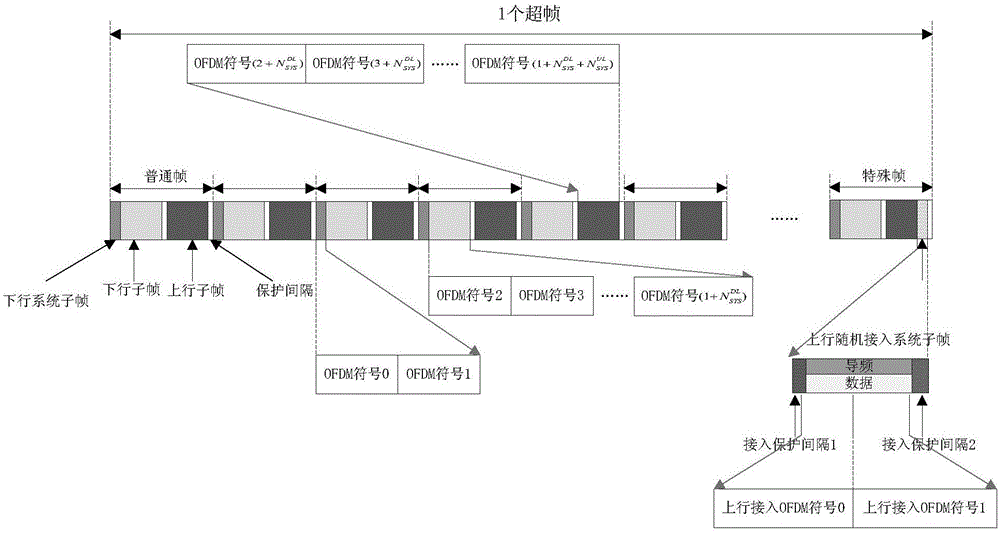

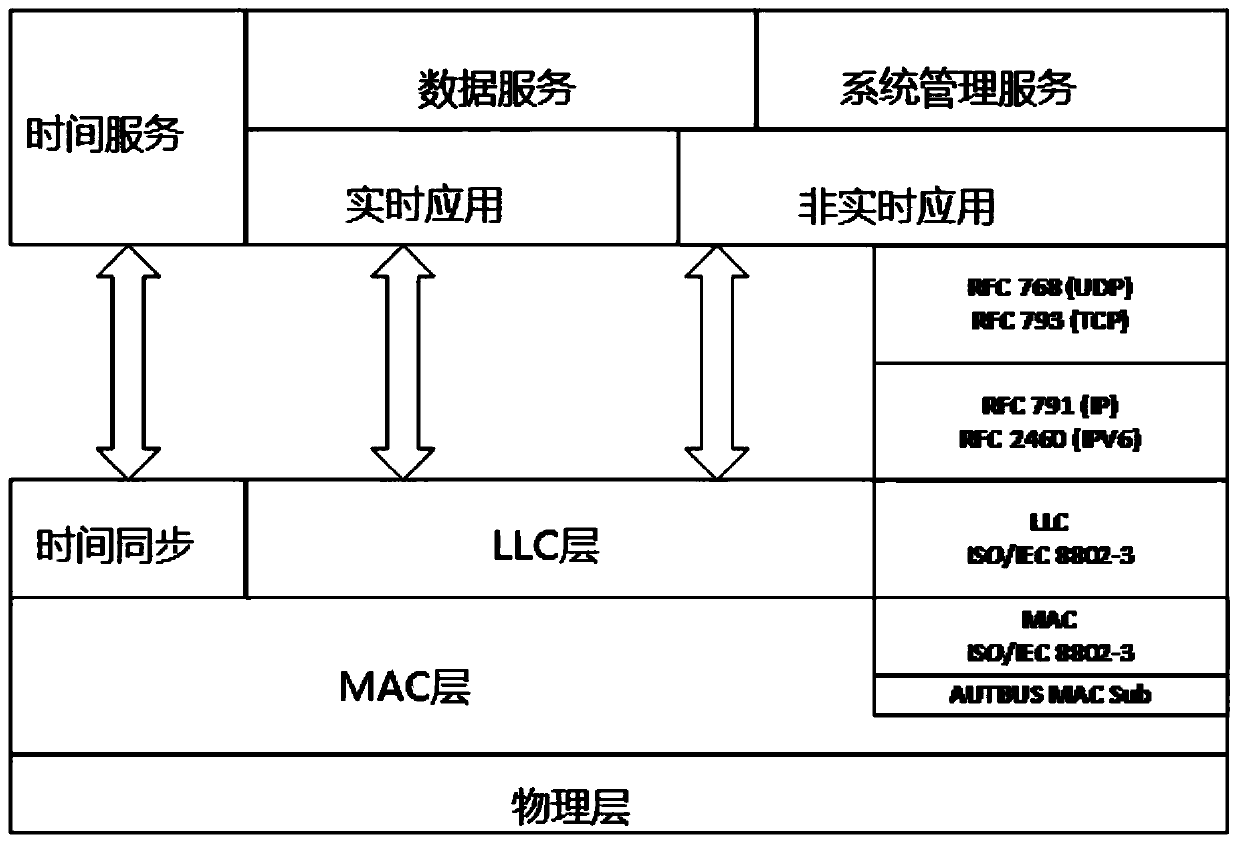

Node device, high-speed industrial communication system and communication method

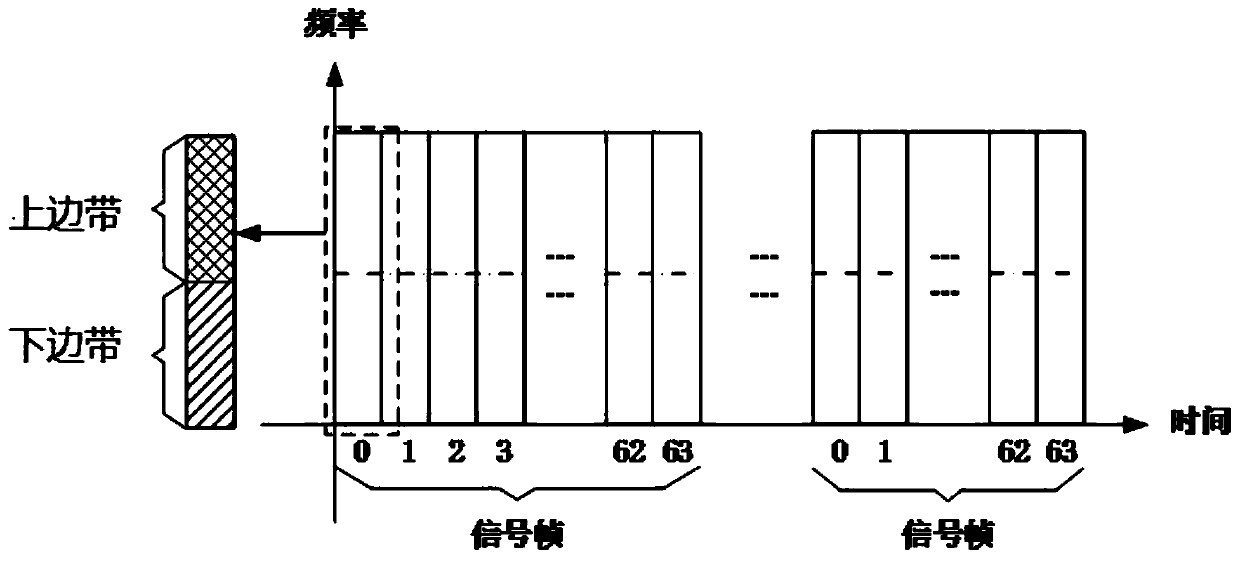

InactiveCN110247834AHigh bandwidthSolve real-timeMulti-frequency code systemsForward error control useNon real timeControl communications

The invention relates to a node device capable of being connected to an industrial control bus. The node device comprises a data sending conversion module which converts a to-be-sent data symbol stream, and the data sending conversion module comprises a resource mapping unit which can receive a pilot signal and the to-be-sent data symbol stream and map the to-be-sent data symbol stream to a corresponding effective subcarrier; and an OFDM signal generation unit which is used for generating OFDM symbols from the pilot signals and / or the data symbol streams according to the effective subcarriers obtained by the resource mapping unit. The invention also relates to a high-speed industrial communication system comprising the node device. The high-speed industrial communication system is mainly used for solving the problems that a traditional bus on an industrial site is low in bandwidth, real-time and non-real-time cannot be borne at the same time, and the network structure is complex. The high-speed industrial communication system can support IPV6 address communication, time-triggered industrial control communication, TSN and safety mechanisms such as a white list, deep detection and data encryption.

Owner:北京神经元网络技术有限公司

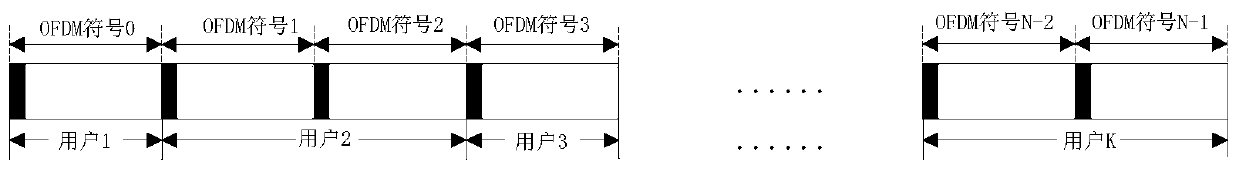

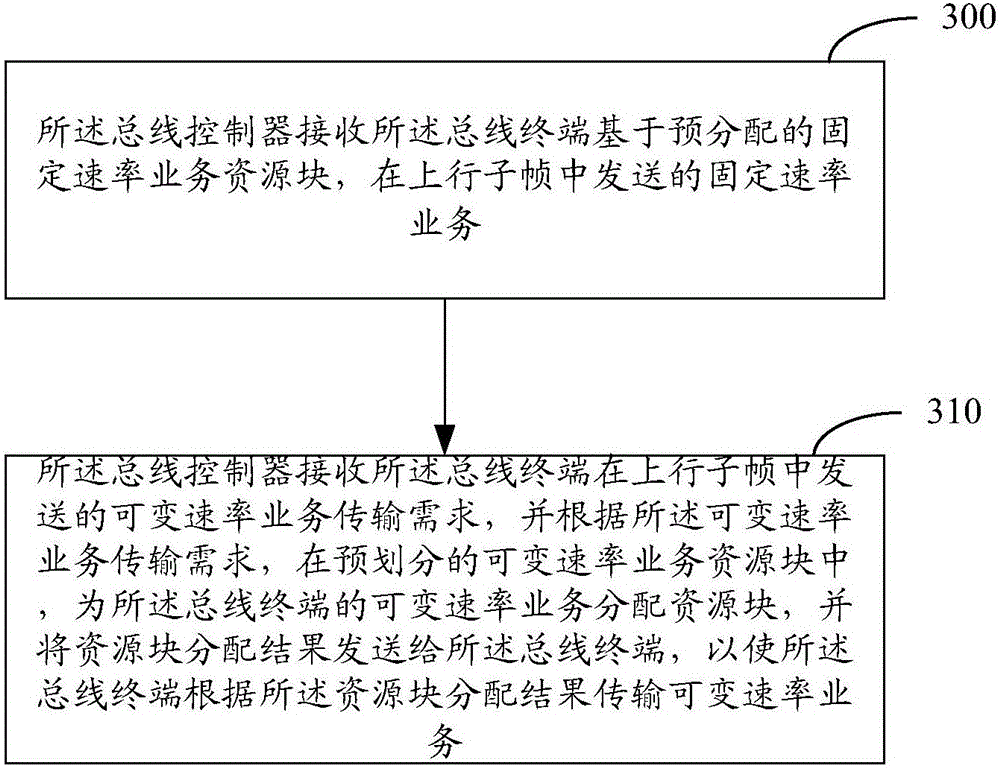

Real-time transmission method and device of field layer bus architecture based on industrial Internet

ActiveCN107528680AImprove transmission bandwidthIncrease speedProgramme controlBroadband local area networksResource blockThe Internet

The invention relates to a real-time transmission method and device of a field layer broadband bus architecture based on the industrial Internet, belonging to the field of industrial communication. The field layer broadband bus architecture based on the industrial Internet comprises a bus controller, at least one bus terminal and a two wire bus; the bus controller and bus terminals are connected by the two wire bus to form a network; and the communication between the bus controller and any one bus terminal and the communication between the bus terminals are based on the OFDM technology, and non interference occurs between the sub carriers occupied by each bus terminal. The real-time transmission method of the field layer broadband bus architecture based on the industrial Internet comprises the following steps: the bus controller receives a fixed rate service sent by the bus terminal based on pre-assigned fixed rate service resource blocks; and in the variable rate business resource blocks, the resource blocks are assigned to the bus terminal variable rate service dynamically in real time. According to the invention, the OFDM technology is introduced to the industrial field bus, and the data service and the channel resources are divided, therefore, the reliability, high speed and real time of the data transmission is realized.

Owner:KYLAND TECH CO LTD +1

Synchronization method and device for high-speed industrial communication system, network equipment and storage medium

ActiveCN110166400AHigh precisionMeet the needs of real-time transmissionTime-division multiplexMulti-frequency code systemsStructure of Management InformationCarrier signal

The embodiment of the invention discloses a synchronization method and device for a high-speed industrial communication system, network equipment and a storage medium. Control equipment broadcasts a frame header synchronous pilot signal, the frame header synchronous pilot signal comprises two continuous synchronous OFDM symbols, and frequency domain subcarriers of the two synchronous OFDM symbolsload the same pilot sequence. The synchronization method comprises the following steps: extracting continuous first and second target synchronization OFDM symbols; performing time domain autocorrelation operation on the first target synchronous OFDM symbol; and determining the initial moment of the signal according to the result of the time domain autocorrelation operation. According to the high-speed industrial communication system and method, the problems that an industrial field traditional bus is low in bandwidth, cannot simultaneously bear real-time and non-real-time and is complex in network structure can be solved, IPV6 address communication is supported, time triggered industrial communication is supported, and TSN, white list, deep detection, data encryption and other safety mechanisms are supported.

Owner:北京神经元网络技术有限公司

Method for Transmitting Messages in a Redundantly Operable Industrial Communication Network and Communication Device for the Redundantly Operable Industrial Communication Network

ActiveUS20140040657A1Quickly reconfiguredNon-redundant fault processingData switching networksTopology informationProtocol for Carrying Authentication for Network Access

A method for transmitting messages in a redundantly operable communication network includes a first subnetwork with a tree topology and a second subnetwork, wherein messages are transmitted in the first subnetwork in accordance with a spanning tree protocol, communication devices associated with network nodes of the first subnetwork interchange messages containing topology information with one another in order to form a tree topology, messages are transmitted in the second subnetwork in accordance with a parallel or ring redundancy protocol, and a virtual network node which is connected to all network nodes of the second subnetwork via a respective virtual connection which is uninterruptable by an error is configured as the root network node of the first subnetwork.

Owner:SIEMENS AG

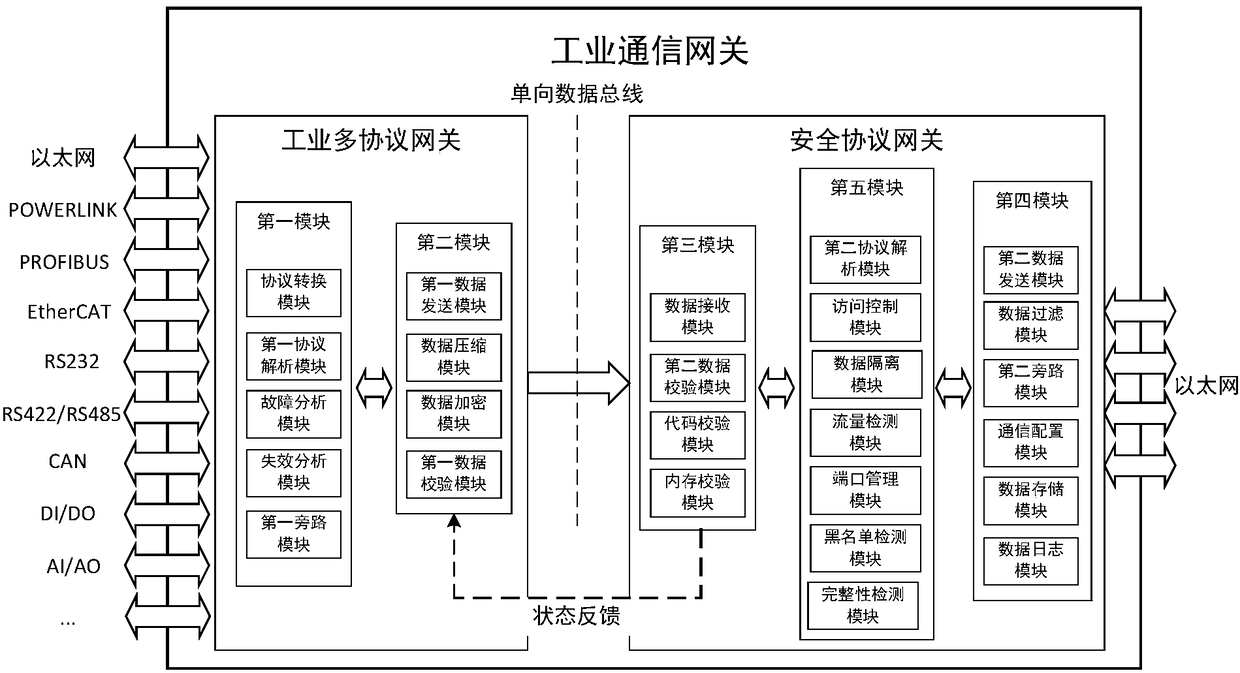

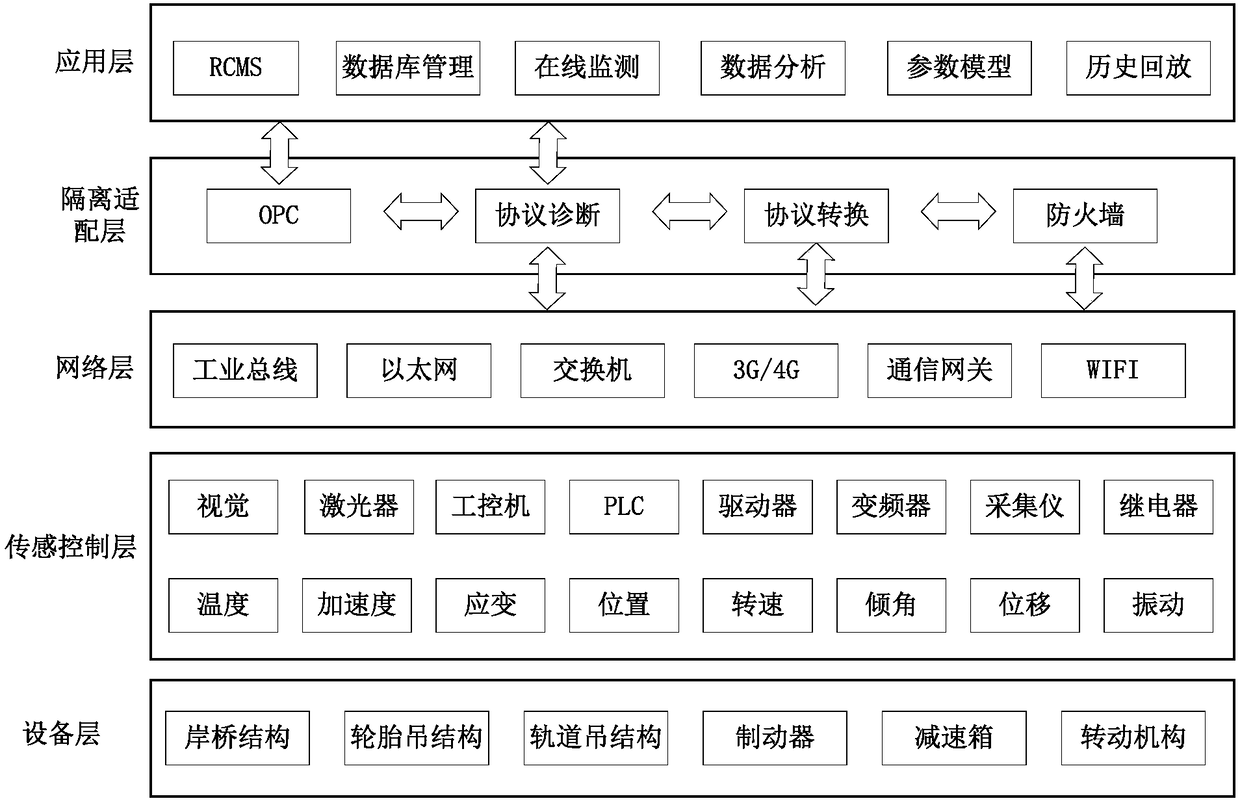

Industrial communication gateway, and industrial data security isolation system and method

InactiveCN108494672ACompletely isolatedImprove securityNetwork connectionsIsolation effectCryptographic protocol

The invention relates to an industrial communication gateway comprising: an industrial multi-protocol gateway used for collecting, converting and transmitting data; and a security protocol gateway used for receiving the data transmitted by the industrial multi-protocol gateway through a one-way data bus. The data are sent to the security protocol gateway by the industrial multi-protocol gateway byusing the one-way data bus, so that the security protocol gateway cannot access or modify the data of a collection layer. This physical link layer isolation mode is different from the existing software layer isolation mode, the isolation effect is more thorough, and the security performance is better.

Owner:SHANGHAI ZHENHUA HEAVY IND

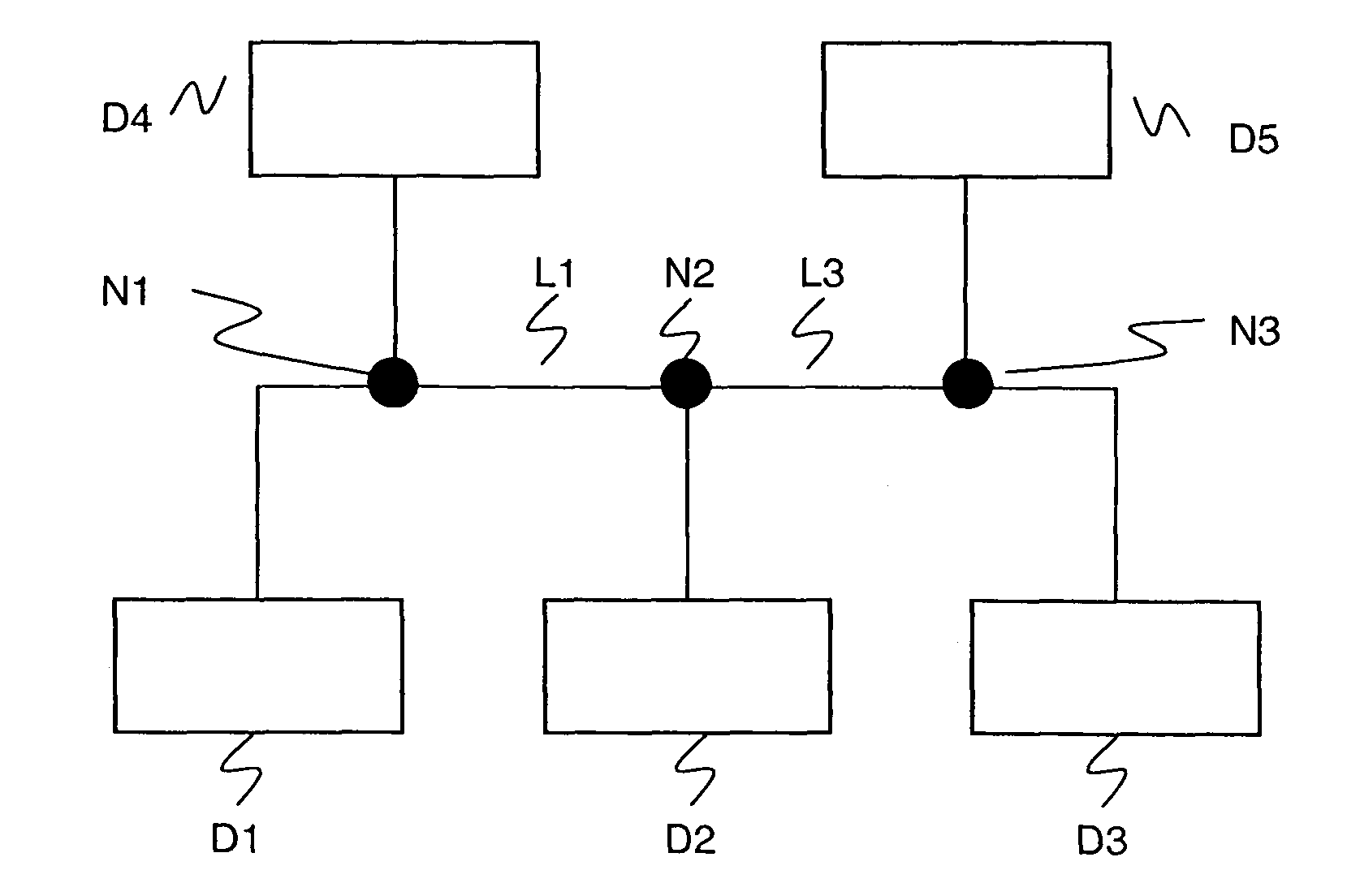

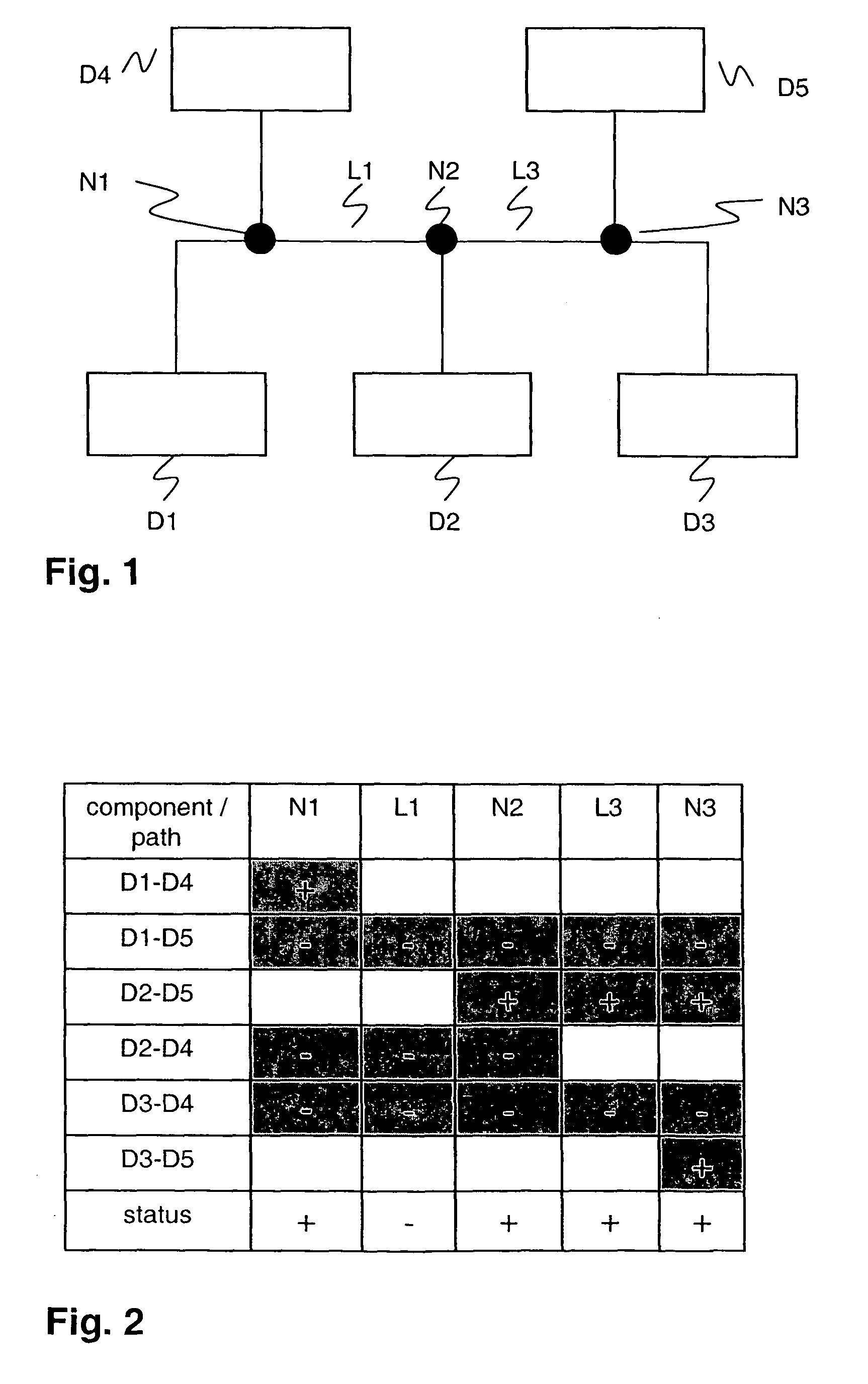

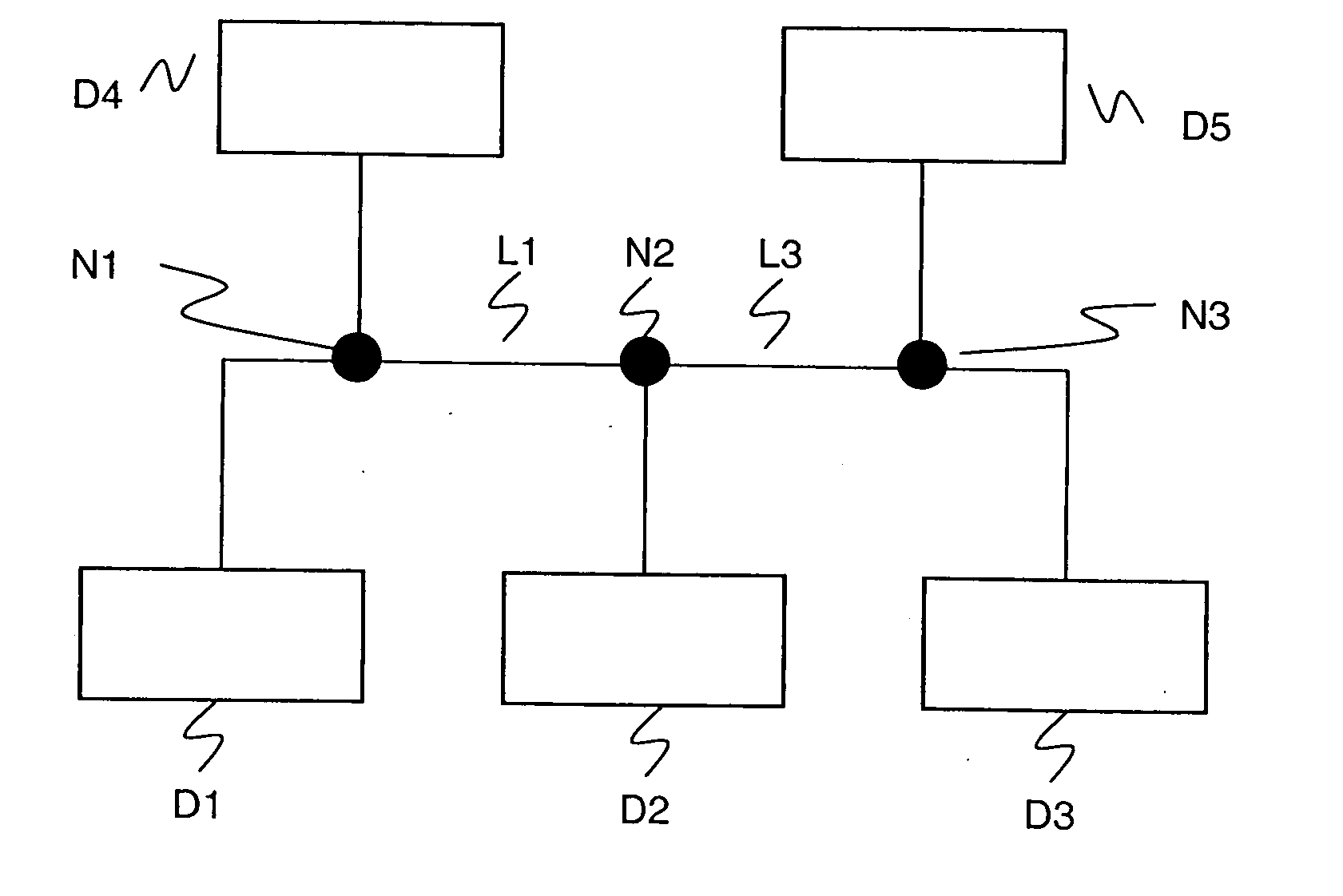

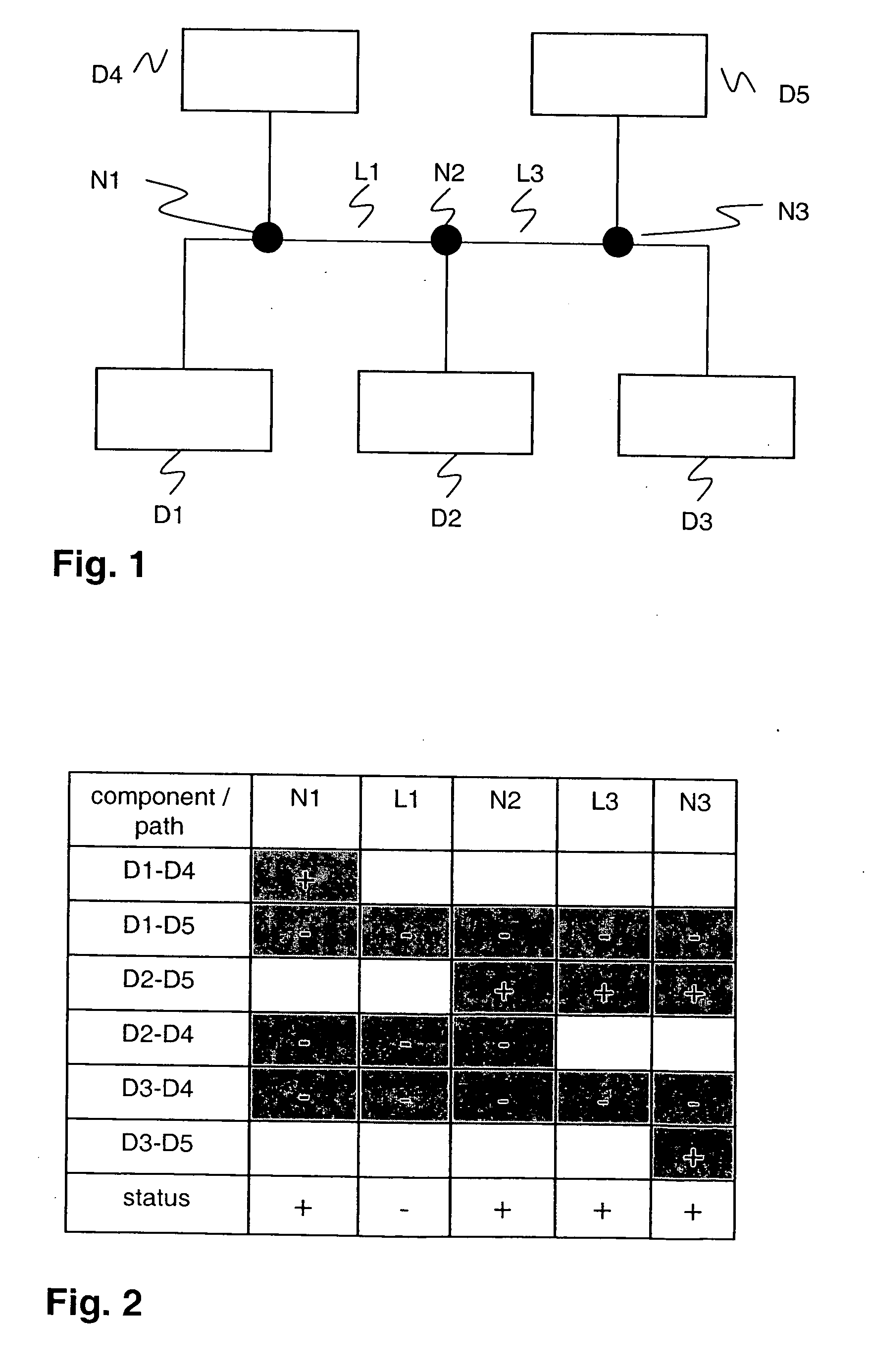

Monitoring an industrial communication network

InactiveUS20070057782A1Error preventionFrequency-division multiplex detailsTerminal equipmentIntelligent equipment

The present invention is concerned with the identification of a failed communication network component of an industrial communication network and of a substation automation system in particular. This is achieved by supervising a limited number of all the communication paths (D1-D4, D2-D5) constituting the communication network, wherein each of the supervised paths includes a distinct set of network components (N1; N2, L3, N3) and is delimited by two end-devices (D1,D4; D2,D5). A failure status or operating status of each communication path is determined and reported. Any network component that is part of an operating path is itself regarded as operating, i.e. failure-free, whereas all other network components are considered as non-operating or potentially failed. If there is more than one non-operating component, additional suitable communication paths are evaluated, until one single failed network component is identified and subsequently reported as requiring repair or replacement. The invention is particularly applicable in cases where some of the network components, i.e. the lines or some nodes of the communication paths, are passive components or non-intelligent devices that are unable to report an operating status themselves.

Owner:ABB TECH AG

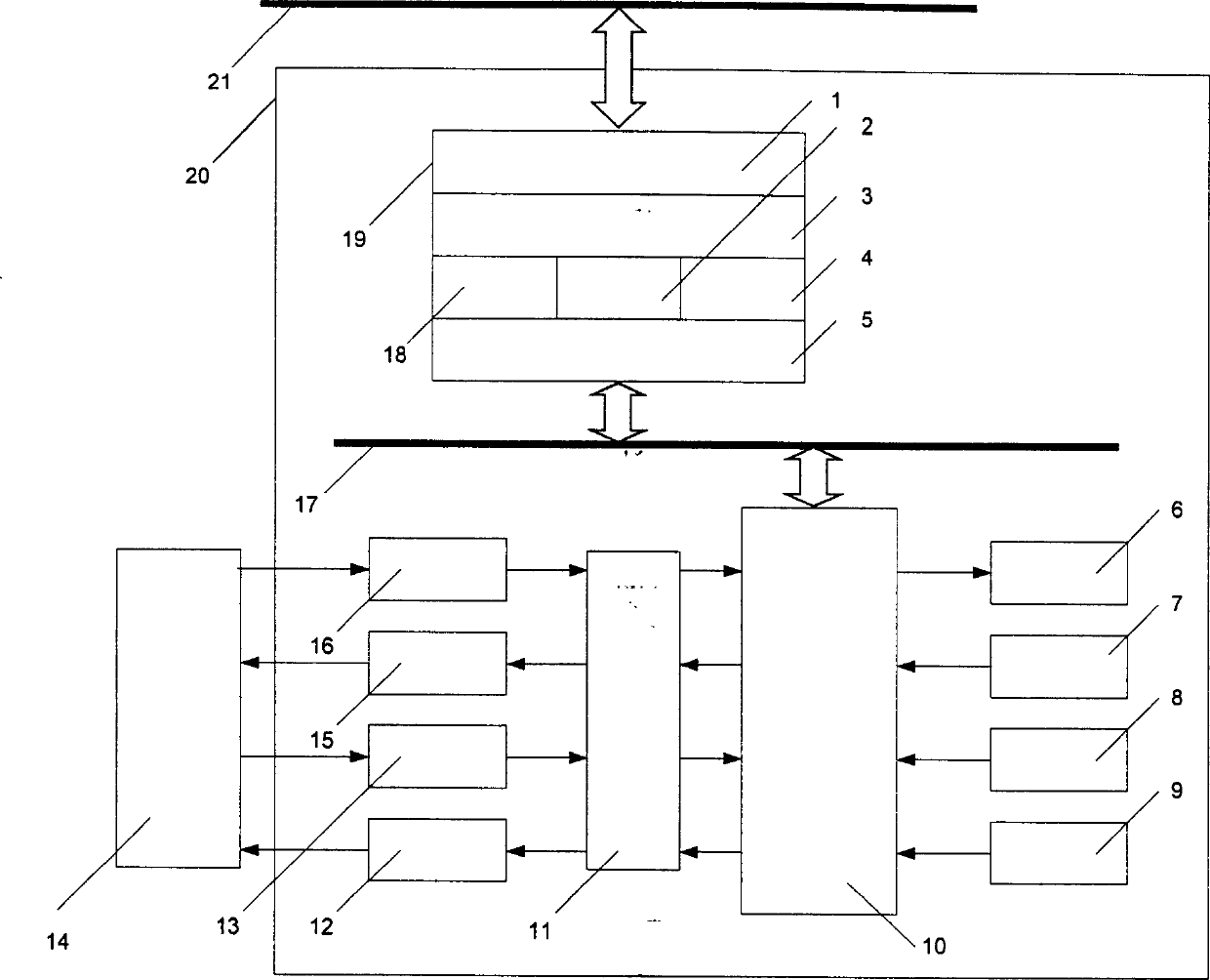

On-site intelligent unit supporting industrial communication protocol and operating method thereof

InactiveCN1604582AImplement agreementImplement Profibus-DP protocolData switching networksElectric digital data processingĆuk converterControl unit

This invention relates to a spot intelligent unit and its operation method supporting industry communication network agreement, which comprises control unit and communication port module. The communication port module realizes the MODBUS / TCP industry Ethernet agreement or DeviceNet spot bus agreement or Profibus-DP spot bus agreement. The control unit has a microprocessor connected with A / D converter, D / A converter through light couple device, wherein its switch input, output and A / D converter and D / A converter are connected with the control subject.

Owner:SHANGHAI UNIV

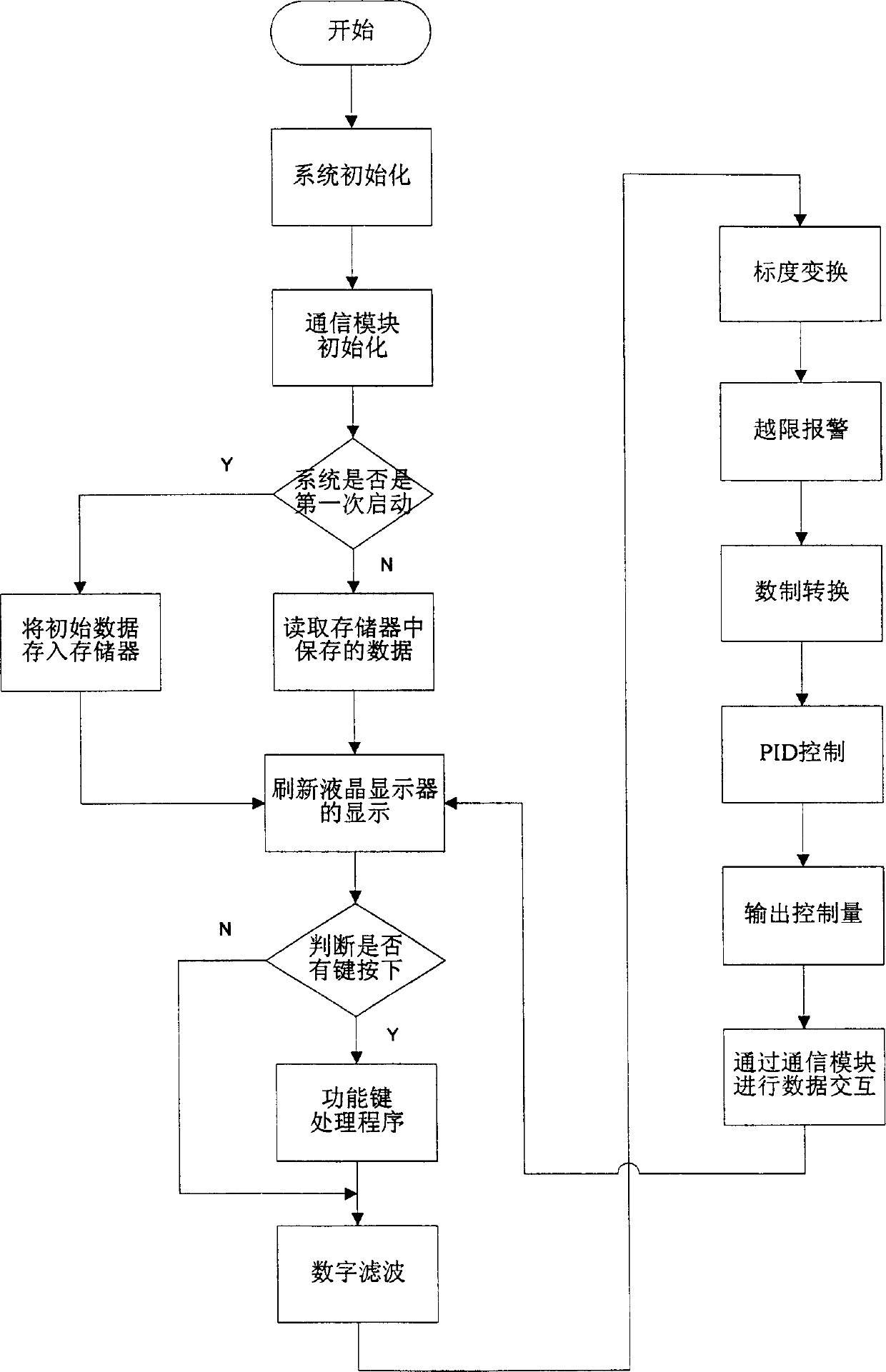

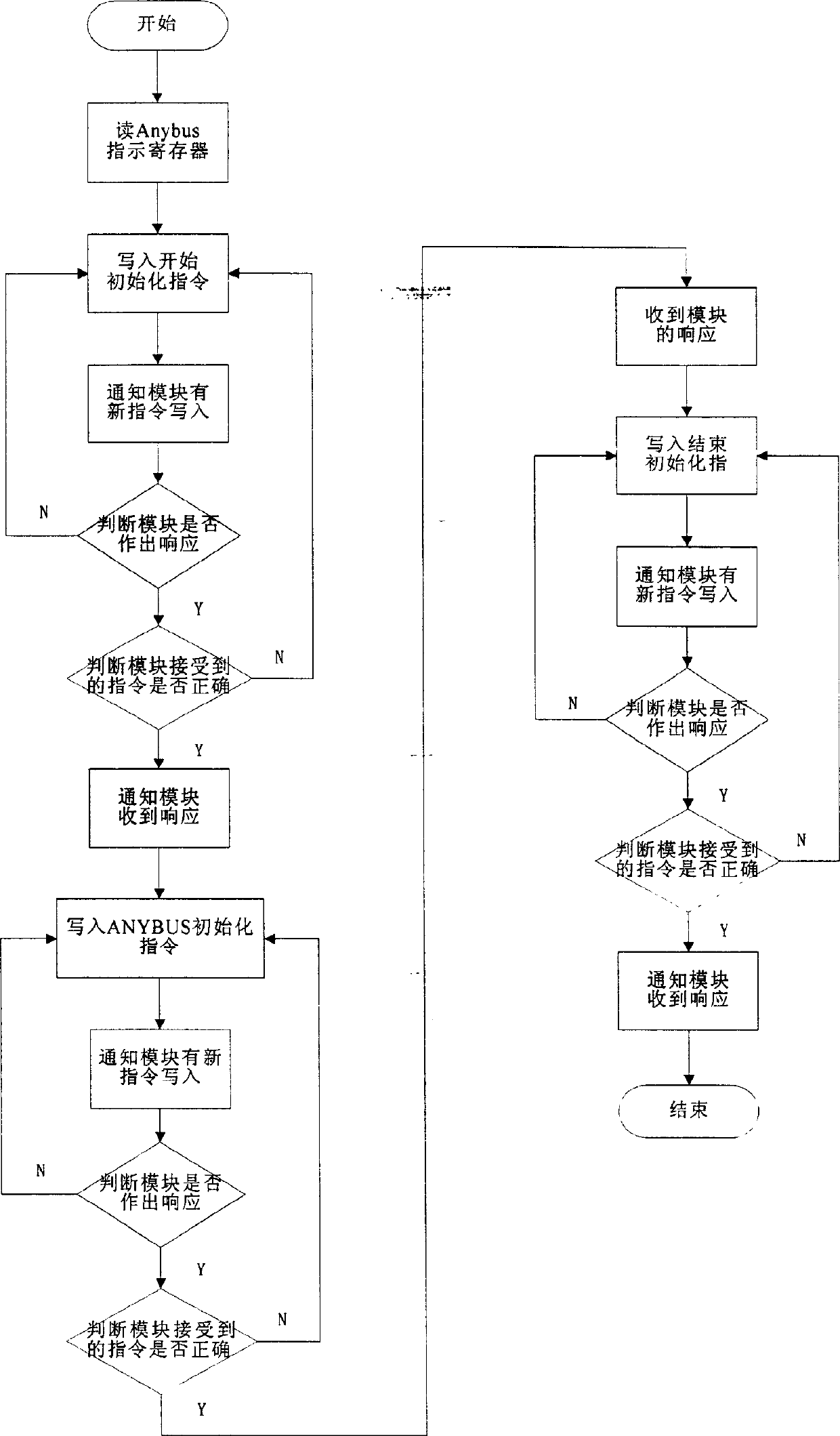

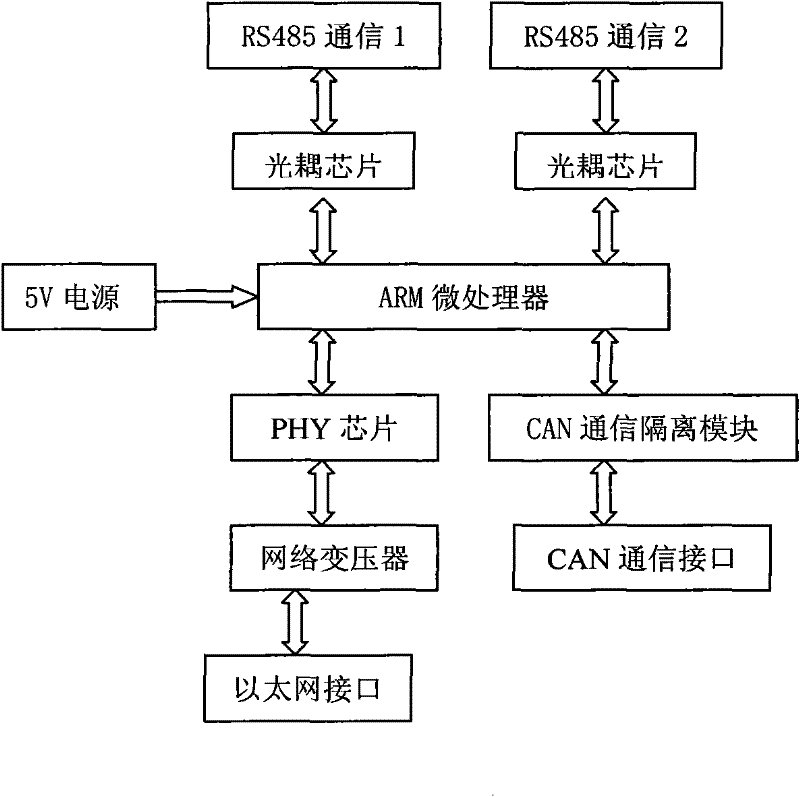

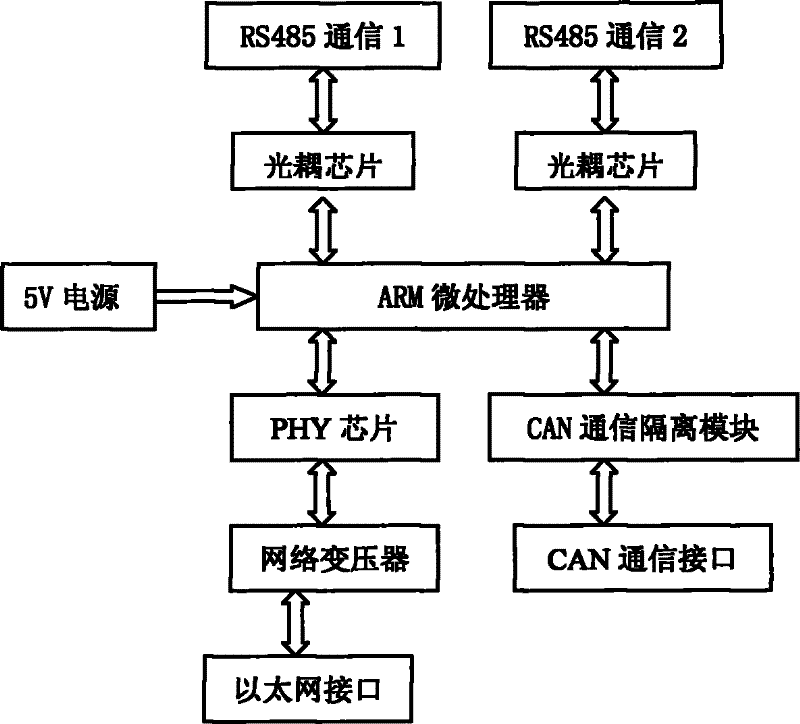

Intelligent communication controller based on ARM (Advanced RISC Machines) technology

InactiveCN102195946ATransmissionProgramme control in sequence/logic controllersAsynchronous communicationArea network

The invention discloses an intelligent communication controller based on an ARM (Advanced RISC Machines) technology, and in particular relates to an intellectualized interconnected communication controller which can meet the conventional major communication modes: a TCP / IP (Transmission Control Protocol / Internet Protocol) Ethernet, a MODBUS (Macro-block Mode for B-blocks) industrial communication standard protocol, a PROFIBUS (Process Field Bus) industrial communication standard protocol and a CAN (Controller Area Network) bus communication protocol, belonging to the technical field of communication. The intelligent communication controller takes an ARM-7 chip as a core processor and is provided with configurations such as an Ethernet MAC (Media Access Control) communication processor, an asynchronous communication processor, a CAN communication processor, a timer, a counter, an AD (Analog to Digital) converter and the like; and a UCOS / II (Uprange Computer Output System / II) embedded operating system is adopted for a hardware part, and good interconnection and conversion functions are realized in various communication modes by using the perfect real-time multi-task and multi-thread management function of the operating system. The intelligent communication controller has the advantages of high programming flexibility, high response speed, low bit error rate, high communication efficiency and compatibility with a plurality of mainstream communication modes.

Owner:COSCO SHIPPING TECH CO LTD

Communication Device and Method for Redundant Message Transmission in an Industrial Communication Network

ActiveUS20150049639A1Smooth transmissionFirmly connectedNetworks interconnectionError prevention/detection by transmission repeatTelecommunications linkCommunication link

For redundant message transmission in an industrial communication network having an arbitrarily meshed network topology, mutually independent paths are ascertained for a communication link that is redundant at least in sections between two network nodes within the industrial communication network, where the mutually independent paths comprise separate network nodes of a single communication network, and messages with duplicate identifiers are interchanged between transmission and reception units of communication devices of the industrial communication network in accordance with forwarding rules that correspond to the ascertained paths.

Owner:SIEMENS AG

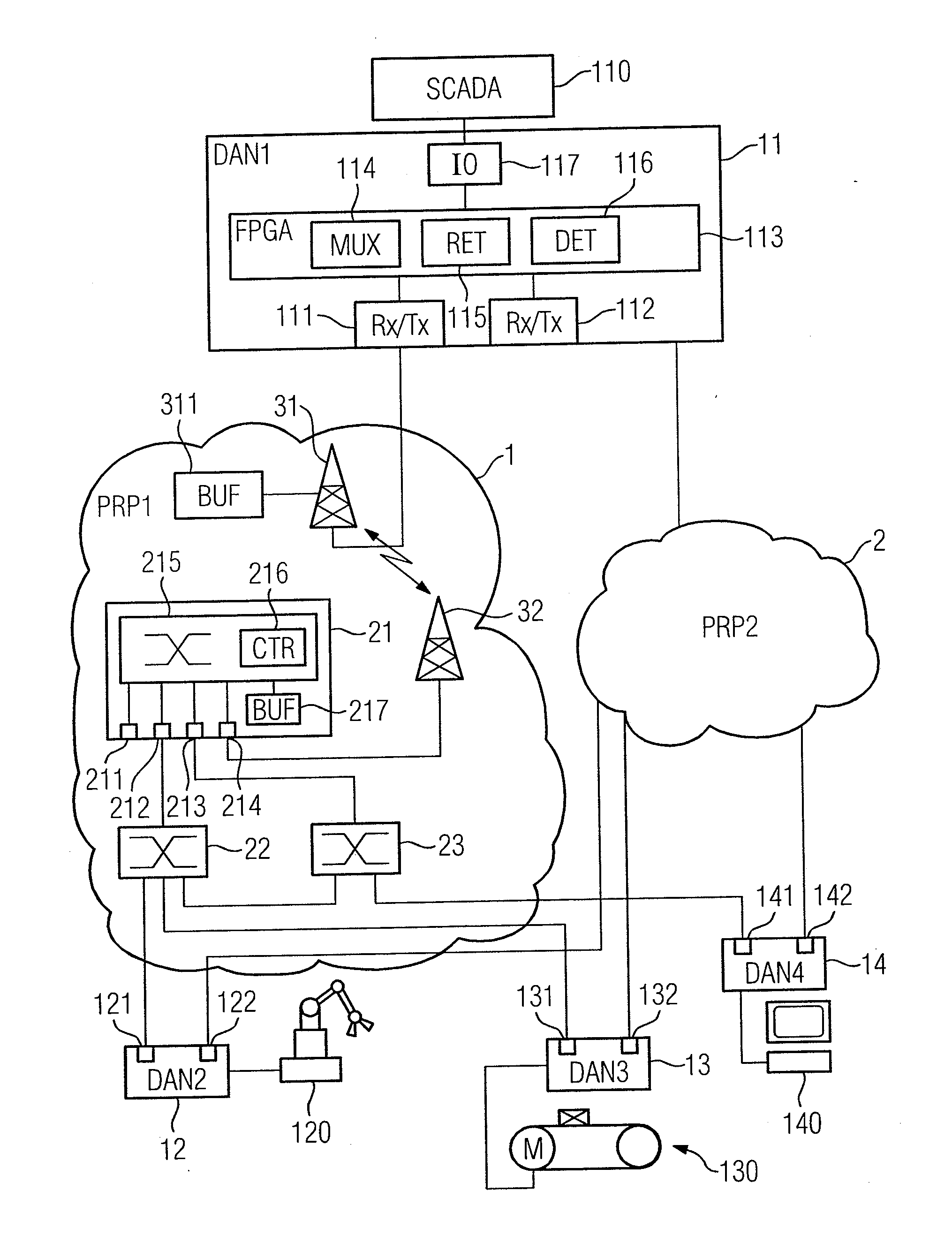

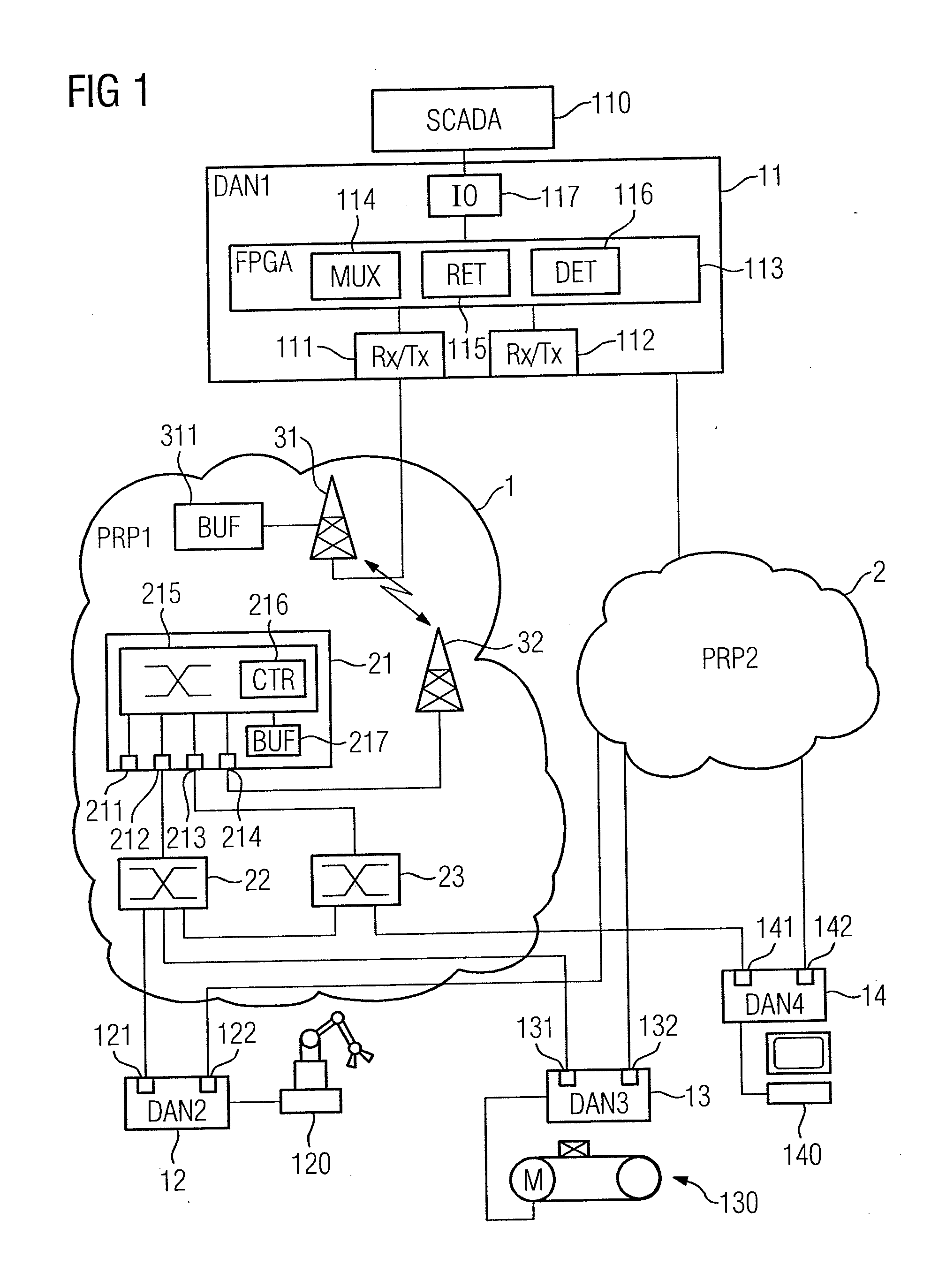

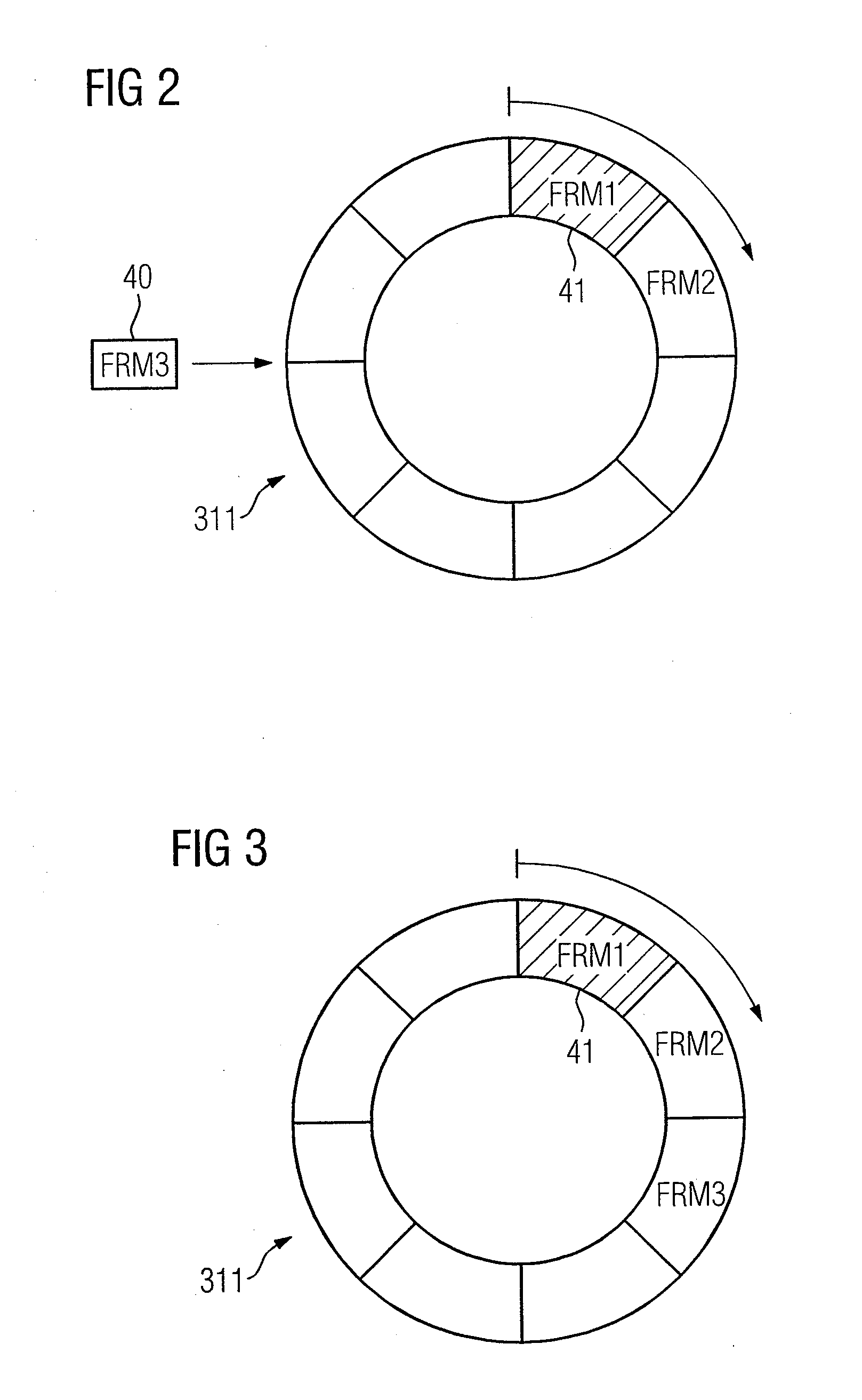

Redundantly Operable Industrial Communication System and Method for Operation Thereof

ActiveUS20140086136A1Lower latencyEasy to handleBroadcast transmission systemsData switching by path configurationCommunications systemCommunication device

A redundantly operated industrial communication system includes communication devices that are redundantly linked to an industrial communication network and includes network infrastructure devices associated with the industrial communication network, wherein message transmission occurs wirelessly at least in sections. The industrial communication network contains a plurality of buffer memory units for message elements that are received at a network node by wire and message elements that are to be sent by the network node wirelessly. When a maximum buffer size is exceeded, an oldest message element situated in a respective buffer memory unit is erased. Until the maximum buffer size is exceeded, the oldest message element is selected as the next message element to be sent wirelessly.

Owner:SIEMENS AG

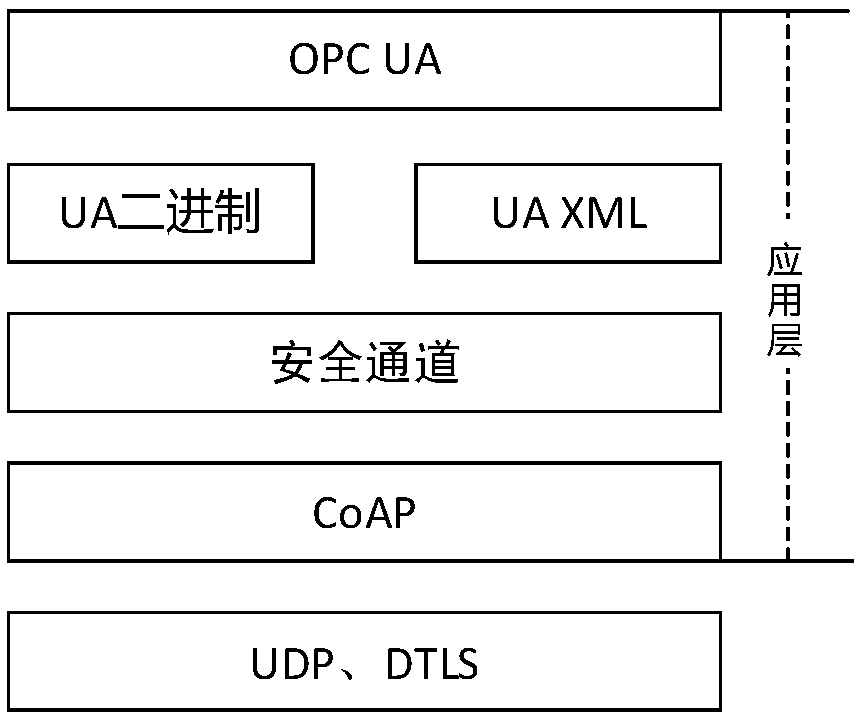

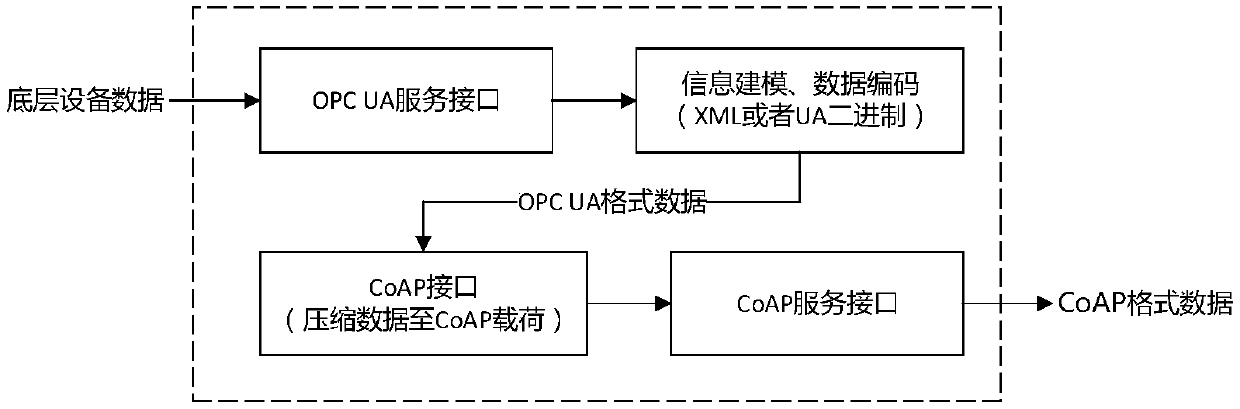

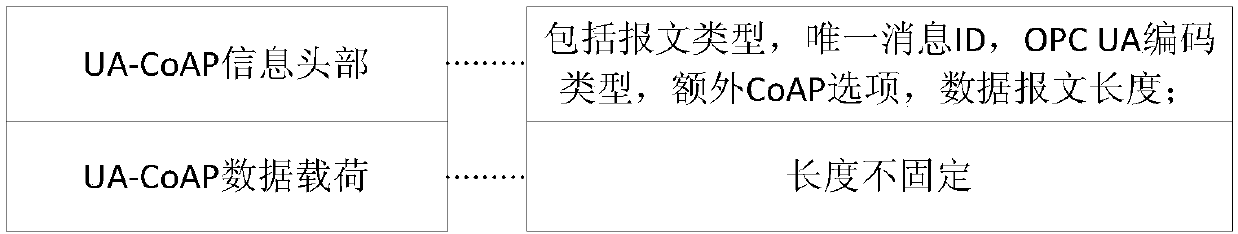

OPC UA message transmission method based on CoAP for resource-constrained industrial field equipment

ActiveCN109687995AMeet the needs of accessing Web servicesData switching networksWeb serviceClient-side

The invention relates to an OPC UA message transmission method based on CoAP for resource-constrained industrial field equipment, and belongs to the technical field of industrial communication. The method comprises the following steps: encapsulating and encoding data with an OPC UA information model, re-encapsulating the entire OPC UA data message into a load part of a CoAP message, and then querying whether a HTTP-to-CoAP proxy server exists in a network based on a UA-CoAP server; and if so, sending the UA-CoAP data message to the HTTP-to-CoAP proxy server, converting the received data message into a HTTP protocol and sending the HTTP protocol to an OPCUA client. Through adoption of the method, the problem that data of the resource-constrained industrial field equipment cannot be uniformly described and cannot be uniformly accessed is solved, and meanwhile the demand of the industrial field equipment for accessing Web services is met.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

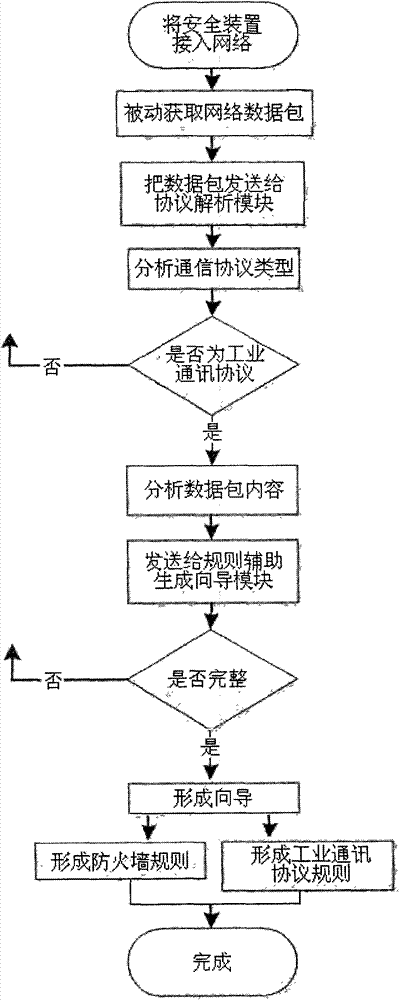

Method for automatically establishing Ethernet communication safety rules

The invention relates to a method for automatically establishing an Ethernet communication safety rule. The steps are as follows: 1, a safety device is connected to a network; 2, the safety device acquires a data packet in the Ethernet passively; 3, the safety device sends the acquired data packet to a protocol analysis module; 4, the protocol analysis module analyzes the content of the data packet, acquires information of the type of a communication protocol, and determines whether the communication protocol is an industrial communication protocol or not; 5, if the communication protocol is the industrial communication protocol, key information in the data packet is analyzed and extracted; 6, the extracted information is sent to a rule auxiliary generation guide module; and 7, the rule auxiliary generation guide module receives the information and forms the safety rule after judging the information is complete. The method provided by the invention form the safety rule according to data information in actual communication, enables setting of the safety rule to be targeted, not missing and convenient for labor saving, and ensures the real-time performance of transmission and the integrity of data in an industrial network.

Owner:BEIJING LIKONG HUACON TECH

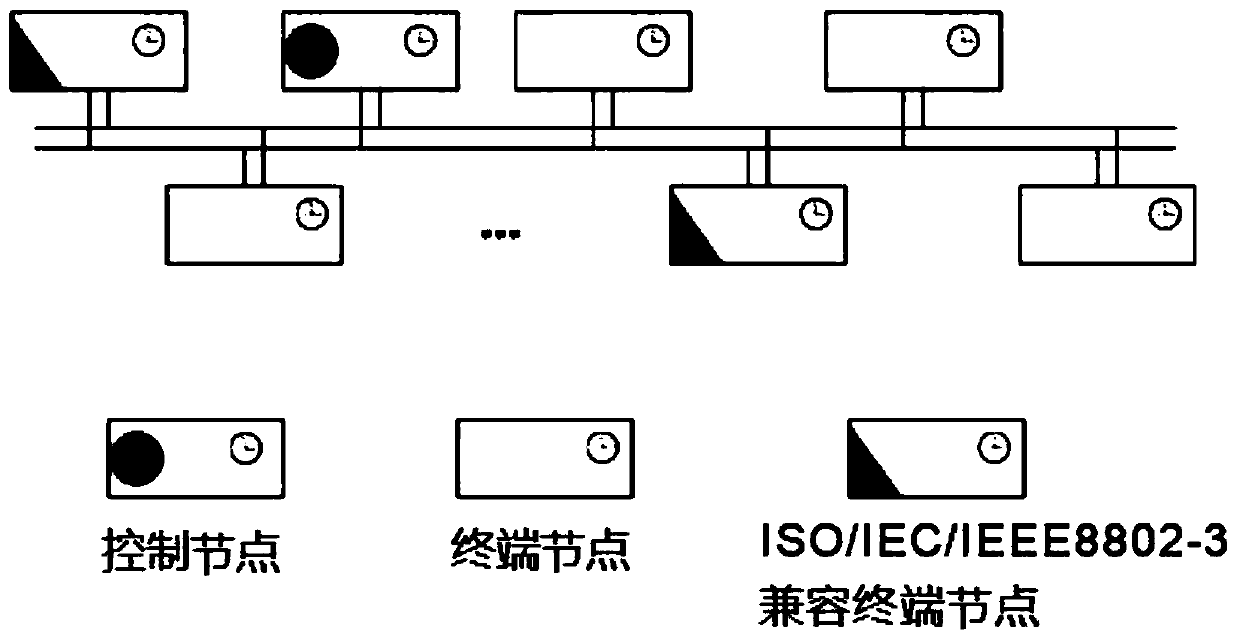

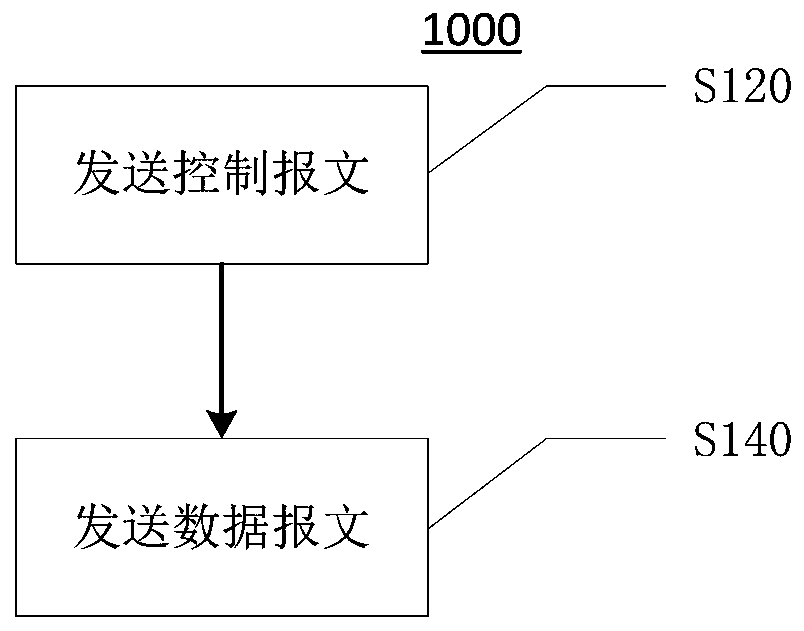

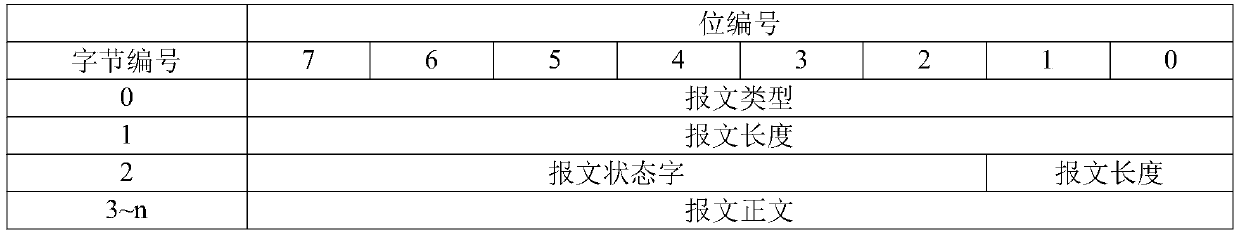

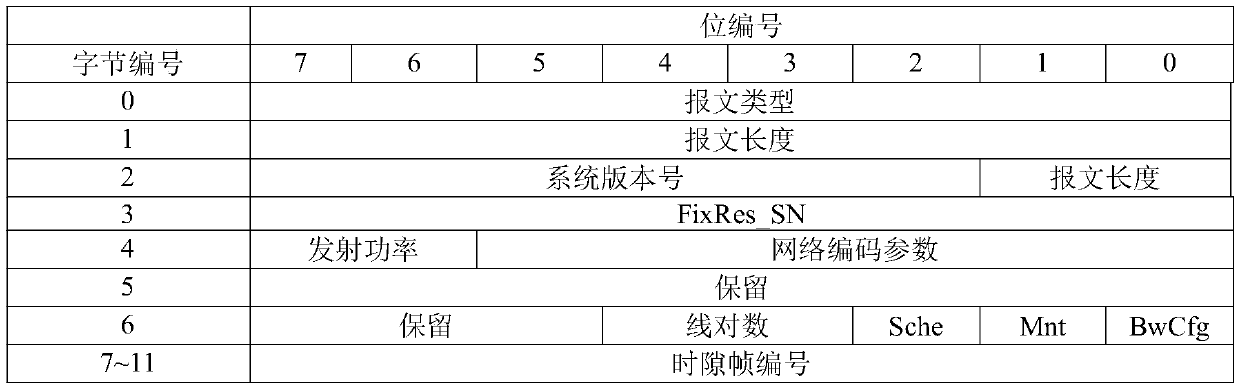

High-speed industrial communication system and communication method

ActiveCN110336727ASolve conflictsImprove efficiencyMulti-frequency code systemsBus networksNon real timeControl communications

The invention relates to a communication method of a high-speed industrial communication system. The communication system comprises a control node and a terminal node, the control node manages a communication system, the terminal node is in communication connection with the control node, the method comprises the steps that the control node is used for sending a control message to a first terminalnode so as to allocate communication resources to the terminal node, and the communication resources comprise time slice resources, frequency band resources and intra-network address resources; and the data message is sent by using the terminal node according to the communication resource allocated by the terminal node. The high-speed industrial communication system is mainly used for solving theproblems that an industrial field traditional bus is low in bandwidth, cannot bear real-time and non-real-time at the same time and is complex in network structure. The high-speed industrial communication system can support IPV6 address communication, time-triggered industrial control communication, TSN, white list, deep detection, data encryption and other security mechanisms.

Owner:北京神经元网络技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com