Patents

Literature

2057 results about "Industrial Internet" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

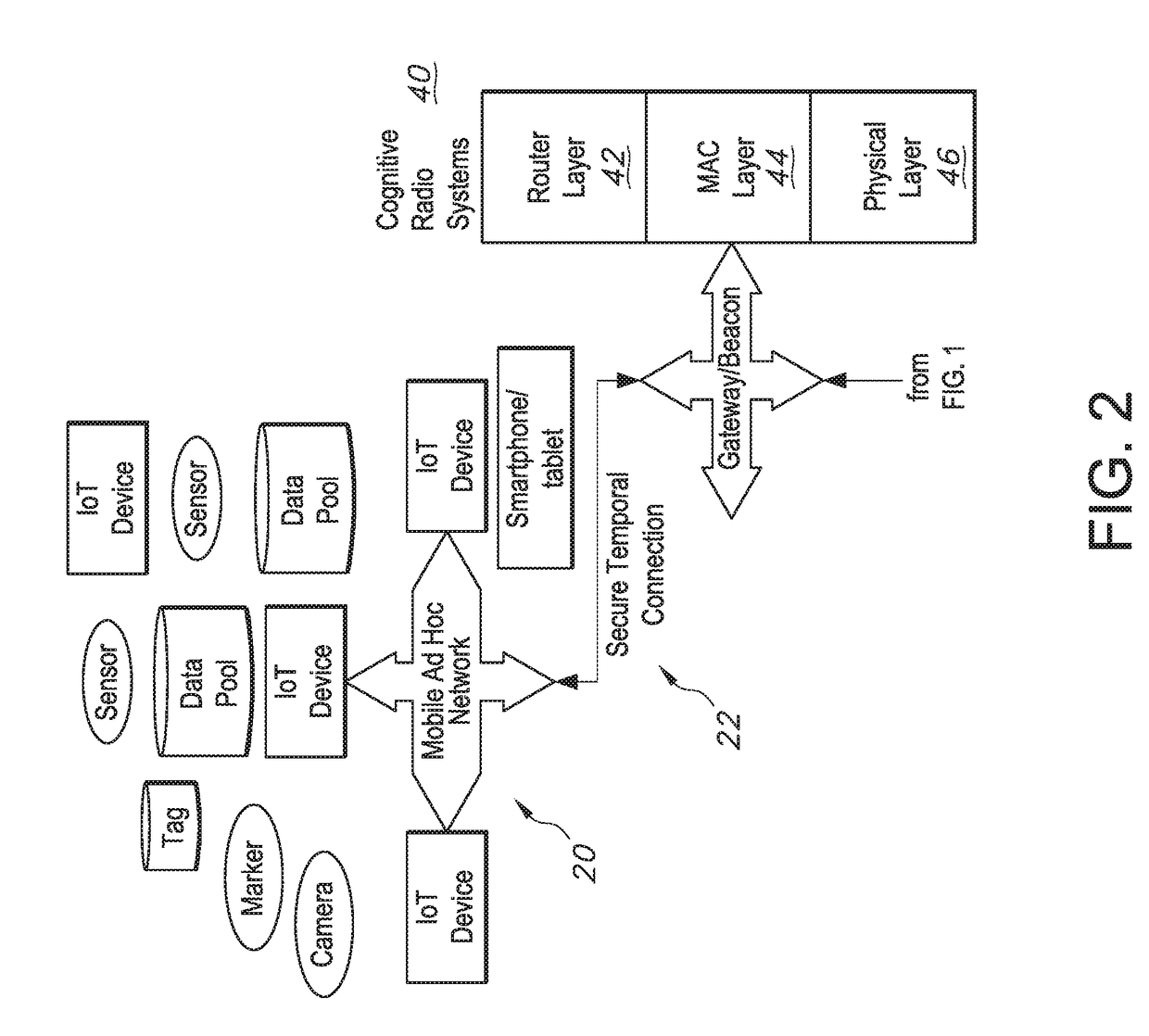

Methods and systems for the industrial internet of things

ActiveUS20180188704A1Improve signal-to-noise ratioLow sampling rateVibration measurement in solidsMachine part testingData streamData acquisition

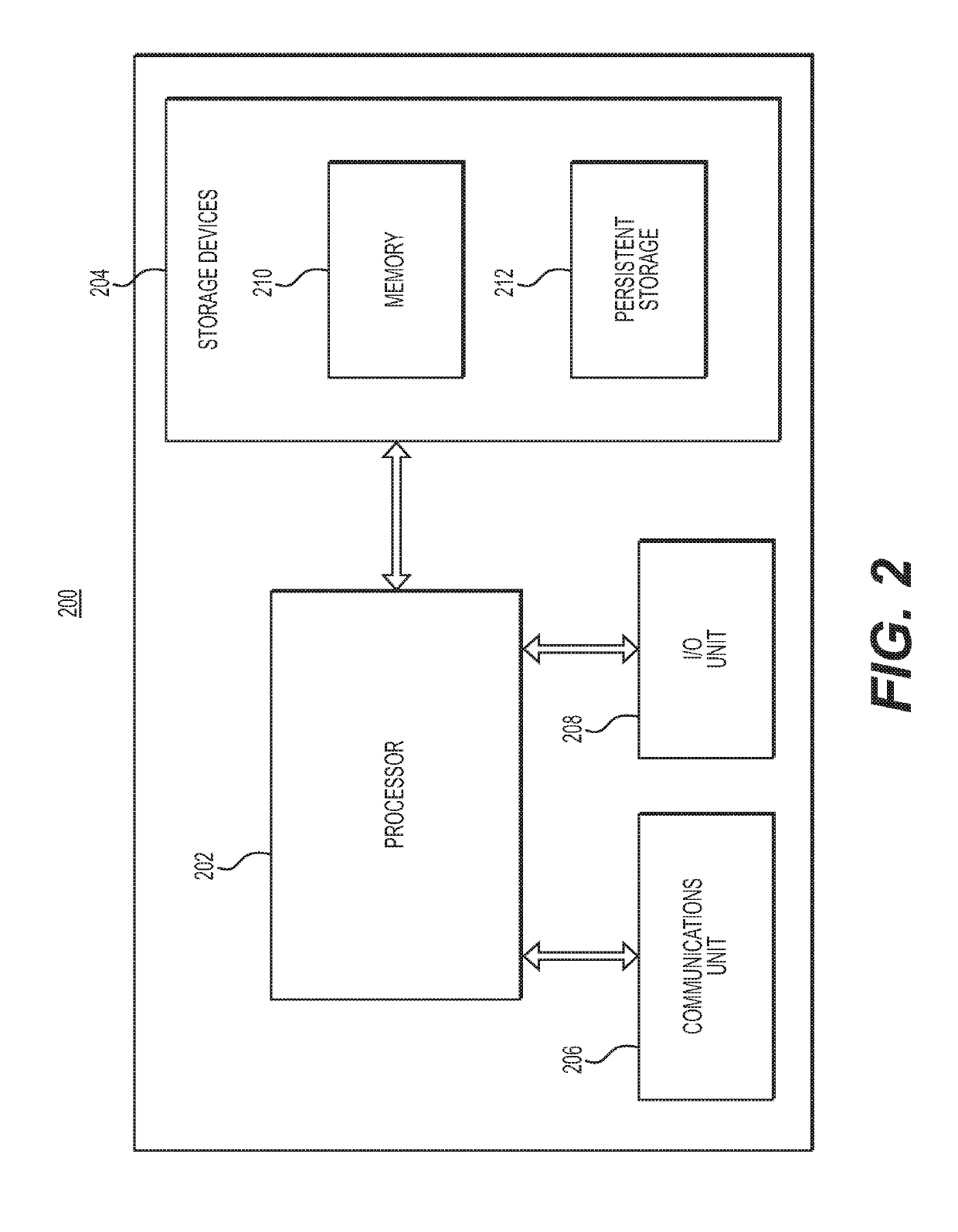

The system generally includes a crosspoint switch in the local data collection system having multiple inputs and multiple outputs including a first input connected to the first sensor and a second input connected to the second sensor. The multiple outputs include a first output and a second output configured to be switchable between a condition in which the first output is configured to switch between delivery of the first sensor signal and the second sensor signal and a condition in which there is simultaneous delivery of the first sensor signal from the first output and the second sensor signal from the second output. Each of multiple inputs is configured to be individually assigned to any of the multiple outputs. Unassigned outputs are configured to be switched off producing a high-impedance state. The local data collection system includes multiple multiplexing units and multiple data acquisition units receiving multiple data streams from multiple machines in the industrial environment. The local data collection system includes distributed complex programmable hardware device (CPLD) chips each dedicated to a data bus for logic control of the multiple multiplexing units and the multiple data acquisition units that receive the multiple data streams from the multiple machines in the industrial environment. The local data collection system is configured to manage data collection bands.

Owner:STRONG FORCE IOT

Methods and systems for the industrial internet of things

ActiveUS20180188714A1Reduce sampling rate outputMinimize anti-aliasing filter requirementVibration measurement in solidsMachine part testingIndustrial InternetMultiple input

The system generally includes a crosspoint switch in the local data collection system having multiple inputs and multiple outputs including a first input connected to the first sensor and a second input connected to the second sensor. The multiple outputs include a first output and a second output configured to be switchable between a condition in which the first output is configured to switch between delivery of the first sensor signal and the second sensor signal and a condition in which there is simultaneous delivery of the first sensor signal from the first output and the second sensor signal from the second output. Each of multiple inputs is configured to be individually assigned to any of the multiple outputs. Unassigned outputs are configured to be switched off producing a high-impedance state. The crosspoint switch includes a third input that is configured with a continuously monitored alarm having a pre-determined trigger condition when the third input is unassigned to any of the multiple outputs.

Owner:STRONG FORCE IOT

Methods and systems for the industrial internet of things

ActiveUS20180210425A1Improve signal-to-noise ratioLow sampling rateVibration measurement in solidsMachine part testingData acquisitionEngineering

The system generally includes a crosspoint switch in the local data collection system having multiple inputs and multiple outputs including a first input connected to the first sensor and a second input connected to the second sensor. The multiple outputs include a first output and a second output configured to be switchable between a condition in which the first output is configured to switch between delivery of the first sensor signal and the second sensor signal and a condition in which there is simultaneous delivery of the first sensor signal from the first output and the second sensor signal from the second output. Each of multiple inputs is configured to be individually assigned to any of the multiple outputs. Unassigned outputs are configured to be switched off producing a high-impedance state. The crosspoint switch includes a third input that is configured with a continuously monitored alarm having a pre-determined trigger condition when the third input is unassigned to any of the multiple outputs. The local data collection system is configured to manage data collection bands.

Owner:STRONG FORCE IOT

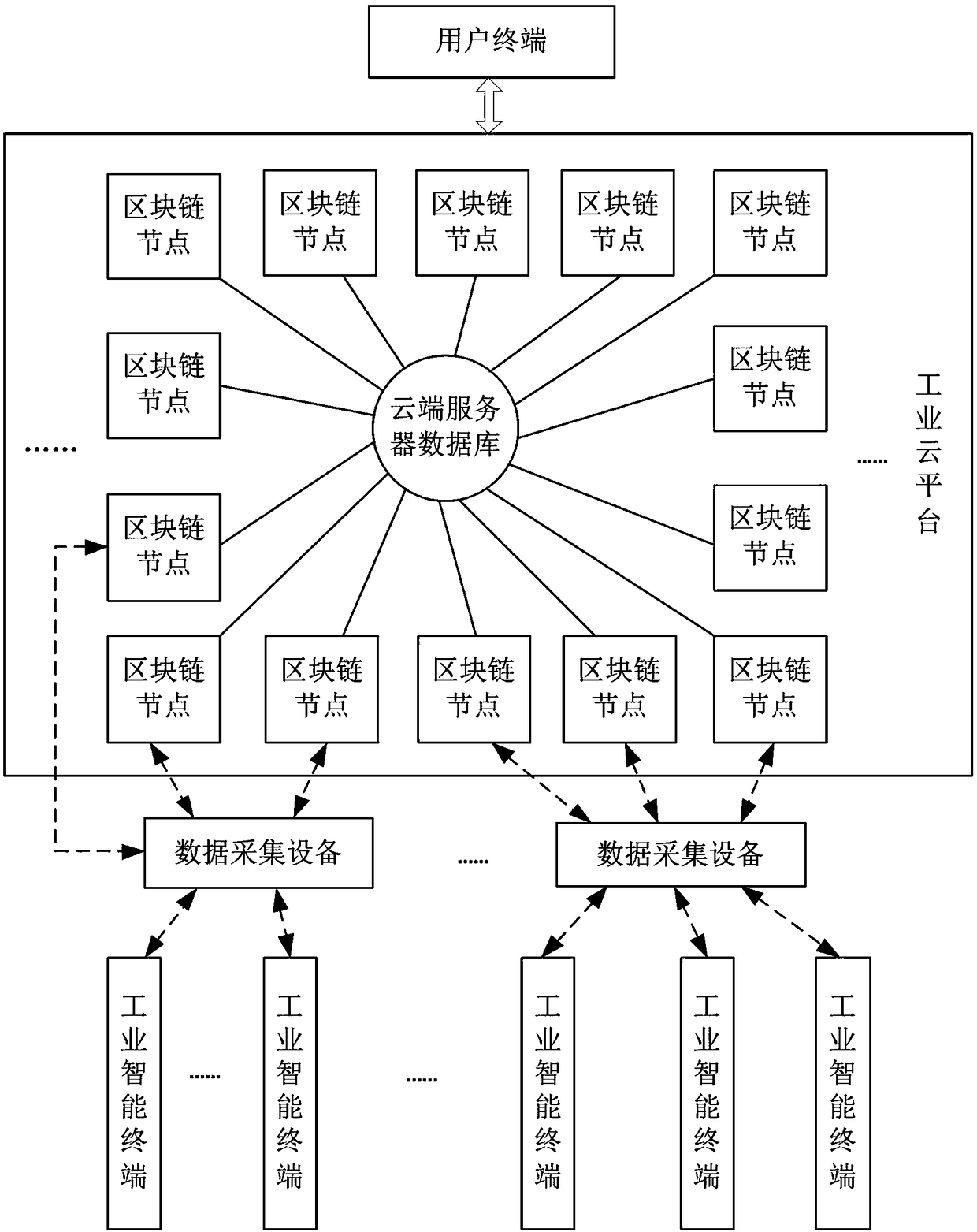

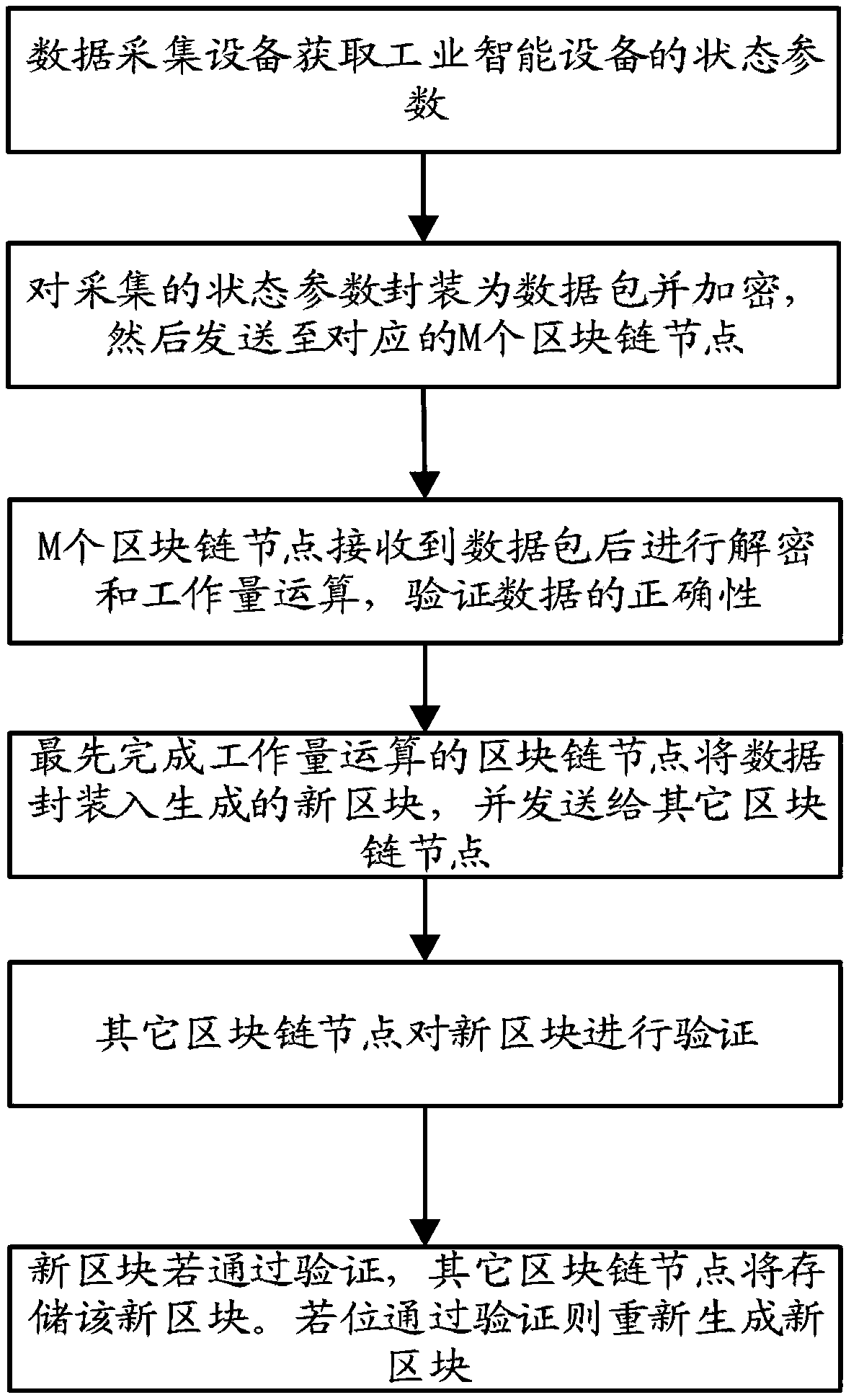

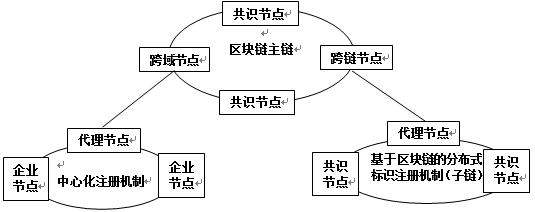

Blockchain-based industrial Internet architecture, and operation method thereof

InactiveCN109302491AVerify integrityVerify correctnessUser identity/authority verificationThe InternetData acquisition

The invention provides a blockchain-based industrial Internet architecture, comprising a user terminal, an industrial cloud platform, an industrial intelligent terminal and a data collection device, wherein the user terminal performs data interaction with the industrial cloud platform to display parameter states of various systems and devices on an industrial site and to control an intelligent device connected to the industrial intelligent terminal; the industrial cloud platform constructs a plurality of distributed blockchain nodes by using the virtualization technology, the blockchain nodesare connected with a cloud server database, and the blockchain node verify each other by constructing a small world network to ensure the trustworthiness of the nodes; and the data collection device is configured to connect and collect the data of at least one industrial intelligent terminal, and transmit the collected data to the industrial cloud platform through the Internet, a virtual machine is created in the data collection device, and a virtualized data encryption program is operated in the virtual machine.

Owner:IAP FUJIAN TECH CO LTD +1

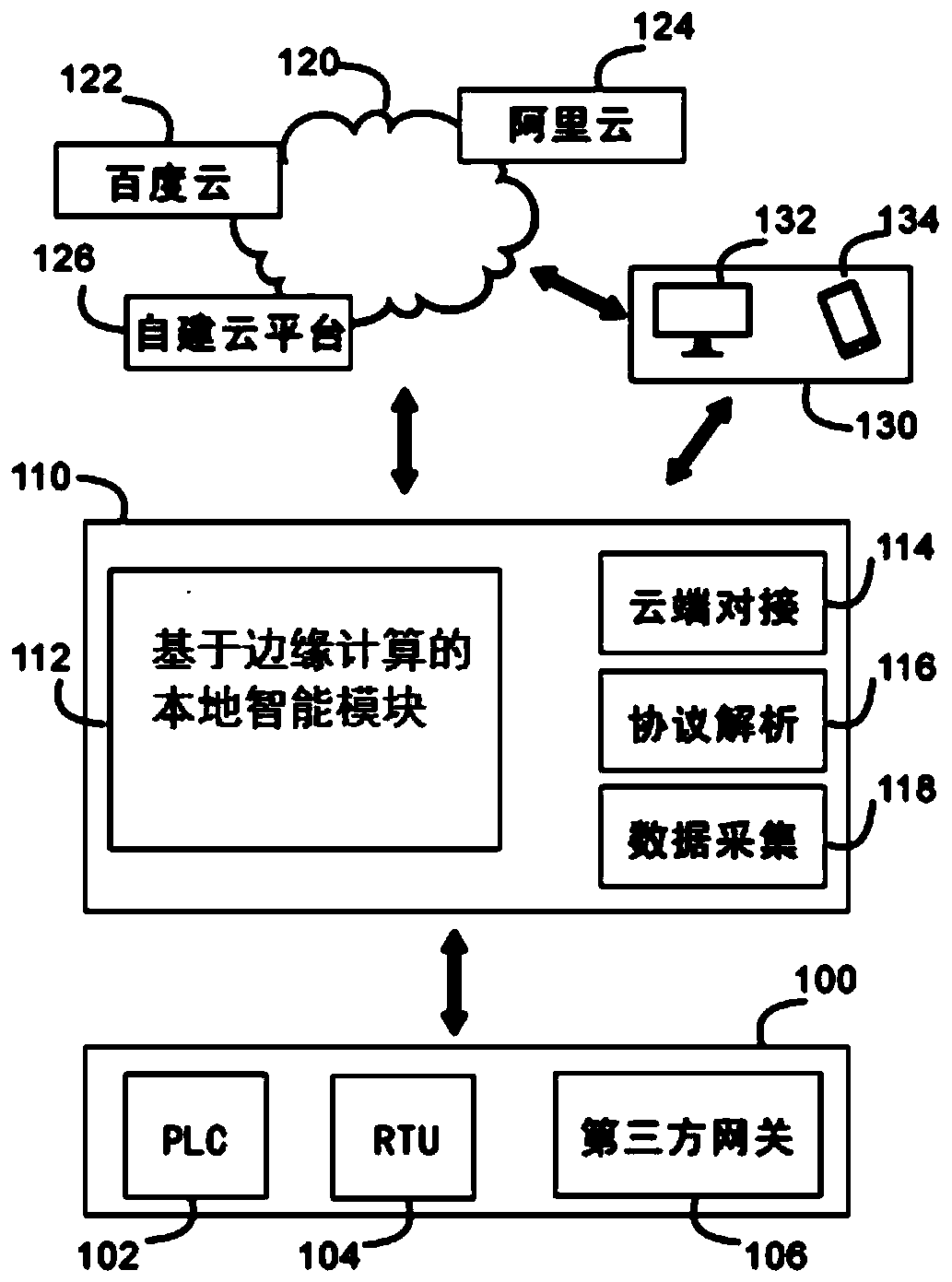

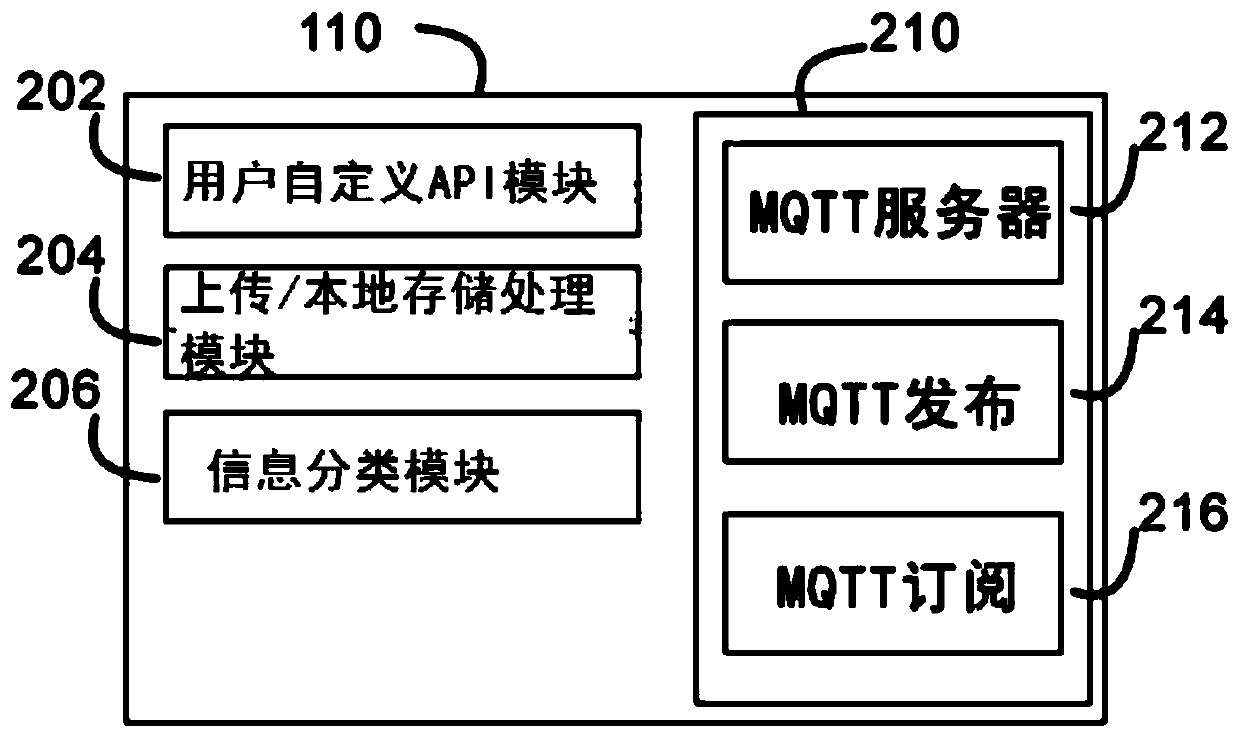

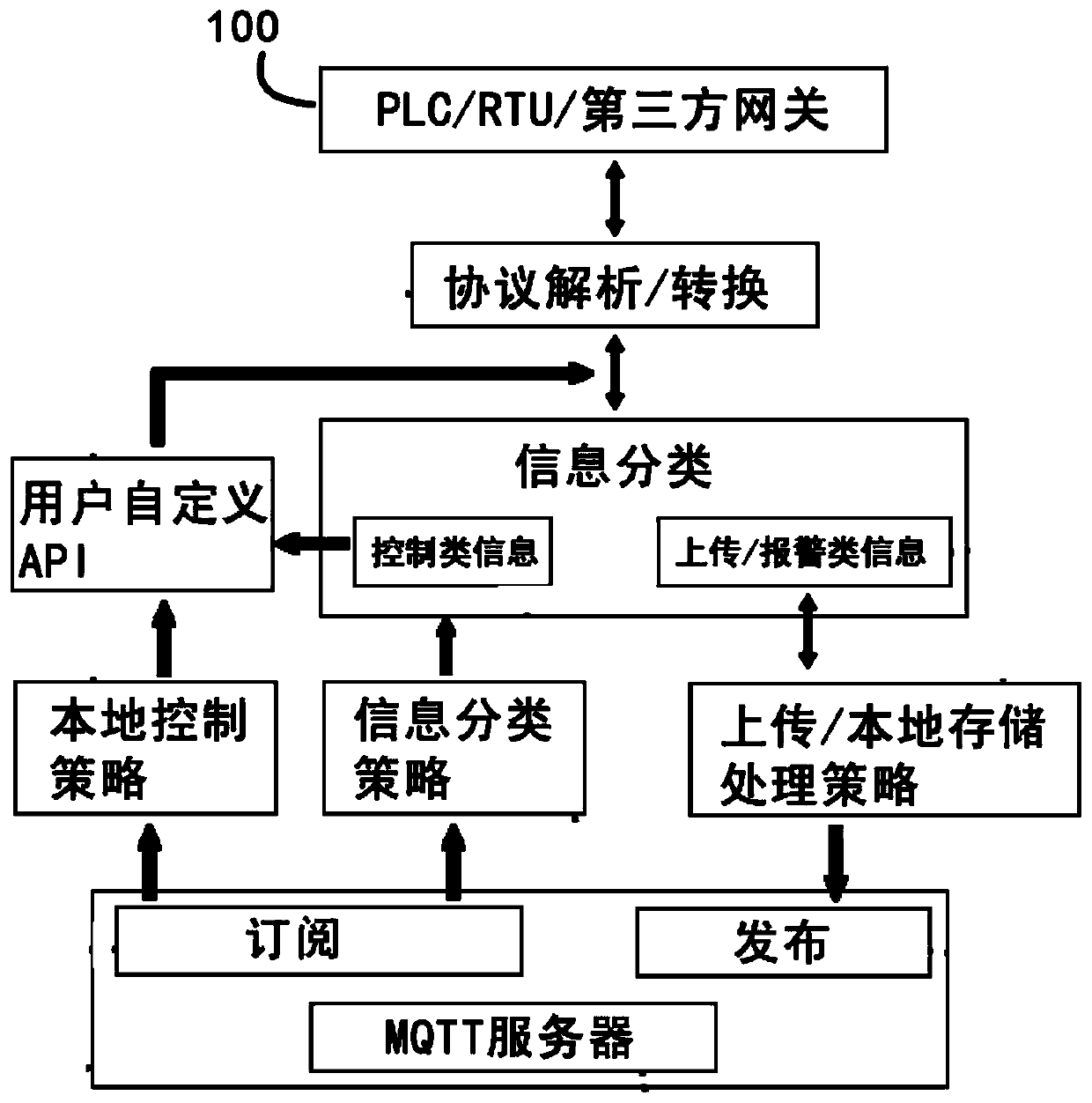

Industrial Internet of Things intelligent gateway, networking system and data processing method

ActiveCN110650084AImprove application performanceQuick decisionNetwork connectionsIntelligent NetworkReal-time data

The invention provides an industrial Internet of Things intelligent gateway, a networking system and a data processing method. By combining edge computing and a cloud technology, an industrial Internet of Things intelligent gateway which has rich interfaces, supports MQTT and other industrial control protocols and has local real-time data analysis and rule-based decision processing capabilities isset. A solution combining local intelligent processing of data acquired by edge equipment and transmission of original data to a cloud server is realized, so that events occurring on site can be quickly responded, and the operation condition of the system can be macroscopically obtained and known at the cloud.

Owner:SHANDONG ACAD OF SCI INST OF AUTOMATION

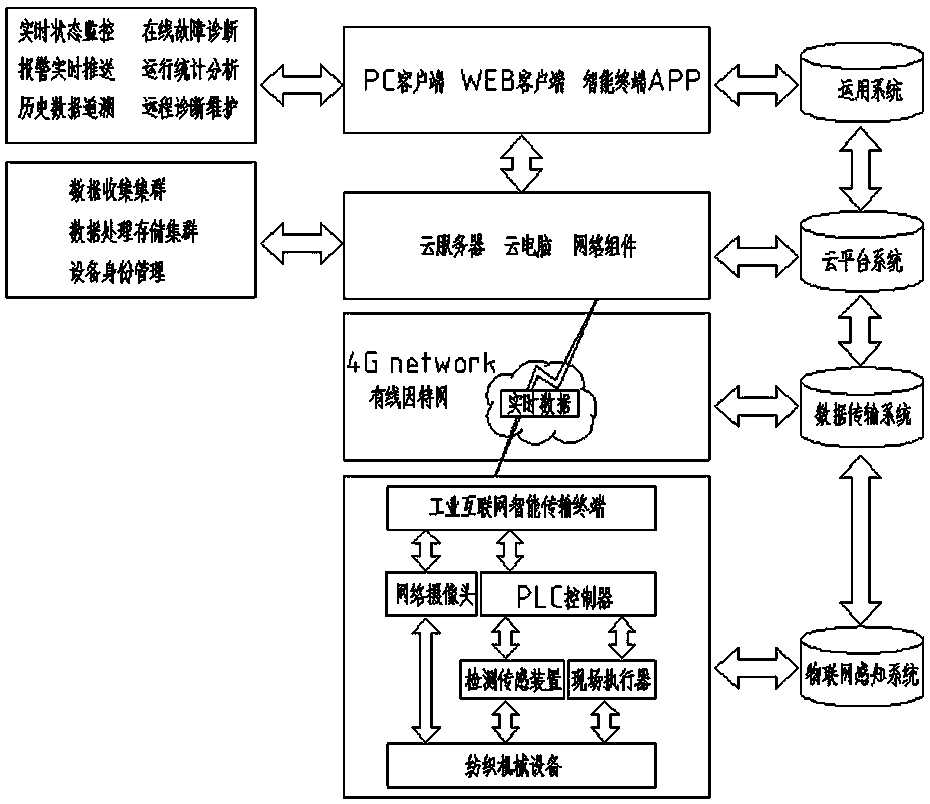

Remote operation and maintenance system for textile machine, and implementation method for remote operation and maintenance system

PendingCN109246223AResume normal productionRealize remote diagnosisClosed circuit television systemsTransmissionStatistical analysisThe Internet

The invention discloses a remote operation and maintenance system for a textile machine, and an implementation method for the remote operation and maintenance system. The system comprises a textile machine IOT (Internet of Things) sensing system, a data transmission system, a cloud platform system and an operating system. The textile machine IOT sensing system comprises a textile machine device, aPLC controller, an industrial Internet intelligent transmission terminal connected with the PLC controller, a web camera installed on the textile machine device, a detection sensing device installedin textile machine device and a field actuator. The system achieves the real-time condition monitoring service, operation statistical analysis service, fault / abnormal condition alarm service, device failure rate distributed analysis service, online fault diagnosis service, remote maintenance and real-time video surveillance service of the textile machine device. The system realizes remote diagnosis and maintenance of the textile machine through taking the textile machine IOT sensing system and industrial cloud platform as the basis, centralizes and integrates the original piecemeal management,and promotes the whole life cycle management of equipment.

Owner:HAINING TEXTILE MACHINERY FACTORY

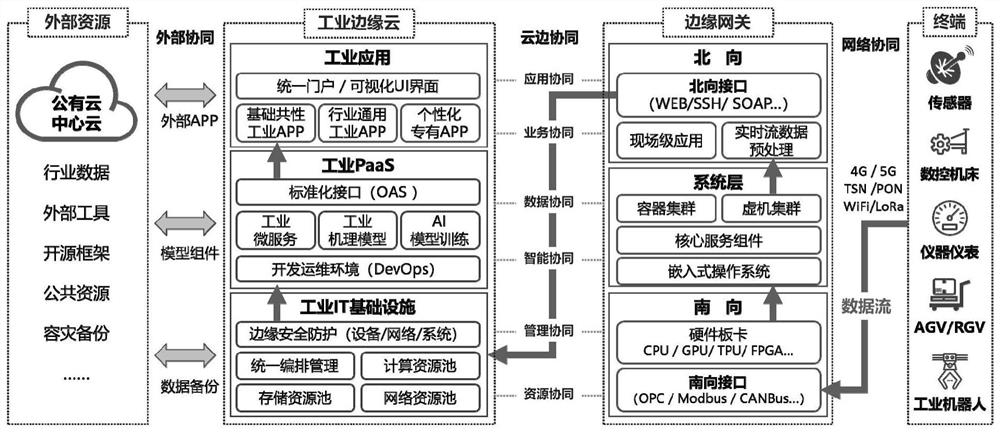

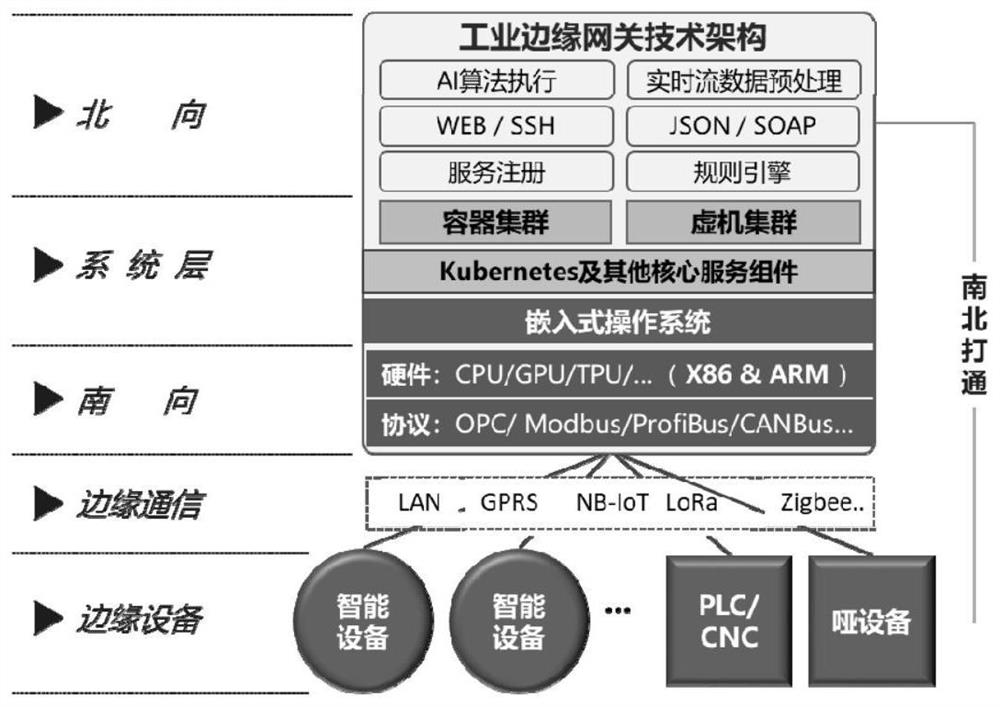

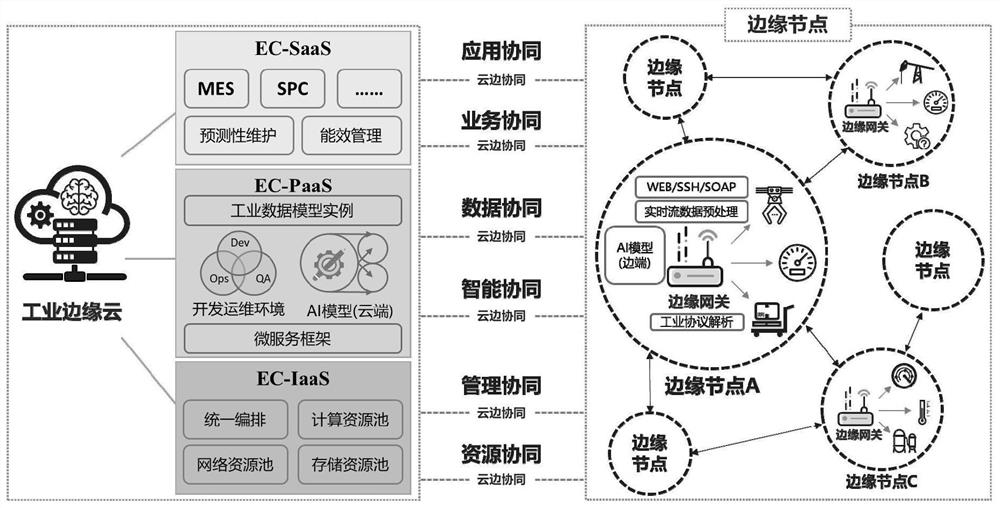

Industrial Internet system based on cloud-side cooperation

ActiveCN112073461AClear and easy developmentClear and easy to buildTransmissionManufacturing computing systemsNumerical controlPrivate network

The invention discloses an industrial Internet system based on cloud-side cooperation. The system comprises industrial terminal equipment, an edge gateway and industrial edge cloud, which are sequentially connected through an intranet or private network environment, and the industrial edge cloud is in resource connection with an extranet. The industrial edge cloud is used for carrying out storage,processing and modeling analysis on data processed by the edge gateway, production lines, pipelines, PLCs, robots, numerical control machine tools and other equipment on an industrial site can be connected to form an organic whole so as to meet the requirements of low time delay, high reliability and diversification of on-site application, and intelligent data processing is carried out in cooperation with the industrial edge cloud. The edge gateway carries out unified acquisition on production data of enterprises, supports data preprocessing on an edge side, and pushes the data to the industrial edge cloud for storage, processing and further modeling analysis, and cloud-side cooperation of resources, data, intelligence and services is realized through an edge cloud network topology relationship.

Owner:FENGHUO COMM SCI & TECH CO LTD

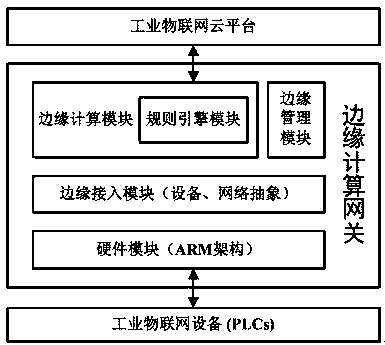

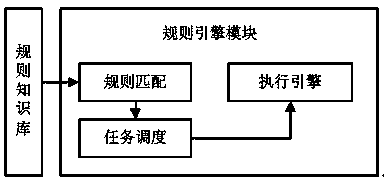

Edge computing gateway based on rule engine

InactiveCN109617796ASolve without edge computingSolve processingProgram loading/initiatingNetwork connectionsComplex event processingData acquisition

The invention provides an edge computing gateway based on a rule engine. In the prior art, a gateway basically has no edge computing and data storage functions, and only carries out data path-through,thus high-frequency data acquisition, real-time data processing and low-delay feedback response capabilities required by the industrial Internet of Things cannot be met. The invention proposes the novel edge computing gateway based on the rule engine. The invention creates and proposes an edge computing module based on the rule engine, so that an industrial Internet of Things gateway has edge computing, edge decision and local survival capabilities, and the problem that the current Internet of Things gateway has no edge computing and complex event processing capabilities is solved.

Owner:江苏东洲物联科技有限公司

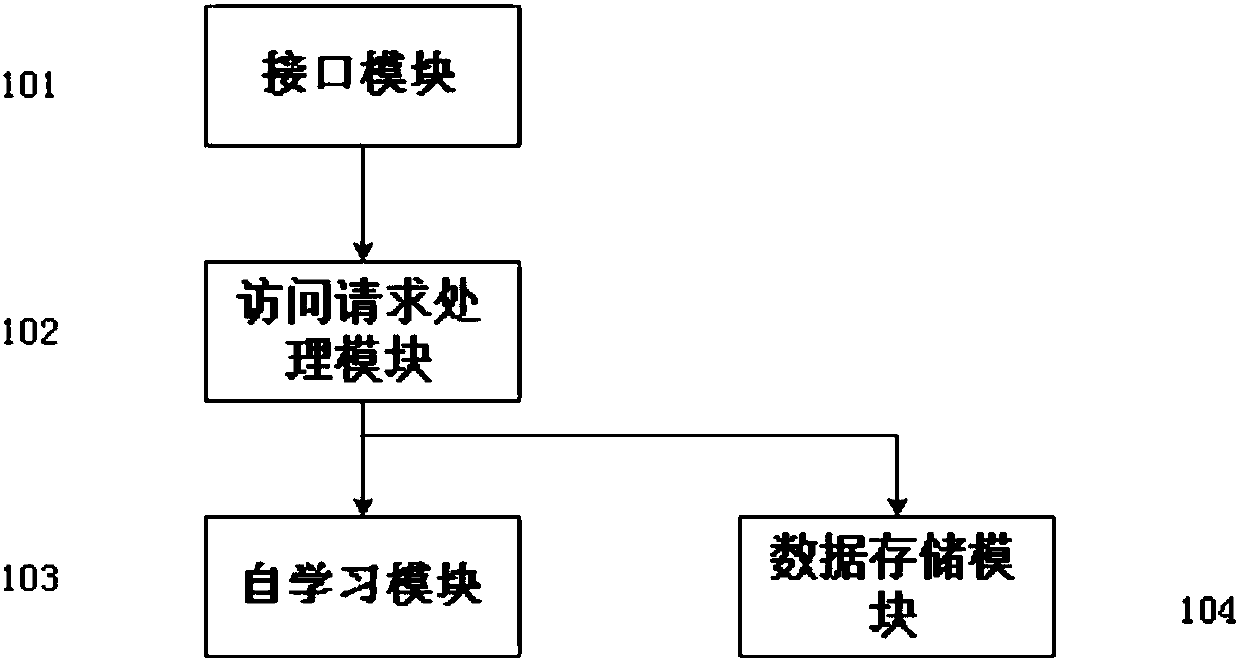

Industrial control protocol honey pot with self-learning function oriented to industrial internet and application

The invention belongs to the technical field of the network security, and provides an industrial control protocol honey pot with a self-learning function oriented to the industrial internet, and an application. The honey pot comprises an interface module, an access request processing module, a self-learning module, and a data storage module. A standard interface required by the industrial internetcorresponding to the current honey pot is realized through the interface module. When the malicious attack invades, the honey pot receives a malicious program according to different communication protocol, thereby trapping the malicious program to regard that the honey pot is the real industrial control equipment; an access request processing module receives and analyzes an access request so as to judge whether the honey pot can respond to the received access request at present, if the honey pot cannot respond, the access request is submitted to the self-learning module, and a corresponding response is acquired and stored through a self-learning method, thereby deeply simulating the scanned real industrial control equipment; at last, the data storage module is responsible for analyzing and processing the space address and the network data flow, thereby analyzing the malicious behavior therein.

Owner:NORTHEASTERN UNIV

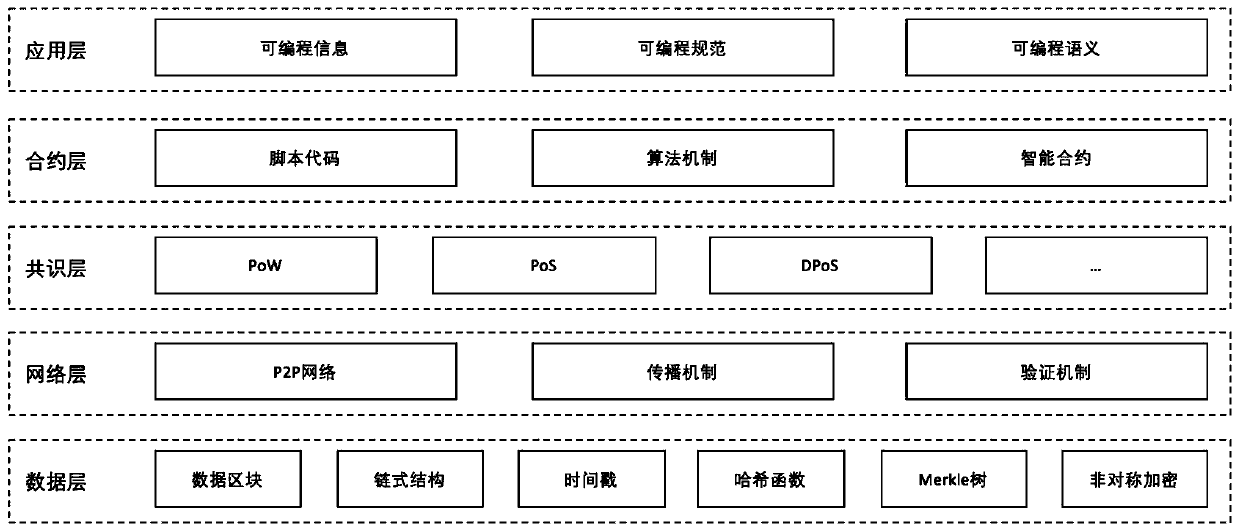

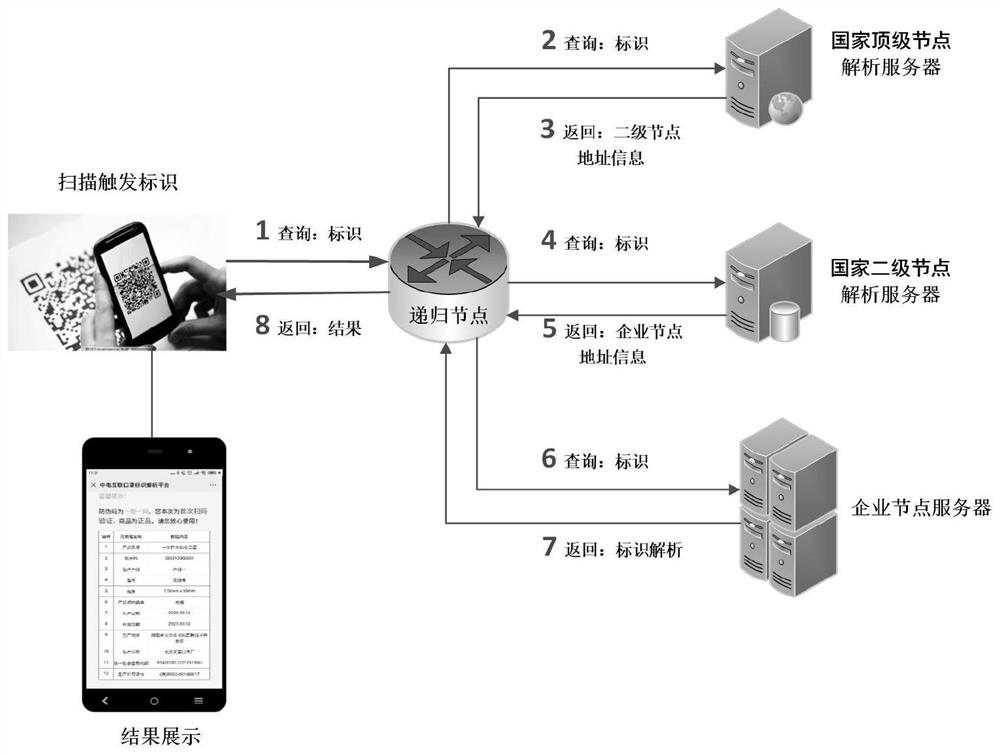

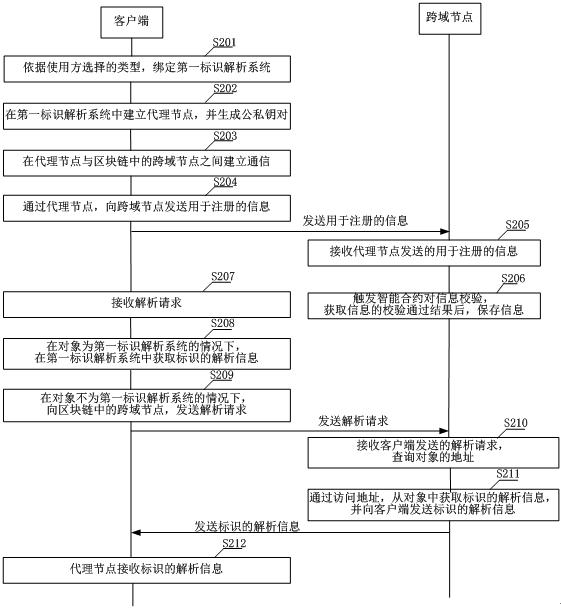

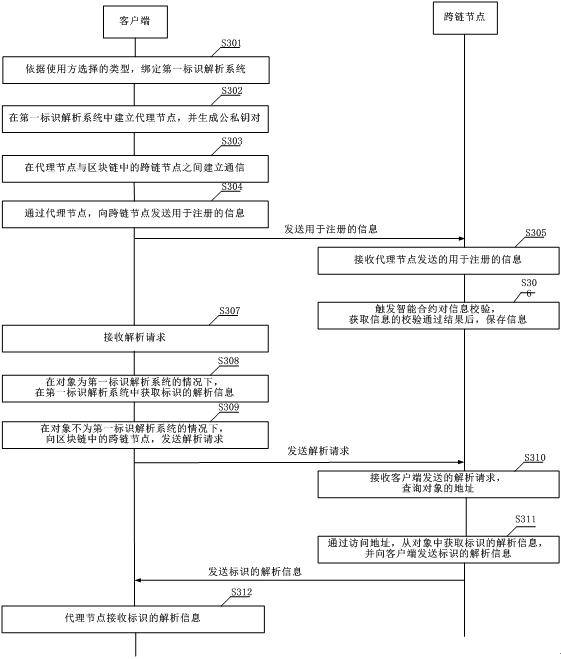

Identification analysis system implementation method based on blockchain technology and identification coding technology

ActiveCN110941611AEnsure safetyGuaranteed reliabilityDatabase distribution/replicationSpecial data processing applicationsThe InternetEngineering

The invention discloses an identification analysis system implementation method based on a blockchain technology and an identification coding technology. The method comprises the following steps: A, establishing a consensus node mechanism; B, carrying out on-chain deployment by utilizing an intelligent contract technology so as to guarantee an identification rule; cC generating a data tree management mode for producing a full link based on a distributed account book technology; D, establishing a component model; E, querying the component model; if a result is inquired, directly entering the step G, otherwise, entering the step F; F, performing intercommunication analysis of the identification system; and G, outputting identification information. According to the method, the management efficiency of the identification data can be effectively enhanced, identification codes are unified, the method is unified with the construction of a national identification analysis system, the identification information management of all elements and all links of an industrial internet identification analysis ecosphere is realized, and an interconnected and intercommunicated data ecological chain isformed between the method and other identification systems.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

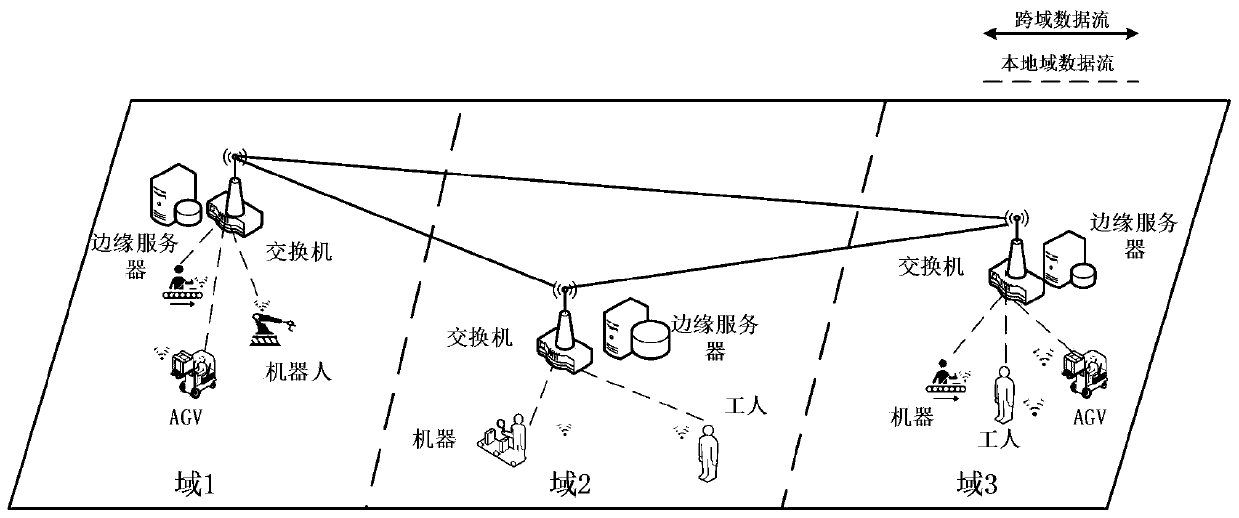

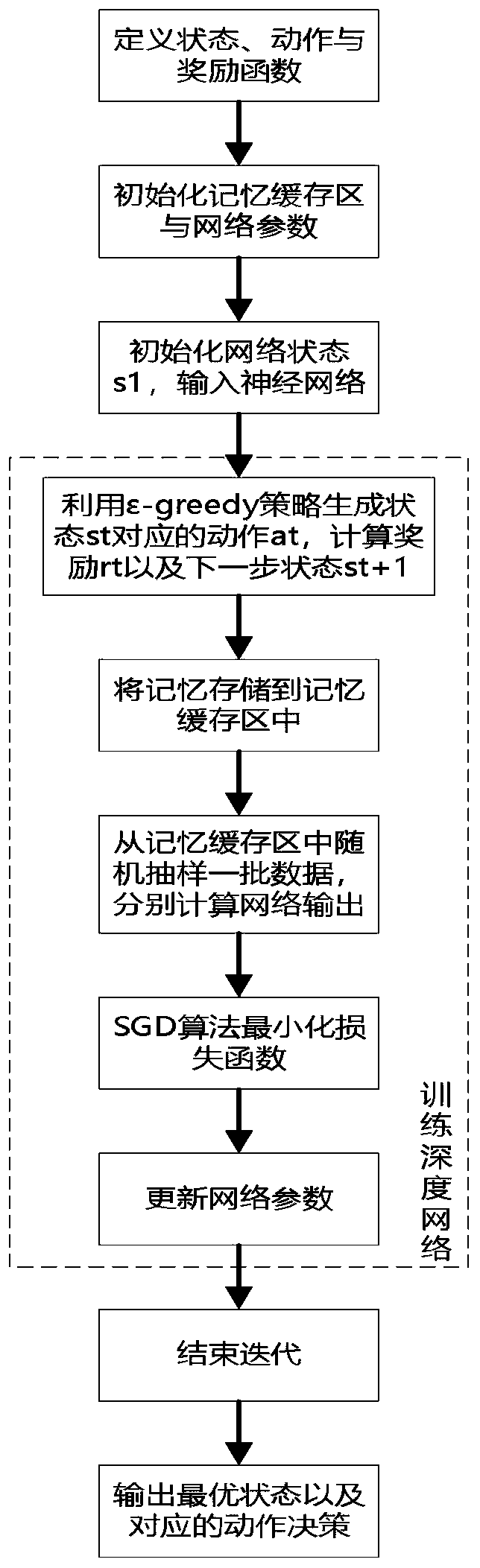

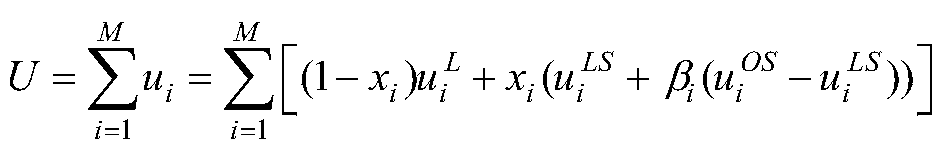

Task unloading method based on power control and resource allocation

ActiveCN111245651AReduce offload overheadReduce time complexityData switching networksQuality of serviceOptimal decision

The invention discloses a task unloading method based on power control and resource allocation, and relates to the field of industrial Internet of Things. The method comprises the steps: establishinga cross-domain network model of an industrial field; constructing a calculation model of an equipment task; according to the model, constructing a mixed integer nonlinear programming model for communication power control, resource allocation and calculation unloading problems; decomposing a problem into three sub-problems; solving an optimal communication power and a resource allocation strategy by utilizing convex optimization knowledge, a Lagrange multiplier method and a KKT (Karush-Kuhn-Tucker) condition; after substituting an original target function, solving an optimal decision of a taskcalculation position by utilizing a deep reinforcement learning algorithm, and obtaining an optimal strategy of communication power, resource allocation and the calculation position of task unloading.The method can obtain the optimal strategy in industrial network task unloading, and has the technical effects of reducing the task delay, reducing the equipment energy consumption and ensuring the service quality.

Owner:SHANGHAI JIAO TONG UNIV

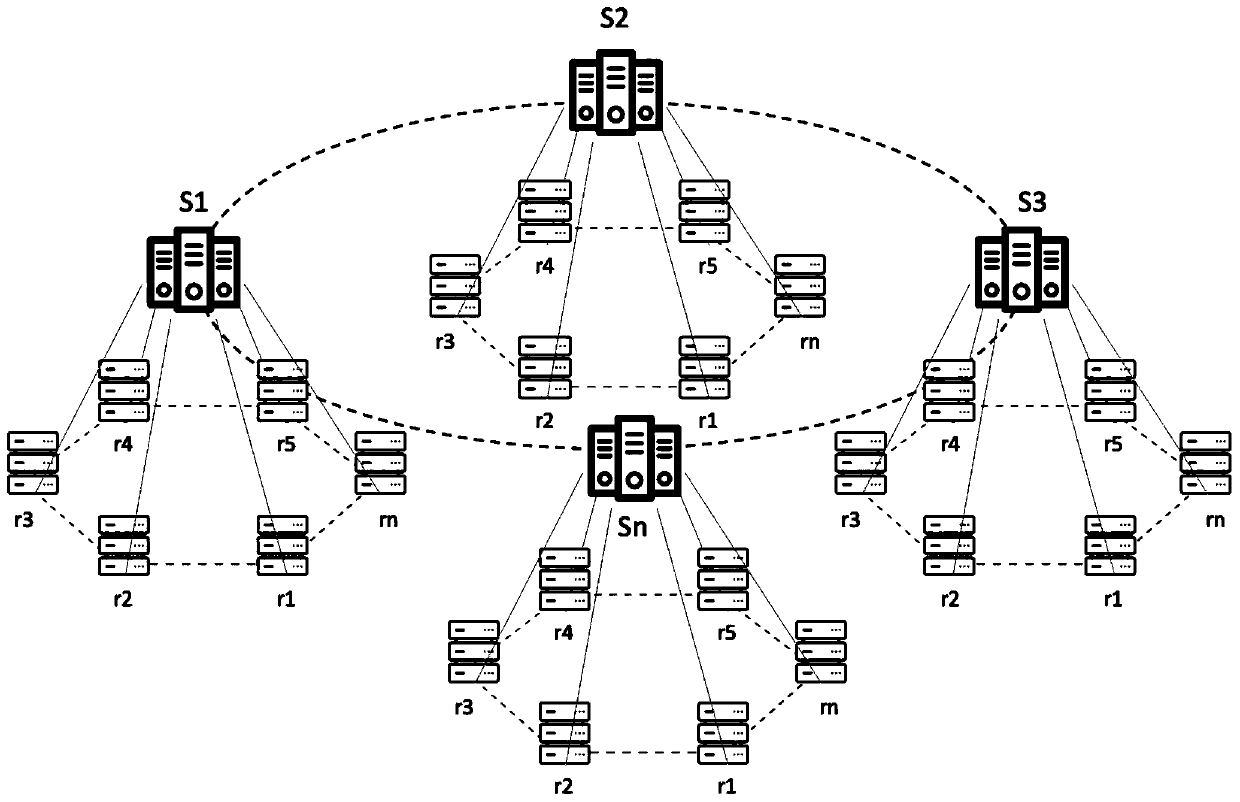

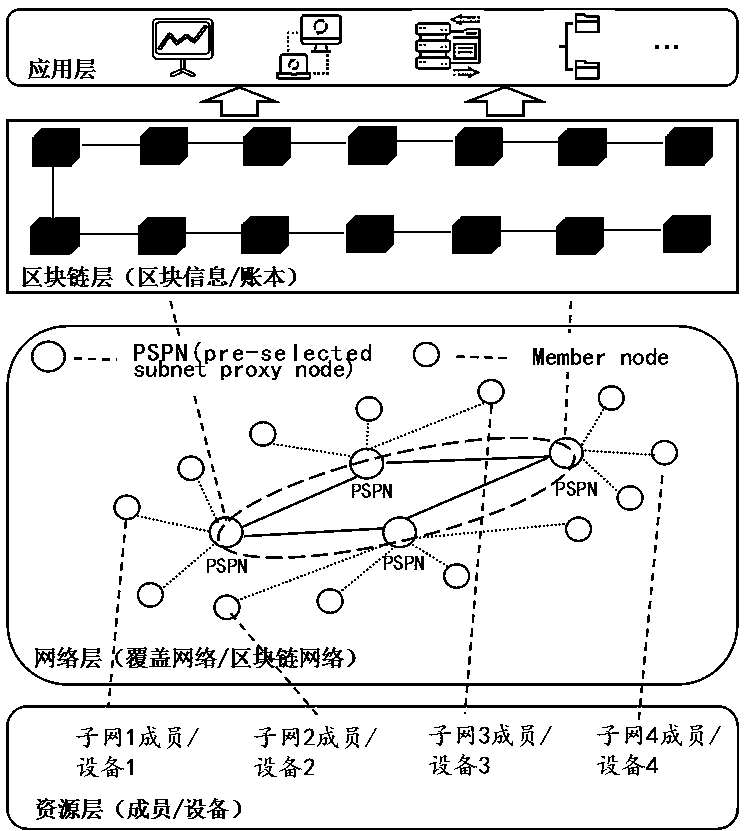

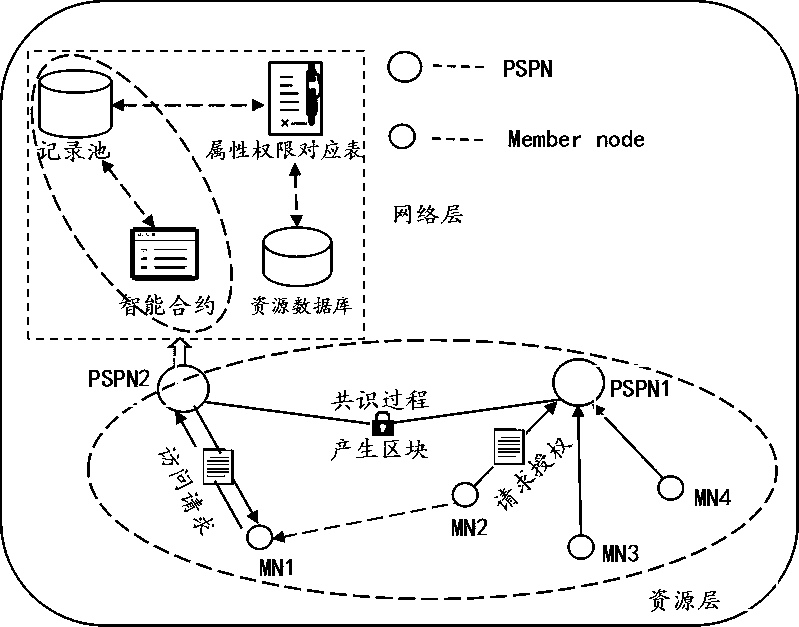

Internet of Things credible distributed data sharing method based on block chain

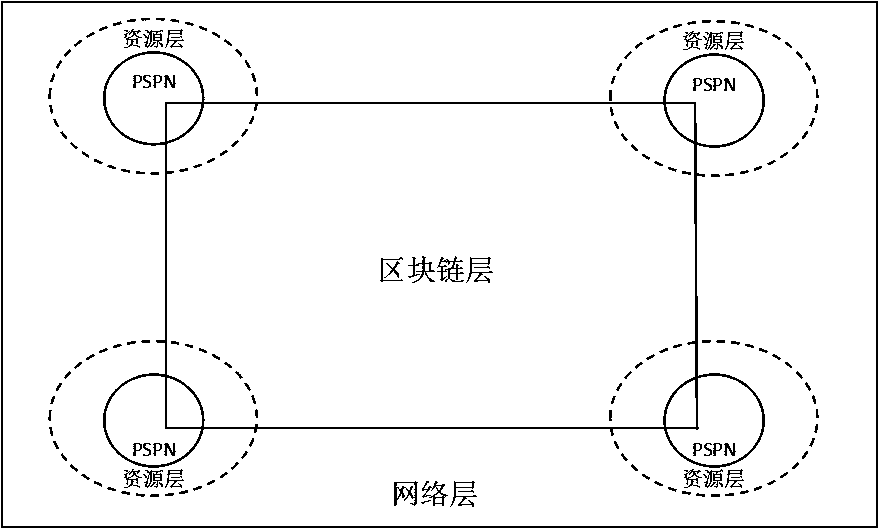

ActiveCN110351381ASolve the problem of effective communicationSolve critical problems that are difficult to trustUser identity/authority verificationData sourceIndustrial Internet

The invention discloses an Internet of Things credible distributed data sharing method based on a block chain. A system realized by the method comprises system structure elements such as a resource layer, a network layer, a block chain layer and an application layer. All the equipment / user nodes are logically combined to form a double-layer overlay network, and a pre-selected edge gateway node with large storage and calculation capacity is arranged in each subnet to serve as a super node. The PSPNs form a block chain layer at the same time, and safe and efficient decentralized distributed datasharing access control is realized by utilizing an intelligent contract and combining on-chain and off-chain storage. According to the method, the P2P technology is utilized, and the problem of effective communication between different data source entities in the industrial Internet of Things environment is solved on the aspect of system structure; the sharing efficiency problem of mass data in an Internet of Things scene is solved; the problems of decentralization and auditing of credible sharing of data are effectively solved, and the operation and maintenance cost of the system is reduced.

Owner:HUNAN UNIV

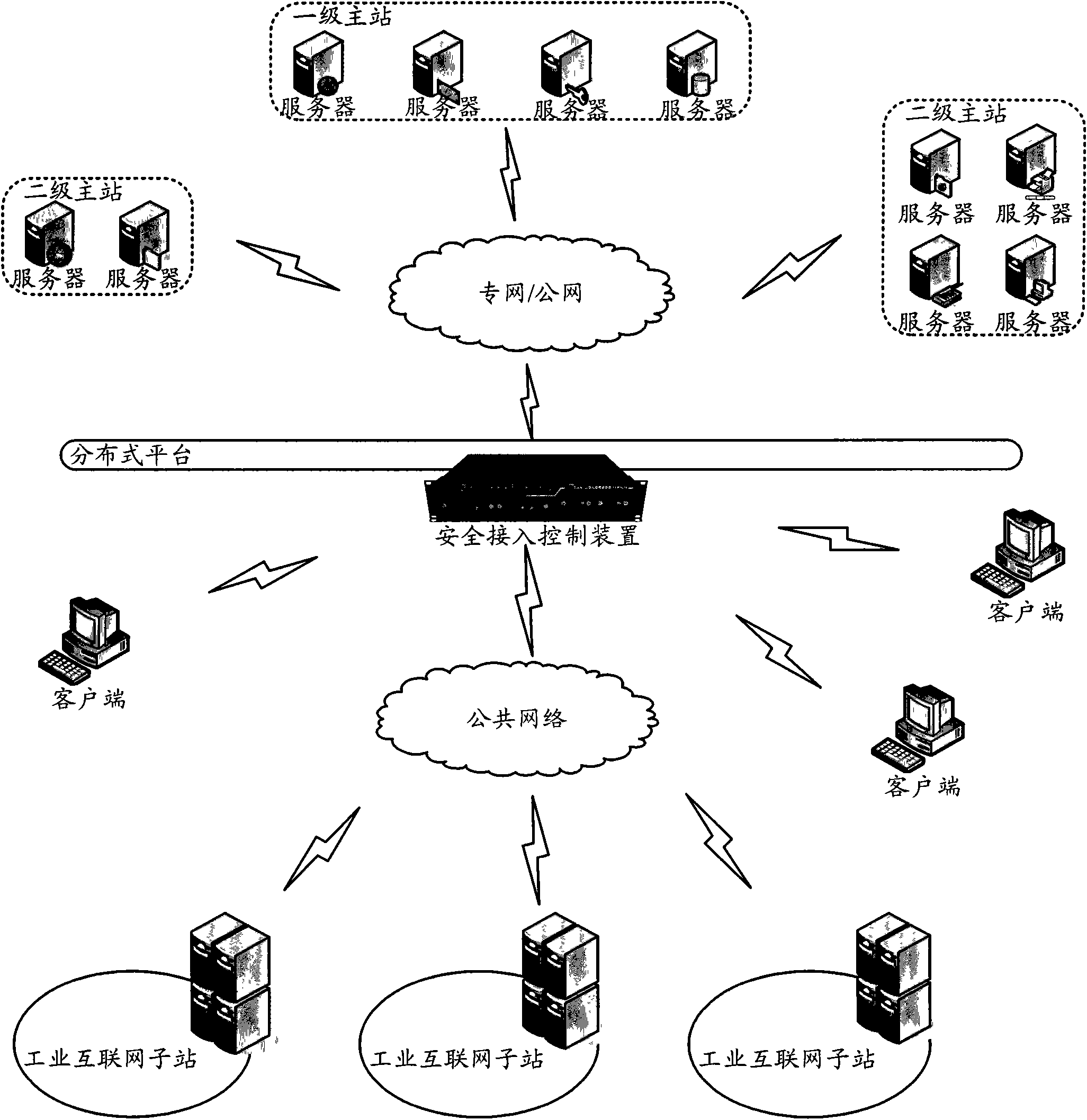

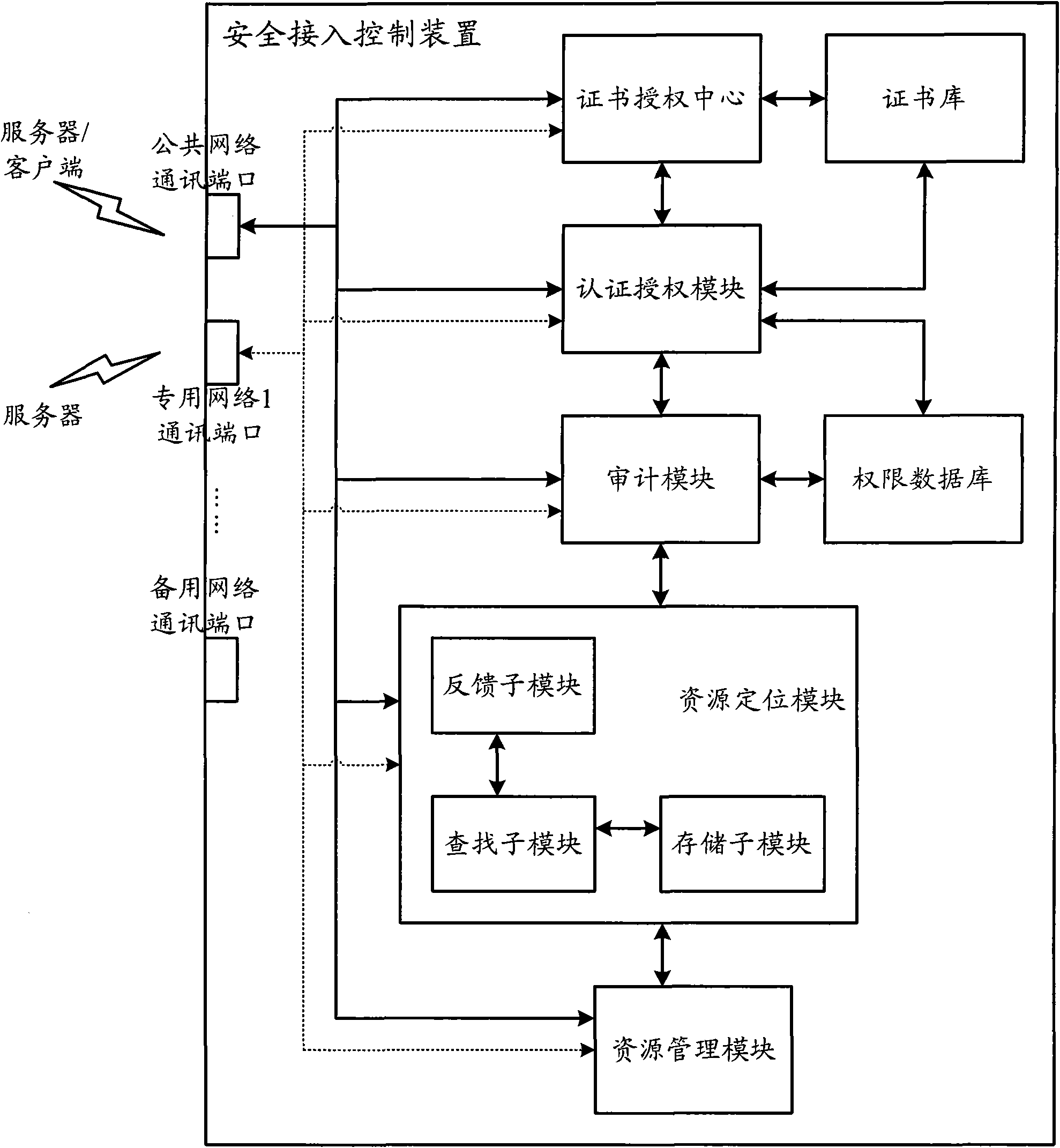

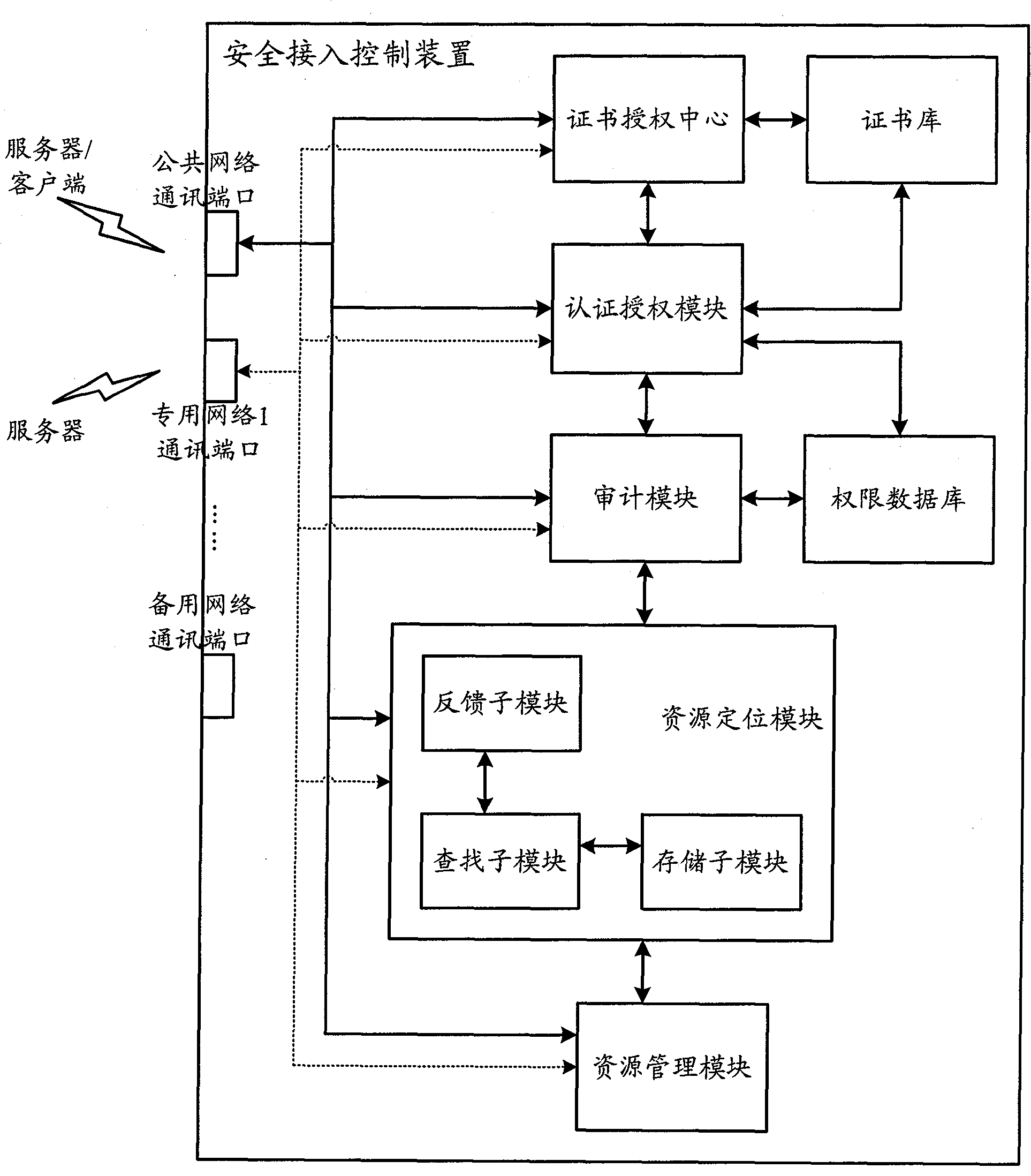

Industrial Internet distributed system safety access control device

ActiveCN102487383AGuaranteed legalityPrevent theftUser identity/authority verificationThe InternetIndustrial Internet

The invention discloses an industrial Internet distributed system safety access control device. The device integrates a module which is used to carry out authentication and authorization to identities and access operations of a user and a server, the module which is used to audit the access operations of the user and the server and the module which is used to carry out uniform resource positioning to object resources accessed by the user and the server. Identity security and authority validity of the user or the server which access to the industrial Internet distributed system and acquire information / service can be effectively ensured. In addition, the user and the server in the industrial Internet do not need to know an actual storage position of the needed object resources. Through a uniform resource positioning platform of the distributed system, the corresponding server can be positioned and the needed object resources can be acquired. A demand in a distributed environment can be rapidly and conveniently satisfied.

Owner:ASAT CHINA TECH

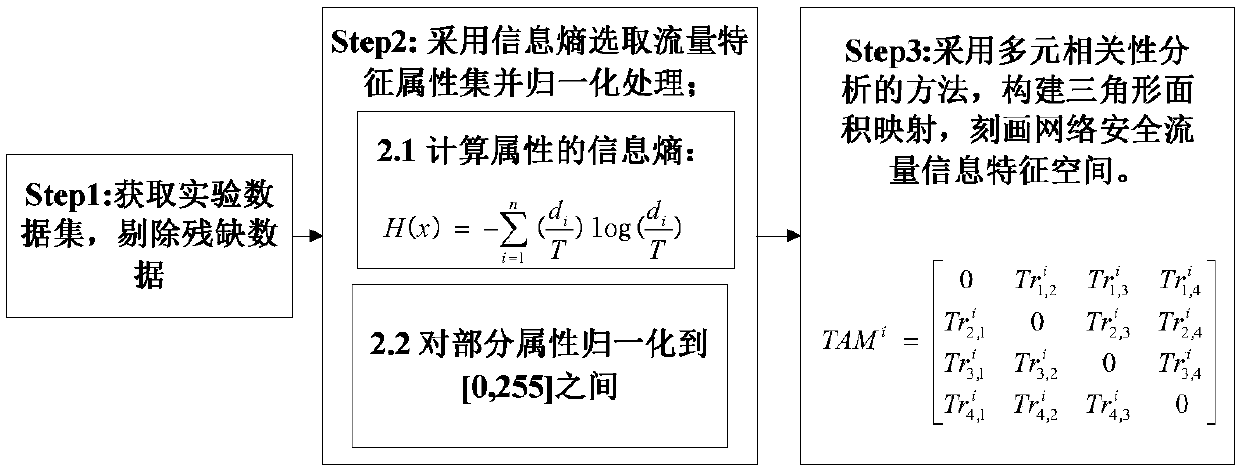

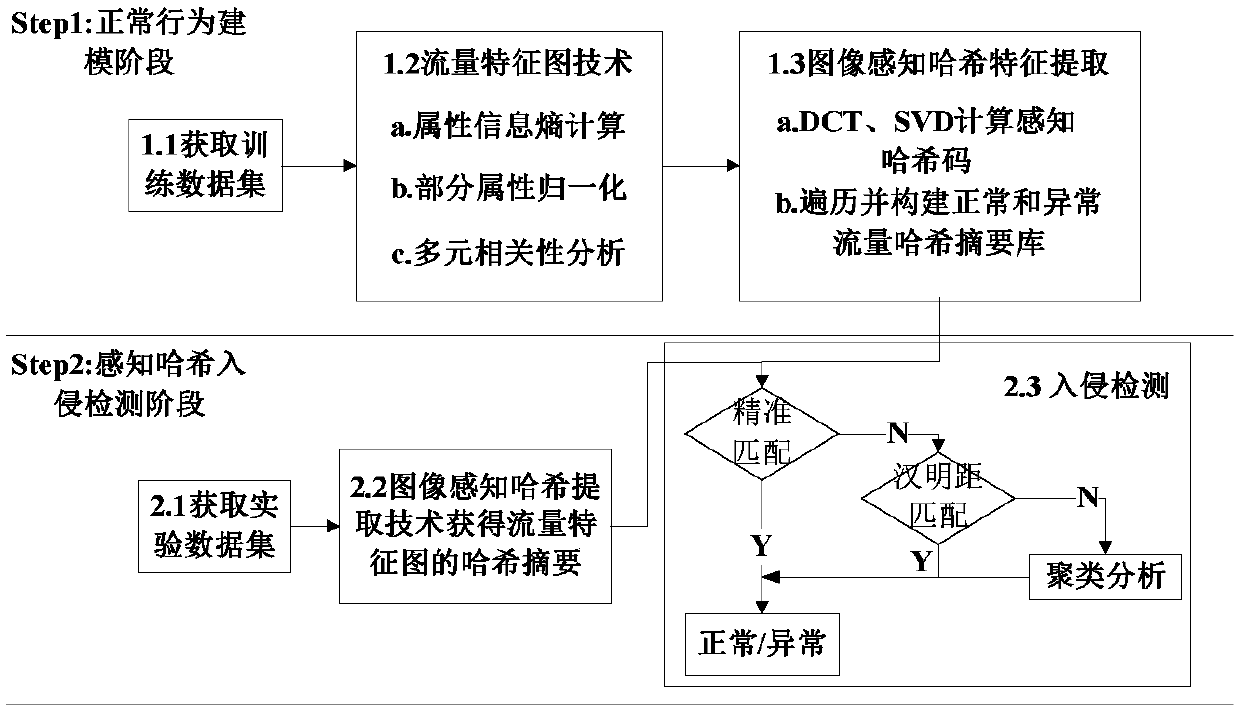

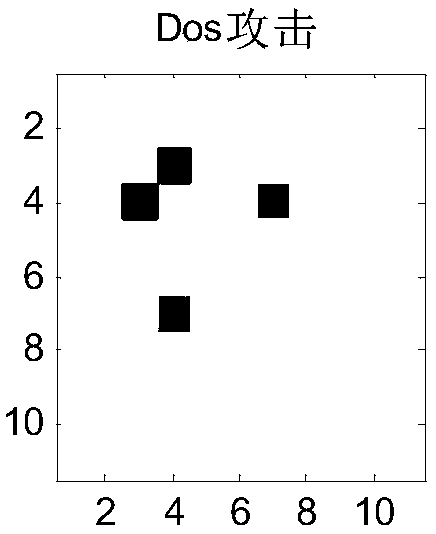

Industrial Internet intrusion detection method based on flow feature map and perception hash

InactiveCN107070943AMeet the robustnessGood intrusion detection performanceData switching networksSingular value decompositionData set

The invention provides an industrial Internet intrusion detection method based on a flow feature map and perception hash for mainly solving the problems of low detection performance and poor adaptability of the existing industrial Internet intrusion detection method. The industrial Internet intrusion detection method draws lessons from an image processing method and comprises the following steps: firstly obtaining a standard test bed experimental data set, performing feature selection by using an information entropy method to construct a flow feature vector, and performing a normalization operation on a part of attributes; then, converting the flow feature vector into a triangle area mapping matrix by using a multivariate correlation analysis method to construct the flow feature map; and finally, obtaining a hash abstract of the flow feature map by using an image perception hash algorithm based on discrete cosine transform SVD and singular value decomposition SVD, and generating an intrusion detection rule set in the form of a binary character string. Moreover, hash matching is performed by using an accurate matching method based on character strings, a similarity measurement method based on a normalized Hamming distance and a clustering analysis method based on a Euclidean distance so as to detect abnormal flow and malicious intrusion in the industrial Internet.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

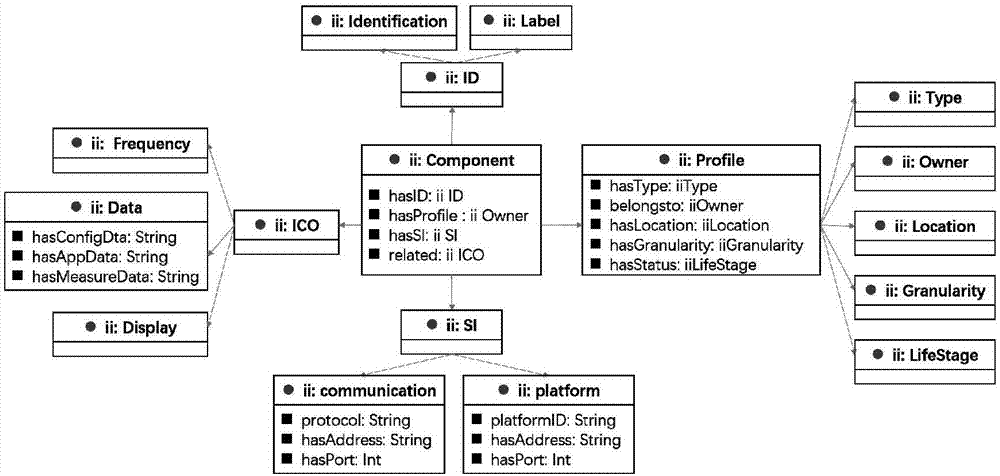

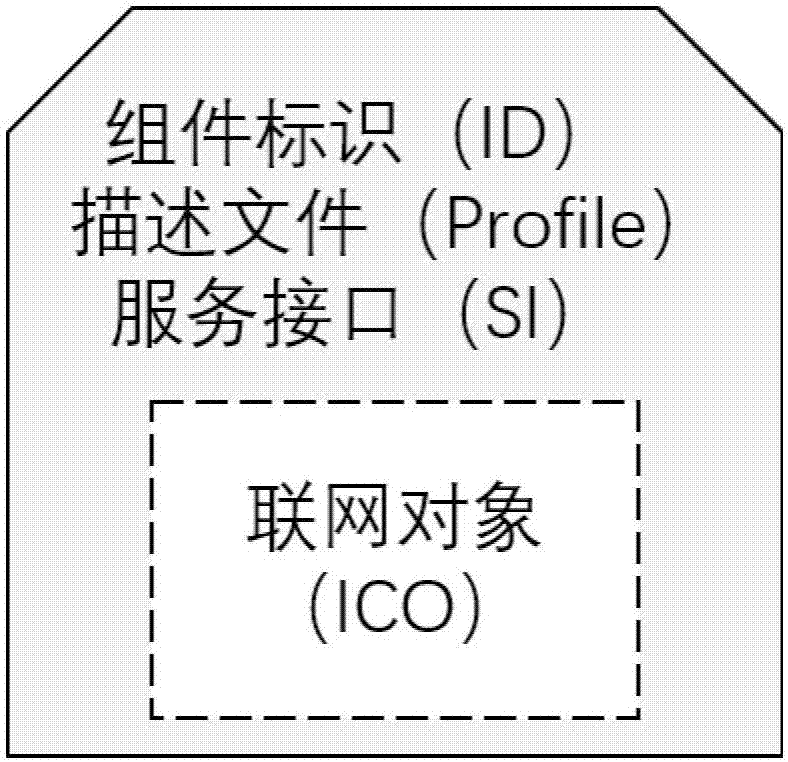

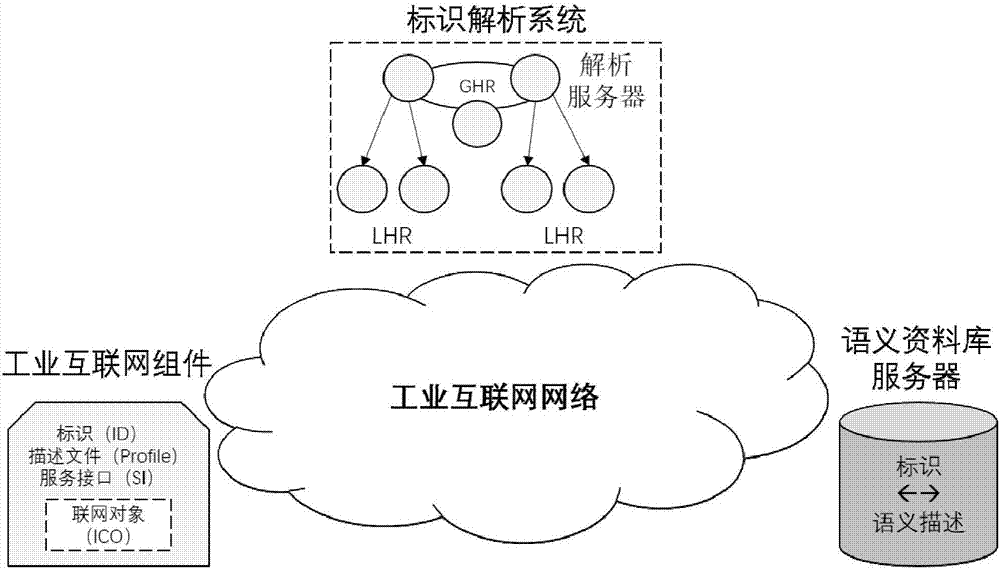

Industrial internet component information identification method

ActiveCN107197001AAchieving Compatibility IdentificationTransmissionInternet groupwareObject composition

The invention provides an industrial internet component information identification method, which comprises the steps of: configuring a component identifier, a description file and a service interface for a networking object according to a semantic database, and constituting industrial internet component models by means of the component identifier, the description file, the service interface and the networking object; acquiring a component identifier of an industrial internet component to be identified; initiating a query request to an identifier analysis system; receiving a semantic database address returned by the identifier analysis system; querying an industrial internet semantic vocabulary corresponding to the component identifier from a corresponding semantic database server according to the received semantic database address; and receiving semantic description information obtained through querying the industrial internet semantic vocabulary which corresponds to the component identifier and is returned by the semantic database server, and mapping information in the corresponding industrial internet component model into semantic vocabulary capable of identifying the industrial internet component according to the semantic description information. The industrial internet component information identification method can realize the compatibility identification of heterogeneous information within the component.

Owner:CHINA ACADEMY OF INFORMATION & COMM

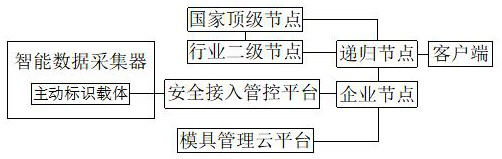

Industrial Internet identifier analysis method

PendingCN112200502AImprove monitoringRealize full lifecycle managementOffice automationResourcesBusiness enterpriseThe Internet

The invention discloses an industrial Internet identifier analysis method. The method comprises the steps that an active identifier carrier initiates an identity authentication request; the security access management and control platform initiates a registration request to the enterprise node; the enterprise node obtains unique identification registration information and stores the unique identification registration information in the national top-level node through the industry secondary node; the security access management and control platform writes the identification registration information into an active identification carrier; the intelligent data collector collects various data of the injection mold, generates a database and sends the database to the active identification carrier;the active identification carrier sends the database to the mold management cloud platform; a query request is initiated to a recursive node through a client, the recursive node sends an addressing request to a secondary node, and a national top-level node provides identification registration information for the client; and the recursion node sends an identifier analysis request to the enterprisenode, and the enterprise node provides a database for the client. According to the industrial internet identifier analysis method, the monitoring strength of the injection mold is effectively improved, and full-life-cycle management of the injection mold is achieved.

Owner:苏州协同创新智能制造科技有限公司

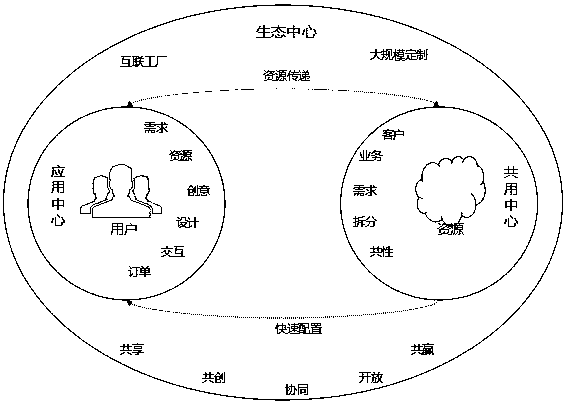

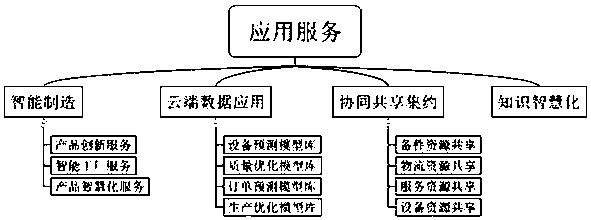

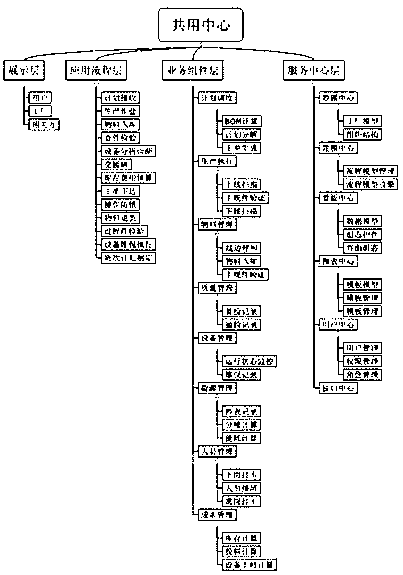

Industrial internet cloud platform

ActiveCN107734059AQuick configurationRealize the integration of product and effectBuying/selling/leasing transactionsResourcesMass customizationThe Internet

An industrial internet cloud platform comprises an application service platform: a small front-end mode for meeting differentiated demands of users; and a common center: a large platform mode for extracting the same service attributes of the manufacturing industry and realizing quick configuration of customers in different industries. The industrial internet cloud platform has the advantages: userlifetime value is created based on user experience; one-off consumption is converted into interactive experience of sustained and deep participation of users by encouraging the users to participate in the whole process of interaction, virtual design, manufacturing, delivery and the like; based on the upgrade from "electrical appliances" to "network devices", a whole-process solution of sustainedand iterative upgrade is provided for the users; the fusion of large-scale customization using internet factories as a carrier and personalized customization solves the contradictions of the both on cost and efficiency, and realizes merit goods; and through parallel and open ecological platforms created by enterprise platforms, the source value is maximized, and parallel and collaborative benign ecological closed loops at resource ends are formed.

Owner:卡奥斯物联科技股份有限公司 +1

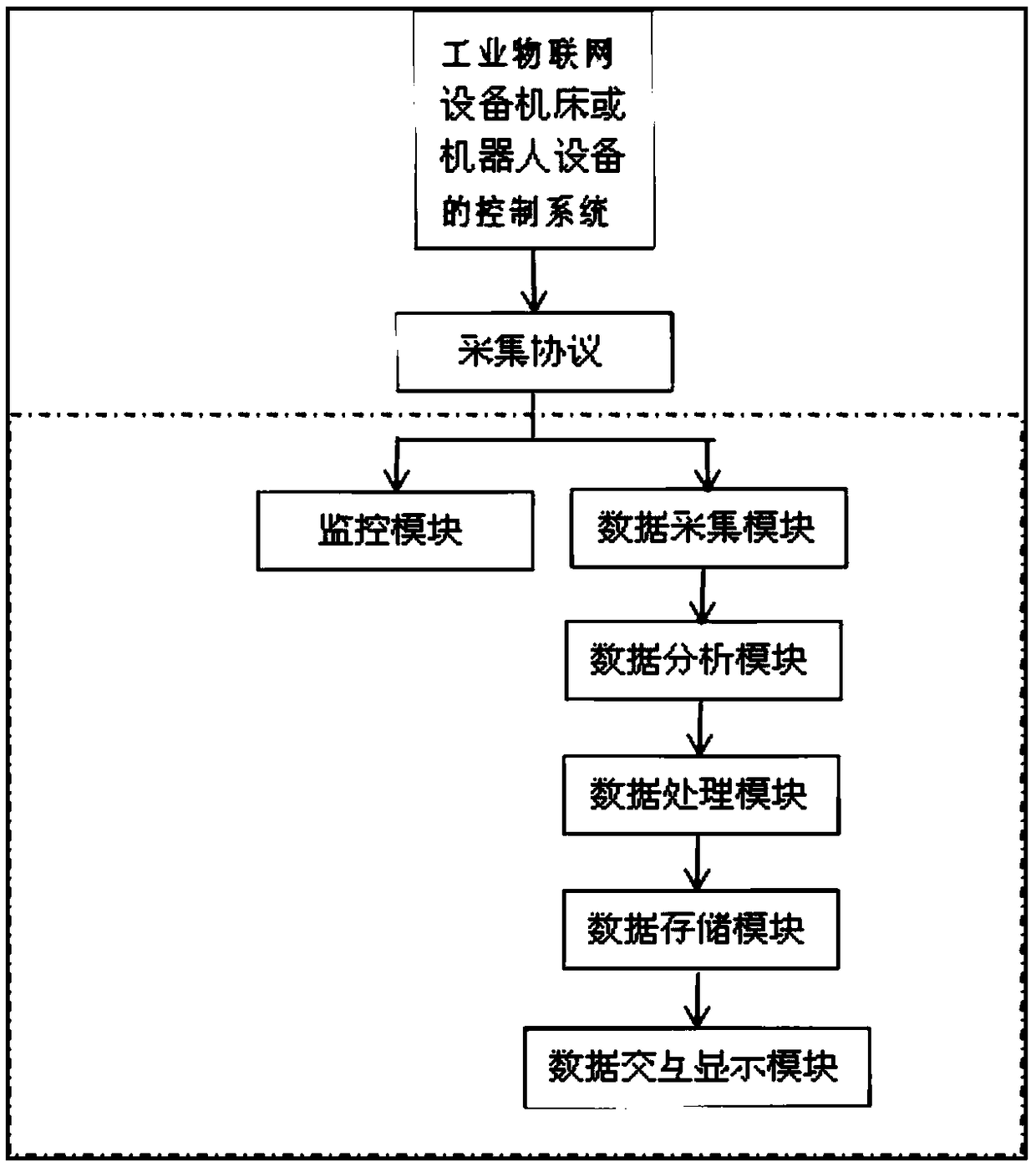

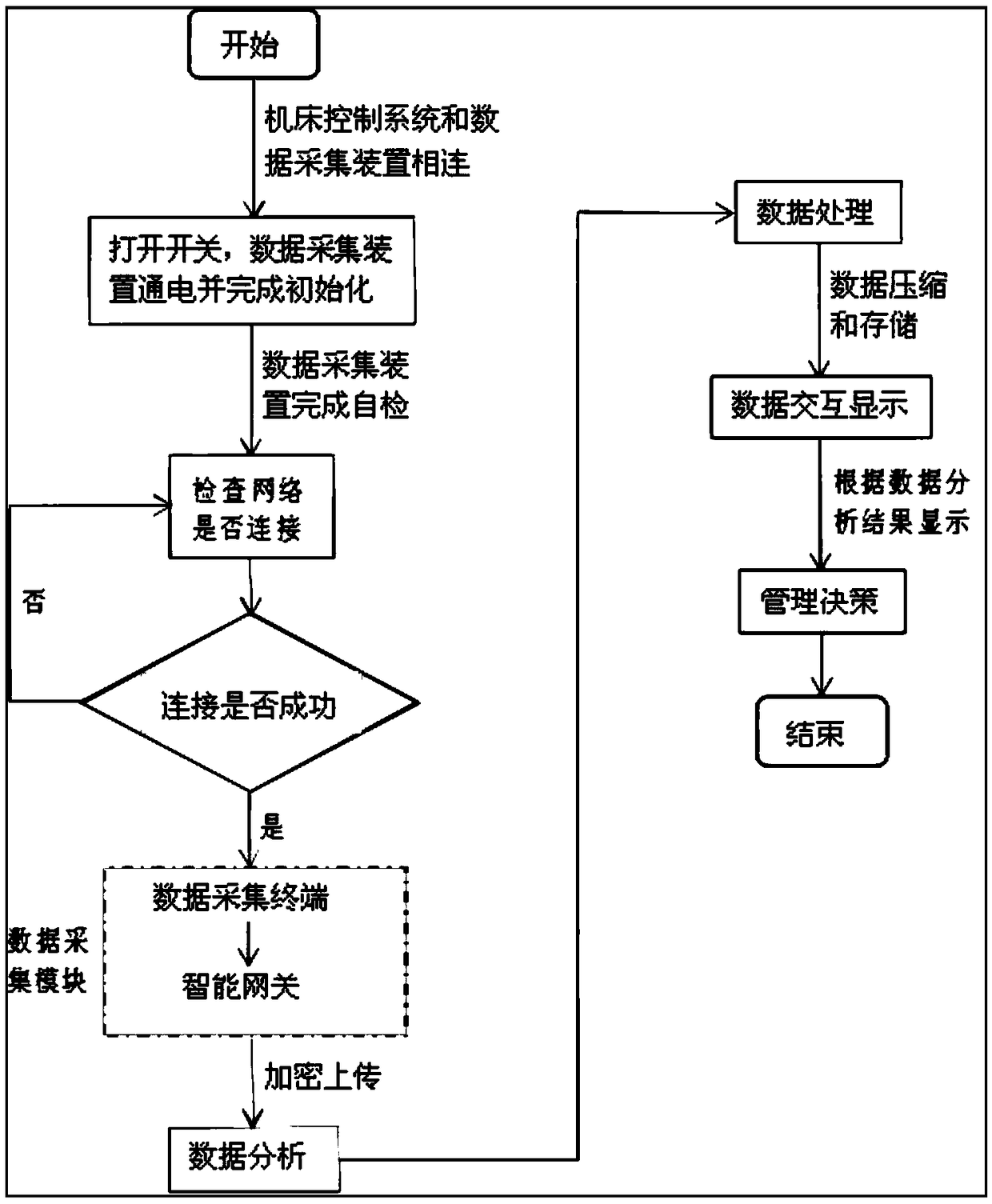

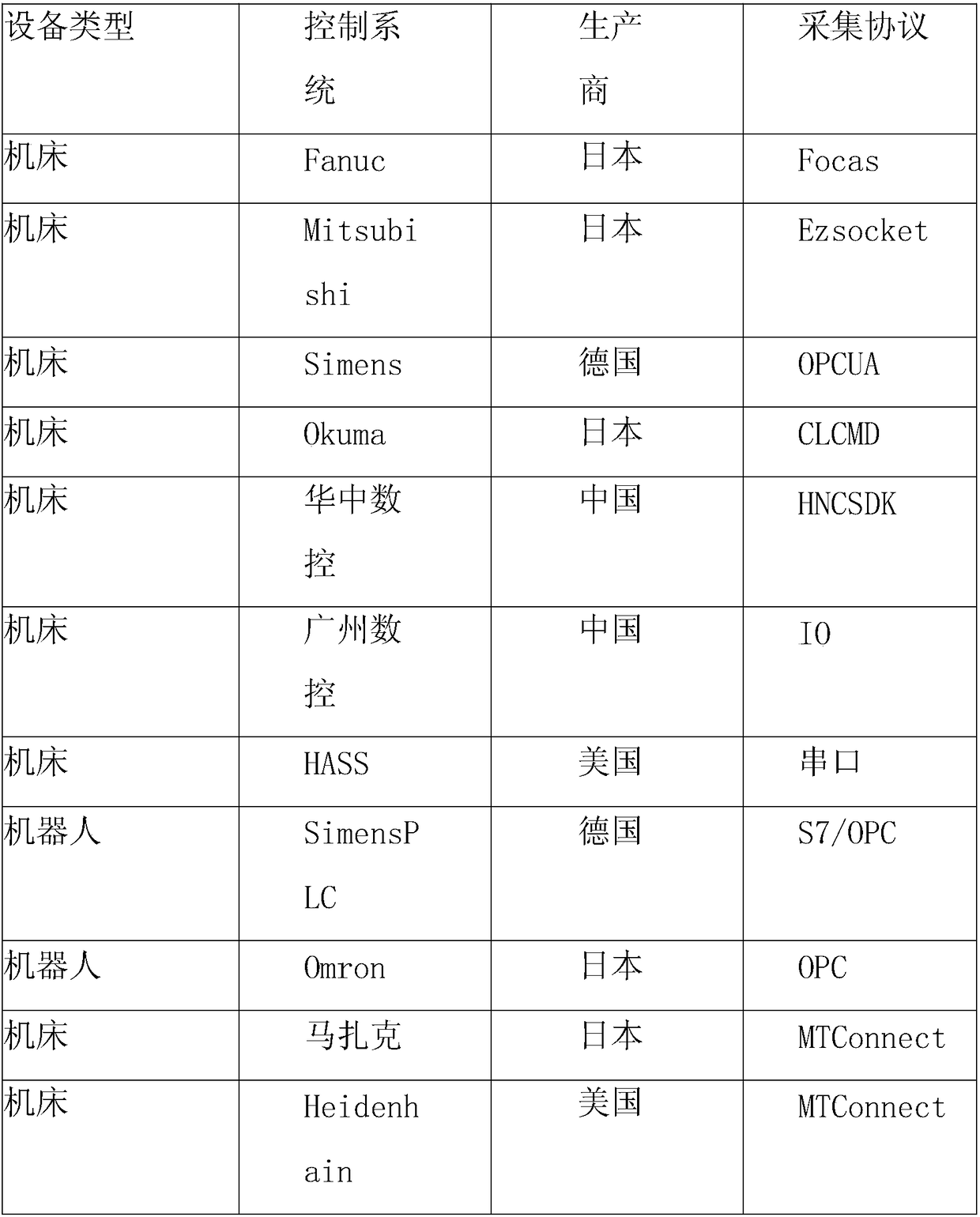

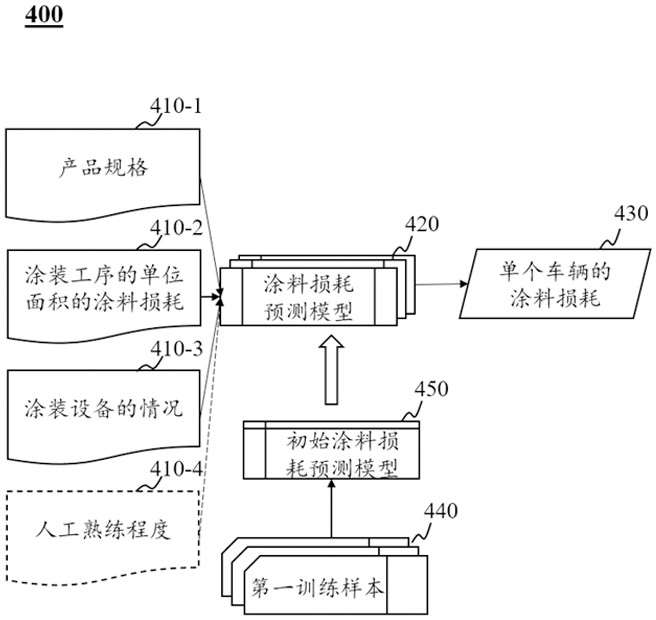

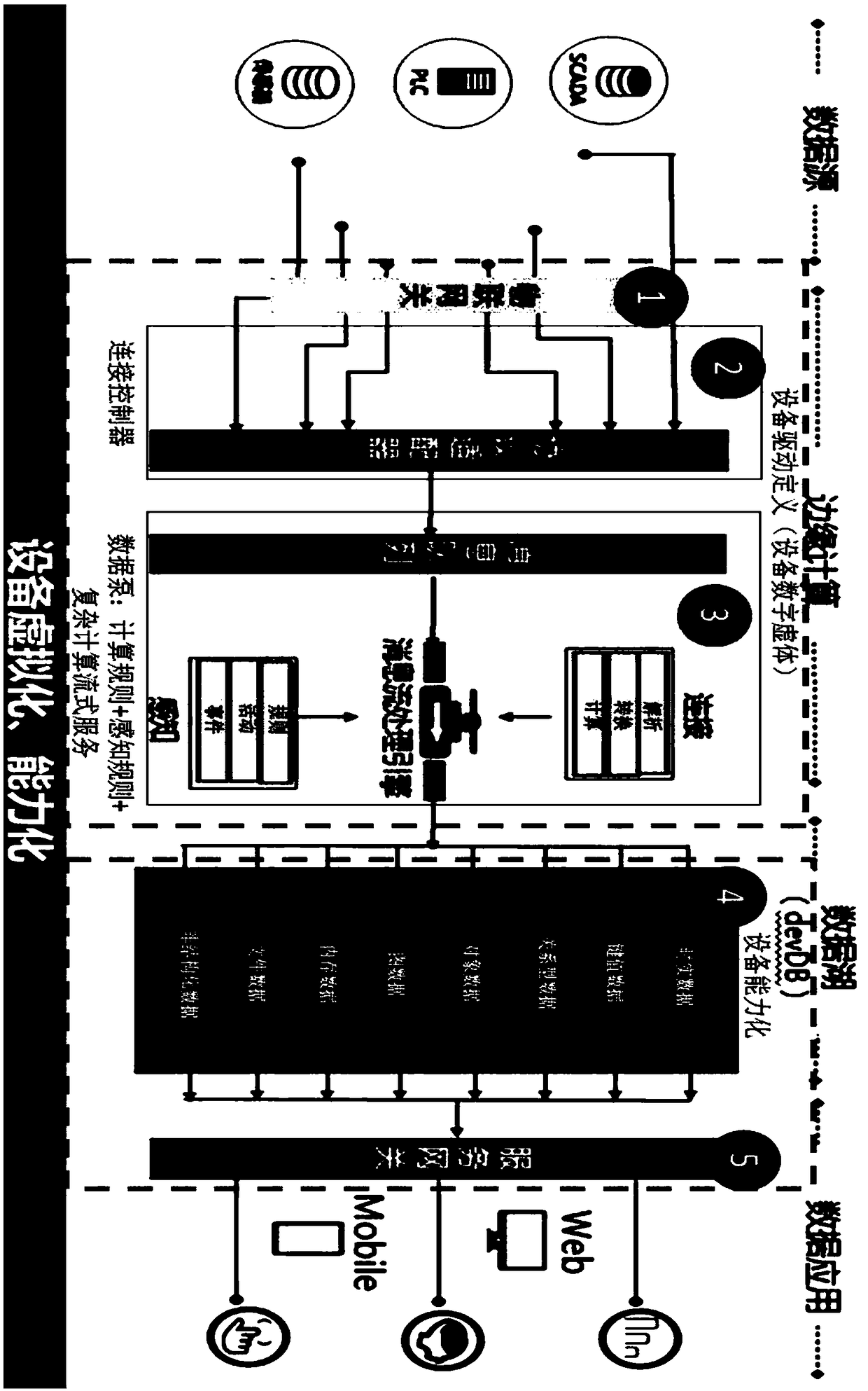

Industrial intelligent manufacturing data acquisition apparatus and method based on Internet of Things

PendingCN108762210AEasy to exportRefined production managementTotal factory controlProgramme total factory controlIndustrial equipmentThe Internet

The invention discloses an industrial intelligent manufacturing data acquisition apparatus and method based on the Internet of Things. The apparatus comprises a data acquisition module, a data transmission module, a data analysis module, a data processing module, a data storage module, a data interaction display module and a monitoring module, the data acquisition module is connected with a control system of an industrial Internet of Things equipment machine tool through an acquisition protocol, the data acquisition module, the data transmission module, the data analysis module, the data processing module, the data storage module and the data interaction display module are connected in sequence, and the monitoring module is connected with the control system of the industrial Internet of Things equipment machine tool through the acquisition protocol. According to the method and apparatus, data acquisition, analysis, transmission, storage and monitoring are performed for industrial Internet of Things factory equipment machine tools and robot equipment etc., the work efficiency is improved, the production cost is reduced, the information interaction between industrial equipment and production management personnel is enhanced, the efficiency of the equipment is improved, and intelligent and datamation management of factory processing equipment can be realized.

Owner:银川华信智信息技术有限公司

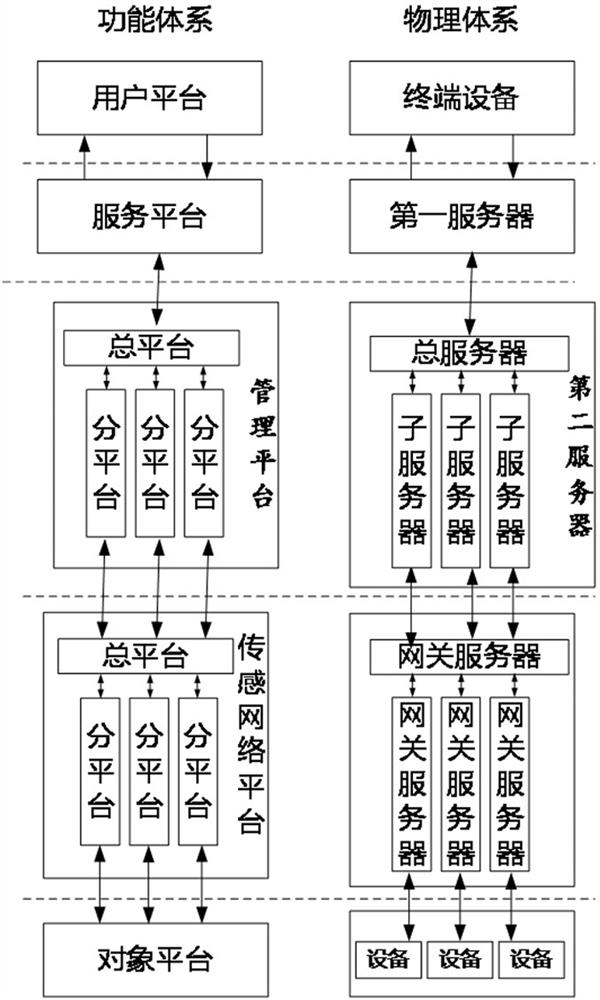

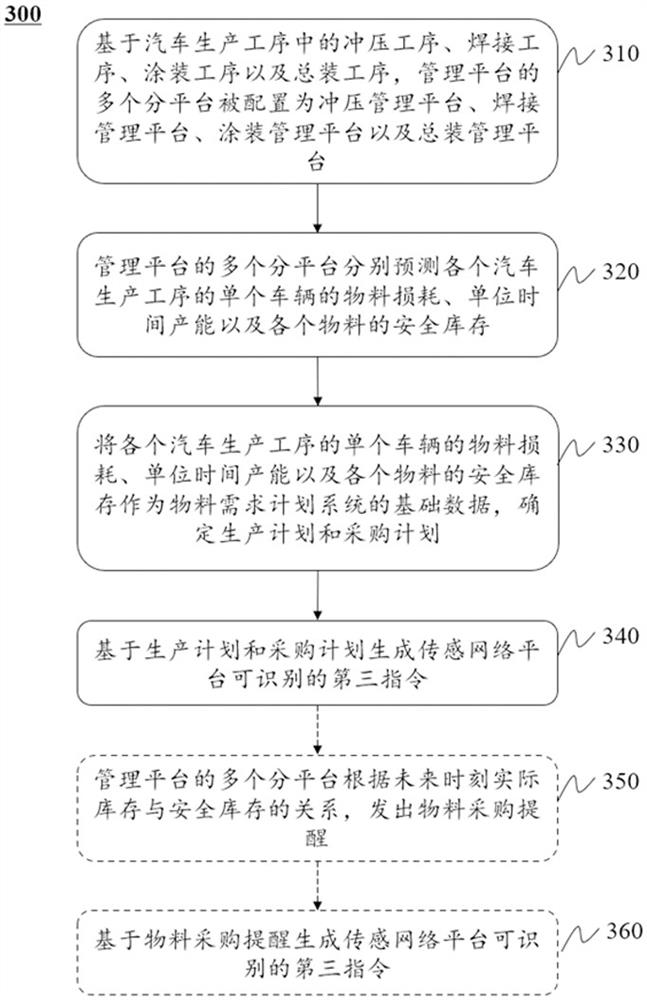

Double-front-split-platform type industrial internet of things and control method thereof

ActiveCN114449023AReasonable increase in productionReasonable production reductionProgramme controlResourcesComputer networkTransmission channel

The invention discloses a double-front-split-platform type industrial internet of things and a control method, and belongs to the field of intelligent manufacturing. The industrial internet of things comprises a user platform, a service platform, a management platform, a sensing network platform and an object platform which are interacted in sequence; the service platform is arranged in a centralized mode, and the management platform and the sensing network platform are arranged in a front-divided platform mode. The control method is applied to the industrial Internet of Things. In order to coordinate product manufacturing parameters of all production line equipment, a sensing network platform and a management platform are arranged in a front sub-platform manner, data are uniformly sorted, received and transmitted through a main platform, and different sub-platforms are used as data processing or transmission channels of different production line equipment, so that a large amount of data are stored and processed in a classified manner; the overall data processing amount and calculation pressure of the platform are reduced, data are processed on the sensing network platform, and safe and rapid product manufacturing control and data receiving and transmitting are achieved.

Owner:CHENGDU QINCHUAN IOT TECH CO LTD

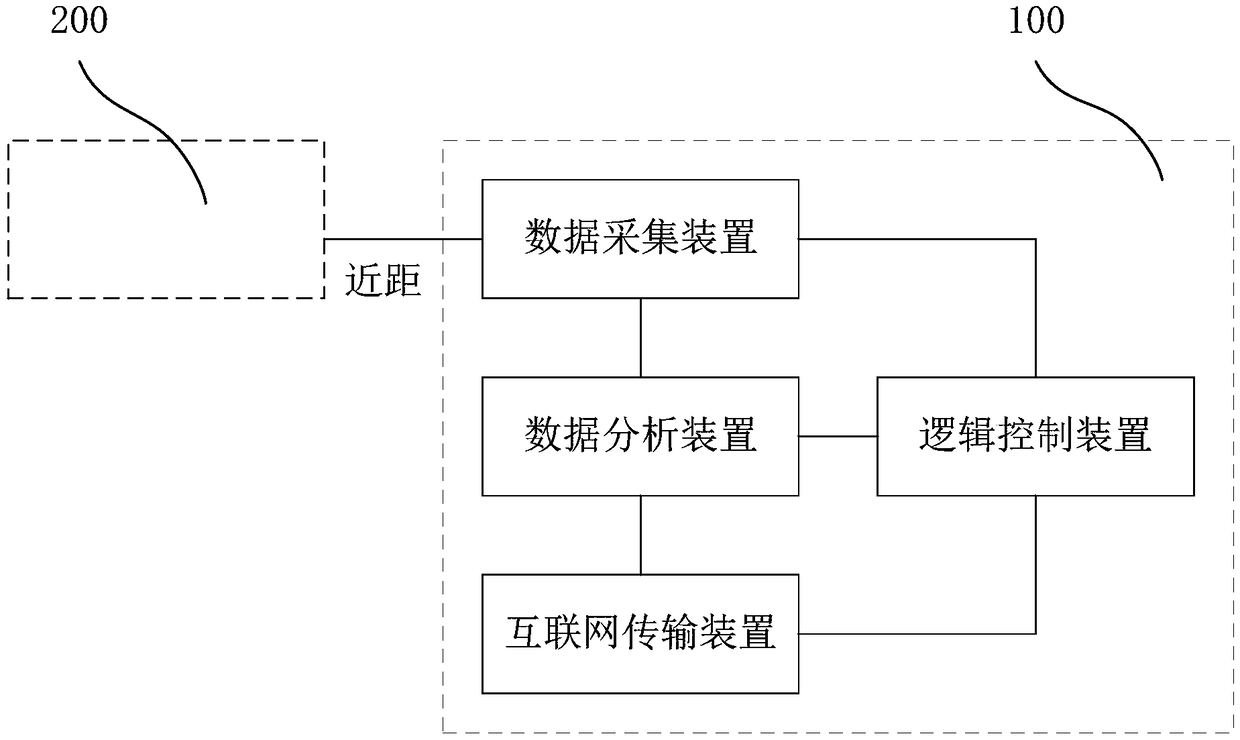

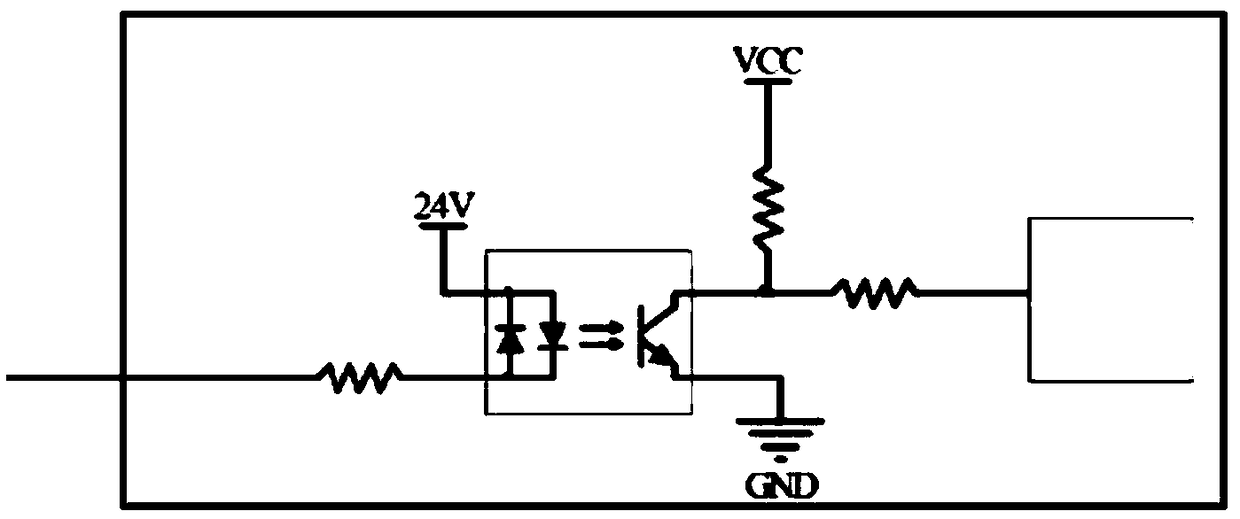

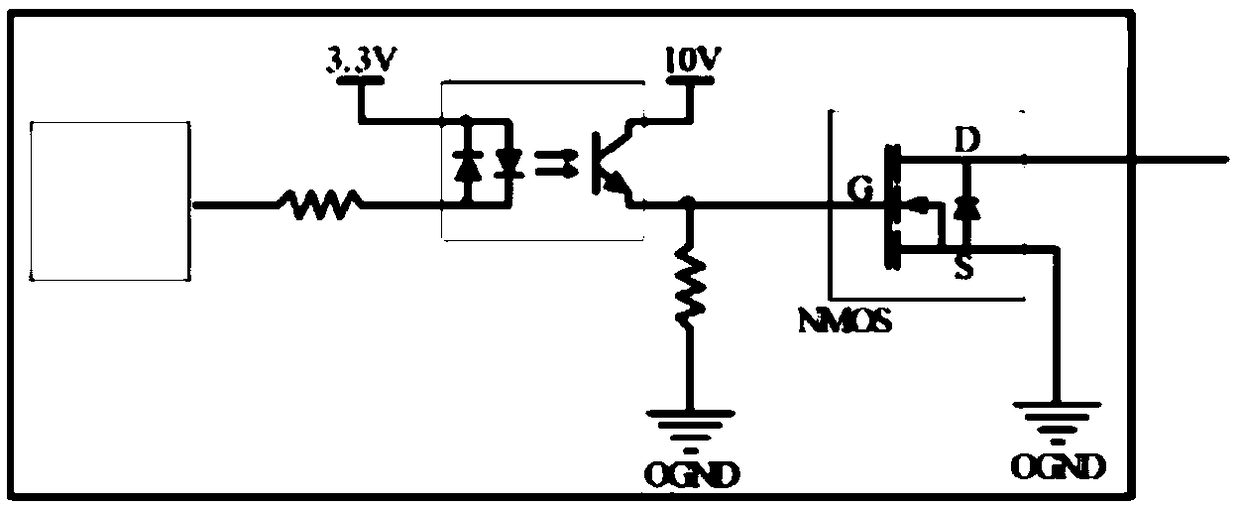

Industrial-internet intelligent controller based on edge computing system architecture

InactiveCN109491301ASolve the problem of limited transmission rateSolve the blockageProgramme controlComputer controlThe InternetIndustrial equipment

The invention relates to an industrial internet intelligent controller based on edge computing system architecture. A logic control device is connected with a data collecting device, a data analysis device and an internet transmission device; the data collecting device collects equipment data on the edge side; the data analysis device computes and analyzes the equipment data on the edge side, andan analysis result is obtained; the internet transmission device is used for uploading the analysis result, and control information is transmitted to the logic control device. The data is collected, analyzed and put on the edge side close to a data source, operation is also dispersed on the edge side, the problem that the data-path transmission rate of industrial equipment and a cloud terminal islimited is solved, the problems that as the traditional PLC data throughout is poor, the network is congested, a processing beat is slow, and the efficiency is low are solved, and perfect combinationof edge computing and cloud computing is achieved in cooperation with the internet transmission device.

Owner:东莞固高自动化技术有限公司

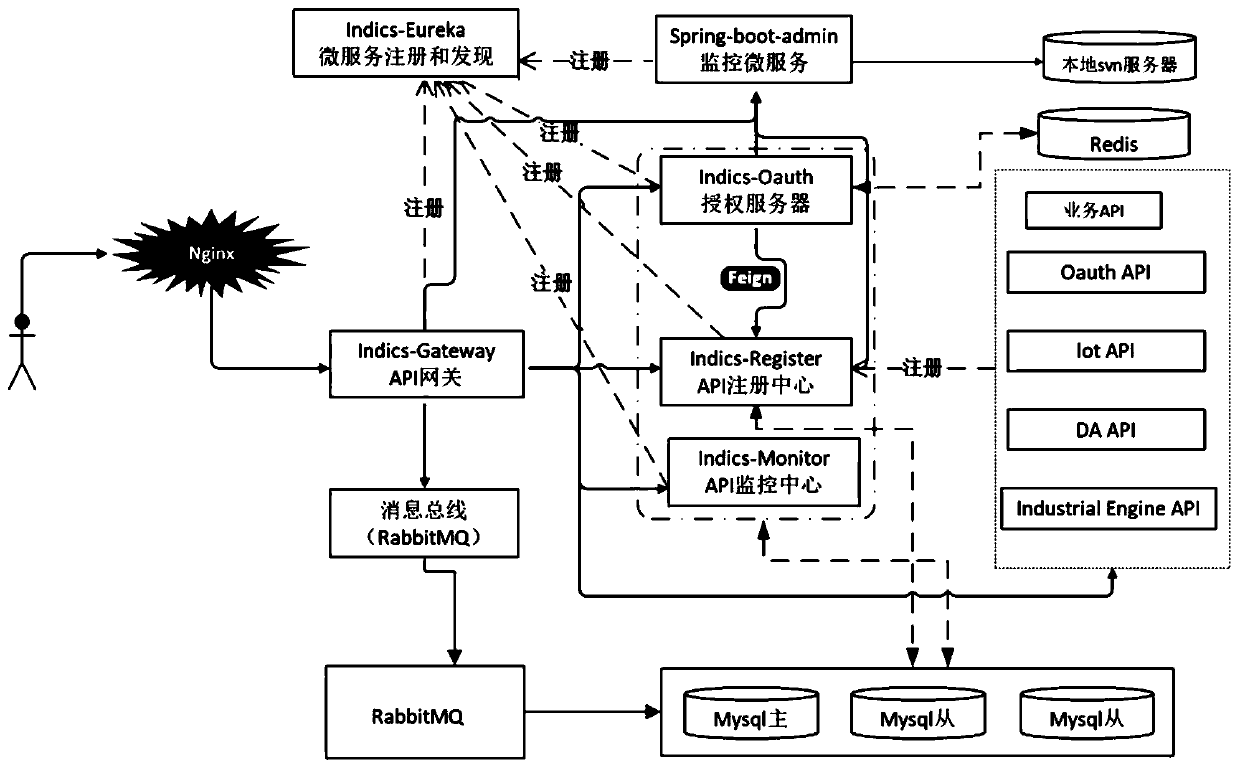

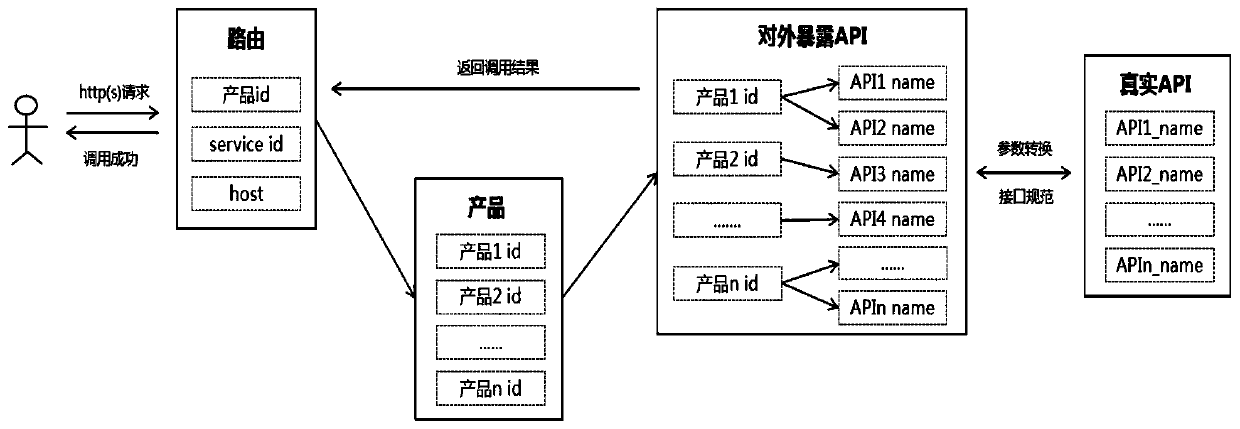

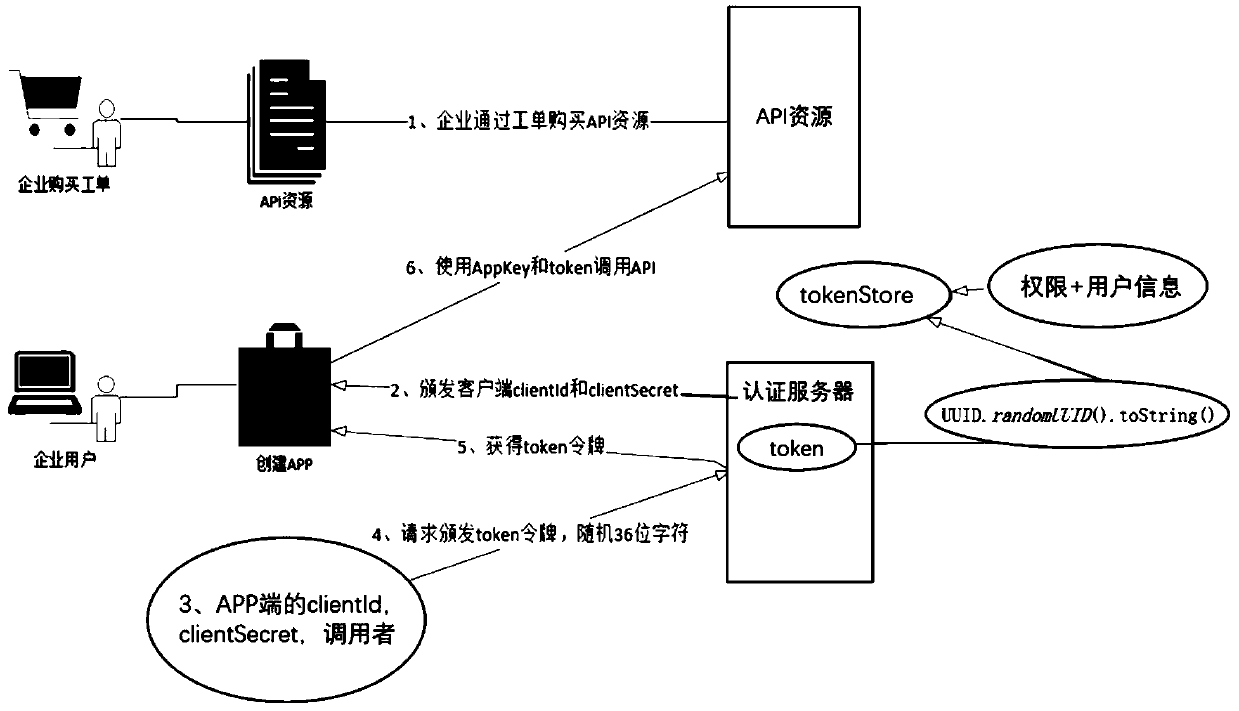

Open API full-life-cycle management method based on micro-service

ActiveCN111181727AEasy maintenanceImprove abilitiesUser identity/authority verificationSoftware engineeringThe Internet

The invention relates to an open API full-life-cycle management method based on micro-service. According to the method, an open API full-life-cycle management system composed of an API gateway, an APIauthorization authentication center, an API registration center and an API monitoring center is established on the basis of a micro-service technology in combination with INDICS industrial Internet platform service requirements; and realizing flexible calling of API interface services through full-life-cycle management of APIs, wherein the full-life-cycle management of APIs comprises creation, release, test and offline of API interfaces. The method is characterized in that APIs of different systems can be opened and managed in a unified mode; multi-tenant isolation of data is supported; a perfect authority management and control method is achieved; and safe, reliable and rich-function API interface services are provided for developers.

Owner:北京航天智造科技发展有限公司

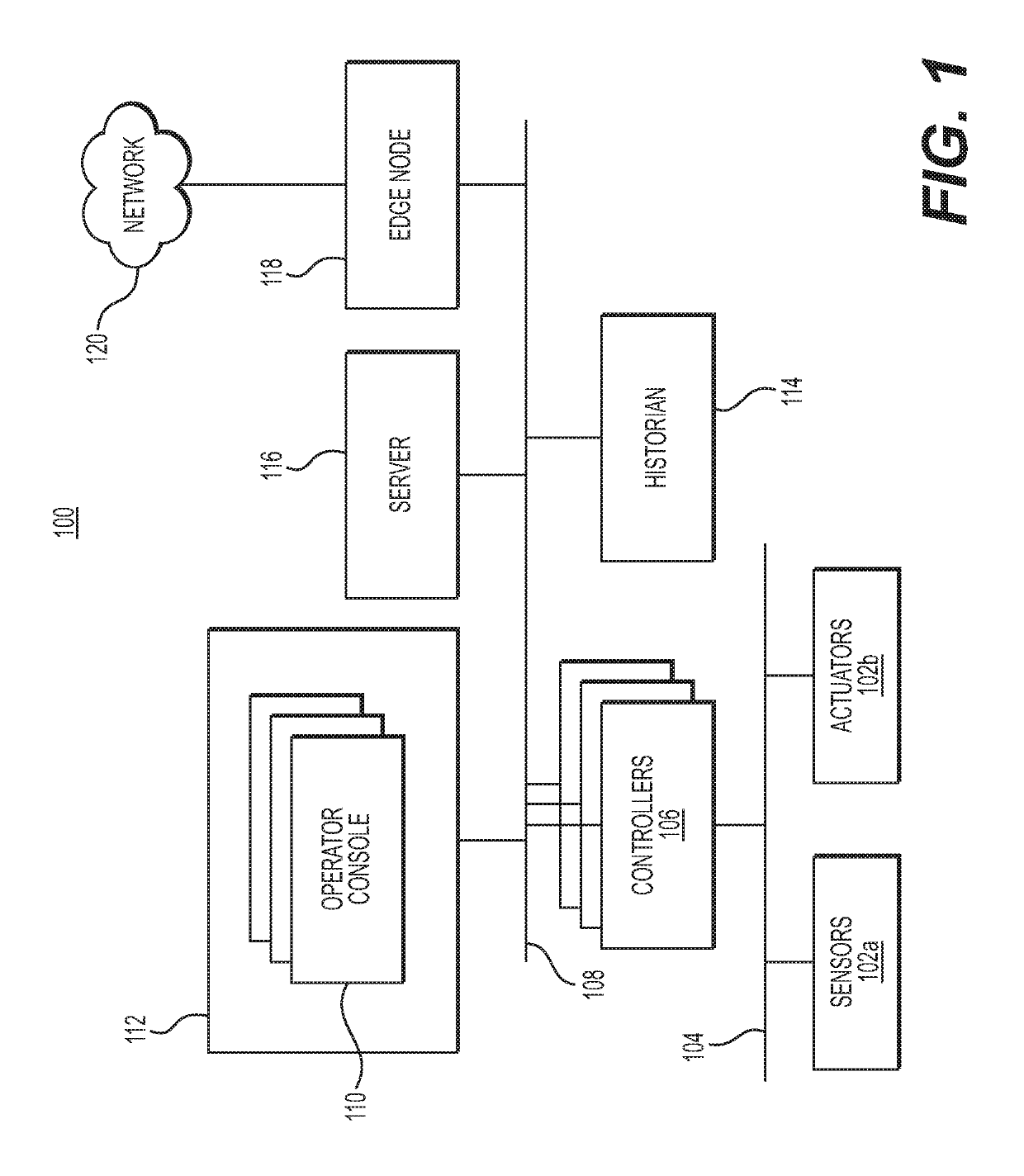

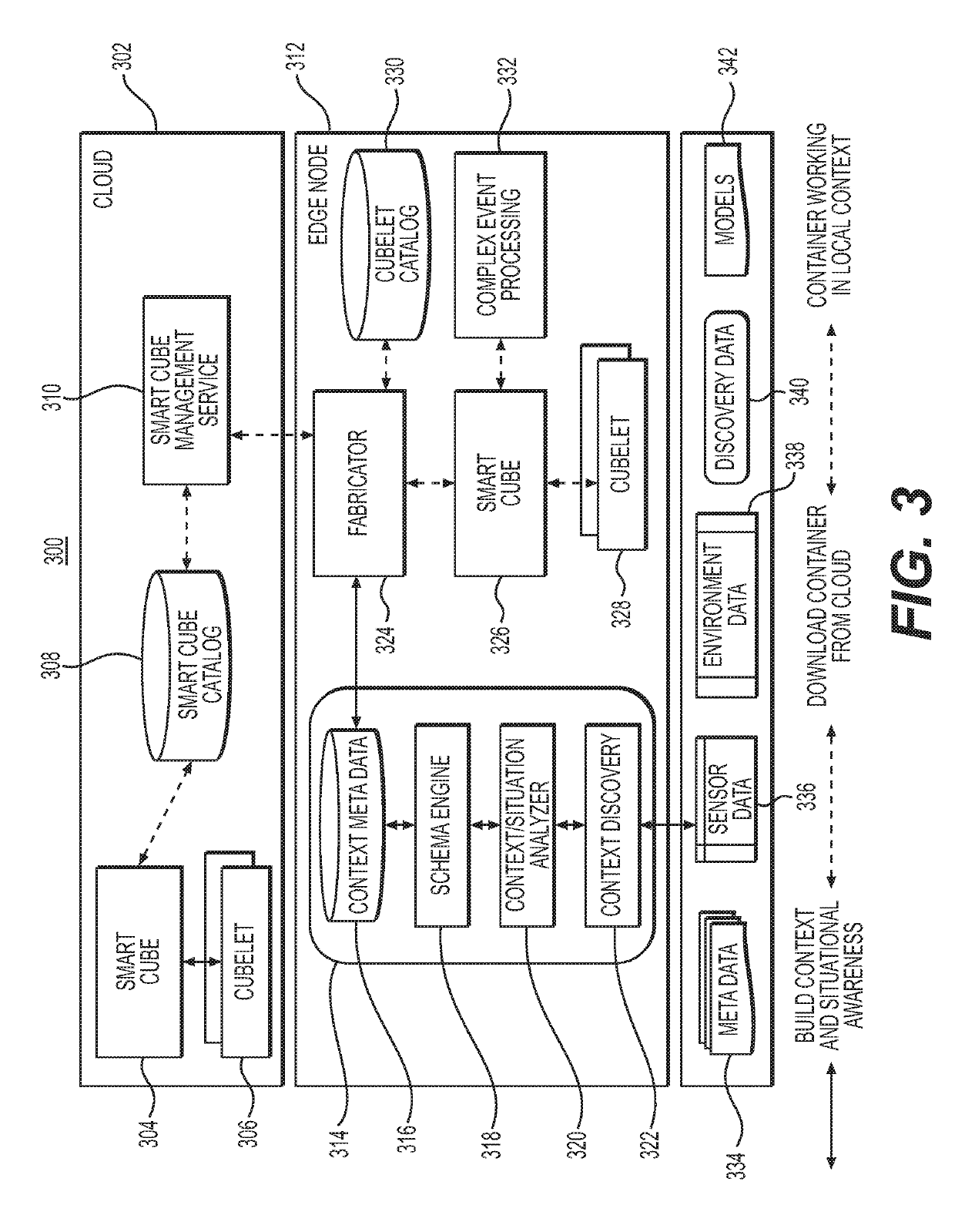

Systems and methods for adaptive industrial internet of things (IIOT) edge platform

Computer-implemented methods for configuring an Industrial Internet of Things (IIoT) edge node in an IIoT network to perform one or more functions, comprising: performing a situation analysis to determine a required change in one or more of an analytical model, a runtime component, and a functional block of the IIoT edge node based on a change in the one or more functions; and automatically provisioning a new or updated functional module to the IIoT edge node, based on the situation analysis, the new or updated functional module including one or more components, wherein each component includes at least one of a rules set, a complex domain expression with respect to a process industry, an analytical model, and a protocol decoder.

Owner:HONEYWELL INT INC

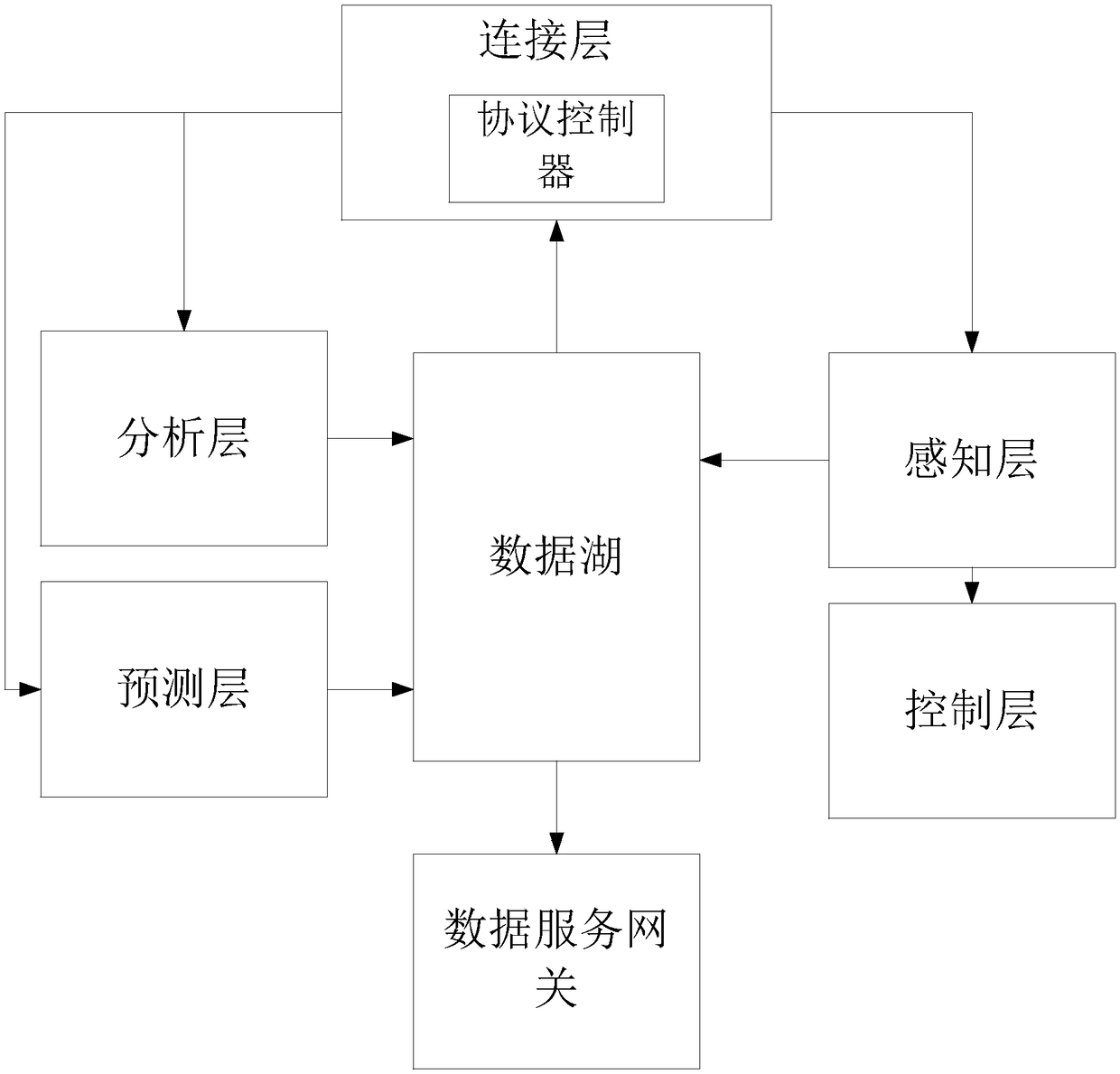

Industrial Internet edge calculating device and realizing method thereof

ActiveCN109388117ASolve communication protocol differencesEnsure diversityTotal factory controlProgramme total factory controlControl layerOriginal data

The invention discloses an industrial Internet edge calculating device which comprises a connecting layer, a sensing layer, an analyzing layer, a control layer, a predicating layer, a data lake and adata service gateway. The connecting layer is used for establishing a protocol controller, converting data pump original data to a data message and forming an equipment driver which is introduced andled out by a data pump. The sensing layer is used for defining a sensing condition and establishing a triggering action response event. The analyzing layer is connected with the data pump, analyzes real-time original data which are acquired by the connecting layer and generates an analysis result event. The control layer is used for acquiring an abnormal action response event and adjusts an operation parameter of industrial equipment which is connected with a bus. The predicating layer is connected with the connecting layer, establishes an equipment fault predicating model through a deep convolutional neural algorithm, acquires the original data and outputs a control suggestion event. The data lake stores data messages, alarm events, analysis result events and control suggestion events. The invention further discloses a realizing method of the industrial Internet edge calculating device.

Owner:CHONGQING SIOU INFORMATION TECH CO LTD

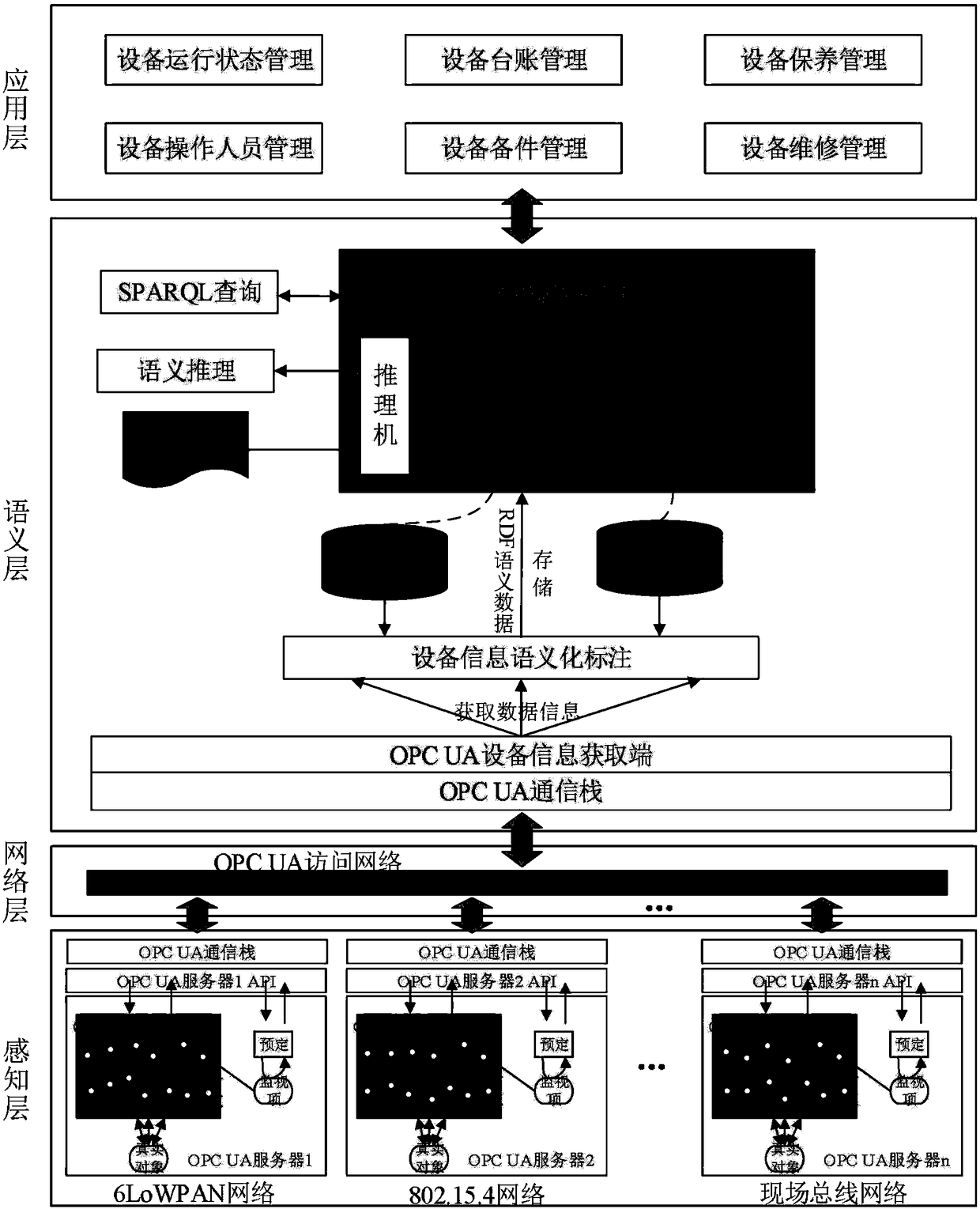

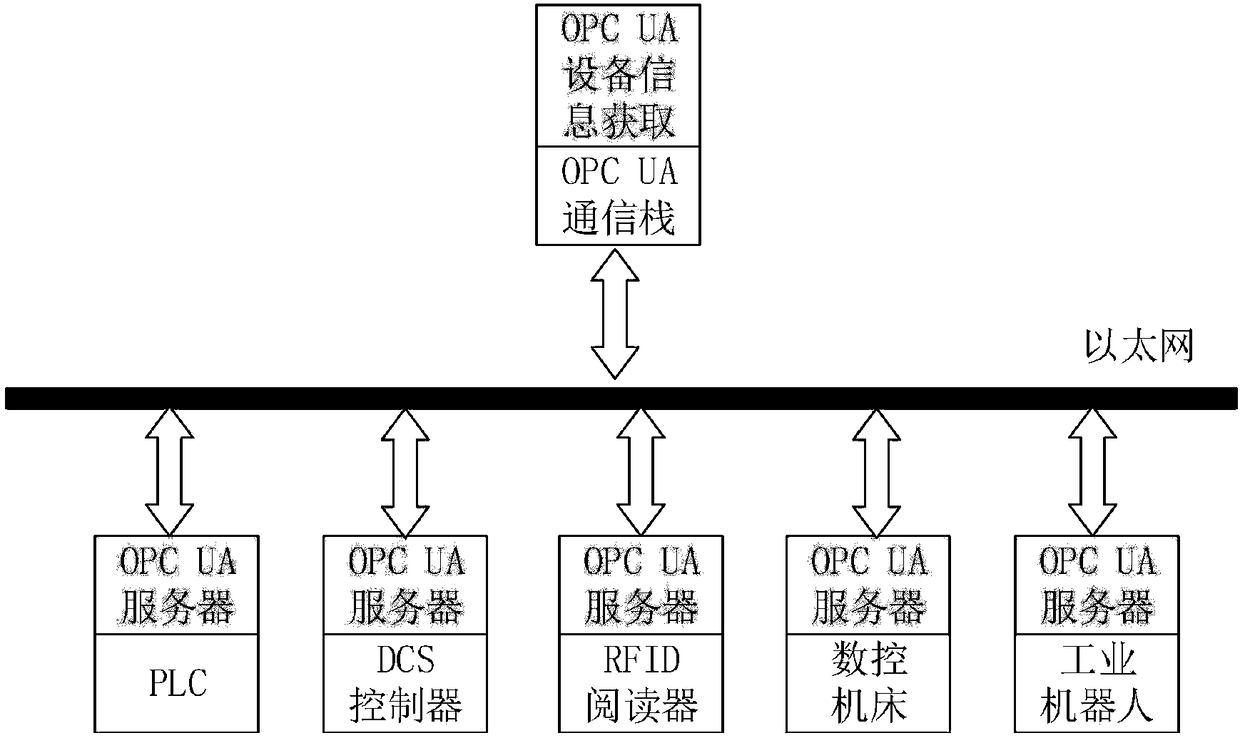

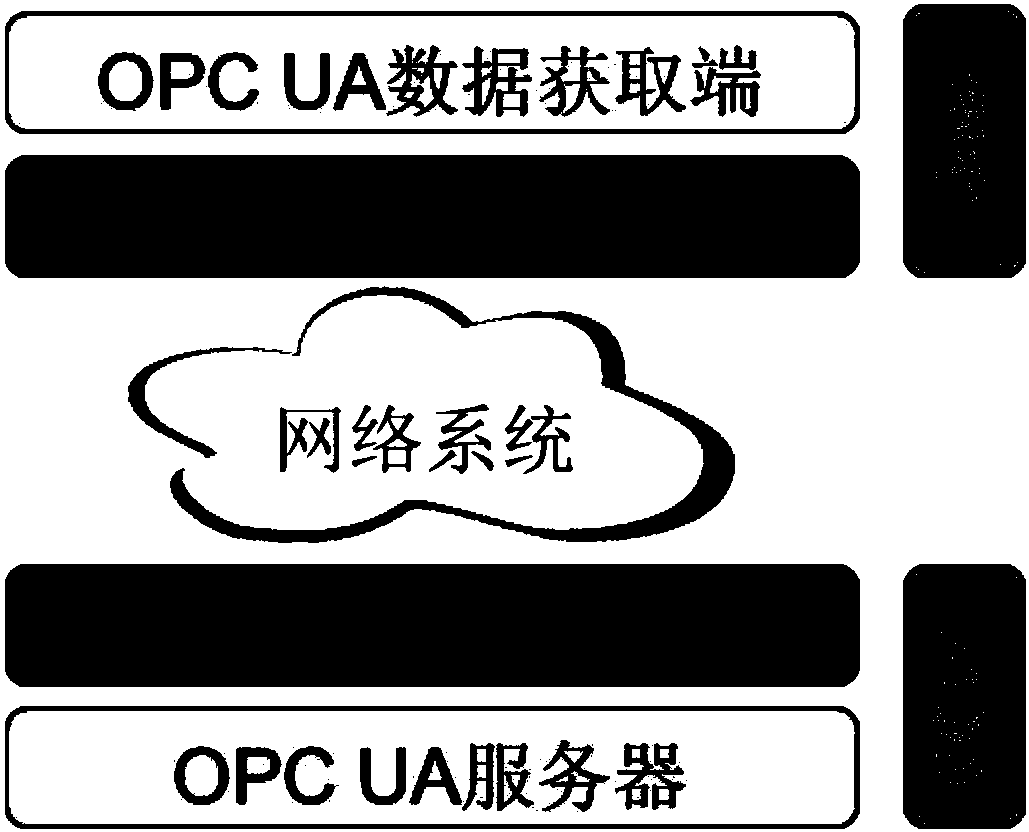

Field device information management system based on semantics and OPC UA

InactiveCN108459574AGuaranteed interoperabilityRealize intelligent management servicesTotal factory controlProgramme total factory controlIndustrial InternetSemantic Web

The invention relates to a field device information management system based on semantics and OPC UA and belongs to the combined field of the semantic network and the industrial Internet of things. Theintegral configuration of the system comprises a sensing layer, a network layer, a semantic layer and an application layer, wherein the sensing layer comprises a bottom field device and an OPC UA server, the network layer comprises each network system accessed by the OPC UA, the semantic layer comprises an OPC UA device information acquisition end, a device information management domain knowledgeontology model, a device information semantic annotation module, a semantic reasoning and query module, an ontology database and a semantic rule file, and the application layer comprises a device running state management module, a device operator management module, a device machine account management module, a device spare part management module, a device maintenance management module and a device repair management module. The management system is advantaged in that semantic integration of the heterogeneous device information is realized, through semantic reasoning and query, the relatively rich semantic knowledge in the field can be acquired, and needs of each functional module of the system are satisfied.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

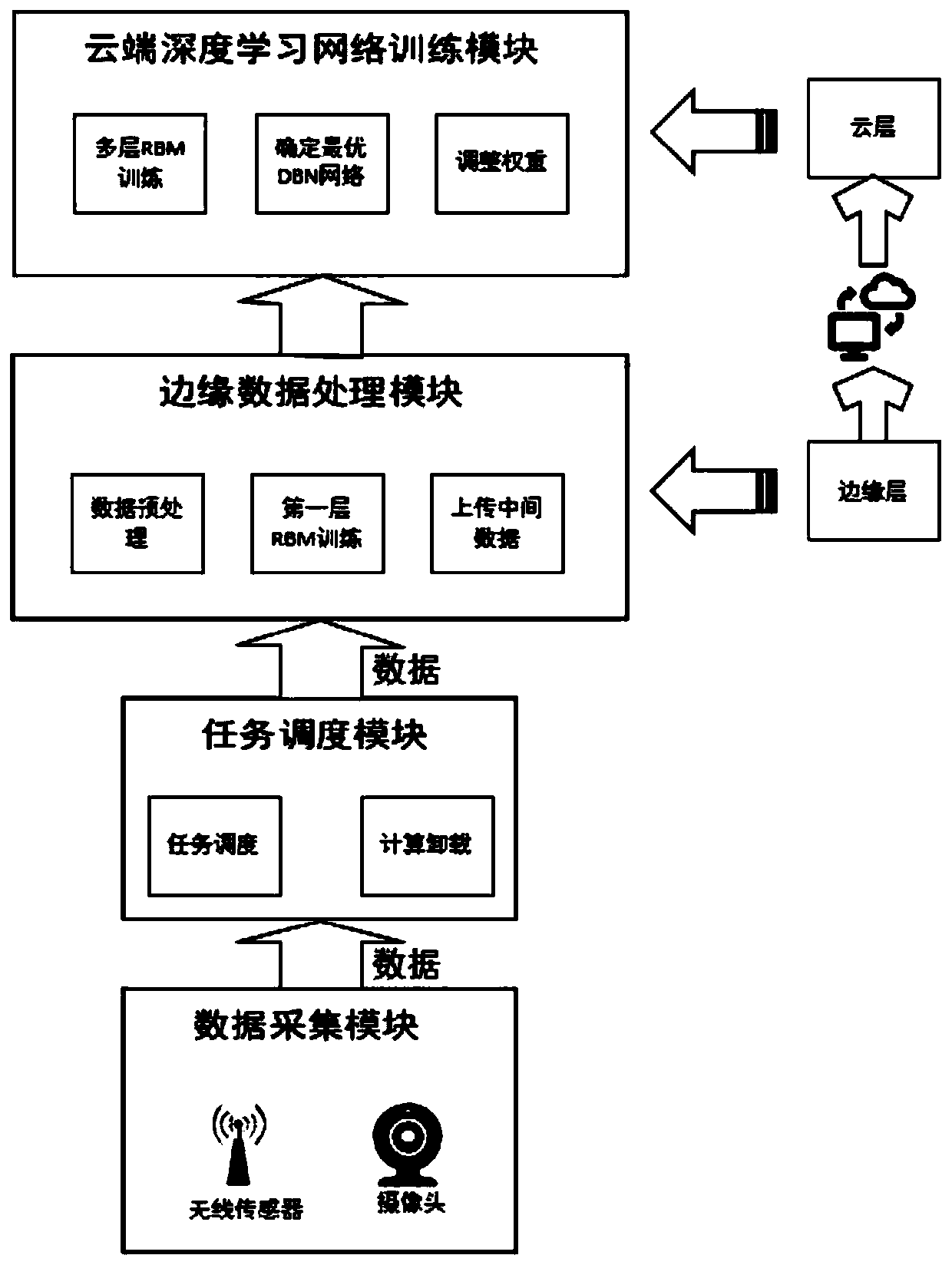

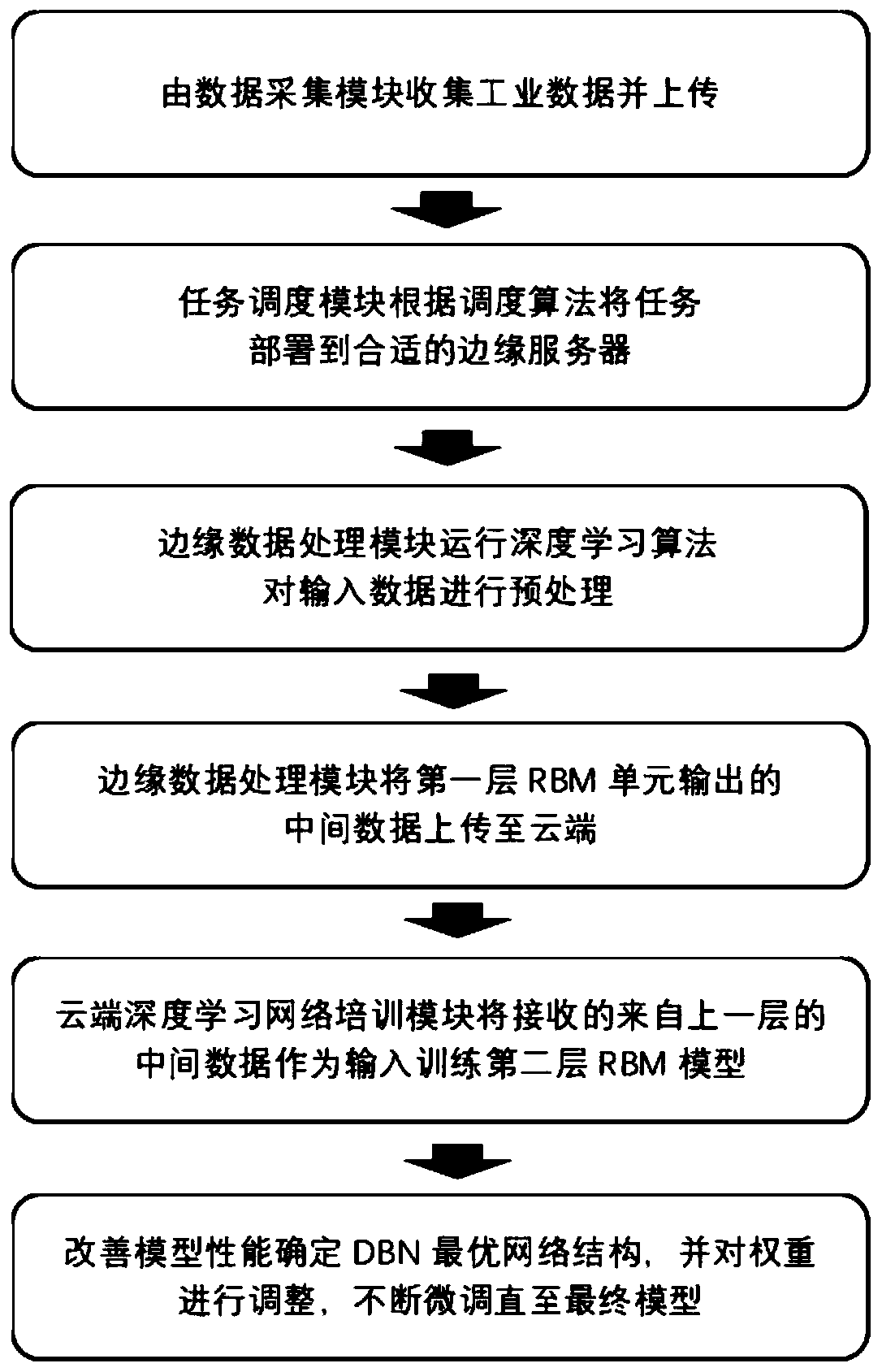

Industrial Internet-of-Things edge resource intelligent scheduling system and method based on deep learning

ActiveCN111245950AReliable MiningImprove performanceResource allocationTransmissionEdge nodeData acquisition

The invention provides an industrial Internet-of-Things edge resource intelligent scheduling system based on deep learning. The system comprises a data collection module which monitors an intermediatelink of an industrial process, and schedules a data processing task to an edge server with surplus processing capability, a task scheduling module which is used for scheduling a task to a proper edgeserver according to the AoT and sending the task to a deep learning network layer for preliminary data processing, an edge data processing module which is used for processing and analyzing the monitoring data and uploading the output intermediate data to a cloud server, and a cloud deep learning network training module which is used for receiving the data and carrying out training by utilizing the preprocessed data so as to determine a DBN optimal network structure, and adjusting the weight to obtain a final model. According to the invention, the accuracy and timeliness of data acquisition ofthe deep learning model can be improved, and the number of deep learning tasks is maximized by using limited network bandwidth and the service capability of edge nodes.

Owner:NANJING UNIV OF POSTS & TELECOMM

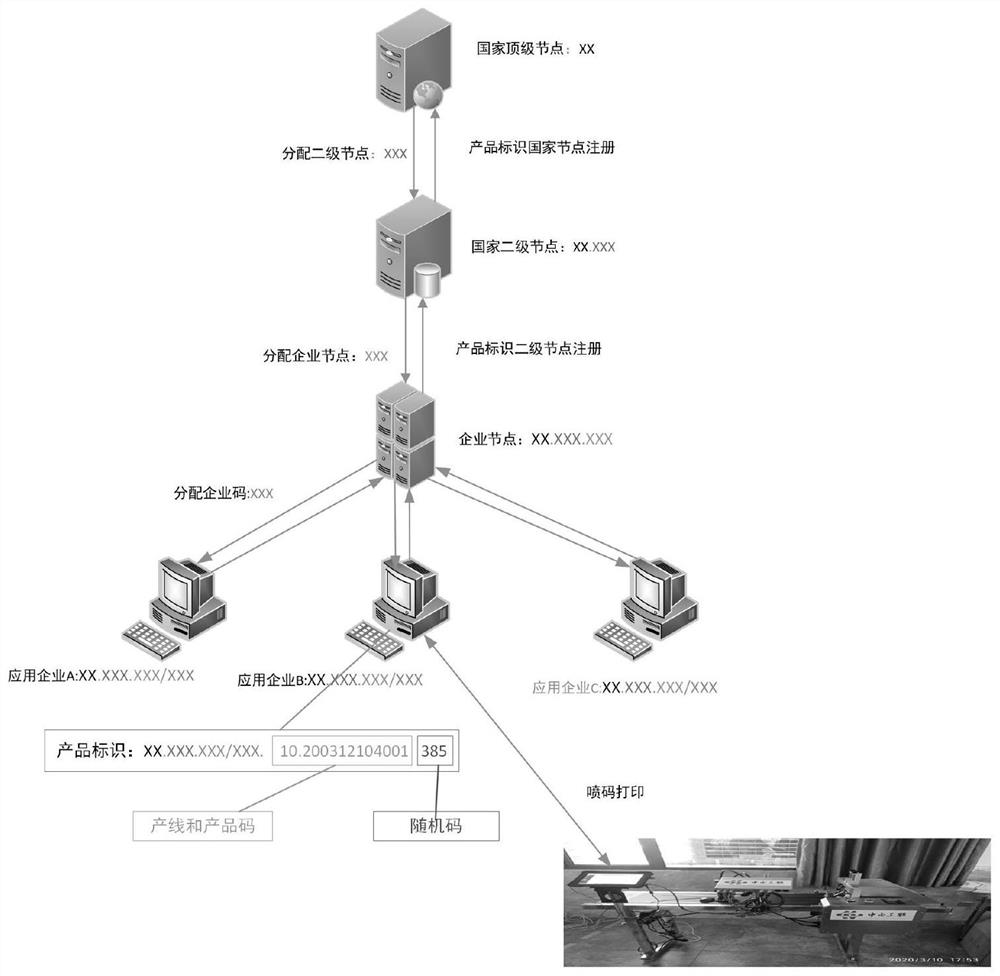

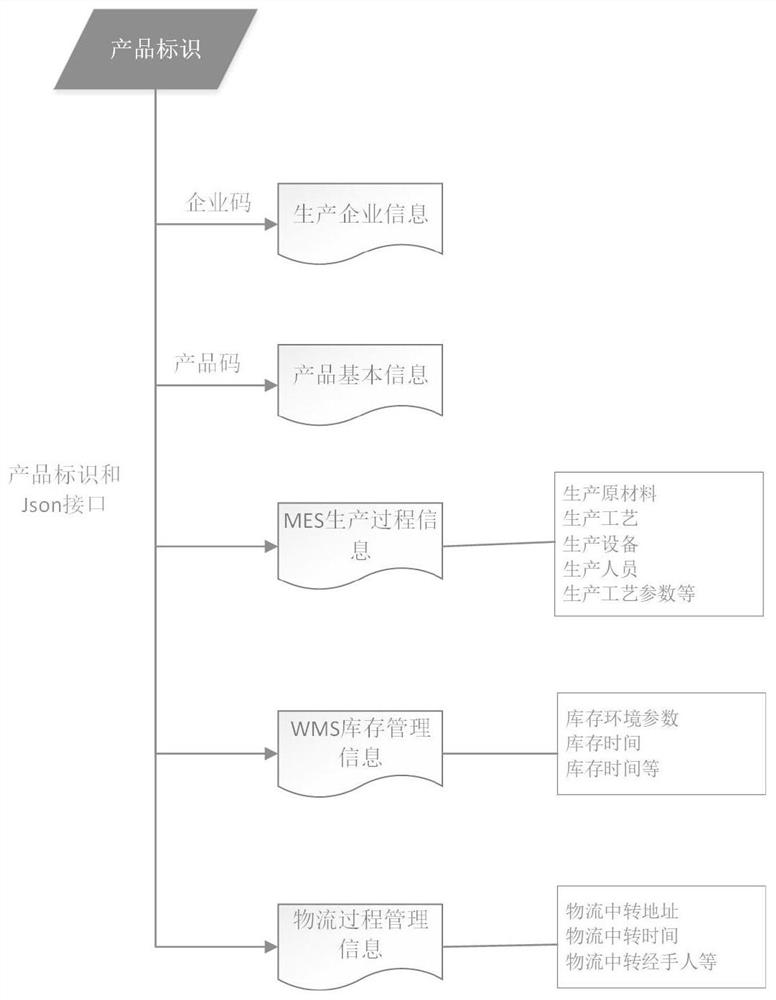

Anti-counterfeiting tracing method and platform for products based on industrial Internet identifier analysis system

PendingCN111612478AEnsure uniquenessEnsure unpredictabilityCommerceSensing by electromagnetic radiationTheoretical computer scienceThe Internet

The invention discloses a anti-counterfeiting tracing method and platform for products based on an industrial Internet identifier analysis system. The method comprises the following steps of generating product identifiers and performing anti-counterfeiting tracing on the products; generating a product identification code composed of a country node number, a secondary node number, an enterprise node number, an enterprise code, a product production information code and a random code; and triggering the anti-counterfeiting tracing request based on the product identification two-dimensional code obtained by conversion of the product identification code to obtain anti-counterfeiting tracing information and send the anti-counterfeiting tracing information to clients. Uniqueness and unpredictability of the identifiers are ensured through the node number and the random code, and a powerful guarantee is provided for unimitability of the two-dimensional code of the product identifier. Meanwhile,on the basis of a national industrial internet identifier analysis system, data on a platform is public and open, interconnection and intercommunication of the data can be achieved conveniently, andsafety and authority of data can be guaranteed on the basis of the national industrial internet identifier analysis system.

Owner:CHINA POWER IND INTERNET CO LTD

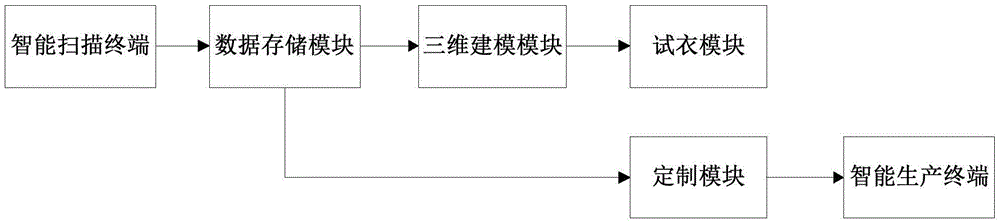

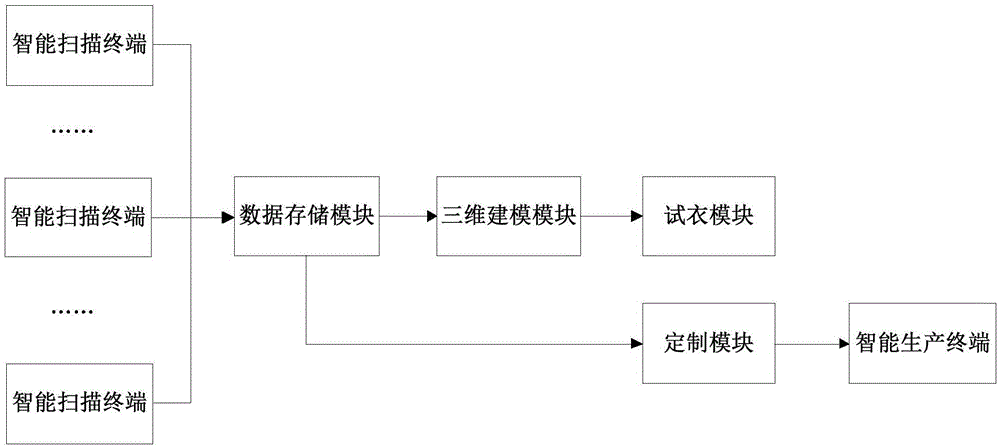

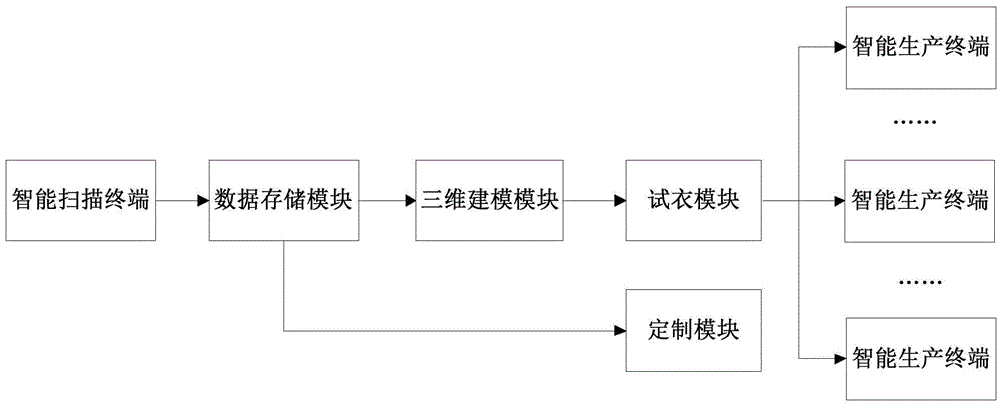

Rapid garment system and method based on industrial Internet

InactiveCN105527946AMeets requirementsNo time consumptionTransmissionTotal factory controlThe InternetComputer module

The present invention relates to the technical field of information and discloses a rapid garment system and method based on an industrial Internet. According to the system, a data storage data is used for storing the body data and clothing data of a user, a three-dimensional modeling module which is used for establishing a body three-dimensional model according to the outer contour size of a body, a fitting module which is used for generating virtual clothes according to the clothes style and the outer contour size of the body and also is used for generating a virtual image according to the virtual clothes an the body three-dimensional model, a customization module which is used for generating a clothes sample according to the instruction submitted by the user and sending the clothes sample to an intelligent production terminal, and the intelligent production terminal is used for carrying out production processing according to the received clothes sample. Through the above system, the industry Internet is used to realize the whole garment customization process, the production cycle is shortened, the cost is reduced, and the wide application of the system is facilitated.

Owner:TIBET YIDETI INFORMATION TECH CO LTD

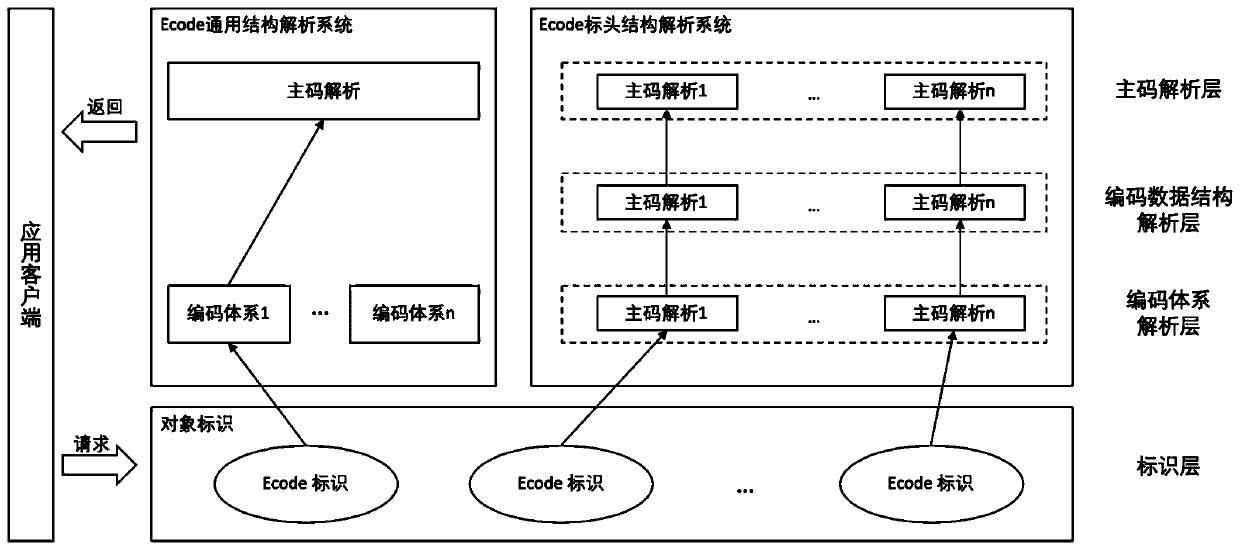

Industrial Internet identifier analysis method and related device

ActiveCN111767484AEnsure safetySpecial data processing applicationsWeb data retrieval using information identifiersComputer networkTheoretical computer science

The embodiment of the invention provides an industrial Internet identifier analysis method, a client and a node of a block chain. According to the method, a client receives a parsing request, whereinthe parsing request comprises a to-be-parsed identifier, the to-be-parsed identifier comprises an identifier prefix and an identifier suffix, and the identifier prefix indicates an object storing theparsing information of the identifier; and the client sends the parsing request to a target node in a blockchain, and the target node obtains the parsing information from the object according to the identifier in the parsing request and sends the parsing information to the client. According to the invention, due to the fact that the identifier prefix indicates the object for storing the analysis information, even if different identifier analysis systems are incompatible or no to-be-queried identifier exists in the system bound with the client, and the analysis information can also be obtainedthrough the identifier prefix, so that mutual access of different analysis systems taking the node in the blockchain as a bridge is realized; and the method is based on the characteristics of the consensus mechanism of the block chain, and the security under the mutual access condition is ensured.

Owner:CHINA ACADEMY OF INFORMATION & COMM

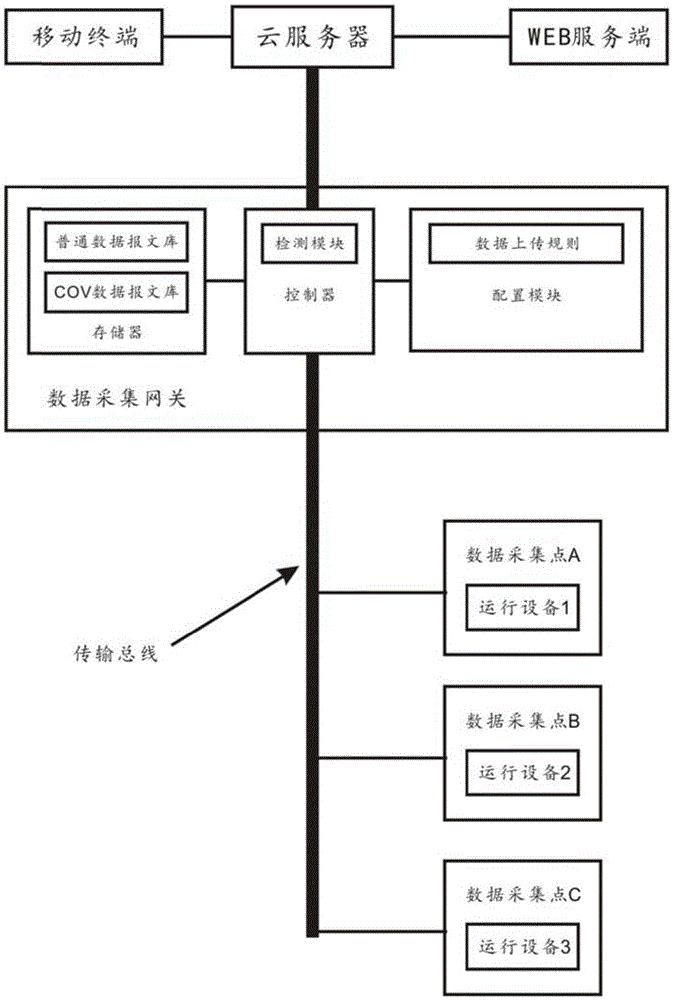

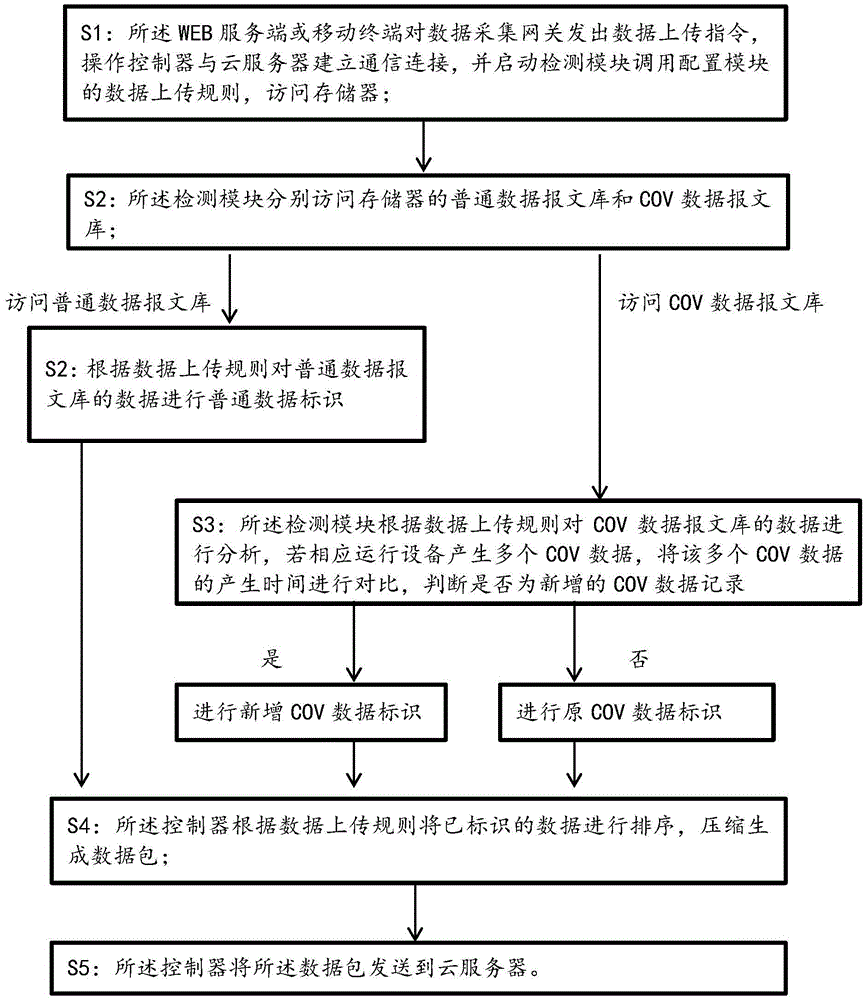

Data uploading method and system based on industrial Internet of Things

ActiveCN105656722AAccurate judgmentIncreased abnormalityData switching networksWeb serviceData acquisition

The invention discloses a data uploading method and system based on industrial Internet of Things. The system comprises a data collection gateway and a cloud server; the data collection gateway is equipped with a controller and a memory; the data collection gateway also comprises a configuring unit; the cloud server is connected with a WEB server and a mobile terminal for providing man-machine interaction operations; the configuring unit is equipped with data uploading and sorting rules for identifying the collection data of the memory and configuring the parameters of the cloud server; and the controller of the data collection gateway invokes and defines the data uploading and sorting rules through the configuring unit, classifying and identifying the data of the memory according to the rules and uploads to the processed data cloud server. According to the method and the system provided by the invention, on the basis of the prior data uploading technique, the abnormal data generated by the device are further finely analyzed; therefore, the actual operation states of the device are accurately judged and are uploaded to the cloud server for corresponding cloud application operations; and the integral operation efficiency based on the whole Internet of Things system is effectively improved.

Owner:广州能迪云服务科技有限公司

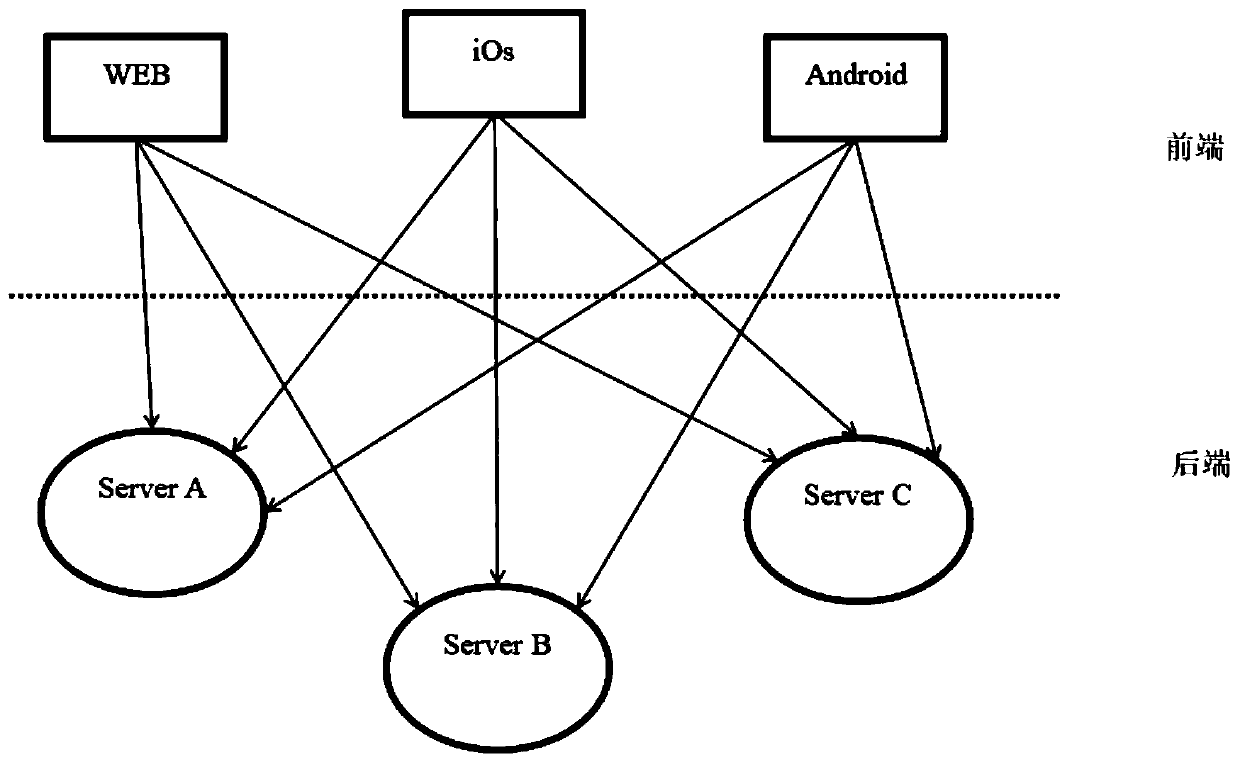

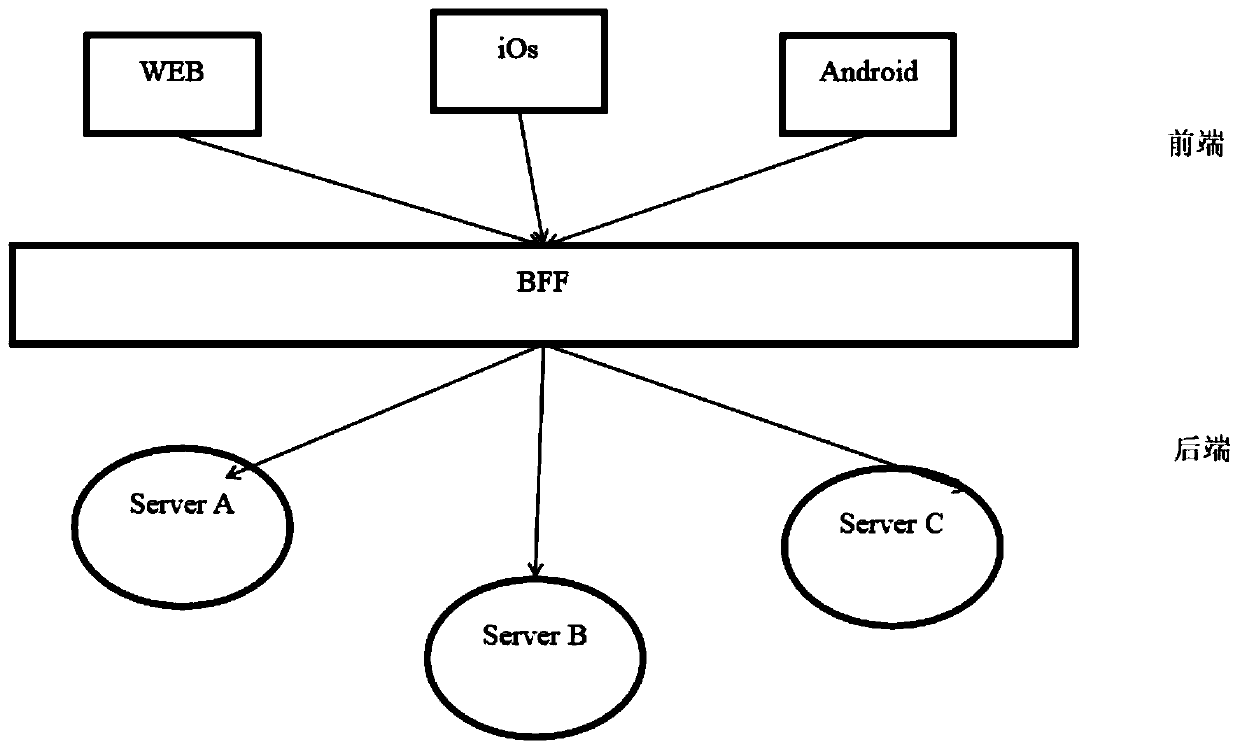

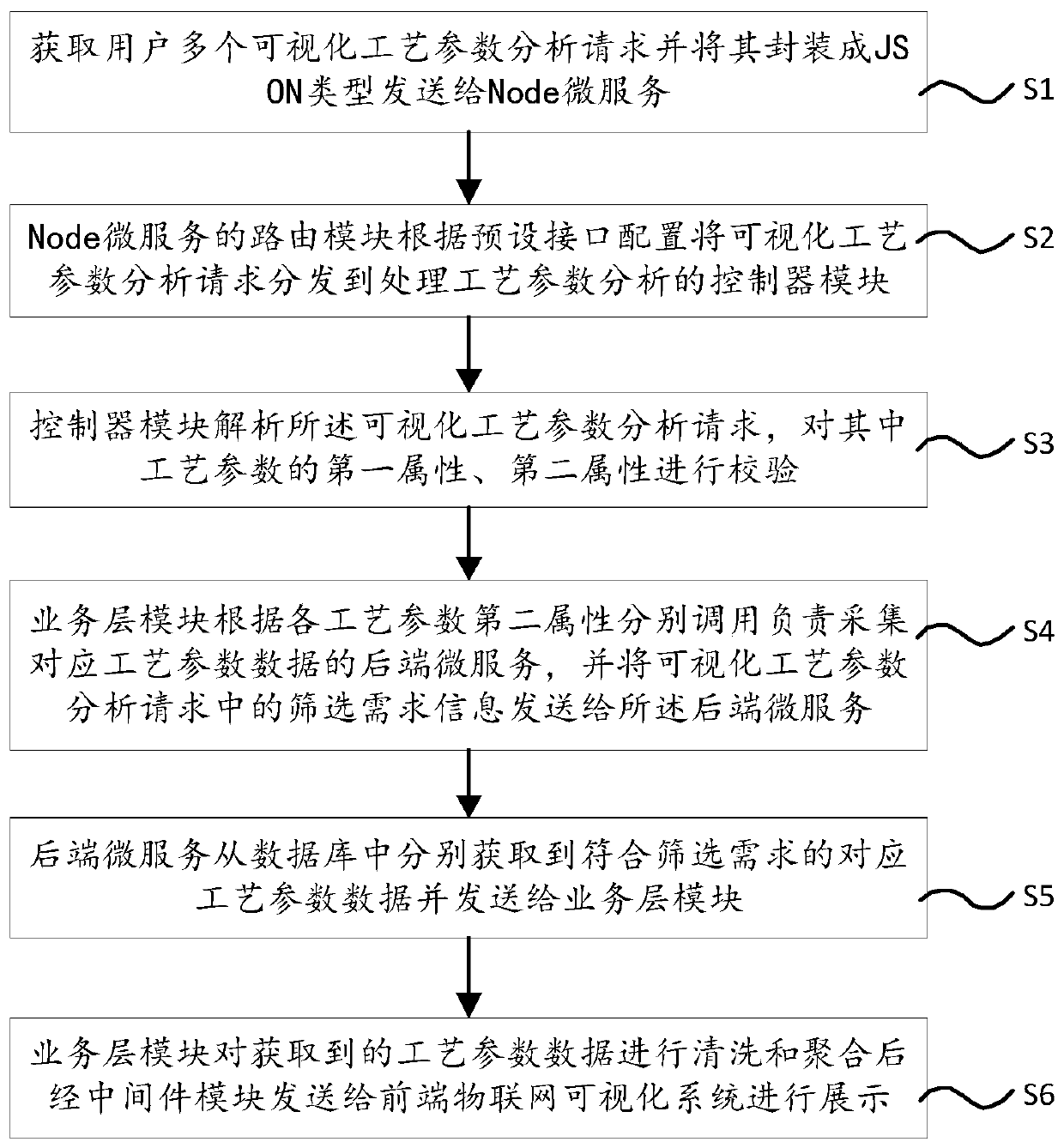

Industrial internet of things information visualization method, server and storage medium

ActiveCN110086853AReduce business pressureDigital data information retrievalTransmissionCouplingComputer module

The invention discloses an industrial Internet of Things information visualization method. The method comprises the following steps of obtaining a plurality of visualization process parameter analysisrequests of a user and sending the visualization process parameter analysis requests to a Node micro service; using the routing module to distribute the visual process parameter analysis request to the controller module according to the preset interface configuration; using the controller module to analyze the visual process parameter analysis request; using the business layer module to respectively call back-end micro-services responsible for collecting corresponding process parameter data and send the screening demand information in the visual process parameter analysis request to the back-end micro-services; using the back-end micro-service to obtain the corresponding process parameter data meeting the screening requirement from the database and send the data to the business layer module; and using the service layer module to clean and aggregate the obtained process parameter data and send the process parameter data to the front-end Internet of Things visualization system for display through the middleware module, so that the problem that an existing micro-service architecture is high in service coupling degree and is difficult to adapt to the flexible and changeable service requirements is solved.

Owner:MINGDU ZHIYUN (ZHEJIANG) TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com