Double-front-split-platform type industrial internet of things and control method thereof

An industrial Internet of Things, sub-platform technology, applied in manufacturing computing systems, data processing applications, instruments, etc., can solve the problems of inability to achieve overall coordination, long costs and man-hours, inability to control and manage the output of production equipment, and reduce The effect of data transmission volume, reduction of data processing volume and calculation pressure, safe and fast product manufacturing control and data sending and receiving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the purpose, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the examples and accompanying drawings. As a limitation of the present invention.

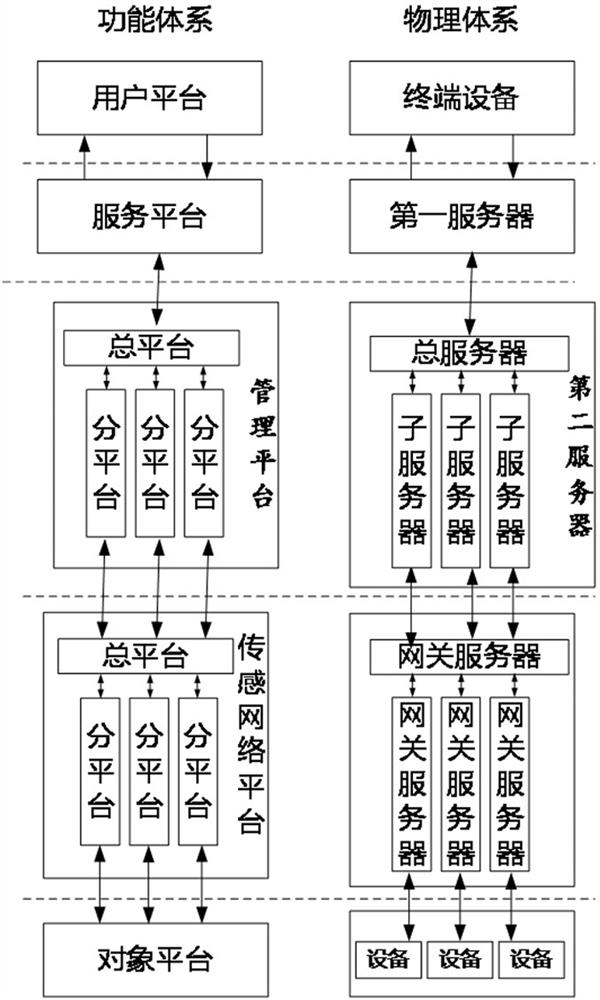

[0022] Such as figure 1 As shown, the first embodiment of the present invention aims to provide a dual-front sub-platform industrial Internet of Things, including sequentially interacting user platform, service platform, management platform, sensor network platform and object platform; the service platform adopts Centralized arrangement, both the management platform and the sensor network platform are arranged in a pre-separated platform; the centralized arrangement means that the service platform uniformly receives data, processes data and sends data in a unified manner; the pre-separated platform arrangement refers to The corresponding platform is equipped with a general platform and multiple sub-platform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com