Patents

Literature

2713 results about "Production control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production control is the activity of monitoring and controlling any particular production or operation. Production control is often run from a specific control room or operations room. With inventory control and quality control, production control is one of the key functions of operations management.

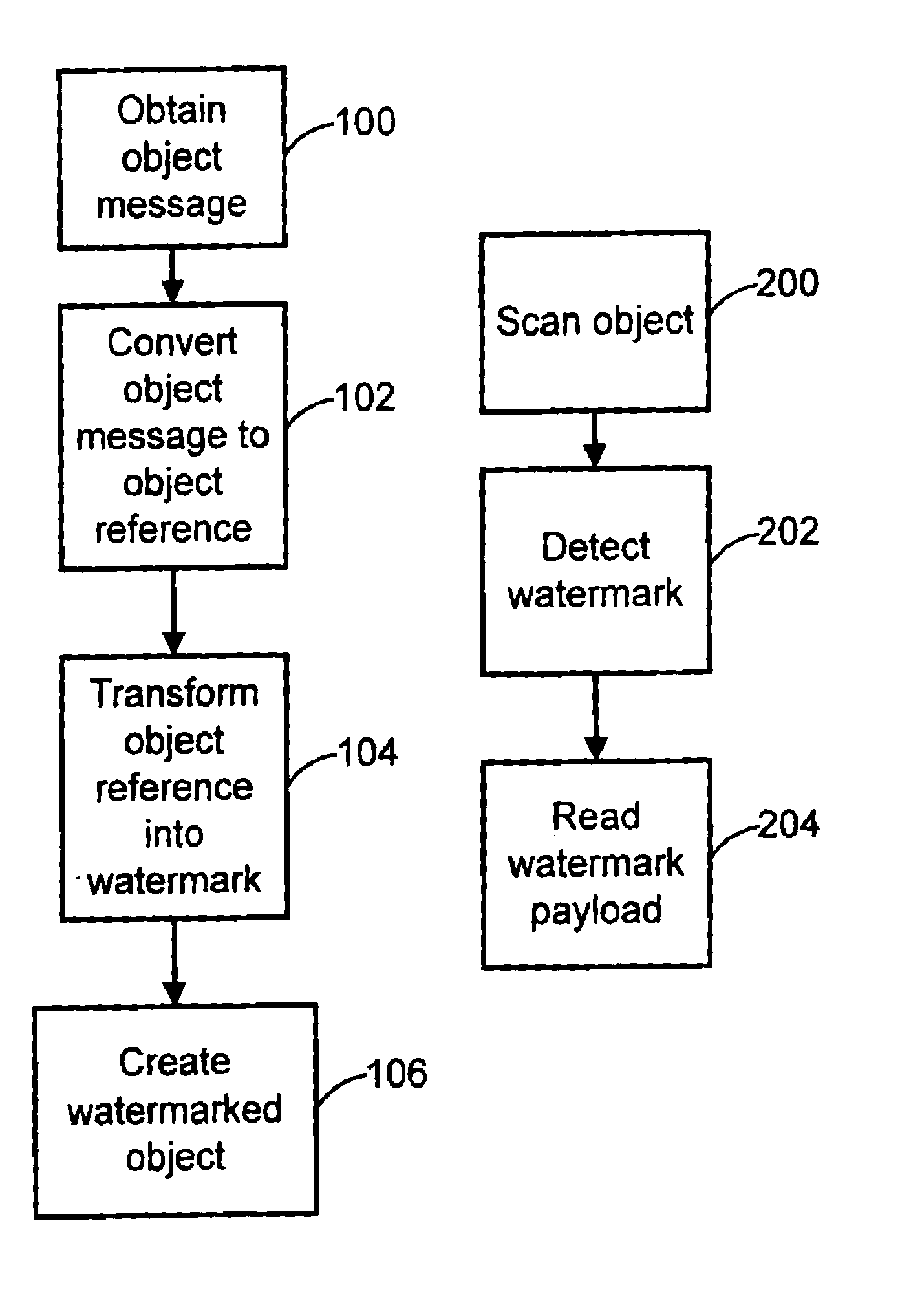

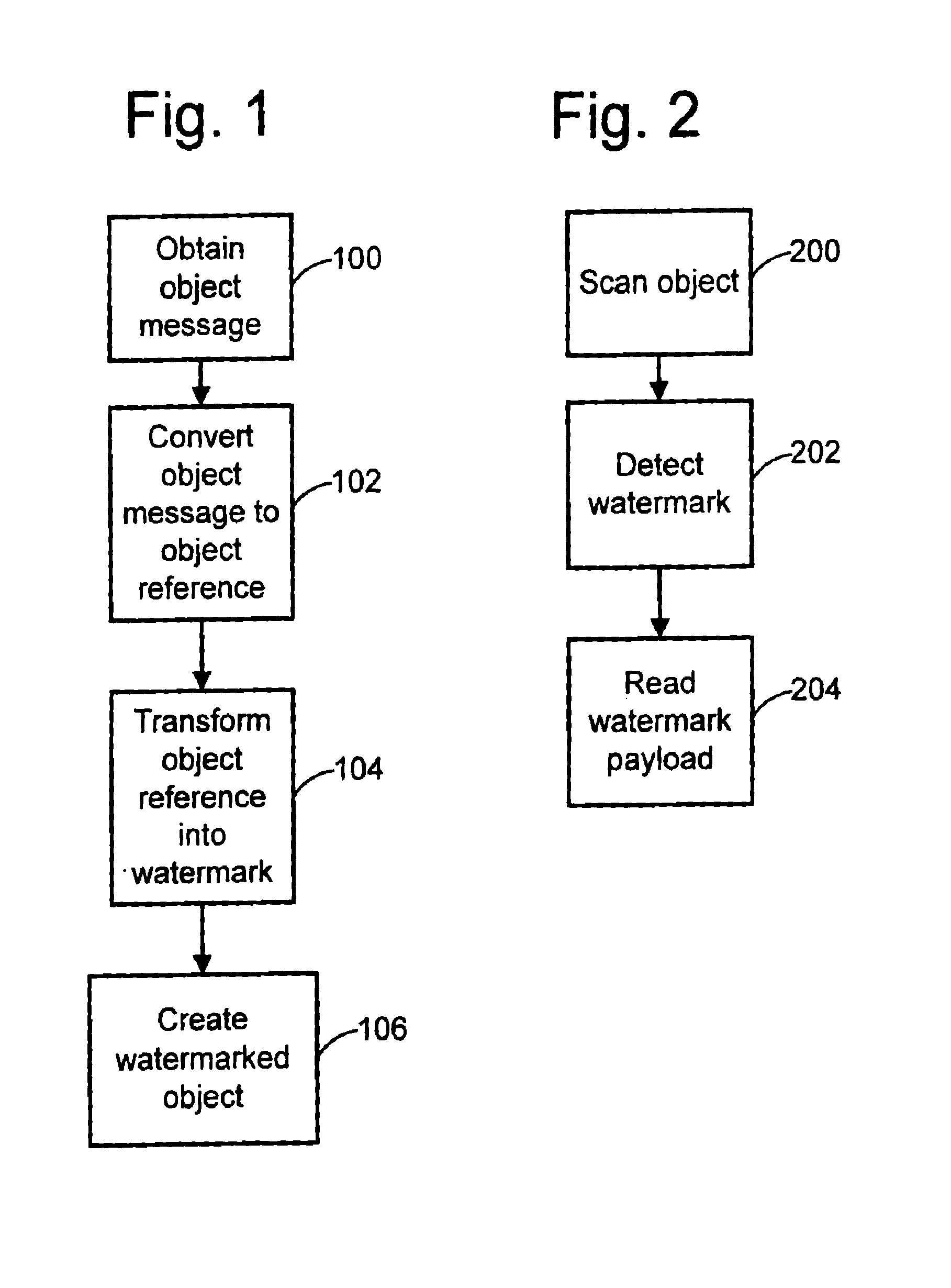

Embedding and reading imperceptible codes on objects

InactiveUS7044395B1Detracts from its aesthetic appearanceImage data processing detailsRecord carriers used with machinesBarcodeMachine instruction

Watermarks and related machine-readable coding techniques are used to embed data within the information content on object surfaces. These techniques may be used as a substitute for (or in combination with) standard machine-readable coding methods such as bar codes, magnetic stripes, etc. As such, the coding techniques extend to many applications, such as linking objects with network resources, retail point of sale applications, object tracking and counting, production control, object sorting, etc. Object message data, including information about the object, machine instructions, or an index, may be hidden in the surface media of the object. An object messaging system includes an embedder and reader. The embedder converts an object message to an object reference, and encodes this reference in a watermarked signal applied to the object. The reader detects the presence of a watermark and decodes the watermark signal to extract the object reference.

Owner:DIGIMARC CORP

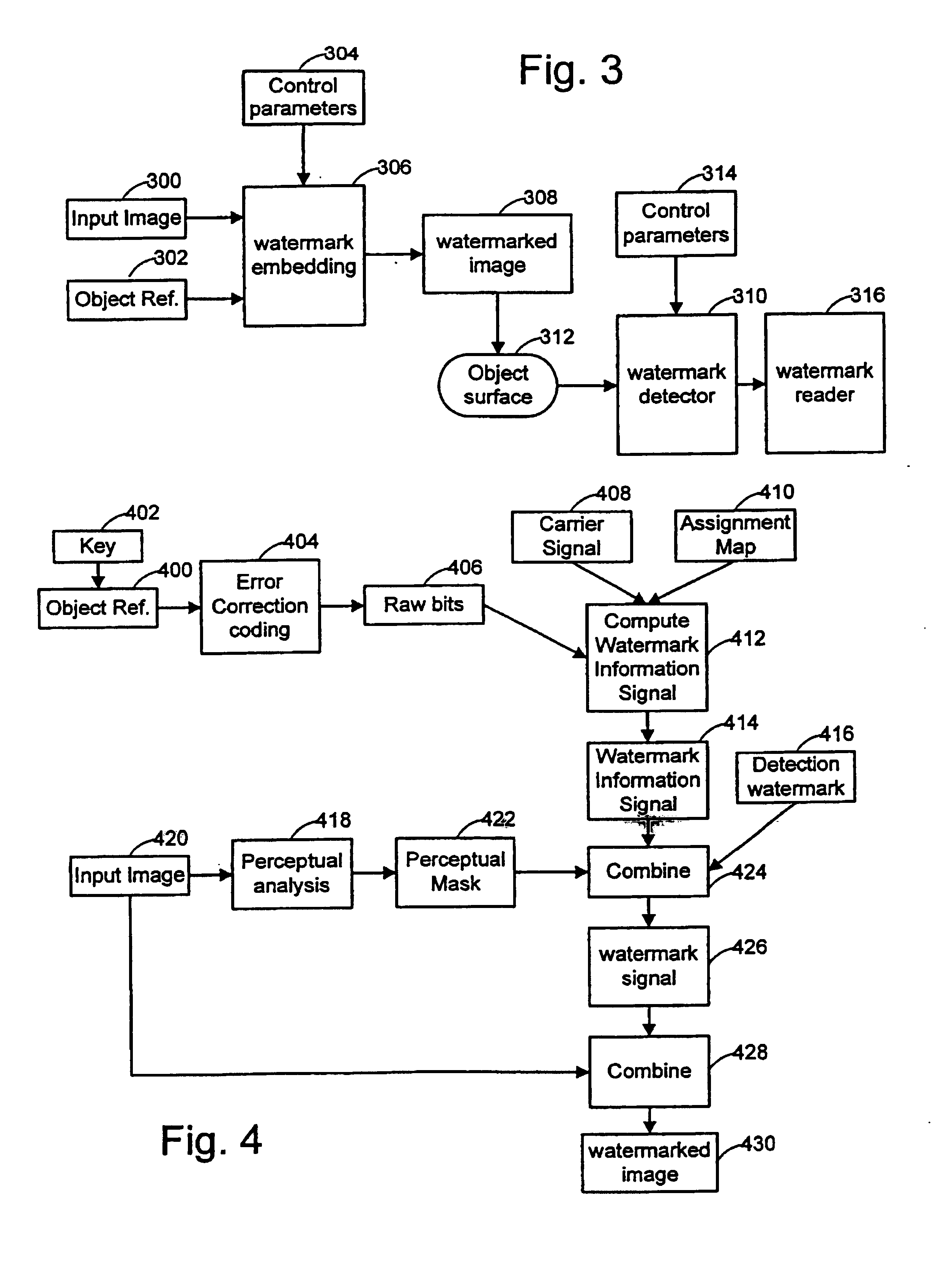

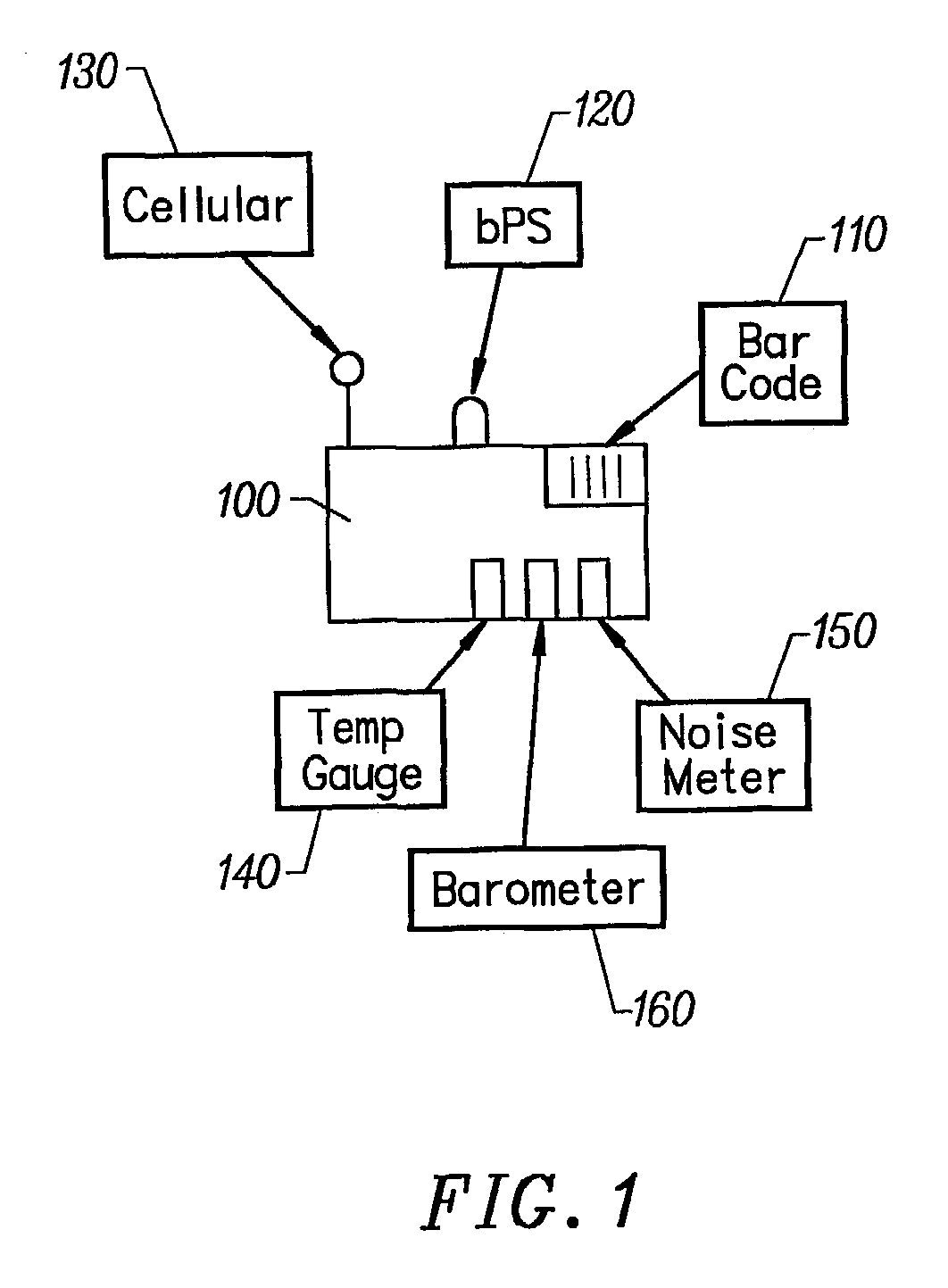

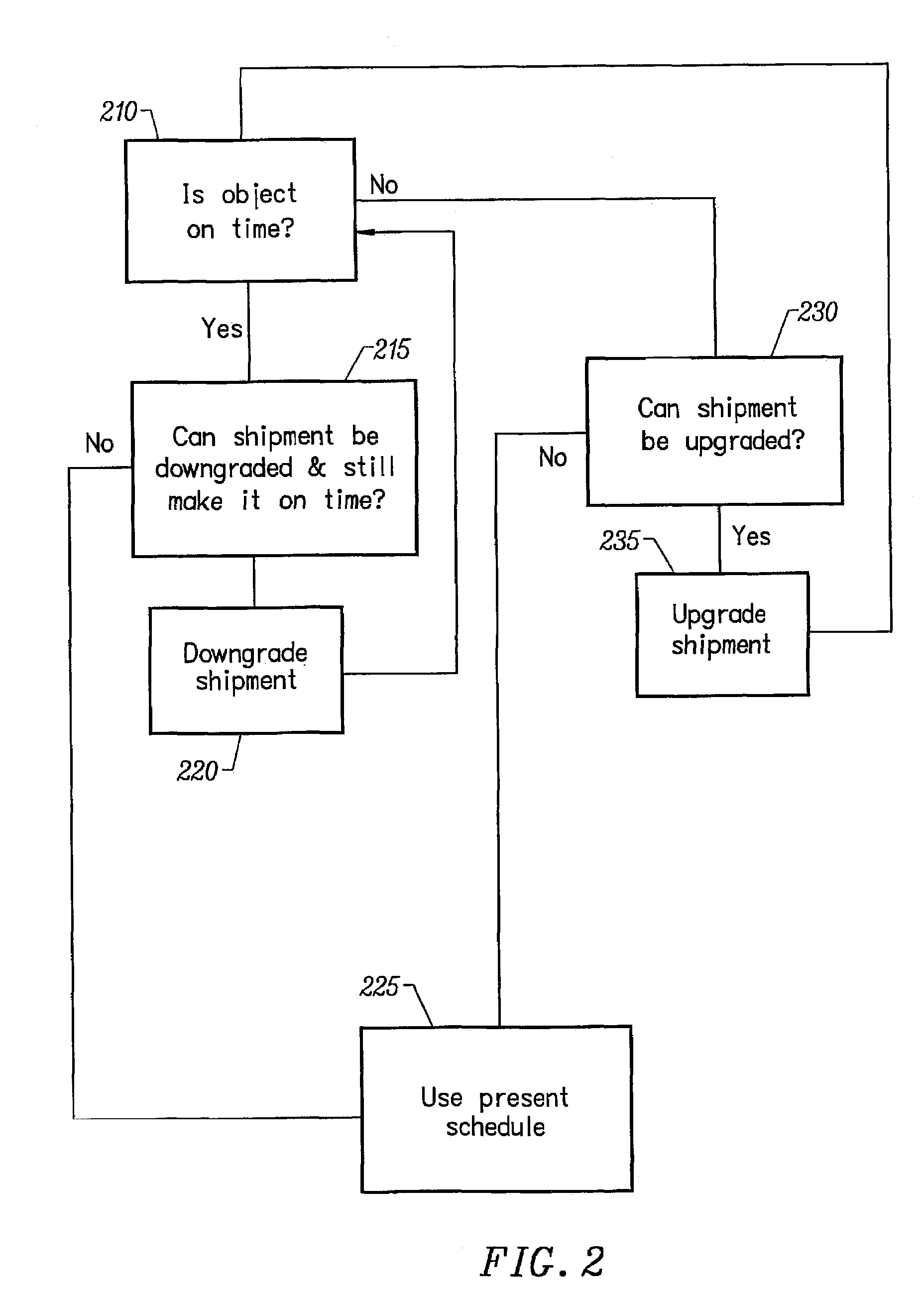

Rule based proximity and time based tracking system

A method and apparatus that automatically tracks, monitors and schedules the shipping of objects through carriers such as delivery trucks, ships, or planes is disclosed. A tracking tag is attached to each shipped object. The tracking tag and transportation system uses such techniques as GPS, cellular technology, and bar coding, and sensors such as those that make temperature, pressure, and noise measurements as sources of tracking information. Logic rules and hierarchical weights are given to each source, for any given condition so that the most accurate tracking is made. Tracking is continuous throughout the object's trip. Another set of logic rules is applied to take actions to intervene in the shipping process. For example if it seems the object is off schedule, upgrades or downgrades to the shipping are made. The transportation system can be integrated within a customer's company to facilitate easy scheduling, and production management. A user-friendly graphical user interface is available which displays item, time and distance related information.

Owner:BIFFAR PETER

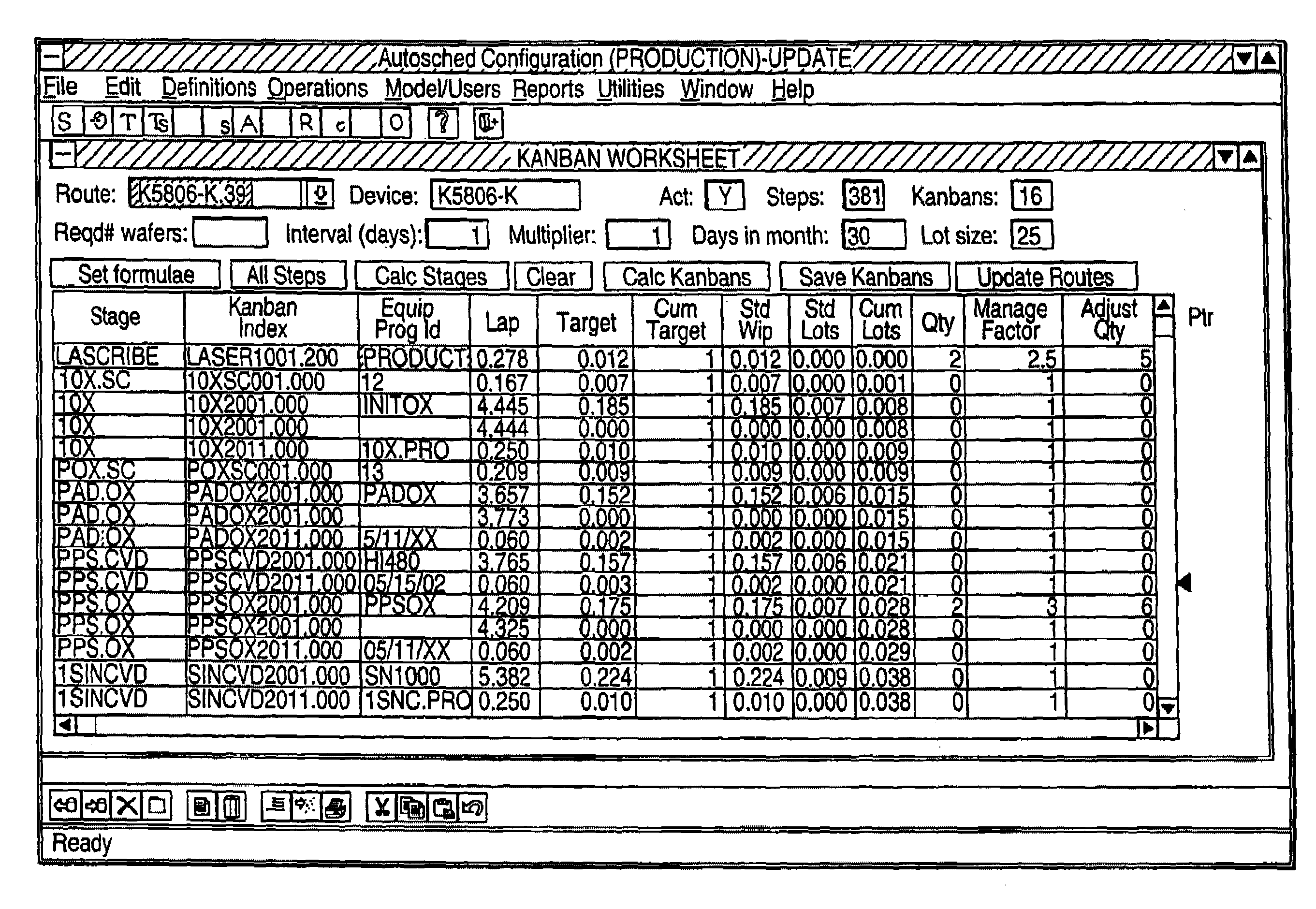

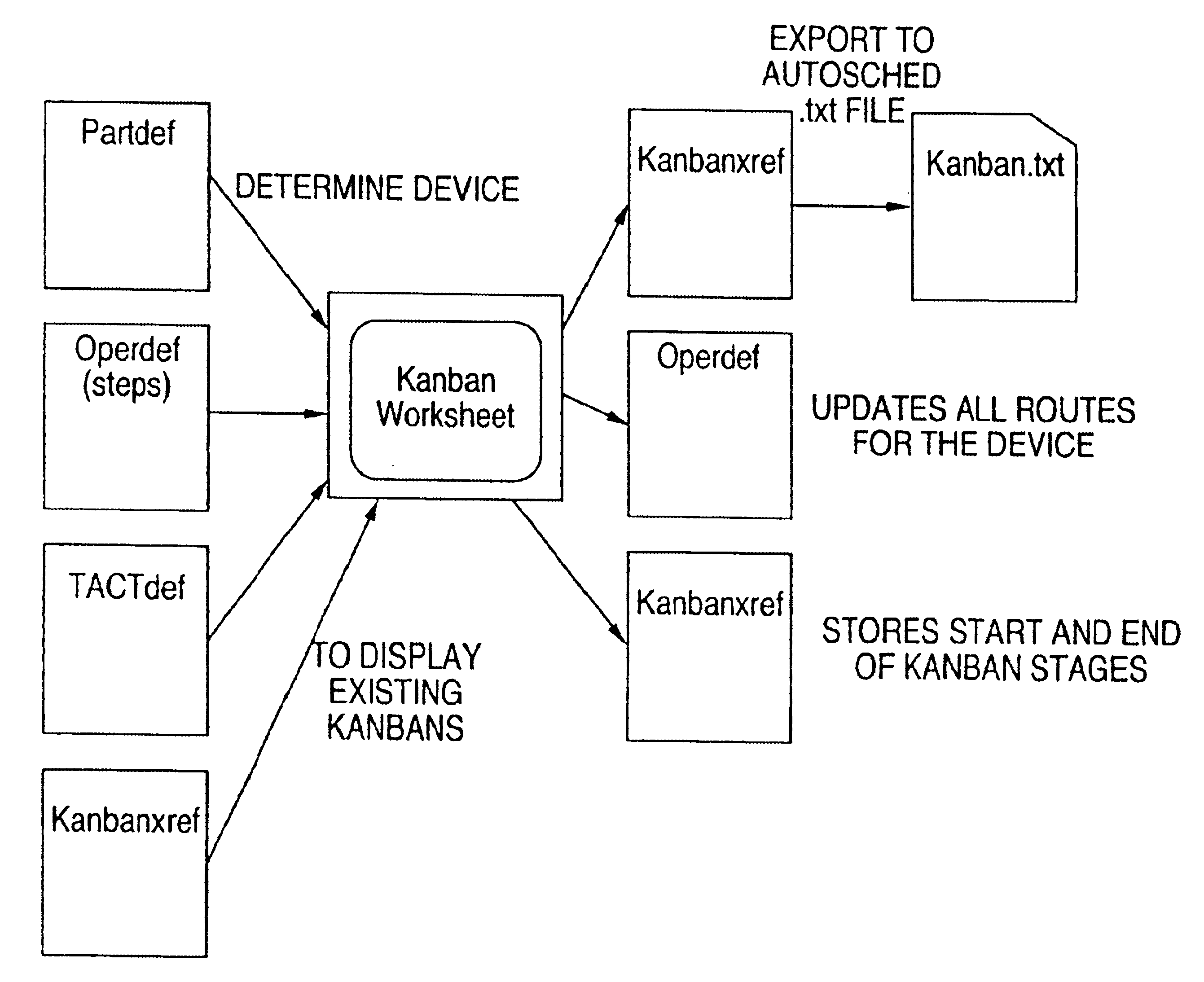

Electronic Kanban worksheet for the design and implementation of virtual or electronic Kanban systems

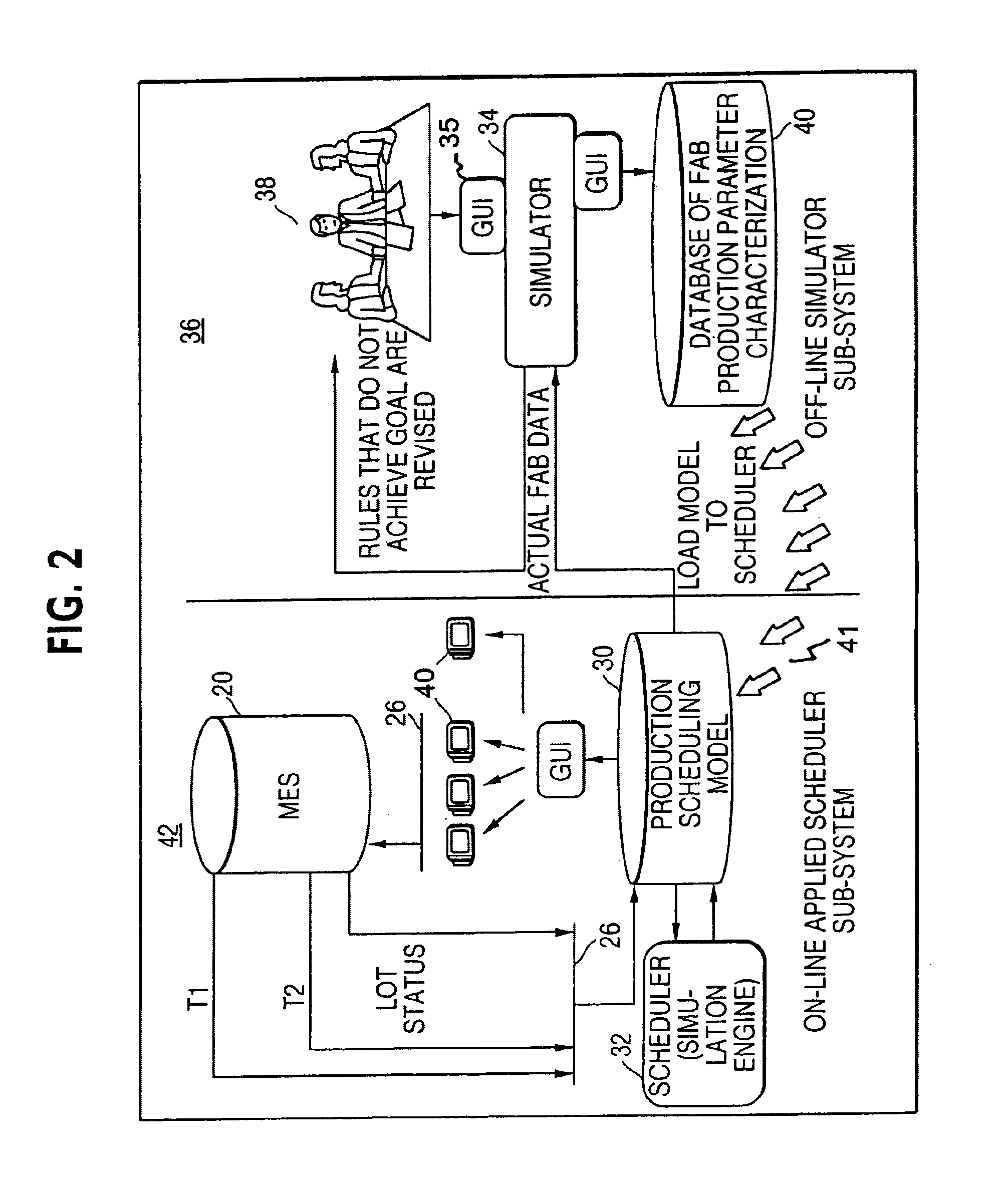

InactiveUS7020594B1ForecastingSpecial data processing applicationsManufacture execution systemSystems design

An integrated wafer fab production characterization and scheduling system incorporates a manufacturing execution system with a scheduling system based on simulation. The integrated characterization / scheduling system provides manufacturing with a simulation tool integrated with the manufacturing execution system to evaluate proposed production control logic as a practical alternative to expensive experimentation on actual production system. Furthermore, simulation models are used to create short term dispatch schedules to steer daily manufacturing operations towards planned performance goals. Innovative features include integration of preventive maintenance scheduling, Kanban based WIP control, an integrated time standard database, a, and real time lot move updates.

Owner:SONY CORP +1

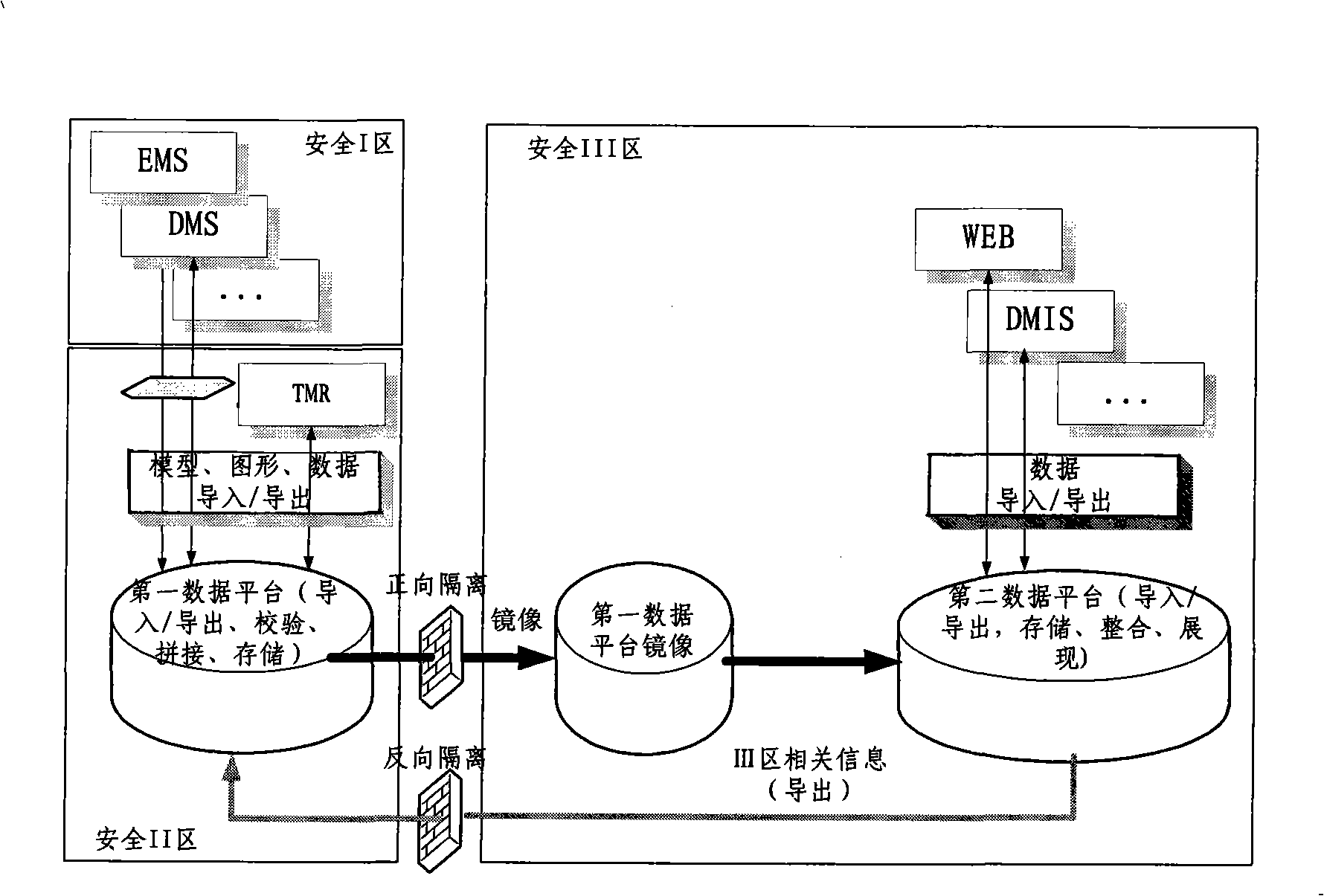

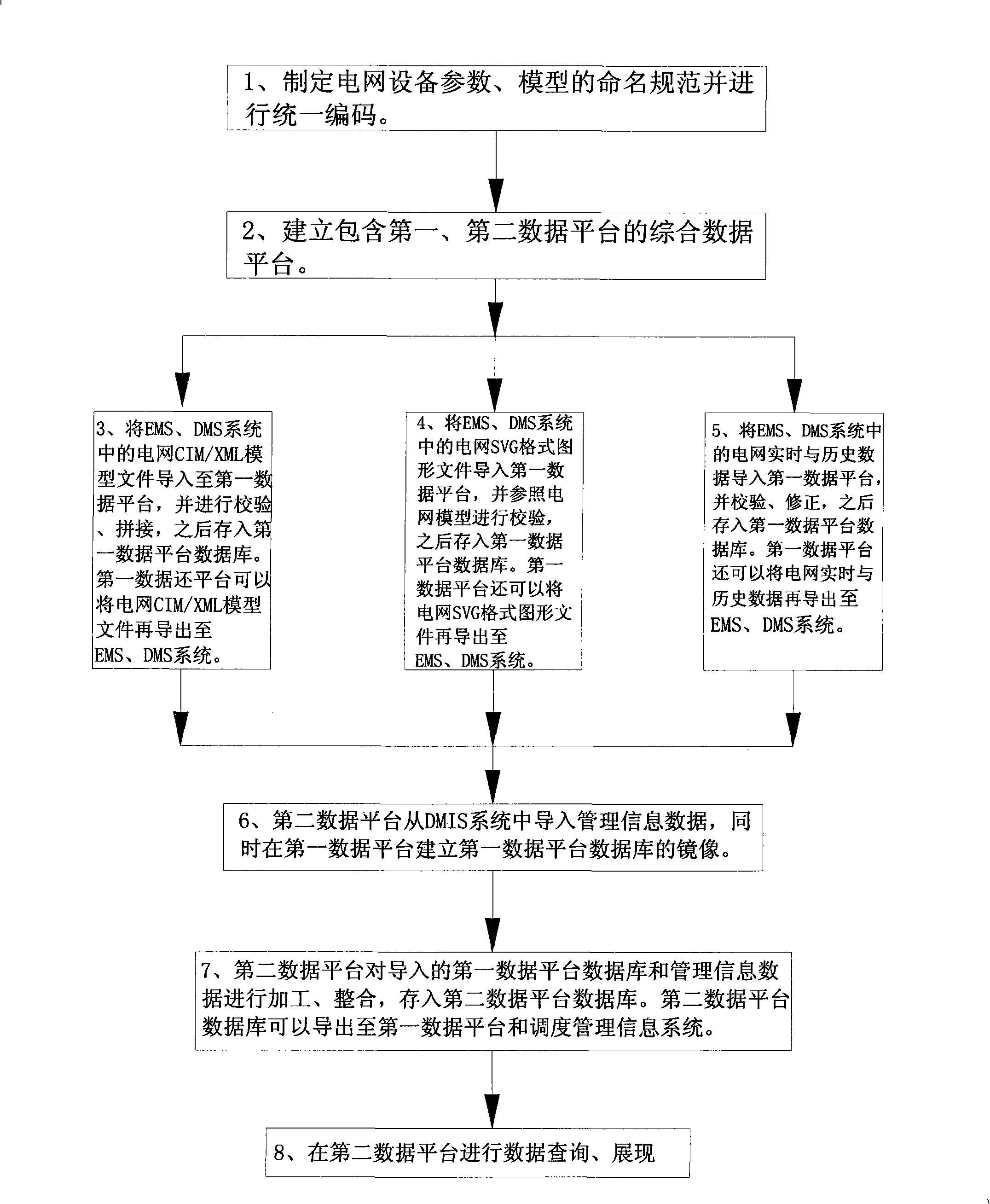

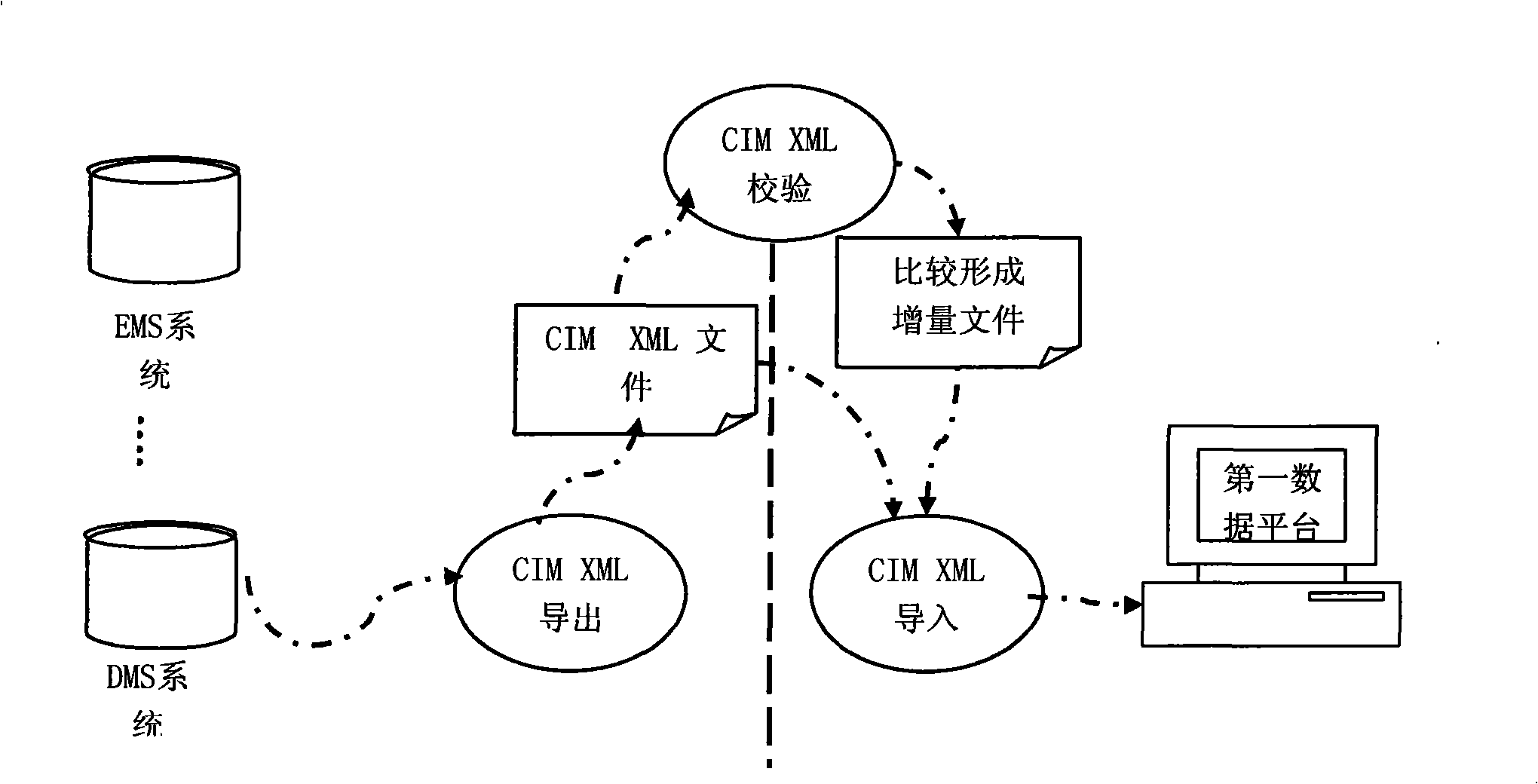

Information system integration method of electric network production control region and management information region

ActiveCN101272051AImprove scheduling automationImprove information management levelData processing applicationsEnergy industryData platformSynthetic data

The invention relates to an information system integration method for power network manufacture control macrozone and management information macrozone which belongs to the technical field of power network control and management systems. The method includes coding for power network devices uniformly; a comprehensive data platform is established, consisting of a first data platform and a second data platform arranged in the power network manufacture control macrozone and the management information macrozone; the model, graphs and real time data as well as historical data of the power network manufacture control macrozone are transmitted into the first data platform and stored into a first data platform database; a mirror image of the first data platform database is set up on the second data platform; the management information data of the power network management information macrozone are transmitted into the second data platform; the first data platform database and the management information data are integrated and then displayed by the second data platform carries out conformity. The method practically realizes the integration on the information systems of the power network manufacture control macrozone and the management information macrozone, thereby improving the information using efficiency of each system of the power network and promoting the automatization of the power network dispatching and the information management level.

Owner:JIANGSU ELECTRIC POWER CO

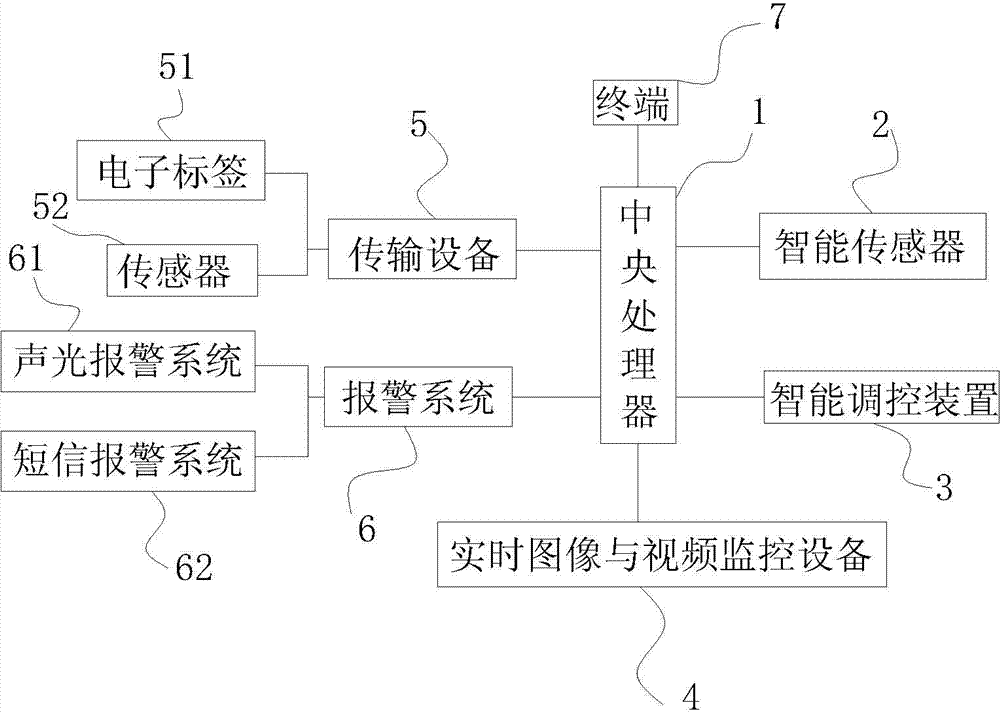

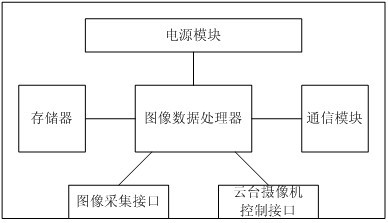

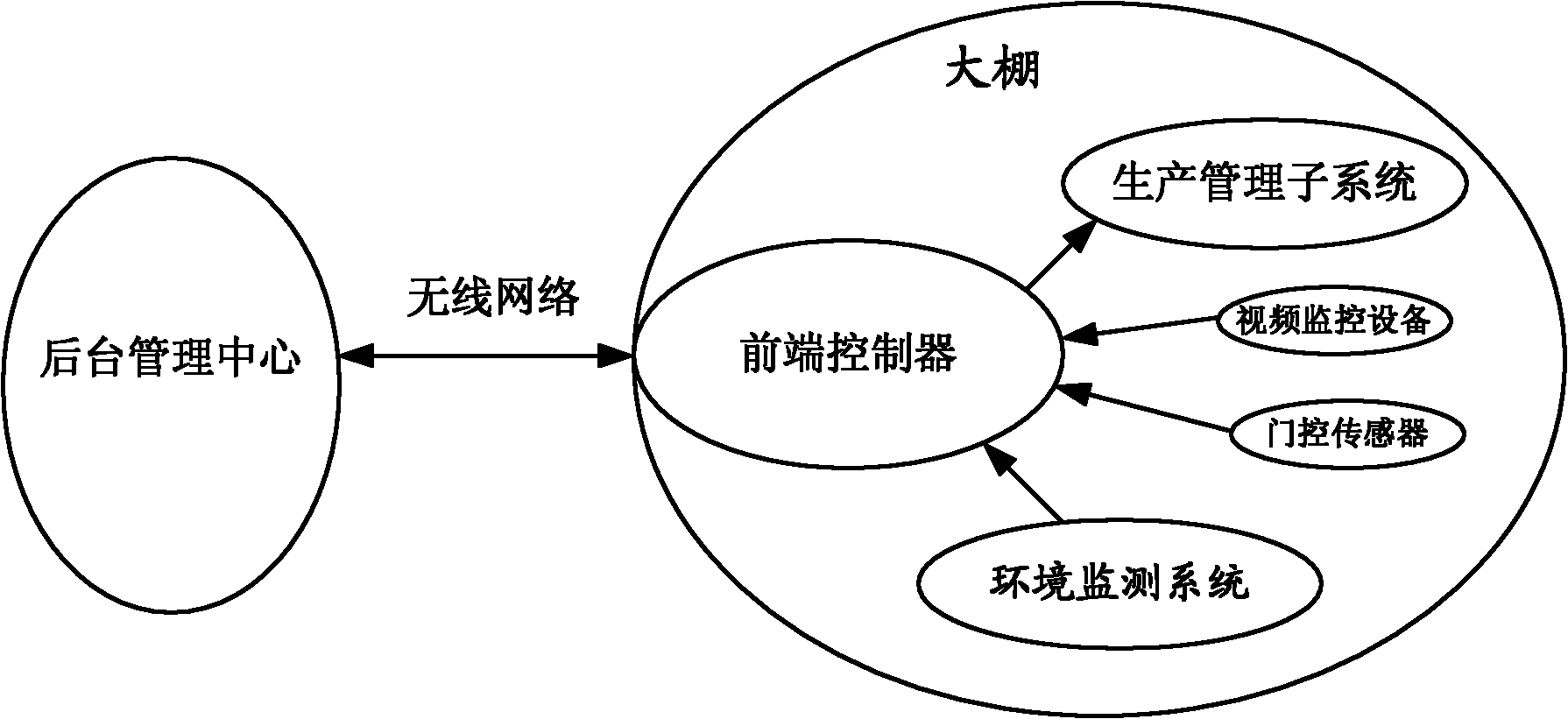

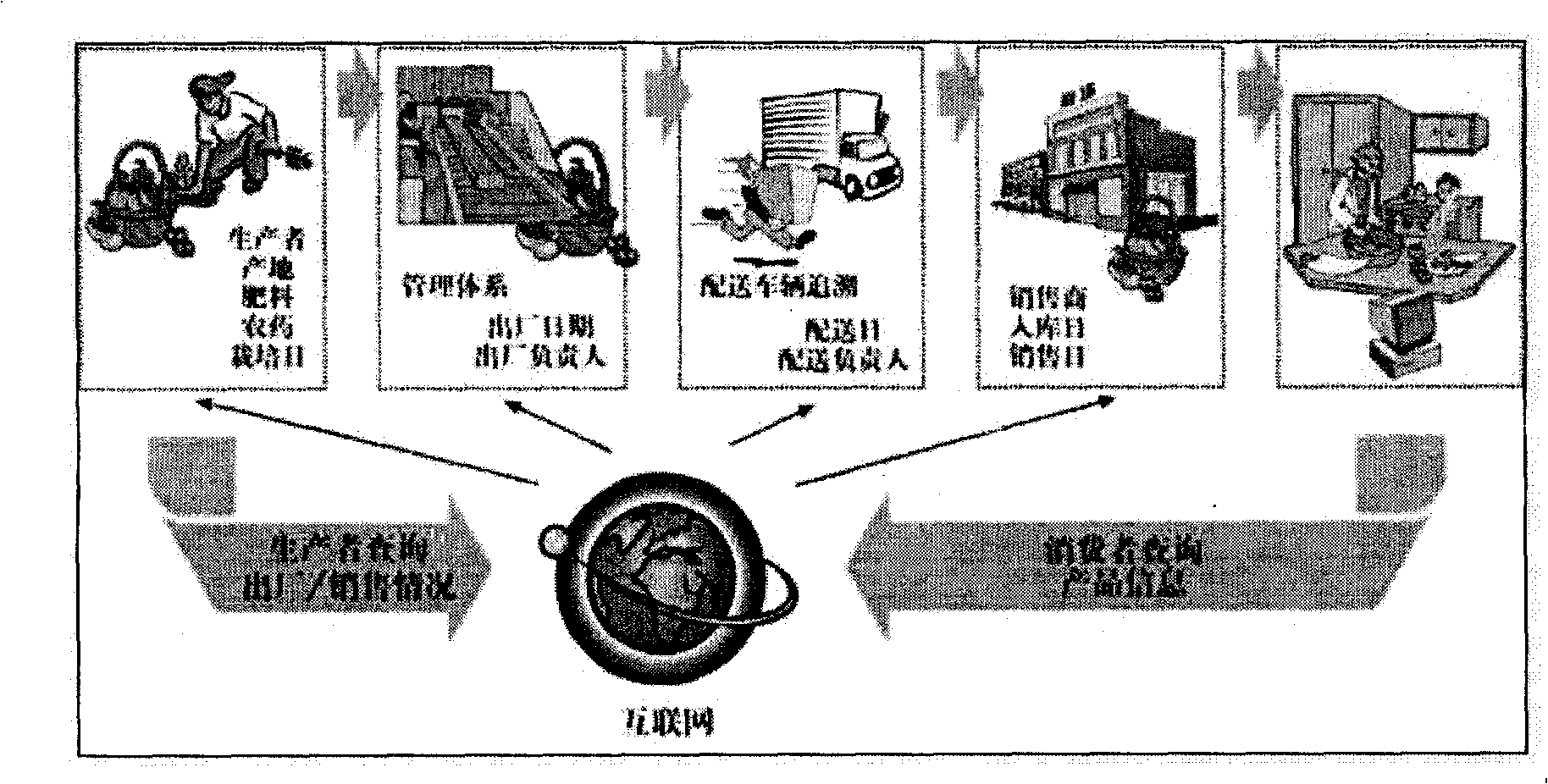

A smart agriculture monitoring system based on Web of Things

InactiveCN104852989AImprove production management efficiencyLabor savingTransmission systemsTransmissionVideo monitoringWireless networked control system

The present invention relates to a smart agriculture monitoring system based on a Web of Things. The system includes a CPU, connected with a smart sensor, a smart adjusting and controlling device, a real-time image and video monitoring apparatus, a transmission apparatus, an alarm system and a terminal; the CPU is connected with the smart sensor, the smart adjusting and controlling device, the real-time image and video monitoring apparatus, the transmission apparatus, the alarm system and the terminal via the wireless network controlling system; and the smart agriculture monitoring system is powered via a solar energy powering apparatus. The Web of Things agriculture smart detection and control system can greatly increase manufacturing and managing efficiency, save manpower, and can conveniently provide a strong scientific data theoretical support to aspects such as various agricultural fields or researches; and the important function thereof is obvious in the highly automated and intelligentized society.

Owner:北京东方海岸物联网科技有限责任公司

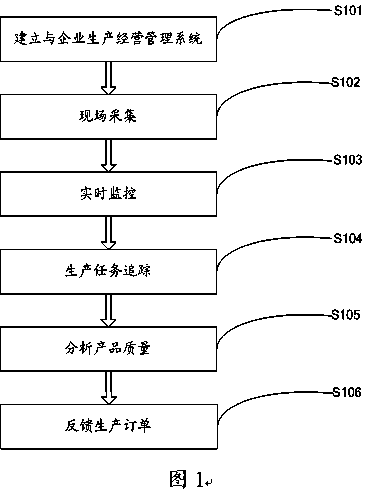

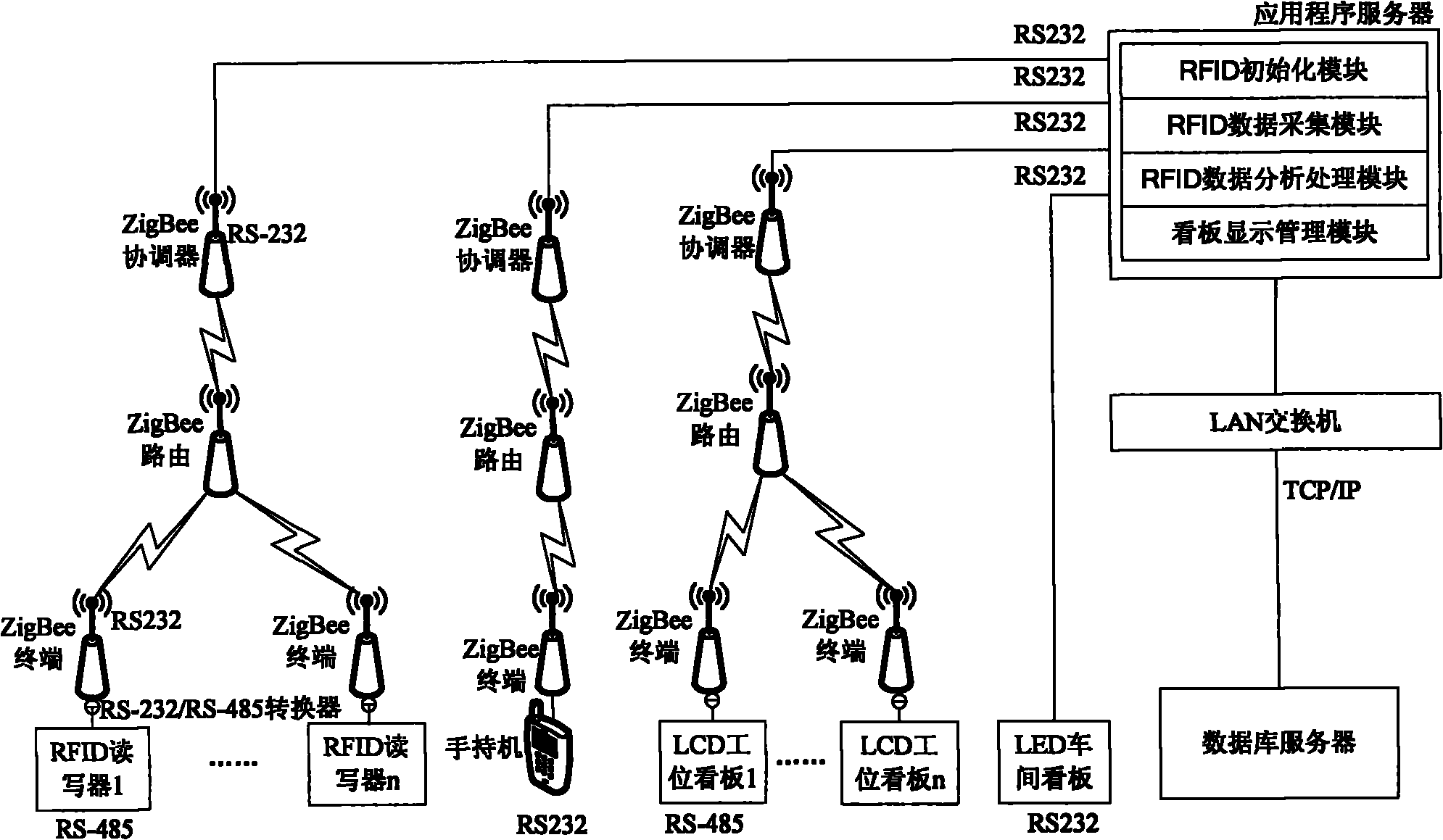

Workshop production management method and system based on Internet of Things

InactiveCN103810576AAchieve integrationAchieve sharingCo-operative working arrangementsResourcesData informationManufacturing execution system

The invention discloses a workshop production management method and system based on Internet of Things. The management method includes the steps of establishment of an enterprise production and operation management system, on-site acquisition, real time monitoring, productive task tracking, product quality analyzing and production order feeding back. The workshop production management system based on Internet of Things comprises a terminal management server, a receiving computer, a mobile phone with bluetooth or wireless fidelity (WiFi), a ZigBee coordinator, a ZigBee router, a station controller, a radio frequency identification (RFID) reader-writer, an electronic tag and a process displayer. According to the workshop production management method and system based on Internet of Things, workshop site is connected with an upper decision system by the aid of the RFID reader-writer and electronic tag manufacturing execution system (MES), integration and sharing of various data information of workshops can be achieved, thereby, the 'fault' phenomenon caused by incomplete sharing and exchange of enterprise data information in enterprises can be avoided, the management process is simplified, and the management efficiency is increased.

Owner:XIAN TECHNOLOGICAL UNIV

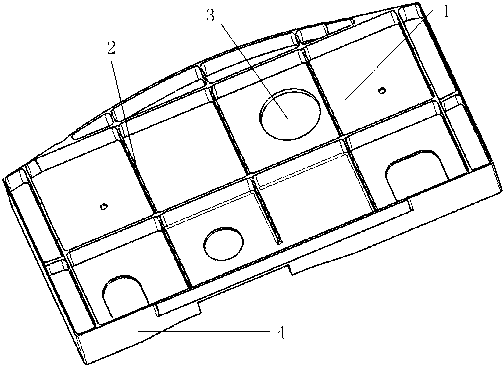

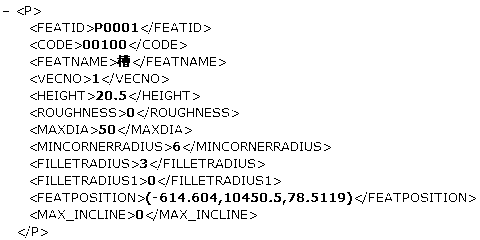

Feature-based numerical-control method for processing and manufacturing complicated parts

ActiveCN103235556AAchieve integrationAchieve deliveryProgramme controlComputer controlNumerical controlClosed loop

Disclosed is a feature-based numerical-control method for processing and manufacturing complicated parts. The feature-based numerical-control method includes expressing features on the basis of a body and an object-oriented process; expressing geometrical and technological information of a part in an integral manufacturing procedure on the basis of the features; utilizing the features as carriers of manufacturing knowledge and experience to implement effective integration and closed-loop control for information of manufacturing stages of designing, processing, detecting and the like; and carrying out automatic technological decision, automatic numerical-control programming, post-processing, control for a processing procedure, online detection, technology optimization and working hour prediction on the basis of automatic feature identification and the features. The feature-based numerical-control method has the advantages that information links are effectively connected with one another in the processing procedure, the manufacturing procedure is automatic and intelligent, dependence on manual experience is reduced in the manufacturing procedure, production management for the manufacturing procedure is facilitated, the manufacturing efficiency is improved, and the production cost is reduced.

Owner:SUZHOU MACHINING PRECISION ELECTRONICS

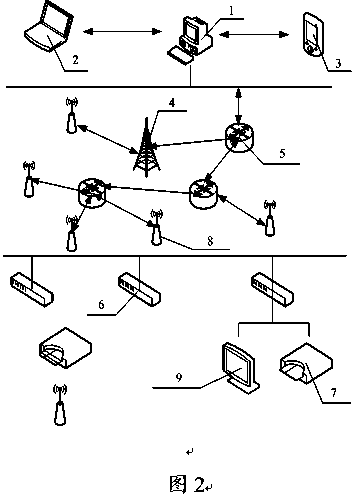

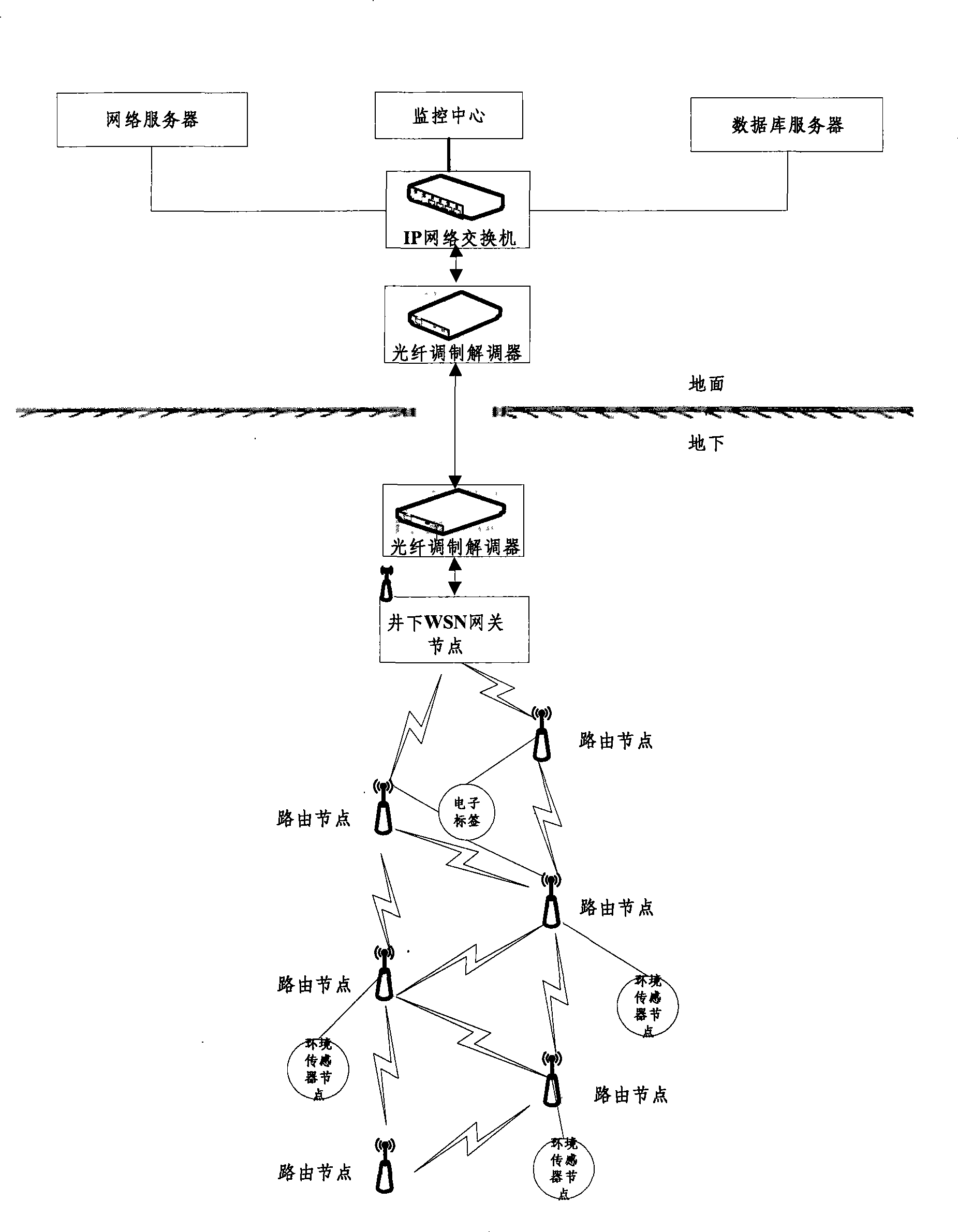

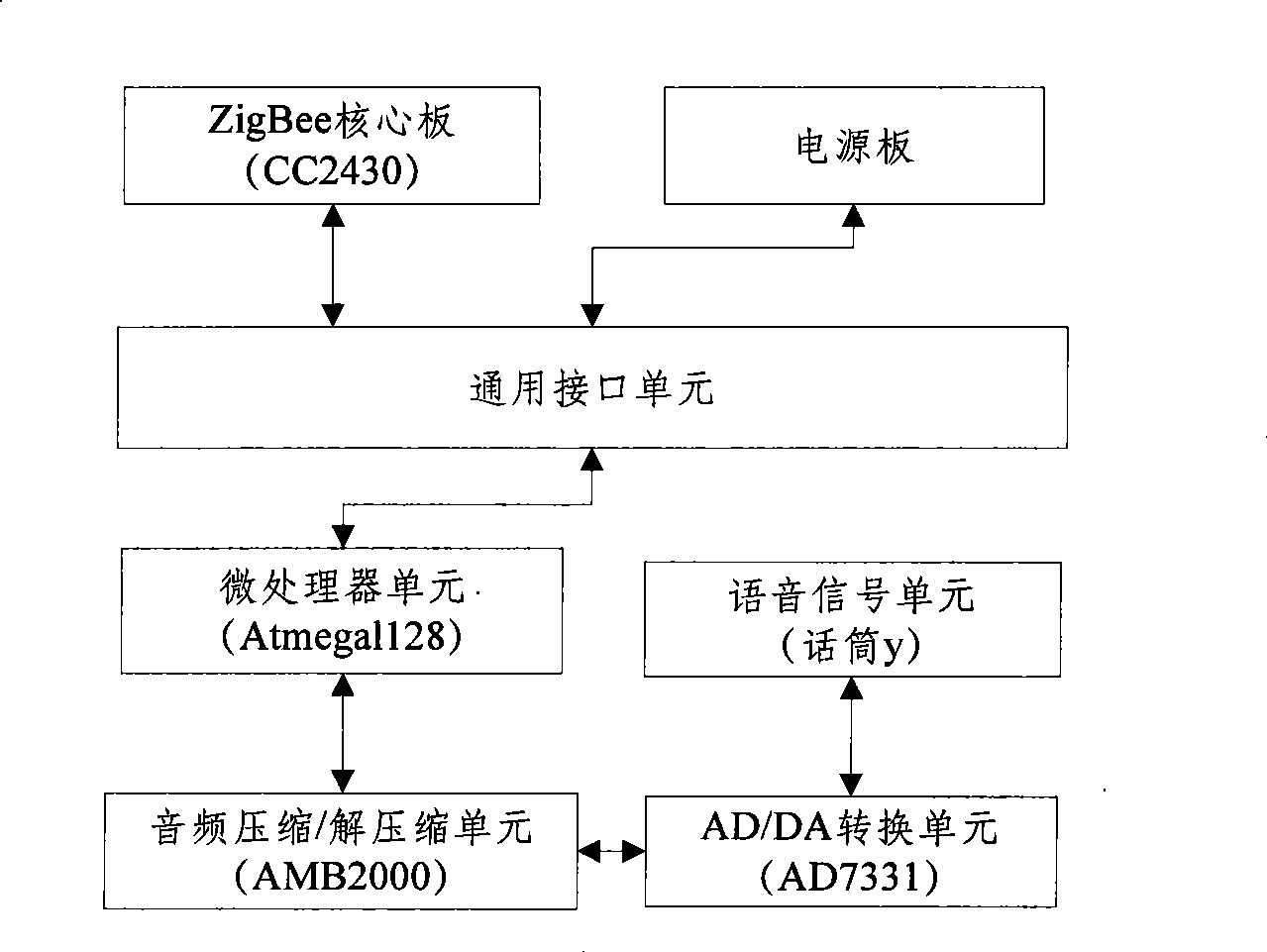

Mine environment probing and search and rescue emergency response system based on wireless sensor network

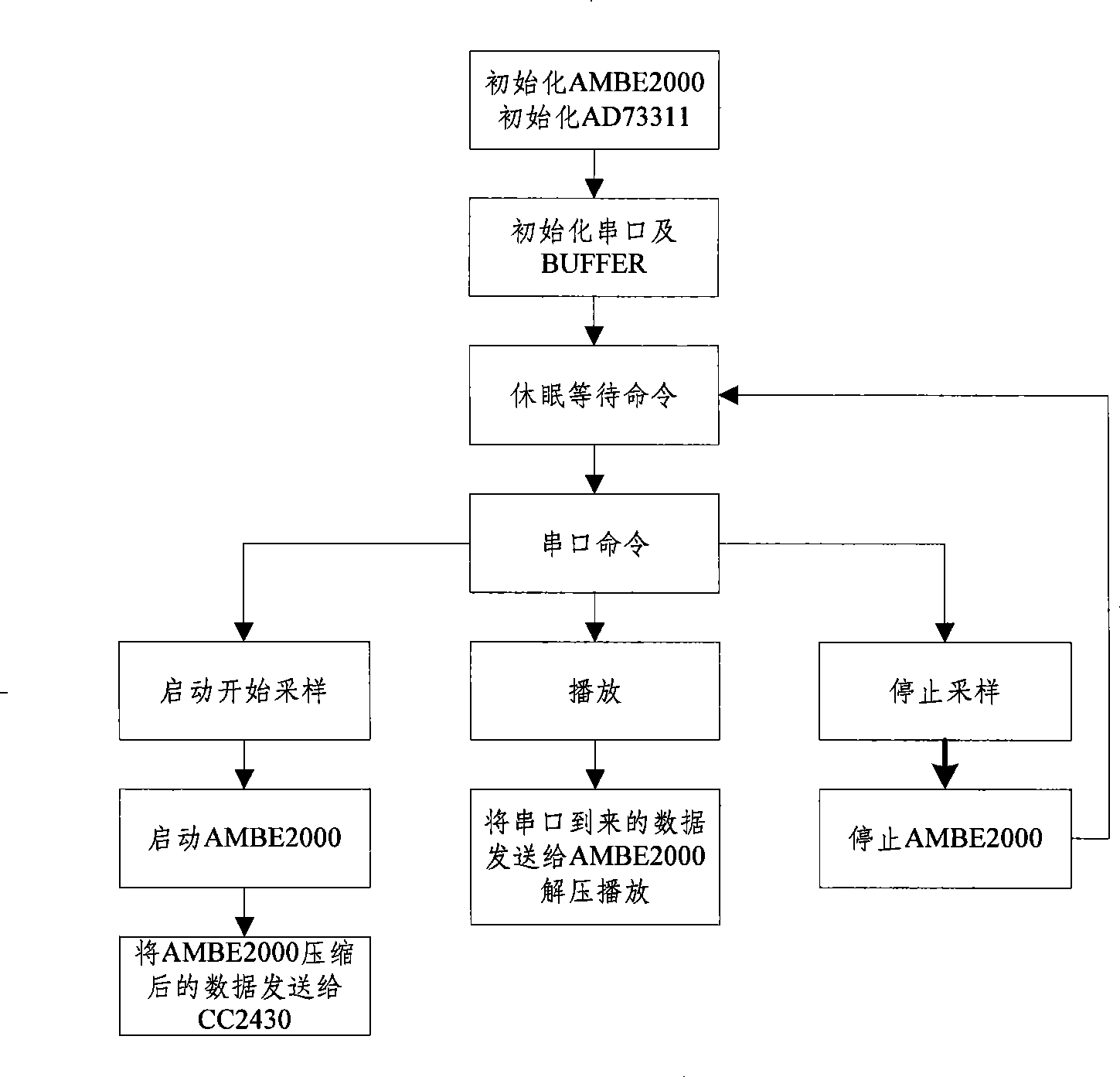

InactiveCN101505546AImprove safety production management levelPromote information constructionMeasurement devicesNetwork topologiesVideo monitoringLine sensor

The invention relates to a mine environment probing and search and rescue emergency response system based on a wireless sensor network, which comprises various intelligent wireless sensor network nodes, a plurality of backbone routing nodes of an underground wireless network, an underground wireless sensor network gateway, a fiber optic modem, an attendance reader, an IP network switch, a network server, a database center and a monitoring center, and has environment monitoring function before occurrence of accidents, positioning and tracking function in mine operation, electronic attendance function on operating miners, dynamic network repair function after the occurrence of the accidents, wireless voice calling function between ground and underground, and video monitoring and search and rescue function. The system can improve mine safety production management level, promote mine information construction, reduce occurrence of coalmine accidents, quicken the search and rescue process in mine disasters and the like, provides important information platform and has great application value.

Owner:TSINGHUA UNIV

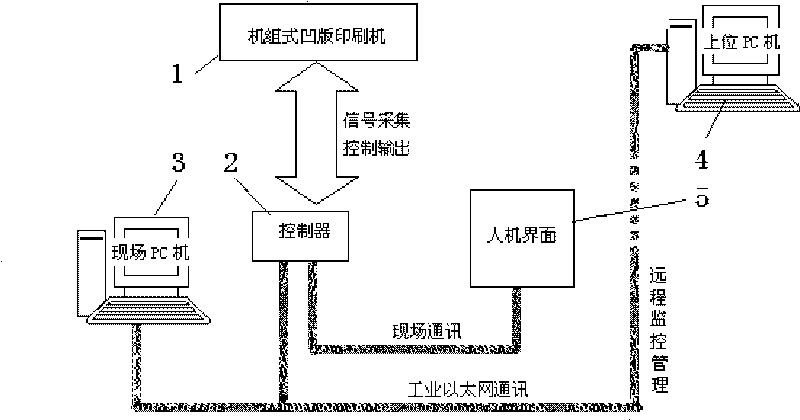

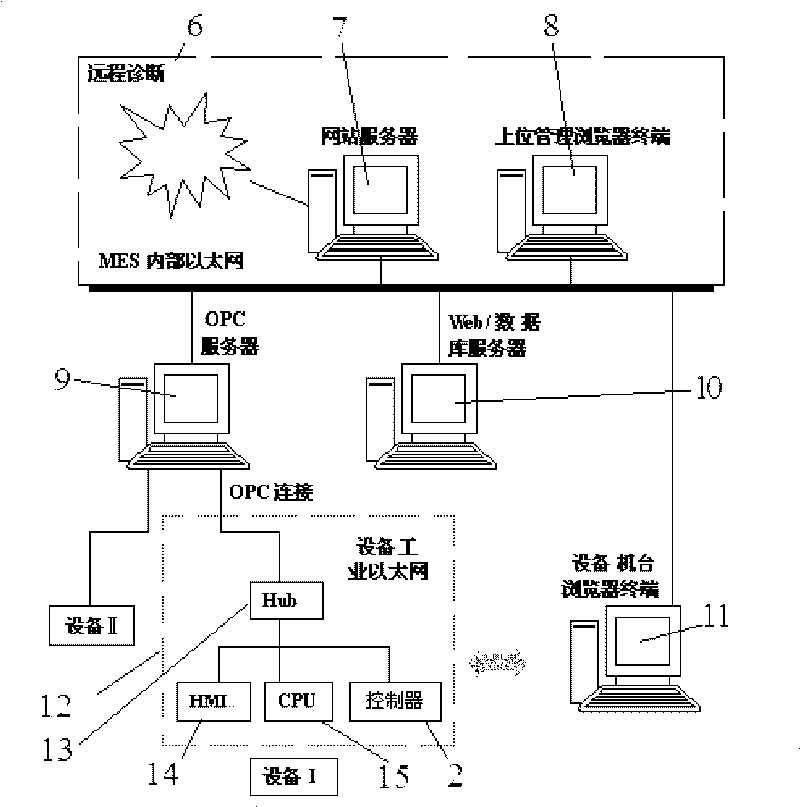

Information management system for on-line production of printing machine and method thereof

ActiveCN101713994AImprove efficiencyChange efficiencyData switching by path configurationTotal factory controlEmbedded systemReal time networks

The invention discloses an information management system for on-line production of a printing machine, which is characterized in that a web server and an upper management browser terminal which are mutually connected are arranged in an MES internal Ethernet to be used for realizing on-line remote diagnosis and maintenance; the MES internal Ethernet is respectively connected with an OPC server and an equipment station browser terminal, and the MES internal Ethernet is also connected with an equipment industrial Ethernet of a plurality of printing machine units through the OPC server; an Hub, an HMI, a CPU and a controller are arranged in the equipment industrial Ethernet; the Hub is externally connected with the OPC server; the Hub is respectively connected with the HMI, the CPU and the controller; and the controller is connected with a PLC control system in the printing machine equipment. The invention also discloses a method of on-line control and real-time data acquisition of the control system. The invention realizes the real-time network monitoring, parameter reporting, production management and analytic statistics under the B / S structure in an Ethernet communication mode, and realizes multi-browser and multi-user operation.

Owner:SHAANXI BEIREN PRINTING MACHINERY

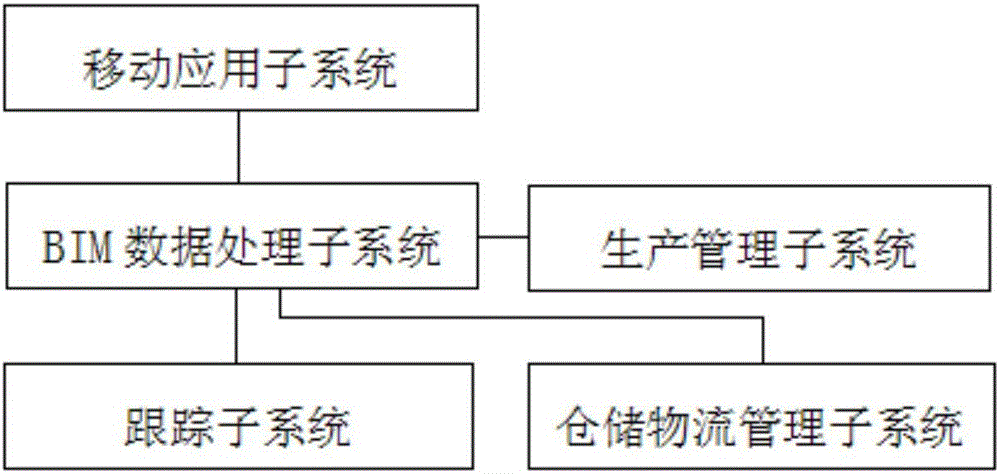

Assembly type building construction full process data cooperation management system based on BIM

InactiveCN106600239AIncrease productivityImprove interaction efficiencyOffice automationLogisticsComputer scienceManagement system

The invention discloses an assembly type building construction full process data cooperation management system based on BIM. The system comprises a BIM data processing subsystem, the BIM data processing subsystem is used for storing an assembly type building BIM model capable of being disassembled into multiple component models into a database, the unique code information is provided for each component model, each component model is associated with the attribute information, including the geometric information and the material information; a production management subsystem, the production management subsystem is used for acquiring the geometric information and the material information of each component model to make production equipment produce corresponding components; and a tracking subsystem, identity label generation equipment is used for generating a unique identity label according to the code information of each component model, multiple pieces of code information identification equipment are distributed at multiple nodes of production, storage, transportation and assembly links, and the tracking subsystem is used for updating the state information of the component models. The system is advantaged in that assembly type building construction full process cooperation management is realized, and assembly type building production efficiency is improved.

Owner:CHINA CONSTR SCI & TECH CO LTD

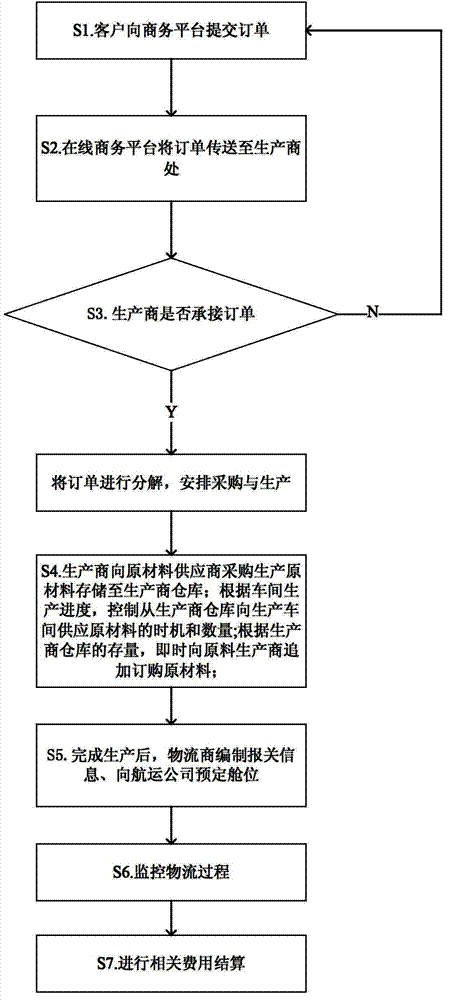

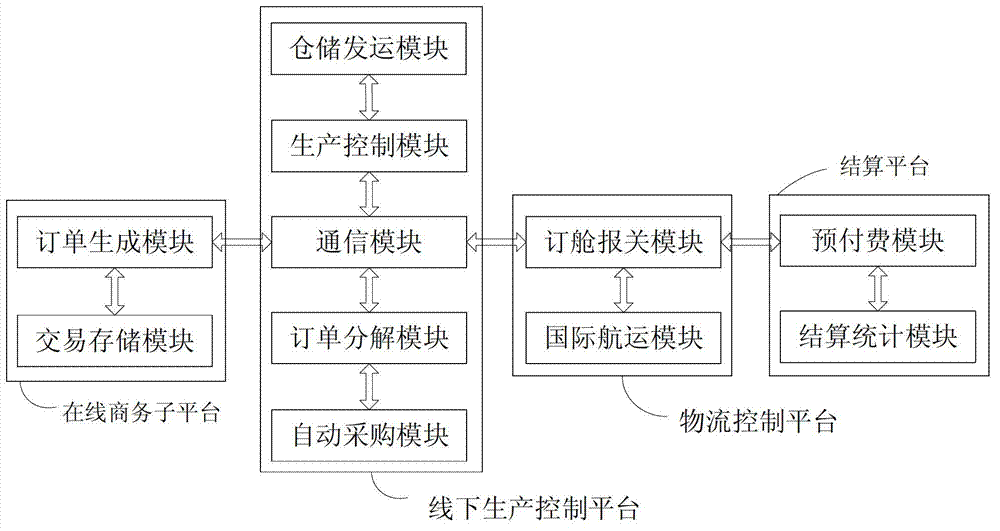

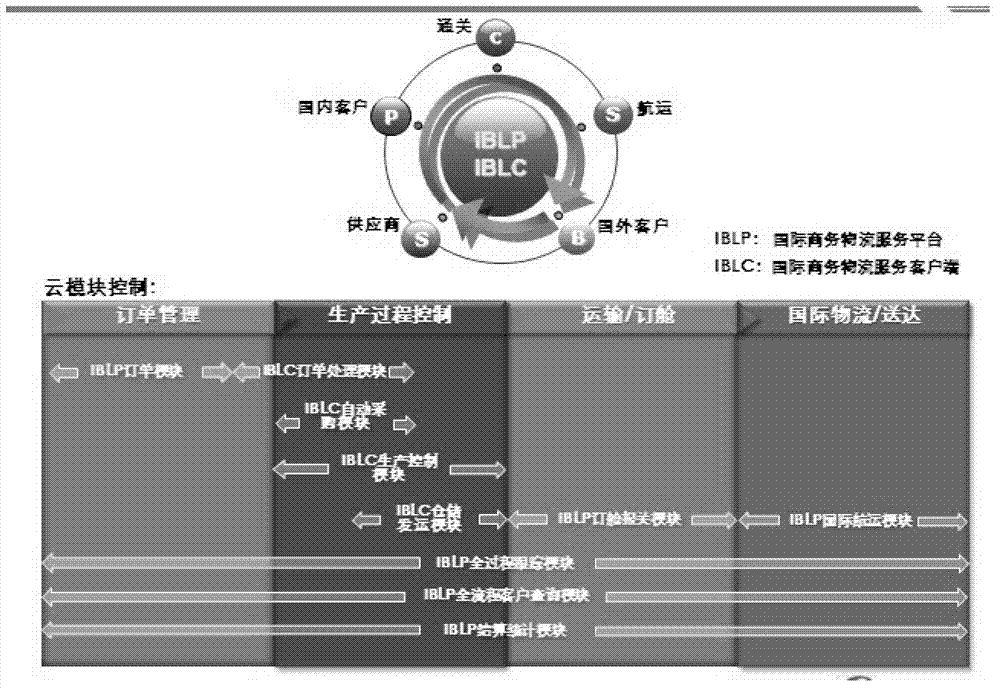

Online trading platform for international E-commerce and logistics and operating method thereof

InactiveCN102779315AAdapt to the new trend of circulationLow costBuying/selling/leasing transactionsInternational shippingLogistics management

The invention discloses an online trading implementation method and system for international E-commerce and logistics. The online trading implementation method comprises such modules as an order generating module, an order processing module, an automatic purchasing module, a production control module, a storage forwarding module, a booking and customs-declaring module, an international shipping module, and the like. The online trading platform can effectively assist clients and manufacturers in completing transactions across borders in the international business transactions, so as to finally achieve reduction of various costs and transaction expenses, information updating, a win-win situation for all parties of the whole supply chain, therefore, the serviced enterprises are more professional, diversified and knowledge-based in management, and are objectively adaptive to a new commodity circulation trend.

Owner:DALIAN TIANCHENG ENTERPRISE SERVICE

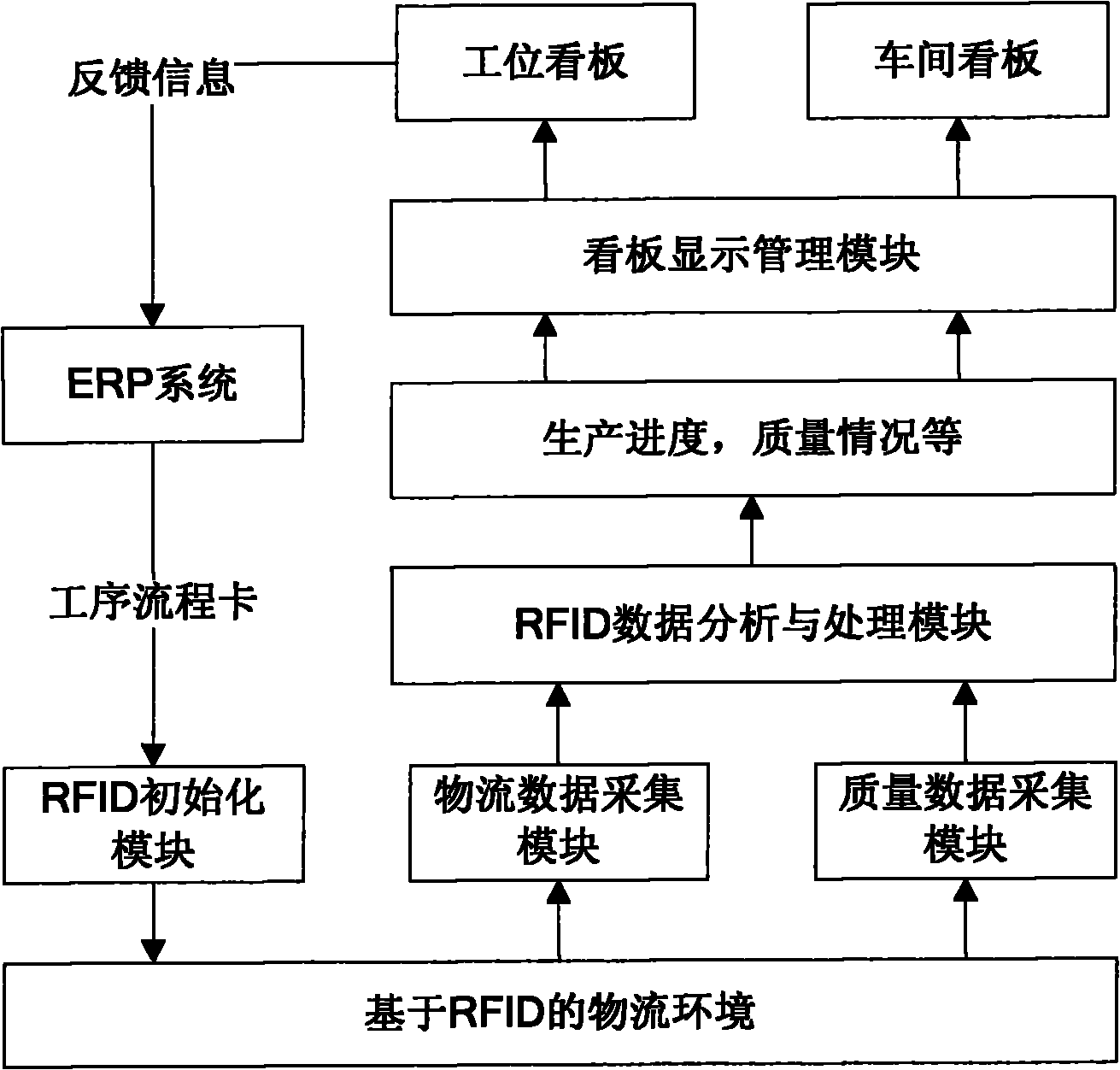

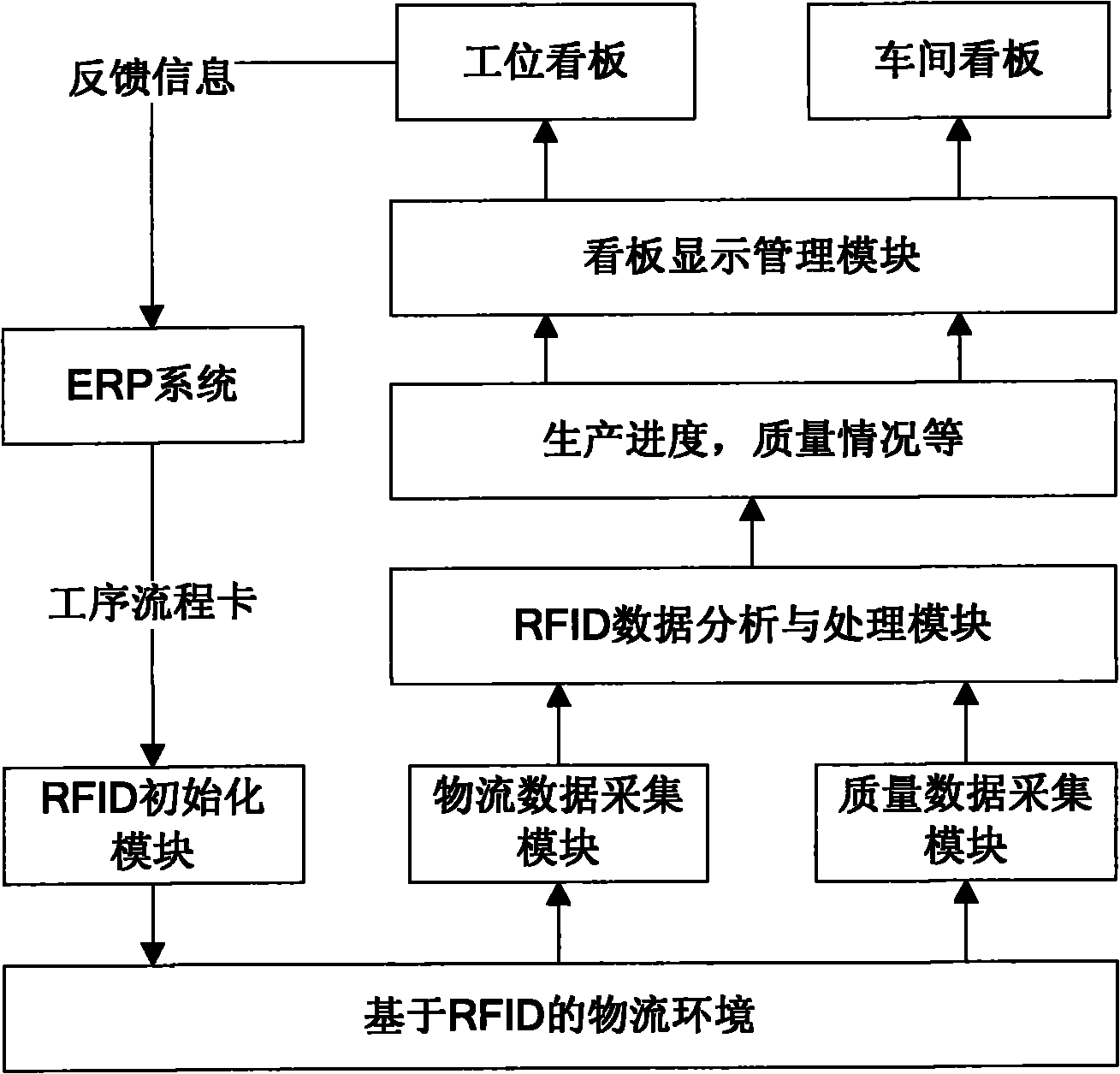

Visual production management and control method for discrete workshop

InactiveCN101819658AEffective Quality MonitoringQuality data to realize effective monitoring of production management in discrete manufacturing workshopsCo-operative working arrangementsProduction scheduleProcess module

The invention discloses a visual production management and control method for a discrete workshop. The method comprises the following steps of: establishing an association relationship between an RFID tag which is taken as a carrier for data acquisition of a workshop and a process flow card; acquiring information of the tag when the RFID tag passes through a working position; displaying the information of the process flow card associated to the tag on an electronic billboard; reading the RFID tag and filling quality information by using a handset at a quality testing working position; processing acquired information to form production schedule information and the quality information of the workshop; and displaying the production schedule information and the quality information on a working position billboard and a workshop billboard by using a billboard display management system. The method adopts a device which comprises an RFID initializing module, an RFID-based data acquisition module, an RFID data analyzing and processing module and a billboard display management module. By using the method, logistics and quality data in a production process can be acquired and transmitted in real time, paperless and visual production management of a discrete manufacturing workshop is realized, the information of logistics, quality and the like is effectively monitored, and the workshop management level of an enterprise is improved.

Owner:ZHEJIANG UNIV

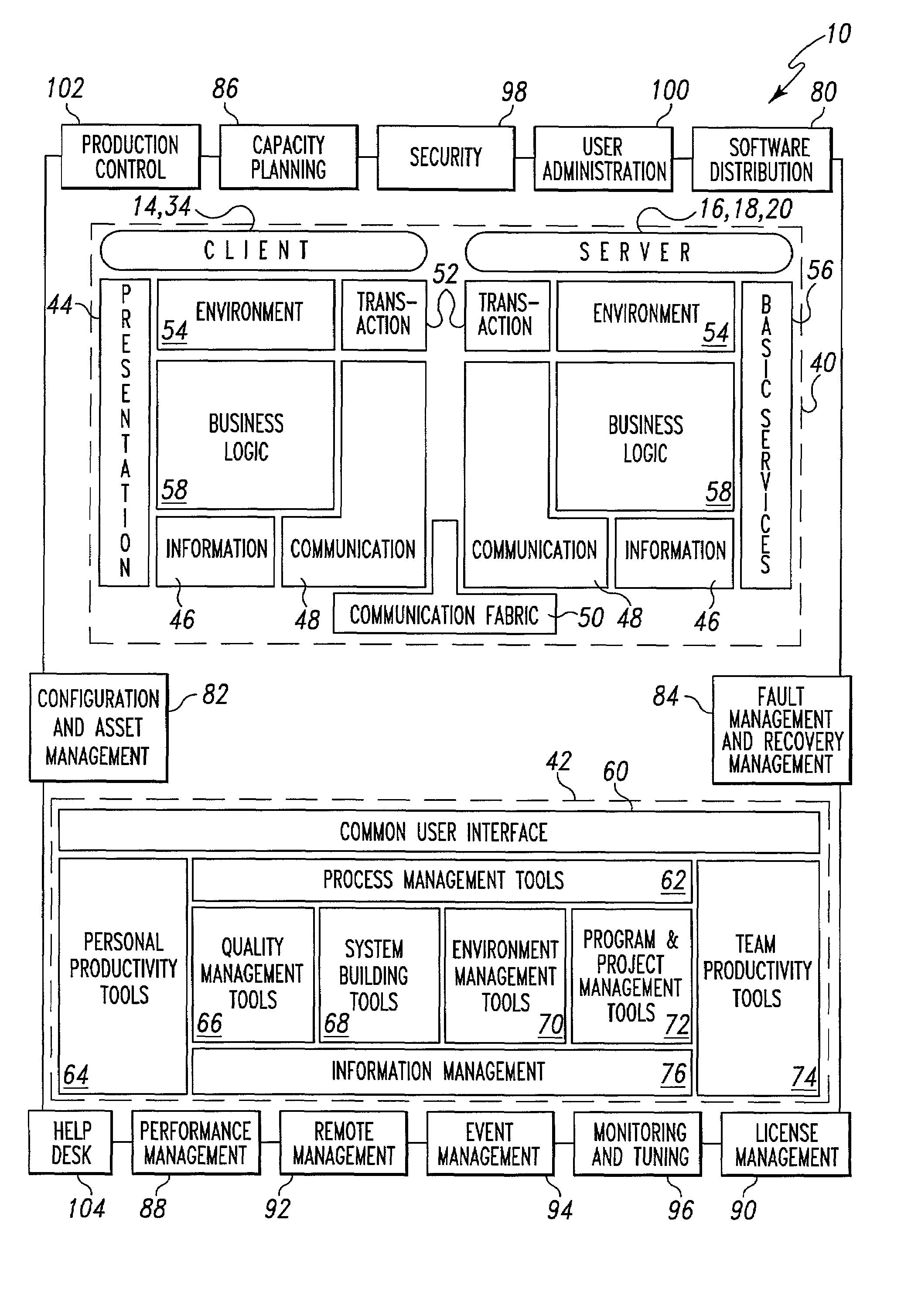

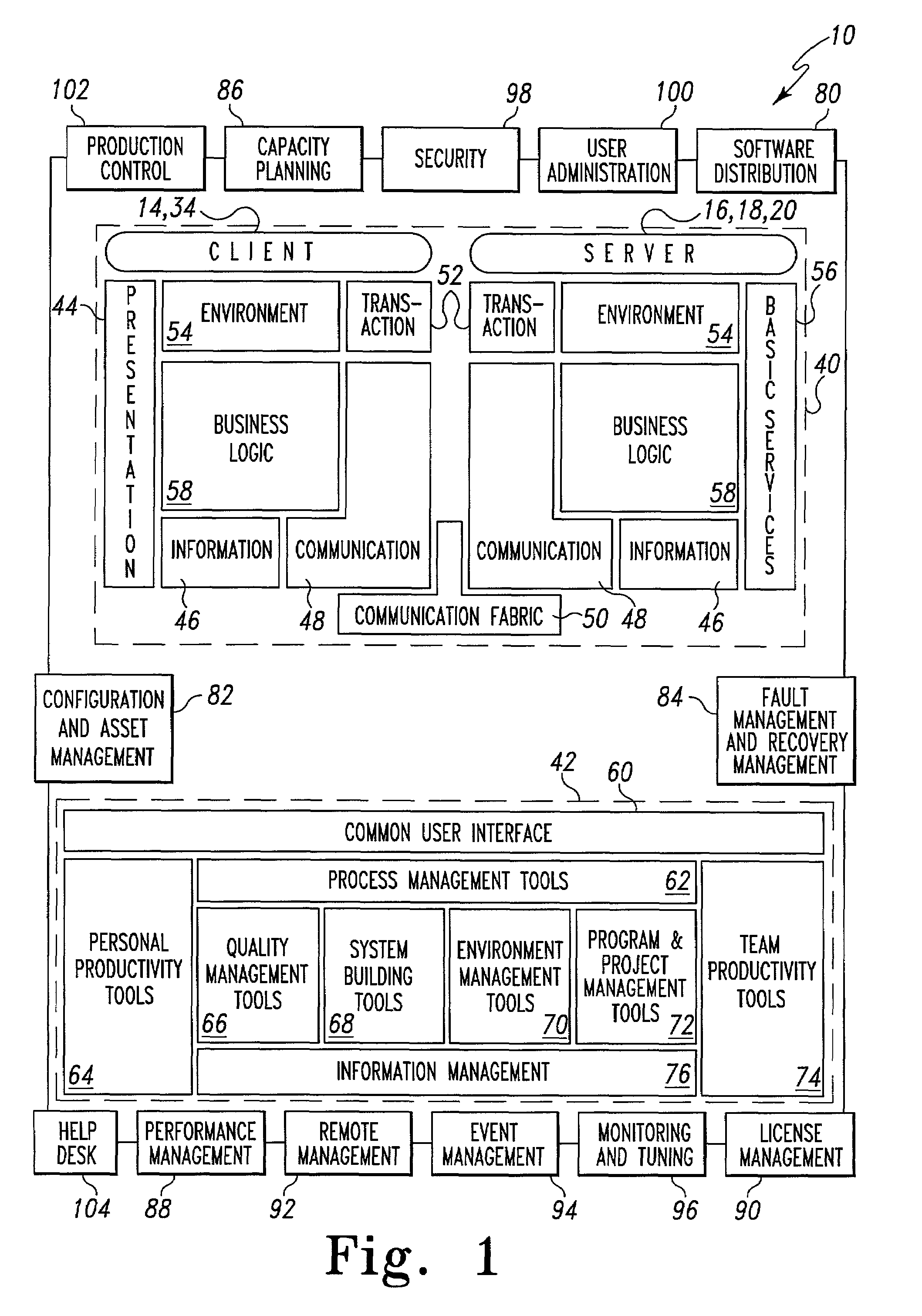

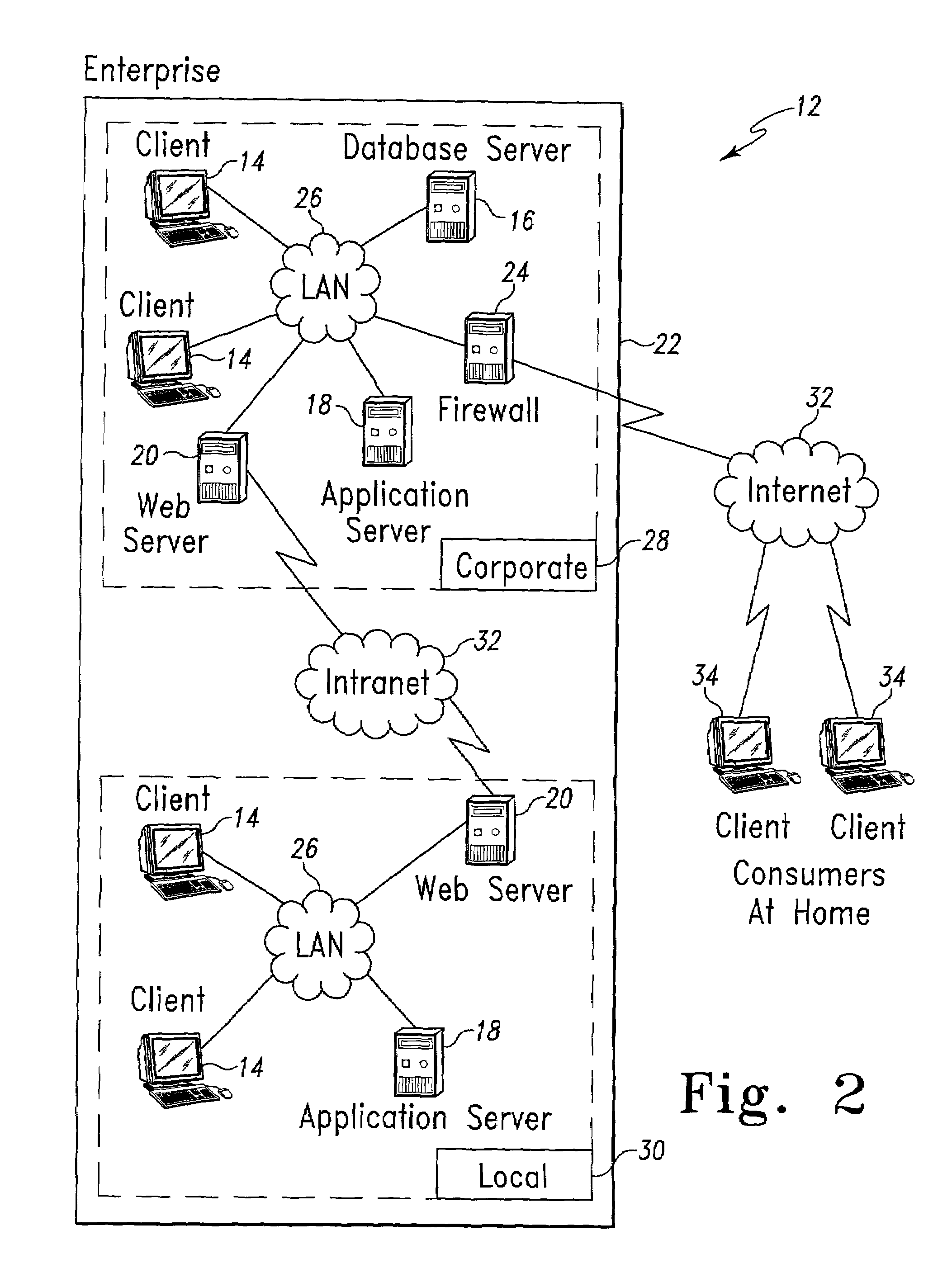

Operations architectures for netcentric computing systems

InactiveUS7415509B1Data processing applicationsWeb data retrievalManagement toolSoftware distribution

An operations architecture for a netcentric computing system including a server connected with a client. The preferred operations architecture includes a software distribution tool, a configuration and asset management tool, a fault management and recovery management tool, a capacity planning tool, a performance management tool, a license management tool, a remote management tool, a event management tool, a systems monitoring and tuning tool, a security tool, a user administration tool, a production control application set and a help desk tool that support the server and the client in the netcentric computing system.

Owner:ACCENTURE GLOBAL SERVICES LTD

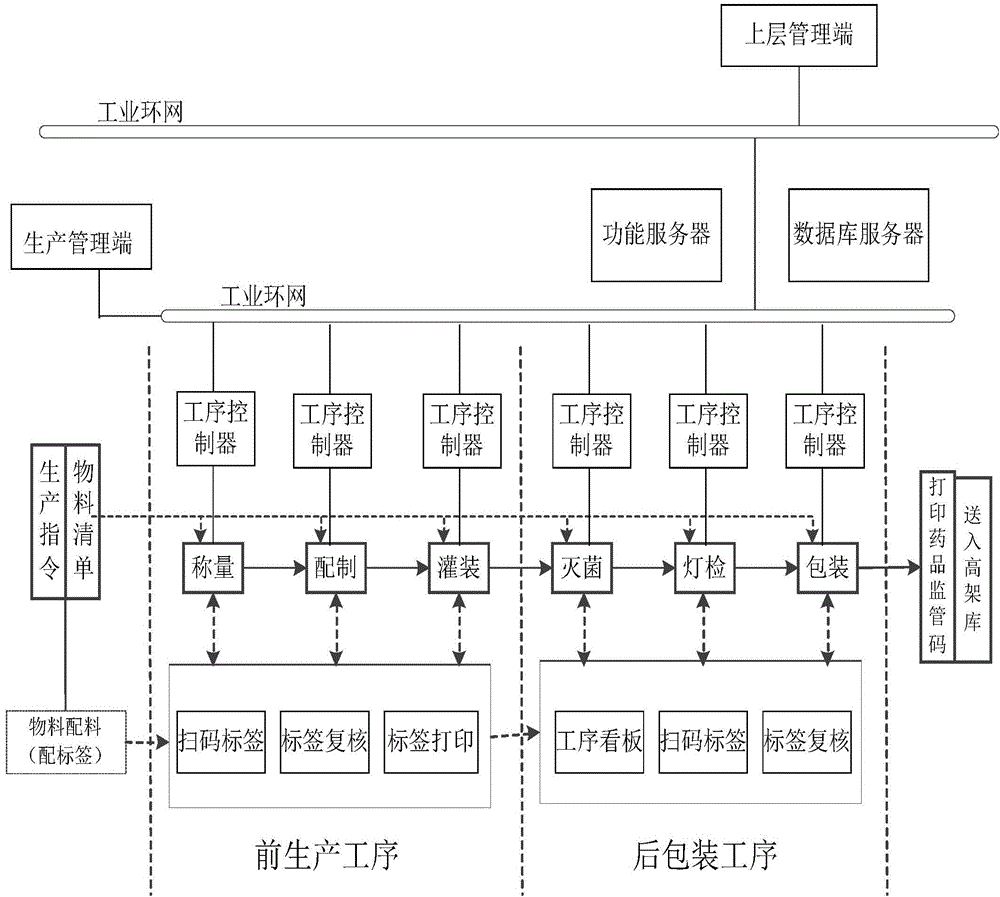

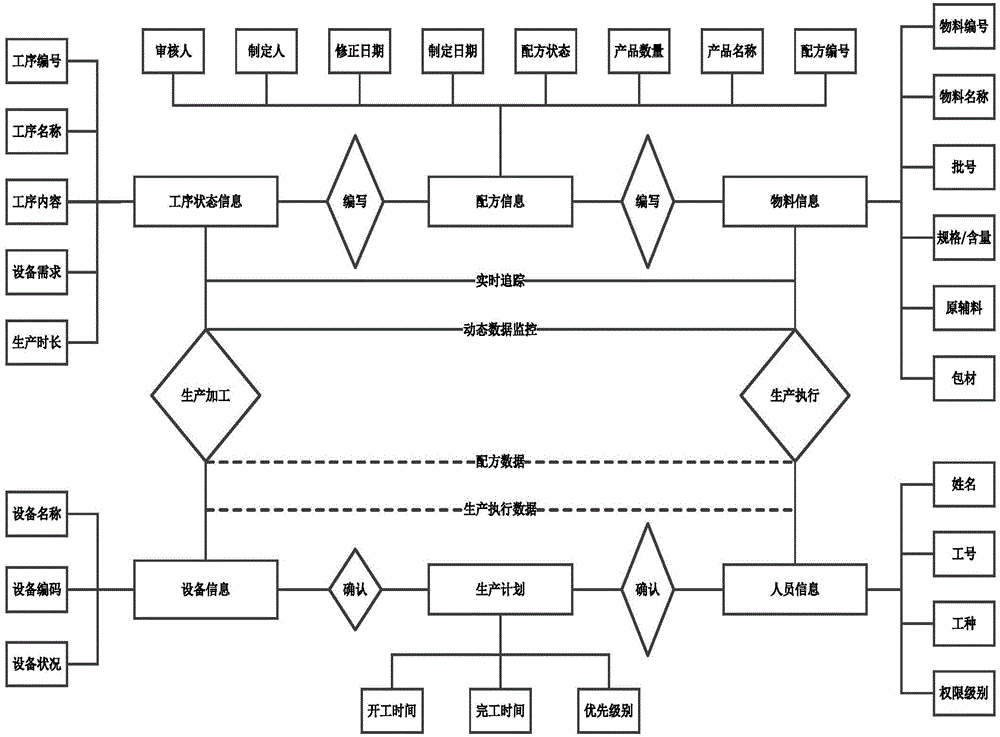

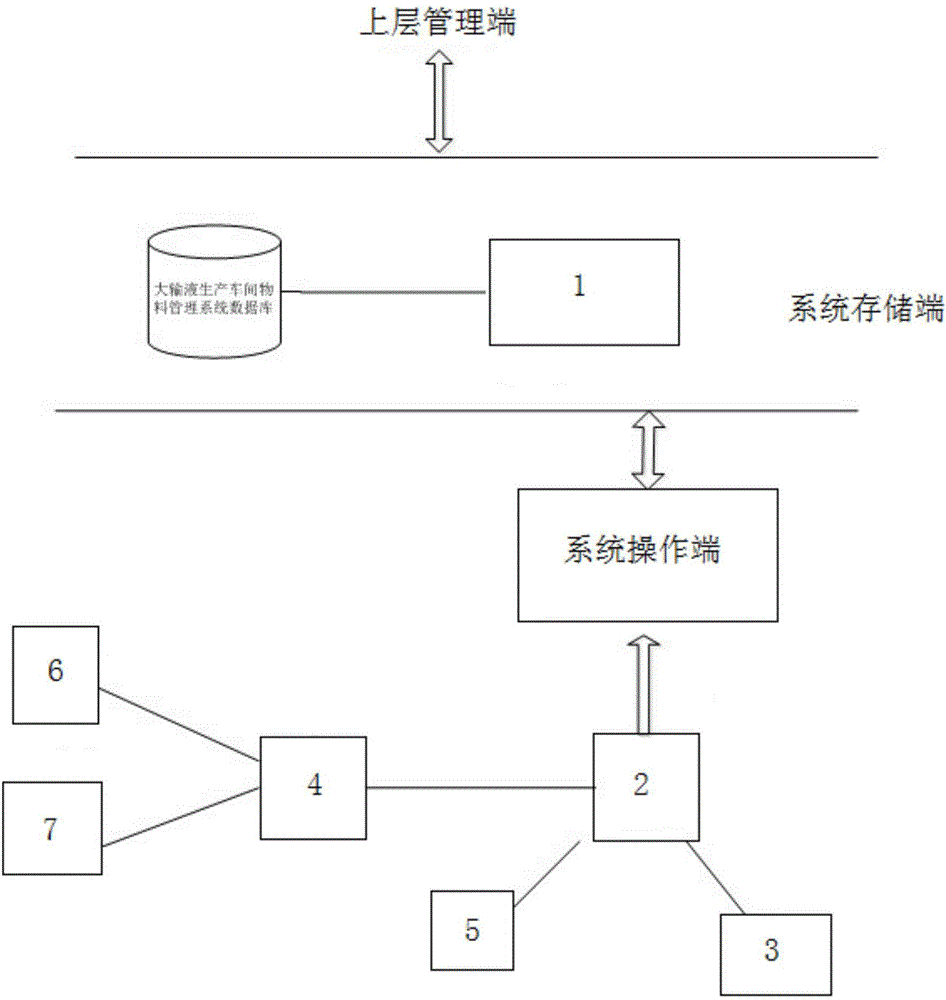

Pharmaceutical product manufacturing execution system and method

InactiveCN104808639AImprove development efficiencyImprove maintainabilityTotal factory controlProgramme total factory controlDatabase serverManufacturing execution system

The invention discloses a pharmaceutical product manufacturing execution system and method. The method includes connecting a manufacturing execution system function server and a manufacturing execution system database server to an upper-level management terminal through an industrial loop network; allowing the manufacturing execution system function server to perform data exchange with a production management terminal through the industrial loop network; allowing the production management terminal to connect to a bottom procedure controller through the industrial loop network; allowing the production management terminal to receive a production planning instruction from the upper-level management terminal, divide the production planning instruction into a production instruction and a material list and transmit the production instruction to the bottom procedure controller, and allowing the bottom procedure controller to control corresponded production procedures and acquire staff producing operation information and corresponded equipment information. The method has the advantages that the corresponded material is encoded correspondingly and respectively, the workshop producing material data management and tracking are implemented, the statistical graph and report support is provided, and the material management is simplified.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

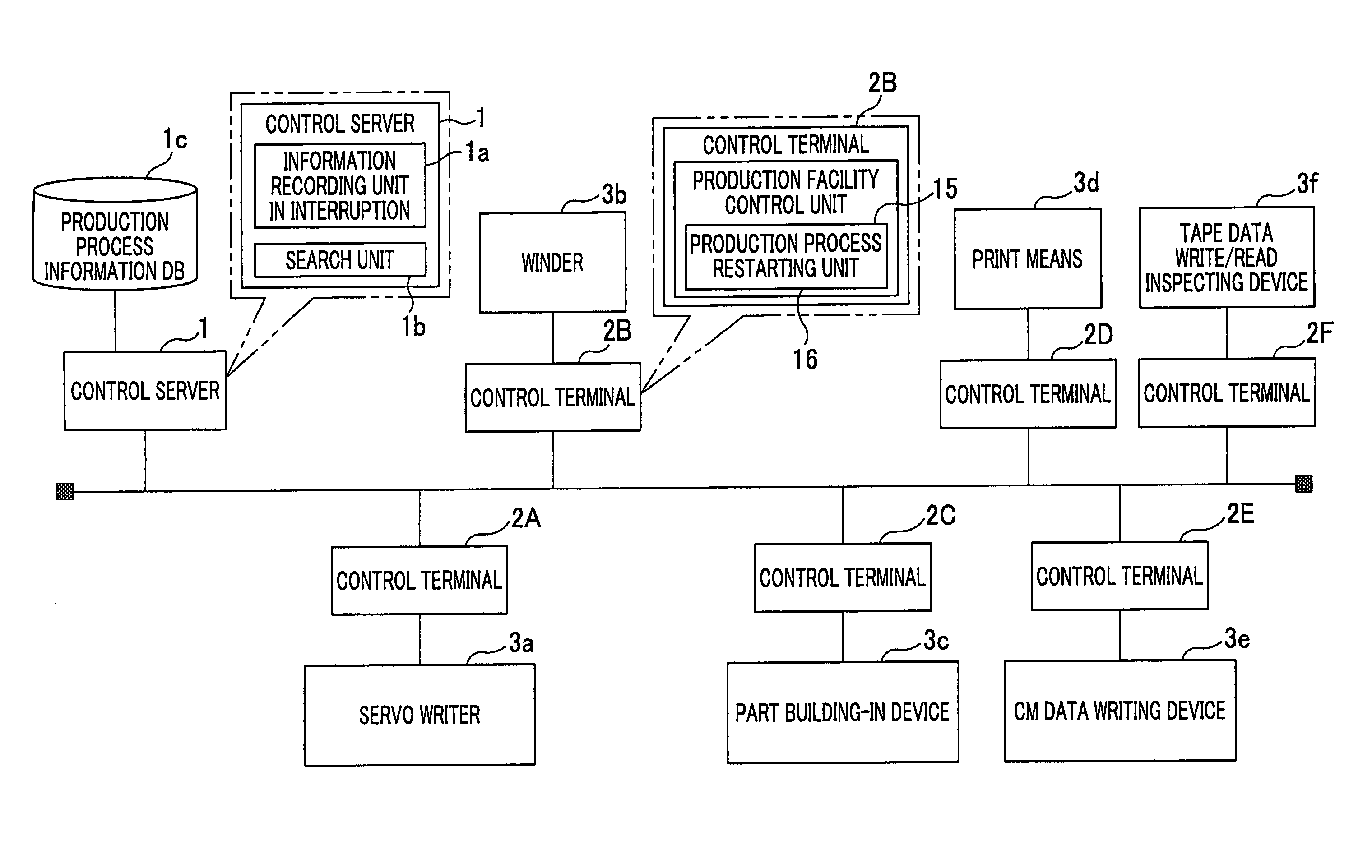

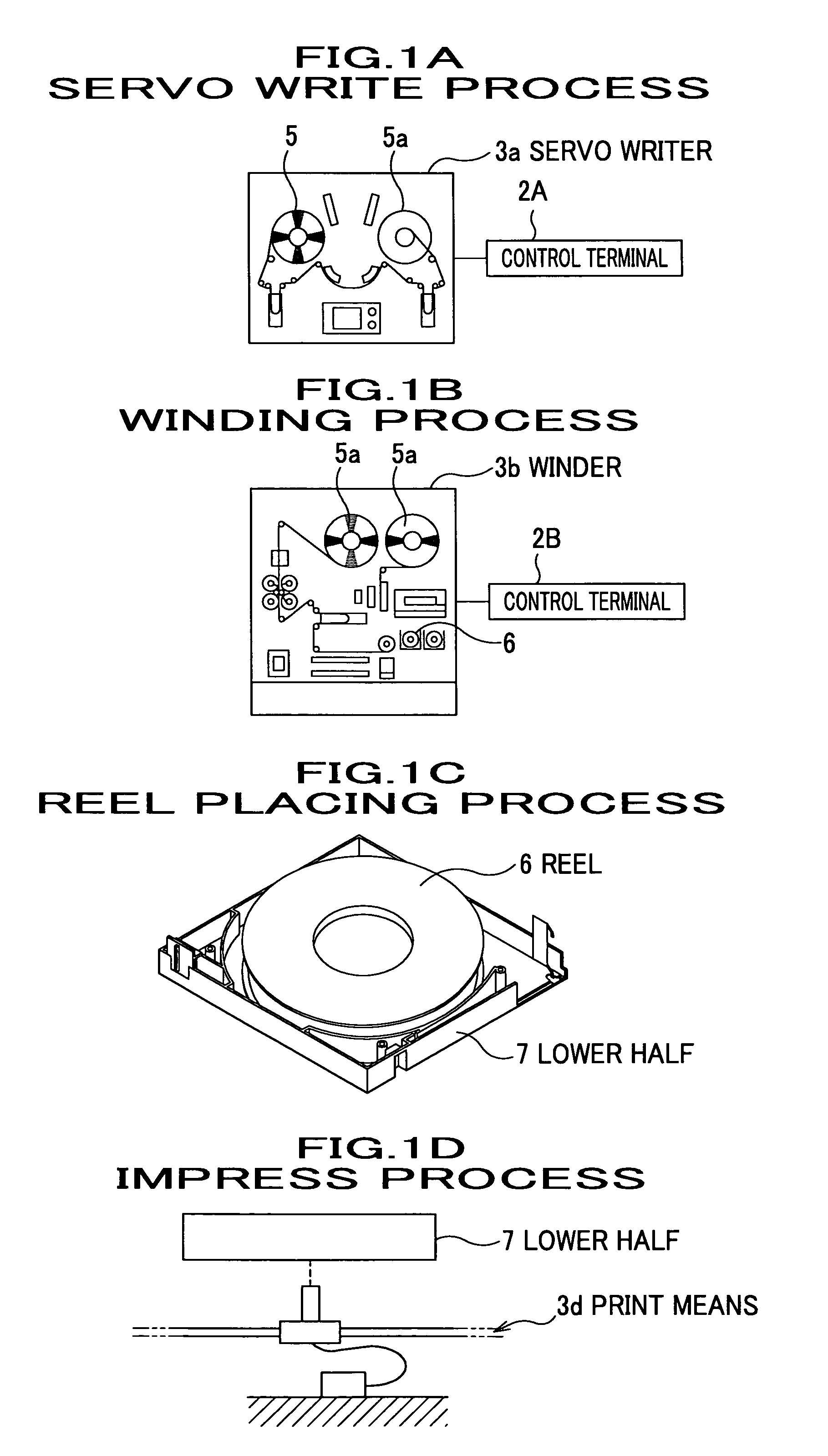

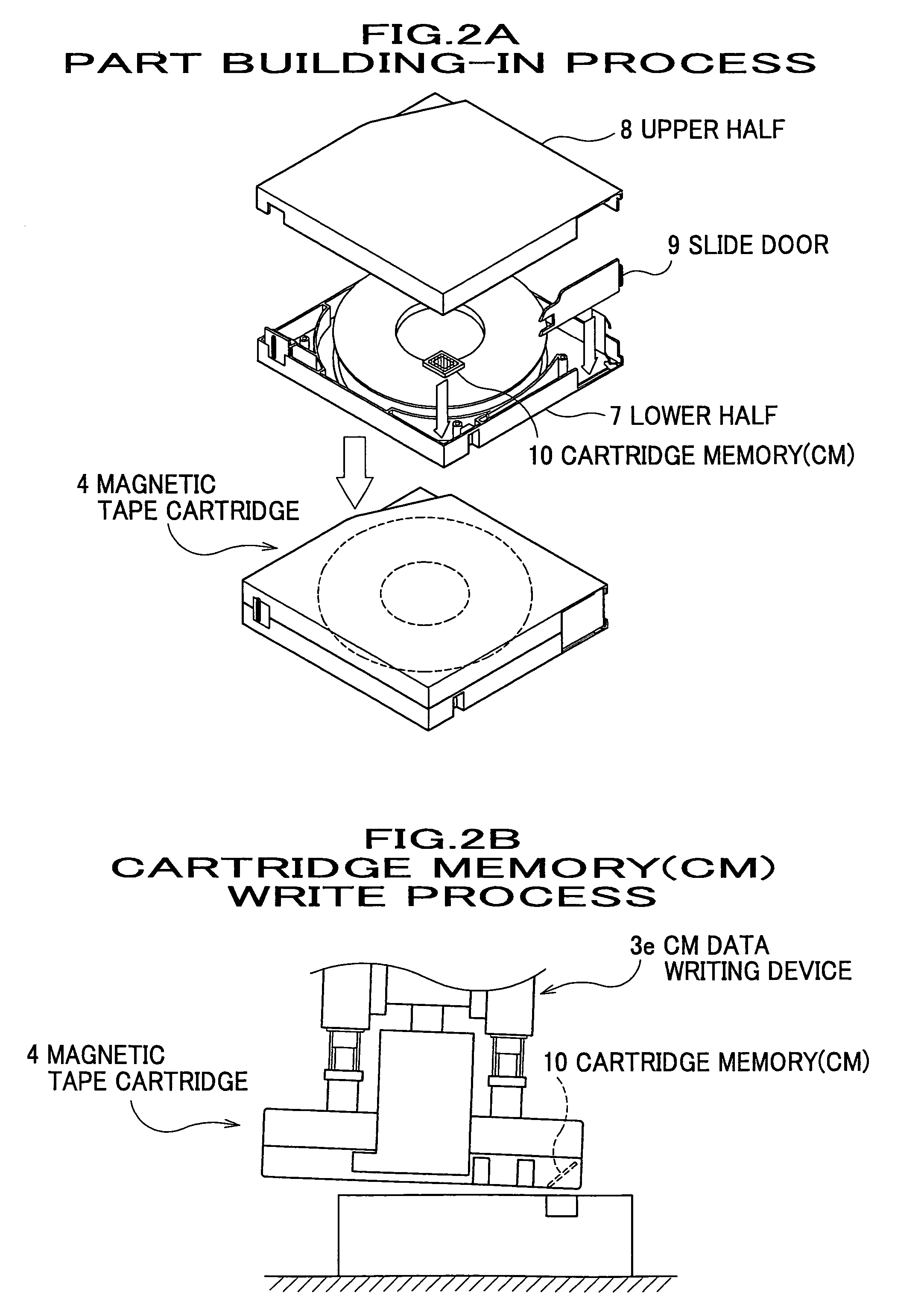

Production process control system

ActiveUS6973366B2Data processing applicationsComputer controlManufacturing engineeringProduction control

A production process control system, which includes a production process control server controlling production process information of a product and a control terminal controlling production operation of a production facility connected with the production process control server via a network, is equipped with a production process information data base being a data base of the production process information of the product; an information recording means in interruption receiving the production process information data base in interrupting production operation on the way of a production process of the product, and storing the production process information data base; and a search means searching production process information stored by the information recording means in interruption from the production process information data base in restarting interrupted production operation.

Owner:FUJIFILM CORP +1

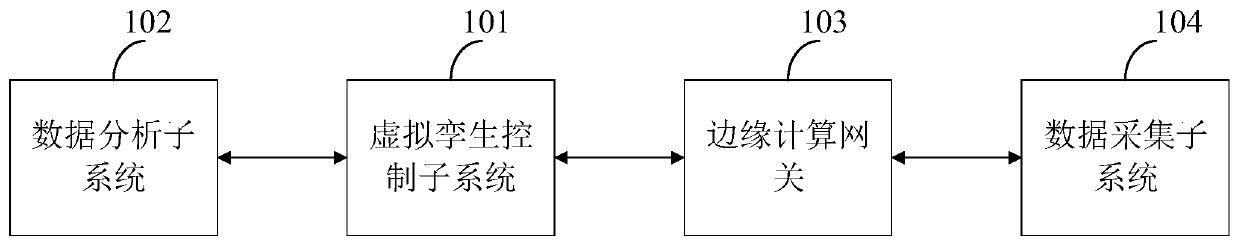

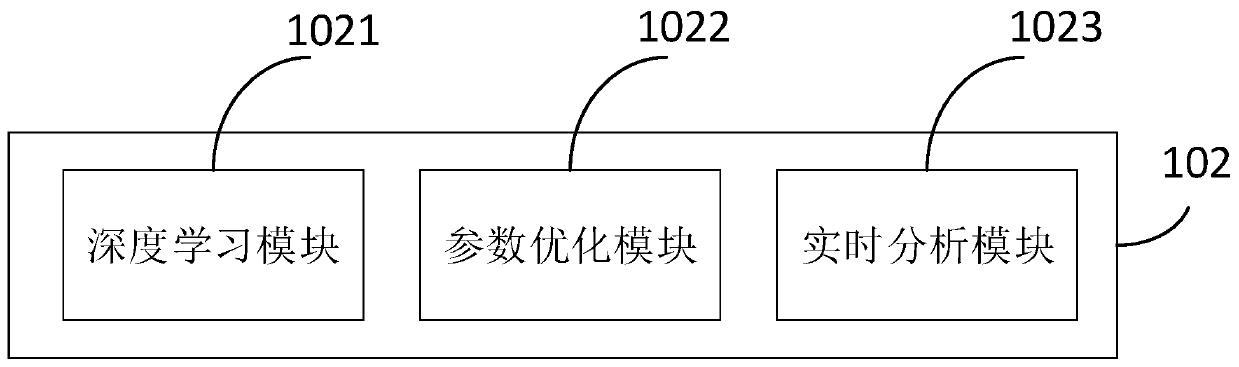

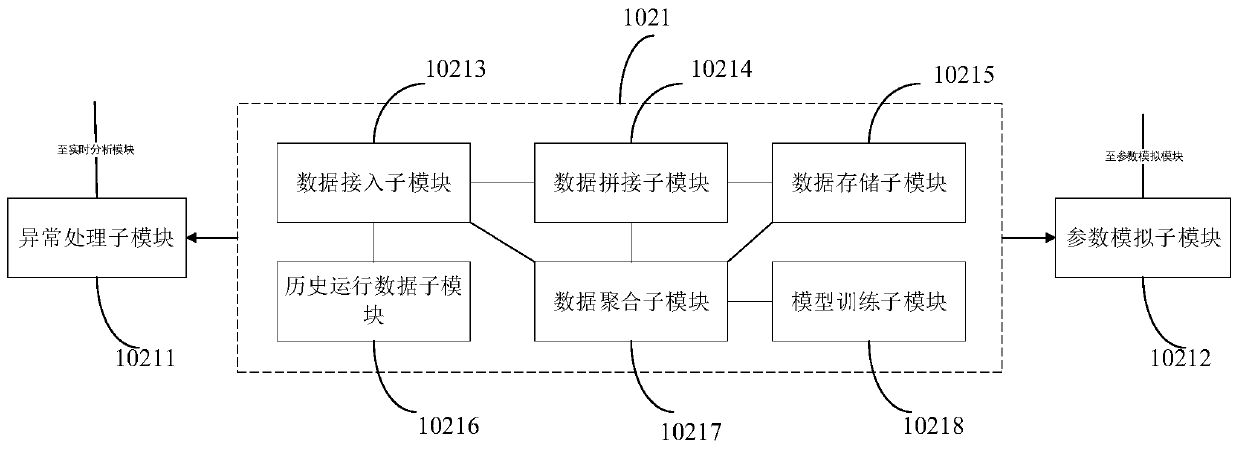

Production line control system and method based on digital twinning, and production system

InactiveCN109933035ASupport remote data accessSupport commandTotal factory controlProgramme total factory controlProduction lineControl system

The invention discloses a production line control system based on digital twinning, and the system comprises a data collection subsystem which collects the current operation state data of a productionline in real time; a virtual twinning control subsystem which is used for generating a digital twinning model representing physical equipment at each station of the production line according to the historical operation state data of the production line and the current operation state data of the production line; a data analysis subsystem which generates new operation state data according to a recommendation algorithm, the historical operation state data of the production line, the current operation state data and the target operation state data of the production line. The digital twinning model simulates the operation state of the production line according to the new operation state data, and the data analysis subsystem is further used for finally generating optimal operation state data according to a simulation result of the digital twin model. The system also comprises an edge computing gateway which is used for realizing data interaction between the virtual twinning control subsystem and the data acquisition subsystem.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

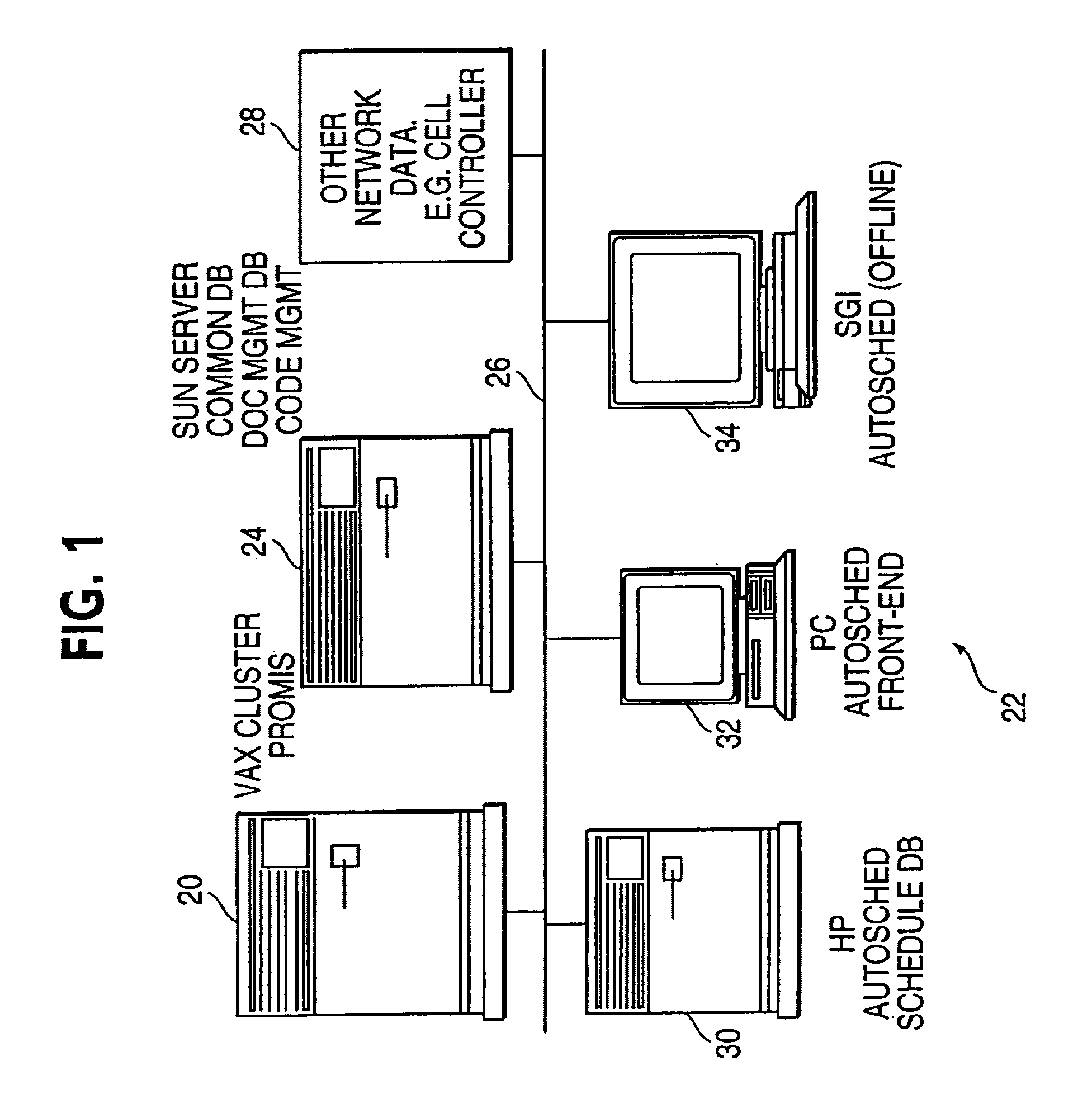

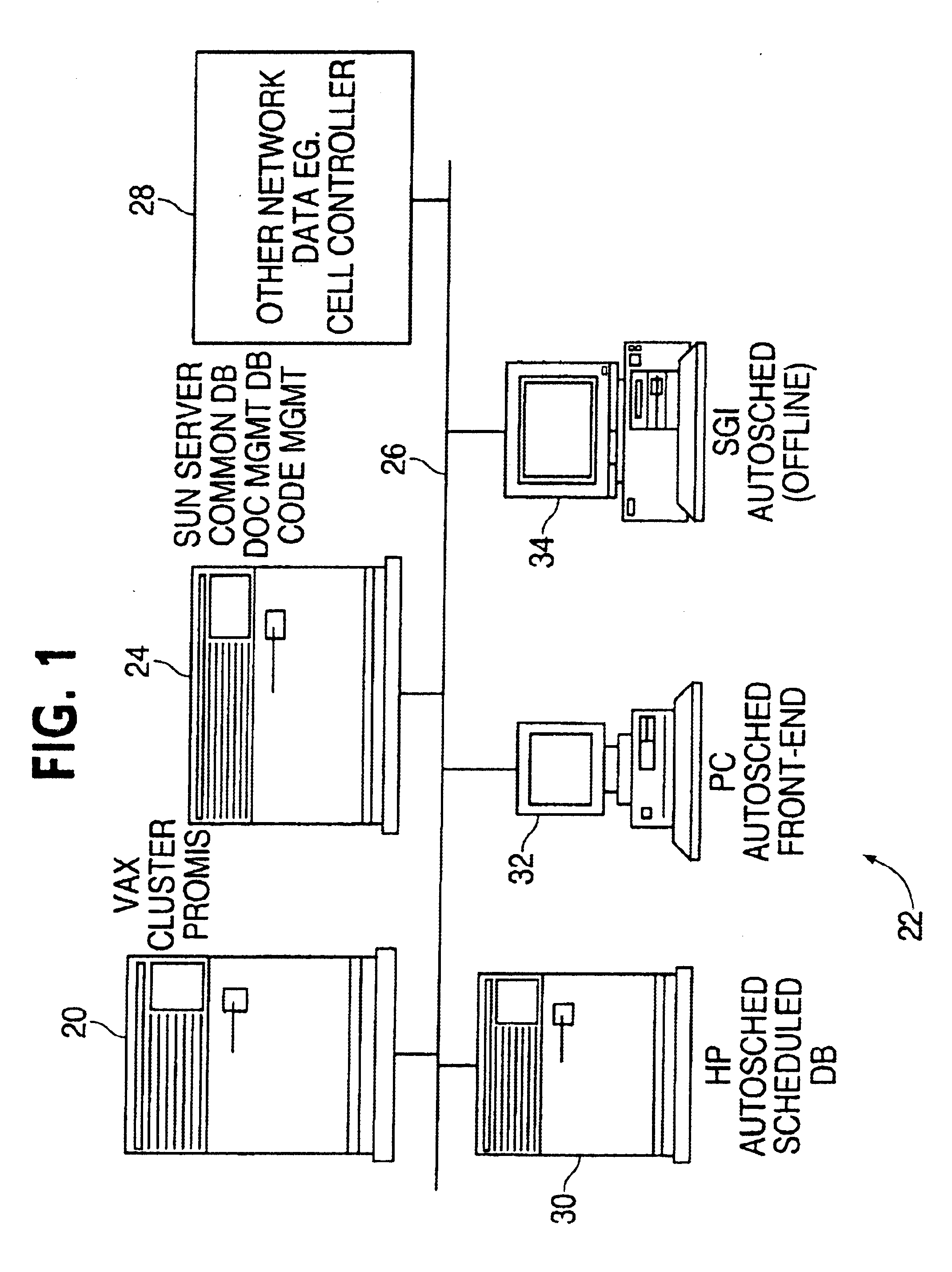

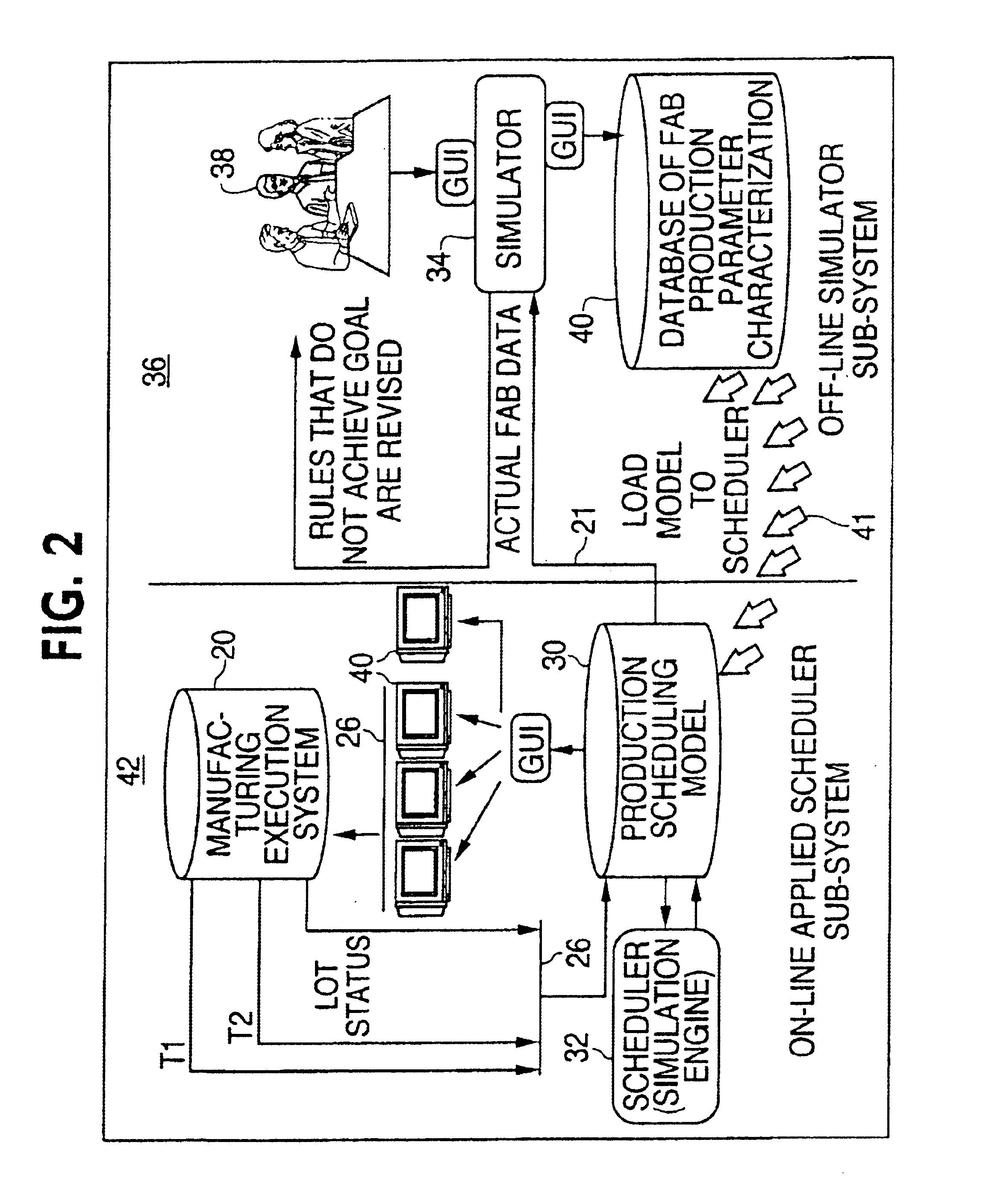

Integrated wafer fabrication production characterization and scheduling system

InactiveUS6889178B1Technology managementTotal factory controlManufacture execution systemWafer fabrication

An integrated wafer fab production scheduling and simulation system incorporates a manufacturing execution system with a scheduling system based on simulation. The integrated system provides manufacturers with a simulation tool integrated with the manufacturing execution system to evaluate proposed production control logic as a practical alternative to expensive experimentation on an actual production system. Furthermore, simulation models are used to create short-term dispatch schedules to steer daily manufacturing operations towards planned performance goals. Innovative features include integration of preventive maintenance scheduling, Kanban based WIP control, an integrated time standard database, and real time lot move updates.

Owner:SONY CORP +1

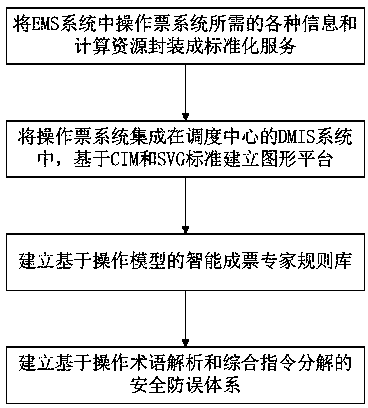

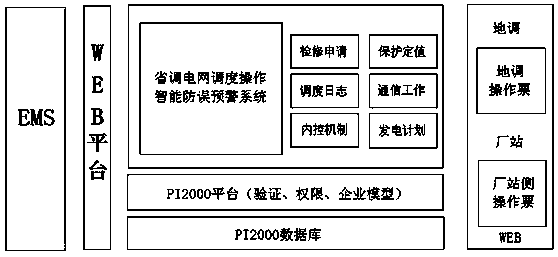

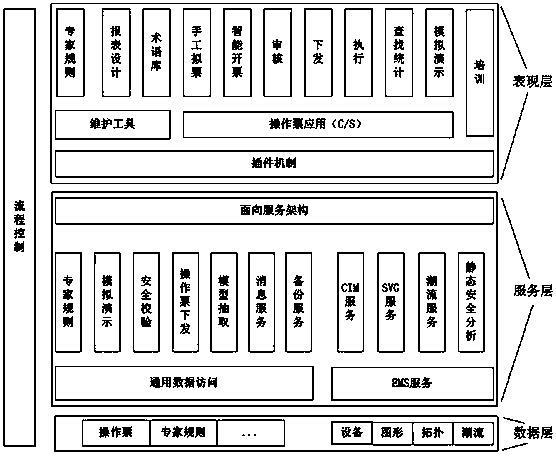

Implementing method of integrated power grid dispatching operation intelligent mistaken-early-warning preventing system

InactiveCN103761624AReduce the impactStable supportResourcesSystems intergating technologiesPower gridOperation model

The invention provides an implementing method of an integrated power grid dispatching operation intelligent mistaken-early-warning preventing system. The implementing method comprises the following steps that various information and computing resources required by an operation ticket system in an EMS system of a dispatching center are packaged into standardized service; the operation ticket system is integrated a DMIS system of the dispatching center, and a graphic platform is built according to the CIM and SVG standard; an intelligent ticket-making expert rule base based on an operation model is built, and a safe mistake preventing system based on operation term analysis and comprehensive instruction analysis is built. The implementing method has the advantages of having little influence on the EMS system, being beneficial for popularization and the like, and can improve billing efficiency and circulation speed of dispatching operation tickets. During equipment maintaining peaks in spring and autumn, equipment operation safety is guaranteed, rapidness of equipment operation is guaranteed, work efficiency and the production and management level of the power grid are improved, prevention of large-area power outage accidents is facilitated, and safe production of an electric power company is guaranteed.

Owner:STATE GRID ANHUI ELECTRIC POWER

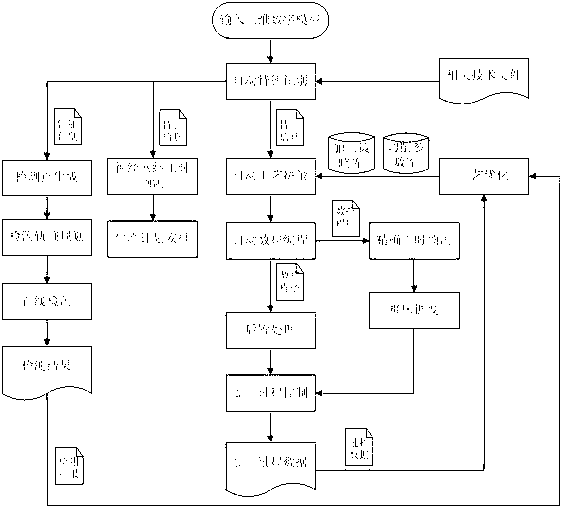

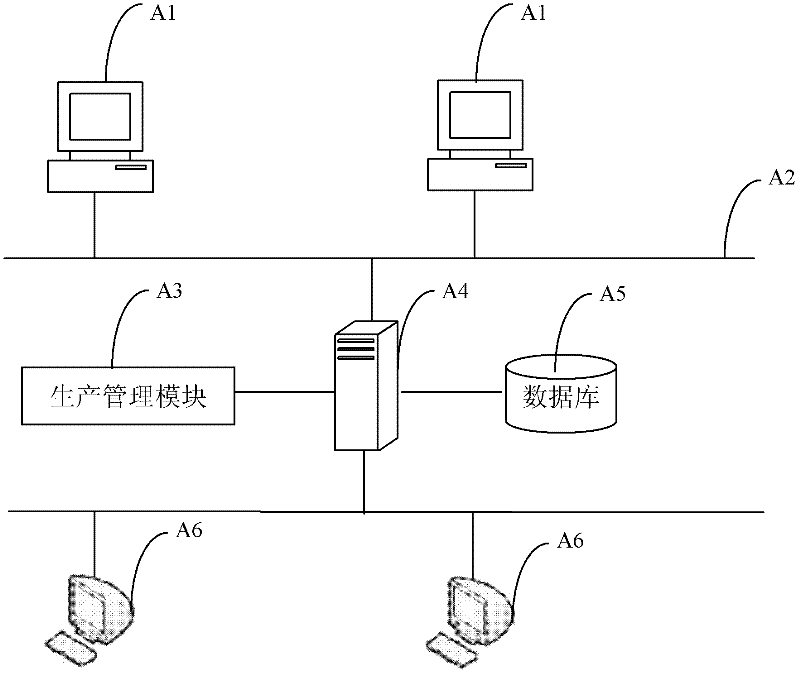

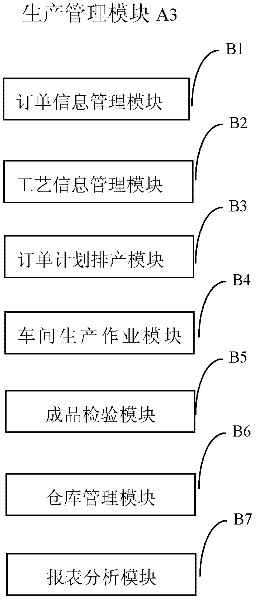

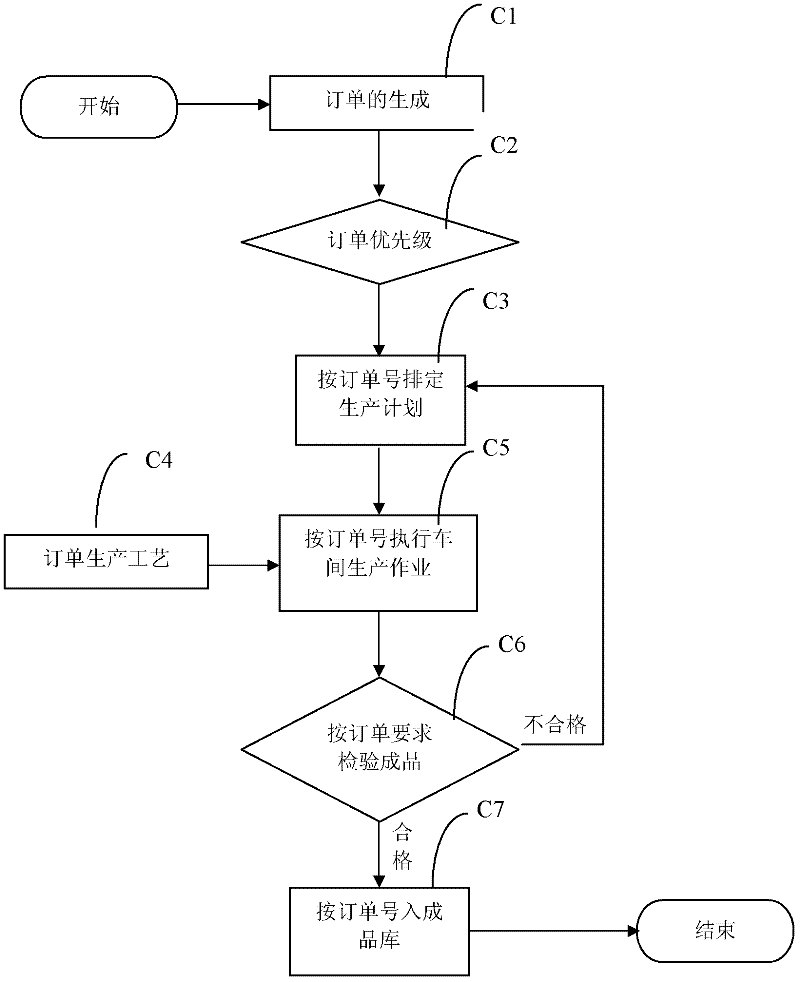

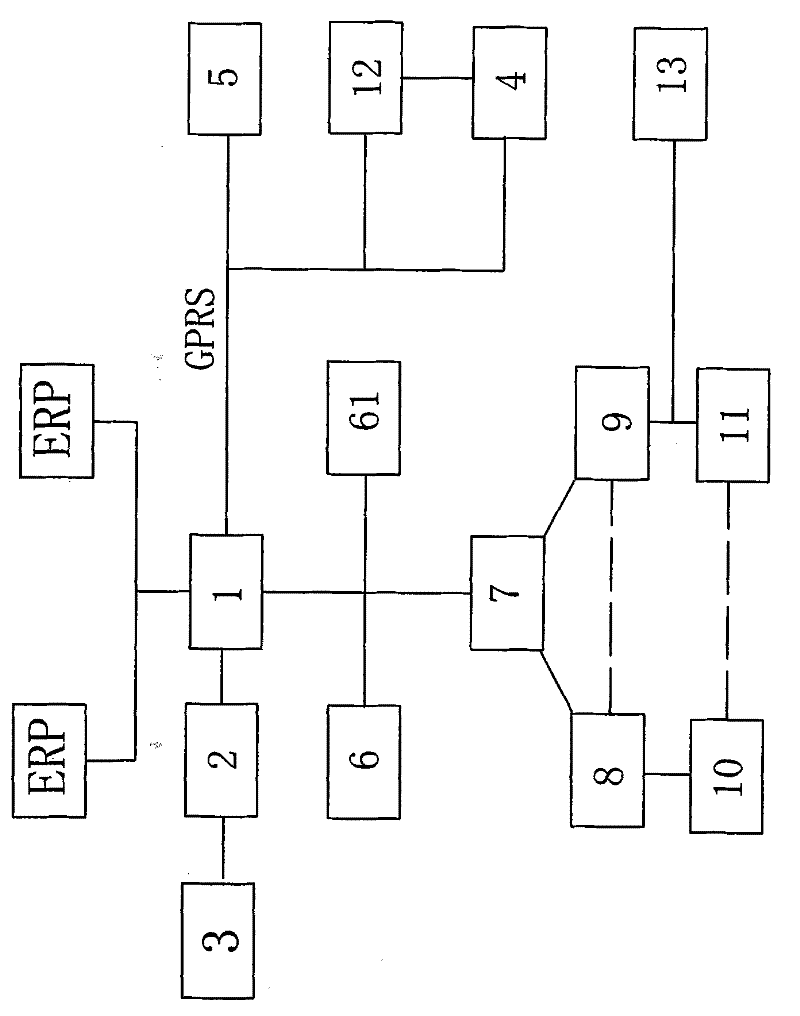

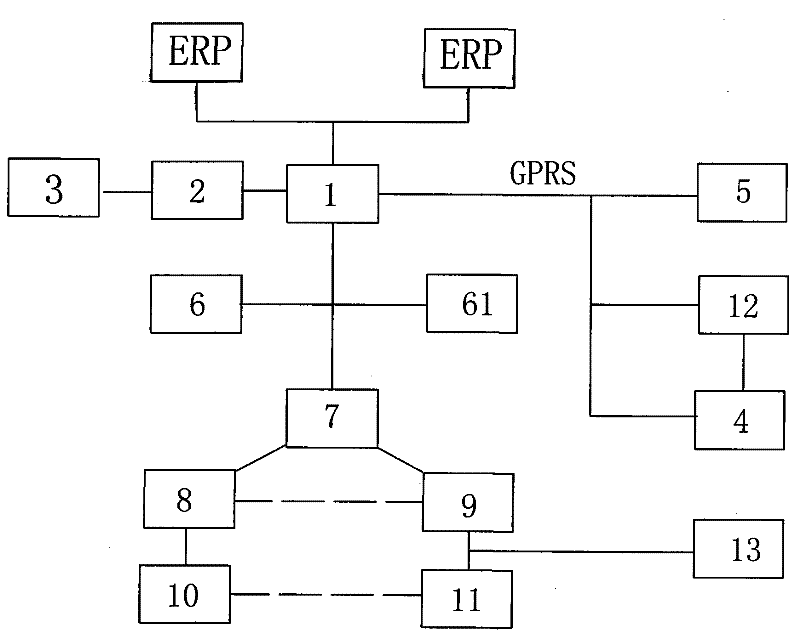

Production management system and method adopting order lists as core

The invention discloses a production management system adopting order lists as a core, comprising a WEB server, a database and series clients, wherein the WEB server comprises a production management module for receiving an inquiry condition of production management information, which is input by a user, retrieving the production management information according to the input inquiry condition of the production management information, processing the production management information and giving commands; the database is connected with the WEB server and used for storing and collecting the production management information; the series clients are connected with the WEB server through a network; each client logs on the WEB server in a browser manner to obtain an interactive interface of the production management module; and the interactive interface is used for inputting and displaying the production management information. The production management system disclosed by the invention can be used for clearly and conveniently tracking and managing each order list through the production management module, and calculating the cost of each production order list through a statement analysis module, thereby enabling the management to have more pertinence and scientificity, and improving operation efficiency of enterprises.

Owner:杭州开源电脑技术有限公司

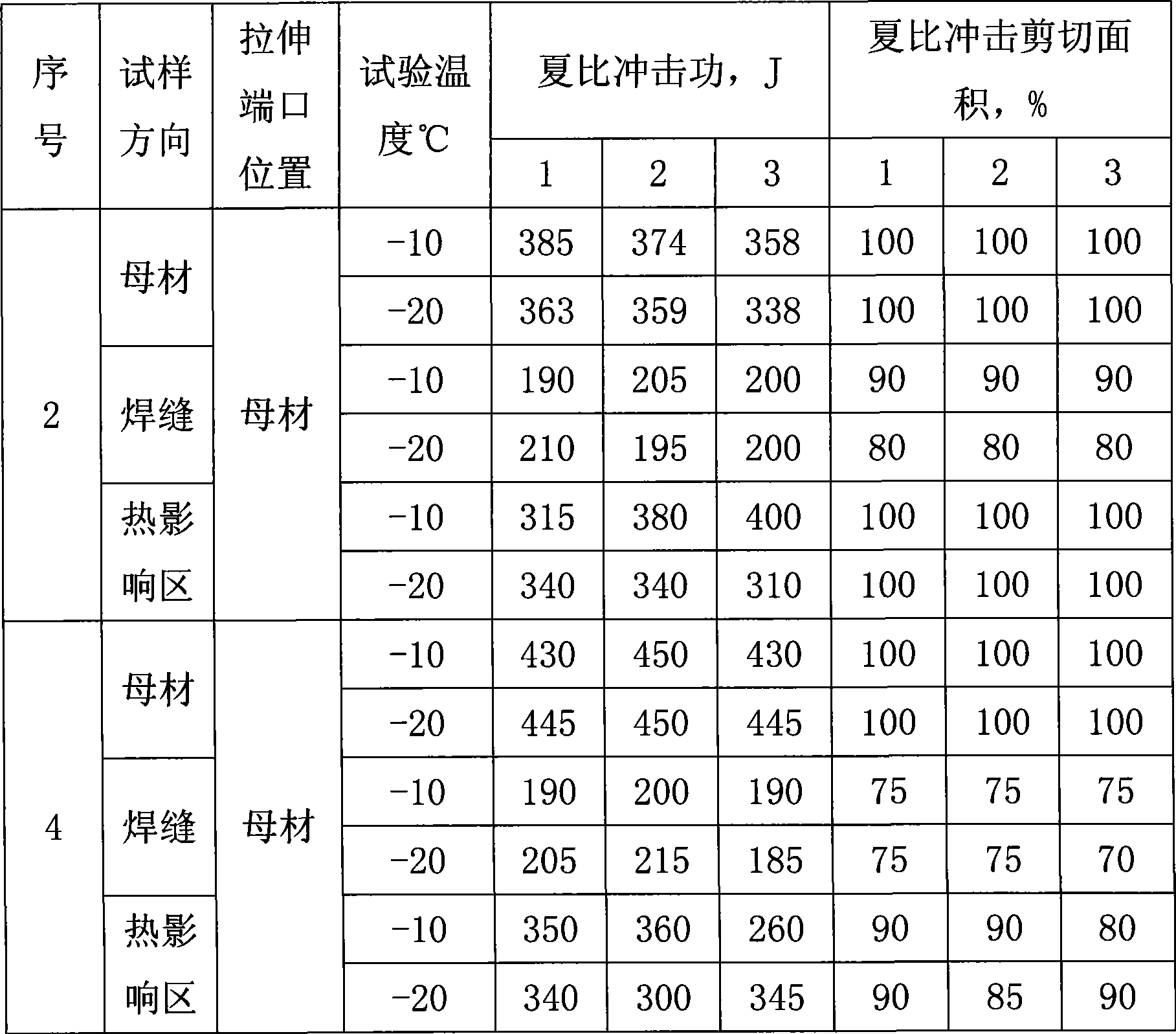

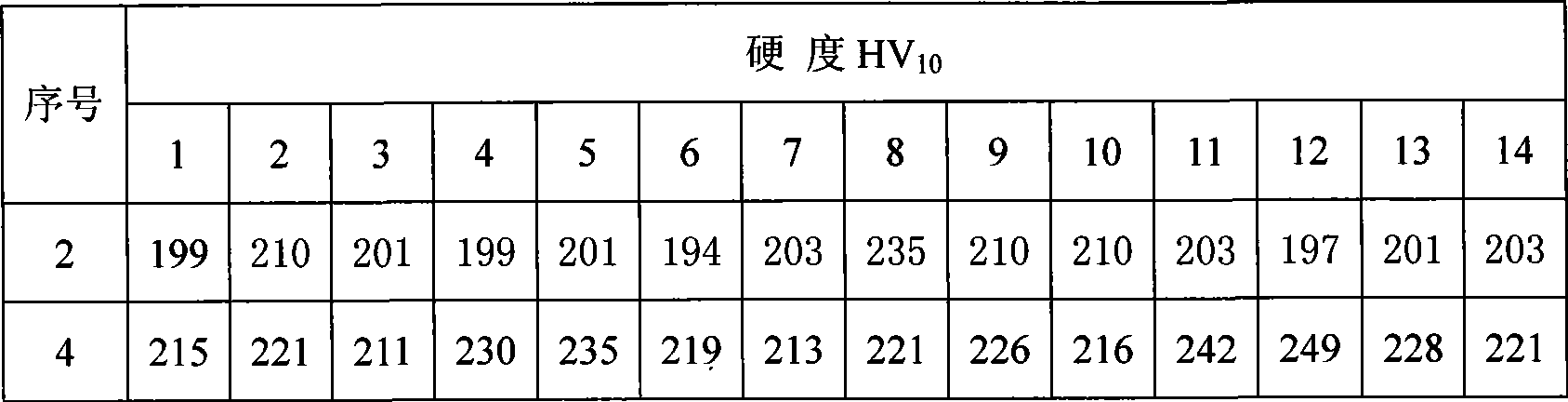

High intensity and high-toughness hot-rolled steel sheet and method for producing the same

ActiveCN101397626ALow costReduced Hot Brittle TendencyTemperature control deviceLiquid ironProduction control

The invention discloses a high strength and high toughness hot-rolled steel plate, the chemical components thereof and the weight percentages of the component are: 0.03 to 0.09 percent of C, 0.15 to 0.35 percent of Si, 1.40 to 2.0 percent of Mn, 0.02 to 0.05 percent of Al, 0.05 to 0.13 percent of Nb, 0.010 to 0.025 percent of Ti, being equal to or less than 0.30 percent of Cu, being equal to or less than 0.30 percent of Cr, being equal to or less than 0.012 percent of P, being equal to or less than 0.004 percent of S, being equal to or less than 0.004 percent of N and the rest are Fe; and Ceq can not be more than 0.44, crack sensitive index Pcm can not be more than 0.23, the production steps thereof are: liquid iron pre-desulphurization, bessemerizing, LF refining, RH(VD) processing, slab blank continuous casting, slab blank reheating, temperature controlling rolling, controlled cooling, hot straightening, cold bed cooling and cooling in heap; the advantages thereof are as follows: molybdenum can be omitted and nickel can be saved, thus reducing the cost; the steel plate has good weldability, high rolling efficiency and precise production control.

Owner:SHAGANG GROUP

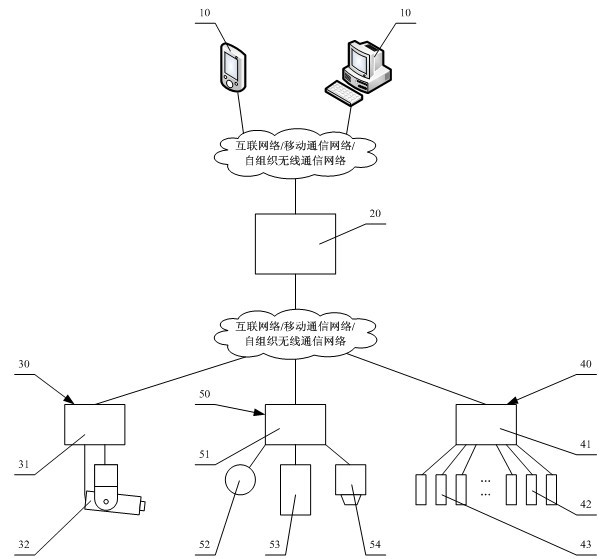

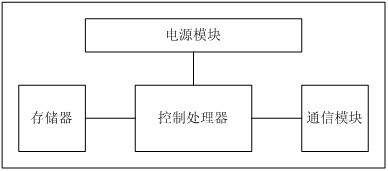

Remote automatic monitoring system for aquaculture and monitoring method thereof

InactiveCN101995875AReduce labor intensityReduce labor costsTotal factory controlProgramme total factory controlMonitoring systemWater quality

The invention provides a remote automatic monitoring system for aquaculture and a monitoring method thereof. The system is implemented by combining the conventional electronic products such as a water quality parameter sensor, an environmental parameter sensor, an aquaculture execution device and the like and a communication network; centralized setting and monitoring management are performed by adopting a monitoring device; a controller independently analyzes the monitoring data of the sensors according to the setting and controls the operating process of an executor according to the analysis result so as to improve the production management efficiency of the aquaculture and adapt the requirement of modern integrated management; the working personnel can monitor the actual condition of an aquaculture unit without going to the aquaculture site, and the system automatically gives an alarm in emergency, so the system is favorable for improving the management efficiency, saving the management cost and reducing the risk of the aquaculture; and the management of the aquaculture unit can be quantitatively set through the monitoring device so that the management is more digitalized and standardized, the system is favorable for unifying the management standards, and technical guarantee is provided for large-scale development of the aquaculture.

Owner:CHONGQING ACADEMY OF SCI & TECH

Environment-friendly type moldable aqueous transfer coating, preparation and use thereof

ActiveCN101407656AReduce contentReduce manufacturing costCoatings with pigmentsPolyurea/polyurethane coatingsSolvent basedPolyresin

The invention relates to an environment-friendly moldable waterborne transfer coating, a preparation method and an application thereof, wherein, the waterborne transfer coating takes the following components with the contents (parts by weight) as raw materials: 40 to 70 parts of waterborne resin; 10 to 20 parts of cosolvent; 18 to 40 parts of deionized water; 0.1 to 2 parts of pH value regulator; 0.1 to 0.5 part of wetting agent; 0.1 to 0.2 part of leveling agent; and 0.05 to 0.2 part of defoamer. Compared with the prior art, the environment-friendly moldable waterborne transfer coating has the following advantages of environmental protection and cost advantages, good printing adaptability, relatively wide range of suitable molding temperature during the molding, good molding effect and easy production control; furthermore, the environment-friendly moldable waterborne transfer coating can be directly used for replacing the existing solvent laser transfer coating by the pilot scale production confirmation.

Owner:SHANGHAI WEIKAI CHEM

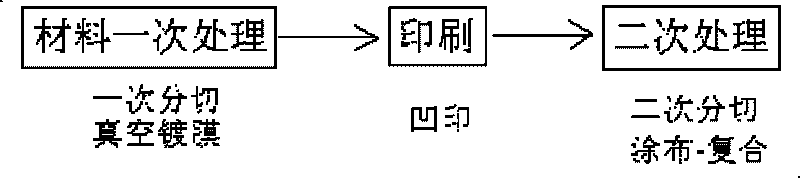

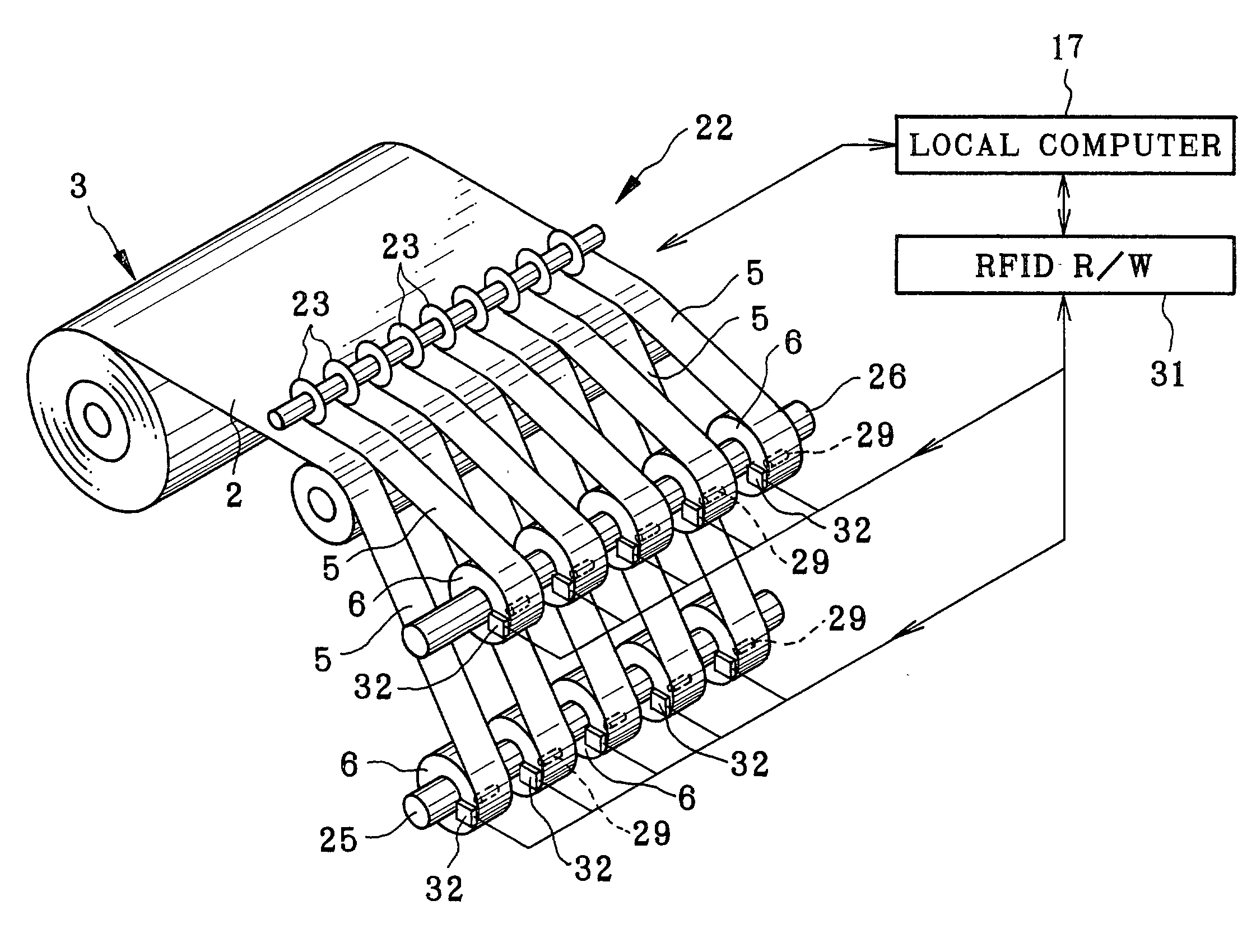

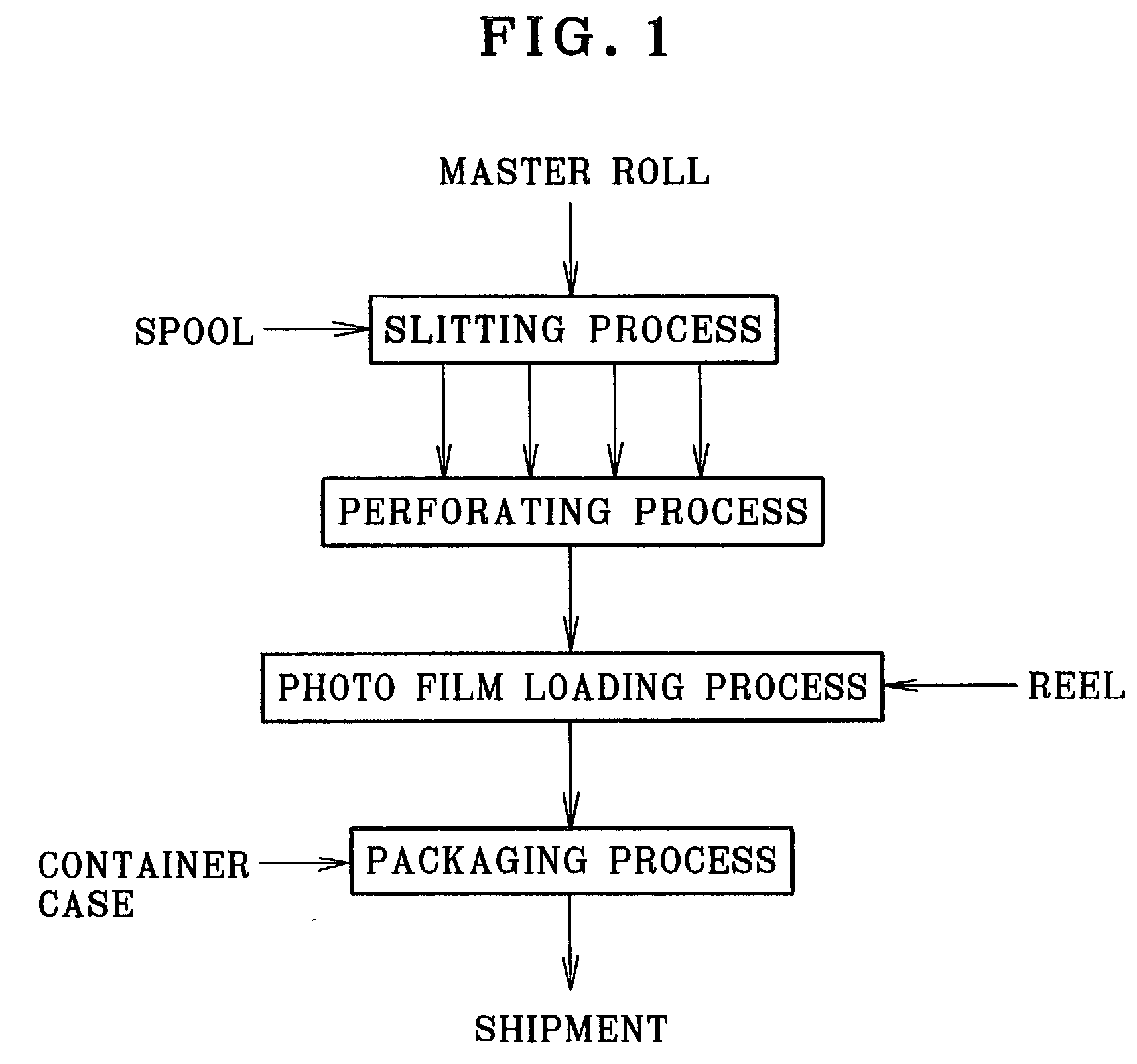

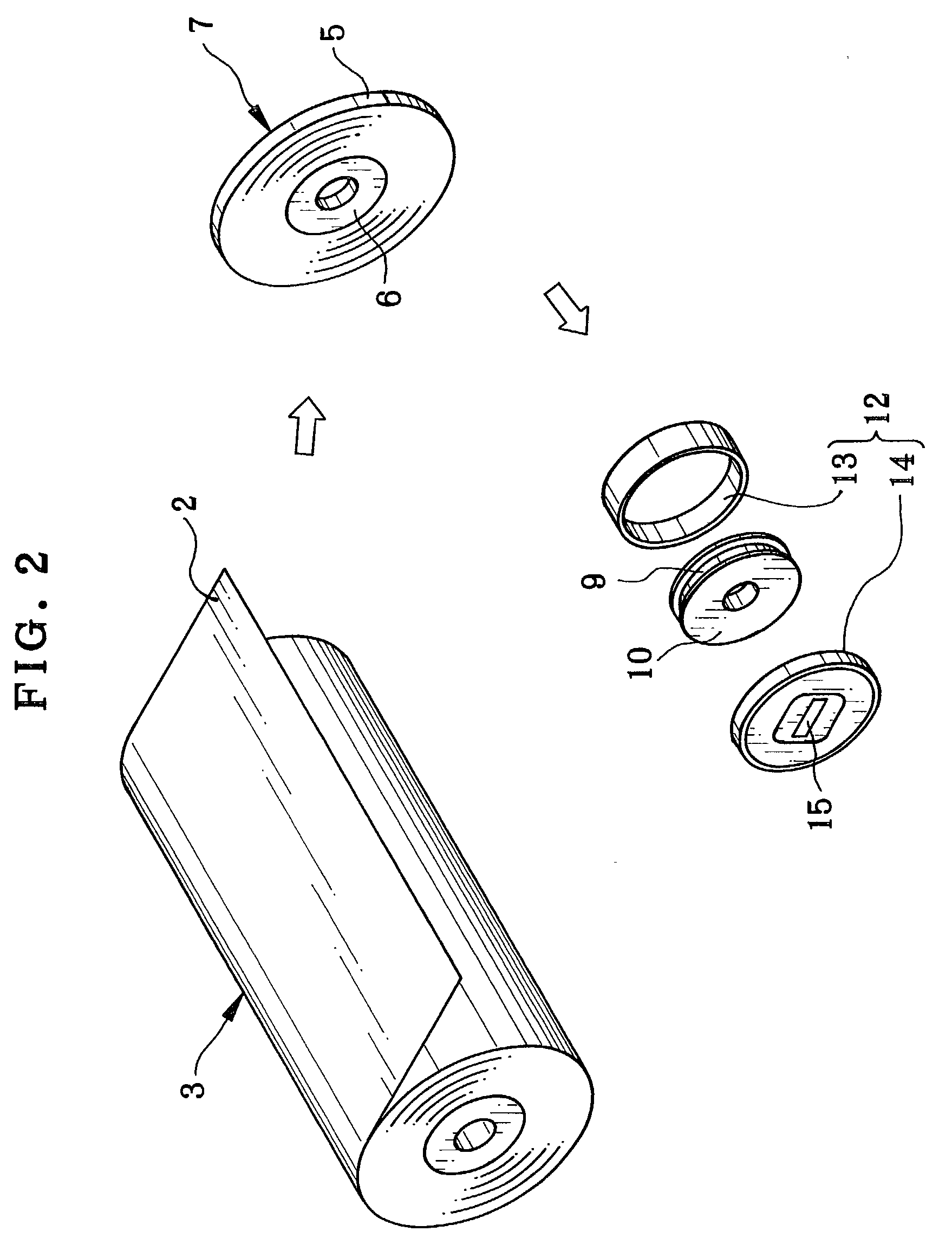

Production managing method for photo film production

InactiveUS20030025027A1Improve product qualityProne to defectPhotosensitive materialsMachines/enginesSheet filmEngineering

A production managing method for production of motion picture photo film is provided. At first, film web is slitted to produce continuous photo film having a predetermined width. Production managing information is written to an RFID (radio frequency identification) tag, and includes a roll number and slitting number, which are related to the film web and the continuous photo film. The continuous photo film is cut to produce motion picture photo film. The production managing information is stored in association with the motion picture photo film. The motion picture photo film is checked. If the motion picture photo film has a defect, the production managing information may be referred to for detecting a portion of the film web or the continuous photo film from which the defect derives. Other motion picture photo films with a defect will be traced.

Owner:FUJIFILM HLDG CORP +1

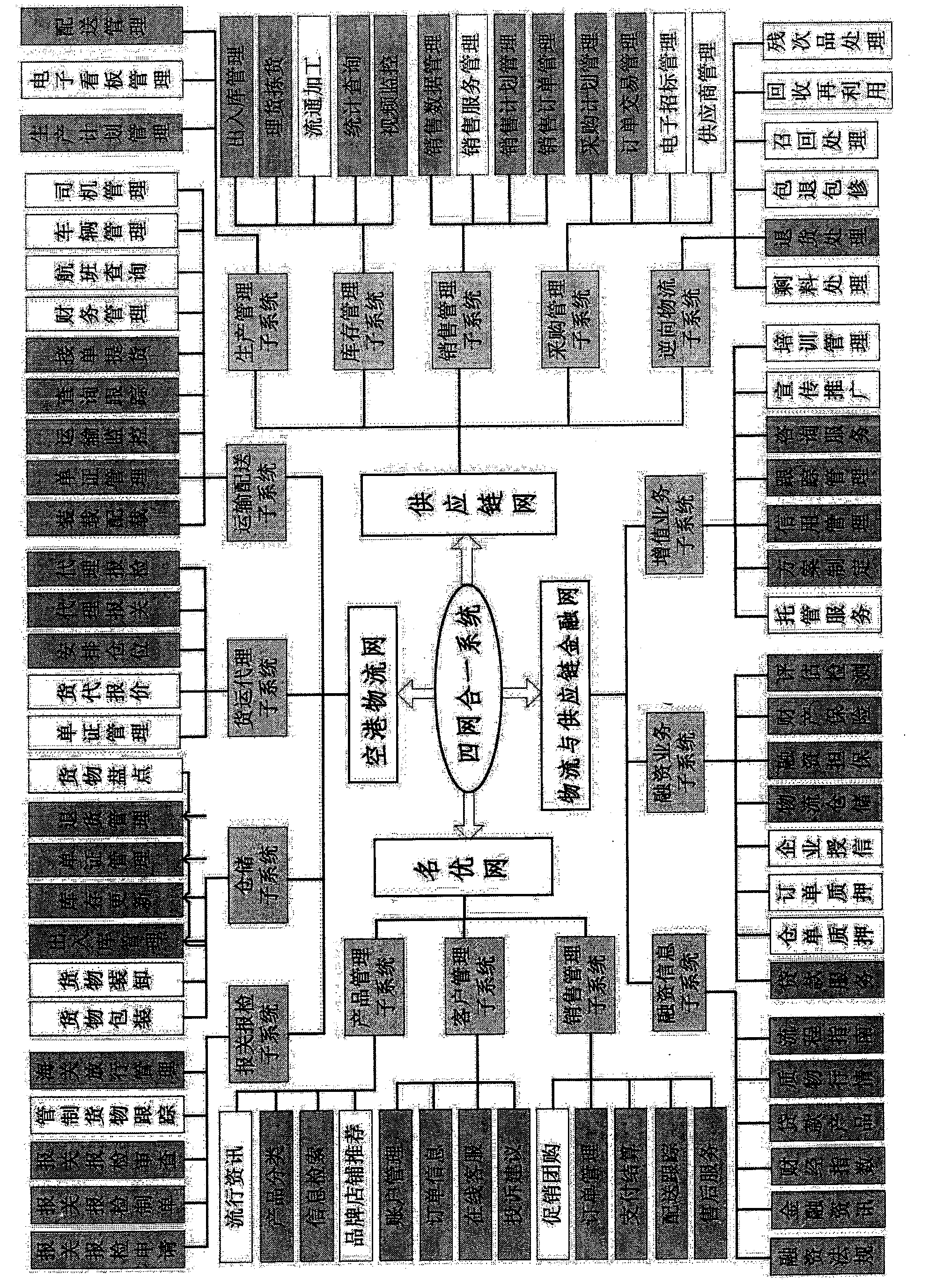

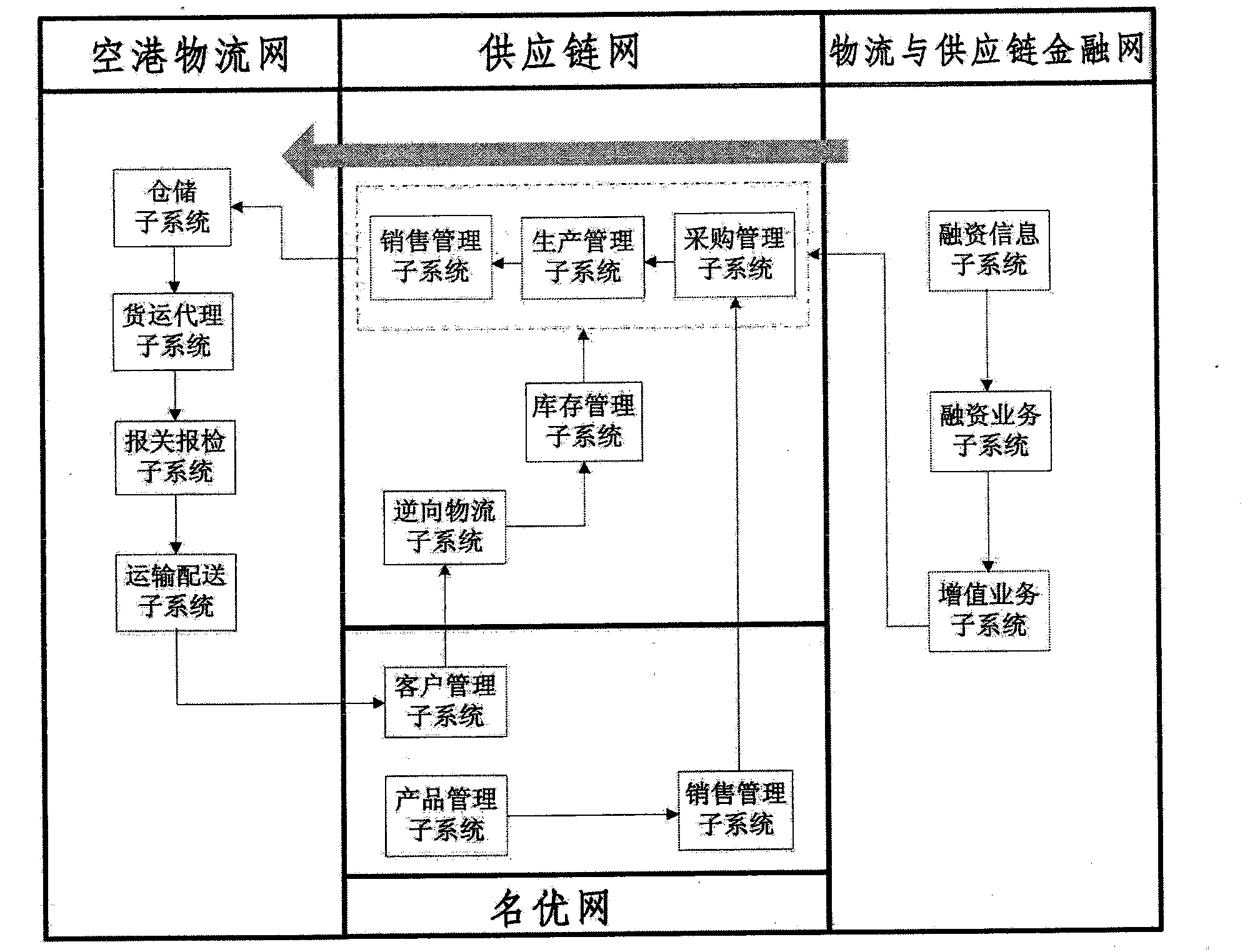

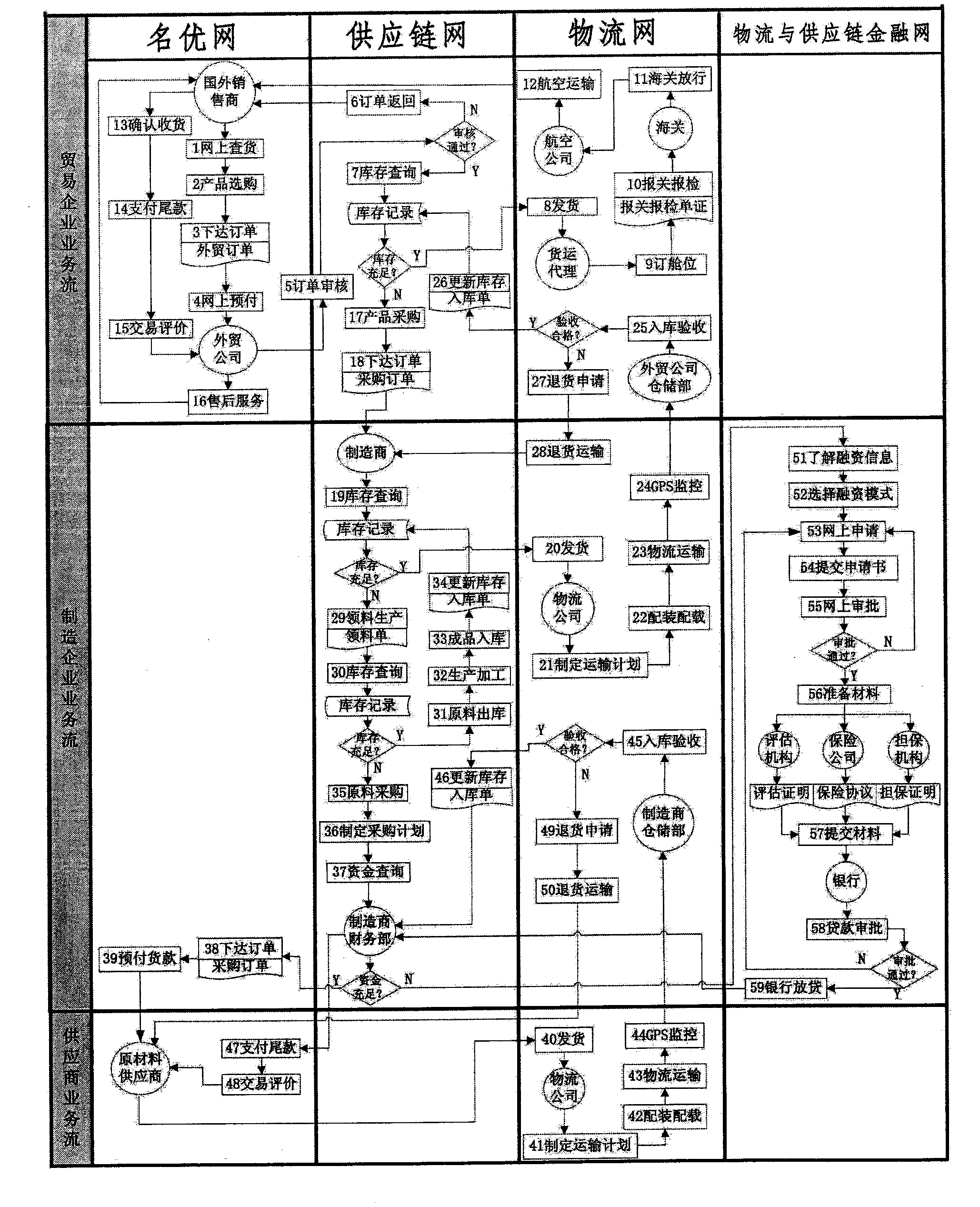

Quadruple net system and work method thereof

InactiveCN104077674AAchieve seamless connectionGood logistics serviceLogisticsInventory managementManufacturing enterprises

The invention provides a quadruple net system and a work method of the quadruple net system. Logistics, supply chains, electronic commerce and finance are integrated and jointly serve main bodies such as manufacturing enterprises and trade enterprises. The quadruple net system comprises four nets which are the airport logistics net, the supply chain net, the brand-name and high-quality net and the logistics and supply chain financial net. The airport logistics net, the supply chain net, the brand-name and high-quality net and the logistics and supply chain financial net have the unified standard specification and safety authentication and are interconnected through butt joint of platforms. The airport logistics net comprises a storage subsystem, a freight forwarder subsystem, a customs declaration and commodity inspection subsystem and a transport and distribution subsystem. The supply chain net comprises a purchasing management subsystem, a production management subsystem, a marketing management subsystem, an inventory management subsystem, a reverse logistics subsystem and a logistics park management subsystem. The brand-name and high-quality net comprises a product management subsystem, a client management subsystem and a marketing management subsystem. The logistics and supply chain financial net comprises a financing information subsystem, a financing service subsystem and a value added service subsystem.

Owner:桂寿平

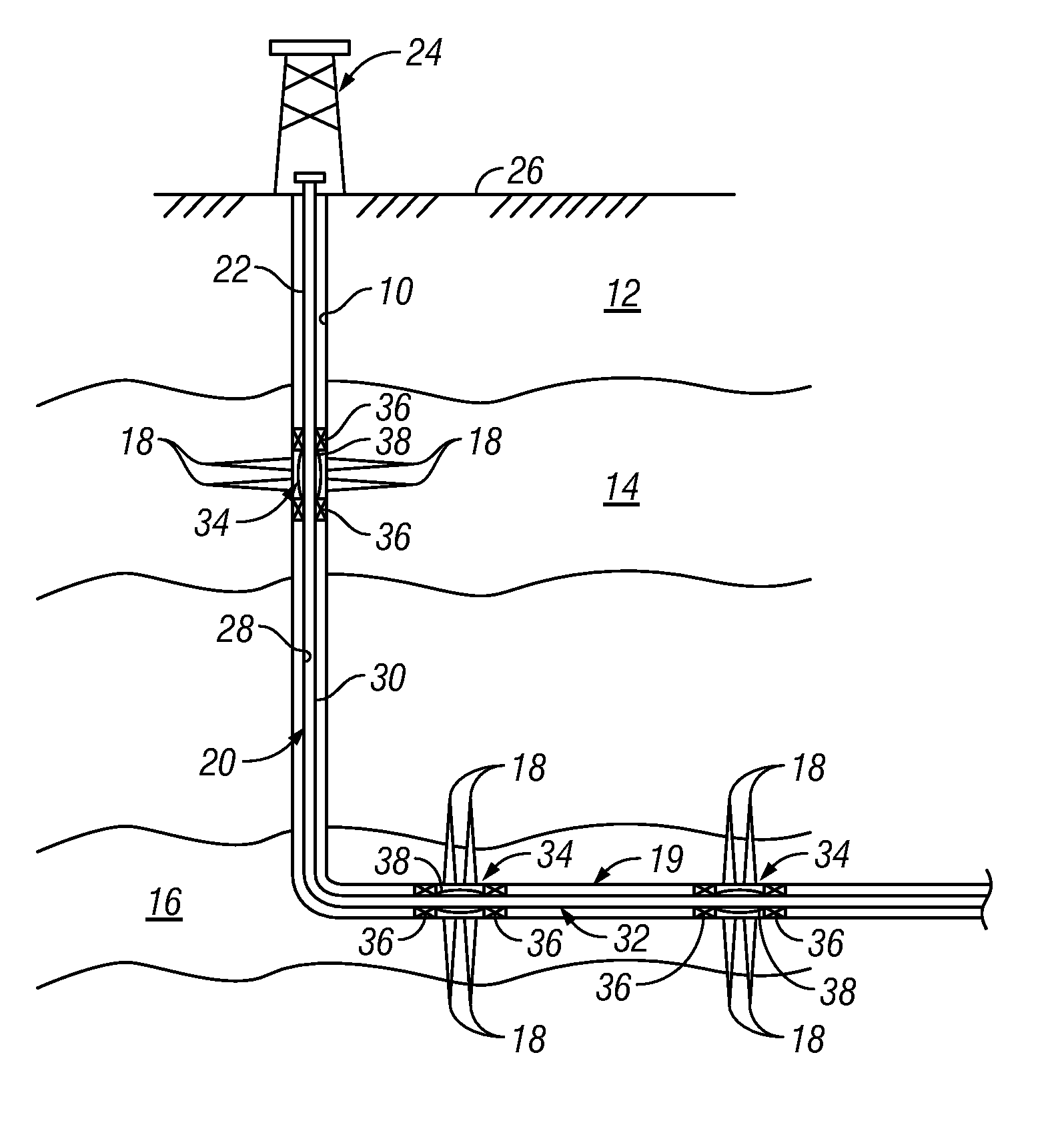

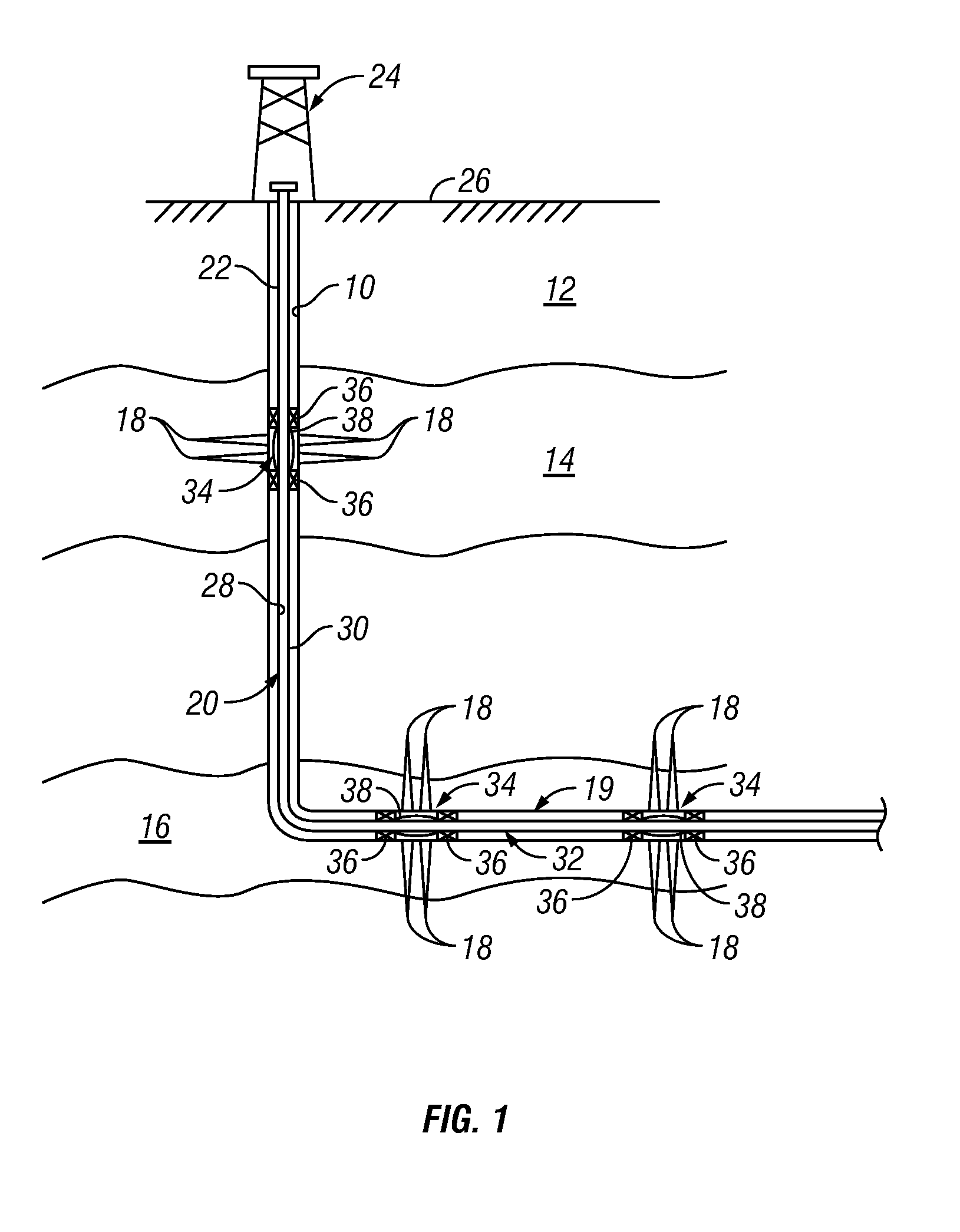

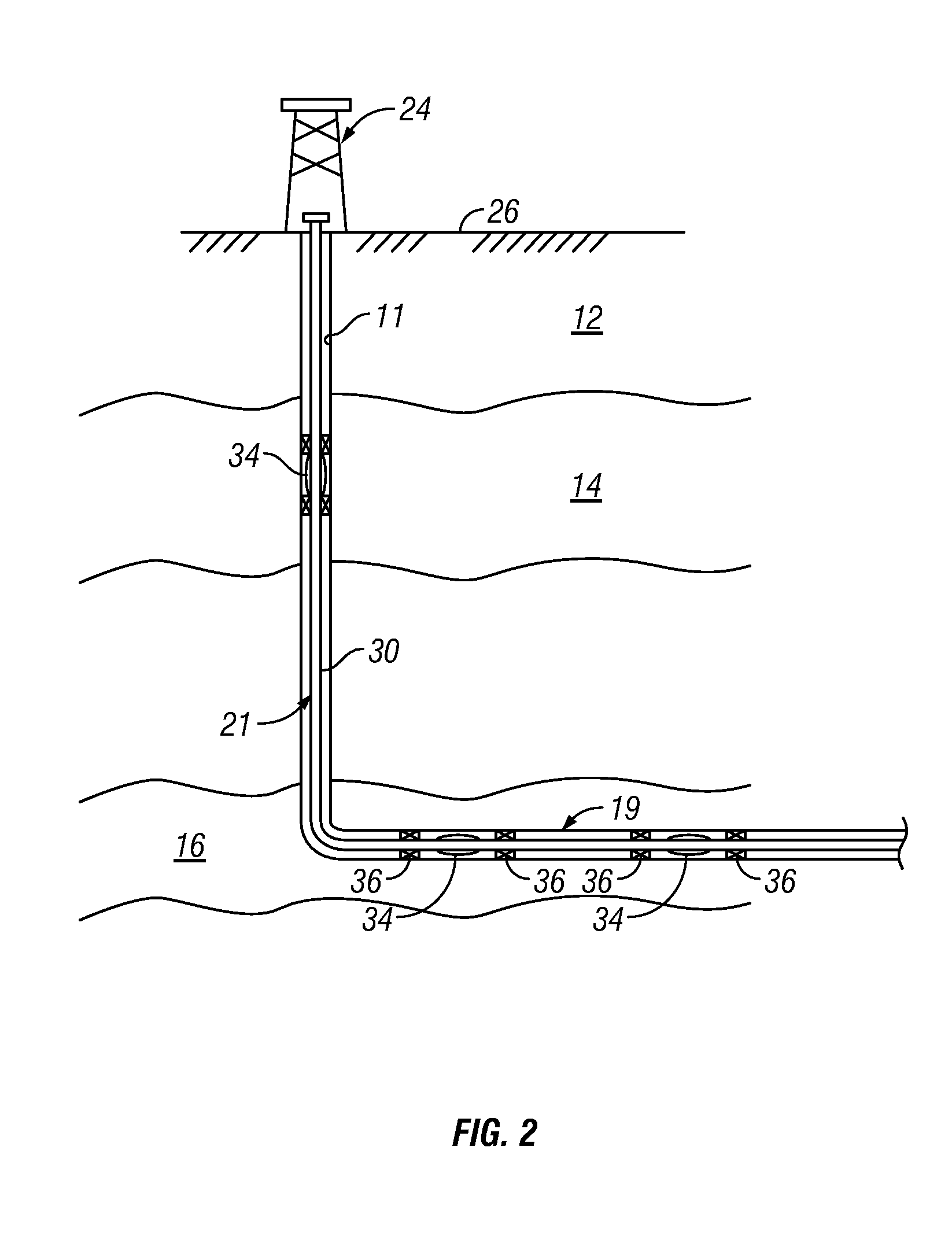

Flow Control Device Utilizing a Reactive Media

An apparatus for controlling a flow of a fluid into a wellbore tubular includes a flow path associated with a production control device; an occlusion member positioned along the flow path that selectively occludes the flow path, and a reactive media disposed along the flow path that change a pressure differential across at least a portion of the flow path by interacting with a selected fluid. The reactive media may be a water swellable material or an oil swellable material. The reactive media may be selected or formulated to change a parameter related to the flow path. Illustrative parameters include, but are not limited to, (i) permeability, (ii) tortuosity, (iii) turbulence, (iv) viscosity, and (v) cross-sectional flow area.

Owner:BAKER HUGHES INC

aps/mes lean manufacturing management system

InactiveCN102262757AImprove reaction speedImprove reaction efficiencyInstrumentsSoftware systemHand held

APS / MES lean manufacturing management system, including system hardware and system software, the software in the hardware is integrated in the main system software, and is seamlessly connected with the main system; the system hardware includes: industrial touch all-in-one machine connected to the host server and LED electronic kanban and The RFID card reader used to read the RFID card, the wireless receiving and transmitting device is connected with the host server, the handheld terminal and the terminal touch screen through the sensor, and the host server is also connected with the host of the logistics distribution center and the host of the delivery center; the system software includes: Supply chain management, sales management, procurement management, warehouse management, subcontract processing, production order, process route, workshop scheduling plan, handheld terminal module, terminal touch screen, material distribution, LED electronic kanban control system software module; system software The management module is divided into: basic data module, supply chain management module, equipment management module, production management module, and handheld terminal module; each module is composed of its corresponding sub-modules.

Owner:王圣亮

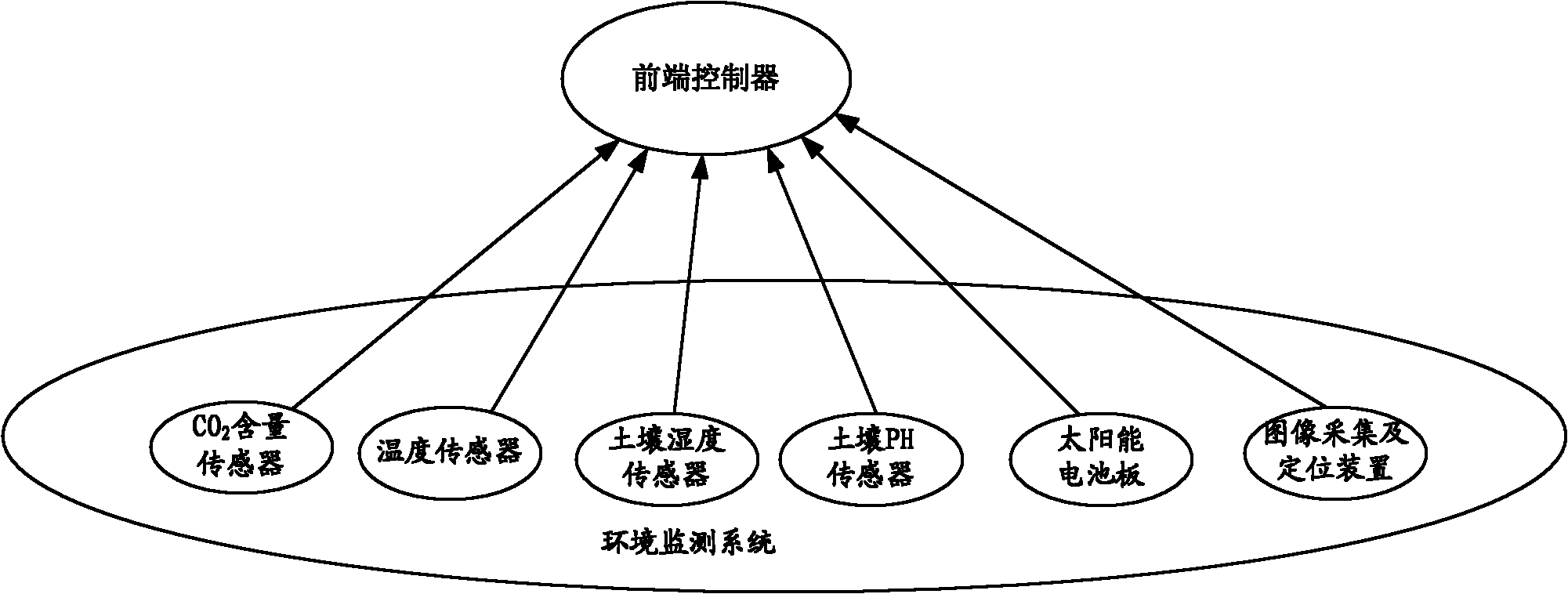

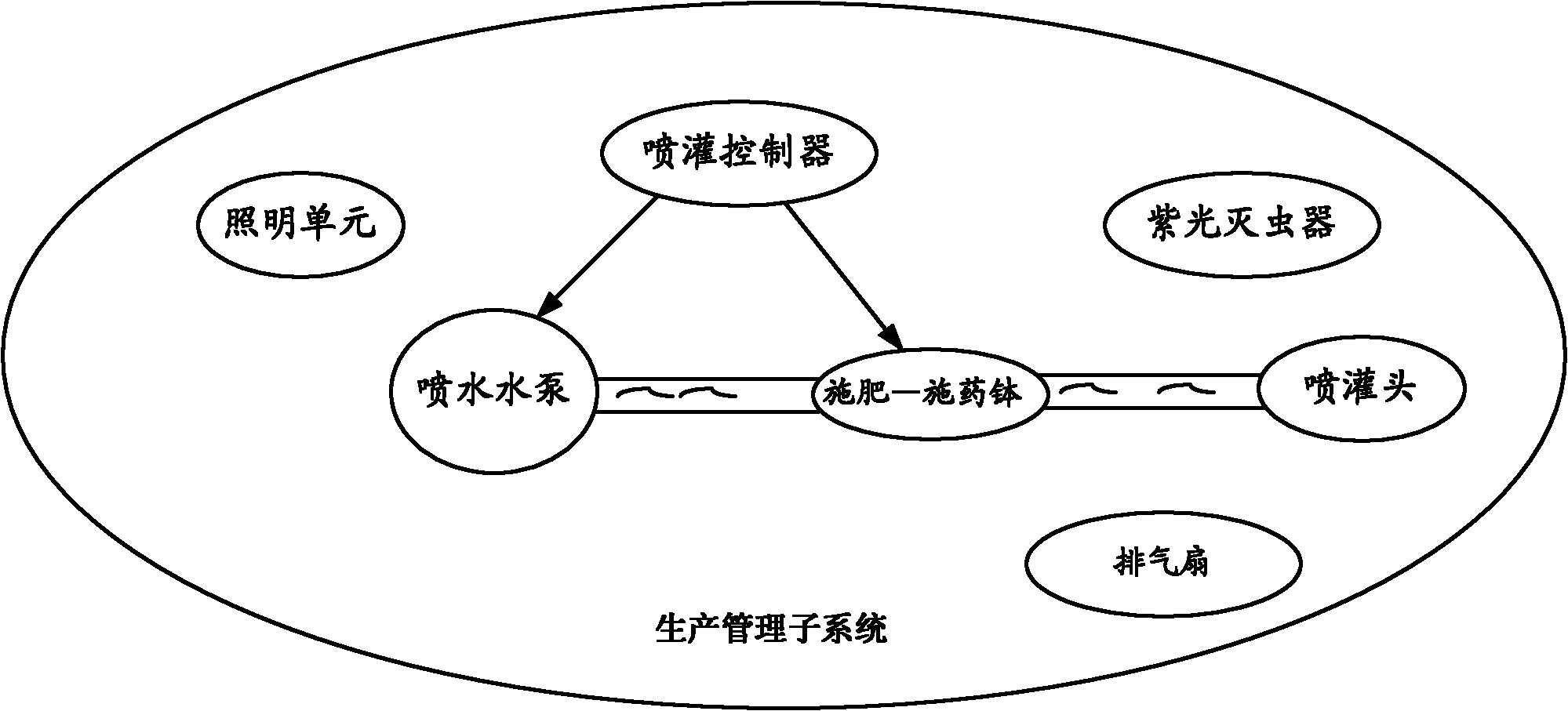

Comprehensive plant production management system and method

InactiveCN102156923ARealize fully automatic collection and monitoringThe growth environment is clearly understoodData processing applicationsWatering devicesMonitoring systemEngineering

The invention discloses a comprehensive plant production management system and an implementation method thereof. The comprehensive plant production management system comprises an environment monitoring system, a front controller and a background management center, wherein the environment monitoring system acquires growth environment parameters and growth status parameters of plants in a production field; the front controller uploads the growth environment parameters and the growth status parameters to the background management center, and controls a production management subsystem to execute corresponding production management operations according to control instructions sent by the background management center; and the background management center receives the growth environment parameters and the growth status parameters uploaded by the front controller, and sends the control instructions to the front controller. In the system, as the growth environment parameters and the growth status parameters of the plants in the field are acquired, and are uploaded to the background management center through a network, the background management center can automatically analyze the growth environment parameters and the growth status parameters, or sends the control instructions to the front controller through a human-machine interaction means to control the production management subsystem to perform corresponding production management operations on the plants according to the control instructions, therefore the probability of needing a person to visit the production field is reduced, and the production efficiency is improved.

Owner:华建武 +1

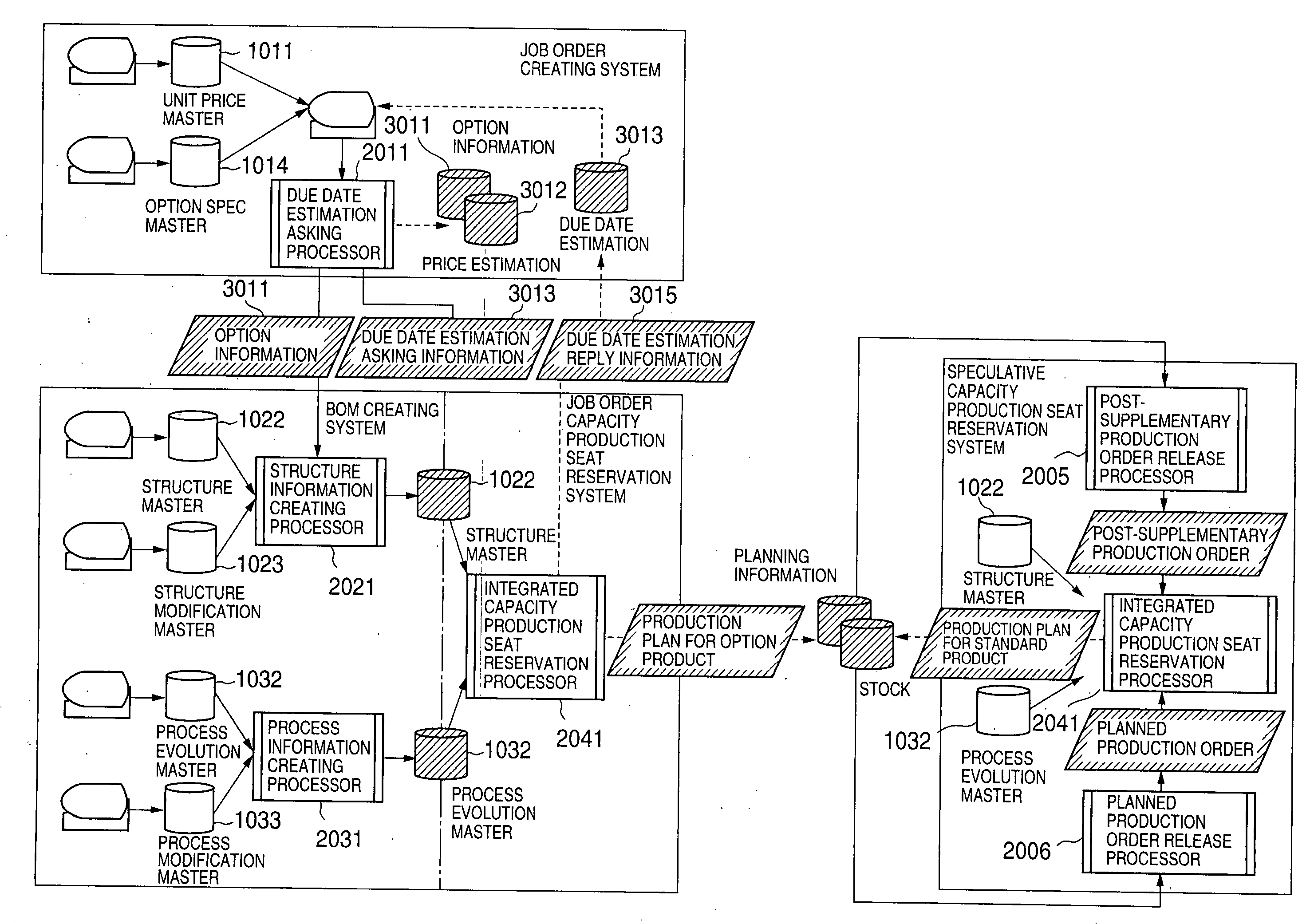

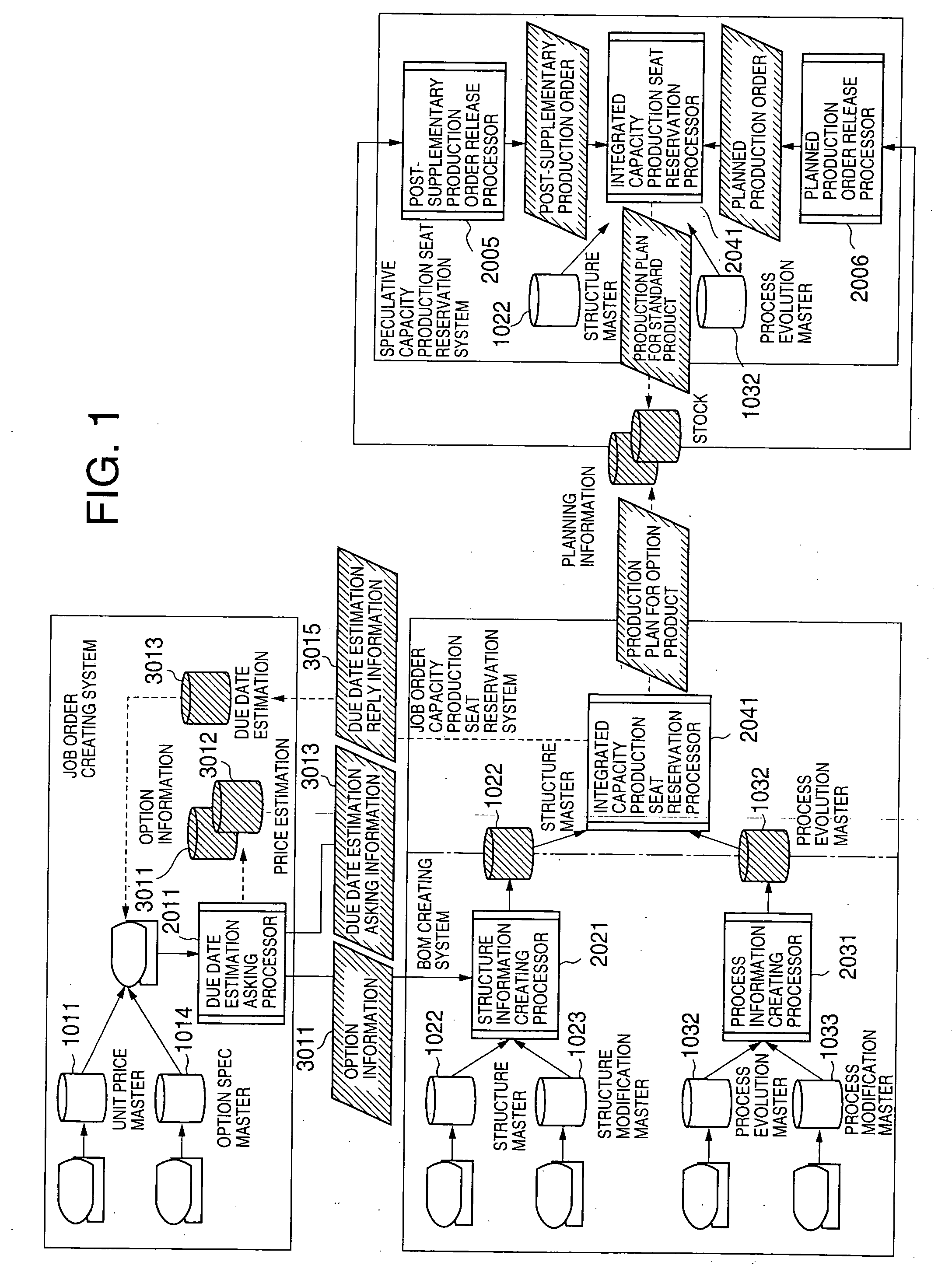

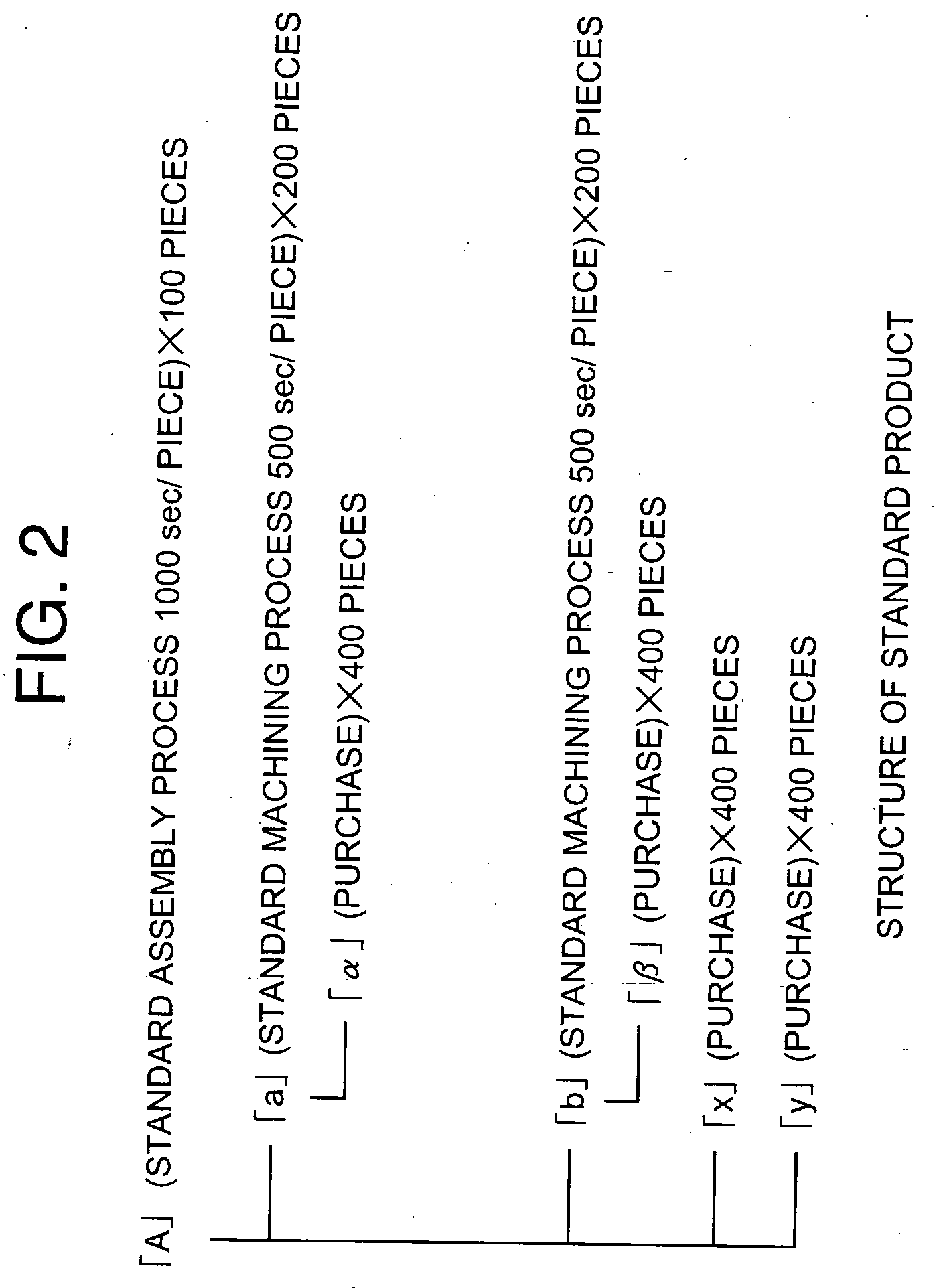

Production management system production management method

InactiveUS20040210467A1Buying/selling/leasing transactionsResourcesProgram planningProcess information

Here is disclosed a system and a method for production management. In response to a job order created by a job order creating system, which indicates option to be applied to parts and processes associated with a standard specification product, a structure information creating processor creates, with reference to a structure modification master recording option applicable to the parts, a second structure master by applying the parts of an option specification product to a first structure master while a process information creating processor creates, with reference to a process modification master recording the option applicable to the process, a second process evolution master by applying processes for the option specification product to a first process evolution master. Then a capacity production seat reservation processor applies the parts of the option specification product and processes for the option specification product to a production planning for the standard specification product in order to create a production planning for the option specification product and stores the production planning for the option specification product created in this manner.

Owner:YOKOYAMA HIROSHI

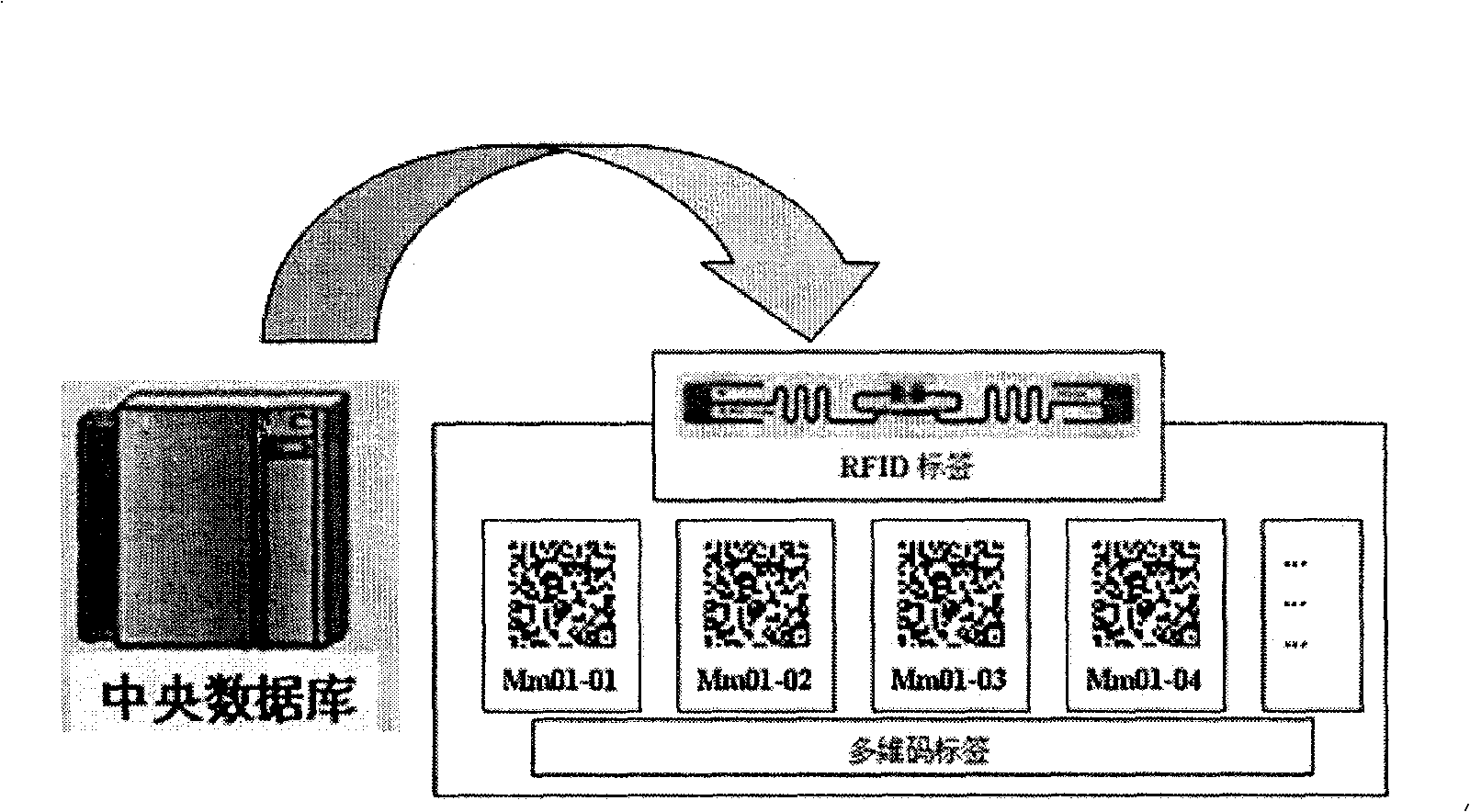

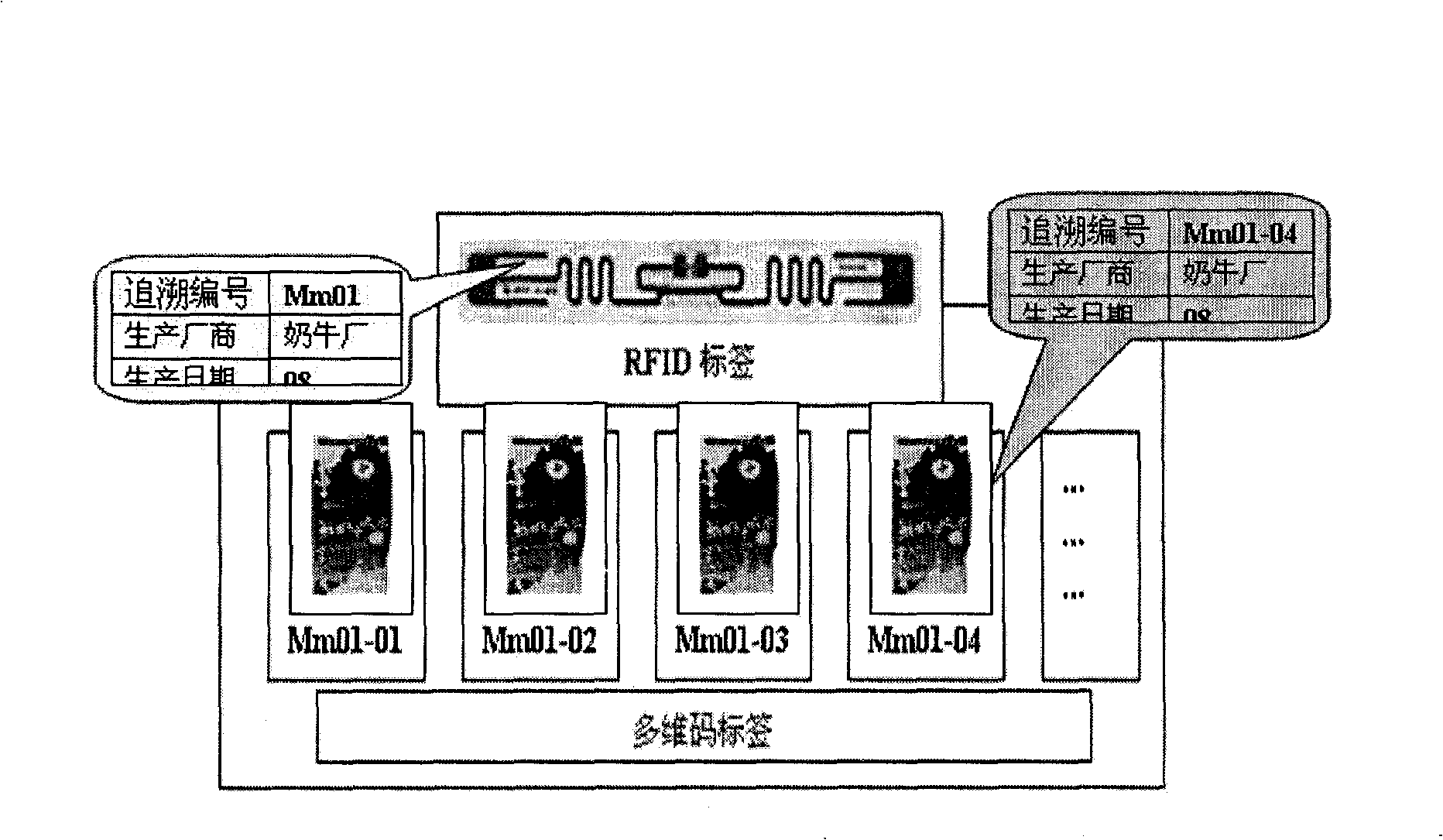

Article anti-counterfeiting system combining radio frequency identification and two-dimension code

InactiveCN101515352AIncrease active participationCompress living spaceCo-operative working arrangementsCommerceLogistics managementConfidentiality

The invention discloses an article anti-counterfeiting system combining radio frequency identification and two-dimension code, which consists of a center database, a radio-frequency identification label, and a two-dimension code icon, wherein the center database consists of a production management module, a logistics and storage module, a sales module, and a consumption query module; the radio-frequency identification label is stuck to an outer packing of a product, and information in a chip of the radio-frequency identification label is related to product information of the two-dimension code icon; the two-dimension code icon is stuck to a single product or an inner packing in the outer packing; and a user compares the information stored in the radio-frequency identification label with the center database to realize identification and tracing of the outer packing, and compares the product information of the two-dimension code icon with the center database through a verification terminal to realize verification of the single product or the inner packing. The article anti-counterfeiting system has the advantages of physical uniqueness, non-contact information identification, high confidentiality, strong tracing property, good fouling resistance, low price, simple implementation and the like.

Owner:段建国

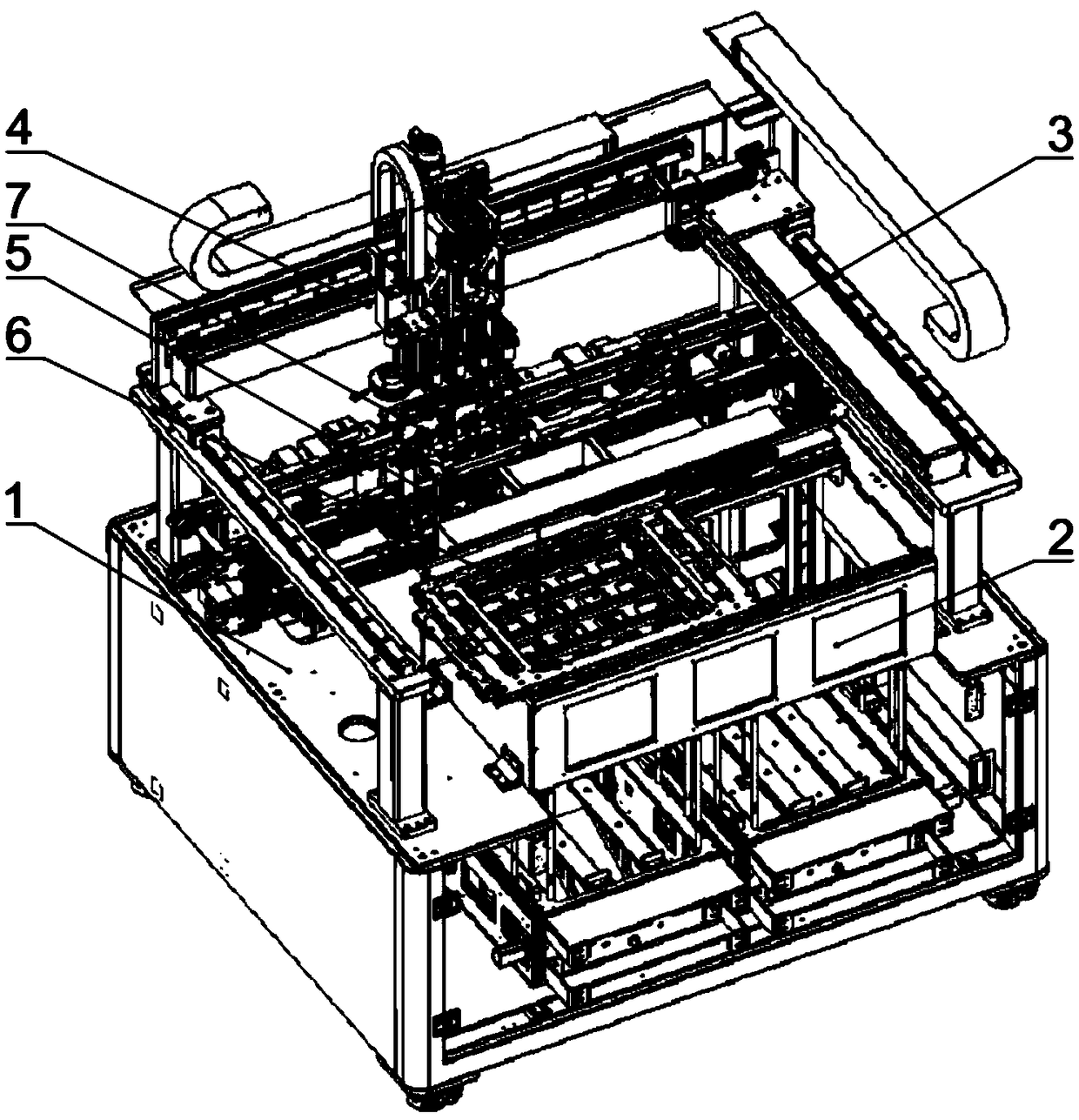

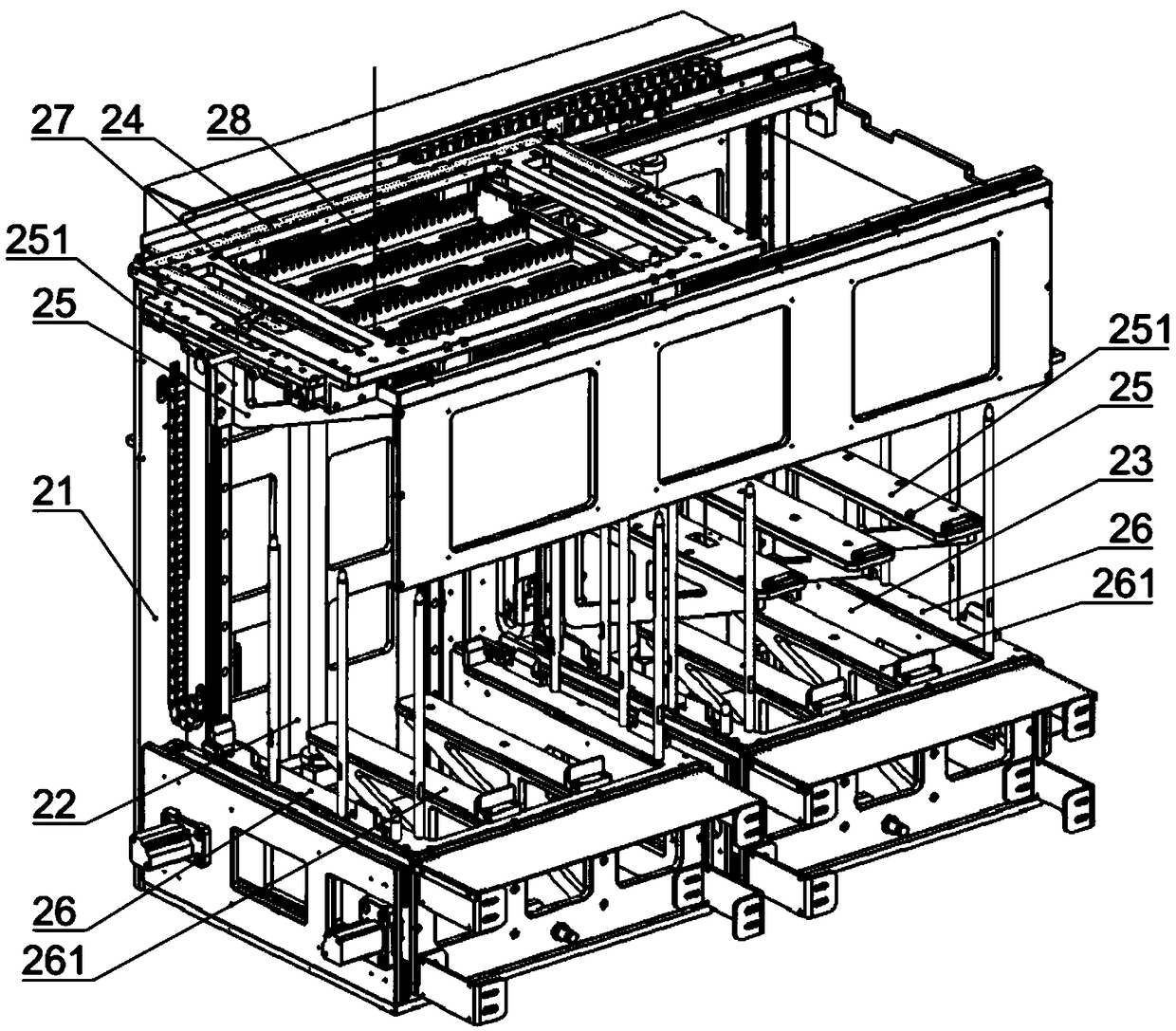

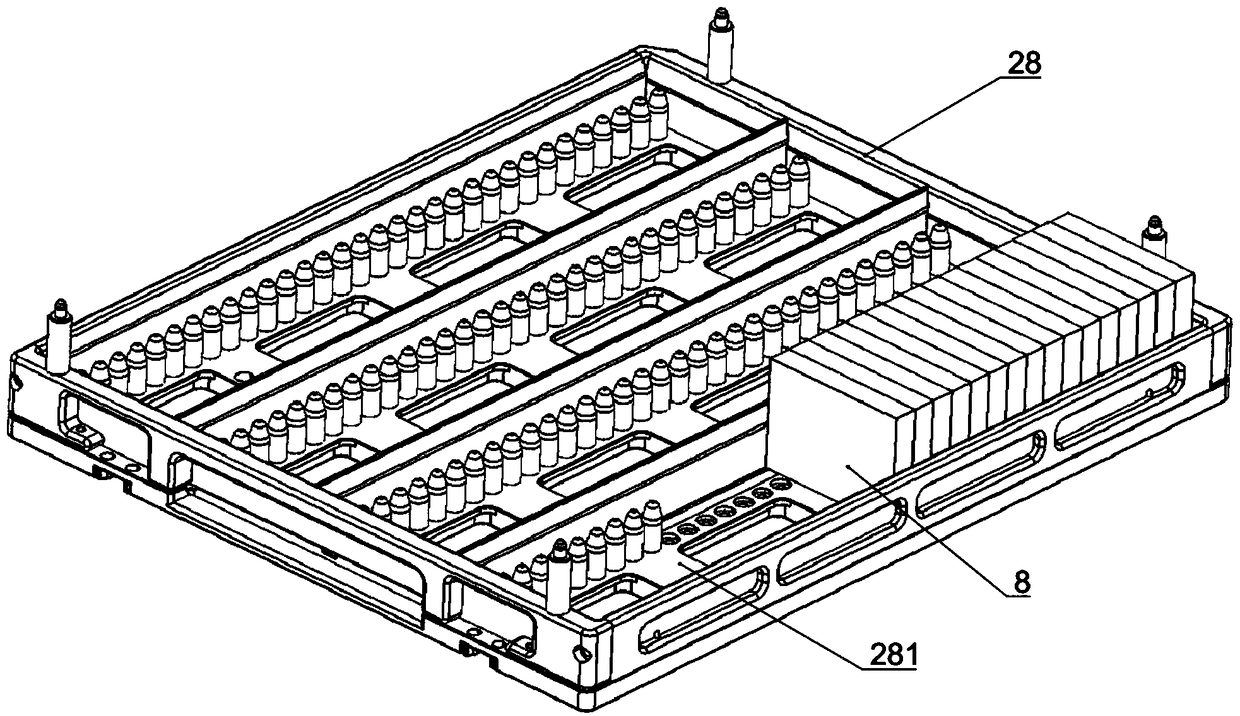

Workpiece feeding device and method

PendingCN109132526AAchieve continuous supplyRealize the loading function of magazine typeConveyorsControl devices for conveyorsEngineeringMechanical engineering

The invention provides a workpiece feeding device. The workpiece feeding device comprises a working platform, a supplying mechanism, a conveying line mechanism, a workpiece carrying mechanism and a screening mechanism, wherein a supplying position is arranged on the supplying mechanism; a mounting position is arranged on the conveying line mechanism. According to the device, the workpiece carryingmechanism is capable of clamping a workpiece from the supplying position; the workpiece subjected to detecting and screening of the screening mechanism moves and then is mounted to a target carrier at the mounting position; the supplying mechanism and the workpiece carrying mechanism realize automatic workpiece supplying and feeding and mounting; the workpiece can be detected through the screening mechanism in the carrying process, so that the qualification rate of the workpiece is ensured; the workpiece is carried through the conveying line mechanism utilizing the carrier, and thus the flow-line type processing work is realized. The invention also provides a workpiece feeding method. With the adoption of the device and the method, the workpiece is automatically fed and detected, and thusthe convenience of production management is ensured.

Owner:SUZHOU RS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com