Visual production management and control method for discrete workshop

A control method and production management technology, applied in the field of visual production management and control, can solve the problems of poor real-time performance, error-prone data, and large workload, and achieve the effect of improving the level of workshop management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

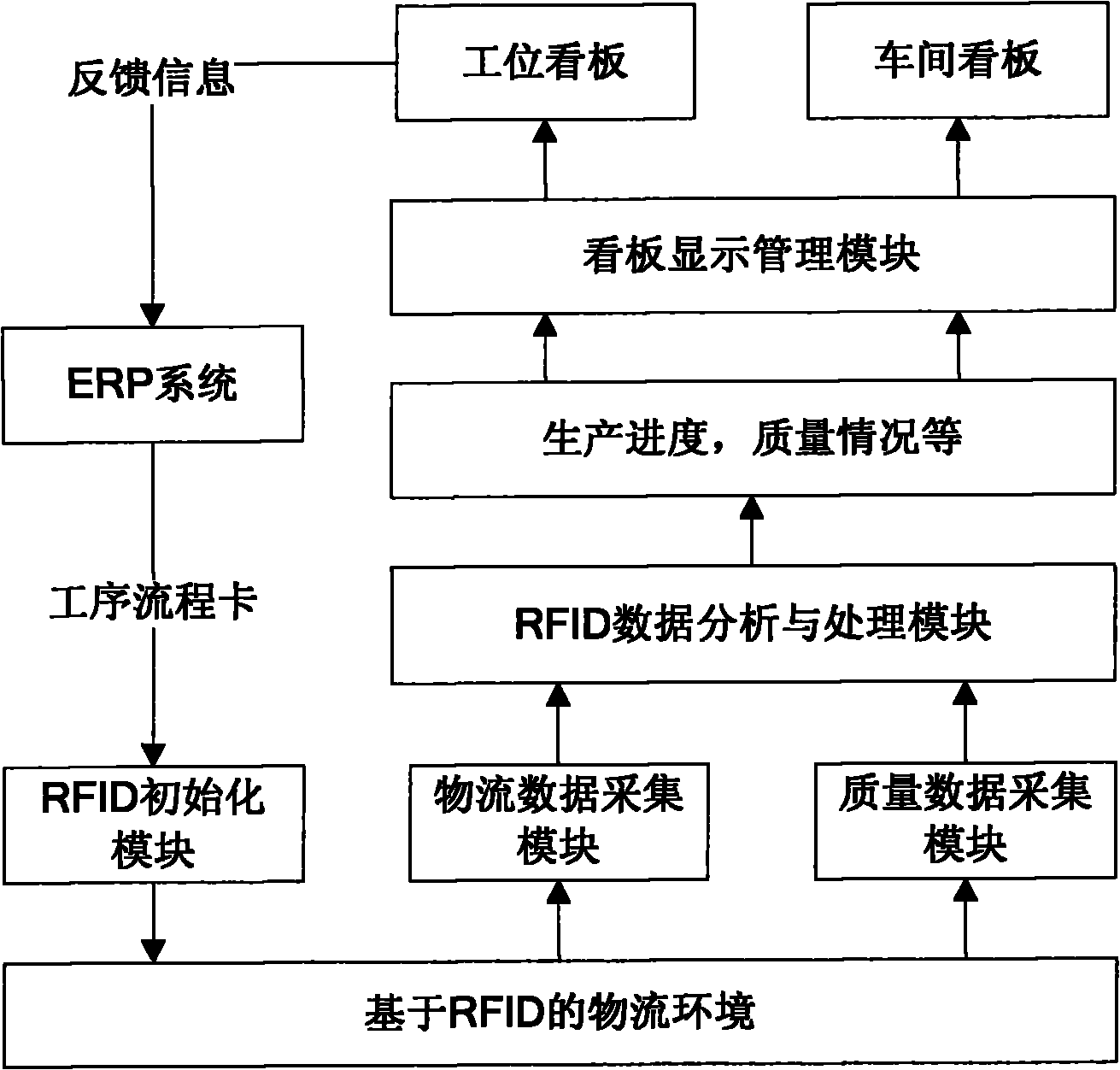

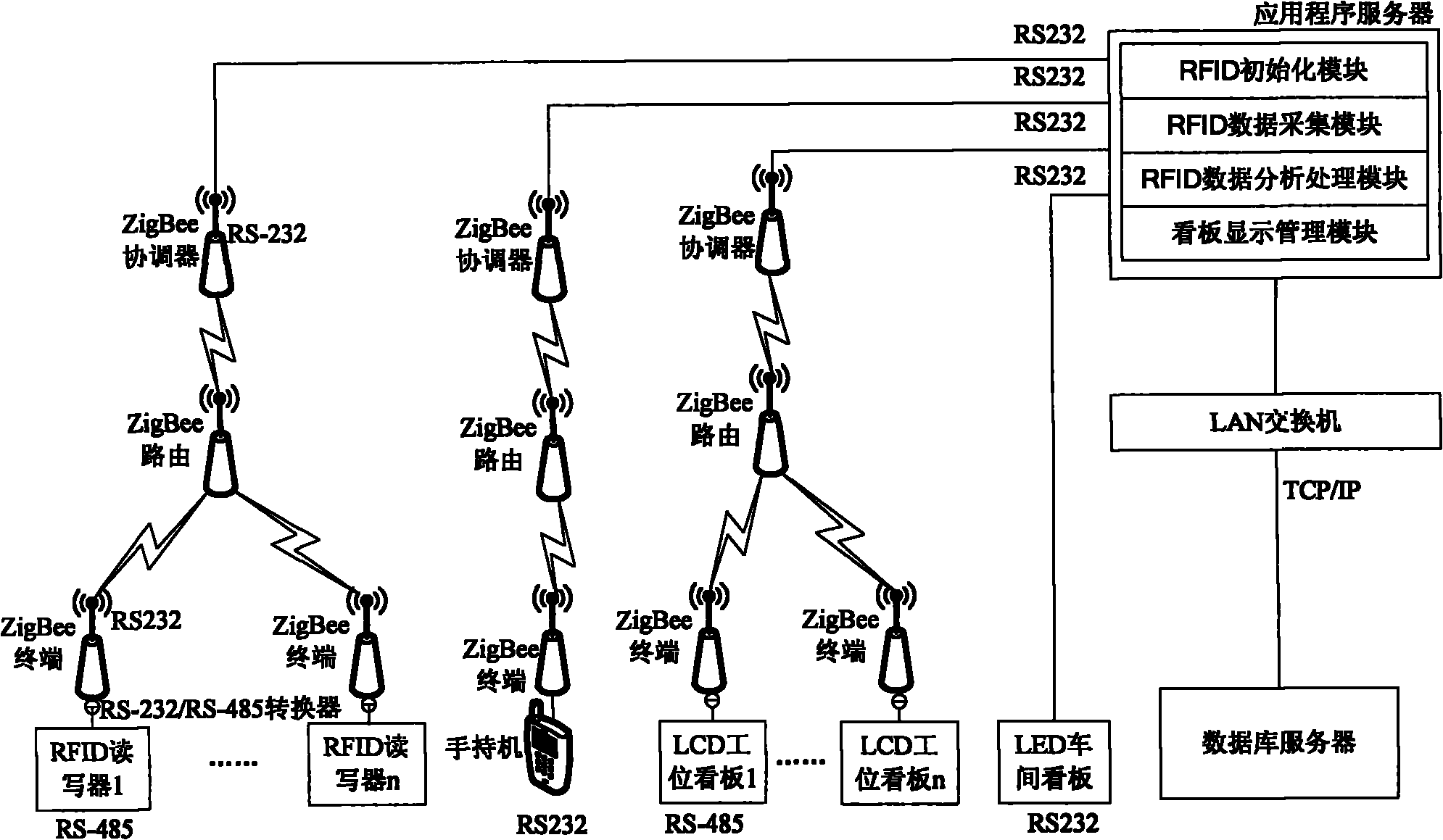

[0030] like figure 1 As shown, the system adopted by the present invention includes an RFID initialization module, an RFID-based data acquisition module, an RFID data analysis and processing module, and a Kanban display management module.

[0031] 1. The RFID initialization module includes the RFID tag initialization module and the RFID reader initialization module. The RFID tag initialization module establishes the relationship between the unique number UID of the RFID tag and the process flow card number; the RFID reader initialization module establishes the RFID reader The relationship between the address, the station number and the process number binds the RFID reader to the station and the process. The process flow card is obtained from the interface of the ERP system, including the process flow card number, process name, material code, customer, planned start time, planned end time, etc. The data that establishes the association relationship is stored in the data server...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com