Patents

Literature

143 results about "Discrete manufacturing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Discrete manufacturing is the production of distinct items. Automobiles, furniture, toys, smartphones, and airplanes are examples of discrete manufacturing products. The resulting products are easily identifiable and differ greatly from process manufacturing where the products are undifferentiated, for example oil, natural gas and salt.

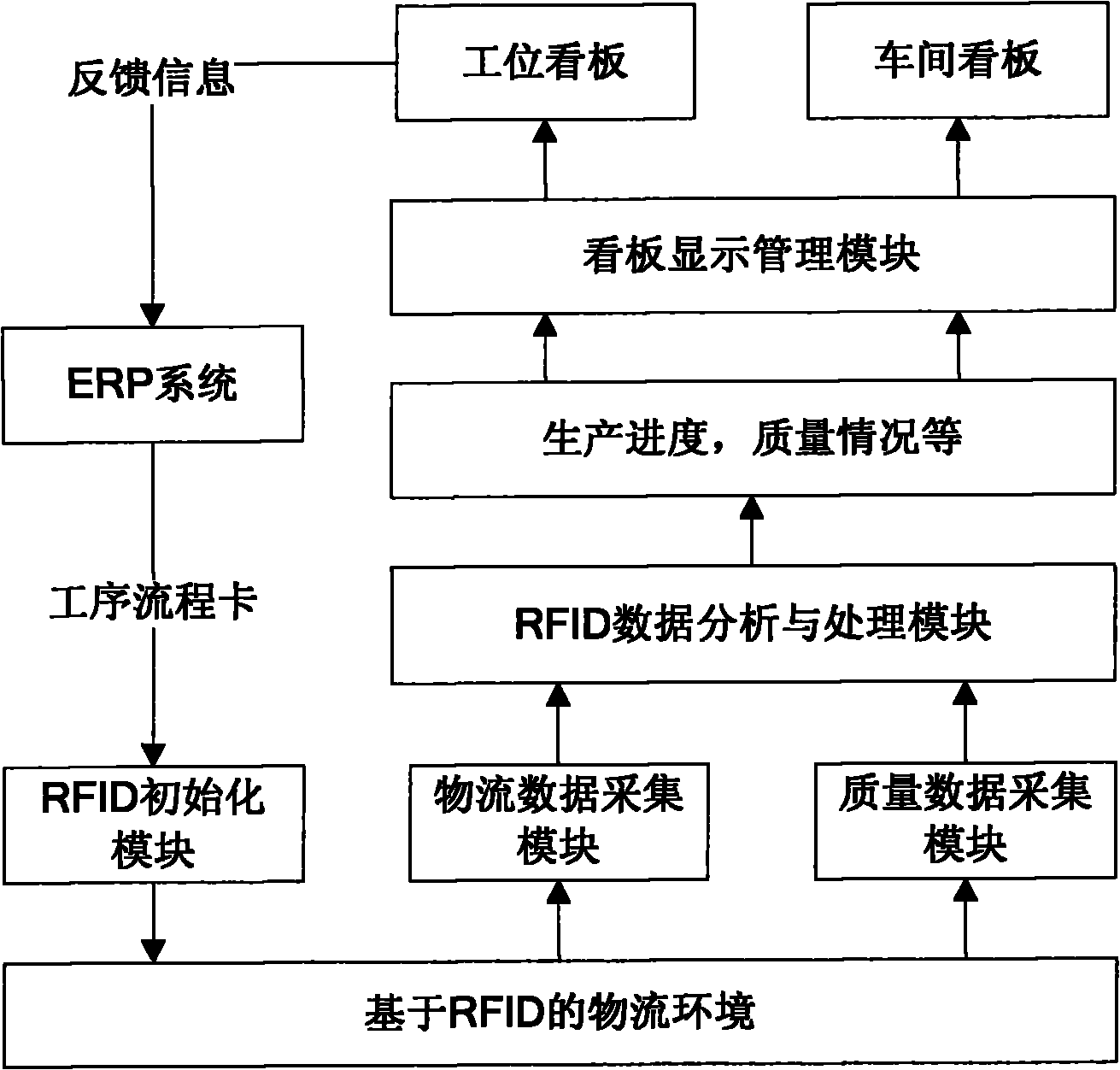

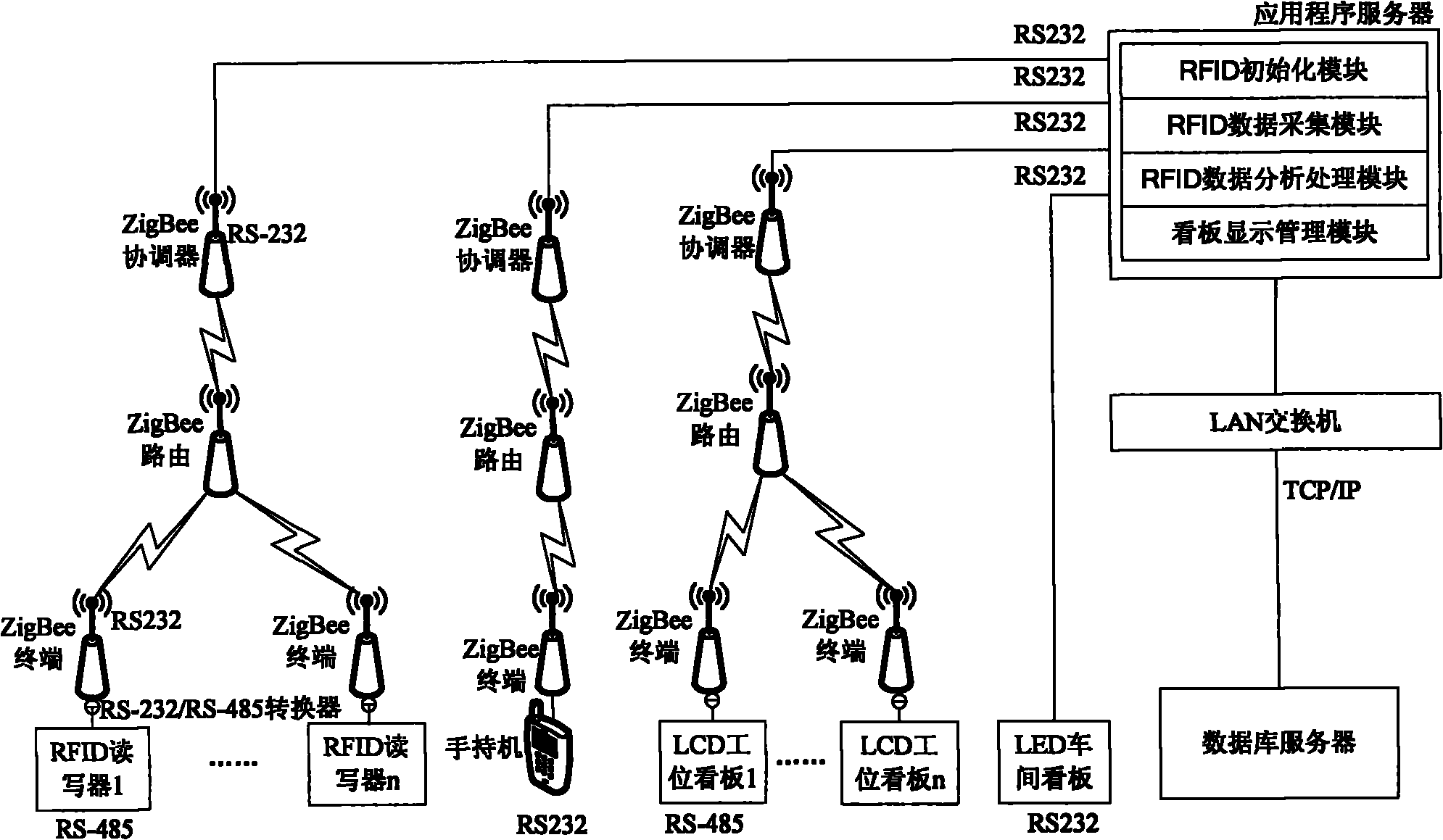

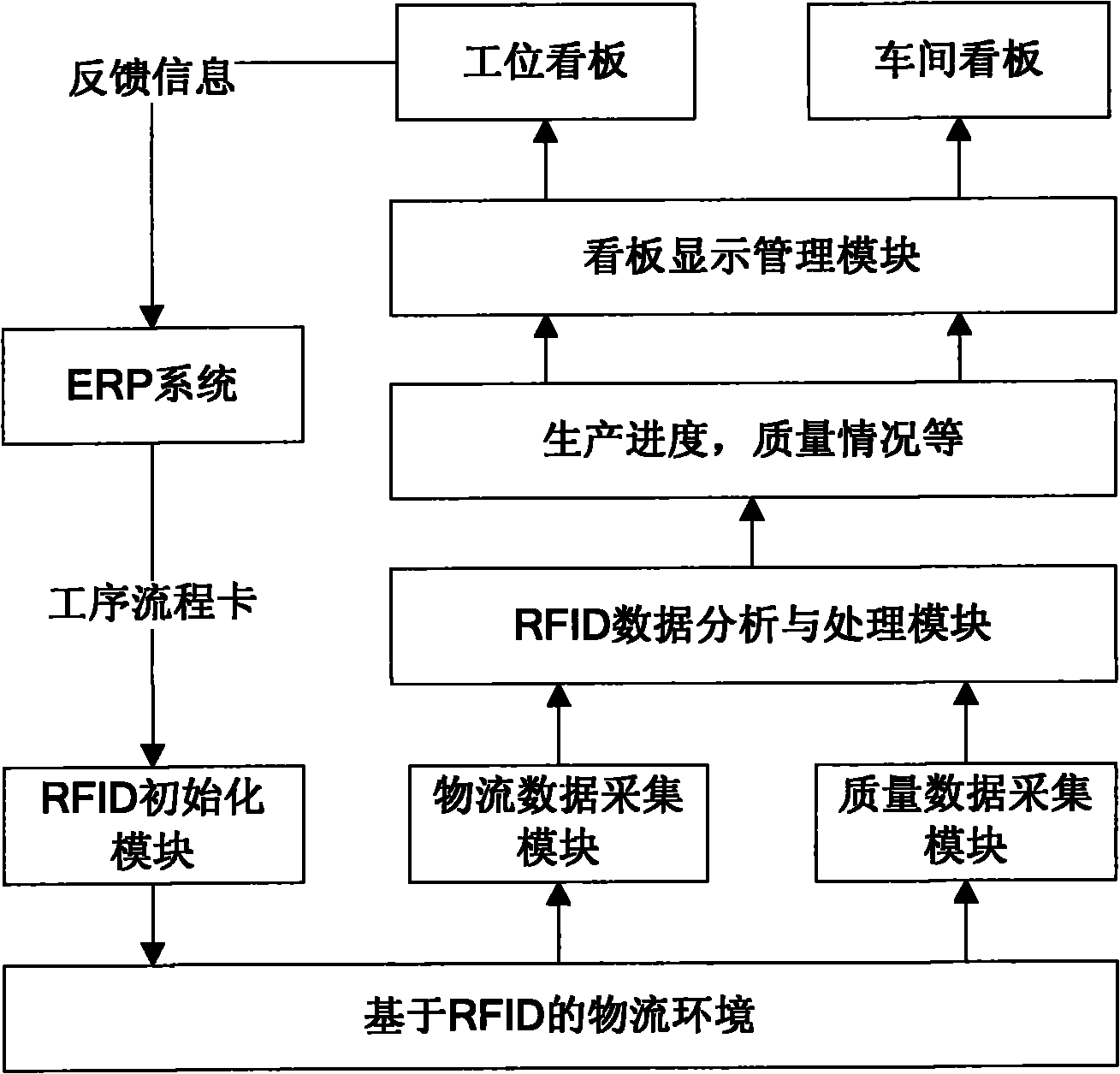

Visual production management and control method for discrete workshop

InactiveCN101819658AEffective Quality MonitoringQuality data to realize effective monitoring of production management in discrete manufacturing workshopsCo-operative working arrangementsProduction scheduleProcess module

The invention discloses a visual production management and control method for a discrete workshop. The method comprises the following steps of: establishing an association relationship between an RFID tag which is taken as a carrier for data acquisition of a workshop and a process flow card; acquiring information of the tag when the RFID tag passes through a working position; displaying the information of the process flow card associated to the tag on an electronic billboard; reading the RFID tag and filling quality information by using a handset at a quality testing working position; processing acquired information to form production schedule information and the quality information of the workshop; and displaying the production schedule information and the quality information on a working position billboard and a workshop billboard by using a billboard display management system. The method adopts a device which comprises an RFID initializing module, an RFID-based data acquisition module, an RFID data analyzing and processing module and a billboard display management module. By using the method, logistics and quality data in a production process can be acquired and transmitted in real time, paperless and visual production management of a discrete manufacturing workshop is realized, the information of logistics, quality and the like is effectively monitored, and the workshop management level of an enterprise is improved.

Owner:ZHEJIANG UNIV

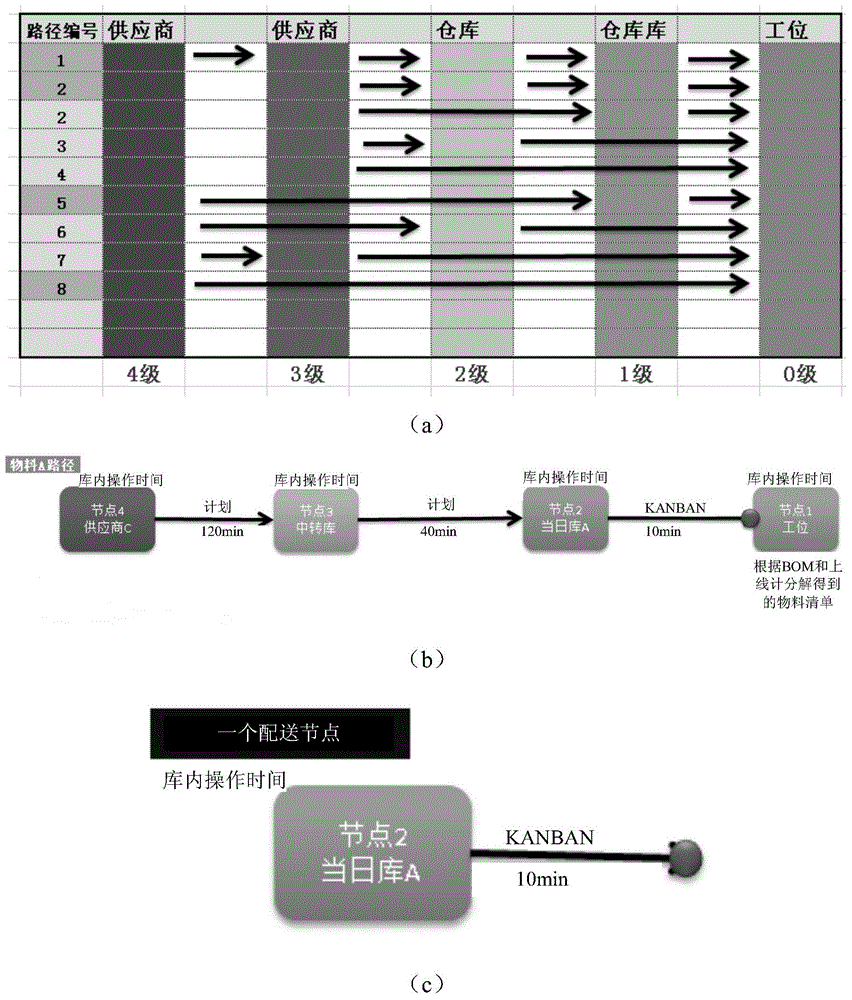

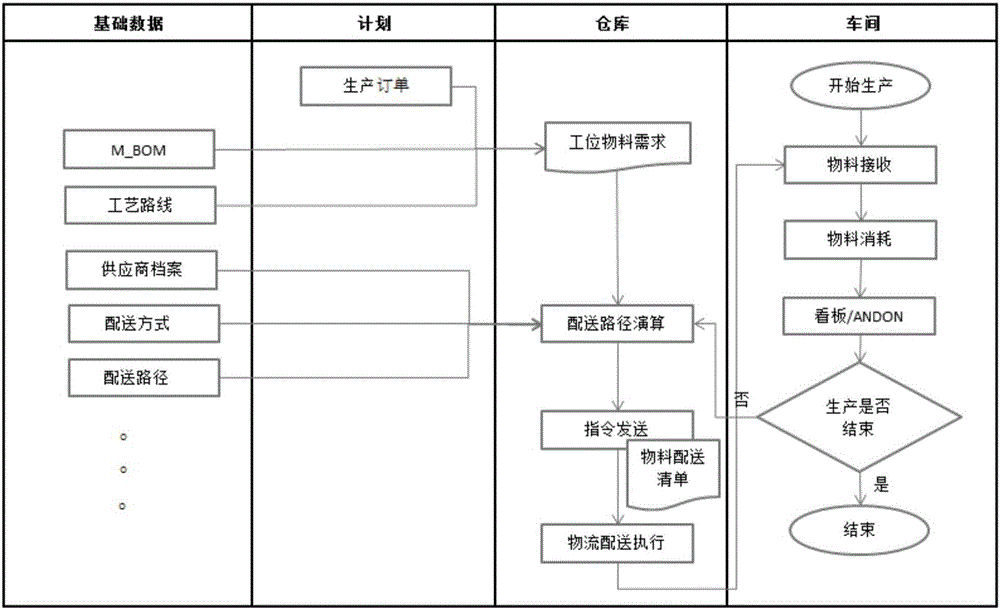

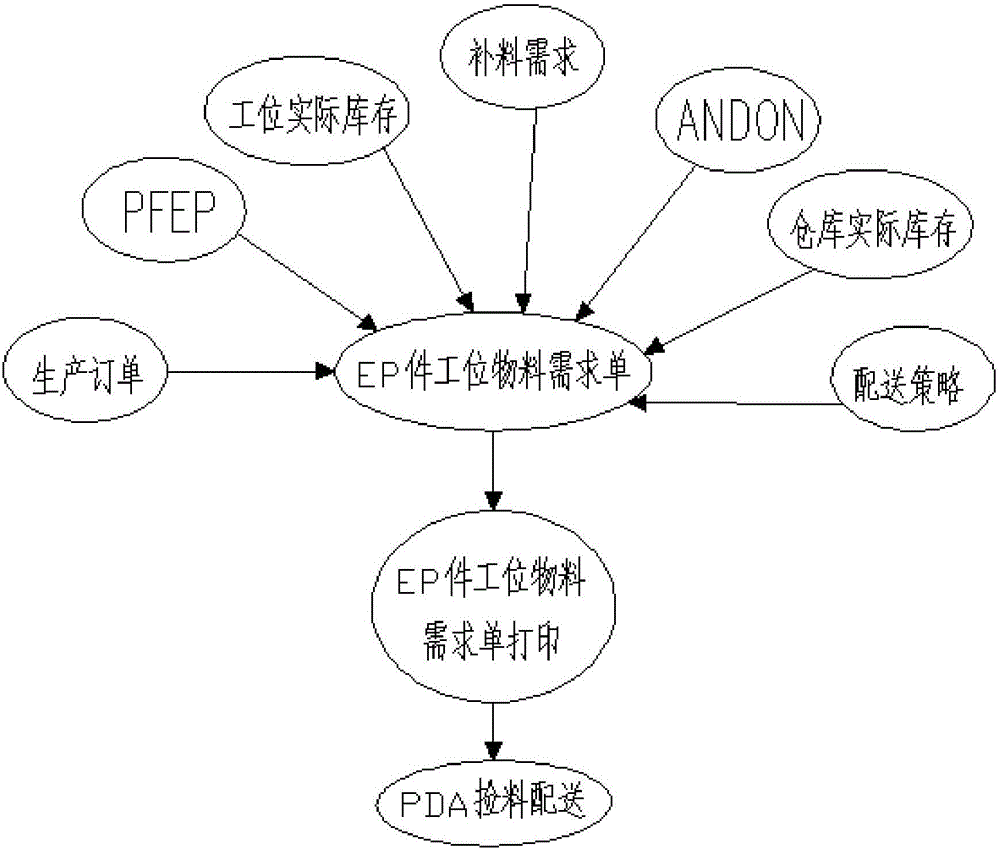

Material distribution method

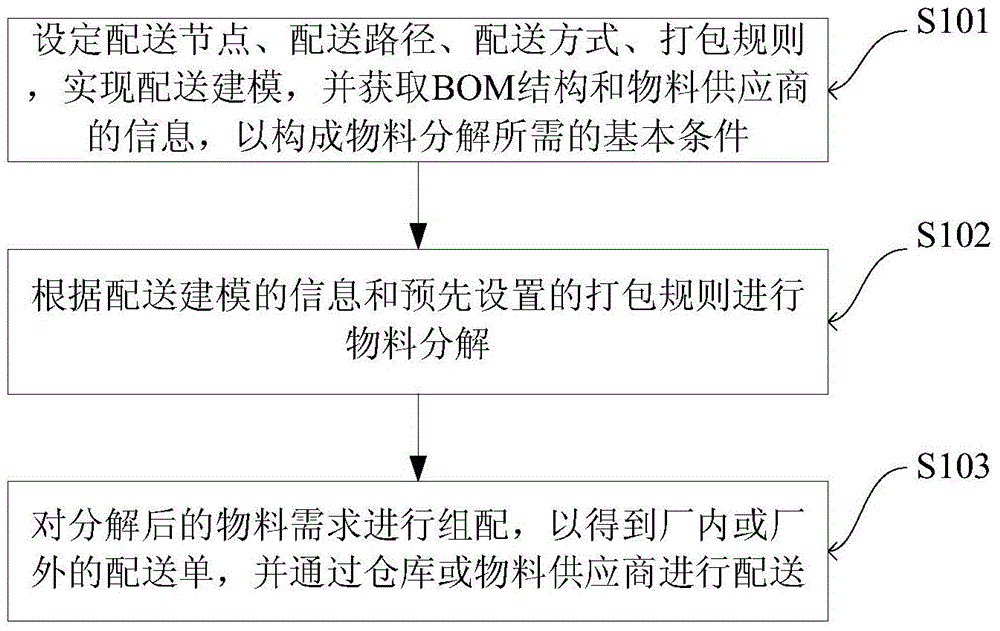

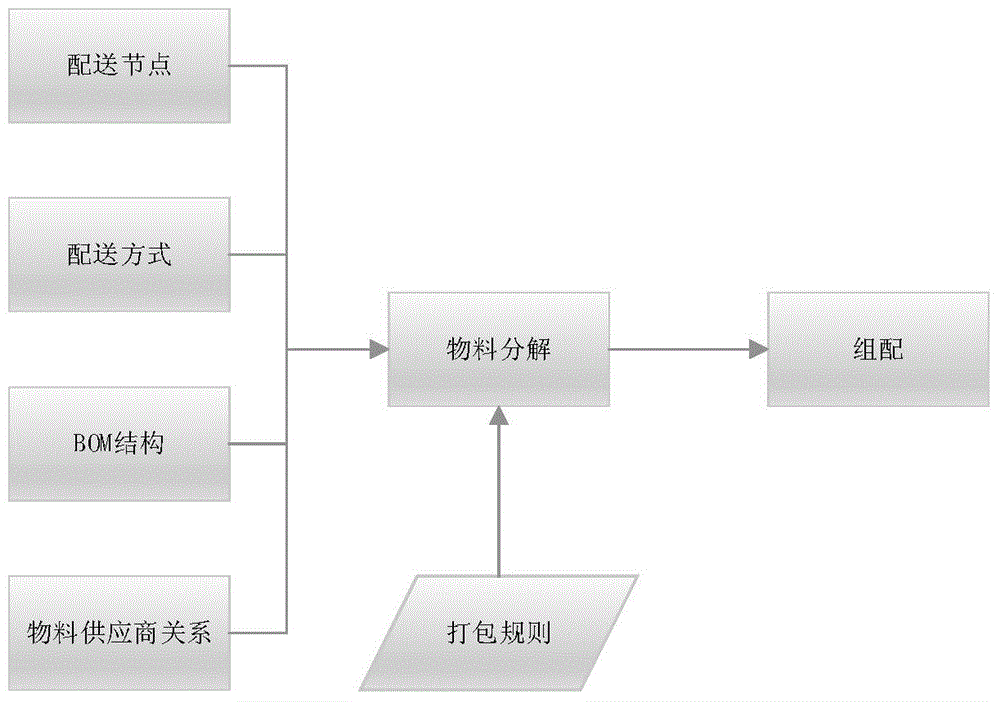

ActiveCN104463521ARealize real-time decomposition and real-time distributionMeet the needs of pull distributionLogisticsDecompositionDistribution system

The invention discloses a material distribution method. The material distribution method includes the following steps that distribution nodes, distribution paths, distribution modes and a packaging rule are set for achieving distribution modeling; information of a BOM structure and a material supplier is acquired, and then basic conditions required for material decomposition are formed; material decomposition is conducted according to distribution modeling information and the preset packaging rule; decomposed material requirements are assembled, in-plant or out-plant distribution bills are acquired, and the materials are distributed through a warehouse or the material supplier. By the adoption of the method, the complexity of an existing distribution system is lowered, the stability and the timeliness of the system are improved, real-time decomposition and real-time distribution (JIT) of the materials are achieved, and the requirements for material pull type distribution in multi-variety, small-batch and mixed flow production in modern discrete manufacturing are met.

Owner:EPIC HUST TECH WUHAN

Discrete manufacturing process product quality information management system based on RFID (radio frequency identification)

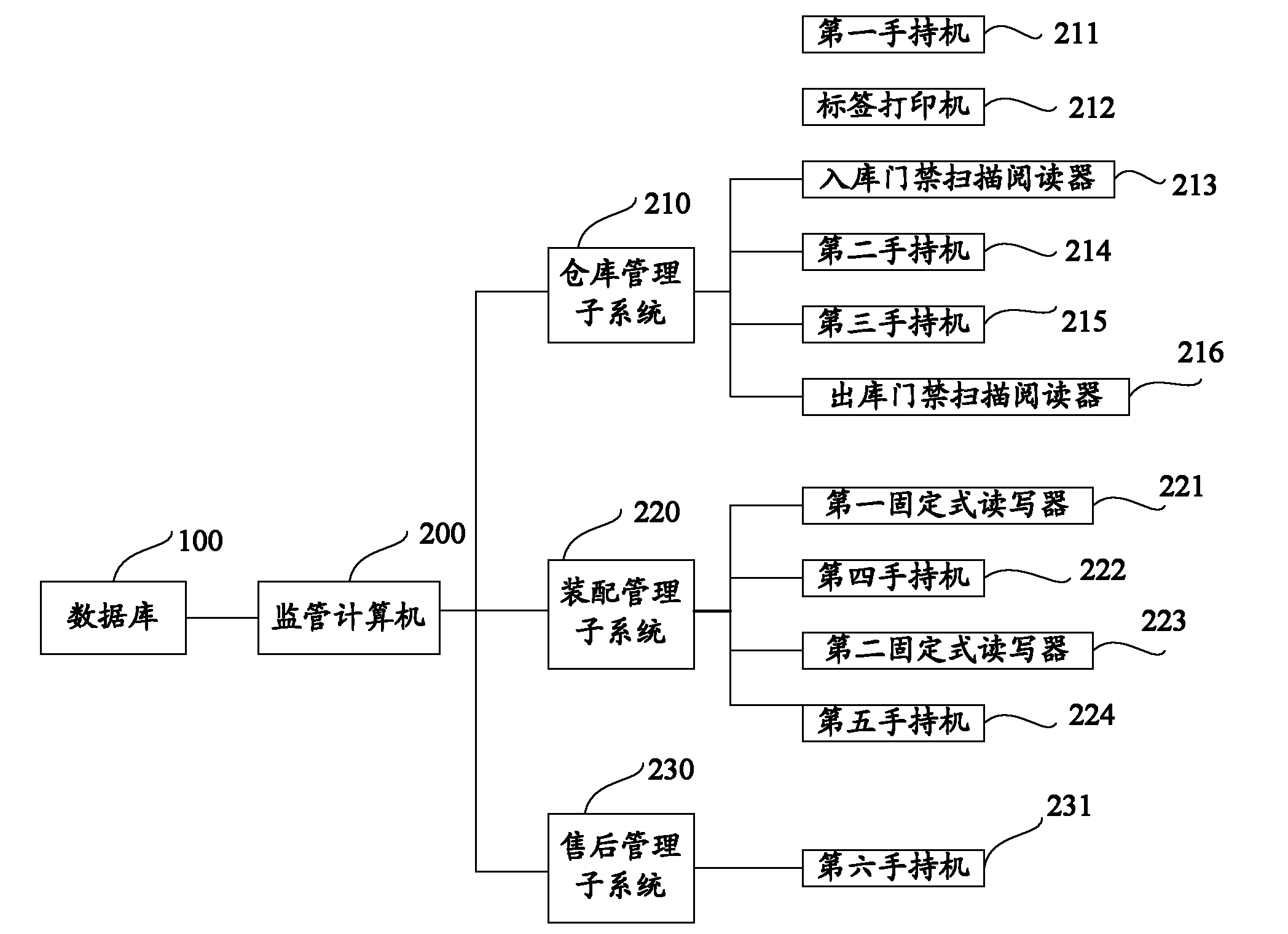

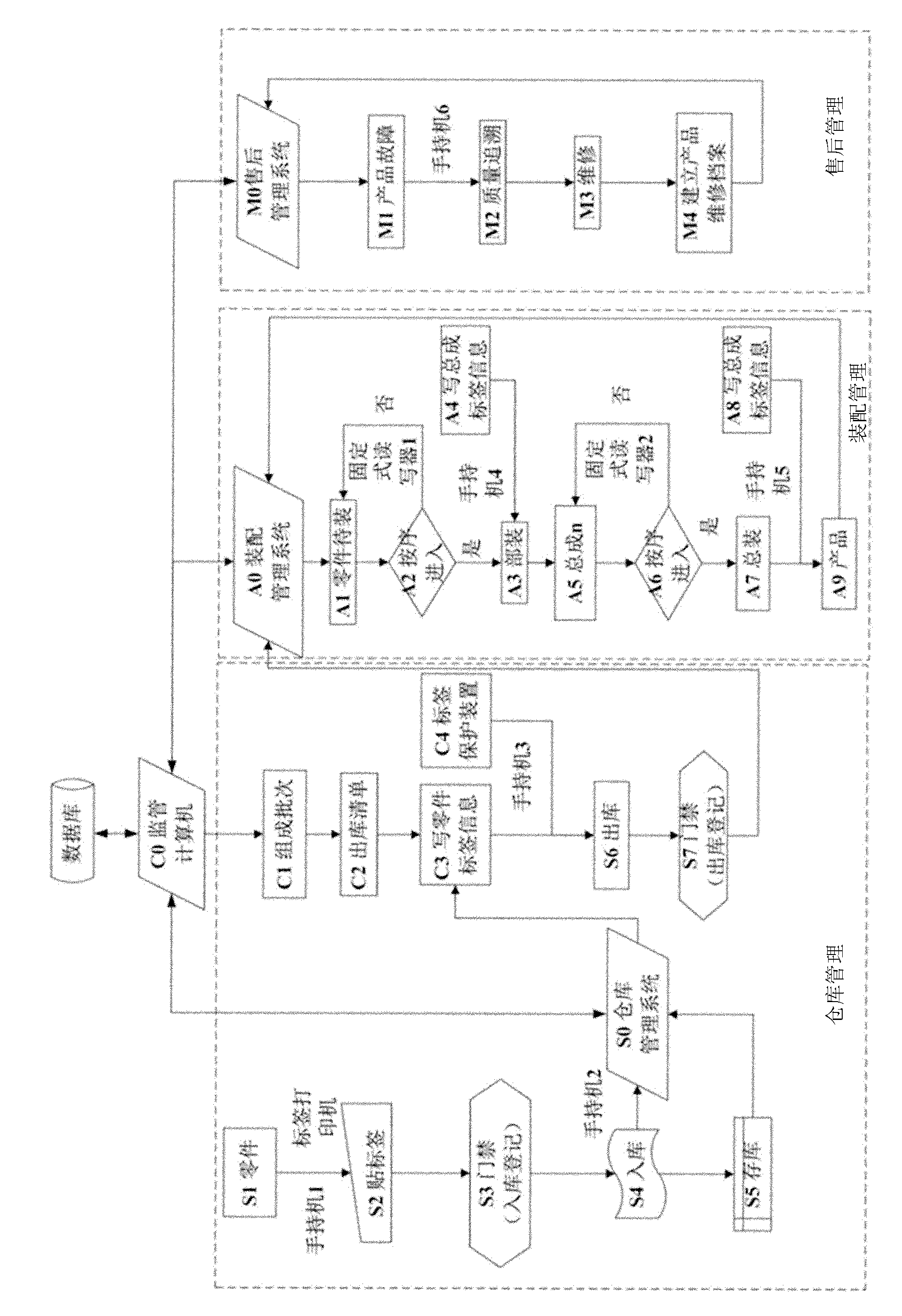

InactiveCN102163306AQuick and efficient deliveryAchieve sharingCo-operative working arrangementsIndividual entry/exit registersDiscrete manufacturingReader writer

The invention discloses a discrete manufacturing process product quality information management system based on RFID (radio frequency identification). The system provided by the invention is characterized in that a first handset, a label printer, an warehousing access control scanning reader, a second handset, a third handset, an ex-warehouse access control scanning reader, a warehouse management sub-system, a monitoring computer and a database are used for completing the warehouse management; a first fixed reader-writer, a fourth handset, a second fixed reader-writer, a fifth handset, an assembling management sub-system, the monitoring computer and the database are used for completing the assembling management; a sixth handset, an after-sale management sub-system, the monitoring computer and the database are used for completing the after-sale management; the product quality information management system is capable of transmitting the quality information between a planning level and a workshop level in an enterprise; and the top management can know the production progress and product quality in real time, can accurately position faulty products, rapidly and accurately find a reason causing the quality defect. The invention further discloses a product quality information management method.

Owner:WUHAN UNIV OF TECH

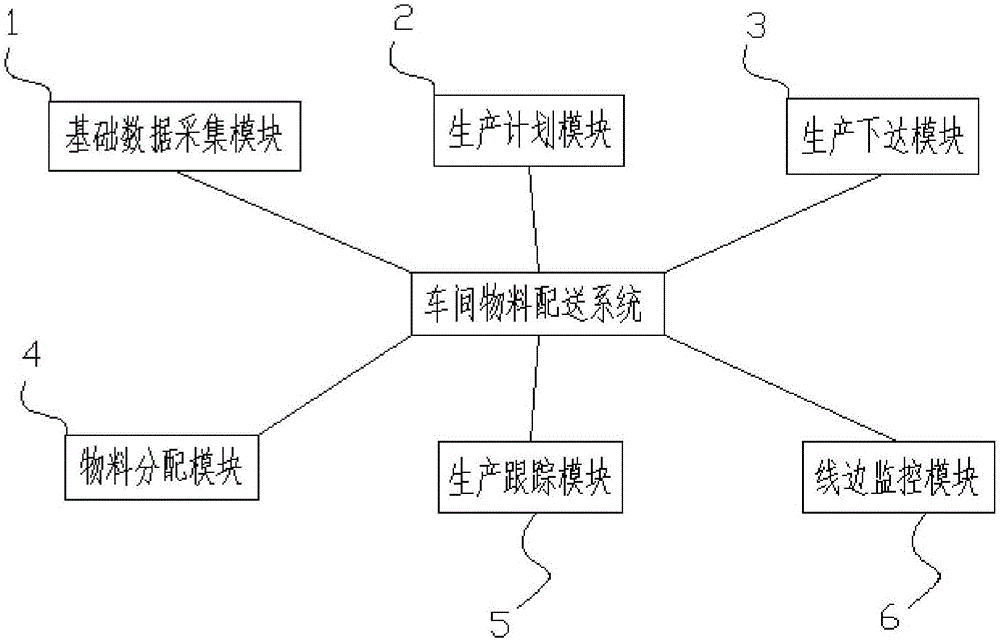

Workshop material distribution device and method

InactiveCN106600197ARealize real-time decomposition and real-time distributionMeet pull delivery needsLogisticsManufacturing computing systemsCurrent distributionMaterial distribution

The invention discloses a workshop material distribution device and method. The system structural frame of the device is simple and clear; an effective distribution model is established; the complexity of a current distribution system is simplified; and a JIT material distribution mode is adopted, so that material-driven distribution needs in multi-type, small-batch and mixed production of modern discrete manufacture can be met.

Owner:苏州宏软信息技术有限公司

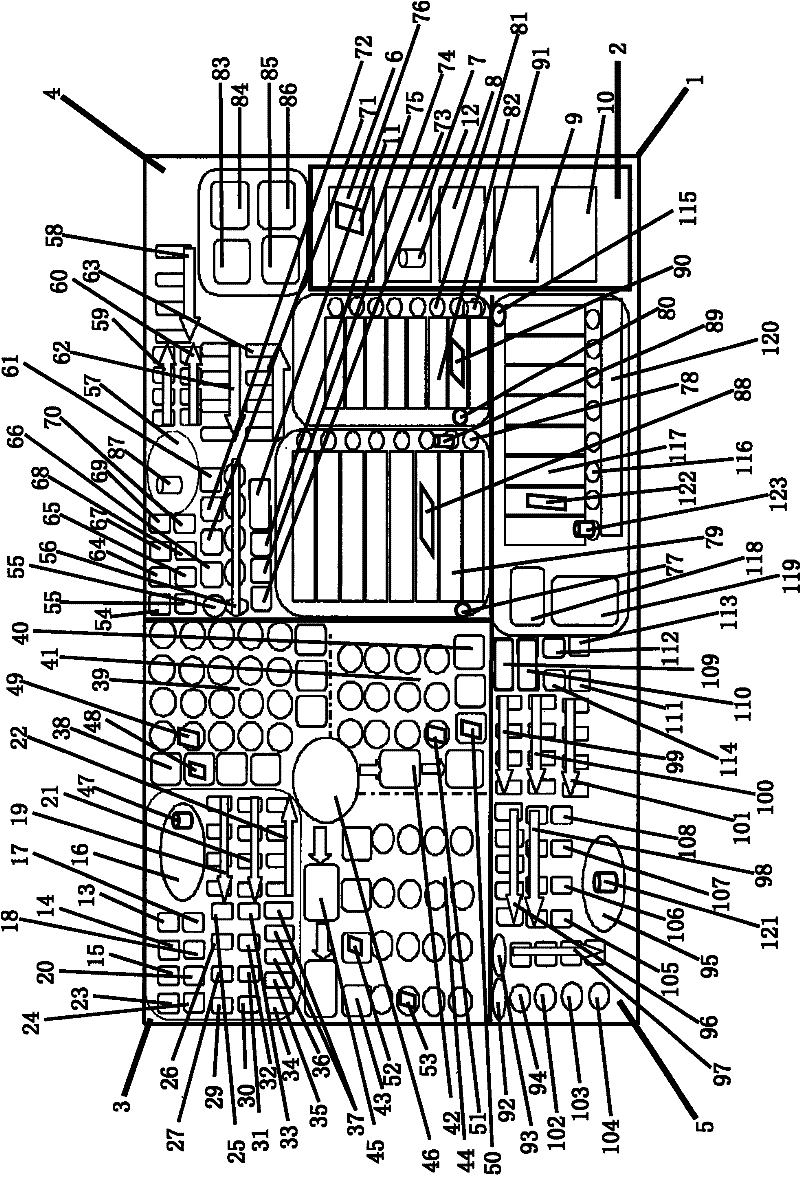

UWB-based discrete manufacturing plant material delivery cart control system

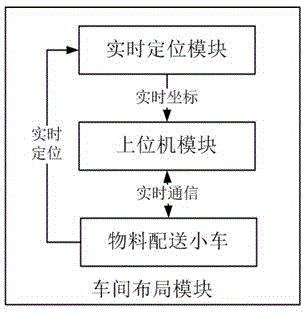

ActiveCN104914869APrecise positioningAccurate trackingPosition/course control in two dimensionsControl systemComputer module

A UWB-based discrete manufacturing plant material delivery cart control system comprises a plant layout module, an upper computer module, a material delivery cart, and a real-time positioning module. The plant layout module is simplified and extracted according to the basic requirement of a discrete manufacturing plant, and is used to map the whole discrete manufacturing plant. The upper computer module is used to realize motion control, real-time positioning and trajectory tracking of the material delivery cart, and display the whole process of material delivery in real time. The material delivery cart completes the whole process of material delivery. The real-time positioning module realizes real-time positioning and tracking of the material delivery cart. By adopting the system of the invention, the flexibility of discrete manufacturing plant material delivery can be enhanced effectively. The position and motion trajectory of the material delivery cart can be displayed in real time, and the process of material delivery is visualized. Each basic function area identifies the types of materials and tracks the materials through an RFID reader. The system has high popularization value for discrete manufacturing plants.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

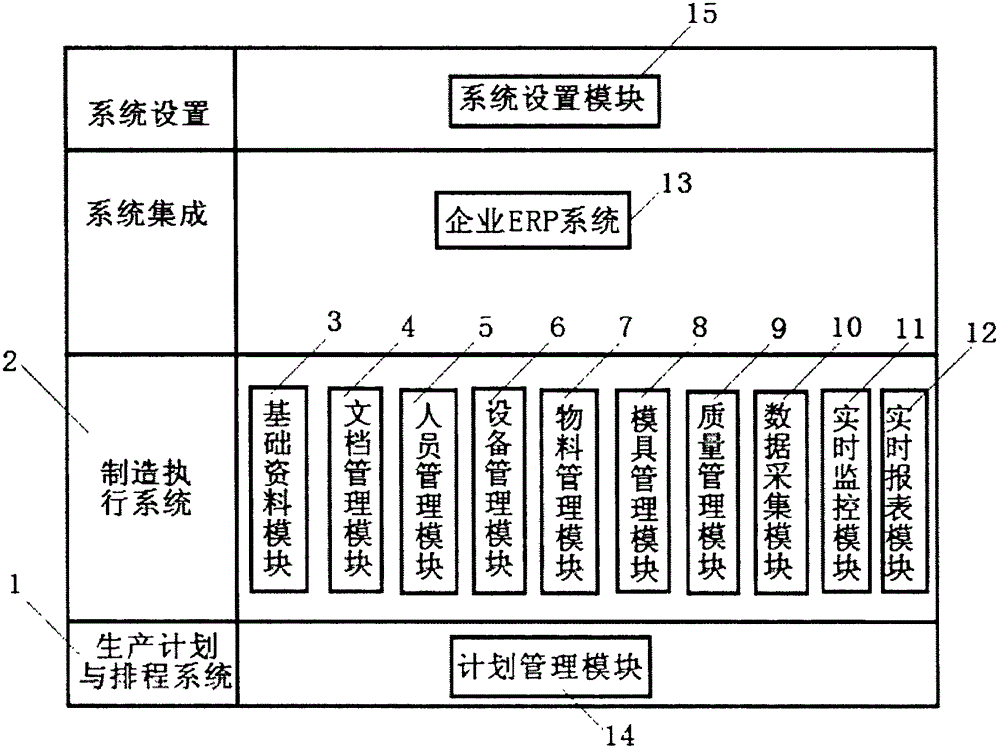

Manufacturing execution system

InactiveCN102945512ASolve the problem of real-time managementSolve the problem of real-time demand informationResourcesManufacturing computing systemsData acquisitionManufacturing execution system

The invention discloses a manufacturing execution system which comprises a production planning and scheduling system, wherein a manufacturing execution system is integrated on the basis of the production planning and scheduling system. The manufacturing execution system comprises a basic material module, a document management module, a personnel management module, an equipment management module, a material management module, a die management module, a quality management module, a data acquisition module, a real-time monitoring module and a real-time reporting module. An upper layer of the manufacturing execution system is integrated with an ERP (Enterprise Resource Planning) system of an enterprise, and a bottom layer of the manufacturing execution system is connected with a data acquisition device and a man-machine interaction terminal interface in a product field. According to the manufacturing execution system provided by the invention, the problem of real-time material demand information in the production field of the discrete manufacturing industry is solved, the material demand information can be timely sent to a warehouse by automatic system triggering or manual triggering, and the problems of monitoring and feeding back the efficiency of production equipment in real time are solved by the scientifically planned OEE (Overall Equipment Efficiency) management.

Owner:SUZHOU JIANGSHAN SOFTWARE SCI & TECH

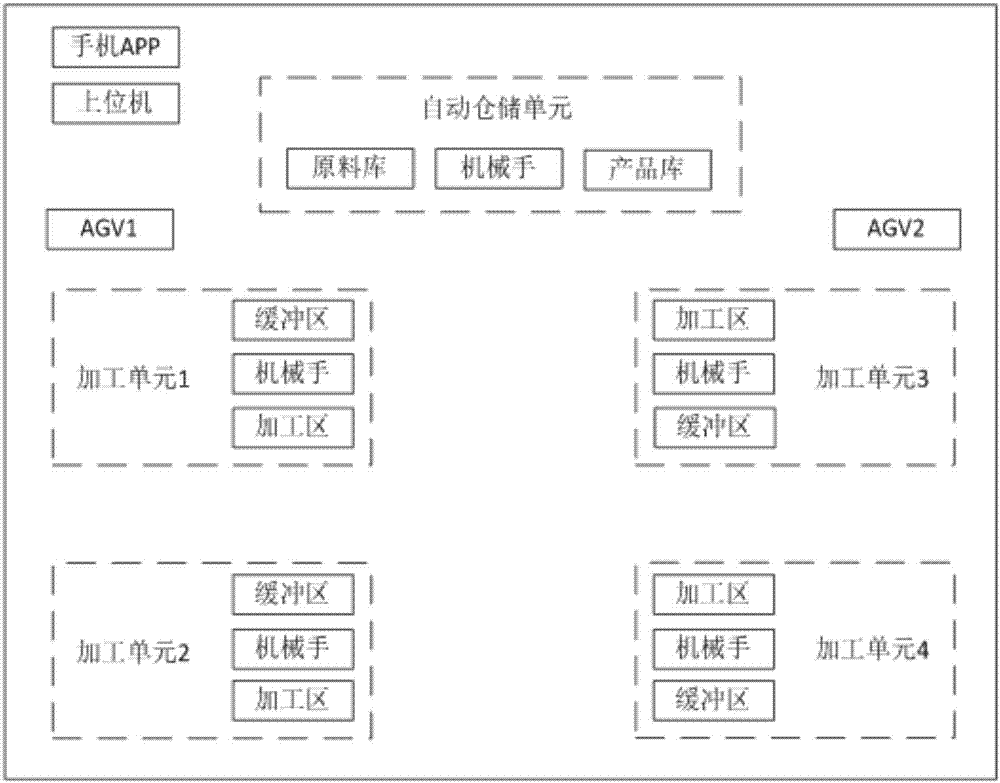

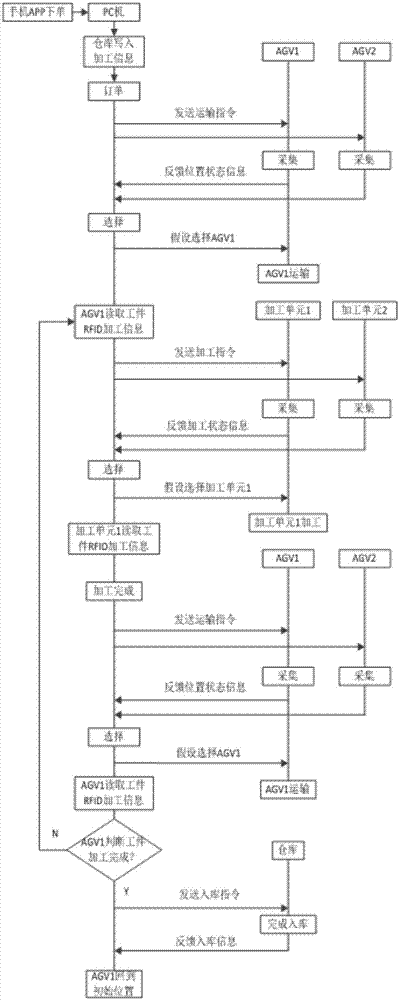

Mobile multi-agent real-time scheduling system and method based on an intelligent workshop

ActiveCN106873564AReal-time power monitoringActively looking for chargingTotal factory controlProgramme total factory controlCommunications systemE communication

The present invention discloses a mobile multi-agent real-time scheduling system and method based on an intelligent workshop. The system comprises a multi-agent manufacturing workshop, which comprises a material storage system, a material transportation system, a material processing system and a communication system. In the invention, workshop agents change along with workpiece movement, and workpiece processing is carried out collaboratively by the material storage system, the material transportation system, the material processing system and the communication system so as to solve the problem that scheduling is too concentrated and a central dispatcher is too busy during discrete manufacturing, thereby improving the scheduling efficiency and enhancing the stability and the expandability of a manufacturing system.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

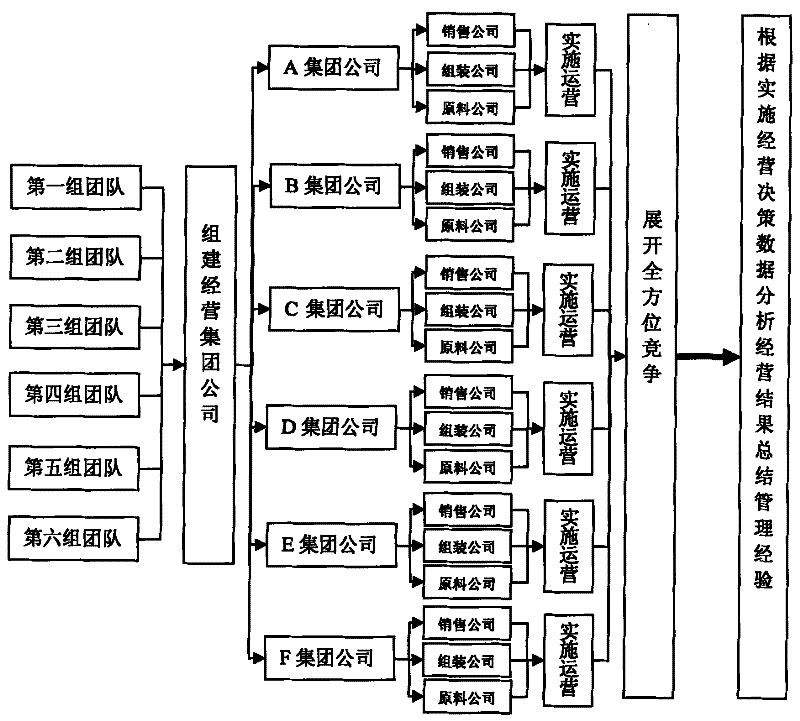

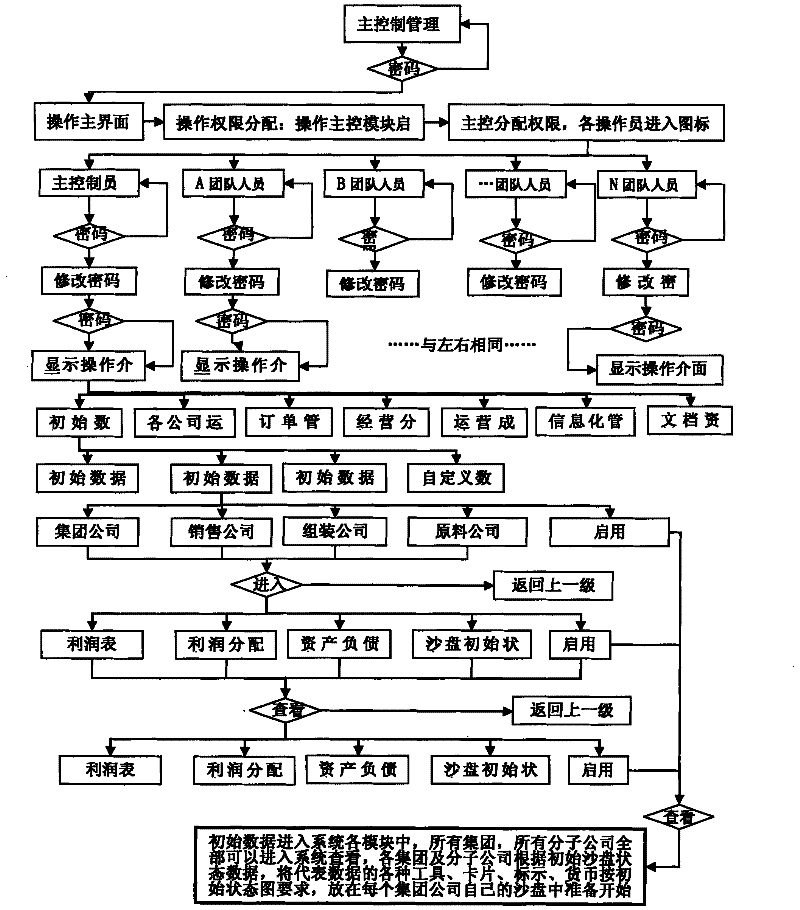

Enterprise resource planning multi-organization business operation sand table system

InactiveCN102184456AImprove management levelOptimize resource allocationTeaching apparatusDecision makerSoftware system

The invention discloses an enterprise resource planning (ERP) multi-organization business operation sand table system. A business operation simulation sand table and a business management software system based on characteristics of a discrete manufacturing industry, a currency industry and the like are exploited by a design; the business operation simulation sand table and the business management software system are combined to form a complete multi-organization operation simulation platform; no matter the system is used by a business decision maker or a business manager or applied to the field of teaching, by adoption of the ERP multi-organization business operation sand table system, changeable decision methods and decision results can be simulated. A set of complete management and decision platform is provided for the decision maker on the aspects of realizing a decision idea, finding out a new management method, researching a new production management flow, solving and searching the decision risk and the like.

Owner:詹亚辉

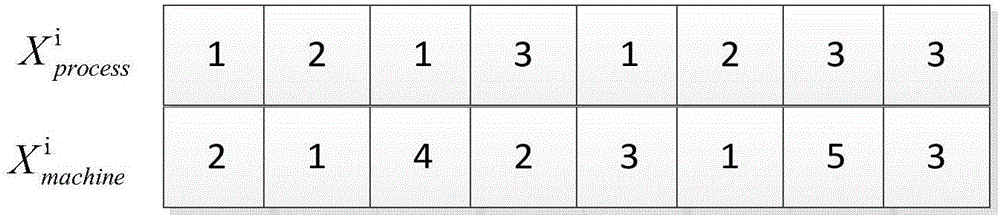

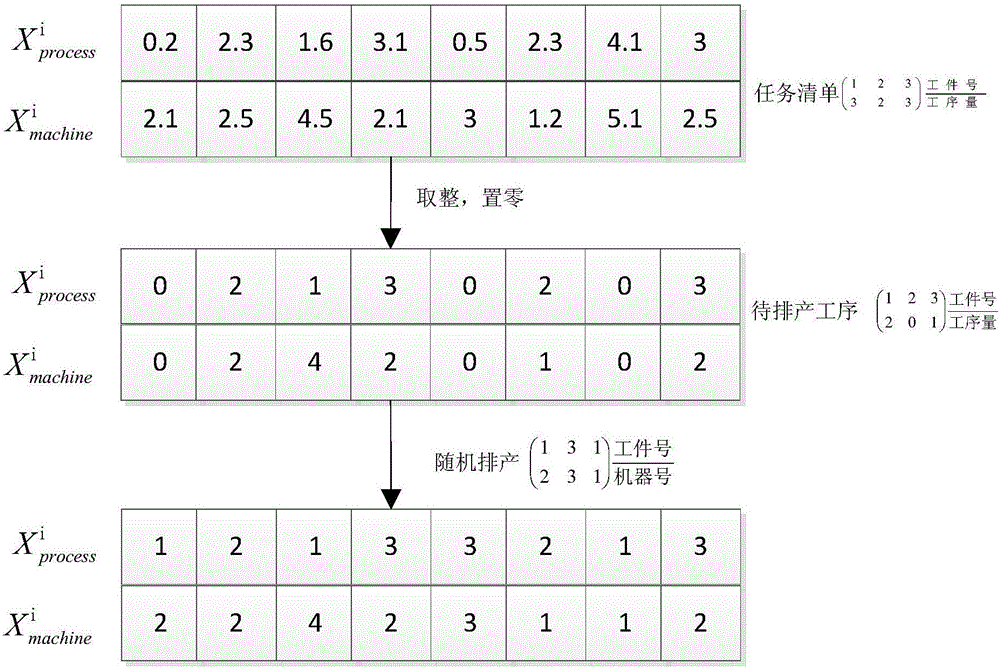

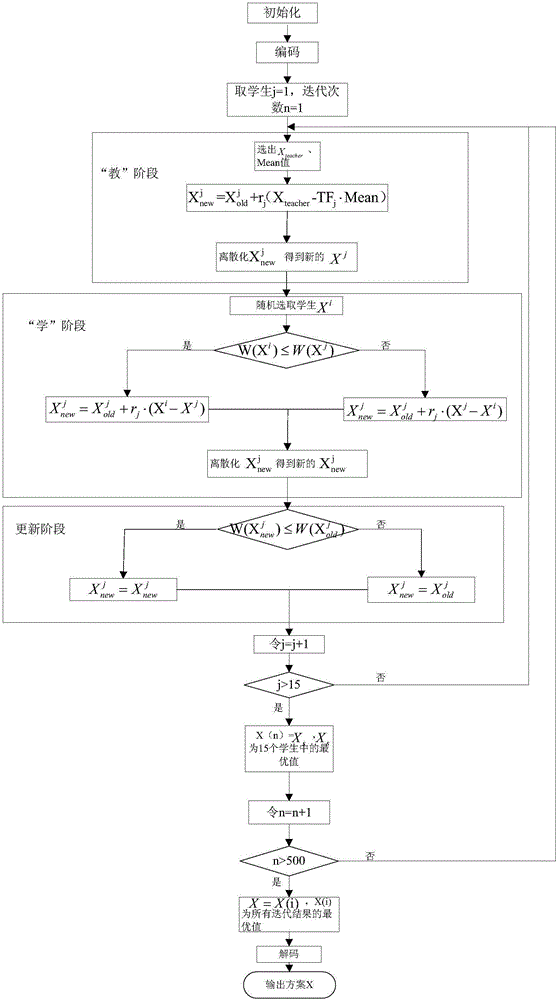

Teaching-and-learning-algorithm-based static scheduling optimization system for discrete manufacturing shop

InactiveCN105843197ANormal production orderContribute to rationalityTotal factory controlProgramme total factory controlStatic dispatchDiscrete manufacturing

The invention discloses a teaching-and-learning-algorithm-based static scheduling optimization system for a discrete manufacturing shop. The system comprises a data server, an operation server, and a terminal display screen. A scheduling optimization client is embedded into the operation server and is used for carrying out optimization-algorithm-based reasonable scheduling arrangement on a processing task on the day by analyzing the processing task and consulting various detailed information of the data server, wherein the specific optimization algorithm employs a teaching and learning algorithm. A generation scheduling scheme is decoded; de-compilation processing is carried out according to dual-layer definition on a student during coding; a processing tool and a processing sequence of a workpiece are expressed successively. And then the optimized scheduling scheme is displayed on a terminal display screen, so that the production staff and the management staff in the shop can obtain current specific processing task arrangement information in real time. According to the invention, with the teaching and learning algorithm, the system has advantages of fast convergence speed and high optimization searching capability and adapts to the complex situation in practical production well.

Owner:JIANGNAN UNIV

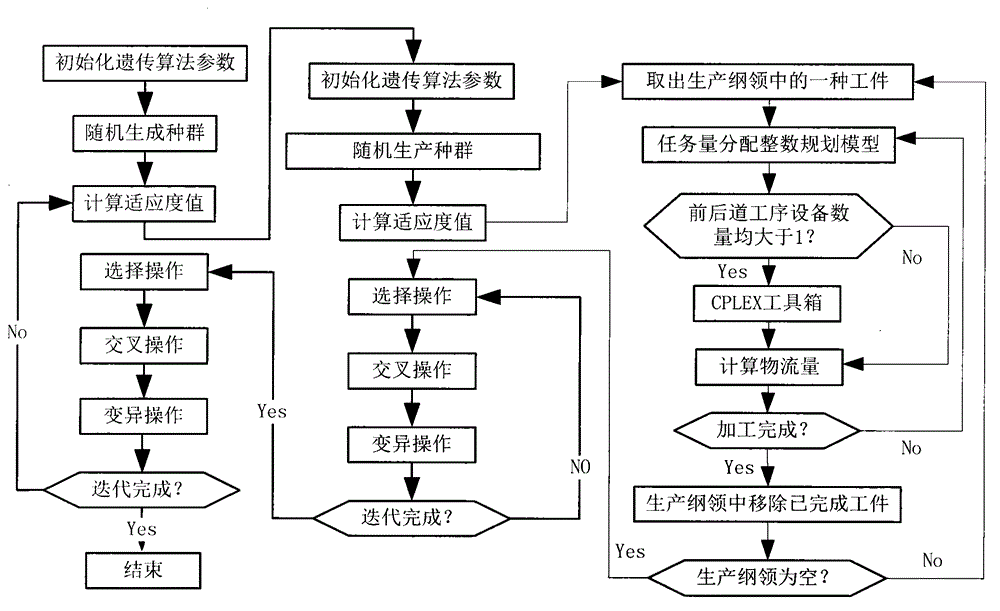

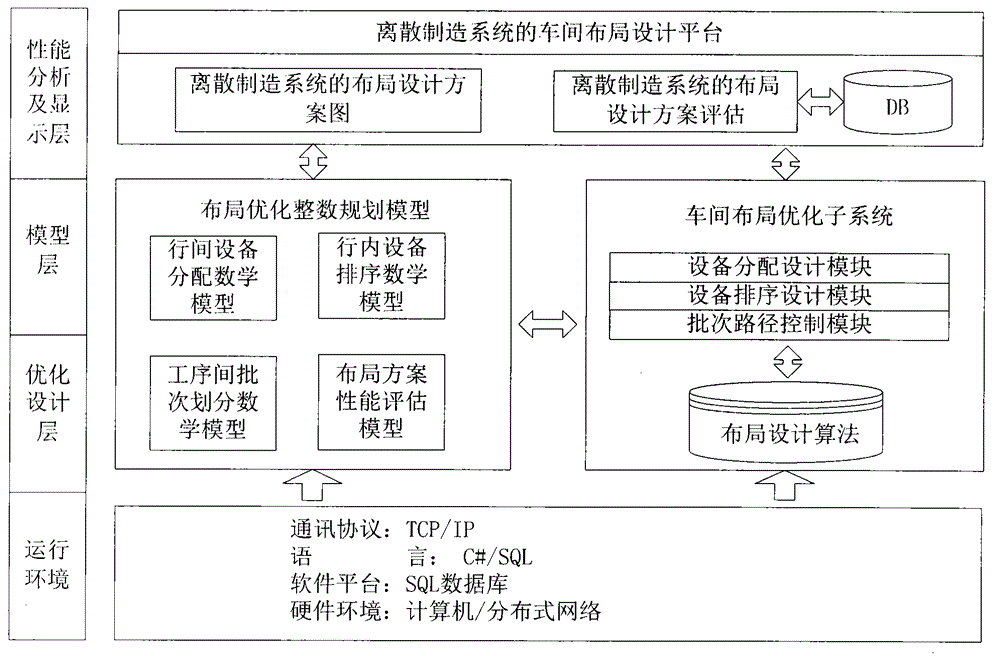

Workshop layout method of discrete manufacturing system

InactiveCN104808627AGuaranteed global searchImprove solution efficiencyTotal factory controlProgramme total factory controlLogistics managementComputer module

The invention discloses a workshop layout method of a discrete manufacturing system. The workshop layout method comprises the specific steps: a system UI layer is used for recording workshop equipment and production information to a layout design platform; a model establishing layer is arranged; an inter-row equipment distribution mathematic model, an in-row equipment sorting mathematic model, an inter-procedure batch division mathematic model and a layout scheme performance estimation model are established respectively according to the recorded workshop information; a workshop layout optimization subsystem is arranged; a workshop layout design result estimation and display module is arranged. A user sends a layout design scheme to a server through module permission and workshop management staffs execute optimized results. The workshop layout method has the advantages that the defects that the workshop layout overall performance is reduced, caused by the fact that common layout optimization only considers block layout of a machining station, are avoided. Meanwhile, the optimal distribution of task amounts of an equipment workshop is considered under the condition that a plurality of sets of equipment of front and rear procedures are utilized, and the logistics transportation amount is further reduced by utilizing third-grade optimization.

Owner:HAIAN COUNTY SHENLING ELECTRICAL APPLIANCE MFG

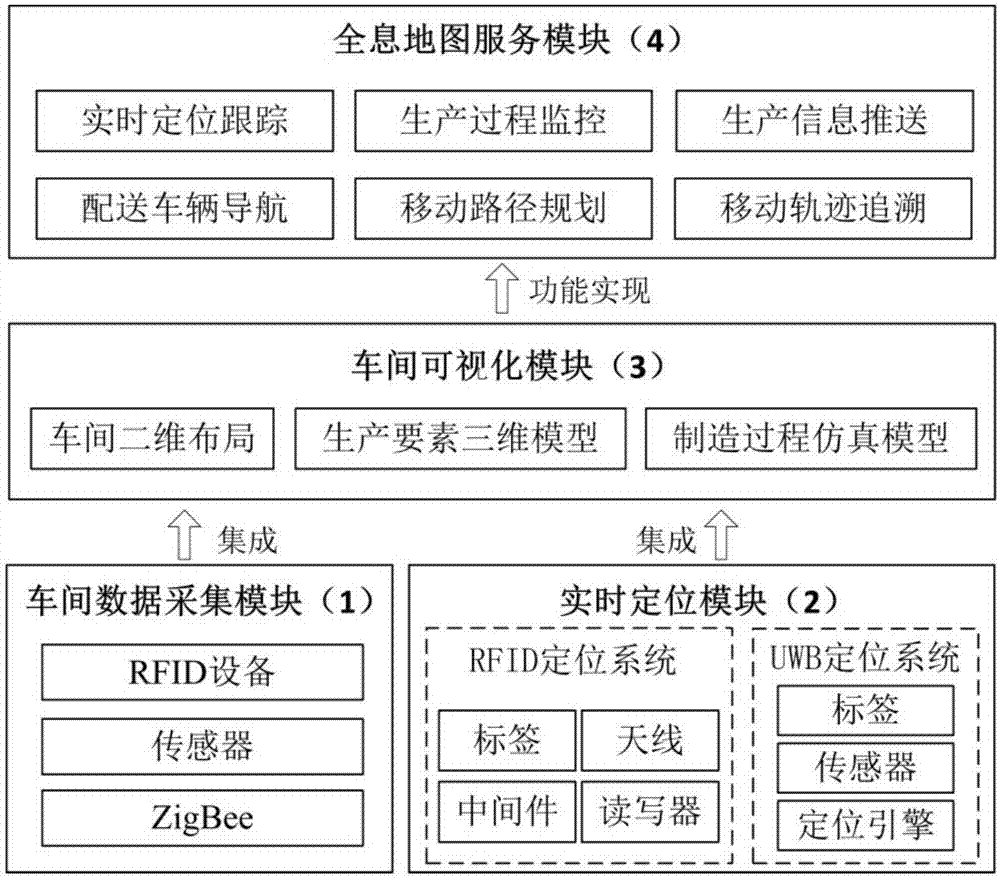

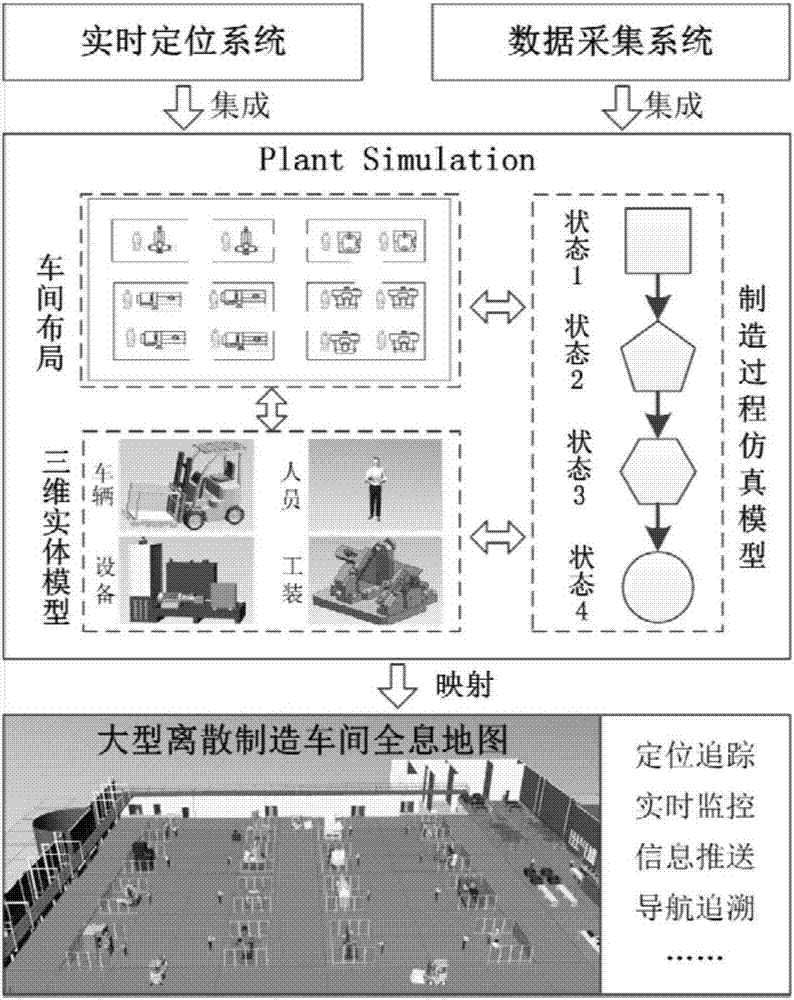

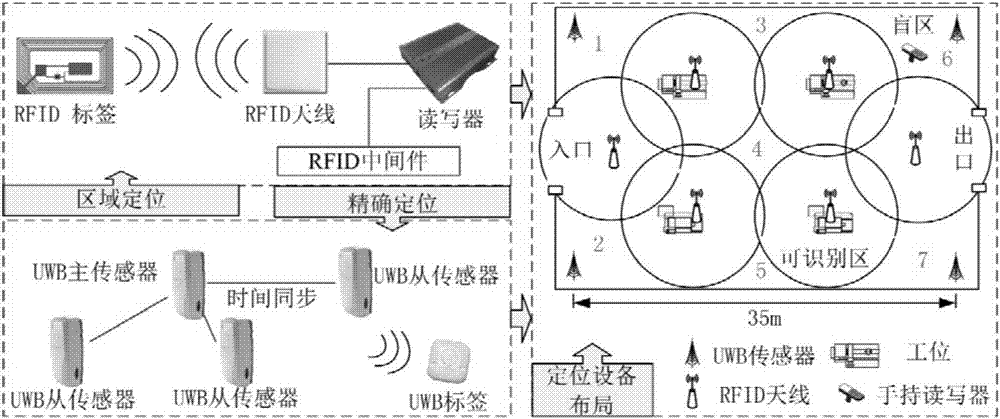

Large-sized discrete manufacturing workshop holographic map based on RFID and UWB and realization method

ActiveCN106940713AAccurately reflect the layoutReaction space constraintsGeometric image transformationGeographical information databasesAmbient dataIntelligent management

The invention provides a large-sized discrete manufacturing workshop holographic map based on RFID and UWB. The large-sized discrete manufacturing workshop holographic map comprises a workshop data acquisition module (1), a real-time positioning module (2), a workshop visualization module (3) and a holographic map module (4), wherein the workshop data acquisition module (1) is used for acquiring production factor attribute data, production state data, manufacturing process data and workshop environment data in real time; the real-time positioning module (2) is used for providing a real-time position coordinate of each factor; the workshop visualization module (3) is used for constructing a three-dimensional visualization model of a workshop and a simulation model of a manufacturing process. According to the large-sized discrete manufacturing workshop holographic map provided by the invention, an intelligent management and control level of the large-sized discrete manufacturing workshop can be effectively improved, and a modeled and visualized manufacturing field map is provided for production staff and management staff in the workshop; the large-sized discrete manufacturing workshop holographic map has very high application and popularization value on intelligent construction of the large-sized discrete manufacturing workshop.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

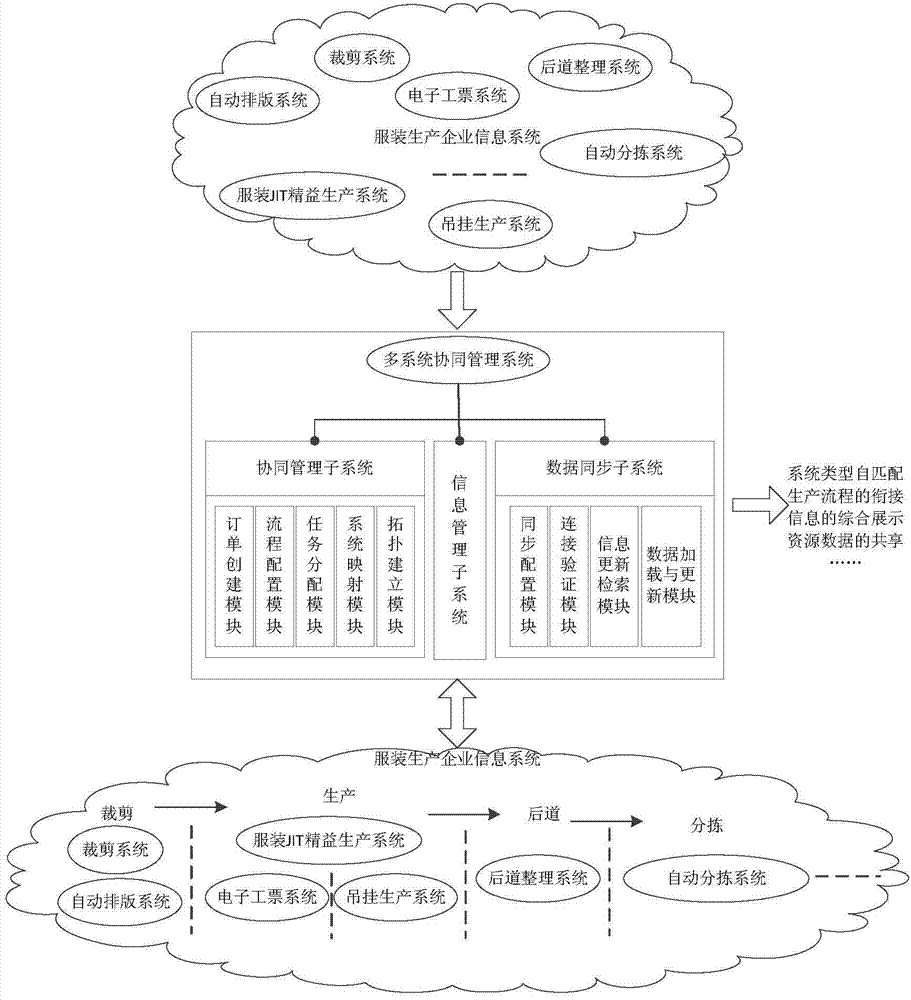

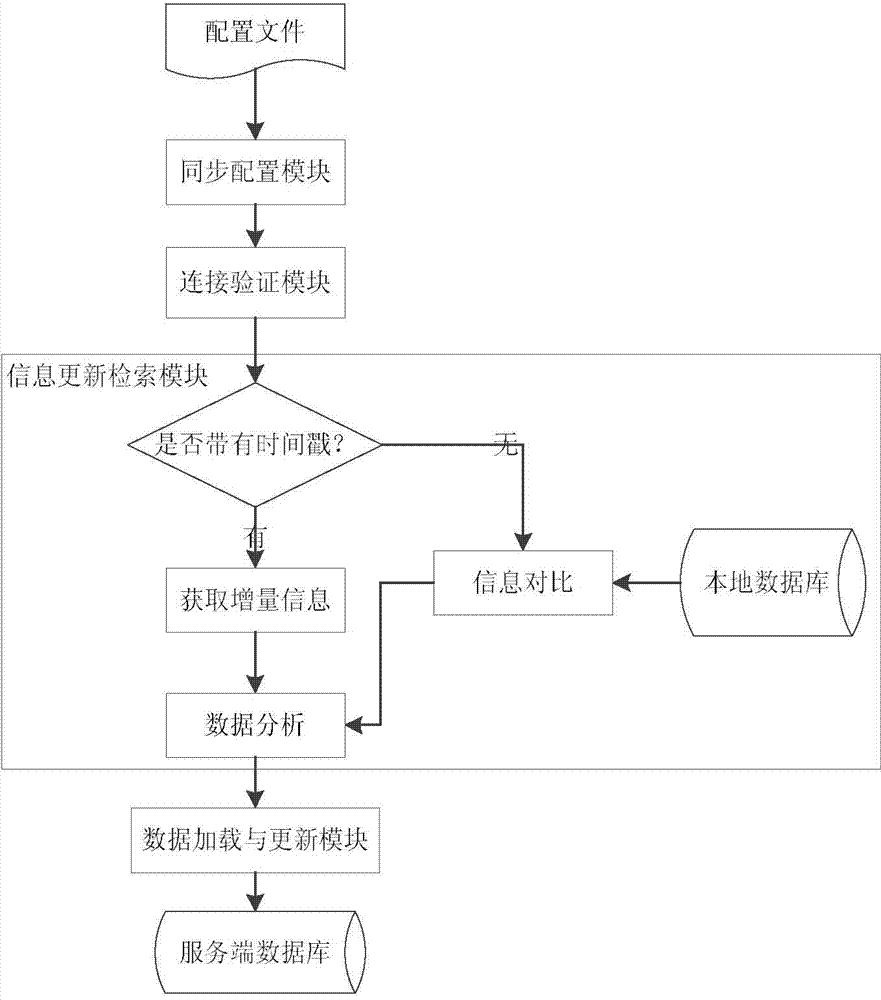

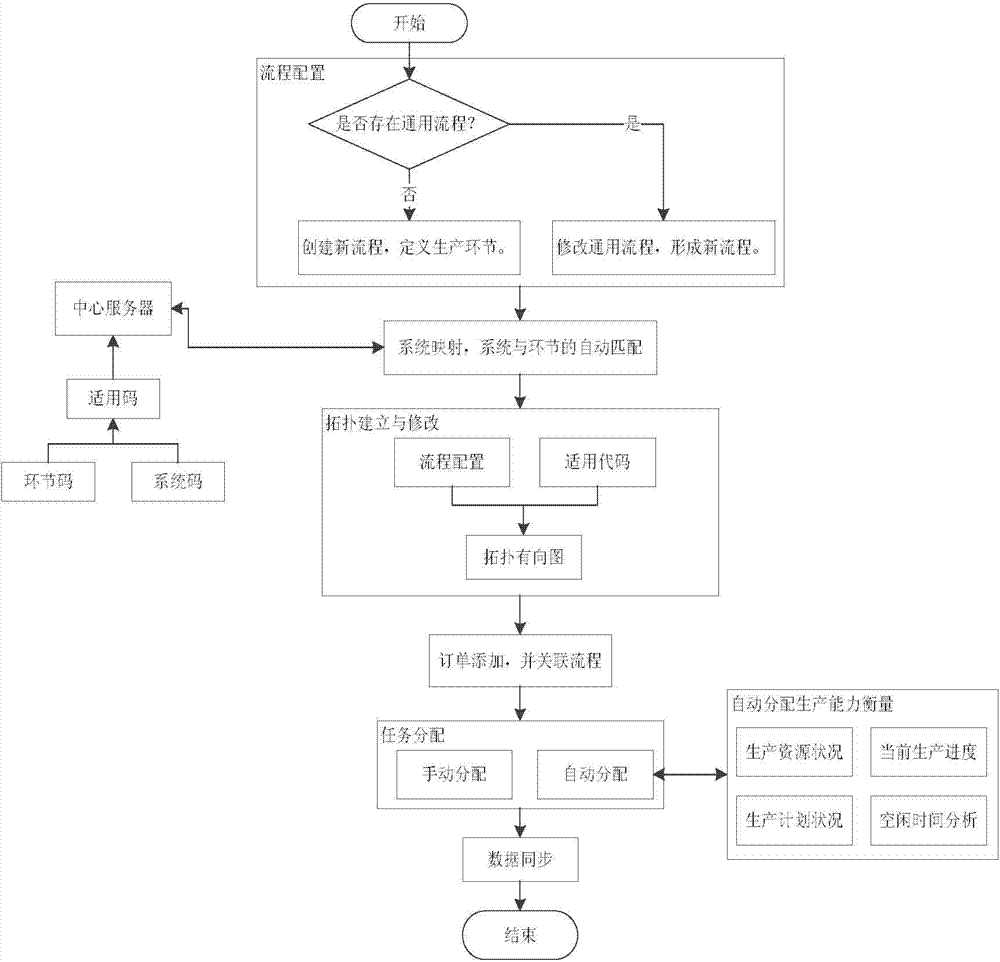

Multi-system cooperative system and method for production process control of discrete manufacturing enterprises

ActiveCN104331767AGet production dataImprove efficiencyResourcesManufacturing computing systemsData synchronizationProduction schedule

The invention discloses a multi-system cooperative system and method for production process control of discrete manufacturing enterprises. The multi-system cooperative system is used for cooperative work and data sharing of a production management system with multiple production chains during production, and comprises an information management subsystem, a cooperative management subsystem and a data synchronization subsystem. The multi-system cooperative method includes: configuring the process and defining the production chains; conducting system mapping to finish automatic correlation of the systems and the production chains; building topology, and displaying topology connection directed graphs of systems in real time according to the production process configuration and regular files; dynamically adjusting the topology relation and building a final connection directed graph of the production systems; adding orders and selecting corresponding production processes for the orders; distributing tasks; synchronizing and updating data and mastering the production schedule in real time. The multi-system cooperative system and method achieves organic interconnection and data sharing of independent systems through effective integration of the discrete systems, achieves smart production of the enterprises and improves the whole efficiency.

Owner:NANTONG MINGXING TECH DEV CO LTD +1

Reinforcement learning reward self-learning method in discrete manufacturing scene

ActiveCN111241952ARealize self-learningAdaptableCharacter and pattern recognitionMachine learningFunction learningData set

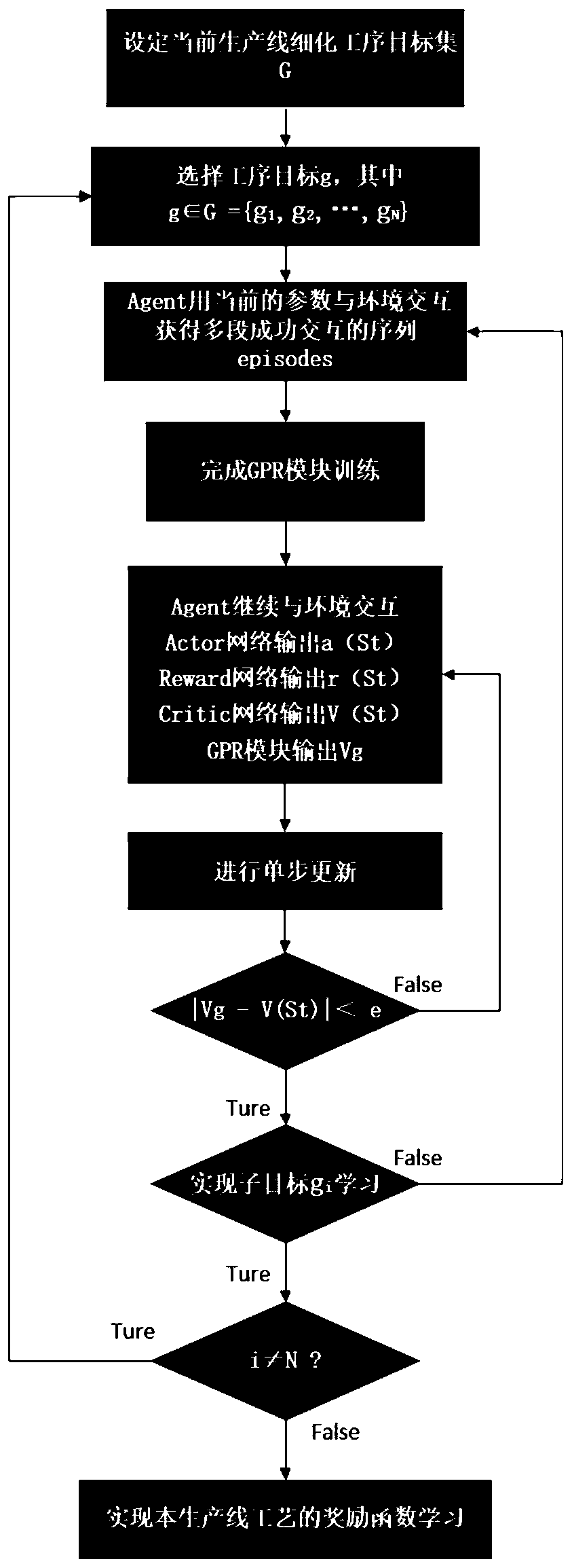

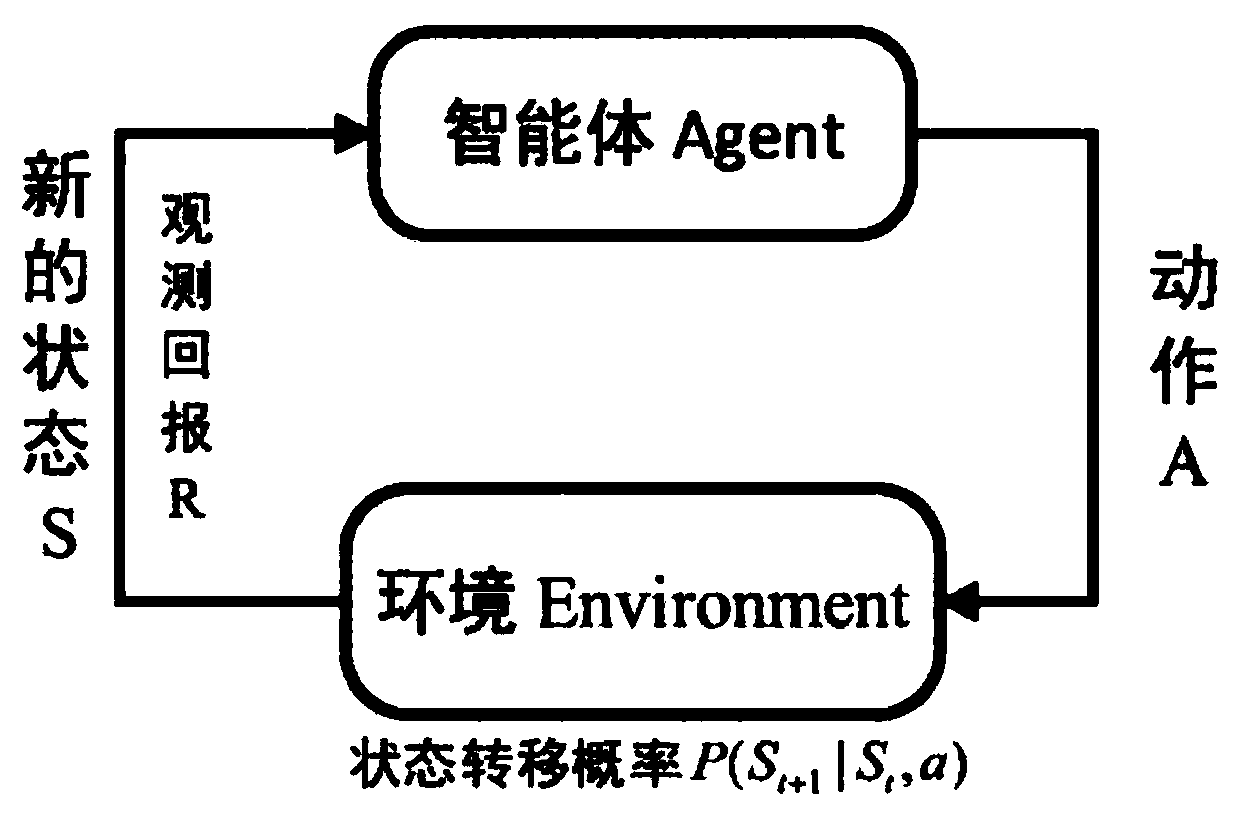

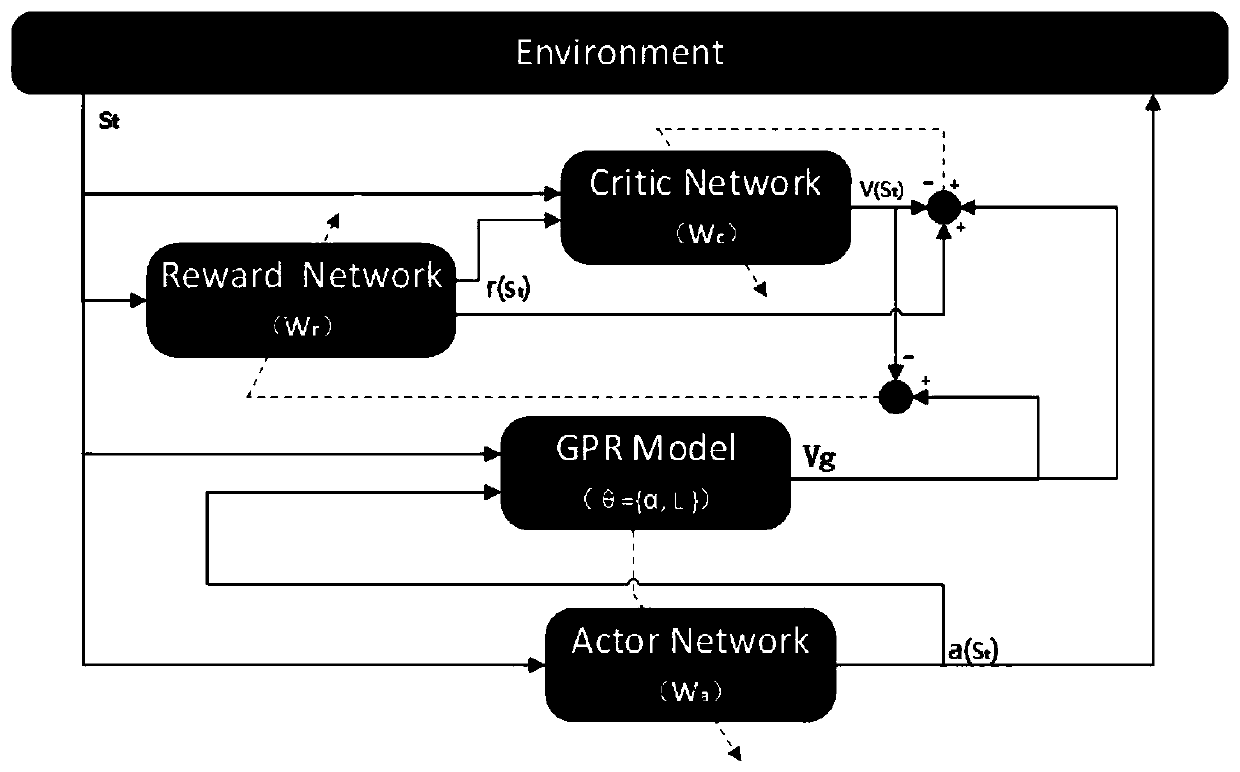

The invention discloses a reinforcement learning reward self-learning method in a discrete manufacturing scene. The method comprises the following steps: 1, refining the process of the current production line, wherein g belongs to G = {g1, g2,..., gN}, and the intelligent agent reaches a preset target g and is recorded as an interaction sequence episode; according to the initial parameters, obtaining multiple sections of episodes corresponding to the g1 as a target, taking state actions in the episodes and a state difference value delta as a training data set to be input into a GPR module, andobtaining a system state transition model based on state difference; enabling the intelligent Agent to continue to interact with the environment to obtain a new state st, and enabling a Reward network to output r (st), enabling an Actor network to output a (st), enabling a Critic network to output V (st) and enabling a GPR module to output value function Vg as the updating direction of the whole;when the absolute value of Vg-V (st) is smaller than epsilon, considering that award function learning under the current procedure is completed, and carrying out parameter storage of the Reward network; continuously carrying out interaction, and generating the following sub-target g < n + 1 > as the episodes of the updating direction for updating the GPR; and when the set target G = {g1, g2,...,gN} is all realized in sequence, finishing the process learning of the production line.

Owner:GUANGDONG UNIV OF TECH

Intelligent factory management method and system

InactiveCN109308057AIncrease productivityReduce manufacturing costTotal factory controlProgramme total factory controlOrder formManufacturing execution system

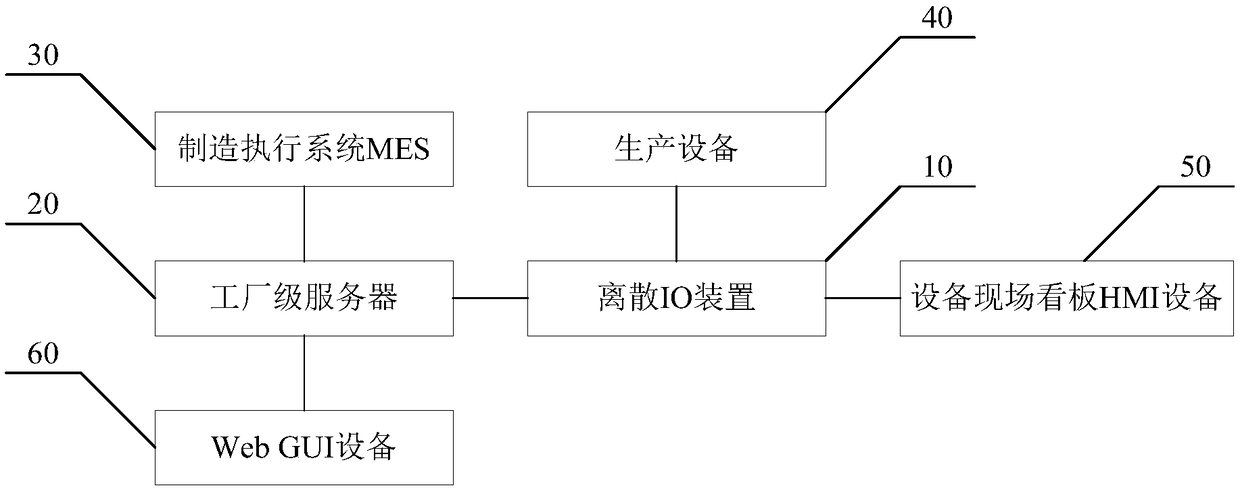

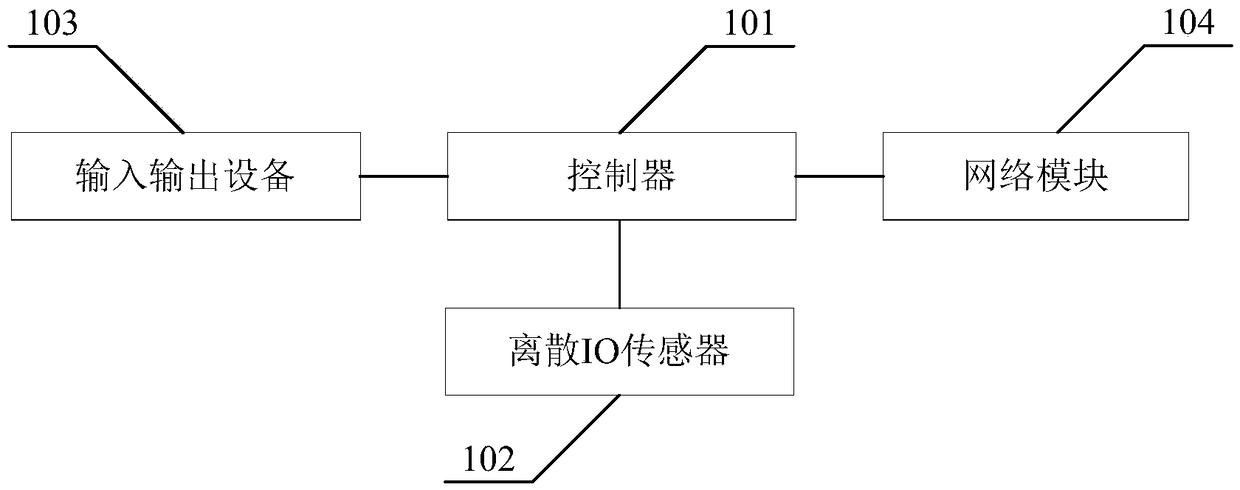

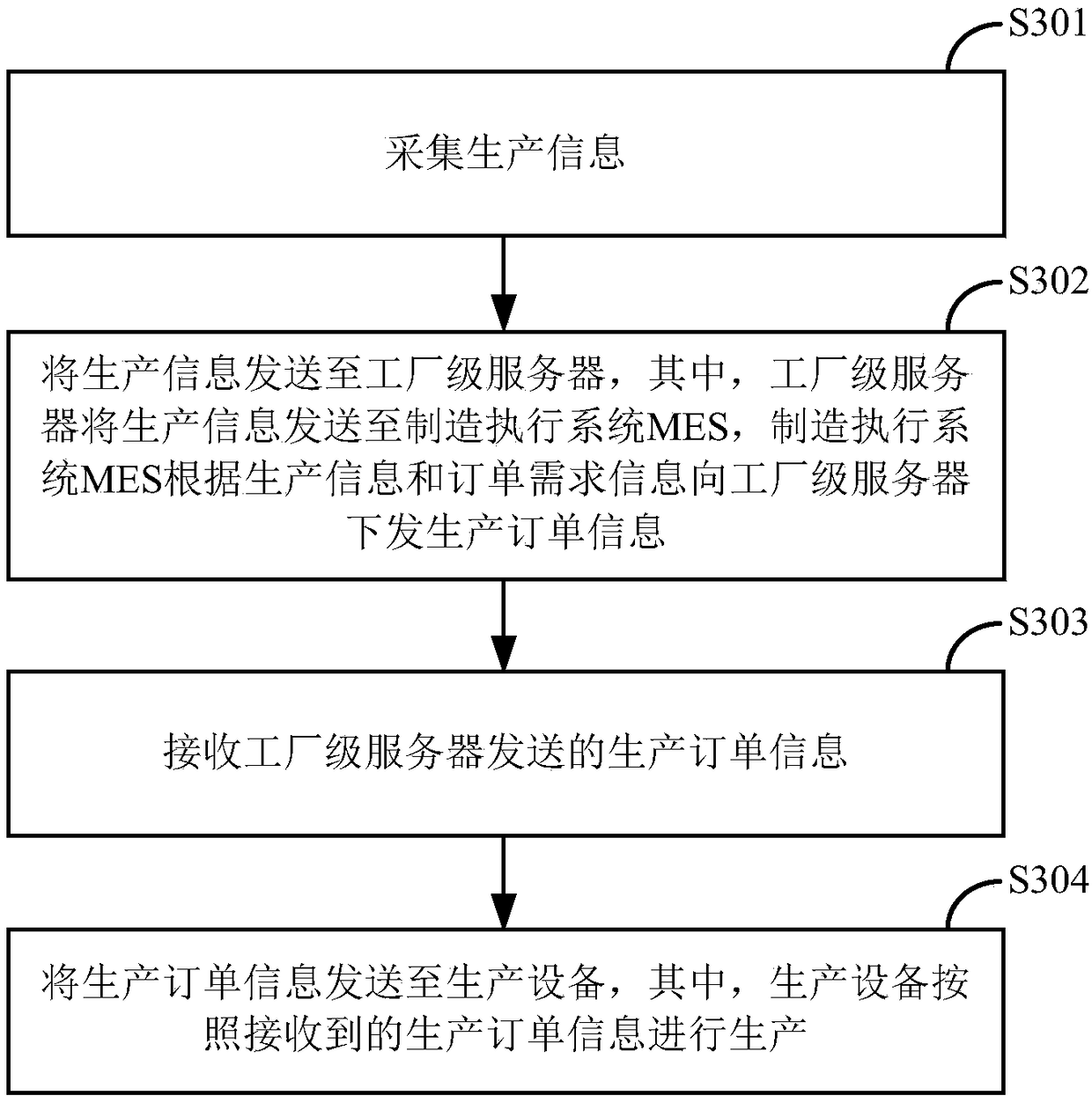

The invention provides an intelligent factory management method and system. The system comprises a discrete IO device used for collecting production information, a factory-level server communicating with the discrete IO device and used for receiving the production information sent by the discrete IO device, and a manufacturing execution system (MES) communicating with the factory-level server andused for receiving the production information sent by the factory-level server and issuing production order information according to the production information and order demand information, wherein the factory-level server is further used for receiving the production order information issued by the MES, and sending the received production order information to production equipment through the discrete IO device; and the production equipment is used for carrying out production according to the received production order information. According to the intelligent factory management method and system, the technical effect of carrying out comprehensive digital information management on a production process of a discrete manufacturing enterprise is achieved.

Owner:SOOAR BEIJING INVESTMENT MANAGEMENT GRP

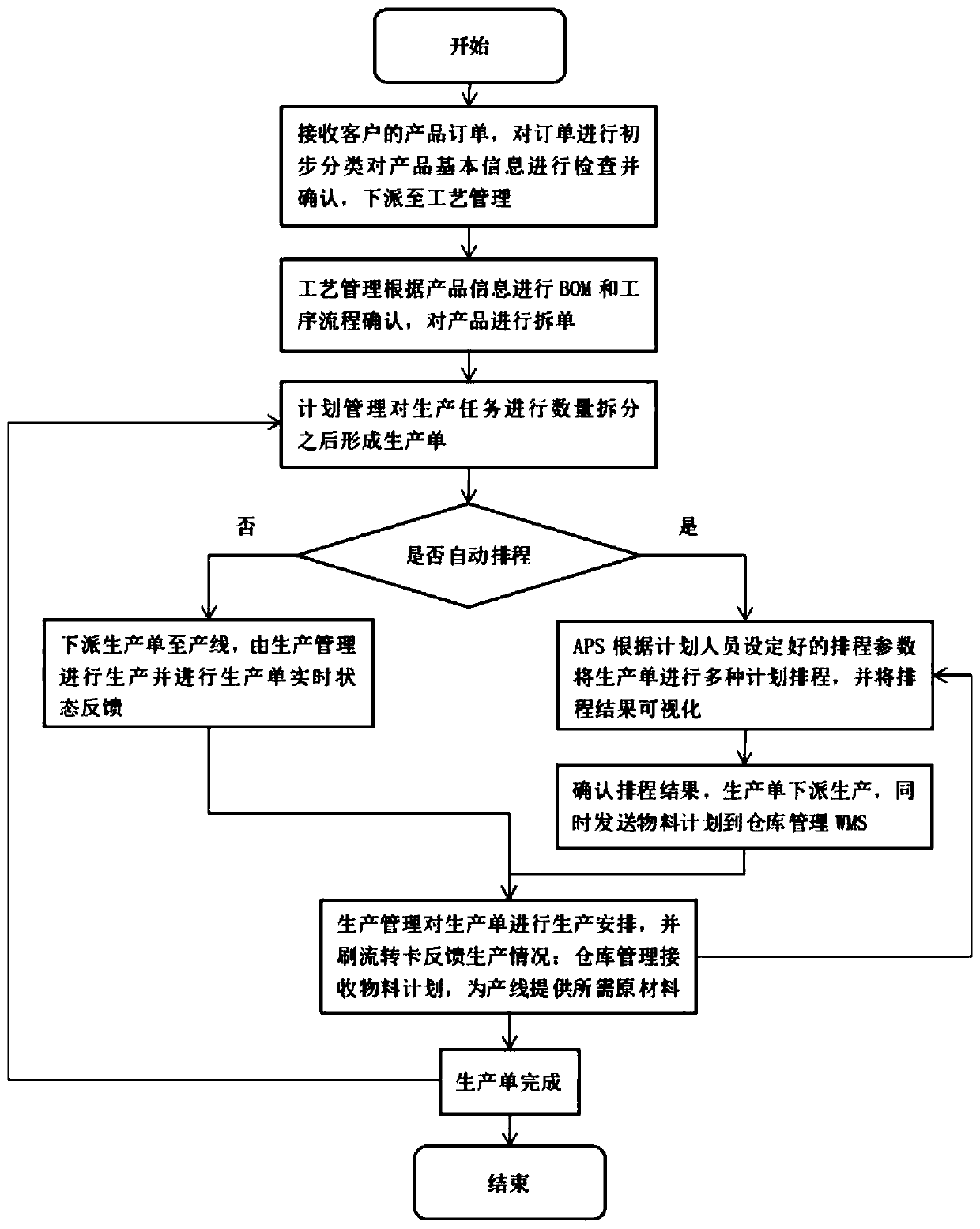

Discrete manufacturing industry-oriented dynamic production plan scheduling method

PendingCN111126748ARealize dynamic adjustmentAvoid influenceResourcesManufacturing computing systemsClosed loop feedbackResource utilization

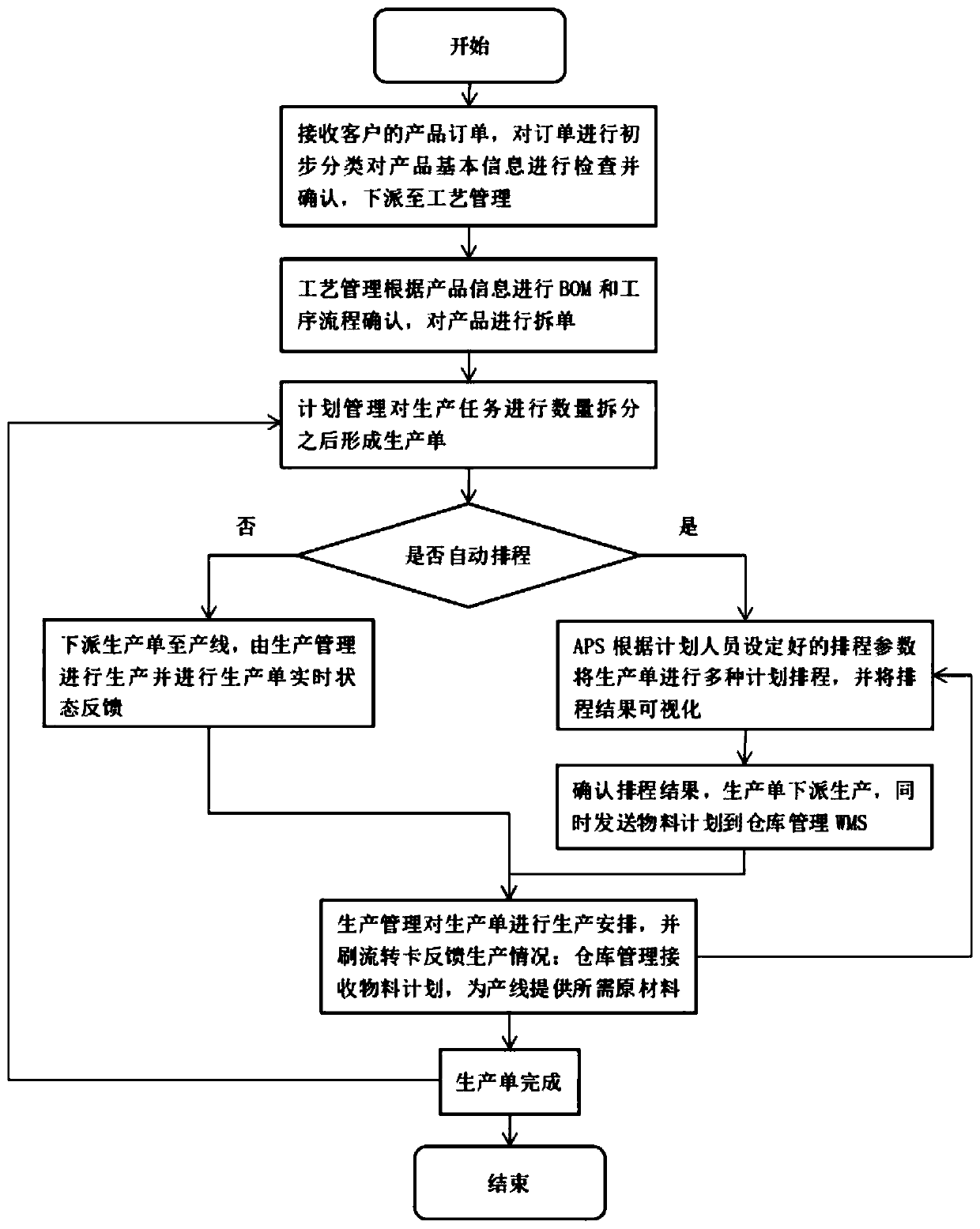

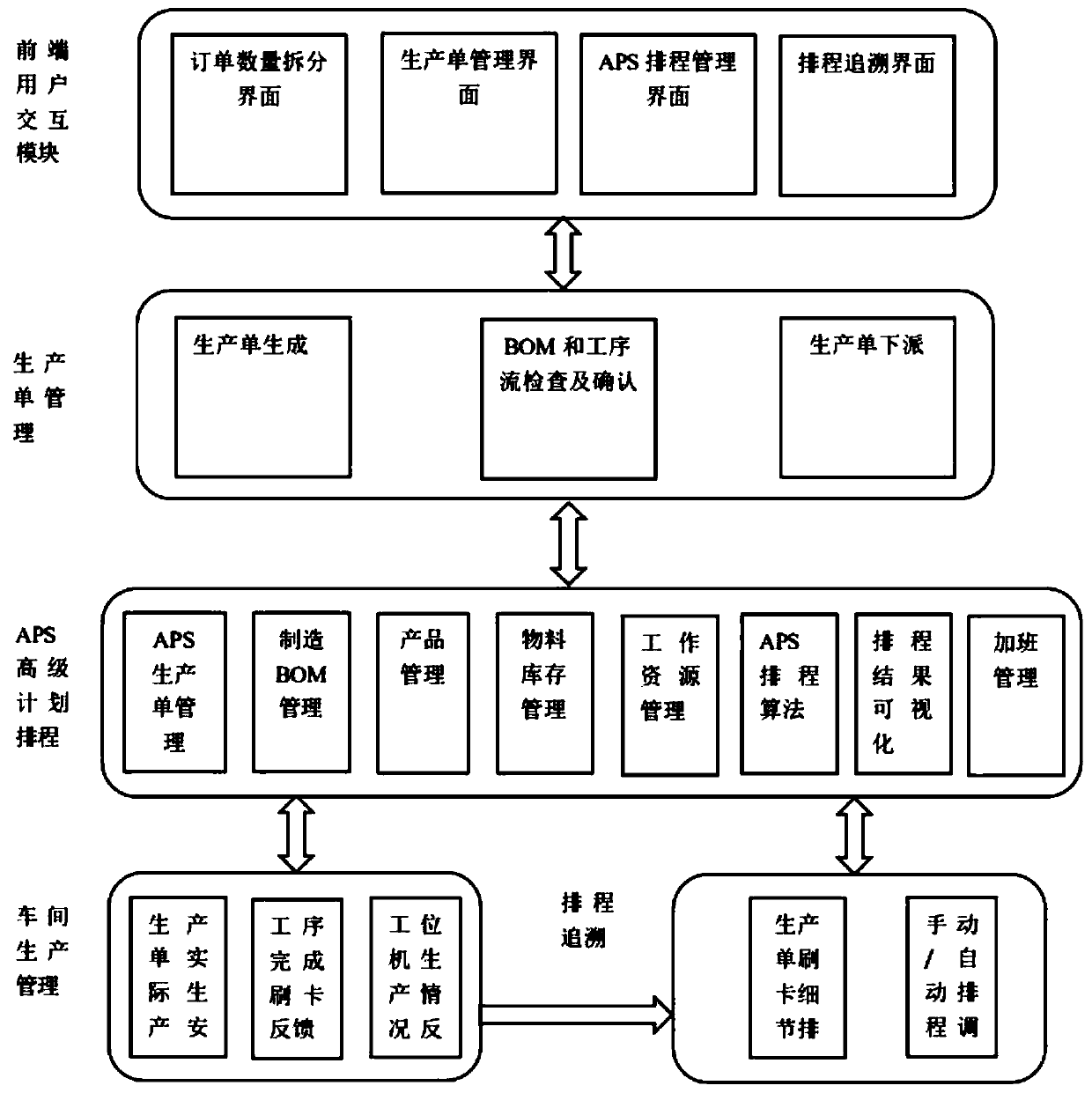

The invention discloses a discrete manufacturing industry-oriented dynamic production plan scheduling method, which comprises the following steps of: firstly, a customer order is received, and a process management module splits the customer order to generate a production task according to product information; a plan management module generates a production order according to the production task, and an advanced plan scheduling module automatically schedules the production order according to scheduling parameters set by a planner and dispatches the production order for production according to ascheduling result; a production management module receives the production list and arranges production; a warehouse management module receives the material plan and prepares raw materials for the production line; and a scheduling tracing module feeds back the actual production information to the plan management module, dynamically adjusts a scheduling result, and forms closed-loop feedback from plan scheduling to actual production. According to the method, the scheduling result is dynamically adjusted according to unstable factors in actual production, the reasonable resource utilization rateis ensured, and the visual material plan and production plan are generated from multiple angles under the condition of considering enterprise resources, a production field and a dispatching method.

Owner:盐城雷来钧智能制造技术有限公司

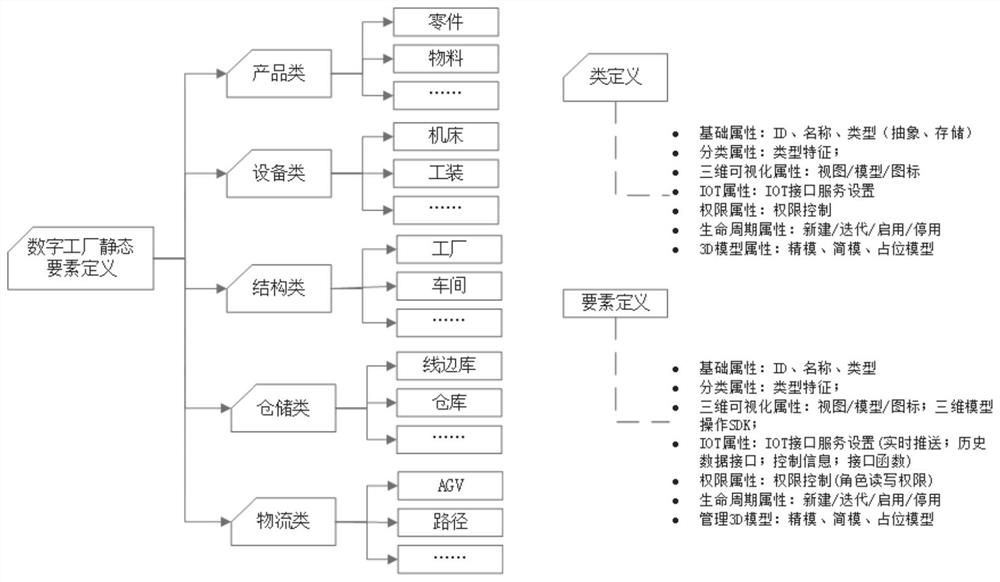

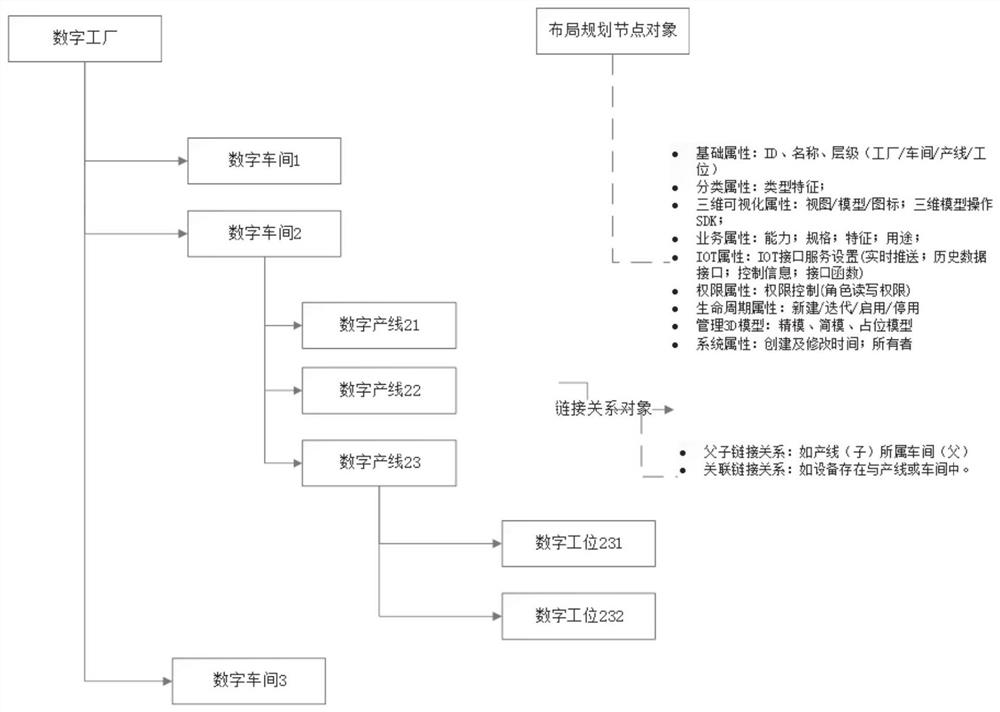

Digital twinning application-oriented three-dimensional digital factory modeling method and system

ActiveCN113033001ASupport simulationWith 3D visualization propertiesForecastingDesign optimisation/simulationDigital transformationBusiness enterprise

The invention provides a digital twinning application-oriented three-dimensional digital factory modeling method and system, and the method comprises the steps: carrying out the abstract analysis of a core entity object related to a digital factory, and constructing a basic three-dimensional entity model object; carrying out abstract analysis on a core business process object related to the digital factory, and constructing a basic three-dimensional process business model object; carding an association relationship between the entity model and the business model, and constructing a basic association relationship object; and constructing a composite digital factory service model based on the constructed entity model, the constructed service model and the model relationship. According to the method and system, the dynamic and static models of the digital factory are constructed according to the business attributes, a model basis and a heterogeneous business system and equipment integration application mechanism are provided for digital twinning application, and a basis is provided for digital transformation and digital brocade construction of discrete manufacturing enterprises.

Owner:山东山大华天软件有限公司

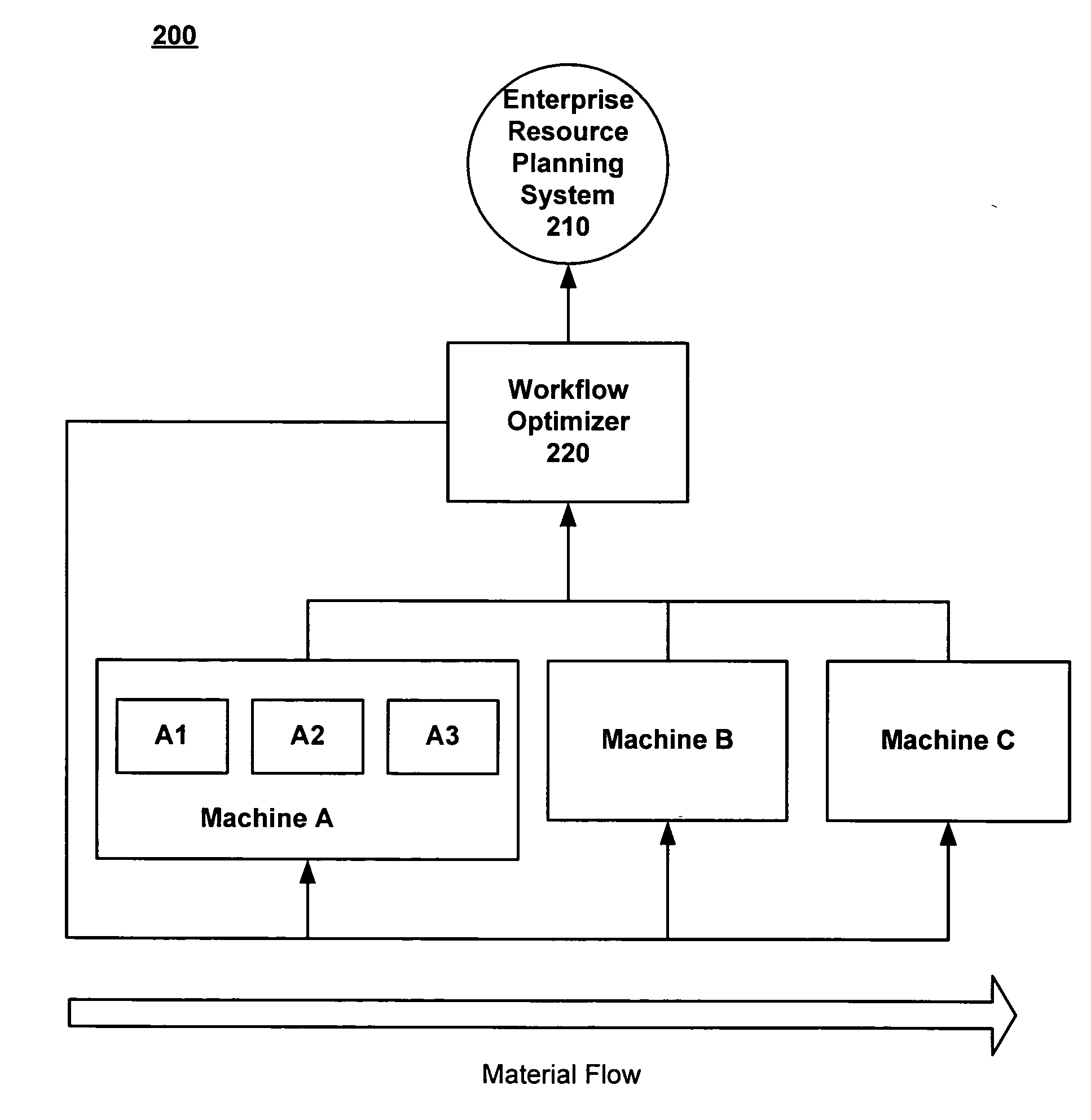

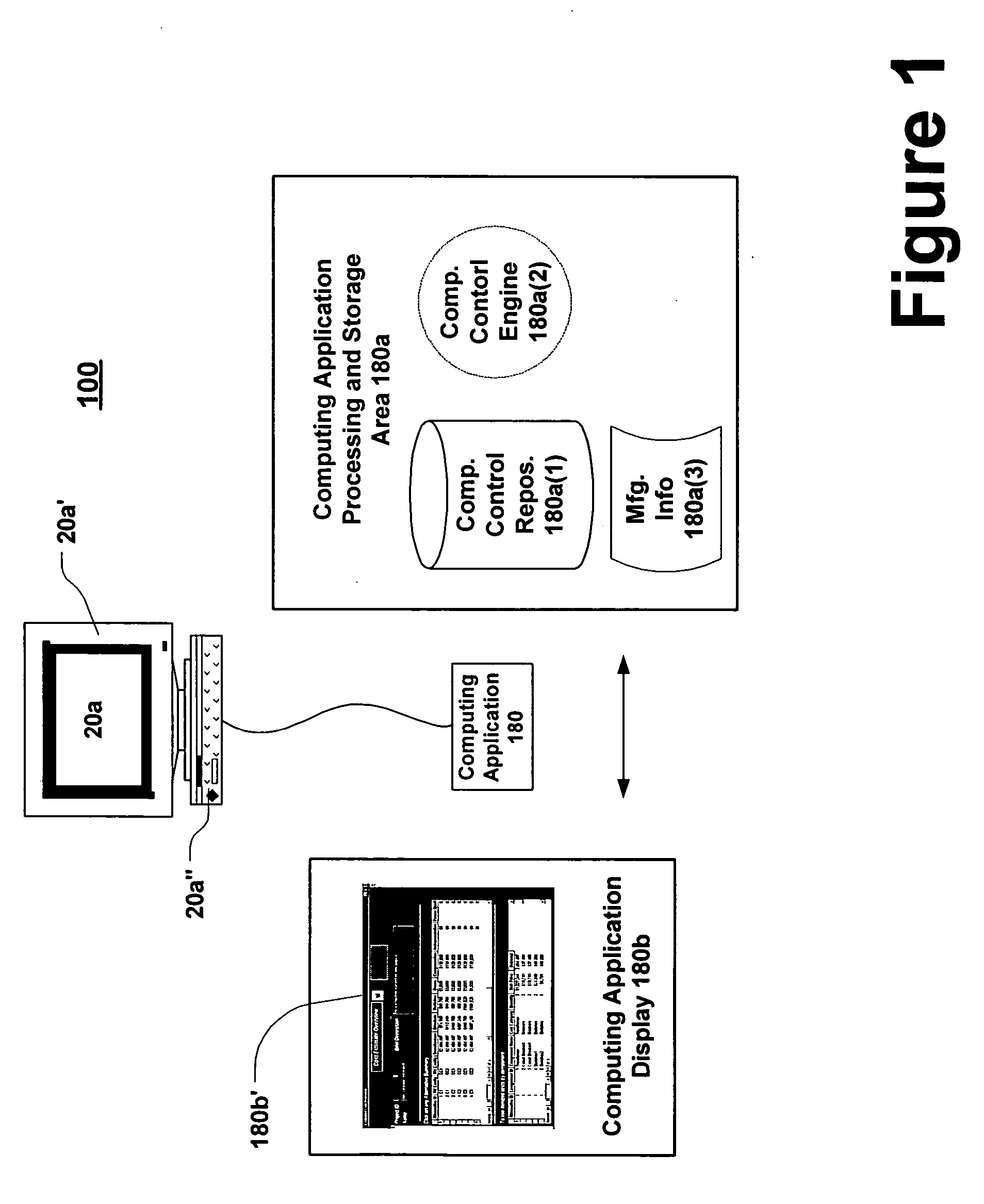

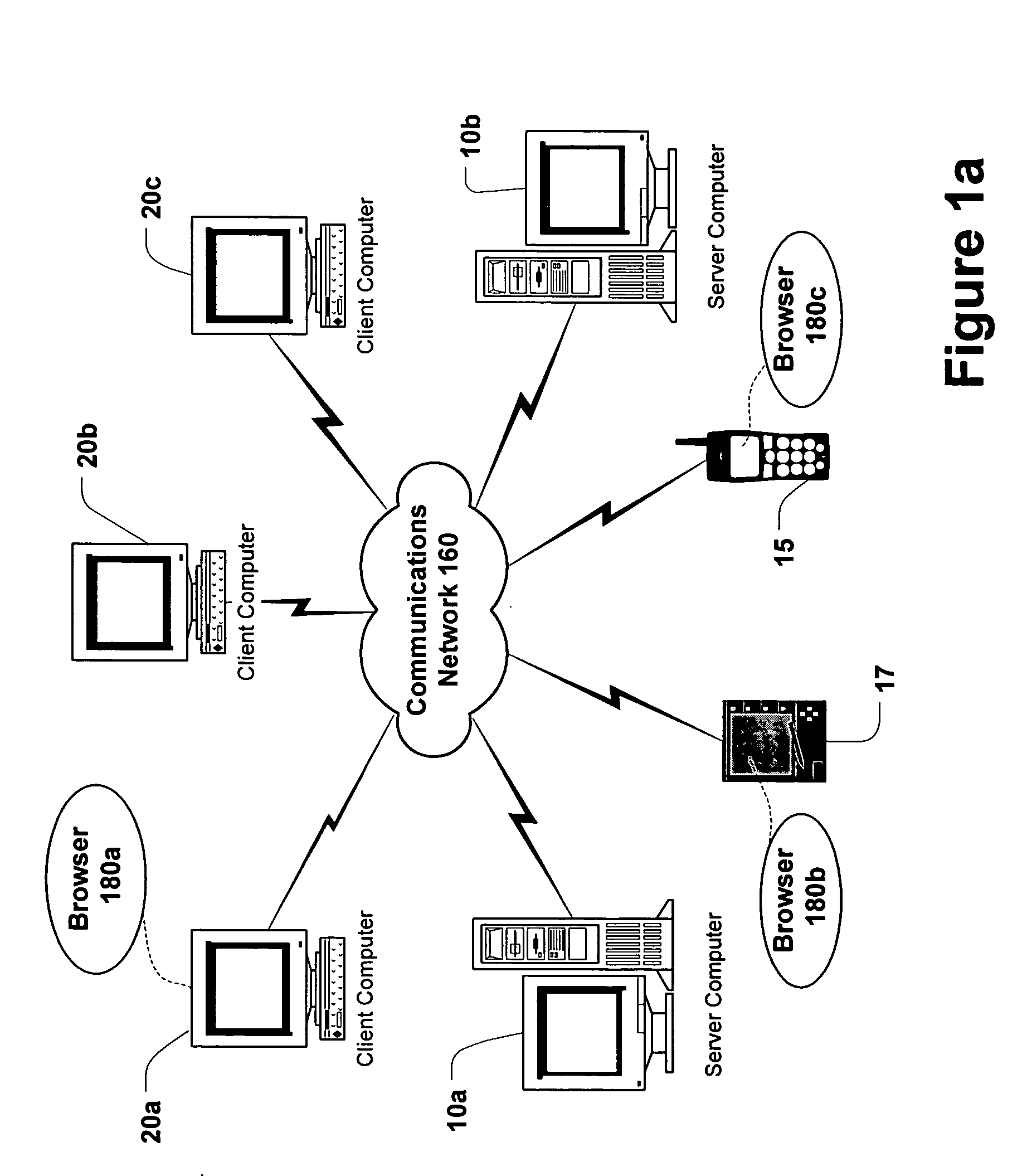

Industrial information technology (IT) workflow optimizer for discrete manufacturing

InactiveUS20050096769A1Improve manufacturing capacityAvoid manufacturing down-timeForecastingSpecial data processing applicationsProcess optimizationManufacturing data

The invention contemplates a system and method offering optimization and management of manufacturing resources to obtain optimal manufacturing capacities and to avoid manufacturing down-time currently realized through manual operation and control of manufacturing resources. In an illustrative implementation, the present invention contemplates an exemplary optimization computing application operating in a computing environment which communicates with, cooperates with, and provides optimization data for use in managing manufacturing resources (e.g. manufacturing machines). The computing application accepts a variety of manufacturing related information as input, processes such manufacturing data and generates optimization suggestions for use to manage manufacturing processes and to optimize manufacturing capacities. The optimization data may be applied to a particular manufacturing environment to control the operation of manufacturing resources such that optimization is realized.

Owner:ABB RES LTD

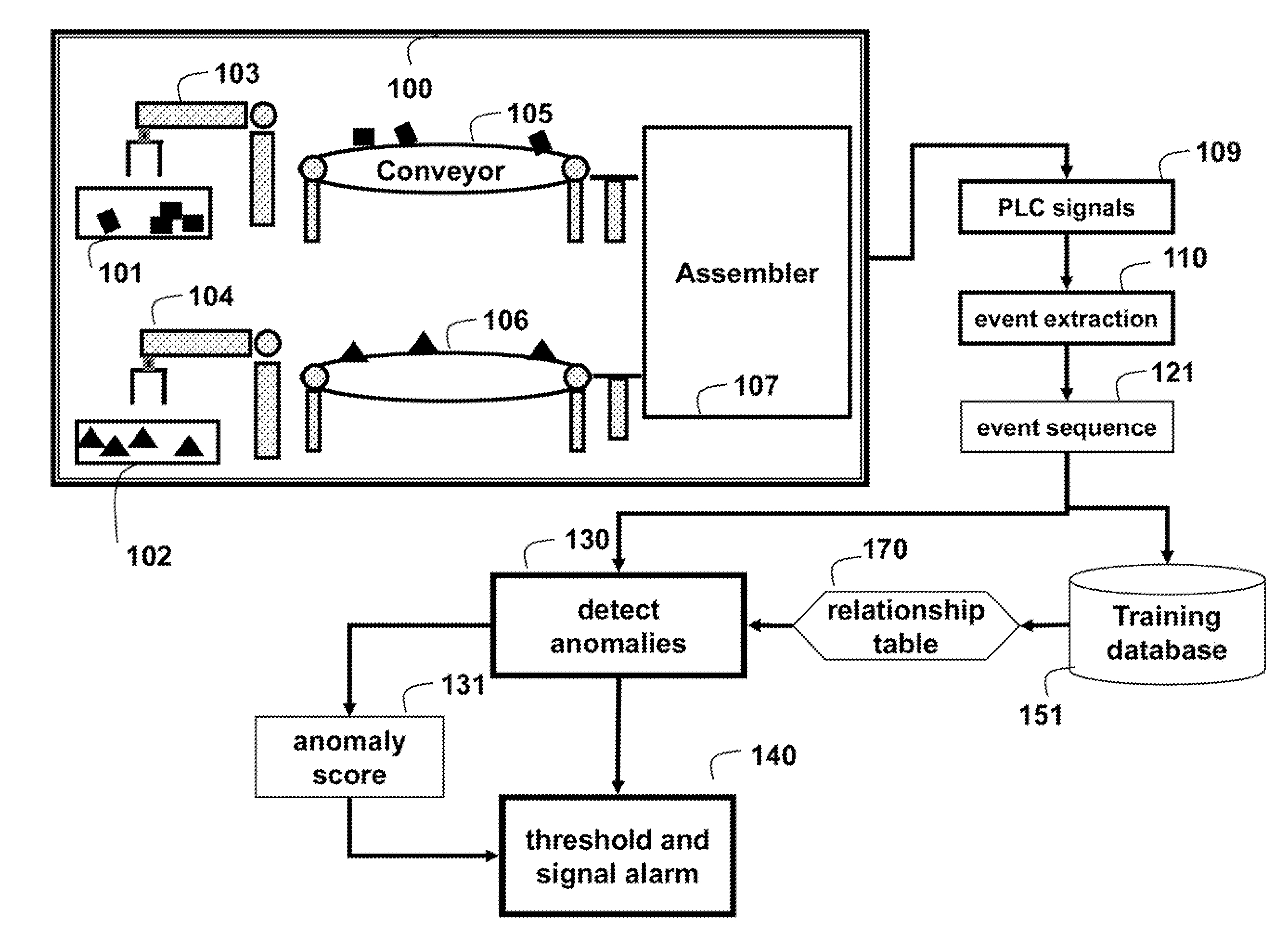

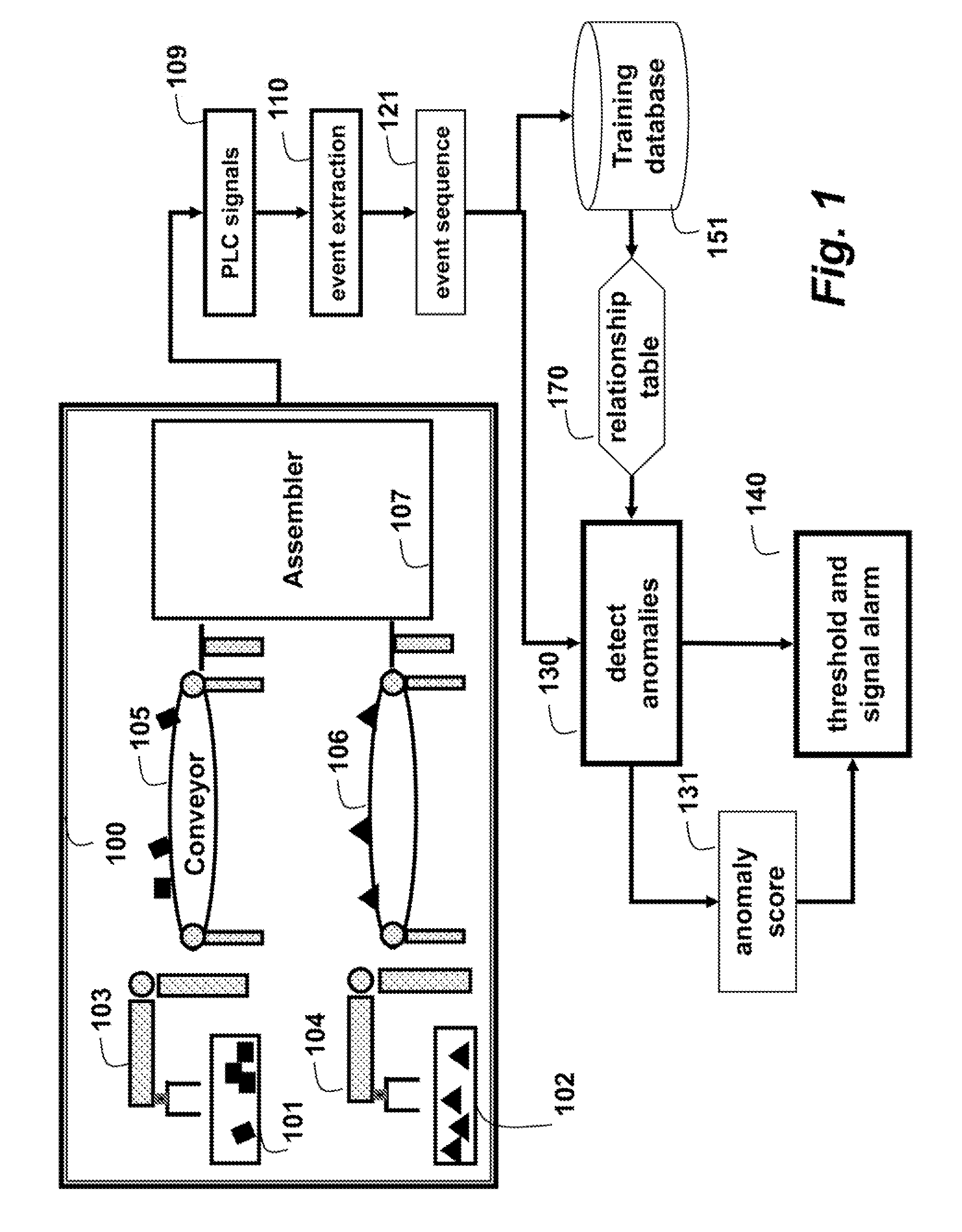

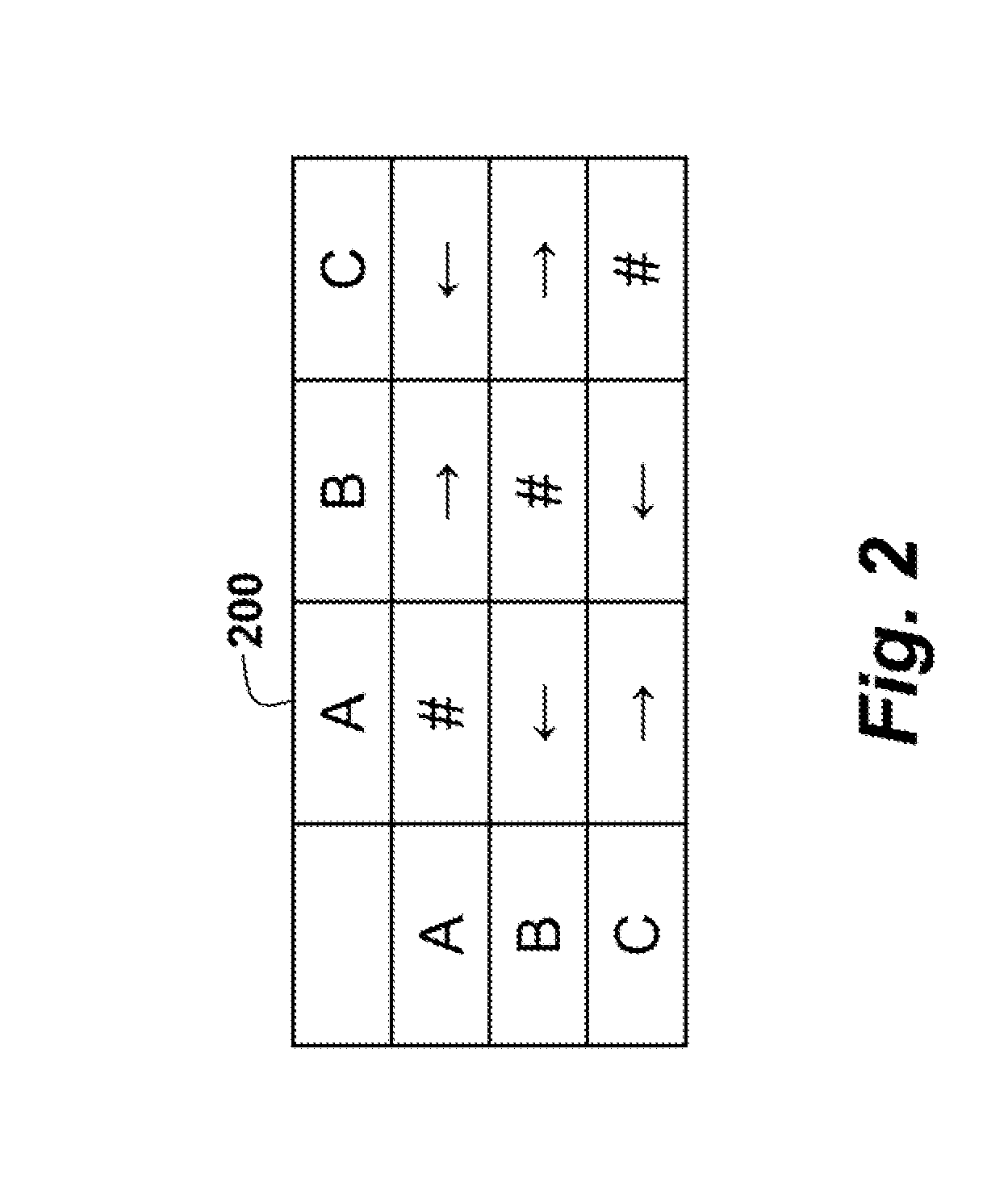

Method for Anomaly Detection in Discrete Manufacturing Processes

InactiveUS20150277416A1Accurate operationTesting/monitoring control systemsProbabilistic networksAnomaly detectionAlgorithm

A method detects an anomaly in a discrete manufacturing process (DMP) by first acquiring signals from the DMP. Events are extracted from the signals as a sequence. Then, it is determined whether the sequence is inconsistent with a normal behavior as represented by a log-based ordering relationship table. If true, then an alarm is signaled.

Owner:MITSUBISHI ELECTRIC RES LAB INC

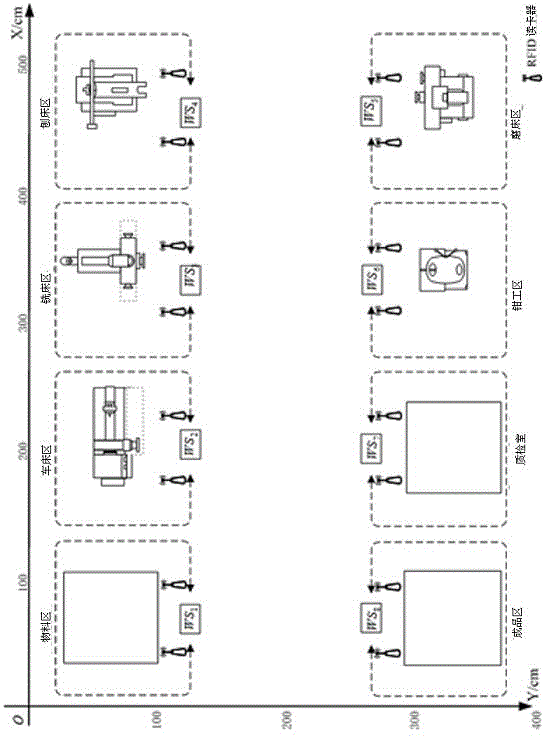

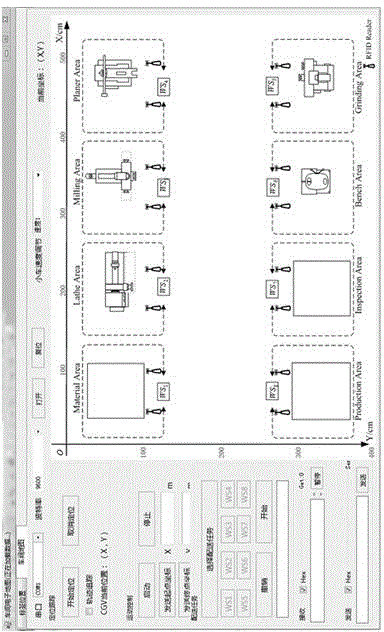

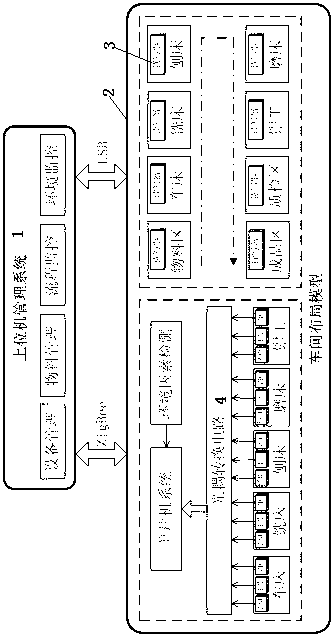

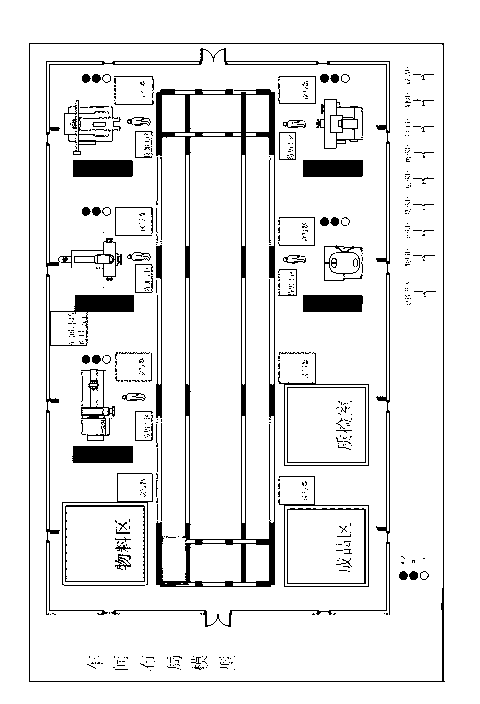

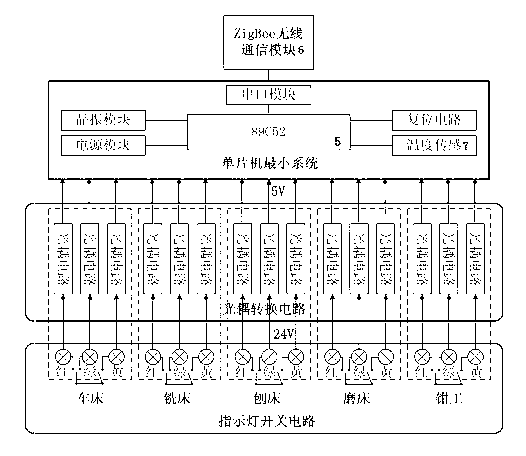

Monitoring teaching demonstration method and system of internet-of-things-based discrete manufacturing workshop

ActiveCN103165014AHigh degree of automationEfficient management modeEducational modelsData acquisitionThe Internet

The invention discloses a monitoring teaching demonstration method and a monitoring teaching demonstration system of an internet-of-things-based discrete manufacturing workshop and relates to a workshop layout model and upper computer management software. The complex environment of a manufacturing workshop field is modeled, and a demonstration platform on which a material machining process is controlled and managed by a discrete manufacturing workshop monitoring system is simulated. The workshop layout model is used for simulating the layouts of machine tools and data acquisition equipment in the whole production workshop. The upper computer management software is used for simulating a workshop internet-of-things monitoring and management system. According to the invention, the management and monitoring of staff and materials in a machining flow process in the discrete manufacturing workshop monitoring system are demonstrated in a concentrated mode. Compared with the conventional manufacturing workshop, the discrete manufacturing workshop monitoring system is high in degree of automation and has an efficient management mode. The invention has a great popularization value on application of the internet of things to a manufacturing workshop.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

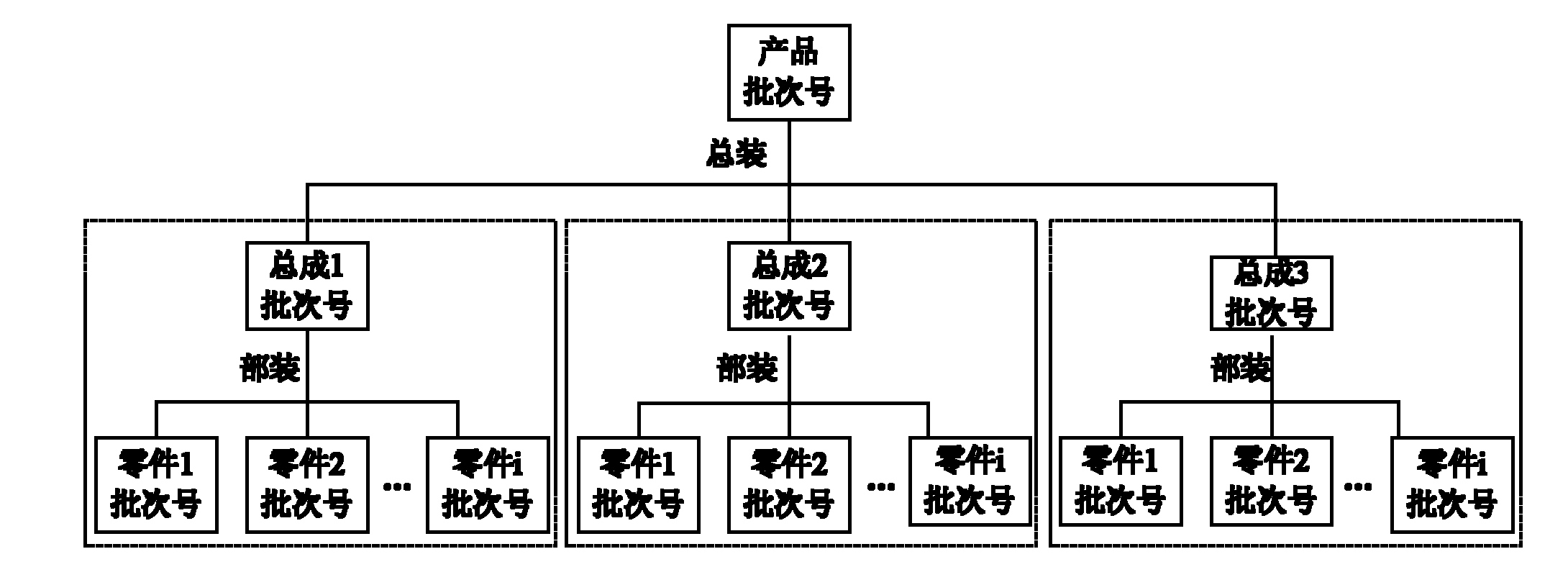

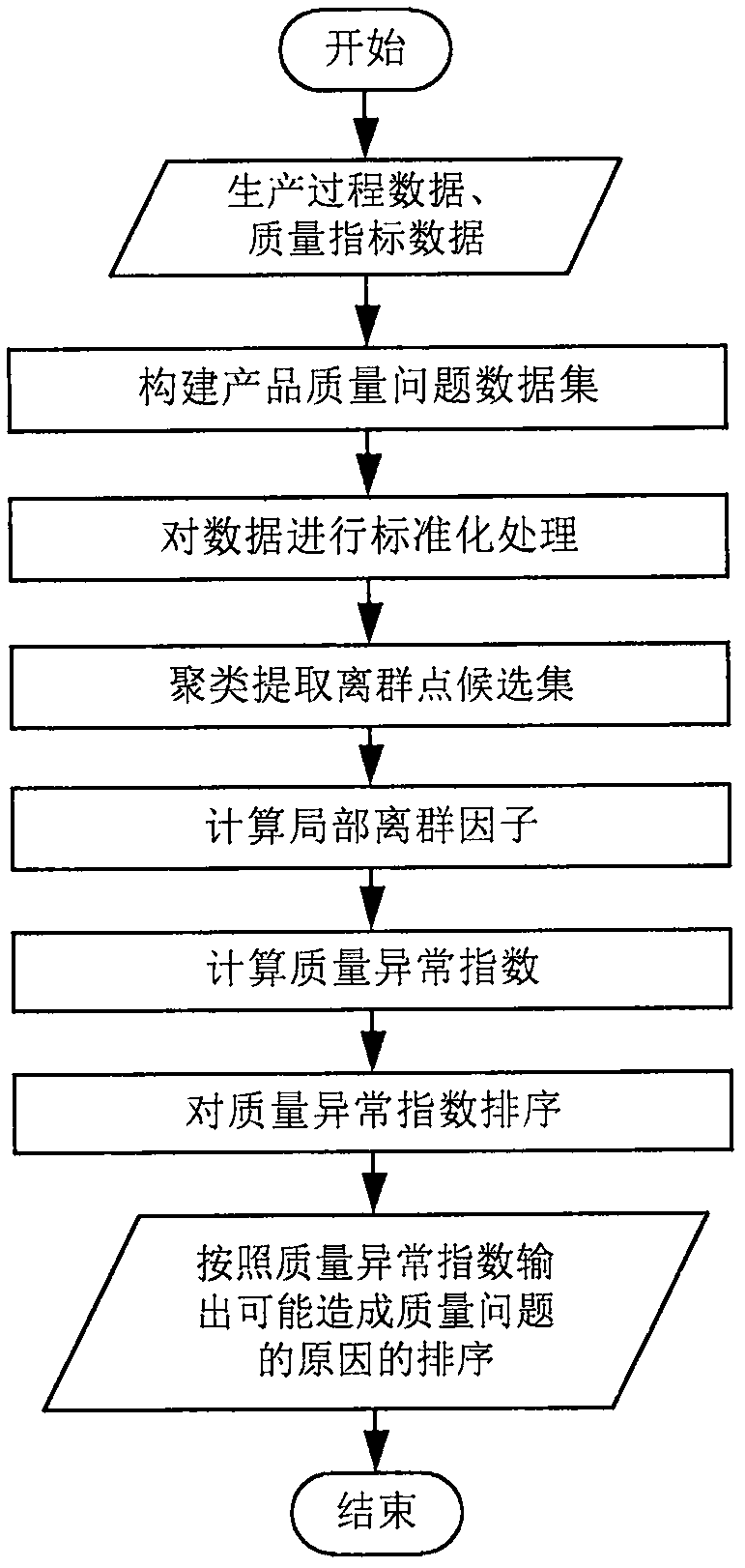

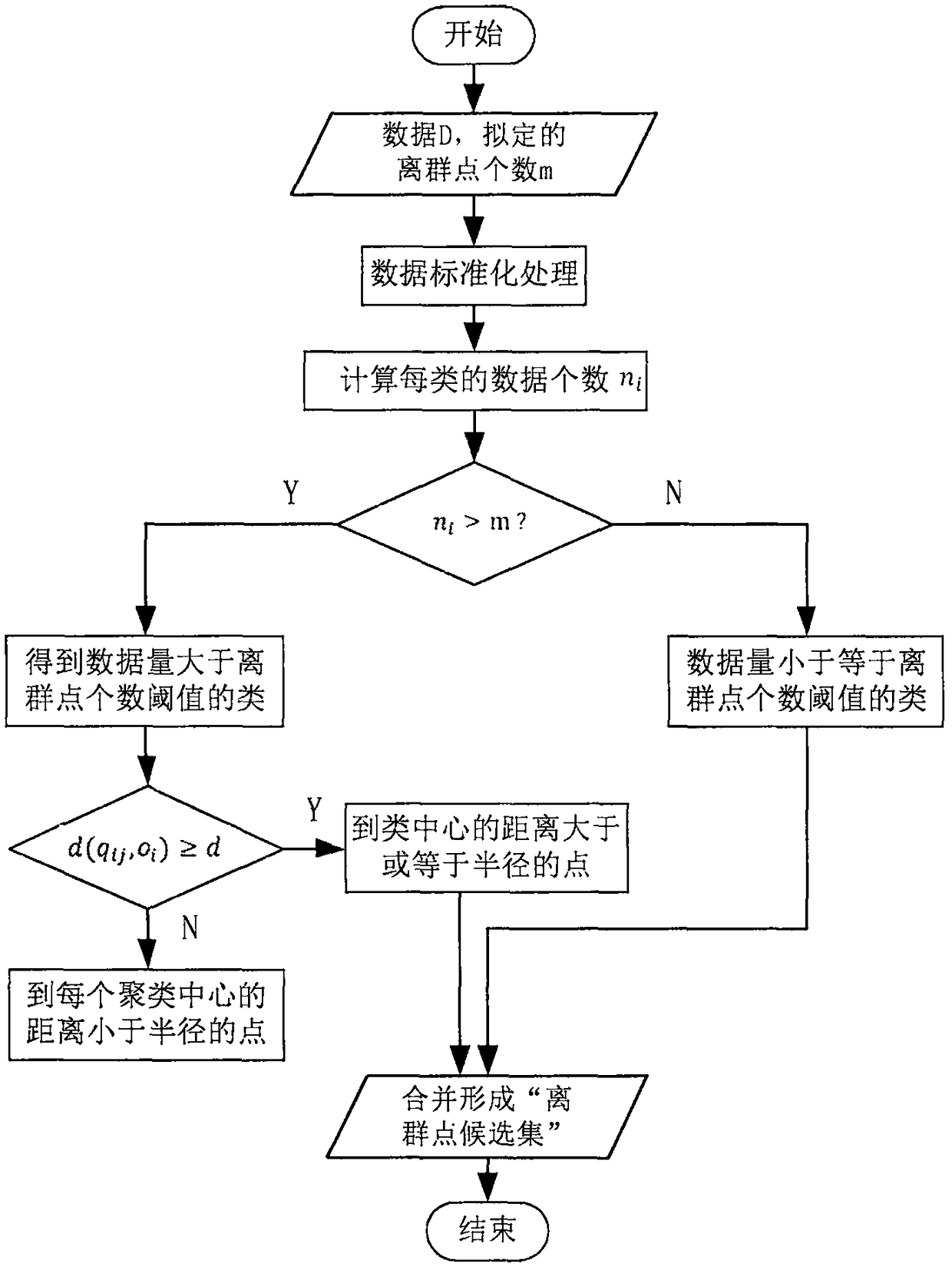

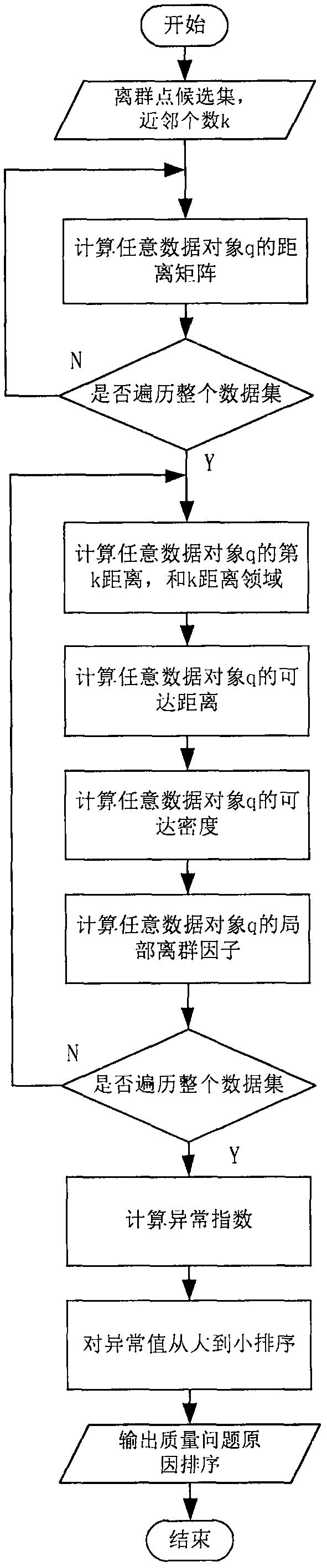

Discrete manufacturing machinery product quality tracing method based on outlier detection

The invention discloses a discrete manufacturing machinery product quality tracing method based on outlier detection, which belongs to the technical field of informationization of manufacturing industries. In view of the problem that the quality tracing method in the current discrete manufacturing process can not accurately analyze the causes of the quality problems of machinery products, a discrete manufacturing machinery product quality tracing method based on outlier detection is put forward. Firstly, m causes that possibly cause quality problems under various production conditions are extracted; then, according to the tracking data in the production process, n quality index data of the products produced under the potential causes are respectively counted, the data are used to build anm*n quality problem tracing data set, an outlier factor for the quality index data under each potential cause is then calculated, and a quality anomaly index is calculated; and finally, by comparing the sizes of the quality anomaly indexes, the possibility of a cause of a quality problem is analyzed, and important information is provided for product quality tracing.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

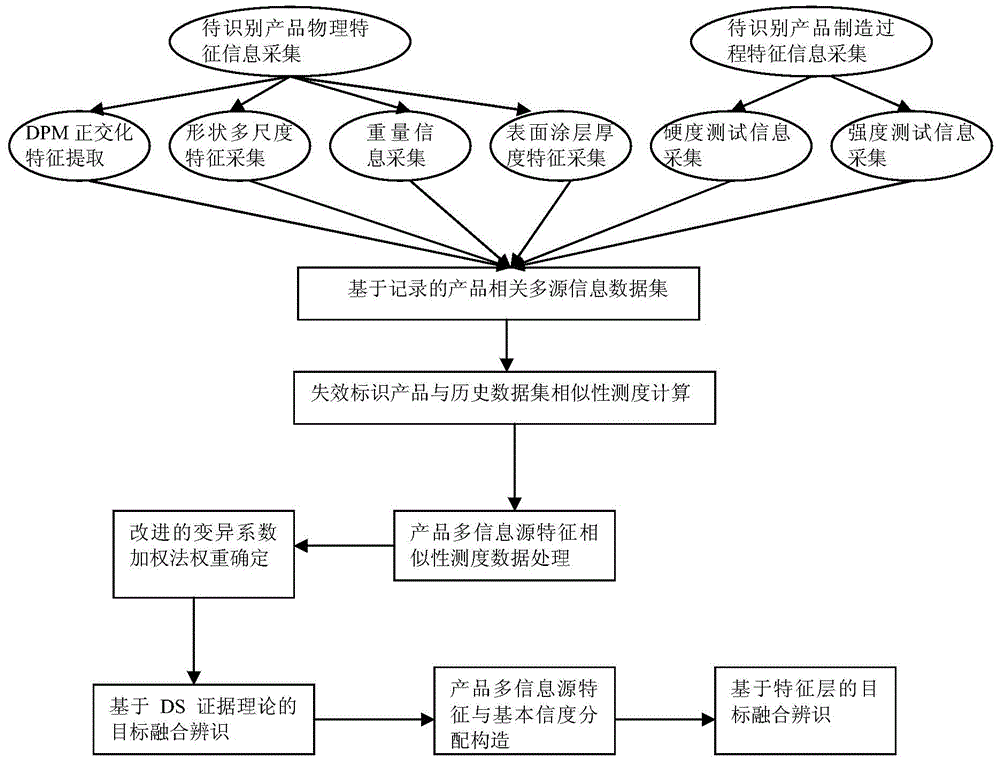

Product multi-information fusion identification failure remedying method based on D-S evidence theory

ActiveCN104091078APrevent trace breaksPrevent recognition accuracySpecial data processing applicationsFeature dataDegree of similarity

The invention discloses a product multi-information fusion identification failure remedying method based on the D-S evidence theory. The technical problem that tracking disconnection is caused by an existing method in the production process of individual products is solved. According to the technical scheme, the method comprises the steps that multi-source information correlation and data structure existing in the product physical and manufacturing process is analyzed, a product scattering and incomplete multi-source information model needed in the scattering process is built, the feature data of failure identification parts and product historical database similarity measure are calculated through a class-center-based Euclidean distance and improved variable coefficient weighting method, fusion identification is carried out on a feature layer through the D-S evidence theory, the identifications of the failure products are effectively recovered and remedied, and then the technical problem that tracking disconnection is caused in the production process of the individual products due to DM code failure is solved. Experimental results show that the identification accuracy of preventing tracking failure is larger than 95%, efficiency is high, recovering and remedying are reliable, and practicability is good.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

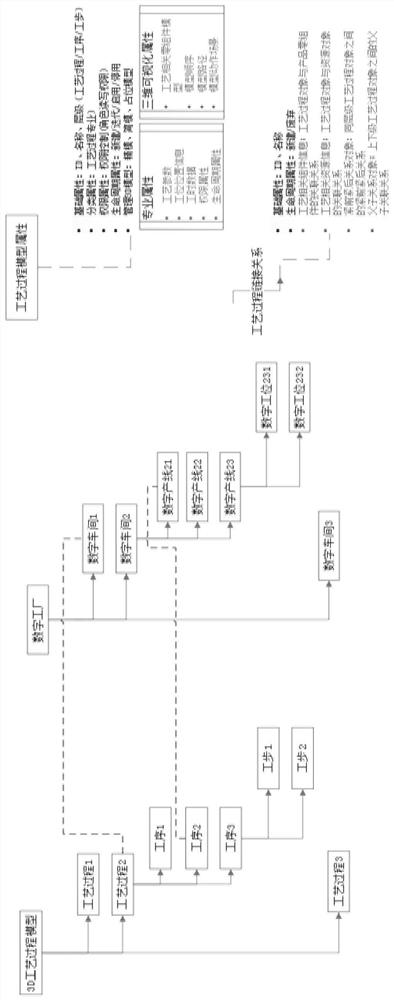

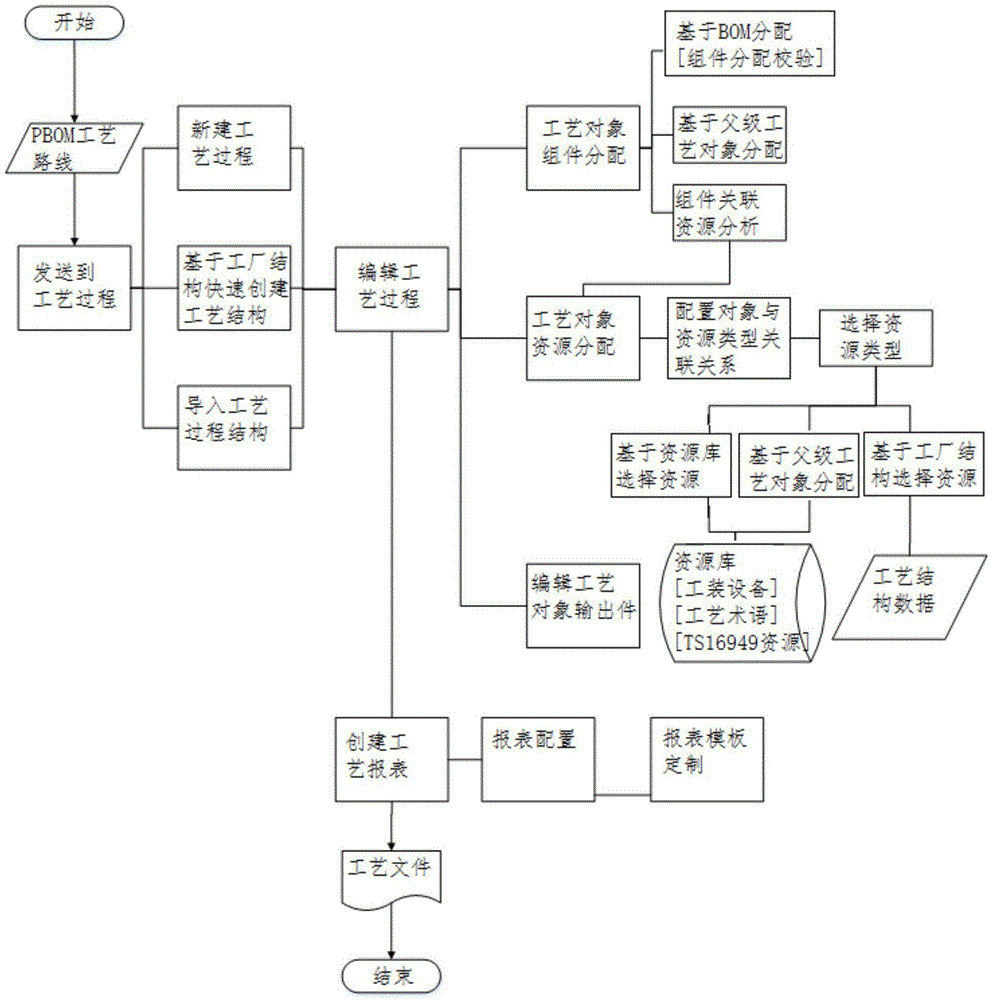

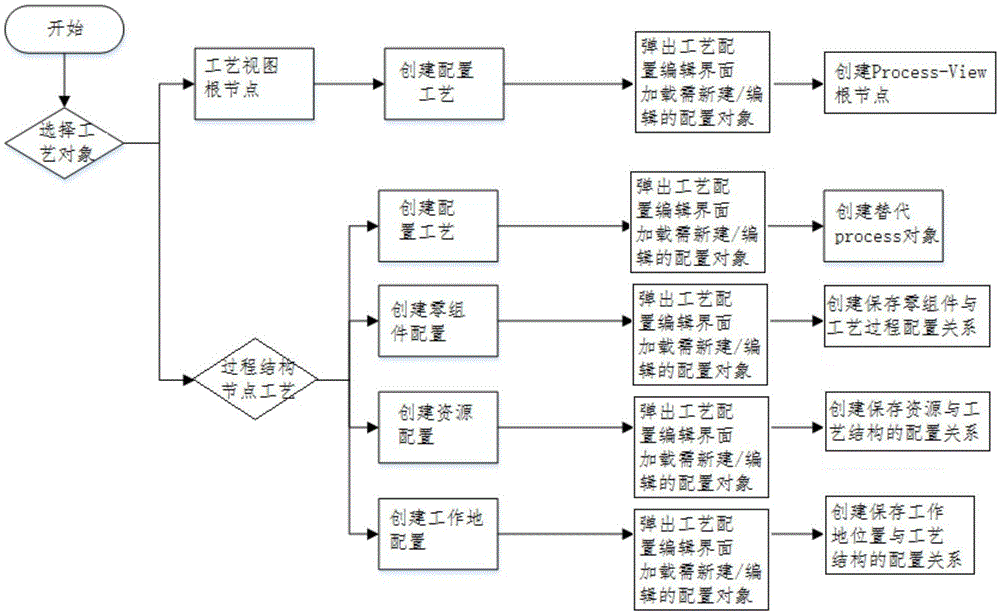

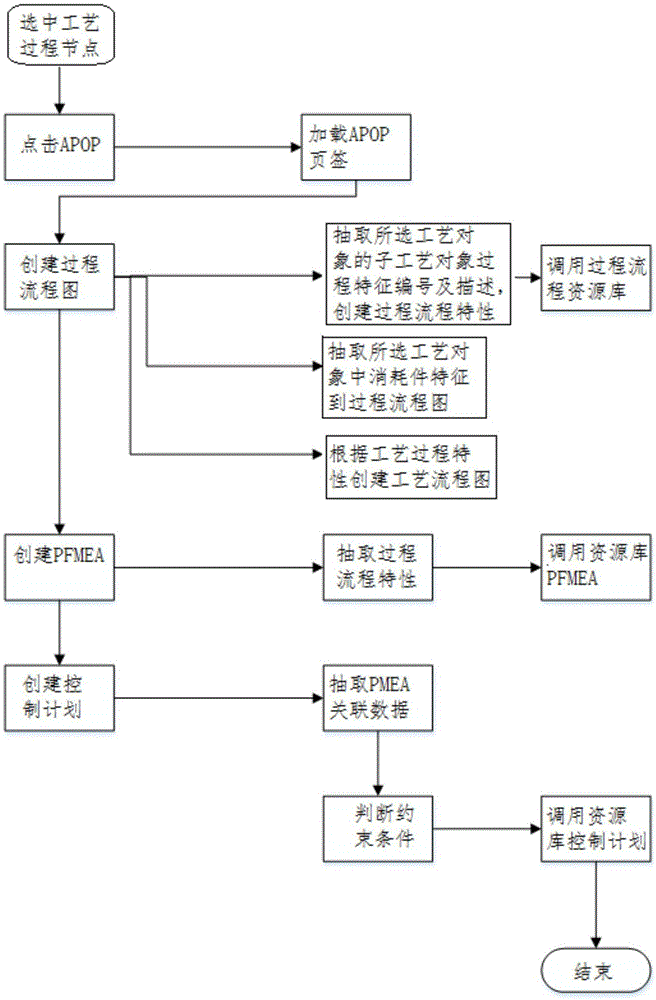

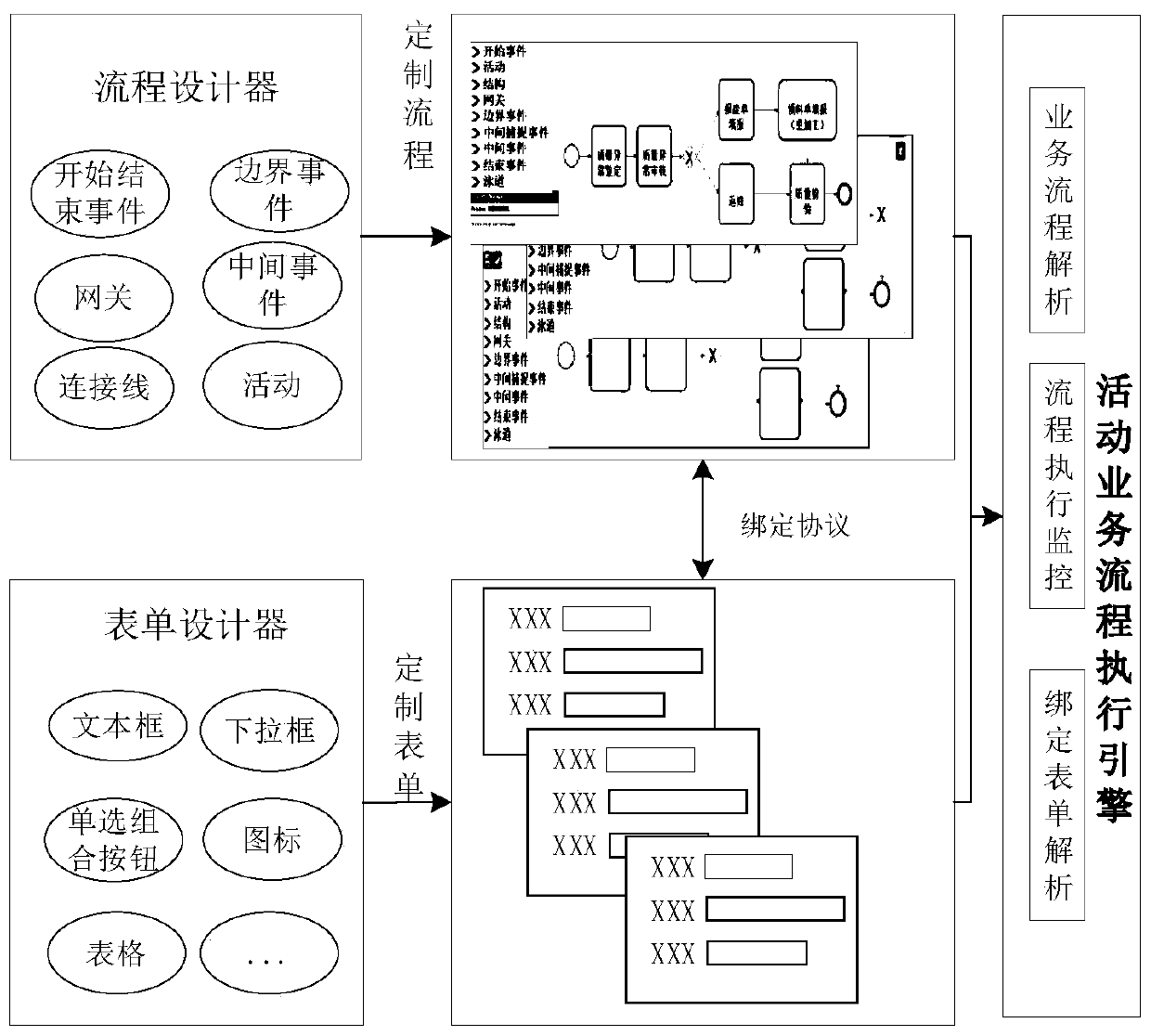

Structured process design method for discrete manufacturing industry

InactiveCN105631581AEnsure consistencyReduce redundancyResourcesManufacturing computing systemsGraphical toolsDiscrete manufacturing

The invention discloses a structured process design method for a discrete manufacturing industry. The method comprises the following steps: process service data are determined according to a process object, a process object model is built, structured process planning is carried out, and a corresponding process is designed; the consumption relation between the process object and a part, the assigned distribution relation between the process object and a resource object and a special relation between the process part and the resource object are verified; the structured process is designed and supported in a graphical environment, and a two-way interactive relation between a graphical tool and already-defined service data is built; and process nodes are selected, a process flow chart is generated based on an APQP object, and the process features and the control plan for PFMEA are built. For a whole enterprise production technology preparation process, consistency, effectiveness and reuse of the data are ensured; and a data base and a support mechanism are provided for visualization, analysis and optimization of a subsequent manufacturing process.

Owner:山东山大华天软件有限公司

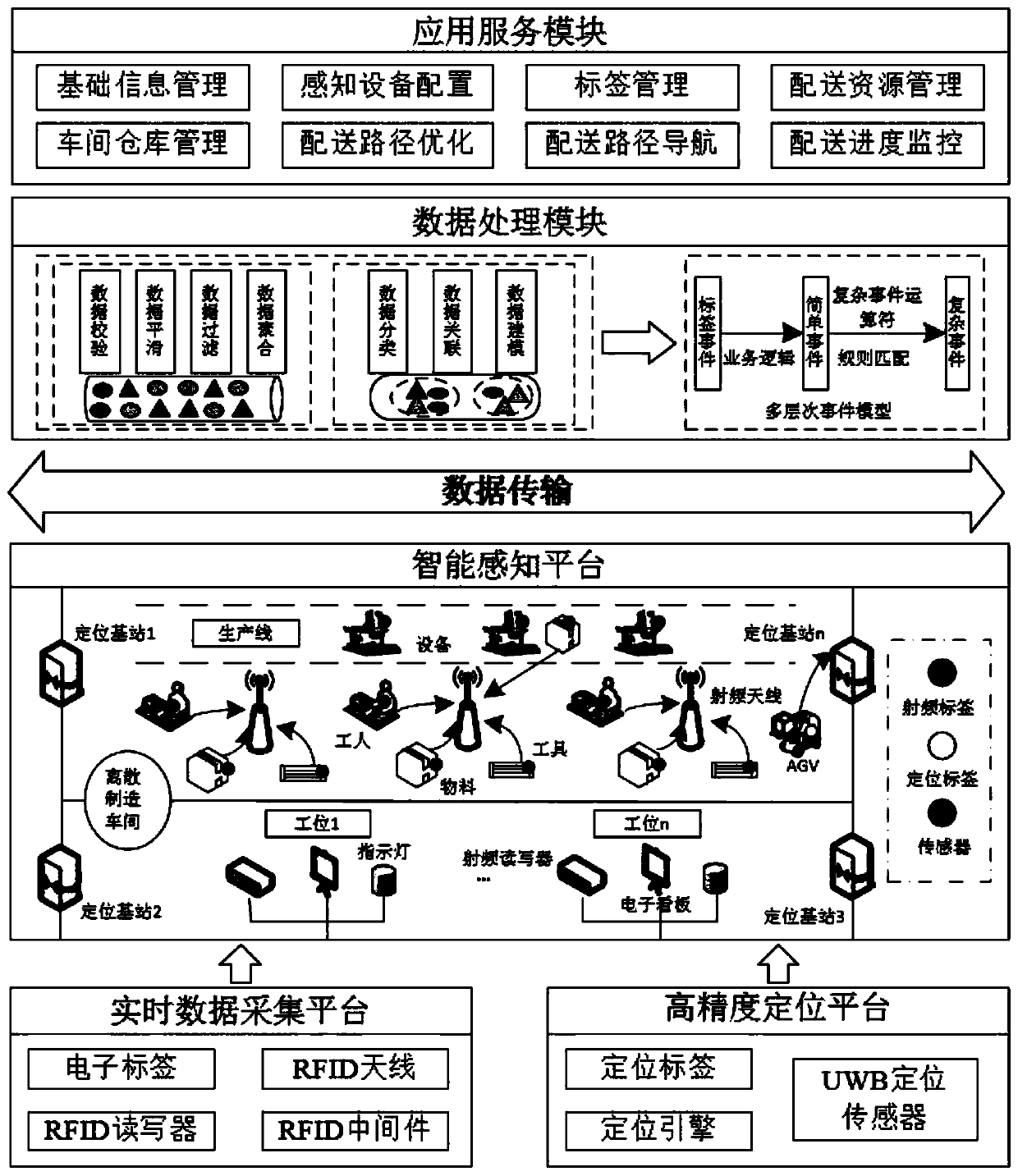

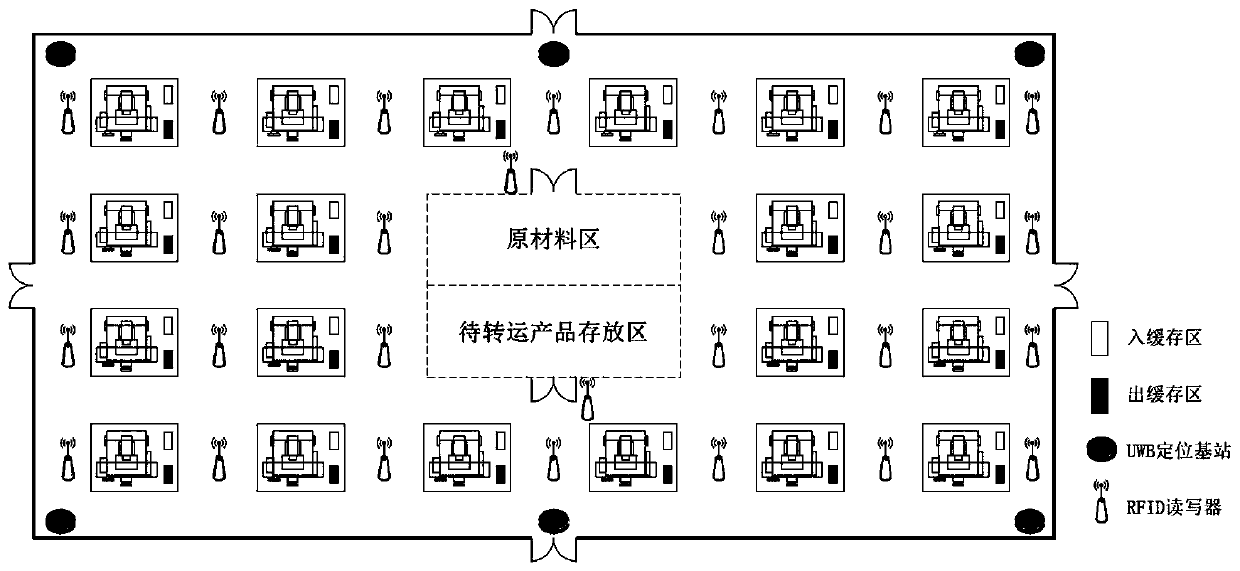

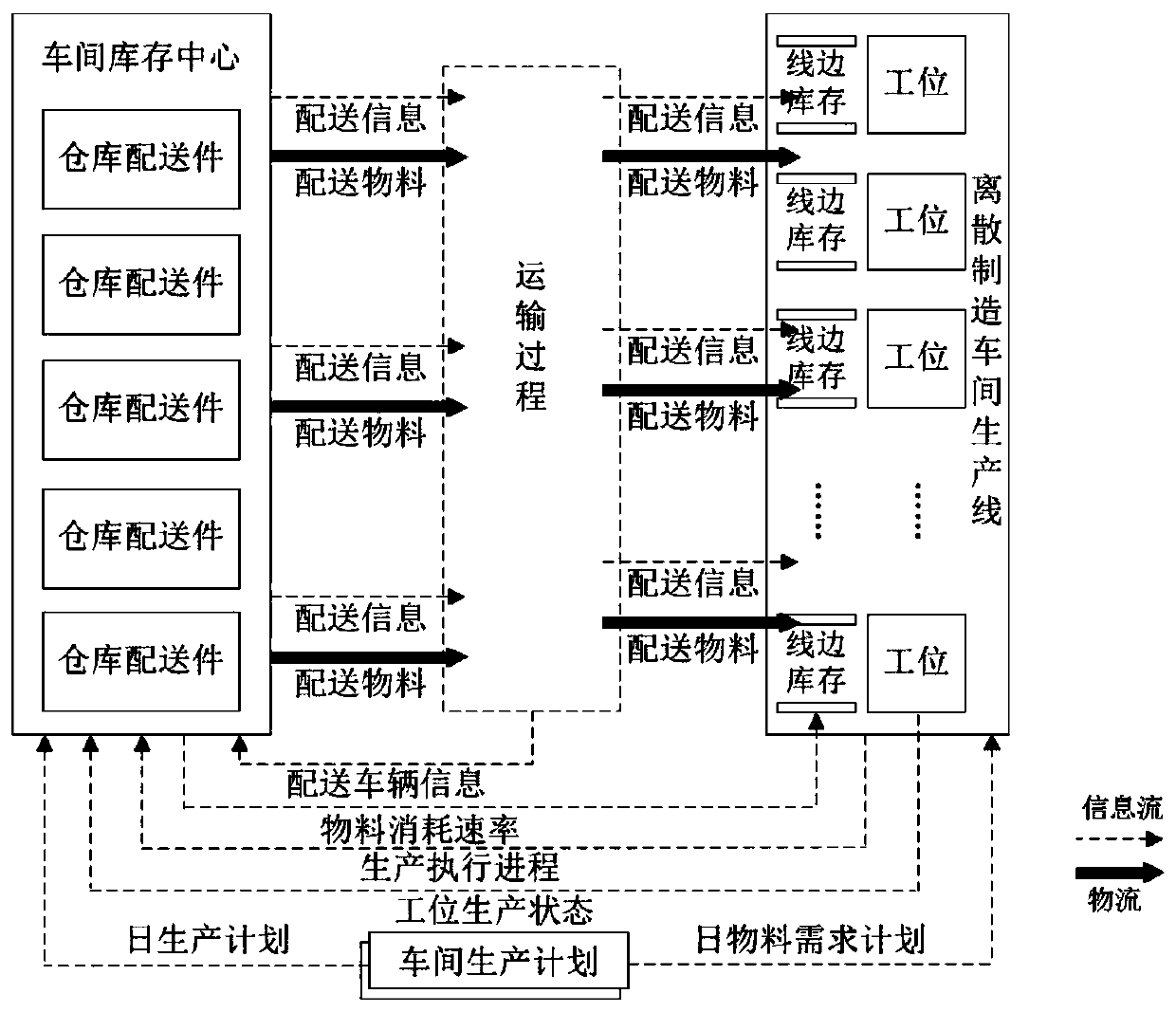

Discrete manufacturing workshop material dynamic distribution system and method based on intelligent perception network

ActiveCN110018672AReal mappingImprove accuracyTotal factory controlProgramme total factory controlDistribution systemPattern perception

The invention discloses a discrete manufacturing workshop material dynamic distribution system and method based on an intelligent perception network. The discrete manufacturing workshop material dynamic distribution system comprises an intelligent perception platform, a data processing module, an application service module and a PC terminal; the intelligent perception platform collects material information of a workshop, remaining quantity information of materials in a station cache area, consuming quantity information of the materials in the station cache area per unit time and position information of material tools, distribution personnel and distribution vehicles in real time, and the collected information is transmitted to the data processing module; the data processing module convertsthe format of the received data into a format which can be identified by the application service module and transmits the data to the application service module; and the application service module transmits the received information to the PC terminal of management personnel, and an improved ant colony algorithm is used for calculating a group of optimum distribution routes. According to the discrete manufacturing workshop material dynamic distribution system and method based on the intelligent perception network, uncertain factors in the distribution process of the materials are reduced, thedistribution procedures of the materials in the workshop are optimized, the response capacity of the workshop towards elastic requirements of the materials is improved, and the distribution efficiencyis improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

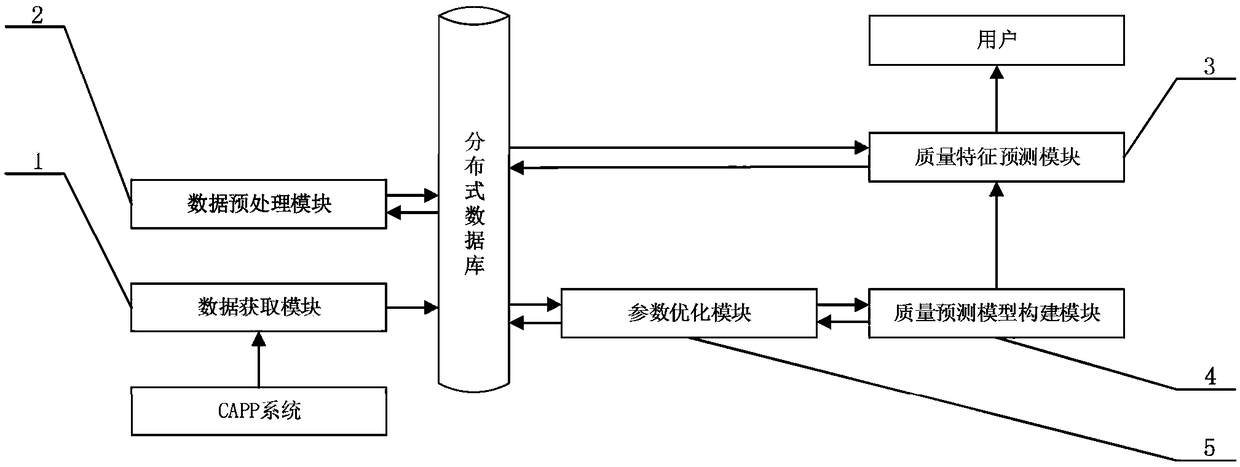

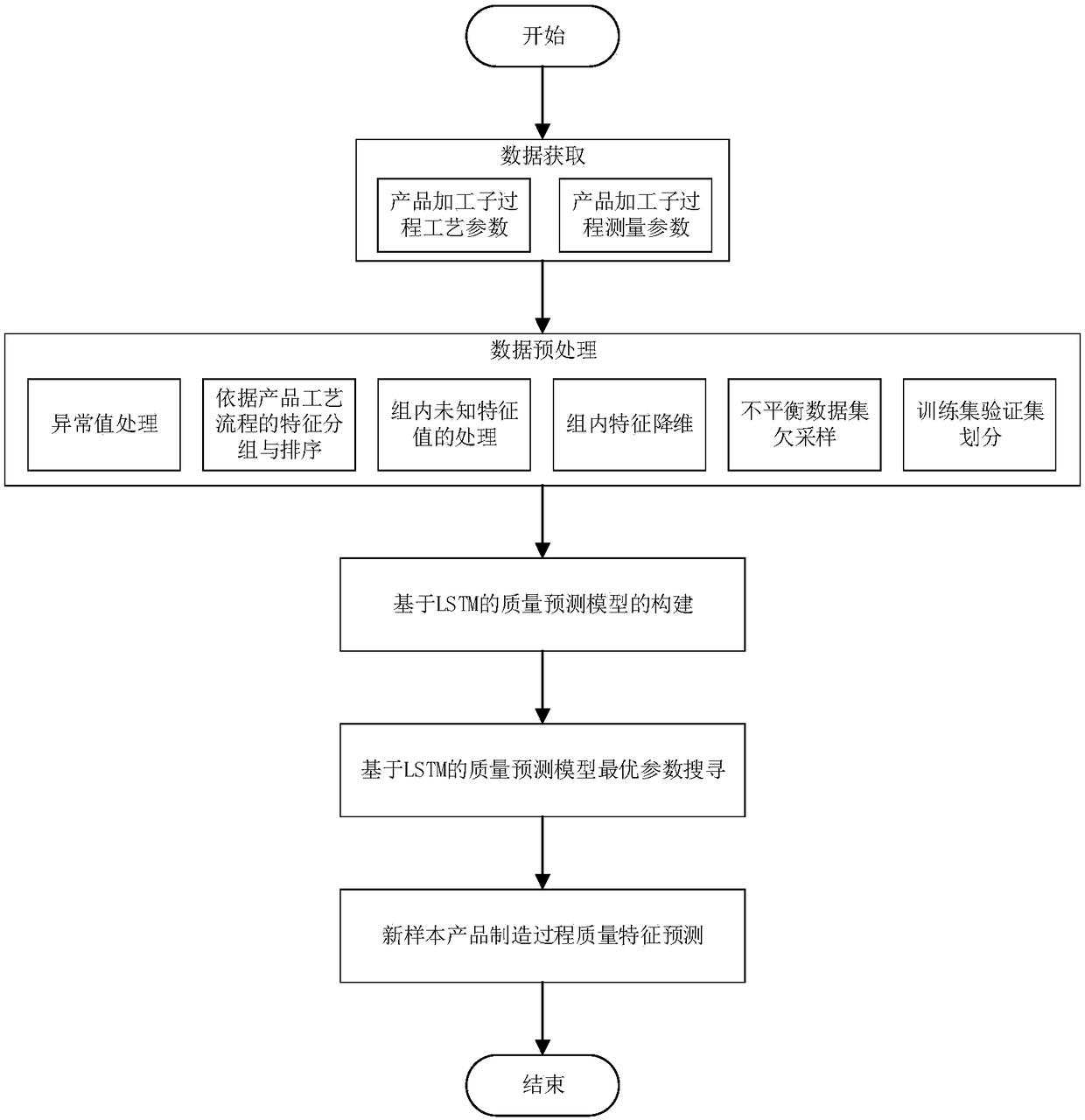

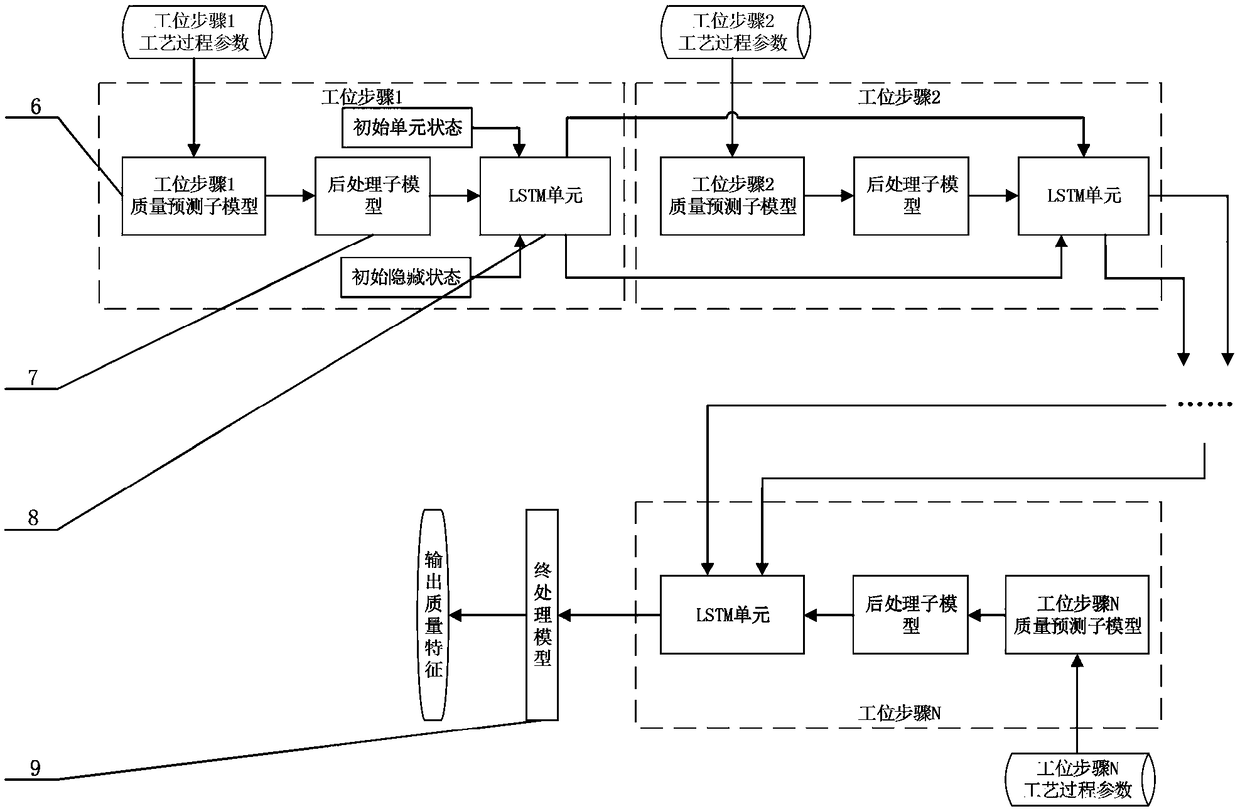

Apparatus and method for predicting product processing quality based on cross-step implicit parameter memory

ActiveCN109472057AReduce complexityHigh product quality prediction accuracyDesign optimisation/simulationNeural architecturesData setData acquisition

The invention discloses a device and a method for predicting the processing quality of a product based on the memory of implicit parameters across steps. The device comprises a data acquisition module, a data preprocessing module, a quality prediction model construction module, a parameter optimization module, a quality characteristic prediction module and an online update module. Methods includedata acquisition; Data preprocessing (outlier processing of sample data, grouping and sorting according to the characteristics of the product manufacturing process, processing of unknown input characteristics in the group, sample equalization and random resampling in the workstation step of unbalanced data set, dimension reduction of the characteristics in the group); Construction of quality prediction model (construction of quality prediction model structure, optimization training of model parameters); A step of predicting quality characteristics of a sample to be measured. The invention canautomatically obtain the influence between the process parameters of the discrete manufacturing process across the working steps, and has higher product quality prediction accuracy, flexibility, prediction efficiency and model reusability.

Owner:ZHEJIANG UNIV

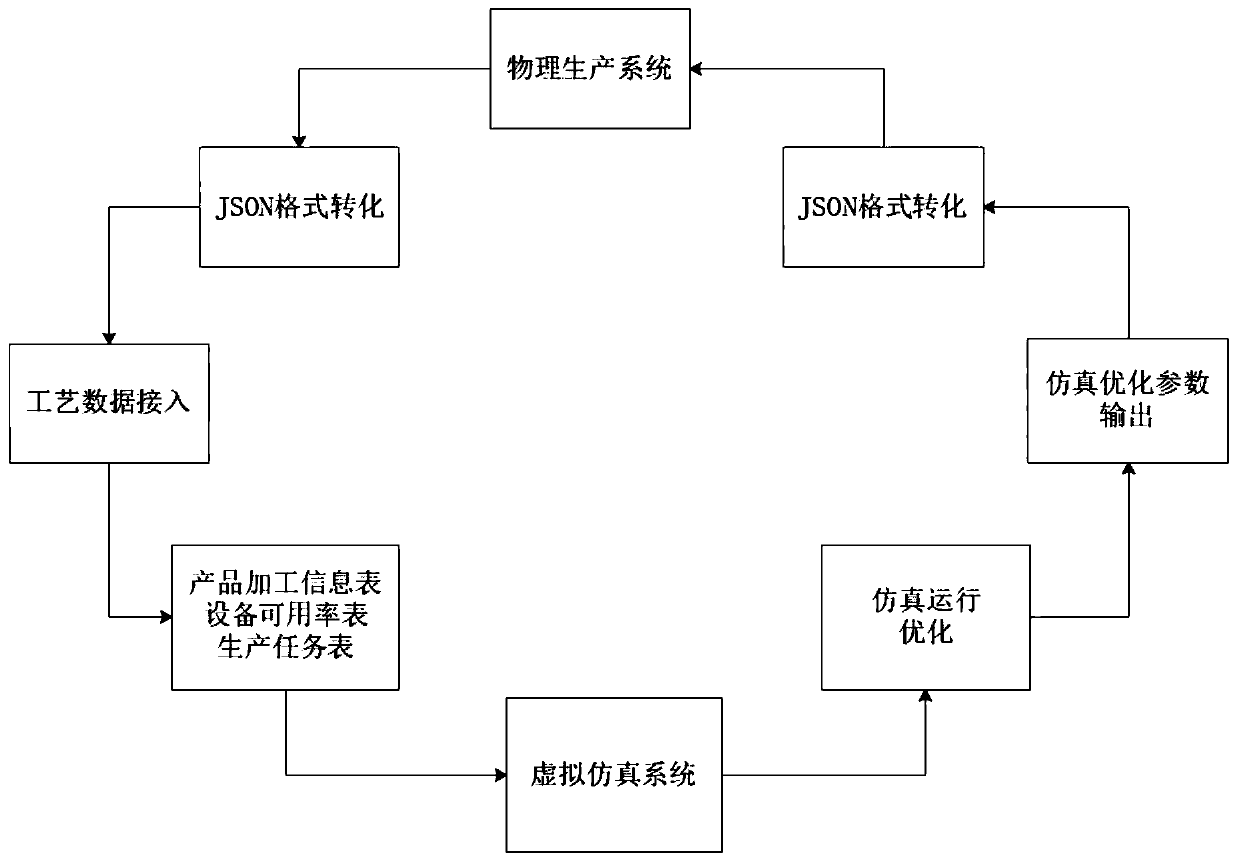

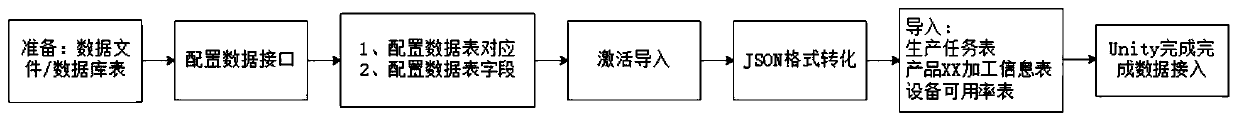

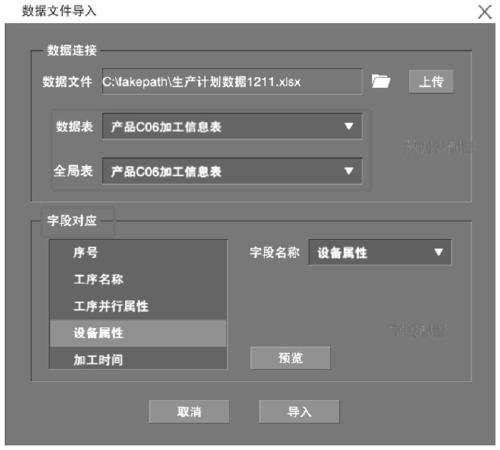

Production line production process data docking and simulation model rapid modeling method and system in cloud manufacturing mode

InactiveCN111177897ARealize associationReduce workloadData processing applicationsDesign optimisation/simulationProduction lineModelSim

The invention relates to a production line production process data docking and simulation model rapid modeling method and system in a cloud manufacturing mode. The method comprises the steps that production task data of a production line and machining process data of each type of products are imported into a production task table, a product machining information table and an equipment availabilitytable; simulation object resource calling, simulation parameter imbedding and process flow relationship establishment are achieved by utilizing data in the three tables to obtain a discrete manufacturing production line simulation model; key indexes in the production process are analyzed through the simulation model, the advantages and disadvantages of a current production scheme are judged, adjustment and optimization are conducted according to existing problems, obtained optimized production scheme data are output to a physical production system, and synchronous adjustment of the physical production system is completed. Rapid modeling of a production line virtual simulation model and real-time production process data butt joint can be achieved, and rapid modeling of a production line virtual simulation system and rapid imbedding of simulation parameters are supported so as to adapt to flexible production of a production line.

Owner:北京航天智造科技发展有限公司

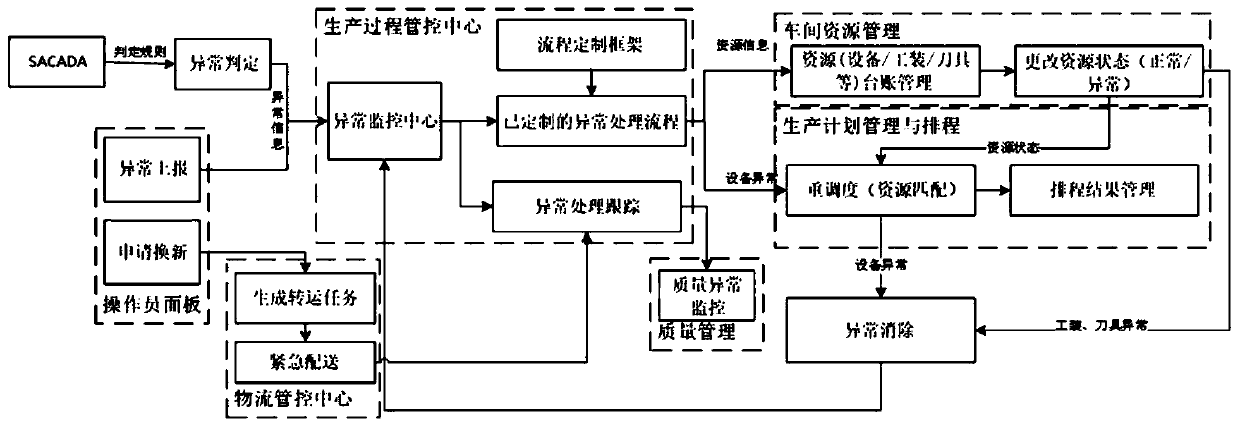

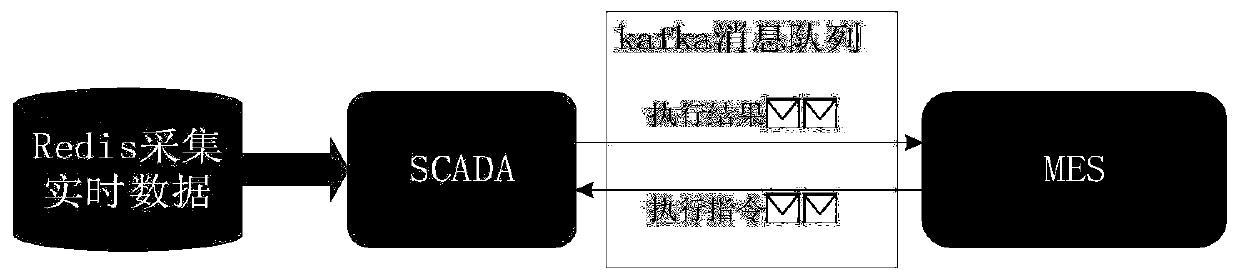

Workshop real-time production abnormity judging and processing method based on MES

PendingCN111507859AMeet individual needsImprove responseInterprogram communicationTechnology managementManufacture execution systemPersonalization

The invention discloses a workshop real-time production abnormity judging and processing method based on MES. Aiming at the sudden abnormal condition in the production process of a production and manufacturing workshop, in combination with the strong personalized demand of a current discrete manufacturing enterprise for a manufacturing execution system MES, the abnormal information real-time acquisition and judgment method, the processing flow framework, the flow customization process and the integrated application of the framework in the MES system are integrated; according to the invention,the real-time judgment of the exception and the universal configuration of the processing flow framework are realized, the individual requirements of enterprises can be effectively met, and the quickresponse and processing capacity of the enterprises to the exceptional events are improved.

Owner:SOUTHWEST JIAOTONG UNIV

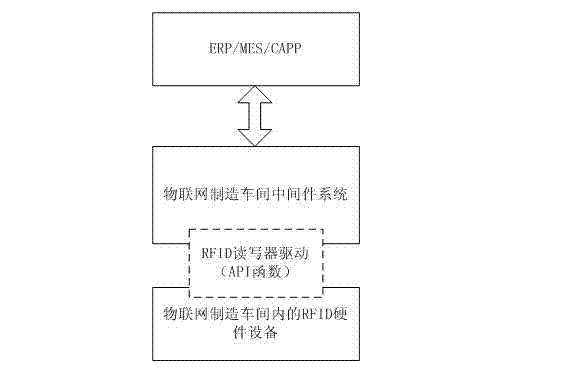

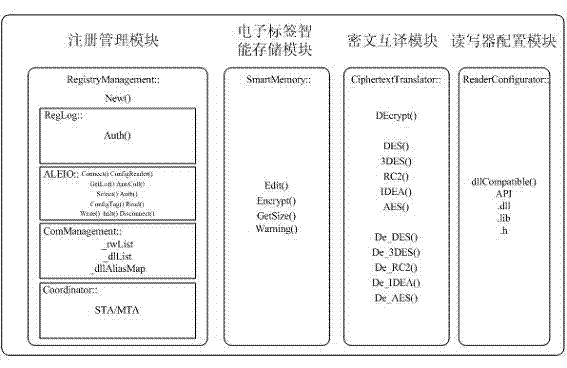

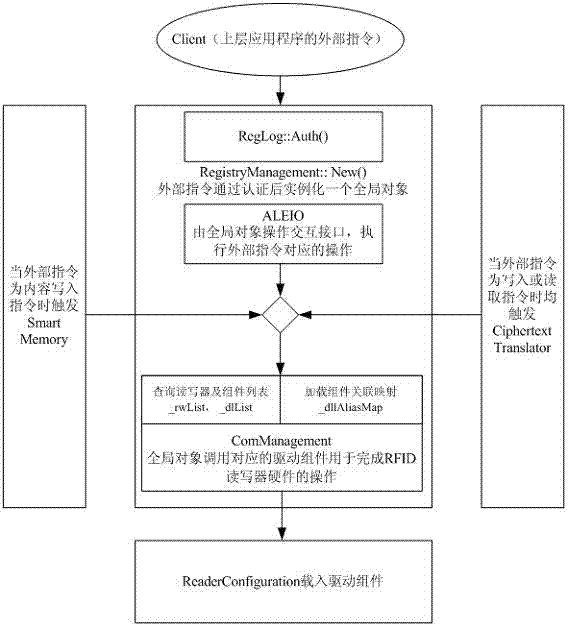

Implementation method of RFID middleware for discrete manufacturing workshop

ActiveCN103197928ASeamlessPrevent leakageCo-operative working arrangementsSpecific program execution arrangementsManufacture execution systemKnowledge organization

An implementation method of an RFID (radio frequency identification) middleware for a discrete manufacturing workshop is characterized in that through arranging four modules, information relevant with the characteristics of the discrete manufacturing workshop is integrated into the event messaging service, and the RFID hardware equipment is driven to operate, and carried information of an electronic tag is organized and packaged into the data source which can be directly provided for the upper-layer application module for use, so as to realize interaction of bottom-layer production data and upper-layer application module data of the discrete manufacturing workshop. The implementation method fully takes the actual operation situation of the discrete manufacturing workshop into consideration, can realize seamless joint of the RFID system and the enterprise-class application programs including MES (manufacturing execution system), CAPP (computer-aided process planning), ERP (enterprise resource planning) and the like, can effectively prevent leakage of record content, and can quickly support upgrading or change of the RFID reader hardware through the minimum program change.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Full life cycle management system of internet of things in discrete manufacturing industry

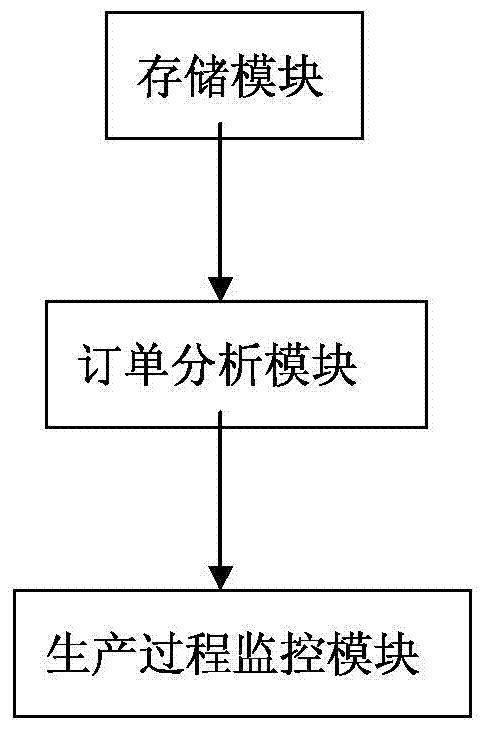

ActiveCN104504539AImprove processing efficiencyPrecise deliverySensing record carriersResourcesFull life cycleOrder form

The invention provides a full life cycle management system of the internet of things in the discrete manufacturing industry. The full life cycle management system comprises a storage module stored with order information, an order analysis module for discomposing the order information into first order sub-information and second order sub-information and meanwhile storing the first order sub-information and the second order sub-information in the storage module, a first RFID card sender for writing the first order sub-information into corresponding first RFID cards, a card reader for reading the first order sub-information in each corresponding first RFID card and second order sub-information and second RFID card information in second RFID cards and uploading the information to the storage module, a controller for retrieving corresponding second order sub-information from the storage module, sending the second order sub-information to second RFID cards and writing the second order sub-information into the second RFID cards. The full life cycle management system establishes a perfect and integrated production quality monitoring and management system suitable for the discrete manufacturing industry.

Owner:GUANGXI UNIVERSITY OF FINANCE AND ECONOMICS +1

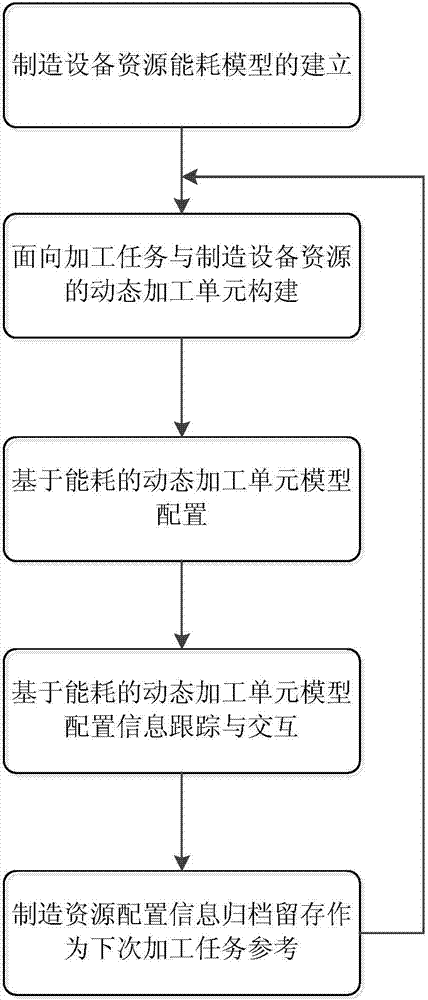

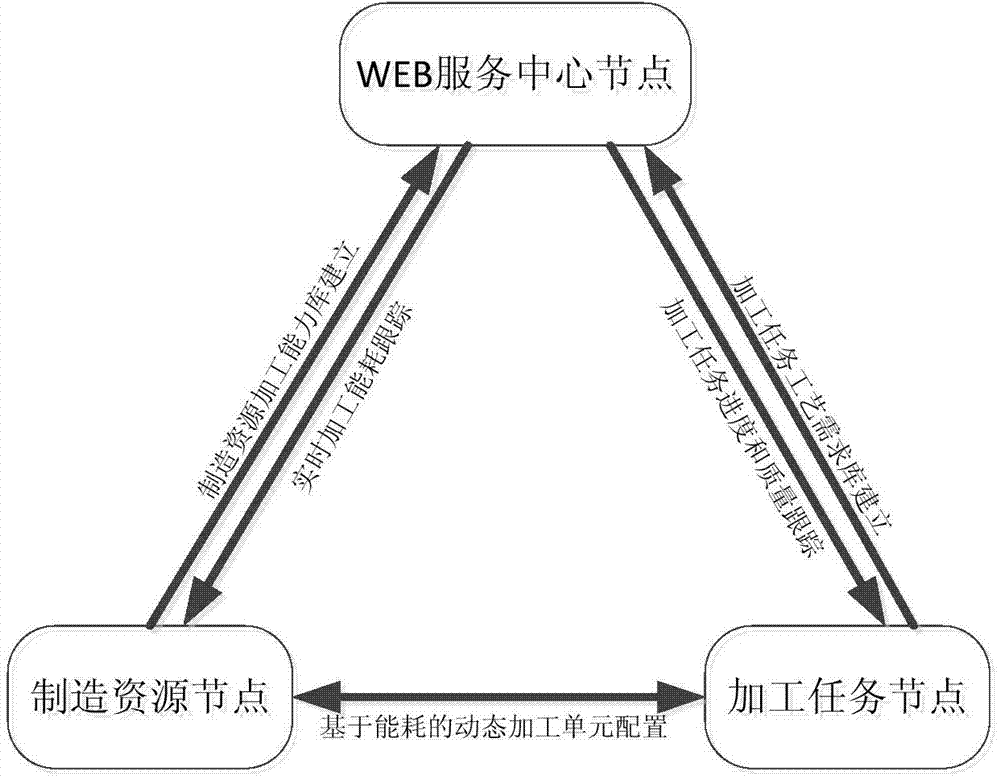

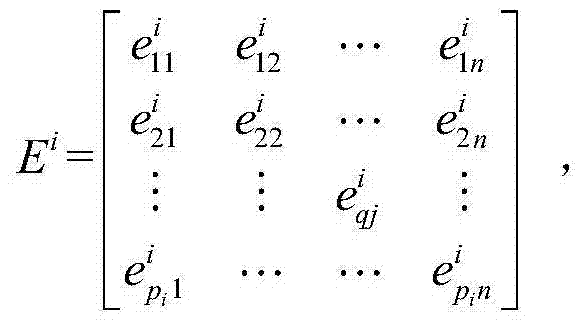

Dynamic configuration method for energy-consumption-oriented discrete manufacturing system resources

ActiveCN104751275AIncrease flexibilityImprove scalabilityResourcesManufacturing computing systemsProcess engineeringHuman–robot interaction

The invention relates to a dynamic configuration method for energy-consumption-oriented discrete manufacturing system resources. The dynamic configuration method comprises the following steps: establishing a processing mask energy consumption model, constructing a dynamic processing unit which is orientated to the processing task and the manufacturing equipment resources, configuring the dynamic processing unit model based on energy consumption, tracking and interacting the dynamic processing unit configuration information based on energy consumption, sorting and storing the configuration scheme. According to the dynamic configuration method disclosed by the invention, the manufacturing equipment resources and the processing task are grouped to form a dynamic processing unit, the task process set and the manufacturing equipment processing capacity are mapped based on the energy consumption to establish the dynamic unit configuration model of the manufacturing system resources oriented to the smallest energy consumption; the resource configuration method base is established through a resource configuration server, and detailed data support is established for searching the optimal energy consumption scheme; the discrete manufacturing environment is processed and networked to reinforce the relationship between the equipment node and the task mode, information window is provided for the dynamic configuration and the optimization of the manufacturing equipment resources, and the man-machine interaction speed is increased.

Owner:JIANGNAN UNIV

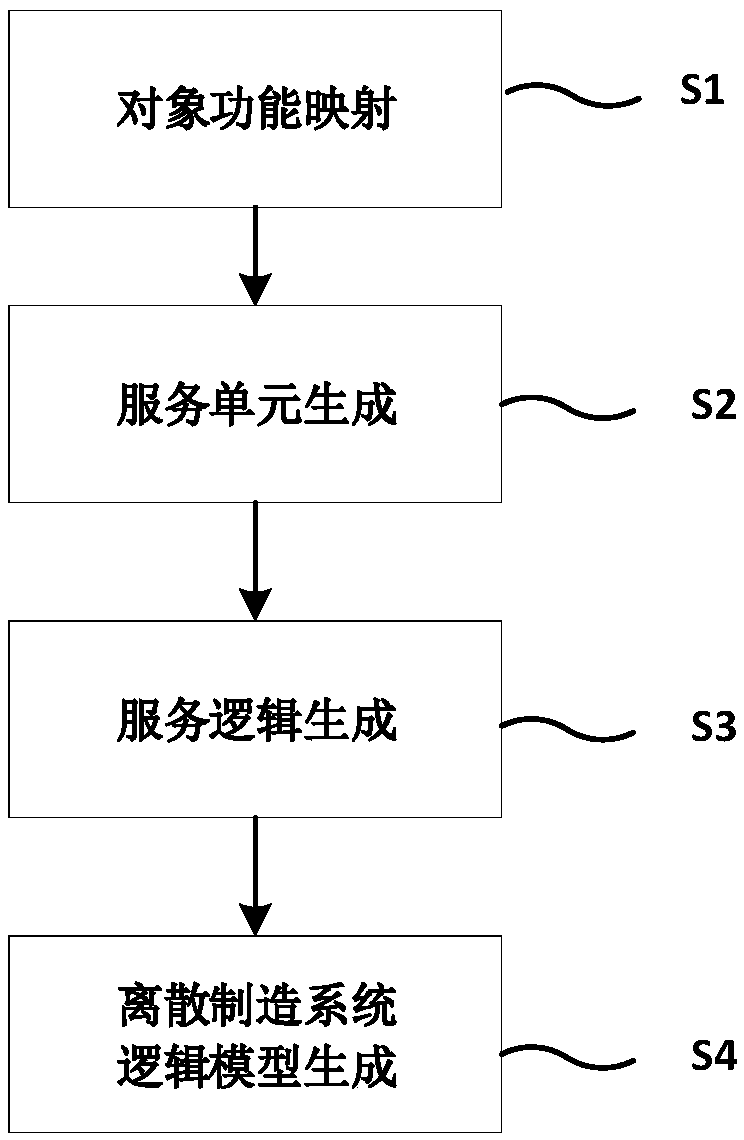

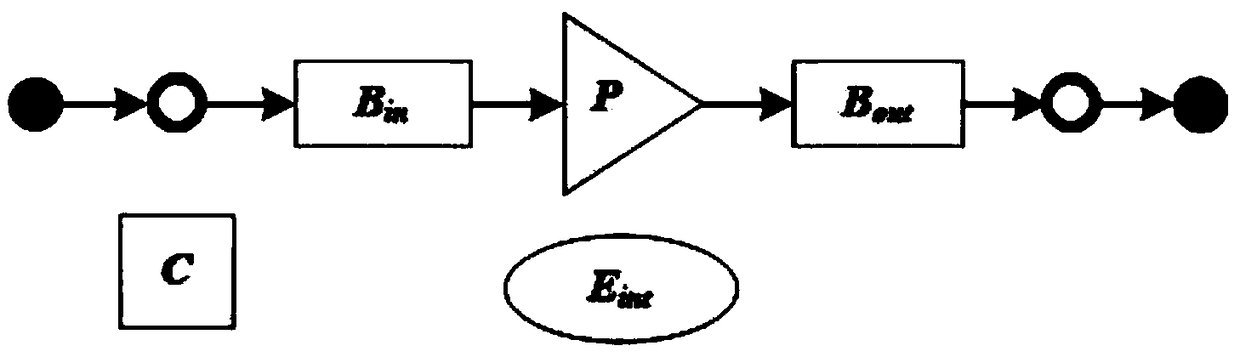

Method for establishing a discrete manufacturing system local model through adoption of septet and service unit

ActiveCN109407632AImprove reusabilityReduce Model ComplexityTotal factory controlProgramme total factory controlActuatorDiscrete manufacturing

The present invention discloses a method for establishing a discrete manufacturing system local model through adoption of septet and a service unit. The method comprises the steps of: 1. performing object function mapping, mapping the discrete manufacturing system composition to a septet according to the roles of each object served as in the system, wherein the septet comprises a controller, a processor, an executer, a cache, a flow entity, a logistical path and a virtual service node; 2. employing the septet or a sub set thereof, employing the virtual service node to associate a system to generate a service unit; 3. Allowing the flow entity to access the service unit through the virtual service node, under the assistance of the executer, allowing the flow entity to flow in order accordingto the sequence of the input cache, the processor or the cache and the output cache to finally leave through the virtual service node to generate service logic; and 4. generating the discrete manufacturing system logic model. The concept of the septet and the service unit is suitable for uniform modeling of various complex discrete manufacturing systems, and has universality, uniformity and the systematicness.

Owner:SOUTHWEST JIAOTONG UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com