Workshop real-time production abnormity judging and processing method based on MES

A technology of abnormal judgment and processing method, which is applied in data processing applications, electronic digital data processing, technical management, etc., to meet individual needs and improve rapid response and processing capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

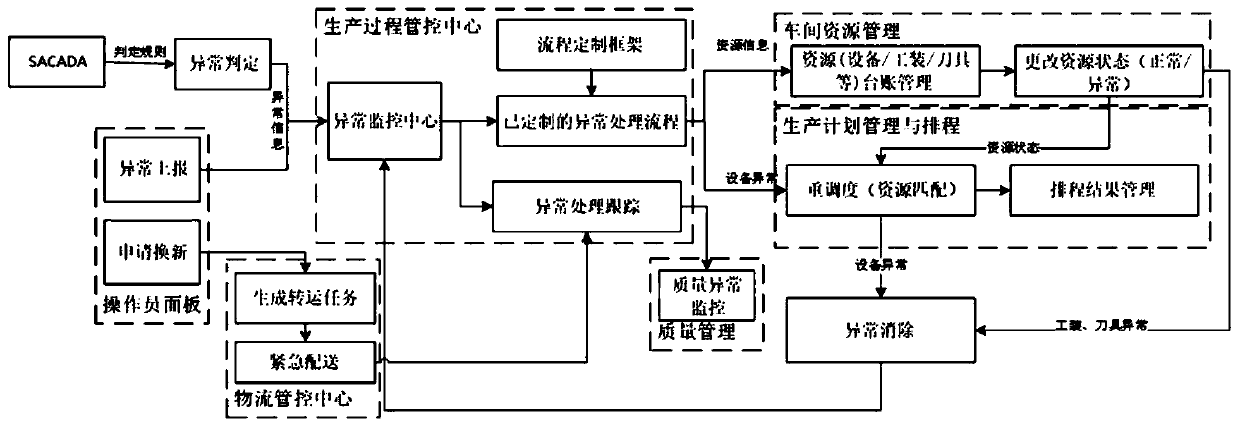

[0075] Combined with the needs of a university's intelligent manufacturing demonstration line platform, a self-developed MES system is adopted, which mainly includes workshop resource management, virtual workshop production organization, production planning and scheduling, production process control center, logistics control center, quality management, Inventory Management, Operator Panels and Operator Panels, see Image 6 .

[0076] (1) Workshop resource management is the management of production resources in the workshop, such as production equipment, collection equipment, logistics equipment, cutting tools, tooling, etc.;

[0077] (2) The virtual workshop production organization is a two-dimensional virtual construction of the workshop and a visual display of the workshop;

[0078] (3) Production planning and scheduling is to manage the production planning and scheduling scheme, respond to various dynamic interference factors in real time, and realize the rescheduling of p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com