Patents

Literature

251 results about "Manufacture execution system" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

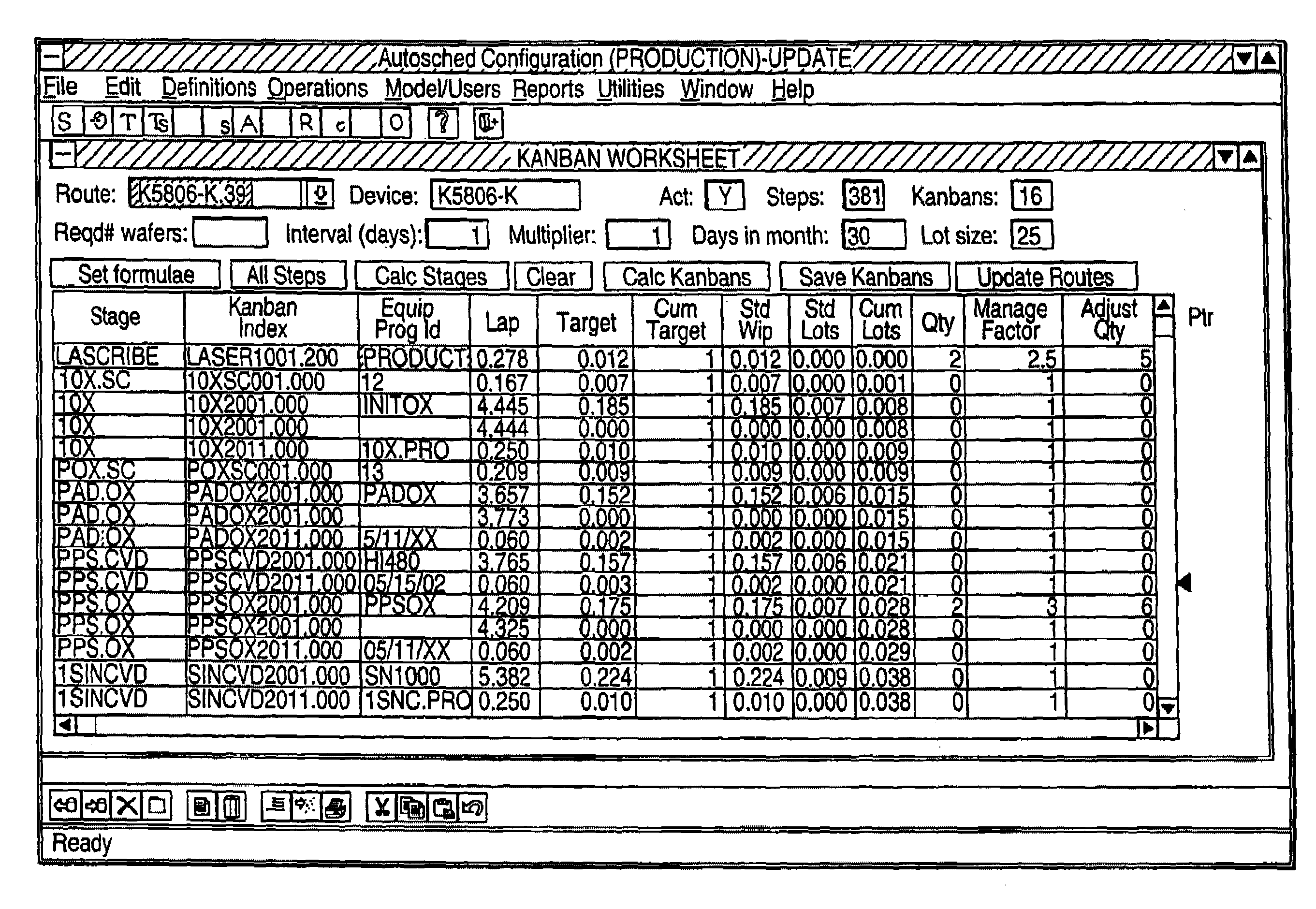

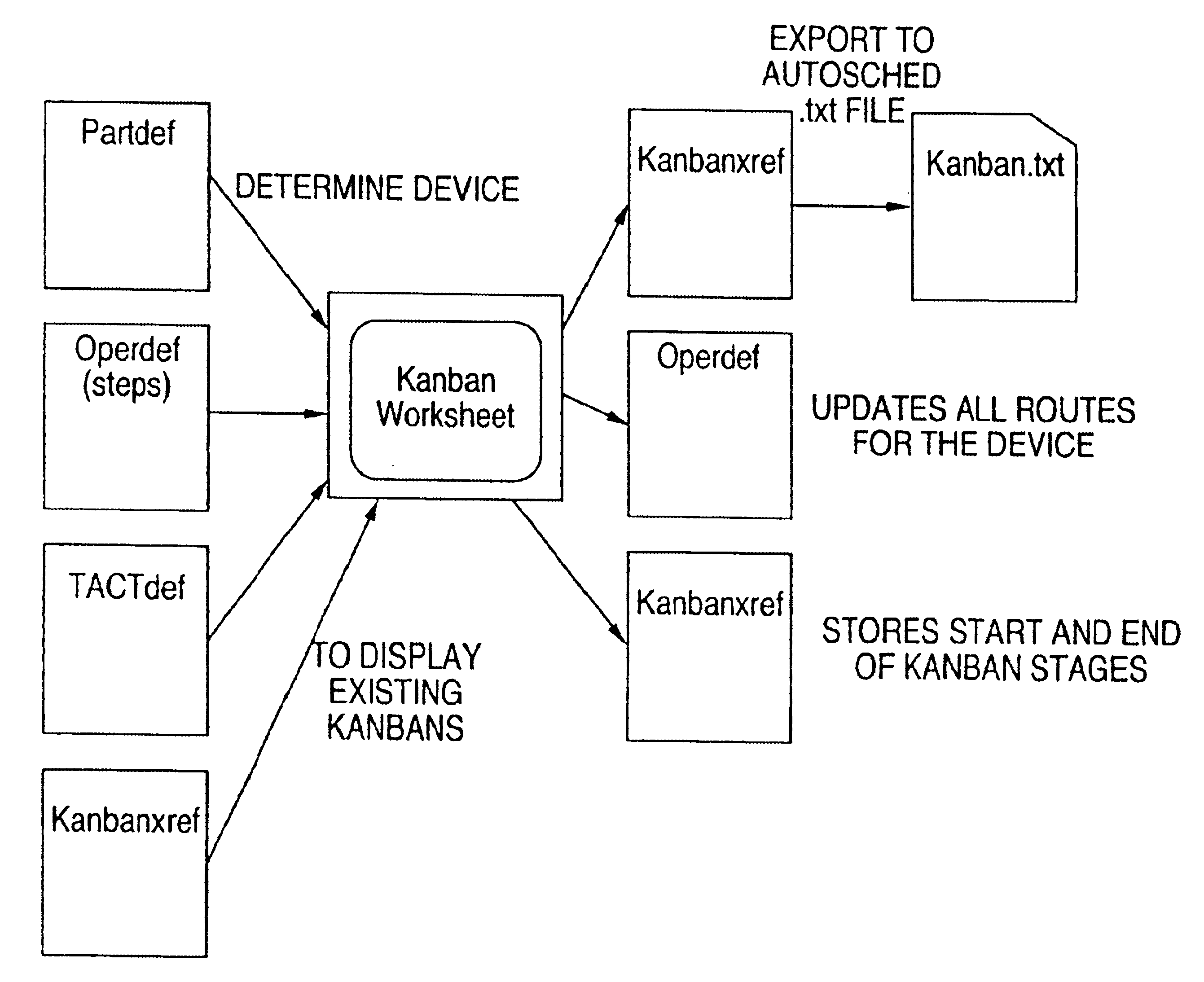

Electronic Kanban worksheet for the design and implementation of virtual or electronic Kanban systems

InactiveUS7020594B1ForecastingSpecial data processing applicationsManufacture execution systemSystems design

An integrated wafer fab production characterization and scheduling system incorporates a manufacturing execution system with a scheduling system based on simulation. The integrated characterization / scheduling system provides manufacturing with a simulation tool integrated with the manufacturing execution system to evaluate proposed production control logic as a practical alternative to expensive experimentation on actual production system. Furthermore, simulation models are used to create short term dispatch schedules to steer daily manufacturing operations towards planned performance goals. Innovative features include integration of preventive maintenance scheduling, Kanban based WIP control, an integrated time standard database, a, and real time lot move updates.

Owner:SONY CORP +1

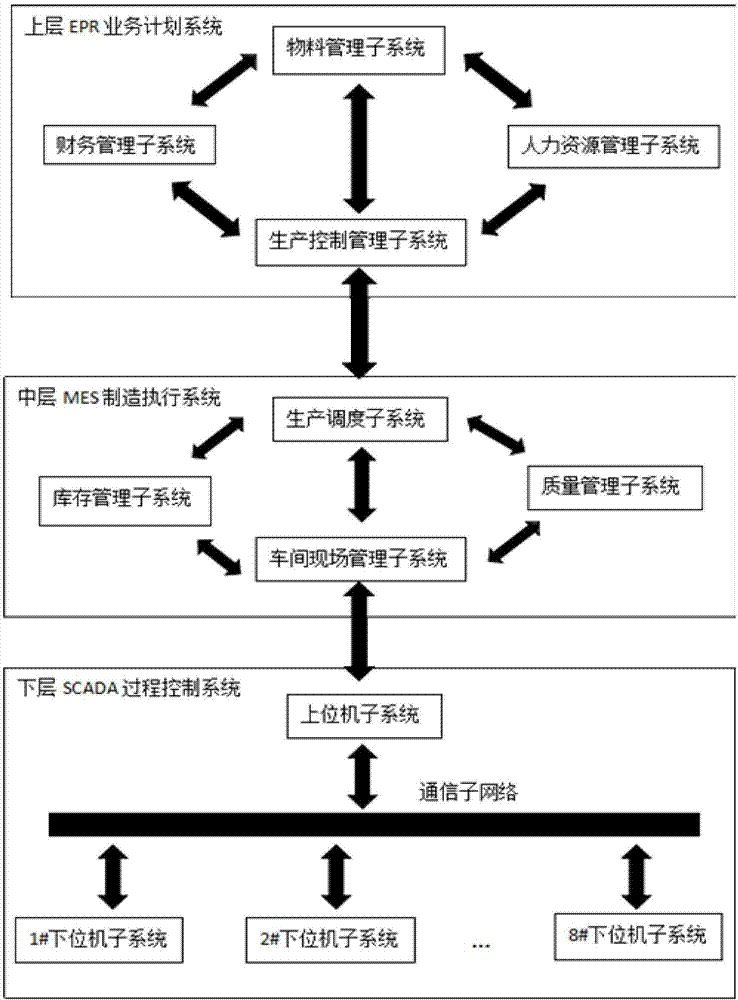

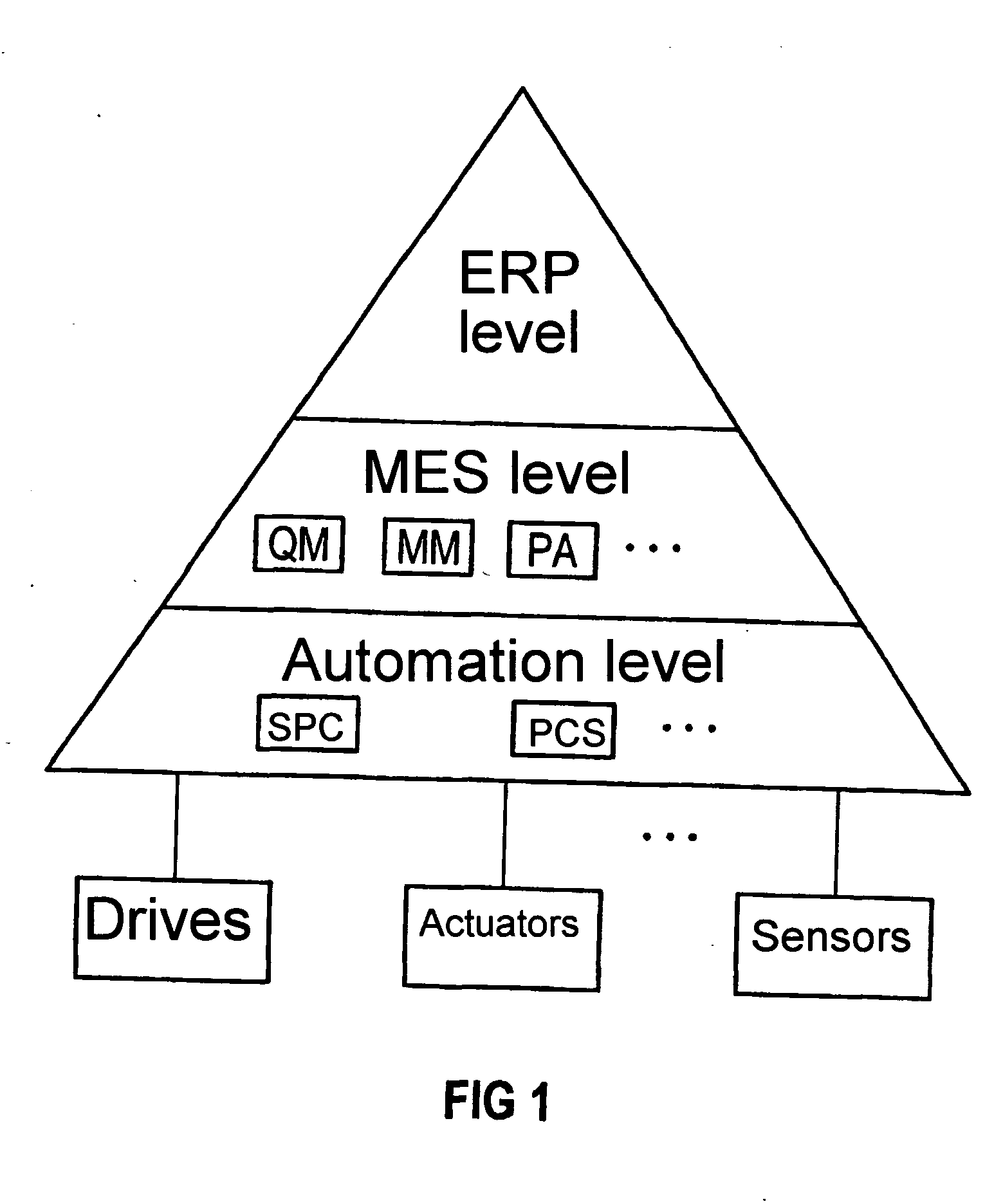

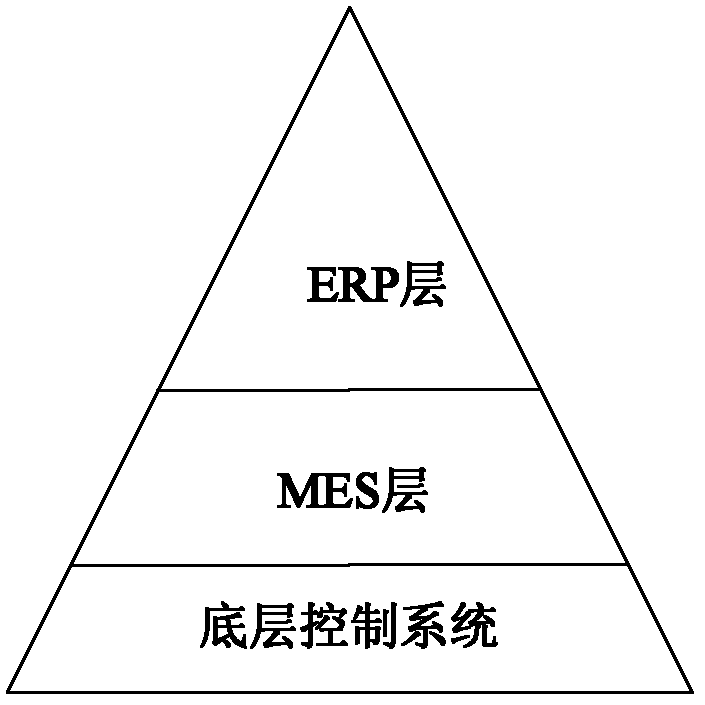

Intelligent factory system based on internet of things technology and industrial big data

InactiveCN107272629AIncrease productionReduce energy consumptionTechnology managementTotal factory controlManufacture execution systemReal time analysis

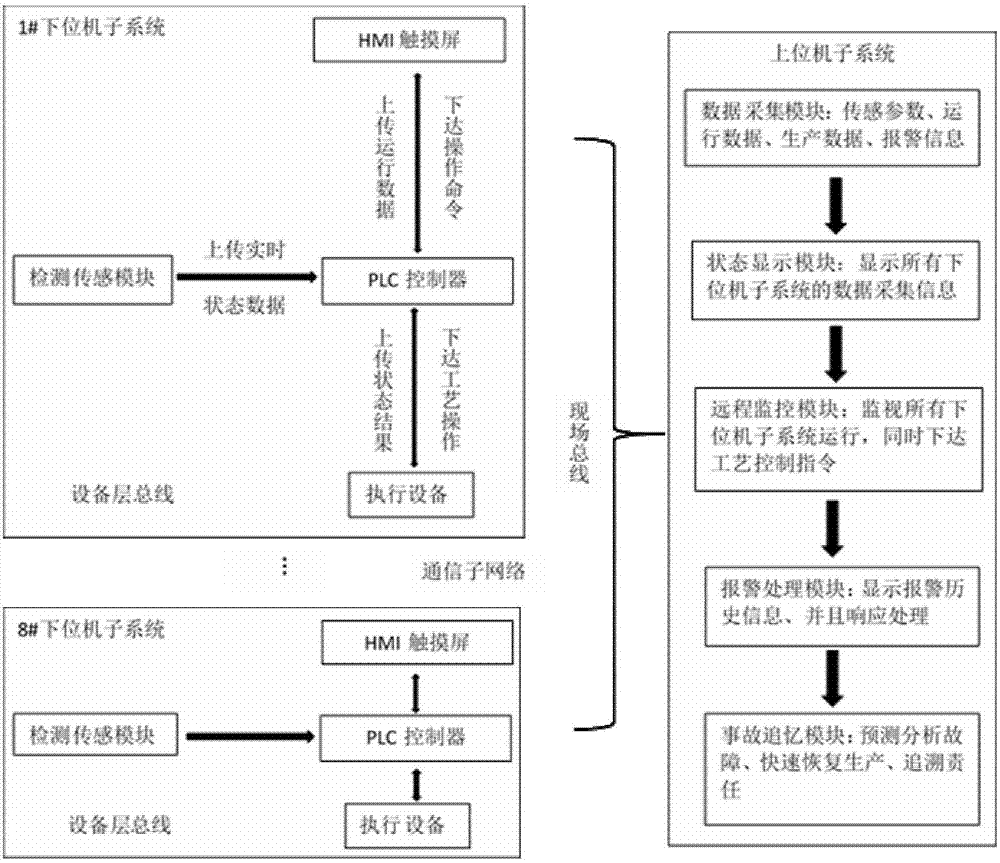

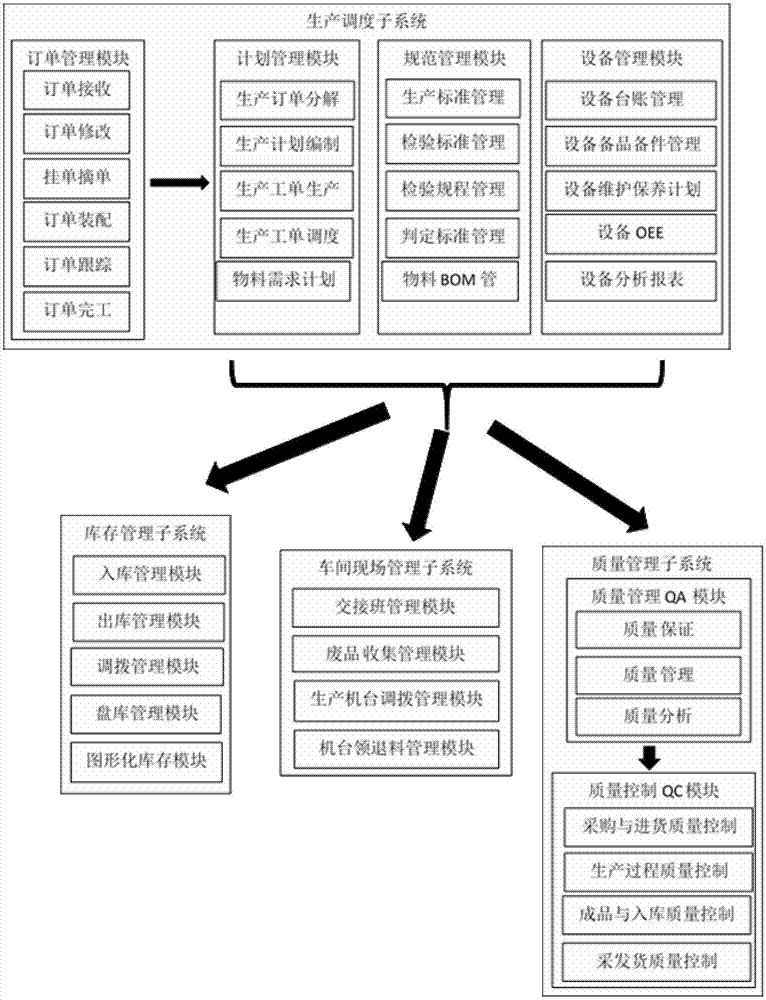

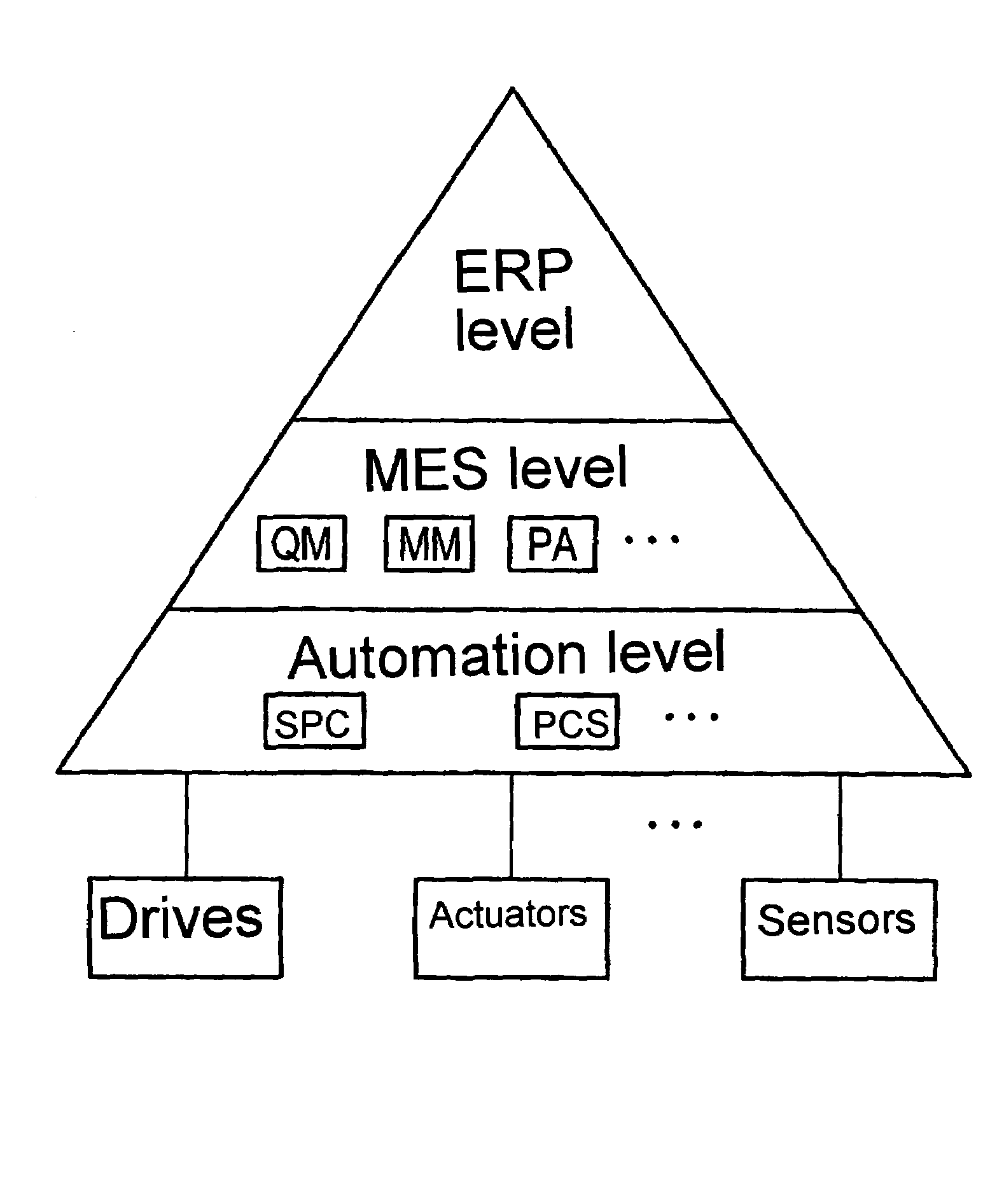

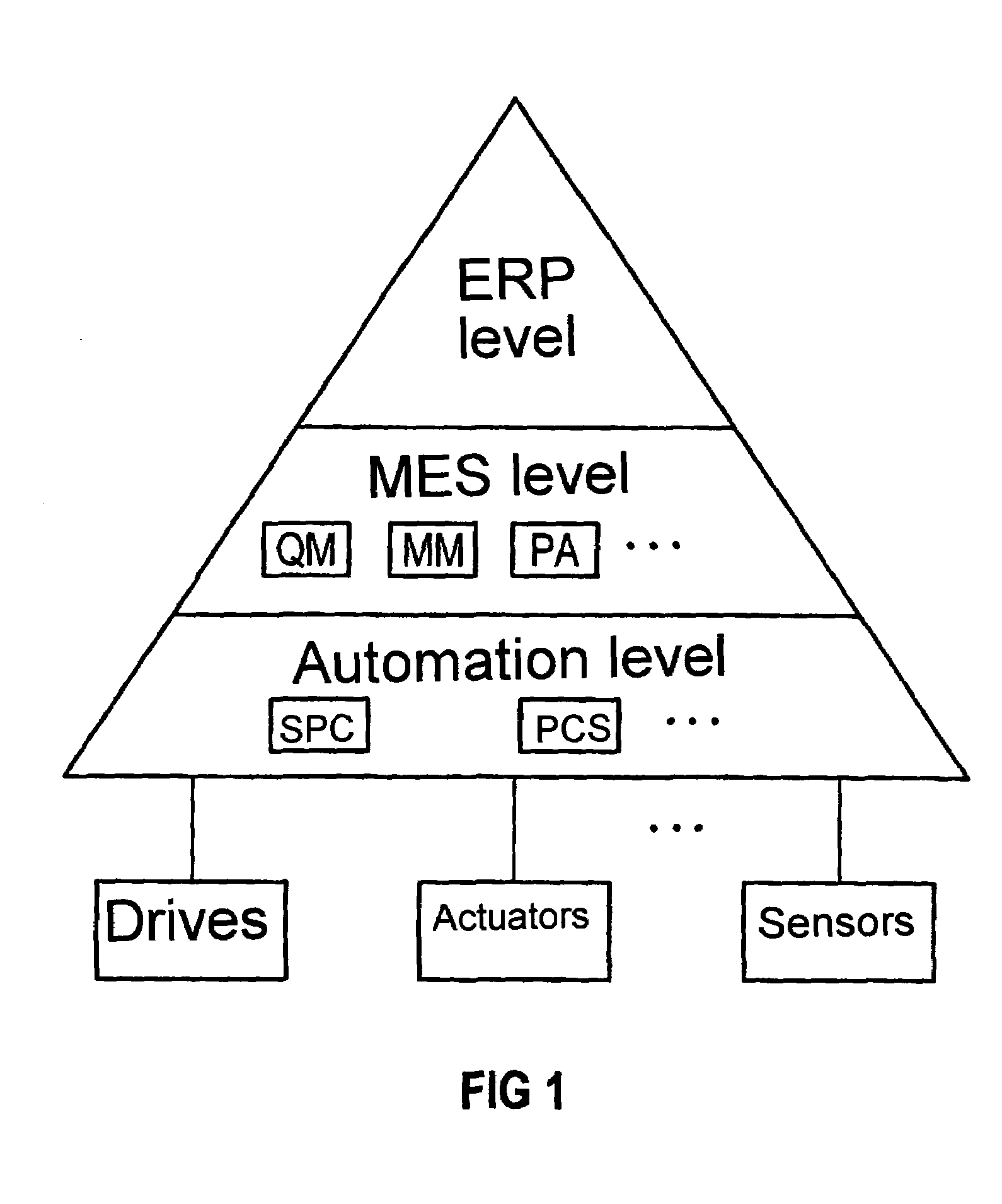

The invention relates to the field of intelligent production and manufacturing management technology, particularly to an intelligent factory system based on the internet of things technology and industrial big data. The intelligent factory system comprises a lower SCADA process control system, an intermediate MES manufacturing execution system, and an upper ERP business planning system. Therefore, problems of difficult real-time analysis and calculation, difficult accident tracing and restoration, high non-planned parking frequency, low work production efficiency, difficult non-transparent decision-making and difficult cooperation among the regional personnel are solved so as to improve the product output, reduce energy consumption and reduce the cost; the a humanized intelligent factory with equipment intelligence, modern management, and information computerization is established truly; and the core competitiveness of enterprise is enhanced.

Owner:科睿特软件集团股份有限公司

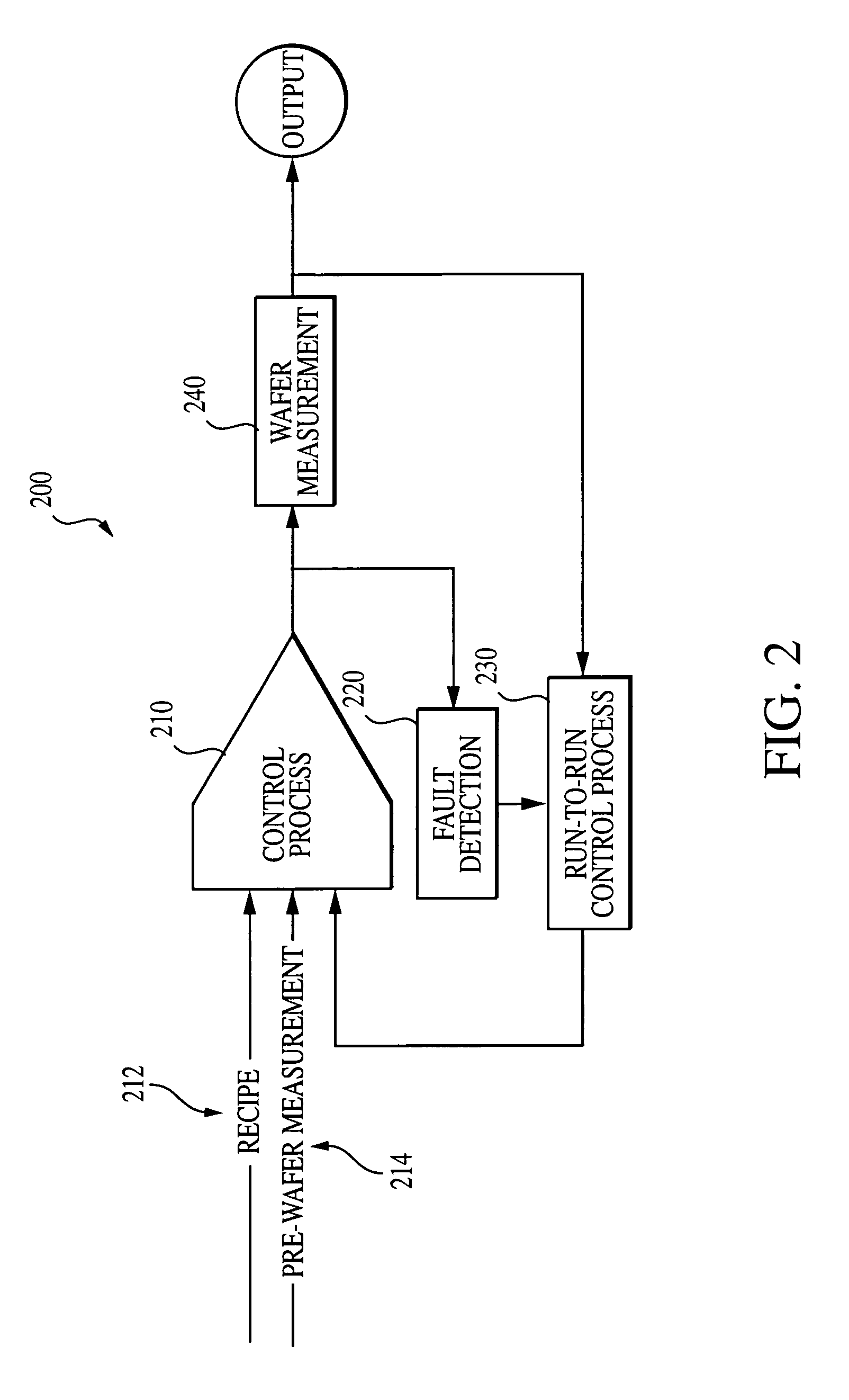

Integration of fault detection with run-to-run control

InactiveUS7337019B2Maintain propertiesSemiconductor/solid-state device testing/measurementElectric heatingManufacture execution systemSemiconductor

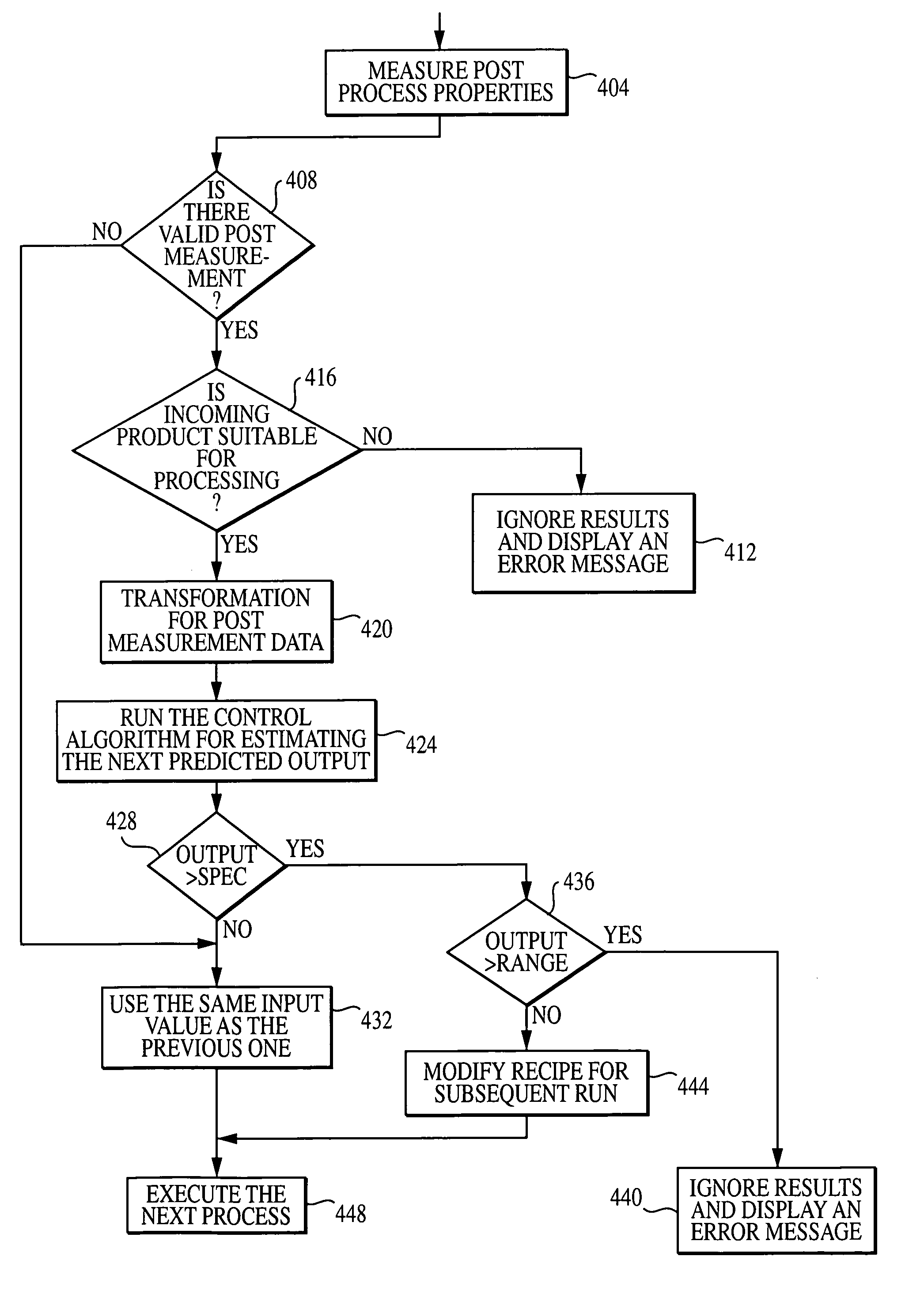

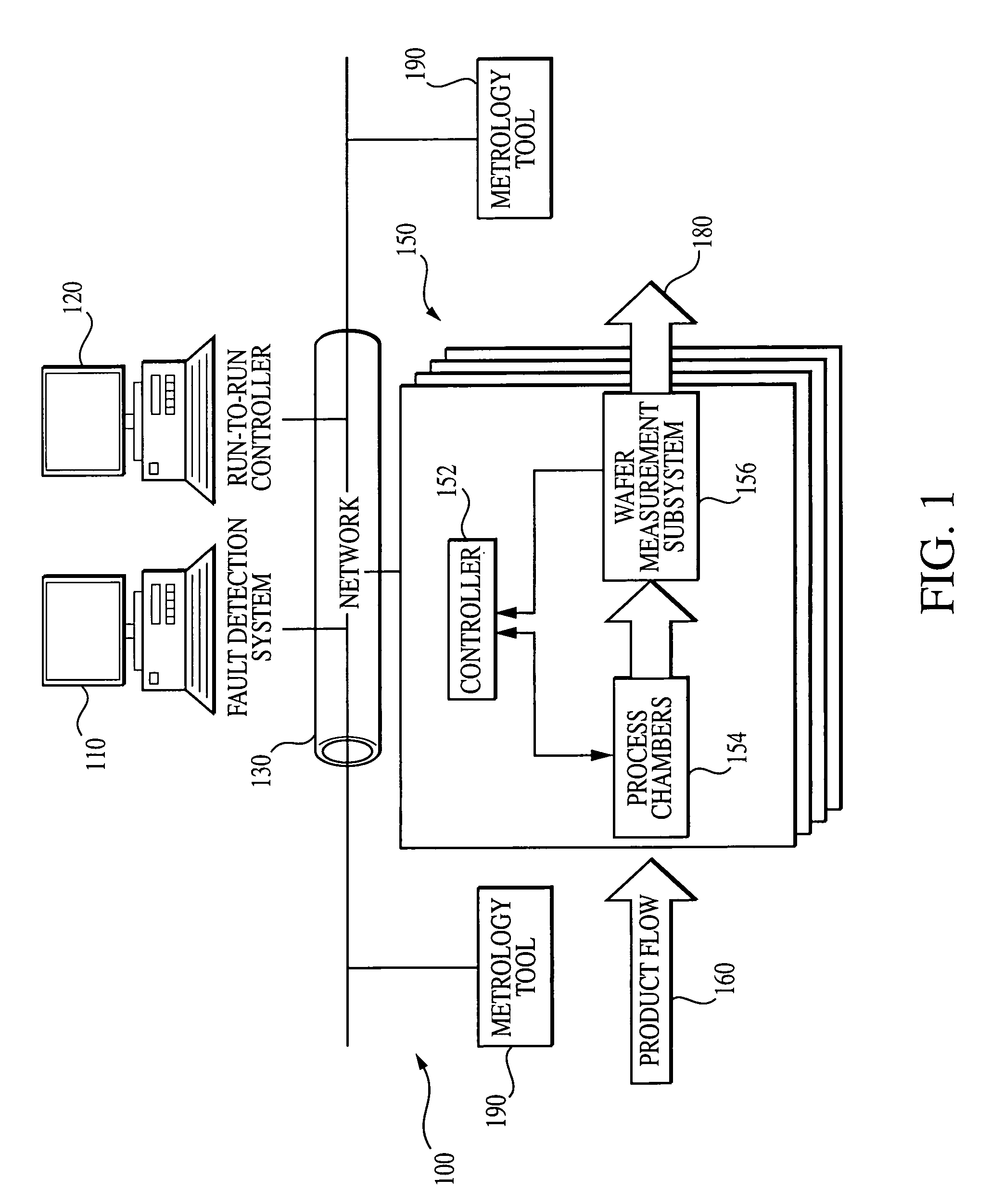

Semiconductor wafers are processed in conjunction with a manufacturing execution system using a run-to-run controller and a fault detection system. A recipe is received from the manufacturing execution system by the run-to-run controller for controlling a tool. The recipe includes a setpoint for obtaining one or more target wafer properties. Processing of the wafers is monitored by measuring processing attributes including fault conditions and wafer properties using the fault detection system and one or more sensors. Setpoints of the recipe may be modified at the run-to-run controller according to the processing attributes to maintain the target wafer properties, except in cases when a fault condition is detected by the fault detection system. Thus, data acquired in the presence of tool or wafer fault conditions are not used for feedback purposes. In addition, fault detection models may be used to define a range of conditions indicative of a fault condition. In these cases, the fault detection models may be modified to incorporate, as parameters, setpoints of a recipe modified by a run-to-run controller.

Owner:APPLIED MATERIALS INC

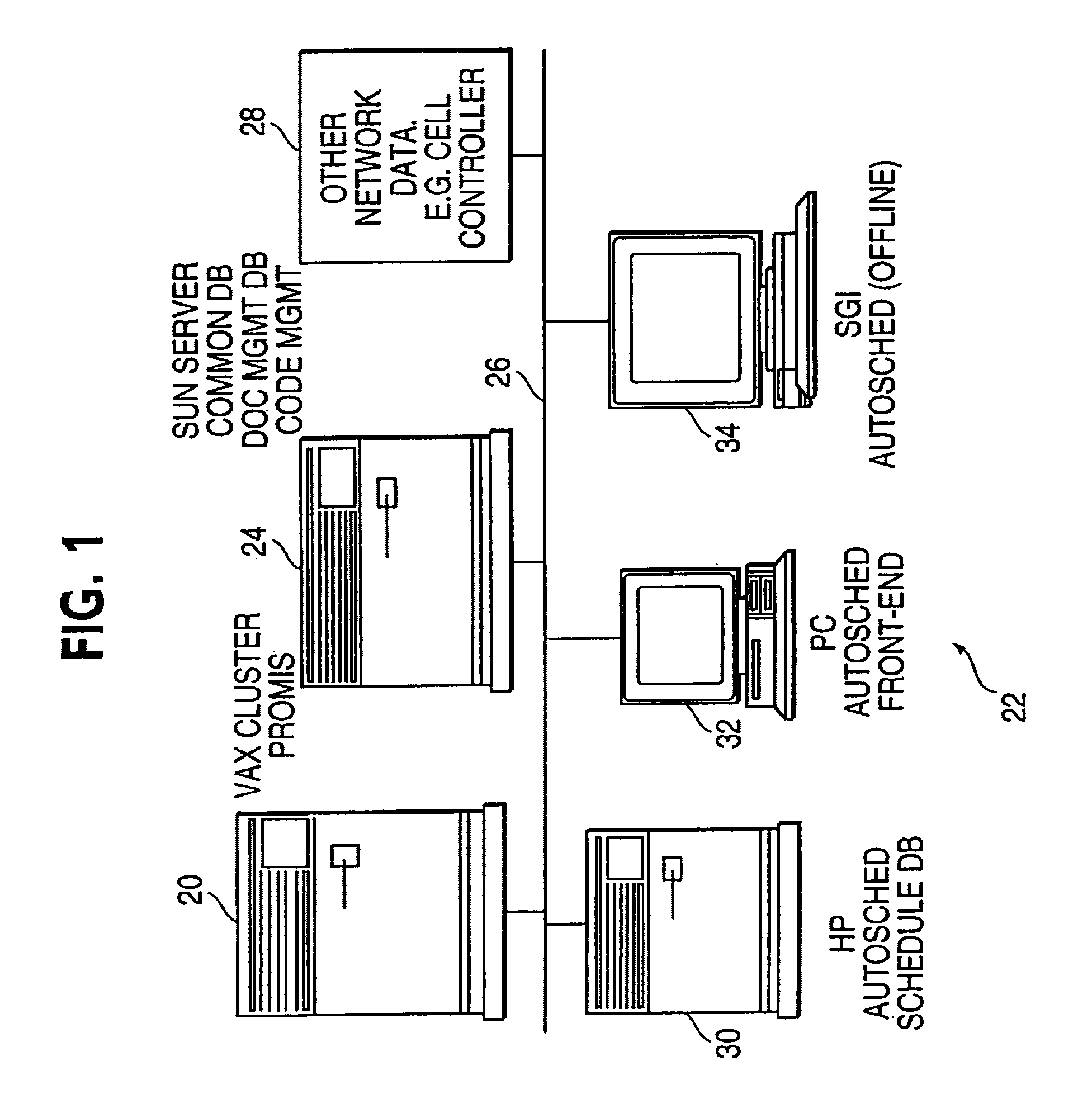

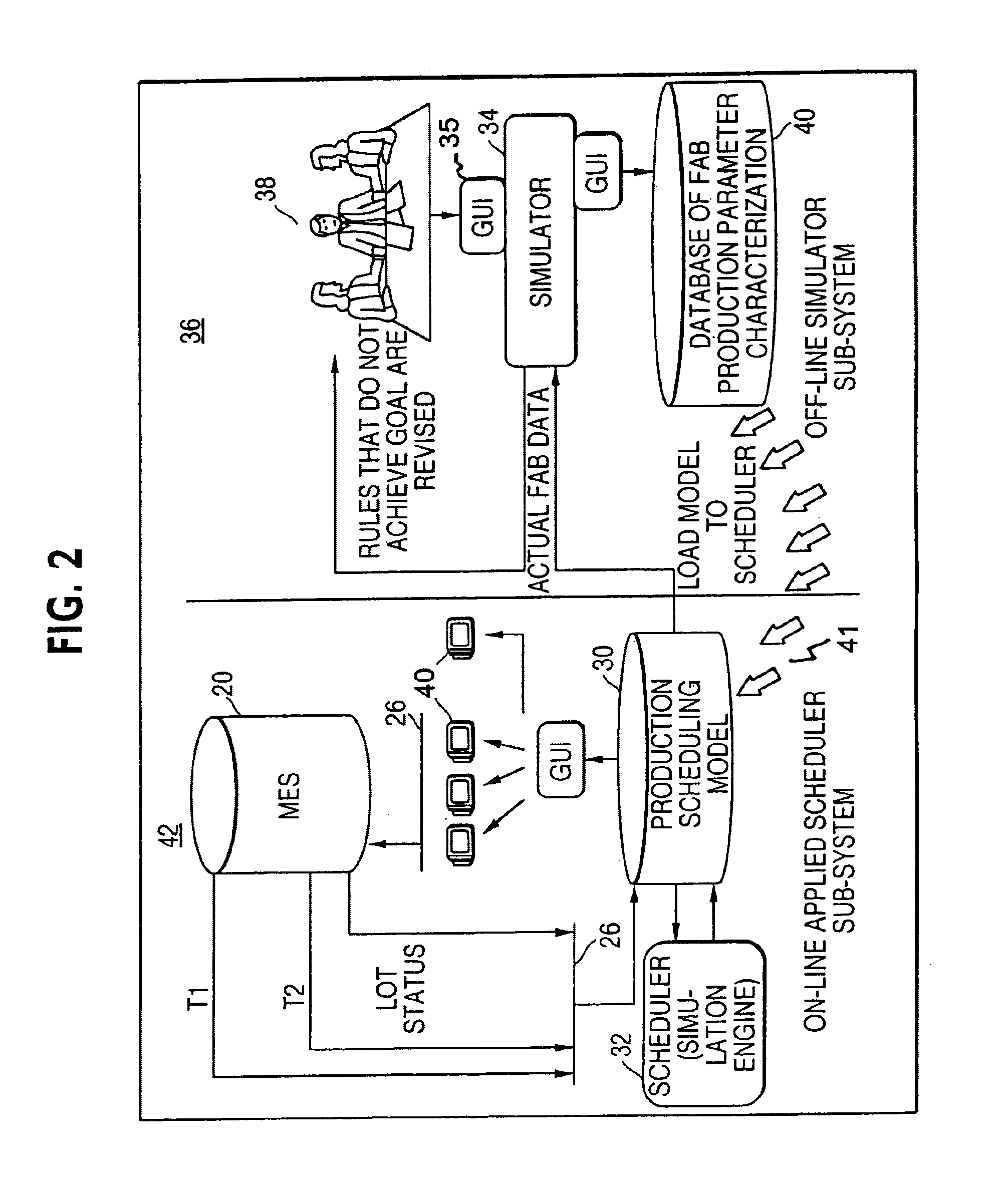

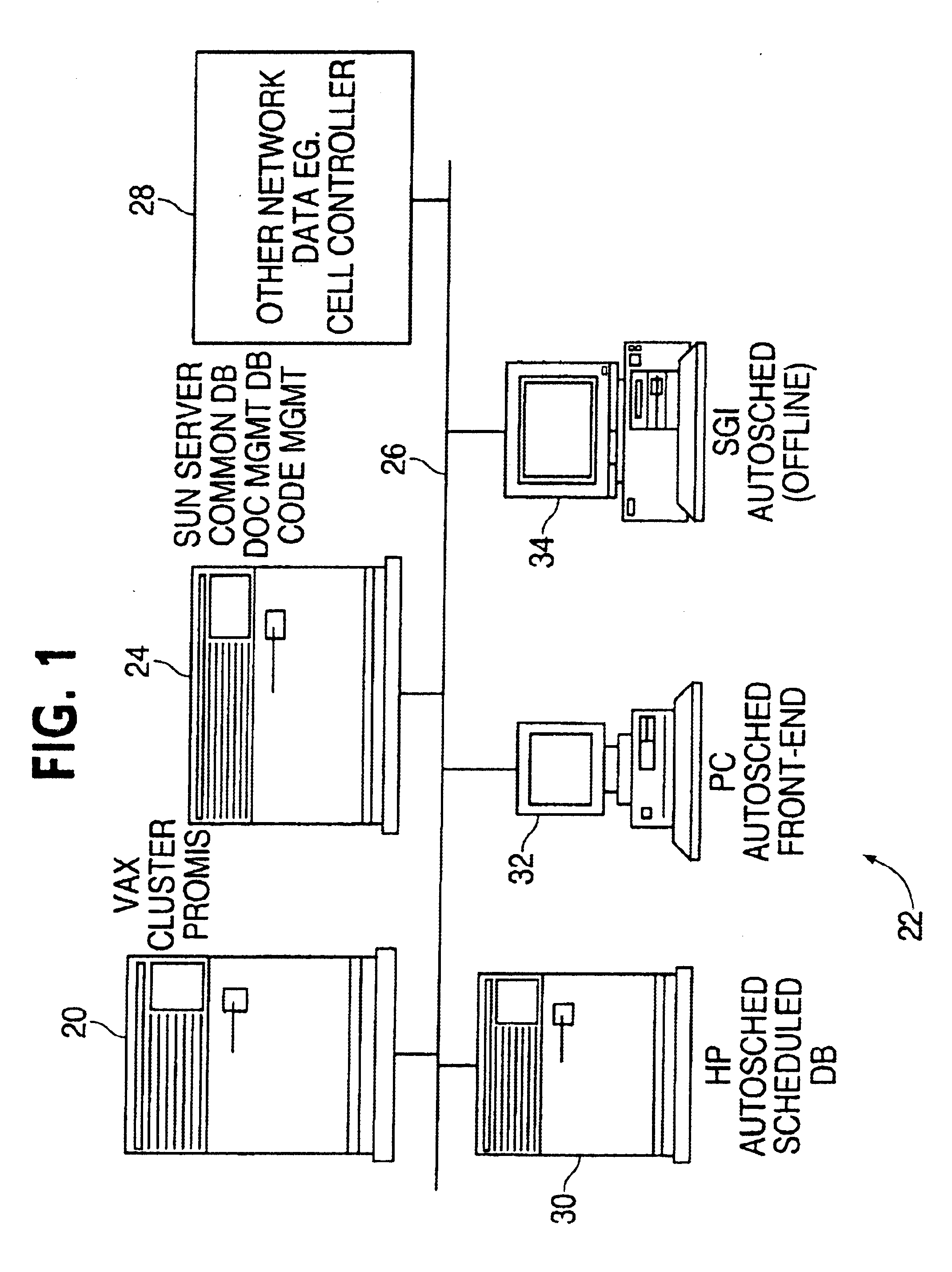

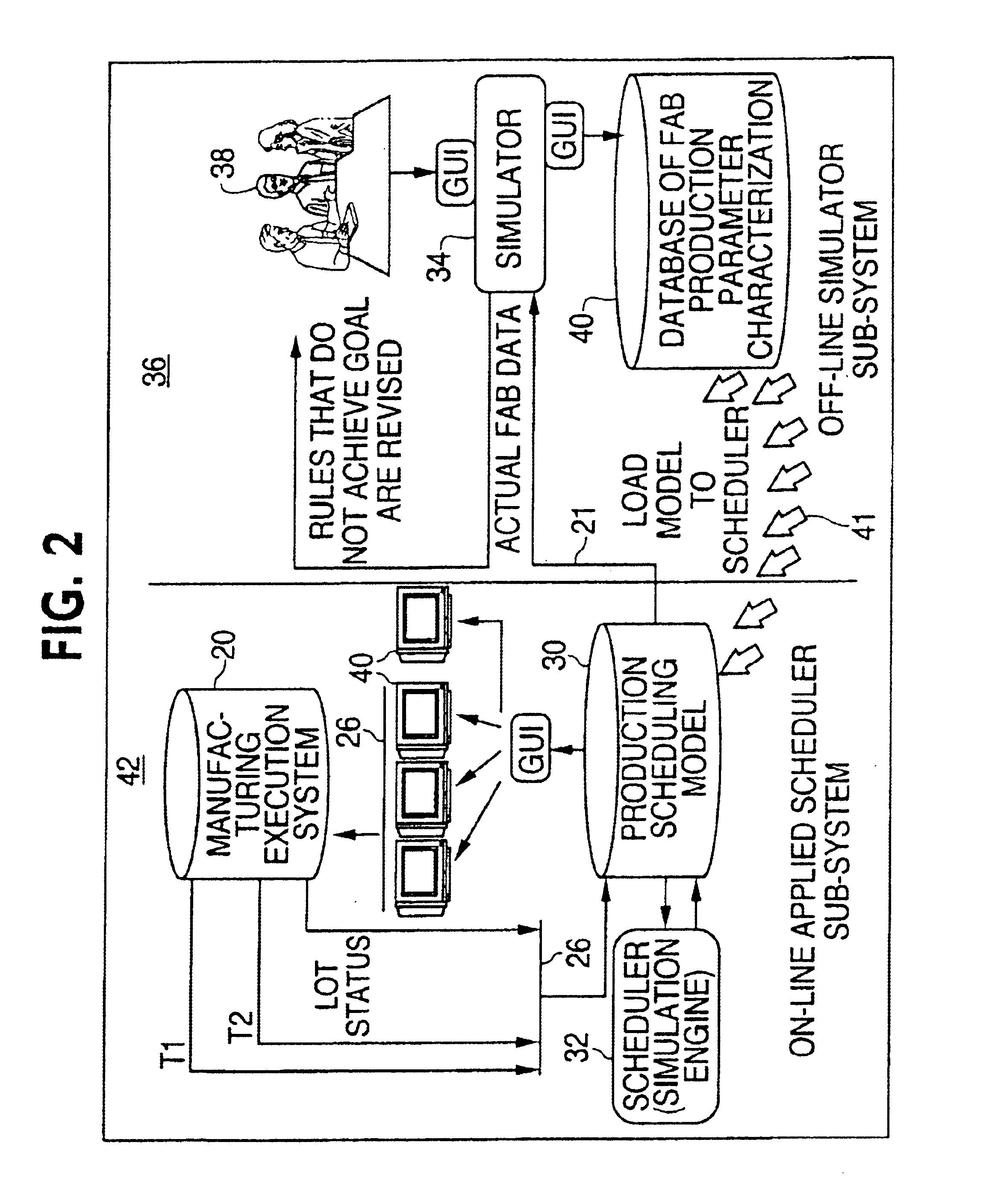

Integrated wafer fabrication production characterization and scheduling system

InactiveUS6889178B1Technology managementTotal factory controlManufacture execution systemWafer fabrication

An integrated wafer fab production scheduling and simulation system incorporates a manufacturing execution system with a scheduling system based on simulation. The integrated system provides manufacturers with a simulation tool integrated with the manufacturing execution system to evaluate proposed production control logic as a practical alternative to expensive experimentation on an actual production system. Furthermore, simulation models are used to create short-term dispatch schedules to steer daily manufacturing operations towards planned performance goals. Innovative features include integration of preventive maintenance scheduling, Kanban based WIP control, an integrated time standard database, and real time lot move updates.

Owner:SONY CORP +1

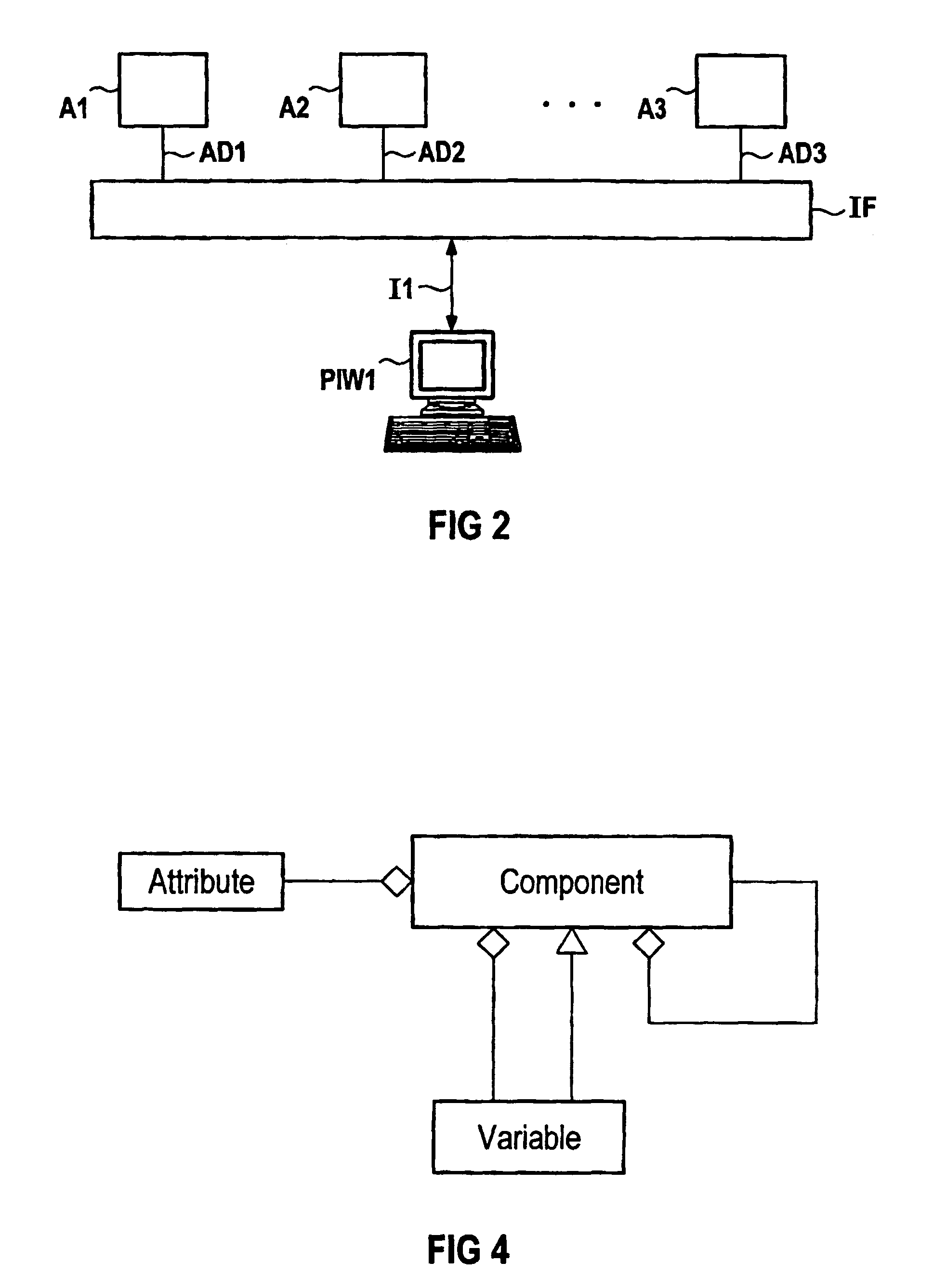

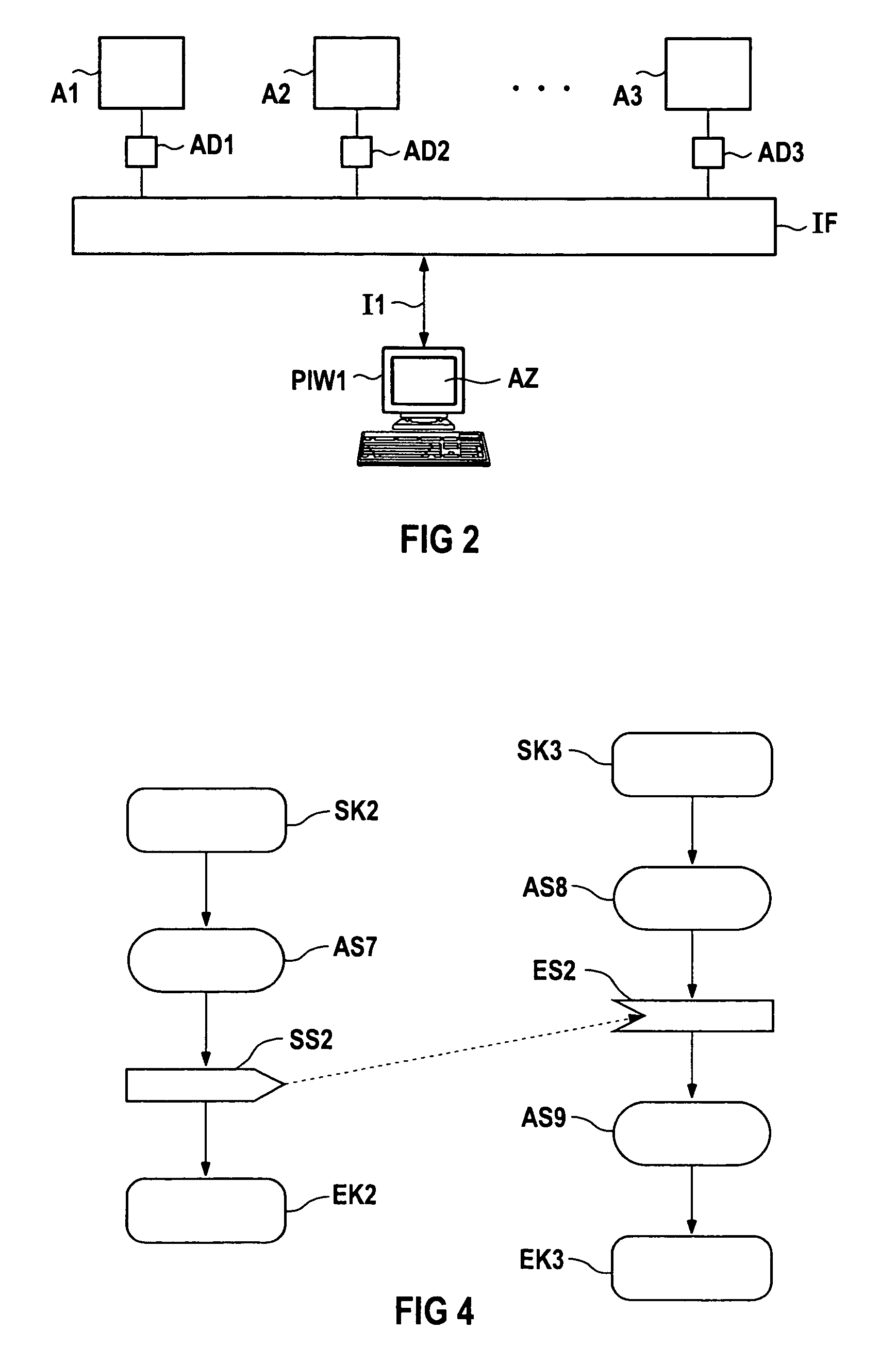

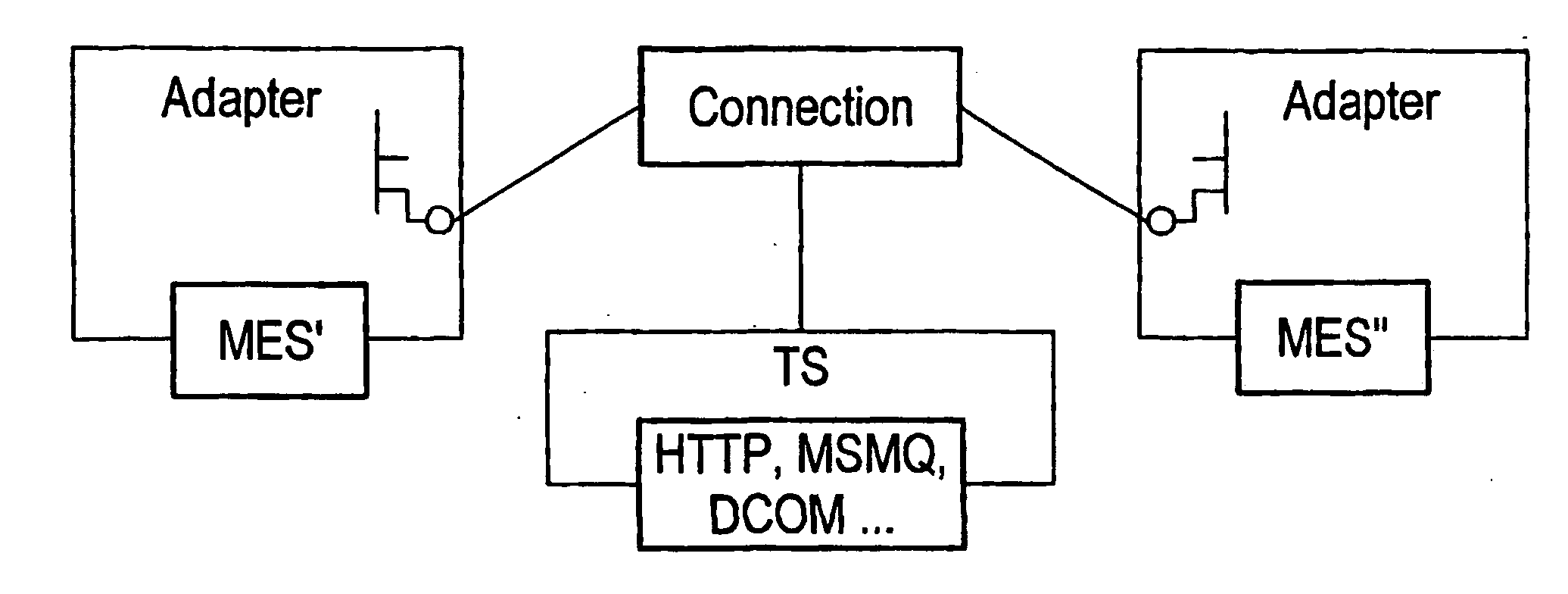

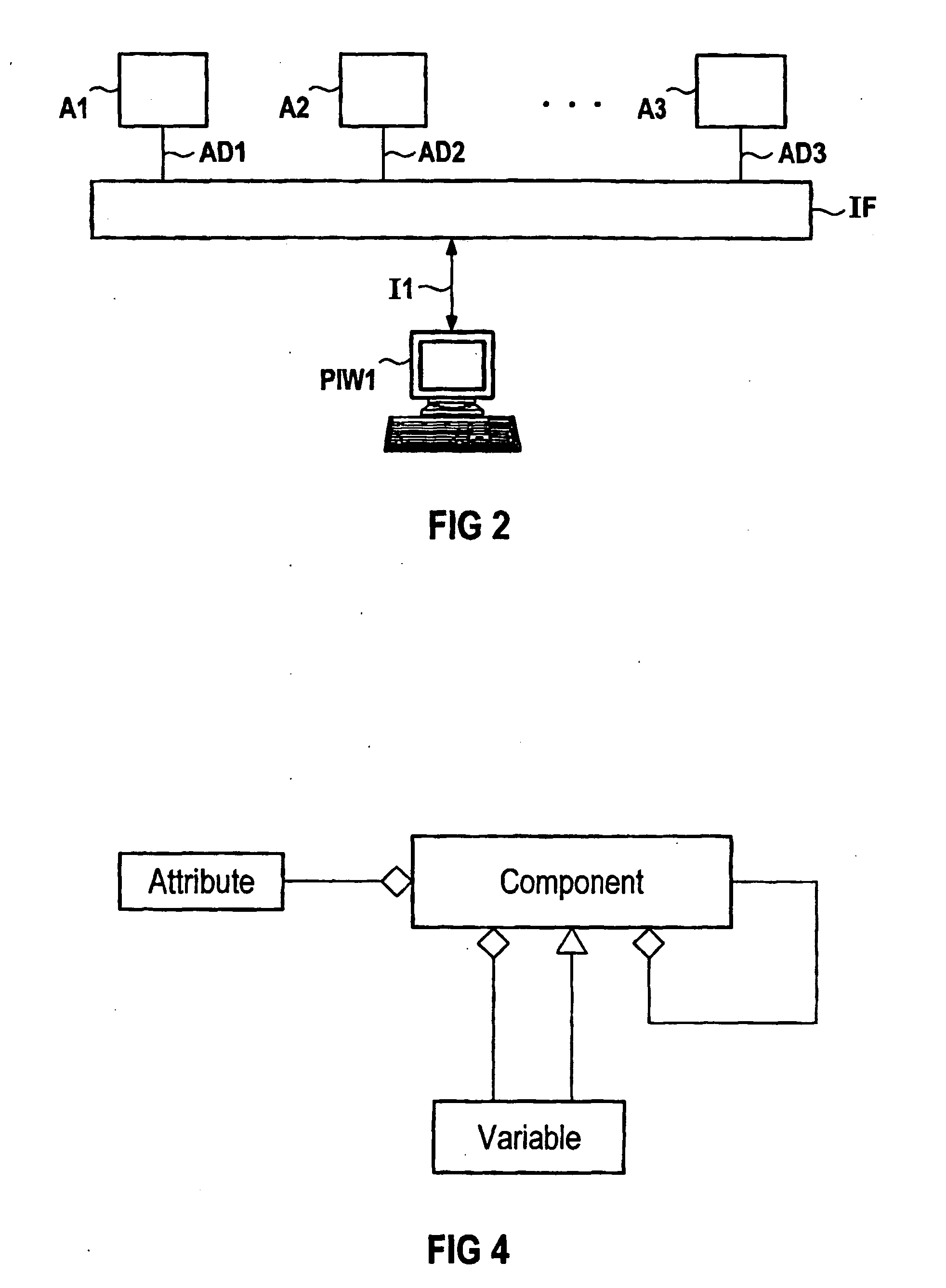

System and method for communicating between software applications, particularly MES (manufacturing execution system) applications

InactiveUS7343605B2Easy to integrateEfficient exchangeProgram control using stored programsComputer controlManufacture execution systemApplication software

Applications to be connected, particularly MES (manufacturing execution system) applications, as well as the communications mechanisms are depicted in the object model of the framework (IF; IF meaning industrial framework) by using wrappers and / or adapters and, as a result, can be manipulated in a uniformly homogenous manner in the framework. The invention is advantageous in that the very heterogeneous structures of the applications are depicted on a common model and can be comfortably and easily used by a user by means of generic mechanisms. That is to say that the effort of programming is eliminated and, as a result, this communication can be easily projected by establishing a so-called connection.

Owner:SIEMENS AG

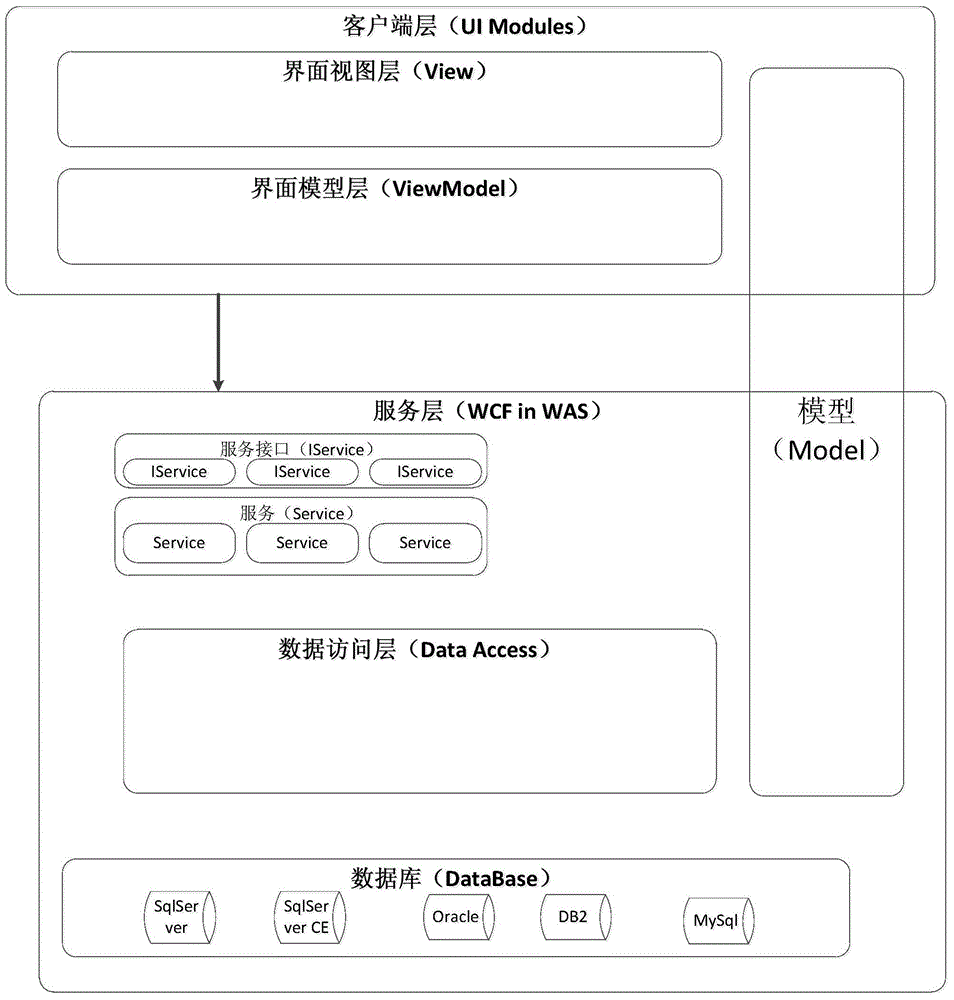

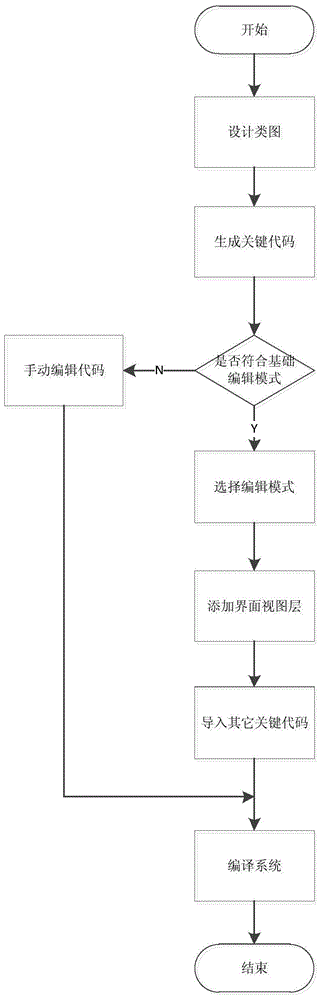

Quick client development frame for manufacturing execution system and software development method for frame

InactiveCN105630472AImprove robustnessReduce technical difficultySpecific program execution arrangementsSoftware development processCode writing

The invention relates to a quick client development frame for a manufacturing execution system and a software development method for the frame. The frame comprises a client layer and a service layer, wherein the client layer is used for realizing client interface interaction and comprises an interface view layer, an interface model layer and a model; and the service layer is used for realizing a business logic and data storage, receiving data sent by a client, reconstructing the data of the client according to a business requirement and sending the data to a database. The software development method for the frame comprises the steps of determining a data structure and the business logic of a development page as needed; designing UML class graph automatic generation codes; adding the codes into corresponding layers of project engineering in sequence; and compiling the project engineering to generate system software. According to the frame and the method, the code writing workload of the manufacturing execution system can be greatly reduced and the code quality and the system stability can be improved; and meanwhile, by applying a layered architecture and a configuration file, the software generated by the frame can be conveniently transplanted in different database systems.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

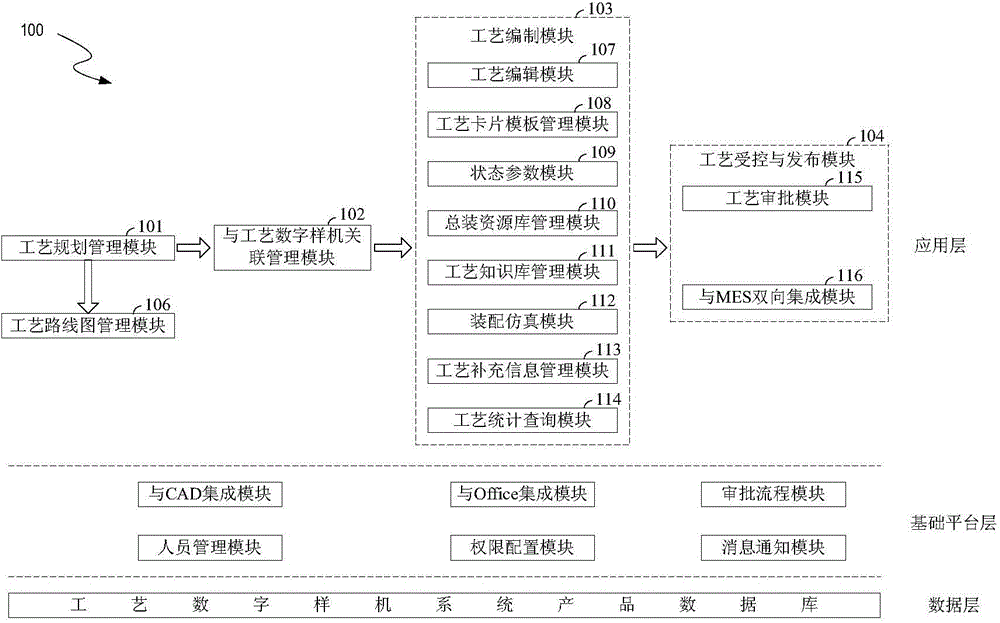

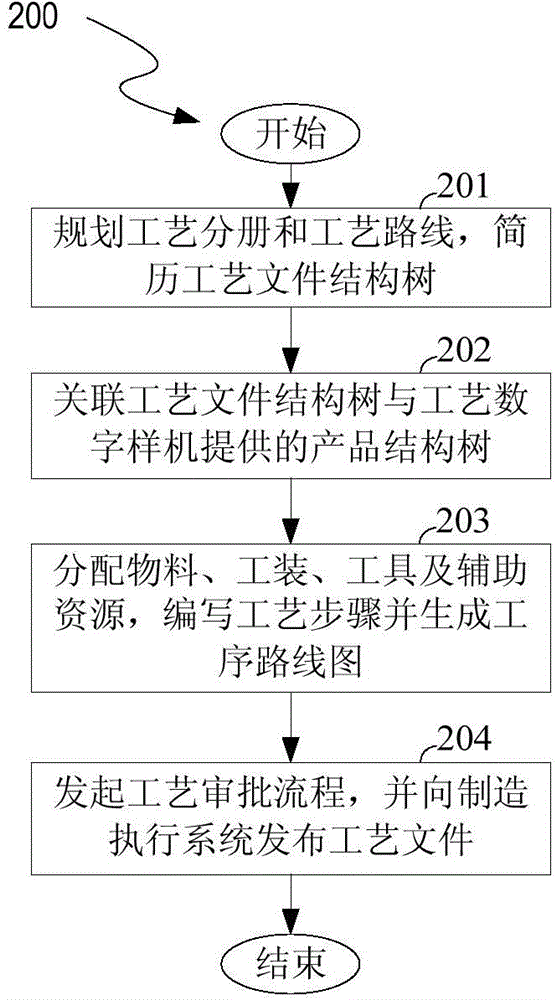

Spacecraft assembly oriented three-dimensional structured process design system and method

InactiveCN103605857AClosely relatedRealize the structureSpecial data processing applicationsManufacture execution systemData source

The invention discloses a spacecraft assembly oriented three-dimensional structured process design system and method. The three-dimensional structured process design system comprises a process planning management module, a process digital prototype associated management module, a process compiling module, a process controlled and publishing module. The process planning management module is used for planning process volumes and a process route and establishing a process file structure tree; the process digital prototype associated management module is used for being associated to the process file structure tree and a product structure tree provided by a process digital prototype; the process compiling module is used for allocating materials, tooling, tools and auxiliary resources, compiling process sequences and generating a working procedure route map; the process controlled and publishing module is used for initiating a process approval flow and publishing process files to a field manufacturing execution system. By the spacecraft assembly oriented three-dimensional structured process design system and method, the process digital prototype is taken as a unique data source, close association between the process file structure tree and the product structure tree is realized, and process compiling efficiency is improved by taking typical process statements as templates.

Owner:BEIJING INST OF SPACECRAFT ENVIRONMENT ENG

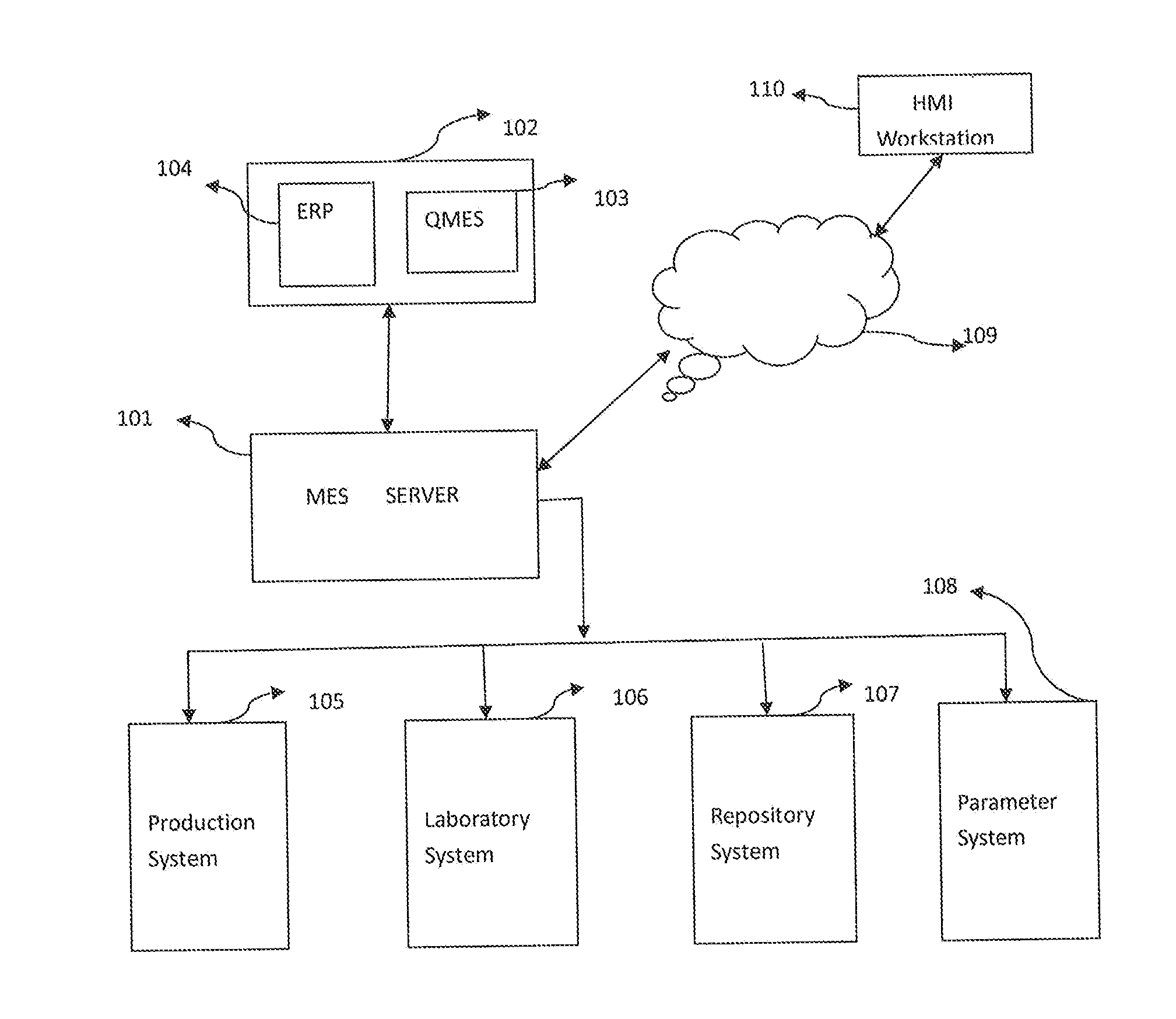

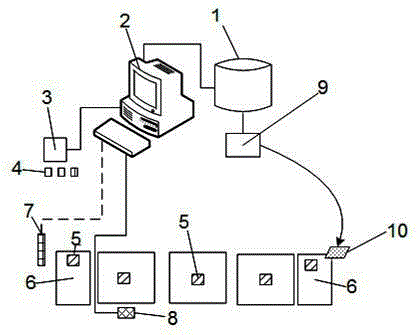

Network-based control method and system for controlling a whole-flow production process

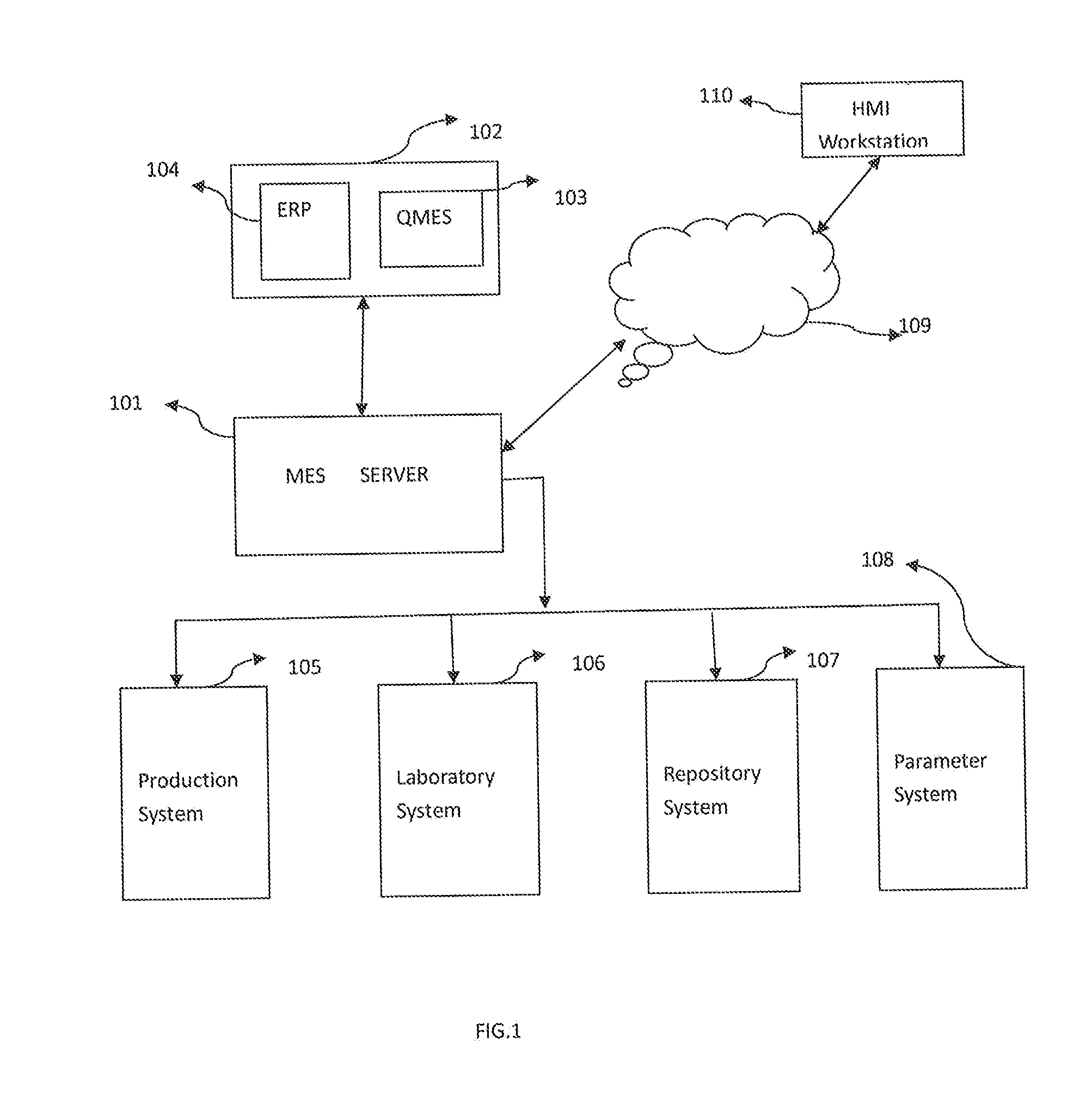

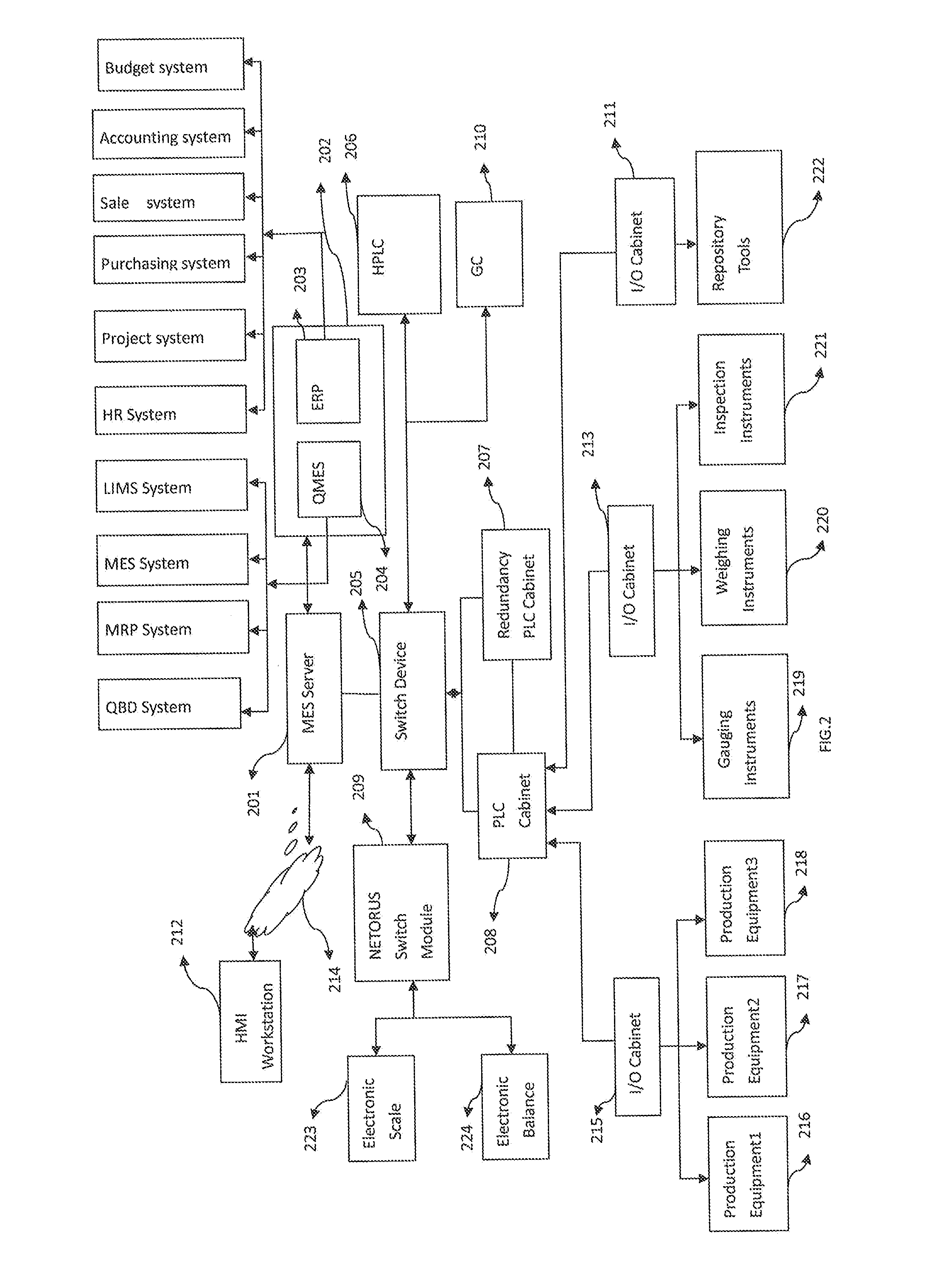

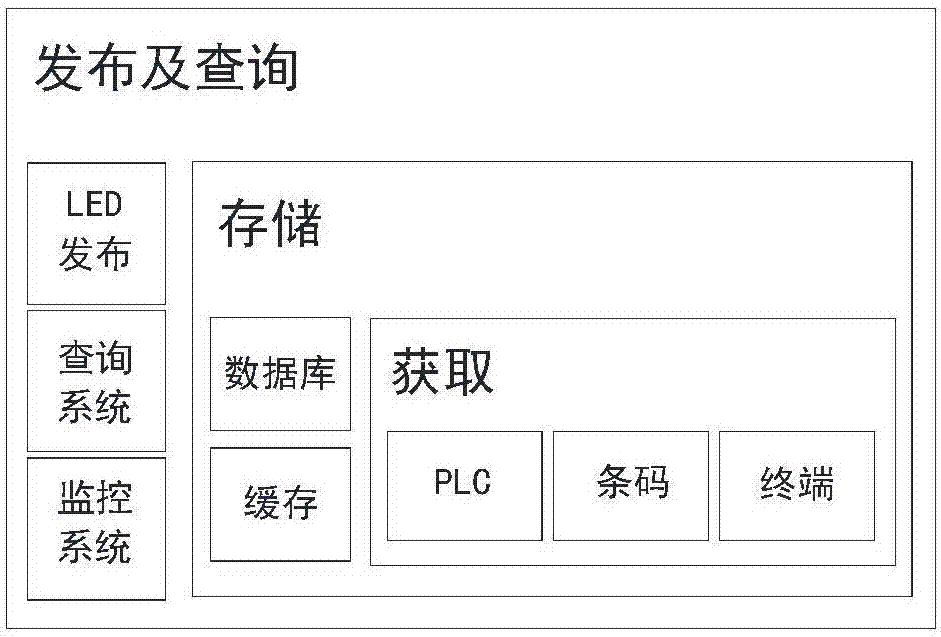

InactiveUS20130297055A1Easy to useHigh strengthTotal factory controlSpecial data processing applicationsManufacture execution systemProgrammable logic controller

A web-based automation control method and system for controlling a whole-flow production process are provided. The system includes a first production equipment; an inspection equipment; a warehouse controlling instrument designed to collect or monitor some elements concerning warehouse; an environmental parameter controlling instrument for collecting and monitoring variable environment elements; an input / output (I / O) cabinet connected to the first production equipment, the inspection equipment, the warehousing controlling instrument, environmental parameter controlling instrument; a programmable logic controller (PLC) cabinet connected to the I / O cabinet; a switch for connecting the PLC control cabinet with a manufacturing execution systems (MES) server; and a terminal connected to the manufacturing execution systems (MES) server via a communications network.

Owner:WANG FEI

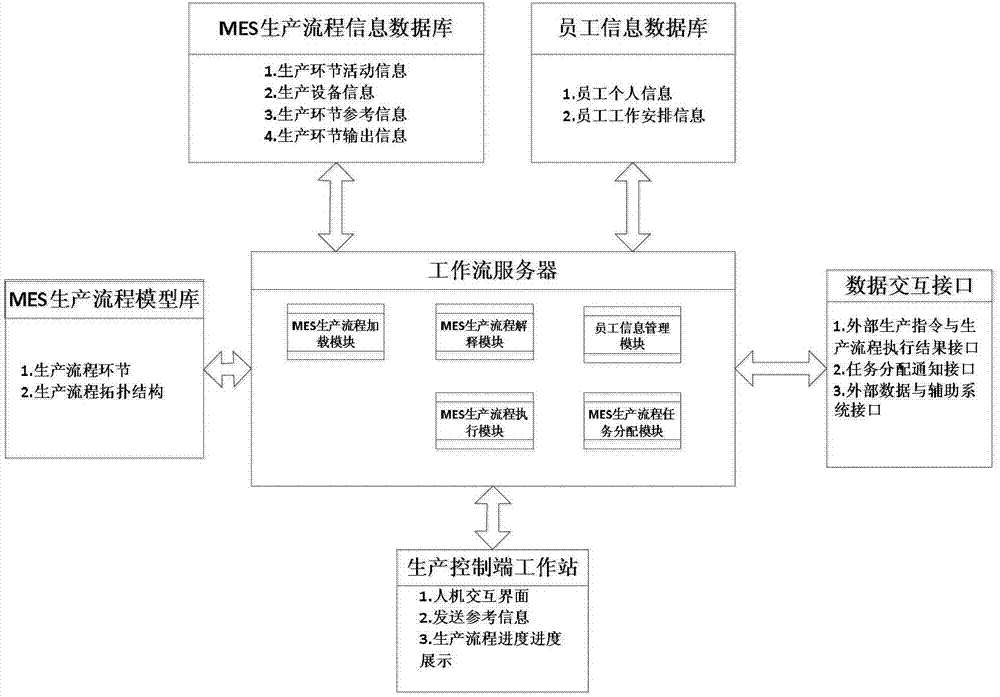

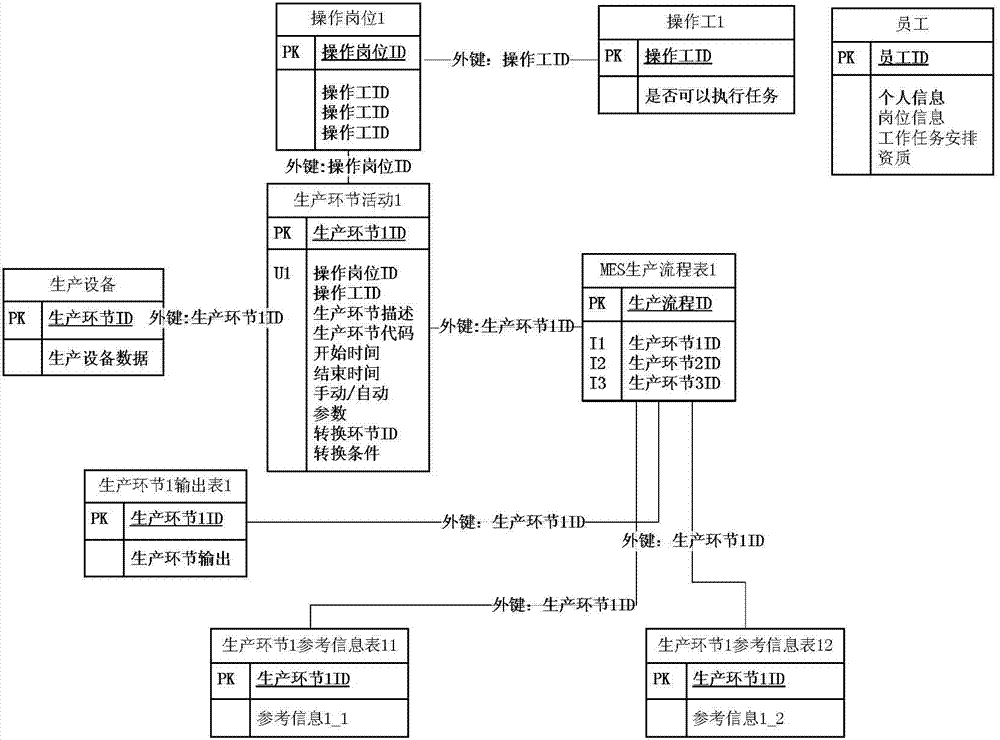

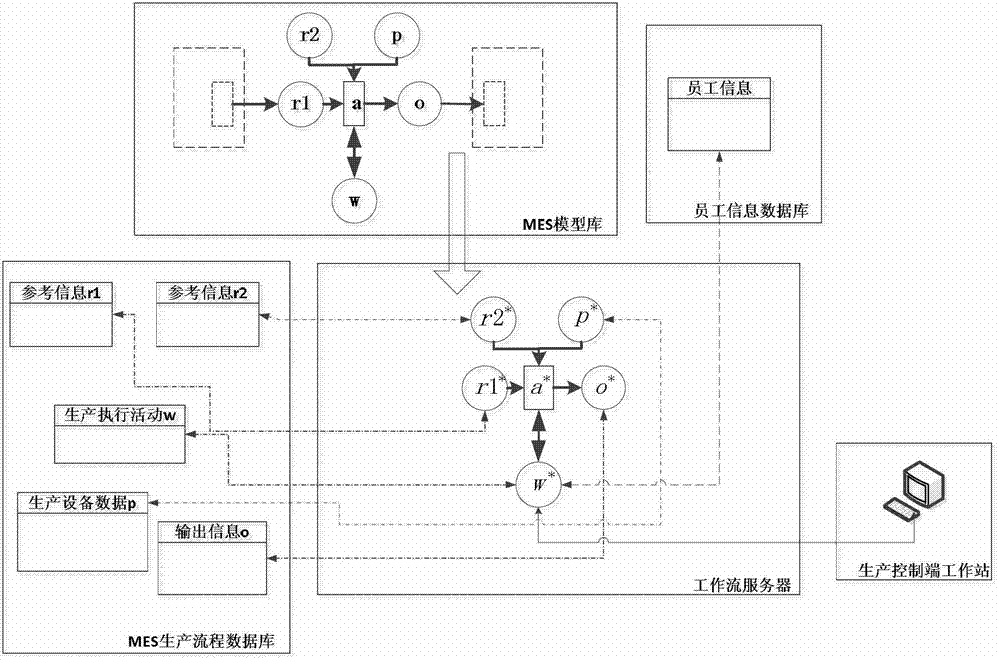

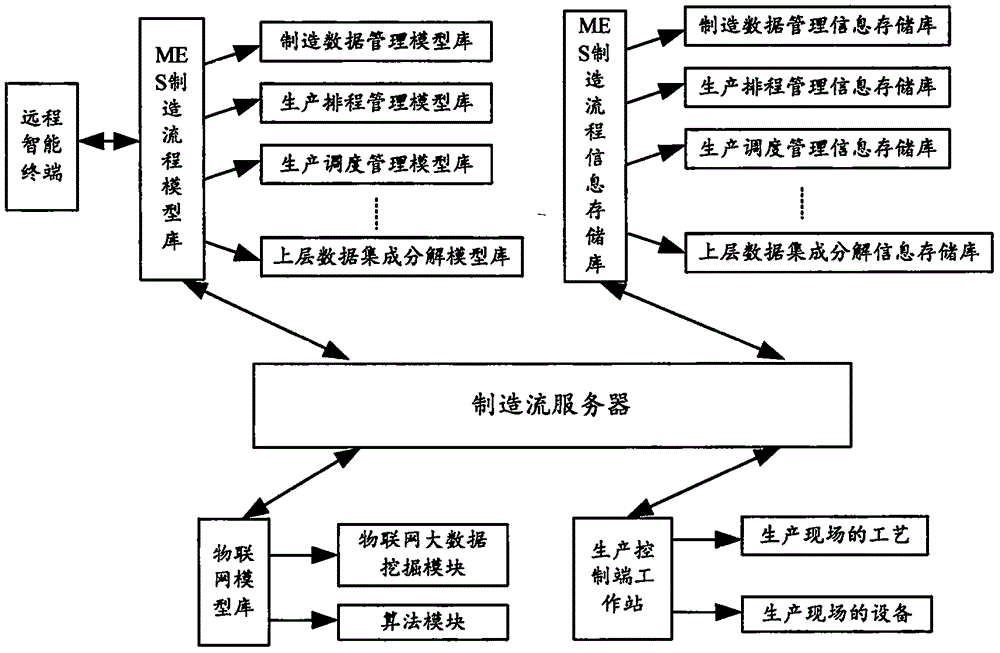

System and method for controlling production process of petrochemical enterprise on basis of manufacturing execution system (MES) workflow

InactiveCN102880123ARealize real-time controlIncrease productivityTotal factory controlProgramme total factory controlLink modelManufacture execution system

The invention discloses a system for controlling the production process of a petrochemical enterprise on the basis of manufacturing execution system (MES) workflow. The system comprises an MES production flow model base, an MES production flow information database, a workflow server, a production control terminal workstation and a data interaction interface, wherein the MES production flow model base is used for storing MES production flow link models and an MES whole production flow model for describing topological structures among the MES production flow link models; the MES production flow information database is used for storing production execution data in each link of the MES production flow; and the workflow server is used for invoking the MES production flow model base and the MES production flow information database to execute an MES workflow task. The invention also discloses a control method of the system for controlling the production process of the petrochemical enterprise on the basis of MES workflow. The system and the method provide activity execution information of panoramic production links for operators in a graphical mode so as to control the progress of the production flow in real time and improve the production efficiency.

Owner:ZHEJIANG UNIV

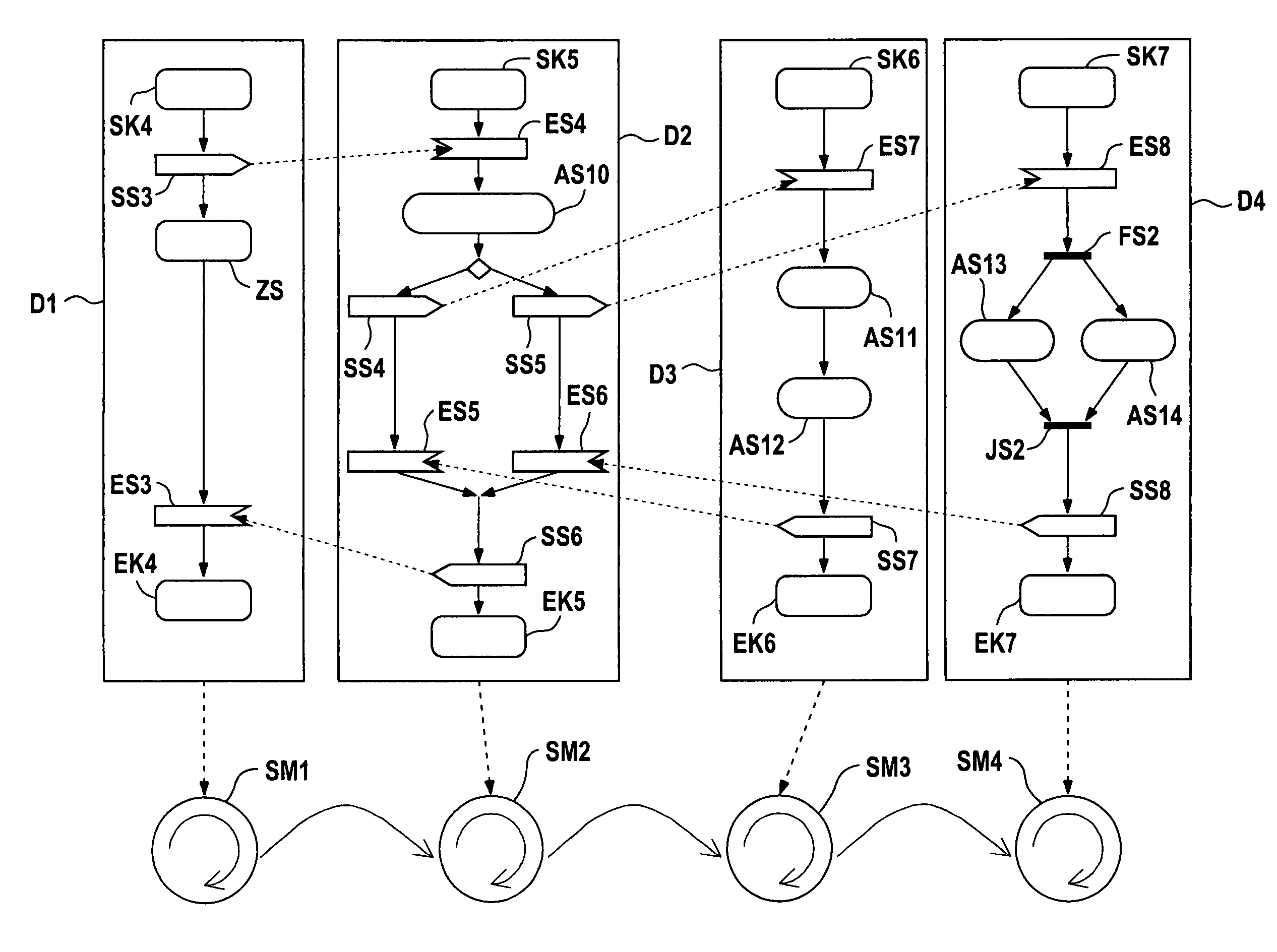

System and method for testing and/or debugging runtime systems for solving MES (manufacturing execution system) problems

InactiveUS7543276B2Easy to manageComputer controlSimulator controlGraphicsManufacture execution system

The invention relates to a system and method for testing and / or debugging runtime systems, particularly runtime systems used for solving MES (manufacturing execution system) problems. According to the invention, a user uses an editor to link graphic elements to an activity diagram that can be visually depicted on a display device. Communication relationships can be established between the activity diagrams by using appropriate means. In addition, the operation of an asynchronously cooperating state machine is described by an activity diagram.

Owner:SIEMENS AG

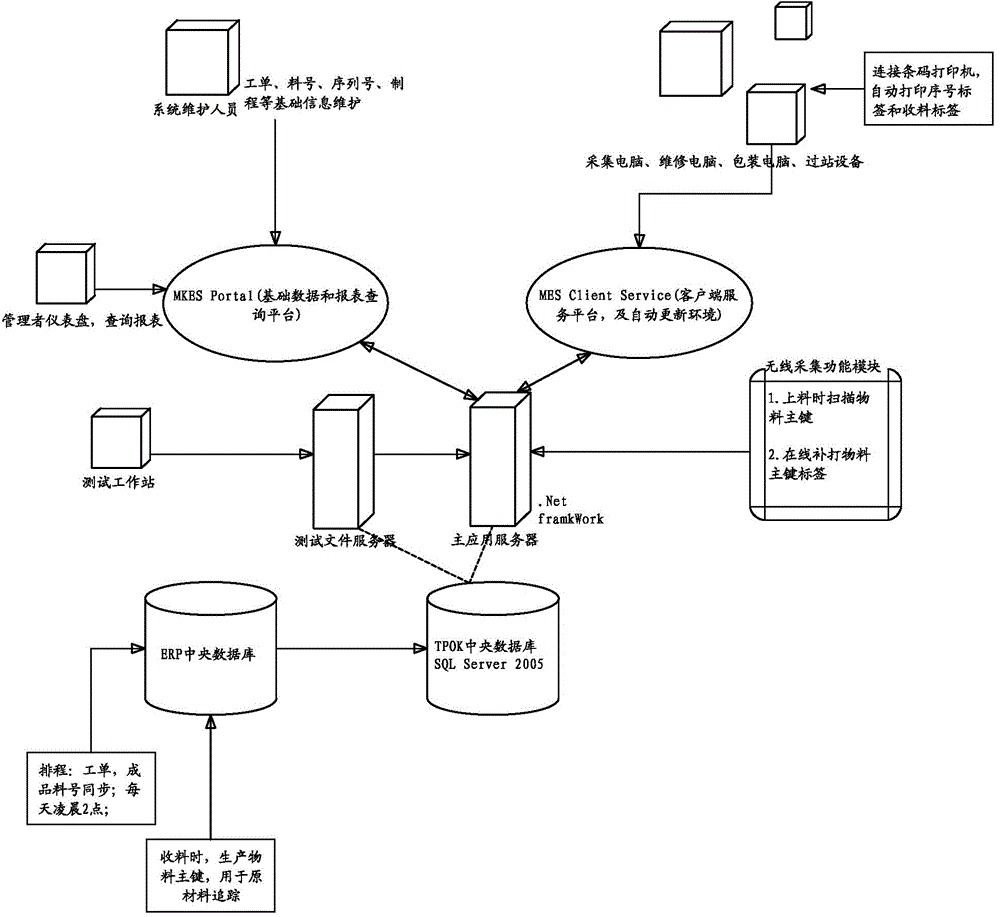

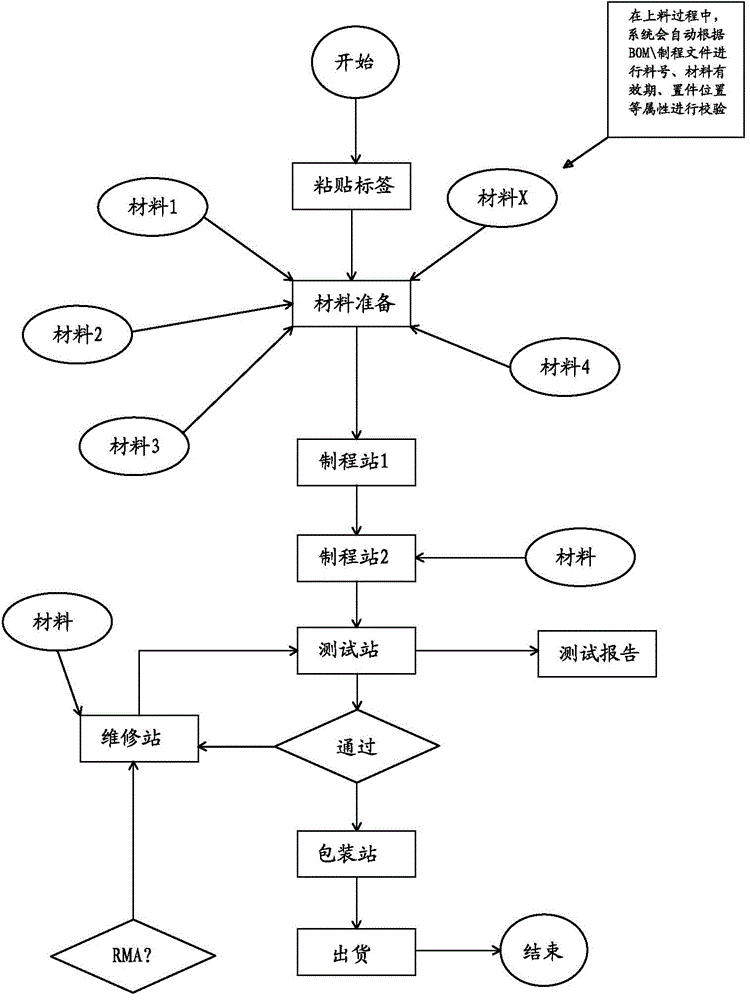

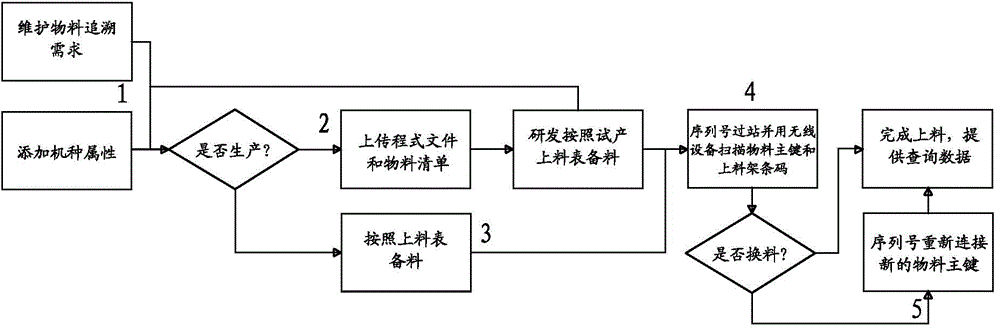

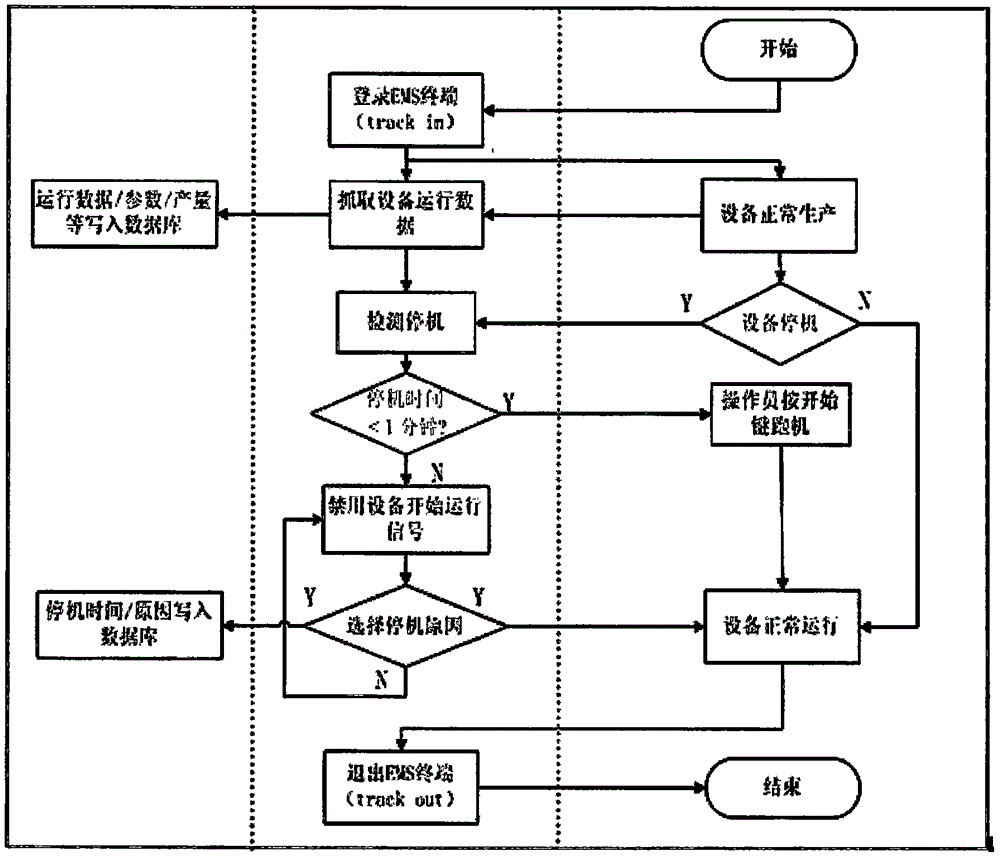

Process control and manufacturing execution system in industrial production line

ActiveCN105404243AMeet customized requirementsAvoid repetitionTechnology managementTotal factory controlProduction lineManufacture execution system

The invention discloses a process control and manufacturing execution system in an industrial production line, and the system comprises a central server which comprises a TPOK central database server and a main application server; a client service platform connected to the main application server; a base data and report query platform connected to the main application server; a test file server connected to the main application server; an information collection terminal connected to the main application server; and an ERP central database server connected to the TPOK central database server. The mutual transmission between the information of the main application server and the test file server and the information of the TPOK central database server is carried out. The system combines an internal coding method, a client coding method and a method of internal coding and client coding integration, completely meets the customization requirements of a client for a bar code, avoids the repeating of bar code information to the greatest extent, improves the production precision and information query speed, and achieves the traceability of raw materials and products.

Owner:梯梯电子集成制造服务(苏州)有限公司

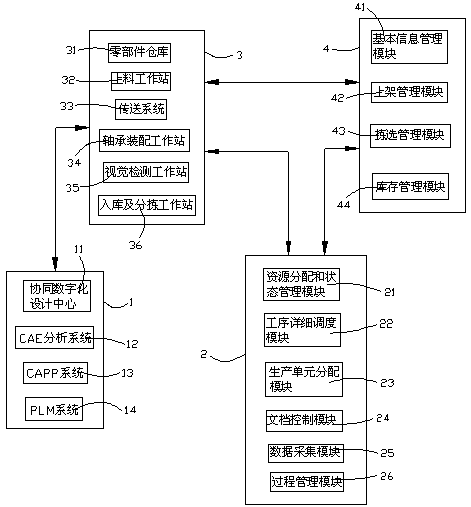

Bearing assembly line based on industrial cloud platform intelligent manufacturing

InactiveCN107861490AEffective combinationRealize smart factoryTotal factory controlProgramme total factory controlProduction lineManufacture execution system

The invention relates to the design of bearing assembly lines, in particular to a bearing assembly line based on industrial cloud platform intelligent manufacturing, comprising a cloud design and manufacture system, an MES (manufacturing execution system), an intelligent production system capable of automatically assembling bearings, and a parts WMS (warehouse management system); the cloud designand manufacture system provides collaborative design and inputs an optimized process to the intelligent production system; the MES generates a planning scheduling program according to acquired information of the WMS and input order information; the intelligent production system schedules production according to the planning scheduling program and performs automatic assembly and warehousing of bearings. The cloud design and manufacture system, the MES, the intelligent production system capable of automatically assembling bearings and a parts WMS are used herein to provide assembly, detection, warehousing and the like for bearings, the cloud design and manufacture system is effectively combined with the production line, an intelligent factory is achieved, and production efficiency is effectively improved.

Owner:长沙智能制造研究总院有限公司

Platform-based intelligent MES

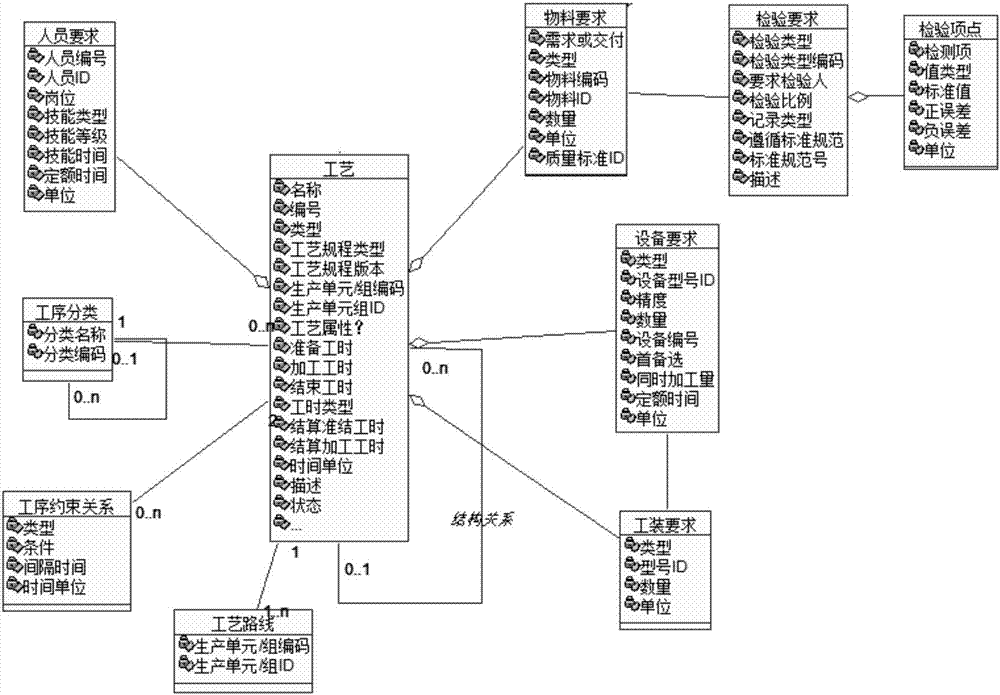

The invention provides a platform-based intelligent MES (Manufacturing Execution System). The system includes a business domain model base and an integrated collaborative manufacturing subsystem. The business domain model base is used for storing a business model, a domain model and a database model. The business model includes the corresponding requirements and associations of personnel, technology, materials, equipment, tooling and test. The domain model includes the work dependence and decomposition relations, the association between work and material and production units, and a field problem component. The database model stores relevant data and data associations in the business model and in the domain model. The integrated collaborative manufacturing subsystem makes an operation plan based on the data and data association in the business domain model base, and manages and schedules the whole operation process. Through a business domain model, all kinds of basic models can be specified, and the association relation can be established. The integrated collaborative manufacturing subsystem executes production planning and management scheduling.

Owner:北京兰光创新科技有限公司

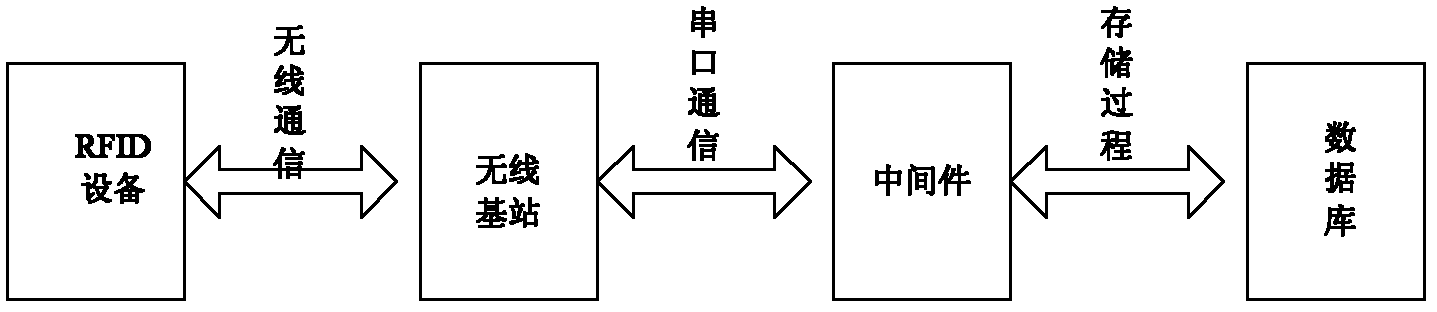

MES (Manufacturing Execution System) based on RFID (Radio Frequency Identification)

ActiveCN106779406AImprove the efficiency of obtaining informationImprove automationCo-operative working arrangementsResourcesManufacture execution systemProduction line

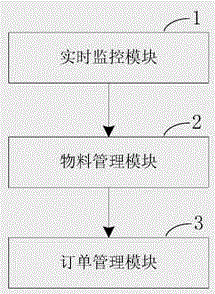

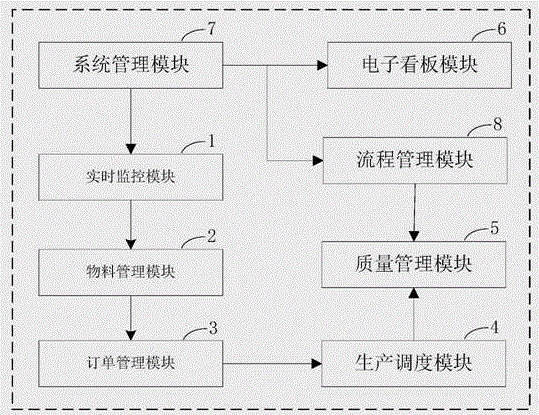

The invention provides an MES (Manufacturing Execution System) based on RFID (Radio Frequency Identification). The MES comprises a real-time monitoring module, a material management module and an order form management module, wherein the real-time monitoring module is used for monitoring the dynamic information of the process flow, the material accessories and the tooling equipment of each manufacturing shop in real time according to an RFID data collection system; the material management module is used for carrying out statistics on the material data of the produced product, the raw material accessories and the tooling equipment of each manufacturing shop according to the collected dynamic information; and the order form management module is used for receiving order form data, decomposing the order form data into a plurality of product order forms according to product categories according to production factors on the basis of the material data, configuring different ID (Identity) numbers according to product order forms, disassembling the products to form working procedure sections corresponding to the factors, and distributing composition factors onto the stations of a corresponding production line according to the working procedure sections to form an operational plan. Efficiency for the MES to obtain information is improved, the corresponding operational plan can be generated automatically according to the order form data, respective production capacity can be performed at a maximum degree according to the material data, and the automatic and intelligent level of the MES can be improved.

Owner:CHONGQING CHUANYI AUTOMATION

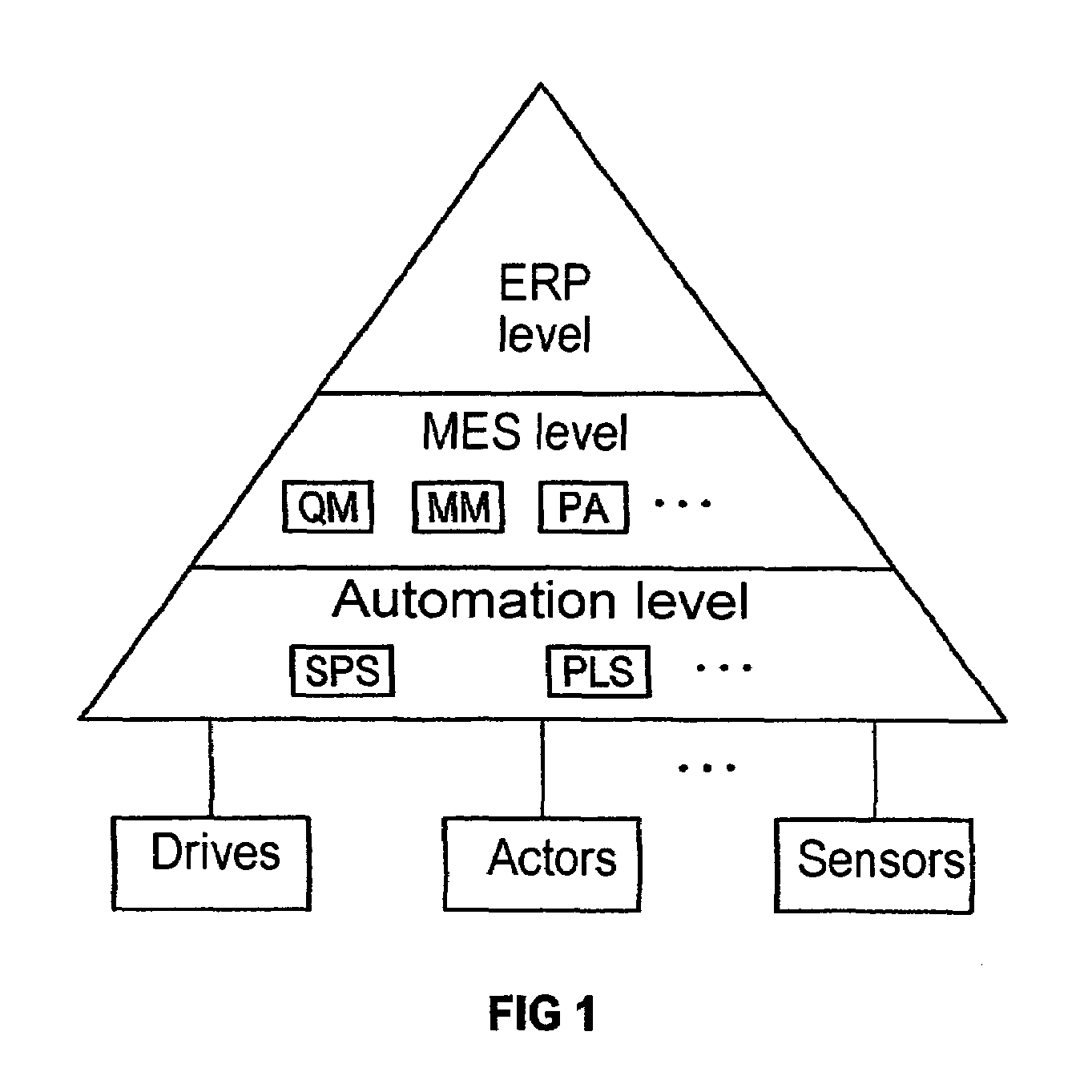

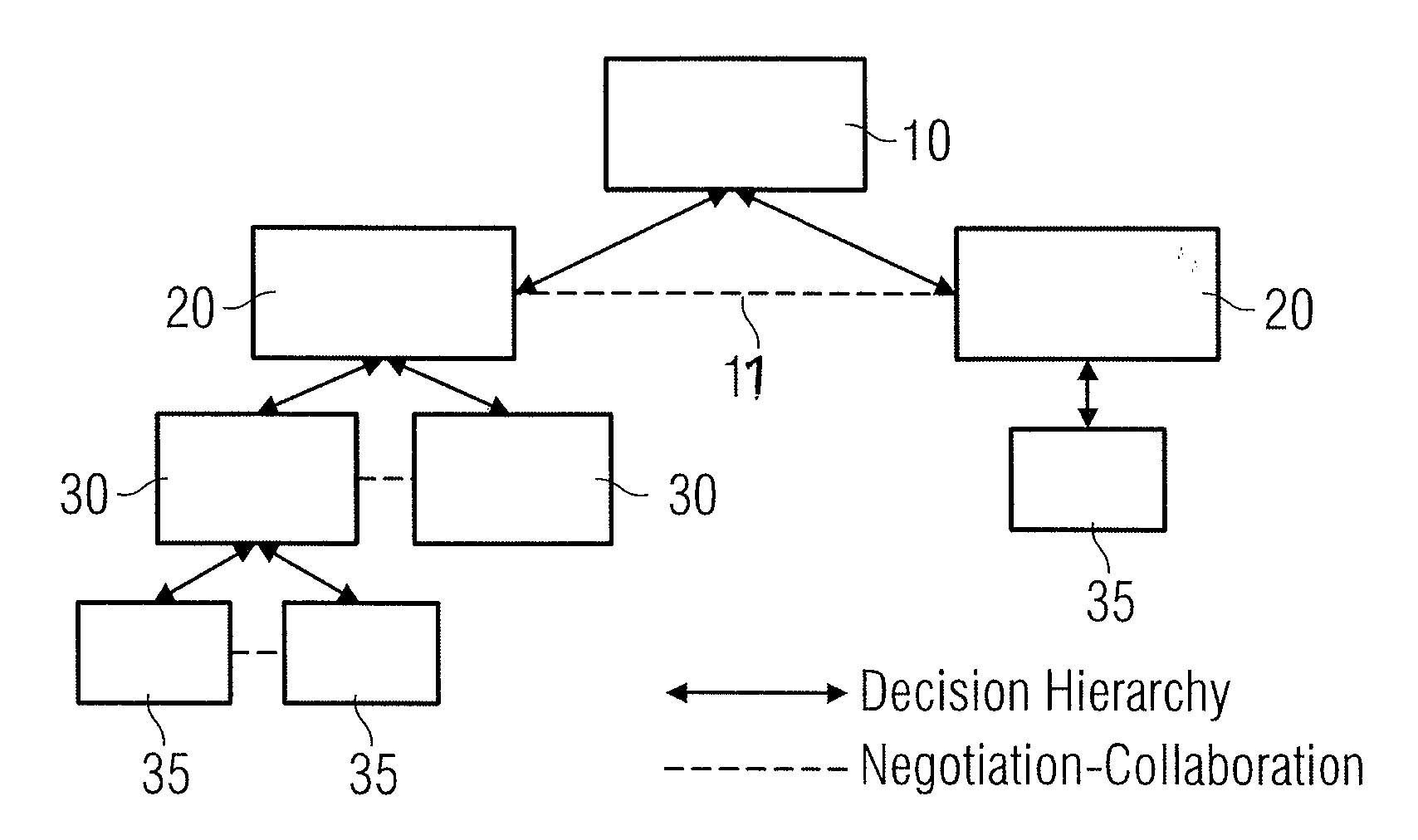

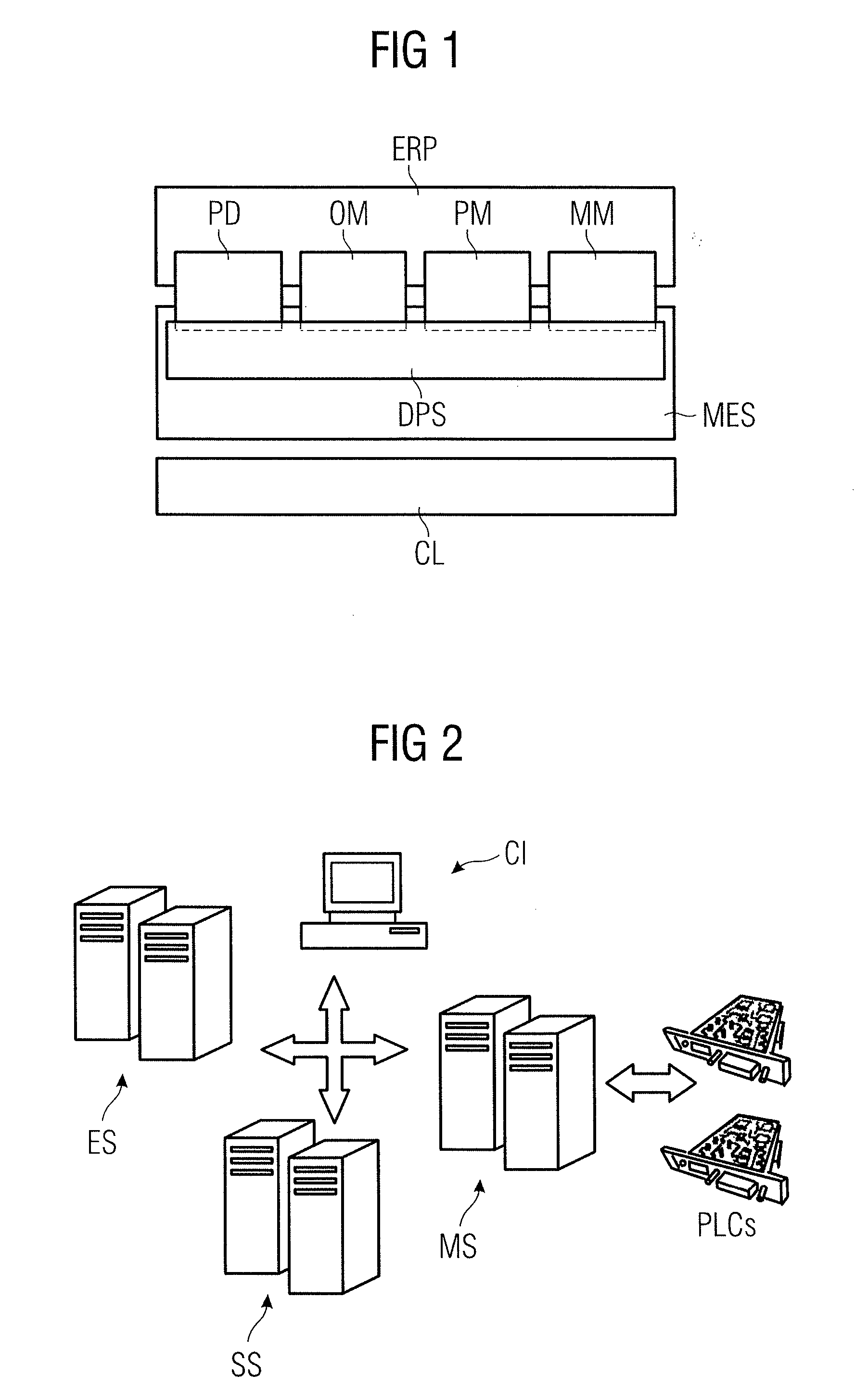

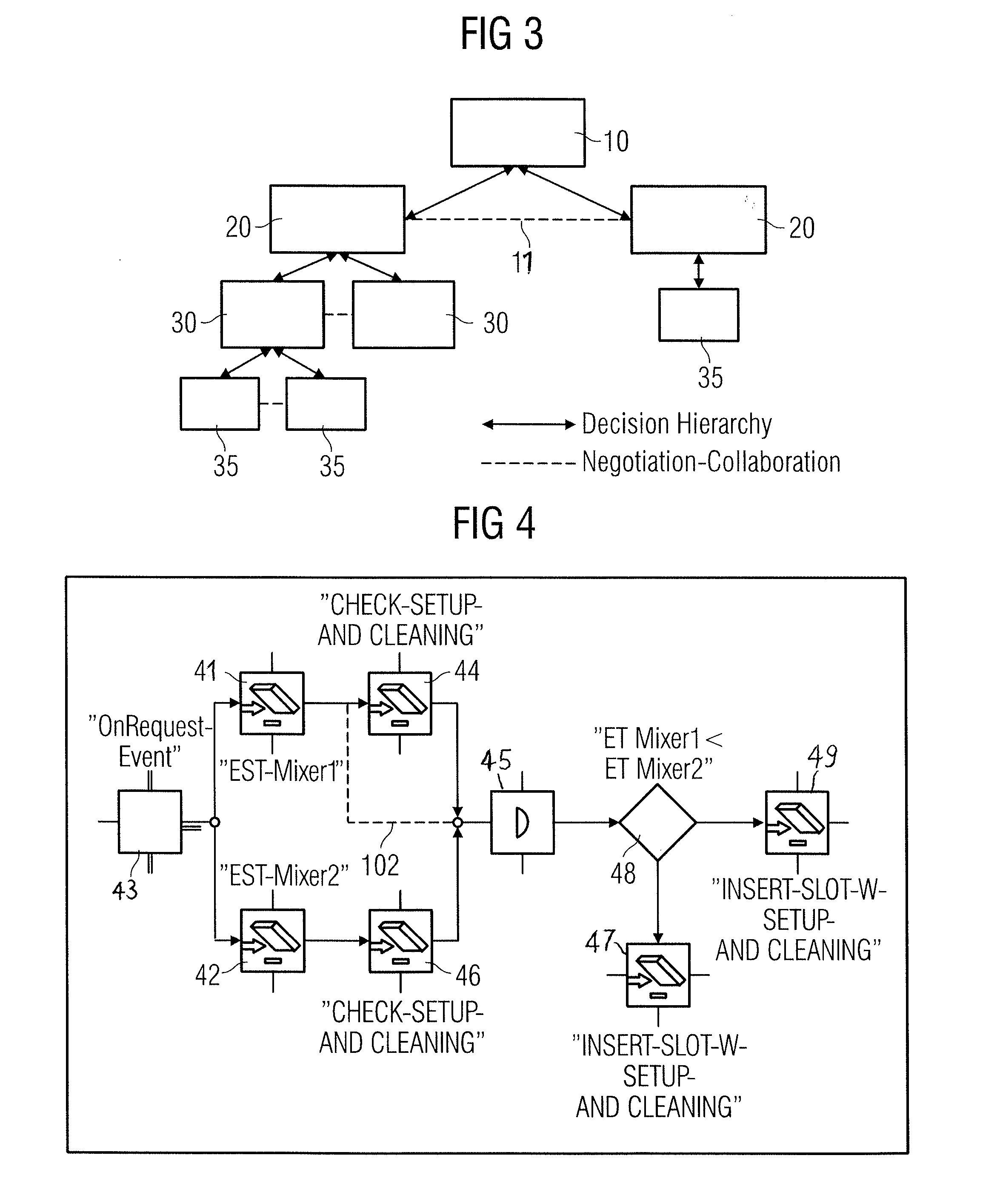

Scheduling System and Work Order Scheduling Protocol for Such a System

InactiveUS20080091289A1Available informationResourcesSpecial data processing applicationsManufacture execution systemOrder scheduling

A scheduling system (DPS) for planning and scheduling production in an industrial production system (CL), which scheduled production is to be executed by the production system (CL) under the control of a manufacturing execution system (MES), wherein: —said scheduling system is a multi-agent scheduling system (DPS); —at least a part of the behavior of the agents in said multi-agent system (DPS) is customizable by means of visually defined scheduling rules; —said scheduling system (DPS) and manufacturing execution system environment comprising: —editor means (CI) for visually defining both said manufacturing execution system (MES), and—an execution engine for executing said scheduling rules and control rules and making scheduling decisions on the basis of the execution of said scheduling rules and control rules.

Owner:SIEMENS AG

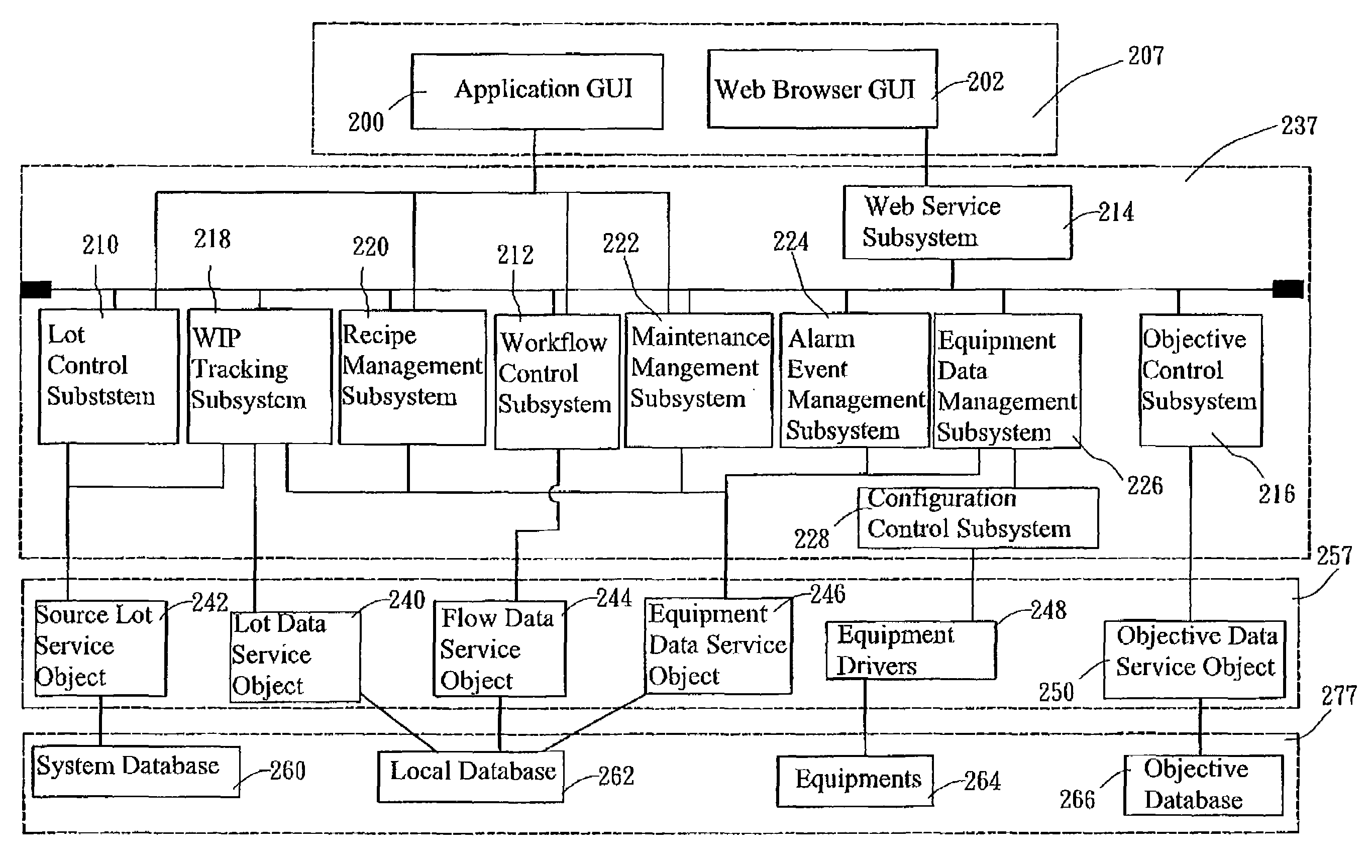

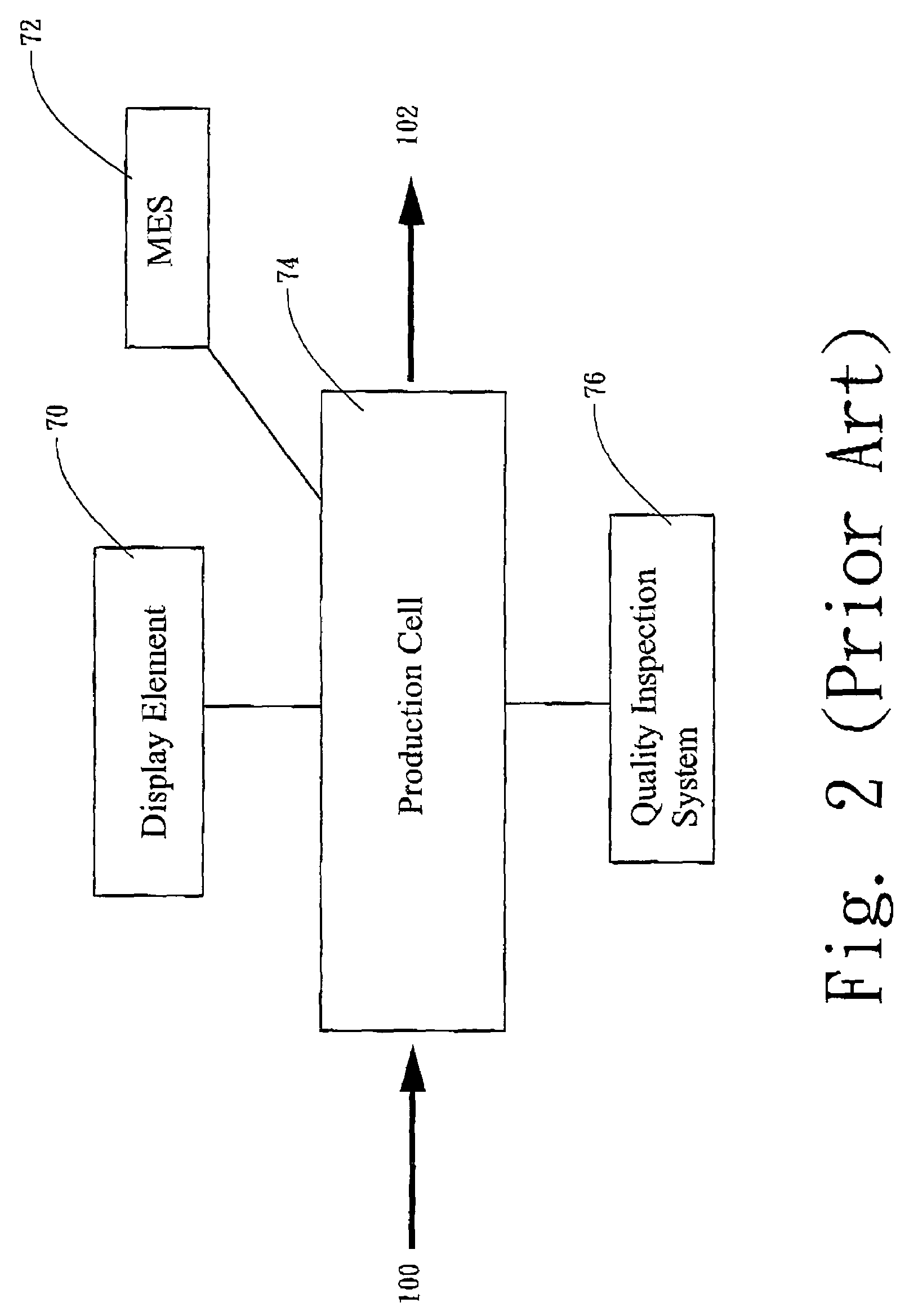

Production cell information system based on activity costs and an architecture therefor

InactiveUS6976033B2Effective distributionResolution problemDigital data processing detailsResourcesCost evaluationManufacture execution system

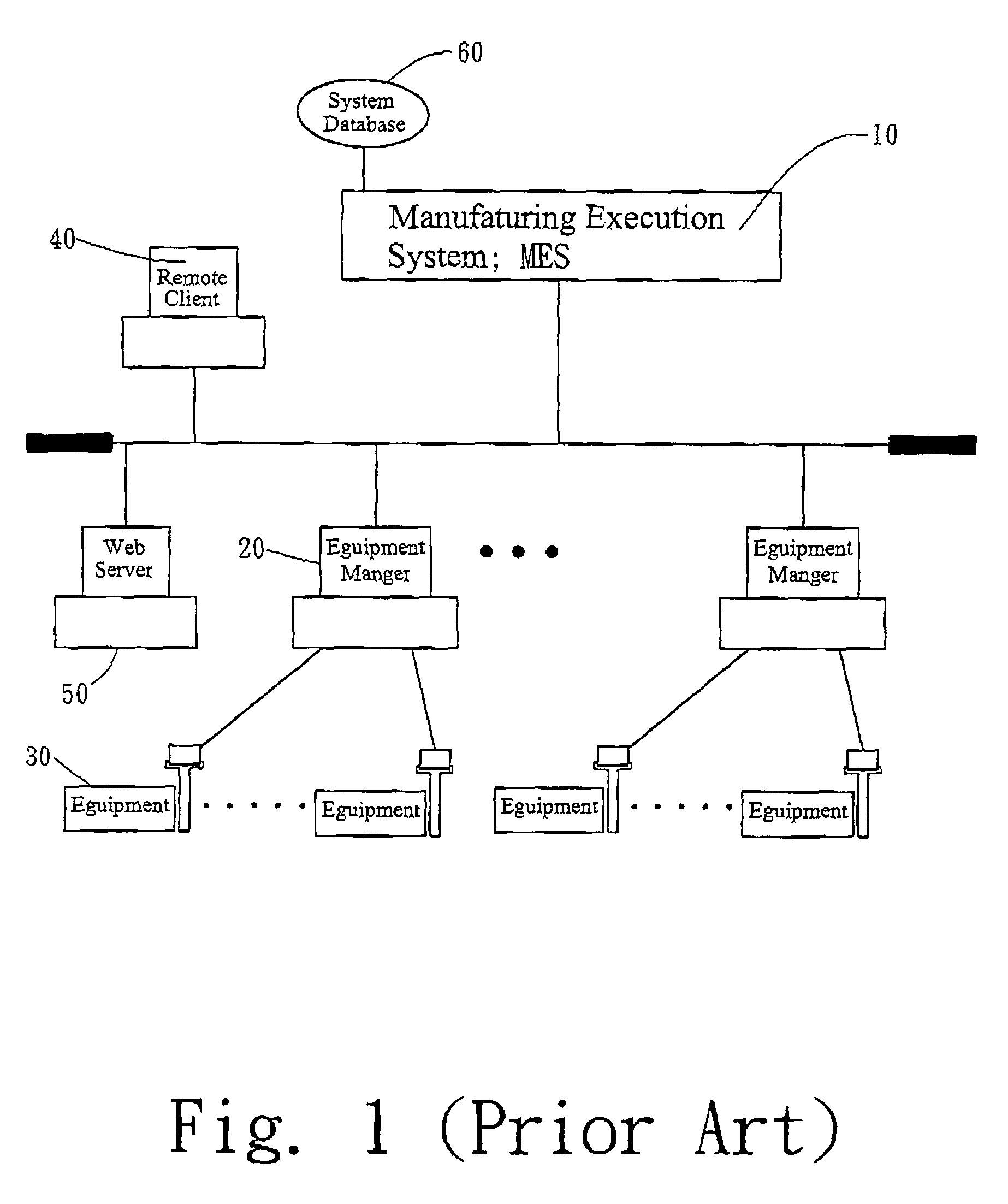

The present invention discloses a production cell information system based on activity costs and an architecture therefore. The present invention allows a plurality of production cells to execute most of the functions originally existing in the conventional MES (Manufacturing Execution System). The present invention not only can effectively overcome the shortcomings of centralized MES, but also can let each production cell collect and display its production information according to its characteristics. Furthermore, the present invention performs a cost evaluation based on all the activity costs spent on each production cell, so as to evaluate the performance of each production cell, and meanwhile, the related personnel is informed in time for achieving the objectives of profit center and consistently improving the production efficacy. According to the present invention, the production cell information system comprises: a cell controller, an equipment manager, a data service means and a web server. The architecture of the present invention for the production cell information system comprises: a presentation layer, a business rules layer, a data object service layer and an entity layer.

Owner:CHARMING SYST CORP

System and method for communicating between software applications, particularly mes (manufacturing execution system) applications

InactiveUS20050010931A1Easy to integrateEfficient exchangeComputer controlInterprogram communicationManufacture execution systemWorkload

Applications to be connected, particularly MES (manufacturing execution system) applications, as well as the communications mechanisms are depicted in the object model of the framework (IF; IF meaning industrial framework) by using wrappers and / or adapters and, as a result, can be manipulated in a uniformly homogenous manner in the framework. The invention is advantageous in that the very heterogeneous structures of the applications are depicted on a common model and can be comfortably and easily used by a user by means of generic mechanisms. That is to say that the effort of programming is eliminated and, as a result, this communication can be easily projected by establishing a so-called connection.

Owner:SIEMENS AG

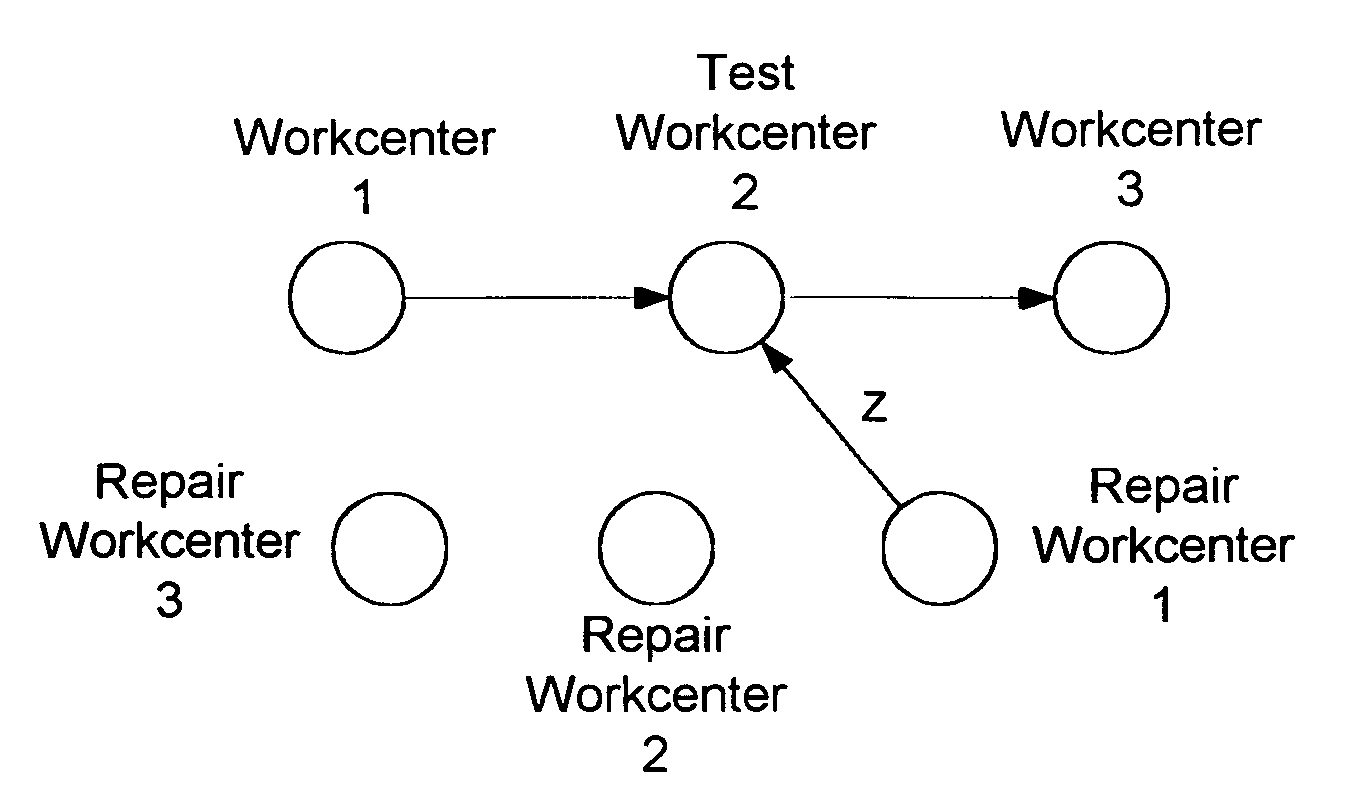

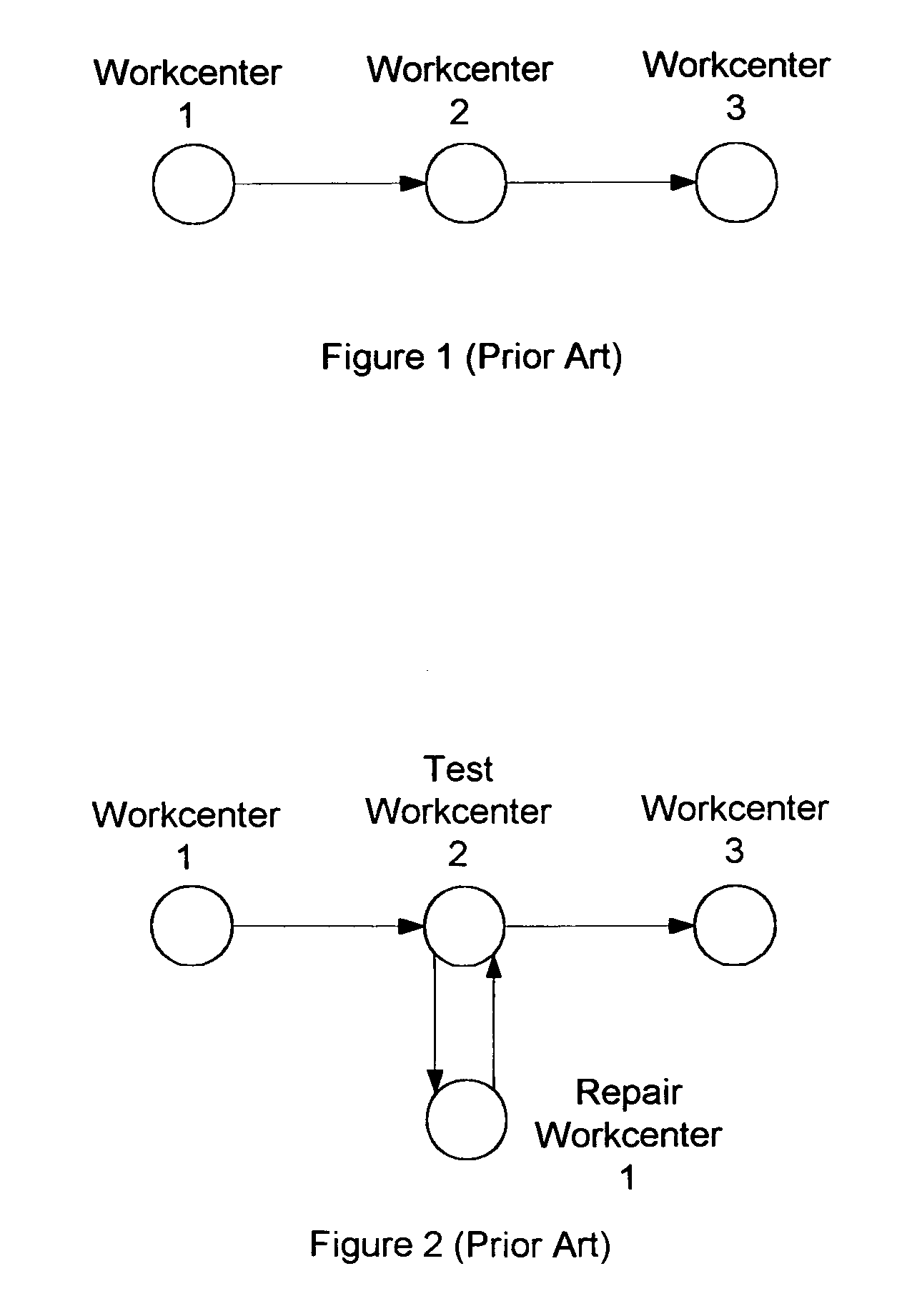

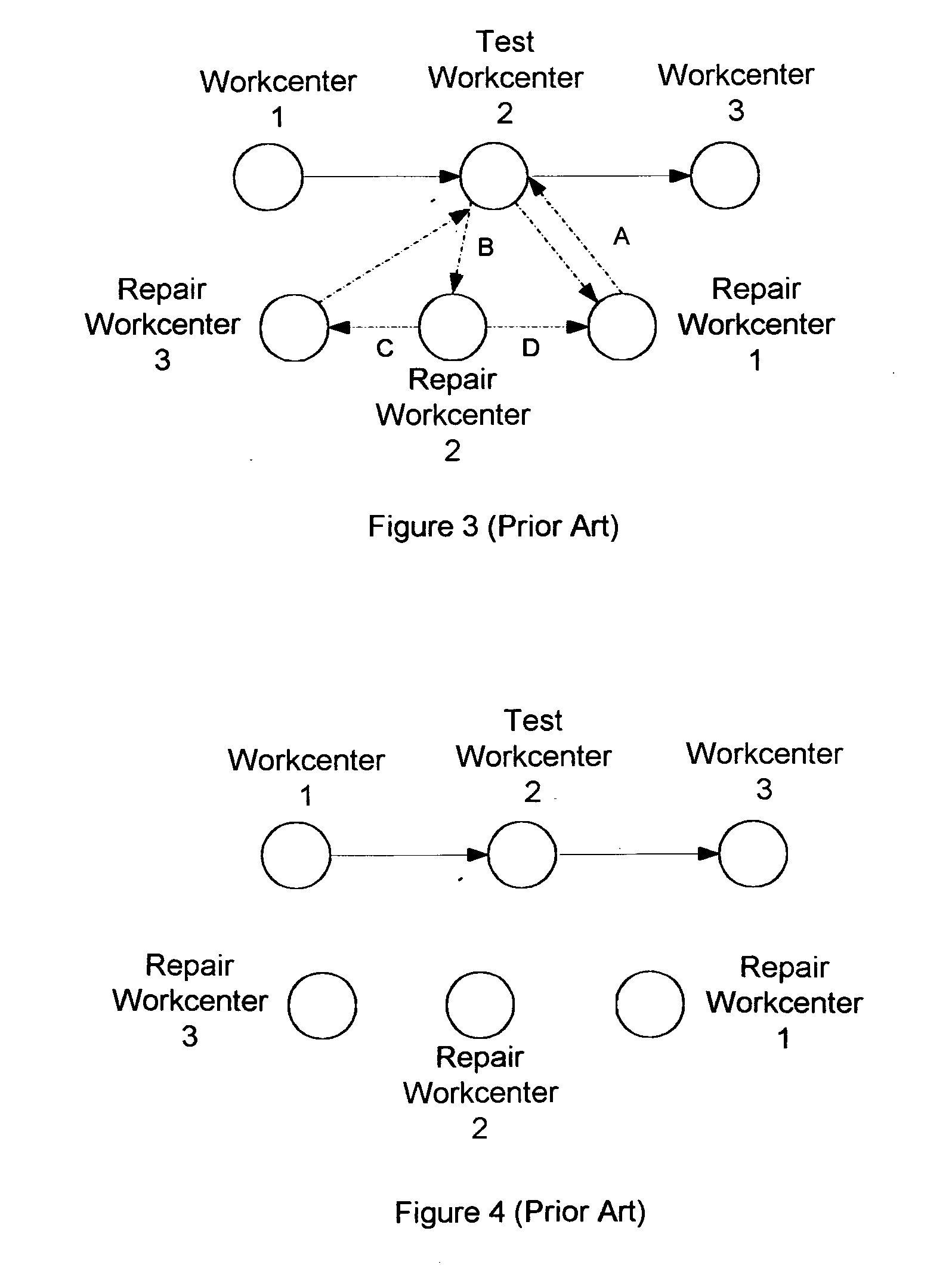

Directed defective item repair system and methods

InactiveUS20060129265A1ResourcesSpecial data processing applicationsManufacturing execution systemComputer science

The field of the present invention is the repair of a defective item where the item is directed through the repair process by a system. In the present invention, a manufacturing execution system controls and tracks an item through a sequence of workcenters that implement a process. A route defines the sequence of work centers for the process without repairing a defective item. An item is tested at a test workcenter and fails. A defect symptom describes the defect. A quality information screen collects quality information for the defect and presents a list of repair workcenters. Based on the defect symptom description, a repair workcenter is selected. The manufacturing execution system suspends the route and directs the item to the repair workcenter. The item is repaired at the repair workcenter and the quality information screen presents a list of workcenters including the test workcenter. If the repair of the item is complete, the test workcenter is selected. The manufacturing execution system directs the item to the test workcenter. The test workcenter tests the item. When the item passes the test, the route is resumed and the item is directed to the workcenter in the route after the test workcenter. If the repair is not complete, the repair workcenter selects the workcenter to continue the repair and the manufacturing execution system directs the item to the selected workcenter.

Owner:OUCHI NORMAN KEN

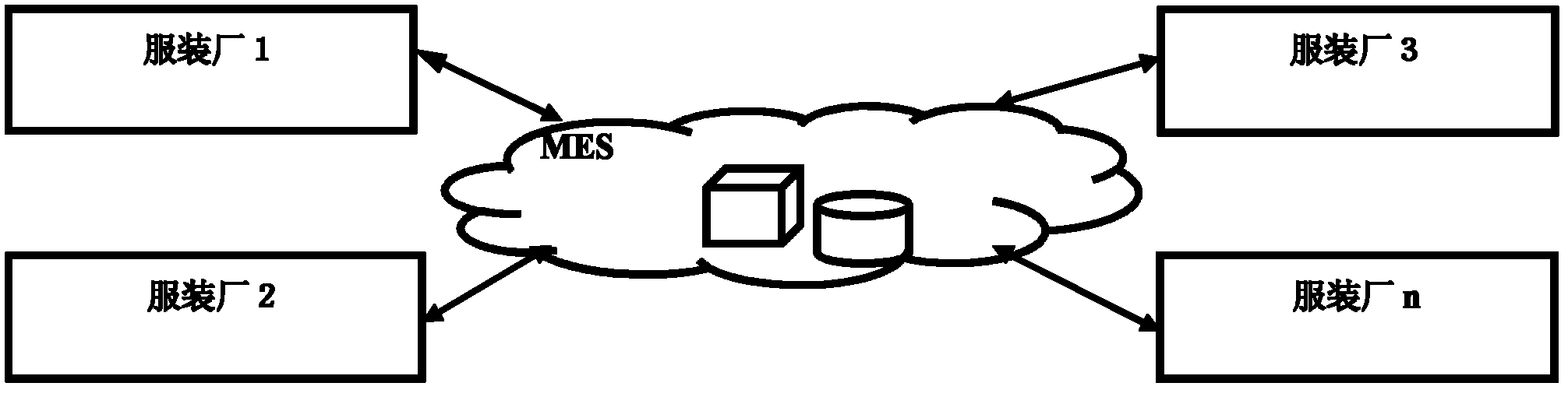

Method and manufacturing execution system (MES) framework for production management and control process of clothing industry

InactiveCN103164754ATimely and complete controlResourcesTransmissionManufacture execution systemControl system

The invention relates to a method and a manufacturing execution system (MES) framework for production management and a control process of clothing industry. The MES framework comprises a production management module (101), an enterprise plan system, a data bank (100) and a cloud storage module (105), wherein the enterprise plan system is connected with the production management module through a data bus of a hyper text transport protocol (HTTP), the data bank (100) is connected with the production management module, and the cloud storage module (105) is connected with the production management module and the enterprise plan system. A management and control system further comprises a terminal device (104) connected with the cloud storage module, and a network safety device (103) respectively connected with the terminal device and the cloud storage module. The method and the system for production management and the control process of a software as a service (SaaS) framework are based on cloud computation. Main users of the method and the MES framework are small-and-medium-sized clothing manufacturers in the clothing production industry. The process of the clothing production is driven by orders obtained by enterprises, production plans are generated, and tasks are assigned. In the execution process of the clothing production, the MES is used for executing and implementing the planned production process, and executing on a plant and a group.

Owner:王艳 +1

Intelligent integrated type semiconductor manufacturing execution system

InactiveCN106292580ATotal factory controlProgramme total factory controlManufacture execution systemInteraction interface

Owner:深圳市益普科技有限公司

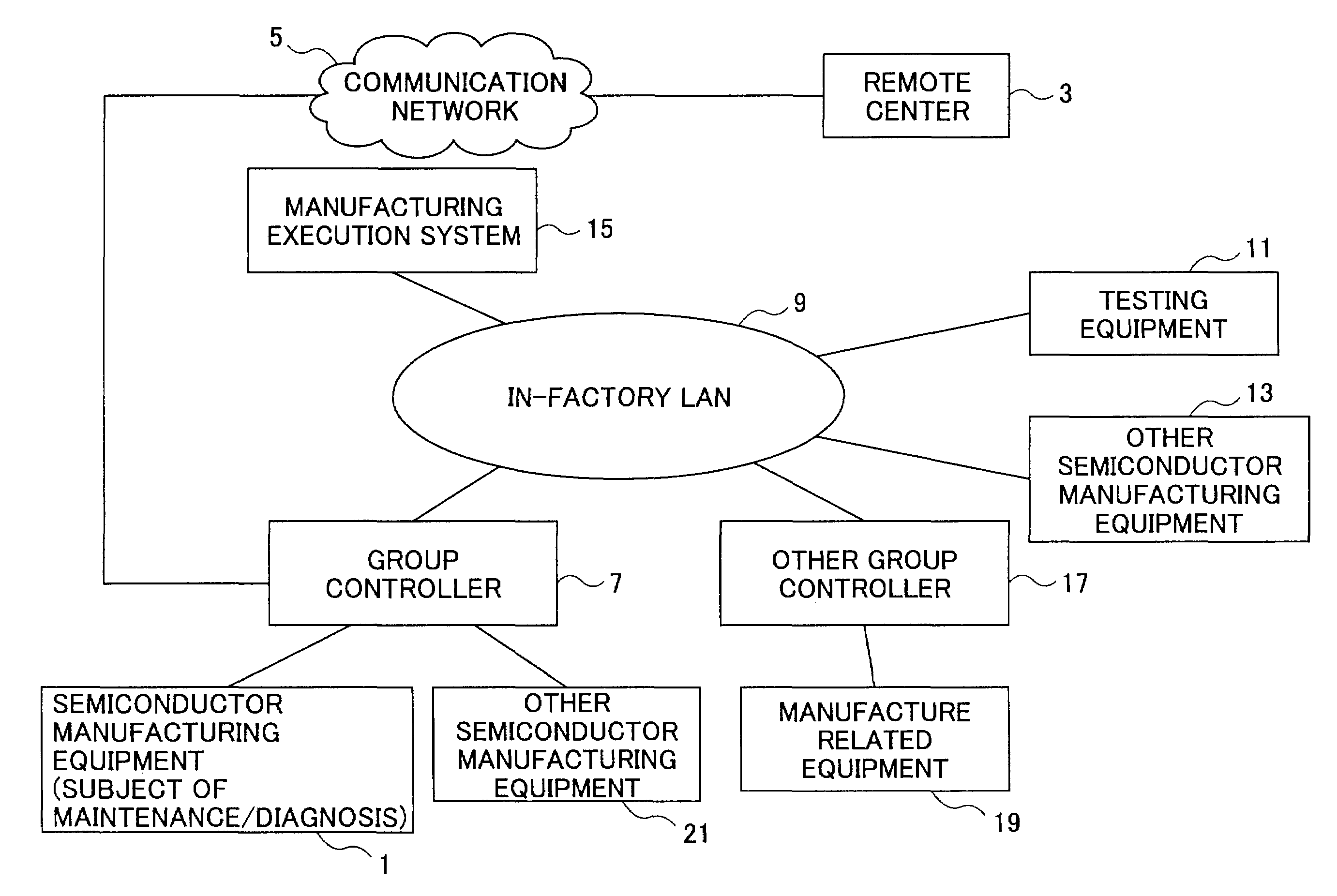

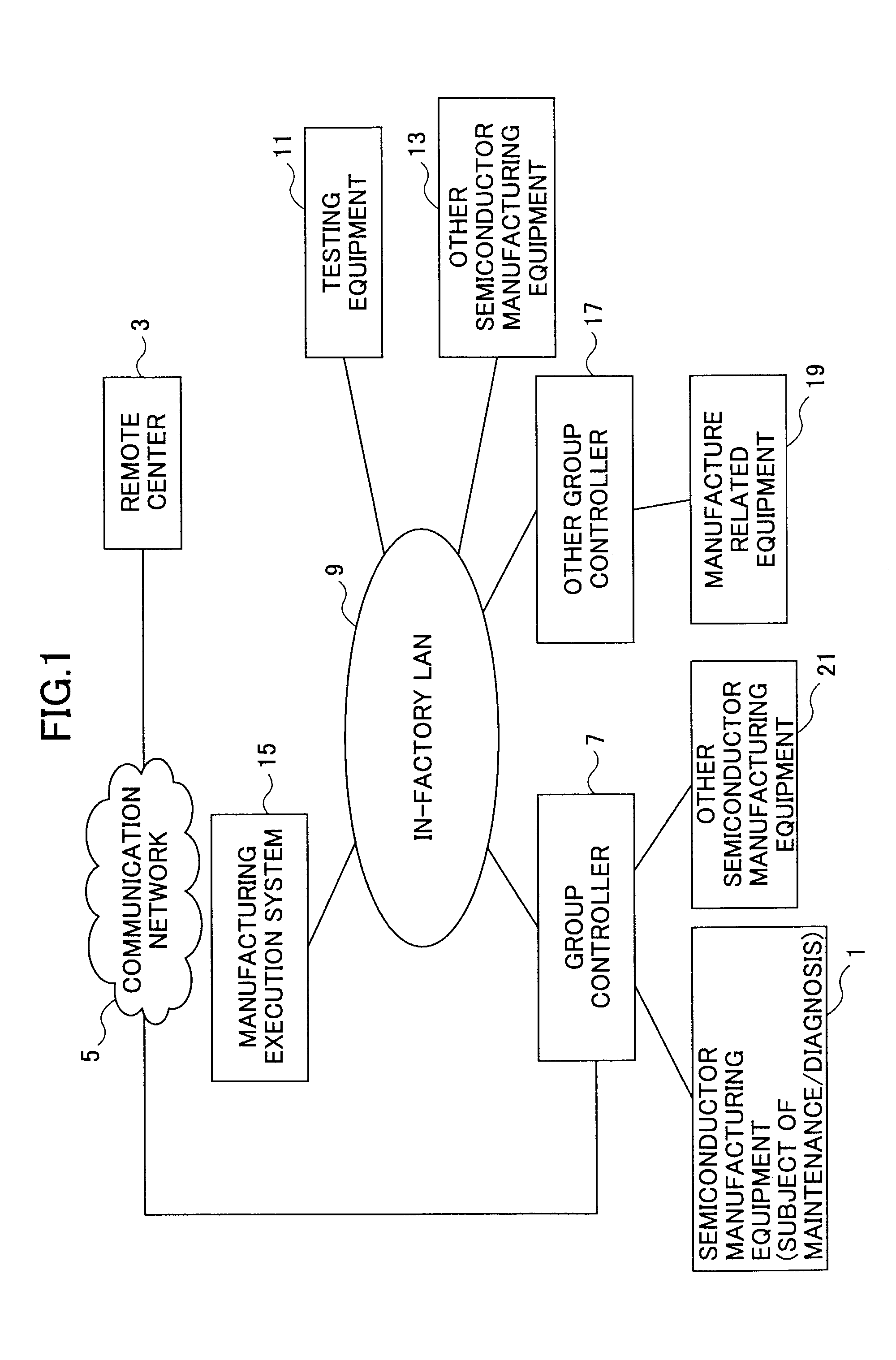

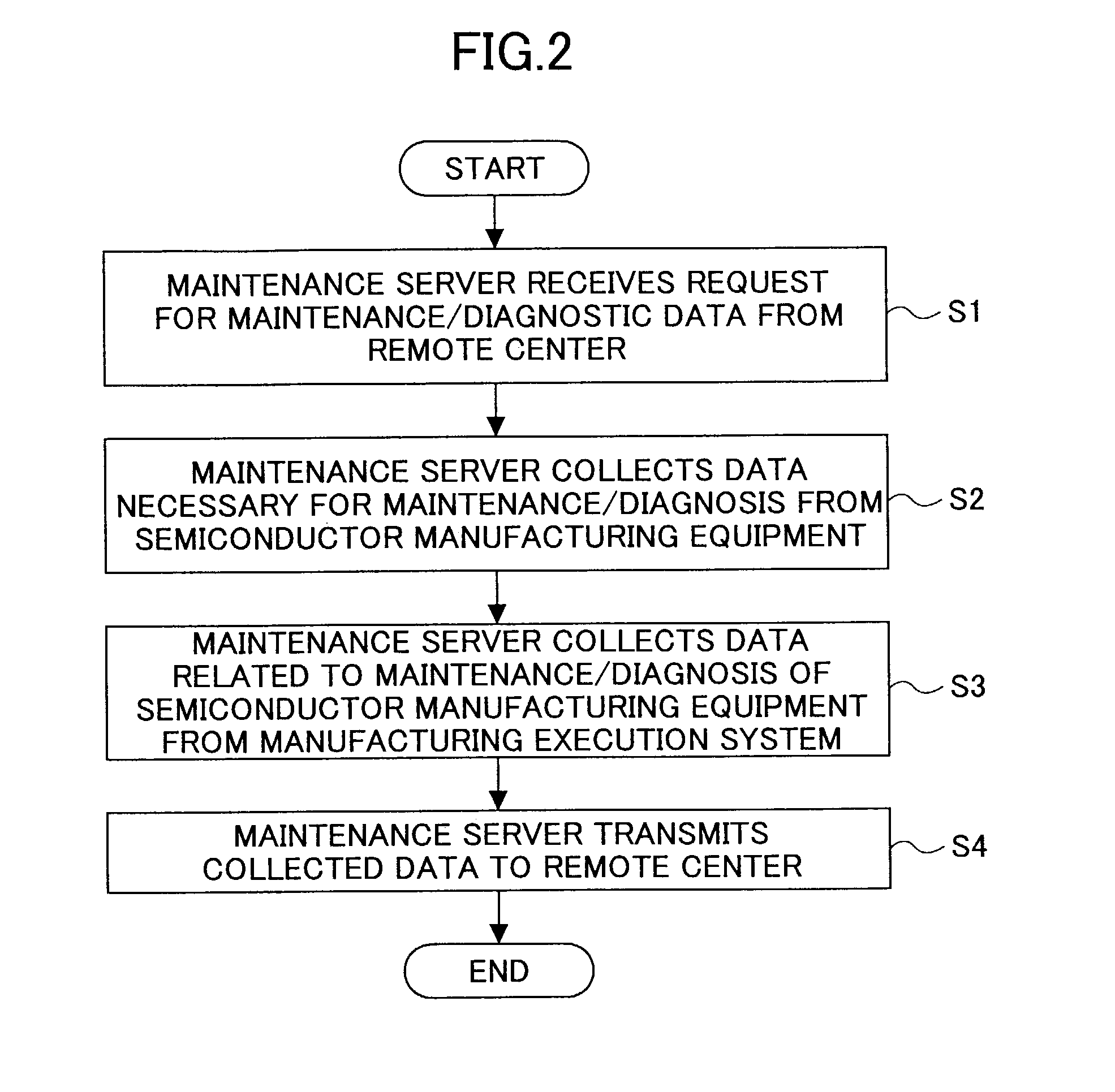

Method for collecting remote maintenance and diagnostic data from subject equipment, other device and manufacturing execution system

InactiveUS7035768B2Facilitate communicationProgramme controlElectric testing/monitoringManufacture execution systemDiagnostic data

Owner:TOKYO ELECTRON LTD

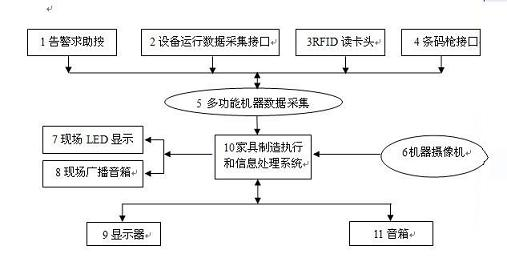

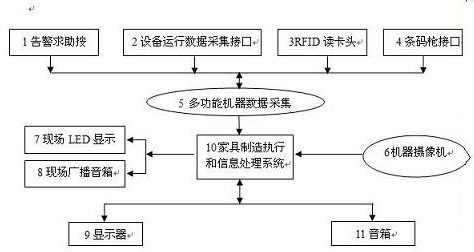

Information acquisition monitoring system and method for large-scale customized furniture manufacturing shop

ActiveCN102193552AIncrease profitReduce consumptionTotal factory controlProgramme total factory controlInformation processingManufacture execution system

The invention relates to an information acquisition monitoring system for a large-scale customized furniture manufacturing shop, which is characterized in that a signal output end of a multifunctional machinery data acquisition device is connected to a signal input end of a furniture manufacturing executing and information processing system; the signal output end of a camera is connected to the signal input end of the furniture manufacturing executing and information processing system; and the signal output end of the furniture manufacturing executing and information processing system is connected to the signal input ends of an on-site LED (light-emitting diode) display screen and an on-site broadcast loudspeaker box. The system has the advantages that the manufacturing process in the whole manufacturing shop is optimized, a new manufacturing shop management mode is established by utilizing an informatization management method, the material use ratio is increased, the cost is lowered,a function of collecting data in real time in the manufacturing process is provided and corresponding analysis and processing are performed, a quick response, elastic and fining manufacturing environment is provided to the furniture enterprises, and the problem that the MES (manufacturing execution system) can realize the enterprise information integration through the continuous information flow of the furniture enterprises by performing information interaction with the plan layer and control layer is solved.

Owner:海太欧林集团股份有限公司

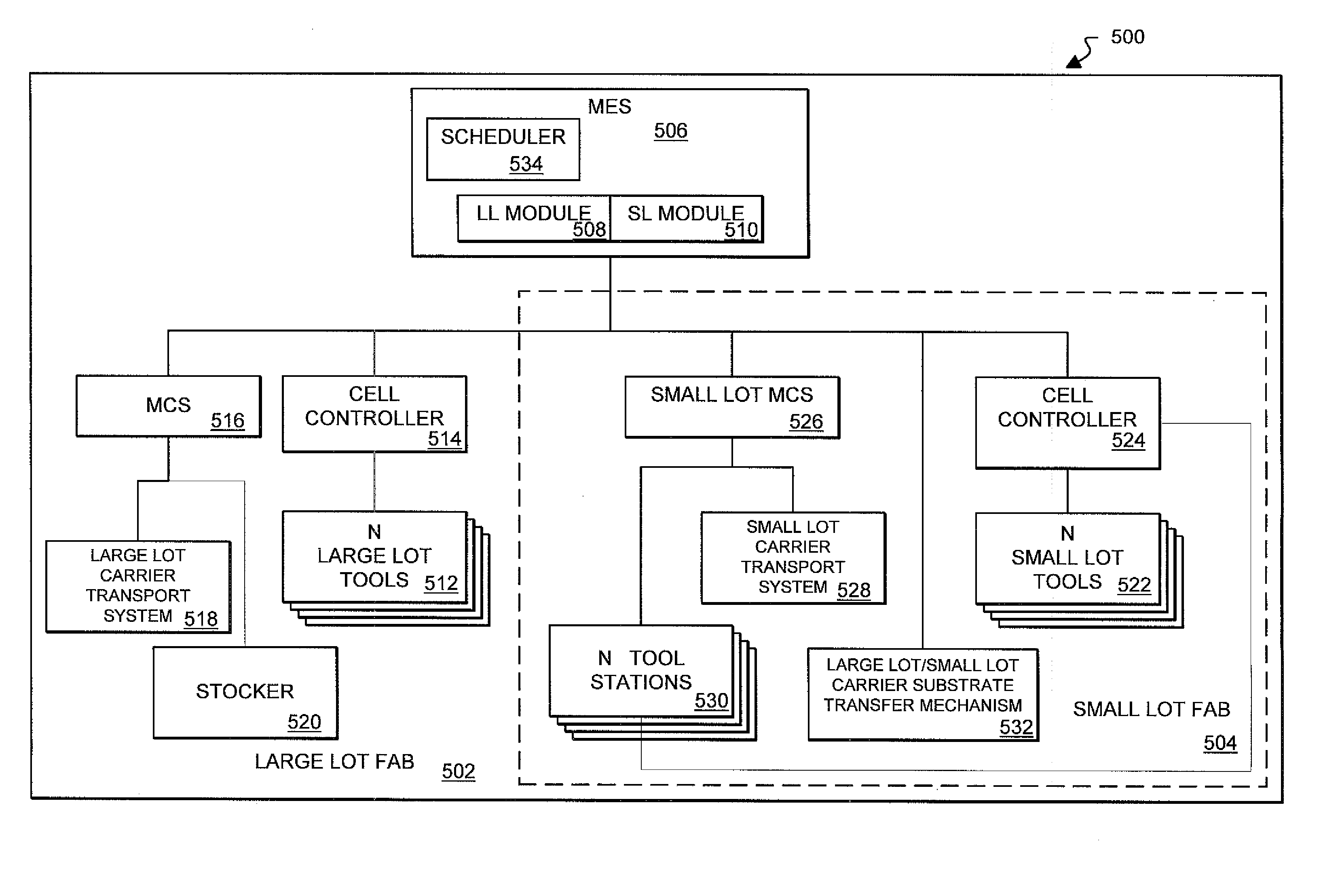

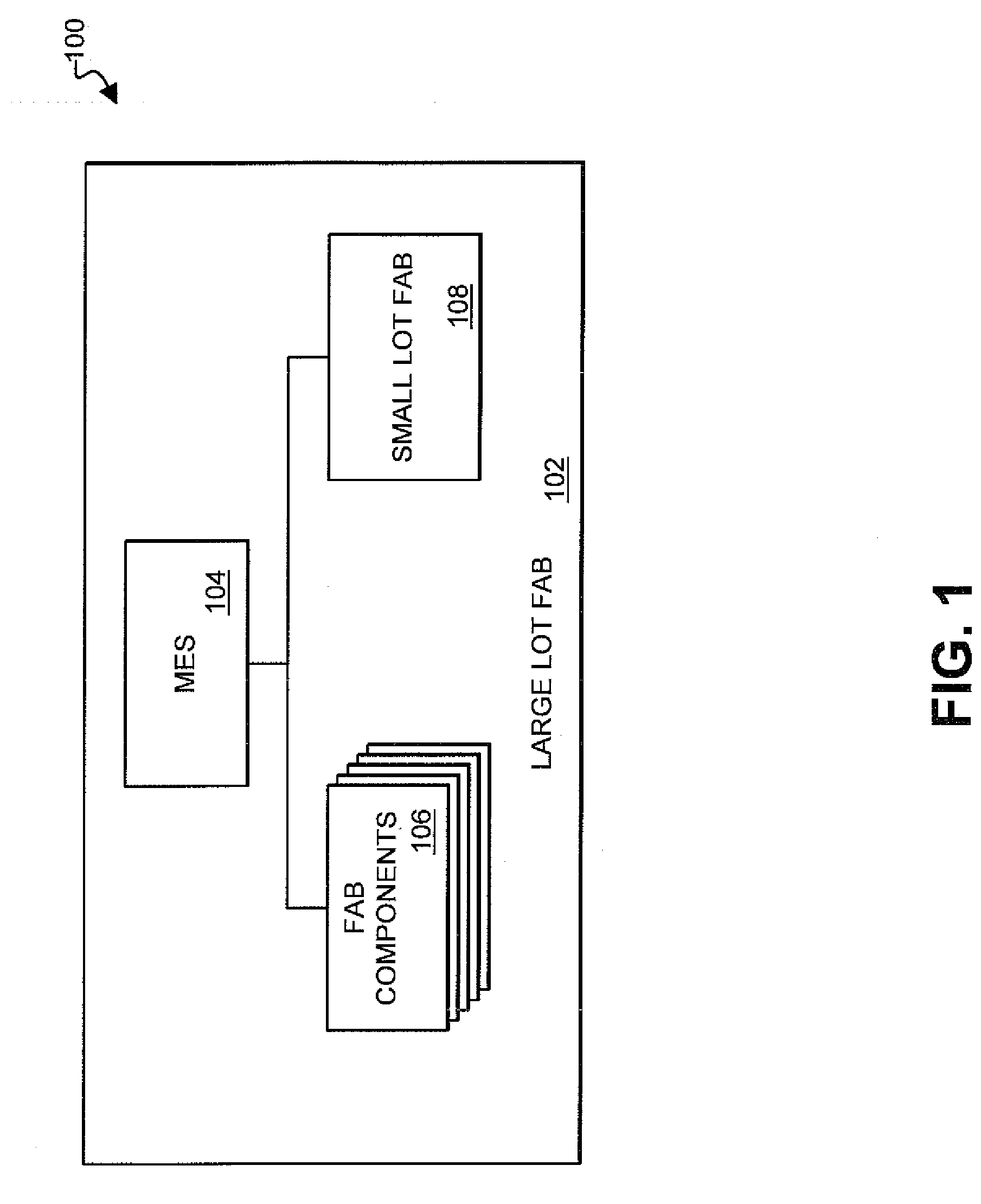

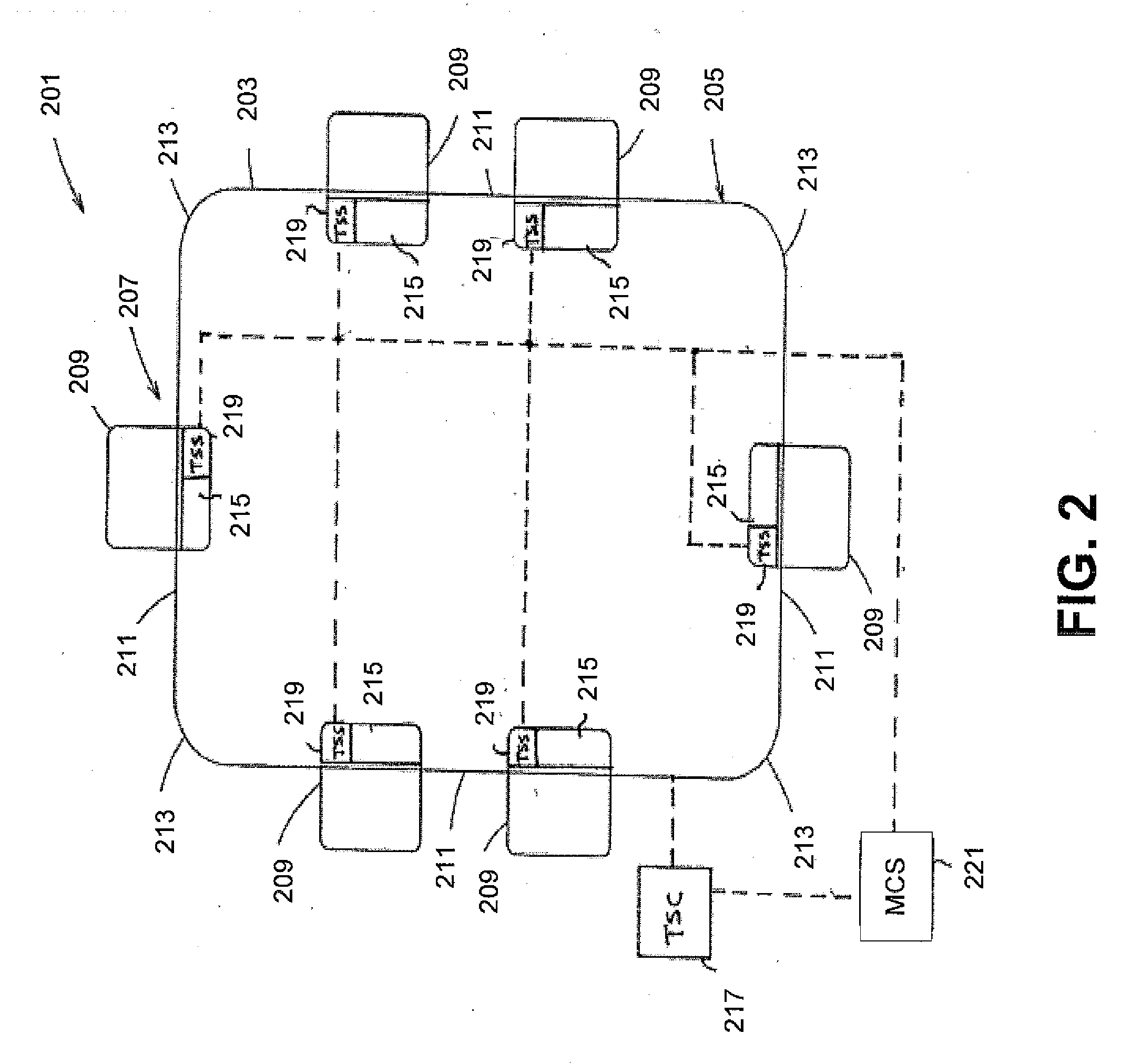

Methods and apparatus for integrating large and small lot electronic device fabrication facilities

ActiveUS20070061034A1Semiconductor/solid-state device manufacturingCharge manipulationManufacture execution systemIndustrial engineering

Owner:APPLIED MATERIALS INC

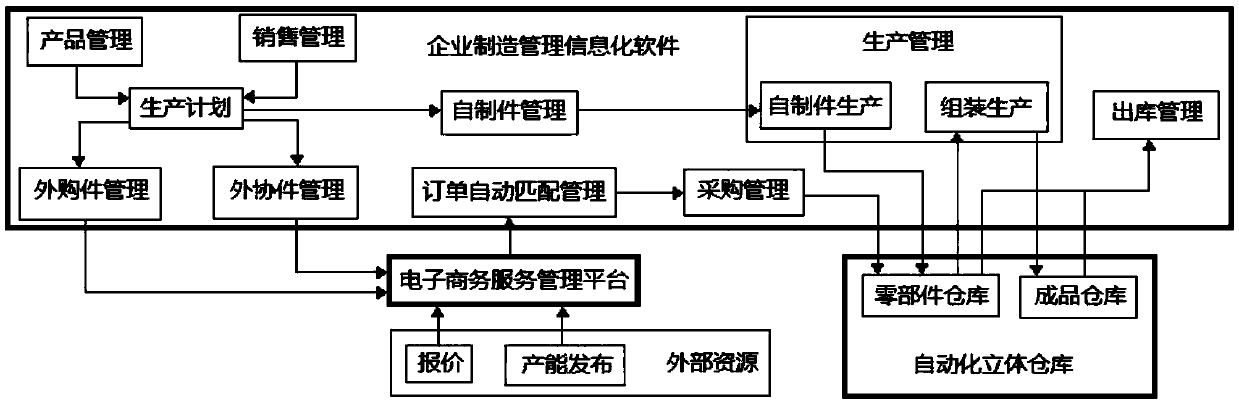

An enterprise manufacturing management and procurement integration platform

InactiveCN109523108AEfficient and convenient scientific managementQuick response to demandForecastingBuying/selling/leasing transactionsManufacture execution systemEnterprise resource planning

A manufacture management and purchasing integrate platform of enterprise is disclosed, including e-commerce service management platform, Sales management module, Production management module, Procurement management module, product management module, Production planning module, outsourcing component management module, Outsourcing part management module, homemade part management module, order automatic matching management module, issue management module and automated warehouse. The functional modules cover product life cycle management (PLM), enterprise resource planning (ERP), manufacturing execution system (MES), warehouse management system (WMS) and other aspects in enterprise management. And the information tools are streamlined, and then integrated with the e-commerce service platform as an integrated platform, so as to effectively improve the production and manufacturing management process in the interconnection of each link, and ultimately achieve the improvement of enterprise production efficiency and product quality.

Owner:SAIMO ELECTRIC

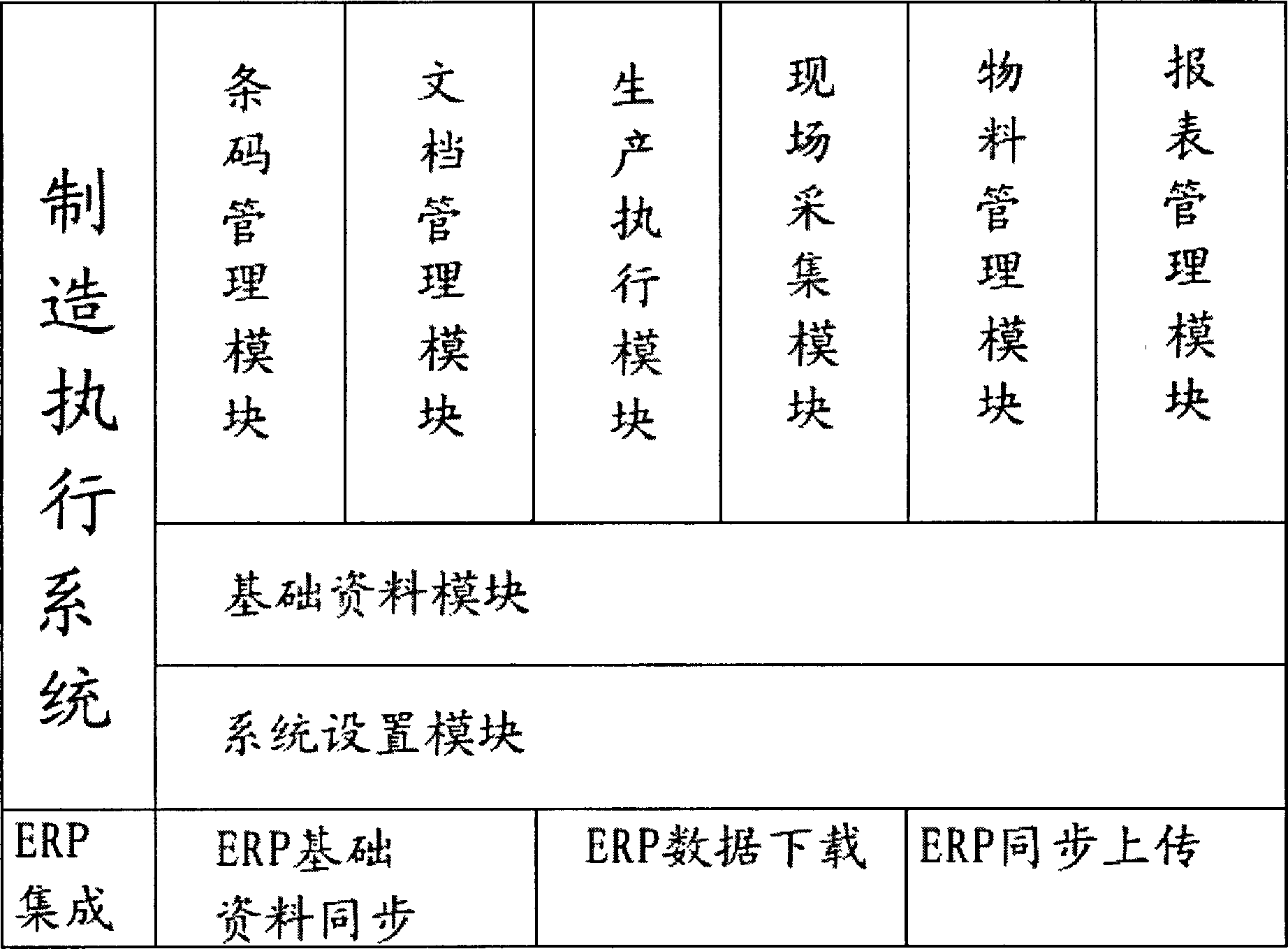

Manufacturing execution system

InactiveCN103530733ARealize transparent managementRealize electronic managementResourcesManufacturing computing systemsManufacture execution systemSystem integration

The invention discloses a manufacturing execution system. A software management system of the manufacturing execution system is integrated into eight modules, including a base data module, a system setting module, a bar code management module, a document management module, a production execution module, an on-site acquisition module, a material management module and a reporting platform module. According to the manufacturing execution system, a whole production process from order placing to product completion can be managed through information transfer, responses and reports about production conditions can be further made in time and guided and processed by current accurate data, activities without added values in enterprises can be reduced by the aid of the rapid response to sate changes can reduced, and production and operation processes of factories can be effectively guided, so that the in-time delivery capacity of the factories can be improved, the circulation performance of materials can be improved, and meanwhile, the production return rate can be increased.

Owner:苏州盟思软件科技有限公司

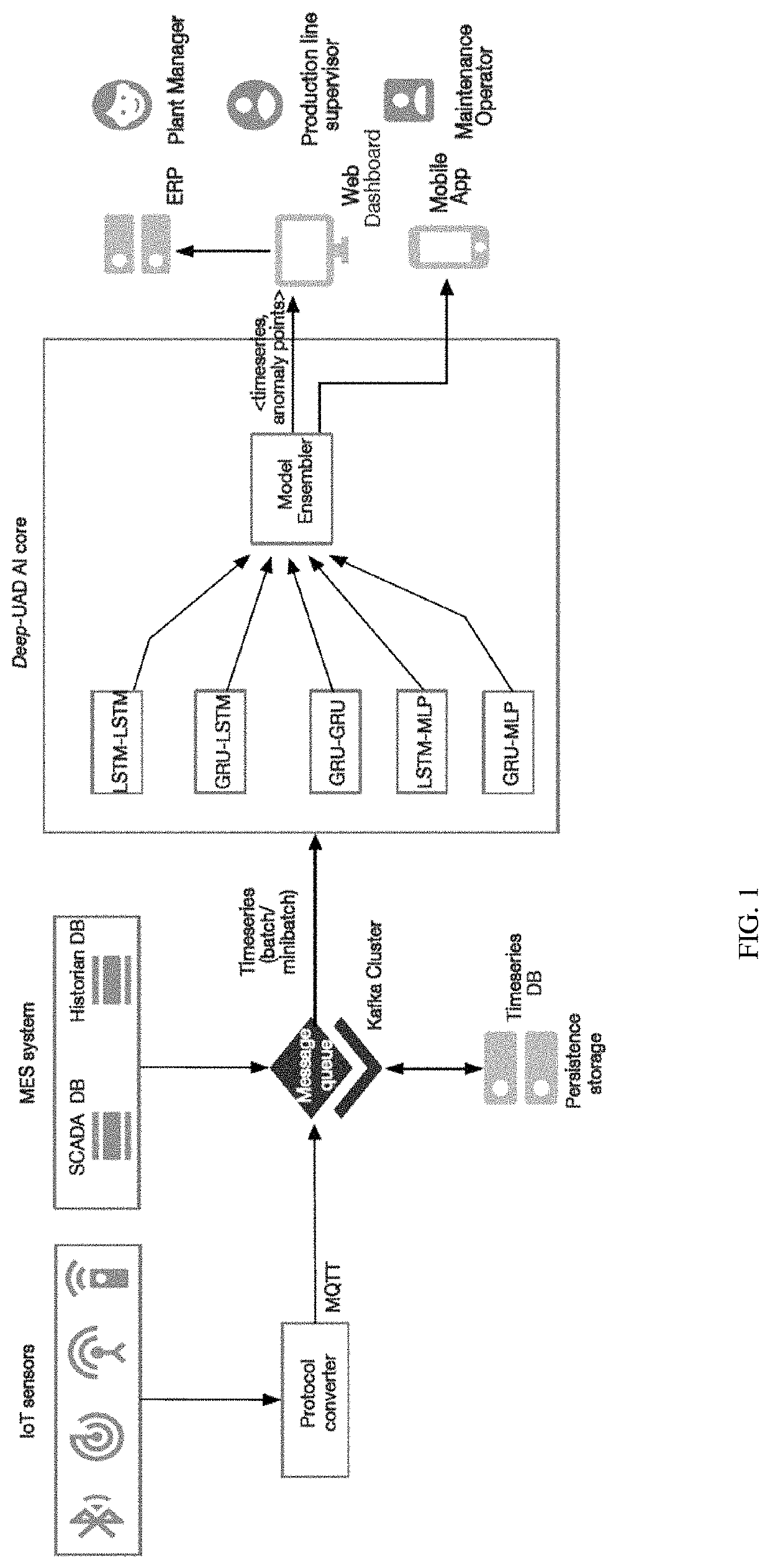

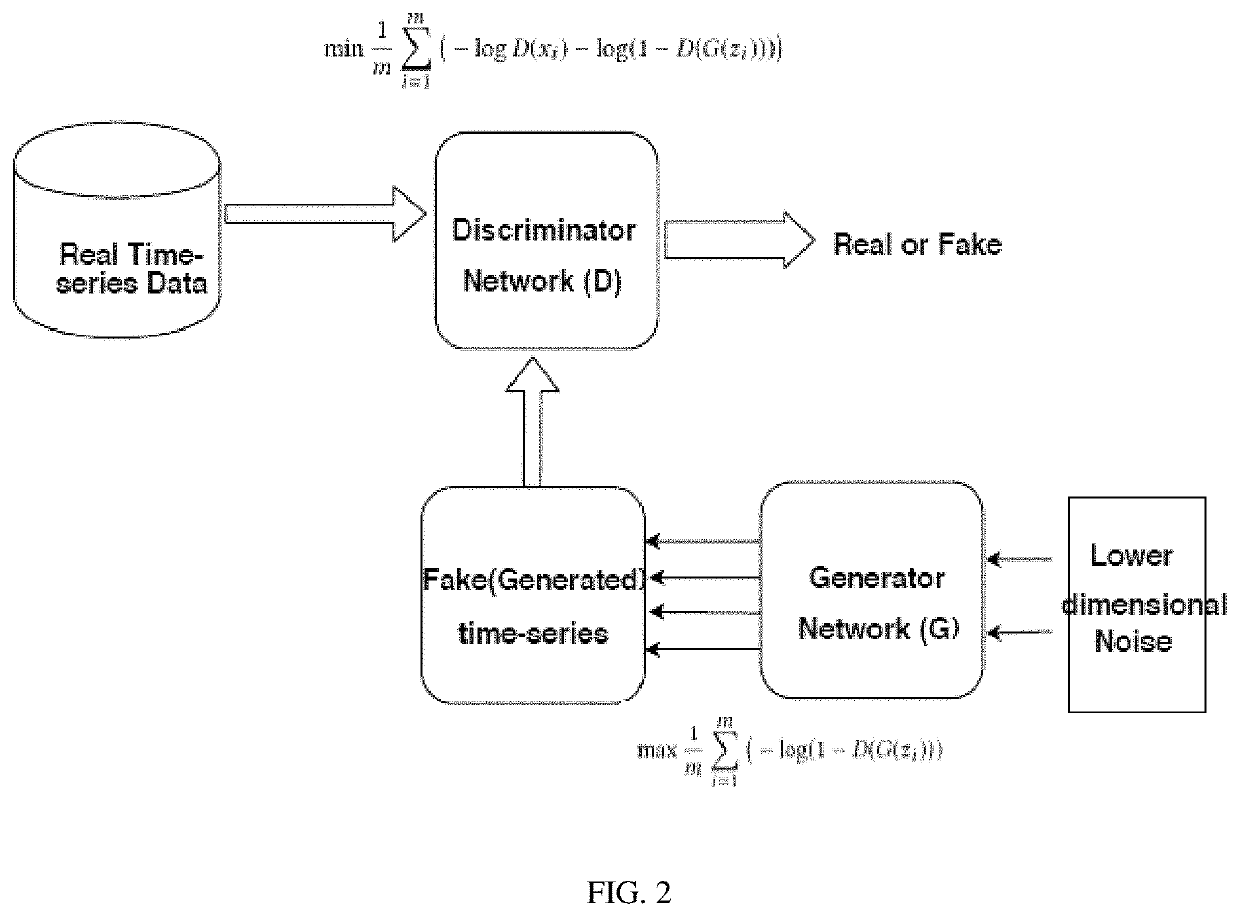

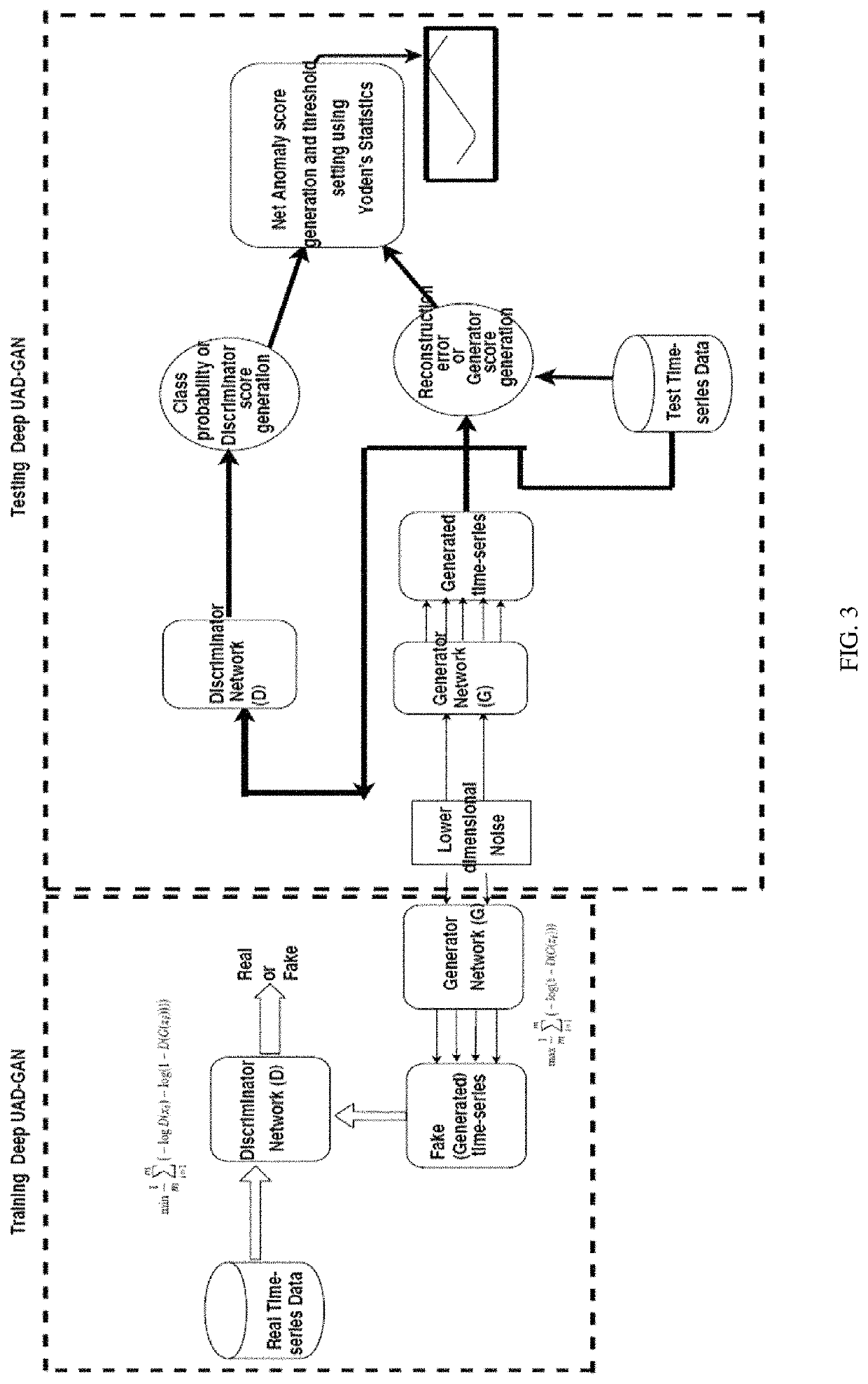

System and method for unsupervised anomaly detection

ActiveUS10956808B1Improve true positive rateIncrease the number ofDigital data information retrievalNeural architecturesManufacture execution systemAnomaly detection

Some embodiments are associated with a system and method for deep learning unsupervised anomaly detection in Internet of Things (IoT) sensor networks or manufacturing execution systems. The system and method use an ensemble of a plurality of generative adversarial networks for anomaly detection.

Owner:EUGENIE AI INC

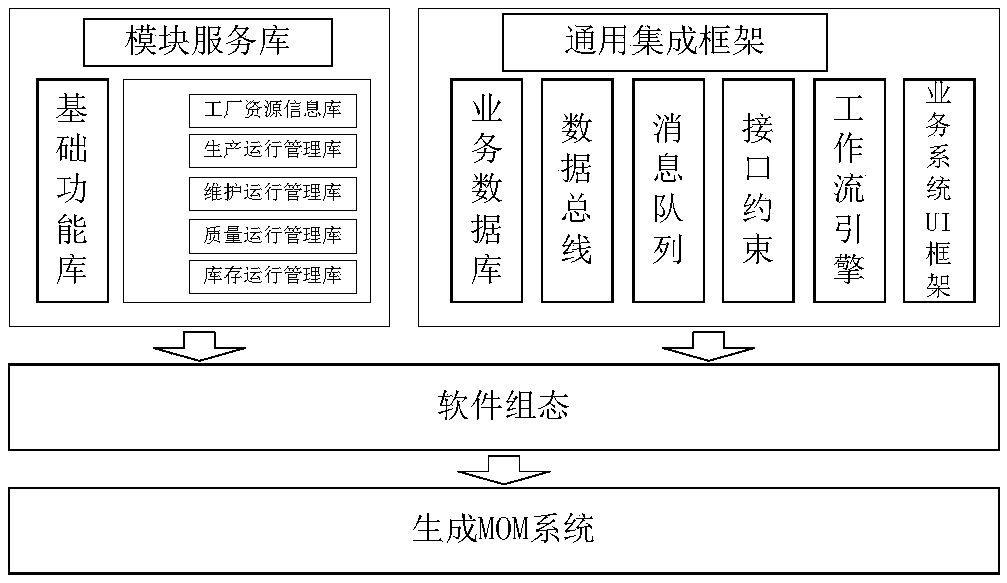

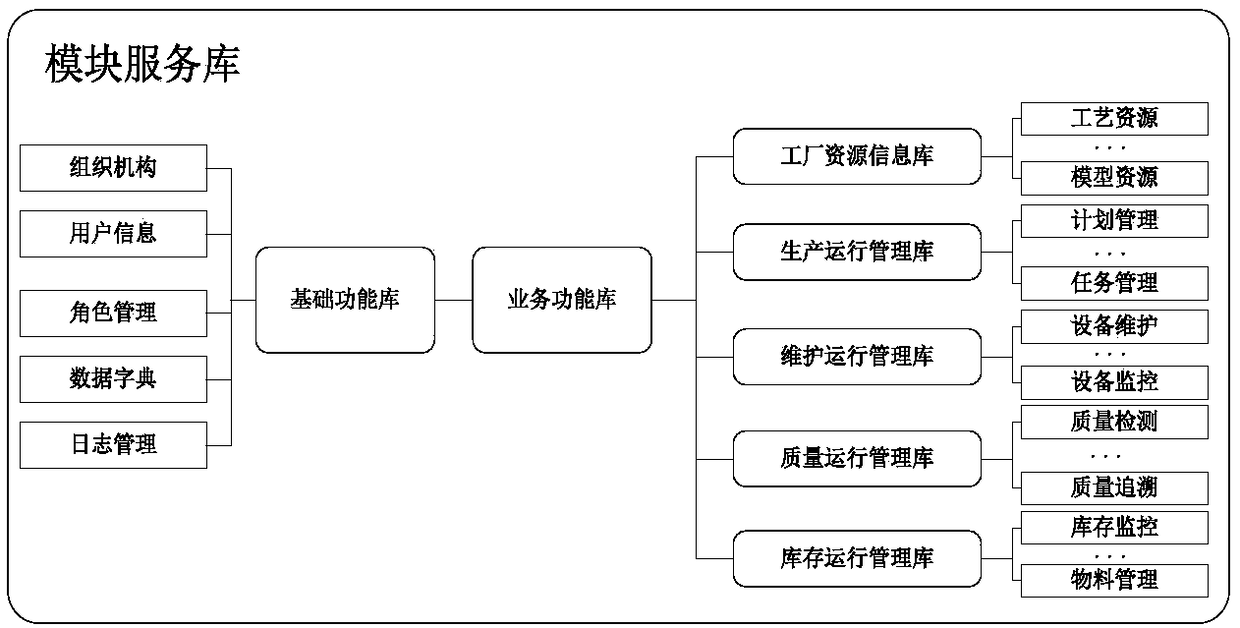

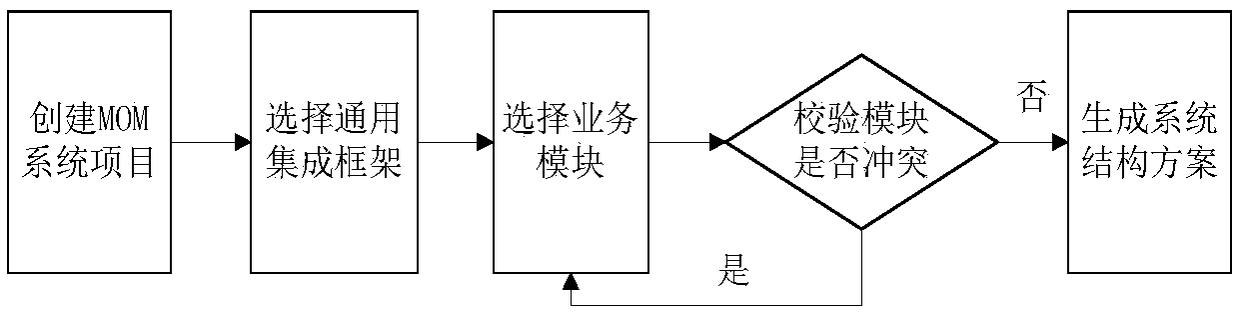

A manufacturing execution system architecture based on component and service

InactiveCN109308582AImprove developmentEasy to start and stopResourcesManufacturing computing systemsManufacture execution systemCode coupling

The invention discloses a manufacturing execution system architecture based on component and service, which comprises a module service library, a general integration framework, a software configuration program, a MOM system and a data center. Starting from the service-based software architecture, the manufacturing execution system is divided into service modules, and the management of module library is established. The module library is improved and expanded, the modules can be divided into more detailed according to the needs, the development and deployment of the system is faster, and the performance of the system is brought into full play. The application of micro-service architecture can effectively reduce the code coupling degree, reduce the difficulty of collaborative development, and micro-service can be started and stopped conveniently according to the demand, so that the computing resources can be effectively utilized; On the basis of module library, when a new manufacturing execution system needs to be built, appropriate modules are selected and configured through software configuration, or modules with similar functions are improved to build a new version of the module,and finally a new software system is formed through configuration.

Owner:CHINA SOUTH IND GRP AUTOMATION RES INST

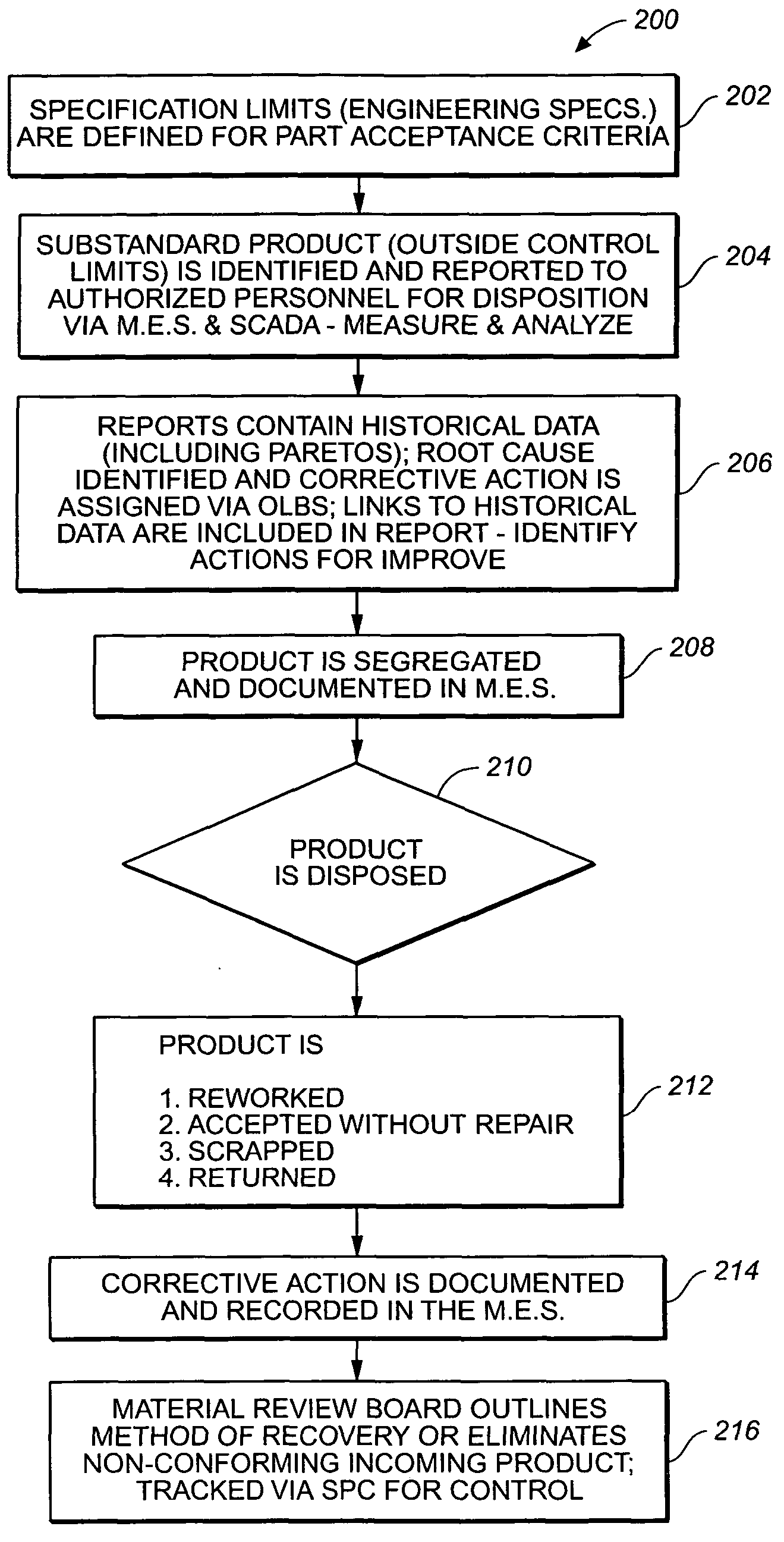

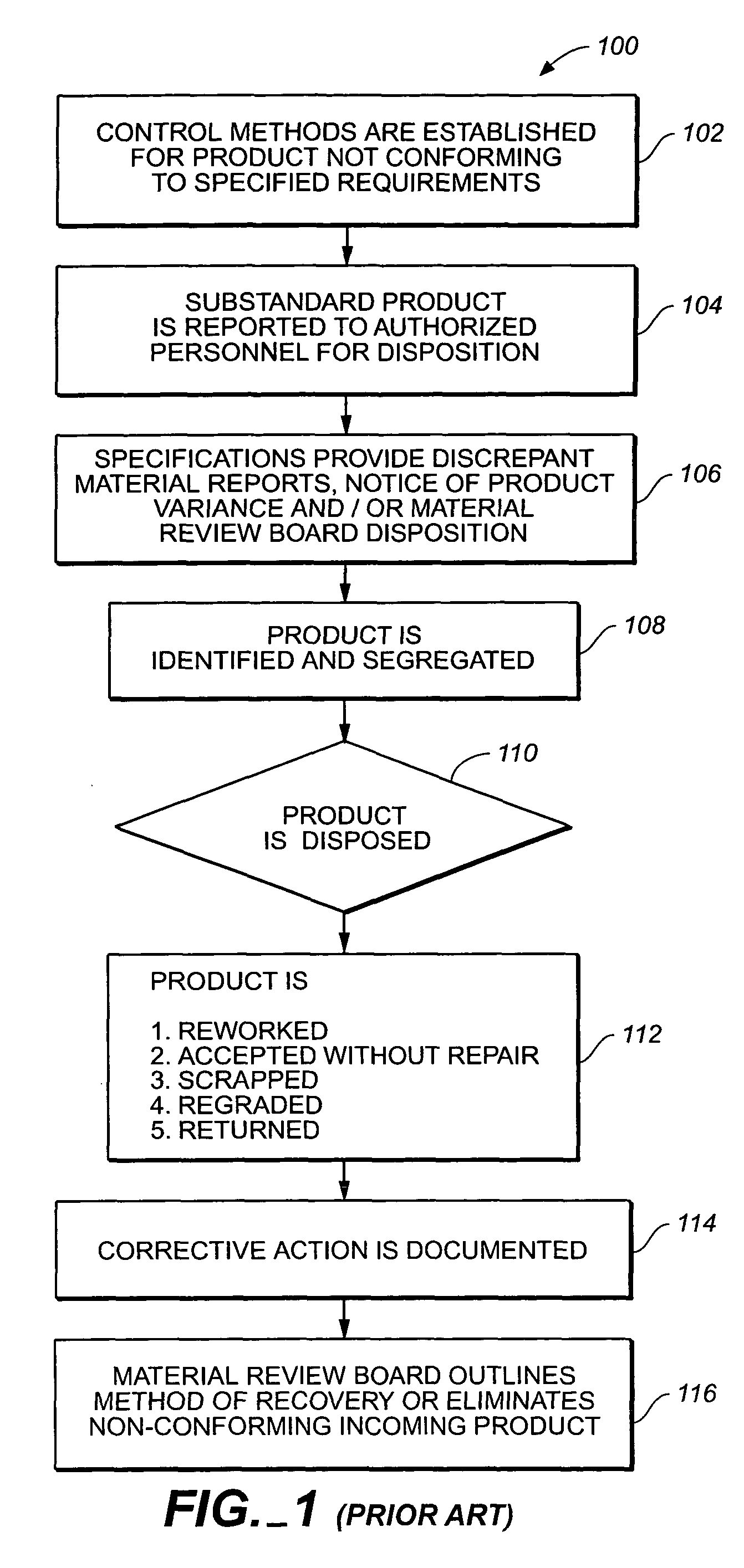

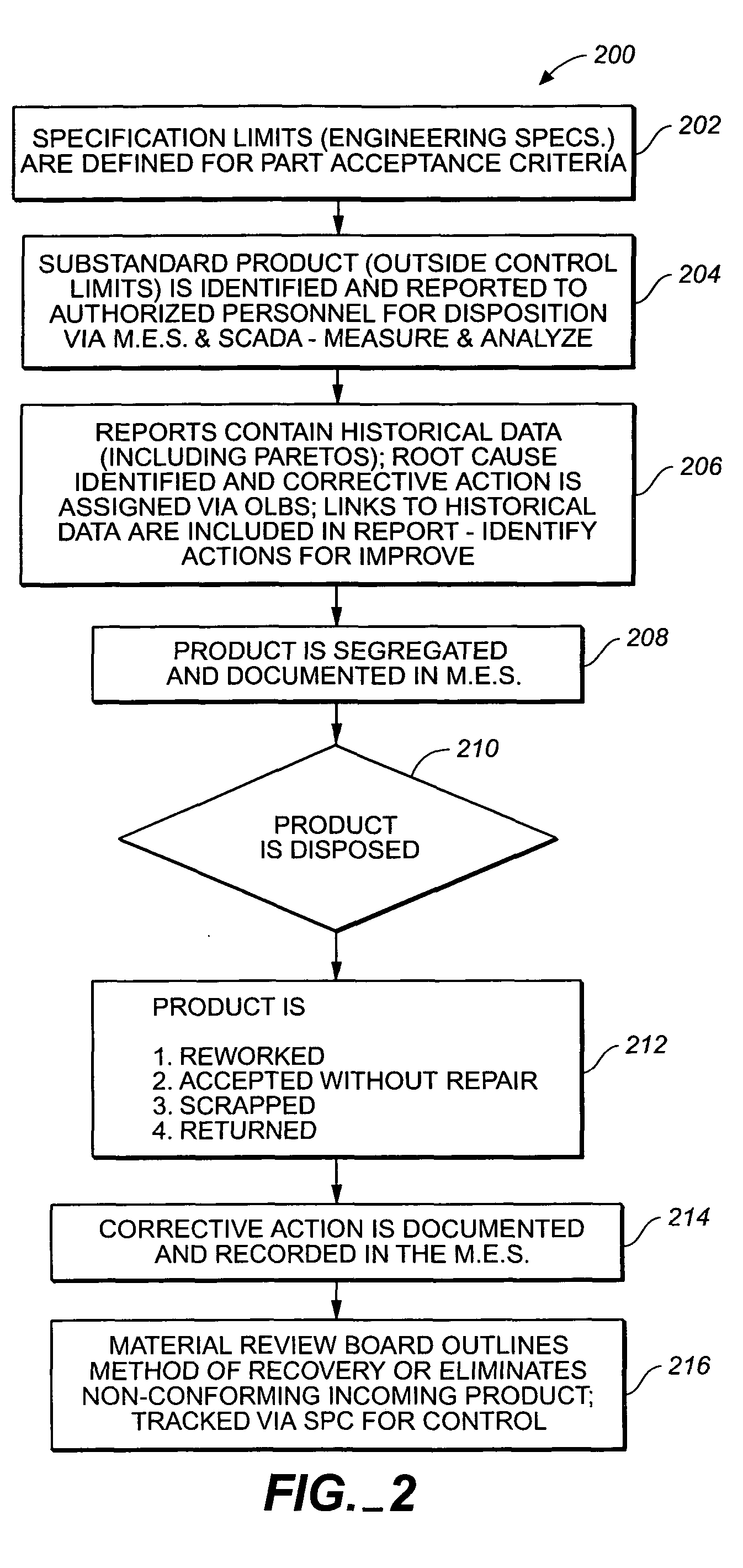

Method and apparatus for integrating Six Sigma methodology into inspection receiving process of outsourced subassemblies, parts, and materials: acceptance, rejection, trending, tracking and closed loop corrective action

ActiveUS20050033468A1Nuclear monitoringDigital computer detailsManufacture execution systemPresent method

A method for integrating Six Sigma into an inspection receiving process of outsourced products may include the following steps: defining specification limits for product acceptance criteria; identifying and reporting a substandard product to authorized personnel for disposition via a MES (manufacturing execution system) and SCADA (supervisory control and data acquisition); preparing a report containing historical data, identifying root cause and assigning a corrective action; segregating the substandard product, and documenting the substandard product in the MES; disposing the substandard product; documenting and recording the corrective action in the MES; and outlining a method of recovery and eliminating a non-conforming incoming product. The present method may provide a means for a Closed Loop Corrective Action (CLCA).

Owner:BELL SEMICON LLC

Data tracking method of boiler steam drum manufacture process

ActiveCN105224904AReduce labor costsRecord carriers used with machinesSensing by electromagnetic radiationCommunication interfaceManufacture execution system

The invention relates to a data tracking method of a boiler steam drum manufacture process. The data tracking method comprises the following steps: compiling the original data of a boiler steam drum manufacture execution system into a material number, and directly printing a tag in a way of a two-dimensional code or a barcode; inserting the tag with the material number into a tag box of which the bottom is provided with strong magnetism, and fixing the tag box on a processing component; then, entering different manufacture process sections, returning processing process data to the boiler steam drum manufacture execution system through a code reader with a communication interface in each process section; after the boiler steam drum manufacture execution system binds the data of a whole preparation process and original data, sending the bound data into an MES (Manufacturing Execution System) database; and storing all data of the whole manufacture process of the steam drum into an RFID (Radio Frequency Identification) tag by the MES data, wherein the RFID tag is installed on a steam drum finished product. The whole-process tracking of workpiece processing information and the whole-process traceability of product quality in the boiler steam drum manufacture process can be realized, production efficiency and product quality can be greatly improved, and labor cost is saved.

Owner:SHANGHAI INST OF PROCESS AUTOMATION & INSTR

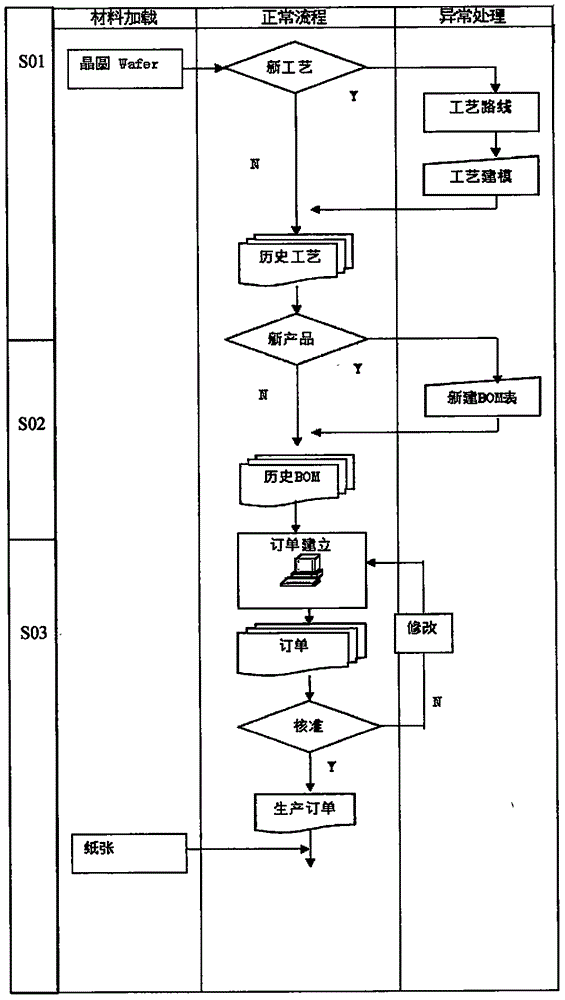

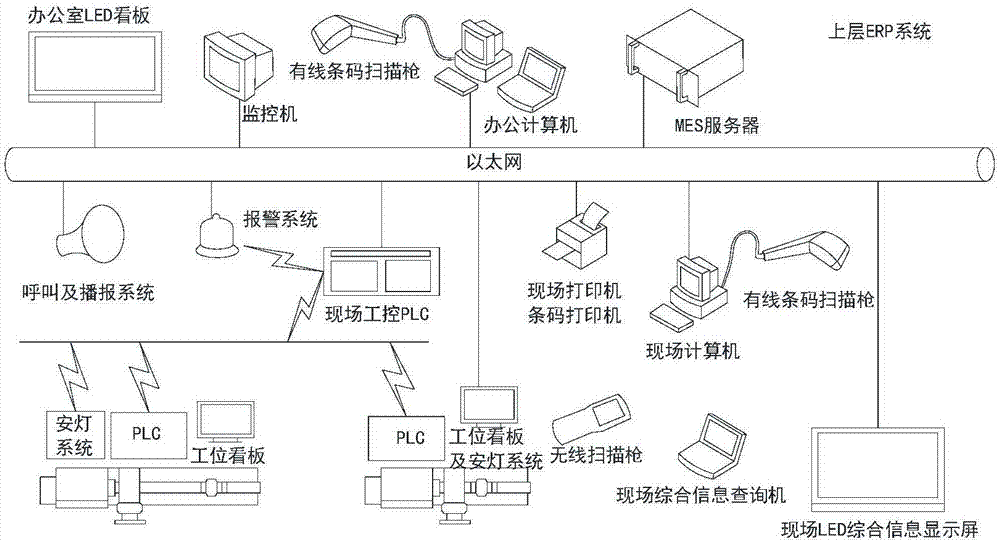

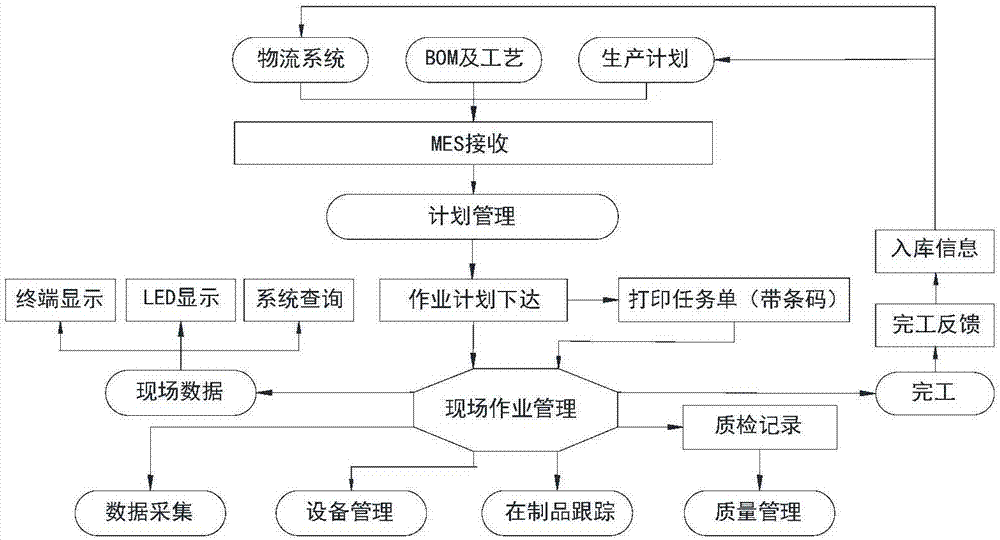

Production line data acquisition and billboard management system and method for manufacturing enterprise

InactiveCN106990761AAdjust production balanceRealize automatic countingTotal factory controlProgramme total factory controlManufacture execution systemBill of materials

The invention provides a production line data acquisition and billboard management system for a manufacturing enterprise. The production line data acquisition and billboard management system for a manufacturing enterprise includes a production line data acquisition system and a billboard management system, wherein the production line data acquisition system and the billboard management system are communicated through Ethernet. The invention also provides a production line data acquisition and billboard management method for a manufacturing enterprise. The production line data acquisition and billboard management method for a manufacturing enterprise includes an MES reception process, an on-site operation management process, an MES (Manufacturing Execution System) reception logistics system, BOM (Bill of Material) and technology, information of production plan, and plan management, wherein the operation plan in plan management is issued, and then on-site operation management is executed; the on-site operation management process includes data acquisition, equipment management, tracking of articles being processed, and quality inspection recording; after collection of the quality inspection record information, quality management is performed; during the on-site operation management process, the on-site data is formed, and terminal display, LED display and system query are performed on the on-site data; the warehousing information is formed during the completion feedback process; and the warehousing information, the production plan and the logistics system are merged, and then the MES reception process begins.

Owner:ZHEJIANG BLUE CLOUD INFORMATION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com