Patents

Literature

518 results about "Collaborative design" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

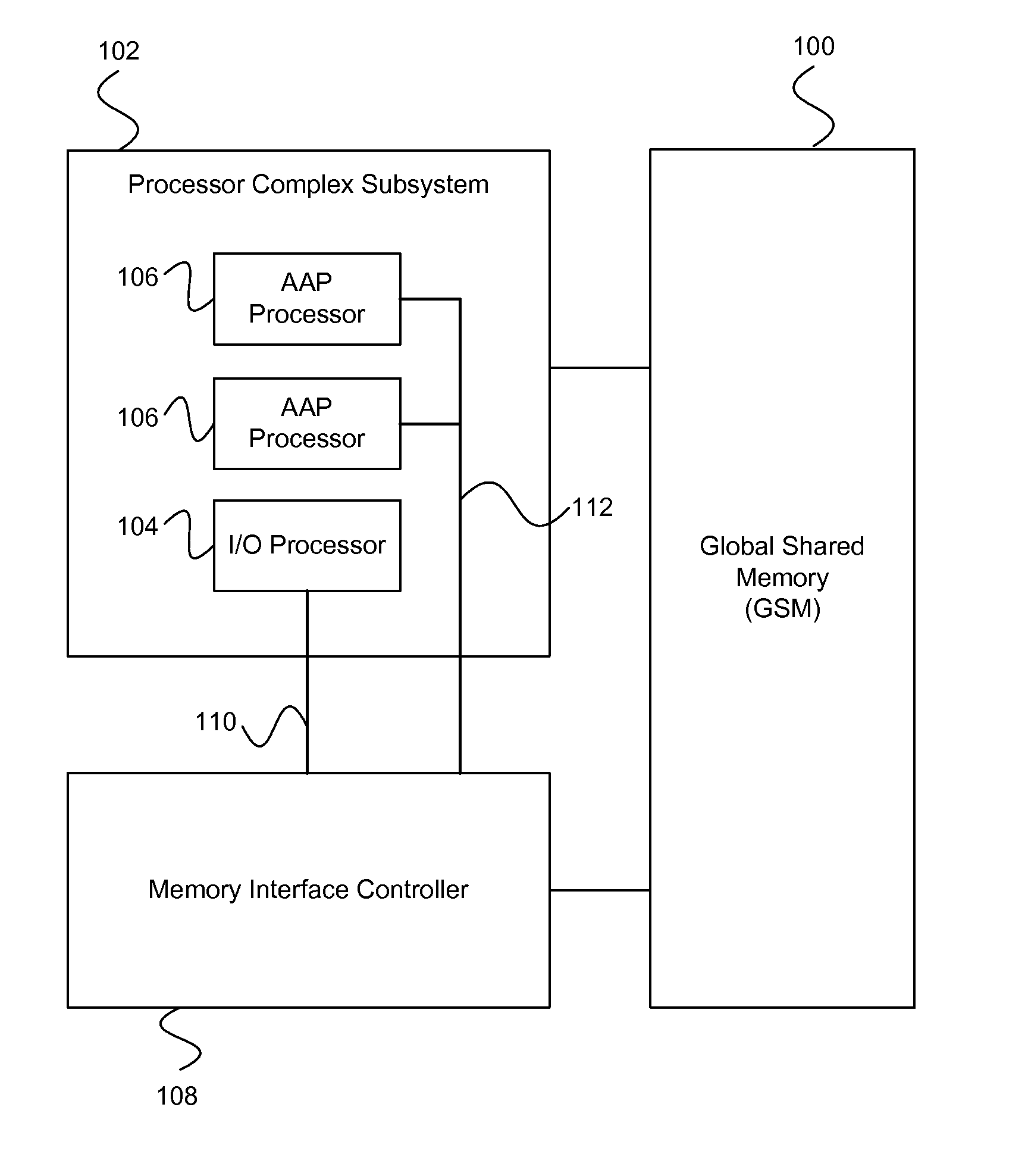

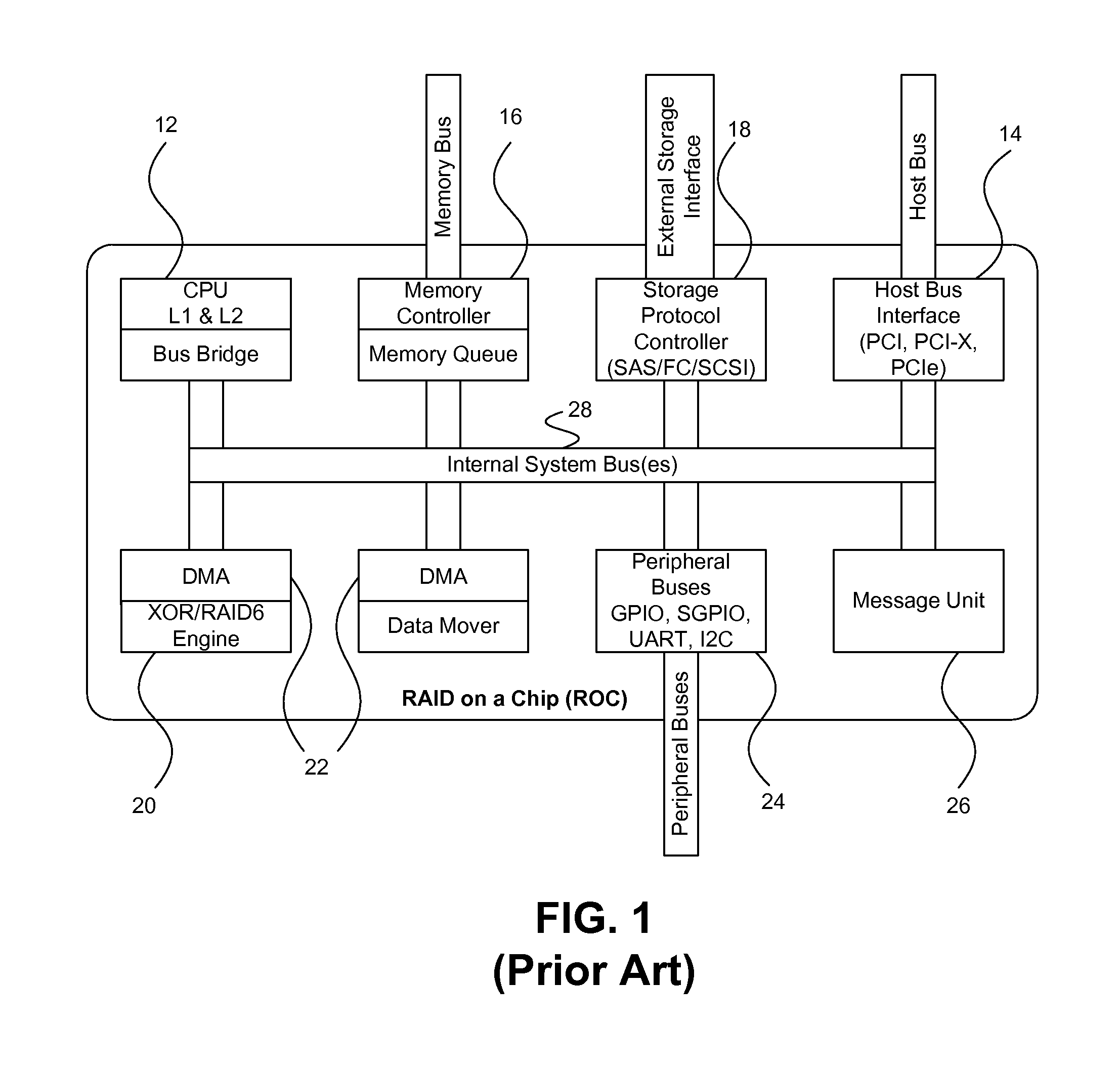

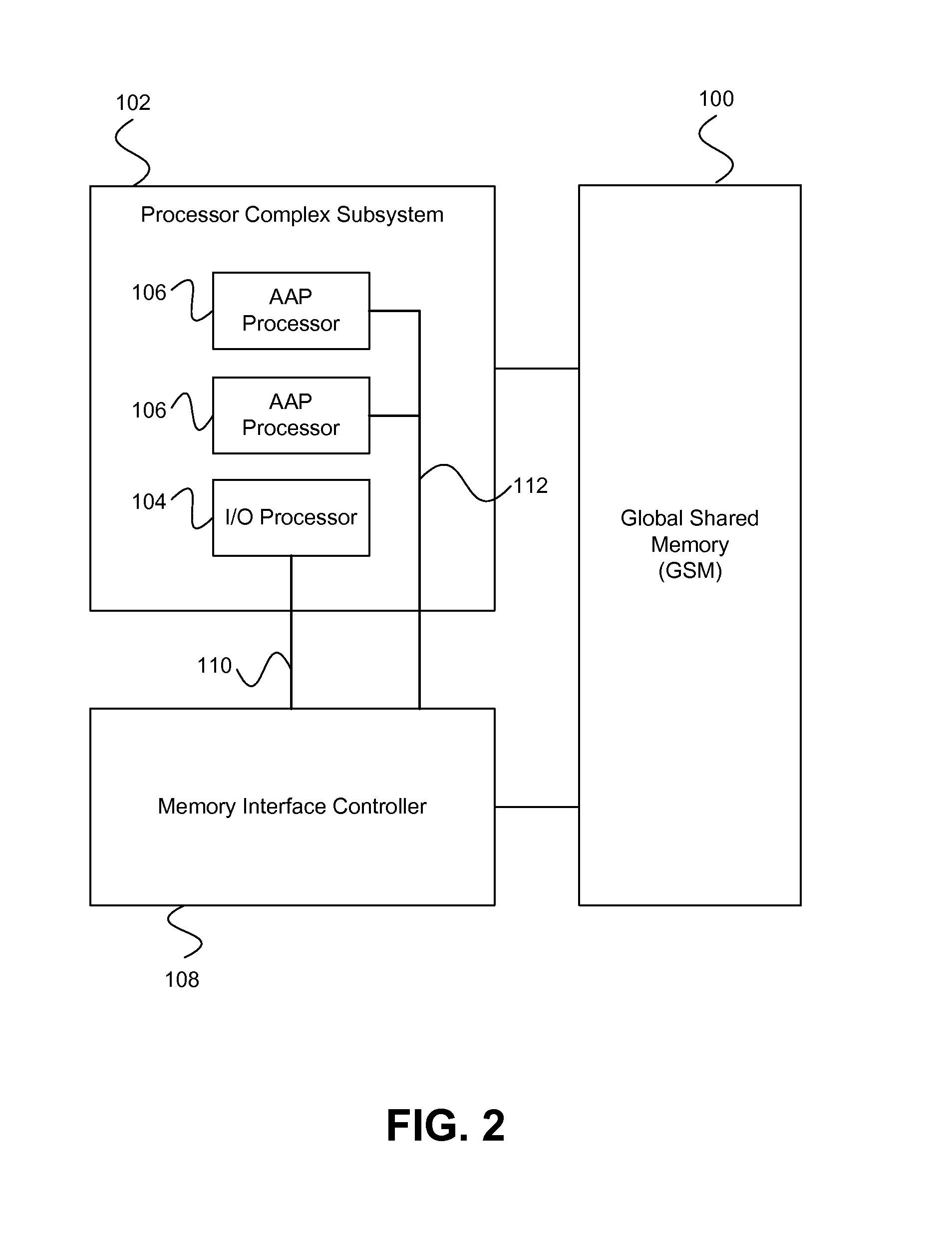

On-chip shared memory based device architecture

ActiveUS7743191B1Reduce disadvantagesLow costRedundant array of inexpensive disk systemsRecord information storageExtensibilityRAID

A method and architecture are provided for SOC (System on a Chip) devices for RAID processing, which is commonly referred as RAID-on-a-Chip (ROC). The architecture utilizes a shared memory structure as interconnect mechanism among hardware components, CPUs and software entities. The shared memory structure provides a common scratchpad buffer space for holding data that is processed by the various entities, provides interconnection for process / engine communications, and provides a queue for message passing using a common communication method that is agnostic to whether the engines are implemented in hardware or software. A plurality of hardware engines are supported as masters of the shared memory. The architectures provide superior throughput performance, flexibility in software / hardware co-design, scalability of both functionality and performance, and support a very simple abstracted parallel programming model for parallel processing.

Owner:MICROSEMI STORAGE SOLUTIONS

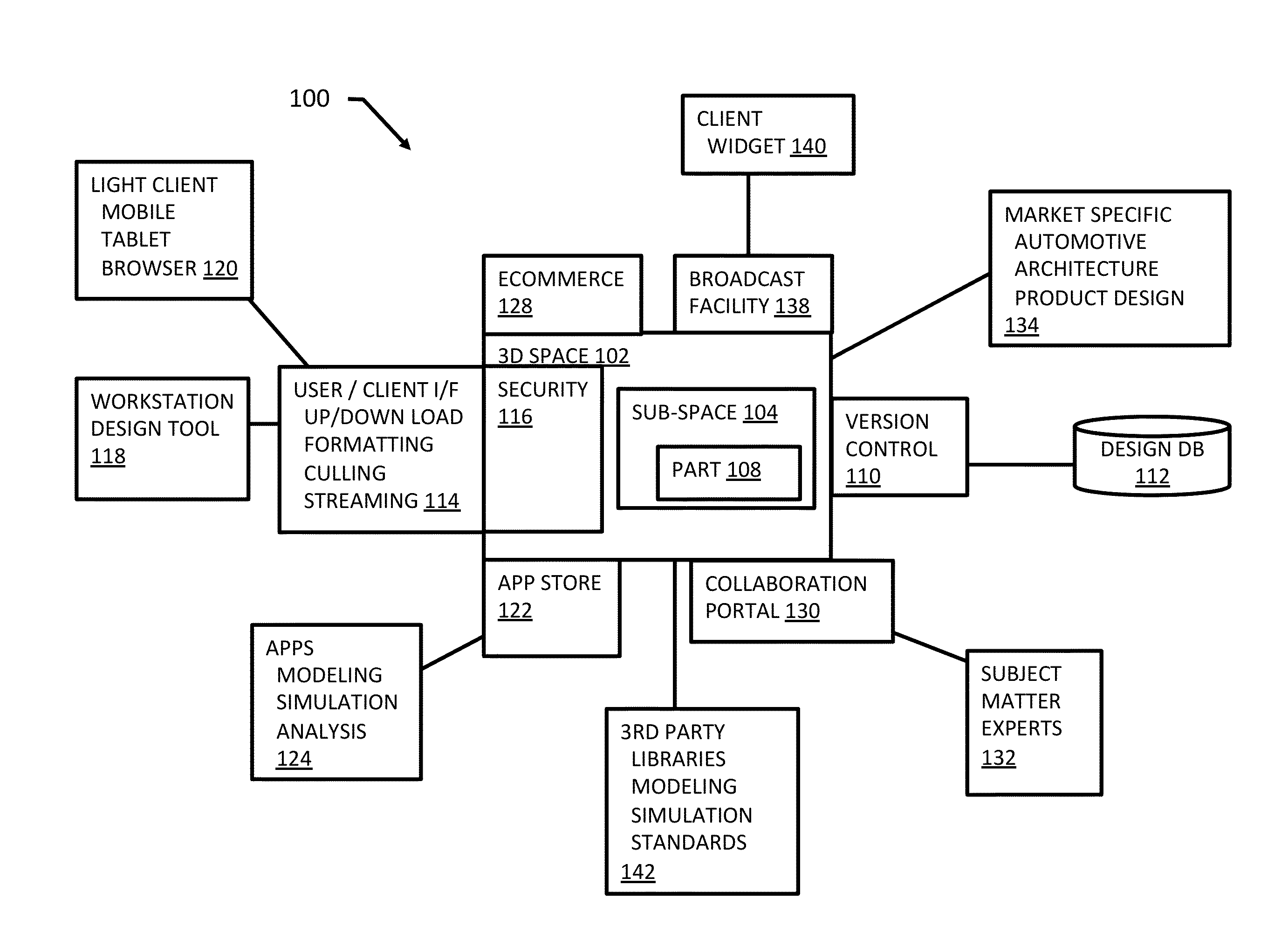

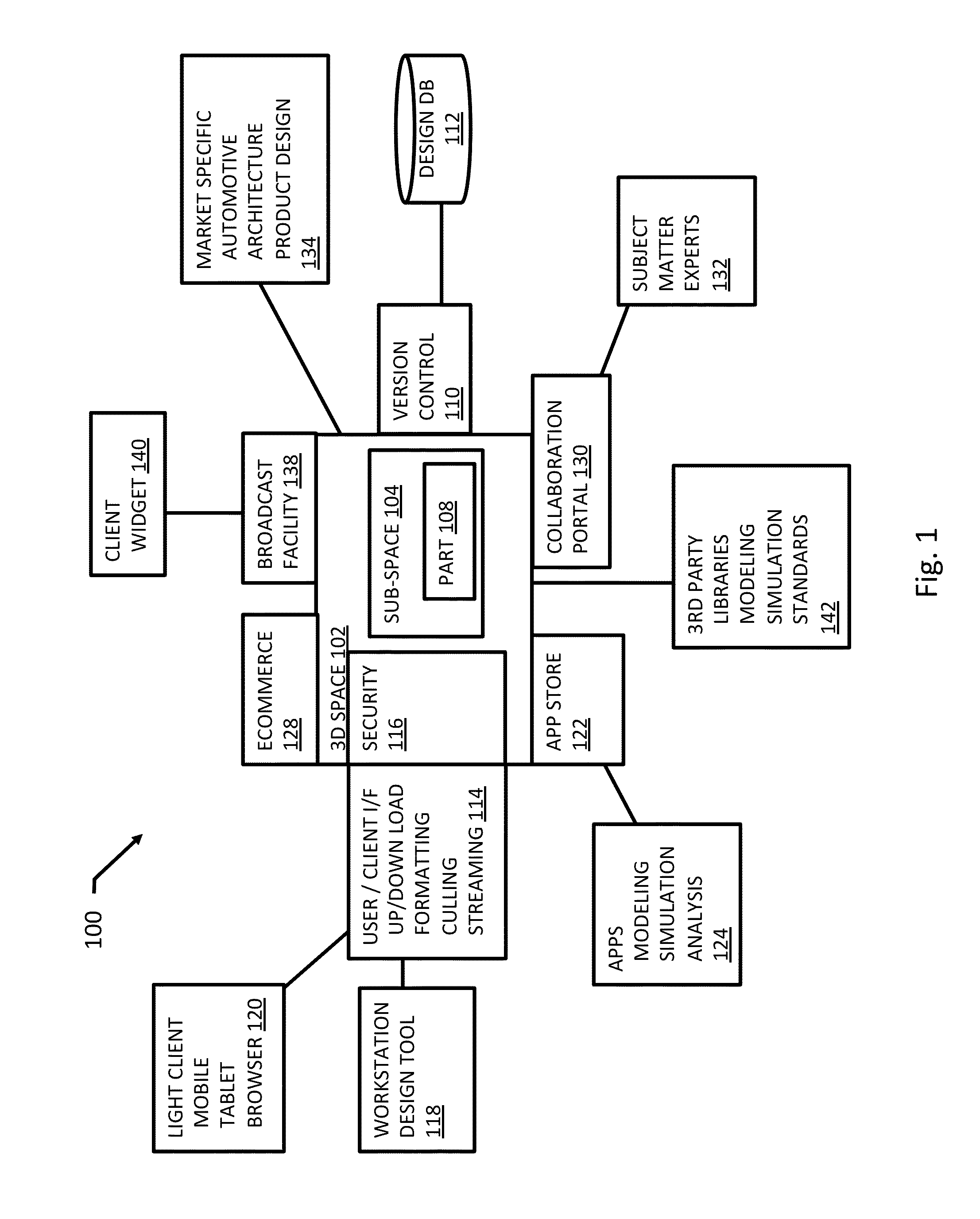

Real-time collaborative design platform

InactiveUS20130144566A1Promote collaborationEasy to participateAdditive manufacturing apparatusVersion controlComputer graphics (images)The Internet

A real-time collaborative design platform provides a hierarchical 3D model space as a plurality of nodes and branches. Each node may include at least one version of a sub-component and each version may include one or more attributes. The platform facilitates selecting a hierarchical tree from the 3D model space based, at least in part, upon at least one of the one or more attributes associated with sub-components. The platform also facilitates making the 3D model space accessible by multiple users over a network, such as the Internet. Also, each version of a sub-component is accessible in a library associated with the 3D model space.

Owner:DESIGN PLAY TECH

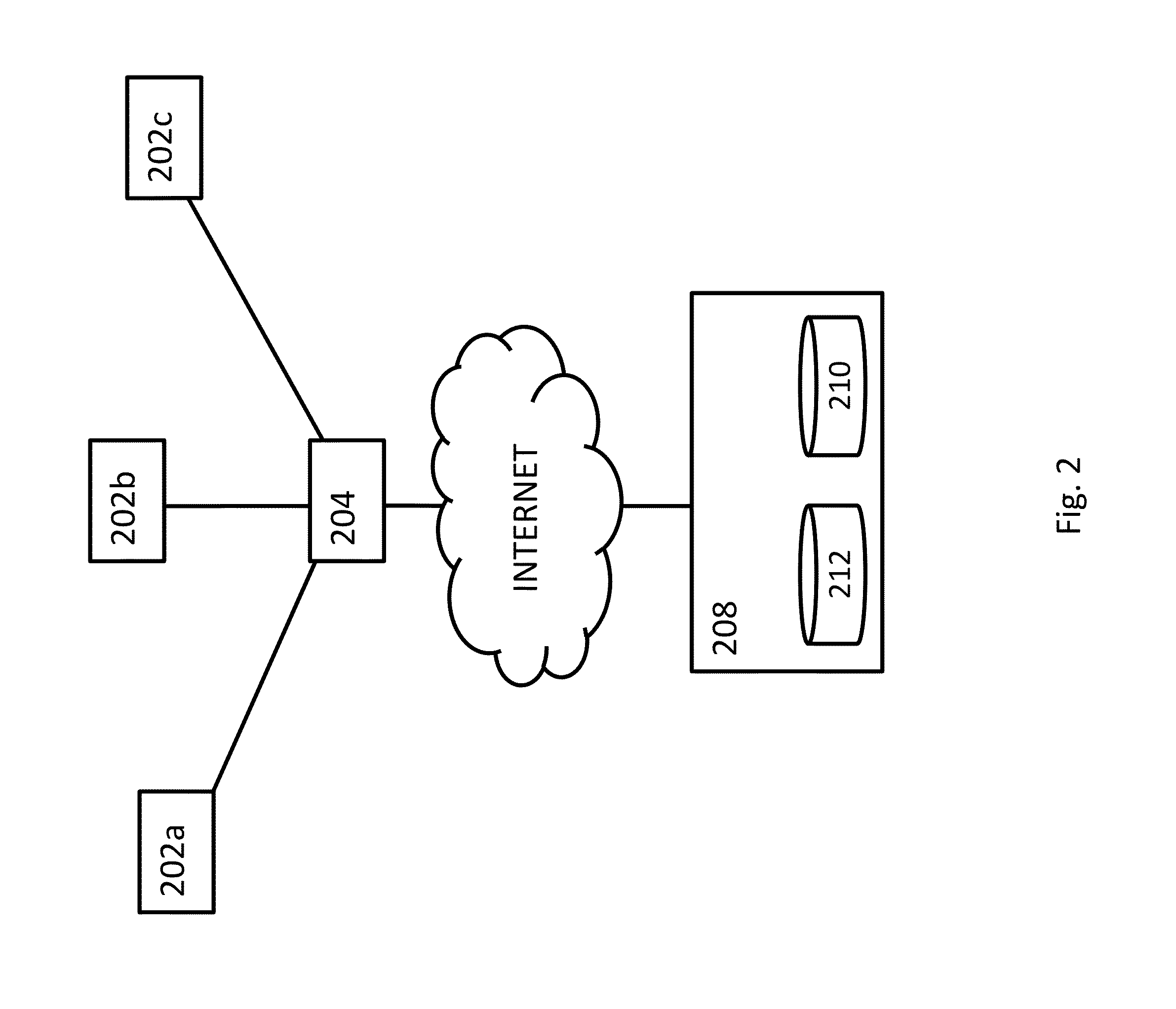

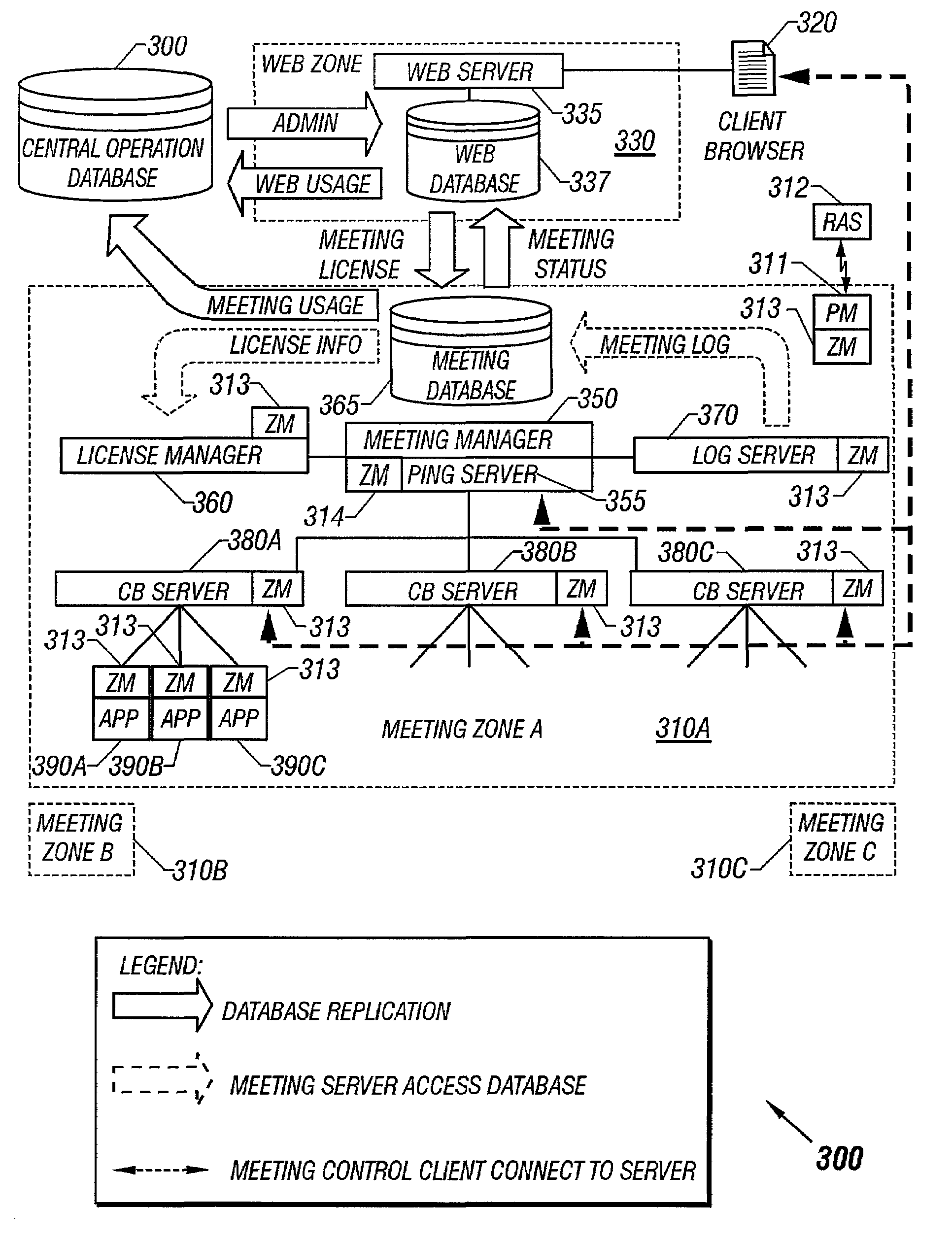

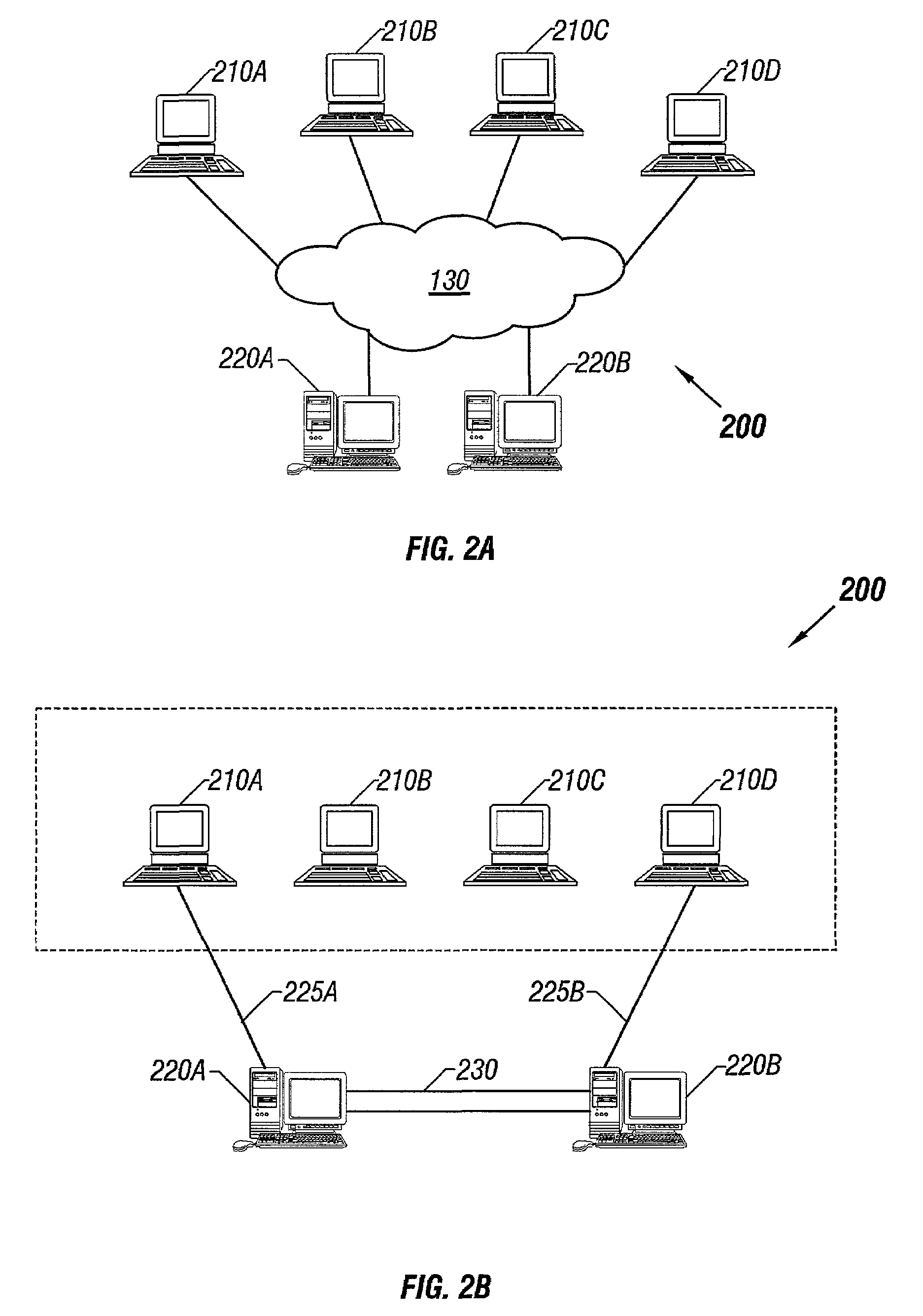

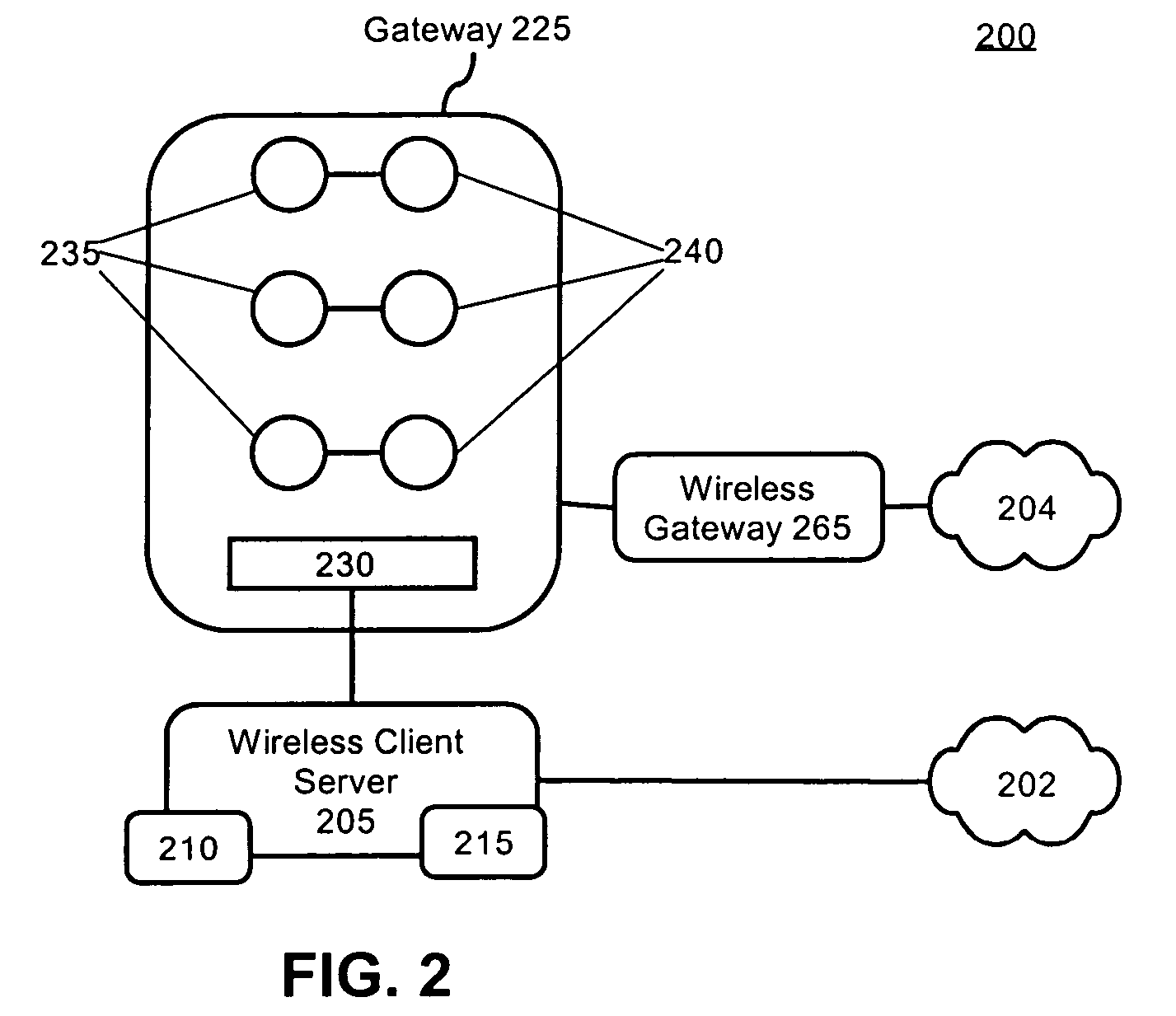

System and method for application sharing in collaborative setting

InactiveUS7203755B2Supporting applicationSpecial service provision for substationMultiple digital computer combinationsHigh-speed linkClient-side

A distributed collaborative computer system that supports application sharing is provided that comprises a plurality of server computers interconnected via a high-speed link. Client computers can connect to any available server computer and start or join a conference hosted on either the server computer to which the client computer is connected or any other server in the system. As a result, the system and method of the present invention allow application sharing among an arbitrary number of client computers.

Owner:CISCO TECH INC

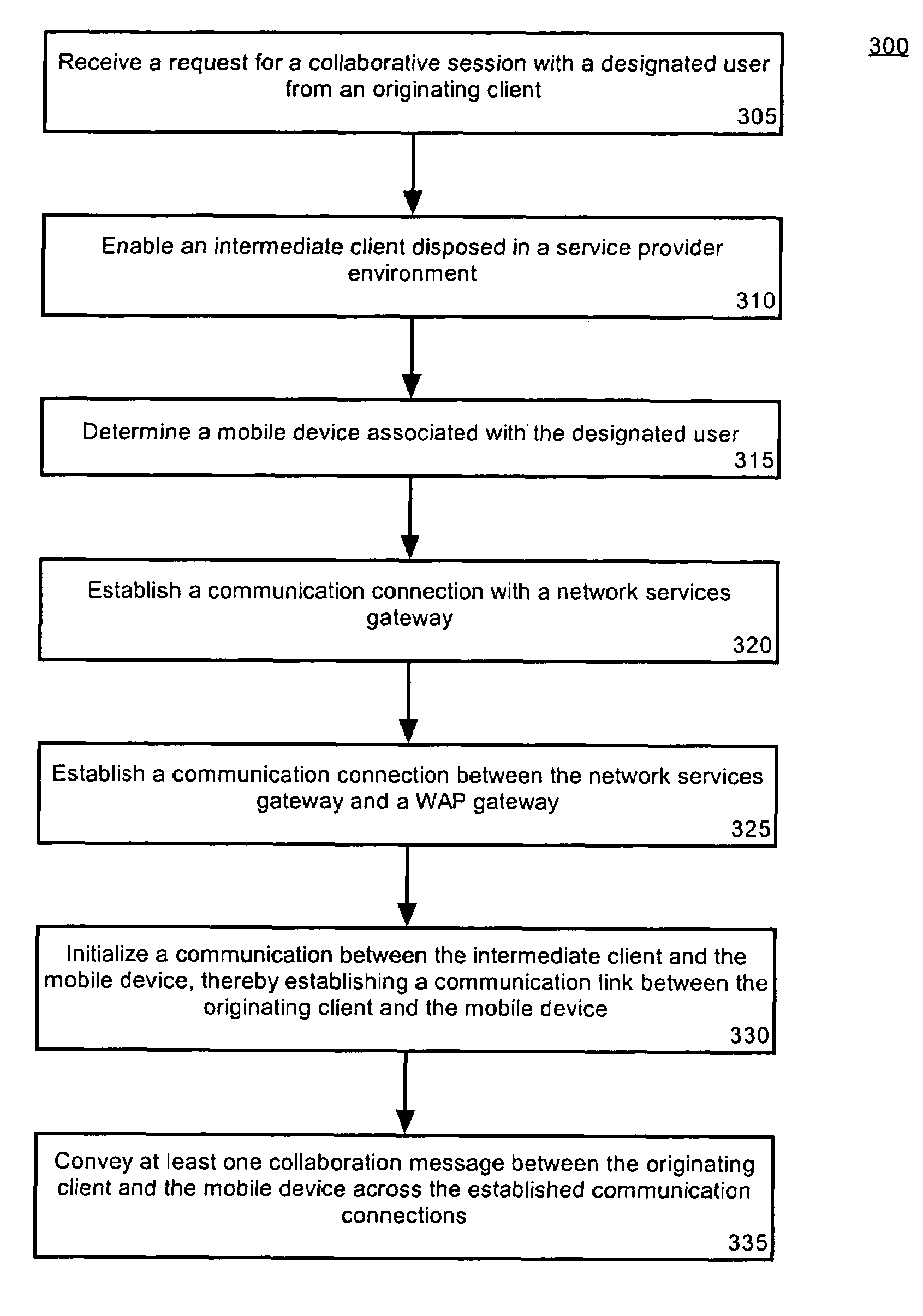

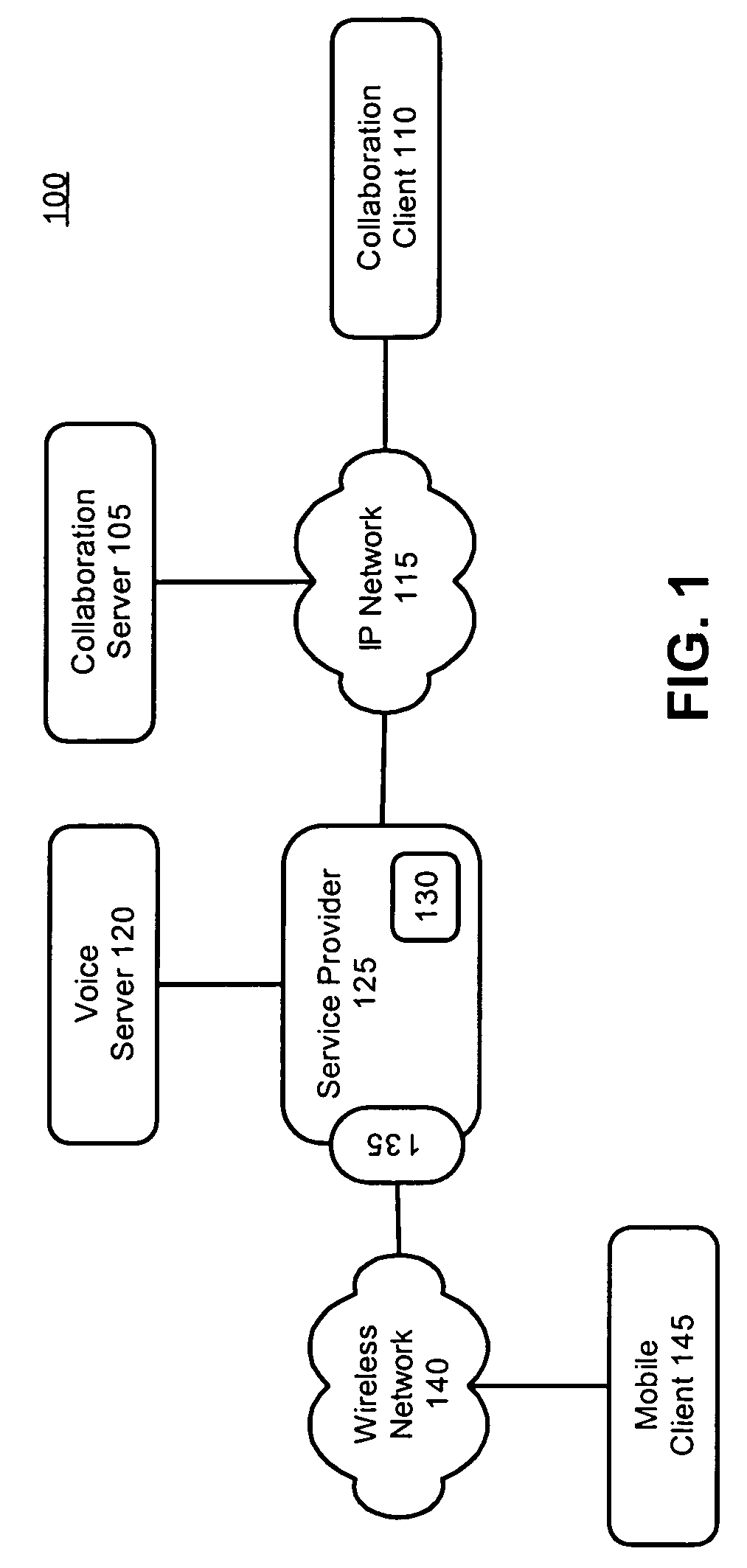

Providing collaboration services to a wireless device

ActiveUS7734691B2Special service provision for substationMultiple digital computer combinationsClient-sideMobile device

A method for establishing collaborative communications can include the step of receiving a request for a collaborative session with a designated user from an originating client. An intermediate client can be enabled, where the intermediate client can be deployed within a server that is communicatively linked to the originating client through an Internet protocol network. A mobile device associated with the designated user can be determined. A communication session can be initialized across a wireless network between the intermediate client and the mobile device. At least one collaboration message can be conveyed between the originating client and the mobile device using the intermediate client as a communication intermediary.

Owner:ACTIVISION PUBLISHING

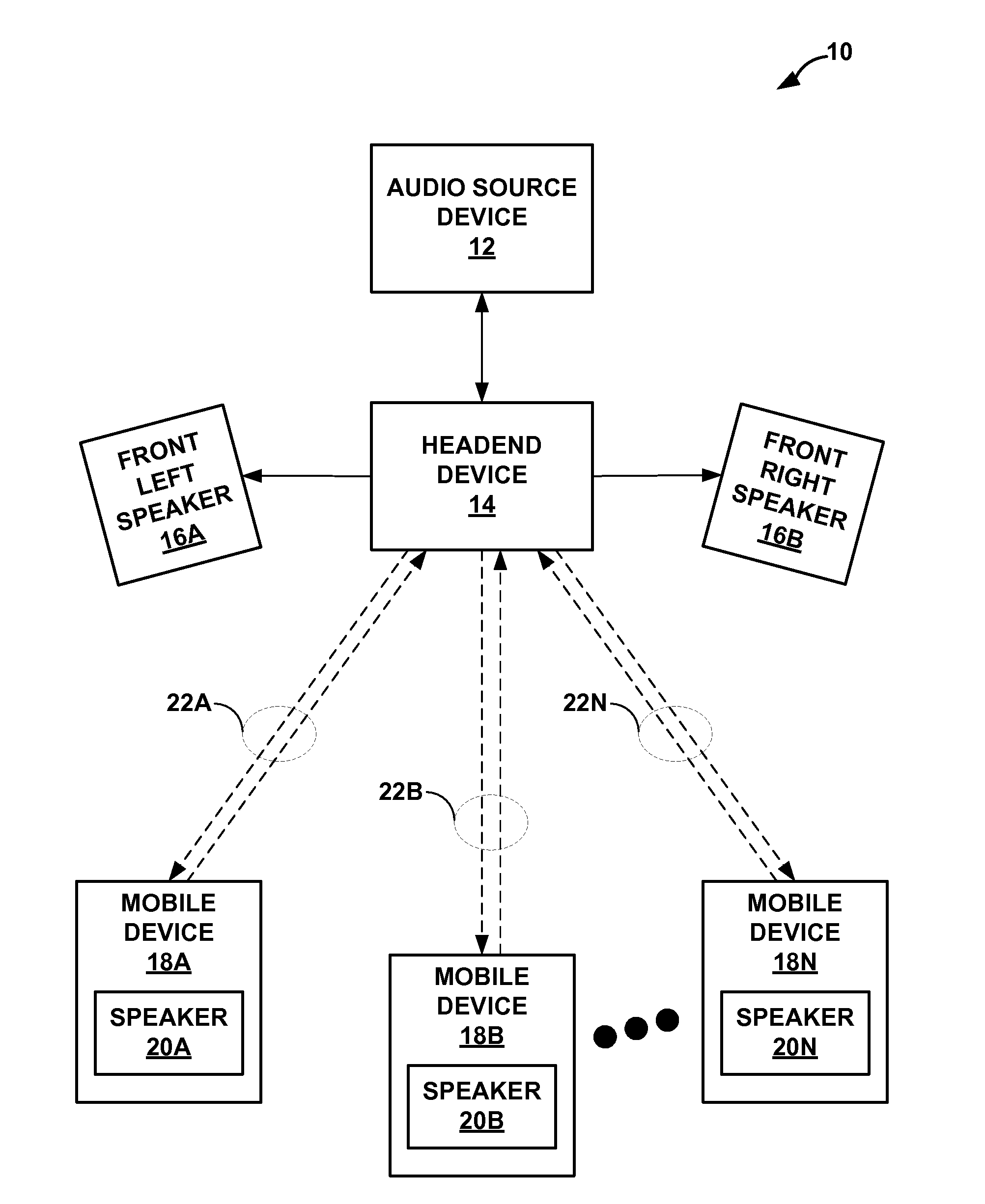

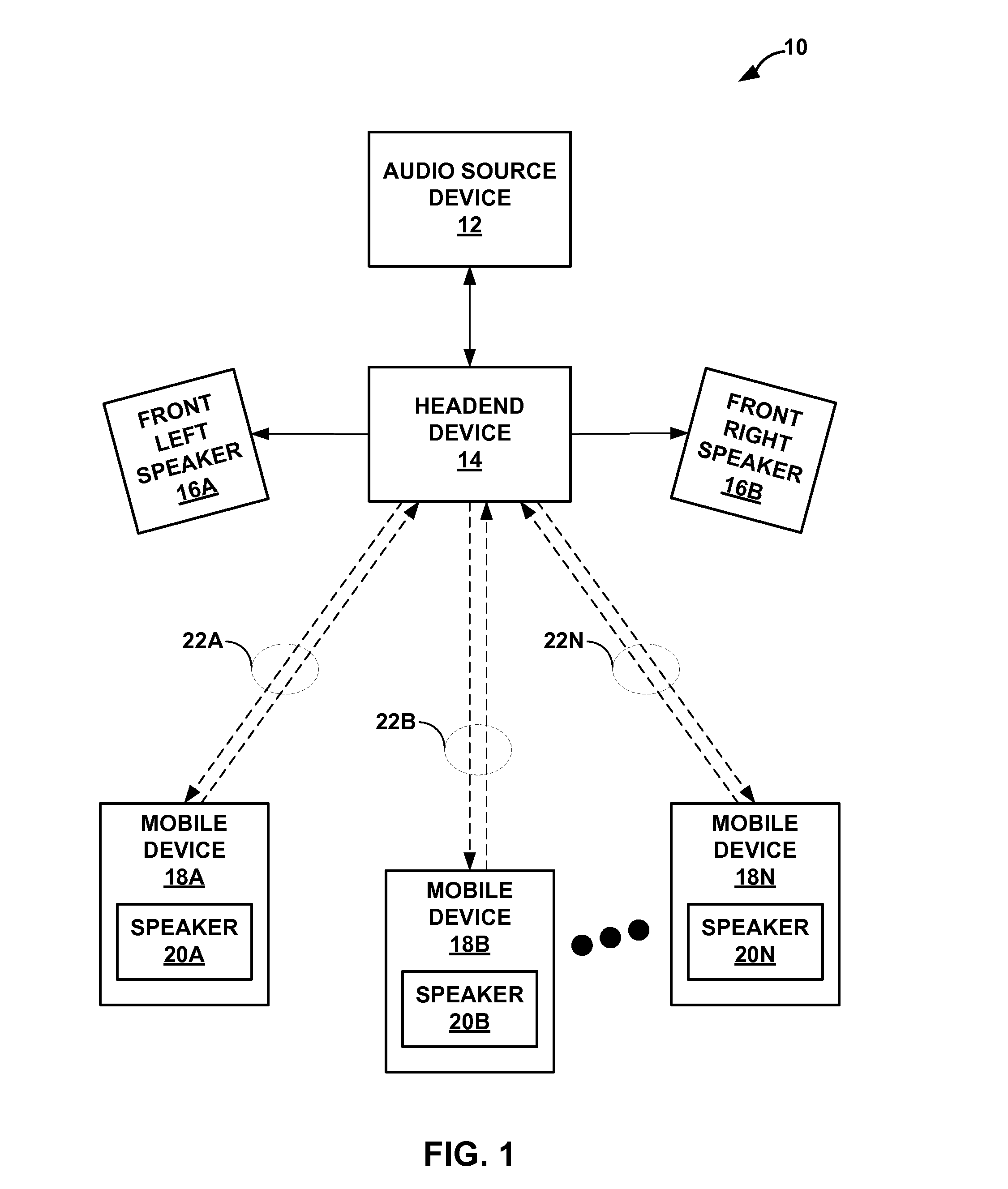

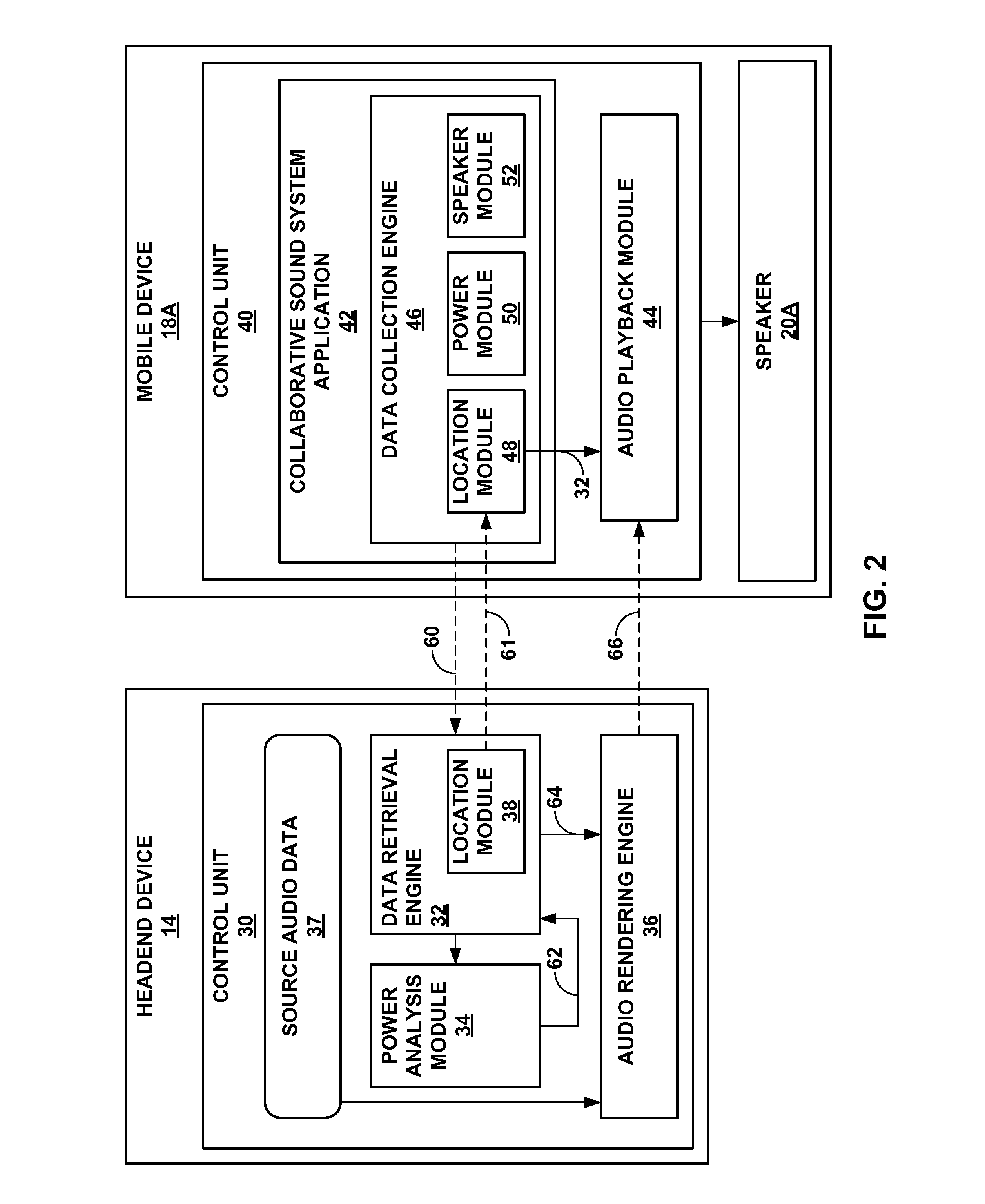

Image generation for collaborative sound systems

ActiveUS20140146983A1Reducing and avoiding costEase and flexibility of configurationLoudspeaker enclosure positioningStereophonic systemsLoudspeakerMobile device

In general, techniques are described for image generation for a collaborative sound system. A headend device comprising a processor may perform these techniques. The processor may be configured to determine a location of a mobile device participating in a collaborative surround sound system as a speaker of a plurality of speakers of the collaborative surround sound system. The processor may further be configured to generate an image that depicts the location of the mobile device that is participating in the collaborative surround sound system relative to the plurality of other speakers of the collaborative surround sound system.

Owner:QUALCOMM INC

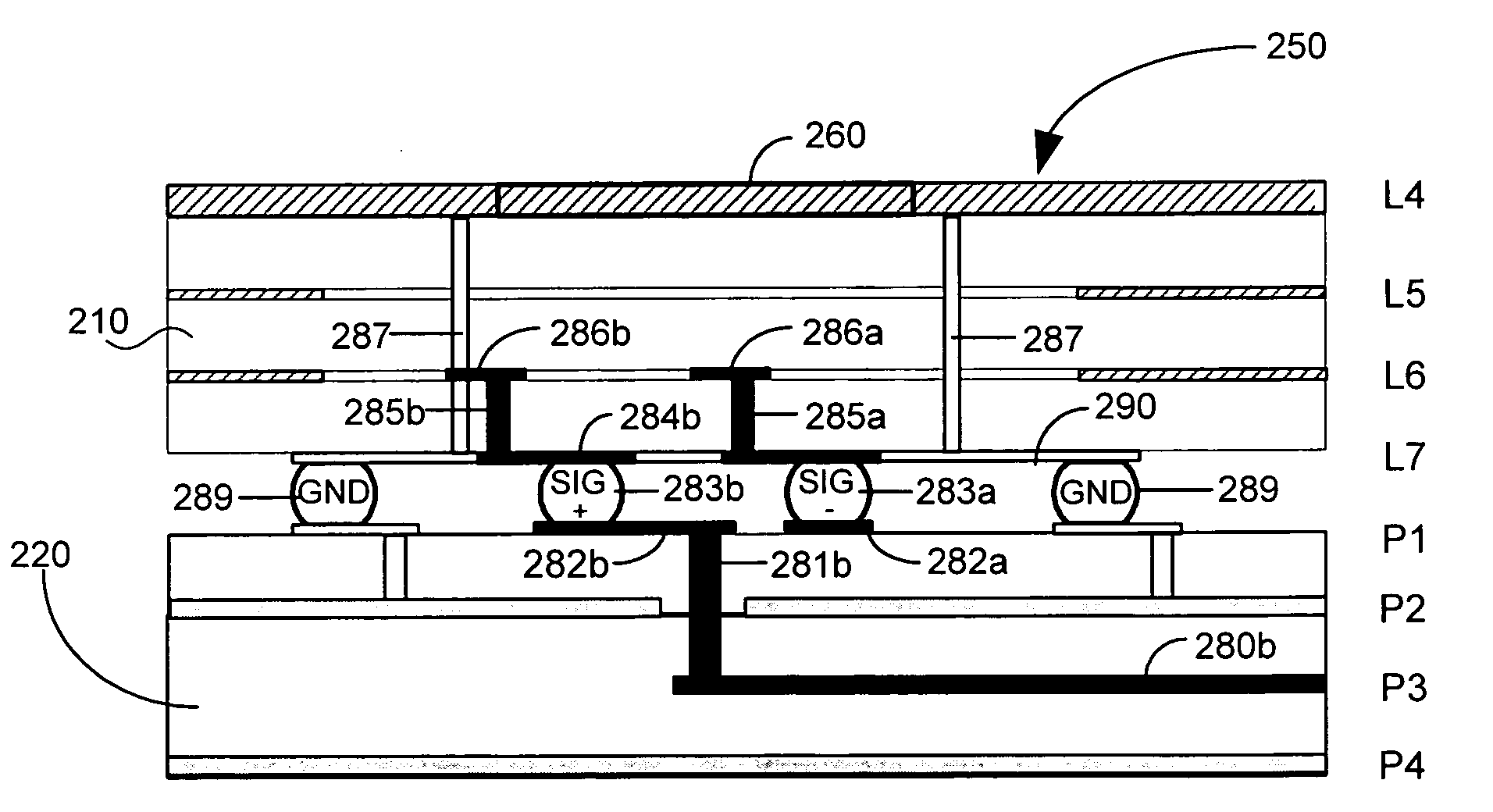

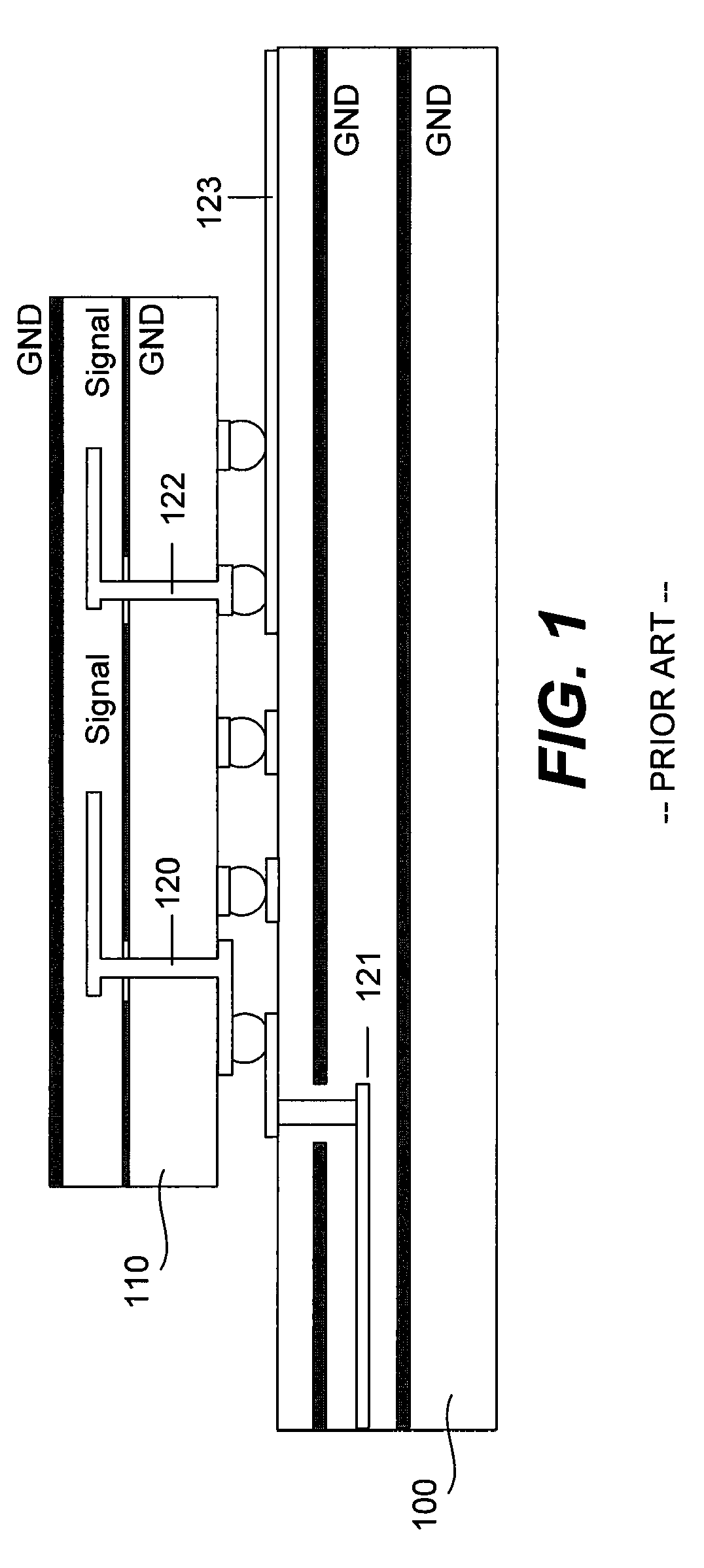

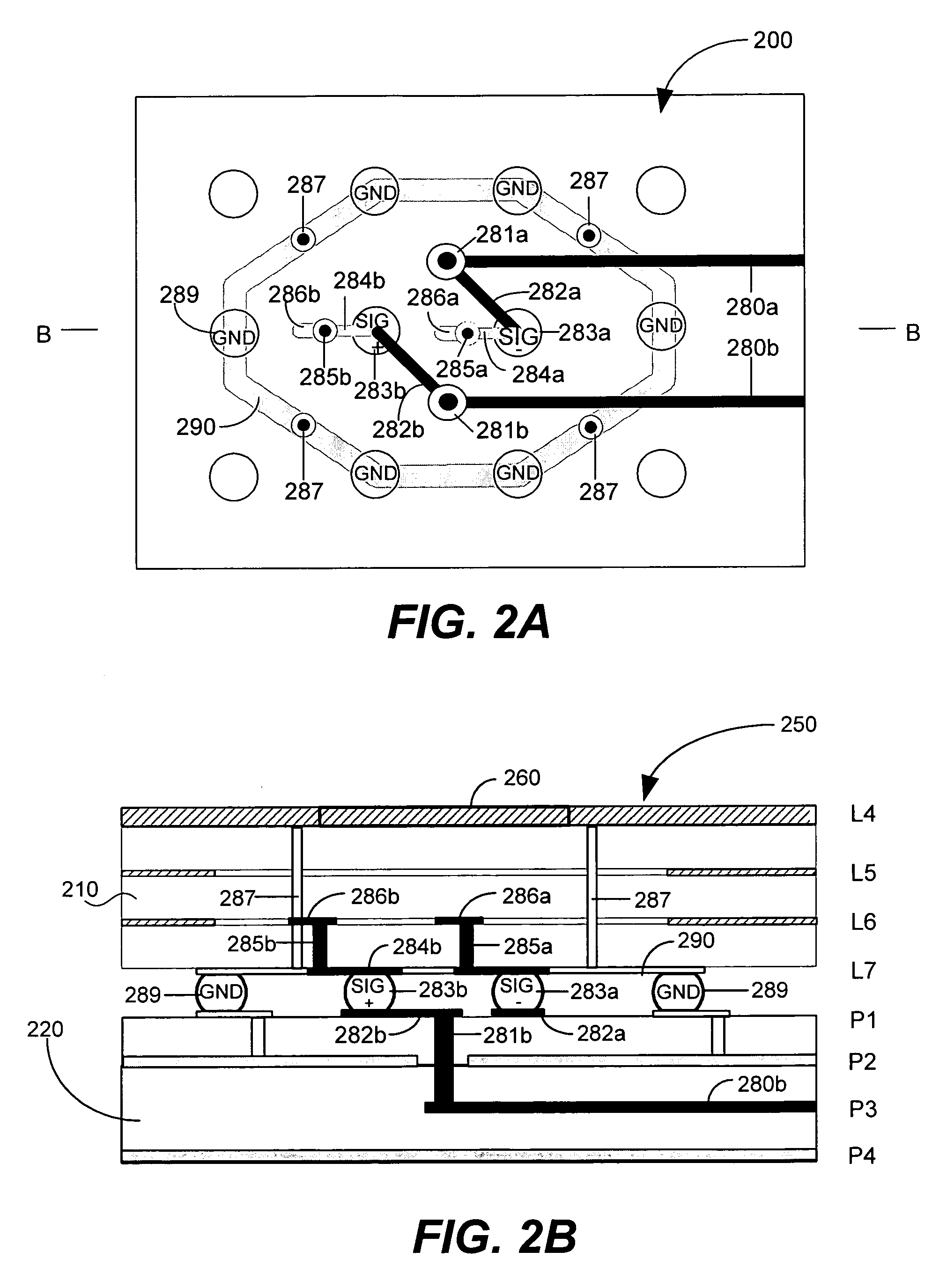

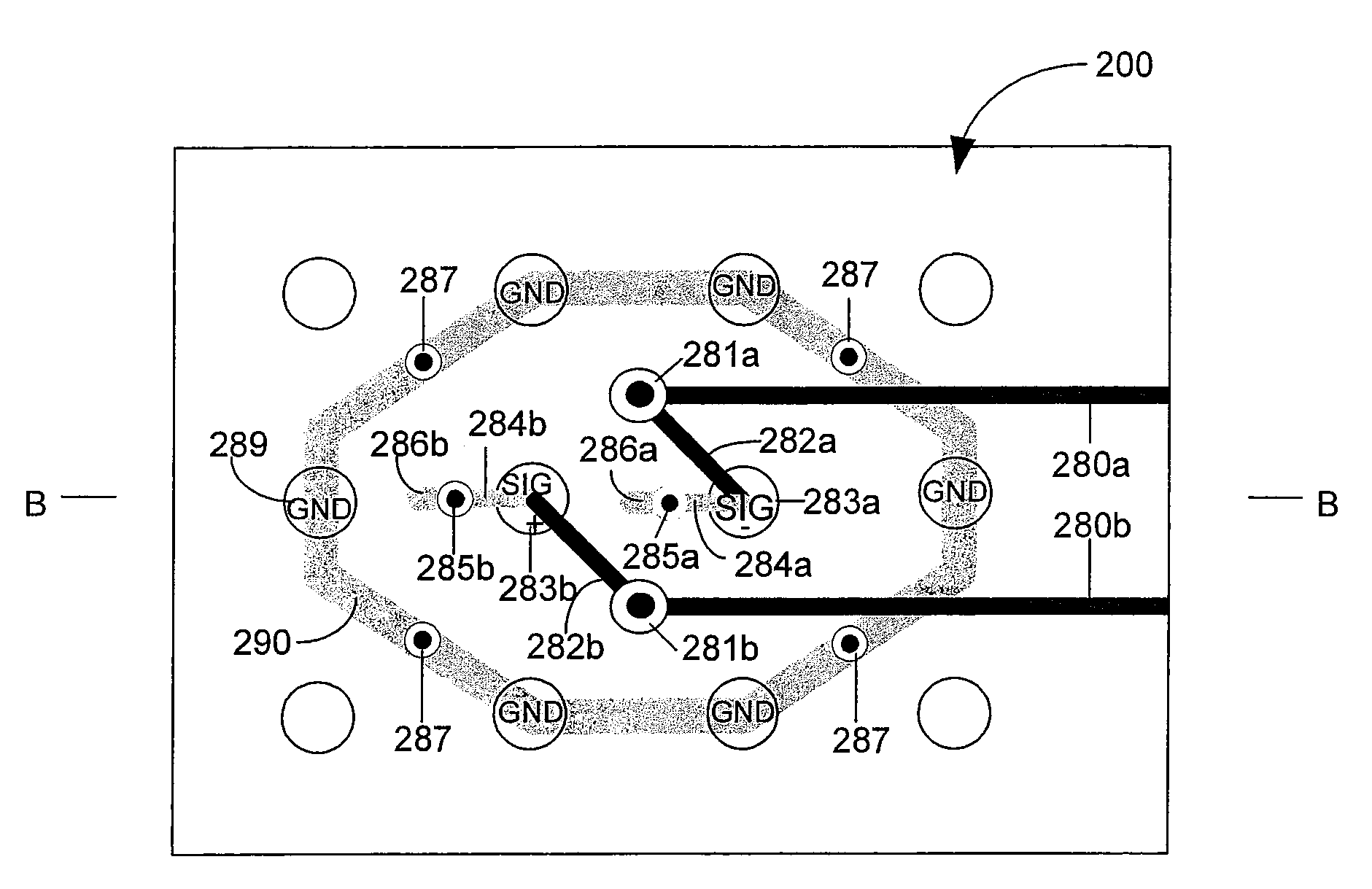

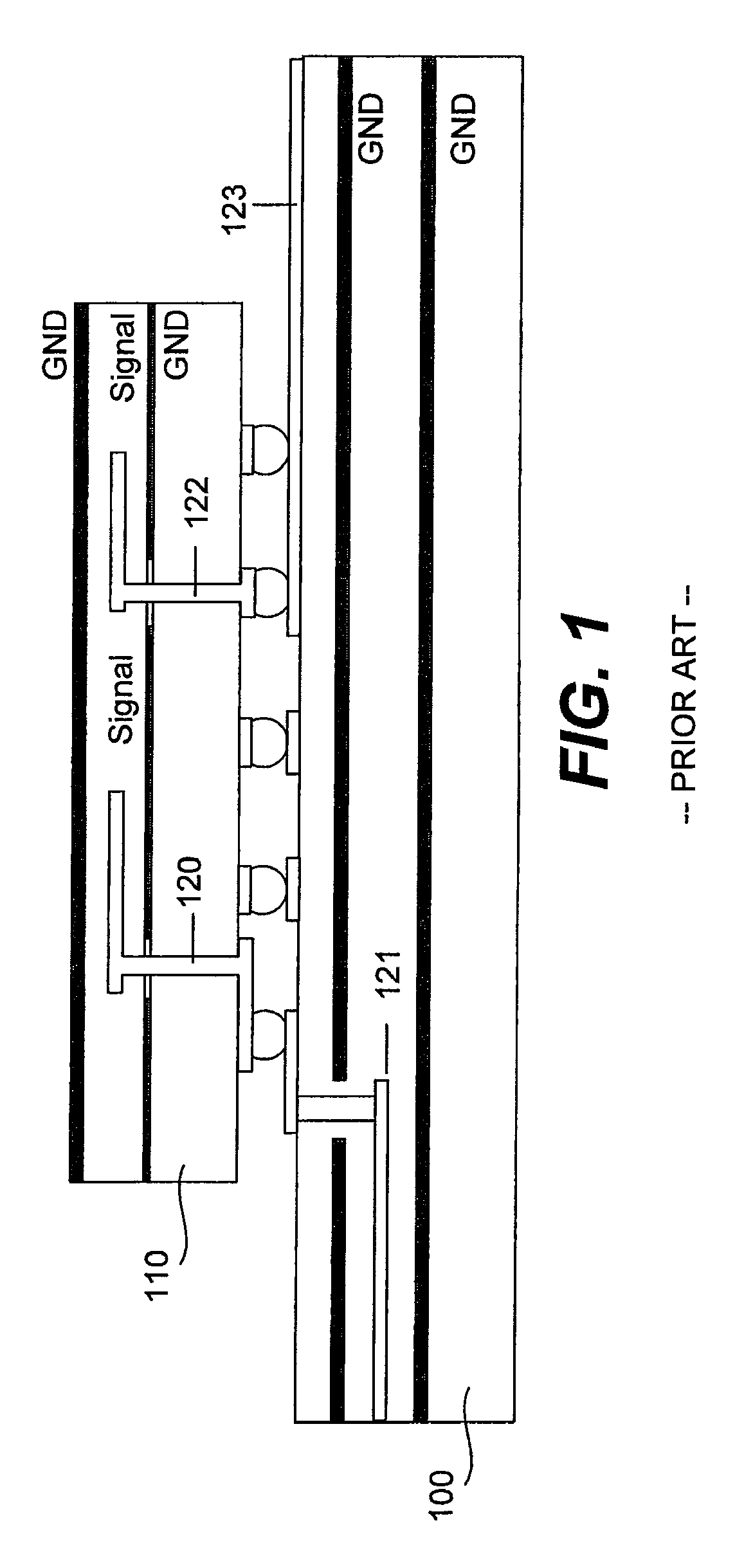

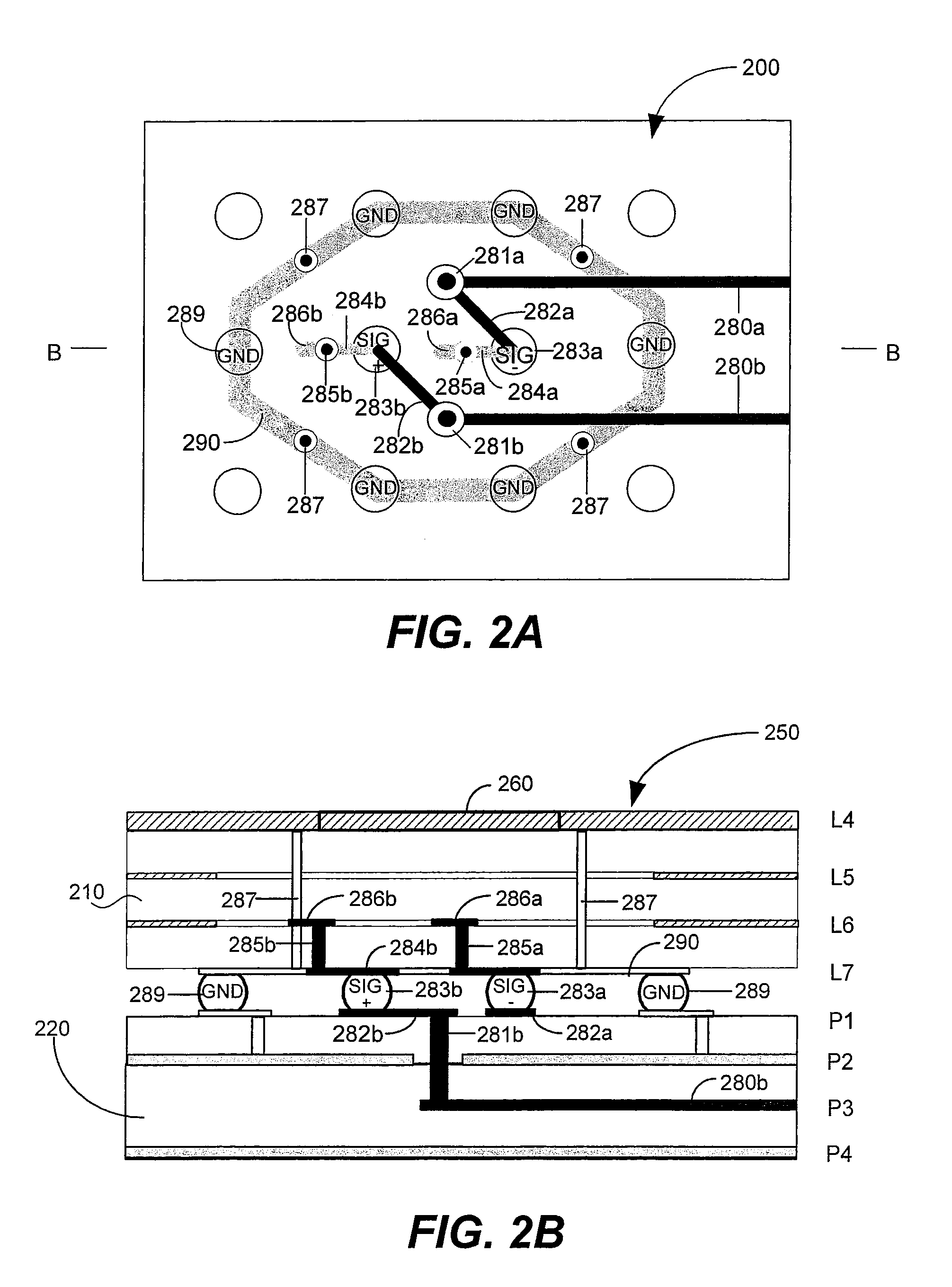

Ball grid array package-to-board interconnect co-design apparatus

InactiveUS7405477B1Signal transmission is convenientAvoid reflectionsSemiconductor/solid-state device detailsPrinted circuit aspectsCopper interconnectData stream

A package-board co-design methodology preserves the signal integrity of high-speed signals passing from semiconductor packages to application PCBs. An optimal architecture of interconnects between package and PCB enhances the signal propagation, minimizes parasitic levels, and decreases electromagnetic interference from adjacent high frequency signals. The invention results in devices with superior signal quality and EMI shielding properties with enhanced capability for carrying data stream at multiple-gigabit per second bit-rates.

Owner:TAHOE RES LTD

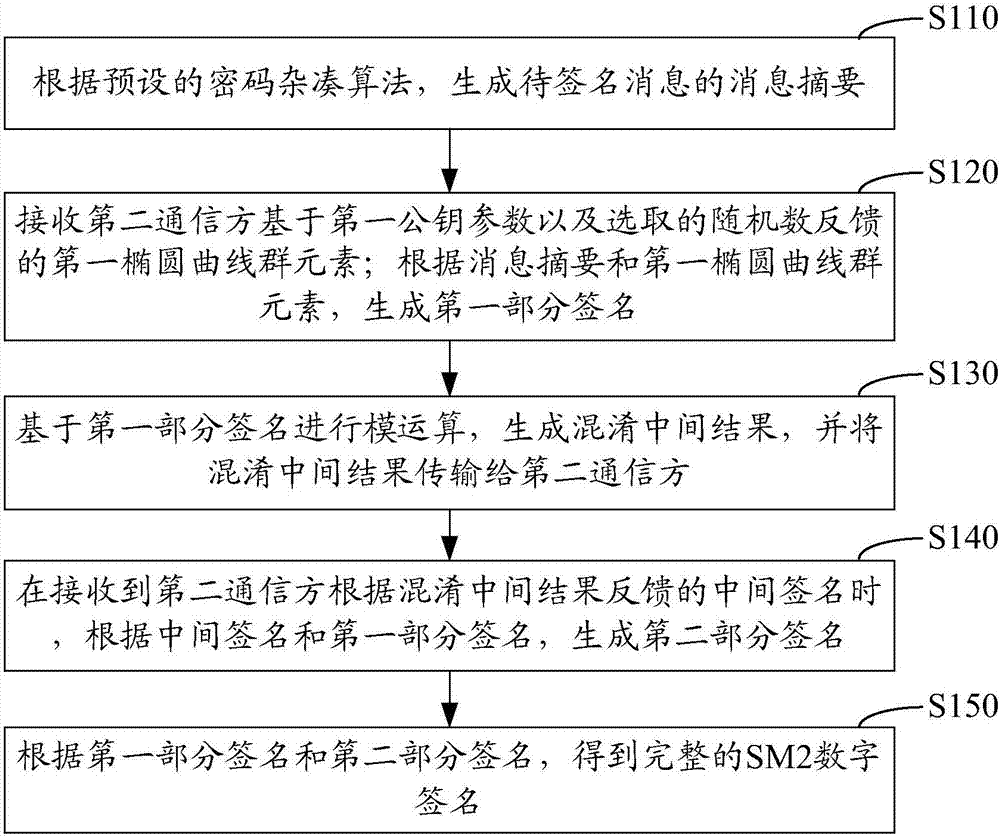

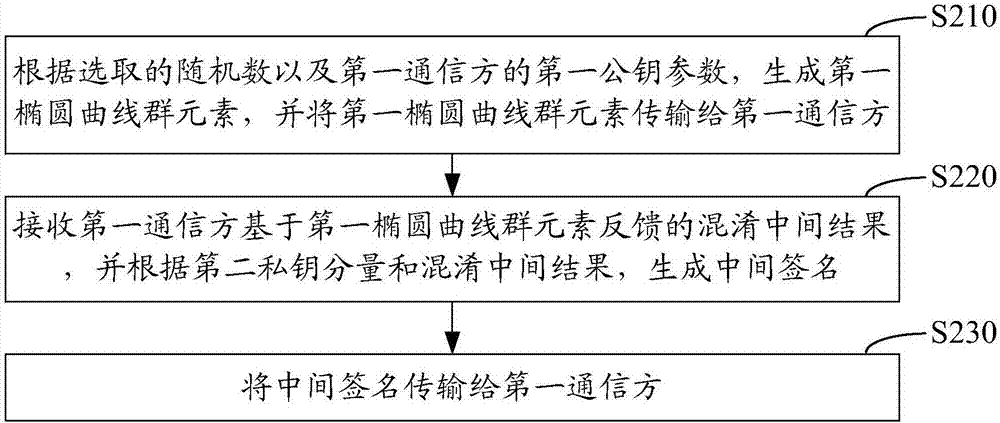

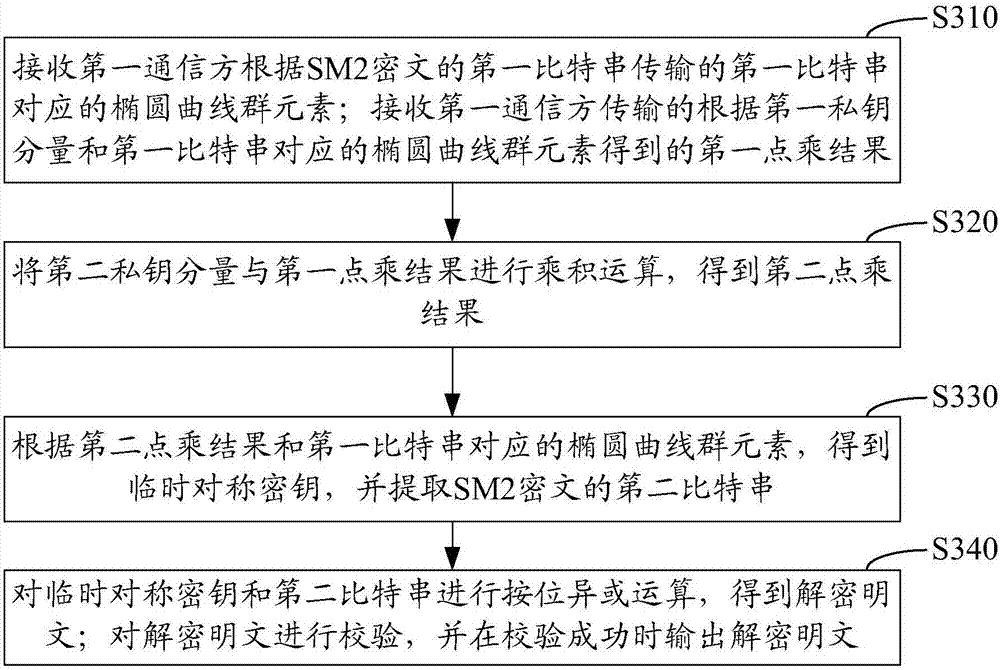

Collaborative signature and decryption method, apparatus and system of SM2 algorithm

ActiveCN107196763APrivacy protectionPrevent forgeryPublic key for secure communicationUser identity/authority verificationPasswordDigital signature

The invention relates to a collaborative signature and decryption method, apparatus and system of an SM2 algorithm. The collaborative signature method of the SM2 algorithm implemented from the angle of a first communication party comprises the following steps: generating a message abstract of a to-be-singed message according to a preset password hash algorithm; receiving a first elliptic curve group element fed back by a second communication party based on a first public key parameter and a selected random number; generating a first part signature according to the message abstract and the first elliptic curve group element; performing modular arithmetic based on the first part signature to generate a confused intermediate result, and transmitting the confused intermediate result to the second communication party; when the intermediate signature fed back by the second communication party according to the confused intermediate result is received, generating a second part signature according to the intermediate signature and the first part signature; and obtaining a complete SM2 digital signature according to the first part signature and the second part signature.

Owner:GUANGDONG CERTIFICATE AUTHORITY +1

Collaborative design

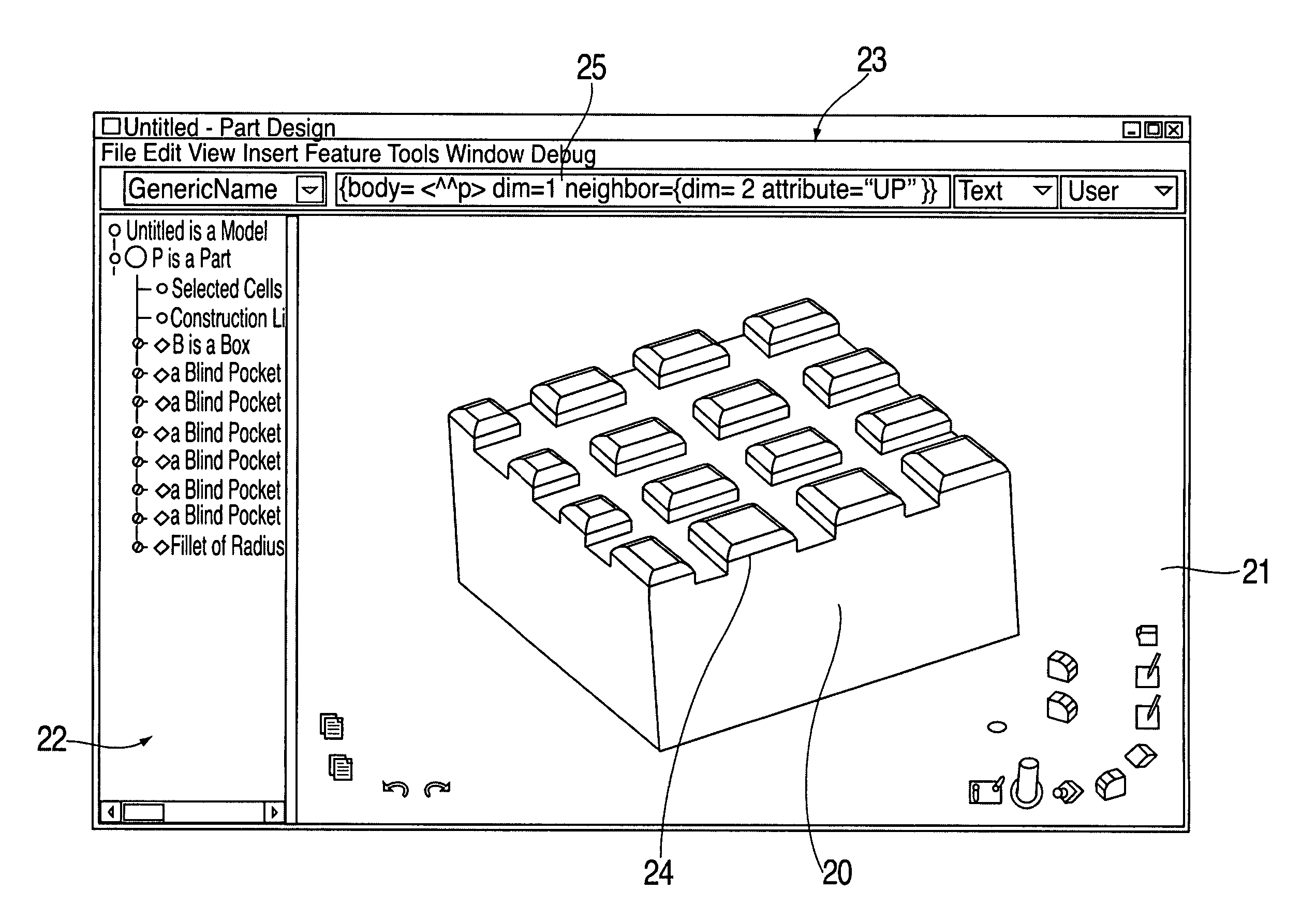

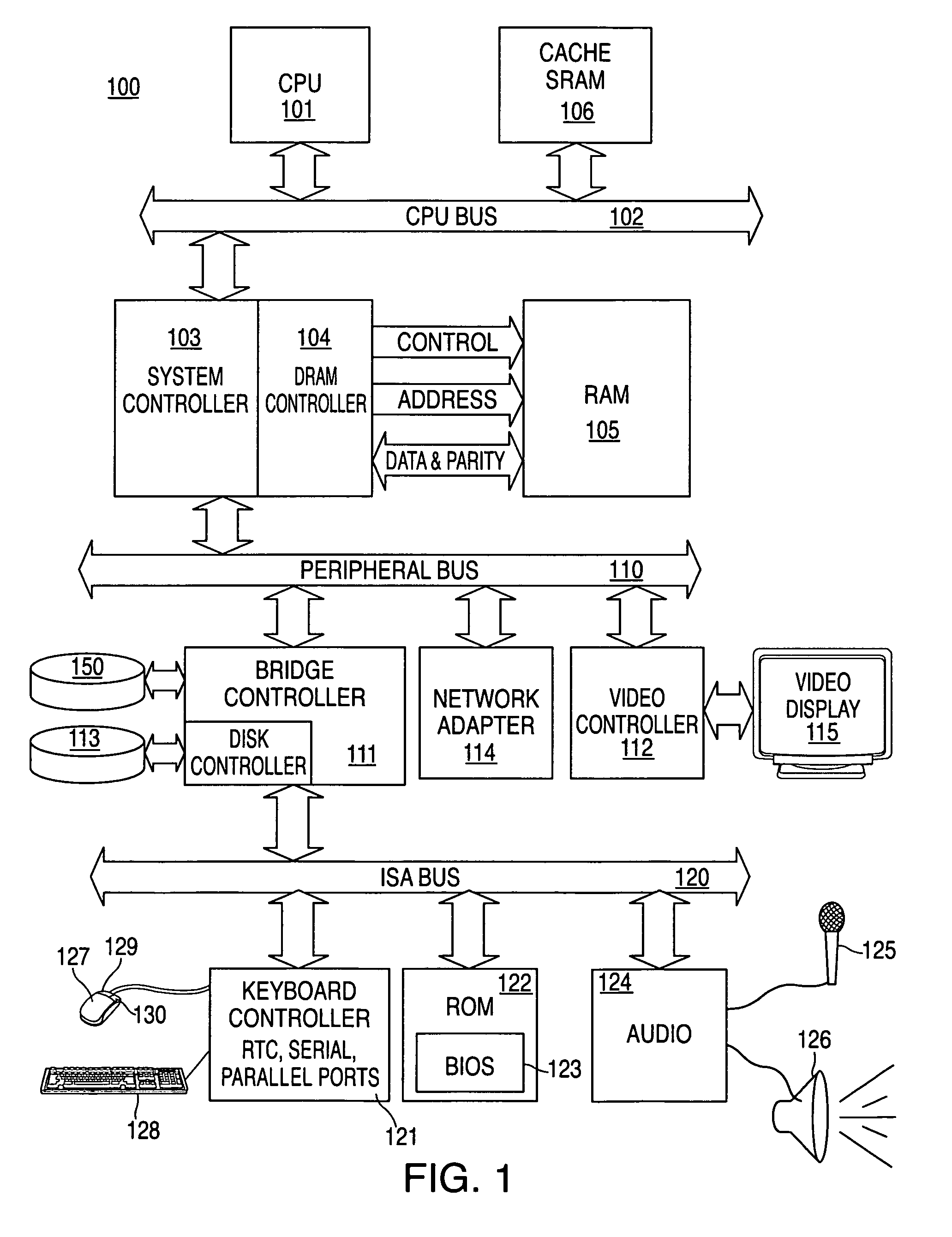

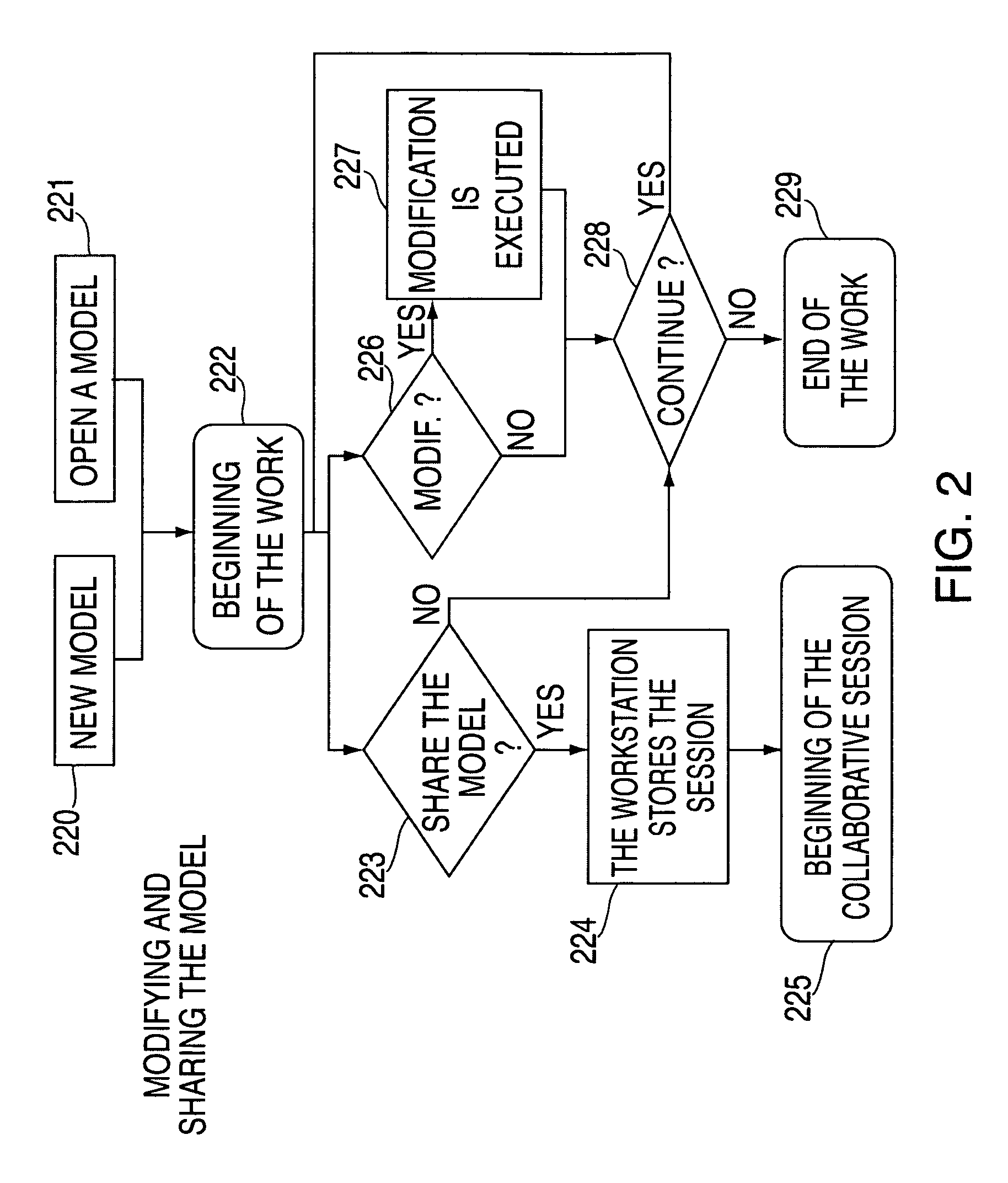

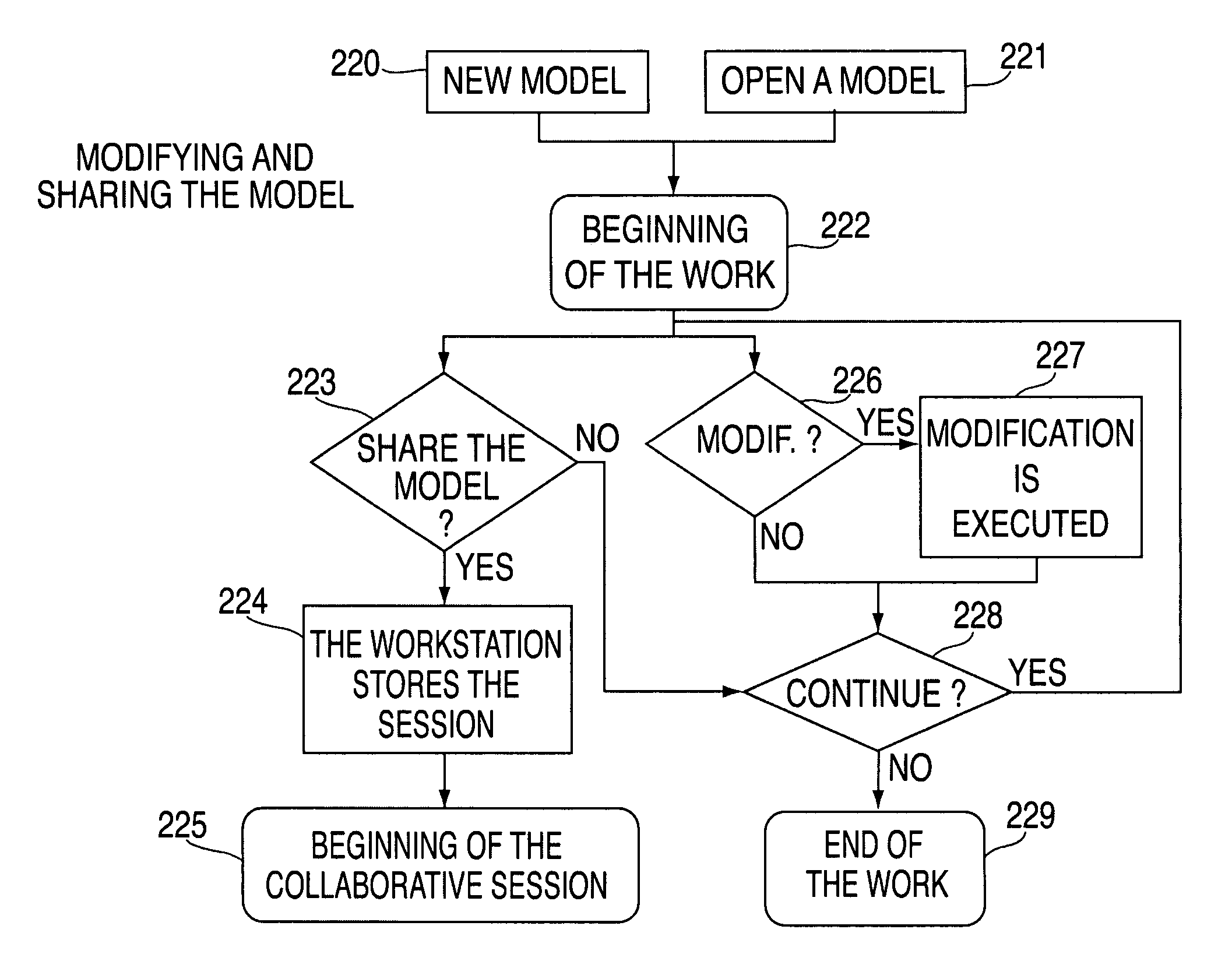

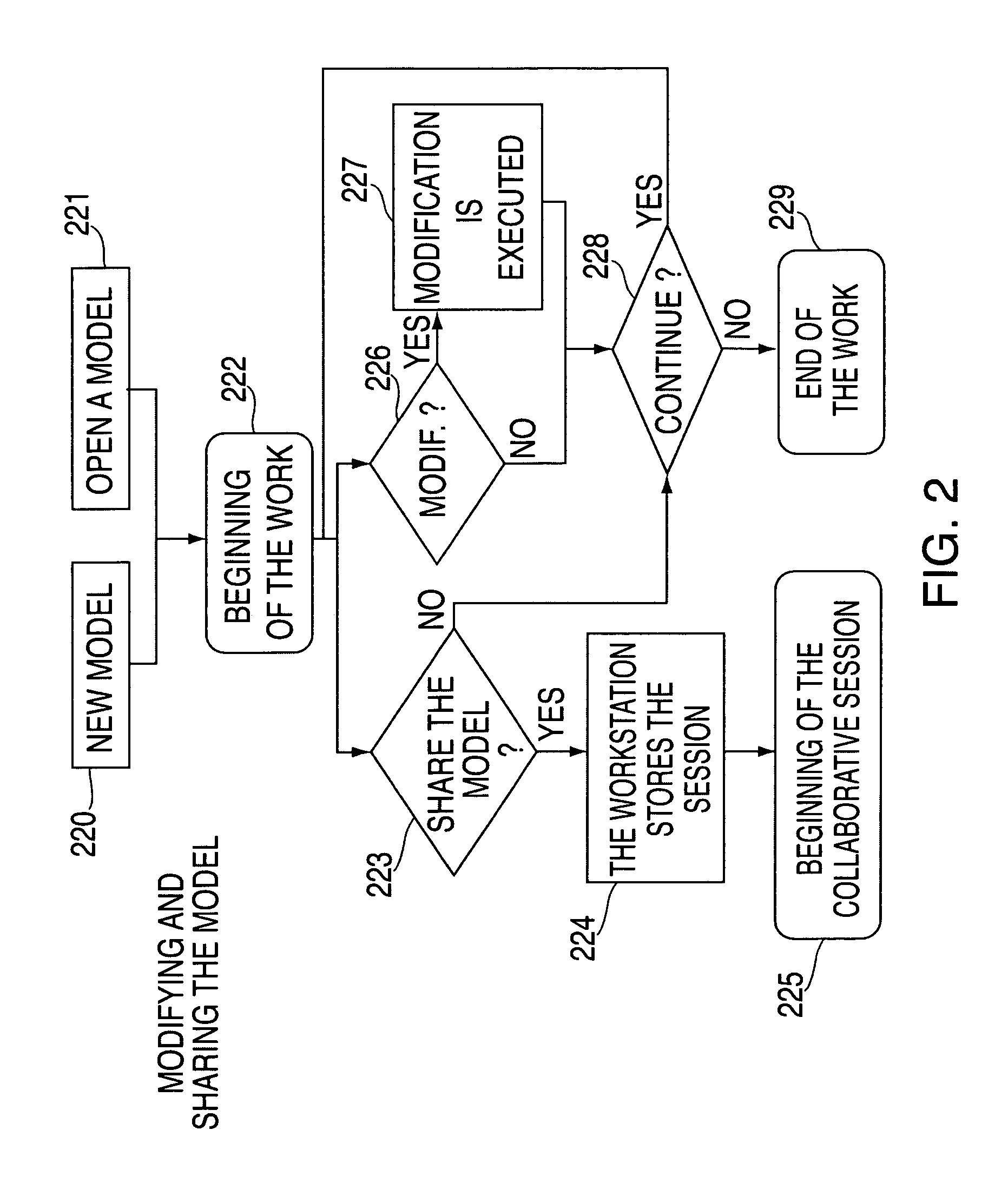

InactiveUS20060250418A1Improve productivityLess timeData processing applicationsDrawing from basic elementsSoftware engineeringWorkstation

A method, system and apparatus for use in computer-aided design, computer-aided manufacturing, computer-aided engineering and product lifecycle management. An efficient, non-centralized communications framework makes “synchronous” collaborative design possible. Users are resident at workstations that are connected in a peer-to-peer arrangement. In a collaborative design session, the model is resident in memory at each workstation. Modifications are made at any workstation, and commands, which are interpreted at each workstation to effect the modifications, are transmitted over the network. In addition, cell descriptors may be used to identify one or more geometric cells of a model. The cell descriptors are in the form of scripts specifying constraints or filters for identifying cells. The constraints are based on characteristics of items in the model, or associations between items in a model, that are readily discernable to the user, and are therefore easily written and susceptible to easy distribution to other systems.

Owner:DASSAULT SYSTEMES

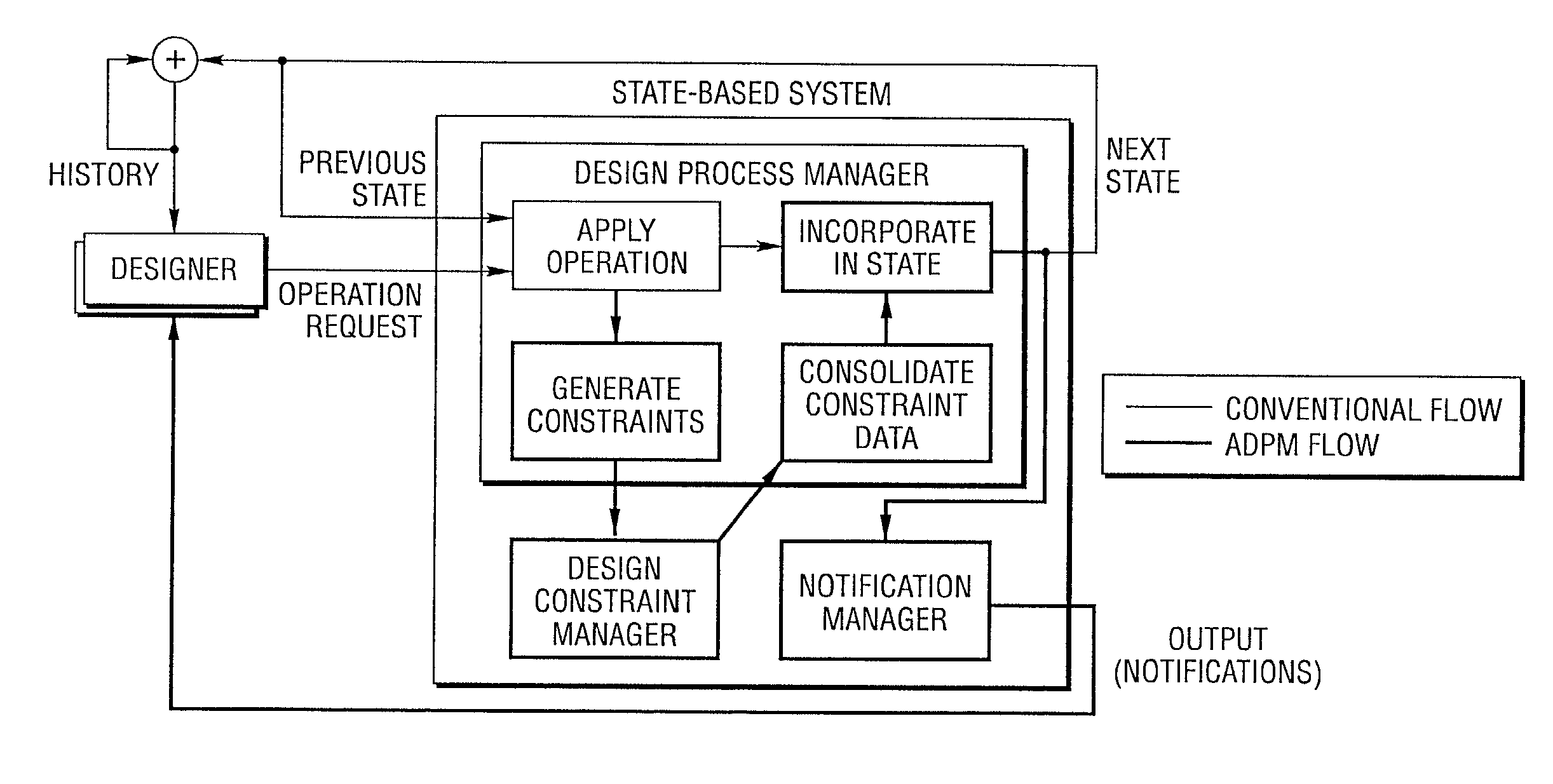

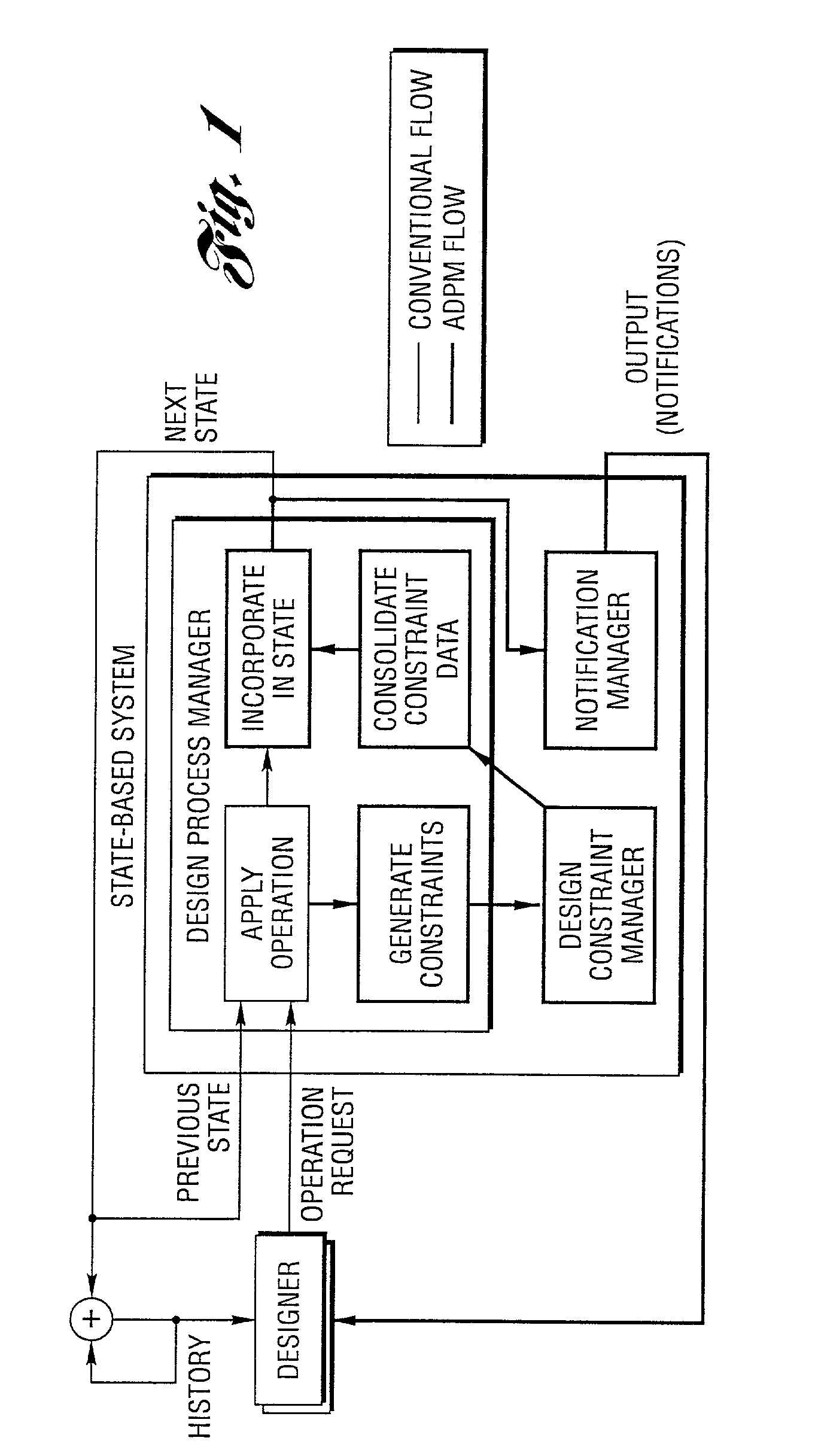

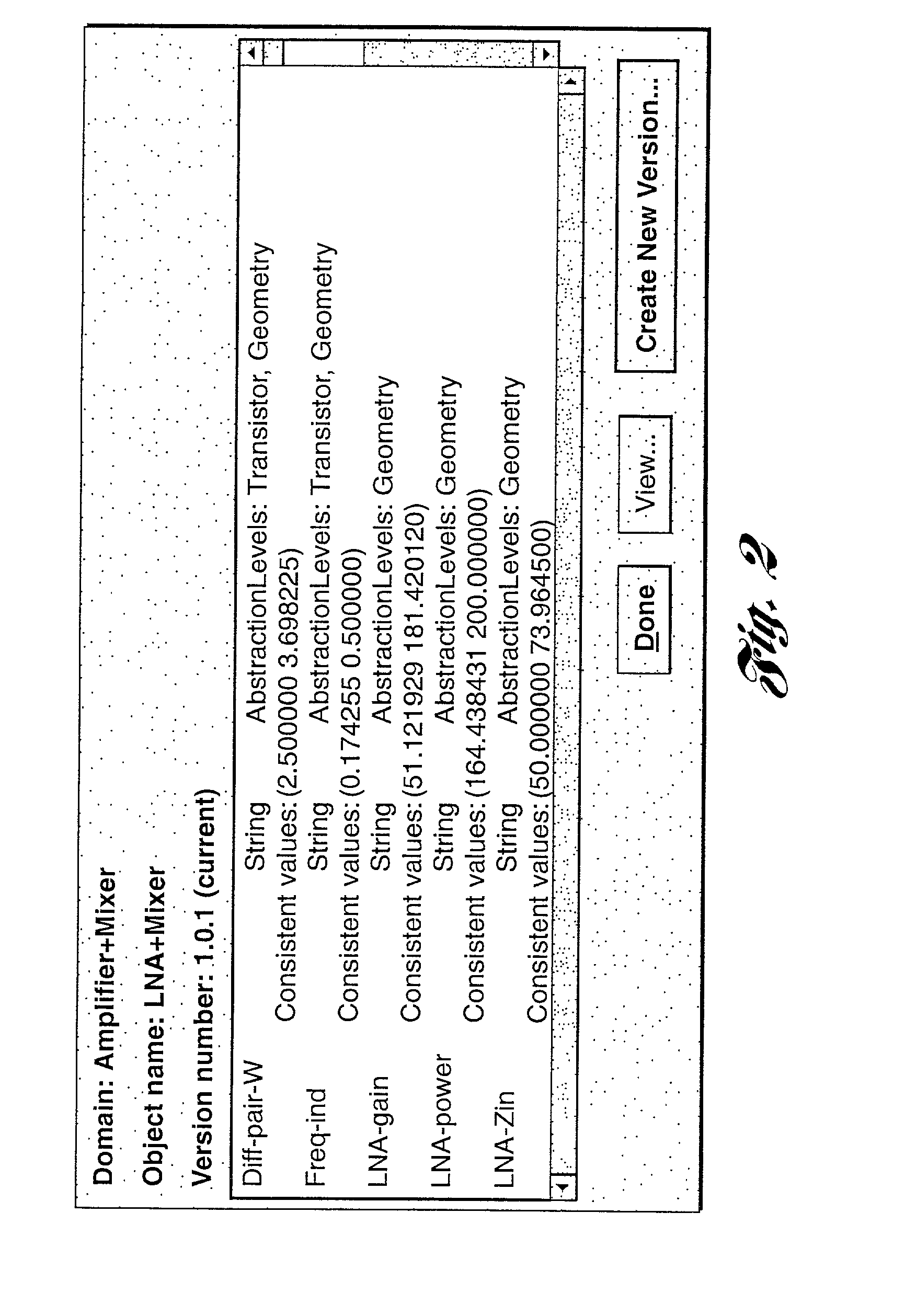

Method and system for providing constraint-based guidance to a designer in a collaborative design environment

InactiveUS7047168B2Reducing late conflictReduce violationsFinanceComputation using non-denominational number representationHeuristicHuman–computer interaction

Method and system are provided for providing constraint-based guidance to a designer to support the application of useful constraint-based heuristics in complex collaborative design, thus reducing late conflicts and facilitating their resolution when they happen. The invention can be applied to any collaborative problem-solving task such as a collaborative engineering activity or the design of corporate strategies. In the method and system, designers receive constraint-based feedback that enables them to apply constraint-based heuristics that consider the simultaneous effect of all design constraints.

Owner:RGT UNIV OF MICHIGAN

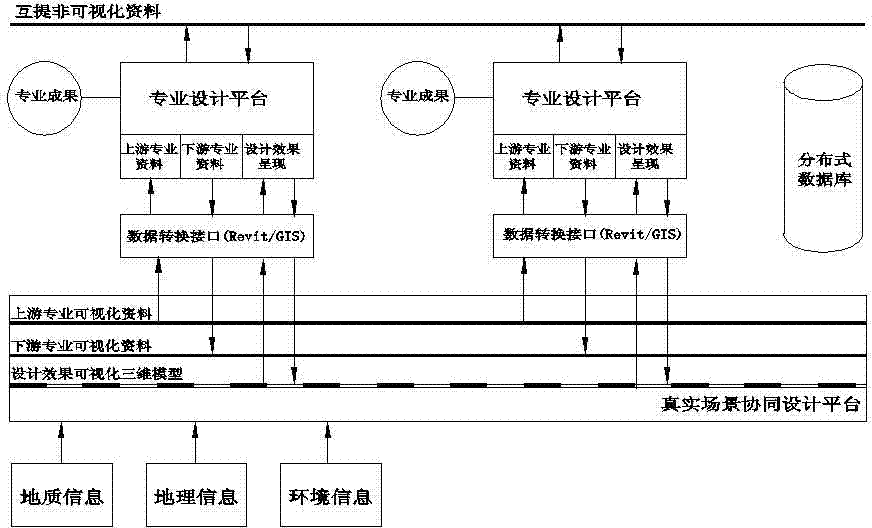

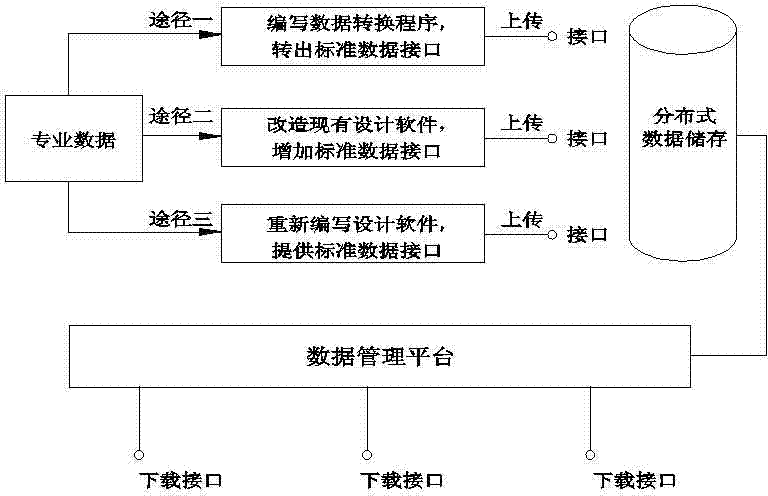

Method for constructing real scene model collaborative design platform of railway engineering

ActiveCN103699731AAccurate understandingEfficient responseSpecial data processing applications3D modellingData setDistributed database

The invention relates to a method for constructing a real scene model collaborative design platform of railway engineering. Railway and urban rail transit projects are distributed in a strip shape, engineering data are large, numerous professions are involved, and therefore, the efficient and stable collaborative design platform needs establishing. According to the method, the strip-shaped continuous three-dimensional real scene model is established along the whole range of the project, and fusion processing is performed on all professional three-dimensional building information models (BIM) and the three-dimensional real scene model. Under the management mode of a distributed database, management is performed on a global data base of the three-dimensional real scene model collaborative design platform and special databases of all professional BIM design platforms which only transmit upstream data and downstream data involved in collaborative design and generated BIM three-dimensional design results onto the three-dimensional real scene model collaborative design platform. By means of the method, the strip-shaped project information model along the whole range of the project is established, all professional interactive data are integrated into a continuous three-dimensional real scene, and collaborative design is achieved.

Owner:CHINA RAILWAY FIRST SURVEY & DESIGN INST GRP

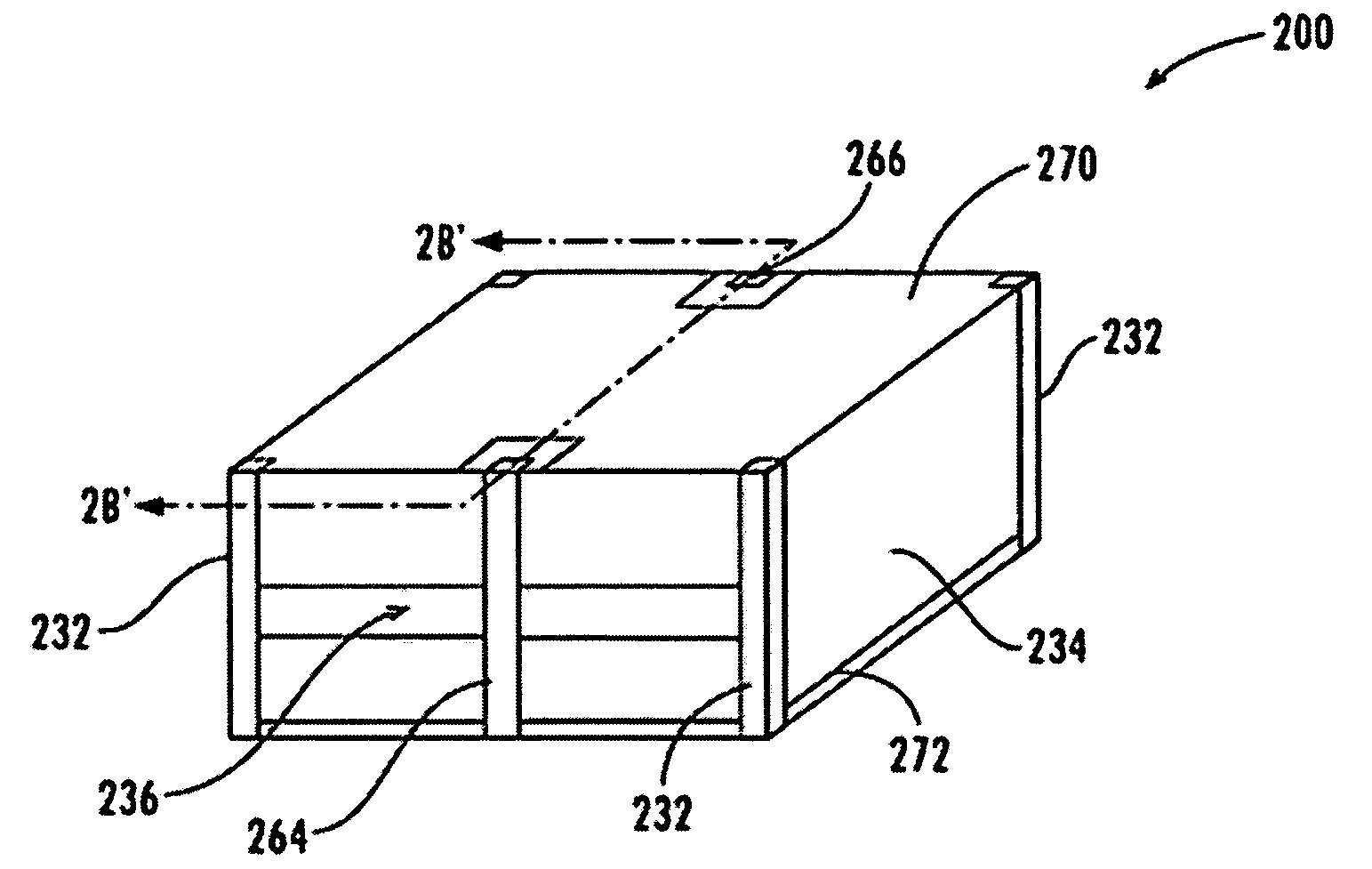

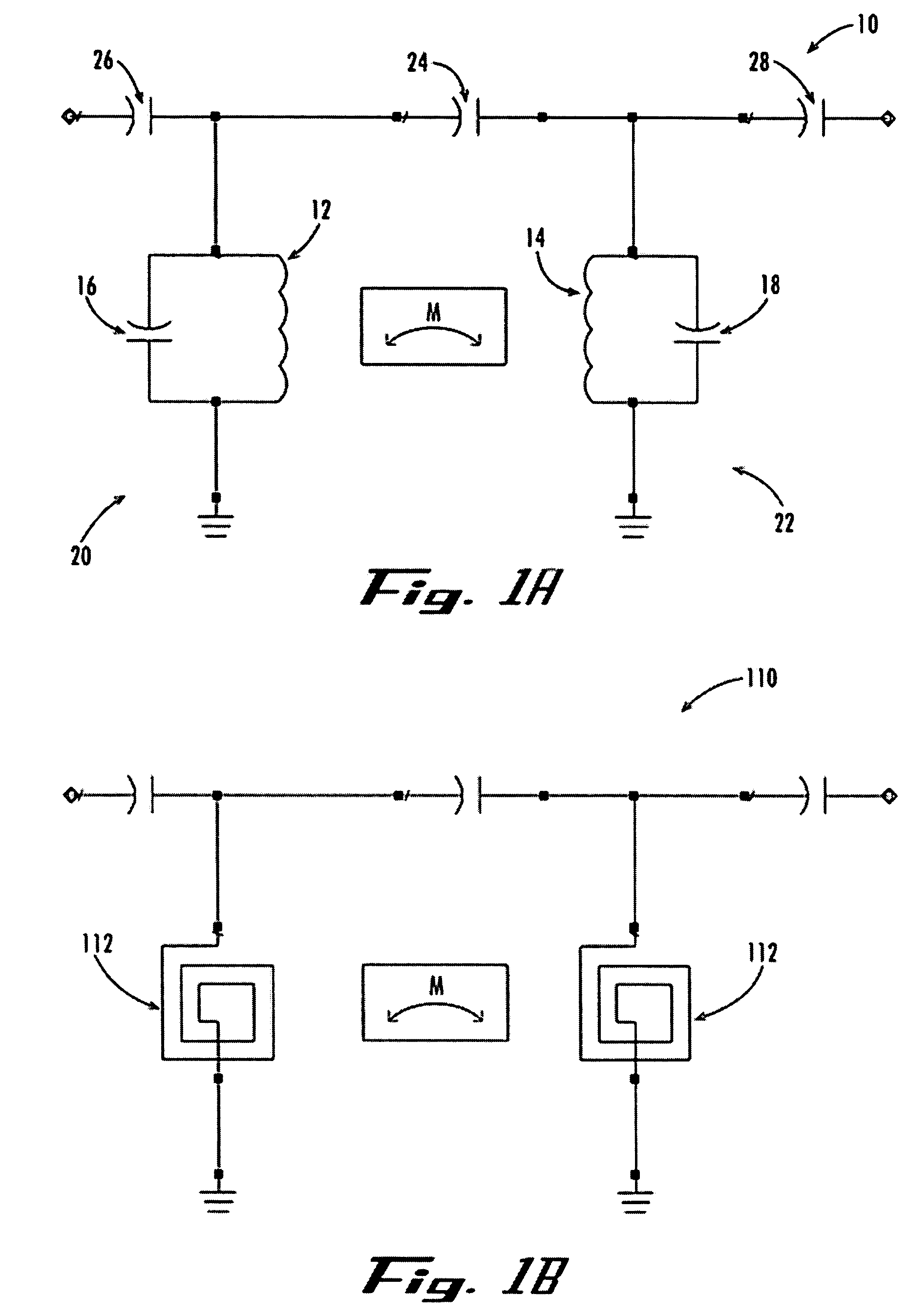

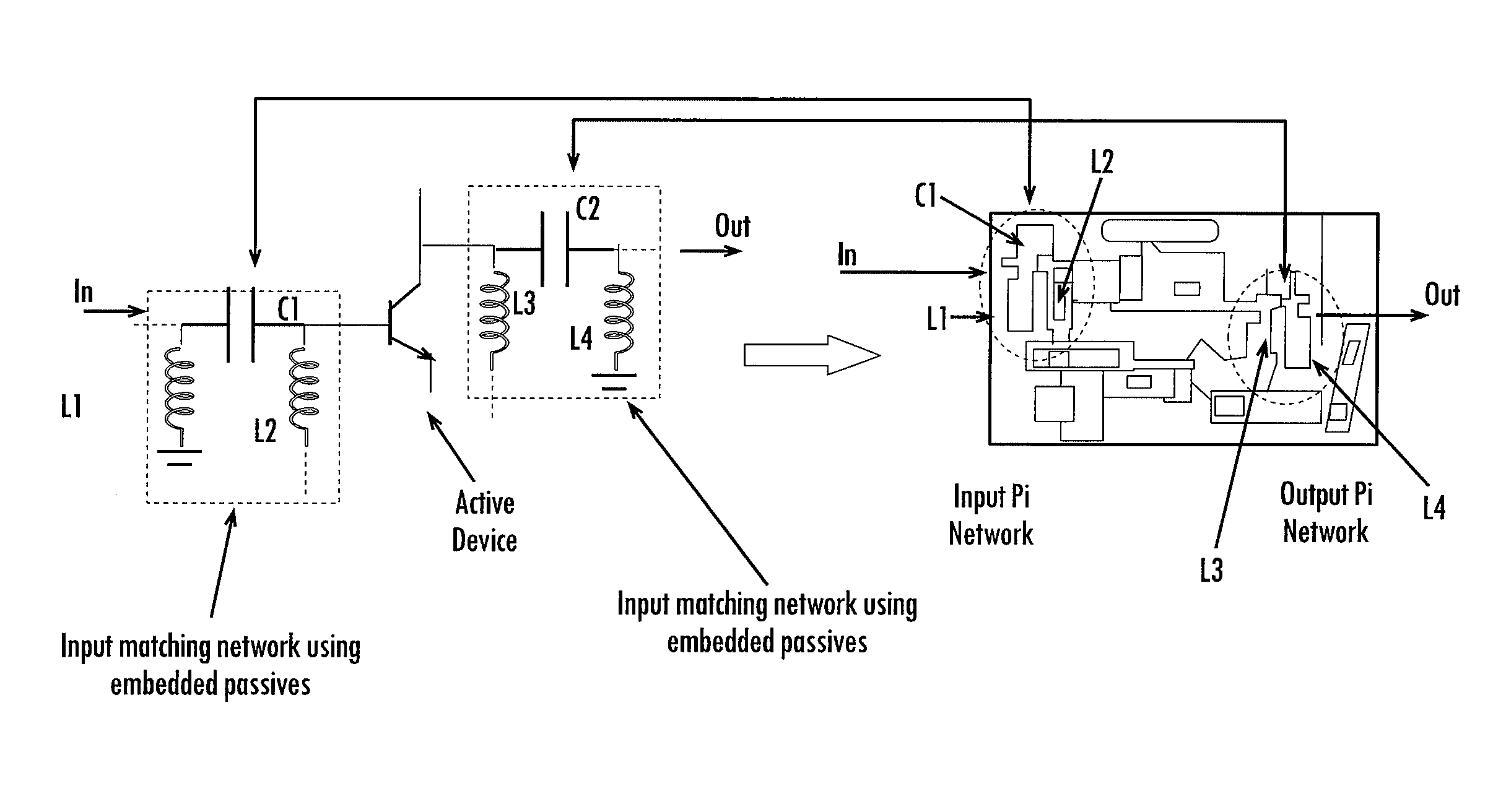

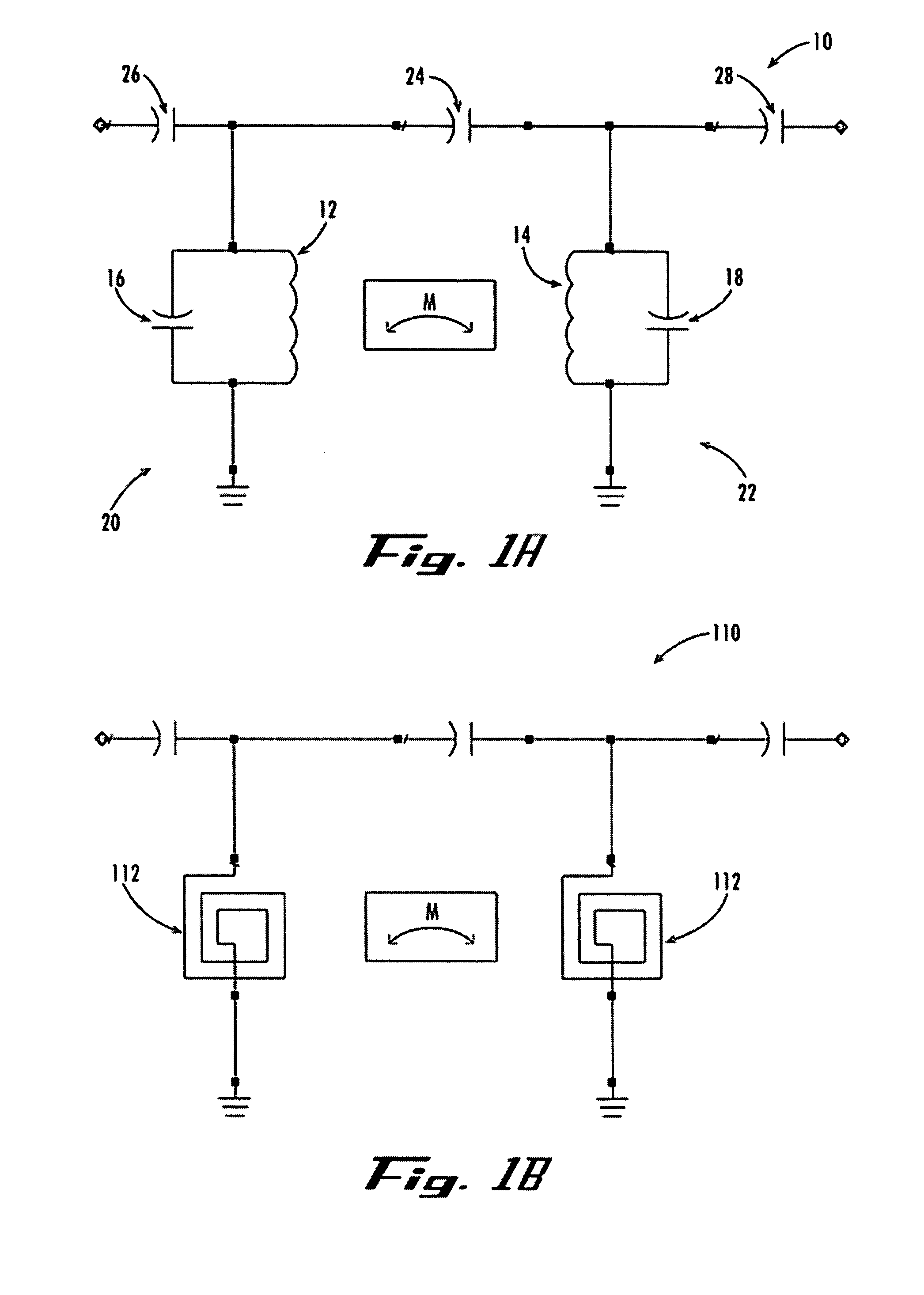

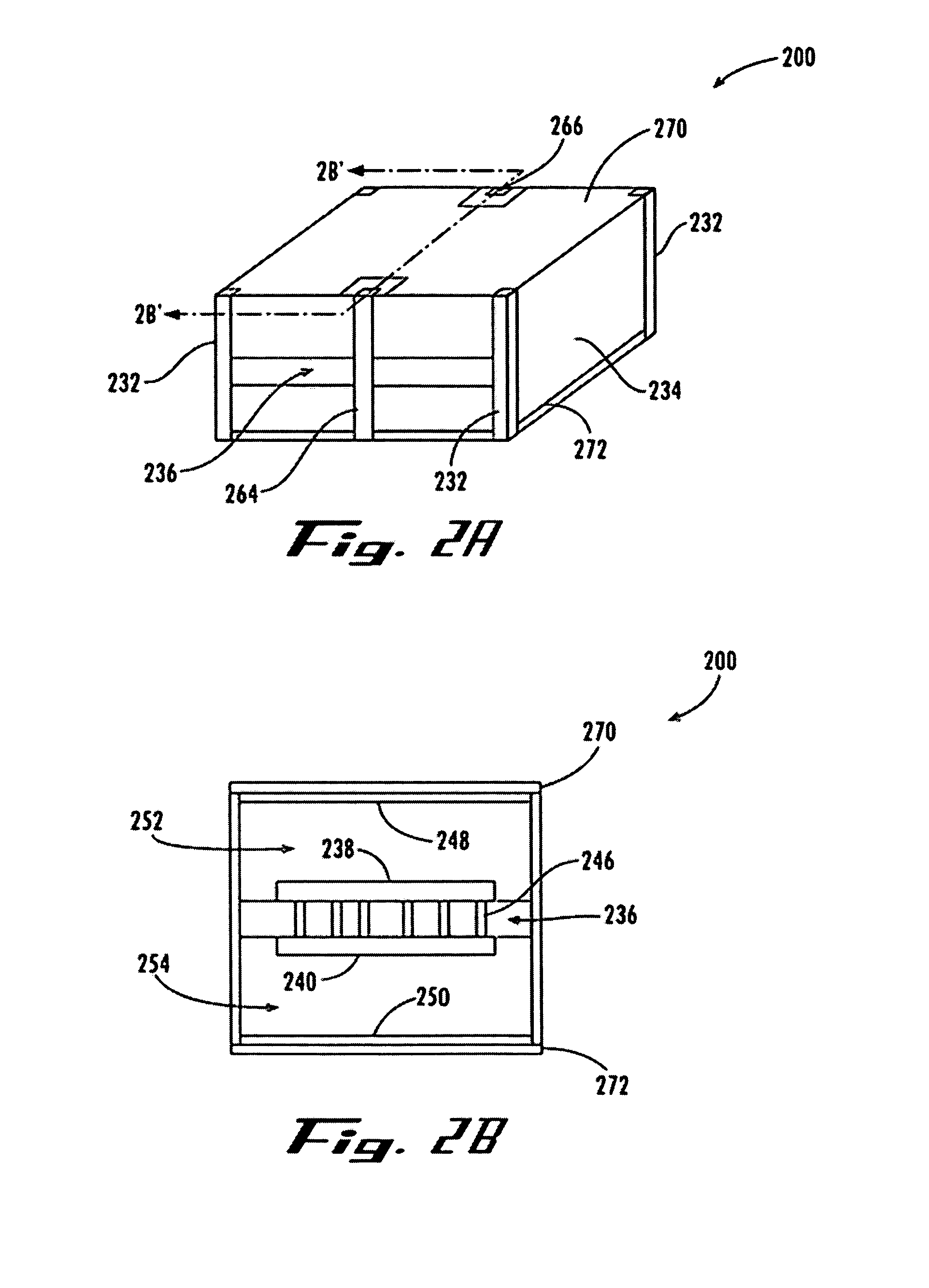

Multi-band RF transceiver with passive reuse in organic substrates

ActiveUS20050248418A1Reduce in quantityReduce phase noiseMultiple-port networksSemiconductor/solid-state device detailsMulti bandLow noise

The present invention allows for the use of chip-package co-design of RF transceivers and their components by using discrete active devices in conjunction with passive components. Two particular components are described, including voltage controlled oscillators (VCOs) and low noise amplifiers (LNAs). The high quality passive components for use in the VCOs and LNAs may be obtained by the use of embedded passives in organic substrates. Further, the embedded passives may have multi-band characteristics, thereby allowing multi-band VCOs and LNAs to be implemented with fewer components. In situations where size is a concern, the active devices and passive components utilized in an RF transceiver may be implemented in a low form factor module of less than 1.1 mm thick according to an embodiment of the invention.

Owner:GEORGIA TECH RES CORP

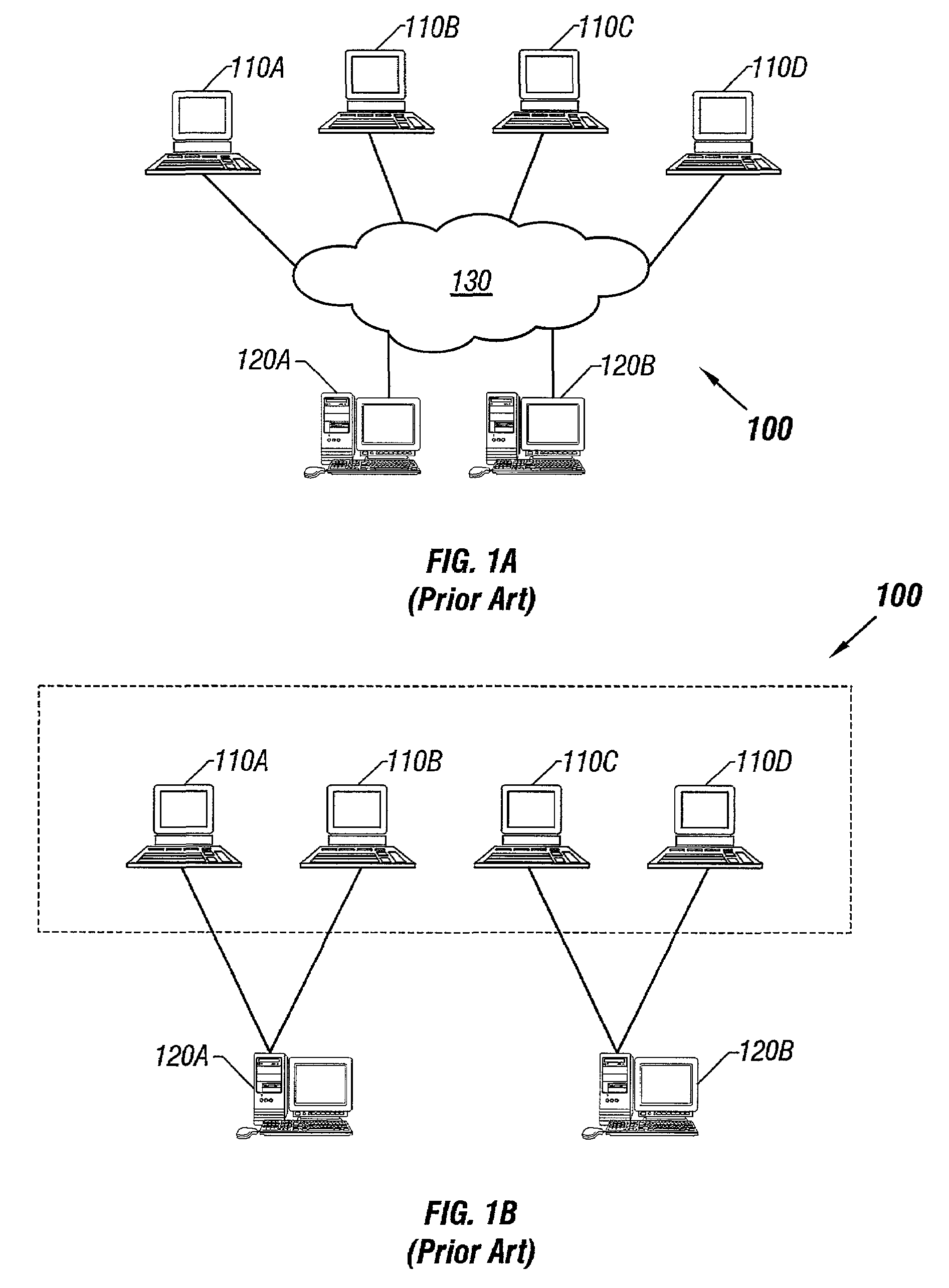

Collaborative design

InactiveUS7176942B2Improve productivityLess timeData processing applicationsDigital computer detailsApplication lifecycle managementWorkstation

A method, system and apparatus for use in computer-aided design, computer-aided manufacturing, computer-aided engineering and product lifecycle management. An efficient, non-centralized communications framework makes “synchronous” collaborative design possible. Users are resident at workstations that are connected in a peer-to-peer arrangement. In a collaborative design session, the model is resident in memory at each workstation. Modifications are made at any workstation, and commands, which are interpreted at each workstation to effect the modifications, are transmitted over the network. In addition, cell descriptors may be used to identify one or more geometric cells of a model. The cell descriptors are in the form of scripts specifying constraints or filters for identifying cells. The constraints are based on characteristics of items in the model, or associations between items in a model, that are readily discernable to the user, and are therefore easily written and susceptible to easy distribution to other systems.

Owner:DASSAULT SYSTEMES

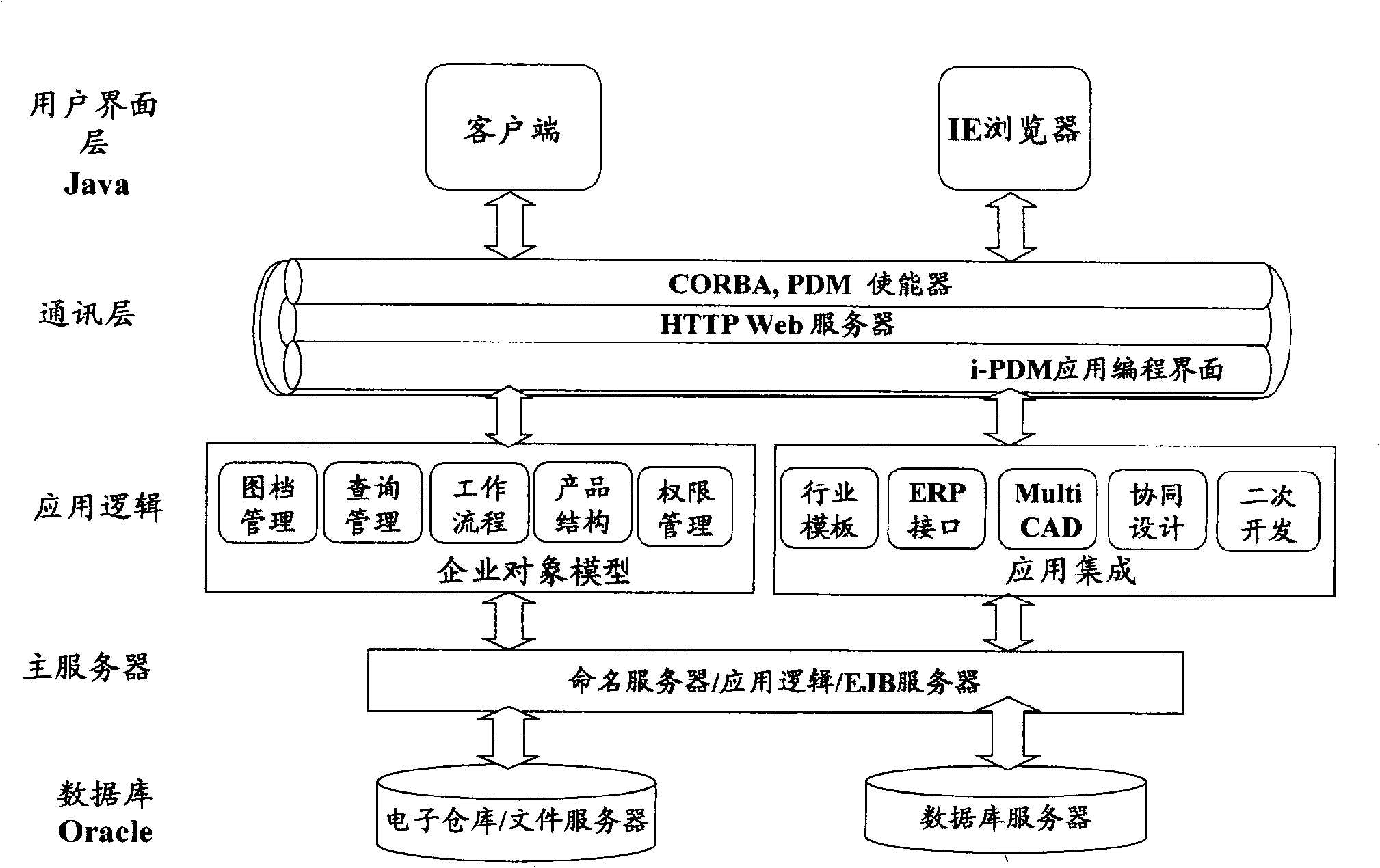

Data management system for vehicle products and collaborative design method thereof

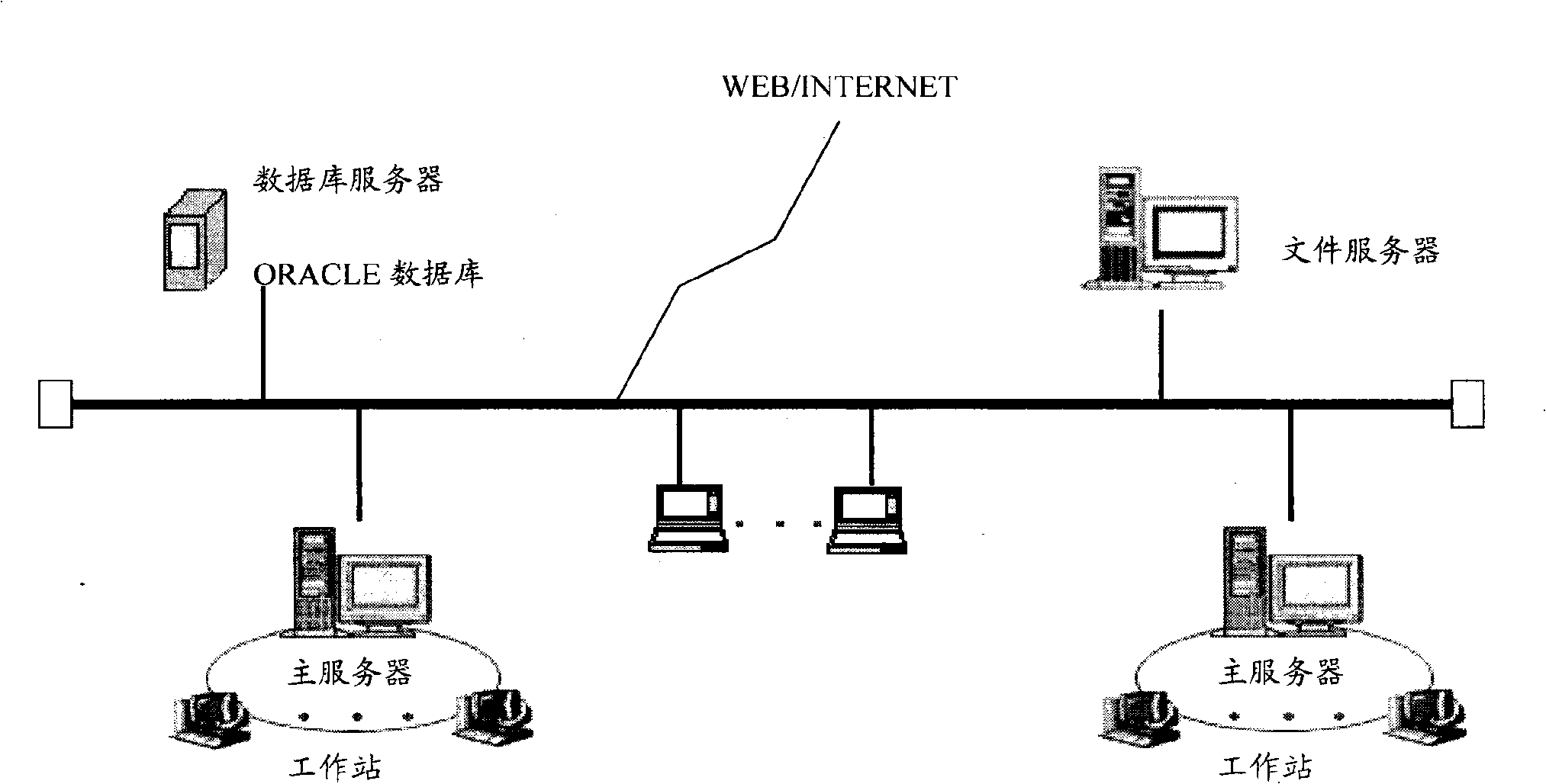

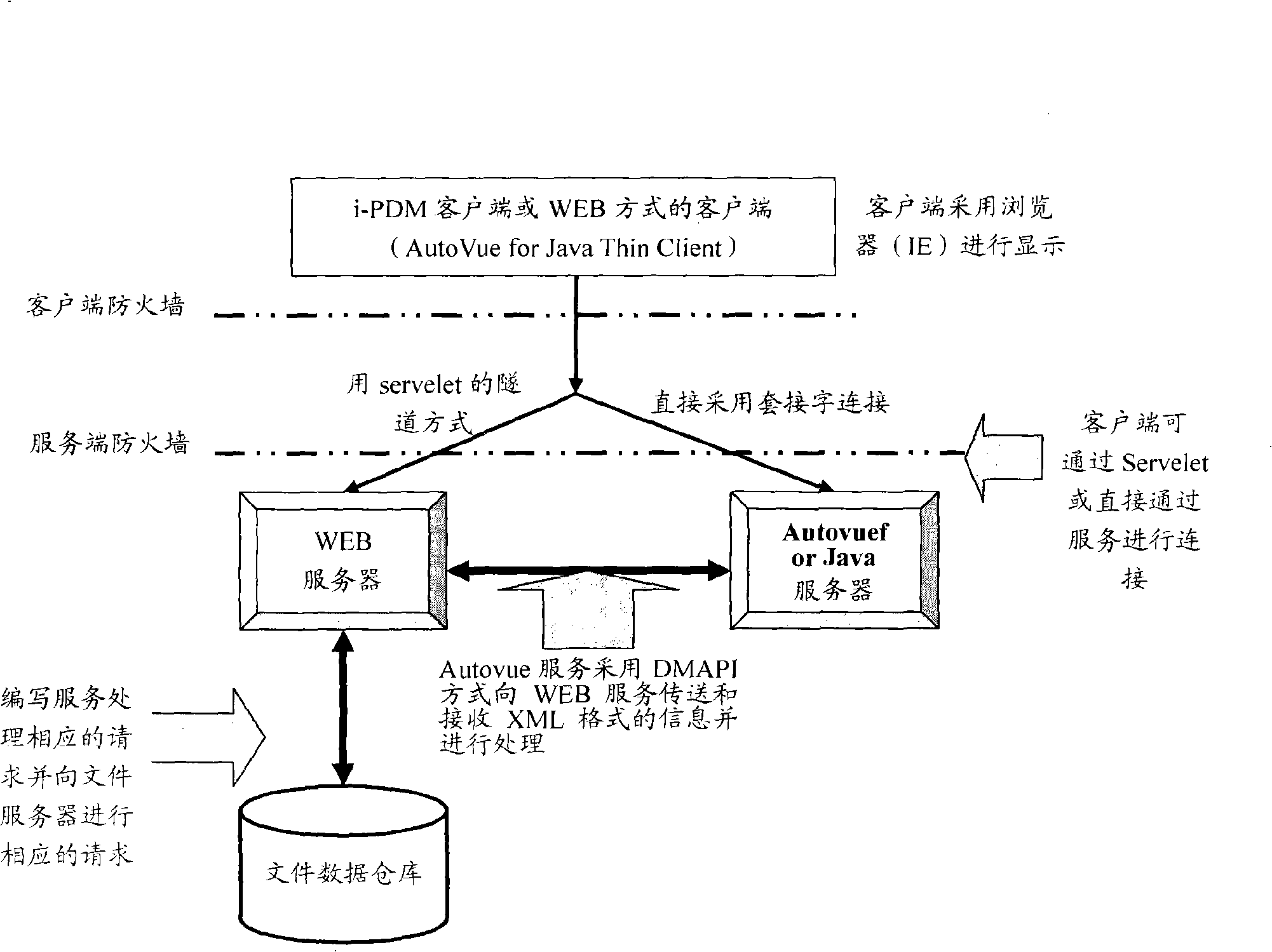

InactiveCN101515308AShorten the development cycleImprove design qualityAerodynamics improvementSpecial data processing applicationsData synchronizationData query

The invention relates to a data management system for vehicle products and a method thereof, wherein the system comprises a user interface layer, a communication layer, an application logic layer, a main sever layer and a database layer, the use interface layer is connected with the database layer through the communication layer, the application layer and the main sever layer in sequence. The method comprises a graph document management and processing operation, a vehicle production structure management operation, a right management operation and a data query processing operation. By using the data management system for vehicle products and the collaborative design method thereof, the collaborative design of the vehicle development process is jointly achieved, and the real-time collaboration in the CAD environment and data sync update of associated parts are creatively achieved to effectively reduce the development period of the vehicle styles, and increase design quality, therefore the development period of the vehicle styles is reduced by about 20%, and the design alteration is reduced by over 30%, then, the system has simple and practical structure, fast and convenient usage process, high-efficient development design, stable and reliable working performance, and wider applicable range.

Owner:TJI INNOVA ENG & TECH

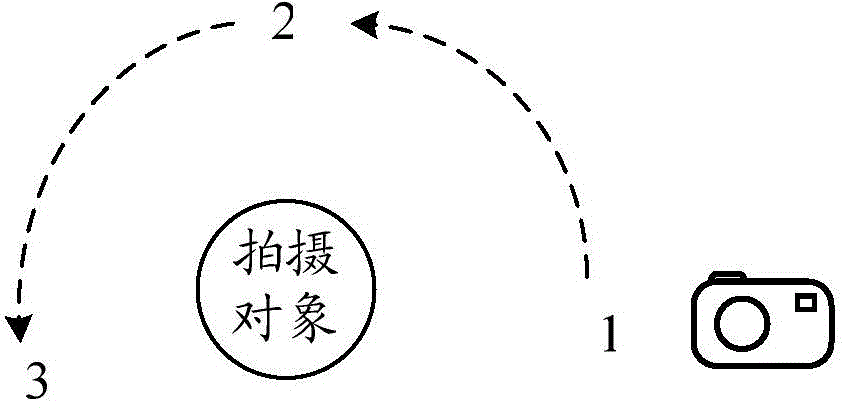

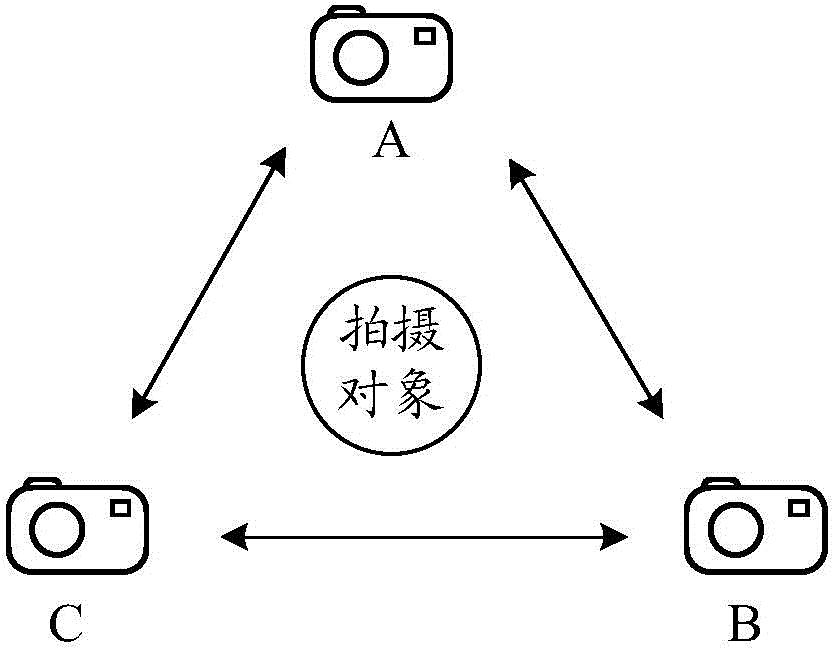

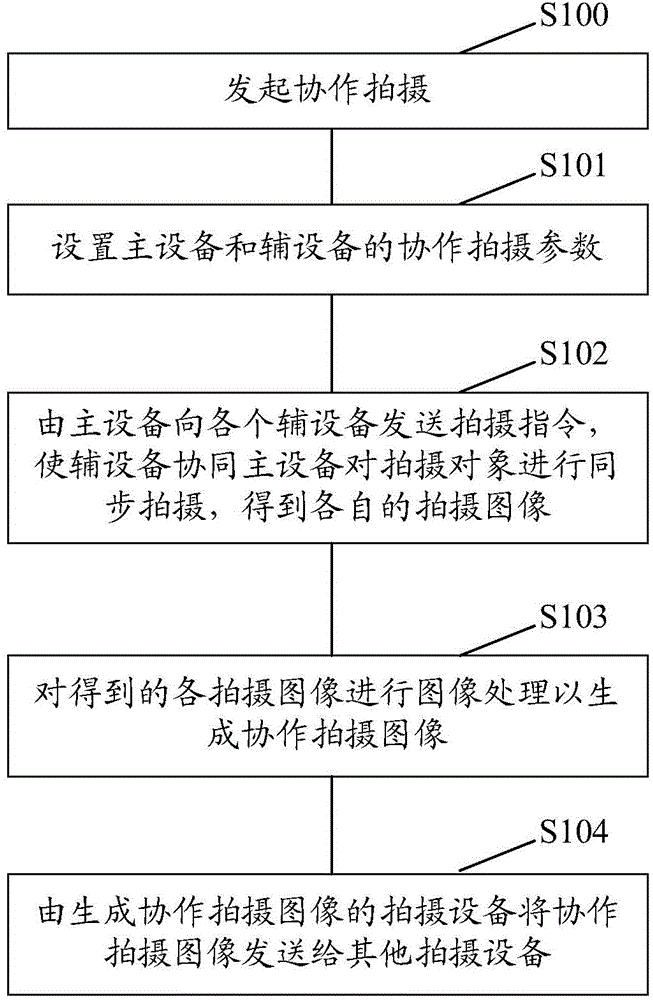

Collaborative shooting system and shooting method thereof

ActiveCN104427228ALow costEasy to operateTelevision system detailsColor television detailsCommunication unitImaging processing

The invention discloses a collaborative shooting system and a shooting method thereof. The shooting system comprises two or more pieces of shooting equipment suitable for performing collaborative shooting. The shooting equipment comprises a control processing unit, a communication unit and a shooting unit. The shooting method of the shooting system comprises the following steps: using any shooting equipment initiating a collaborative shooting request in the collaborative shooting system as main equipment, and using other shooting equipment making responses to the collaborative shooting request as auxiliary equipment; sending a shooting command to each auxiliary equipment by the main equipment in order that the auxiliary equipment collaboratively performs synchronous shooting on a shooting object with the main equipment to obtain respective shot images; and performing image processing on each obtained shot image to generate a collaborative shot image. Through adoption of the technical scheme of the invention, the problem of difficulty in well completing the complicated shooting functions of high-accuracy shooting, three-dimensional shooting, panorama shooting and like due to the adoption of a low-configuration image processing chip in current shooting equipment can be solved. Moreover, the collaborative shooting system and the shooting method thereof are easy to implement, and are low in implementation cost.

Owner:SPREADTRUM COMM (SHANGHAI) CO LTD

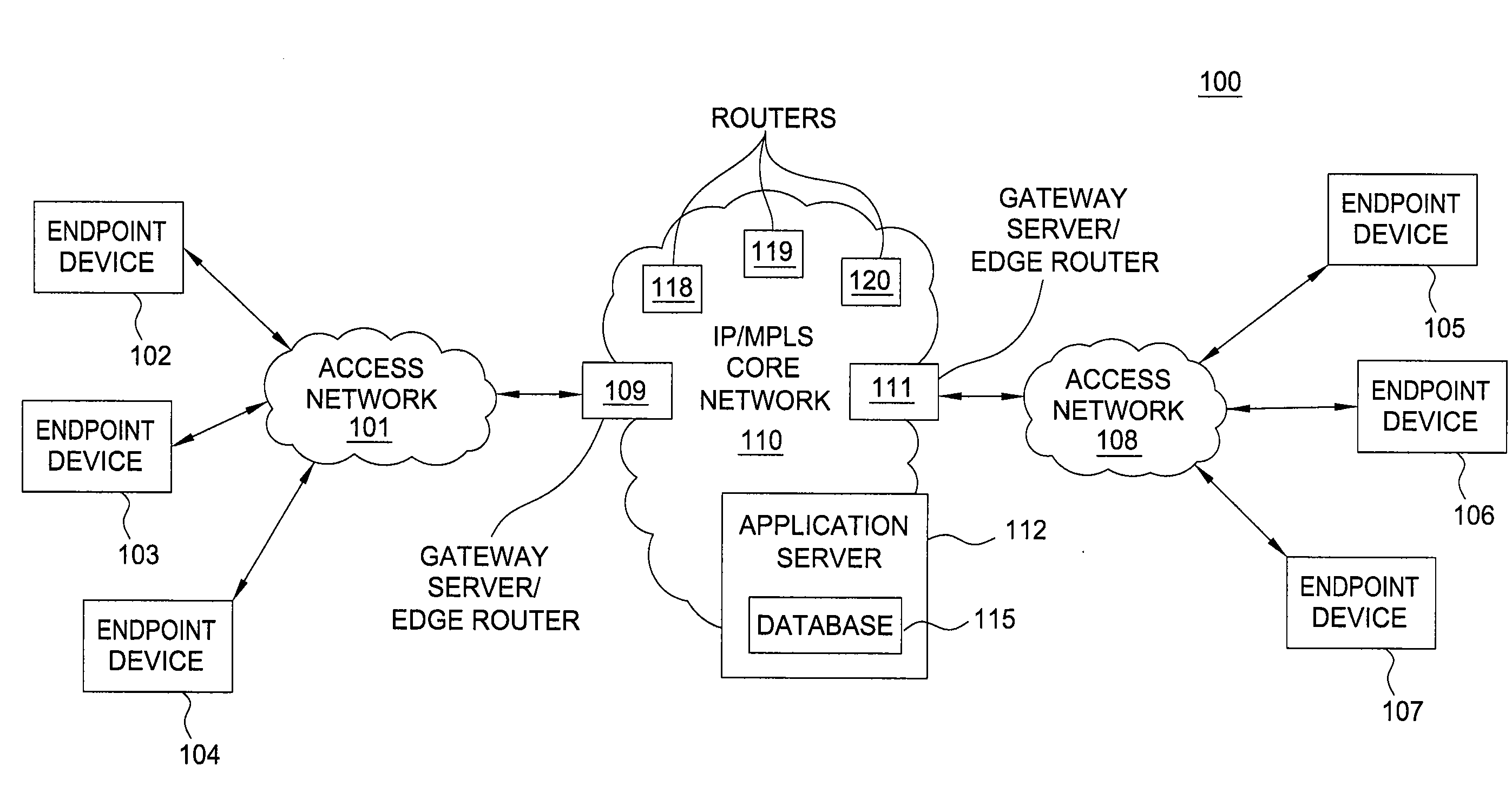

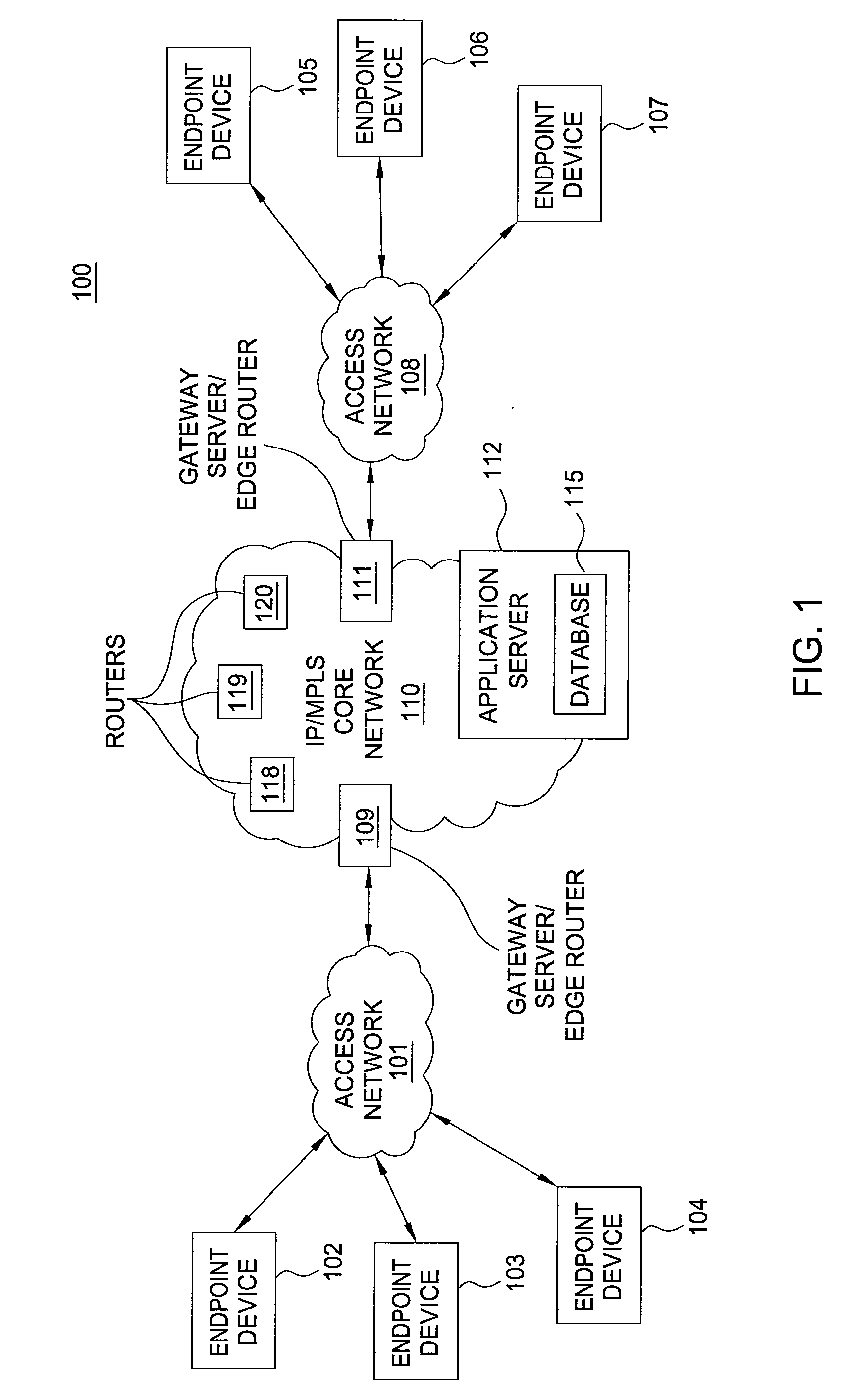

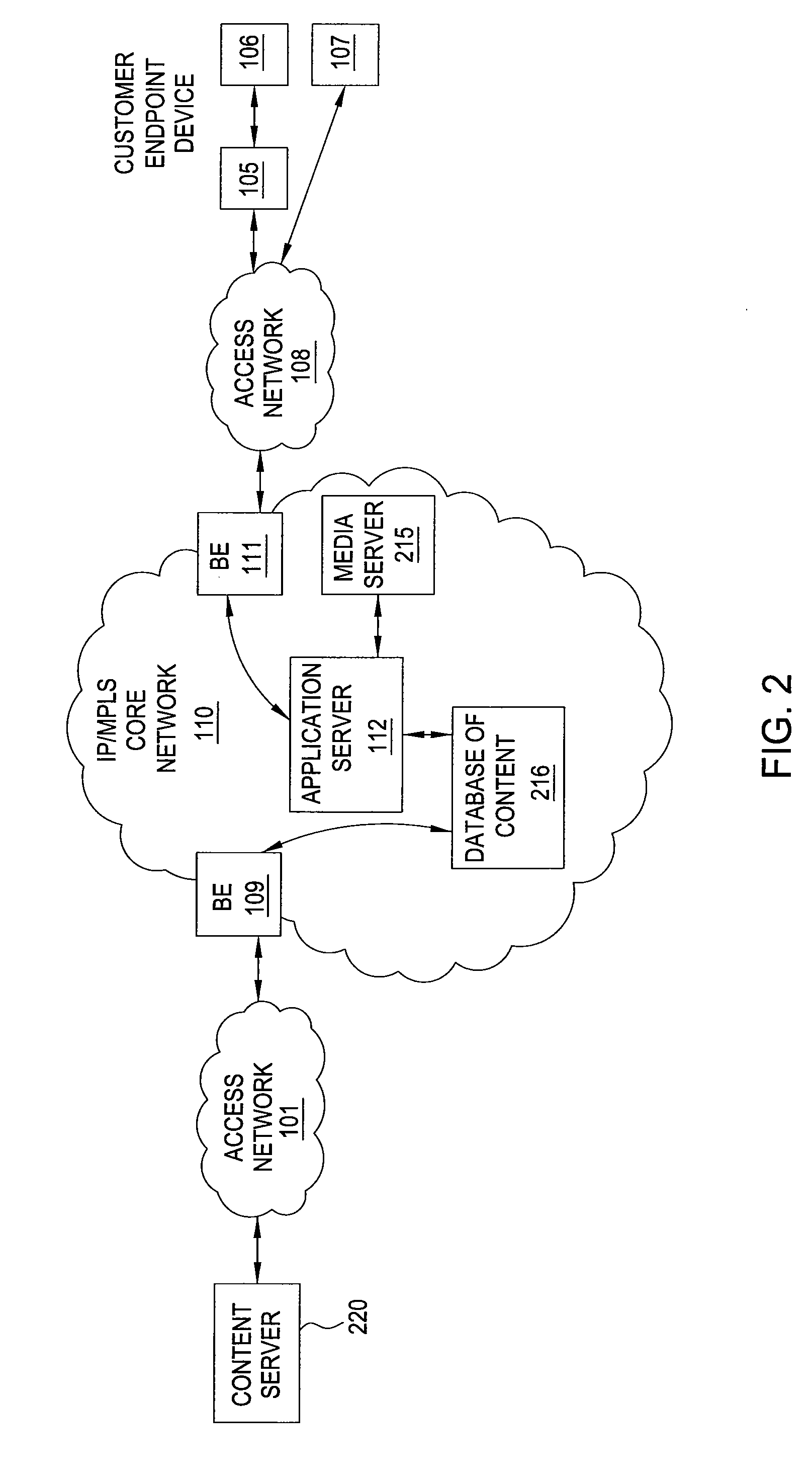

Method and apparatus for providing collaborative viewing of a media stream

InactiveUS20090183220A1Two-way working systemsSelective content distributionCollaborative designAnnotation

A method and apparatus for providing collaborative viewing of a media stream are disclosed. For example, the method establishes a viewing group having a plurality of members, and provides at least one media stream that is accessible by the plurality of members of the viewing group. The method then receives one or more annotations from at least one of the plurality of members of the viewing group relating to the at least one media stream, and saves each of the one or more annotations with a temporal marker. The method then provides the one or more annotations to at least one of the plurality of members of the viewing group.

Owner:AT&T INTPROP I L P

Multi-band RF transceiver with passive reuse in organic substrates

ActiveUS7489914B2Reduce in quantityReduce phase noiseMultiple-port networksSemiconductor/solid-state device detailsMulti bandLow noise

The present invention allows for the use of chip-package co-design of RF transceivers and their components by using discrete active devices in conjunction with passive components. Two particular components are described, including voltage controlled oscillators (VCOs) and low noise amplifiers (LNAs). The high quality passive components for use in the VCOs and LNAs may be obtained by the use of embedded passives in organic substrates. Further, the embedded passives may have multi-band characteristics, thereby allowing multi-band VCOs and LNAs to be implemented with fewer components. In situations where size is a concern, the active devices and passive components utilized in an RF transceiver may be implemented in a low form factor module of less than 1.1 mm thick according to an embodiment of the invention.

Owner:GEORGIA TECH RES CORP

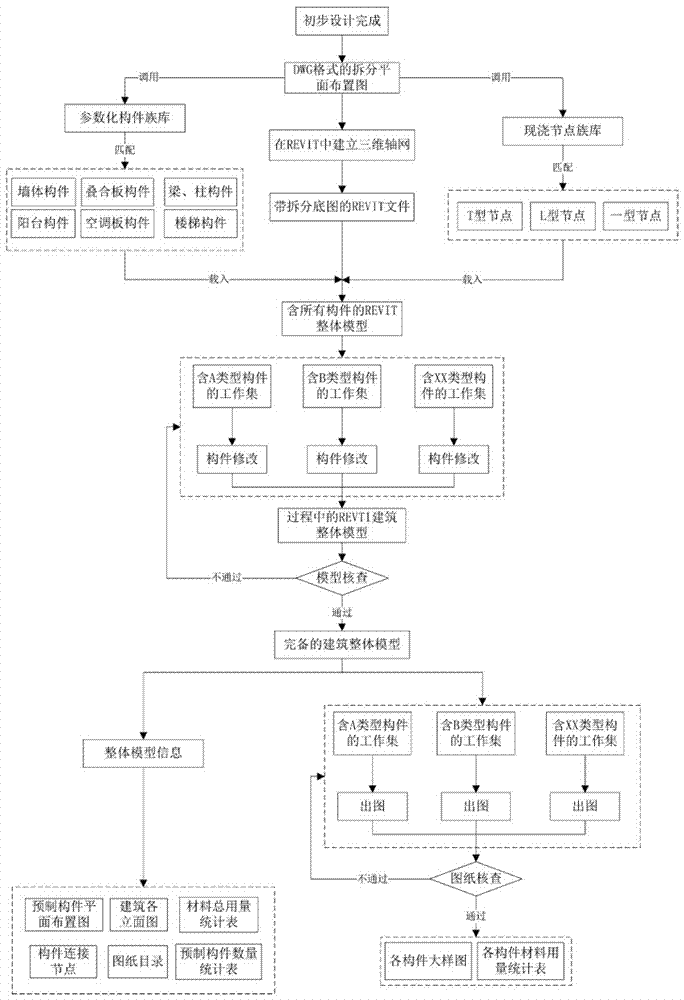

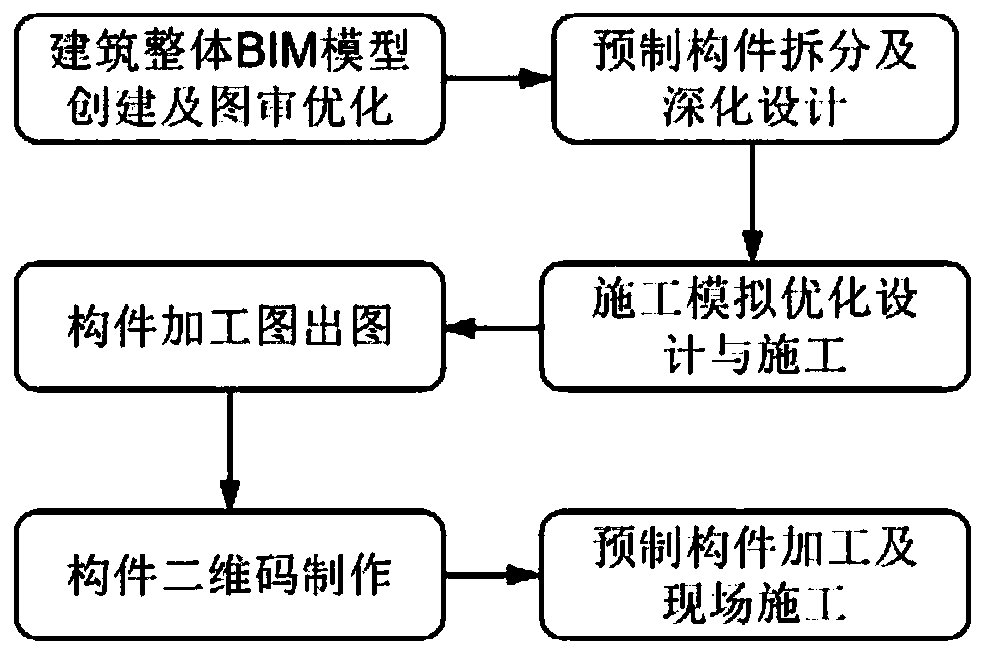

Assembled type concrete structure three-dimensional collaborative design method

ActiveCN107391862ARealize visualizationShortened modelingGeometric CADSpecial data processing applicationsDimensional modelingEntity model

The invention discloses an assembled type concrete structure three-dimensional collaborative design method. The assembled type concrete structure three-dimensional collaborative design method comprises the steps of completing assembled type building splitting design according to drawing data, preparing a Revit item center file, establishing parameter models of a prefabricated member and a cast-in-situ node, loading the parameter member and the cast-in-situ node into a Revit item center file to form an overall model, revising members of all types, completing model overall information input and single member plotting and the like. Based on a Revit platform, by establishing a visualized three-dimensional entity model, then design, revising and plotting are conducted through a synergetic mode. The assembled type concrete structure three-dimensional collaborative design method has the following advantages that regardless of a two-dimensional abstract drawing mode, visualized three-dimensional modeling is achieved; the same model jointly represents all profession information, professional interaction is achieved, and repetitive adjusting and revising is avoided; modeling and plotting time of members of the same type is shortened, the efficiency is improved, the quality is unified, and management is facilitated.

Owner:CHINA CONSTR FIRST DIV GROUP CONSTR & DEV

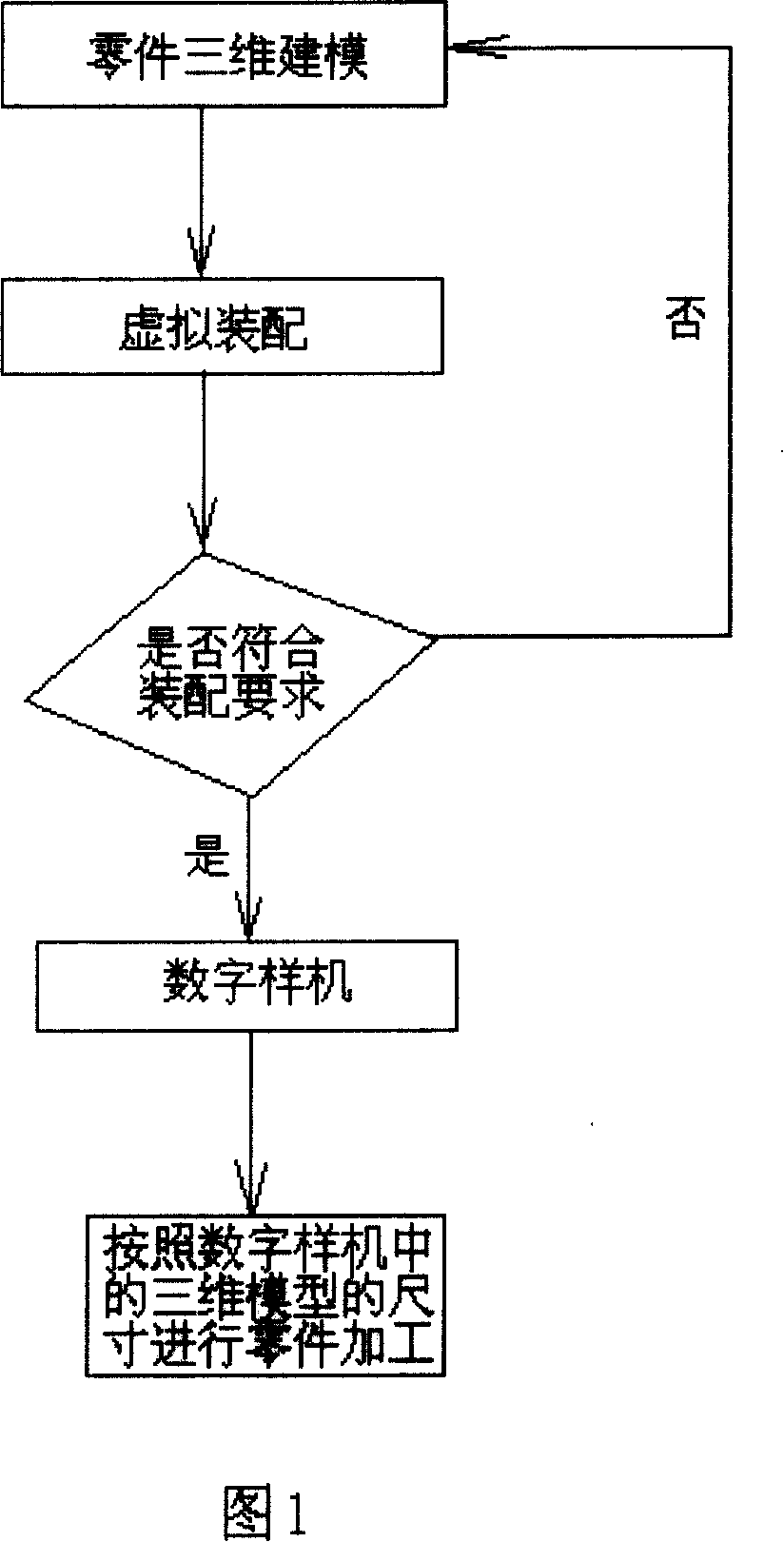

Digitization mechanical design method

InactiveCN101082993AReduce changesCorrectly designedSpecial data processing applications3D modellingEngineeringDimensional modeling

The invention discloses a precise-design high-efficiency designing method of digital machine, which is characterized by the following: finishing three-dimensional modeling of element based on superior CAD software platform; forming digital prototype through virtual assemblage; realizing structure optimizing design of combined harvester with longitudinal axial flow through analyzing and optimizing the property of digital prototype; manufacturing the element according to optimized three-dimensional model of digital prototype; proceeding virtual test and preparation of product under digital condition; realizing precise design; reducing the modification of project greatly; saving large quantity of working model and preparing time.

Owner:CHINESE ACAD OF AGRI MECHANIZATION SCI

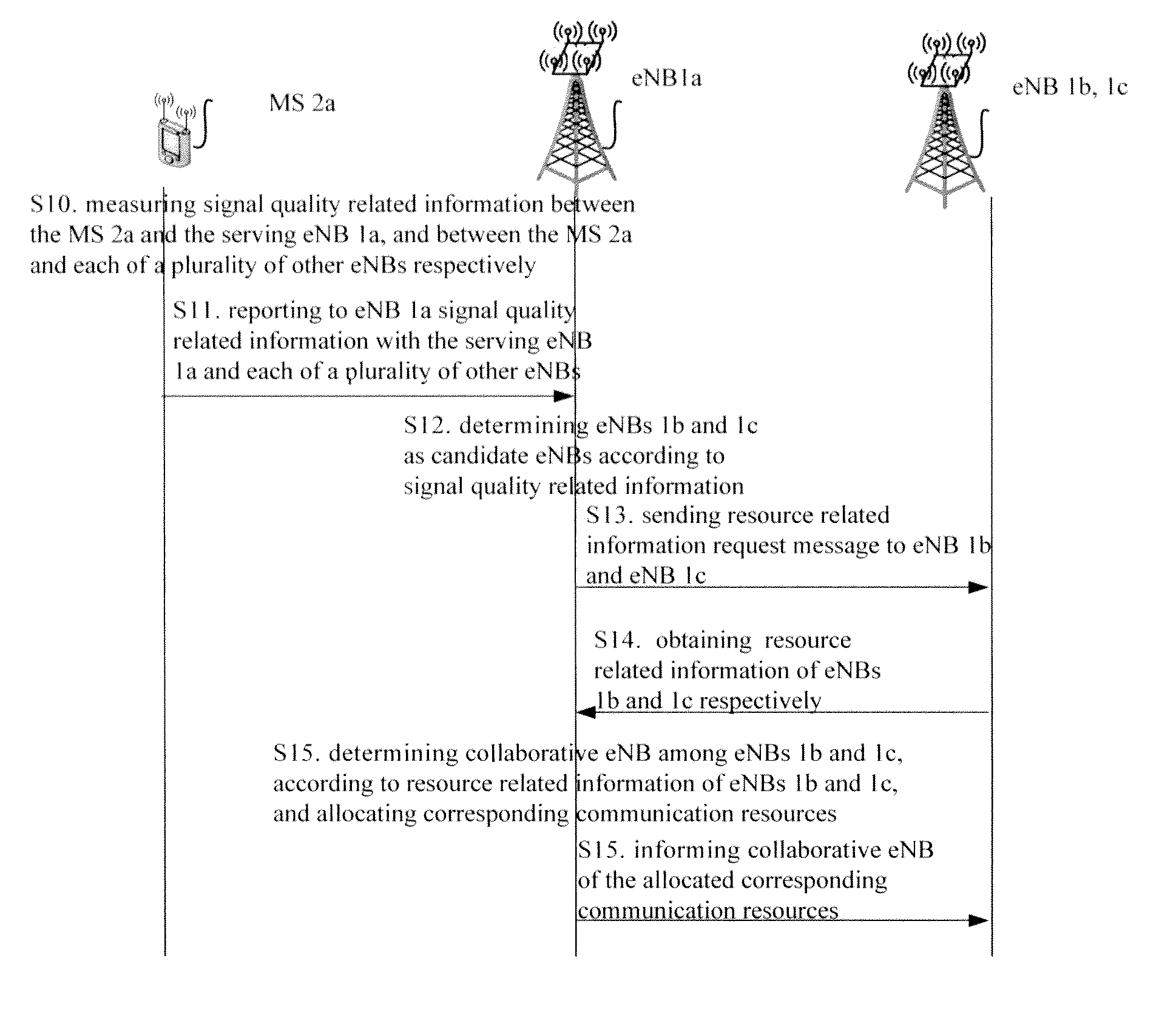

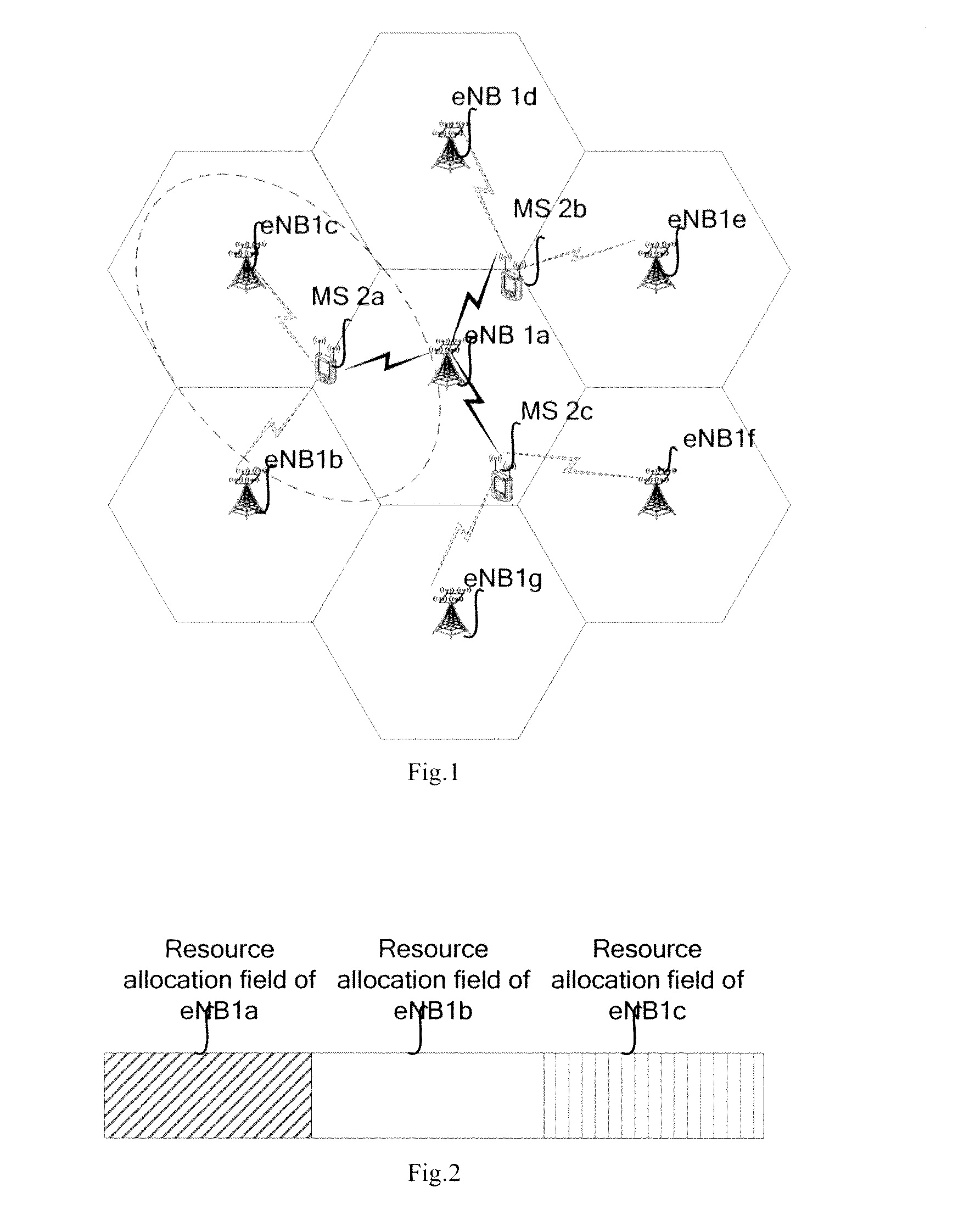

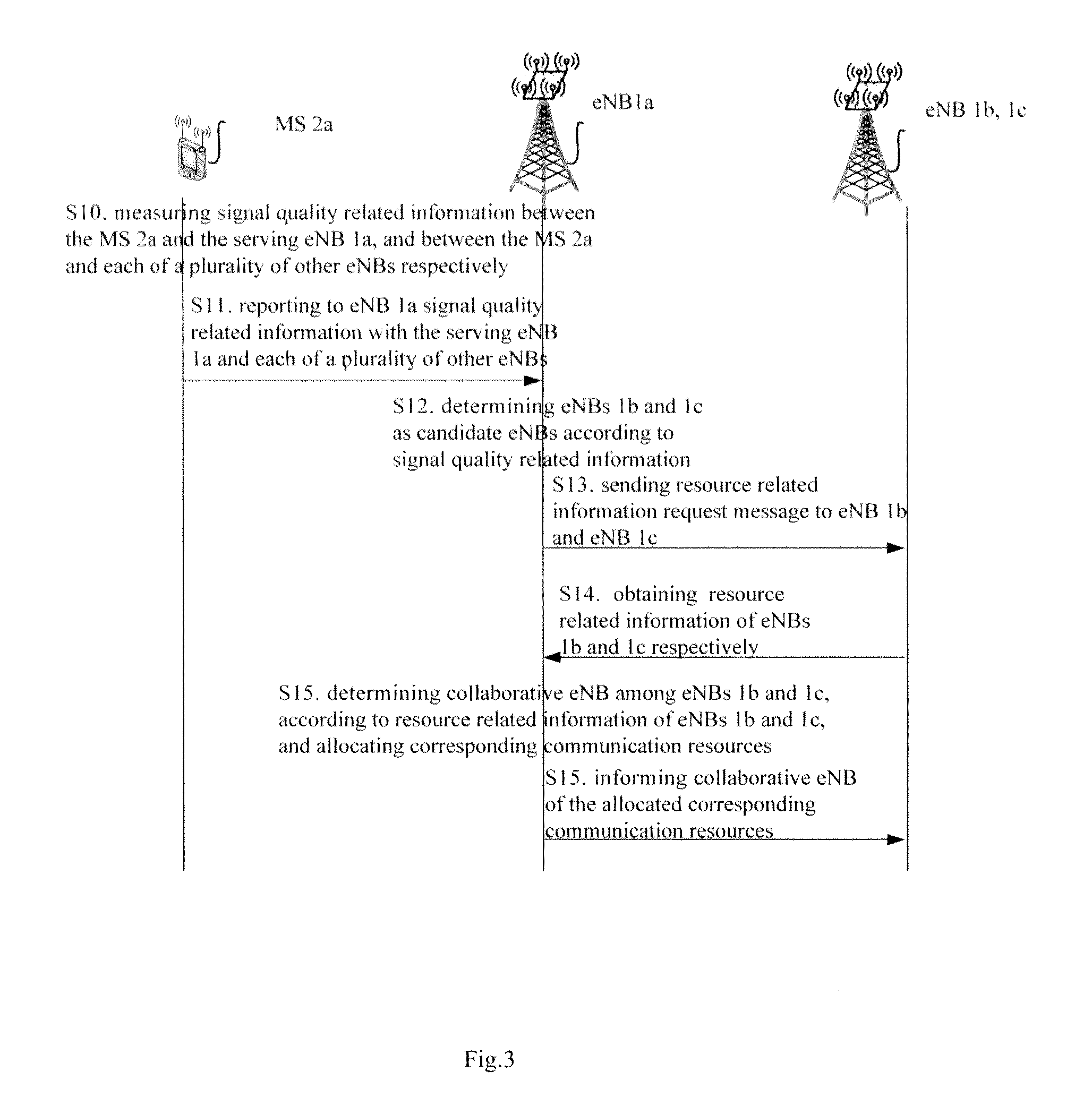

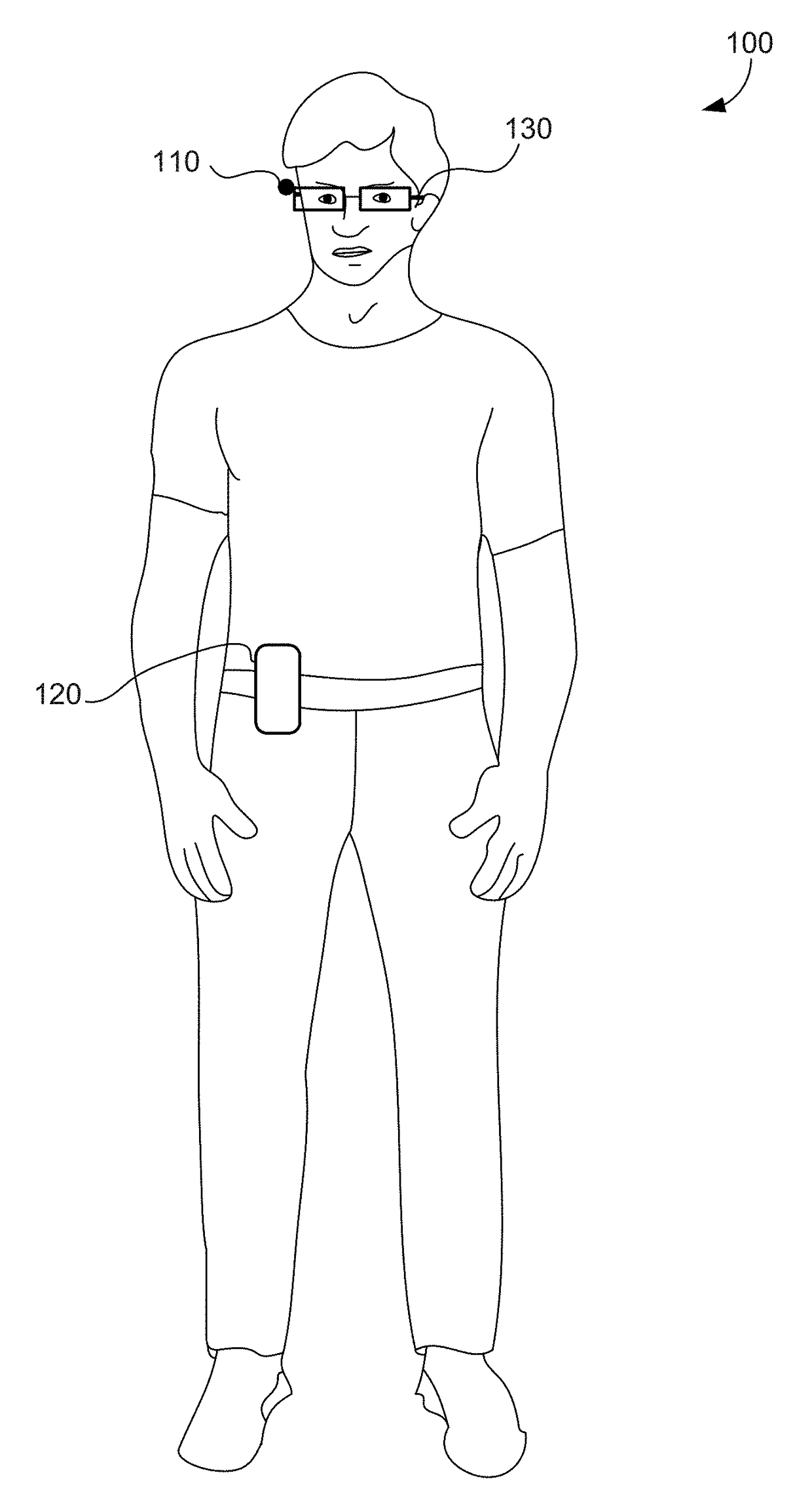

Method and device for allocating same resource for a plurality of enbs of collaborative MIMO

ActiveUS20120088535A1Reduce waste of resourcesIncrease success rateSite diversityOrthogonal multiplexMobile stationMultiple input

The present invention provides a method and device for allocating same resource for a plurality of eNBs of collaborative Multiple-input-Multiple-output (MIMO). Wherein a serving eNB firstly determines, in the one or more other eNBs, at least one candidate eNB recommended to cooperate with the serving eNB, according to measurement report reported by mobile stations or according to report information of the recommended candidate eNB reported by mobile station, then obtains resource related information of the at least one candidate eNB, then determines one or more collaborative eNBs from the at least one candidate eNB according to the resource related information, and allocates corresponding communication resources for the serving eNB and the one or more collaborative eNBs. The solution according to the present does not need to reserve special resource for collaborative MIMO, reduces waste of resource, and meets the requirement of resource for implementing collaborative MIMO by different serving eNBs flexibly, and increases the success rate of implementing collaborative MIMO.

Owner:ALCATEL LUCENT SAS

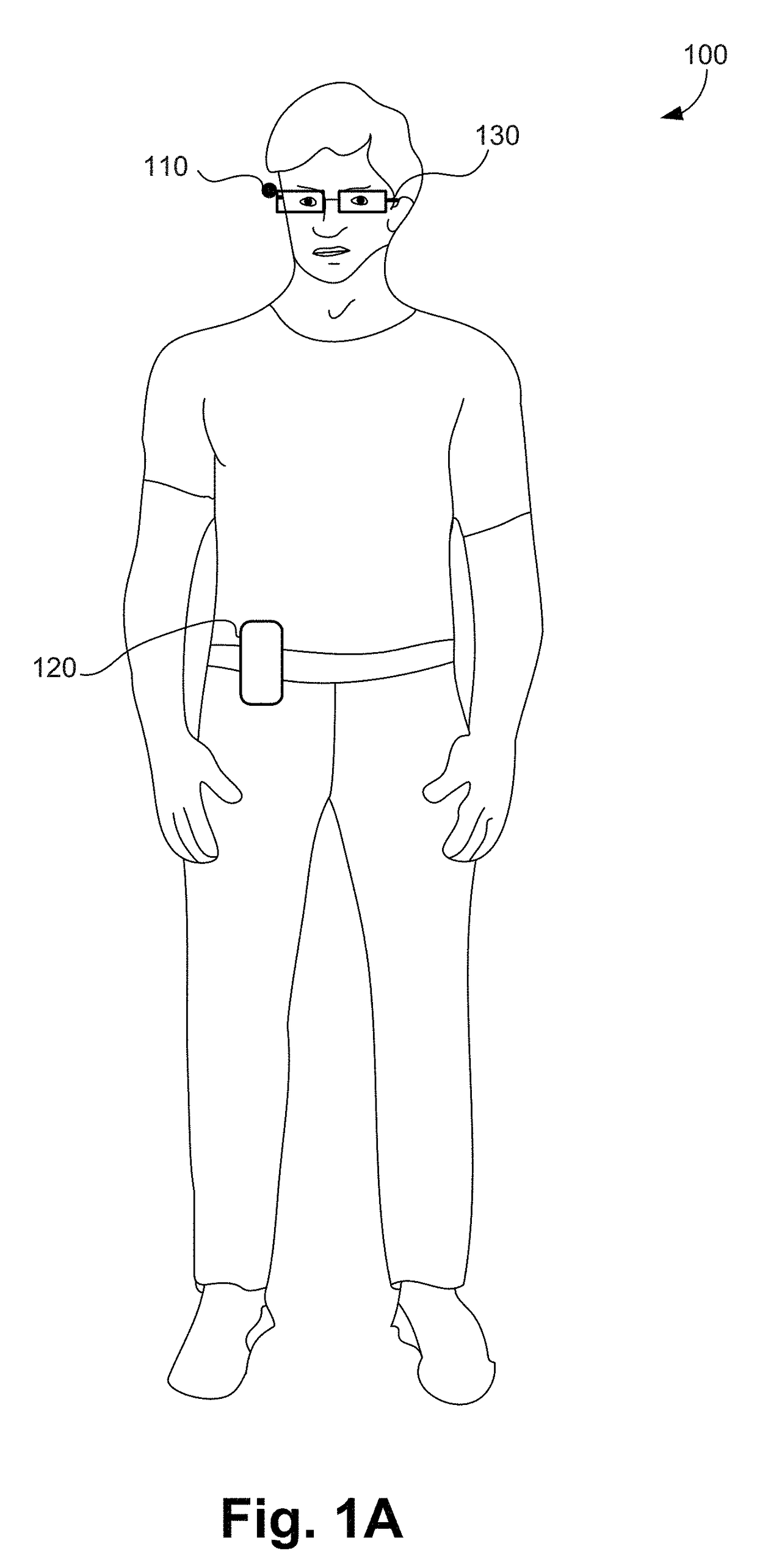

Collaboration facilitator for wearable devices

ActiveUS20170195629A1Promote collaborationTelevision conference systemsStill image data indexingTransceiverHuman–computer interaction

A wearable apparatus is provided for capturing and processing images from an environment of a user. In one implementation, a system for facilitating collaboration between individuals includes a transceiver and at least one processing device. The at least one processing device is programmed to obtain and analyze one or more images captured by an image sensor included in a wearable apparatus. The at least one processing device is further programmed to detect, by the analysis, a visual trigger in an environment of a wearer of the wearable apparatus. The visual trigger may be associated with a collaborative action to be taken. The at least one processing device may be further programmed to use the transceiver to transmit an indicator relating to the visual trigger associated with the collaborative action to be taken.

Owner:ORCAM TECH

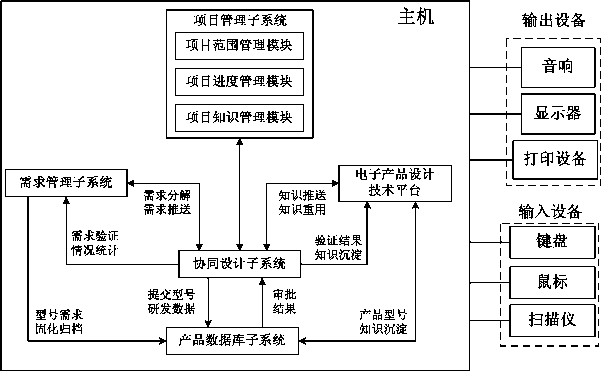

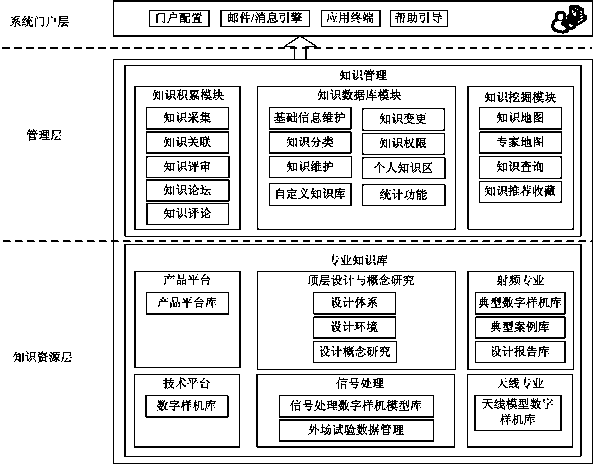

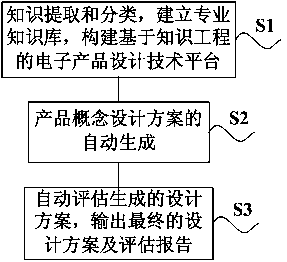

Knowledge-engineering-based automatic scheme generation and evaluation system and method

InactiveCN103646149AImprove reusabilityAchieve traceabilitySpecial data processing applicationsRequirements managementProject management

The invention discloses a knowledge-engineering-based automatic scheme generation and evaluation system. The automatic scheme generation and evaluation system comprises a project management subsystem, a demand management subsystem, a product database subsystem, a collaborative design subsystem and an electronic product design technology platform, wherein the project management subsystem is in charge of providing solving ideas and tools; the demand management subsystem is used for decomposing the product design demand, converting into task indicators and multi-level task sequences, realizing dependence mapping and providing real-time monitoring of the indicators; the product database subsystem is used for managing design data and setting data standards and regulations; the collaborative design subsystem plays the role of a bridge; the electronic product design technology platform is in charge of generalizing and managing typical data, design methods and digital prototype models of all products and pushing information to the collaborative design subsystem. A method comprises the steps of knowledge extraction and classification, professional knowledge base setting, knowledge-engineering-based platform construction and automatic design scheme generation and evaluation. According to the invention, knowledge engineering is introduced into the electronic product design, so that the reuse rate of knowledge and other resources is effectively improved, automatic generation and evaluation of product schemes are realized, the product research and development time is shortened and the intelligence degree is high.

Owner:SICHUAN UNIV +1

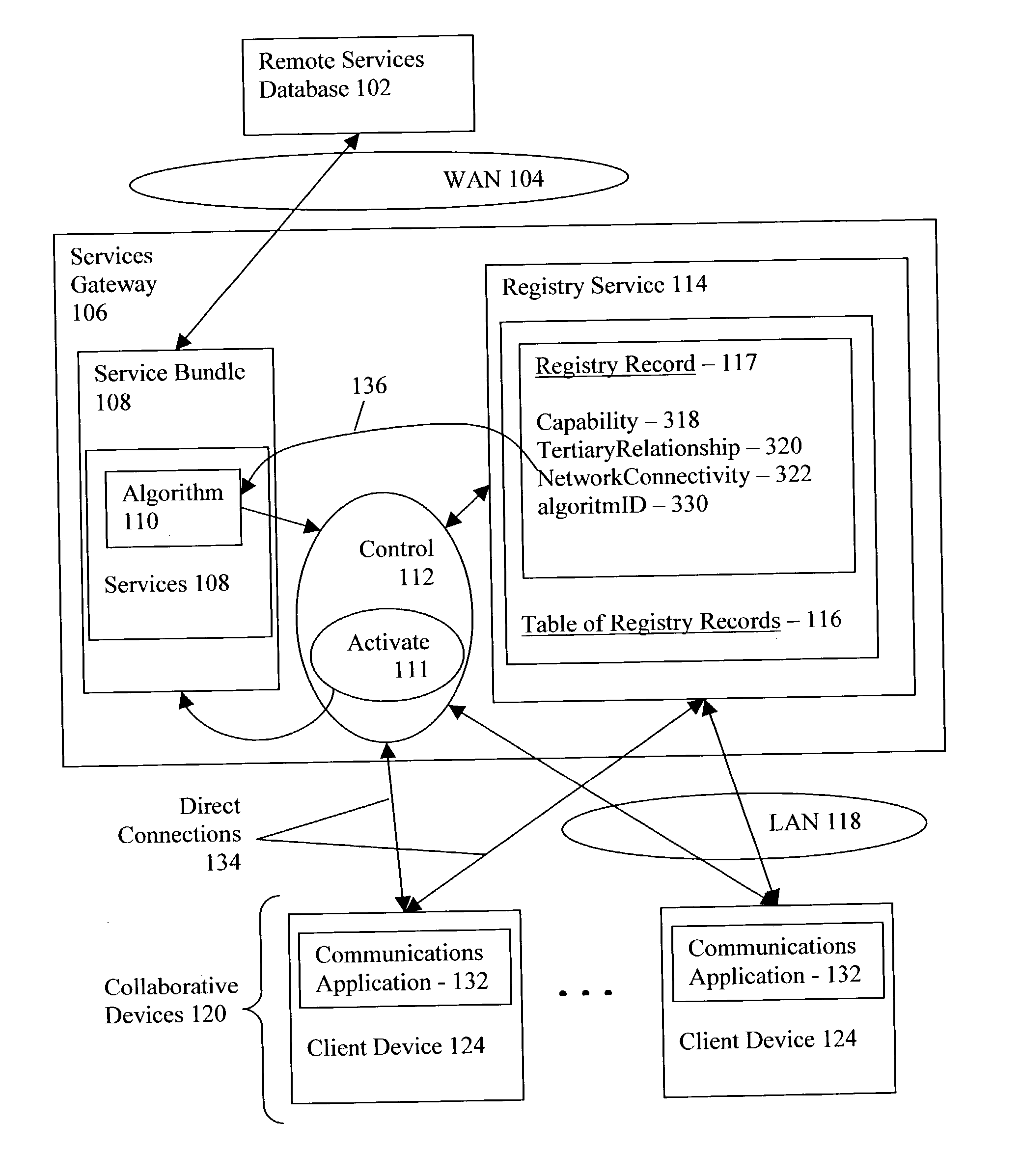

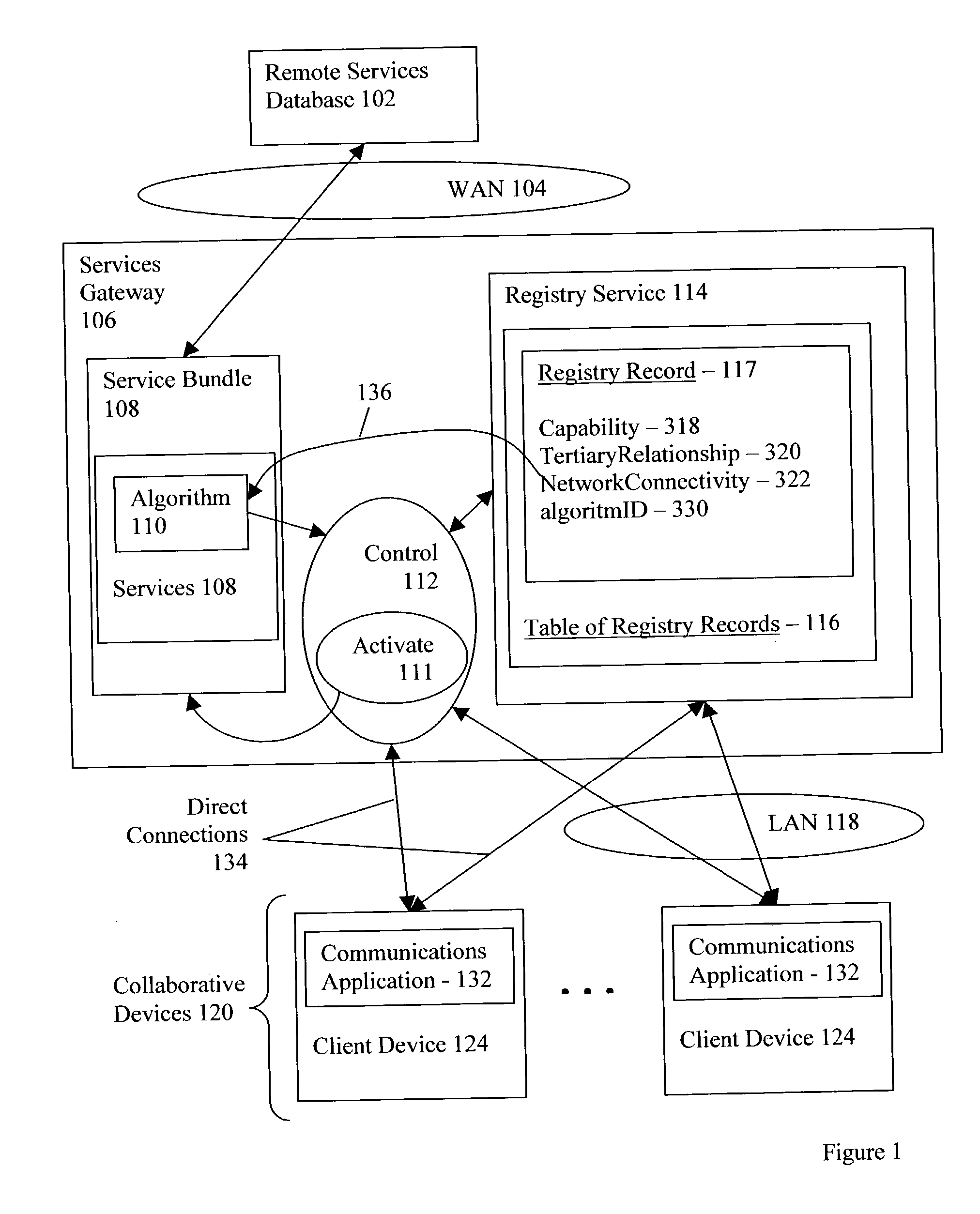

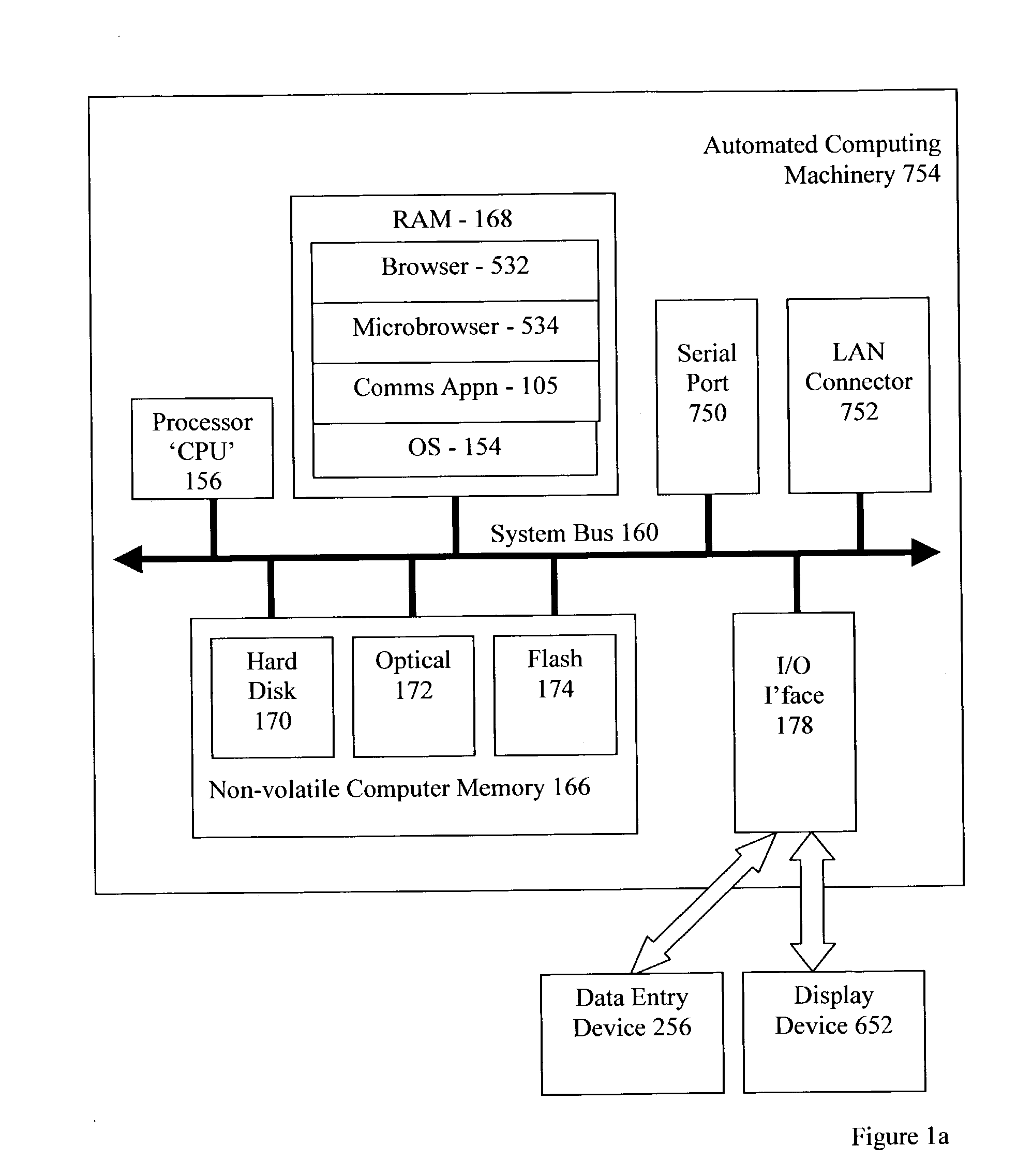

Active control of collaborative devices

InactiveUS20040143629A1Multiple digital computer combinationsSecuring communicationClient-sideData element

Controlling collaborative devices, including providing at least two collaborative devices, in which each collaborative device includes a client device and a client communications application, each collaborative device being coupled for data communications to an OSGi-compliant services gateway, and providing registry records describing collaborative devices, in which each registry record represents a capability of the collaborative device pertinent to a tertiary relationship for control of collaborative devices, each registry record including data elements describing, for each collaborative device, at least one capability, at least one tertiary relationship, and at least one network connectivity. Embodiments include providing, in dependence upon the tertiary relationship, a service bundle including at least one predetermined algorithm for controlling the collaborative devices, and controlling the collaborative devices in accordance with the predetermined algorithm.

Owner:IBM CORP

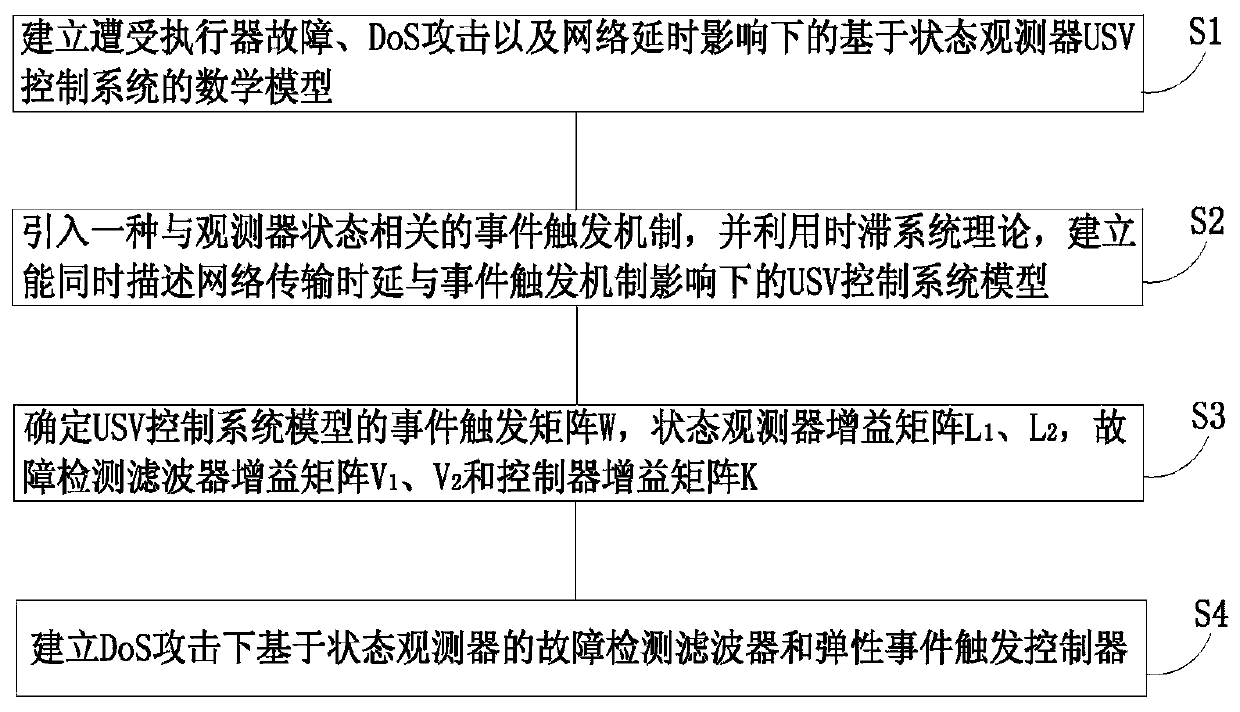

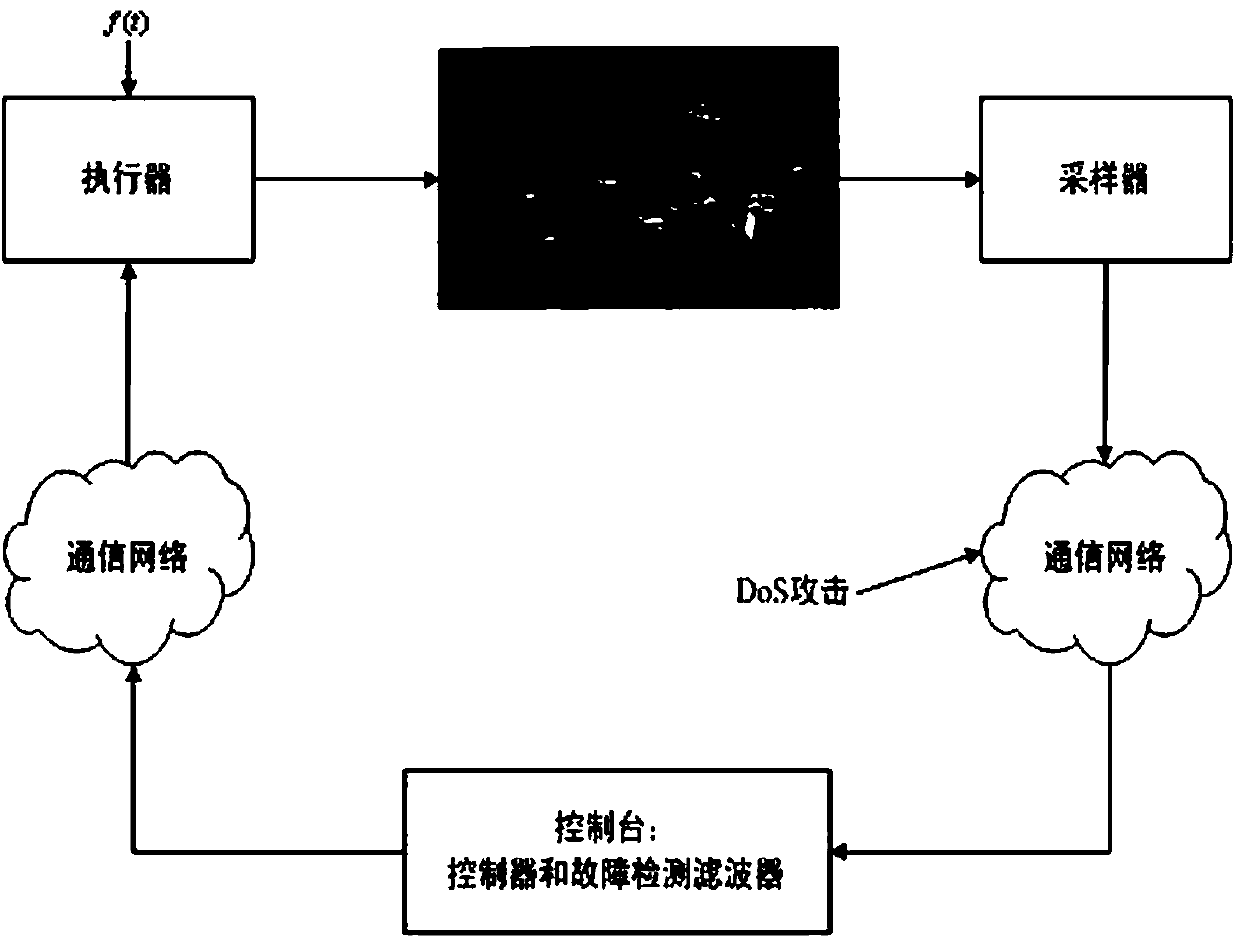

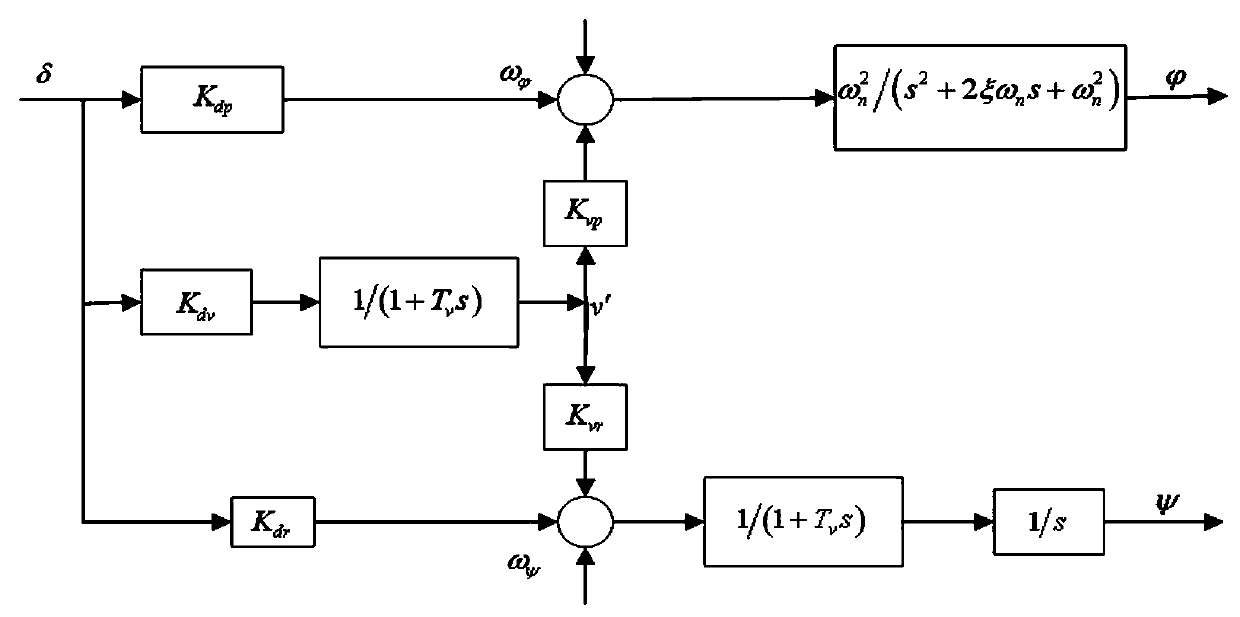

Collaborative design method of fault detection filter and controller under DoS attack

InactiveCN108629132AReduce delivery pressureReduce transfer volumeDesign optimisation/simulationTransmissionEvent triggerTime delays

The invention discloses a cooperative design method of fault detection filter and controller under DoS attack. The method is applied to a USV course control system, and is a cooperative design methodof a fault detection filter and an elastic event trigger controller based on a state observer, and the method comprises the following steps of: establishing a mathematical model based on the state observer USV control system under the influence of an actuator fault, a DoS attack and a network delay; introducing an event trigger mechanism related to the state of the observer, and establishing the model of the USV control system capable of simultaneously describing the time delay of the network transmission and the influence of the event trigger mechanism by using the time-delay system theory, determining an event trigger matrix W of the USV control system model, a state observer gain matrix L1, L2, a fault detection filter gain matrix V1, V2 and a controller gain matrix K; establishing a fault detection filter and an elastic event trigger controller based on a state observer under the DoS attack. The cooperative design method of fault detection filter and controller under DoS attack caneffectively resist the DoS attack and detect the fault in time.

Owner:NANJING UNIV OF POSTS & TELECOMM

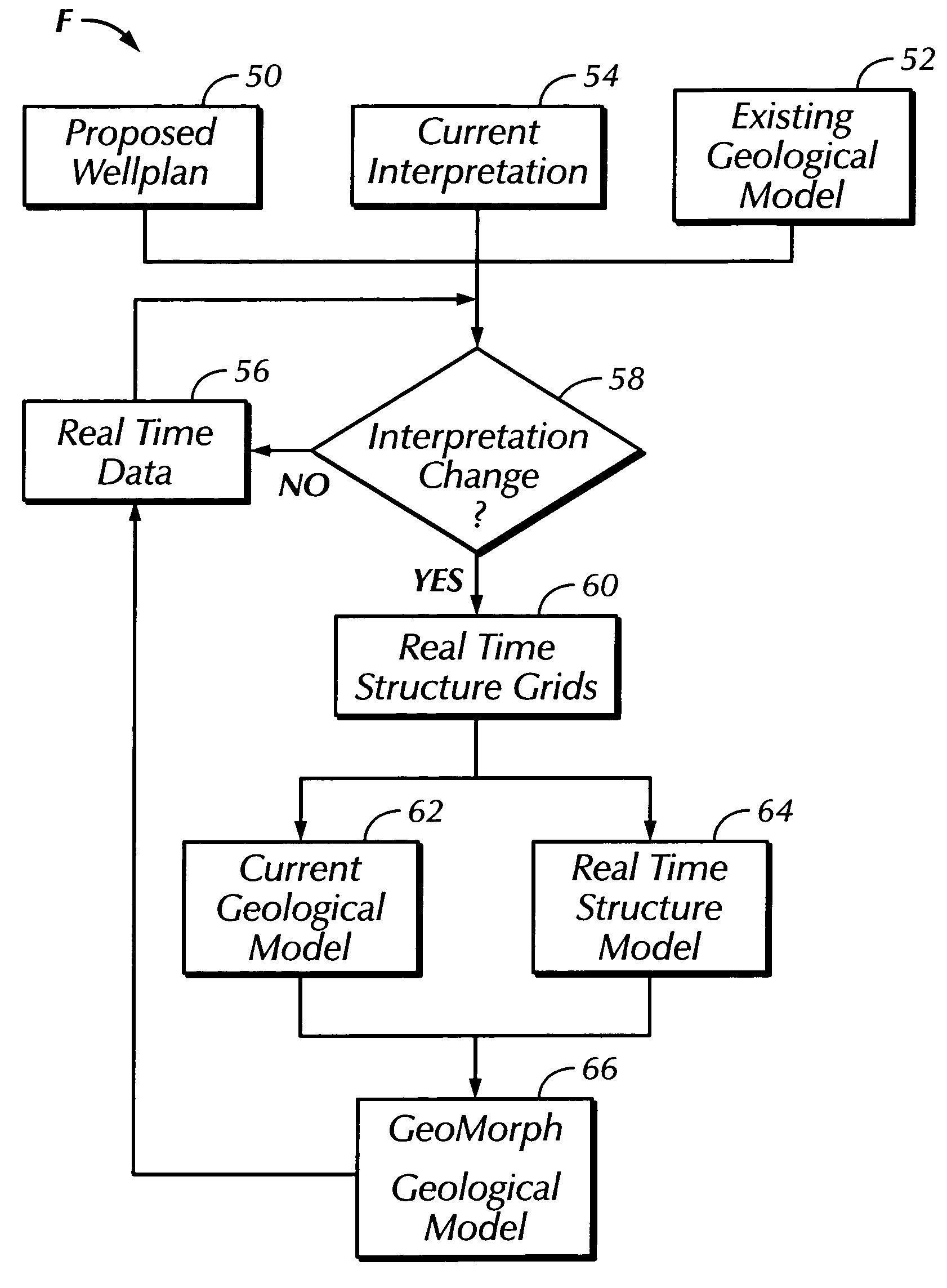

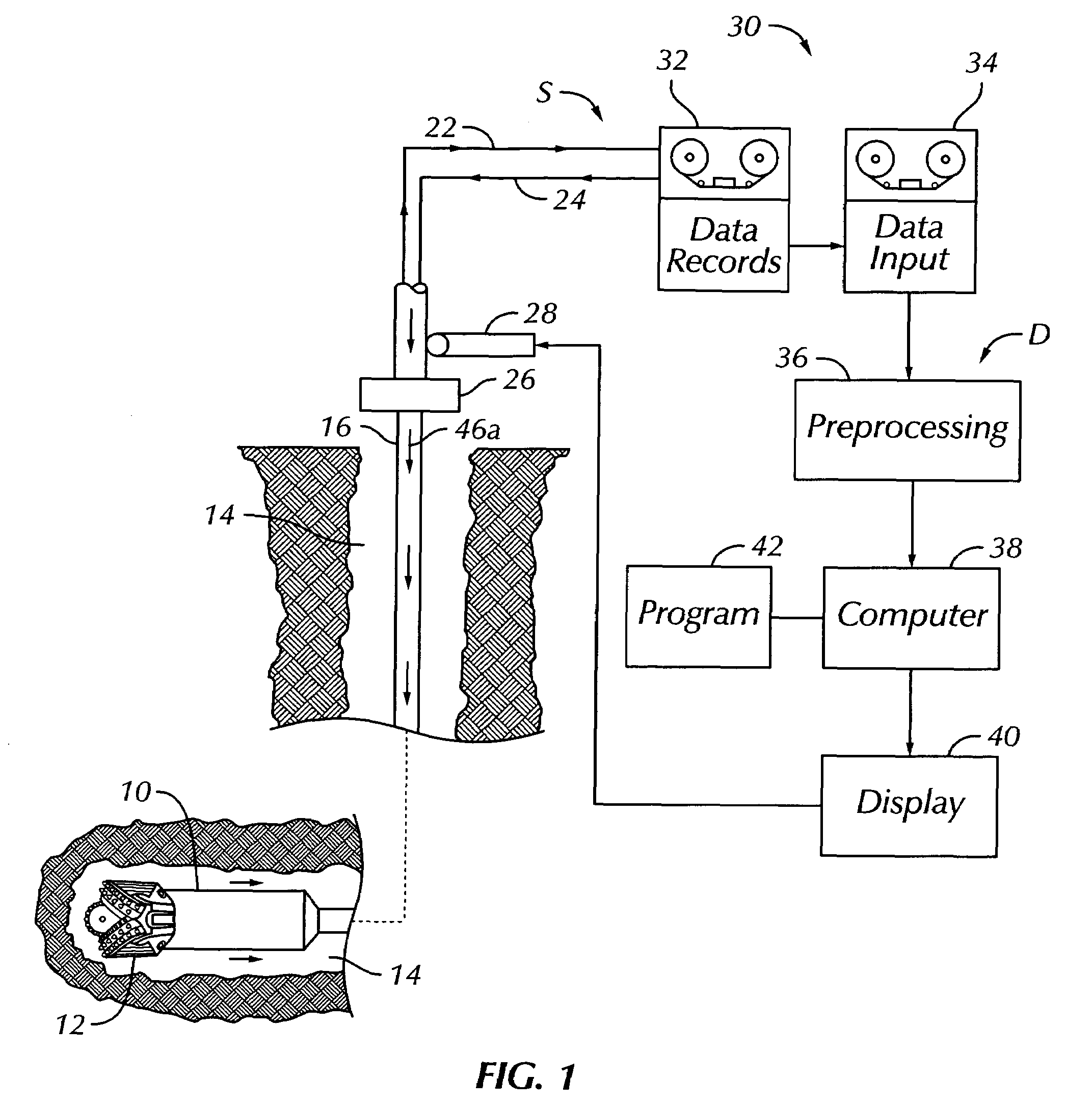

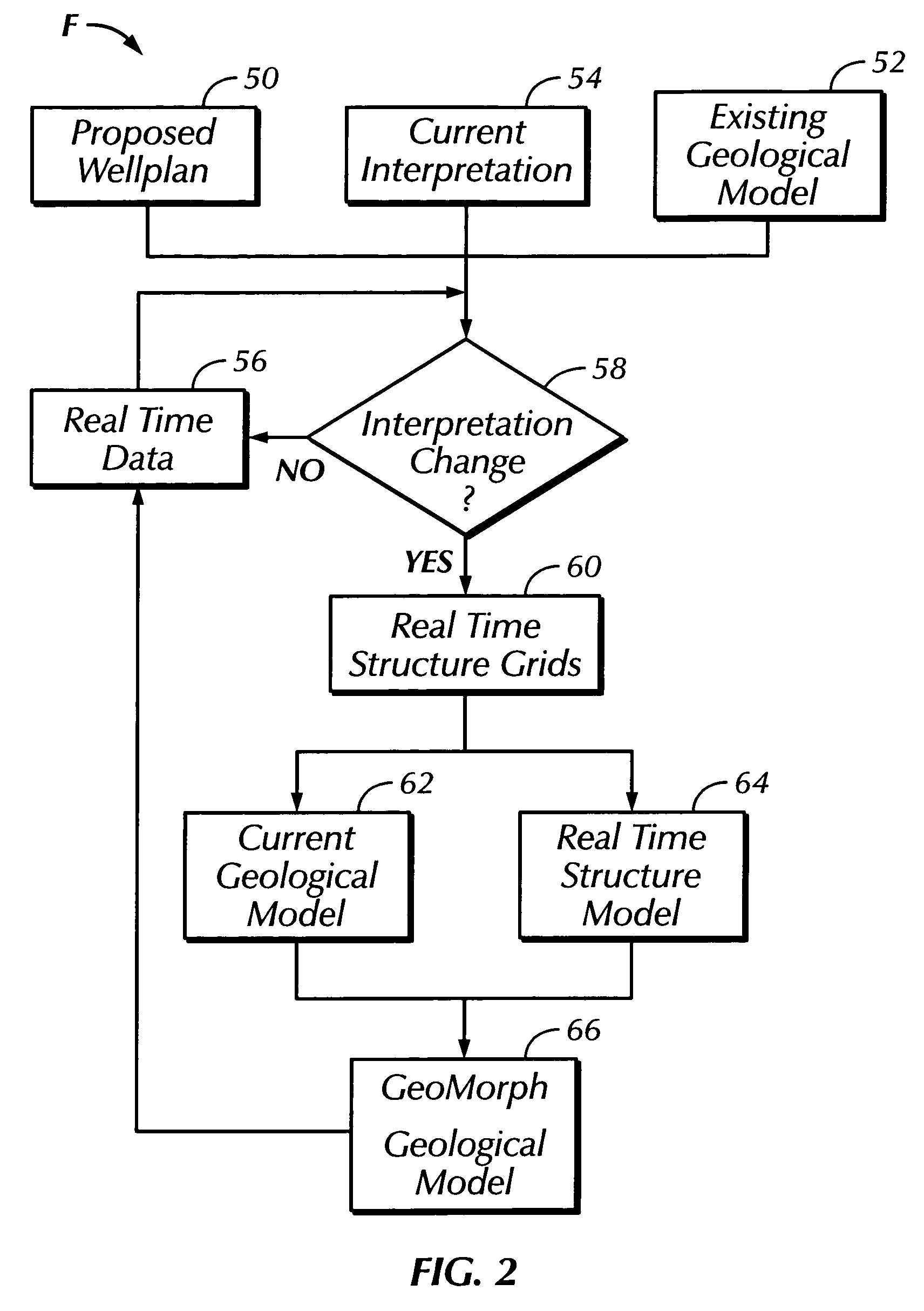

Real time earth model for collaborative geosteering

ActiveUS7359844B2Improve efficiencyElectric/magnetic detection for well-loggingSeismology for water-loggingGeosteeringWell drilling

An earth model is formed in real time during drilling of a well by incorporating up-to-the-minute knowledge derived from geology, seismic, drilling, and engineering data. The process of forming the model utilizes Logging-While-Drilling (LWD) or Measuring-While-Drilling (MWD) data directly from the drilling rig as the well is drilled. The LWD or MWD data is sent to visualization centers and compared with other data such as existing geological models, the proposed well plan and present interpretation of the subsurface stratigraphy. The results of the comparison enable experts to analyze anomalous results and update the geological model within minutes of penetration of a formation during drilling. Well drilling efficiency is improved, and an “on-the-spot” road map is provided for maximal reservoir contact and pinpoint accuracy.

Owner:SAUDI ARABIAN OIL CO

House overall finishing simulation display method and system based on BIM technology

InactiveCN107515991AQuick fixReduce communication costsGeometric CADSpecial data processing applicationsPersonalizationGraphics

The invention discloses a house overall finishing simulation display method based on the BIM technology. Firstly, a room is sub-modularized by utilizing revit software; secondly, a special family member library is built by using a 3D scanner; thirdly, a site construction process video of a room sub-module is established by utilizing the revit software; fourthly, the BIM parameterization design technology is used, and a drive geometry three-dimensional model, a linkage model, a graph and various documents are parameterized; fifthly, according to different decoration design requirements, house styles are designed according to the BIM technology, and the three-dimensional model is mapped; sixthly, model parameterization and rendering processing are carried out on furniture models in different house styles, and then the overall finishing simulation display effect based on the BIM technology is obtained. The invention further discloses a house overall finishing simulation display system based on the BIM technology. The interior decoration models can be quickly built on the basis of BIM software, and personalized design intentions of clients are represented; besides, through collaborative design of the same working set, conflicts between decoration design and construction design can be eliminated in advance, and rework and the communication cost are reduced.

Owner:北京市金龙腾装饰股份有限公司

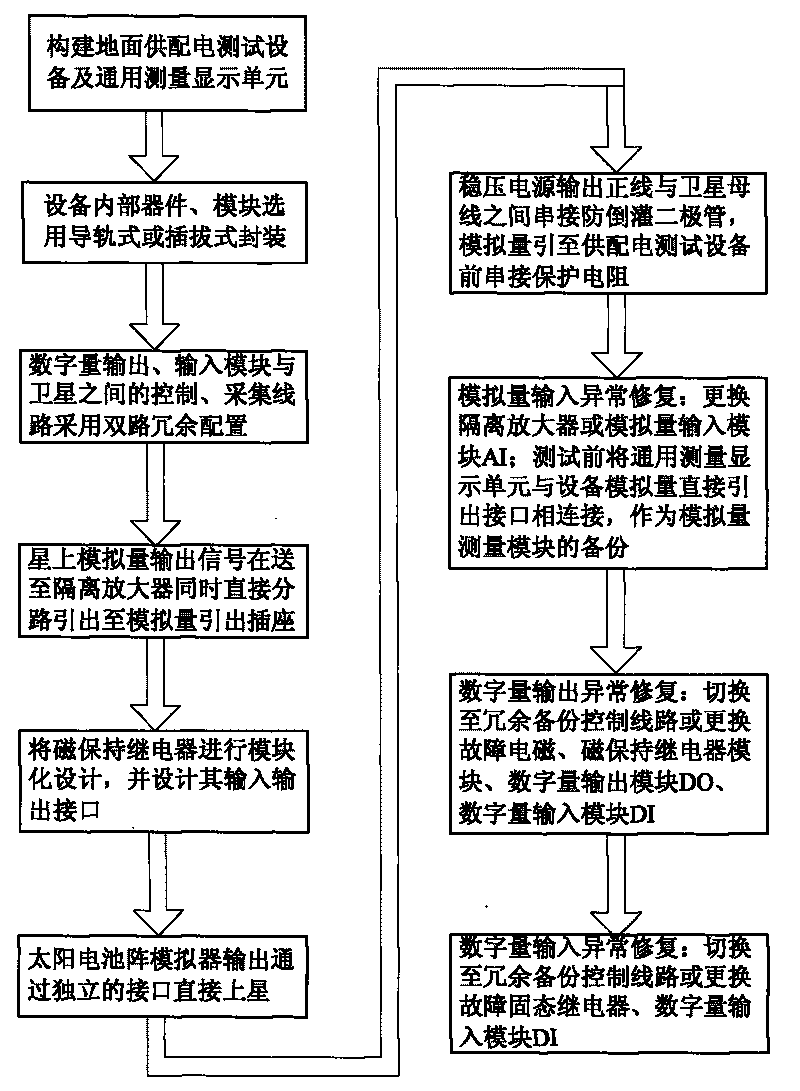

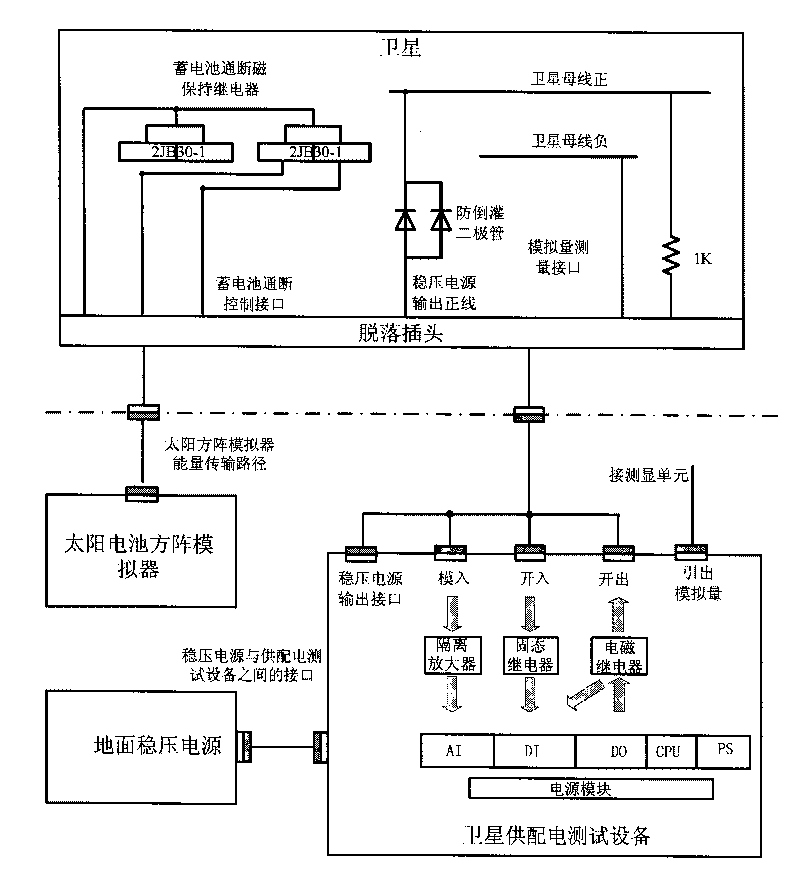

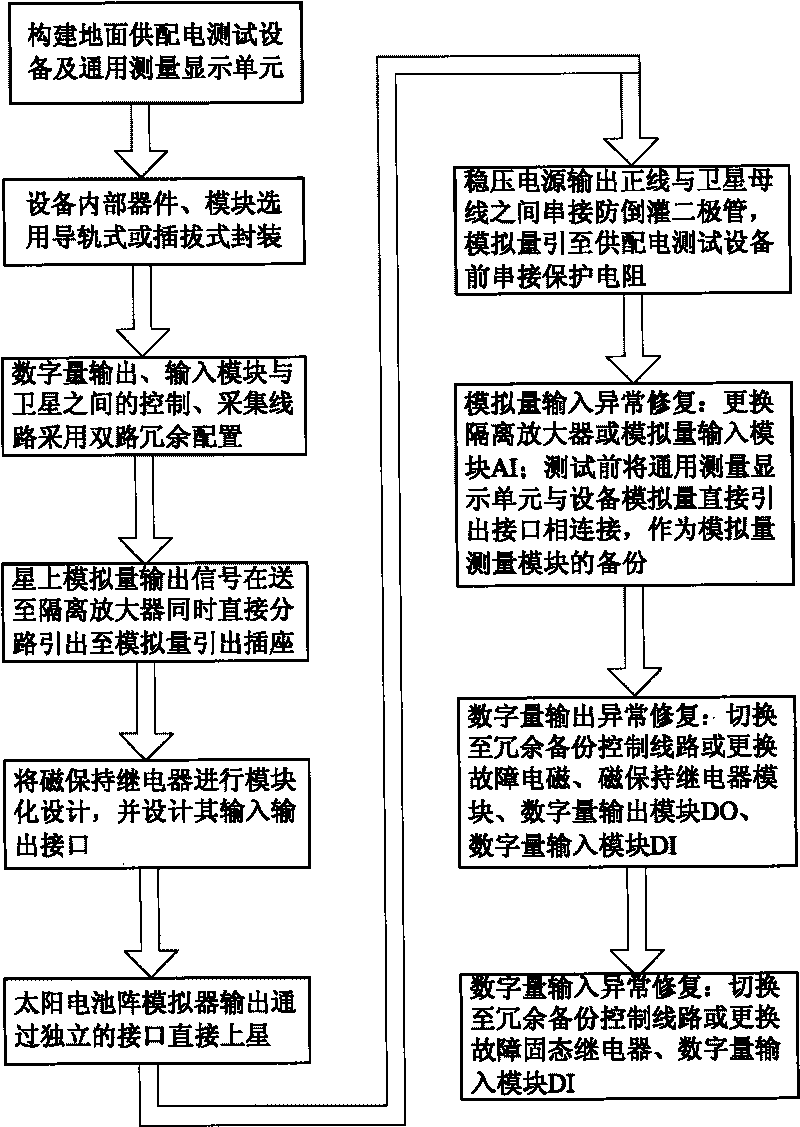

Fault on-line repairing method for satellite power supply and distribution test system

ActiveCN101713802AWith fault online repair functionFor quick replacementElectrical testingEngineeringSolar cell

The invention discloses a fault on-line repairing method for satellite power supply and distribution test system, which can fast repair the fault of power supply and distribution test equipments on line in thermal tests, aging tests and other tests in which the satellite needs continuous powering up. The internal components of the power supply and distribution test equipments are encapsulated in the plug-in or guide-way form, and simultaneously modular structure designing method is adopted to lead a magnetic latching relay can be fast replaced when in fault; the digital quantity output and input adopt dual redundant configuration, and the analog quantity output signals are displayed by a measurement display unit; the solar cell array simulator output is directly loaded on the satellite via independent interface; a flow backward resisting diode is connected in series between a voltage stabilization source power supply positive line, and an analog quantity outgoing line is connected with a protective resistor in series to prevent the on-satellite products from being influenced by cable plugging when the satellite is powered up; on the basis of satellite-ground synergic design, the redundant resources can be started by fast replacing the faulted modules one faults occur to the equipments to realize equipment on-line repairing.

Owner:AEROSPACE DONGFANGHONG SATELLITE

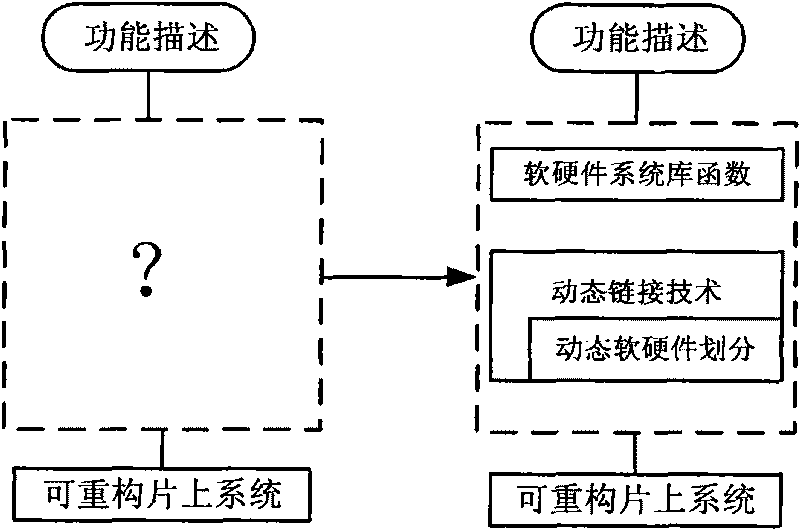

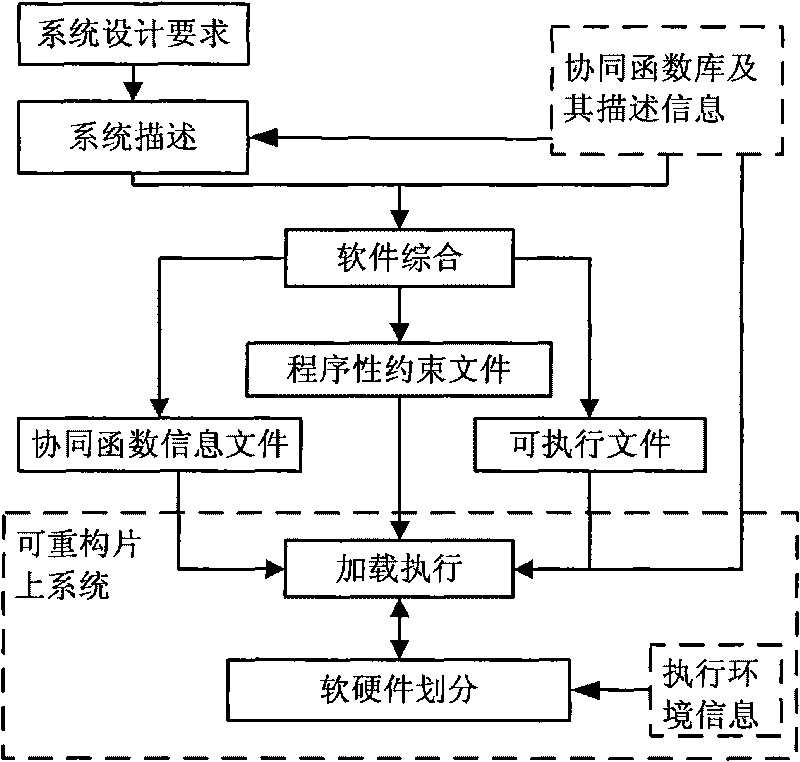

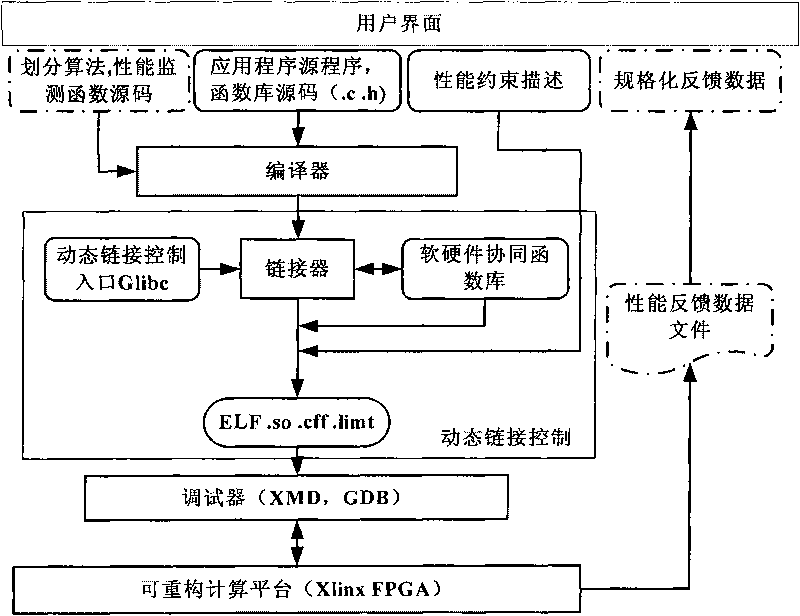

Procedure level software and hardware collaborative design automatized development method

InactiveCN101763265AIncrease profitEasy to divideSpecific program execution arrangementsHigh-level programming languageHardware implementations

The invention provides a procedure level software and hardware collaborative design automatized development method, which is characterized in that the method comprises the following steps: step 1, using high level languages to complete the system function description which comprises the transfer of the software and hardware collaborative functions; step 2, dynamically dividing the software and hardware functions; step 3, linking and executing the step; and step 4, judging and ending the step (judging whether the execution of all functions is completed, ending the step if the execution of all functions is completed, and otherwise, returning parameters used for dividing to the second step to enter a next circulation). The invention uses the procedure level software and hardware uniform programming model for shielding the difference realized by bottom layer hardware to realize the goal of transparent effect of reconstruction devices on program users. The programming model encapsulates the hardware accelerator into C Language functions for bringing convenience for the programming by users, and in addition, the dynamic software and hardware division during the operation is supported, so the division is transparent to programmers, and the utilization rate of reconstruction resources is improved.

Owner:HUNAN UNIV

Ball grid array package-to-board interconnect co-design apparatus

ActiveUS7514789B1Reduce electromagnetic interferenceSuperior signal quality and EMI shielding propertySemiconductor/solid-state device detailsPrinted circuit aspectsData streamCopper interconnect

A package-board co-design methodology preserves the signal integrity of high-speed signals passing from semiconductor packages to application PCBs. An optimal architecture of interconnects between package and PCB enhances the signal propagation, minimizes parasitic levels, and decreases electromagnetic interference from adjacent high frequency signals. The invention results in devices with superior signal quality and EMI shielding properties with enhanced capability for carrying data stream at multiple-gigabit per second bit-rates.

Owner:TAHOE RES LTD

BIM-based concrete fabricated building construction method

PendingCN110929328AGuaranteed design qualityGuaranteed constructabilityGeometric CADDesign optimisation/simulationConstruction engineeringCollaborative design

The invention discloses a BIM-based concrete fabricated building construction method, comprising the following steps: creating a building full-professional integral BIM model, optimizing integral design, splitting prefabricated parts, deepening prefabricated part nodes, performing construction simulation optimization design, performing engineering quantity statistics, drawing a prefabricated partprocessing drawing, and manufacturing a prefabricated part two-dimensional code. By creating the visual informationized BIM model, the BIM-based concrete fabricated building construction method improves the collaborative design of information of the building, the structure and the electromechanical specialty, avoids the problems of mistakes, omissions, collisions and lacks of the design specialties, and improves the design quality. Meanwhile, the assembly type construction process is visually simulated through BIM, and the problem optimization design in construction is found in time, and the design and construction barrier is broken through. Besides, the BIM technology can perform rapid drawing according to the model, and the design quality is improved through automatic statistics of the engineering quantity, and visual construction simulation can further guide field construction, and the generated two-dimensional code can be used for information tracing of the prefabricated part, andthe overall construction quality of the prefabricated building is improved.

Owner:中国电建集团江西省水电工程局有限公司

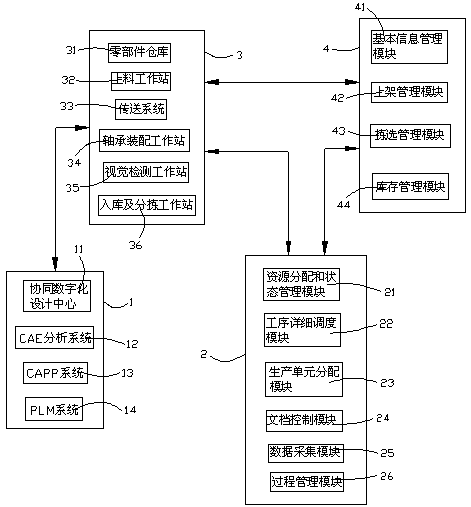

Bearing assembly line based on industrial cloud platform intelligent manufacturing

InactiveCN107861490AEffective combinationRealize smart factoryTotal factory controlProgramme total factory controlProduction lineManufacture execution system

The invention relates to the design of bearing assembly lines, in particular to a bearing assembly line based on industrial cloud platform intelligent manufacturing, comprising a cloud design and manufacture system, an MES (manufacturing execution system), an intelligent production system capable of automatically assembling bearings, and a parts WMS (warehouse management system); the cloud designand manufacture system provides collaborative design and inputs an optimized process to the intelligent production system; the MES generates a planning scheduling program according to acquired information of the WMS and input order information; the intelligent production system schedules production according to the planning scheduling program and performs automatic assembly and warehousing of bearings. The cloud design and manufacture system, the MES, the intelligent production system capable of automatically assembling bearings and a parts WMS are used herein to provide assembly, detection, warehousing and the like for bearings, the cloud design and manufacture system is effectively combined with the production line, an intelligent factory is achieved, and production efficiency is effectively improved.

Owner:长沙智能制造研究总院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com