Assembled type concrete structure three-dimensional collaborative design method

A technology of concrete structure and collaborative design, applied in computing, image data processing, special data processing applications, etc., can solve problems such as insufficient meeting the requirements of building structure form, lack of design ideas, restricting prefabricated structures, etc. Type component modeling and drawing time, shortening modeling and drawing time, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

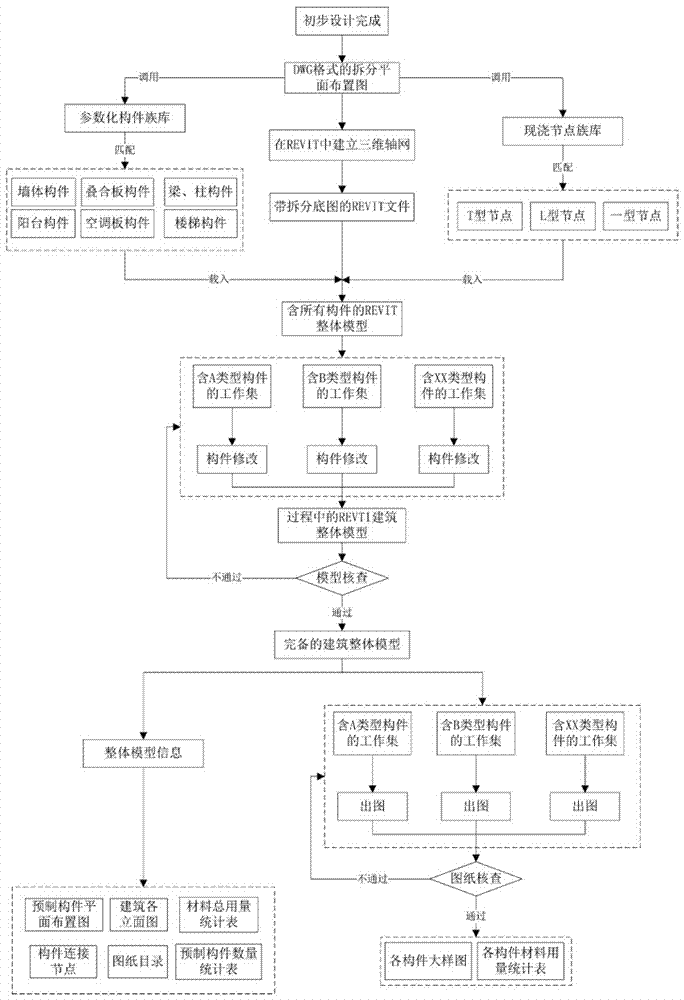

[0035] The method proposed in this invention is applicable to fabricated concrete structures, including shear wall structures and frame structures. Here we only take the assembled integral shear wall structure as an example for illustration. It should be noted that all the operation processes involved in this method are completed based on the network storage environment. The relevant process of this method is described in detail as follows:

[0036] 1. Complete the split design of the prefabricated building according to the schematic design and drawings after the preliminary design is completed

[0037] Main operation process:

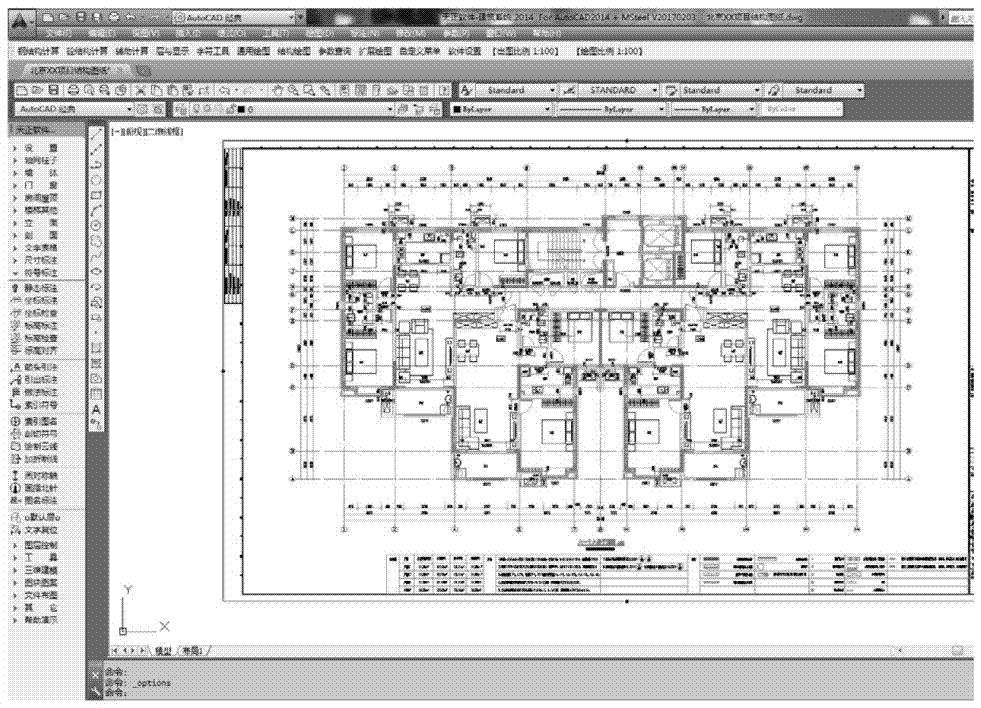

[0038] ① if figure 2 As shown, start the AutoCAD program, click the open option in the menu bar, and select the project structure drawing in .dwg format (Beijing XX project structure drawing) in the file selection pop-up box;

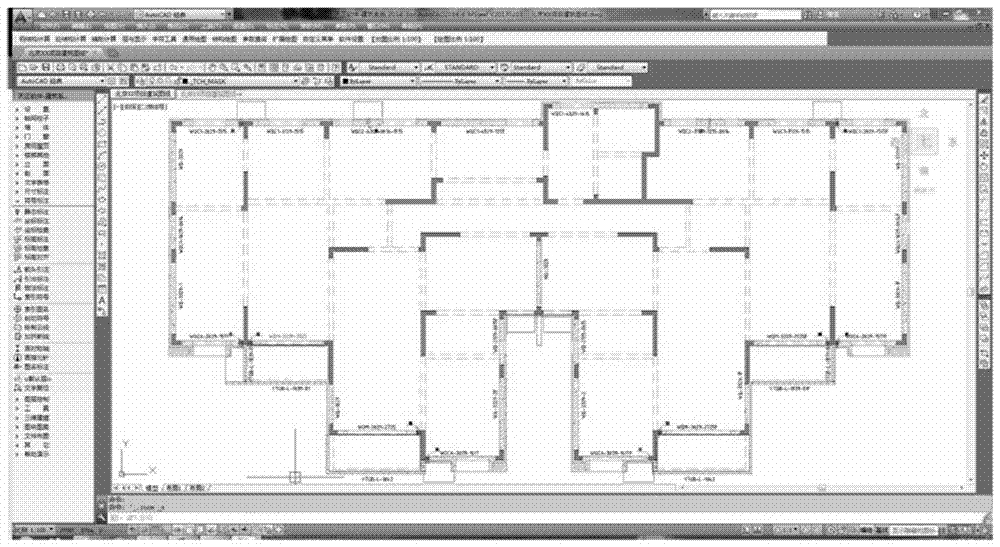

[0039] ② if image 3 As shown in , create a new structure split edge layer, complete the split layout of the correspondi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com