Digitization mechanical design method

A technology of mechanical design and digital prototyping, applied in the direction of electrical digital data processing, calculation, image data processing, etc., can solve the problems of dependence and lack of persuasion, achieve precise design, reduce engineering changes, and save production preparation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation of the digital mechanical design method of the present invention will be described in further detail below in conjunction with the accompanying drawings, but it is not used to limit the scope of protection of the present invention.

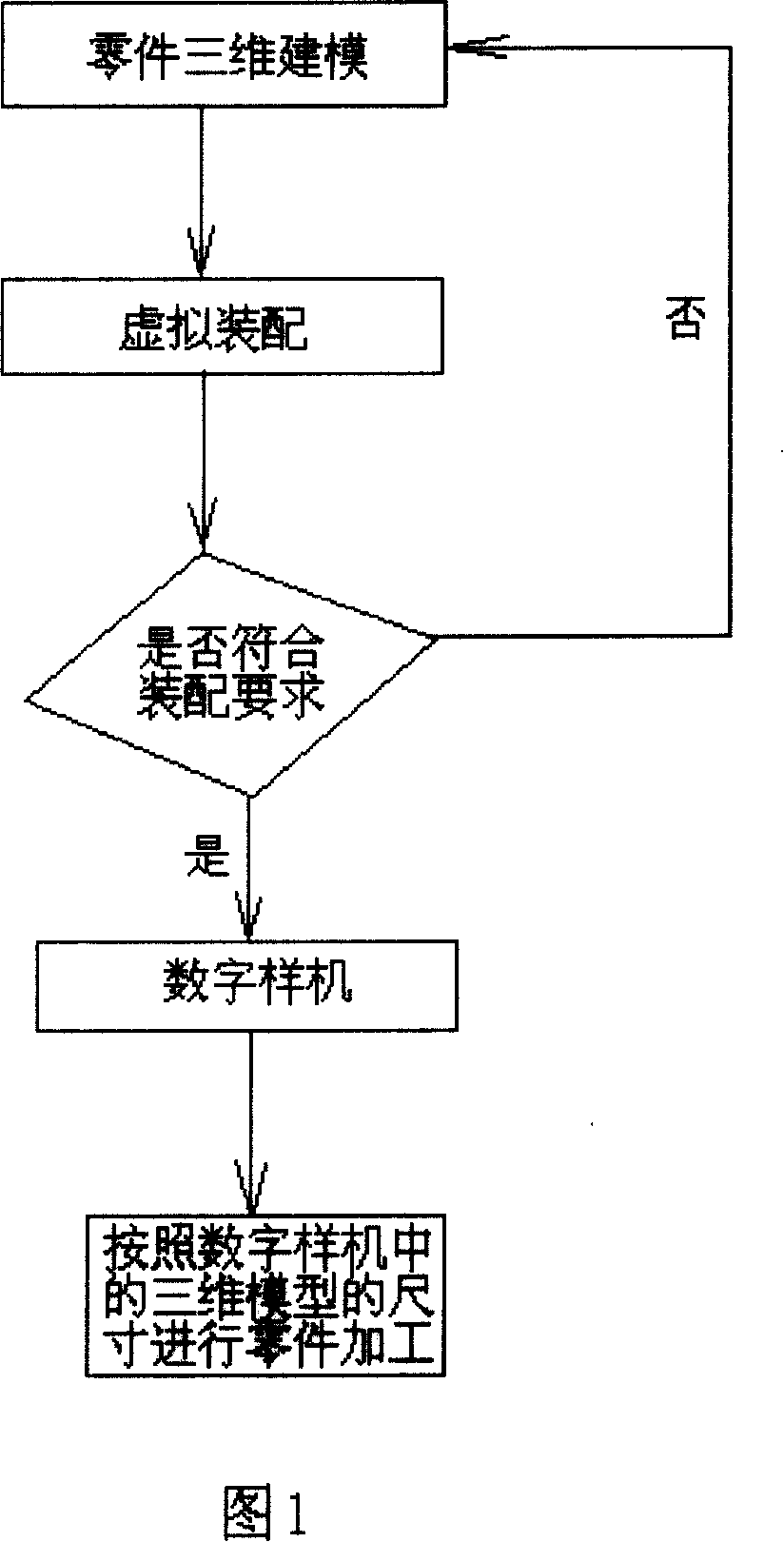

[0024] See Figure 1. The digital mechanical design method of the present invention comprises the following steps:

[0025] A. Use the computer to carry out three-dimensional modeling of each part that makes up the mechanical product;

[0026] B. According to the structure of each part and the positional relationship and assembly relationship between each part, carry out virtual assembly of the above-mentioned three-dimensional models to form a virtual product model;

[0027] C. Check whether the assembly relationship between the various 3D models in the virtual product model fully meets the requirements. If it fully meets the requirements, a digital prototype is formed. If it does not fully meet the requirements...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com