Separate oil gallery for piston cooling with electronic oil flow control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

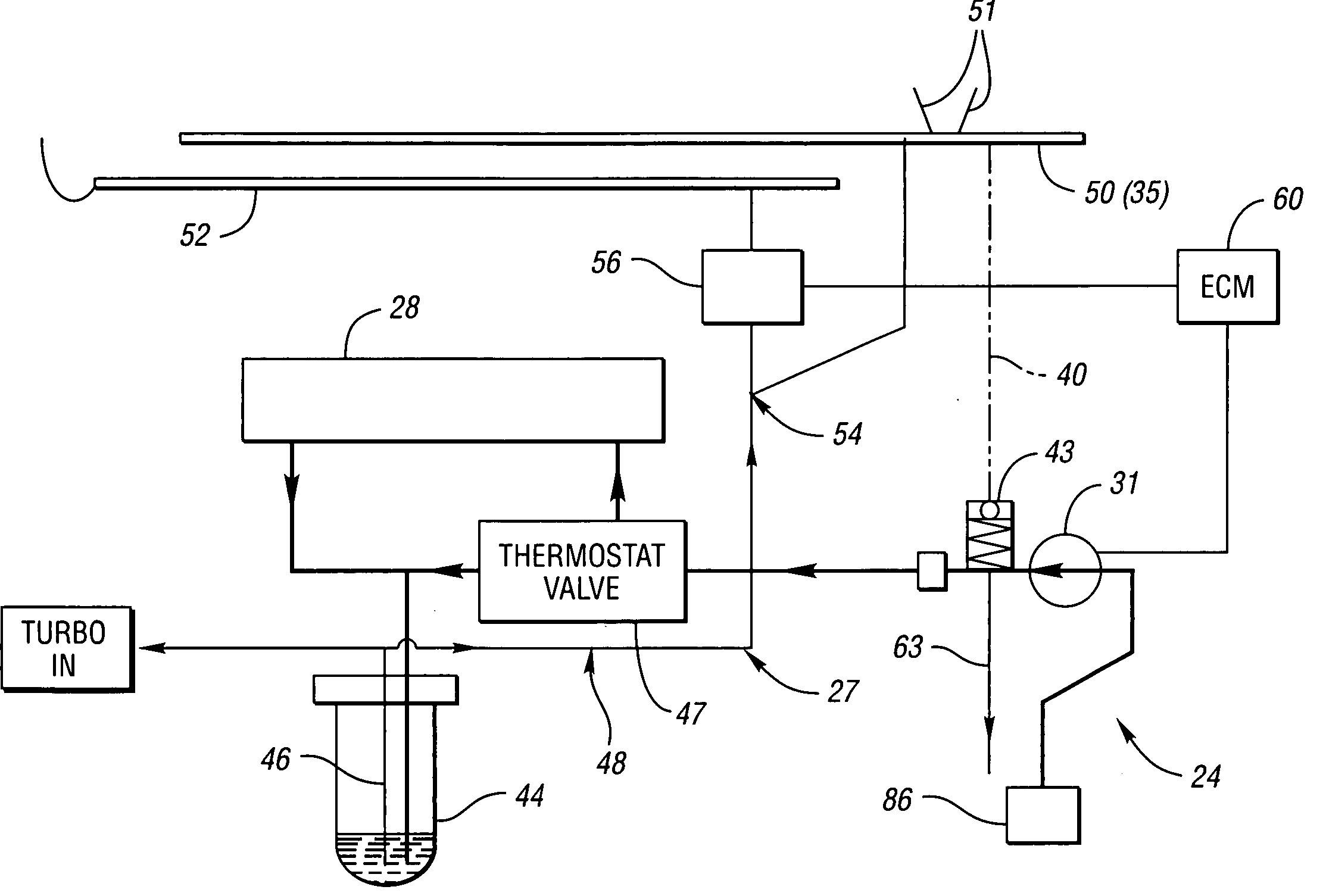

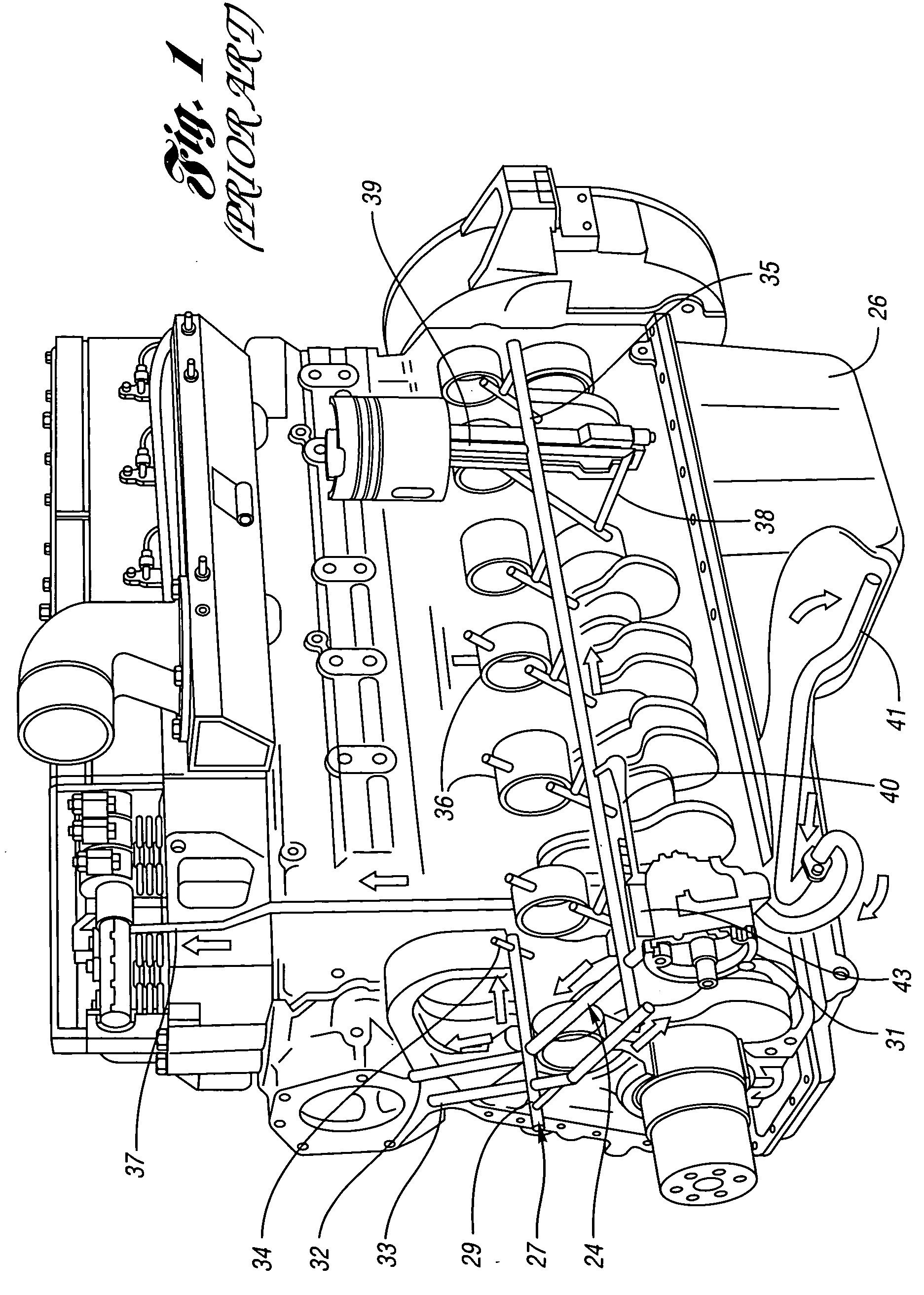

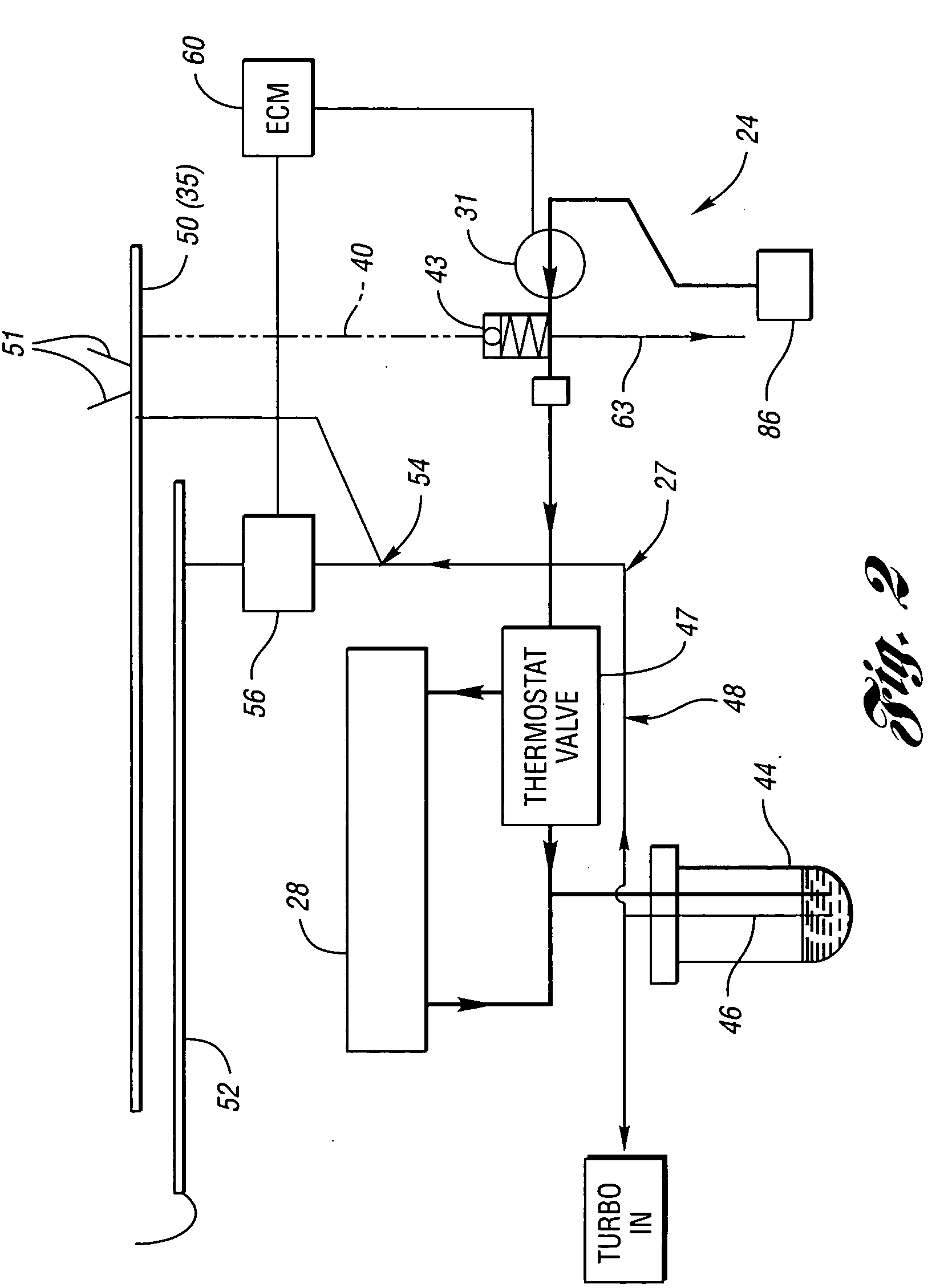

[0015] Referring first to FIG. 1, an internal combustion engine 10 is shown in a piece of equipment such as a vehicle or machinery diagrammatically represented by reference character 12. In a well known manner, the engine includes a plurality of pistons 16 (one shown) displaced in a cylinder 18 by connecting pin 20 engaged on a crank rod lobe 22. As the piston 16 compresses air and fuel injected into the cylinder 18, the heated and pressurized fuel vapor ignites and drives the piston to a retracted position within the cylinder. Since the combustion can transfer extreme heat energy to the piston and cylinder walls, the oil system often used for lubrication includes a manifold 29 that directs some of the lubricating oil to flow to the surface of the piston for cooling purposes. Oftentimes, such system provides additional heat transfer capability by passing the oil flow through a cooler coupled with the engine's coolant system. As a result, the cooled oil can absorb greater heat energ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com