Sintered bearing

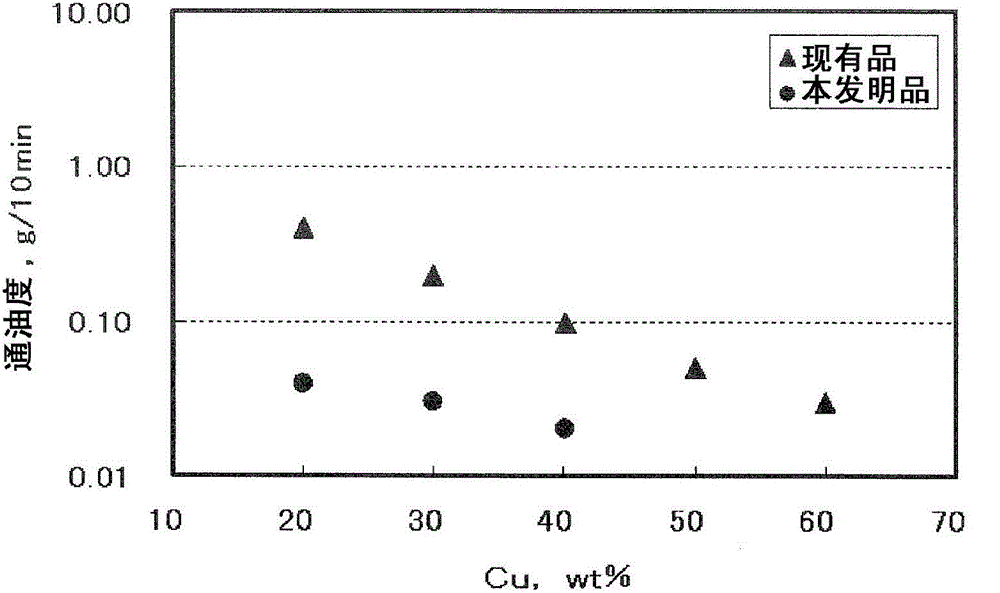

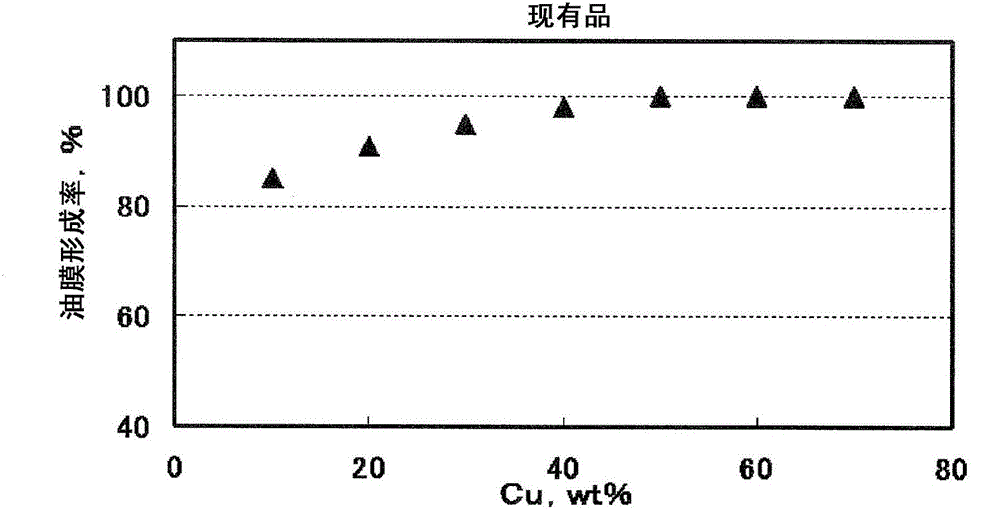

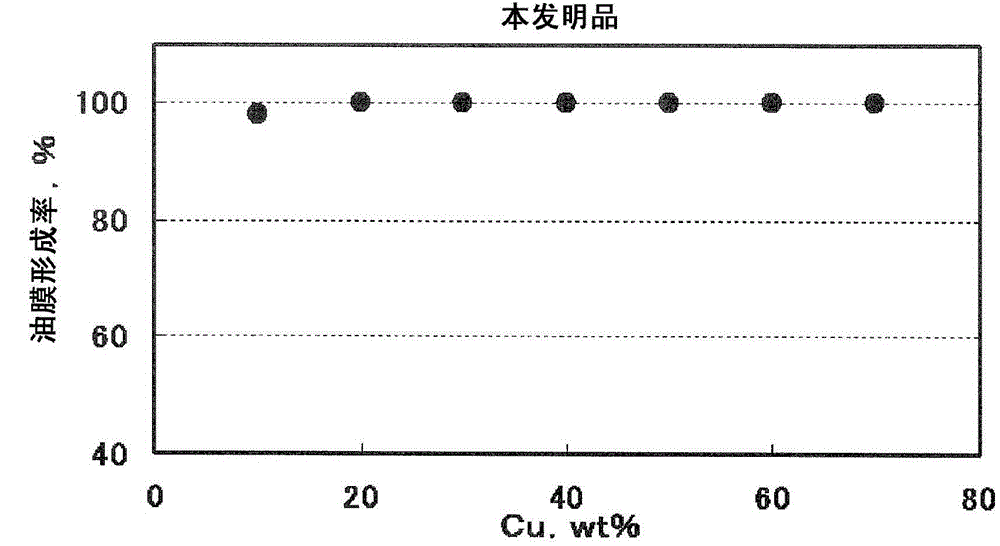

A technology of sintered bearings and sintered metals, applied in bearings, liquid cushion bearings, bearing components, etc., can solve problems such as narrow degrees of freedom, and achieve the effects of expanding degrees of freedom, high wear resistance, and reducing oil penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Hereinafter, embodiments of the present invention will be described based on the drawings.

[0040] Figure 6 The spindle motor shown is used in a disk drive device such as an HDD, and includes: a fluid dynamic pressure bearing device 1 that supports a shaft member 2 in a non-contact manner so as to be rotatable; a hub 3 mounted on the shaft member 2; and a stator opposed to each other through a gap. Coil 4 and rotor magnet 5. The stator coil 4 is mounted on the outer periphery of the motor bracket 6 , and the rotor magnet 5 is mounted on the inner periphery of the hub 3 . Disc hub 3 maintains one or more sheets (in Figure 6 Two in the middle) Disk D. In the spindle motor configured in this way, when the stator coil 4 is energized, the rotor magnet 5 rotates, and accordingly, the disk hub 3 and the disk D held by the disk hub 3 rotate integrally with the shaft member 2 .

[0041] Such as Figure 7 As shown, the main structural elements of the fluid dynamic pressur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com