Patents

Literature

288results about "Liquid cushion bearings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Turbomachine with a long lasting position-holding system

ActiveUS20090311089A1Minimize more penalizingMinimize length of timeRotary combination bearingsPump componentsImpellerLow speed

A turbomachine arranged with a rotor and a stator, including radial positioning means ensuring that the rotor is radially position; and a contactless axial balancing device arranged on at least one bladed wheel for axially balancing the rotor at high speed. The turbomachine includes a thrust bearing distinct from the radial positioning means serving to balance the rotor axially at low speed, and without contact at high speed. In addition, the radial positioning means are hydrostatic bearings, the turbomachine including hydrostatic bearing feed circuits suitable for connecting said bearings to a source of fluid under pressure. As a result, it is possible to obtain operation at high speeds with a very long lifetime.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

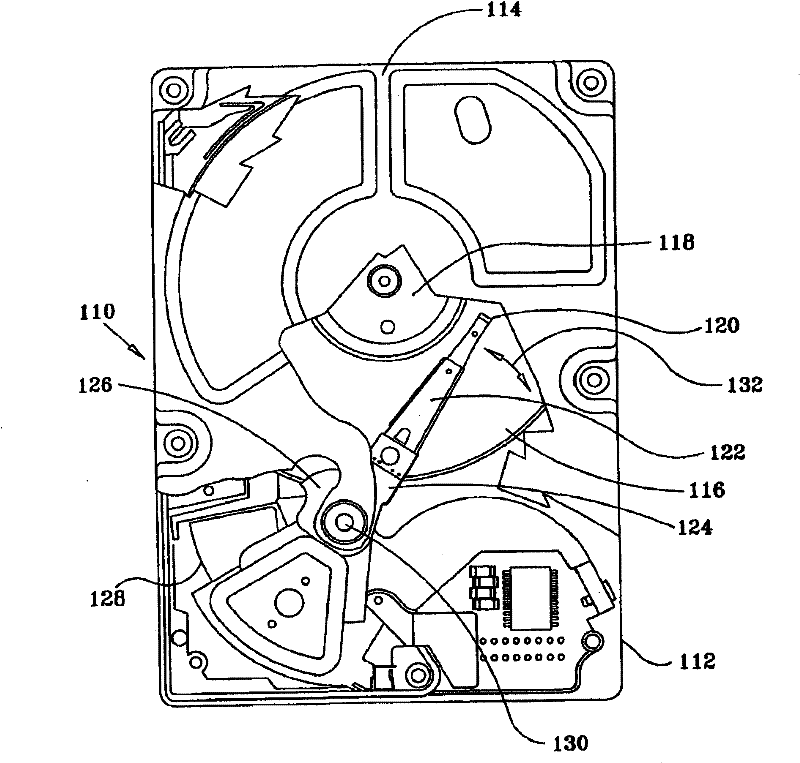

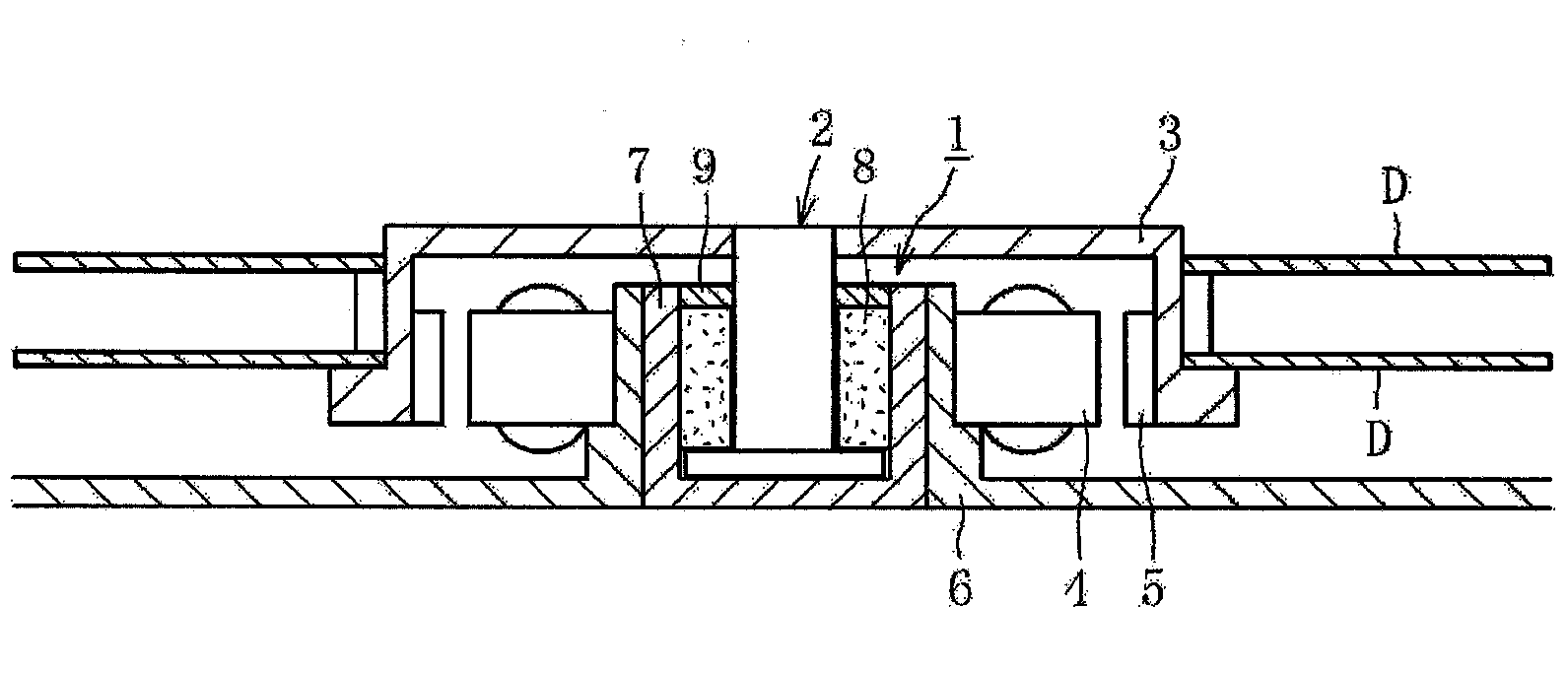

Hub and spindle assembly having asymmetrical seals for a disc drive memory system

A rotating hub and fixed spindle assembly with first and second fluid dynamic journal bearings and first and second fluid dynamic thrust bearings for a disc drive memory system has a pump seal and a radial ring seal at a first axial terminus for lubricant containment, and a capillary seal and a labyrinth seal at a second axial terminus for lubricant containment and storage. Lubricant fluid pressure differences between first and second seals are minimized through one or more lubricant fluid communicating channels in the hub assembly, in order to minimize lubricant fluid loss through a seal. Lubricant fluid can also be purged of any air bubbles by lubricant fluid circulation through the channel.

Owner:SEAGATE TECH LLC

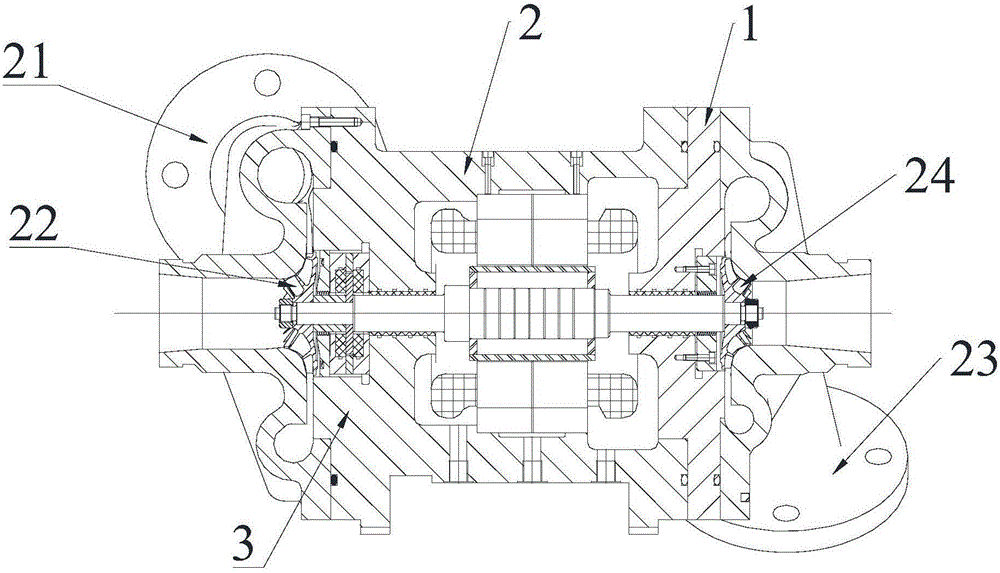

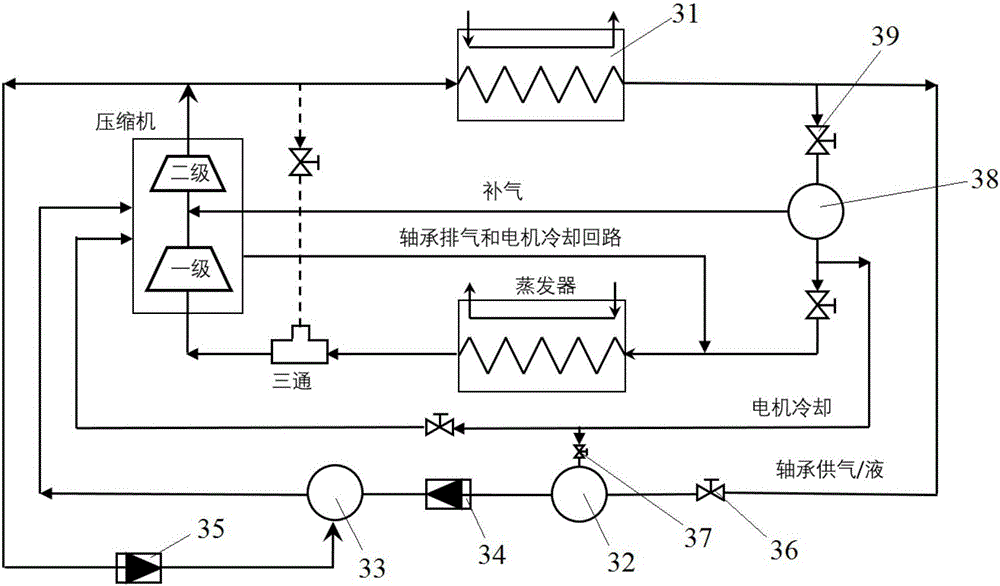

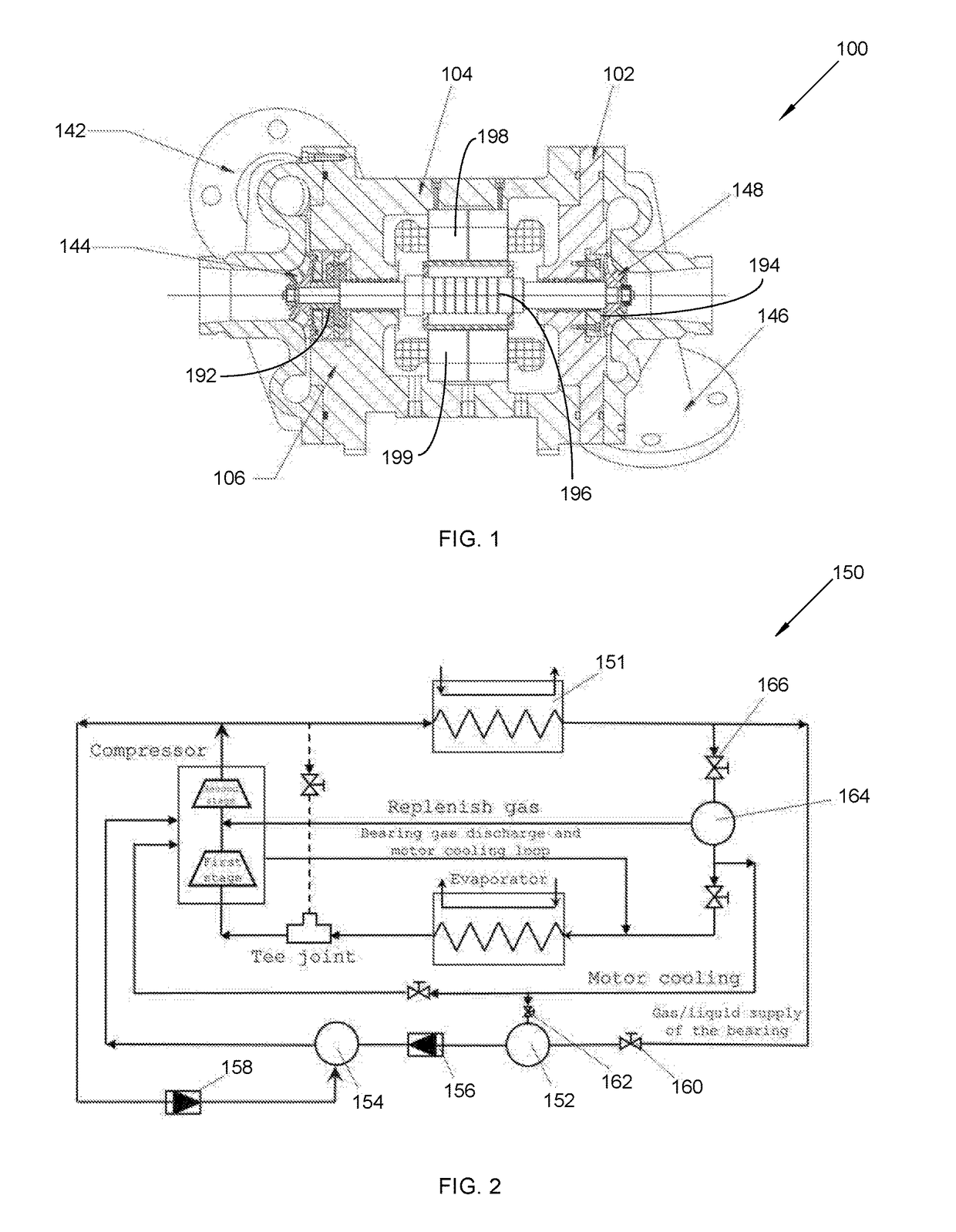

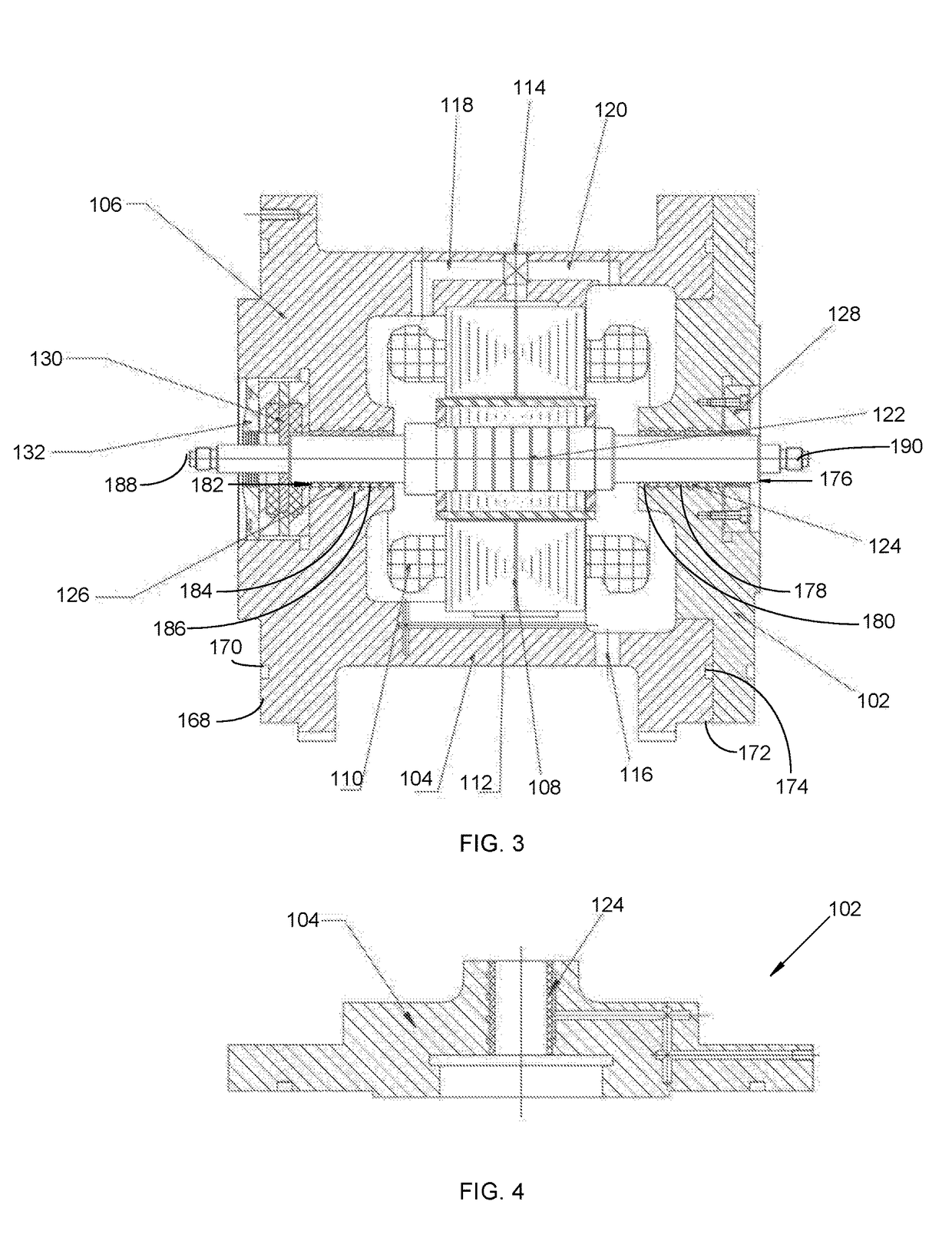

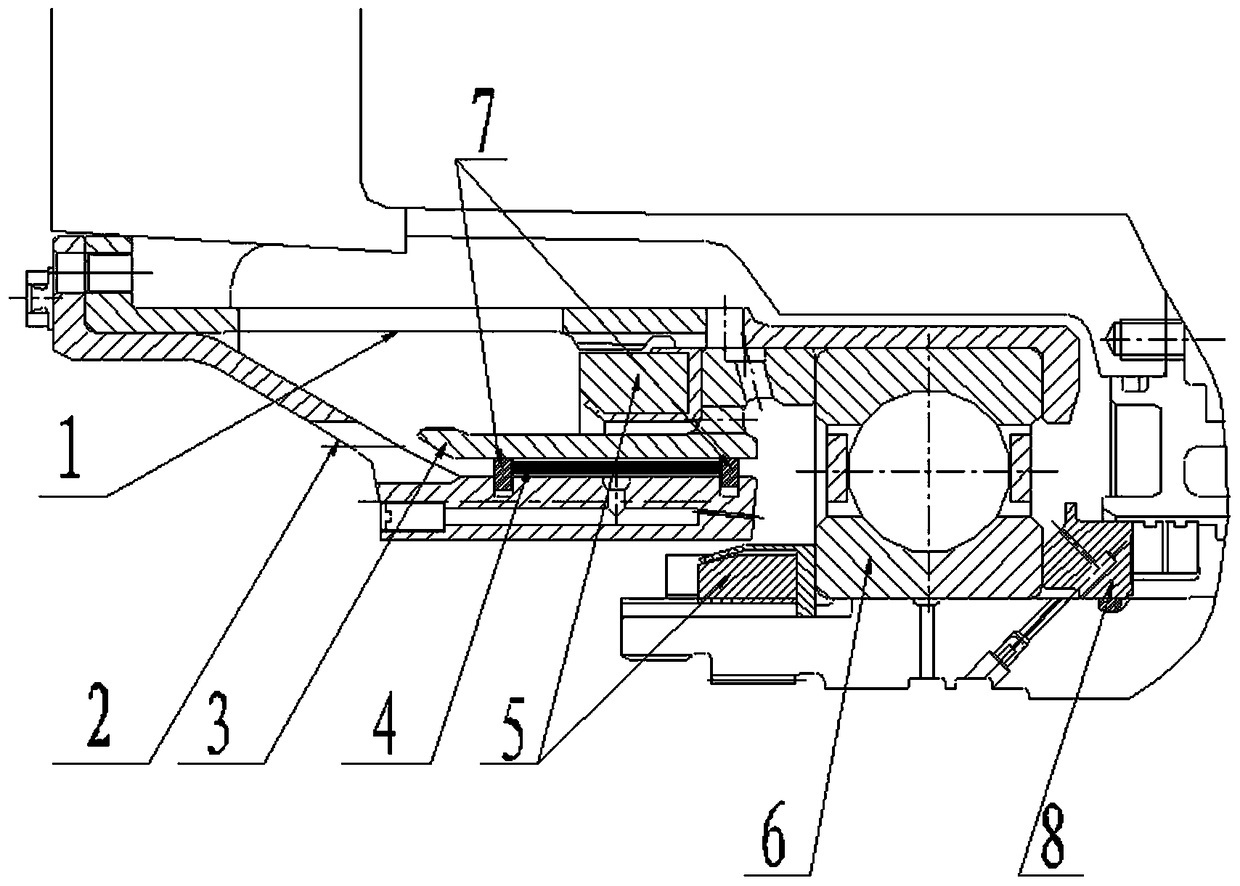

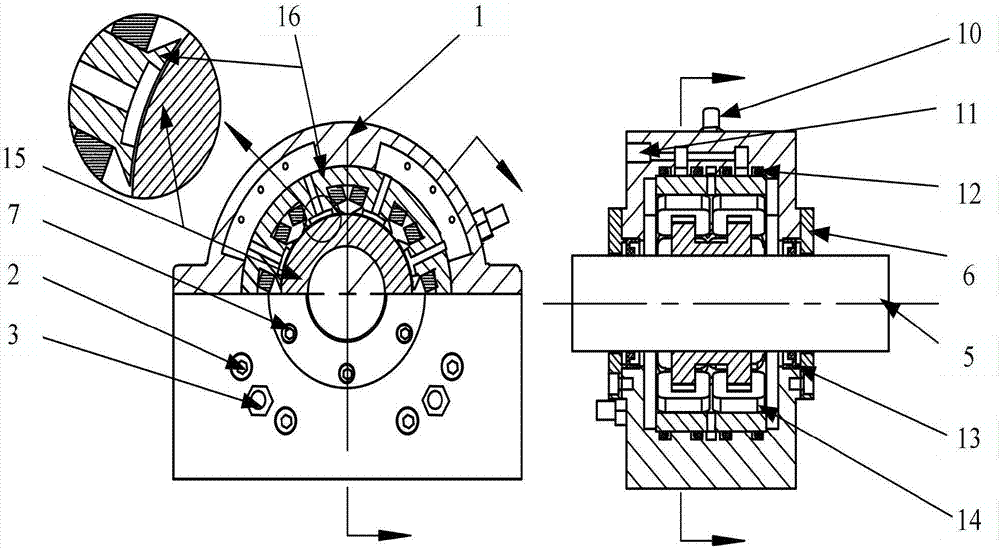

Centrifugal compressor

The invention discloses a centrifugal compressor. The centrifugal compressor comprises a motor and a first-level compressor body. The motor drives the first-level compressor body to run. A motor rotor of the motor is supported by a radial hydrostatic bearing to rotate, and the axial force of the motor rotor is balanced through an axial hydrostatic bearing. Gas and liquid double-phase low-viscosity fluid is adopted as lubrication media for the radial hydrostatic bearing and the axial hydrostatic bearing. According to the centrifugal compressor, low-velocity liquid and gas double-phase refrigerant porous material hydrostatic air bearings are adopted as the radial hydrostatic bearing and the axial hydrostatic bearing supporting the motor rotor, the radial and axial waggling of the rotor is reduced, and therefore gaps and sealing gaps between the tops of blades of impellers and volutes are allowed to be reduced by a half, and accordingly the efficiency of the centrifugal compressor can be improved by 10% or above.

Owner:ZHEJIANG FUTENG FLUID TECH CO LTD

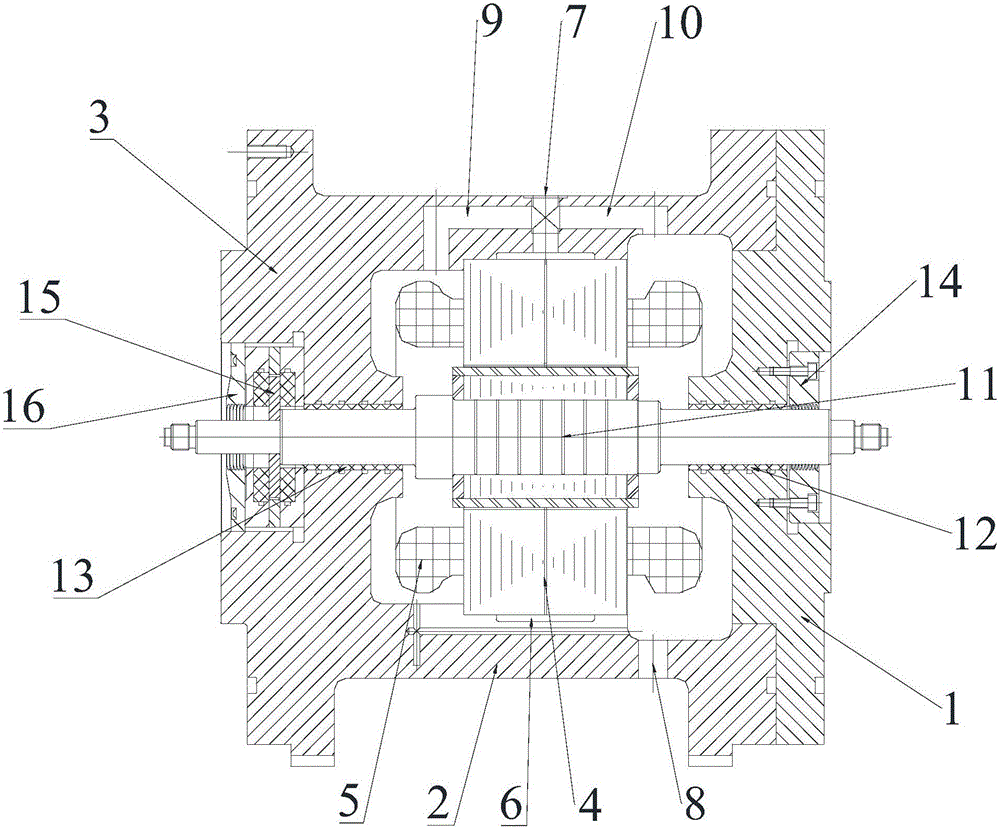

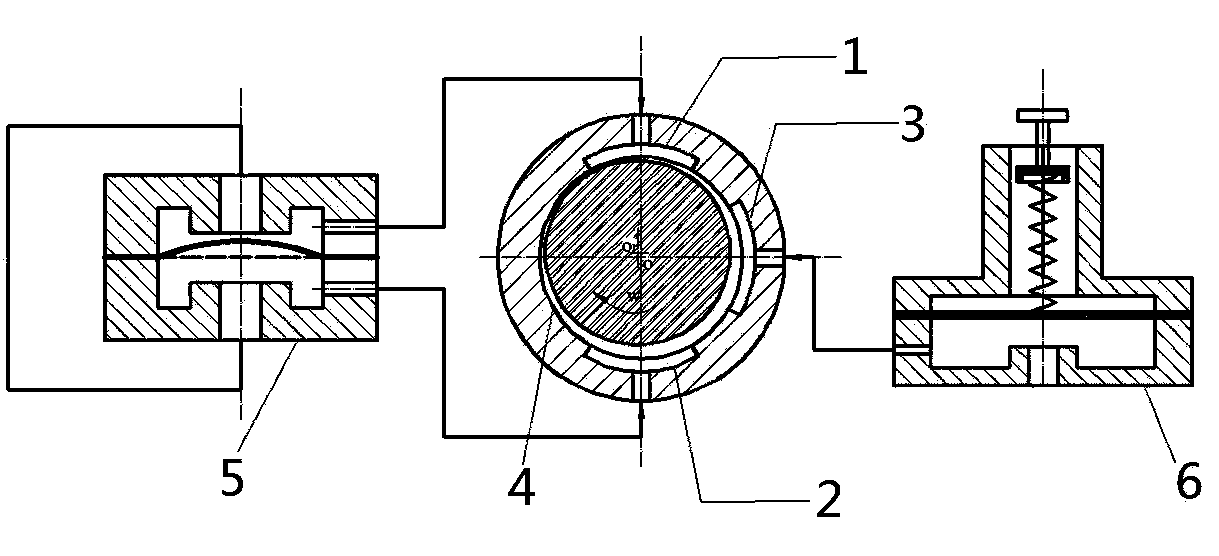

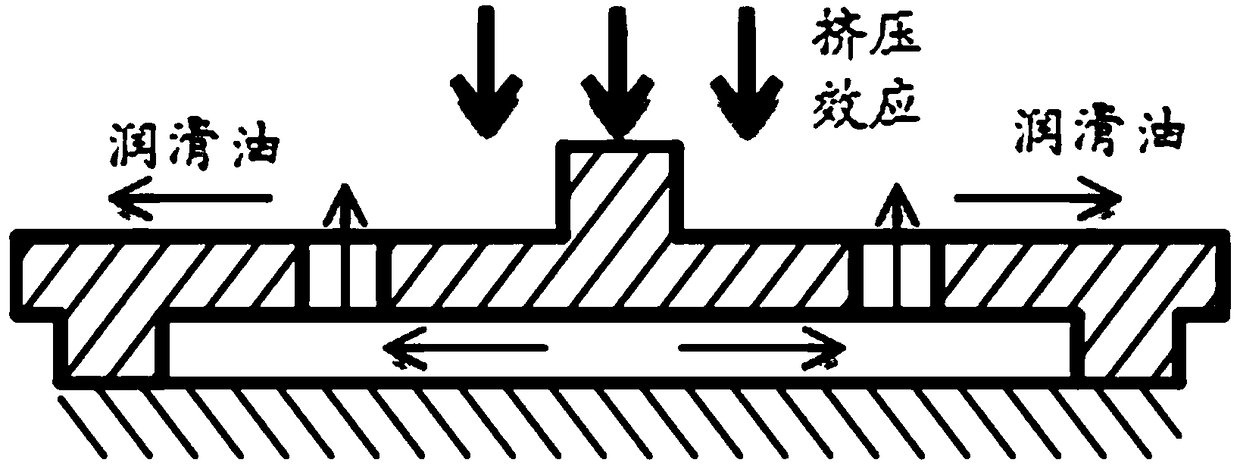

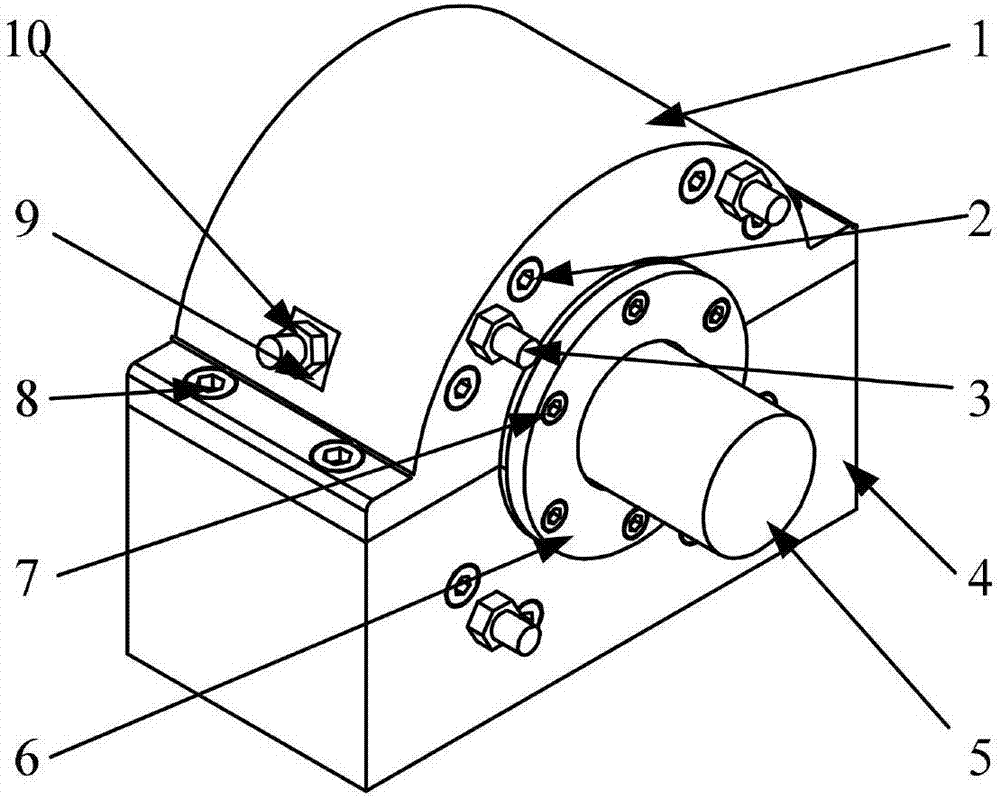

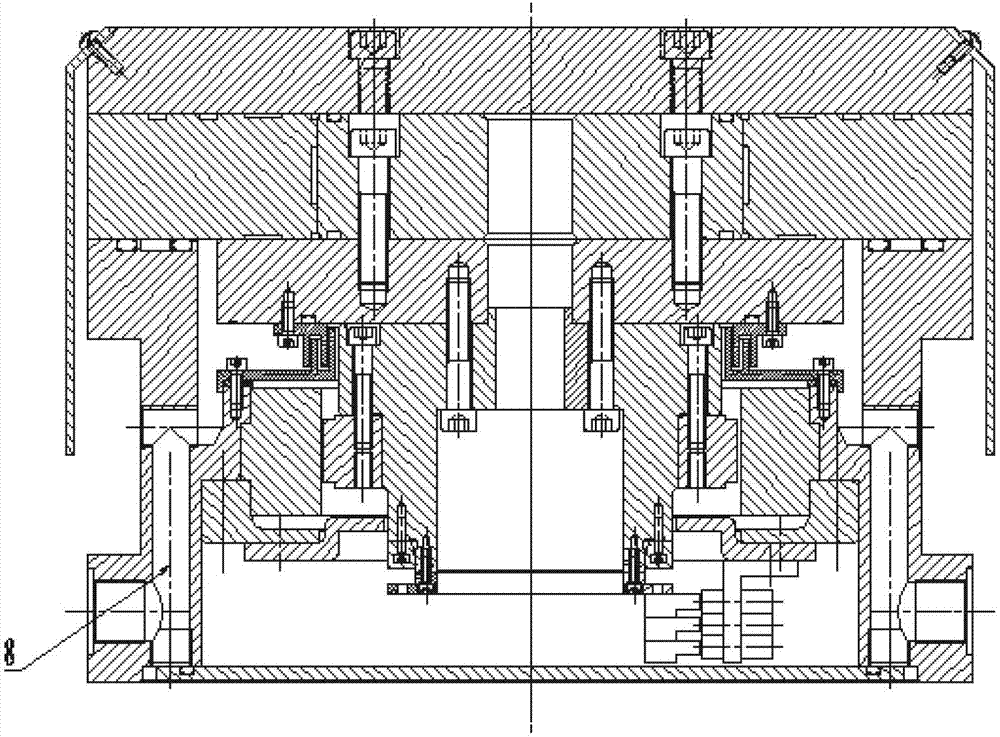

Thin-film restrictor hybrid bearing for roll grinder grinding wheel spindle

The invention provides a thin-film restrictor hybrid bearing for a roll grinder grinding wheel spindle. The bearing comprises an upper static pressure cavity and a lower static pressure cavity, wherein the upper static pressure cavity and the lower static pressure cavity are symmetrically arranged. The upper static pressure cavity and the lower static pressure cavity are connected with an external oil inlet hole and connected with a double-sided thin film restrictor through an oil way. The bearing further comprises a front static pressure cavity and a rear static pressure cavity. The front static pressure cavity is connected with the external oil inlet hole and communicated with a single-sided thin film restrictor through the oil way. According to the thin-film restrictor hybrid bearing, the design problem of a thin-film restrictor hybrid bearing for a roll grinder grinding wheel spindle is solved. Compared with a traditional capillary restrictor hybrid bearing, the thin-film restrictor hybrid bearing has higher rigidity under the condition of starting static pressure; meanwhile, the thin-film restrictor hybrid bearing has higher bearing capacity, higher rigidity and lower temperature rise under the hybrid condition when the spindle rotates at a high speed, and therefore the thin-film restrictor hybrid bearing meets the requirements of modern development of roll grinders for high efficiency, high rigidity, high accuracy and the like.

Owner:HUNAN UNIV +1

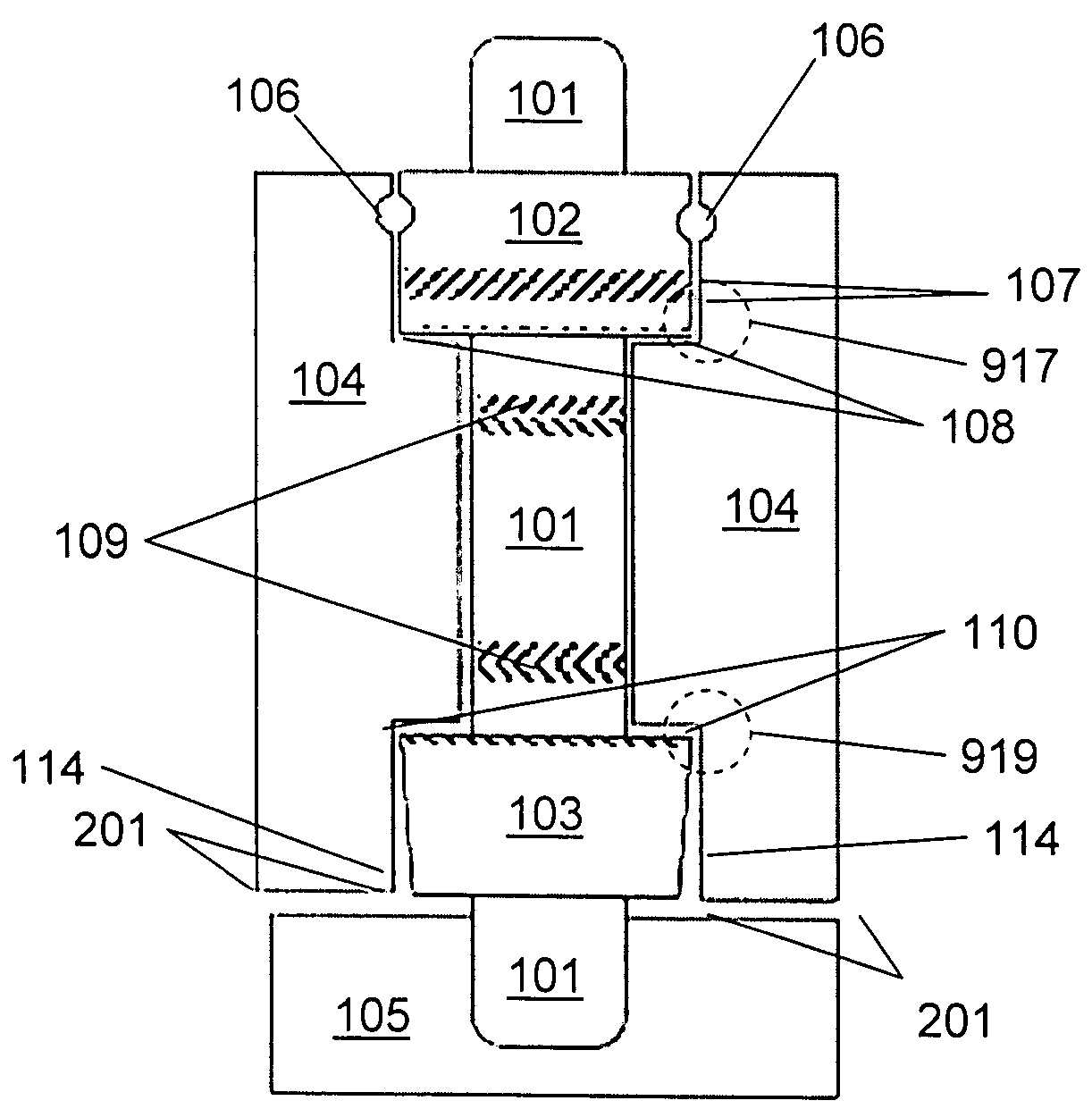

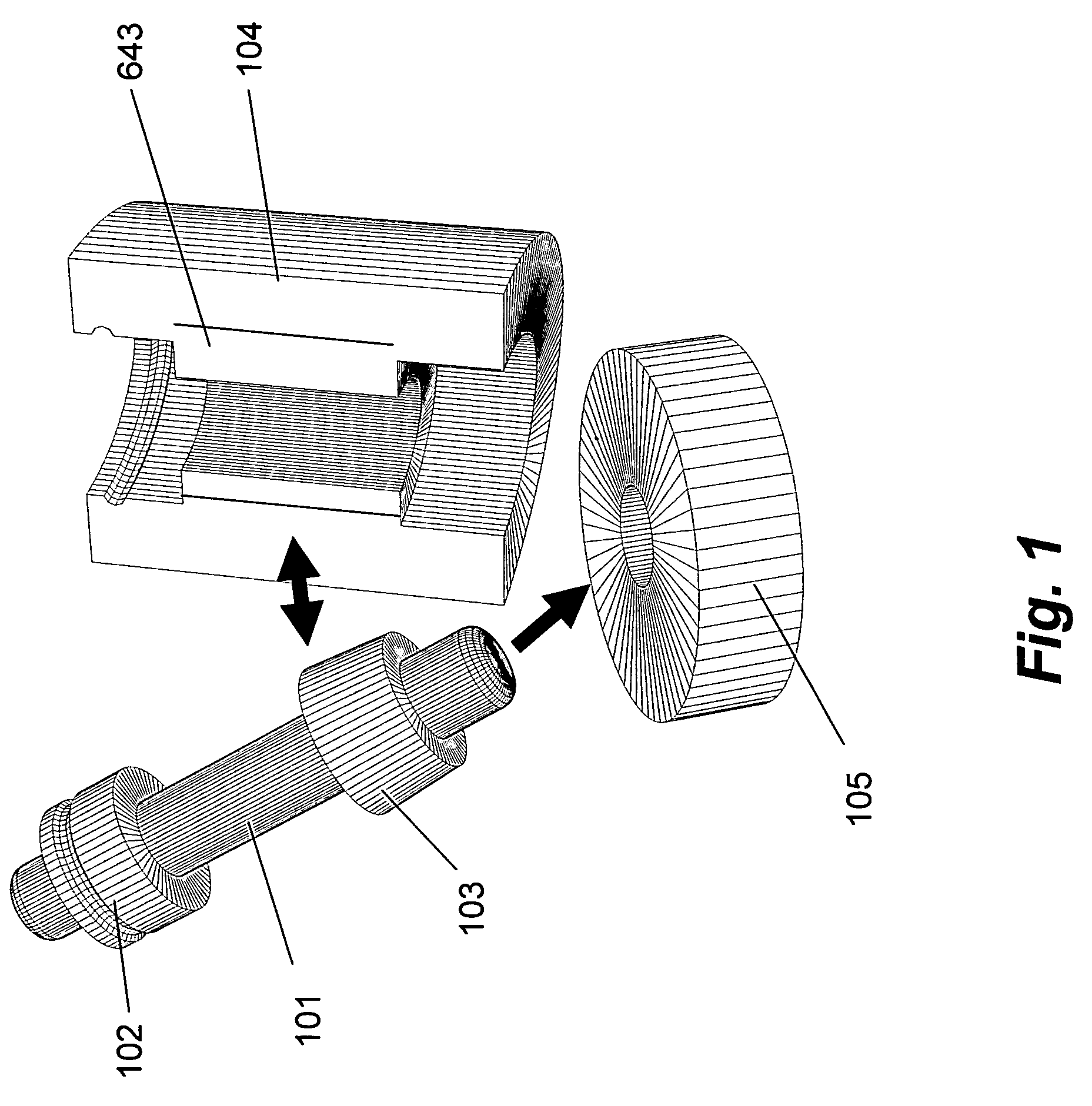

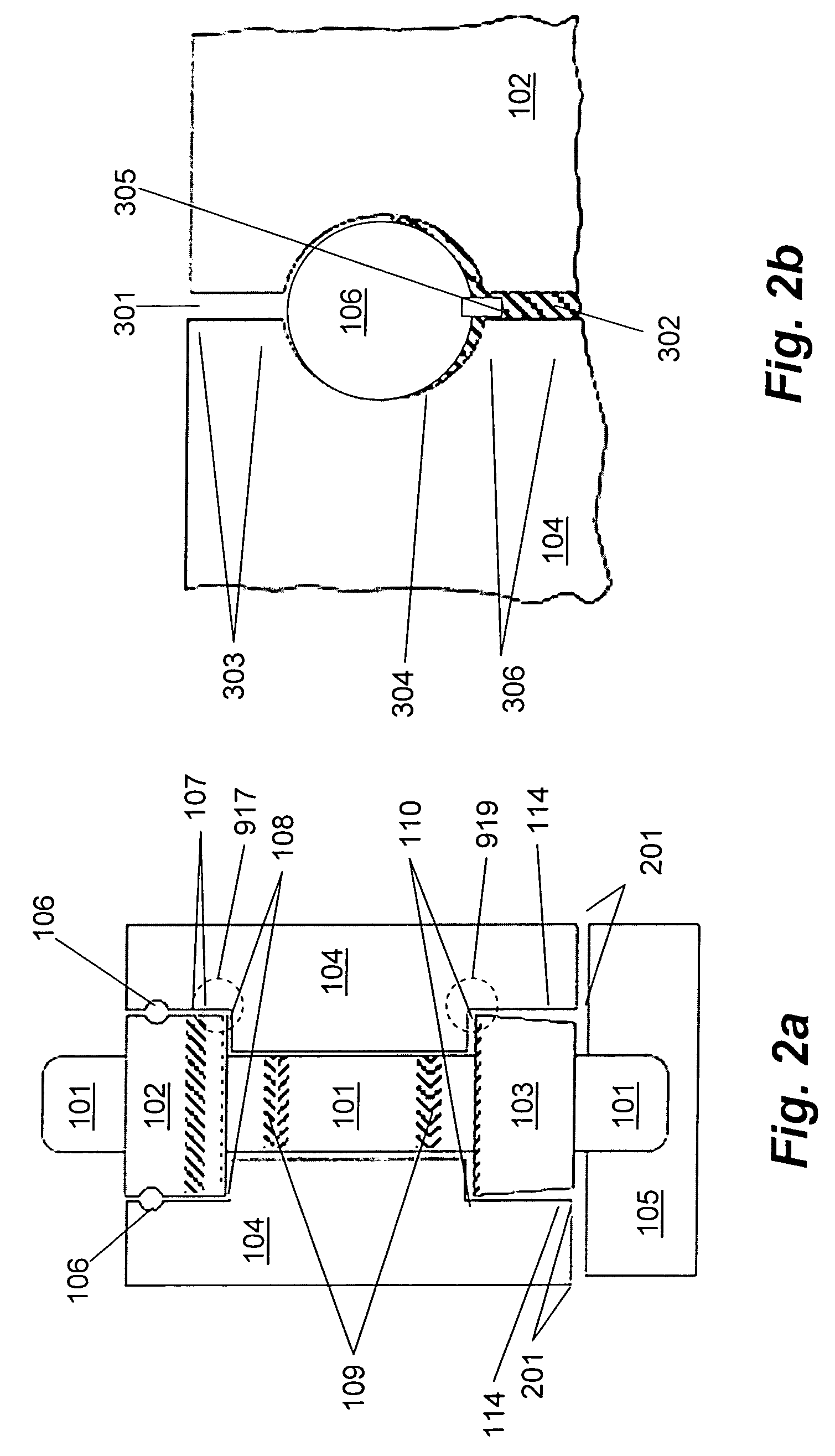

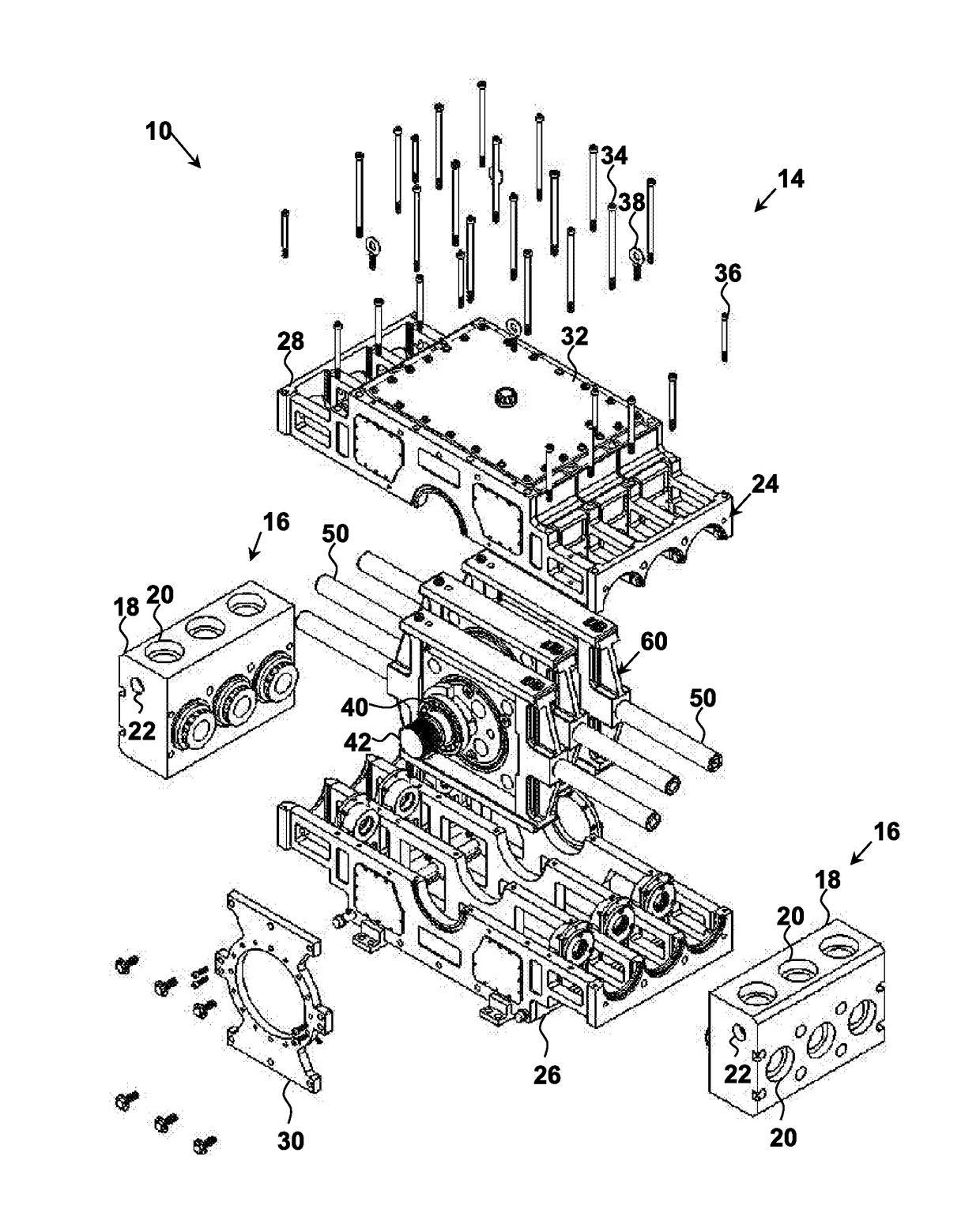

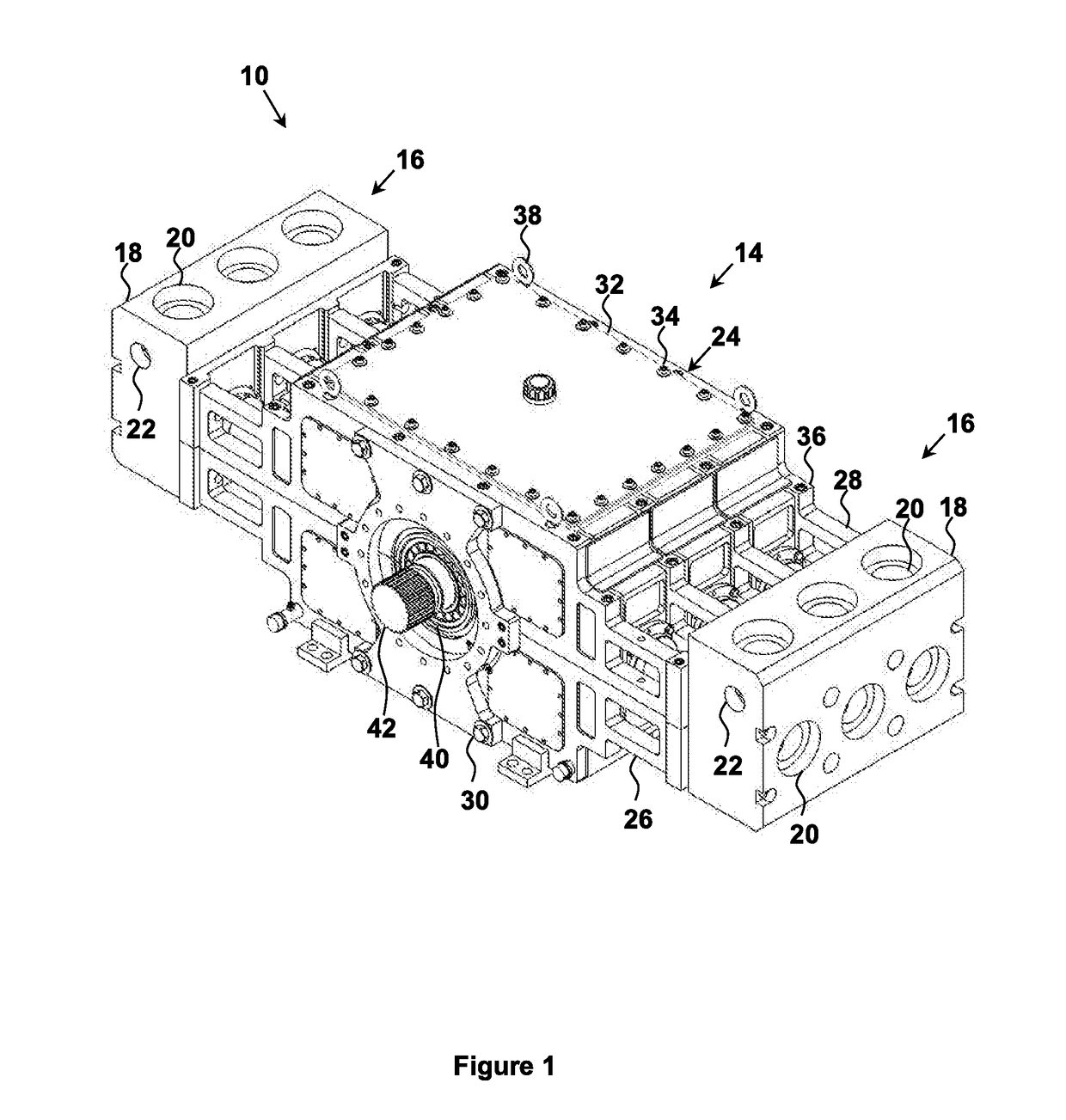

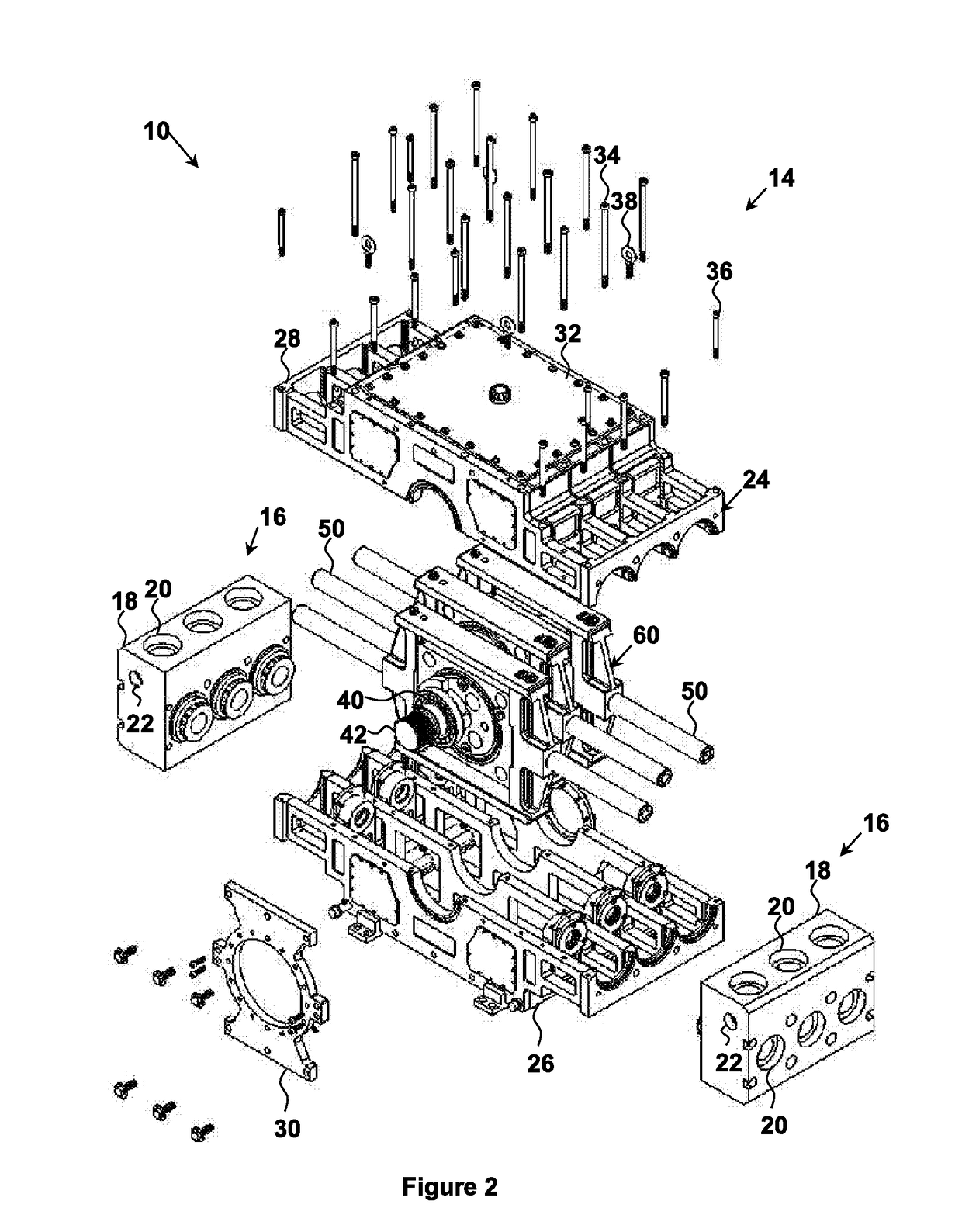

Drive mechanism module for a reciprocating pump

A drive mechanism module for use in a reciprocating pump converts rotational movement of a drive shaft to reciprocating movement of a reciprocating pump component transversely to the drive shaft. The drive mechanism module includes a connection member for attachment to the reciprocating pump component, a translating member that drives movement of the connection member in a first transverse direction while reciprocatingly translating in a second transverse direction relative to the connection member, a rotating member that rotates eccentrically with the drive shaft, and a rotary bearing assembly that permits rotation of the rotating member relative to the translating member while driving transverse movement of the translating member. The drive mechanism module may define a bearing fluid path for creating a hydrostatic or hydrodynamic fluid bearing at the interface of the connection member and the translating member.

Owner:A H M S INC

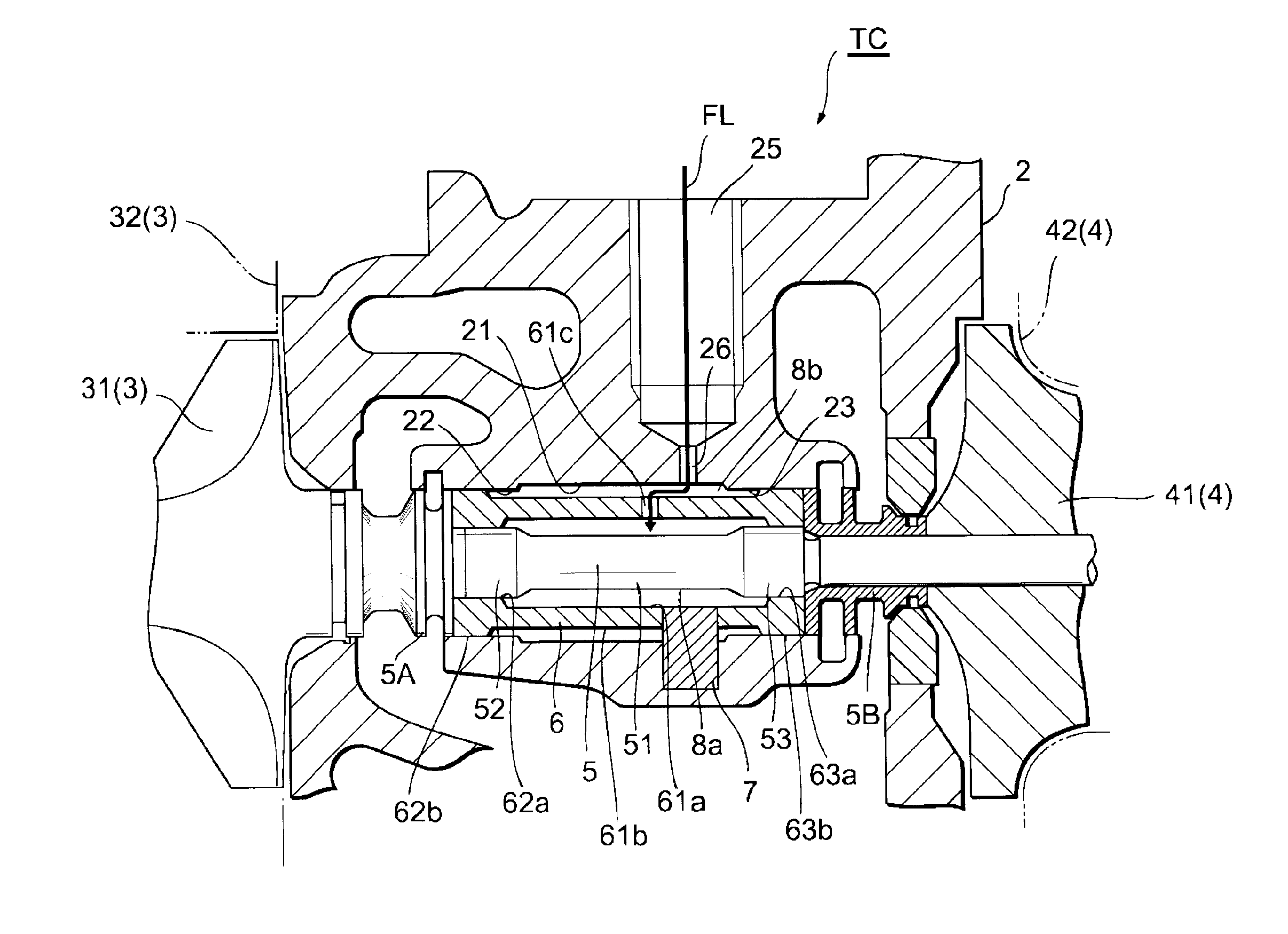

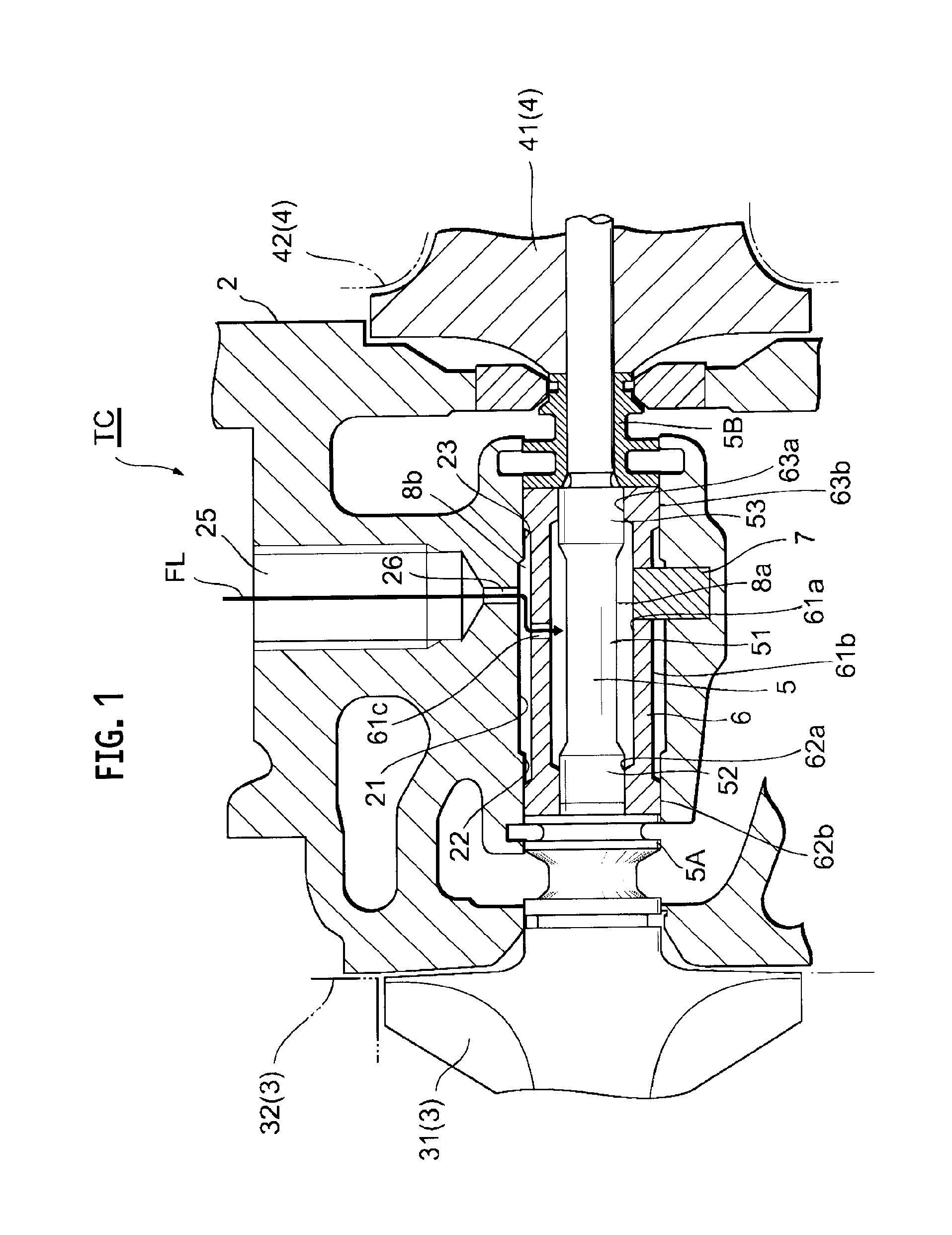

Centrifugal compressor assembly and method of operation with an airconditioner

ActiveUS20170370364A1Minimize oscillationReduce clearancePump componentsShaftsAxial displacementVapor liquid

A centrifugal compressor assembly and method of operation provides a motor that drives a first stage compressor. The motor comprises a rotor. The motor uses radial aerostatic bearings to stabilize rotation and axial displacement of the rotor. The motor also uses a thrust aerostatic bearing to balance an axial force of the rotor. The radial aerostatic bearings and the thrust aerostatic bearing use a low-viscous vapor-liquid two-phase fluid as a lubricating medium. The radial aerostatic bearings supports the rotor. The thrust aerostatic bearing uses porous aerostatic bearings that use a low-viscous vapor-liquid two-phase fluid, so as to reduce radial and axial oscillation of the rotor. This enables clearance between a blade tip of an impeller and a volute. This causes a seal clearance to be reduced by a half; thereby increasing efficiency of the centrifugal compressor by at least 10 percent.

Owner:ZHEJIANG FLOWTECH INC

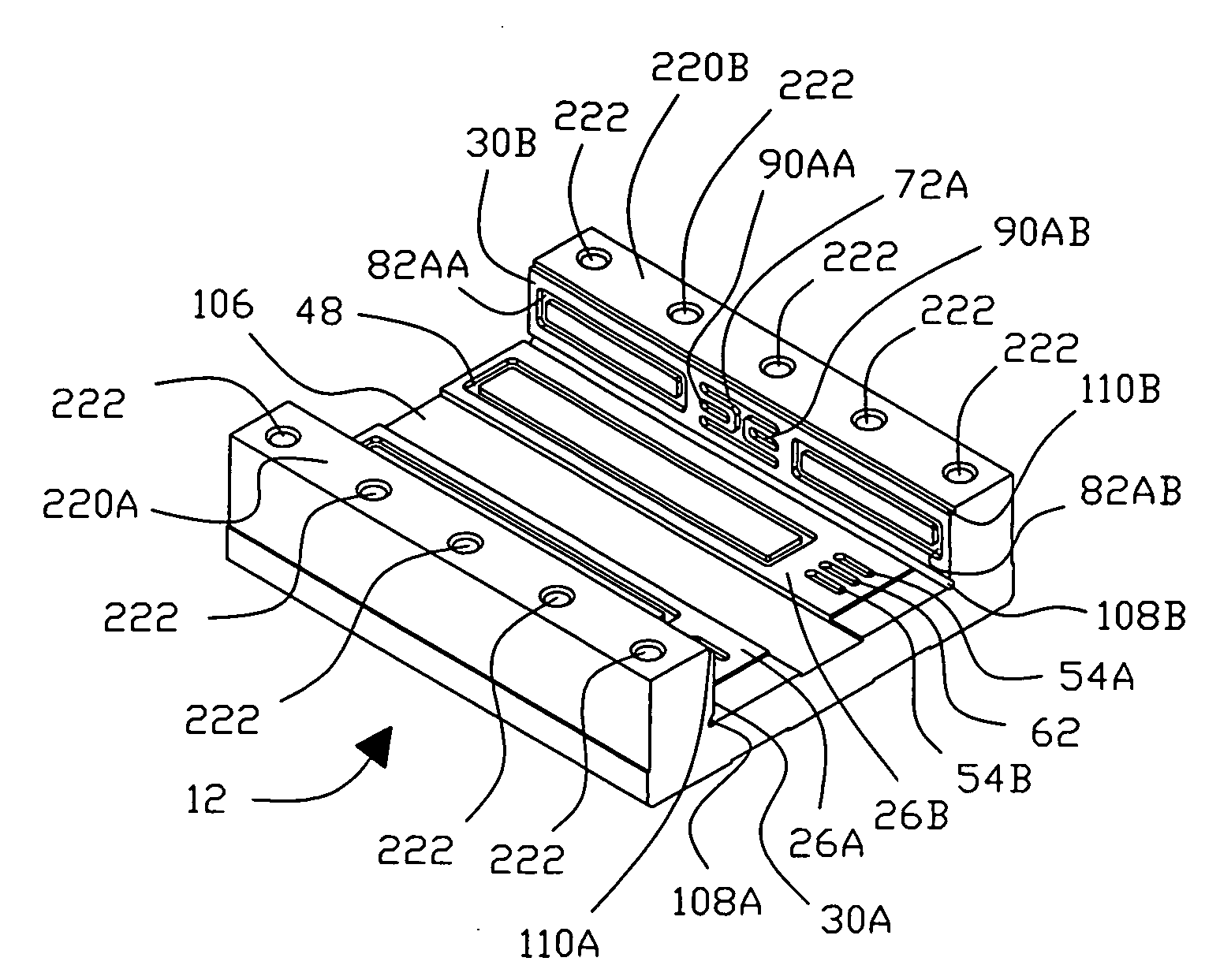

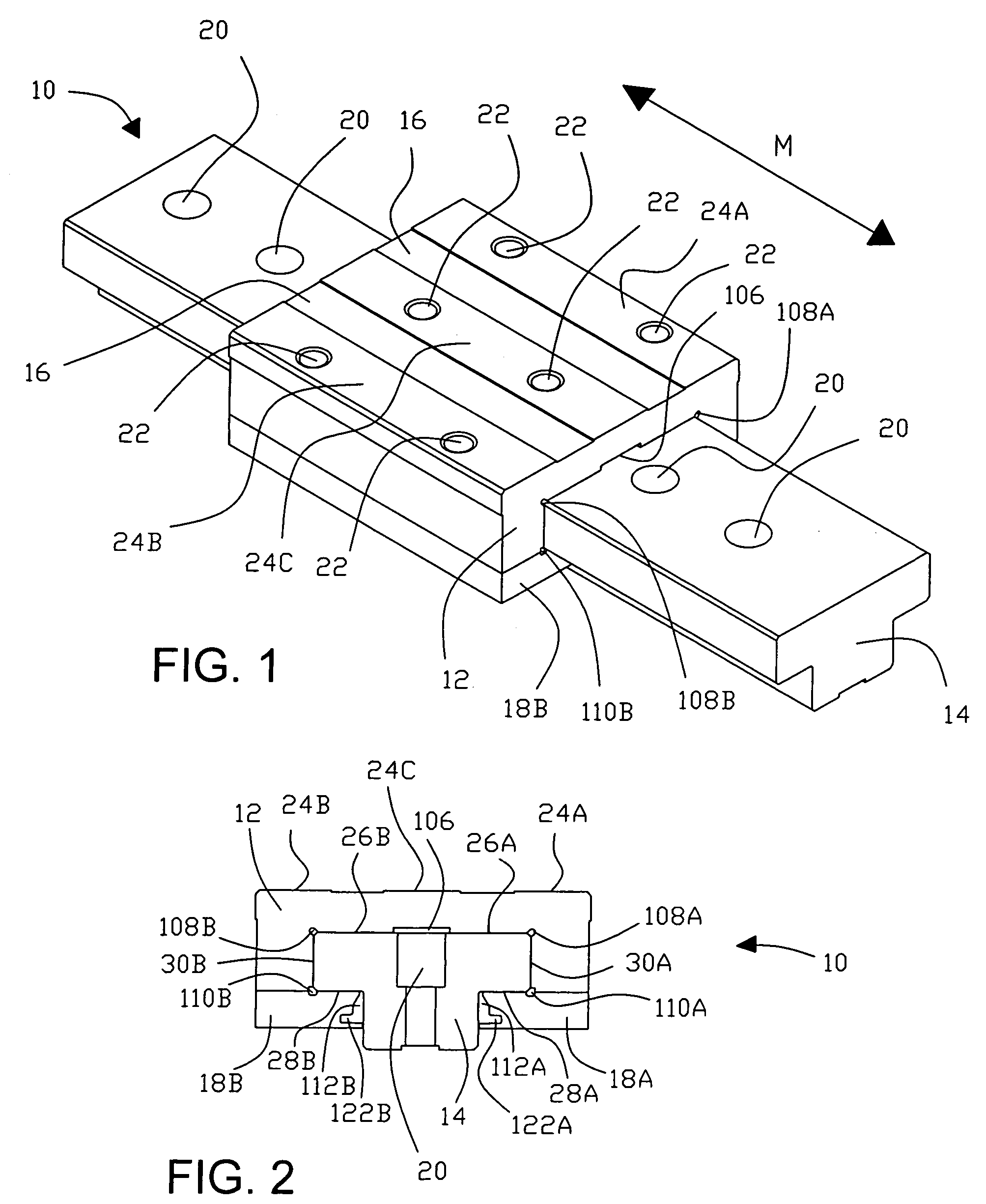

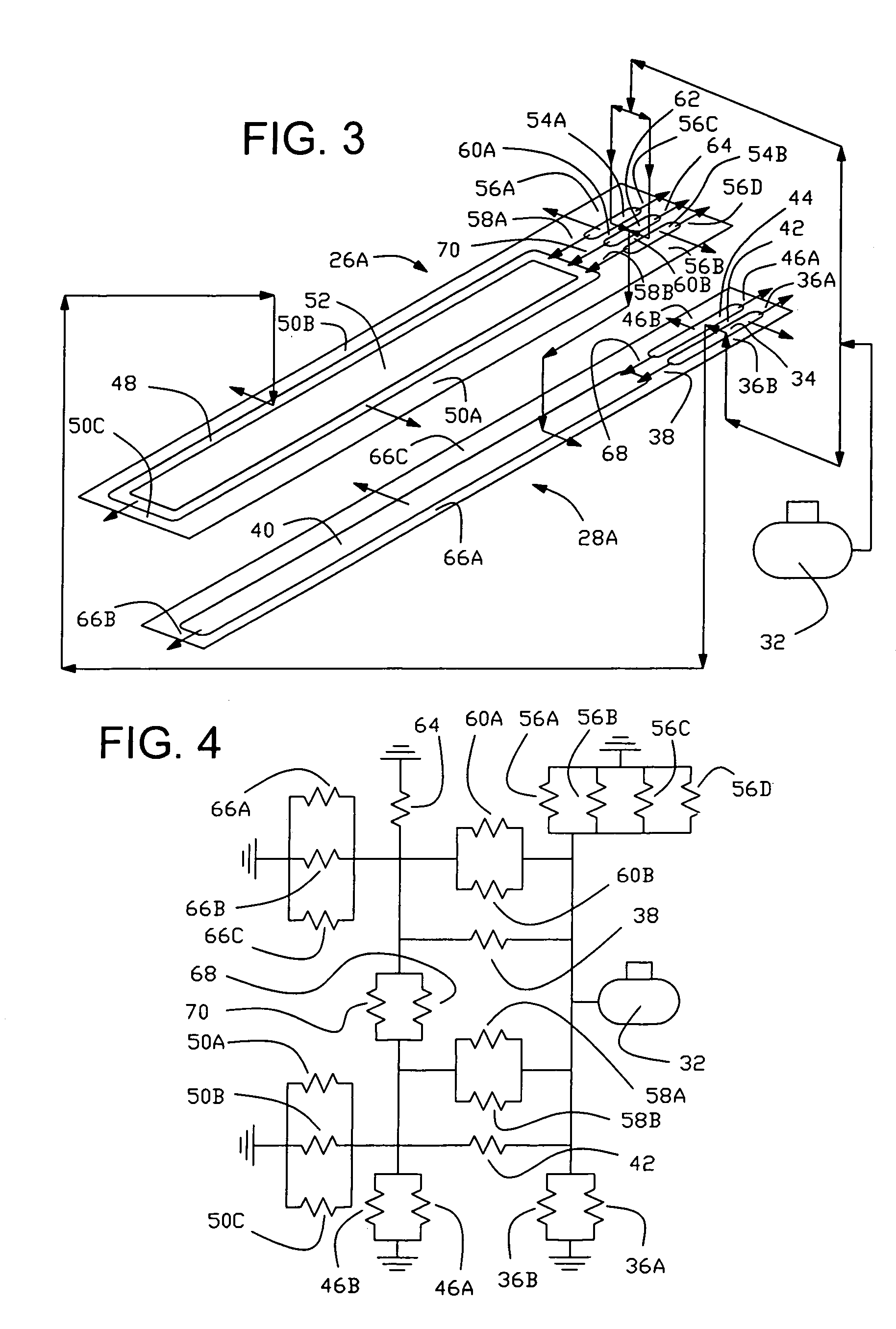

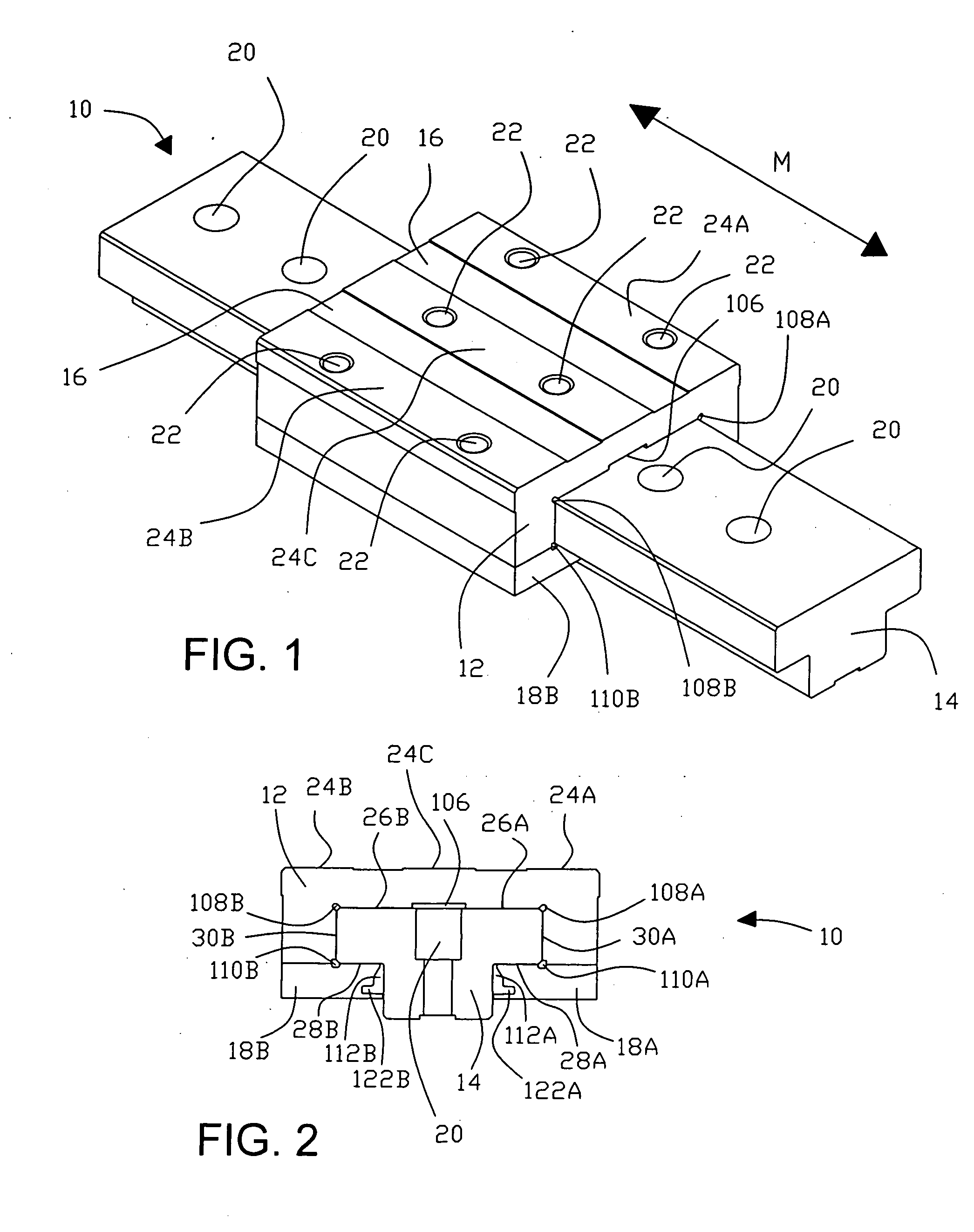

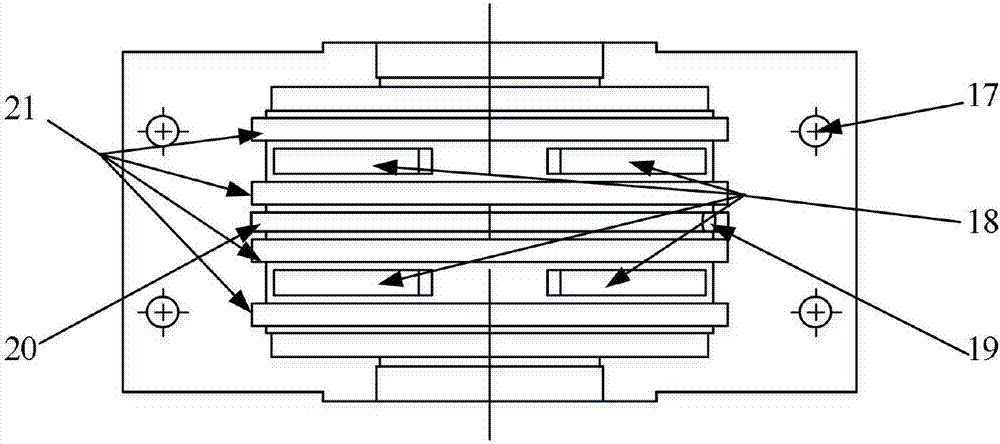

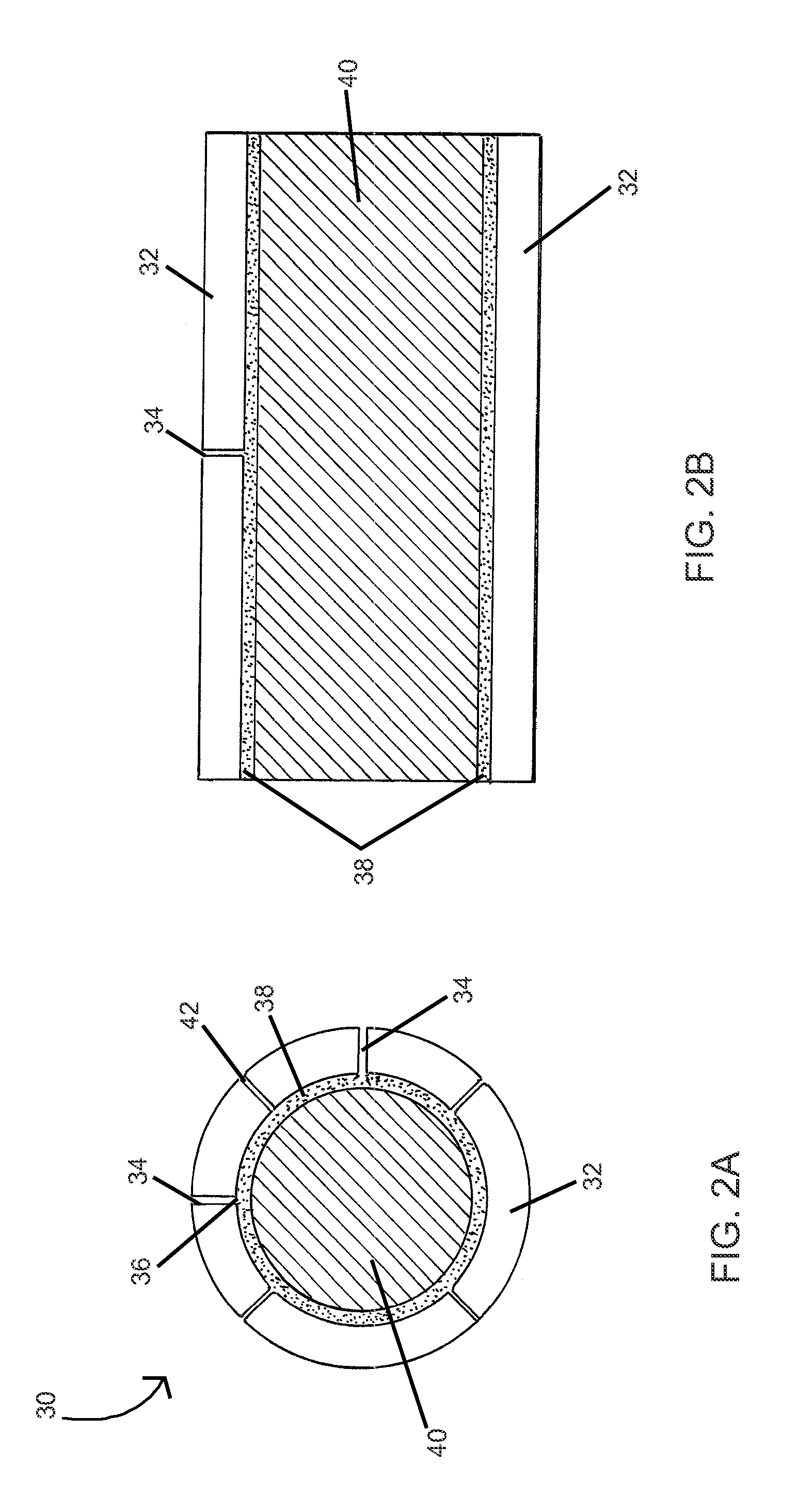

Hydrostatic bearing for linear motion guidance

InactiveUS7287906B2Prevent leakageAvoid flowLinear bearingsLiquid cushion bearingsLinear motionHigh stiffness

A self-compensating hydrostatic (pressurized fluid film) linear bearing that maintains a fluid gap between a carriage and a rail when relative forces are applied. The geometric shape of the rail and mating carriage enable the bearing to have very high stiffness and load capacity without exessive detrimental carriage deformation. The carriages contain bearing grooves and lands which control and use fluid pressure to provide a very high degree of restoring force in response to changes in the fluid gap. The fluid emanating from the bearing gap is prevented from immediately leaking from the bearing carriage, and is instead routed back to the source from which it is pumped, thereby sealing the bearing carriage and simplifying the handling of the lubricating fluid. The hydrostatic bearing is particularly designed to be compact and to be bolt-for-bolt compatible with conventional linear bearings.

Owner:MFR & TRADERS TRUST COMPANY AS AGENT

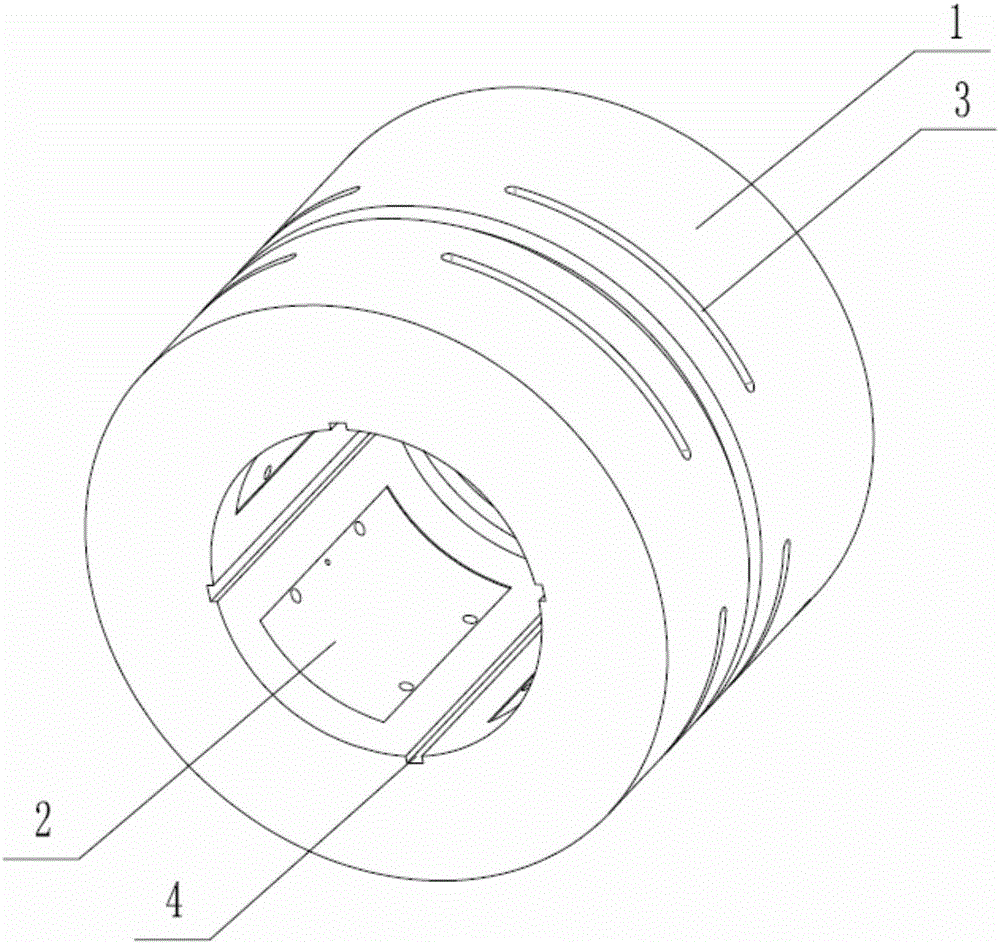

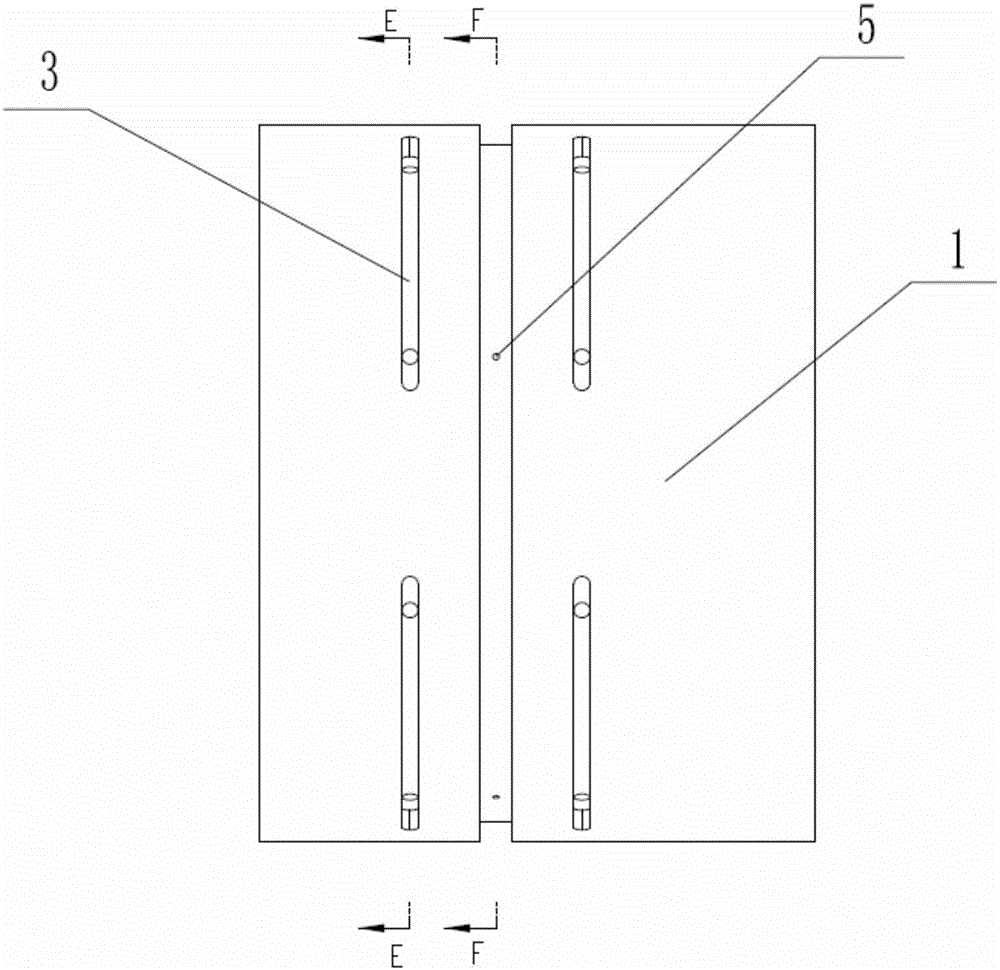

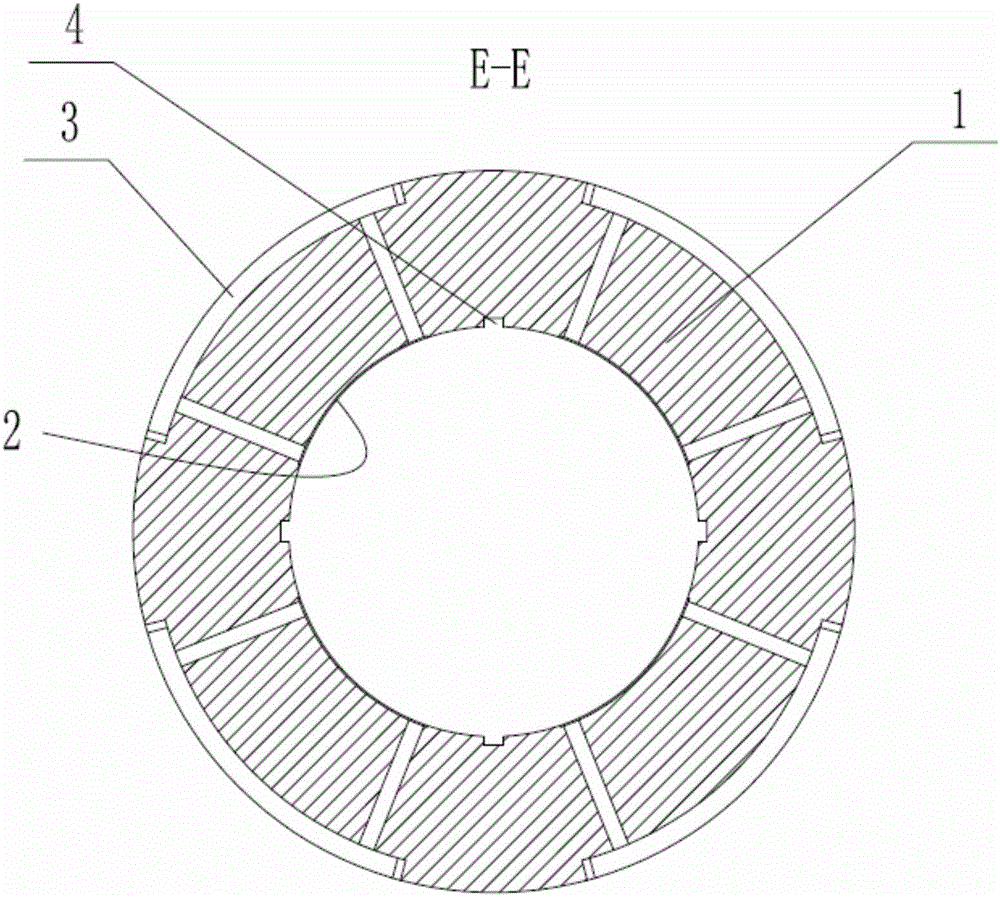

Hybrid bearing and main shaft provided with hybrid bearing

ActiveCN105673689ARelieve pressureIncrease speedLiquid cushion bearingsHigh-pressure areaDrive motor

The invention discloses a hybrid bearing. The hybrid bearing comprises a bearing body (1). At least two oil grooves (2) are formed in the annular inner wall of the bearing body (1) in the radial direction of the bearing body (1) in an inwards concave mode. The hybrid bearing is characterized in that the bearing body (1) is provided with circulation channels (3), and the two ends of each circulation channel (3) communicate with two ends corresponding to the oil grooves (2) in the circumferential direction of the bearing body (1) correspondingly. According to the hybrid bearing provided by the invention, the pressure difference of an oil liquid high-pressure area and an oil liquid low-pressure area in an oil cavity can be balanced, accordingly, the purpose of reducing the radial acting force on a rotating shaft is achieved by reducing the pressure of oil liquid in the oil liquid high-pressure area, finally, the rotation speed of the rotating shaft is high, and the load of a driving motor is small.

Owner:钟勇军

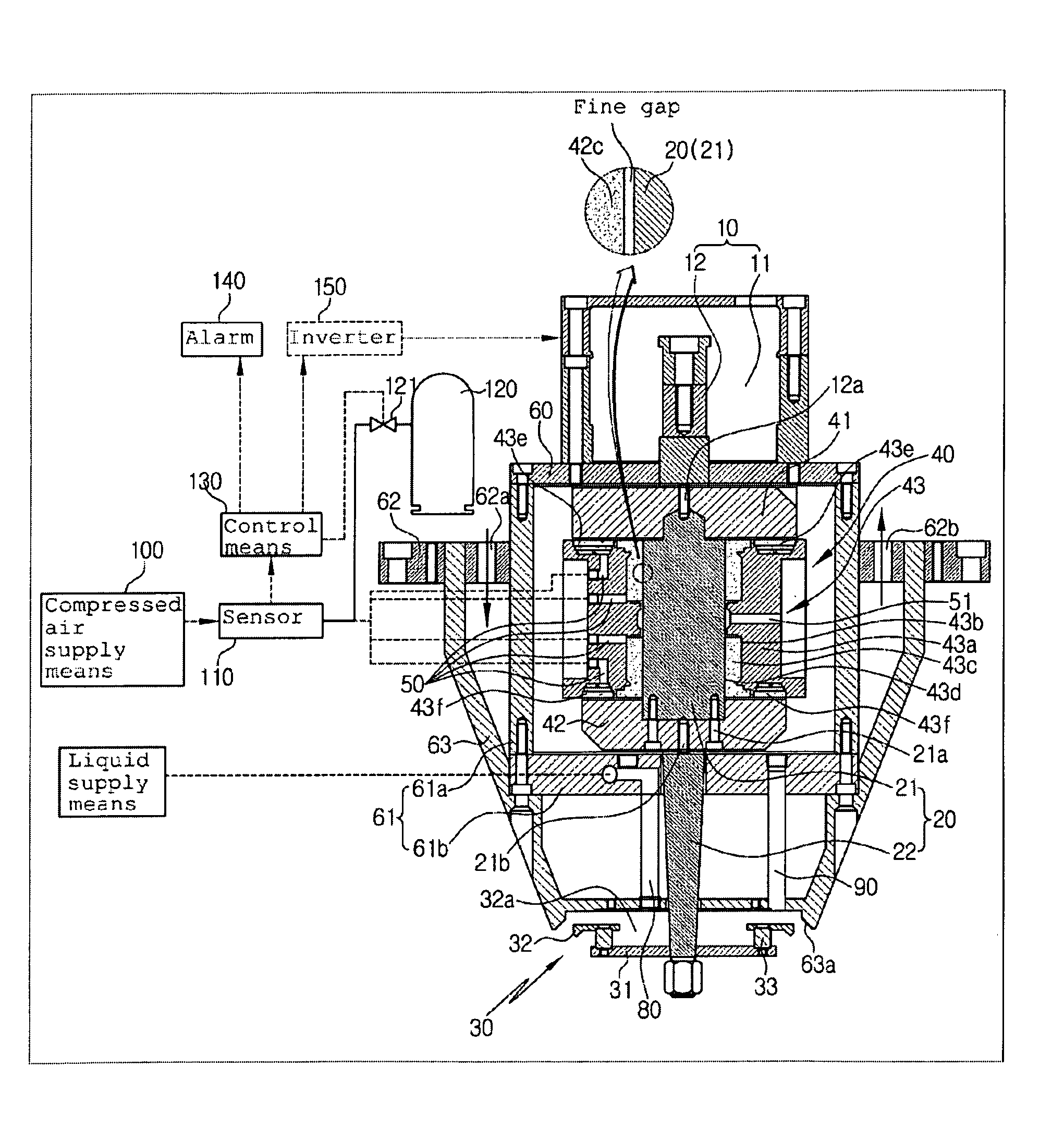

Rotary atomizer, and air bearing protection system for rotary atomizer

InactiveUS7344092B1Reduce manufacturing costReduce maintenance costsBurnersMovable spraying apparatusManufacturing cost reductionAir bearing

Disclosed herein are a rotary atomizer and an air bearing protection system for the rotary atomizer. The structure of the system is simplified to reduce the manufacturing cost. An air bearing is used to enable high-speed rotation along with savings in the maintenance and repair cost. Compressed air can be temporarily supplied at emergency such as interruption of the compressed air. Thus the stability and durability of the entire system are improved, such as prevention of air bearing failure.

Owner:KIM JUNG WON

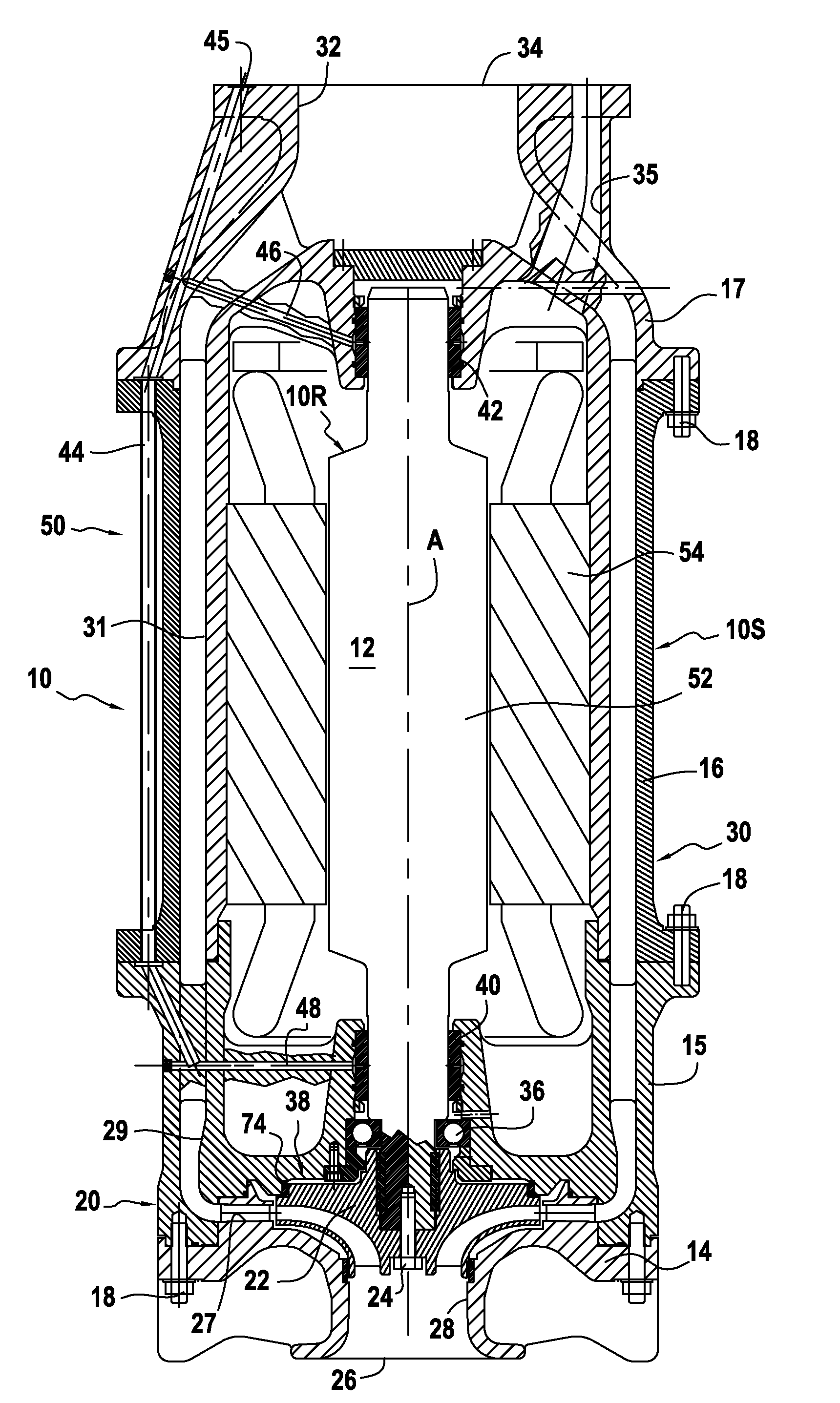

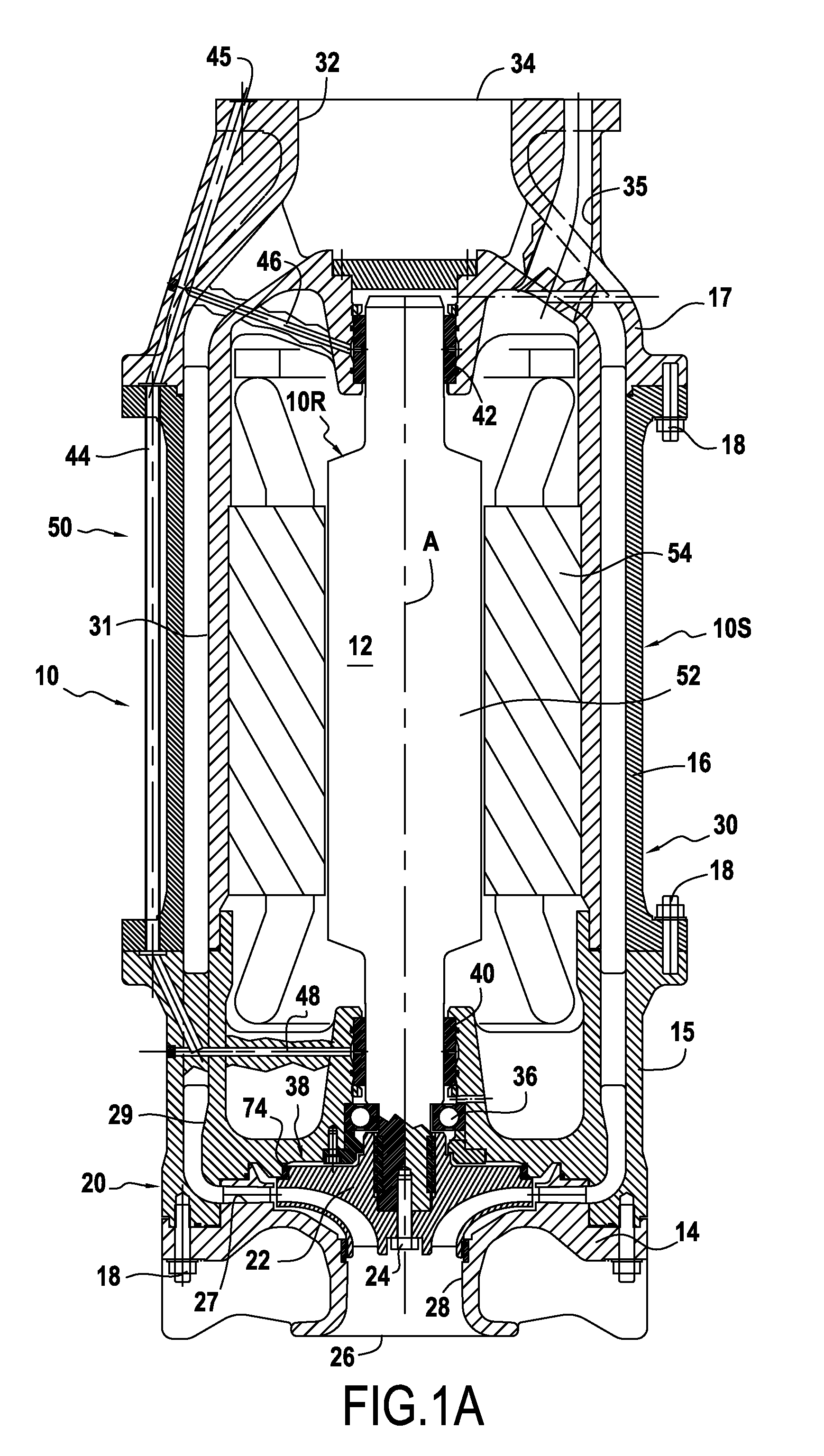

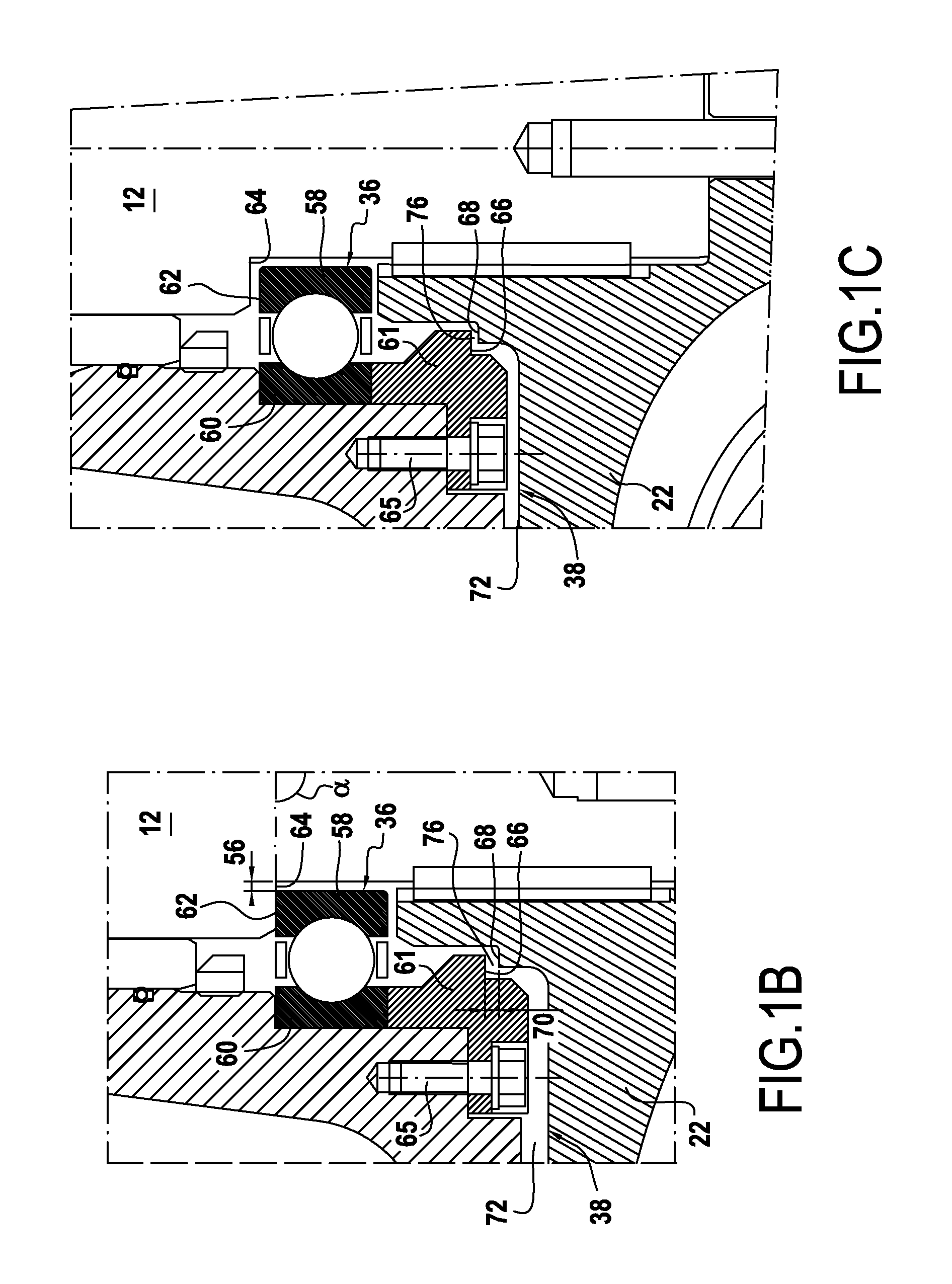

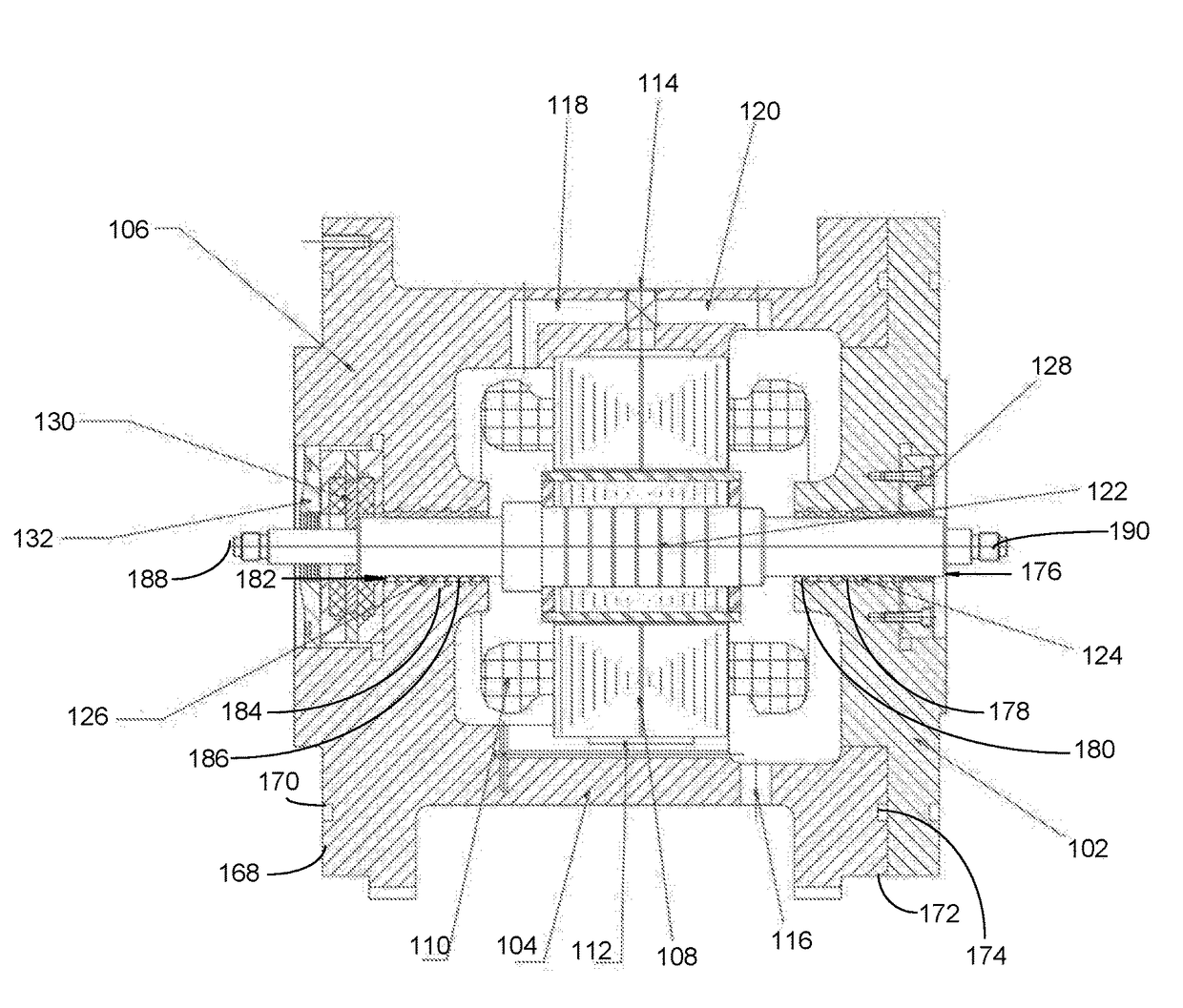

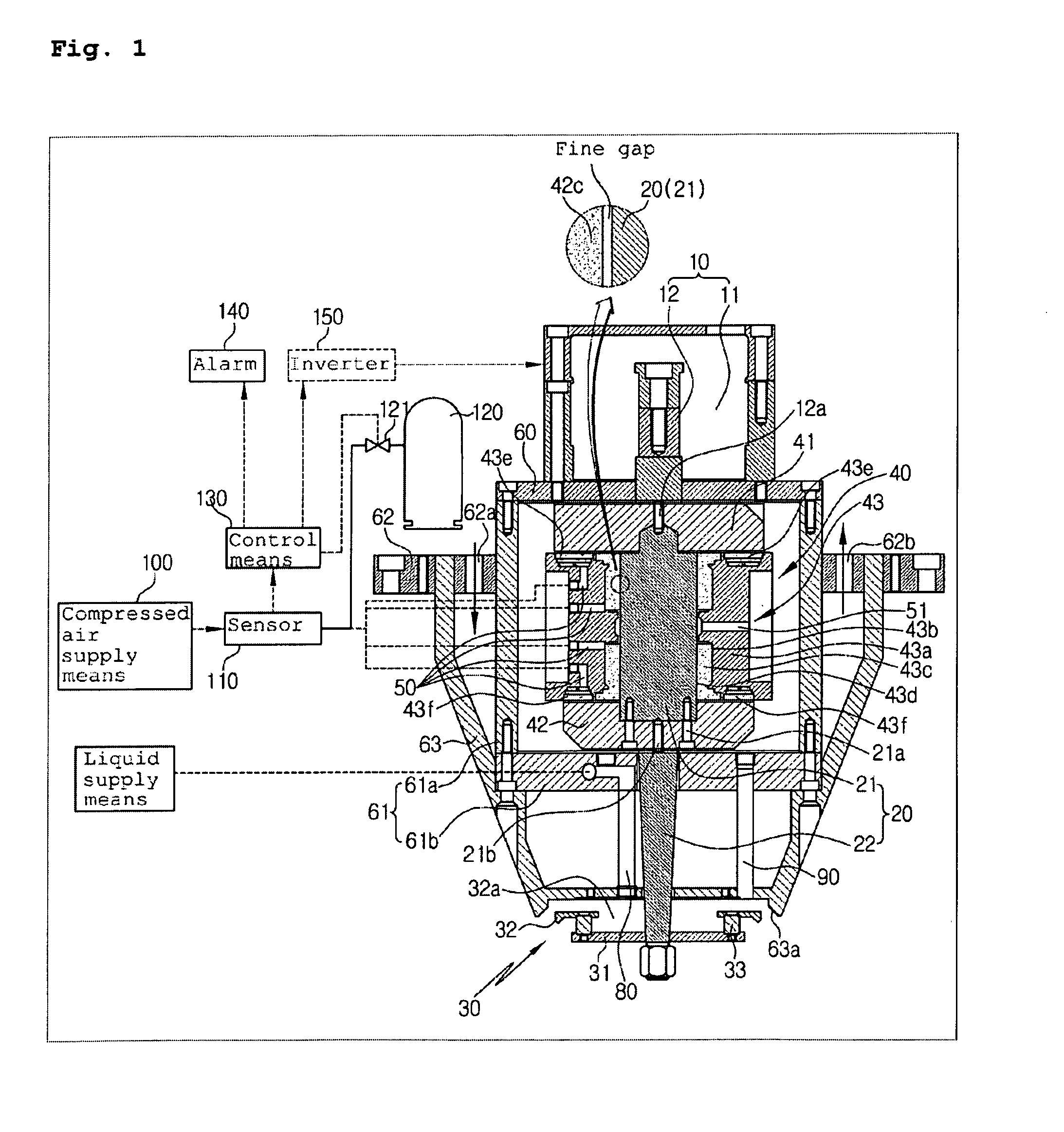

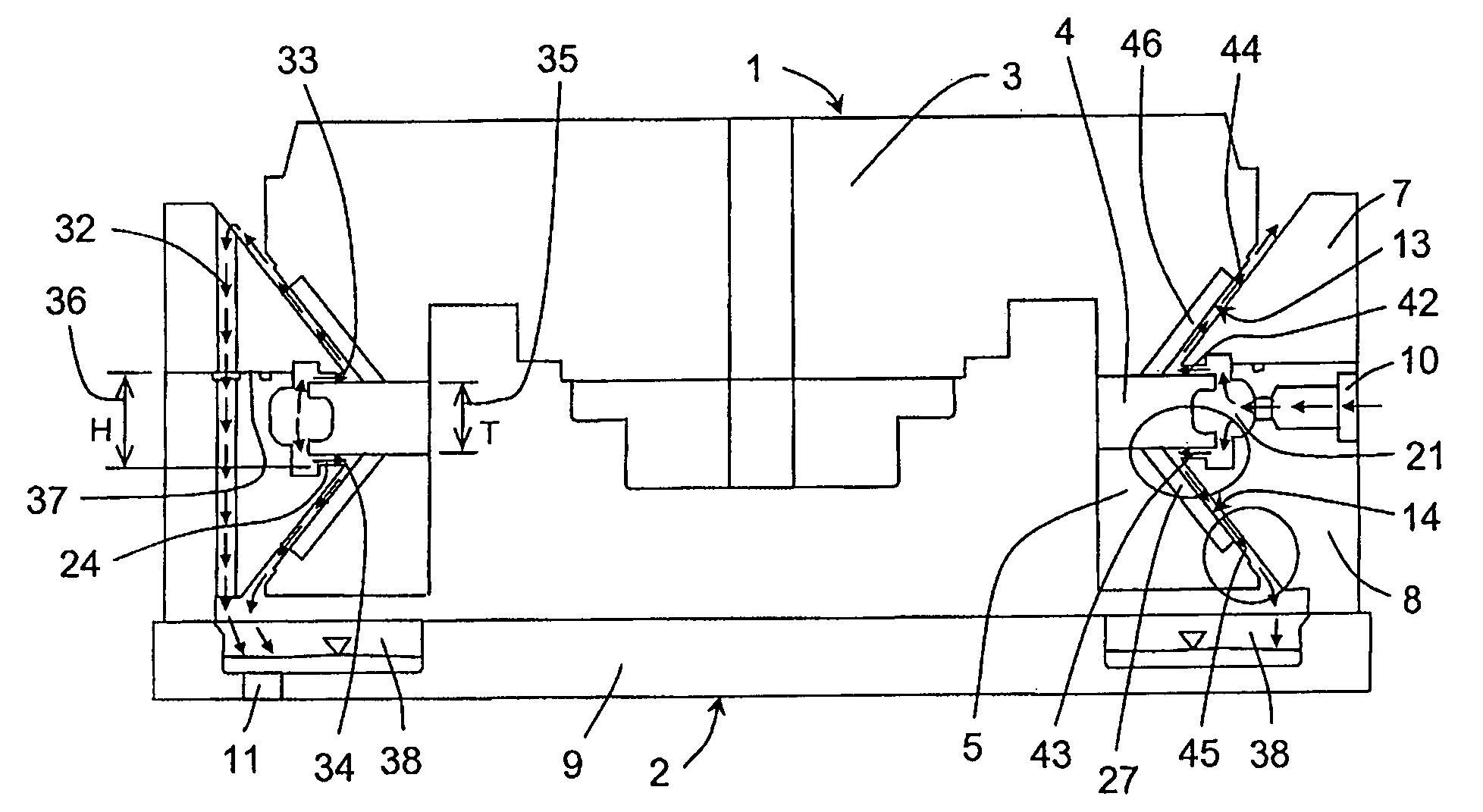

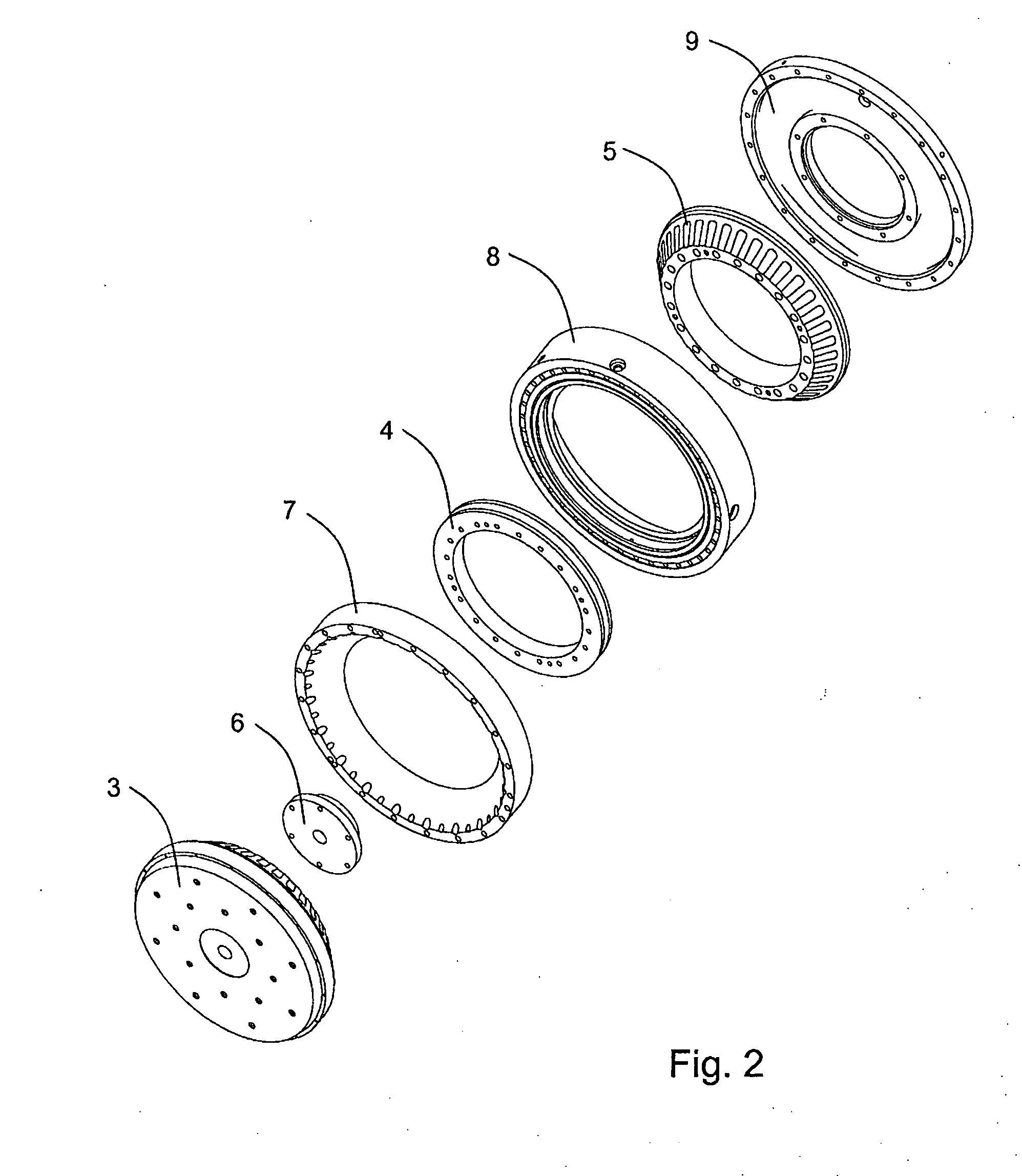

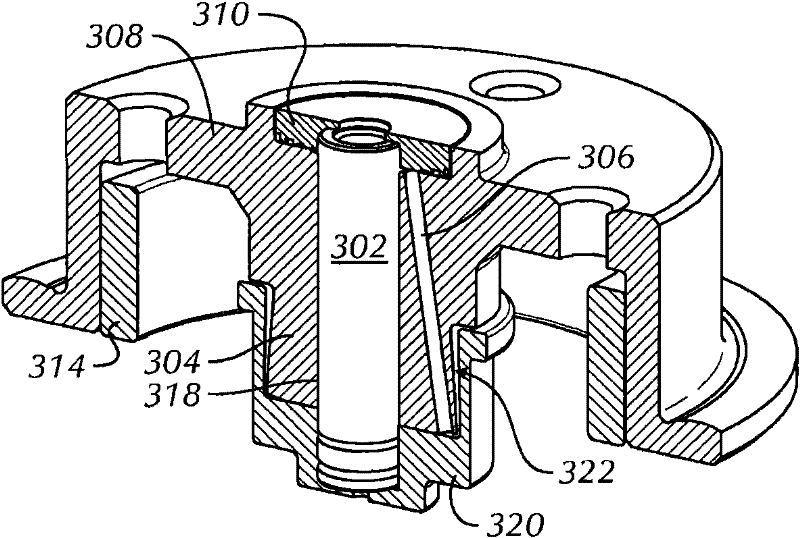

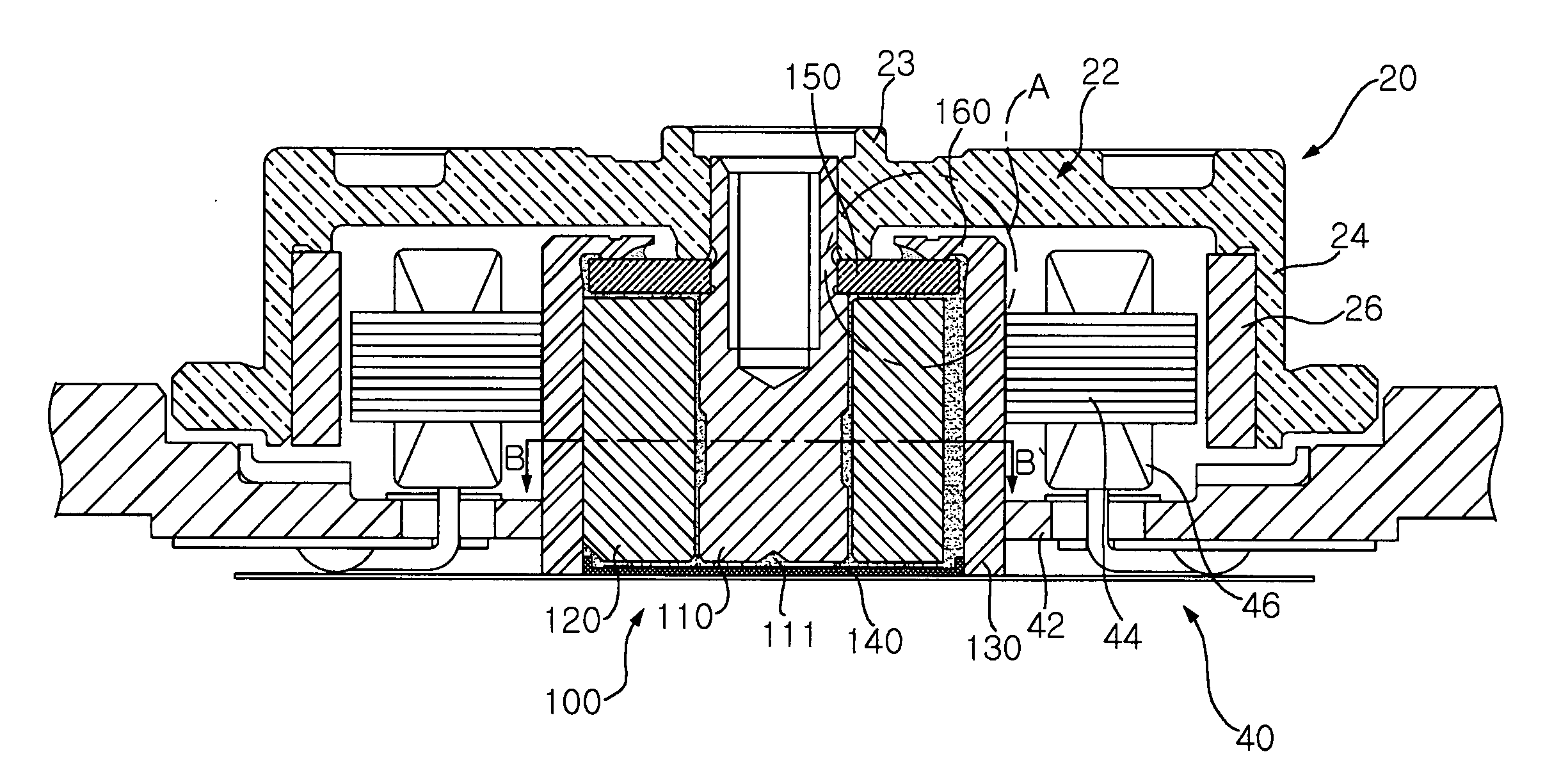

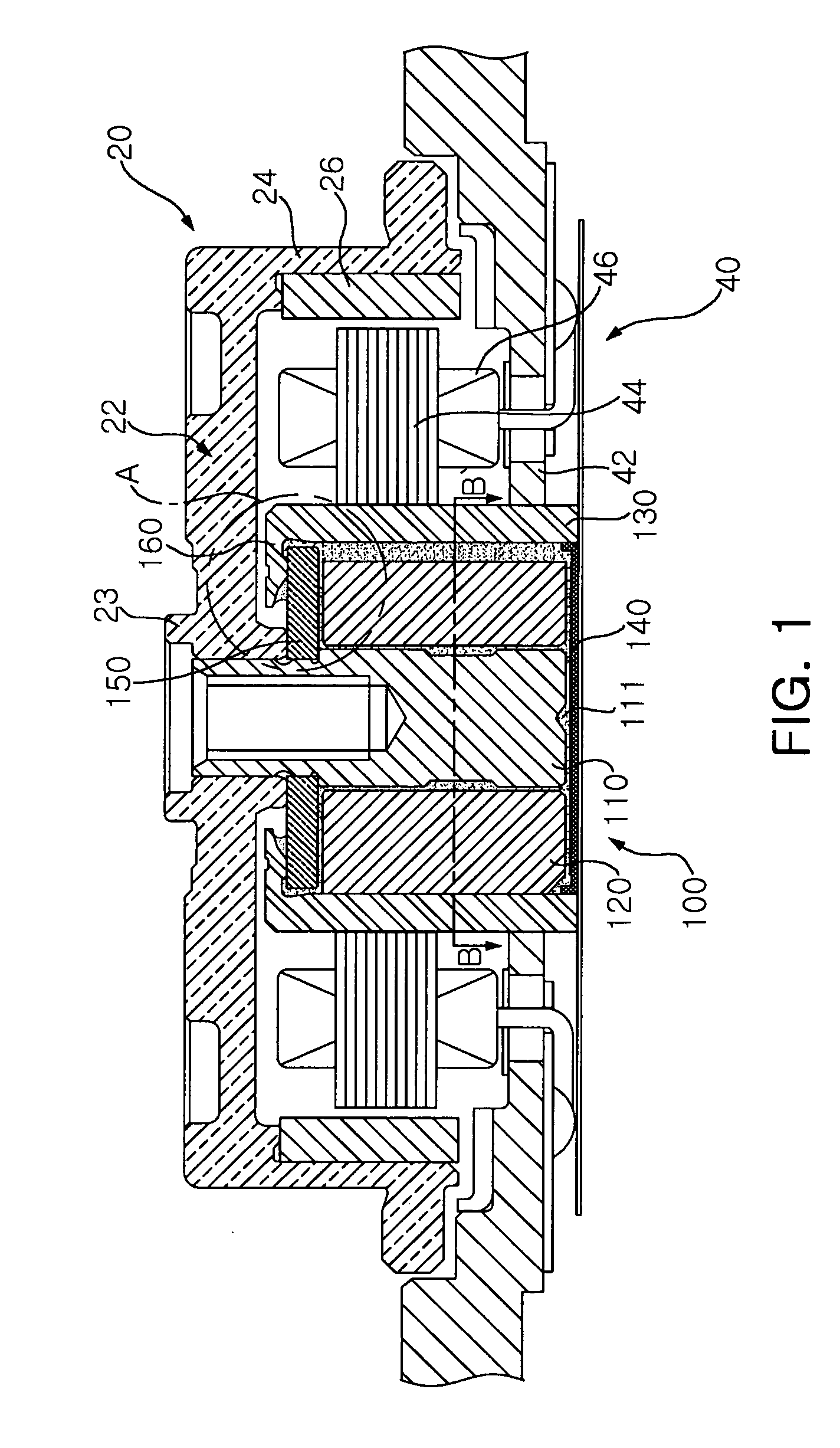

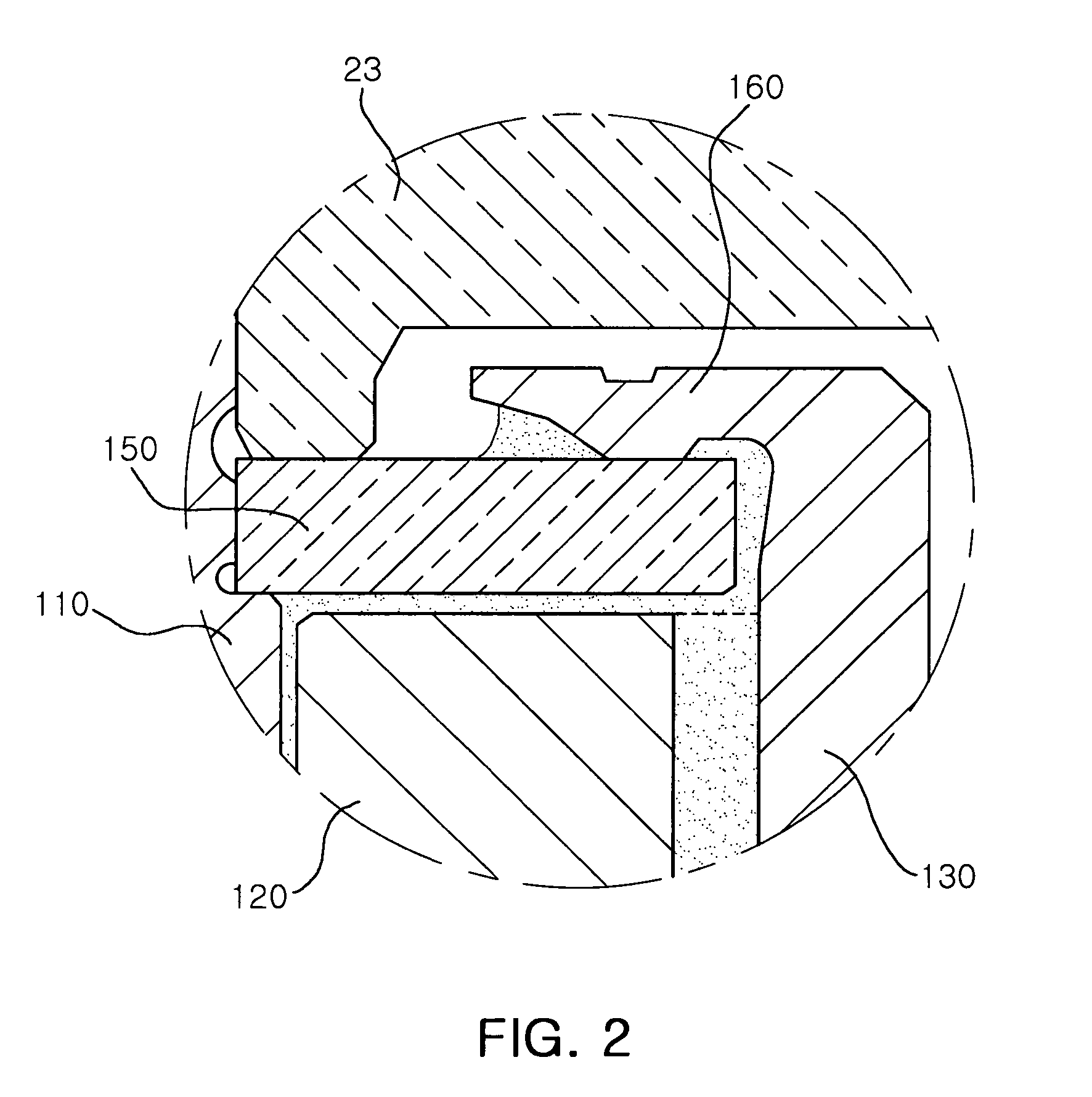

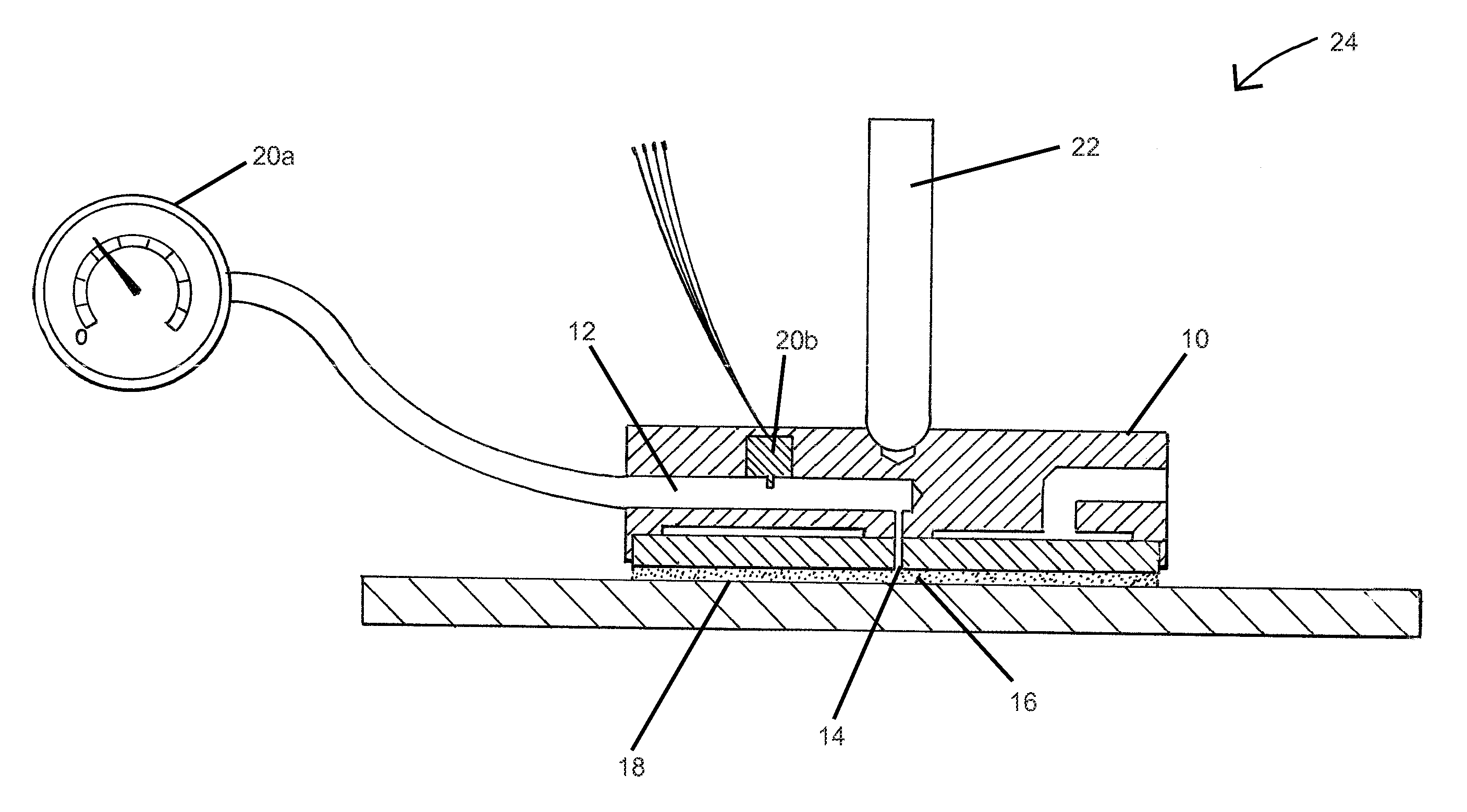

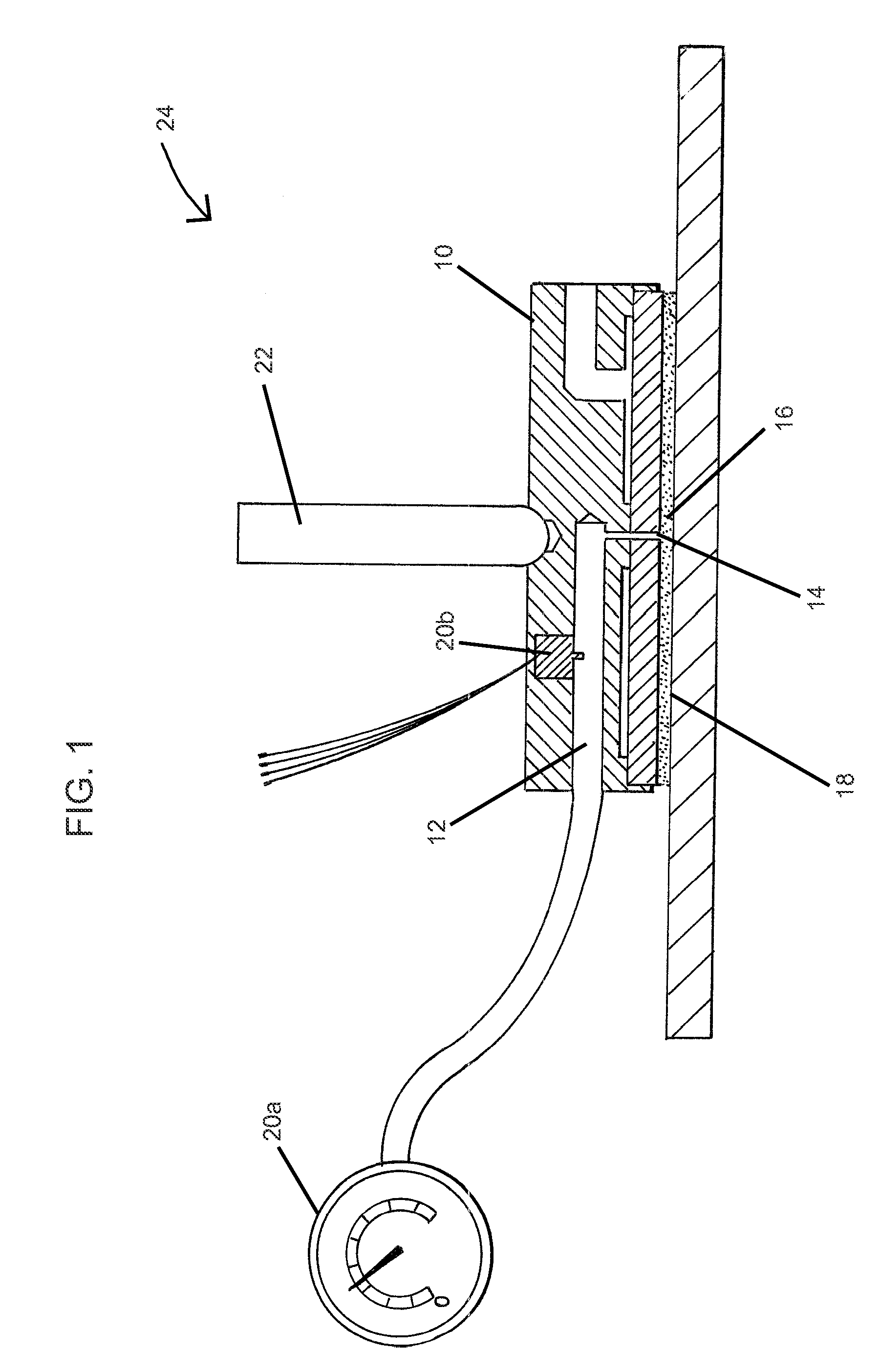

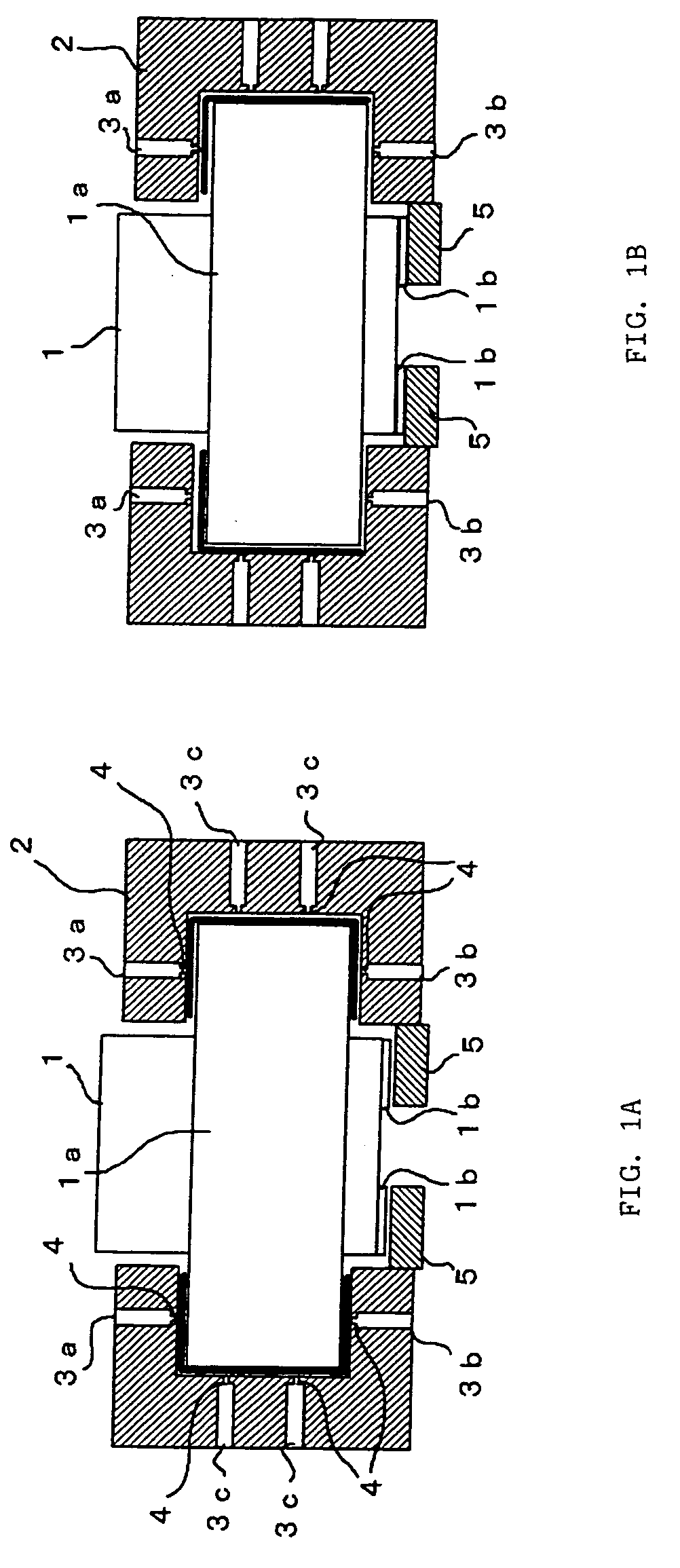

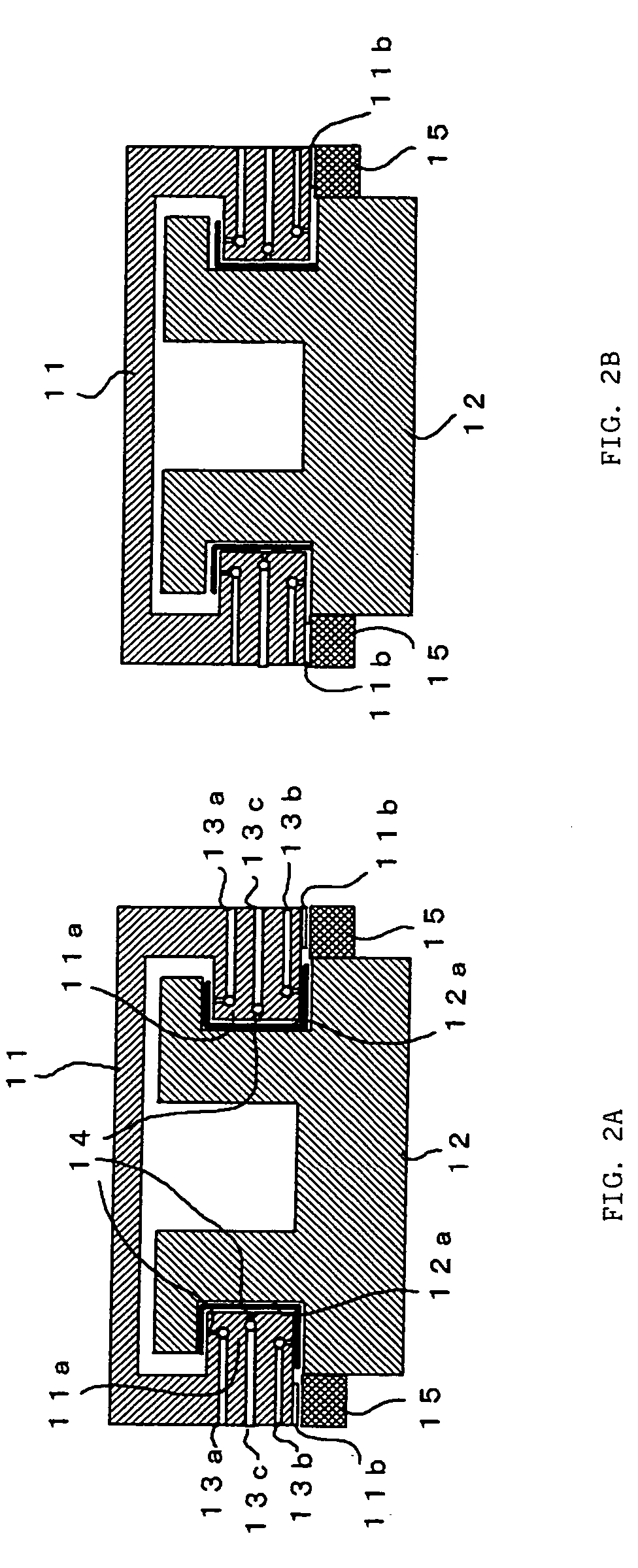

Compact surface self-compensated hydrostatic bearings

A compact surface self-compensated hydrostatic bearing includes a rotor assembly including a rotor plate having upper and lower fluid restricting faces, a rotor top and bottom, each having bearing surfaces angled with respect to an axis of rotation of the rotor assembly; a stator assembly including a stator top and a stator bottom housing the rotor assembly therebetween, the stator top and bottom having bearing surfaces facing and spaced apart from the rotor top and bottom bearing surfaces forming upper and lower bearing gaps, respectively, therebetween; the stator top and bottom including a lower and an upper fluid restricting surface, respectively, facing and spaced apart from the rotor upper and rotor lower fluid restricting faces, respectively, forming upper and lower restricting gaps, respectively, therebetween; and a fluid supply system configured to supply pressurized fluid to the bearing gaps and into the upper and lower fluid restricting gaps.

Owner:AMETEK PRECITECH

Thrust bearing structure and supercharger equipped with said thrust bearing structure

A thrust bearing structure is equipped with a thrust collar having a collar pad, and a thrust bearing having a bearing pad at a position corresponding to the collar pad on a surface facing the thrust collar. The bearing pad has a tapered section, and a land section continuously formed on the outer edge of the tapered section. Assuming that oil droplets are supplied between the bearing pad and the collar pad, and assuming that the rotation speed of a rotor shaft is constant, the tapered section would have a sloping surface formed in such a manner that a wall thickness gradually becomes thicker toward the downstream side along the trajectory of given oil droplets based on the centrifugal forces acting on the droplets due to the rotation of the rotor shaft.

Owner:IHI CORP

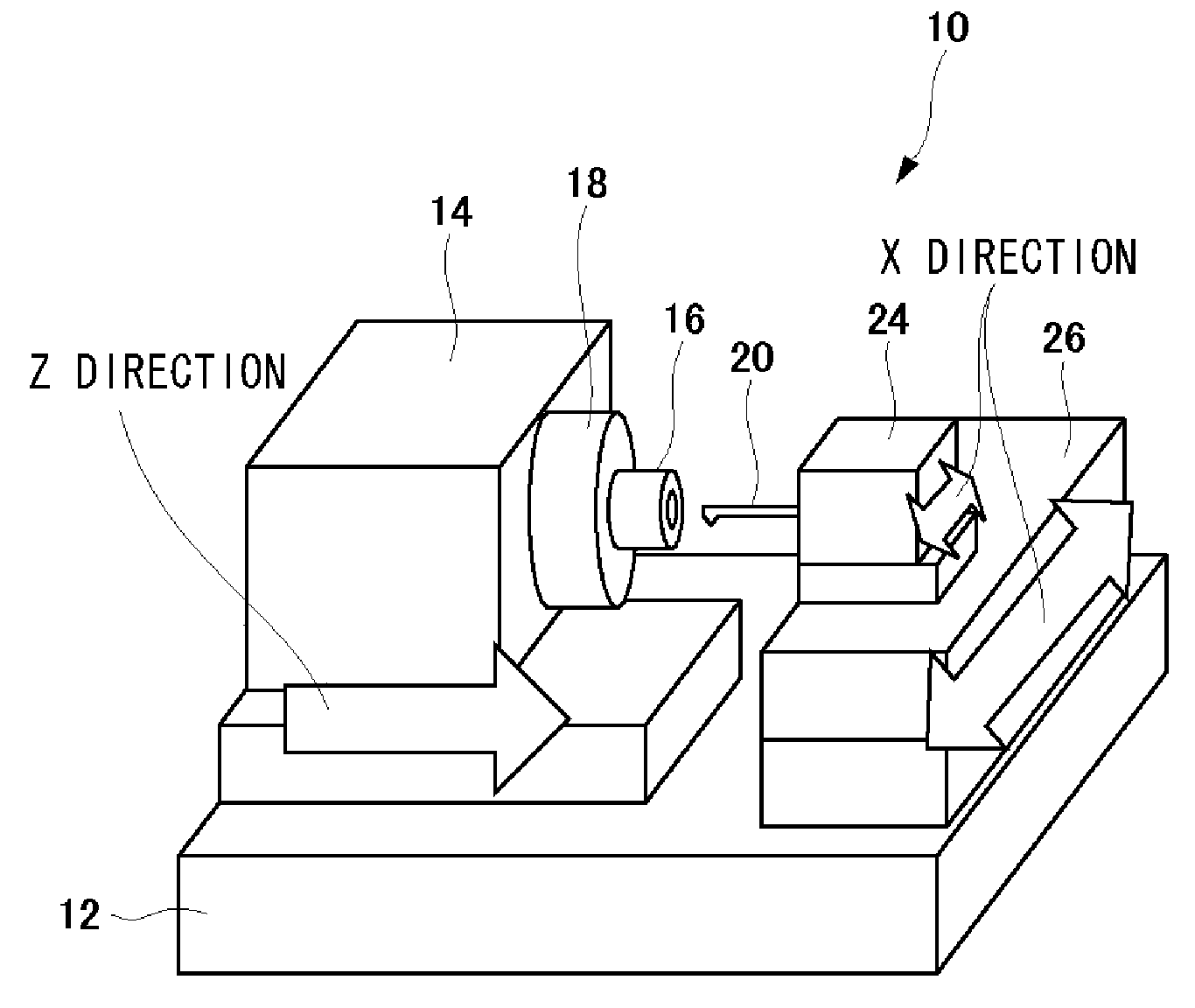

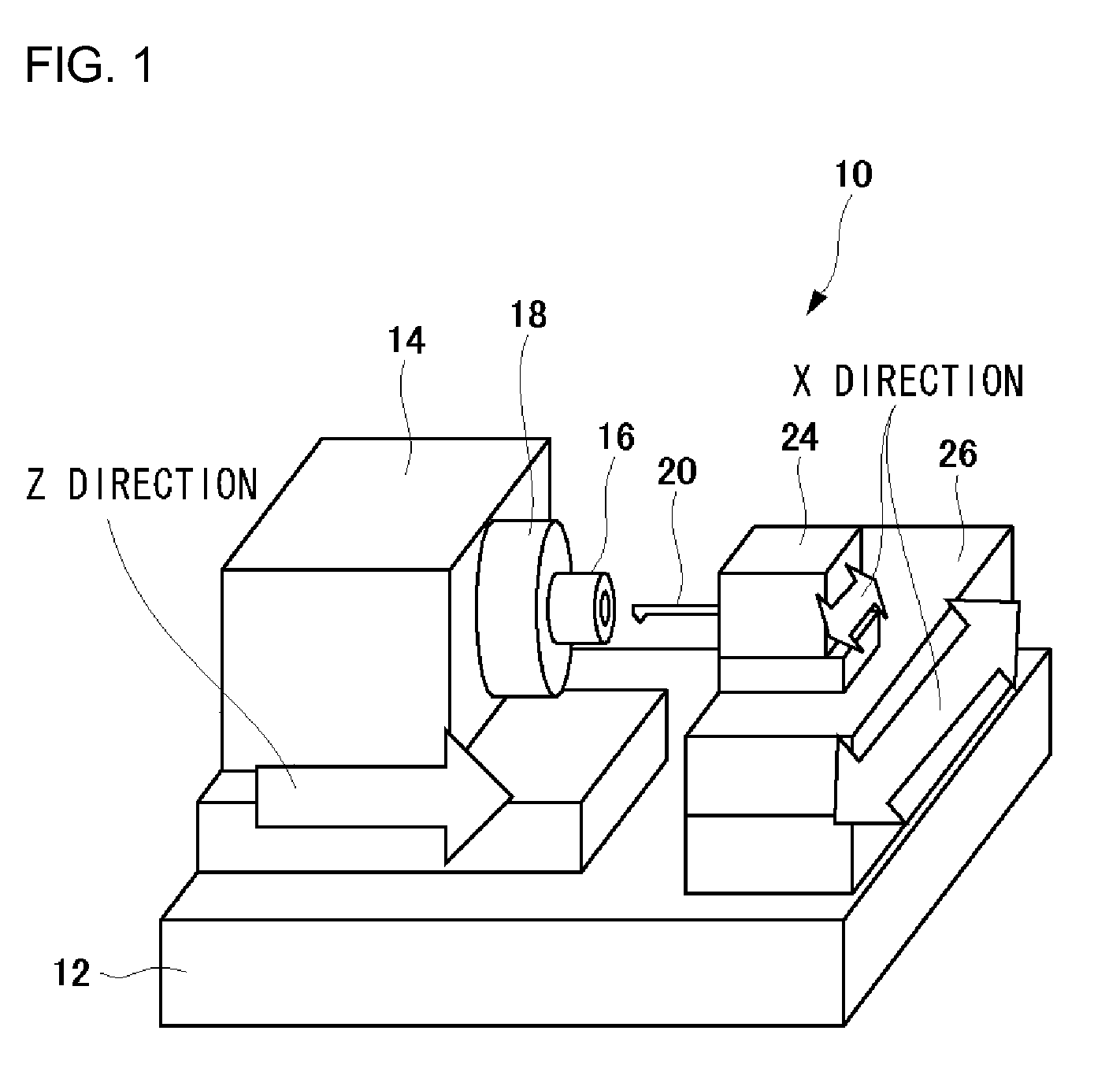

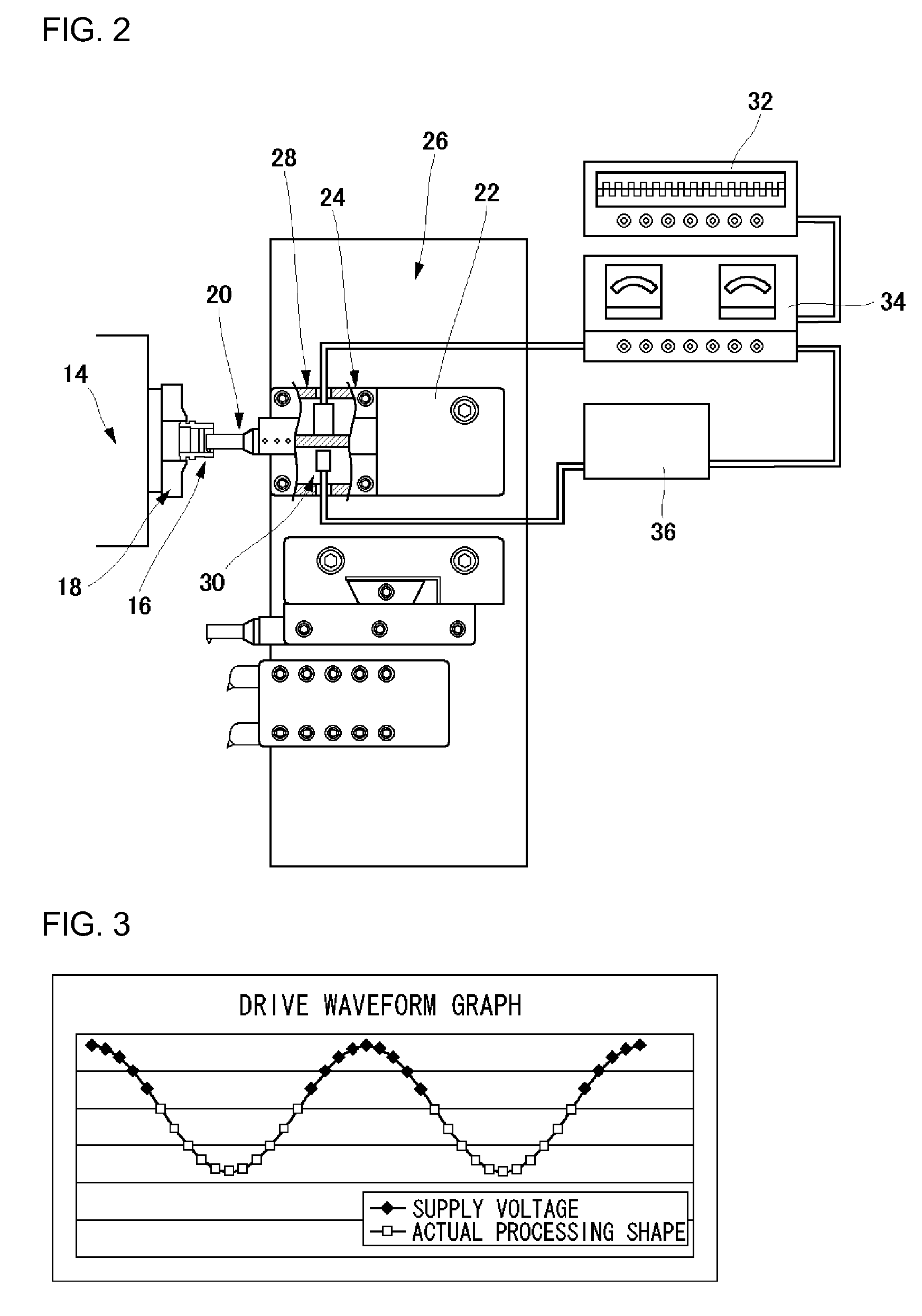

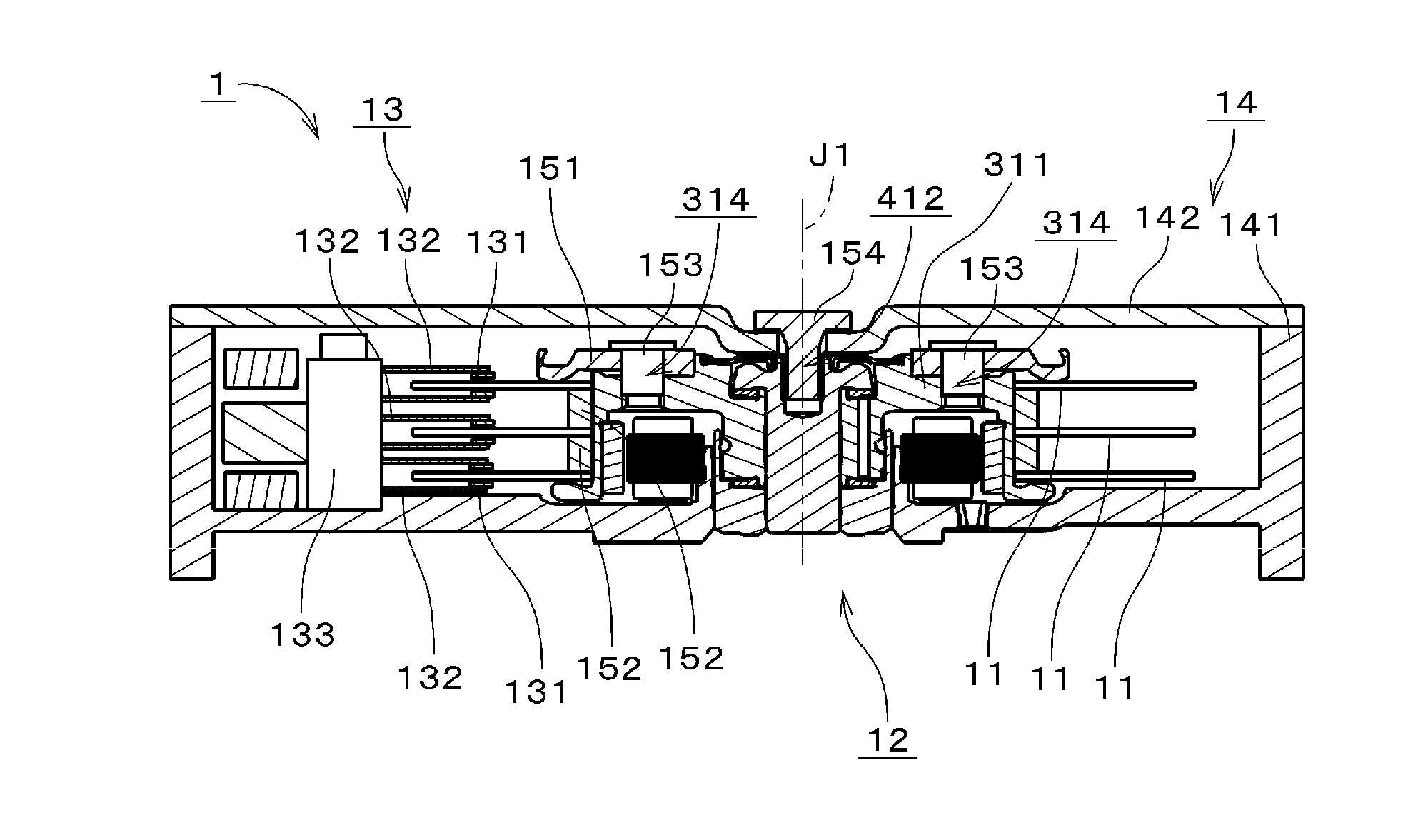

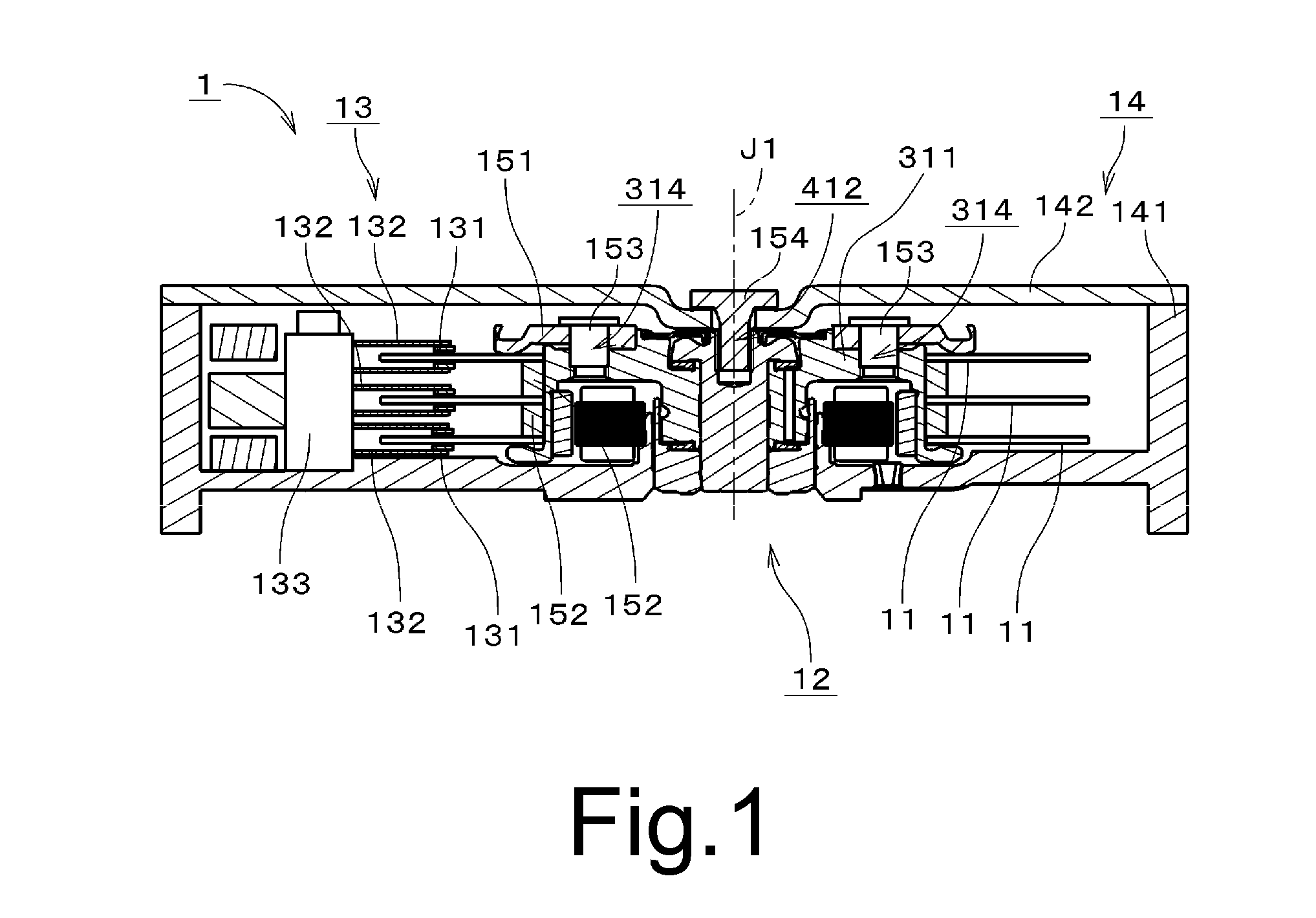

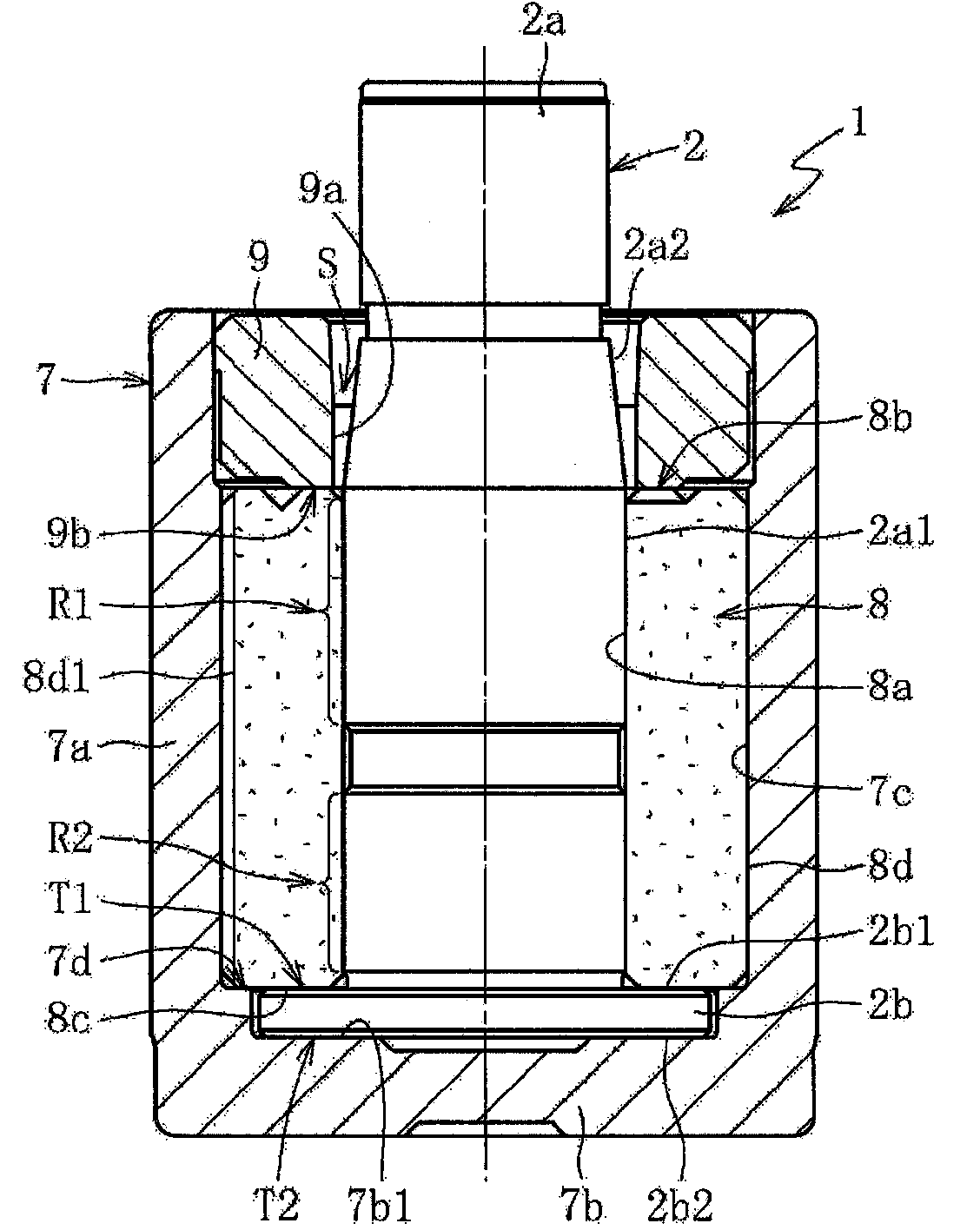

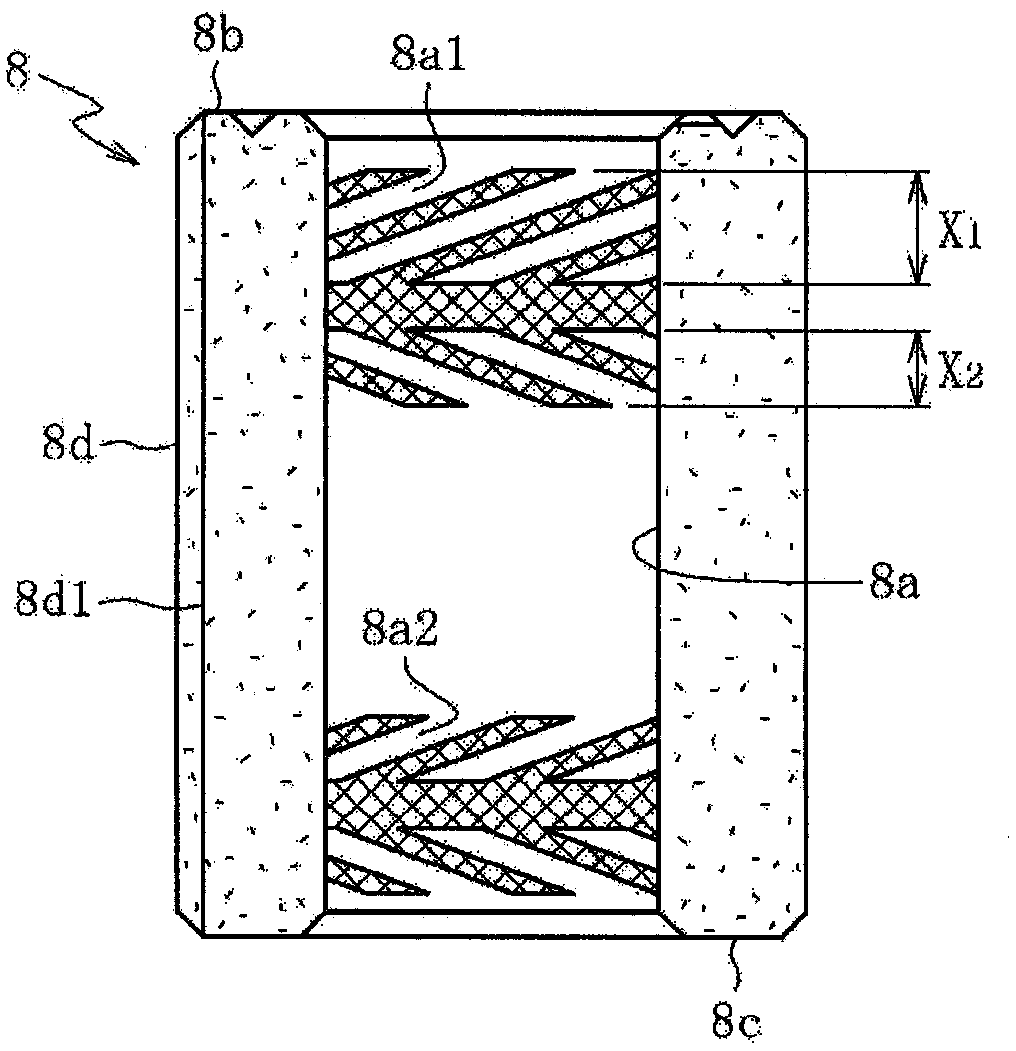

Method manufacturing of fluid dynamic bearing using cutting tool that performs micro alternating drive, fluid dynamic bearing manufactured by using the method, and disk drive device using the bearing

A method manufacturing of a fluid dynamic bearing includes: forming a substantially linear groove having a length corresponding to a circumferential direction width of the dynamic pressure groove formed on the inner circumferential surface of a shaft housing hole portion, along the circumferential direction of a surface orthogonal to a first processing direction along the central axis direction of a work, by a byte that performs a micro alternating drive in a second processing direction orthogonal to the first processing direction; and extending the dynamic pressure groove that extends in the first processing direction by continuously forming the substantially linear grooves in the first processing direction by displacing the relative positions of the work and the byte in the first processing direction.

Owner:SAMSUNG ELECTRO MECHANICS JAPAN ADVANCED TECHNOLOGY CO LTD

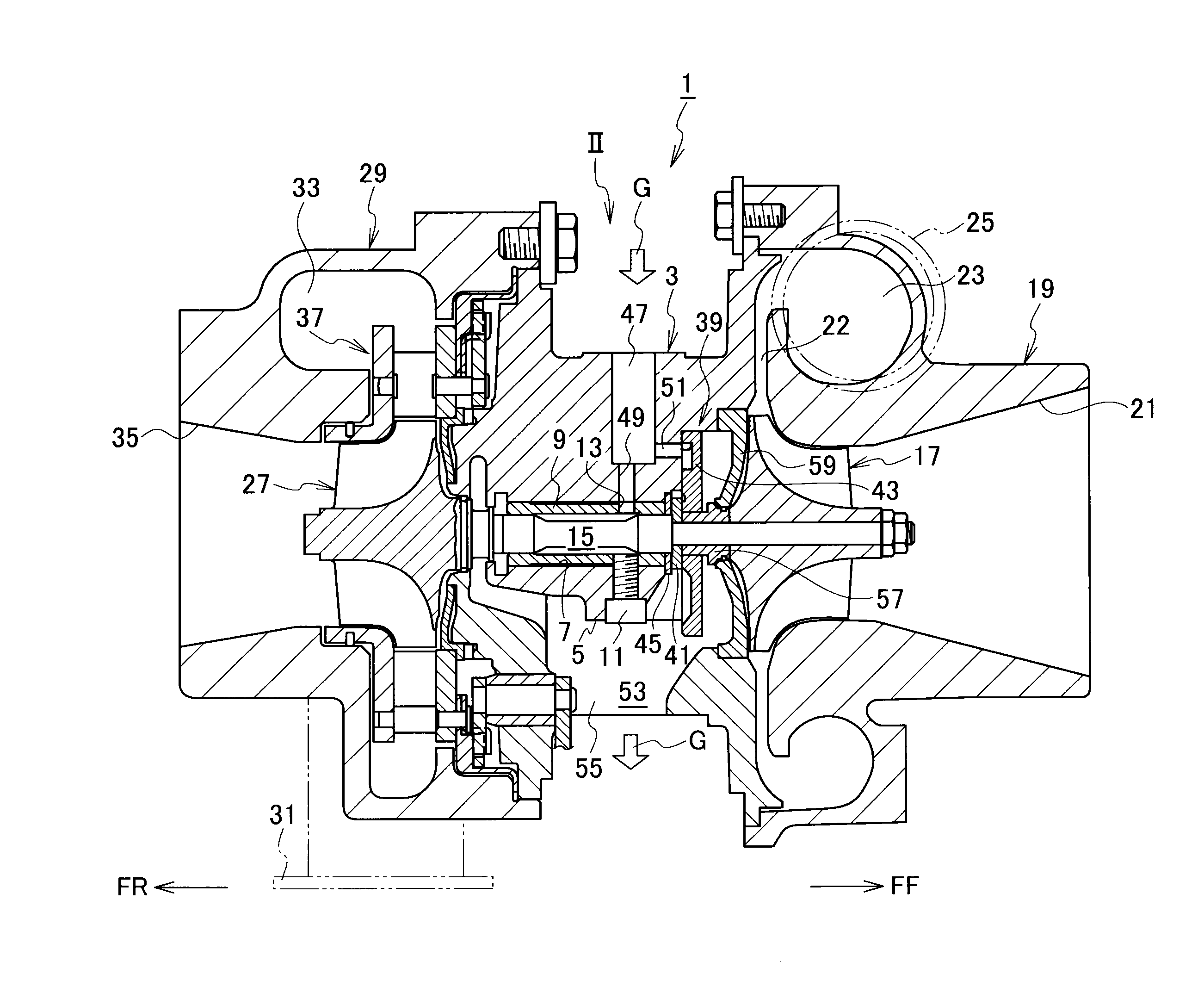

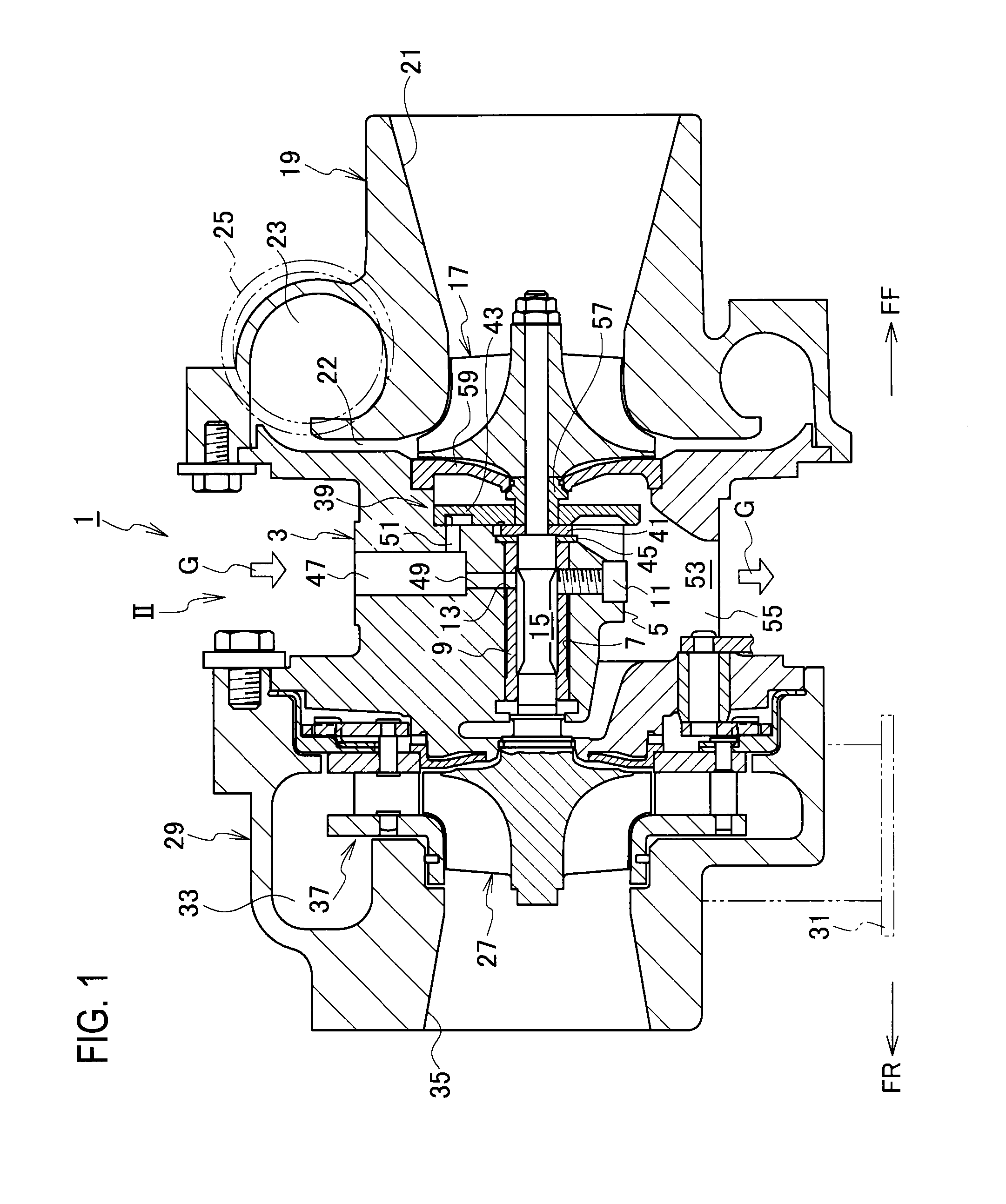

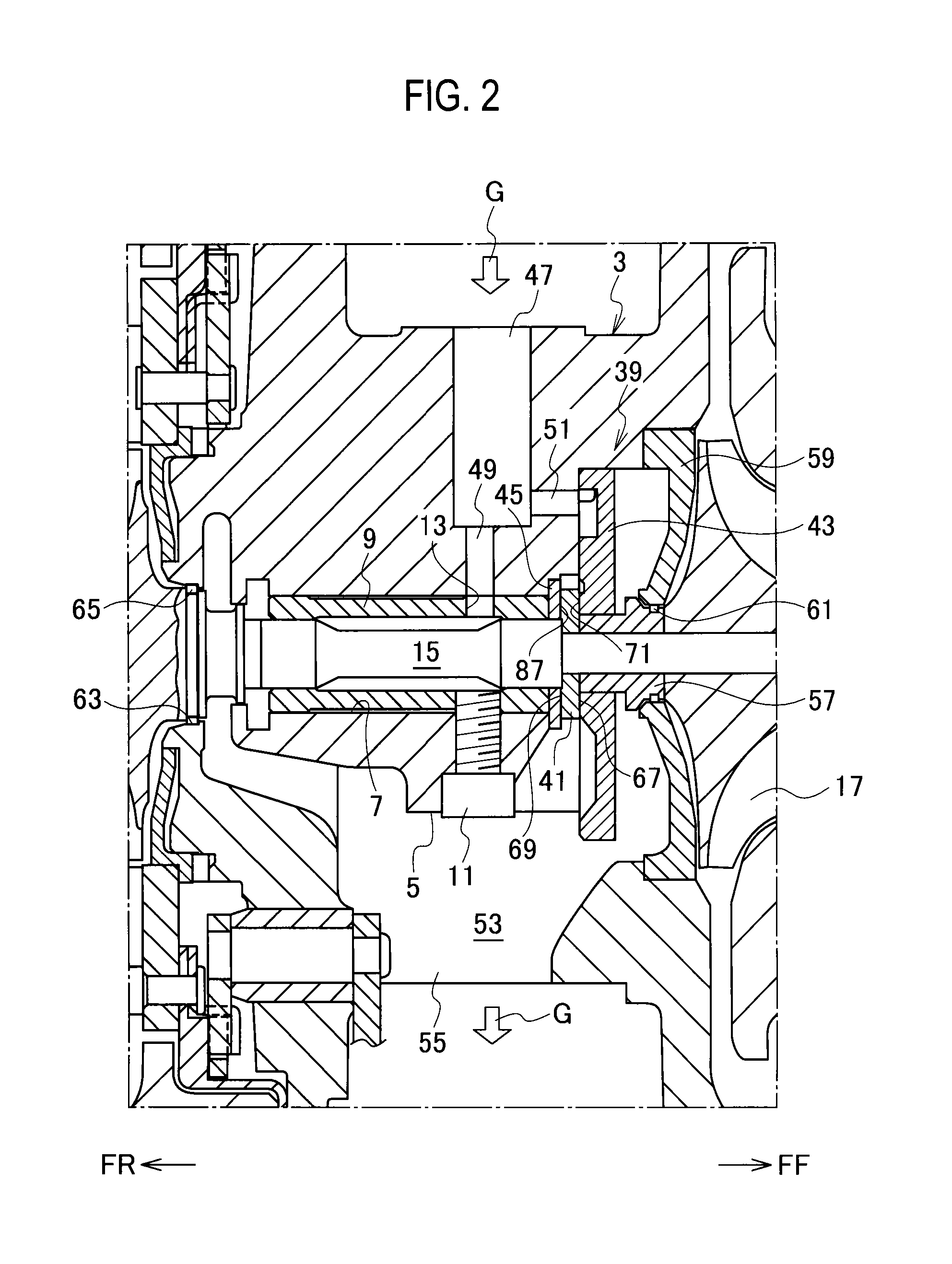

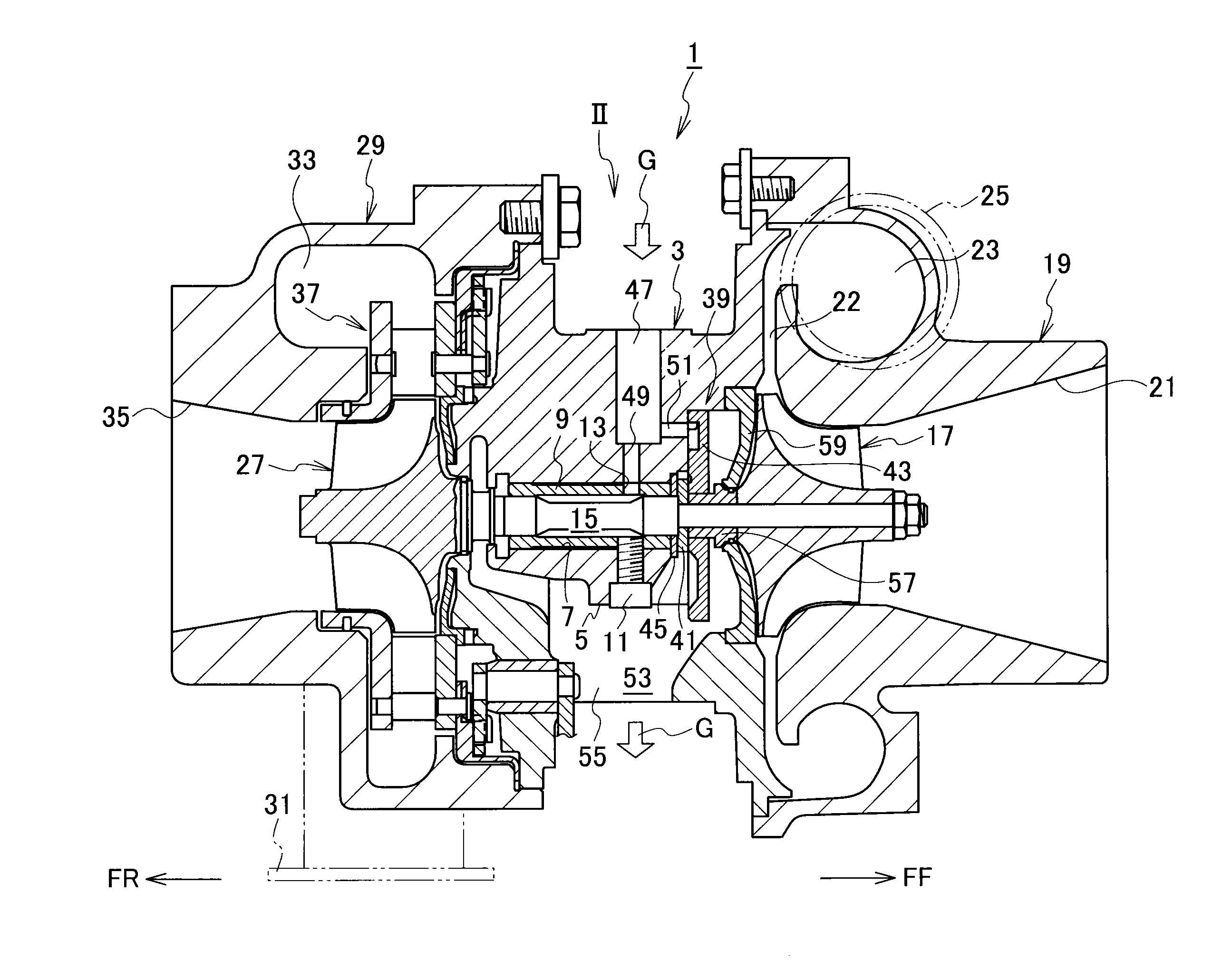

Turbocharger

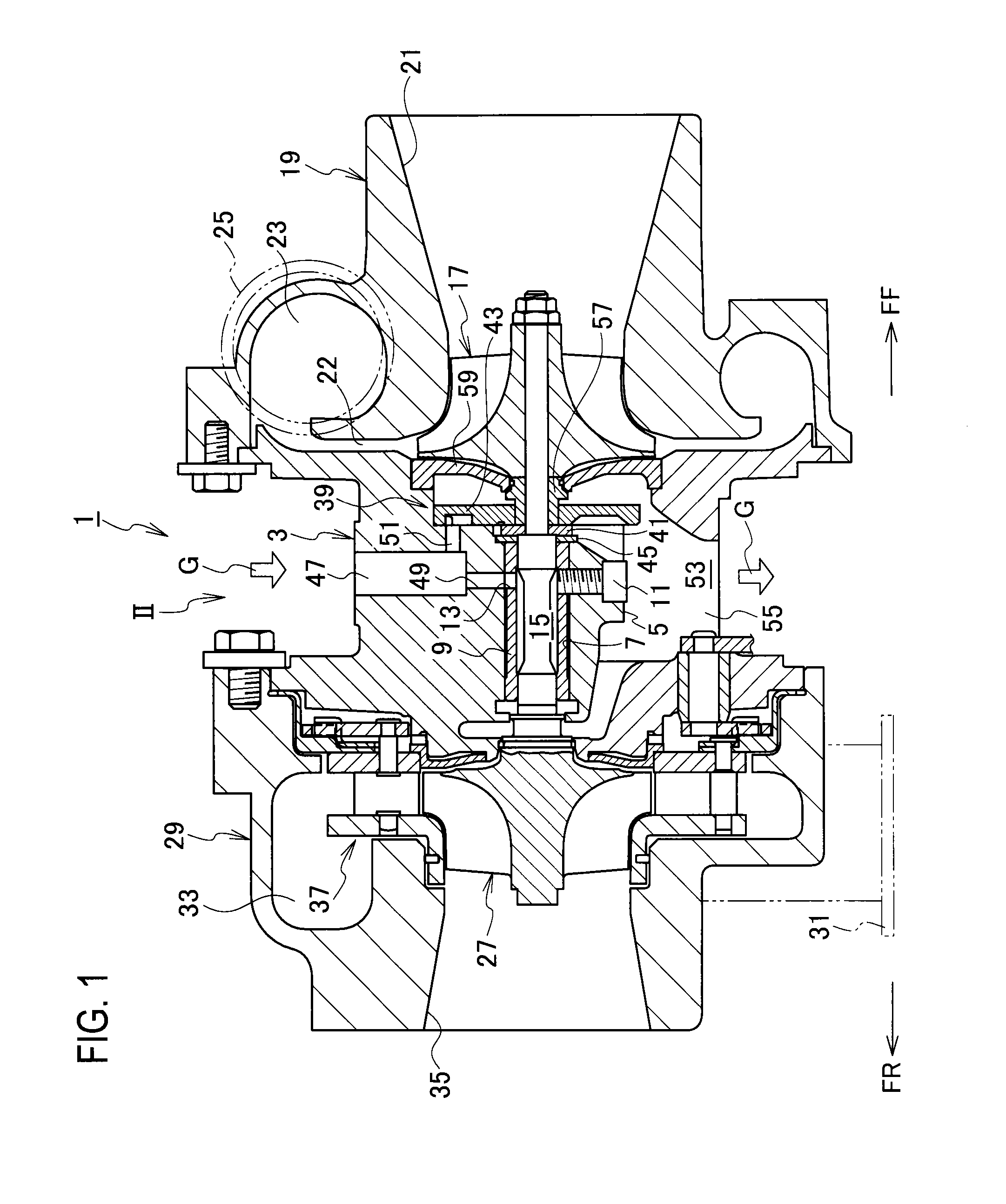

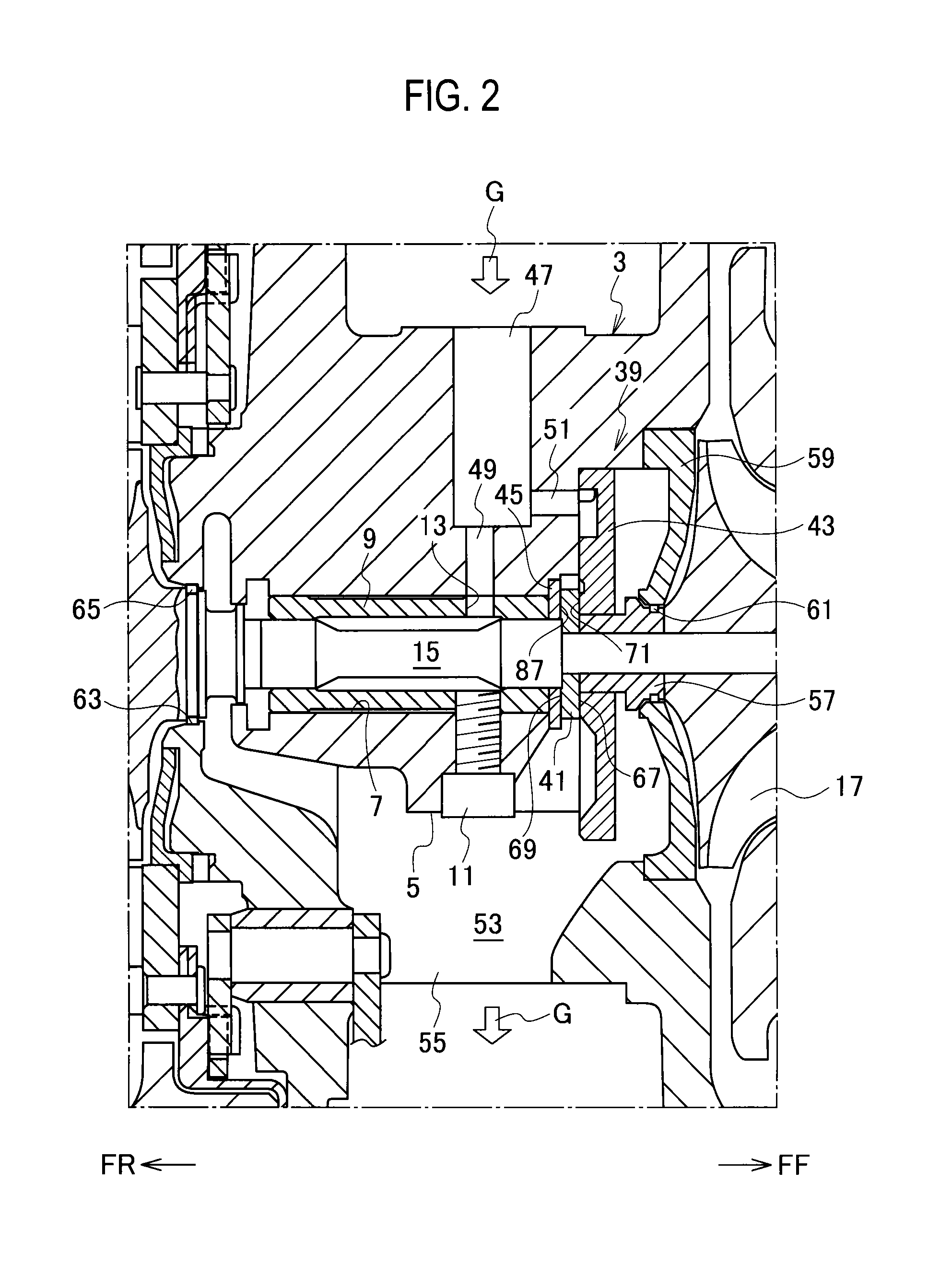

ActiveUS20140127051A1High speed rotationMinimize entryEngine fuctionsShaftsForeign matterTurbocharger

A turbocharger includes a semi-floating metal. The semi-floating metal is provided with a supply opening configured to supply oil to an inner bearing section. The turbocharger is provided with: an oil supply path which extends from inside of a bearing housing to the supply opening, and feeds the oil to be supplied to the inner bearing section; a removal section which changes a flowing direction of the oil supplied from an upstream side to separate minute foreign matter in the oil; and a conveyance path and a retaining region which collect the minute foreign matter separated by the removal section so as to prevent the minute foreign matter from mixing again with the oil flowing toward the supply opening.

Owner:IHI CORP

Principal axis device

InactiveCN1485172ASimple structureRaise the natural frequencyShaftsLiquid cushion bearingsRotational axisEngineering

A bottomed hole opened to an end part on the opposite side to the holding side of a drill is formed around a rotation axis of the spindle. A center guide provided with a plurality of air supply holes of a journal gas bearing at the outer periphery is fitted to the bottomed hole and supported to a housing. Compressed air is blasted from the air supply holes to support the spindle radially from the center side. Since the spindle of such constitution can reduce mass, natural frequency is heightened to obtain structure causing no unstable phenomenon even if rotated at high speed.

Owner:HITACHI SEIKO LTD

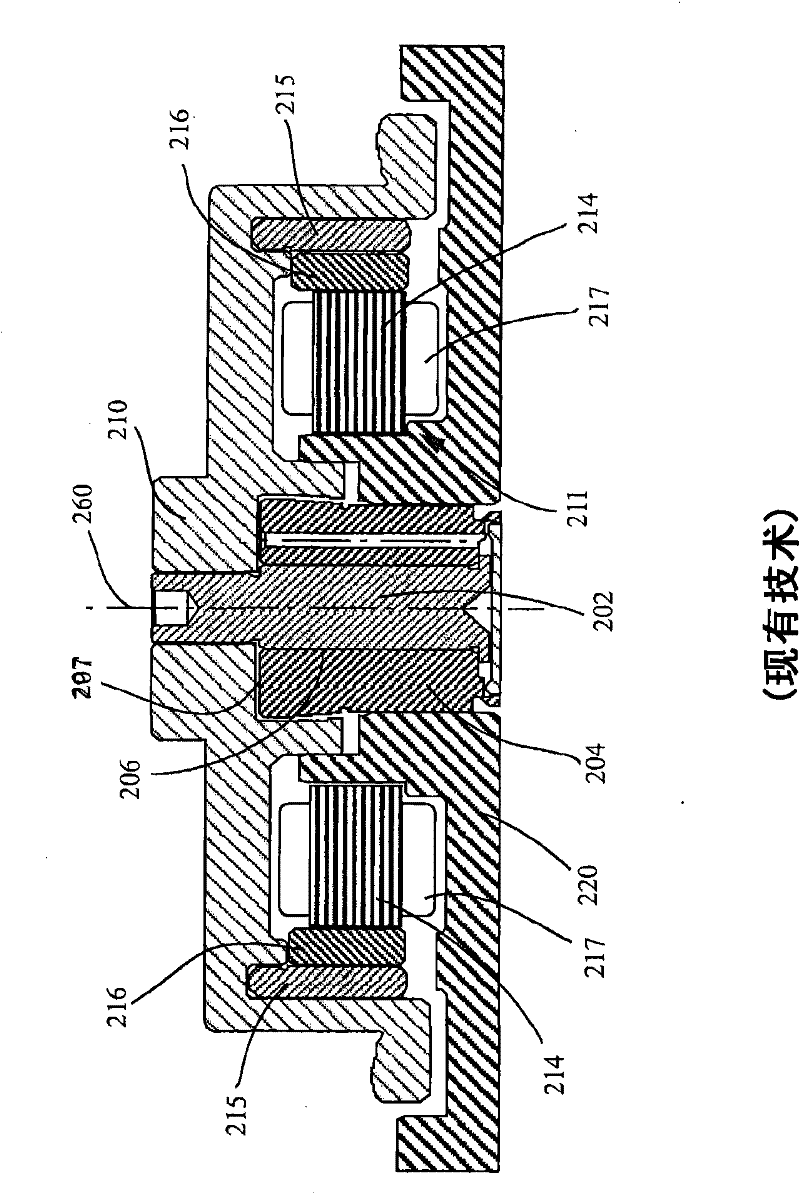

Fluid pumping capillary sealing element for hydrodynamic bearing

The invention provides a device and a method for forming a hard and vibration-resisting hydrodynamic bearing. A fluid sealing system which is characterized by fluid pumping and capillary feature is a small disc driving storage system having an improved reliability and property which solves the problem of the slow motion of a motor, wherein the slow motion means the rapidly repeat opening and closing of the spaces between the parts which can relatively rotate and drains oil from these spaces or absorbs air in these spaces. A fluid pumping capillary sealing system comprises a fluid pumping slot for pumping fluid which has a rib part and a slot part. The fluid pumping capillary sealing system further comprises a capillary sealing element. A sweeping rib sweeps the fluid towards the bearing; a docking rib is positioned close to the sweeping rib; and the docking rib extends for a shorter radial distance than the sweeping rib so as to form a pressurizing area.

Owner:SEAGATE TECH LLC

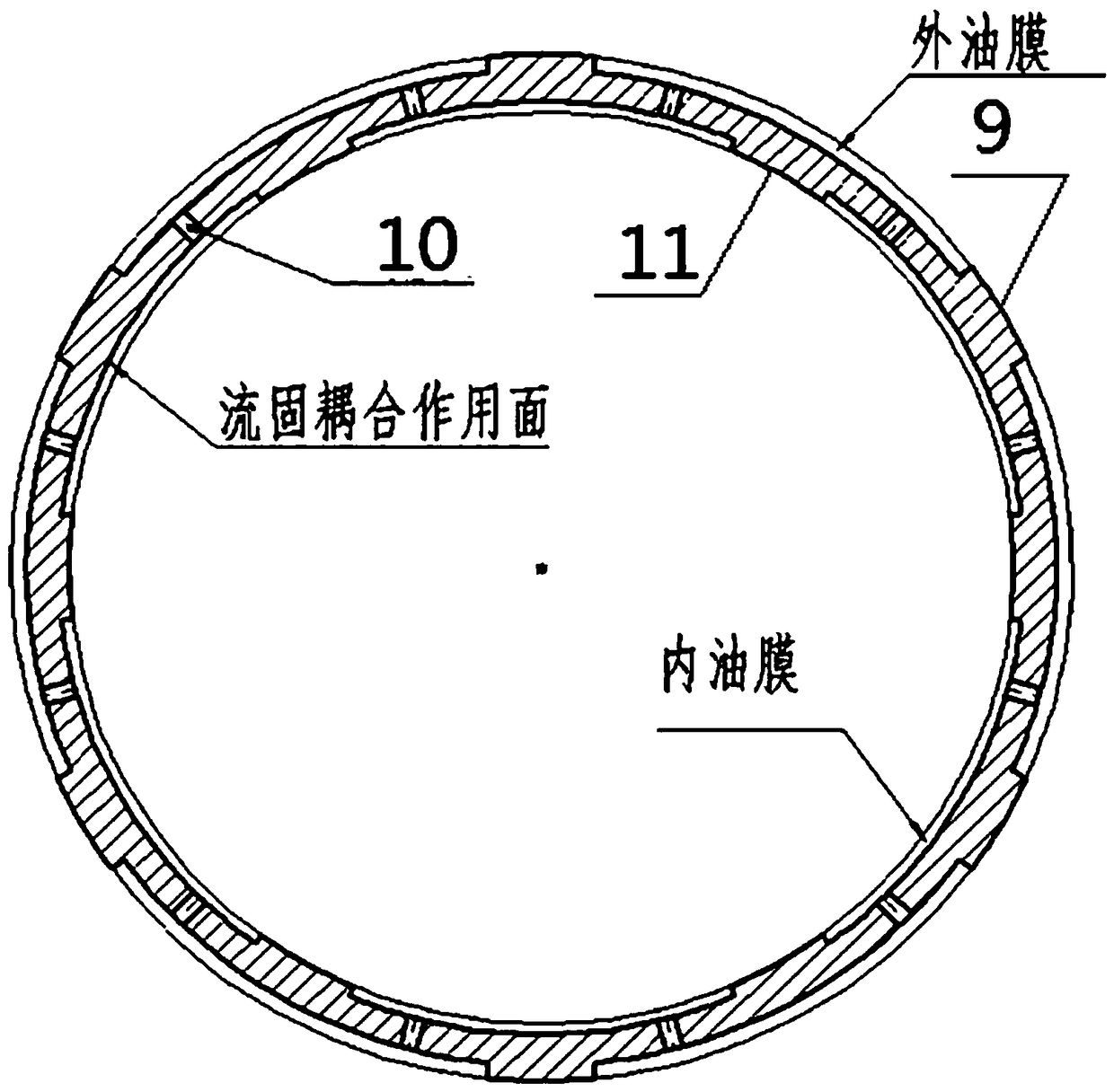

Coupling elastic-support type oil film damper bearing system for gas turbine

PendingCN108223580AGuaranteed peace of mindGuaranteed uniformityLiquid cushion bearingsBearing unit rigid supportSupporting systemBall bearing

The invention belongs to the technical field of gas turbine equipment, in particular to a coupling elastic-support type oil film damper bearing system for a gas turbine. The coupling elastic-support type oil film damper bearing system comprises a mouse cage bearing seat, a damper housing, a sleeve, an elastic ring, a locknut, a ball bearing, sealing rings and an oil injection ring; the elastic ring is installed and clamped between the damper housing and the sleeve; the two ends of the elastic ring are each equipped with the sealing ring for controlling oil drainage of the corresponding end part; a flange end of the mouse cage bearing seat and a flange end of the damper housing are fixedly connected with a stator case of the gas turbine by virtue of bolts which are uniformly distributed inthe circumferential direction; the ball bearing for supporting a rotor and a shaft neck is installed inside a cantilever end of the mouse cage bearing seat; the locknut is used for twisting and fixingthe axial positions of the sleeve and the ball bearing; and the sleeve is matched with the cantilever end of the mouse cage bearing seat in a contacting manner. The coupling elastic-support type oilfilm damper bearing system provided by the invention improves the stability of the oil film damper so that a rotor-support system of the gas turbine can steadily get through the critical speed of rotation in each stage and stably runs under a main working state.

Owner:中船重工龙江广瀚燃气轮机有限公司

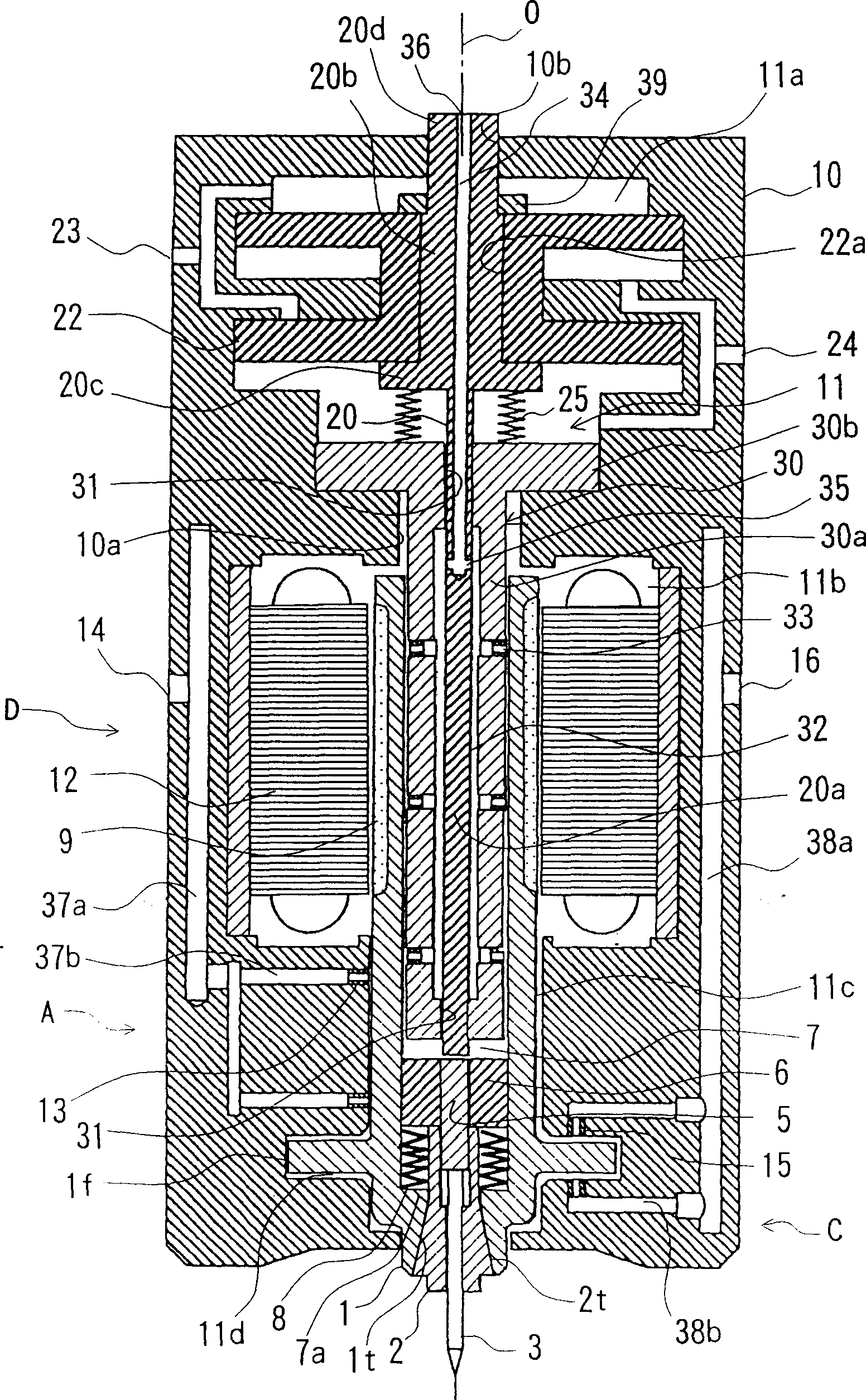

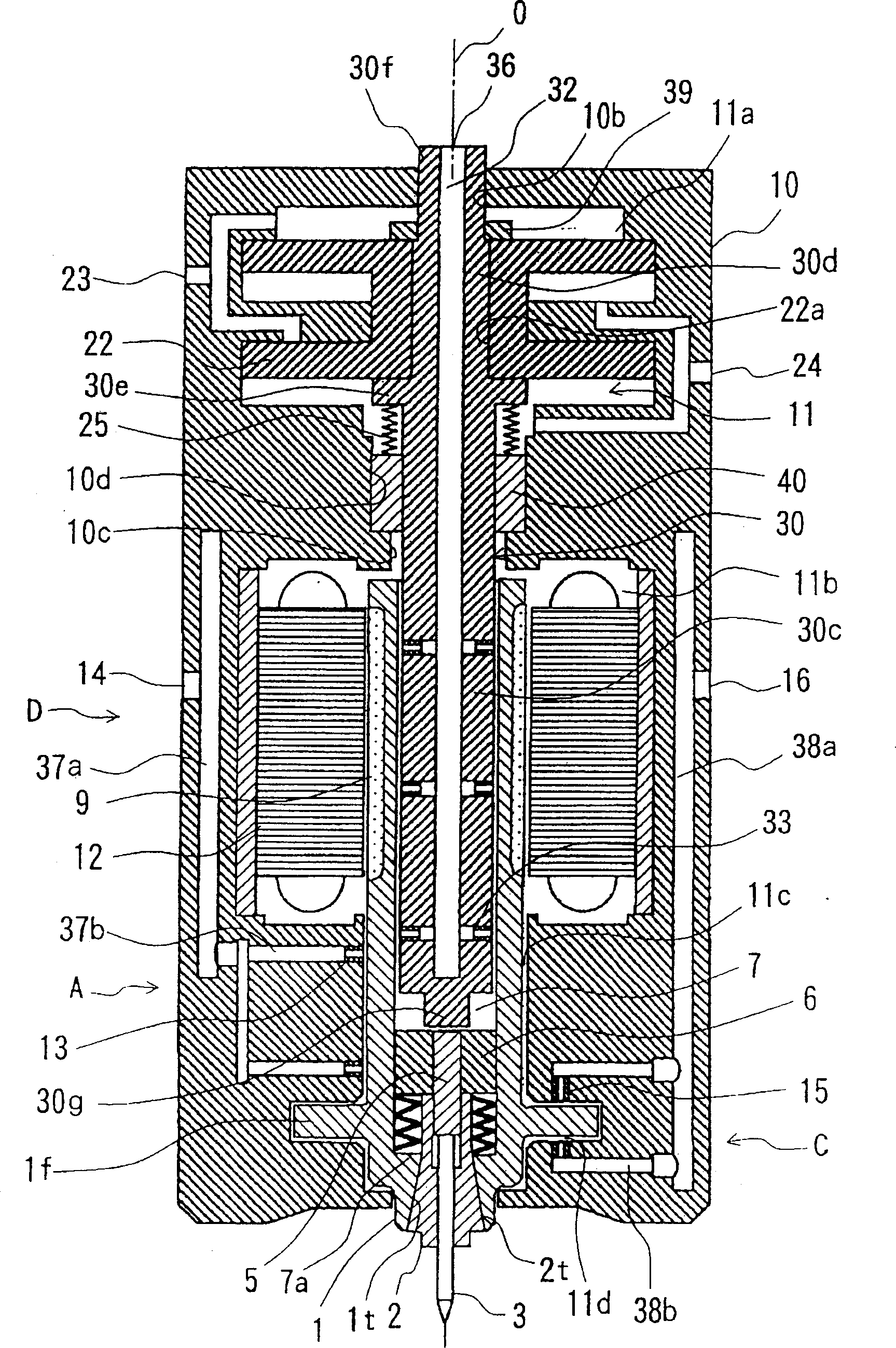

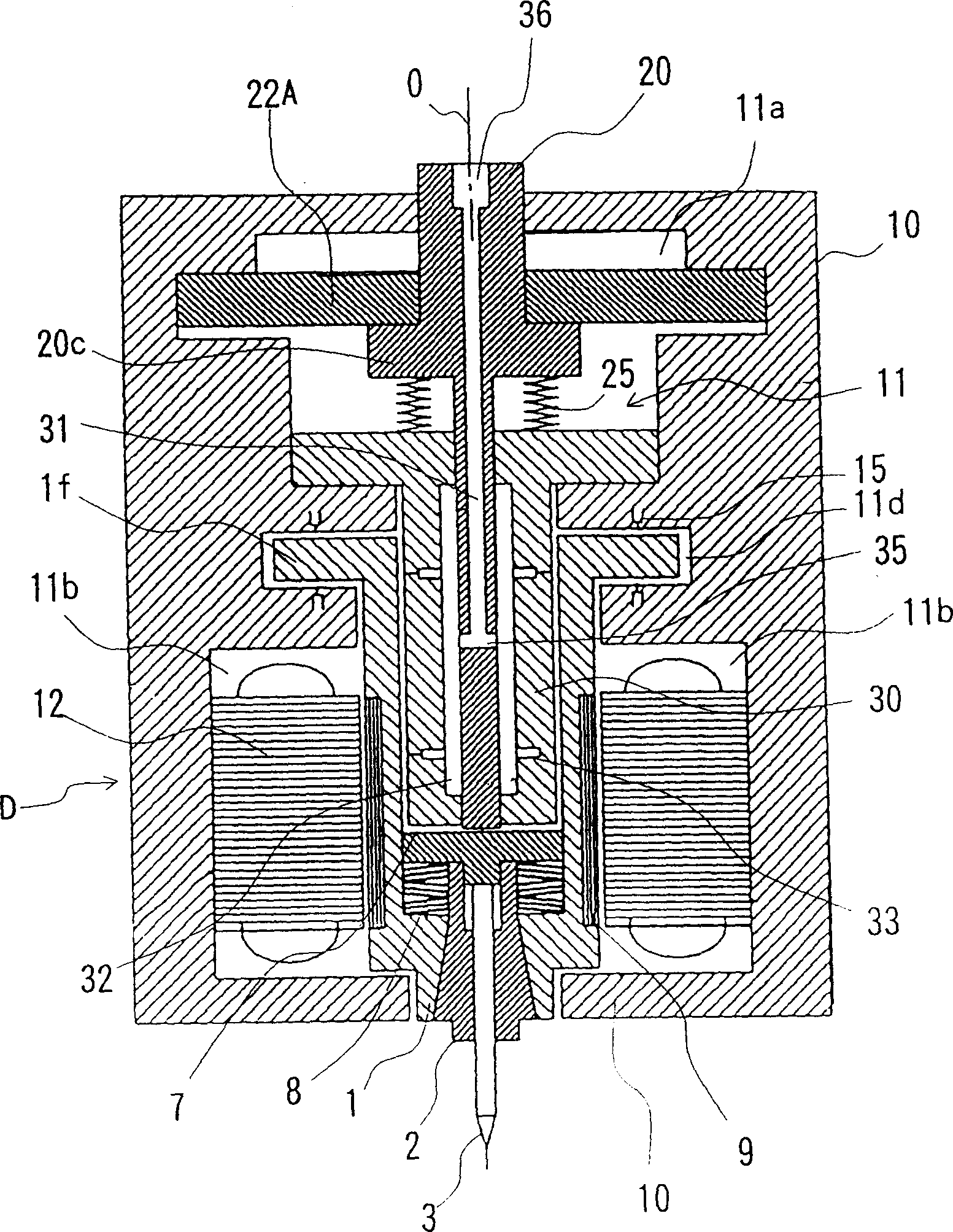

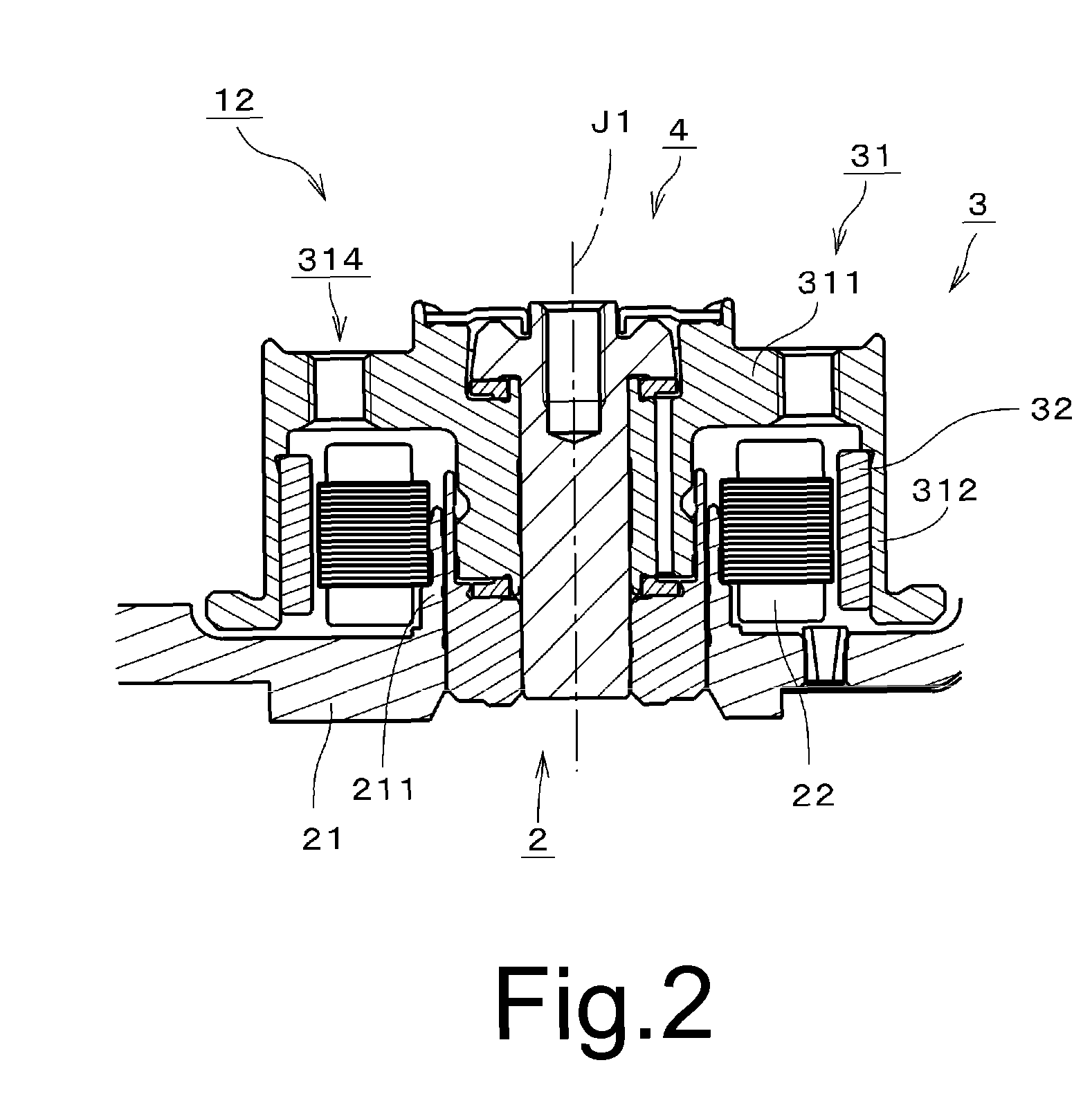

Bearing mechanism, motor and disk drive apparatus

Owner:NIPPON DENSAN CORP

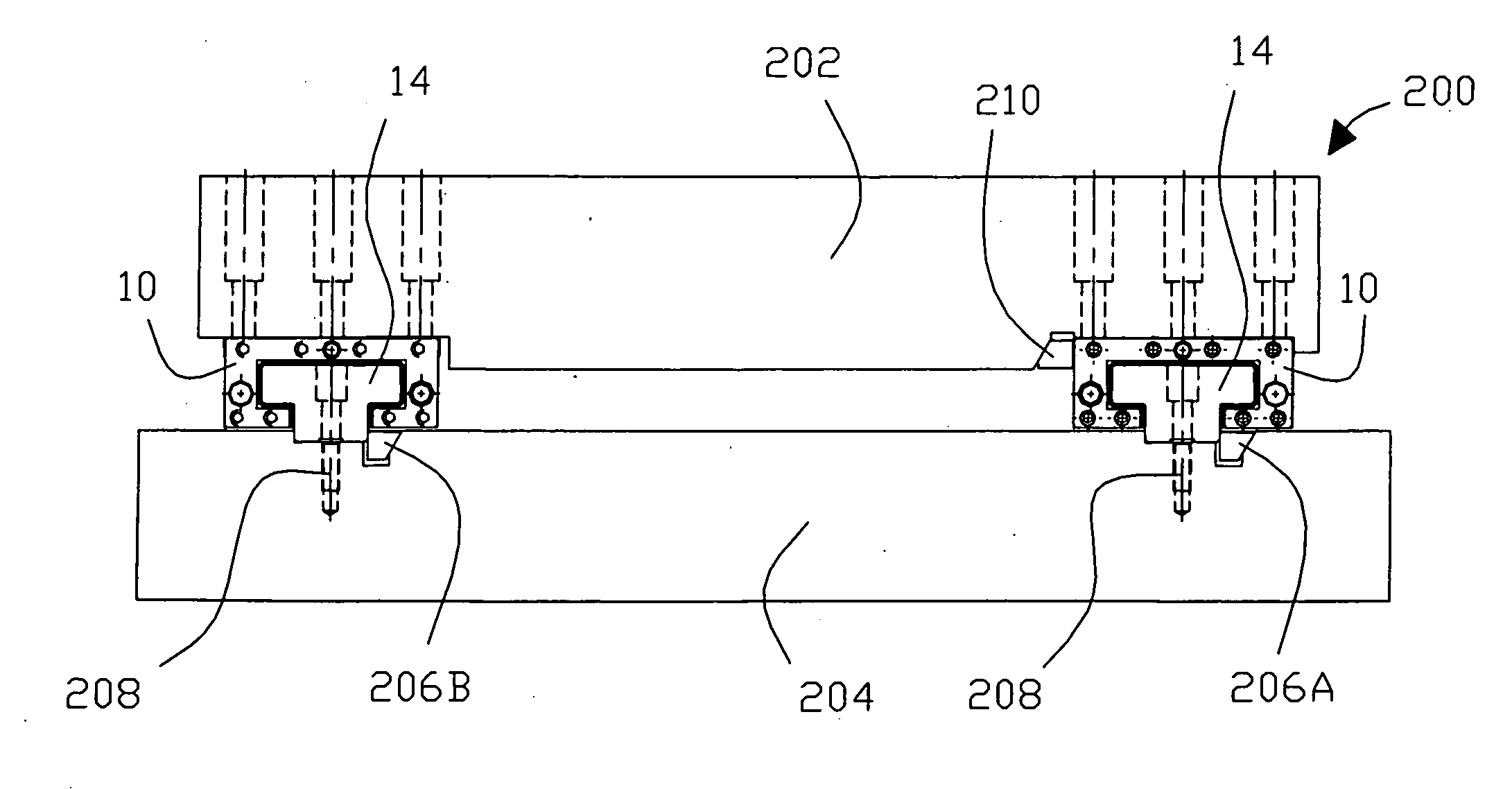

Hydrostatic bearing for linear motion guidance

InactiveUS20060251346A1Prevent leakageAvoid flowLinear bearingsLiquid cushion bearingsEngineeringLoad capacity

A self-compensating hydrostatic (pressurized fluid film) linear bearing that maintains a fluid gap between a carriage and a rail when relative forces are applied. The geometric shape of the rail and mating carriage enable the bearing to have very high stiffness and load capacity without exessive detrimental carriage deformation. The carriages contain bearing grooves and lands which control and use fluid pressure to provide a very high degree of restoring force in response to changes in the fluid gap. The fluid emanating from the bearing gap is prevented from immediately leaking from the bearing carriage, and is instead routed back to the source from which it is pumped, thereby sealing the bearing carriage and simplifying the handling of the lubricating fluid. The hydrostatic bearing is particularly designed to be compact and to be bolt-for-bolt compatible with conventional linear bearings.

Owner:MFR & TRADERS TRUST COMPANY AS AGENT

Double-suspension passive support radial bearing for magnetic fluid

InactiveCN107191488AImprove carrying capacityIncrease stiffnessLiquid cushion bearingsSupporting systemInterference fit

The invention discloses a double-suspension passive support radial bearing for magnetic fluid. The bearing comprises a bearing cover, a bearing base, a stator, a permanent magnetic ring and a shaft, wherein the stator is arranged on the bearing base; the bearing base 4 is in transition fit with the stator; the permanent magnetic ring is sleeved in the stator; the stator is in clearance fit with the permanent magnetic ring; the permanent magnetic ring is sleeved on the shaft and is in interference fit with the shaft; the bearing cover is sleeved on the stator and fixed on the bearing base; and the bearing cover is in transition fit with the stator. According to the bearing disclosed by the invention, the advantages of two support systems of liquid static pressure and magnetic suspension are integrated, so that the bearing capability and rigidity of the bearing can be greatly increased without separately arranging an auxiliary support and circulating cooling system, a complicated electric control system is not needed, so that the design limitation of an oil return tank can be released, and the precision and the rigidity of the bearing system are improved.

Owner:YANSHAN UNIV

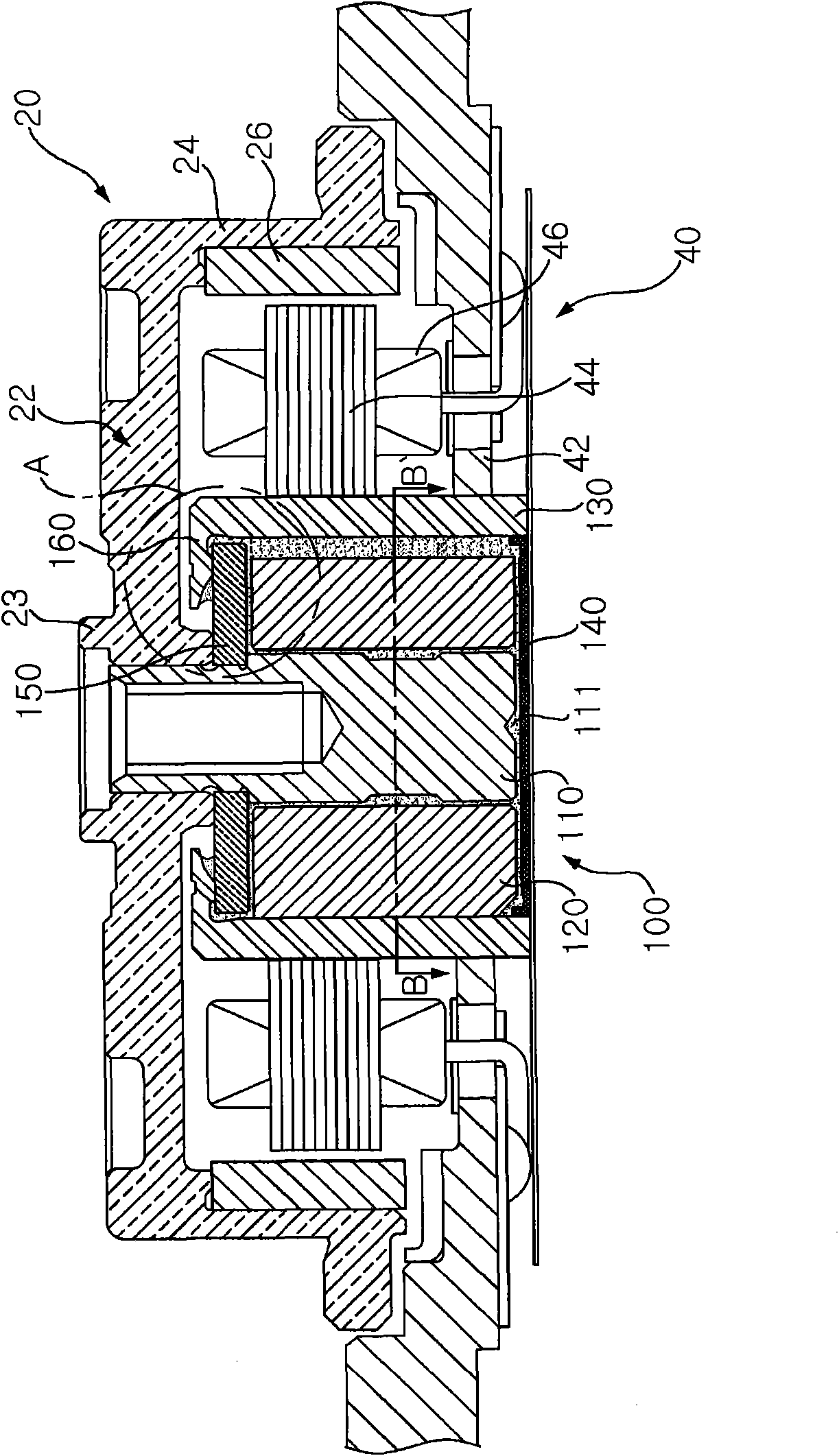

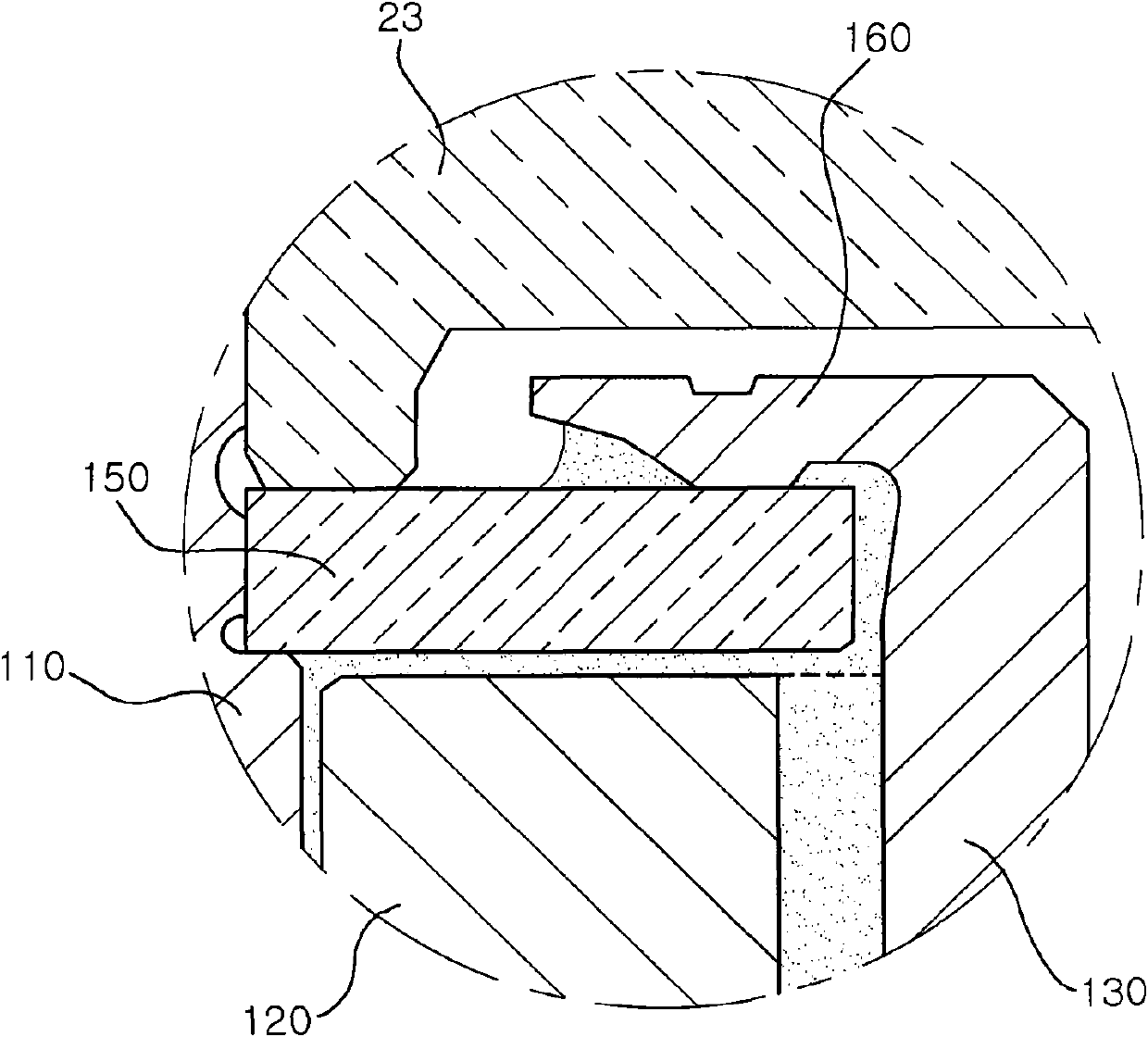

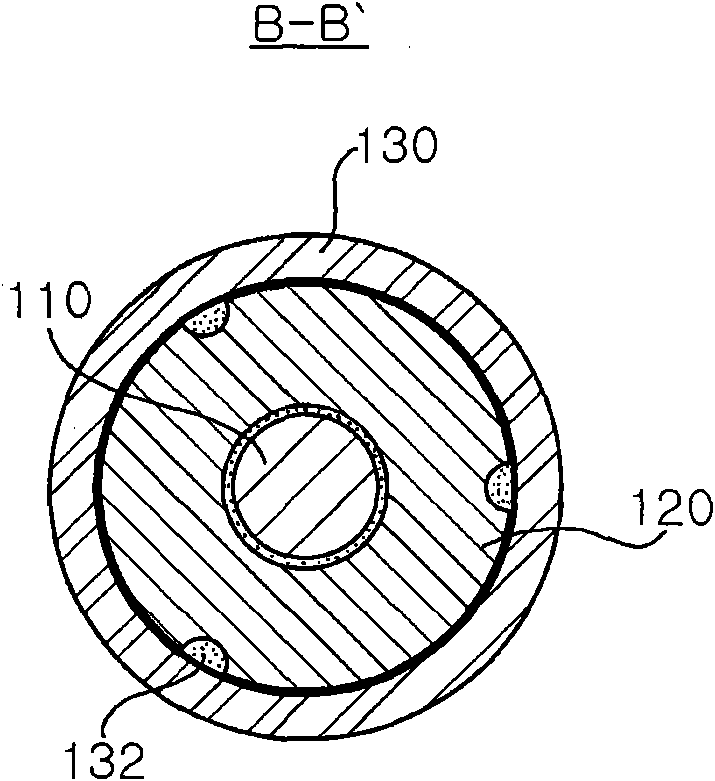

Fluid dynamic bearing assembly and motor having the same

InactiveUS20120049676A1Improve productivityConservation of manufacturing costShaftsLiquid cushion bearingsEngineeringFluid power

There are provided a fluid dynamic bearing assembly and a motor having the same. The fluid dynamic bearing assembling according to the present invention may include: a sleeve formed to have a hollow into which a shaft is inserted; a sleeve housing formed to insert the sleeve therein; a bypass passage formed to axially communicate the upper portion and the lower portion of the sleeve between the sleeve and the sleeve housing dispersing pressure of a lubricating fluid in the hollow; and an oil sealing cap having an oil passage communicated with the bypass passage and taper-sealing the lubricating fluid within the oil passage.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Sintered metal bearing

InactiveCN104204574AImprove wear resistanceReduced oil permeabilityShaftsLiquid cushion bearingsMicroparticleCopper

Provided is a sintered metal bearing formed from a starting material power of which a copper based powder and an iron based powder are principal components, and having a radial bearing surface on the inside periphery, wherein the copper based powder used is one in which an ultrafine copper powder of a particle size distribution in which the proportion of particles less than 45 µm in diameter is 80 wt% or more constitutes one-third or more, expressed as ratio by weight, of the total copper based powder; and the compact obtained by compaction molding of the starting material power is sintered at 900ºC to 1000ºC inclusive.

Owner:NTN CORP

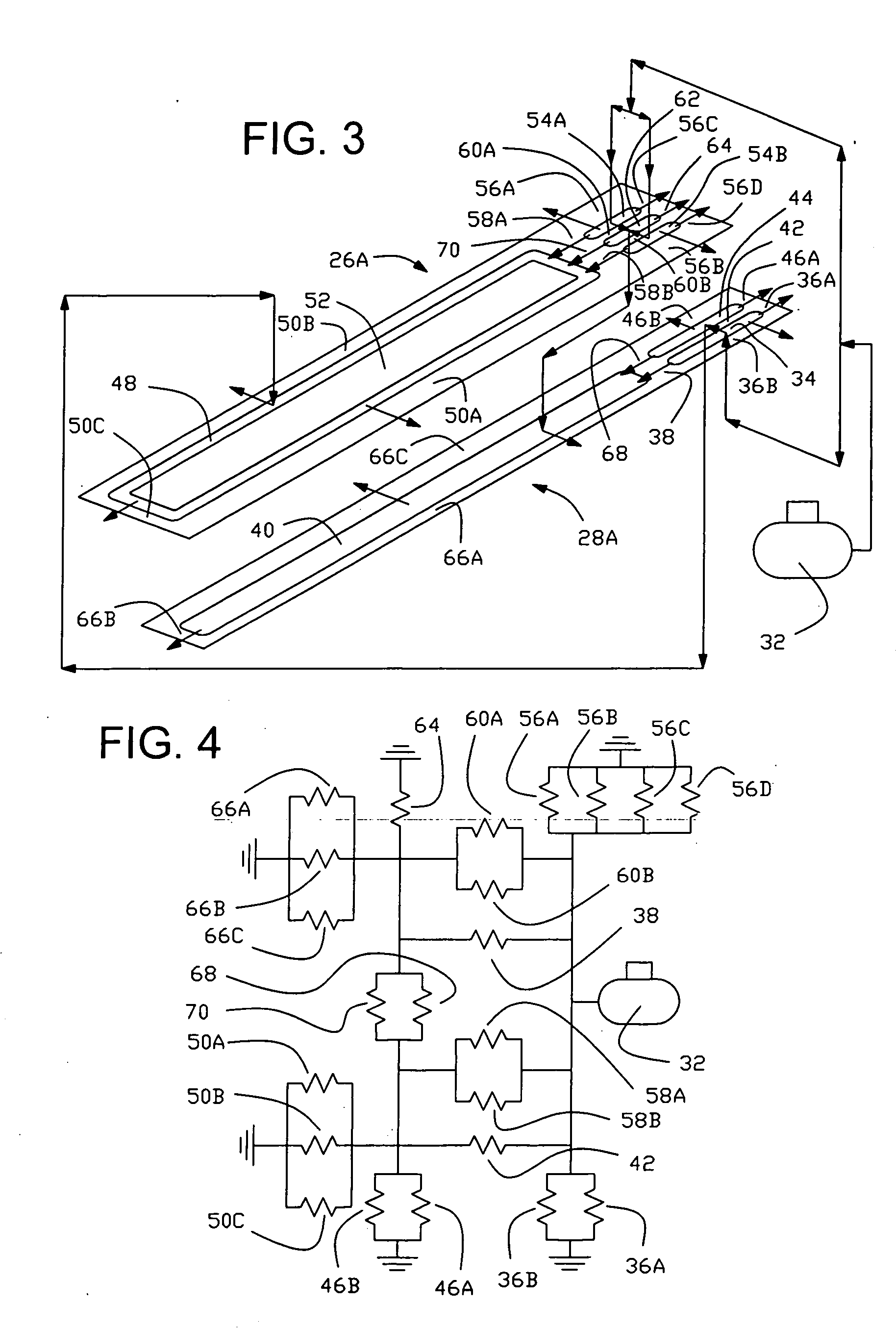

Gap Sensing Method For Fluid Film Bearings

A method for adjusting a fluid gap in fluid film bearings comprising the steps of applying a load to the bearing, measuring fluid pressure of the fluid film, determining the fluid gap using a known relationship between the bearing load applied versus gap and corresponding fluid pressure and adjusting the gap to a desired width using the known relationship between the bearing load applied versus gap and corresponding fluid pressure. Predetermined measurements of film gage pressure, supply gage pressure and gap distance can be used to determine the ratio of absolute film pressure to absolute input pressure which, in turn, can be used to determine a formula for calculating unknown gap distances.

Owner:SPECIALTY COMPONENTS

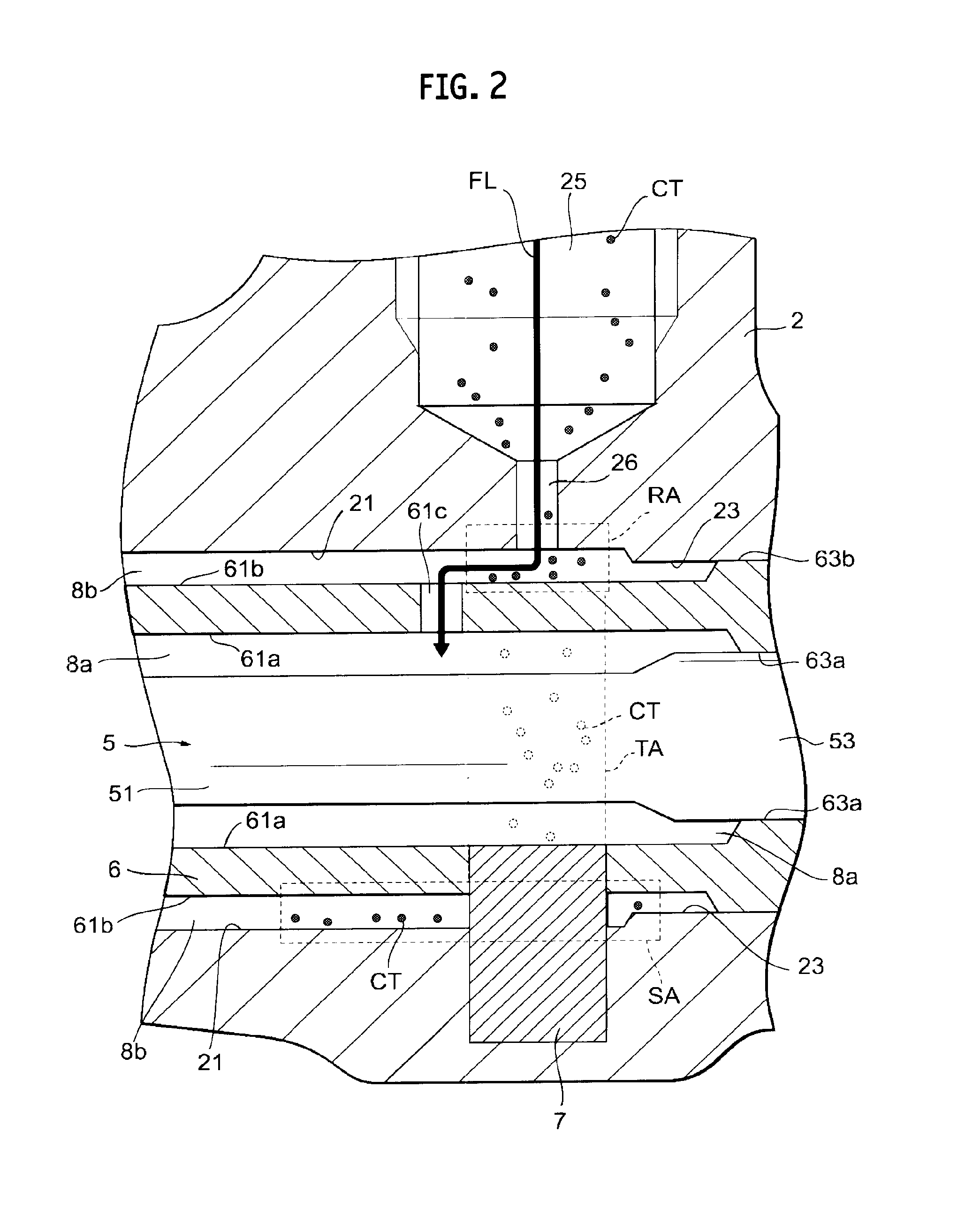

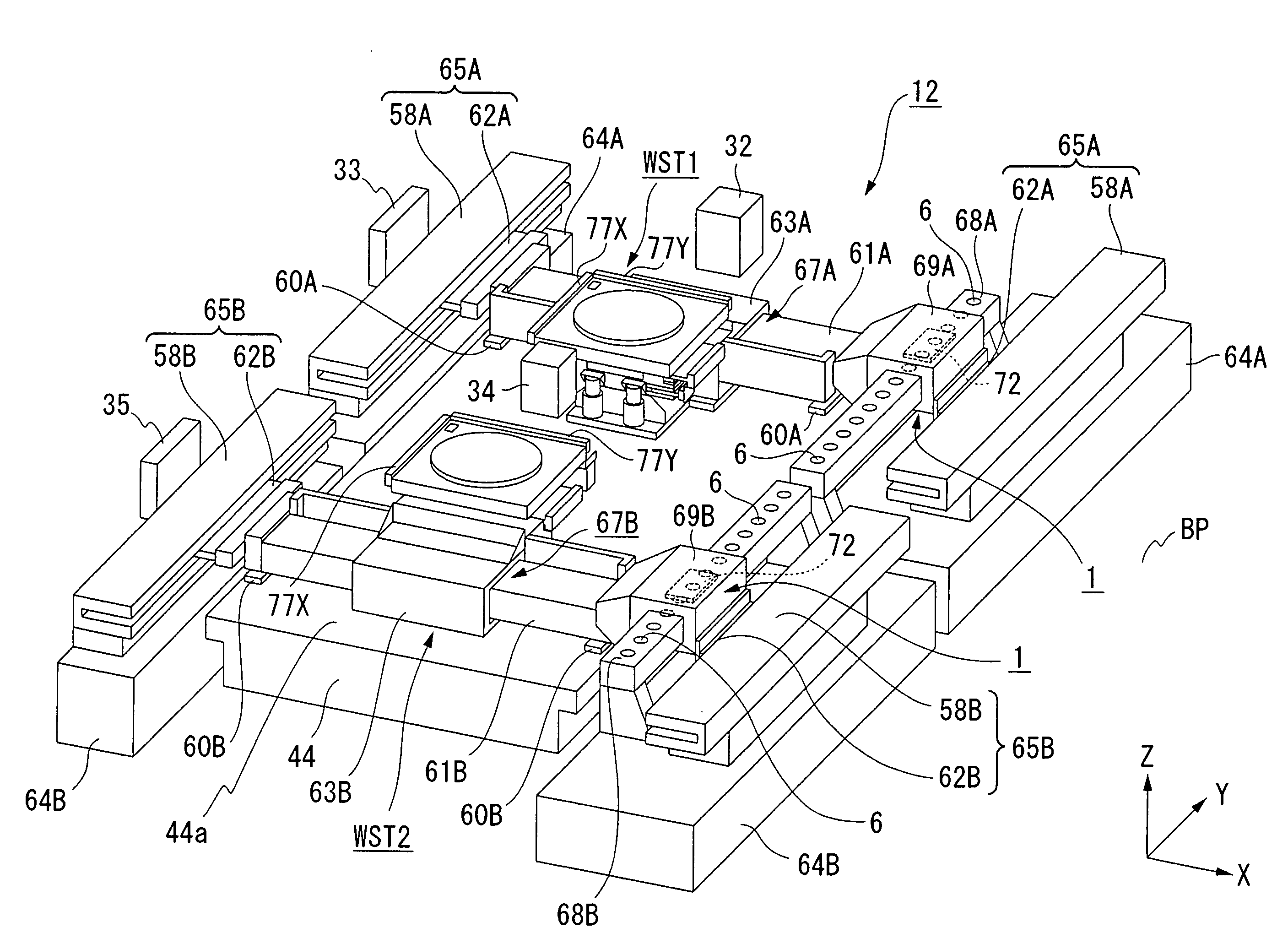

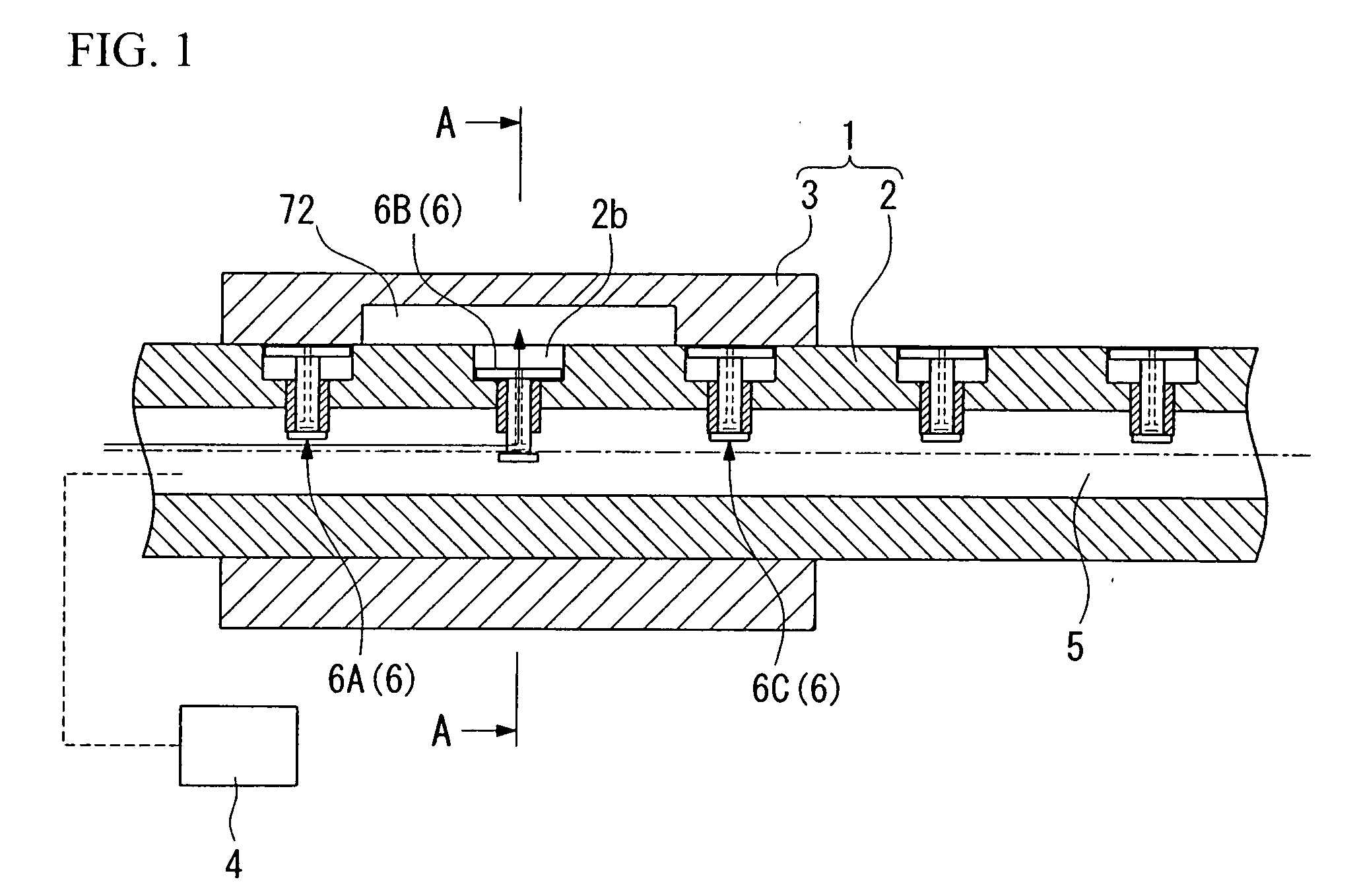

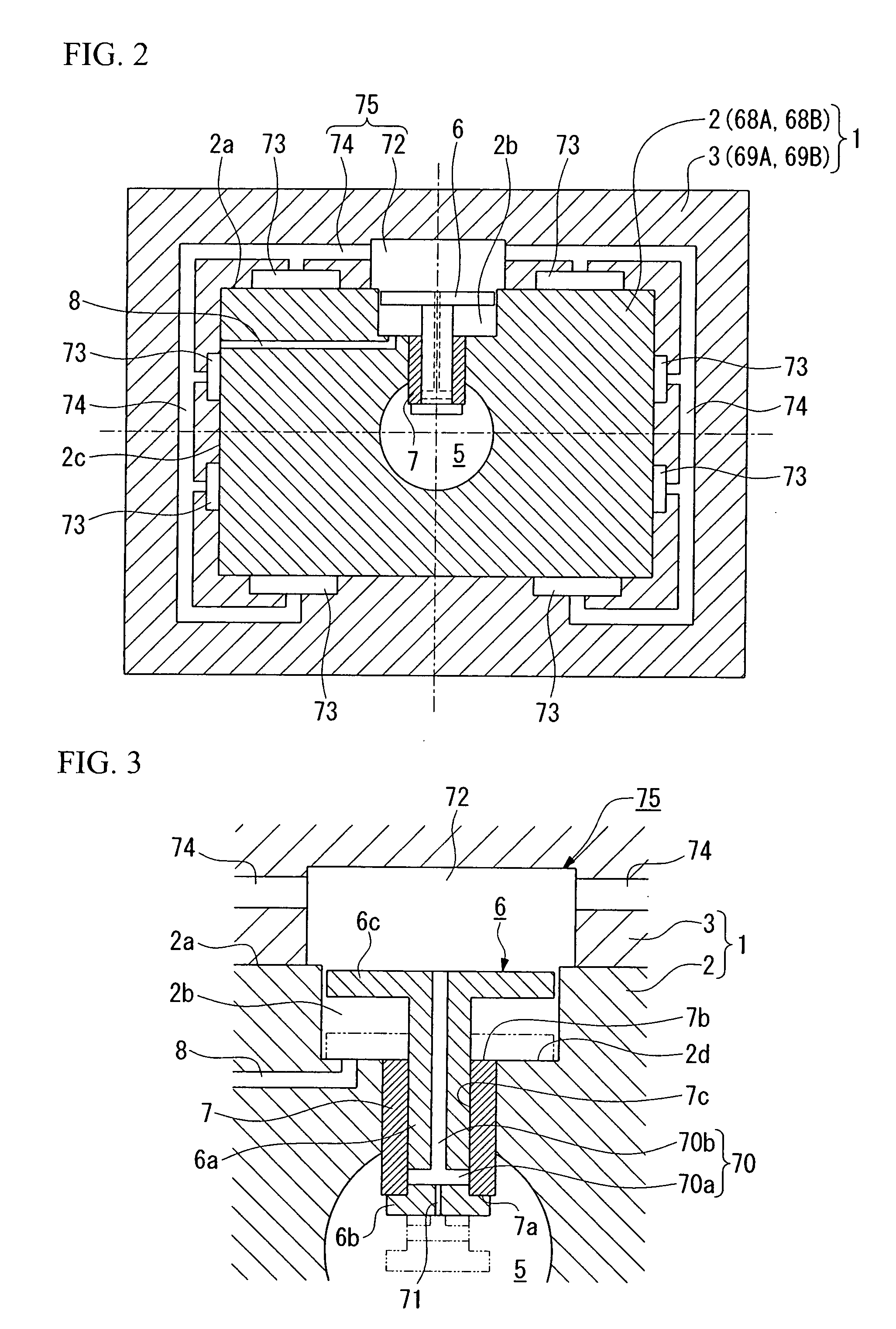

Bearing Device, Stage Device, and Exposure Apparatus

InactiveUS20080151213A1Sufficient moving strokeOperating means/releasing devices for valvesLinear bearingsEngineeringMechanical engineering

A sufficient moving stroke can be secured without connecting a tube, etc. for supply of air. A movable body (3) having a pad part (73) and a fixed body (2) are provided. The movable body (3) is movably supported by the fixed body (2) by supplying the medium to the pad part (73). A supply part (5) which is provided in the fixed body (2) and to which the medium is supplied; a connecting part (75) which connects the supply part (5) with the pad part (73); and an opening and closing unit (6) which opens and closes the connecting part (75) according to the position of the movable body (3) with respect to the fixed body (2), are provided.

Owner:NIKON CORP

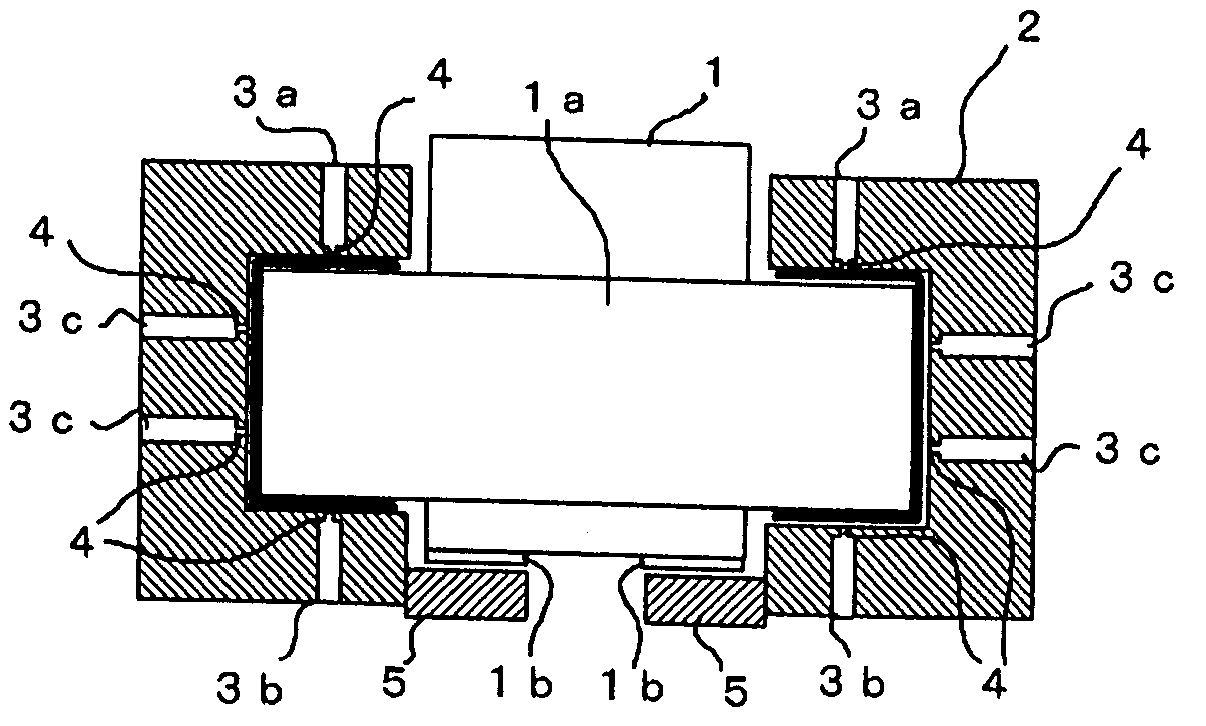

Brake

InactiveUS20050269868A1Simple structureLinear bearingsAxially engaging brakesCircular discThrust bearing

Upper and lower thrust bearing faces and a peripheral radial bearing face are formed to surround peripheral and end portions of a disk provided to a rotating shaft supported by a fluid bearing. Pressurized fluid is supplied to the respective bearing faces from first to third fluid passages to thereby form fluid bearing faces. In order to rotate the rotating shaft, the pressurized fluid is supplied to all the passages to keep the rotating shaft and the disk from contact with a bearing member. In order to brake the rotating shaft, fluid supply to the second passage is interrupted. Thus, the rotating shaft is moved down by pressure on the bearing face on the first passage side and, as a result, the brake member comes in contact with the static portion to apply the brakes.

Owner:FANUC LTD

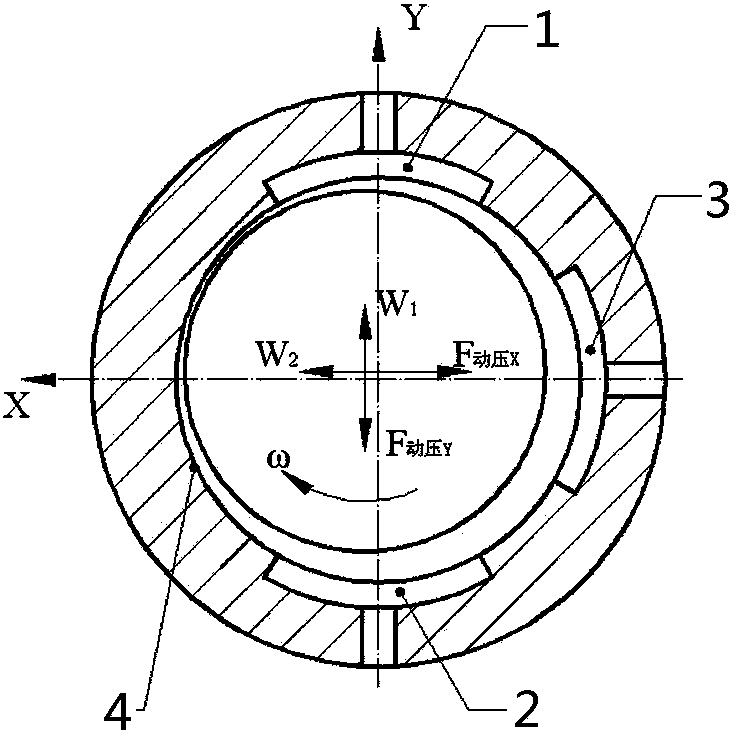

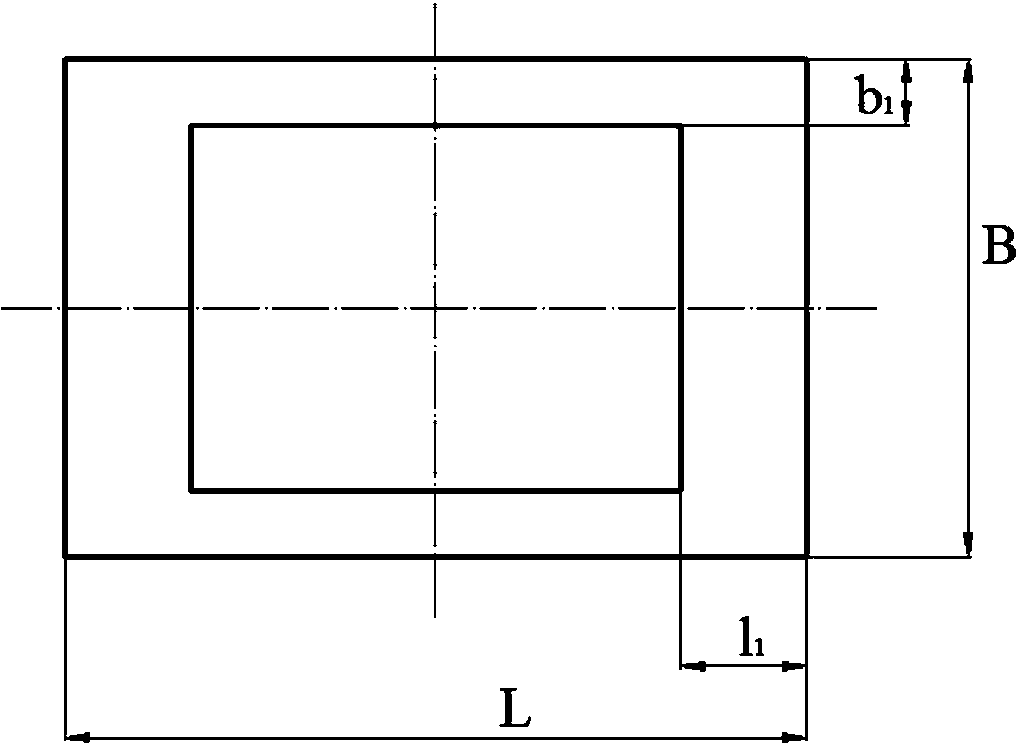

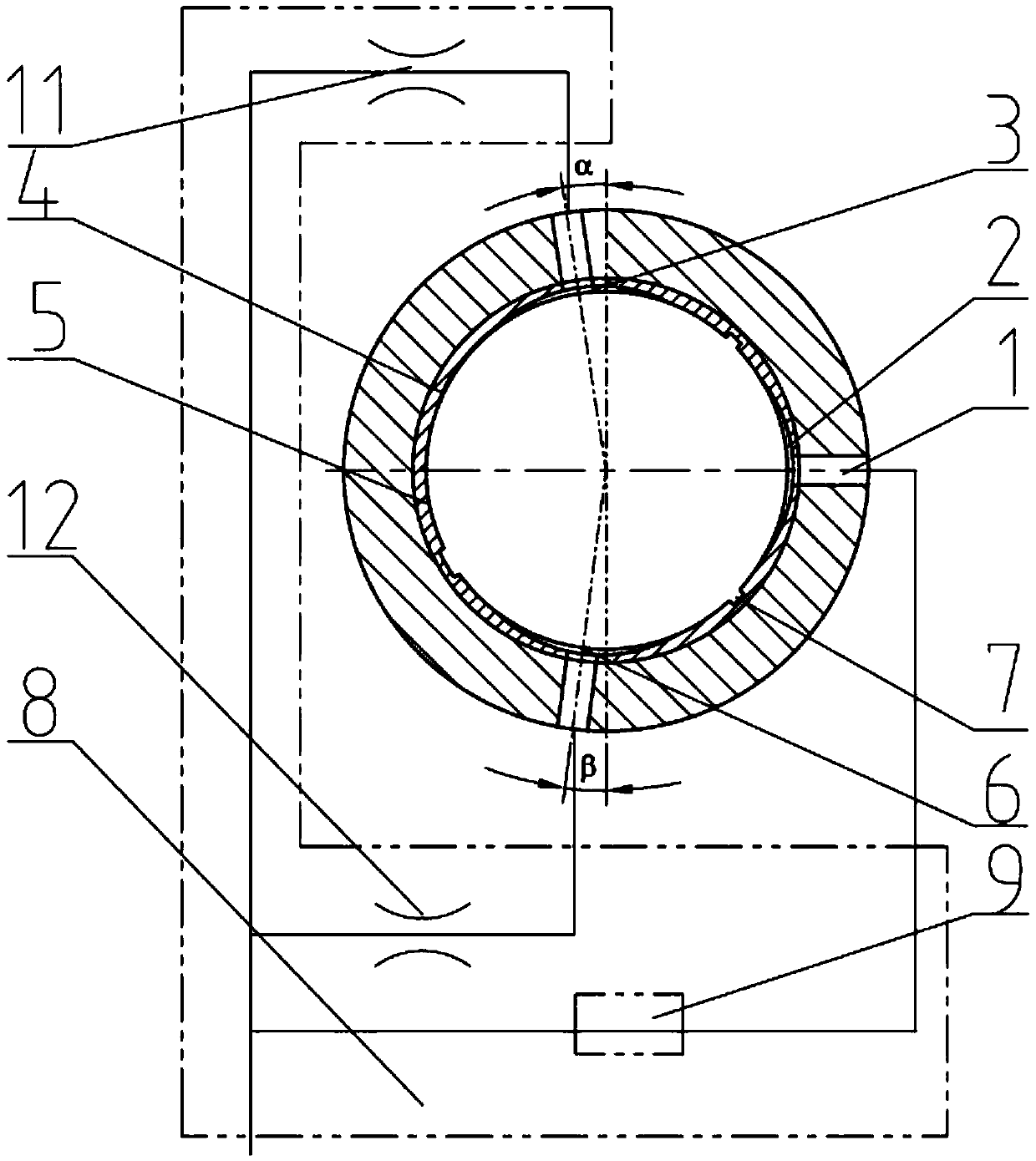

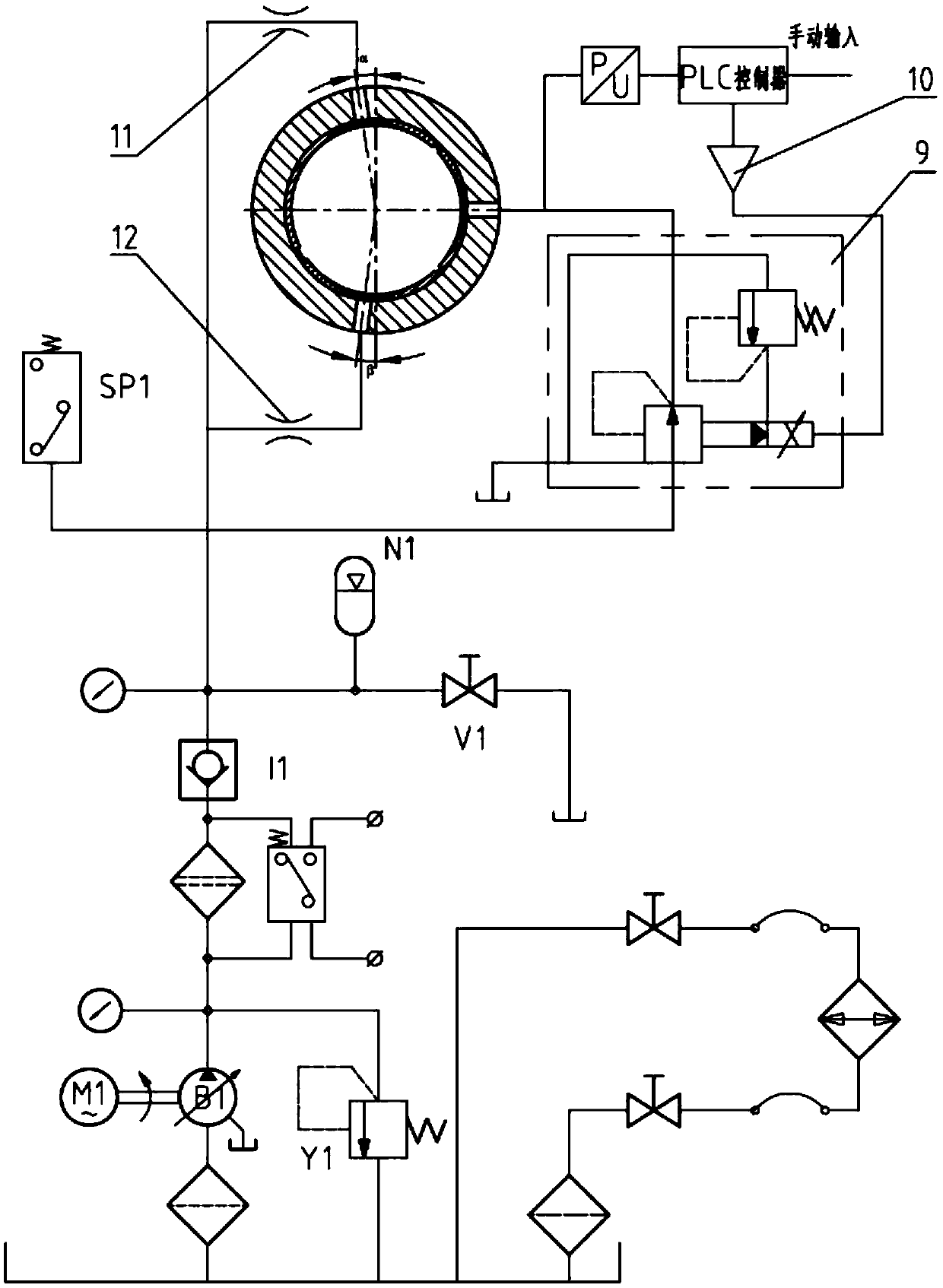

Oil film rigidity-adjustable fluid dynamic and static pressure slide bearing

ActiveCN105508426AEnhance the dynamic pressure effectAdjust oil film rigidityShaftsLiquid cushion bearingsDynamic pressurePetroleum engineering

The invention relates to an oil film rigidity-adjustable fluid dynamic and static pressure slide bearing. The bearing comprises a front static pressure oil cavity, an upper static pressure oil cavity, a lower static pressure oil cavity, a dynamic pressure cavity, three oil inlet holes, three axial oil return grooves and an oil supply system; the three oil inlet holes are respectively communicated with the front static pressure oil cavity, the upper static pressure oil cavity and the lower static pressure oil cavity, and are connected with the oil supply system; a wedged cavity is formed between the upper static pressure oil cavity and the dynamic pressure cavity; and the section of the wedged cavity is an Archimedes spiral oil cavity molded surface. The bearing overcomes and makes up the defects of other dynamic and static pressure slide bearings, preferably solves the wear problem caused by friction contact with the dynamic and static pressure bearing during starting of a main shaft, has the prominent characteristic of adjustability of oil film rigidity, and facilitates guarantee of revolving precision of a main shaft system and prolonging of service life.

Owner:SHANGHAI MACHINE TOOL WORK +1

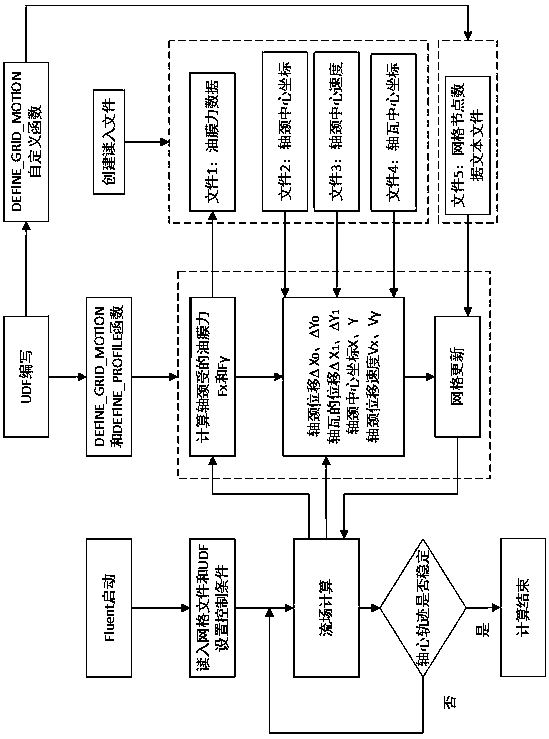

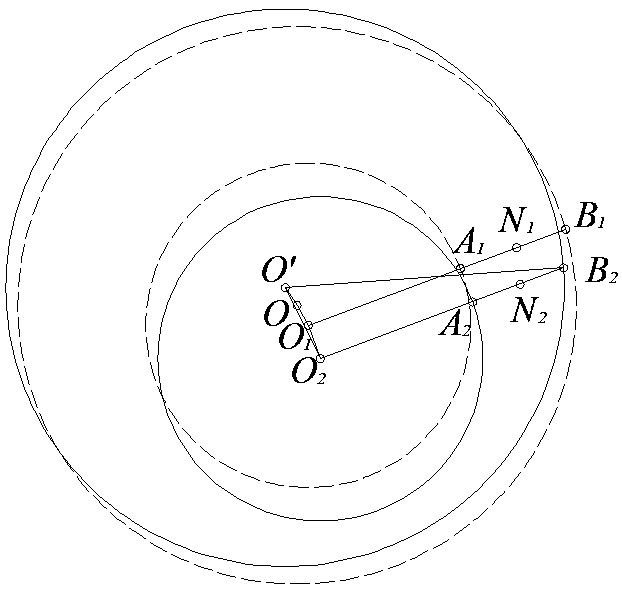

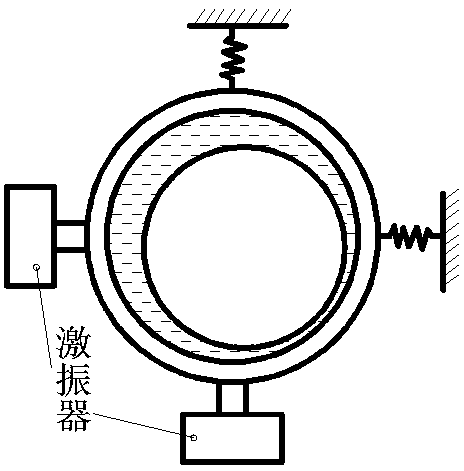

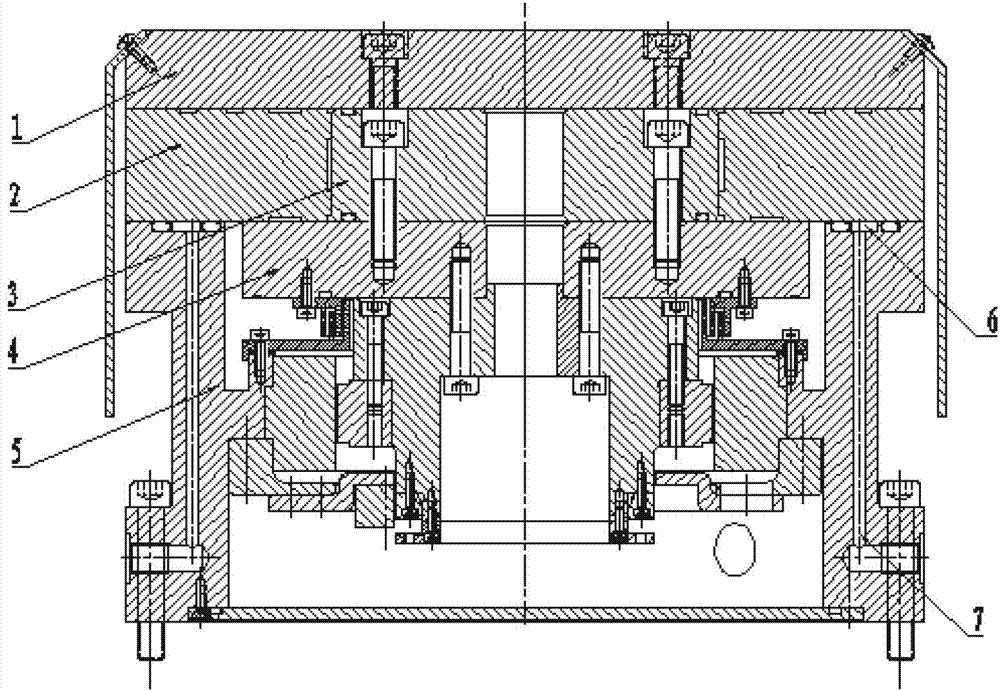

Radial oil film bearing dynamic mesh updating method based on Fluent

InactiveCN107269700AAvoid Cumulative ErrorsCalculation speedLiquid cushion bearingsDesign optimisation/simulationNeck surfaceData file

The invention provides a radial oil film bearing dynamic mesh updating method based on Fluent. The method comprises the following steps that (1), a bearing oil film mesh file is established; (2), a UDF control macroprogram in Fluent software is compiled; (4) a data file obtained in the third step is treated with an Excel tool; (5) fluid calculation software Fluent is started, the mesh file is imported, a UDF program is mounted, and UDF control conditions are set; (6), flow field calculation is controlled through a UDF dynamic mesh program; and (7) whether a bearing neck center track is convergent or not is judged. According to the radial oil film bearing dynamic mesh updating method based on the Fluent, the problem that due to the fact that the length-width ratio of bearing oil film meshes is too large, mesh distortion is prone to occur in the dynamic mesh moving process is solved, and equal-interval distribution, in the circumferential direction, of mesh lines in the radial direction before and after the moving process is guaranteed. When the method is used for calculating node coordinates of dynamic meshes, the mesh lines are always perpendicular to the bearing neck surface, the meshes are not prone to distortion, accumulated errors of mesh calculation are avoided, and the bearing performance calculating speed is increased.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

High-precision static pressure rotary working table for public oil supply track

InactiveCN103317360AIncrease stiffnessImprove dynamic performanceShaftsLiquid cushion bearingsStructural deformationStructural stability

A high-precision static pressure rotary working table for a public oil supply track performs simultaneous identical-pressure oil supply to a static pressure system through the public oil supply track. No less than three independent axial supporting oil cavities are respectively arranged on two end faces of a bearing bush of a hydrostatic bearing, no less than three independent radial supporting oil cavities are arranged on an inner hole wall, hydraulic oil is respectively supplied to the axial oil cavities and the radial oil cavities through the public oil supply track and oil holes positioned on the bearing bush of the hydrostatic bearing, synchronous establishment of oil film pressure is achieved, and structural deformation is reduced. The public oil supply track is provided with symmetrically distributed oil inlets, the number of the oil inlets is even, and a random oil inlet can be selected according to the assembly requirements so as to feed oil; the static pressure rotary working table is provided with symmetrically distributed oil returning openings, the number of the oil returning openings is even, thermal symmetry of the rotary working table structure is guaranteed, and thermal tilt of a table top of the rotary working table is reduced. The static pressure rotary working table has high rigidity and dynamic performance, improves structural stability and rotation precision and is compact in structure and convenient to install.

Owner:XI AN JIAOTONG UNIV +1

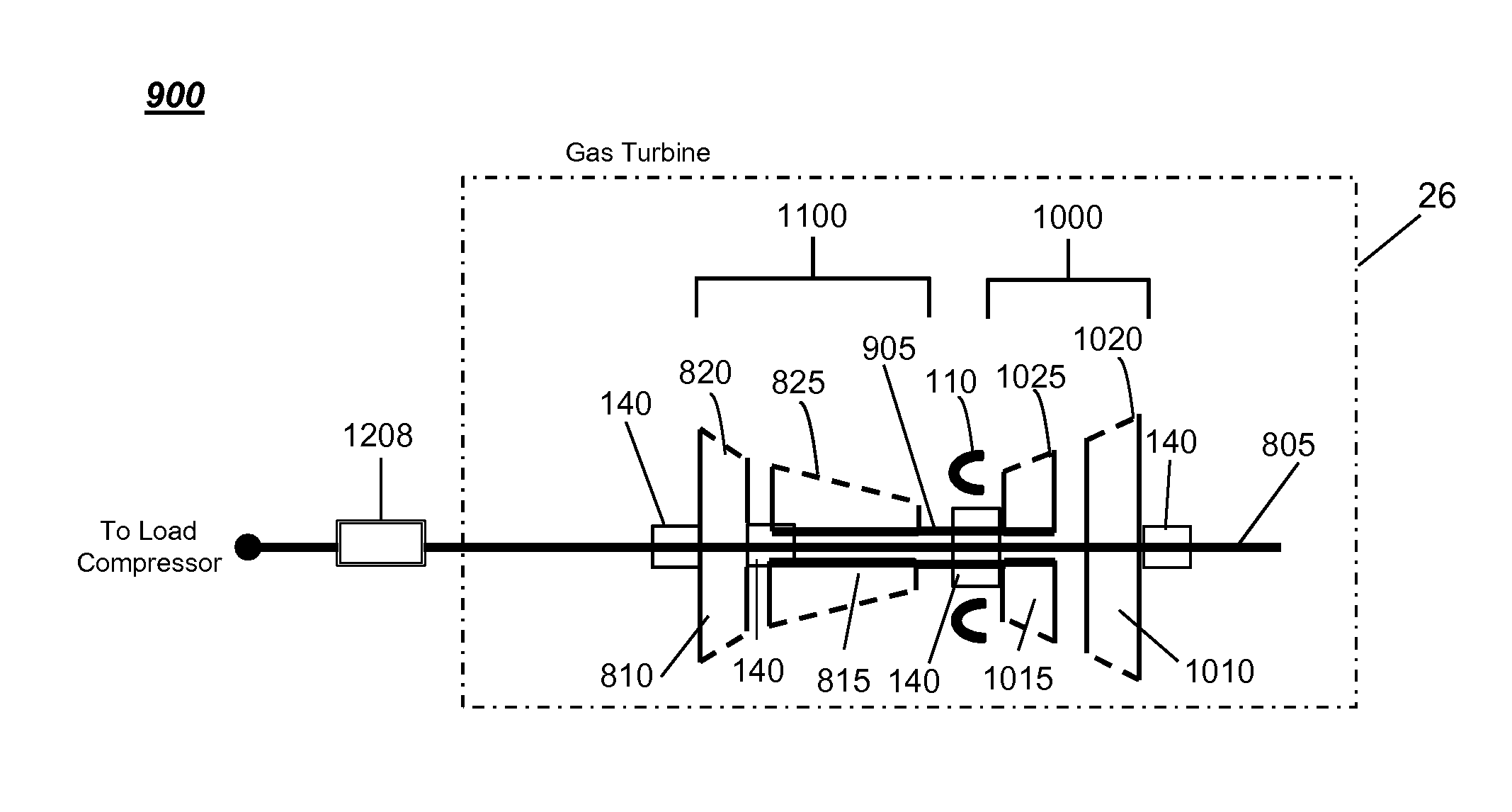

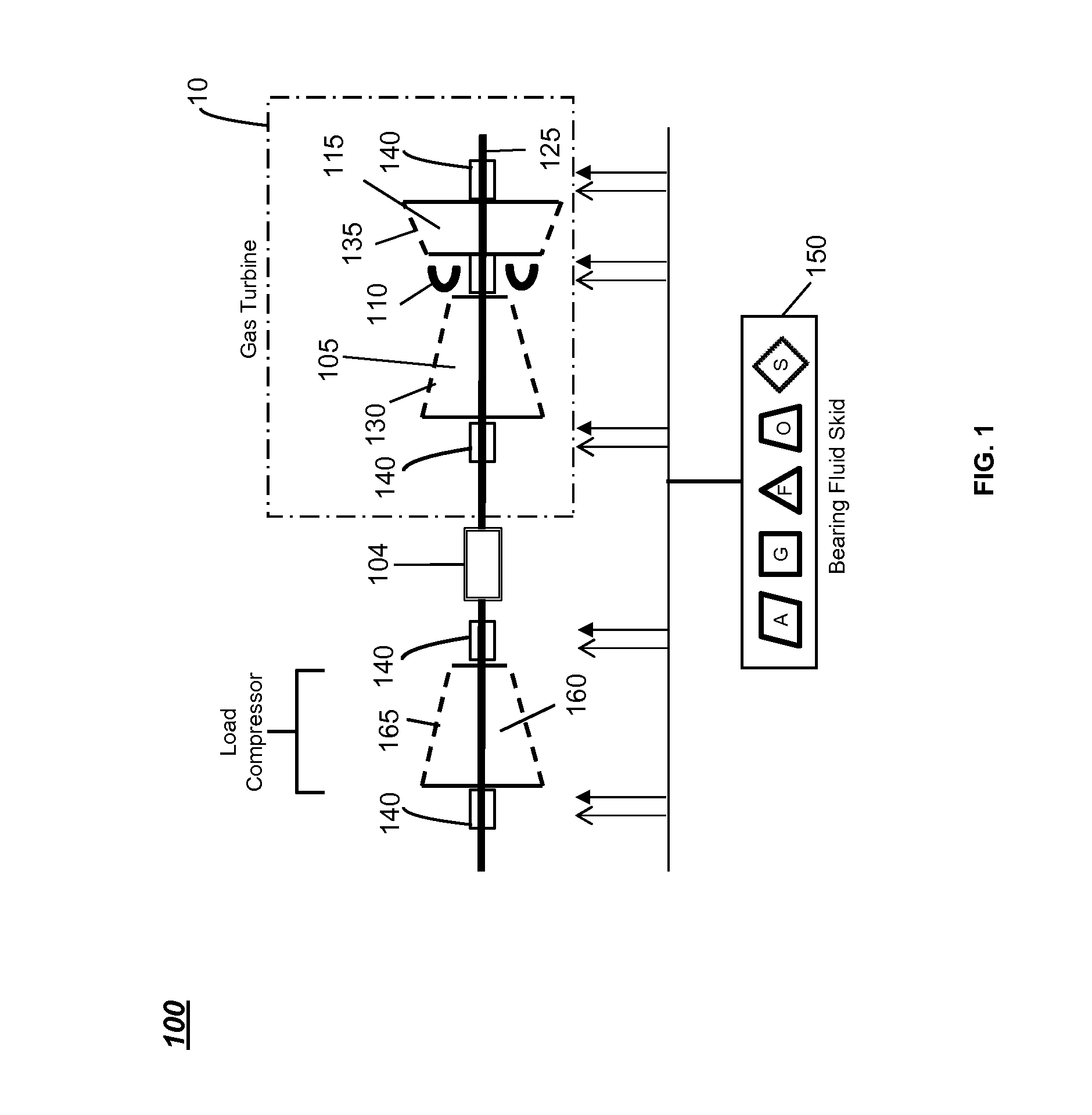

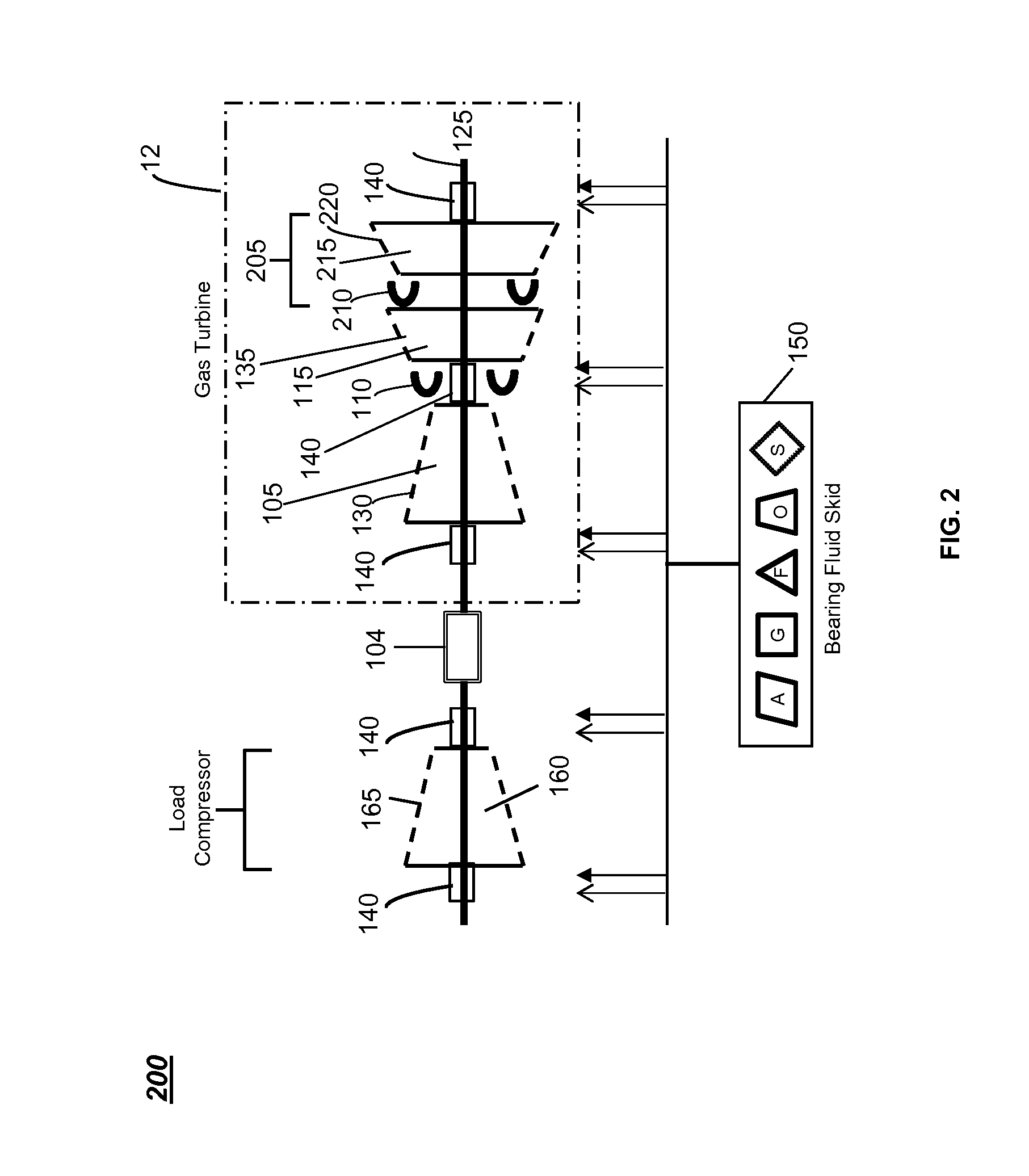

Mechanical drive architectures with hybrid-type low-loss bearings and low-density materials

Mechanical drive architectures can include a gas turbine having a compressor section, a turbine section, and a combustor section. A load compressor is driven by the gas turbine. A rotor shaft extends through the gas turbine and the load compressor. The rotor shaft has rotating blades arranged in a circumferential array to define a plurality of moving blade rows in the gas turbine and the load compressor. At least one of the rotating blades in one of the gas turbine and the load compressor includes a low-density material. Bearings support the rotor shaft within the gas turbine and the load compressor, wherein at least one of the bearings is a hybrid-type low-loss bearing.

Owner:GENERAL ELECTRIC CO

Fluid dynamic bearing assembly and motor having the same

There are provided a fluid dynamic bearing assembly and a motor having the same. The fluid dynamic bearing assembling according to the present invention may include: a sleeve formed to have a hollow into which a shaft is inserted; a sleeve housing formed to insert the sleeve therein; a bypass passage formed to axially communicate the upper portion and the lower portion of the sleeve between the sleeve and the sleeve housing dispersing pressure of a lubricating fluid in the hollow; and an oil sealing cap having an oil passage communicated with the bypass passage and taper-sealing the lubricating fluid within the oil passage.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com