Fluid pumping capillary sealing element for hydrodynamic bearing

A technology for hydrodynamic bearings and seals, applied in the direction of bearing elements, sliding contact bearings, bearings for rotational motion, etc., which can solve problems such as failure, spindle motor or disk drive component performance degradation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

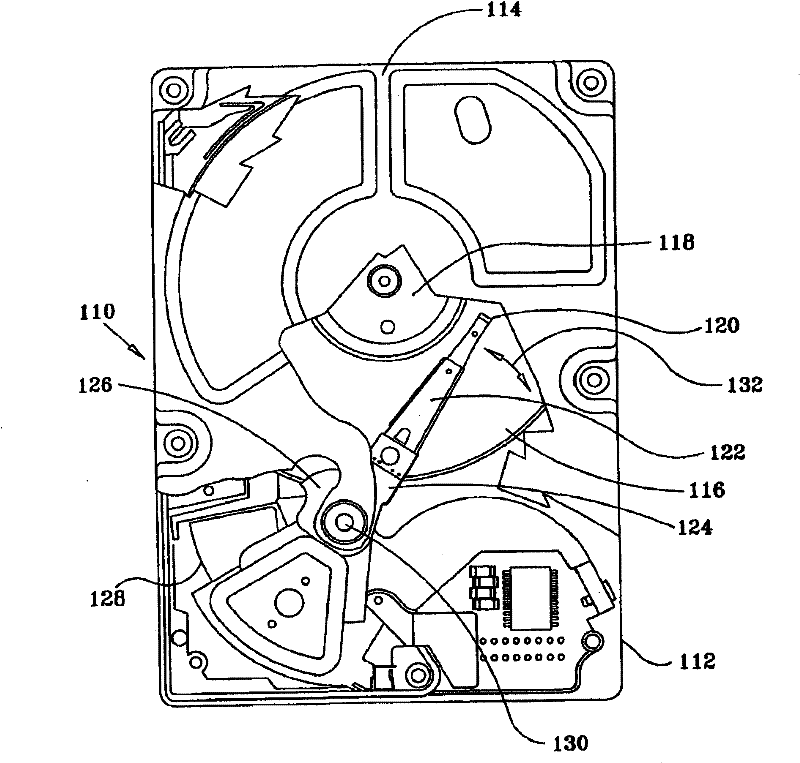

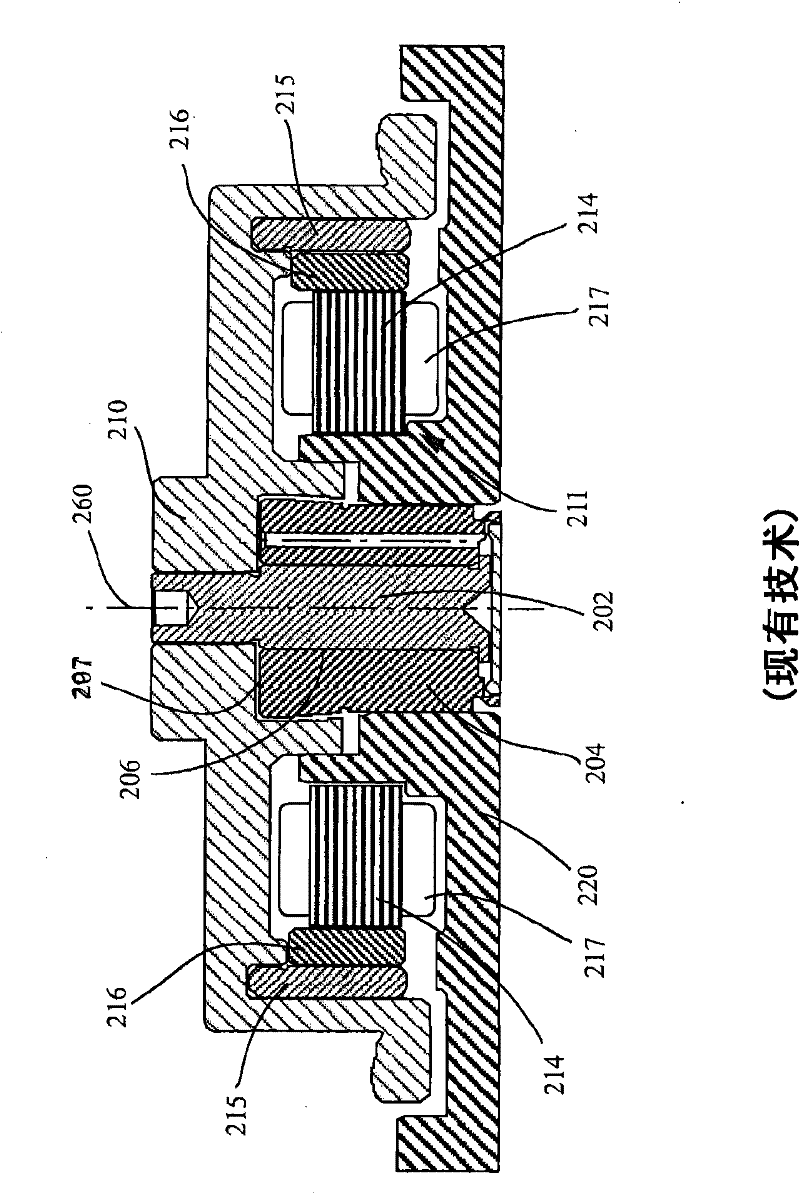

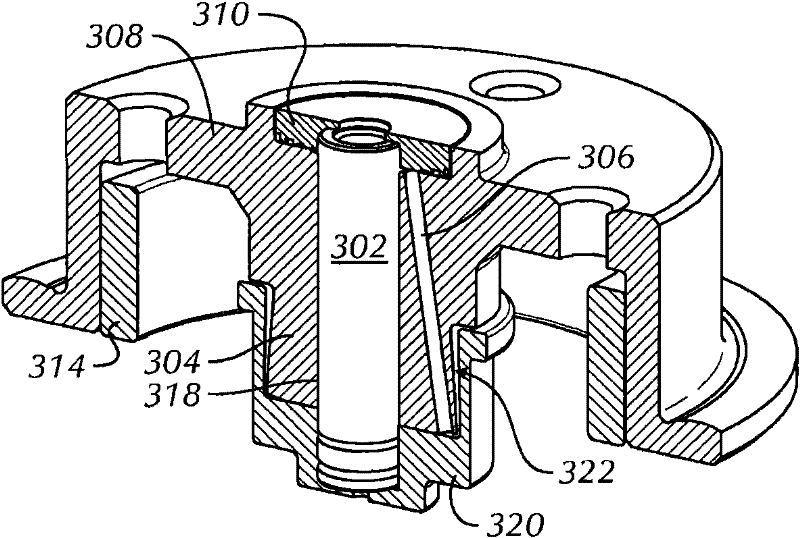

[0095] Described herein is an apparatus and method for providing a compact, robust and efficient fluid sealing system with fluid pumping and capillary features for hydrodynamic bearings. The present invention provides improved shock resistance and vibration response, thereby improving the reliability and performance of disk drive storage systems. Solve the problem of motor jogging, which is the rapid repeated opening and closing of axial spaces between relatively rotatable parts, which expels oil from or draws air into these spaces. The present invention is particularly useful for small disc drives such as 2.5 inch disc drives where motor height is a constraint and which require high performance including high rotational speed and high areal density.

[0096] It will be apparent that the features of the specification and claims are applicable to disk drive storage systems, low profile disk drive storage systems, spindle motors, brushless DC motors, various hydrodynamic bearing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com