Hybrid bearing and main shaft provided with hybrid bearing

A dynamic and static pressure bearing and bearing technology, which is applied to bearings, liquid cushion bearings, shafts and bearings, etc., can solve the problems of inability to meet the production requirements of high-speed spindles and high energy consumption, and achieve high rigidity, large contact area, and low wear. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0038] The directions of m, n, o and p marked in the accompanying drawings are only for better understanding of the directions of the embodiments of the patent of the present invention. It should be changed accordingly, so its outlet and inlet must also be reversed, which should be understood by those of ordinary skill in the art, and the outlet or inlet of the ring channel described herein cannot be used as a limitation to the scope of protection of the present invention .

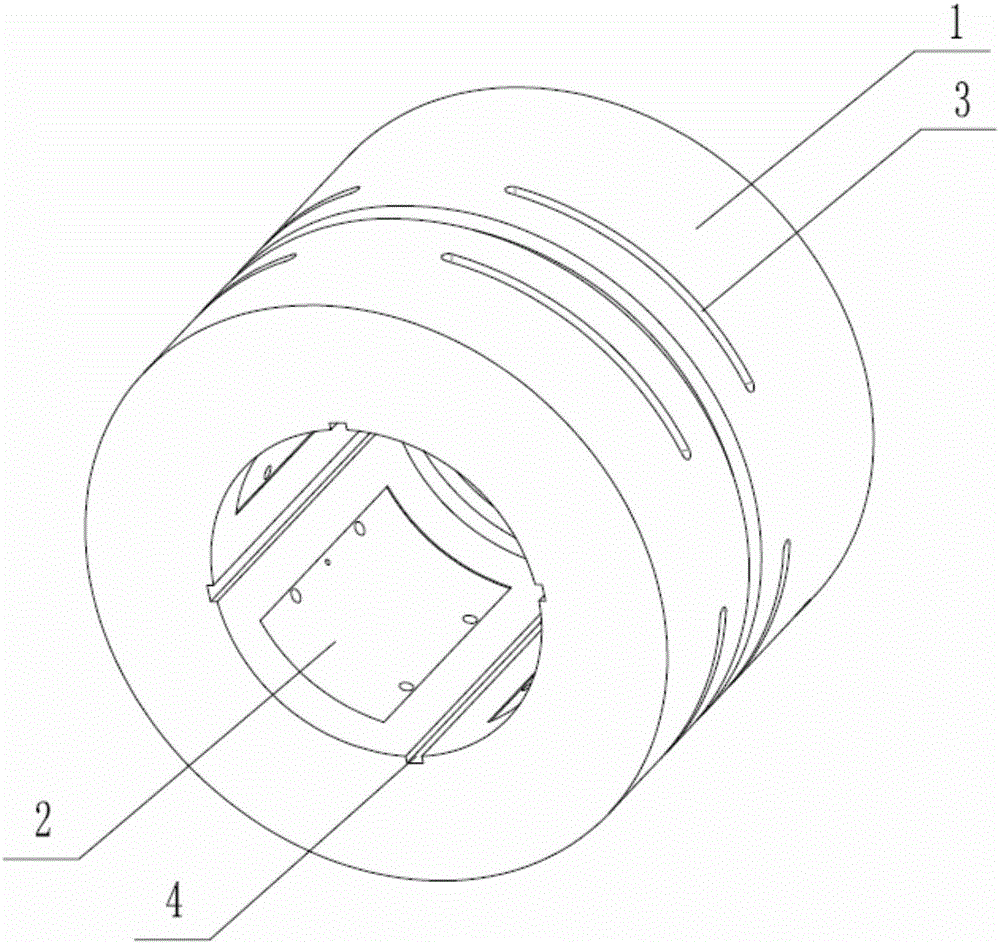

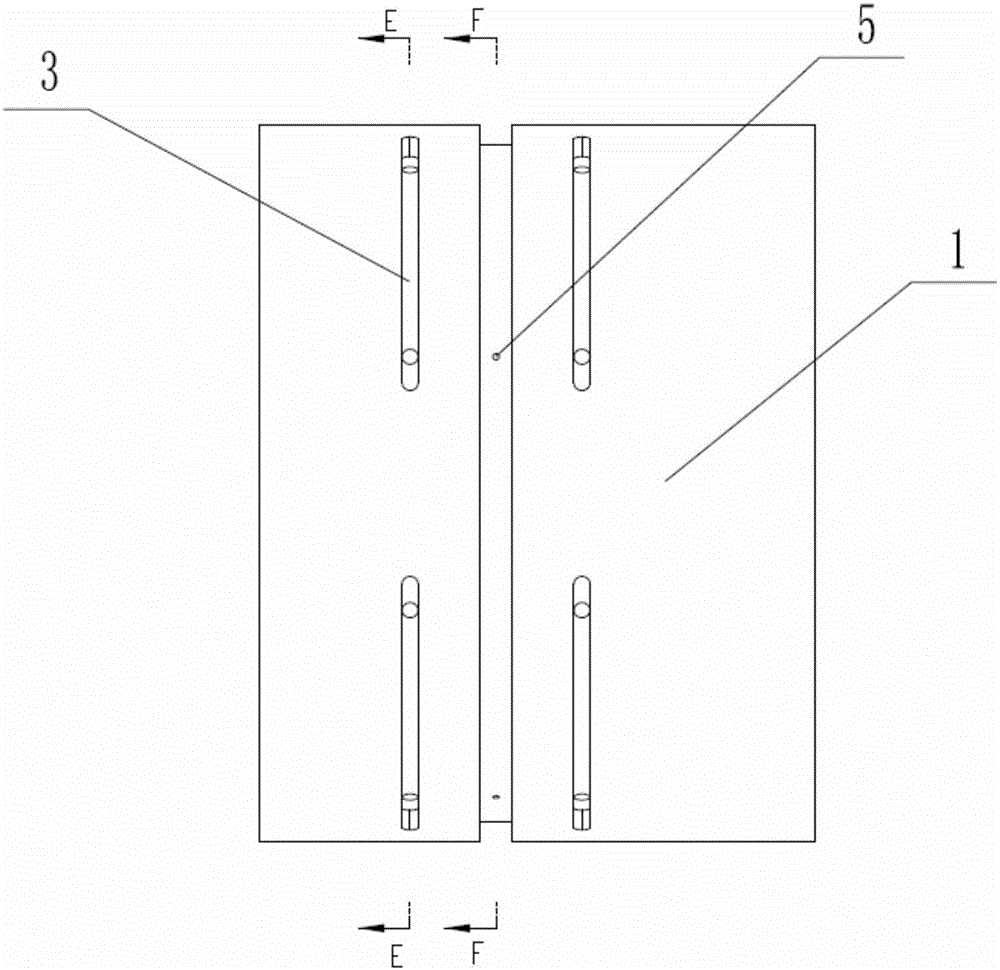

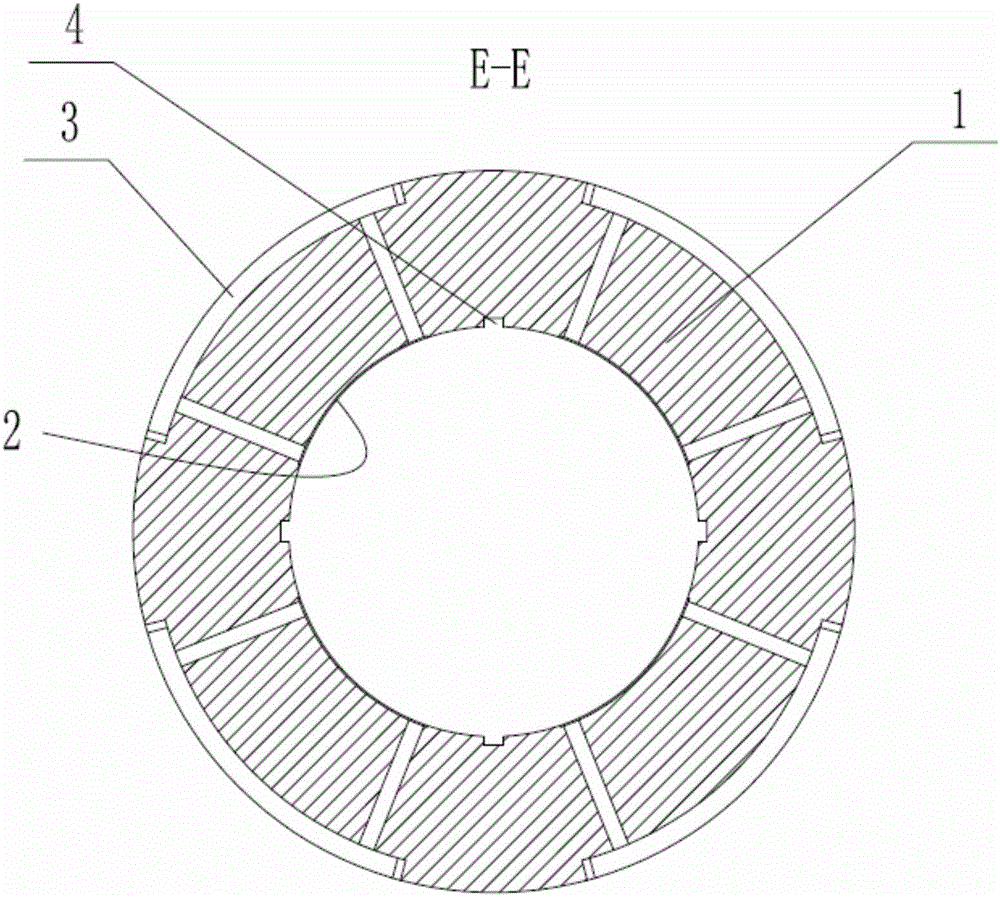

[0039]The present invention provides a dynamic and static pressure bearing, which includes a bearing body 1, at least two oil grooves 2 are formed on the annular inner wall of the bearing body 1 along the radial direction of the bearing body 1, and a circulation channel 3 is provided on the bearing body 1. Both ends of the circulation channel 3 communicate with the corres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com