High-precision static pressure rotary working table for public oil supply track

A technology of rotary table and oil supply track, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problem of affecting the stiffness and dynamic performance of the static pressure turntable, reducing the rotation accuracy of the static pressure turntable, and inconsistent pressure, etc. problems, to achieve the effect of ensuring structural stability and rotation accuracy, improving stiffness and dynamic performance, and reducing structural deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

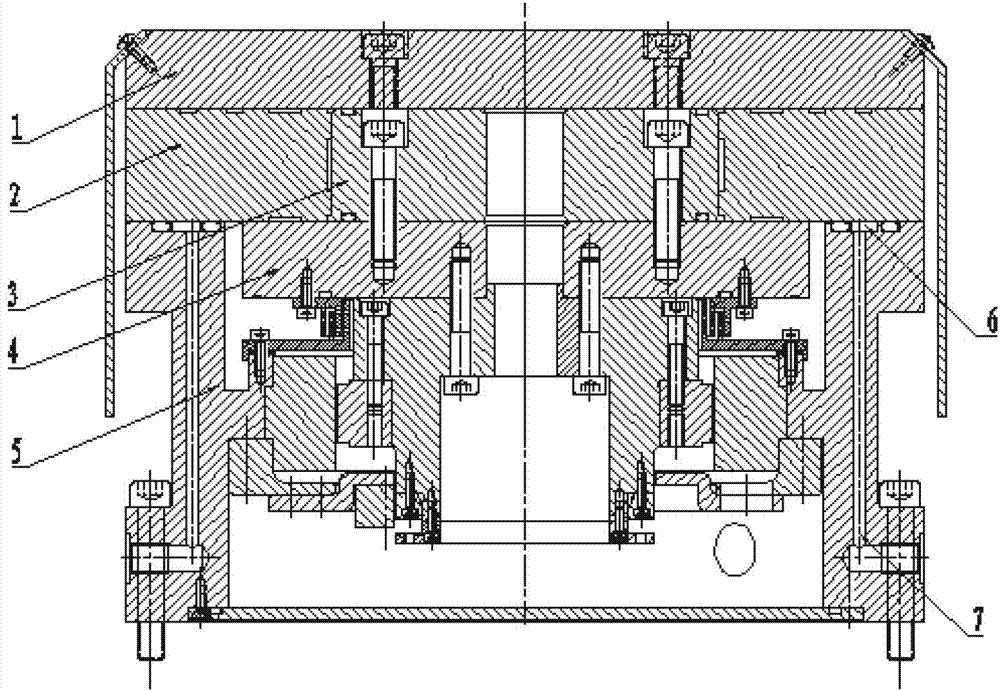

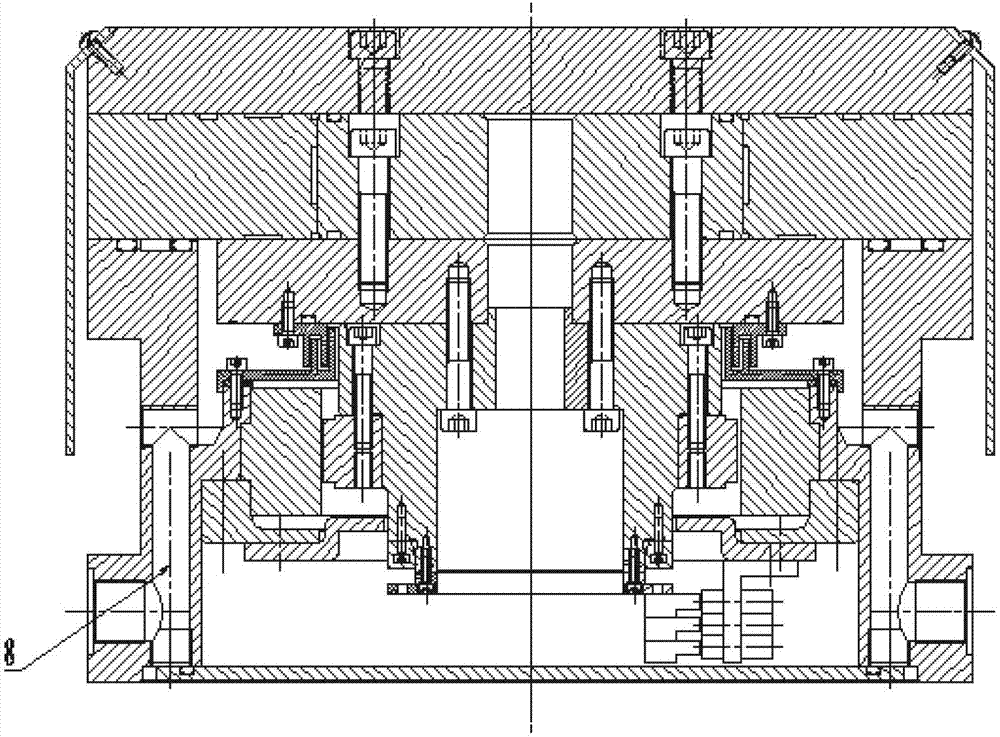

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0013] see figure 1 , figure 2 . The present invention comprises a turntable frame 5 and a hydrostatic bearing bush 2 fixed on the turntable frame 5. The radial support 3 of the hydrostatic bearing is arranged on the inner side of the hydrostatic bearing bush 2, and the axial support of the hydrostatic bearing is arranged on the lower side. 4. The turntable table surface 1 is installed on the upper end surface of the radial support 3 of the static pressure bearing, and a common oil supply rail 6 is arranged between the turntable frame 5 and the bearing bush 2 of the static pressure bearing. The oil inlet port 7 and the oil return port 8 are arranged symmetrically on the turntable frame 5 .

[0014] The two end faces of the hydrostatic bearing bush of the rotary table of the present invention and the inner hole wall are provided with no less than 3 indepen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com