Patents

Literature

300results about How to "Guaranteed rotation accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

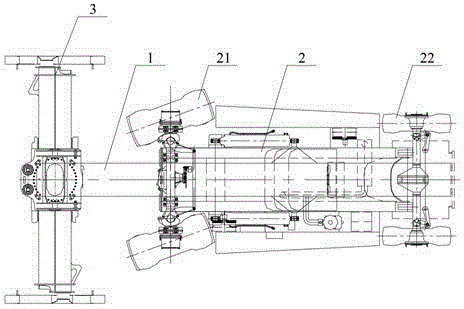

Front lifting crane and hydraulic steering system thereof

InactiveCN103332220ASuitable for complex working conditions in the fieldImprove mobilityFluid steeringDeflectable wheel steeringControl signalActive steering

The invention discloses a hydraulic steering system for a front lifting crane. The hydraulic steering system is provided with a front shaft, a rear shaft and a steering device which is used for controlling the steering loop of a driving steering shaft, wherein both the front shaft and the rear shaft are both steering shafts, either the front shaft or the rear shaft serves as the driving steering shaft, and the other one serves as a driven steering shaft. The steering system further comprises a hydraulic valve and a controller, wherein the hydraulic valve is used for controlling the steering loop of the driven steering shaft, and the controller is used for outputting a control signal to the hydraulic valve according to a steering mode determined by user instructions, so as to adjust the flowing direction and flow rate of the steering loop of the driven steering shaft. Compared with the prior art, the steering system for the front lifting crane, disclosed by the invention, has the advantage that the requirements on two aspects, namely the performance of the steering system and the service lives of wheels, can be met effectively. Based on the steering system, the invention further provides the front lifting crane using the steering system.

Owner:XUZHOU HEAVY MASCH CO LTD

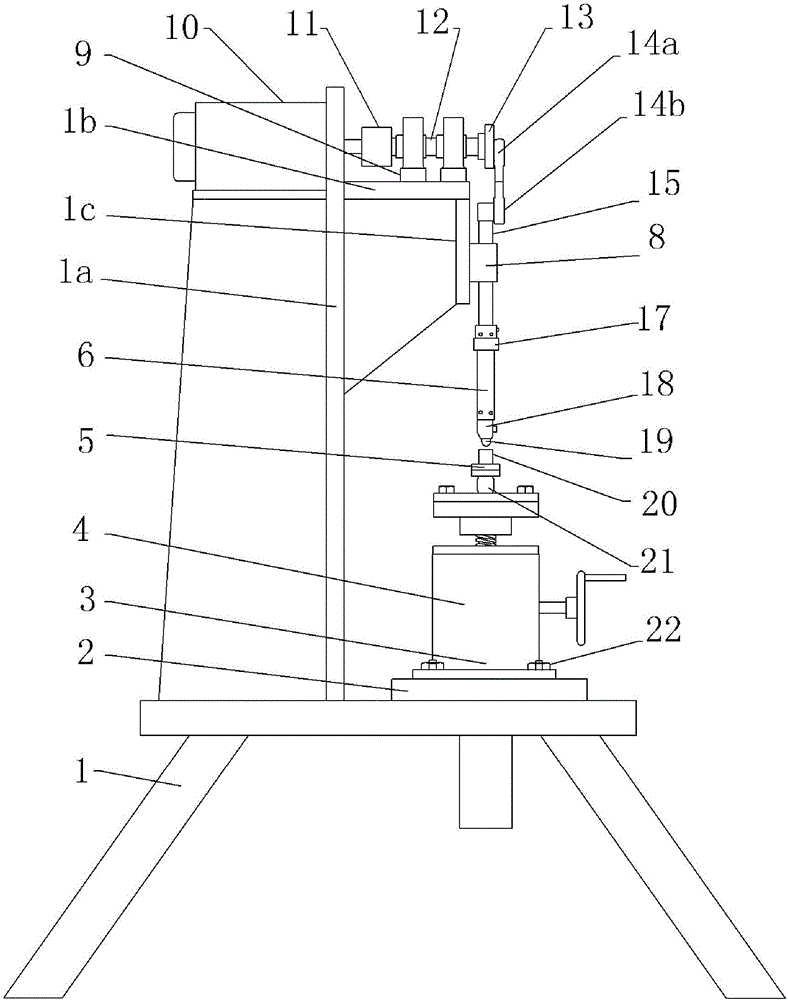

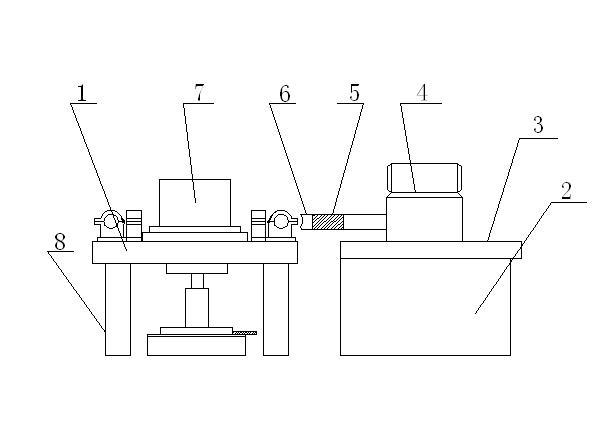

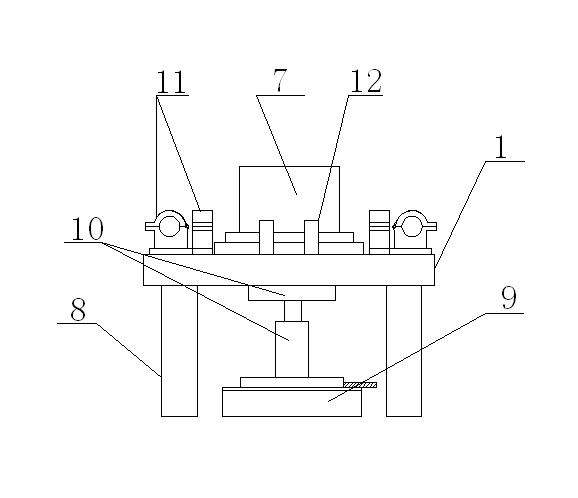

Impacting-sliding composite frictional wear testing device and method thereof

ActiveCN105891036ASimple structureReduce processing costsInvestigating abrasion/wear resistanceElectricityWear testing

The invention discloses an impacting-sliding composite frictional wear testing device and a method thereof. The method comprises the following steps that a spherical upper test piece is clamped on an upper clamp and a planar lower test piece is clamped by using a lower clamp; the lower clamp is controlled to move up and down by a precise screw lifting platform so that the upper test piece and the lower test piece come into contact; a servo motor drives the upper test piece to do up-down reciprocating motion at set frequency f, times N and displacement S by an eccentric disc, an upper knuckle bearing, a lower knuckle bearing, an impacting shaft, a spring leaf and an upper clamp, and carries out reciprocating impact on the lower test piece; in the impacting process, the spring leaf is deformed under the action of stress, so that impacting-sliding composite frictional wear between the upper test piece and the lower test piece is realized; and simultaneously, the force borne by the lower test piece is tested by a three-dimensional dynamic piezoelectric sensor connected with the lower clamp and is transmitted to a data acquisition control system, and a friction coefficient-cycle time curve is obtained by analysis. The impacting-sliding composite frictional wear testing device and the method disclosed by the invention have the advantages that the material can conveniently generate rigidity-adjustable impacting-sliding composite frictional wear, the automation degree is high and the repeatability of experimental data is good.

Owner:SOUTHWEST JIAOTONG UNIV

High speed spindle box structure

ActiveCN104889425ANo bending deformationGuaranteed rotation accuracyLarge fixed membersMaintainance and safety accessoriesBall bearingDynamic balance

The invention discloses a high speed spindle box structure, and belongs to the machine tool part device field. The high speed spindle box structure comprises a spindle box, a spindle device, a front bearing seat, a rear bearing seat, a spindle drive mechanism, a cooling system, a lubrication system and a dynamic balance regulating mechanism, wherein a spindle of the spindle device is supported by a front bearing component and a rear bearing component, and installed in a spindle hole in the spindle box, bearings of the front bearing component are two pairs of front ball bearings and rear ball bearings, which are arranged at a certain interval, bearings of the rear bearing component are roller bearings, the cooling system comprises a spindle cooling mechanism and a bearing cooling mechanism which respectively have functions of cooling the spindle and cooling the interiors of the bearings, and the lubrication system comprises a front bearing lubrication mechanism and a rear bearing lubrication mechanism, and respectively have functions of lubricating the front bearing component and lubricating the rear bearing component. The high speed spindle box structure solves the problems that an existing spindle box mechanism is poor in cooling effect, temperature of bearings of the existing spindle box mechanism easily rise, and then rotation speed and processing accuracy of the existing spindle box mechanism are influenced.

Owner:浙江日发精密机床有限公司

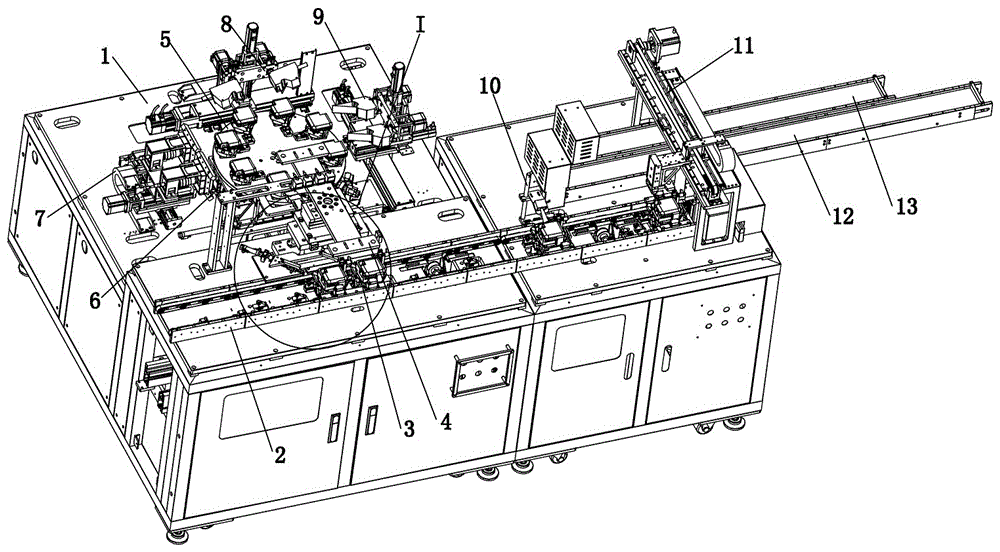

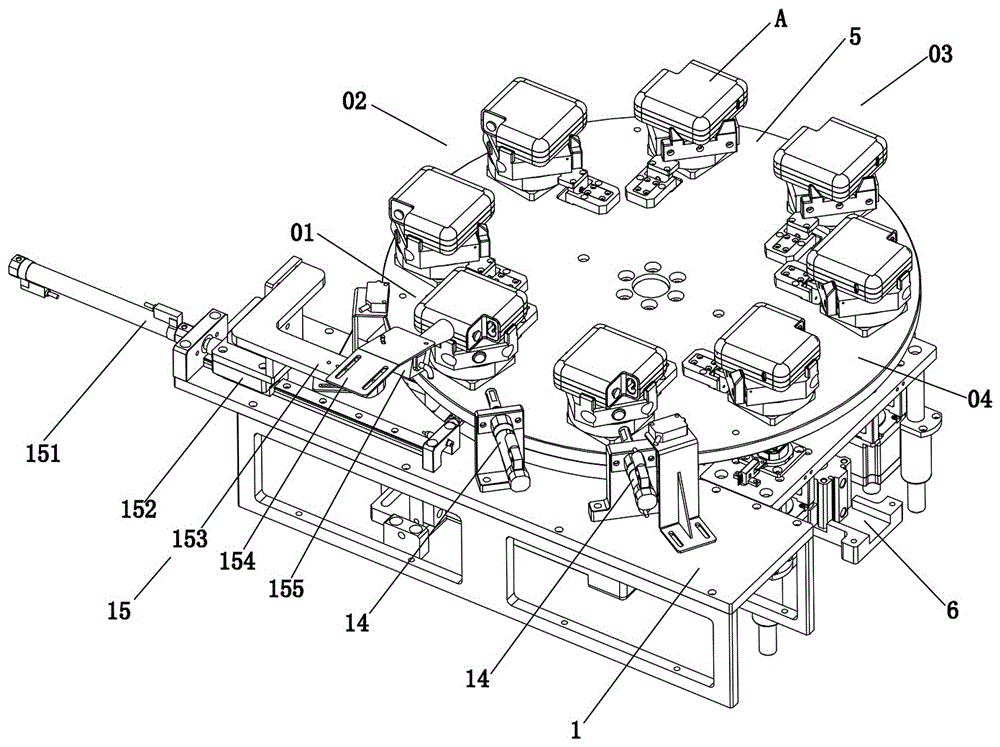

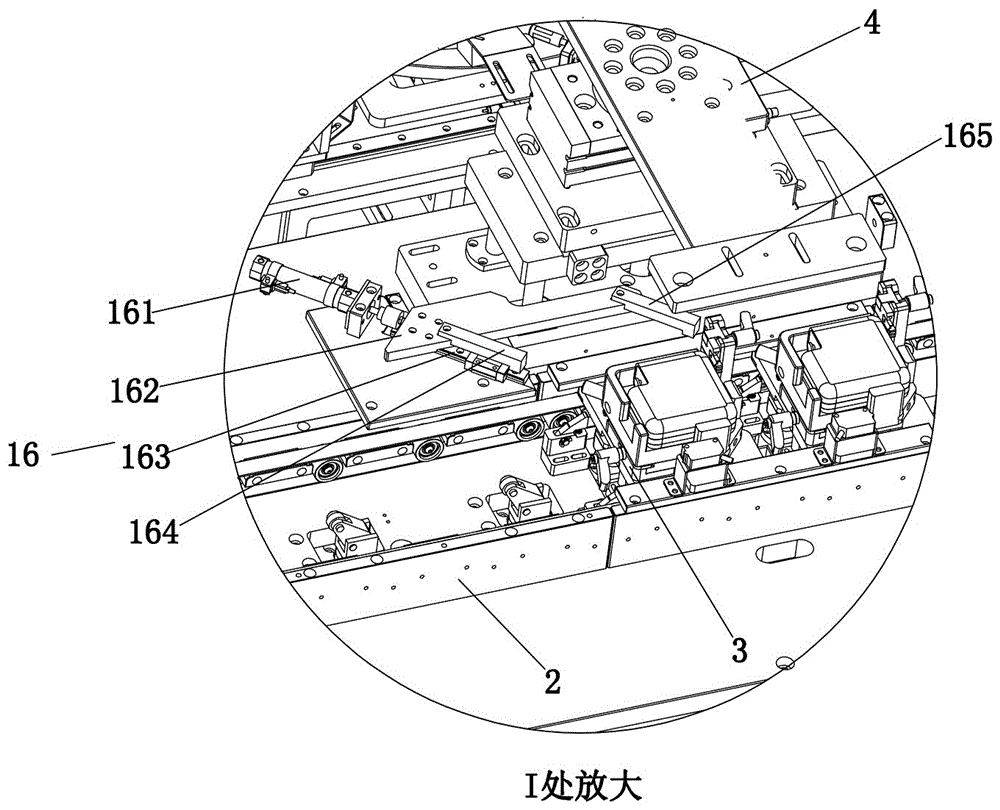

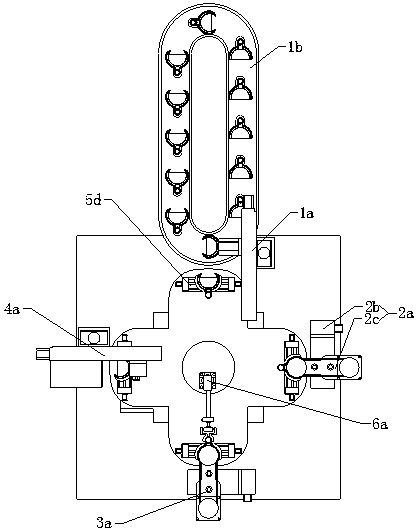

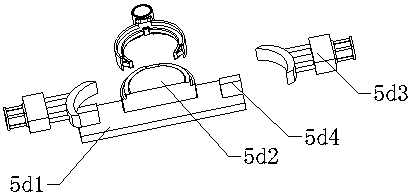

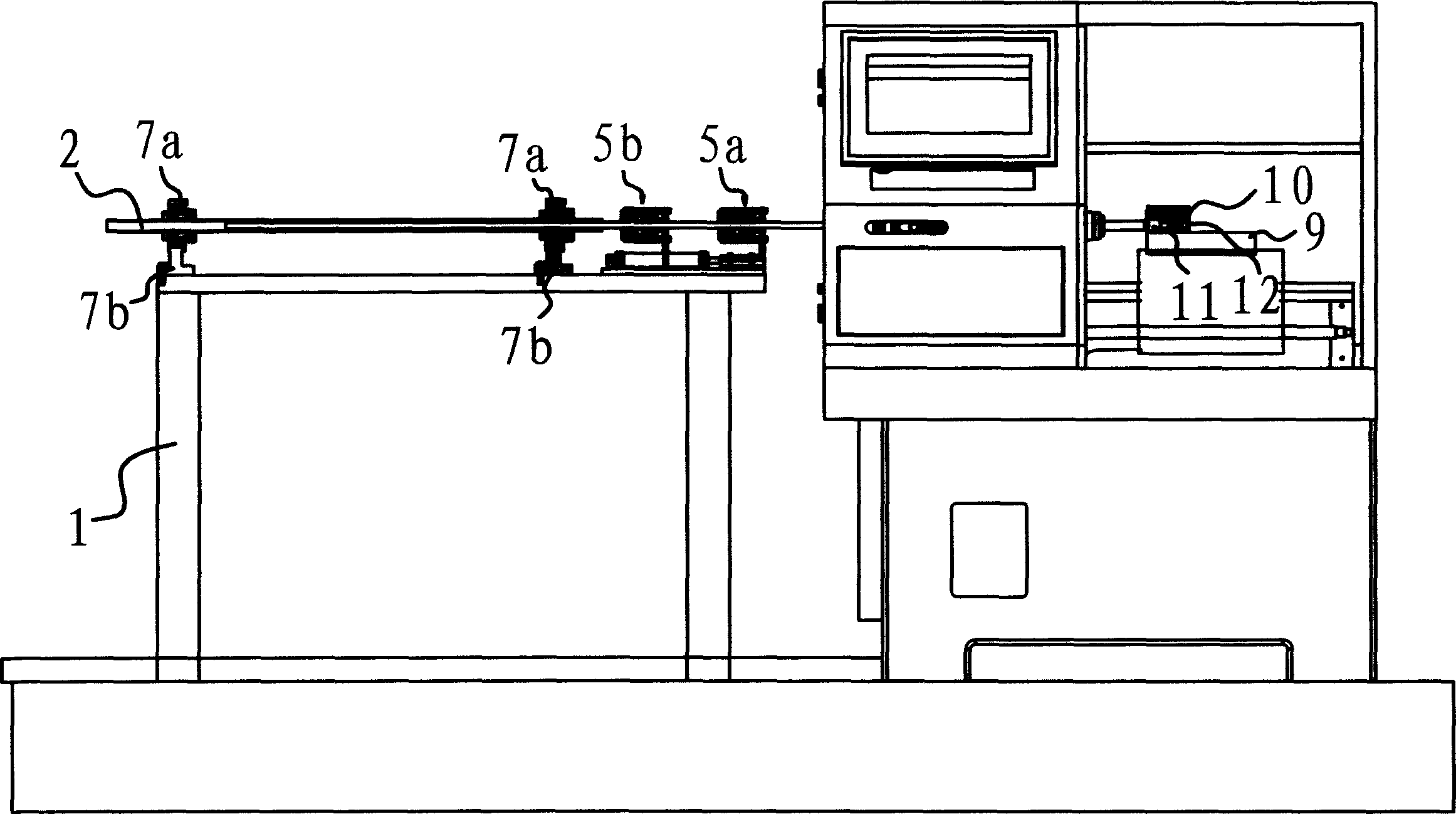

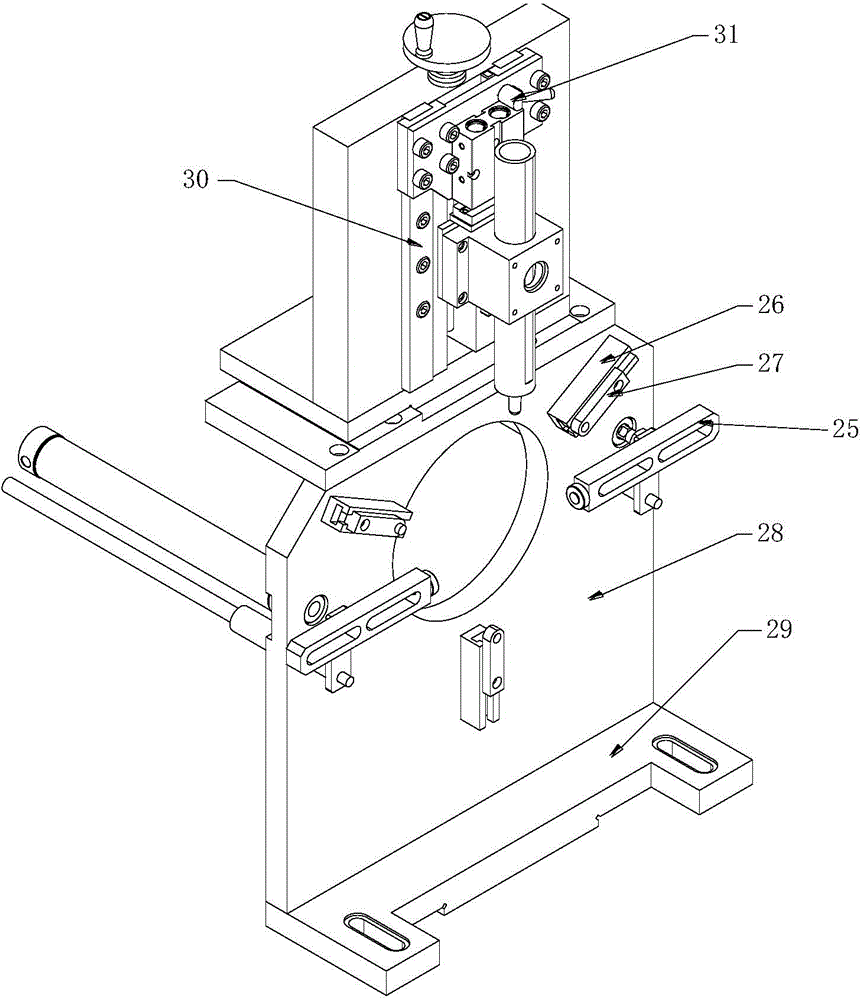

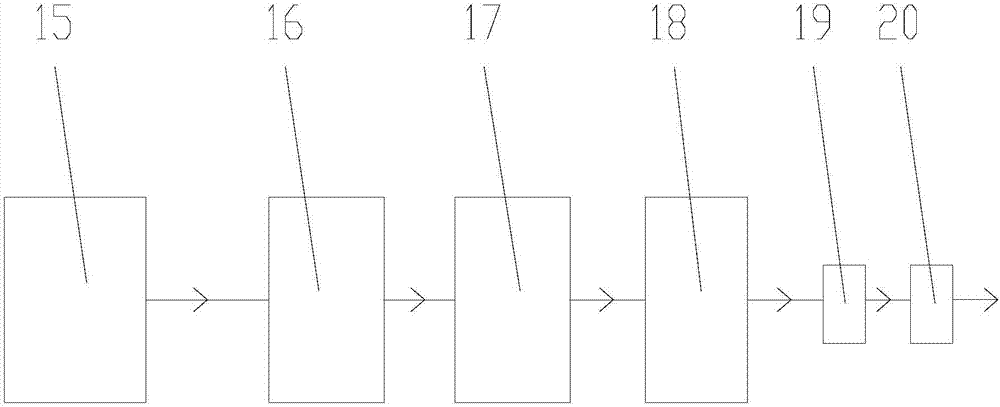

Automatic product GAP and STEP detection production line and detection process

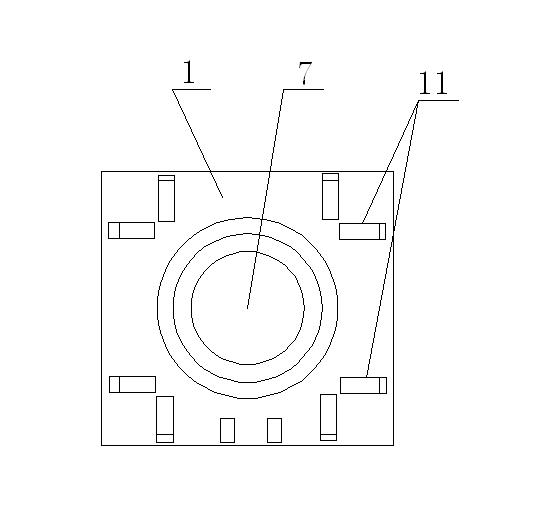

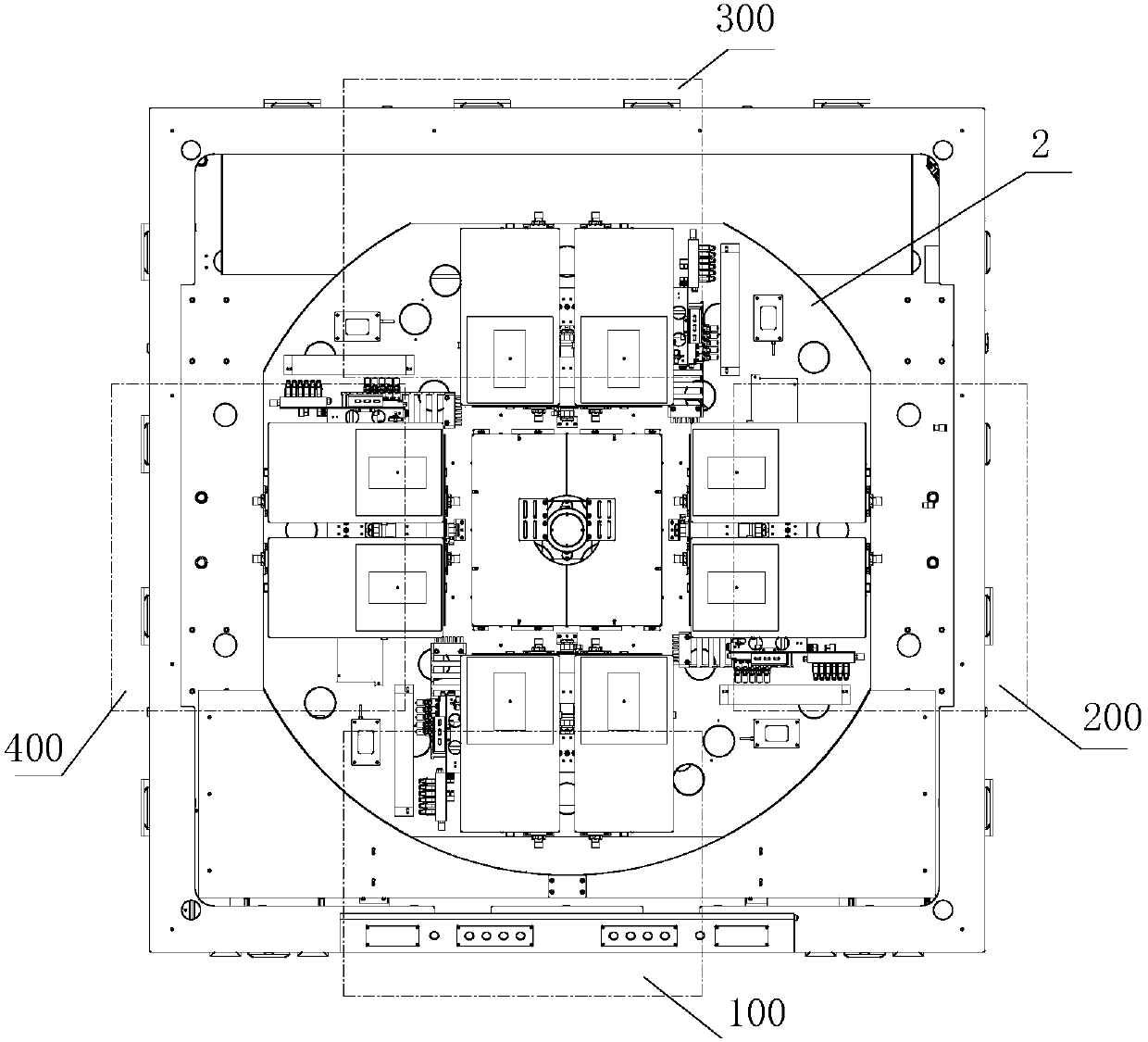

ActiveCN106053482AGuaranteed rotation accuracyPrevent slidingOptically investigating flaws/contaminationUsing optical meansEngineeringWorkstation

The invention discloses an automatic product GAP and STEP detection production line and a detection process. The automatic product GAP and STEP detection production line comprises a stander, a material belt which is arranged at the outer side of the stander, and a non-defective product material belt and a defective product material belt which are arranged at the rear end of the stander in parallel, wherein the defective product material belt is disposed at the inner side of the non-defective product material belt. The automatic product GAP and STEP detection production line also comprises a fixture, a positioning mechanism of the fixture, a loading mechanism, a rotating plate, a rotating and clamping mechanism, a product GAP detection mechanism, a first product STEP detection mechanism, a second product STEP detection mechanism and an unloading mechanism, and successively completes the steps of loading by the rotating plate, code scanning at the front end, GAP detection, first STEP detection, second STEP detection, unloading by the rotating plate, code scanning at the rear end and unloading. The GAP detection and the STEP detection are integrated to automatically complete the loading, unloading, workstation switching and 360-degree overall detection of products, so that the automation degree and the detection precision are high.

Owner:SHENZHEN XING GRAIN AUTOMATION CO LTD

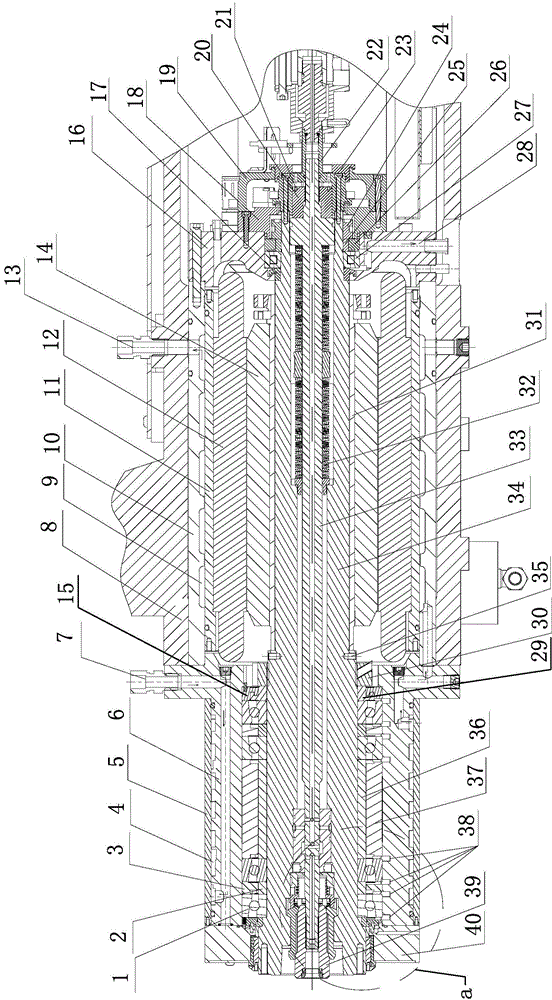

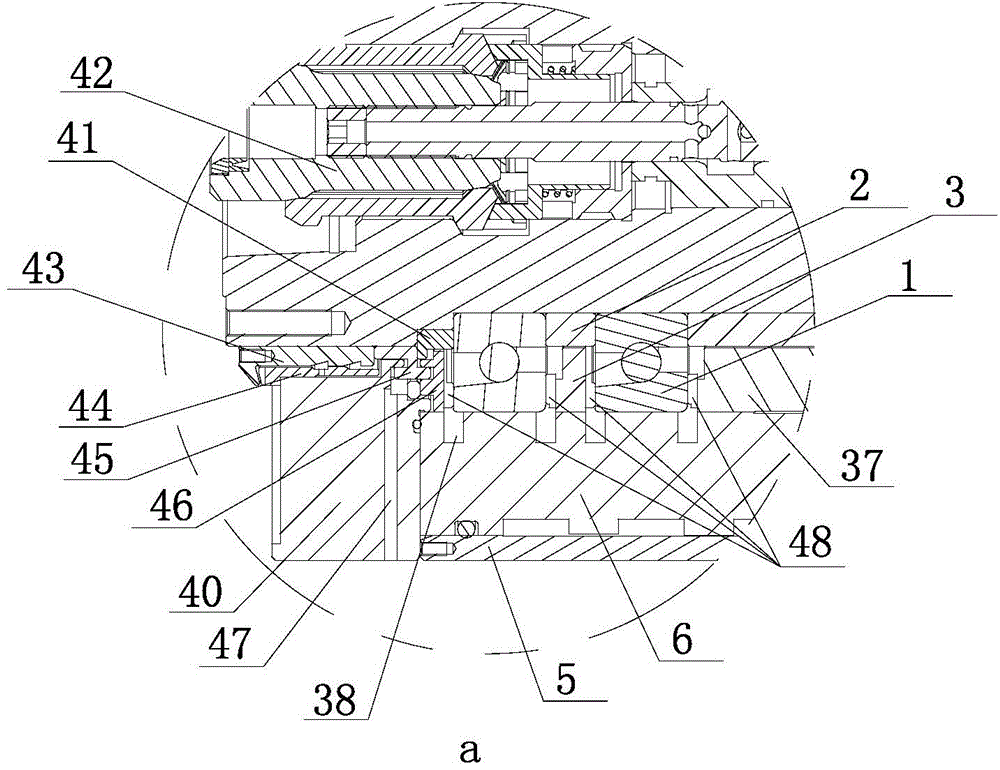

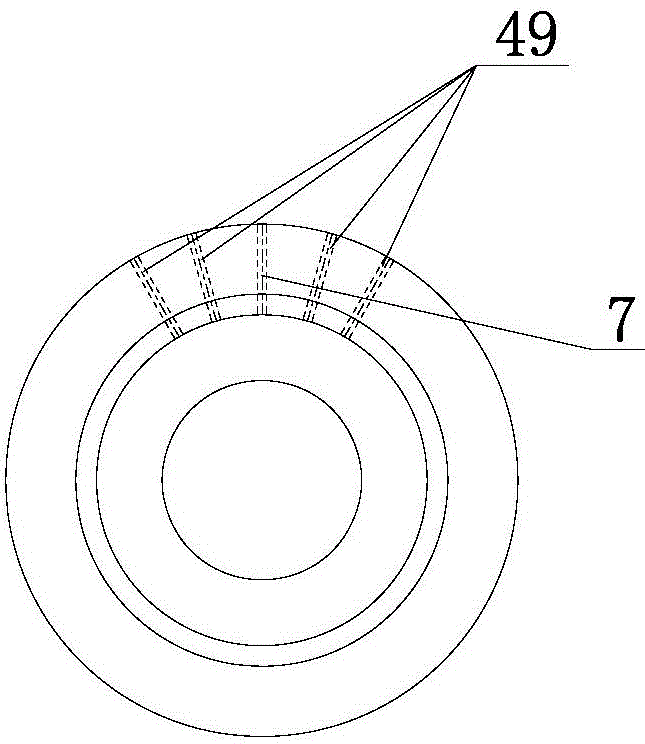

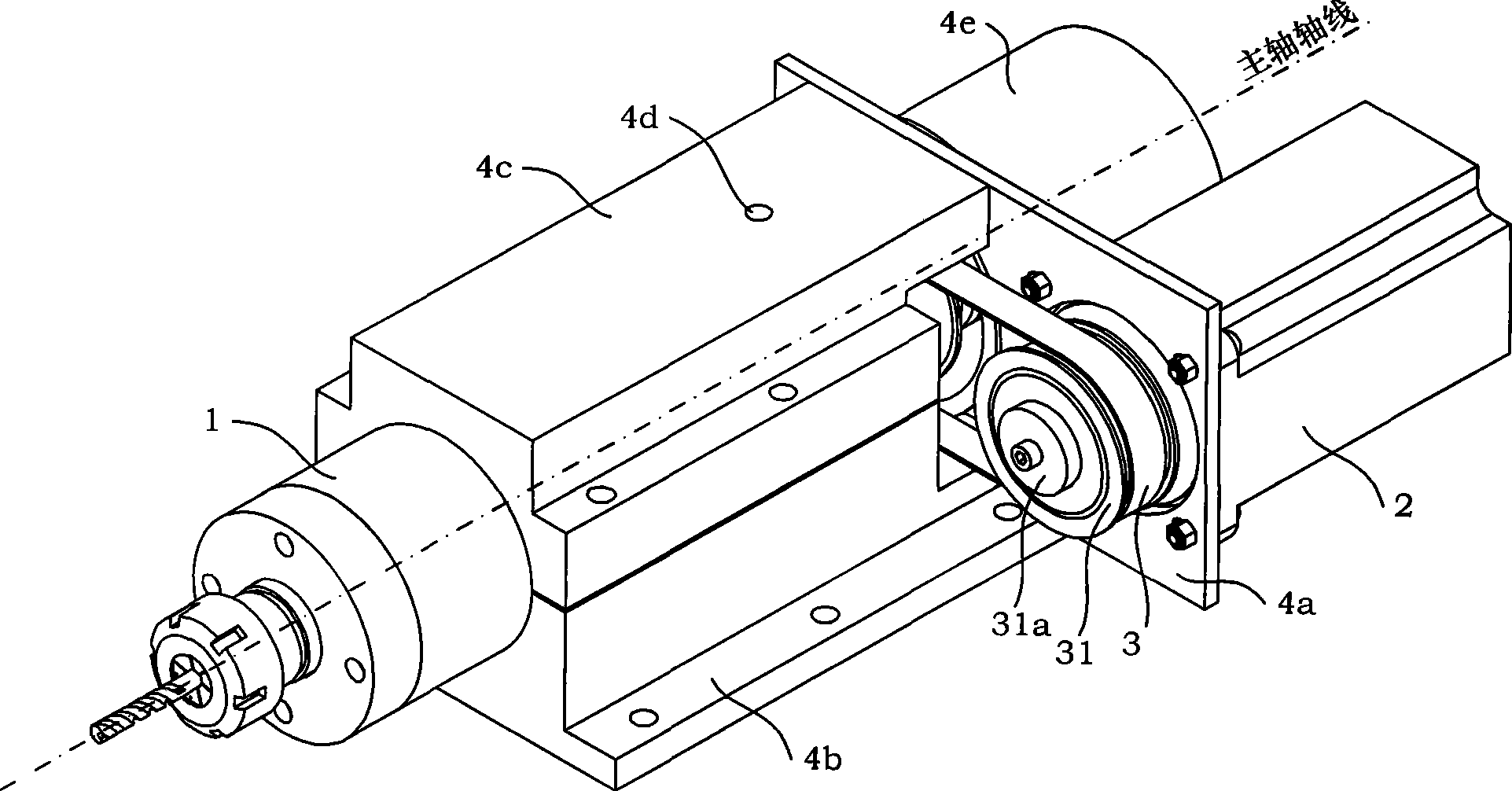

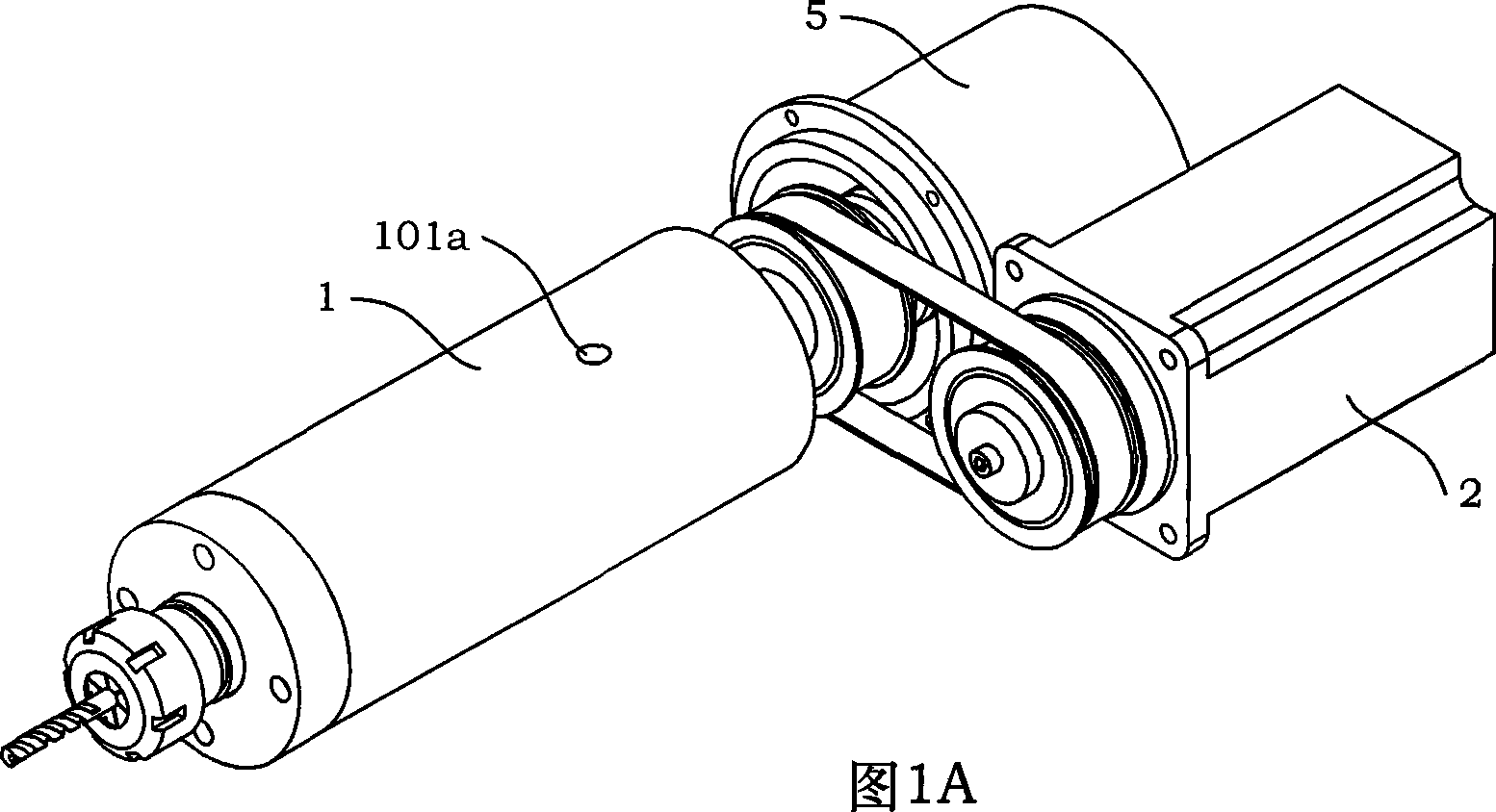

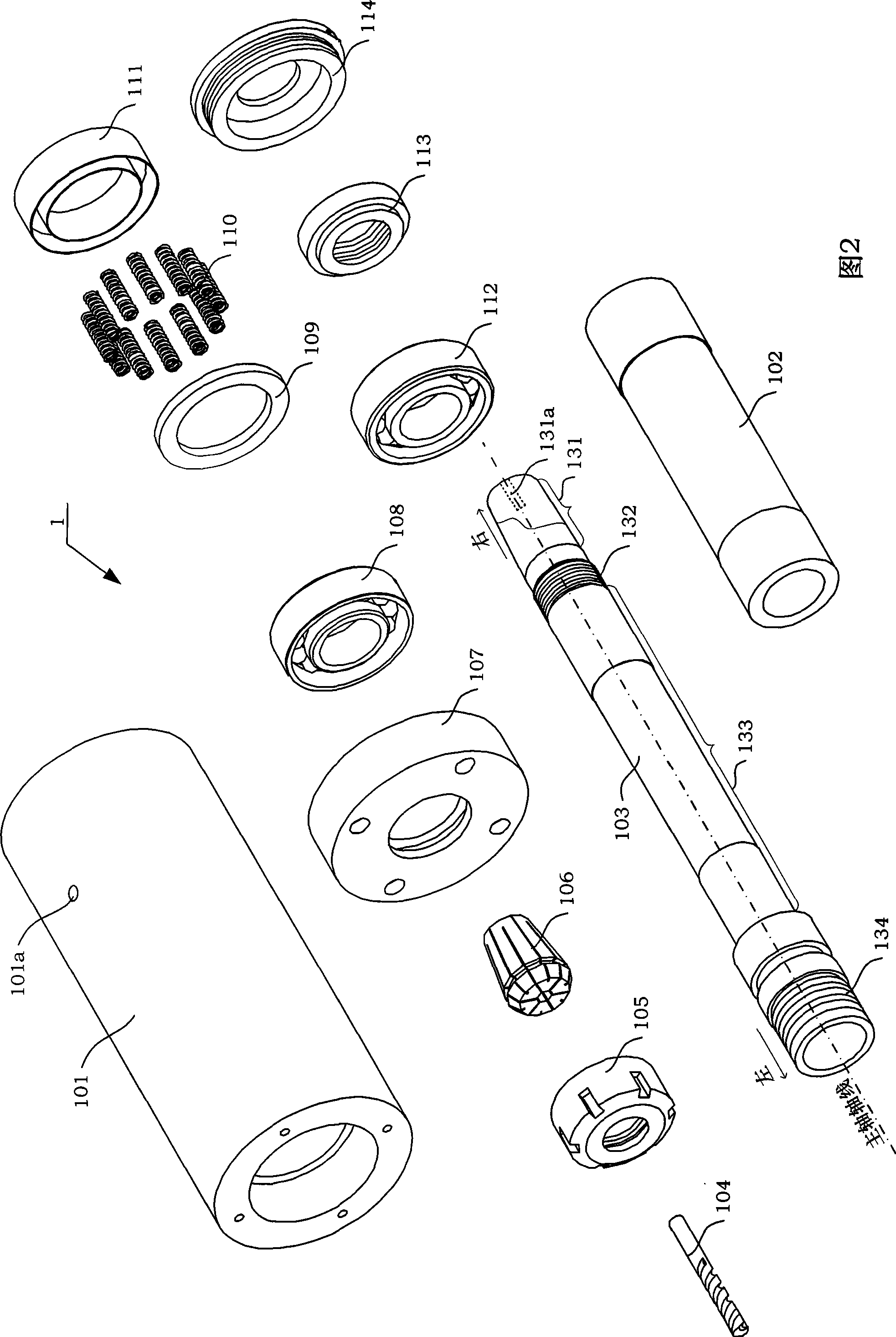

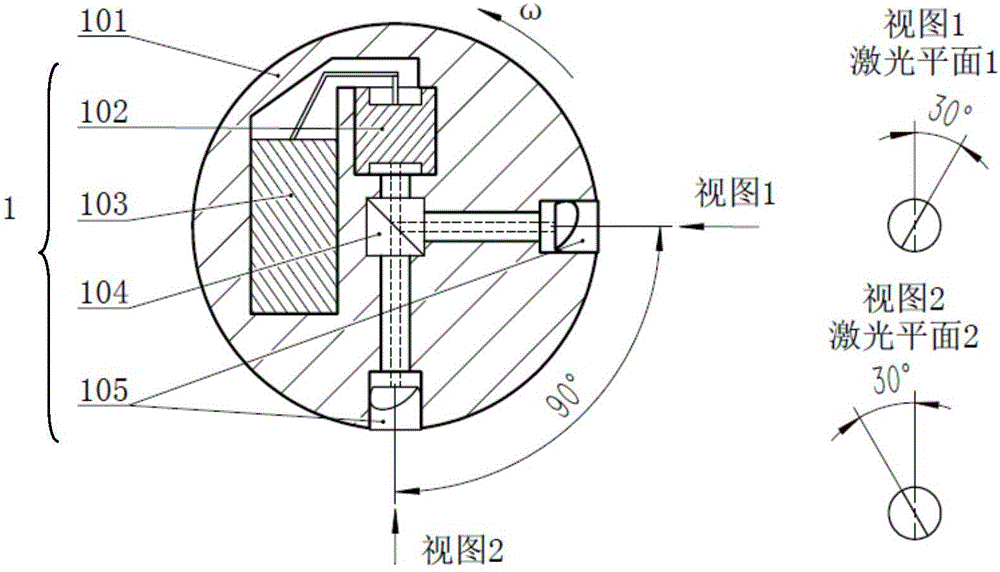

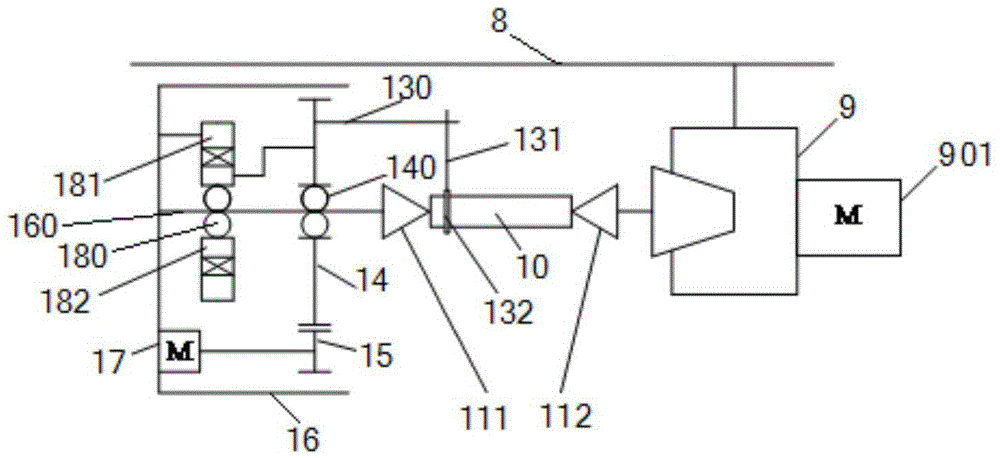

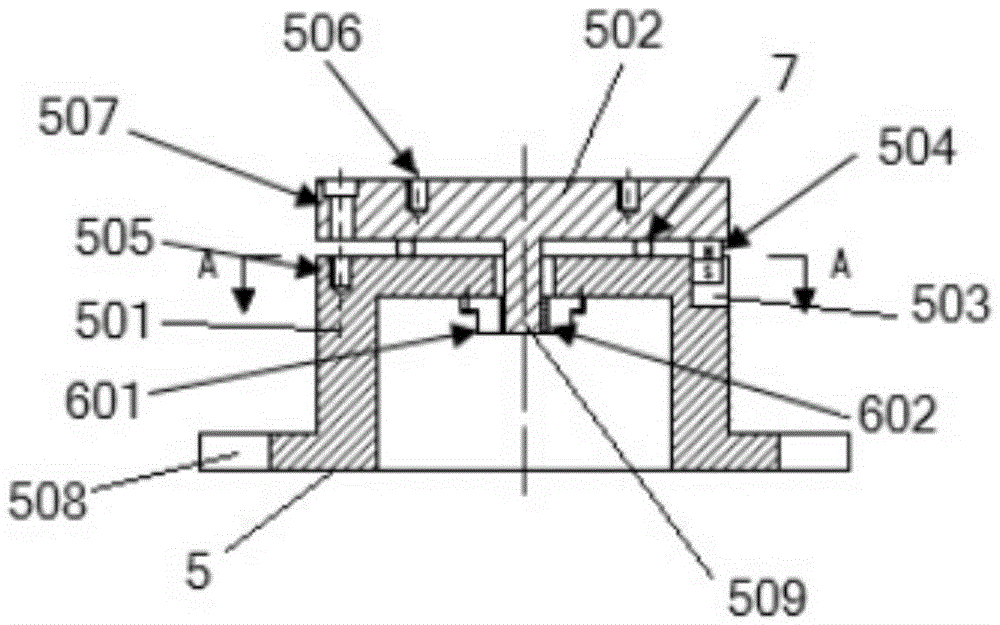

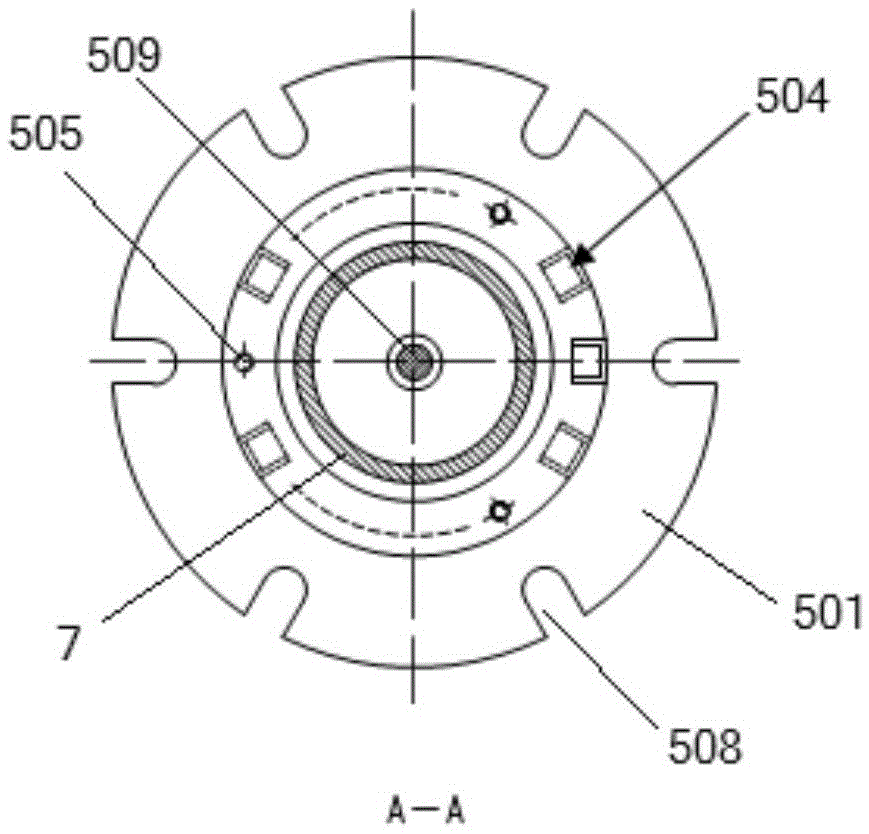

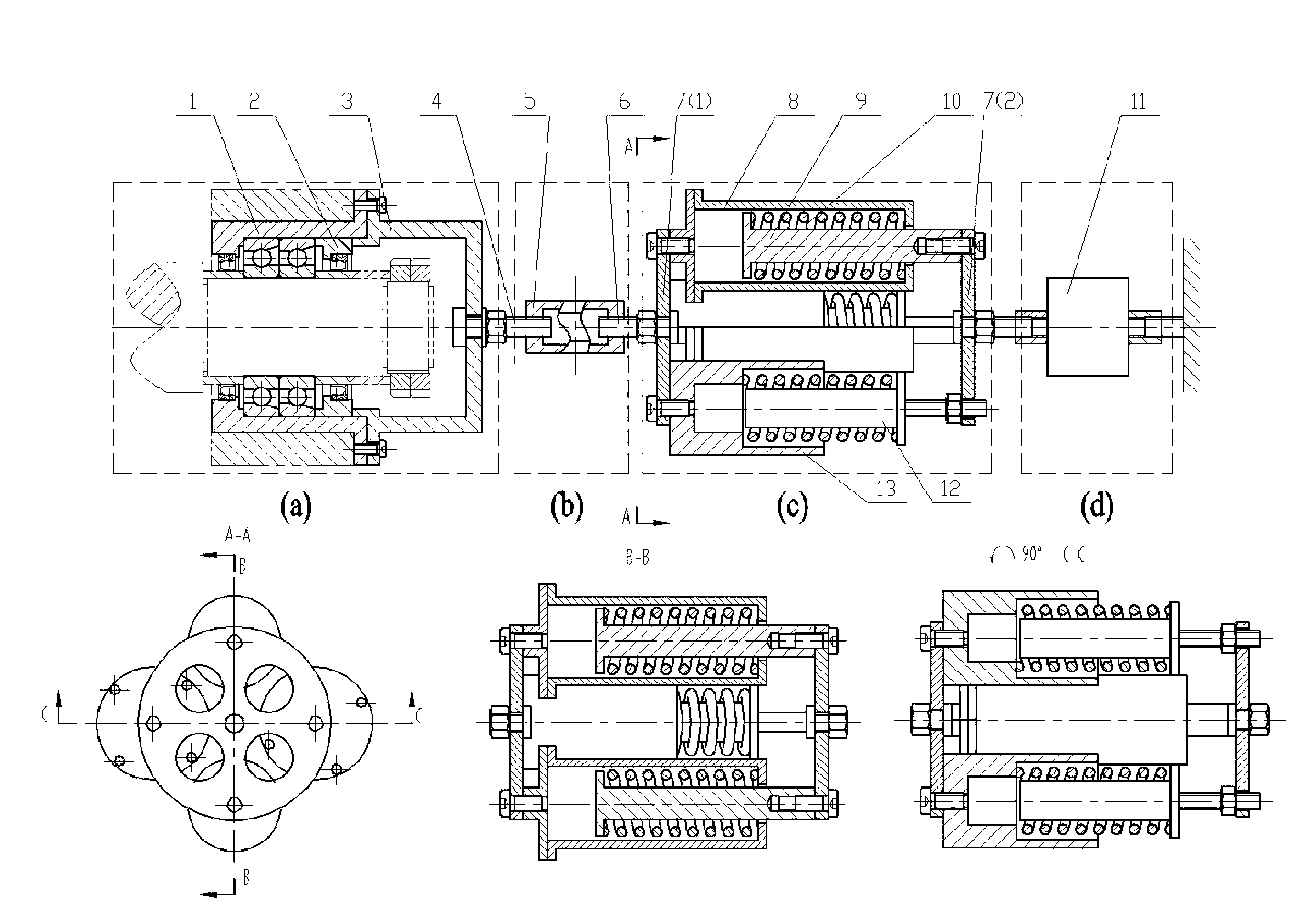

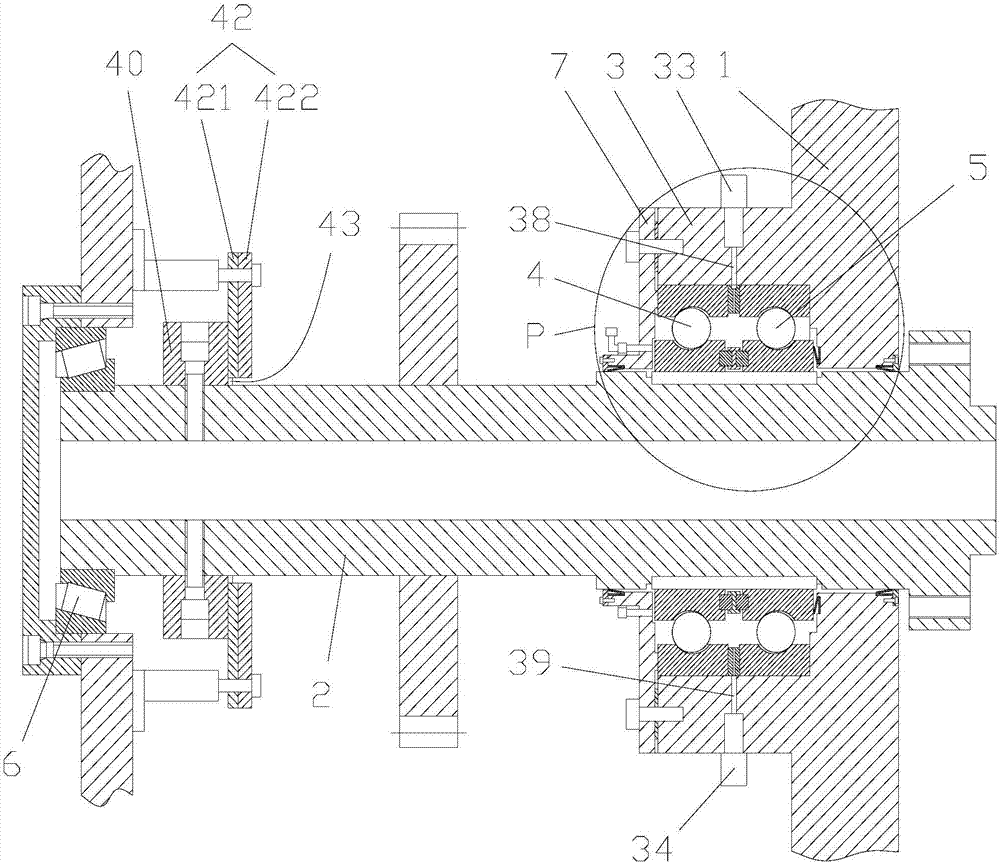

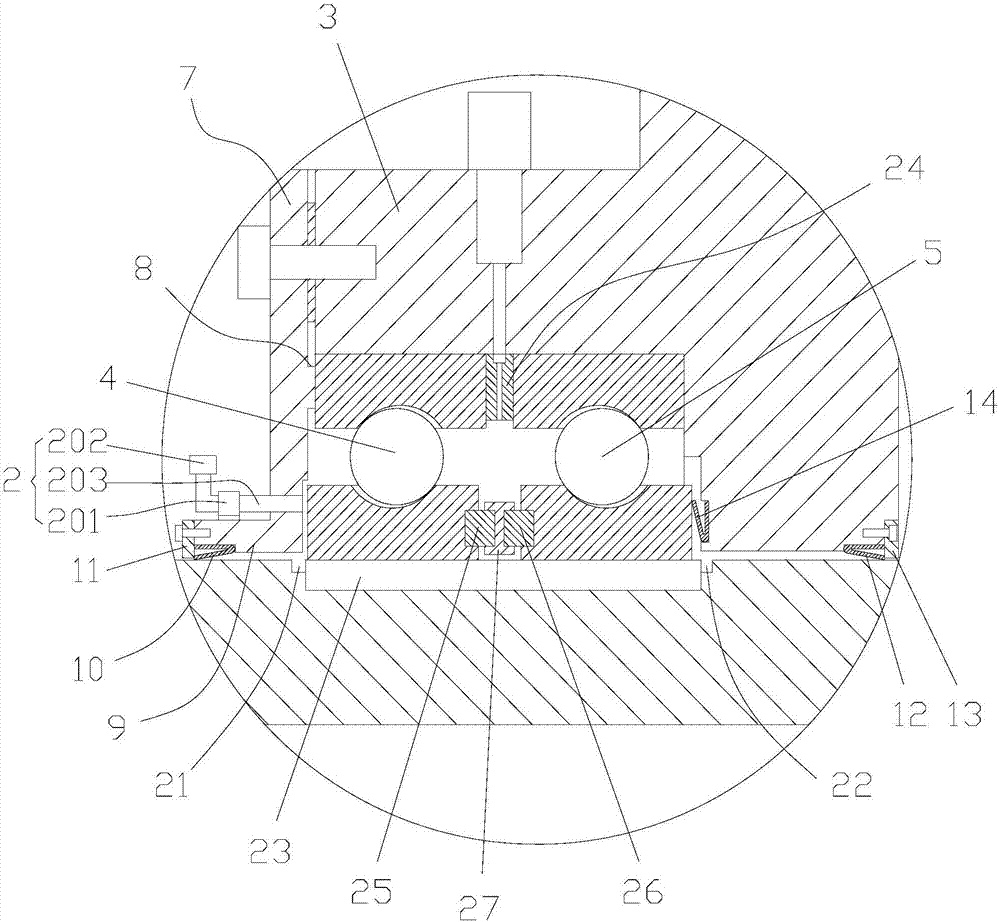

Rotary type transducer main shaft device of supersonic vibrated drill

InactiveCN101376175AAchieved by ultrasonic vibrationGuaranteed rotation accuracyMechanical vibrations separationElectricityElectric machine

The invention discloses a main shaft device of a rotary type energy converter for supersonic vibration drilling, which comprises a main shaft component (1), an electric machine driving component, an energy converter power supply component (5) and a shell component; a housing screw (510) of the energy converter power supply component (5) is connected to a screw hole (131a) of the main shaft (103) of the main shaft component (1); and a slave driving belt wheel (32) of the electric machine driving component is sleeved on the main shaft (103) of the main shaft component (1), and an initiative belt wheel (31) and the slave driving belt wheel (32) are in transmission connection through a driving belt (3). The rotary ultrasonic energy converter main shaft device can be arranged on a bench drill, and the device can process workpieces when feed control components are added thereto, so that the device can lead an electric motor of the system to operate and provide electricity for the ultrasonic energy converter by using a slip ring (502a), thereby generating supersonic vibration along the axial direction of the main shaft while ensuring high-speed rotation of the the main shaft (103), and obtaining the compound movement of the rotary supersonic vibration by overlapping; a bit or a reamer are clamped at an end of the main shaft, thereby realizing the rotary supersonic vibration drilling or reaming.

Owner:BEIHANG UNIV

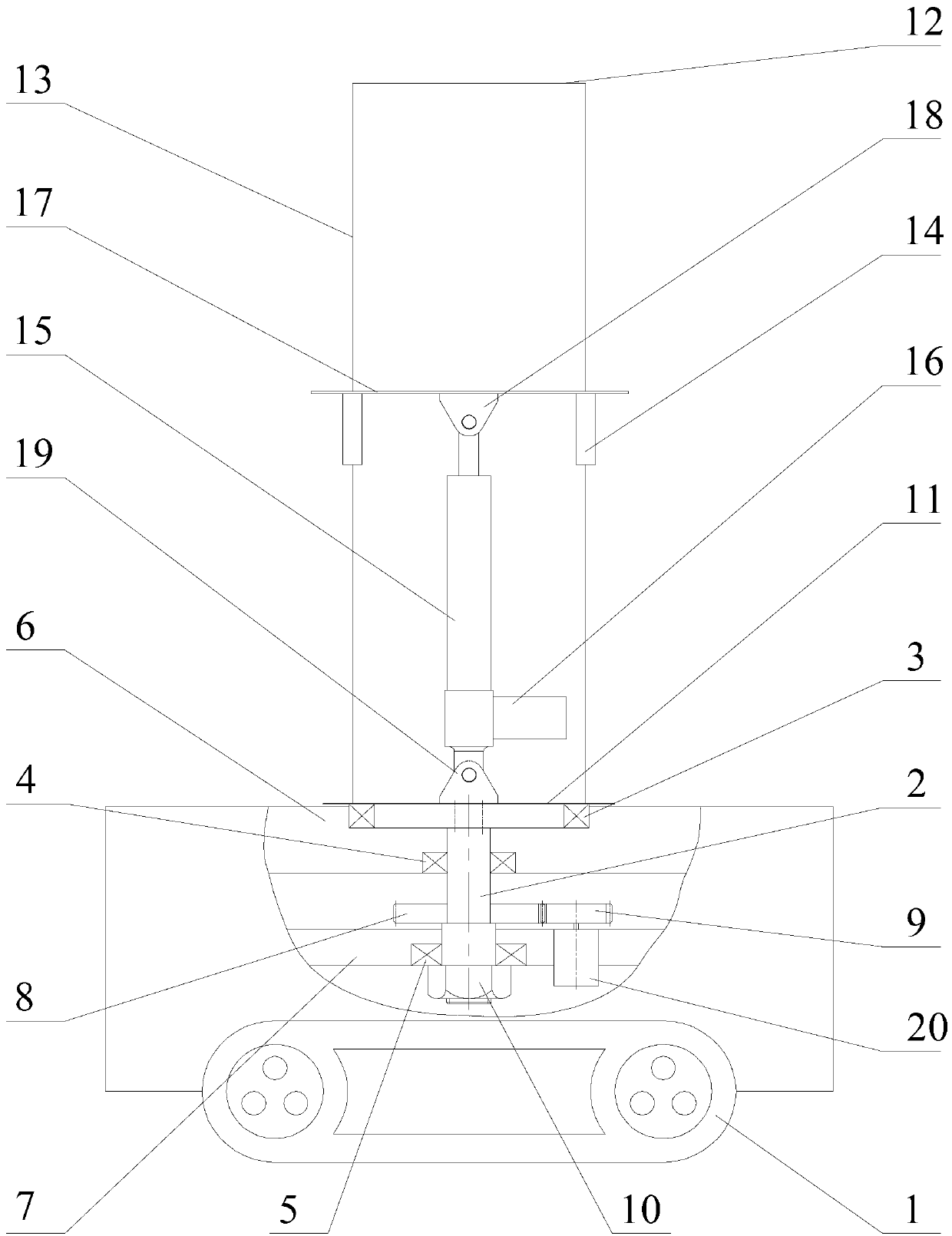

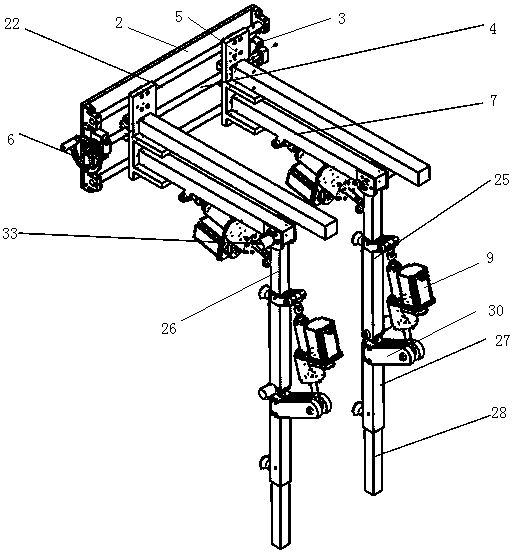

Movable and rotatable lifting platform used for picking agricultural products

ActiveCN103270849AImprove rigidityImprove general performancePicking devicesControl systemAgricultural engineering

The invention discloses a movable and rotatable lifting platform used for picking agricultural products. The movable and rotatable lifting platform comprises a walking mechanism, a rotating mechanism, a lifting platform body and a control system. The rotating mechanism comprises a rotating machine frame, a main shaft, a bearing set, a bearing seat board set, a gear set and a rotating driving motor, wherein the main shaft is connected with the bearing set in a matched mode, the bearing set is fixed on the bearing seat board set, the rotating driving motor transmits rotating power to the main shaft through the gear set, the rotating driving motor is installed on the rotating machine frame, the top end of the main shaft is fixedly connected with the lifting platform body, the bottom of the rotating machine frame is connected with the walking mechanism, and the control system is in signal connection with the rotating driving motor and the lifting platform body. The movable and rotatable lifting platform has the advantages of being capable of bearing larger loads and capsizing moment, small in motion resistance, high in motion precision, large in motion stroke, strong in universality of parts, convenient to produce and maintain, low in manufacturing cost, and the like. Large-load and mass mechanized harvesting of crops can be achieved only through that a corresponding agricultural harvesting operation device is arranged on the movable and rotatable lifting platform.

Owner:SOUTH CHINA AGRI UNIV

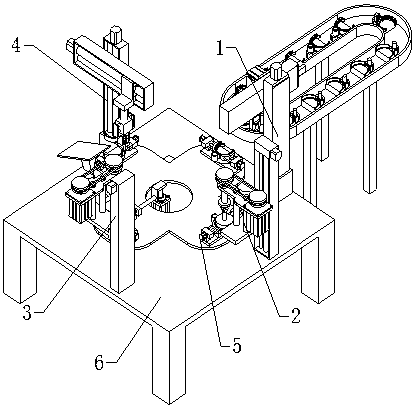

Automatic grinding machine for automobile shifting fork

ActiveCN108581771APlay a fixed rolePlay a stabilizing roleGrinding carriagesGrinding machinesWork statusMechanical engineering

The invention relates to the field of automobile part machining, in particular to an automatic grinding machine for an automobile shifting fork. The automatic grinding machine comprises a base and further comprises a feeding station, a first grinding station, a second grinding station, a discharging station and a rotating workbench; the rotating workbench comprises a fixture installing table, thefixture installing table is horizontally arranged on an index plate and provided with four workpiece fixtures used for containing and clamping workpieces, and the feeding station, the first grinding station, the second grinding station and the discharging station are clockwise and sequentially arranged along the periphery of the fixture installing table and correspond to the workpiece fixtures arranged on the fixture installing table one to one in a working state; the feeding station comprises a feeding mechanical arm used for putting the workpieces on the workpiece fixtures; the first grinding station comprises a first grinding mechanism used for grinding the workpieces; the second grinding station comprises a second grinding mechanism used for grinding the workpieces; and the dischargingstation comprises a discharging mechanical arm. Therefore, the problems that the human cost input is high, and the yield is low are solved.

Owner:南理工泰兴智能制造研究院有限公司

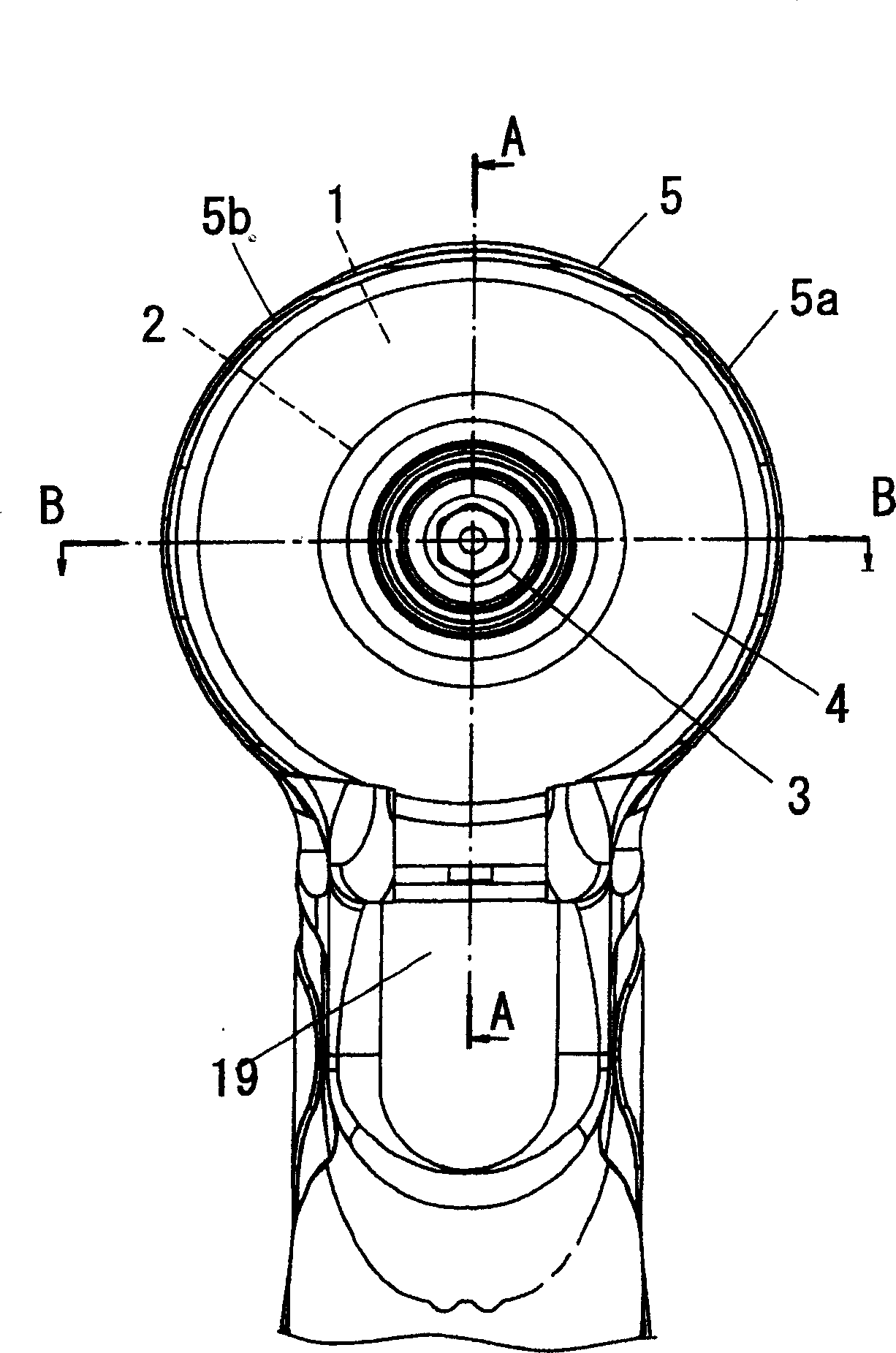

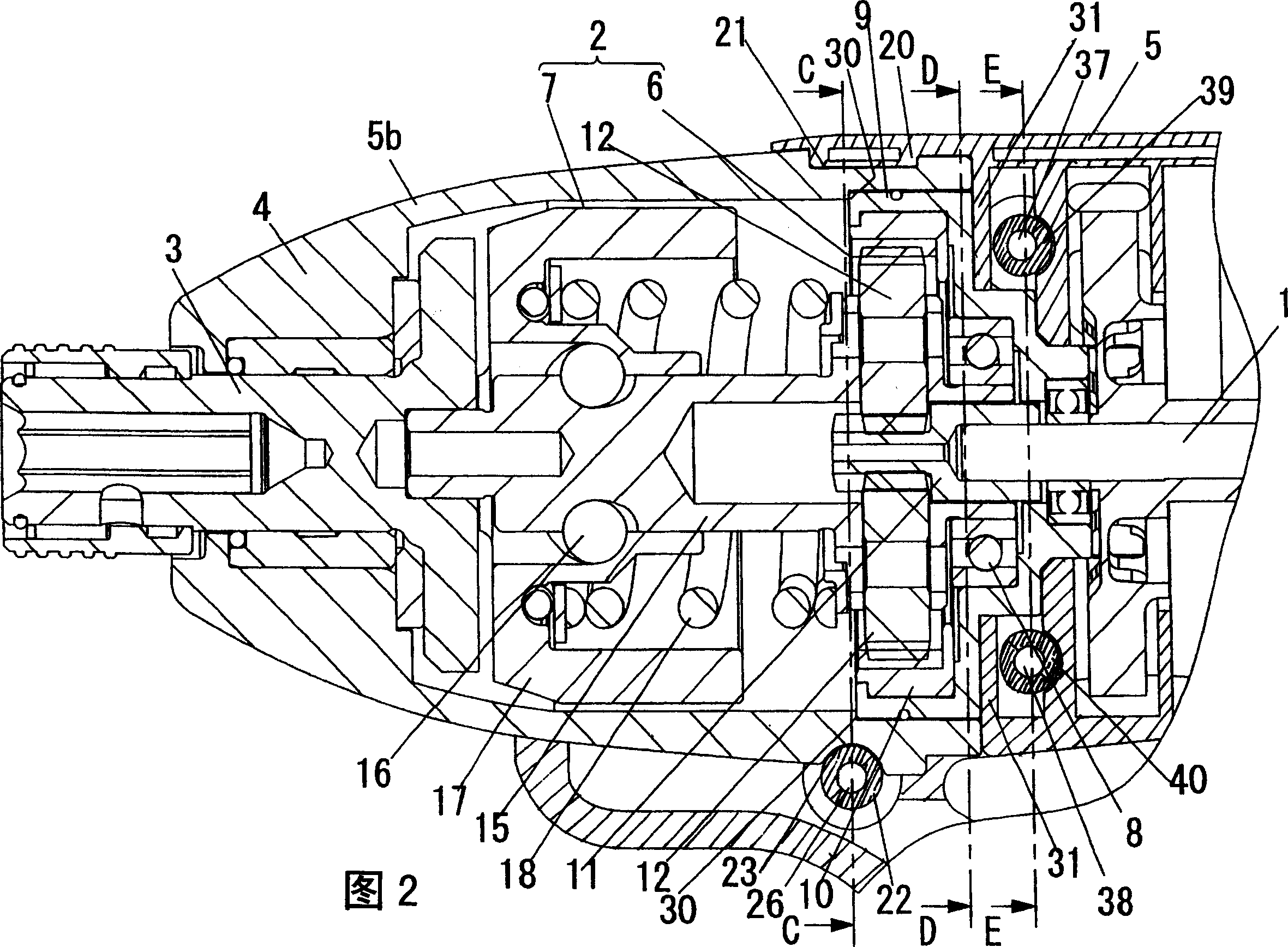

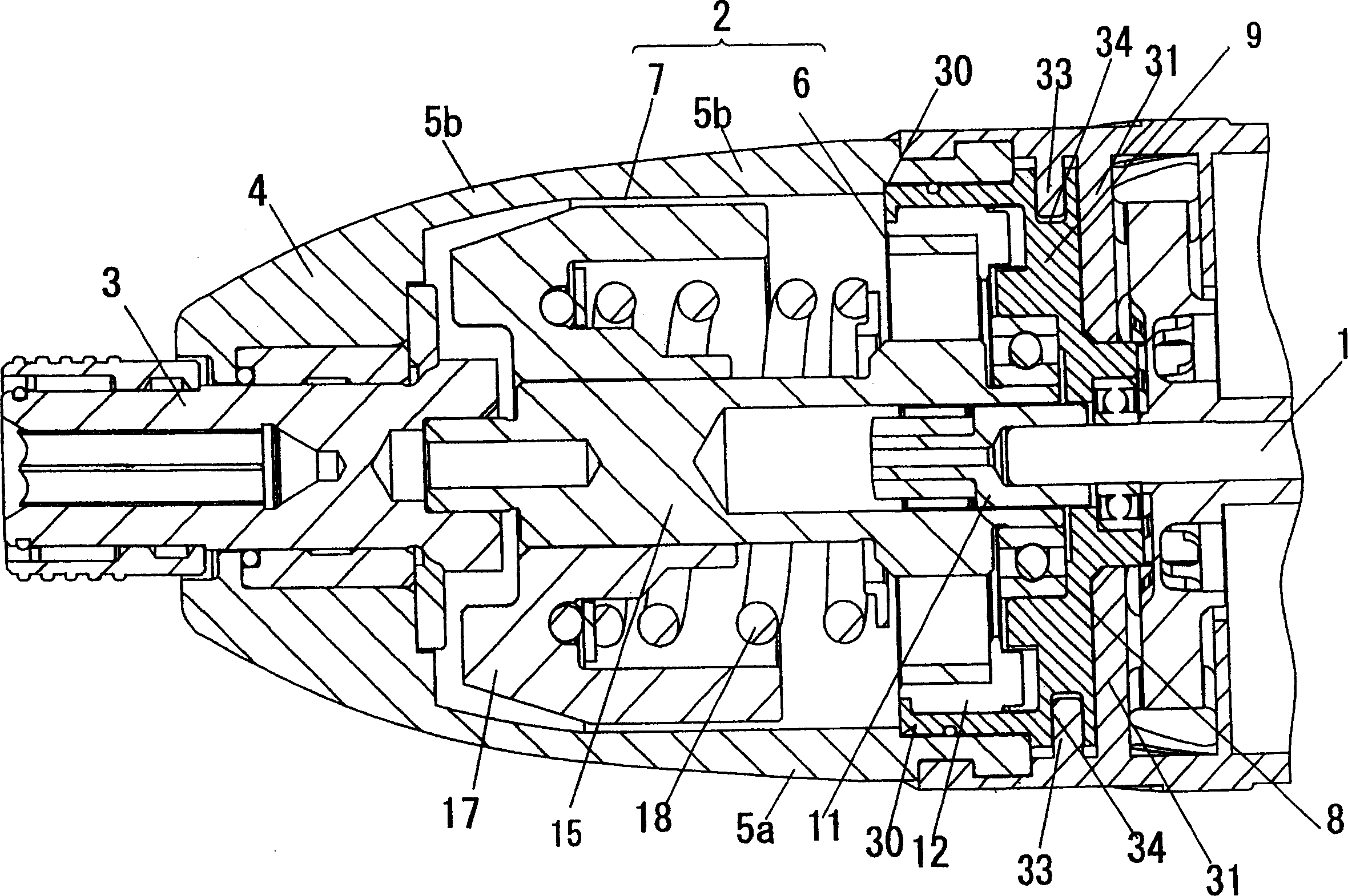

Movable electric tool

ActiveCN1575932APrevent keepPrevent leakage to the outsidePortable percussive toolsSpannersPower toolDrive motor

The present invention provides a mobile power tool which is compact and has high reliability. This mobile power tool is provided with a motor 1, a driving transmission section 2 for transmitting the driving power of the motor 1 to the output section 3, a mounting rack for supporting the driving transmission section 2, a body housing 5 for covering the motor 1 and maintaining the mounting rack, and a tubular cover 4 for covering and rotatablely supporting the output section 3. Furthermore, by fitting the body housing 5 and the driving section cover 4 so that the internal space of the two can communicate in the mobile power tool, wherein the body housing 5 is provided with an advance or retreat engaging section of the driving section cover for constraining the advance or retreat movement of the driving section cover 4 by being engaged with the driving section cover 4, and a rotational engaging section of the diving section cover for constraining the rotational movement of the driving section cover 4 by being engaged with the driving section cover 4.

Owner:MATSUSHITA ELECTRIC WORKS LTD

Conical air floating shaft system

The invention relates to a conical air floating shaft system, which comprises an air floating main shaft, an air floating inner shaft sleeve, an air floating outer shaft sleeve, and positioning plates, wherein the air floating inner shaft sleeve is arranged on the outer side of the air floating main shaft, and is matched with the air floating main shaft, the air floating outer shaft sleeve is arranged on the outer side of the air floating inner shaft sleeve, and is matched with the air floating inner shaft sleeve, and the positioning plates are arranged on both ends of the air floating main shaft. The positioning plates are fixedly connected with the air floating main shaft. Both ends of the air floating outer shaft sleeve are provided with an anti-thrust plate. The anti-thrust plate is fixedly connected with the positioning plate. In the prior art, the positioning accuracy of the existing air floating shaft system is not high, and the dry friction is easily generated. With the present invention, the technical problems in the prior art are solved, and the conical air floating shaft system is provided, wherein the conical air floating shaft system integrates the advantages of the air floating main shaft, the air floating main shaft is matched with the air floating shaft sleeves so as to effectively improve the stiffness of the shaft system, the conical surface match is adopted so as to provide high centering accuracy, and it can be ensured that the air floating shaft system of the present invention has high accuracy when the off-axis end surface is high.

Owner:西安威而信精密仪器有限公司

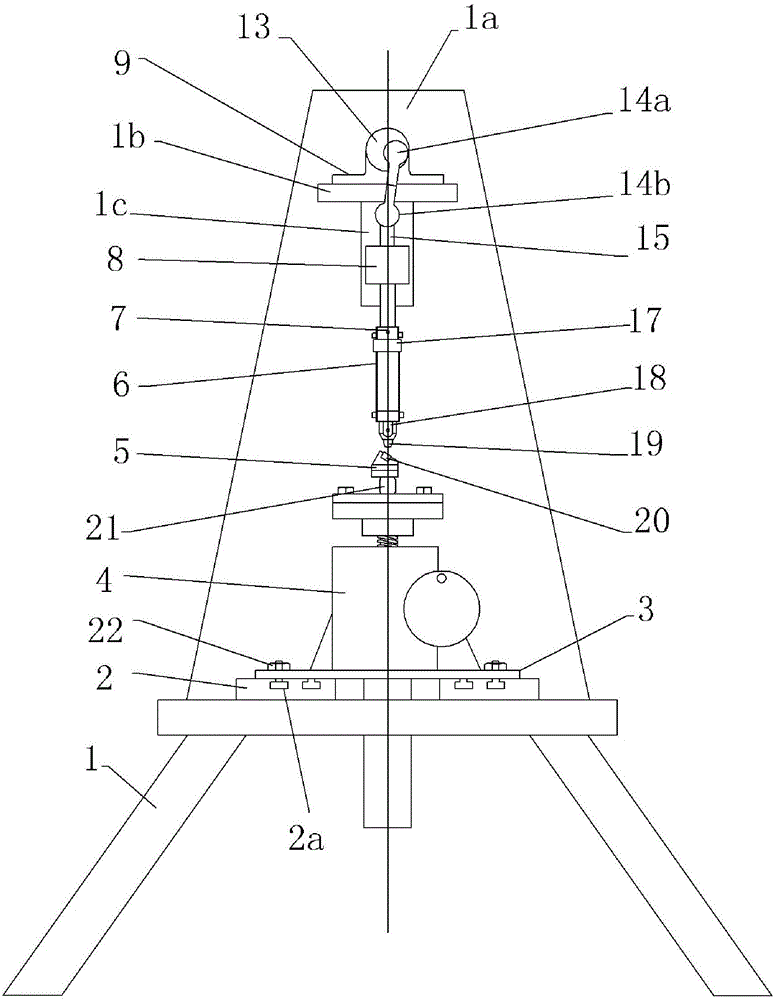

Double-fan-shaped rotating laser automatic theodolite device

The invention discloses a double-fan-shaped rotating laser automatic theodolite device. The automatic theodolite device comprises a double-fan-shaped rotating laser emitting head, a non-contact power supply device, a datum laser emitting device and a transmission shaft system; a point laser device and a cubic spectroscope of the double-fan-shaped rotating laser emitting head are fixed to a rotating base, collimation light emitted by the point laser device passes through a rotating shaft of the rotating base and is divided into two light beams by the cubic spectroscope at the rotating shaft of the rotating base, and the two light beams are irradiated to divergence arrises of two Powell prisms; the non-contact power supply device is used for supplying power to a driving circuit of the point laser device; the transmission shaft system comprises a transmission shaft, and the transmission shaft is connected with the double-fan-shaped rotating laser emitting head and a rotating encoder code disc of the datum laser emitting device. The horizontal angle and pitch angle of the target position can be automatically measured in the mode of externally arranging a photoelectric sensor without manual alignment, and a measured object can be traced and measured in real time on site.

Owner:XI AN JIAOTONG UNIV

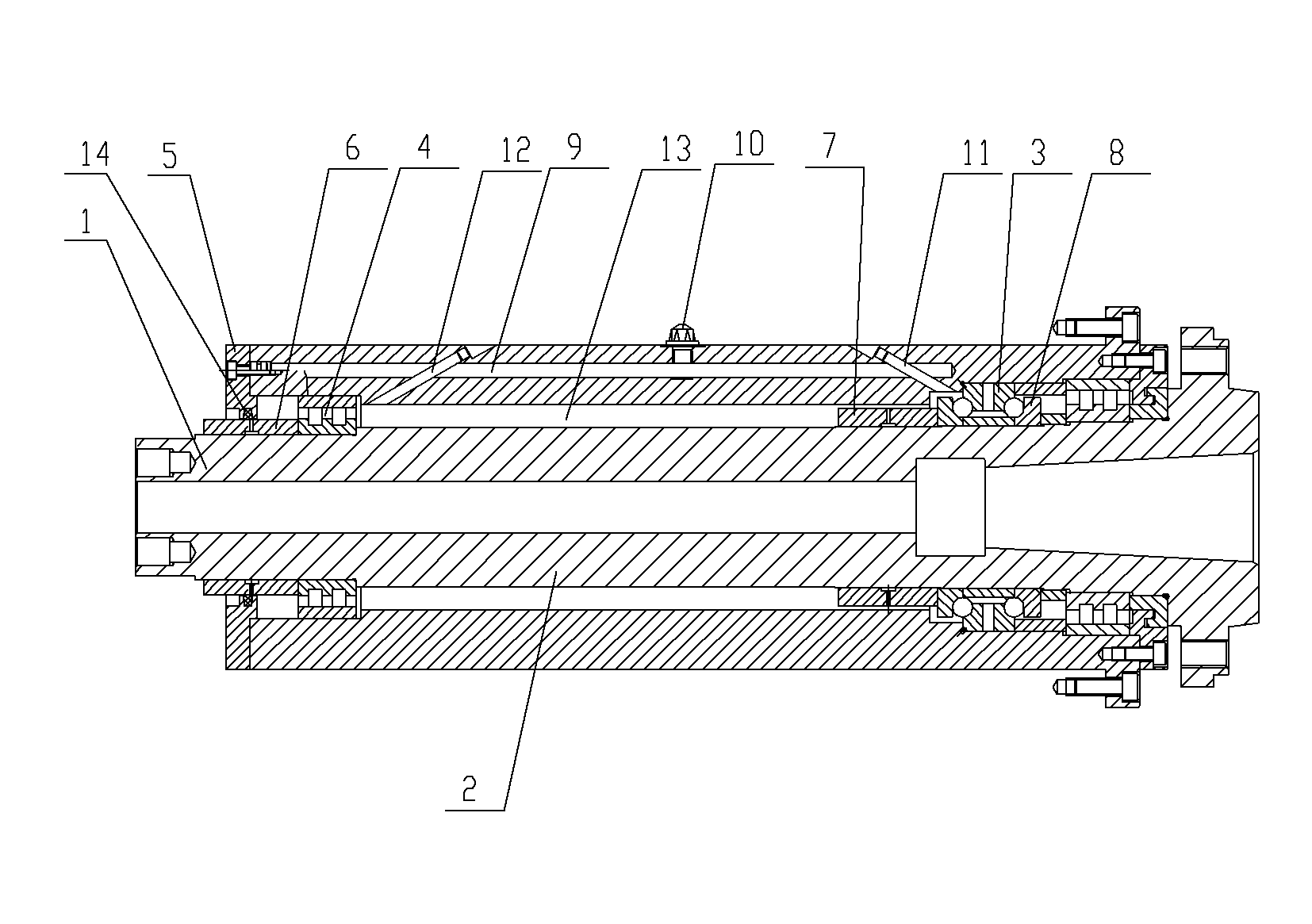

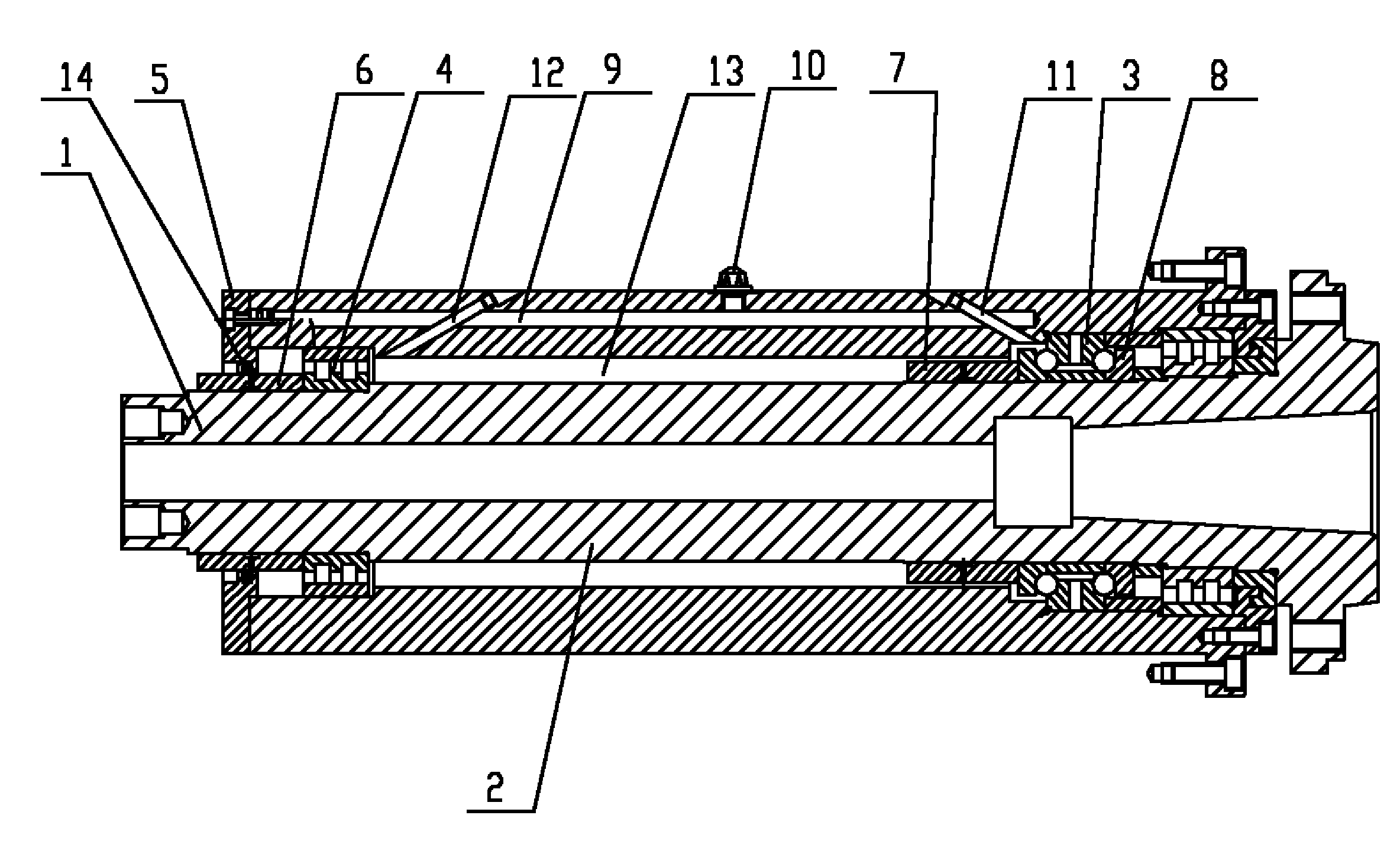

High-accuracy sleeve main shaft structure for machine tool

InactiveCN102059357AWon't skewGuaranteed rotation accuracyMetal-working apparatusInterference fitEngineering

The invention provides a high-accuracy sleeve main shaft structure for a machine tool, which prevents a bearing from deflection during preloading, ensures the running accuracy of a main shaft, and further ensures the high accuracy of the sleeve main shaft. The high-accuracy sleeve main shaft structure for the machine tool comprises the main shaft and a sleeve, wherein the main shaft penetrates through the sleeve and is supported at the inner sleeve wall via a front-end bearing and a back-end bearing, the front end part of the main shaft is embedded and sleeved at the front end part of the sleeve, and a back end press cover is arranged at the back end part of the sleeve; and the high-accuracy sleeve main shaft structure for the machine tool is characterized in that the back end of the main shaft is sleeved with a back end oil press sleeve, the back end oil press sleeve is in interference fit with the back end of the main shaft, the inner end surface of the back end oil press sleeve is in close contact with the back-end bearing, the external circular surface at the outer end of the back end oil press sleeve is in close contact with the internal circular surface of the back end press cover, the front end of the main shaft is sleeved with a front end oil press sleeve, the front end oil press sleeve is in interference fit with the front end of the main shaft, and one end surface of the front end oil press sleeve is in close contact with the front-end bearing.

Owner:WUXI MACHINETOOL

Two-dimensional electric mirror adjustment device

ActiveCN106773022AReduce manufacturing costIncrease the itineraryOptical elementsLight beamEngineering

The invention discloses a two-dimensional electric mirror adjustment device, relates to the technical field of beam control and overcomes defects that an existing fast steering mirror has a small rotation angle range and is high in manufacturing cost to realize automatic two-dimensional adjustment of a planar mirror. The device comprises a support base, a mirror seat, a planar mirror, a central shaft, a bearing press ring, a lens press block, two telescopic sliders, two slider guide seats, a knuckle bearing, two stepping motors, a backlash spring, an adjusting screw seat, an adjusting screw, two reset spring seats and two reset springs. Through threaded connection of the stepping motors and the telescopic sliders and limited guide of the slider guide seats, rotation movement of the stepping motors is converted into linear movement, further, the mirror seat and the mirror are directly driven by balls at the end parts of the telescopic sliders to deflect at a small angle, the cost is low, the two-dimensional electric mirror adjustment device can realize angle adjustment in a range of plus or minus 5-degree level through travel increase of a driver, and the adjustment range is increased by almost a hundred times than that of plus or minus 5' level of the fast steering mirror.

Owner:长春长光精密仪器集团有限公司

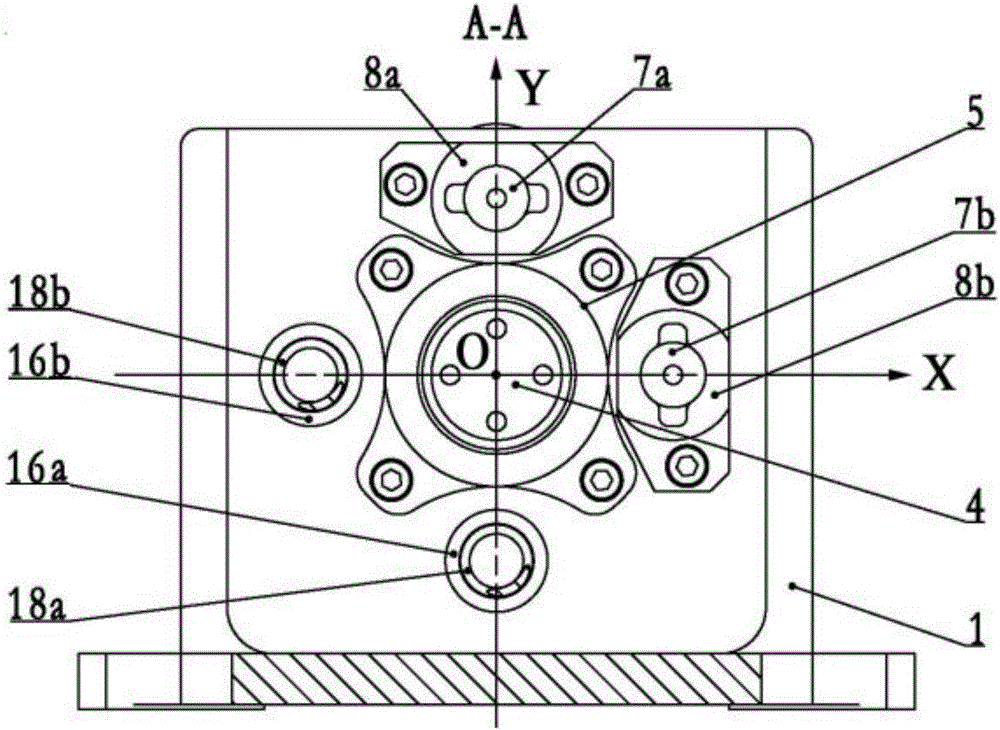

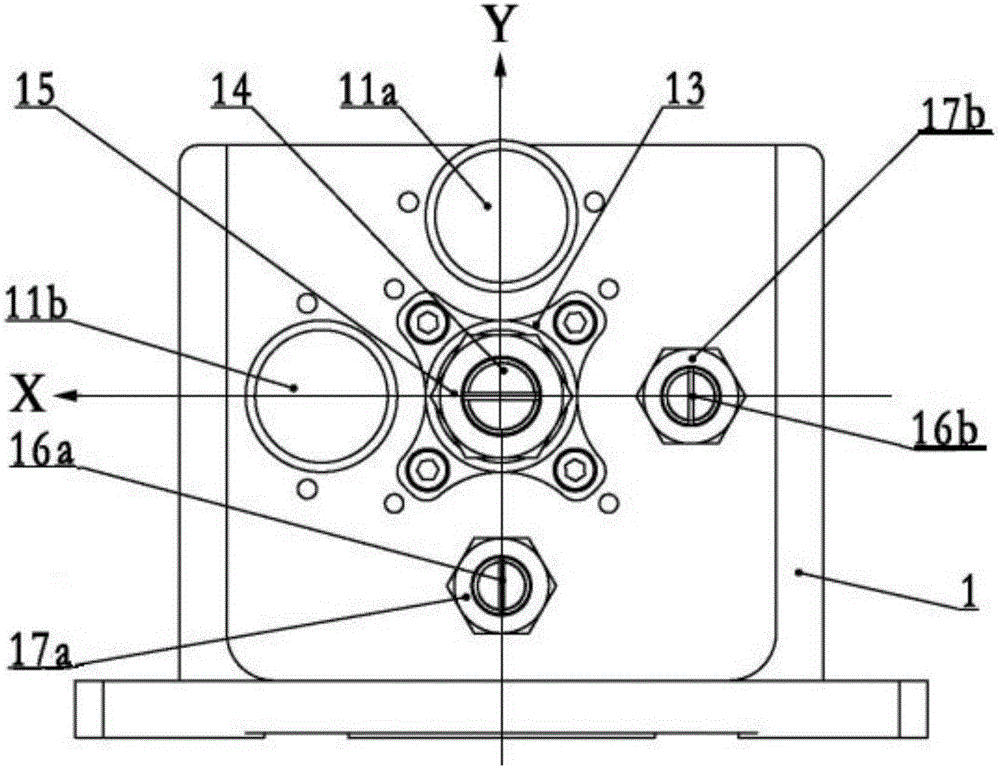

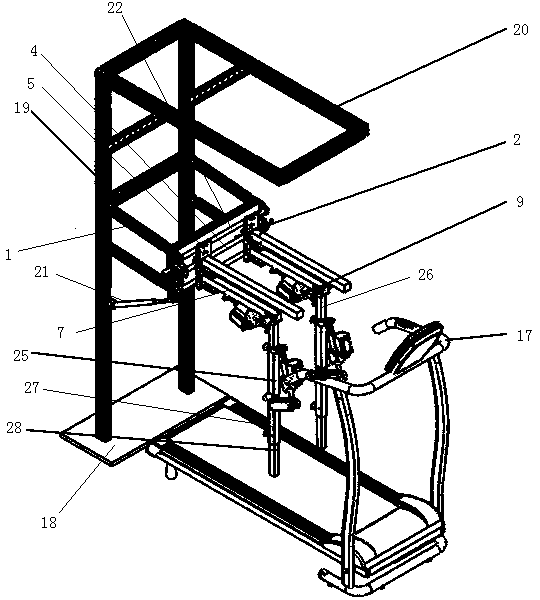

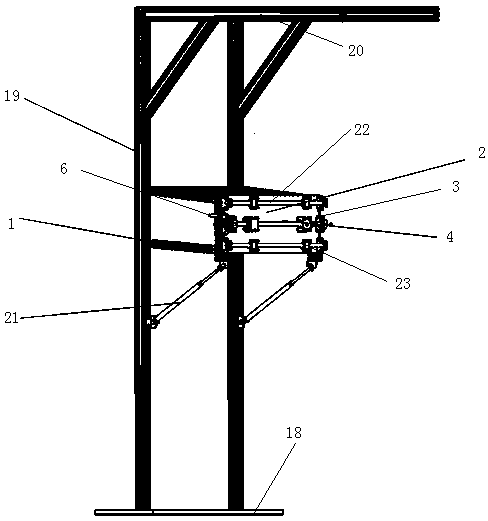

Lower limb rehabilitation robot

InactiveCN108969296AReduce up and down vibrationReduce coefficient of frictionChiropractic devicesVibration massageDrive wheelAnkle rehabilitation

The invention relates to the technical field of rehabilitation medical instruments, in particular to a lower limb rehabilitation robot, which is provided with a bracket and a treadmill, and is characterized in that the bracket is provided with a parallel buffer mechanism and a leg tralvel assisting mechanism,the parallel buffer mechanism consists of four connecting rods and a back plate. The leg travel assisting mechanism is arranged on the front surface of the back plate; the leg travel assisting mechanism consists of a group of width adjusting components, two groups of leg travel assisting components and four groups of driving adjusting components; the width adjusting component consists of a support, an tooth-reversed screw rod, a sliding seat plate and a hand wheel; the leg travel assisting component consists of a transverse hip rod and a vertical swing rod; the driving adjusting component consists of a support plate, a servo motor, a belt, a driving wheel, a driven wheel, a sleeve,a sleeve rod, a ball screw rod and a mounting hinge head. The treadmill is arranged below the leg travel assisting mechanism to assist the patient in performing ankle rehabilitation training, and therobot has the advantages of simple structure, low cost, convenient use, high popularity, and convenient household use.

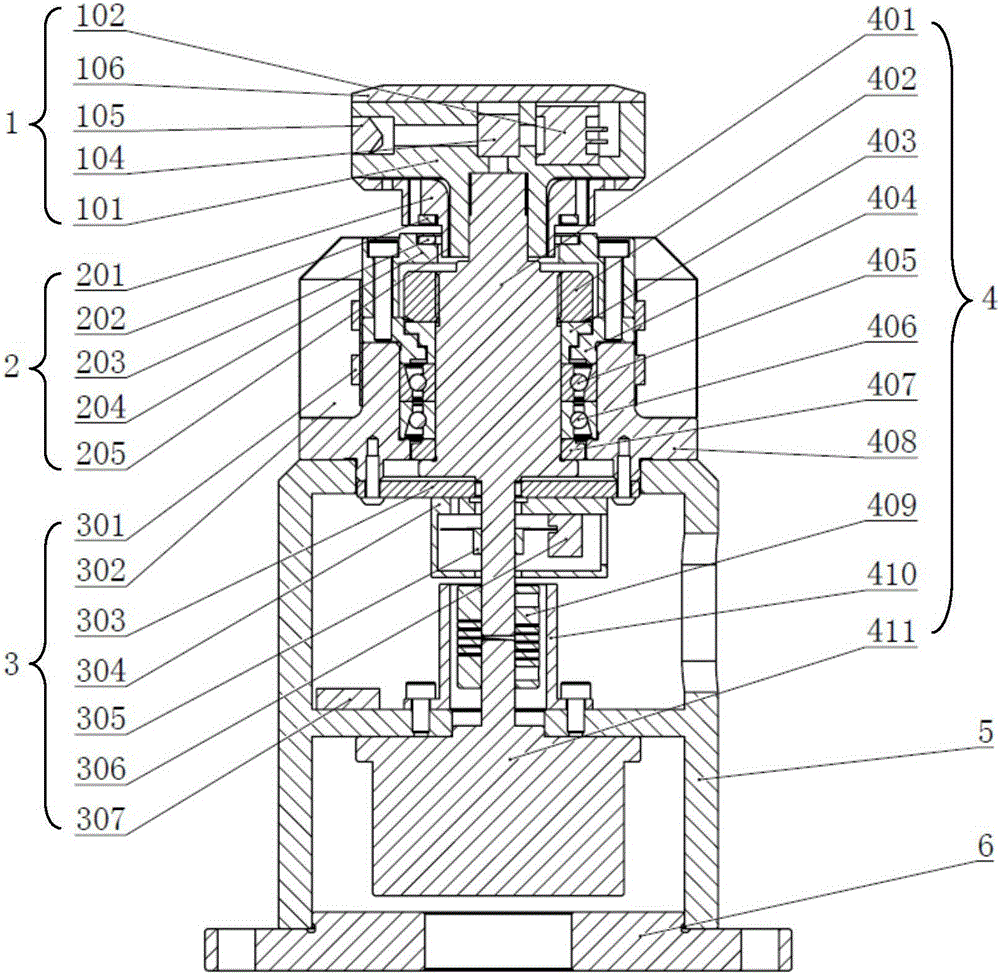

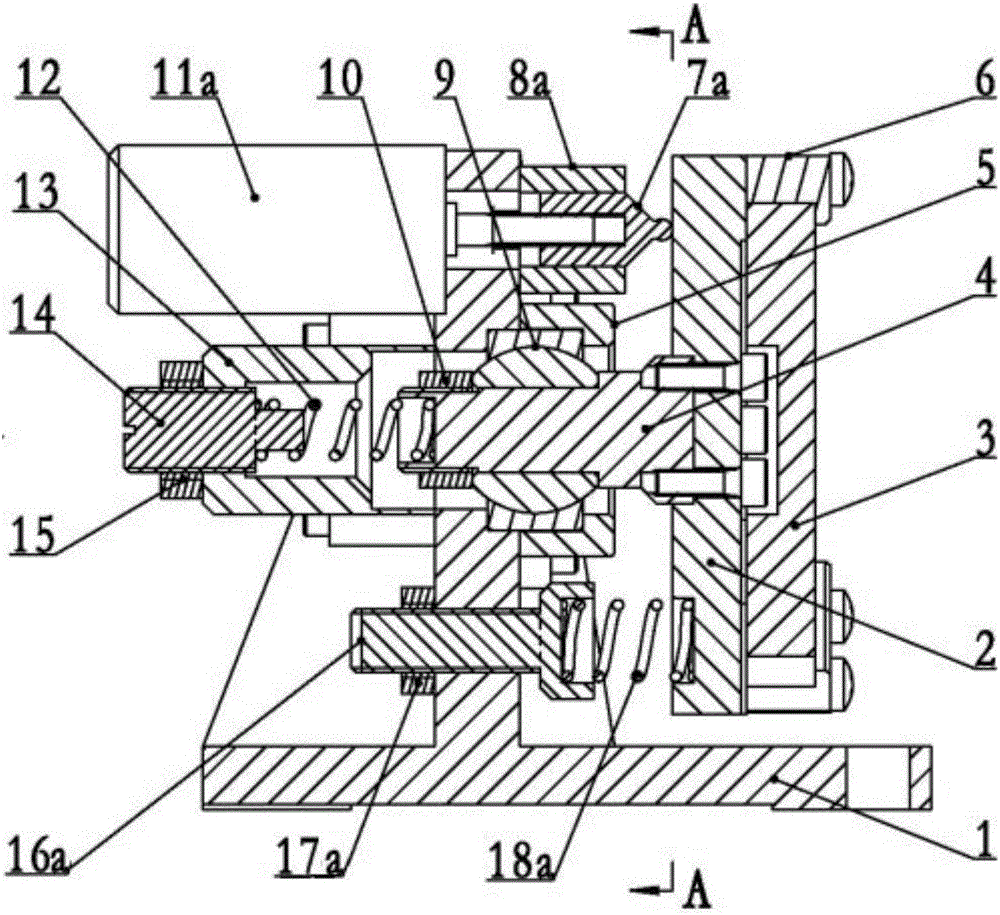

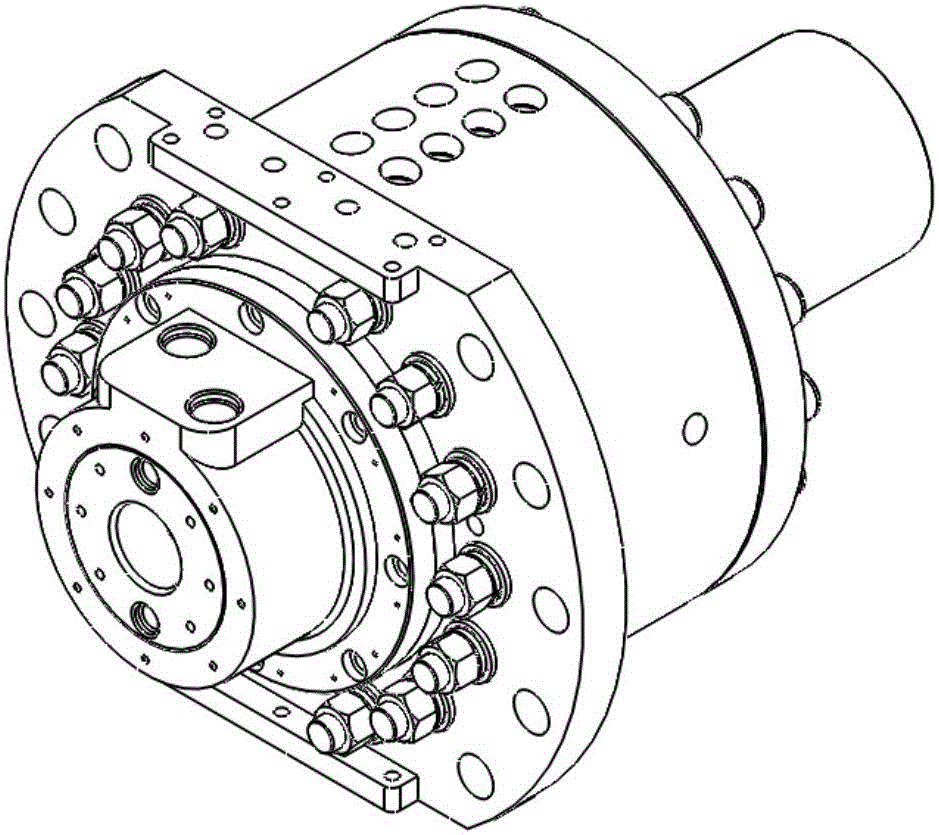

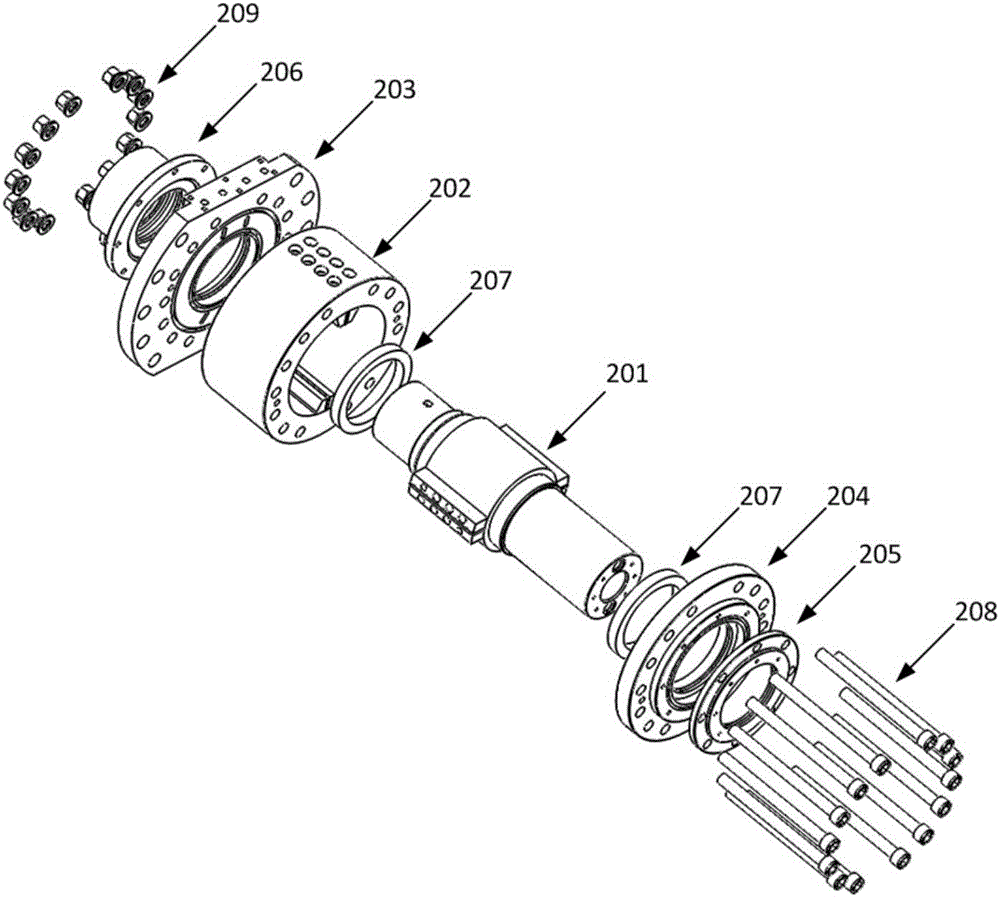

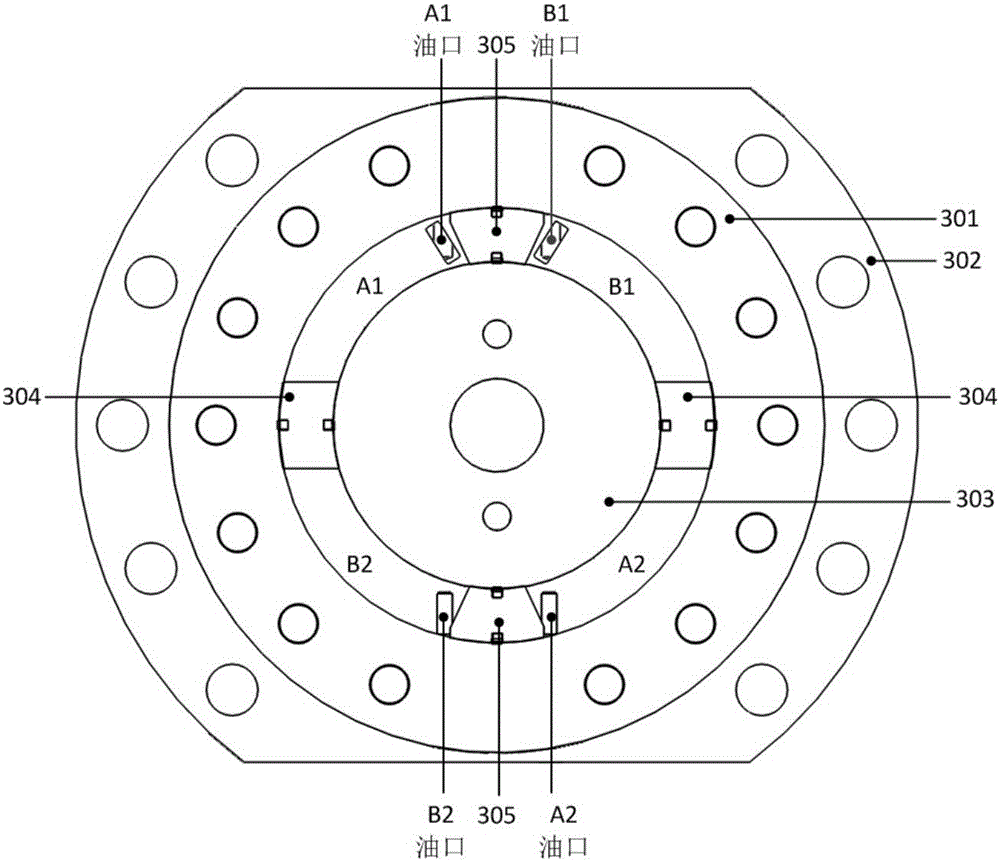

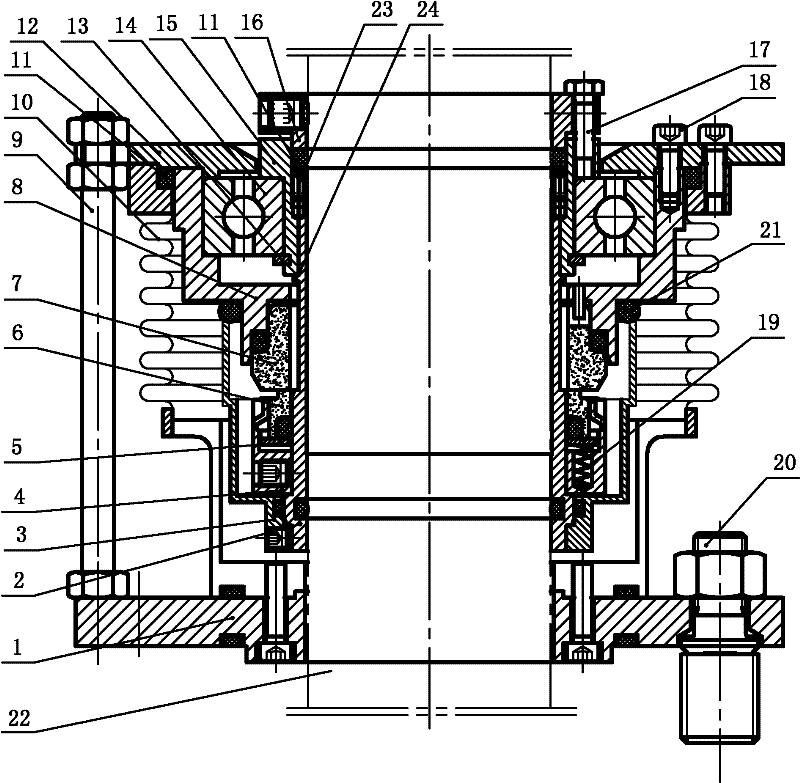

Frame-type sealed hydraulic swing motor

ActiveCN106499690AGuaranteed rotation accuracyEngine sealsFluid-pressure actuatorsHydraulic motorMechanical energy

The invention provides a hydraulic swing motor. The airtightness of the motor is improved since the sealing mode that blades of the motor adopt frame type sealing and shaft ends adopt combined sealing is adopted. The hydraulic swing motor comprises a cylinder, two fixed blades, a front cylinder cover, a rear cylinder cover, a main shaft and two movable blades, wherein the two fixed blades are arranged in the cylinder and form an included angle of 180 degrees; the front cylinder cover and the rear cylinder cover are arranged at the two ends of the cylinder correspondingly; the main shaft penetrates through the cylinder, the front cylinder cover and the rear cylinder cover and is provided with an oil in / out way; and the two movable blades are arranged on the main shaft and form an included angle of 180 degrees. The two movable blades and the two fixed blades divide the interior of the cylinder into four cavities which are used as working cavities for oil to convert pressure potential energy into mechanical energy, and combined sealing parts are arranged on the end face of the front cylinder cover and the end face of the rear cylinder cover and used for preventing oil in the cavities from flowing out along the main shaft. The two movable blades and the two fixed blades are provided with frame type sealing parts which are used for preventing oil in the cavities from communicating.

Owner:北京航辰机载智能系统科技有限公司

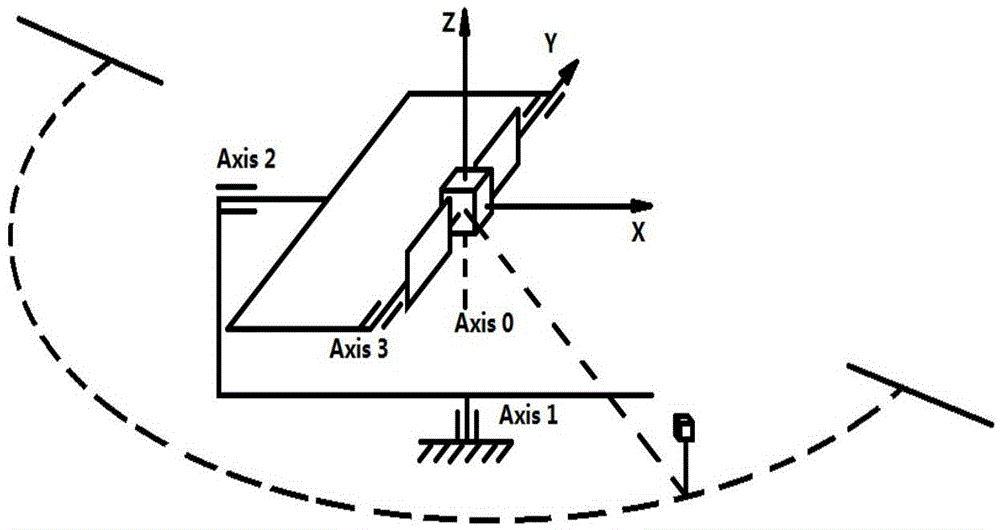

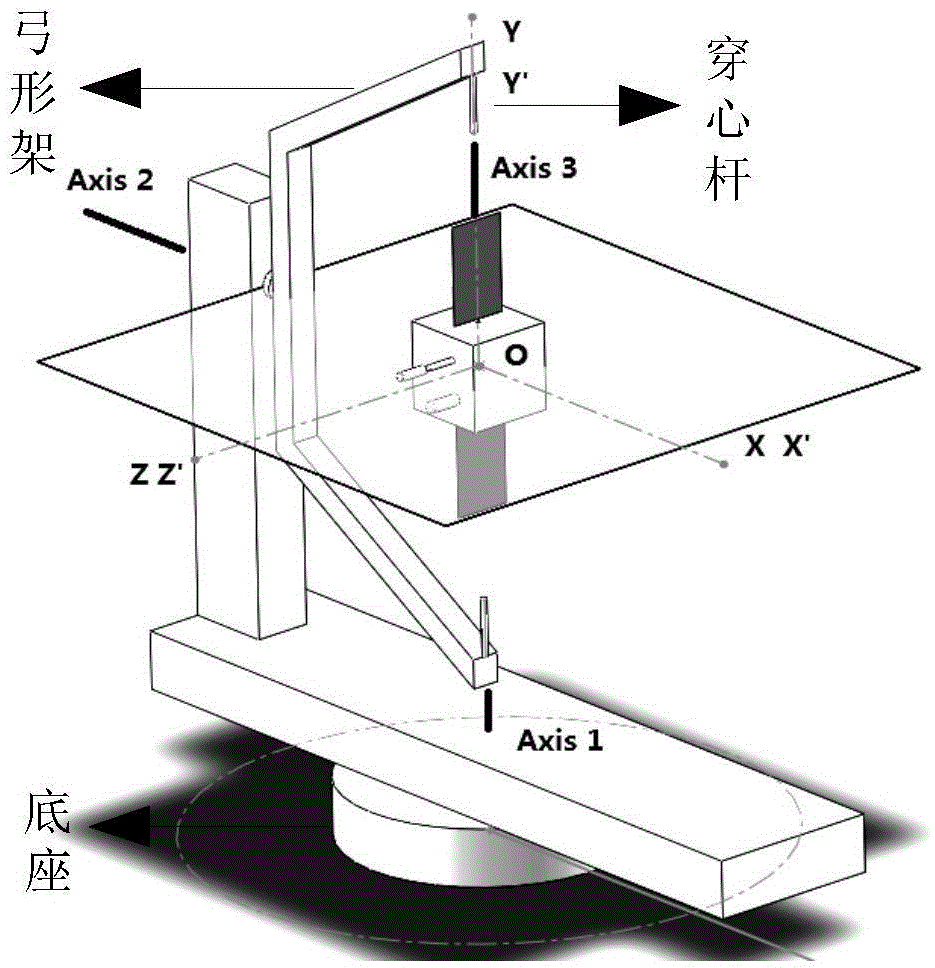

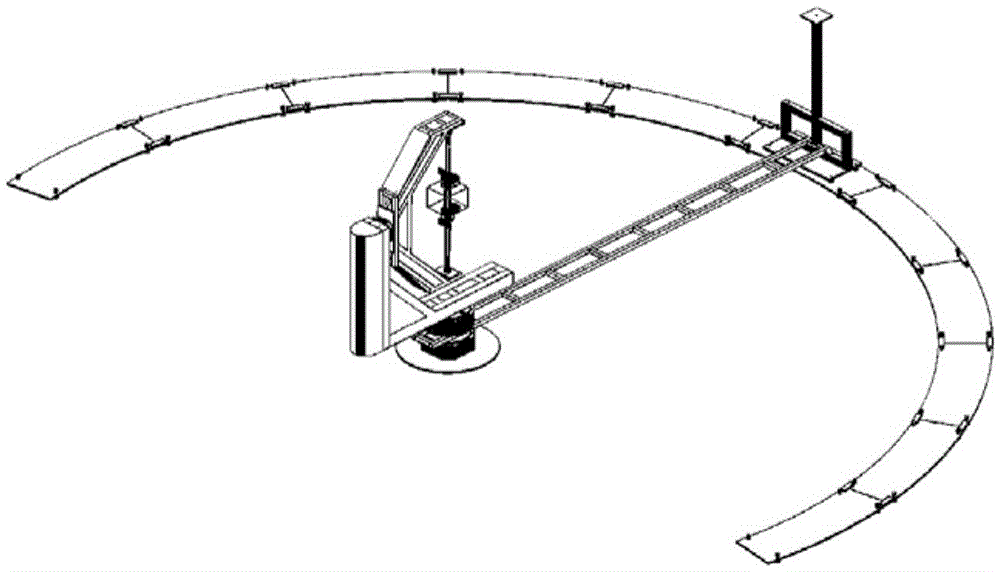

Laboratory measurement method for optical properties of satellites

InactiveCN105466476AGuaranteed rotation accuracyGuaranteed rotational stabilityTesting optical propertiesOptical propertyRelative motion

The invention discloses a laboratory measurement method for the optical properties of satellites, comprising the following steps: step 1, simulating the attitude motion of a satellite and establishing a satellite attitude motion model; step 2, establishing a light source model projected to a satellite model based on the satellite attitude motion model, and simulating the illumination of the sun to the satellite; and step 3, establishing a detector model simulating the detection angle of a detector based on the satellite attitude motion model and the light source model, wherein the direction of the detector in the detector model faces the satellite model in the satellite attitude motion model. Through equivalent treatment of the process of space optical observation, optical observation of a satellite is simulated in the laboratory; through satellite attitude control turntable scheme design, turntable rotation shafts clamping a target model are designed to simulate satellite attitude control; an around-center rotating part controlling the rotation of the detector is designed to simulate the relative motion of the optical detector; and a three-axis turntable and a detector are designed in a combined manner to simulate omni-directional observation based on a semicircular detection slide rail.

Owner:张雅声

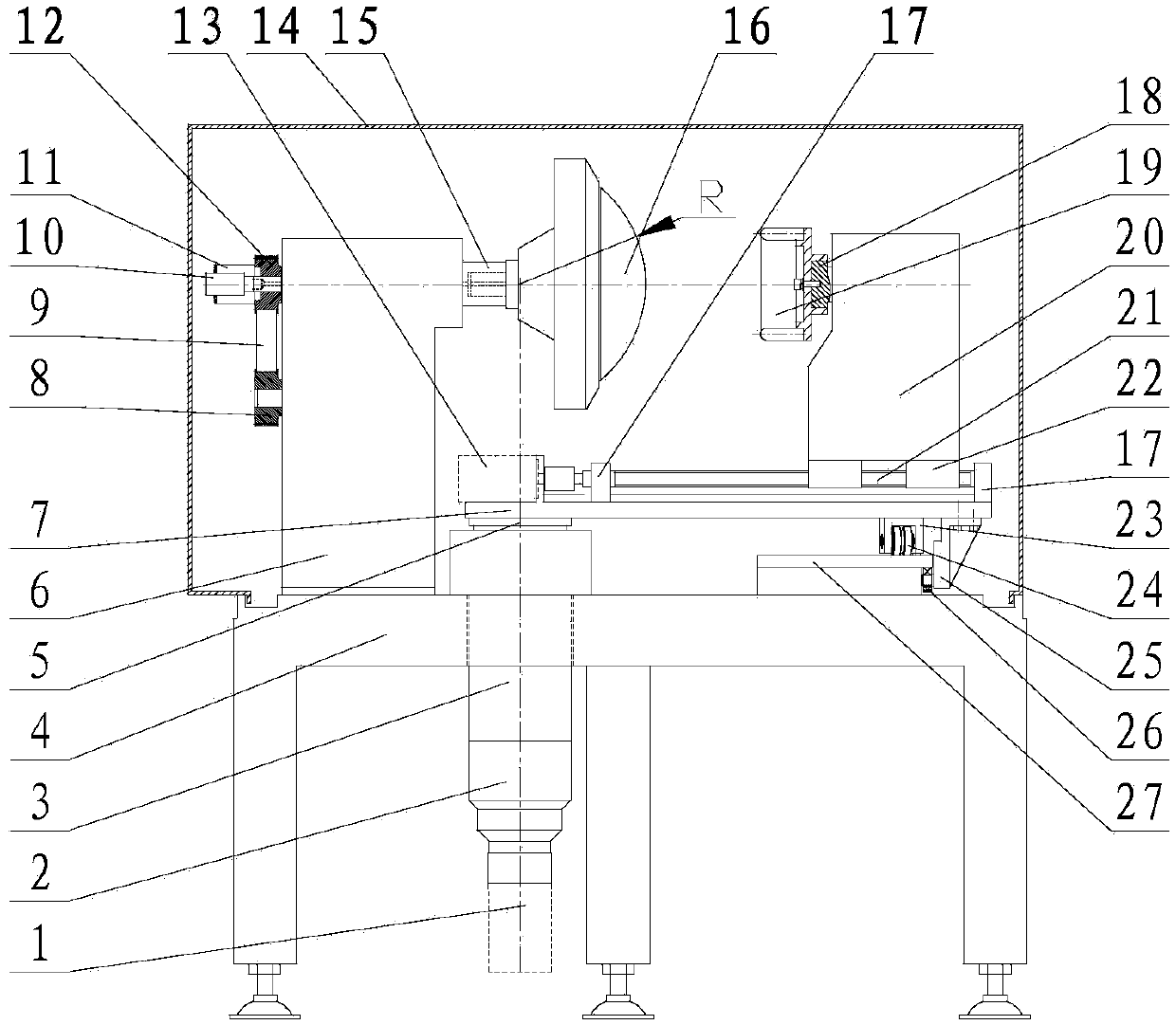

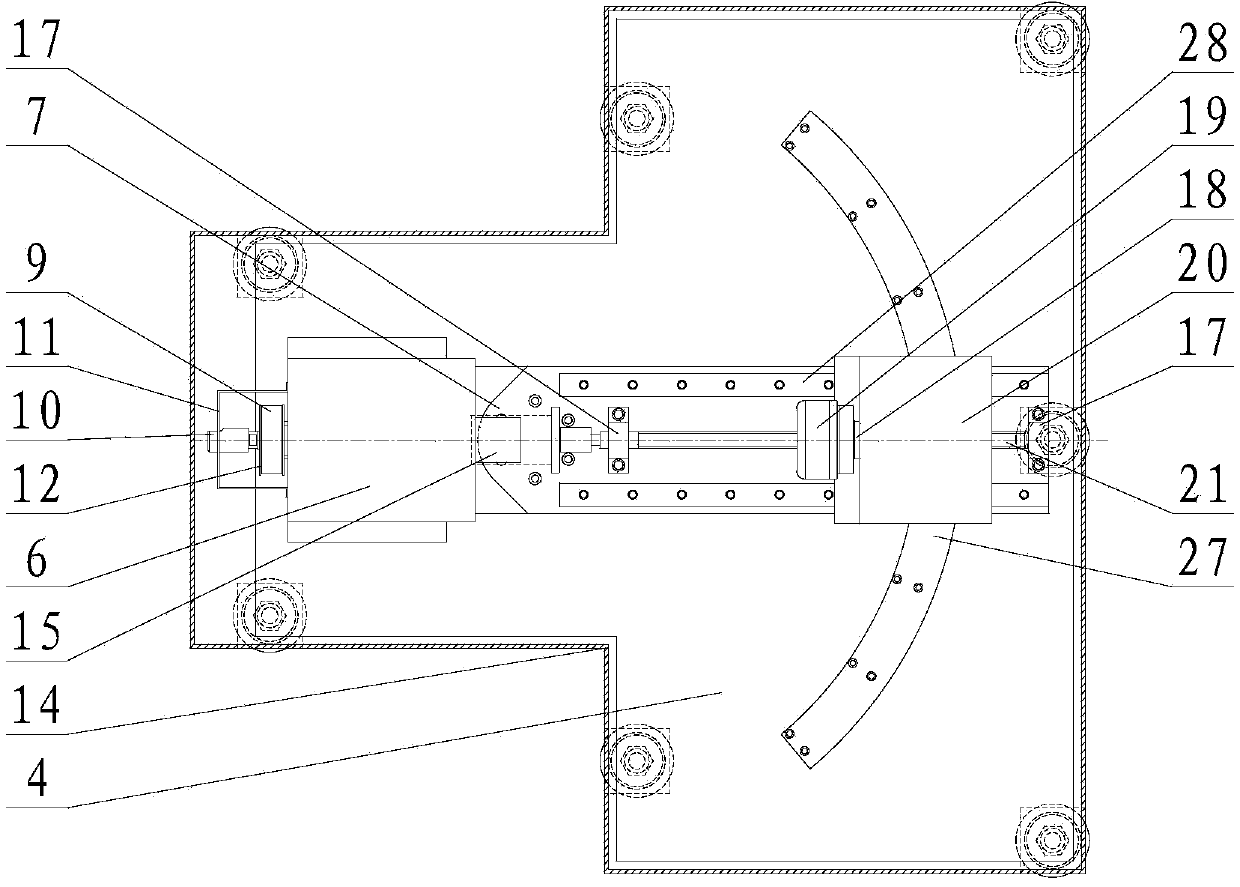

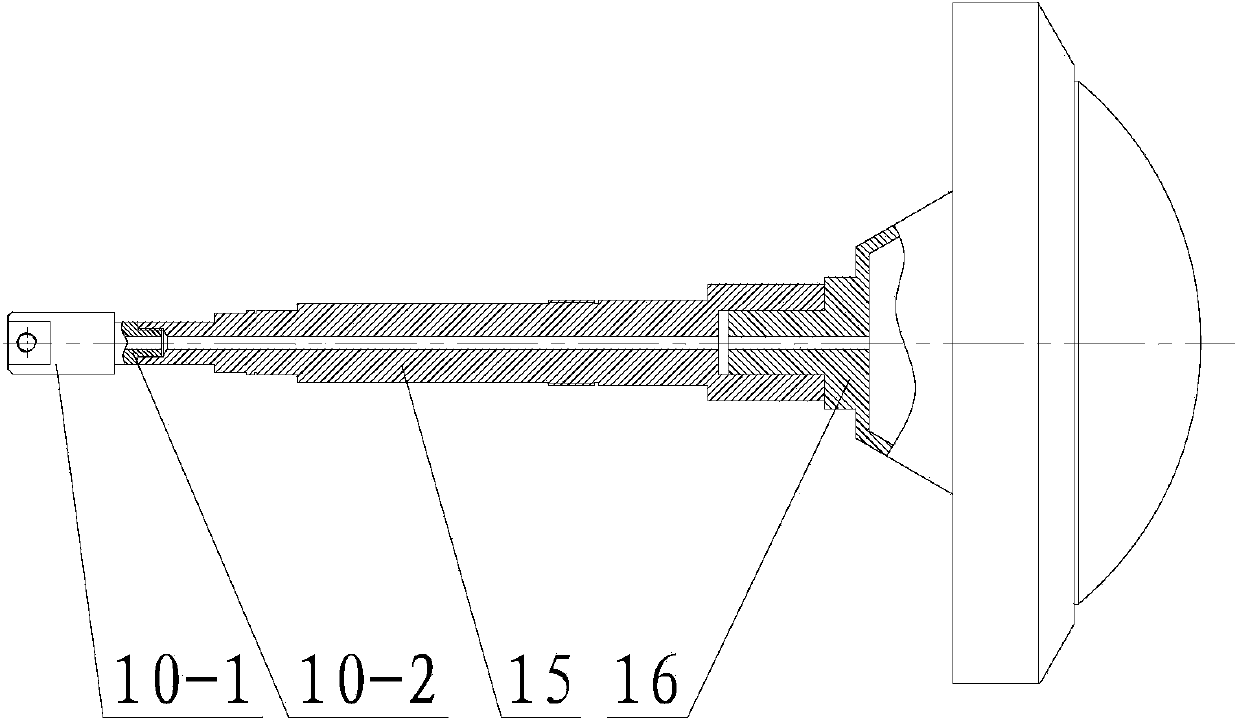

Off-line-type gas bag polishing tool finisher

ActiveCN103586775AWill not affect normal workImprove work efficiencyAbrasive surface conditioning devicesDrive wheelReducer

The invention discloses an off-line-type gas bag polishing tool finisher, and relates to a gas bag polishing device. The off-line-type gas bag polishing tool finisher is high in efficiency, low in cost, easy to operate and high in reliability. The off-line-type gas bag polishing tool finisher is provided with a swing motor, a planetary reducer, a swing main shaft box, a base, a swing shaft, a gas bag main shaft box, a swing arm, a driving wheel, a belt, a rotary connector, a rotary connector support, a driven wheel, a feeding motor, a protective cover, a gas bag main shaft, a gas bag tool, a lead screw support, a grinding wheel main shaft, a finishing grinding wheel, a grinding wheel main shaft box, a lead screw, a sliding block, a swing arm supporting base, a supporting bearing, a barb frame, a barb bearing, an arc guide rail, a guide rail, a gas bag driving motor and a grinding wheel driving motor. The off-line-type gas bag polishing tool finisher can effectively improve the working efficiency of a gas bag polishing machine and meanwhile has obvious effects in the aspects of improving the finishing efficiency of the gas bag tool, improving the reliability of the finishing process, reducing the cost and the size of finishing equipment and the like.

Owner:XIAMEN UNIV

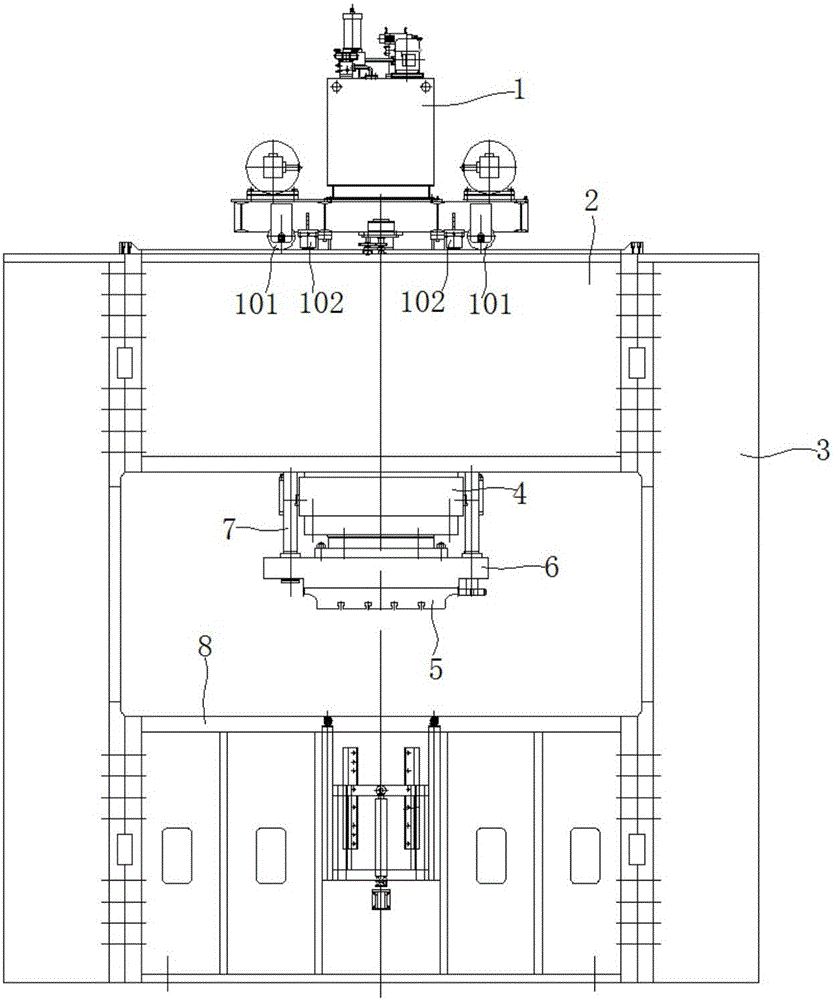

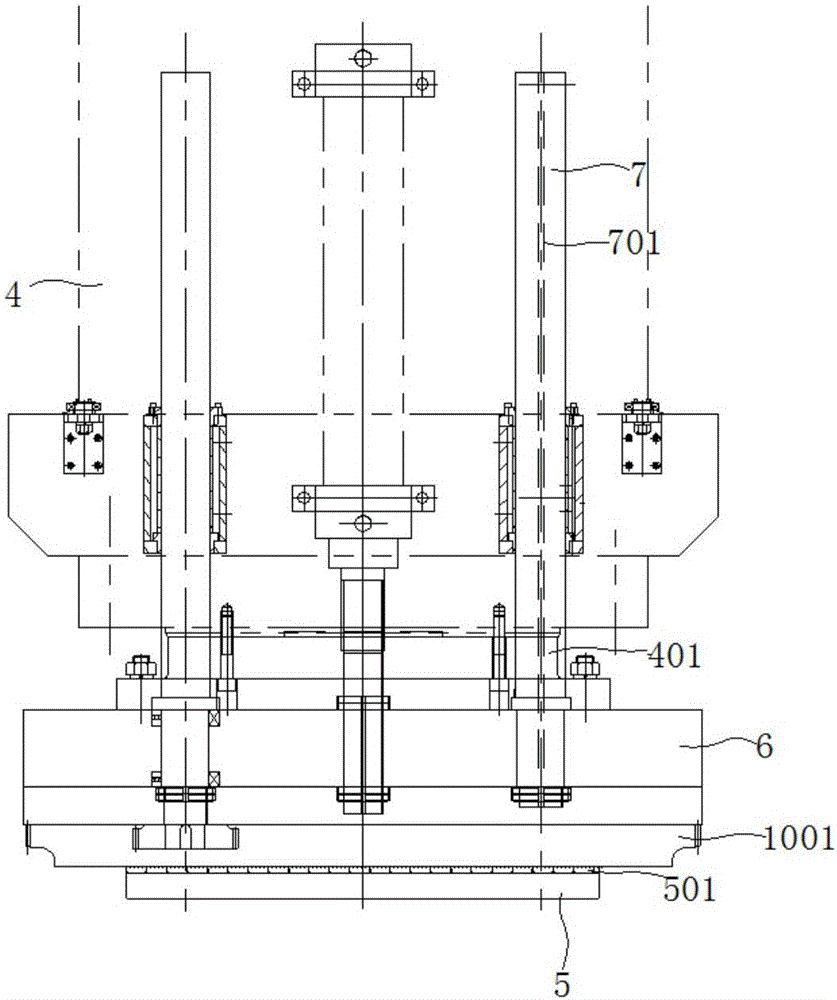

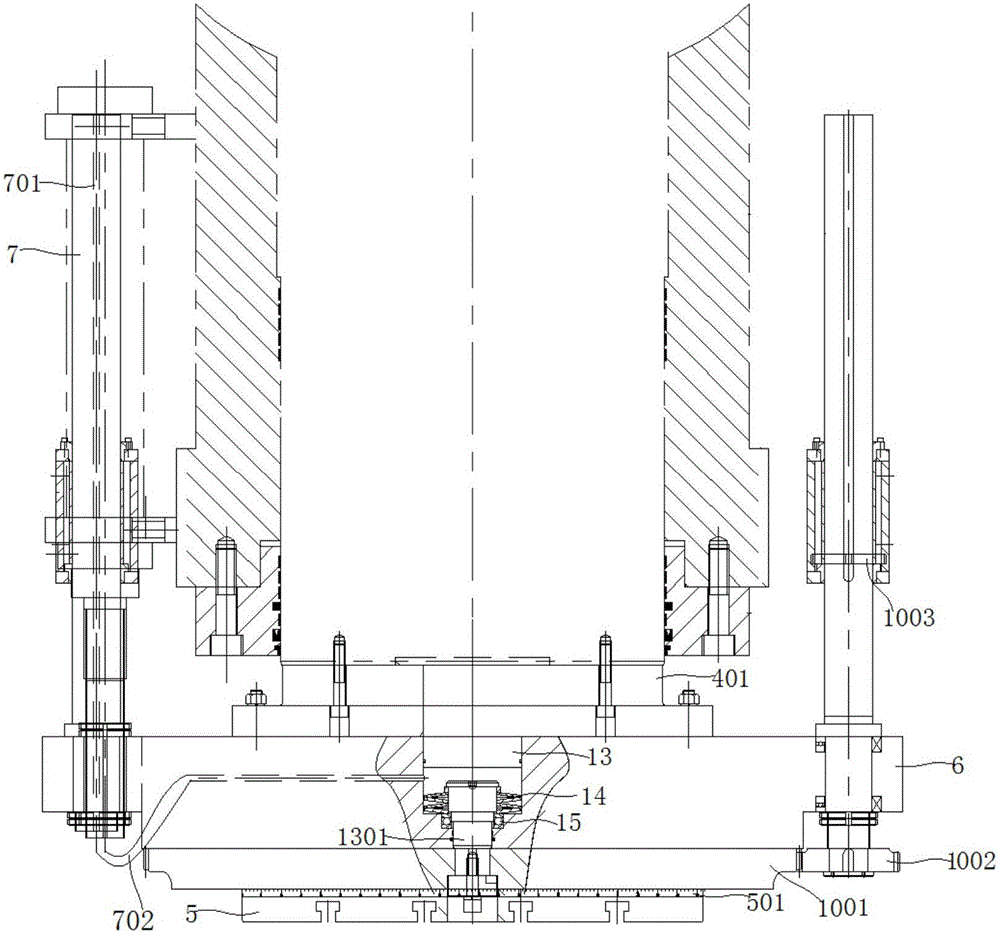

Large-tonnage rotation movement hydraulic machine

ActiveCN106003783AImprove machining accuracyIncrease productivityPress ramControl engineeringEngineering

The invention provides a large-tonnage rotation movement hydraulic machine, and belongs to the technical field of hydraulic machines. The large-tonnage rotation movement hydraulic machine comprises a hydraulic machine frame, a hydraulic station, a pressure head mechanism and a workbench, wherein the hydraulic machine frame comprises an upper beam, a lower beam and stand columns. The hydraulic station is located on the top of the hydraulic machine frame. The pressure head mechanism is hoisted below the hydraulic station. The workbench comprises a movement workbench and a rotation workbench, wherein the rotation workbench is located on an inner cavity of the movement workbench. Four travelling jack-up cylinders are symmetrically arranged below the movement workbench, three rotation jack-up cylinders which are evenly distributed are arranged below the rotation workbench in the circumferential direction of the rotation workbench, rolling wheels are arranged at the bottoms of the travelling jack-up cylinders, and rolling bearings are arranged between the rotation jack-up cylinders and the rotation workbench. The large-tonnage rotation movement hydraulic machine can be used for forming and machining large-tonnage plates, and the machining accuracy of the large-tonnage rotation movement hydraulic machine can be effectively guaranteed.

Owner:ANHUI DONGHAI MACHINE MFG CO LTD

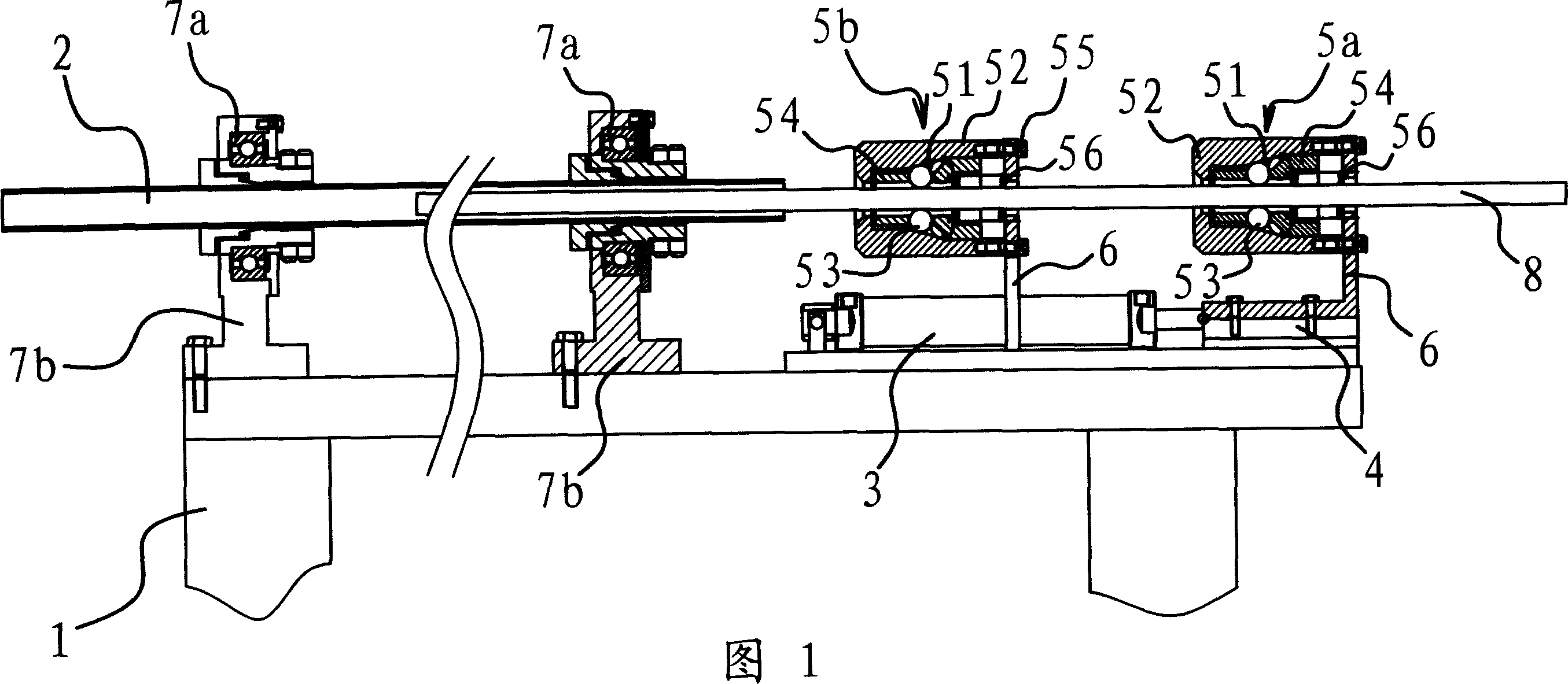

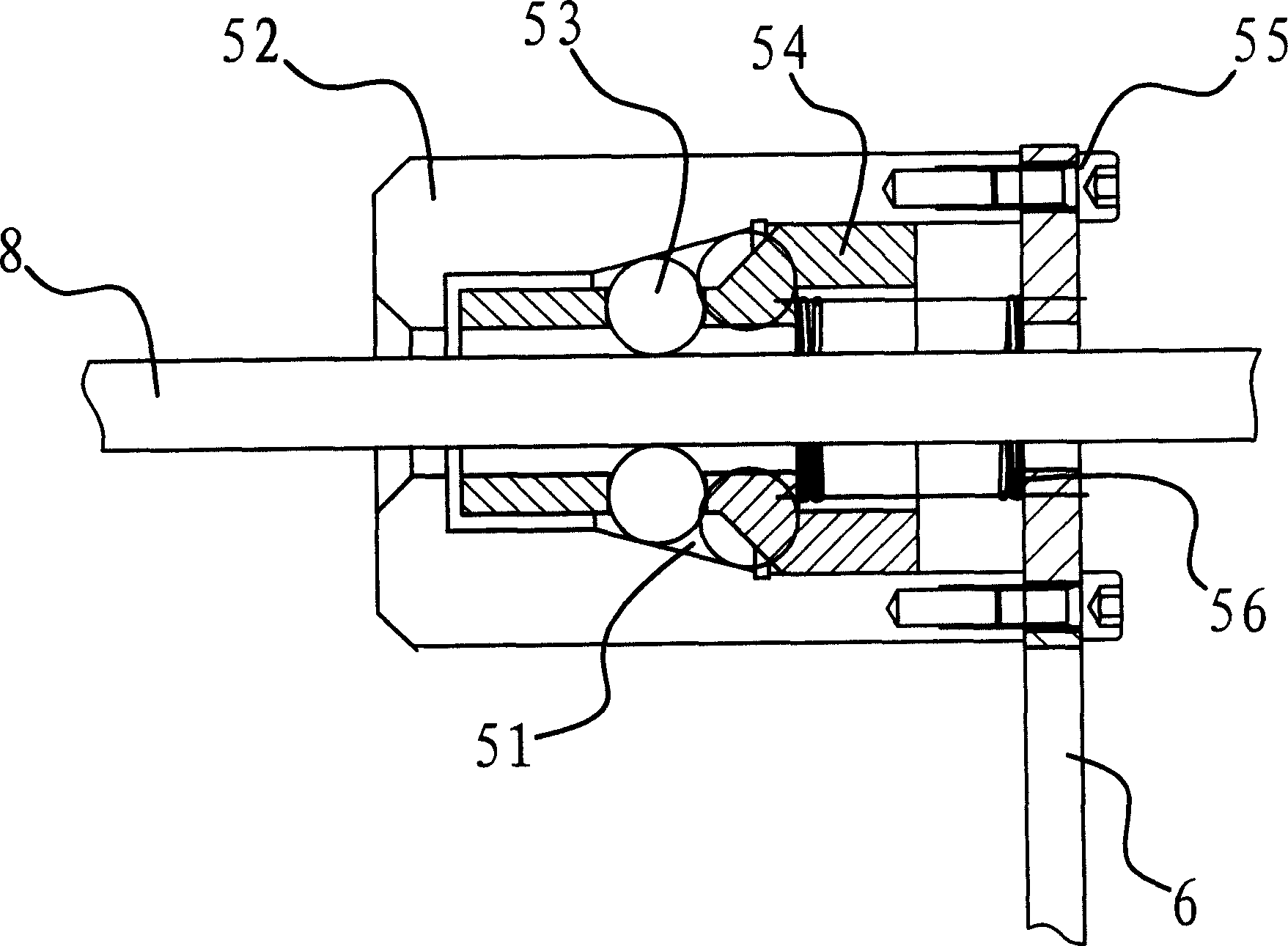

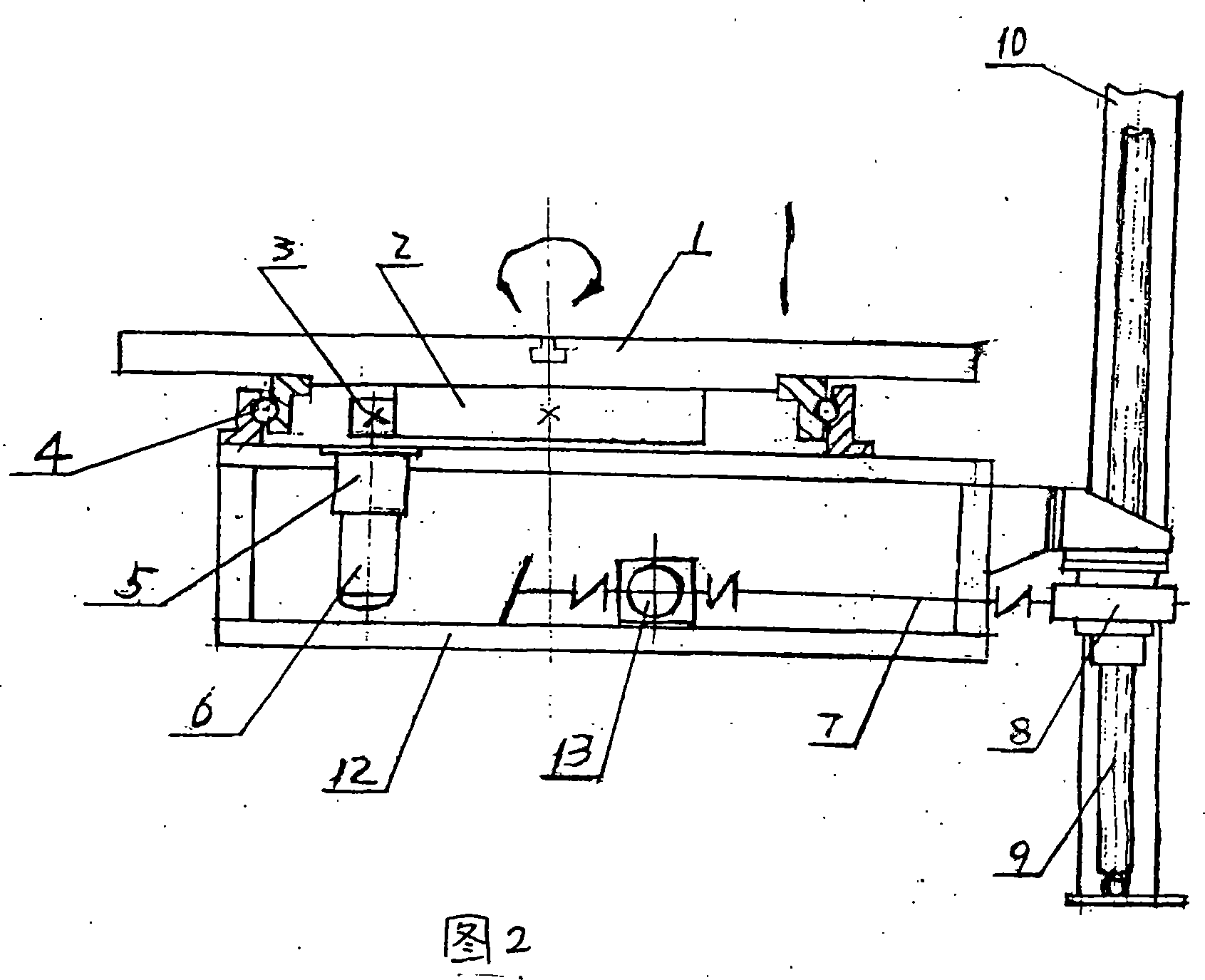

Automatic feeding device for lathe

ActiveCN1850400AReduce disturbanceGuaranteed rotation accuracyAutomatic conveying/guiding stockSlide plateEngineering

The present invention provides an automatic feeder device for lathe. Said automatic feeder device is placed by workpiece holder of lathe, and includes the following several portions: material-supporting pipe placed on the machine frame, material-feeding cylinder placed at one side of said material-supporting pipe, slide plate fixedly connected on said material-feeding cylinder and can be axially moved along the material-supporting pipe and two material-feeding devices through which the rod material can be passed are placed on the machine frame. Said two material-feeding devices include one mobile material-feeding device and one fixed material-feeding device. Its operation is convenient, stable and reliable.

Owner:浙江海德曼智能装备股份有限公司

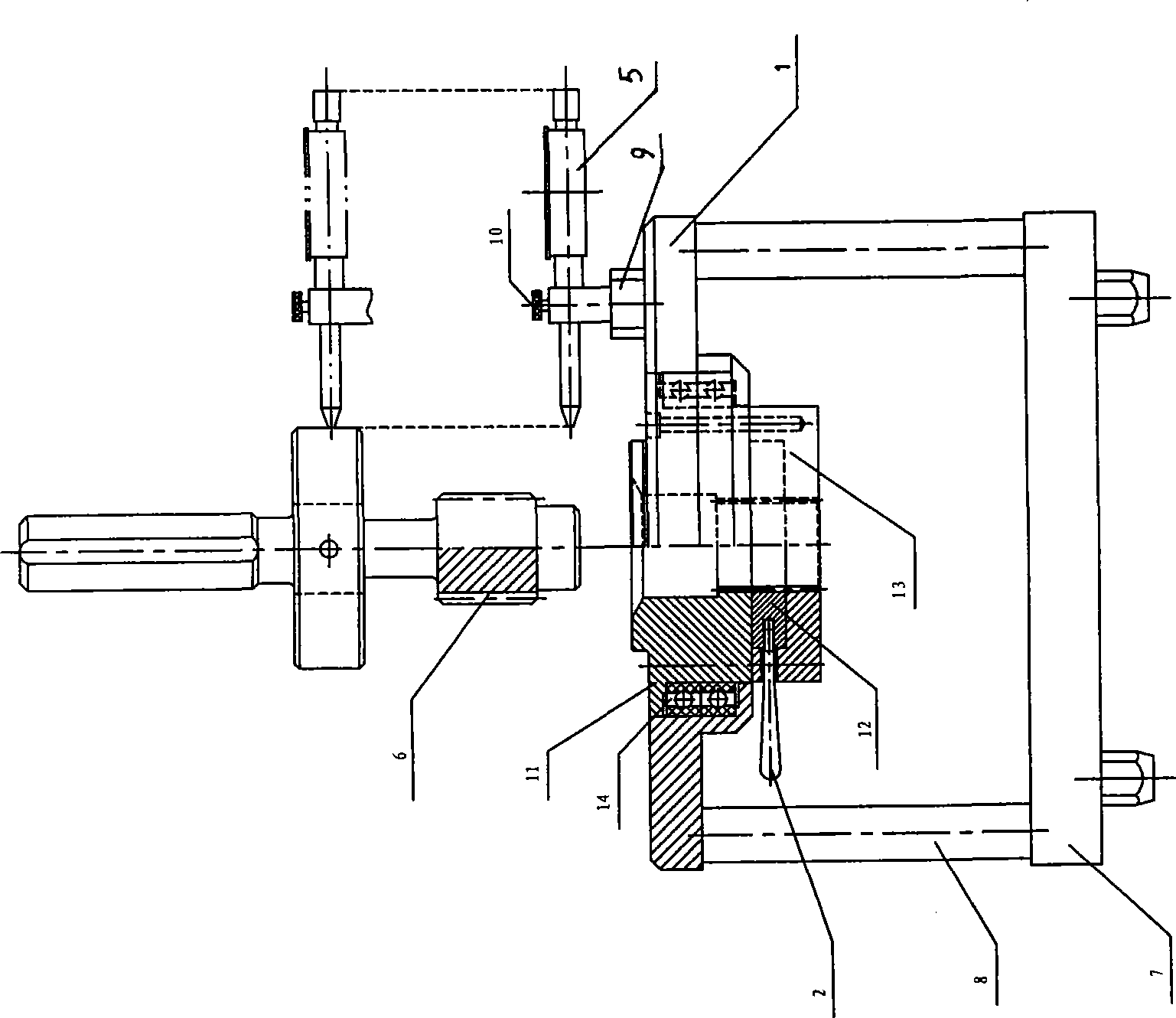

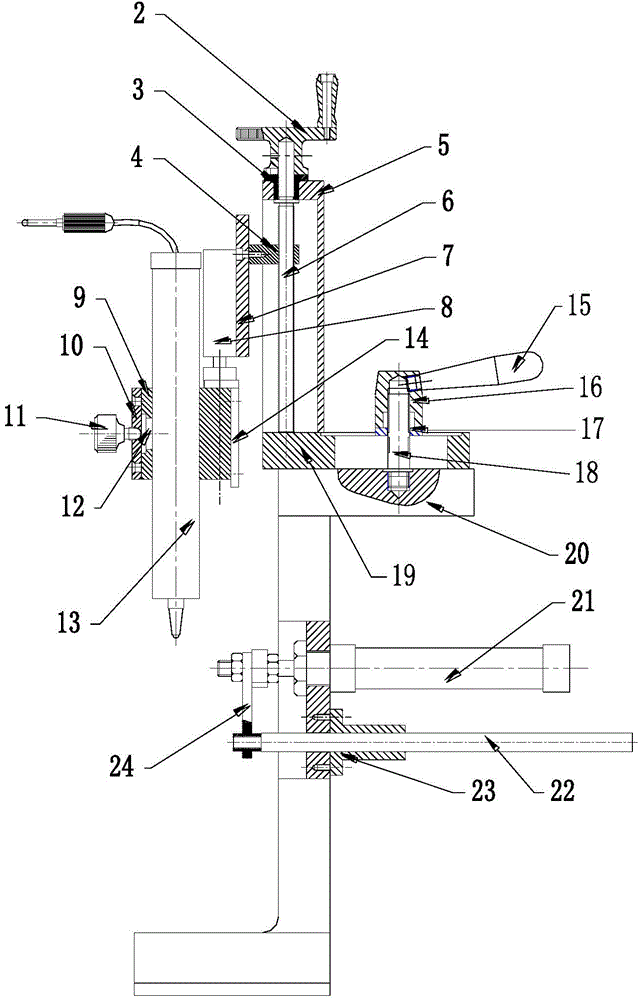

On-machine detection device and detection method of worm gear pair transmission precision

ActiveCN105598534AAvoid installation structuresEasy to measureGear-cutting machinesGear teethAngular degreesEngineering

The invention discloses an on-machine detection device of the worm gear pair transmission precision. The detection device comprises a rotary table for installing a worm gear and a tool for installing a worm, a worm gear angular displacement sensor which detects the rotation angle of the worm gear is installed in the rotary table, a worm angular displacement sensor which detects the rotation angle of the worm is installed on the tool, the worm gear angular displacement sensor and the worm angular displacement sensor are in output connection with a worm gear detector, the tool is provided with a bracket, a sliding plate located above the bracket and a pair of fixed centers for supporting the two ends of the worm, a driving motor is arranged on the bracket and drives a gear transmission set, and a rotor of the worm angular displacement sensor and a tail end gear coaxially and synchronously rotate to measure the rotation angel of the worm; the rotary table comprises an installation table and a base which can rotate relatively, a rotor of the worm gear angular displacement sensor is coaxially installed on a protruding column of the installation table, and a stator of the worm gear angular displacement sensor is fixedly connected with the base. The invention further discloses an on-machine detection method of the worm gear pair transmission precision. By means of the on-machine detection device and detection method of the worm gear pair transmission precision, the on-machine detection problem of the worm gear pair transmission precision is solved.

Owner:CHONGQING UNIV OF TECH

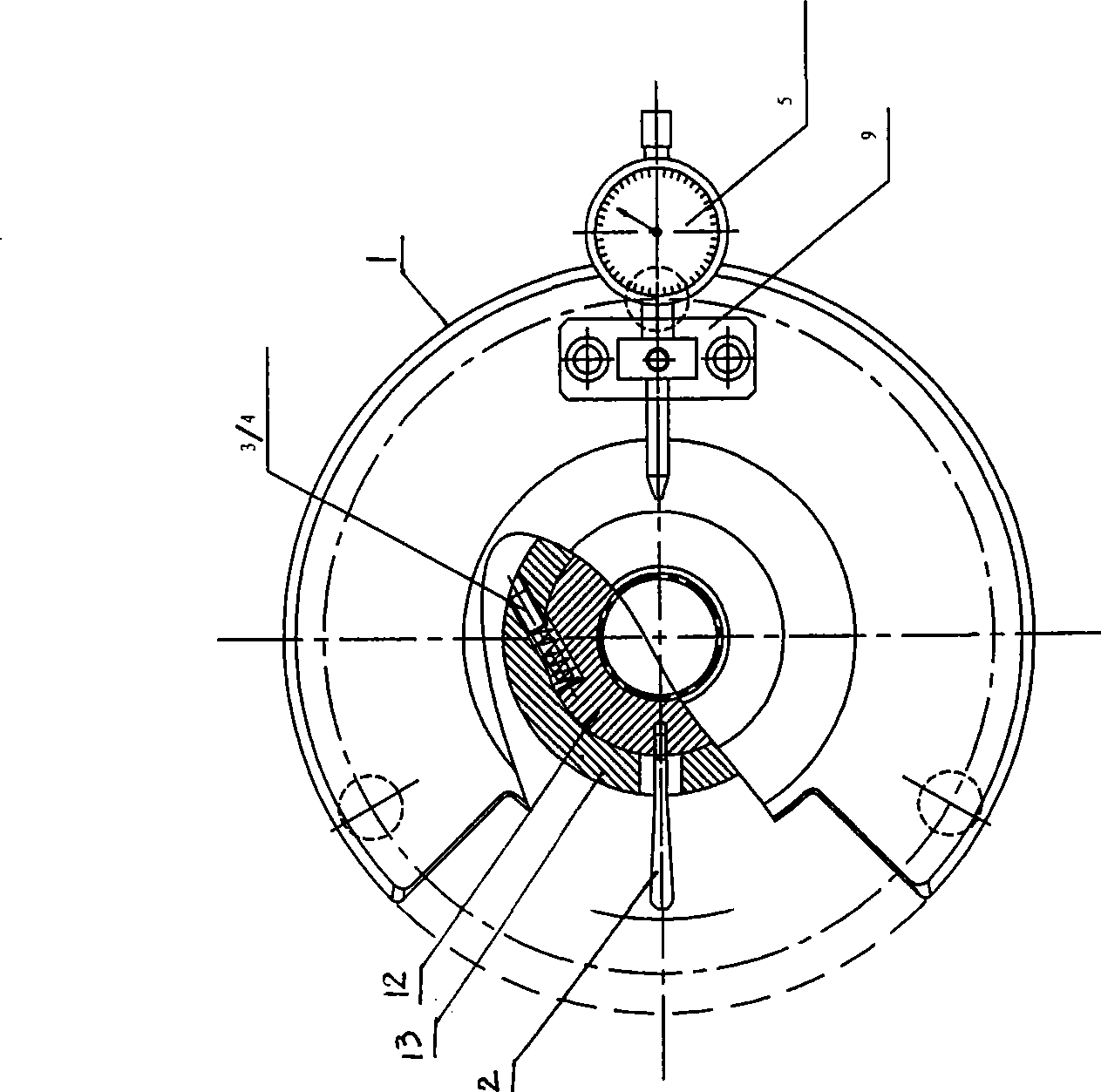

Radial pulsation measurement instrument for external spline gear ring

ActiveCN101476855AGuaranteed rotation accuracyEasy to measureMechanical measuring arrangementsEngineeringField detection

The invention discloses a dial external spline gear ring radial pulsation measuring apparatus, which comprises a measuring stand, an internal spline ring, an adjusting handle, an adjusting screw, a pressure spring and a measuring indicator, wherein the internal spline ring and the measuring indicator are arranged on the measuring stand respectively; the internal spline ring is formed by assembling three coaxial internal splines, namely a first spline, a second spline and a third spline; the first spline and the third spline are fixedly connected with each other and have completely corresponding tooth shape; the second spline is movably connected between the first spline and the third spline and can perform concentric rotation; the adjusting handle is inserted into the second spline and the third spline; and the adjusting screw and the pressure spring are arranged inside concave holes which are arranged inside the second spline and the third spline. The measuring apparatus has the advantages of convenient, accurate and direct measurement, easy maintenance, low requirement on a measuring environment, low cost, high efficiency and the like, and is particularly suitable for mass production field detection.

Owner:EST TOOLS

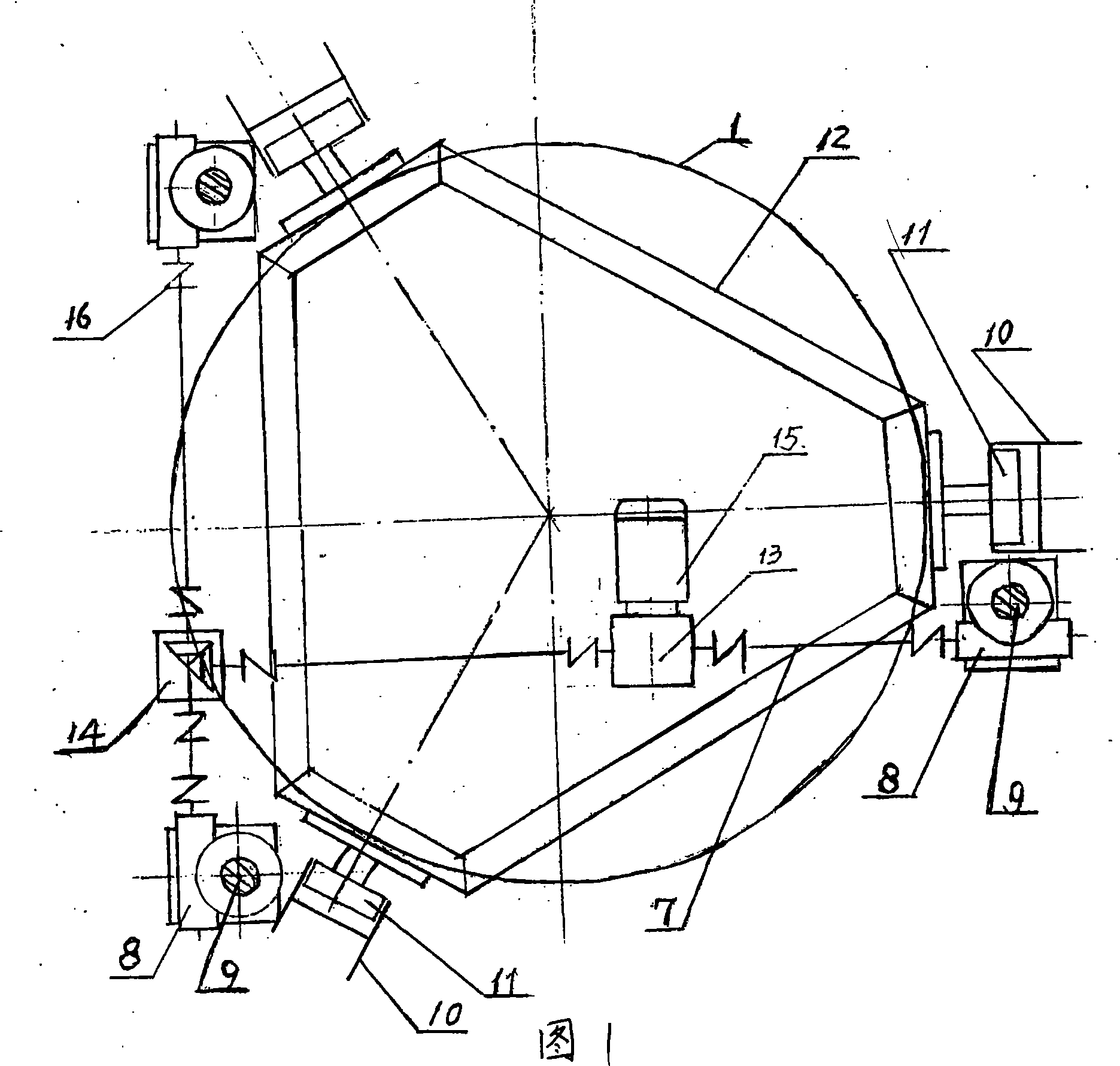

Dry transformer coil vertical coiling machine

ActiveCN101162647ASynchronized and smooth vertical liftGuaranteed rotation accuracySafety devices for lifting equipmentsMechanical energy handlingWinding machineTransformer

The invention relates to a big slewing ring bearing three guide post worm gear screw lifting vertical type coil winding machine, comprising a lifting system and a winding slewing system connected with the lifting system, wherein the lifting system comprises a lifting base, three or four worm gear screw lifters which are fixed on the lifting base and move on the lead screws, and a lifting driving device which drives the worm gear screw lifters to lift; the winding system comprises a slewing face plate connected with the lifting base by the big slewing ring bearing, a big gear fixed on the lower part of the slewing face plate, a small gear meshed with the big gear, a slewing reducer and a variable frequency main motor; the slewing reducer and the variable frequency main motor are directly connected with the small gear. The invention has the advantages of high efficiency, multifunction, stable running, high automatization control level, easy operation, fault-free, correct number of turns of the coiling and low manufacturing cost, etc.

Owner:SHANDONG JULI ELECTRO MACHINERY

Electrochemical polishing method for bearing retainer

ActiveCN102995099AGood self-lubricating performanceEliminate chromatic aberrationElectrolysisSquare decimeter

The invention relates to an electrochemical polishing method for a bearing retainer. The electrochemical polishing method for the bearing retainer comprises the steps of: preparing, electrochemical polishing, electrolyte mixing, cleaning by using cold water, passivating, cleaning by using hot water, drying and rust preventing; the electrolyte is prepared from phosphoric acid, water and chromic anhydride in a volume ratio of 8:4:1; the temperature of the electrolyte is controlled to be below 40 DEG C; in the electrochemical polishing step, the current density is 35A / square decimeter, the working voltage is 8-10V, the distance between the negative pole of an electrochemical polishing machine and a processed workpiece is 5-10mm, and the electrochemical polishing time is 90s; the preparing step comprises the sub-steps of: preparing the electrolyte, adding the electrolyte in an electrolytic vessel, placing a lead plate in the electrolytic vessel, connecting the lead plate and the negative pole of the electrochemical polishing machine, and preparing the processed workpiece; and the step of preparing the processed workpiece comprises the following sub-steps of: performing oil removing and cleaning on the processed workpiece, cleaning by using hot water, cleaning by using cold water, hanging on a hanger, and connecting the processed workpiece with the positive pole of the electrochemical polishing machine. According to the electrochemical polishing method, the clamping as well as the material charging and discharging are convenient, the occupying area is small, the cost is low, the burr removing effect is good, the labor intensity is obviously reduced, and the time and the labor are saved.

Owner:DEQING TIANMA BEARING CO LTD

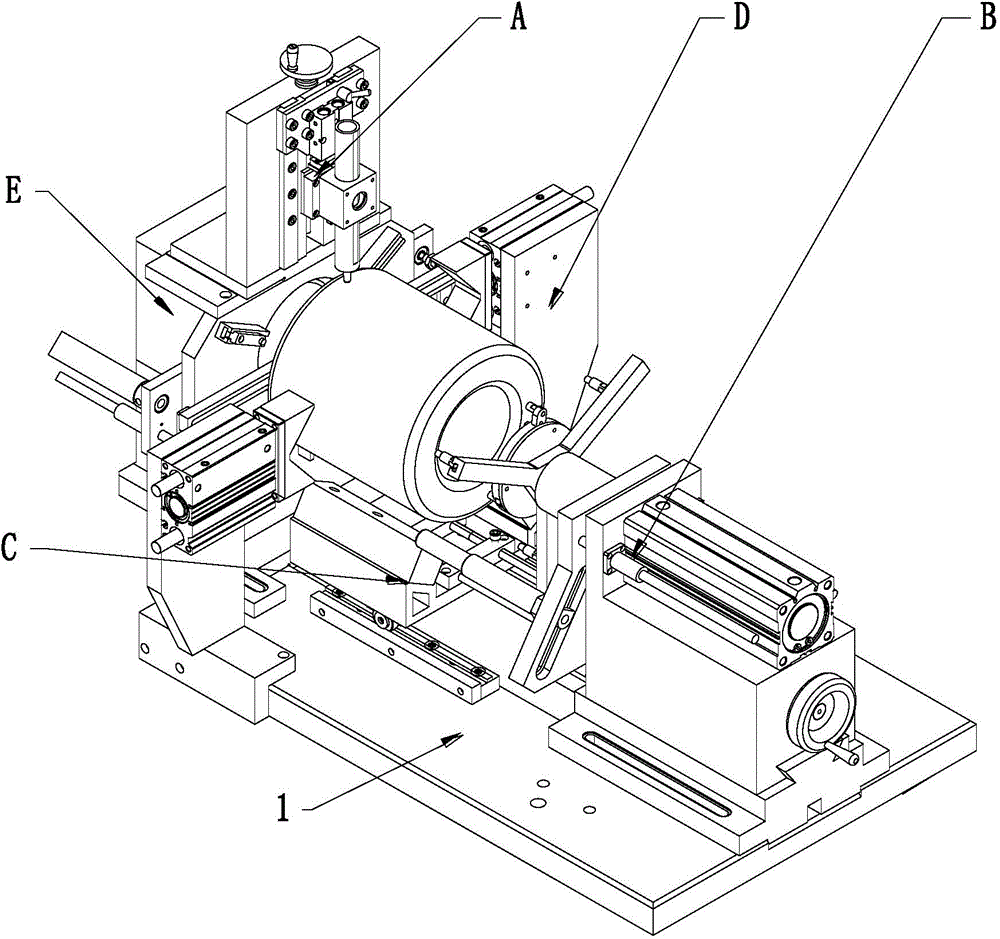

Vibration measuring instrument for super-large or super-heavy bearing

ActiveCN104964825AGuaranteed rotation accuracyHigh measurement accuracyMachine bearings testingMeasuring instrumentMechanical engineering

Disclosed is a vibration measuring instrument for a super-large or super-heavy bearing. The vibration measuring instrument comprises a measuring device, an axial reinforcing device, a vehicle conveying device, and radial reinforcing devices. One end of a main shaft penetrates a through hole in a supporting plate of the measuring device, a pedestal of the measuring device is fixed to one end of a platform, and the other end of the main shaft fixes a to-be-measured bearing through a mandrel. The radial reinforcing devices are placed on the left side and the right side of the to-be-measured bearing respectively, and cylinder support plates on the radial reinforcing devices clamp the to-be-measured bearing in a reinforcing manner. The axial reinforcing device is arranged on the other end of the platform. With the center of the mandrel being a reference, a first contact on the axial reinforcing device is in alignment with the outer ring of the to-be-measured bearing, and a second contact is in alignment with the inner ring of the to-be-measured bearing. The vehicle conveying device is arranged below the to-be-measured bearing, slides on a track formed by an outer baffle plate, an inner baffle plate with a slideway, a bearing connection shaft and a bearing, and is in cooperation with the to-be-measured bearing. The to-be-measured bearing is placed on the vehicle conveying device. Both a large-scale and a heavy bearing can be measured on the same instrument.

Owner:大连贝林轴承仪器有限公司

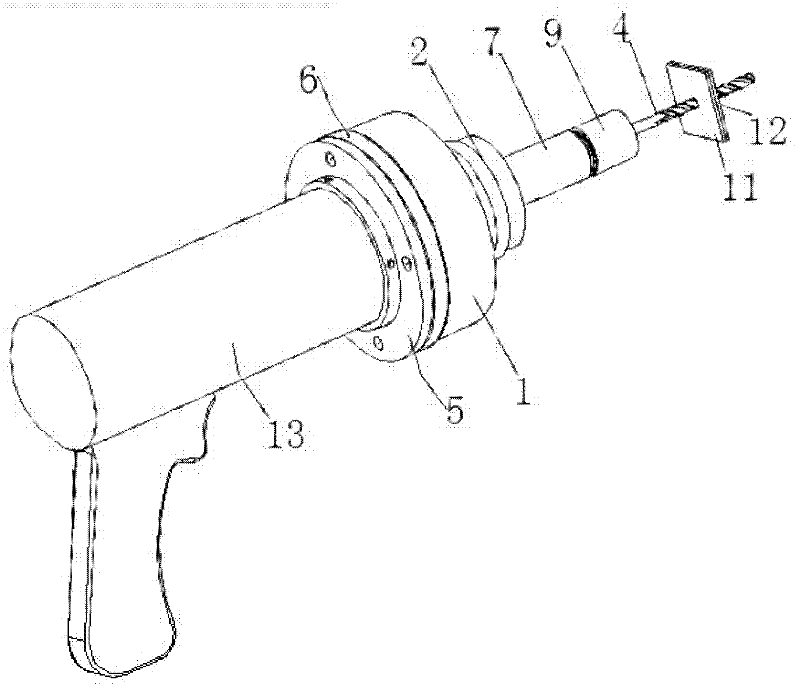

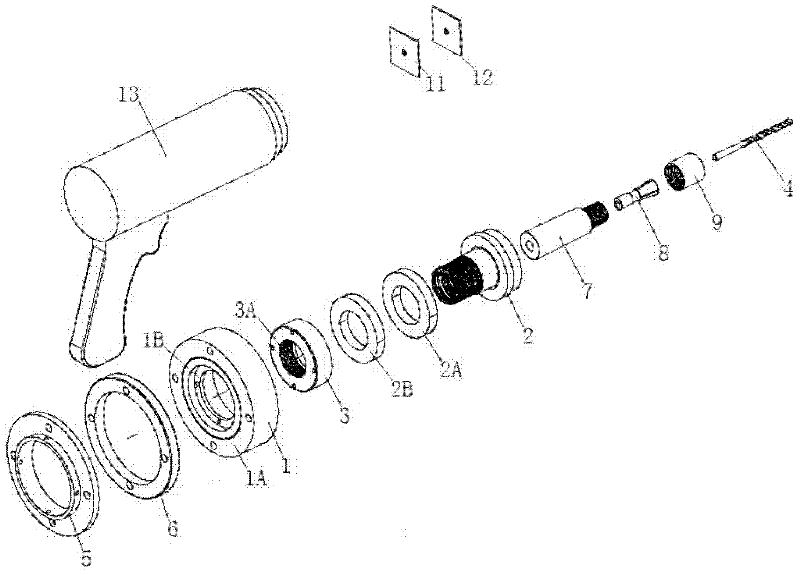

Ultrasonic vibration sleeve reaming machining device applied to air drill

ActiveCN102229001ASimple structural designRealize rotating power supplyReaming devicesTransducerUltrasonic vibration

The invention discloses an ultrasonic vibration sleeve reaming machining device applied to an air drill. The device comprises a slip ring, a front cover plate, a ceramic plate A, a ceramic plate B, a rear cover plate, a flange plate, a retainer ring, a manual air drill, a drill shaft sleeve, a spring chuck and a fastening cap; the main shaft of the manual air drill is connected into an internal thread hole of the front cover plate; after the ceramic plate A and the ceramic plate B are sequentially sleeved at the external thread section of the front cover plate, the front cover plate is in threaded connection into an internal thread hole of the rear cover plate; an inner ring of the slip ring is arranged on the rear cover plate, and an outer ring of the slip ring is connected with the retainer ring and the flange plate through bolts; and the inner conical section of one end of the drill shaft sleeve is connected with the outer cylindrical section of the spring chuck, the outer cylindrical section of the other end of the drill shaft sleeve is thermally fed into the inner cylindrical section of the front cover plate, and the chuck section of the spring chuck chucks a reamer or a coredrill and is finally locked through the fastening cap. By assembly design of the spring chuck, the clamped tool bit form is varied, a transducer, the main shaft of a common air drill and a cutter aredetached conveniently, and the rotary precision of the whole air drill tool is ensured.

Owner:BEIHANG UNIV

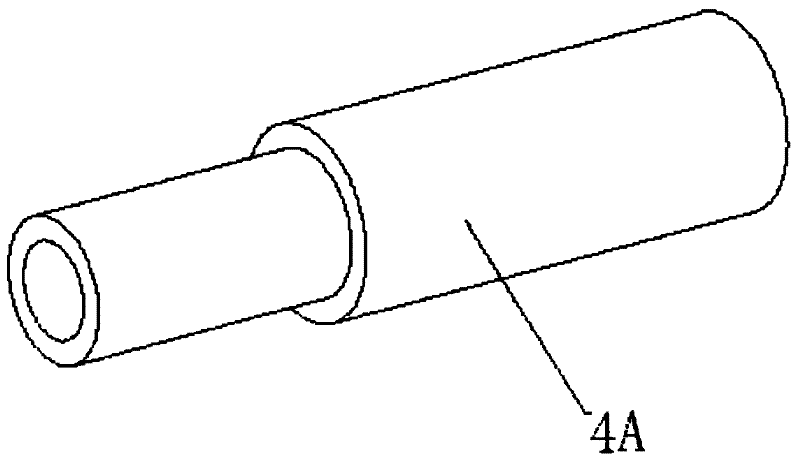

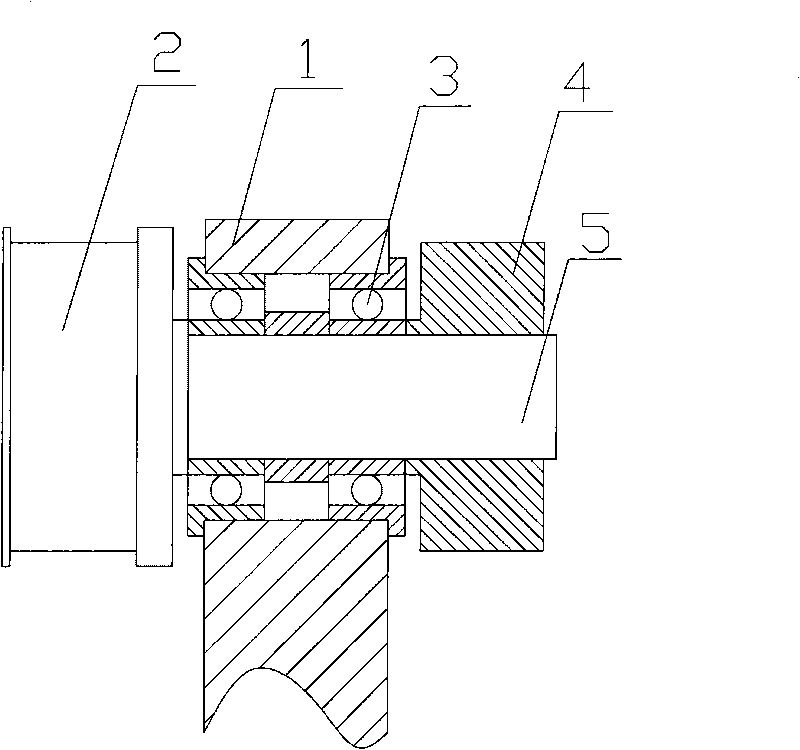

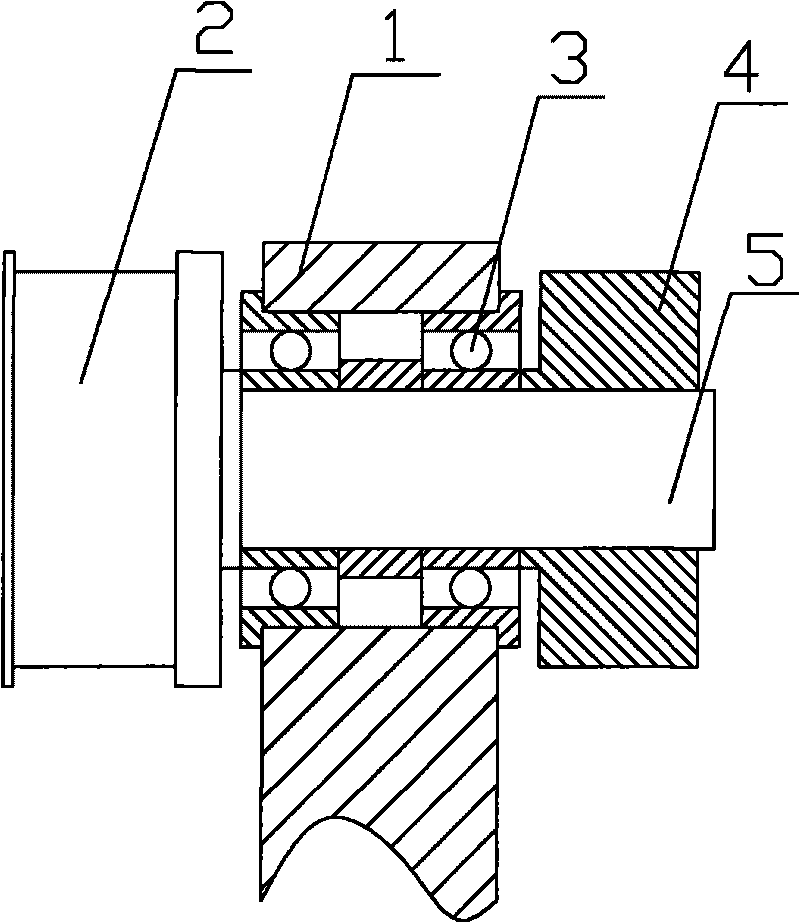

Belt pulley rotating device

The invention discloses a belt pulley rotating device. The rotating device comprises a rotary shaft (5) connected with a belt pulley (2) and a bearing arranged around the rotary shaft (5), wherein the bearing is provided with a locking ring (4), the locking ring (4) and the belt pulley (2) are arranged on both sides of the bearing respectively, and the outer surface of the bearing is provided with a fixed sleeve (1). The belt pulley turning device has the advantage that the belt pulley turning device can avoid the positional deviation of the belt pulley.

Owner:SUZHOU MINGFU AUTOMATIC SCI & TECH

Energy-storing type compensator of stirrer

ActiveCN102537362ASolve the sealing problemSolve dry-running problems of sealsEngine sealsDrive shaftEngineering

An energy-storing type compensator of a stirrer belongs to the technical field of mechanical sealing and comprises a press sleeve, a bearing press cover, an end cover, an expansion joint assembly and a shaft sleeve, a bearing inner sleeve, a bearing, an oil storage sleeve internally provided with lubricating oil and a mechanical seal, wherein the shaft sleeve, the bearing inner sleeve, the bearing, the oil storage sleeve internally provided with lubricating oil and the mechanical seal are arranged in the expansion joint assembly. Two ends of the expansion joint assembly are respectively connected with the bearing press cover and the end cover, the shaft sleeve is arranged in the expansion joint assembly, the bearing inner sleeve and the oil storage sleeve are respectively sleeved at two ends of the shaft sleeve, the bearing is installed on the bearing inner sleeve, the mechanical seal is installed in a cavity defined by the bearing press cover, the expansion joint assembly, the bearing inner sleeve, the bearing and the oil storage sleeve, and the press sleeve is connected with the end portion of the bearing inner sleeve. When the energy-storing type compensator works, the shaft sleeve is installed on a driving shaft of the stirrer, and the end cover is fixed on a stirrer machine body. The compensator organically combines the mechanical seal and the expansion joint assembly, is compact in structure, convenient to disassemble and stable and reliable in use and resolves the problem of sealing of rotating shafts of such equipment, thereby being suitable for sealing of vertical rotating shafts with swinging and axial jumping.

Owner:DANDONG BELLOWS SEALINGS

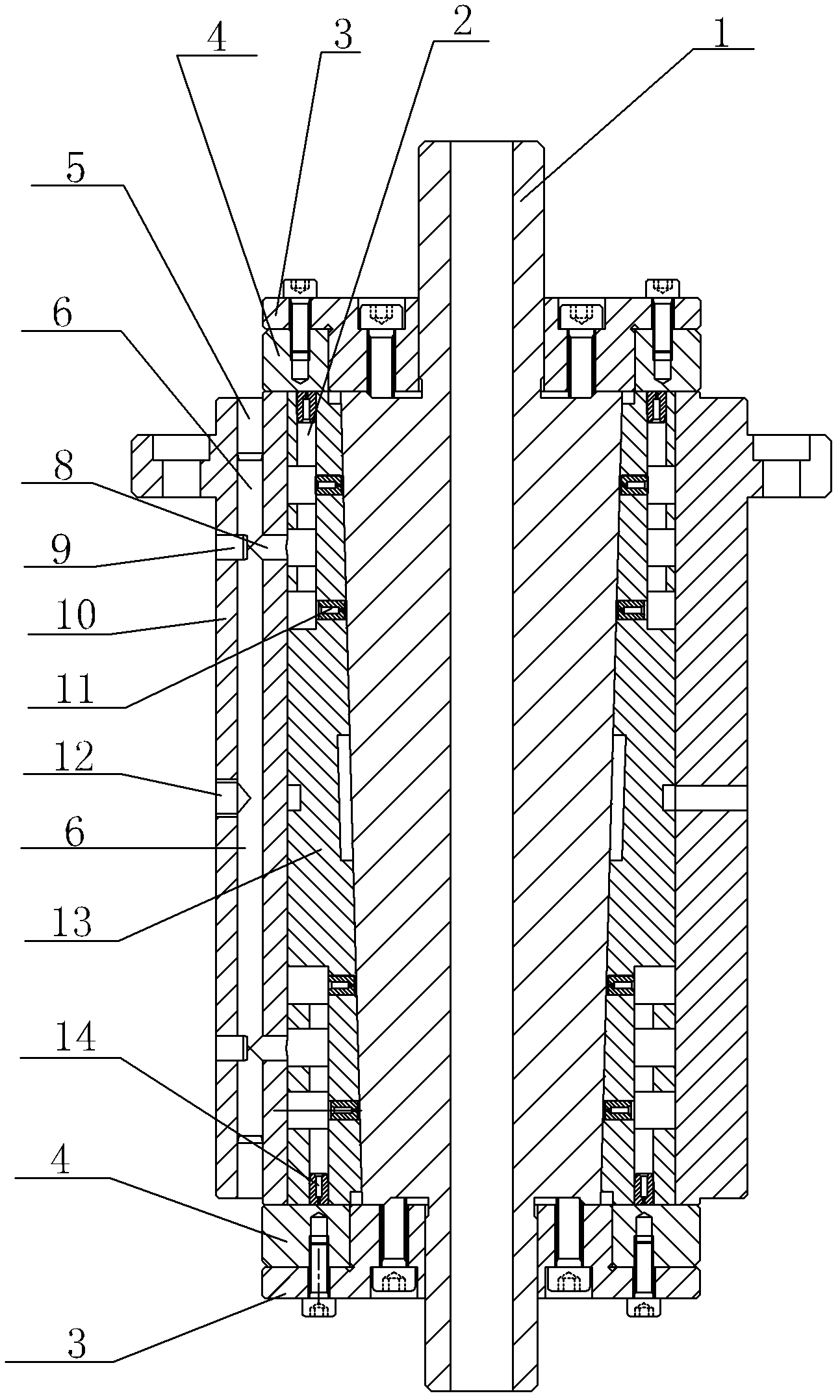

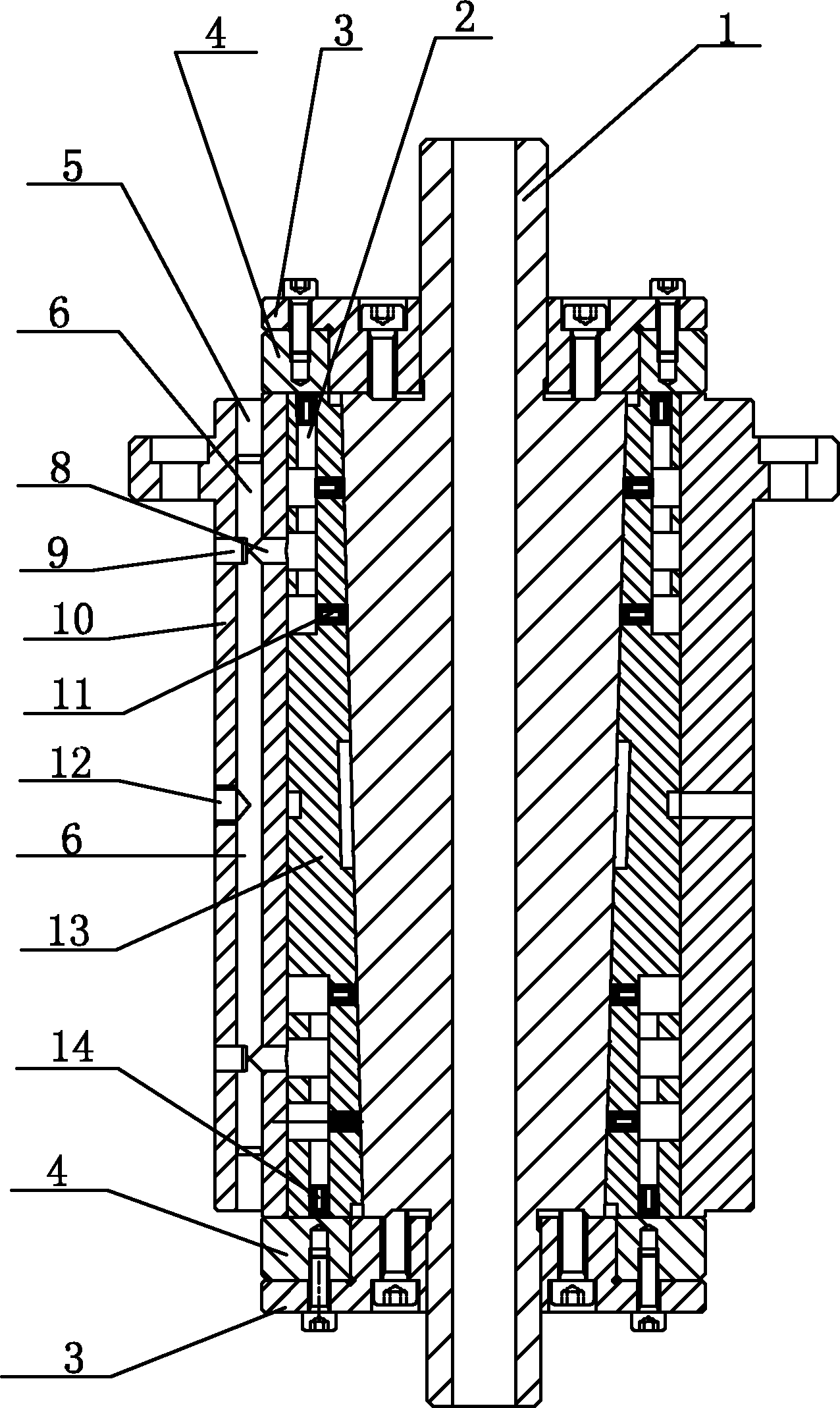

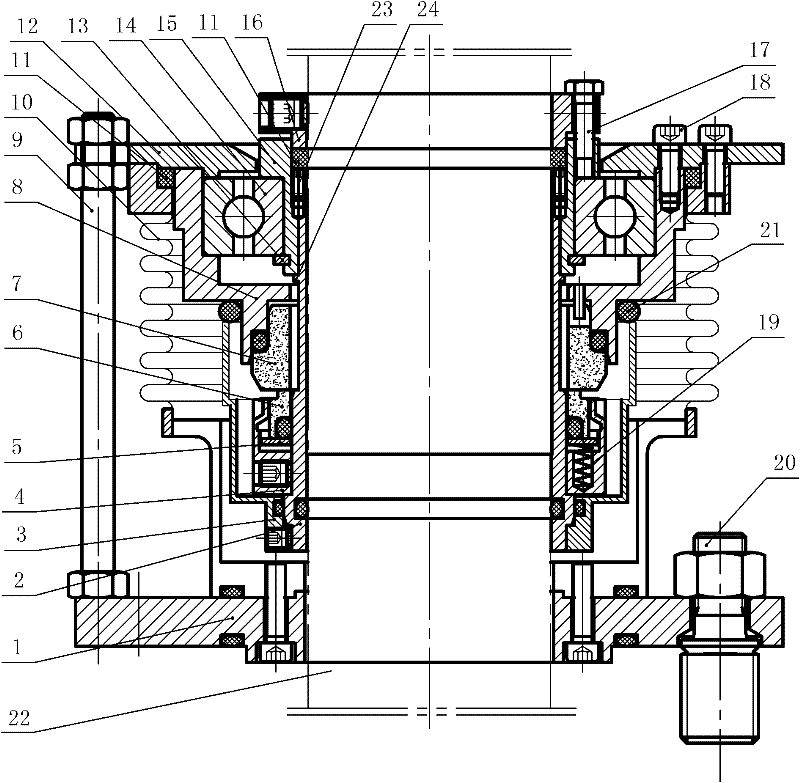

Bidirectional pressure regulating pre-tensioner for electric spindle angular contact ball bearing

InactiveCN103182534AEnsure constant axial preloadSpeed upBearing assemblyAxial displacementElectricity

The invention relates to a bidirectional pressure regulating pre-tensioner for an electric spindle angular contact ball bearing and belongs to the field of mechanical design and manufacturing. The bidirectional pressure regulating pre-tensioner comprises a pressure ring (a), a load-adding sheath (b), an elastic element (c) and a bidirectional force sensor (d), wherein the pressure ring is formed by a bearing outer ring supporting sleeve, a bearing sealing ring and a thrust ring; the load-adding sheath consists of a left-handed stud, a hexagonal sleeve and a right-handed stud; and the elastic element consists of both left and right fixed plates, two tension spring sleeves which are symmetrically distributed, two pull rods which are symmetrically distributed, four compression springs, two pressure rods which are symmetrically distributed, and two pressing sleeves which are symmetrically distributed. The bidirectional pressure regulating pre-tensioner realizes bidirectional quantitive constant-pressure pre-tensioning on a bearing pack, can ensure that an axial pre-tensioning force of the bearing pack is constant when the electric spindle bearing generates axial displacement, ensures rotating accuracy and rigidity of the electric spindle bearing in the high-speed rotating process, also can quantitively regulate the pre-tensioning force and avoids the phenomenon that the bearing is blocked and burnt down due to excessively high heat generation.

Owner:BEIJING UNIV OF TECH

Device for precisely boring lug hole of hinge beam

InactiveCN102126032AEasy to installGuaranteed rotation accuracyBoring barsPositioning apparatusUniversal jointCoupling

The invention discloses a device for precisely boring a lug hole of a hinge beam, which comprises a boring jig frame, a power device and a boring rod, wherein one end of the boring rod is connected with an output shaft of the power device through a universal joint coupler, the bottom of the boring jig frame is provided with a lifting rotating mechanism, a plurality of groups of boring rod supports are symmetrically arranged on the boring jig frame, positioning holes of each group of boring rod supports are positioned on the same axle line; the boring rod supports comprise bases, glands and bearing bodies, the bases and the glands are of a split structure, the bearing bodies are arranged in the boring rod supports; and a smaller gap between the boring rod and a sliding connecting sleeve ofthe bearing bodies is in the term of meeting the requirement of precision processing. The device has high processing precision, saves processing time and increases production efficiency by above 50 percent.

Owner:洛阳齐瑞金刚石设备制造有限公司

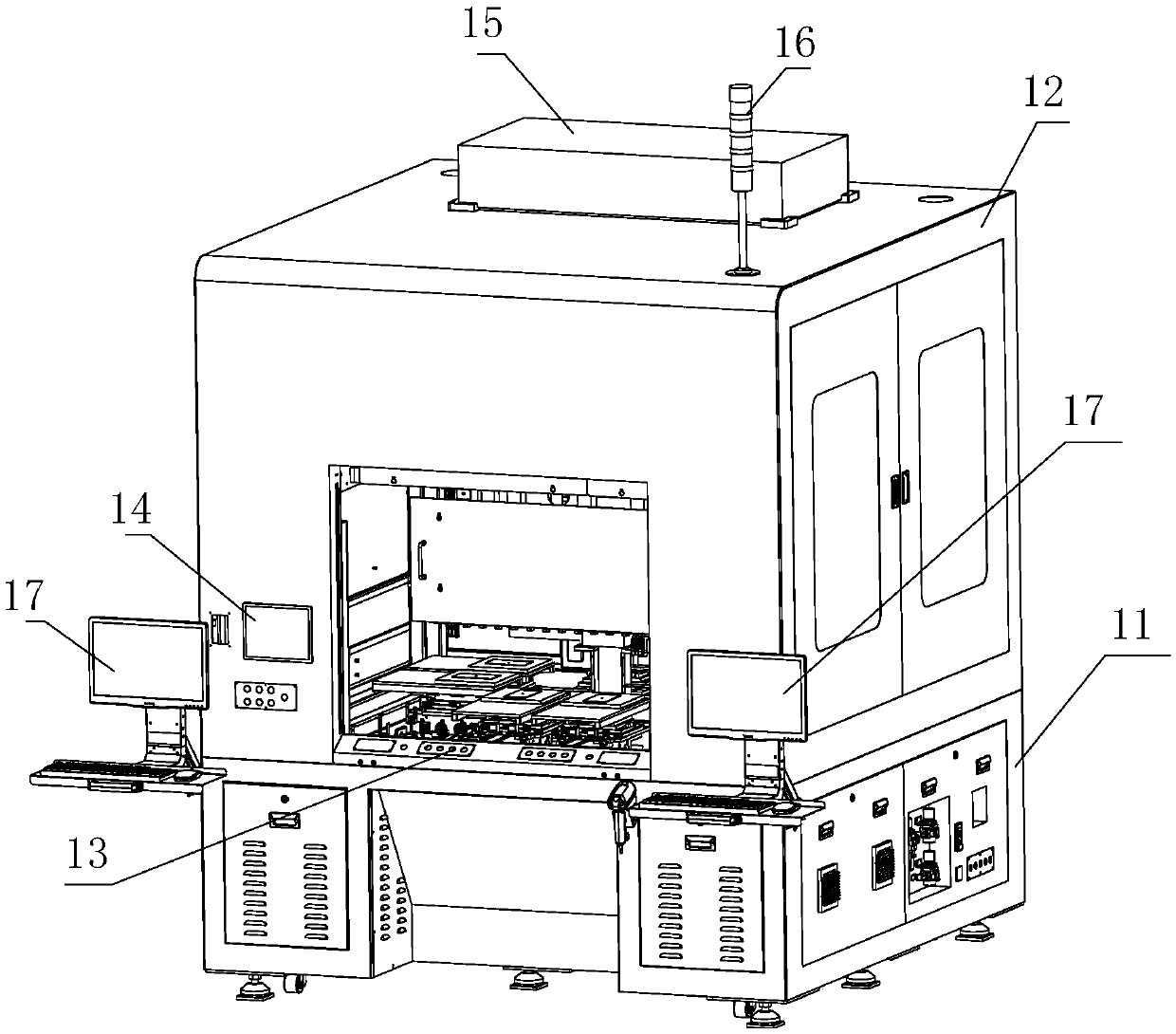

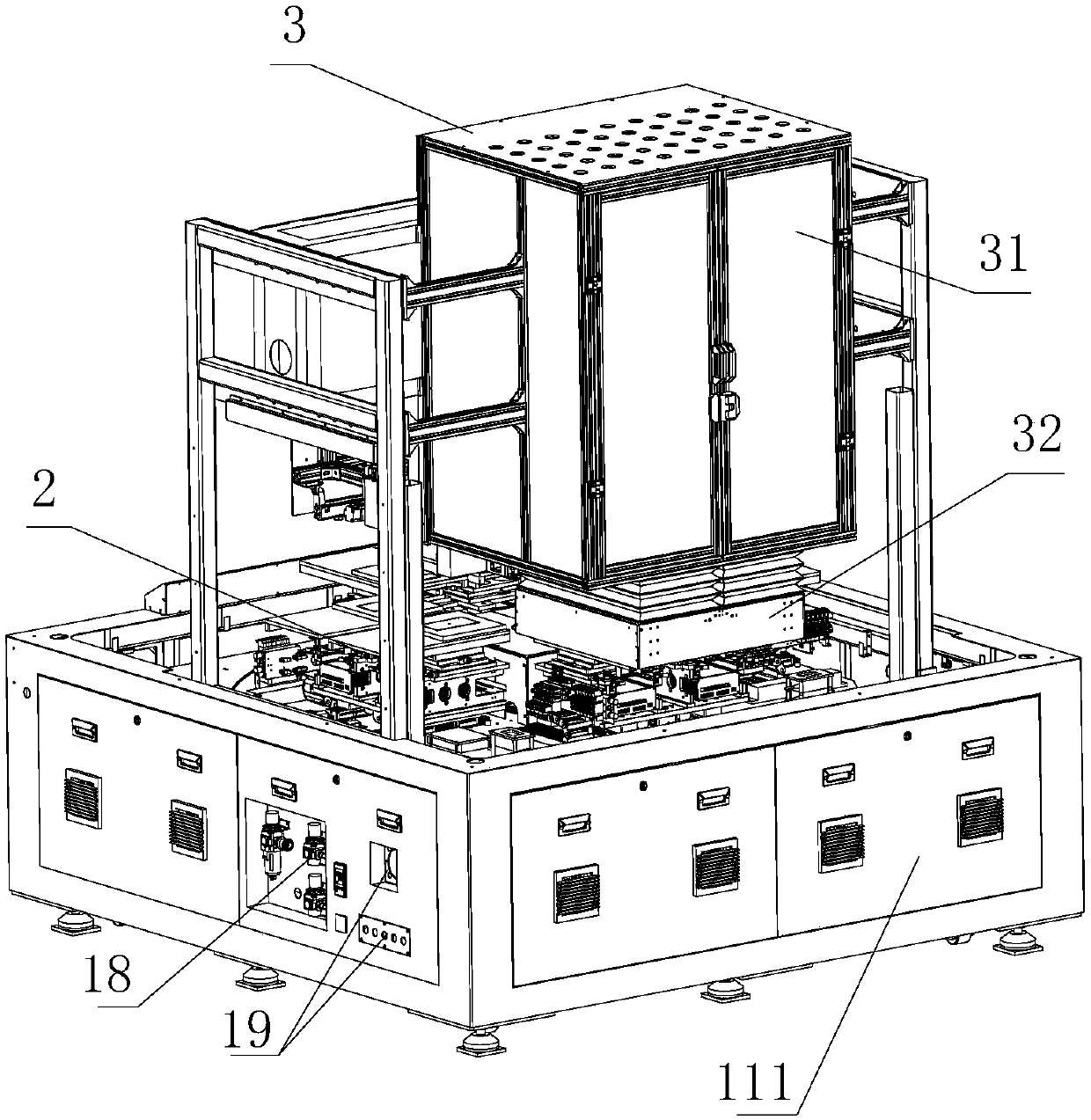

Rotary display panel detection device

PendingCN109612691AShorten the production cycleGuaranteed rotation accuracyTesting optical propertiesGratingHuman–machine interface

The invention relates to a rotary display panel detection device. The rotary display panel detection device comprises a rotating disc assembly and an optical-mechanical assembly. Four stations are arranged at positions corresponding to the four directions of the rotating disc assembly; the rotating disc assembly rotates; display panels on rotating disc jigs sequentially penetrate through the fourstations to complete operations on the corresponding stations; and an operator can complete feeding and discharging, erasing, camera photographing detection and burning re-judgment on one of the stations through a set of equipment, so that the production cycle of the display panels is greatly shortened. A cam divider and a four-index inductor are arranged at the bottom of a rotating disc to ensurethe rotating precision of the rotating disc. An outer cover is provided with a safety door lock, a safety grating, a man-machine interface, an operation window and the like, and doors and windows arearranged on the upper and lower peripheries to facilitate maintenance. The optical-mechanical assembly is composed of two sets of optical-mechanical modules, linkage servo modules are arranged, and an optical-mechanical part is provided with a quick-disassembling type darkroom, so that simple and quick up and down joint debugging on an optical machine is achieved.

Owner:WUHAN JINGLI ELECTRONICS TECH +1

Numerical control machine tool spindle box system with embedded braking mechanism

PendingCN107570733AAchieve brakingBraking time is shortDriving apparatusMetal working apparatusNumerical controlBall bearing

The invention discloses a numerical control machine tool spindle box system with an embedded braking mechanism. The numerical control machine tool spindle box system comprises a box body and a spindleand further comprises a spindle brake, a bearing sealing system, a bearing pre-tightening clearance eliminating device and a bearing lubricating system. According to the spindle box system, during active braking, braking resistance is provided mainly through a braking protrusion embedded in a radial groove, the friction abrasion speed of an embedding ring in the braking process is small, and theservice life is long. The bearing sealing system of the spindle box system can have a dust and dirt preventing protection function on a bearing and can also have a temperature reducing and cooling function on the inner ring of the bearing and the spindle, the rigidity of the spindle and the inner ring of the bearing can be improved, and the spindle rotation precision is kept. The bearing pre-tightening clearance eliminating device can automatically eliminate clearances generated due to bearing abrasion, the rigidity of a first deep groove ball bearing and a second deep groove ball bearing is greatly improved, the rigidity of the spindle system can be greatly improved, and the spindle rotation precision and the machine tool machining precision are improved.

Owner:重庆市普创长顺机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com