Frame-type sealed hydraulic swing motor

A hydraulic swing and motor technology, which is applied in the direction of engine sealing, fluid pressure actuators, engine components, etc., can solve problems such as limited application, decreased dynamic characteristics of hydraulic servo system, and difficult sealing of fixed blades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] A hydraulic swing motor according to an embodiment of the present invention is described below with reference to the accompanying drawings.

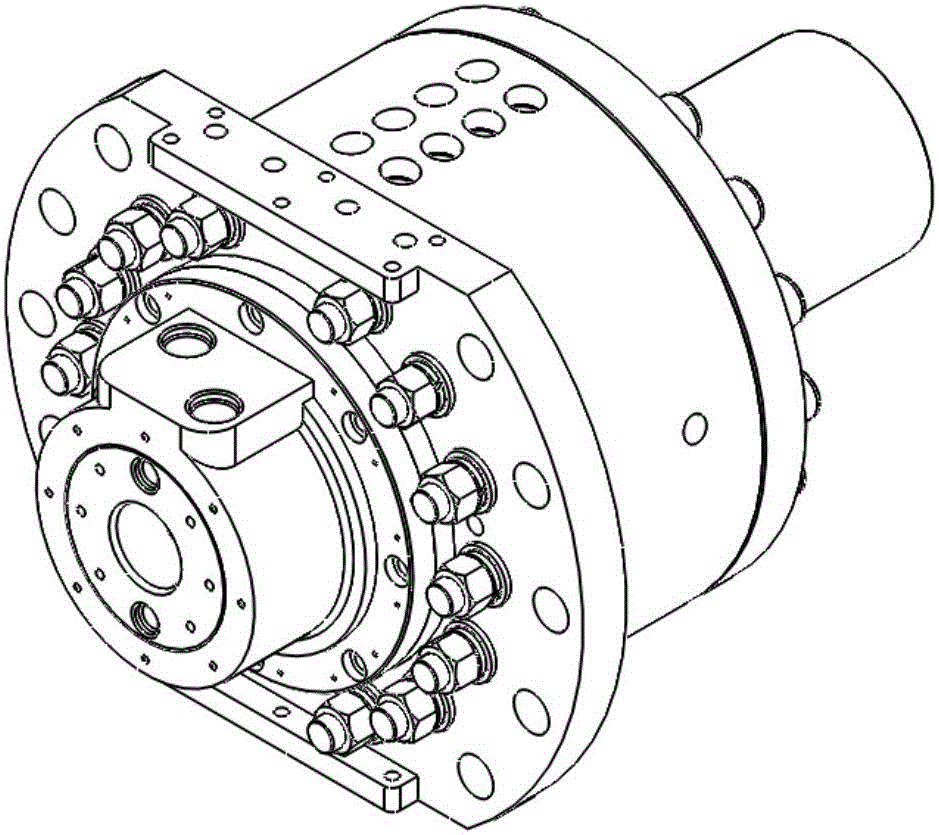

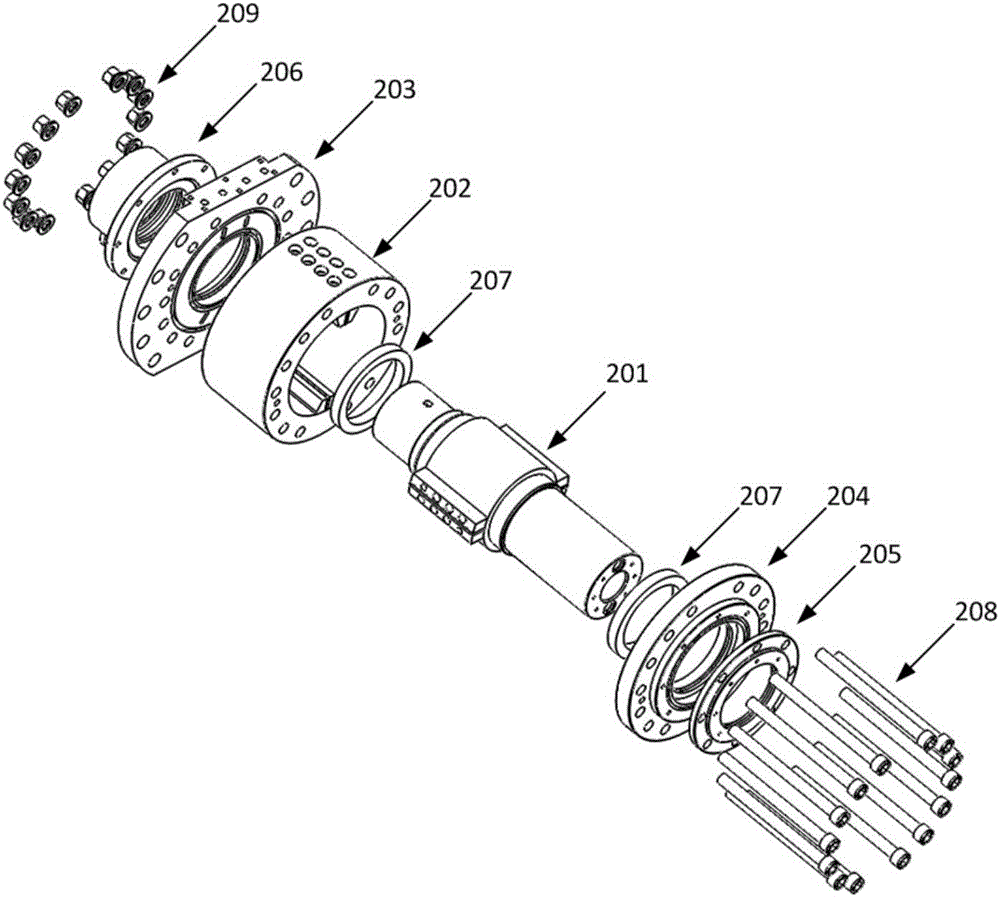

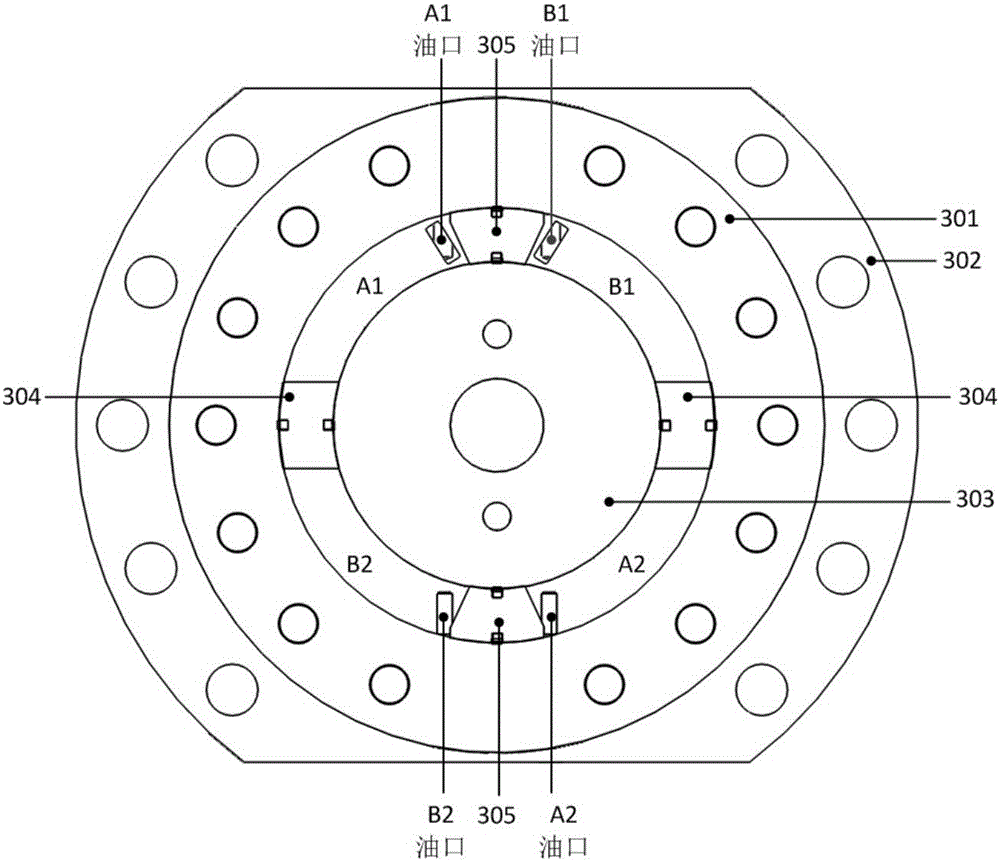

[0027] figure 1 and 2 General and exploded structural views of a hydraulic swing motor according to an embodiment of the present invention are shown. Such as figure 1 and 2 As shown, the hydraulic swing motor of this embodiment includes: a cylinder body 202, in which two fixed vanes 180 degrees apart are arranged; a front cylinder cover 204 and a rear cylinder cover 203 arranged at both ends of the cylinder ; Through the cylinder block 202, the front cylinder head 204 and the rear cylinder head 203, the main shaft 201 is provided with inlet and outlet oil passages, wherein the main shaft 201 is provided with two moving blades 180 degrees apart. In this embodiment, the movable and fixed blades are fixed on the main shaft 201 and inside the cylinder 202 by screws, but the present invention is not limited thereto, and any suitabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com