Rotary display panel detection device

A display panel and detection device technology, which is applied in the direction of measuring devices, optical instrument testing, optical performance testing, etc., can solve the problems of long detection cycle, restricting the production of display panels, time-consuming and labor-consuming, etc., and achieves easy maintenance, up-down connection The effect of easy and quick adjustment and shortened production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

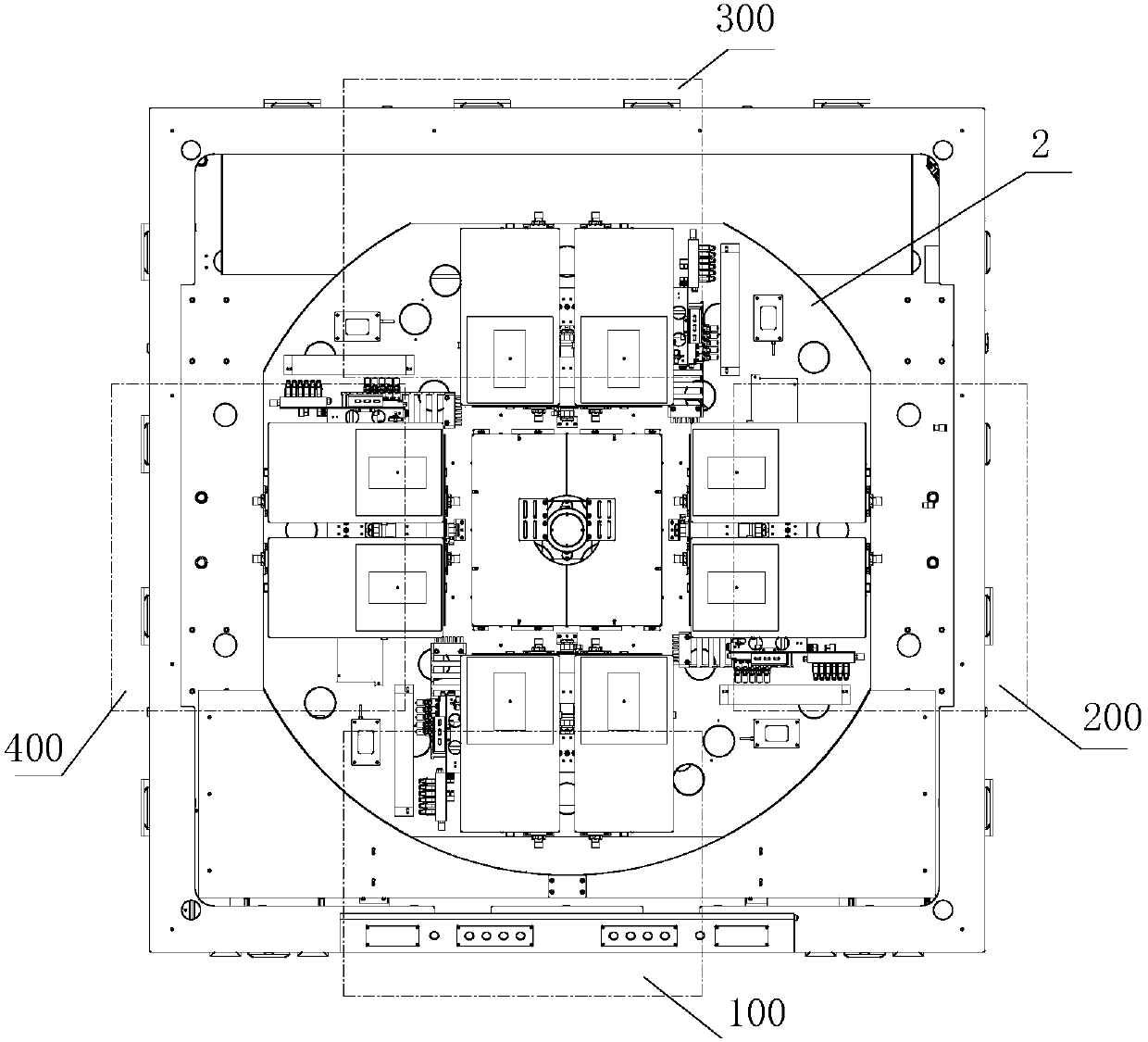

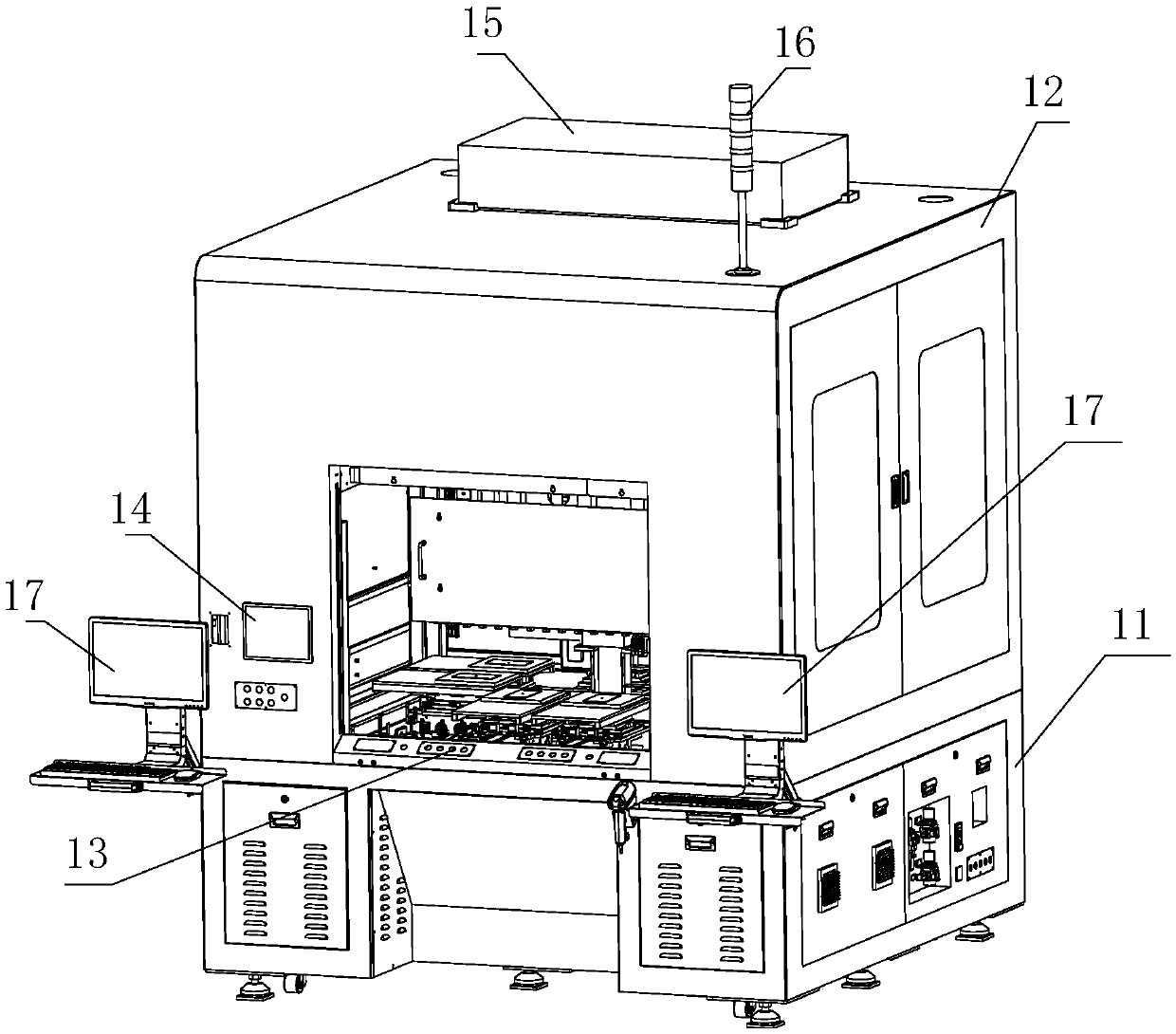

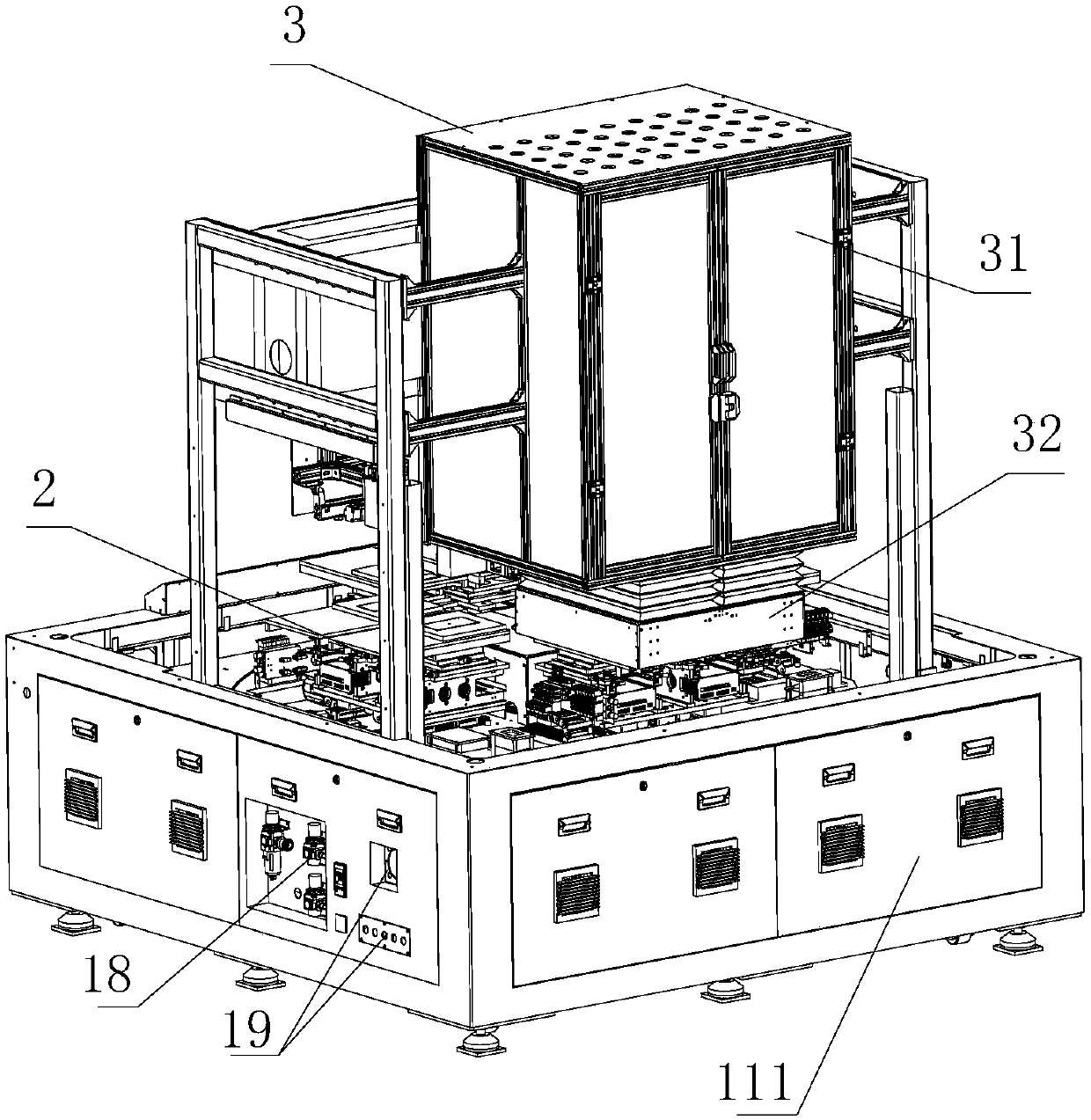

[0020] Such as figure 1 As shown, a rotary display panel detection device of the present invention includes a turntable assembly 2 and an optical-mechanical assembly 3, and four stations are arranged at corresponding positions in the four directions of the turntable assembly 2, which are respectively: a loading and unloading station 100, a wiping station In addition to the station 200, the camera photo inspection station 300 and the burning rejudgment station 400, the upper end surface of the turntable 20 of the turntable assembly 2 is evenly provided with a number of jigs 6, and the several jigs 6 correspond to the positions of the four stations. 2 rotates, the display panel on the jig 6 of the turntable assembly 2 passes through four stations in sequence, and when the turntable assembly 2 rotates to the corresponding station, the correspondin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com