Recycling detection, screening and matching method and device for battery module

A battery module and detection method technology, which is applied in the direction of measuring devices, secondary battery testing, battery recycling, etc., can solve the problems of low efficiency in group matching, and achieve the effects of low manufacturing cost, high consistency, and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

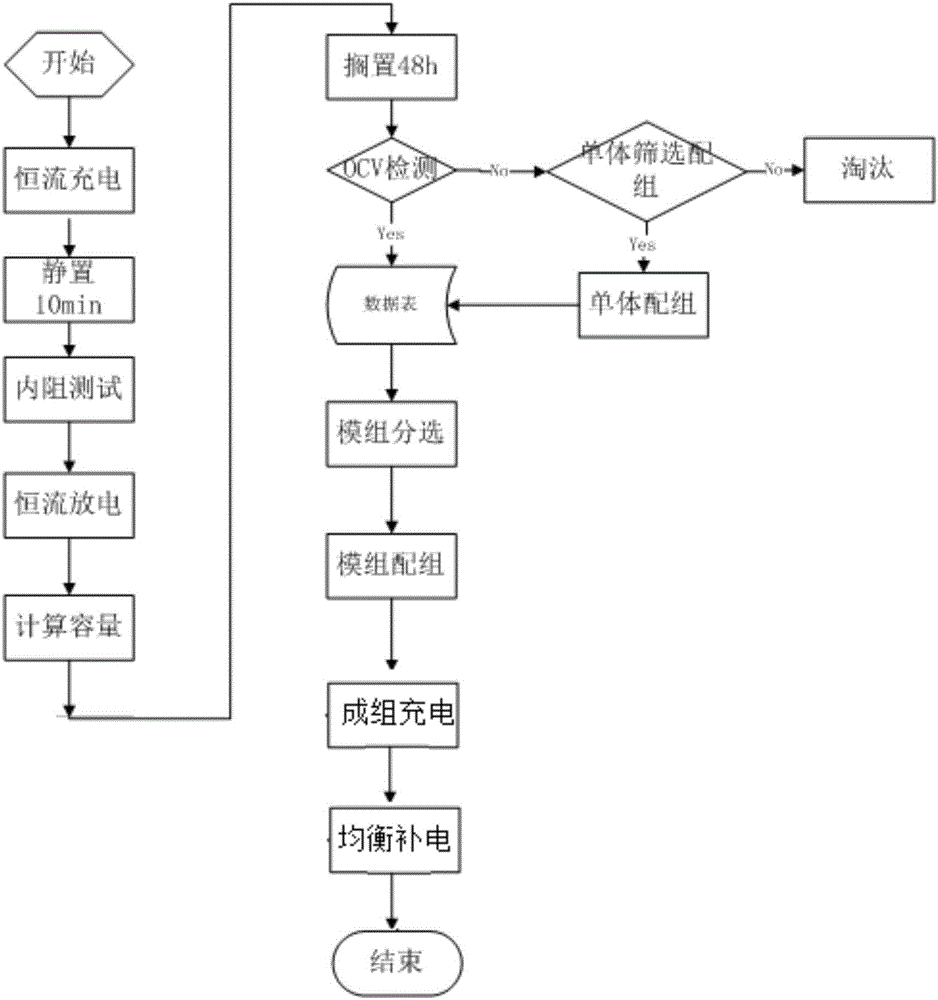

[0031] An embodiment of a battery module screening and matching method of the present invention:

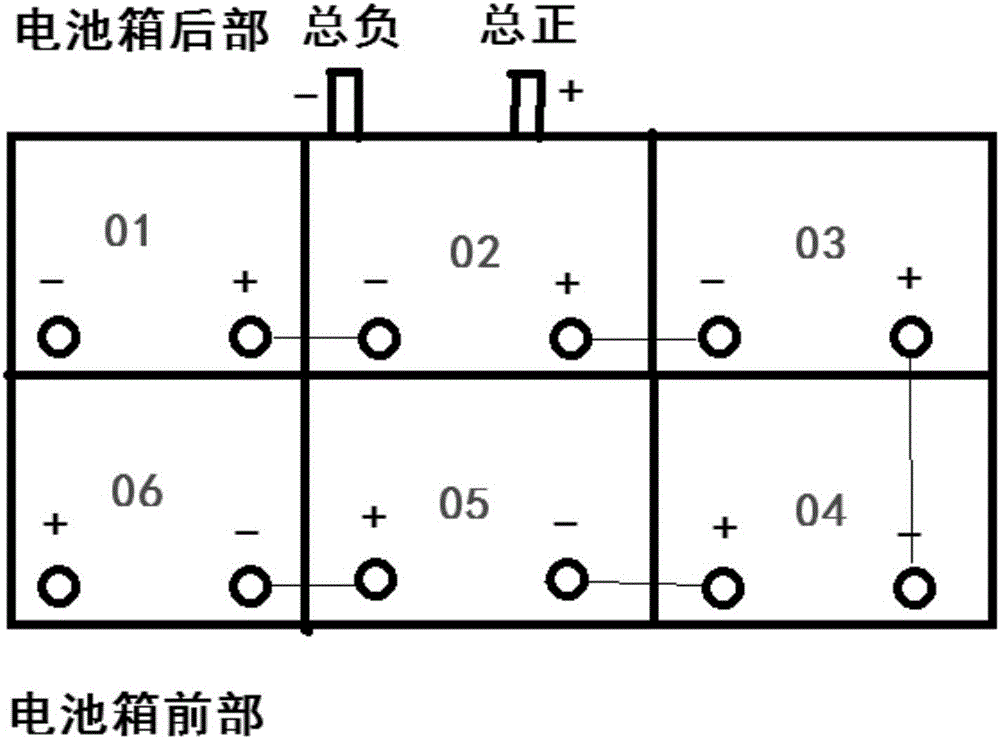

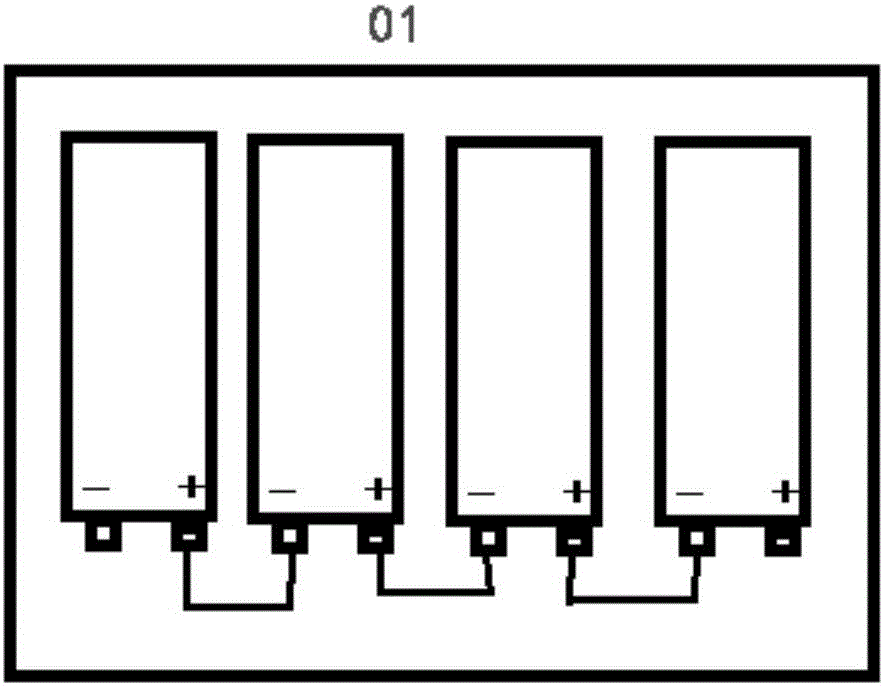

[0032] The module mentioned in the present invention refers to a small battery pack packaged in an aluminum-plastic case in a decommissioned power battery pack. The connection form of the single cells in the module is series, parallel or a combination of series and parallel. figure 2 The module shown is a series-parallel combination of single batteries. This module is composed of 4 battery units in series to form a small battery pack. Each 300Ah battery unit includes 6 parallel-connected 50Ah single batteries.

[0033] The battery module composed of more than two single cells is used as the minimum screening unit, and the capacity and internal resistance of the battery module are obtained through testing, and the battery module is screened acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com