Patents

Literature

23332results about "Natural extract food ingredients" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Taste-improving composition and application of the same

The present invention provides a method for improving the taste of sweeteners, and a method for improving the taste of edible products containing sweeteners. The present invention can be worked by using sclareolide and 2-acetylpyrrole in combination with a sweetener. By using the method of the present invention, an astringent taste, bitter taste or aftertastes such as lingering taste originating especially in high-intensity sweeteners can be reduced, so that edible products with an improved taste can be provided.

Owner:SAN EI GEN F F I

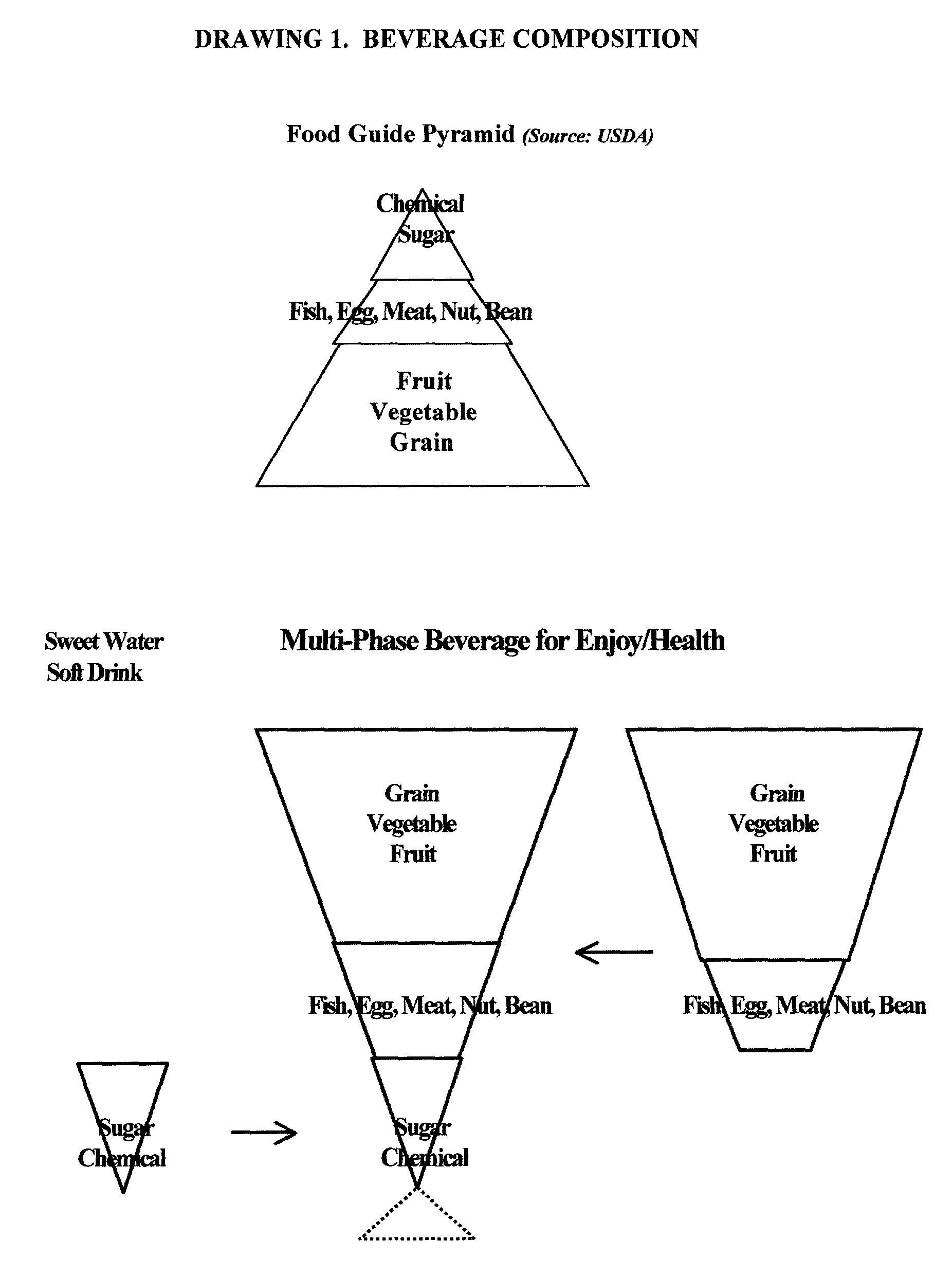

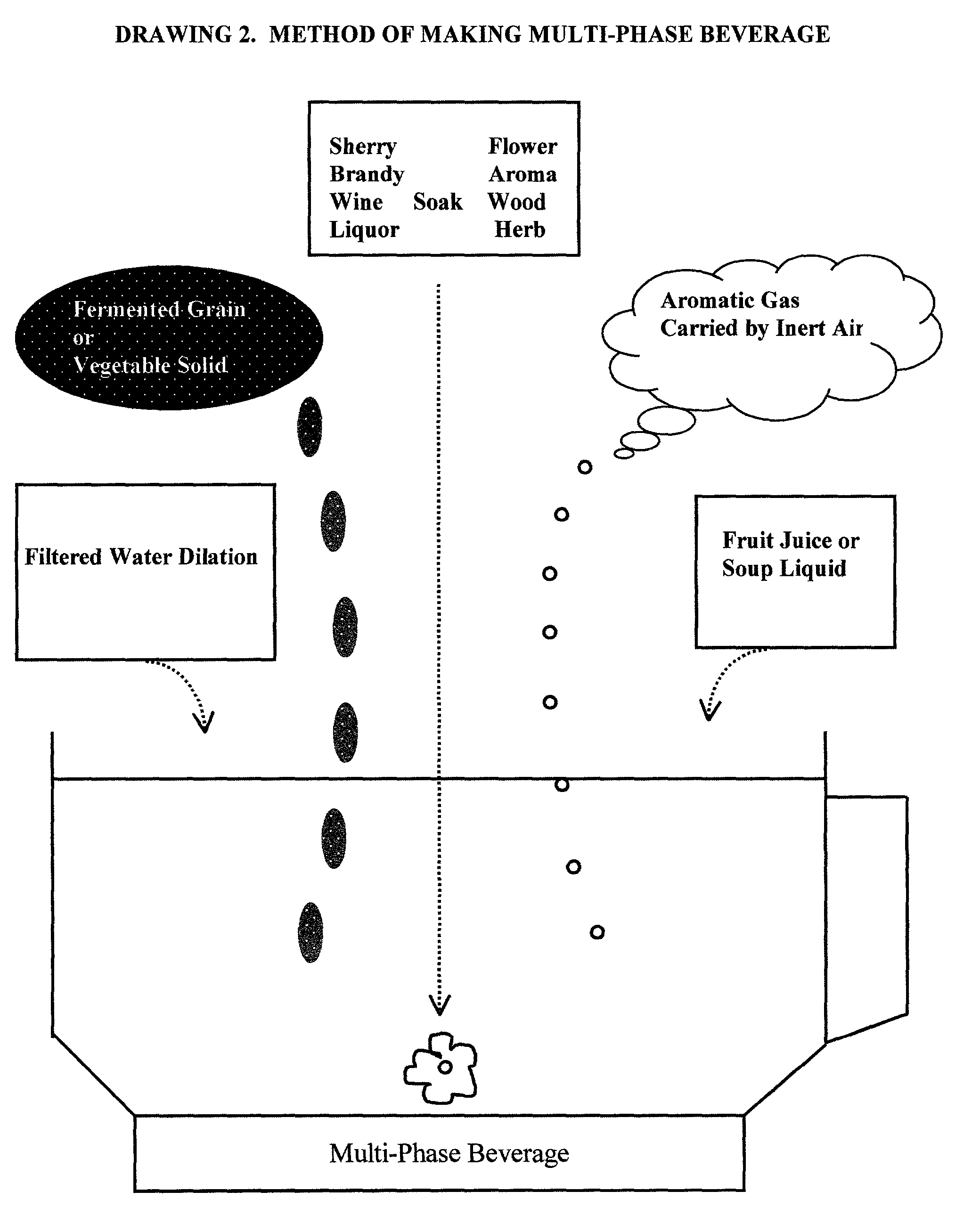

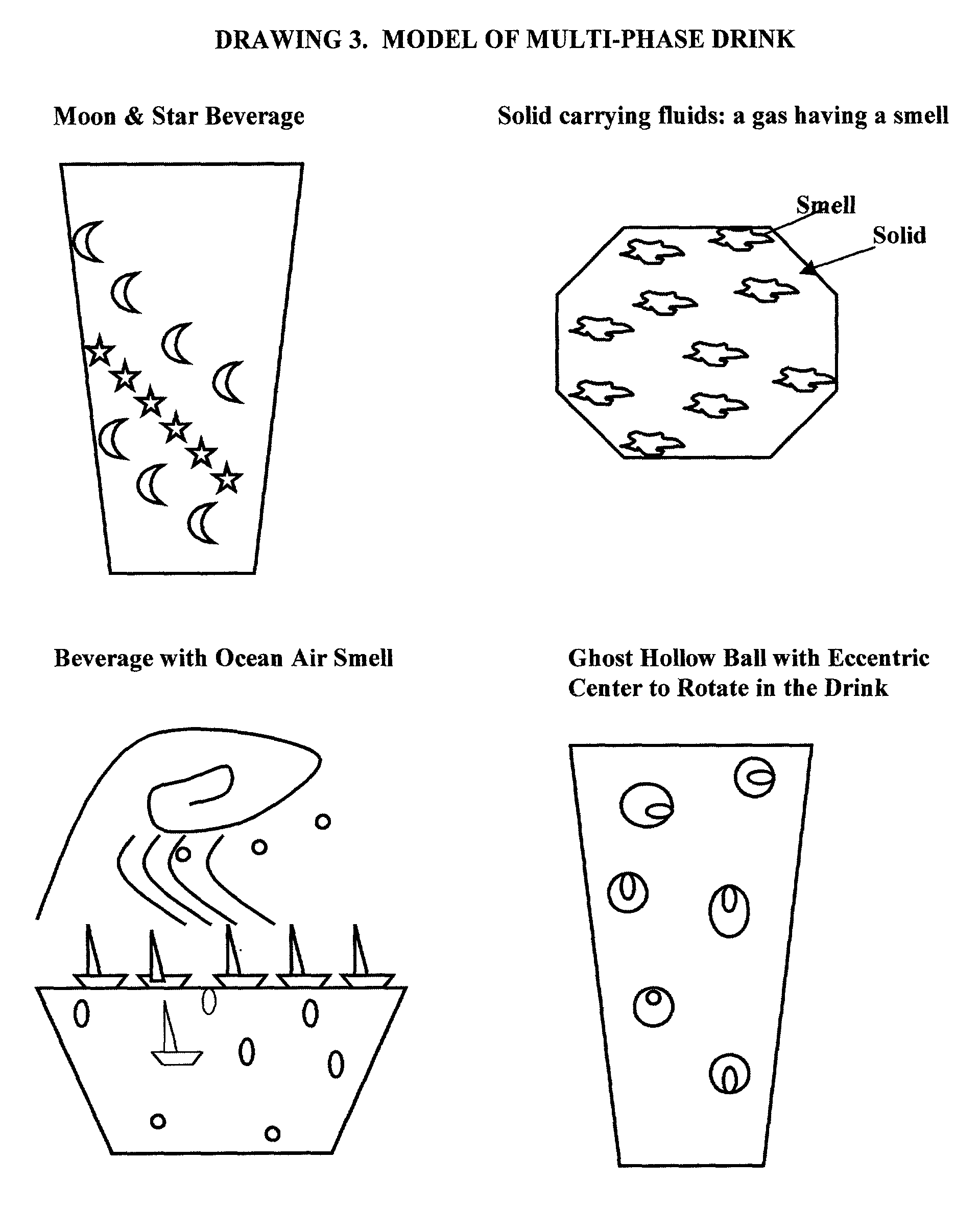

Multi-phase food & beverage

A method of making, combining, and using a balanced multi-phase food mixture and a multi-phase beverage made thereof is incorporated into carbonated herb beverage, aerated tea, fast fermented grain drink, amino acid flavored beverage, alcohol soaked cocktail drink, and aerated vegetable beverage. The liquid phase comprises total small molecular mineral and sugar up to 350 mOsm, pH 3.5-7.8, sweetener up to 7 wt %, alcohol up to 3 wt %, protein up to 30 wt %, fiber 20-37 gram per 2000 calories, at least 30% of calories are derived from complex carbohydrate, and up to 5% by volume gas, which will release a meaningful smell when being consumed. The solid phase includes at least 10% by weight plant mix, complex carbohydrate, protein, fat, and a combination thereof The beverage is natural and balanced referred to physiological body composition for normalizing body composition and fluid metabolism toward optimal body fitness with increased sensory experience and satiety.

Owner:ZHAO IRIS GINRON

Anti-inflammatory supplement compositions and regimens to reduce cardiovascular disease risks

InactiveUS20060172012A1Relieve symptomsPromotes fast digestionOrganic active ingredientsBiocideBlueberry extractApple extract

Disclosed are improvements in human nutrition involving a unique combination of natural products constituting anti-inflammatory compositions which can reduce cardiovascular disease risks as well as play a positive role in other conditions and diseases for which key indicators, especially selected from the group consisting of C-reactive protein (CRP) levels, cyclooxygenase-2 (COX-2), 5-lypoxygenase (5-LOX) expression and prostaglandin E2 (PGE-2) biosynthesis or any combination of these, are indicators. Therapeutic compositions preferably comprise curcumin, bilberry extract, grape seed extract, green tea extract and apple extract, in effective amounts individually and combined to provide a therapeutically significant reduction in one or more key indicators. Another exemplified therapeutic composition comprises: omega-3 rich refined fish oil, resveratrol, blueberry extract, grape seed extract, green tea extract and gamma and / or delta tocopherol, in effective amounts individually for the above benefits.

Owner:A M TODD

High-Potency Sweetener Composition With Phytoestrogen and Compositions Sweetened Therewith

The present invention relates generally to functional sweetener compositions comprising non-caloric or low-caloric natural and / or synthetic, high-potency sweeteners and methods for making and using them. In particular, the present invention relates to different functional sweetener compositions comprising at least one non-caloric or low-caloric natural and / or synthetic, high-potency sweetener, at least one sweet taste improving composition, and at least one functional ingredient, such as phytoestrogens. The present invention also relates to functional sweetener compositions and methods that can improve the tastes of non-caloric or low-caloric high-potency sweeteners by imparting a more sugar-like taste or characteristic. In particular, the functional sweetener compositions and methods provide a more sugar-like temporal profile, including sweetness onset and sweetness linger, and / or a more sugar-like flavor profile.

Owner:THE COCA-COLA CO

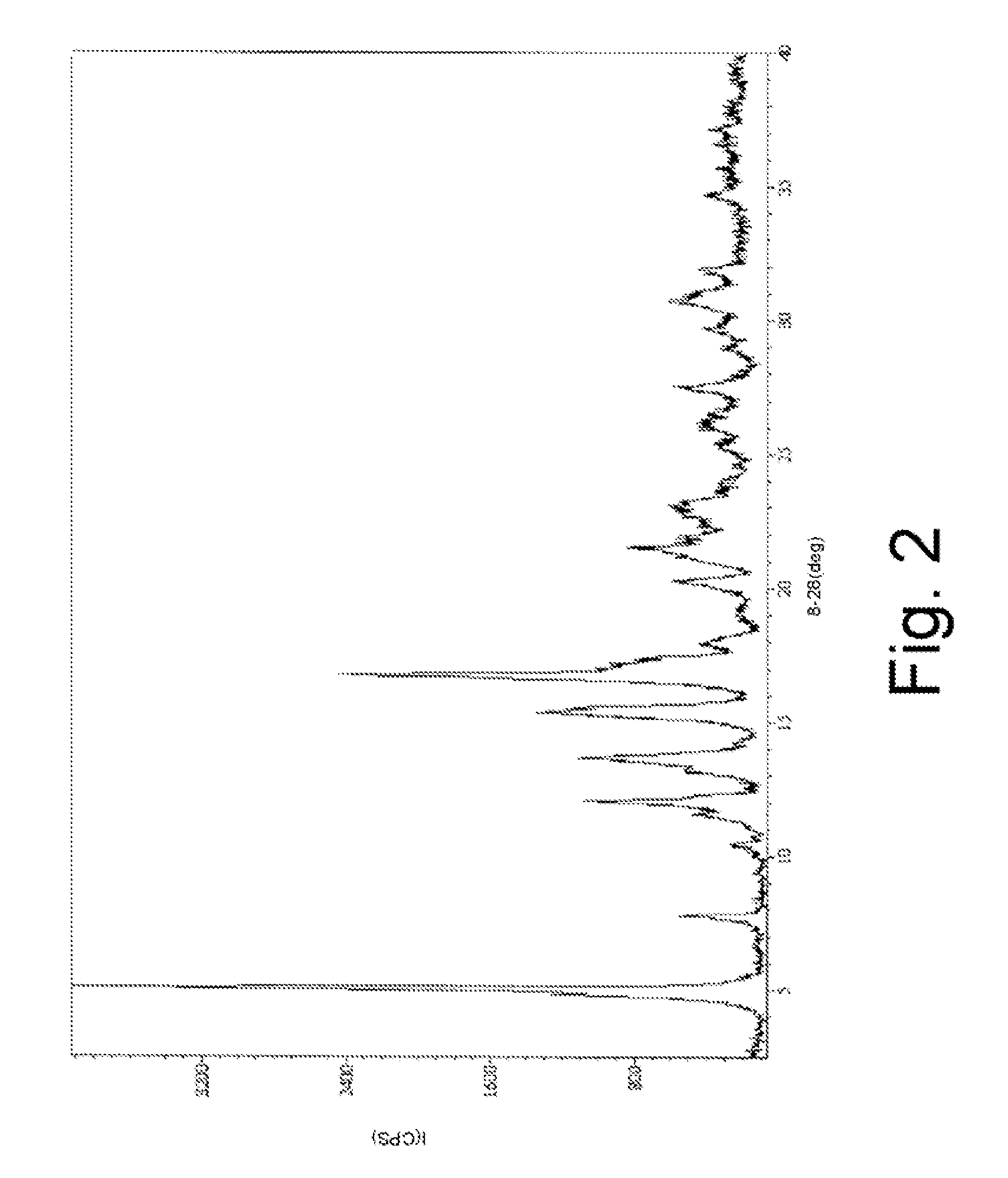

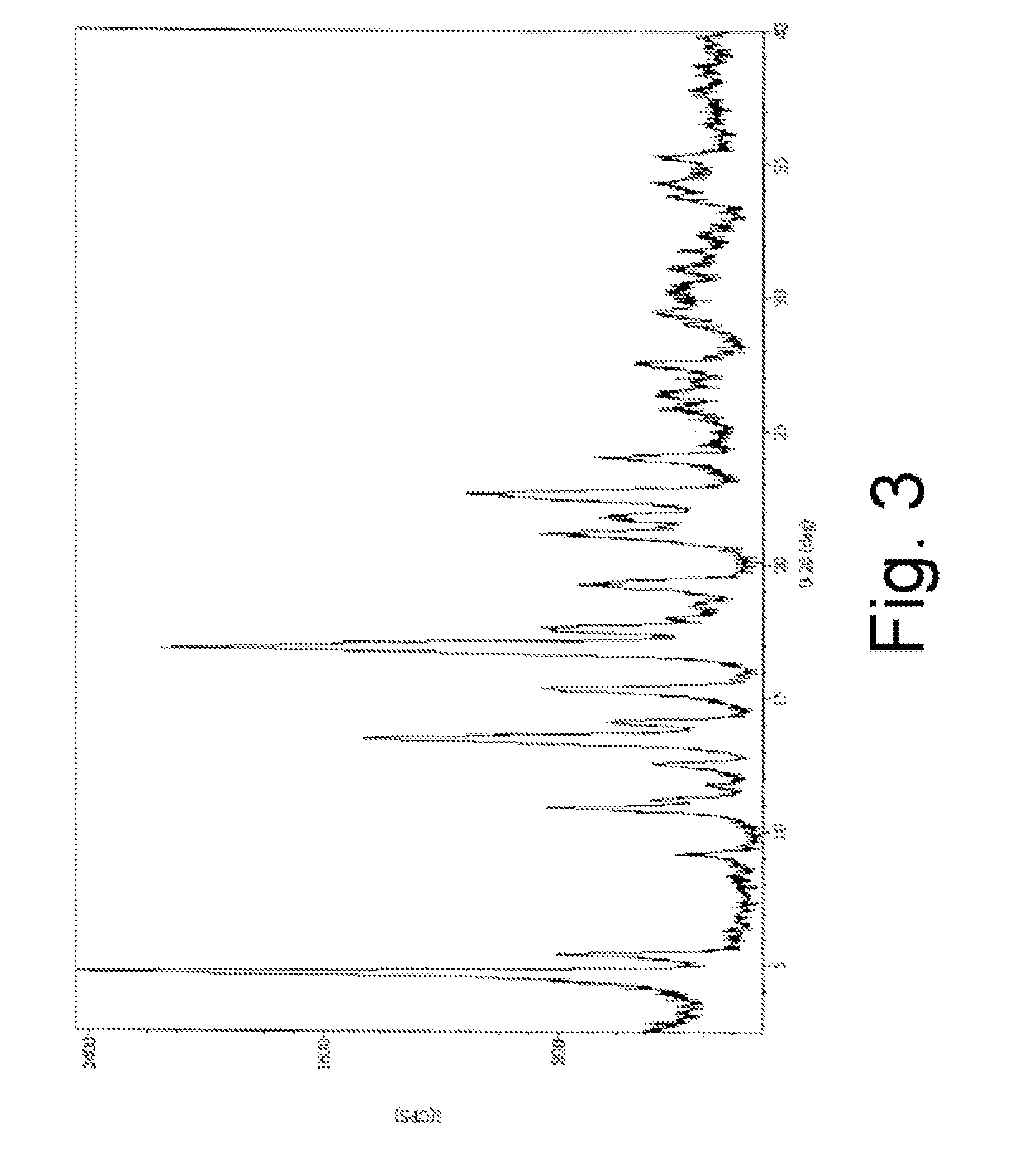

Uniform films for rapid-dissolve dosage form incorporating anti-tacking compositions

The present invention relates to water-soluble films incorporating anti-tacking agents and methods of their preparation. Anti-tacking agents may improve the flow characteristics of the compositions and thereby reduce the problem of film adhering to a user's mouth or to other units of film. In particular, the present invention relates to edible water-soluble delivery systems in the form of a film composition including a water-soluble polymer, an active component selected from cosmetic agents, pharmaceutical agents, vitamins, bioactive agents and combinations thereof and at least one anti-tacking agent.

Owner:AQUESTIVE THERAPEUTICS INC

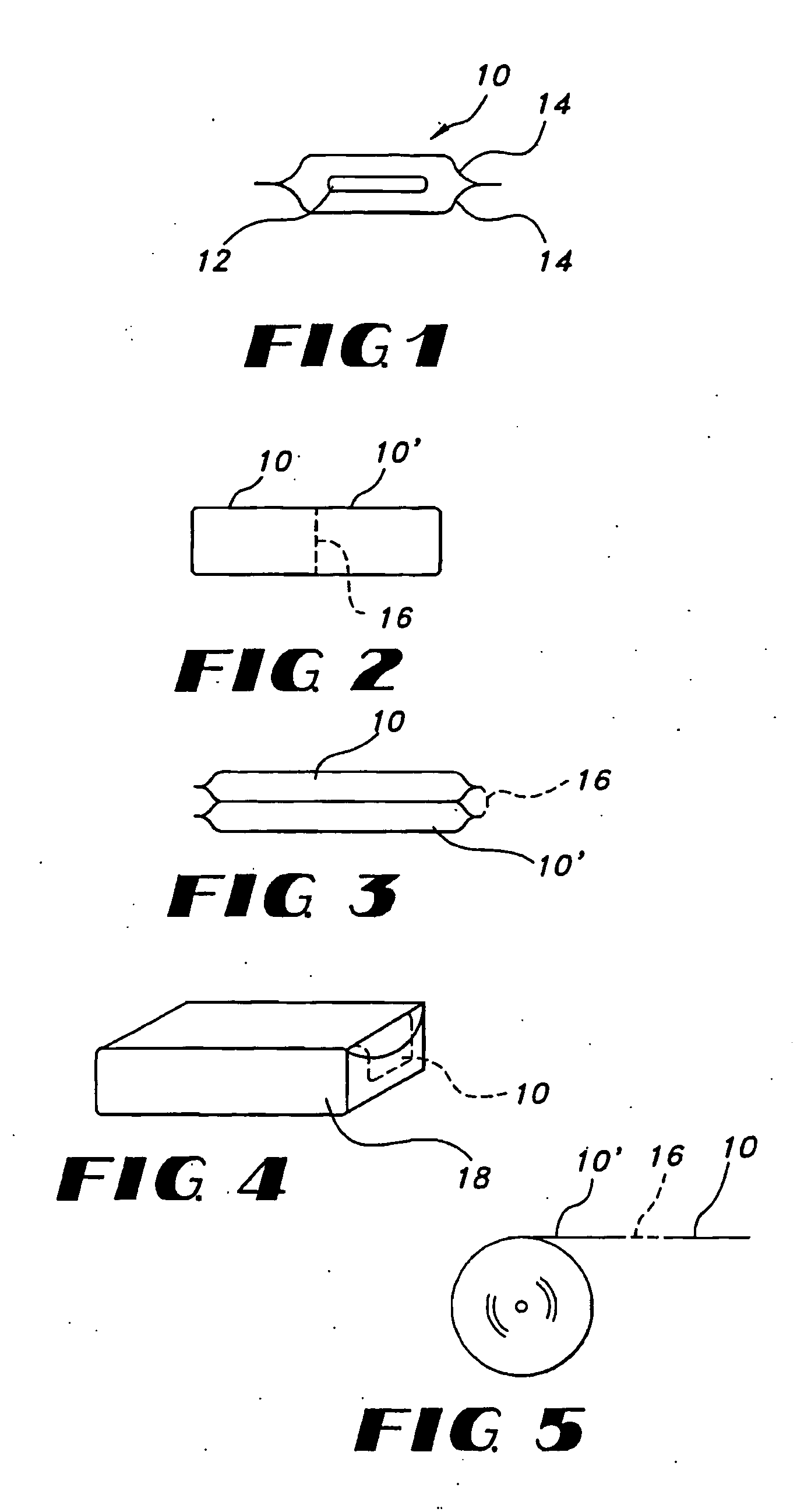

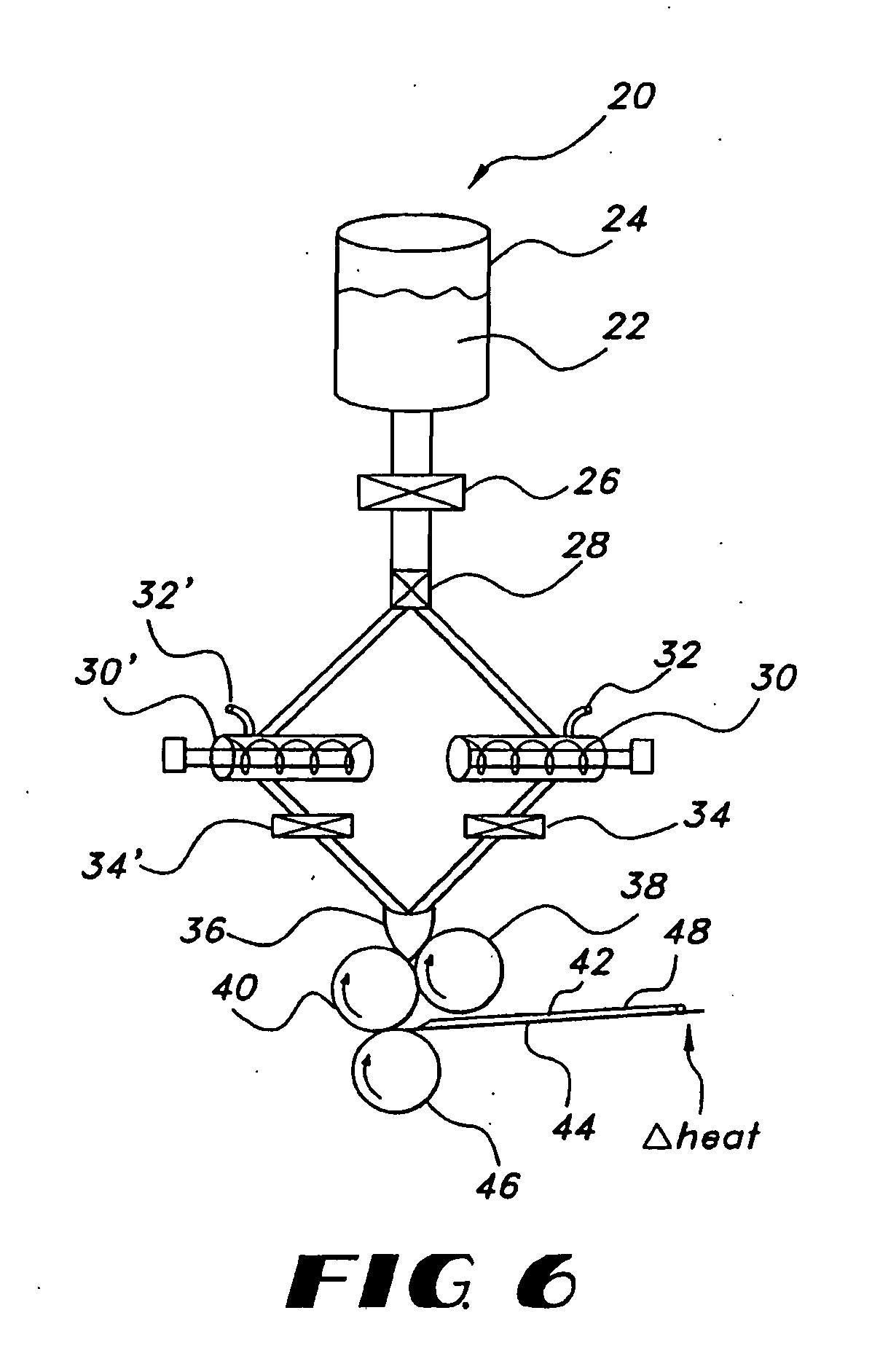

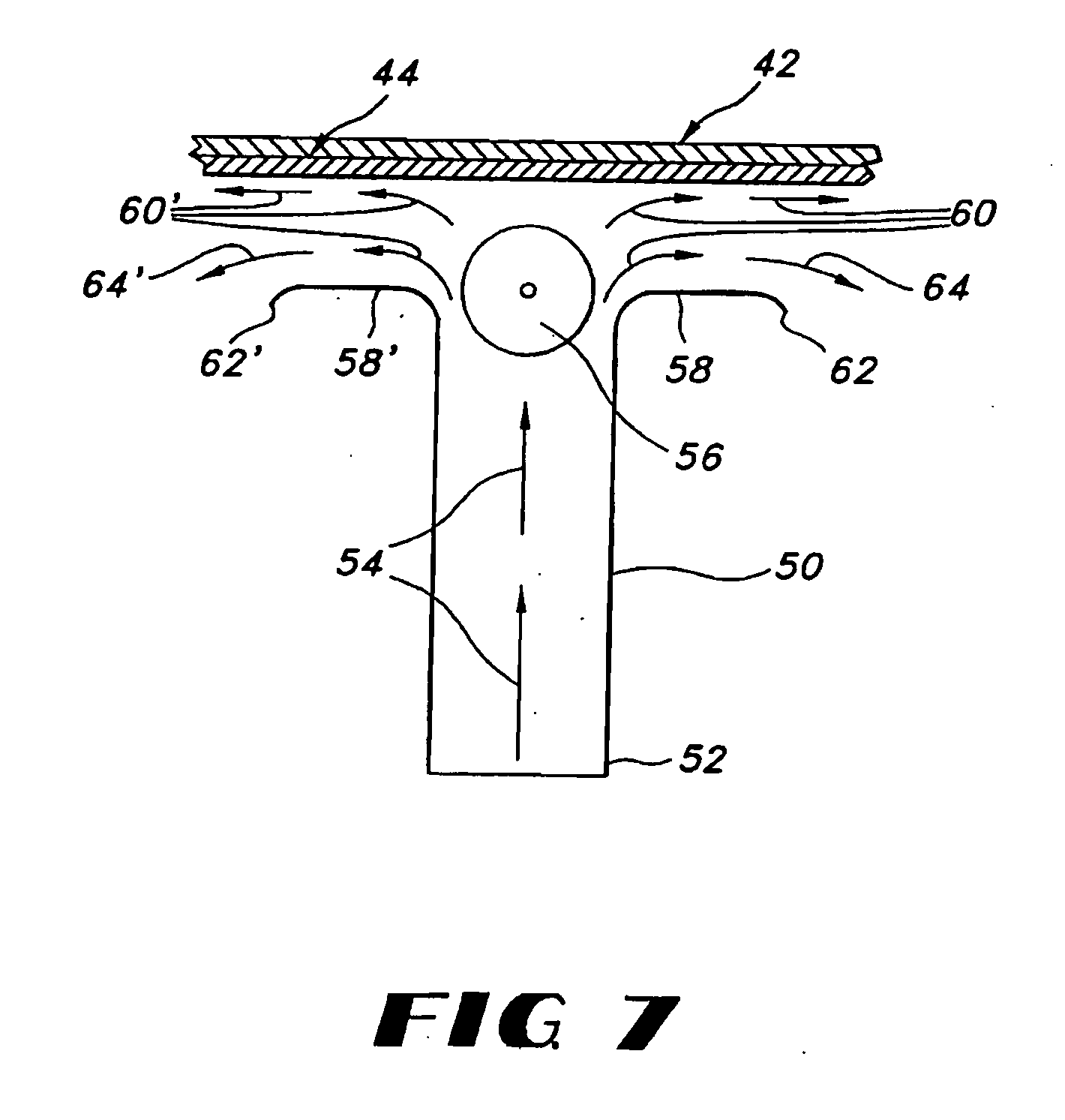

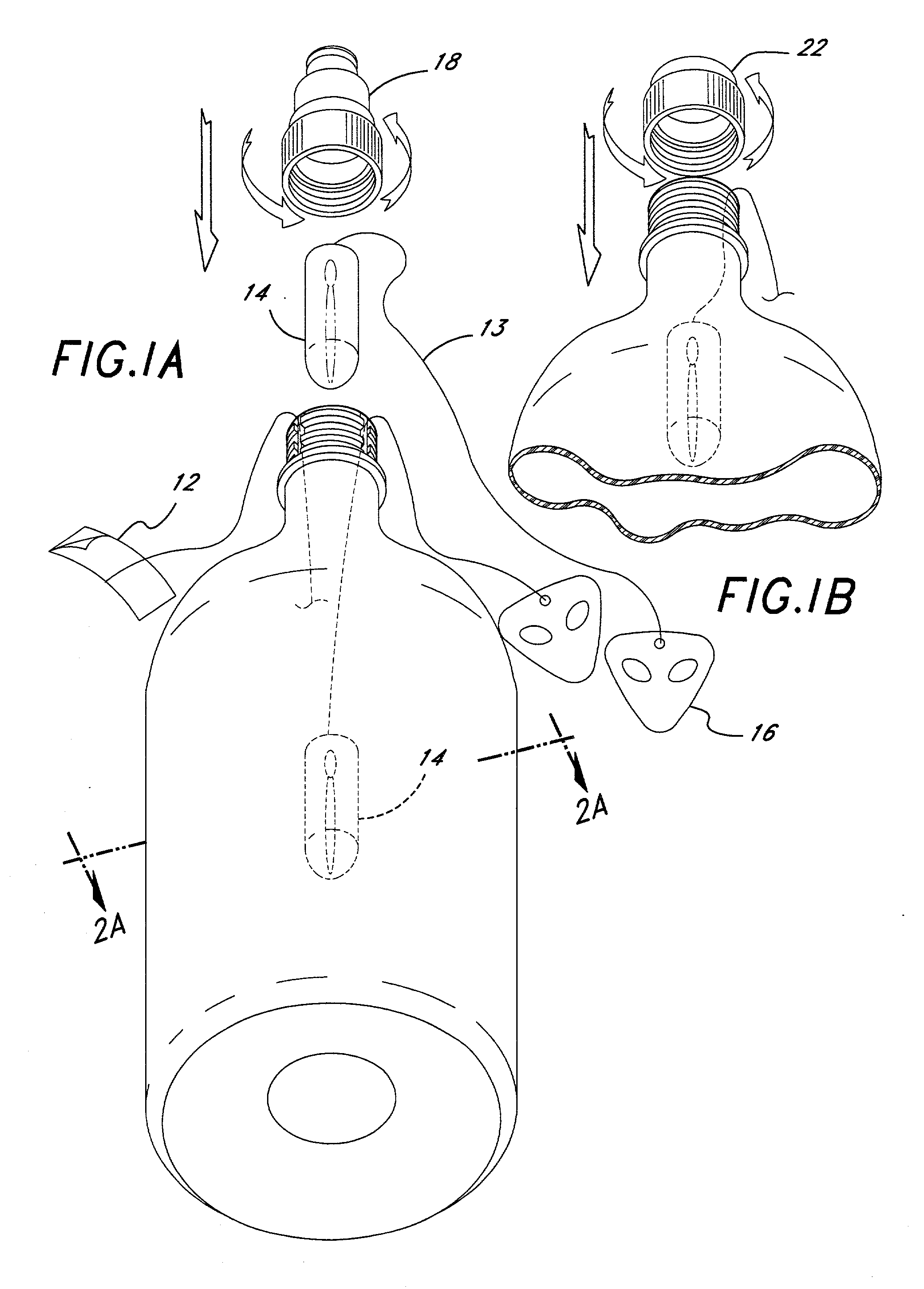

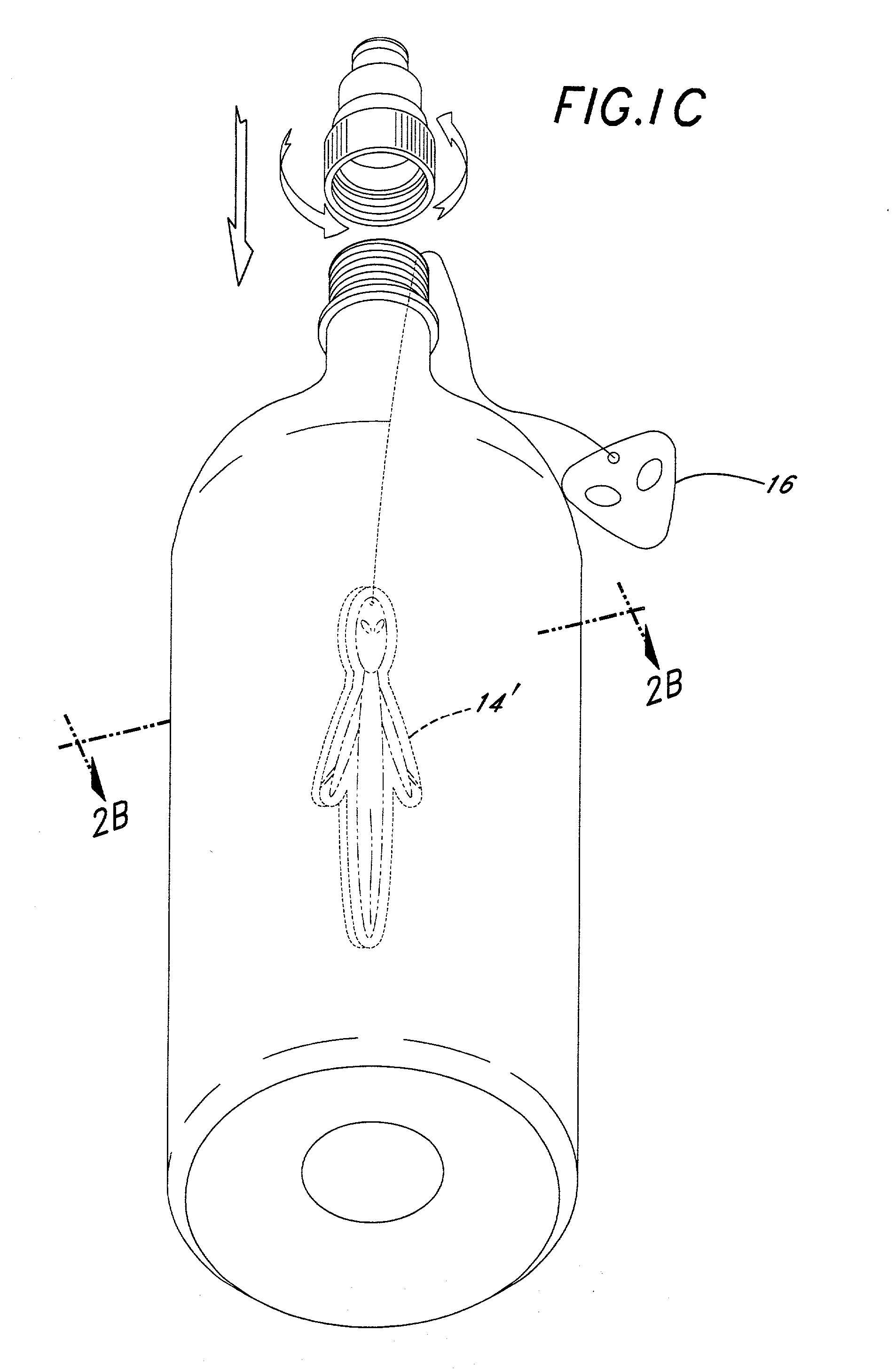

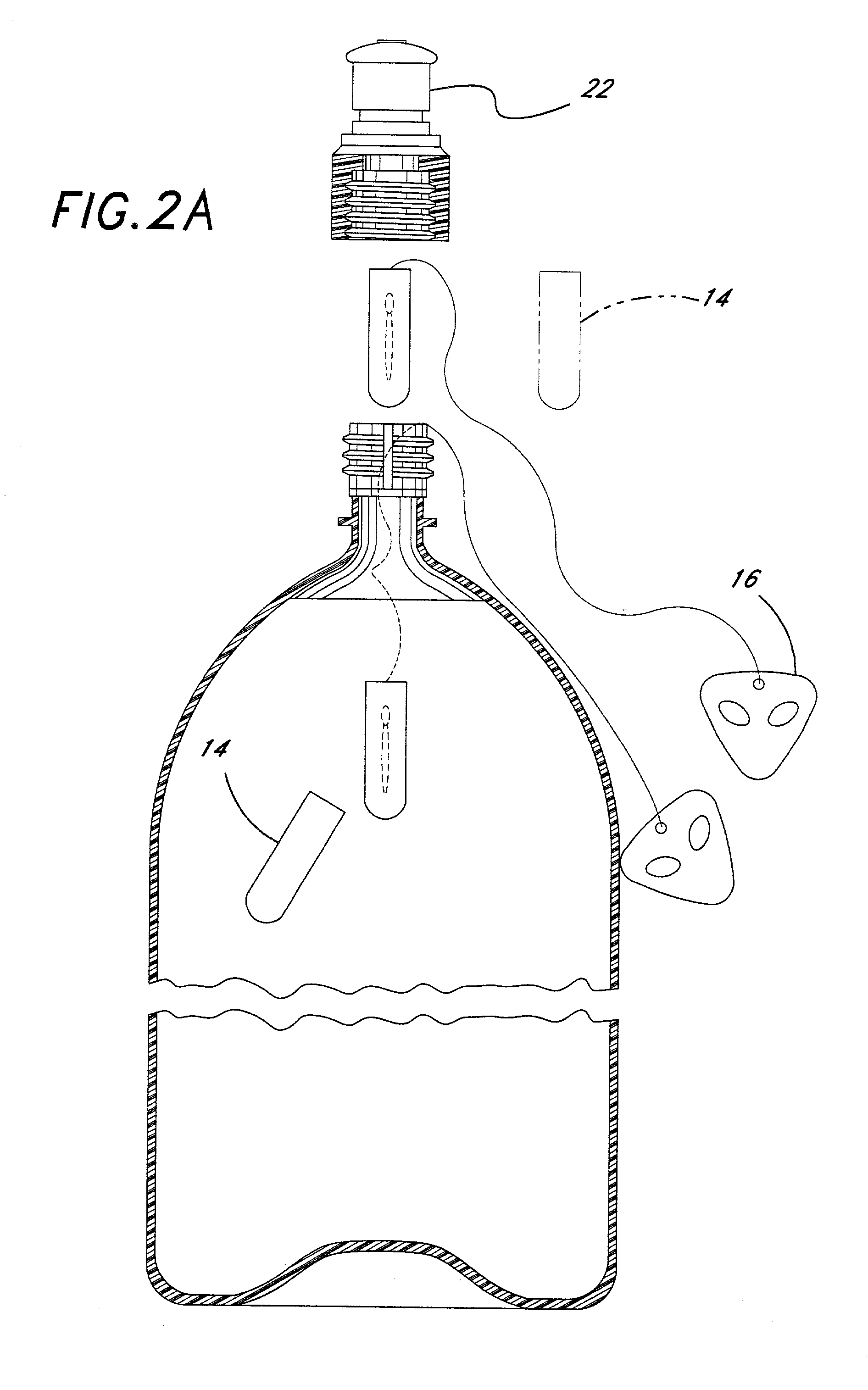

Method of hydration; infusion packet system(s), support member(s), delivery system(s), and method(s); with business model(s) and Method(s)

InactiveUS20020012689A1Constant deliveryUniform deliveryBiocideOrganic active ingredientsDiagnostic Radiology ModalityDietary supplement

Liquid activated infusion packet(s) / system, promoting hydration, containing active and / or inactive ingredients and / or a support member(s). Infusion Packet(s) / System is one or more individual compartments, and / or group(s), whereby the enveloping material(s) may be totally or partially dissolvable, edible, transparent, opaque, decorated, etc. Further, including of one or more: color(s), flavor(s), aroma(s), pharmaceutical(s), nutraceutical(s), dietary supplement(s), enzyme(s), pre / pro-biotic(s), amino-acid(s), soluble-fiber(s), diagnostic agent(s) etc. regardless of form, + / - effervescence, + / - uniform / controlled-release encapsulations into liquid for humans and / or animals. Enveloping material may be in whole and / or in combination; non-synthetic / porous, and / or synthetic porous / non-porous with deliberate perforations. Infusion Packet(s) / System + / - tag, support member for assistance, consumer compliance: promotion, advertising, education, entertainment, (toy / game), etc. Manual and / or power operated parts, lights, noise, etc. Additionally incorporated; unique business modalities with test market opportunities and / or the ability to provide income and / or esteem for the health challenged.

Owner:STILLMAN SUZANNE JAFFE

Strawberry-flavor peony compound beverage and preparation method thereof

InactiveCN103960721AThe proportion is scientific and reasonableEliminate toxins from the bodyNatural extract food ingredientsFood preparationAdditive ingredientNutrient content

The invention relates to the field of beverages compounded by fruits and vegetables as well as flowering tea and preparation methods thereof, and provides a strawberry-flavor peony compound beverage and a preparation method thereof. The compound beverage is formed mainly by strawberries, white gourds, mung beans and a mixed extracting solution of peonies and greenish lily flowers in proportion, wherein the mixed extracting solution of peonies and greenish lily flowers is obtained in the manner that an ethanol solution with the concentration of 90 percent is adopted to be added with tartaric acid used as an extracting agent for extraction; the preparation method comprises the following steps: strawberries and white gourds are respectively juiced for standby use, then the juiced strawberries and white gourds are mixed with ground mung bean milk and the mixed extracting solution of peonies and greenish lily flowers, then high fructose corn syrup, citric acid and potassium sorbate are added into the mixture, and homogenizing, degassing, sterilization and filling are performed, so that finished products are obtained. The compound beverage provided by the invention is complete in nutrition and delicious in taste, greatly reserves respective nutritional ingredients, and has the health functions of preventing hypertension and arteriosclerosis and weight loss.

Owner:LUOYANG CHUNKUI AGRI DEV

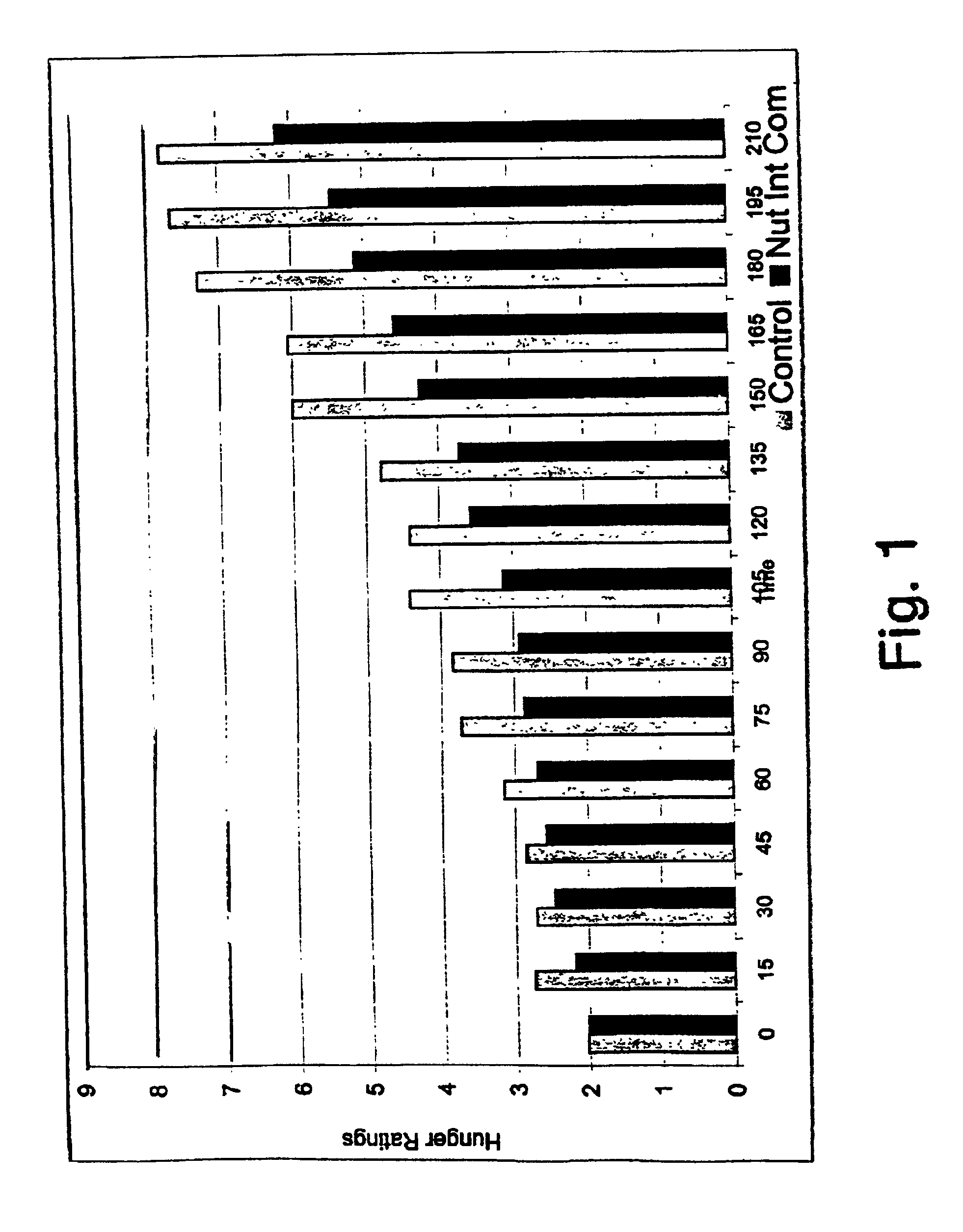

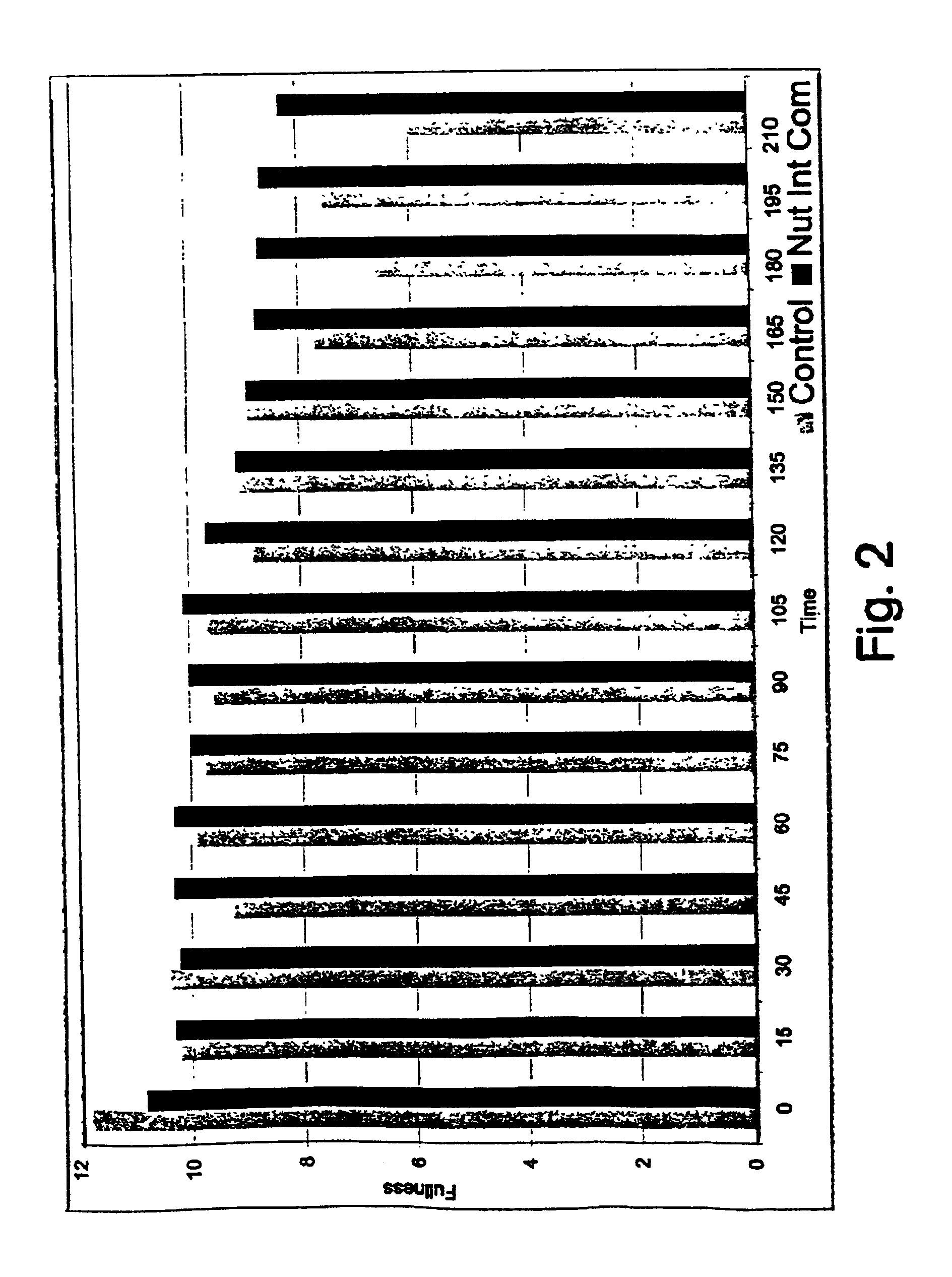

Nutritional intervention composition containing a source of proteinase inhibitor extending post meal satiety

InactiveUS6838431B2Effective quantityBiocidePeptide/protein ingredientsSolanum tuberosumOleic Acid Triglyceride

The invention relates to a nutritional intervention composition in powder form that is taken before a meal and that extends post meal satiety. The compositions of the invention are comprised of at least one protein, C12-18 fatty acids, preferably oleic acid, all of which stimulate CCK release in the body, and a source of proteinase inhibitor which acts to prevent the deactivation of CCK. The subject compositions preferably additionally contain a source of calcium and are advantageous in that they utilize a source of proteinase inhibitor as opposed to the more costly extracts. The source of proteinase inhibitor is advantageously an extract of potato, soy, or beans containing about 10 weight percent of proteinase inhibitor. The powder compositions are mixed with a suitable liquid, preferably water, prior to ingestion.

Owner:ANAYA PERSONAL CARE PROD LLC +1

High-potency sweetener composition with saponin and compositions sweetened therewith

InactiveUS20070116822A1Improve flavor profileImproving temporal profile profileNatural extract food ingredientsFood preparationAdditive ingredientSweetness

The present invention relates generally to functional sweetener compositions comprising non-caloric or low-caloric natural and / or synthetic high-potency sweeteners and methods for making and using them. In particular, the present invention relates to different functional sweetener compositions comprising at least one non-caloric or low-caloric natural and / or synthetic high potency sweetener, at least one sweet taste improving composition, and at least one functional ingredient, such as saponin. The present invention also relates to functional sweetener compositions and methods that can improve the tastes of non-caloric or low-caloric high-potency sweeteners by imparting a more sugar-like taste or characteristic. In particular, the functional sweetener compositions and methods provide a more sugar-like temporal profile, including sweetness onset and sweetness linger, and / or a more sugar-like flavor profile.

Owner:THE COCA-COLA CO

Benefit agent containing delivery particle

The present invention relates to benefit agent containing delivery particles, compositions comprising said particles, and processes for making and using the aforementioned particles and compositions. When employed in compositions, for example, compositions for cleaning, fabric care, or coating onto various substrates, textiles or surfaces, such particles increase the efficiency of benefit agent delivery, thereby allowing reduced amounts of benefit agents to be employed. In addition to allowing the amount of benefit agent to be reduced, such particles allow a broad range of benefit agents to be employed.

Owner:THE PROCTER & GAMBLE COMPANY

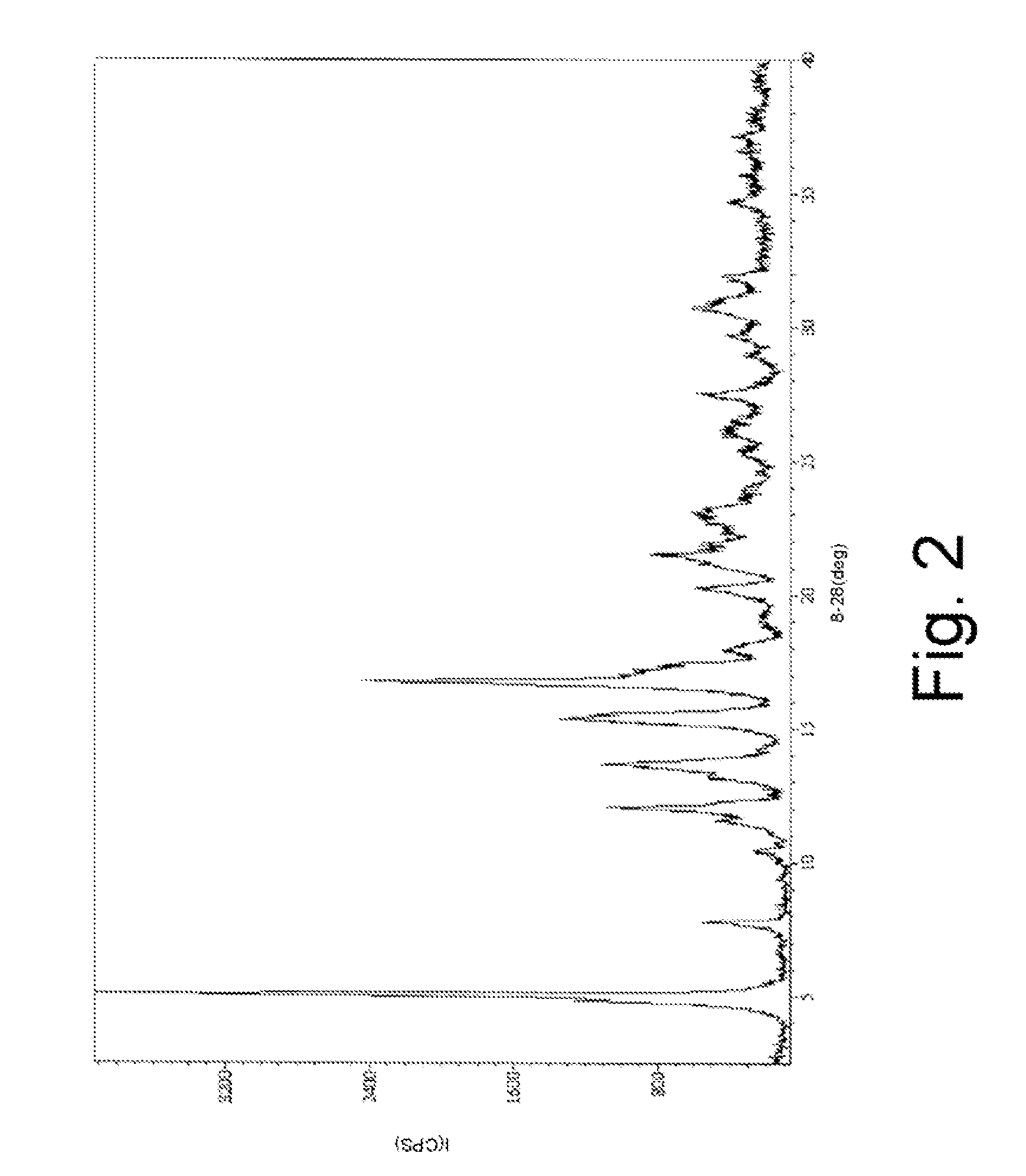

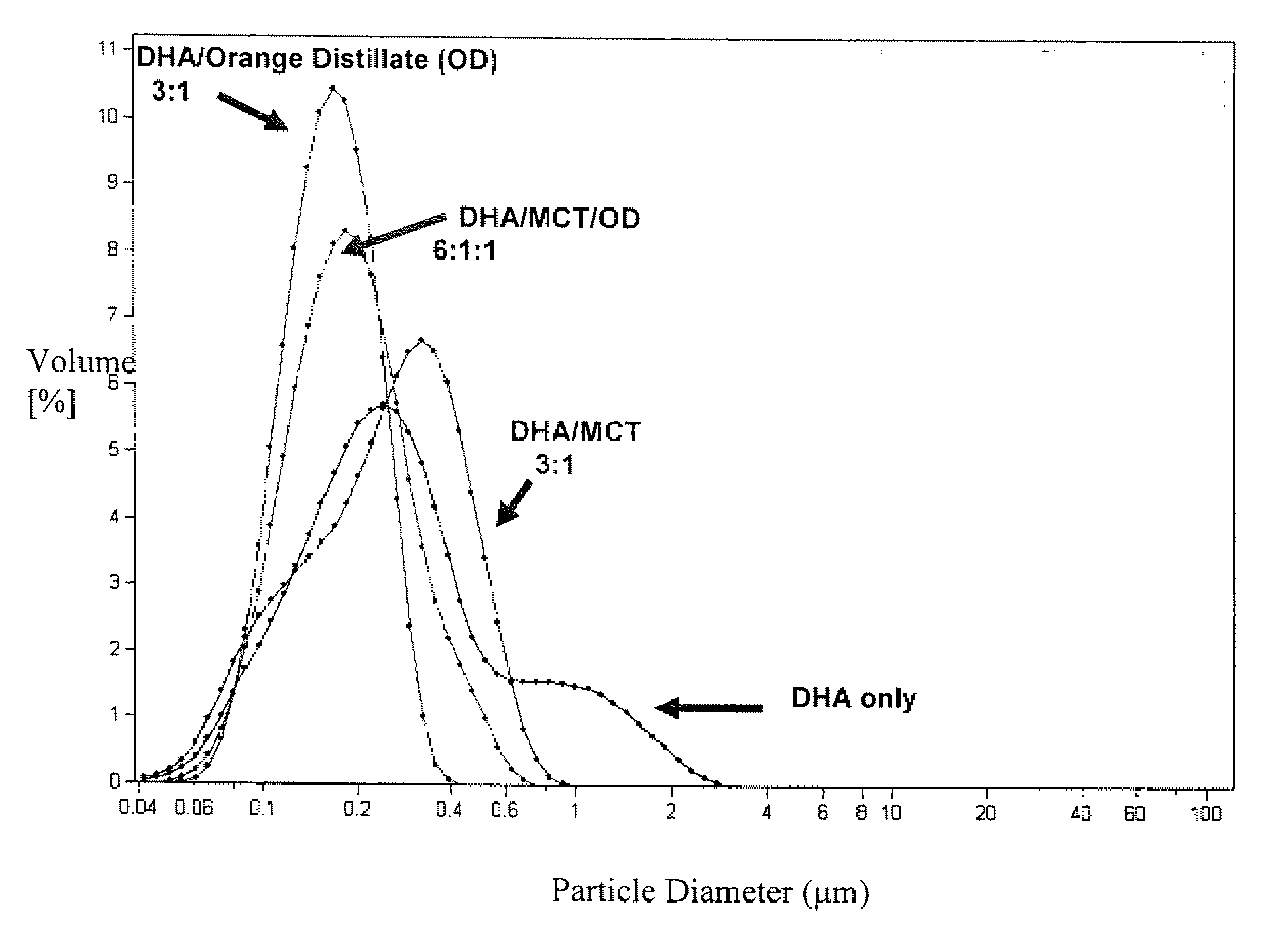

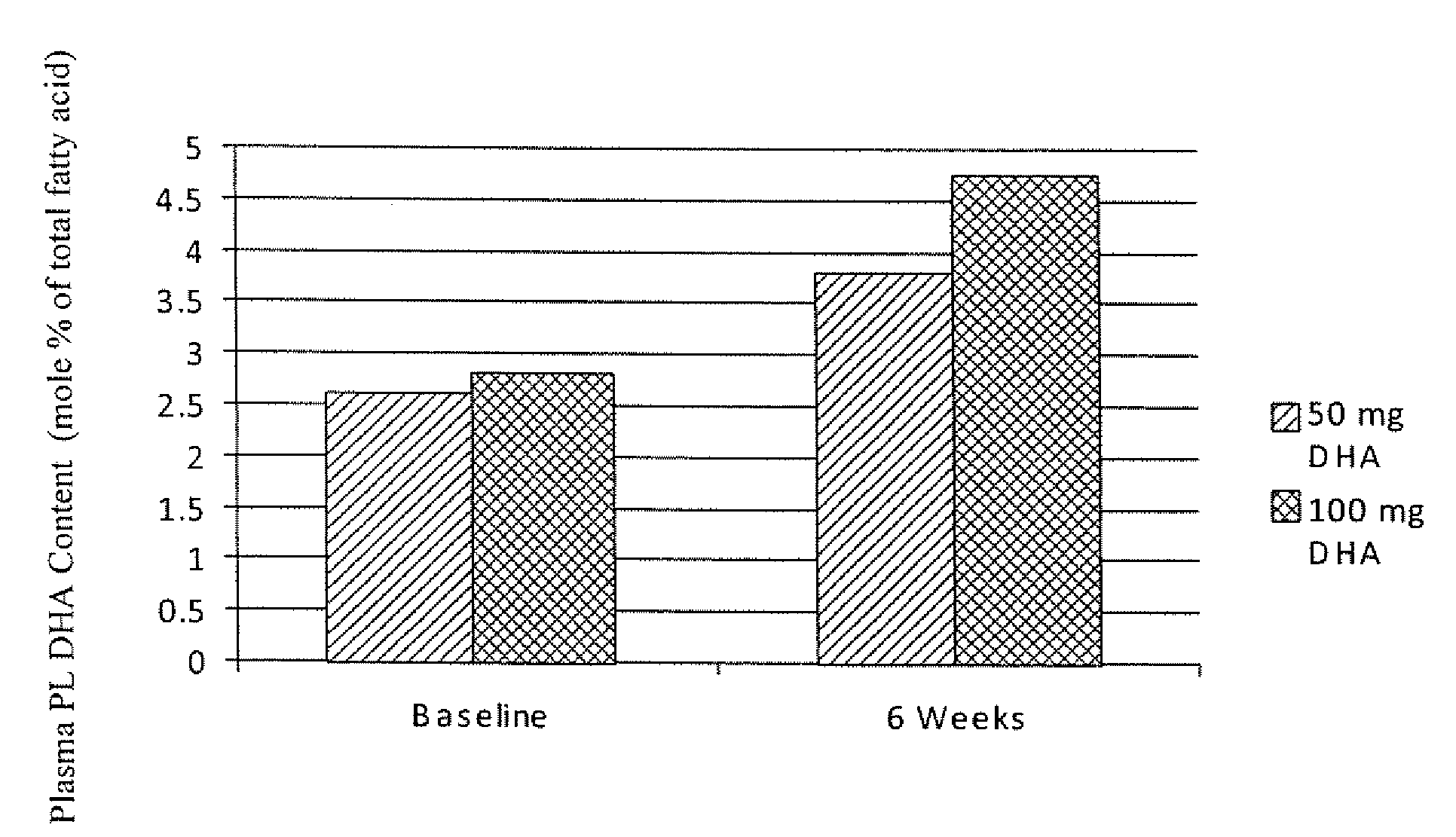

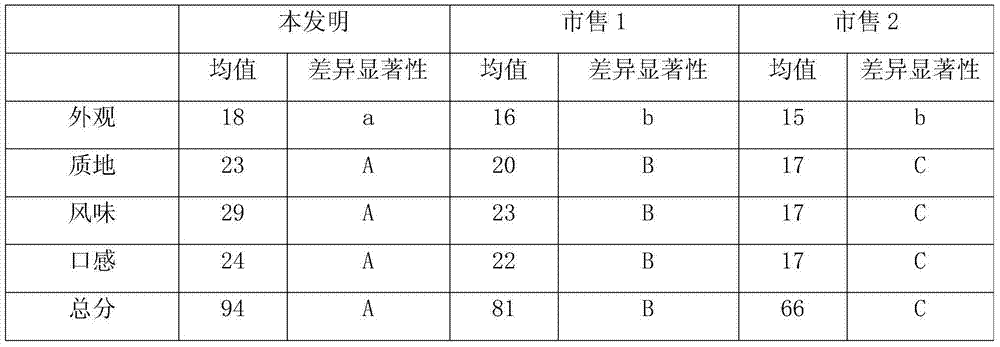

Stable polyunsaturated fatty acid emulsions and methods for inhibiting, suppressing, or reducing degradation of polyunsaturated fatty acids in an emulsion

InactiveUS20080058418A1Inhibiting and suppressing and reducingBiocideHydroxy compound active ingredientsEmulsionAntioxidant

An emulsion comprising a continuous liquid phase, an emulsifier, and a discontinuous liquid phase comprising a blend including a polyunsaturated fatty acid source and a dispersing agent. The polyunsaturated fatty acid source comprises at least one polyunsaturated fatty acid and the weight ratio of the fatty acid source to the dispersing agent in the blend ranges from about between 9:1 and 1:10. A method for making an emulsion. The stability of the emulsion can be protected by antioxidants such as tea polyphenols.

Owner:THE COCA-COLA CO

Pressure lowering and lipid lowering sweet corn soup and preparation method thereof

InactiveCN104799176AEasy to storeEasy to eatNatural extract food ingredientsFood ingredient functionsGinkgo bilobaLipid lowering

The invention discloses pressure lowering and lipid lowering sweet corn soup and a preparation method thereof. The pressure lowering and lipid lowering sweet corn soup consists of the following raw materials in parts by weight: 40-50 parts of corn, 10-15 parts of oat, 5-10 parts of leek, 5-10 parts of pawpaw, 5-8 parts of cucumber, 4-6 parts of celery, 5-8 parts of chicken meal, 3-5 parts of coix seed, 3-4 parts of tangerine peel, 2-4 parts of mulberry leaf, 1-3 parts of cochinchinese asparagus root, 2-3 parts of ginkgo leaf, 1-3 parts of gynostemma pentaphyllum, 2-4 parts of medlar, 1-3 parts of egg, 2-3 parts of lactic acid bacteria tablet, 5-6 parts of grape juice and 5-7 parts of nutritional additive. The pressure lowering and lipid lowering sweet corn soup prepared by the invention is convenient to store, carry and eat, can be eaten after a can is opened, contains various nutrient substances, is rich in nutrition, has good mouthfeel, can also lower the lipid and can be eaten by various kinds of people; the formula contains natural plant compositions such as the tangerine peel, the mulberry leaf, the cochinchinese asparagus root and ginkgo leaf; the sweet corn soup has the effects of lowering lipid, lowering pressure, tonifying lung, strengthening spleen, protecting liver and nourishing kidney, can be eaten for a long time, can nourish the five internal organs, improves the immunity and has a health care effect of strengthening the body.

Owner:HEFEI YUEJIE ECOLOGICAL AGRI TECH

Chia seed beverage and related method

InactiveUS20090181114A1Enhancing heart healthImprove regularityBiocideDigestive systemFruit juiceFlavored water

A beverage is disclosed that is effective for enhancing gastrointestinal regularity and heart health. It is formed by a liquid comprising fruit derived juices, water or naturally or artificially flavored water. A composition of matter is mixed within the liquid in a shelf stable pasteurized beverage form and formed from sterilized whole seed extracted from Salvia hispanica L. The resulting beverage exhibits a pH dependent viscosity requiring no additional thickening agents and suitable as a beverage for human consumption.

Owner:US NUTRACEUTICALS LLC

Appetite satiation and hydration beverage

InactiveUS20050276839A1Sufficient nutritional valueAvoid malnutritionBiocideTetrapeptide ingredientsBetaineAdditive ingredient

Appetite satiation and hydrating beverages and methods of delivering appetite satiation ingredients and nutrients are disclosed. According to one embodiment of the invention, the appetite satiationhydrating beverage comprises at least one complex carbohydrate, at least one chelated electrolyte, hoodia gordonii cactus, gymnema sylvestre, betaine and piperine.

Owner:RIFKIN CALMAN H

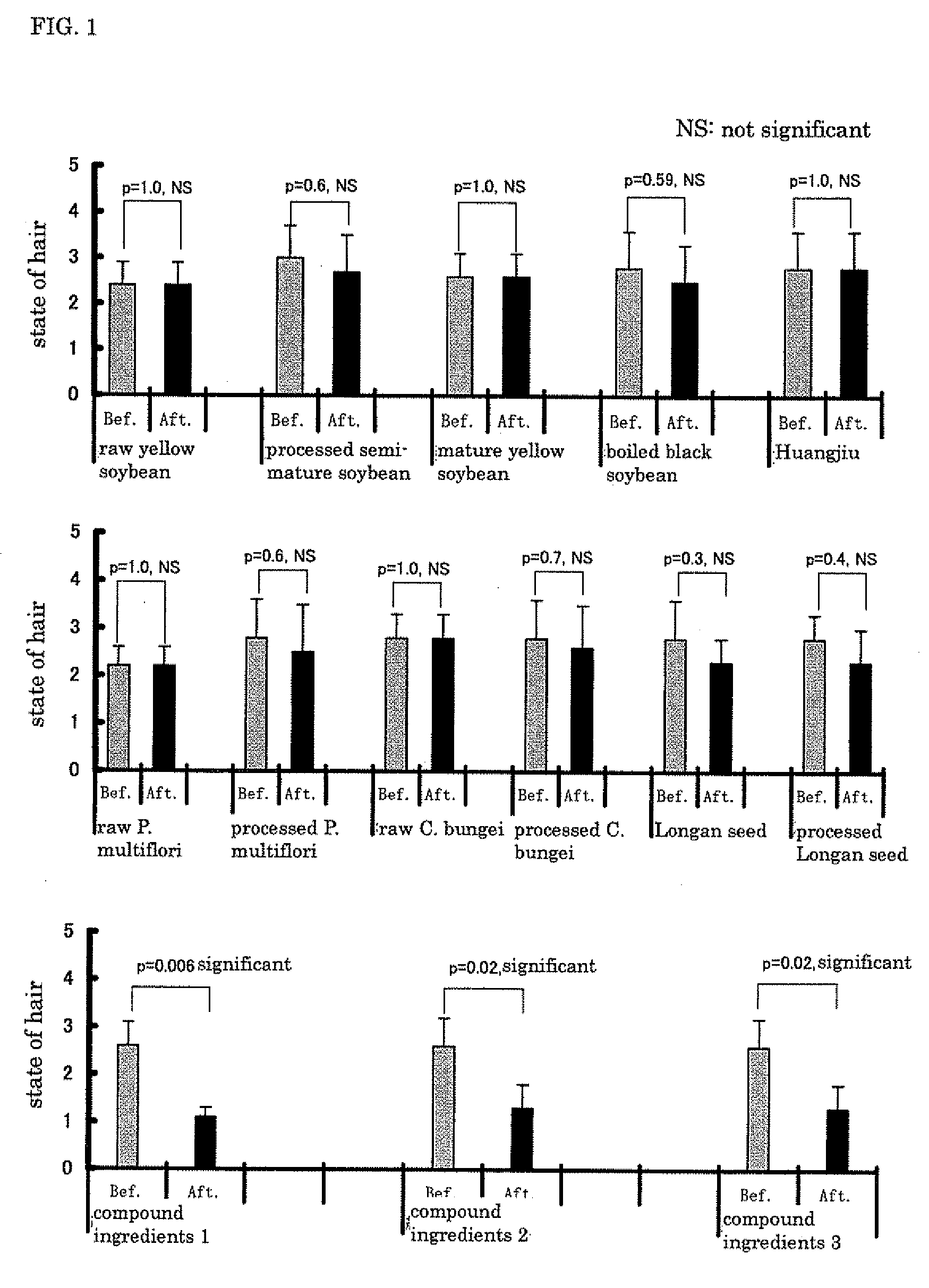

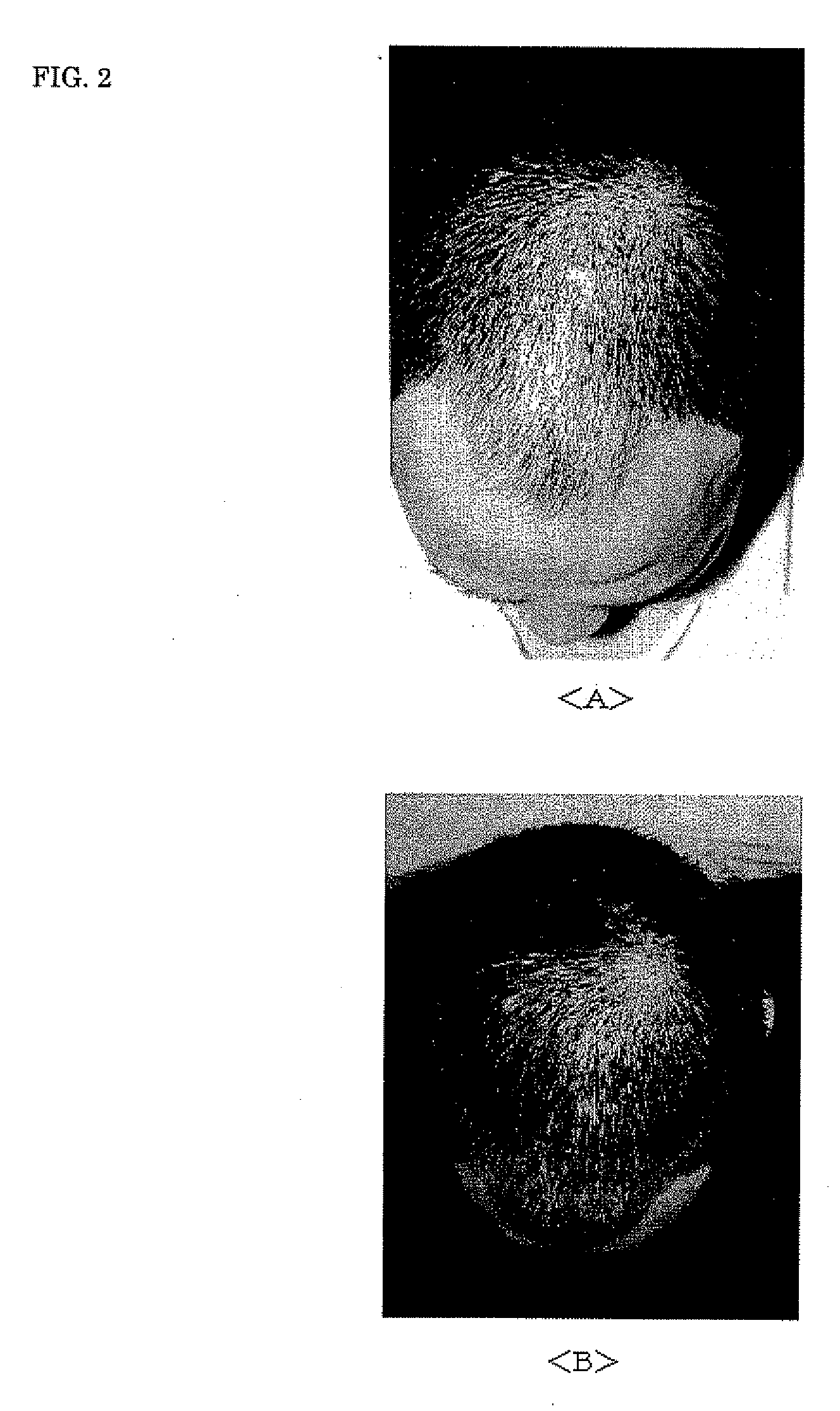

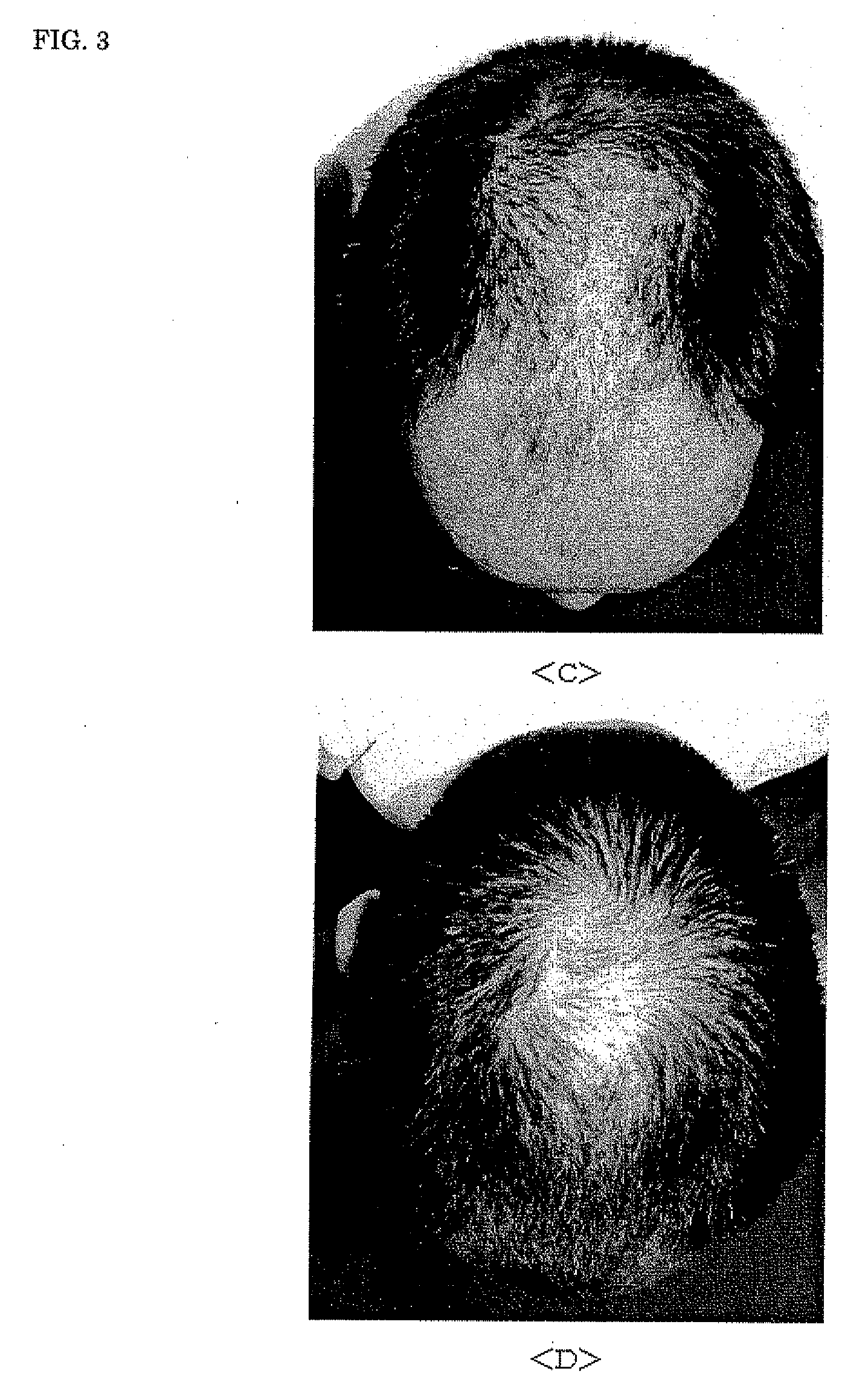

Agent for Hair Growth

The aim of this invention is to offer a novel agent for hair growth, which has excellent hair growth effects but not side effects. The agent for hair growth of the present invention is characterized by comprising a processed semi-mature soybean and / or a processed semi-mature soybean extracts and at least one substance selected from the group consisting of a processed Polygoni Multiflori Radix, processed Polygoni Multiflori Radix extracts, a processed Cynanchum bungei Decne or processed Cynanchum bungei Decne extracts, preferably further comprising Longan seed and / or Longan seed extracts as active ingredients. This agent for hair growth has no side effects when used externally or internally, it can notably improve hair growth within a short period of time; ranging from 6 to 12 weeks, can return hair to its normal hair colour (for example from white to black) and can improve the gloss of hair.

Owner:KOHNO KENJI

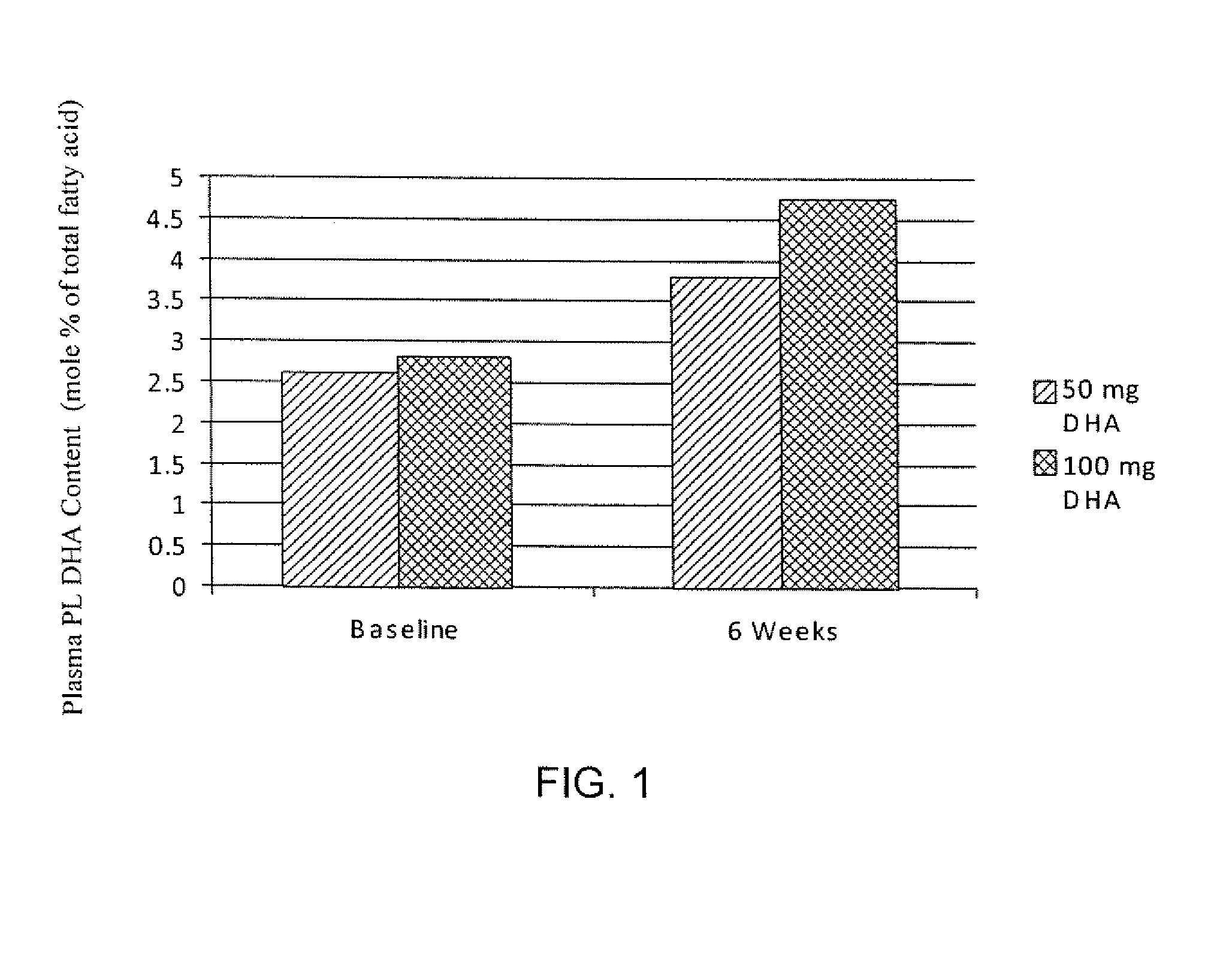

Methods and Kits For Administering Probiotics

InactiveUS20080241226A1Improve tolerability and perception of benefitBiocideNervous disorderMedicineDrug loading dose

Methods for administering probiotics comprising the steps of: administering a loading dose of a loading probiotic for a loading time period; and administering a dose of a botanical and / or additional materials for the loading time period are disclosed. The methods also include administering a maintenance dose of a maintenance probiotic, and / or a botanical and / or an additional material for a maintenance time period. Also disclosed are kits for use in administering probiotics.

Owner:THE PROCTER & GAMBLE COMPANY

Nutritional supplements for healthy memory and mental function

InactiveUS20080213401A1Optimizing mental energyImprove mental functionBiocideNervous disorderMental functionsMental nerve

Owner:APPLIED COGNITIVE SCI

Refrigeration-shelf-stable ultra-pasteurized or pasteurized infant formula

InactiveUS6194009B1Maintain qualityReduce degradationSugar food ingredientsVitamin food ingredientsPasteurizationRefrigeration

Refrigeration-shelf-stable ready-to-feed and concentrated infant formulas can be prepared through a ultra-pasteurization and / or pasteurization process. The ultra-pasteurized and / or pasteurized infant formulas contain complete balanced quantities of nutrients.

Owner:KAMAREI ARZHANG +1

Labiatae herb extracts and hop extracts for extending the color life and inhibiting the growth of microorganisms in fresh meat, fish and poultry

InactiveUS20040131709A1Good colorDecreases color lifeBiocideUnknown materialsHops extractMicroorganism

Compositions comprising a Labiatae herb extract and a hop extract containing beta acids and methods of using them to extend the color life and retard the growth of microorganisms in fresh meat, fish and poultry stored in an atmosphere that contains 20% or more oxygen.

Owner:KALSEC

Compositions and methods for weight loss

InactiveUS20050238654A1Normalize fatNormalize carbohydrate metabolismBiocideMetabolism disorderDietary supplementWeight decreasing

Owner:TAKEDA YOSHINORI

Stable beverage products comprising polyunsaturated fatty acid emulsions

A beverage product comprising at least one beverage base and at least one polyunsaturated fatty acid emulsion, said emulsion comprising a continuous liquid phase; an emulsifier; and a discontinuous liquid phase comprising a blend including a polyunsaturated fatty acid source and a dispersing agent, the polyunsaturated fatty acid source comprising at least one polyunsaturated fatty acid, wherein the weight ratio of the fatty acid source to the dispersing agent in the blend ranges from about 9:1 to about 1:10.

Owner:THE COCA-COLA CO

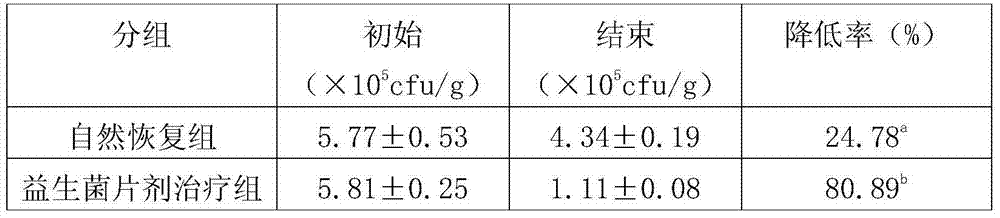

Fruit and vegetable probiotic tablet and preparation method thereof

ActiveCN104489646AHigh survival rate of live bacteriaImprove stabilityNatural extract food ingredientsFood ingredient functionsCelluloseDrug biological activity

The present invention discloses a fruit and vegetable probiotic tablet and a preparation method thereof. The fruit and vegetable probiotic tablet uses probiotic powders such as lactobacillus plantarum powder as the main raw material, and the preparation method scientifically mixes modified dietary fibers, fruit and vegetable powder, oligosaccharides, plant extracts, protein powder, tea leaf extracts and traditional Chinese medicine extracts and etc., thus improves the content of soluble celluloses which are of real significance for probiotic flora, enhances the physiological activity of celluloses, thereby increases the species of intestinal probiotic flora as well as significantly enhances the colonization ability and time of endogenous and exogenous probiotics in the human intestinal tracts, effectively inhibits the growth and reproduction of harmful intestinal bacteria, especially gram-negative bacteria, and fully regulates the composition of the intestinal probiotic flora. The prepared fruit and vegetable probiotic tablet has a high biological activity, a long human intestinal colonization time, and a significant weight loss effect, and is suitable for a wide range of people.

Owner:南京旭优食品技术有限公司

Chia seed composition

InactiveUS20090181127A1Enhancing gastrointestinal regularityEnhancing heart healthMilk preparationDough treatmentVitamin antagonistGlycoside formation

A composition of matter is disclosed and formed from a stable, defatted whole grain flour derived from Salvia hispanica L. whole ground seed using a suitable solvent that is free of cyanogenic glycosides, vitamin antagonists, and gluten. The composition includes minerals, about 30% wt / wt protein, about 30-40% insoluble fiber and about 2-3% of fructo-oligosaccarides.

Owner:US NUTRACEUTICALS LLC

Synergistic salivation agents

Owner:TAKASAGO INTERNATIONAL CORPORATION

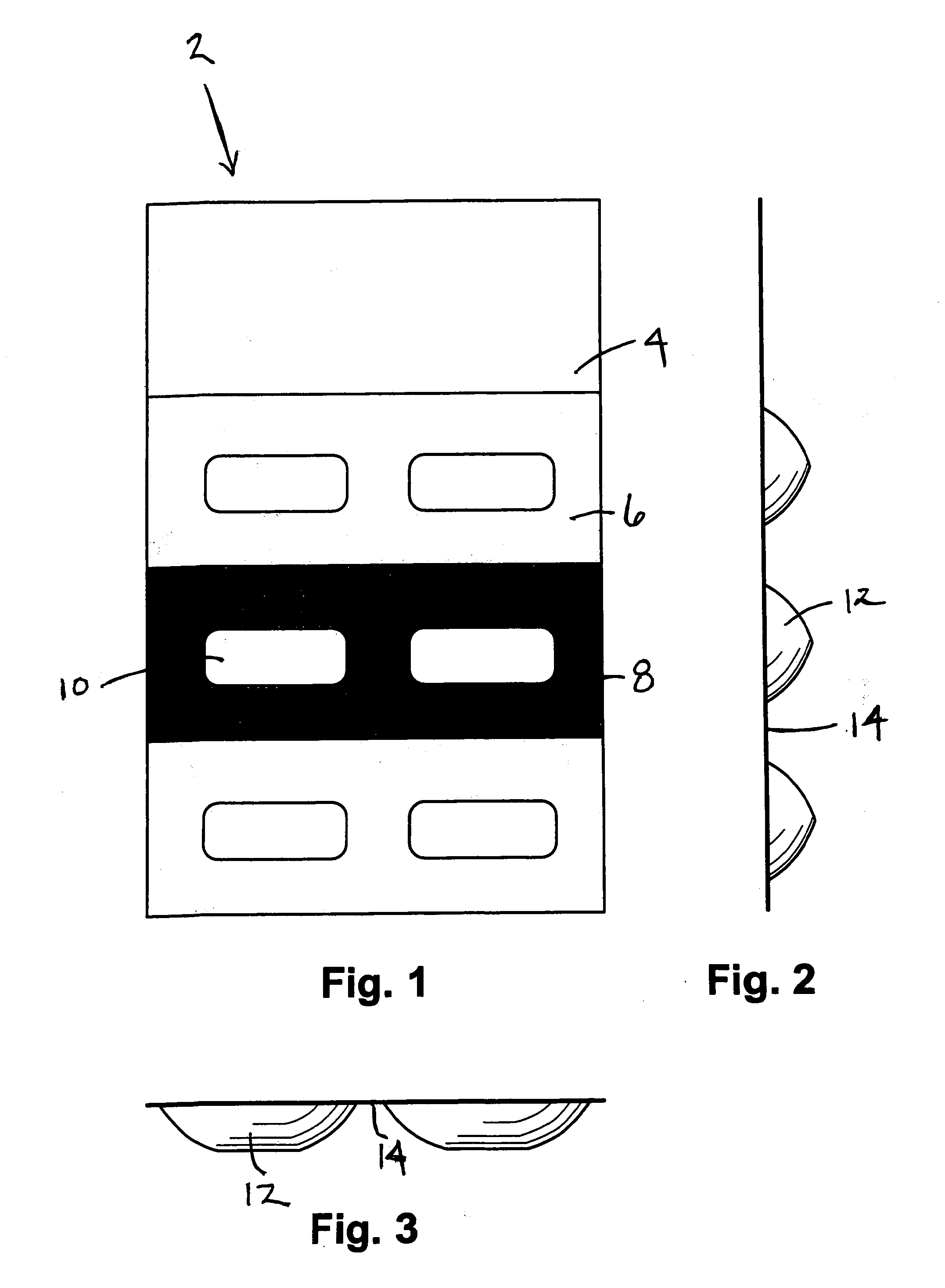

Fatty acid compositions and methods of use

InactiveUS20090011012A1Easy to carryConvenient travelBiocideCapsule deliveryCyclosporine toxicityAntioxidant

The invention relates to highly concentrated DHA and EPA formulations in a soft gel capsule. A capsule may contain at least 80% omega-3 fatty acids, salts or derivatives thereof, where EPA and DHA are present in relative amounts of greater than or equal to 3:1 or less than or equal to 1:3, and constitute at least 75% to greater than 95% of the total fatty acids present in the capsule. Capsules of the invention may be provided in a blister package so as to provide clean and protected oils that are easy to travel with. Compliance is improved with one-pill-a-day dosing and the days of the week imprinted on the foil packing. Anitoxidant protection may be provided by rosemary and vitamin C. The invention also provides a methods of treatment, modulation or prophalaxis of coronary disease, altering serum LDL-cholesterol and / or HDL-cholesterol, lowering serum triglycerides, lowering blood pressure, pulse rate, altering the activity of the blood coagulation factor VII complex, mild hypertension, protection from cyclosporine toxicity in kidney transplant, rheumatoid arthritis, development and progression of retinopathy, hypertriglyceridemia, and neurological disorders in a subject.

Owner:BAUM SETH J

Method of producing high flavonol content polyphenol compositions

Disclosed is a method of producing a polyphenol-containing composition derived from grapes, the method including: preparing a liquid grape extract which includes polyphenols; contacting the liquid extract with a separation medium which fractionates the components of the extract; and recovering that fraction in which the polyphenols are present. Also disclosed is a method of enriching the composition with added flavonol.

Owner:HOWARD FOUND

Compositions and foods for improving lipid metabolism

InactiveUS20060233902A1Improve insulin resistanceImprove glucose toleranceBiocideSenses disorderDiseaseSecondary hyperlipidemia

It is intended to provide compositions and foods for use in the treatment, prophylaxis, or amelioration of diseases or symptoms which can be treated, prevented or ameliorated by activating PPAR, in particular, insulin resistant diabetes and hyperlipidemia. Namely, medicinal compositions usable in treating, preventing or improving diseases or symptoms which can be treated, prevented or ameliorated by activation PPAR which contain humulones, isohumulones or lupulones or pharmaceutically acceptable salts or solvates thereof.

Owner:KIRIN BREWERY CO LTD

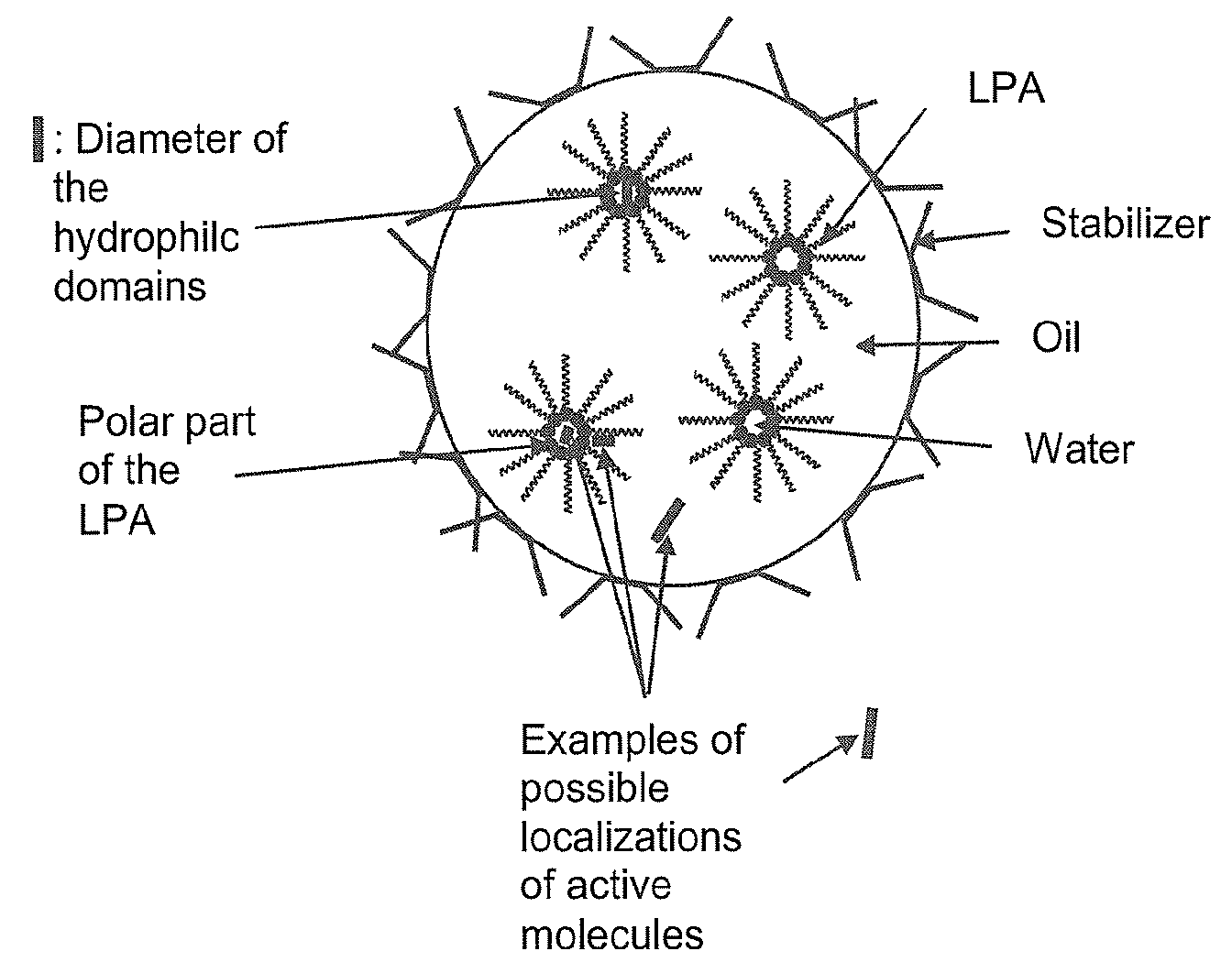

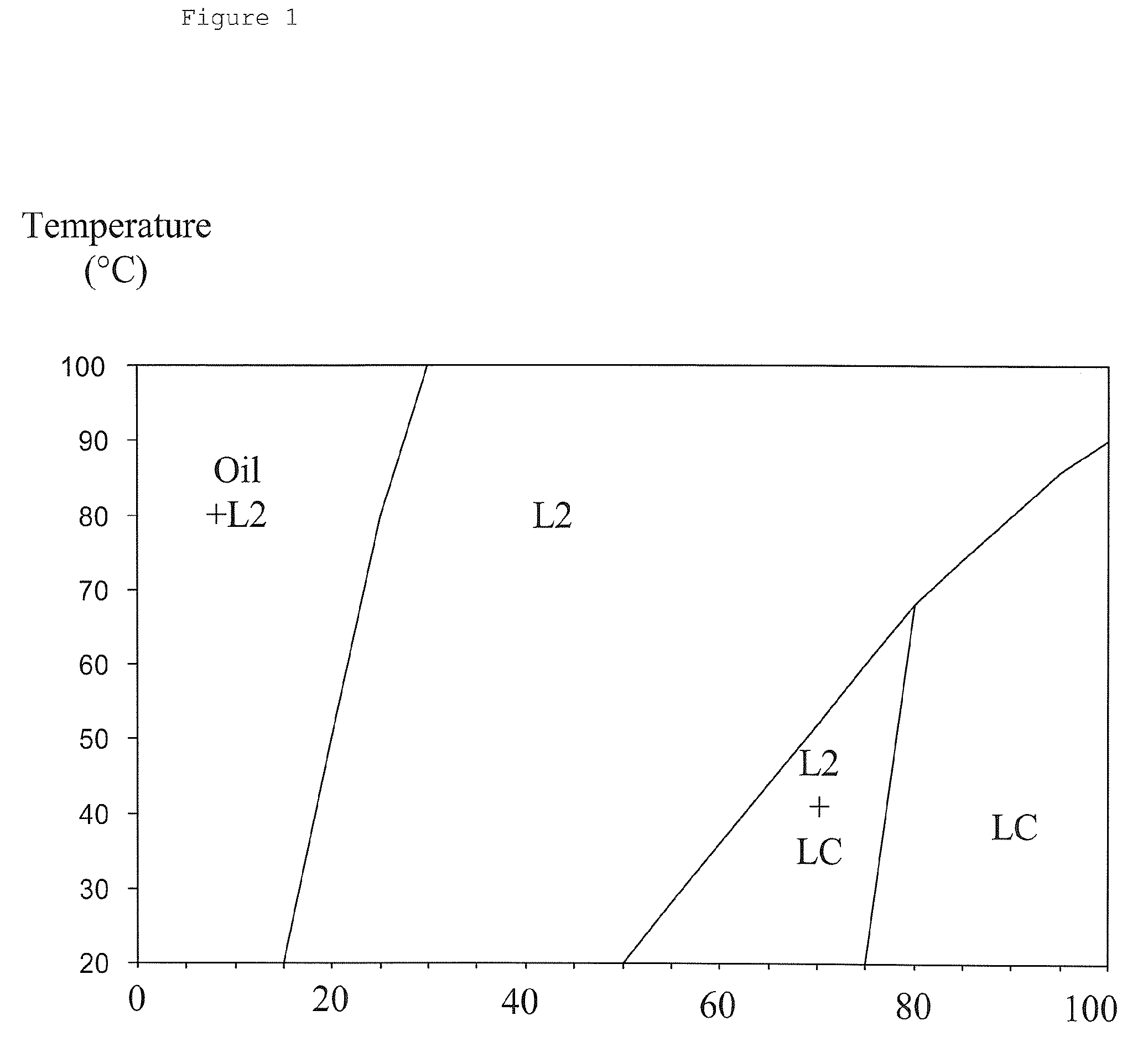

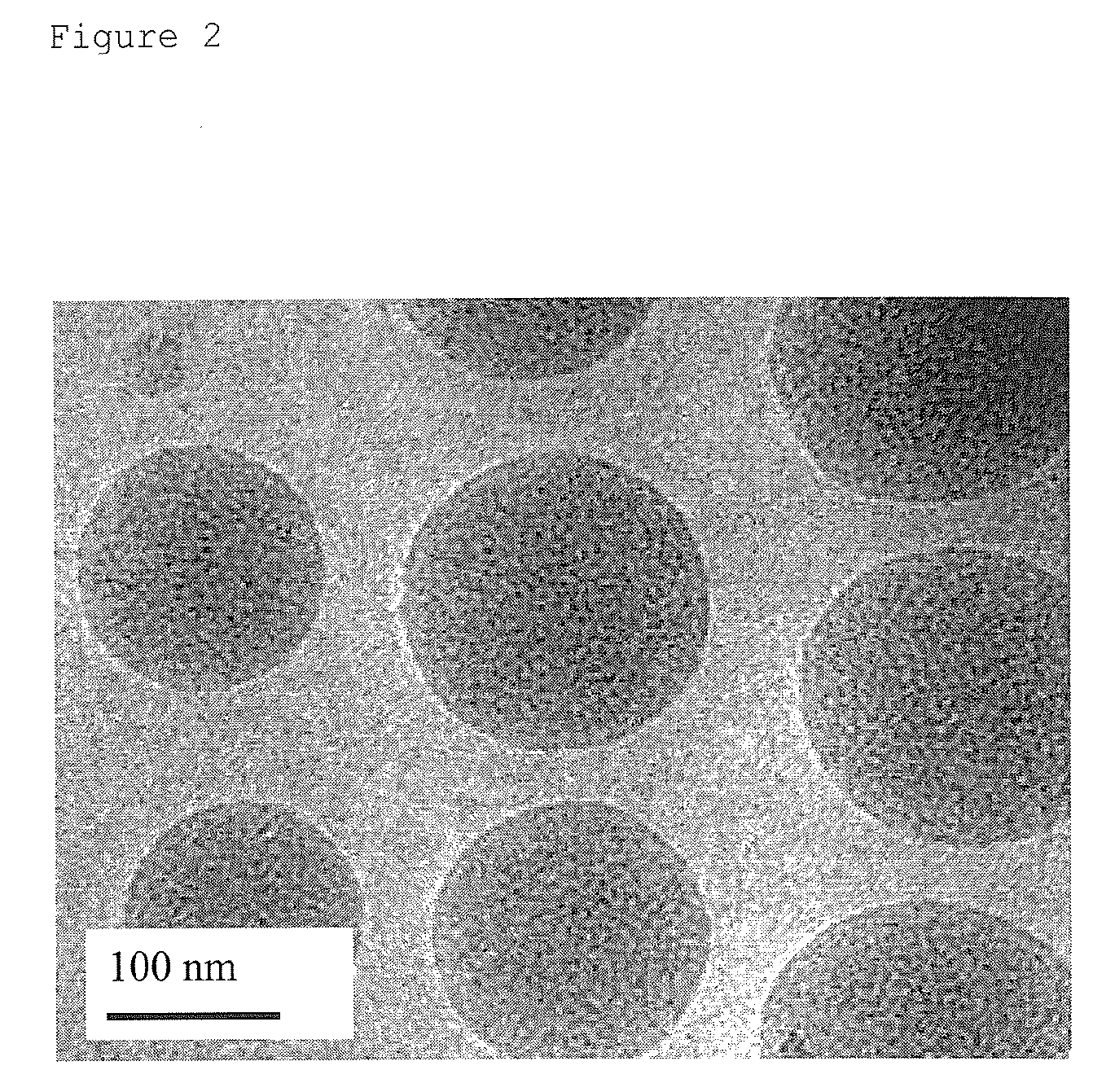

Oil-In-Water Emulsion and Its Use for the Delivery of Functionality

InactiveUS20080255247A1Improve protectionImprove stabilityBiocideCosmetic preparationsMicrometerNanometre

The present invention concerns an oil-in-water emulsion wherein the oil droplets of a diameter in the range of 5 nm to hundreds of micrometers exhibit a nano-sized self-assembled structurization with hydrophilic domains having a diameter size in the range of 0.5 to 200 nm, due to the presence of a lipophilic additive and the oil-in-water emulsion contains an active element being present in the range comprised between 0.00001 and 79% based on the total composition.

Owner:NESTEC SA

Composition comprising the extract of Actinidia arguta and related species for the prevention and treatment of allergic disease and non-allergic inflammatory disease

ActiveUS9131722B2Reduce actionTreat and prevent allergic diseaseBiocideSenses disorderFood additiveDisease

The present invention provides a pharmaceutical composition comprising the extract of hardy kiwifruit as an active ingredient in an effective amount to treat and prevent allergic disease and non-allergic inflammatory disease by reducing inflammation action, by inhibiting histamine release from mast cell, and by increasing the level of Th1 cytokines, IgG2a in serum and reducing the level of Th2 cytokines and IgE in serum. The present invention also provides a use of above extract for the preparation of pharmaceutical composition. The present invention also provides a health food or food additives, a cosmetic composition, a feed or feed additives comprising above extract for prevention or alleviation of allergic disease and non-allergic inflammatory disease by reducing inflammation action, by inhibiting histamine release from mast cell, and by increasing the level of Th1 cytokines, IgG2a in serum, and reducing the level of Th2 cytokines and IgE in serum.

Owner:VIROMED CO LTD

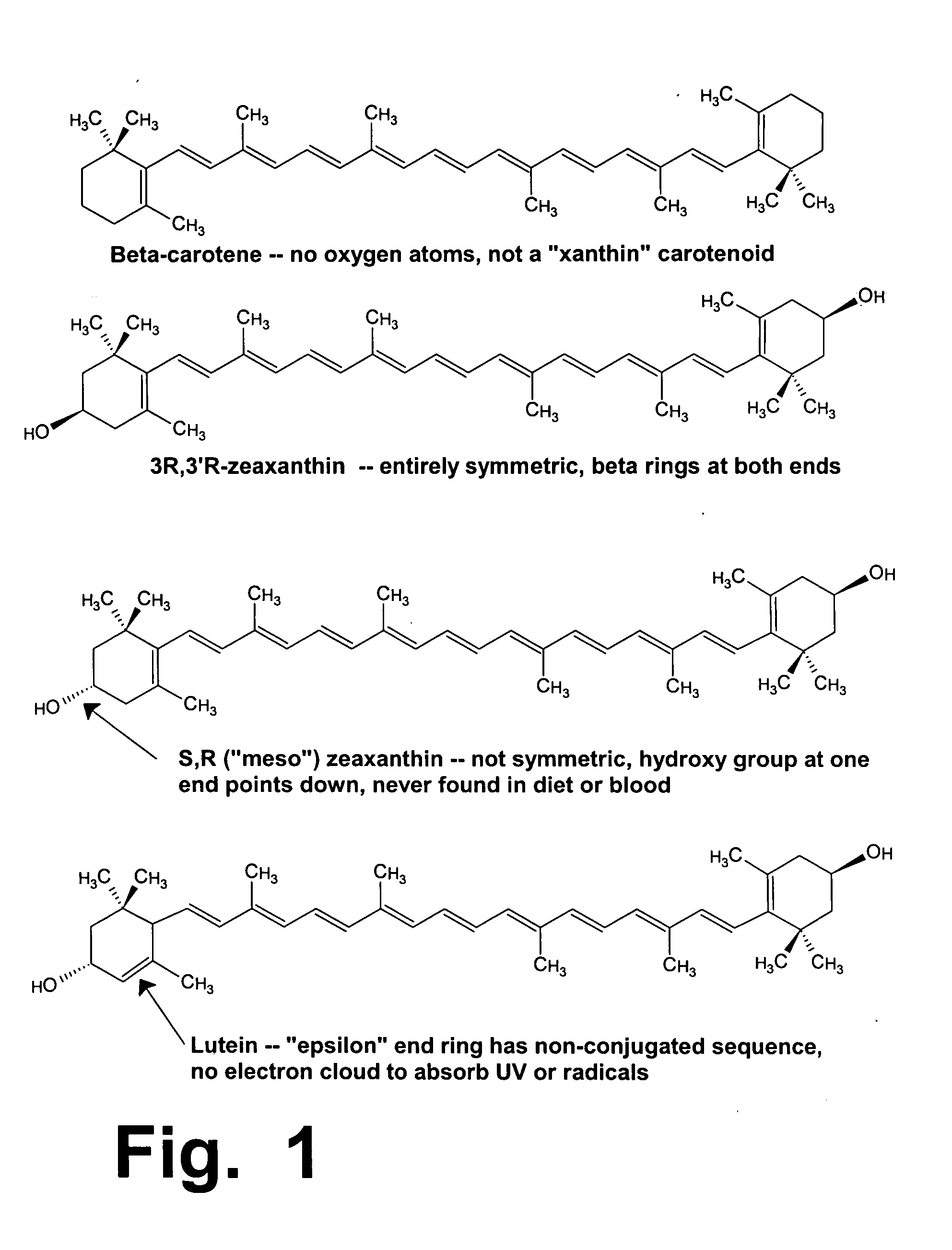

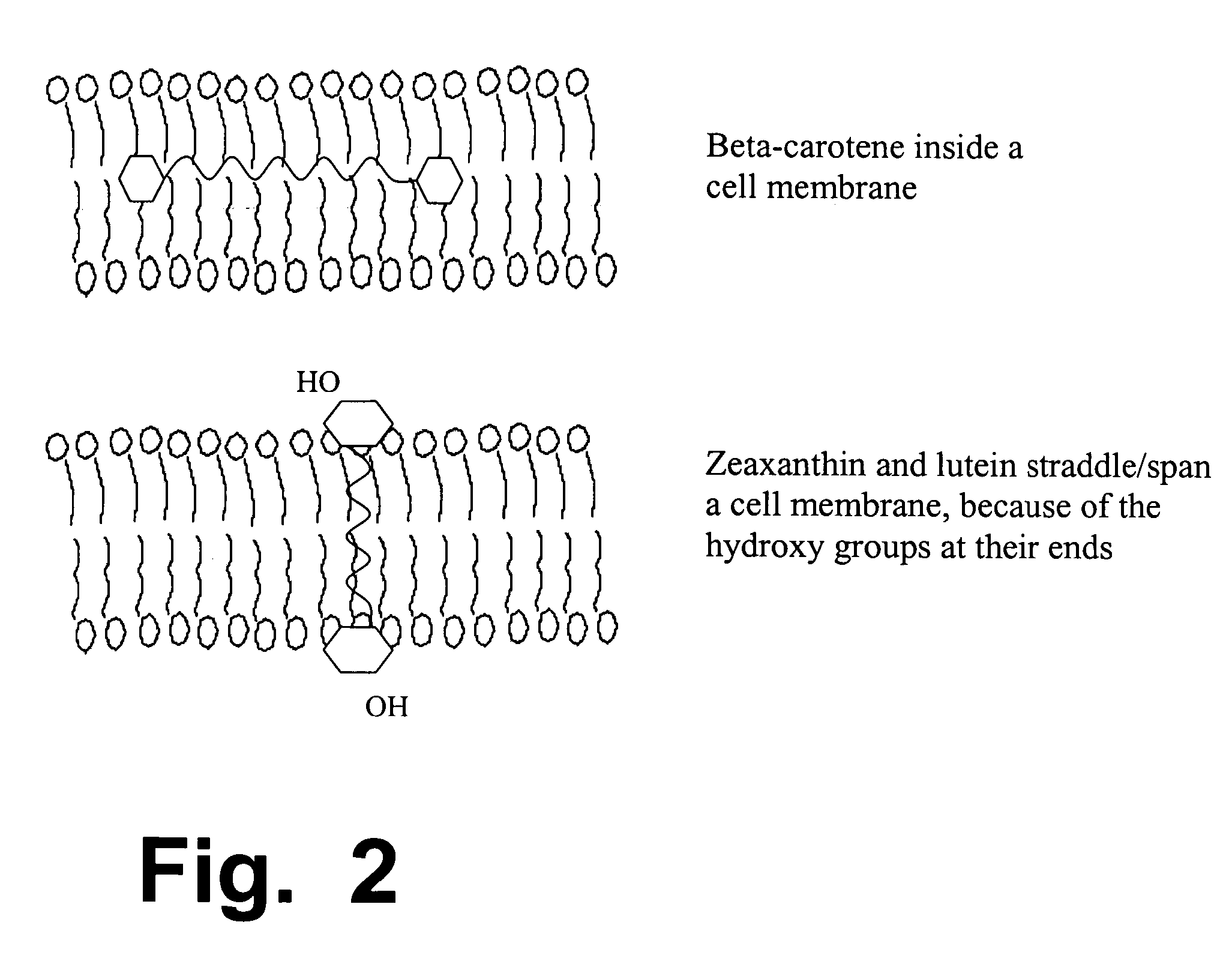

Ocular formulations with neuroprotectants to reduce Alzheimer and neurotoxic risks created by large zinc dosages

InactiveUS20060039954A1Reduce riskIncreased riskBiocideInorganic active ingredientsBeta-CaroteneClinical trial

Formulations marketed to elderly consumers for preventing or treating age-related eye diseases such as macular degeneration are modified in various four ways, compared to the formulations tested in the first “Age-Related Eye Disease Study” (AREDS-1) clinical trial. Zinc dosages are substabtially reduced, to reduce the risk of Alzheimer's disease and other neurotoxic damage in the brains of elderly people, and zeaxanthin is substituted for a substantial portion of any beta-carotene. Additional useful agents are also disclosed.

Owner:GIERHART DENNIS L +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com