Patents

Literature

127results about How to "Improve flavor profile" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-Potency Sweetener Composition With Antioxidant and Compositions Sweetened Therewith

ActiveUS20070116838A1Improve flavor profileImproving temporal profile profileCosmetic preparationsDispersion deliveryAdditive ingredientAntioxidant

The present invention relates generally to functional sweetener compositions comprising non-caloric or low-caloric natural and / or synthetic, high-potency sweeteners and methods for making and using them. In particular, the present invention relates to different functional sweetener compositions comprising at least one non-caloric or low-caloric natural and / or synthetic, high-potency sweetener, at least one sweet taste improving composition, and at least one functional ingredient, such as antioxidants. The present invention also relates to functional sweetener compositions and methods that can improve the tastes of non-caloric or low-caloric high-potency sweeteners by imparting a more sugar-like taste or characteristic. In particular, the functional sweetener compositions and methods provide a more sugar-like temporal profile, including sweetness onset and sweetness linger, and / or a more sugar-like flavor profile.

Owner:THE COCA-COLA CO

High-Potency Sweetener Composition With Dietary Fiber and Compositions Sweetened Therewith

InactiveUS20070116837A1Improve flavor profileImproving temporal profile profileMetabolism disorderConfectioneryChemistryDietary fibre

The present invention relates generally to functional sweetener compositions comprising non-caloric or low-caloric natural and / or synthetic, high-potency sweeteners and methods for making and using them. In particular, the present invention relates to different functional sweetener compositions comprising at least one non-caloric or low-caloric natural and / or synthetic, high-potency sweetener, at least one sweet taste improving composition, and at least one functional ingredient, such as a dietary fiber source. The present invention also relates to functional sweetener compositions and methods that can improve the tastes of non-caloric or low-caloric high-potency sweeteners by imparting a more sugar-like taste or characteristic. In particular, the functional sweetener compositions and methods provide a more sugar-like temporal profile, including sweetness onset and sweetness linger, and / or a more sugar-like flavor profile.

Owner:THE COCA-COLA CO

High-potency sweetener compositon with rubisco protein, rubiscolin, rubiscolin derivatives, ace inhibitory peptides, and combinations thereof, and compositions sweetened therewith

ActiveUS20080107775A1Improve flavor profileImproving temporal profile profileNervous disorderTobacco treatmentRubiscolinAdditive ingredient

The present invention relates generally to functional sweetener compositions comprising non-caloric or low-caloric natural and / or synthetic high-potency sweeteners and methods for making and using them. In particular, the present invention relates to different functional sweetener compositions comprising at least one non-caloric or low-caloric natural and / or synthetic high potency sweetener, at least one sweet taste improving composition, and at least one functional ingredient, such as rubisco protein, rubiscolin, rubiscolin derivatives, ACE inhibitory peptide, and combinations thereof. The present invention also relates to functional sweetener compositions and methods that can improve the tastes of non-caloric or low-caloric high-potency sweeteners by imparting a more sugar-like taste or characteristic. In particular, the functional sweetener compositions and methods provide a more sugar-like temporal profile, including sweetness onset and sweetness linger, and / or a more sugar-like flavor profile.

Owner:THE COCA-COLA CO

Anti-Diabetic Composition with High-Potency Sweetener

InactiveUS20080107787A1Improve flavor profileImproved temporal profile profileMetabolism disorderFood preparationDiabetes mellitusSweetness

The present invention relates generally to anti-diabetic compositions comprising non-caloric or low-caloric high-potency sweeteners and methods for making and using them. In particular, the present invention relates to different anti-diabetic compositions comprising at least one non-caloric or low-caloric natural and / or synthetic high-potency sweetener, at least one sweet taste improving composition, and an anti-diabetic substance. The present invention also relates to anti-diabetic compositions and methods that can improve the tastes of non-caloric or low-caloric natural and / or synthetic, high-potency sweeteners by imparting a more sugar-like taste or characteristic. In particular, the anti-diabetic compositions and methods provide a more sugar-like temporal profile, including sweetness onset and sweetness linger, and / or a more sugar-like flavor profile.

Owner:THE COCA-COLA CO

High-Potency Sweetener Composition With Phytosterol and Compositions Sweetened Therewith

InactiveUS20070116824A1Improve flavor profileImproving temporal profile profileSugar food ingredientsAntipyreticPlant sterolAdditive ingredient

The present invention relates generally to functional sweetener compositions comprising non-caloric or low-caloric natural and / or synthetic high-potency sweeteners and methods for making and using them. In particular, the present invention relates to different functional sweetener compositions comprising at least one non-caloric or low-caloric natural and / or synthetic high-potency sweetener, at least one sweet taste improving composition, and at least one functional ingredient, such as phytosterols, phytostanols, esters thereof, or combinations thereof. The present invention also relates to functional sweetener compositions and methods that can improve the tastes of non-caloric or low-caloric high-potency sweeteners by imparting a more sugar-like taste or characteristic. In particular, the functional sweetener compositions and methods provide a more sugar-like temporal profile, including sweetness onset and sweetness linger, and / or a more sugar-like flavor profile.

Owner:THE COCA-COLA CO

Toasted soybean flakes and method of making same

InactiveUS7169432B2Improve flavor profileReduces undesirable beany and off-flavorsVegetable proteins working-upFood preparationSolanum tuberosumCereal grain

The invention relates to toasted full fat, enzyme active soybean flakes, and method of making same. The inventive flakes are excellent for use in hot and cold cereal compositions including with rolled oats, in soybean flakes-potato flakes compositions for making soy protein enriched mashed potato products, in granola and power bar type compositions, in shake-and-bake type compositions, and in meat analogue veggie-burger type compositions. The inventive toasted full fat, enzyme active soybean flakes are prepared by subjecting full fat, enzyme active soybean flakes made from dehulled soybeans to relatively high heat from dry heated air for a relatively short time while moving on and / or above a moving or vibrating surface. The invention further relates to use of the inventive toasted soybean flakes in soybean flakes-potato flakes compositions, and said compositions per se.

Owner:DEDHAM COOP ASSOC

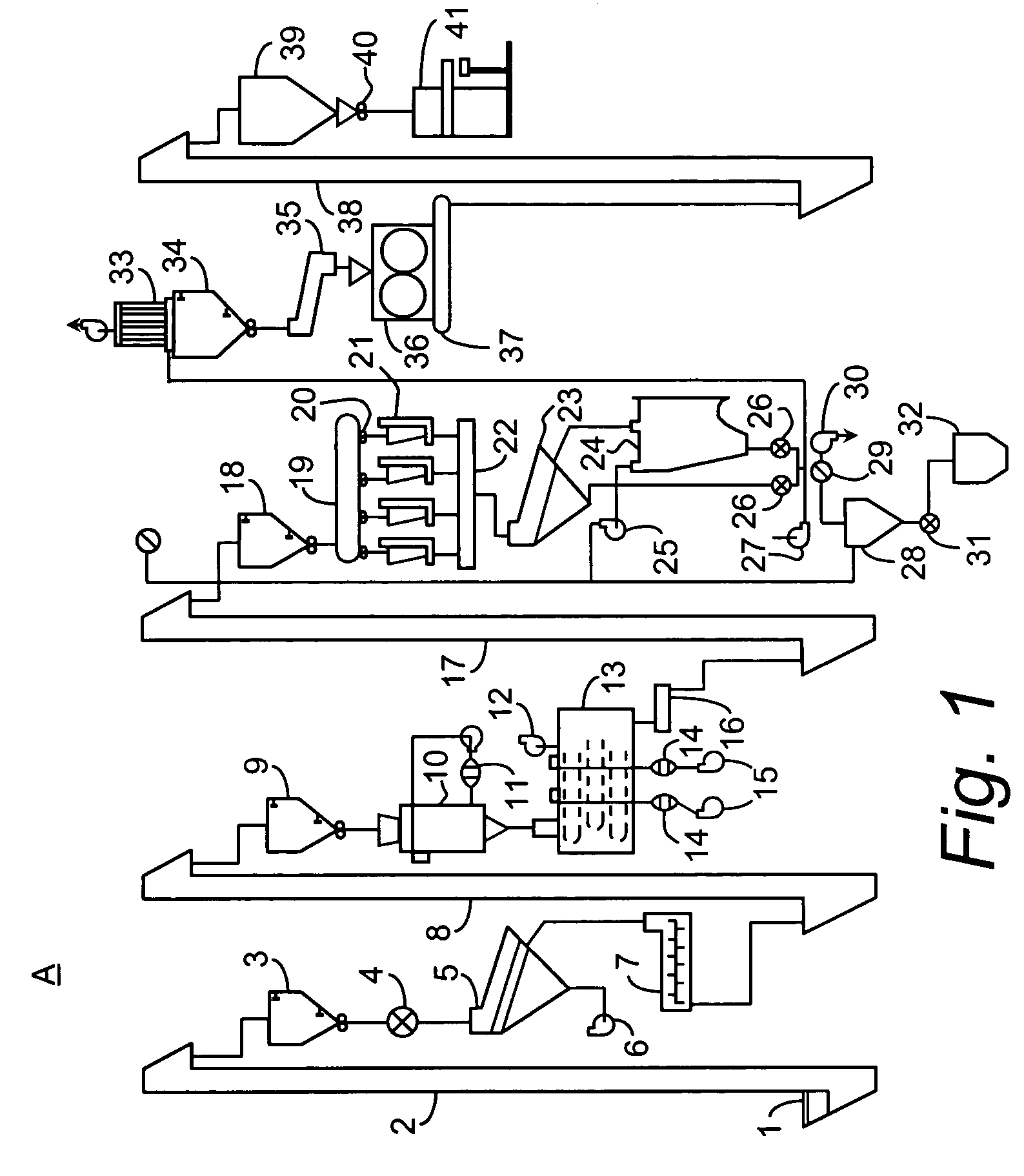

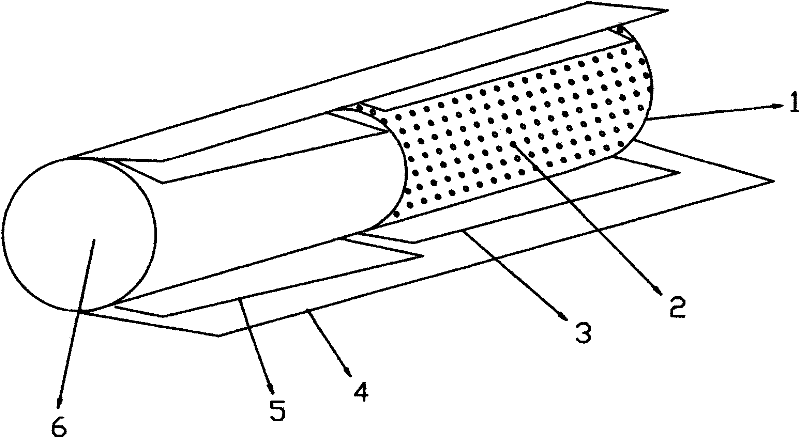

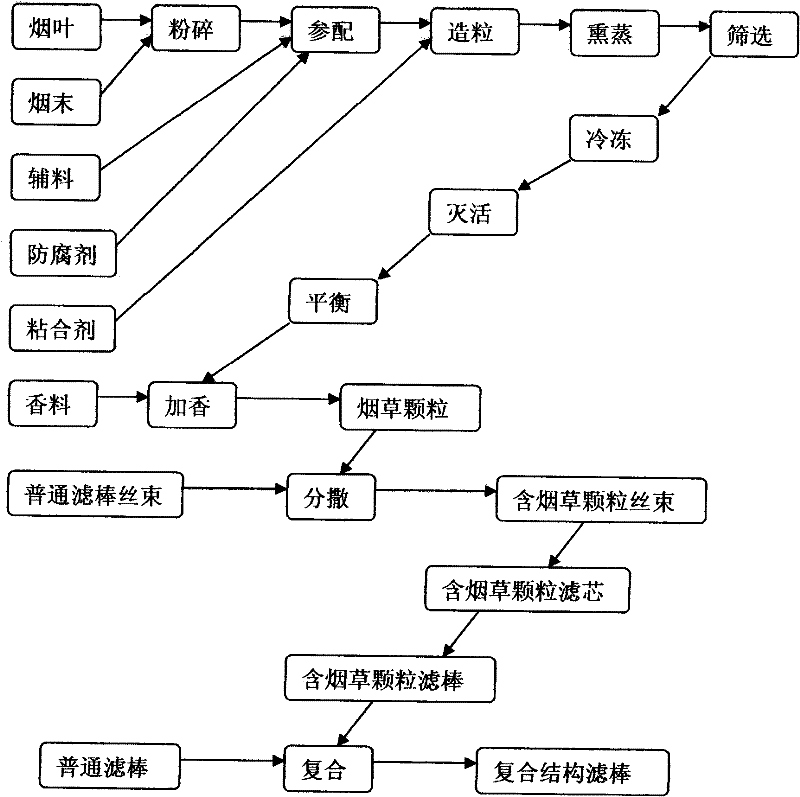

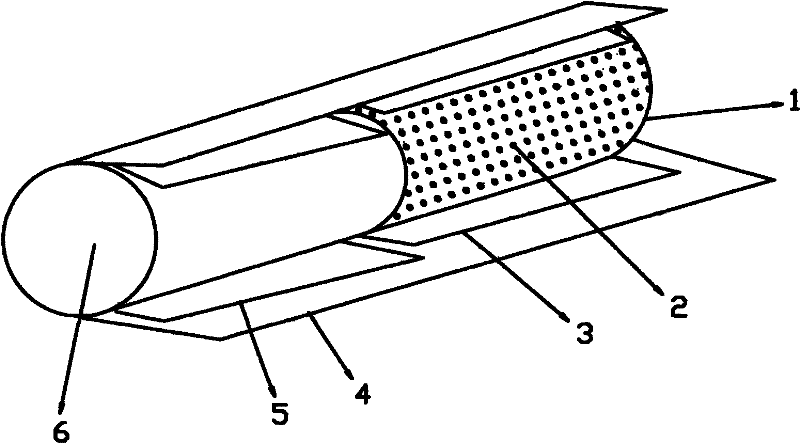

Filter stick containing tobacco particles and preparation method thereof

The invention provides a novel filter stick for cigarettes and a preparation method thereof. Tobacco particles are added in a filter core of the filter stick, tobacco leaves and tobacco smalls are adopted as main raw materials of the tobacco particles and are used as additives after the technical processing such as pulverizing, rotten prevention, granulating, fumigating, perfuming and the like tobe thrown into tows of the filter stick, and then the filter stick containing the tobacco particles or the filter stick with a composite structure can be prepared by adopting a filter stick forming machine. The filter stick can strengthen the adsorption function, can reduce the tar and alleviating the harm, and fragrance of the tobacco particles also can effectively compensate the decreased fragrance of the cigarette caused by the filtering of the filter stick. At the same time, the filter stick is easy to cut and is friendly to the environment.

Owner:NANTONG CIGARETTE FILTER

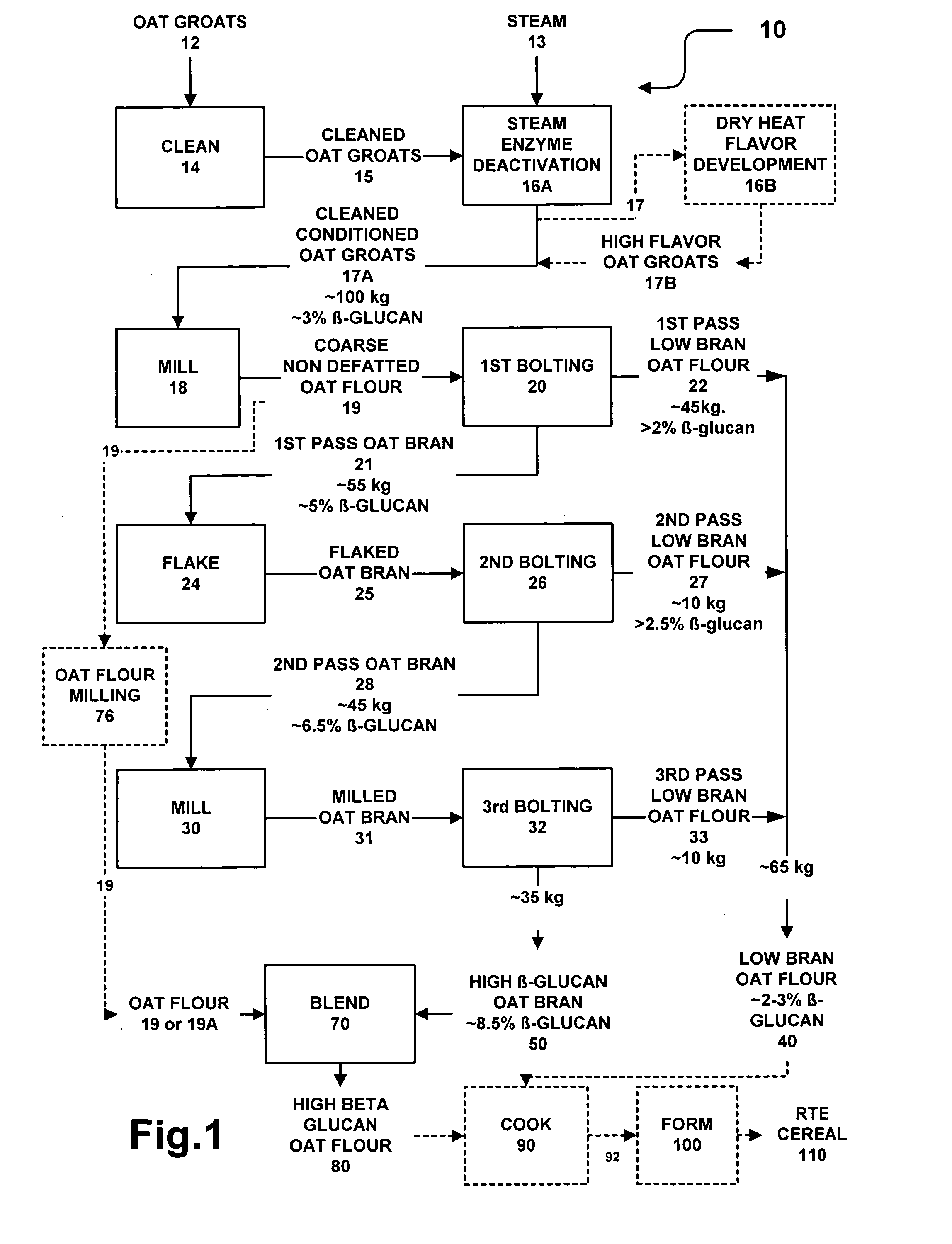

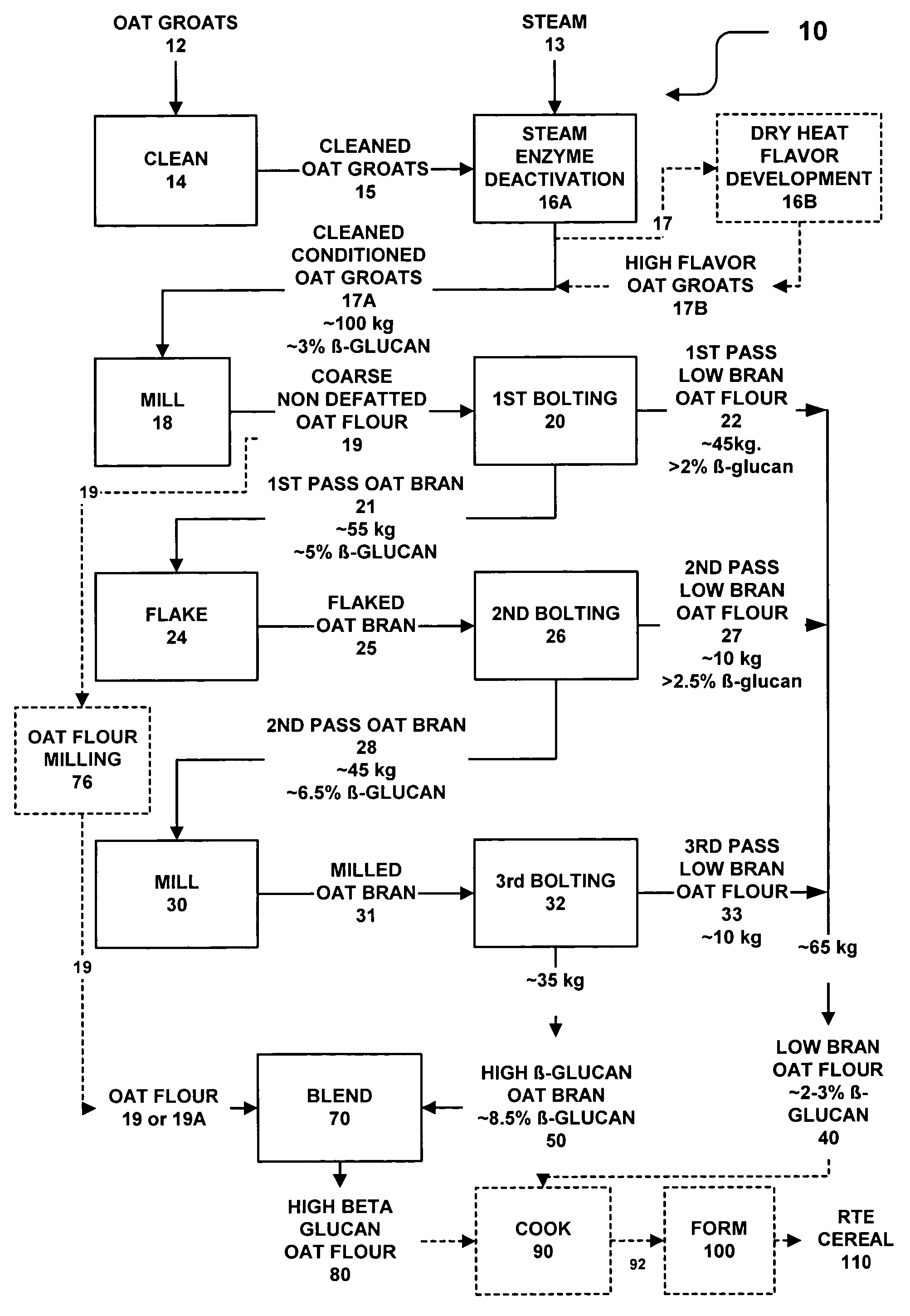

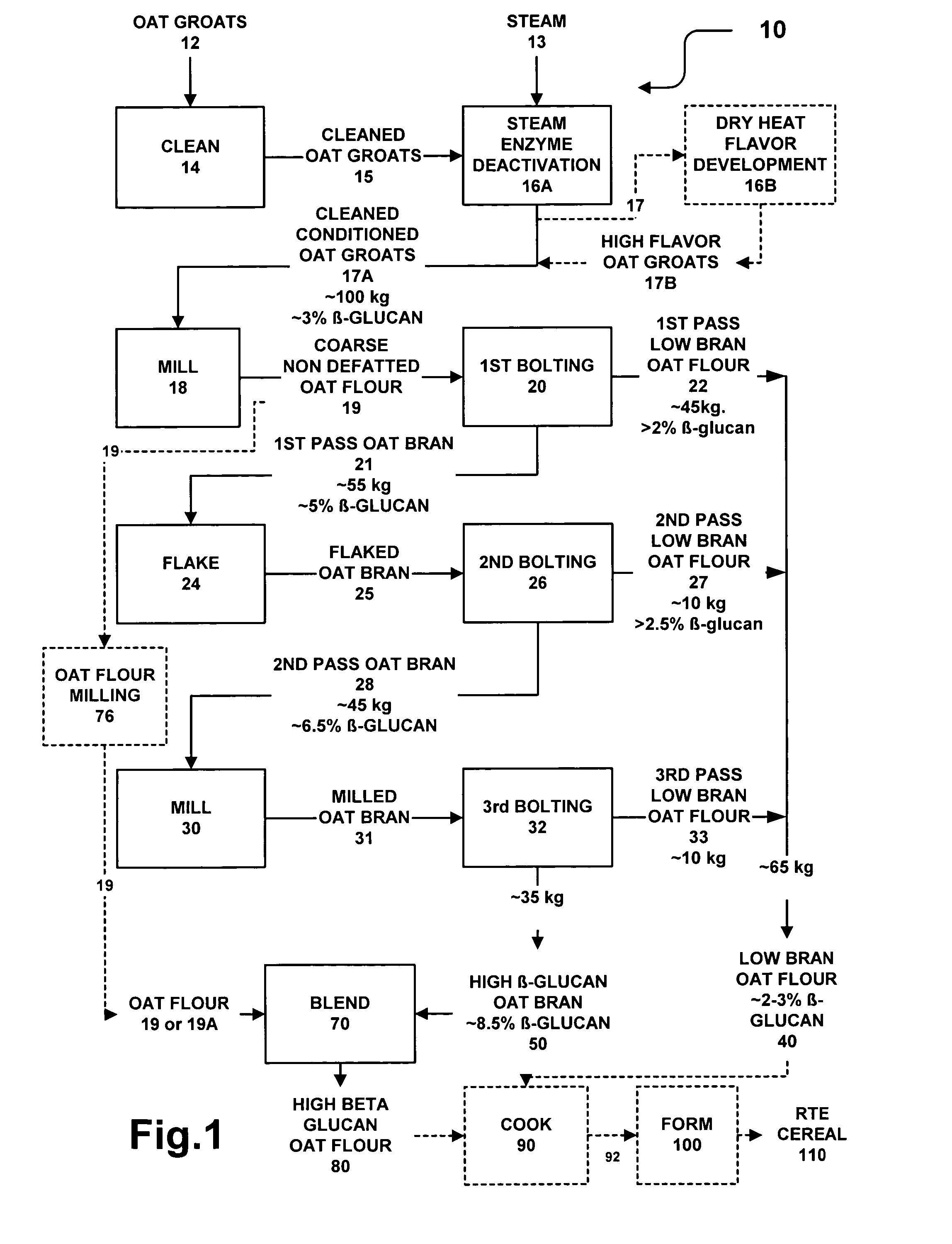

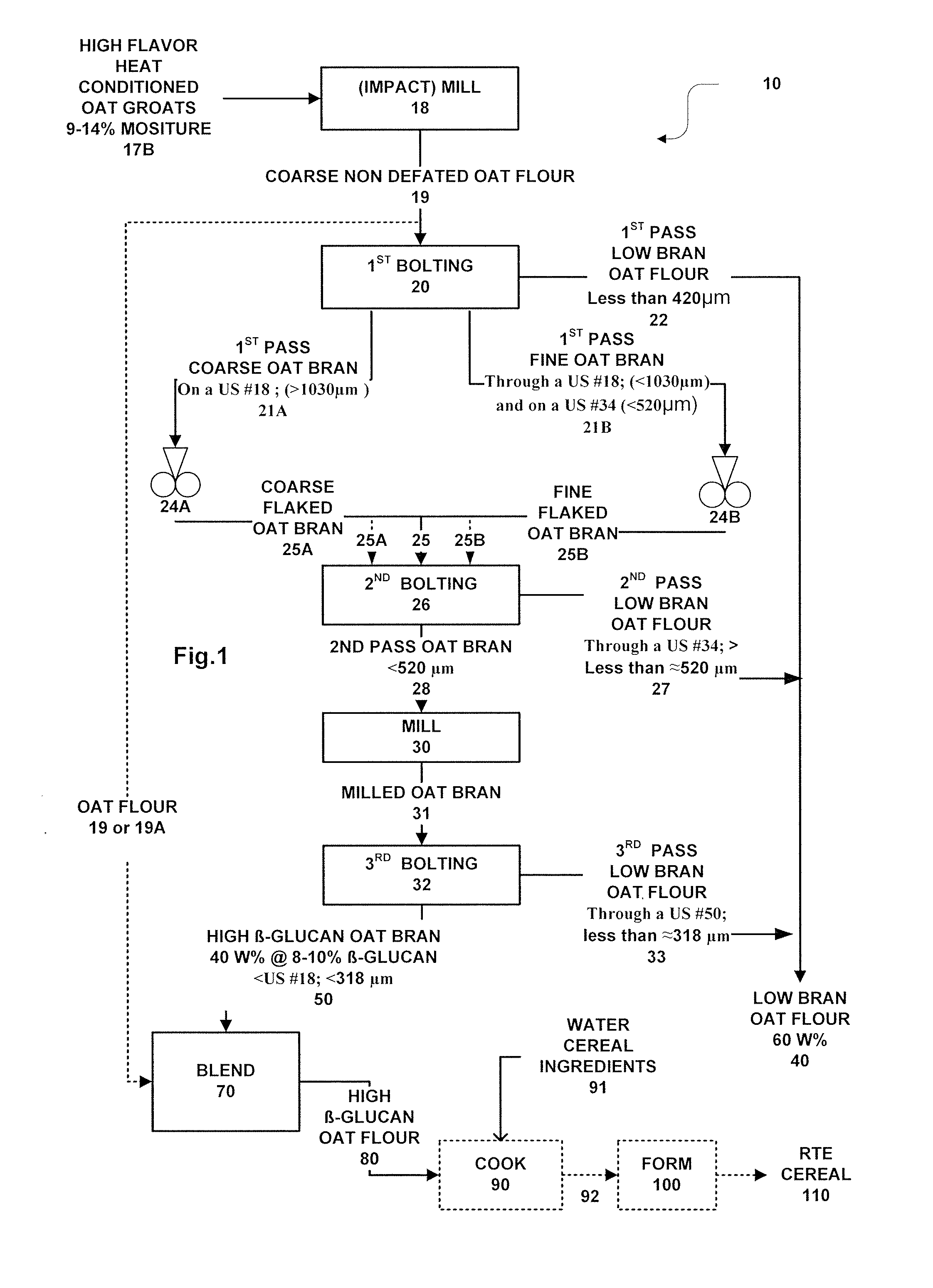

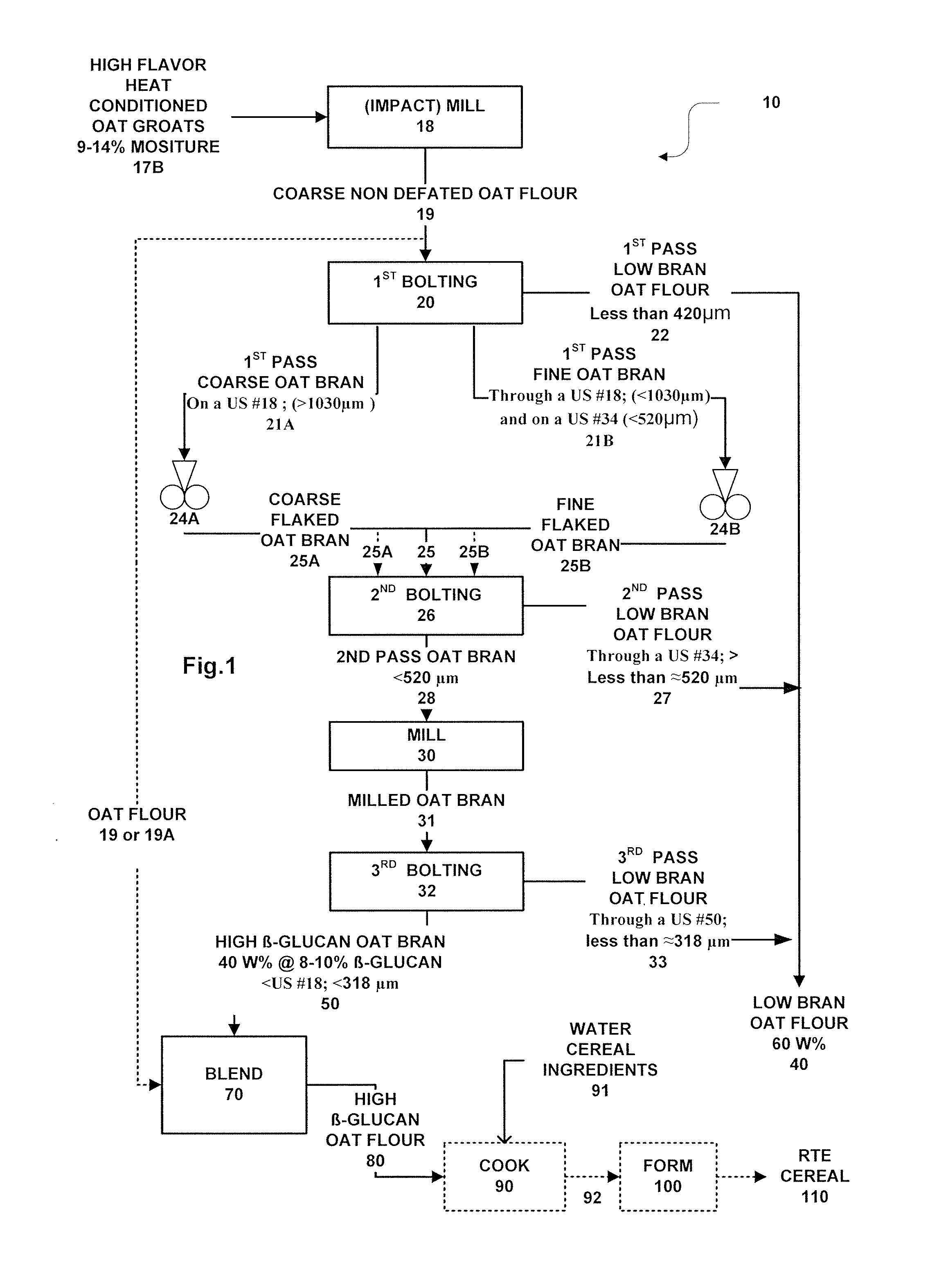

Methods for preparing oat bran enriched in beta-glucan and oat products prepared therefrom

ActiveUS20050153044A1Add flavorEnhance cooking characteristicsDough treatmentBaking mixturesFood flavorCereal grain

Dry milling methods for preparing oat products enriched in the content of β-glucan and methods for preparing foodstuffs incorporating such an enriched oat product especially ready-to-eat cereals are provided. Heat conditioned dehulled oats are dry milled to form a coarse whole non defatted oat flour and then, without a preceding removal of fat, dry fractionated into coarser bran and finer oat flour fractions at multiple stages. The coarse oat flour is first dry classified to separate or form a coarser fraction oat bran containing more concentrated β-glucan and a finer oat flour or starch containing or endosperm containing fraction. The oat bran is subjected to second and third rounds of milling and classification to form a high β-glucan content (>7-9%) oat bran and a low β-glucan content (3%) oat flour. The methods are low cost and commercially practical. Preferably, the high β-glucan content oat bran and oat flour fractions can have a syringic acid to ferulic acid ratio of at least 2.5:1 indicating improved flavor. Preferably, the oat bran and oat flour have a Farinograph value of 5 to 20 minutes indicated partial gelatinization. The oat bran and oat flours can be used to prepare foodstuffs such as ready-to-eat cereals.

Owner:GENERAL MILLS INC

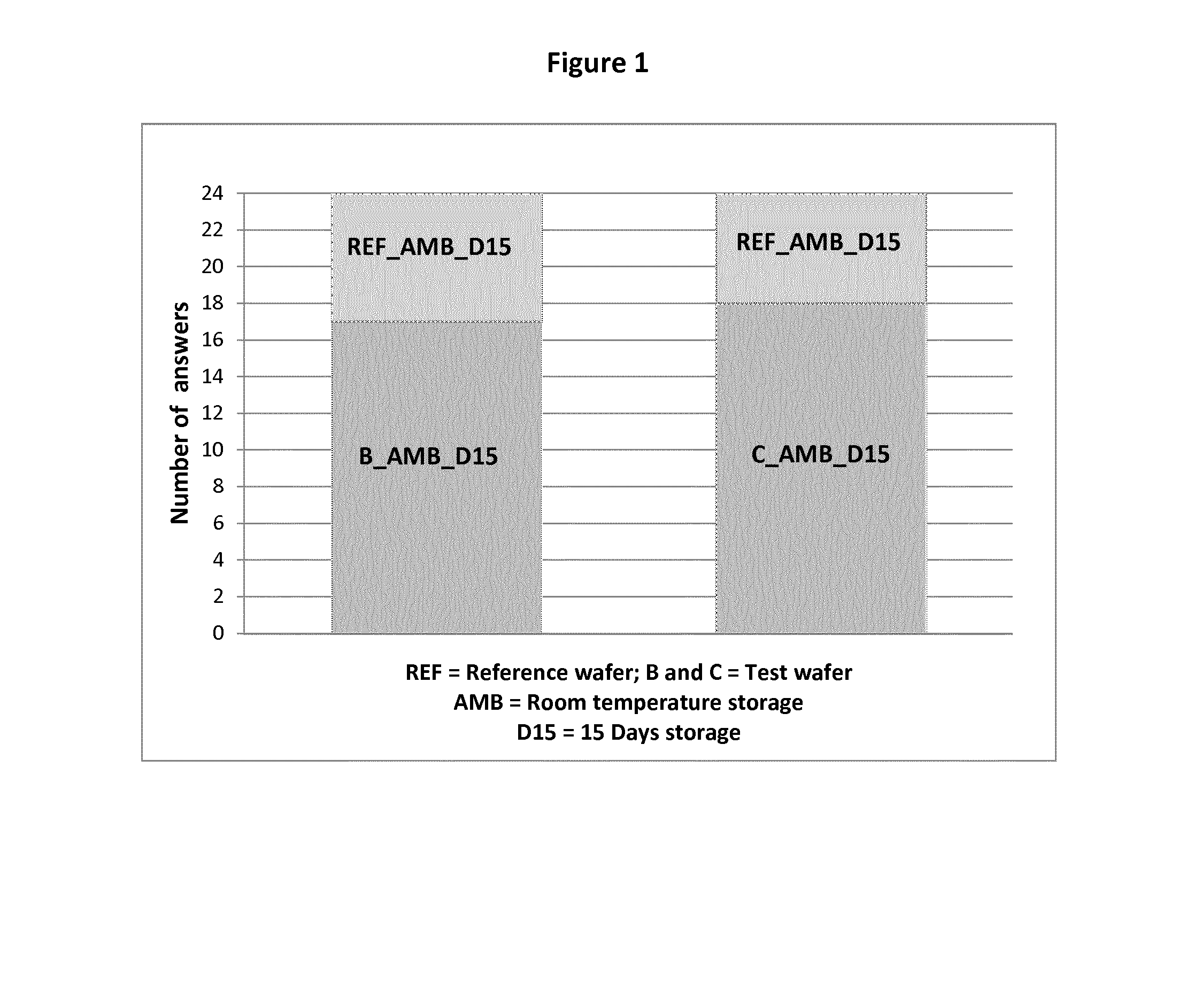

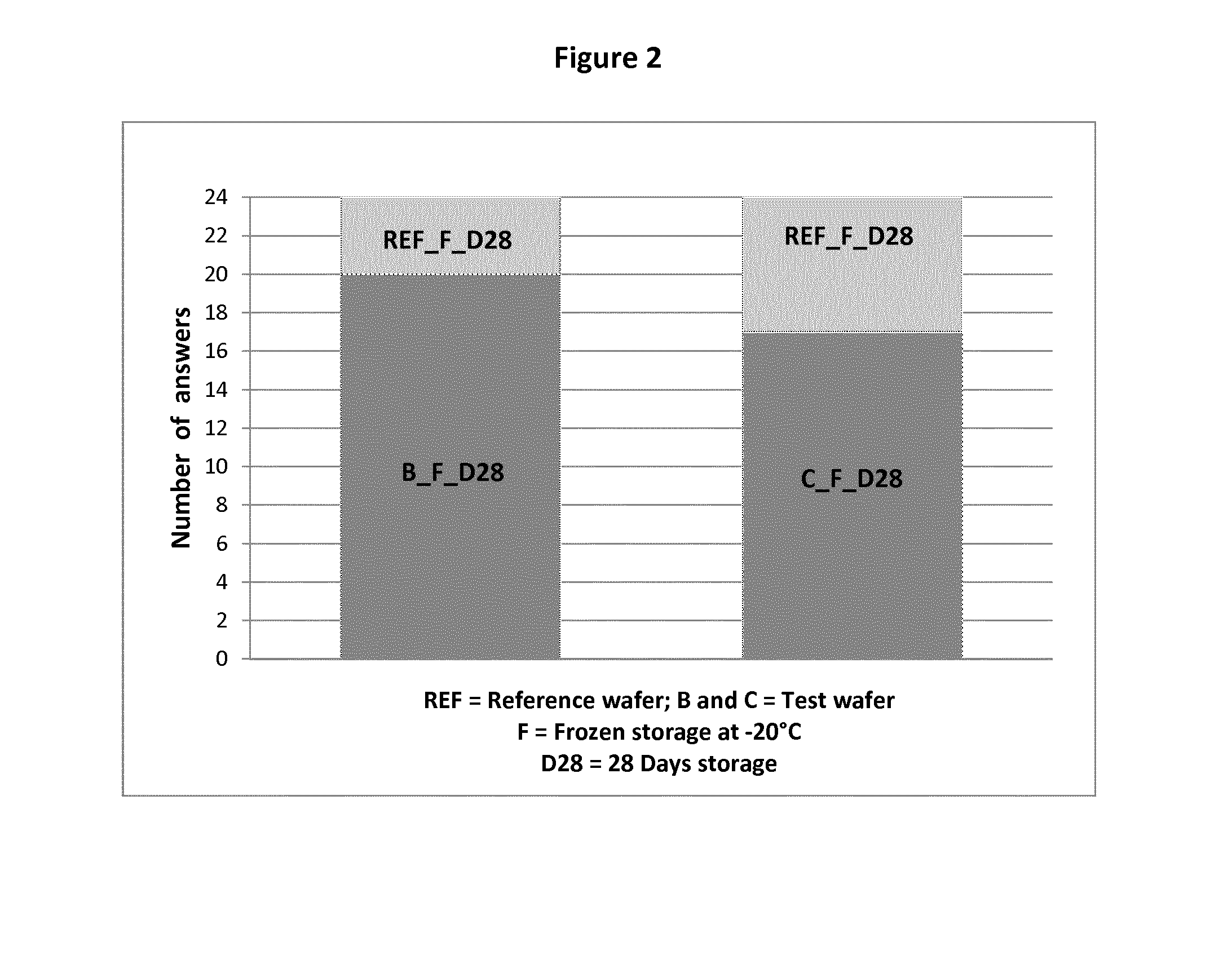

Bakery product with improved flavour properties

InactiveUS20140065270A1Improves long lastingnessAdd flavorDough treatmentBakery productsAlkanePolyol

The present invention relates to a bakery product with improved flavour properties and in particular an improved flavour shelf life. The product is prepared from a dough comprising flour, water, proline and an alkane polyol preferably wet, present in an effective amount to improve the flavour properties of said product when baked.

Owner:NESTEC SA

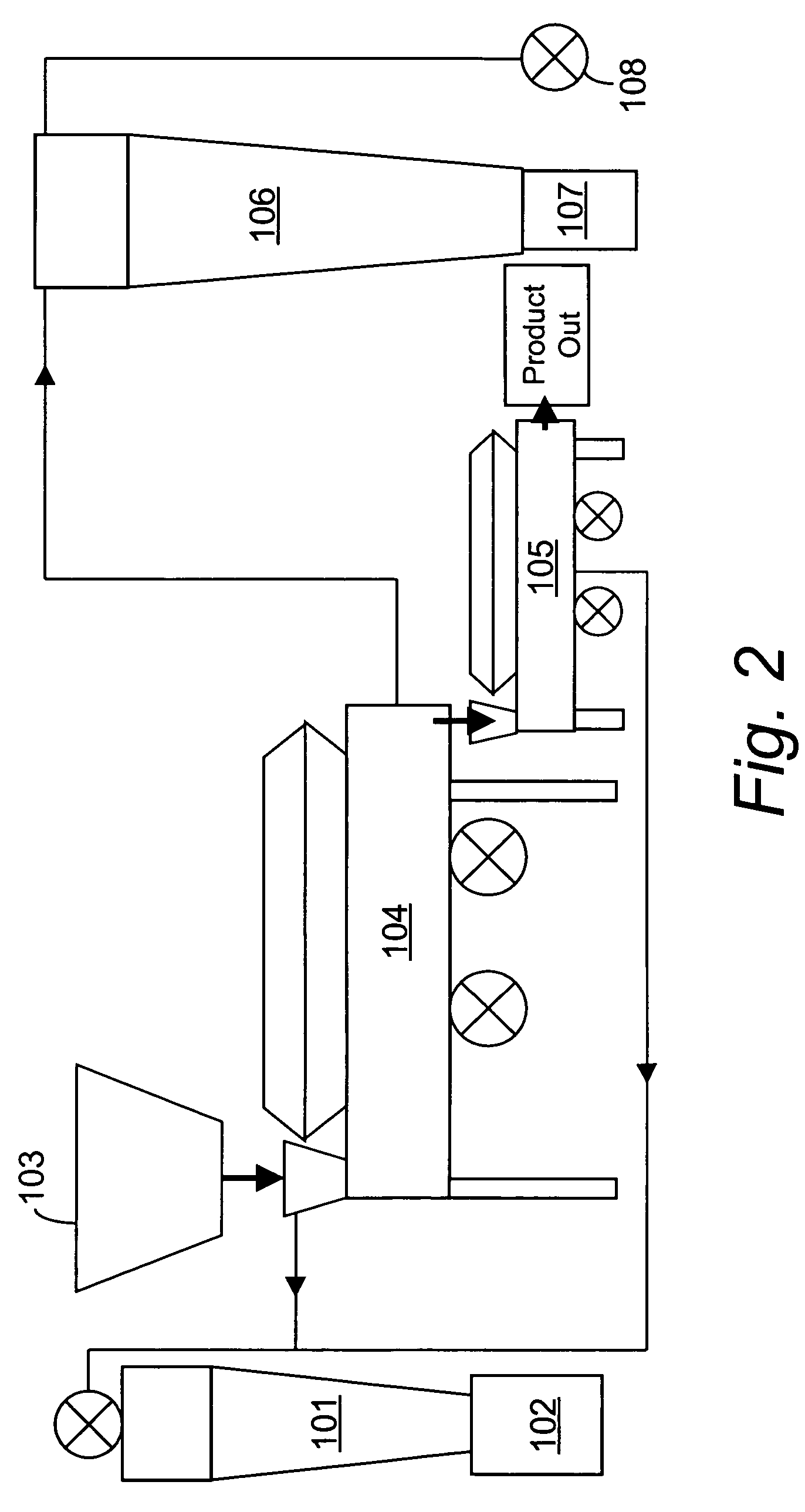

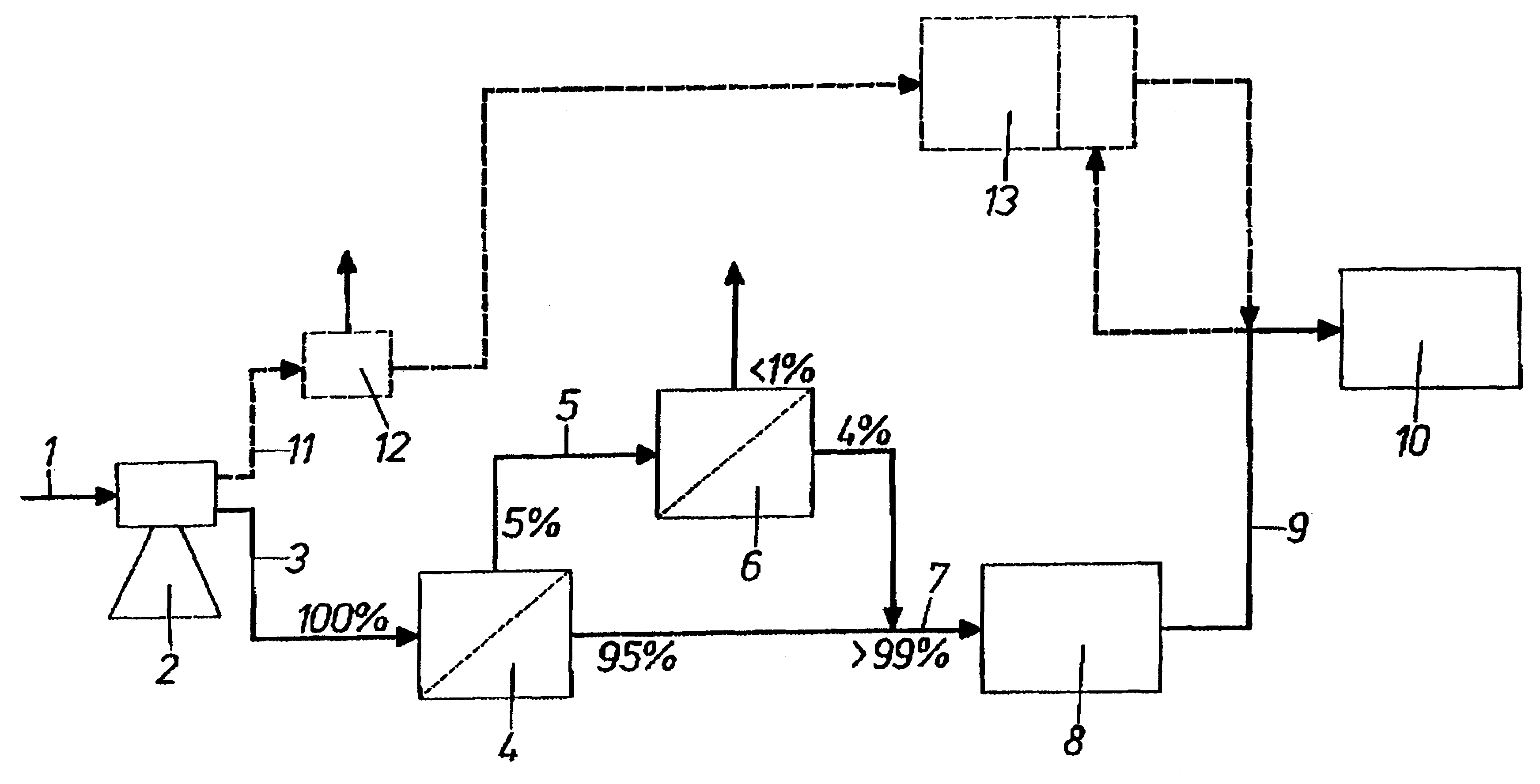

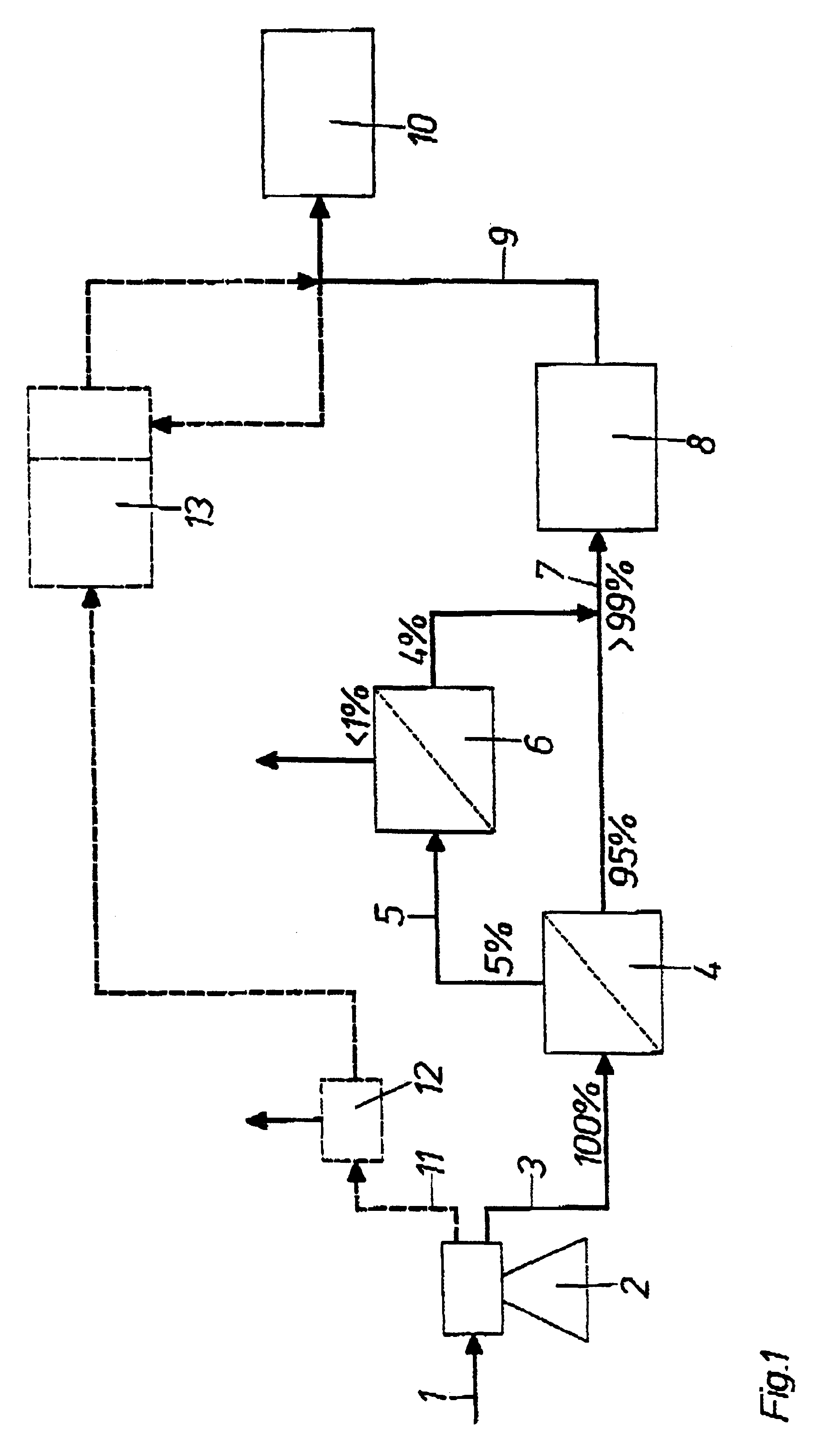

Filter apparatus and method for the production of sterile skimmed milk

InactiveUS6326044B1Improve flavor profileMilk preparationSemi-permeable membranesMicroorganismMicrofiltration

The present invention relates to a method for the production of commercially sterile skimmed milk. After separation, the skimmed milk fraction is treated by microfiltration in one or more steps. The microfiltration gives a permeate flow and a retentate flow, in which all microorganisms of a given size have effectively been separated from the permeate flow. After the microfiltration, the permeate flow is heat treated at a temperature of 72-134°C. during a requisite period of time. In order to obtain a sterile skimmed milk which is as good as free of destroyed microorganisms, the retentate flow is not employed.

Owner:TETRA LAVAL HLDG & FINANCE SA

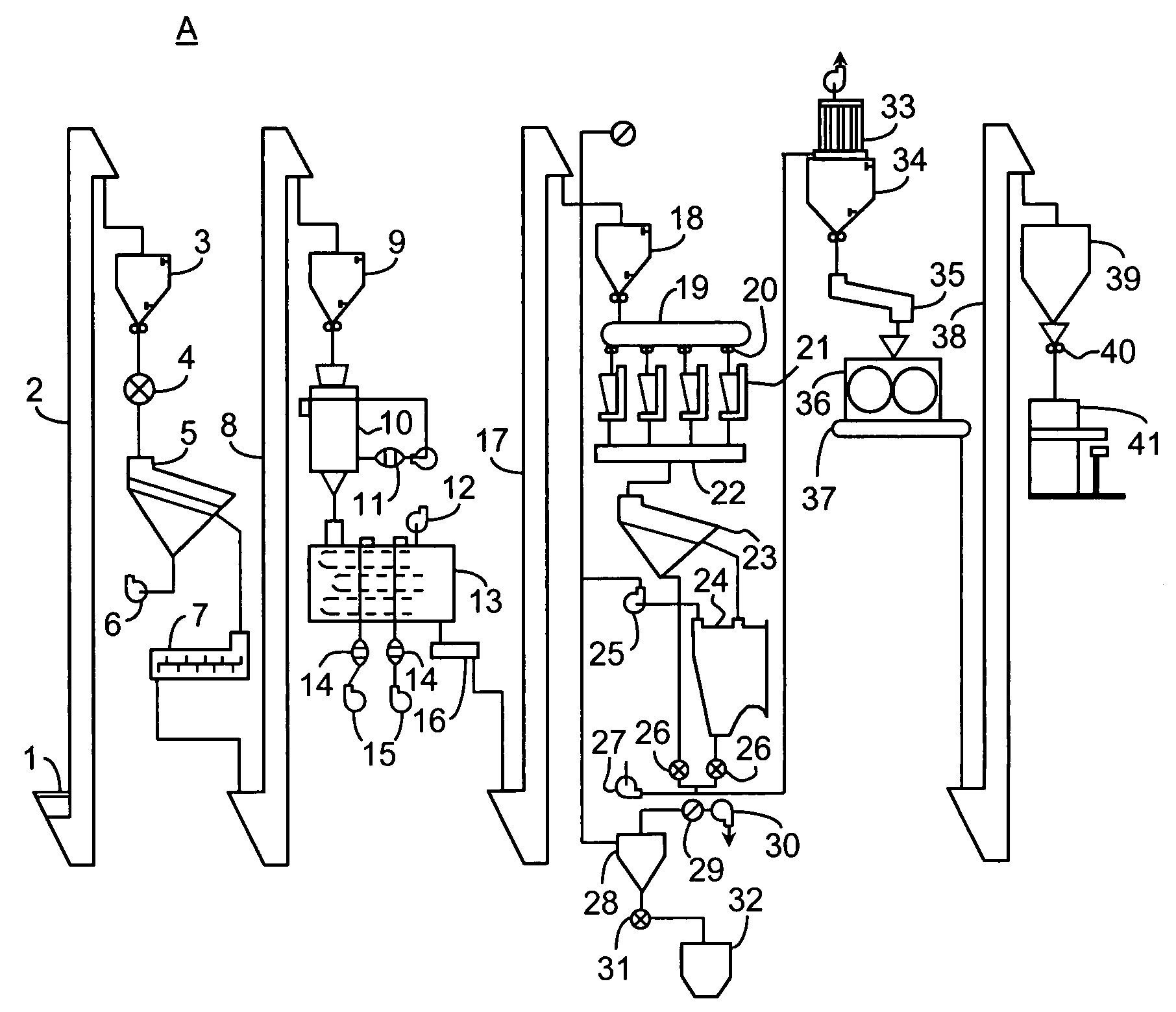

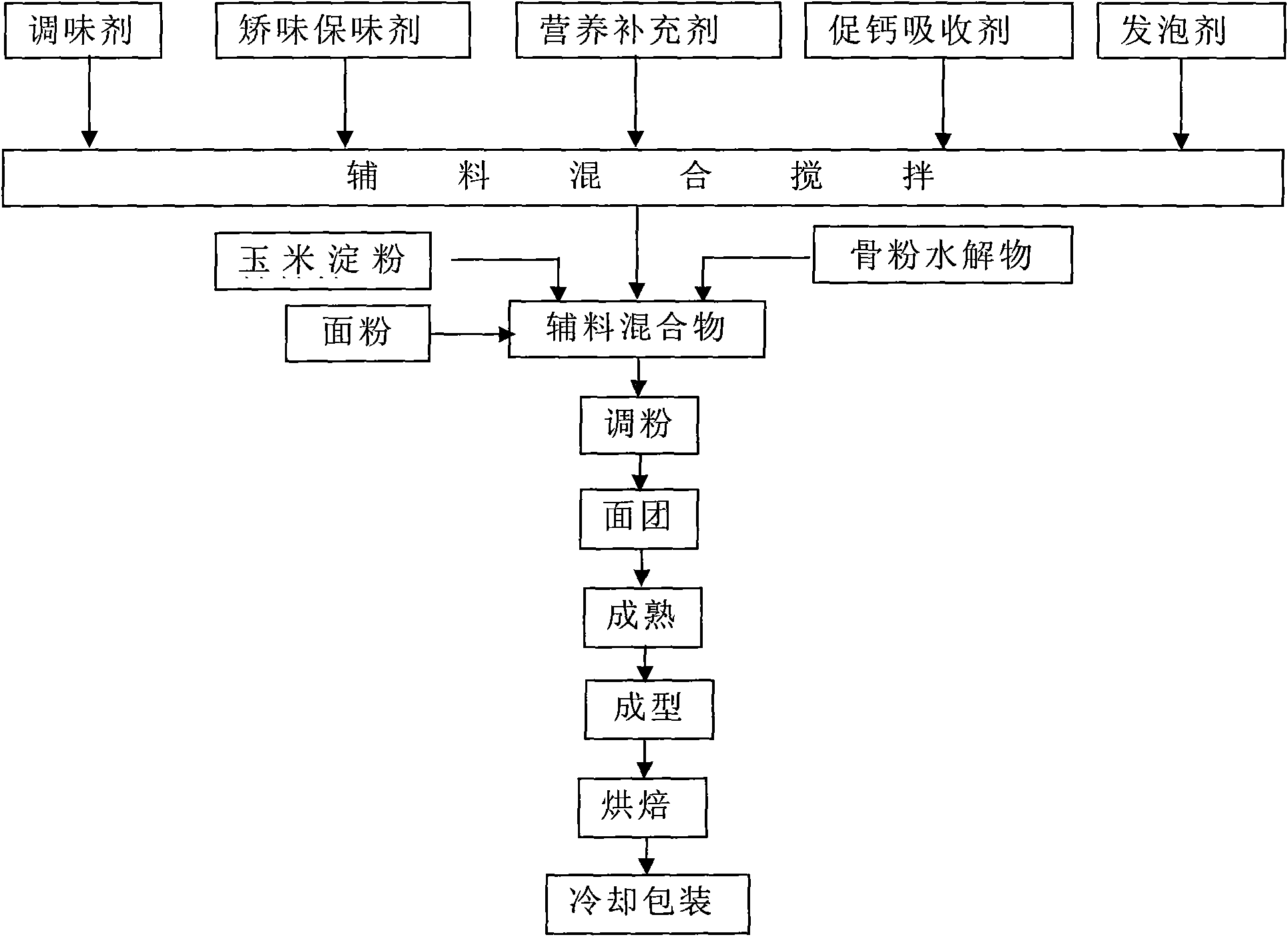

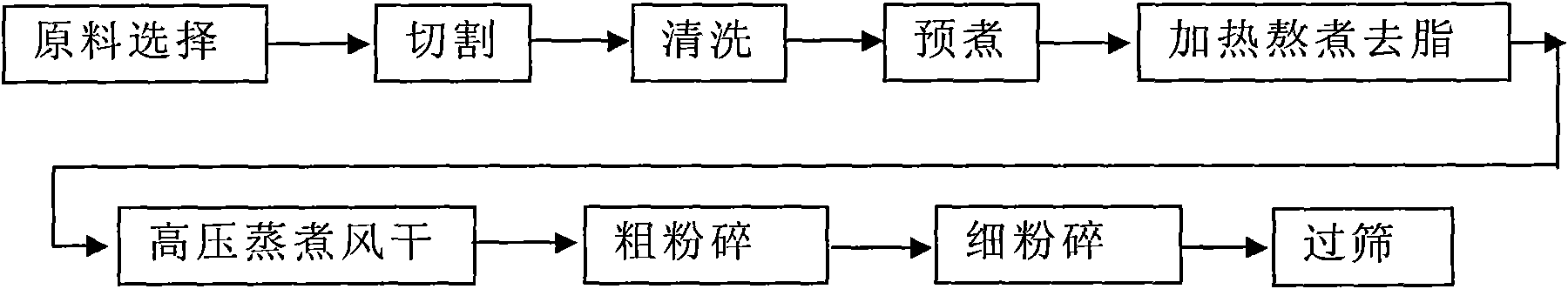

Nutritional biscuit with high bone calcium and making method thereof

InactiveCN101606545AIt has the effect of correcting and preserving flavorImprove and improve organizational structureDough treatmentBakery productsFlavorFoaming agent

The invention relates to a nutritional biscuit with high bone calcium and a making method thereof, belonging to a processing and making technique of foods required by the life of human beings. The nutritional biscuit is formed by preparing and processing the following raw materials according to a certain proportion formula and a certain production technology and comprises the following raw materials according to the formula and the mixture ratio: 950g of flour, 50g of corn starch, 350g to 450g of cattle bone powder hydrolyzing substance, 240g to 260g of flavoring agent, 140g to 160g of flavoring taste-retaining agent, 280g to 300g of nutritional extender, 80g to 100g of calcium absorption promoter, 6g to 8g of foaming agent and 1ml of butter essence. The product contains high effective calcium and abundant nutrition, the color of the surface of the biscuit is bright, and the biscuit has a deep red brown color, has the special flavor of bone, is soft, savory and crisp and has no peculiar odor. The processing procedure of the invention is shown as the attached drawing of the abstract.

Owner:GUIZHOU UNIV

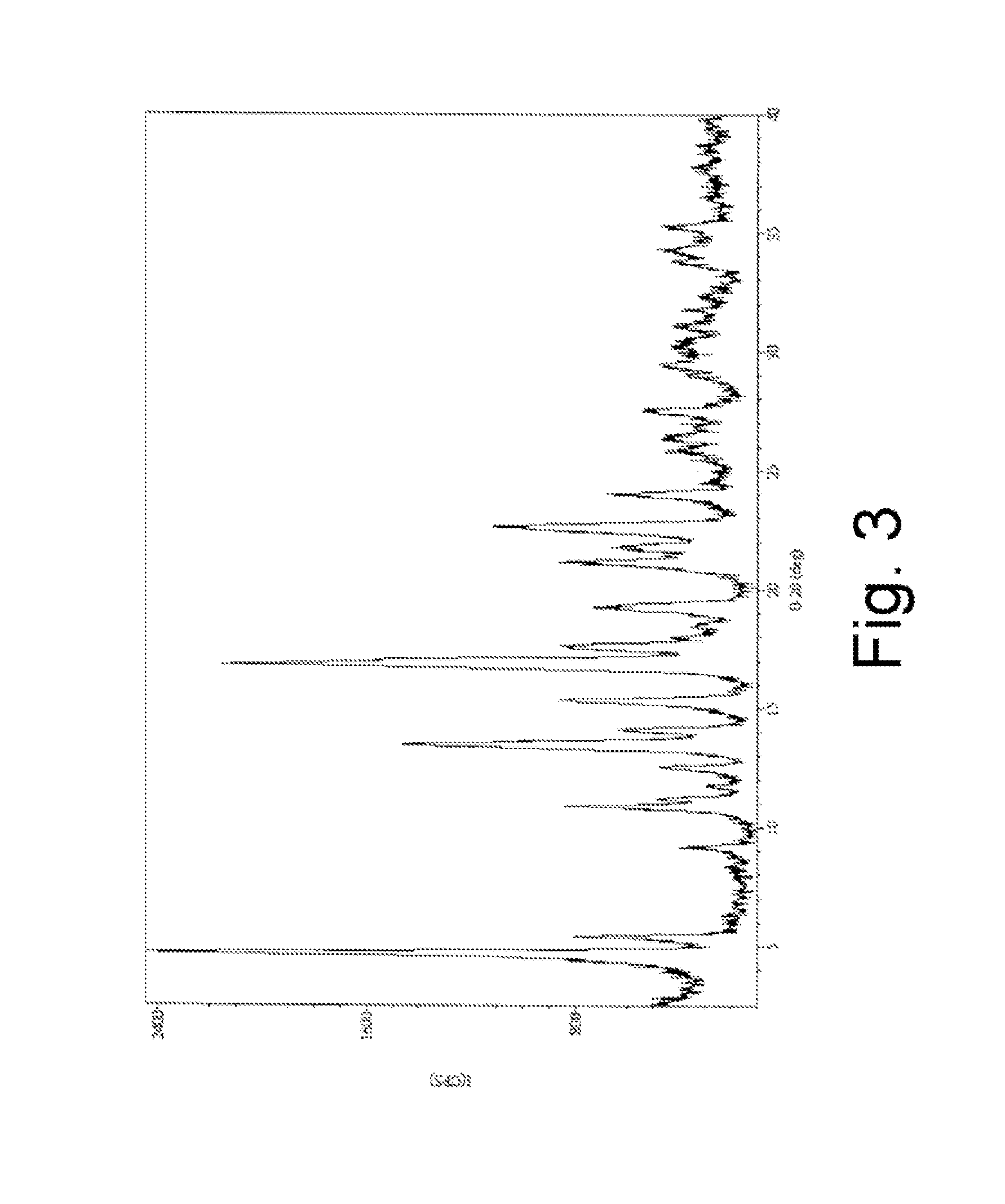

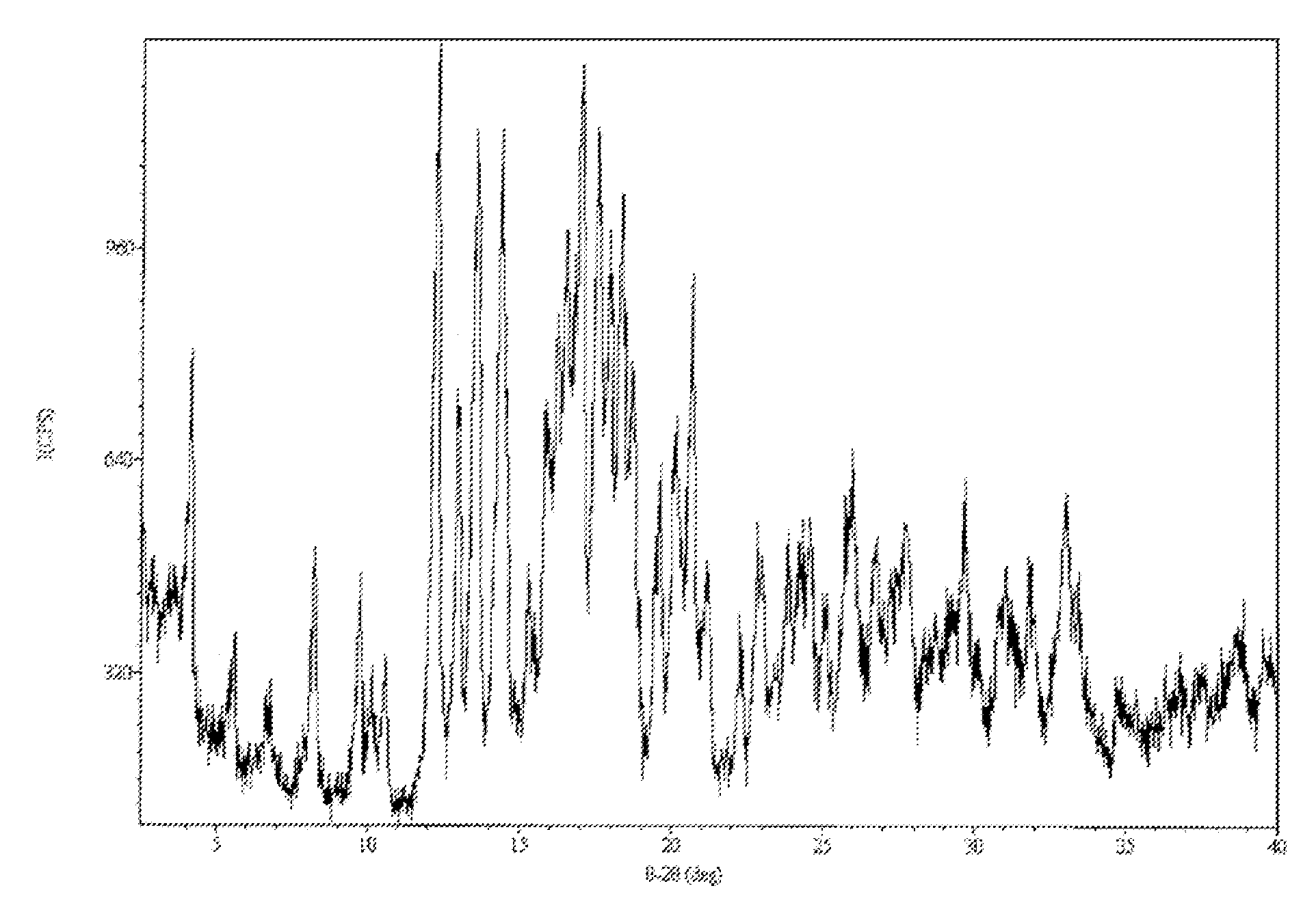

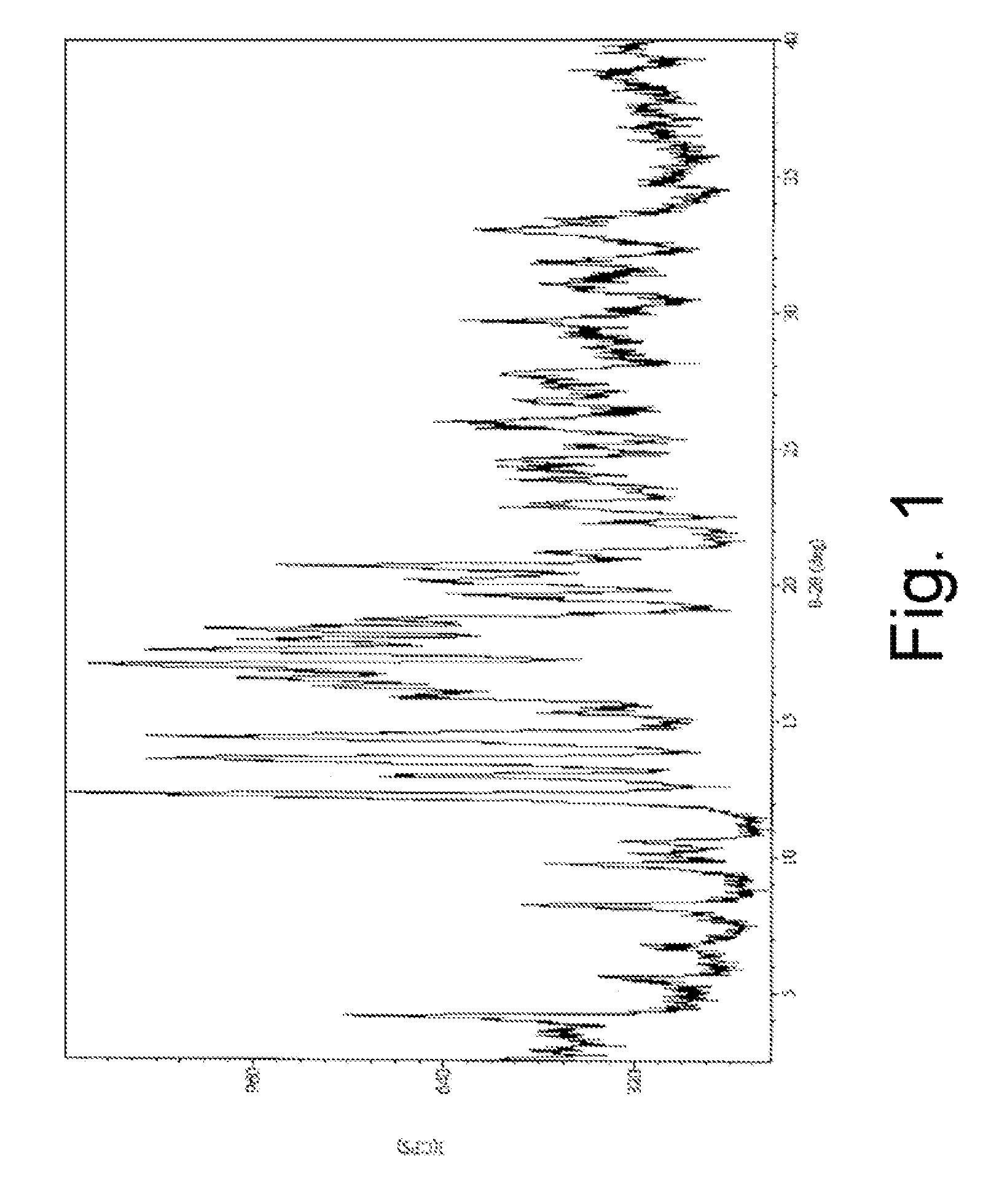

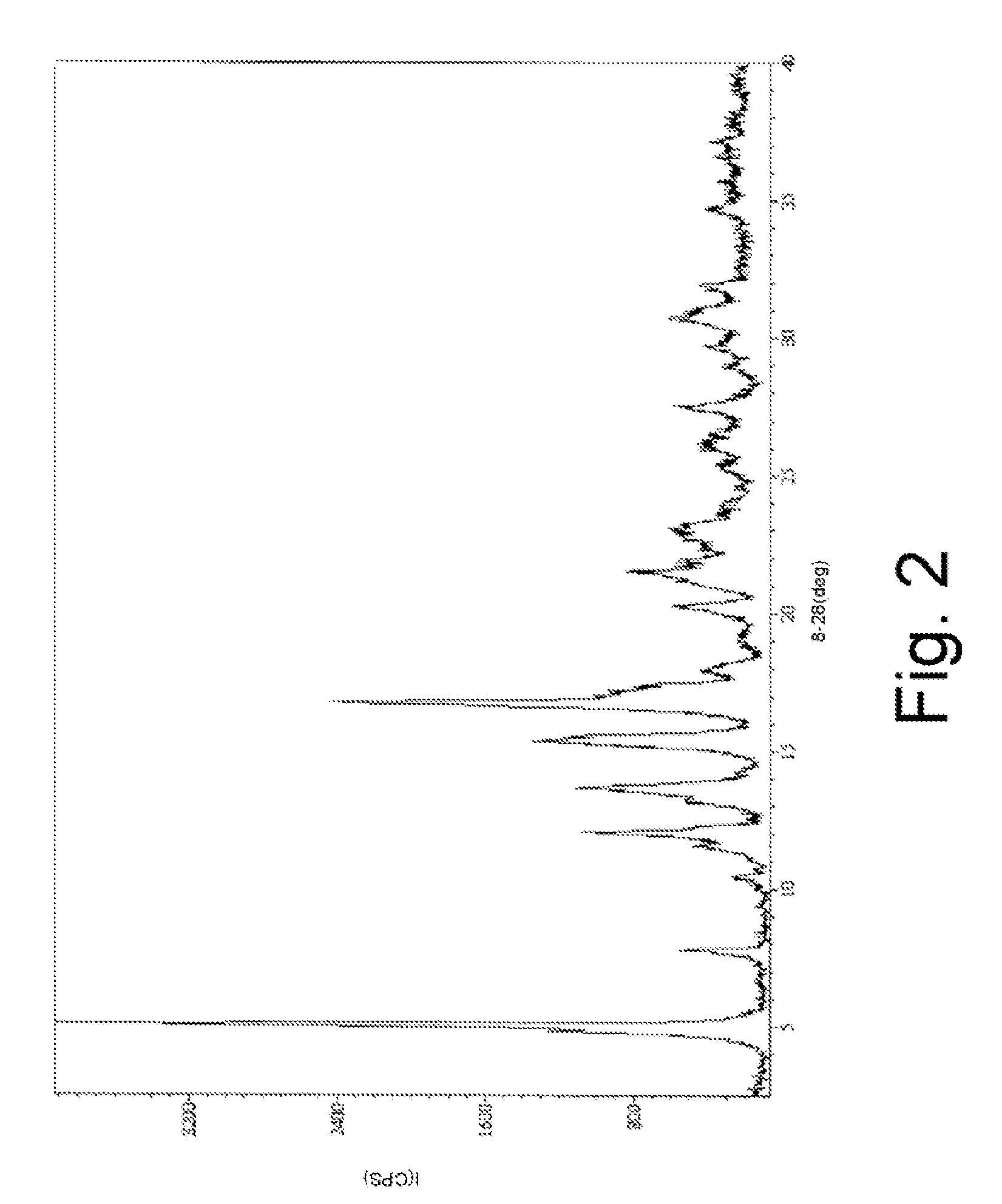

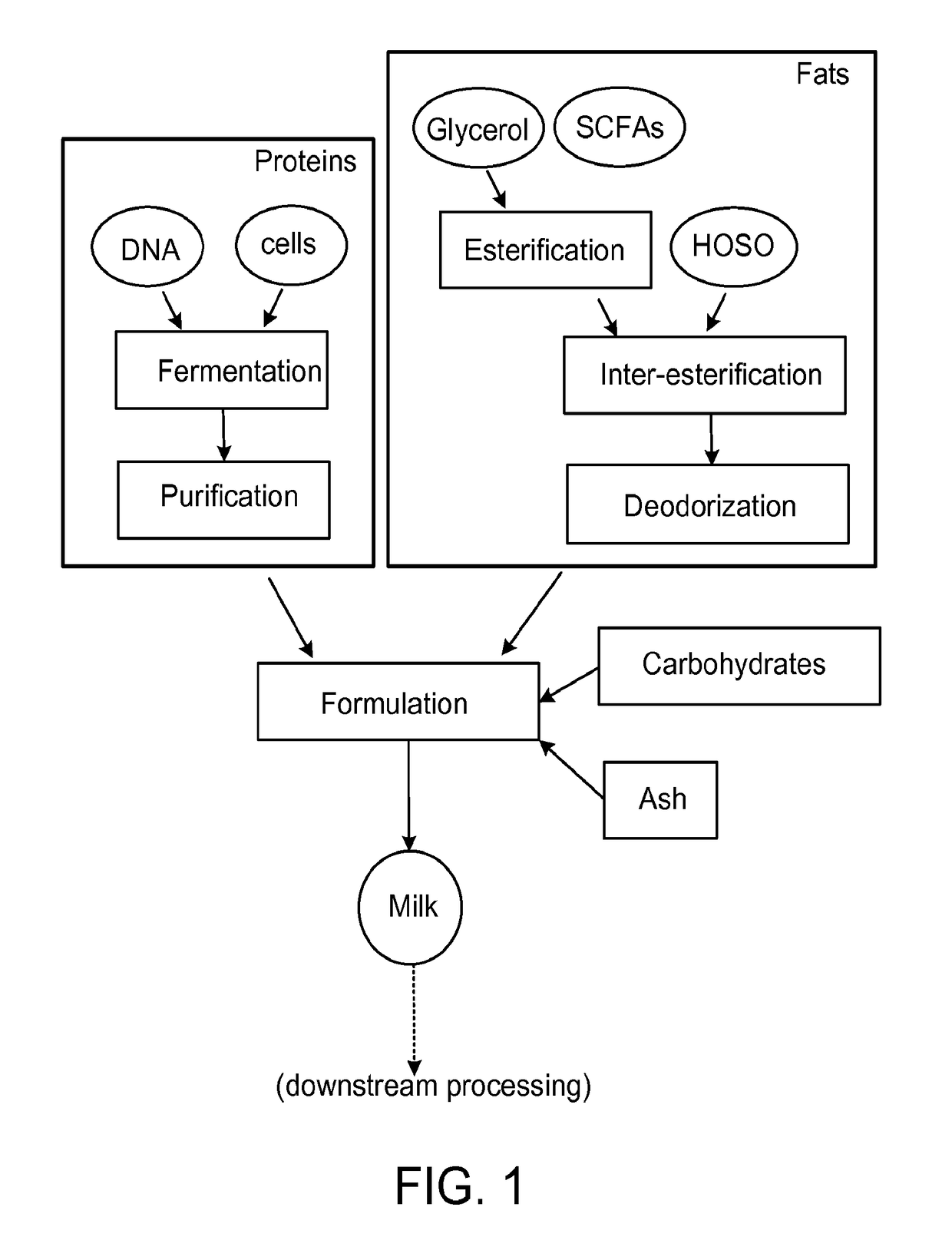

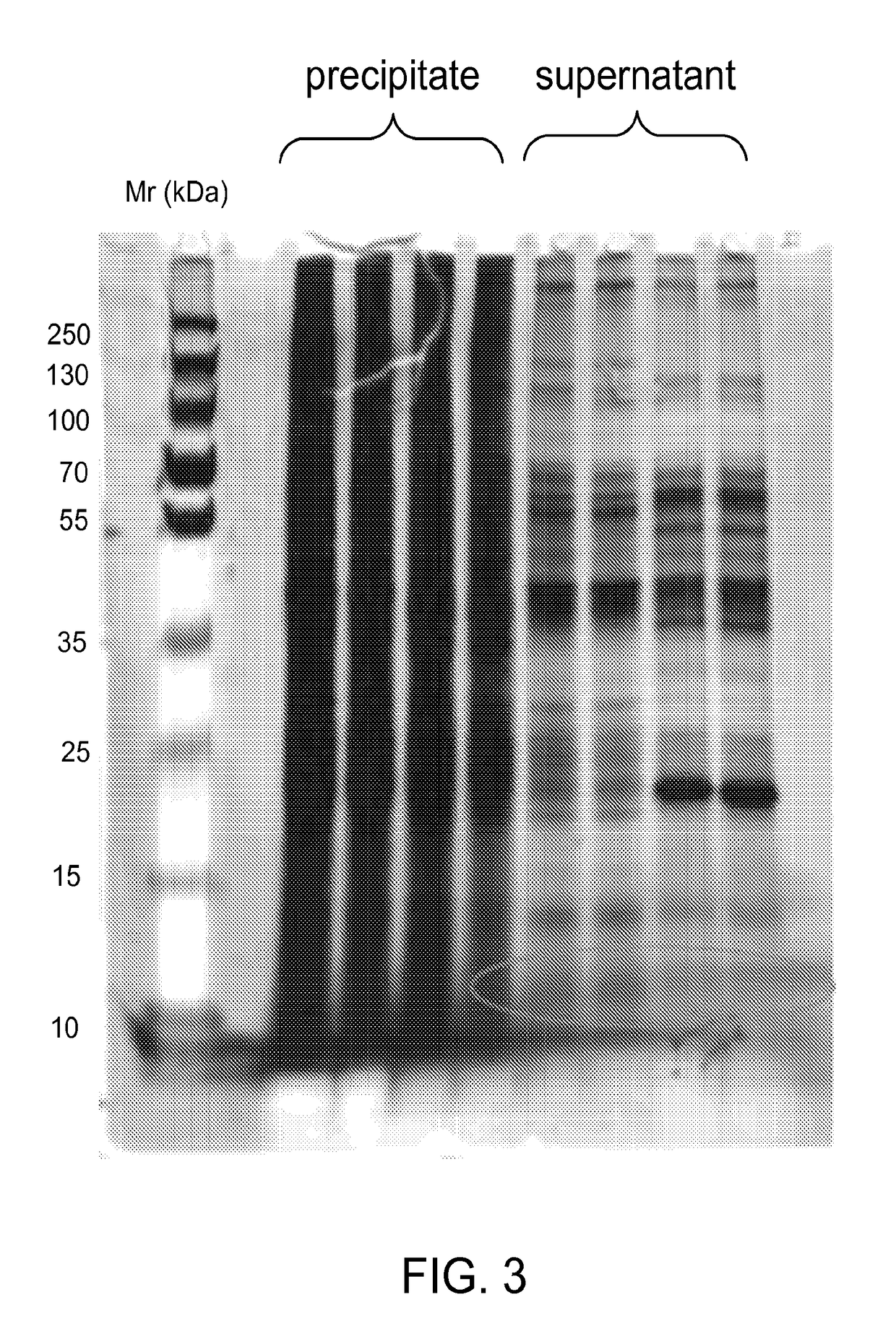

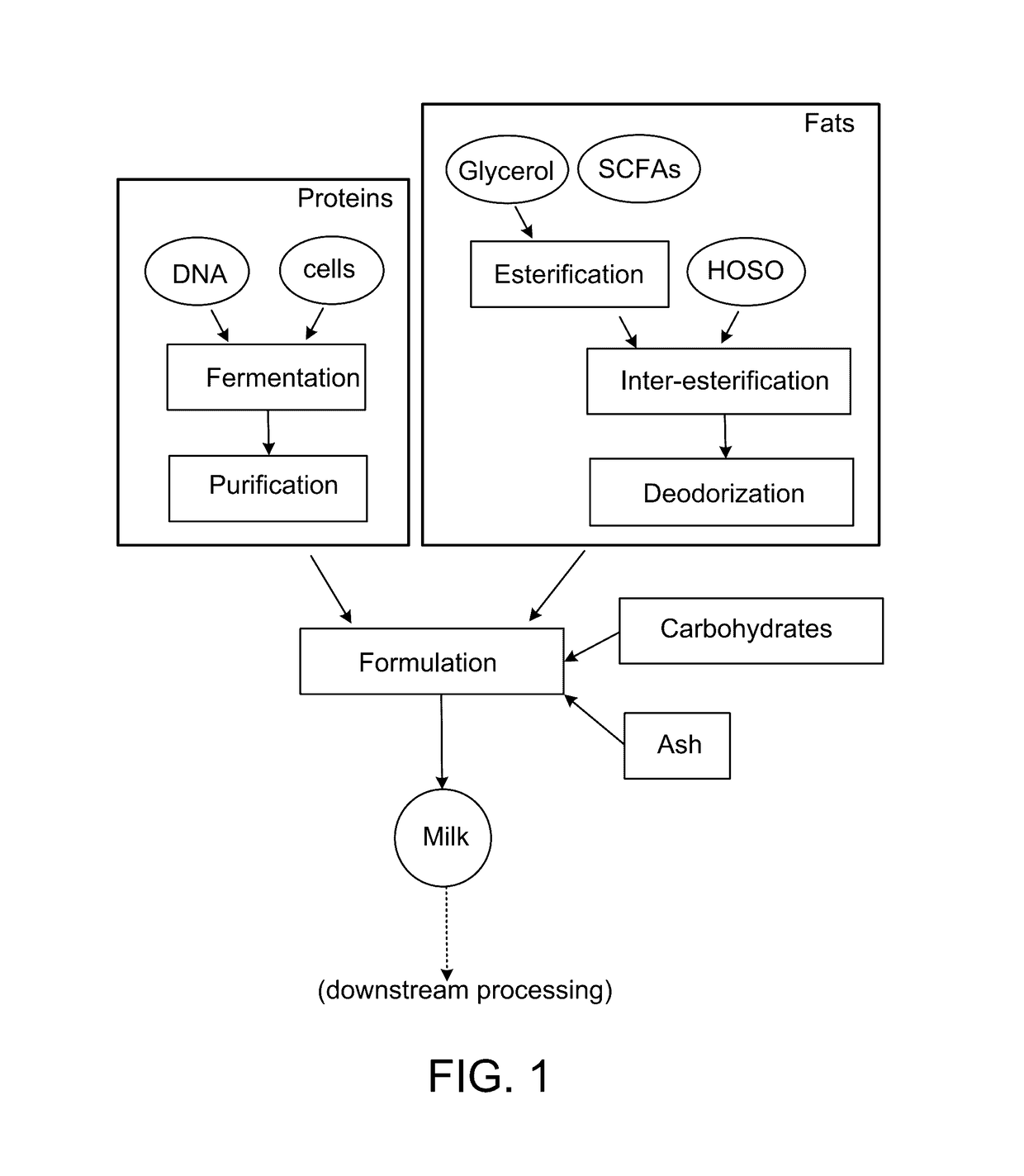

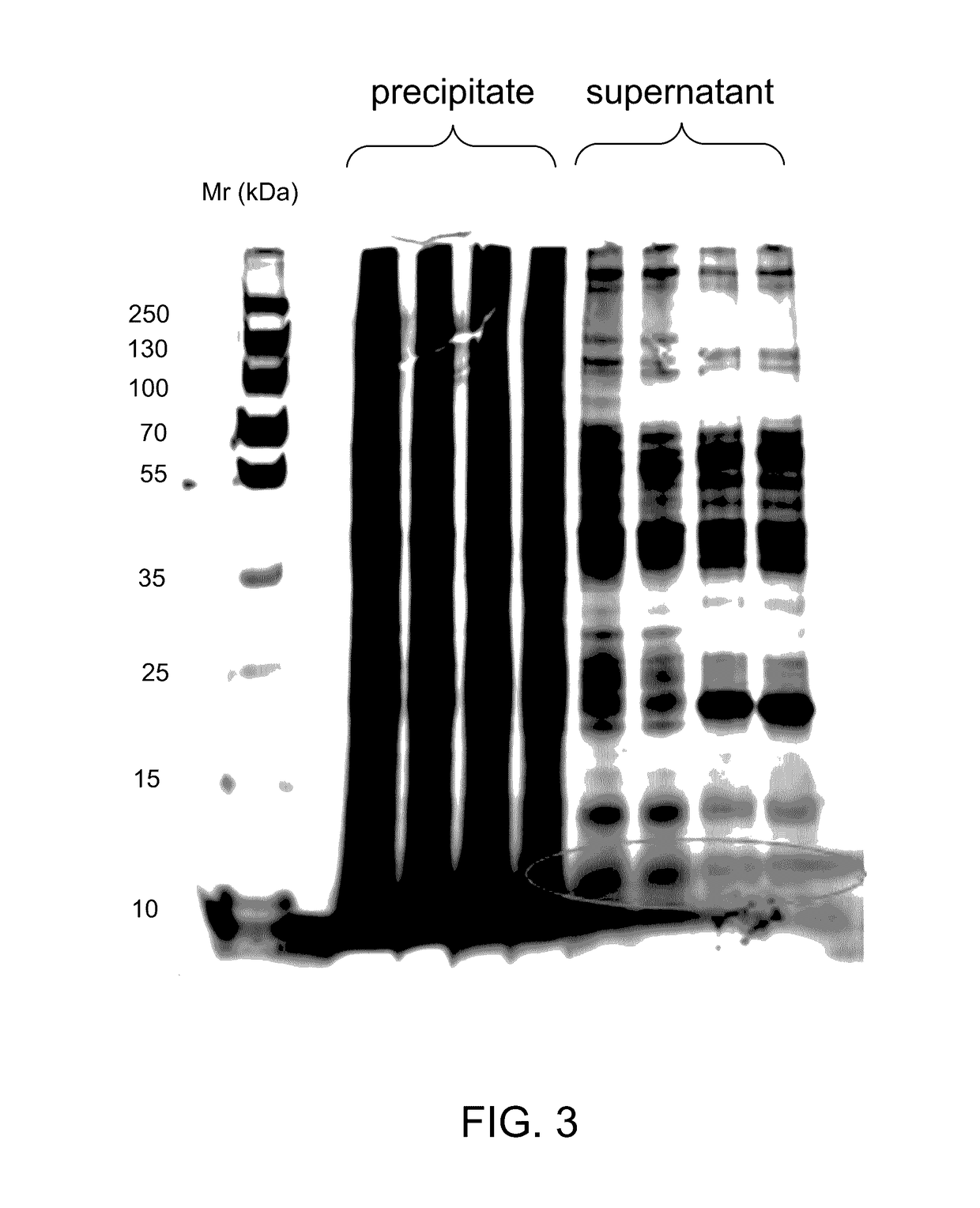

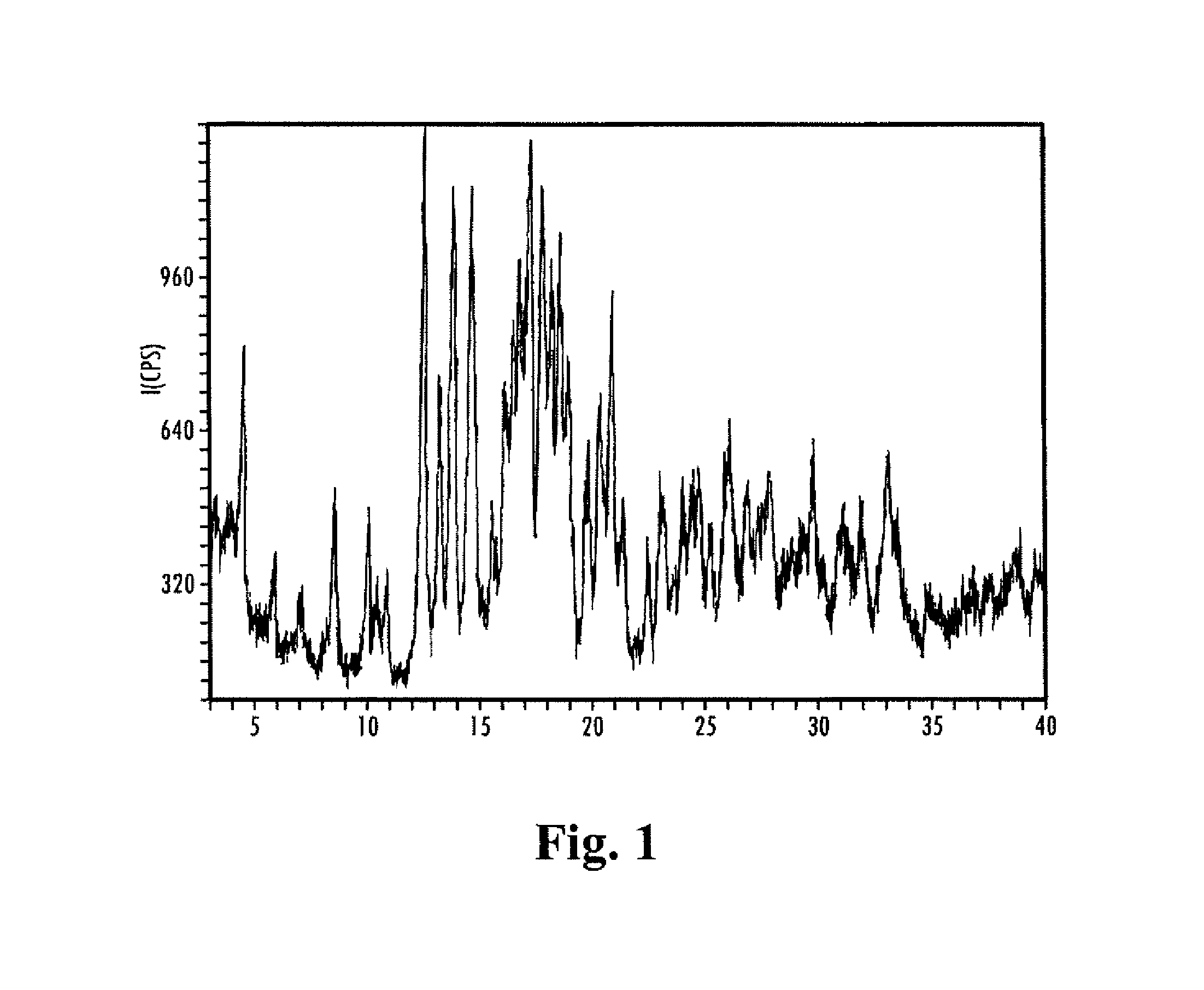

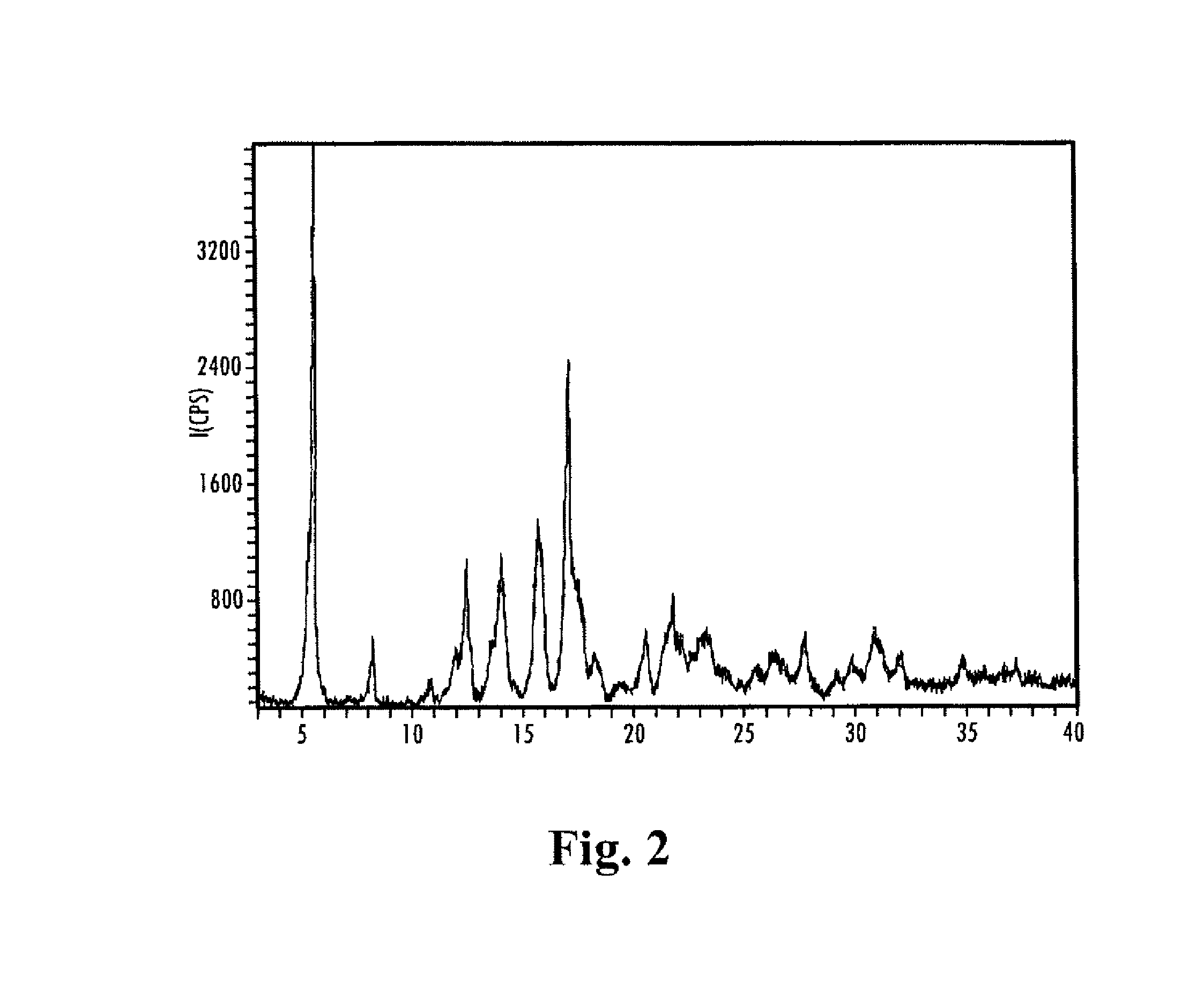

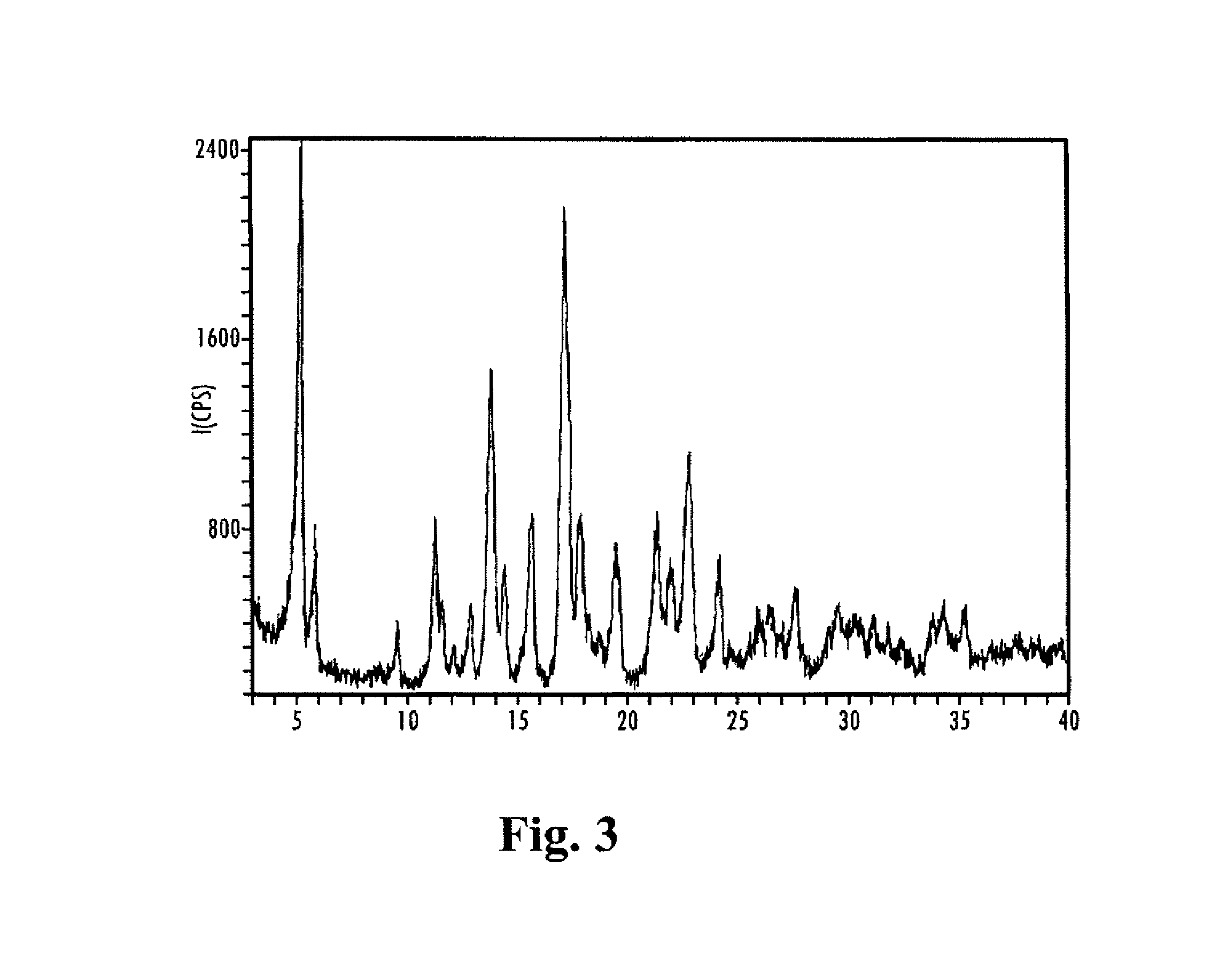

Compositions comprising a casein and methods of producing the same

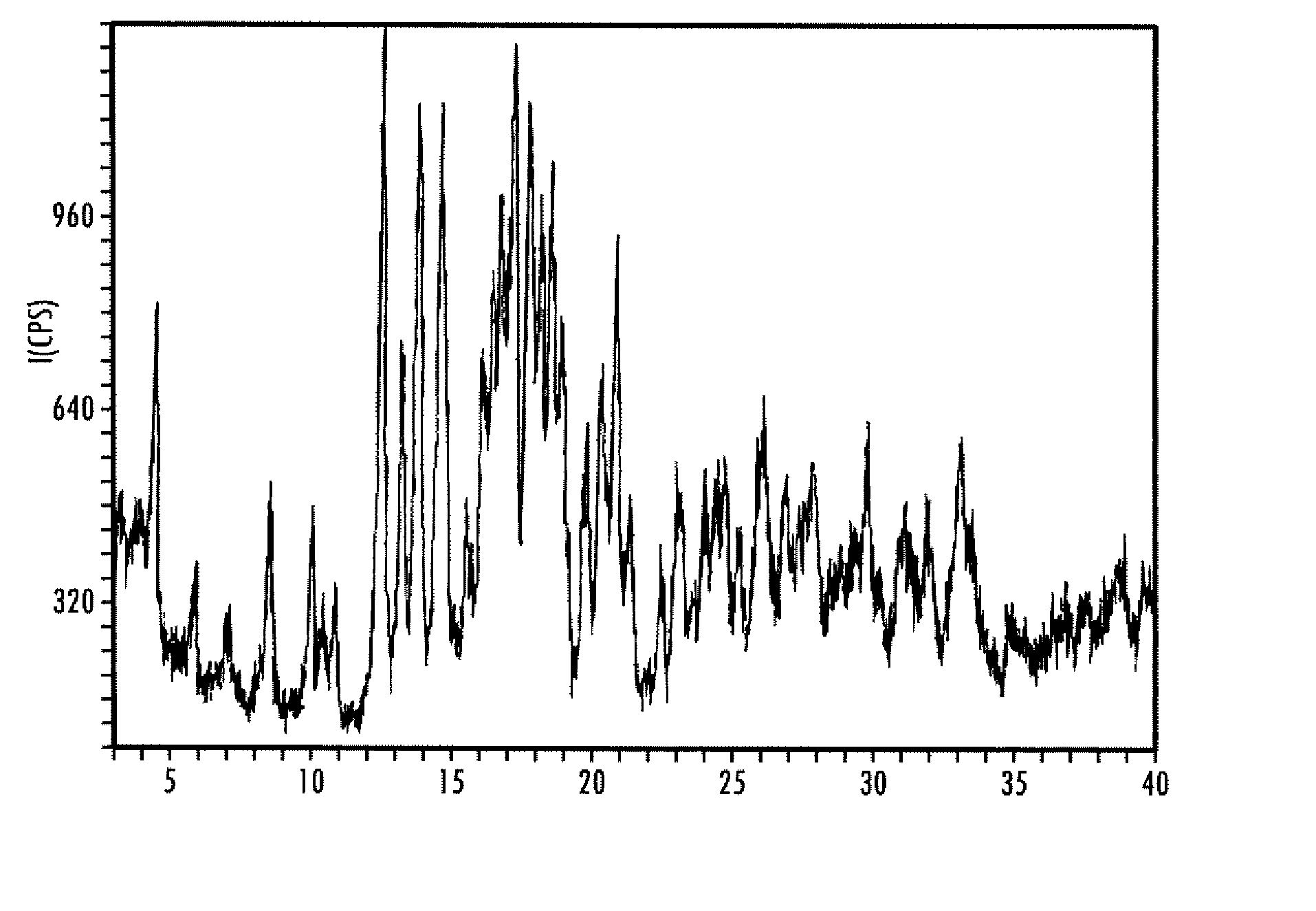

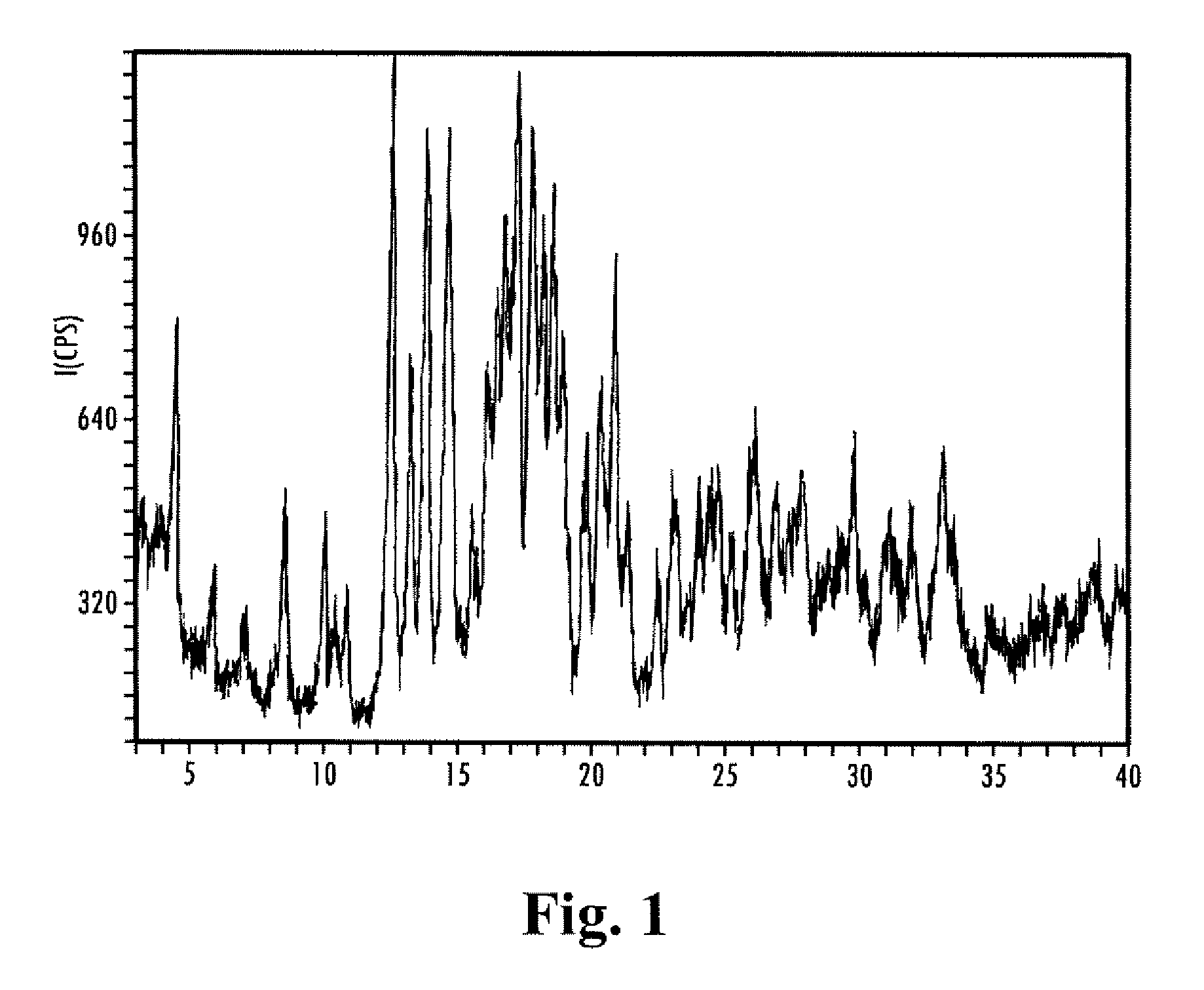

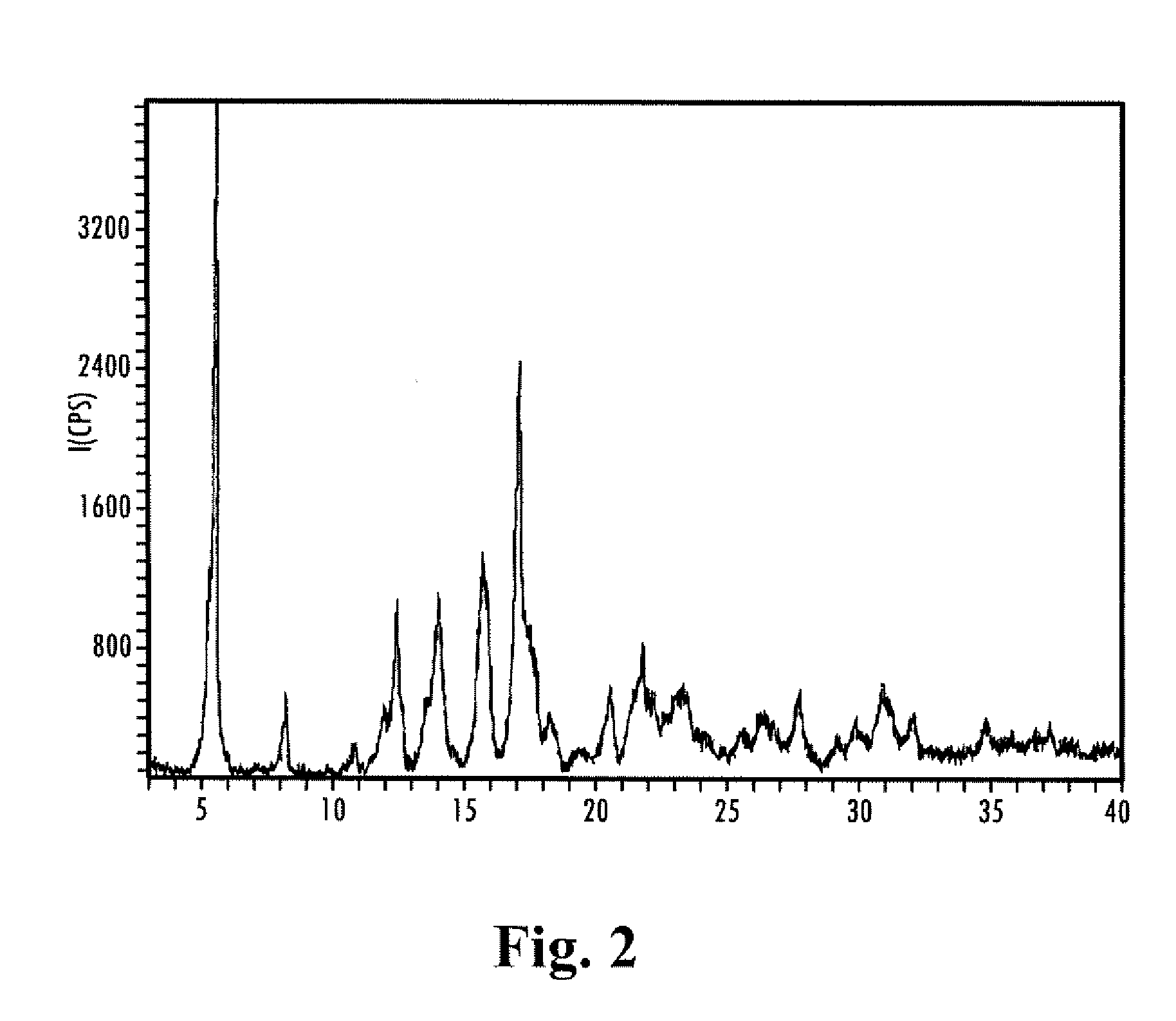

ActiveUS20170273328A1Improve flavor profileReduce removalMilk preparationFrozen sweetsCrystallographyCasein

Disclosed herein are methods and compositions including casein, and methods for making these compositions.

Owner:PERFECT DAY INC

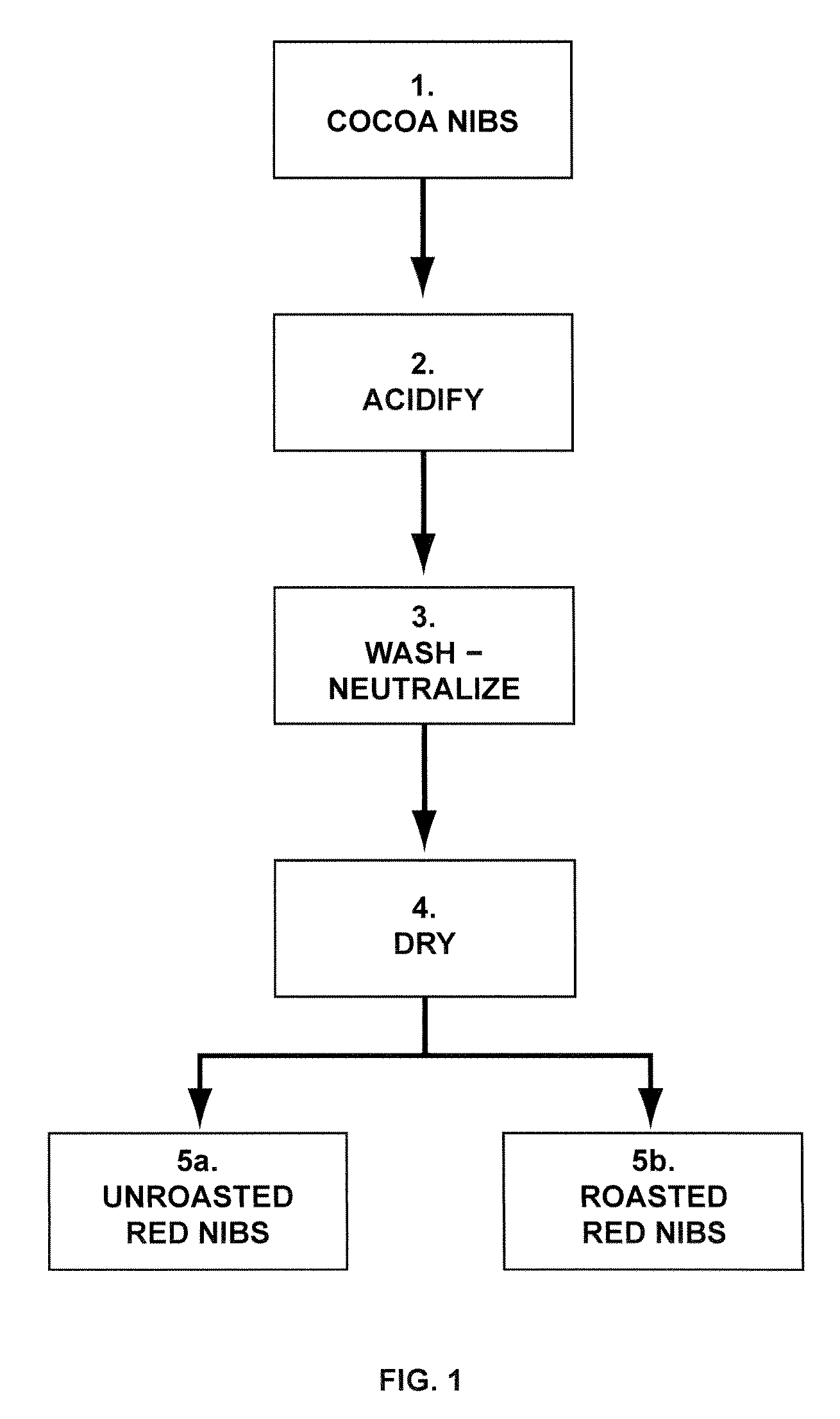

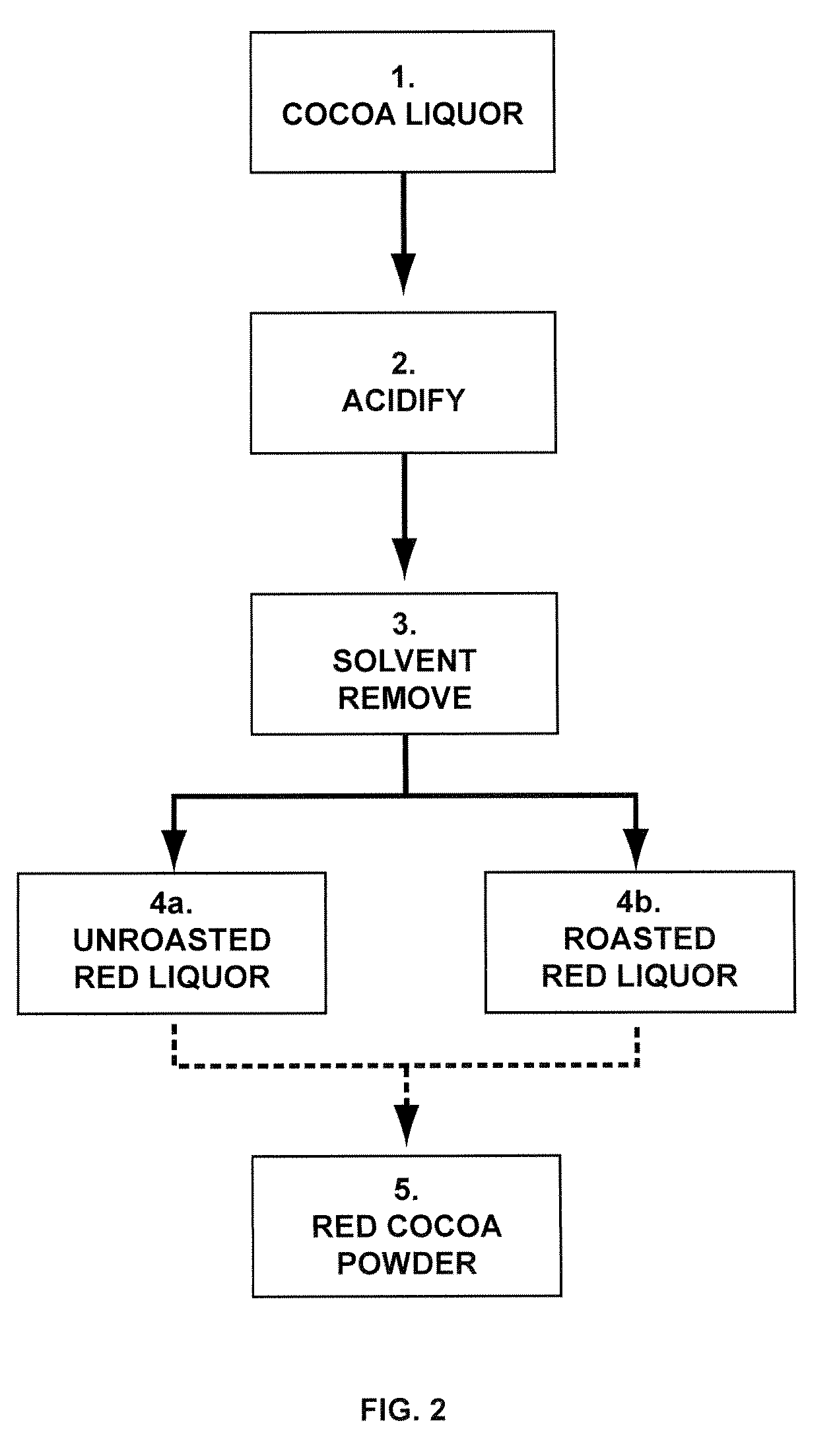

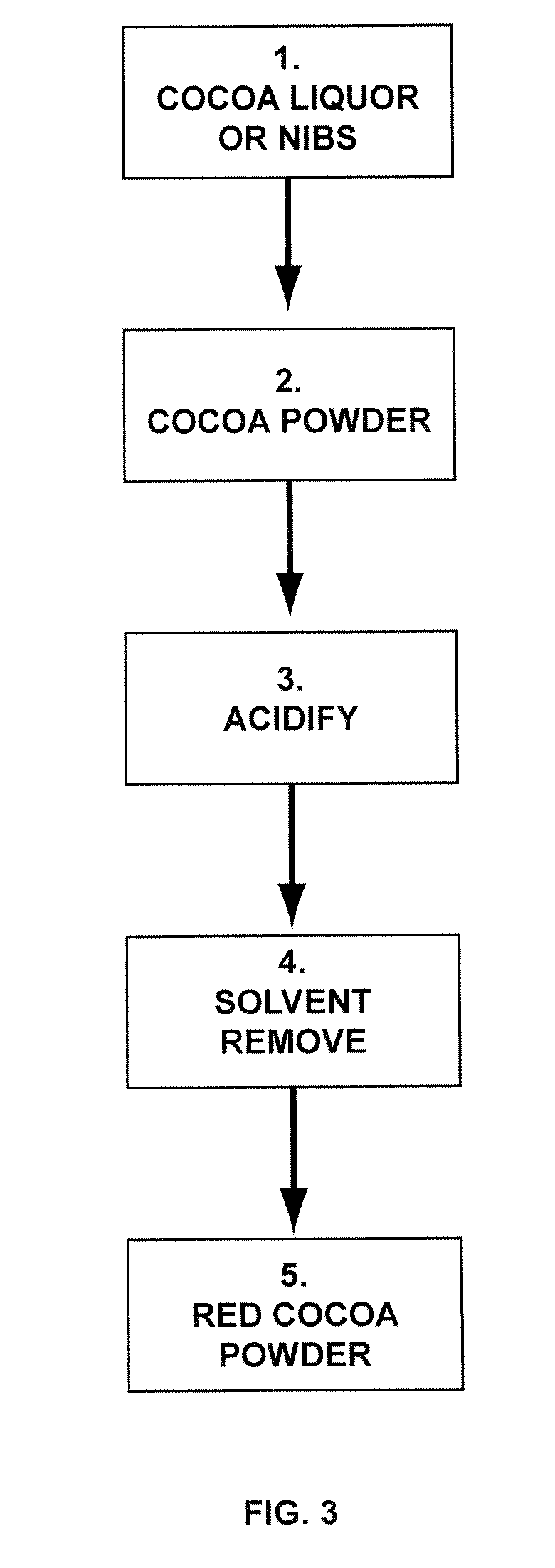

Process for preparing red cocoa ingredients, red chocolate, and food products

ActiveUS20090130284A1High level of antioxidantUnique tasteFatty substance preservation using additivesCocoaCocoa PowdersAntioxidant

The invention provides acidified red cocoa products and ingredients, such as acidified red cocoa bean nibs, red cocoa liquor, and red cocoa powder. The acidified cocoa products and ingredients are generally made from under-fermented or unfermented cocoa beans that are treated with an acid composition. The methods include those of making food products and ingredients where the levels cocoa antioxidants are maintained by the use of an acid treatment and the avoidance of dutching, and the food products and ingredient have a distinctive red color. Cocoa nibs, chocolate or cocoa liquor and cocoa powders having a red hue or color and having high levels of cocoa antioxidants are disclosed, as well as food products made from them.

Owner:THE HERSHEY COMPANY

Stewed beef sauce bag and preparation method thereof

InactiveCN102342489AImprove flavor qualityIncrease osmotic pressureFood preparationMonosodium glutamateFood flavor

The invention relates to a stewed beef sauce bag and a preparation method thereof. The stewed beef sauce bag is prepared from the following raw materials in parts by weight: 30-35 parts of palm oil, 5-10 parts of refined beef lard, 10-15 parts of fresh beef, 8-10 parts of ginger, 15-20 parts of raw onion, 10-15 parts of raw garlic, 3-5 parts of dry yellow soybean sauce, 5-7 parts of soy sauce, 4-5 parts of table salt, 1-1.5 parts of white granulated sugar, 2-2.5 parts of monosodium glutamate, 1-1.5 parts of hot pepper powder, 0.2-0.3 part of star aniseed powder, 0.2-0.3 part of cassia bark powder, 0.3-0.4 part of pepper powder, 0.5-0.6 part of yeast extract, 0.5-0.6 part of HVP (Hydrolyzed Vegetable Protein), 1.5-2 parts of beef cream essence, 1-1.5 parts of hot reaction beef powder and 0.2-0.3 part of shallot oily essence. Due to the adoption of the sauce bag, the kitchen flavor characteristic can be displayed, and the requirement on the shelf life of industrial foods is met simultaneously.

Owner:TIANJIN CHUNFA BIO TECH GRP

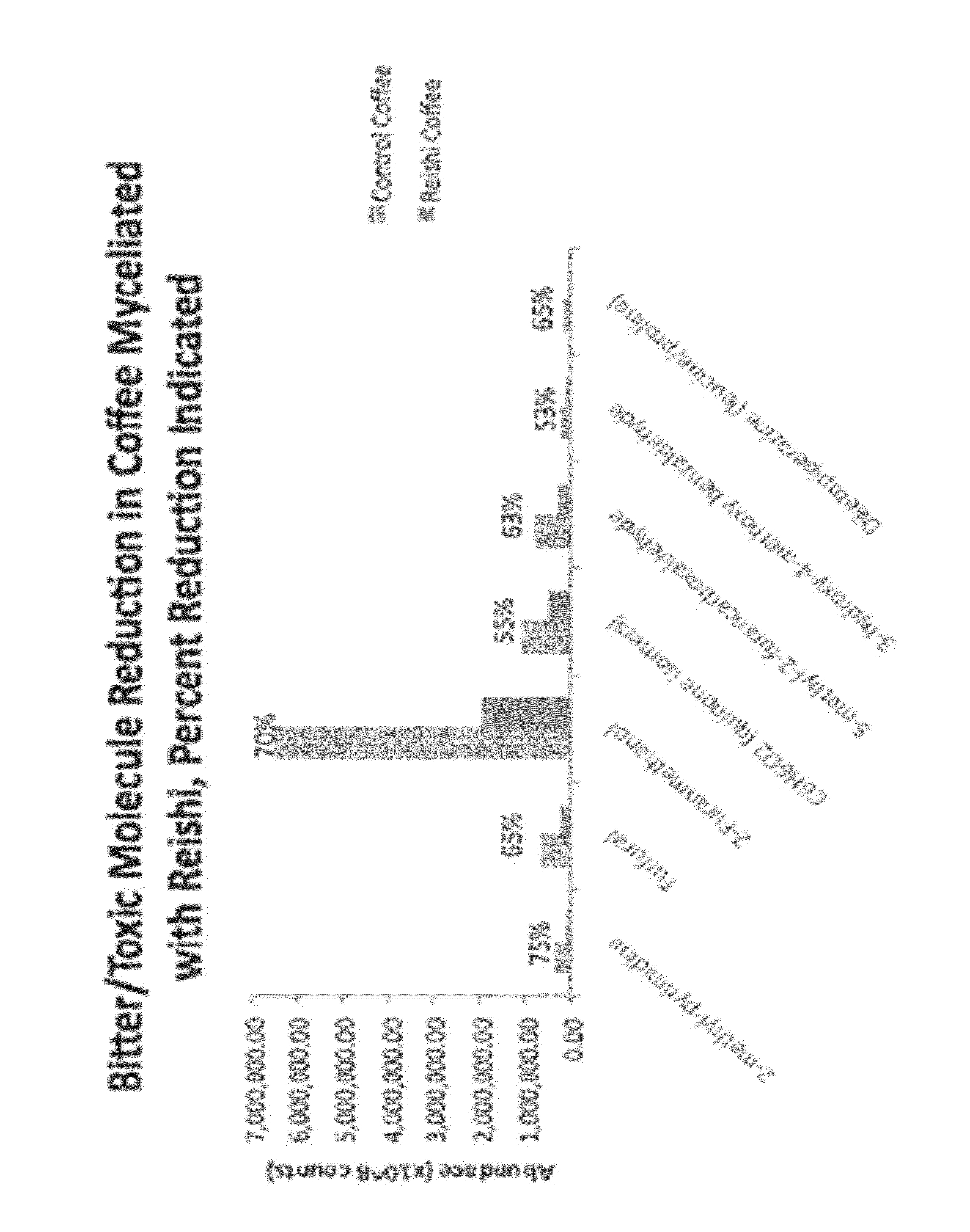

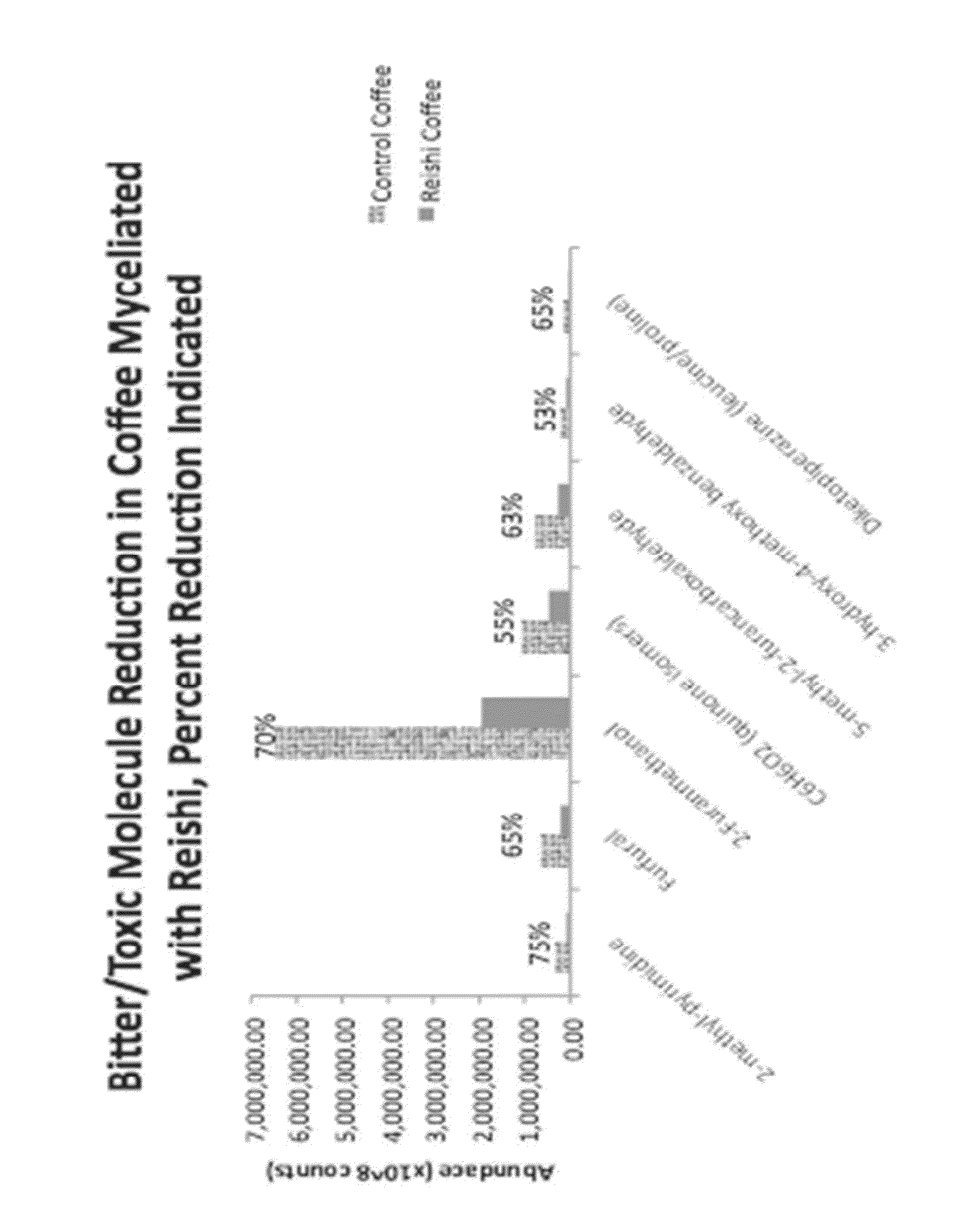

Myceliated Coffee Products and Methods for Making Myceliated Coffee Products

InactiveUS20150257405A1Increase valueRendering it more drinkableGreen coffee treatmentBiotechnologyMycelium

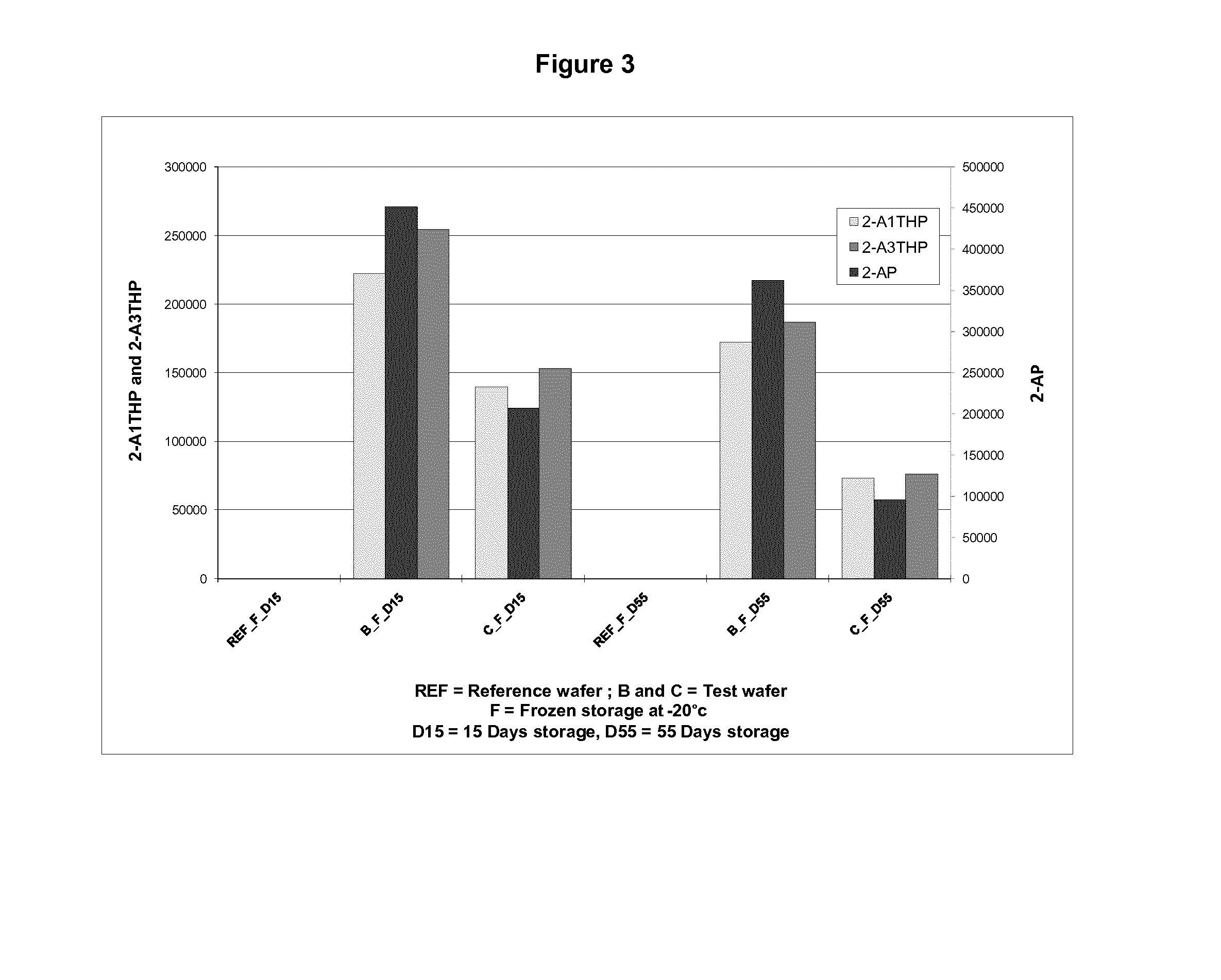

The present invention provides a method for the preparation of a myceliated coffee product. This method comprises providing green coffee beans and optionally heat treating the green coffee beans to provide prepared green coffee beans. Furthermore, a step of inoculating the prepared green coffee beans with a prepared fungal component and culturing the inoculum to prepare the myceliated coffee product is included. The present invention discusses different embodiments of the invention and the various products that can be developed by altering certain parameters, such as green coffee bean moisture content. The methods of the instant invention result in prepared green coffee beans and myceliated coffee products having reduced levels of undesirable taste components, such as 2-furanmethanol, and increased levels of fungal metabolites, such as β-glucans and other polysaccharides, relative to starting green coffee beans.

Owner:MYCOTECH

Compositions comprising a casein and methods of producing the same

ActiveUS20170164632A1Improve flavor profileReduce removalMilk preparationFrozen sweetsCrystallographyCasein

Disclosed herein are methods and compositions including casein, and methods for making these compositions.

Owner:PERFECT DAY INC

Flavored extruded food product

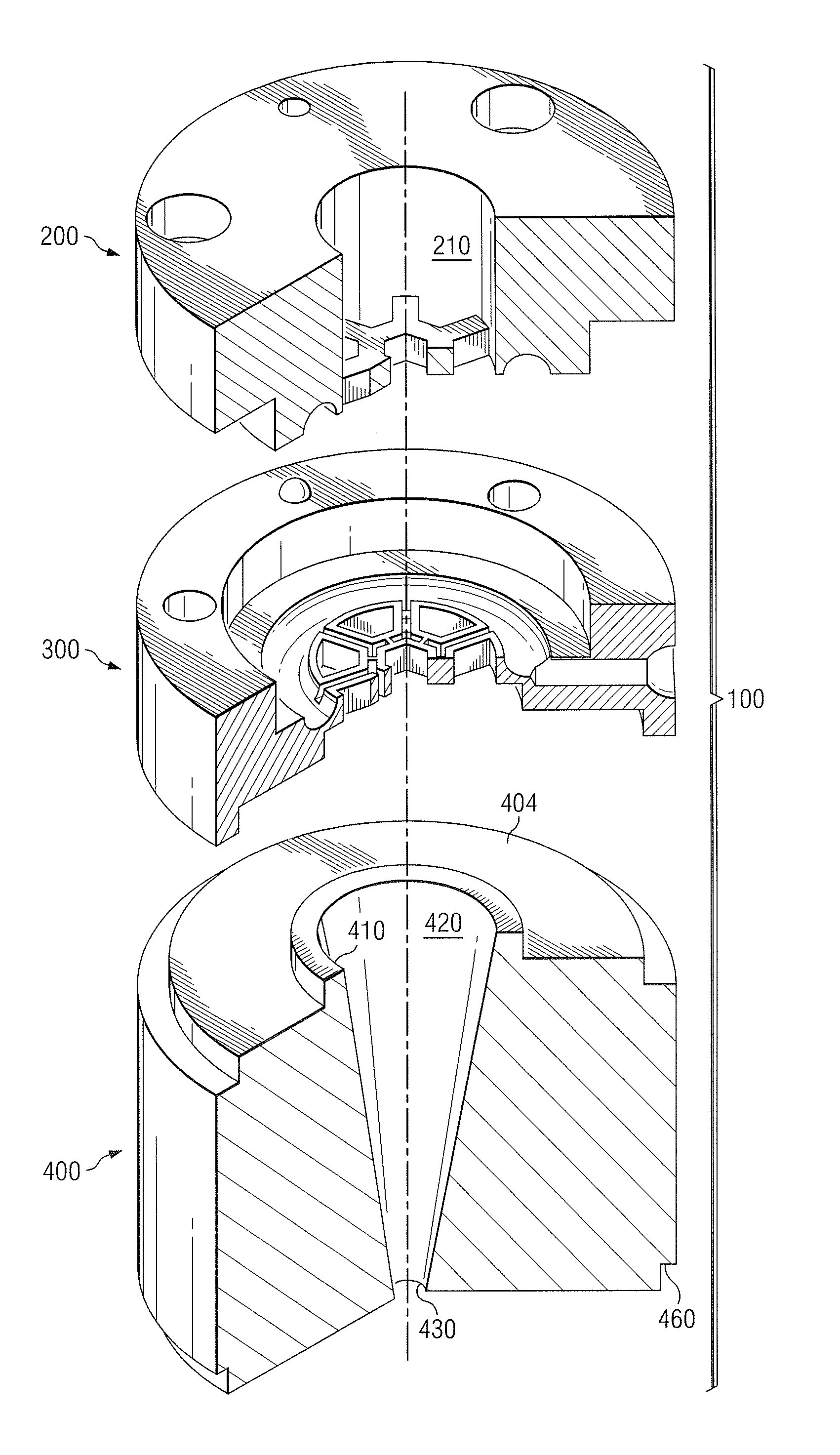

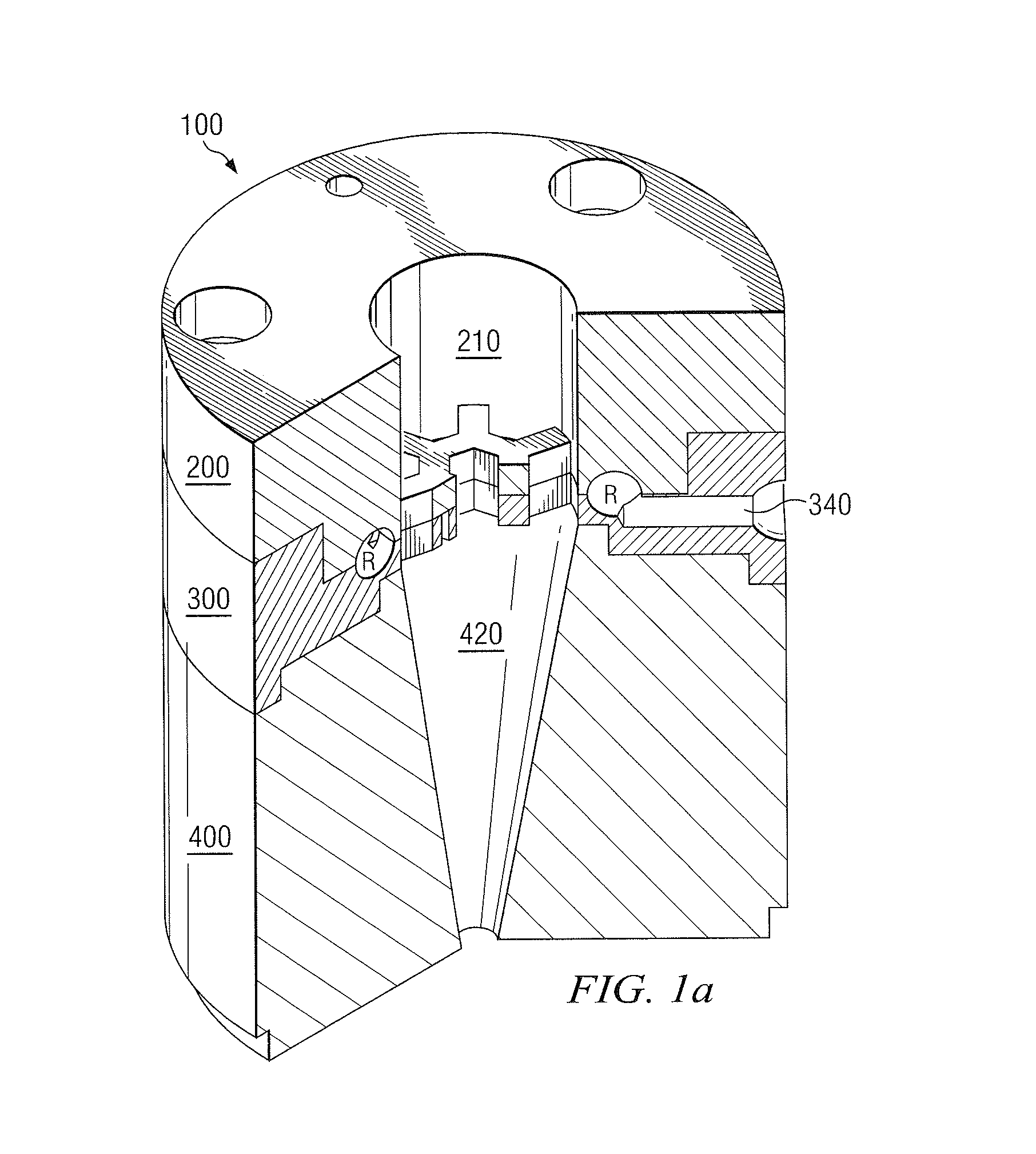

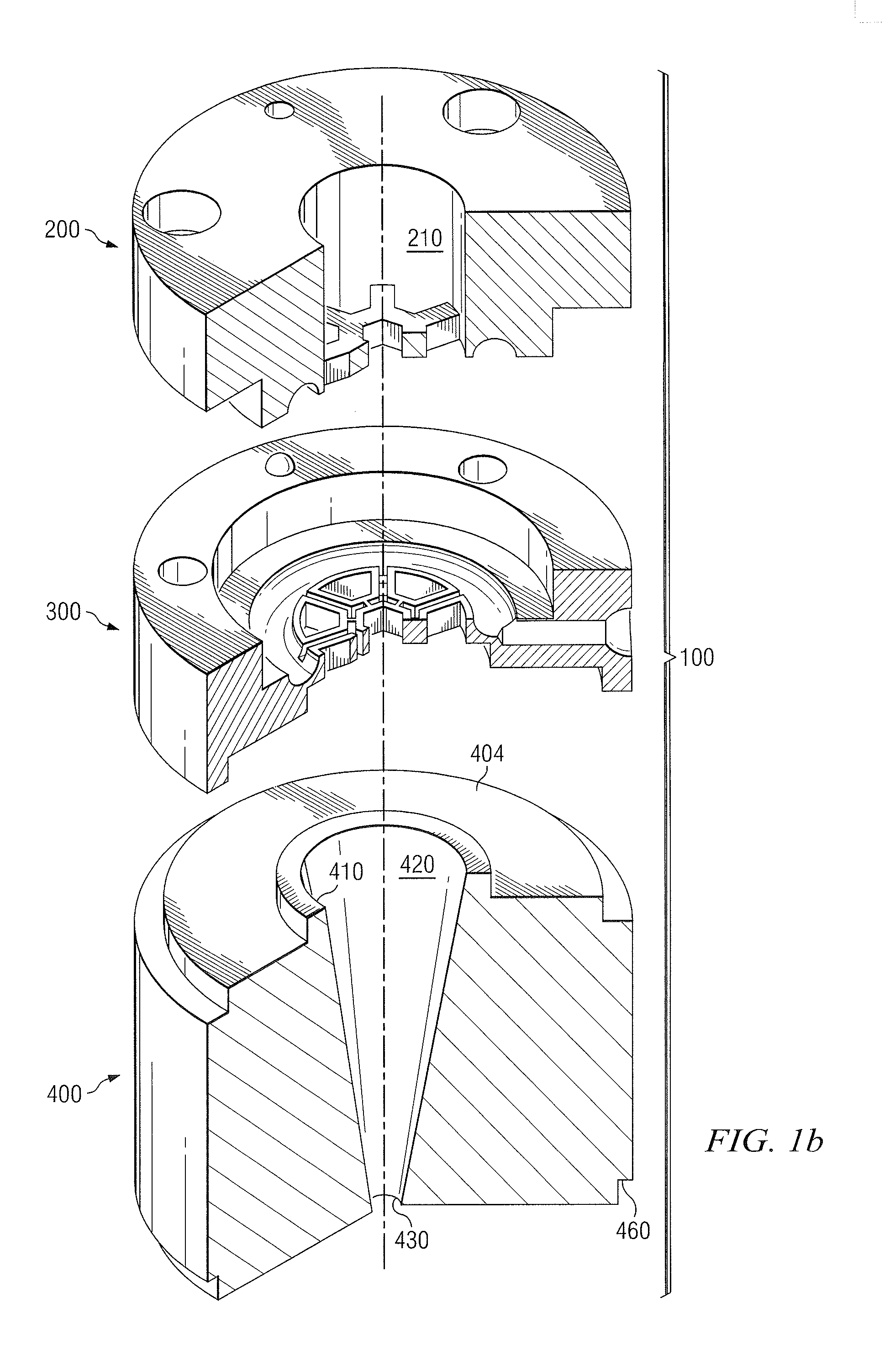

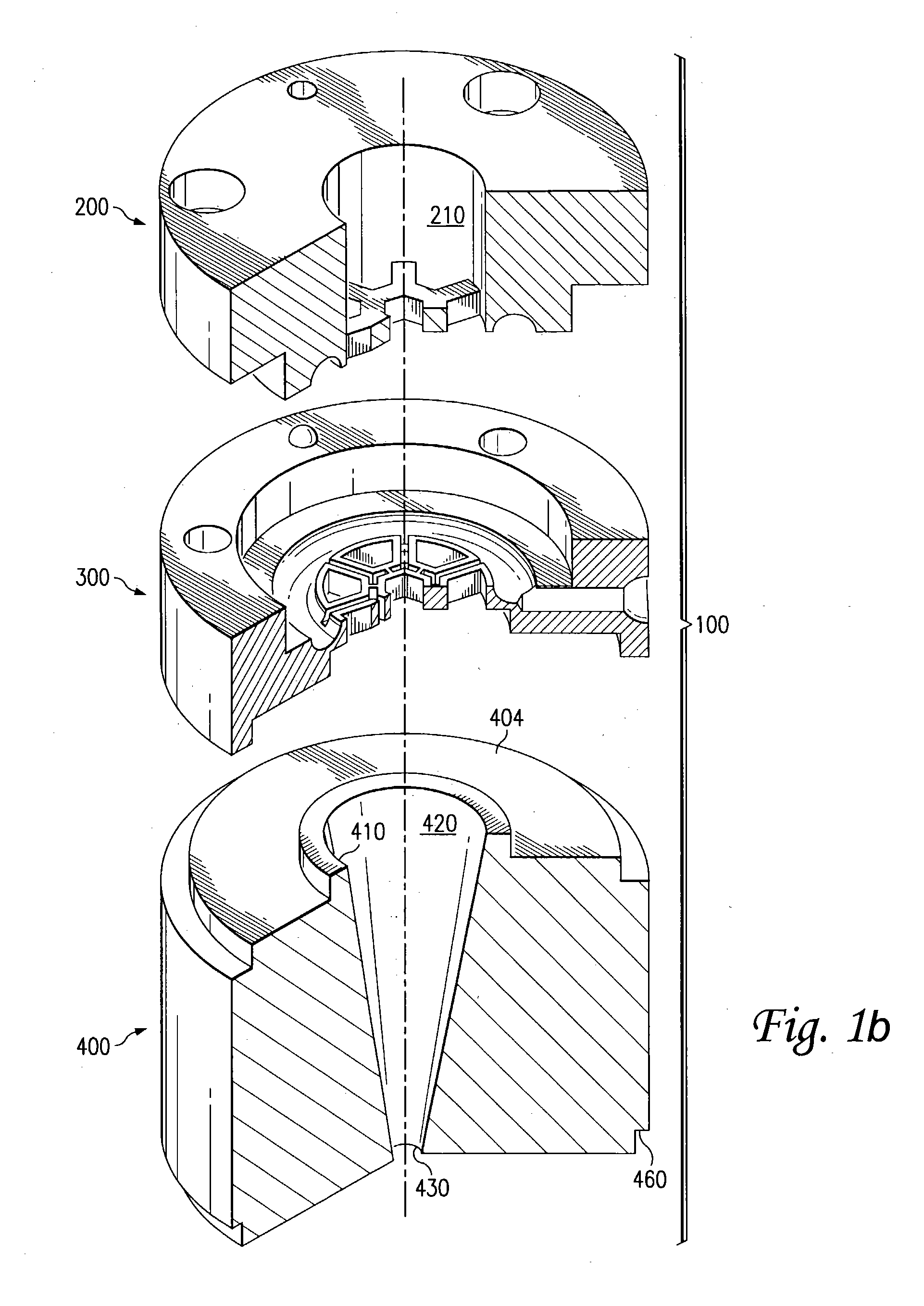

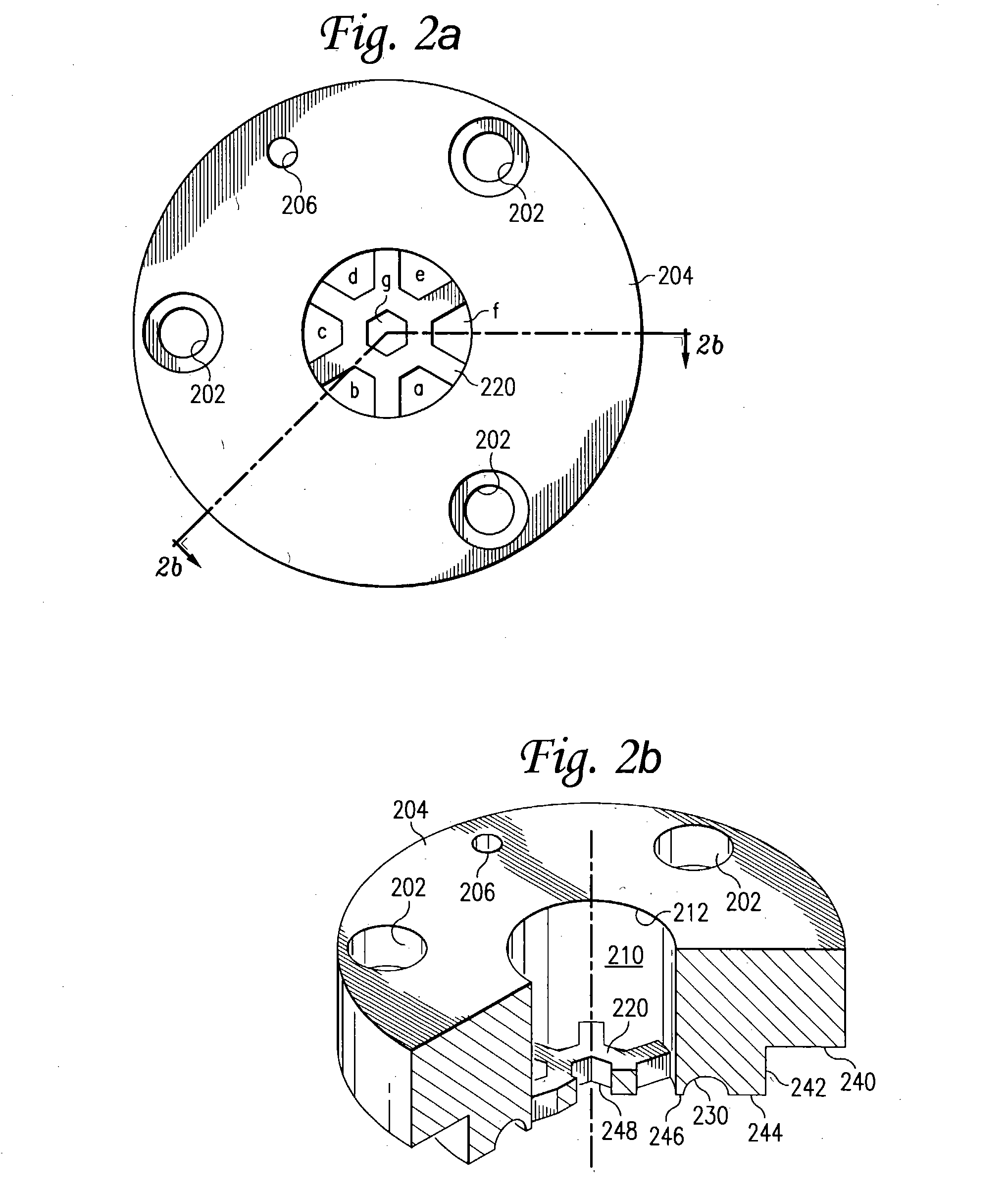

InactiveUS7252847B2Improve sealing propertiesSimpler and easy to maintainConfectionerySweetmeatsFood industryEngineering

An extruder die assembly and method for using same is disclosed that may be adapted to a wide variety of commercial-grade extrusion devices common in the food industry. The disclosed method comprises extruding a known composition of a farinaceous food product through the extruder die assembly of the present invention to produce a flavored direct-expanded food product exhibiting enhanced flavor characteristics, but requiring no post-extrusion drying or seasoning process. The injection section of the extruder die assembly is used to impart flavoring additives into the extrudate mass shortly before expansion, thereby preserving the flavoring characteristics of the additive by minimizing the heat exposure of the flavoring additive. The extruder die assembly may also include static mixing elements downstream from the injection section to homogenize the flavoring or seasoning media into the flowing mass of extrudate.

Owner:FRITO LAY NORTH AMERICA INC

Myceliated Coffee Products and Methods for Making Myceliated Coffee Products

InactiveUS20160120201A9Reducing concentration of undesirable taste componentImprove abilitiesGreen coffee treatmentBiotechnologyBeta-glucan

The present invention provides a method for the preparation of a myceliated coffee product. This method comprises providing green coffee beans and optionally heat treating the green coffee beans to provide prepared green coffee beans. Furthermore, a step of inoculating the prepared green coffee beans with a prepared fungal component and culturing the inoculum to prepare the myceliated coffee product is included. The present invention discusses different embodiments of the invention and the various products that can be developed by altering certain parameters, such as green coffee bean moisture content. The methods of the instant invention result in prepared green coffee beans and myceliated coffee products having reduced levels of undesirable taste components, such as 2-furanmethanol, and increased levels of fungal metabolites, such as β-glucans and other polysaccharides, relative to starting green coffee beans.

Owner:MYCOTECH

Methods for preparing oat bran enriched in beta-glucan and oat products prepared therefrom

ActiveUS7494683B2Increase contentImprove flavor profileDough treatmentBaking mixturesCereal grainBeta-Glycan

Dry milling methods for preparing oat products enriched in the content of β-glucan and methods for preparing foodstuffs incorporating such an enriched oat product especially ready-to-eat cereals are provided. Heat conditioned dehulled oats are dry milled to form a coarse whole non defatted oat flour and then, without a preceding removal of fat, dry fractionated into coarser bran and finer oat flour fractions at multiple stages. The coarse oat flour is first dry classified to separate or form a coarser fraction oat bran containing more concentrated β-glucan and a finer oat flour or starch containing or endosperm containing fraction. The oat bran is subjected to second and third rounds of milling and classification to form a high β-glucan content (>7-9%) oat bran and a low β-glucan content (3%) oat flour. The methods are low cost and commercially practical. Preferably, the high β-glucan content oat bran and oat flour fractions can have a syringic acid to ferulic acid ratio of at least 2.5:1 indicating improved flavor. Preferably, the oat bran and oat flour have a Farinograph value of 5 to 20 minutes indicated partial gelatinization. The oat bran and oat flours can be used to prepare foodstuffs such as ready-to-eat cereals.

Owner:GENERAL MILLS INC

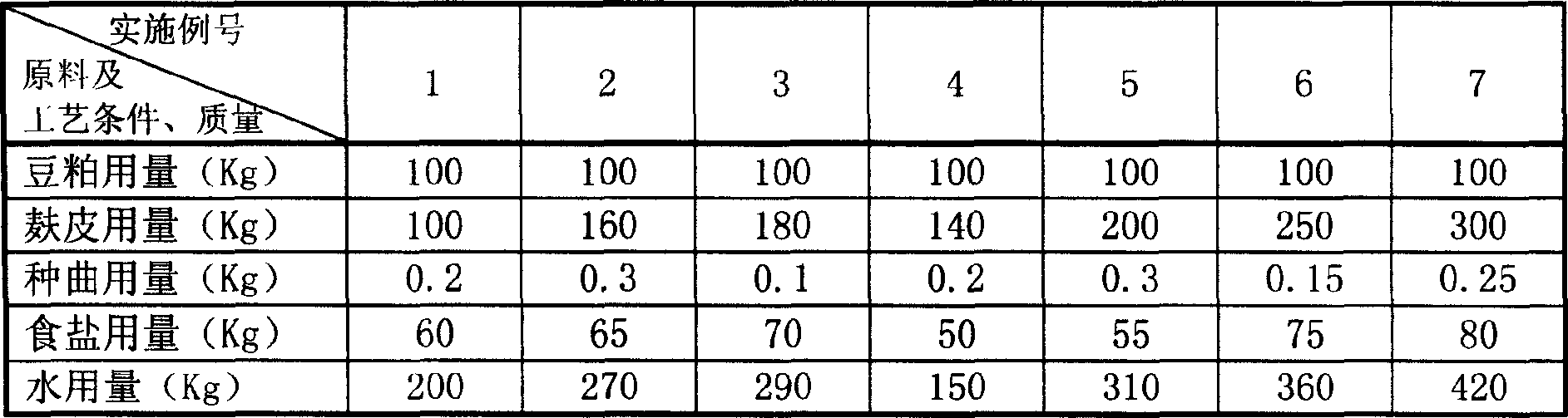

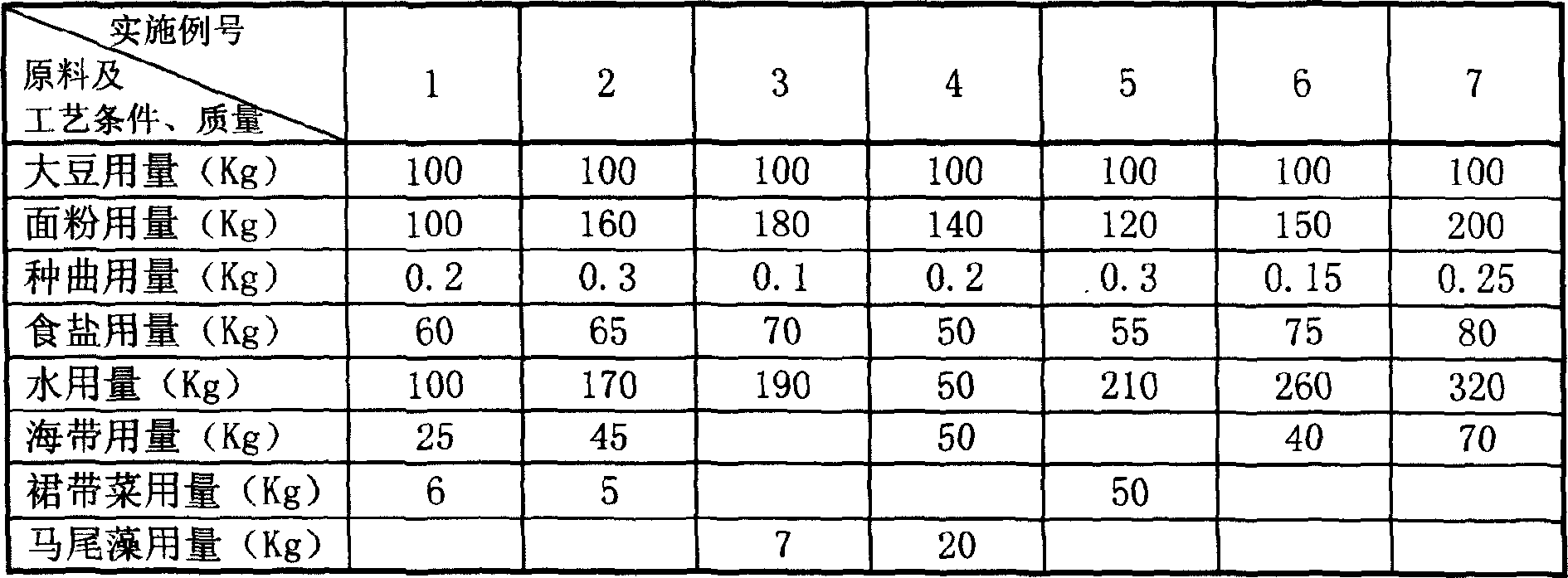

Method for preparing alga soy sauce

A seaweed soy (or seaweed bean paste) for improving immunity and preventing tumor is prepared through washing seaweed, cutting to become seaweed dust, breaking bean dregs, immersing it along with bran, steaming, mixing them with yeast, adding edible saline and said seaweed dust, stirring, fementing, squeezing filtering, regulating quality and sterilizing.

Owner:孟亮

Natural high-potency sweetener compositions with improved temporal profile and/or flavor profile, methods for their formulation, and uses

ActiveUS9011956B2Improve flavor profileImproving temporal profile profileOrganic active ingredientsMilk preparationSweetnessFood flavor

The present invention relates generally to improving the taste of natural high-potency non-caloric or low-caloric sweeteners and compositions sweetened therewith. In particular, the present invention relates to compositions that can improve the tastes of natural high-potency non-caloric or low-caloric sweeteners by imparting a more sugar-like taste or characteristic. In particular, the compositions and methods provide a more sugar-like temporal profile, including sweetness onset and sweetness linger, and / or a more sugar-like flavor profile, including osmotic taste.

Owner:THE COCA-COLA CO

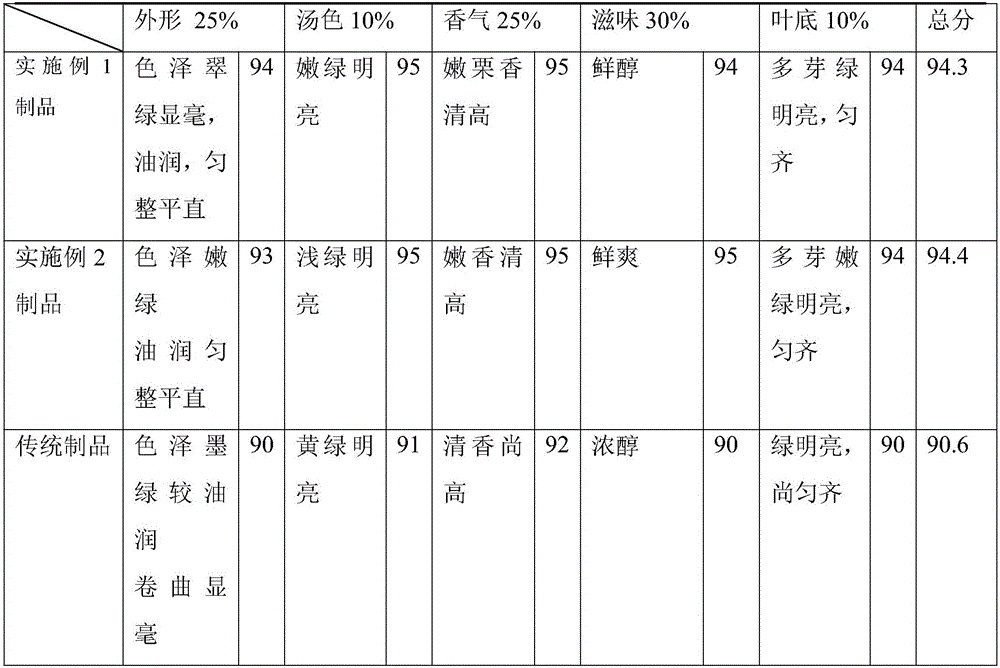

Processing method of Laoshan green tea

InactiveCN106578162ARich in amino acidsAvoid disadvantages such as damage and rednessPre-extraction tea treatmentCooking & bakingVitamin C

The invention belongs to the field of processing of tea leaves, and relates to a processing method of Laoshan green tea, and particularly relates to a processing method of clean and fresh type high-grade special Laoshan green tea capable of erecting after being brewed. The processing method comprises the following steps of picking, spreading, deactivation of enzymes, strip tidying, spreading for cooling and moistening regain, primary baking, secondary spreading for cooling and moistening regain, and re-baking to be enough dry, wherein a fresh leaf which is subjected to the deactivation of enzymes is directly subjected to the treatment of the strip tidying without being subjected to the spreading for cooling and temperature lowering; after the primary baking, the leaf is subjected to the secondary spreading for cooling and moistening regain; the re-baking to be enough dry is carried out by selecting and using a temperature which is lower than that of the primary baking. The Laoshan green tea processed through the processing method of the Laoshan green tea is tall and graceful in appearance, green and sleek in color and luster, apricot-green and transparent in liquor color, clean and fresh in fragrance, fresh and mellow in taste, and bright, complete and lobate in brewed leaf; after being brewed, the tea leaf erectly spreads in a cup and is high in viewing and admiring performance; the contents of an amino acid and a vitamin C which are beneficial to a human body are higher than those of ordinary Laoshan green tea.

Owner:QINGDAO ACAD OF AGRI SCI

Antioxidant and immune boosting composition and methods of using

InactiveUS20050142226A1Improve flavor profileHigh ORAC scoresBiocideAntinoxious agentsAntioxidant capacityFood flavor

Compositions are shown having high ORAC scores correlating with antioxidant capabilities. Such a composition, when combined with other food products can either maintain or increase ORAC scores while enhancing flavor characteristics of the final food product. The compositions have also been shown to increase immune activity of a mammal.

Owner:AROMATIC RES TECH L C

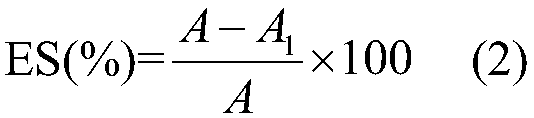

Sesame sauce and processing method thereof

The invention provides sesame sauce and a processing method thereof. The sesame sauce includes the following constituents in parts by weight: sesame 100, oil 6.5-7.5, an emulsifying agent 0.001-0.25,wherein the emulsifying agent includes the following constituents in parts by weight: sucrose esters 0.03-0.18 and monostearin 0.07-0.18. The sesame sauce is prepared by the method including the processes of roasting and grinding the sesame. According to the invention, through adopting a scientific formula and preparation process, the viscosity coefficient of the sesame sauce is increased from 2.3778 to 29.0216 and the stability coefficient of the sesame sauce is increased from 81.60% to 99.31%. Meanwhile, no oil phase is precipitated and yield is increased by about 23%.

Owner:HUAZHONG AGRI UNIV

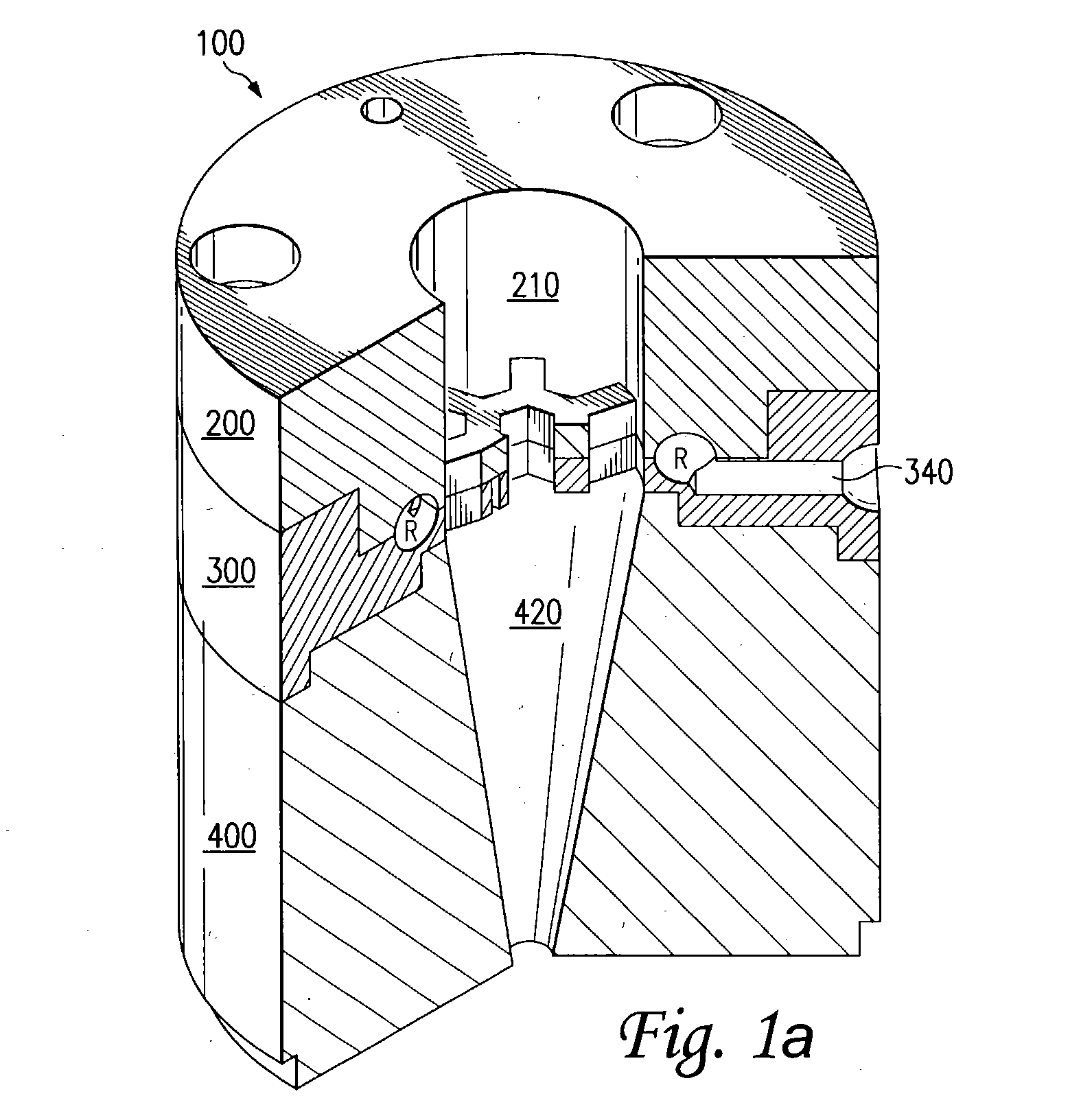

Flavored extruded food product

InactiveUS20040022910A1Less-prone to clogging and blockageImprove seal qualityConfectionerySweetmeatsFood industryEngineering

An extruder die assembly and method for using same is disclosed which is designed for adaptation to a wide variety of commercial-grade extrusion devices common in the food industry. The extruder die assembly is inserted into an appropriate compartment within an extrusion device such that a first extrudate is directed down a coaxially aligned passageway within the forming section and combined with a fluid additive in the injection section whereupon the resulting food mass is compressed through a converging nozzle bore in the nozzle section to produce an extruded food product. The forming section and injection section are fabricated as a matching set. A novel food product is also disclosed. A known composition of a farinaceous food product is extruded through the extruder die assembly of the present invention to produce a flavored direct-expanded food product exhibiting enhanced flavor characteristics, but requiring no post-extrusion drying or seasoning process. The injection section of the extruder die assembly is used to impart flavoring additives into the extrudate mass shortly before expansion, thereby preserving the flavoring characteristics of the additive by minimizing the heat exposure of the flavoring additive. The extruder die assembly may also include static mixing elements downstream from the injection section to homogenize the flavoring or seasoning media into the flowing mass of extrudate.

Owner:FRITO LAY NORTH AMERICA INC

Methods for preparing oat bran enriched in beta-glucan and oat products prepared therefrom

ActiveUS20090078802A1Increase contentImprove flavor profileGrain huskingGrain polishingAmyrisFood flavor

Dry milling methods for preparing oat products enriched in the content of β-glucan and methods for preparing foodstuffs incorporating such an enriched oat product especially ready-to-eat cereals are provided. Heat conditioned dehulled oats are dry milled to form a coarse whole non defatted oat flour and then, without a preceding removal of fat, dry fractionated into coarser bran and finer oat flour fractions at multiple stages. The coarse oat flour is first dry classified to separate or form a coarser fraction oat bran containing more concentrated β-glucan and a finer oat flour or starch containing or endosperm containing fraction. The oat bran is fractionated into a coarse and fine oat bran sub-streams. The oat bran sub-streams are each is subjected to second roller milling step and then bolted. The second bolting of oat bran is then subjected to a third round of milling and classification to form a high β-glucan content (>7-9%) oat bran and a low β-glucan content (3%) oat flour. The methods are low cost and commercially practical. Preferably, the high β-glucan content oat bran and oat flour fractions can have a syringic acid to ferulic acid ratio of at least 2.5:1 indicating improved flavor. Preferably, the oat bran and oat flour have a Farinograph value of 5 to 20 minutes indicated partial gelatinization. The oat bran and oat flours can be used to prepare foodstuffs such as ready-to-eat cereals.

Owner:GENERAL MILLS INC

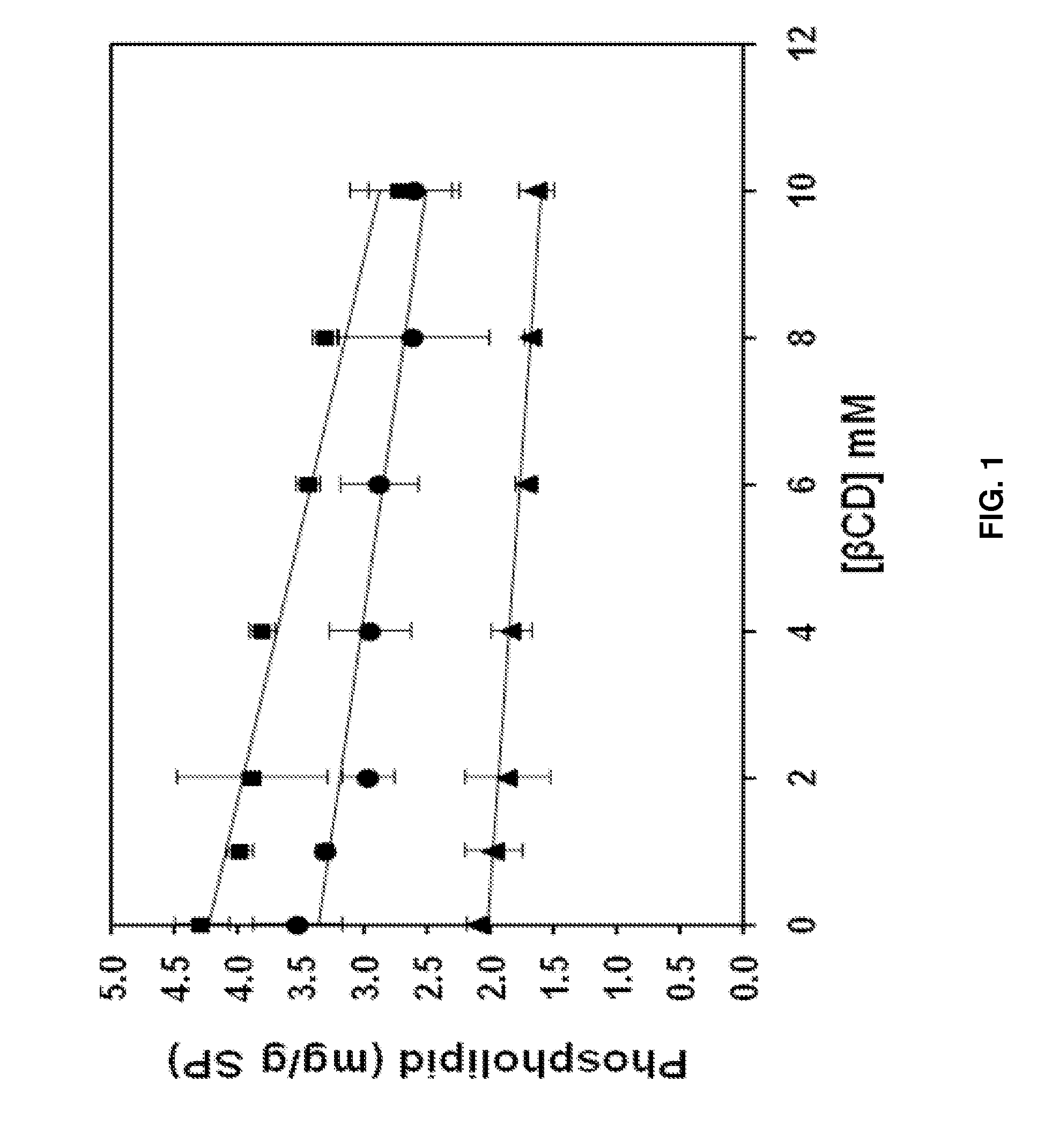

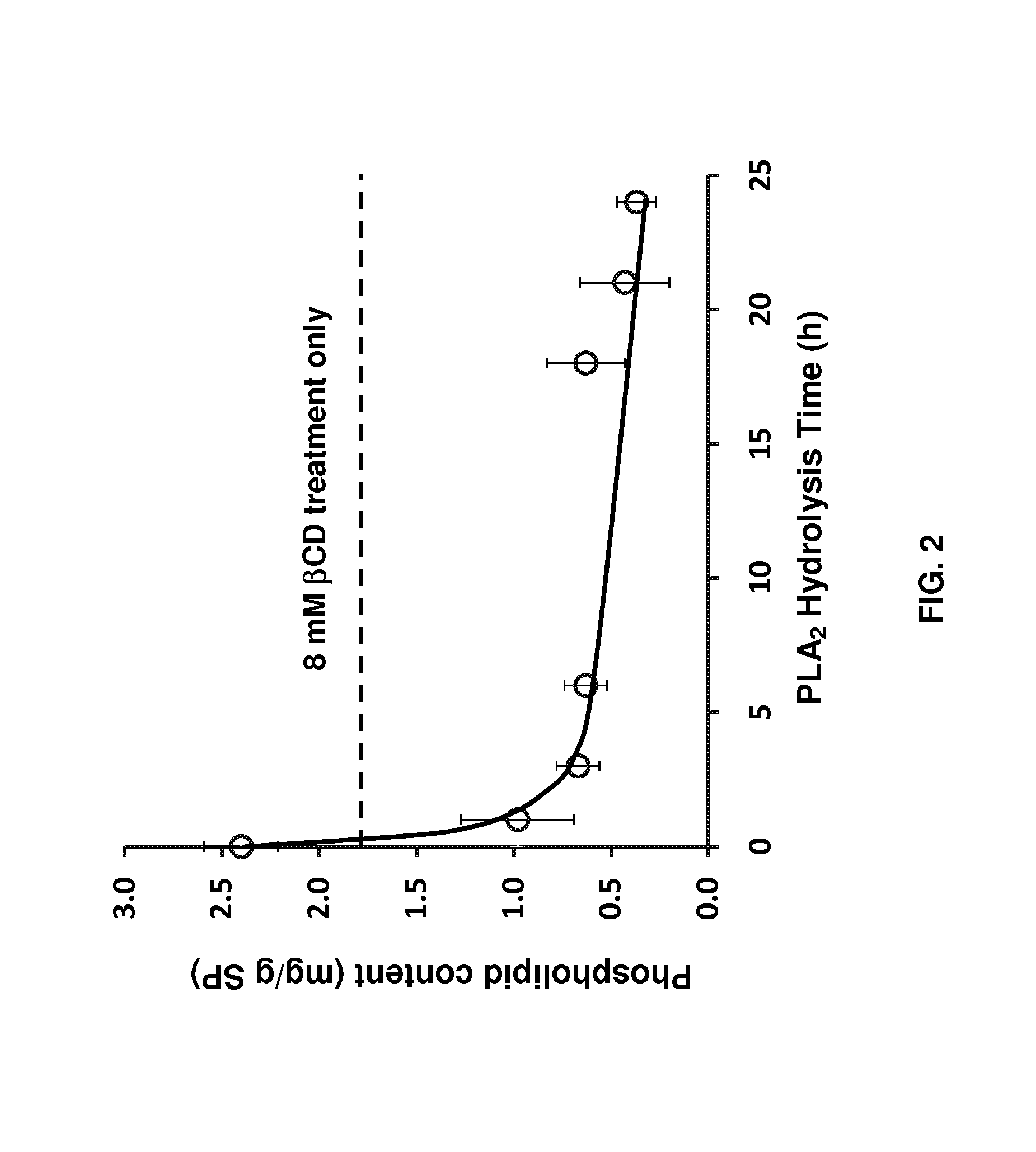

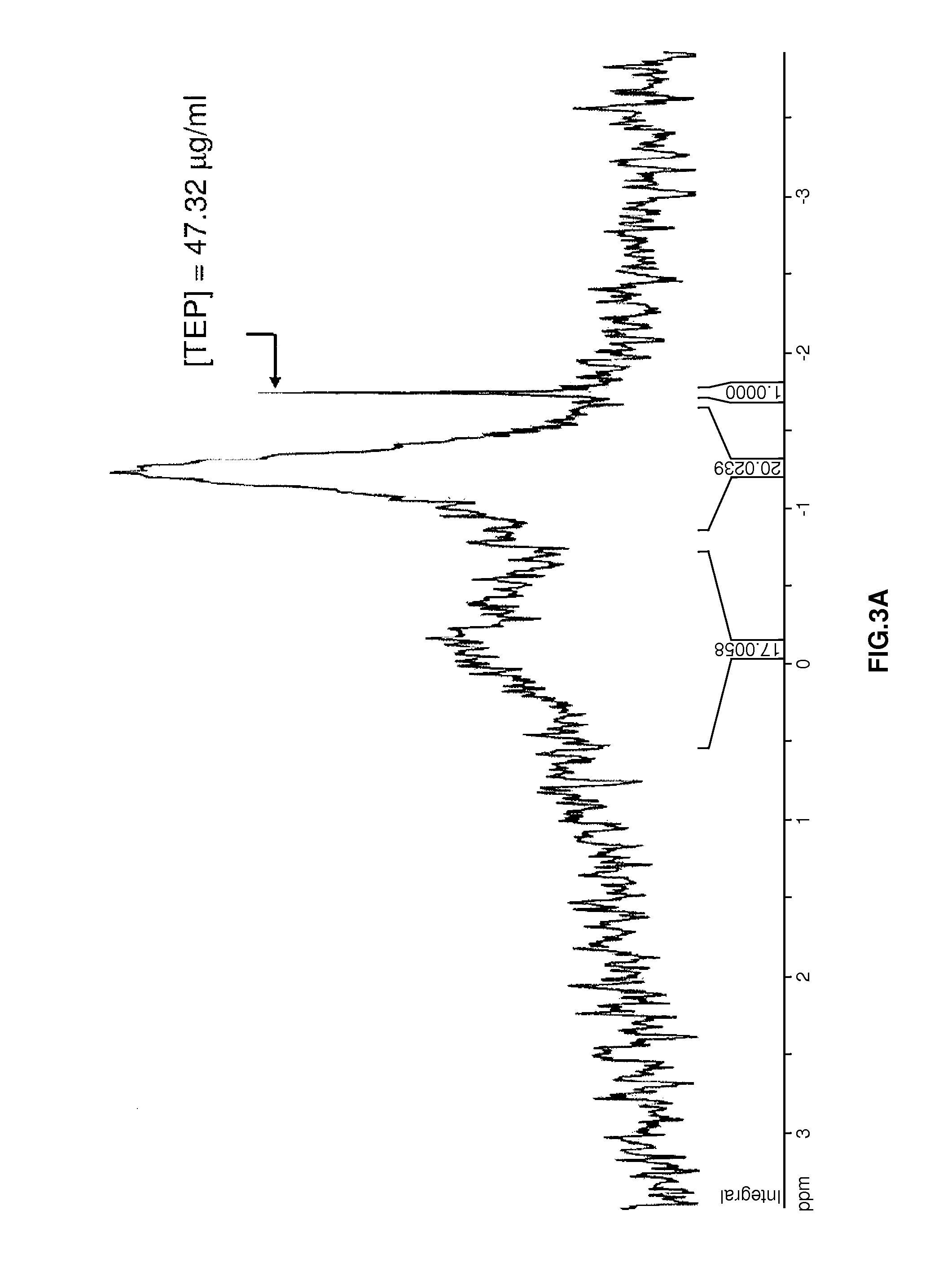

Process for removing phospholipids and off-flavors from proteins and resulting protein product

ActiveUS20110045128A1Improve stabilityEasy to integrateMilk preparationDough treatmentFlavorPhospholipase

Described are methods of removing phospholipids and other off-flavor-causing compounds from edible proteins using a cyclodextrin treatment. The methods include treating soy protein with cyclodextrins such as β-cyclodextrin to form cyclodextrin-compound complexes and then separating the resulting complexes from the protein. Optionally, prior to treating the protein with cyclodextrin, the protein is sonicated and then treated with a phospholipase, such as phospholipase A2. Versions of the methods described herein are capable of removing more than 99% of phospholipids from soy protein.

Owner:WISCONSIN ALUMNI RES FOUND

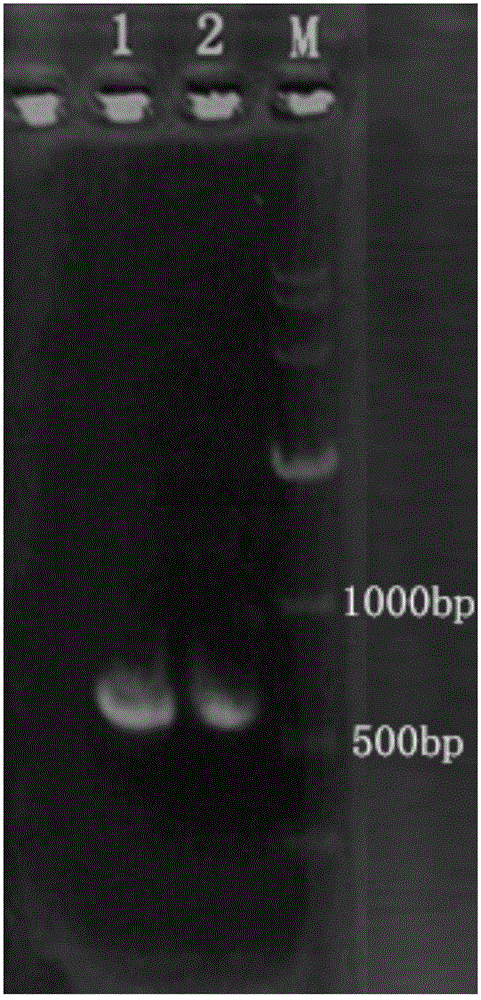

Aroma producing yeast and application thereof in fermented soybean milk

ActiveCN105039187ASolve the problem that the beany smell is difficult to removeImprove flavor profileFungiMicroorganism based processesYeastFlavor

The invention discloses an aroma producing yeast and an application thereof in fermented soybean milk. The aroma producing yeast is Pichia amethionina Y, which is assigned the accession number CGMCC No.10183 with a 26S rDNA sequence being represented as the SEQ ID No.1. The application includes the following steps: inoculating a lactic acid bacteria XPL-1 seed solution with a Pichia amethionina Y seed solution to sterilized soybean milk and fermenting the soybean milk at 32-36 DEG C for 12-16 h to remove beany odor in the soybean milk and meanwhile generate an aroma flavor. The novel soybean milk fermentation agent solves the problem that the beany odor in the soybean milk is difficult to remove, thereby improving flavor character of the fermented soybean milk. The bacteria strain is quick in growth, is wide in growth temperature range, is simple in culture condition, is high in efficiency of producing aroma flavor and deodorizing the soybean milk, and is easy to product industrially.

Owner:SOUTH CHINA UNIV OF TECH

Concentrated and odorless omega 3 fatty acids

InactiveUS20070299134A1Slight to no fishy flavorMild to slight fishy odorFatty oils/acids recovery from wasteBiocideMonoglycerideGlycerol

A blend of triglycerides having the general formula CH2(OOC-R1)—CH(OOC—R2)—CH2(OOC—R3), wherein at least about 50% of the R1, R2 and R3 groups have a chain length of C19 or more. The blend of triglycerides has less than about 50 parts per billion (ppb) of trimethyl amine, that is, they are substantially odor free. Also provided is a process for preparing an enriched blend of triglycerides by taking an oil comprising a mixture of polyunsaturated fatty acids and reacting the oil with a lower alcohol to form a mixture of esters. The mixture of esters is then distilled to remove a portion of the esters having a chain length of about C18 and below to form an enriched stream of enriched esters having at least about 50% of the esters with chain length of about C20 or more. The enriched stream of esters is then reacted with glycerine to form a triglyceride mixture, wherein the triglyceride mixture has less than about 10%, by weight of diglycerides and less than about 5%, by weight monoglycerides. The triglyceride mixture preferably comprises less than 5% diglyceride and less than 1% monoglyceride. The triglyceride mixture most preferably comprises less than 2.5% diglyceride and less than 0.2% monoglyceride. Finally, the triglyceride mixture may optionally be treated by water washing, bleaching, evaporation, steam stripping and mixtures of these, to remove residual free fatty acids, aldehydes, color bodies, odor bodies, peroxides and esters.

Owner:THE PROCTER & GAMBLE COMPANY

Sheep appetite promoting feed taking apple pomace as raw material

InactiveCN105851542AGreat tasteEnhance digestionFood processingAnimal feeding stuffSodium lactateDisease

The invention discloses sheep appetite promoting feed taking apple pomace as a raw material. The feed is prepared from the following raw materials in parts by weight: 500-550 parts of apple pomace, 20-30 parts of sodium lactate, 54-56 parts of moringa leaf, 25-27 parts of flower of kudzuvine, 5-7 parts of blueberry jam, 84-92 parts of peanut meal, 32-36 parts of locust powder, 3-5 parts of garlic paste, 15-17 parts of metapenaeus ensis, 3-4 parts of lentinus edodes powder, 4-5 parts of spinach powder, 72-76 parts of barley flour, 3-5 parts of aromatic vinegar, 55-58 parts of sweet potato residue, 34-36 parts of buckwheat bran, 0.4-0.5 part of candida utilis, 33-35 parts of bamboo leaf powder, 24-26 parts of pawpaw residue, 0.4-0.5 part of table salt and 2-3 parts of bone meal. The feed disclosed by the invention is sour and sweet and fragrant, has good taste, promotes the digestive function of sheep, improves the sheep appetite, promotes the sheep absorption of nutrient substances and enhances the stress resistance and disease resistance of sheep; and moreover, the feed has abundant nutrition and ensures that sheep can quickly grow and has strong immunity, robust body and good mutton quality.

Owner:SHOUXIAN LINHUAI ANIMAL HUSBANDRY BREEDING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com