Patents

Literature

503results about How to "Improve seal quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

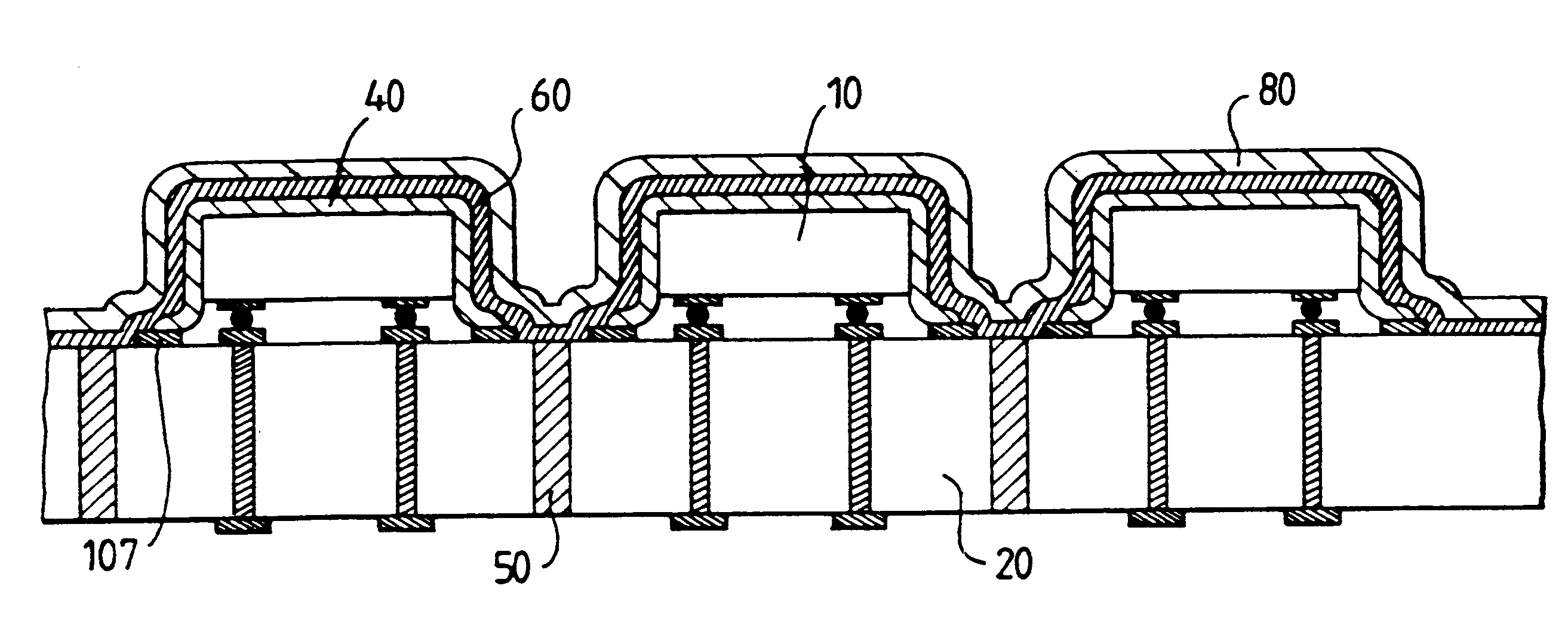

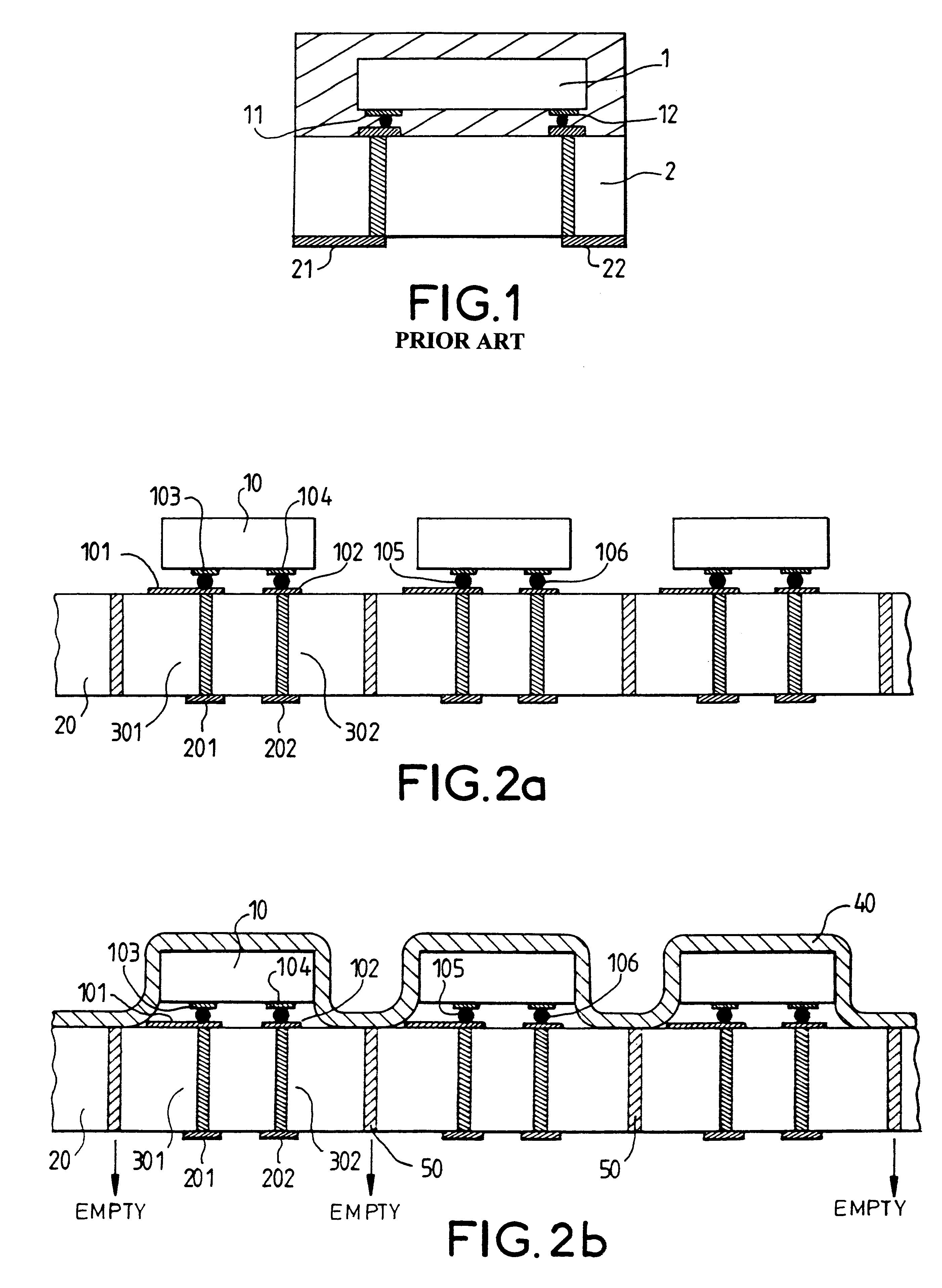

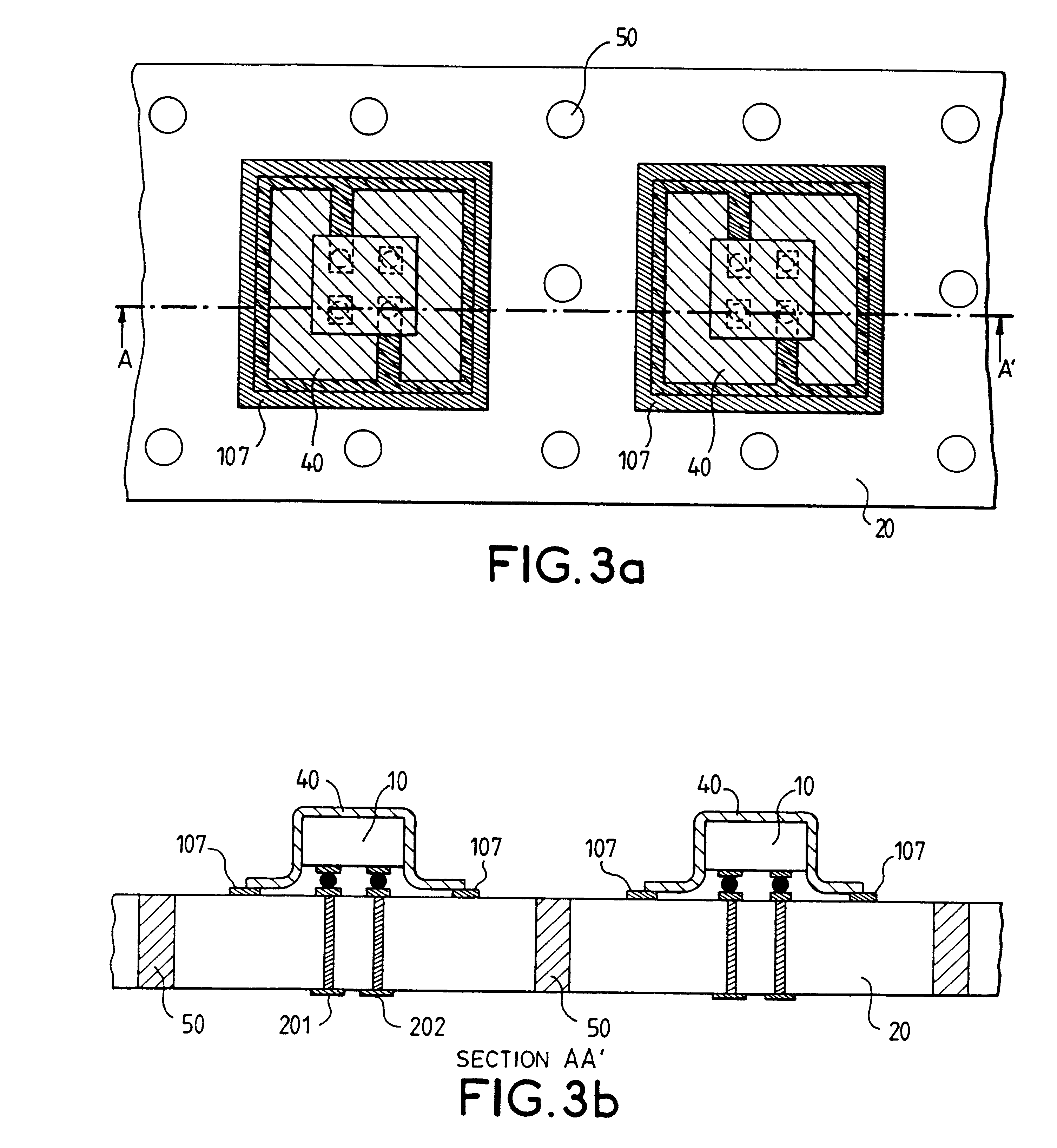

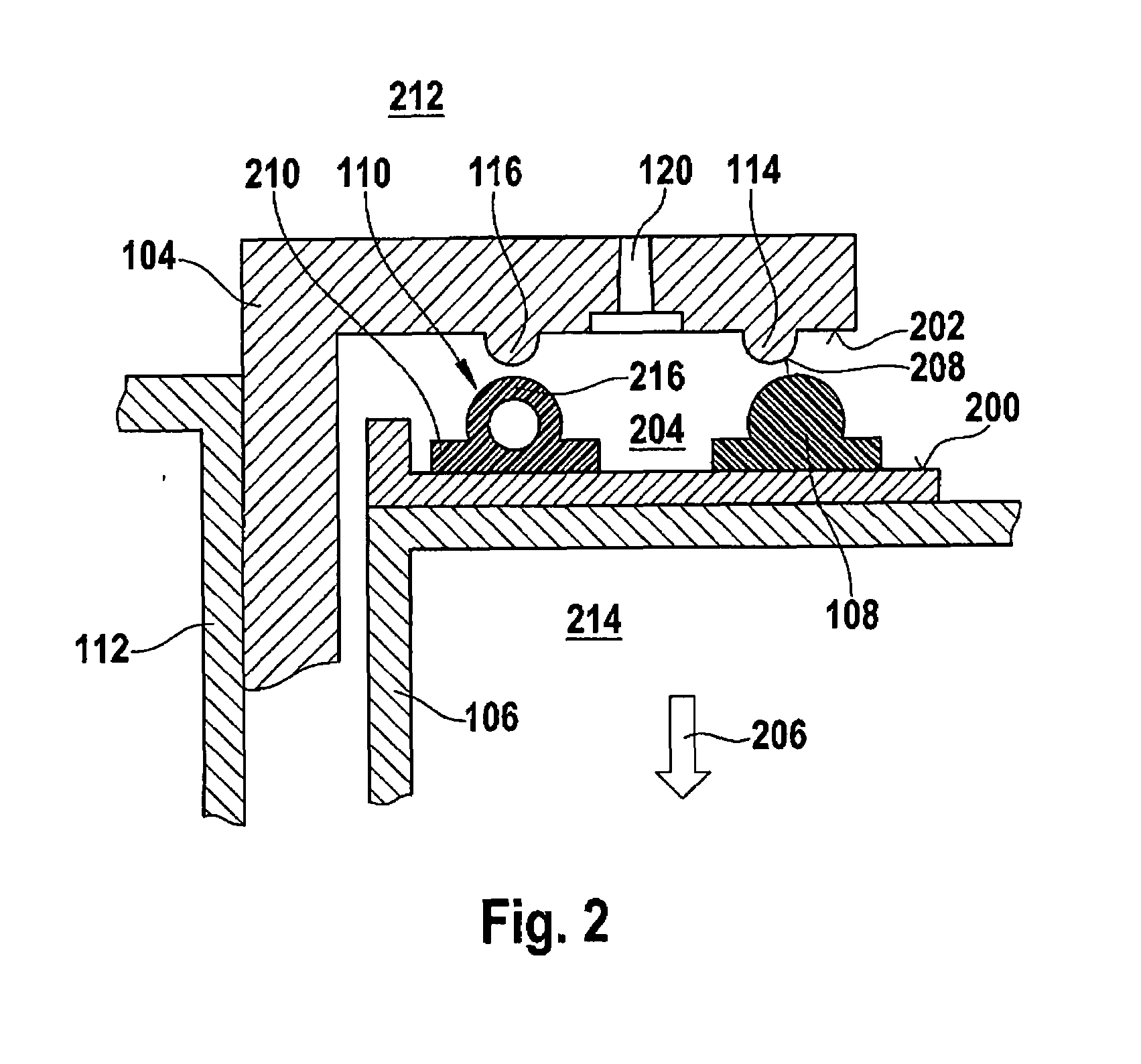

Method for the packaging of electronic components

InactiveUS6492194B1Improve seal qualityEfficient electromagnetic shieldingImpedence networksSemiconductor/solid-state device detailsHermetic sealElectronic component

A method for the packaging of electronic components, including the mounting of at least one electronic component on its active face side to a base, the base including electrical contacts on an external face and connection pads on a face opposite the external face, and including a first series of via holes connecting the electrical contacts and the connection pads and a second series of holes for use in aspiration. A deformable film is deposited on the face opposite to the active face of the electronic component or components. The deformable film is aspirated through the second series of holes from the face opposite the external face of the base, so as to sheath the electronic component or components. The method may furthermore include, on top of the deformable film, a mineral deposition to provide for the hermetic sealing of the components and a conductive deposition to provide for the shielding. Such an application may find particular application to surface wave filters.

Owner:THOMSON CSF SA

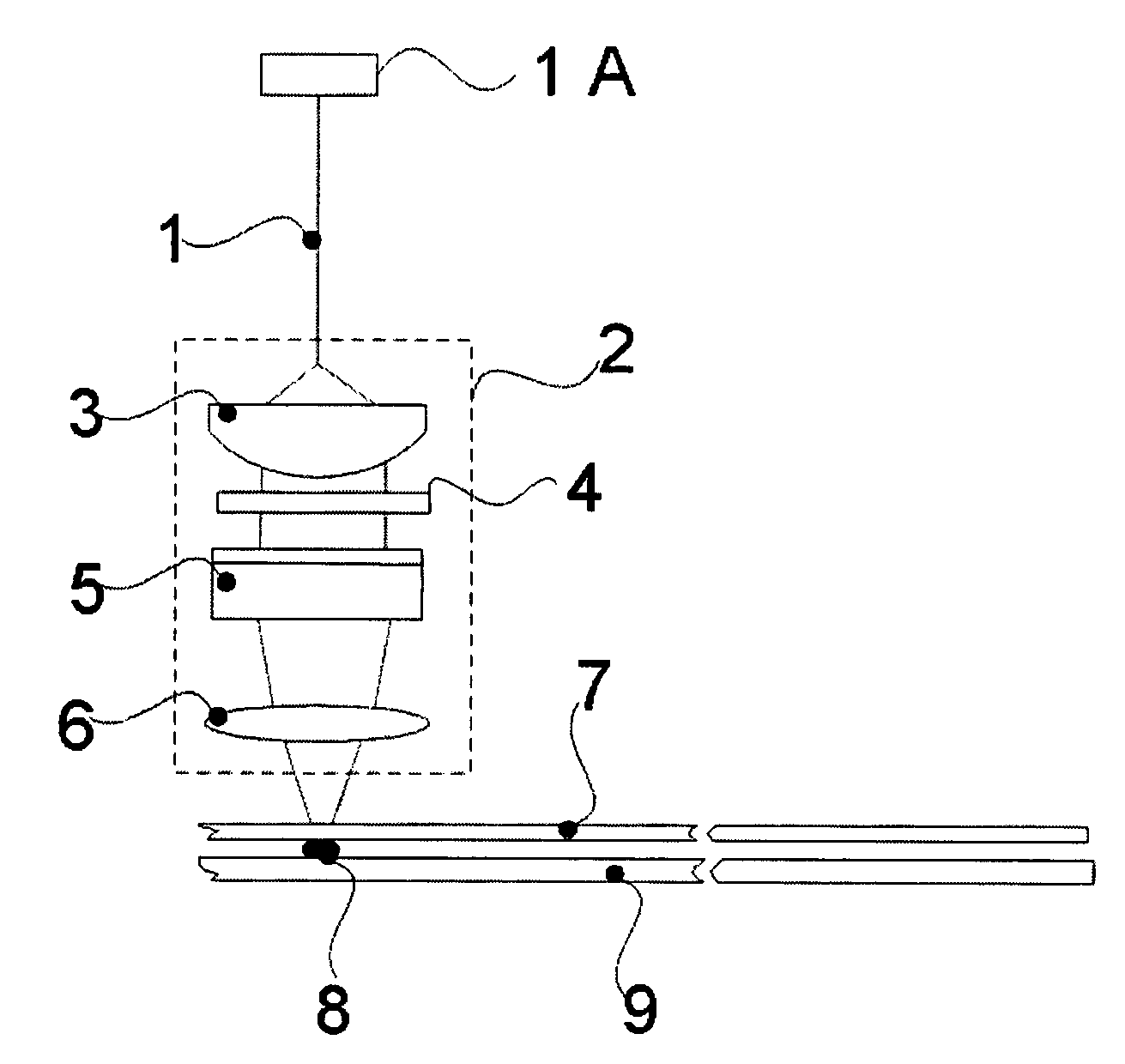

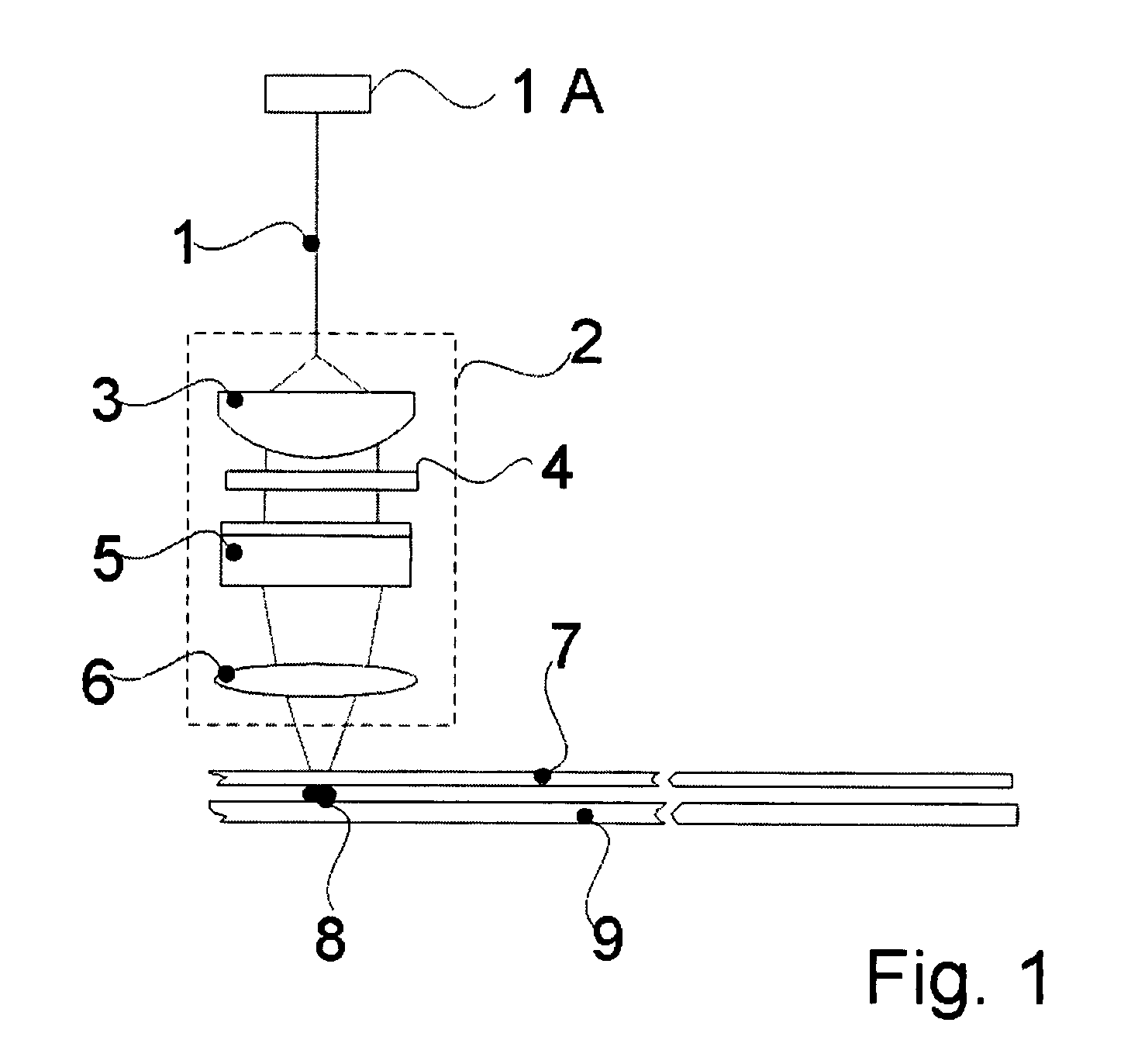

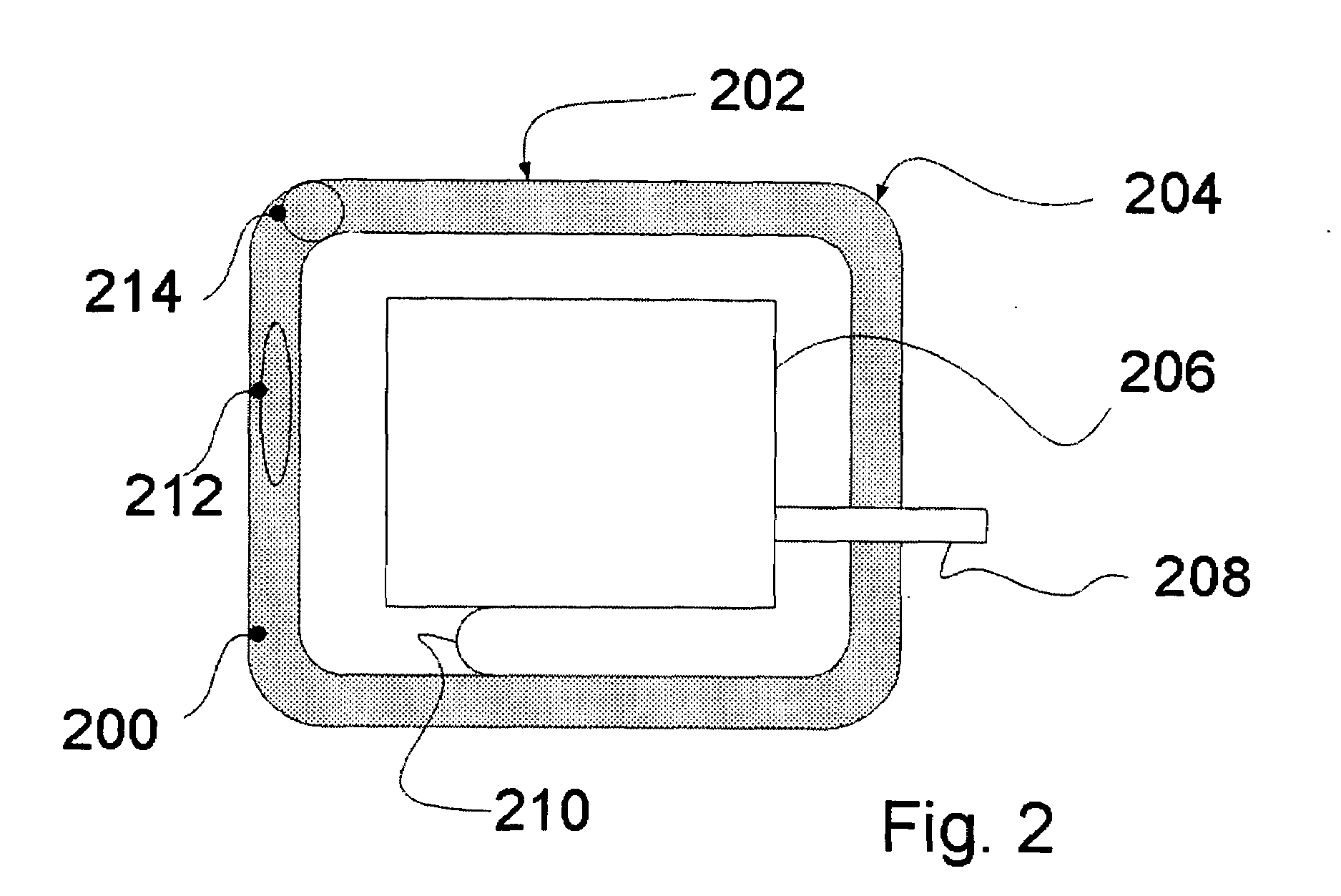

Method and apparatus for frit sealing with a variable laser beam

InactiveUS20090086325A1Uniform temperature distributionImprove overall utilizationDiffusing elementsElectroluminescent light sourcesFritLight beam

A beam shaper is implemented to seal an OLED. The beam shaper comprises a first and second lens and a beam shaper. Changing the relative position of the first, second lens and beam shaper relative to each other enables the beam shaper to generate laser beams with different shapes and intensity profiles.

Owner:CORNING INC

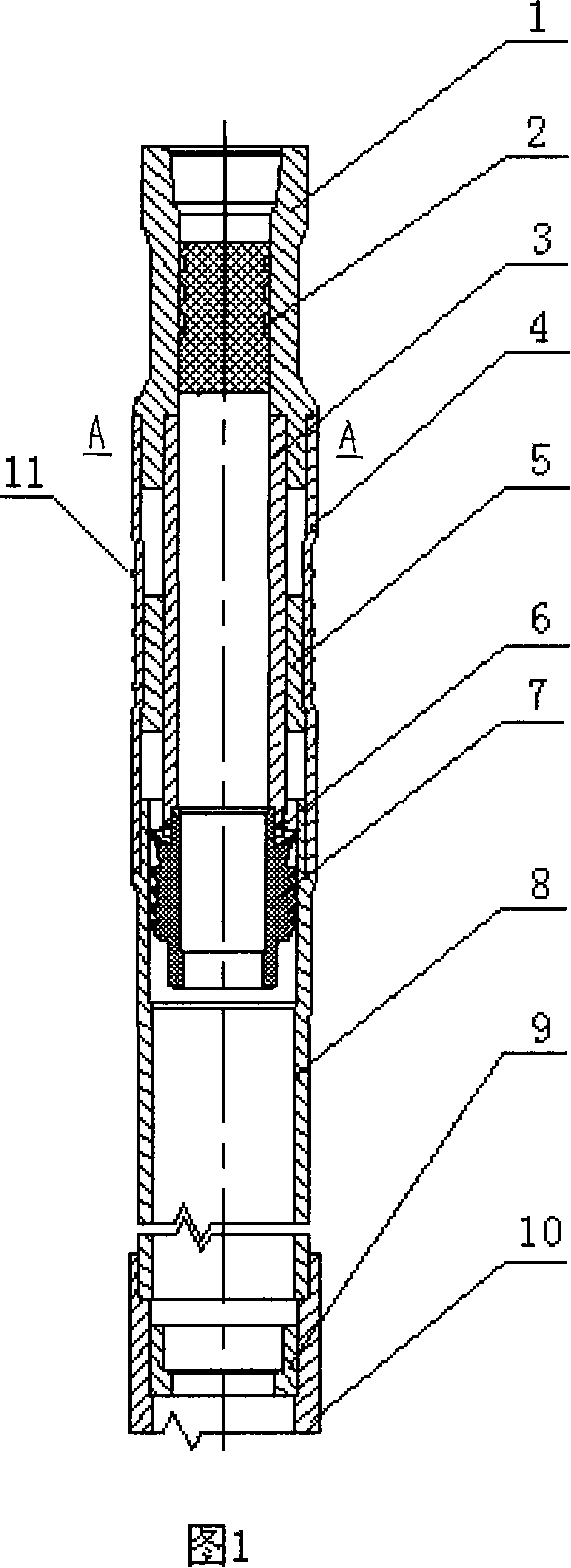

High-pressure high-temperature edge sealing method for vacuum glass

ActiveCN103145325AImprove adhesionImprove the level ofGlass reforming apparatusAdhesion forceMetallurgy

The invention relates to a high-pressure high-temperature edge sealing method for vacuum glass. The high-pressure high-temperature edge sealing method for the vacuum glass comprise the steps of (1) of coating one circle of closed low-melting-point glass powder onto the edge periphery of a lower glass piece with a support object, and combining an upper glass piece with the lower glass piece; (2) putting the combined glass into a high-pressure high-temperature heating pot in a manner of vertically arranging the glass or flatly putting the glass on a bracket; and (3) increasing the temperature in the high-pressure high-temperature heating pot to the melting point of the glass powder 350 DEG C to 480 DEG C, increasing the pressure 0.1MPa to 5MPa into the pot by an air compressor, keeping the temperature and the pressure for 0.2 hour to 2 hours, and decreasing the pressure and the temperature to obtain a vacuum glass finished product. With the adoption of the high-pressure high-temperature edge sealing method for the vacuum glass, the low-melting-point glass powder is put between the edges of the two glass pieces; the temperature is increased to 350 DEG C to 480 DEG C under the normal pressure in the high-pressure pot; after the low-melting-point glass powder is molten, the pressure increase is performed, so that the two glass pieces are extruded in a vacuum way; therefore, the molten low-melting-point glass powder contacts with the upper glass piece and the lower glass piece fully and closely; the heat conduction speed and the heat conduction amount are increased; the adhesion force and the leveling performance of the molten powder are enhanced; the sealing quality of edges sealed with the low-melting-point glass powder is improved; and the technical difficulty of air leakage after the edge sealing is effectively solved.

Owner:TIANJIN GUSHANG VACUUM GLASS MFG

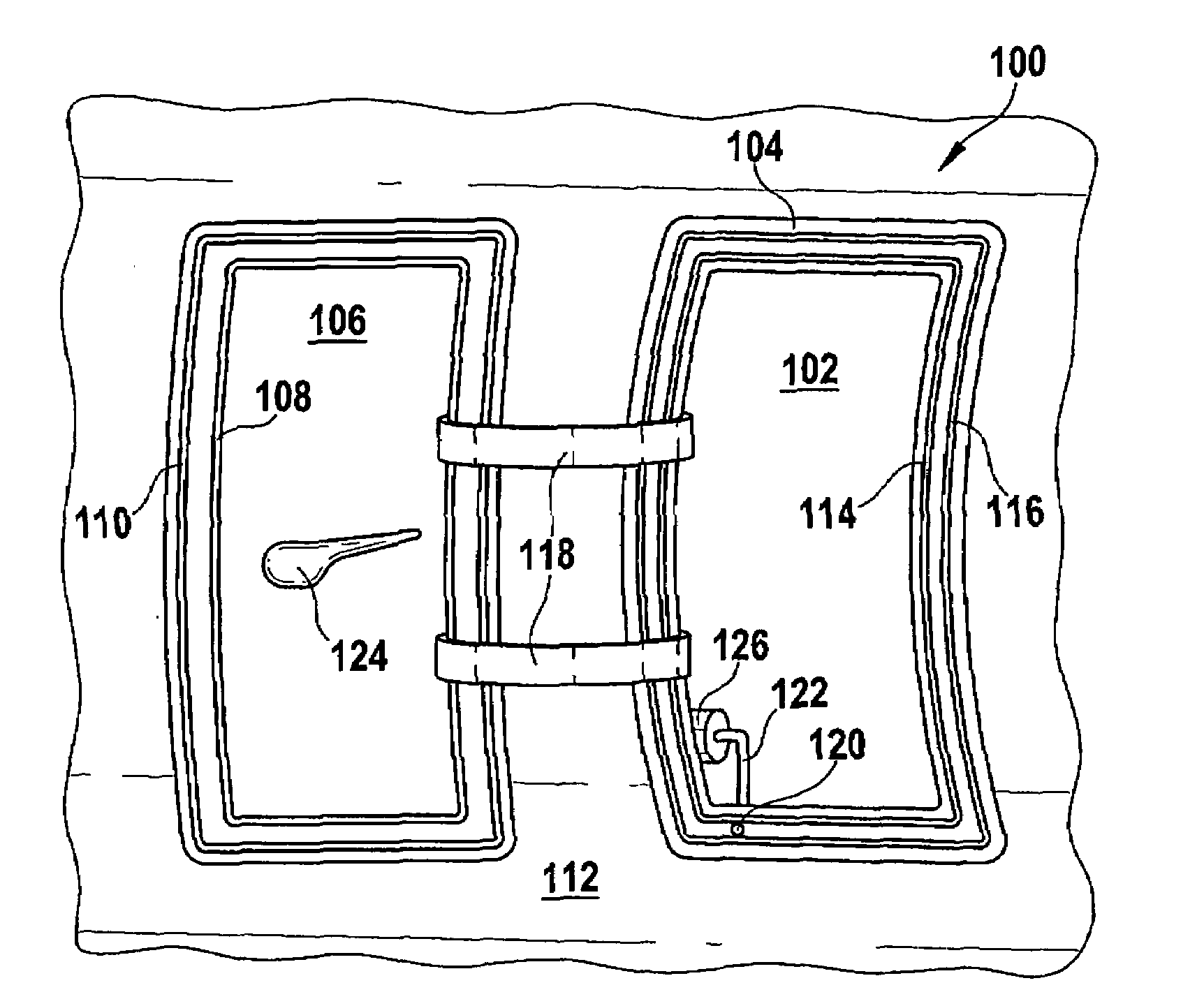

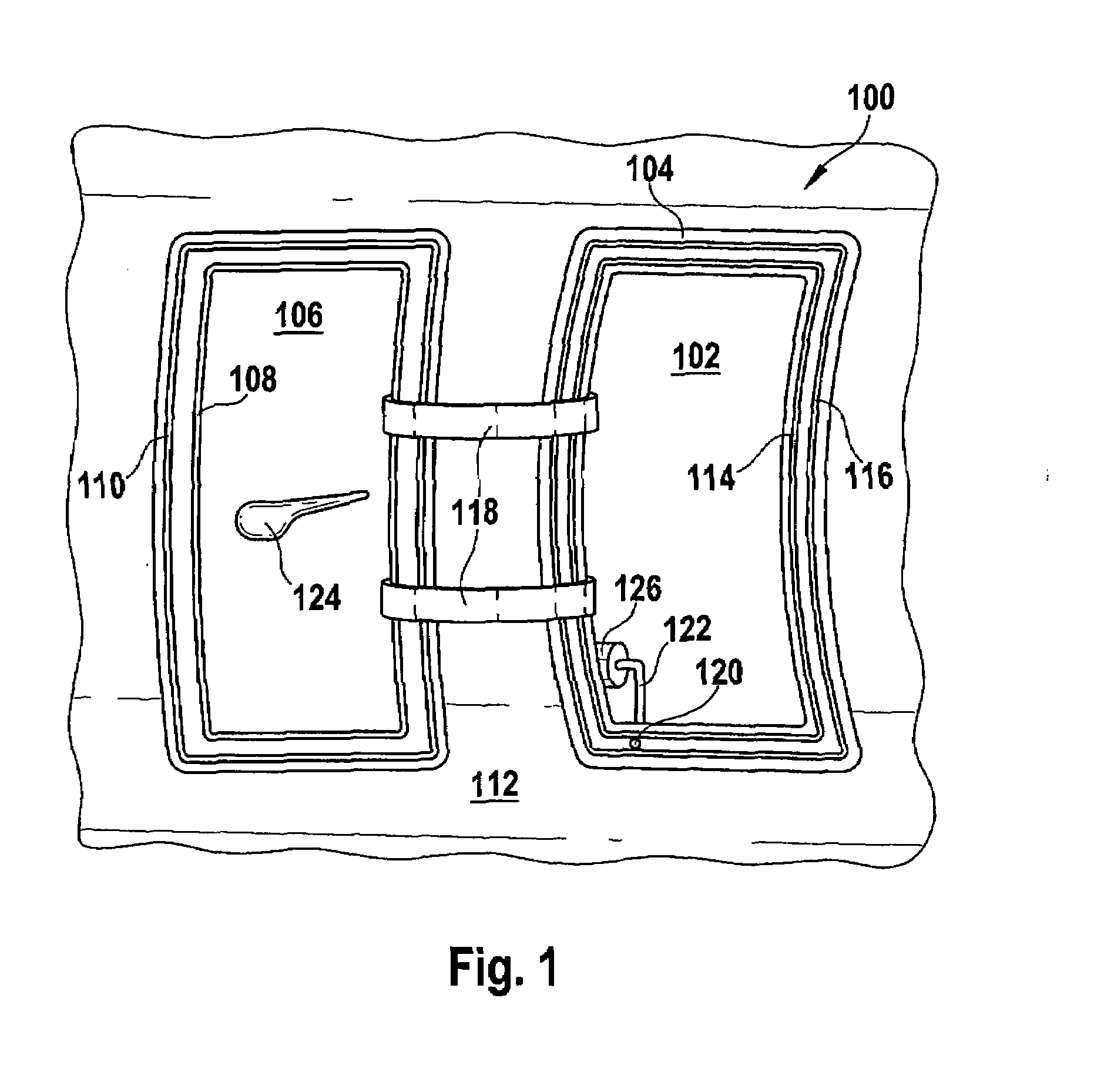

Door arrangement and aircraft

InactiveUS20080164373A1Promote absorptionEasy to interceptEngine sealsSealing arrangementsAirplaneElectrical and Electronics engineering

Owner:AIRBUS OPERATIONS GMBH

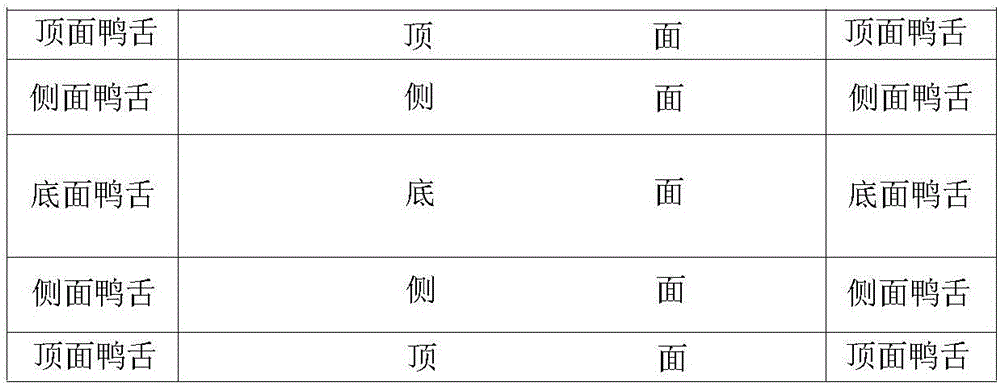

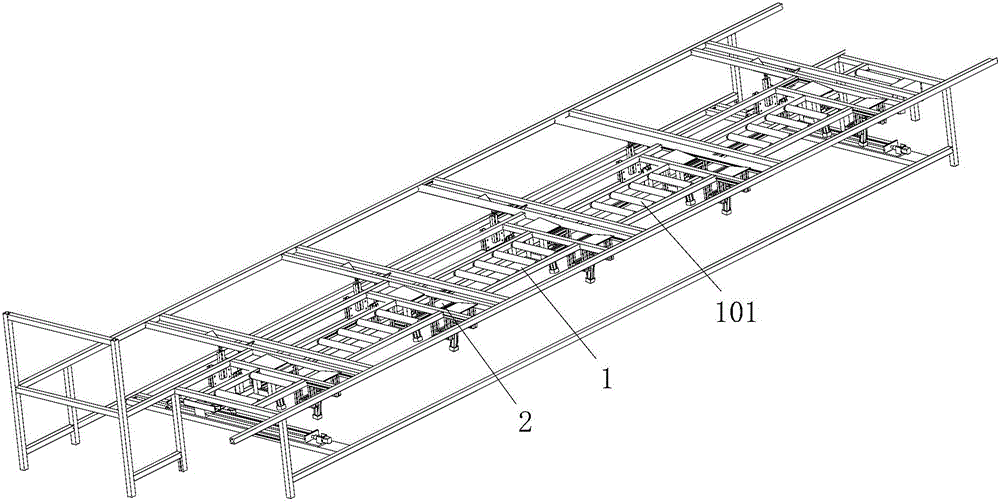

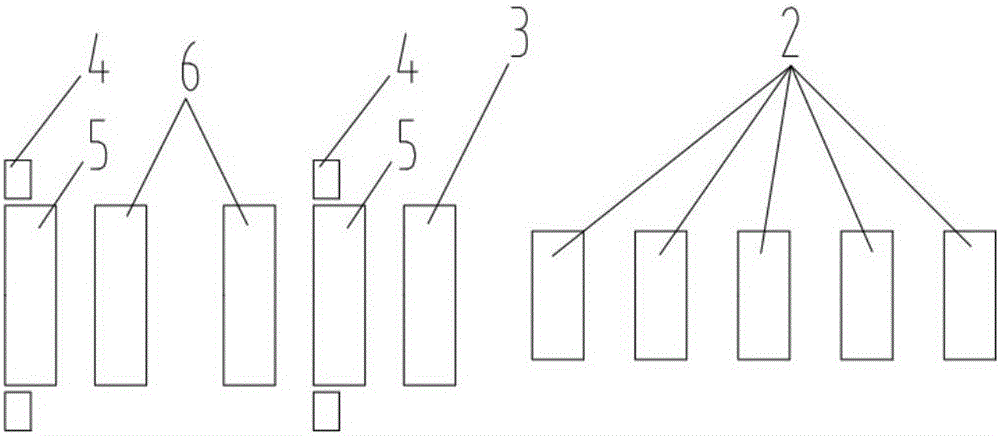

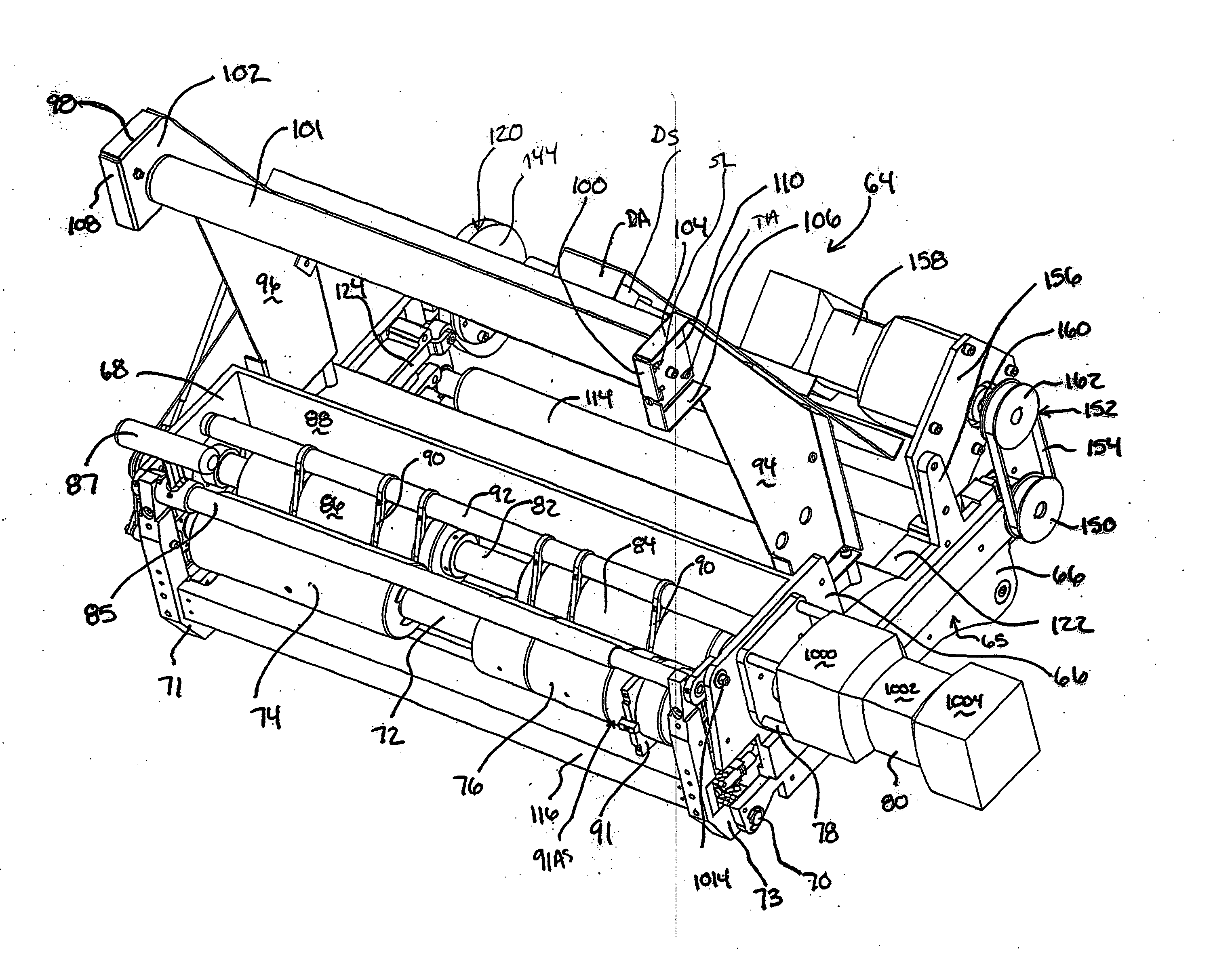

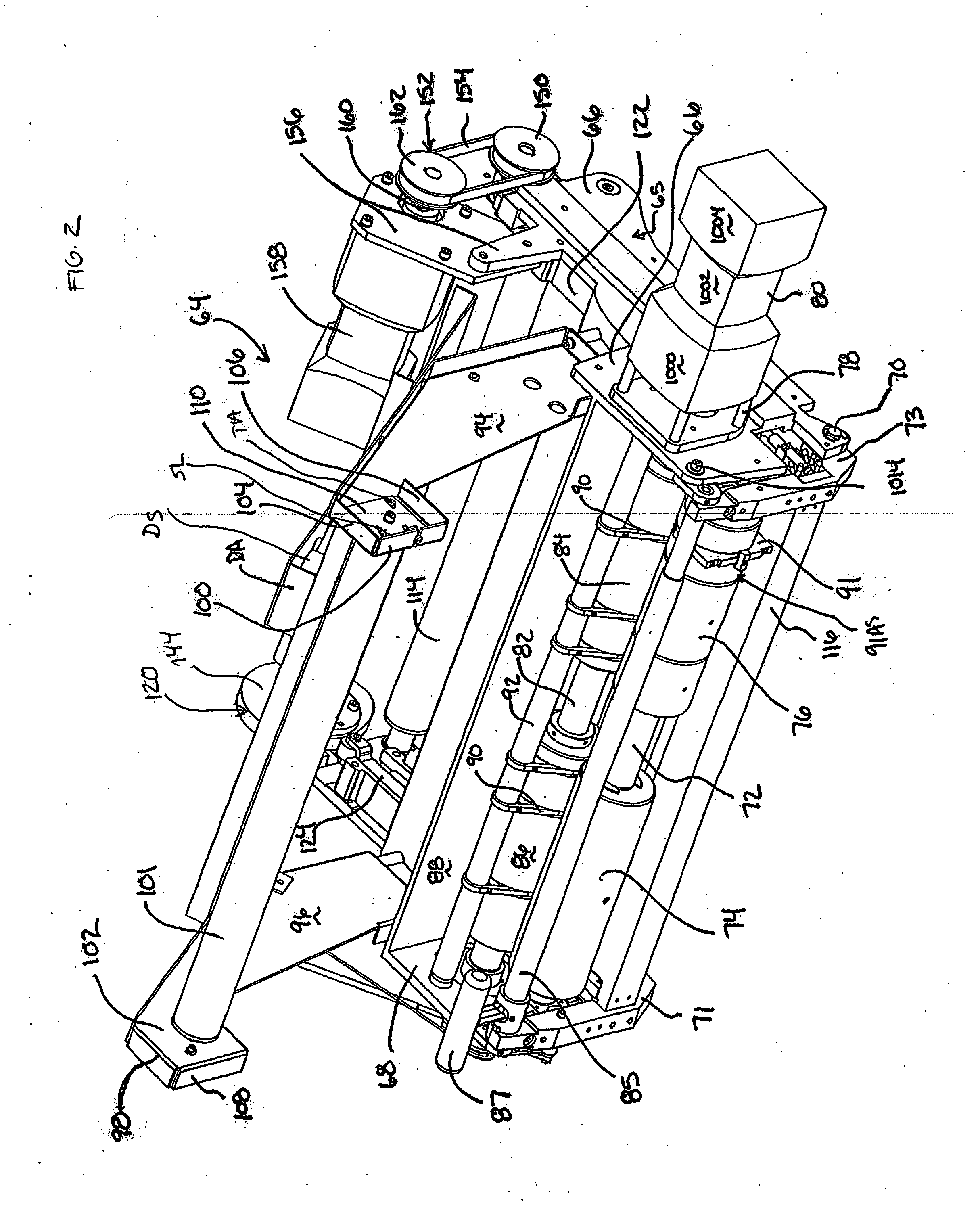

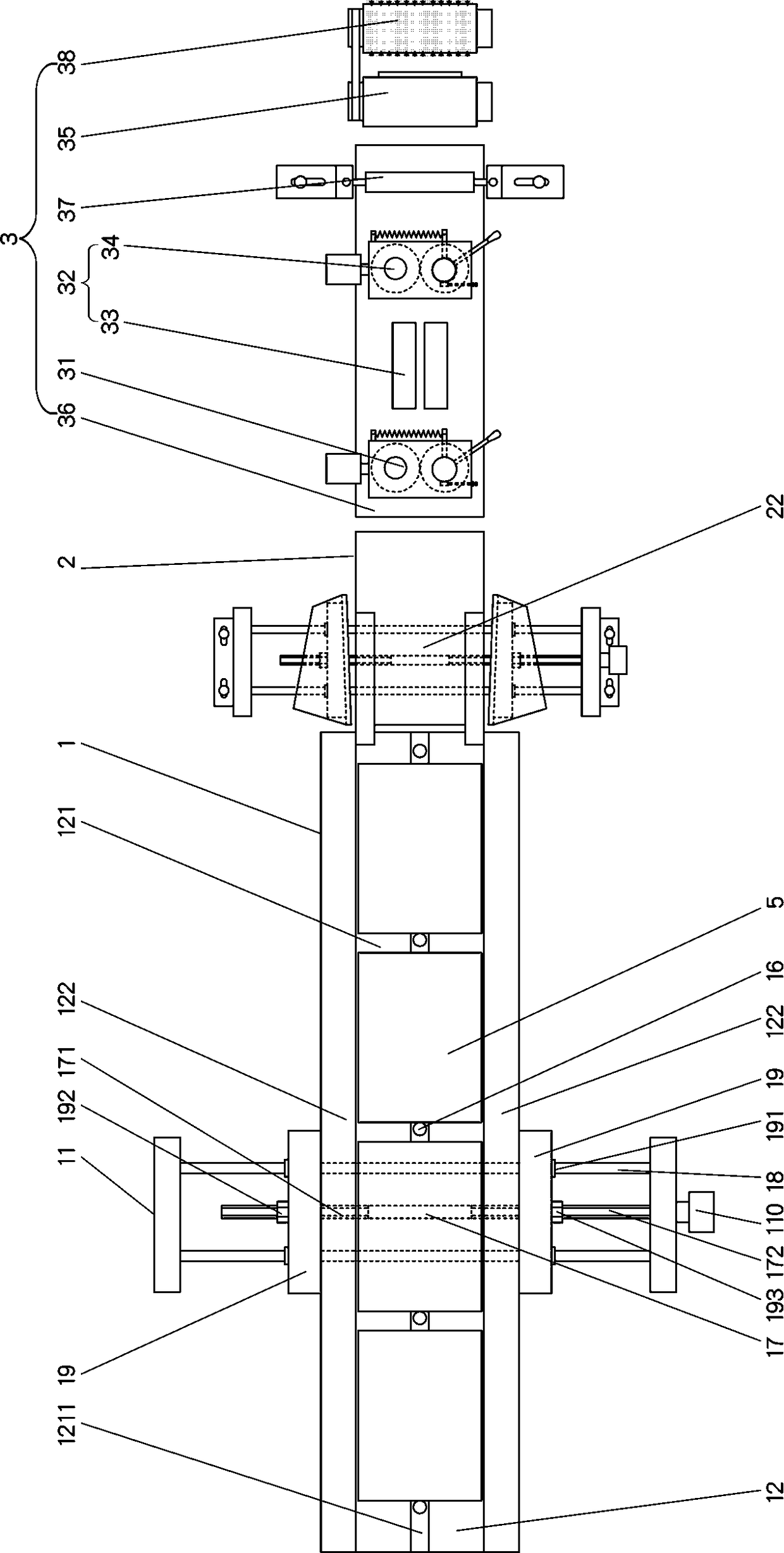

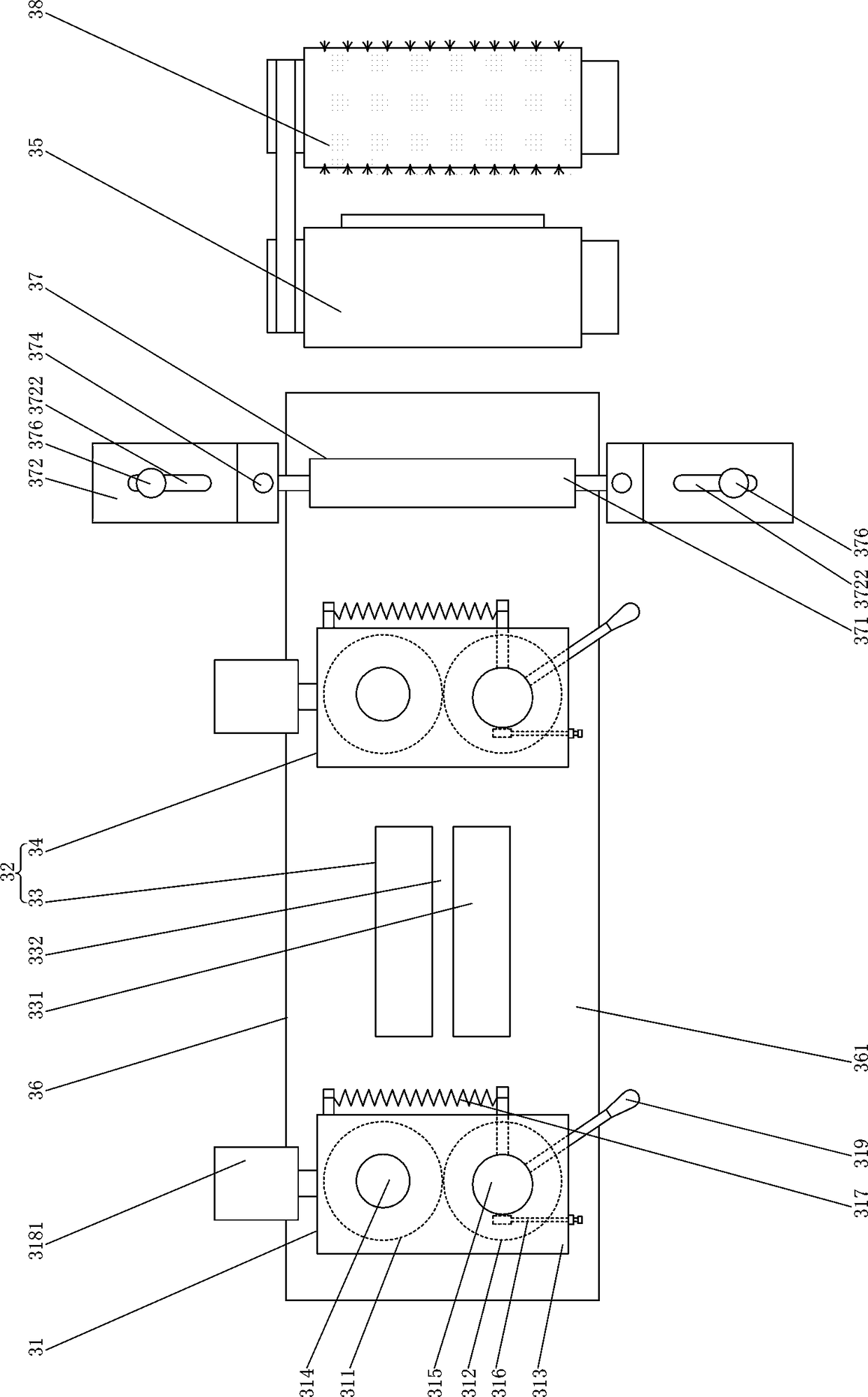

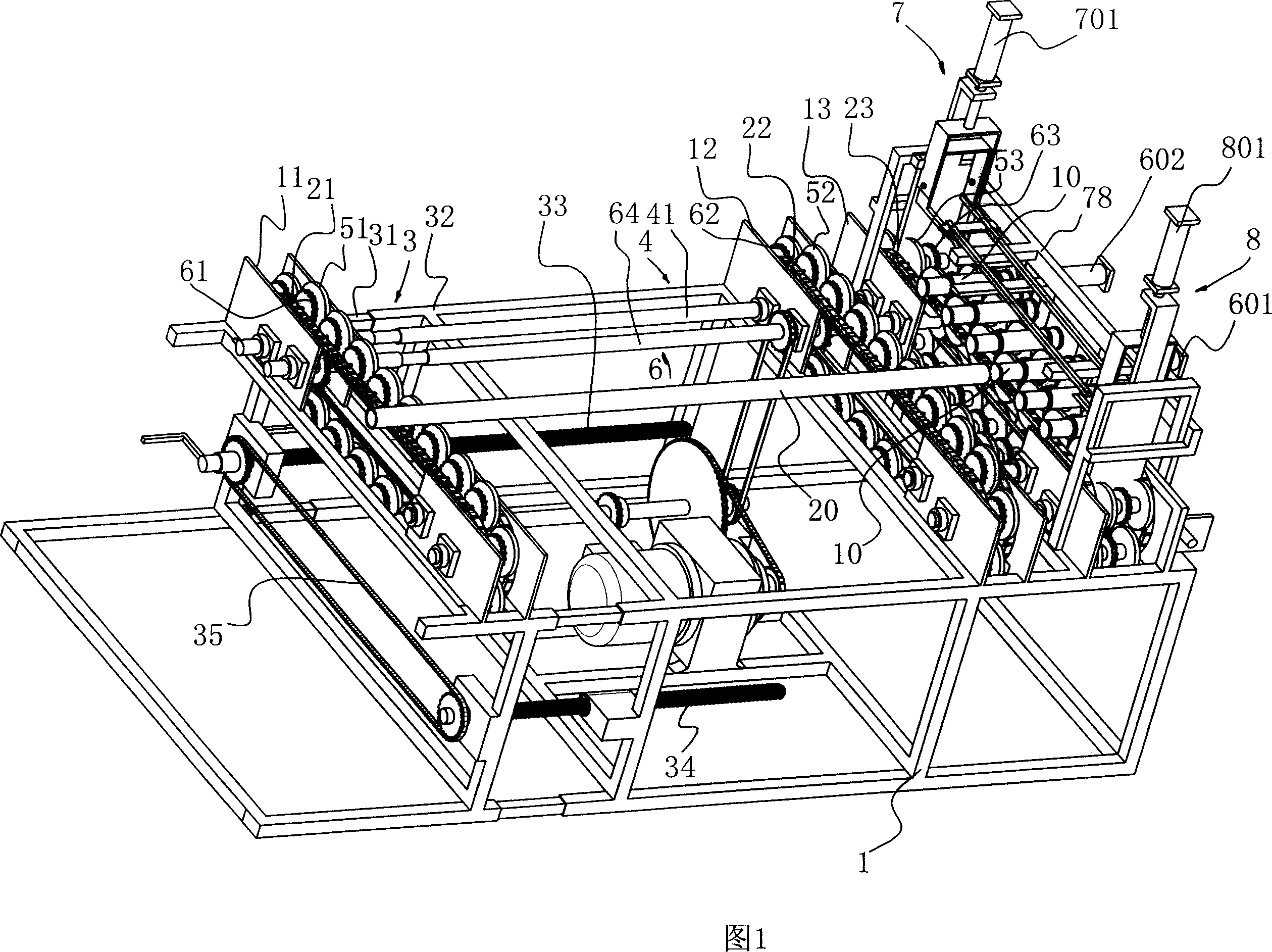

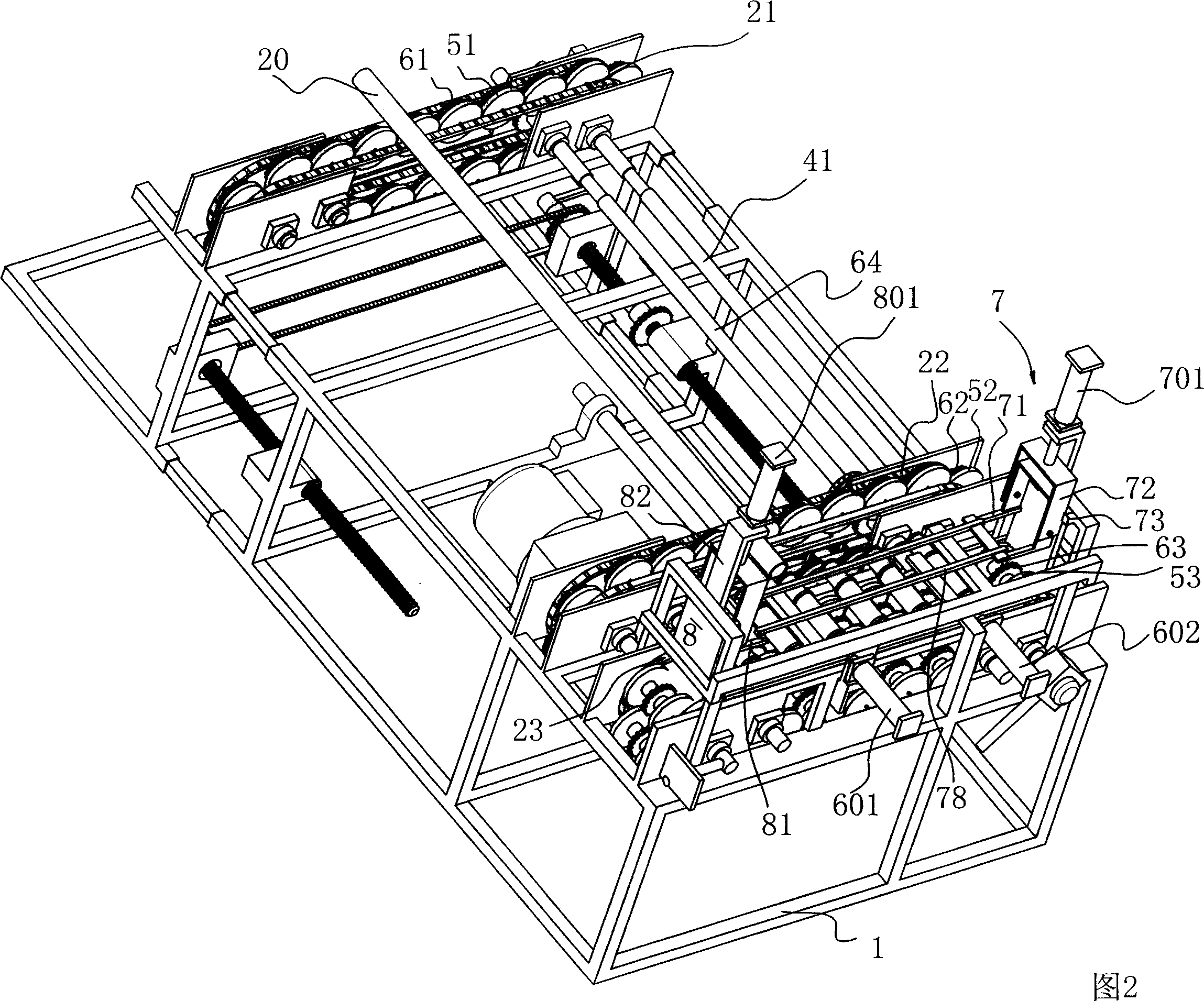

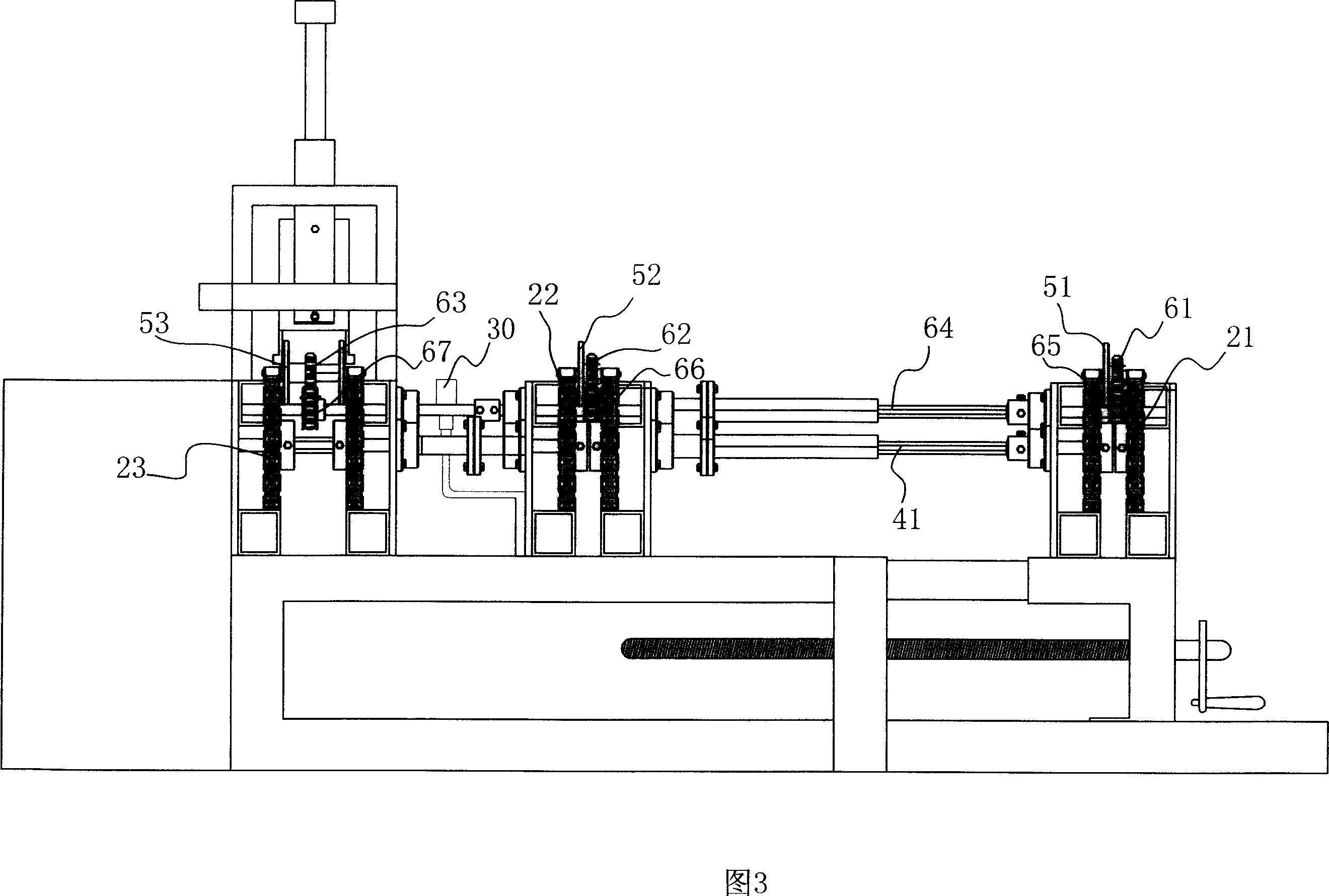

Automatic package machine for corrugated cartons with different lengths

InactiveCN105730772AHigh conveying precisionModerate delivery speedWrapper twisting/gatheringCartonEngineering

The invention discloses an automatic package machine for corrugated cartons with different lengths. The automatic package machine comprises a rack. An initial material position containing area, a wrapping forming area and a carton sealing area are sequentially arranged on the rack in the carton conveying direction. A material conveying device is arranged below the initial material position containing area. A carton containing area is arranged in the wrapping forming area. A top face folding mechanism, a front end folding system and a tail end folding system are arranged in the carton containing area. A side face folding mechanism is arranged below the carton containing area. Each of the front end folding mechanism and the tail end folding mechanism comprises a side face duck tongue folding mechanism, a top face duck tongue folding mechanism and a bottom face duck tongue folding mechanism. A plurality of powerless transmission rollers are arranged in the carton sealing area in the length direction of the carton sealing area. A two-end carton sealing mechanism, a length direction carton sealing system and a width direction carton sealing system are arranged in the carton sealing area in the carton conveying direction. By means of the automatic package machine, packaging of carton type products of different specifications and different sizes can be achieved, and the application range is wide.

Owner:SHANDONG UNIV OF SCI & TECH

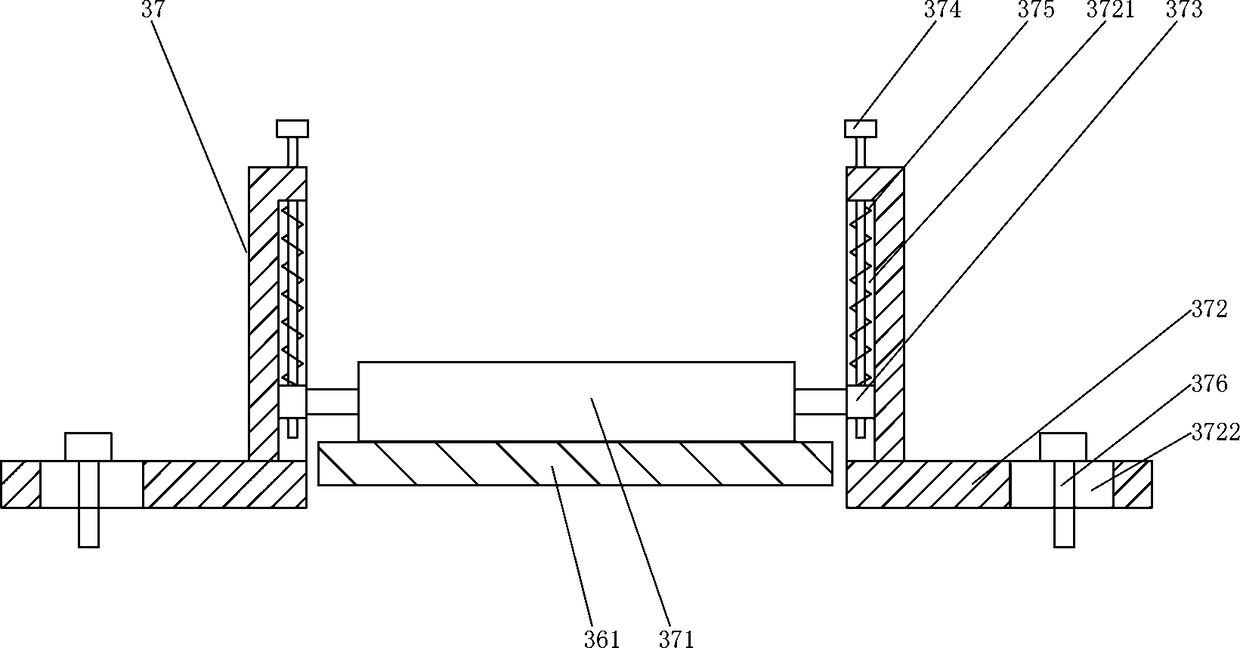

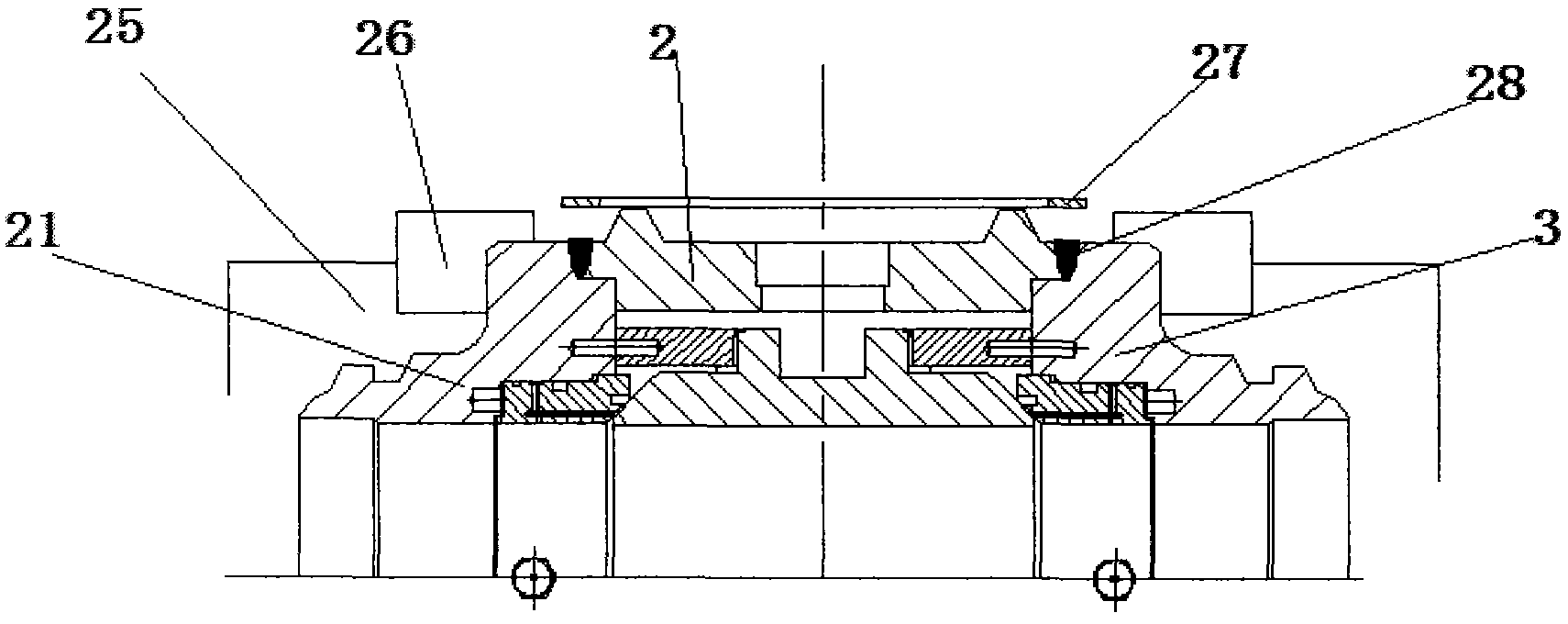

Sealing device

InactiveUS20070068632A1Reduce decreaseAvoid the needOhmic-resistance heating detailsWrapper twisting/gatheringEngineeringPlastic film

A sealing device with film sealer for localized heating to bond film material as in one having a high temperature resistance (e.g., ceramic) substrate with a properly sized groove for receiving a heater element as in a flat faced wire band in a tight, flush to adjacent film presentation surface arrangement. A stacked ceramic plate set with a wire band received within a groove defined by a smaller height intermediate stack insert is a suitable substrate. The band is retained flush by a positioner fixer system that securely locks down one end for band tightening and the other end is provided at an access location of said housing body for clamping and tensioning the heater element into ready for use position within the groove. The edge sealer is suited for use as a product-in-bag sealing device (products such as air, foam, foodstuff, etc.) with the heater element placed in contact with film material to form a seal. A drag seal arrangement, where film layers are drawn past a fixed or adjustably mounted heater element to achieve bonding of one plastic film layer to another, is an example. The invention avoids repeated sealer replacement particularly when the film source (e.g., a film roll) has yet to run out.

Owner:PREGIS INTELLIPACK CORP

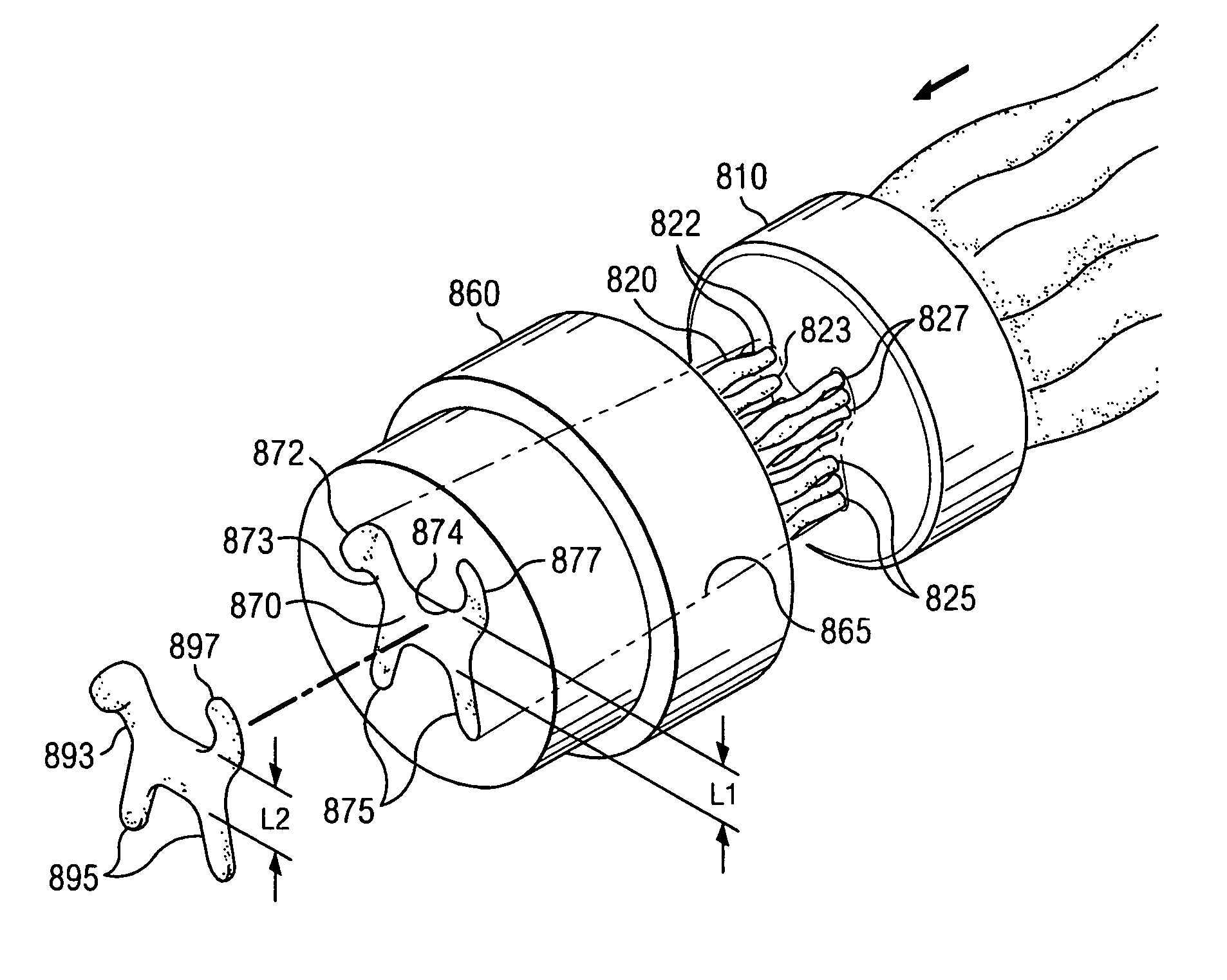

Apparatus and method for improving the dimensional quality of extruded food products having complex shapes

InactiveUS20050048180A1Quality improvementImprove sealing propertiesConfectionerySweetmeatsEngineeringFood flavor

The present invention comprises an improved extruder die assembly and method for using same to improve the quality of dimensional design aspects of extruded, complexly shaped, direct expanded food products. The improved system includes an improved die assembly comprising a first die and a second die having at least one orifice. A majority of the total pressure drop occurs in the first die to pre-expand the dough prior to the dough entering the second die. The orifices in the first die can be individually configured to obtain differing dough flow speeds resulting in a desired flow pattern. A plurality of extruded dough ropes formed at each orifice exit of the first die can meld together in the bore and exit the second die. Color or flavor can be added at the first die to enhance the food product.

Owner:FRITO LAY NORTH AMERICA INC

Wafer-level packaging of chip and packaging method thereof

ActiveCN101552263AImprove sealingIncrease relative bonding areaSemiconductor/solid-state device detailsSolid-state devicesEpoxyEngineering

The present invention discloses a wafer-level packaging of chip and a packaging method thereof. The wafer of upper cover plate is installed with an upper sealing ring strip. The wafer of lower cover plate is installed with a lower sealing ring strip matched with the lower sealing ring strip. The upper sealing ring strip and the lower sealing ring strip are eutectic or hot-pressed and spread for realizing packaging. Or the wafer of upper cover plate is coated with a bonding layer of epoxy resin, polymer, metal or alloy material. The wafer of lower cover plate is installed with a lower sealing ring strip matched with the upper sealing ring strip. The lower sealing ring strip squeezes the bonding layer for realizing packaging. The wafer-level packaging of chip can increase the sealing performance of internal and external environments. The packaging period can greatly increase the finished product rate after bonding, increase the sealing quality and guarantees the long-time reliability.

Owner:THE 13TH RES INST OF CHINA ELECTRONICS TECH GRP CORP

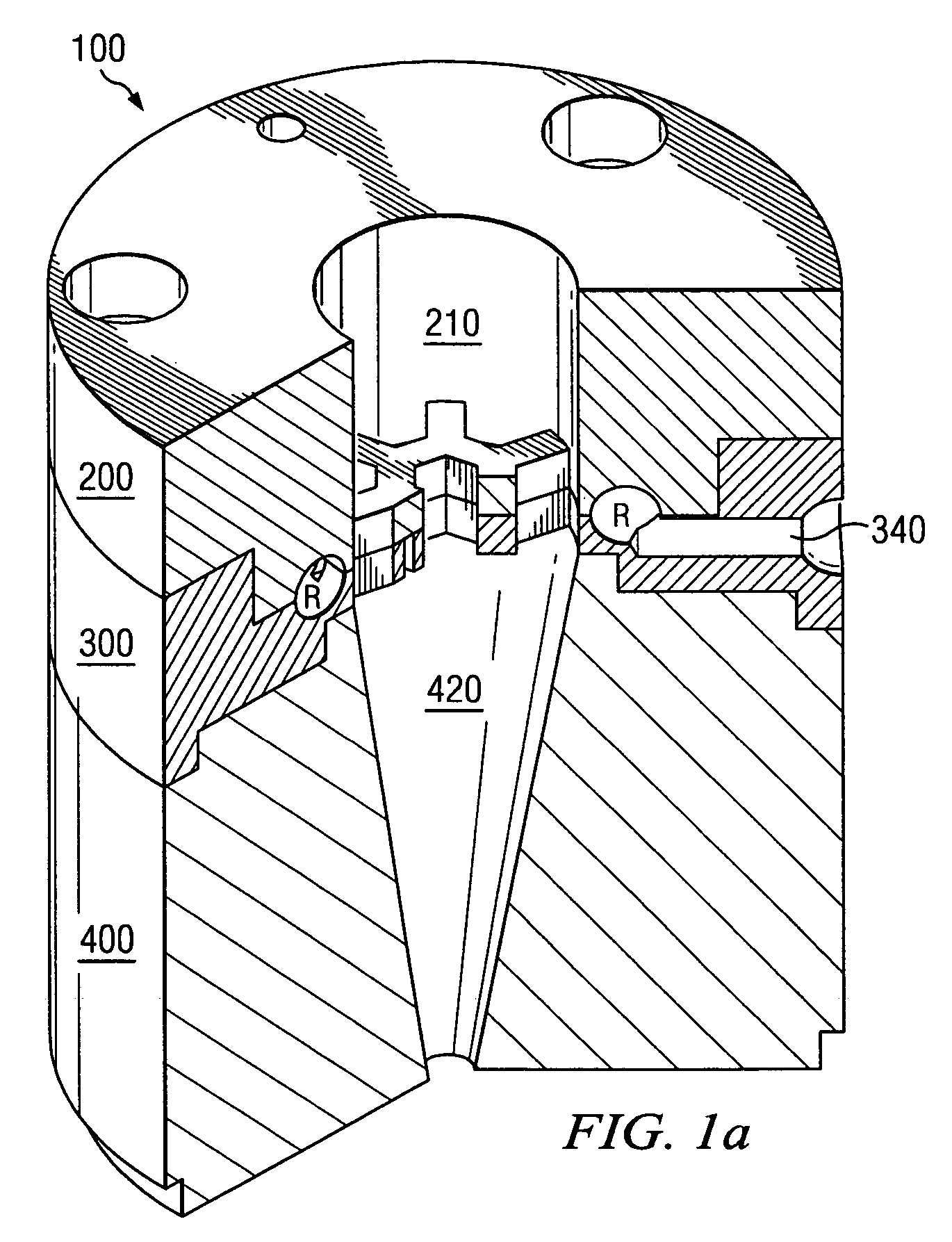

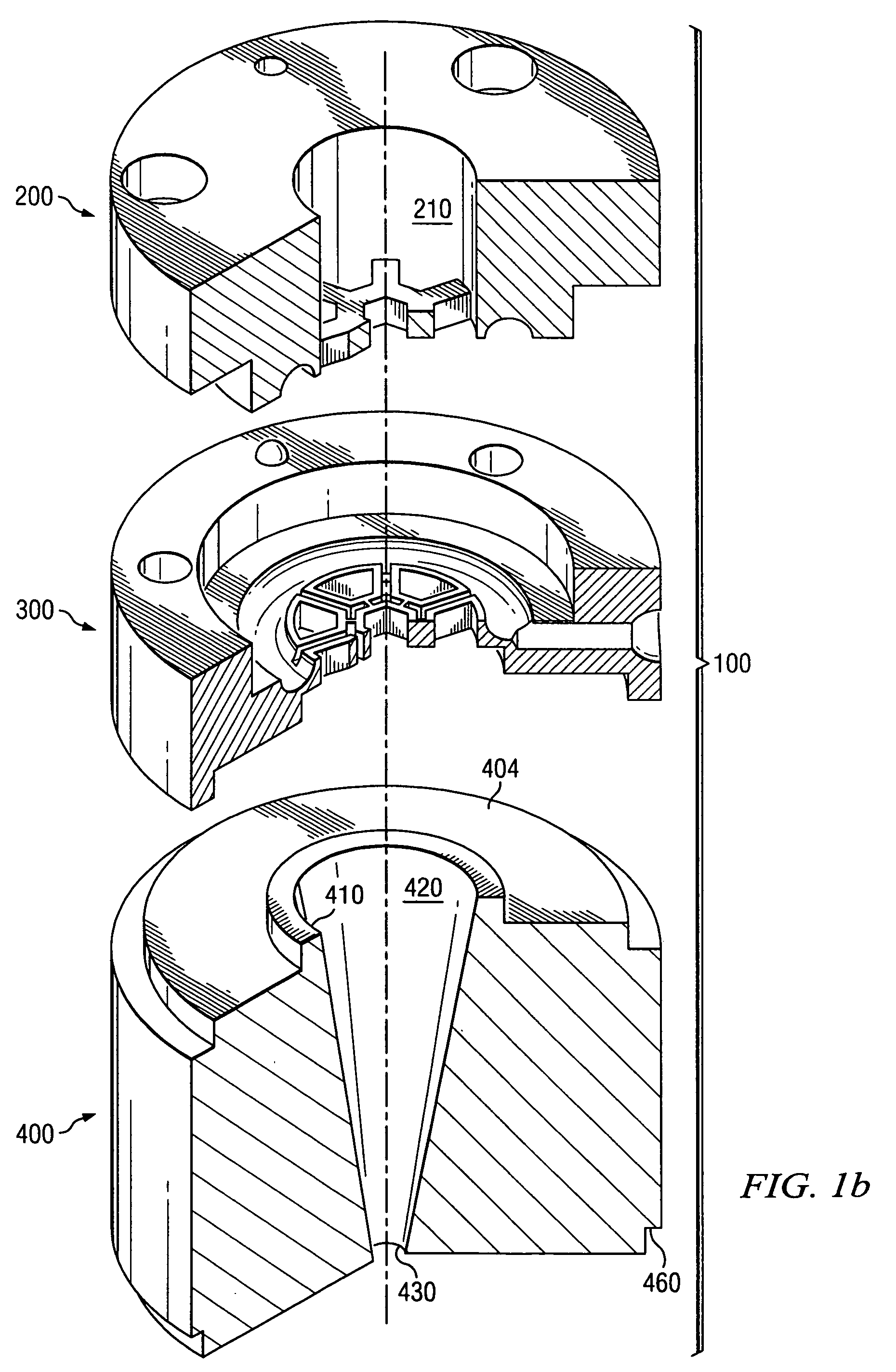

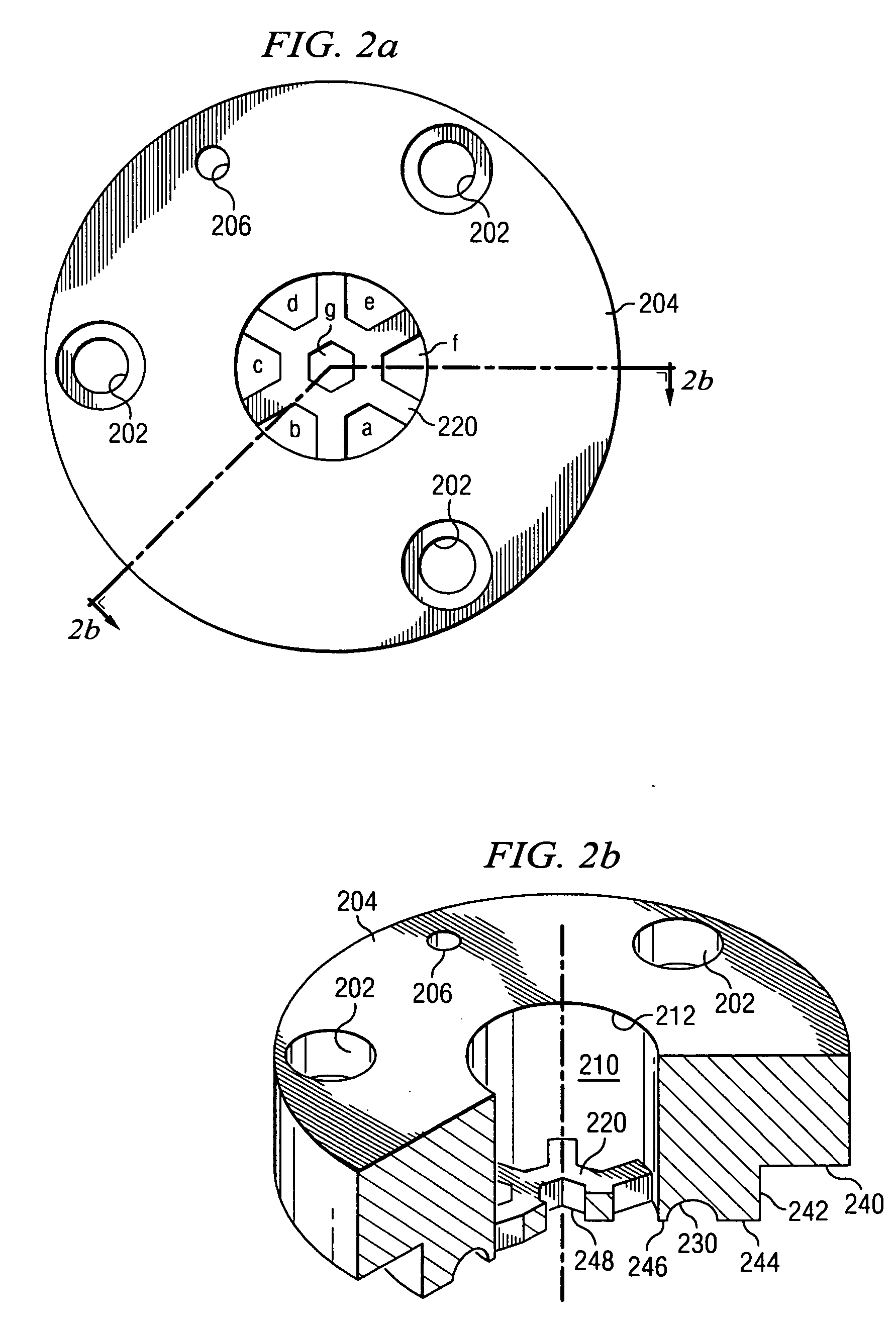

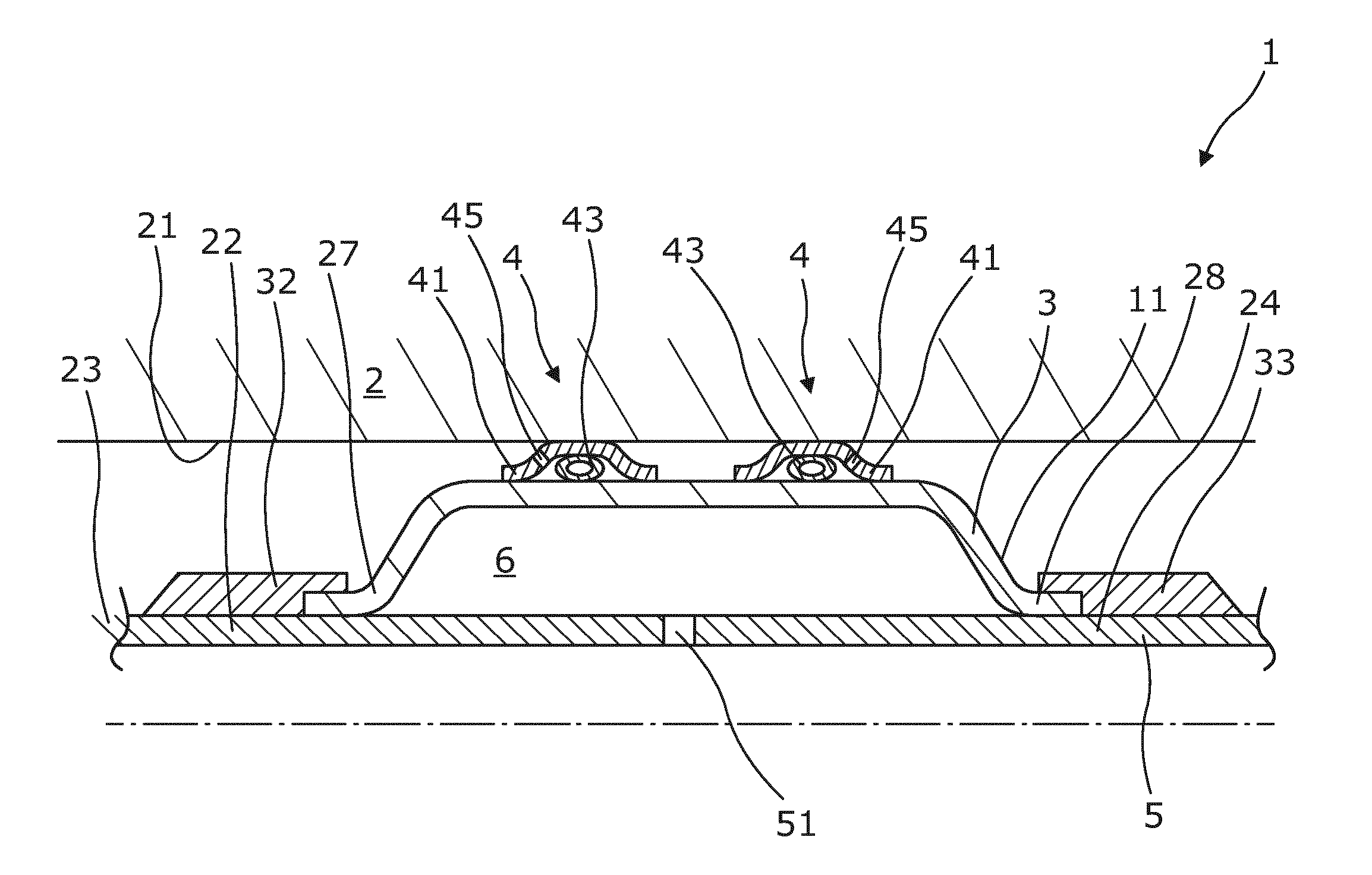

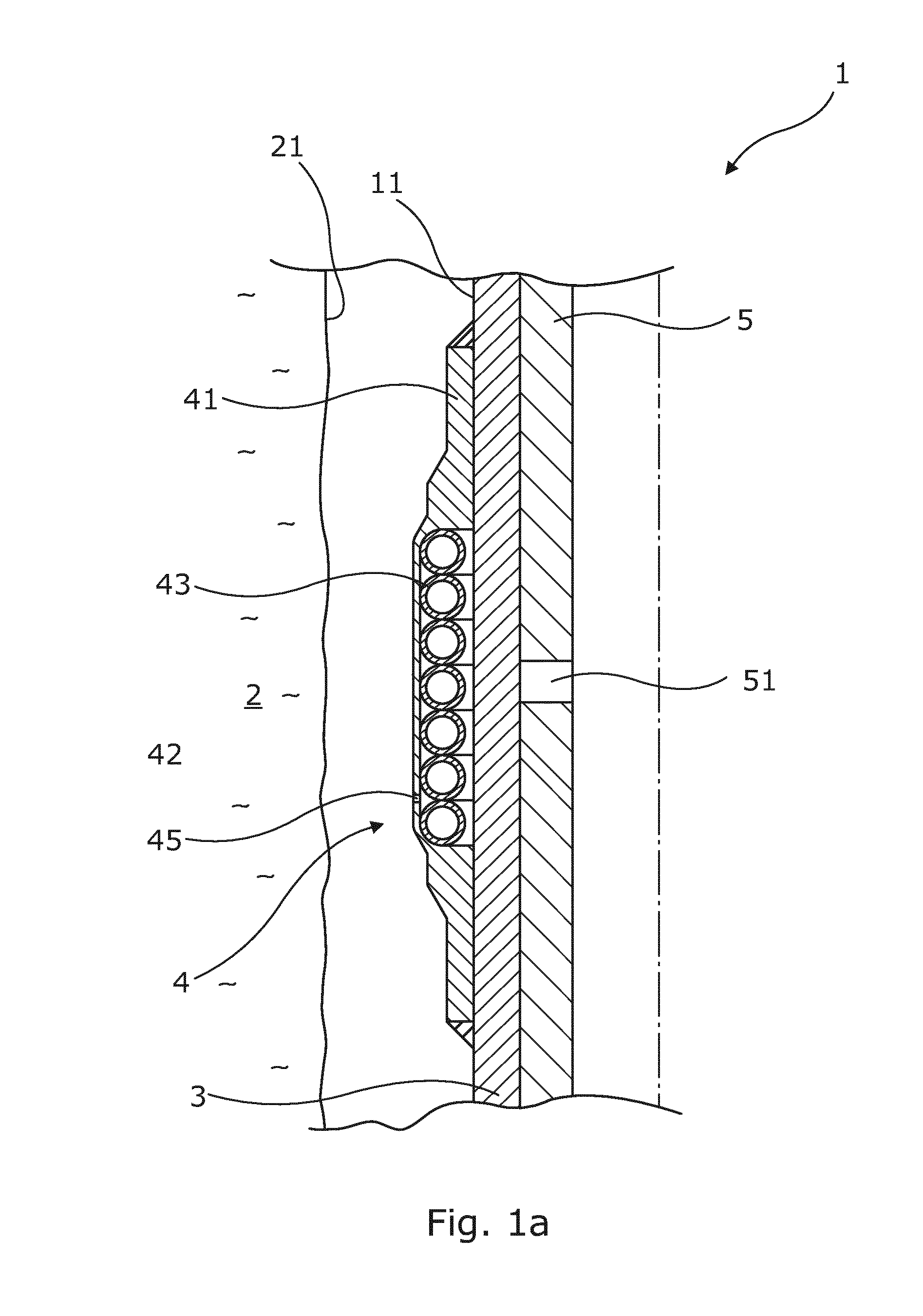

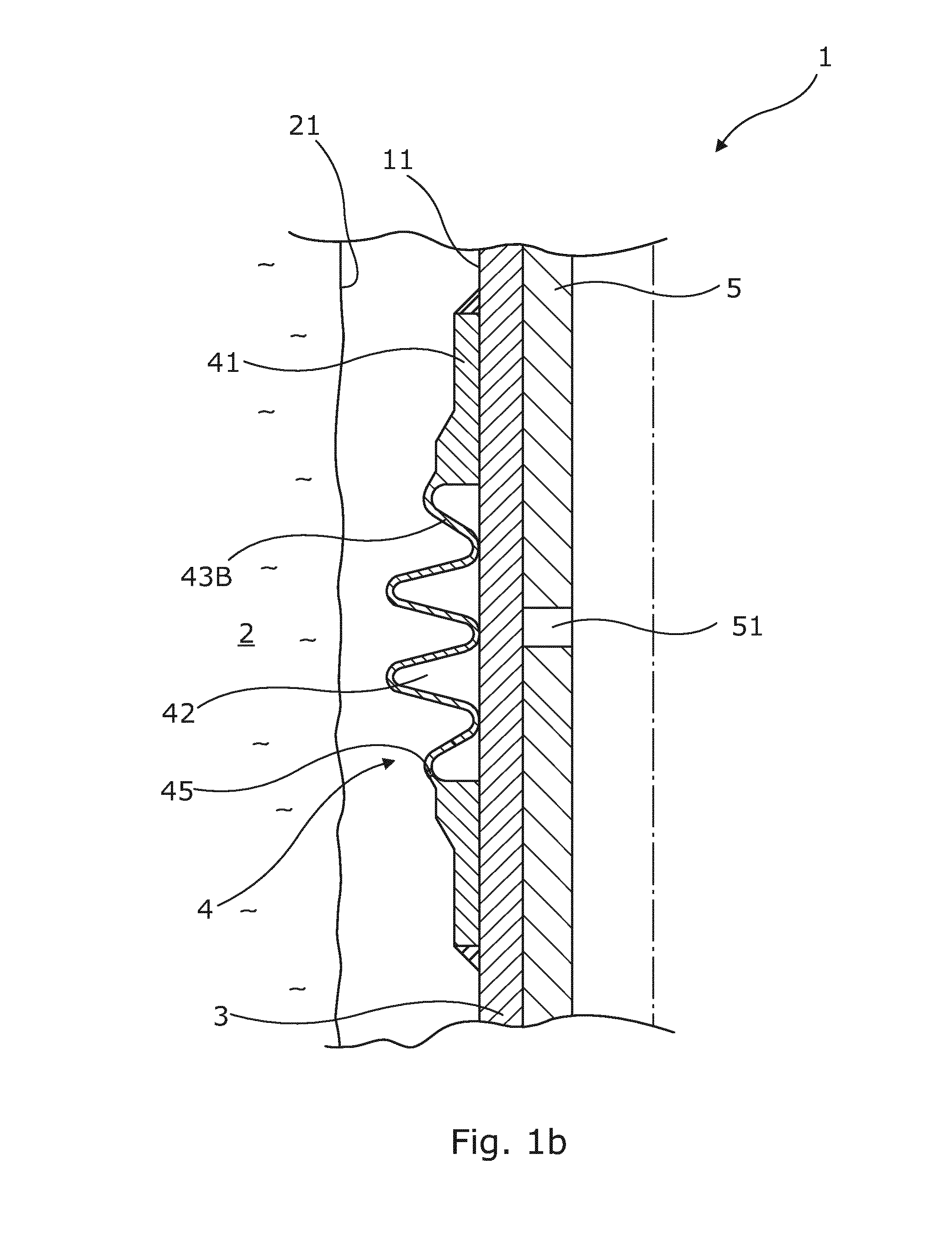

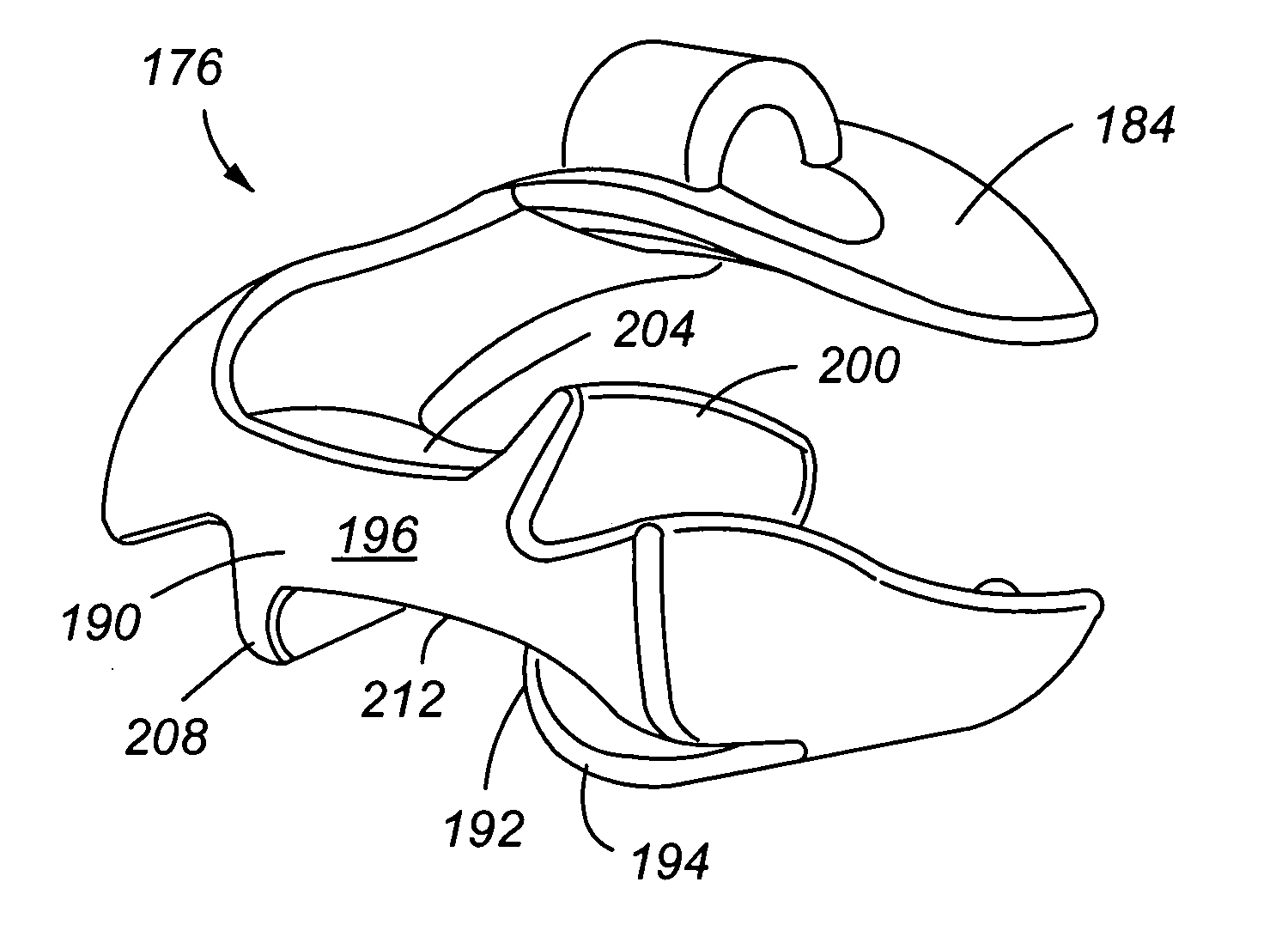

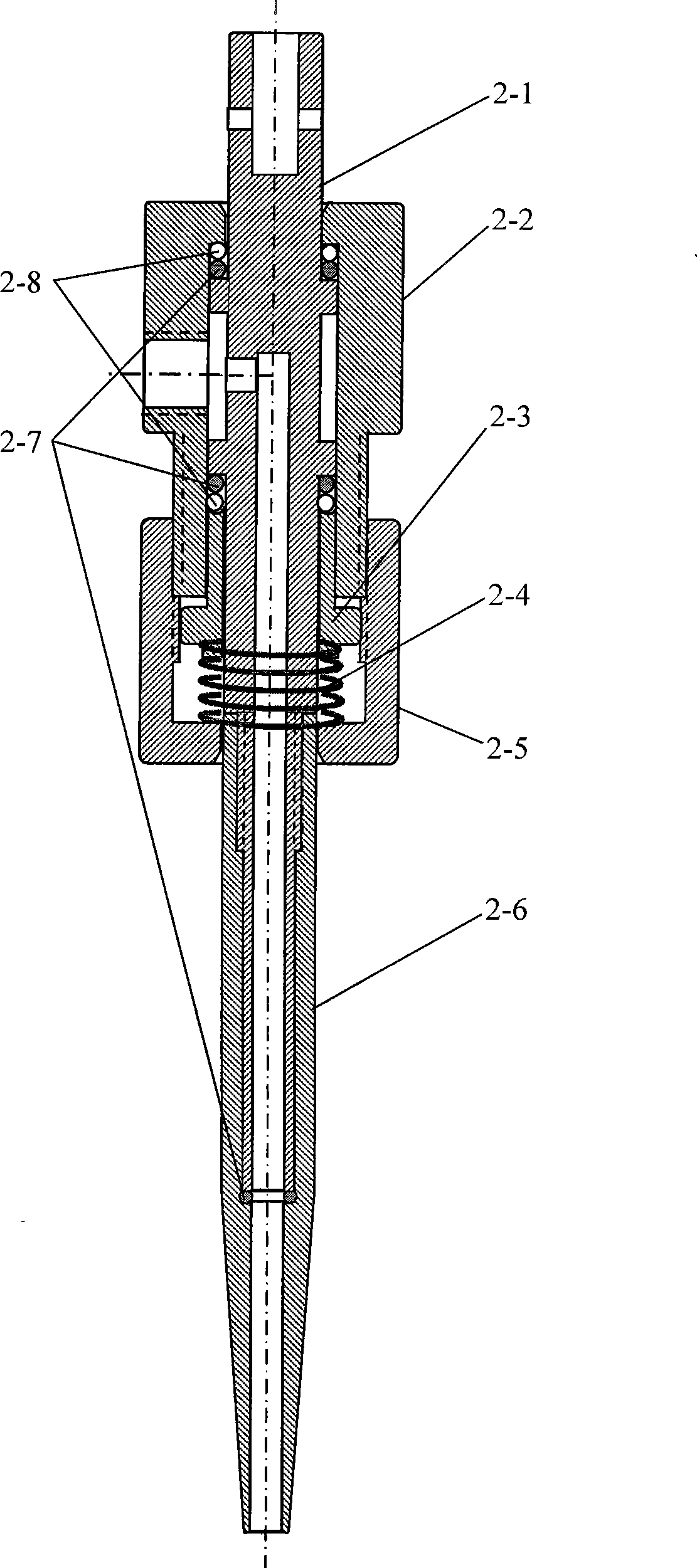

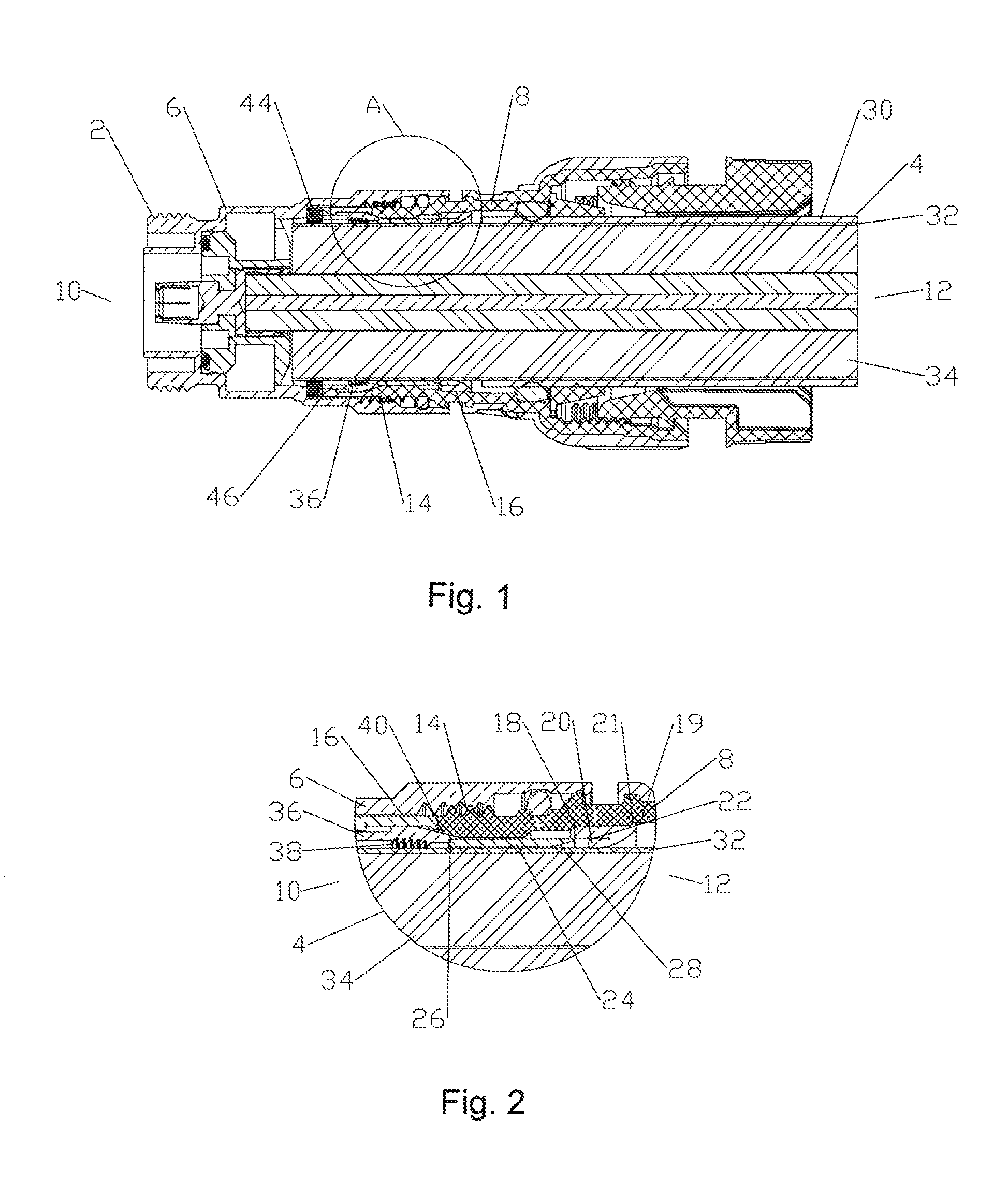

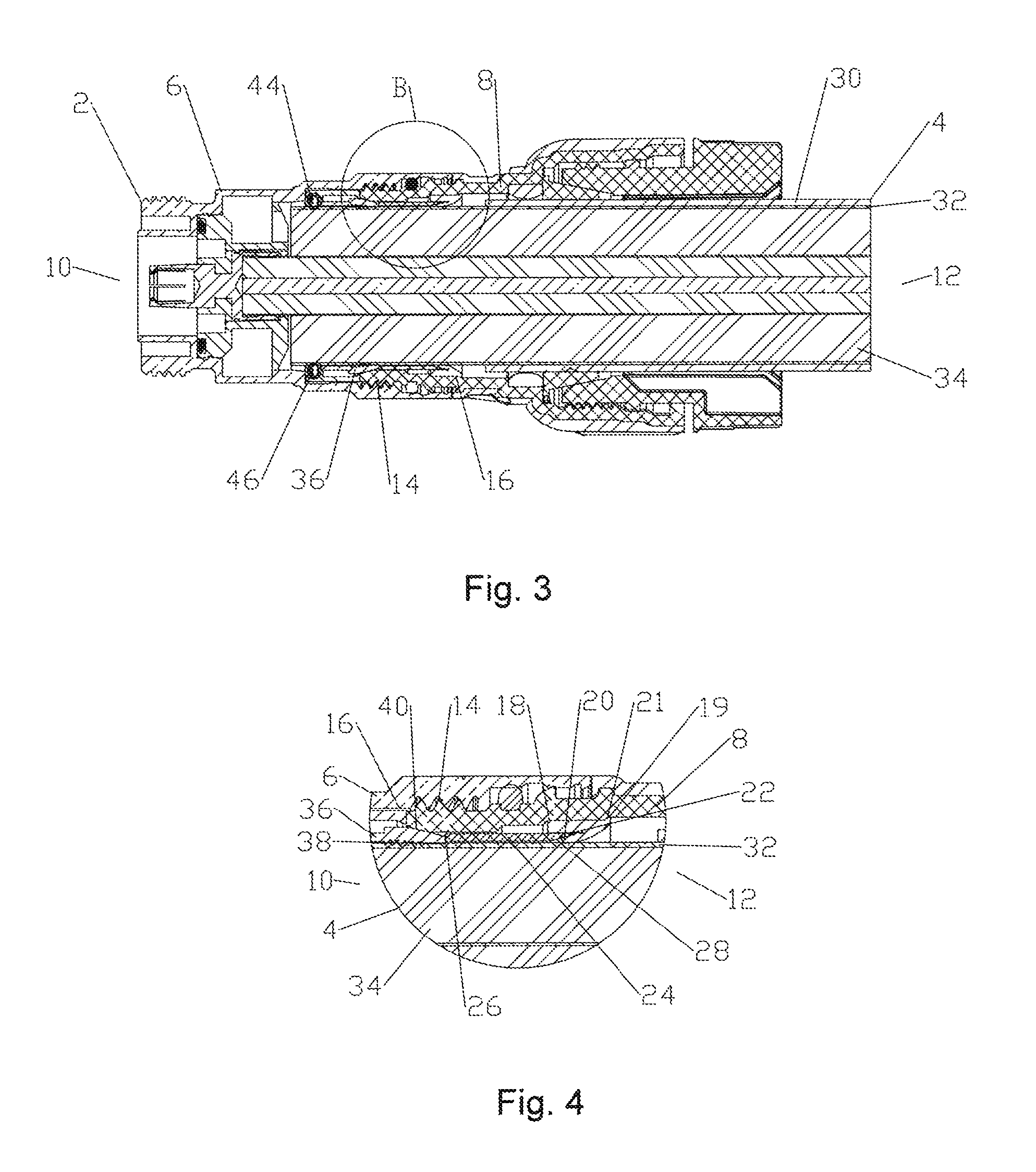

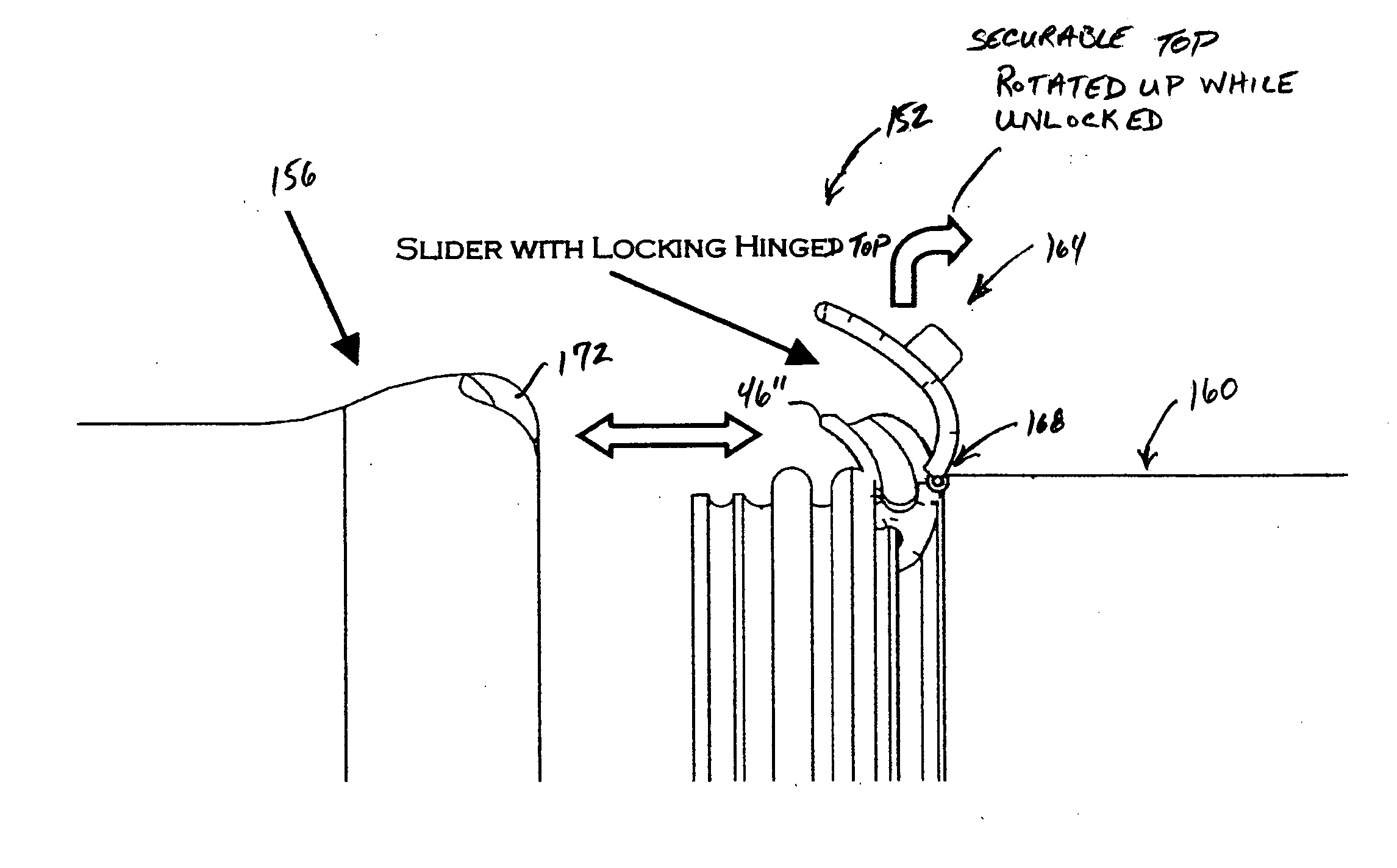

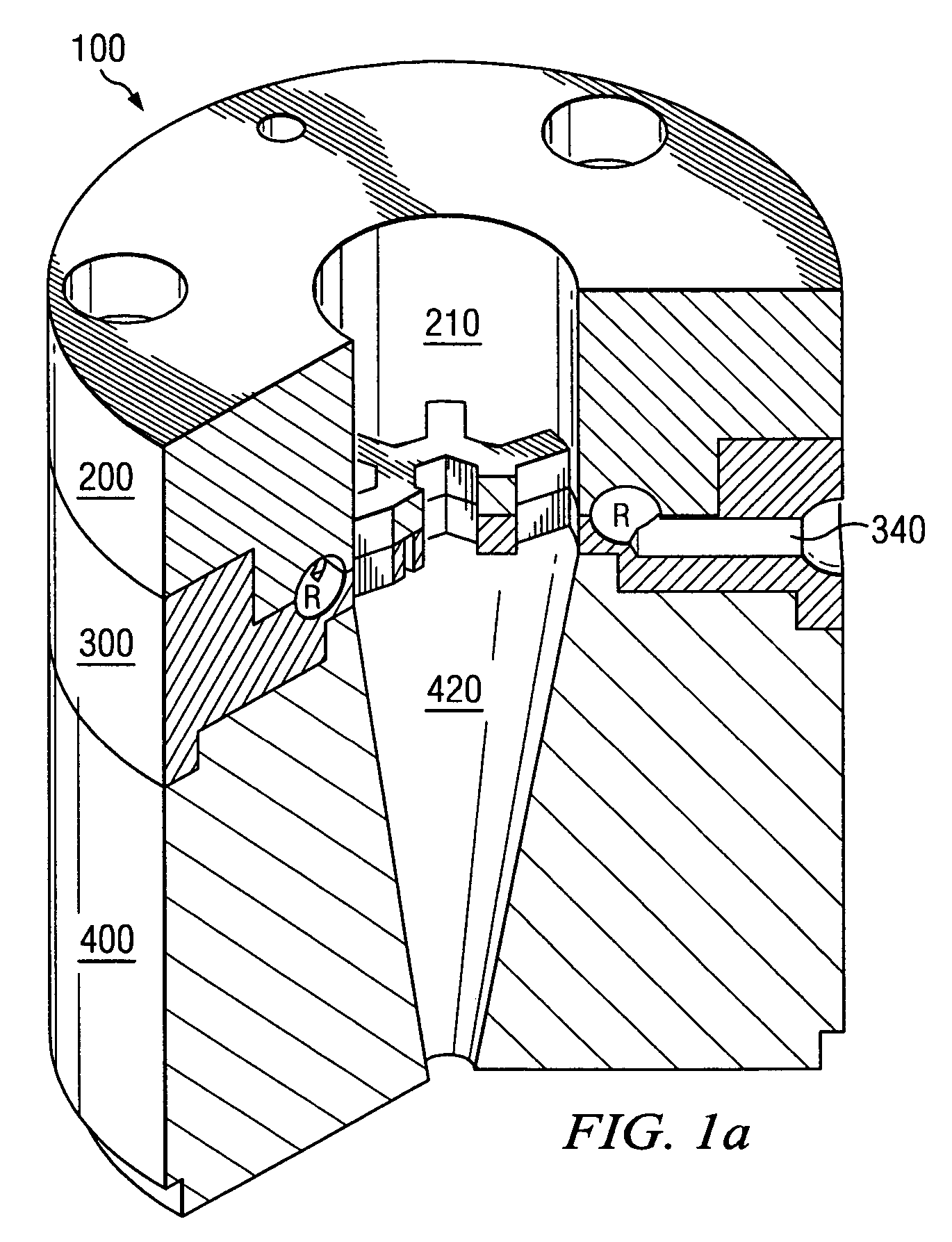

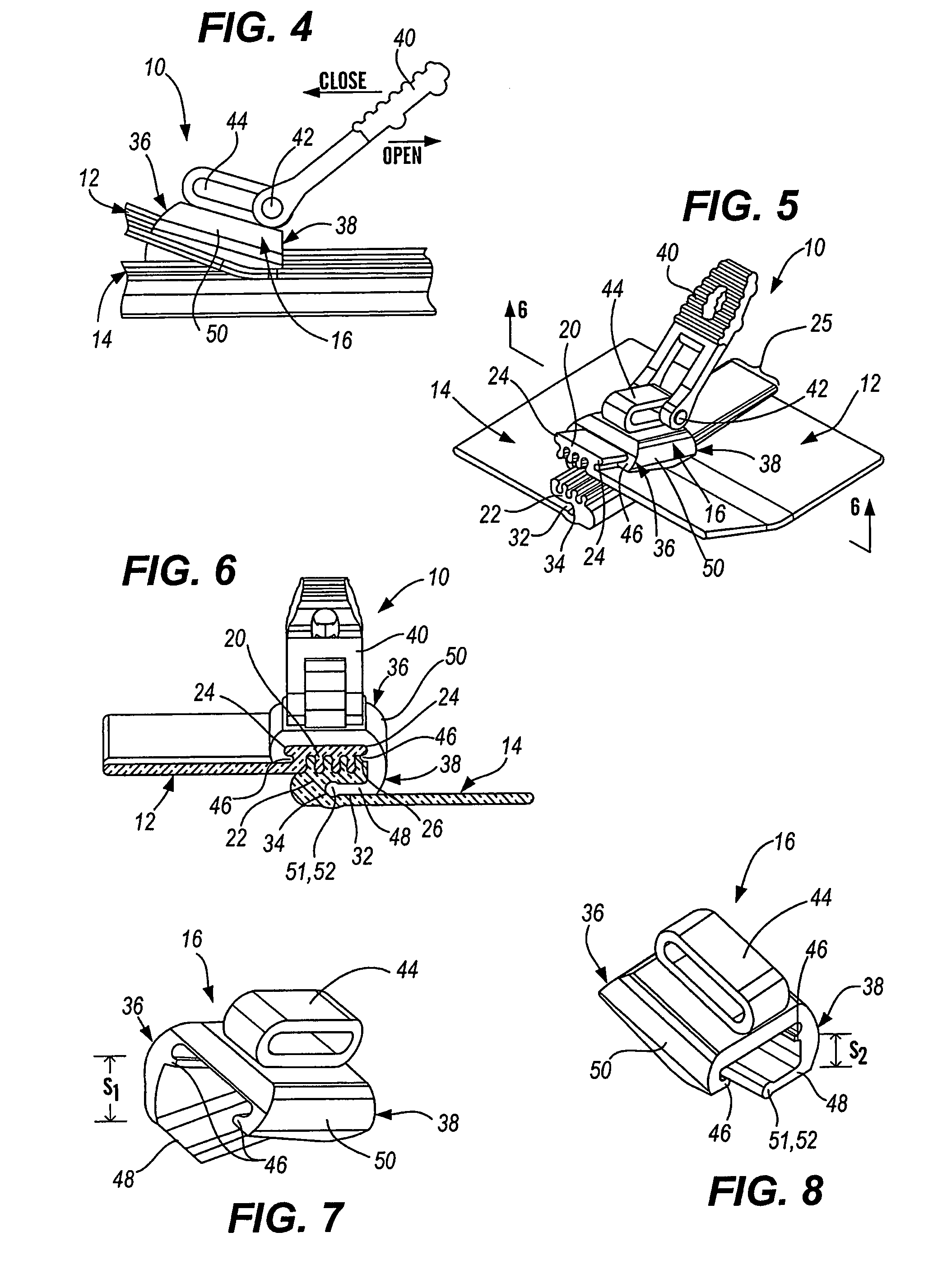

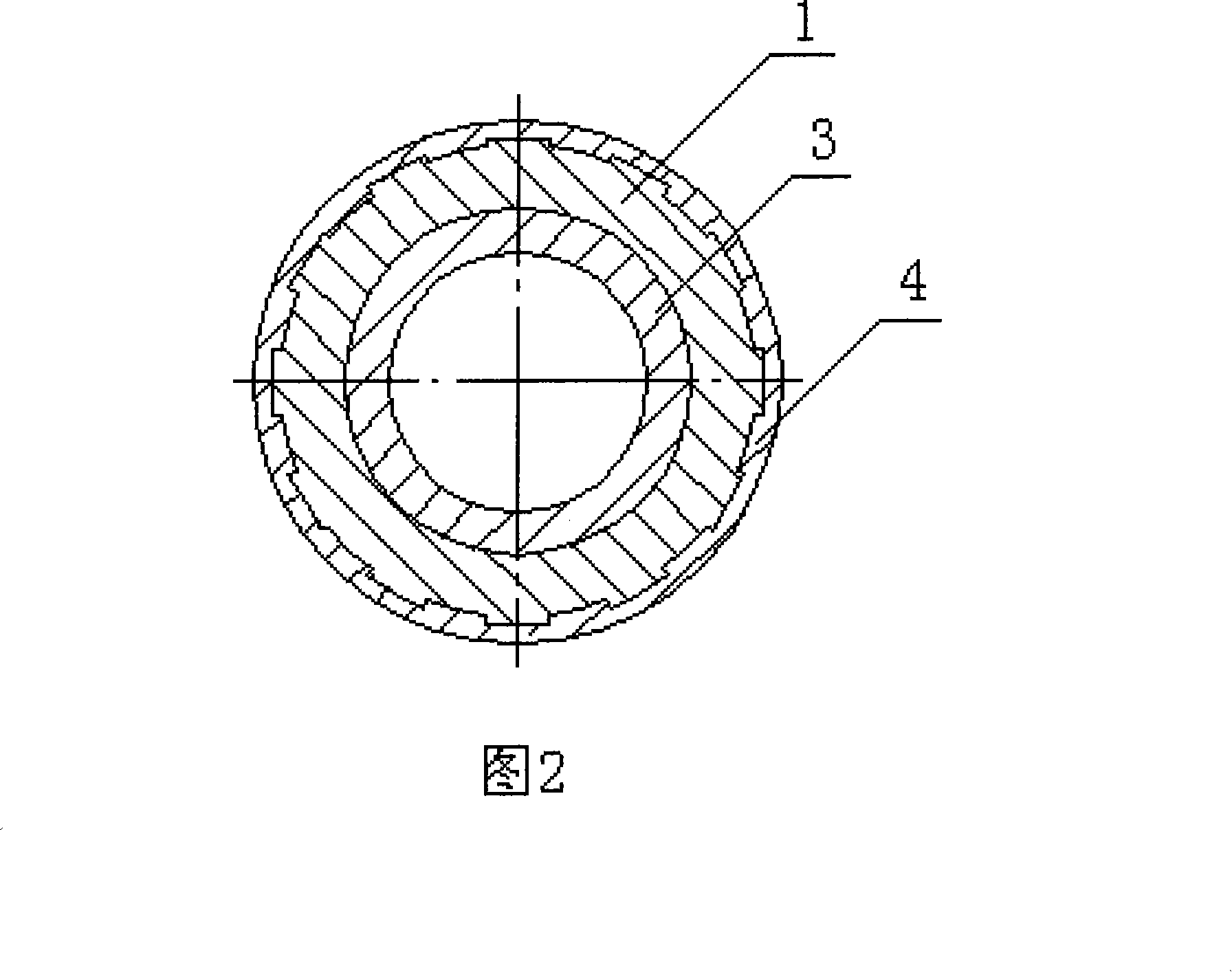

Annular barrier with a seal

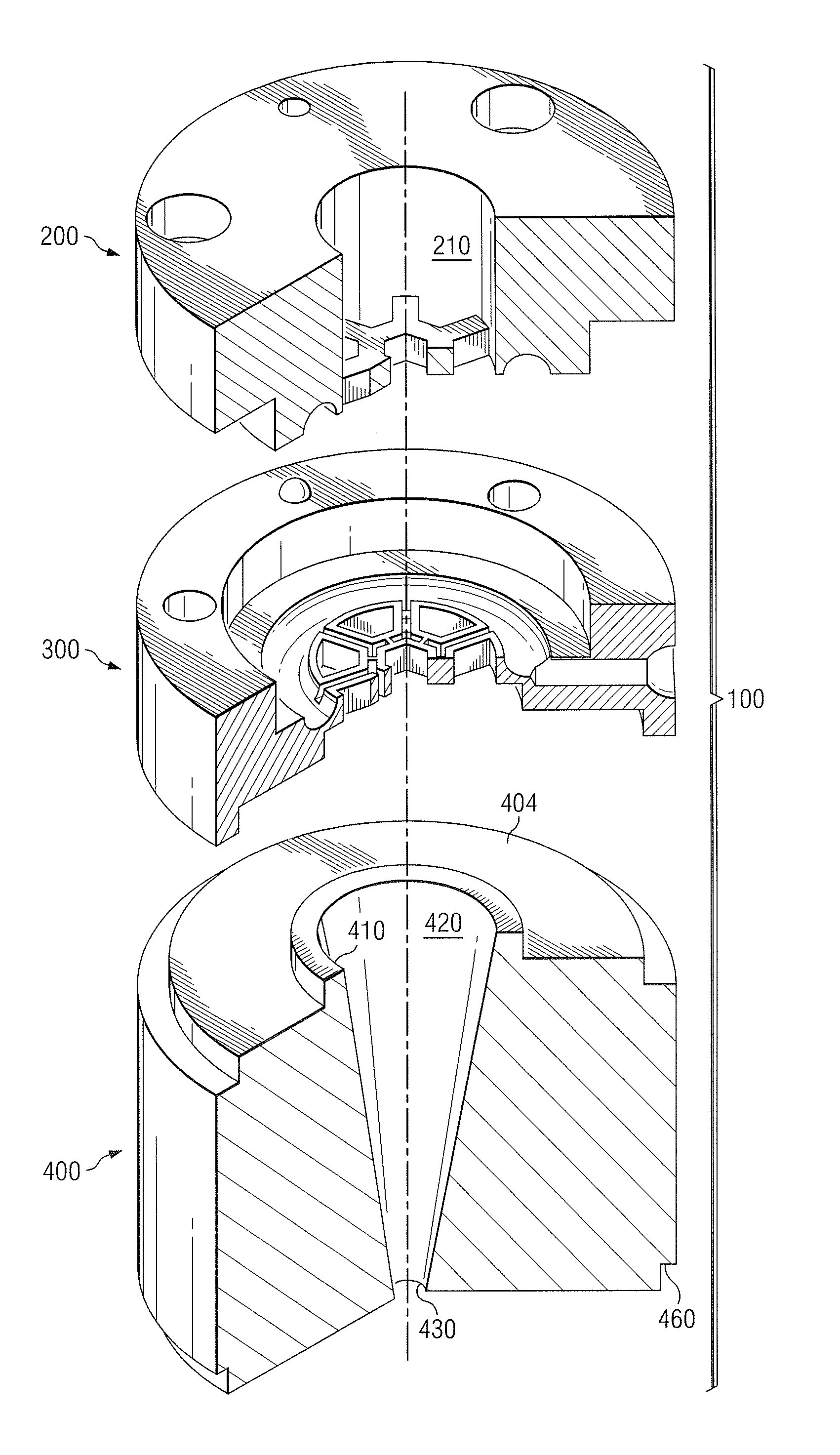

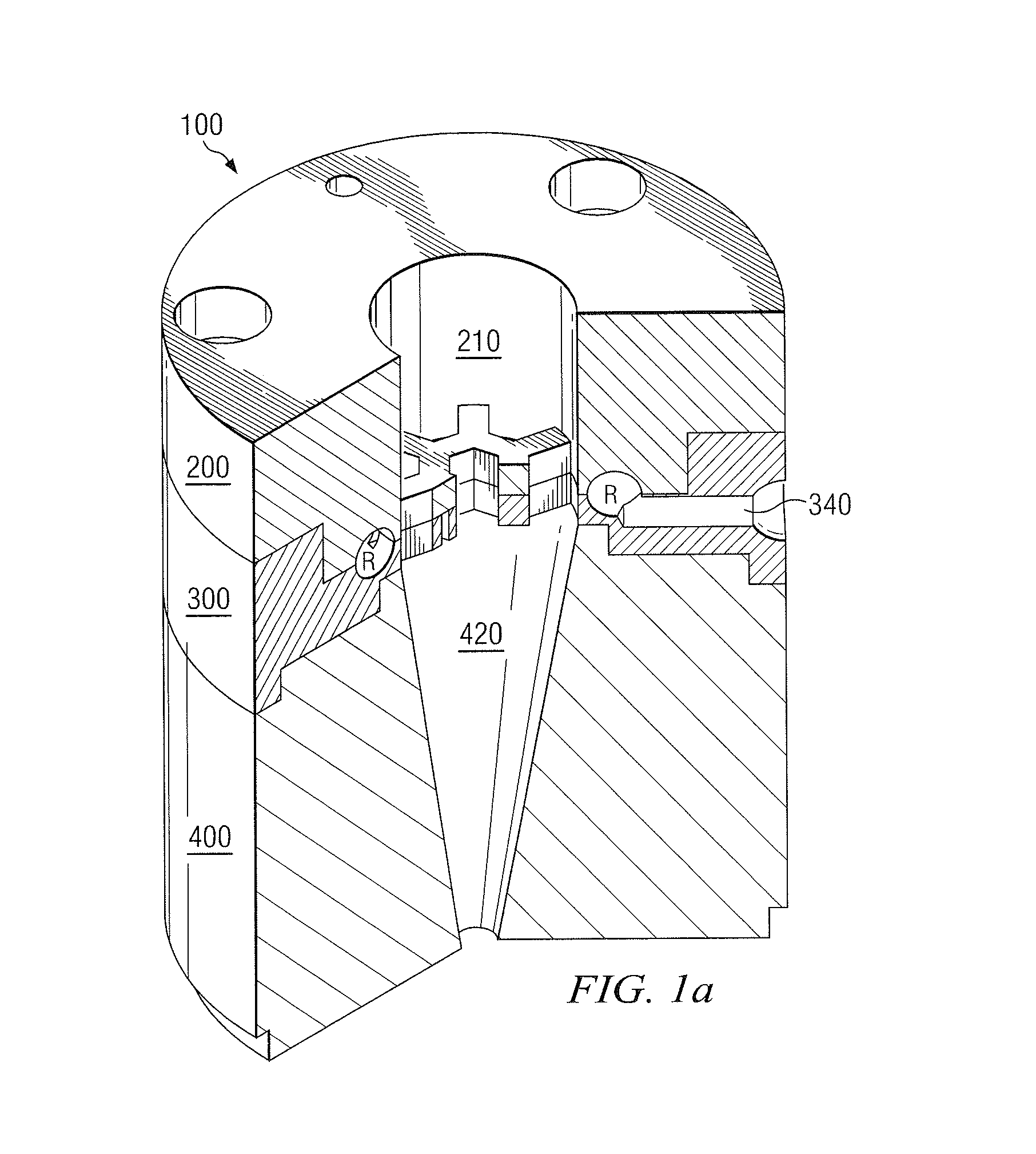

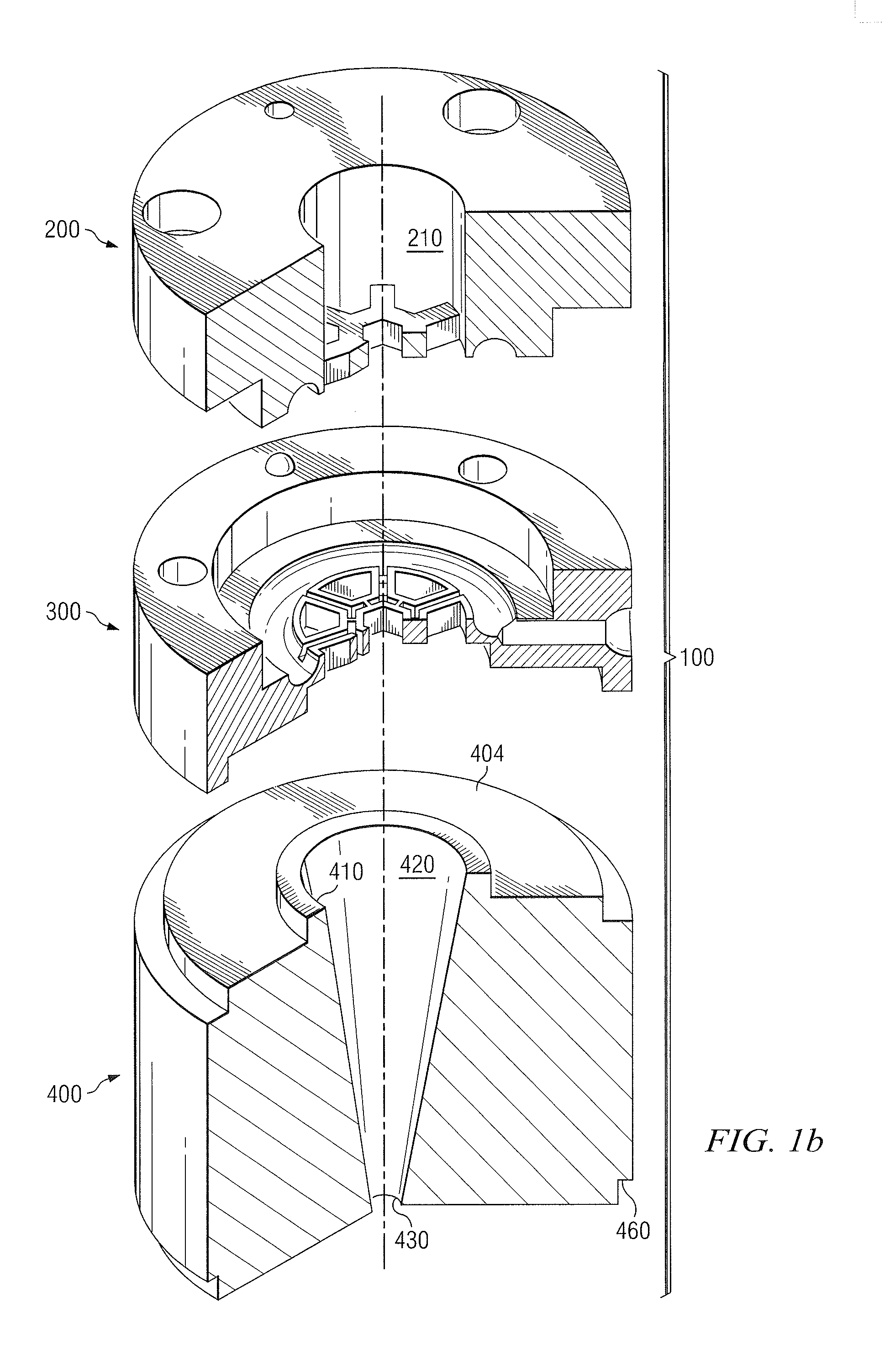

ActiveUS20150068774A1Improve seal qualityKeep tightFluid removalSealing/packingMechanical engineeringAxial length

The present invention relates to a downhole annular barrier (1) with an axial extension having an outer surface facing an inner surface of an outer structure (2). The downhole annular barrier comprises a tubular part (5), an expandable part (3), and at least one annular sealing element (41). The annular sealing element (41) is connected with the expandable part (3) and has an axial length along the axial extension of the downhole annular barrier which is less than 50% of a length of the downhole annular barrier along the axial extension of the downhole annular barrier. The annular sealing element comprises a spring element (43). Also, the present invention relates to a downhole system and to a seal providing method.

Owner:WELLTEC OILFIELD SOLUTIONS AG

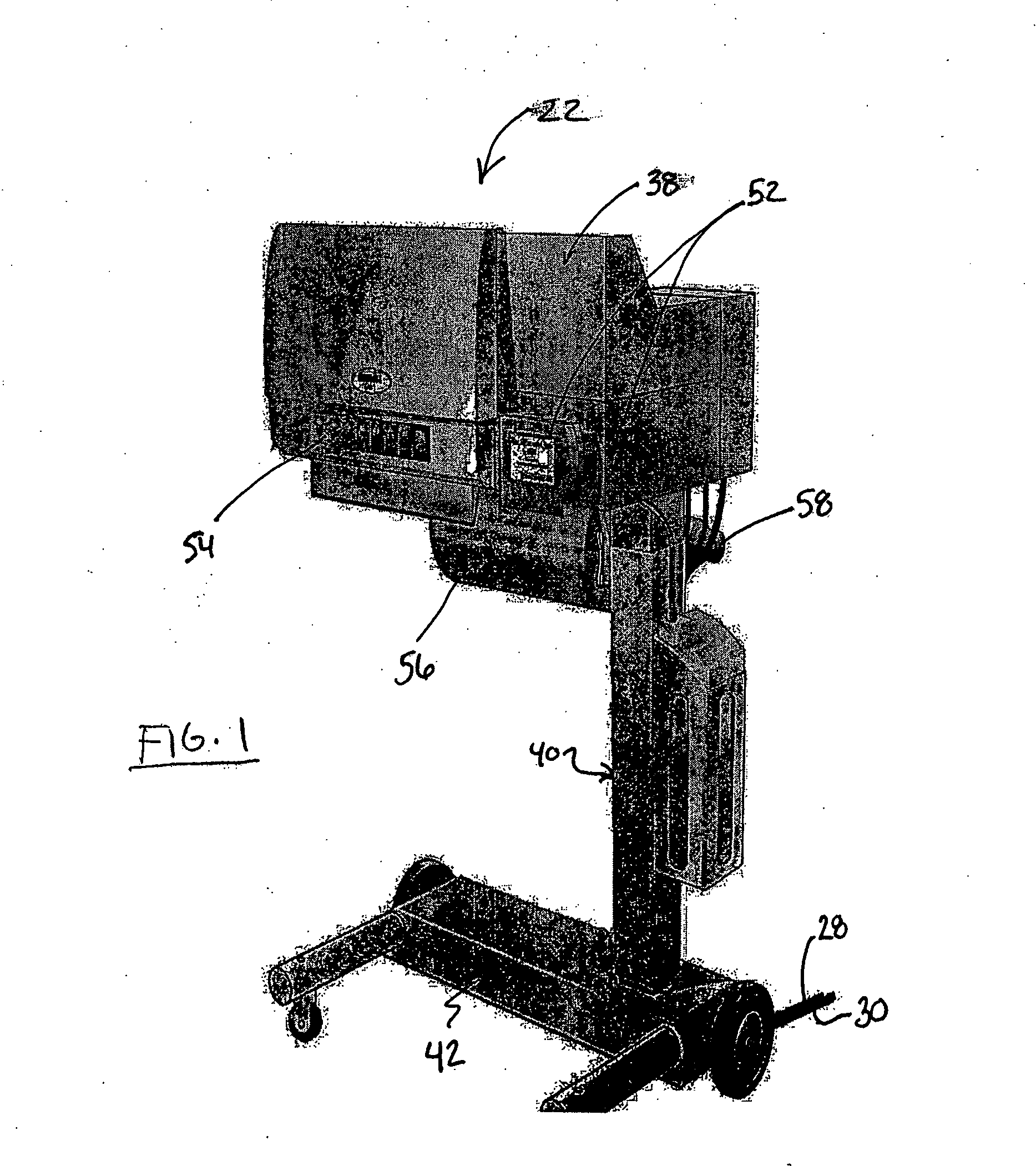

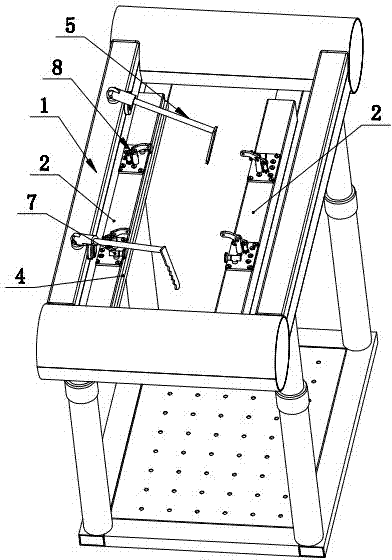

Automatic face mask packer

PendingCN108275321AEasy alignmentLongitudinal sealing position is accurateWrapper twisting/gatheringEngineeringConveyor belt

An automatic face mask packer comprises a rack, a face mask conveying mechanism, a bag molding device and a sealing device, wherein the sealing device comprises a drawing mechanism, a longitudinal sealing mechanism, a transverse sealing and cutting mechanism, a conveyor belt and an exhaust mechanism; the longitudinal sealing mechanism comprises a longitudinal heating mechanism and a longitudinal pressure-tight sealing mechanism; the longitudinal heating mechanism comprises two longitudinal heater strips which are arranged side by side right and left; the drawing mechanism, as well as the longitudinal pressure-tight sealing mechanism, comprises a first runner and a second runner which are in press fit with each other and rotate relative to each other; the conveyor belt is provided with an advancing segment which moves from front to back; the drawing mechanism and the longitudinal sealing mechanism are located right above the advancing segment of the conveyor belt; the exhaust mechanismis located between the longitudinal sealing mechanism and the transverse sealing and cutting mechanism and comprises an exhaust compression roller in a left-and-right direction; and the exhaust compression roller and the advancing segment of the conveyor belt are in pressure fit with each other. According to the automatic face mask packer, gas in a package film which is longitudinally sealed can be exhausted by the sealing device to ensure that the transverse sealing and cutting mechanism can perform transverse sealing and cutting in an accurate position of a transverse sealing part, such thatthe sealing quality is improved.

Owner:汕头市泰恩康医用器材厂有限公司

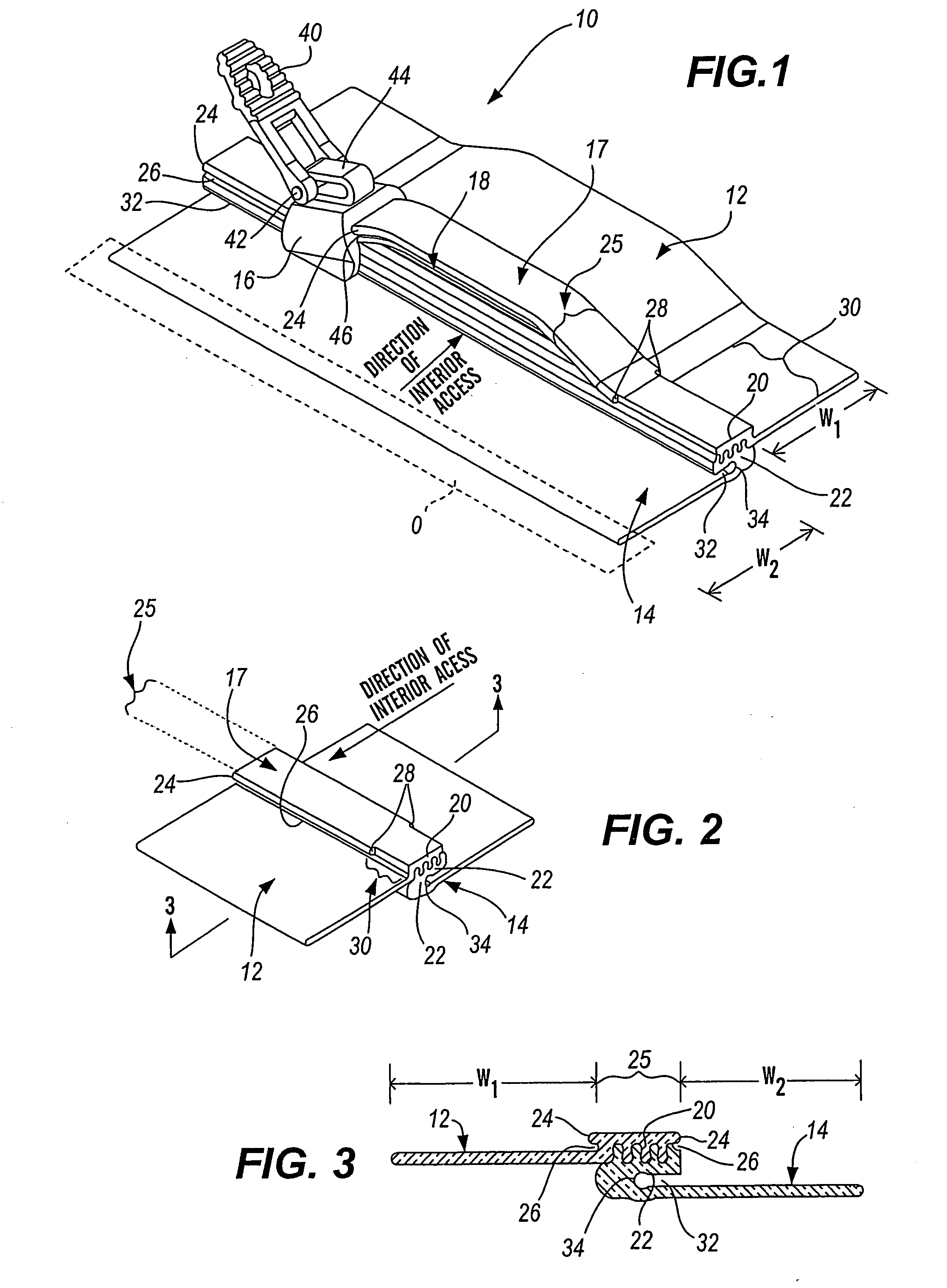

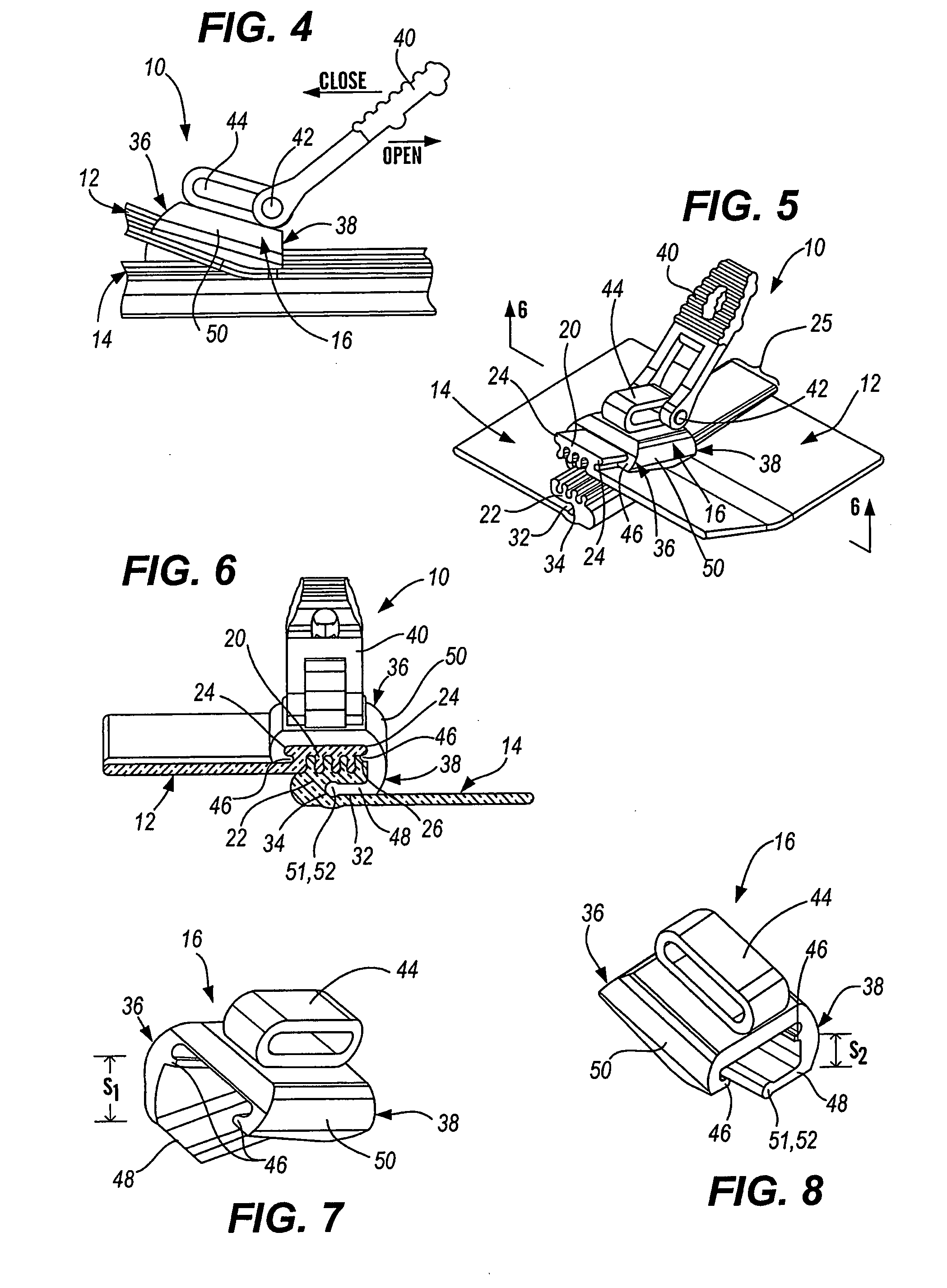

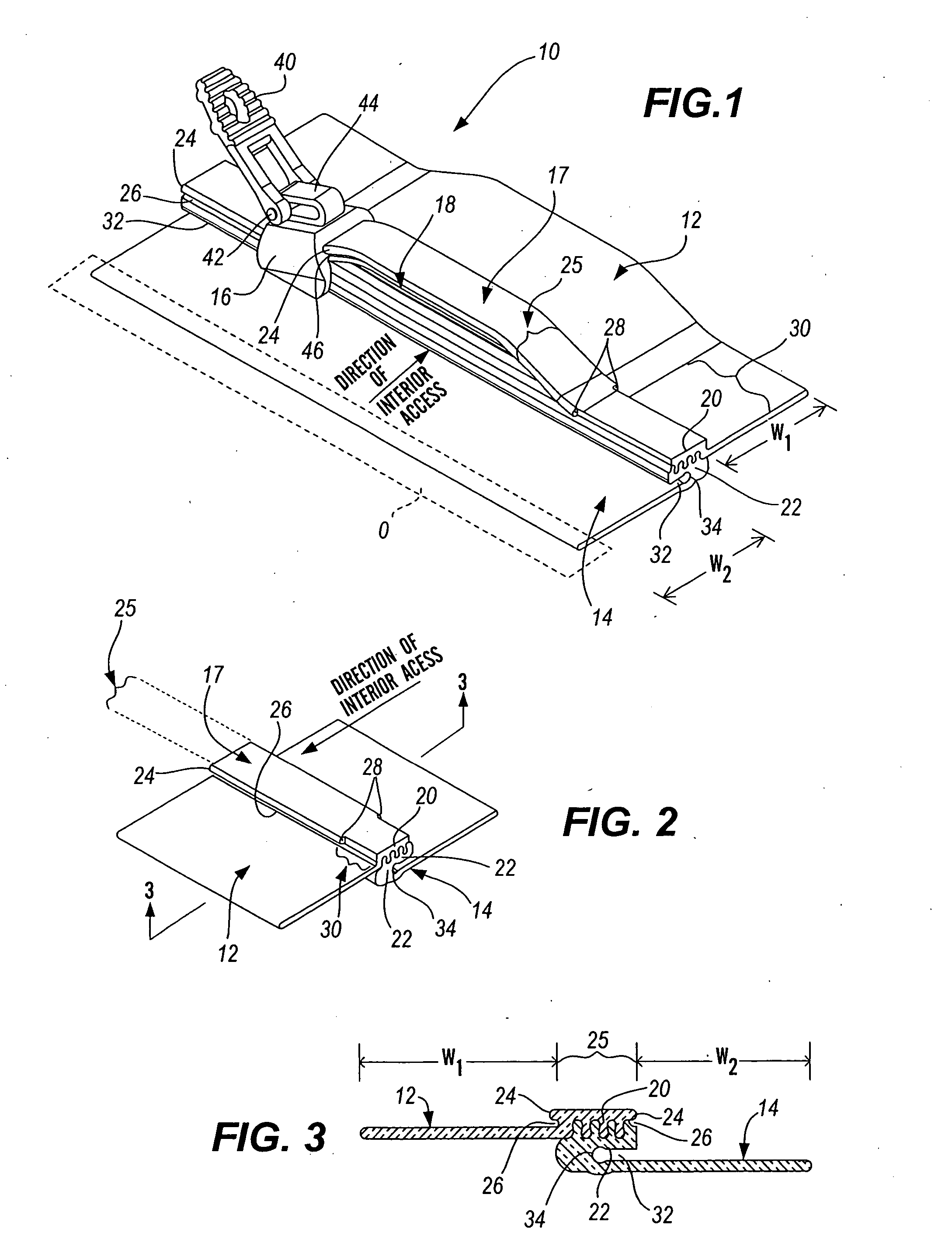

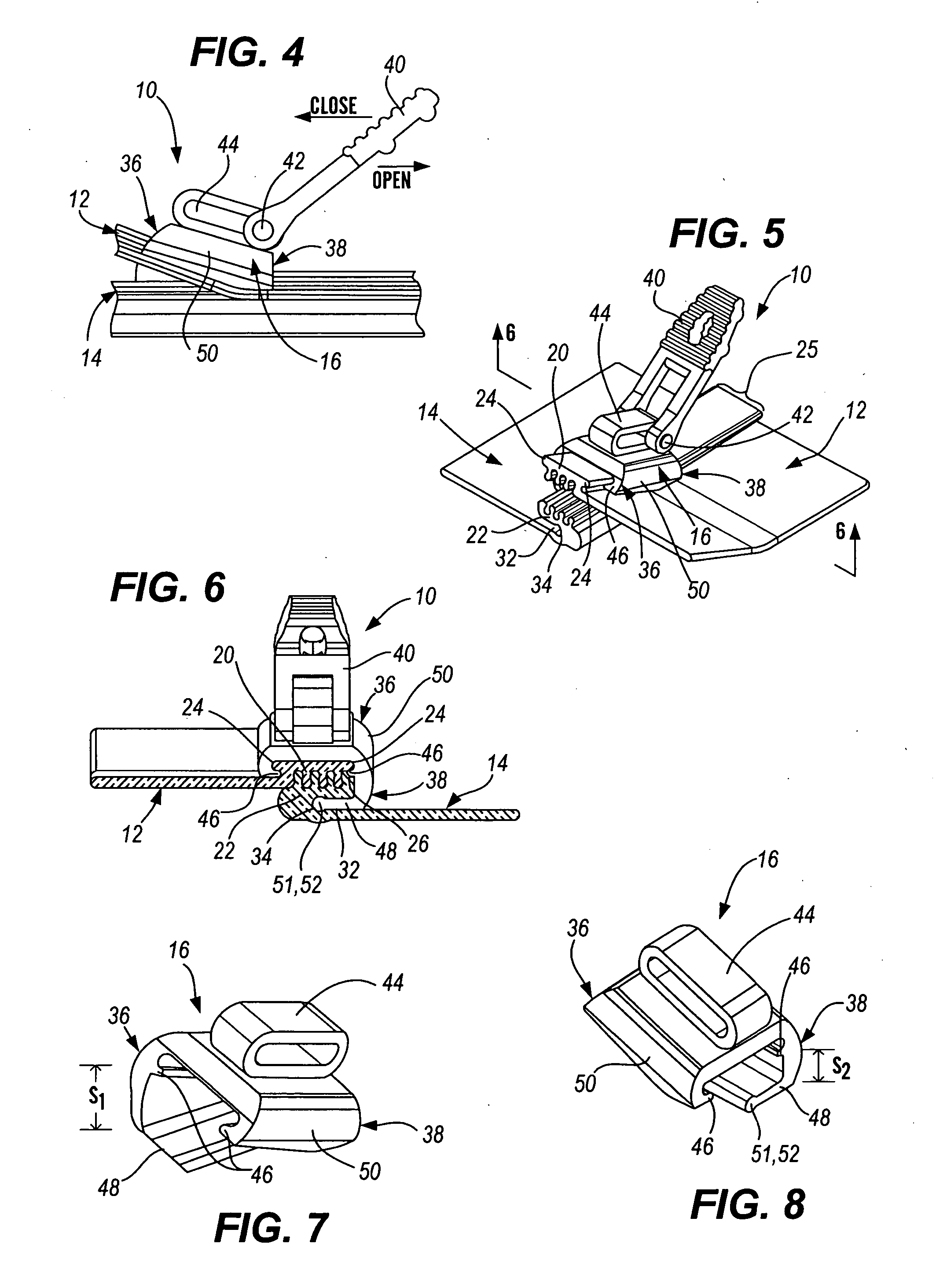

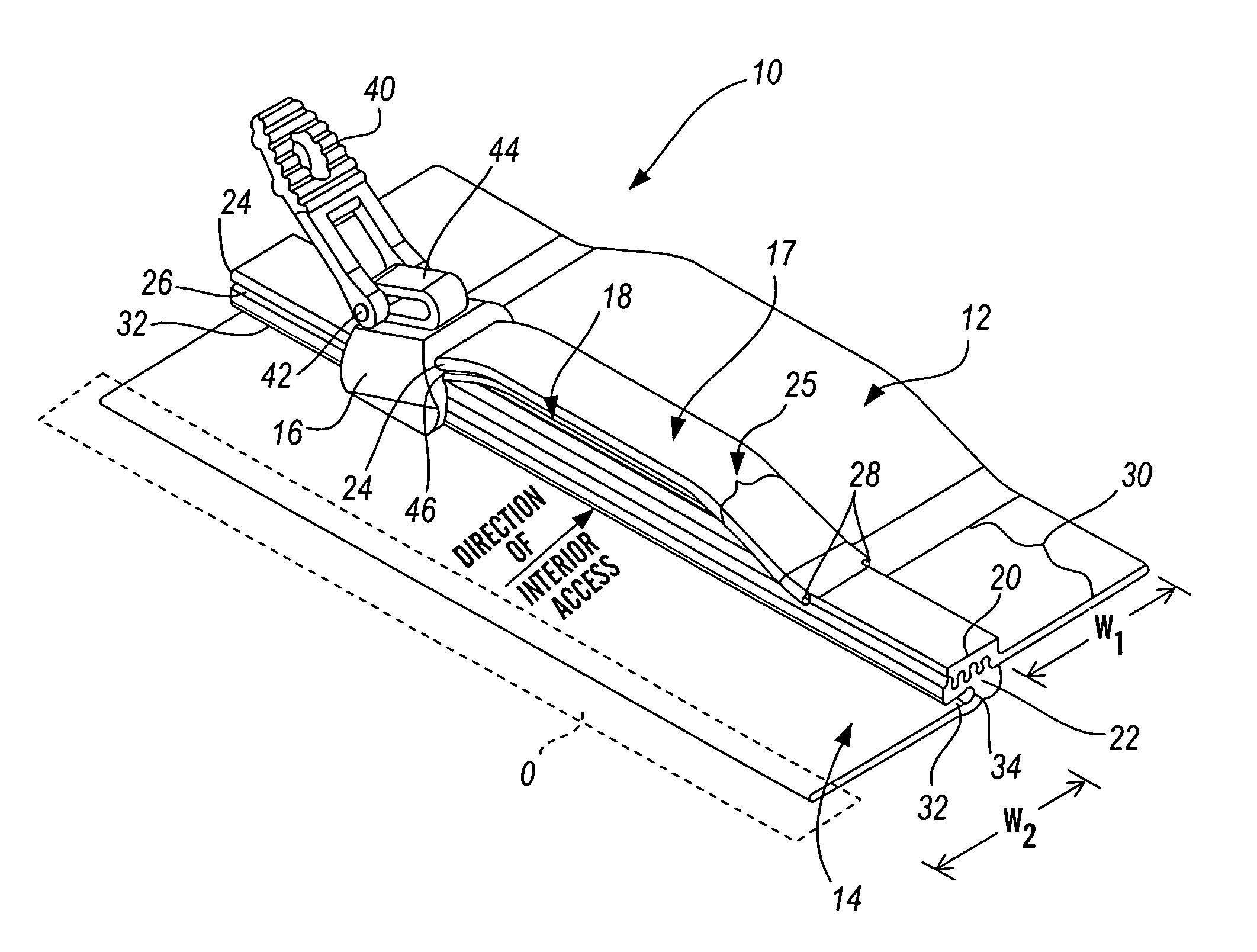

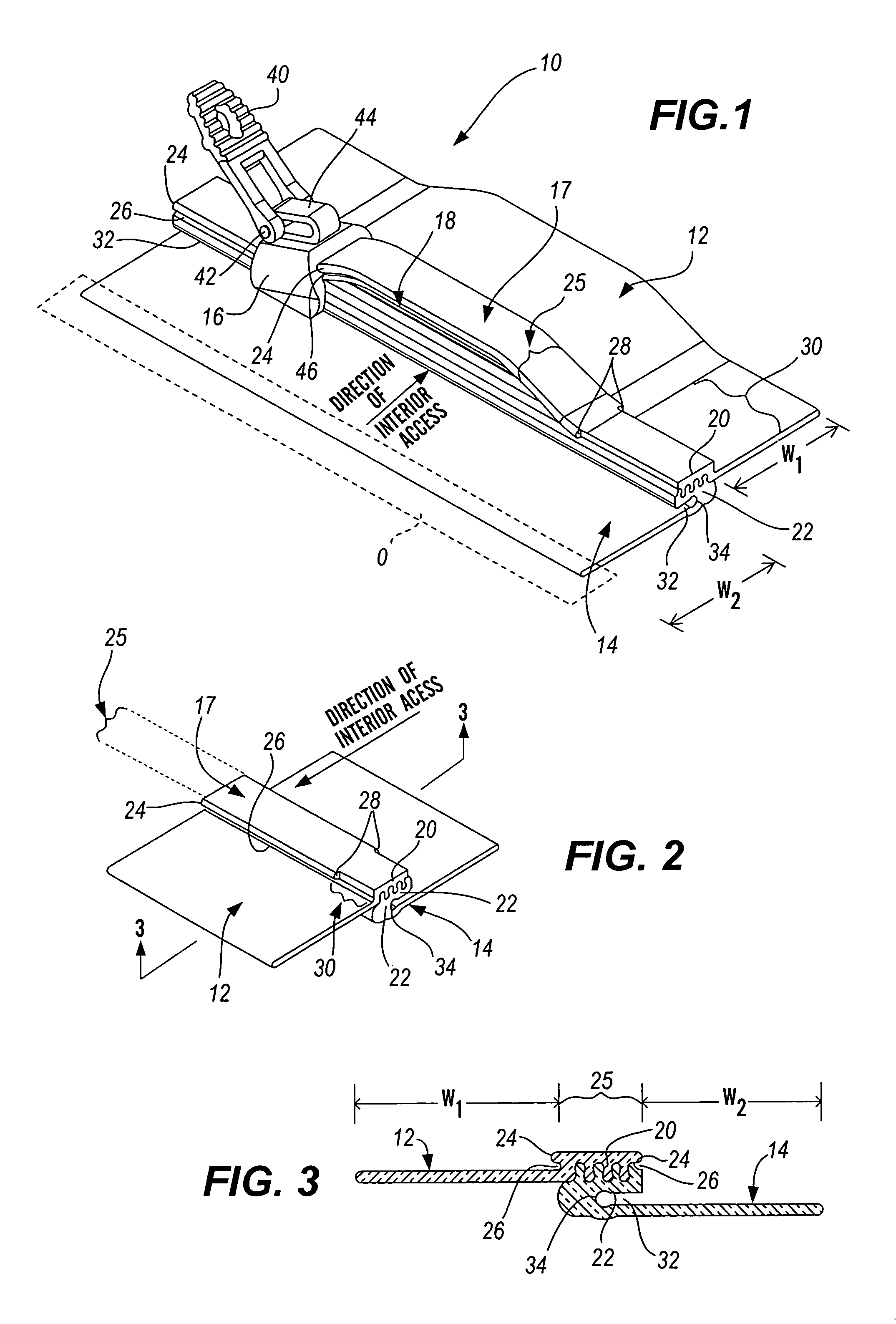

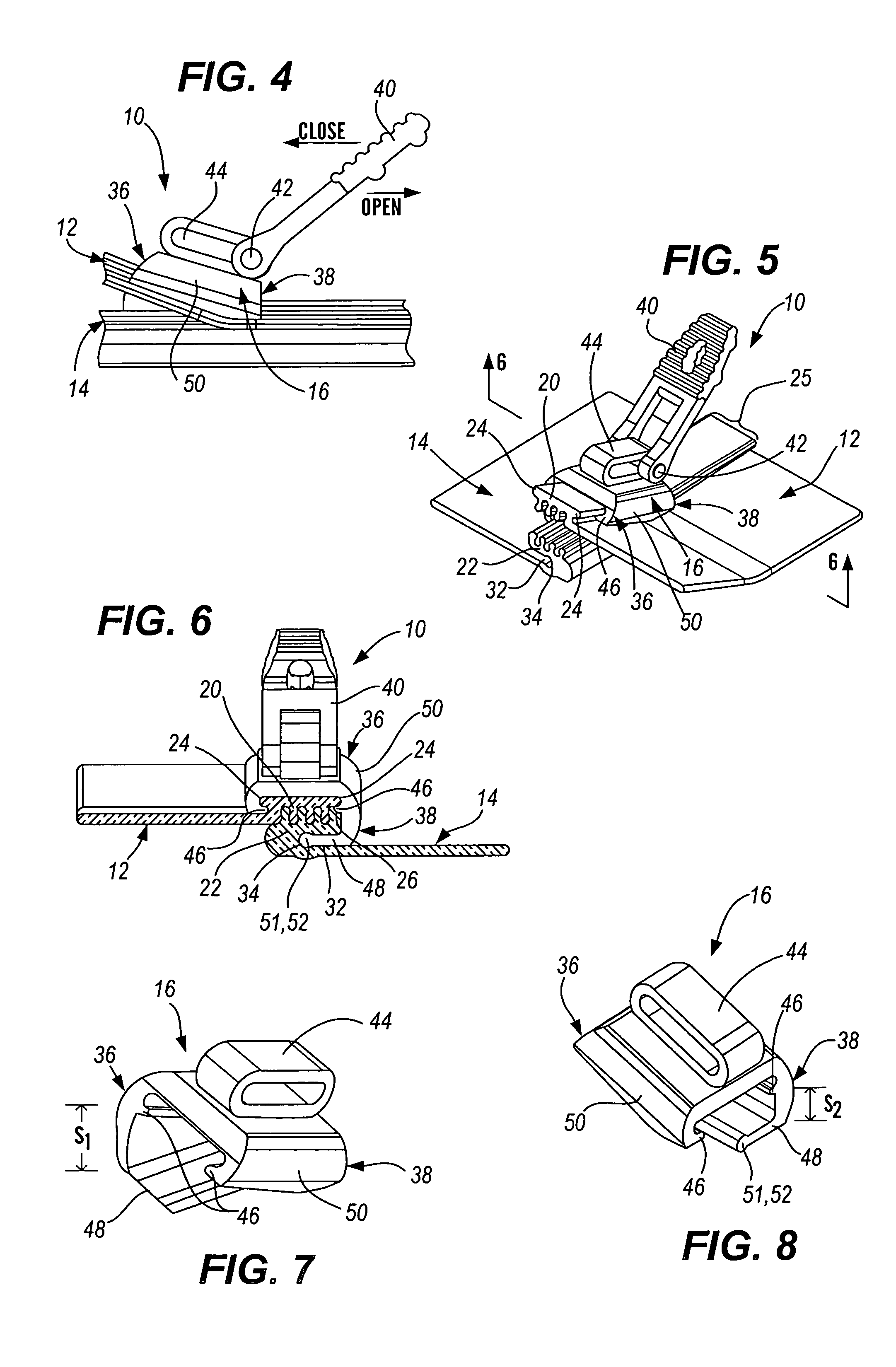

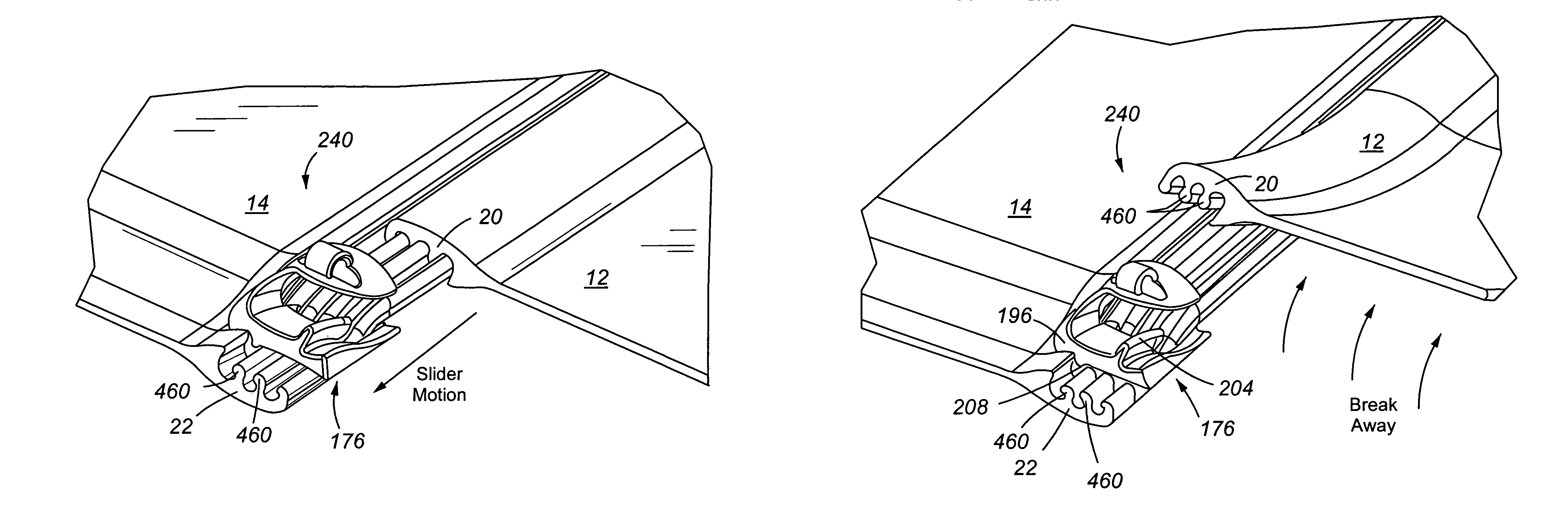

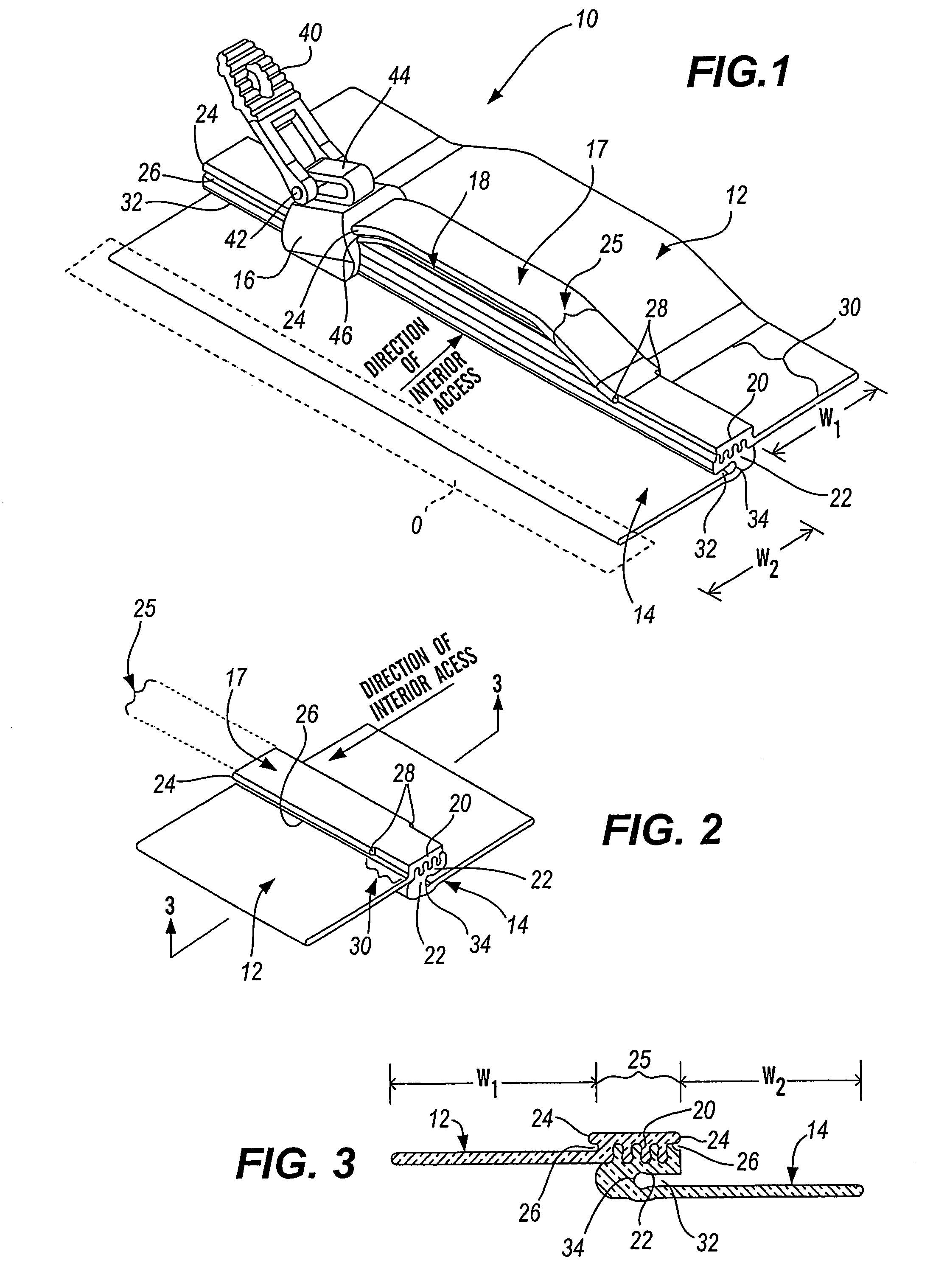

Device for creating a seal between fabrics or other materials

ActiveUS20060107500A1Precise alignmentImprove usabilitySnap fastenersSlide fastenersEngineeringMechanical engineering

A device for forming a seal includes upper and lower seal members, and a slider, wherein mating surfaces of the seal members interlock. In at least one embodiment, a lifting rib and closure bar on the slider cooperate with a lifting wing and closure bar groove on the upper and lower seal members, respectively. By moving the slider in one direction, the lifting rib lifts the upper seal member from the lower seal member. Moving the slider in the opposite direction causes the upper and lower seal members to interlock. In another embodiment, a slider has an intermediate lateral member connected on one side the slider top, and connected on the other side to the slider bottom. A breakaway sealing device is also provided, allowing a person to break the closed seal. A beginning stop block is also provided that includes a means for securing the upper seal member.

Owner:ABSOLUTE CLOSURE INNOVATIONS

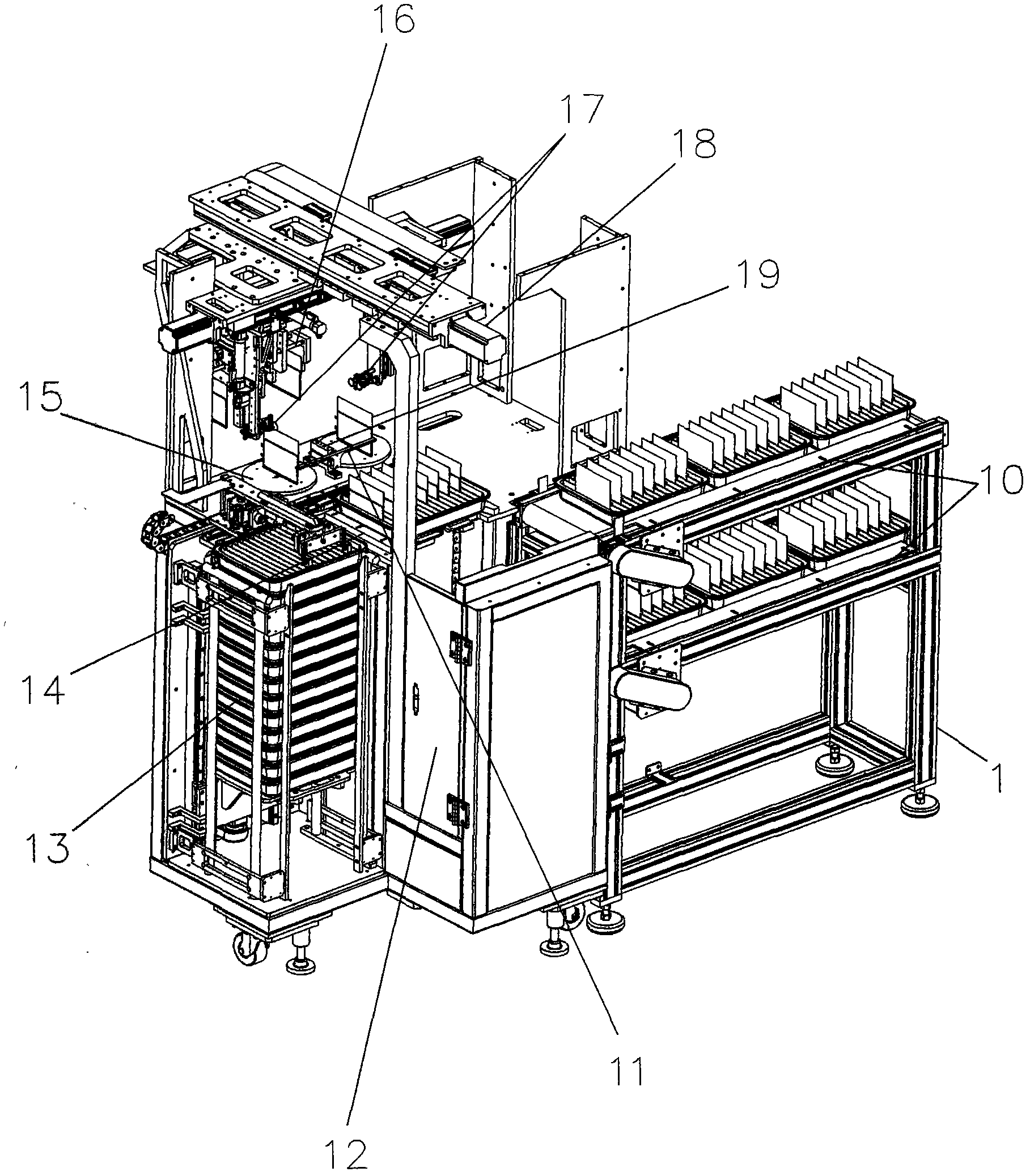

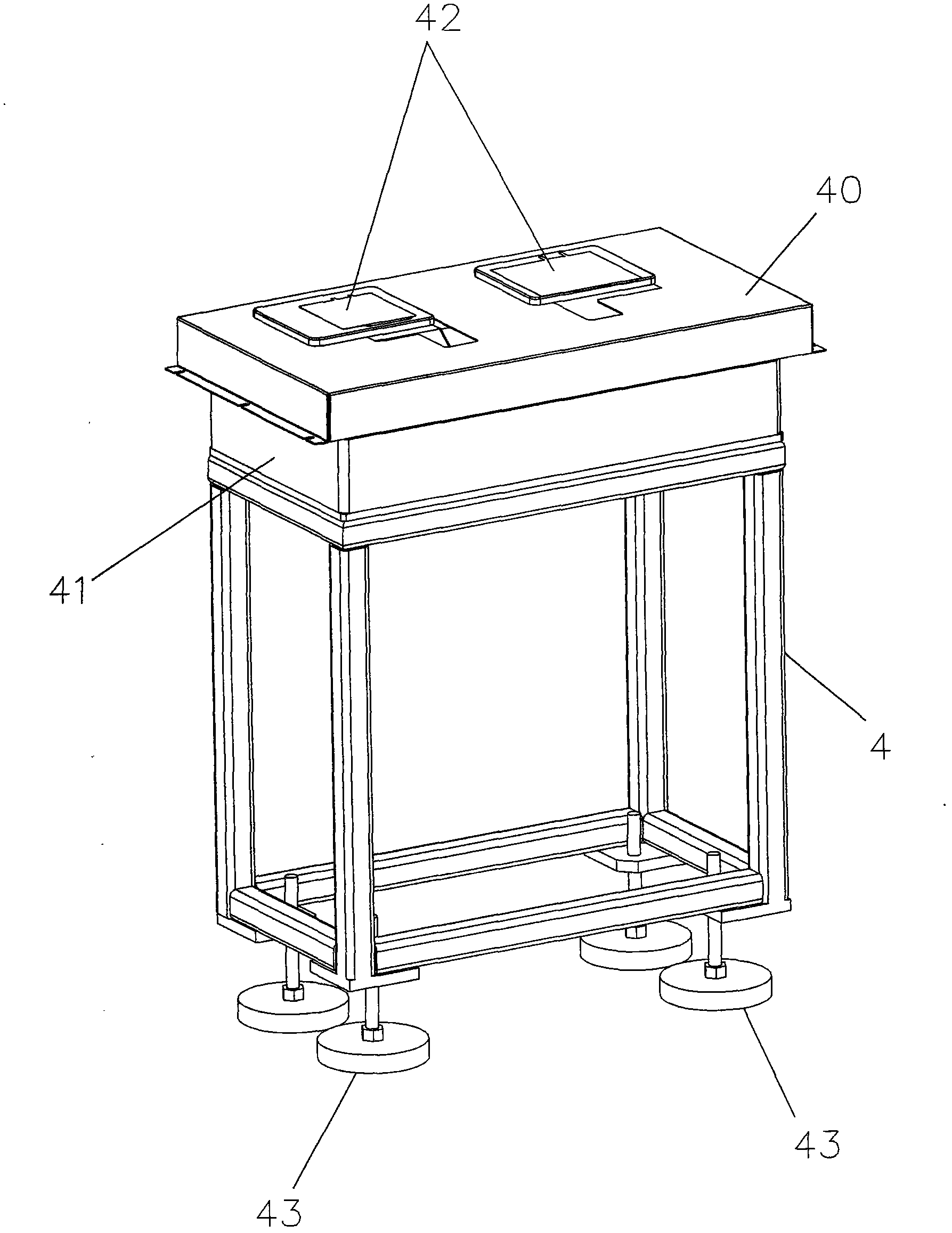

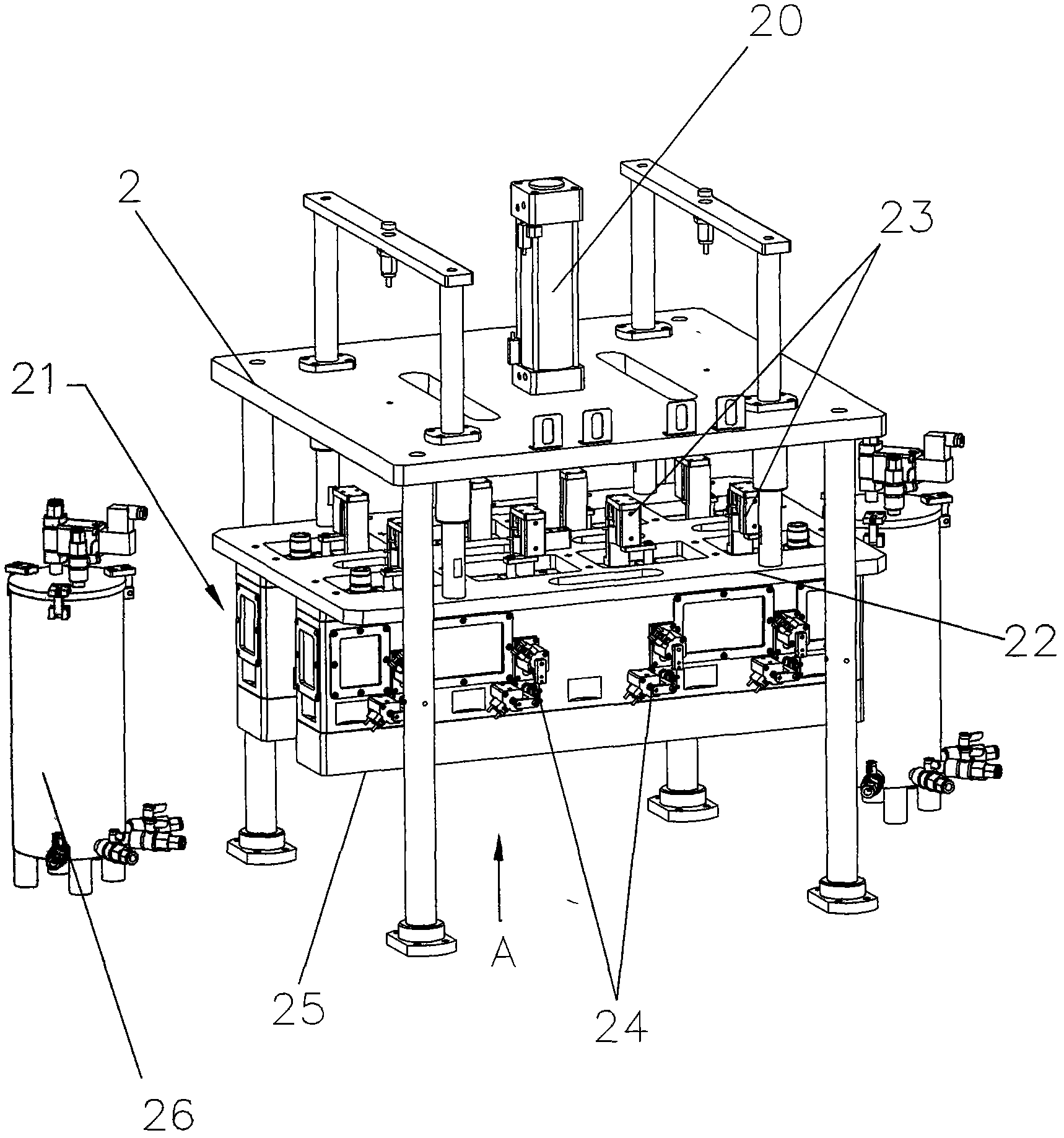

Vacuum injection equipment of flexibly-packaged lithium battery

ActiveCN102306740AIncrease productivityImprove detection accuracyCell component detailsInjection equipmentManipulator

The invention relates to the technical field of lithium battery production equipment, and particularly relates to vacuum injection equipment of a flexibly-packaged lithium battery. The equipment sequentially comprises a material loading device, a weighing and detecting device, a flat fixture for clamping air bags, an injection device, a first standing room, a second standing room, a third standing room, a sealing device, a weighing and detecting device, a blanking mechanical arm and an unloading mechanism from left to right. The equipment provided by the invention can be used for improving the production efficiency, the detection precision, the judgment accuracy of the product quality, the sealing quality and the product quality, reducing the electrolyte waste, effectively avoiding the phenomenon of a loading direction error and reducing the working strength of workers.

Owner:DONGGUAN ALI AUTOMATION CO LTD

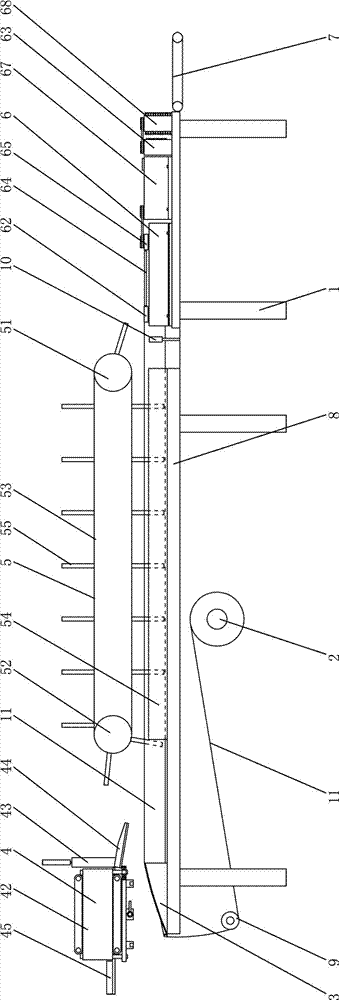

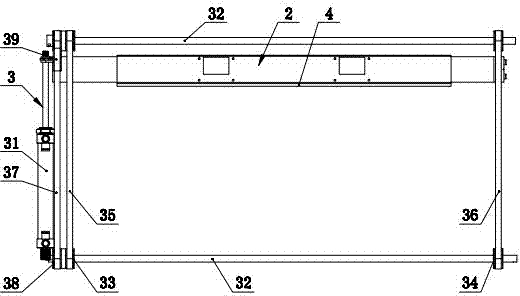

Adjustable omnibearing automatic folding and carton sealing machine

The invention provides an adjustable omnibearing automatic folding and carton sealing machine. The adjustable omnibearing automatic folding and carton sealing machine comprises a carton sealing machine body, a carton clamping mechanism and a carton drive unit. The carton drive unit is transversely and symmetrically mounted on a rack and driven by a built-in motor. Machine cores are mounted above the carton drive unit, in the middle of the carton drive unit and at the symmetric positions of the two sides of the carton drive unit, and therefore middle sealing of carton tops and carton bottoms and corner sealing of cartons are achieved, and the sealing effect of packaging materials is improved. The carton clamping mechanism is mounted on a carton conveying belt, and a gear and gear racks are pushed by a both-way air cylinder to achieve actions of carton clamping, carton loosening and the like. The adjustable omnibearing automatic folding and carton sealing machine is simple in structure, ingenious in concept and high in work efficiency, and manpower is effectively saved. According to the rubber belt carton sealing machine, when the carton conveying speed is higher than the carton sealing speed, the cartons are clamped and loosened through the part of the carton clamping mechanism, and therefore the cartons are prevented from passing through a cover folding mechanism too densely.

Owner:JIANGSU UNIV OF SCI & TECH

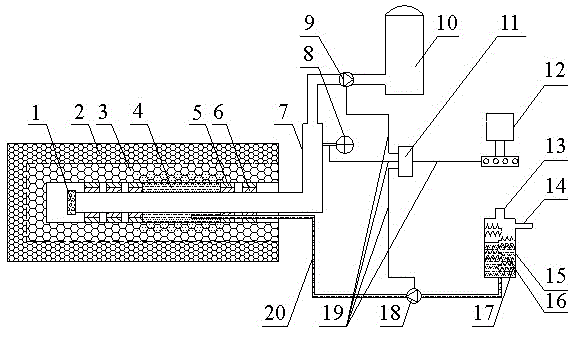

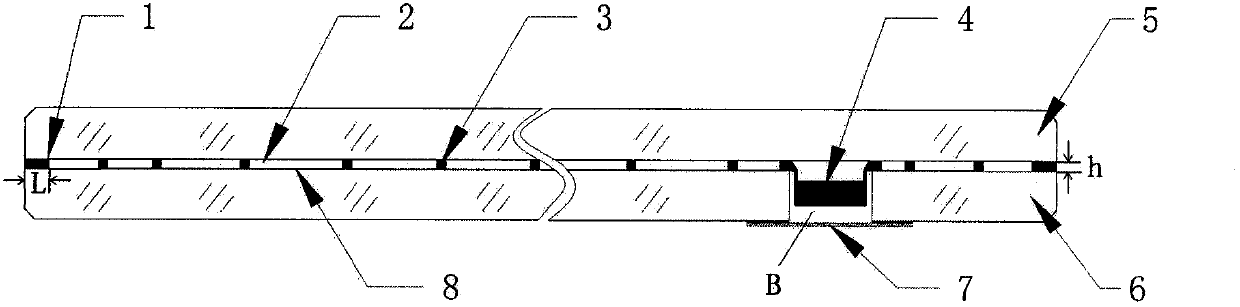

Autonomous dynamic sealing and gas extraction intelligent system for coal mine

ActiveCN102913273ATo overcome the poor sealing qualityImprove seal qualityGas removalSealing/packingIntegratorData acquisition

The invention provides an autonomous dynamic sealing and gas extraction intelligent system for a coal mine, which is suitable for underground sealing and gas intelligent extraction in the coal mine. The autonomous dynamic sealing and gas extraction intelligent system comprises a gas reservoir connected with a gas extraction tube; the gas reservoir is connected with an automatic gas extraction pump for automatically adjusting the extraction negative pressure; the gas extraction tube positioned nearby a borehole is connected with an automatic gas concentration detector; five groups of polyurethane sealing bags are wound outside the gas extraction tube positioned in a coal bed; five groups of plugging cloth capable of being tightly fitted with a coal wall are wound outside the polyurethane sealing bags; a stocker is connected with an automatic feed pressure control pump through a feed pipe; the feed pipe positioned in the coil bed is colligated between the polyurethane sealing bags and the plugging cloth; data signals of the automatic gas concentration detector, the automatic gas extraction pump and the automatic feed pressure control pump are connected with a data line integrator through a data collection line; and the data line integrator is connected with an automatic monitoring controller through a data line. The autonomous dynamic sealing and gas extraction intelligent system has the advantages of simple structure, convenience in operation, convenience in intelligent control and better use effects.

Owner:CHINA UNIV OF MINING & TECH

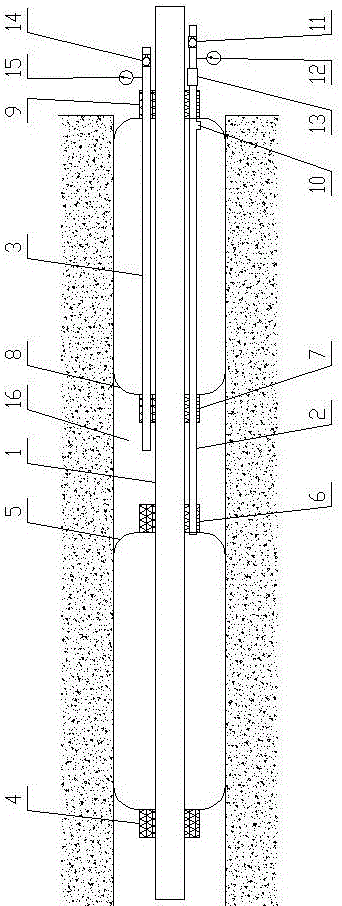

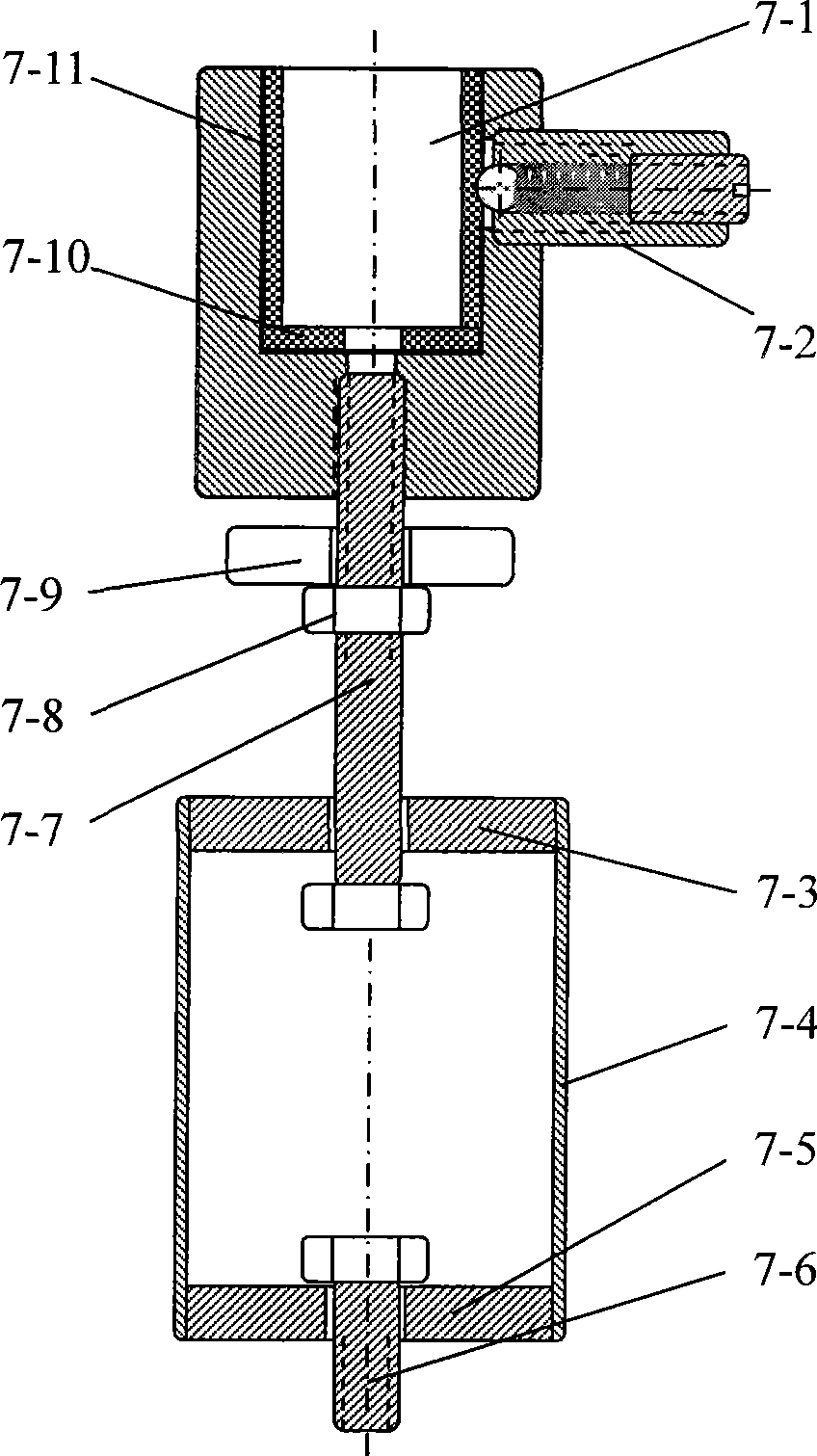

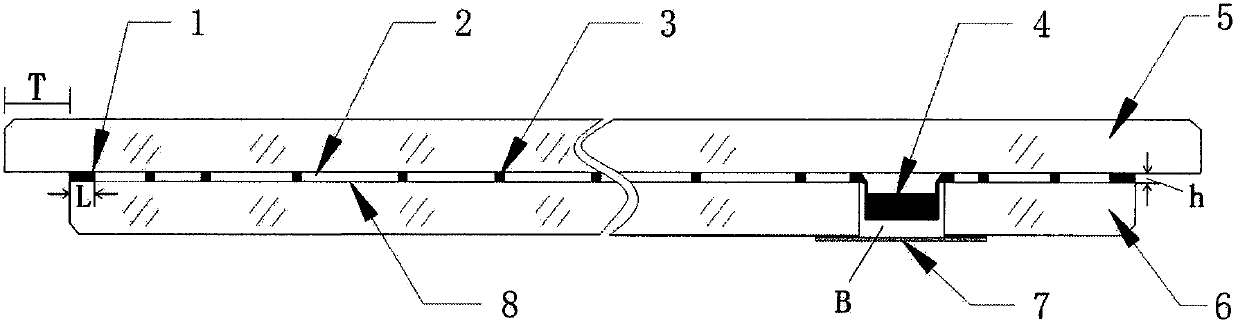

Coal mine two-end gas plug and middle water seal layer penetrating drill hole sealing device and method

InactiveCN105756599ALow costEasy to operateGas removalSealing/packingAir compressionCoal mine methane

A coal mine two-end gas plug and middle water seal layer penetrating drill hole sealing device comprises a gas extraction pipe, a gas injection pipe and a water injection pipe which are arranged in parallel.A first limiting block, a first expansion gas bag, a second limiting block, a third limiting block, a second expansion gas bag and a fourth limiting block are sequentially arranged on the gas extraction pipe from inside to outside, an inner end opening of the gas injection pipe is communicated with the interior of the first expansion gas bag, a gas injection hole communicated with the interior of the second expansion gas bag is formed in the gas injection pipe, and an inner end opening of the water injection pipe is located between the second limiting block and the third limiting block.The invention further discloses a hole sealing method.Cheap water and air are adopted as hole sealing materials in the device and the method and can be supplemented through an underground air compression system and a water supply system as needed to ensure good hole sealing quality, the whole device can be recycled and reused after the extraction work is finished, pollution to a coal body, underground water and underground air can be avoided, the safety level of a mine is improved, and popularization of the novel coal mine gas treatment technology can be easily promoted.

Owner:关红星

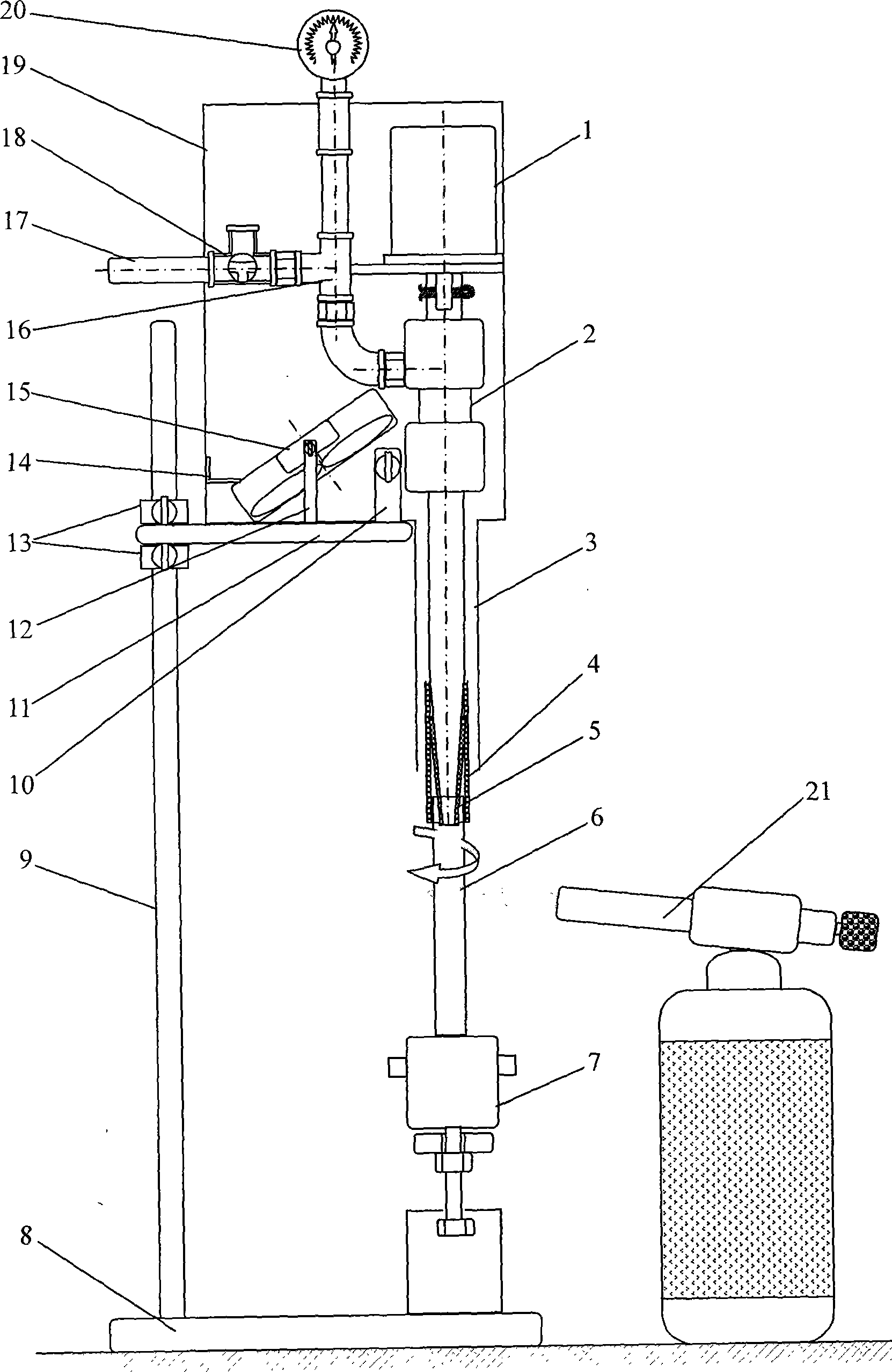

Vacuum ampoule fusion sealing machine

InactiveCN101475303AGuaranteed vacuumGuaranteed drynessGlass reforming apparatusFlavorWhole blood product

The invention provides a vacuum ampoule sealing machine, and relates to the technical field of biochemical experiment equipment. The vacuum ampoule sealing machine mainly comprises a rotary type vacuum connector, a rotary drawing ampoule or a test tube clamp, a lifting bracket and a sealing and heating device. The vacuum ampoule sealing machine has the advantages that the vacuum ampoule sealing machine overcomes the defects of the prior art, has the characteristics of simple structure, convenient operation, high efficiency, good sealing quality and high qualification rate (as high as 100 percent), is particularly suitable for long-term oxygen isolation sealing preservation of little biochemical products or samples which are easily oxidized, decomposed, denatured and inactivated in air and frozen and dried in an ampoule or a test tube, such as microbe strains, animal and plant cells or tissues, vaccine, viable bacteria preparation, enzyme preparation, active protein, blood products, flavor food, health-care food and biochemical drugs, and suitable for vacuum sealing preservation of all oxygen-sensitive biological and chemical substances.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

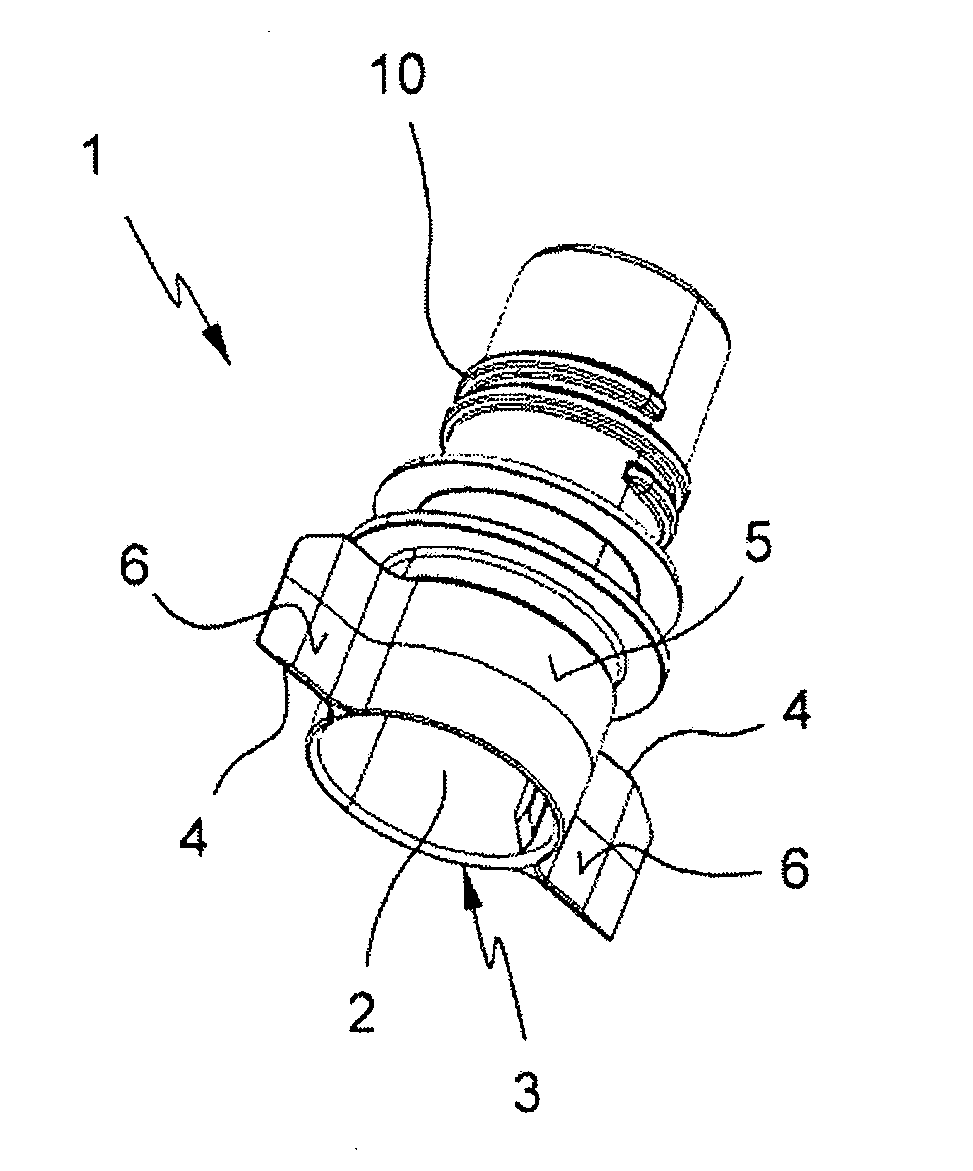

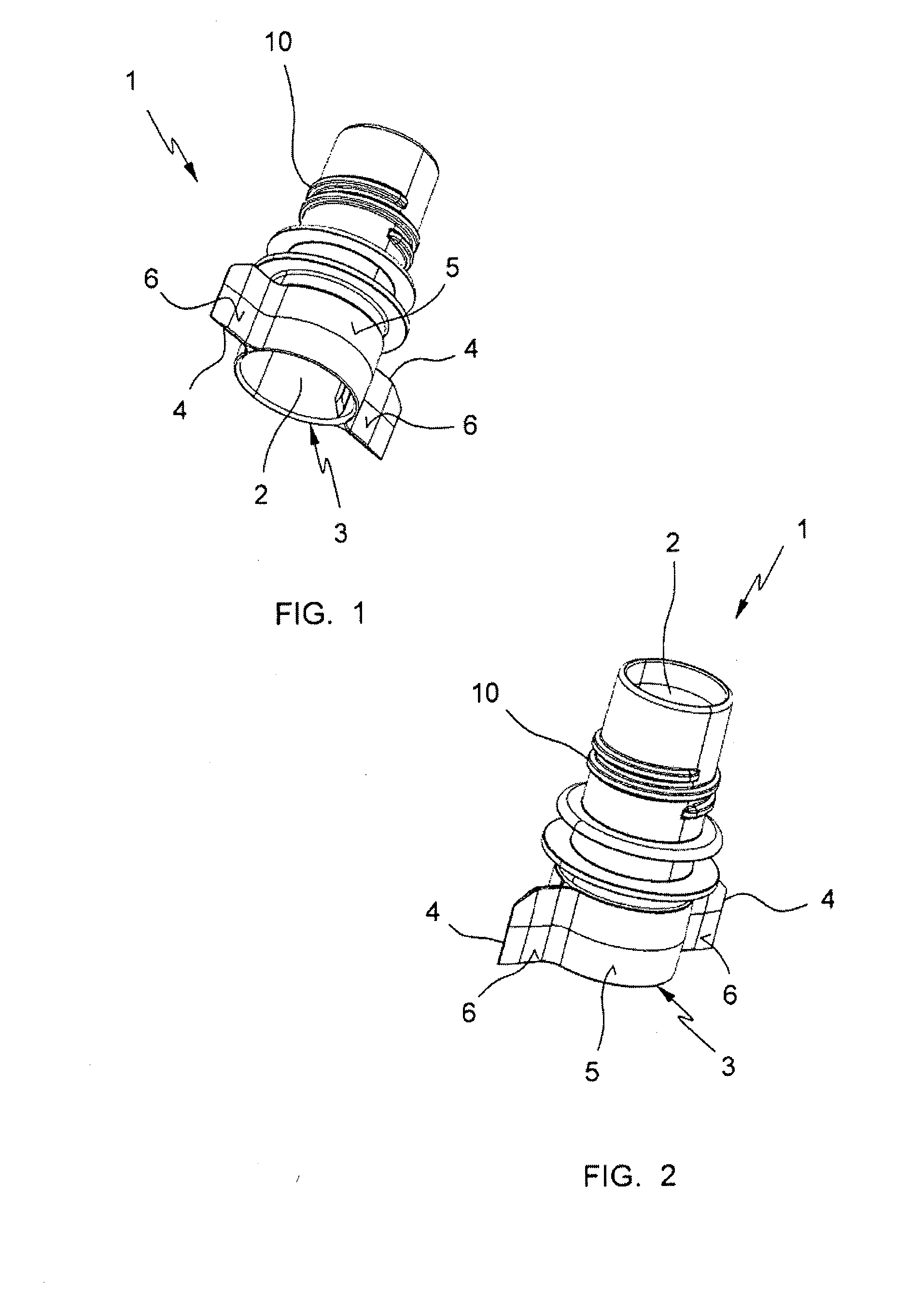

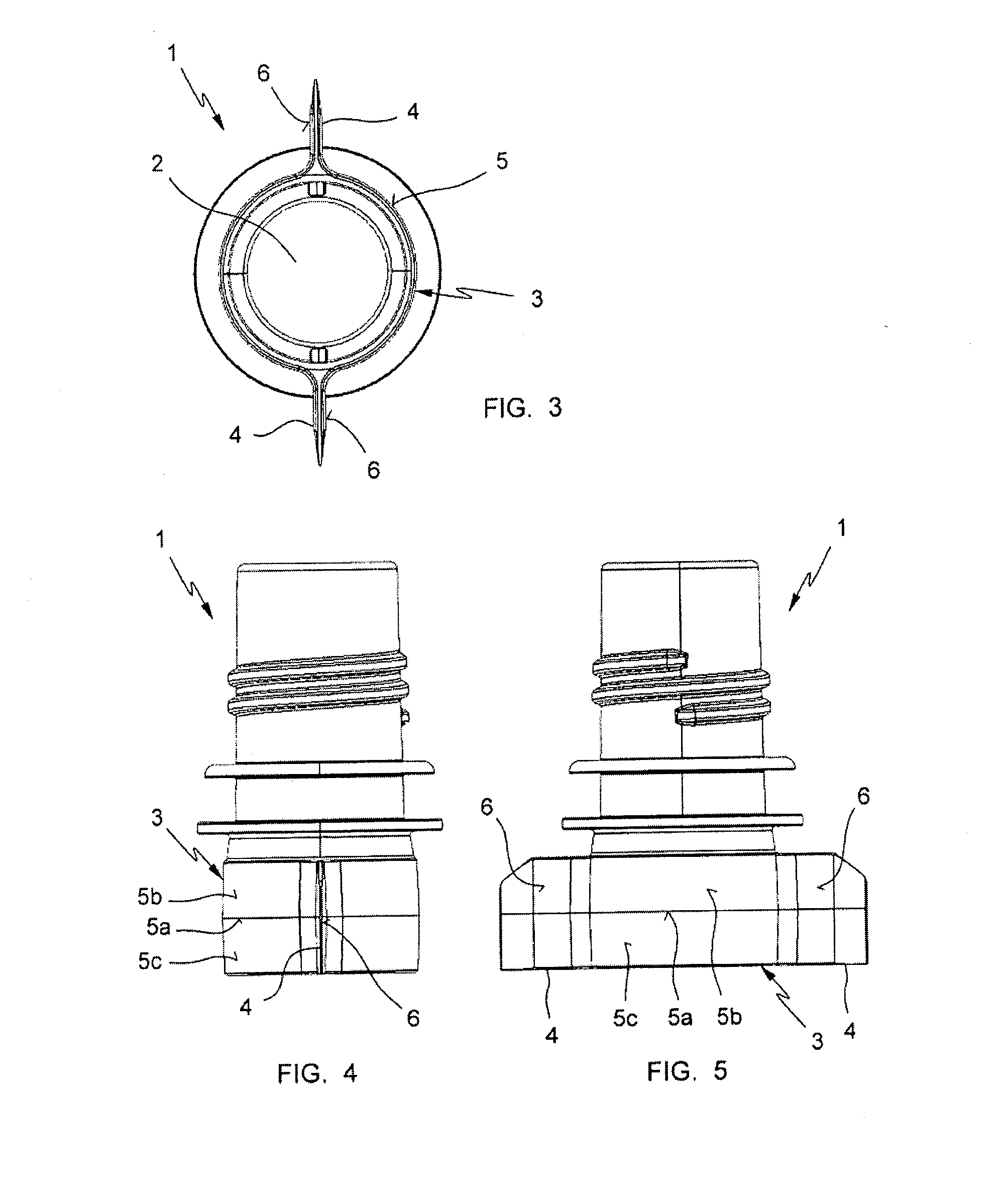

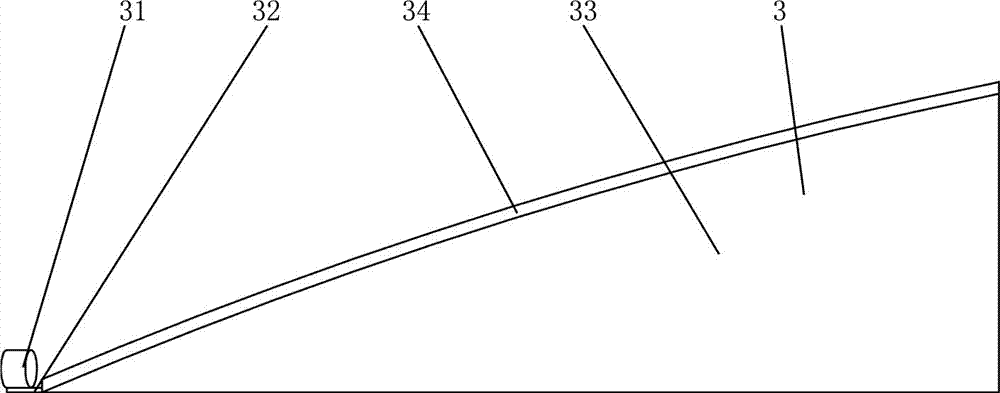

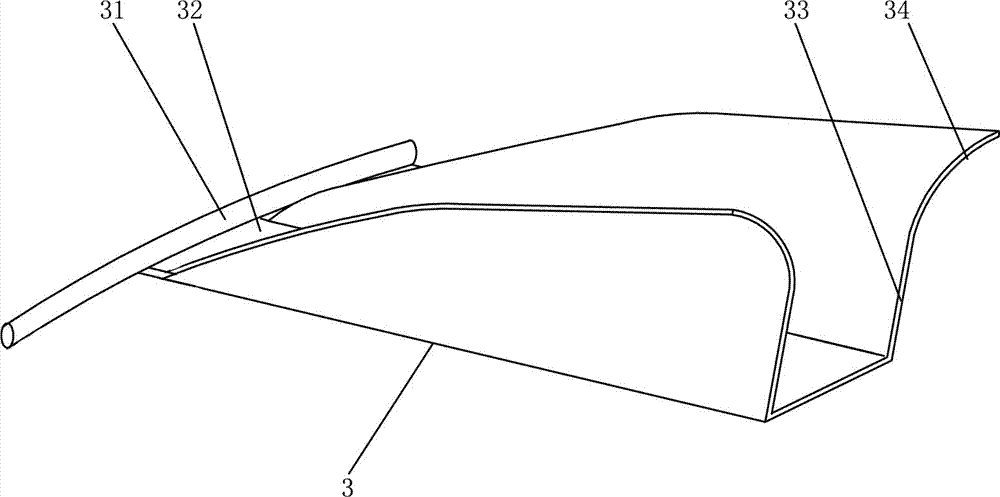

Discharge spout for flexible bags

InactiveUS20110147421A1Easy maintenanceImprove seal qualityClosuresClosure using stoppersEngineeringMechanical engineering

The invention relates to a discharge spout for flexible bags, of the type comprising a rigid plastic body forming a discharge passage and having a tube (3) intended to be inserted between two walls of a flexible bag and joined to such walls by means of sealing. The tube (3) has a smooth outer surface and two opposite flat flaps (4) extending externally in a mid-plane of said tube (3). The outer surface of the tube (3) forms, together with the surface (6) of the flat flaps (4), a sealing surface. The outer surface of the tube (3) is a dished surface in the axial direction of the tube, and it has a middle area (5a) in which the distance to the axis (7) of the tube is maximum, separating two side sections (5b, 5c) in which the distance to the axis (7) is decreasing toward the ends of the tube.

Owner:VOLPAK

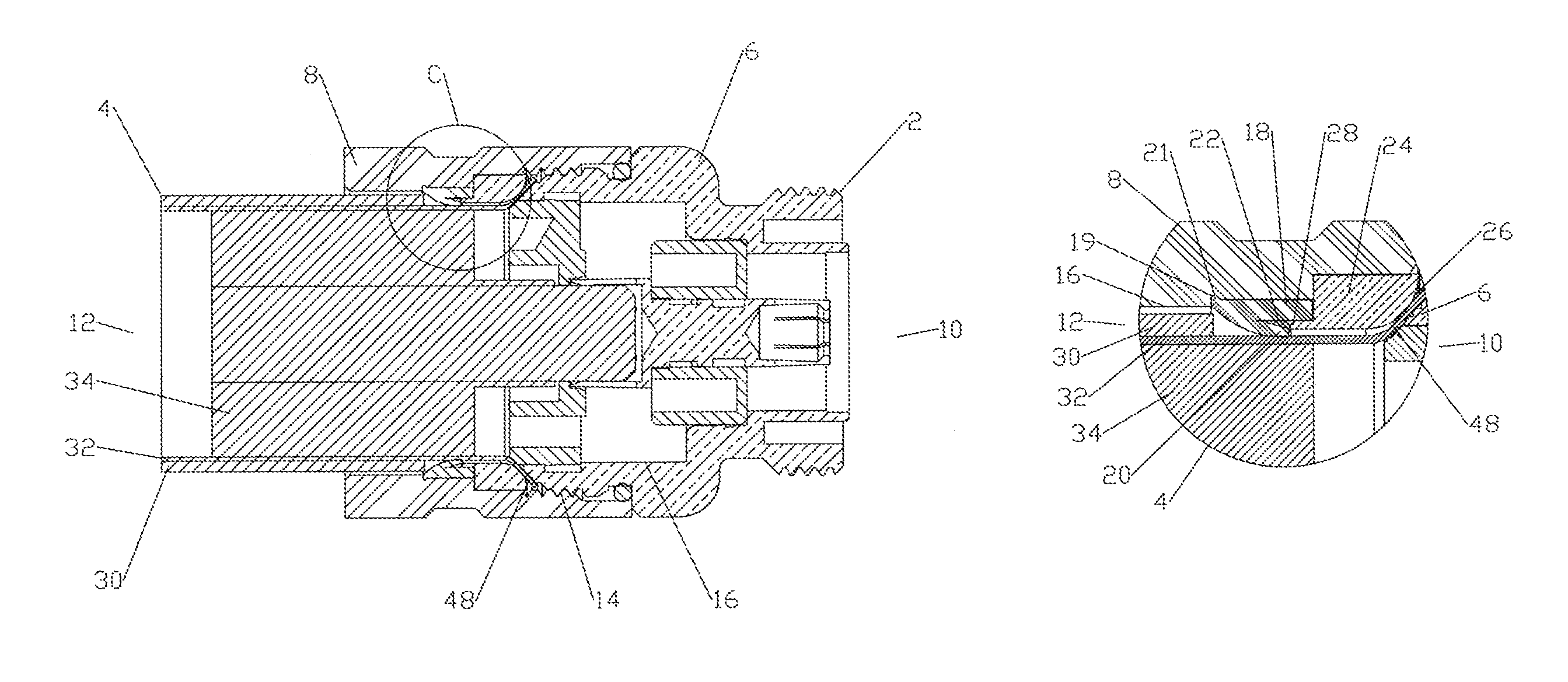

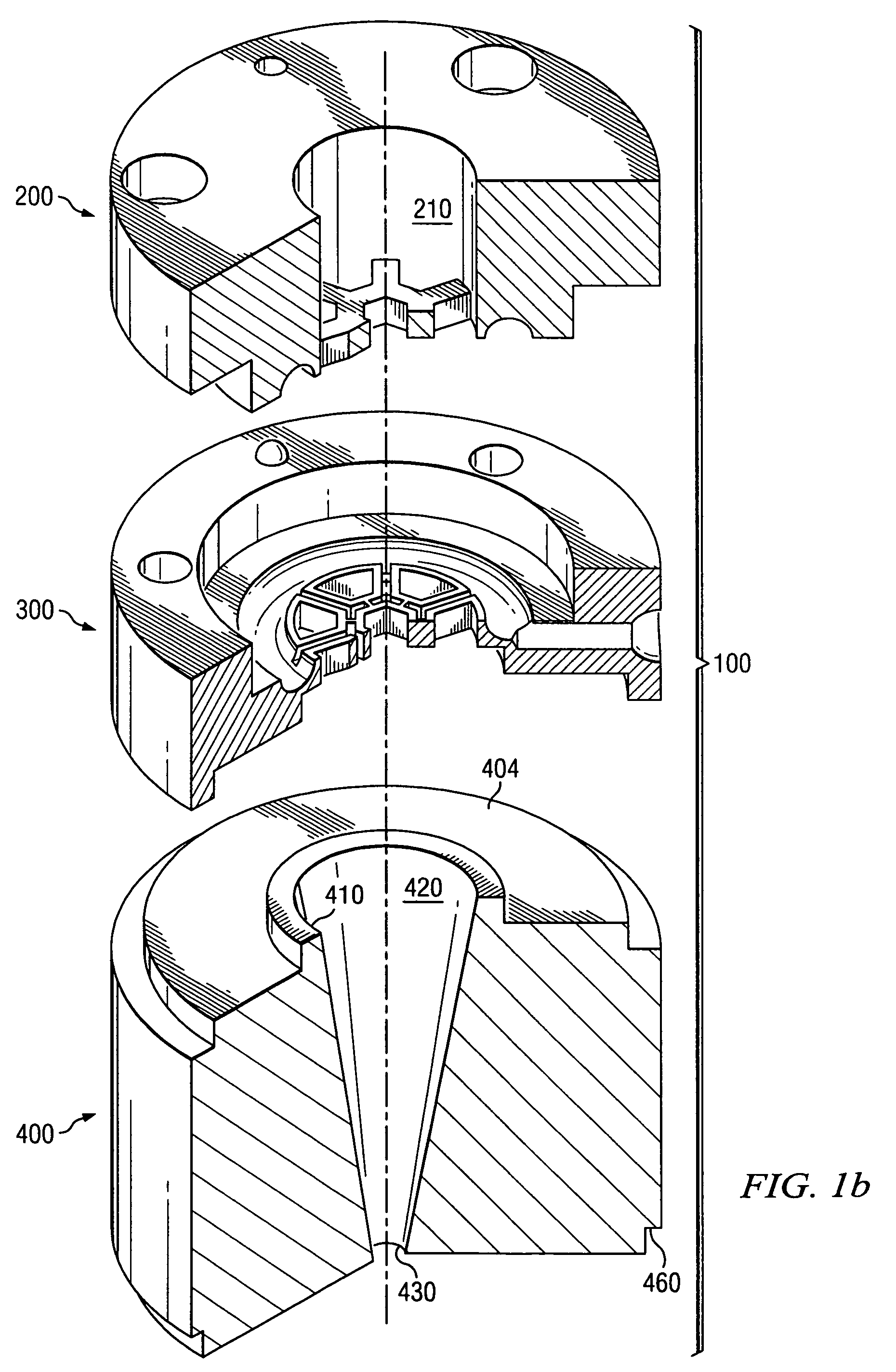

Coaxial connector with cable diameter adapting seal assembly and interconnection method

InactiveUS8460031B2Improve seal qualityImprove sealingElectrically conductive connectionsTwo pole connectionsCoaxial cableInterconnection

A coaxial connector for interconnection with a coaxial cable provided with a connector body and a clamp ring dimensioned to couple with a cable end of the connector body. The clamp ring and the connector body provided with a bore along a longitudinal axis therethrough. A gasket with a radially inward protrusion coupled to an inner diameter of the clamp ring. An outer diameter sidewall of the radially inward protrusion and an inner diameter sidewall of the gasket forming an annular gasket groove open to a connector end of the clamp ring. An annular shim seated within the bore; the shim contacting the gasket groove, biasing the radially inward protrusion radially inward, as the clamp ring is advanced toward the connector body along the longitudinal axis.

Owner:COMMSCOPE TECH LLC

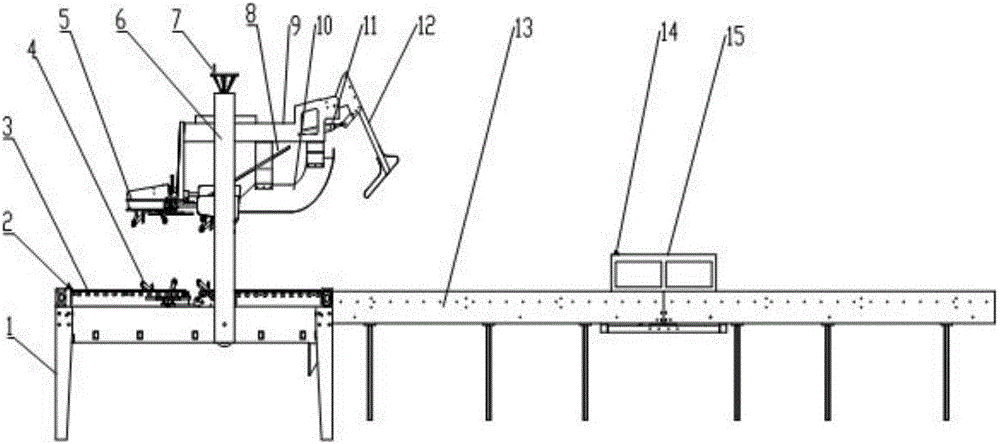

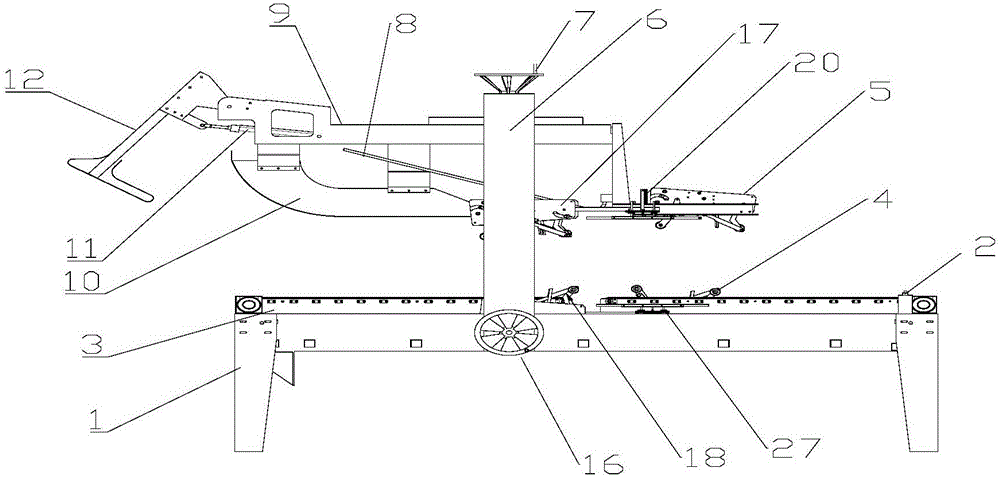

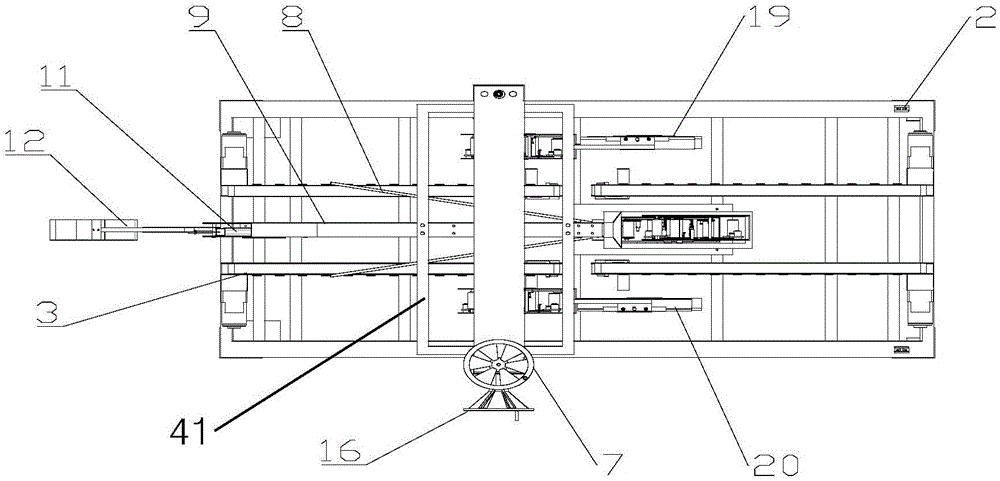

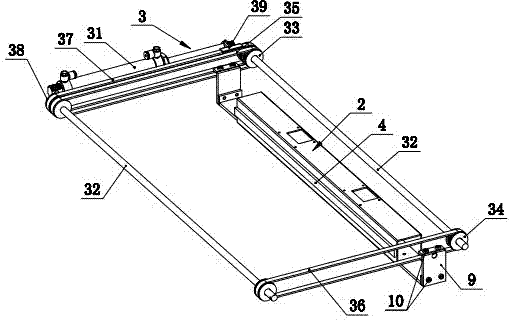

Full-automatic horizontal type food packer

PendingCN107054748AImprove protectionGuaranteed shelf lifeWrapping material feeding apparatusWrappingPhysicsFood packaging

A full-automatic horizontal type food packer comprises a rack, a packaging film unreeling device, a former, a feeding device, a positioning and conveying device, a sealing device and a discharging conveying belt; the positioning and conveying device comprises an annular chain and a strip-shaped guide groove; a plurality of stirring forks are installed on the annular chain at equal intervals; the strip-shaped guide groove is located below the advancing section of the annular chain; the sealing device comprises a drawing mechanism, a longitudinal sealing mechanism and a transverse sealing and cutting mechanism; the transverse sealing and cutting mechanism comprises a first transverse sealing shaft and a second transverse sealing shaft which rotate relatively and are both in the vertical direction; two first transverse hot sealing strips are arranged on the first transverse sealing shaft; a transverse cutter is arranged between the two first transverse hot sealing strips; two second transverse hot sealing strips are arranged on the second transverse sealing shaft; and a gap is formed between the two second transverse hot sealing strips. The full-automatic horizontal type food packer is suitable for packaging of three-edge sealed bags, integrates automatic bag making, feeding and sealing, is simple and compact in structure, stable in operation and good in sealing quality, and can well protect food.

Owner:汕头市东升食品有限公司

Device for creating a seal between fabrics or other materials

InactiveUS20060037180A1Precise alignmentImprove usabilitySnap fastenersSlide fastenersEngineeringMechanical engineering

A device for forming a seal includes upper and lower seal members, and a slider, wherein mating surfaces of the seal members interlock. In at least one embodiment, a lifting rib and closure bar on the slider cooperate with a lifting wing and closure bar groove on the upper and lower seal members, respectively. By moving the slider in one direction, the lifting rib lifts the upper seal member from the lower seal member. Moving the slider in the opposite direction causes the upper and lower seal members to interlock. In another embodiment, a slider has an intermediate lateral member connected on one side the slider top, and connected on the other side to the slider bottom. A breakaway sealing device is also provided, allowing a person to break the closed seal. A beginning stop block is also provided that includes a means for securing the upper seal member.

Owner:ABSOLUTE CLOSURE INNOVATIONS

Full-automatic solar heat-collecting tube sealing machine

InactiveCN1951844AIncrease productivityImprove seal qualityGlass reforming apparatusGlass productionEngineeringMechanical engineering

The invention discloses a sealing machine of solar energy gathering pipe in the solar boiler, which comprises the following parts: paralleling working piece station transfer driving chain set on the rack anchored by gap driving system synchronously, multiple two adjacent working-piece rotation friction wheels and core rotation friction wheels anchored by driving device on the chain set, wherein the multiple cores are set between two adjacent core rotation friction wheels, which rotate with working piece concentrically with the same speed.

Owner:冯方军

Device for creating a seal between fabrics or other materials

InactiveUS7536758B2Improve usabilityImprove seal qualitySnap fastenersSlide fastenersEngineeringTongue and groove

Disclosed is a device for creating a seal which includes an upper seal member, a lower seal member, and a slider, wherein mating surfaces of the upper and lower seal members interlock. A lifting rib on the slider cooperates with a lifting wing on the upper seal member and a closure bar cooperates with a closure bar groove of the lower seal member. By moving the slider in one direction, the lifting rib lifts the upper seal member from its interlocking relationship with the lower seal member. Moving the slider in the opposite direction causes the upper and lower seal members to interlock. Also disclosed is a seal device which includes upper and lower seal members and a cooperating slider and plug. Each of the slider and plug cooperate with first and second mating surfaces of the upper and lower seal members. In addition, the slider and plug have an exterior tongue and groove portion which cooperate to interlock the slider and the plug.

Owner:ABSOLUTE CLOSURE INNOVATIONS

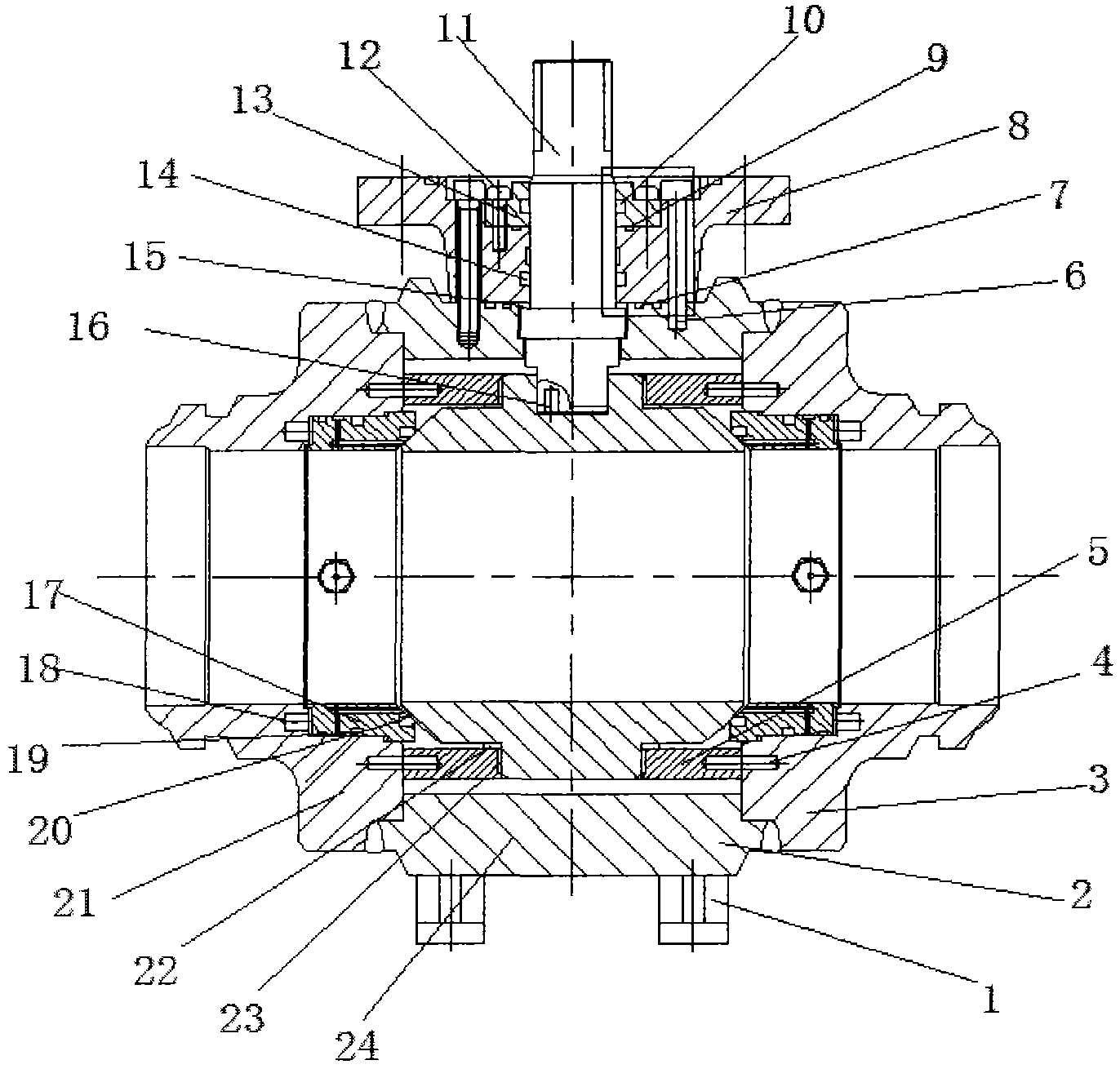

Ball valve with all-welded valve bodies and welding method of ball valve

InactiveCN103672008AReduce labor intensityImprove sealingPlug valvesHigh frequency current welding apparatusEngineeringValve stem

The invention discloses a ball valve with all-welded valve bodies and a welding method of the ball valve. The ball valve comprises a spherical valve spool, a left valve body, a right valve body, a middle valve body, a valve stem, a valve seat, sealing rings, a press plate, a lining plate and the like. The ball valve is applicable to valve systems in gas and liquid delivery pipelines, and a high-frequency welding process is adopted to produce sealed parts. The spherical valve spool is placed in a spherical cavity in the middle valve body together with the lining plate, a thrust plate, a sliding bearing and the like, the sealing rings are mounted on the left and right sides of the spherical valve spool, the valve seat and a valve-seat support ring thereof are mounted on the inner walls of the valve bodies on the left and right sides together with an elastic mechanism, joint parts between the middle valve body and the left and right valve bodies are all sealed by welding, and one end of the valve stem penetrates the middle valve body and is connected with the internal valve spool. The valve stem rotates to drive the spherical valve spool in the cavity to rotate, so that the valve is controlled to be turned off. The ball valve is simple in structure, good in sealing performance, stable in welding and sealing quality, high in production efficiency and applicable to pipeline delivery systems for petroleum, natural gas and the like, and the problem of leakage of conventional valves is solved.

Owner:CRETE GRP CO LTD

Full-automatic plastic bag sealing machine

The invention discloses a full-automatic plastic bag sealing machine which comprises a machine body, wherein two oppositely moving cross beams are mounted on the machine body; a group of transmission mechanisms for driving the cross beam to horizontally and linearly move in a reciprocating way are connected to each cross beam; electric heating sealing clips are fixedly mounted on the opposite side surfaces of the two cross beams; supporting rods and swinging mechanisms are arranged above the cross beams; the supporting rods are used for supporting and tensioning a plastic bag; the swinging mechanisms are used for driving the supporting rods to swing, so that the operation of supporting the plastic bag can be full-automatically finished; therefore, the automation degree of the sealing machine is greatly enhanced, the whole operation process is more consistent and automatic and the production efficiency can be obviously increased. Suckers and plastic bag locking mechanisms are also mounted on the cross beams, wherein the suckers are used for fixing the plastic bag; therefore, the plastic bag is more stably and reliably fixed on the cross beams, so that greater convenience for filling follow-up products and sealing the plastic bag is achieved.

Owner:浙江亚光科技股份有限公司

Flavored extruded food product

InactiveUS7252847B2Improve sealing propertiesSimpler and easy to maintainConfectionerySweetmeatsFood industryEngineering

An extruder die assembly and method for using same is disclosed that may be adapted to a wide variety of commercial-grade extrusion devices common in the food industry. The disclosed method comprises extruding a known composition of a farinaceous food product through the extruder die assembly of the present invention to produce a flavored direct-expanded food product exhibiting enhanced flavor characteristics, but requiring no post-extrusion drying or seasoning process. The injection section of the extruder die assembly is used to impart flavoring additives into the extrudate mass shortly before expansion, thereby preserving the flavoring characteristics of the additive by minimizing the heat exposure of the flavoring additive. The extruder die assembly may also include static mixing elements downstream from the injection section to homogenize the flavoring or seasoning media into the flowing mass of extrudate.

Owner:FRITO LAY NORTH AMERICA INC

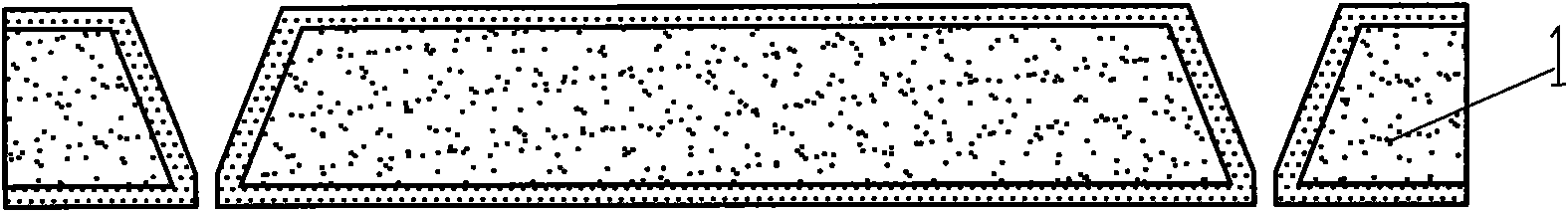

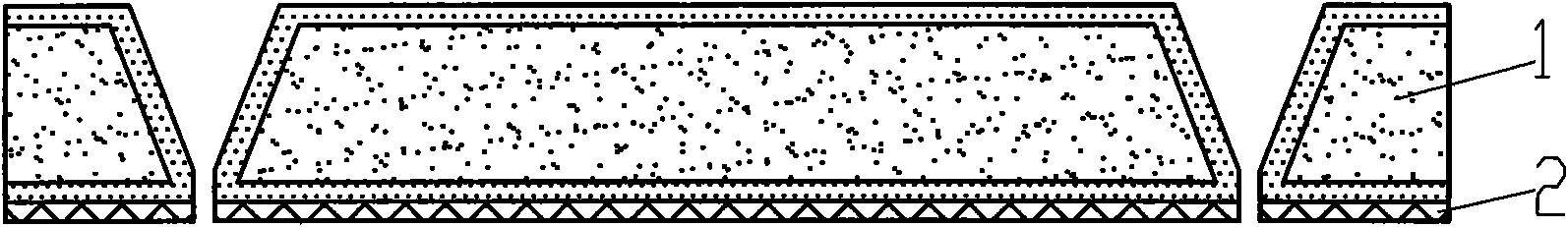

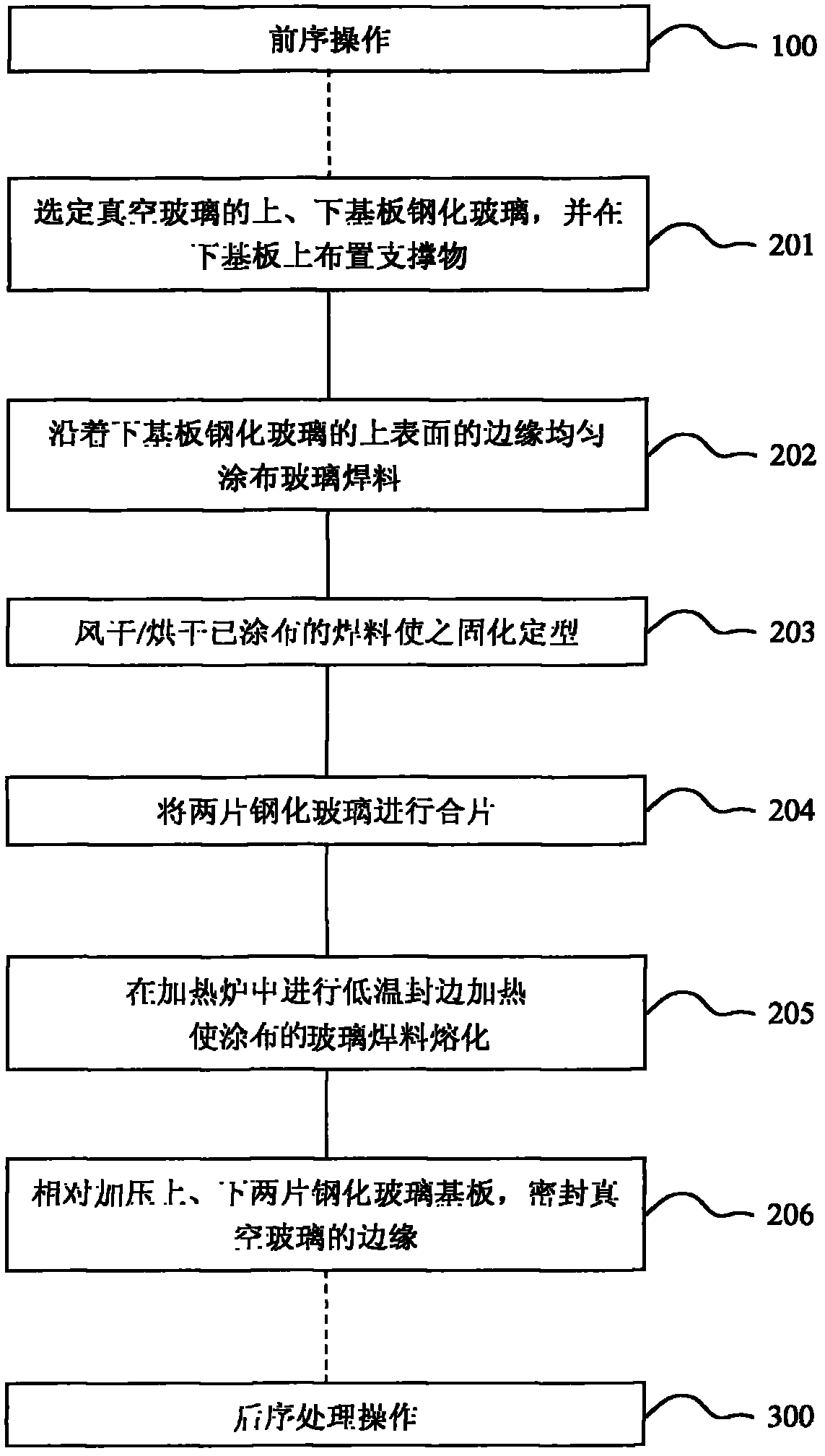

Tempered/semi-tempered vacuum glass and method for manufacturing same

ActiveCN103373805AImprove sealingObvious tempering propertiesGlass reforming apparatusFlat glassSolid component

The invention discloses tempered / semi-tempered vacuum glass and a method for manufacturing the same. The method comprises the following steps of: selecting two pieces of tempered flat glass as upper and lower base plates of the vacuum glass; uniformly coating glass solders on the surface of the upper base plate or the lower base plate, namely the tempered flat glass, along the edge of the tempered flat glass, wherein the thickness of the glass solders is greater than the height of a used support; performing natural or heating type airing / drying on the coated glass solders, and removing liquid components and volatile solid components to solidify and shape the glass solders; combining the two pieces of tempered flat glass, namely compositing the two pieces of tempered flat glass together; adding the two pieces of tempered flat glass, composited together, into a heating furnace for edge sealing and heating so as to melt the coated glass solders; cooling, and starting to uniformly pressurize the two pieces of tempered flat glass before the glass solders are solidified, so as to enable the thicknesses of the solidified glass solders to be equal to one another and equal to the height of the support in an intermediate layer, and complete the edge sealing of the vacuum glass.

Owner:新立基节能玻璃(天津)有限公司

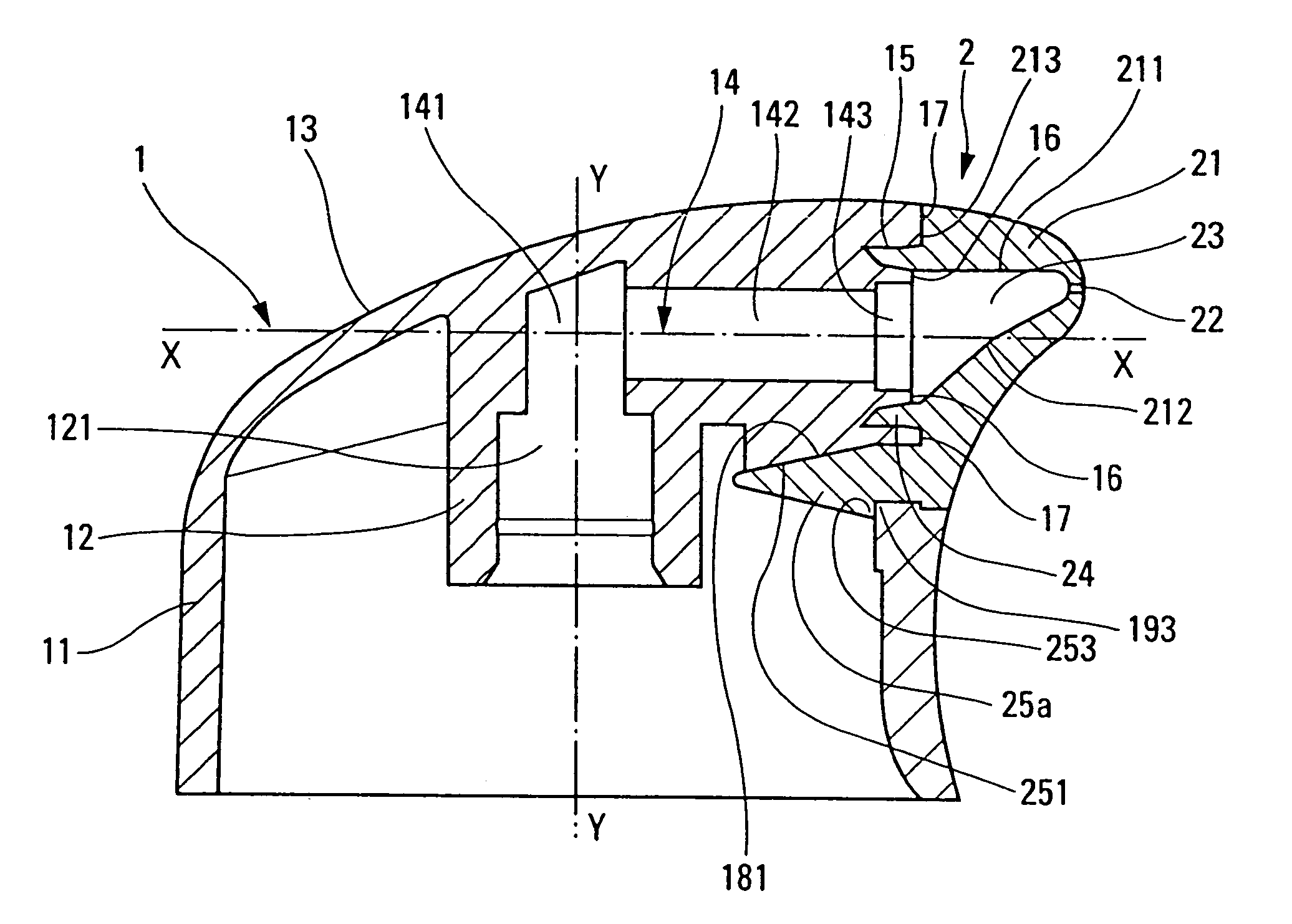

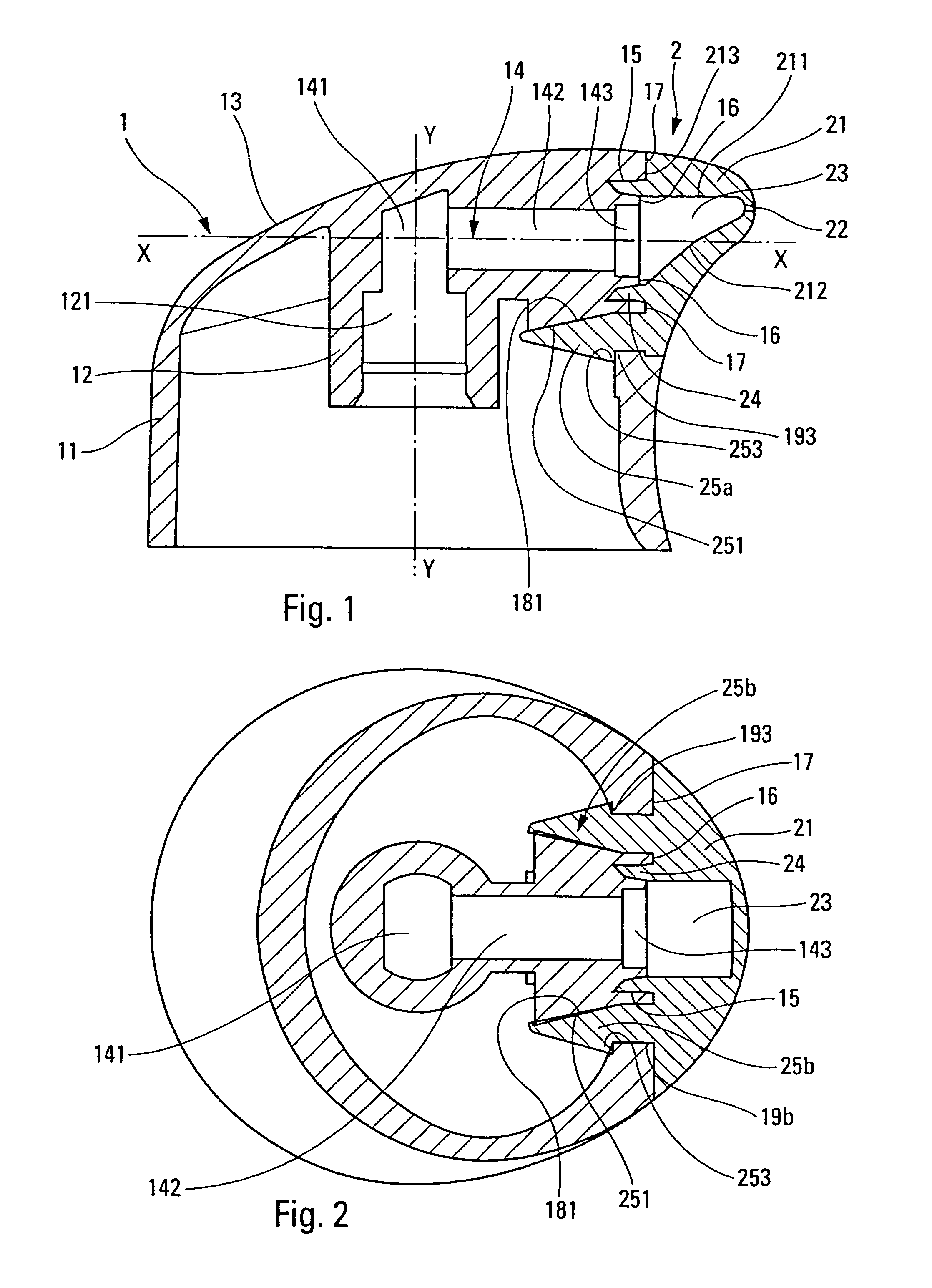

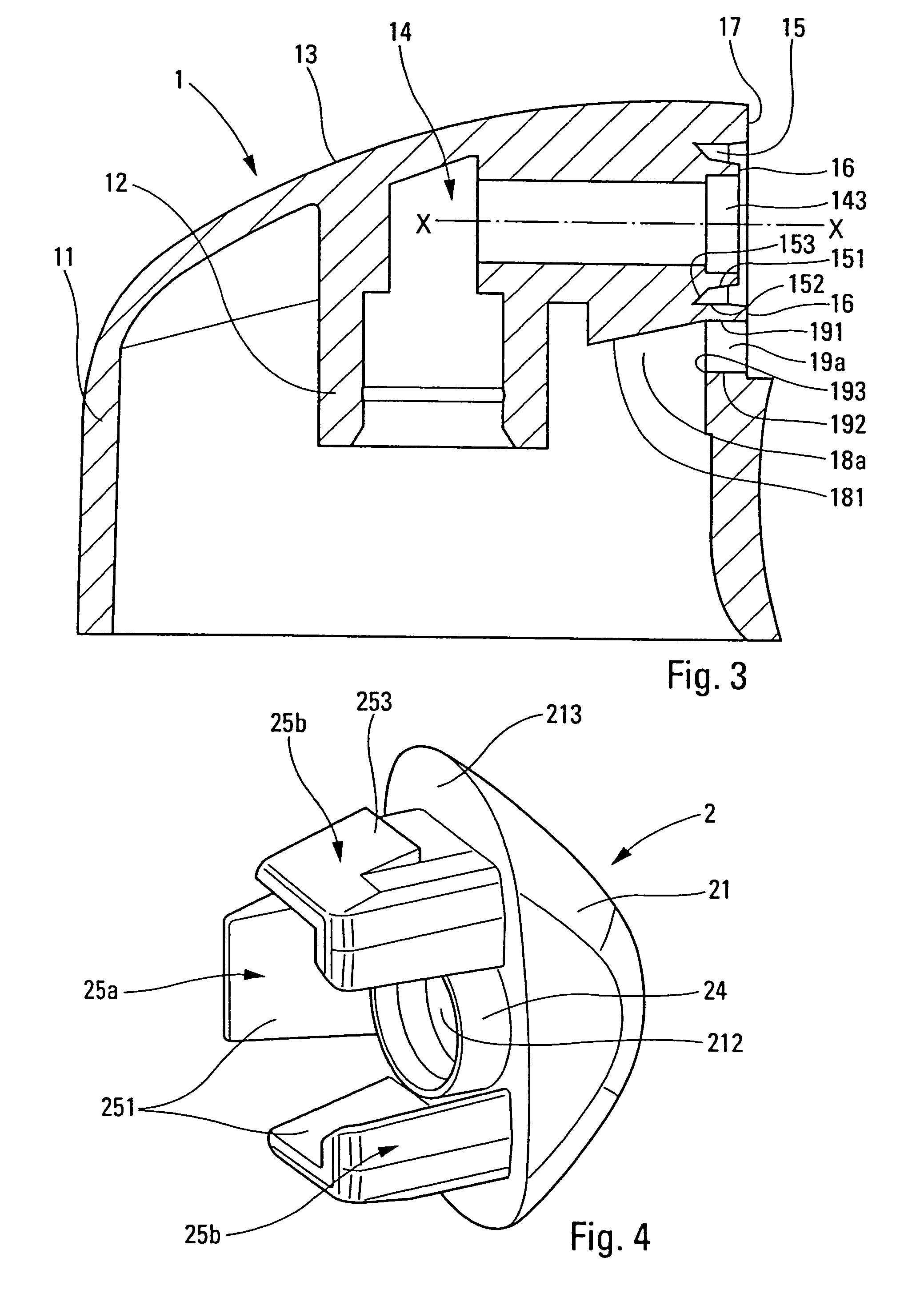

Fluid dispenser head

ActiveUS6991139B2Improved sealing and fixing functionEasy to disassembleLiquid dispensingDischarging meansEngineeringMechanical engineering

A fluid dispenser head comprising a body (1) forming a dispensing duct (14) having an outlet (143) defining an outlet axis X, and a shutter (2) fitted to the body (1) for the purpose of selectively closing off the dispensing duct (14) at its outlet (143), the shutter forming a dispensing orifice (22) that is closed in the absence of fluid under pressure in the dispensing duct, said shutter being provided with sealing means (24) and with fixing means (25a) co-operating respectively with complementary seal-receiving means (15) and with complementary holding means formed by the body (1), the fixing means comprising at least one fixing profile (253) facing radially outwards relative to the outlet axis X, and the holding means comprising at least one holding profile (193) facing radially inwards towards the outlet axis X.

Owner:APTAR FRANCE SAS

Apparatus and method for improving the dimensional quality of extruded food products having complex shapes

InactiveUS7585532B2Quality improvementImprove sealing propertiesConfectionerySweetmeatsFood flavorMechanical engineering

The present invention comprises an improved extruder die assembly and method for using same to improve the quality of dimensional design aspects of extruded, complexly shaped, direct expanded food products. The improved system includes an improved die assembly comprising a first die and a second die having at least one orifice. A majority of the total pressure drop occurs in the first die to pre-expand the dough prior to the dough entering the second die. The orifices in the first die can be individually configured to obtain differing dough flow speeds resulting in a desired flow pattern. A plurality of extruded dough ropes formed at each orifice exit of the first die can meld together in the bore and exit the second die. Color or flavor can be added at the first die to enhance the food product.

Owner:FRITO LAY NORTH AMERICA INC

Device for creating a seal between fabrics or other materials

ActiveUS7574780B2Improve usabilityImprove seal qualitySnap fastenersSlide fastenersEngineeringMechanical engineering

A device for forming a seal includes upper and lower seal members, and a slider, wherein mating surfaces of the seal members interlock. In at least one embodiment, a lifting rib and closure bar on the slider cooperate with a lifting wing and closure bar groove on the upper and lower seal members, respectively. By moving the slider in one direction, the lifting rib lifts the upper seal member from the lower seal member. Moving the slider in the opposite direction causes the upper and lower seal members to interlock. In another embodiment, a slider has an intermediate lateral member connected on one side the slider top, and connected on the other side to the slider bottom. A breakaway sealing device is also provided, allowing a person to break the closed seal. A beginning stop block is also provided that includes a means for securing the upper seal member.

Owner:ABSOLUTE CLOSURE INNOVATIONS

Rotatable hydraulic expanding type tail pipe hanger

A rotatable hydraulically expandable liner hanger is used in liner cementing construction. The feature is that the upper end of the feed-in joint is threaded and can be connected with a drilling tool. The outer wall of the lower end of the feeding joint is splined with the expansion pipe; the inner wall of the lower end of the feeding joint is screwed into the central pipe. The lower end of the central tube is fixed with a sealing rubber plug by shear nails; the expansion plug is in the annular space between the central tube and the expansion tube; the rubber plug conduit is connected to the lower end of the expansion tube; the lower end of the rubber plug conduit is threadedly connected to the lower connecting pipe; the blocking ring is placed on the inner shoulder of the lower connecting pipe. The diameter of the central hole at the upper part of the blocking ring is the same as the outer diameter of the lower end of the sealing rubber plug, and the diameter of the central hole at the lower part of the blocking ring is smaller than the outer diameter of the lower end of the sealing rubber plug. The effect is that the tailpipe is suspended by utilizing the hydraulic pressure to expand the expansion pipe to closely contact with the casing inner wall. High hanging success rate, good sealing quality; large internal diameter of the pipe string. The spline connection between the feeding joint and the expansion pipe can be drilled with the drill bit rotating during the lowering process.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com