Automatic face mask packer

A packaging machine and mask technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of inconvenient storage and carrying, packaging bags occupying a large space, easy to produce defective products and waste products, etc., to achieve accurate vertical sealing position Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

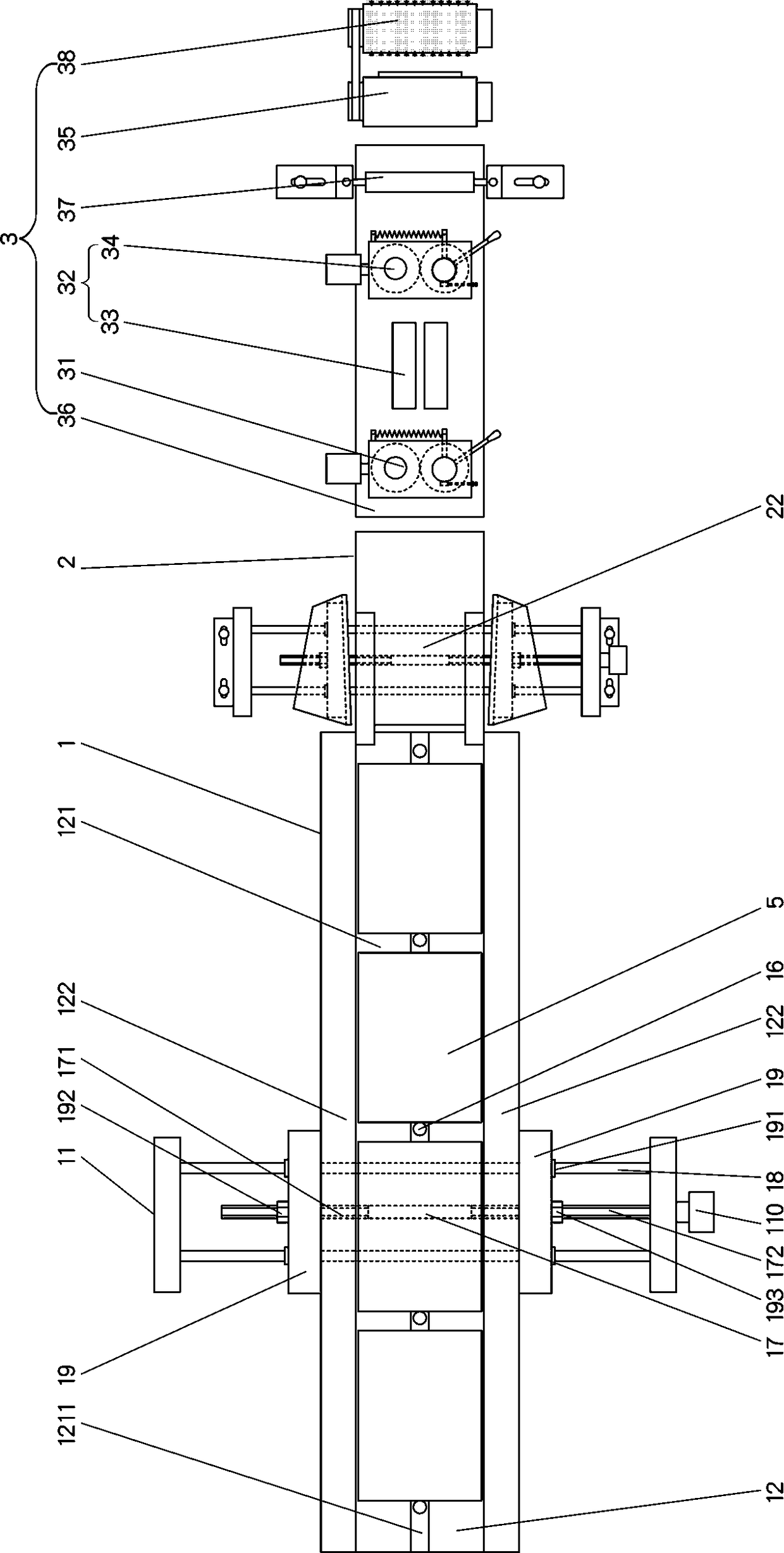

[0035] like figure 1 As shown, this automatic mask packaging machine includes a frame (not shown in the figure), mask conveying mechanism 1, bag forming device 2 and sealing device 3, mask conveying mechanism 1, bag forming device 2 and sealing device 3 from the front Finally, install them on the rack one by one.

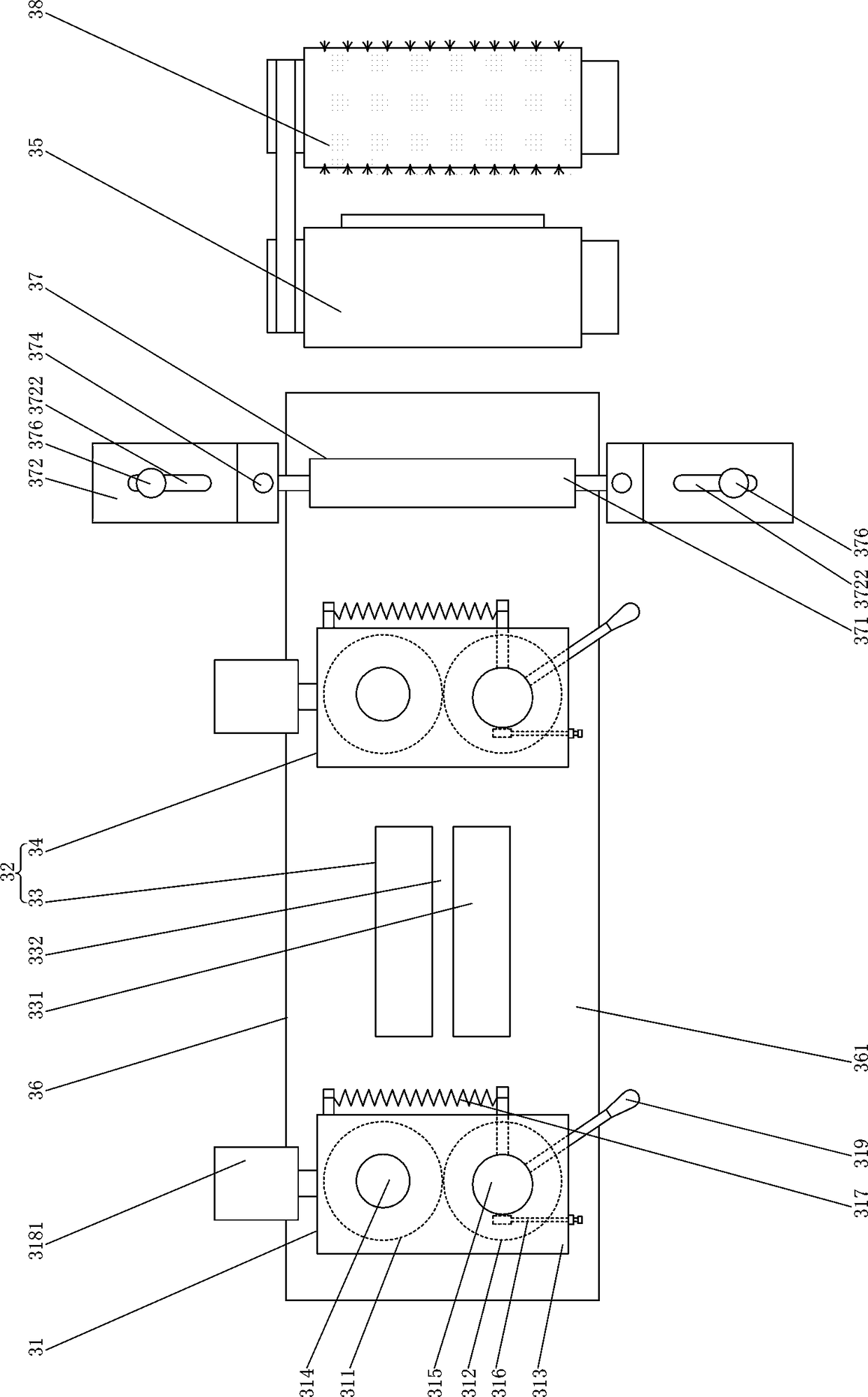

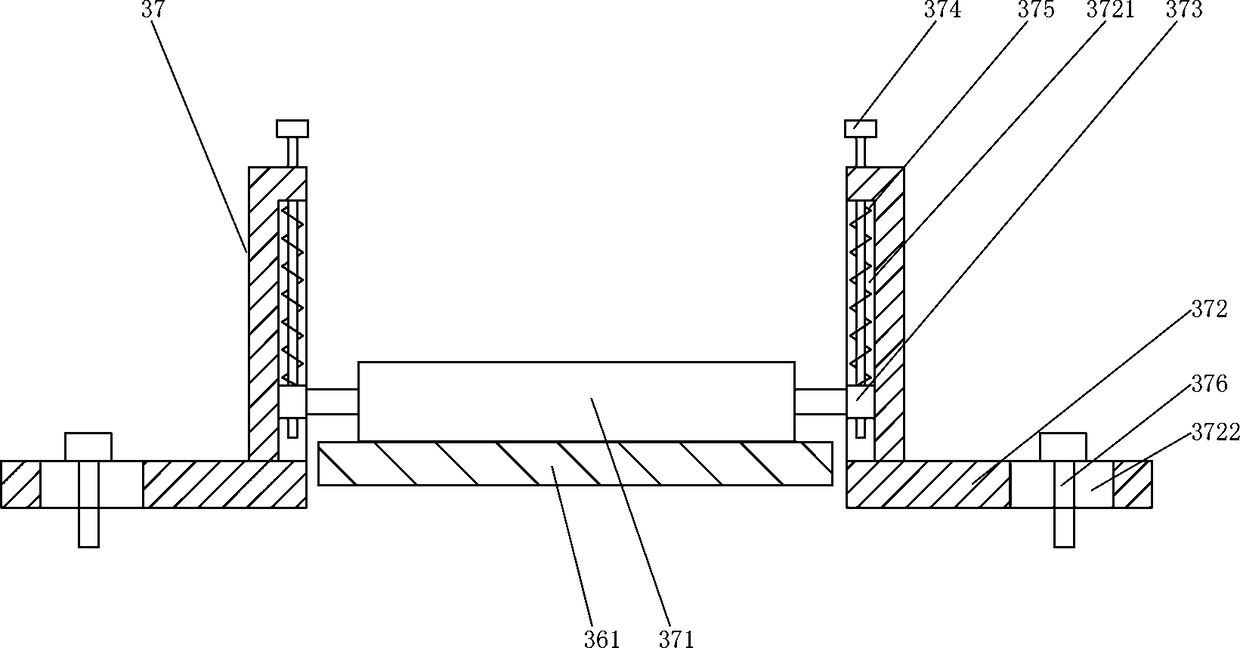

[0036] refer to figure 2The sealing device 3 includes a traction mechanism 31, a longitudinal sealing mechanism 32 and a horizontal sealing and cutting mechanism 35. The traction mechanism 31, the longitudinal sealing mechanism 32 and the horizontal sealing and cutting mechanism 35 are sequentially installed on the frame from front to back, and the longitudinal sealing mechanism 32 includes longitudinal heating. The mechanism 33 and the longitudinal sealing mechanism 34, the longitudinal sealing mechanism 34 is arranged behind the longitudinal heating mechanism 33; the longitudinal heating mechanism 33 includes two longitudinal heating strips 331 arranged side by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com