Full-automatic solar heat-collecting tube sealing machine

A solar collector tube, fully automatic technology, applied in glass remolding, glass manufacturing equipment, glass molding and other directions, can solve the problems of slow production speed, time-consuming, low efficiency, etc., to reduce the overall cost of products, improve Production efficiency, the effect of improving sealing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

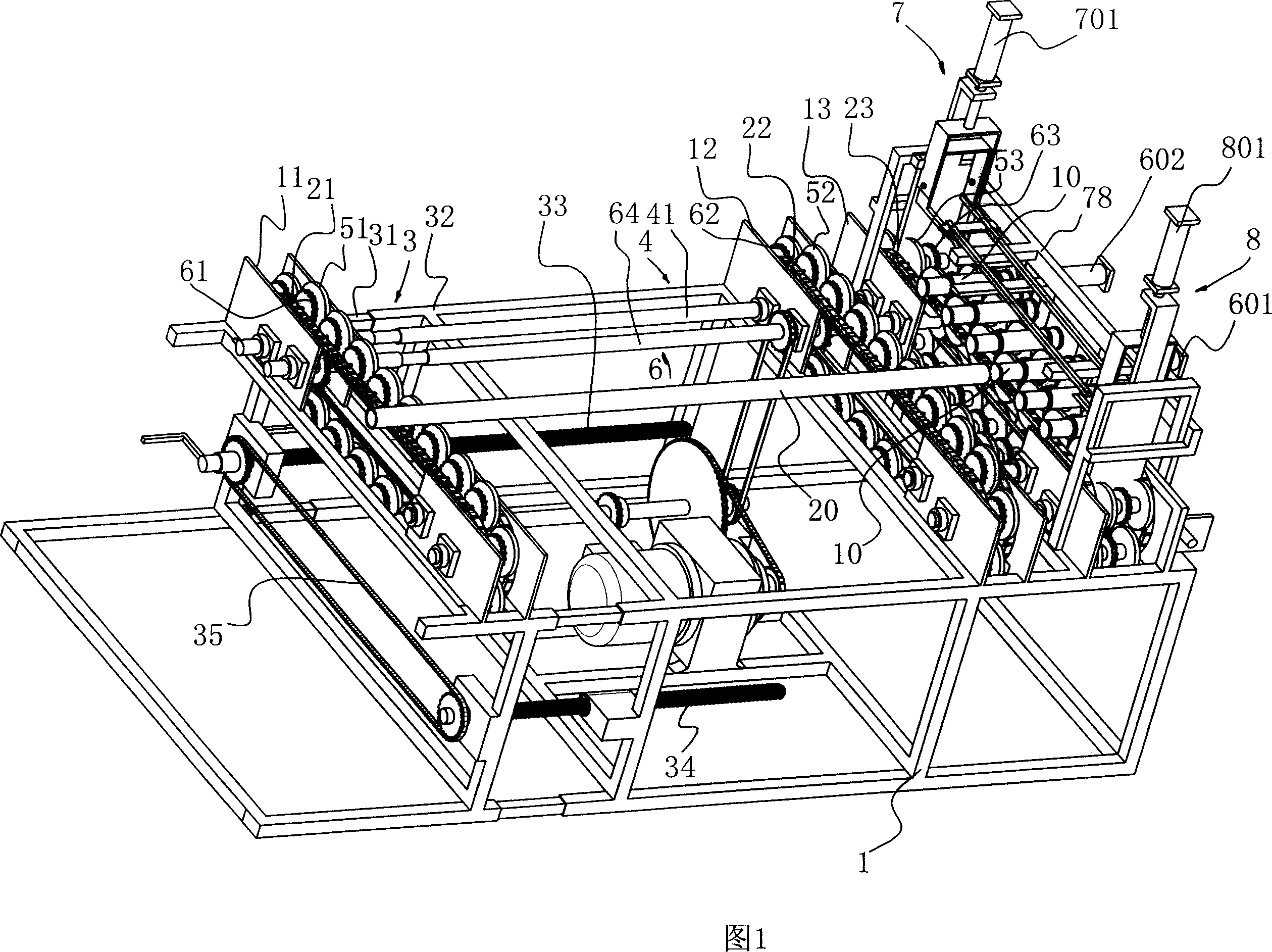

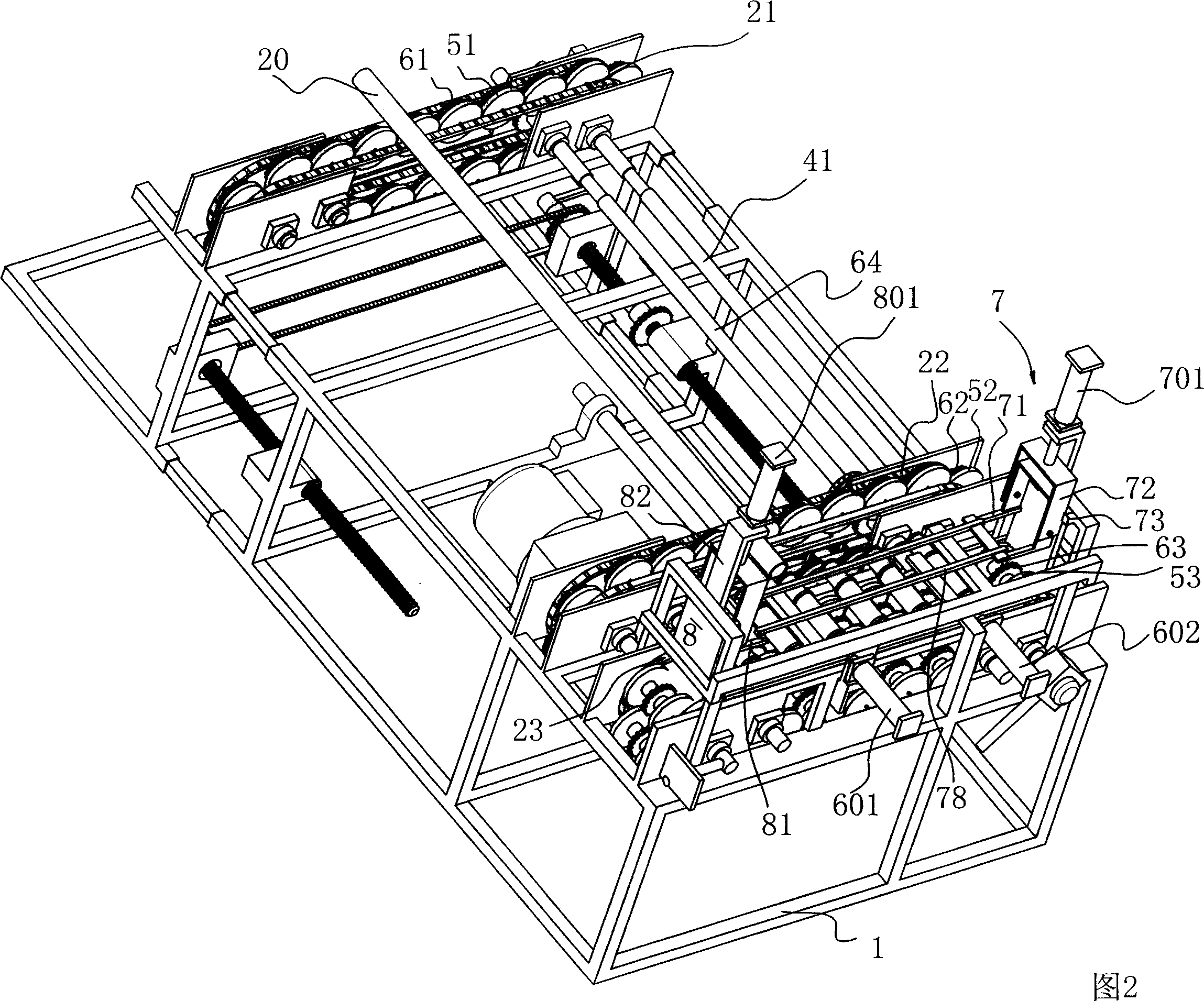

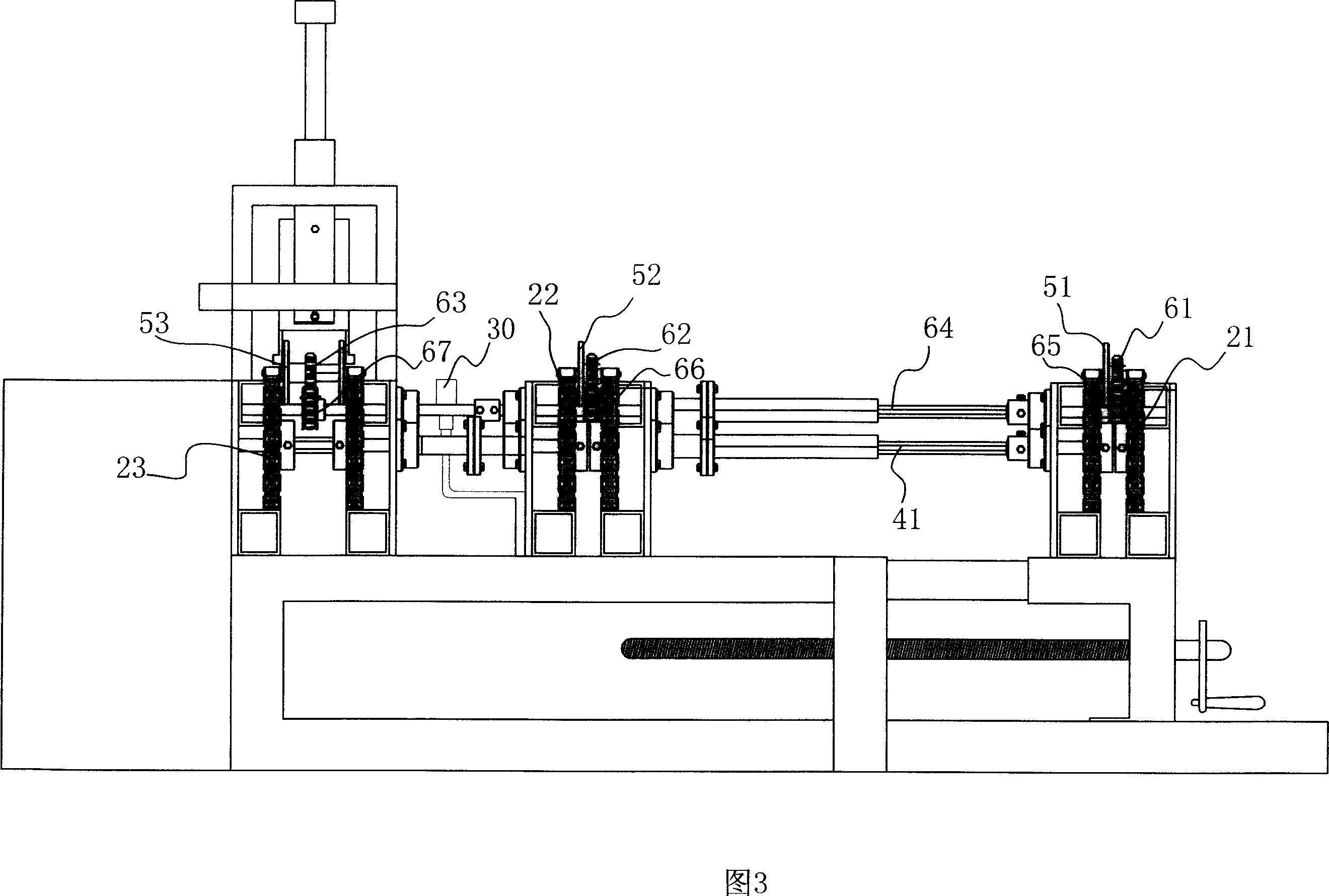

[0025] 1-10, the frame 1 of the automatic solar collector tube sealing machine of the present invention has three mutually parallel rails 11, 12, 13, which are respectively used to set the mandrel station transfer transmission chain group 23 and two Workpiece station transfer transmission chain groups 21, 22, wherein the rails 11, 12 used to set the two workpiece station transfer transmission chain groups are adjustable through an adjustment device 3 relative distance to adjust the two workpiece station transfer transmission chain groups 21, 22 to meet the needs of processing workpieces 20 of different lengths. Specifically, the track position of the workpiece station transfer transmission chain group 12 is fixed, and the track of the workpiece station transfer transmission chain group 11 installed on the outside can pass through the inner tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com