Patents

Literature

1628results about How to "Guaranteed dryness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

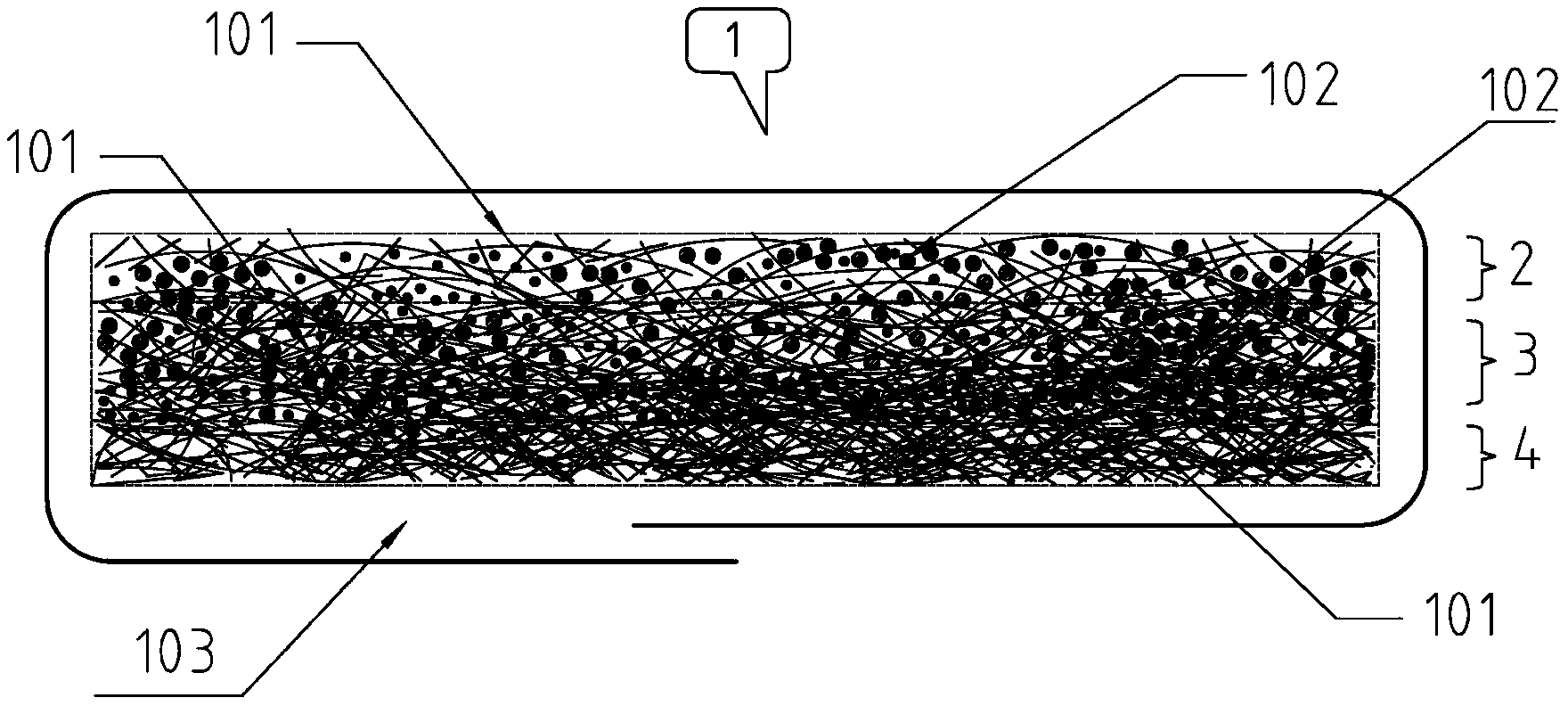

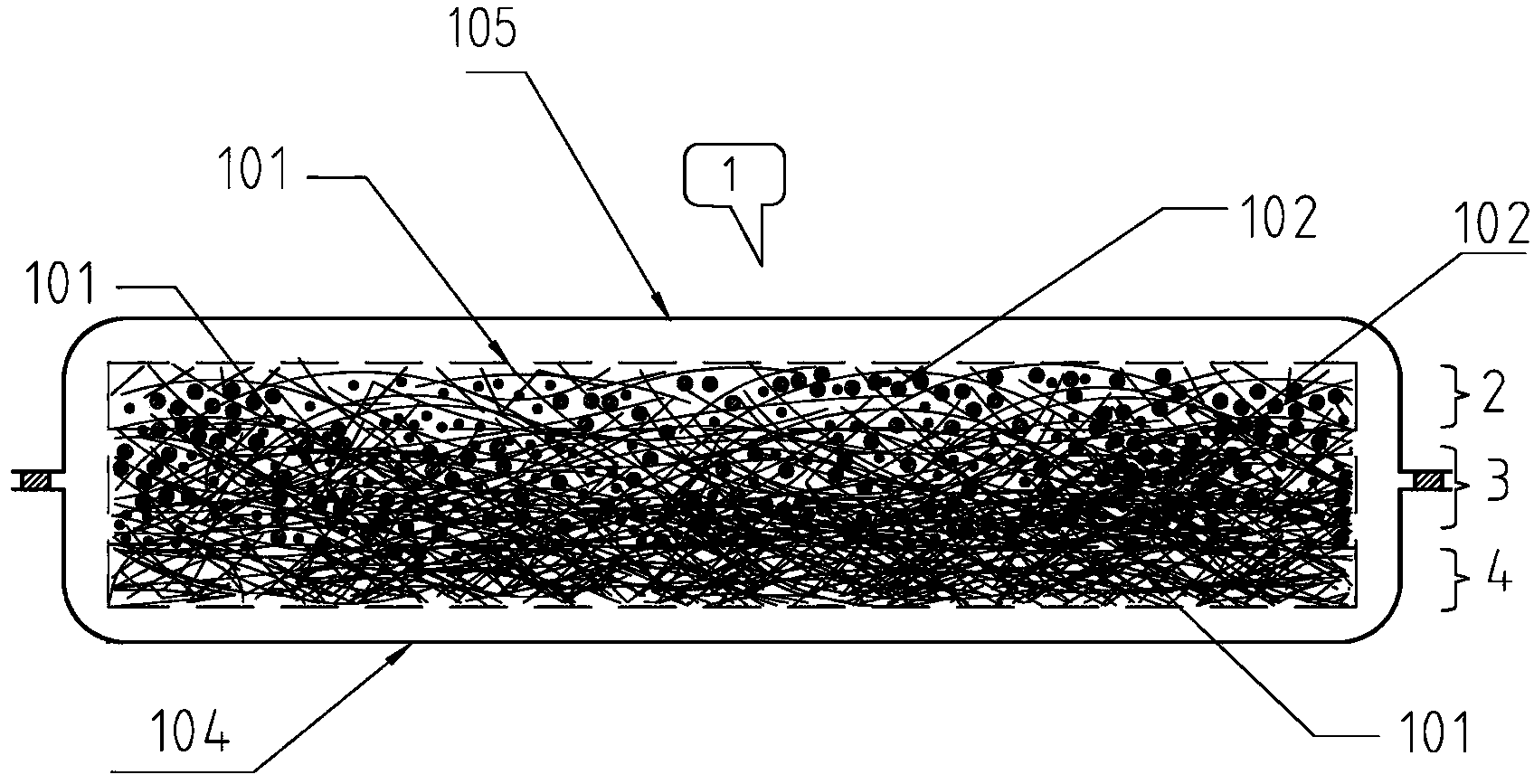

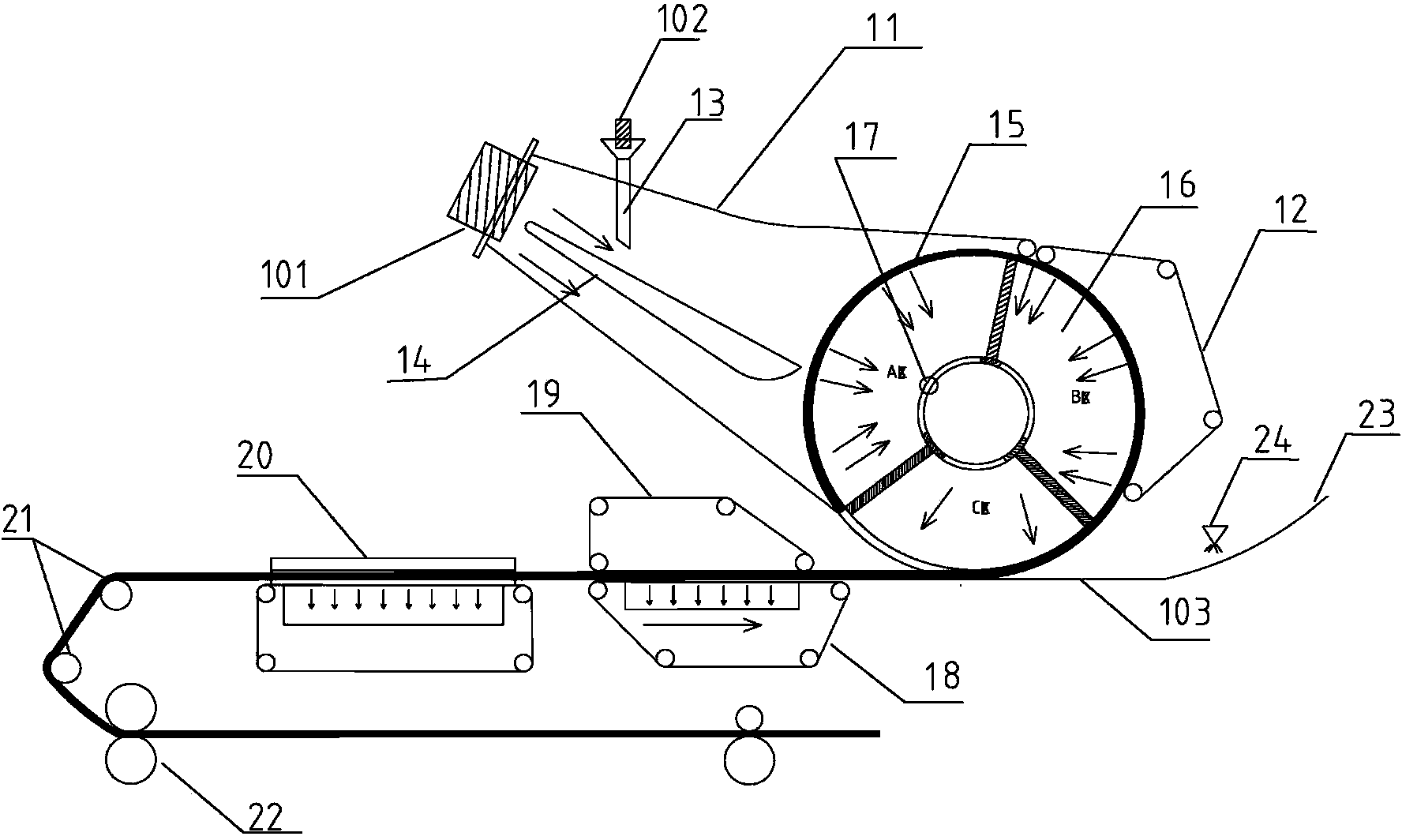

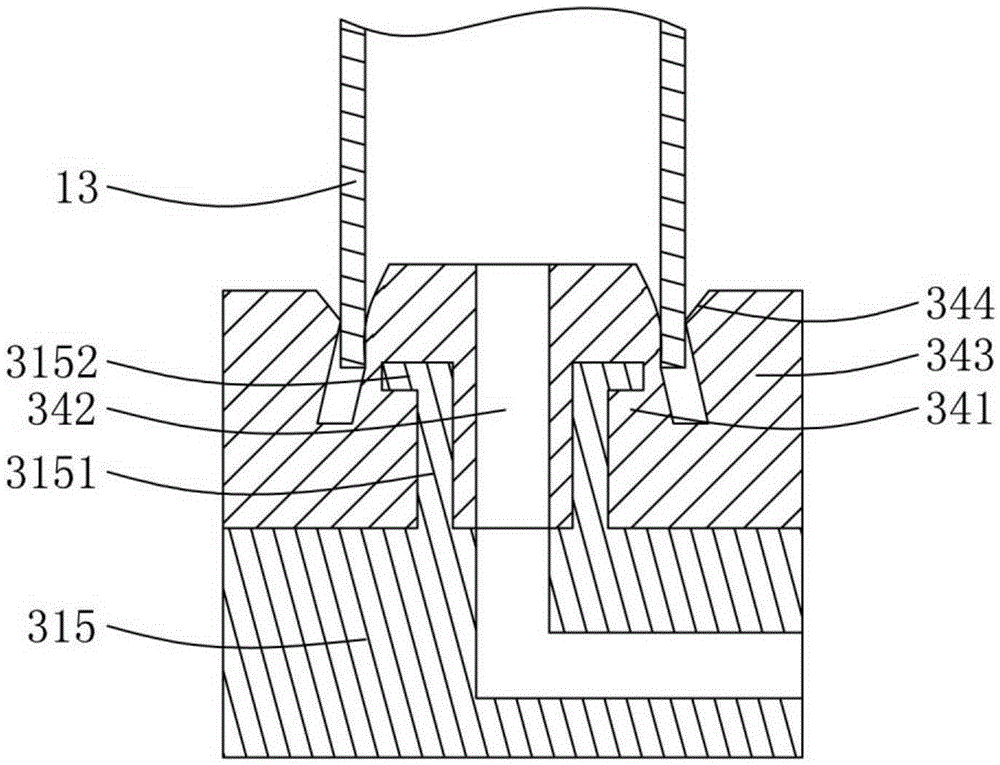

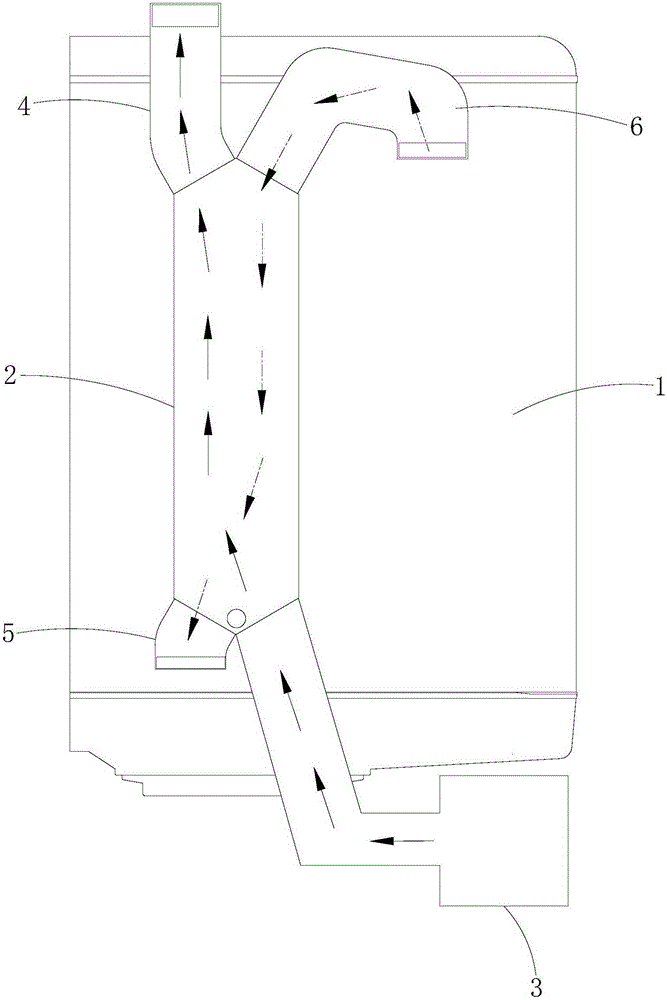

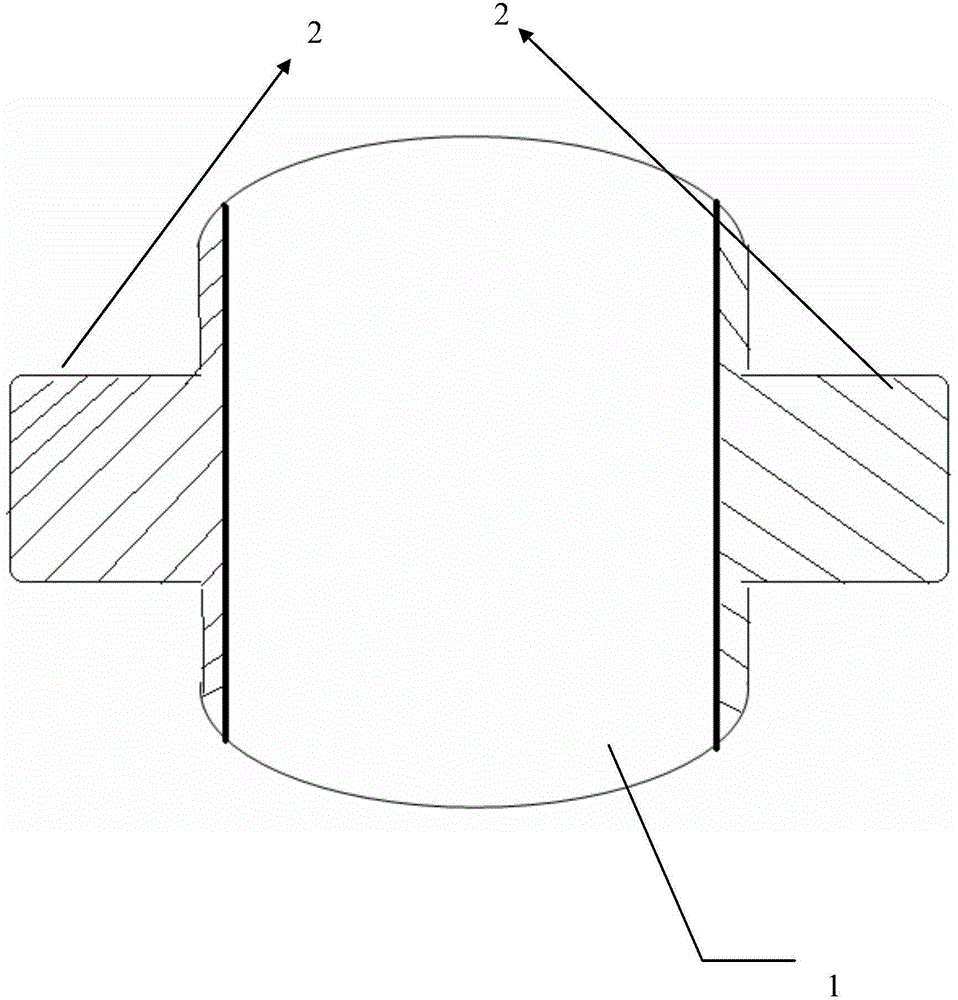

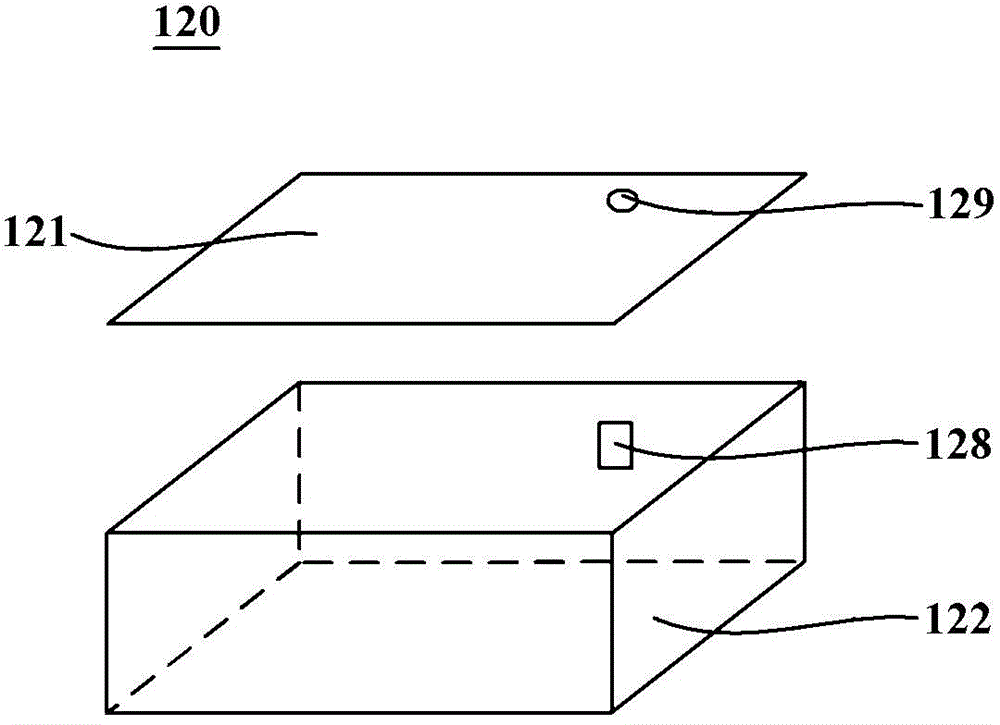

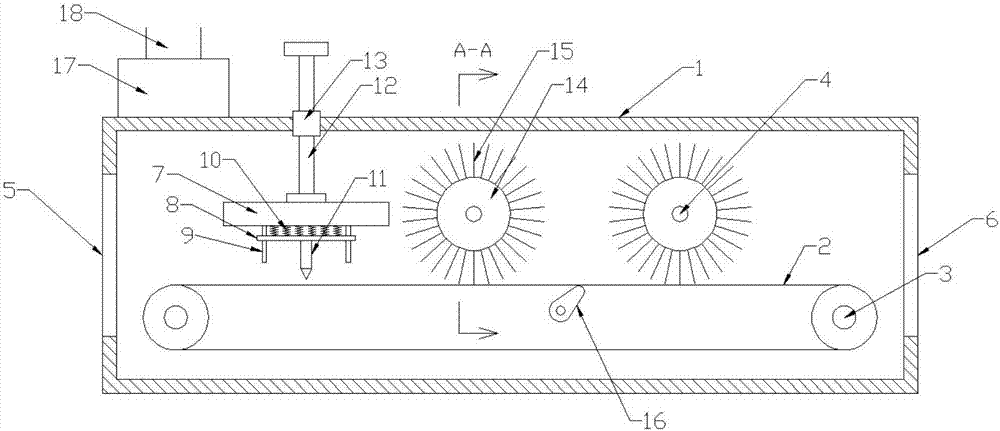

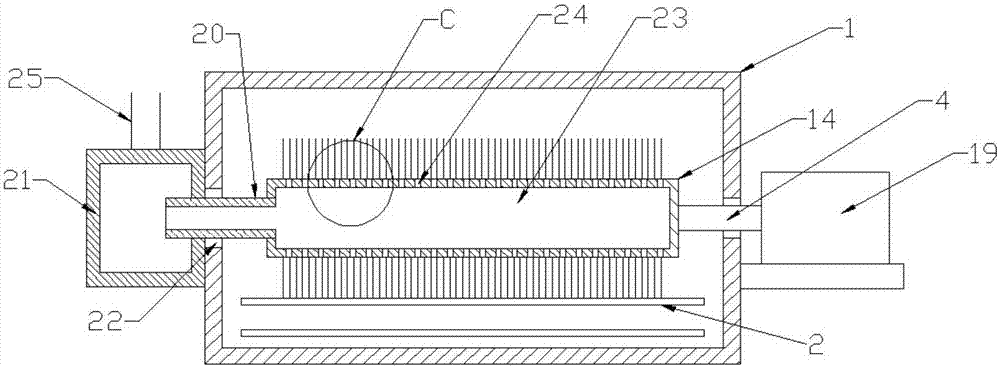

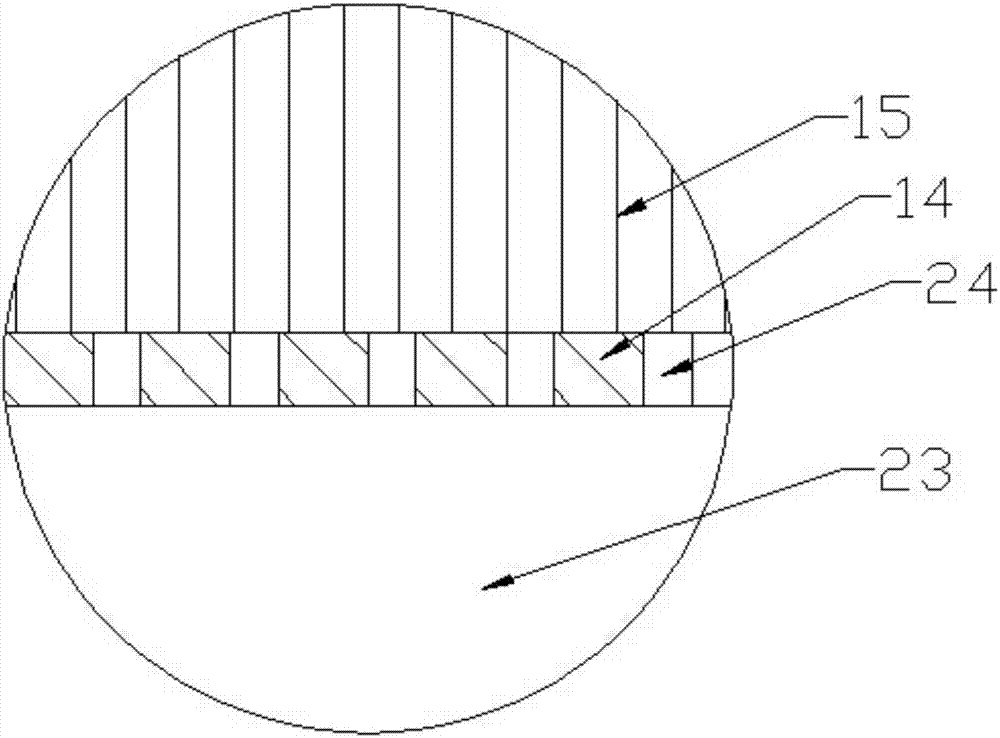

Absorptive core, absorptive core molding equipment and absorptive core manufacture method

The invention relates to the manufacture field of absorptive sanitary articles and automatic production equipment and discloses an absorptive core. The absorptive core comprises an absorptive core surface layer, an absorptive core middle layer and an absorptive core bottom layer, wherein the tightness degrees of the absorptive core middle layer and the absorptive core bottom layer are larger than the tightness degree of the absorptive core surface layer. The invention further discloses absorptive core molding equipment and an absorptive core manufacture method. The gathering degrees of fluff pulp fibers in the surface layer, the middle layer and the bottom layer of the absorptive core are from relative looseness to compactness, and the gradient density design can rapidly absorb body fluid, is favorable to fluid permeation and effectively reduces the possibility that the body fluid leaks from the absorptive sanitary articles. When the absorptive core of the structure is manufactured, a molding screen is effectively prevented from being blocked by high molecular absorption resin granules, time and cost which are spent on cleaning and maintaining the molding screen are saved, and the production efficiency of the absorptive core molding device is further improved.

Owner:ZUIKO (SHANGHAI) CORP

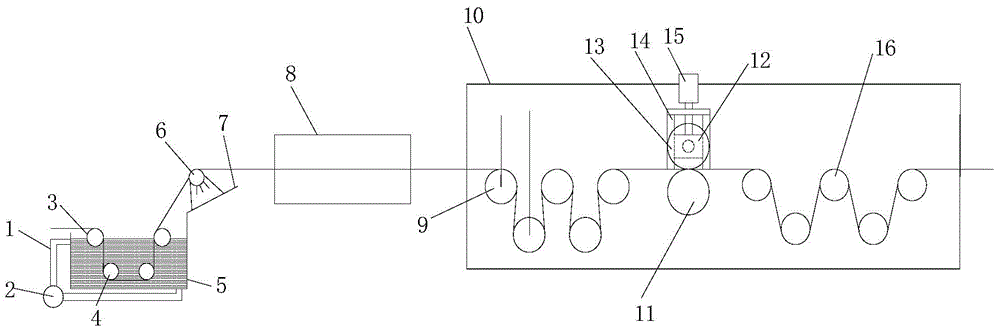

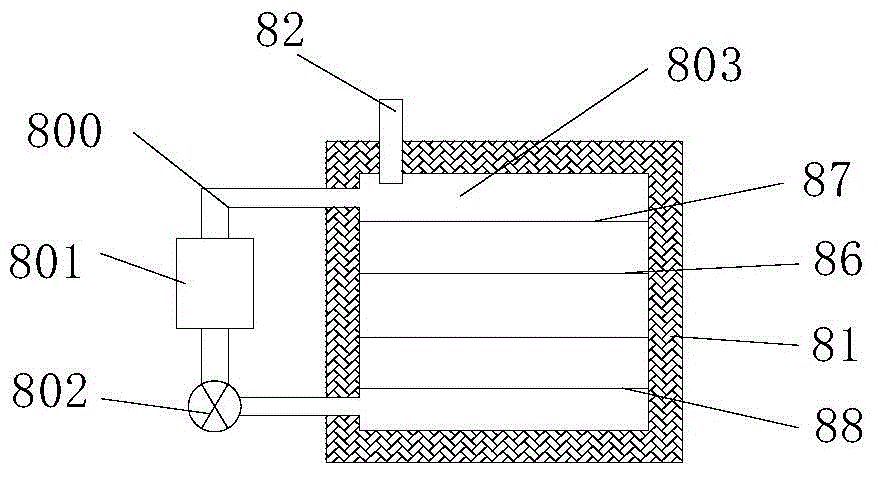

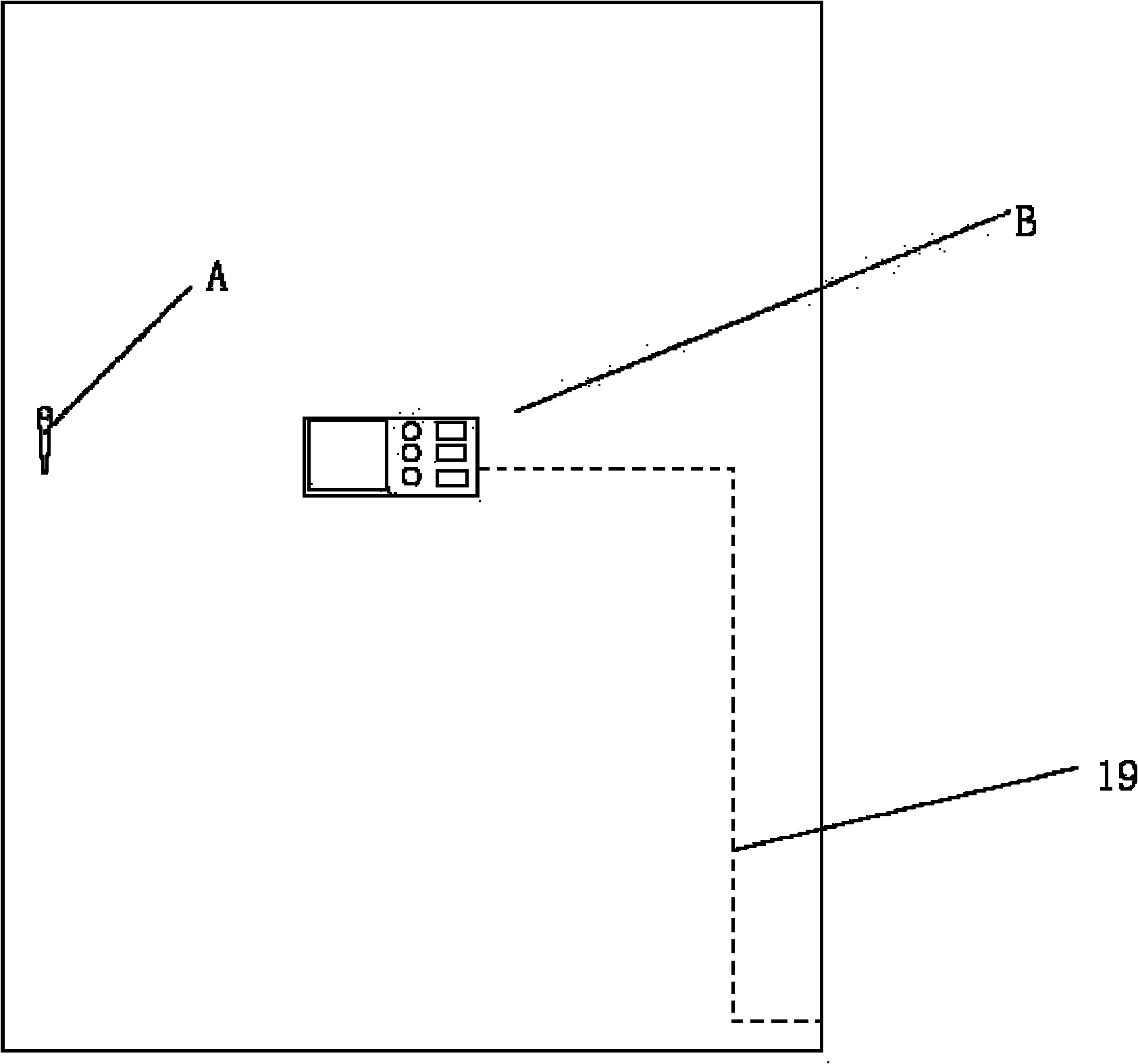

Sizing, drying and shaping device for polyacrylonitrile-based carbon fiber

ActiveCN103334246AGuaranteed uniformityImprove uniformityHeating/cooling textile fabricsLiquid/gas/vapor removal by gas jetsCarbon fibersWorking environment

The invention belongs to a generation device for a polyacrylonitrile-based carbon fiber and particularly relates to a sizing, drying and shaping device for the polyacrylonitrile-based carbon fiber. The sizing, drying and shaping device comprises a sizing device for sizing a carbon fiber, a drying device for the sized carbon fiber as well as a shaping device for shaping the dried carbon fiber, wherein the sizing device comprises a sizing groove for accommodating slurry; a circulating pipeline is arranged on the outer side of the sizing groove; one end of the circulating pipeline is connected with the bottom of the sizing groove; the other end of the circulating pipeline is connected with the upper edge of the sizing groove; a circulating pump is arranged on the circulating pipeline; a guiding roller which is partially immersed in the slurry and an immersing roller which is completely immersed in the slurry are arranged in the sizing groove; a reflowing plate which is arranged in an extending manner is arranged on the outlet edge of the sizing groove; and an air purge device is fixedly arranged above the reflowing plate. According to the sizing, drying and shaping device disclosed by the invention, the sizing is uniform, the shape of tows is good; the pollution of air to the carbon fiber is reduced in the sizing and drying; and meanwhile, the work environment is improved and the work comfortableness of workers is improved.

Owner:ZHONGJIAN TECH CO LTD

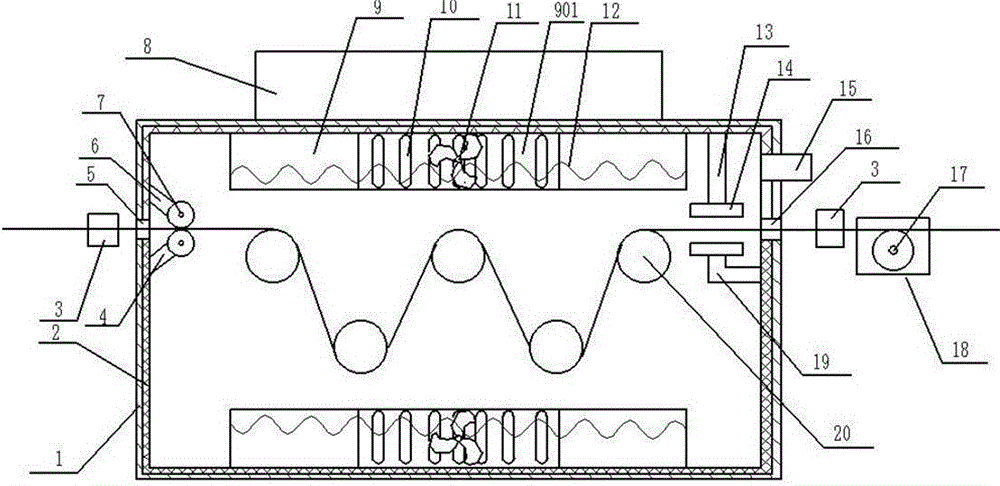

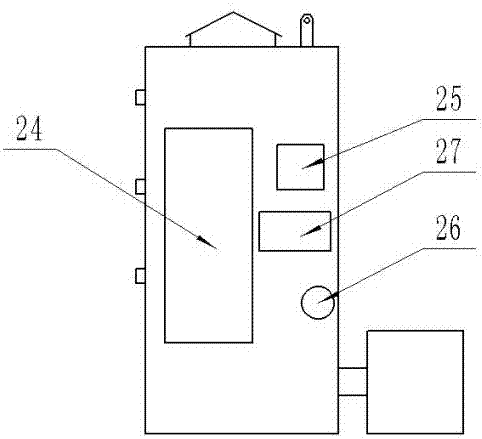

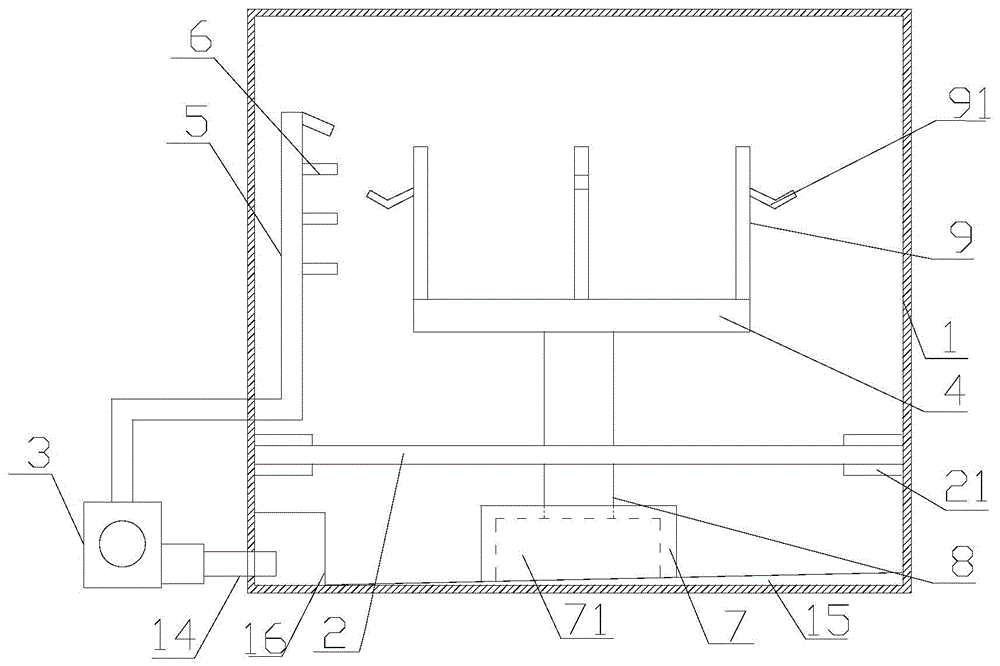

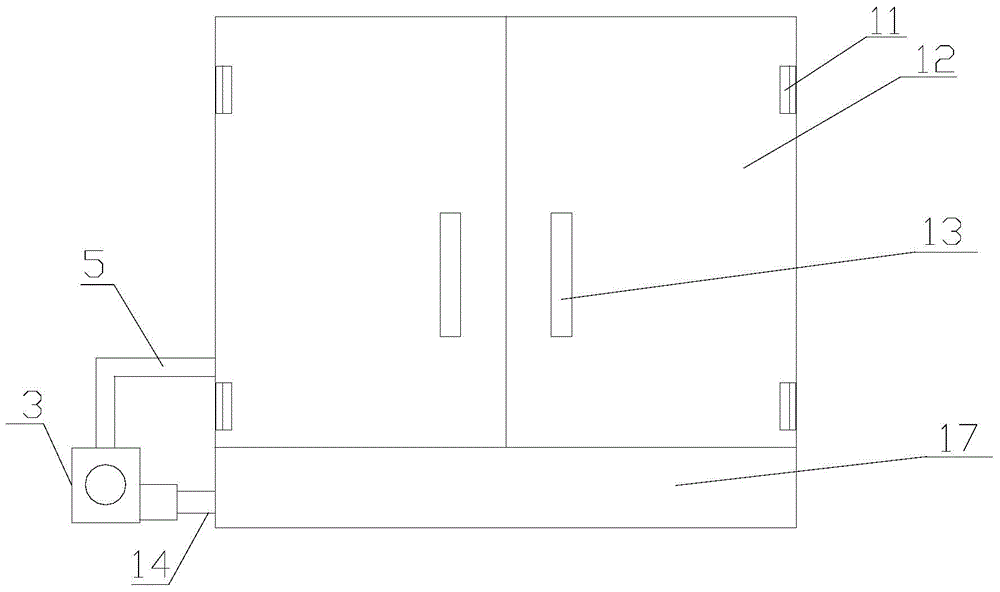

Silk fabric drying device

InactiveCN106766786AQuality improvementAvoid knotsDrying gas arrangementsDrying machines with progressive movementsElectricityInductor

The invention relates to the textile technical field, in particular to a silk fabric drying device. The silk fabric drying device comprises a box body, wherein a control box is arranged on the top of the box body, and a charge hole, a discharge hole, an exhaust fan interface and a traction roller are arranged on the side wall of the control box; a first heating deice is arranged in the charge hole; a second heating device, a guide roller and a temperature sensor are arranged in the box body; a humidity inductor is further arranged outside the charge hole and the discharge hole; the traction roller is arranged outside the discharge hole, and is connected with a traction motor; the traction motor is electrically connected with the control box; a control main board is arranged inside the control box; the control box is electrically connected with a touch display screen; the touch display screen is arranged on a front panel of the box body for receiving a user operation order, so that temperature setting is realized on the heating device; after the temperature sensor senses the temperature in the box body, the corresponding temperature value is directly displayed through the touch display screen; and after the humidity sensor senses material humidity information, the corresponding humidity value is directly displayed through the touch display screen.

Owner:ANHUI SHAWOSI CLOTHING CO LTD

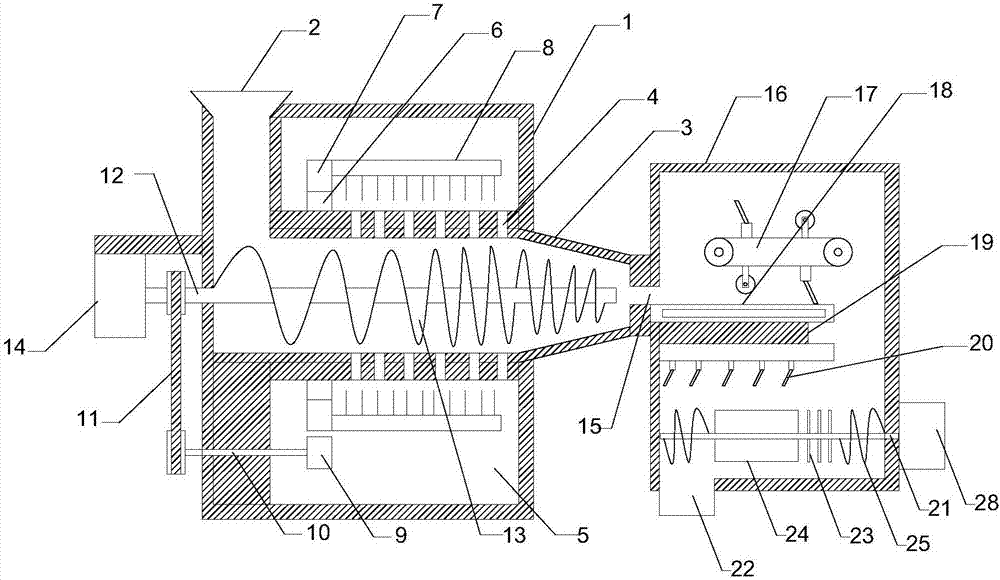

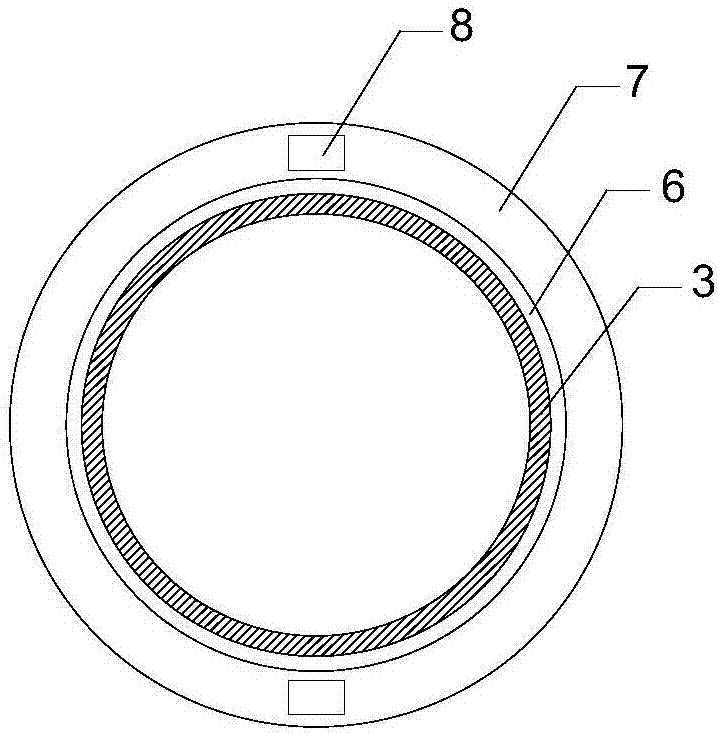

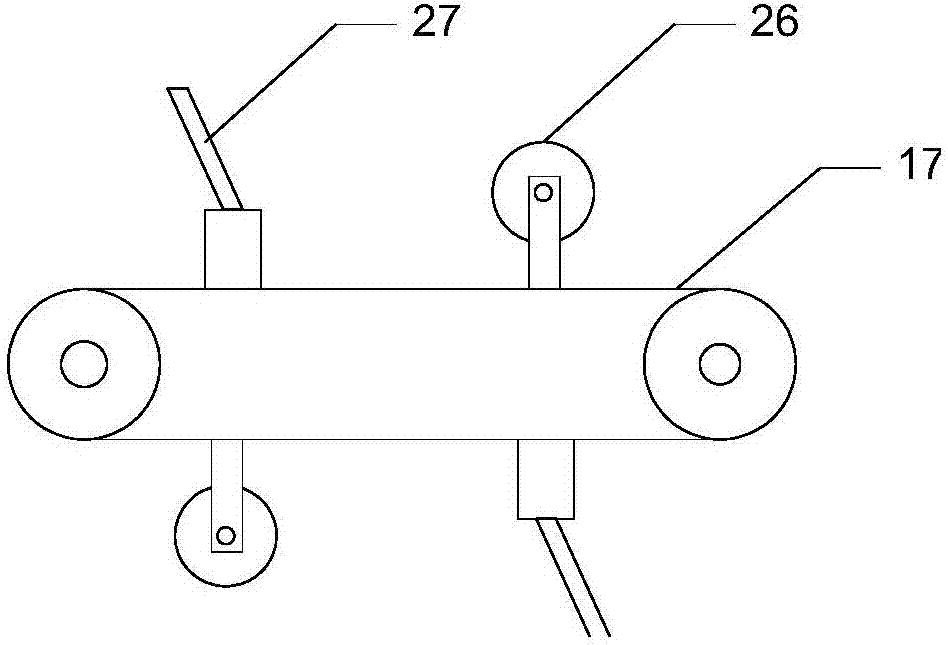

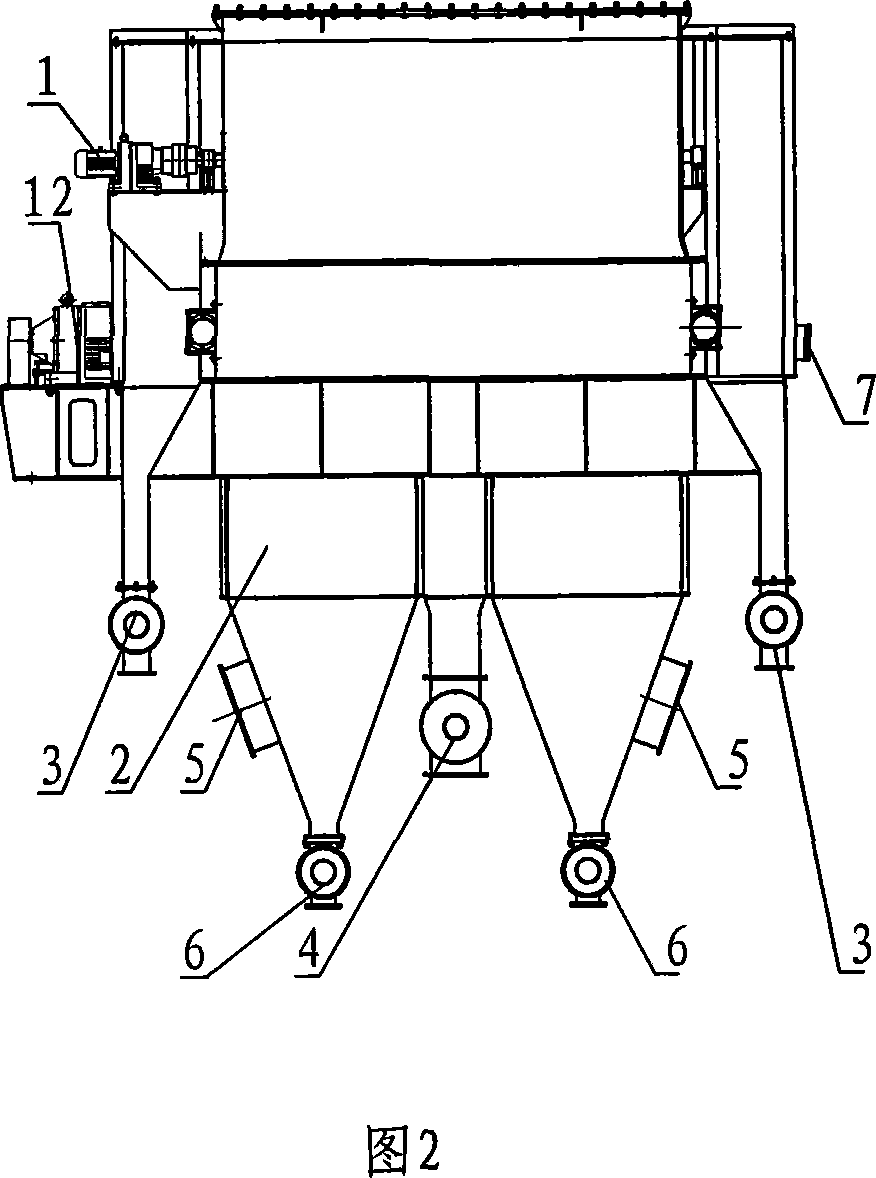

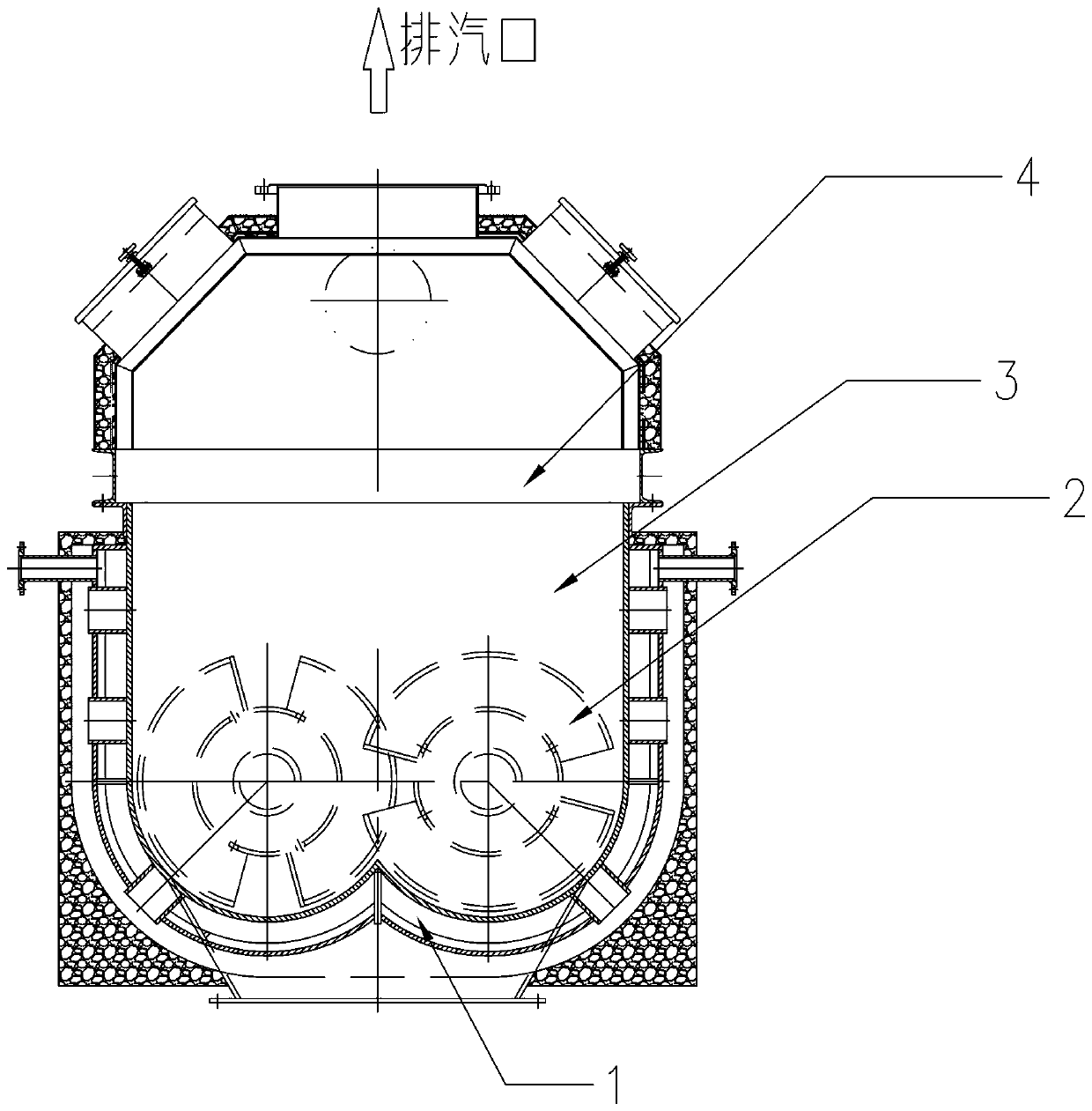

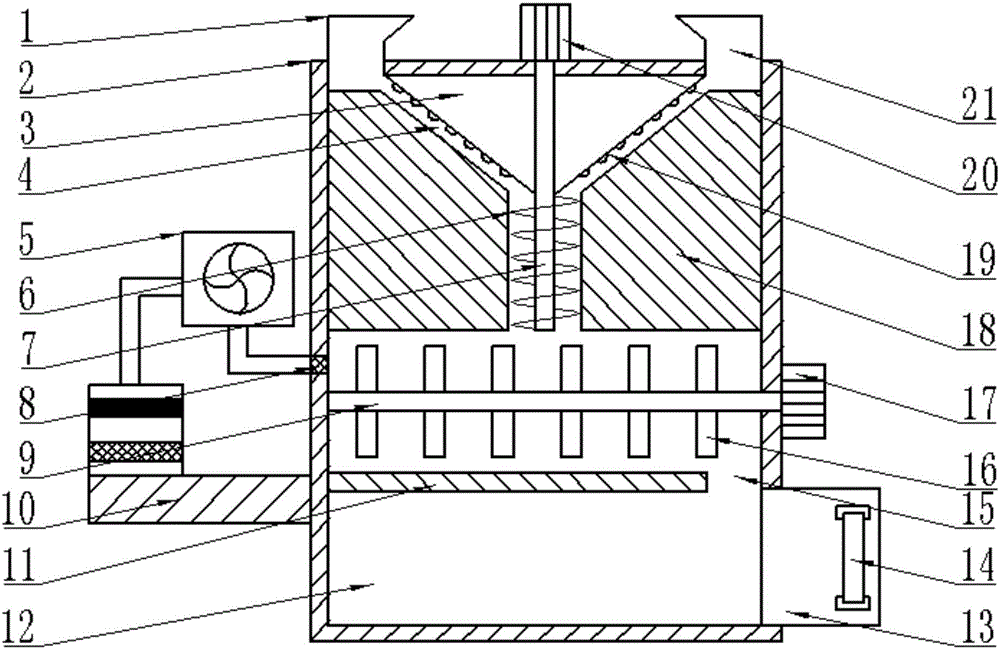

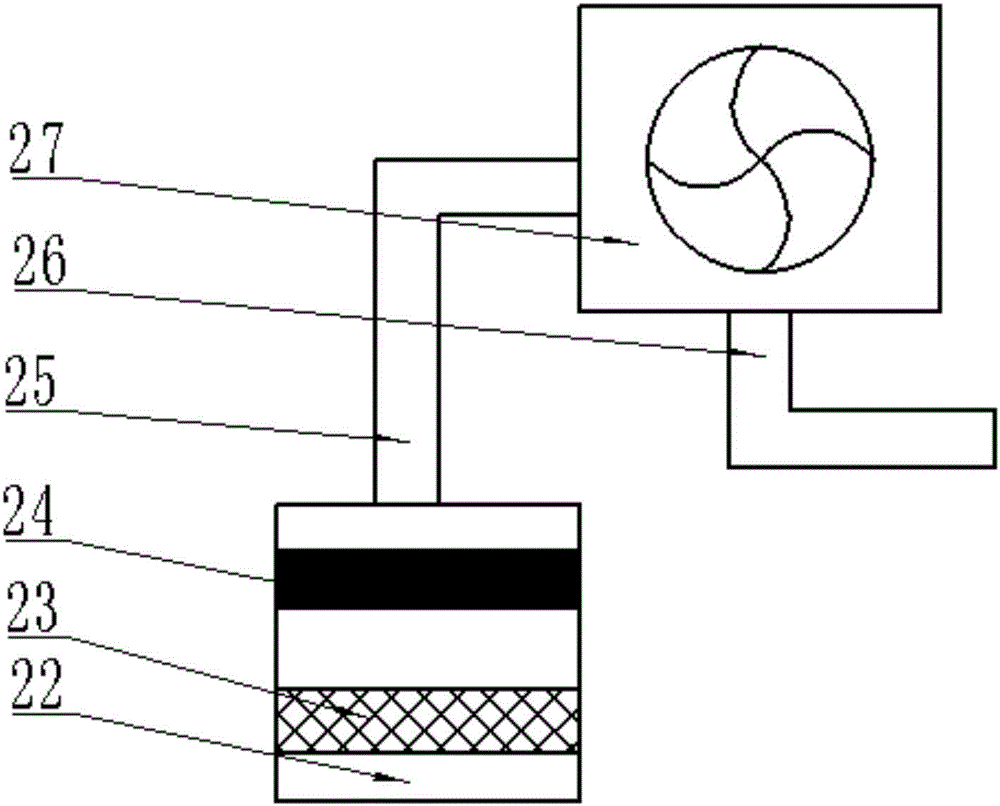

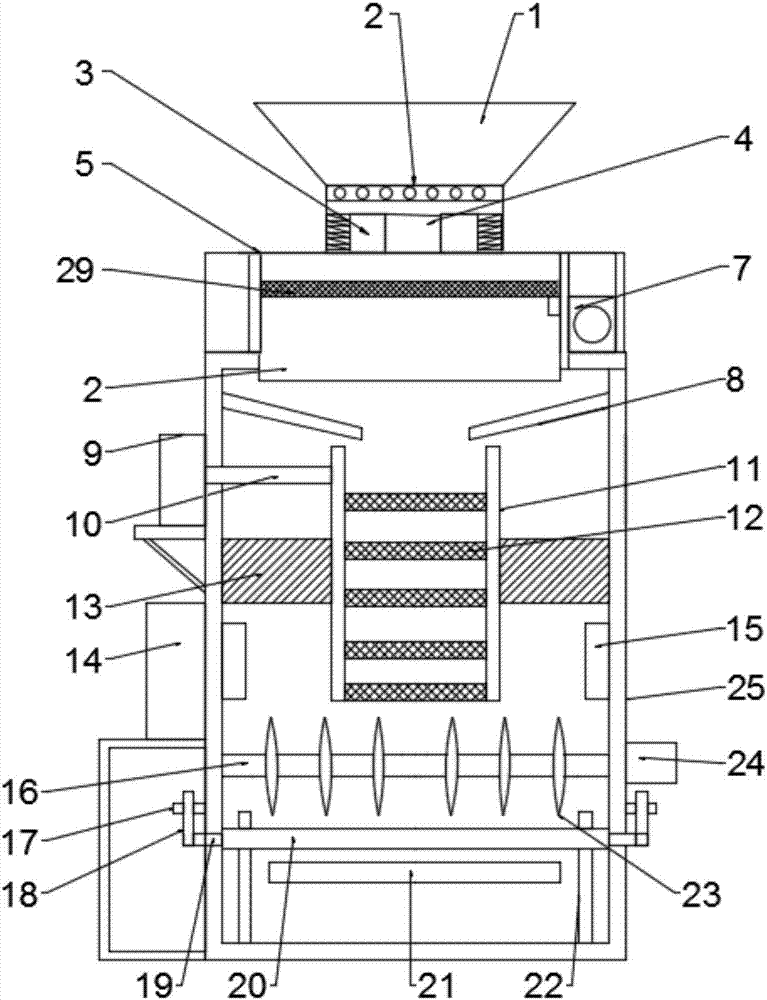

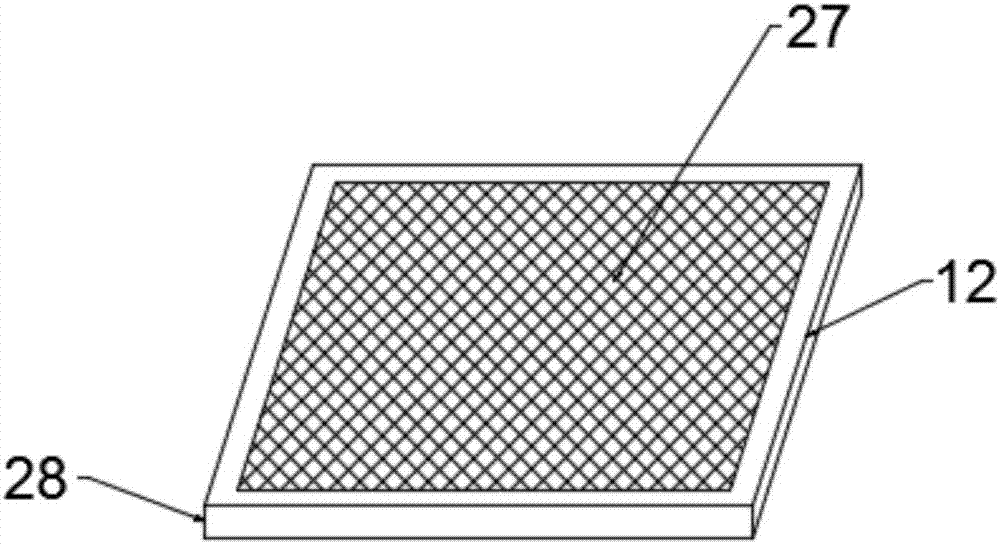

Continuous sludge treatment device

InactiveCN107176780AAvoid cloggingEfficient heatingSludge treatment by de-watering/drying/thickeningSludgePulp and paper industry

The invention discloses a continuous sludge treatment device. The continuous sludge treatment device comprises a feeding hopper, a first driving motor and a second driving motor, wherein the feeding hopper is communicated with a dewatering box, a screen drum is arranged in the dewatering box and sleeved with a rack ring, and the rack ring is rotationally connected with the screen drum through a bearing; strip-shaped brushes which are symmetrically arranged are fixedly connected with the right side wall of the rack ring; a drying box is communicated with the right side of the screen drum through a sludge pipe. With the arrangement of a screw extrusion dewatering device provided with the rotating brushes, sieve meshes are prevented from being blocked, continuous dewatering work is guaranteed, and the continuous sludge treatment device has higher dewatering efficiency; the continuous sludge treatment device is equipped with a drying device consisting of a heating plate, flat spreading rollers and scrapers, therefore, sludge is efficiently and uniformly heated, and drying efficiency is improved; an auxiliary drying device consisting of hot air spray nozzles, smashing blades and a turning plate is arranged, so that the sludge is thoroughly dried, and the drying effect is guaranteed.

Owner:李群珍

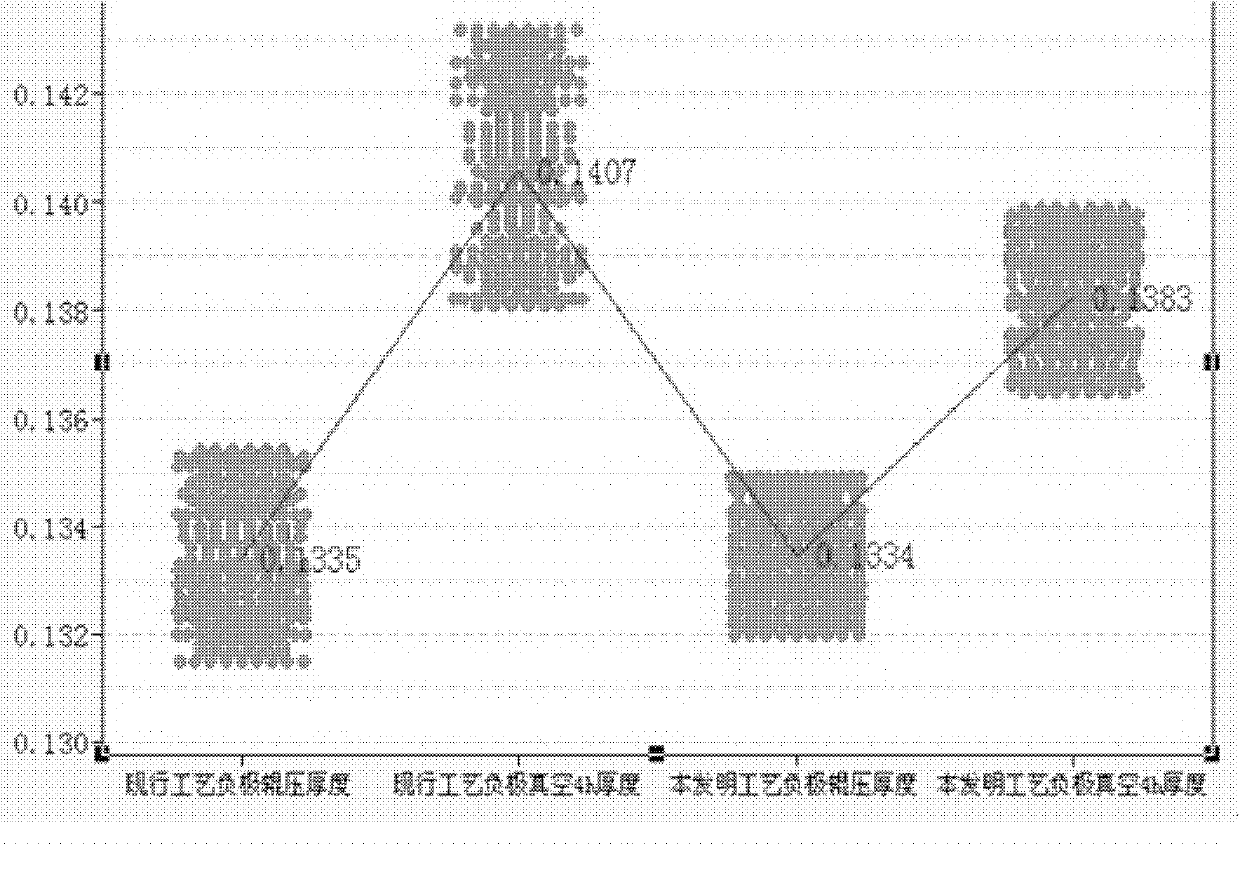

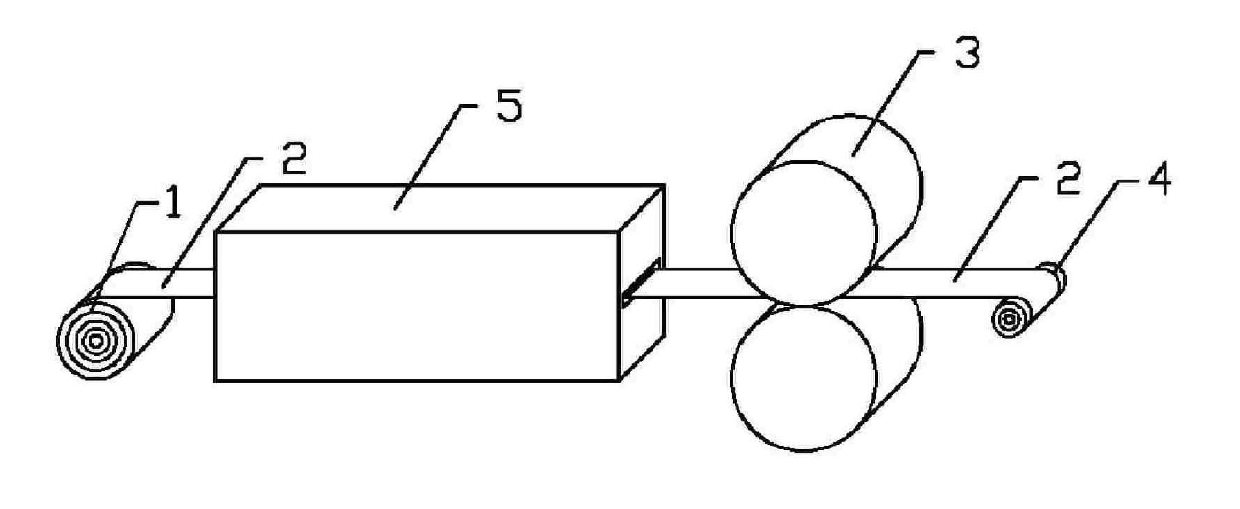

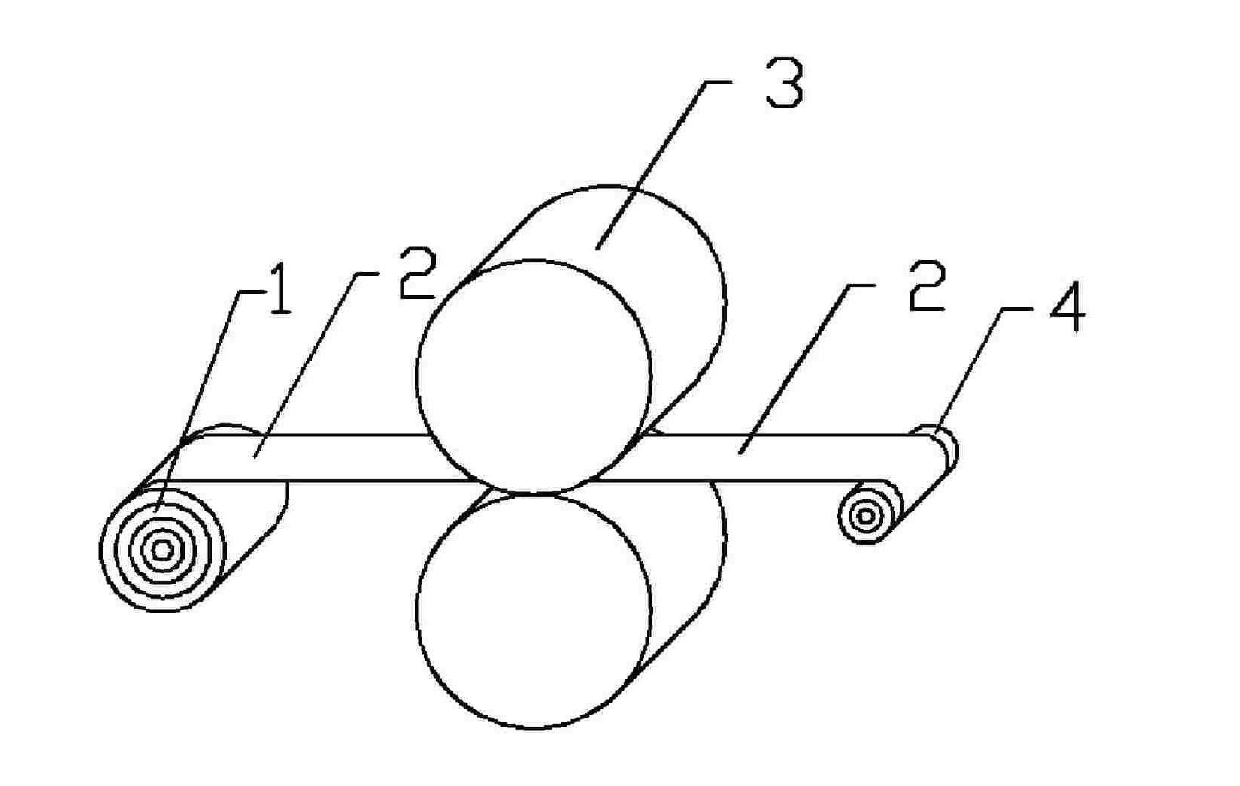

Continuous rolling process for lithium-ion battery electrode and device thereof

InactiveCN101877397AIncrease volume capacityImprove plasticityElectrode manufacturing processesRotary pressBiochemical engineeringVolumetric Mass Density

The invention discloses a continuous rolling process for a lithium-ion battery electrode and a device thereof. The process is characterized in that an electrode plate adopts a low-temperature hot rolling process. The used device is characterized in that a heating device is increased between an unrolling shaft and a roll. The process has the advantages of ensuring the dryness of the electrode, increasing the plasticity of the electrode plate, reducing the rebound rate of the rolled electrode plate and properly increasing the single-side density of the electrode plate, thereby promoting the volume rate capacity of the battery; and the device has a simple structure and convenient operation.

Owner:NINGBO VEKEN BATTERY

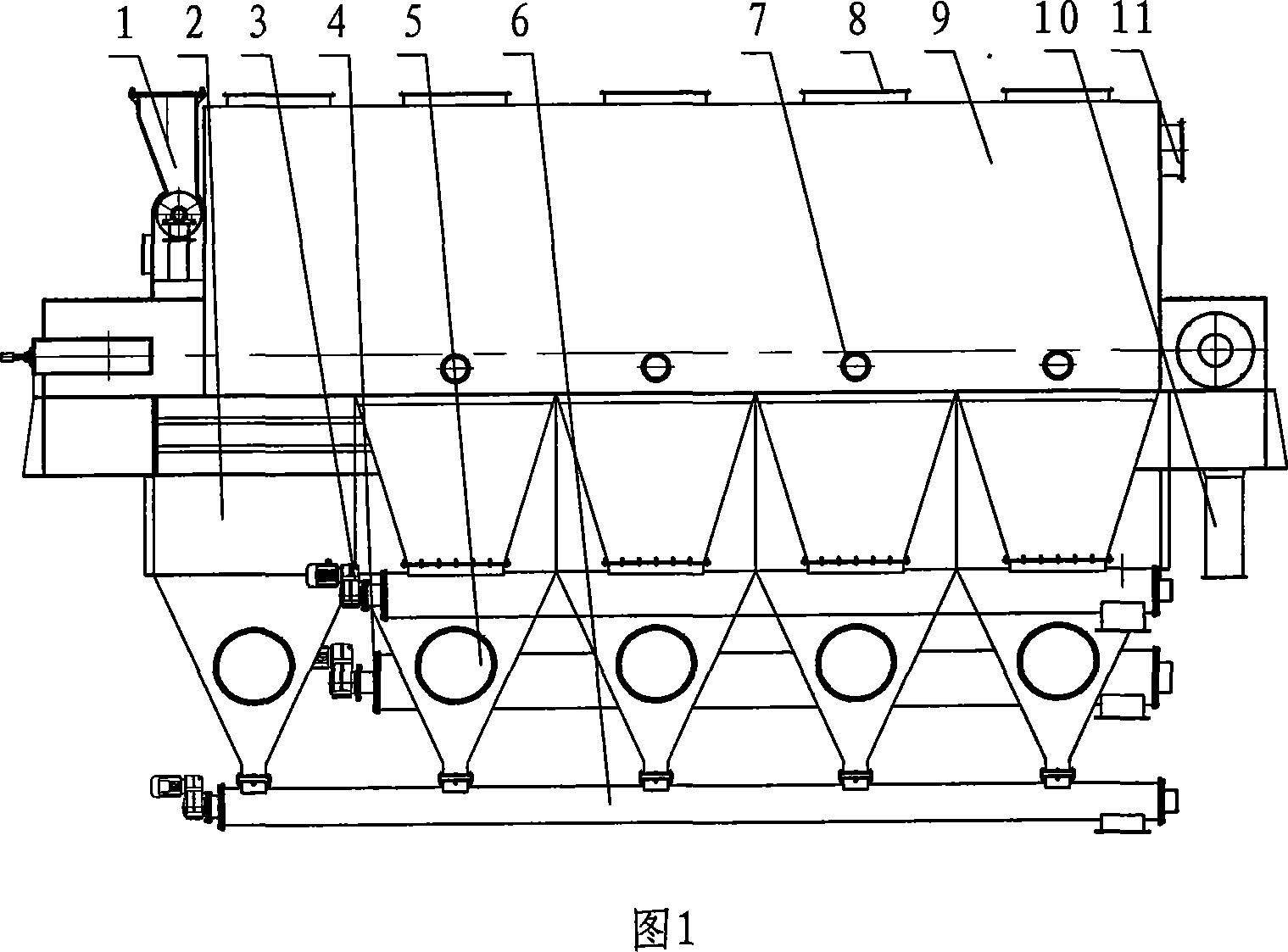

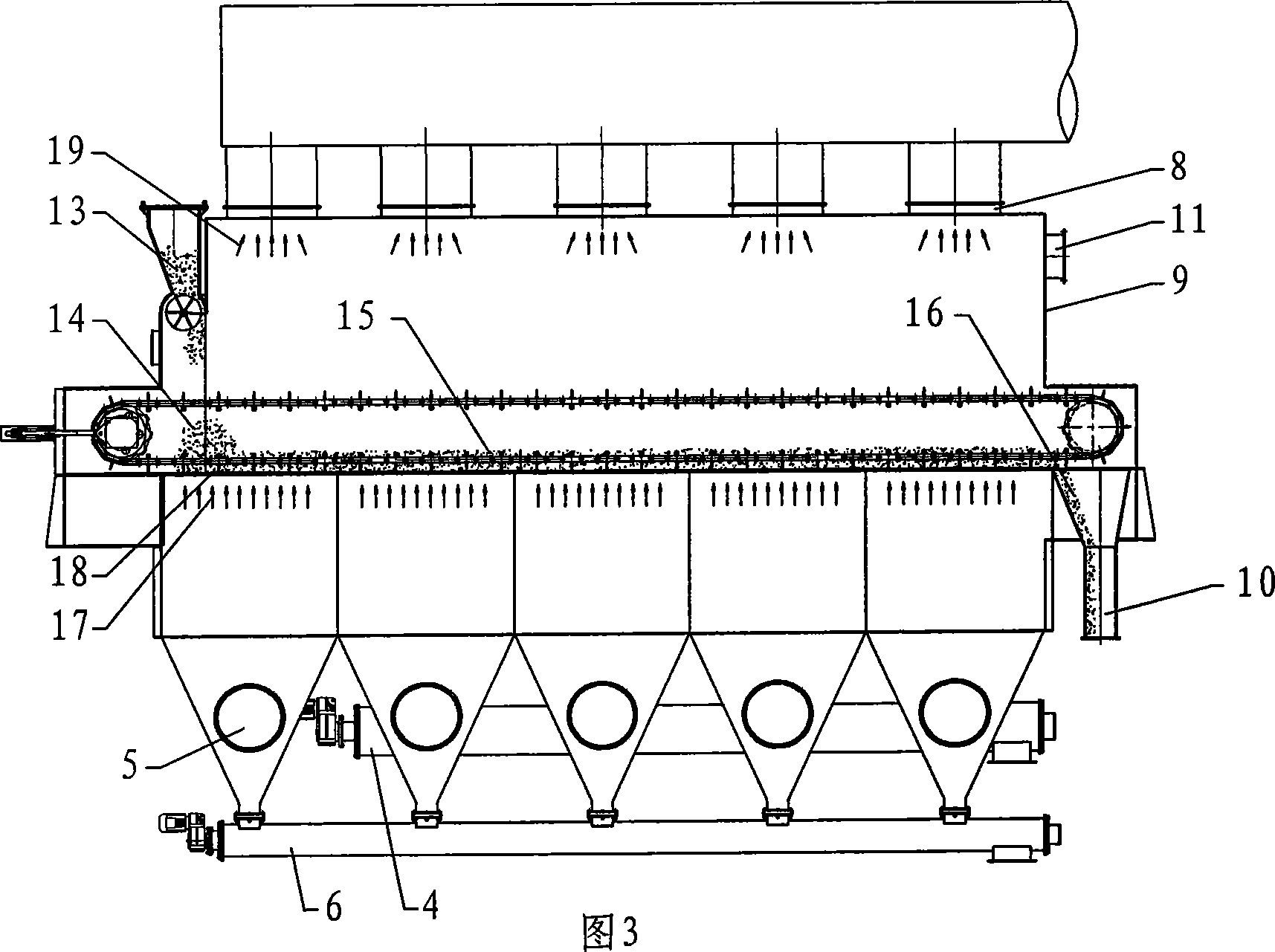

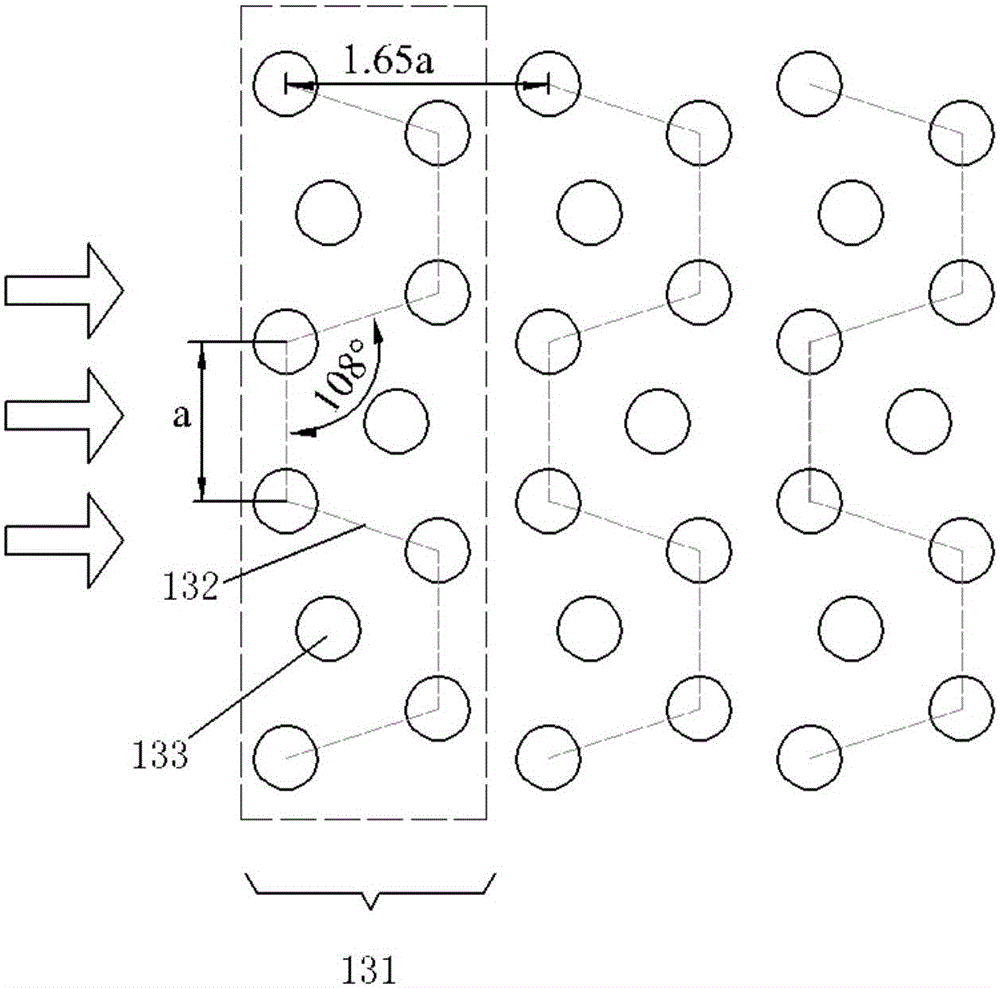

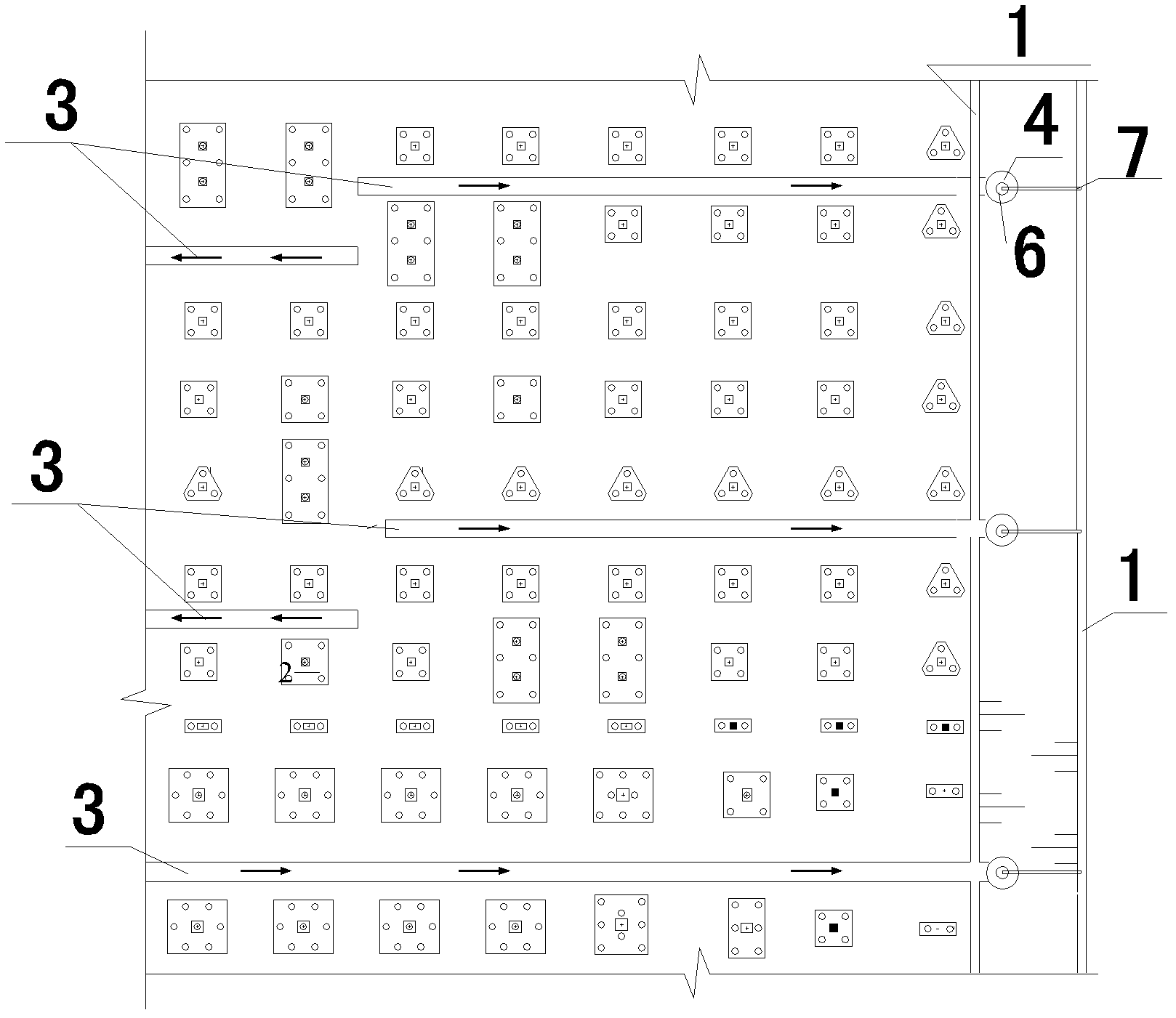

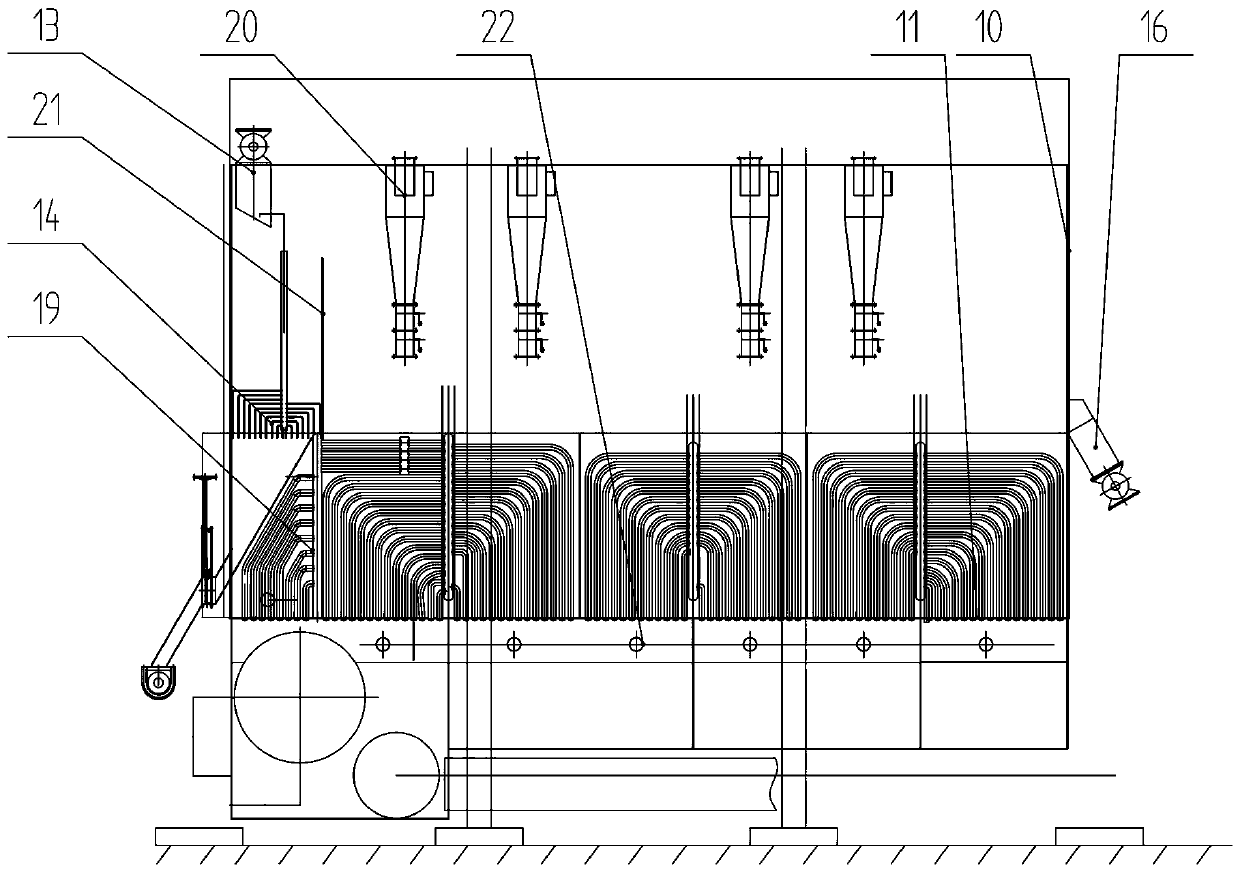

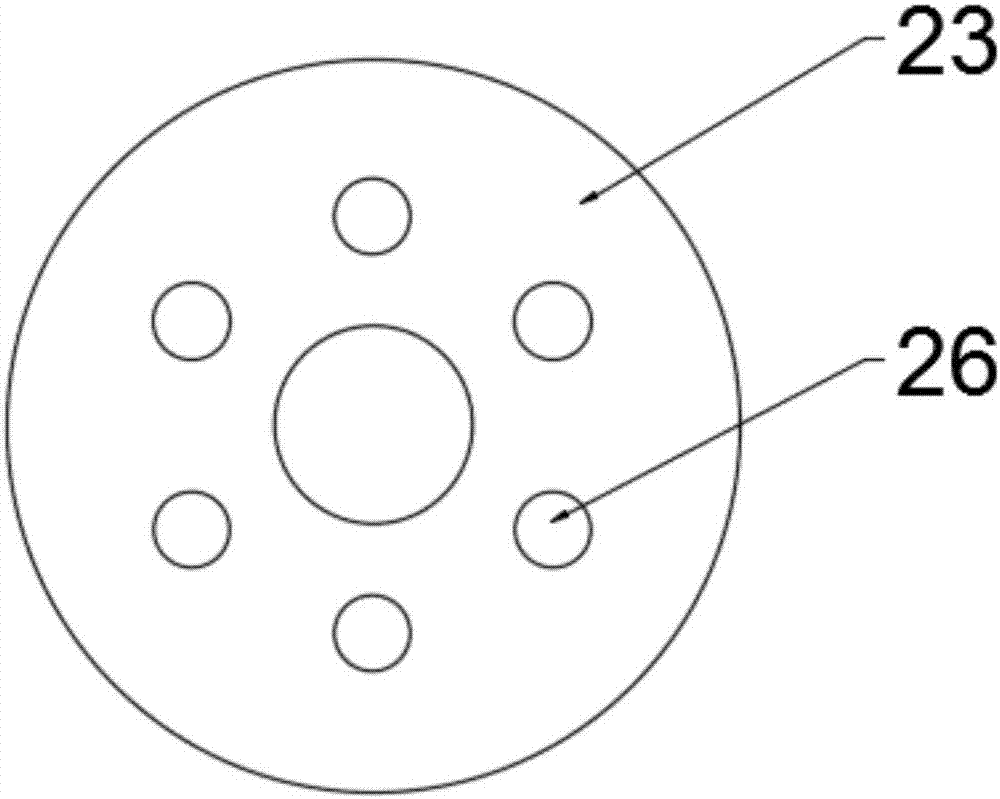

Moving iris type fluidized bed

InactiveCN101063059AImprove the fluidization effectGuaranteed drynessSievingDrying solid materials with heatFluidized bedCoke oven

The invention discloses a mobile iris type fluid bed, which is characterized by the following: adopting multiple separating air chamber; assembling a plurality of air chamber arrangement in length direction; adopting double air chamber arrangement in width direction; adopting a rotary pocket feeder to feed; equipping mobile iris type device in the bed body; keeping mobile and fluid effect of raw material coal; adjusting with four grade sizing overflow dam to control fluid time and grading effect; transporting the fine particle raw coal to fine material belt of tail through three auger conveyor; transporting the coarse grain to coarse material belt of tail through chute. This invention can increase output of coke oven, which can utilize lost heat of stack waste gas to realize waste heat energy utilization.

Owner:SHANDONG IRON & STEEL CO LTD +1

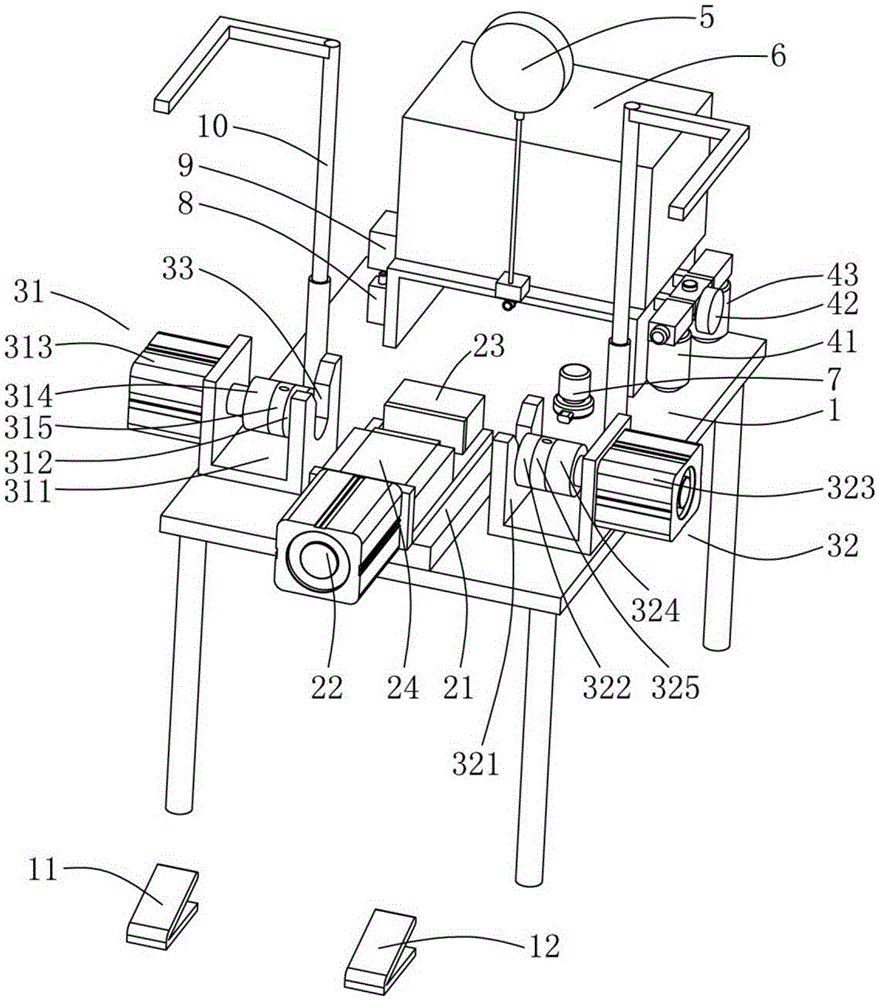

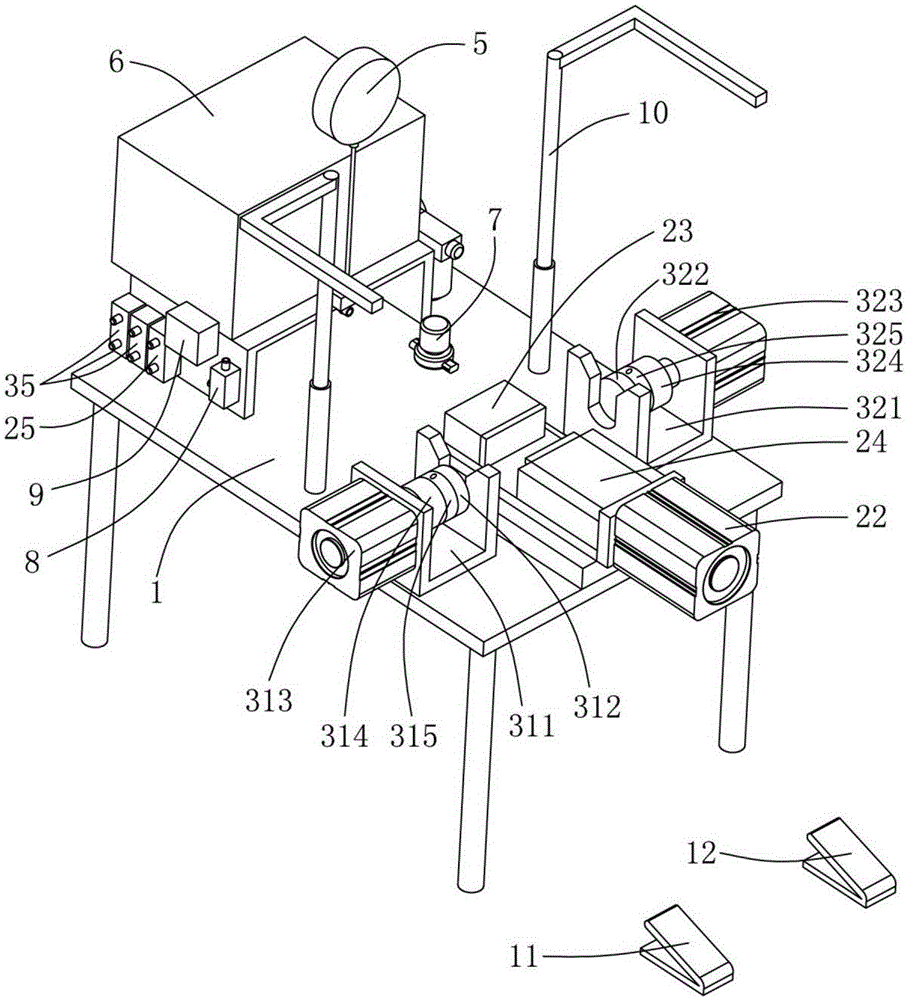

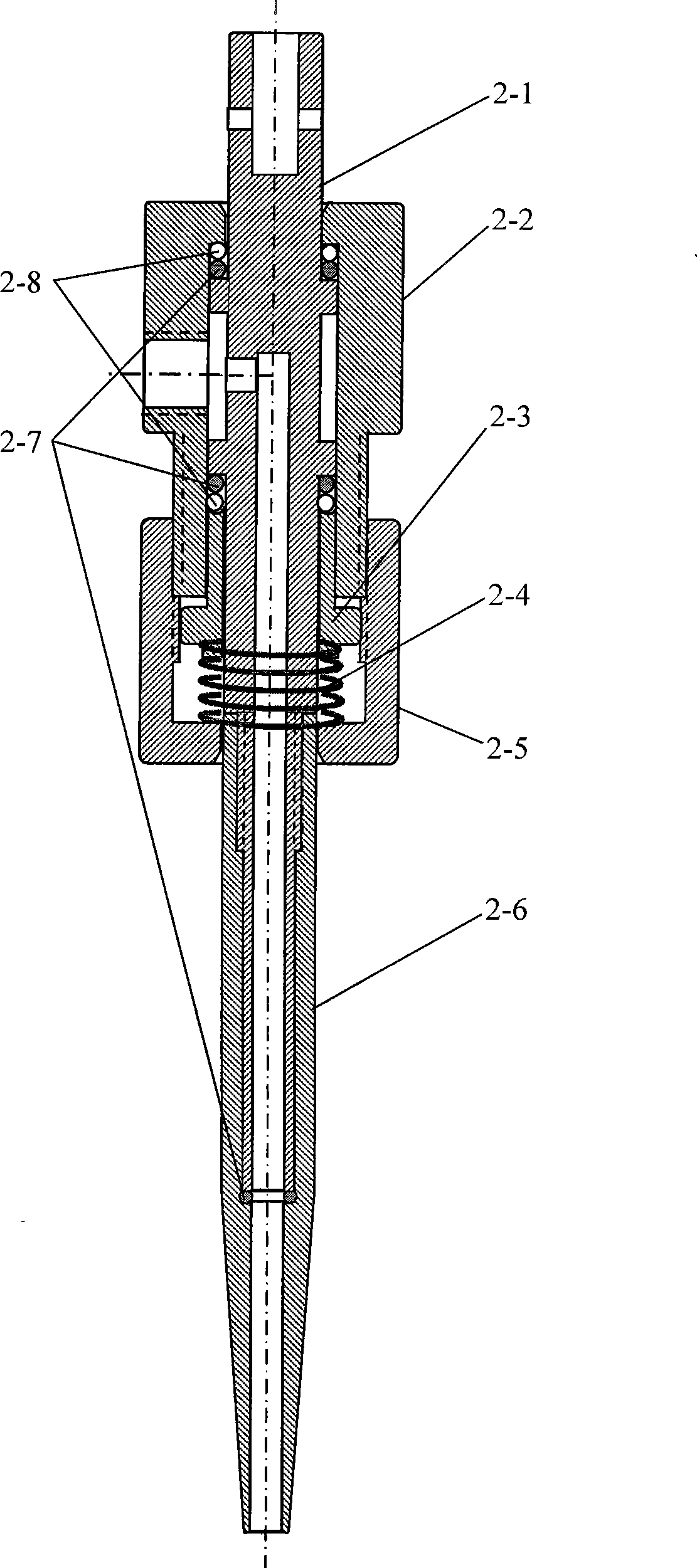

Hermetic sealing program control testing stand

InactiveCN105300630ANo leaksSealing up to standardMeasurement of fluid loss/gain rateHermetic sealSolenoid valve

The invention discloses a hermetic sealing program control testing stand, comprising a working platform, a clamping positioning device, a sealing plugging device, a gas source processing device, a compression gauge and an electric control cabinet. The clamping positioning device comprises a pedestal, a clamping air cylinder and a position limiting block; the output terminal of the clamping air cylinder is provided with a clamping block; the sealing plugging device comprises two sealing plugging mechanisms which are identical in structures; each sealing plugging mechanism comprises a support base, a sealing plug and a sealing plugging air cylinder; the output terminal of the sealing plugging air cylinder is fixedly connected to an installation block which is fixedly connected to the sealing plug through a gas channel joint and the sealing plug; the air inlet terminal of a gas processing device is in communication with an air source; the air outlet terminal is in communication connection with the corresponding gas channel joint of the sealing plugging mechanism through a first switch solenoid valve; and the corresponding gas channel joint of another sealing plugging mechanism is in communication connection with the pressure gauge. The hermetic sealing program control testing stand is simple in structure, easy in operation, low in manufacture cost, high in testing accuracy and wide in application range, and does not affect the pipe fitting quality during the detection process.

Owner:NINGBO GUANTONG MACHINERY

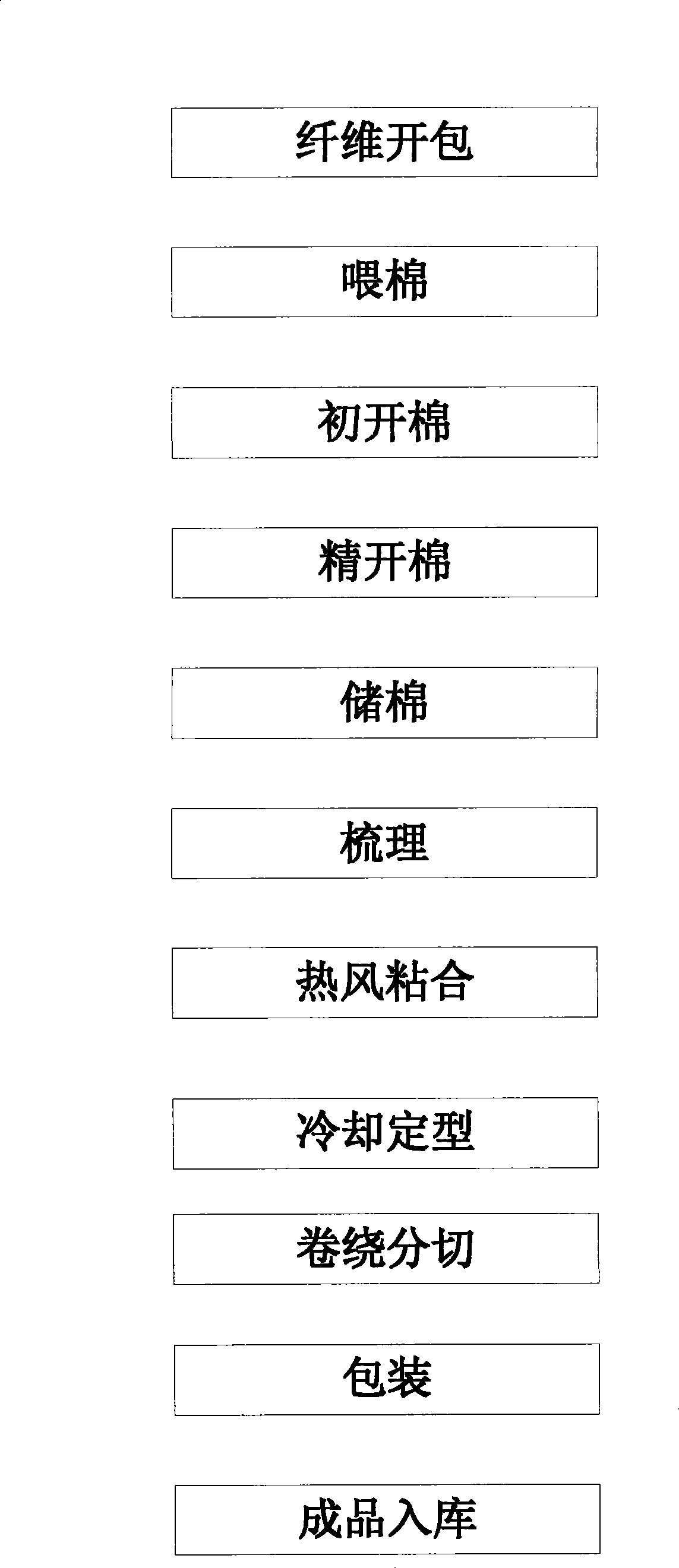

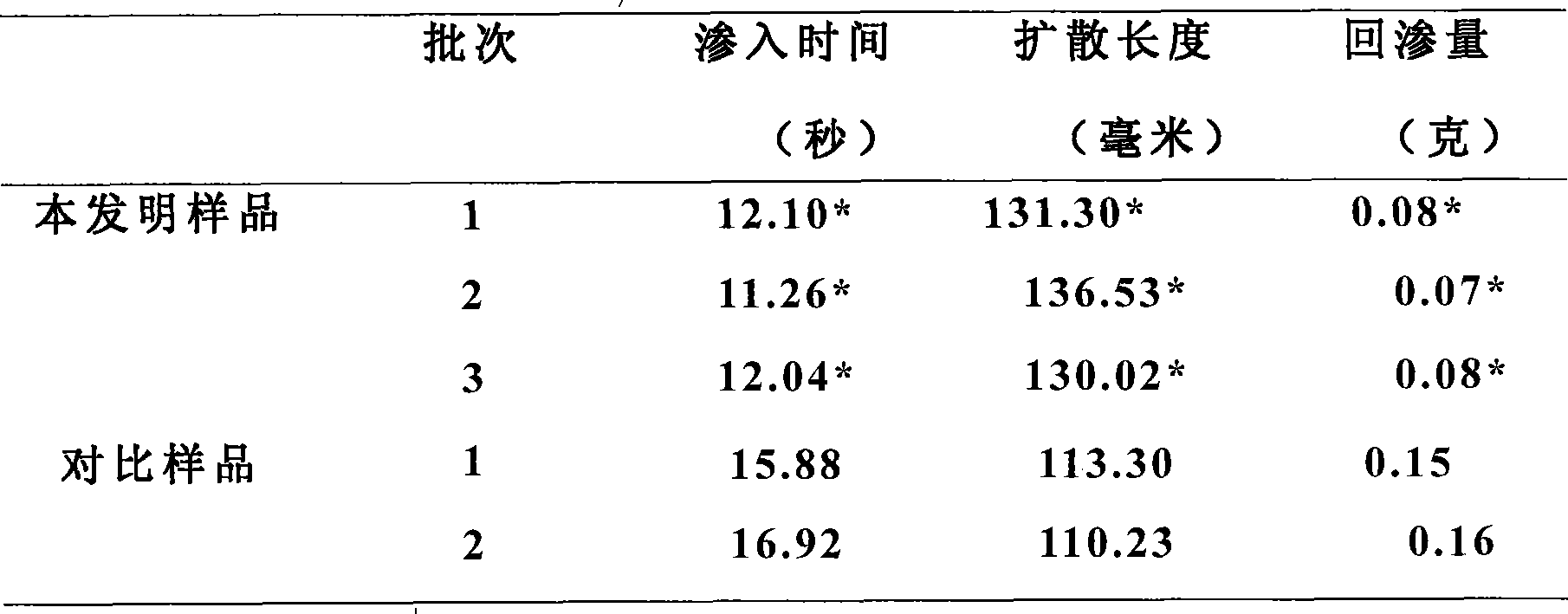

Nonwoven fabric containing polyester complex fiber, preparation thereof and use as hydroscopic substance flow guiding layer

InactiveCN101481852AGood flexibilityLow melting pointFilament/thread formingAbsorbent padsPolyesterPolymer science

The invention discloses a nonwoven fabric. The nonwoven fabric is characterized by comprising a polyethylene / polyester complex fiber material and a polyethylene / polypropylene complex fiber material, wherein, the polyethylene / polyester complex fiber material is 1-100% of the nonwoven fabric of a diversion layer, and the polyethylene / polypropylene complex fiber material is 0-99% of the nonwoven fabric of the diversion layer. The nonwoven fabric has the advantages of good diversion effect, excellent reverse osmosis effect, as well as good bulkiness and softness.

Owner:SUZHOU KIMBONDLY NONWOVENS FABRIC

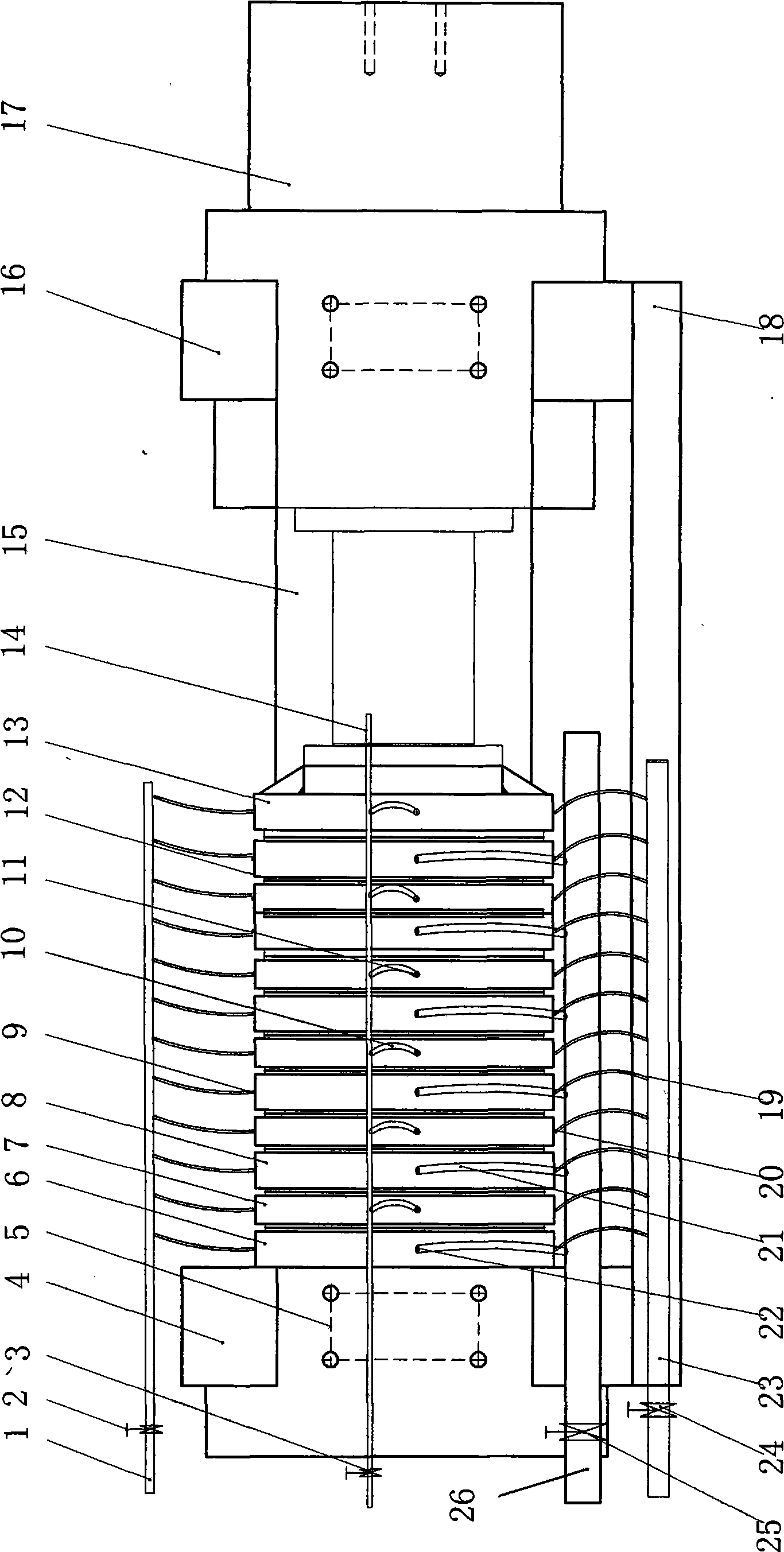

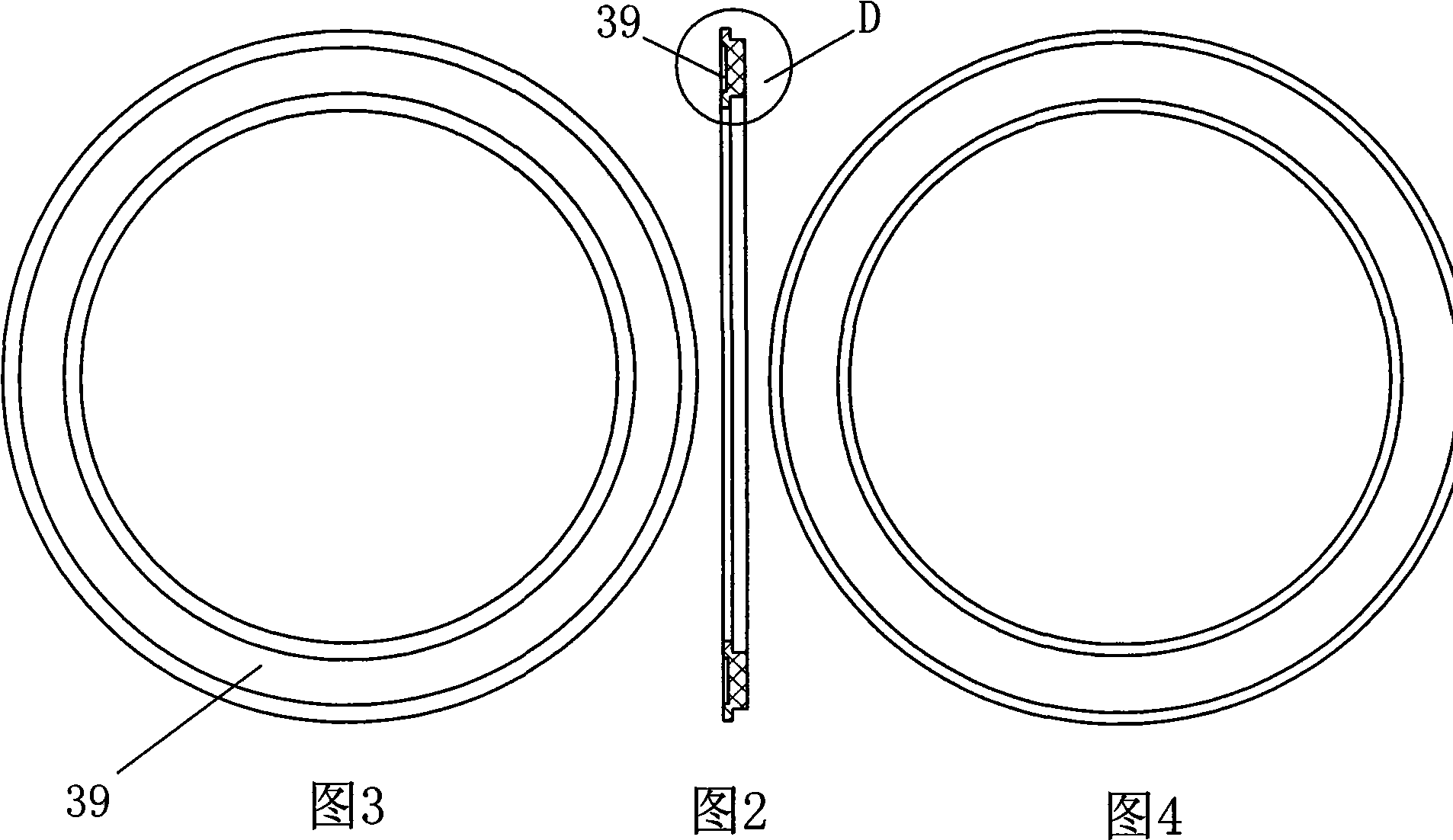

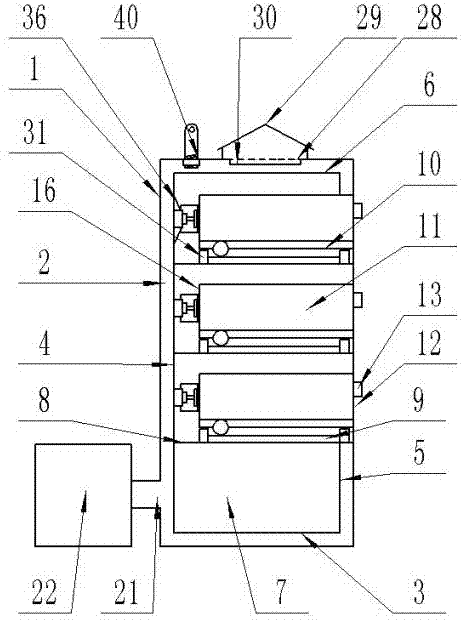

Plate-type sludge dewatering machine and dewatering method therefor

InactiveCN101544459AReasonable structureImprove dehydration efficiencySludge treatment by de-watering/drying/thickeningElastomerHigh pressure

The invention discloses a plate-type sludge dewatering machine and a dewatering method therefore. The plate-type sludge dewatering machine adopts elastomers positioned among pressing filter plates, adjacent anti-thrust filter plates, air-inlet filter plates, feeding filter plates and thrust filter plates to form at least three hermetic pressing filter chambers variable in volume, utilizes the compression deformation and resilience of the elastomers to deep squeeze and dewater a filter cake, and adopts sealing plugs which are arranged in front of air-inlet holes of the air-inlet filter plates and the thrust filter plates and are on positions opposite to feeding holes on the feeding filter plates and the anti-thrust filter plates, wherein the feeding filter plates are adjacent and involutory to the air-inlet filter plates. After low-pressure filter dewatering is over and feeding is stopped, the sealing plugs block and seal the feeding holes so as to prevent sludge from flowing back and entering pipelines during pressing filtration. The dewatering method adopts the variable hermetic pressing filter chambers formed by the elastomers to perform pressing filtration and dewatering, and adds the operation of adopting the sealing plugs to block the feeding holes before high-pressure squeezing-dewatering operation. The invention has the advantages of high dewatering efficiency, strong adaptability, low energy consumption, low use cost and the like.

Owner:ZHEJIANG HUAZHANG TECH

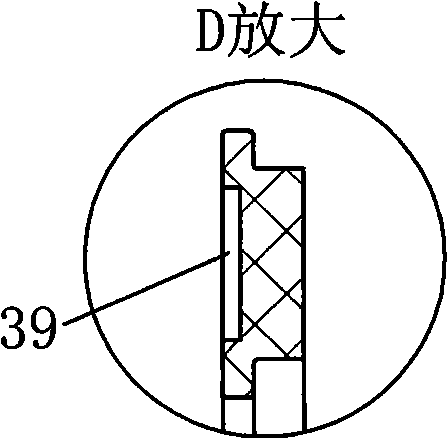

Vacuum ampoule fusion sealing machine

InactiveCN101475303AGuaranteed vacuumGuaranteed drynessGlass reforming apparatusFlavorWhole blood product

The invention provides a vacuum ampoule sealing machine, and relates to the technical field of biochemical experiment equipment. The vacuum ampoule sealing machine mainly comprises a rotary type vacuum connector, a rotary drawing ampoule or a test tube clamp, a lifting bracket and a sealing and heating device. The vacuum ampoule sealing machine has the advantages that the vacuum ampoule sealing machine overcomes the defects of the prior art, has the characteristics of simple structure, convenient operation, high efficiency, good sealing quality and high qualification rate (as high as 100 percent), is particularly suitable for long-term oxygen isolation sealing preservation of little biochemical products or samples which are easily oxidized, decomposed, denatured and inactivated in air and frozen and dried in an ampoule or a test tube, such as microbe strains, animal and plant cells or tissues, vaccine, viable bacteria preparation, enzyme preparation, active protein, blood products, flavor food, health-care food and biochemical drugs, and suitable for vacuum sealing preservation of all oxygen-sensitive biological and chemical substances.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

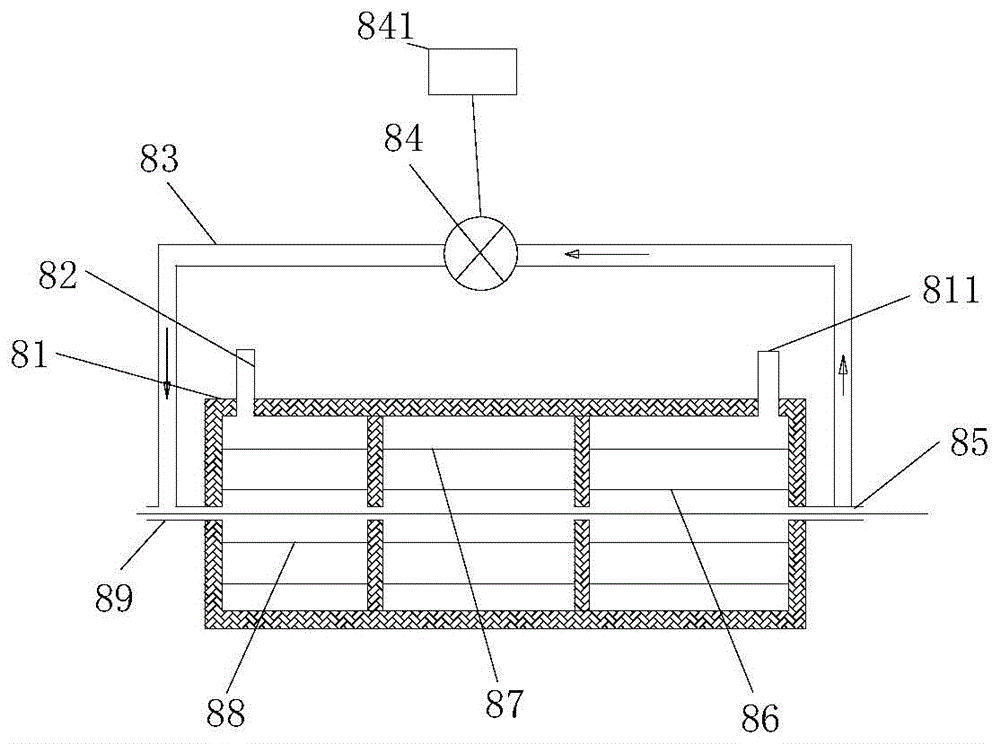

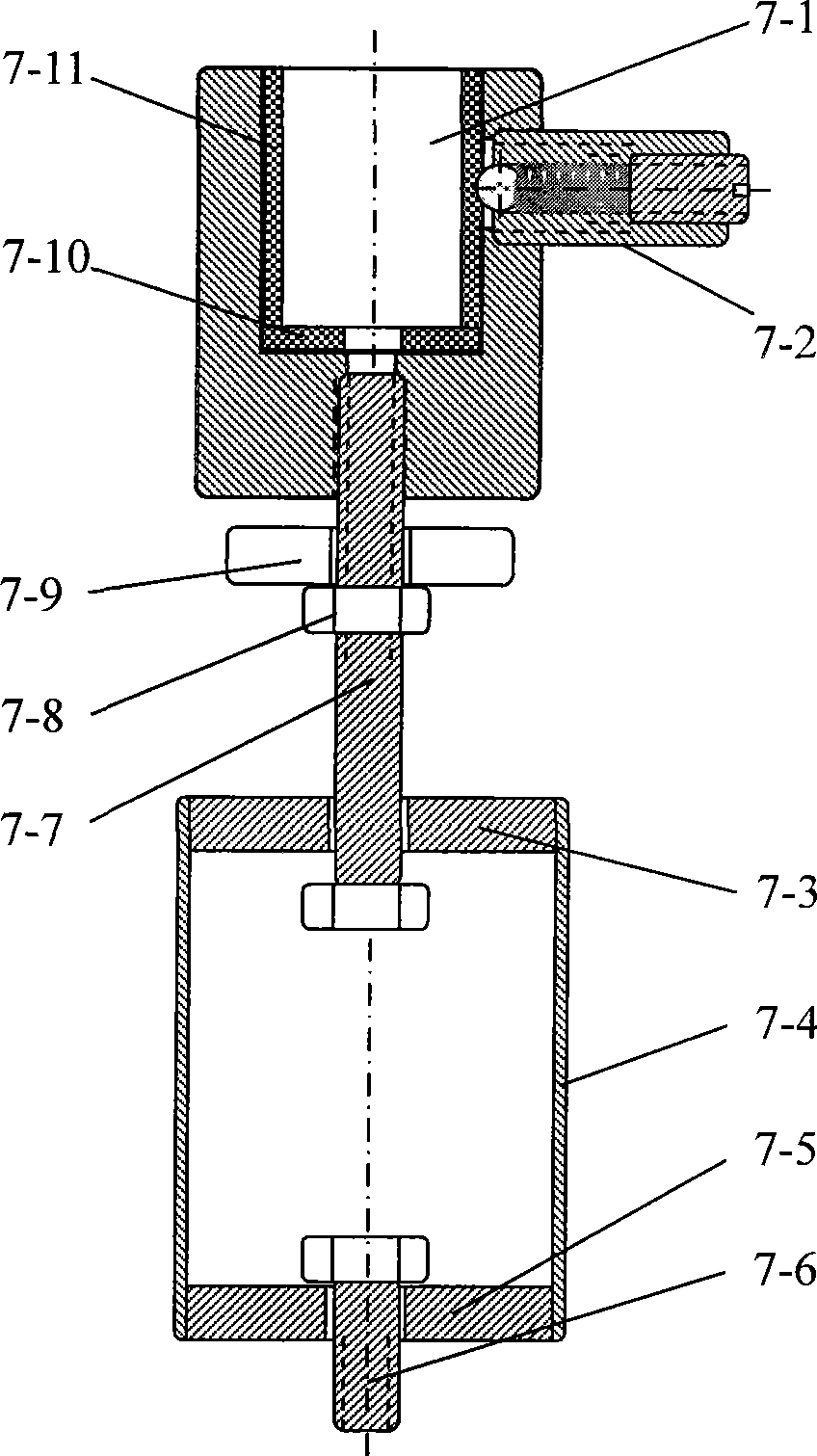

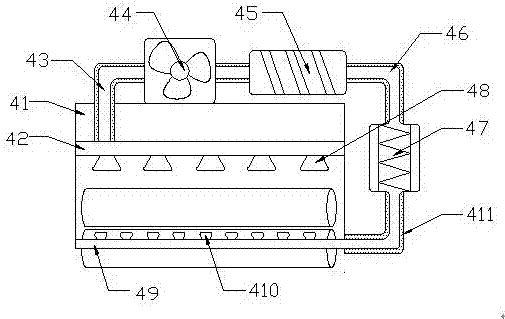

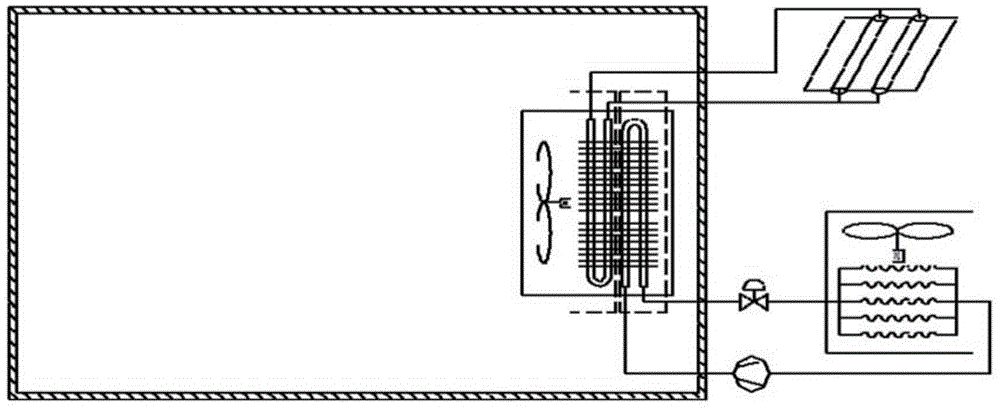

Draught fan drying system of dish-washing machine

ActiveCN105147219AImprove drying efficiencyReduce drynessTableware washing/rinsing machine detailsCold airEngineering

The invention is suitable for the field of dish-washing machines, and discloses a draught fan drying system of a dish-washing machine. The draught fan drying system comprises an inner container with an inner cavity, a heat exchanger installed outside the inner container and a first draught fan installed outside the inner container. The heat exchanger is provided with at least one cold air flow passage and at least two hot air flow passages. The cold air flow passages and the hot air flow passages are alternately arranged in the heat exchanger at intervals. Inlets of the cold air flow passages are communicated with an air outlet of the first draught fan, outlets of the cold air flow passages and inlets of the hot air flow passages are communicated with the inner cavity, an outlet of at least one hot air flow passage is communicated with the inner cavity, and an outlet of at least one hot air flow passage is communicated with external air. According to the draught fan drying system, air obtained after heat exchanging is carried out through the hot air flow passages is divided into two parts to be exhausted out of the heat exchanger, one part of the air is directly exhausted out of the dish-washing machine, and the other part of the air flows back to the inner cavity again; in this way, bad influences on objects around the dish-washing machine can be avoided, cost is low, and the drying effect and the drying efficiency are also high.

Owner:WUHU MIDEA SMART KITCHEN APPLIANCE MFG CO LTD

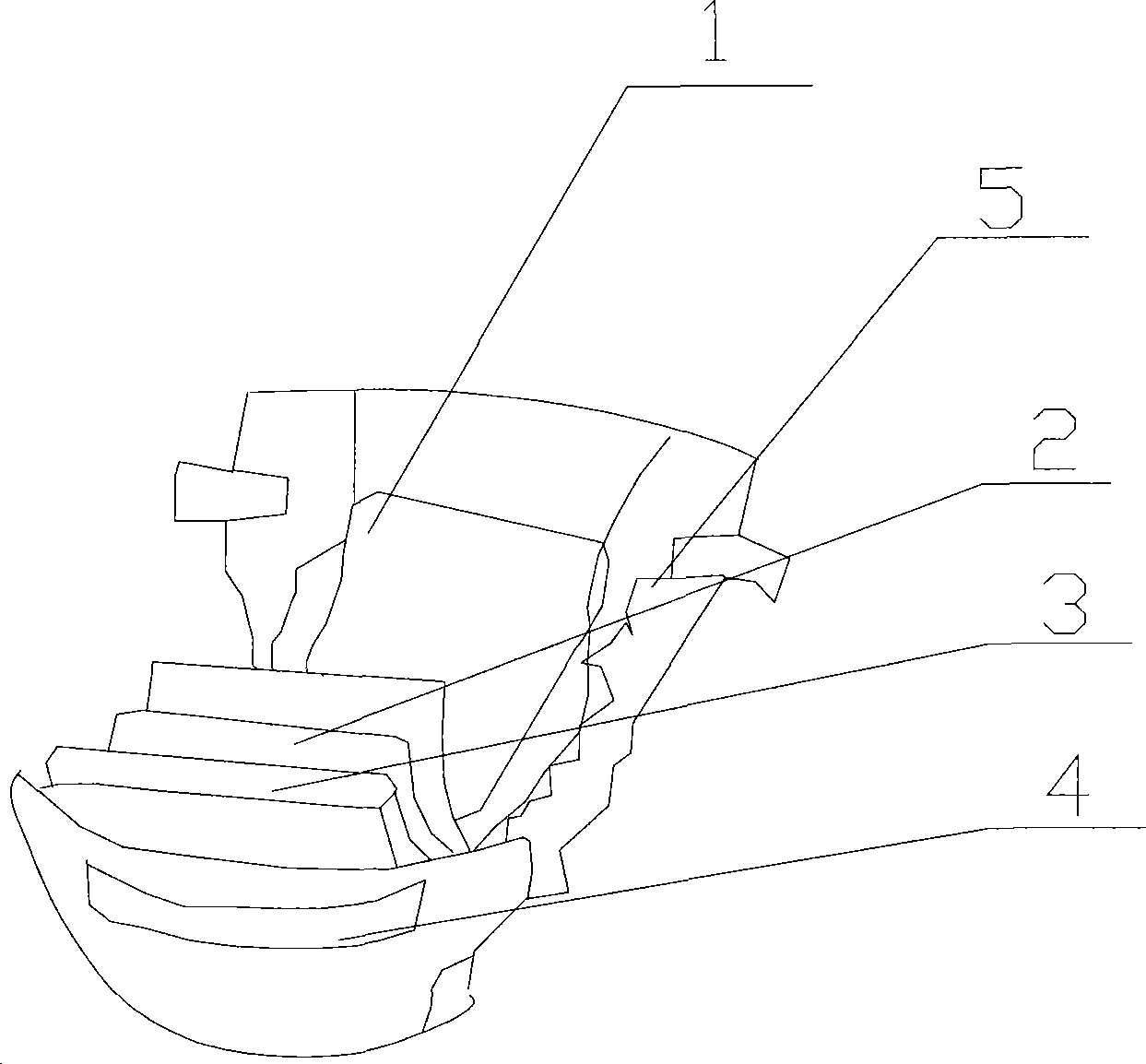

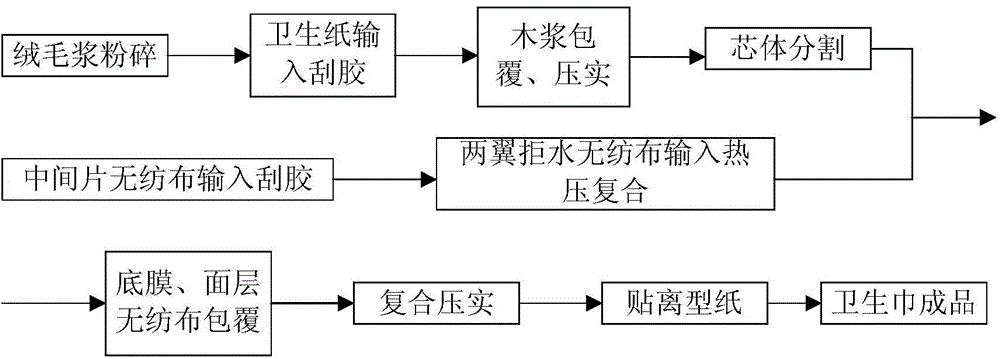

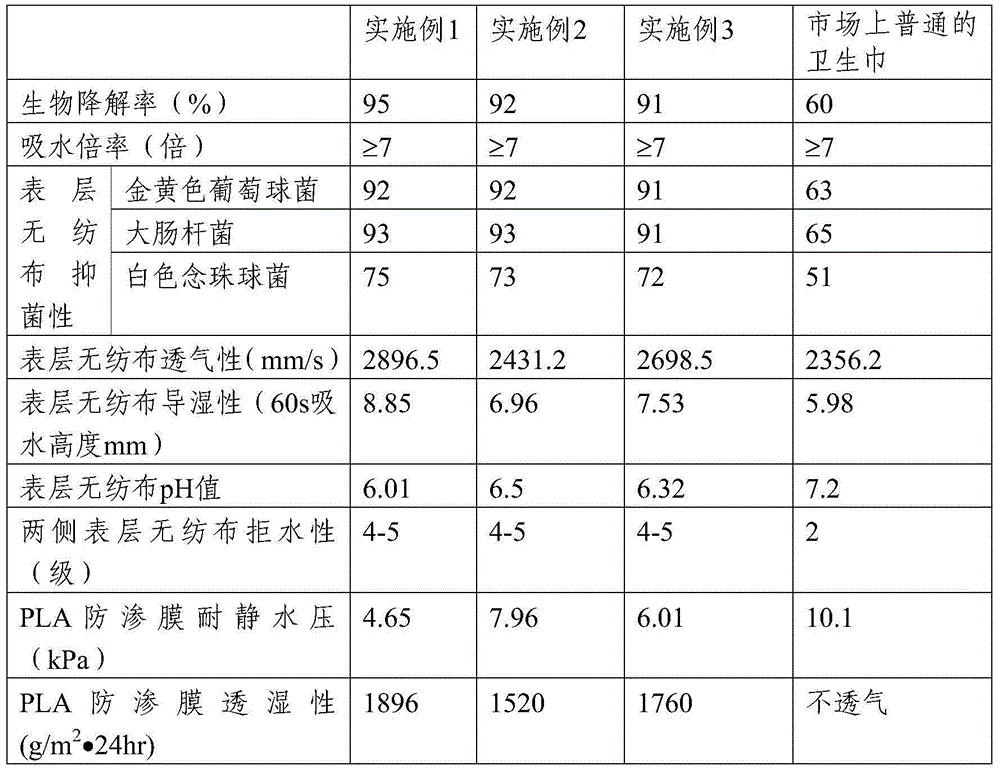

Anti-side leakage degradable polylactic acid sanitary napkin and preparation method thereof

The invention provides an anti-side leakage sanitary napkin, which includes a surface non-woven fabric and a bottom impermeable membrane disposed from the inside out. The surface non-woven fabric has a three-piece structure, the intermediate piece of surface non-woven fabric and the two-wing surface non-woven fabrics are sticked together, and the space between the intermediate piece of surface non-woven fabric and the bottom impermeable membrane is filled with a toilet paper coated wood pulp cellulose absorption core. The surface of the sanitary napkin provided by the invention is composed of 100% polylactic acid fiber or PLA / PBHV fiber hot blast nonwoven fabric. The polylactic acid fiber retains the original characteristics and does not cause any damage. As polylactic acid is formed by polymerization of lactic acid molecules as monomers and spinning, polylactic acid molecules with short molecular chains possibly exist on the fiber surface, so that the pH value of a polylactic acid non-woven fabric surface shows weak acidity and is consistent with that of human body skin. Also an odor removal function is provided. The lateral two pieces of non-woven fabrics have greater gram weight and thickness than the intermediate piece, and side leakage cannot be caused.

Owner:马鞍山同杰良生物材料有限公司

Treatment method of gas cylinder used for storing electronic grade ultra-pure gas

The invention relates to a treatment method of a gas cylinder used for storing pure or ultra-pure gas, which has a strict demand upon the cleanness inside the gas cylinder. The method comprises the steps of: gas cylinder cleaning and drying, internal rust removing, re-cleaning, inner wall grinding, third-time cleaning, deionizing, and deep vacuuming and displacing. With the method provided by the present invention, impurities inside the gas cylinder can be removed, internal cleanness and draught of the gas cylinder can be maintained, and the gas cylinder satisfies the requirements of electronic grade ultra-pure gas storing.

Owner:SUZHOU JINHONG GAS CO LTD

Drawer low-voltage power switchgear cabinet capable of automatically adjusting temperature

InactiveCN107453268ARapid and effective heat dissipationEasy to useSwitchgear with withdrawable carriageSubstation/switching arrangement cooling/ventilationLED displayEaves

The invention discloses a drawer low-voltage power switchgear cabinet capable of automatically adjusting temperature. The power switchgear cabinet comprises a cuboid cabinet body. A sliding drawer device is arranged in the cabinet body. Vents are uniformly distributed on the surface of the backboard of a drawer. A ventilating device is arranged at the vents. Fan-shaped ventilating channels are arranged on the outer walls of left and right side plates of the cabinet body. Waterproof eaves are welded over the fan-shaped ventilating channels. The position, opposite to the fan-shaped ventilating channels, of the inner wall of the cabinet body is covered with a dust filter net 1. The lower end of the backboard of the cabinet body is provided with an induced draft fan at a position where a circular opening is located. A temperature sensor is arranged on the left side plate of the drawer. An observation window is arranged on the right side plate of the cabinet body. A side of the observation window is provided with a PLC controller, a buzzer and an LED display screen. Uniformly distributed heat dissipation holes are arranged on the top of the top cover of the cabinet body. A conical baffle is fixedly installed above the heat dissipation holes. A dust filter net 2 is fixedly installed on the inner wall of the top cover of the cabinet body and under the heat dissipation holes. The drawer low-voltage power switchgear cabinet is simple in structure and good in practicability.

Owner:焦彭彭

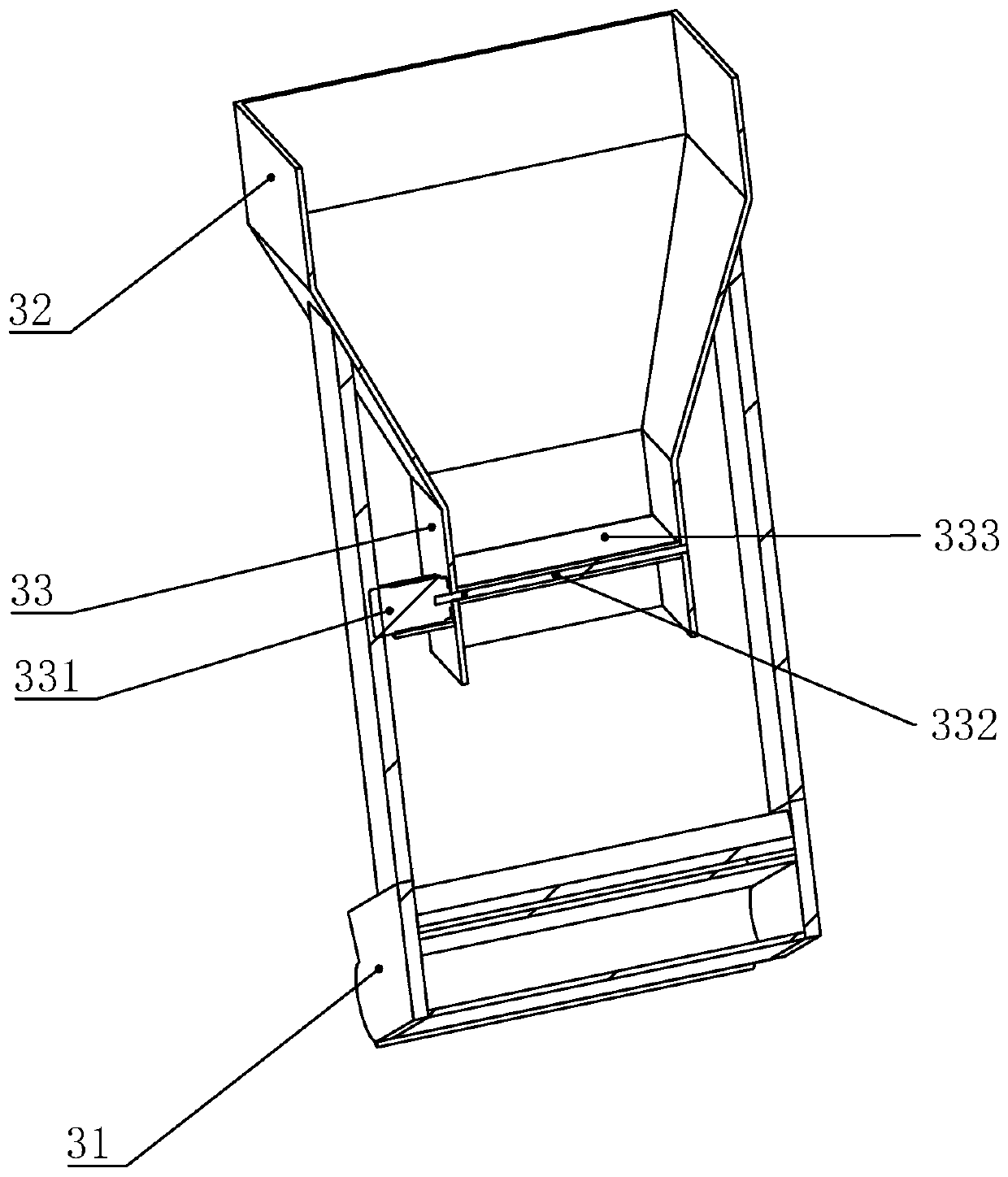

Concrete waste recycling device and method

The invention relates to a concrete waste recycling device and method. The device comprises a first support, a crusher, a screening machine, a guide chute and a feeding mechanism, wherein the screening machine comprises a second support, a U-shaped fixing frame and a vibrating motor; a fixing plate protrudes out of the side wall of the U-shaped fixing frame; a spring is arranged between the top ofa supporting leg of the second support and the fixing plate; at least one filter screen is arranged on the U-shaped fixing frame and is parallel to the long edge of the U-shaped fixing frame; the filter screens are vertically arranged in parallel; the apertures of the filter screens from the upper layer to the lower layer are gradually reduced; a cleaning mechanism is arranged above the screeningmachine; a transmission mechanism is correspondingly arranged on one side, far away from the crusher, of the screening machine; and a drying mechanism is arranged above the transmission mechanism. According to the device, ash adhered to the surface of the materials is removed while the concrete materials are screened, so that the surface of the materials is kept clean, the proportion of each material is accurately controlled when a user subsequently prepares the concrete, the interfacial strength between the gel material and the aggregate can be enhanced, and the quality of the recycled concrete is ensured.

Owner:陕西秦汉恒盛新型建材科技股份有限公司

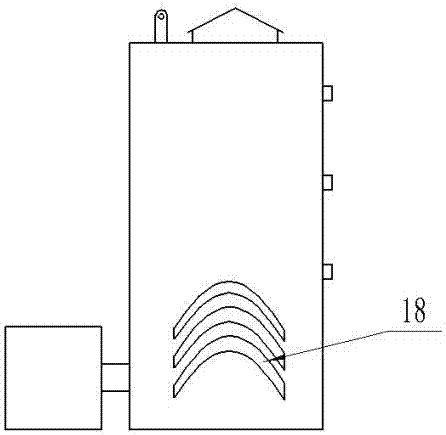

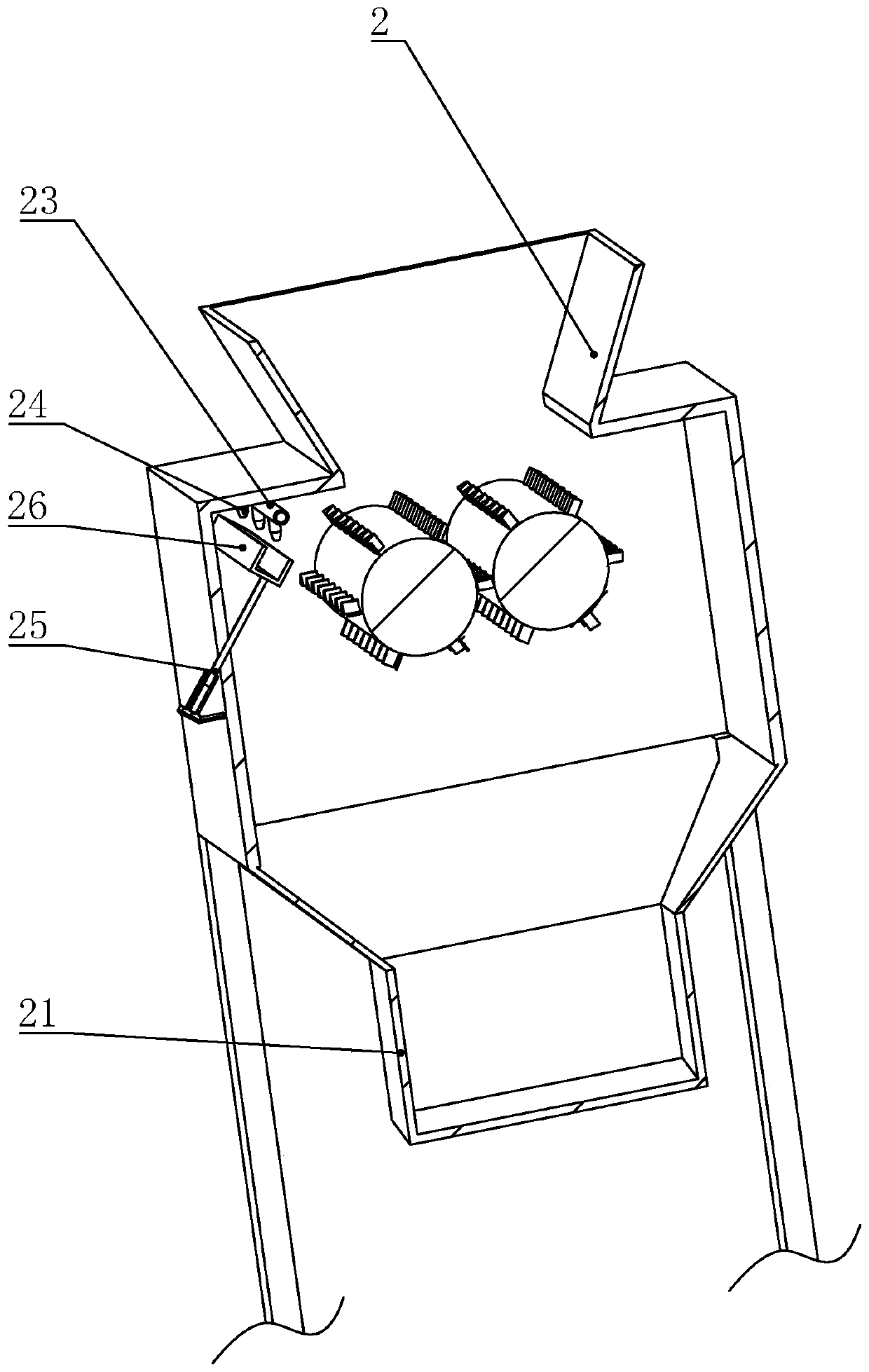

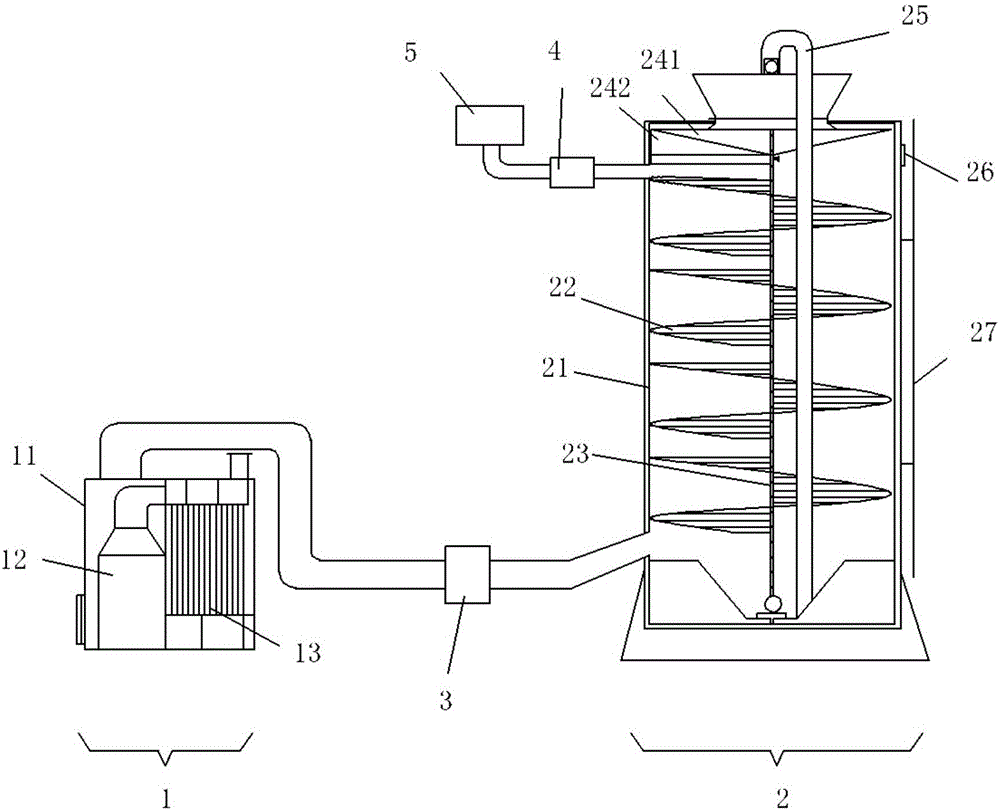

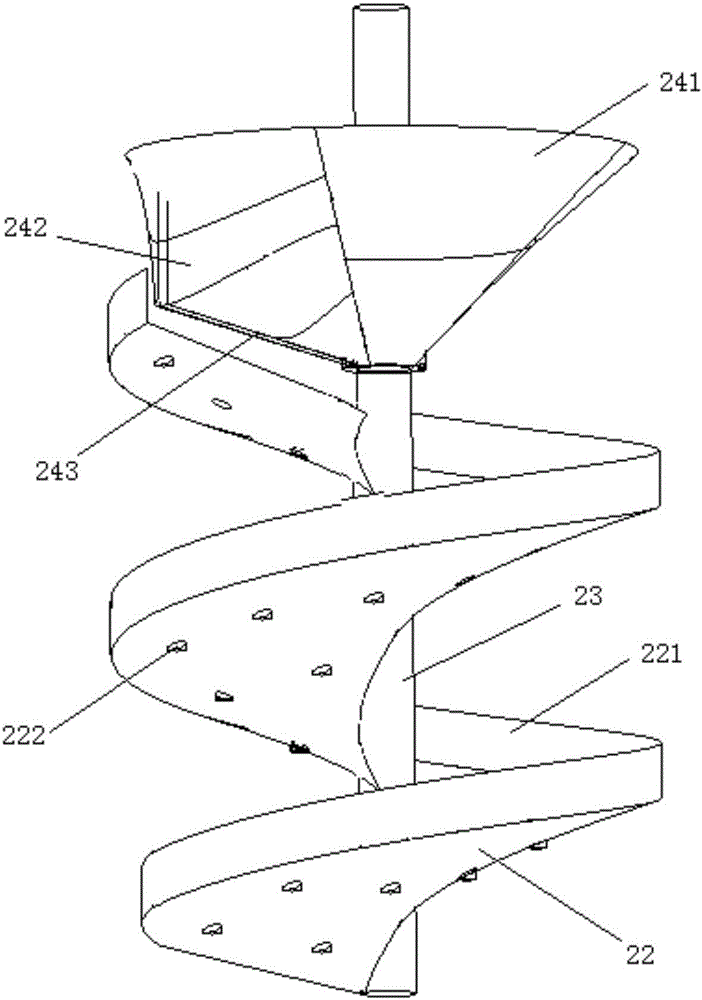

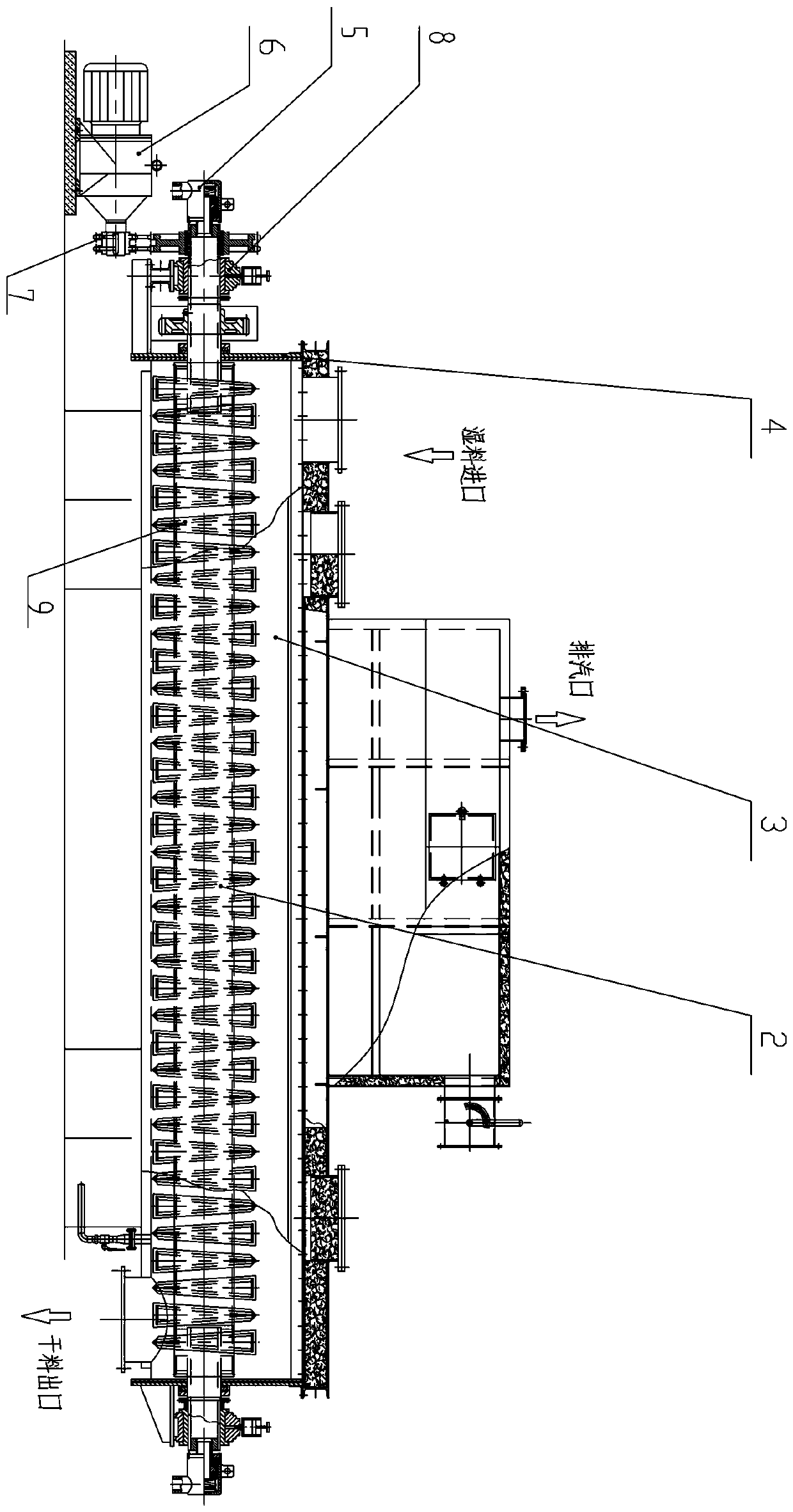

Grain drying device

ActiveCN107178987AExtended retention timeUniform qualityFood processingDrying gas arrangementsSpiral bladePorous medium

The invention discloses a grain drying device. The grain drying device comprises a hot-blast stove, an air blower and a drying tower, and is characterized in that a shaft rod is arranged in a tower body of the drying tower; spiral plates are arranged on the shaft rod; the spiral plates outwards extend from the surface of the shaft rod; two or more stages of spiral plates are arranged on the shaft rod; blowing holes are formed in the spiral plates, and penetrate through the surfaces of the spiral plates; and the hot-blast stove adopts the scheme of arranging heat exchange pipes in a pentagonal form and filling porous mediums in the heat exchange pipes. Compared with the prior art, the grain drying device has the following advantages: the drying speed can be adjusted through adjusting the rotating speed of a rotating shaft according to different grain characteristics; the overturning of materials is realized through multiple sections of spiral blades; the heat exchange efficiency is improved through arranging the heat exchange pipes in a pentagonal form and filling the porous mediums in the pipes; the problems of high production cost, energy consumption and low drying efficiency in the grain drying device can be effectively solved; and the grain drying device is used for drying grains, and reduces the drying cost, saves the energy, and improves the drying efficiency.

Owner:HEFEI UNIV OF TECH

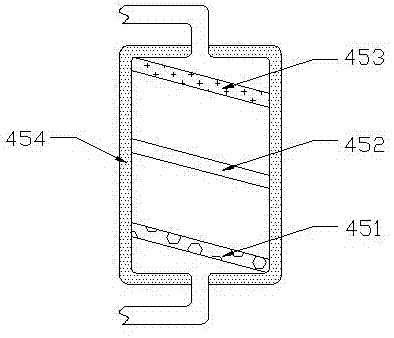

Condensation water residual heat first-effect flash evaporation natural air dehumidifying, preheating and drying baking oven system

ActiveCN102506564AIncrease temperatureGood hygroscopicityDrying gas arrangementsDrying machines with local agitationAir preheaterCooking & baking

The invention relates to a condensation water residual heat first-effect flash evaporation natural air dehumidifying, preheating and drying baking oven system. A baking oven is internally provided with a coil heat exchanger set; the outlet of the coil heat exchanger set is respectively provided with a water draining valve and is connected with a high-temperature condensation water pipe; the high-temperature condensation water accesses to a flash evaporation tank; flash evaporation steam enters a flash evaporation steam pipe from a constant-pressure overflow valve; one way of the outlet of the flash evaporation steam pipe is connected to a lithium bromide refrigerating machine, and the other way of the outlet of the flash evaporation steam pipe is connected to an air preheater through a front pressure automatic regulating valve; the refrigeration water outlet of the refrigerating machine is connected with the water inlet of a cooler of a superficial cooling mist extractor, and the water outlet of the cooler is connected with refrigeration water inlet of the lithium bromide refrigerating machine; and natural air accesses to the humid air inlet of the superficial cooling mist extractor, the dry air outlet of the superficial cooling mist extractor accesses into an air blower, and is sent into the air inlet of the baking oven through the air preheater by the air blower. The system not only can guarantee the drying degree of materials to achieve the technological requirements, but also the utilization efficiency of steam can be improved, and the dissipation of energy of unit product is reduced.

Owner:YIHENG ENERGY SAVING TECH JIANGSU

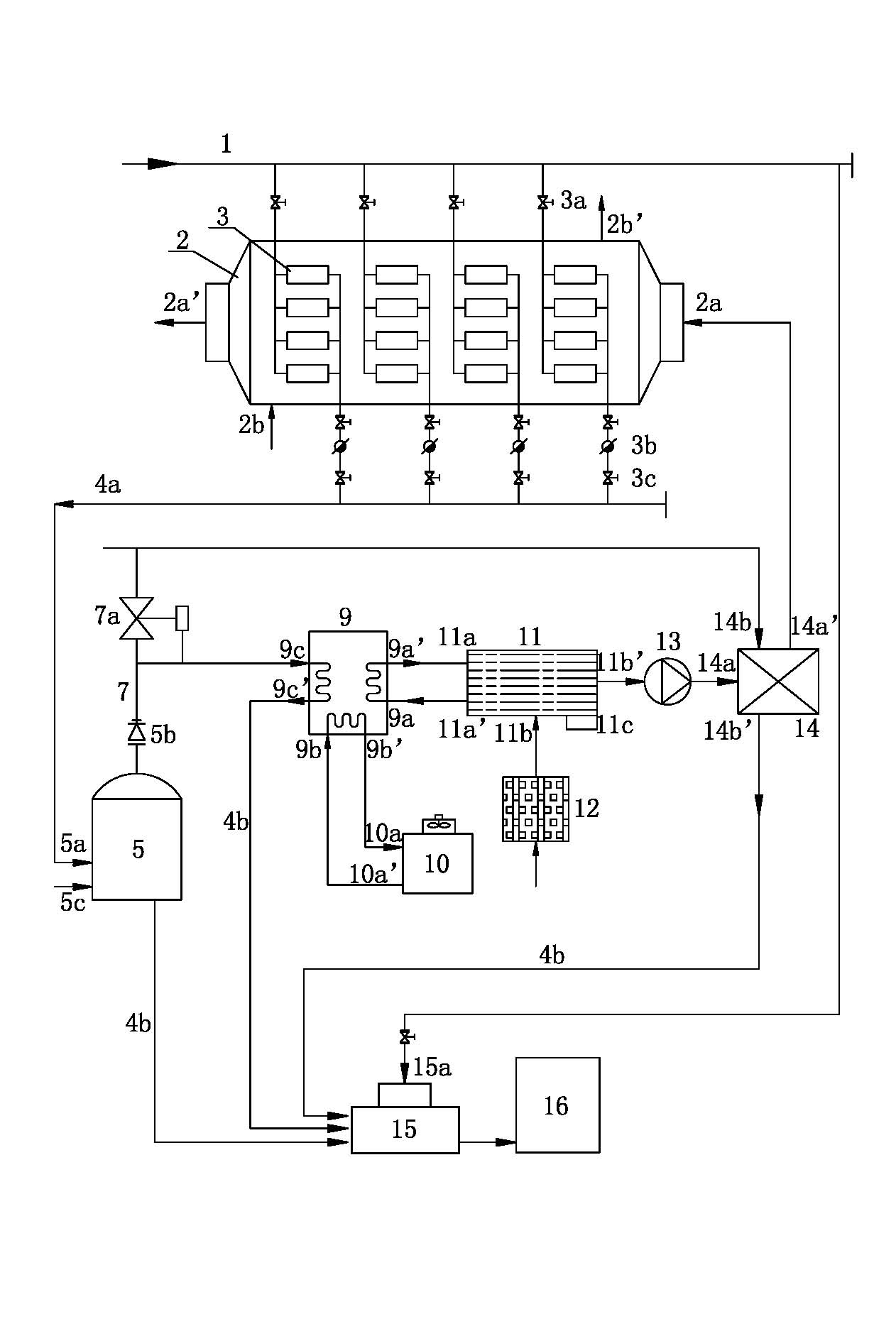

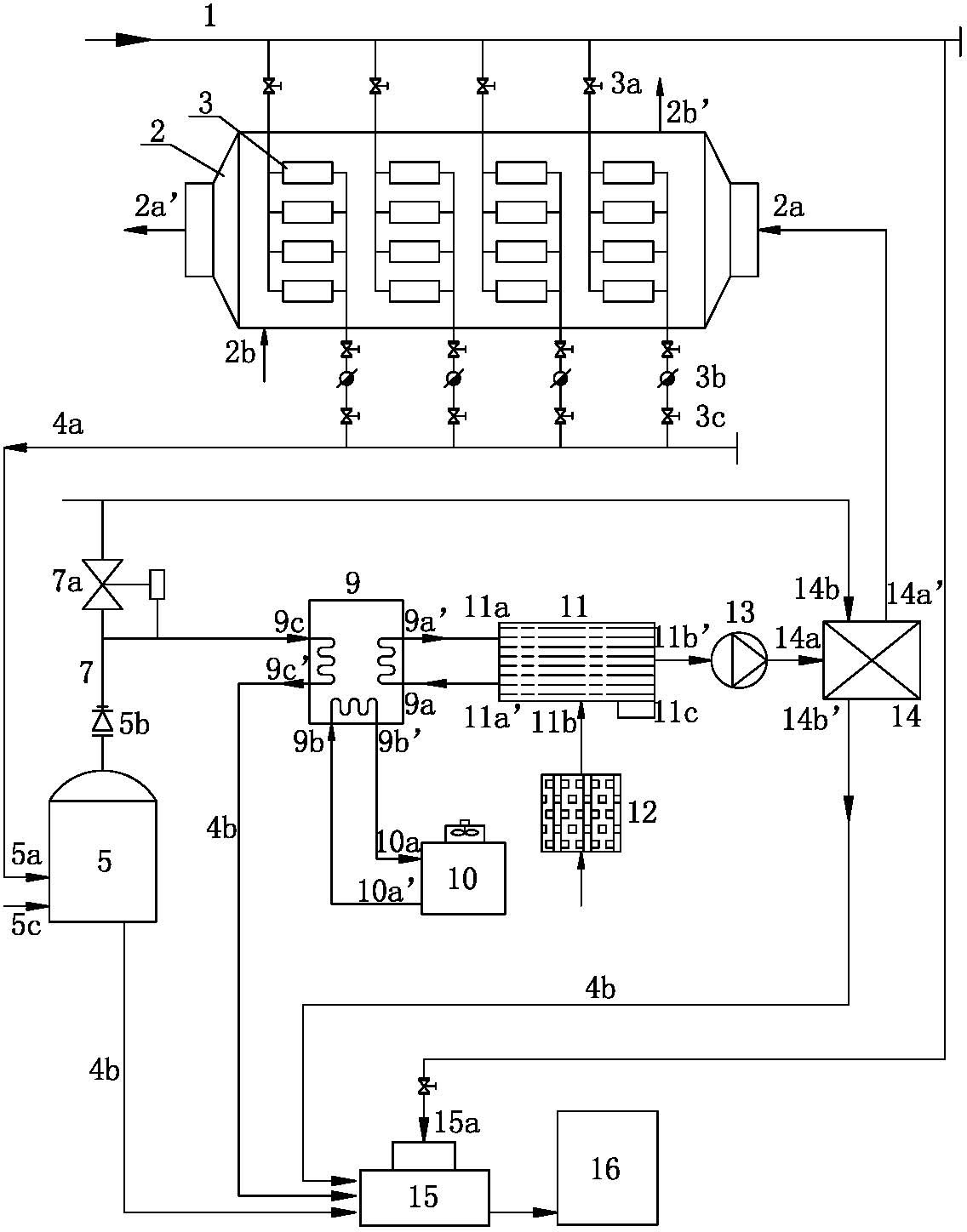

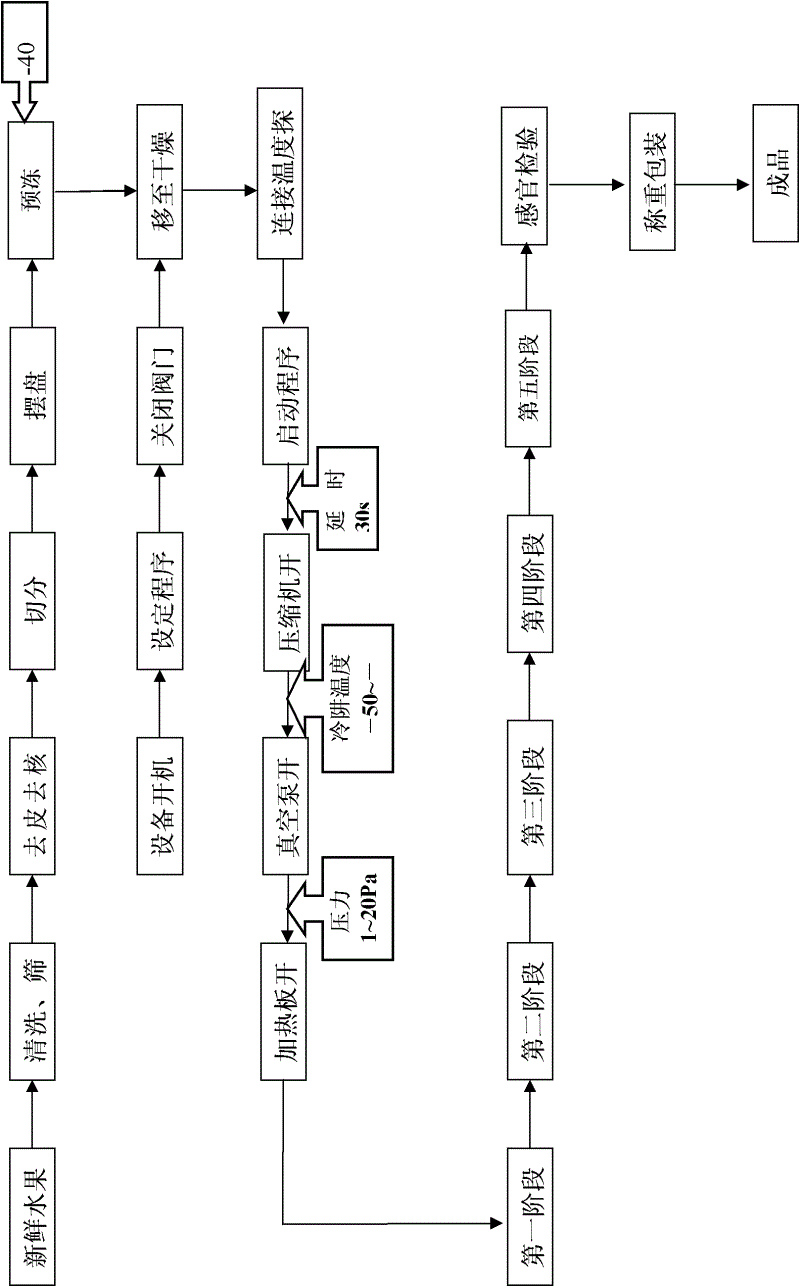

Fruit vacuum freeze drying method

ActiveCN102613283AInhibition of dissolutionSolution volumeFruit and vegetables preservationFreeze-dryingProcess engineering

The invention which is suitable for the technical field of drying provides a fruit vacuum freeze drying method. The method comprises the following steps: prefreezing: refrigerating fruits to be dried; and carrying out five-stage drying under vacuum conditions. The fruit vacuum freeze drying method of the invention, which adopts a five-step gradient cooling mode of the heating temperature, allows heat required by water sublimation to be guaranteed, cooling to be timely, the basic balance of the heat supply and demand to maintained, the material dissolving caused by too fast heating to be prevented, and the water sublimation rate to be accelerated.

Owner:SHENZHEN POLYTECHNIC

Waterproof construction method and system for bottom plate of high-water-level basement

ActiveCN102535488AAvoid situations where you cannot enter a processShorten the construction periodFoundation engineeringBasementStructure of the Earth

The invention discloses a waterproof construction method for a bottom plate of a high-water-level basement. The method comprises the following steps of: (1) partitioning water on a soil layer in a depth range of a foundation pit from the periphery of the foundation pit by using a waterproof curtain of a foundation pit support, and forming drainage ditches on the ground surface of the foundation pit support and at the bottom periphery of the foundation pit; (2) forming more than one dredging ditch below partitioning positions among pile bearing platforms, wherein the distance between the bottom of each pile bearing platform and the top of the dredging ditch is 500 to 1,000mm; and (3) forming a corresponding dewatering well at the periphery of the foundation pit according to a water outlet end of the dredging ditch, and arranging a submerged pump in the dewatering well, wherein the submerged pump is communicated with the drainage ditches through water suction pipes. The invention also discloses a waterproof system for the bottom plate of the high-water-level basement. By the method and the system, the problems of low dryness of flexible waterproof layer construction surfaces, over-high cost of jet grouting piles, high water seepage degree, high labor consumption, high material consumption and the like in the prior art are solved; and the system has the characteristics of effectively dewatering the basement, shortening construction periods, saving the cost and conveniently controlling construction quality, along with a simple structure, low manufacturing cost and the like.

Owner:广东中城建设集团有限公司 +1

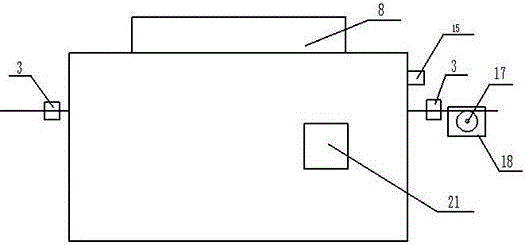

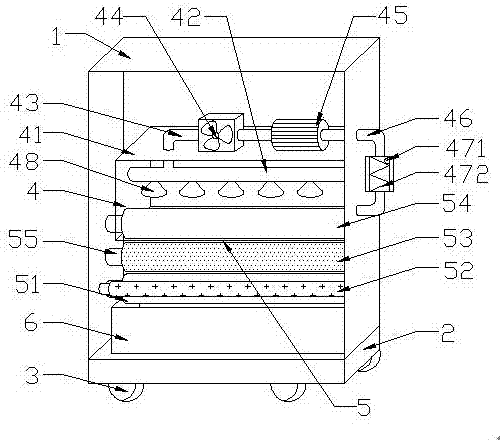

Printer capable of drying ink by circulating air

InactiveCN107160850ASimple and reasonable structurePrevent heat lossPrinting press partsHigh intensityPrinting press

The invention discloses a printing machine for drying ink by circulating air, which comprises a printing machine shell and a machine base, the printing machine shell is fixedly installed on the top of the machine base, and also includes moving wheels, a temperature-controlled circulating air system, a printing press device and an ink supply box, the moving wheel is fixedly installed at the bottom of the machine base, and the moving wheel adopts a high-strength rubber silent roller; the invention has a reasonable and simple structure, and can dry the ink on the printing paper of the printing machine by circulating air to prevent Heat dissipation, energy saving and environmental protection, high printing quality, and the wind that dries the ink circulates in the air cover, so that the flowing air used to dry the ink on the paper is isolated from the ink supply box, which can avoid the accelerated evaporation of the ink in the ink supply box caused by the air flow , the filter can filter the dust and dehumidify the air in the process of circulation, to ensure the cleanliness and dryness of the air that enters the circulation air hood to dry the ink, and the heated air can be recycled to prevent heat loss, which can reduce the ink of the printing machine Drying costs, energy saving and environmental protection.

Owner:广东云印科技有限公司

Bearing washing machine

InactiveCN105013737APrevent fallingGuaranteed cleaning qualityCleaning using liquidsWater storage tankWater resources

The invention provides a bearing washing machine. The bearing washing machine comprises a closed type box body, a first filter screen, a water pump, a rotary table, a first water pipe, a motor chamber rotary shaft and a hanging frame, and the bearing washing machine further comprises a hinge, a box door, a door handle and a water storage tank; and the box door is connected with the box body through the hinge, the door handle is located in the middle portion of the box door, and the water storage tank is located at the bottom of the box body. By means of the bearing washing machine, used water can be recycled to be reutilized, the water resource is saved, the water can be collected into the portion of a second water pipe by a sloping plate, water is convenient to recycle, bearing can be washed from multiple angles by means of the design of a nozzle, and the bearing washing quality is guaranteed; and the water cannot be splashed in the washing process due to the sealing structure of the box body, and dry of a working place is guaranteed. Compared with the prior art, the equipment investment cost can be reduced, the washing cost can be reduced, and the structure is simple.

Owner:XINCHANG COUNTY SANHE BEARING

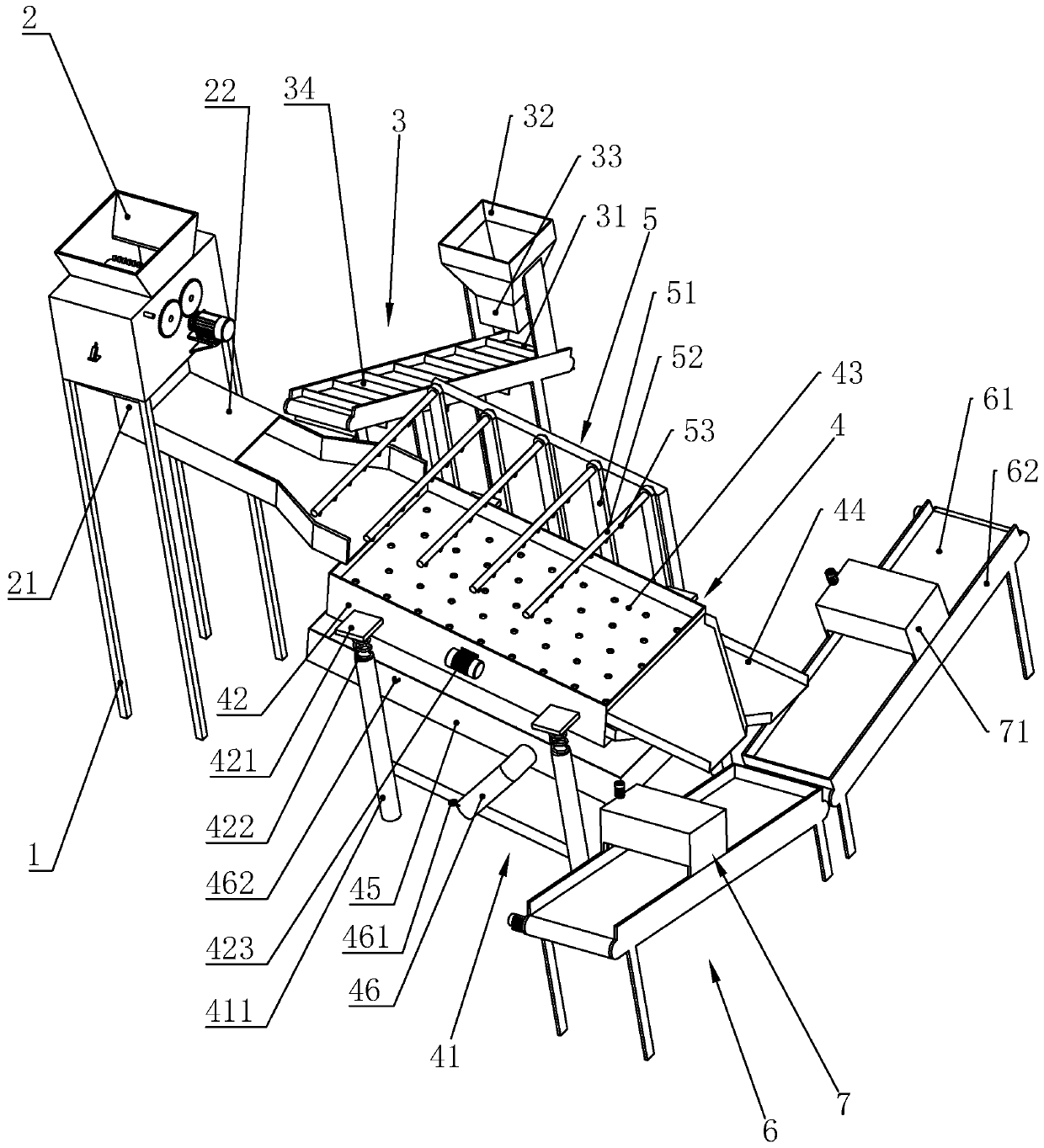

Production system for producing building plaster by using desulphurization gypsum and realization method of production system

The invention discloses a production system for producing building plaster by using desulphurization gypsum. The production system comprises a feeding system, a drying system, a calcining system, a dust removing system, a burning system and a material storing and packaging system, wherein the feeding system is used for feeding plaster materials; the drying system is used for drying the plaster materials; the calcimining system and the burning system are used for calcining the plaster materials into the building plaster; the material storing and packaging system is used for packaging the building plaster; the dust removing system is applied to all subsystems of the production system for removing dust in the production. The production system has the following advantages that the building plaster is prepared by a drying and calcining two-step method of a spiral dryer and a fluidized bed combustion boiler; the production system has remarkable advantages of low energy consumption, simple technology, stable quality of a product, easiness in control and the like.

Owner:山东海蓝阳光环境服务有限公司

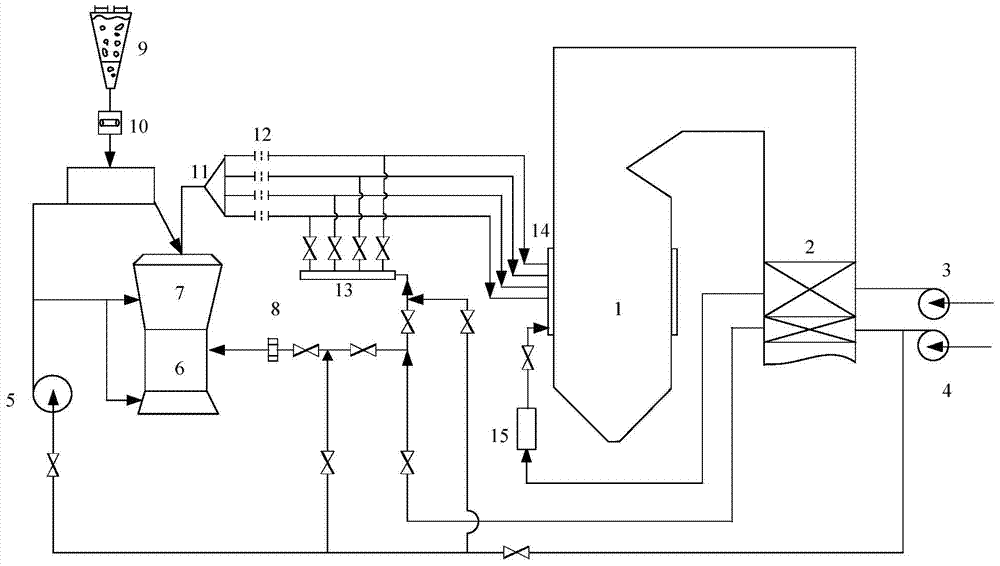

Positive-pressure direct-firing pulverizing system based on segmented temperature control and control method thereof

ActiveCN103925607AGuaranteed drynessGuaranteed ventilation effectAir supply regulationIndirect carbon-dioxide mitigationAir preheaterPositive pressure

The invention discloses a positive-pressure direct-firing pulverizing system based on segmented temperature control and a control method of the positive-pressure direct-firing pulverizing system. The positive-pressure direct-firing pulverizing system comprises an air preheater, an air feeder, a primary air fan, a seal air fan, a coal mill, a tailing separator, a raw coal hopper, a coal feeder, a pulverized coal distributor, an isolation door, a pulverized coal feeding system adjustment bellows, a pulverized coal burner and a secondary bellows. According to the control method, an inlet and an outlet of the coal mill are taken as a segment, an inlet and an outlet of a pulverized coal feeding system are taken as another segment, cold air and hot air are fed into the corresponding inlets of the two segments through corresponding pipelines, the temperatures of the two segments are monitored respectively, and then segmented control over the temperature of the pulverizing system is achieved. By means of the control method, the temperature of the pulverizing system and the temperature of the pulverized coal feeding system can be independently controlled, the air speed of the pulverized coal feeding system is kept not decreased under the condition that the air quantity of the pulverizing system is changed, and the demands for conveying pulverized coal and preventing a nozzle from being burnt out are met.

Owner:XIAN TPRI BOILER ENVIRONMENTAL PROTECTION ENG CO LTD +1

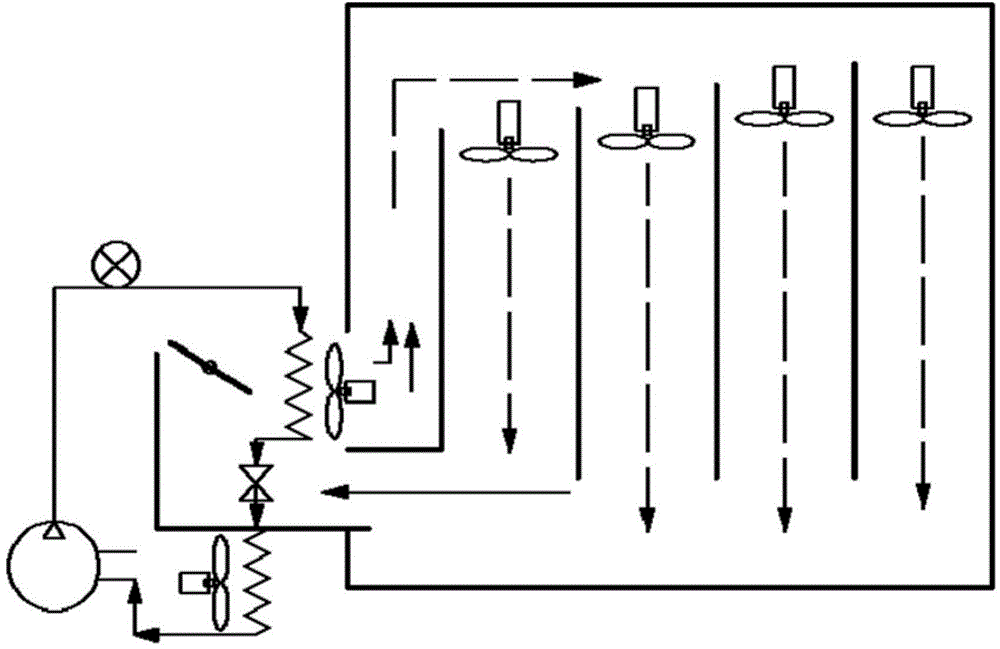

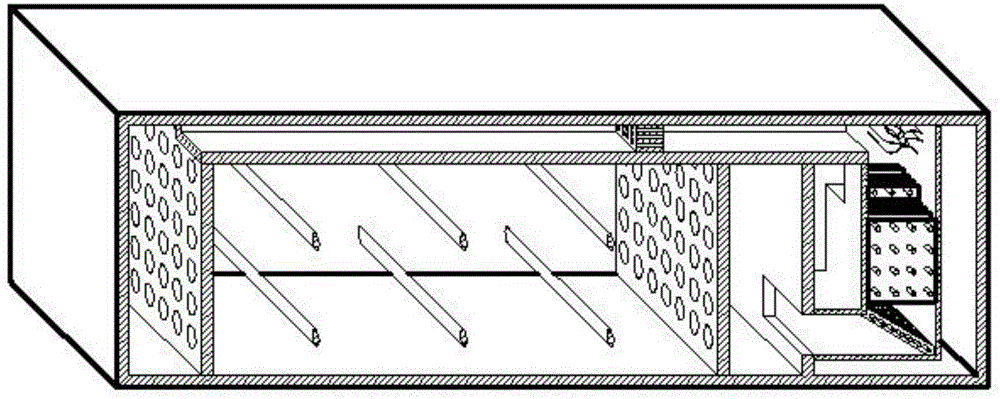

Energy recycling type edible mushroom drying device

ActiveCN104082397AUniform treatmentAchieve recyclabilityFood processingFruits/vegetable preservation by dehydrationAir treatmentFresh air

The invention discloses an energy recycling type edible mushroom drying device. The drying device comprises an external fresh air introducing device, a total heat exchanger, a multistage pressing type airflow-adjustable air hole, an edible mushroom drying device and an induced draft fan, wherein the total heat exchanger is used for recycling the energy; the edible mushroom drying device sequentially comprises a drying room, an air pre-heater, a flow guiding plate, a variable cross-section air flue, an airflow pressure sensor, a blowing pore plate, an air return pore plate, and flow guiding devices arranged on an inlet of the blowing pore plate and an outlet of the air return pore plate, and the blowing pore plate and the air return pore plate are arranged in the drying room in parallel. According to the energy recycling type edible mushroom drying device, by combining a completely-new air supplying drying mode and a direct return-air self-circulation drying mode with a stairstep-energy-supplying air heating manner and the variable cross-section air flue according to different drying conditions of the edible mushroom, the stable distribution of air in the device is guaranteed, meanwhile, the air supplying temperature is decreased, and the drying quality is guaranteed; air is uniformly processed, and the energy consumption is reduced.

Owner:NANJING NORMAL UNIVERSITY

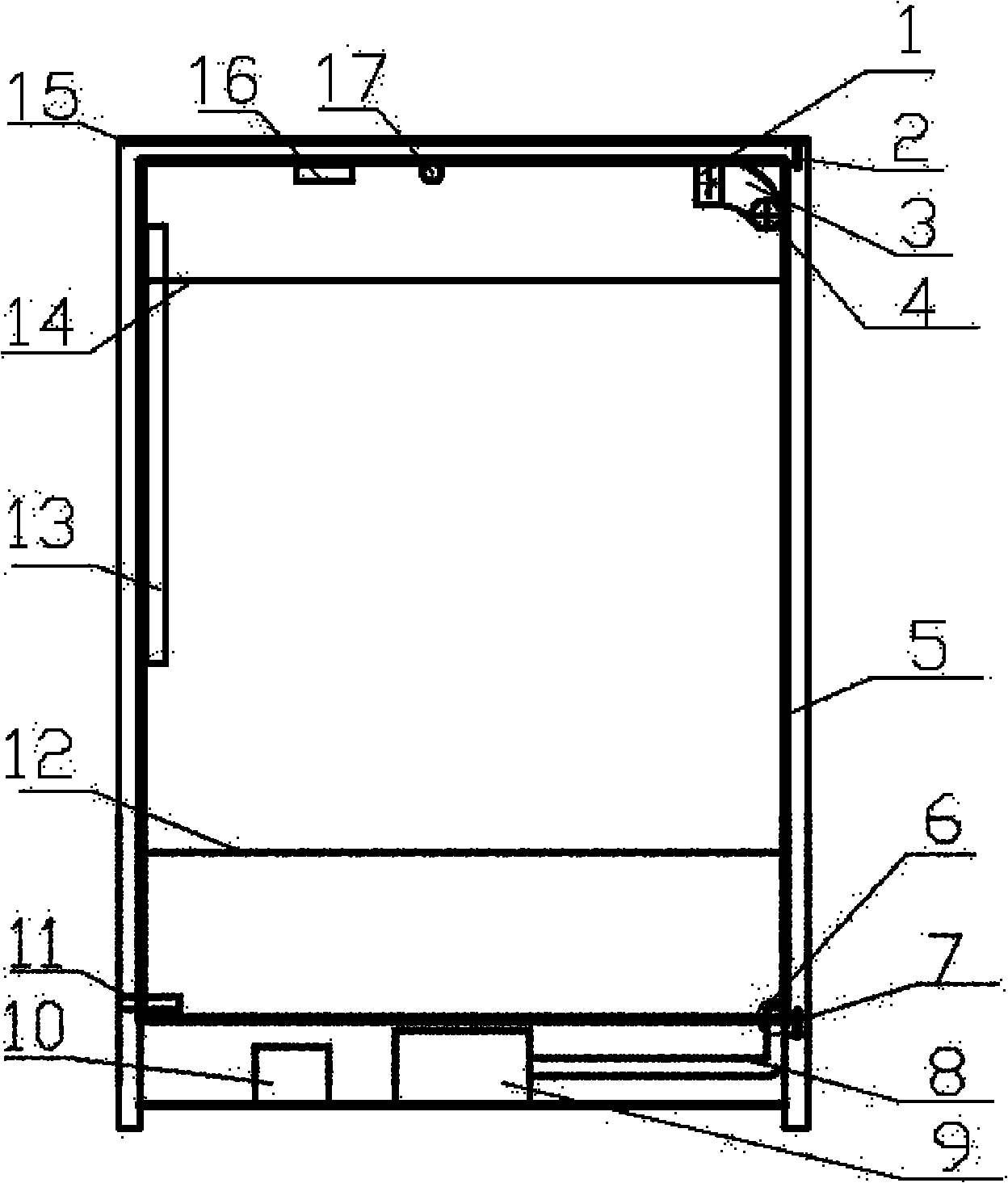

Vacuum and moistureproof sterilizing dry wardrobe

InactiveCN102041670AAvoid secondary moistureGuaranteed drynessTextiles and paperChemicalsExhaust valveEngineering

The invention provides a vacuum and moistureproof sterilizing dry wardrobe which is characterized in that a sealing ring is arranged at the periphery of the contact part of a wardrobe body and a wardrobe door; the inner top layer of the wardrobe is connected with a pressure sensor, a temperature sensor, an ozone generator, a ventilation fan and a fan air channel; a clothes rail is connected between two side walls of the upper part of the interior of the wardrobe; the inner side surface of the wardrobe is connected with a far infrared air heater; the middle lower part of the interior of the wardrobe is provided with hollow clapboards of the wardrobe; an electromagnetic vent valve is arranged at the bottom of the side face of the wardrobe, and a vacuum pump and a power supply are arranged at the external bottom of the wardrobe; an upper wardrobe door dowel and a lower wardrobe door dowel are respectively connected with the upper and lower ends of the wardrobe door; a door lock is arranged at the edge of the middle part of the door; a control panel is arranged at the middle of the wardrobe door; and the control panel is provided with a liquid crystal electronic display screen, an indicator light series and a starting / closing button series. In the vacuum and moistureproof sterilizing dry wardrobe, by using a far infrared dry method, a vacuum technology and an ozone sterilization device, clothes are not moistured again after being dried, and the clothes are sterilized. The vacuum and moistureproof sterilizing dry wardrobe is safe and convenient to use, is time-saving and energy-saving, and is especially suitable for rainy and moist regions and seasons.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Chinese herbal medicine grinding, crushing and dehumidifying device

InactiveCN106622482AConvenient two-way crushingUniform particlesGas treatmentDispersed particle filtrationEngineeringAir blower

The invention provides a Chinese herbal medicine grinding, crushing and dehumidifying device. The Chinese herbal medicine grinding, crushing and dehumidifying device comprises a box body, a placing plate and a bin door; a left feed hopper, a right feed hopper, a grinding and crushing device, a stirring device and a storage bin are arranged in the box body; the grinding and crushing device includes an upper grinding table, a rotating shaft, a lower grinding table and a grinding motor; the stirring device includes a stirring shaft, a stirring rod and a stirring motor; the storage bin is arranged at the lower end of the stirring device; a baffle plate and a bin door are arranged in the storage bin; the placing plate is fixed on the box body through a welding manner, and is provided with a dehumidifying device; the dehumidifying device includes a filter box, an air blowing channel, an intake pipe and an air blower; an absorbing layer and a dehumidifying layer are arranged in the filter box; the intake pipe is connected with the air blower and the box body; the intake pipe penetrates through the box body, and is provided with an anti-blockage net at the tail end; the bin door is arranged at the right lower end of the box body; and a handle is arranged on the bin door. The Chinese herbal medicine grinding, crushing and dehumidifying device is uniform in particle crushing, thorough in crushing, capable of dehumidifying and convenient to preserve medicines.

Owner:郑州吉音动漫科技有限公司

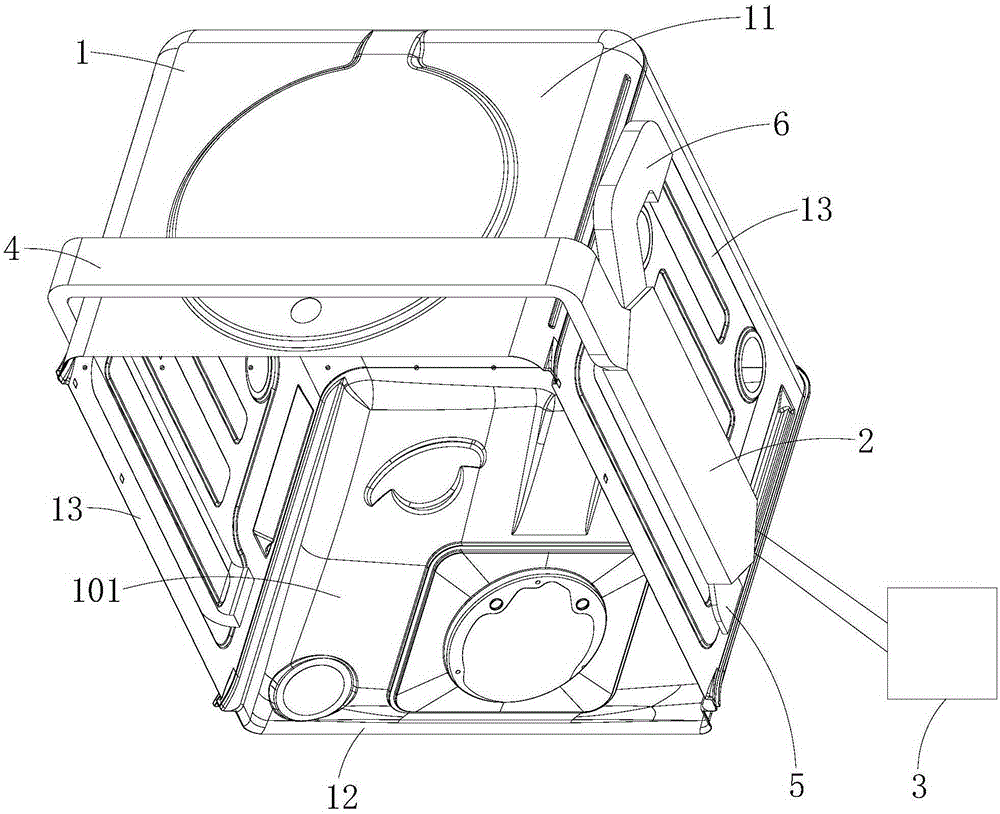

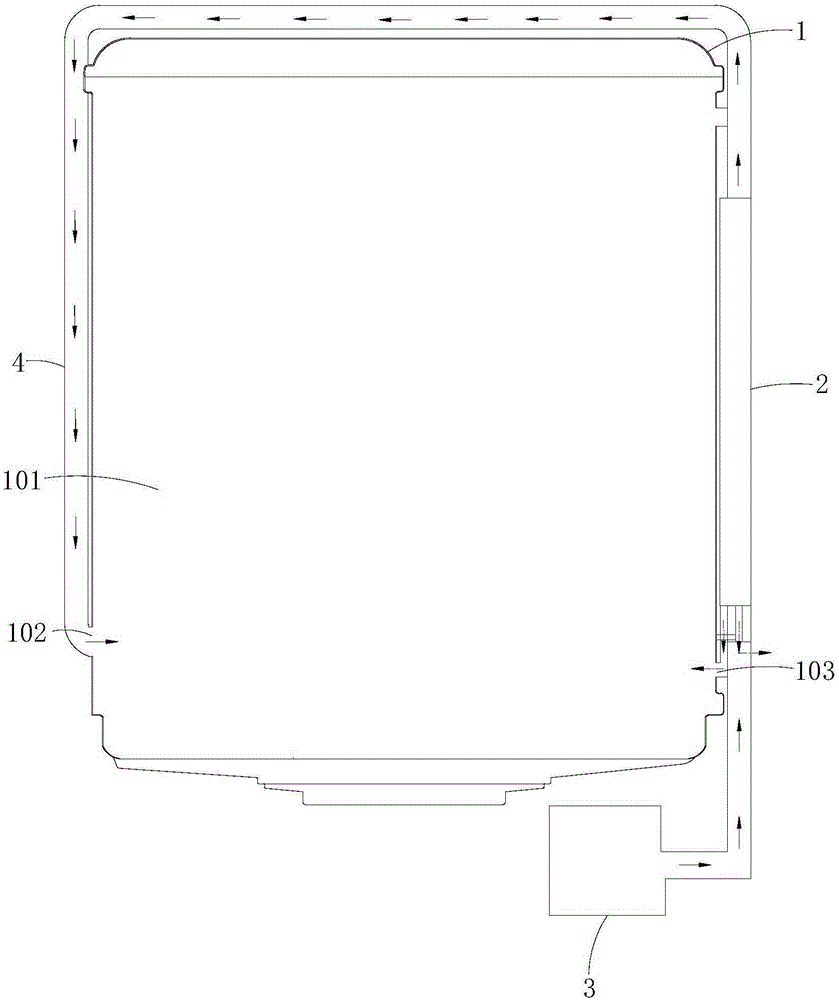

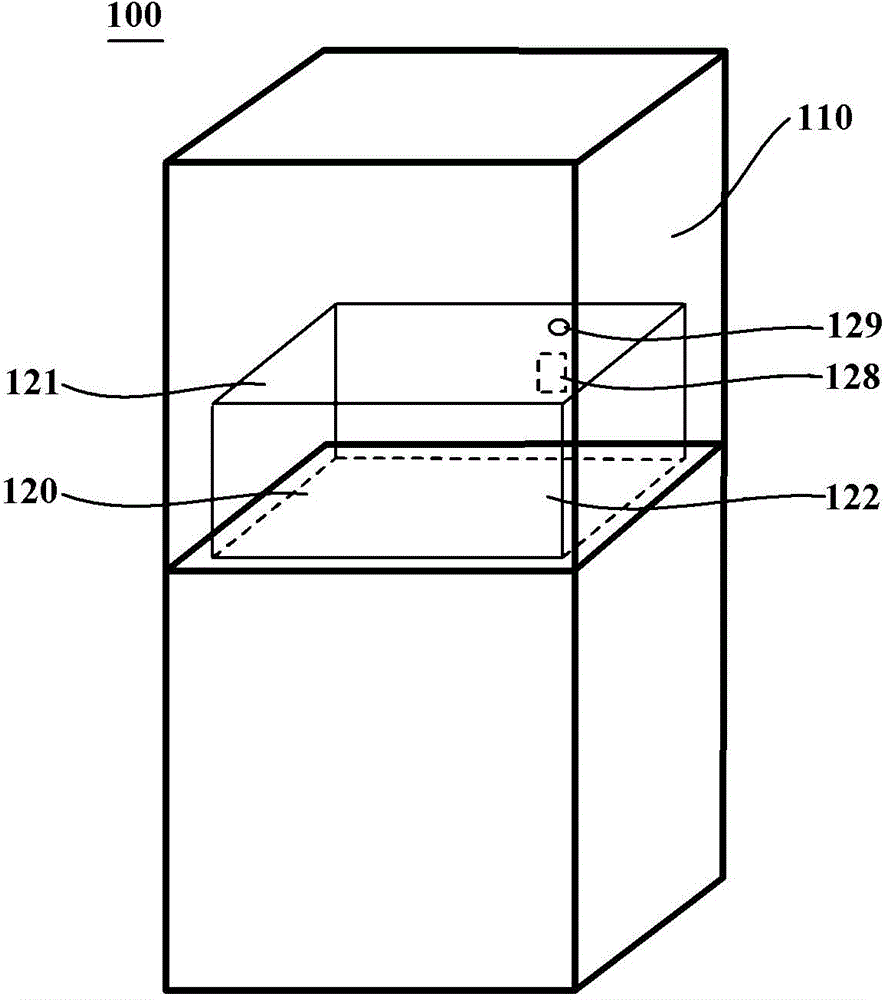

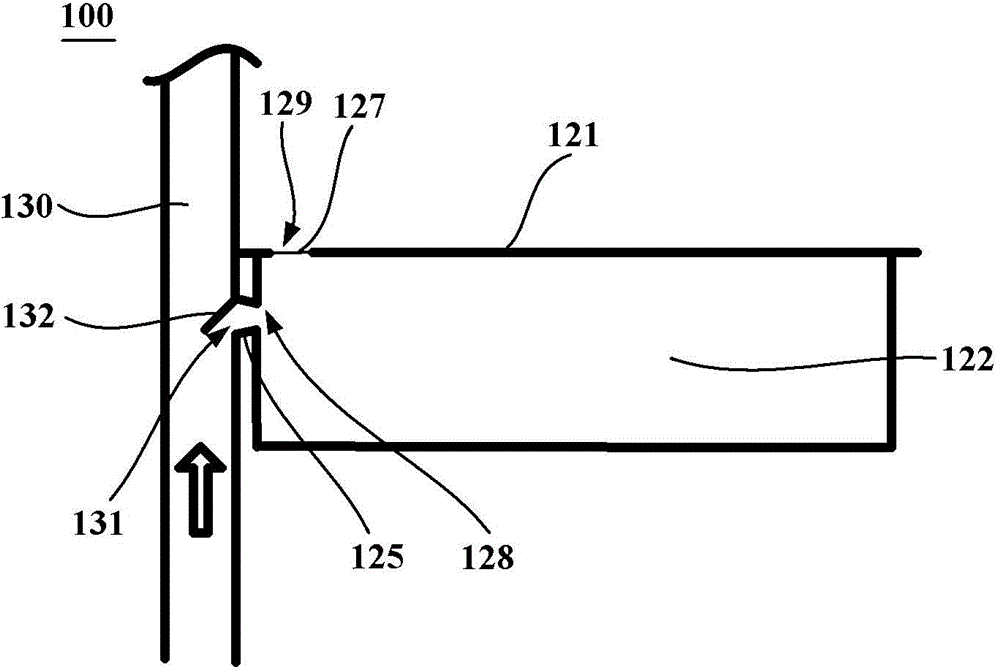

Air-cooled refrigerator

PendingCN105806003AGuaranteed drynessSimple designLighting and heating apparatusDomestic refrigeratorsHigh humidityCold store

The invention provides an air-cooled refrigerator. The air-cooled refrigerator comprises a refrigerating chamber and further comprises a drying chamber provided with an independent closed space and arranged in the refrigerating chamber. The drying chamber is provided with an air inlet allowing air cooled by a cold source to flow in and an air return opening allowing displaced air to flow out, and a waterproof gas-permeable membrane is arranged at the air return opening. The waterproof gas-permeable membrane is arranged at the air return opening of the drying chamber, and the waterproof gas-permeable membrane is used for achieving airflow circulation so as to ensure that fed low-temperature air can replace damp air in the drying chamber, and external high-humidity moisture is prevented from entering the drying chamber after air replacing is completed. The drying chamber of the air-cooled refrigerator is simpler in design and better in performance, and the manufacturing cost is reduced.

Owner:QINGDAO HAIER SMART TECH R & D CO LTD

Vibrating drying device for plate production and processing

InactiveCN107576182AImprove drying efficiencyShorten drying timeDrying solid materials without heatDrying gas arrangementsBristleEngineering

The invention discloses a vibrating drying device for plate production and processing. The vibrating drying device for plate production and processing comprises a box body, a conveying belt, a transmission wheel and a motor, wherein a plurality of bulges are uniformly distributed on the outer surface of the conveying belt; and a water scraping mechanism is arranged above the conveying belt, a camis installed at the inner side of the conveying belt, horizontal brush rolls are installed above the conveying belt, a hollow shaft is fixed to the other end of the brush roll, a hot-air box is communicated to the tail end of the hollow shaft, a cavity is formed in the brush roll, and bristles are uniformly distributed on the outer wall of the brush roll. According to the vibrating drying device for plate production and processing, hot air is also capable of flowing through the lower surface of a plate through projections arranged on the conveying belt to dry the lower surface of the plate, and the drying dead angles of the lower surface are avoided in combination with the vibration of the cam; and the brush roll absorbs water on the upper surface of the plate into the bristles, and contacts with the hot air during rotation to rapidly evaporate water, and meanwhile, the entering hot air is uniform, and high in flowability.

Owner:邱钱勇

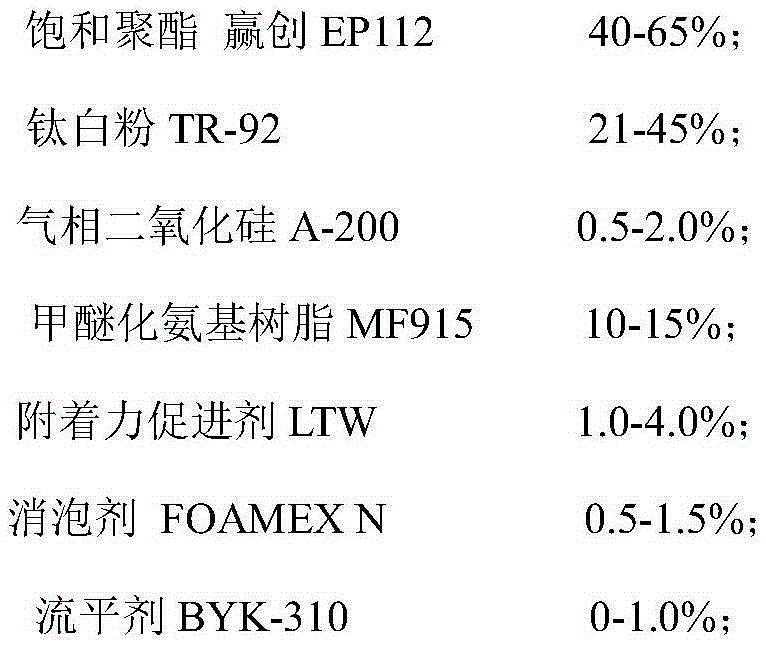

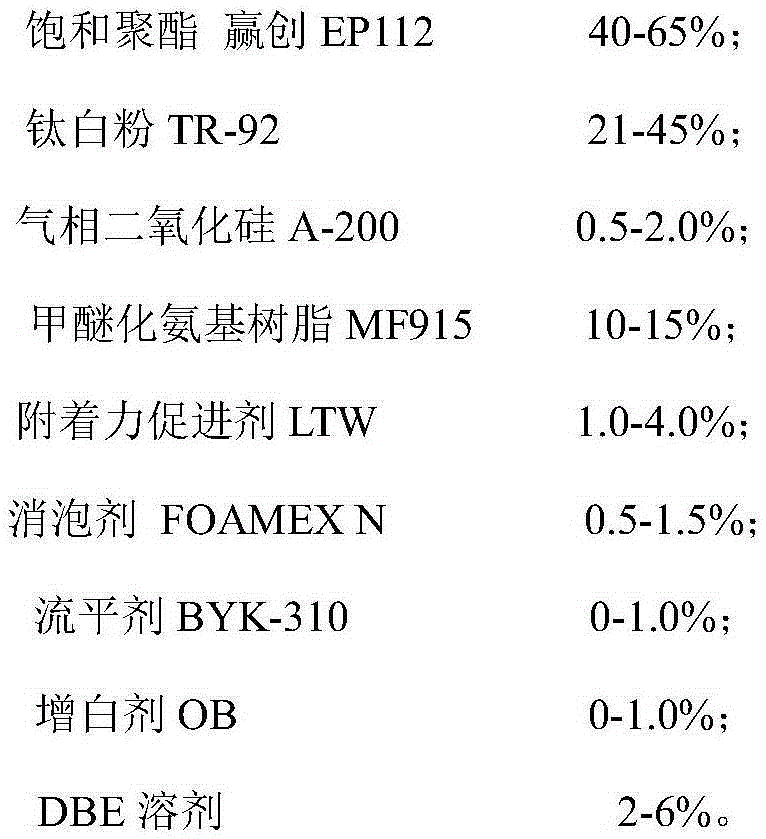

Thermosetting type glass screen printing ink and preparation method thereof

The invention discloses thermosetting type glass screen printing ink. The thermosetting type glass screen printing ink includes, by weight, 40%-65% of Evonik EP112 saturated polyester, 21%-45% of titanium dioxide TR-92, 0.5%-2.0% of fumed silica A-200, 10%-15% of methylated amino resin MF915, 1.0%-4.0% of adhesion promoters LTW, 0.5%-1.5% of antifoaming agents FOAMEXN, 0-1.0% of flatting agents BYK-310, 0-1.0% of brightening agents OB and 2%-6% of DBE solutions. A preparation method of the thermosetting type glass screen printing ink includes the steps that the saturated polyester, the titanium dioxide and the fumed silica are firstly stirred evenly, then the methylated amino resin, the adhesion promoters, the antifoaming agents, and / or the flatting agents, and / or the brightening agents are added into the mixture, and the DBE solutions are added finally. The thermosetting type glass screen printing ink has good adhesion, water resistance, acid and alkali resistance, cold and hot impact resistance, butanone dissolution resistance, fast yellowing resistance, high temperature yellowing resistance, flexibility, constructability and ultraviolet resistance.

Owner:WUHU CHUNFENG NEW MATERIAL

Agricultural drying machine for rice type small-size particle grain

InactiveCN107062872AEasy dischargeTake advantage ofDrying gas arrangementsSeed preservation by dryingRubber ringAgricultural engineering

The invention discloses an agricultural rice grain small-diameter grain dryer, which comprises a machine shell, and a first-stage sieve-shock feeding mechanism is arranged at the top of the machine shell; The bottom of the screening cavity is connected to the discharge port, a screen is arranged in the inner cavity of the screen, a vibration motor is provided at the bottom of the screen, and the discharge port is located below the screen; the bottom of the discharge port is surrounded by The inner side wall of the casing is provided with a circle of material guide plates, and a deceleration device is arranged below the material guide plate. The deceleration device includes a deceleration cylinder, a rubber ring and a deceleration frame; the lower end of the deceleration cylinder is provided on the side wall of the casing corresponding to the A circle of hot air cavity; a stirring shaft is horizontally arranged below the reduction drum, and the outer end of the stirring shaft passes through the casing and is fixedly connected to the second drive motor, and a stirring blade is fixedly installed on the stirring shaft. The bottom wall of the body is provided with a discharge channel.

Owner:段华勇

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com