Moving iris type fluidized bed

A fluidized bed and baffle-type technology, which is applied in the field of large-scale industrial devices, can solve the problems of difficult implementation, limited use, and many equipment, and achieve the effects of reducing crushing energy consumption, improving fluidization effect, and ensuring drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

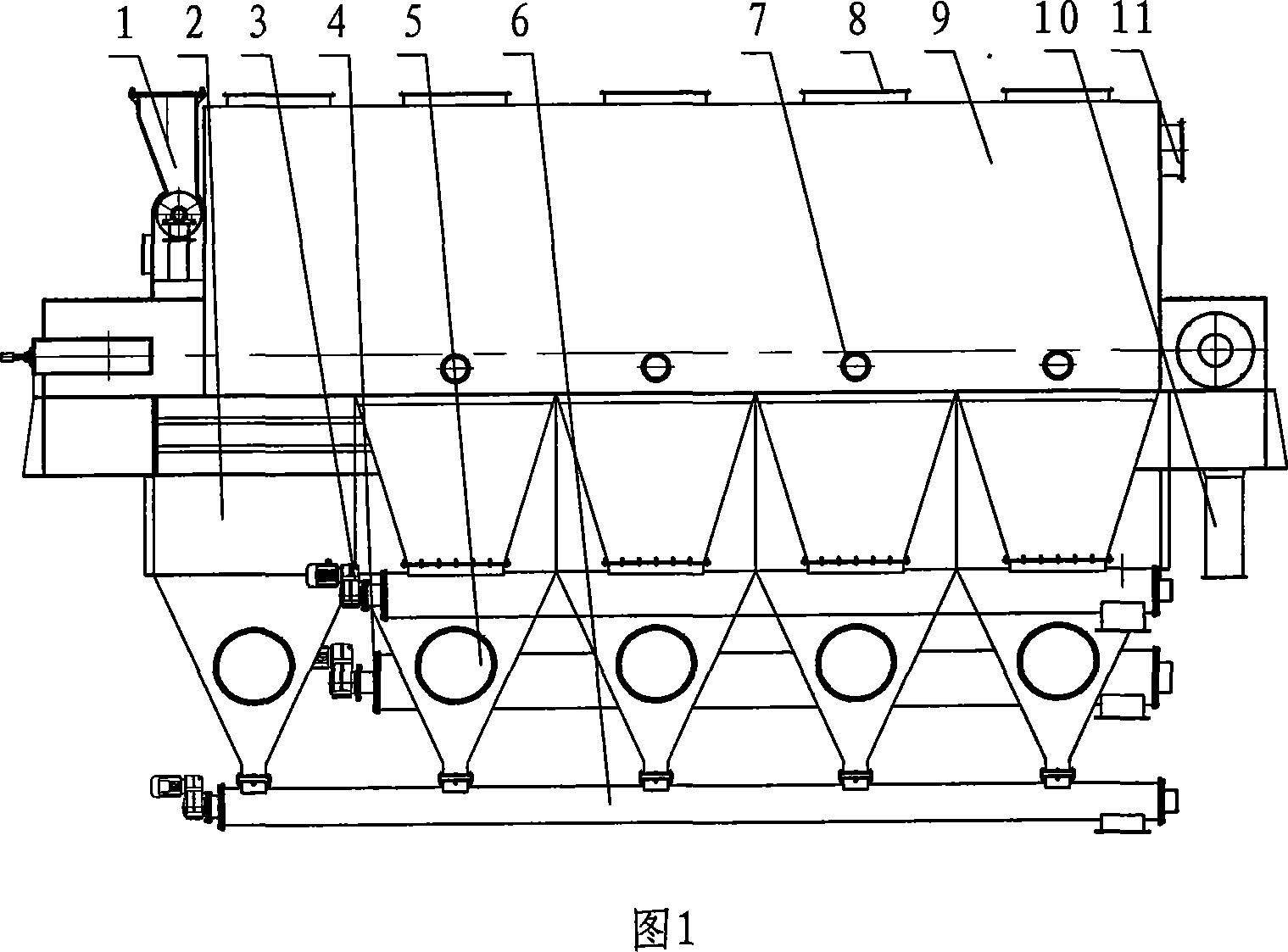

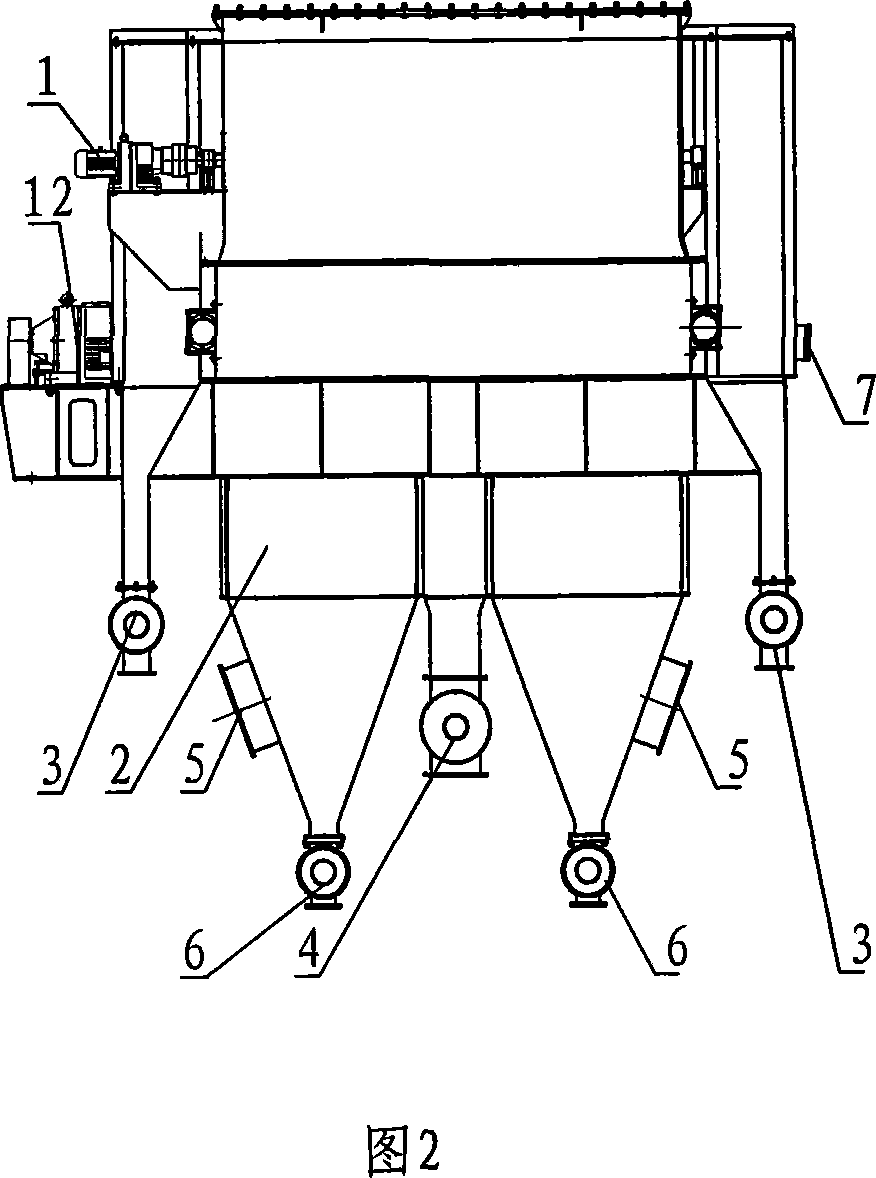

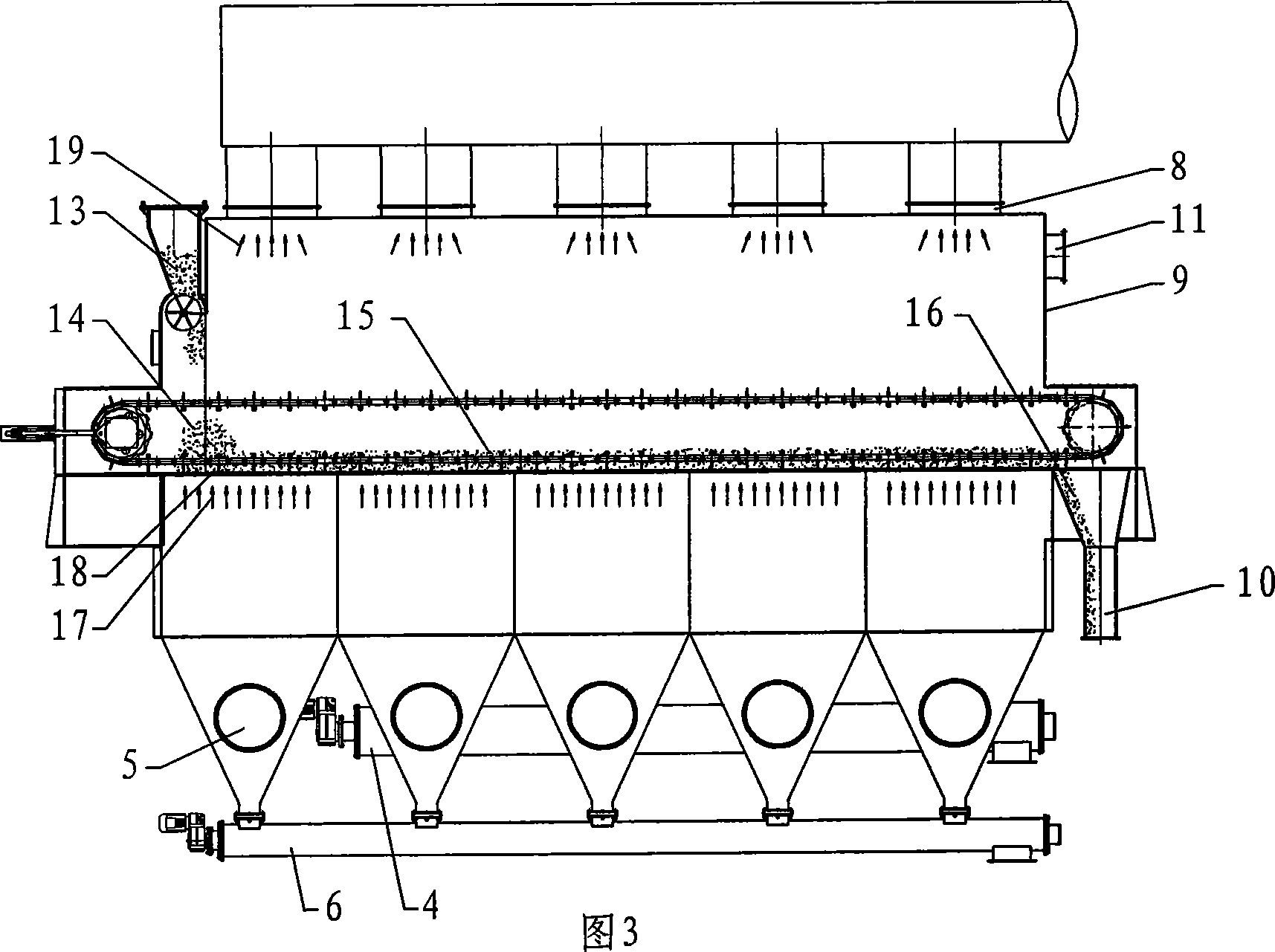

[0019] The movable partition fluidized bed includes a fluidized bed body, a feeding device and a discharging device, an air supply structure and an air outlet structure, and a moving partition device located in the fluidized bed body.

[0020] Figure 1, Figure 2, Figure 3. The 9 chambers of the fluidized bed adopt a rectangular box-shaped structure, length × width × height = 12.5 × 5.2 × 3 (m); the effective area of the fluidized bed is 32m 2 , The effective length is 10m, the effective width is 0.8×2=1.6m, and the graded length is 8m. The upper left side is a star-shaped feeding device 1, and the coking raw coal enters the fluidized bed sieve plate 18 in the bed through the star-shaped feeding device 1; the bottom is a fluidized bed sieve plate with mesh holes. 2 independent air chambers.

[0021] In order to ensure the fluidization effect, ten independent air chambers 2 are used, five air chambers are arranged in the length direction, and two air chambers are arranged in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com