Thermosetting type glass screen printing ink and preparation method thereof

A glass fiber, thermosetting technology, applied in inks, household appliances, applications, etc., can solve the problems of ink easily rubbed off, long drying time, VOC emission, etc., to ensure dryness and water resistance, simple preparation method, Meet the effect of industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

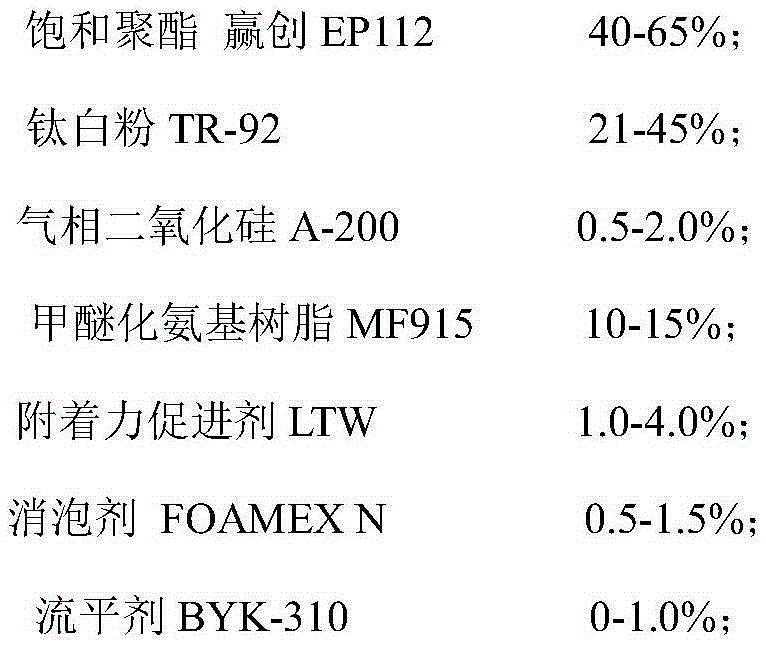

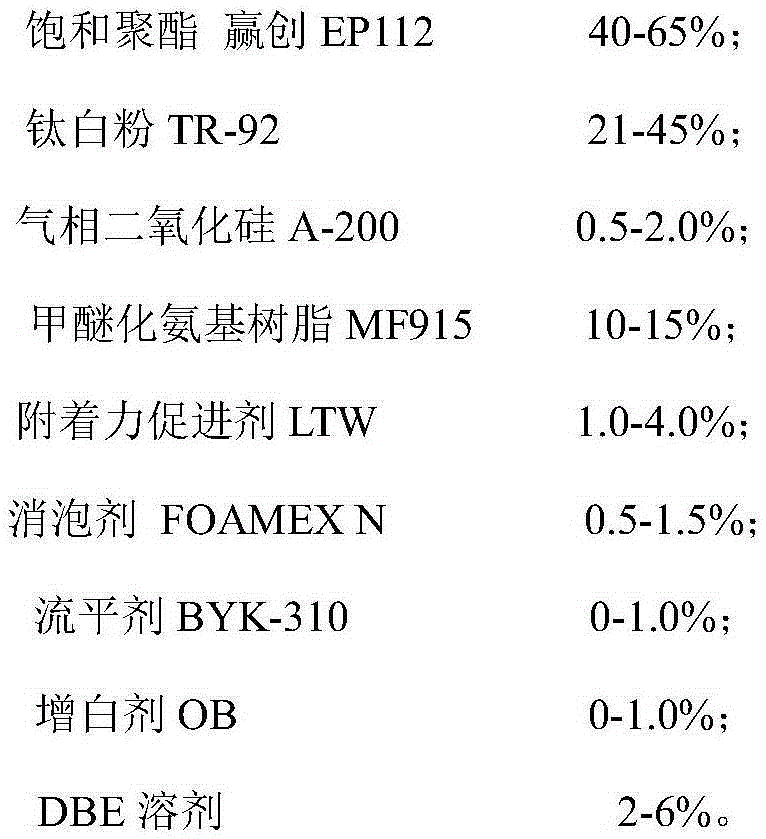

[0031] A thermosetting glass screen printing ink, its raw materials are as shown in Example 1 in Table 1:

[0032] The preparation method of the above-mentioned thermosetting glass screen printing ink is as follows:

[0033] (a) Stir the amount of saturated polyester at a rate of 300 rpm, add titanium dioxide and fumed silicon dioxide while stirring, stir at 50°C for 30 minutes at a rate of 700 rpm, and grind and pulverize to a particle size The diameter is below 10um;

[0034] (b) After cooling to 25°C, at a stirring rate of 100 rpm, sequentially add methylated amino resin, adhesion promoter, and defoamer, and stir at 50°C for 30 minutes at a rate of 700 rpm;

[0035] (c) Add DBE solvent at a stirring rate of 100 rpm, stir at 60°C for 30 minutes, cool to 25°C, filter through a 200-mesh sieve, pack, and measure the viscosity of the system to be 25000mPa.S / 25°C.

Embodiment 2

[0037] A kind of thermosetting glass screen printing ink, its raw material is as shown in embodiment 2 in table 1:

[0038] The preparation method of the above-mentioned thermosetting glass screen printing ink is as follows:

[0039] (a) Stir the amount of saturated polyester at a rate of 400 rpm, add titanium dioxide and fumed silicon dioxide while stirring, stir at 60°C for 35 minutes at a rate of 850 rpm, and grind and pulverize to granules The diameter is below 10um;

[0040] (b) After cooling to 28°C, at a stirring rate of 200 rpm, add methylated amino resin, adhesion promoter, defoamer and leveling agent in sequence, and at a rate of 500 rpm at 60°C Stir for 40 minutes;

[0041] (c) Add DBE solvent at a stirring rate of 200 rpm, stir at 50°C for 35 minutes, cool to 28°C, then filter through a 200-mesh sieve, pack, and measure the viscosity of the system as 27000mPa.S / 25°C .

Embodiment 3

[0043] A kind of thermosetting glass screen printing ink, its raw material is as shown in embodiment 3 in table 1:

[0044] The preparation method of the above-mentioned thermosetting glass screen printing ink is as follows:

[0045] (a) Stir the amount of saturated polyester at a rate of 500 rpm, add titanium dioxide and fumed silicon dioxide while stirring, stir at 70°C for 50 minutes at a rate of 950 rpm, and grind and pulverize to a particle size The diameter is below 10um;

[0046] (b) After cooling to 30°C, add methyl etherified amino resin, adhesion promoter, defoamer and whitening agent in sequence at a stirring rate of 300 rpm, and stir at a rate of 300 rpm at 80°C 30 minutes;

[0047] (c) Add DBE solvent at a stirring rate of 300 rpm, stir at 50°C for 25 minutes, cool to 28°C, filter through a 200-mesh sieve, and pack. The measured viscosity of the system is 30000mPa.S / 25°C .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com