Coating method of radar wave absorbing coating

A radar wave-absorbing coating and wave-absorbing coating technology, which can be applied to devices, coatings, special surfaces, etc. that apply liquid to the surface, which can solve the problem of thick coating design thickness, affecting the mechanical properties and stealth performance of the coating, and absorbing The problem of high density of wave coatings, etc., to achieve the effect of ensuring performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

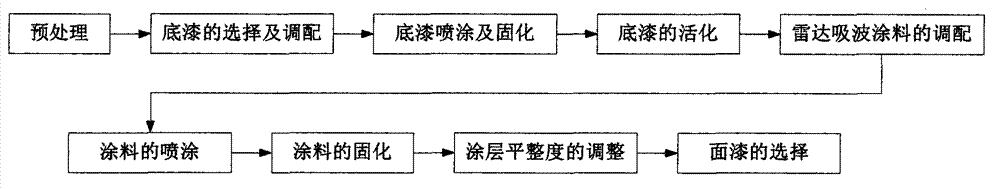

[0029] The coating method of a kind of radar absorbing coating provided by the present invention is introduced below in conjunction with accompanying drawing and embodiment:

[0030] like figure 1 Shown, a kind of coating method of radar wave-absorbing coating comprises the steps:

[0031] Step S1: Pretreatment of the base material of the radar absorbing coating;

[0032] Step S2: selection and deployment of primer;

[0033] Step S3: spraying and curing of primer;

[0034] Step S4: activation of primer;

[0035] Step S5: deployment of radar absorbing paint;

[0036] Step S6: spraying of radar absorbing paint;

[0037] Step S7: Curing of the paint.

[0038] Additionally, it may include:

[0039] Step S8: Adjustment of coating surface roughness;

[0040] Step S9: Selection of top coat.

[0041] In order to obtain better results, the above steps can be selected or optimized as follows:

[0042] ① Pretreatment. The base material of the radar absorbing coating is a metal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com