Composite emulsion for water-based plastic base paint and preparation method of composite emulsion

A composite emulsion, water-based technology, applied in coatings and other directions, can solve the problems of large structural differences, increased coating costs, complicated operations, etc., and achieves the effect of fast drying and accelerated drying.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

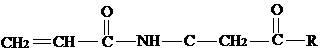

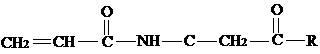

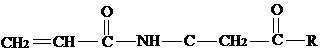

Image

Examples

Embodiment 1

[0057] Example 1 Aqueous room temperature self-crosslinking polyacrylate copolymer emulsion

[0058] The preparation of the water-based room-temperature self-crosslinking polyacrylate copolymer emulsion of this embodiment adopts the semi-continuous method in the seed emulsion polymerization method.

[0059] The emulsifier adopts 0.7g sodium lauryl sulfate.

[0060] The initiator adopts 0.67g of potassium persulfate to dissolve in 120g of water and mix well to obtain the required aqueous solution of potassium persulfate.

[0061] The total amount of nuclear monomer is 135.2g, and the nuclear monomer is composed of methyl methacrylate, butyl acrylate and methacrylic acid, wherein the molar ratio of methyl methacrylate to butyl acrylate is 1:1, and methyl Acrylic acid is 10g; the Tg value of the core layer is about -5°C.

[0062] The total amount of shell monomer is 112.88g, and the shell monomer is composed of 8.46g diacetone acrylamide, penetrant, 33.5g methyl methacrylate, 4...

Embodiment 2

[0065] Example 2 Aqueous room temperature self-crosslinking polyacrylate copolymer emulsion

[0066] The preparation of the water-based room-temperature self-crosslinking polyacrylate copolymer emulsion of this embodiment adopts the semi-continuous method in the seed emulsion polymerization method.

[0067] The emulsifier adopts 0.7g sodium lauryl sulfate.

[0068] The initiator adopts 0.67g of potassium persulfate to dissolve in 120g of water and mix well to obtain the required aqueous solution of potassium persulfate.

[0069] The total amount of nuclear monomer is 135.2g, and the nuclear monomer is composed of methyl methacrylate, butyl acrylate and methacrylic acid, wherein the molar ratio of methyl methacrylate to butyl acrylate is 1:1, and methyl Acrylic acid is 10g; the Tg value of the core layer is about -5°C.

[0070] The total amount of shell monomer is 112.88g, and the shell monomer is composed of 8.46g diacetone acrylamide, penetrant, 33.5g methyl methacrylate, 4...

Embodiment 3

[0073] Example 3 Aqueous room temperature self-crosslinking polyacrylate copolymer emulsion

[0074] The preparation of the water-based room-temperature self-crosslinking polyacrylate copolymer emulsion of this embodiment adopts the semi-continuous method in the seed emulsion polymerization method.

[0075] The emulsifier adopts 0.7g sodium lauryl sulfate.

[0076] The initiator adopts 0.67g of potassium persulfate to dissolve in 120g of water and mix well to obtain the required aqueous solution of potassium persulfate.

[0077] The total amount of nuclear monomer is 110g, and the nuclear monomer is composed of methyl methacrylate, butyl acrylate and methacrylic acid, wherein the molar ratio of methyl methacrylate to butyl acrylate is 1.28:1, and methacrylic acid It is 10g; the Tg value of the core layer is about -2°C.

[0078] The total amount of shell monomer is 100.48g, and the shell monomer is composed of 8.46g diacetone acrylamide, penetrant, 37.9g methyl methacrylate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com