Patents

Literature

214results about How to "Does not affect adhesion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Concrete superficial hardener and construction method thereof

InactiveCN101407428AHigh mechanical strengthHigh surface hardnessUltimate tensile strengthMaterials science

The invention discloses a concrete surface hardener and a construction method thereof, wherein, the concrete surface hardener comprises the compositions by weight percent of 10-40 percent of inorganic silicate, 1-10 percent of alkali, 0.1-5 percent of catalyst, 0.1-2 percent of wetting dispersant, 1-5 percent of stabilizer and rest of water. The hardener prepared by the invention is characterized by easily-obtained material, simple production and convenient construction, unhealthy and environmentally harmful VOC avoidance, etc. In addition, the hardener can penetrate into the interior of the concrete to seal the capillary of the concrete, thus improving the surface density of the concrete, strengthening the impervious capability and strength of the concrete and prolonging the service life of the concrete. As the hardener does not comprise unhealthy and environmentally harmful substances, the increasingly improved requirements of the present environmental protection can be met, thus having extensive application prospect.

Owner:GUANGZHOU SUPER CHEM COATING CO LTDGUANGZHOU SUPER CHEM COATING CO LTD

Water-cured polyurethane waterproof coating

InactiveCN102181225AImprove mechanical propertiesGood chemical propertiesPolyurea/polyurethane coatingsSolventMechanical property

The invention discloses a single-component water-cured polyurethane waterproof coating. The single-component coating is a NCO group terminated prepolymer obtained by the reaction of polyether polyol and polyisocyanate after the polyether polyol is hydrated in vacuum; and the weight ratio of the polyether polyol to the polyisocyanate is (2-10): 1. The coating is ecological and environment-friendly, has excellent mechanical property, good high and low temperature resistance and good solvent resistance and corrosion resistance, can be constructed on moist basal planes, does not affect adhesive property, and has high cost performance, low specific weight, low consumption in unit area and low comprehensive manufacturing cost.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD +2

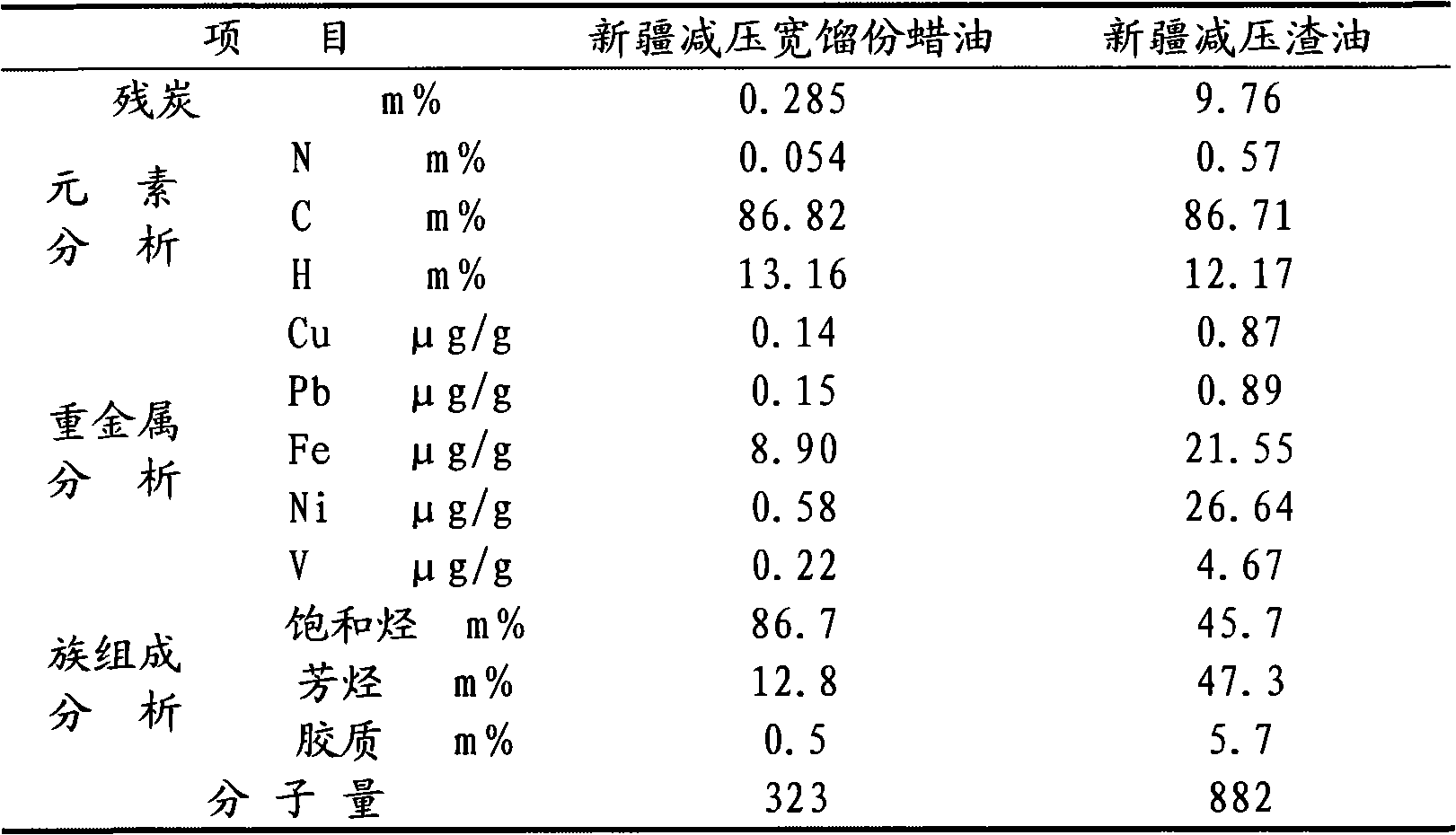

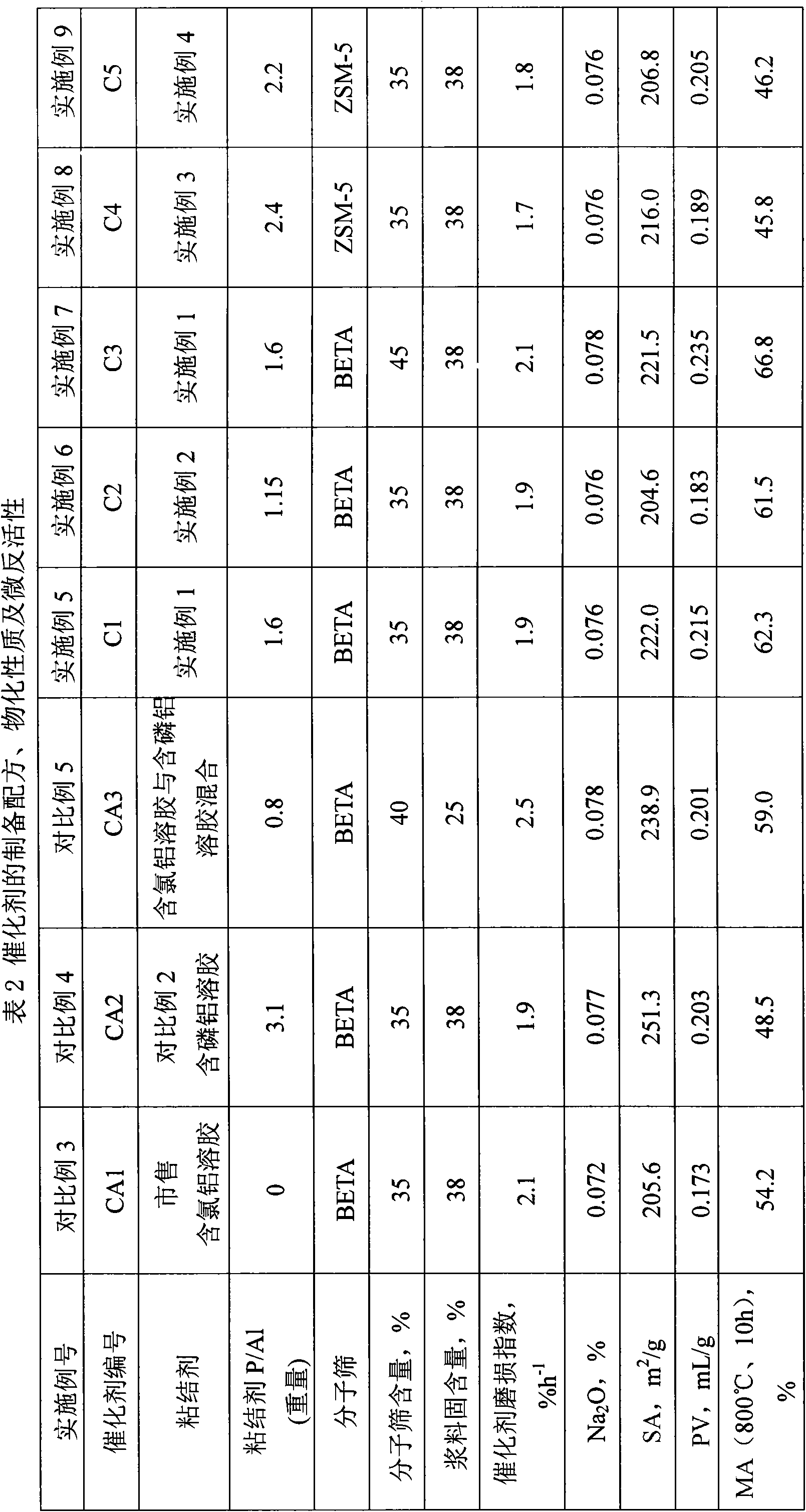

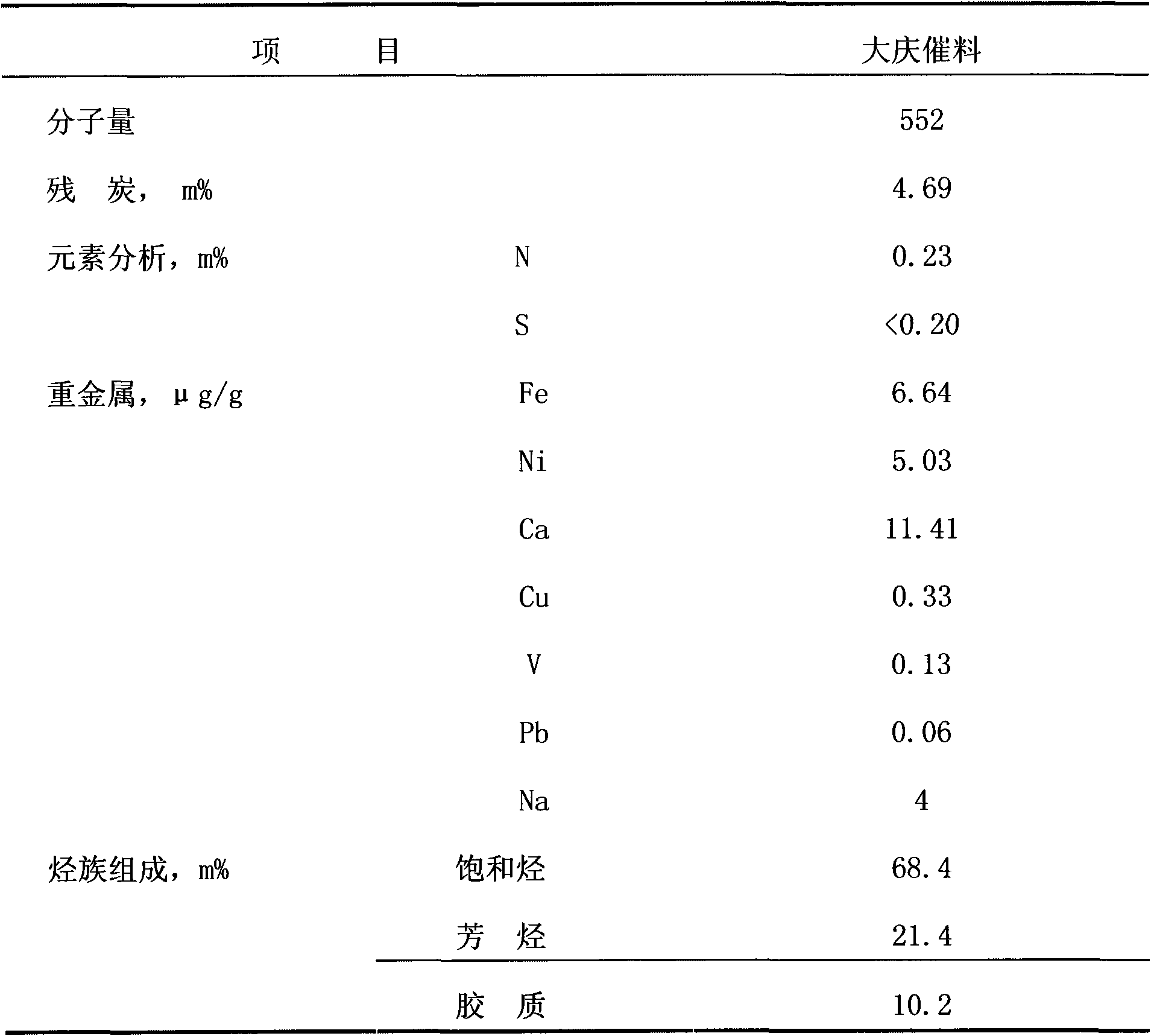

Aluminium phosphate sol used for catalyst and preparation method thereof

ActiveCN102050434AHigh activityHigh yieldPhysical/chemical process catalystsCatalytic crackingHydrogen NitratePhosphoric acid

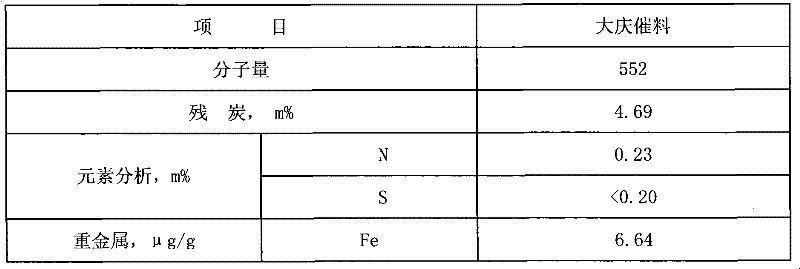

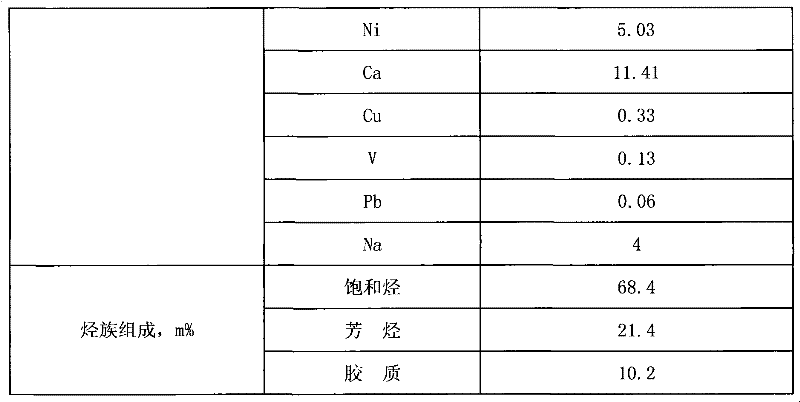

The invention relates to a preparation method of aluminium phosphate sol used for a petroleum hydrocarbon cracking catalyst, which is characterized by comprising the steps of: mashing and dispersing an acid soluble aluminum precursor and decationed water into serous liquid with solid content of 15-35 percent, slowly adding phosphoric acid with concentration of 60-98 percent into the serous liquidunder the stirring according to the weight proportion of P / Al=1.0-2.5; then adding hydrogen nitrate with concentration of 40-98 percent according to the weight proportion of HNO3 / Al2O3=0.2-2.0, rapidly reacting and releasing a large quantity of heat; and generating colorless transparent thick liquid after the reaction. The microactivity of the catalytic cracking catalyst prepared by adopting the aluminium phosphate sol bonder provided by the invention is remarkably improved. The selectivity of the aluminium phosphate sol is improved, the yields of gas and coke are remarkably reduced, and the yields of light oil and propylene are improved.

Owner:PETROCHINA CO LTD

Ultraviolet cured paint composition and preparation thereof

InactiveCN101275054AImprove wear resistanceHigh hardnessPolyurea/polyurethane coatingsInput/output processes for data processingOrganic solventUV curing

The present invention provides an uv curing coating compound and its preparing method, wherein, the weight percentage of the uv curing coating compound is: polyurethane acrylate 35-60%, reactive diluents 10-20%, uv photoinitiator 3-5%, promoter 0-1.5%, fluoride-containing modified polyurethane acrylic 10-20%, organic solvent 10-40%. The protective layer formed by the uv curing coating compound has high rigidity and excellent wear resistance, especially fit for mobile phone keyboard.

Owner:BYD CO LTD

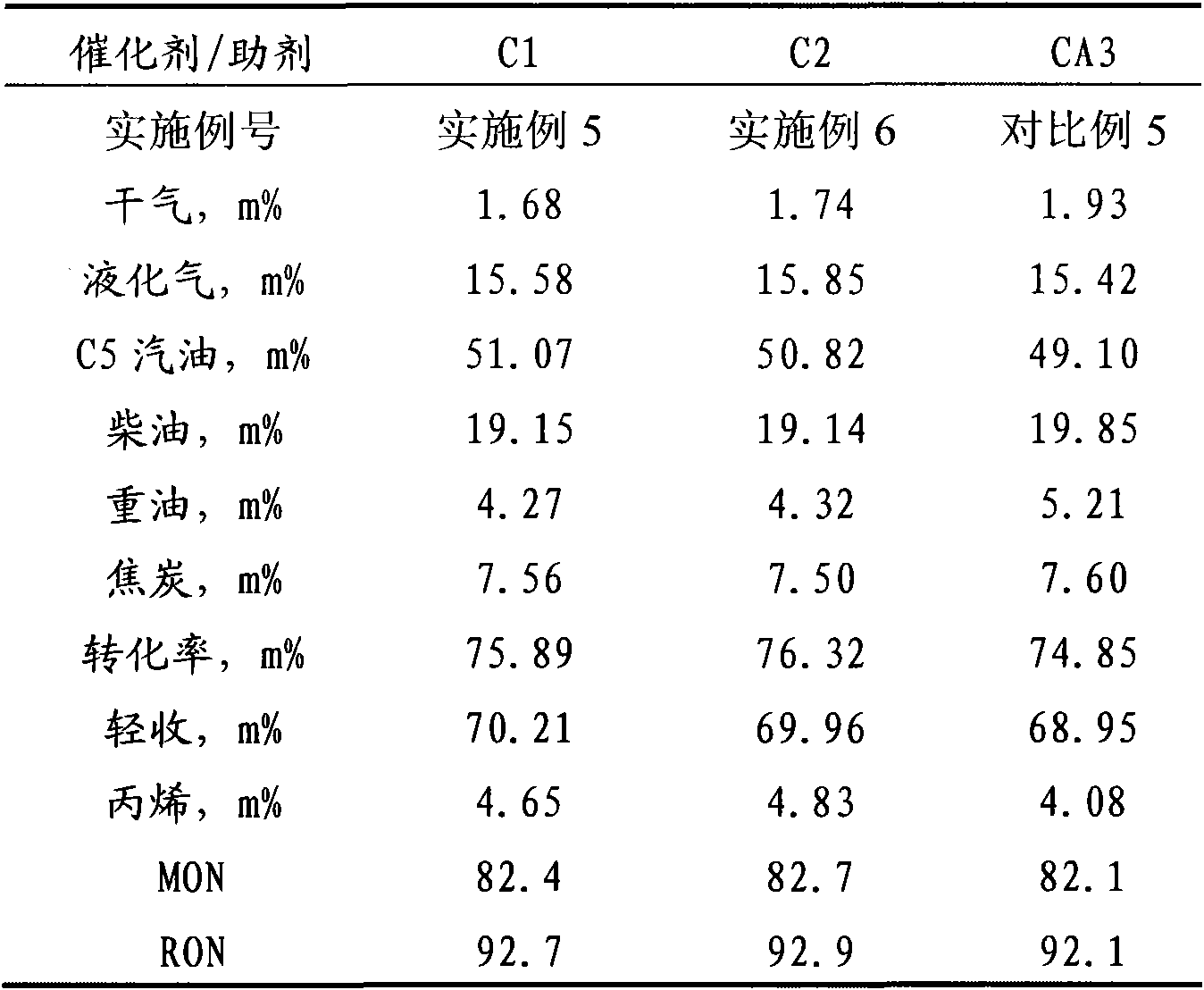

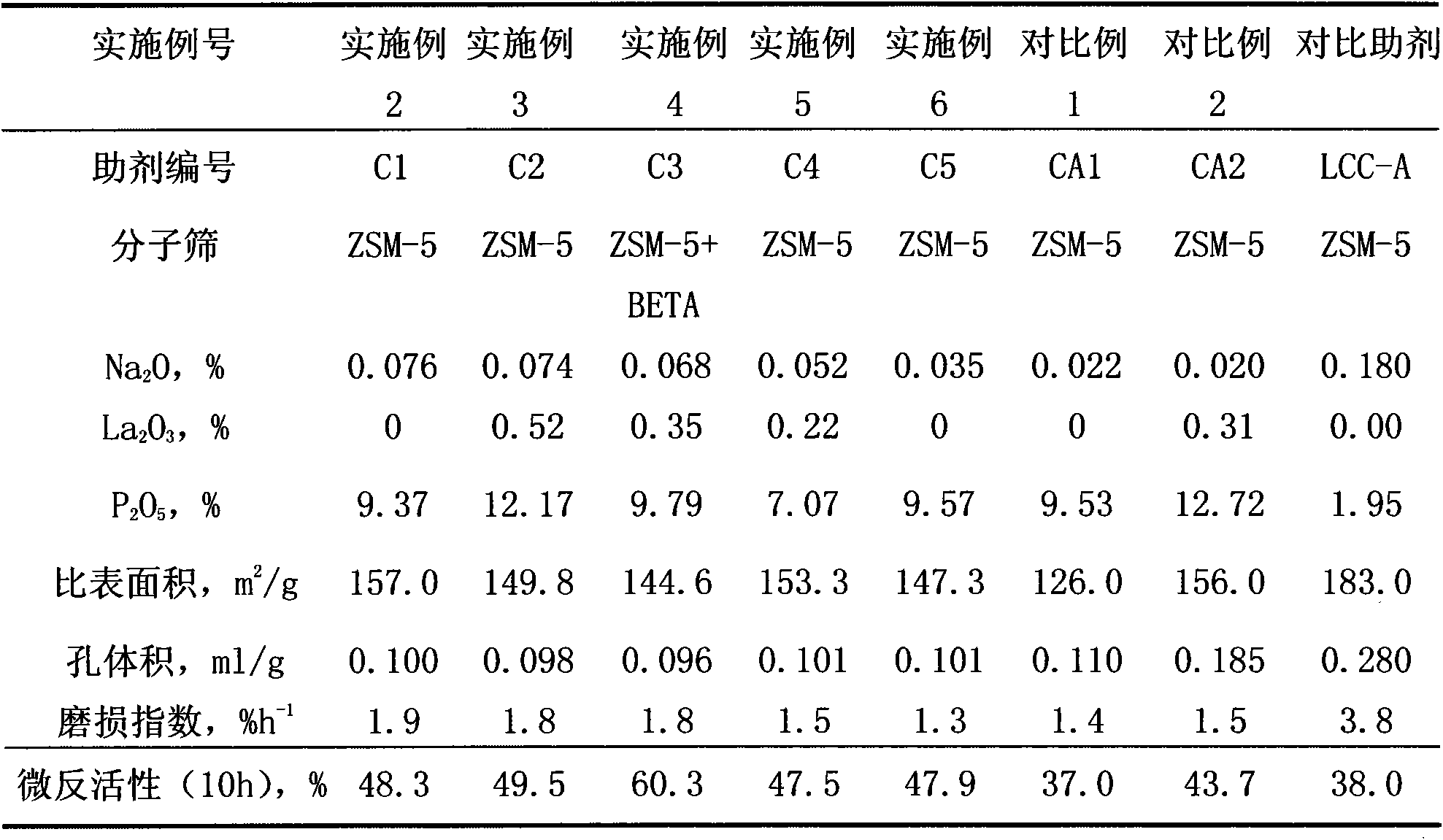

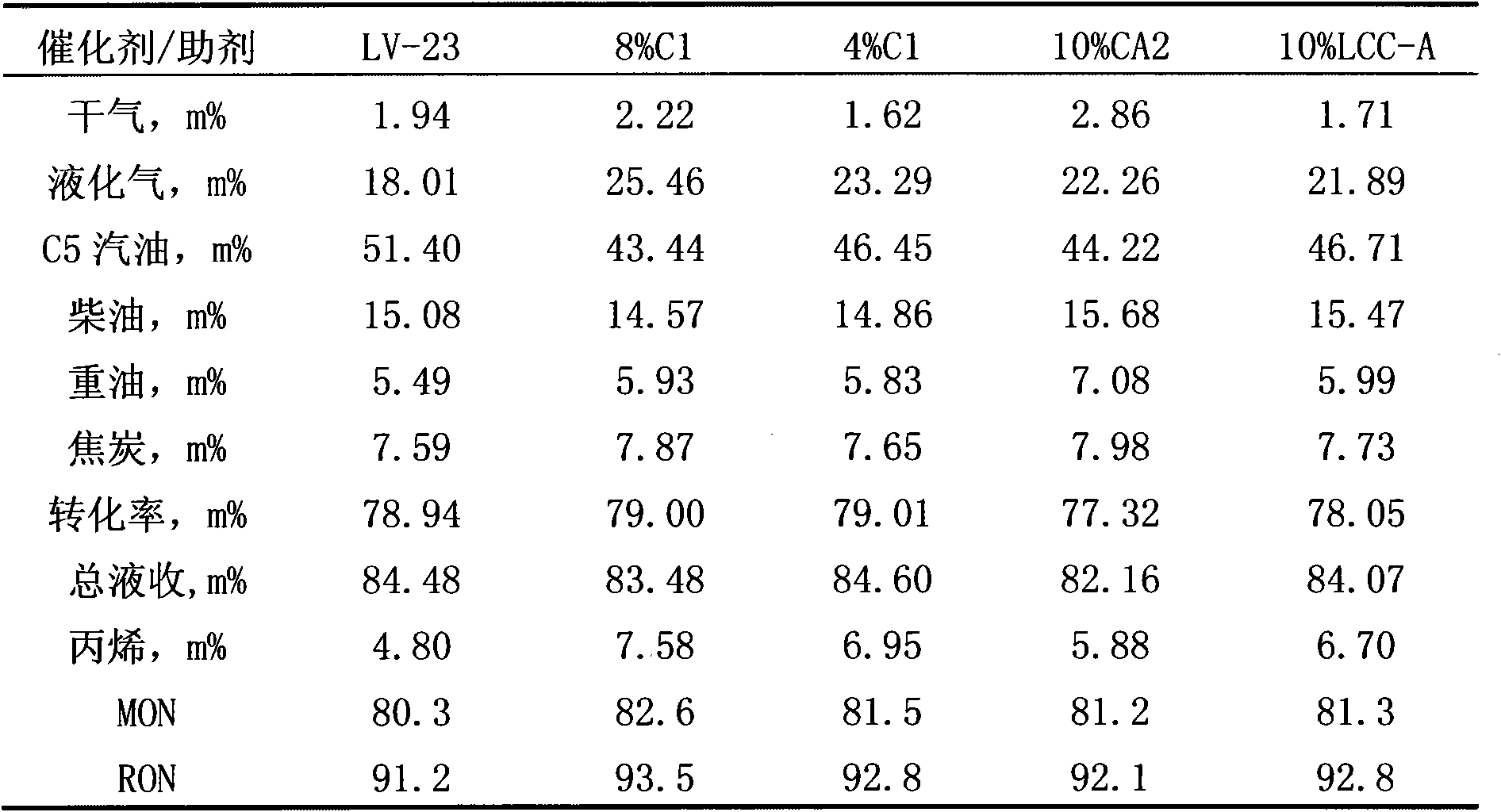

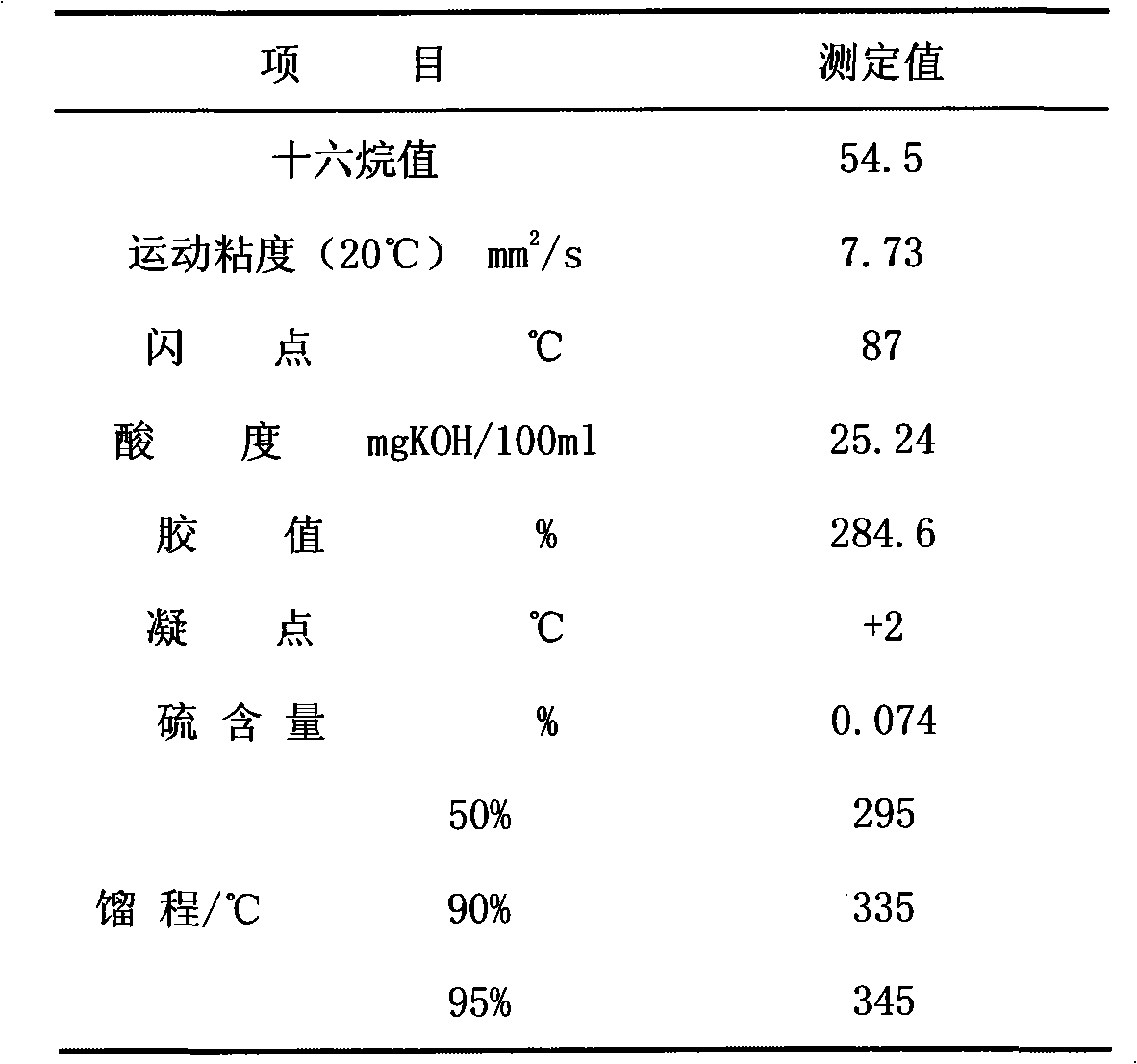

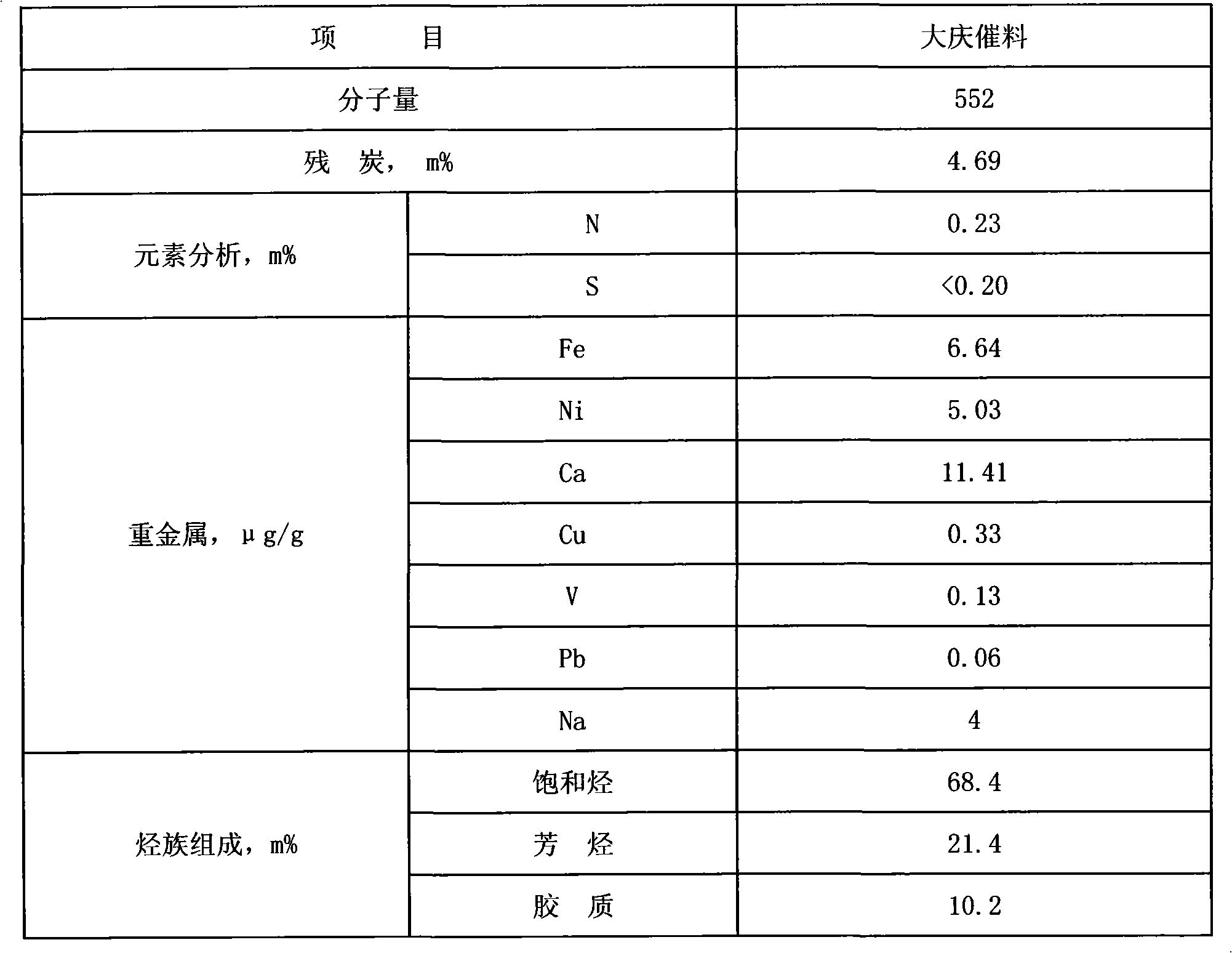

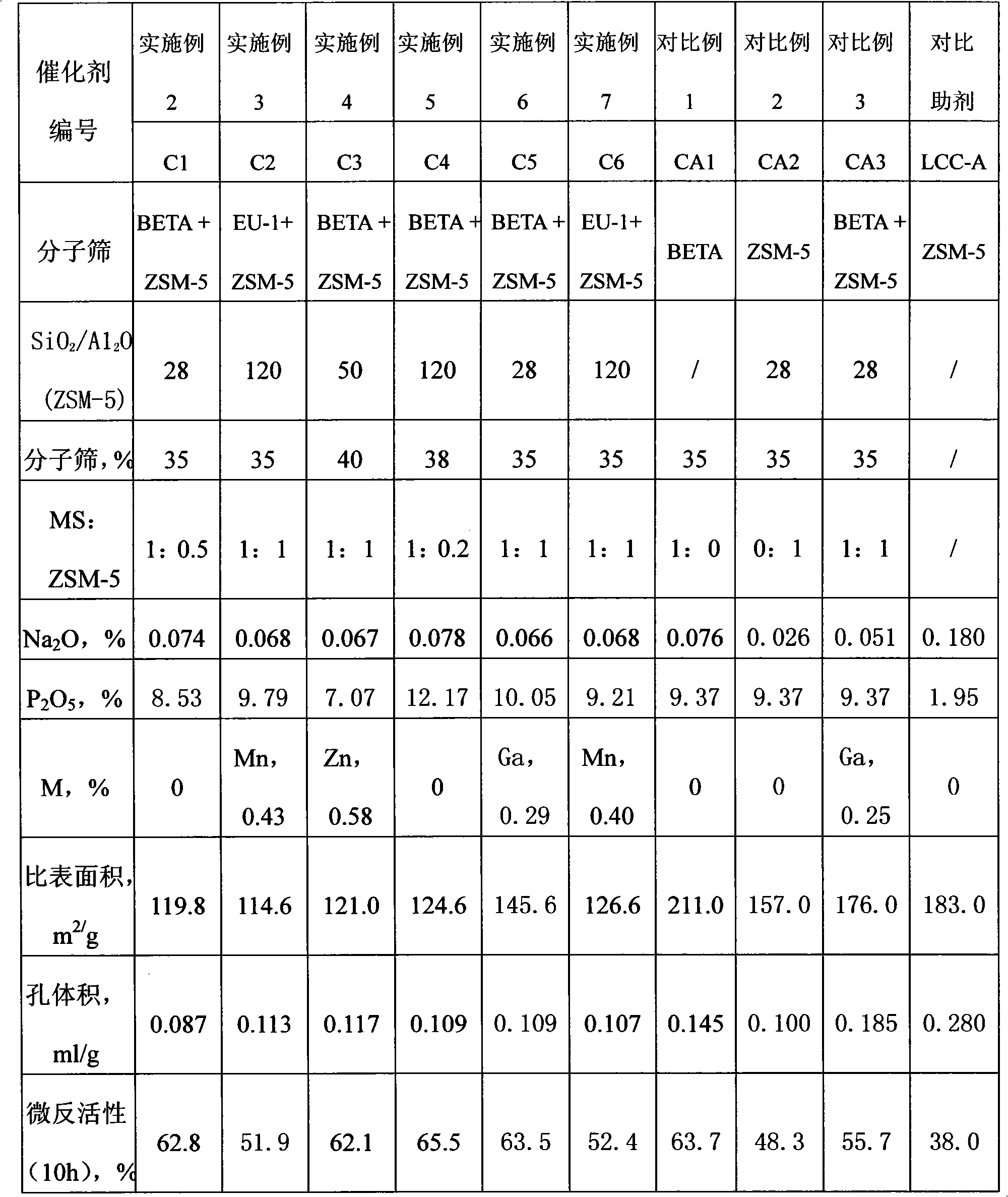

Catalytic cracking propylene additive and preparation method thereof

ActiveCN102049284AImprove stabilityReduce viscosityCatalytic crackingMolecular sieve catalystsAdhesiveALUMINUM PHOSPHATE

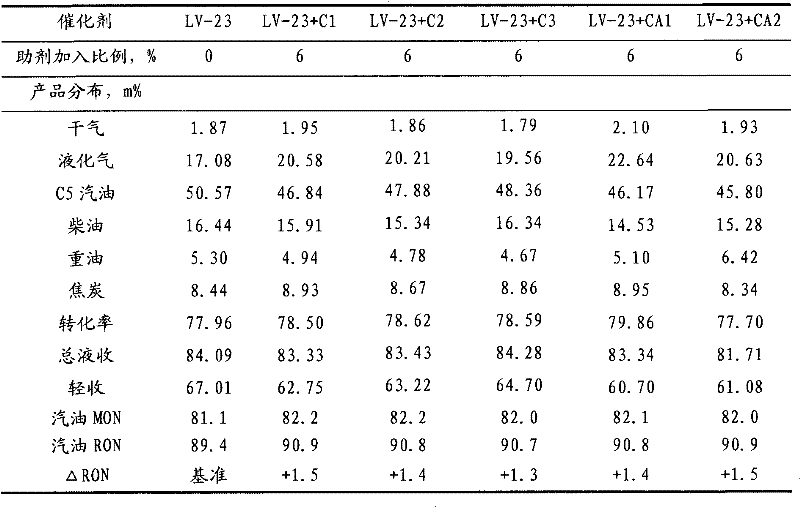

The invention relates to a catalytic cracking propylene additive. The additive measured in the total weight of 100 percent is characterized by being prepared from the following components in percentage by weight: 30-80 percent of molecular sieve including 28-78 percent of ZSM-5 zeolite, 10-65 percent of clay and 5.0-20.0 percent of P2O5, preferable 7.0-15.0 percent as well as 0-1.0 percent of La2O3. Aluminum phosphate sol is adopted as an adhesive to improve the abrasive strength of the additive, improve the solid content of spraying slurry and avoid the chlorine contents of the spraying slurry and the additive. The prepared catalytic cracking propylene additive remarkably improves the activity, slightly lessens the activity of a main catalyst when mixing with the main catalyst for use, can improve the product distribution, have favorable dry gas and coke selectivity and simultaneously improve the propylene yield and the gasoline octane number.

Owner:PETROCHINA CO LTD

Aqueous adhesive for binding rubber and metal and preparation thereof

The invention discloses a water-based adhesive used for the bonding between rubber and metal; according to the parts by weight, the adhesive comprises 60-90 parts of soft monomer, 30-60 parts of hard monomer, 2-8 parts of functional monomer, 3-10 parts of emulsifier, 0.4-0.8 part of initiator, 0.6-1.0 part of pH buffer, 100 parts of deionized water or distilled water, 0.05-0.1 part of anticorrosive bactericide, and 1.4-1.6 parts of pH regulator. The invention also discloses a preparation method for preparing the water-based adhesive. The adhesive can replace the existing solvent-typed adhesive, effectively realizes the bonding between the rubber and the metal, has no poison, no combustion and no explosion, is safe and protects the environment. The preparation method which applies the seed latex polymerization has simple preparation process and high production efficiency and is beneficial for the industrial production.

Owner:GUANGDONG HENGDA NEW MATERIALS TECH

RFCC high octane gasoline additive and preparation method thereof

ActiveCN102049290AHigh strengthSimple preparation processCatalytic crackingMolecular sieve catalystsHydrogenAdditive ingredient

RFCC (Resid Fluid Catalytic Cracking) high octane gasoline additive contains the following ingredients by weight percentage taking the total weight of the additive as 100%: 5-90 of H-type (Hydrogen) composite molecular sieve, 1-60 of BETA or EU-1 molecular sieve, 1-30 of ZSM-5 molecular sieve adopting modified or non-modified chemical elements, 2-60 of clay, and 7.0-15.0 of P(calculated based on P205) wherein the precursor of the P is aluminum phosphate sol; and 2-10 of A1 and 5-15 of P are contained in the aluminum phosphate sol, and the PH value of the aluminum phosphate sol is 1.0 to 2.5; and 2-20 of the aluminum phosphate sol is calculated based on HNO3. By adopting the preparation method provided by the invention, the activity of the FCC additives is significantly enhanced; and owing to mixing use with main catalytic agent, the product distribution can be improved, the gasoline octane value is improved, and the gasoline productivity is improved at the same time.

Owner:PETROCHINA CO LTD

Foaming-free fast-curing high-strength leak-stopping waterproof polyurethane grouting material

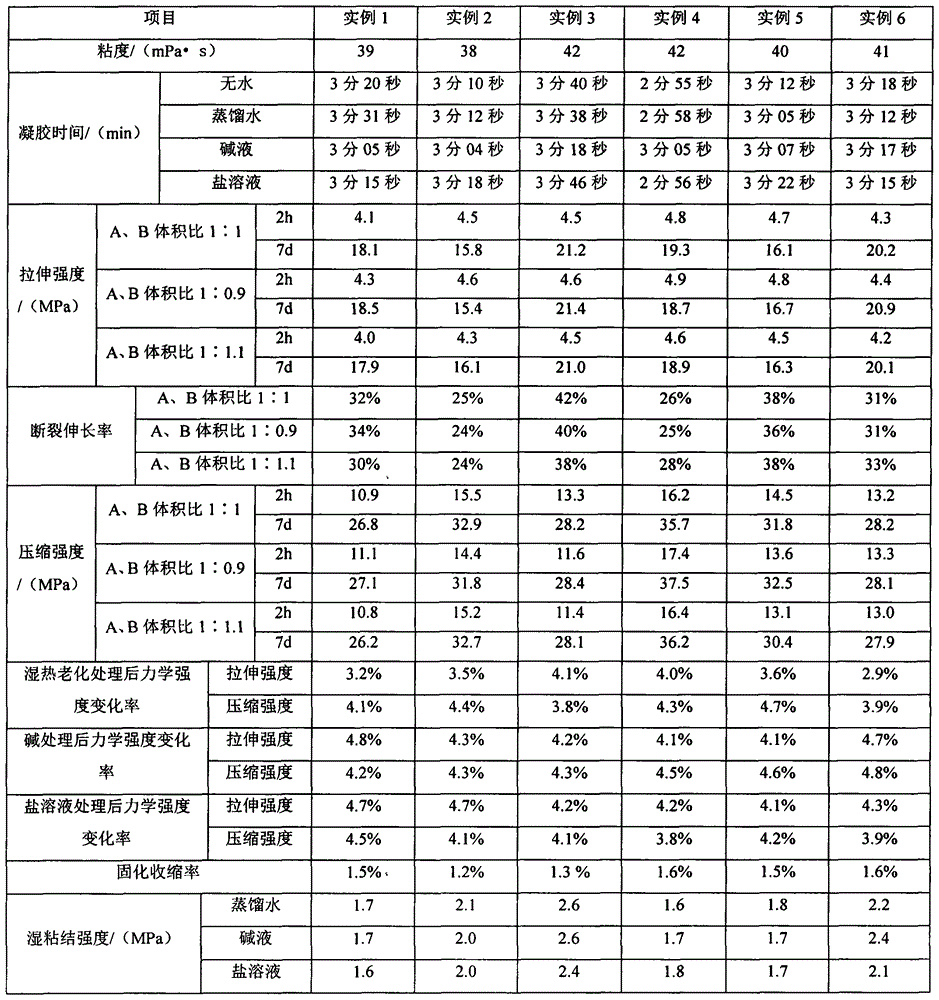

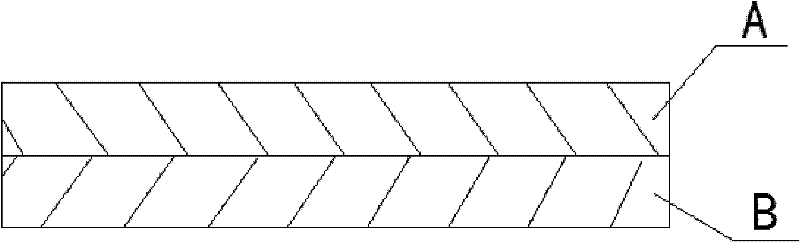

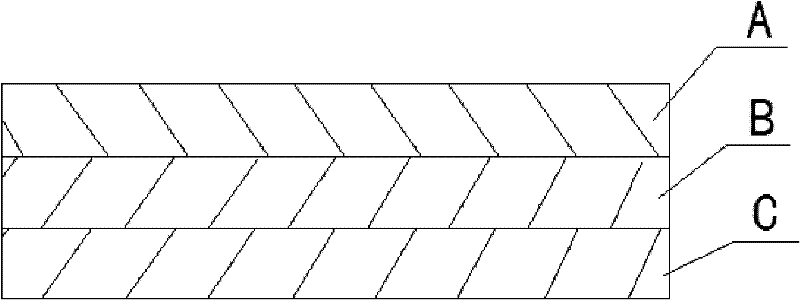

The invention provides a foaming-free fast-curing high-strength leak-stopping waterproof polyurethane grouting material. The material is composed of a component A and a component B, wherein the component A comprises isocyanate monomer, isocyanate prepolymer and highly-hydrophobic environment-friendly plasticizer, the component B comprises high-activity polyether polyol, chain-extending cross-linking agent, highly-hydrophobic environment-friendly plasticizer and antioxidant, and a volume ratio of the component A to the component B is 1: 1. The leak-stopping waterproof polyurethane grouting material has low viscosity, is convenient to grout, has the characteristics of no foaming and fast curing and the advantages of good leak-stopping effect, high mechanical strength and wet bonding strength and excellent aging resistance, and is applicable to rapid leak stopping, water prevention and reinforcement of distress in concrete of an underground construction.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +1

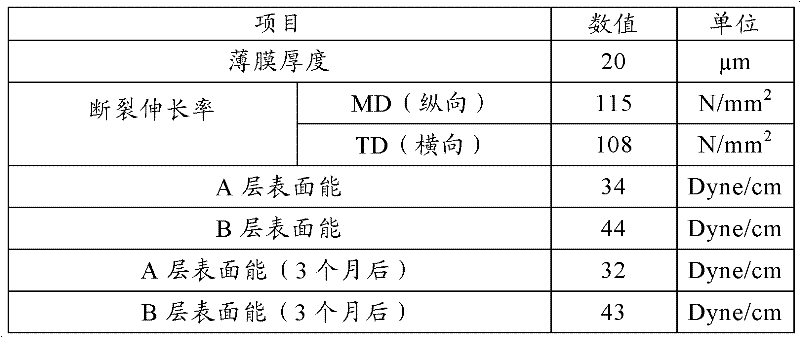

Low surface energy polyester film and preparation method and application thereof

ActiveCN102218881ASimple structurePreparation method scienceSynthetic resin layered productsSurface energyPolyester

The invention discloses a low surface energy polyester film and a preparation method and application thereof. One side of the low surface energy polyester film is a modified polyester layer, and the other side is a low surface energy polyester layer, wherein the modified polyester layer comprises the following components in percentage by weight: 300 to 5,000ppm of antiblocking agent, and the balance of modified polyester; the low surface energy polyester layer comprises the following components in percentage by weight: 90 to 99.9 percent of modified polyester, 0.1 to 10 percent of low surface energy additive, and 300 to 5,000ppm of antiblocking agent. The low surface energy polyester film is simple in structure, scientific in formula and simple and convenient in preparation method, overcomes lots of defects of the prior art, has the advantages of safety, sanitation, corrosion resistance, no conglutination to packaged contents and tight connection with a metal base material, and can be widely applied to metal can food packing industry.

Owner:ORG TECH CO LTD

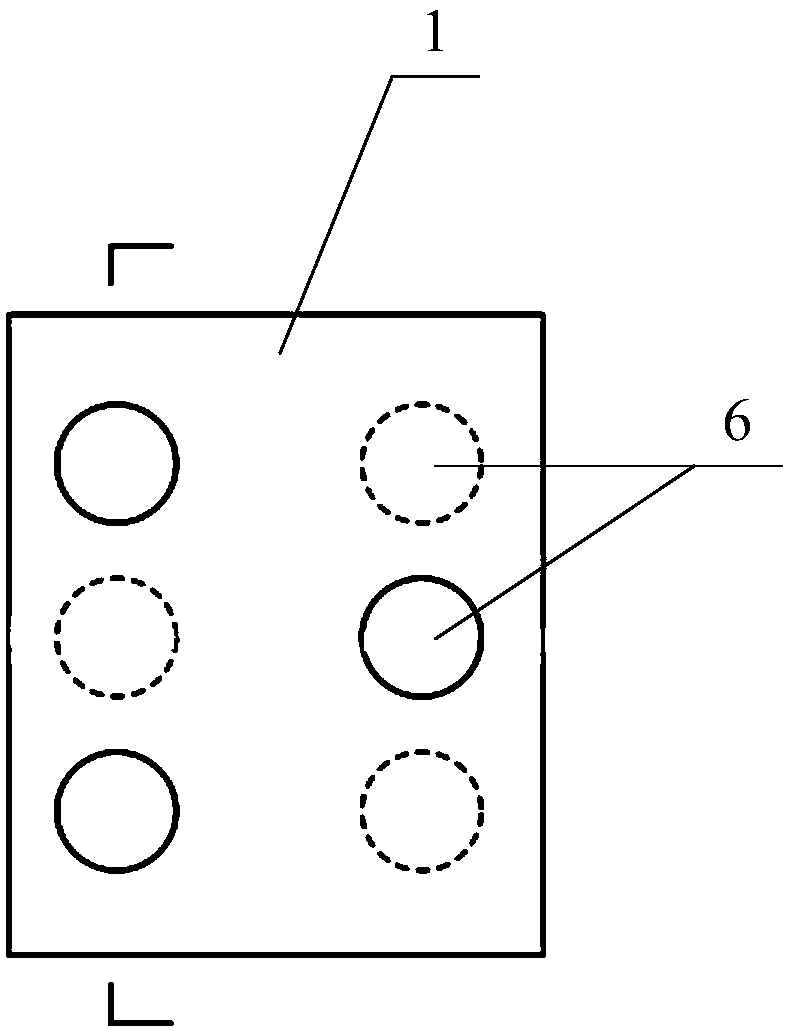

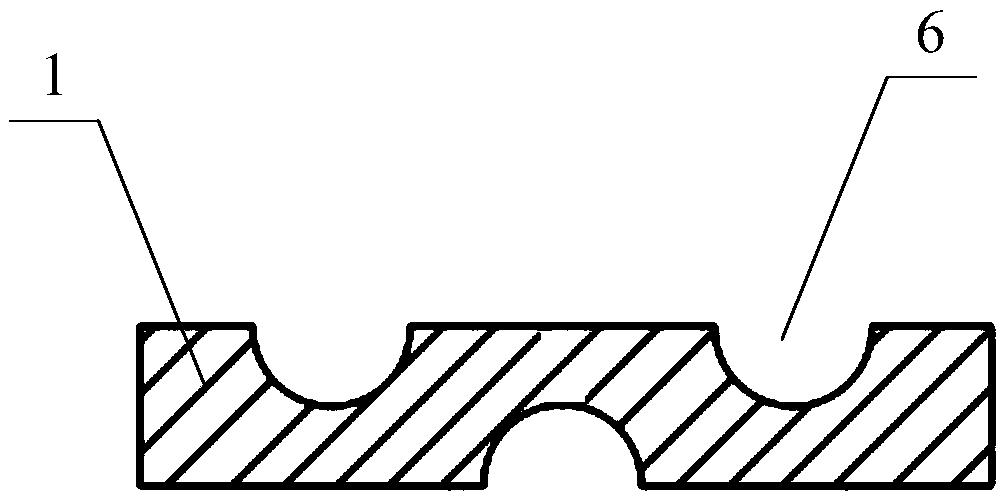

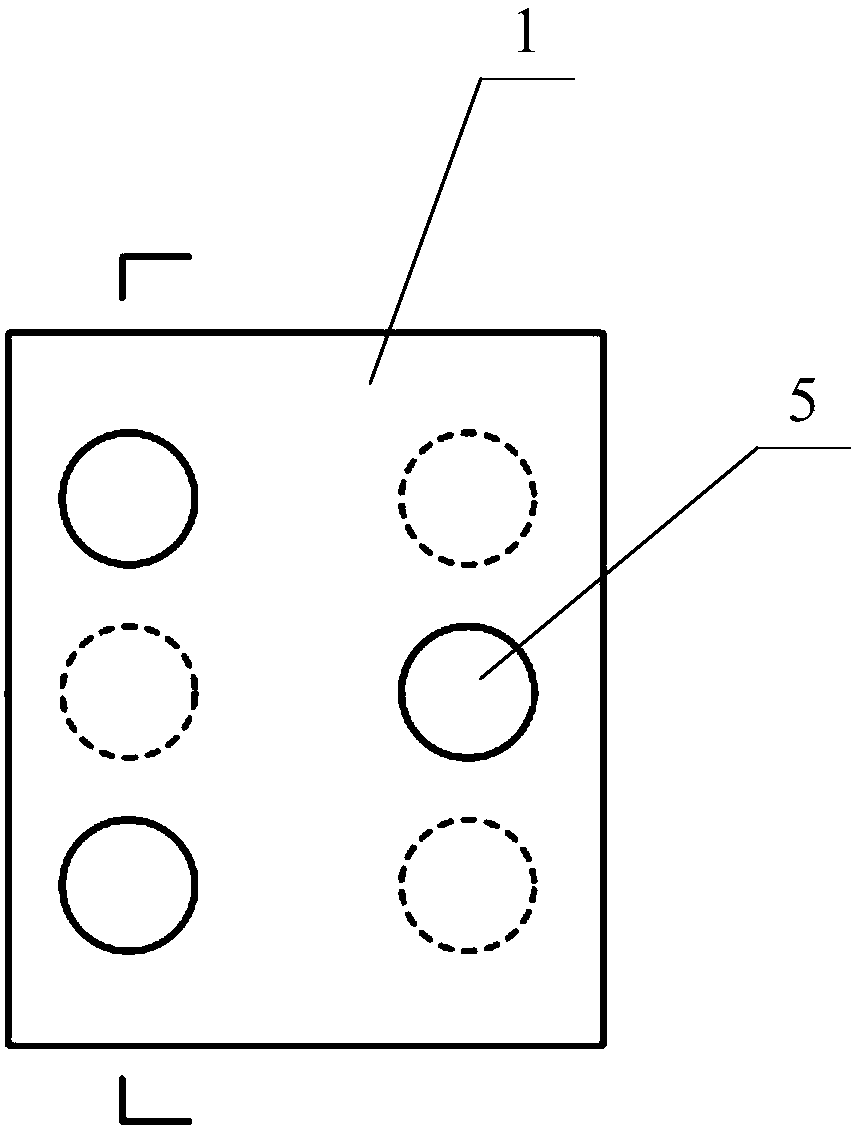

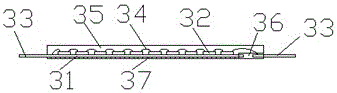

Micro-textured negative plate for preliminary lithium supplementing and preparation method thereof

ActiveCN108847474AAlleviate volume expansionDisperse expansion stressElectrode carriers/collectorsElectrode collector coatingConvex structureLithium

The invention discloses a micro-textured negative plate for preliminary lithium supplementing and a preparation method thereof. The micro-textured negative plate for preliminary lithium supplementingcomprises a negative current collector, micro-textures, preliminary lithium supplementing layers covering the surfaces of pits of the corresponding micro-textures, and active material dressing layerscovering the negative current collector and filling the pits, wherein the micro-textures are arranged on single or double side surfaces of the negative current collector and are of a concave-convex structure. The preliminary lithium supplementing layers are arranged between the negative current collector and the active material dressing layers and are only located on the surfaces of the pits of the micro-textures, so that the cohesive force between active materials and the current collector is not affected, the expansion stress of the active materials can be dispersed, the irreversible capacity is effectively compensated and the first efficiency is improved. Therefore, according to the micro-textured negative plate for preliminary lithium supplementing disclosed by the invention, effectivelithium supplementing can be achieved, volume expansion of the negative plate is relieved, the stability of a negative electrode system is ensured and the problem in the field at the present stage issolved.

Owner:SOUNDON NEW ENERGY TECH CO LTD

Noble metal monolithic catalyst for purifying organic waste gas and preparation method thereof

InactiveCN101811046ASimple processReduce manufacturing costDispersed particle separationCatalyst activation/preparationManganeseCordierite

The invention provides a noble metal monolithic catalyst for purifying organic waste gas and a preparation method thereof. The catalyst is a noble metal monolithic catalyst which uses cordierite ceramic pretreated by dilute nitric acid as a carrier and is loaded with zirconium-manganese mixed oxide serving as a first coating layer and a noble metal palladium active ingredient serving as a second coating layer. The method for preparing the catalyst comprises the following steps of: acidifying the carrier by adopting the dilute nitric acid to increase the specific surface area and the surface coarseness of the carrier, soaking and roasting a precursor loaded with zirconium and manganese serving as the first coating layer, and soaking a precursor loaded with noble metal palladium serving as the second coating layer of the main active ingredient. The catalyst has uniformly-loaded active ingredients, high catalytic performance, little using amount and low cost of noble metal, easy popularization, high catalytic combustion removal efficiency of triphenyl, polycyclic aromatic hydrocarbon and other organic waste gas and low ignition temperature and can be widely applied to the purification treatment of industrial organic waste gas.

Owner:SOUTH CHINA UNIV OF TECH

Expanding type concrete mold releasing agent and preparation method thereof

ActiveCN102229848ANo pollutionDoes not affect adhesionCeramic shaping apparatusLubricant compositionLiquid waterStearic acid

The invention discloses an expanding type concrete mold releasing agent and a preparation method thereof. The expanding type concrete mold releasing agent comprises 12-20 parts of bentonite, 0.5-2 parts of stearic acid, 5-15 parts of coal ash, 15-26 parts of ethanol, 0.3-1.5 parts of liquid water glass, 3-8 parts of nitric acid and 39-55 parts of water. The mold releasing effect of the concrete mold releasing agent is achieved by control on expansion, after mold releasing, the surface of concrete is clean and dense; reinforcing steel bars cannot be polluted, cohesive force between concrete and the reinforcing steel bars is not affected; after the expanding type concrete mold releasing agent is coated, concrete pouring can be performed immediately or when the mold releasing agent is dry; formworks can be cleaned conveniently; the mold releasing agent can be coated conveniently and only needs to be coated once; the mold releasing agent has a certain maintenance function; cost is loweredbecause of the adoption of coal ash and other industrial byproducts; the mold releasing agent can be stored for a long term; and no environmental pollution is caused in the production and utilizationprocesses of the mold releasing agent.

Owner:安徽维东建材股份有限公司

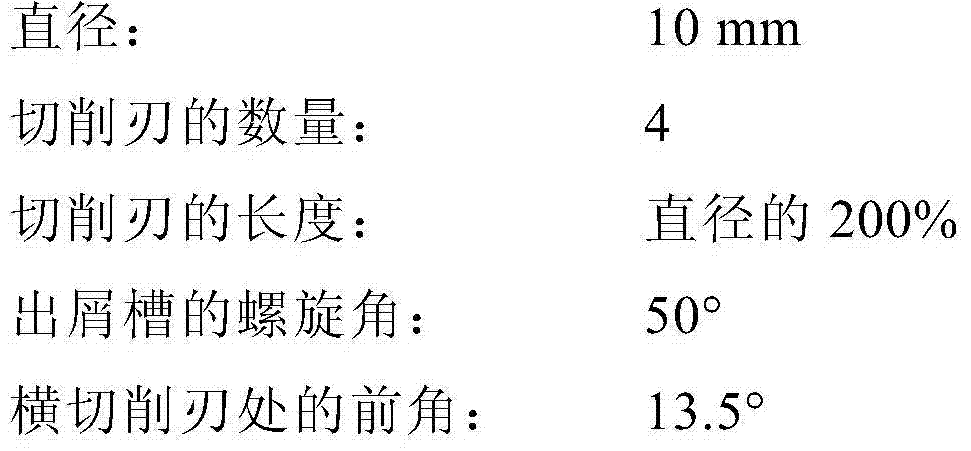

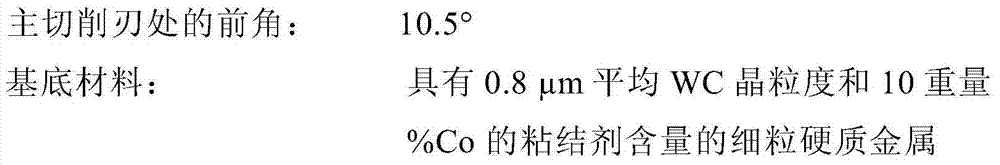

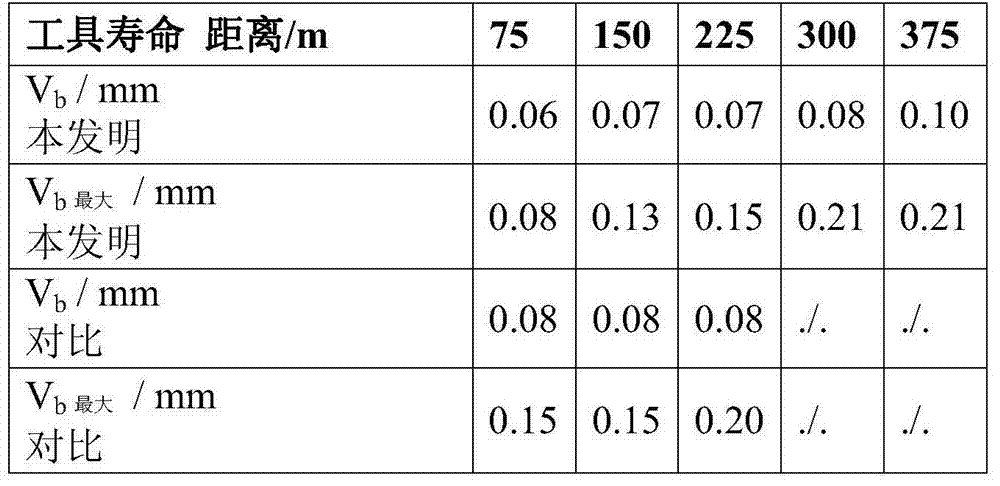

Tialn-coated tool

ActiveCN104520472ASmall sizeReduce crackingMilling cuttersVacuum evaporation coatingPeriodic alternatingWear resistant

A tool with a main body made of hard metal, cermet, ceramic, steel or high-speed steel and a single- or multi-layered wear resistant coating applied thereto in a PVD process, wherein at least one layer of the wear resistant coating is a titanium aluminium nitride layer, TixAlyN where x + y = 1, which can contain, depending on the process used, up to 5 percent by weight of further metals, characterised in that the TixAlyN layer is a multilayer substructure with a plurality of periodically alternating Tix (A)Aly(A)N layers (A), where x(A)+ y(A) = 1 and Tix(B)Aly(B)N layers (B), where x(B) + y(B) = 1, wherein the Al concentration y(B) in layers (B) is at most 70 atomic weight percent (y(B) <= 0.70), and wherein the Al concentration y(B) in layers (B) is 10 to 25 atomic weight percent higher than the Al concentration y(A) in layers (A) (y(B) = (y(A) + 0.10) to (y(A) + 0.25)).

Owner:WALTER AG

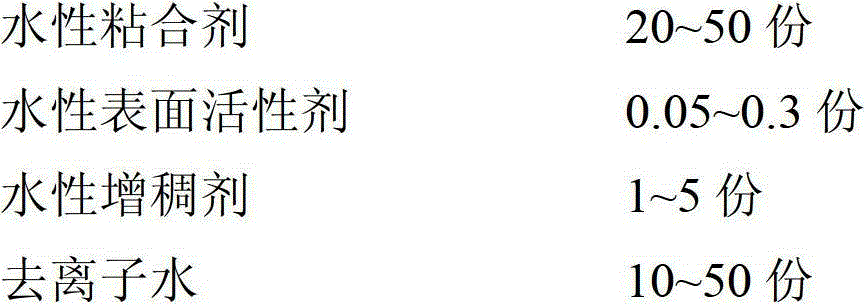

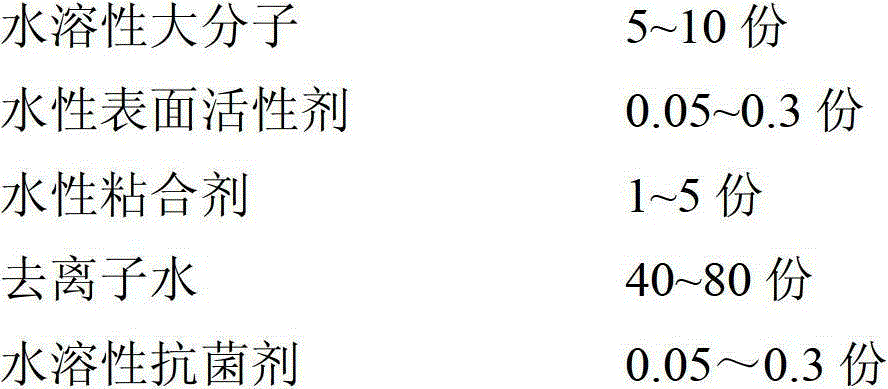

Antimicrobial coat on surface of water system, and its preparation method

ActiveCN103143067ASimple preparation stepsGood water resistanceCatheterCoatingsAntimicrobial effectAdhesive

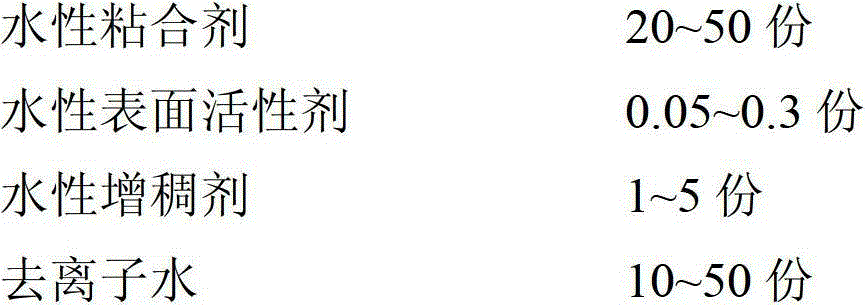

The invention relates to an antimicrobial coat on the surface of a water system, and its preparation method. The antimicrobial coat is characterized in that the antimicrobial coat comprises a primer coat attached to the surface of a medical apparatus matrix, and a surface coat attached to the primer coat, wherein the primer coat is composed of 20-50 parts by weight of an aqueous adhesive, 0.05-0.3 parts by weight of an aqueous surfactant, 1-5 parts by weight of an aqueous thickening agent, and 10-50 parts by weight of deionized water; and the surface coat is composed of 5-10 parts by weight of an aqueous macromolecule, 0.05-0.3 parts by weight of the aqueous surfactant, 1-5 parts by weight of the aqueous adhesive, 40-80 parts by weight of deionized water, and 0.05-0.3 parts by weight of an aqueous antimicrobial agent. Compared with coats in the prior art, the antimicrobial coat provided by the invention has the advantages of environmental protection, effective reduction of the surface friction resistance, and good antimicrobial effect.

Owner:宁波保税区安杰脉德医疗器械有限公司

Composite molecular sieve catalyst capable of improving octane number of gasoline and preparation method of composite molecular sieve catalyst

ActiveCN102451753AA component and B component adjustmentMeet the different needs of the distributionCatalytic crackingMolecular sieve catalystsProduction rateCompound a

The invention relates to a composite molecular sieve catalyst for preparing high-octane gasoline. The catalyst comprises 5-60 parts by weight of molecular sieve dry basis, and the molecular sieve comprises 1-45% of BETA molecular sieve, 1-40% of ZSM-5 molecular sieve, and the balance being clay and other molecular sieves selected from one or more of EU-1, NU-87, SAPO-11, L, and the ITQ, MCM-22, MCM-49, MCM-56, USY and REUSY according to 100%; and a compound A containing the BETA molecular sieve and a compound B containing the ZSM-5 molecular sieve are respectively prepared and are mixed according to the weight ratio of 1:0.1 to 10 to obtain the composite molecular sieve catalyst. In a catalytic cracking unit, the catalyst is used as an addition agent to be mixed with a main catalyst to prepare high-octane gasoline, the gasoline production rate is high, and the production rate of liquefied petroleum can be flexibly adjusted.

Owner:PETROCHINA CO LTD

Composite emulsion for water-based plastic base paint and preparation method of composite emulsion

The invention discloses composite emulsion for water-based plastic base paint and a preparation method of the composite emulsion. The composite emulsion is prepared by blending water-based room temperature self-crosslinked polyacrylate copolymer emulsion with high adhesive force and polyacrylate copolymer emulsion of water-based core-shell structure with high drying speed and high hardness, wherein both the water-based room temperature self-crosslinked polyacrylate copolymer emulsion and the polyacrylate copolymer emulsion of the water-based core-shell structure are emulsion with core-shell structures prepared by adopting a seminal emulsion polymerization method. The raw materials have low price, the synthesis method is simple, the reaction conditions are mild, synthesis of the material can be finished in a reaction vessel, and the method has wide applicability. The composite emulsion for the water-based plastic base paint can have high adhesive force with multiple plastic base materials, and has high drying speed and good paint film performance. The composite emulsion for the water-based plastic base paint can be used for the plastic base materials, can also be used for substances which cannot be baked at a high temperature such as woodenware and the like, and has energy conservation in application and good performance.

Owner:HUAZHONG UNIV OF SCI & TECH +1

Room-temperature curing conductive adhesive

InactiveCN108410388AImprove conductivityImprove adhesionEpoxy resin adhesivesElectrically-conducting adhesivesAdhesiveRoom temperature

The invention discloses a room-temperature curing conductive adhesive which is prepared from, by weight, 5-30% of substrate resin, 40-70% of conductive fillers, 5-20% of curing agents, 1-7% of accelerators, 15-40% of diluting agents and 1-5% of additives. According to the indoor-temperature curing conductive adhesive, indoor-temperature curing can be achieved, indoor-temperature long-term storageis achieved, curing time is short, volume resistivity is low, adhesive force is high, and the conductive adhesive has good conductive performance. The conductive adhesive is stored at the indoor temperature for a long time, the volume resistivity and the adhesive force are not affected, and the conductive adhesive is high in stability, convenient to store and can be used for a long time.

Owner:TAIYUAN HYPERION NEW MATERIAL CO LTD

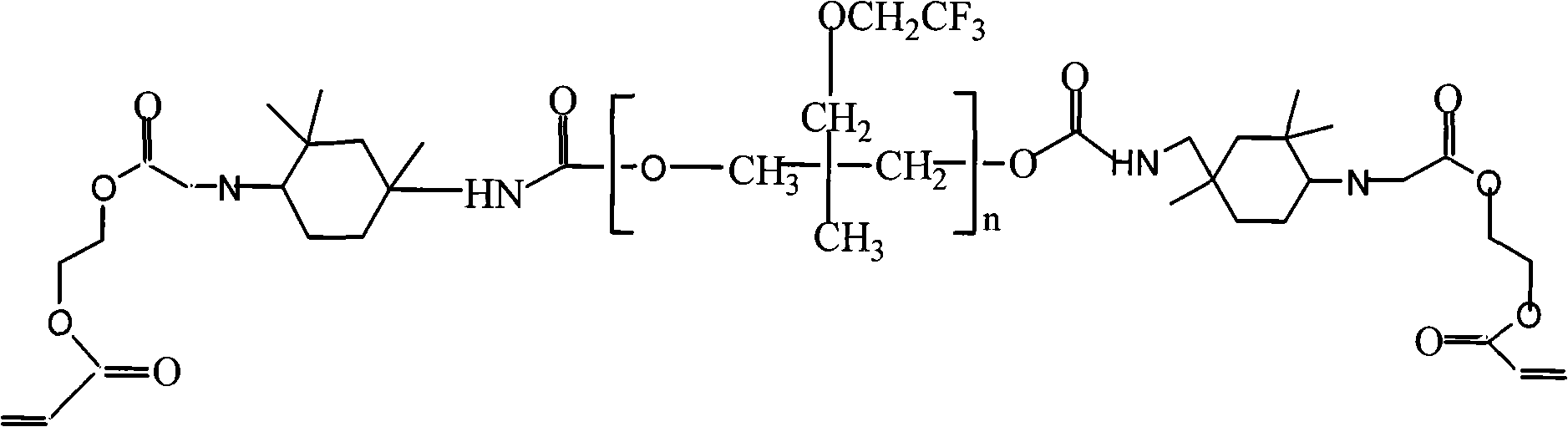

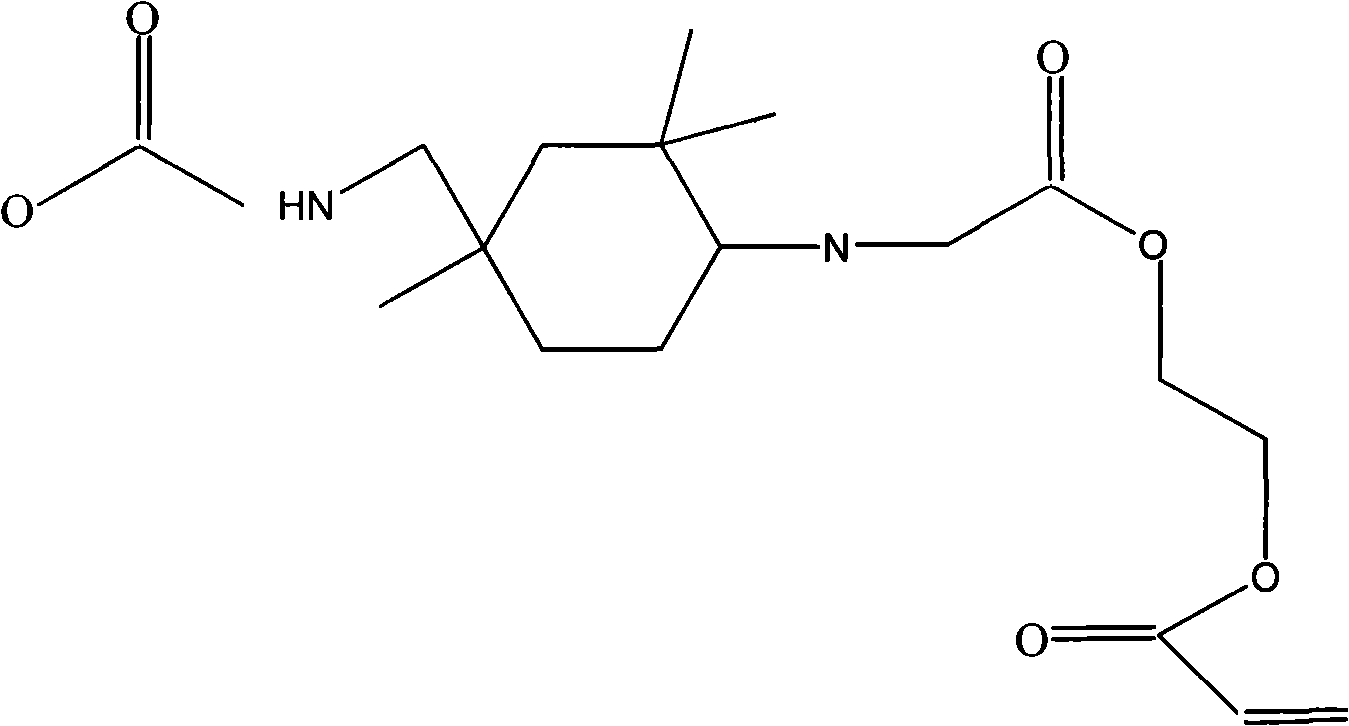

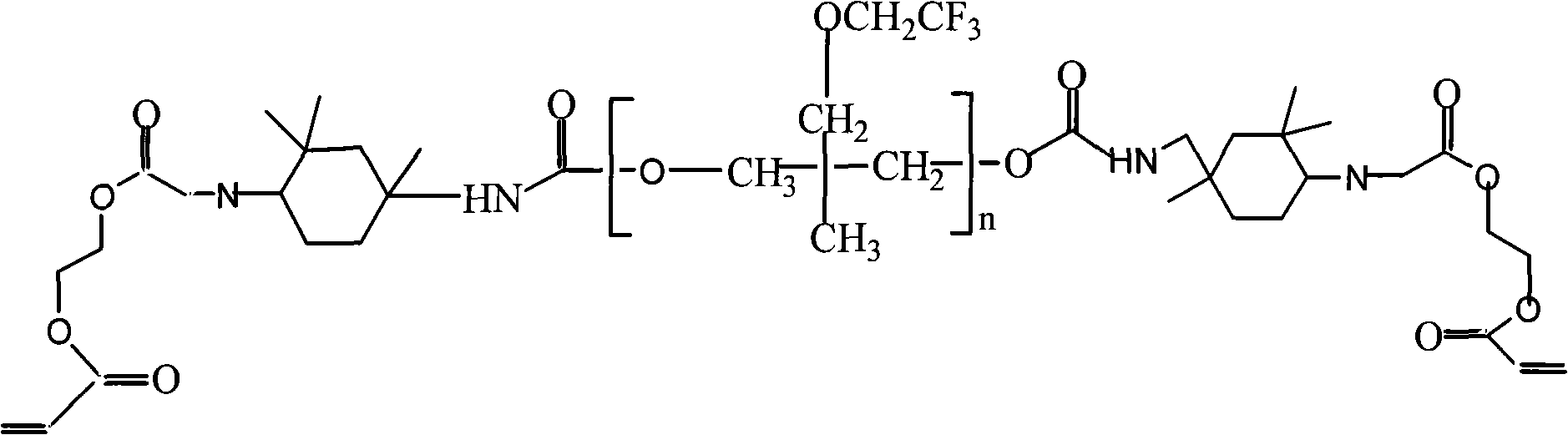

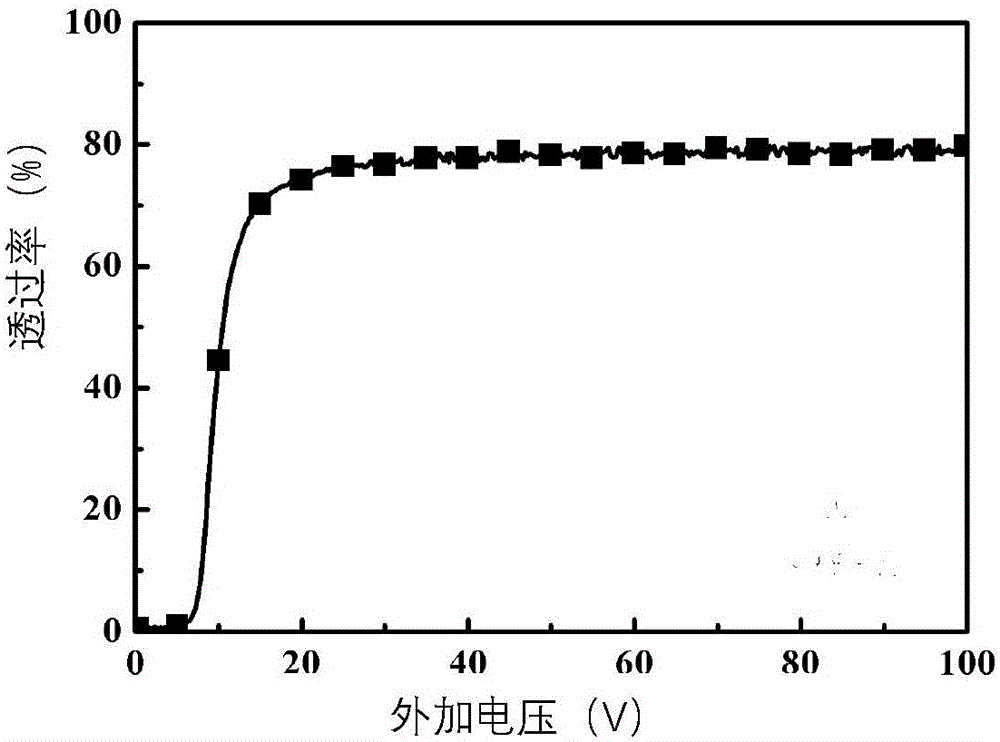

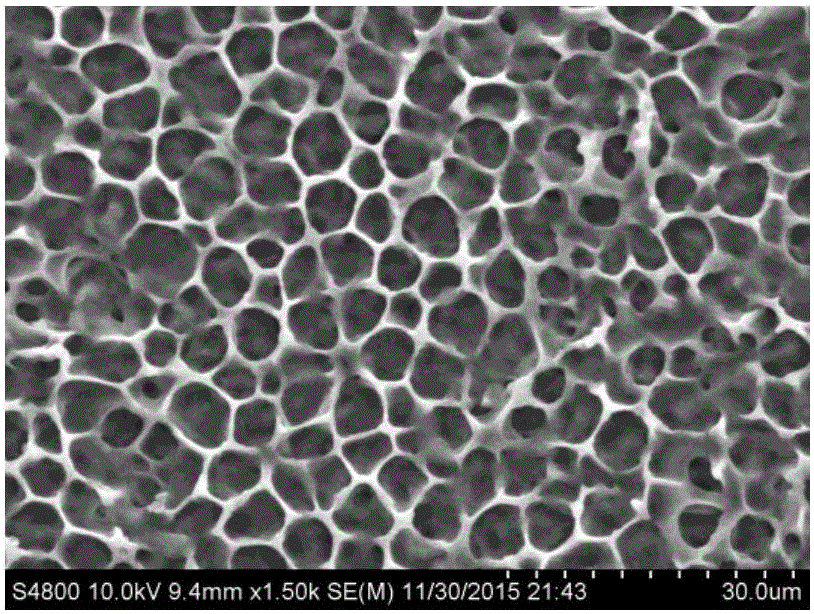

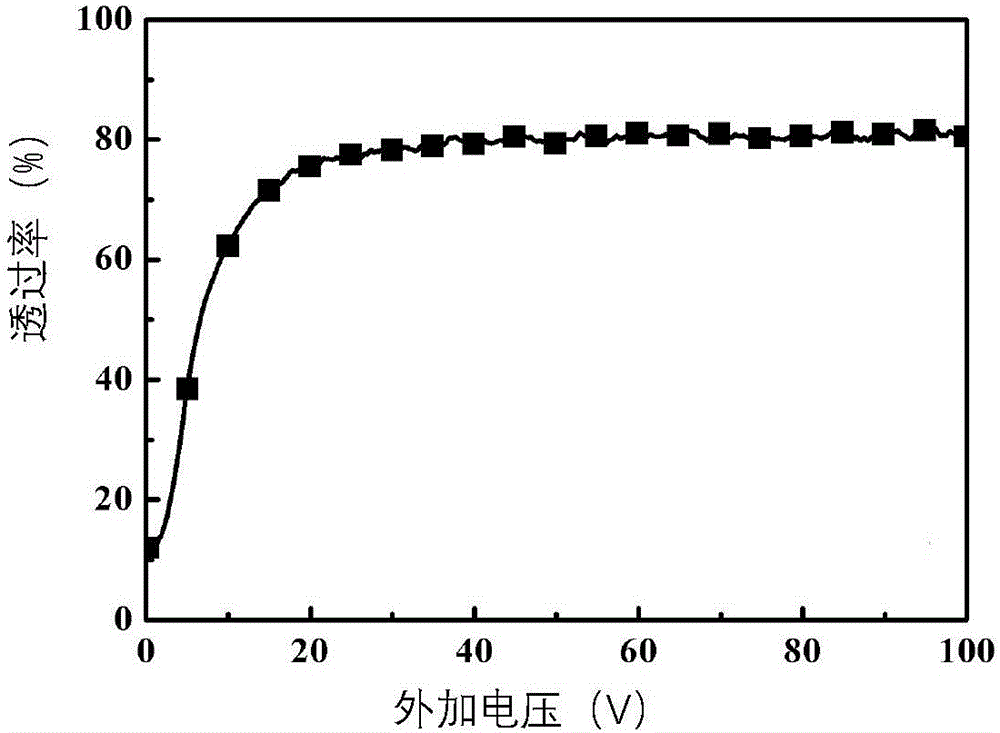

Low-voltage-driven mercaptan-containing polymer dispersed liquid crystal thin film material and preparation method of same

InactiveCN105906762AReduce the driving voltageIncrease contrastLiquid crystal compositionsThiolLow voltage

The invention discloses a low-voltage-driven mercaptan-containing polymer dispersed liquid crystal thin film material and a preparation method of the same. The thin film material includes liquid crystal, a mercaptan-containing photo-polymerizable monomer, glass micro beads, and a photo-initiator. The mass ratio of the liquid crystal to the mercaptan-containing photo-polymerizable monomer is 7:3-8:2. The content of the glass micro beads is 0.1-5% of the total mass of the liquid crystal and the mercaptan-containing photo-polymerizable monomer. The content of the photo-initiator is 0.1-1% of the mass of the mercaptan-containing photo-polymerizable monomer. The polymer dispersed liquid crystal thin film material has low driving voltage.

Owner:BEIJING CAVISION PHOTOELECTRIC TECH CO LTD +1

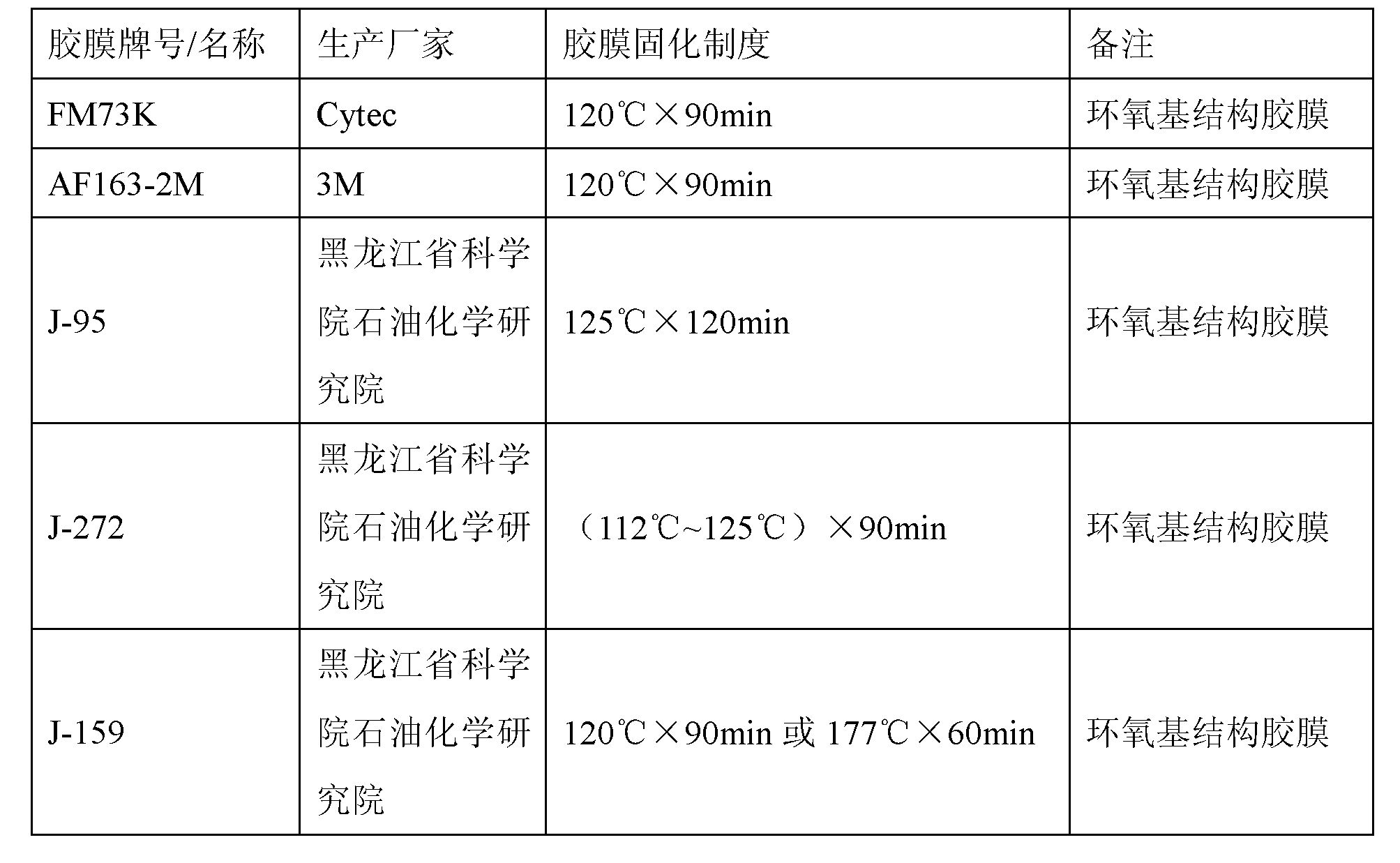

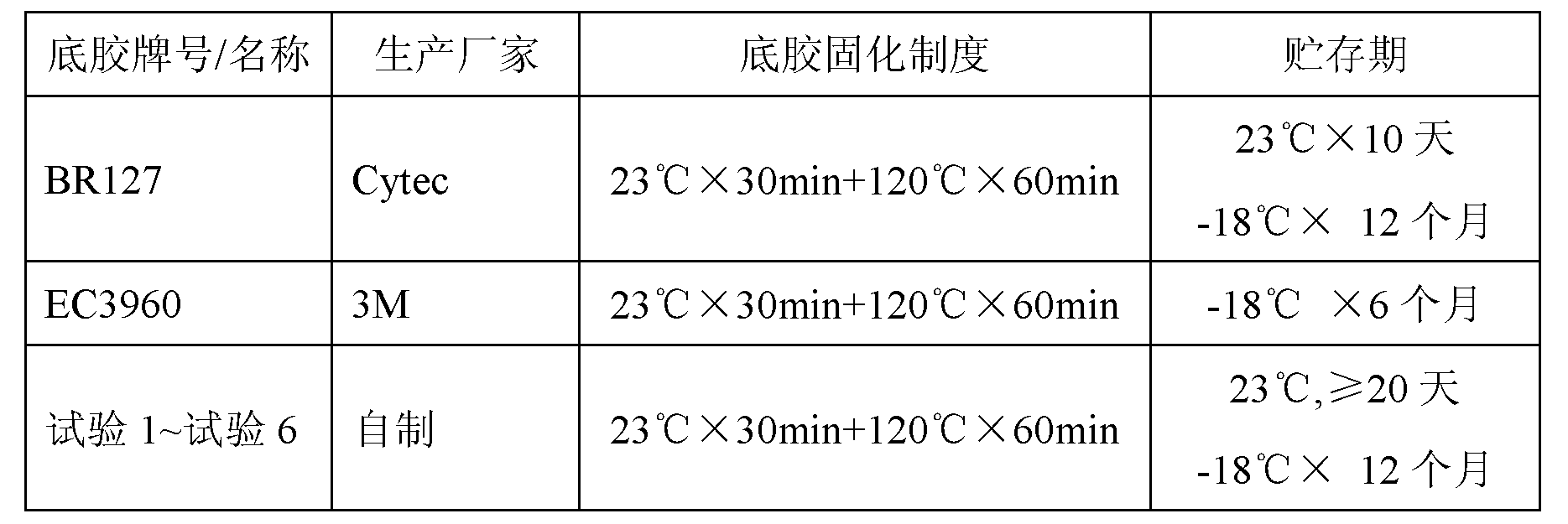

Primer for metal substrate structural bonding and preparation method thereof

InactiveCN103242792AEasy to prepareLow viscosityNon-macromolecular adhesive additivesFilm/foil adhesivesMetallic substrateMetal substrate

The invention relates to a primer for metal substrate structural bonding and a preparation method thereof. The invention aims to solve the problems of narrow technical applicability and short storage period in the existing primer for metal substrate structural bonding. The primer for metal substrate structural bonding is prepared from the following components in parts by mass: 5.6-24.7 parts of epoxy resin system, 1.5-4.1 parts of curing system and 68.4-92.3 parts of solvent system. The preparation method comprises the following steps: 1. preparing the epoxy resin system; 2. preparing the curing system; and 3. weighing 5.6-24.7 parts of epoxy resin system, 1.5-4.1 parts of curing system and 68.4-92.3 parts of solvent system, putting in a stirring unit, and sufficiently stirring until no precipitate exists to obtain the primer for metal substrate structural bonding. The invention is applicable to the field of preparation of primers for metal substrate structural bonding.

Owner:INST OF PETROCHEM HEILONGJIANG ACADEMY OF SCI

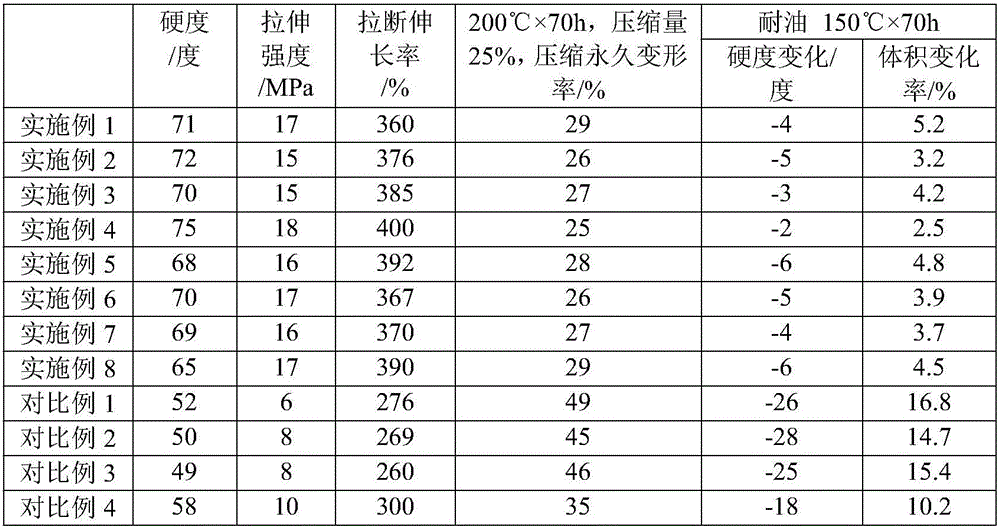

Seal ring for special fluororubber motor for nuclear power and preparation method of seal ring

ActiveCN106589709AGood oil resistance at high temperatureImprove performanceNuclear powerEngineering

The invention discloses a seal ring for a special fluororubber motor for nuclear power and a preparation method of the seal ring. The seal ring for the special fluororubber motor for the nuclear power is prepared from the following raw materials in parts by weight: 85 to 90 parts of fluororubber, 5 to 8 parts of acid-acceptor, 2 to 5 parts of compound vulcanizing agent, 8 to 10 parts of reinforcing agent and 1 to 2 parts of additive. The fluororubber motor seal ring is high in mechanical strength, excellent in oil resistance under high temperature, and suitable for a motor of a nuclear-powered ship.

Owner:南阳天一密封股份有限公司

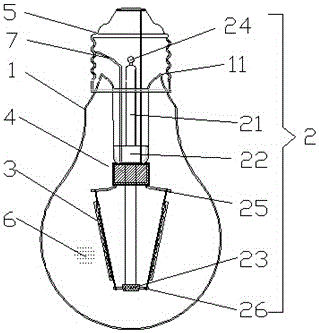

LED lamp filament lamp with built-in power source and thermal radiation material

PendingCN106090663AImprove cooling effectOvercome the problem of being easily charged with high voltage and unsafeLight source combinationsElectrical apparatusCooling effectEngineering

The invention discloses an LED lamp filament lamp with a built-in power source and a thermal radiation material and relates to the technical field of lighting. The LED lamp filament lamp with the built-in power source and the thermal radiation material comprises a blister body, a core column with a support, at least one LED lamp filament, a driver and a lamp holder; the blister body and the core column are sealed in vacuum to form a vacuum sealed cavity; high-heat-conductivity gas is arranged in the vacuum sealed cavity; the core column, the LED lamp filament and the driver are all located in the vacuum sealed cavity; and the outer surface of the LED lamp filament and the outer surface of the driver are each provided with a thermal radiation material layer. The LED lamp filament lamp with the built-in power source and the thermal radiation material has the beneficial effects of being high in production efficiency, good in cooling effect, long in service life, low in cost and the like.

Owner:SHANDONG PROSPEROUS STAR OPTOELECTRONICS TECH CO LTD

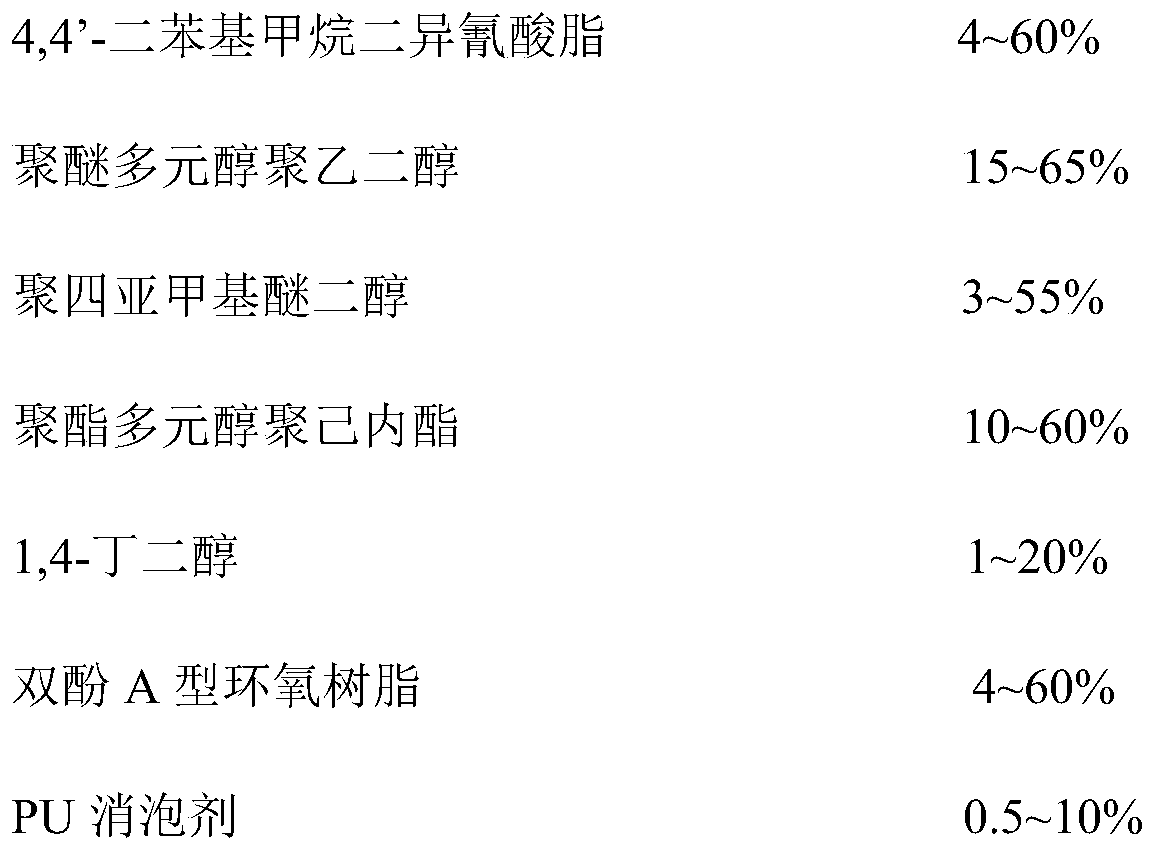

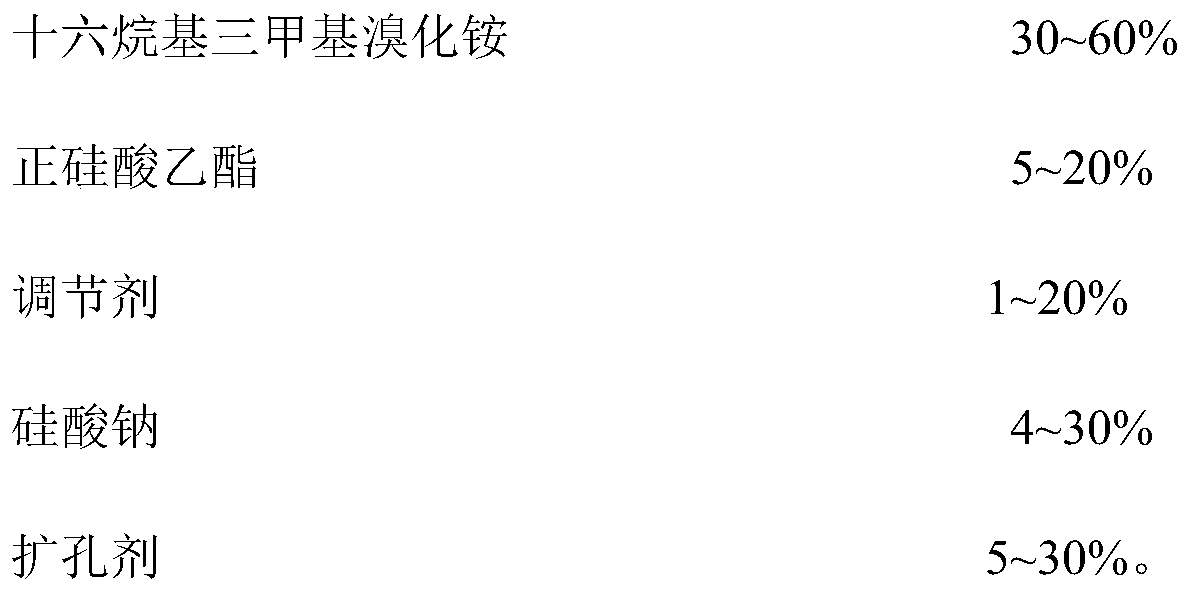

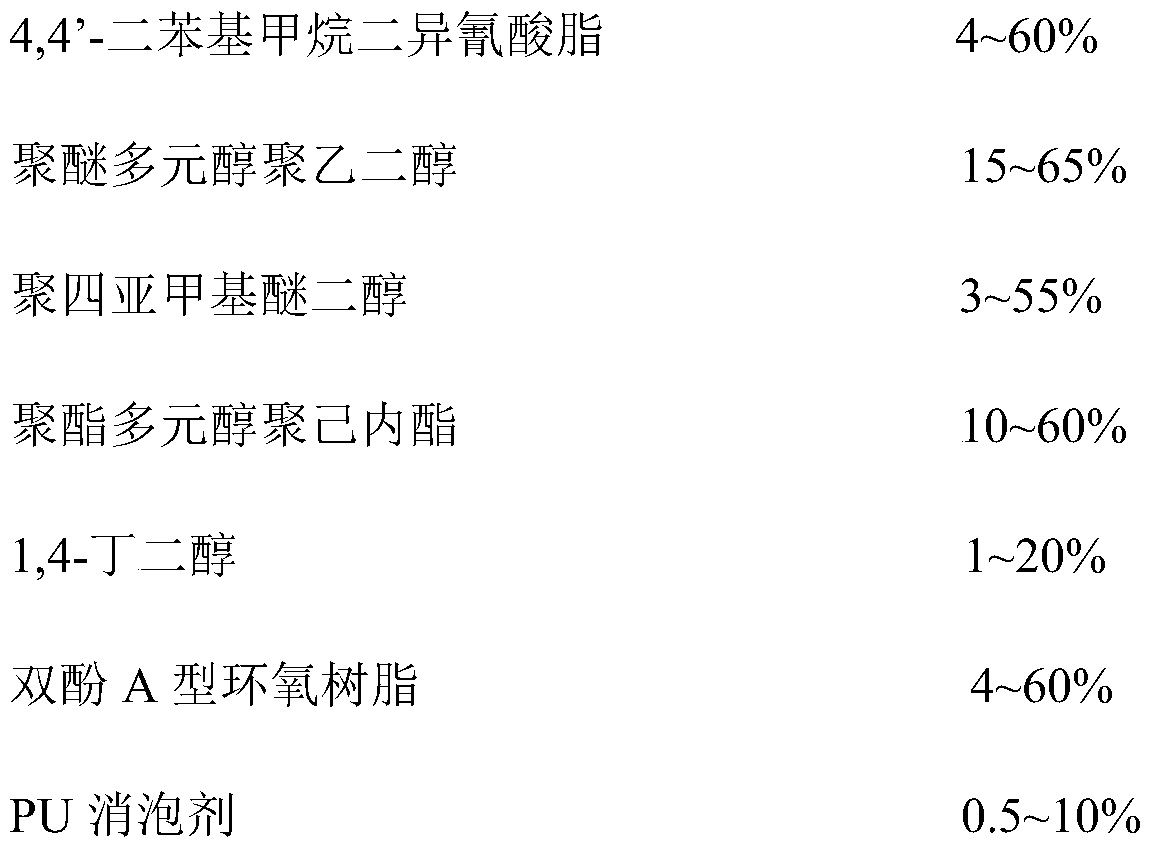

Anti-fouling coating capable of releasing anti-fouling agent and preparation method thereof

ActiveCN109749616AImprove wear resistancePlay a role in sheddingAntifouling/underwater paintsPaints with biocidesPolyesterToxicant

The invention discloses an anti-fouling coating capable of releasing an anti-fouling agent and a preparation method thereof. The coating comprises 4,4'-diphenylmethane diisocyanate, polyether polyol polyethylene glycol, polytetramethylene ether glycol, polyester polyol polycaprolactone, 1,4-butanediol, bisphenol-A epoxy resin and a PU defoamer. A second component comprises mesoporous silica particles and an anti-fouling component. A first component is mixed with the second component according to a mass ratio of (20-50):1, so the anti-fouling coating capable of releasing the anti-fouling agentcan be obtained. The anti-fouling coating is capable of introducing oligomer polyalcohol and polycyanate, in the precondition of guaranteeing controllable release performance of the anti-fouling agent, not affecting excellent mechanical property and adhesive power and the like of polyurethane. At the same time, mesoporous silica has high wear resistance, wear resistance of the coating can be improved, and service life is prolonged. The method is simple in process, lower in cost, and suitable for industrial production without a toxicant release problem, so the coating has good application prospect in the ocean anti-fouling field.

Owner:XI AN JIAOTONG UNIV

Environment-friendly high-performance organic high-temperature-resistant paint

InactiveCN105462485ADoes not affect adhesionDoes not affect weather resistancePolyester coatingsMulticolor effect coatingsTemperature resistanceWear resistance

The invention discloses an environment-friendly high-performance organic high-temperature-resistant paint. The paint comprises, by weight, 40 to 100 parts of resin, 10 to 20 parts of high-temperature-resistant pigments, a filling material and an auxiliary agent. According to the invention, through addition of the high-temperature-resistant pigments, the paint has various colors instead of a single color and is high-temperature resistant; and while having diversified colors and high temperature resistance, the paint is not influenced in the original adhesion, weatherability, wear resistance and high temperature resistance.

Owner:王寿高

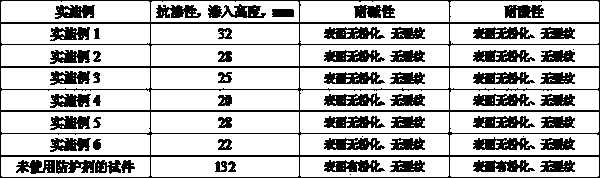

A kind of preparation method of water-based permeable concrete protective agent

The invention relates to a preparation method of a water-based permeable concrete protective agent, which is prepared from the following raw materials: potassium aluminum sulfate dodecahydrate, sodium hydroxide, citric acid, silane coupling agent, sodium silicate aqueous solution and deionized water. The specific preparation steps are as follows: add potassium aluminum sulfate dodecahydrate to deionized water, stir; then add sodium hydroxide, stir; then add citric acid, stir; then add sodium silicate aqueous solution, silane coupling agent in turn, stir , to obtain a mixed solution; standing still, to obtain a water-based penetrating concrete protective agent. The invention forms an integral protective layer by penetrating into the concrete and reacting with it, which can minimize the penetration of water and salts into the concrete, and help reduce freeze-thaw, carbonation, erosion, alkali-aggregate reaction, cracks and other damages and corrosion; the protective agent of the invention has good waterproof effect, simple construction process, long product storage period and wide application range.

Owner:ANHUI TRANSPORT CONSULTING & DESIGN INST +1

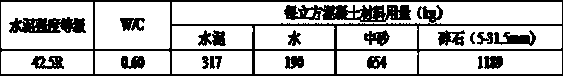

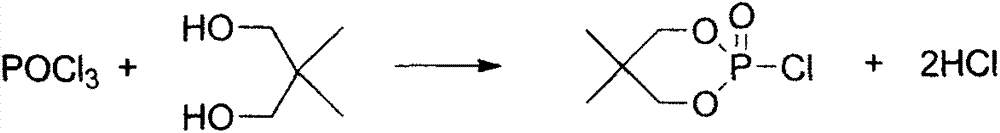

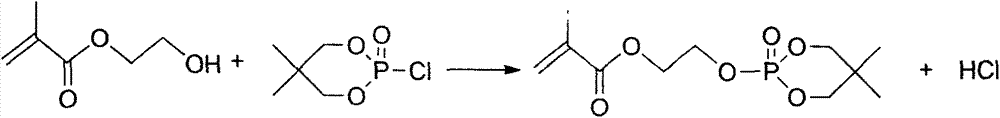

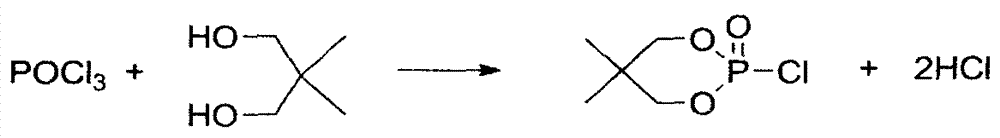

Method for preparing reactive type halogen-free flame retardant for coating

InactiveCN104497051AImprove flame retardant performanceDoes not affect adhesionFireproof paintsGroup 5/15 element organic compoundsPolymer science(Hydroxyethyl)methacrylate

The invention provides a method for preparing a reactive type halogen-free flame retardant for a coating, and belongs to the field of flame retardant synthesis. The method is characterized by comprising the following steps: firstly, implementing reaction on neopentyl glycol and phosphorus oxychloride so as to prepare 2-oxo-2-chloro-5,5-dimethyl-1,3,2-dioxaphosphorinane; implementing condensation reaction on hydroxyethyl methacrylate and 2-oxo-2-chloro-5,5-dimethyl-1,3,2-dioxaphosphorinane so as to prepare a final product 5,5-dimethyl-2-hydroxyethyl methacrylate-2-oxo-1,3,2-dioxaphosphorinane. The method is simple in process, easy in obtaining of raw materials and high in conversion rate, and the prepared reactive type halogen-free flame retardant is good in flame retardancy, does not affect properties such as the adhesion property and the weather resistance of the coating after being added into the coating, can be widely used for preparing various acrylic acid and acrylic flame-retardant coating emulsions, and can be also applied to flame retardancy of plastic, rubber and textile as a reactive type flame retardant additive.

Owner:王树礼

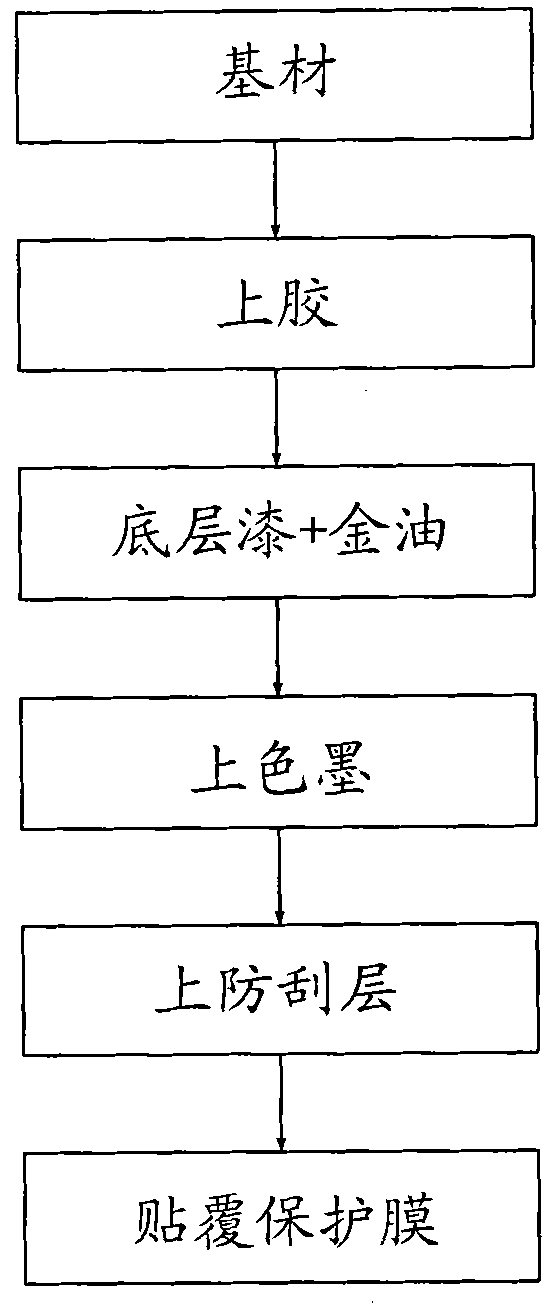

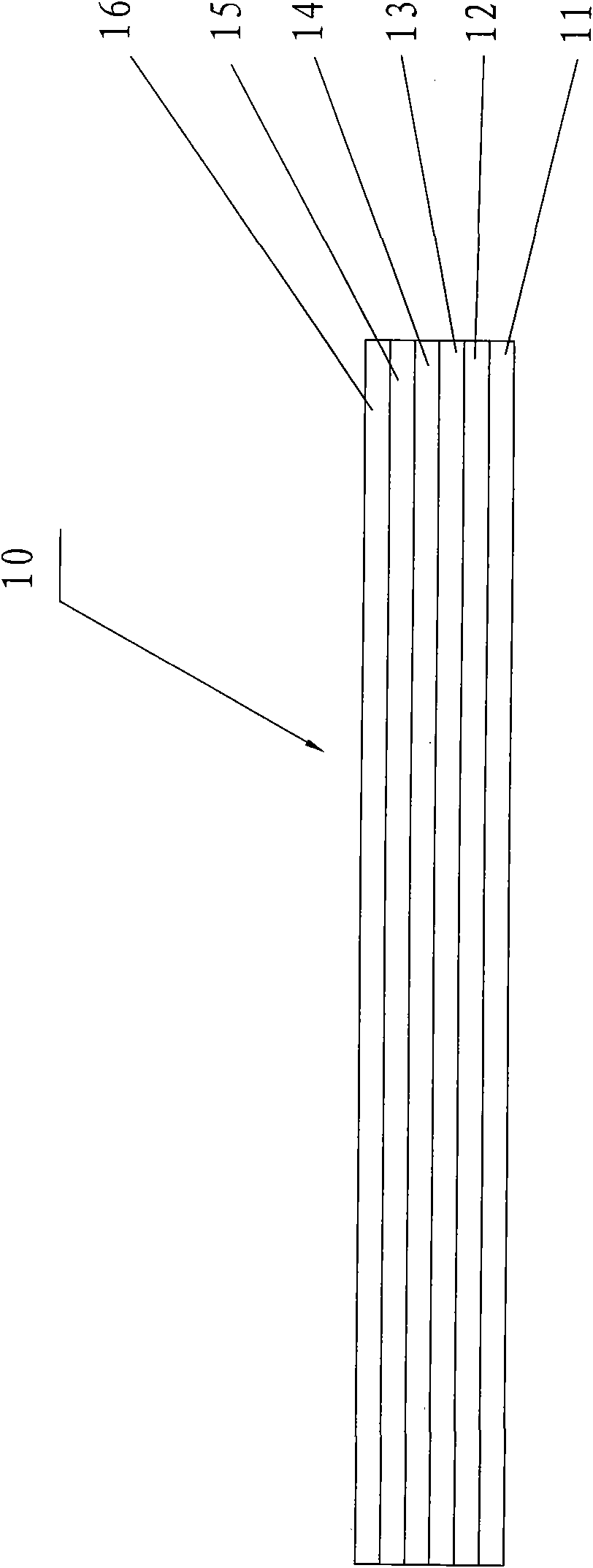

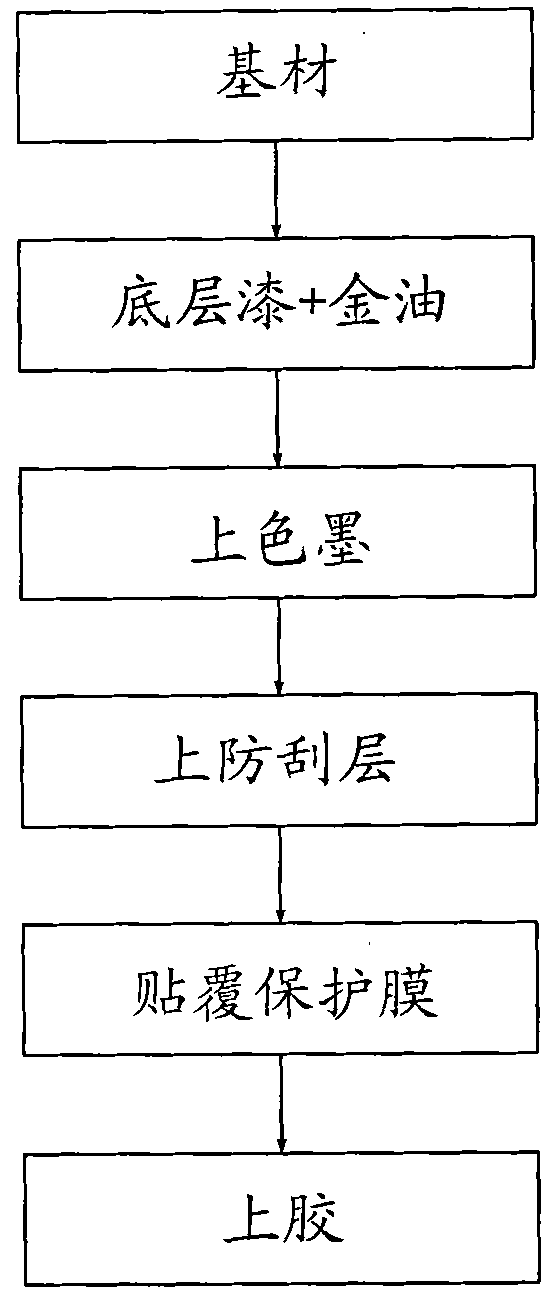

Scrape-prevention heat transfer film and preparation method thereof

The invention discloses a method for preparing a scrape-prevention heat transfer film. The method comprises the following steps of: (1) substrate preparation, wherein a substrate can be stickness-resistance release paper which can be recycled and reused or a polar material with a plastic laminating film on the surface; (2) gluing: printing hot-melting glue on the surface of the release paper or the polar material to form a hot-melting glue layer; (3) priming paint and golden oil applying: printing or jet-printing priming paint, and adding golden oil for mutual blending on the surface of the hot-melting glue layer; (4) color ink layer preparation, wherein a color ink layer is provided with various patterns, colors, decorative lines or trademarks; (5) scrape-prevention layer preparation: printing or jet-printing a scrape-prevention layer on the surface of the color ink layer and heating and drying with ultraviolet rays at high temperature; and (6) protective film covering: attaching a protective film on the surface of the scrape-prevention layer in a pseudo way, and stripping the protective film off a product after heat transfer. A scrape-prevention heat transfer film prepared with the method disclosed in the invention has high hardness and scrape-prevention effect and has a wear-resisting surface. The invention also discloses a scrape-prevention heat transfer film prepared with the method disclosed in the invention.

Owner:潘明冲

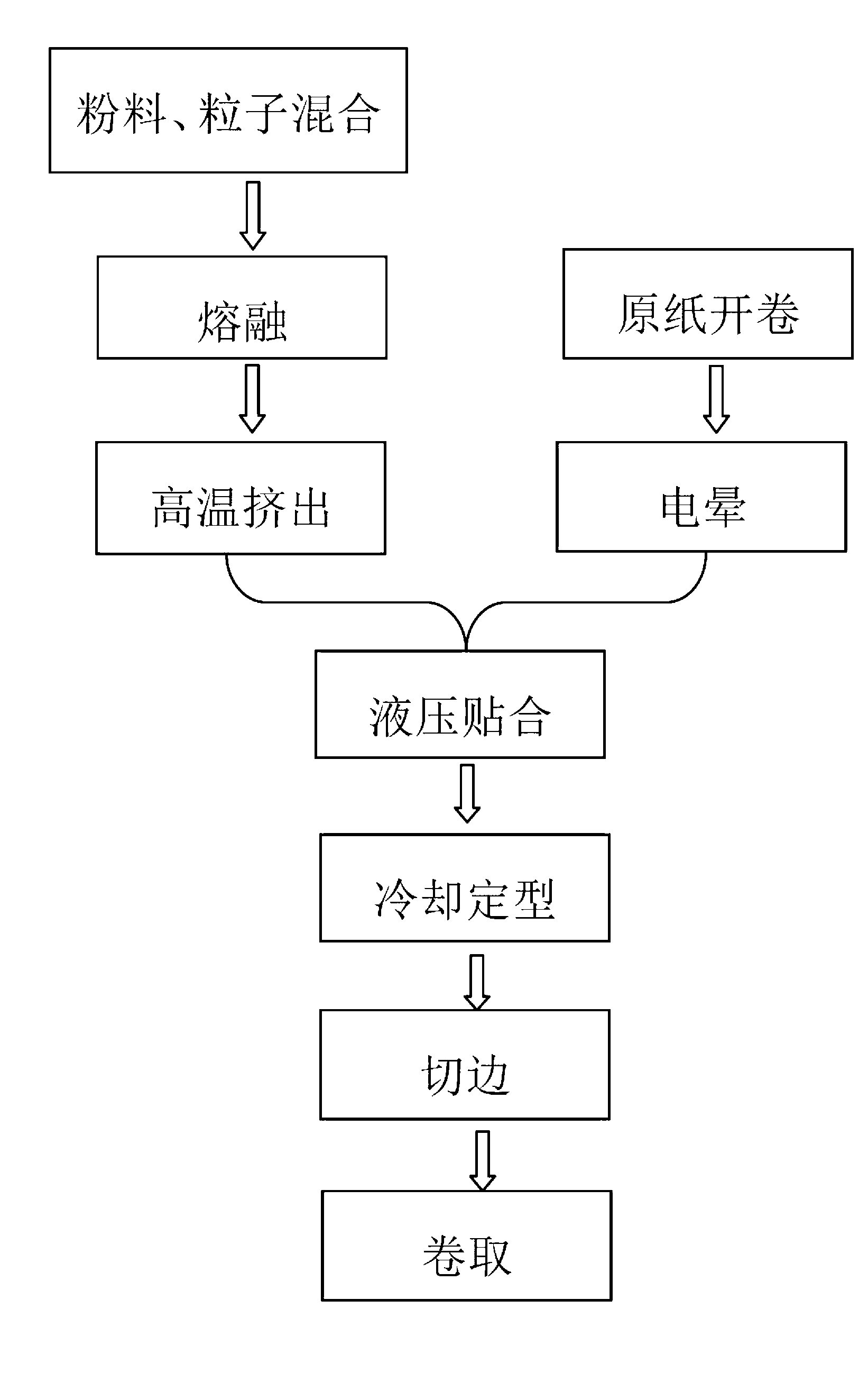

Modified polyethylene (PE) coated paper and manufacturing method thereof

InactiveCN103132395AImprove thermal stabilityImprove rigiditySpecial paperSynthetic resin layered productsPulp and paper industryThermal stability

The invention provides a modified polyethylene (PE) coated paper which is manufactured by the high pressure plying of modified PE or modified polypropylene (PP) films which are extruded under high temperature and double glue raw paper. The producing process of the modified PE coated paper comprises the following steps: raw materials mixing--raw paper decoiling--electric aureoling--high temperature coating membrane--hydraulic plying--cooling and forming--edge cutting--reeling up. The modified PE coated paper uses nano modifying powder to carry out modification on PE resin or PP resin, and the thermal stability and the rigidity of the PE coated paper are both improved. A modified PE coated film and the double glue raw paper, silicone oil and the modified coating membrane are all have strong adhesive force. Due to the fact that nano powder materials are mixed to modify the resin, compared with existing products, the modified polyethylene (PE) coated paper presents a unique matte finish effect, and a unique thick and solid feeling is obvious. Meanwhile, production cost is reduced.

Owner:南通百纳数码新材料有限公司

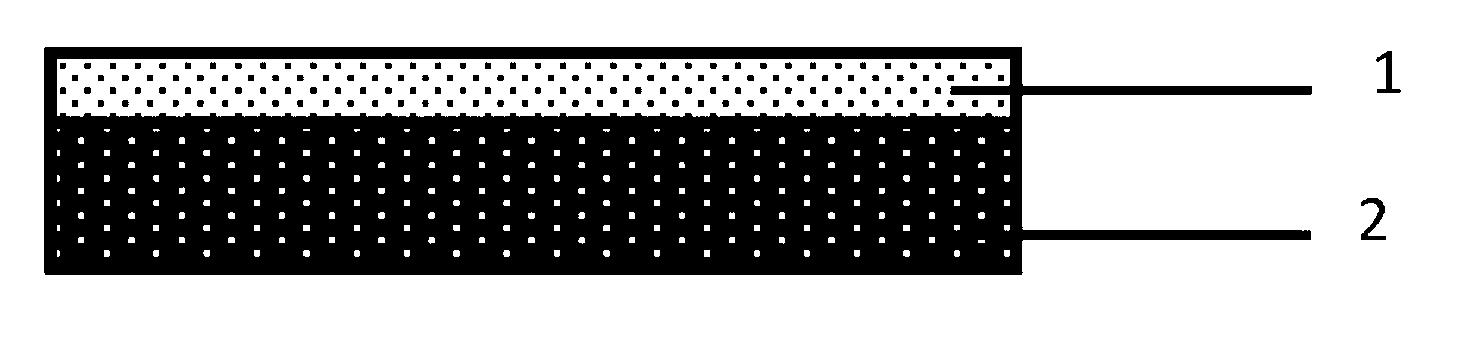

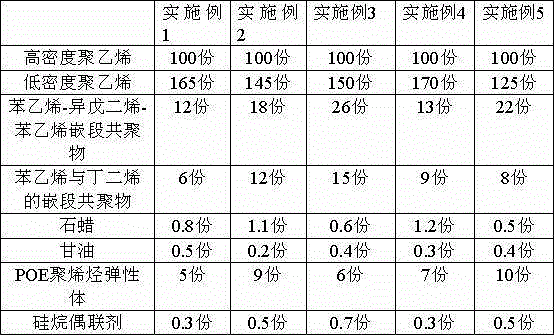

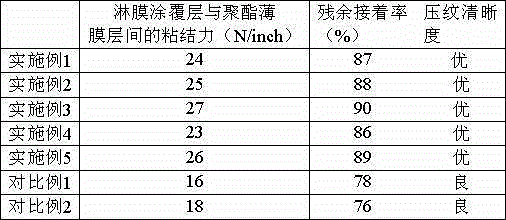

Embossing release film

ActiveCN104999751ANot easy to fall offImprove anti-static effectNon-fibrous pulp additionSynthetic resin layered productsLow-density polyethyleneElastomer

The invention discloses an embossing release film. The embossing release film comprises a polyester film layer and a spraying film coating layer with which the surface of the polyester film layer is coated. The surface, back on to the polyester film layer, of the spraying film coating layer is provided with an embossing pattern area, and the surface of the embossing pattern area is coated with an organosilicone release agent layer. The spraying film coating layer comprises, by weight, 100 parts of high-density polyethylene, 120-180 parts of low-density polyethylene, 10-30 parts of styrene-isoprene-styrene triblock copolymers, 5-15 parts of segmented copolymers of styrene and butadiene, 0.5-0.15 part of paraffin, 0.1-0.5 part of glycerinum, 5-10 parts of POE and 0.3-0.8 part of coupling agent, wherein the POE is a high polymer of ethylene and butane or a high polymer of ethylene and octylene. Netted grain formed through the embossing release film is clear and uniform in depth, and distribution lines are uniform. When formed embossing spraying film release paper is pasted on a pressure-sensitive adhesive, no bubble will be generated between the embossing spraying film release paper and the pressure-sensitive adhesive, and therefore the use effect will not be affected.

Owner:太仓斯迪克新材料科技有限公司

Preparing method of Chinese medicine catablasm base material

InactiveCN101254215AImprove comfortDoes not affect adhesionAerosol deliveryOintment deliveryGlycerolSodium hydroxide

The invention relates to a preparation method of matrix material for Chinese medicinal plaster, particularly to a preparation method of Chinese medicinal cataplasma matrix containing Chinese medicinal extracts. The method comprises the following steps of completely dissolving gelatin in 60 DEG C water, respectively adding sodium carboxymethyl cellulose, polyvinylpyrrolidone, gum arabic, Indian gum, triethanolamine and magnesium hydroxide into gelatin solution, and adding water for completely dissolving to obtain solution I; dispersing sodium polyacrylate, carbomer, polyvinyl alcohol, agar, gum tragacanth, colloidal silicon dioxide and sodium hydroxide in glycerol to obtain solution II; and mixing the solutions I and II to obtain cataplasma matrix. The inventive matrix has the advantages of good transdermal effect, good air permeability, no skin irritation, no anaphylaxis, comfortable application, good reusability, stable matrix properties, safe and environmentally friendly preparation process, good affinity with various drugs, and no reaction with principal drug.

Owner:JIANGSU 707 NATURAL PHARMA

Aluminium ware special-purpose noctilucence paint and application

InactiveCN104893492AGood dispersionImprove adhesionLuminescent paintsSpecial surfacesAdditive ingredientLight extinction

The invention discloses an aluminium ware special-purpose noctilucence paint and application, the aluminium ware special-purpose noctilucence paint is characterized by including the following ingredients by weight: 20-80% of resin, 5-60% of a curing agent, 0.1-20% of a levelling agent, 0.01-20% of a gloss enhancer, 1-40% of a pigment, 0.1-10% of a spice, 1-50% of barium sulfate, 0-50% of a light extinction curing agent, and 1-50% of noctilucent powder. Compared with the existing technology, th aluminium ware special-purpose noctilucence paint has low manufacturing cost, strong adhesion, good pigment dispersion and other characteristics, the prepared coating has the characteristics that the surface is smooth, and may not be too bright and blinkering, and is especially suitable for processing of aluminum curtain walls, aluminum doors, aluminum windows and sun room frames.

Owner:何炳贵

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com