Primer for metal substrate structural bonding and preparation method thereof

A technology for metal substrates and structural adhesives, applied in the direction of adhesives, epoxy resin adhesives, adhesive types, etc., can solve the problems of narrow applicability, short storage period, etc., and achieve enhanced adhesion, stable performance, and easy coating Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

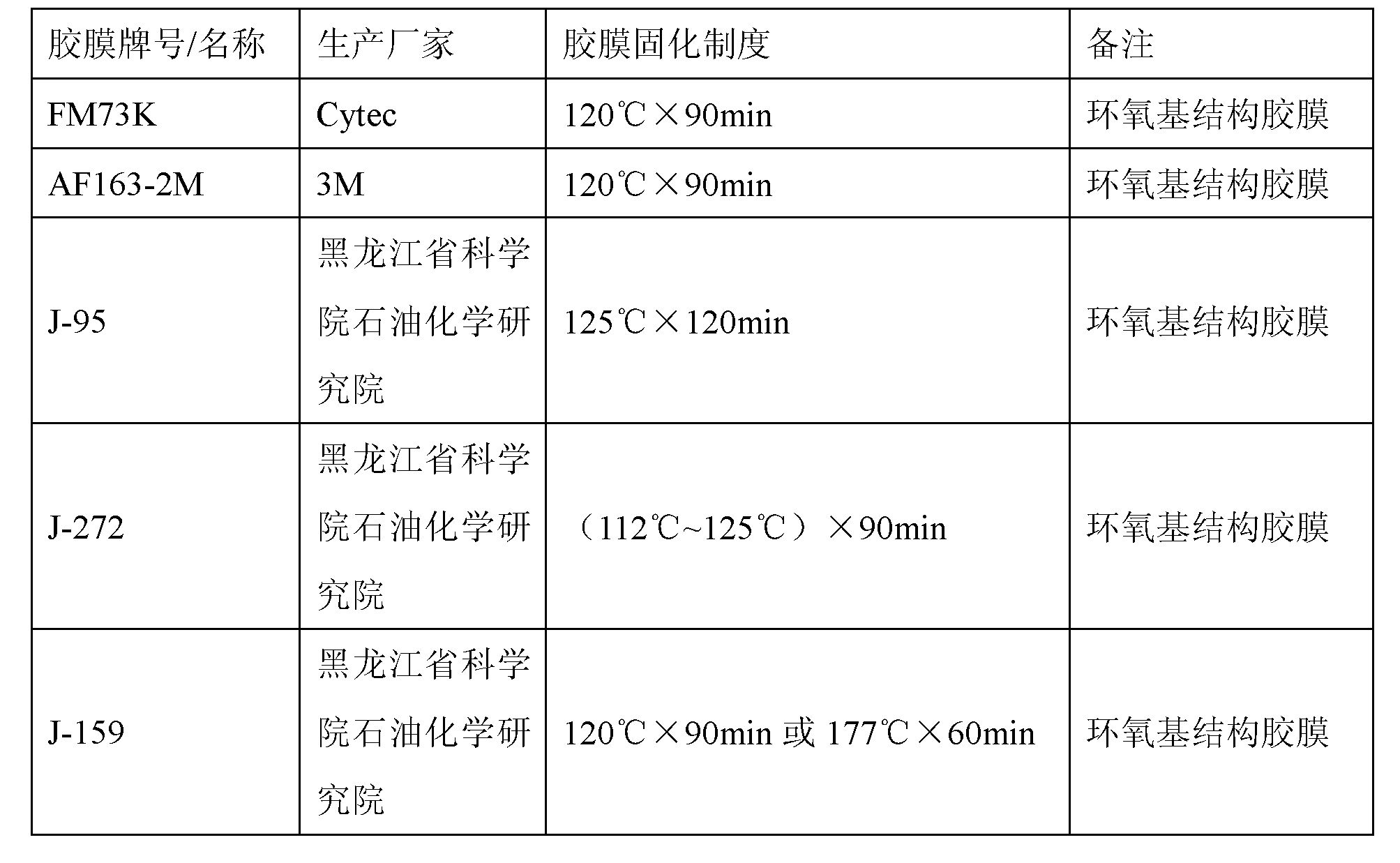

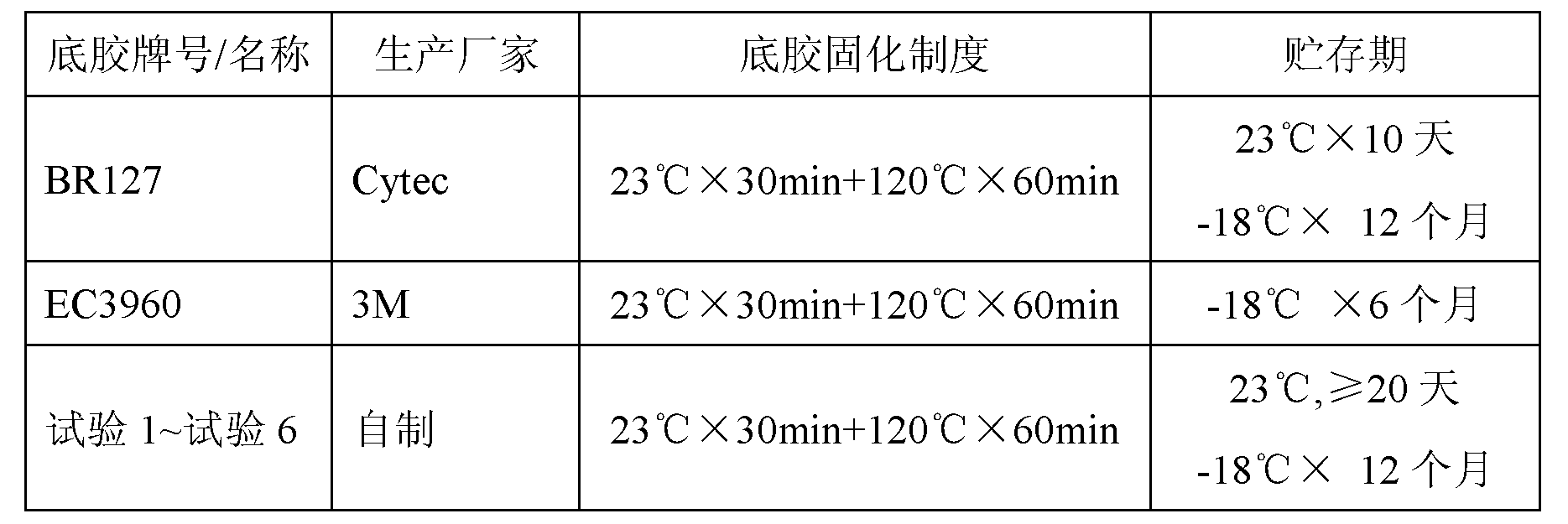

[0012] Specific implementation mode 1: In this embodiment, a primer for structural bonding of metal substrates is characterized in that the primer for structural bonding of metal substrates is composed of 5.6 to 24.7 parts of epoxy resin system, 1.5 to 24.7 parts by mass. 4.1 parts of curing system and 68.4 to 92.3 parts of solvent system; wherein the epoxy resin system is composed of epoxy resin, toughener and diluent in a mass ratio of (8~12.5):(2~5):1 ; The curing system is composed of an amine curing agent and a curing accelerator in a mass ratio (6-12): 1.

[0013] The primer for metal substrate structure bonding in this embodiment can be used for epoxy resin-based system adhesive films cured at 110°C to 180°C, without affecting the adhesive performance of the adhesive film. The storage period at room temperature is 20 days, and it can be stored at -18°C. There is no change in performance for 12 months. Brush or spray the metal base material structure adhesive primer of t...

specific Embodiment approach 2

[0014] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the epoxy resin is one or both of bisphenol A type epoxy resin, bisphenol F type epoxy resin and novolak epoxy resin than the composition of the mixture. Others are the same as the first embodiment.

specific Embodiment approach 3

[0015] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the toughening agent is carboxyl-terminated liquid nitrile rubber, polysulfide rubber, liquid silicone rubber, polyether, polysulfone, polyethersulfone and polyamide A mixture of one or more imines in any ratio. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com