RFCC high octane gasoline additive and preparation method thereof

A high-octane gasoline and heavy oil catalysis technology, applied in catalytic cracking, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of reducing the yield of light oil and not making it public, and achieve improved reaction performance and reduced additives Carbon deposition, increase the effect of slurry solid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] This example illustrates the preparation of an aluminum phosphate sol binder for use with catalysts according to the invention.

[0064] 4.39 kg of pseudoboehmite (containing Al 2 o 3 3 kilograms) and 5.4 kilograms of decationized water beating for 30 minutes, under stirring, add 10.3 kilograms of 85% concentrated phosphoric acid in the slurry, then add 5.28 kilograms of 68% concentrated nitric acid, continue to stir and react for 45 minutes, and the colorless and transparent phosphoraluminum sol is obtained. Its pH is 1.5. After analysis, the aluminum phosphate sol contains P 11.1% by weight, Al 6.5% by weight, P / Al (weight)=1.77, HNO 3 The content is 11% by weight.

Embodiment 2

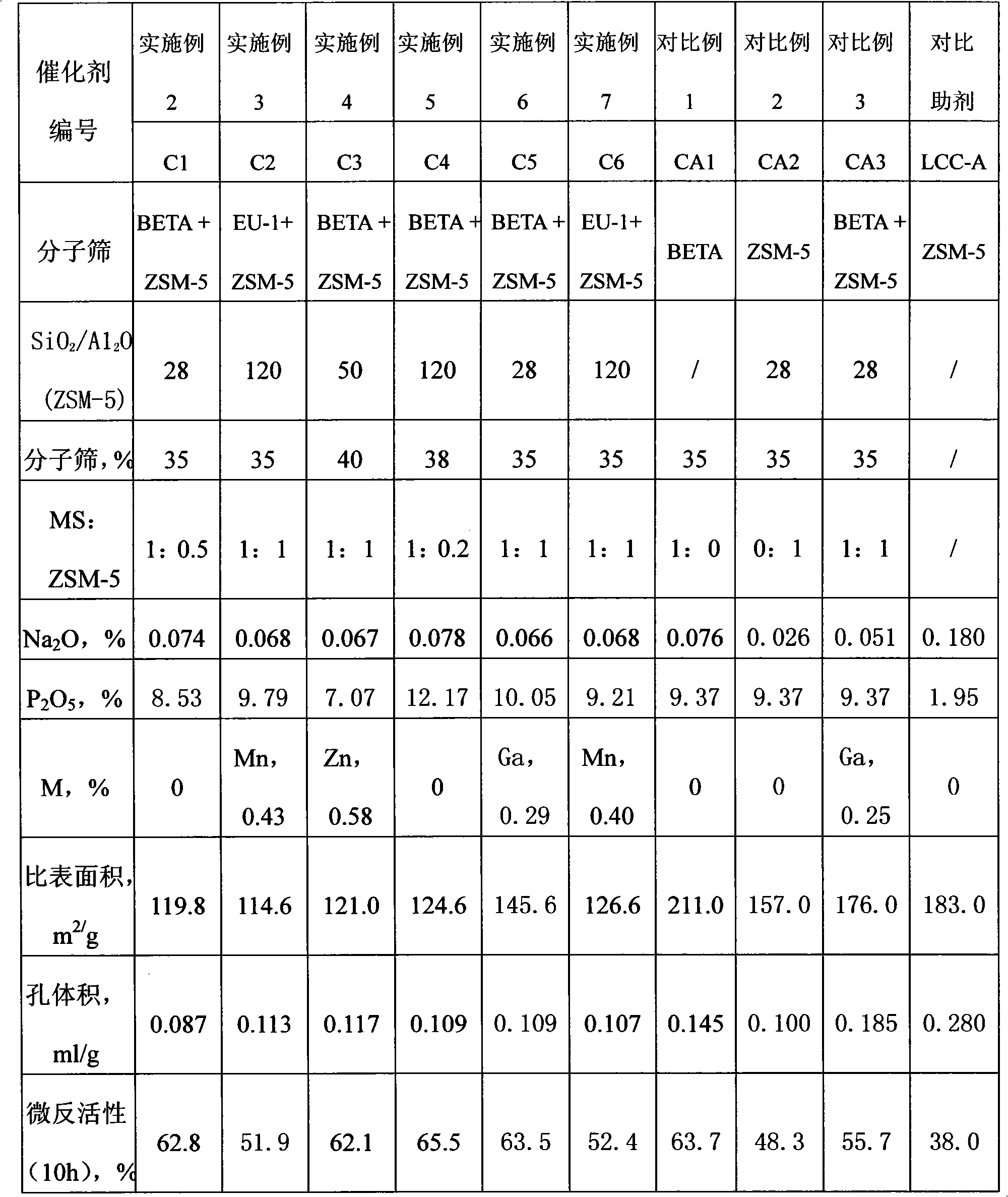

[0066] Examples 2-5 illustrate the preparation of molecular sieve cracking aids using aluminum phosphate sol as a binder according to the present invention.

[0067] In 0.70 kg (dry basis) BETA and 0.35 kg (dry basis) ZSM-5 (SiO 2 / Al 2 o 3 )=28) Add 1.18 kg of water to the molecular sieve, homogenize with a shearing machine, stir for 2 hours, and make a mixed molecular sieve slurry.

[0068] Under stirring, 1775g kaolin and 2170ml water were mixed and beaten for 30min, 1.5kg of the binder prepared according to the method in Example 1 was added to the kaolin slurry, and the stirring was continued for 1h, then the above-mentioned ZSM-5 and BETA (ZSM -5 and BETA (1:2) mixed the molecular sieve slurry, stirred for 2 hours, and the solid content of the obtained slurry was 38% by weight. After the slurry is homogenized, it is sprayed into shape and calcined at 550° C. for 6 hours to obtain a catalytic additive containing 35% by weight of molecular sieve, which is denoted as C1. ...

Embodiment 3

[0070] First, EU-1 molecular sieves were prepared referring to Example 1 of CN101054183A (method for preparing molecular sieves with EUO structure from silicon-aluminum oxide powder). Add 60g of sodium hydroxide (96%) into water to dissolve, then add 250g of hexamethyldiammonium bromide, 25g of EUO molecular sieve powder, heat and stir at 80°C to fully dissolve and disperse, and cool to room temperature; then 180g of silicon aluminum micro Balls (SiO 2 / Al 2 o 3 =10) and 320g of white carbon black premixed materials were added to the above solution and stirred evenly; finally added to a stainless steel reactor and reacted at 170°C for 64h to obtain the former powder of EU-1 molecular sieve, the ratio of silicon to aluminum (SiO 2 / Al 2 o 3 ) is 30.

[0071] Second, preparation of H-type EU-1 molecular sieve: the above EU-1 molecular sieve raw powder was calcined in a muffle furnace at 500° C. for 6 hours. Take EU-1 molecular sieve 1000g (dry basis) after roasting and pou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com