Patents

Literature

665results about How to "High hydrothermal stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method for Beta zeolite molecular sieve with hierarchical porous structure

InactiveCN102826564APlay a structurally oriented roleThe synthesis steps are simpleCrystalline aluminosilicate zeolitesMolecular sieveActive agent

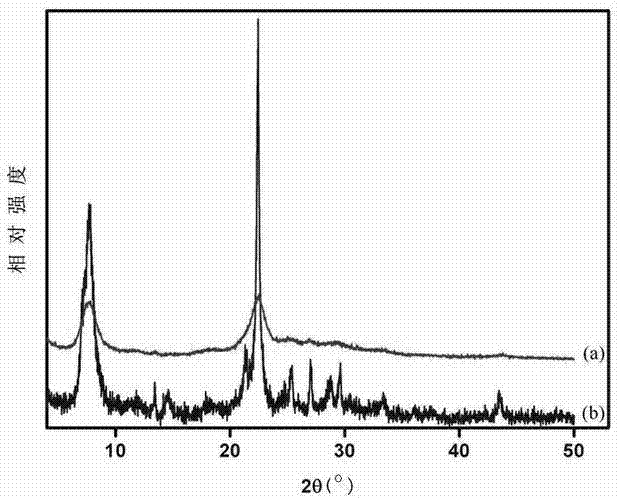

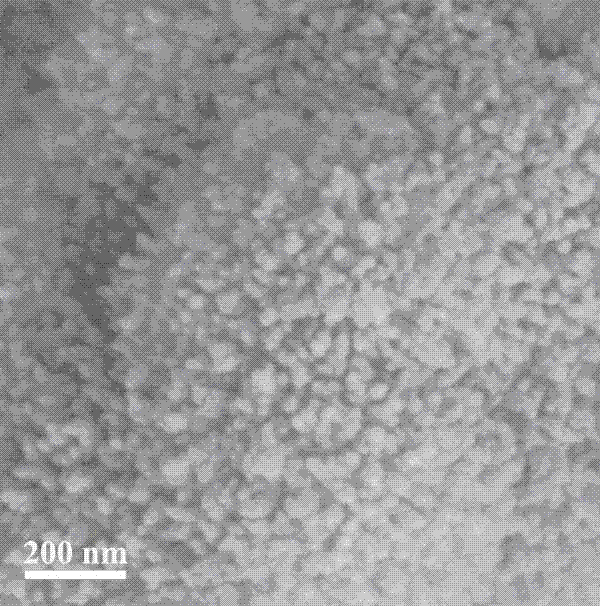

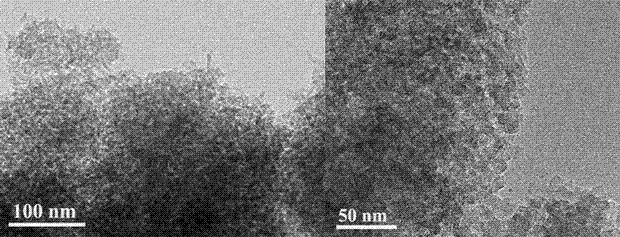

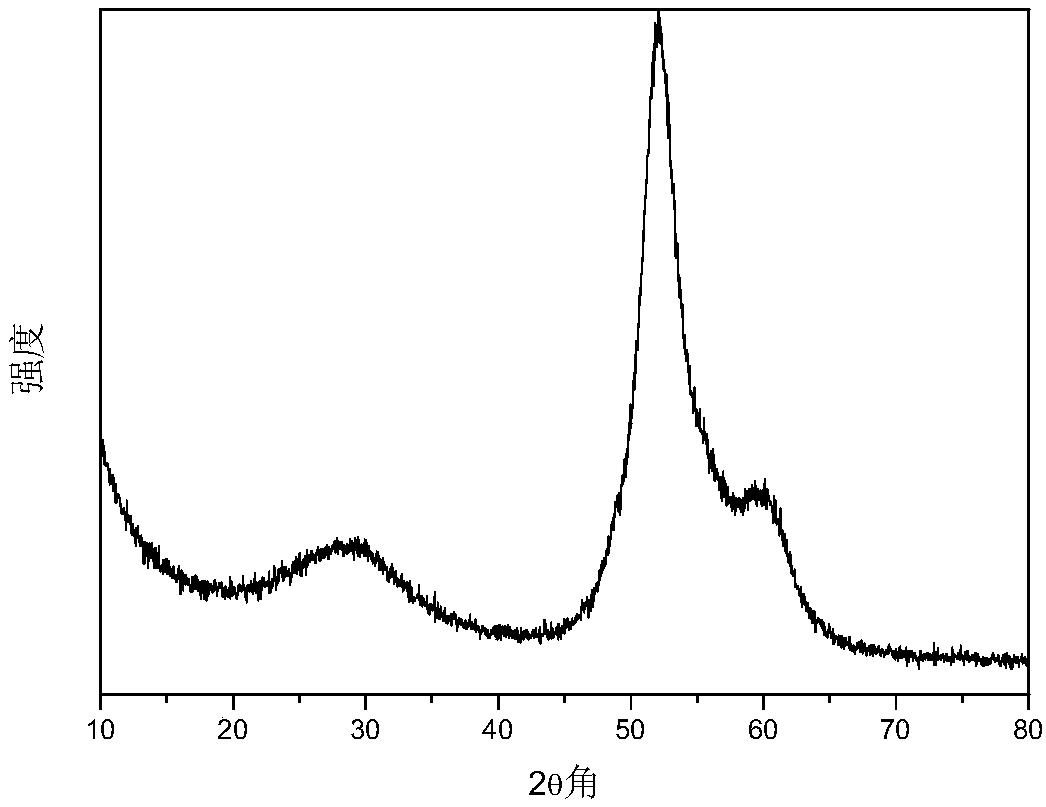

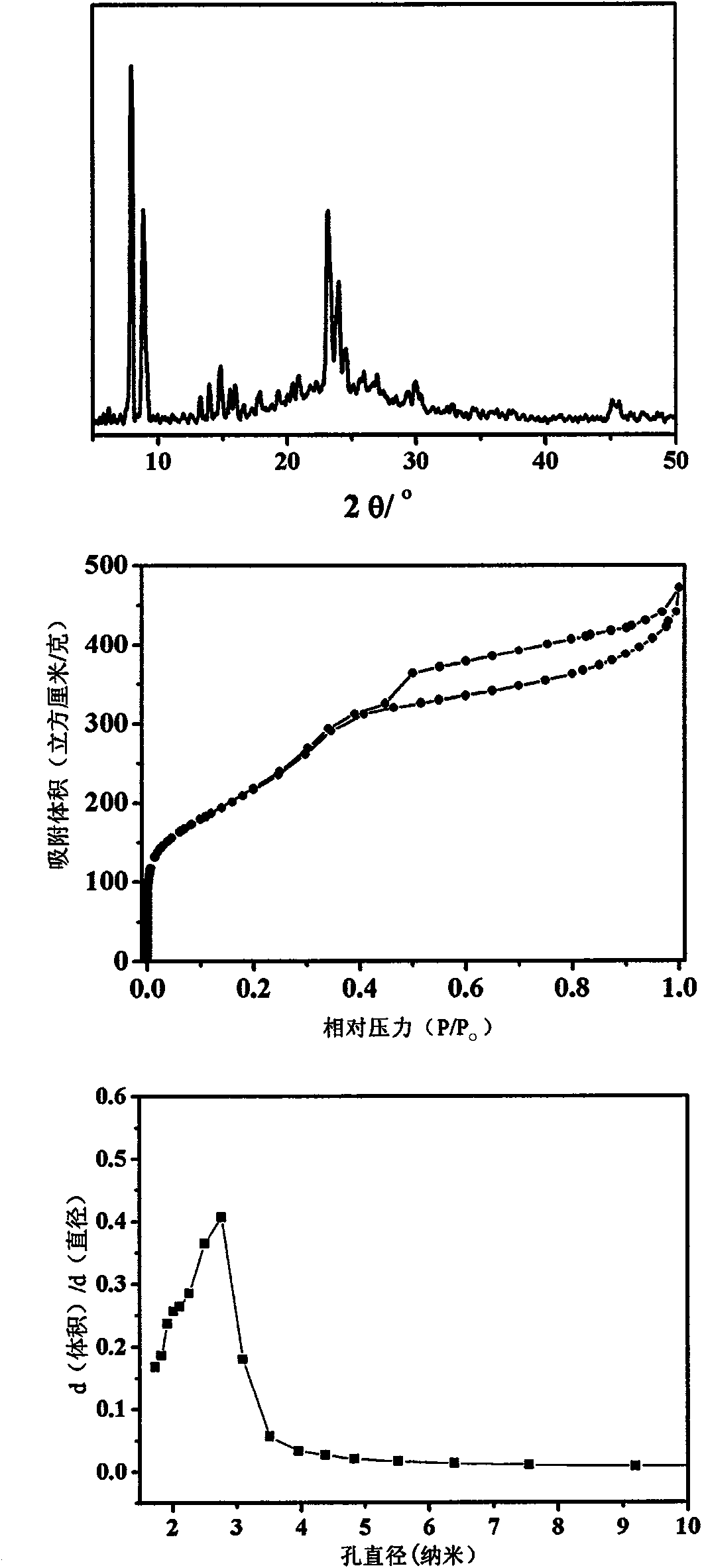

The invention discloses a preparation method for a Beta zeolite molecular sieve with a hierarchical porous structure. Ethyl orthosilicate is used as a silicon source, sodium metaaluminate is used as an aluminum source, hexaammonio cationic quaternary ammonium surfactant is used as a template, and then the hierarchical porous zeolite molecular sieve containing meso pores and Beta zeolite micropores is prepared by using a hydro-thermal synthesis process under an alkaline condition. According to the invention, the hexaammonio cationic quaternary ammonium surfactant is used as a Beta zeolite structure guiding agent and generates micropores, aggregation of hydrophobic long-chain alkyl groups on the surfactant forms the meso pores, so the prepared Beta zeolite molecular sieve has both meso pores and the crystalline micropores. The structure with both the meso pores and the micropores enables defects of a single pore structure to be avoided and mass transfer efficiency to be improved, and the Beta zeolite molecular sieve has a wide application prospect in aspects of macro-molecular catalysis, adsorption, separation, etc.

Owner:SOUTH CHINA UNIV OF TECH

High-stability metal organic skeleton hybrid material, preparation method and application thereof

ActiveCN103694260AHigh hydrothermal stabilitySimple methodOrganic-compounds/hydrides/coordination-complexes catalystsCopper organic compoundsMass ratioHybrid material

The invention discloses a high-stability metal organic skeleton hybrid material. The metal organic skeleton hybrid material has high hydrothermal stability, and comprises metal organic skeleton and attapulgite, wherein the mass ratio of the attapulgite to the metal organic skeleton is (0.005-0.7):1.

Owner:NANJING TECH UNIV

Nano ZSM-5 molecular sieve based catalyst and preparation and use methods

ActiveCN104941695AShorten the diffusion pathEasy to spreadMolecular sieve catalystsHydrocarbon from oxygen organic compoundsStrong acidsZSM-5

The invention discloses a nano ZSM-5 molecular sieve based catalyst and preparation and use methods. The molecular sieve catalyst consists of molecular sieves and metal components, wherein the molecular sieves are nano ZSM-5 molecular sieves with a short b-axis, a medium high silica-alumina ratio, less strong acid, high Lewis acid content, and resistance to hydrothermal deactivation. The preparation method is as follows: mixing a silicon source, an aluminum source, a template agent, a structure promoter, an additive and alkali with water, and stirring to prepare a precursor solution, then crystallizing, separating solid from liquid, and calcinating to obtain molecular sieve raw powder; mixing the molecular sieve raw powder with an ammonium salt solution, stirring, filtering, mixing with the ammonium salt solution for several times, stirring, filtering, and calcinating to obtain hydrogen-type ZSM-5 molecular sieves; mixing with the metal precursor solution, drying and calcinating to obtain the aromatization catalyst. The use method is as follows: transforming oxy-compound raw materials to aromatic hydrocarbon through the catalyst under the reaction conditions. The nano ZSM-5 molecular sieve based catalyst has the characteristics of being high in aromatics yield (reaching up to 99%) and long in service life (the catalyst is alive after 300 hours, and the aromatics selectivity reaches up to 70% after the catalyst is subjected to hydrothermal aging at 760 DEG C for 4 hours).

Owner:TSINGHUA UNIV

Method for preparing low carbon olefin by coupled catalytic cracking of petroleum hydrocarbon

A process for preparing lower carbon number hydrocarbons through linkage petroleum hydrocarbon catalysis decomposition, wherein petroleum hydrocarbon and organic oxygen compounds are used as raw material, and fluid bed reactor is utilized under the action of solid acid catalyst and high temperature water vapor through linkage petroleum hydrocarbon catalysis decomposition to prepare lower carbon number hydrocarbons. The reaction condition is, temperature 500-720 deg.C, the weight ratio of the catalyst and the petroleum hydrocarbons is 5-40:1, the weight ratio of the organic oxygen compounds and the petroleum hydrocarbons is 0-2:1, the weight ratio of the water vapor and the petroleum hydrocarbons is 0-1:1.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Hydrocarbons conversion catalyzer

ActiveCN101134172AStrong hydrocarbon conversion abilityHigh hydrothermal stabilityCatalytic crackingOrganic chemistryOxidation stateInorganic oxide

The hydrocarbon converting catalyst contains zeolite mixture in 1-60 wt%, heat resistant inorganic oxide in 5-99 wt% and clay in 0-70 wt%. The zeolite mixture contains phosphorus and transition metal modified beta-zeolite 1-75 wt%, zeolite in MFI structure 25-99 wt% and macroporous zeolite 0-74 wt%. The phosphorus and transition metal modified beta-zeolite has the anhydrous chemical expression of (0-0.3)Na2O.(0.5-10)Al2O3.(1.3-10)P2O5.(0.7-15)MxOy.(64-97)SiO2, where, the M transition metal is one or several selected from Fe, Co, Ni, Cu, Mn, Zn and Sn, x is atom number of M and y is M is one number for meeting the requirement of oxidation state. The catalyst of the present invention has high hydrocarbon converting capacity and high low carbon olefin yield, especially high propylene yield. It may be applied in the catalytically cracking of hydrocarbon to prepare low carbon olefin.

Owner:CHINA PETROLEUM & CHEM CORP +1

Molecular sieve catalyst for preparing low-carbon olefin and preparation method thereof

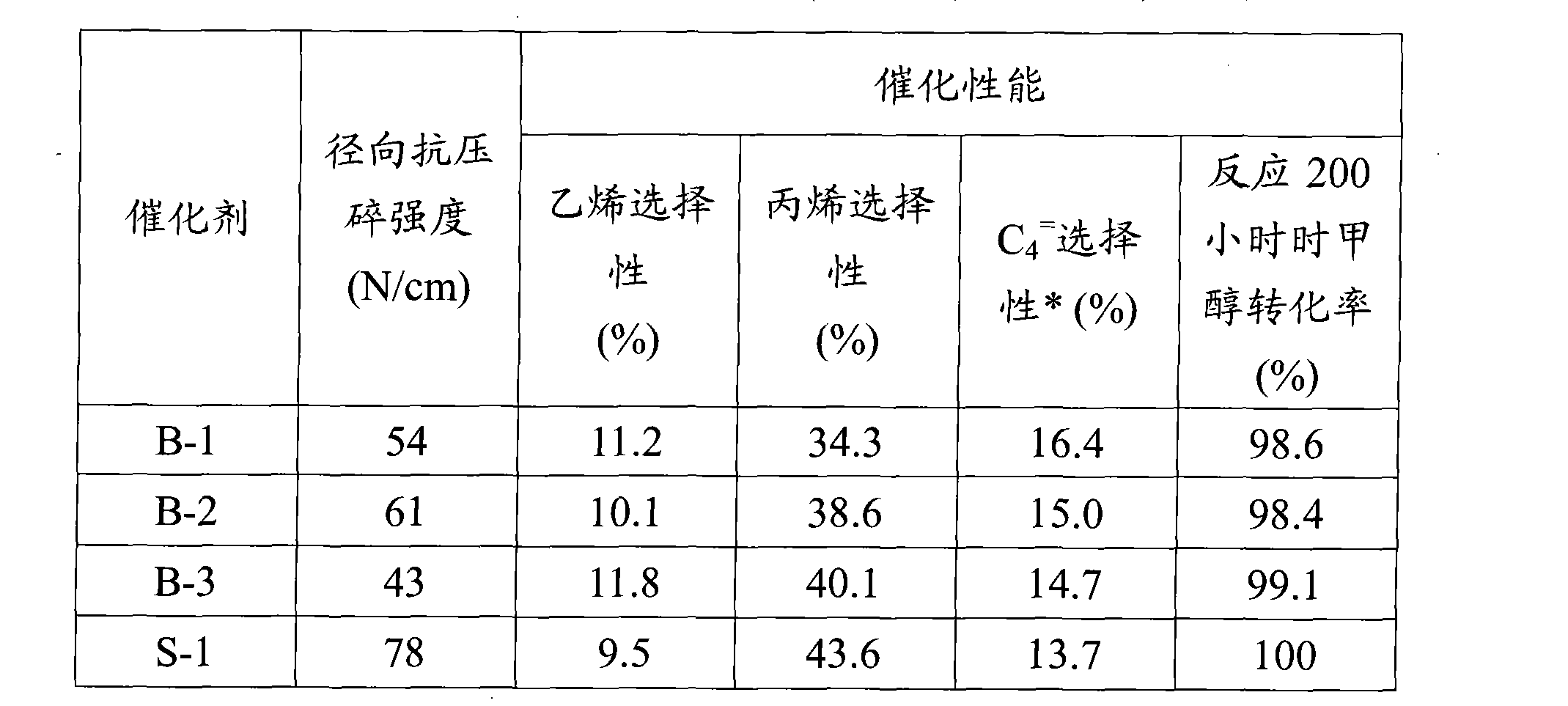

ActiveCN101628242ATotal pressure is smallSimplify production stepsMolecular sieve catalystsCatalyst activation/preparationMolecular sieveHigh activity

The invention provides a molecular sieve catalyst for preparing low-carbon olefin, and the catalyst comprises the following raw materials by parts by weight: 30-93.7 parts of Na-ZSM-5 zeolite, 5-40 parts of bonding agent, 0.1-10 parts of modifier of mixed elements, 1-15 parts of hole structure regulator and 0.1-5 parts of extrusion assistant, and the modifier of the mixed elements is a soluble substance containing one or a plurality of elements of B, P, La, Ca, Mg, Sr, Zn, Cu, Mn, Cd, Ga and In. The invention further provides a prepration method of the catalyst. The molecular sieve catalyst adopts the extrusion assistant and adds an appropriate amount of hole structure regulator, thereby improving product strength and hole structure, effectively improving diffusion performance of the catalyst and further improving selectivity of the low-carbon olefin. The catalyst has the advantages of appropriate strength, high hydrothermal stability, high activity and high selectivity of propylene.

Owner:DATANG INT CHEM TECH RESINST

Catalyst for liquid phase alkylation of ethylene to prepare ethylbenzene

InactiveCN1506340AHigh hydrothermal stabilityImproved water resistance and regenerationMolecular sieve catalystsHydrocarbonsOrganic acidMolecular sieve

The present invention relates to one kind of catalyst for liquid phase alkylation of ethylene to prepare ethylbenzene and aims at raising the stability and regeneration performance of catalyst. The present invention adops beta-zeolite molecular sieve with SiO2 / Al2O3 molar ratio of 10-50 as catalyst, and the catalyst is processed first with high temperature steam and then with organic acid before use, and this raises the stability and regeneration performance of catalyst. The present invention may be used in the industrial production of liquid phase alkylation to prepare ethylbenzene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Coal gasification catalyst completely methanated by synthesis gas and preparation and application thereof

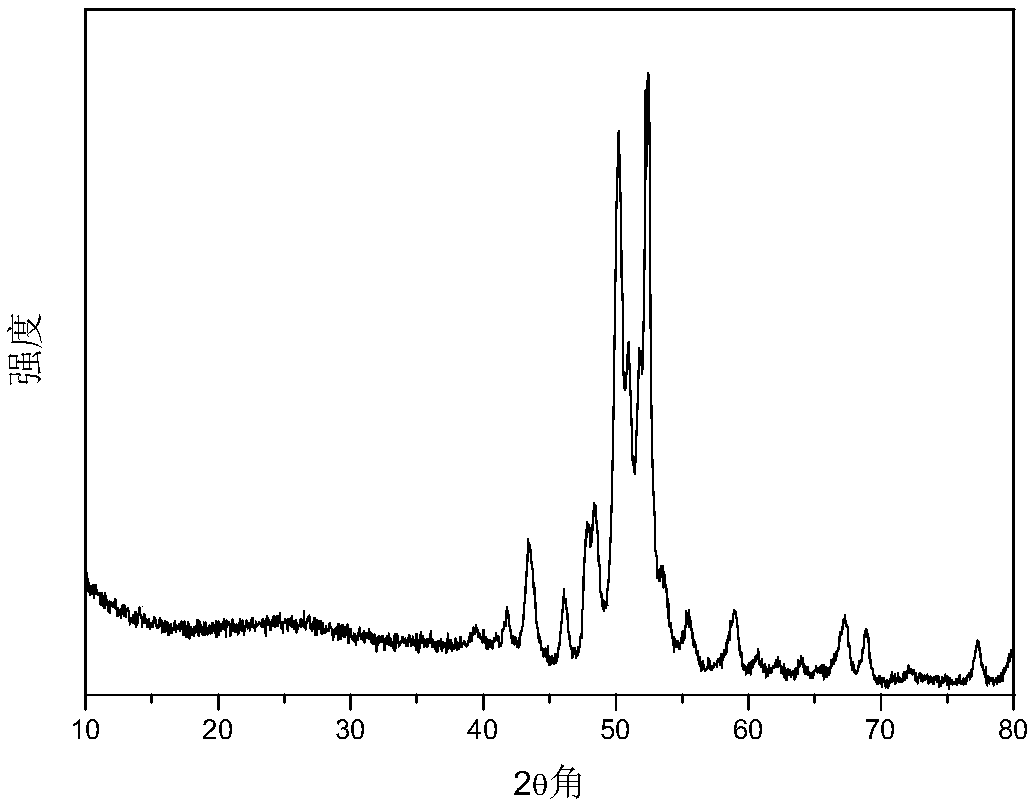

ActiveCN101716513AGood hydrothermal stabilityHigh hydrothermal stabilityHydrocarbon from carbon oxidesGaseous fuelsOxidePrecipitation

The invention relates to a coal gasification catalyzer completely methanated by synthesis gas and a preparation and application thereof. The catalyzer contains an active component, a carrier and an accessory ingredient, wherein the active component is a transition metal oxide NiO, and the content of NiO is 10-75 percent of the total weight of the catalyzer; the carrier is a CeO2-based rare earth metal oxide, and the content of the rare earth metal oxide is 10-19 percent of the total weight of the catalyzer; and the accessory ingredient is La2O3, and the content of La2O3 is 0.1-15 percent of the total weight of the catalyzer; the preparation method adopts a simple homogeneous phase chemical precipitation process. The invention has the advantages of low cost on raw materials and simple preparation method, meets the current increasing needs of clean energies and meanwhile has the irreplaceable important role in the enhancement of international energy sources and resource security.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Cu-SSZ-13 catalyst, and preparation method and application thereof

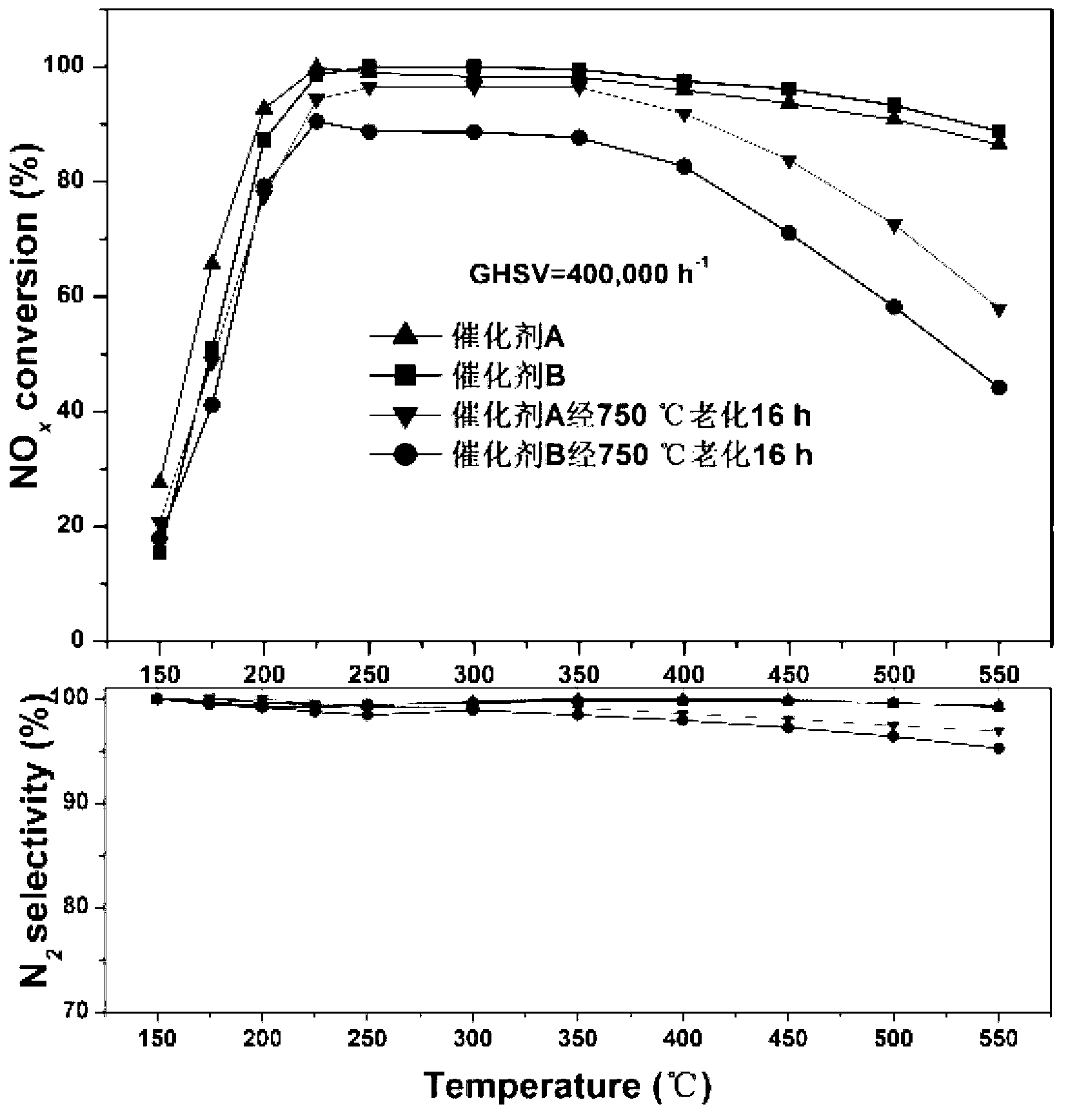

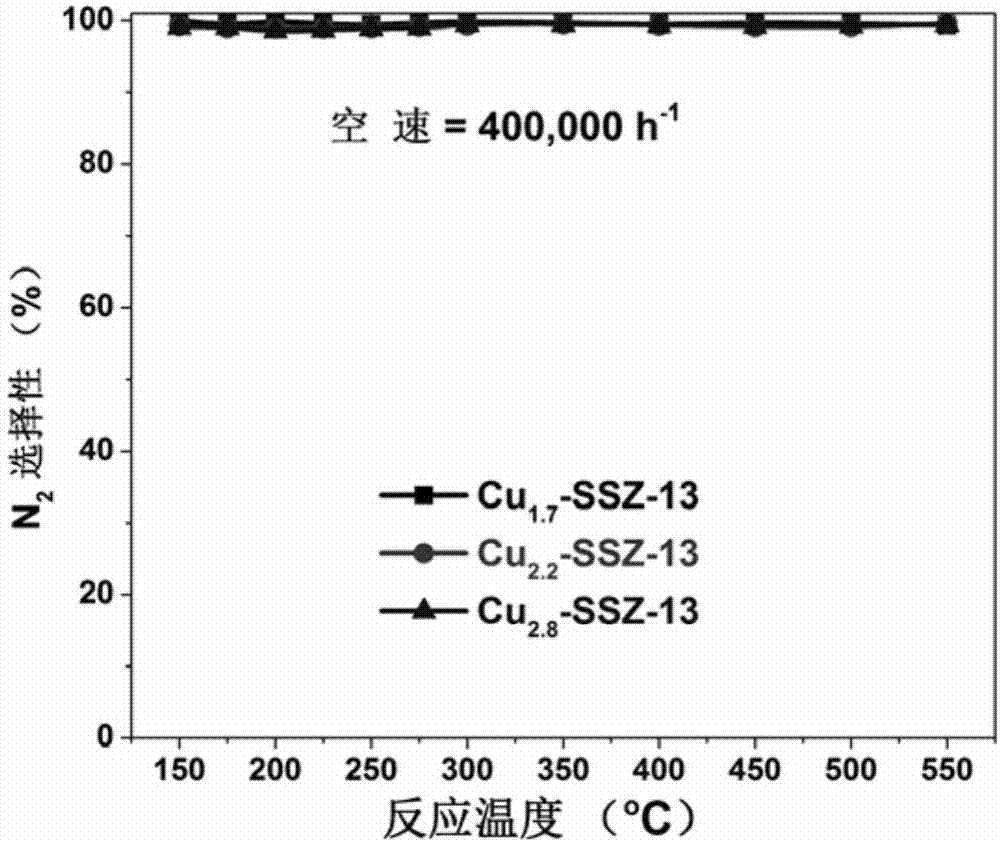

ActiveCN103157505ASolve pollutionImprove activity stabilityMolecular sieve catalystsDispersed particle separationAfter treatmentSynthesis methods

The invention discloses a method for preparing a Cu-SSZ-13 catalyst through an in-situ synthesis method. A Cu-SSZ-13 molecular sieve sample is prepared by taking acid as an exchange reagent and treating through an in-situ synthesis method. Compared with the currently used ammonium nitrate ion exchange method, the after treatment method for the Cu-SSZ-13 molecular sieve prepared through an in-situ synthesis method is more environment-friendly and effective; the activity of the prepared catalyst is higher; and the hydrothermal stability is better. According to the method, the silica-alumina ratio of the molecular sieve structure is increased while the catalyst having high catalytic activity is obtained; and the obtained Cu-SSZ-13 catalyst has excellent hydrothermal stability, wide temperature window and excellent N2 selectivity, and is very applicable to purification of tail gas from diesel cars.

Owner:江西中科鸿虔新材料有限公司

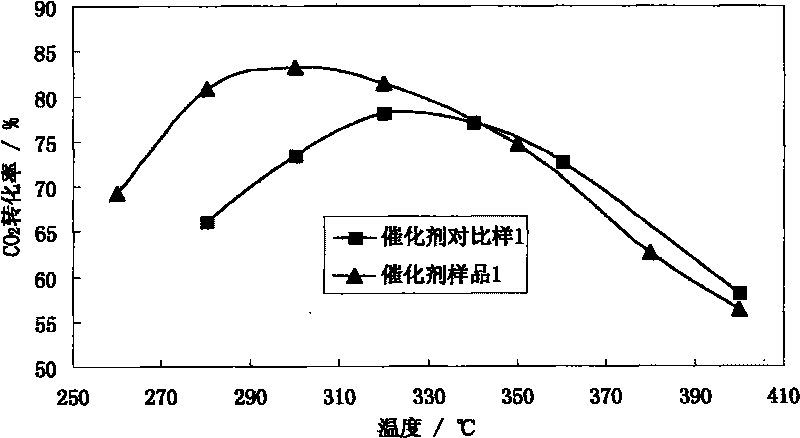

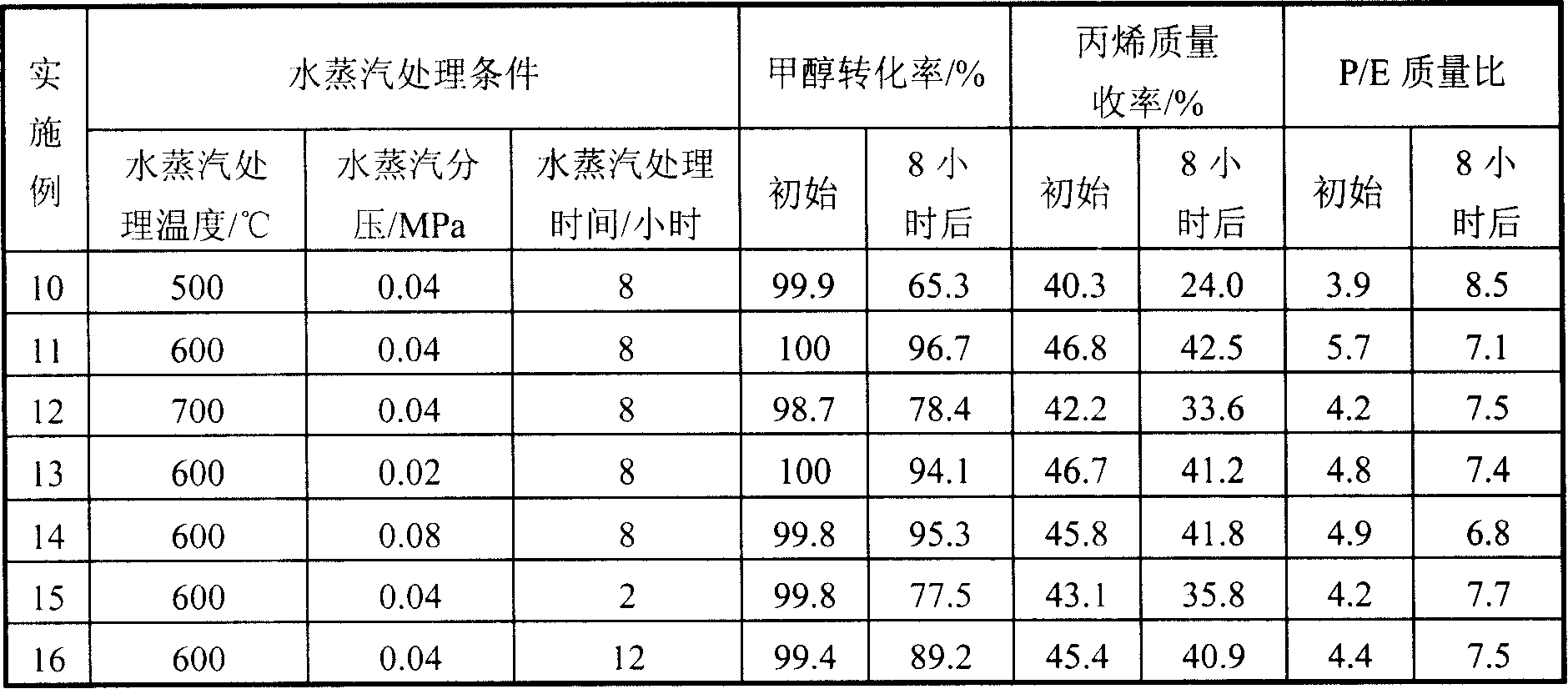

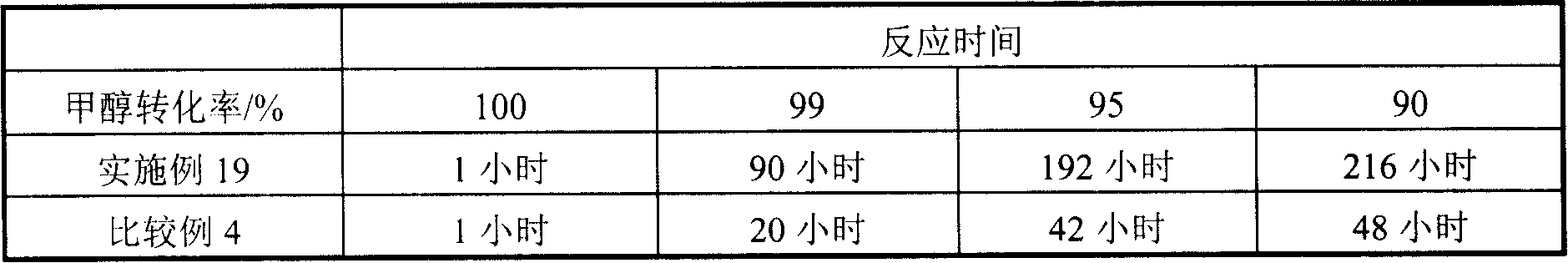

Process for preparation of propylene catalysts with methanol conversion

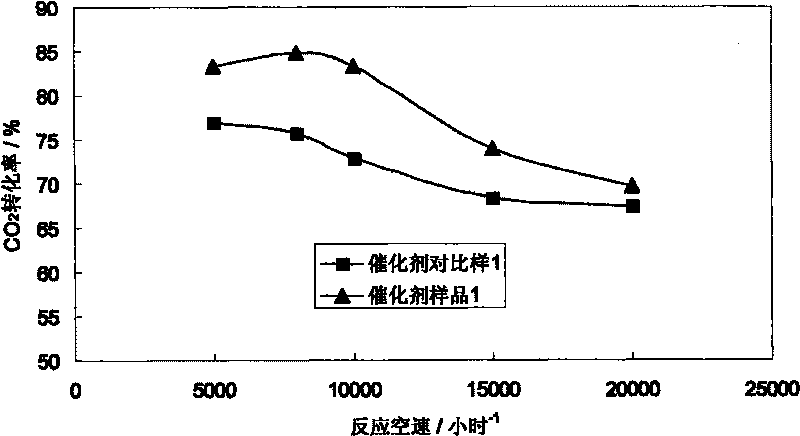

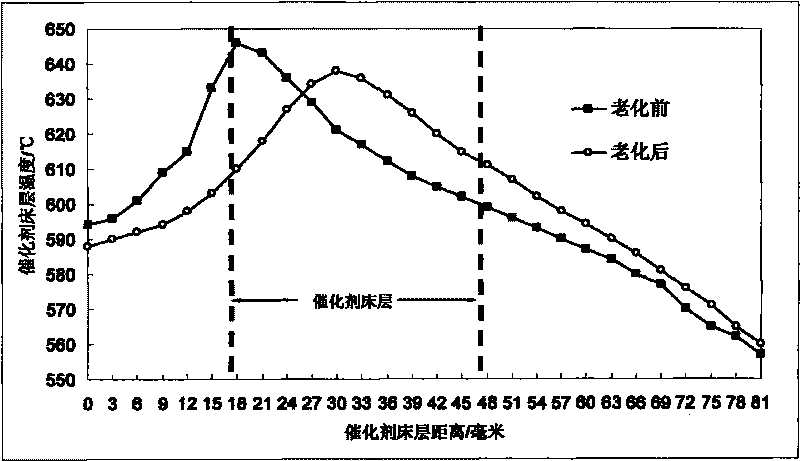

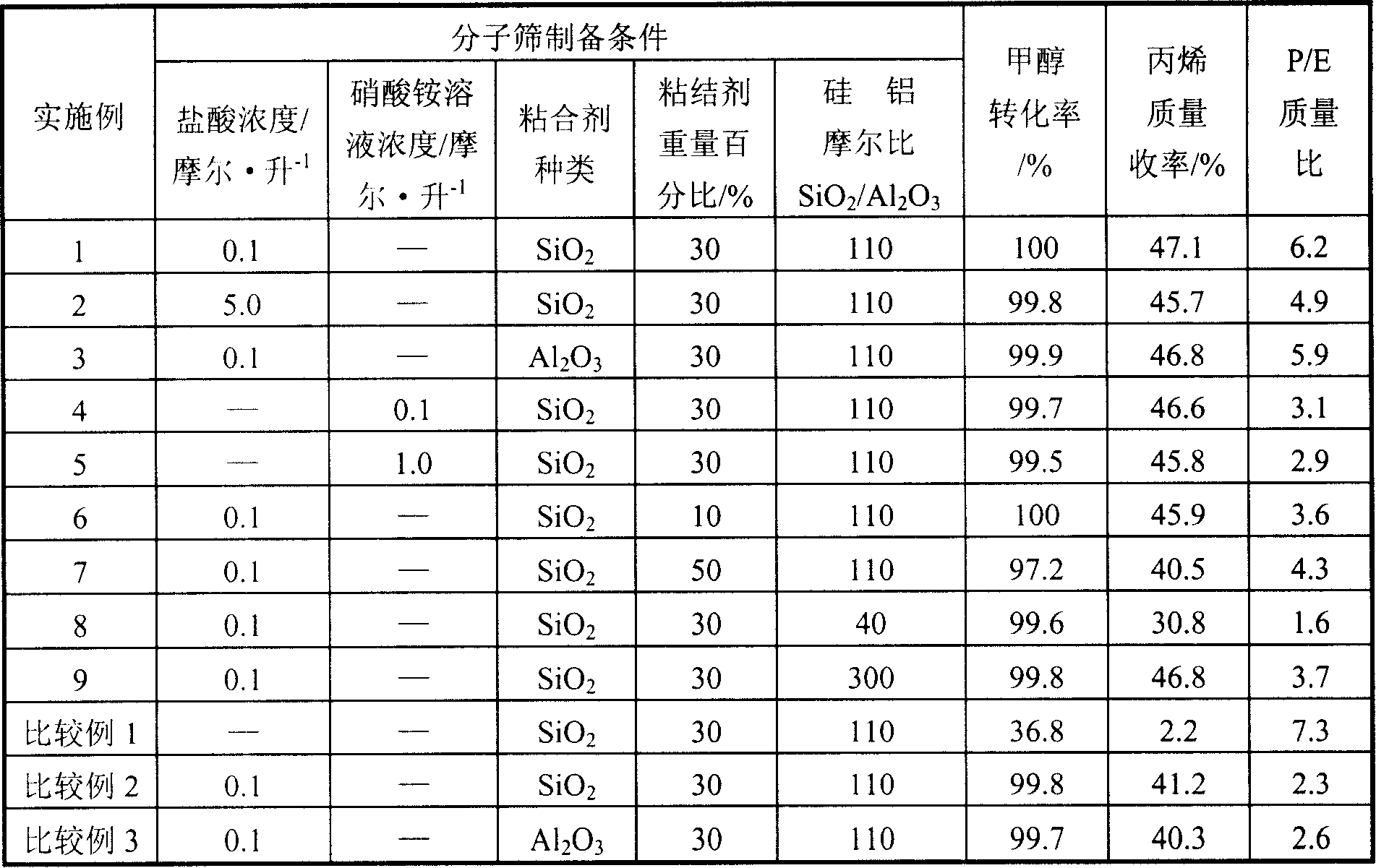

ActiveCN101172246AHigh hydrothermal stabilityMolecular sieve catalystsHydrocarbon from oxygen organic compoundsAdhesiveMethanol

The invention relates to a preparation method for converting methanol into propylene catalyst, which mainly solves the problems existing in the former art that the yield rate of the target product propylene is low, the P and E ratio (propylene / ethylene mass ratio) is low, and the hydrothermal stability is poor. The invention better solves the problems through adopting a technical proposal that ZSM-5 molecular sieve with the mol ratio SiO2Al2O3 from 20 to 1000 and adhesive are roasted after being mixed, and converted at the temperature of 20 to 100 DEG C and in 0.1 to 3 mol / L of ammonium acetate or 0.1 to 8.5 mol / L of acid solution, and steam treated for 1 to 15 hours after being roasted at the temperature of 400 to 700 DEG C and under the fluid water phase weight space velocity of 0.1 to10 hours <-1>, and then the precursor of the ZSM-5 molecular sieve is soaked with acid solution, and roasted to obtain the modified ZSM-5 molecular sieve catalyst. The invention can be used for the industrial production of converting methanol into propylene catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Wide-temperature full methanation catalyst and preparation method thereof

ActiveCN102029162AEfficient preparation methodEasy to prepareHydrocarbon from carbon oxidesCatalyst activation/preparationPtru catalystMethanation

The invention provides a wide-temperature full methanation catalyst and a preparation method thereof. The methanation catalyst is characterized in that: nickel is used as a main active ingredient, a composition formed by zirconium oxide and one or more of aluminum oxide and nickel-aluminum compounds is used as a main carrier, and lanthanum oxide is used as a cocatalyst; and a catalyst precursor is prepared by using a chemical precipitation process, and the catalyst precursor is reduced into the catalyst by filtering, washing, roasting, forming and re-roasting. The methanation catalyst has excellent catalytic activity and stability in a use range of between 260 and 750 DEG C, and fully meets the requirements of a full methanation process of synthesis gas on high temperature resistance, high hydrothermal stability and low-temperature high activity of the catalyst.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Non-noble metal oxide combustion catalyst, and preparation method and use thereof

InactiveCN105381800AEasy to synthesizeLow costDispersed particle separationCatalyst activation/preparationChemical synthesisCobalt(II,III) oxide

The present invention relates to a non-noble metal oxide combustion catalyst and a preparation method and use thereof, and belongs to the technical field of energy utilization and environment protection. The catalyst is iron oxide, cobaltosic oxide, nickel oxide, cupric oxide, vanadium oxide, chrome oxide, manganese dioxide or cerium dioxide prepared according to the following steps: (1) using hydrothermal chemical synthesis to form a precursor of a catalyst; and (b) washing, filtering, shaping, drying and calcinating the obtained precursor of the catalyst, and finally forming a combustion catalyst or coating the precursor of the catalyst on a carrier to form a combustion catalyst. The catalyst prepared by the method can be used in catalytic combustion of methane and other VOC gas, and has the advantages that the synthesis process is simple, the cost is low, the catalytic activity and hydrothermal stability is high, and the light-off temperature and complete combustion temperature of methane are low.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Porous carbon supported Fischer-Tropsch synthesis catalyst as well as preparation method and application thereof

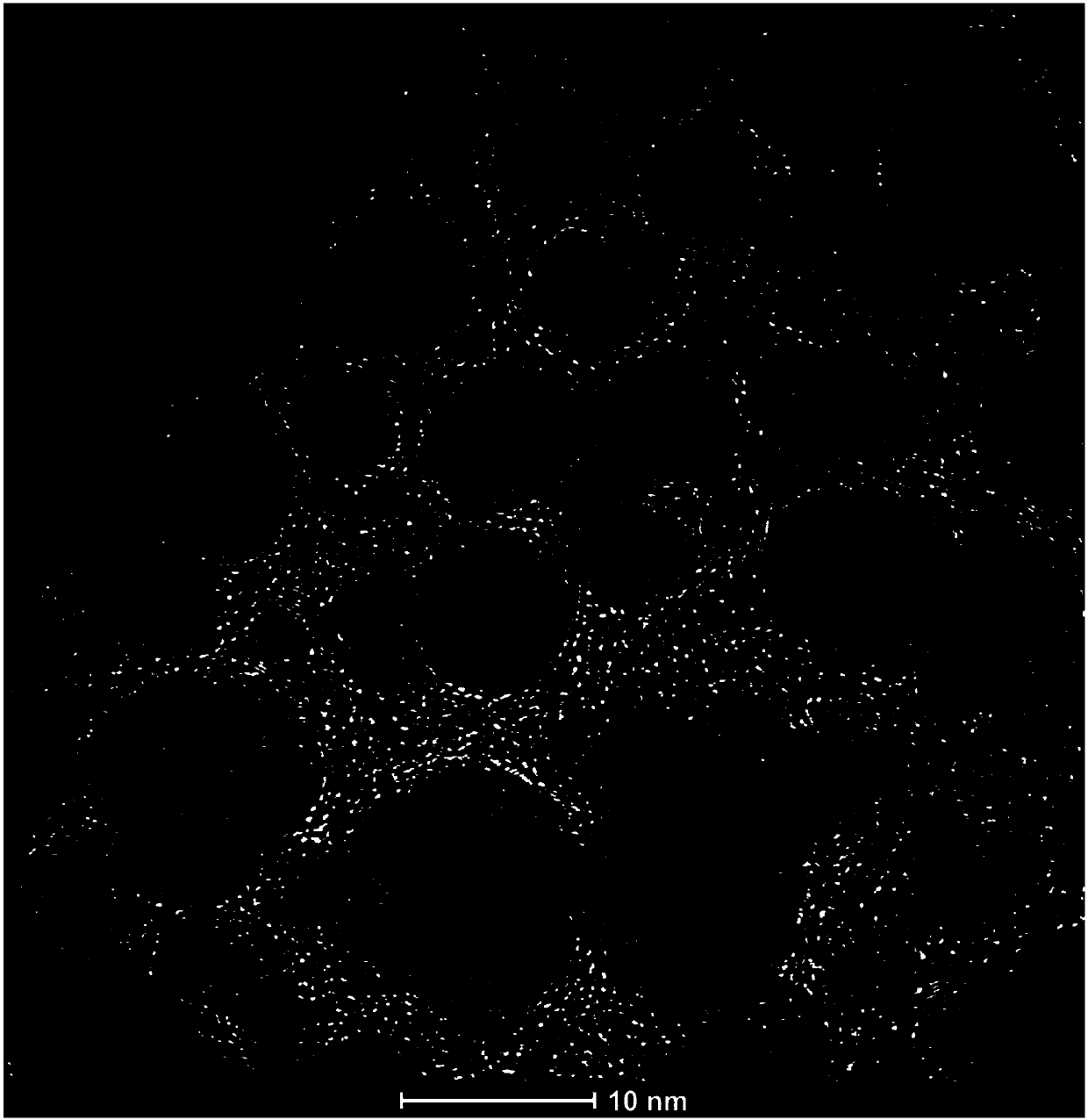

ActiveCN107754793AHigh catalytic activityImprove long-term stabilityLiquid hydrocarbon mixture productionMetal/metal-oxides/metal-hydroxide catalystsPorous carbonActive phase

The invention discloses a porous carbon supported Fischer-Tropsch synthesis catalyst as well as a preparation method and application thereof. The Fischer-Tropsch synthesis catalyst comprises an activephase metal and a porous carbon carrier, wherein the porous carbon carrier is porous graphite or a graphene nano-capsule; the active phase metal is entrapped in a cavity of the porous graphite or graphene nano-capsule; and the active phase metal is selected from at least one of VIIIB family transition metals. The catalyst provided by the invention shows excellent electronic properties, high thermal conductivity, physical and chemical wear resistance, high hydrothermal stability and high mechanical strength in Fischer-Tropsch synthesis application, and rich nano porous structures of the catalyst can promote high dispersion of active phases of the catalyst and diffusion of reaction species, so that the catalyst has excellent Fischer-Tropsch synthesis reaction properties: high activity, lowmethane selectivity and long running life.

Owner:SYNFUELS CHINA TECH CO LTD

Catalyst for producing propylene by catalytic pyrolysis and preparation method thereof

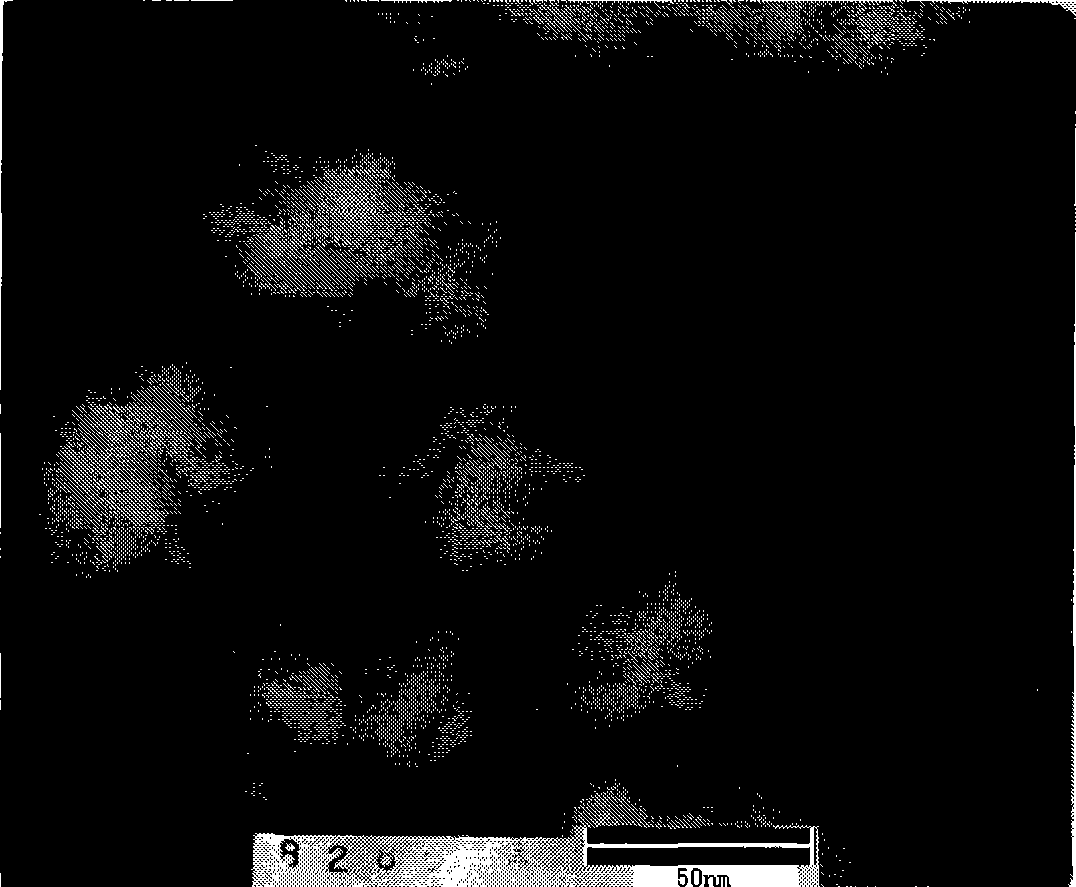

ActiveCN101462071AConducive to diffusionLess side effectsMolecular sieve catalystsBulk chemical productionCrystalliteMolecular sieve

The invention discloses a catalyst for producing propylene by catalytic pyrolysis and a preparation method thereof. Calculated as the total weight of the catalyst, the catalyst comprises 20 to 40 weight percent of element-modified molecular sieve and 60 to 80 weight percent of heat-resistant inorganic oxide, wherein the content of a modified element is between 1 and 10 weight percent calculated as the total weight of the molecular sieve, the average grain diameter of crystal grains of the molecular sieve is between 10 and 100nm, and the modified element is one or a mixture of more of family IB metals and / or phosphorus. The catalyst is used for reactions that low carbon olefin, particularly the propylene is produced by C6-C12 olefins through catalytic pyrolysis, and has higher conversion rate of the C6-C12 olefins and yield of the propylene.

Owner:CHINA PETROLEUM & CHEM CORP +1

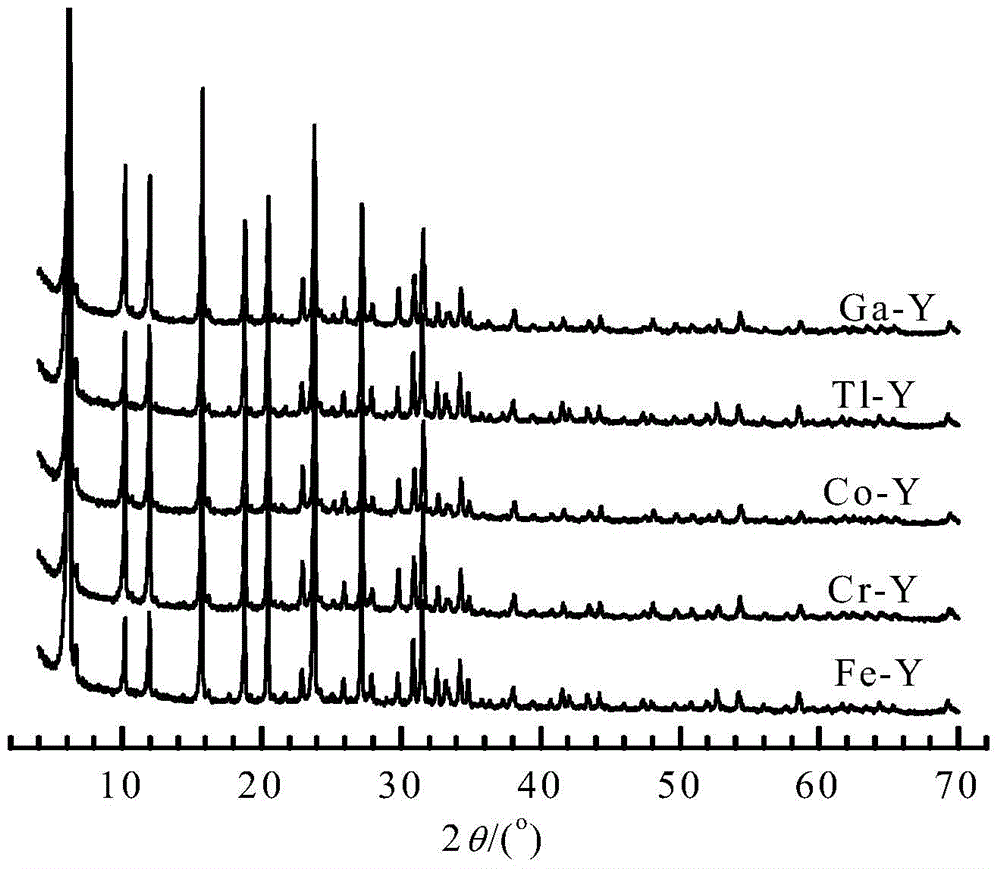

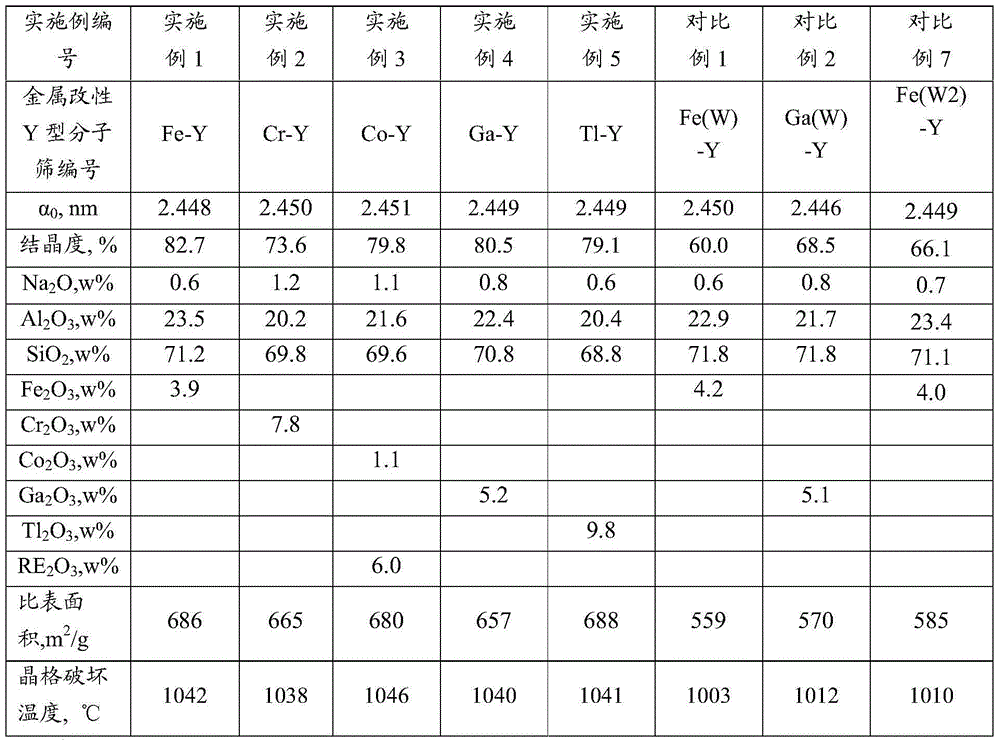

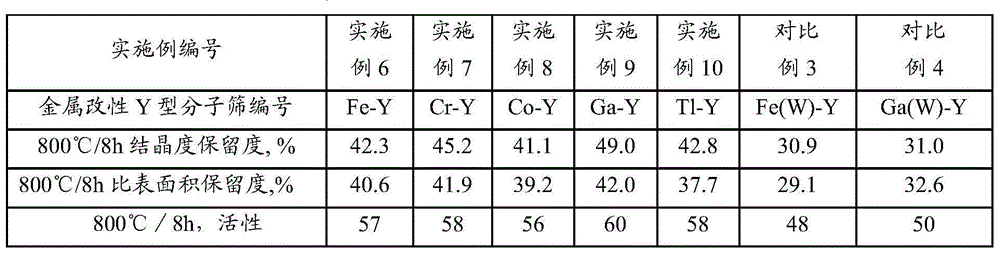

Preparation method of metal modified Y type molecular sieve

ActiveCN104556120AHigh crystallinityHigh hydrothermal stabilityCatalytic crackingMolecular sieve catalystsMolecular sieveAlcohol

The invention discloses a preparation method of a metal modified Y type molecular sieve. The preparation method comprises the following steps: (1) treating the Y type molecular sieve with an acid solution; (2) dehydrating the treated Y type molecular sieve; (3) then dissolving a compound of modified metal elements in a buffer solution of ethyl alcohol-ammonium acetate-water so as to prepare impregnation liquid, mixing and impregnating the impregnation liquid and the molecular sieve obtained in the step (1), and calcining. Wherein modified metal is one or more of Fe, Cr, Ga, In, Tl, Sn and Co. The metal modified Y type molecular sieve obtained by the method is high in hydrothermal stability, and the productive rate for gasoline by cracking hydrocarbon oil is high.

Owner:CHINA PETROLEUM & CHEM CORP +1

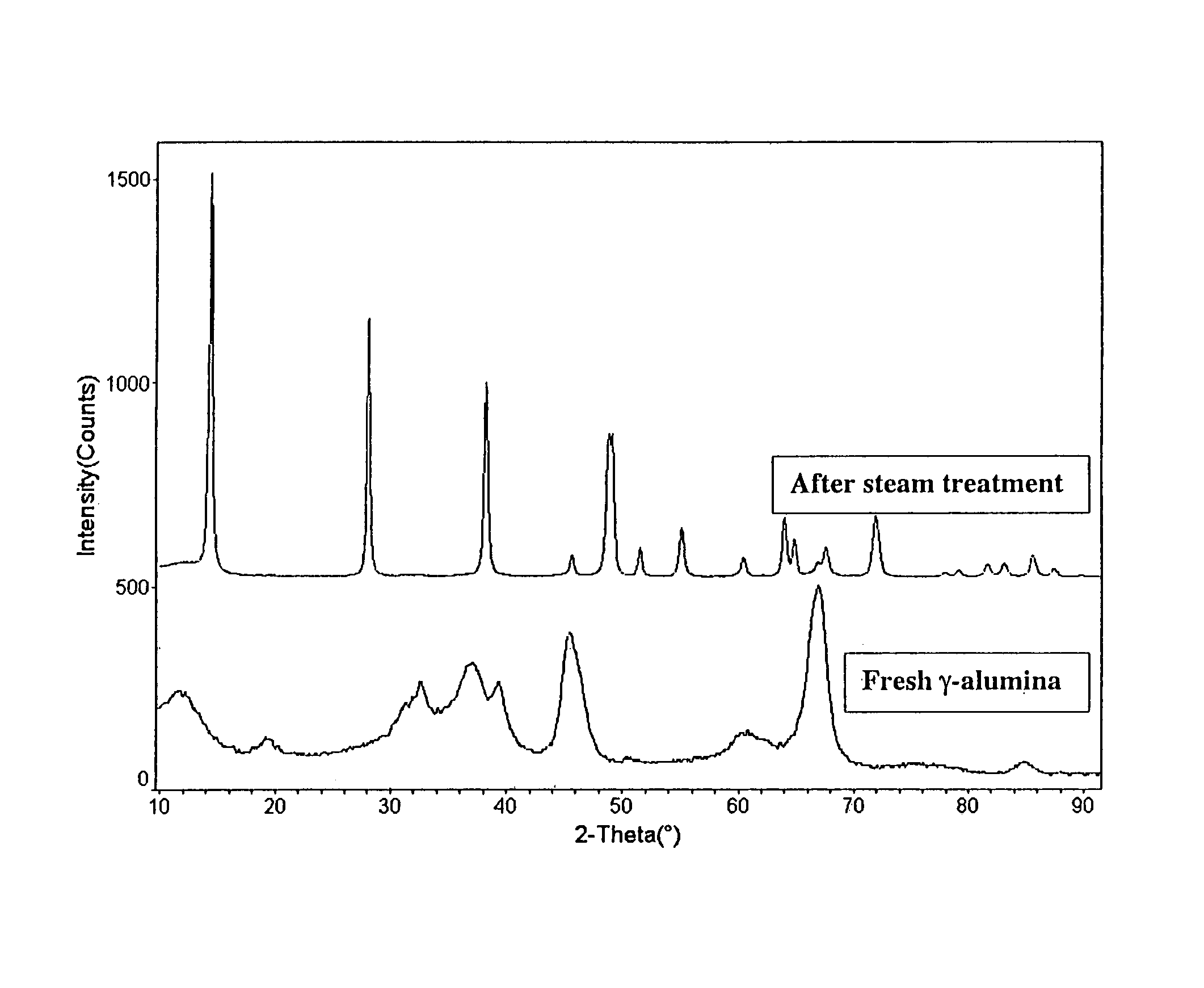

Stabilized transition alumina catalyst support from boehmite and catalysts made therefrom

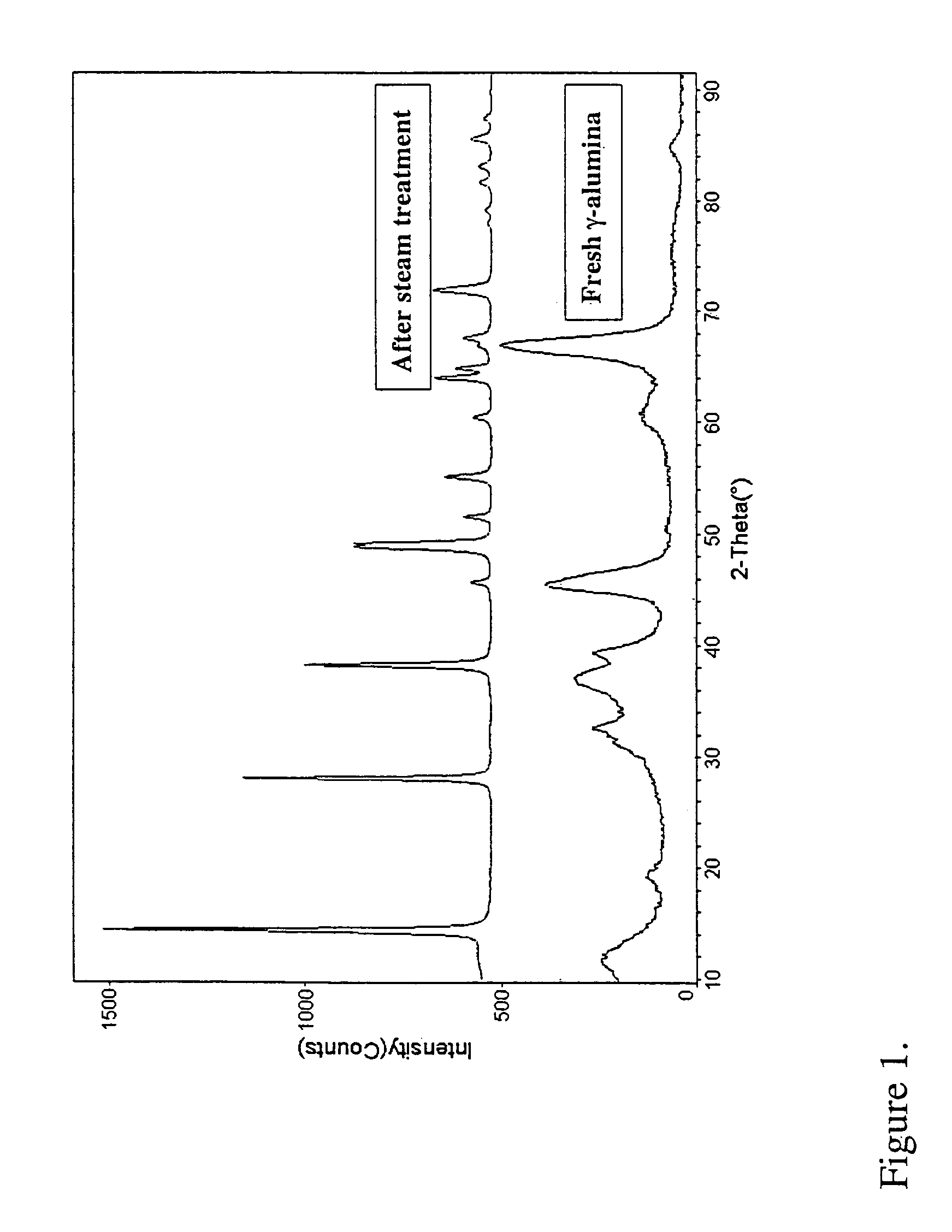

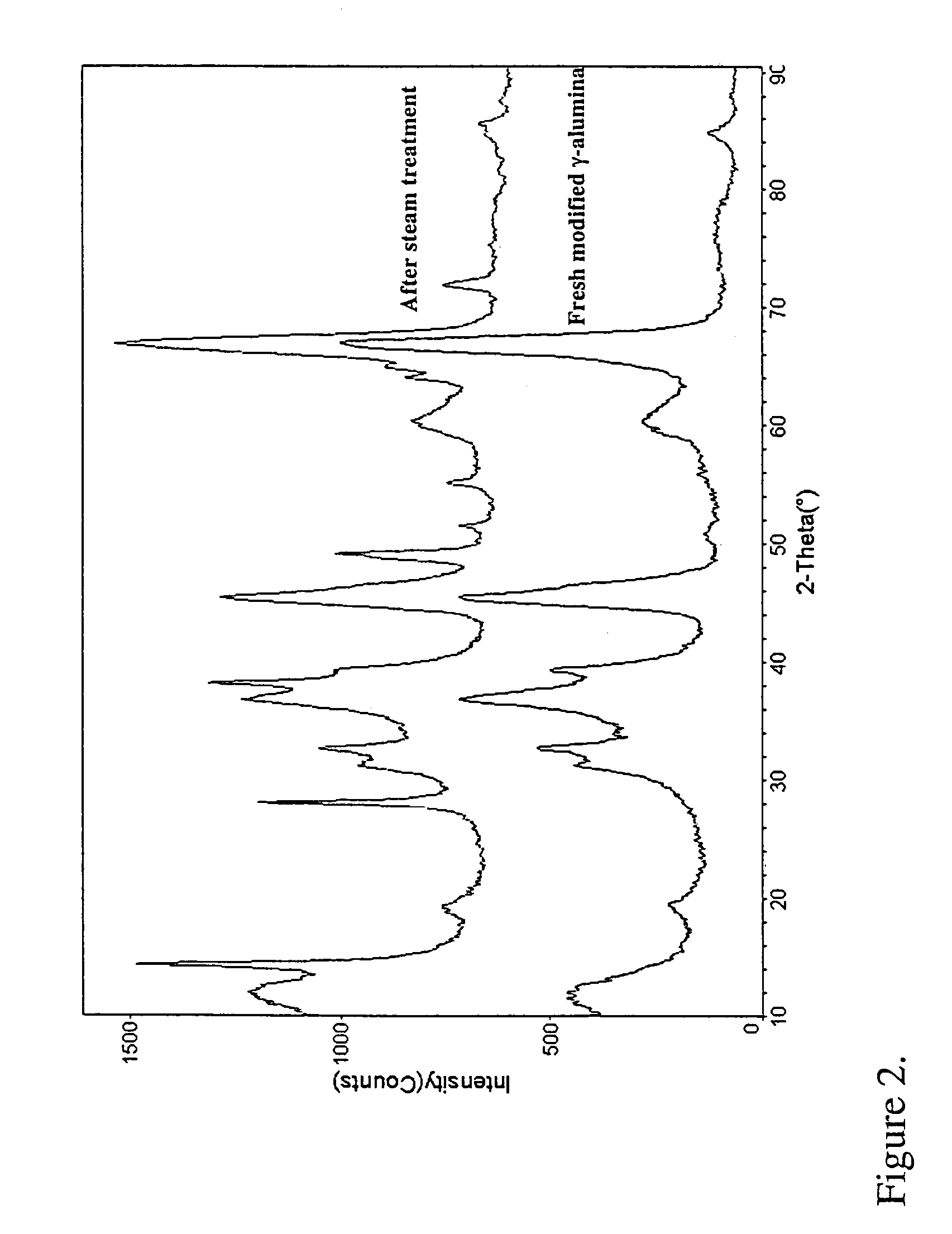

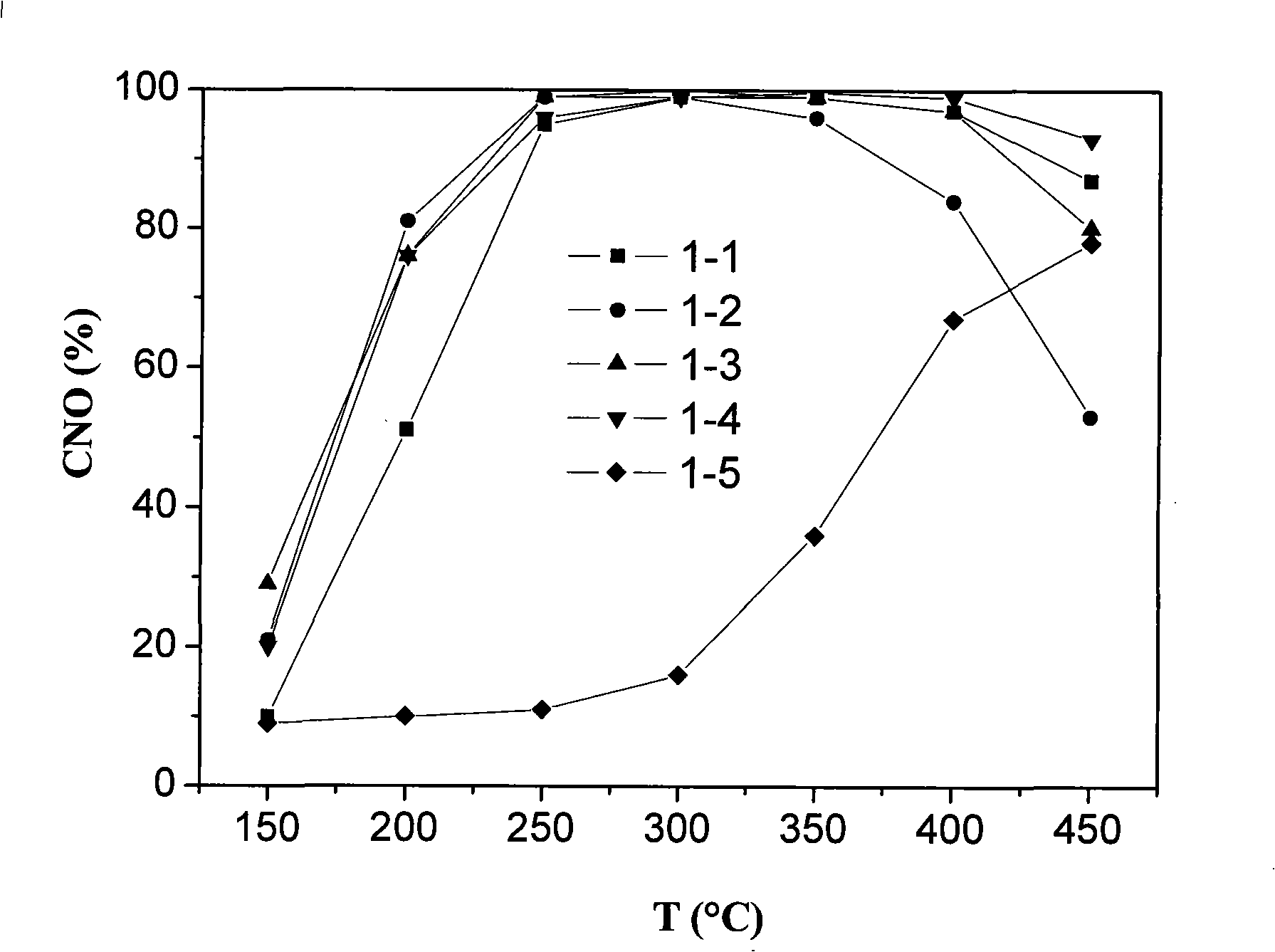

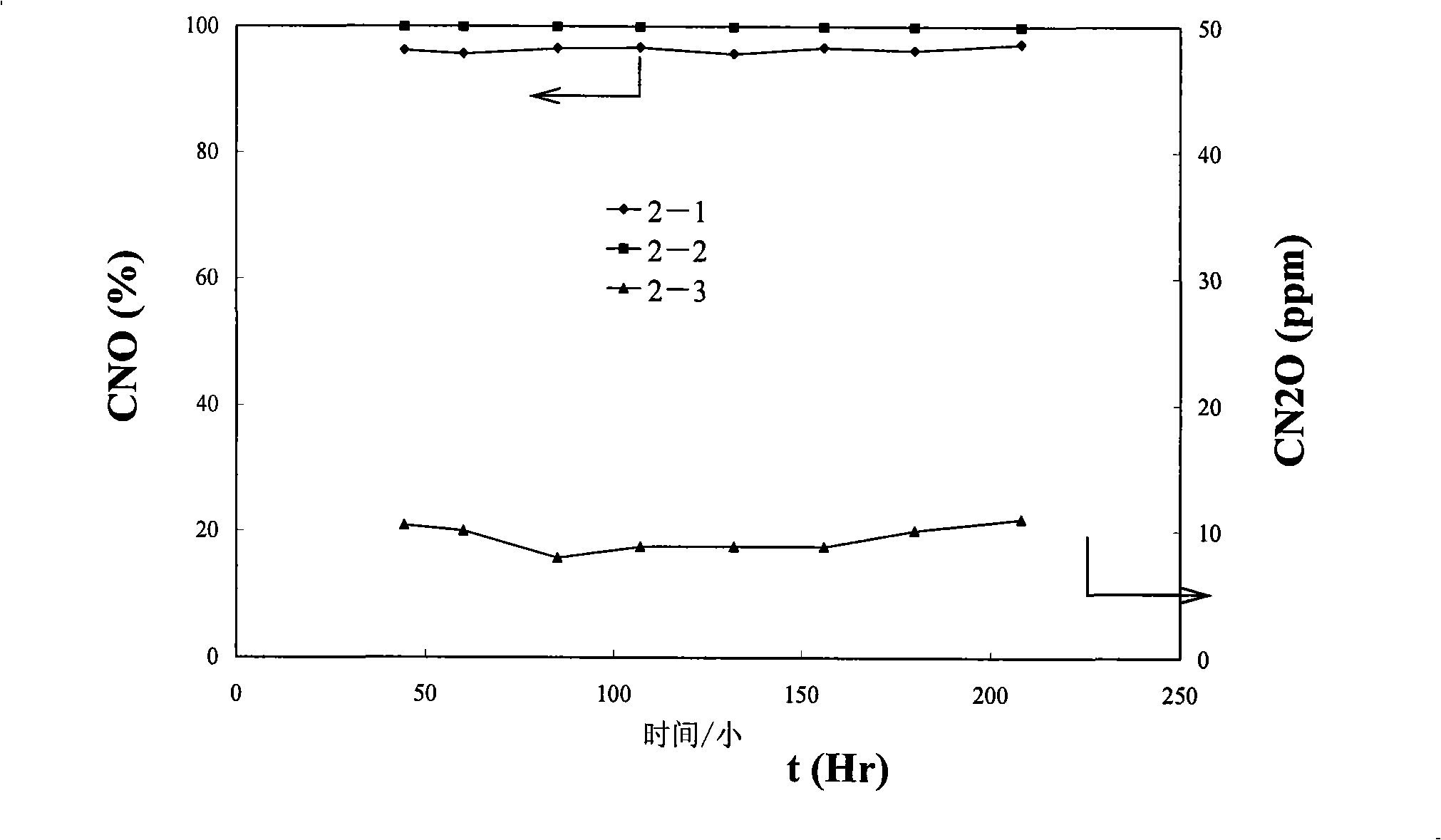

ActiveUS7402612B2Enhance hydrothermal stabilityGood hydrothermal stabilityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsBoehmiteHydrocarbon

This invention relates to methods for making a stabilized transition alumina of enhanced hydrothermal stability, which include the introduction of at least one structural stabilizer; a steaming step before or after the introduction step, wherein steaming is effective in transforming a transition alumina at least partially to boehmite and / or pseudoboehmite; and a calcining step to create a stabilized transition alumina. The combination of the structural stabilizer and the steaming step is believed to impart high hydrothermal stability to the alumina crystal lattice. Particularly preferred structural stabilizers include boron, cobalt, and zirconium. The stabilized transition alumina is useful as a catalyst support for high water partial pressure environments, and is particularly useful for making a catalyst having improved hydrothermal stability. The invention more specifically discloses Fischer-Tropsch catalysts and processes for the production of hydrocarbons from synthesis gas.

Owner:CLARIANT INT LTD

Oxide catalyst for selective reduction of nitrogen oxide, preparation and uses thereof

InactiveCN101314127AHigh hydrothermal stabilityGood hydrothermal stabilityNitrous oxide captureHeterogenous catalyst chemical elementsCeriumCerium oxide

The invention provides a catalyst for selective catalytic reduction of nitrogen oxide, which comprises: a first composition selected from one or a combination of transition metal oxides excluding a second composition, and the second composition selected from one or a combination of cerium oxide, cerium-zirconium compound oxide and cerium-titanium compound oxide. The catalyst can be applied in the form of a granular catalyst, and can also be coated on multiporous integral ceramic to be applied in the form of a honeycomb catalyst. The invention also provides a manufacturing method for the catalyst, which comprises the following steps that: a precursor of the first composition is used to prepare the first composition; the second composition is prepared; and the first composition is loaded onto the second composition. Certain preferable embodiments for the catalyst can ensure that the health of human beings and animals can not be affected when the selective catalytic reduction of nitrogenoxide (NOx) emission is performed.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

Ammonia-selective preparation method of SAPO-34 supported Cu-Fe catalyst for catalytically removing NOx

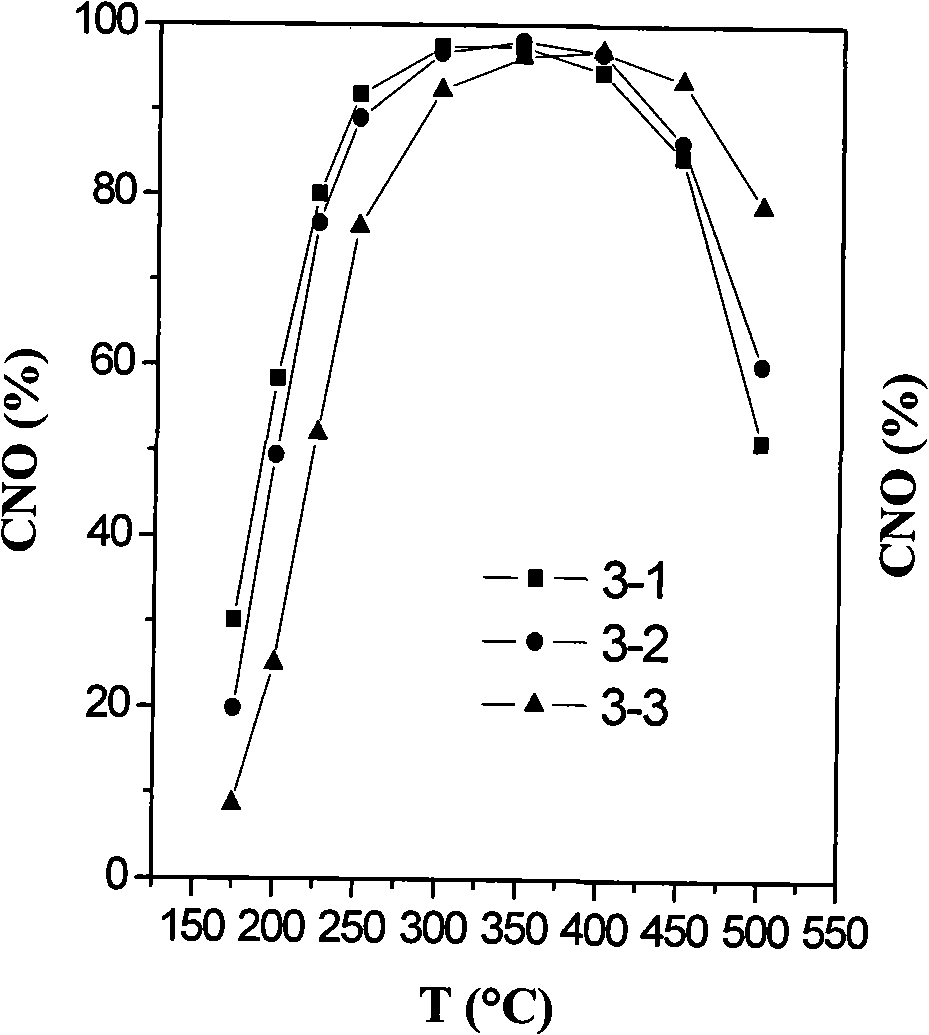

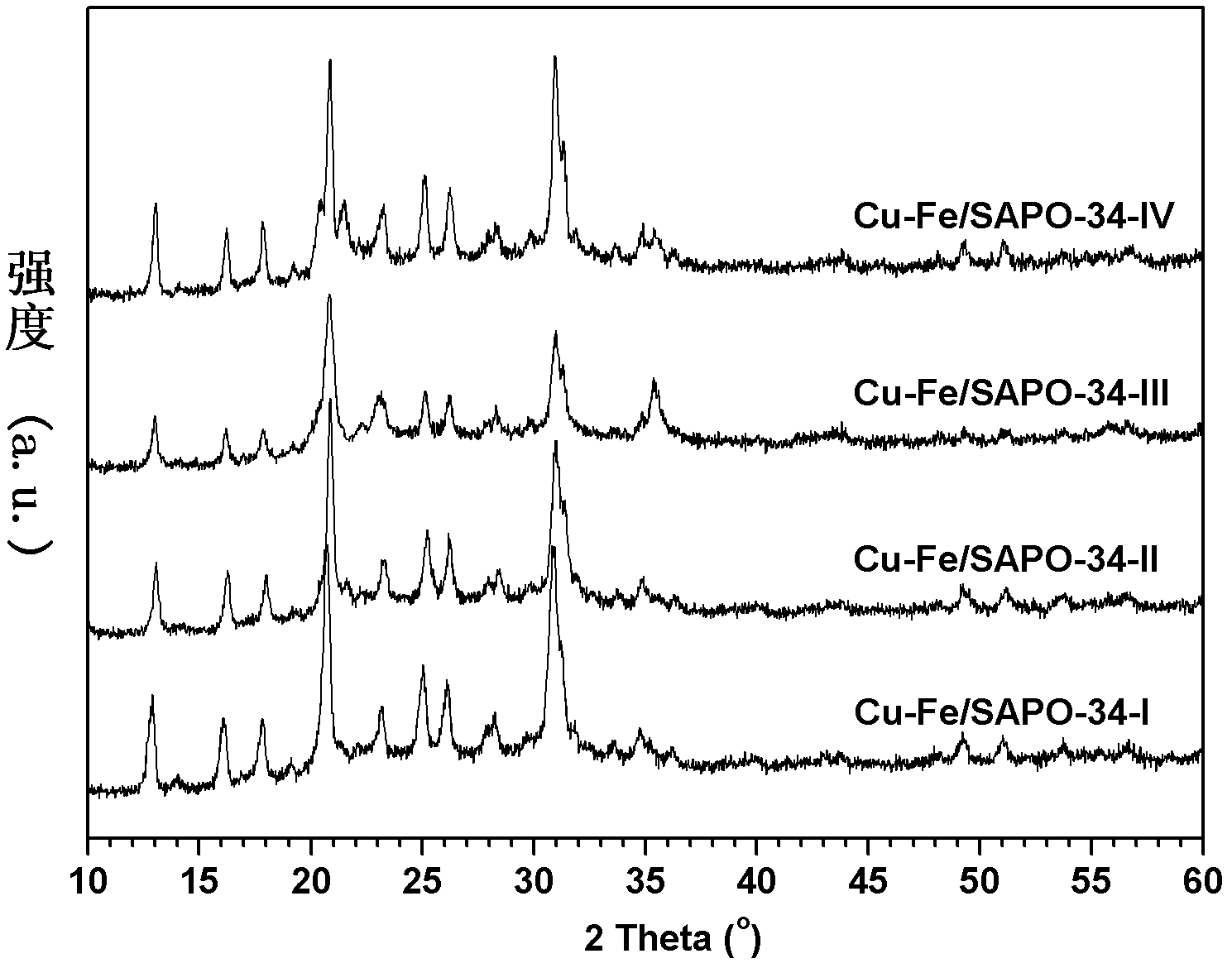

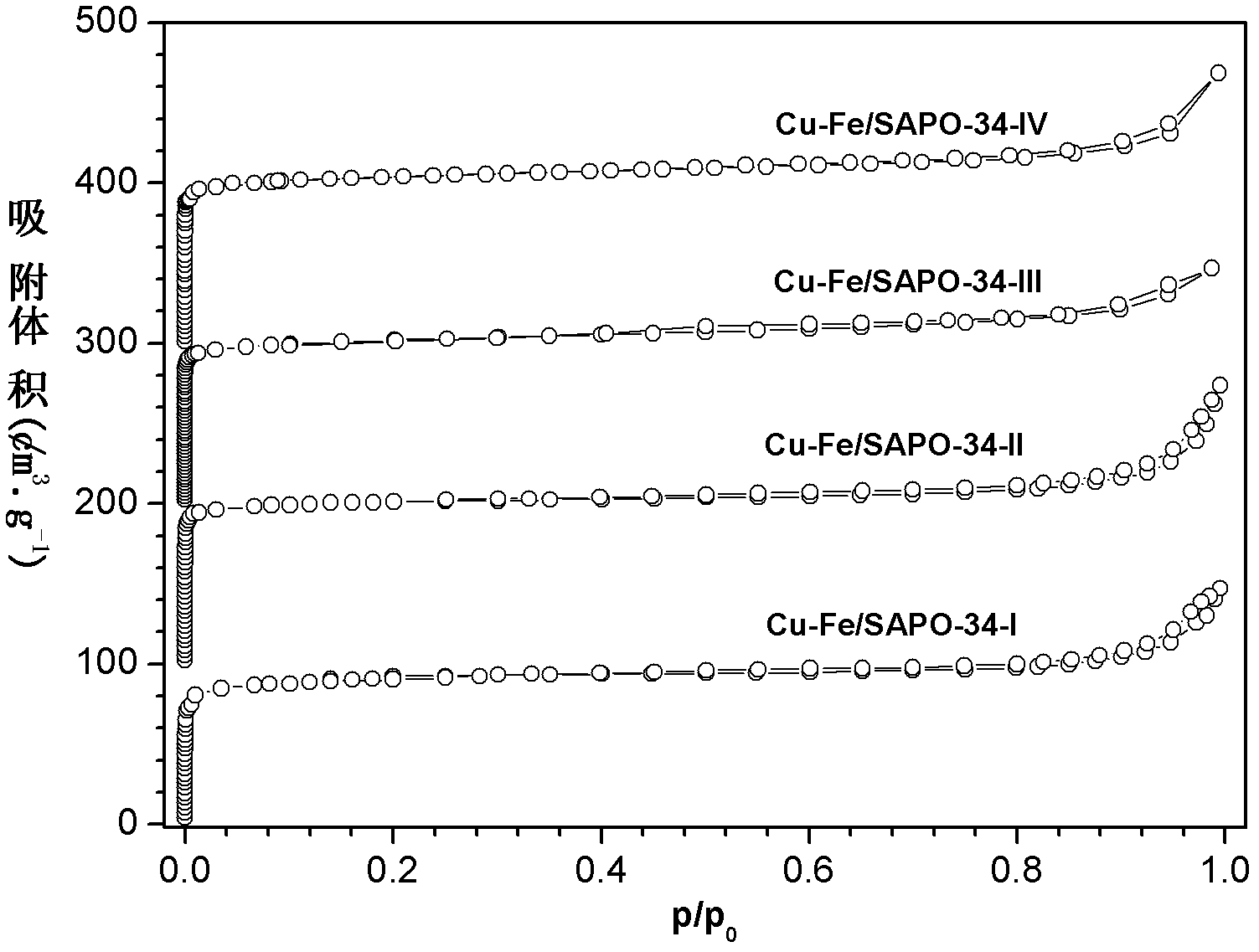

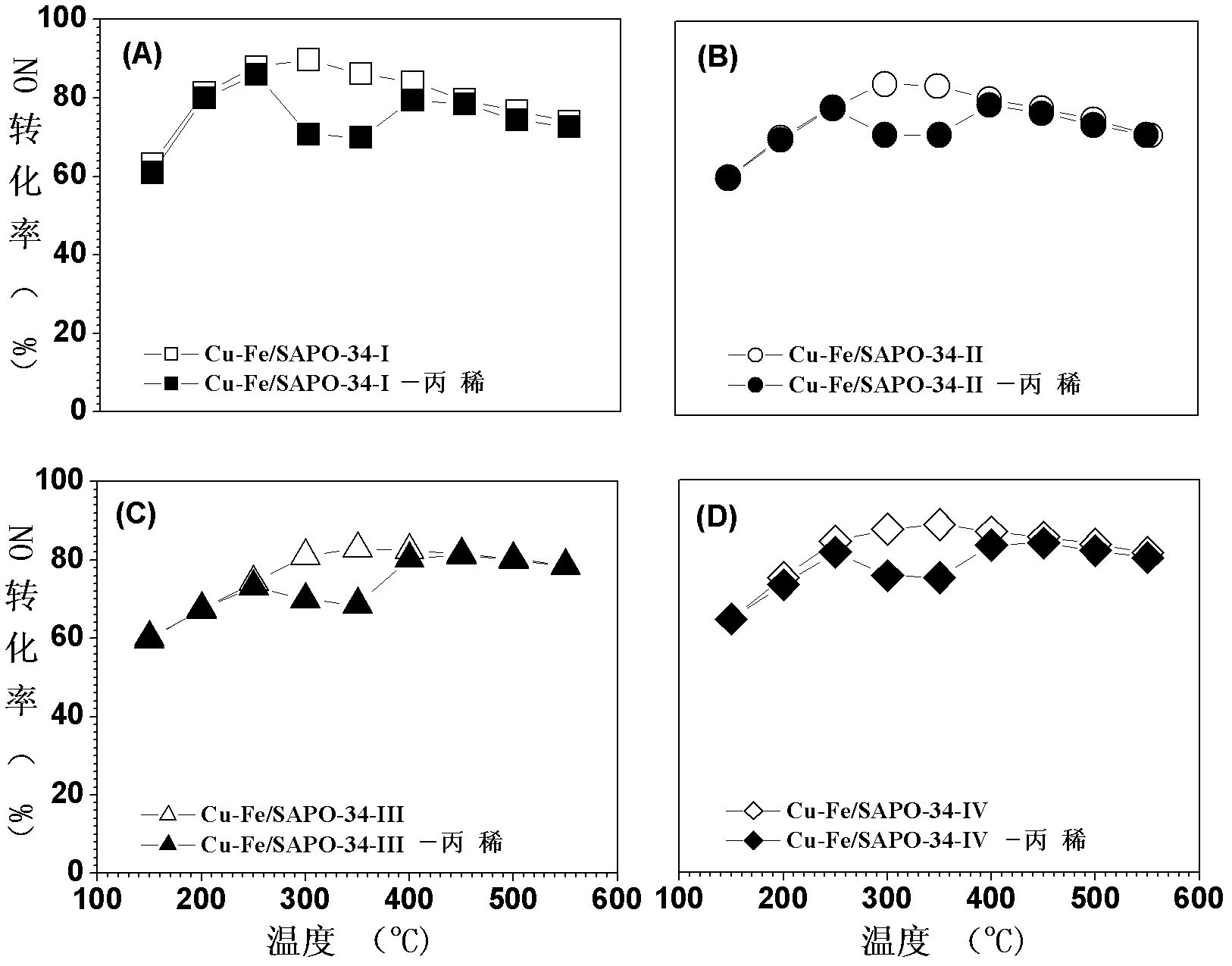

InactiveCN102614910AHigh activityImprove anti-carbon performanceNitrous oxide captureMolecular sieve catalystsMolecular sieveCopper chloride

The invention relates to an ammonia-selective preparation method of an SAPO-34 supported Cu-Fe catalyst for catalytically removing NOx. The catalyst is used for catalytically removing oxynitrides. A soft template method is used for preparing the SAPO-34 micropore molecular sieve carrier with high specific area (400-550m<2> / g); and an iron chloride-copper chloride mixed solution and an SAPO-34 molecular sieve ion-exchange method are utilized to prepare the SAPO-34 molecular sieve supported Cu-Fe composite catalyst. In a wide temperature range (150-550), the invention has high catalytic removal effect and high stability for pollutants with high air speed (120000-360000mL.(g.h)<-1>), high O2 concentration (10-10 vl.%), high H2O content (5-10 wt%) and low NO concentration (300-1000ppm). After adding hydrocarbons (300-1000ppm of propylene) into the reaction system, the catalyst provided by the invention has high anti-carbon performance and high hydrothermal stability.

Owner:BEIJING UNIV OF TECH

Organic phosphonium transition metal salt graded hole material preparing method and the application

InactiveCN101036873AImprove protectionImprove adsorption capacityOther chemical processesPhosphoniumHydrothermal synthesis

The invention relates to a preparation for multiporous material, especially a process for preparing organic and inorganic hetero-material with multiporous structure and application thereof. The hetero-material is a transition metal phosphonate with different organic phosphonic acid groups combined on the surface and skeleton of mesoporous and macroporous structure, wherein, the weight percent of the organic phosphonic acid P is 1% to 17%, and the transition metals can be selected from Ti salt, Al salt, Zr salt, etc. The hetero-material is directly synthesized by hydrothermal synthesis and can be used for heavy metal ion absorption with good absorption effect, the invention is provided with simple equipments and moderate synthesis conditions, and the raw materials is available, accordingly, the multiporous material preparing process is suitable for large-scale production.

Owner:NANKAI UNIV

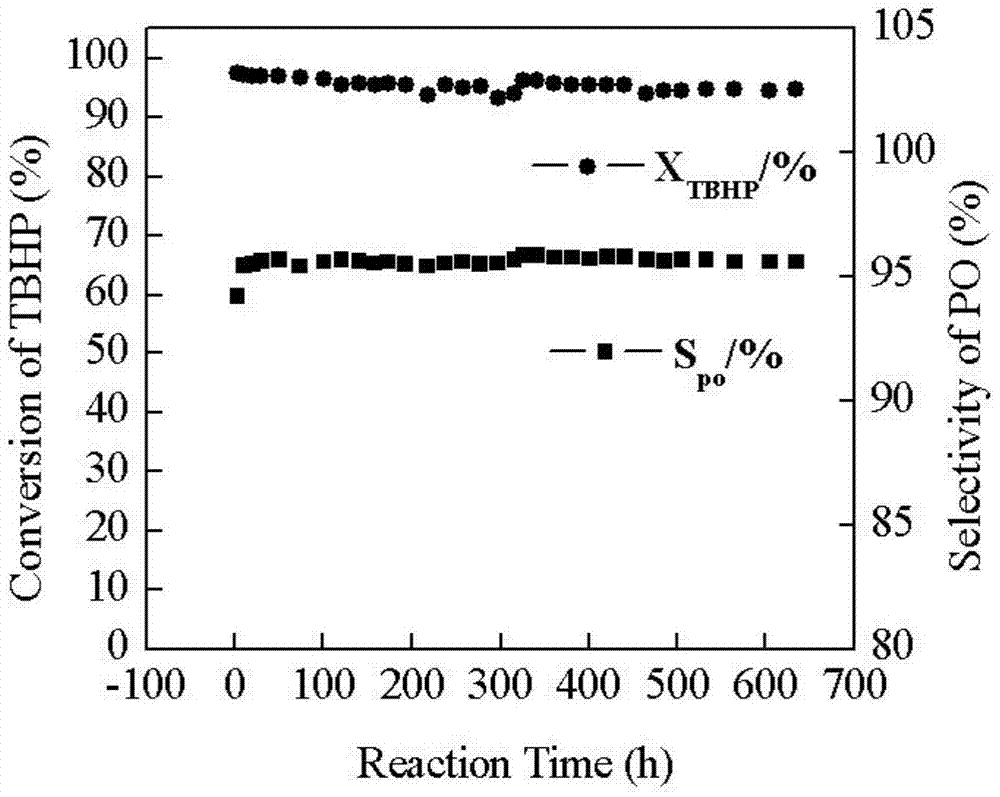

Epoxidation catalyst preparation method and prepared epoxidation catalyst thereof, and applications of epoxidation catalyst

ActiveCN106964337AHigh hydrothermal stabilityImprove stabilityOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsTitanium surfaceGas phase

The present invention relates to an epoxidation catalyst preparation method and a prepared epoxidation catalyst thereof, and applications of the epoxidation catalyst. According to the present invention, titanium is loaded onto a silica gel by using a chemical vapor deposition method, silanization treatment and hydrolysis are performed, and molybdenum is loaded onto the titanium surface by using a liquid phase ion exchange compounding method so as to achieve the directional loading of molybdenum; the epoxidation catalyst has excellent molybdenum stability; and with the application of the epoxidation catalyst in oxidation of olefins to produce the corresponding epoxy compound, the catalytic activity and the selectivity are high.

Owner:WANHUA CHEM GRP CO LTD

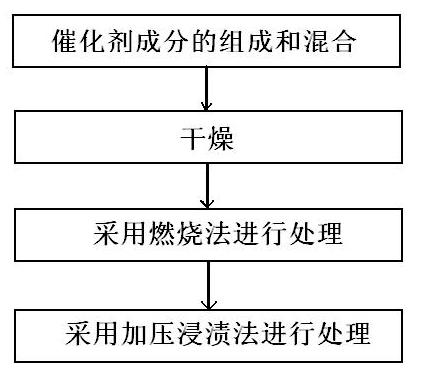

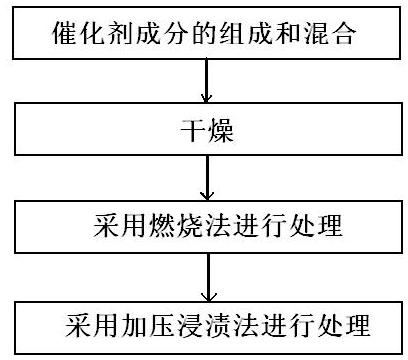

Catalyst used in complete methanation of synthesis gas at high temperature and preparation method thereof

ActiveCN102527405AHigh methanation activityHigh hydrothermal stabilityHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsSyngasPtru catalyst

The invention discloses a catalyst used in complete methanation of synthesis gas at high temperature, and the catalyst comprises the following ingredients in percentage by weight: 10-30wt% of nickel, 11-20wt% of lanthanum, 1-5wt% of cerium, 0.1-2wt% of one or a plurality of manganese, lithium and vanadium and the balance of aluminium oxide, wherein the sum of the weight percentages of all the ingredients is 100%. The preparation method of the catalyst comprises the following steps: (1) combining and mixing catalyst ingredients; (2) drying to obtain a fusant; (3) heating the fusant to 600-800DEG C at the heating speed of 1-4DEG C per minute, and roasting at the temperature of 600-800DEG C for 6-8 hours to obtain particulate matters; and (4) grinding and screening the particulate matters, and processing by a pressure impregnation method to obtain a target product. The catalyst has the positive effects that the prepared catalyst is suitable for being operated and applied under the condition of high temperature, high pressure and high airspeed, and the equipment has higher material processing capability. The catalyst not only can be used for gas with high heating value and coal-derived natural gas in production and used for methanating CO tail gas of the industrial electric furnace but also can be used for purifying and separating synthesis gas and small amounts of CO and CO2.

Owner:EAST CHINA UNIV OF SCI & TECH

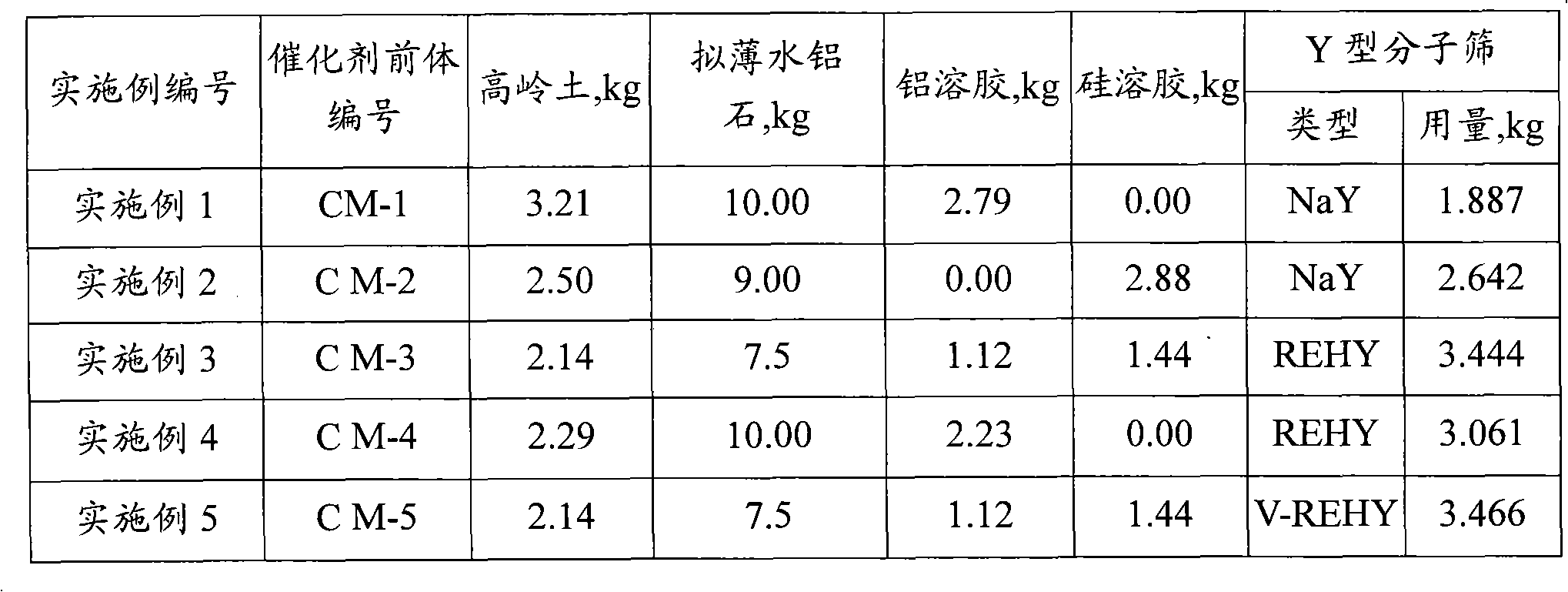

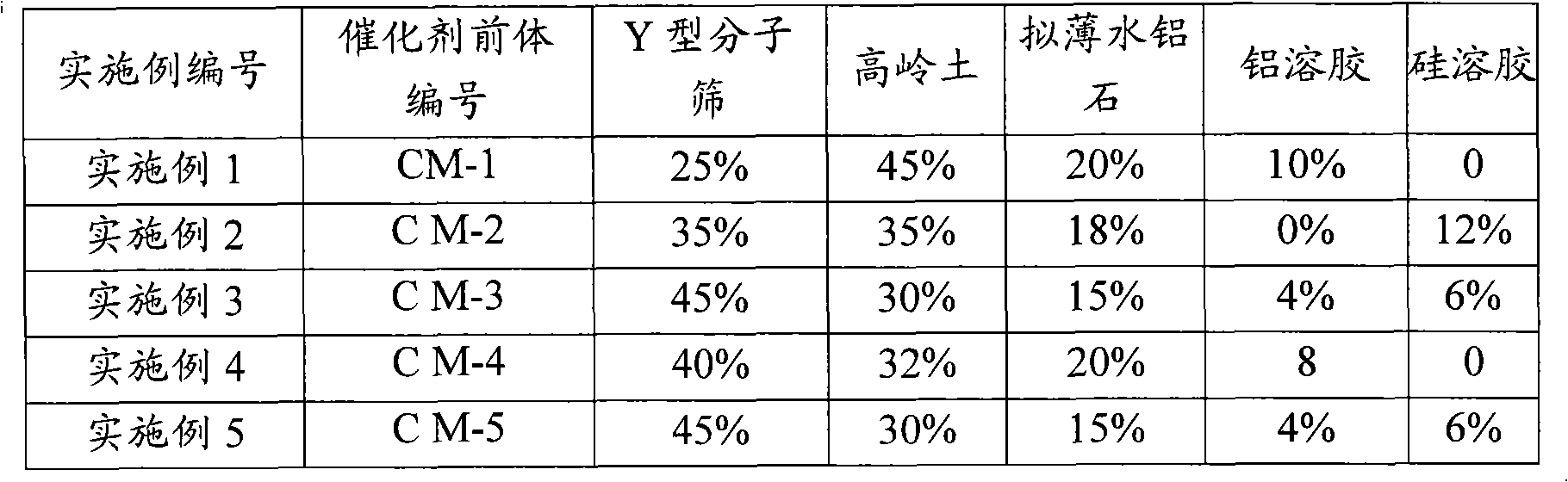

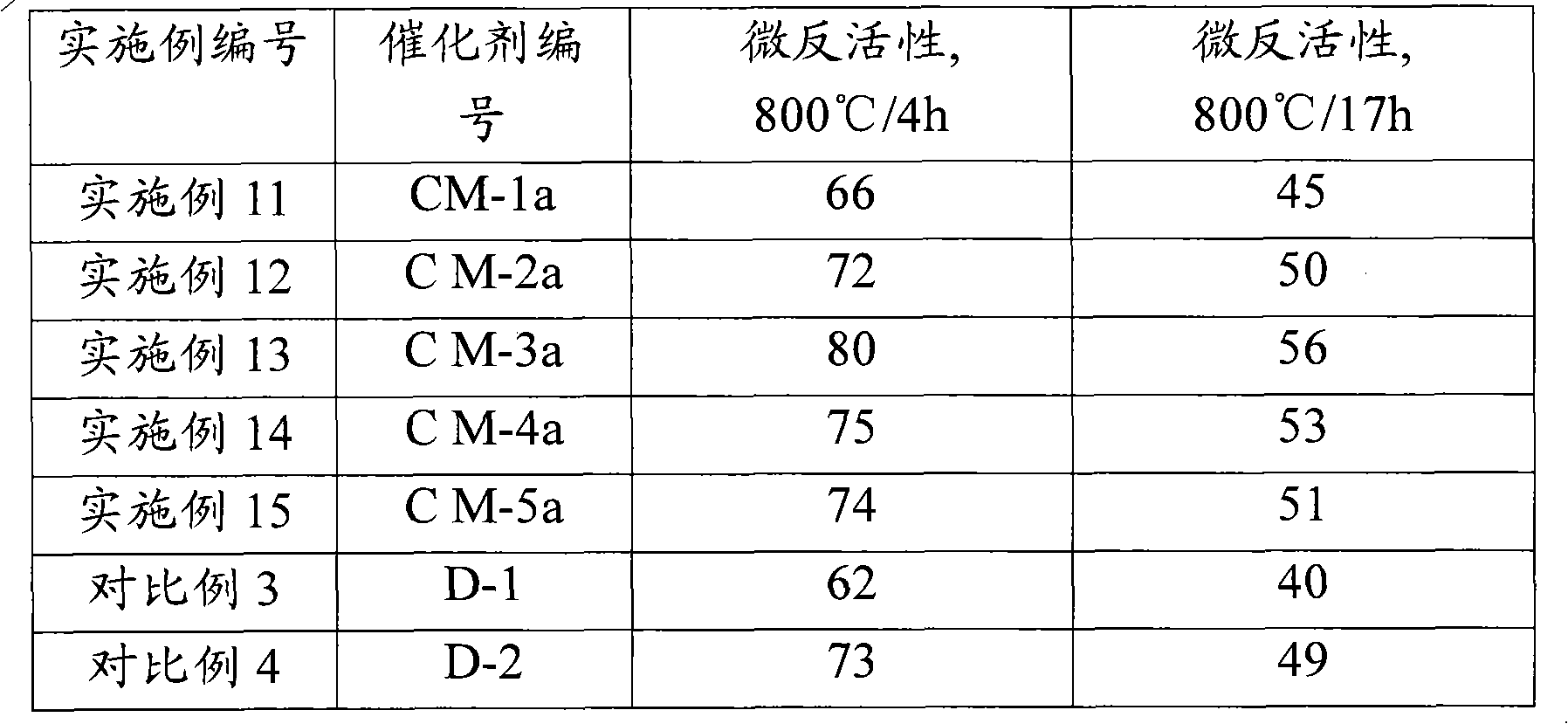

Cracking catalyst and preparation method thereof

ActiveCN102029177AHigh ratio of silicon to aluminumHigh crystallinityCatalytic crackingMolecular sieve catalystsMolecular sieveSulfur

The invention relates to a preparation method of a cracking catalyst, which comprises: raw materials and water are mixed to prepare a slurry solution by utilizing the catalyst containing a Y type molecular sieve and a silicon vector; the slurry solution is dried to obtain a catalyst precursor; the catalyst precursor is baked; and a contact reaction is carried out on the catalyst precursor and an acidic ammonium salt solution. The preparation method of the cracking catalyst can enhance the crystallization retaining degree of the Y type molecular sieve in the catalyst and the stability of the catalyst. The catalyst prepared by utilizing the method is used for the catalytic cracking of heavy oil and has the advantages of strong conversion capability of the heavy oil, high yield of gasoline, and low sulphur content in the gasoline.

Owner:CHINA PETROLEUM & CHEM CORP +1

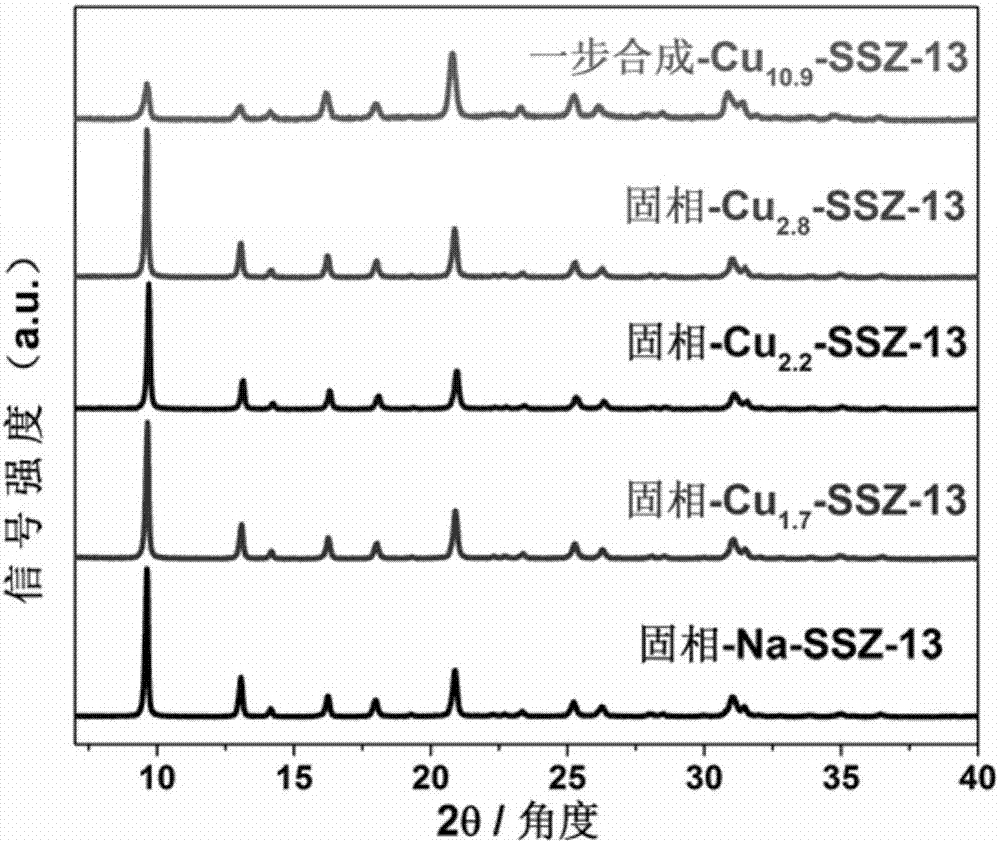

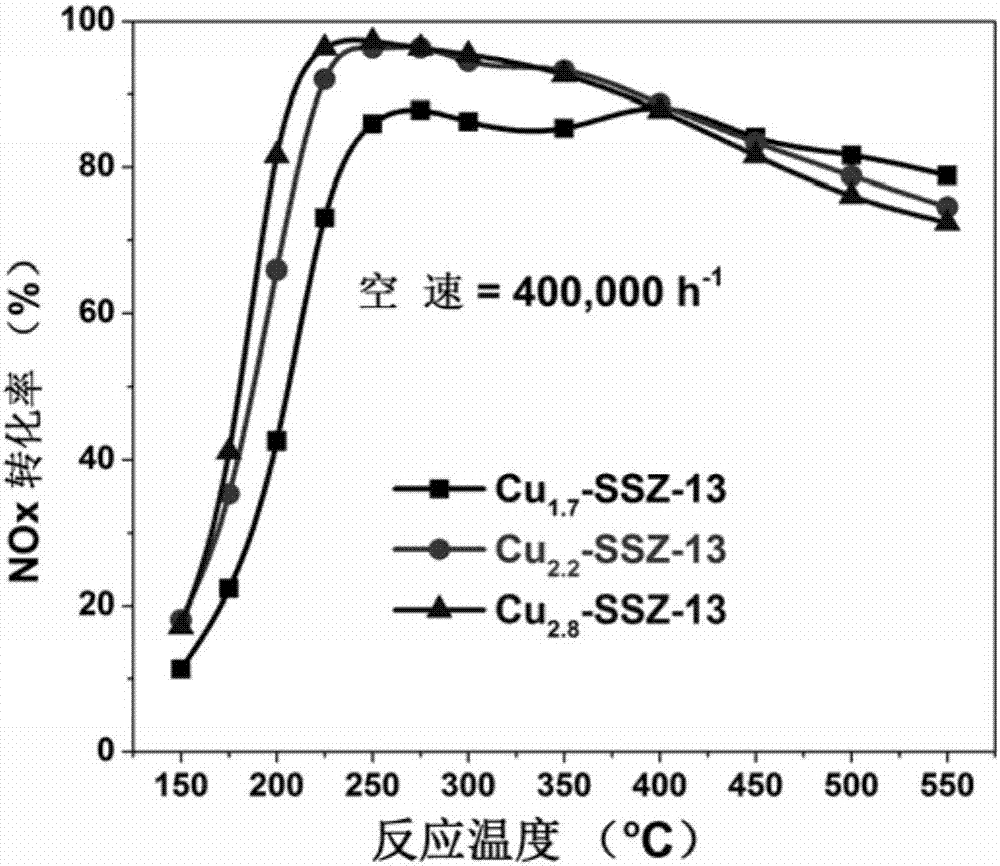

Preparation method and application of Cu-SSZ-13 catalyst

InactiveCN107115888AHigh catalytic activityExcellent resistance to high airspeedGas treatmentMolecular sieve catalystsIon exchangeCopper nitrate

The invention provides a preparation method and application of a Cu-SSZ-13 catalyst. The preparation method comprises the following steps: 1) putting raw materials including a silicon source, an aluminum source, a template agent and seed crystals into a mortar, and grinding to form a uniform mixture; 2) feeding the mixture into a reaction kettle and crystallizing; after cooling, washing and drying, roasting to obtain an Na-SSZ-13 molecular sieve carrier; 3) preparing an ammonium nitrate solution, and adding into the Na-SSZ-13 molecular sieve carrier; after carrying out ion exchange, filtering, washing and drying to obtain an NH4-SSZ-13 molecular sieve; 4) preparing a copper nitrate solution and adding into the NH4-SSZ-13 molecular sieve; after carrying out ion exchange, filtering, drying and roasting to obtain the Cu-SSZ-13 catalyst. The Cu-SSZ-13 catalyst prepared by the preparation method has excellent NH3-SCR (Selective Catalytic Reduction) catalytic activity, N2 selectivity, hydrothermal stability, and H2O and SO2 positioning resisting properties, and is applicable to purification of tail gas of diesel vehicles.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

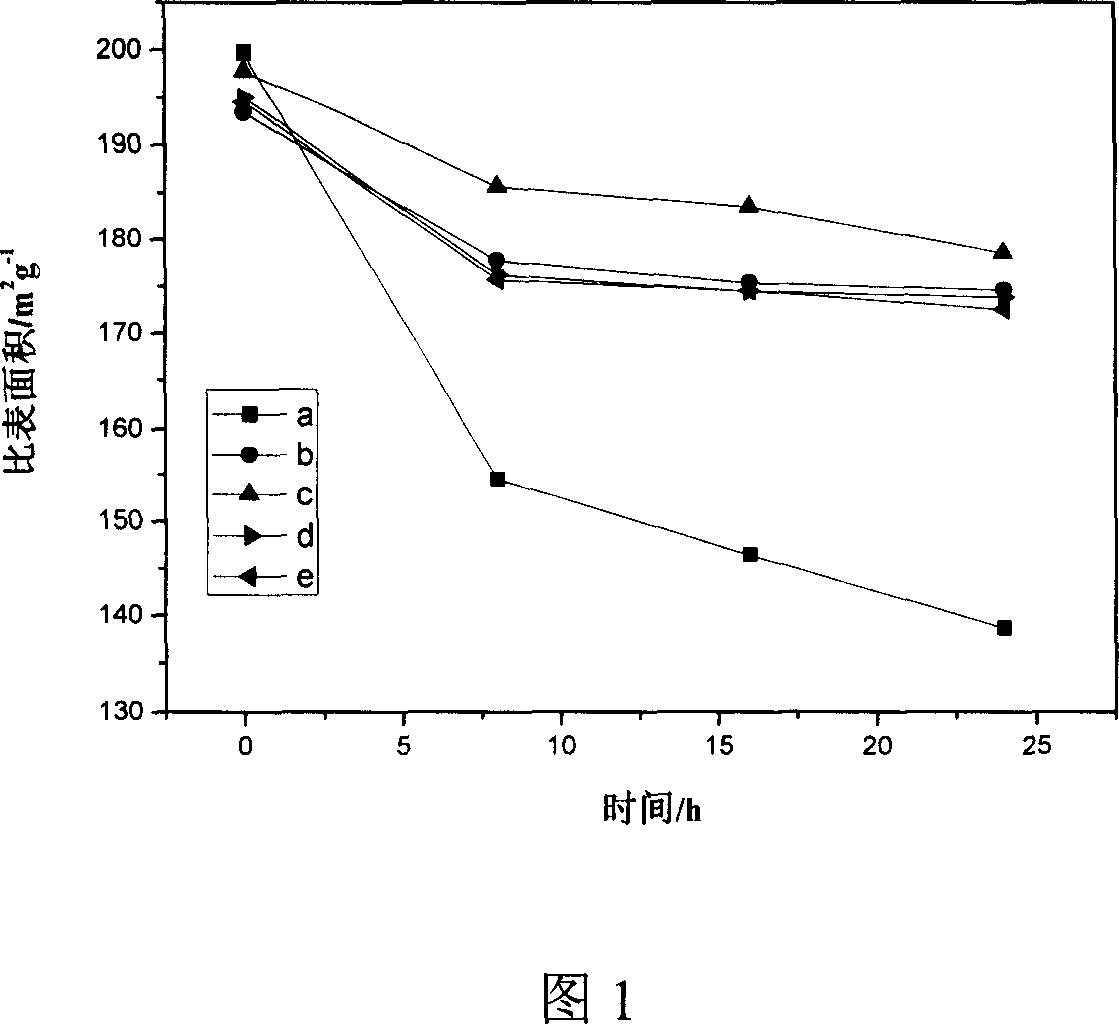

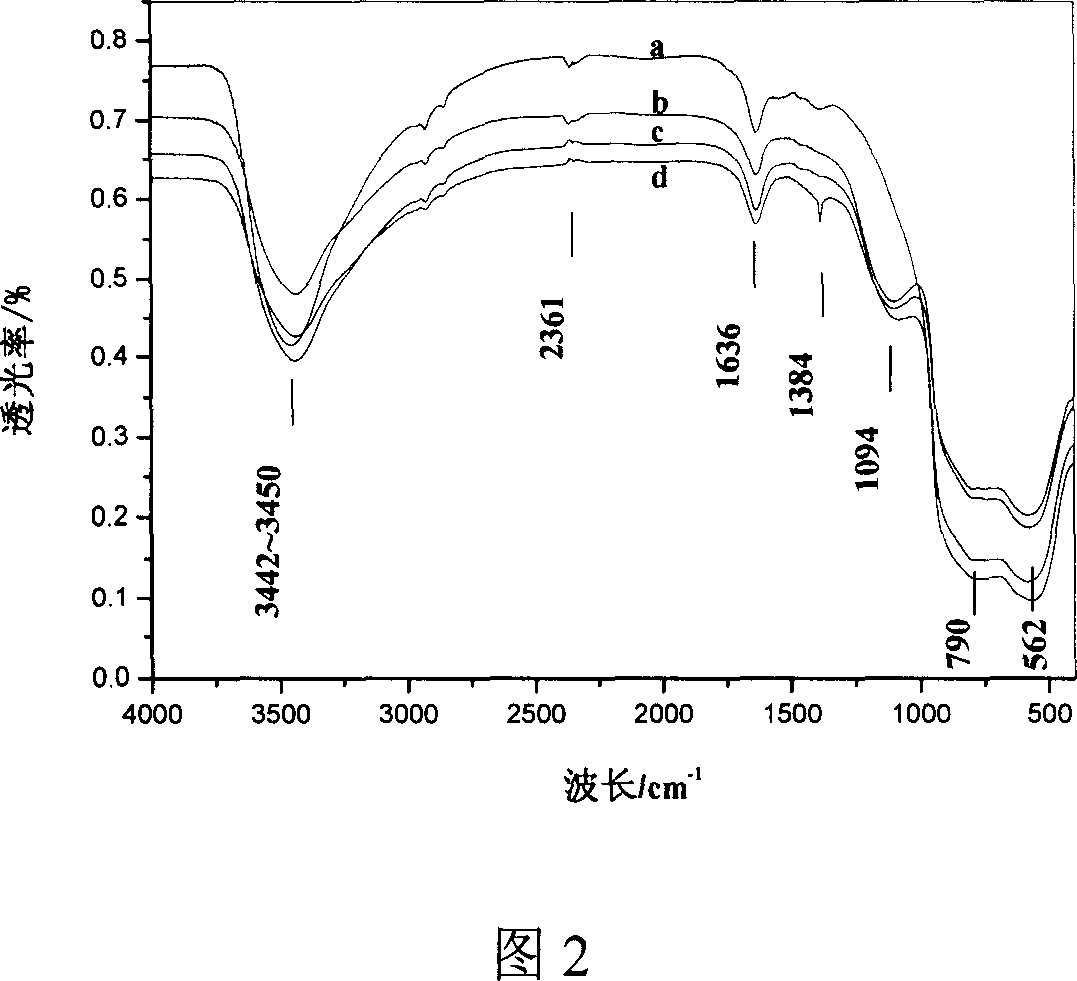

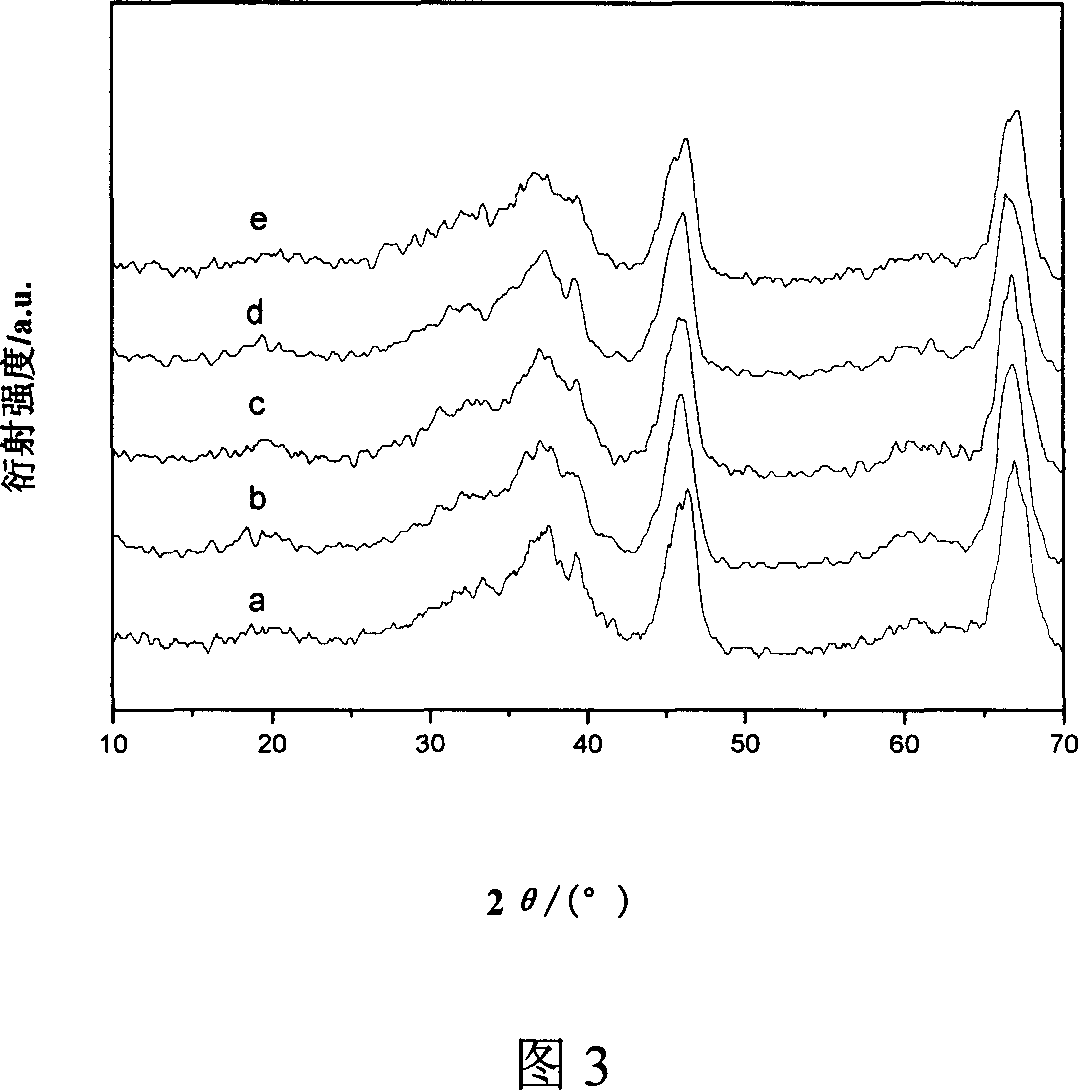

Alumina in high hydrothermal stability, and preparation method

InactiveCN1958456AHigh hydrothermal stabilityPrevent sinteringAluminium oxide/hydroxide preparationAluminium oxides/hydroxidesPhosphate ionPetrochemical

This invention provides a method for preparing spherical Al2O3 with high hydrothermal stability. Based on the mechanisms of Al2O3 sintering and phase change, the method introduces phosphate ions, which can react with OH groups on the pore walls to reduce the quantity of OH groups and change the surface acidity of Al2O3. The method can prevent the sintering and phase change of Al2O3 pore channels, thus can improve the hydrothermal stability of spherical Al2O3 carrier. The hydrothermal stability of modified spherical Al2O3 is much higher than that of unmodified spherical Al2O3. The specific surface area of modified spherical Al2O3 is 190-200 m2 / g, the pore volume is 0.85-1.25 mL / g, the particle diameters are 0.5-5 mm, the packing density is 0.3-0.55 g / cm3, and the weight content of P2O5 is 0.5-5%. The spherical Al2O3 can be used as catalyst or catalyst carrier for petrochemicals and fine chemicals.

Owner:BEIJING UNIV OF CHEM TECH

Nanometer hierarchical pore MFI molecular sieve one-step synthesis method

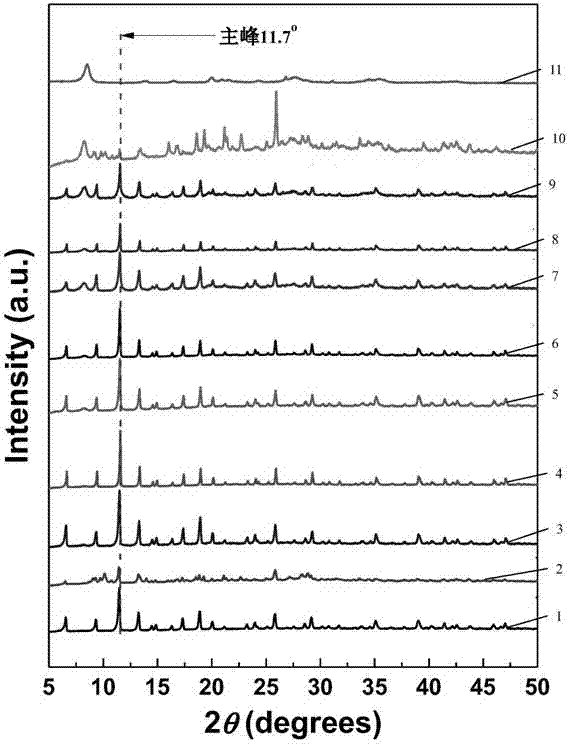

InactiveCN101613113AUniform and orderly mesoporous structureHigh crystallinity of the pore wallPentasil aluminosilicate zeoliteMolecular sieveInorganic Chemical

The invention relates to a nanometer hierarchical pore MFI molecular sieve one-step synthesis method, belonging to the fields of catalytic chemistry, inorganic chemistry and physical chemistry; wherein, MFI molecular sieve can be Silicalite-1, ZSM-5 or TS-1, the specific surface is 400-1100m<2> / g and the total pore volume is 0.15-0.83 cm<3> / g. The preparation method is characterized in that commercial fluorocarbon / hydrocarbon surfactant is used as template agent of the mesoporous structure and the hierarchical pore MFI molecular sieve can be synthesized through one step reaction on the cooperative action between the commercial fluorocarbon / hydrocarbon surfactant and microporous molecular sieve template. The method is easy, the cost is low and the combination of mesoporous and microporous structures can be realized. The material not only has the characteristics of high activity and high hydrothermal stability of microporous molecular sieve, but also eliminates diffusion control, thus facilitating molecule reaction. The new material has wide application prospect in the fields of petrochemical engineering, chemical preparation, environmental catalysis and the like.

Owner:EAST CHINA UNIV OF SCI & TECH

CsPW/Zr-MCM-41 catalyst prepared in supercritical CO2 environment and application of catalyst

ActiveCN105498845AWide variety of sourcesGood dispersionMolecular sieve catalystsOrganic compound preparationAcroleinMCM-41

The invention discloses a CsPW / Zr-MCM-41 catalyst prepared in a supercritical CO2 environment. The preparation method comprises the following steps: Zr-MCM-41 is taken as the carrier, and 10-60% of Cs modified salts is loaded by adopting the supercritical CO2 impregnation technology; with the utilization of the catalyst, the glycerin conversion rate reaches 65.2-100%, the acrolein selectivity reaches 56.8-85.4%; the invention further discloses application of the CsPW / Zr-MCM-41 catalyst to preparation of acrolein through glycerol selective dehydration. Compared with the prior art, the catalyst prepared by adopting the preparation method has the advantages that the dispersion degree of Cs modified salt on the carrier is high, the acting force between the Cs modified salt and the carrier is strong, the hydrothermal stability is high, the acidity loss possibility is low, and meanwhile, when compared with the conventional product, the obtained product is high in glycerin conversion rate and acrolein selectivity, and long in service life.

Owner:SHANDONG XINGQIANG CHEM IND TECH RES INST CO LTD

Alumina coats pulp and preparation method thereof

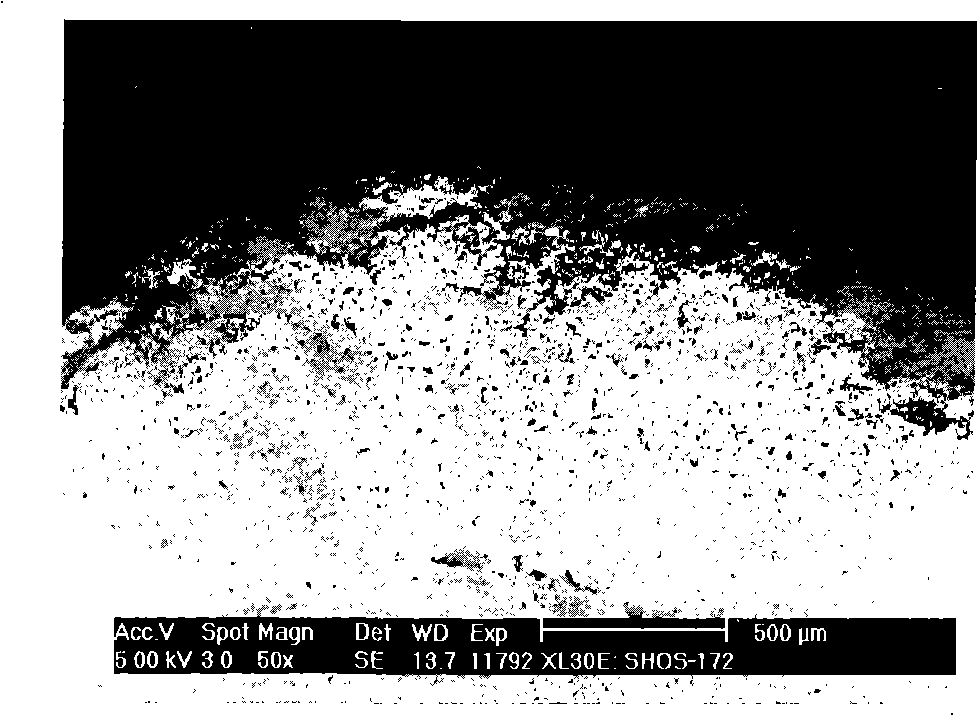

ActiveCN101491776AHigh bonding strengthHigh hydrothermal stabilityCatalyst carriersDispersed particle separationThin shellsAdhesive

The invention relates to alumina coat slurry and a preparation method thereof, and mainly solves the problems of the prior art of poor stability of a prepared laminar composite carrier and short service life of a prepared thin-shelled noble metal catalyst. The alumina coat slurry comprises the following components: aluminum sol with an average granularity of less than 20 micrometres, active alumina, an organic adhesive, an inorganic adhesive, a surfactant, a pH modifying agent and the balance being water, wherein the average granularity of the slurry is less than 10 micrometres. The preparation method comprises the following steps: dissolving the aluminum sol, the organic adhesive, the surfactant and the pH modifying agent in water; mixing the mixture evenly with stirring at a high speed; then adding the inorganic adhesive and active alumina powder for high-speed dispersion; and regrinding the obtained alumina coat slurry to prepare the alumina coat slurry. Thus, the preparation method better solves the problems by adopting the technical proposal, and can be used in the industrial production of laminar composite carrier.

Owner:CHINA PETROLEUM & CHEM CORP +1

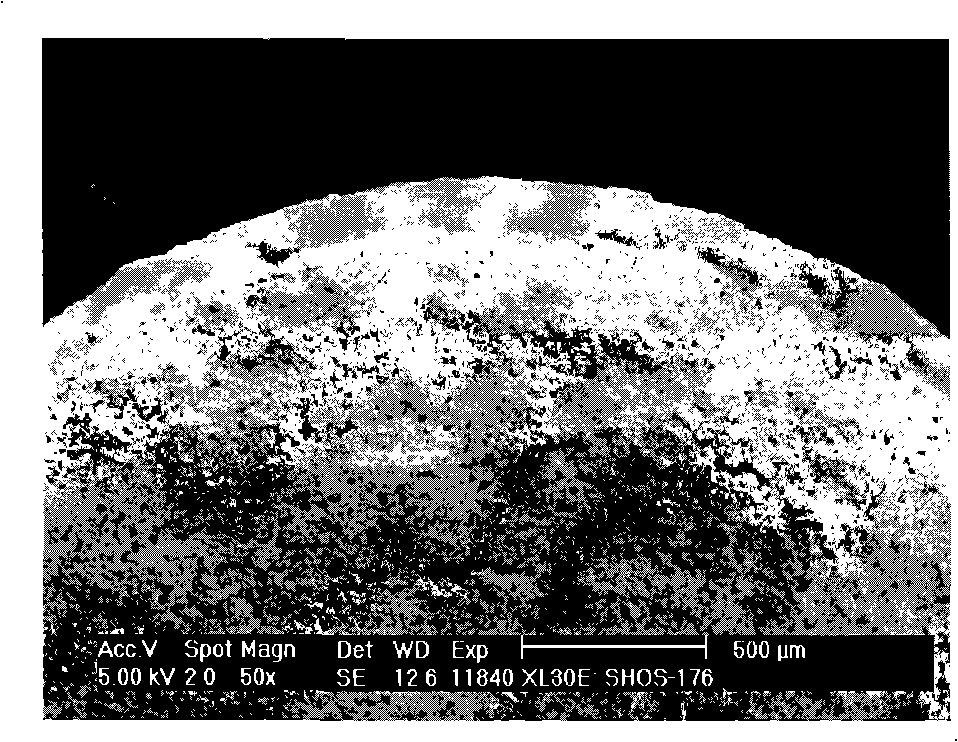

Bi-metal atom modified MCM-41 mesoporous molecular sieve and preparation method thereof

InactiveCN101367528AImprove performanceHigh hydrothermal stabilityCrystalline aluminosilicate zeolitesSaline waterAcetic acid

The invention relates to an improved MCM-41 mesoporous molecular sieve and a preparation method thereof, in particular relates to a dual-metal-atom improved MCM-41 mesoporous molecular sieve and the preparation method thereof. The molecular sieve consists of hexadecyl trimethyl ammonium bromide, ethyl orthosilicate, sodium hydroxide, Me metal salt (Co, Ni, Cr, Fe, Cu, V), lanthanum nitrate and water. The molecular sieve is prepared in the steps: at the room temperature, hexadecyl trimethyl ammonium bromide is mixed and dissolved with the sodium hydroxide, and is added with TEOS in dropping way, and simultaneously added with Me metal salt water solution and lanthanum nitrate solution in dropping way; the pH value of the mixed solution is adjusted by acetic acid to be 10 to 11, and is mixed for 1 to 2 hours after being stabilized; the sol is moved into a polyfluortetraethylene bottle to be heated and crystallized for 2 days in the oven at the temperature of 100 DEG C; after filtering, washing and drying for nights, and being calcined in a muffle at the temperature of 550 DEG C for 3 to 7 hours, the dual-metal-atom improved MCM-41 mesoporous molecular sieve is obtained. The product can simultaneously improve the acid performance and the water heating stability of the MCM-41 mesoporous molecular sieve, and can enlarge the actual application of the MCM-41 mesoporous molecular sieve in the catalyst filed.

Owner:SHANGHAI INST OF TECH

Hydrocarbon catalytic cracking catalyst and preparation method thereof

ActiveCN102049291AReduce dosageReduce manufacturing costCatalytic crackingMolecular sieve catalystsMolecular sieveAluminium phosphate

A hydrocarbon catalytic cracking catalyst is characterized in that in terms of 100wt% of the catalyst, the catalyst comprises 30-80wt% of molecular sieve and 10-65wt% clay; the catalyst comprises 5.0-20.0wt% of P calculated in the form of P2O5, and 0-1.0wt% of La2O3; P in the catalyst is provided by aluminium phosphate sol; and the aluminium phosphate sol adopted by the catalyst comprises 2-10wt%of AI and 5-15wt% of P, wherein the pH of the aluminium phosphate sol is 1.0-2.5, and the aluminium phosphate sol comprises 2-20wt% of P calculated in the form of HNO3. The prepared hydrocarbon catalytic cracking catalyst has great strength and high activity, can be used as an auxiliary to be mixed with a main catalyst, hardly reduces the activity of the main catalyst, can improve product distribution, has excellent selectivity for dry gas and coke, and meanwhile can improve the yield of light oil.

Owner:PETROCHINA CO LTD

Process for preparing super-stable Y zeolite containing rare-earth elements

InactiveCN1159101CAchieve the purpose of exchangeLower activation energyCatalytic crackingMolecular sieve catalystsHigh resistanceRare-earth element

A rare-earth contained super-stable Y zeolite is prepared from the super-stable Y zeolite containing sodium oxide (3-5 wt.%), rare-earth compound and water in wt ratio of 1:(0.001-0.5):(1-10) through preparing solution of rare-earth compound, mixing and the said Y zeolite, and grinding with shearing stress of at least 10 kg / cm2 for at least 1 min. Its advantages are higher hydrothermal stability, high stability of activity, and high resistance to sodium and heavy metal pollutions.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com