Catalyst used in complete methanation of synthesis gas at high temperature and preparation method thereof

A technology for complete methanation and synthesis gas, applied in physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc. Processing ability, good anti-carbon deposition ability, strong interaction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

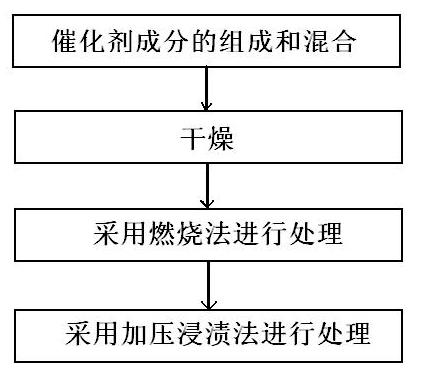

Image

Examples

Embodiment 1

[0032] A method for preparing a high-temperature synthesis gas complete methanation catalyst, comprising the following steps:

[0033] (1) Composition and mixing of catalyst components

[0034] 8.918g nickel nitrate Ni(NO 3 ) 2 . 6H 2 O, 22.066g aluminum nitrate Al(NO 3 ) 3 . 9H 2 O, 2.962g lanthanum nitrate La(NO 3 ) 3 . 6H 2 O and 0.4g of manganese nitrate Mn(NO 3 ) 2 The solution was dissolved in 50ml of deionized water, and stirred magnetically for 1 hour at 60°C to fully dissolve and mix the components of the catalyst;

[0035] (2) dry

[0036] drying the dissolved mixture in step (1) at a temperature of 110° C. for 6 hours to obtain a melt;

[0037] (3) Treated by combustion method

[0038] Heat the melt obtained by drying in step (2) to 600°C at a heating rate of 2°C per minute (during the heating process, combustion occurs spontaneously), and then bake at 600°C for 8 hours to make the melt fully Decompose to get particulate matter;

[0039] (4) Treatm...

Embodiment 2

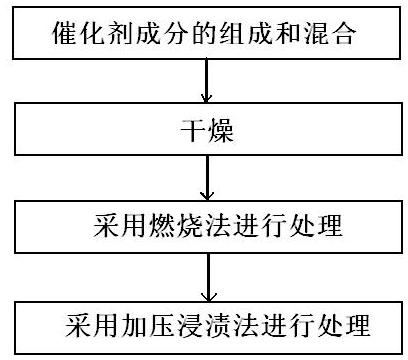

[0050]A method for preparing a high-temperature synthesis gas complete methanation catalyst, comprising the following steps:

[0051] (1) Composition and mixing of catalyst components

[0052] 8.918 g nickel nitrate Ni(NO 3 ) 2 . 6H 2 O, 22.066g aluminum nitrate Al(NO 3 ) 3 . 9H 2 O, 2.962 g lanthanum nitrate La(NO 3 ) 3 . 6H 2 O, 0.4g mass concentration is 50% manganese nitrate Mn(NO 3 ) 2 solution and 0.1 g ammonium metavanadate NH 4 VO 3 Dissolve in 50ml of absolute ethanol, and stir magnetically for 2 hours at 40°C to fully dissolve and mix the components of the catalyst;

[0053] (2) dry

[0054] drying the dissolved mixture in step (1) at a temperature of 90° C. for 6 hours to obtain a melt;

[0055] (3) Treated by combustion method

[0056] Heating the melt obtained by drying in step (2) to 700°C at a heating rate of 1°C per minute and roasting at 700°C for 8 hours to fully decompose the melt to obtain granules;

[0057] (4) Treatment by pressure impr...

Embodiment 3

[0064] A method for preparing a high-temperature synthesis gas complete methanation catalyst, comprising the following steps:

[0065] (1) Composition and mixing of catalyst components

[0066] 8.918 g nickel nitrate Ni(NO 3 ) 2 . 6H 2 O, 22.066g aluminum nitrate Al(NO 3 ) 3 . 9H 2 O, 2.962 g lanthanum nitrate La(NO 3 ) 3 . 6H 2 O and 0.1 g ammonium metavanadate NH 4 VO 3 Dissolve in 50ml of absolute ethanol, and stir magnetically for 2 hours at 40°C to fully dissolve and mix the components of the catalyst;

[0067] (2) dry

[0068] drying the dissolved mixture in step (1) at 90°C for 8 hours to obtain a melt;

[0069] (3) Treated by combustion method

[0070] Heating the melt obtained by drying in step (2) to 700°C at a heating rate of 2°C per minute and roasting at 700°C for 8 hours to fully decompose the melt to obtain granules;

[0071] (4) Treatment by pressure impregnation

[0072] Grinding and screening the particles obtained in step (3);

[0073] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com