Patents

Literature

1152 results about "Lanthanum nitrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lanthanum Nitrate is a highly water soluble crystalline Lanthanum source for uses compatible with nitrates and lower (acidic) pH. All metallic nitrates are inorganic salts of a given metal cation and the nitrate anion.

SCR denitration catalyst and preparation method thereof

ActiveCN101185886AImprove structural stabilityImprove mechanical stabilityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsSilanesAmmonium paratungstate

The invention relates to a preparation method of an SCR denitration catalyst, which comprises the following steps: (1) Al2O3 sol is prepared, which comprises the steps that hot ammonia, the Al2O3 is added in drops into the ammonia and then HCI is added and the mixture is stirred; (2) Al2O3-SiO2-TiO2 composite sol is prepared, which comprises the steps that tetratethoxy-silane, butyl titanate, deionized water are sequentially put into ethanol to be aging and then the sol prepared by step (1) is adding to be stirred and aging; (3) vector is coated, which comprises the steps that cordierite honeycomb immersed into the sol of step (2) and the raffinate in a channel is cleaned, dried and roasted after being taken out; (4) active component impregnating solution is prepared, which comprises the steps that lanthanum nitrate, ammonium metavanadate and ammonium paratungstate are dissolved into the deionized water after being mixed together and oxalate acid is added to be aging; (5) the active component is loaded, which comprises the steps that the vector of the step (3) is immersed into the impregnating solution of the step (4) and then the raffinate in the channel is cleaned to be dried and roasted. The invention also relates to the denitration catalyst which is prepared by the method.

Owner:山西蒲洲博奇环保科技有限公司

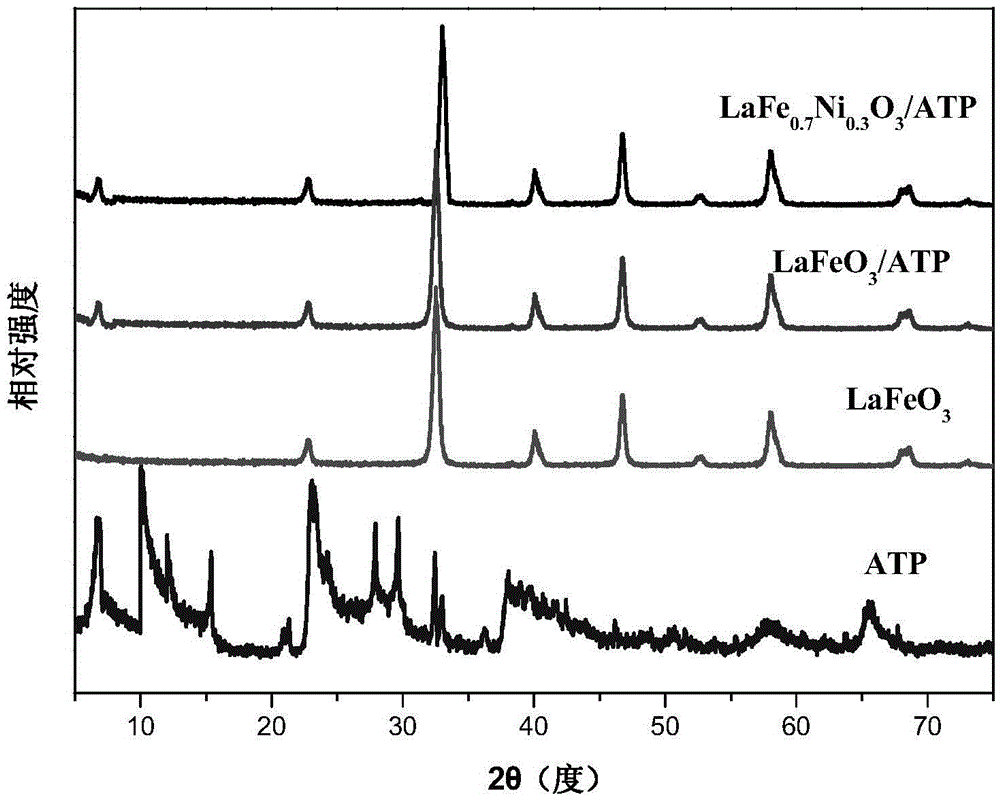

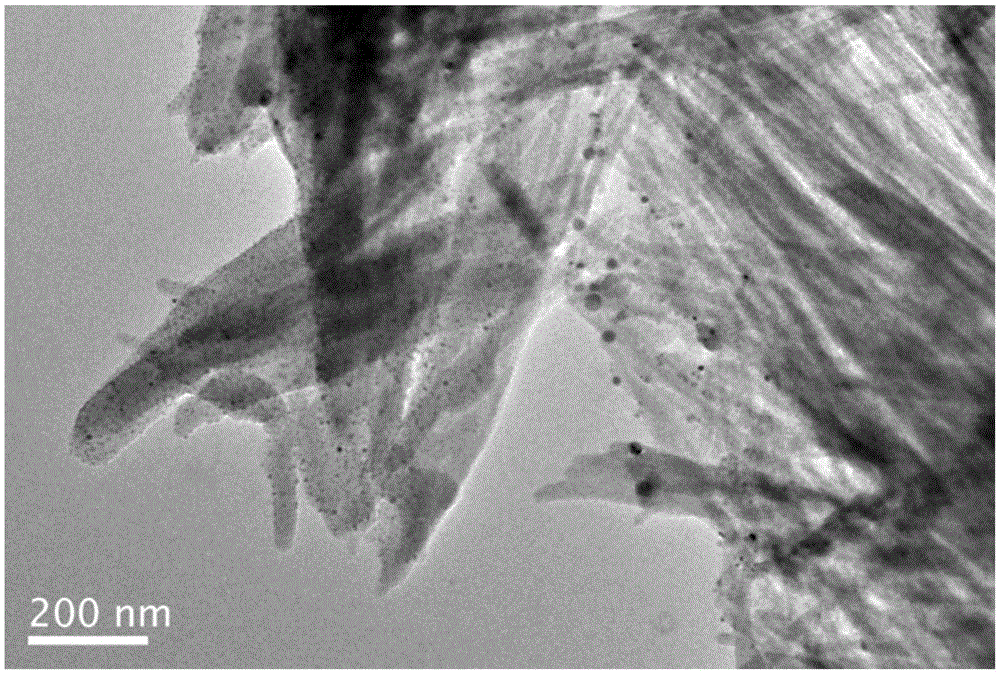

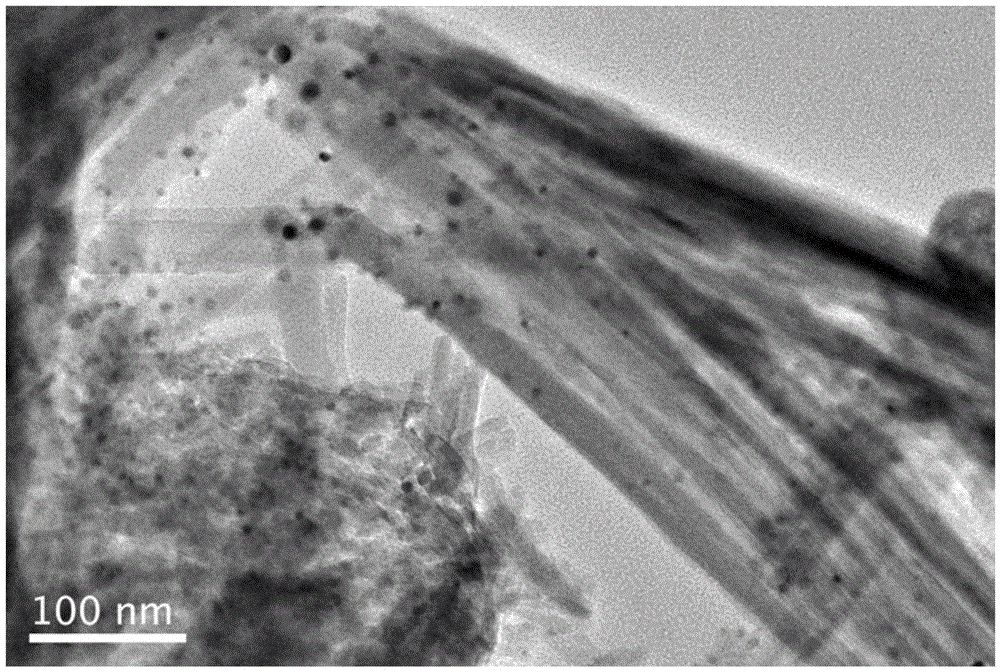

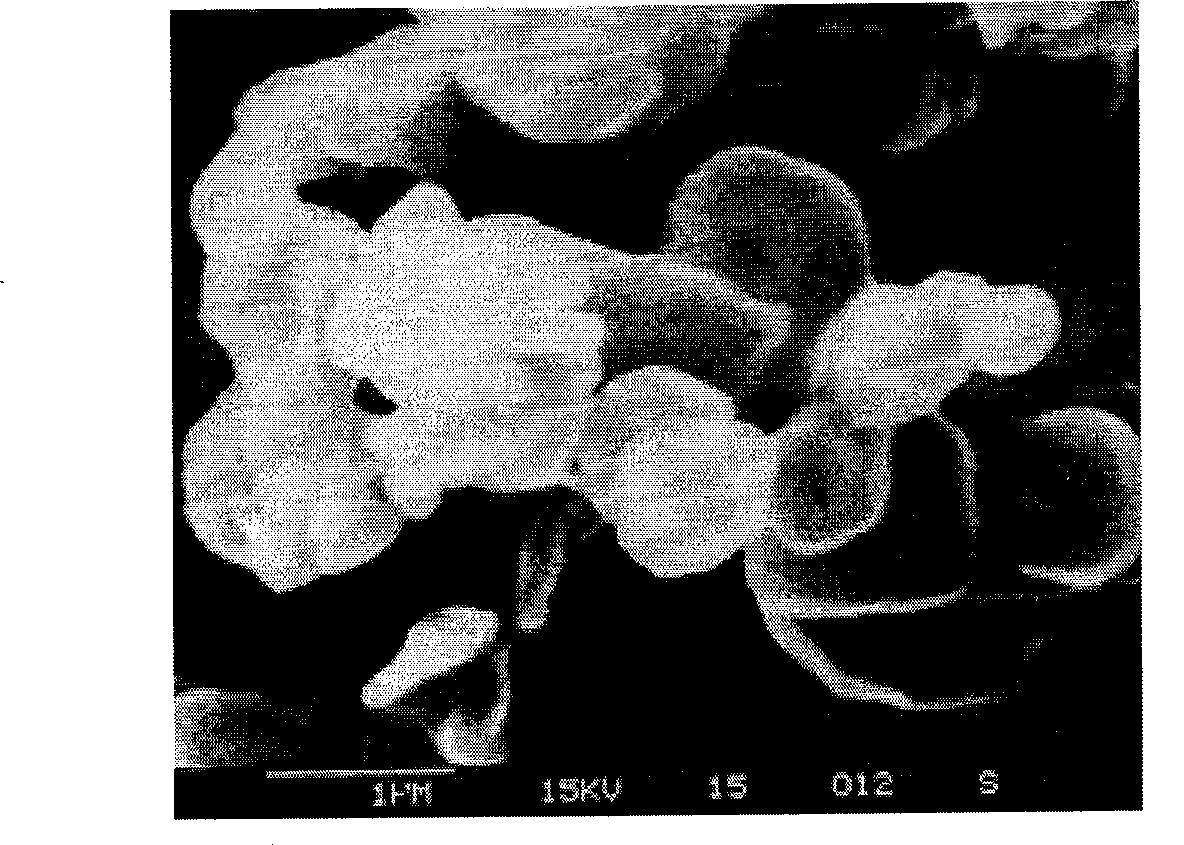

Nickel-doped lanthanum ferrite/clay nano-structure composite and preparation method and application thereof

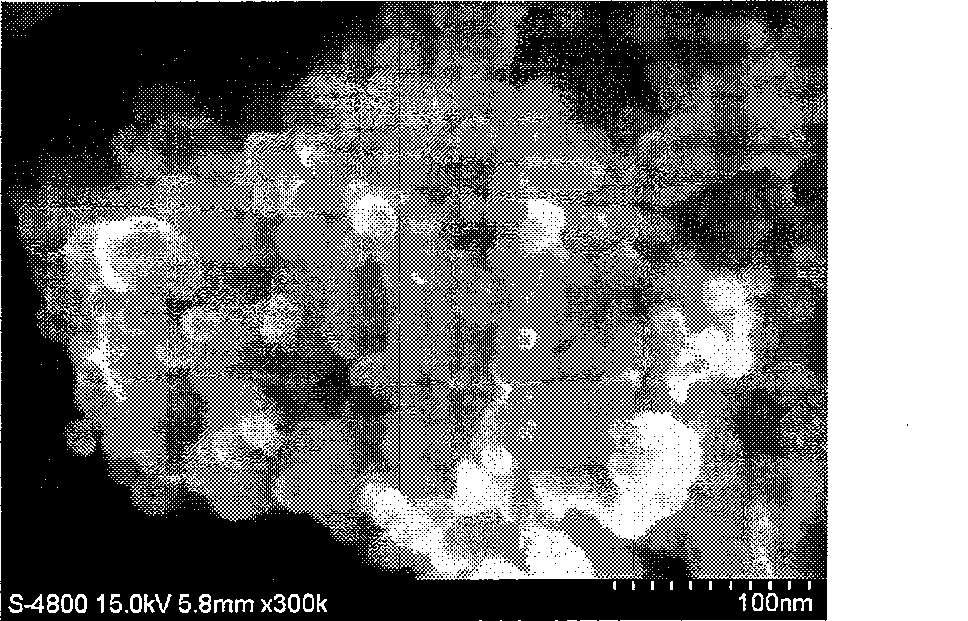

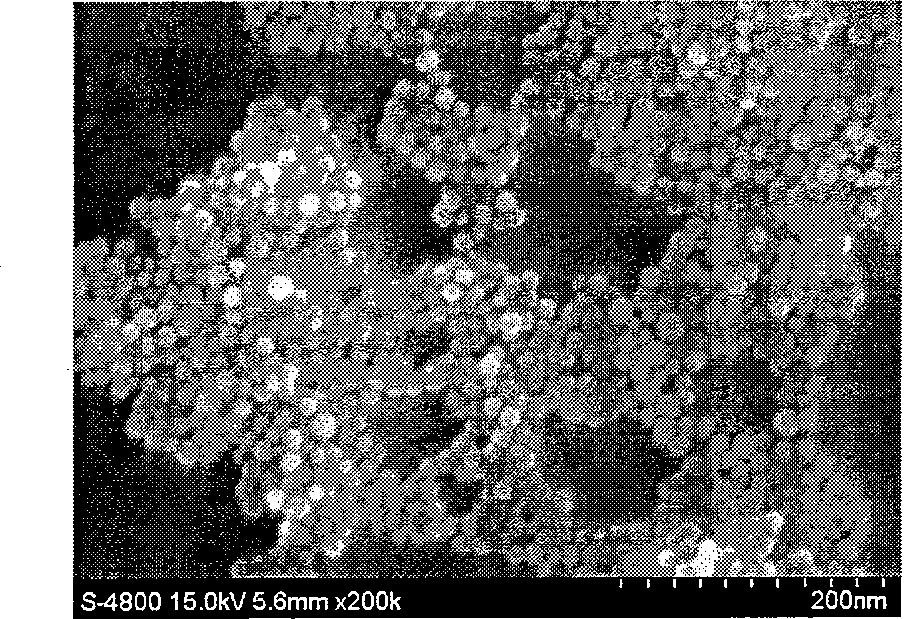

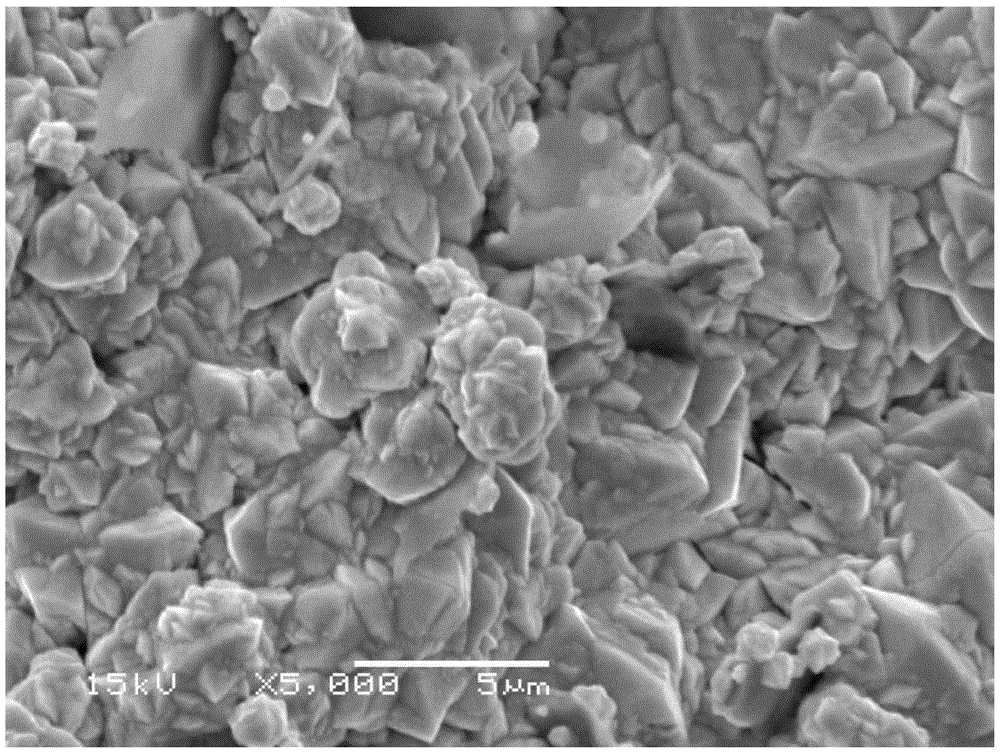

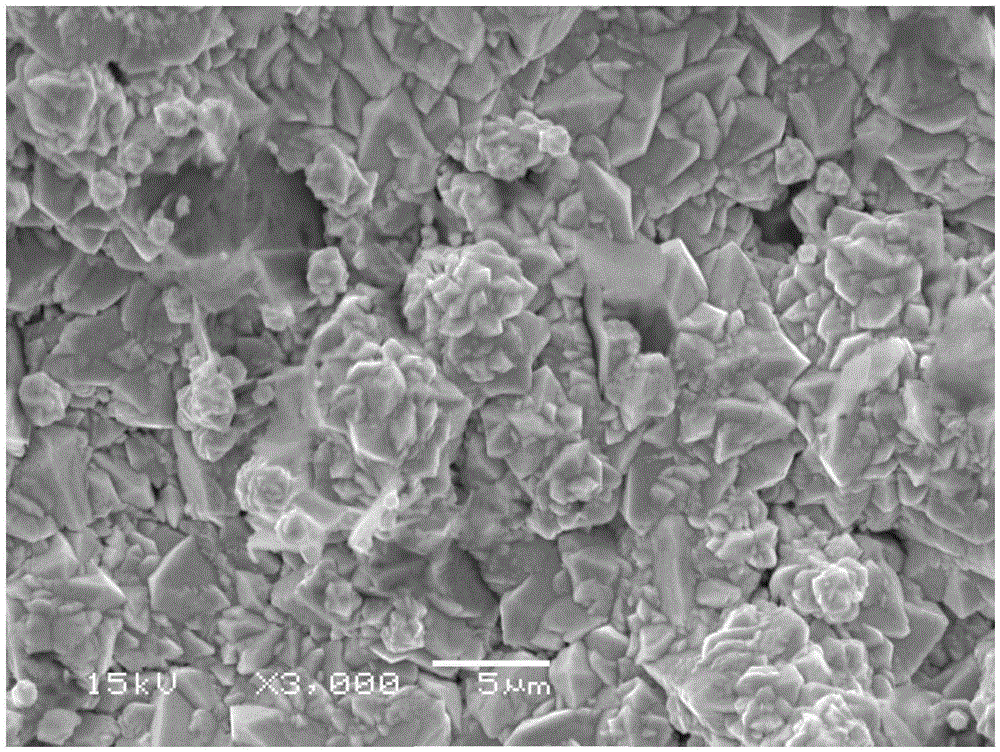

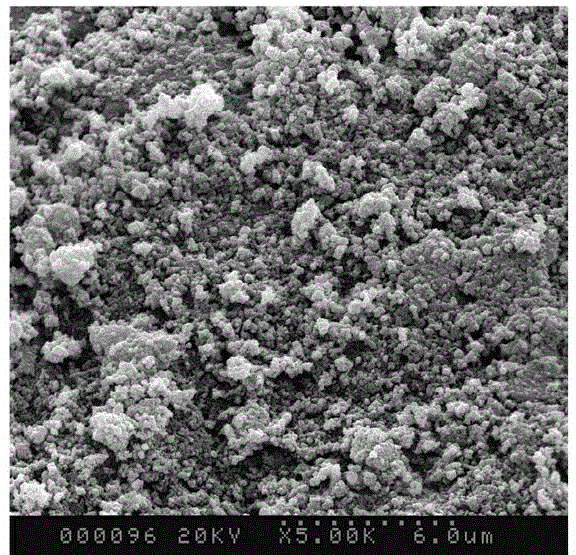

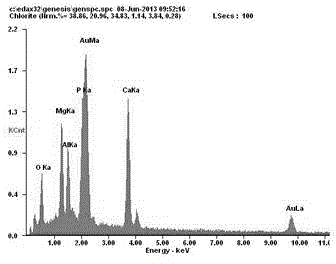

ActiveCN105642299ASmall particle sizeAvoid uneven loadMaterial nanotechnologyDispersed particle separationWater bathsNano structuring

The invention belongs to the new field of chemical engineering, and particularly relates to a nano material with clay as a carrier and perovskite type compound nano particles as active components and a preparation method and application thereof to the field of optical coupling-SCR denitration. Lanthanum nitrate, nickel nitrate, ferric nitrate, citric acid and the clay are added to deionized water to be stirred, then the mixture is transferred into a water bath kettle to evaporate to obtain wet gel, and the nano material can be obtained through drying, calcining and drying. The composite is adopted as a catalyst for photocatalytic denitration, and compared with traditional SCR denitration, the amount of adopted NH3 is reduced, and the conversion efficiency on NO at low temperature is improved.

Owner:CHANGZHOU UNIV

Method for preparing catalyst for preparing synthesis gas by reforming methane and carbon dioxide

InactiveCN101637726ALow costHigh catalytic activityHydrogenMetal/metal-oxides/metal-hydroxide catalystsNickel saltCerium

The invention relates to a method for preparing a catalyst for preparing synthesis gas by reforming methane and carbon dioxide, which comprises the following steps: soaking a carrier into a mixed solution of cerium(III) nitrate and lanthanum nitrate, and drying and roasting the soaked carrier for 2 to 10 hours to obtain a modified carrier (A); soaking the (A) into a soluble nickel salt solution orsoaking the (A) into a chloroplatinic acid solution, and drying and roasting the soaked carrier to obtain (B) or (C); soaking the (B) into the chloroplatinic acid solution or soaking the (C) into thesoluble nickel salt solution, and drying and roasting the soaked carrier to obtain a catalyst precursor, or soaking the modified carrier into a mixed solution of the soluble nickel salt solution andthe chloroplatinic acid, and drying and roasting the soaked carrier to obtain a catalyst precursor; and reducing the precursor in hydrogen and nitrogen mixed gas to obtain the catalyst. The catalyst has the advantages of low cost, good catalytic activity under the reaction condition of large space velocity, high selectivity for H2 and CO, and good sintering resistance and carbon deposition resistance.

Owner:PETROCHINA CO LTD

Iron-base catalyst for Fischer-Tropsch synthesis and its preparation method

ActiveCN1597105AReduce manufacturing costLow priceHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsIron sulfatePotassium silicate

A Fe-based catalyst for the Fischer-Tropsch synthesis contains Re2O3, Fe3O4, La2O3, CuO, K2O and SiO2. It is prepared through using oxidant to oxidize partially the ferrous sulfate to obtain the mixed solution of iron sulfate and ferrous sulfate, mixing with the mixed solution of lanthanum nitrate and copper salt, fast depositing by alkaline compound, washing the deposited slurry, adding potassium silicate-water glass solution, and spray drying.

Owner:SYNFUELS CHINA TECH CO LTD

Preparation method of rare-earth-based composite multi-component denitrification and dioxin removal catalyst

ActiveCN104226301AImprove catalytic oxidation abilityImprove surface acidity and alkalinityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPolymerDenitrification

The invention discloses a preparation method of a rare-earth-based composite multi-component denitrification and dioxin removal catalyst. According to the preparation method, titanium dioxide (titanium white) and silicon powder as carriers and ammonium metatungstate, ammonium metavanadate, cerous nitrate and lanthanum nitrate as active components, the steps of mixing, kneading, molding, drying and roasting are carried out in the presence of auxiliary materials to prepare the catalyst, wherein the auxiliary materials include monoethanolamine, citric acid, ammonium hydroxide, lactic acid, stearic acid, glass fibers, macromolecular polymer fibers RP-CHOP, hydroxypropyl methyl cellulose, polyoxyethylene and water. The prepared catalyst can simultaneously decompose nitric oxides and dioxin and can improve the mercury removal efficiency of the existing smoke control device. The prepared catalyst is not only applicable to new power plants, but also suitable for the modification of a wet-method desulphurization device of an old power plant, 80 to 95 percent of HgO generated in a coal burning power plant can be oxidized to Hg<2+> by utilizing the prepared catalyst, and a majority of particle-state Hg<2+> can be removed by utilizing a dust removal device.

Owner:山东信义汽车配件制造有限公司

High precision rare earth polishing powder and preparation thereof

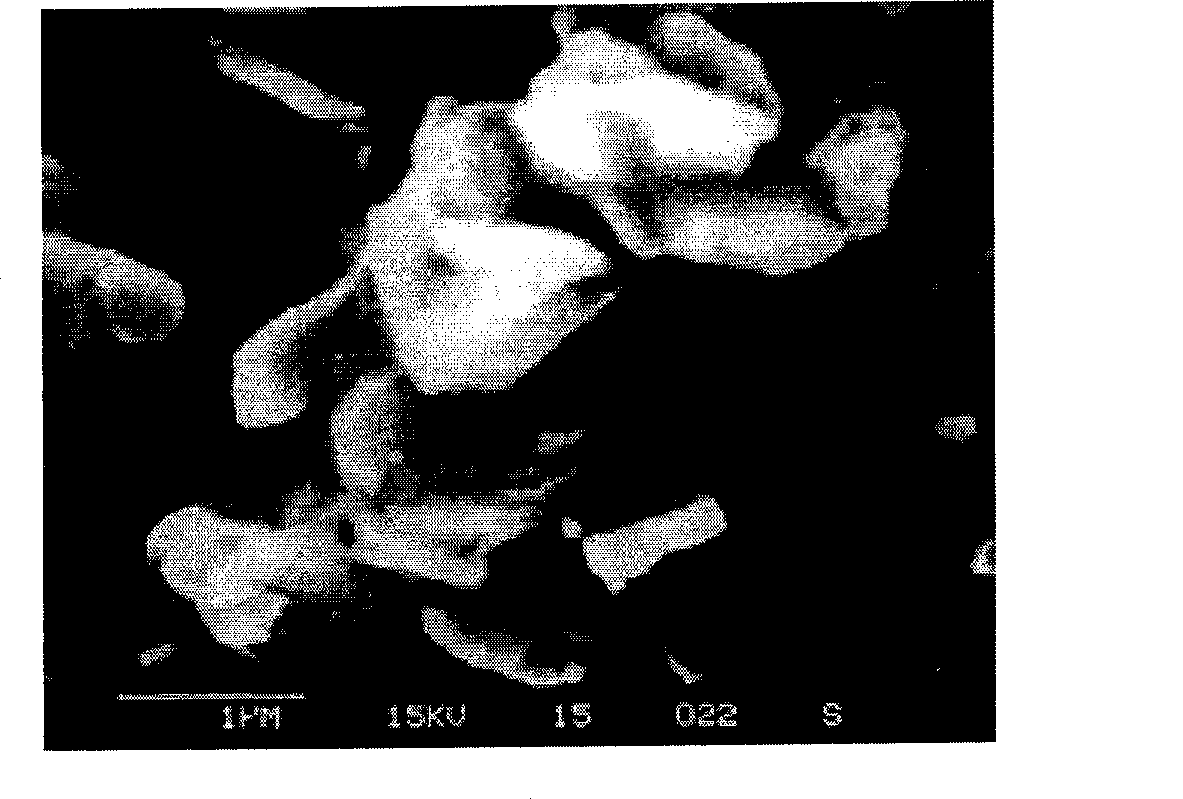

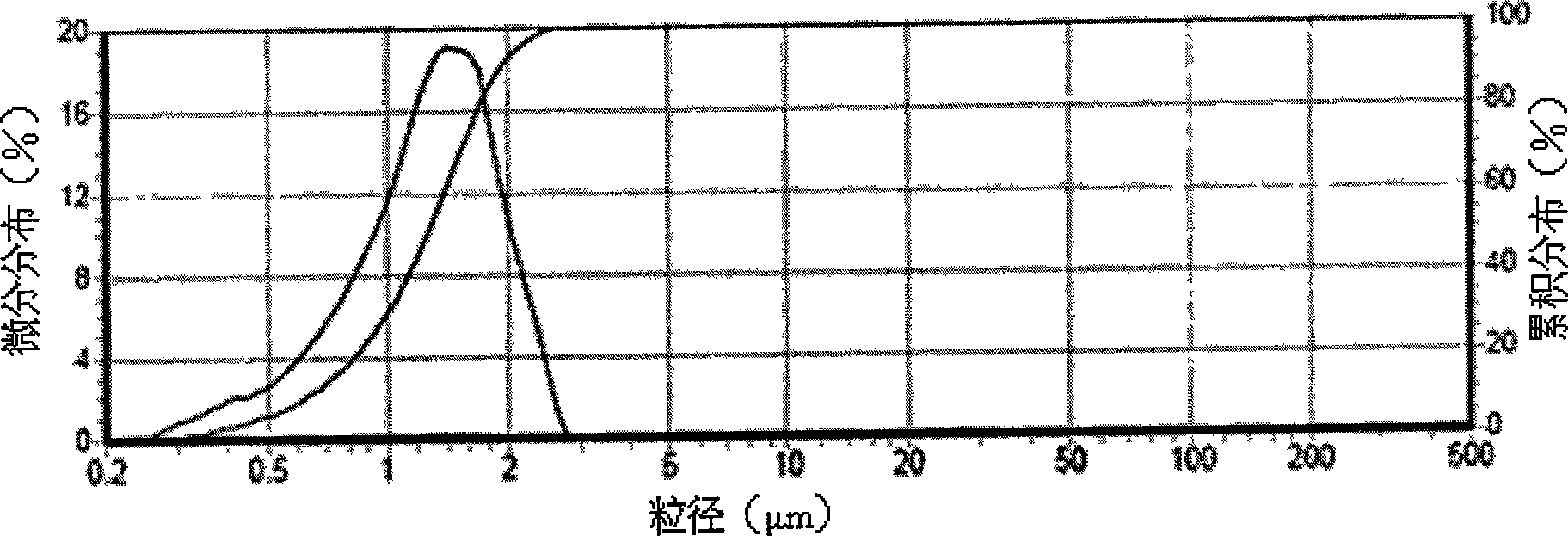

ActiveCN101475777AEasy to control abrasion resistanceImprove control stabilityOther chemical processesPolishing compositions with abrasivesCerium oxalateGranularity

The invention discloses a high-precision rare-earth polishing powder and a method for preparing the same. The high-precision rare-earth polishing powder is characterized in that D50 particle diameter is between 0.5 and 1.80 mu m; the powder also meets the conditions that D10 is more than or equal to 0.5D50, D90 is less than or equal to 2D50, and D100 is less than or equal to 3D50; a cerium lanthanum nitrate or cerium lanthanum chloride solution is added to an ammonium oxalate solution with PH value of between 4.5 and 5.5 to generate monodisperse lanthanum cerium oxalate or lanthanum cerium praseodymium oxalate deposit; and the deposit is used as a crystal seed to prepare the high-precision rare-earth polishing powder. The high-precision rare-earth polishing powder prepared by the method does not need airflow pulverization and precise classification and has the characteristics of small median particle diameter and narrow granularity distribution range; the stability of the wearing resistance and polishing precision is easy to control; and the quality of a product has small fluctuation.

Owner:上海华明高纳稀土新材料有限公司

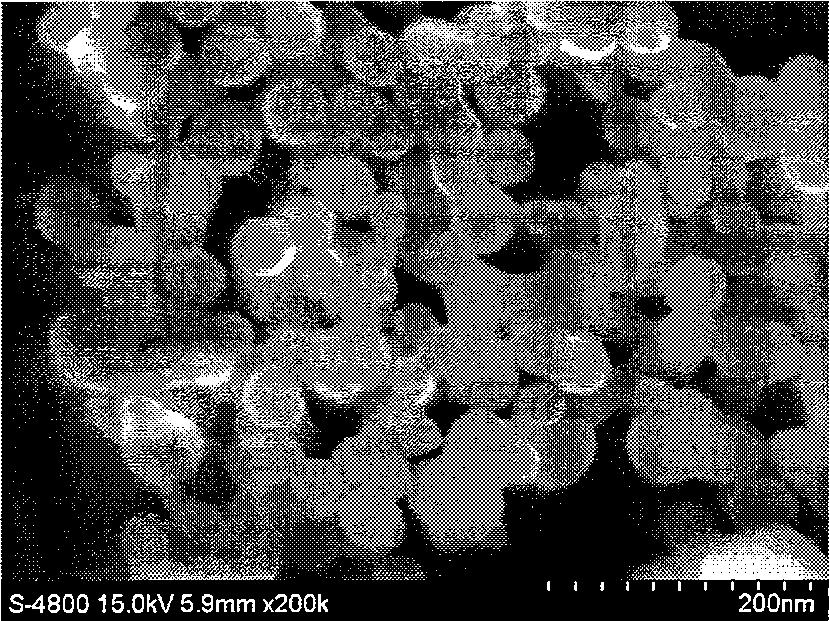

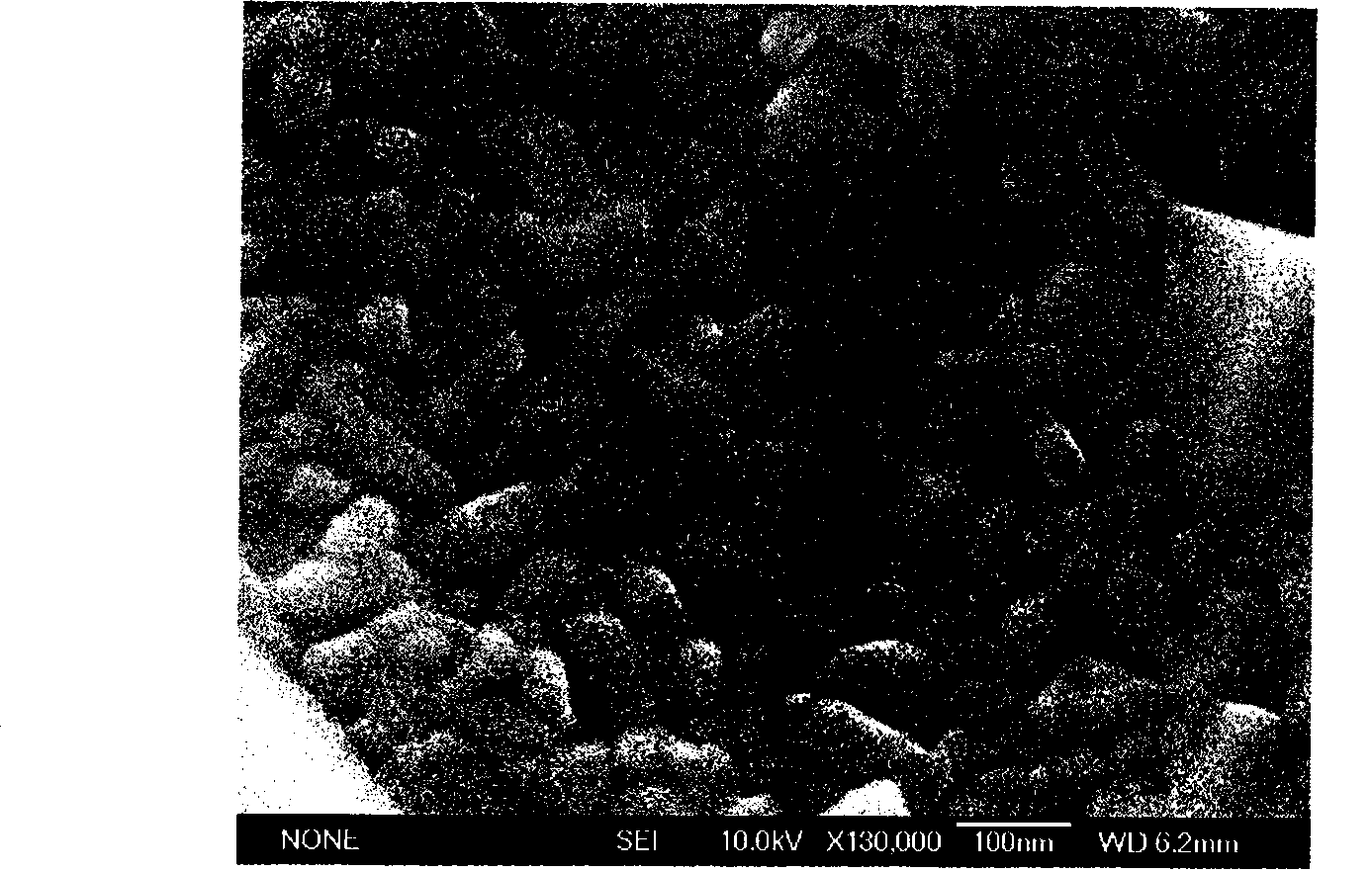

Manufacture method of lithium lanthanum titanium oxide

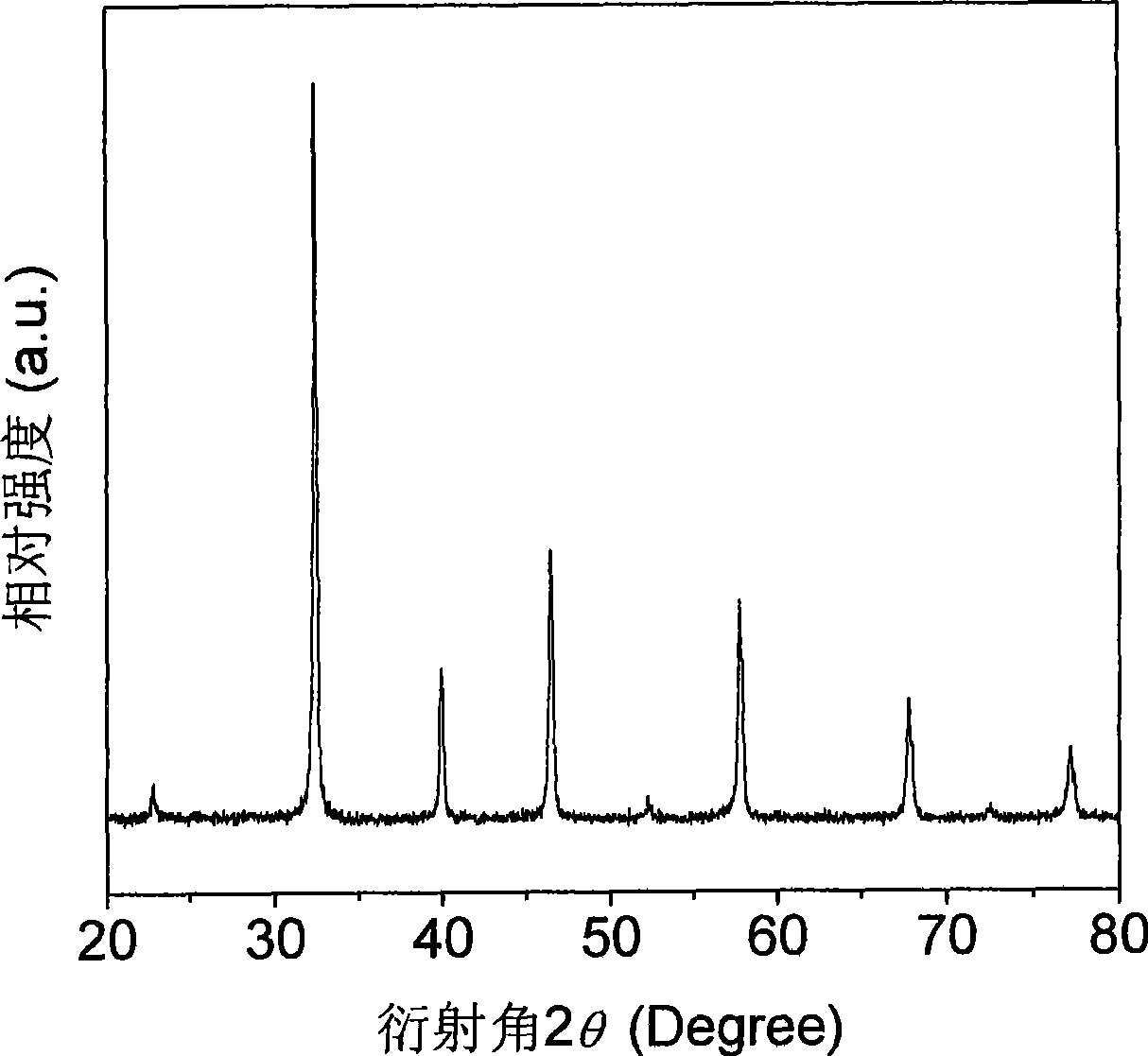

ActiveCN1970455AImprove electrical performanceThe experiment process is simpleCell electrodesLithium compoundsAlcoholLithium-ion battery

The invention discloses a making method of Li-La-Ti oxide in the lithium ion battery domain, which comprises the following steps: adopting lithium nitrate, lanthanum nitrate and butyl titanate as raw material with molecular formula as Li3xLa2 / 3-xTiO3 (0<x<0.16); setting the molar rate of Li, La and Ti at 1: 1: 2; adopting alcohol or ethylene glycol monomethyl ether as solvent; or adjusting pH value under 1 through water and acetate; drying solution; sintering under 800-900 deg.c for 2h; obtaining pure LLTO. the invention shortens experimental period and synthesizing temperature with grain size about 200nm, which possesses excellent compact and electric property.

Owner:TSINGHUA UNIV

Preparation method of high-strength and antioxidant rare-earth-based smoke denitration catalyst

ActiveCN104209117AReduce escape rateReduce productionDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCeriumGlass factory

The invention discloses a preparation method of a high-strength and antioxidant rare-earth-based smoke denitration catalyst. The preparation method of the high-strength and antioxidant rare-earth-based smoke denitration catalyst comprises the following steps: by taking titanium dioxide and montmorillonite as carriers and ammonium metatungstate, cerous nitrate and lanthanum nitrate as active components, mixing, ageing, kneading, forming, drying and roasting with the accompanying of auxiliary materials. The auxiliary materials comprise ammonia water, lactic acid, citric acid, stearic acid, glass fiber, wood pulp, hydroxypropyl methyl cellulose, polyoxyethylene, monoethanolamine and water. The product prepared by the method is separated under a high SO2 smoke condition, nitric oxide in the smoke can be decomposed; meanwhile, the purpose of removing mercury and dioxin can be achieved. According to the preparation method of the high-strength and antioxidant rare-earth-based smoke denitration catalyst, the rare earth elements, namely cerium and lanthanum are used as the active components, so that the addition amount of vanadium is reduced, the toxicity of the product is reduced or the product is non-toxic product, the pressure of the post treatment of the product is reduced; the environmental protection pressure is reduced; the product is environmentally friendly; the product can be widely used in the field of thermal power plants, glass factories and chemical plants.

Owner:山东信义汽车配件制造有限公司

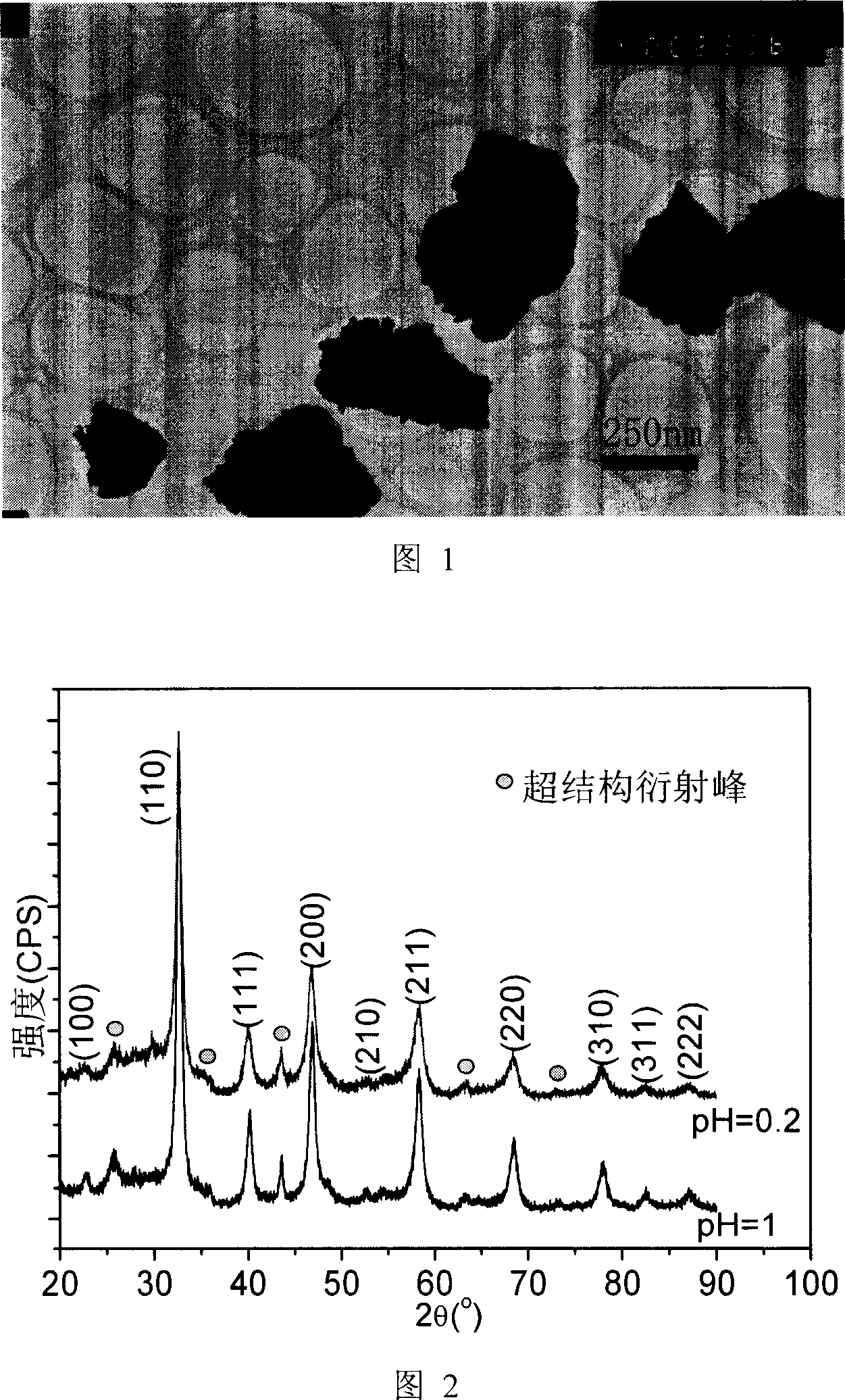

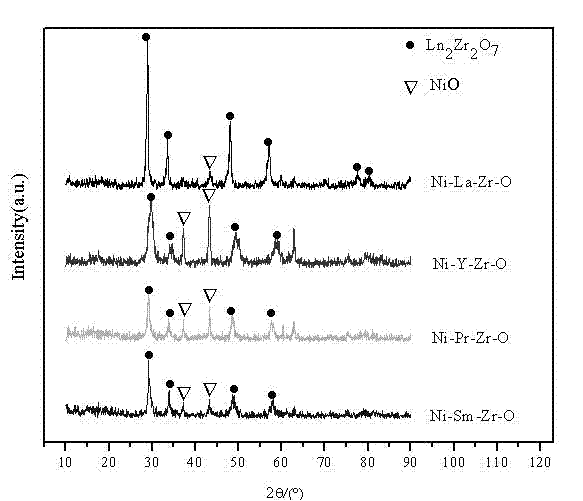

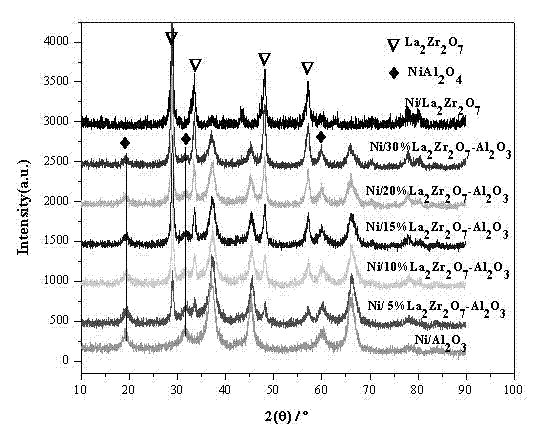

Anti-carbon-deposition Ni-based catalyst for hydrogen production by methane steam reforming and preparation method thereof

ActiveCN103752319AMeet activityMeet service life requirementsHydrogenMetal/metal-oxides/metal-hydroxide catalystsSteam reformingWater vapor

The invention relates to an anti-carbon-deposition Ni-based catalyst for hydrogen production by methane steam reforming and a preparation method thereof. By taking lanthanum nitrate, praseodymium nitrate, samarium nitrate, yttrium nitrate, zirconium nitrate, zirconium carbonate, zirconium oxychloride, and the like as precursors and taking ammonia as a precipitant, a pyrochlore composite oxide is prepared through using a coprecipitation method; and then the pyrochlore composite oxide is mixed with alumina by using a mechanical mixing method so as to obtain a pyrochlore alumina composite carrier. Nickel nitrate, nickel chloride, nickel sulfate, nickel oxalate and the like serving as nickel sources are loaded on the pyrochlore alumina composite carrier through direct immersion. The loading capacity of nickel in the catalyst accounts for 5-30% of the weight of the catalyst, the pyrochlore content of the catalyst is 5-50%, and the alumina content of the catalyst is 20-90%. By taking the pyrochlore alumina composite oxide as a carrier, the reaction activity and anti-carbon-deposition performance of the catalyst can be greatly increased; the preparation method of the catalyst is simple; and the catalyst has excellent catalytic activity and stability to methane steam reforming in a stationary bed.

Owner:NANCHANG UNIV +1

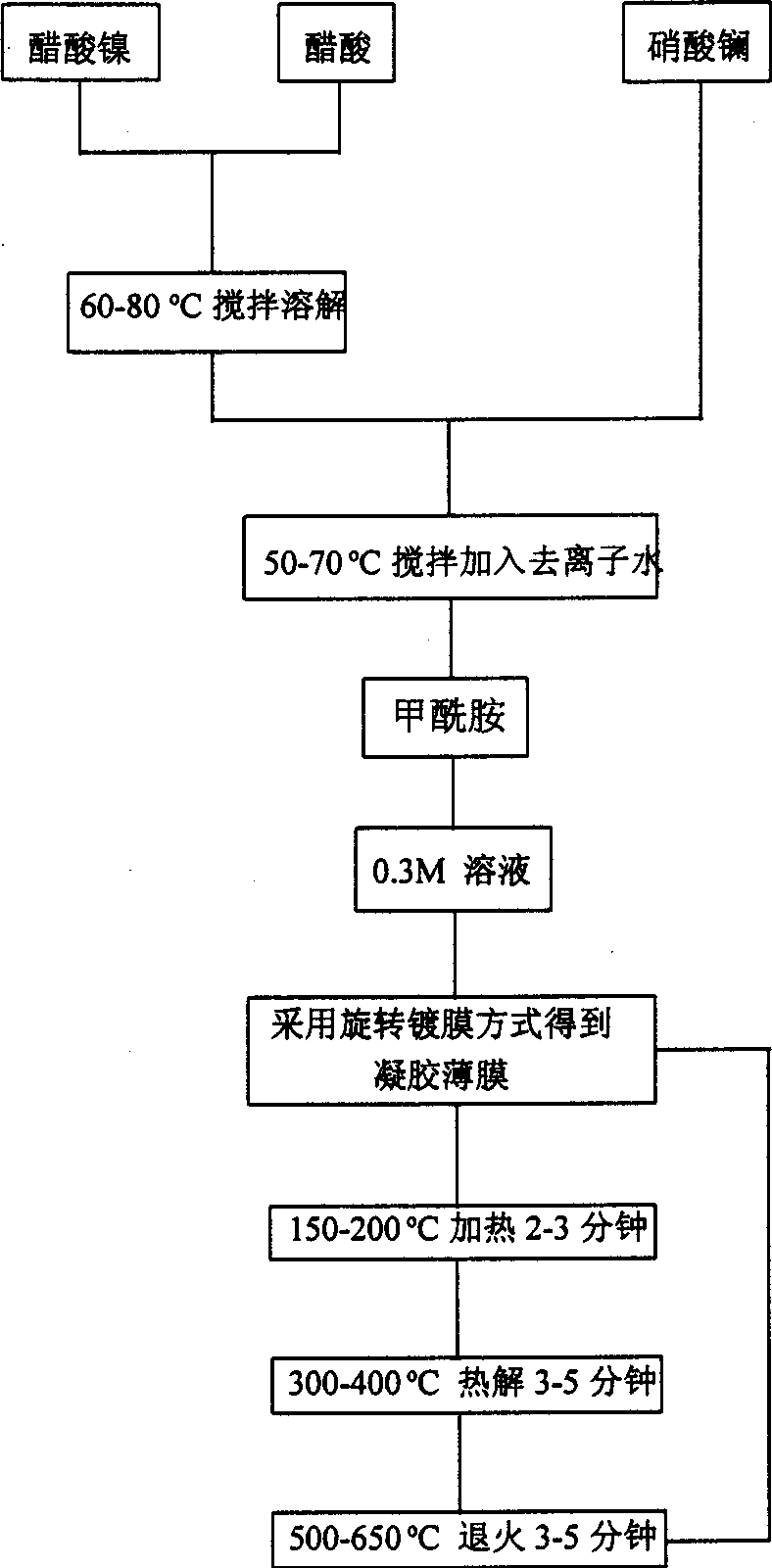

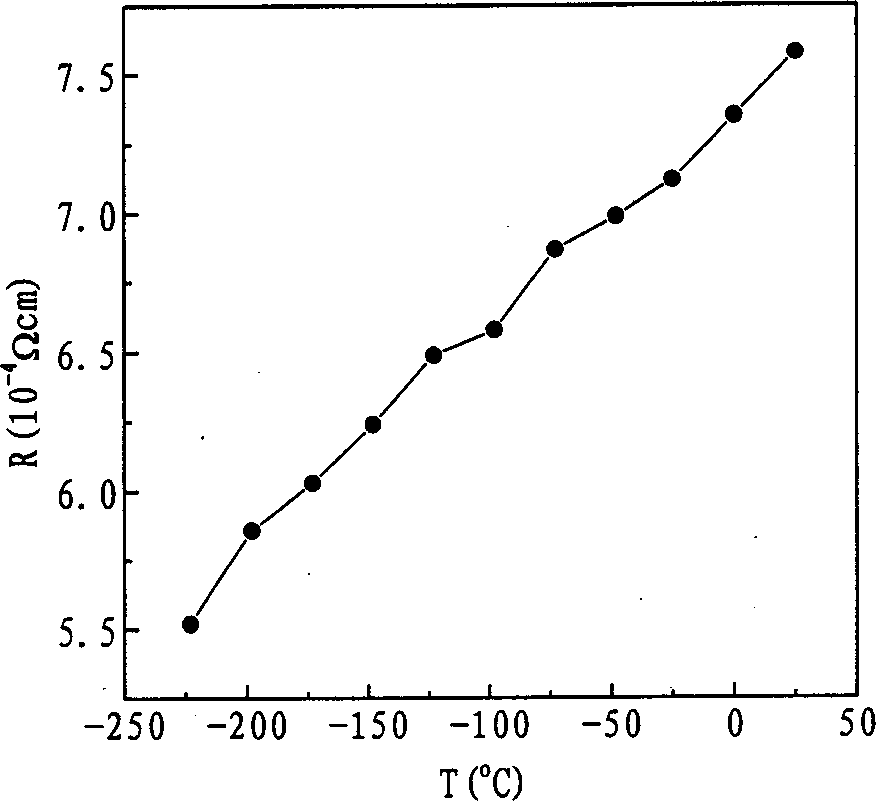

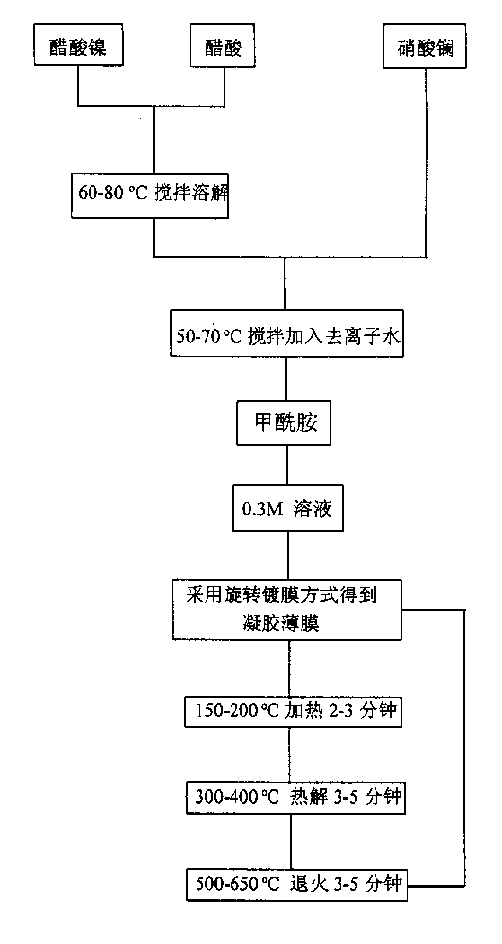

Prepn of lanthanum nickelate-conducting metal oxide film material

InactiveCN1362749ALow costEasy to operatePiezoelectric/electrostrictive/magnetostrictive devicesSolventFilm material

The preparation method for lanthanum nickelate conductive metal oxide film material includes: preparing precursor solution, mixing solvent acetic acid, deionized water and additive methanamide and solute nickel acetate and lanthanum nitrate at a certain temperature in the concentration of 0.3 M to obtain precursor solution, and preparing film material, making the prepared precursor solution form gel film on the substrate by adopting rotating coating mode, then making heat treatment by sections in quick annealing furnace to form film material. Said film material possesses high selective orinetation and good metal characteristics, and its room temp. electric resistivity is about 7.6X10 to the minus fourth ohm cm. Said film material can be used to prepare high-quality ferroelectric film material on it or can be used as bottom electrode of ferroelectric film device.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

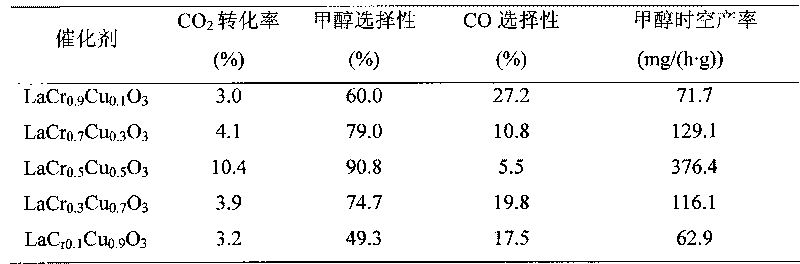

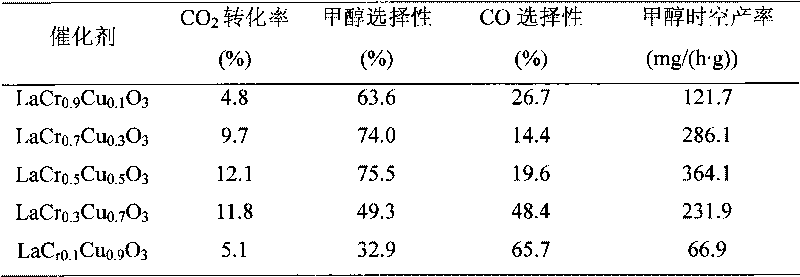

Catalyst for synthesizing methanol by direct hydrogenation of carbon dioxide and preparation method thereof

InactiveCN101690894AImprove performanceOvercome the disadvantages of low conversion rate and poor selectivity of methanolOrganic compound preparationHydroxy compound preparationCopper nitrateHYDROSOL

The invention discloses a catalyst for synthesizing methanol by direct hydrogenation of carbon dioxide and a preparation method thereof and relates to the catalyst. The invention provides the catalyst for synthesizing the methanol by direct hydrogenation of the carbon dioxide and the preparation method thereof. The catalyst is LaCr1-xCuxO3, wherein x is the relative mole fraction of a main component of Cu, x is equal to 0.1-0.9, and La: Cr: Cu is equal to 1: (1-x): x. The preparation method comprises the steps of preparing copper nitrate, chromium nitrate, lanthanum nitrate and citric acid into water solution, forming a sol under the radiation of an infrared lamp, heating, decomposing nitrogen oxides and organic acids, pre-baking in an atmosphere furnace at the temperature of 350-450 DEG C for 2-4h, baking at the temperature of 700-800 DEG C, and obtaining the catalyst for synthesizing the methanol by direction hydrogenation of the carbon dioxide. The citric acid complexation-rapid combustion method is adopted for overcoming the disadvantages of lower conversion rate, poorer selectivity of the methanol and the like during the catalysis of the carbon dioxide by using the existing catalyst for synthesizing the methanol by hydrogenation of the carbon dioxide, and the prepared catalyst has stable performances.

Owner:XIAMEN UNIV

Composite porous activated carbon flue gas adsorbent and preparation method thereof

InactiveCN104437371AImprove toughnessHigh strengthOther chemical processesDispersed particle separationPorositySodium metasilicate

The invention discloses a composite porous activated carbon flue gas adsorbent which is characterized by comprising the following raw materials in parts by weight: 98-105 parts of shell activated carbon, 36-40 parts of diatomite, 2-3 parts of sodium metasilicate, 2-3 parts of rosin, 2-3 parts of VAE emulsion, 2-3 parts of polyvinyl alcohol, 1-2 parts of sodium alcohol ether sulphate, 1-2 parts of sodium citrate, 1-2 parts of gypsum residue, 2.5-3.5 parts of pulverized fuel ash, 4-5 parts of edible corn starch, 2-3 parts of lanthanum nitrate, 9-12 parts of glass fiber powder, 4-6 parts of adsorption aids and a proper amount of water. The composite porous activated carbon flue gas adsorbent disclosed by the invention is reasonable in formula, viscous matters such as polyvinyl alcohol and edible corn starch are added, the toughness and strength of the activated carbon are improved, and the service life is prolonged; and due to the addition of the adsorption aids, the adsorbent has special porosity, the contact time between gas and the adsorbent is prolonged, and the effects of inhibiting bacteria and purifying the air are achieved. Therefore, the adsorption efficiency is high, the production process is simple, and the adsorbent is suitable for industrial dry desulfurization, automobile exhaust desulfurization and daily air purification.

Owner:ANHUI TOPTECHSCR ENVIRONMENTAL SCI & TECH

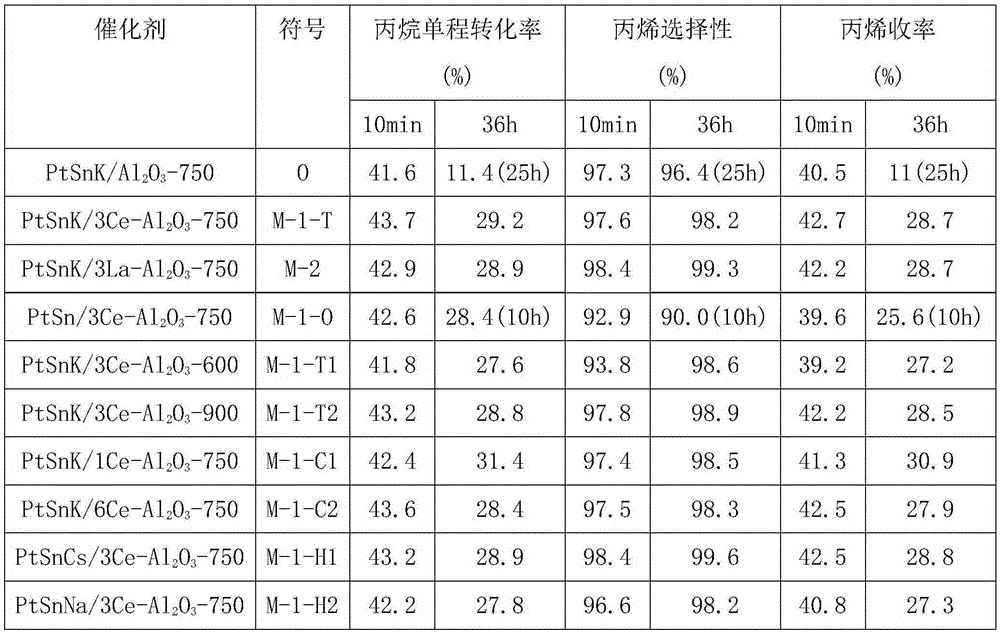

Supported platinum group catalyst applied to propane dehydrogenation propylene preparation and preparation method of supported platinum group catalyst

InactiveCN105251486AImprove thermal stabilityImprove stabilityHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsPtru catalystPhysical chemistry

The invention provides a supported platinum group catalyst applied to propane dehydrogenation propylene preparation and a preparation method of the supported platinum group catalyst and relates to propylene. The catalyst is prepared from PtSnN2 / N1-Al2O3, wherein N1 is selected from rare earth metals of La and Ce, and N2 is selected from alkali metals of Cs, K and Na. The catalyst is prepared from, by mass, 0.1%-0.5% of Pt, 0.2%-1.0% of Sn, 0.5%-6% of N1, 0.5%-5% of N and the balance Al2O3. The preparation method includes the steps that a cerous nitrate solution or a lanthanum nitrate solution containing the N1 component is added in the preparation process or forming process of an alumina precursor, and a modified carrier of the propane dehydrogenation propylene preparation catalyst is prepared after drying and calcination; Pt and Sn are co-steeped or steeped on the carrier step by step, the catalyst precursor PtSn / N1-Al2O3 is obtained after drying and calcination and then steeped in an N2 component solution, and the catalyst is prepared after drying and calcination.

Owner:XIAMEN UNIV

Preparation method of active carbon fiber phosphorous removing agent carrying lanthanum hydroxide

The invention relates to a preparation method of an active carbon fiber phosphorous removing agent carrying lanthanum hydroxide. The invention belongs to the technical field of phosphorous removing agent preparation technology. The novel phosphorous removing agent provided by the invention has advantages of high phosphorous removing rate, high absorption rate, and the like. The phosphorous removing rate reaches above 99.5%. The method of the invention is characterized in that: a mixed suspension composed of a concentration of lanthanum nitrate solution and a concentration of sodium hydroxide solution is adopted; a certain amount of active carbon fiber is added to the mixed suspension; the mixture is stirred, filtered, washed, and a solid phosphorous removing agent is finally obtained. According to the phosphorous removing agent, a weight ratio of active carbon fiber to lanthanum hydroxide is 1:1 to 1:1.2.

Owner:SHANGHAI UNIV

Solar glass self-cleaned high anti-reflection coating and production method thereof

InactiveCN103804966ASelf-cleaning withFunctionalCoatingsPhotovoltaic energy generationHYDROSOLSolvent

The invention relates to a solar glass self-cleaned high anti-reflection coating and a production method thereof, wherein the solar glass self-cleaned high anti-reflection coating is composed of antireflection components, self-cleaning components, latent light conversion components, film coating regulators and solvent water, and simultaneously has triple functions including self-cleaning, antireflection and near ultraviolet light conversion. In the formula of the coating, the antireflection components are nano SiO2 hydrosols of different sizes; the self-cleaning components are lanthanum cerium doped nano TiO2 and nano SiO2; the latent light conversion components are lanthanum nitrate, cerous nitrate, terbium nitrate, ammonium dihydrogen phosphate, phosphoric acid and ascorbic acid; after the latent light conversion components are treated, a silica coated phosphate fluorescent material La1-x-yCexTbyPO4 is generated, wherein x=0.02-0.5, and y=0.02-0.05; the film coating regulators include a surface active agent and an organosilicone coupling agent. Once the solar glass self-cleaned high anti-reflection coating disclosed by the invention is applied to solar glass, the light transmittance of the solar glass and the photoelectric conversion efficiency of crystalline silicon solar batteries can be significantly improved and stabilized, and the manual cleaning cost and maintenance management cost of the solar batteries in the process of running are reduced, therefore, the solar glass self-cleaned high anti-reflection coating can replace existing solar glass anti-reflection coatings.

Owner:天津顺御科技有限公司

Ion thermal growth method of near infrared light upper conversion fluoride nano crystal

InactiveCN101476151ALow melting pointNon-volatilePolycrystalline material growthFrom normal temperature solutionsSolubilityLuminous intensity

The invention relates to an ion thermal growth method for converting fluoride nano crystal near infrared light which includes steps as follows: weighing some solid yttrium nitrate (lanthanum nitrate), ytterbium nitrate, erbium nitrate (thulium nitrate or holmium nitrate) pro rata. Mol ratio of the rare earth ion is that yttrium ion (lanthanum ion) : ytterbium ion : erbium ion (thulium ion, holmium ion) equal to 70-90 : 0 : 0.001-15; adding tetrafluoroborate type ion liquor into the mixing solid, selective adding some NaCl solid according with various basic, then placing the mixing solution into a high pressure reaction kettle with polyfluortetraethylene lining, placing into an oven for heating reacting, finally, washing, centrifugating, drying and obtaining the product. The prepared nano upper converting fluorescence material has small and uniform granule, strong lighting strength, better water-solubility and can satisfy need of biomolecule fluorescence mark material.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

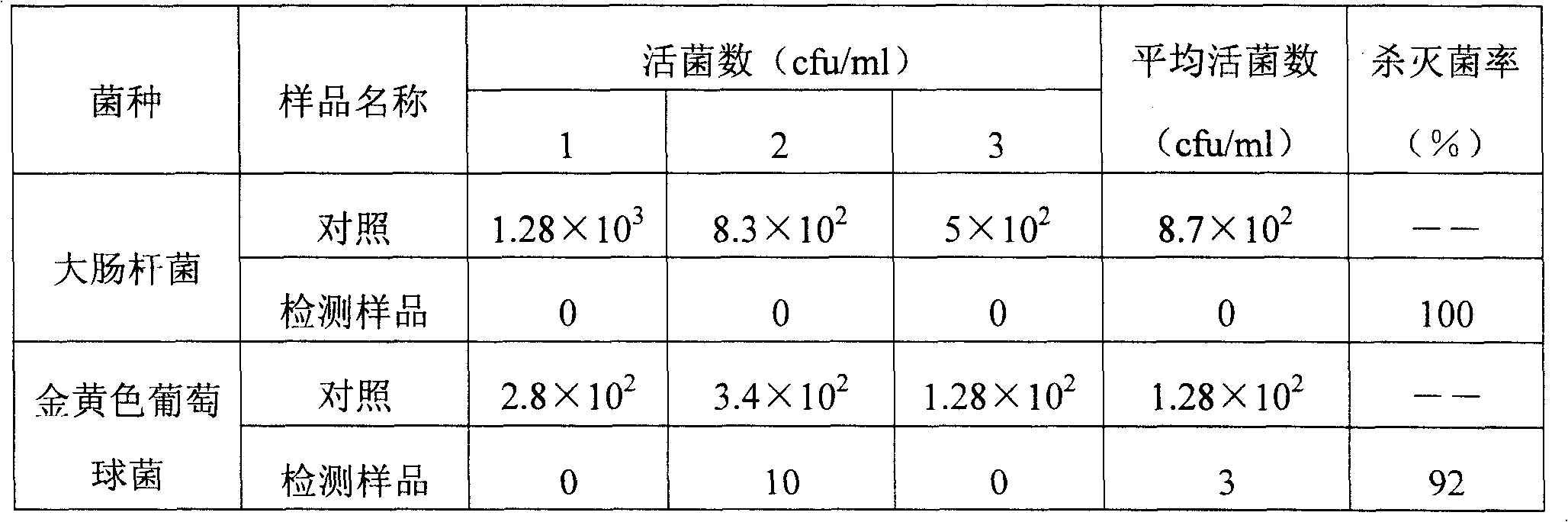

Applique antibacterial ceramic cutter

The invention relates to an applique antibacterial ceramic cutter, and belongs to the technical field of daily ceramics. The cutter comprises a cutter blank, and is characterized in that the outer surface of the cutter blank is covered with a layer of antibacterial self-cleaning ceramic glaze; the antibacterial self-cleaning ceramic glaze is prepared from the following raw materials in percentageby weight: 15 to 30 percent of quartz, 20 to 40 percent of feldspar, 10 to 20 percent of borax, 6 to 18 percent of boric acid, 3 to 7 percent of barium carbonate, 2 to 5 percent of sodium carbonate, 4to 9 percent of bentonite, 0 to 6 percent of phosphorus pentoxide, 10 to 20 percent of zinc oxide, 0 to 6 percent of titanium oxide, 1 to 5 percent of strontium carbonate, 0 to 4 percent of lithium carbonate, 1 to 4 percent of cooked steatite, 1 to 6 percent of alumina, and 1 to 4 percent of rare-earth; and the rare-earth is one or a mixture of arbitrary two of the cerium oxide, the cerium lanthanum chloride and the lanthanum nitrate. The cutter has the effect of antibacterial self-cleaning, has beautiful appearance, and is suitable for the occasion of high-grade application.

Owner:淄博博纳科技发展有限公司

Gold-containing catalyst for preparing vinyl chloride by using acetylene method as well as preparation method and application of catalyst

InactiveCN102327777ANo pollution in the processThere will be no deactivationMolecular sieve catalystsPreparation by halogen halide additionMicro structureEthyl Chloride

The invention discloses a gold-containing catalyst for preparing vinyl chloride by using an acetylene method as well as a preparation method and application of the catalyst. The catalyst contains a gold element, a lanthanum element, a cobalt element, a co-catalytic metal element and a carrier with a porous micro-structure. The gold accounts for 0.3%-2% by mass of the catalyst; the gold element in the catalyst comes from gold chlorides or gold nitrates; the cobalt element comes from chlorides of the cobalt or cobalt nitrates; and the lanthanum element comes from lanthanum chlorides or lanthanum nitrates. The catalyst disclosed by the invention in use is free from inactivation phenomenon caused by sublimation of industrial catalyst mercury chloride, has no pollution to the environment, overcomes defects of high toxicity and high pollution of the conventional industrial catalyst mercury chloride, has the characteristics of simple preparation method, high conversion rate of the acetylene and selectivity of the vinyl chloride, long service life up to 1000 hours or more, high temperature resistance, and high intensity and is renewable, and the conversion rate of the acetylene and selectivity of the vinyl chloride approximate to or exceed the technical indexes of the mercury chloride catalyst.

Owner:TIANJIN UNIV +1

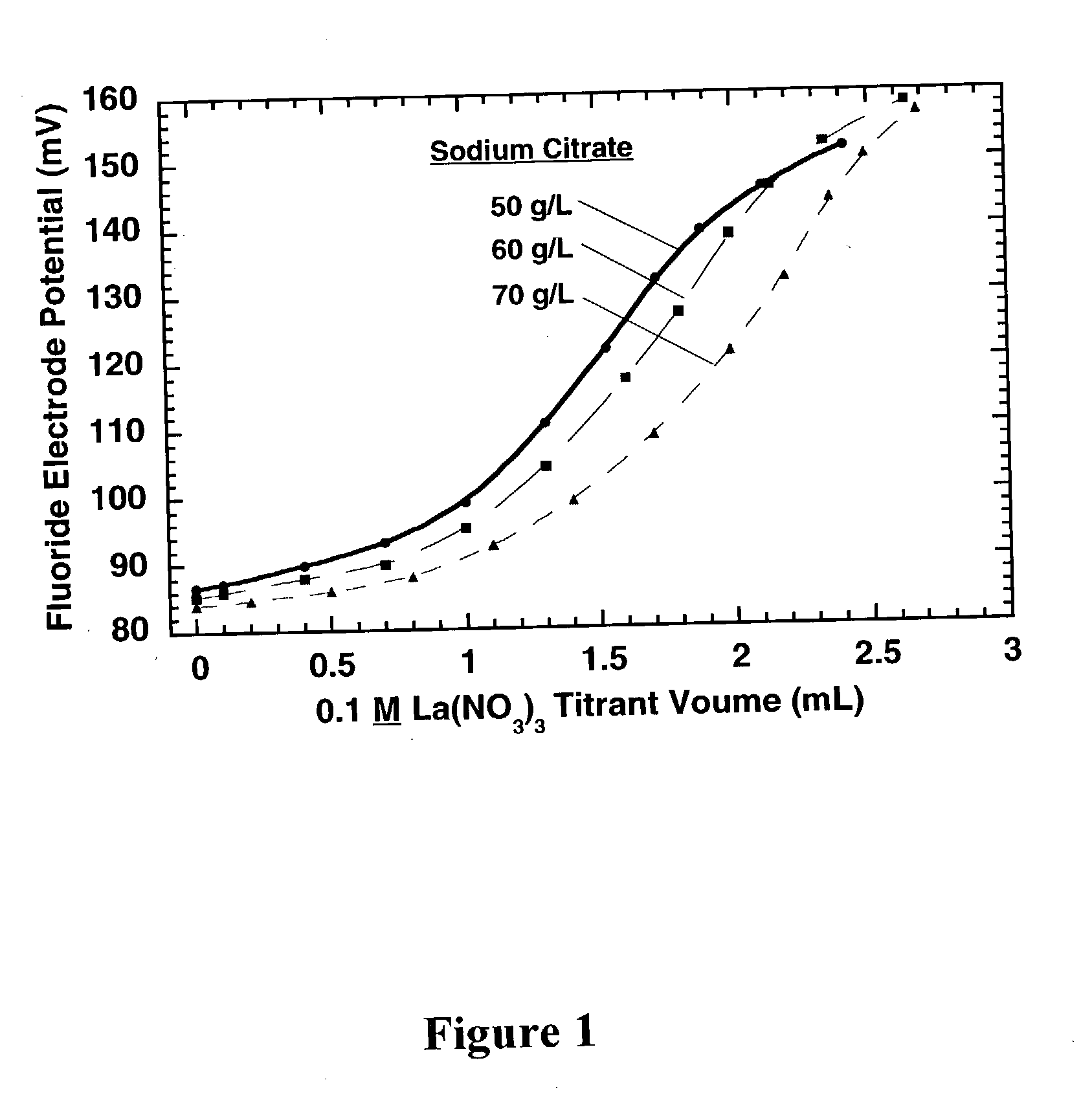

Measurement of complexing agent concentration in an electroless plating bath

ActiveUS20040253740A1Minimize measurement errorEasy to rinseAnalysis using chemical indicatorsChemical analysis using titrationCITRATE ESTERFluoride

The concentration of citrate complexing agent in an electroless cobalt or nickel plating bath is determined by titrating a sample of the electroless plating bath containing a small concentration of free fluoride ion with a standard lanthanum nitrate solution. During the titration, La<3+> ion first reacts preferentially with the citrate complexing agent and then with fluoride ion, which reduces the free fluoride ion concentration. The endpoint for the titration is indicated by a substantial decrease in the free fluoride ion concentration, which is detected via a fluoride ion specific electrode (ISE). The method can be used for analysis of other complexing agents.

Owner:ECI TECH

Method for preparing solid electrolyte by using lithium lanthanum zirconium oxide precursor coated powder

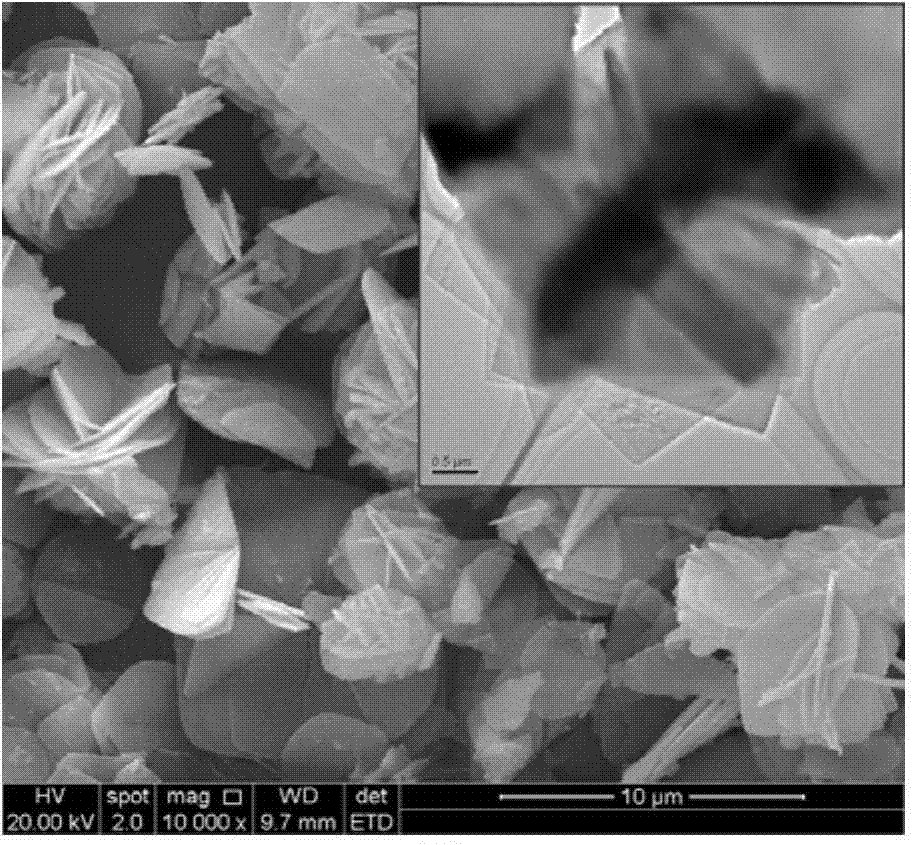

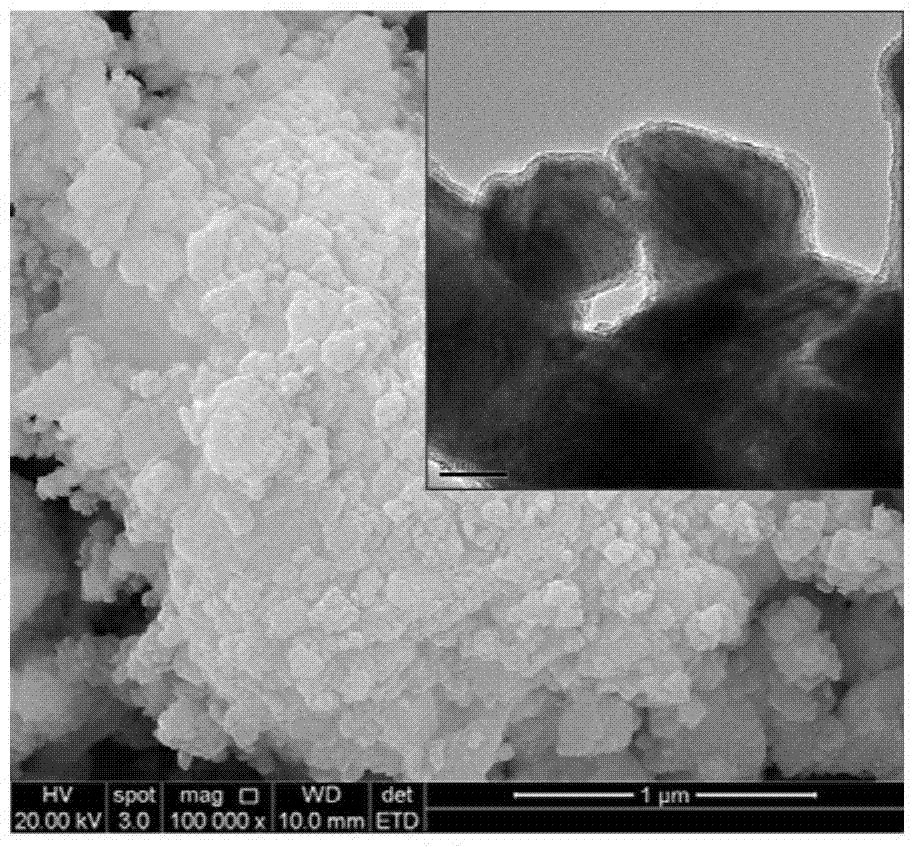

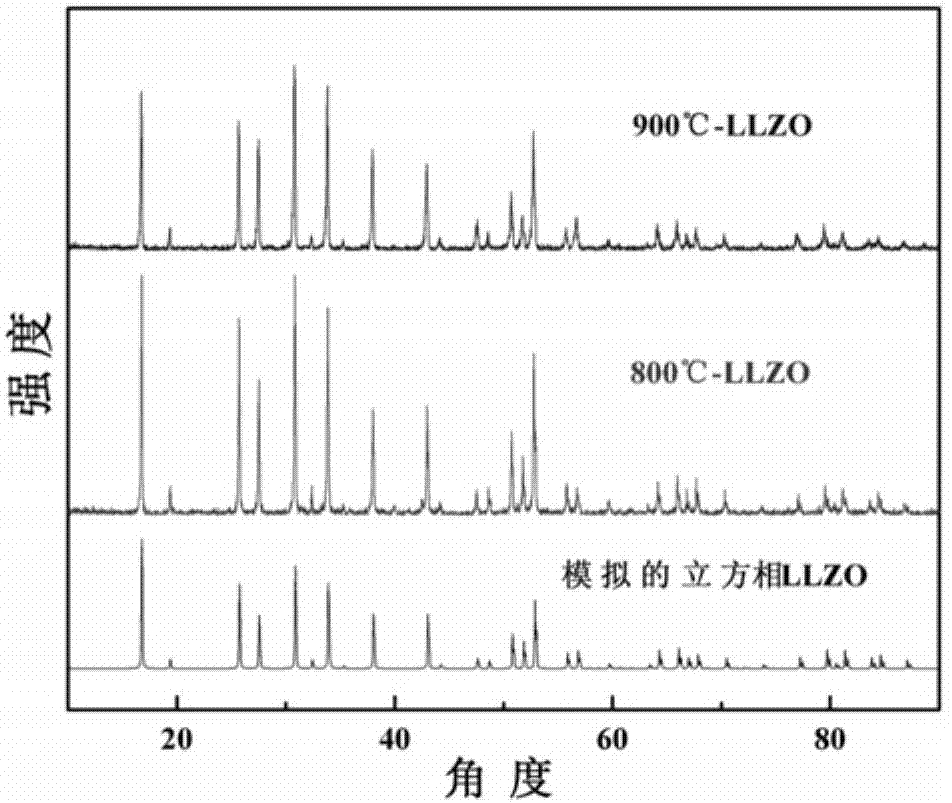

ActiveCN104124467ACalcination temperature is lowHigh sintering activitySecondary cellsElectrical batteryElectrochemistry

The invention discloses a method for preparing a solid electrolyte by using lithium lanthanum zirconium oxide precursor coated powder. The method specifically comprises the steps of dissolving a certain amount of lanthanum nitrate and zirconium nitrate into water, adding a precipitator, namely ammonium carbonate, controlling the pH value to ensure that La<3+> and Zr<4+> ions are simultaneously precipitated, and filtering and washing the precipitate; weighing a certain amount of lithium oxalate, dissolving lithium oxalate into water, adding the precipitate into the lithium oxalate solution, stirring, evaporating, crystallizing, and separating out lithium oxalate crystal on the surface of the precipitate to form precursor powder with a coated structure. The prepared powder has the advantages of uniform mixing, fine grains, high purity and the like; through the formed specific coated structure, the calcination temperature of the powder is low, the sintering time of the powder is short, and the room-temperature lithium ion electric conductivity of the sintered lithium lanthanum zirconium oxide is more than 2.2*10<-4>S / cm. According to the method, the process is simple, the cost is low, the preparation conditions are easy to control, and the prepared solid electrolyte is good in electrochemical stability and high in electric conductivity and can be used for preparing all-solid-state lithium ion batteries.

Owner:WUHAN UNIV OF TECH

Production and use for dimethyl ether by methanol dewater

InactiveCN1745894AEasy to makeEvenly dispersedMetal/metal-oxides/metal-hydroxide catalystsEther preparation by compound dehydrationCopper nitrateSolvent

A catalyst for preparing dimether by dewatering methanol contains CuO (20-40 Wt%), ZnO (5-30), La2O3 (1-10), Sm2O3 (1-10), V2O5 (1-10) and carrier (40-60). Its preparing process includes such steps as dissolving copper nitrate (or acetate), Zinc nitrate (or acetate) and lanthanum nitrate in solvent, adding carrier, stirring, adding superfine (250 meshes) particles of Sm2O3 and V2O5, stirring, infrared drying at 60-100 Deg C., calcining at 350-500 Deg C., pressing and sieving.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

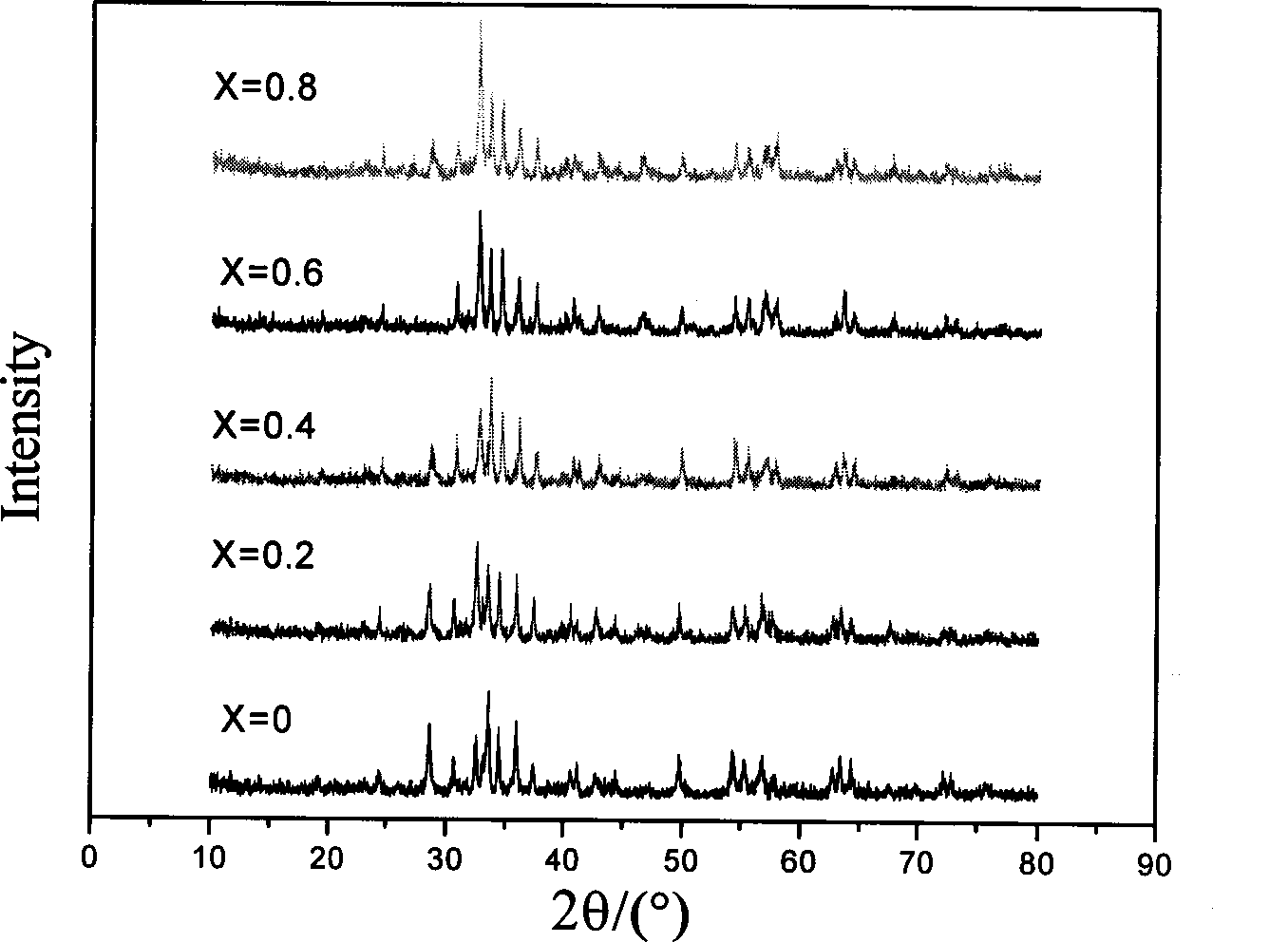

La doped SrTiO3 base oxide pyroelectric material and preparation method

InactiveCN101423243AStoichiometric ratio is accurateUniform compositionTitanium compoundsThermoelectric materialsStrontium titanate

A La-doped strontium titanate (SrTiO3)-based oxide thermoelectric material and a preparation method thereof, belonging to the technical field of energy materials. The method is divided into two parts of powder synthesis and forming of bulk materials. The powder synthesis adopts the sol-gel method, takes tetrabutyl titanate, strontium nitrate and lanthanum nitrate as raw materials, takes deionized water and ethanol as solvents and takes acetic acid and glycerol as a catalyst and a chelating agent to prepare SrTiO3 gel with different La doping amount, and the temperature is kept at the temperature of 500-560 DEG C for 1-2 hours to obtain precursor powder. The bulk forming adopts the spark plasma sintering method, and the sintering conditions are as follows: the vacuum degree is 2-10Pa, the pressure is 40-50MPa, the heating rate is 100 DEG C / min, the sintering temperature is 900-1000 DEG C, and the holding time is 5-10min. The method synthesizes the La-doped SrTiO3-based bulk thermoelectric material with high chemical homogeneity, uniform and fine grains and single-phase perovskite structure under the conditions of lower reaction temperature and shorter reaction time. The preparation method has the advantages of simple and convenient process, short synthesis and forming time, and the like.

Owner:UNIV OF SCI & TECH BEIJING

Preparation of rare earth ammonium bimolybdate

InactiveCN1644512AReduce microhardnessEasy to processMolybdeum compoundsRare earth metal compoundsCerium nitrateNitrate

Production of rare earth ammonium dimolybdate is carried out by adding ammonium tetramolybdate with ammonium tetramolybdate : soft water: ammonia water = 1kg: 4-5L: 1L, heating agitating, forming mother liquid, regulating the pH value of mother liquid between 7-8.5, adding the cerium nitrates, lanthanum nitrates or illinium nitrates into the mother liquid, heating evaporating for 2.0-6.0hrs with heating temperature 100deg.C-130deg.C until the solution transparent, discharging the materials, pumping filtering, drying with temperature 110-150deg.C for 6-8hrs, and obtaining the rare earth ammonium dimolybdate. It achieves low cost, higher material processing and using performance and no environmental pollution.

Owner:临沂市科创材料有限公司

Bi-metal atom modified MCM-41 mesoporous molecular sieve and preparation method thereof

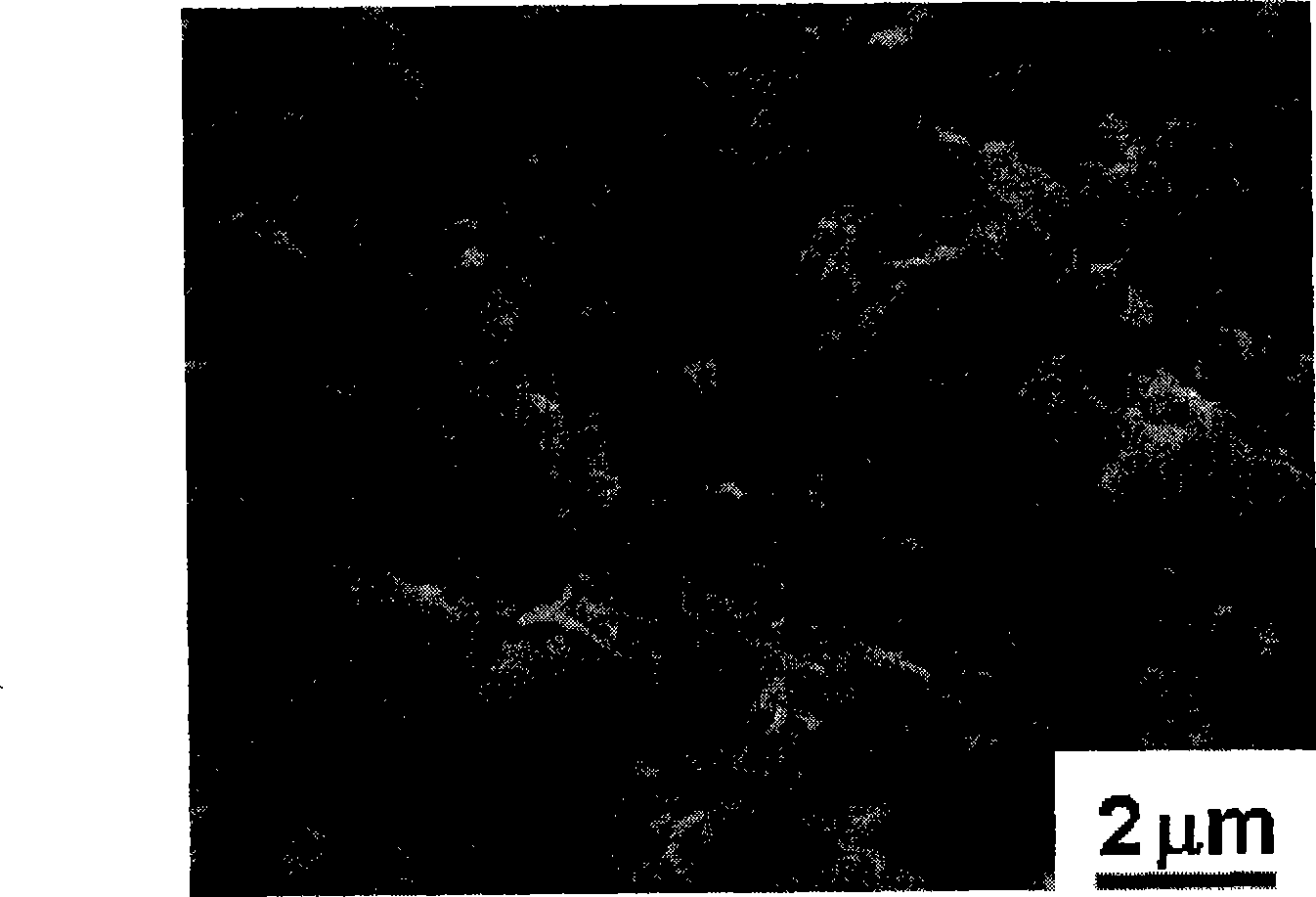

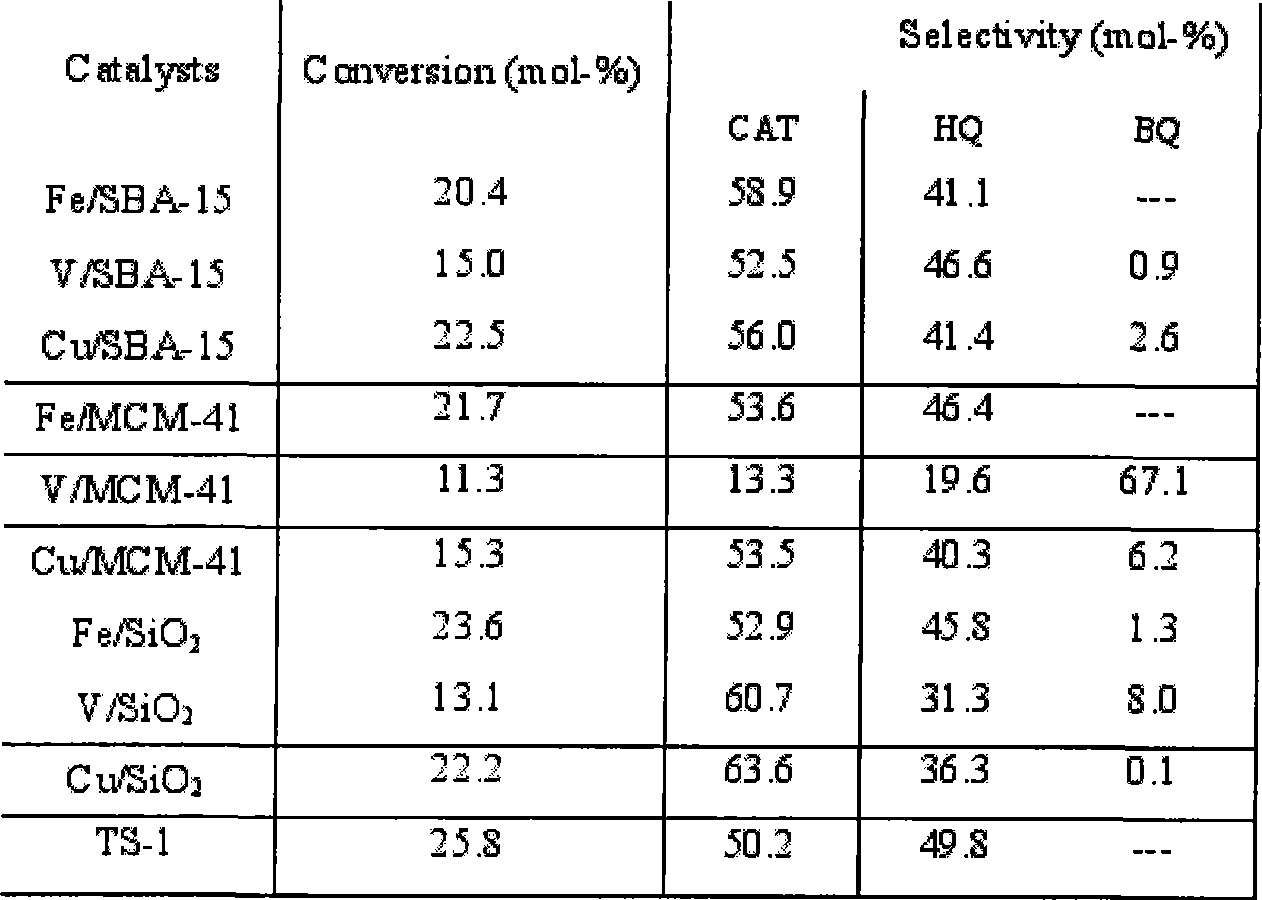

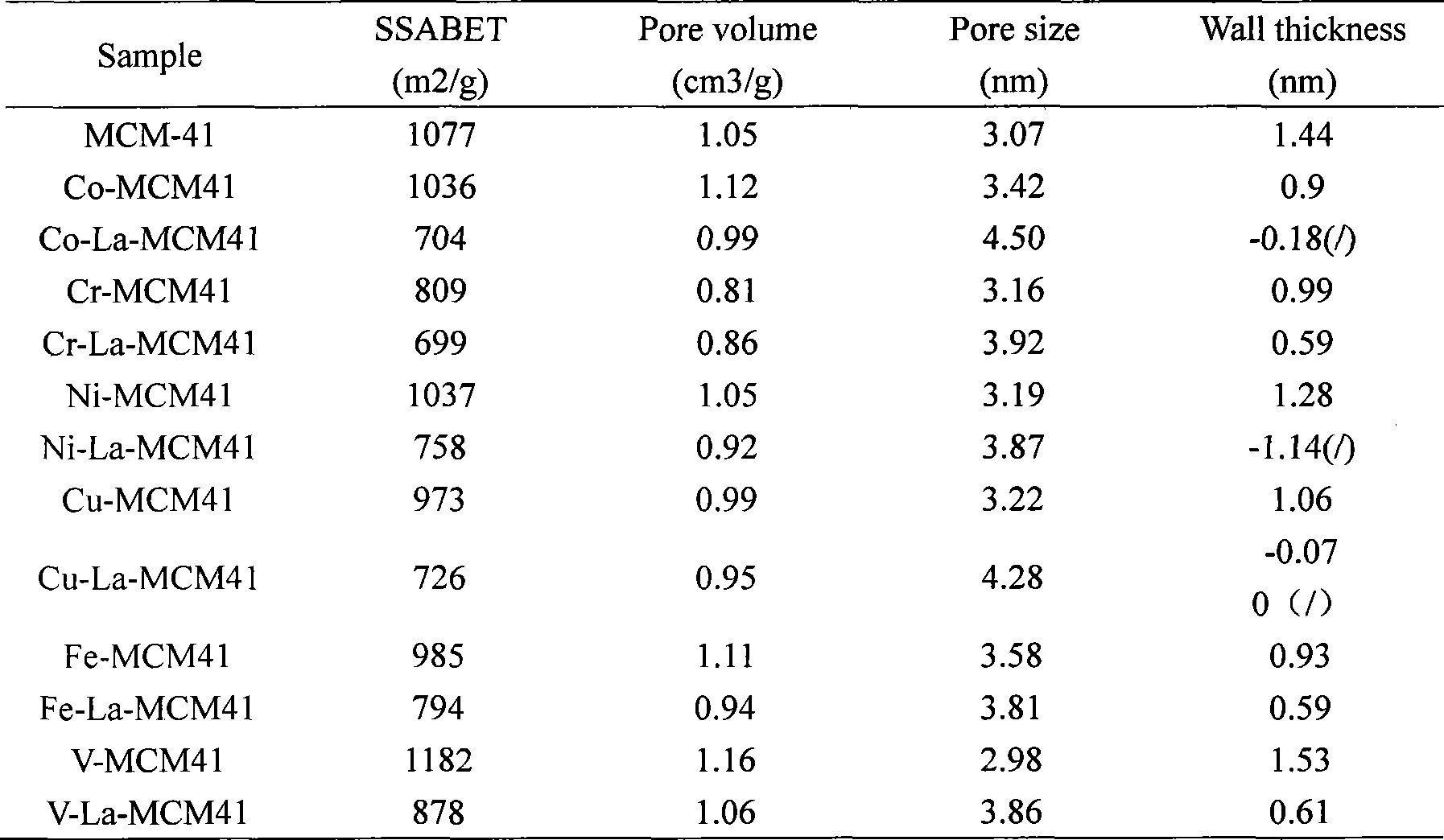

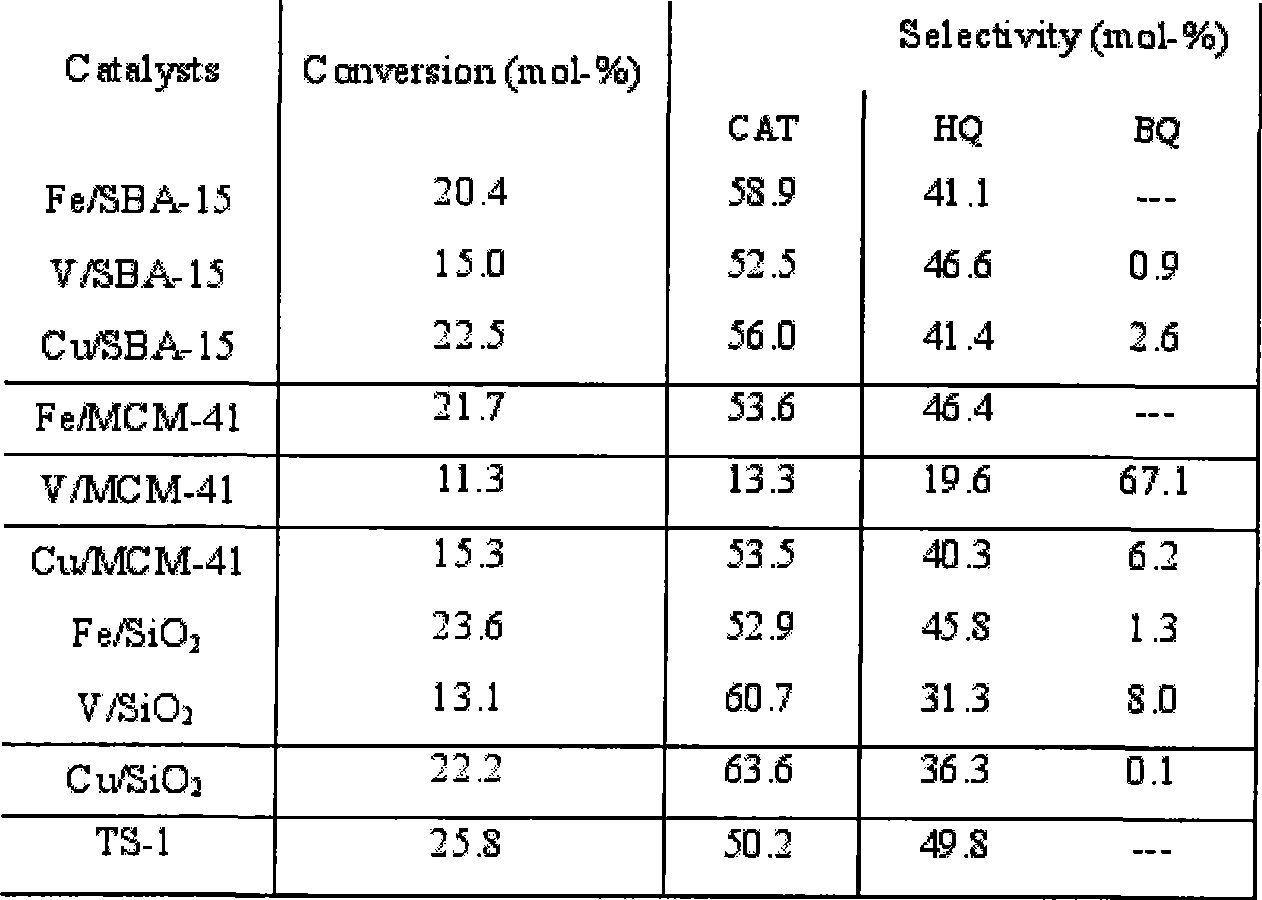

InactiveCN101367528AImprove performanceHigh hydrothermal stabilityCrystalline aluminosilicate zeolitesSaline waterAcetic acid

The invention relates to an improved MCM-41 mesoporous molecular sieve and a preparation method thereof, in particular relates to a dual-metal-atom improved MCM-41 mesoporous molecular sieve and the preparation method thereof. The molecular sieve consists of hexadecyl trimethyl ammonium bromide, ethyl orthosilicate, sodium hydroxide, Me metal salt (Co, Ni, Cr, Fe, Cu, V), lanthanum nitrate and water. The molecular sieve is prepared in the steps: at the room temperature, hexadecyl trimethyl ammonium bromide is mixed and dissolved with the sodium hydroxide, and is added with TEOS in dropping way, and simultaneously added with Me metal salt water solution and lanthanum nitrate solution in dropping way; the pH value of the mixed solution is adjusted by acetic acid to be 10 to 11, and is mixed for 1 to 2 hours after being stabilized; the sol is moved into a polyfluortetraethylene bottle to be heated and crystallized for 2 days in the oven at the temperature of 100 DEG C; after filtering, washing and drying for nights, and being calcined in a muffle at the temperature of 550 DEG C for 3 to 7 hours, the dual-metal-atom improved MCM-41 mesoporous molecular sieve is obtained. The product can simultaneously improve the acid performance and the water heating stability of the MCM-41 mesoporous molecular sieve, and can enlarge the actual application of the MCM-41 mesoporous molecular sieve in the catalyst filed.

Owner:SHANGHAI INST OF TECH

Lanthanum-ferrite-doping formaldehyde gas sensitive material and preparation method thereof

InactiveCN101852754AHigh sensitivityGood choiceIron compoundsMaterial resistanceMicrowaveElectronegativity

The invention relates to a lanthanum-ferrite-doping formaldehyde gas sensitive material and a preparation method thereof, which belong to the formaldehyde gas sensitive material and the preparation method. The material of the invention comprises raw materials such as lanthanum nitrate, ferric nitrate, citric acid, dispersing agents, metal ions with the similar electronegativity and the ion diameter to iron ions or metal ions with the similar electronegativity and ion diameter to lanthanum ions and the like according to the mol ratio of 1 / 1 / (0.05 to 1.5) / (0.001 to 0.1) / (0.1 to 0.5). The preparation method comprises the steps of solution mixing, microwave reaction, gel drying, grinding and the like. Thereby, the formaldehyde gas sensitive material with the advantages of high sensitivity, good selectivity and high response-recovery time is obtained.

Owner:YUNNAN UNIV

Graphene-doped and lanthanum-modified titanium-based lead dioxide electrode and preparation method thereof

ActiveCN105239094AImprove electrocatalytic activityImprove electrodegradabilityElectrolytic inorganic material coatingElectrodesLead dioxideMethyl orange

The invention discloses a graphene-doped and lanthanum-modified titanium-based lead dioxide electrode which comprises a titanium base body, a tin-antimony oxide bottom layer deposited on the titanium base body in a hydrothermal mode, graphene deposited on the tin-antimony oxide bottom layer in an electrolytic mode, and a lanthanum-modified beta-PbO2 active layer. Compared with the prior art, the titanium-based lead dioxide electrode at least can improve removal effect of methyl orange by 15.6% in case of keeping service life of the titanium-based lead dioxide electrode. The invention further discloses a preparation method for the titanium-based lead dioxide electrode. The preparation method comprises the following step: depositing the beta-PbO2 active layer in an acidic deposition liquid by taking the titanium base body which is deposited with the tin-antimony oxide bottom layer in the hydrothermal mode as an anode and taking equal-area graphite as a cathode, wherein the acidic deposition liquid comprises graphene, lanthanum nitrate, lead, nitrate, nitric acid and a surfactant. According to the preparation method, a preparation process for an alpha-PbO2 layer is cancelled, the preparation method for the titanium-based lead dioxide electrode is simplified, and foundation is laid for increasing a finished product qualified rate of an electrode product.

Owner:陕西恒悦材料科技有限公司

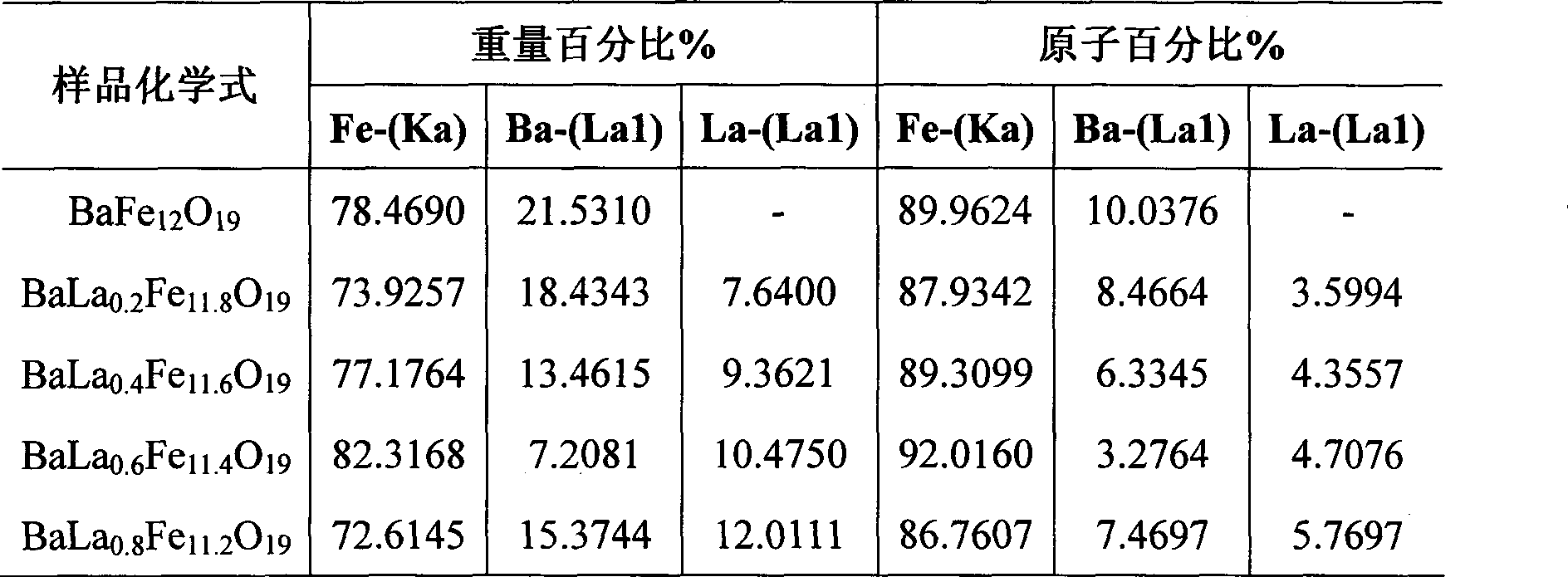

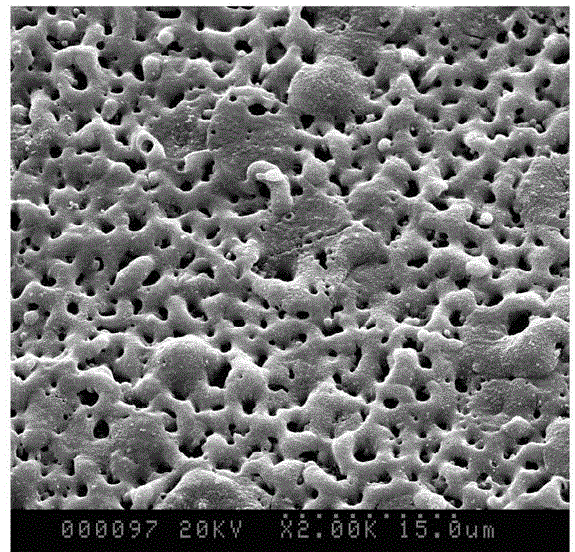

Lanthanum doped nano barium ferrite film and method of manufacturing the same

The invention relates to a lanthanum doping nanometer barium ferrite thin film and a preparation method thereof, which is technically characterized in that the prescription is as follows: 1.48 g / 100 ml to 1.60 g / 100 ml of glycol, 2.51 g / 100 ml to 2.71 g / 100 ml of citric acid, 1.74 g / 100 ml of iron nitrate, 0.125 g / 100 ml of barium nitrate and 0.03 g / 100 ml to 0.125 g / 100 ml lanthanum nitrate. The preparation method is that the iron nitrate, the barium nitrate, the lanthanum nitrate, and the like, serve as raw materials to prepare a forerunner body the forerunner body of the lanthanum doping nanometer barium ferrite in a sol-gel method; sol-gel method; clean silicon dioxide serves as a support base, the iron nitrate, the barium nitrate and the lanthanum nitrate serve as main salt, the citric acid serves as complexing agent, the glycol serves as complexing agent assist, and the soakage-drawing method is adopted to make the film. The method has the advantages of simple process flow and low cost; the method is convenient for preparing the thin film on bases with different shapes, the lanthanum doping nanometer barium ferrite thin film with high purity is obtained, and the thin film can be used for preparing magnetic recording materials and absorbing materials.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

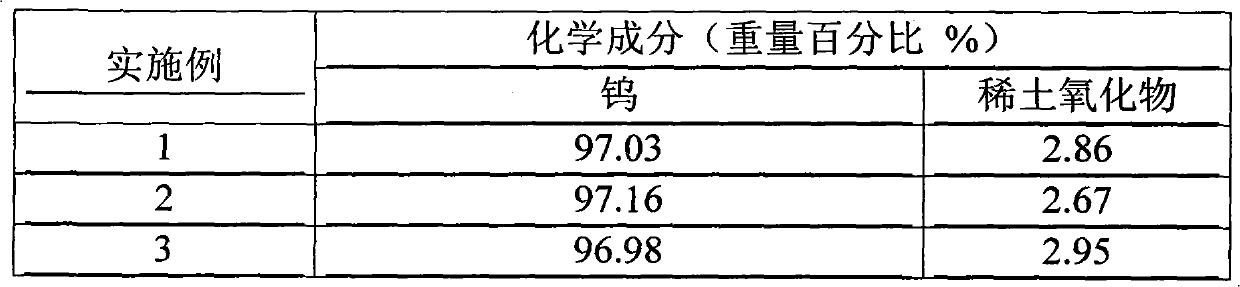

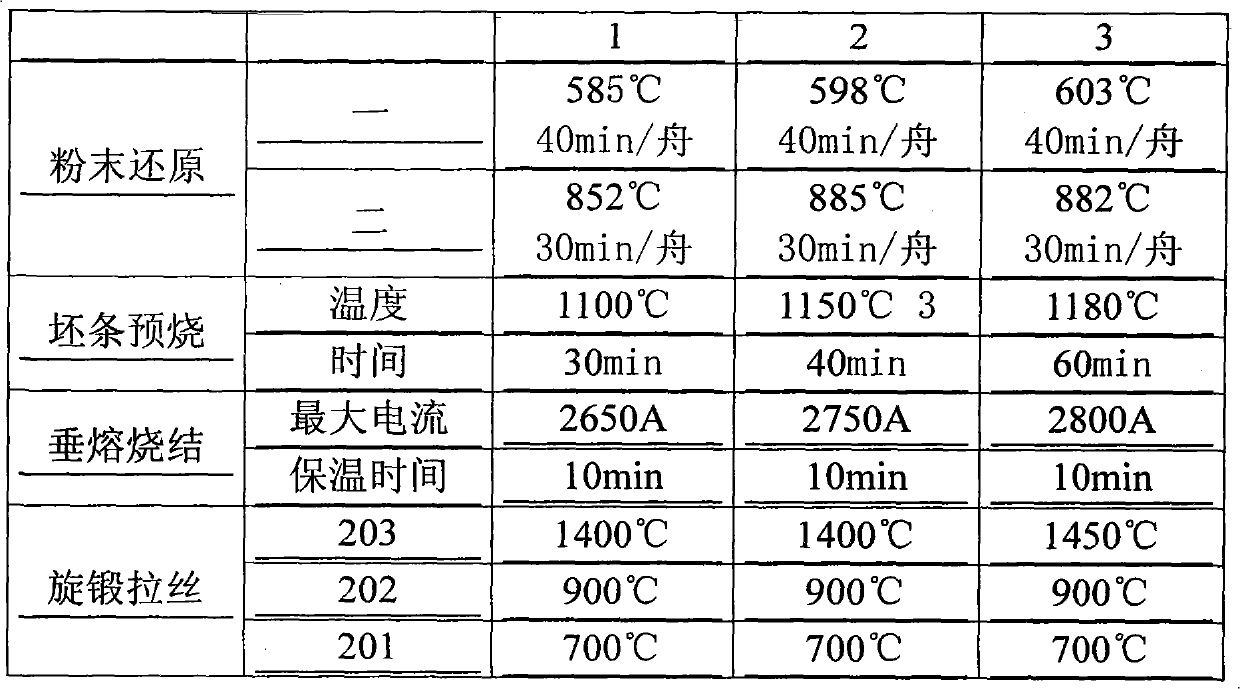

Multi-element composite rare earth tungsten electrode material and preparation method thereof

InactiveCN102000923AGood welding performanceGood thermionic emission performanceWelding/cutting media/materialsSoldering mediaRheniumRare earth

The invention relates to a multi-element composite rare earth tungsten electrode material, which is prepared by adding rare earth oxides in a tungsten metal substrate, wherein the weight percentage of the tungsten metal substrate is 95 to 98%; and the weight percentage of the rare earth oxides is 2.0 to 5.0%. The preparation method comprises: the tungsten substrate powder is weighed according to the proportioning weight and is poured into a mixing pot, and deionized water is added to the mixture to be stirred so as to prepare a uniform suspension; lanthanum nitrate, cerous nitrate, rhenium nitrate and erbium nitrate are weighed according to the required proportioning weight and are prepared into a solution; the solution is added to the suspension to be stirred uniformly, and the mixing solution is heated and dried to prepare the mixing alloy powder; the mixing alloy powder is prepared into the rare earth tungsten composite powder through the twice hydrogen reduction; and the argon arc welding electrodes with various specifications are prepared through tamping, presintering, vertically sintering and rotary swaging. The rare earth tungsten electrode material has the advantages of good welding property, green environment protection type electrode material, good arc strike and retention of electrodes, and rapid heating and cooling properties, and the heat input on welding pieces and the dimension of a melting pool can be accurately controlled.

Owner:天津市春风钨业有限公司 +1

Catalyst for methanation and preparation method thereof

InactiveCN102500379AHigh mechanical strengthImprove stabilityHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsCerium nitrateMethanation

The invention which belongs to the technical field of catalysis relates to a catalyst for methanation and a preparation method thereof. The preparation method comprises the following steps: 1, fully mixing alumina (or pseudoboehmite) with a pore forming agent and a binder, adding deionized water, granulating, drying, compression-molding, and roasting to prepare a catalyst carrier; and 2, dipping the catalyst carrier in a solution of nickel nitrate and lanthanum nitrate (or potassium nitrate, or potassium carbonate, or cerium nitrate, or cerous nitrate), drying, and roasting to prepare the catalyst. The catalyst prepared through the method of the invention, which has the advantages of high mechanical strength and good hydrothermal stability, is suitable for methanation reactions carried out under conditions that the CO content is high and the reaction temperature is high, and can effectively prevent carbon deposition.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of magnesium alloy surface micro-arc oxidation-electrophoresis composite coating

ActiveCN104611699ASmall apertureImprove corrosion resistanceAnodisationVacuum evaporation coatingPlasma electrolytic oxidationMicro arc oxidation

The invention discloses a preparation method of a magnesium alloy surface micro-arc oxidation-electrophoresis composite coating, and belongs to the field of magnesium alloy surface treatment. The preparation method is used for solving problems of conventional magnesium alloy that biological activity is poor, and bonding force with composite membrane is low. According to the preparation method, micro-arc oxidation is adopted so as to form a micro-arc oxidized ceramic coating on magnesium alloy surface, and a composite coating with biological activity is obtained via electrophoresis treatment using a pulsed power supply; and a used electrophoretic liquid is composed of one compound selected from hydroxyapatite, acetic acid, and absolute ethyl alcohol or polyethylene glycol, and one compound selected from lanthanum nitrate or cerous nitrate. Ideal combination of micro-arc oxidation with pulse electrophoresis is realized; compounds such as hydroxyapatite are introduced onto the surface of magnesium alloy; and electrophoresis treatment is used for hole sealing of holes of the micro-arc oxidized ceramic coating so as to improve biological activity and corrosion resistance of magnesium alloy, and bonding strength is relatively high.

Owner:哈尔滨规格科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com