Ion thermal growth method of near infrared light upper conversion fluoride nano crystal

A nano-crystal and near-infrared light technology is applied in the field of preparation of nano-fluorescent materials, which can solve the problems of large hexagonal phase particle size, low product yield and low synthesis amount, and achieve uniform distribution, low reaction temperature and high heat capacity. and the effect of thermal storage density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

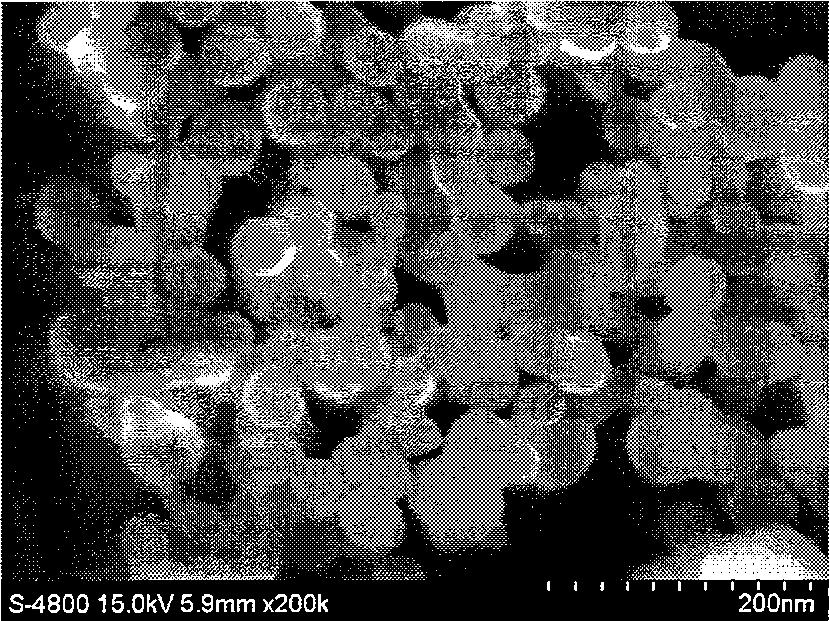

[0030] Using [EMIM][BF 4 ] Synthesis of NaYF from Ionic Liquids 4 : Yb, Er nanocrystals.

[0031] (1) Weigh 0.2985 grams of Y (NO 3 ) 3 ·6H 2 O, 0.093 g Yb (NO 3 ) 3 ·6H 2 O, 0.0092 g Er(NO 3 ) 3 ·6H 2 O, the molar ratio of rare earth ions in the mixed solid is yttrium ion: ytterbium ion: erbium ion is equal to 78:20:2.

[0032] (2) Add 4 ml of 1-ethyl-3-methylimidazolium tetrafluoroboric acid ([EMIM][BF 4 ]) ionic liquid, heated at 150° C. with vigorous stirring for 20 minutes.

[0033] (3) Weigh 0.058 g of NaCl and add it into the above mixed solution, and continue to stir for 30 minutes, so that the rare earth nitrate and NaCl are fully dissolved in the ionic liquid.

[0034] (4) Put the mixed solution obtained in step (3) into a polytetrafluoroethylene-lined autoclave, place it in an oven, heat it at 180° C. for 18 hours, and cool it down to room temperature naturally.

[0035] (5) The precipitate was separated by centrifugation and ultrasonically washed three...

Embodiment 2

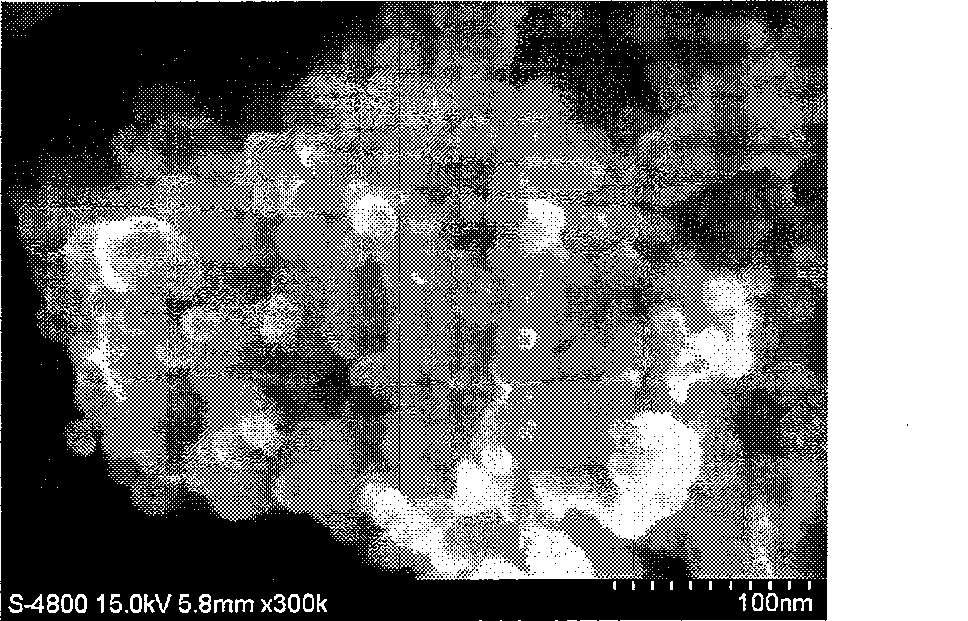

[0037] Using [BMIM][BF 4 ] Synthesis of NaYF from Ionic Liquids 4 : Yb, Er nanocrystals.

[0038] (1) Weigh 0.2985 grams of Y (NO 3 ) 3 ·6H 2 O, 0.093 g Yb (NO 3 ) 3 ·6H 2 O, 0.0092 g Er(NO 3 ) 3 ·6H 2 O, the molar ratio of rare earth ions in the mixed solid is yttrium ion: ytterbium ion: erbium ion is equal to 78:20:2.

[0039] (2) Add 4 ml of 1-butyl-3-methylimidazolium tetrafluoroboric acid ([BMIM][BF 4 ]) ionic liquid, heated at 150° C. with vigorous stirring for 20 minutes.

[0040] (3) Weigh 0.058 g of NaCl and add it into the above mixed solution, and continue to stir for 30 minutes, so that the rare earth nitrate and NaCl are fully dissolved in the ionic liquid.

[0041] (4) Put the mixed solution obtained in step (3) into a polytetrafluoroethylene-lined autoclave, place it in an oven, heat it at 180° C. for 18 hours, and cool it down to room temperature naturally.

[0042] (5) The precipitate was separated by centrifugation and ultrasonically washed three...

Embodiment 3

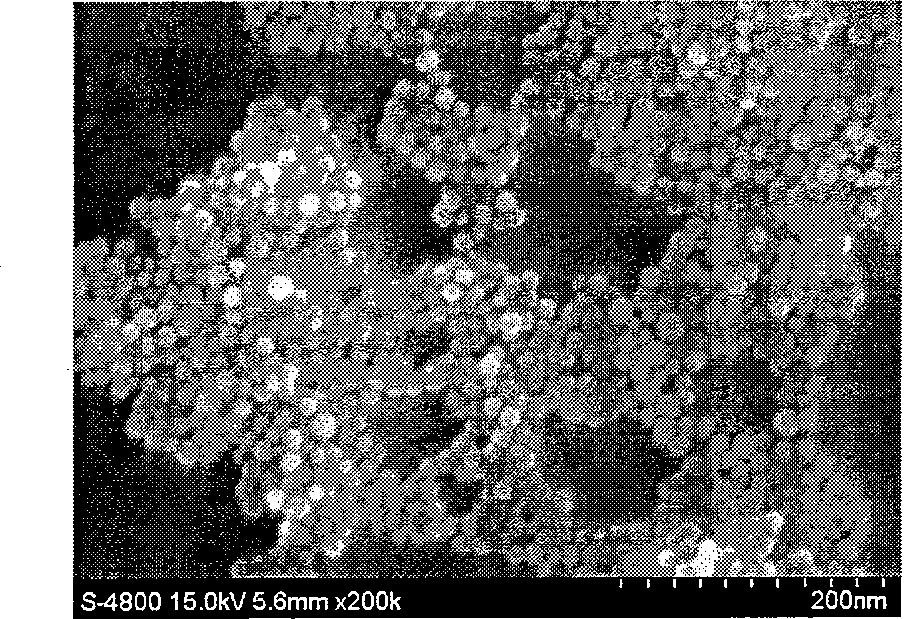

[0044] Using [OMIM][BF 4 ] Synthesis of NaYF from Ionic Liquids 4 : Yb, Er nanocrystals.

[0045] (1) Weigh 0.2985 grams of Y (NO 3 ) 3 ·6H 2 O, 0.093 g Yb (NO 3 ) 3 ·6H 2 O, 0.0092 g Er(NO 3 ) 3 ·6H 2 O, the molar ratio of rare earth ions in the mixed solid is yttrium ion: ytterbium ion: erbium ion is equal to 78:20:2.

[0046] (2) Add 4 ml of 1-octyl-3-methylimidazolium tetrafluoroboric acid ([OMIM][BF 4 ]) ionic liquid, heated at 150° C. with vigorous stirring for 20 minutes.

[0047] (3) Weigh 0.058 g of NaCl and add it into the above mixed solution, and continue to stir for 30 minutes, so that the rare earth nitrate and NaCl are fully dissolved in the ionic liquid.

[0048] (4) Put the mixed solution obtained in step (3) into a polytetrafluoroethylene-lined autoclave, place it in an oven, heat it at 180° C. for 18 hours, and cool it down to room temperature naturally.

[0049] (5) The precipitate was separated by centrifugation and ultrasonically washed three...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com