Patents

Literature

520results about "Wax adhesives" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hot melt adhesive compositions including olefinic polymer blends and articles including the same

A hot melt adhesive composition that includes a non functionalized amorphous poly alpha olefin polymer, a second polymer selected from the group including polypropylene homopolymers, polypropylene copolymers and combinations there of, a functionalized wax and a second wax.

Owner:HB FULLER CO

Adhesive alpha-olefin inter-polymers

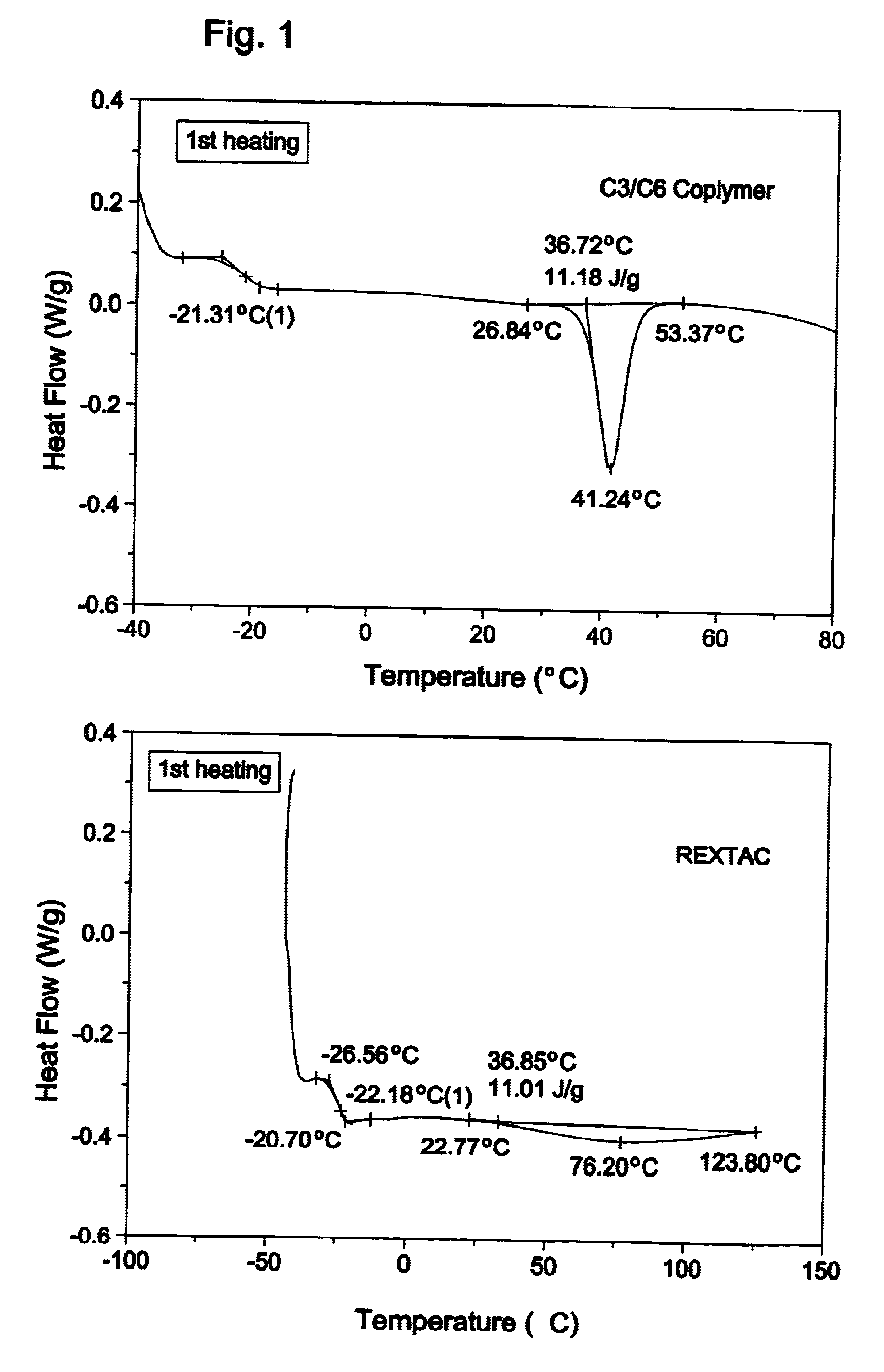

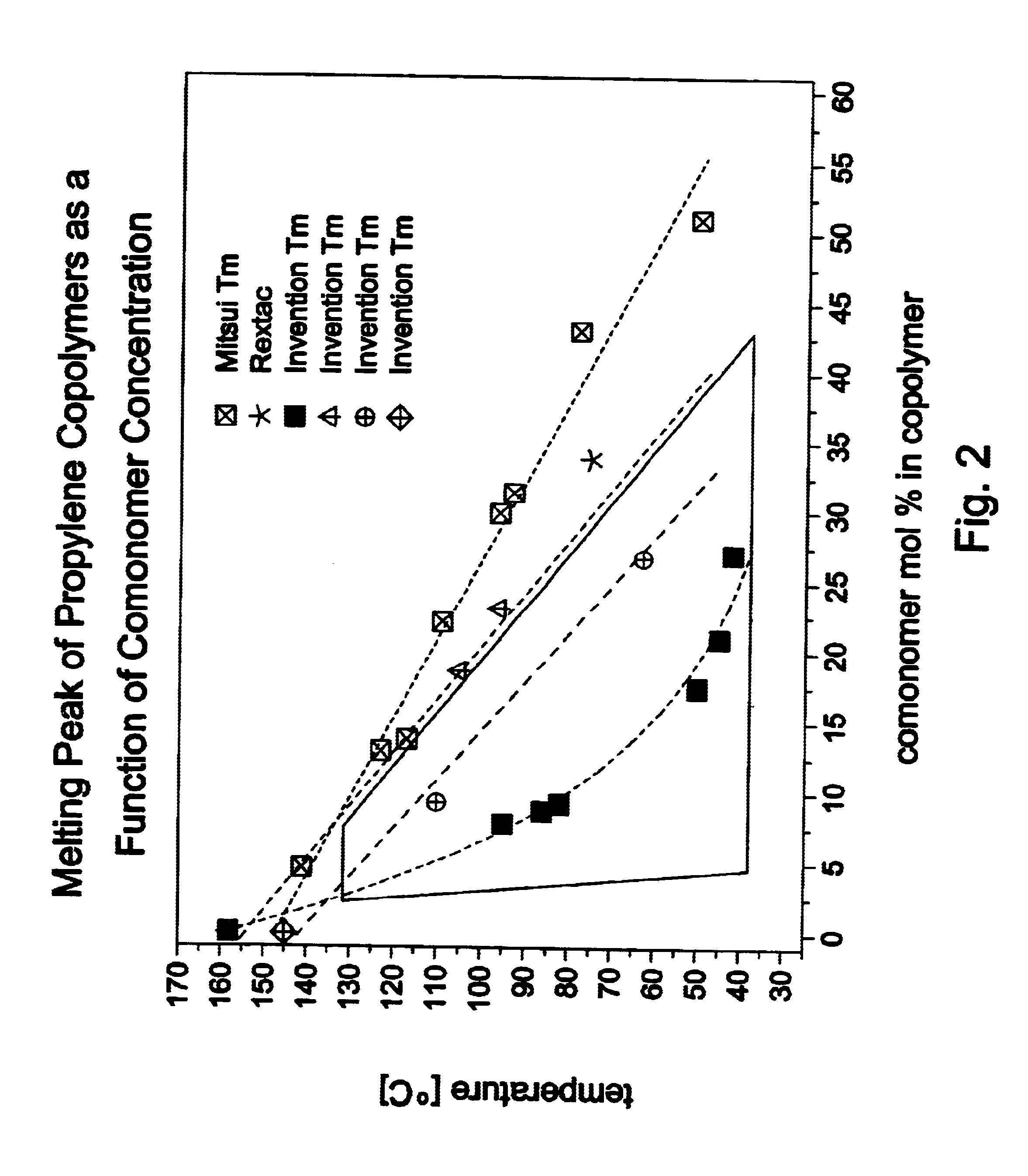

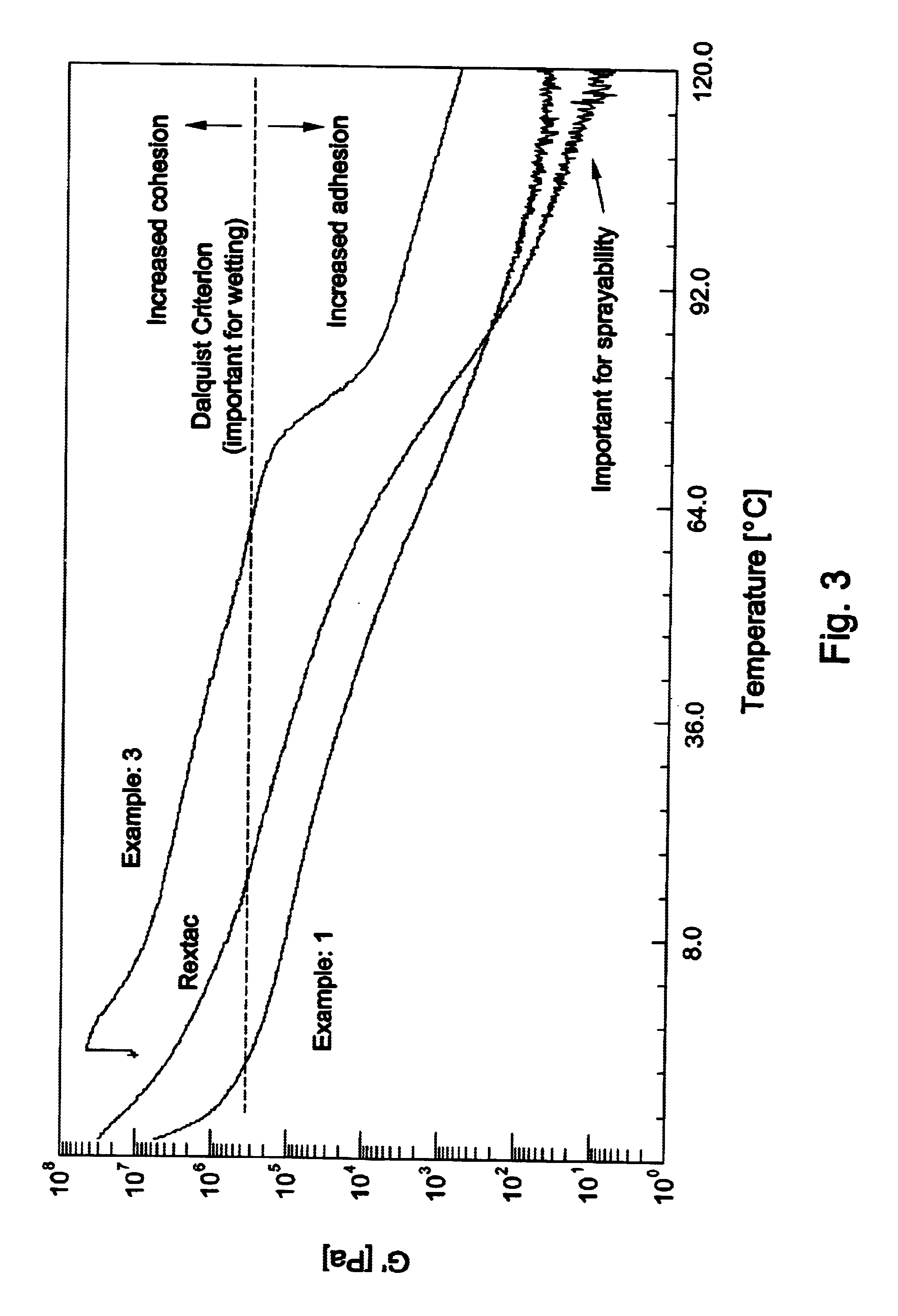

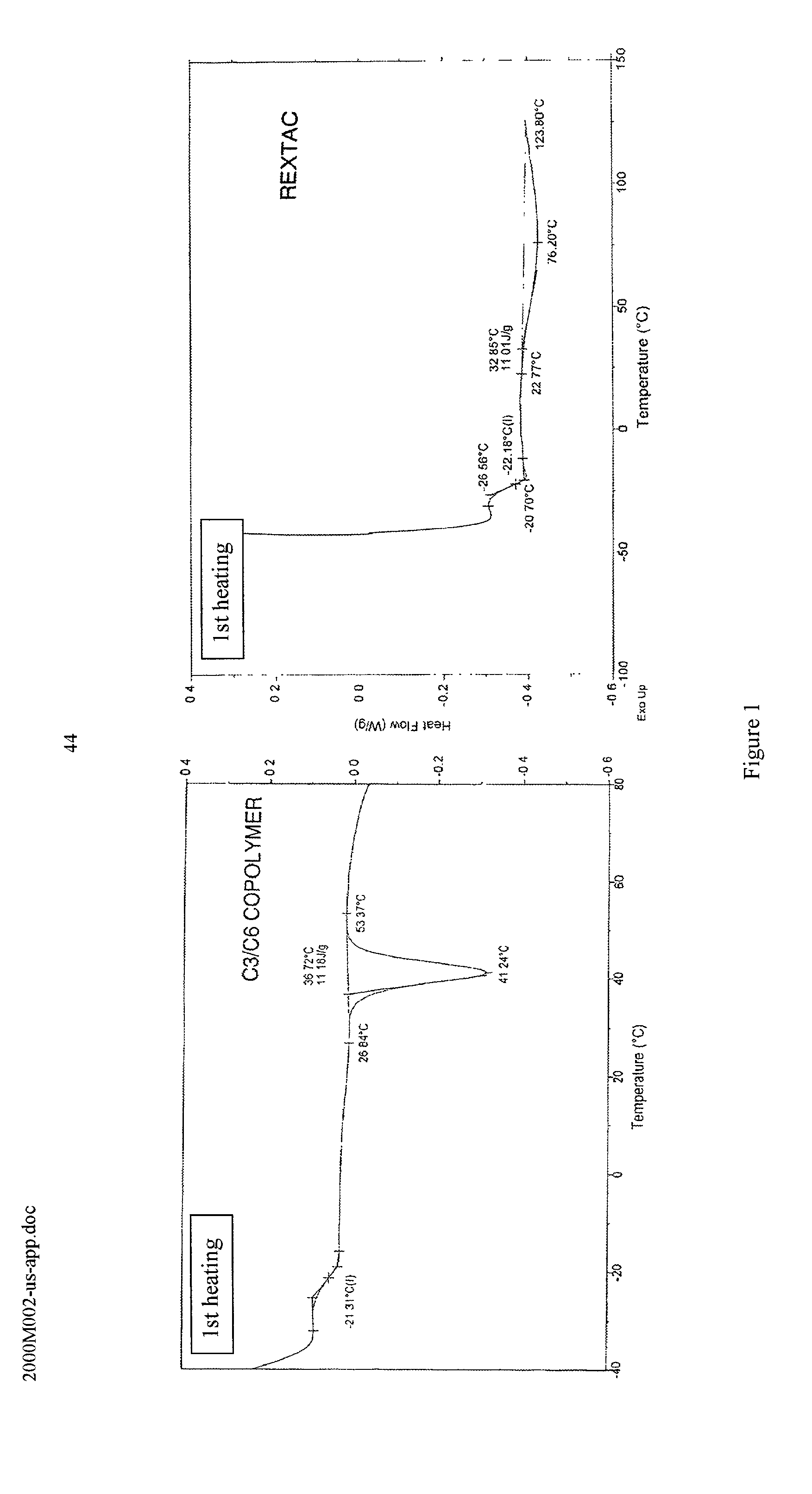

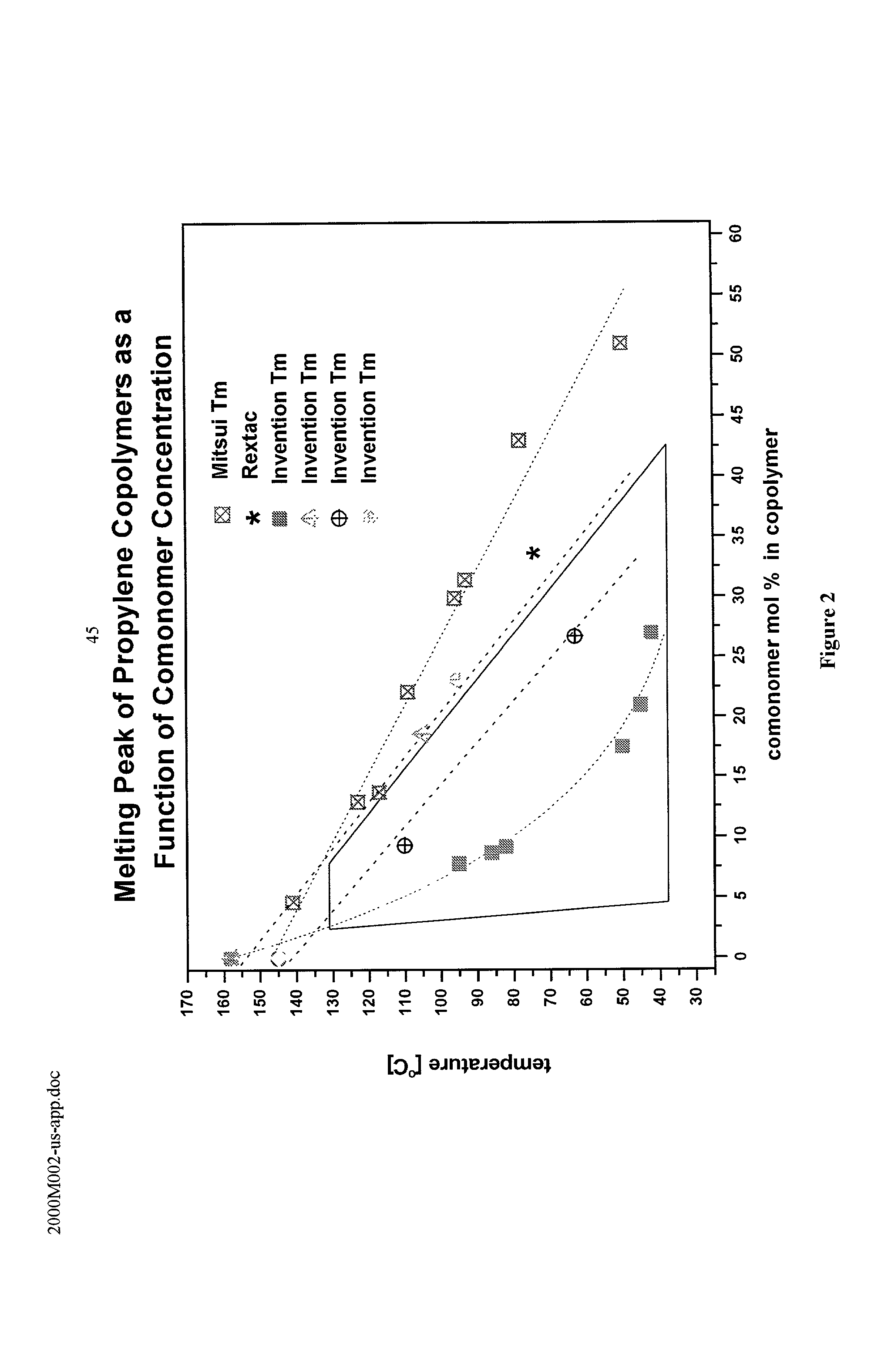

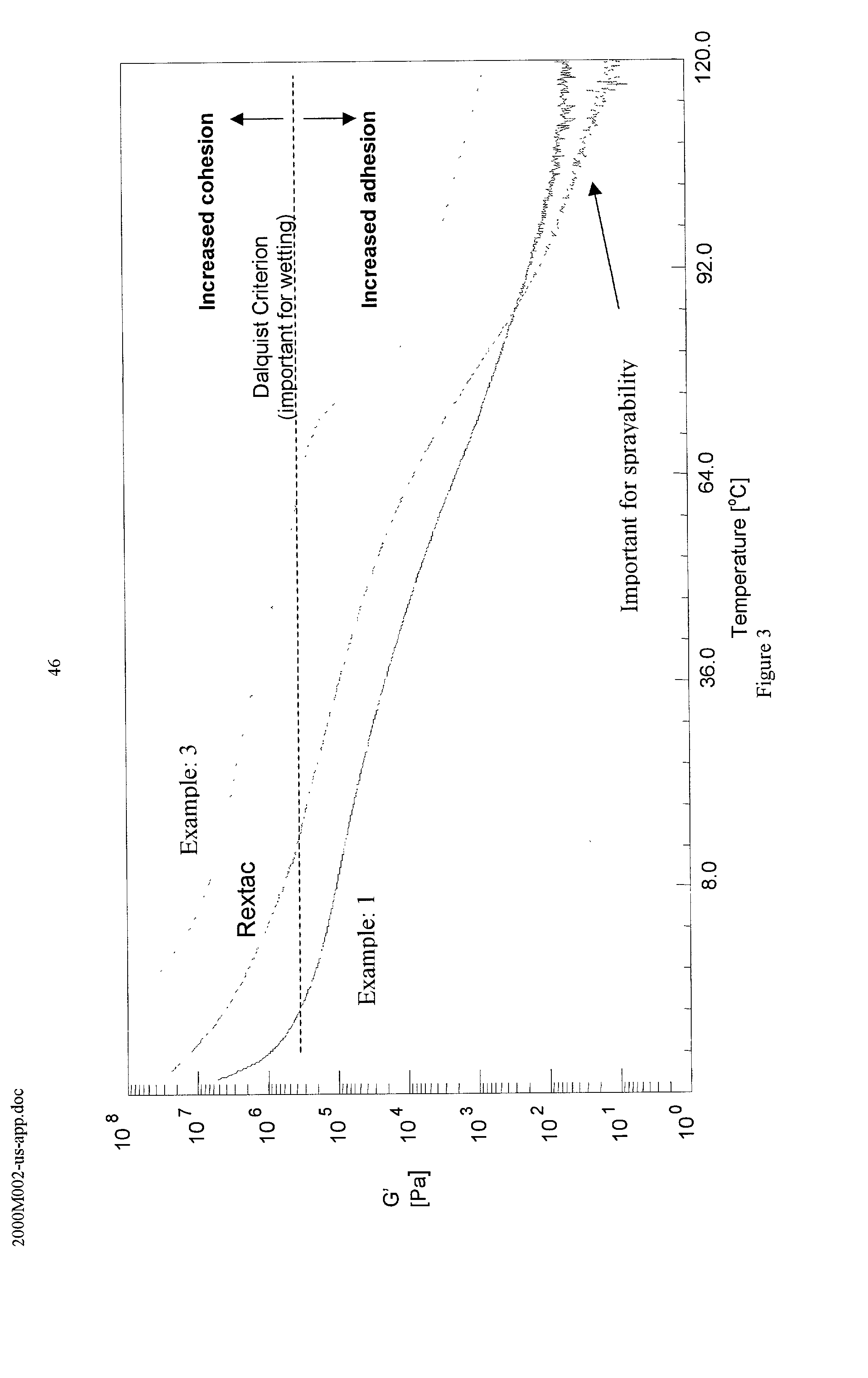

The invention relates to novel adhesive alpha-olefin inter-polymers which are largely amorphous and have a rheological behavior that makes them suitable for adhesive use, both without and with minimized amounts of tackifying resins. Specifically, the invention poly-alpha olefin inter-polymer may be composed of A) from 60 to 94 mol % of units derived from one alpha mono-olefin having from 3 to 6 carbon atoms and B) from 6 to 40 mol % of units derived from one or more other mono-olefins having from 4 to 10 carbon atoms and at least one carbon atom more than A); and C) optionally from 0 to 10 mol % of units derived from another copolymerizable unsaturated hydrocarbon, different from A) and B); the diad distribution of component A in the polymer as determined by <13>C NMR as described herein showing a ratio of experimentally determined diad distribution over the calculated Bernoullian diad distribution of less than 1.07; and the storage modulus G' of said polymer, determined upon cooling as described herein, intersecting a value of 3.10<5 >Pa at a temperature of less than 85° C. The invention also describes polymerization processes suitable for the manufacture of these adhesive alpha-olefin inter-polymers.

Owner:EXXONMOBIL CHEM PAT INC

Adhesive alpha-olefin inter-polymers

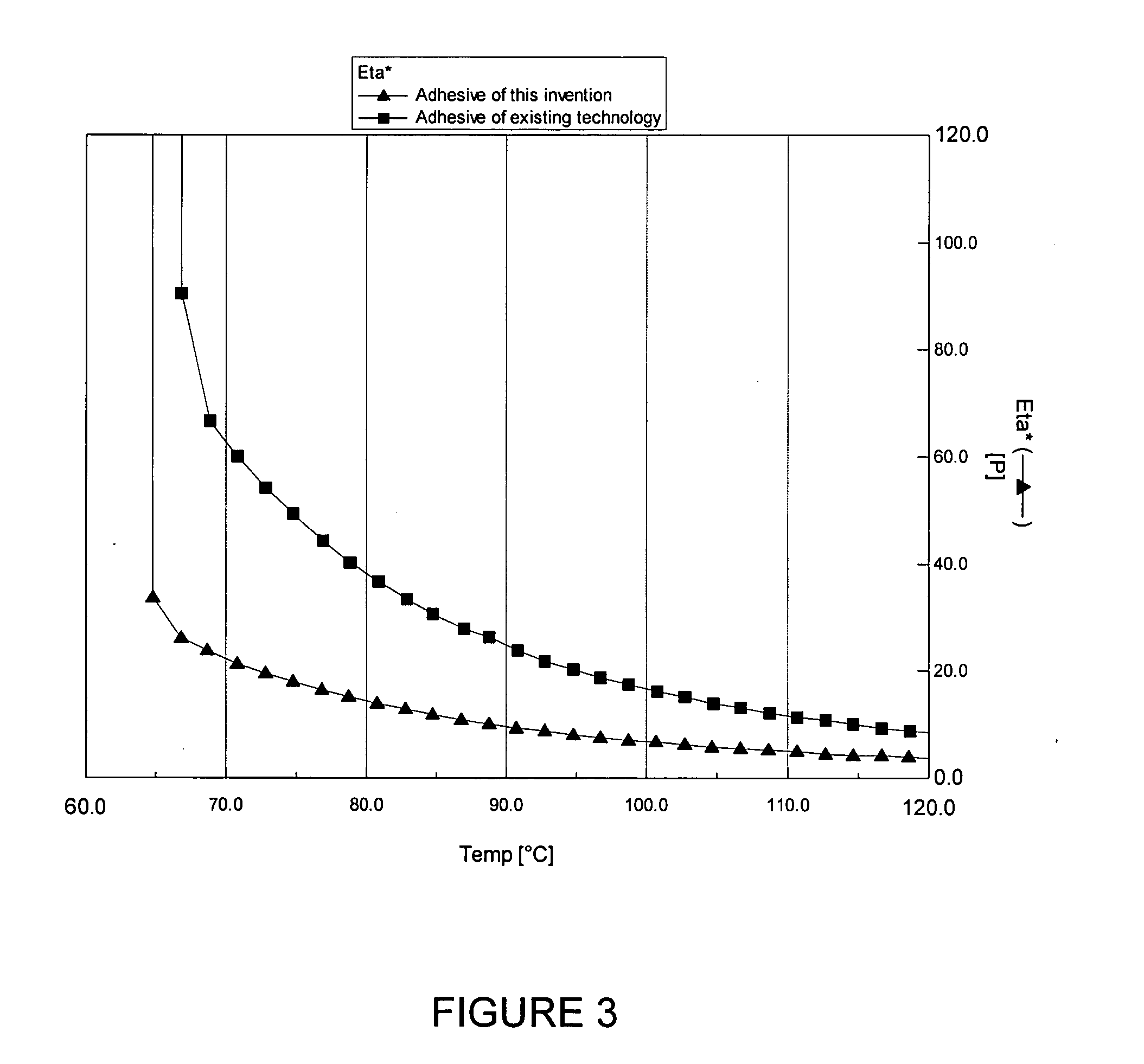

InactiveUS20020007033A1Minimize adverse interactionHigh activityWax adhesivesPolymer scienceUnsaturated hydrocarbon

The invention relates to novel adhesive alpha-olefin inter-polymers which are largely amorphous and have a Theological behavior that makes them suitable for adhesive use, both without and with minimzed amounts of tackifying resins. Specifically, the invention poly-alpha olefin inter-polymer may be composed of A) from 60 to 94 % of units derived from one alpha mono-olefin having from 3 to 6 carbon atoms and B) from 6 to 40 mol % of units derived from one or more other mono-olefins having from 4 to 10 carbon atoms and at least one carbon atom more than A); and C) optionally from 0 to 10 mol % of units derived from another copolymerizable unsaturated hydrocarbon, different from A) and B); the diad distribution of component A in the polymer as determined by 13C NMR as described herein showing a ratio of experimentally determined diad distribution over the calculated Bernoullian diad distribution of less than 1.07; and the storage modulus G' of said polymer, determined upon cooling as described herein, intersecting a value of 3.105 Pa at a temperature of less than 85 ° C. The invention also describes polymerization processes suitable for the manufacture of these adhesive alpha-olefin inter-polymers.

Owner:EXXONMOBIL CHEM PAT INC

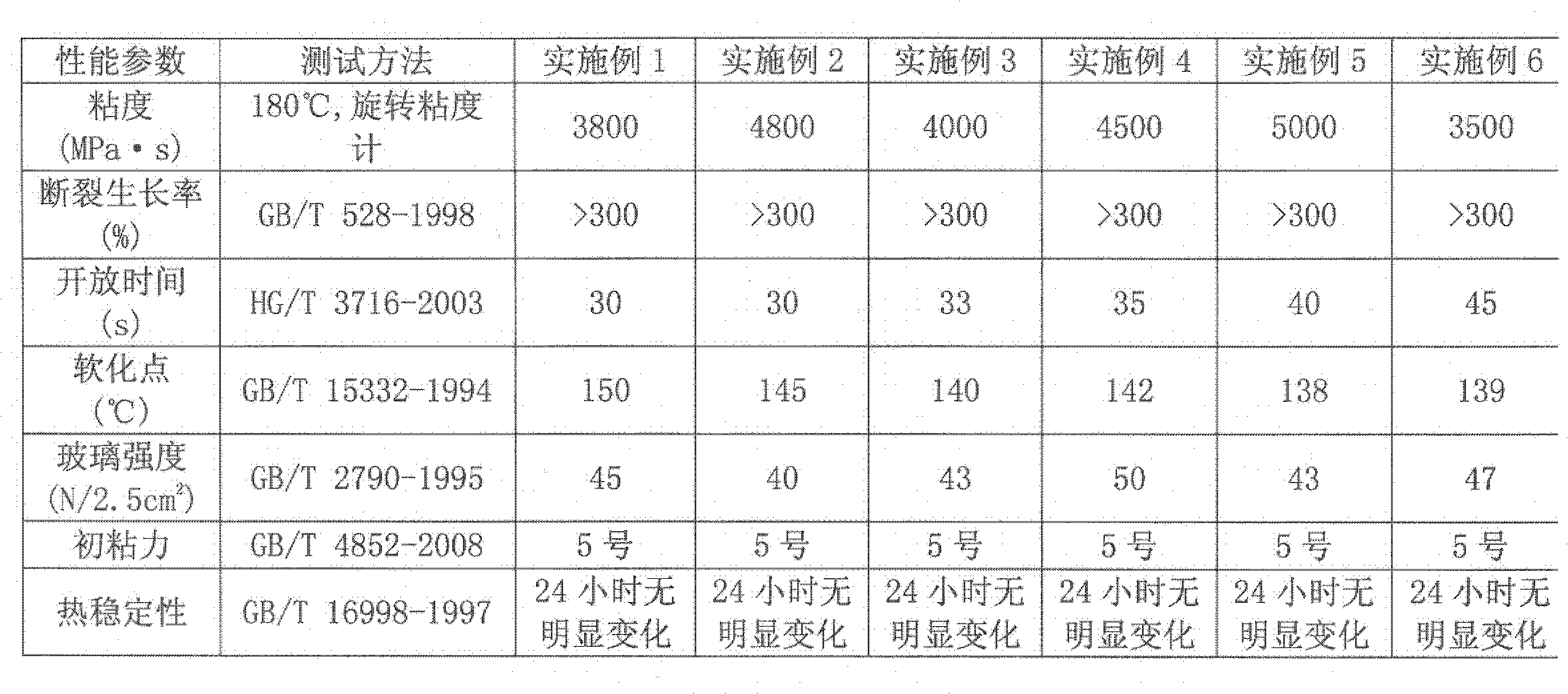

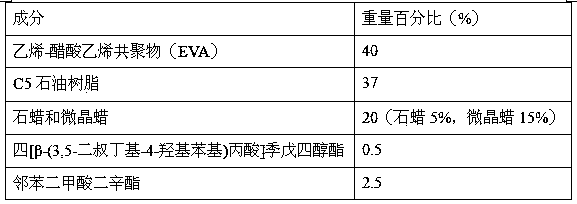

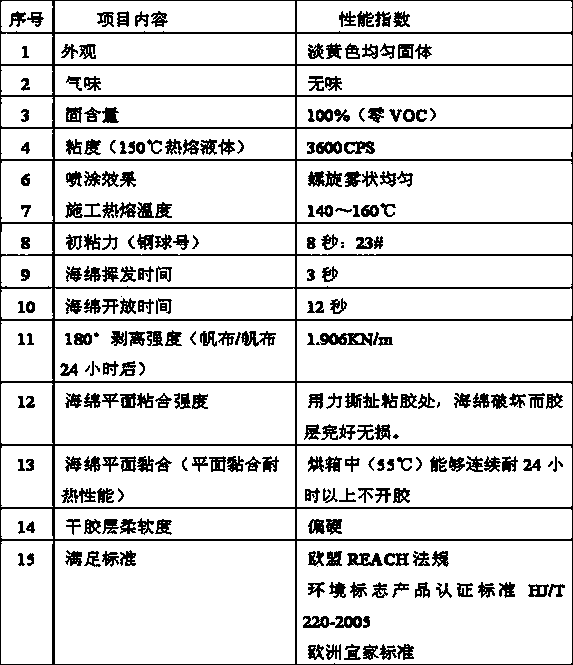

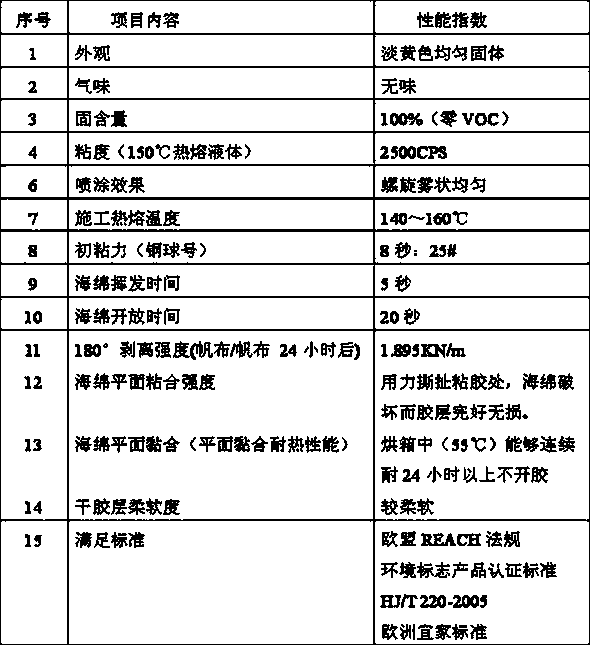

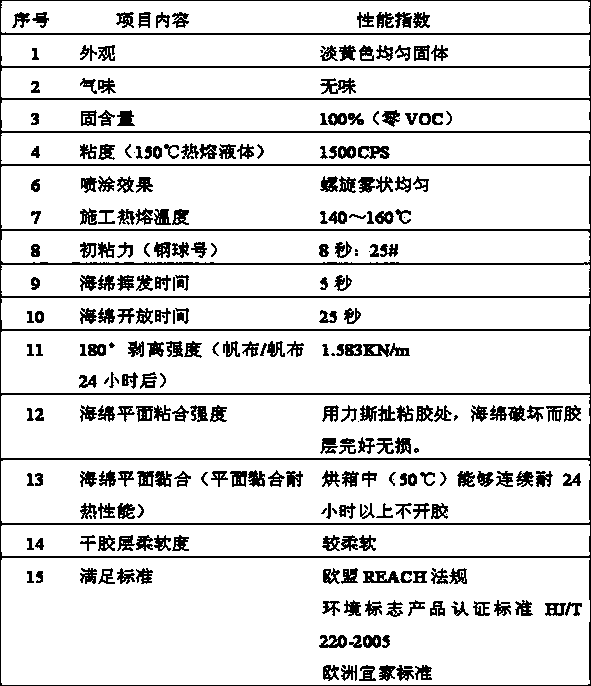

Hot melt adhesive used for automotive interiors, and preparation method of hot melt adhesive

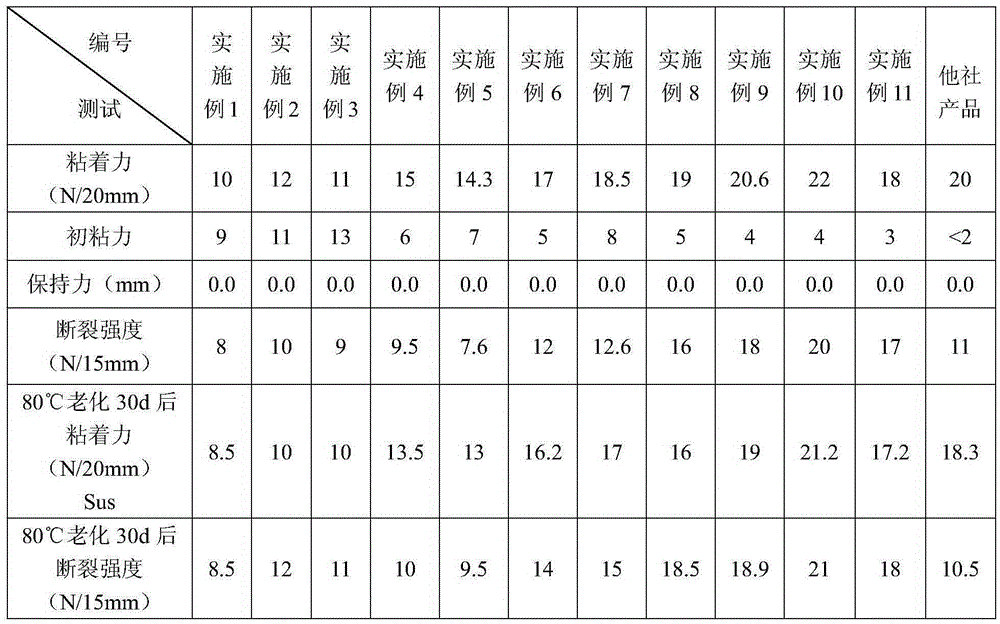

InactiveCN102618211AHarmless to healthHigh bonding strengthWax adhesivesNatural resin adhesivesPolyethylene vinyl acetateParaffin wax

The invention discloses a hot melt adhesive used for automotive interiors, and a preparation method of the hot melt adhesive. The hot melt adhesive used for automotive interiors is characterized by comprising a proportion of paraffin, polyethylene wax, a thermoplastic elastic body SBS, random polyolefin, polyethylene vinyl acetate, C5 petroleum resin, rosin pentaerythritol ester, antioxygen, coupling agent and filler. The preparation method comprising the following steps: heating a stirring kettle to 140 to 160 DEG C, and adding the paraffin and the polyethylene wax; adding the thermoplastic elastic body SBS, vacuum-pumping and keeping warm, adding HMW(high molecular weight) random polyolefin I, HMW random polyolefin II and the antioxygen; adding the coupling agent and the filler; cooling, and adding polyethylene vinyl acetate I and polyethylene vinyl acetate II; cooling and adding the C5 petroleum resin; adding the rosin pentaerythritol ester and keeping warm; and emptying the stirring kettle, pressurizing, discharging and forming. No pollution or poison is produced during the production process of the hot melt adhesive; and the hot melt adhesive has the advantages of high adhesion strength, long opening time, good temperature resistance, strong ageing resistance, good tenacity, strong waterproofness and the like.

Owner:浙江固特新材料科技股份有限公司

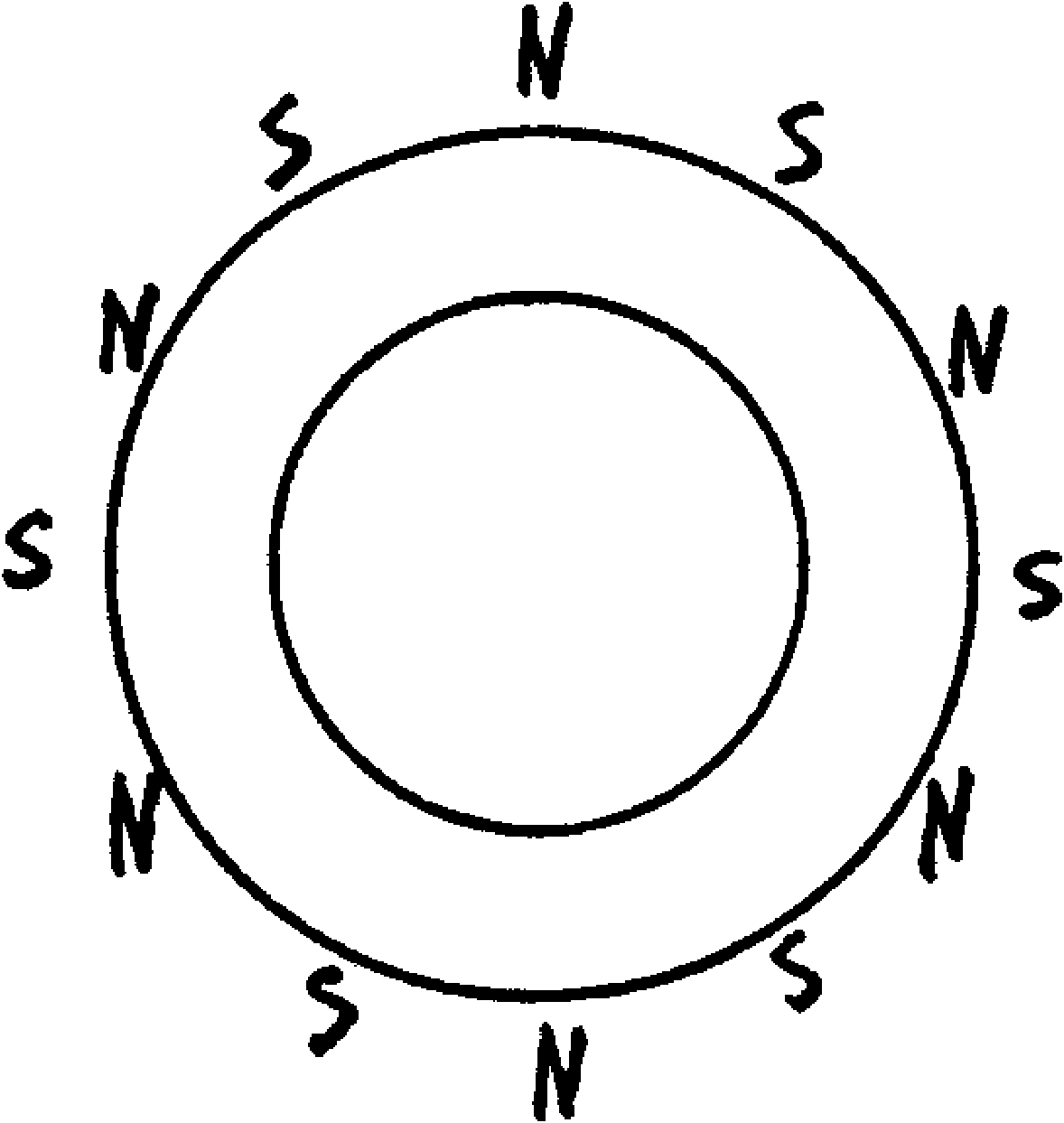

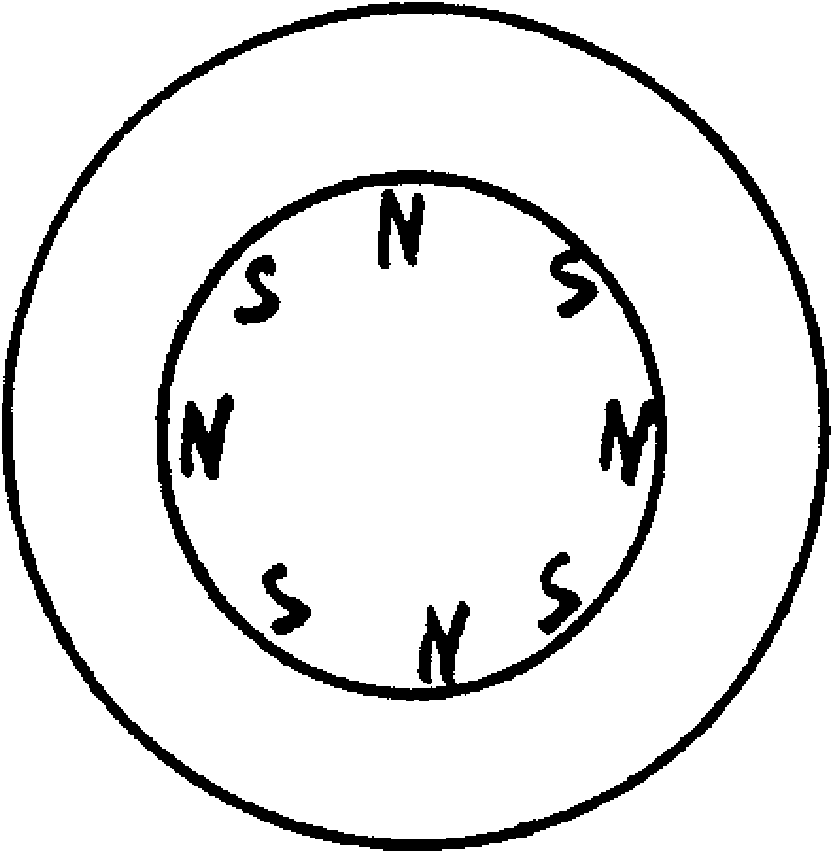

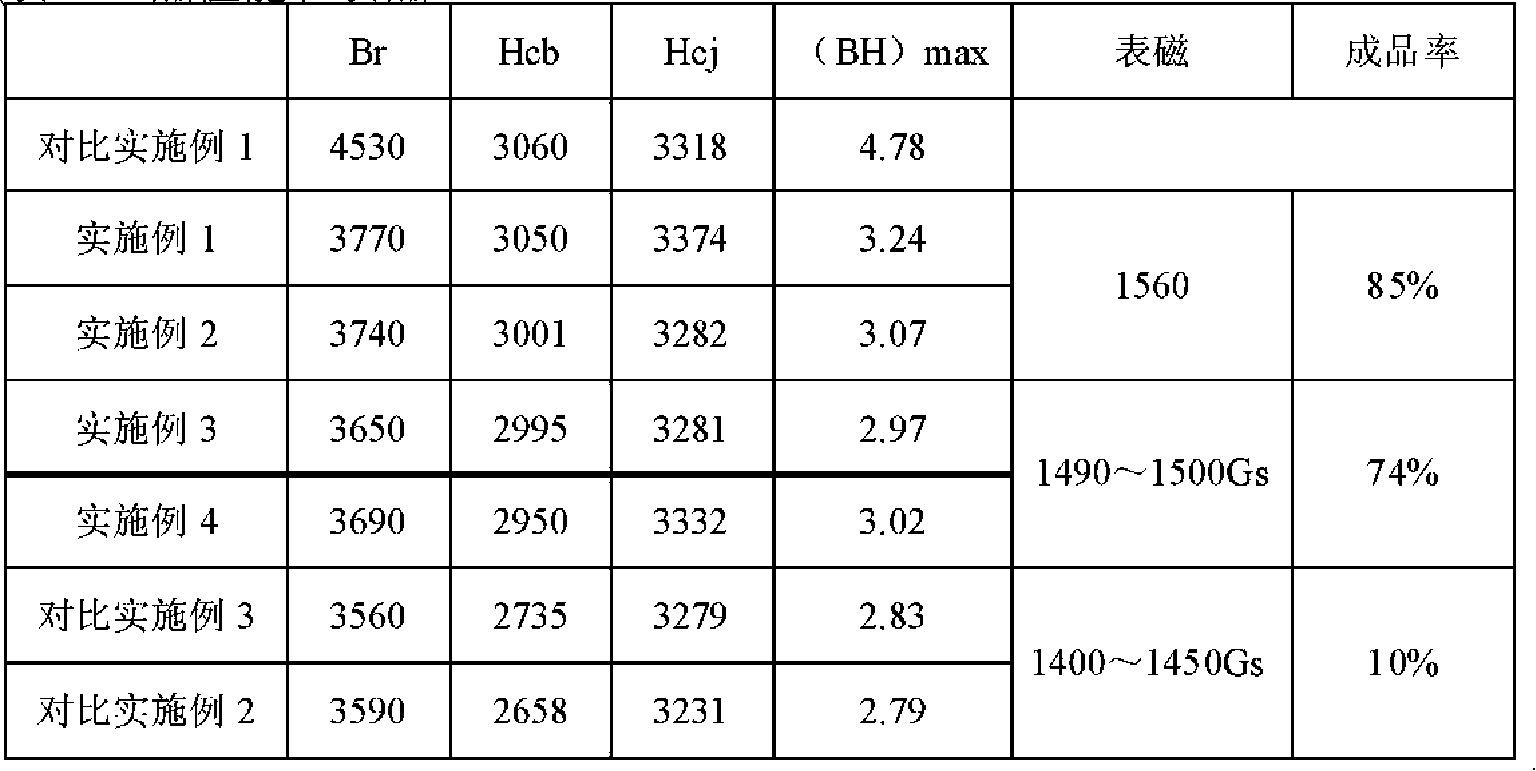

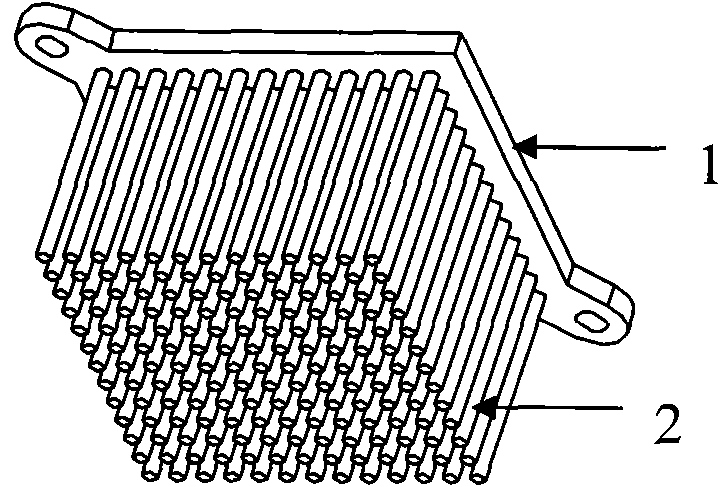

Method for manufacturing anisotropic multi-pole magnetic ring through dry-press forming

ActiveCN101599333AGood orientationWell formedCellulose derivative adhesivesWax adhesivesMetallurgyMagnetization

The invention relates to the field of magnetic materials, in particular to a method for manufacturing an anisotropic multi-pole magnetic ring through dry-press forming. Aiming at the problem that the multi-pole magnetic ring manufactured by the prior art through the dry-press forming is easy to crack, has low yield and the like, the invention provides the method for manufacturing the anisotropic multi-pole magnetic ring through the dry-press forming, and for the multi-pole magnetic ring manufactured by the method, the surface magnetism is more than 1,500 Gs, the Br is more than 3,600 Gs, and the Hcb is more than 3,000 Oe. The aim of the invention is achieved through the following technical proposal: performing wet method pulverization on magnetic powder; adding more than one binding agent and lubricating agent into the magnetic powder which is dried; then performing prepressing and pre-magnetization on the mixture, and then performing a mixing process for mixing the mixture by using a high-speed disintegrator; performing a double-sided equal pressure forming process on the powder in a radial magnetic field; and performing a sintering process for sintering the formed sample, wherein the magnetic powder contains a pre-sintering material and an additive.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

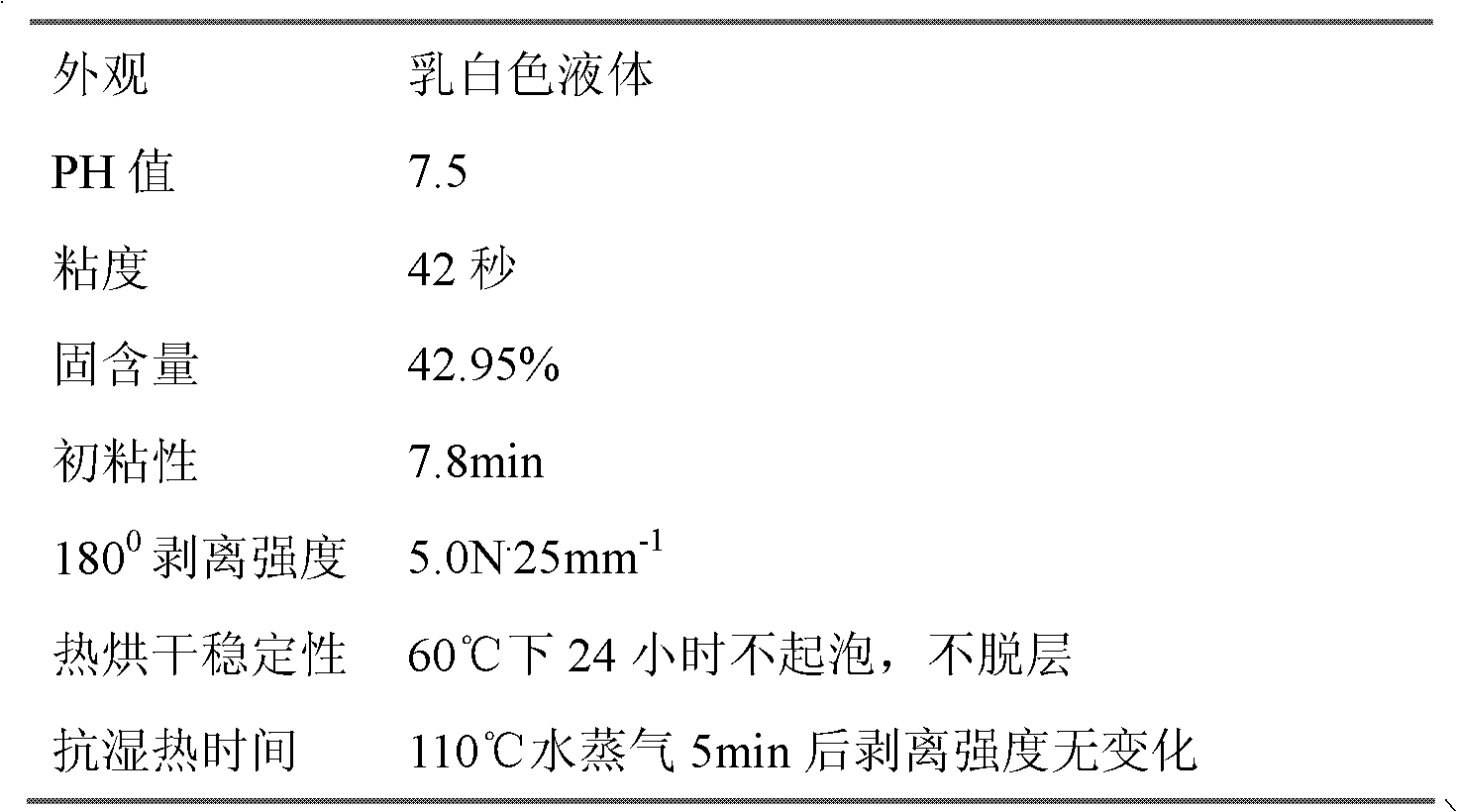

High-temperature-resistant paper-plastic laminating adhesive and preparation method thereof

InactiveCN102433087AImprove high temperature resistanceNon-macromolecular adhesive additivesWax adhesivesCross-linkPolymer science

The invention discloses a preparation method of a high-temperature-resistant paper-plastic laminating adhesive. To calculate by mass percent, the high-temperature-resistant paper-plastic laminating adhesive consists of the following components by mass percent: 60-90 of composite emulsion, 1-15 of vinyl acetate ethylene (VAE) emulsion, 1-15 of tackifying resin, 1-10 of inorganic powder filler, 1-10 of cross-linking agent, 0.2-0.5 of antifoaming agent and 0.2-0.5 of thickening agent. Firstly the composite emulsion of ethylene vinyl acetate (EVA) resin and mixed wax is prepared, then the emulsion is built up with the VAE emulsion, the antifoaming agent, the inorganic powder filler, the tackifying resin, the cross-linking agent and the thickening agent, and finally the high-temperature-resistant paper-plastic laminating adhesive is prepared. The product has the advantages of high-temperature resistance, high initial adhesive force, high peeling strength and high water resistance. After paper and plastic are separated, the bonding surface is dry, paper scraps are not stuck and an adhesive film has a transfer printing effect.

Owner:SOUTH CHINA UNIV OF TECH

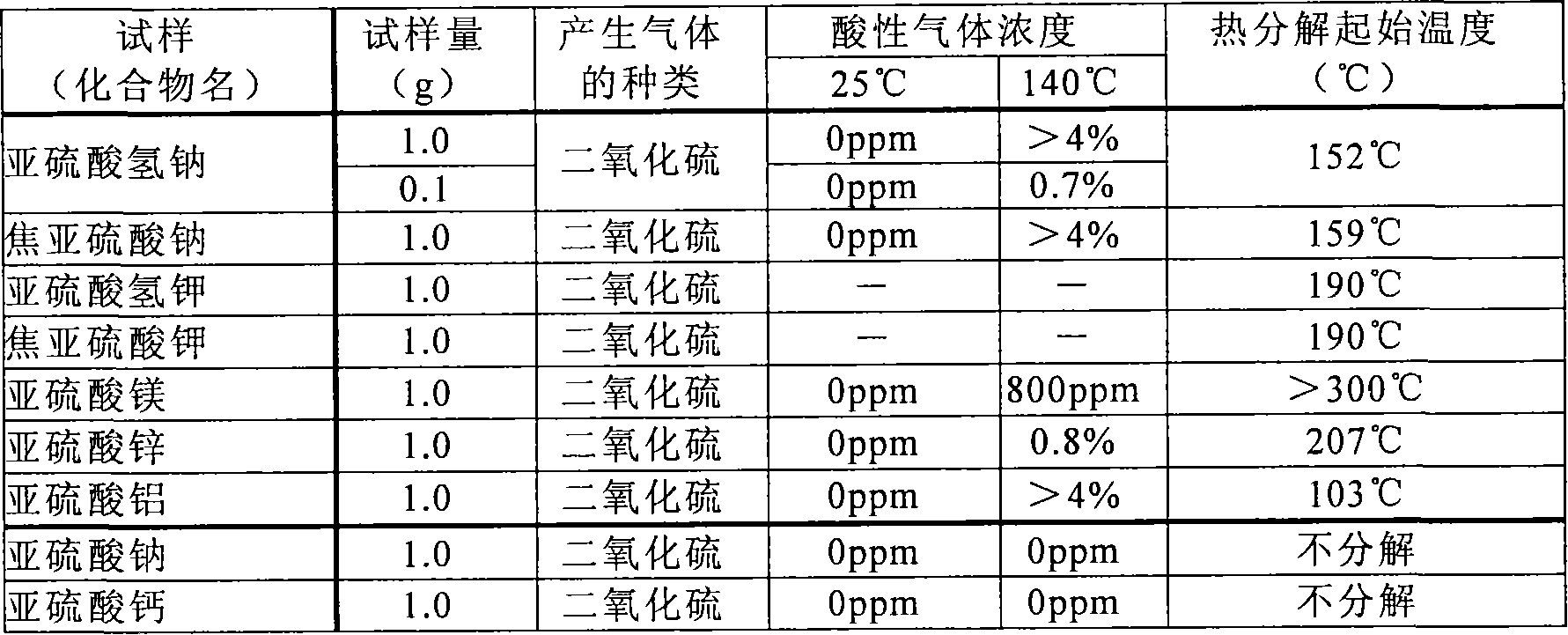

Scavenger for aldehyde(s) and a manufacturing method of a woody panel using the same

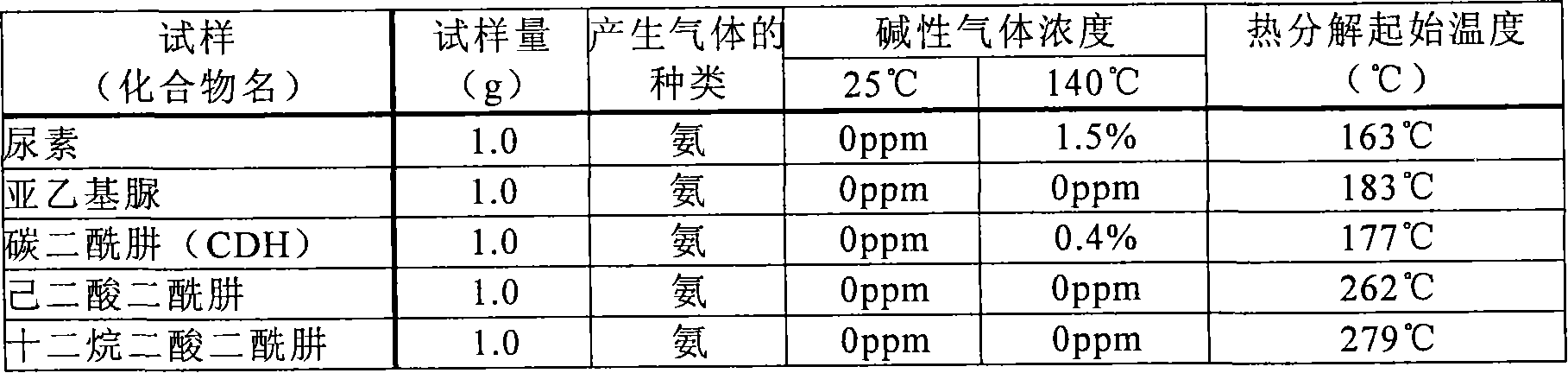

InactiveUS20090130474A1Ease of evaluationImprove trapping efficiencyOrganic chemistrySulfate/bisulfate preparationScavengerRoom temperature

Regarding the scavenger for aldehyde(s) used at the time of manufacturing a woody panel using woody materials and formaldehyde-based binders, the scavenger for aldehyde(s) without lowering of trapping properly even when a surface of said woody panel is sanded and having an excellent trapping property of trapping formaldehyde is provided. Further, the method of manufacturing a woody panel using a scavenger for aldehyde(s) and a woody panel are provided.At least one kind of compound for trapping aldehyde(s) being solid at a room temperature is included and said compound for trapping aldehyde(s) is defined to be a powdery scavenger for aldehyde(s) having a property of generating acidic gas, in particular, sulfurous acid gas by heating and said compound for trapping aldehyde(s) is added to a binder or woody materials followed by a hot press, thereby manufacturing a woody panel.

Owner:IPPOSHA OIL INDS

Hot melt adhesive

InactiveUS20050003197A1High melting pointEnergy efficiencyLamination ancillary operationsFilm/foil adhesivesPolymer scienceHot-melt adhesive

Owner:HENKEL KGAA

Composition and method relating to a hot melt adhesive

The present invention includes compositions relating to a hot melt adhesive that includes a copolymer of butene-1, a wax, and a tackifying resin. The present invention further relates to adhesives initially exhibiting adhesion properties and subsequently non-adhesion qualities. Methods of using these adhesives are also part of the claimed invention.

Owner:HB FULLER CO

Transfer tape

ActiveCN105400440AEasy to operateImprove adhesion strengthMineral oil hydrocarbon copolymer adhesivesNatural rubber adhesivesElastomerUltimate tensile strength

The invention provides a transfer tape which comprises an adhesive layer with the thickness of 80-800 [mu]m, wherein raw materials for preparation of the adhesive layer comprises the following components in parts by weight: 40-50 parts of rubber elastomer, 50-60 parts of tackifying resin, 0-5 parts of a softening agent, 0-5 parts of a plasticizing agent, 1-10 parts of an antioxygen and 0-5 parts of color paste. The transfer tape has the characteristics of being large in sticking strength and long in fixing of the common double-sided adhesive tape, and can be moved only by being pulled out by 0-60 degree when an electronic product is disassembled in maintenance, and so that not only damage to electronic devices of battery and the like in maintenance is avoided, but also great convenience is brought to maintenance personnel.

Owner:NINGBO KELAIEN NEW MATERIAL TECH CO LTD

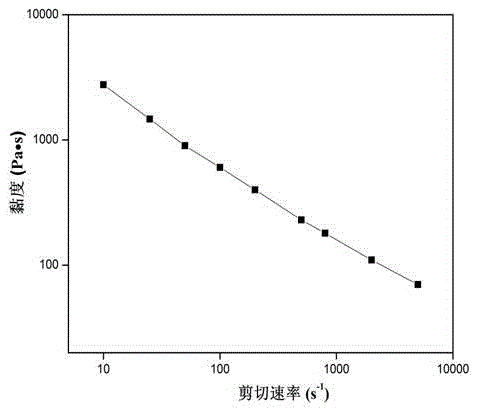

Adhesive and feeding material prepared thereby for metal powder injection molding

InactiveCN101235265AAvoid easy separationHigh strengthNon-macromolecular adhesive additivesWax adhesivesHigh densityVolumetric Mass Density

The invention relates to the metal powder injection forming field, in particular to binding agent and feeding which is used for the metal powder injection forming which is prepared. The binding agent comprises thermoplastic elastic compounded rubber, industrial paraffin, high density polythene HDPE, propene polymer PP and geoceric acid, and the feeding is prepared through procedures of mixing according to material ratio, heating extrusion, cooling disintegration and vacuum packaging and the like. And the effects of the invention are the the solid loadage of feeding is over 60%, liquid and solid are not easy to be separated when in forming, the sticky point technology is simple, cost is low, sticky blank point height is high, sintering blank density is high and the product price is lower.

Owner:王明喜

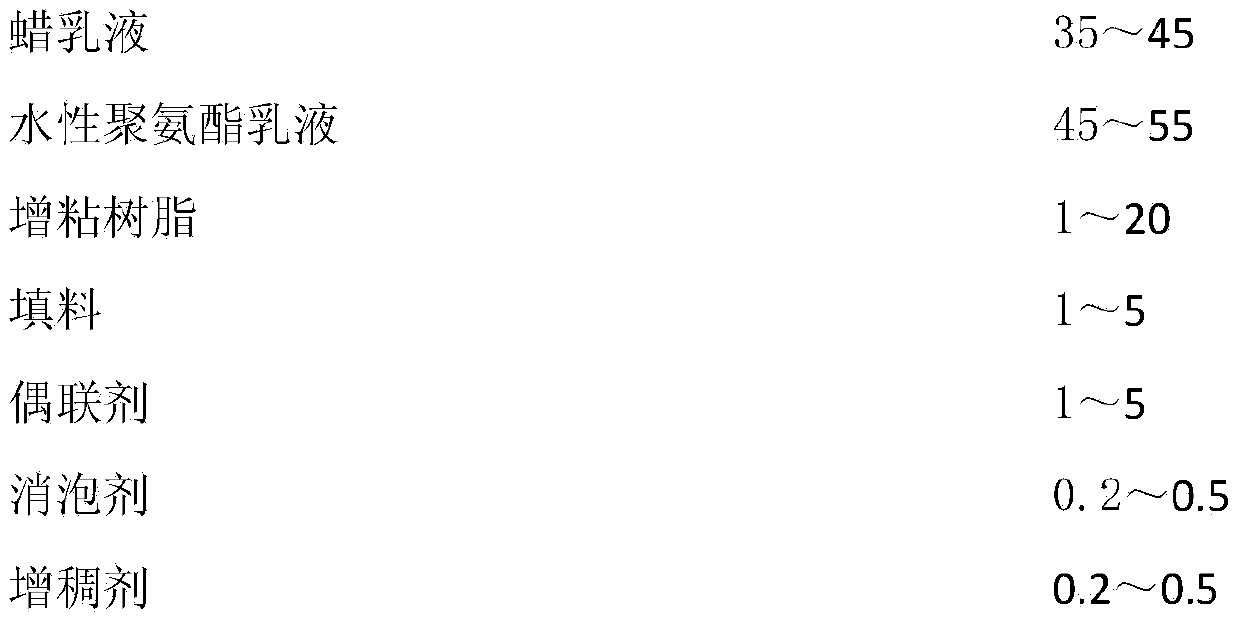

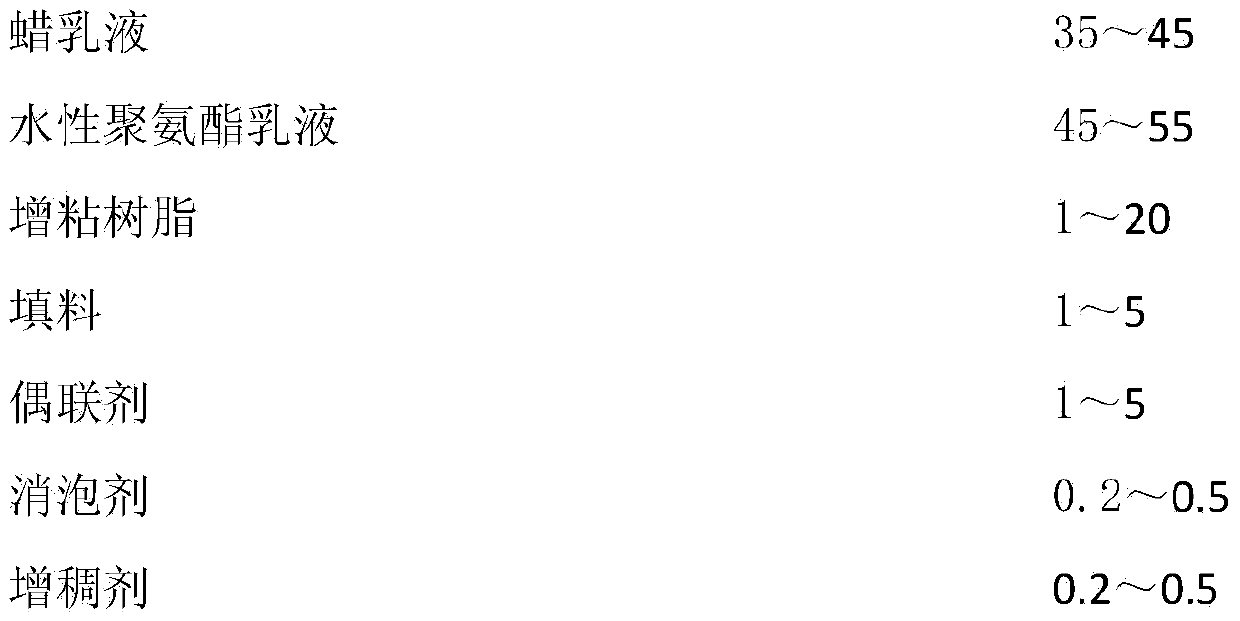

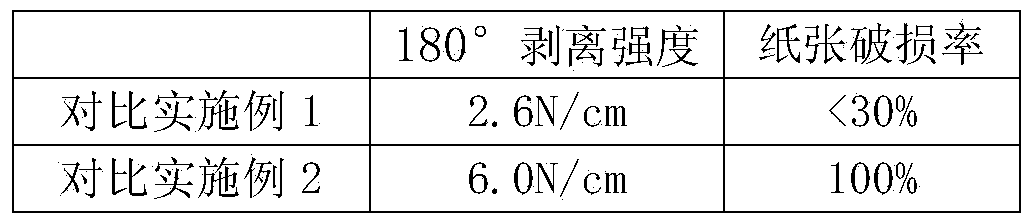

Water-based paper and plastic laminating/peelable adhesive and method for manufacturing same

InactiveCN103421461AGood adhesionAdhesivelyNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesWaxWater based

The invention discloses water-based paper and plastic laminating / peelable adhesive and a method for manufacturing the same. The water-based paper and plastic laminating / peelable adhesive comprises, by mass, 35-45 parts of wax emulsion, 45-55 parts of water-based polyurethane emulsion, 1-20 parts of tackifying resin, 1-5 parts of additives, 1-5 parts of coupling agents, 0.2-0.5 part of defoamers and 0.2-0.5 part of thickeners. The water-based paper and plastic laminating / peelable adhesive and the method have the advantages that the wax emulsion, the water-based polyurethane emulsion, the additives, the tackifying resin, the coupling agents, the thickeners and the defoamers are compounded with one another to finally manufacture the water-based paper and plastic laminating / peelable adhesive, the water-based paper and plastic laminating / peelable adhesive is high-temperature-resistant and is high in initial adhesion, permanent adhesion and peel strength when used for laminating paper and plastics, the paper cannot be torn by an adhesion surface of a film when separated from the plastics, and is prevented from being damaged, and the adhesion surface is not sticky after the paper is separated from the plastics.

Owner:SOUTH CHINA UNIV OF TECH

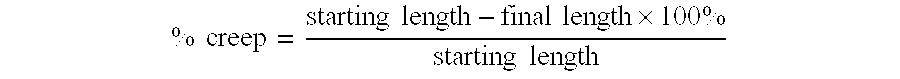

Low temperature hot melt adhesives for disposable articles with high creep resistance

ActiveUS20130202787A1Improve stabilityThin applicationFilm/foil adhesivesWax adhesivesHigh resistanceHot melt

The present invention is directed to adhesives suitable for application using a hot melt process at a relatively low temperature in the range of about 110° C. to about 130° C. Such adhesives exhibit desirable viscoelastic properties and are suitable for bonding an elastic attachment in the manufacture of disposable articles, such as disposable diapers.

Owner:HENKEL KGAA +1

Petrolatum Containing Hot Melt Bottle Labeling Adhesive

InactiveUS20130090421A1Point becomes highHigh temperature resistanceFilm/foil adhesivesWax adhesivesHot meltHot-melt adhesive

A novel hot melt adhesive for bonding labels on plastic bottles is described. The adhesive comprises a blend of a styrenic block copolymer, an ethylene vinyl acetate copolymer, a tackifying resin, petrolatum and optionally a wax. The use of petrolatum instead of mineral oil provides for better elevated temperature resistance than traditional formulations.

Owner:BOSTIK INC

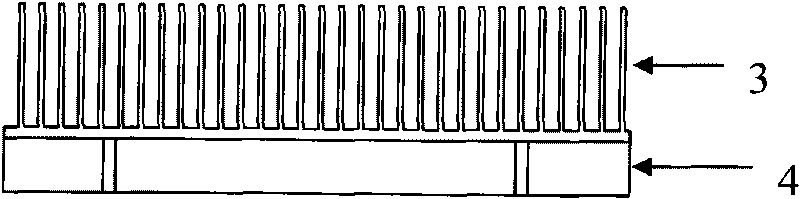

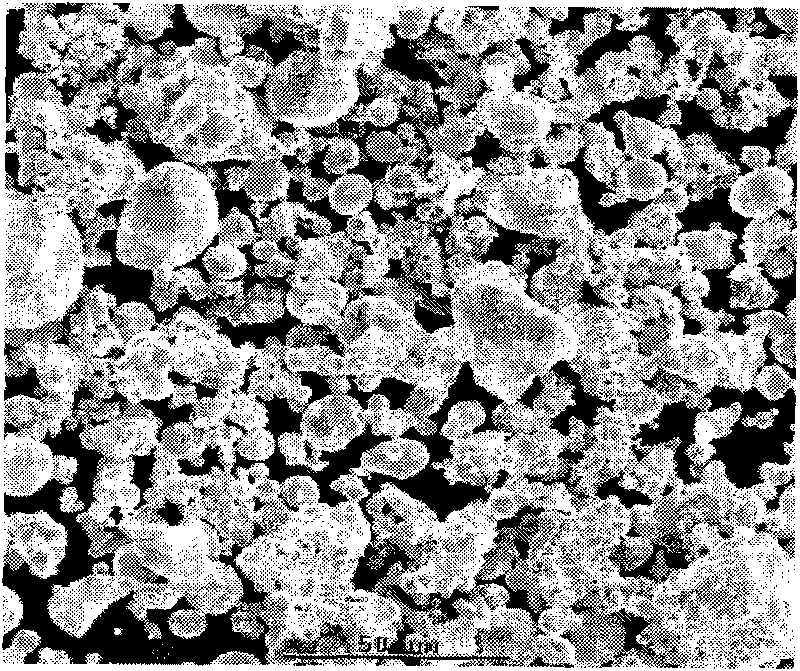

Method for preparing gradient-structure copper radiating rib for electronic element

ActiveCN101712115AIncrease surface areaHigh thermal conductivityWax adhesivesCooling/ventilation/heating modificationsHeat sinkCopper

The invention discloses a method for preparing a gradient-structure copper radiating rib for electronic elements, and belongs to the technical field of powder metallurgy. The gradient-structure copper radiating rib for the electronic elements comprises a radiating part of the radiating rib and a base of the radiating rib, wherein the radiating part of the radiating rib is prepared by adopting the technology of metal powder injection molding, and the base of the radiating rib is prepared by adopting a machining method; the radiating part of the radiating rib and the base of the radiating rib are welded together to prepare the gradient-structure copper radiating rib for the electronic elements. The radiating part of the radiating rib prepared by adopting the method is made of a porous structure material of which the relative density is 50 to 96 percent, which is favorable for improving the superficial area and the radiating efficiency of the radiating rib obviously. The radiating efficiency of the gradient-structure copper radiating rib is 10 to 40 percent higher than that of a radiating rib of which the relative density is 99 percent, and the gradient-structure copper radiating rib fully embodies the high thermal conductivity of copper.

Owner:GRIMAT ENG INST CO LTD

Adhesive for powder injection forming and application method thereof

ActiveCN104559840AThe degreasing process is simple and easy to controlHigh degreasing efficiencyNon-macromolecular adhesive additivesWax adhesivesParaffin waxPolymer science

The invention discloses an adhesive for powder injection forming and a preparation method thereof. The adhesive comprises the following components in percentage by mass: 5-10% of liquid paraffin, 5-15% of naphthalene, 15-20% of solid paraffin, 10-20% of microcrystalline wax, 15-20% of carnauba wax, 15-30% of first high-molecular polymer, 10-20% of second high-molecular polymer and 1-5% of stearic acid. The first high-molecular polymer and second high-molecular polymer are selected from any two of polyethylene, polypropylene, polyacrylate and acrylonitrile-butadiene-styrene copolymer. The method comprises the following steps: after feeding materials of the adhesive, injecting a green compact, putting in a sintering furnace, and carrying out hot removal on the green compact in the furnace by heating to 600 DEG C at the rate of 2-5 DEG C / minute, thereby completely removing the adhesive; and heating for sintering according to the sintering technique, thereby obtaining the finished product. The adhesive has the advantages of simple and controllable degreasing process and high degreasing efficiency; and the degreasing process can not influence the quality of the green compact, and is clean and environment-friendly.

Owner:DONGGUAN HUAJING POWDER METALLURGY

Plastic-based binding agent and method for preparing powder injection molding green bodies through same

ActiveCN105482752AAvoid decompositionEasy to processNon-macromolecular adhesive additivesWax adhesivesAnoxomerStearic acid

The invention discloses a plastic-based binding agent and a method for preparing powder injection molding green bodies through the same. The plastic-based binding agent is prepared from, by weight, 75-88% of polyoxymethylene, 4-10% of modified polylactic resin, 3-10% of microcrystalline wax, 2-8% of pentaerythritol stearate, 1-10% of sebacic acid dibutyl ester and 0.5-2% of an antioxidant. The method for preparing powder injection molding green bodies through the plastic-based binding agent comprises the steps that metal or ceramic powder is preheated and stirred; the binding agent is added and banbury mixing is performed; after banbury mixing is performed, extrusion and pelleting are performed to obtain granular feed; injection molding of the granular feed is performed; green bodies obtained through injection molding are catalyzed and degreased through nitric acid, and the powder injection molding degreased green bodies are obtained. The adopted plastic-based binding agent is low in viscosity and good in flowing performance during injection molding, and the good mold filling capacity and the good green body stability are achieved; the plastic-based binding agent can be widely applied to the powder injection molding industry, and the plastic-based binding agent is particularly applicable to production of parts with the large draw ratio, small wall thickness, micro size and complex three-dimensional shapes.

Owner:广州有研粉体材料科技有限公司

Petrolatum containing hot melt bottle labeling adhesive

InactiveCN103946333AImprove performanceBonding without damageWax adhesivesRosin adhesivesWaxHot melt

A novel hot melt adhesive for bonding labels on plastic bottles is described. The adhesive comprises a blend of a styrenic block copolymer, an ethylene vinyl acetate copolymer, a tackifying resin, petrolatum and optionally a wax. The use of petrolatum instead of mineral oil provides for better elevated temperature resistance than traditional formulations.

Owner:BOSTIK INC

Hot-melt pressure-sensitive adhesive and preparation technology thereof

InactiveCN105694803APrevent agingEliminate oxidationNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesAntioxidantPlasticizer

The invention belongs to the technical field of synthetic adhesives and particularly relates to a hot-melt pressure-sensitive adhesive and a preparation technology thereof. The hot-melt pressure-sensitive adhesive is prepared from raw materials in percentage by mass as follows: 1%-5% of a TPU (thermoplastic polyurethane) elastomer, 10%-15% of hydrogenated SEBS (styrene-ethylene-butadiene styrene), 45%-55% of tackifying resin, 25%-35% of a plasticizer, 0-1% of solid filler and 0-0.5% of an antioxidant. The TPU elastomer is added and blended with SEBS for modification, a framework structure is formed, components such as the tackifying resin, the plasticizer, the solid filler, the antioxidant and the like are added, the problem of damp-heat aging of the adhesive due to seasonal change is solved, the preparation technology of the adhesive is explored, the production cycle is shortened, and energy consumption is reduced.

Owner:BINZHOU POLYTECHNIC

Methods for making lignocellulose composite products with oxidative binders and encapsulated catalyst

In some examples, one or more metal-containing catalysts and one or more waxes can be mixed or otherwise combined to produce an encapsulated catalyst composition. The wax can be at least partially coated on the metal-containing catalyst. A mixture of water and the wax can be agitated or otherwise mixed, and the metal-containing catalyst can be added to or otherwise combined with the water and wax mixture to produce a wax emulsified catalyst. A plurality of lignocellulose substrates, one or more oxidants, and the encapsulated catalyst composition can be mixed or otherwise combined to produce a lignocellulose binder mixture. The lignocellulose binder mixture can be heated to produce a composite product.

Owner:GEORGIA PACIFIC CHEM LLC

Rapid packing hot melt adhesive and preparation method thereof

ActiveCN103881618AMeet the production requirements with large temperature differencesShort curing timeMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesHot meltManufacturing line

The invention discloses a rapid packing hot melt adhesive and a preparation method thereof. The hot melt adhesive is used in a high speed sizing machine production line for straws and box sealing in food and beverage industrial packaging. The packing hot melt adhesive can be cured in short time, and has strong adhesive property and better tear resistance, thermal resistance, antioxidation, ageing resistance and ultraviolet resistance; furthermore, the hot melt adhesive product is applicable to wide temperature range, and the preparation method is simple, does not discharge pollutants or dust, does not generate pungent smell, and has good environmental protection performance.

Owner:GUANGZHOU TAISHENG BIOTECH

Aldehyde collector and manufacturing method of woody panel using it

InactiveCN101175832ABeautiful surfaceHigh (F☆☆☆☆ level) evaluationOther chemical processesWood treatment detailsAdhesiveSurface grinding

The present invention provides an aldehyde capture material to be used in producing plywood by using veneers and a formaldehyde adhesive, which is not lowered in the capturing power even when the resulting plywood is subjected to surface grinding and which exerts a high capturing power for formaldehyde; a process for the production of plywood with the material; and plywood obtained by the process. [MEANS FOR SOLVING PROBLEMS] A powdery aldehyde capture material containing at least one aldehyde-capturing compound which is solid at ordinary temperatures and has the property of generating an acid gas such as sulfurous acid gas on being heated; and a process for production of plywood which comprises incorporating the above aldehyde capture material into an adhesive or veneers and producing plywood through hot pressing by the use of the adhesive and the veneers.

Owner:IPPOSHA OIL INDS

Antimicrobial hot melt adhesive

Hot melt adhesive compositions suitable for a variety of applications, especially in nonwoven disposable articles, are prepared by blending various adhesive components with a bacteriostat. The bacteriostat is incorporated into the adhesive compositions in sufficient amounts to inhibit the growth of various microorganisms, particularly bacteria. The preferred bacteriostat is triclosan in amounts of 0.0 1 % to 5 % by weight.

Owner:ATO FINDLEY

Waterproof hot melt adhesive and preparation method thereof

InactiveCN103214983AIncreased softening point temperatureHigh bonding strengthMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesLow-density polyethyleneLinear low-density polyethylene

The invention discloses a waterproof hot melt adhesive and a preparation method thereof. The waterproof hot melt adhesive is composed of the following raw materials by weight part: 50-60 of an ethylene-vinyl acetate copolymer, 20-30 of microcrystalline wax, 10-15 of low density polyethylene (LDPE), 25-30 of a polyvinyl acetate emulsion, 14-16 of petroleum wax, 28-32 of mixed powder, 0.7-0.9 of an antioxidant 168, 1.2-1.5 of vinyltris(beta-methoxyethoxy)silane, 0.8-1.2 of sodium lauryl sulfate, and 2.5-3.5 of dipropyl ethanolamine. The hot melt adhesive provided in the invention has a reasonable formula and a simple preparation method. The adding of the petroleum wax and microcrystalline wax in the raw materials raises the softening point temperature of the hot melt adhesive. At the same time, the mixed powder and the polyvinyl acetate emulsion are added to make the hot melt adhesive have increased bonding strength and good fluidity. The waterproof hot melt adhesive disclosed in the invention has the advantages of environmental protection, safety, weatherability and low cost.

Owner:马鞍山市中澜橡塑制品有限公司

Sprayable environment-friendly hot melt glue and preparation method thereof

ActiveCN103805098AReduce usageGet rid of severe constraintsMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesMicrocrystalline waxEngineering

The invention discloses sprayable environment-friendly hot melt glue and a preparation method thereof. The spray glue mainly comprises the following components in percentage by weight: 12% of EVA thermoplastic resin with melting index 30, 18% of EVA thermoplastic resin with melting index 65, 10% of water-white rosin, 12% of water-white hydrogenated rosin, 8% of C9 petroleum resin, 14.5% of white tackifying resin, 5% of polyisobutene and 8% of microcrystalline wax. The sprayable environment-friendly hot melt glue disclosed by the invention has comprehensive advantages in multiple aspects such as environmental friendliness and no toxin, no organic solvent, zero VOC, no heavy metal or odor, good initial viscous force, high bonding strength, high permanent adhesion, heat and aging resistance, high drying speed, large spray area of unit weight (saving glue) and efficient and quick spraying construction, and has the advantages of complete environmental friendliness, improvement of the operation and construction environment, low cost, no odor, fire safety and the like, and is widely applied to the upholstered furniture industries such as sofa, swivel chairs, mattress, pillows and screens and especially applicable to the European and American environment-friendly high-grade exported products and children products.

Owner:深圳市顾康力化工有限公司

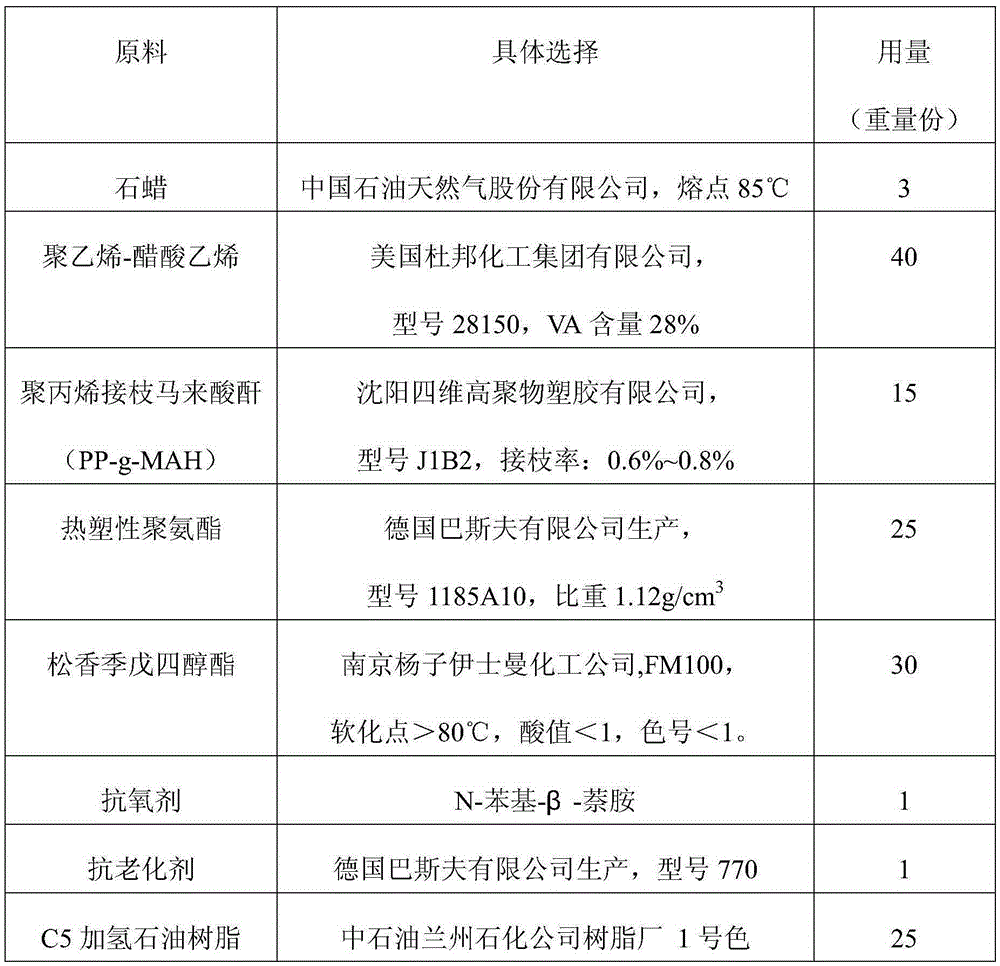

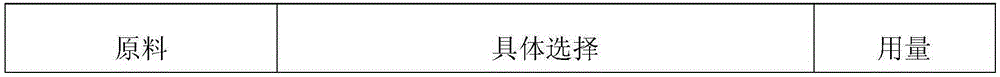

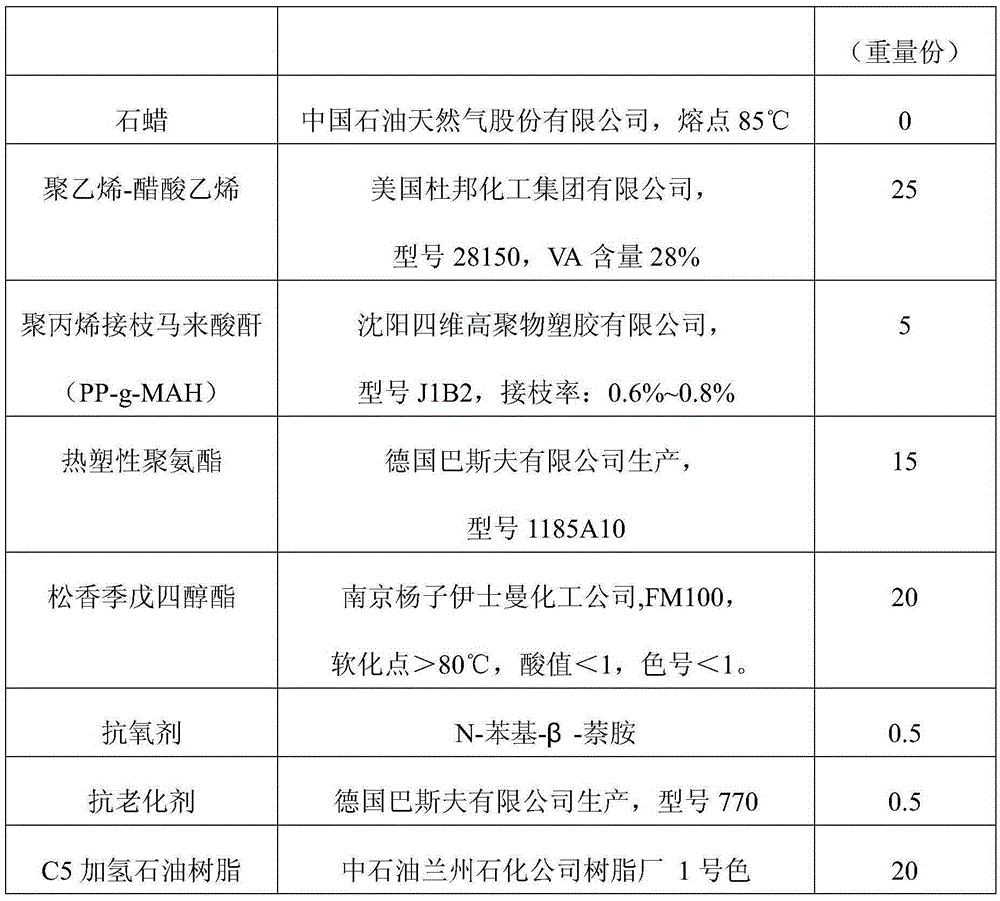

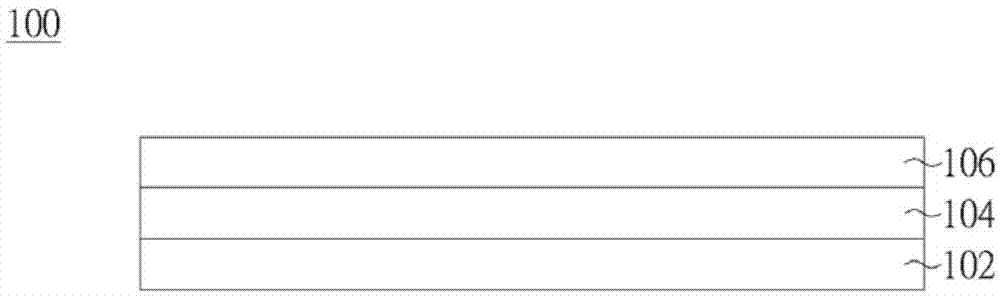

Polyethylene-vinyl acetate hot-melt adhesive and preparation method thereof

ActiveCN105238303AHigh strengthImprove toughnessMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesParaffin waxPolyethylene vinyl acetate

The invention relates to a polyethylene-vinyl acetate hot-melt adhesive and a preparation method thereof. The preparation method comprises the following steps: mixing 1 / 2-2 / 3 of polyethylene-vinyl acetate with 1 / 2-2 / 3 of thermoplastic polyurethanes by weight, heating the mixture, adding 0-3 parts of paraffin and 0.5-1 part of antioxidants into the heated mixture, adding the remaining polyethylene-vinyl acetate and the remaining thermoplastic polyurethanes after the added components are melted completely, and holding a temperature to be greater than or equal to 130 DEG C; and adding 5-15 parts of PP-g-MAH, holding the temperature to be greater than or equal to 120 DEG C, adding pentaerythritol rosin ester and a C5 hydrogenation petroleum resin, reducing the temperature to be 90-110 DEG C, adding an anti-aging agent after the pentaerythritol rosin ester and the C5 hydrogenation petroleum resin are melted completely, holding the temperature and stirring the mixture for 10-30 minutes to obtain the hot-melt adhesive. The polyethylene-vinyl acetate hot-melt adhesive provided by the invention is high in strength and good in toughness, and does not cause secondary pollution to the environment. An automobile-used hot-melt adhesive prepared from the adhesive has high adhesion ability and high chemical stability, and can be used in the field of automobile interior adhesion.

Owner:EAST CHINA UNIV OF SCI & TECH

Benzene-free high-speed alumite stamping gum

InactiveCN103254869AImprove adhesionImprove brittlenessMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesBenzenePolymer science

The invention relates to a benzene-free high-speed alumite stamping gum comprising the following chemical components in weight ratio: 15-30 of adhesion promotion resin, 20-45 of packing resin, 1-5 of wetting agents, 5-10 of additives and 70-90 of organic solvents. The used solvents are all non-benzene and non-benzene-series solvents and meet the requirement for limiting a non-benzene VOC (Volatile Organic Compound) in a special industry; the used special modified chlorinated polyolefin resin and ester soluble acrylic resin are used for improving the adhesion of the gum; the used packing resin is used for ensuring that the gum has better brittleness; the gum and a stamping substrate can achieve an ideal wetting effect by using the wetting agent; the gum is better in coating uniformity and favorable in temperature resistance and exhausting performance by using the additives; the stamping gum belongs to a universal gum and has better adhesion for common untreated paper, inked paper and composite paper; and the benzene-free high-speed alumite stamping gum is integrated in stamping pattern, good in trimming, free of mutilation and leak stamping and good in glossiness.

Owner:GUANGDONG BANGGU CHEM TECH

Hot melt adhesive

InactiveCN103773279AStrong resistance to dissolutionHigh thermal activityWax adhesivesMethacrylateSolubility

The invention discloses a hot melt adhesive, comprising an ethylene-vinyl acetate copolymer and a thinner, wherein the ethylene-vinyl acetate copolymer accounts for from 20% to 90% of the hot melt adhesive by weight. The hot melt adhesive is high in bonding strength, has a good anti-solubility property to high-solubility solvent, accords with related food provisions, and is suitable for food packaging. In addition, the hot melt adhesive is high in thermal activation. A sealing material made of the hot melt adhesive can be subjected to thermal compression at a low temperature, thereby achieving an energy-saving effect. Moreover, the hot melt adhesive is characterized by rapid drying, so that in the process of manufacturing the sealing material, additional drying equipment is not required, and the production efficiency is improved further and the processing energy consumption is reduced.

Owner:广州德渊精细化工有限公司 +1

Hot melt adhesive composition

ActiveUS20050075431A1Avoid excessive degradationLong application periodMonocarboxylic acid ester polymer adhesivesLayered productsPolymer scienceHeat resistance

A low application temperature, high heat resistant hot melt adhesive comprising an ethylene n-butyl acrylate copolymer having a melt index (MI) of 750 grams / 10 minutes or higher and an ethylene vinyl acetate (EVA) polymer having a MI of 750 grams / 10 minutes or higher are particularly well suited for case and carton sealing operations.

Owner:HENKEL KGAA

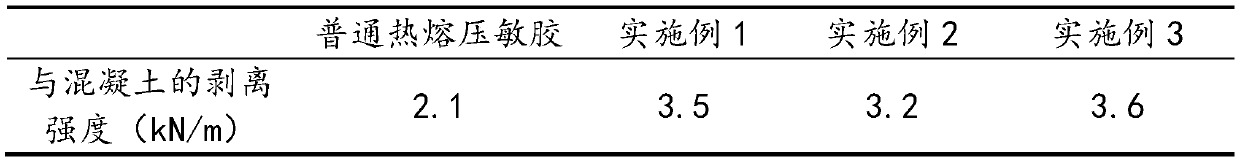

Hot-melt pressure sensitive adhesive for waterproof rolls, and preparation method thereof

InactiveCN109694691AHigh affinityImprove adhesionMineral oil hydrocarbon copolymer adhesivesWax adhesivesPressure sensitiveChemistry

The invention provides a hot-melt pressure sensitive adhesive for waterproof rolls, and a preparation method thereof, and belongs to the technical field of adhesives. The problems of poor heat resistance and poor adhesion to a concrete substrate of existing hot-melt pressure sensitive adhesive for waterproof rolls are solved. The hot-melt pressure sensitive adhesive for waterproof rolls comprises5-30 wt% of a thermoplastic elastomer, 5-15 wt% of a saturated thermoplastic elastomer, 25-50 wt% of tackifying resin, 15-40 wt% of a plasticizer, 0.5-5 wt% of an silicone additive and 0.5-5 wt% of astabilizer, wherein the silicone additive is prepared by a controlled condensation reaction of different silane monomers. The hot-melt pressure sensitive adhesive for waterproof rolls has the advantages of good heat resistance and good adhesion to the concrete substrate, and the preparation method of the pressure sensitive adhesive has the advantages of simple preparation process, low cost and good economic values.

Owner:山东聚东新材料有限责任公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com