Patents

Literature

784results about How to "Adhesively" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

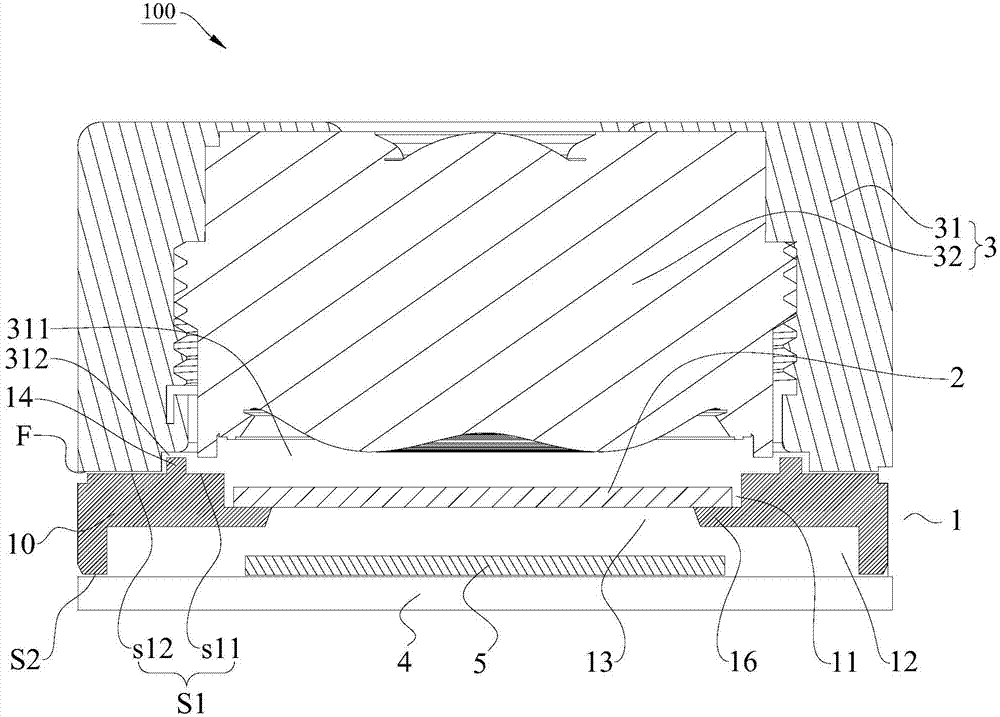

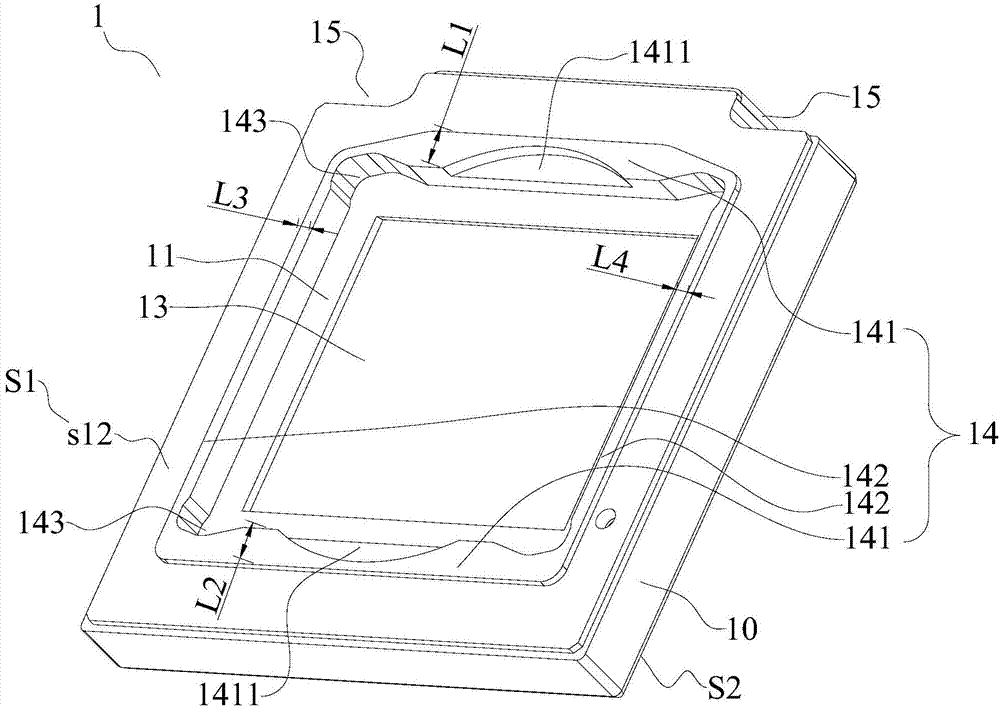

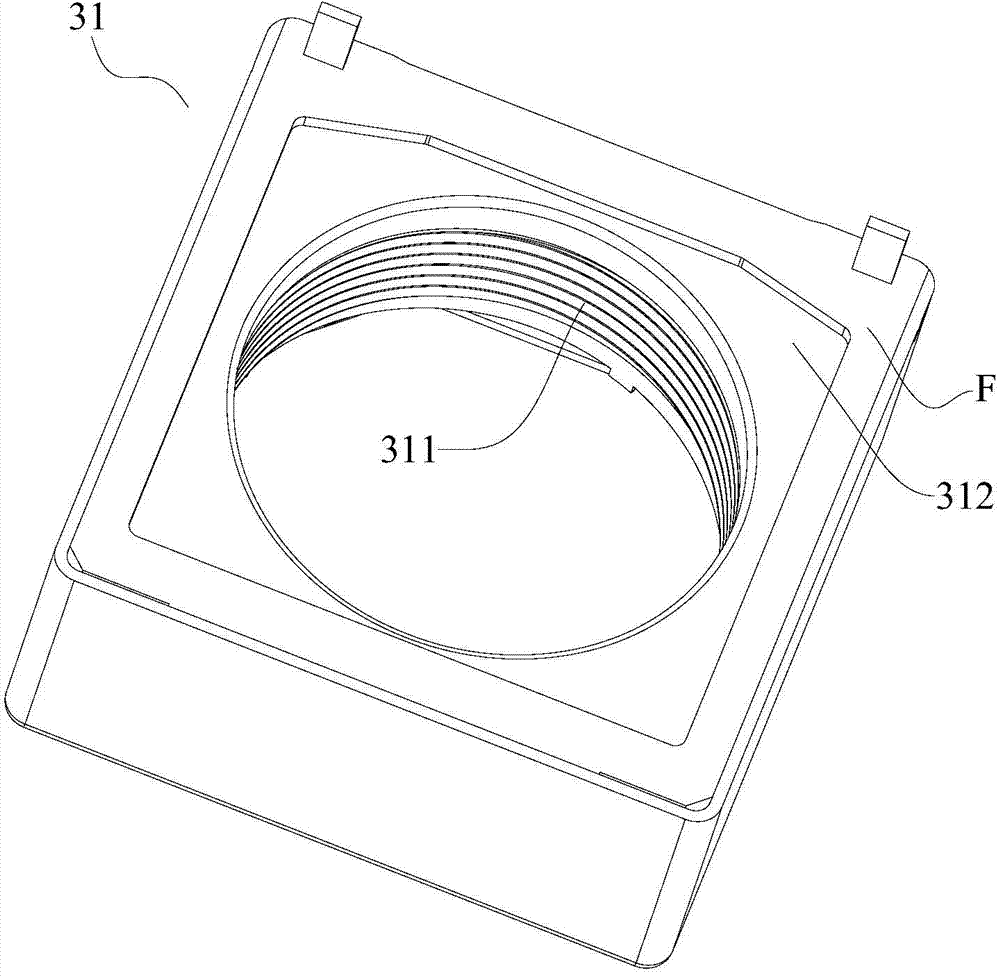

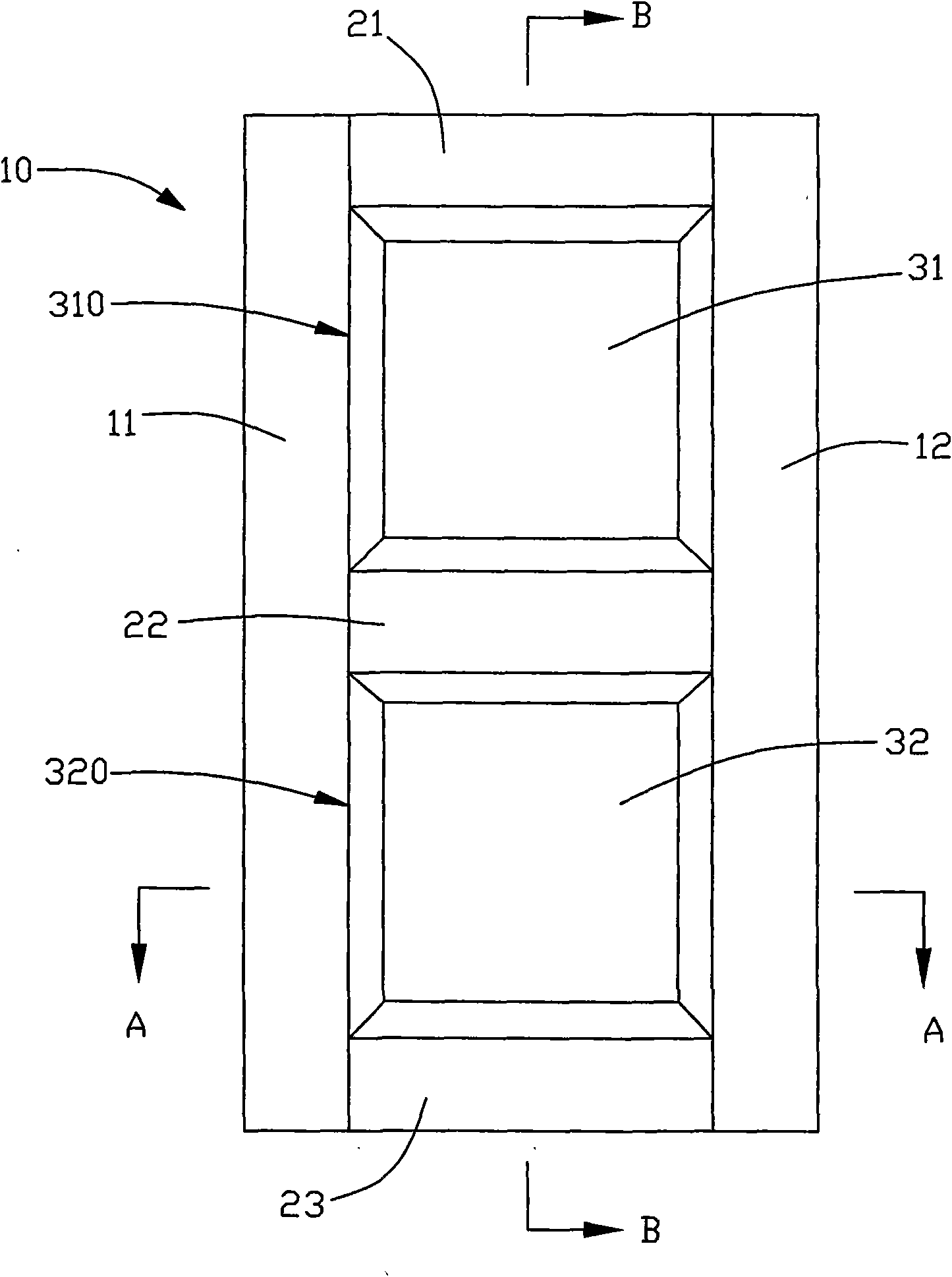

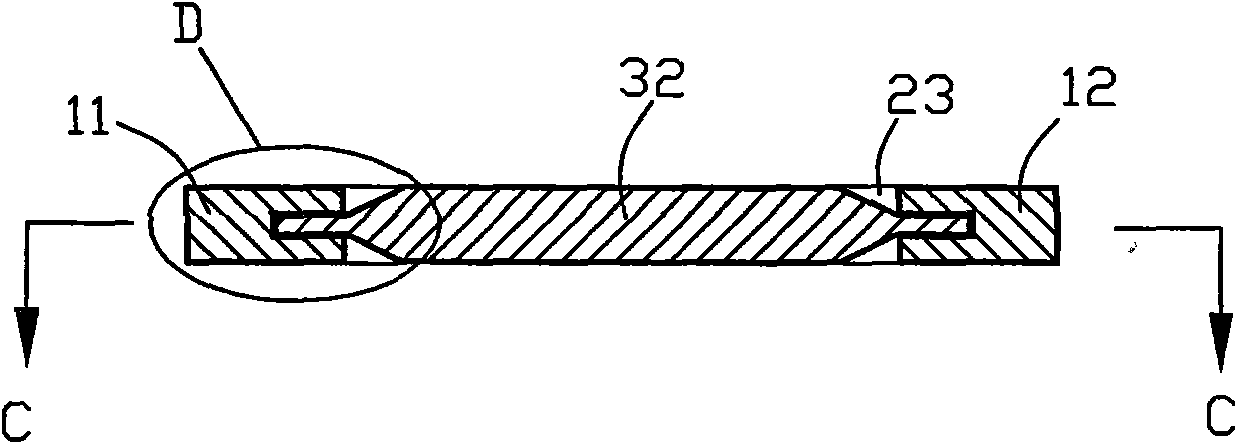

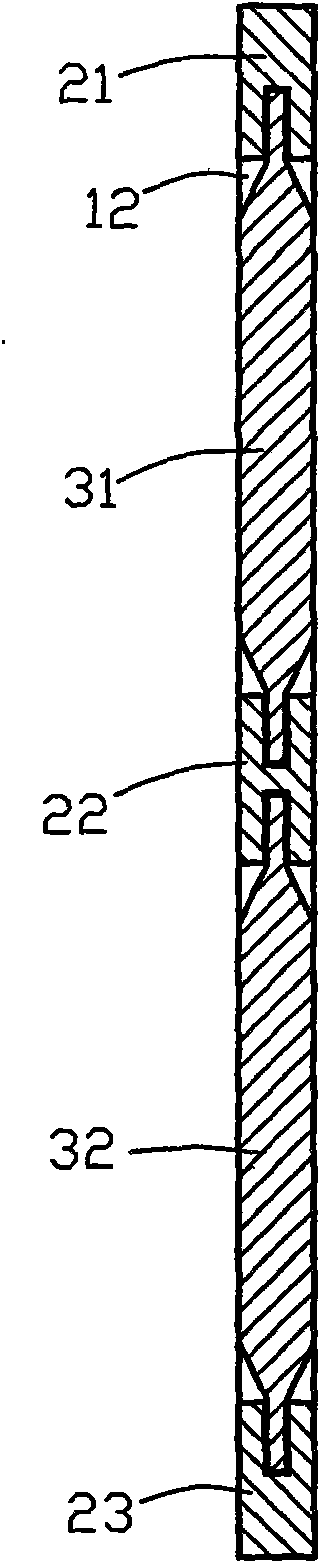

Bracket for camera die set and camera die set

InactiveCN104749858AGood imaging effectSpeed up the flowMountingsCamera body detailsCamera lensAdhesive

The invention discloses a bracket for a camera die set and the camera die set. The bracket comprises a bracket body; the bracket body comprises a first surface and a second surface which are oppositely arranged; a first concave groove and an annular boss are arranged on the first surface, wherein the annular boss is arranged around the outer side of the first concave groove; a second concave groove is formed in the second surface; through holes which pass through the first concave groove and the second concave groove are formed in the bracket body. According to the bracket for the camera die set, when a lens driving assembly is adhered on the part of the first surface, positioned at the outer side of the annular boss through an adhesive, excessive adhesive is difficult to flow to the first concave groove and a lens, so that the adhering firmness of the bracket and the lens driving assembly can be ensured, the adhesive can be prevented from adhering to a light filter and glass, and as a result, the light filtering performance of the light filter and the light transmission performance of the glass can be ensured, and the good imaging effect of the camera die set can be ensured; in addition, the lens is difficult to be adhered and fixed through excessive adhesive, and the focus of the lens can be normally adjusted.

Owner:NANCHANG O FILM OPTICAL ELECTRONICS TECH CO LTD +3

Filter material of tefloncomposite membrane

ActiveCN1565713AHigh strengthLarge circulationSemi-permeable membranesSynthetic resin layered productsDimethyl formamidePolyvinylidene fluoride

The invention relates to polytetrafluoroethylene (PTFE) composite film filtering materials for air filtering industry. The polytetrafluoroethylene composite film filtering materials comprise the following components: fiberglass as basement film; polytetrafluoroethylene as surface film; and adhesive agent which is one of polysulfone, nylon 66 and polyvinylidene fluoride fibre for binding the fiberglass and polytetrafluoroethylene; pore-forming material which is one of metal salt KI and NH#-[4]Cl; solvent which is one of dimethyl acetamide, dimethyl formamide and N-methyl pyrrolidone. The content (by weight) of macromolecular compound and pore-forming material is: 5% to 30% of macromolecular compound, 5% to 15% of pore-forming material. The fiberglass and polytetrafluoroethylene composite materials can improve filtration efficiency and have improved hydrophobicity, high-temperature resistance and corrosion resistance.

Owner:SHANGHAI FILTER

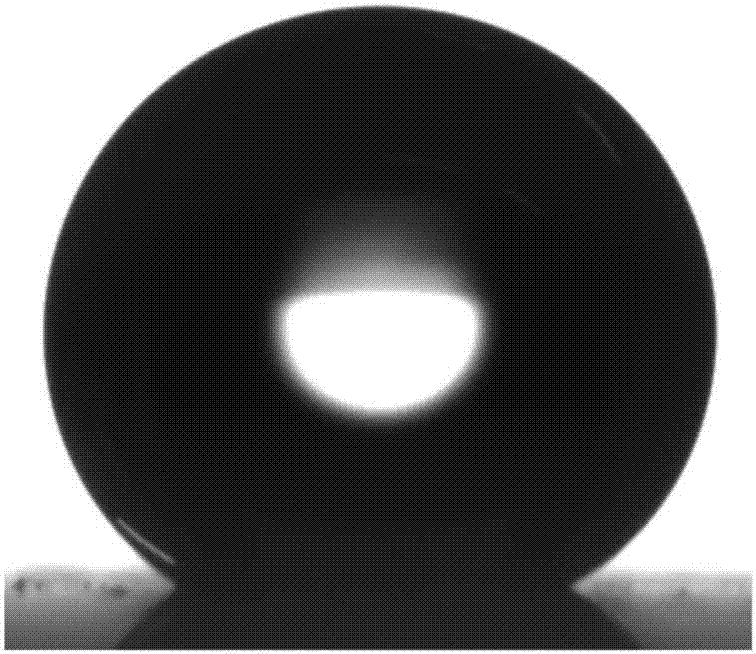

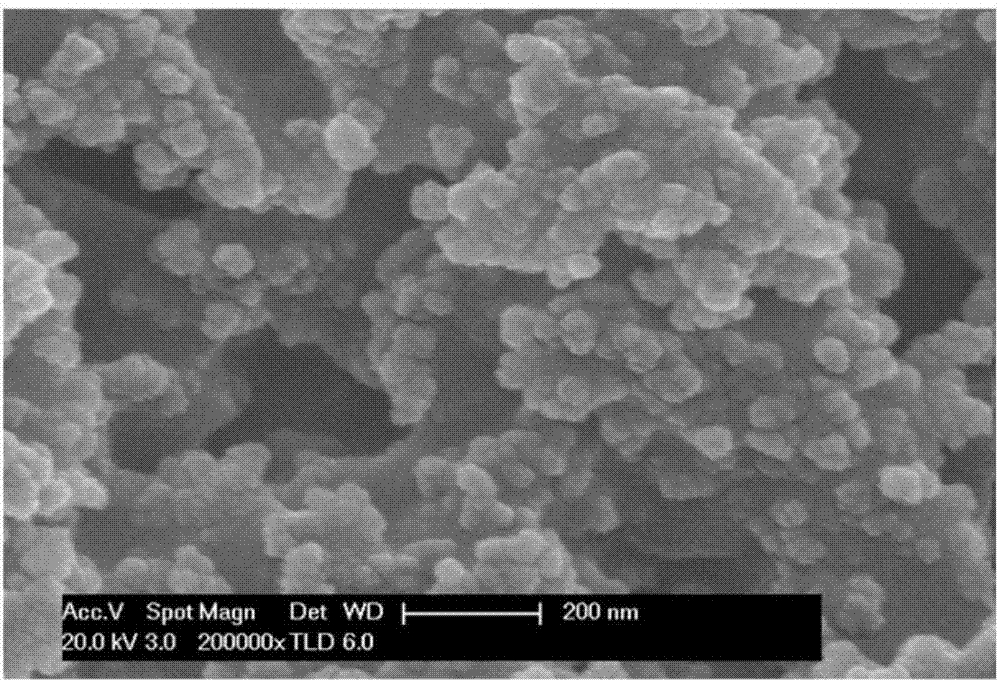

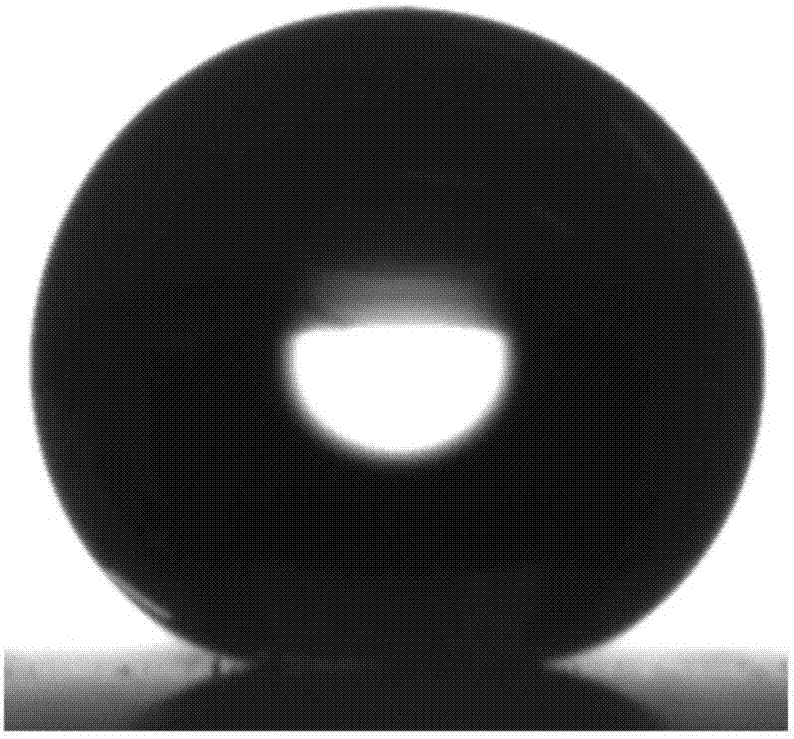

Durable super-hydrophobic coating and preparation method thereof

ActiveCN107384055AAvoid reunionGuaranteed numberAntifouling/underwater paintsPretreated surfacesMicro nanoOrganic solvent

The invention relates to a durable super-hydrophobic coating and a preparation method thereof. The preparation method comprises the following steps: 1) hybrid paint preparation: under low-speed mechanical stirring condition, adding micro nano particles, hydrophobic resin and a curing agent in a volatile organic solvent successively, performing high speed stirring and then ultrasonic dispersion to obtain the hybrid paint; 2) coating semi-solidification: coating the surface of a base material with the hybrid paint and performing semi-solidification; and 3) complete solidification: immersing the semi-solidified coating in a mixed immersion solution of the curing agent and the volatile organic solvent, taking the coating out, and drying the coating to obtain the durable super-hydrophobic coating having good wear resistance. The preparation method has no special requirement for a substrate material and its shape, the coating is suitable for various common base material surfaces such as metal, glass, timber and concrete, the equipment is simple, operation is easy, the cost is low, large-area construction is realized, and the coating has large application value on super-hydrophobic fields of self-cleaning, anticorrosion, mildew resistance, ice and frost resistance, and oil-water separation.

Owner:SOUTHEAST UNIV

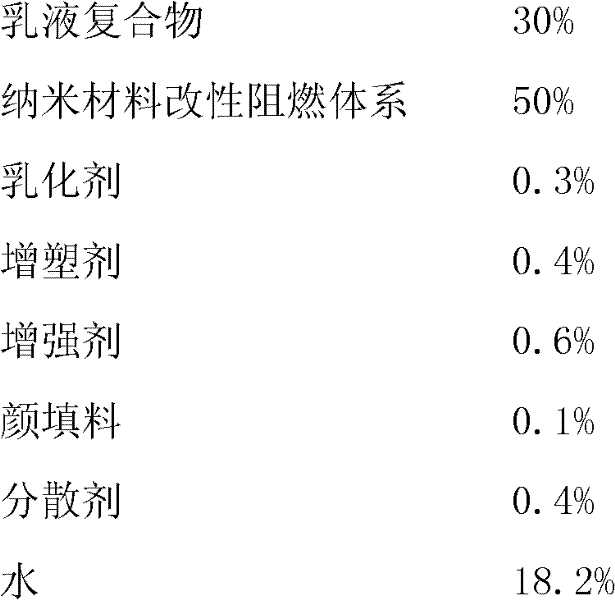

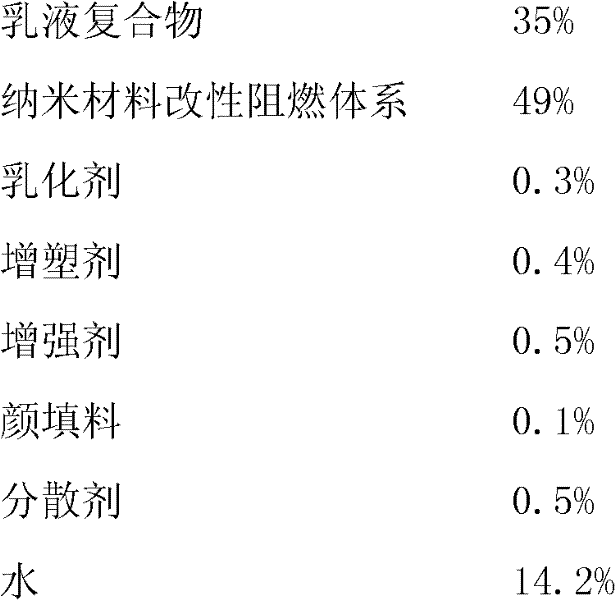

Water-borne inflation type refractory coating and preparation method thereof

The invention discloses a water-borne inflation type refractory coating and a preparation method thereof. The refractory coating is prepared from the following components: 30-40% of emulsion compound, 40-58% of modified antiflaming system of a nanometer material, 0.3-0.6% of emulsifying agent, 0.2-0.4% of plasticizer, 0.4-0.8% of reinforcing agent, 0.1-0.15% of pigment filler, 0.2-0.6% of dispersing agent and the balance of water. Compared with the prior art, the water-borne inflation type refractory coating has the advantages of excellent environmental performance, simple technology, sufficient raw material resources, proper price and the like and can be widely applied.

Owner:湖南新纪元建设发展有限公司

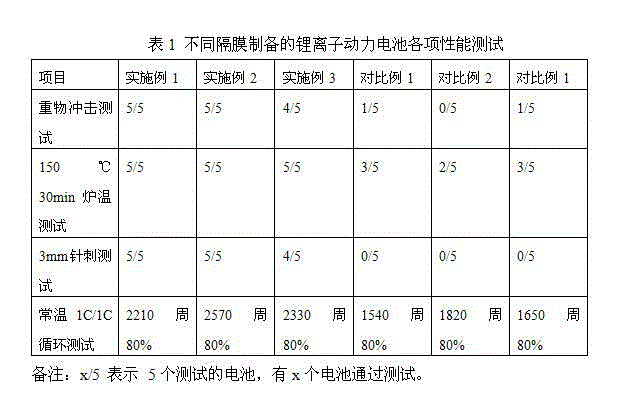

A preparing method of a lithium ion battery composite separating membrane

ActiveCN104681762AImprove mechanical propertiesImprove heat resistanceCell seperators/membranes/diaphragms/spacersPolyamide coatingsHeat resistanceResin coating

A preparing method of a lithium ion battery composite separating membrane is disclosed. A common PP or PE separating membrane is coated with an oxide coating, an aramid fiber resin coating and a PVDF-HFP copolymer layer to obtain the composite separating membrane. The composite separating membrane enhances mechanical performance and heat resistance of the separating membrane and enhances safety performance of batteries.

Owner:WANXIANG 123 CO LTD

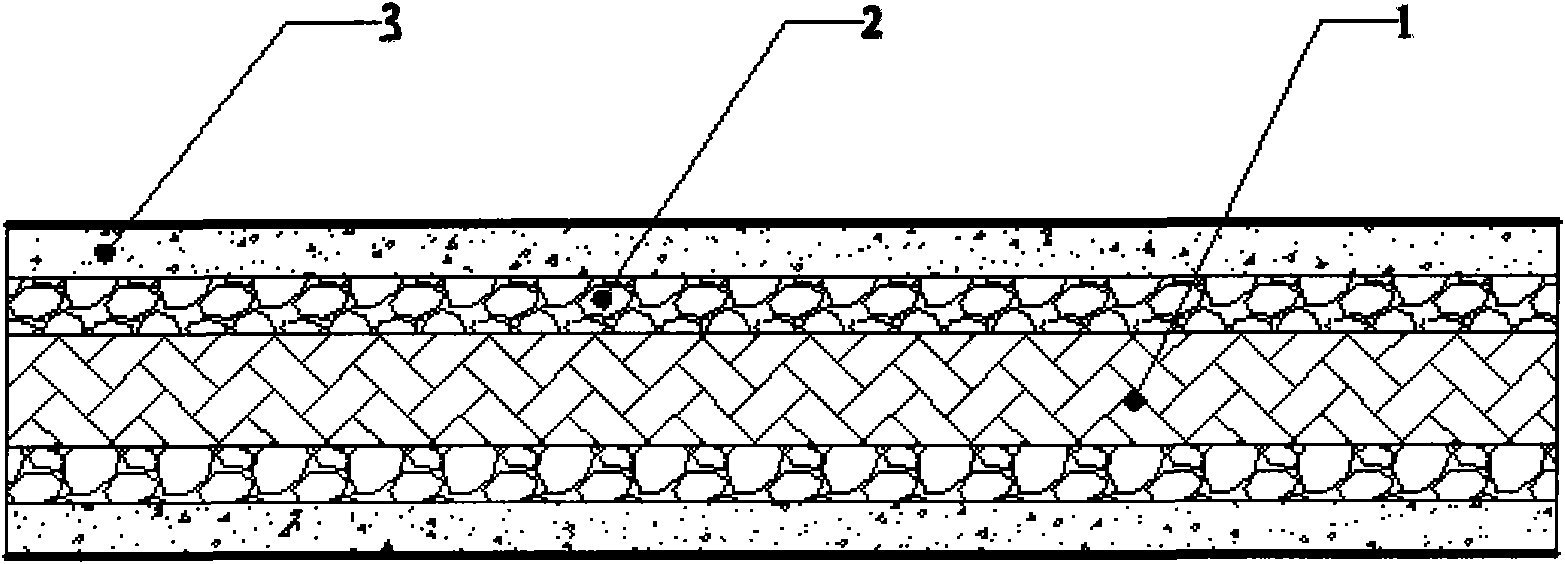

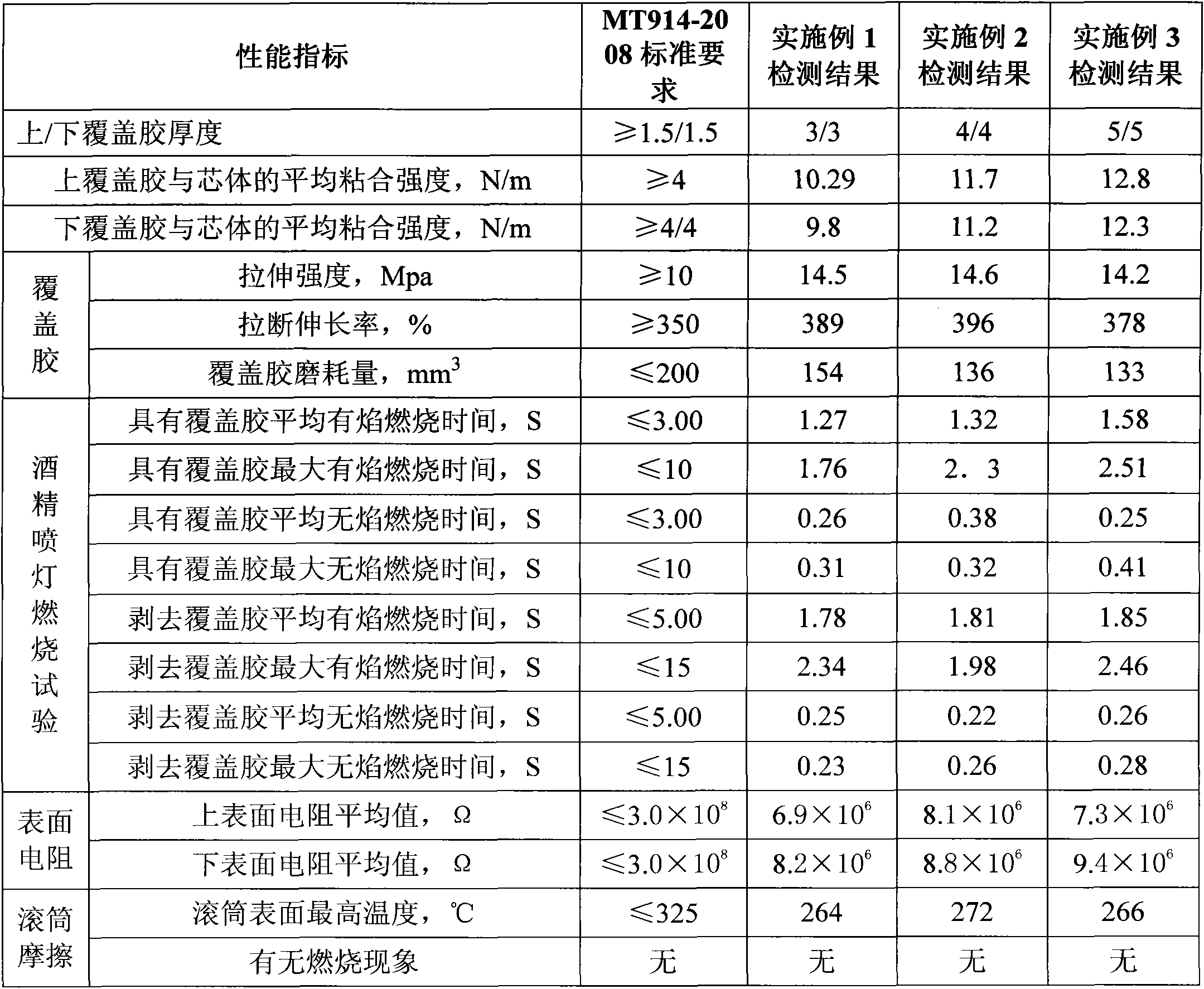

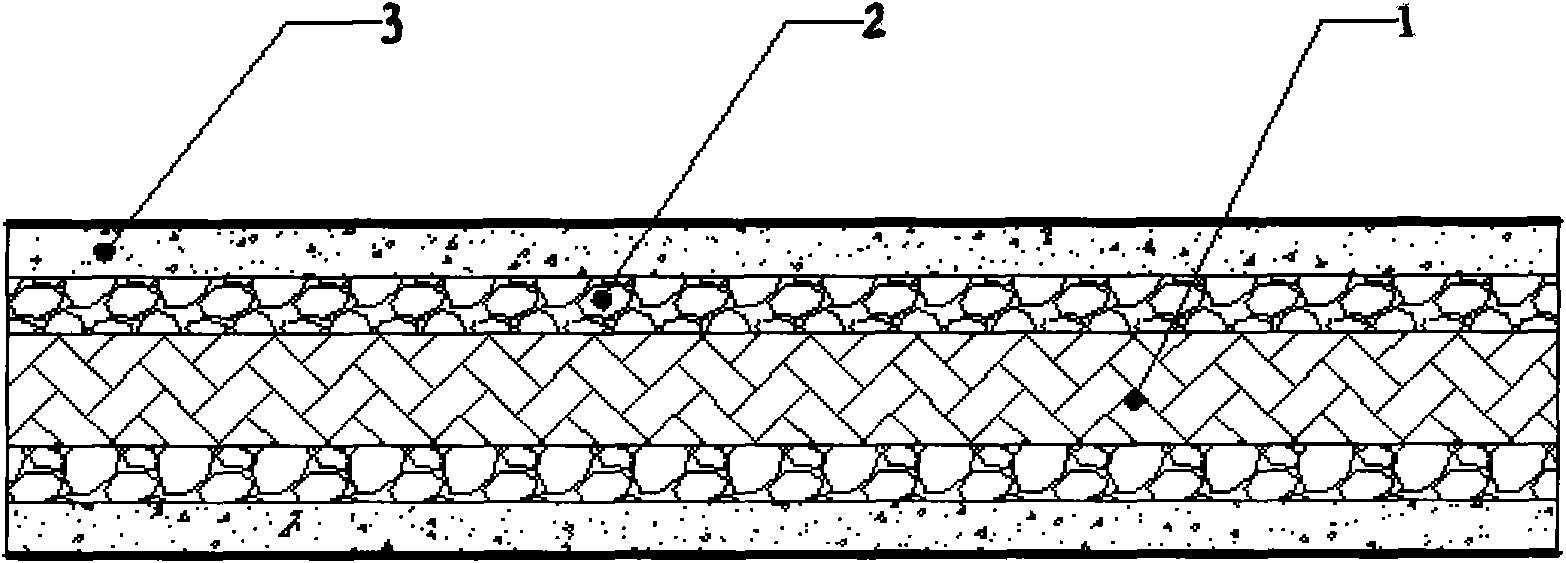

Whole-core antiflaming conveyer belt with transition layer and production method thereof

ActiveCN101973445AHigh bonding strengthAdhesivelyConveyorsLayered productsPolymer scienceVulcanization

The invention provides a whole-core antiflaming conveyer belt with a transition layer, comprising skeleton material, the transition layer and a covering layer, wherein the skeleton material is a solid entirety which is formed by impregnating and plastifying the whole belt core of textile, the transition layer is antiflaming thermoplastic elastomer, and the covering layer is antiflaming anti-static vulcanized rubber composite. The production method comprises the following steps: two extruders bond the transition layer with the skeleton material, and then the two extruders bond the covering layer with the transition layer. Because the transition layer of the thermoplastic elastomer is added between the whole belt core and the covering layer, the covering layer is tightly bonded with the belt core by the transition layer so as to effectively solve the problems of delaminating and foaming for the rubber surface in the prior art; meanwhile, the thickness of the whole covering glue formed by the covering layer and the transition layer is 6 mm, which is 4 times the prior art, thus prolonging the service life of the antiflaming belt; and in addition, because of the thermoplastic elastomer, the technology of extrusion shaping and dynamic vulcanization can be adopted to improve production efficiency and lower energy consumption.

Owner:ANHUI ZHONGYI RUBBER BELTS

Edible bird's nest collagen peptide composite powder and preparation technology thereof

The invention relates to edible bird's nest collagen peptide composite powder. The edible bird's nest collagen peptide composite powder is prepared from the following raw materials in parts by weight: 15-25 parts of fish collagen peptide, 3-7 parts of edible bird's nests, 25-35 parts of apple powder, 8-12 parts of lemon powder, 12-16 parts of blueberry powder, 15-16 parts of water soluble dietary fibers, 1-3 parts of vitamin C, 1-3 parts of vitamin E, 0.01-0.05 part of vitamin B1, 0.01-0.05 part of vitamin B2, 0.01-0.05 part of vitamin B6, 0.01-0.03 part of vitamin B12, 1-3 parts of beta-carotene, and 0.1-0.3 part of nicotinamide and folic acid. A preparation technology of the edible bird's nest collagen peptide composite powder comprises the following steps of removing impurities from edible bird's nests, thoroughly cleaning the edible bird's nests after impurity removal, and performing superfine crushing so as to obtain edible bird's nest powder; and mixing the taken raw materials with the edible bird's nest powder, and performing packaging. According to the edible bird's nest collagen peptide composite powder disclosed by the invention, the raw materials are reasonable in collocation, the edible bird's nest collagen peptide composite powder has multiple health-care effects on skin, hair, skeletons and the like of human bodies, and after the edible bird's nest collagen peptide composite powder is eaten for a long term, the effects of coordinating the intestines and the stomach, building bodies and reducing weight can be achieved.

Owner:LUOYANG HUAYI BIOTECH

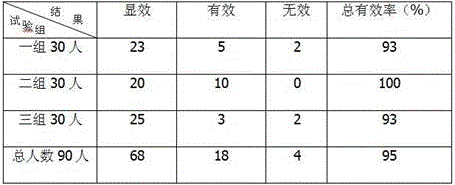

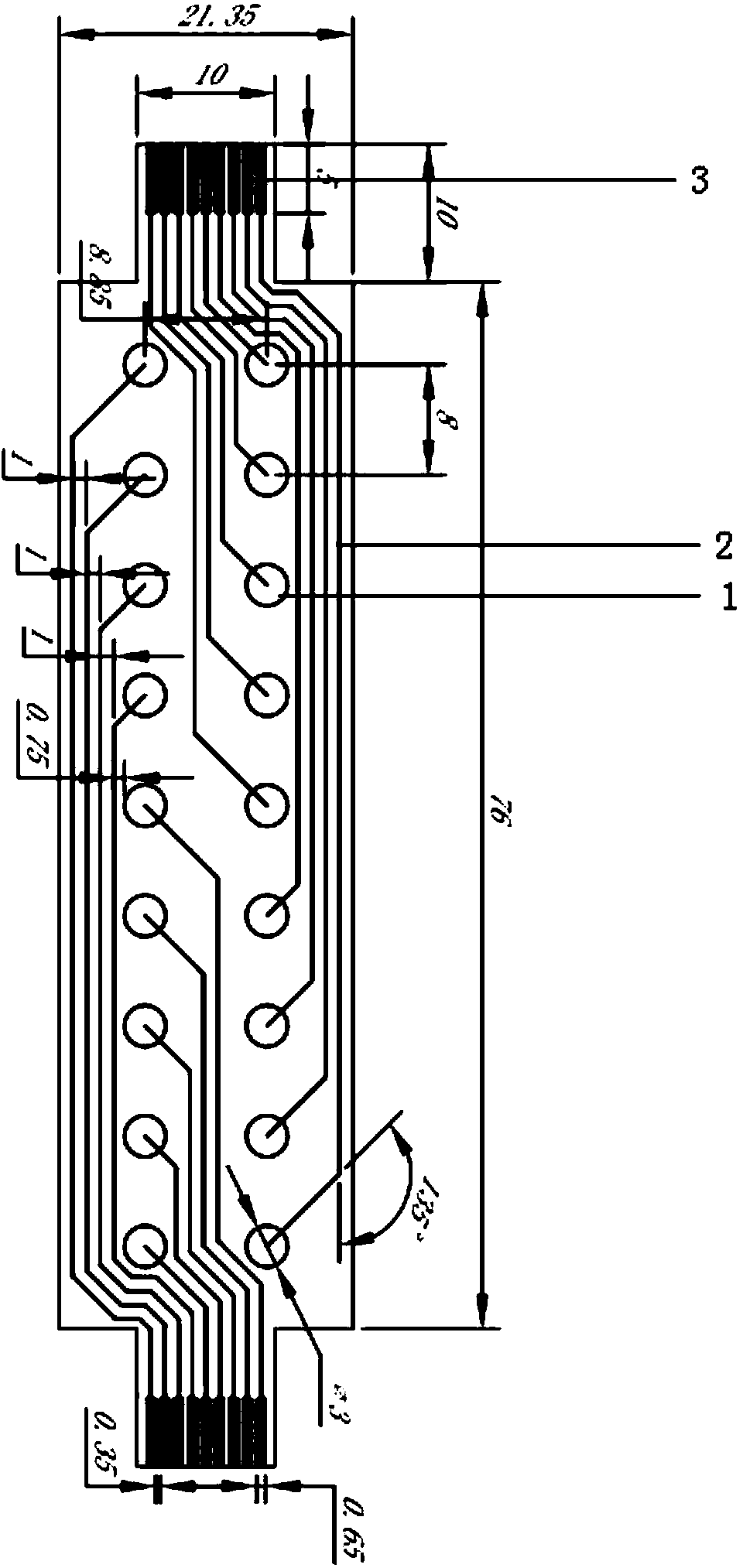

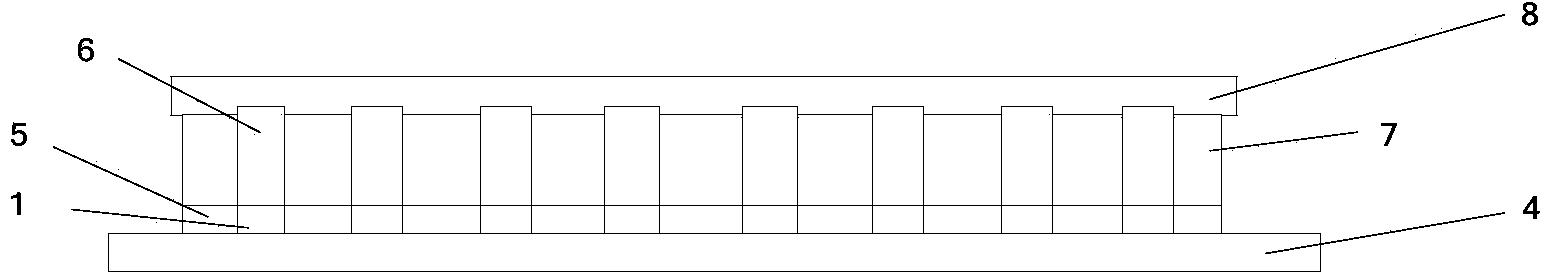

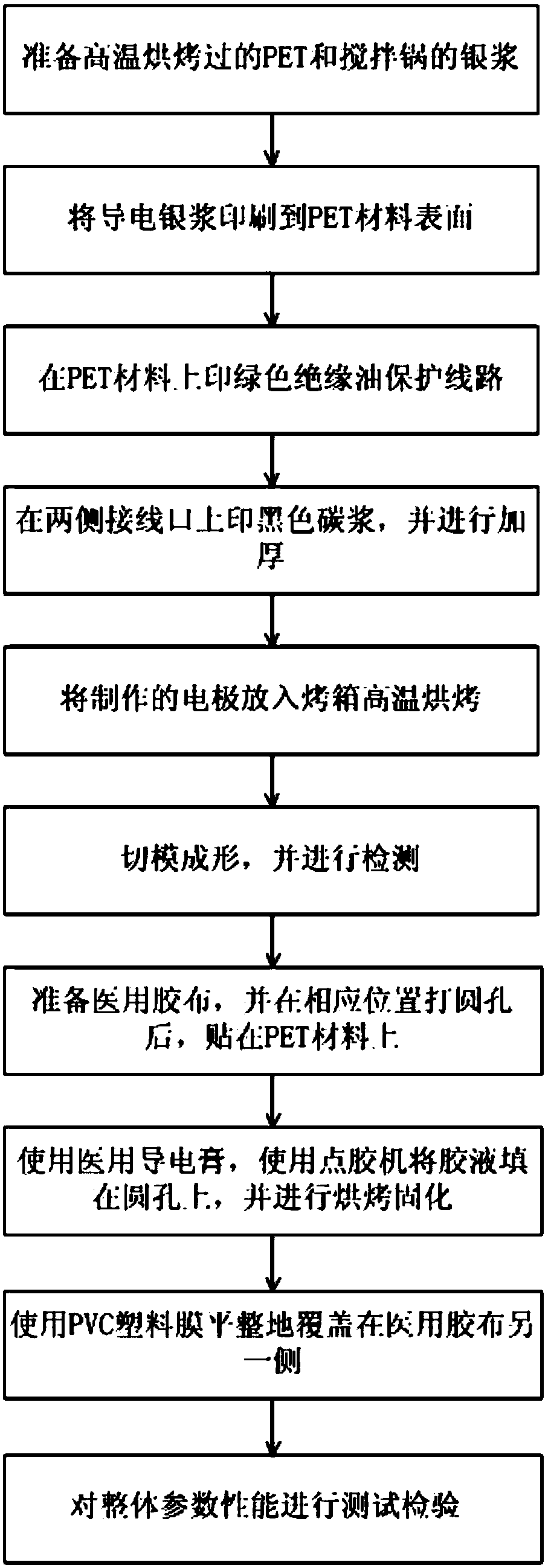

Array type flexible surface electromyography electrode and preparation method thereof

ActiveCN104224170AWith no damageStrong correlationDiagnostic recording/measuringSensorsHuman bodyConductive paste

The invention discloses an array type flexible surface electromyography electrode and a preparation method thereof. The electrode is used for measuring the surface electromyography of a human body, and mainly comprises circular electrode plates, a flexible electrode substrate, insulating oil, medical proof fabric and conductive paste, wherein the circular electrode plates are arranged in an array manner, and depend on the flexible electrode substrate and the insulating oil; the medical proof fabric and the conductive paste are used for improving contact. The array electrode is characterized in that a plurality of electrode units are arranged into a space array, and has relatively good flexibility and adhesivity and relatively strong deformation adaptability. The space distance, the array arrangement and the impedance matching, which are adopted by the invention, can reduce the noise effectively and extract electromyographic signals to be convenient for subsequent signal processing. The electrode array, designed by the invention, can expand to more channels conveniently to obtain an electromyography image with enough space resolution, the adopted surface electrode array can avoid injury to the human body due to an insertion type electrode, and a multi-muscle-group image set can be obtained after enough electrode arrays are formed by expanding.

Owner:ZHEJIANG UNIV

Production process for electric toothbrush casing

ActiveCN105818322AHighlight the aestheticsEasy to assembleLiquid surface applicatorsVacuum evaporation coatingRisk sharingLaser engraving

The invention relates to a production process for an electric toothbrush, in particular to a production process for an electric toothbrush casing. The production process comprises the steps that firstly spraying is conducted, specifically, a shading light oil layer is sprayed on the front or the reverse of a transparent decorating part; secondly laser engraving is conducted, specifically, the laser engraving technique is adopted and the a needed shape is hollowed out on the shading light oil layer; thirdly electroplating is conducted, specifically, a metal layer or a metallic oxide layer is vacuum plated on the front of the transparent decorating part; fourthly injection molding is conducted, specifically, a transparent soft rubber layer is injected on the light source region of an electric toothbrush handle; and fifthly assembling is conducted, specifically, the transparent decorating part is assembled on the transparent soft rubber layer and the reverse of the transparent decorating part is attached to the transparent soft rubber layer. According to the production process, processing risk sharing is achieved; the loss cost caused by processing errors is lowered; and the implicit glowing effect is achieved, and the lighting effect is even and gentle.

Owner:GUANGDONG ROMAN TECH CO LTD

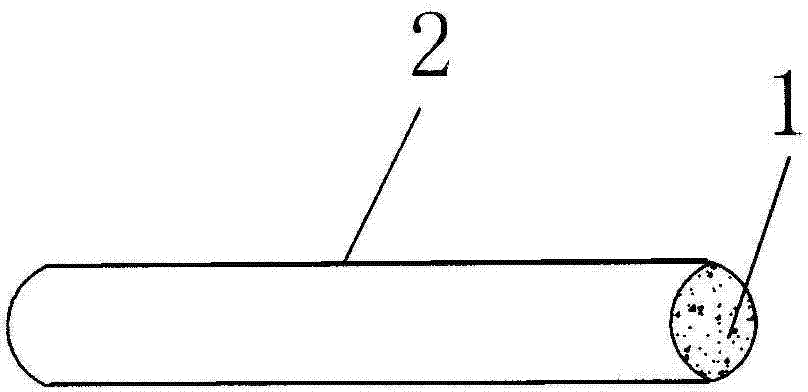

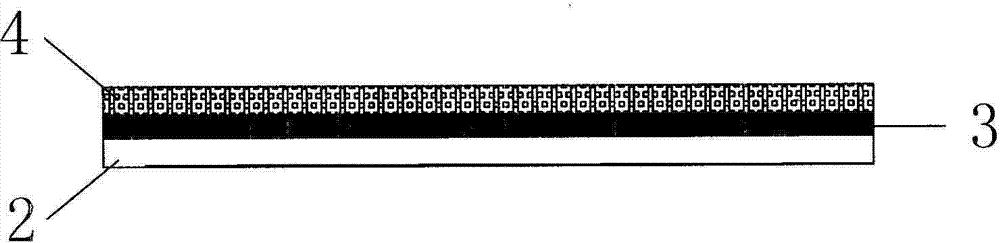

Filtering rod capable of reducing smoke temperature and preparation method of filtering rod

The invention discloses a filtering rod capable of reducing smoke temperature and a preparation method of the filtering rod. Smokers feel obvious hot burning feeling and spicy stimulating feeling when smoking the cigarettes. In order to solve the problem, the invention adopts the following technical scheme: the filtering rod comprises a bundle core rod (1) and externally wrapped molding paper (2). The right side of the molding paper (2) is coated with a microporous aluminum layer (4) through a glue layer (3). The microporous aluminum molding paper is formed by adhering the microporous aluminum onto the the molding paper in a vacuum aluminizing way. Then the molding paper coated with the microporous aluminum is used for coiling to form the filtering rod. The filtering rod containing the microporous aluminum is used, and when high-temperature smoke of smoked cigarettes enters the filtering rod from the tail end of the cigarette, the temperature of smoke entering the mouth can be reduced to 28-32 DEG C because of condensation of the microporous aluminum, thereby enabling harmful substances of the smoke to be easily adhered to the filtering rod and obviously reducing harmful substances of the smoke, so that the hot burning feeling and spicy stimulating feeling of the mouth can be obviously lightened after people smoke.

Owner:ENDIAN SCI & TECH DEV OF YUNNAN

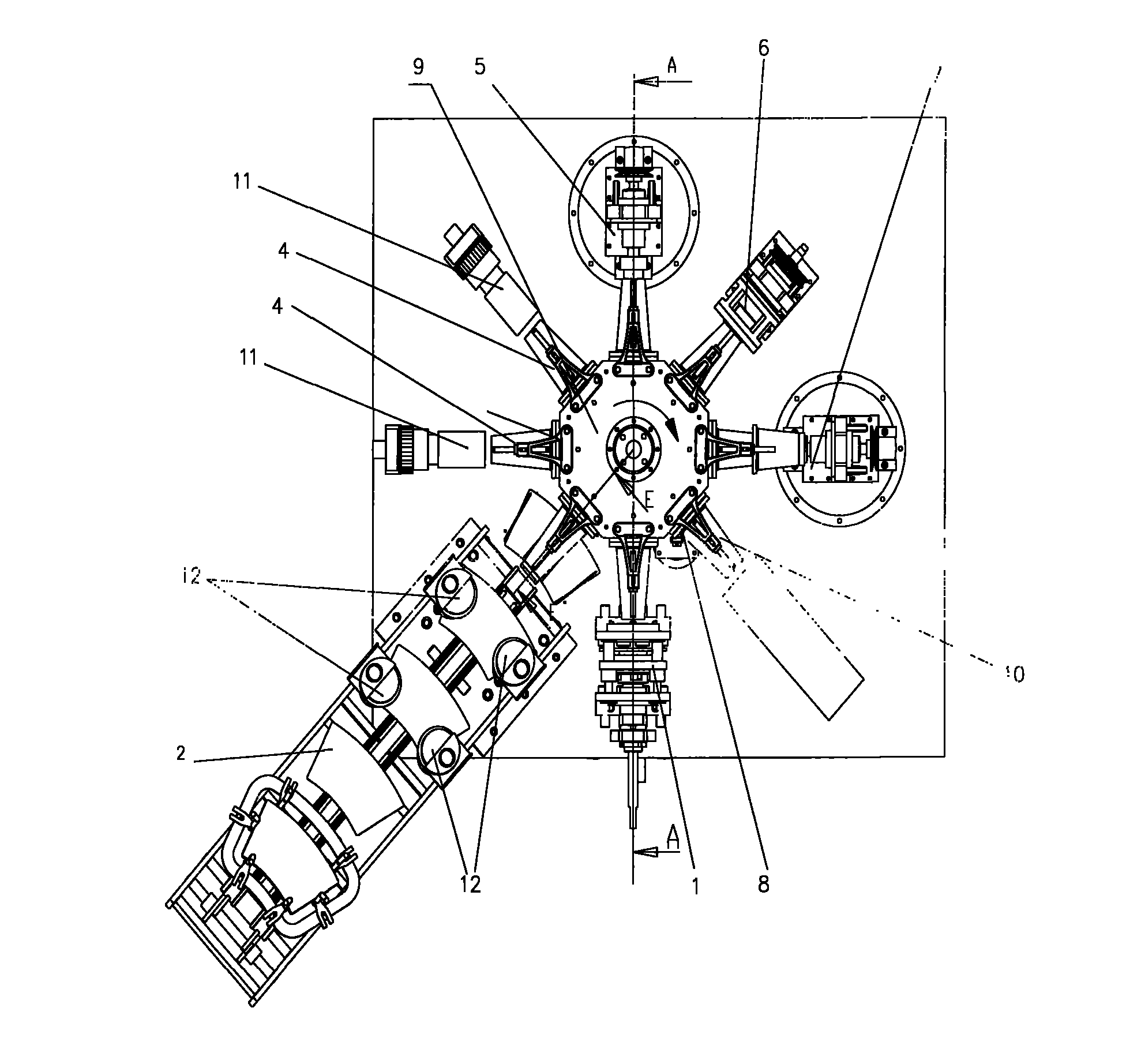

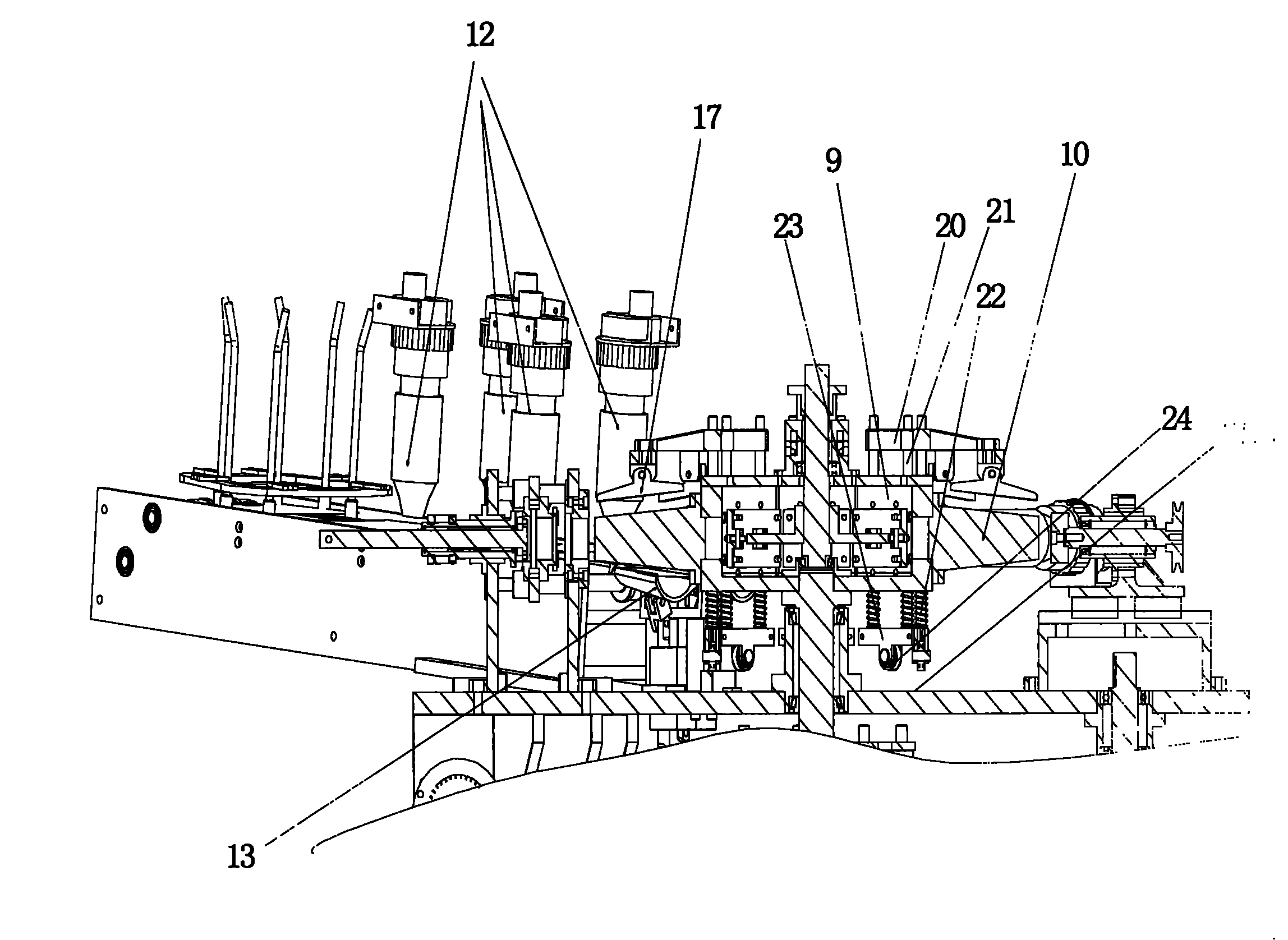

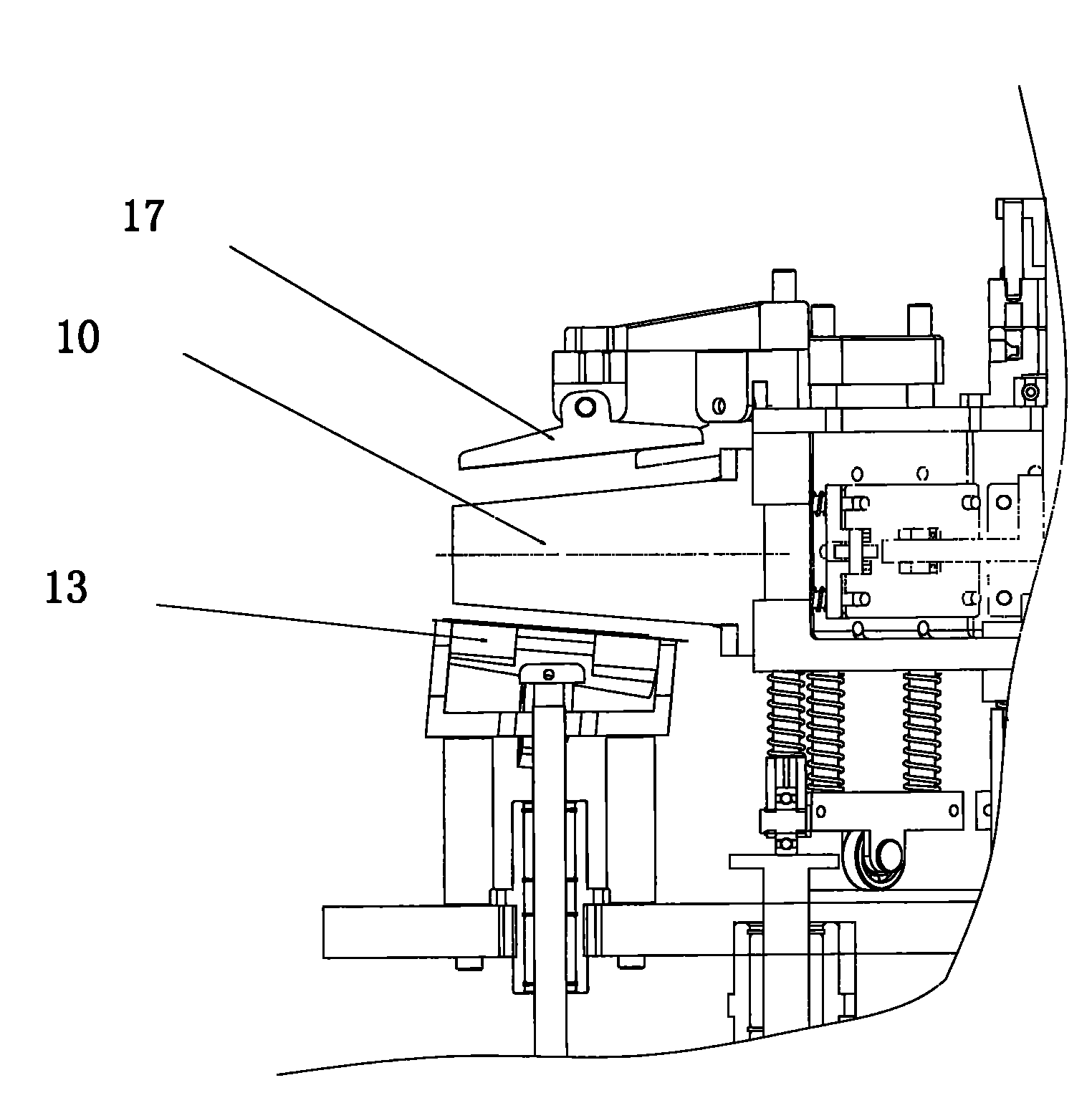

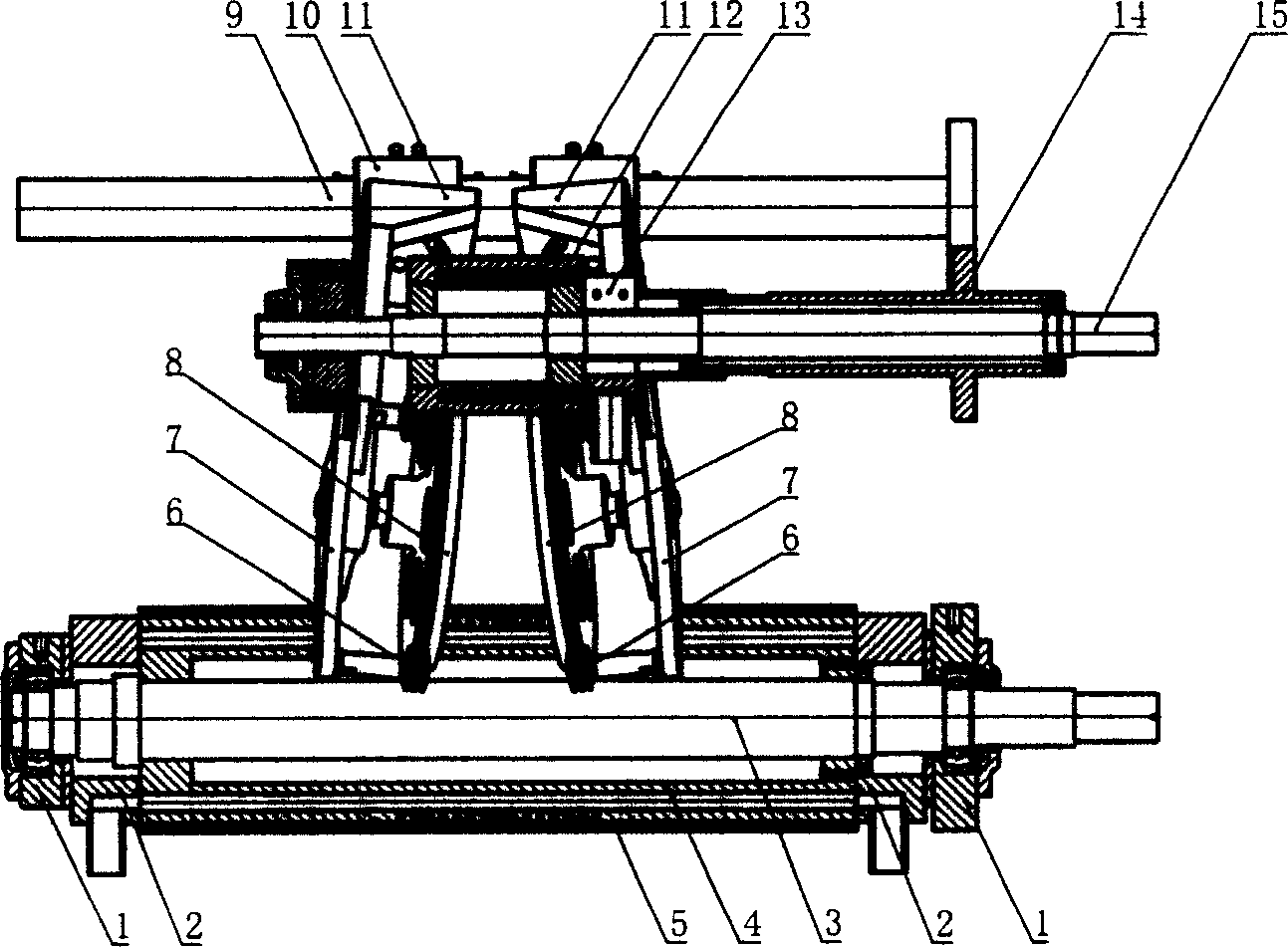

Paper cup machine

The invention discloses an improved invention of a paper cup machine, which is mainly characterized in that the machine body comprises a rotating disc, wherein the periphery of the rotating disc is provided with a horizontal cup mould, a bounding press block is arranged on the position of the horizontal cup mould, when the rotating disc rotates, the cup mould sequentially passes through each station making paper cups, the rolling bottom and the hemming of the invention are formed at one step, and more important, when all the stations work, the cup is always in the bonding state on the cup mould, so that the edge of the heated paper cup has enough time to cool when being bounded, and the paper cup is firmly bounded. The invention has strong movement coherence, can make over 100 paper cups per minute, and can reach the purpose of making the paper cups at a high speed.

Owner:ZHEJIANG NEW DEBAO MACHINERY

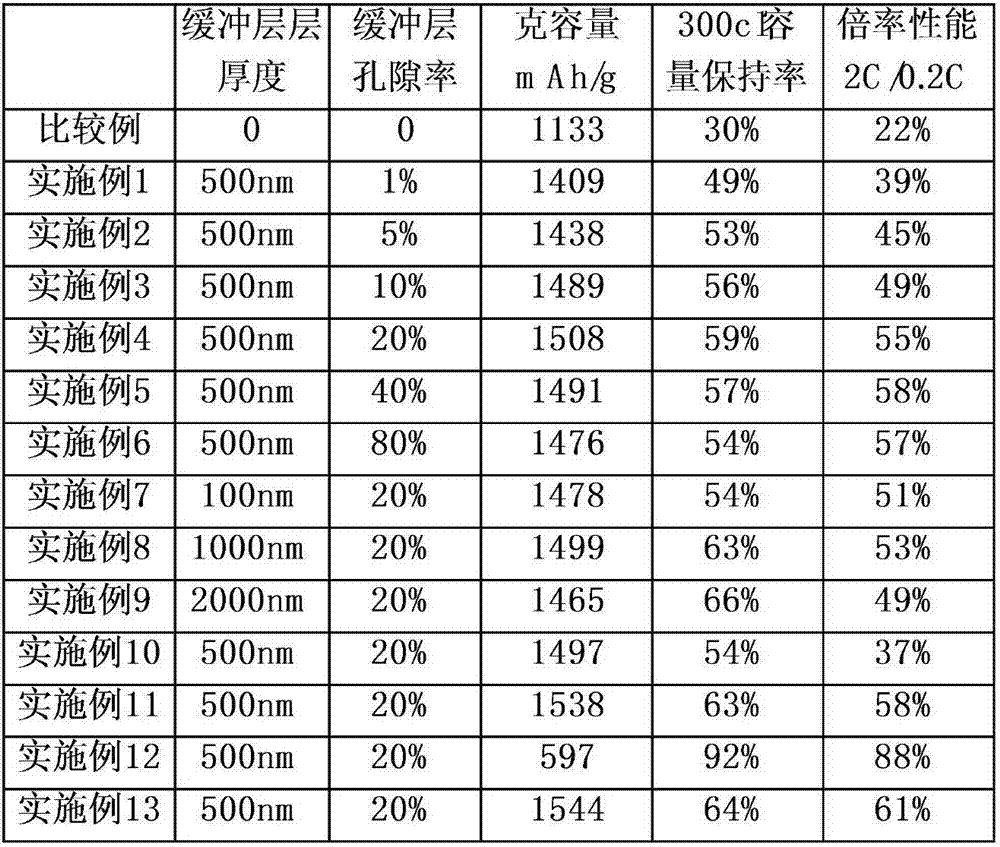

Silicon-carbon negative electrode material and preparation method thereof

InactiveCN106941170AImprove electrochemical performanceClosely connectedMaterial nanotechnologyCell electrodesPorosityCyclic process

The invention belongs to the field of energy storage research and relates to a silicon-carbon negative electrode material. The silicon-carbon negative electrode material comprises a core structure and a shell structure. A buffer layer is arranged between the core structure and the shell structure. The buffer layer is tightly connected to the surface of the core structure. The buffer layer is tightly connected to the inner surface of the shell structure. The buffer layer has a porous structure with porosity of 1% to 80%. The core structure and the shell structure are tightly connected by the buffer layer so that in the whole cycle, the core structure and shell structure of the silicon-carbon negative electrode material are closely linked together. The buffer layer having the sponge porous structure can effectively absorb volume expansion of the core structure in the charging process and relieve the expansion pressure of the shell structure so that the structure of the material is stable and the silicon-carbon negative electrode material having excellent electrochemical properties is obtained.

Owner:GUANGDONG ZHUGUANG NEW ENERGY TECH

Solid wood door leaf and manufacturing method thereof

InactiveCN101638969ANo crackingThere will be no whitening phenomenonWood working apparatusDoor leavesSolid woodMechanical engineering

The invention relates to a solid wood door leaf and a manufacturing method thereof. The solid wood door leaf comprises a door leaf outer frame and at least a door closure plate inlaid in the door leafouter frame, wherein the door leaf outer frame is formed by assembling at least two door vertical beams in horizontal arrangement and at least two crosspieces in vertical arrangement, at least a doorclosure plate assembly port is formed, an assembly groove assembled at the edge of the door closure plate through scarf joint is formed at the periphery of the door closure plate assembly port, the door vertical beams, the crosspieces and the door closure plate are respectively covered with a paint later, an unpainted adhesive position is respectively left at the bottom of the assembly groove andat the periphery of the door closure plate, and the door closure plate, the door vertical beams and the crosspieces are cemented into a whole at the adhesive positions in an elastic adhesive mode. The door vertical beams, the crosspieces and the door closure plate are not easily deformed in the use process, and the phenomena of painted surface break and whiteness exposure do not occur, ensuring that the door leaf outer frame and the door closure plate are tightly bonded in an adhesive mode and can not be tightly bonded because of paint.

Owner:QUANZHOU JIASEN WOOD

Preparation method of TPU and PVC blended improved composite fabrics

ActiveCN102729559AGood weather resistanceImprove wear resistanceSynthetic resin layered productsLaminationEngineeringOxygen

The invention discloses a preparation method of TPU and PVC blended improved composite fabrics. According to the method, TPU and PVC are blended to fully perform respective characteristics of TPU and PVC, so as to achieve the purpose of complementary advantages; calendaring molding is carried out by a four roll calender method to obtain a TPU and PVC blended film; and on-line lamination is carried out on the TPU and PVC blended film and glued base cloth on a calendar so as to obtain the TPU and PVC blended improved composite fabrics. The composite fabrics have characteristics of excellent mechanical property, wear resistance, environmental protection and the like. The coating of the composite fabrics is uniform and thickness error is less than 0.015mm. The composite fabrics has advantages of firm adhesion, wear resistance and flexing resistance, and can be widely used in application fields of inflatable life jacket, chemical splash suit, water pot, oil tank, sphygmomanometer, medical bed, oxygen bag, inflatable cushion, airbed, inflatable tent, air bag, air cushion ship, waterproof moisture permeable high-grade costuming and the like.

Owner:无锡翔隆高分子面料有限公司

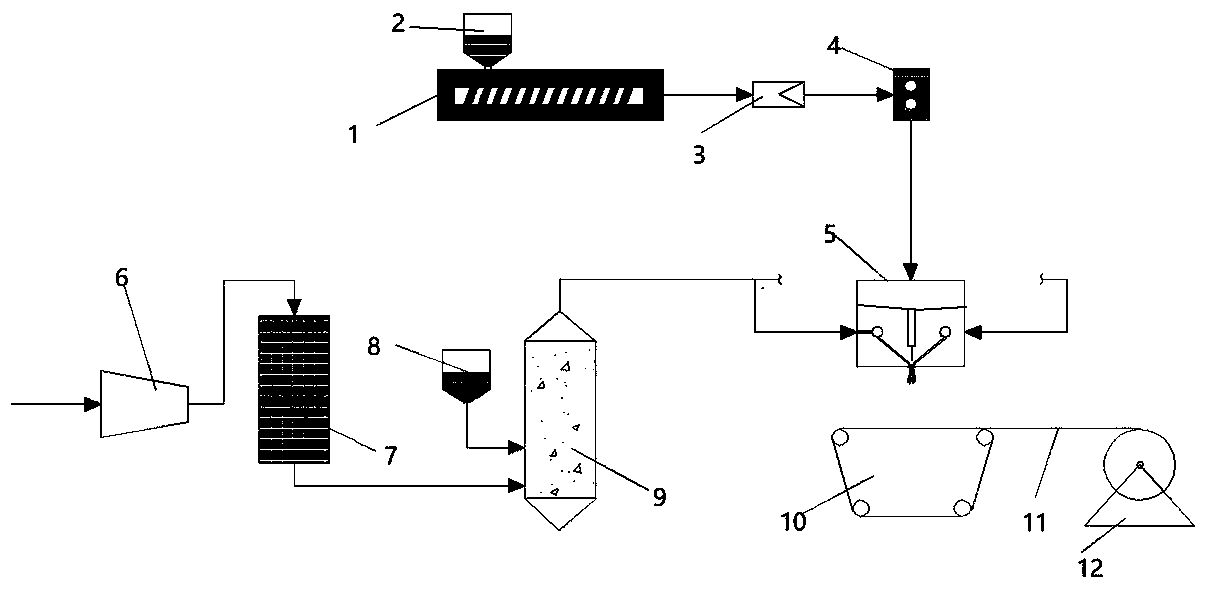

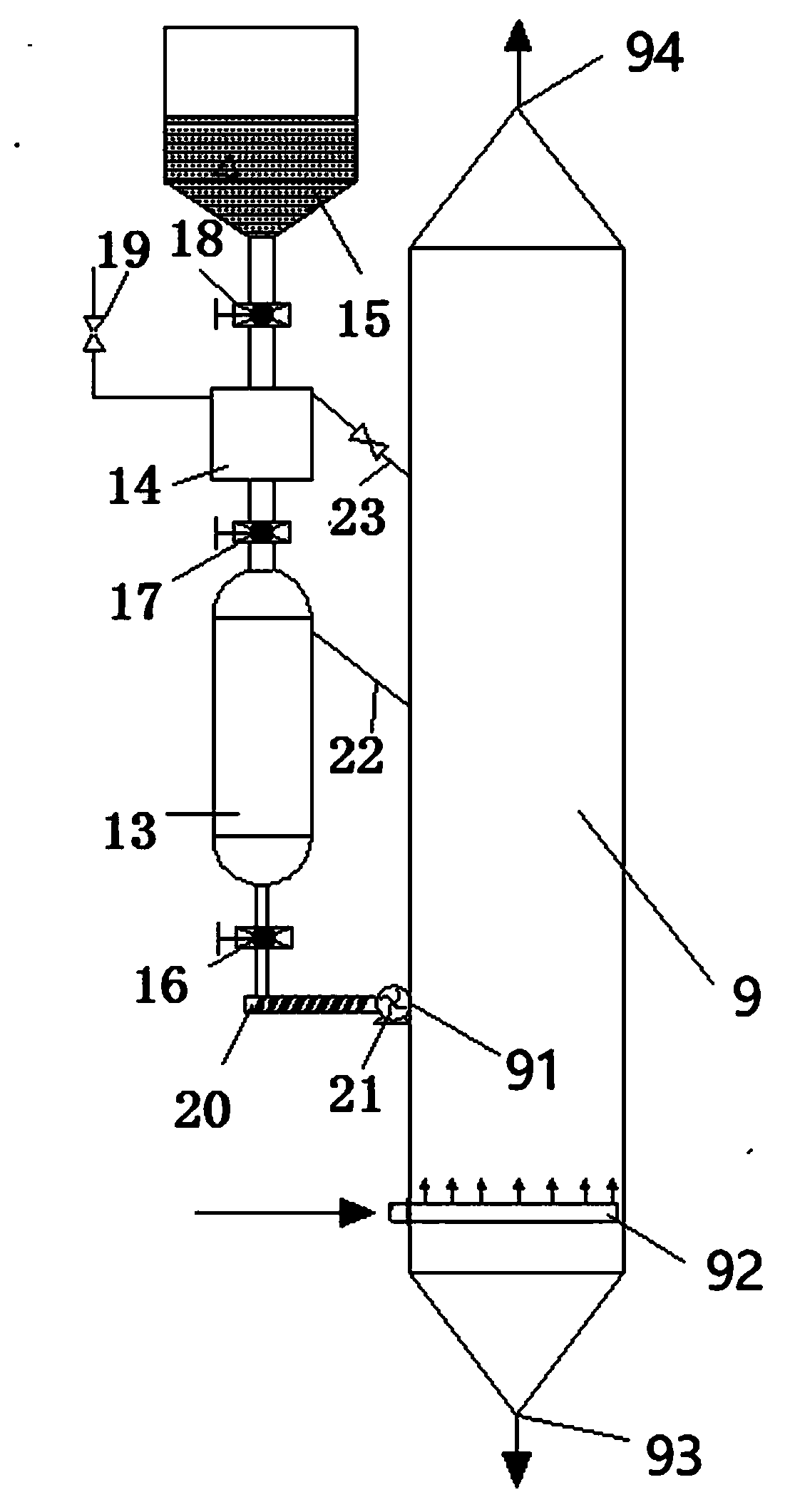

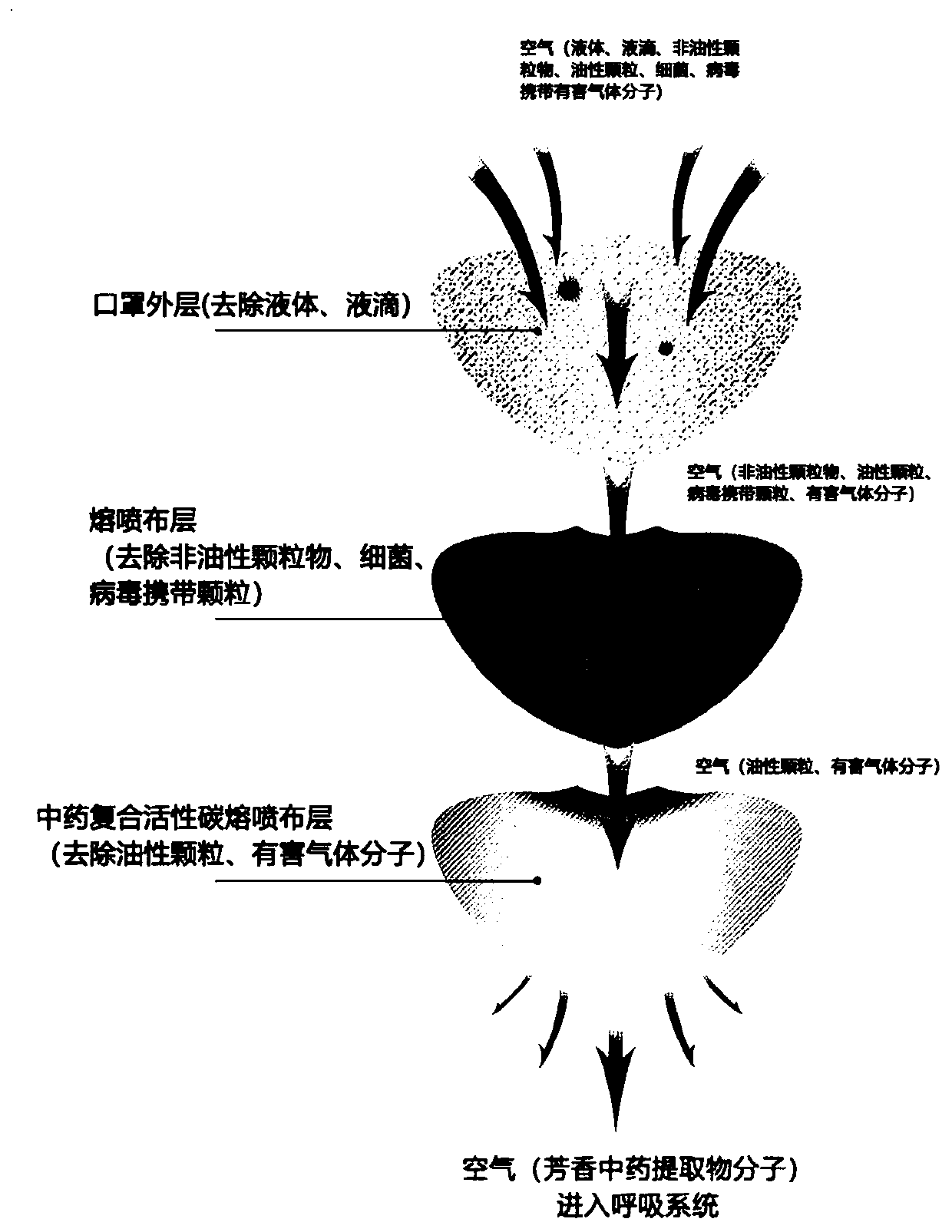

Activated carbon composite melt-blown fabric, preparation method thereof and mask

ActiveCN111424374AReduce sheddingImprove filtering effectDispersed particle filtrationBiochemical fibre treatmentFiberActivated carbon

The invention discloses a preparation method of an activated carbon composite melt-blown fabric. A melt-blown melt is sprayed by using a fluidized state high-temperature high-pressure gas containing activated carbon particles as traction gas, in the process, a gas-liquid-solid three-phase mixed flow field is sprayed forwards, and finally, the melt is cooled and formed and cured in the form of a fiber mesh structure; meanwhile, activated carbon evenly adheres to and is constrained in the fiber mesh structure, and finally the stable activated carbon composite melt-blown fabric is formed. The activated carbon composite melt-blown fabric is soaked in a traditional Chinese medicine extract, so that the melt-blown fabric has the effects of sterilizing, disinfecting, respiratory tract resistanceimprovement, odor freshening and the like. The invention also discloses the activated carbon composite melt-blown fabric obtained through the preparation method and a mask using the activated carbon composite melt-blown fabric. The filtering, sterilizing and protecting effects are good.

Owner:大湾汉唯(广州)医药科技集团有限公司

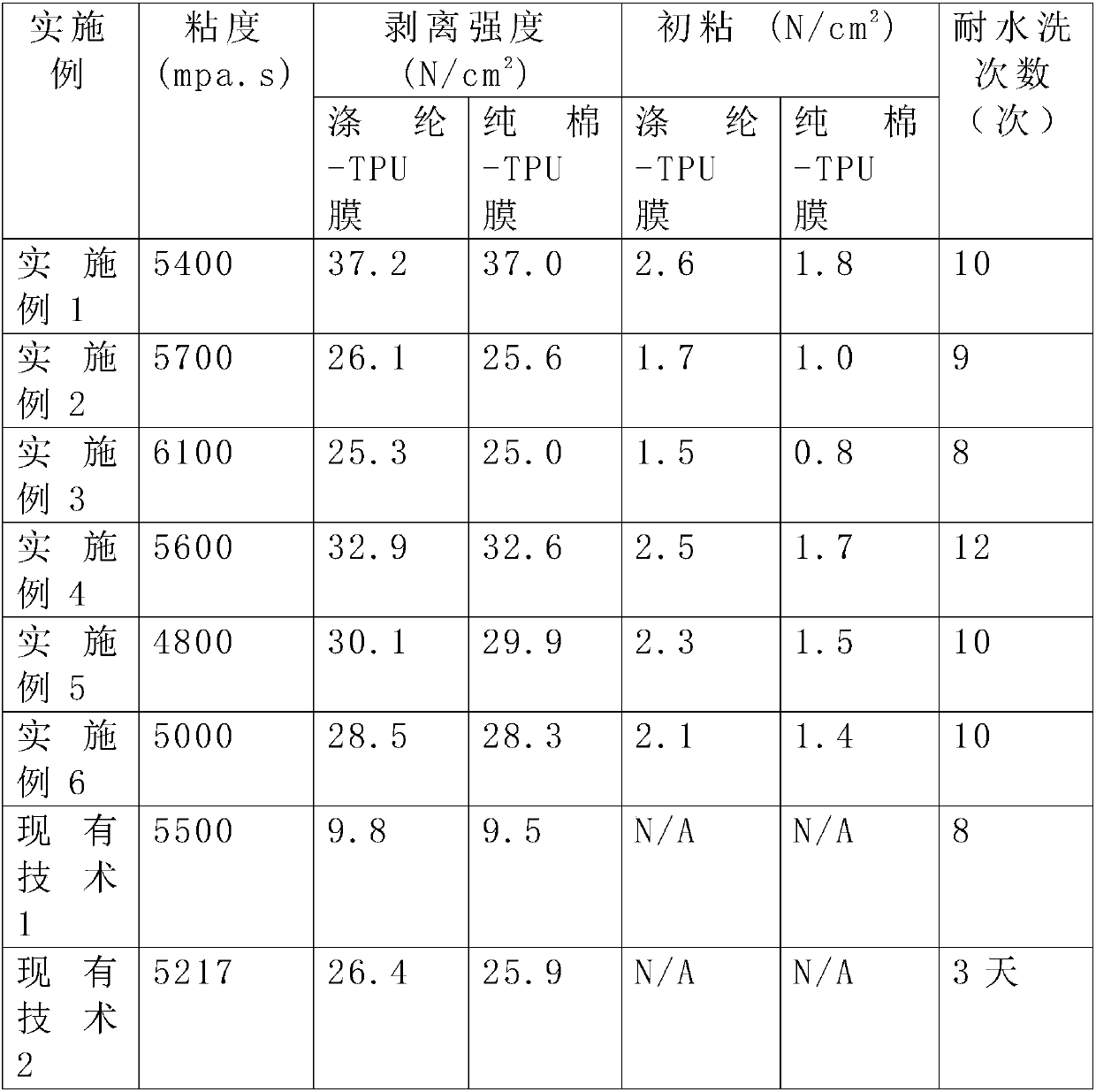

Hyperbranched polyester hot-melt-type polyurethane adhesive for weaving and preparation method thereof

InactiveCN108084948AHighlight cohesionOutstanding initial tackNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyurethane adhesivePolyol

The invention discloses a hyperbranched polyester hot-melt-type polyurethane adhesive for weaving and a preparation method thereof. The hyperbranched polyester hot-melt-type polyurethane adhesive comprises polyether polyol, hyperbranched polyester polyol, MDI and an additive. The preparation method comprises preheating hyperbranched polyester polyol at 100-150 DEG C until melting to obtain hyperbranched polyester polyol pre-melt, checking the hermeticity of a reactor, removing water through replacing with nitrogen gas, carrying out preheating to 50 DEG C, orderly adding MDI and polyether polyol into the reactor, carrying out stirring in vacuum under control of a jacket temperature to 60-80 DEG C for a reaction for 1-3h, fast cooling the reaction system to 55 DEG C to obtain a polyurethaneprepolymer, orderly adding polyester polyol and the hyperbranched polyester polyol pre-melt into the polyurethane prepolymer in vacuum, heating the mixture to 60-80 DEG C, carrying out stirring for areaction for 1-3h, breaking vacuum after the reaction, and removing air bubbles to obtain the hyperbranched polyester hot-melt-type polyurethane adhesive for weaving.

Owner:黄子昕

Polyvinyl chloride powdery plastic dipping composition

The invention relates to a polyvinyl chloride powdery plastic dipping composition, and belongs to the technical field of processing and application of high-molecular materials. The polyvinyl chloride powdery plastic dipping composition is characterized by comprising the following components (in parts by weight): 100 parts of polyvinyl chloride, 2-15 parts of polyvinyl chloride paste resin, 35-65 parts of plasticizing agent, 1-7 parts of stabilizing agent, 1-6 parts of epoxidized soybean oil, 2-10 parts of lubricating agent and 0-10 parts of filler, wherein polyvinyl chloride is suspension method polyvinyl chloride resin, the polymerization degree is 500-800, and the grain diameter is 50-200 micrometers; the polymerization degree of the polyvinyl chloride paste resin is 1000, and the grain diameter is 5-20 micrometers. Compared with the prior art, the polyvinyl chloride powdery plastic dipping composition disclosed by the invention achieves shorter melting and plasticizing time and better leveling property of a plastic dipping product by requiring the polymerization degree of polyvinyl chloride resin powder and the granular size of the composition.

Owner:CHINA PETROLEUM & CHEM CORP

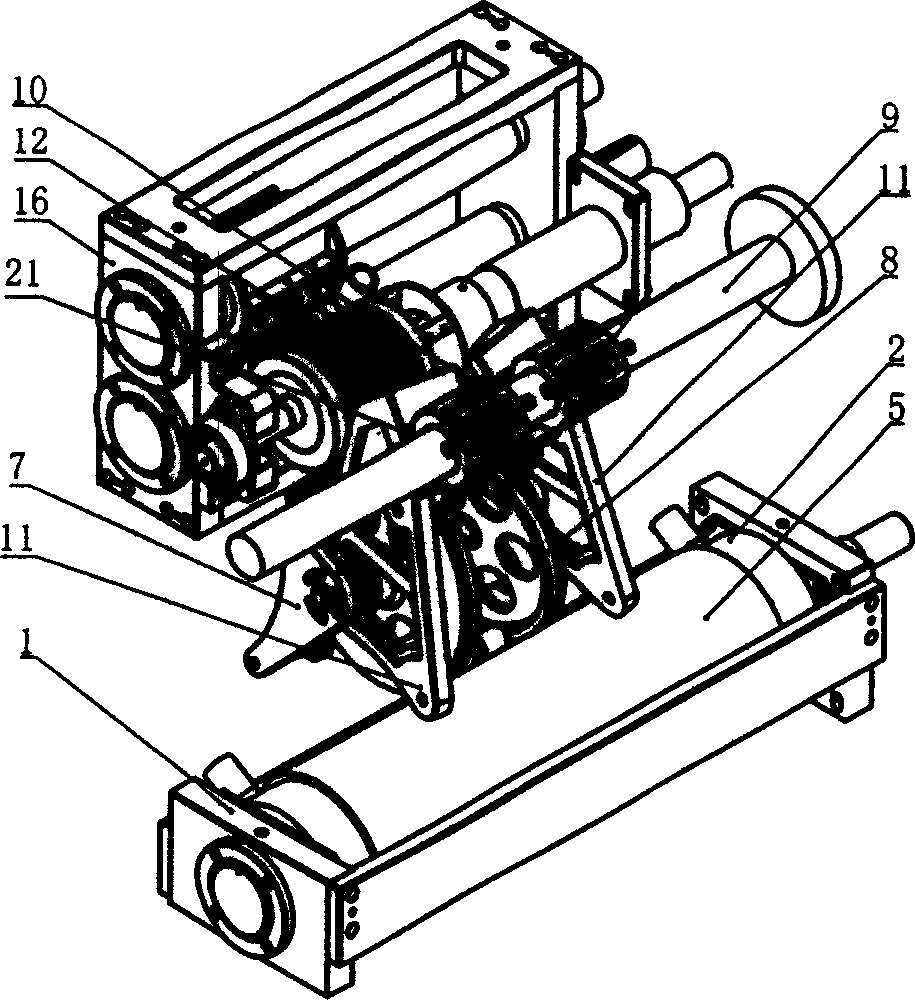

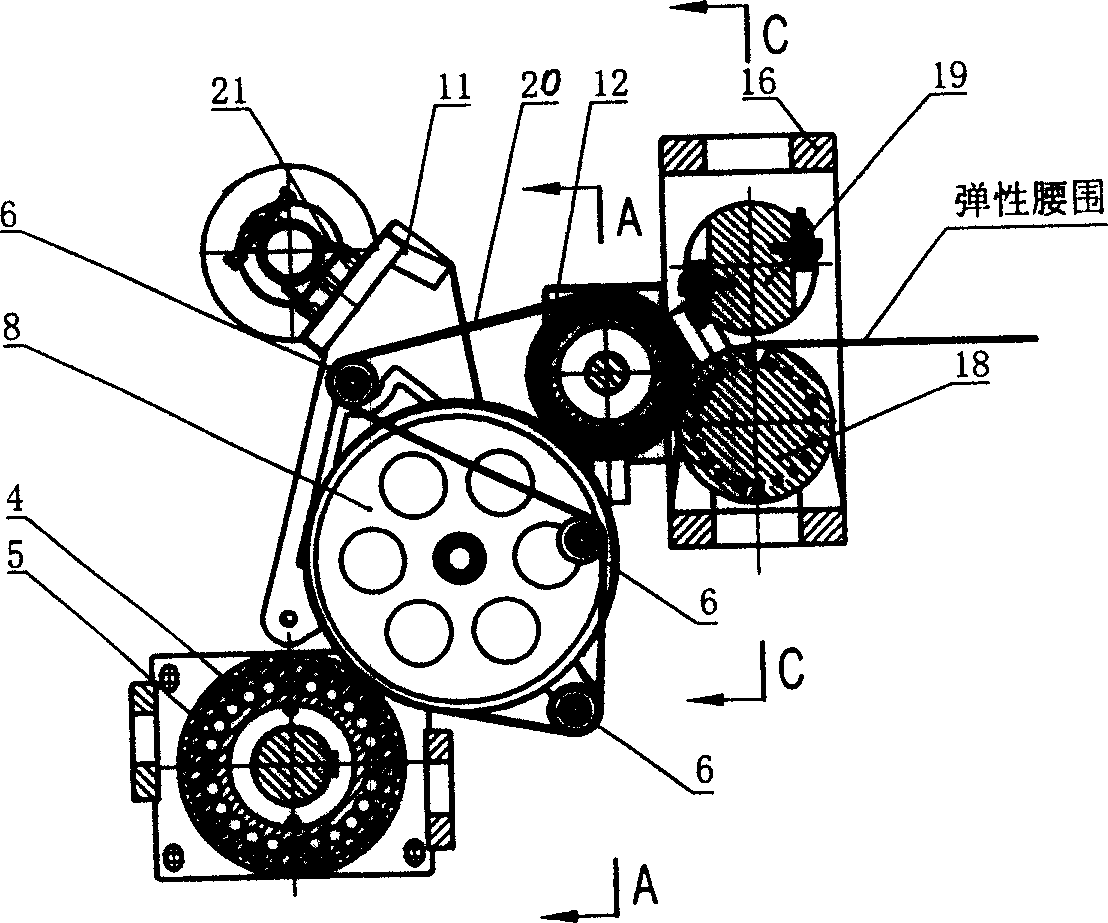

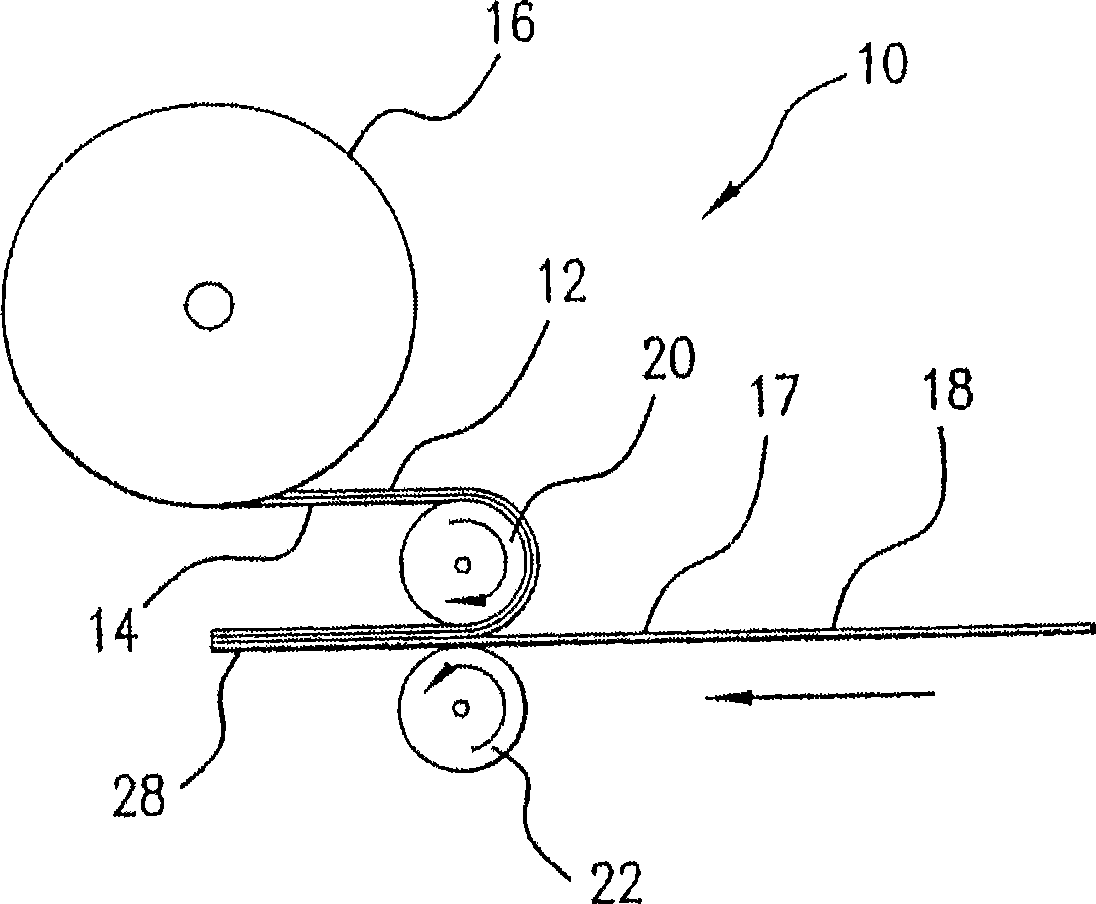

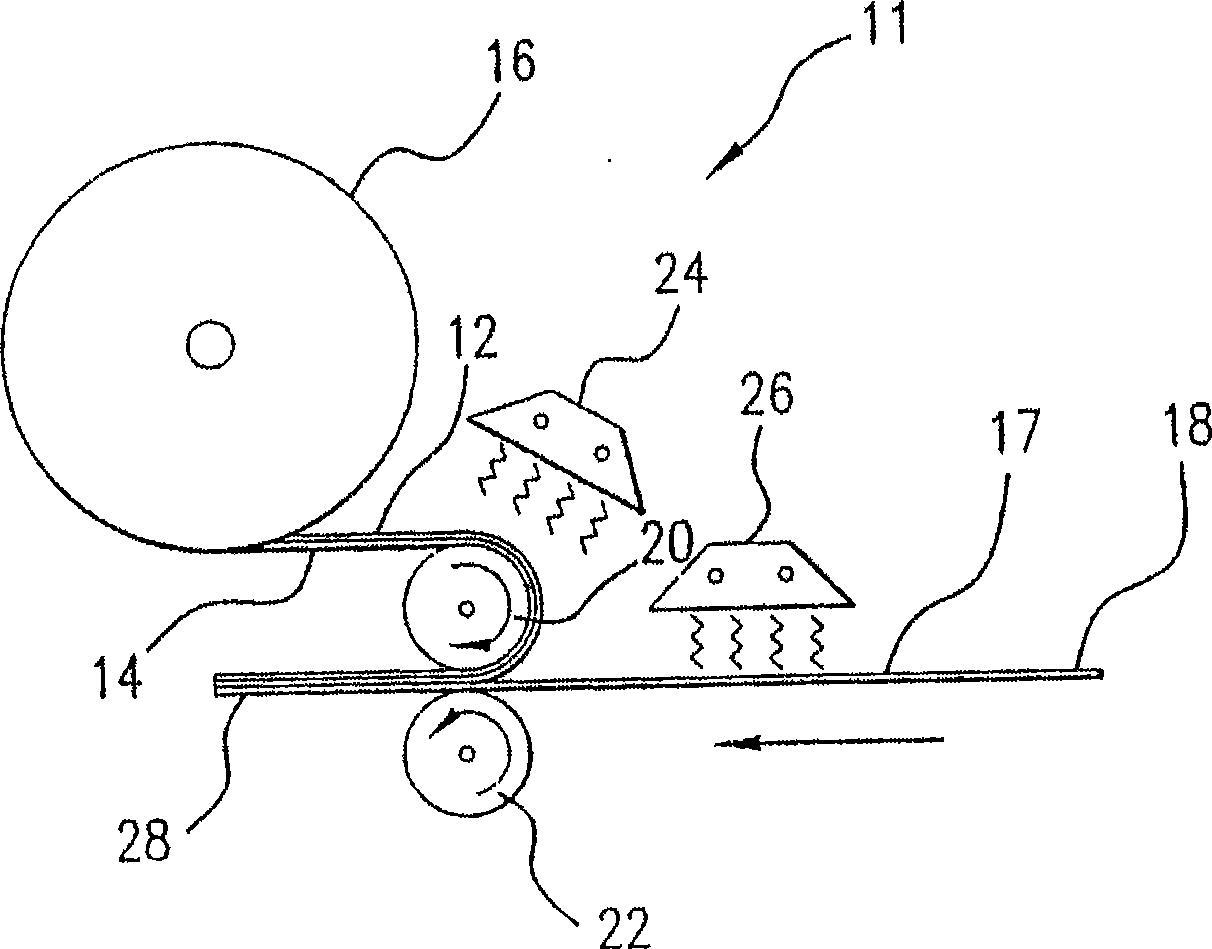

Device for cutting, extending and shifting elastic waistline

ActiveCN1663546AAdhesivelyThe transfer process is smoothSevering textilesAbsorbent padsProtection layerProduction line

The invention relates to equipment on product line for one-time health aids of napkin, that is chopping stretching and shift equipment for elastic waistline. The invention is realized by modifying existing equipment, and characterized in that: 1. setting Octoid gear of stretch mechanism on the stand through side plate, position sleeve and fixed base, realizing that Octoid gear rolls round horizontal and vertical shaft, and can move along horizontal shaft;2. setting transfer snifting valve on the two ends of transfer roller, suction distributes symmetrical and uniform, which overcomes phenomenon of less elasticity, deletion and breaking angle; 3. setting rubber layer on outer surface of transfer roller, which makes the adhesion of elastic waistline and material of garment to firm up, and antiseize protection layer of Octoid gear can not be destroyed. The equipment from this invention can run stably with speed of product line more than 200m / min, fast in adhere, waste rate reduced, improves production efficiency; and simple in structure, convenient to adjust.

Owner:ANQING HENG CHANG MACHINERY

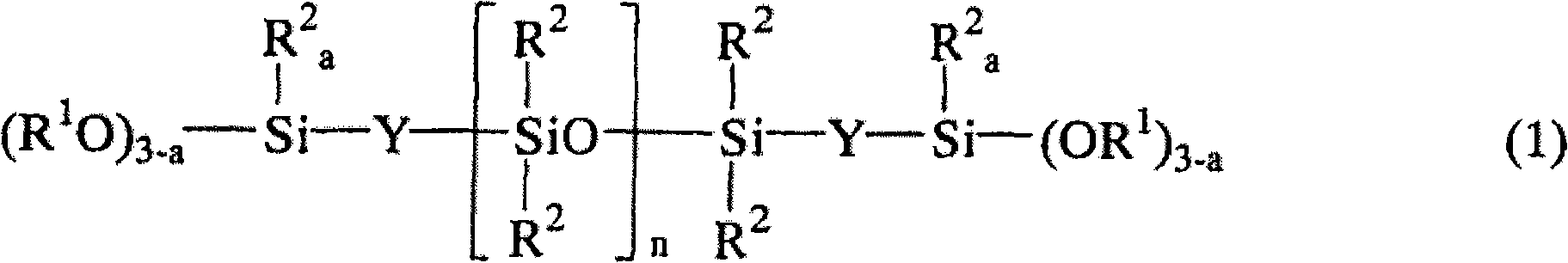

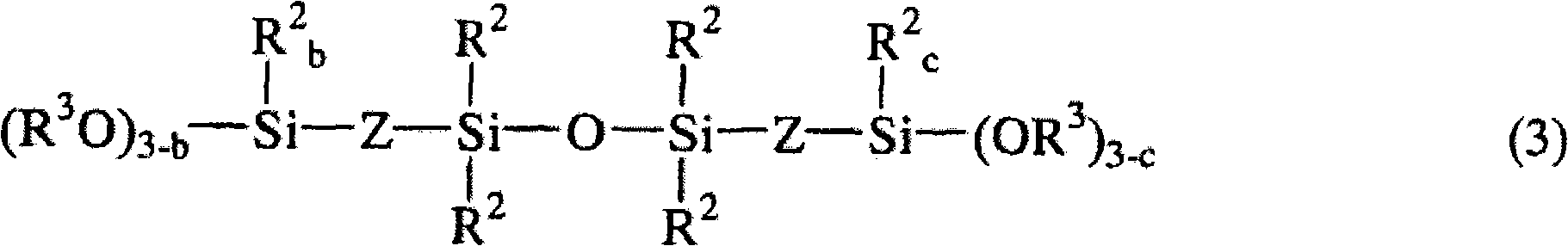

Room temperature curable organopolysiloxane composition

An RTV organopolysiloxane composition is provided comprising (A) a diorganopolysiloxane capped at both ends of its molecular chain with hydroxysilyl, alkoxysilyl or alkoxyalkoxysilyl and having a viscosity of 20-1,000,000 mPa-s at 25 DEG C, (B) a bis(alkoxysilylalkyl)disiloxane compound, and (C) a curing catalyst. The composition is fast curable into a silicone rubber which establishes a firm adhesion to substrates with an active surface such as float glass and maintains the adhesion even in a harsh environment as immersed in hot water over a long term.

Owner:SHIN ETSU CHEM CO LTD

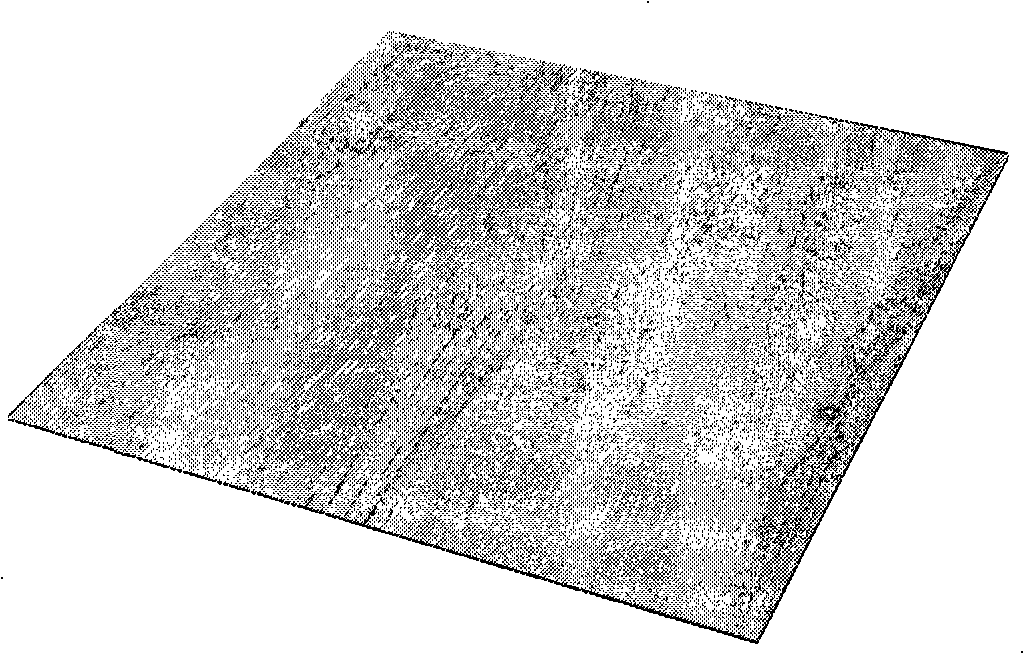

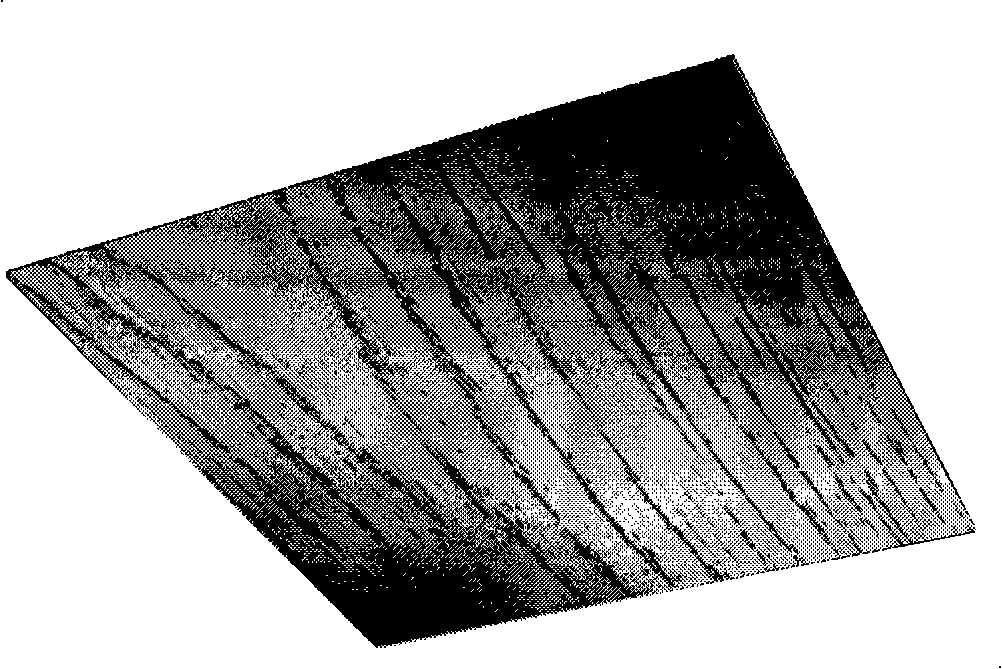

Simulation synchronously impressing patterns and facing artificial board production process

ActiveCN101259626AReflect completeSimple methodLamination ancillary operationsNatural patternsHigh rateEngineering

The invention discloses a manufacturing method of an emulational synchronous lines marked facing man-made panel which consists of the following steps: patterns can be obtained by shooting or according to real objects to design the patterns, and the patterns are decomposed into corresponding two parts by using the technology of computer image processing; a grounding pattern is printed on decoration paper, and a texture pattern is made to be a corresponding solid relief sculpture as a die mold; the decoration paper which is printed with the grounding pattern and other planks that are necessary to lead the facing man-made panel to be folded according to requirements; the die mold is corresponding to the decoration paper with the grounding pattern according to an original real object, and the folded planks are thermally pressed by the die mold; dye needed is coated on the surface of the sinking position of the plank pressed, and the emulational synchronous lines marked facing man-made panel can be obtained by removing the dye on the convex part and solidifying the dye. The emulational synchronous lines marked facing man-made panel uses the method to separate plane patterns on the real object patterns from the patterns which can reflect the solid effect, and the method has the advantages of low cost and high rate of finished products when the emulational man-made plate with the solid effect is made.

Owner:POWER DEKOR GROUP

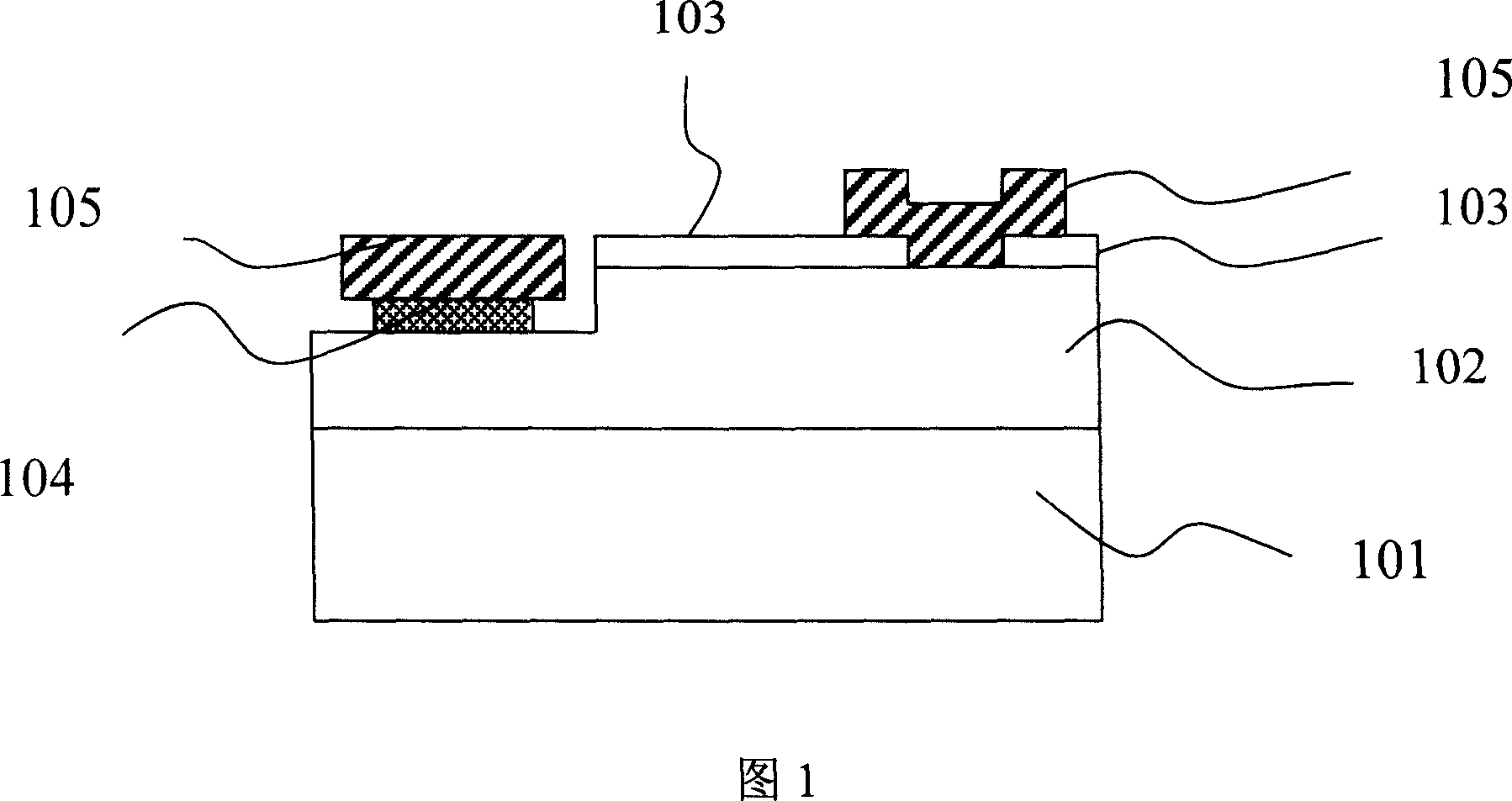

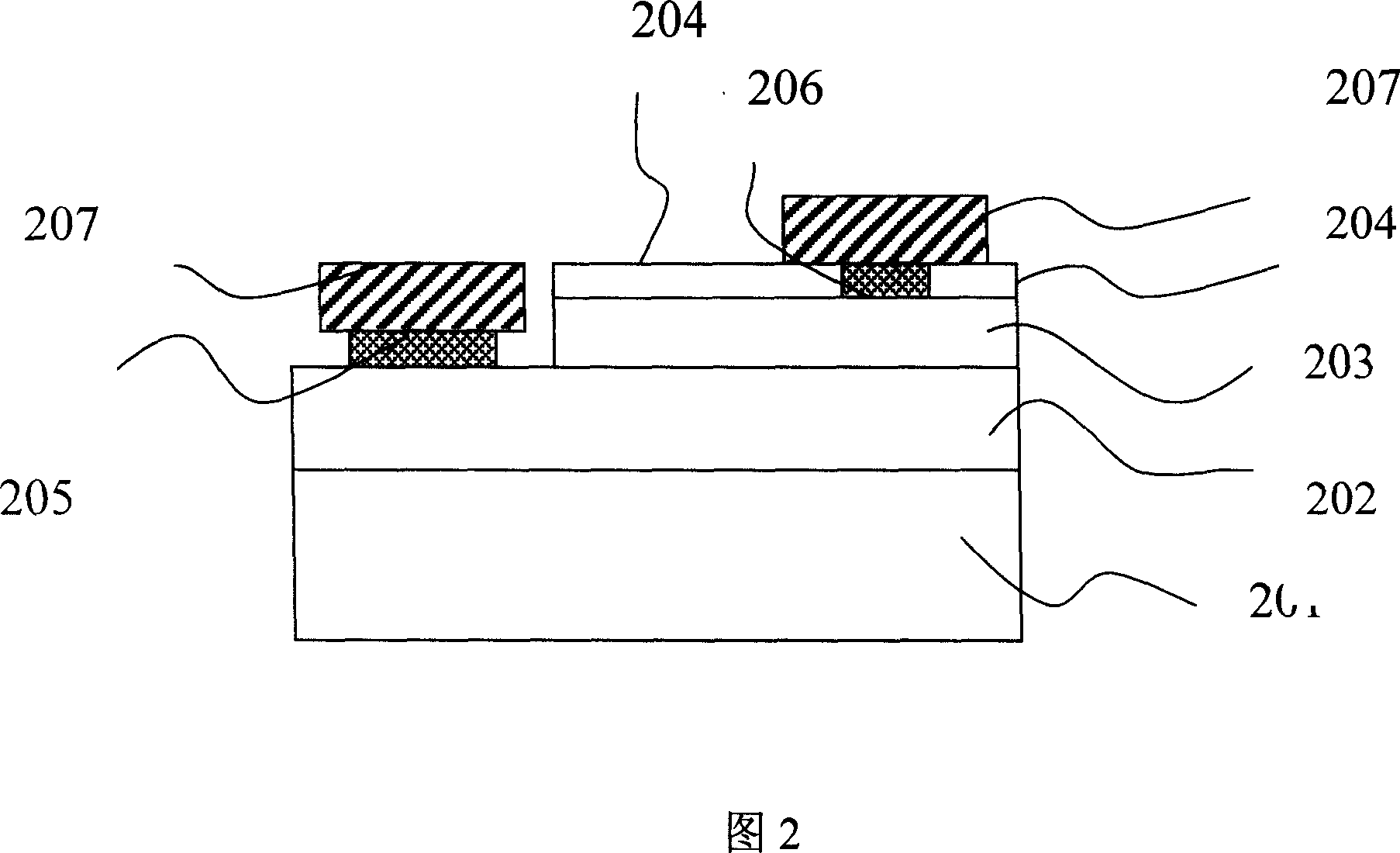

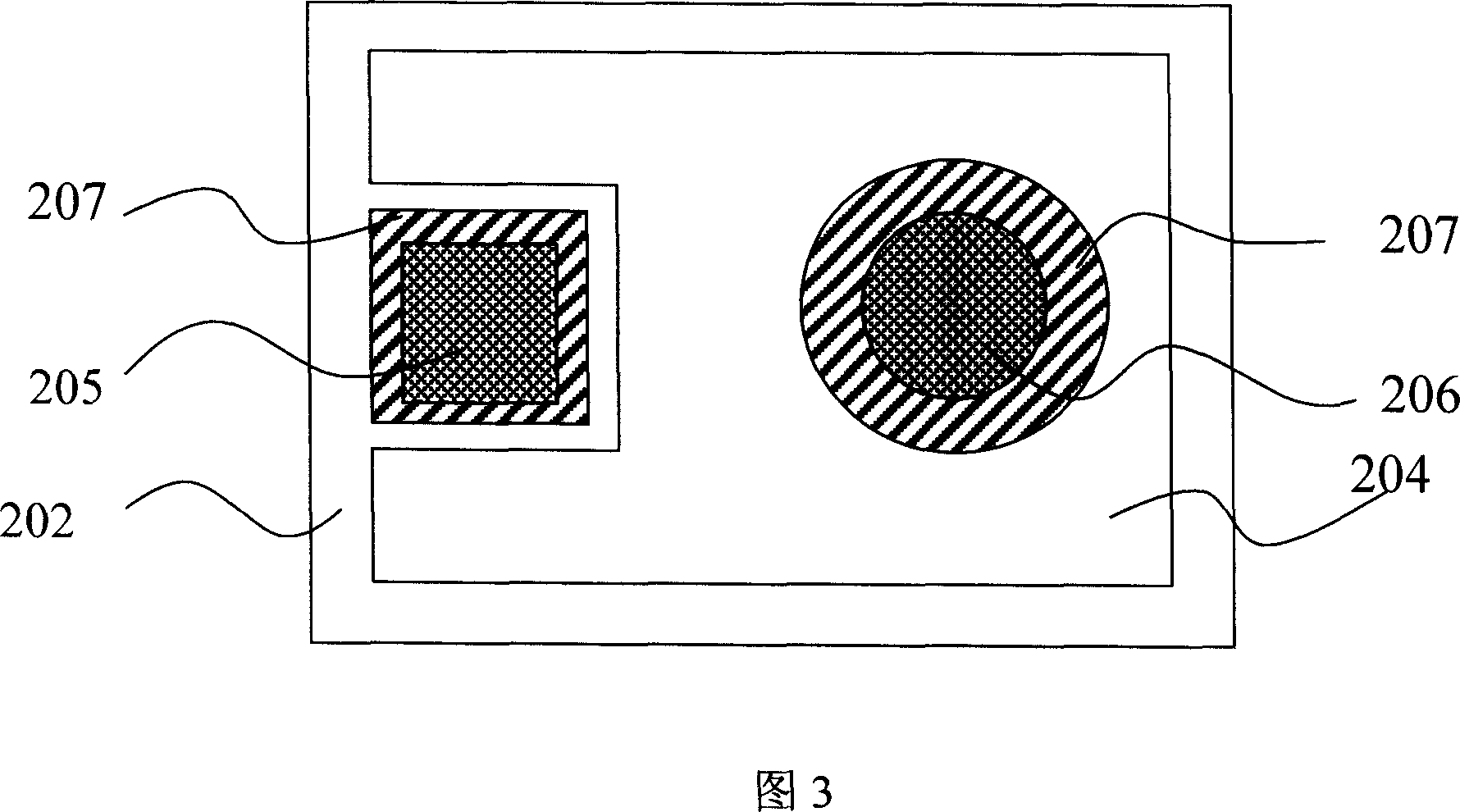

Method for preparing LED electrode

This invention relates to a preparation method for preparing LED chips including: 1, adding an adhered layer of strong adhesion between an ordinary wire winding disk and a semiconductor illumination structure to avoid the disk to be divorced, 2, roughing the surface of the disk to increase the connecting strength of the disk and outside weld lines.

Owner:DAUAN LUMEI OPTOELECTRONICS

Polymer repairing mortar and preparation method thereof

The invention discloses a polymer repairing mortar. The polymer repairing mortar comprises 400-500 parts of cement, 500-600 parts of quartz sand, 1-5 parts of a high-molecular polymer, 5-15 parts of a polymer, 1-5 parts of silicon micropowder and 0.1-0.3 parts of wood fiber, wherein the high-molecular polymer is cellulose ether, and the polymer is re-dispersible latex powder. The purpose of the invention is to provide the polymer repairing mortar with the characteristic of long service life and no cracking, and a preparation method thereof.

Owner:浙江泰正建材有限公司

Self-adhesive flaky material

InactiveCN101443199AHigh Peel ResistanceHigh static shear strengthFilm/foil adhesivesSpecial ornamental structuresSolventAcrylic polymer

A decorative laminate includes a laminate substrate coated with an adhesive layer. The adhesive layer is a layer of a physically setting, solvent-free adhesive material including an acrylic polymer. The adhesive layer is self-adhesive at room temperature. The adhesive-coated laminate substrate has a peeling-off force of at least 0.2 N / mm<2 >, after application on a carrier. A method for the production of the adhesive-coated laminate substrate, its use as a coating material, and a composite of the adhesive-coated laminate substrate and a carrier material are also provided.

Owner:浦瑞玛柯RWP控股公司

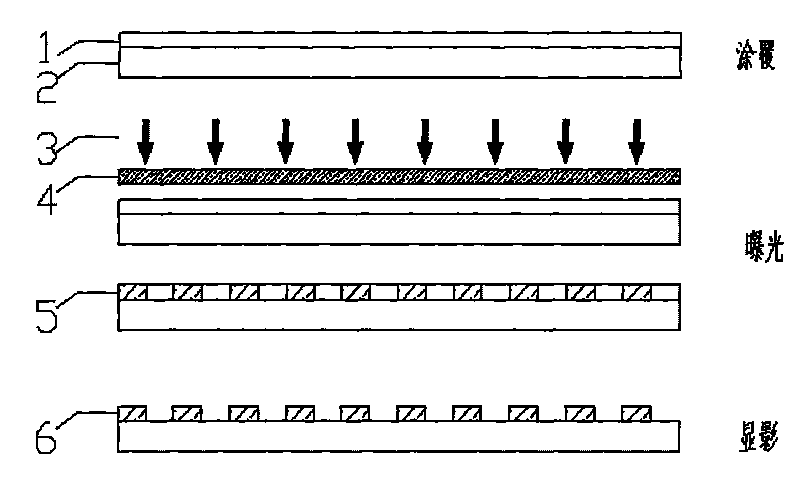

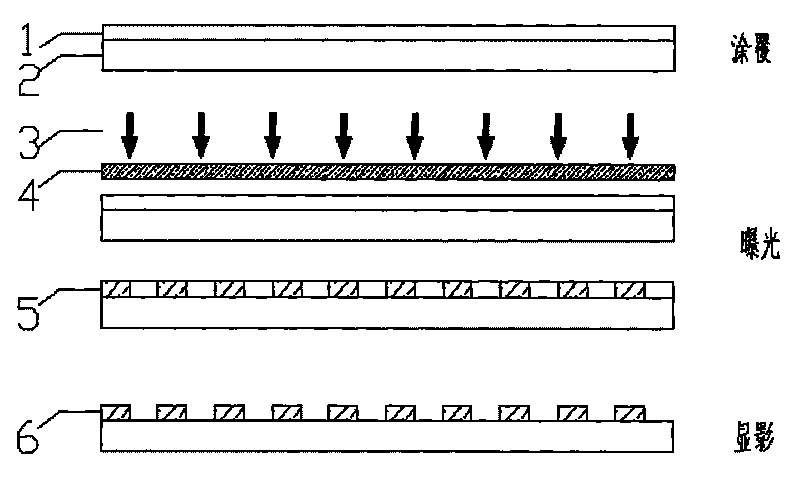

Materials of electronic paper micro-cup and preparation method

The invention relates to materials of an electronic paper micro-cup manufactured on a flexible or rigid substrate and a method for preparing the electronic paper micro-cup. In part by weight, the raw materials of the electronic paper micro-cup comprise 10 to 30 parts of solvents, 15 to 40 parts of resin, 3 to 6 parts of active components, 20 to 70 parts of glass filler and 1 to 4 parts of dispersant; and the coatings can further comprise 1 to 2 parts of defoamer dimethyl polysiloxane in part by weight. The method for preparing the electronic paper micro-cup comprises 1) a base material pretreating process, 2) a coating process, 3) a prebaking process, 4) a masking and exposing process, 5) a developing process and 6) a solidifying process. The method can manufacture a micro-cup figure withhigh resolution, also can simplify the manufacturing processes and reduce the preparation cost of the micro-cup, and is quite suitable for the manufacturing of the electronic paper micro-cup.

Owner:IRICO

Manufacturing technology of basketball

The invention relates to a manufacturing technology of a basketball. The manufacturing technology comprises the steps that firstly, a layer of yarn is wound on a basketball liner, then, the basketballliner is wrapped with rubber, a basketball liner workblank is formed, and vulcanization is not carried out; basketball skin pieces are bonded on the basketball liner workblank through heating and compression; and finally, vulcanization is carried out, so that the basketball skin pieces and the basketball liner workblank are bonded more firmly. The manufacturing technology has the beneficial effects that design of the basketball is reasonable, glue is not utilized, and the technology is more environmentally-friendly; vacuum package and transportation can be adopted, and transportation efficiency is improved; the basketball bounces higher, and rebound is more powerful; and bonding is firmer, and degumming and skin wrapping problems are avoided.

Owner:王冠华

Fractured-vuggy carbonate rock plate model and preparation method thereof

The invention provides a fractured-vuggy carbonate rock plate model and a preparation method thereof. The model is characterized by being prepared by a cementing material after a natural carbonate rock plate is carved, wherein the cementing material is evenly mixed by carbonate rock powder of 0.01-1 micron and curing agent solution according to the mass ratio of 75: 25; the curing agent solution is mixed by furan resins and epoxy resins of 10-15%, m-phenylenediamine and diaminodiphenyl-methane of 35-40% and the balance of glycerin; and the sum of all the components is 100%. The prepared fractured-vuggy carbonate rock plate model can truly reflect the influence on each recovery improvement mode and fractured-vuggy carbonate rocks from such properties as the absorption of a surface active agent on the carbonate rocks, the wettability of the carbonate rocks and the interface electrical property.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

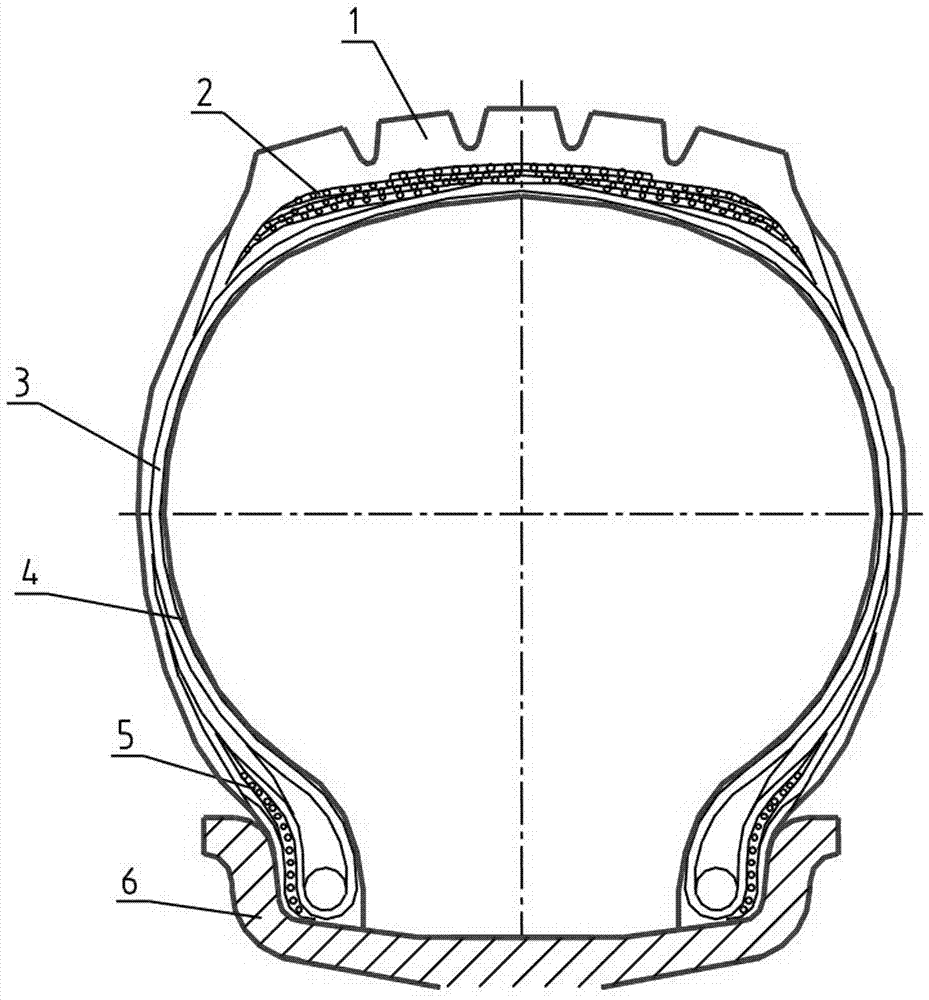

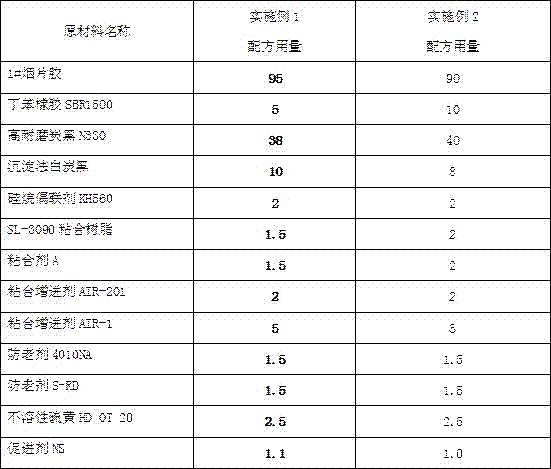

Tread rubber materials for making meridian aircraft tire belt layer cord threads with aramid fiber threads

Disclosed are tread rubber materials for making meridian aircraft tire belt layer cord threads with aramid fiber threads. The rubber materials are prepared according to a certain ratio with 1# smoke sheet rubber as main rubber materials and butadiene styrene rubber, resorcinol bonding resin, formaldehyde bonding resin, a bonding promoter AIR-201 special for the aramid fiber threads, a bonding promoter AIR-1, highly-abrasion-resistant carbon black, precipitated silica, a novel silane coupling agent, insoluble sulfur and a sulfenamide accelerator as main auxiliary materials. The rubber materials have the performance advantages that the bonding strength of the rubber materials and the aramid fiber threads is high, and the bonding retention rate after thermal ageing is high and have the performance characteristics of being high in tensile strength and tearing strength, low in compression fatigue heat generation and high in definite elongation stress. The rubber materials are used as aircraft meridian tire belt layer tread rubber, thus under the high-load and high-speed severe usage conditions, the quality problems of rubber thread loosening or delaminating of layers do not occur to the belt layer position of the aircraft tire, the rubber threads are bonded firmly, and the tire is safe to use.

Owner:中国化工集团曙光橡胶工业研究设计院有限公司

Oil-cooling pipe of automatic gearbox and production process thereof

InactiveCN101660636ATo achieve the effect of bondingSimple production processGear lubrication/coolingFlexible pipesRubber materialFiber

The invention discloses an oil-cooling pipe of an automatic gearbox and production process thereof. The oil-cooling pipe sequentially comprises an inner rubber layer, a fiber-wire strengthening layerand an outer rubber layer from inside to outside. The oil-cooling pipe is manufactured according to the steps of: (1) delivering rubber components of both inner and outer rubber layers to a banburyingmachine for mixing; (2) carrying out rapid detection to the semi-finished rubber material after the banburying process; (3) putting the rubber material into a 90 extrusion machine with straight headto extrude the inner rubber layer out; (4) adopting a 24-spindle vertical braiding machine to weave the fiber-wire strengthening layer on the extruded inner rubber layer; (5) adopting a T-shaped headto extrude the semi-finished product obtained in step (4) on the 90 extrusion machine so as to obtain the outer rubber layer; (6) cutting off the rubber pipe and carrying out vulcanization in a digester; and (7) obtaining the finished products after washing the rubber pipe and cutting pipe heads. The invention simplifies the production process, saves cost and leads the operation to be more convenient; and simultaneously, the binding is stable and the product quality is better.

Owner:ZHEJIANG JUNHE RUBBER TECH

Rubber adhesive strip for shoes and preparation method thereof

InactiveCN102382598AEffective bondingAdhesivelyNatural rubber adhesivesNon-macromolecular adhesive additivesPolymer scienceAdhesive

The invention discloses a rubber adhesive strip for shoes. For the rubber adhesive strip, natural rubber, butadiene styrene rubber, accelerating agent M, accelerating agent DM, accelerating agent TMTD, sulphur, solid ancient malone, anti-aging agent BLE-C, argil, zinc oxide, stearic acid, machine oil, calcium carbonate, carbon black N330, scorch retarder CTP and salicylic acid are selected, and the rubber strip meeting the standard requirement is formed by dicing, plastifying, roling, plastifying again, rolling again, rubber refining, wingding and dividing. The rubber strip disclosed by the invention is adhered on the periphery of a dried sponge innersole coated with natural rubber glue, a dried upper with upper corners brushed with the natural rubber glue is sleeved on a shoe tree, and the sponge innersole adhered with the rubber adhesive strip is placed at the bottom of the shoe tree and pulled by hand or machine to be adhered with the upper. With the adoption of the rubber adhesive strip, a polyester filament yarn upper can be effectively and firmly adhered with the sponge innersole, and the percent of pass of the finished shoes can reach more than 99%.

Owner:QINHUANGDAO JIHUA 3544 SHOES

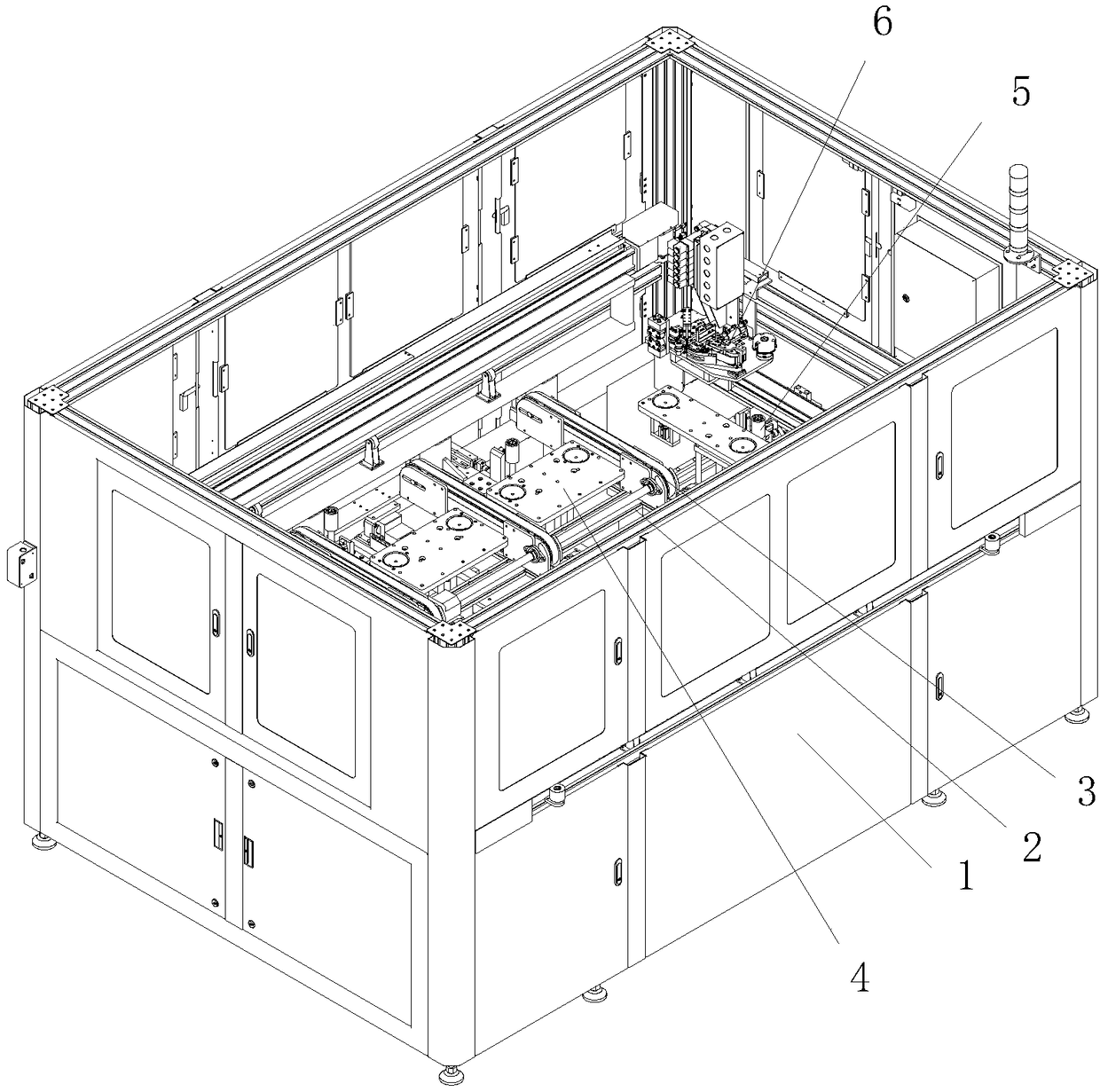

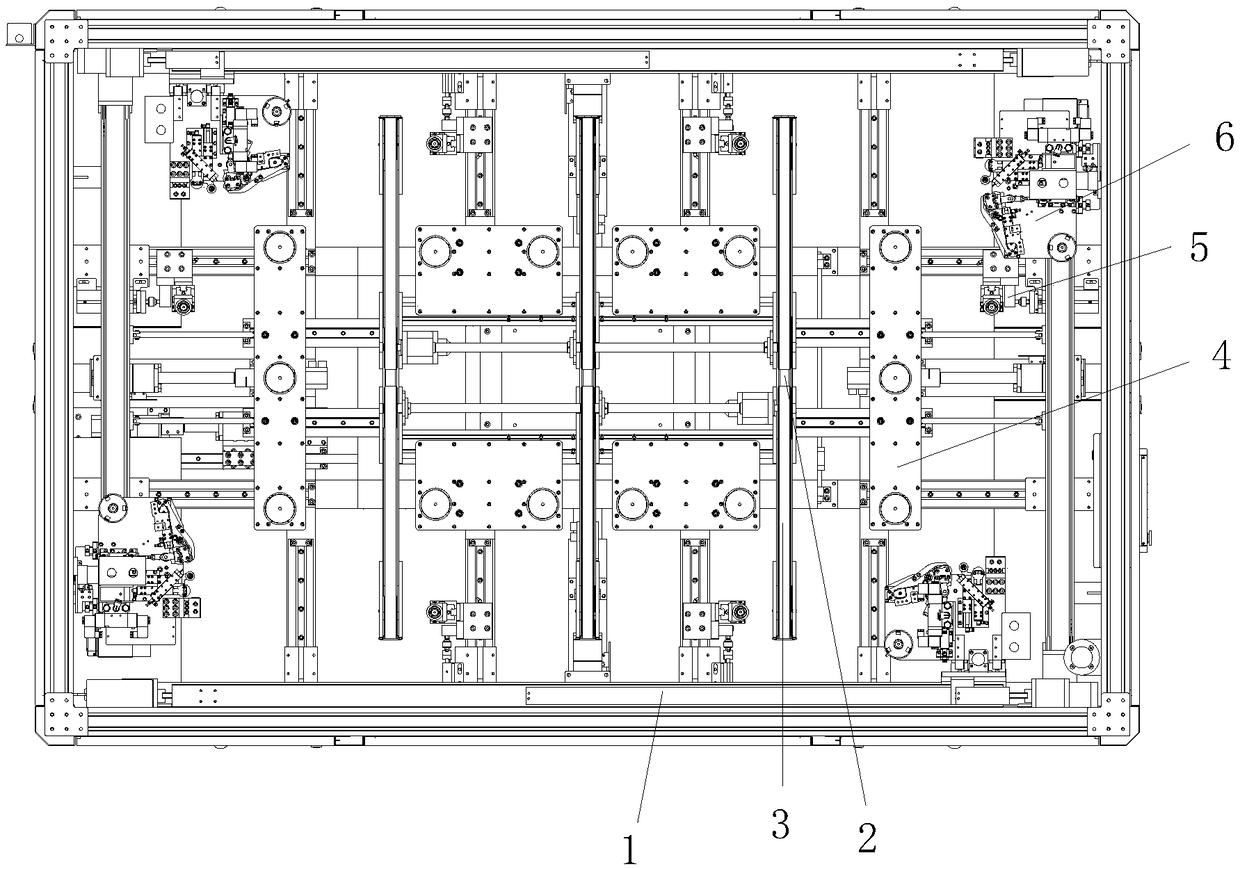

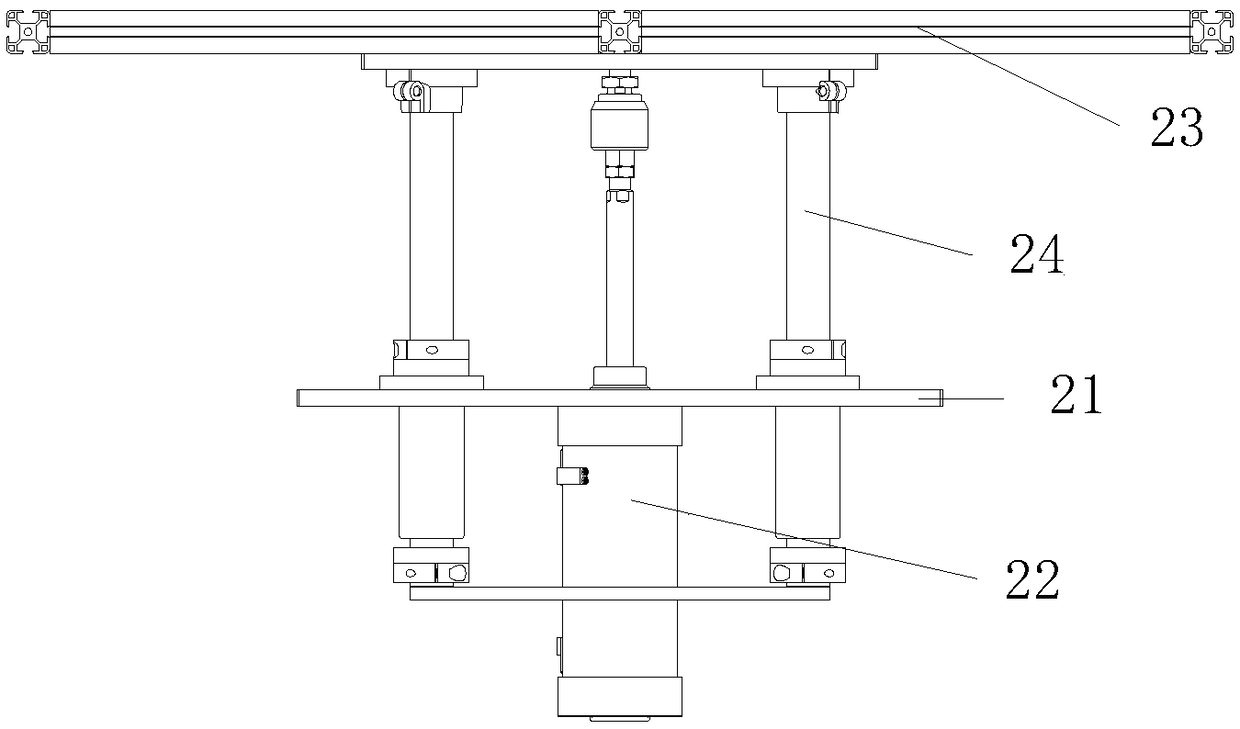

Automatic edge sealing machine for photovoltaic modules

PendingCN109326668AGuaranteed smoothCompact structureFinal product manufacturePhotovoltaic energy generationEngineeringElectric control

The invention discloses an automatic edge sealing machine for photovoltaic modules. The automatic edge sealing machine for the photovoltaic modules comprises a frame, a lifting mechanism, a conveyingmechanism, an edge sealing sucker platform, normalizing mechanisms and adhesive tape sealing modules. The lifting mechanism is mounted on the worktable in the frame, the conveying mechanism for conveying double-glass photovoltaic modules is mounted on a lifting table of the lifting mechanism, the edge sealing sucker platform for controlling lifting and adsorption of products is further arranged onthe worktable in the frame, the normalizing mechanisms and the adhesive tape sealing modules are arranged on the periphery of the conveying mechanism, and an electric control cabinet is arranged in the frame. By the mode, the automatic edge sealing machine is compact in structure, stable in running, high in automation degree and strong in adaptability, and edges of the double-glass photovoltaic modules can be automatically sealed, so that adhesive tapes are smoothly and firmly adhered onto the products.

Owner:SUZHOU SHENGCHENG SOLAR EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com