Patents

Literature

352results about How to "Large circulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

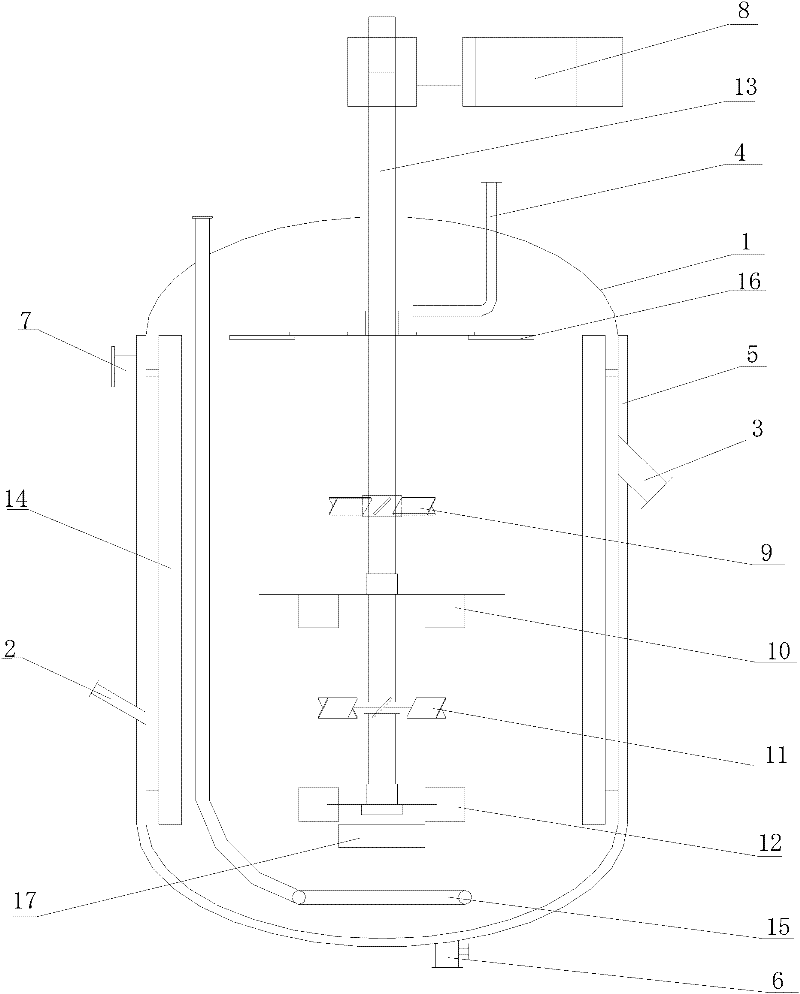

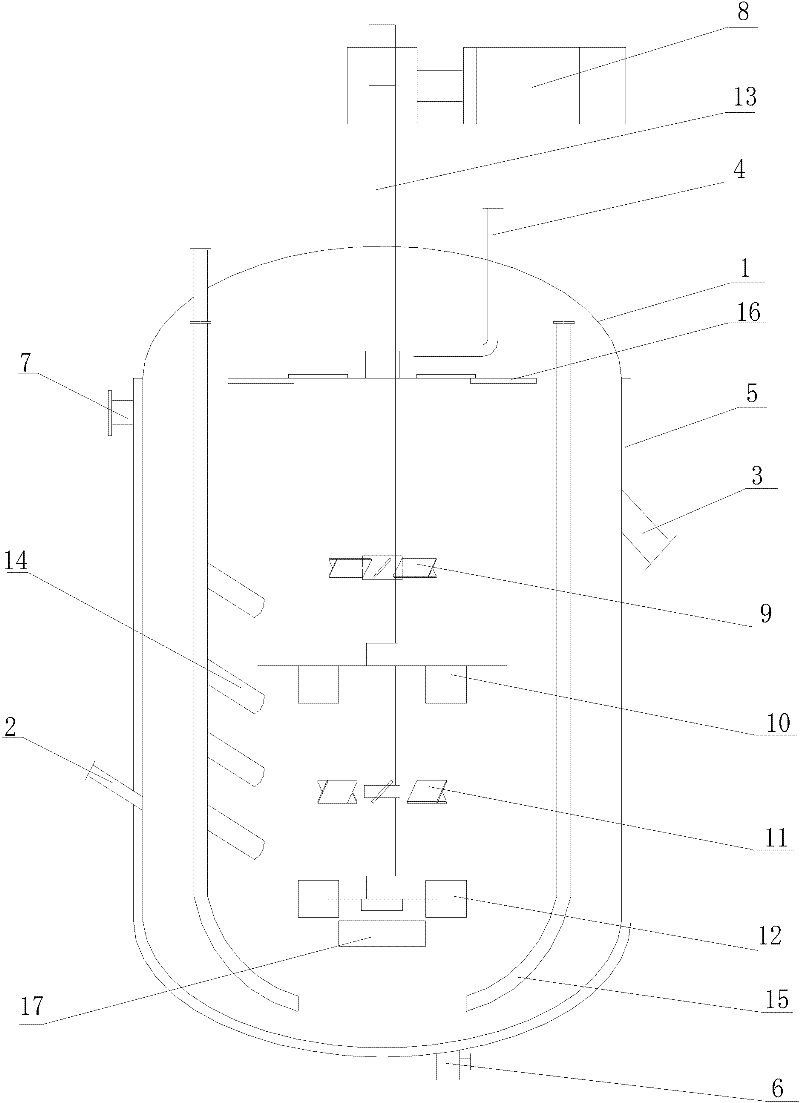

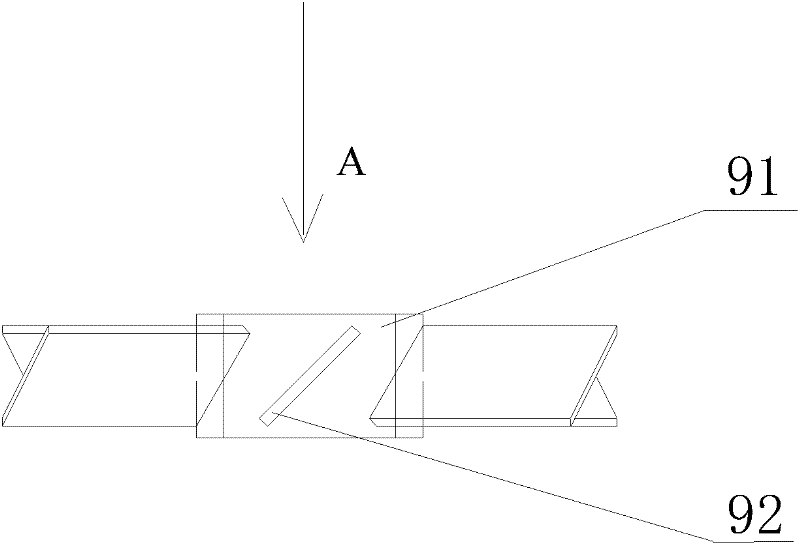

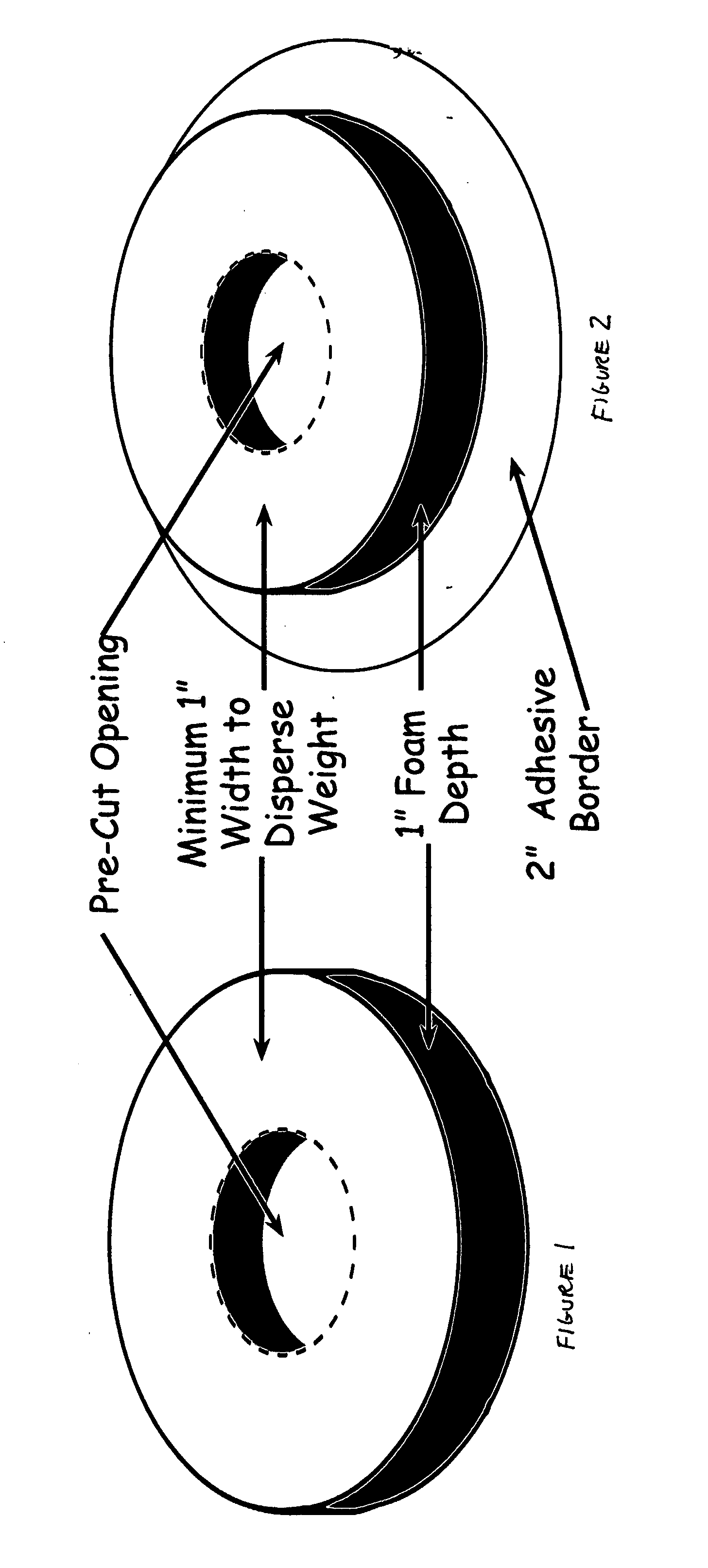

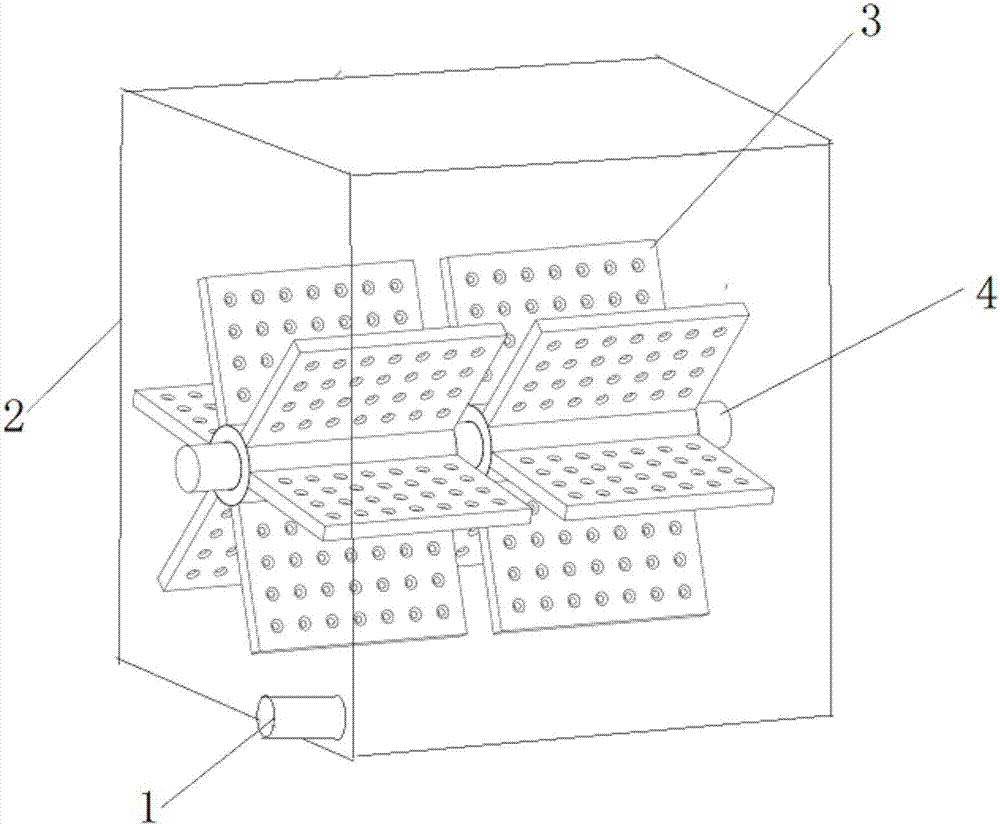

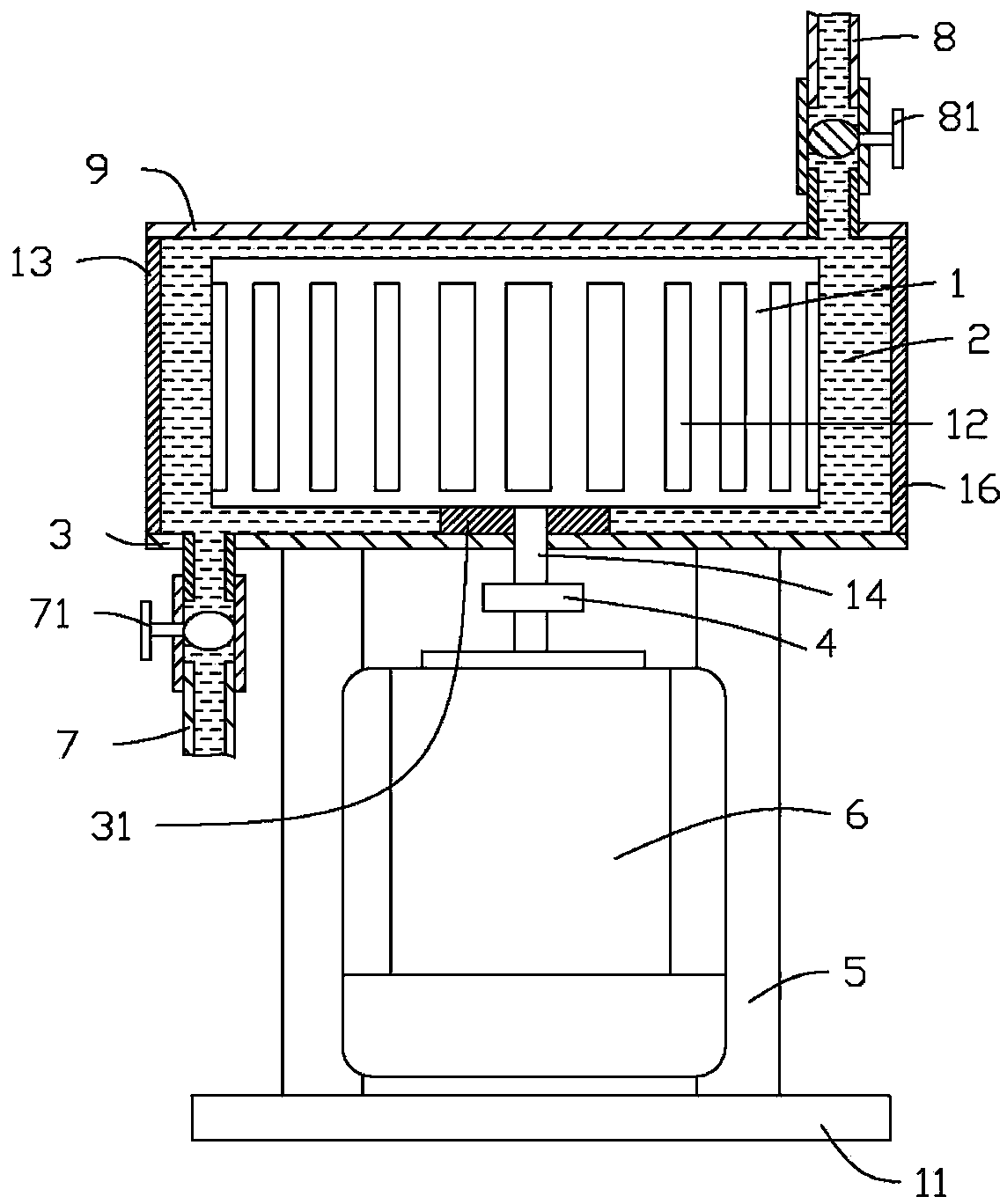

Stirred tank reactor

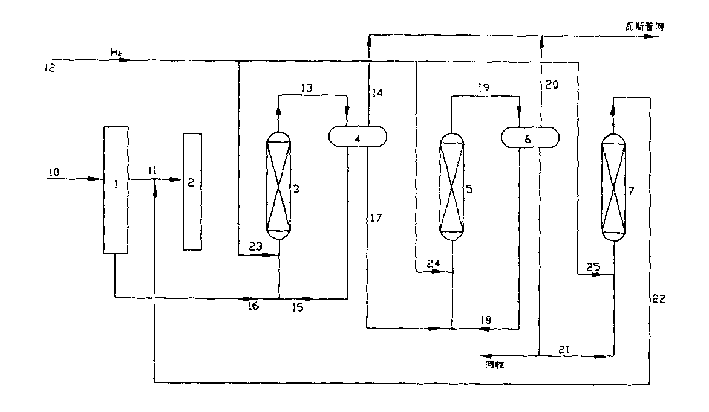

InactiveCN102358760ALarge circulationShort mixing timeRotary stirring mixersChemical/physical/physico-chemical stationary reactorsSizingProcess engineering

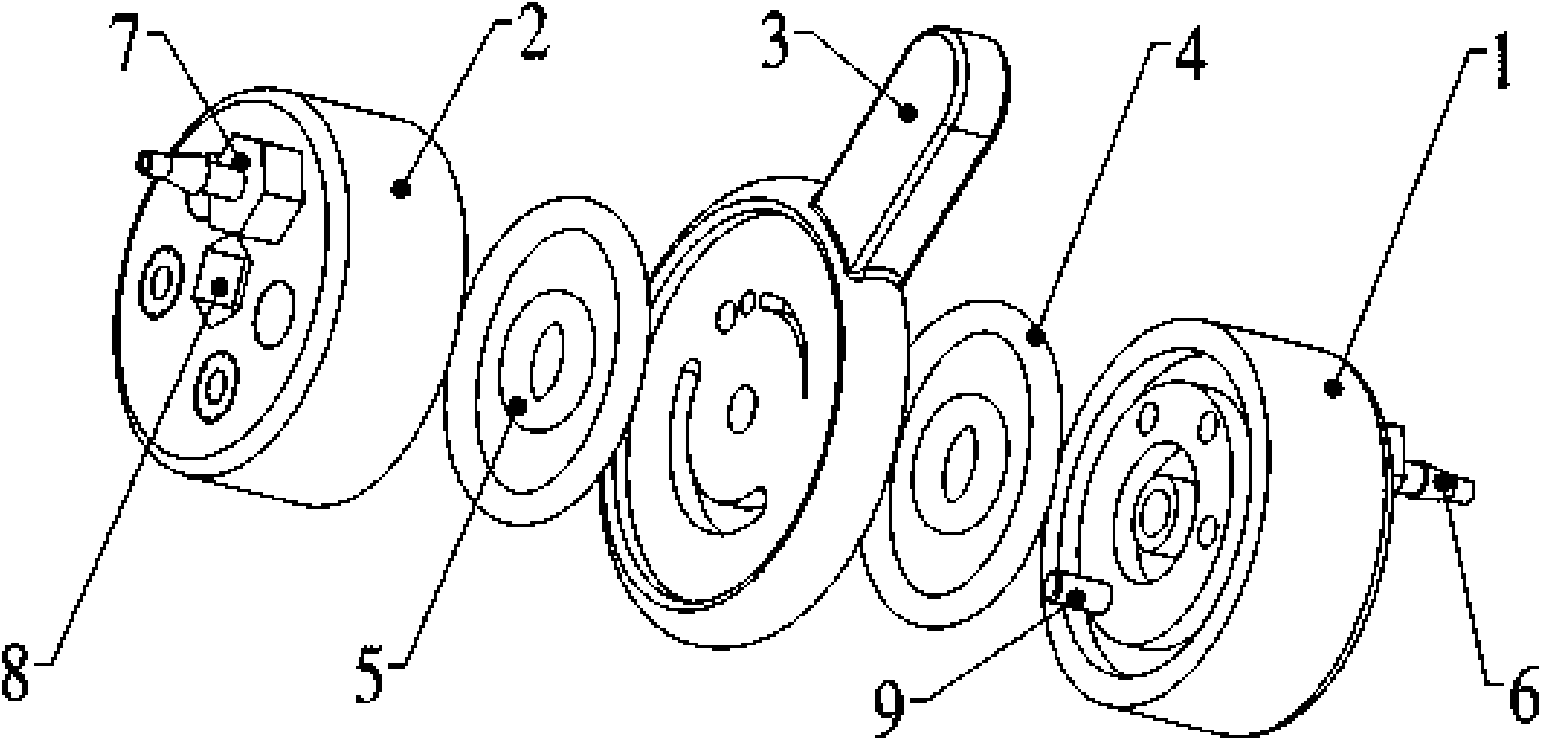

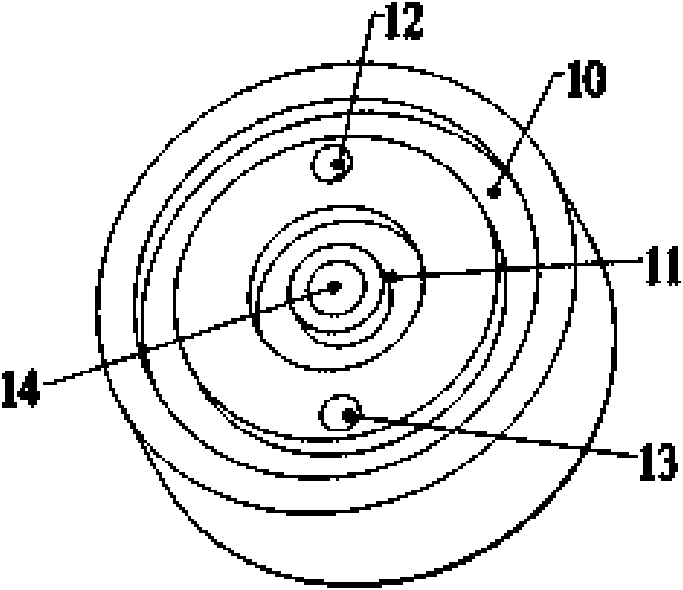

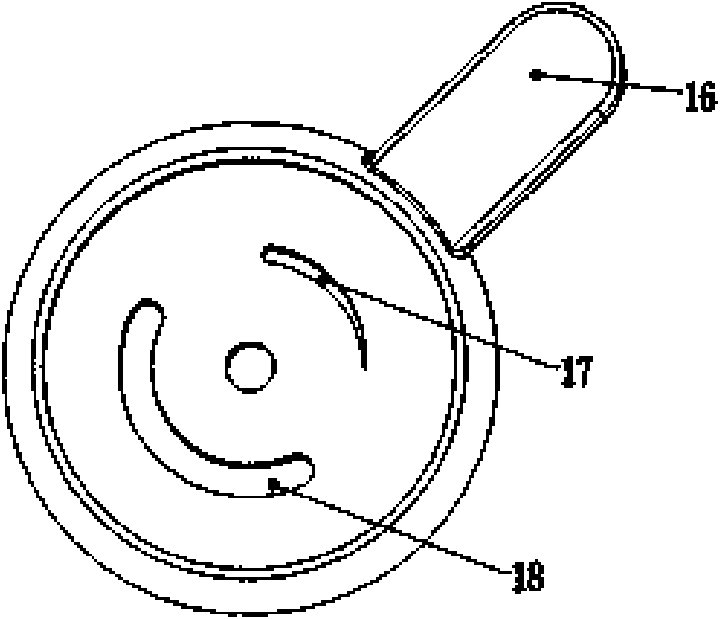

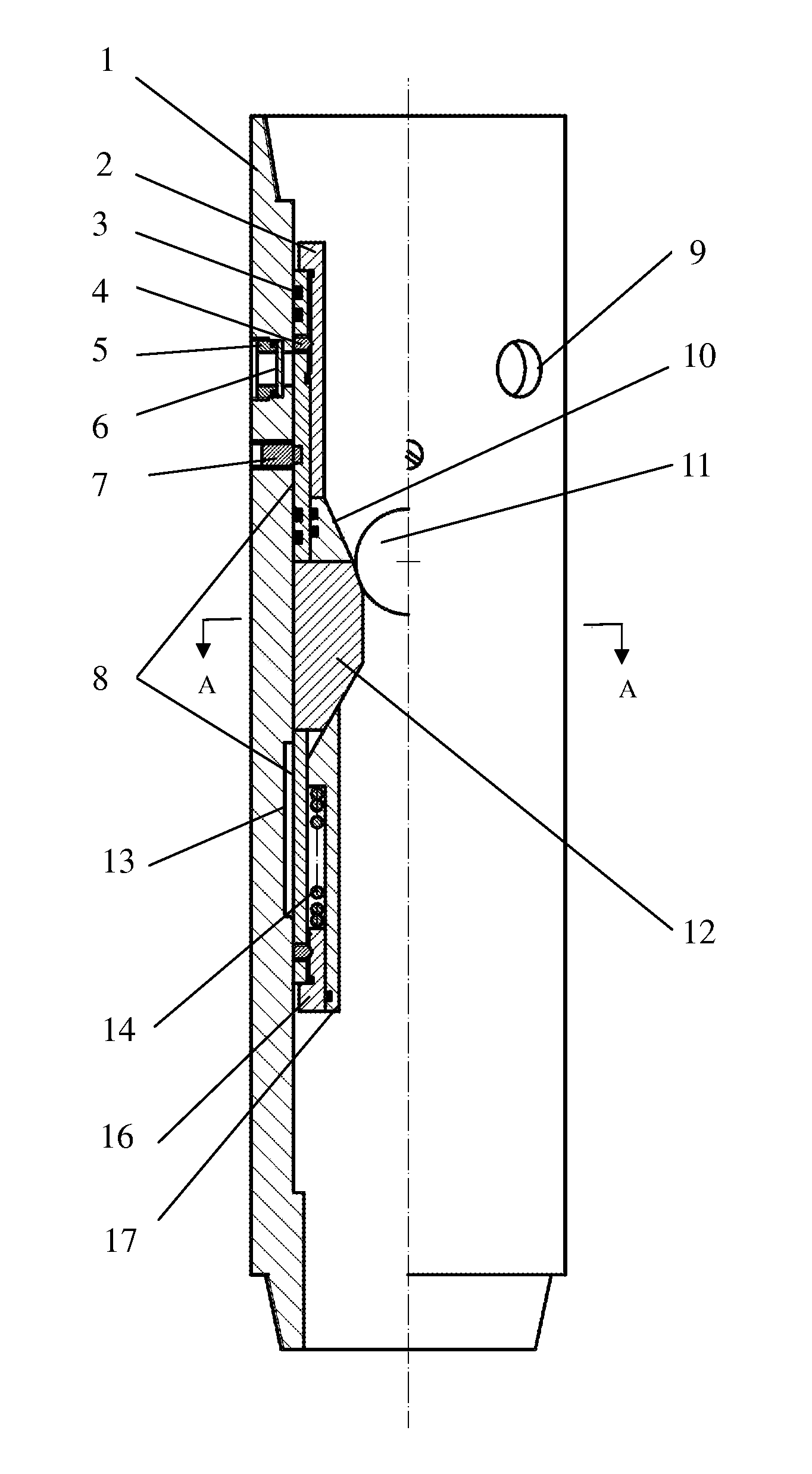

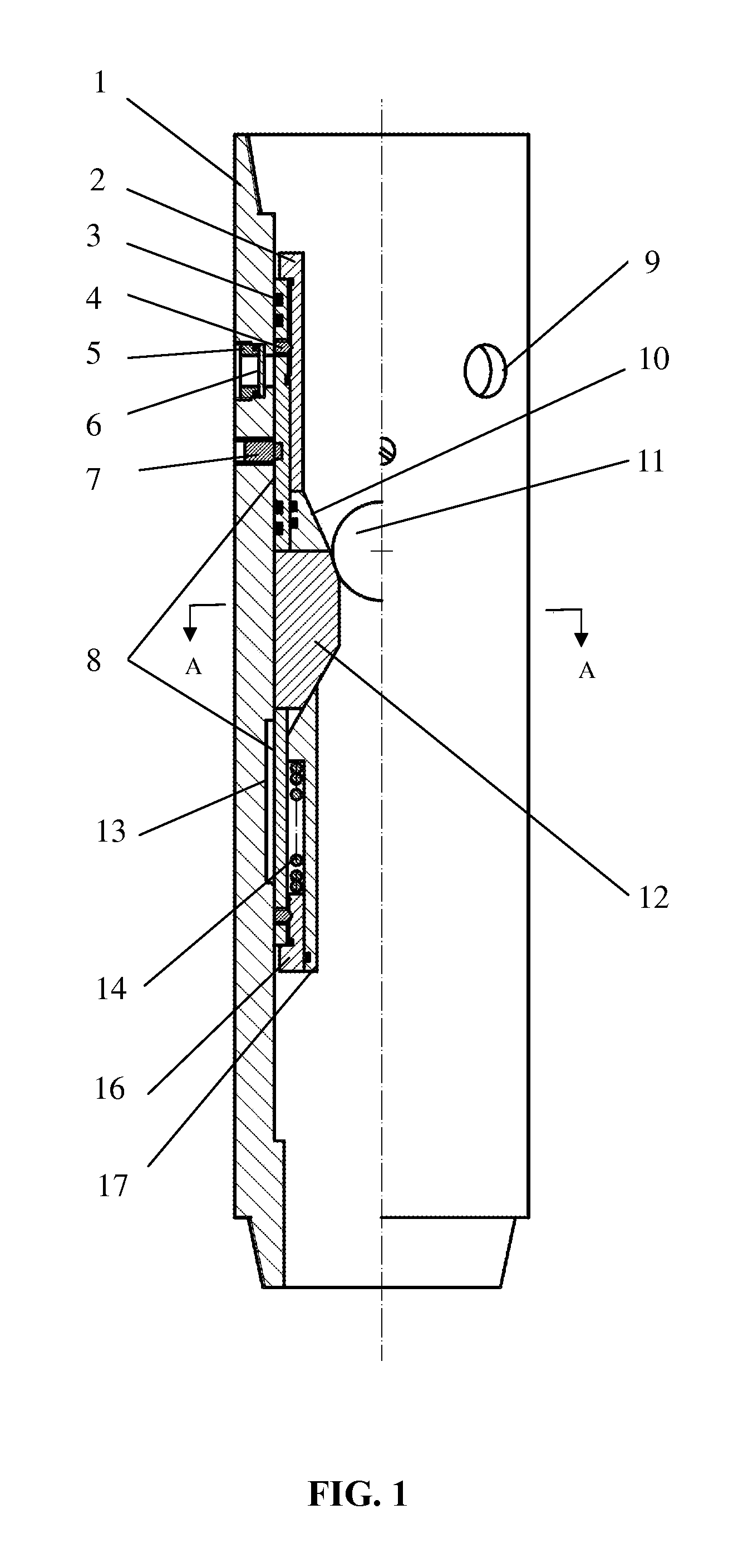

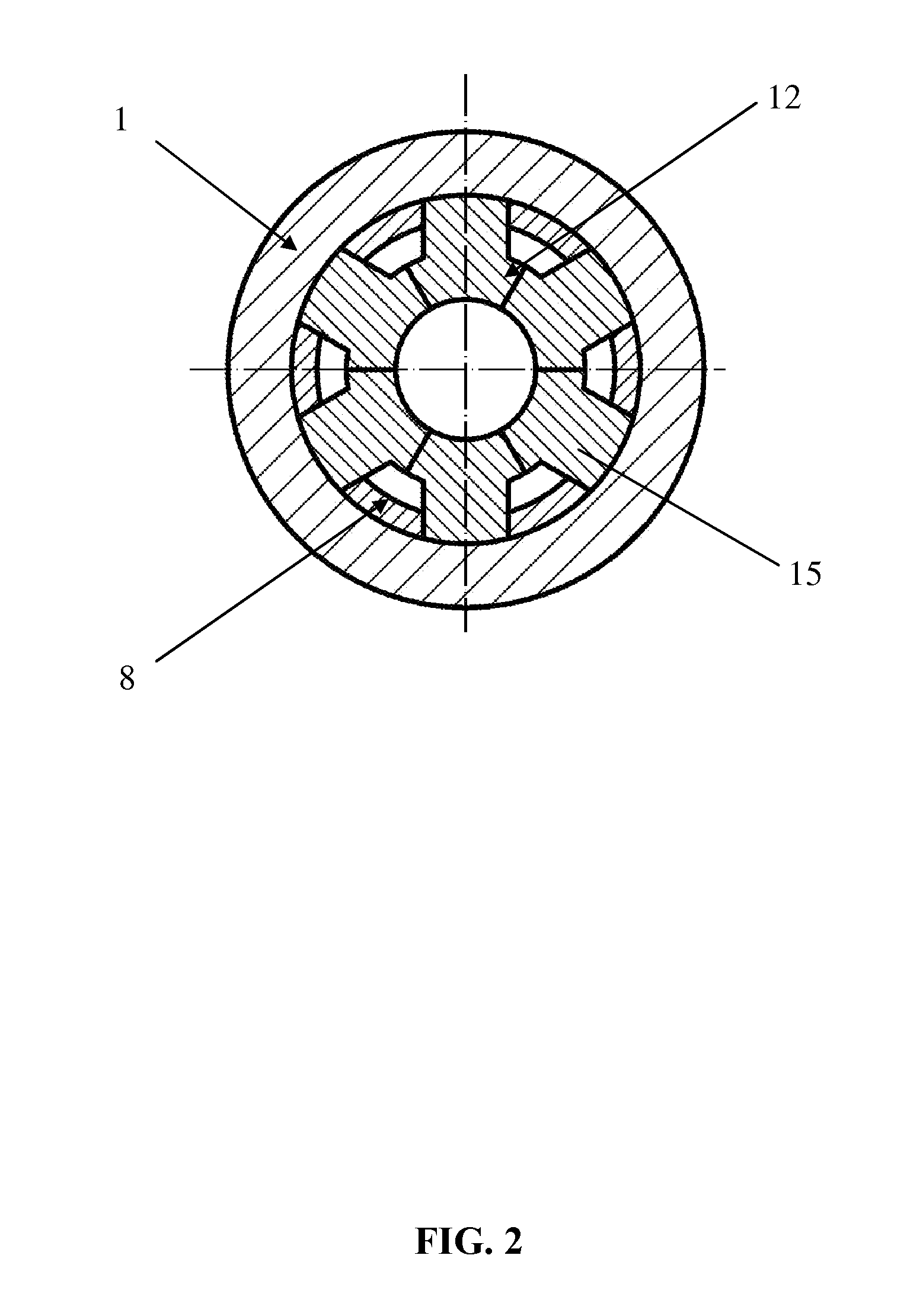

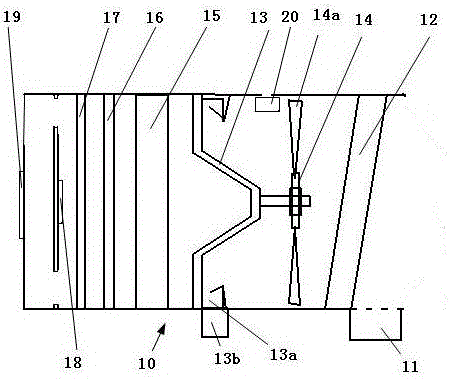

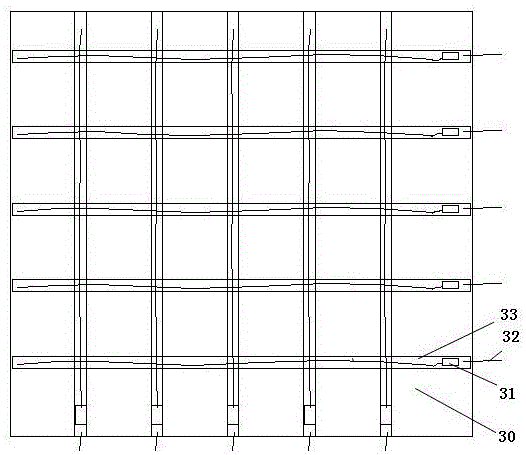

The invention discloses a stirred tank reactor and aims at improving a stirring turbine in the stirred tank reactor by using a four-layer combination stirring turbine. The stirring turbine comprises a first layer turbine, a second layer turbine, a third layer turbine and a fourth layer turbine which are arranged from the middle to the bottom of a stirring shaft sequentially. The first layer turbine is an upward axial flow turbine, the second layer turbine is a disk type turbine, the third layer turbine is an upward axial flow turbine, and the fourth layer turbine is a radial flow turbine. Radial circulation close to a liquid level, radial circulation close to a middle area of a stirred tank and radial circulation in a bottom area of the stirred tank are formed, so that circulation quantity inside the stirred tank is big and mixing time is short. Poor mixing area does not exist, and solid containing rate and gas containing rate are evenly distributed. A mass transfer condition of air and liquid is good, and single transfer efficiency is high. Entrainment quantity of sizing is greatly reduced, fouling of a heat exchanger is reduced, and service life is long. Operation cost is lowered, and production cost is saved.

Owner:ZHEJIANG UNIV

Utilization method of butadiene extraction device residue

InactiveCN1590353AImprove performanceExtend your lifeHydrocarbon by hydrogenationButadiene DioxideFixed bed

A process for reclaiming the residue of butadiene extractor features that said residue rich in acetylene hydrocarbon is selectively hydrogenated under the action of catalyst in the fixed-bed hydrogenating reactor with circulating device to generate fuel, and recover 1-butene and monoolefin.

Owner:CHINA PETROLEUM & CHEM CORP

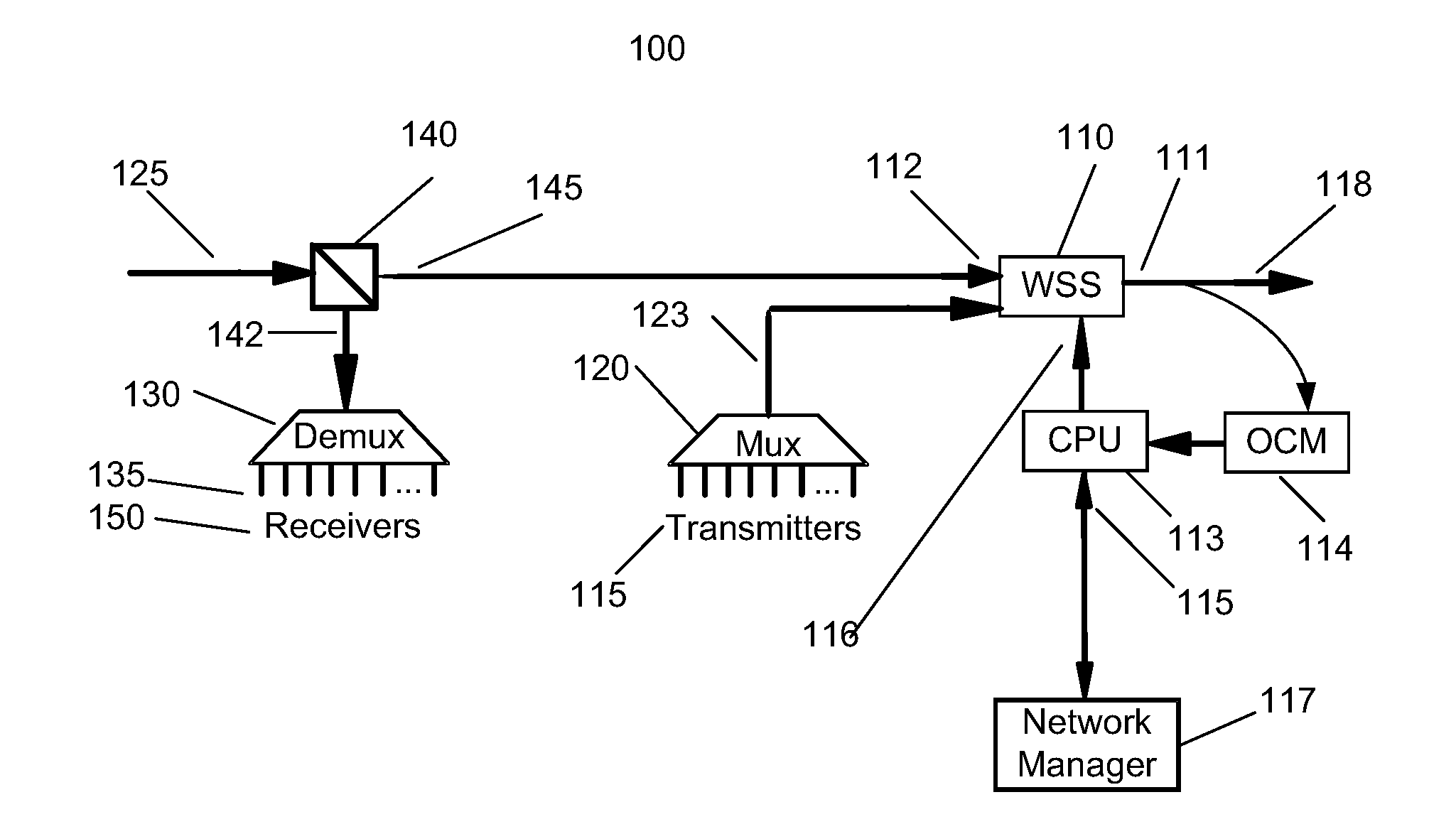

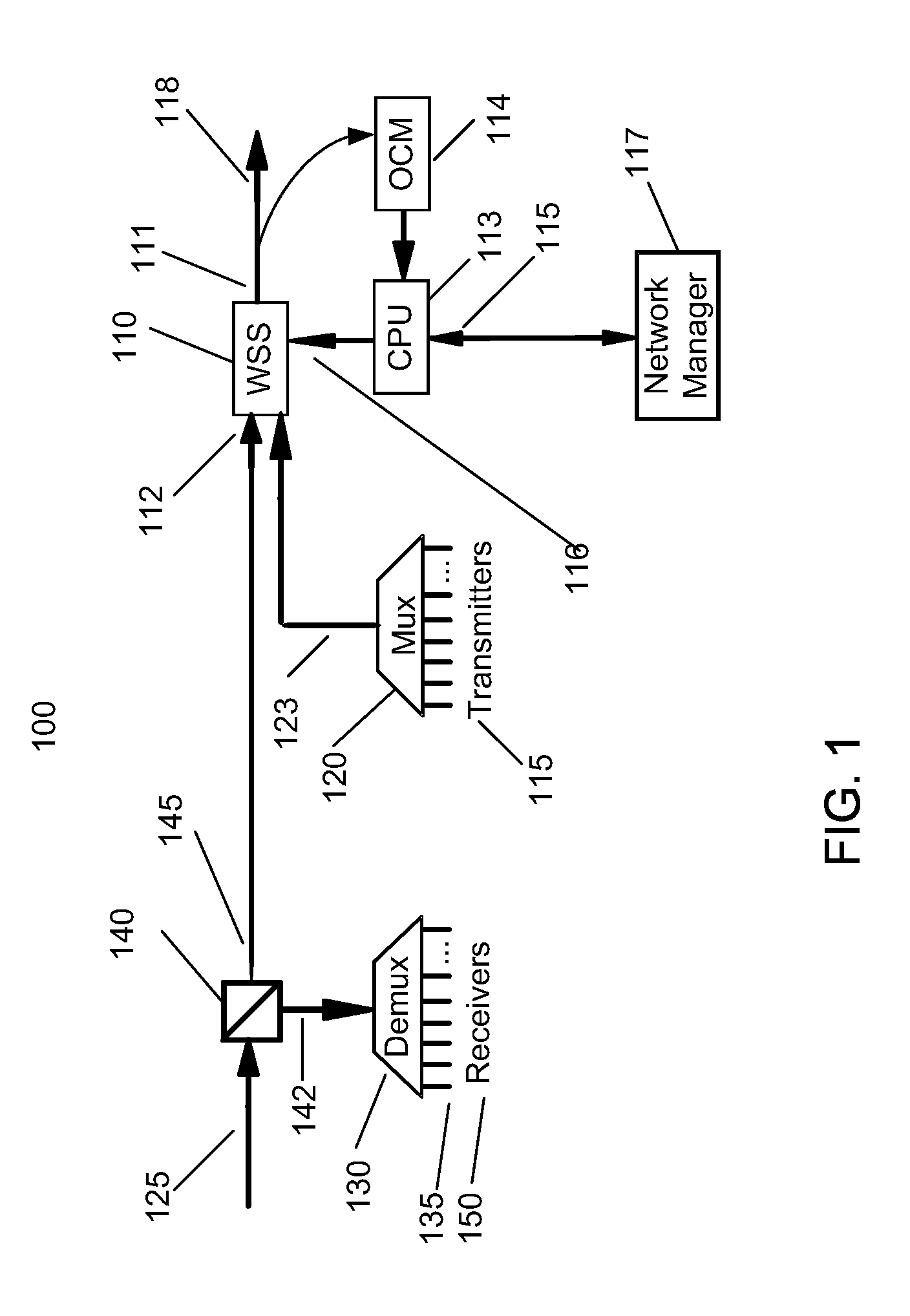

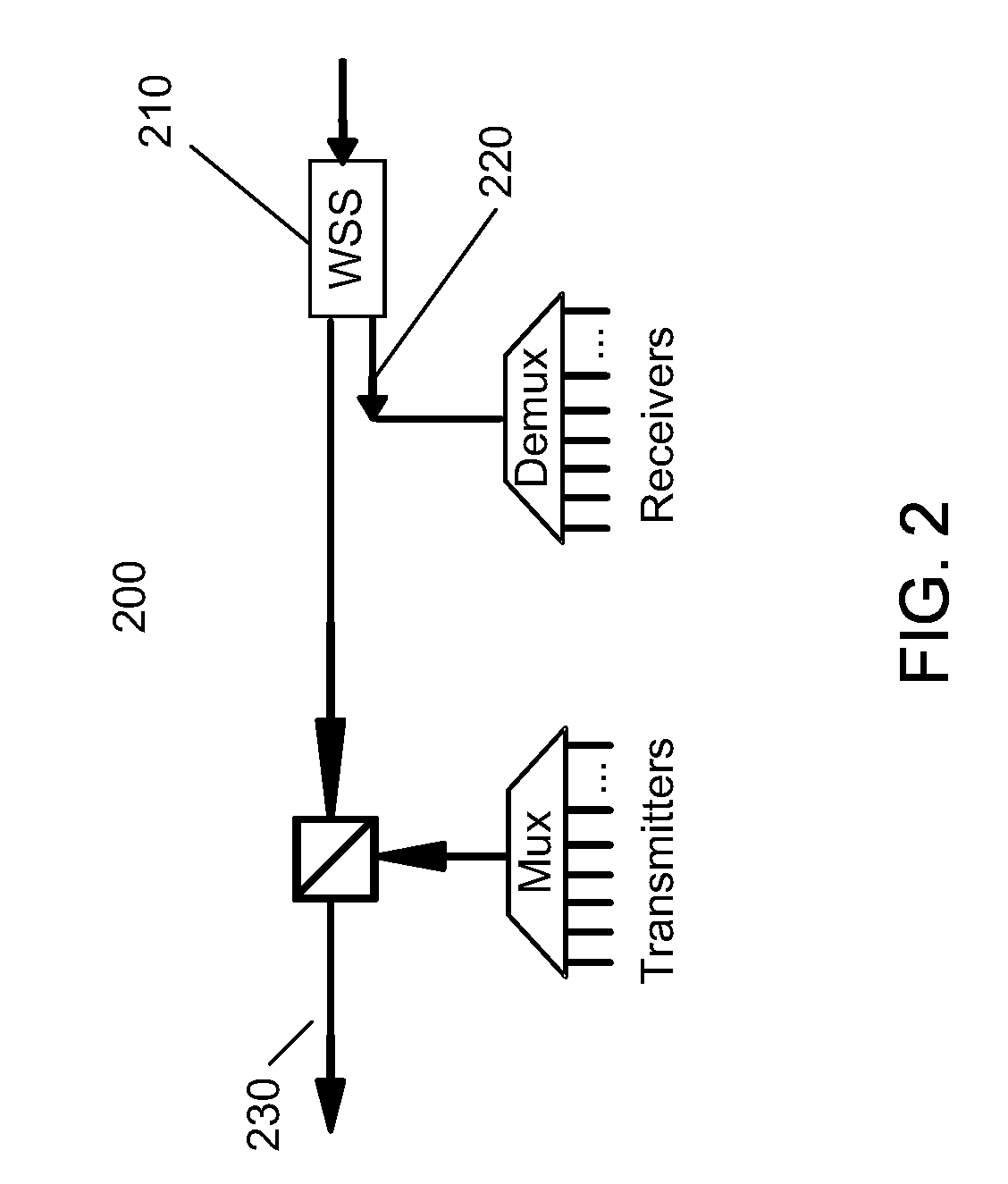

Minimizing Bandwidth Narrowing Penalties in a Wavelength Selective Switch Optical Network

ActiveUS20120195592A1Minimize bandwidth narrowing penaltyReduce in quantityMultiplex system selection arrangementsWavelength-division multiplex systemsEngineeringWavelength

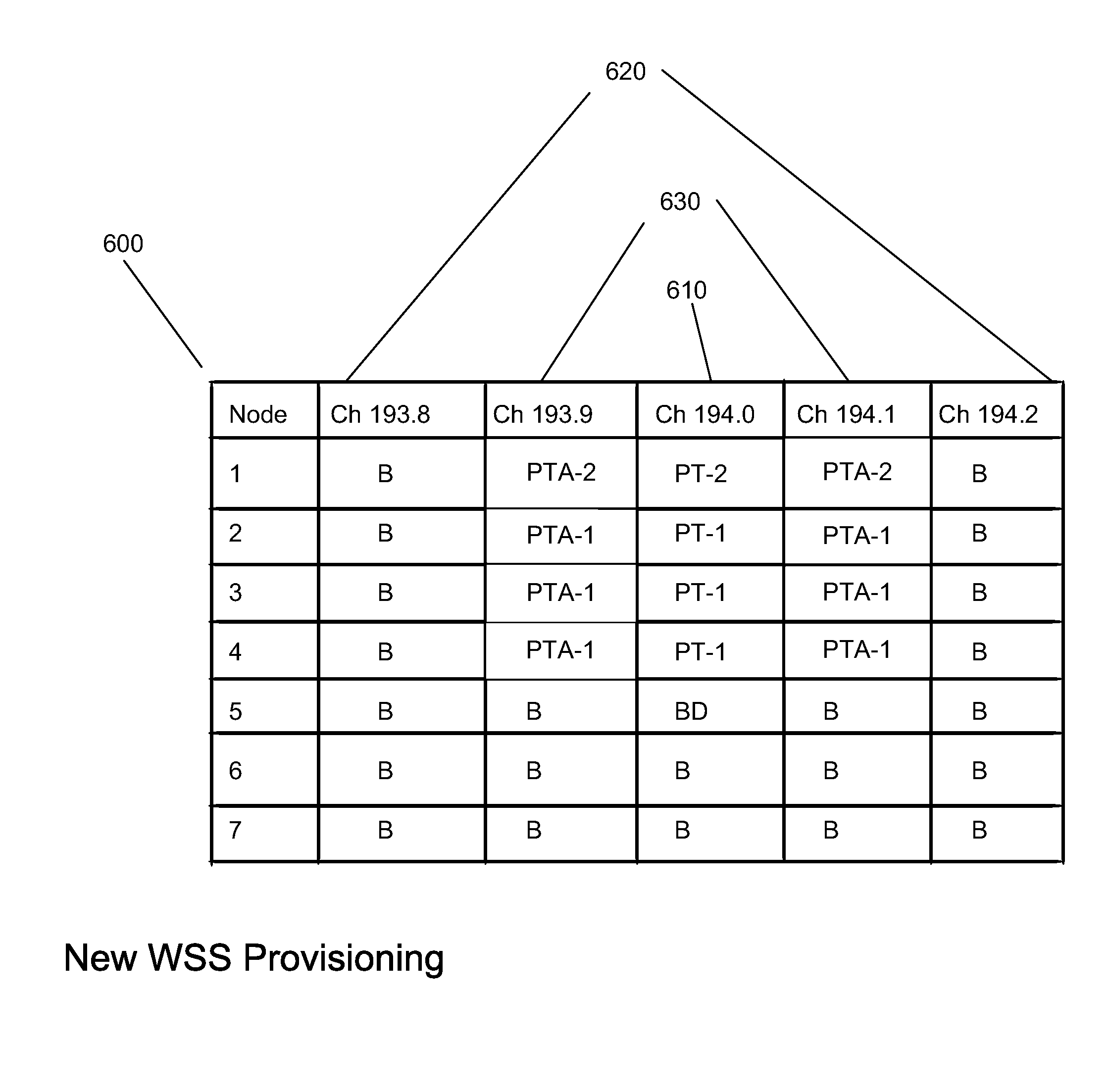

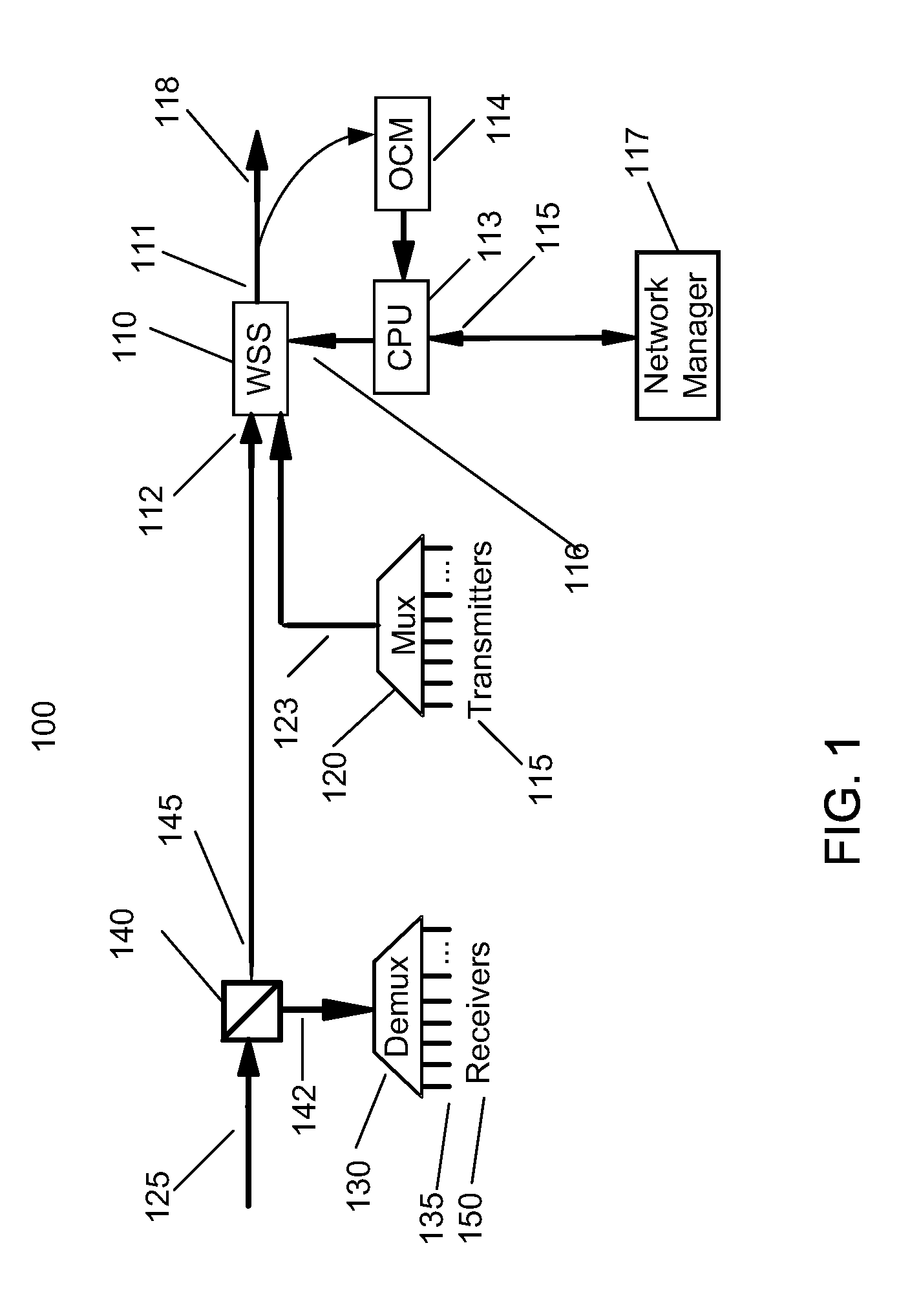

This invention relates to provisioning wavelength-selective switches and reconfigurable optical add-drop multiplexers to minimize the bandwidth narrowing effect from the optical filters. Novel architectures and methods are disclosed that can significantly reduce bandwidth-narrowing on channels in a reconfigurable WDM network where a large number of optical filter elements are cascaded. Instead of blocking unused channels as in the prior art, unused channels are selectively provisioned depending on the state of their adjacent channels. Unused adjacent channels of an active channel are provisioned to follow the same path as the active channels. As each channels is deployed, the channel frequency is selected so as to minimize bandwidth narrowing.

Owner:SNELL HLDG LLC +1

Filter material of tefloncomposite membrane

ActiveCN1565713AHigh strengthLarge circulationSemi-permeable membranesSynthetic resin layered productsDimethyl formamidePolyvinylidene fluoride

The invention relates to polytetrafluoroethylene (PTFE) composite film filtering materials for air filtering industry. The polytetrafluoroethylene composite film filtering materials comprise the following components: fiberglass as basement film; polytetrafluoroethylene as surface film; and adhesive agent which is one of polysulfone, nylon 66 and polyvinylidene fluoride fibre for binding the fiberglass and polytetrafluoroethylene; pore-forming material which is one of metal salt KI and NH#-[4]Cl; solvent which is one of dimethyl acetamide, dimethyl formamide and N-methyl pyrrolidone. The content (by weight) of macromolecular compound and pore-forming material is: 5% to 30% of macromolecular compound, 5% to 15% of pore-forming material. The fiberglass and polytetrafluoroethylene composite materials can improve filtration efficiency and have improved hydrophobicity, high-temperature resistance and corrosion resistance.

Owner:SHANGHAI FILTER

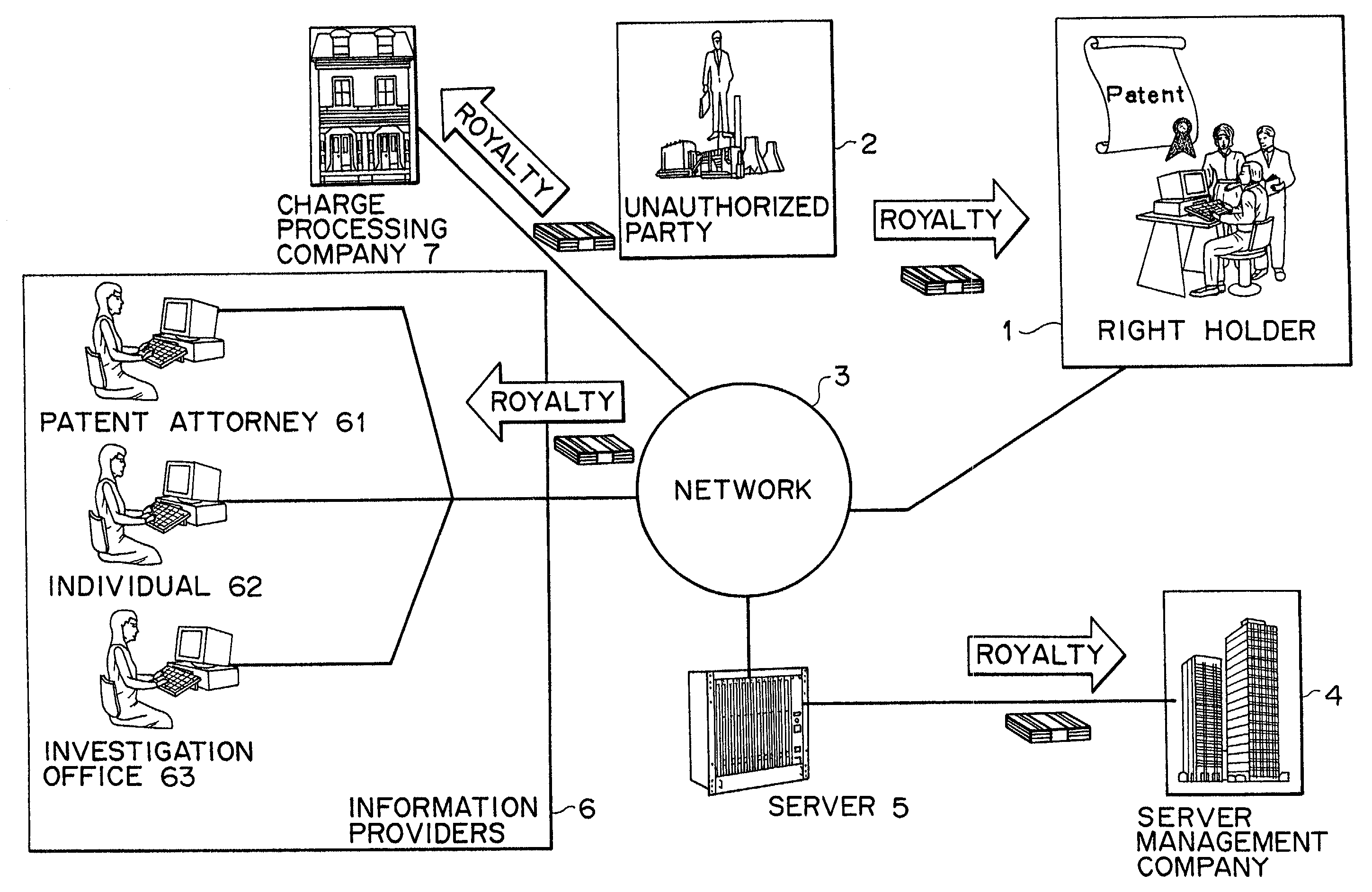

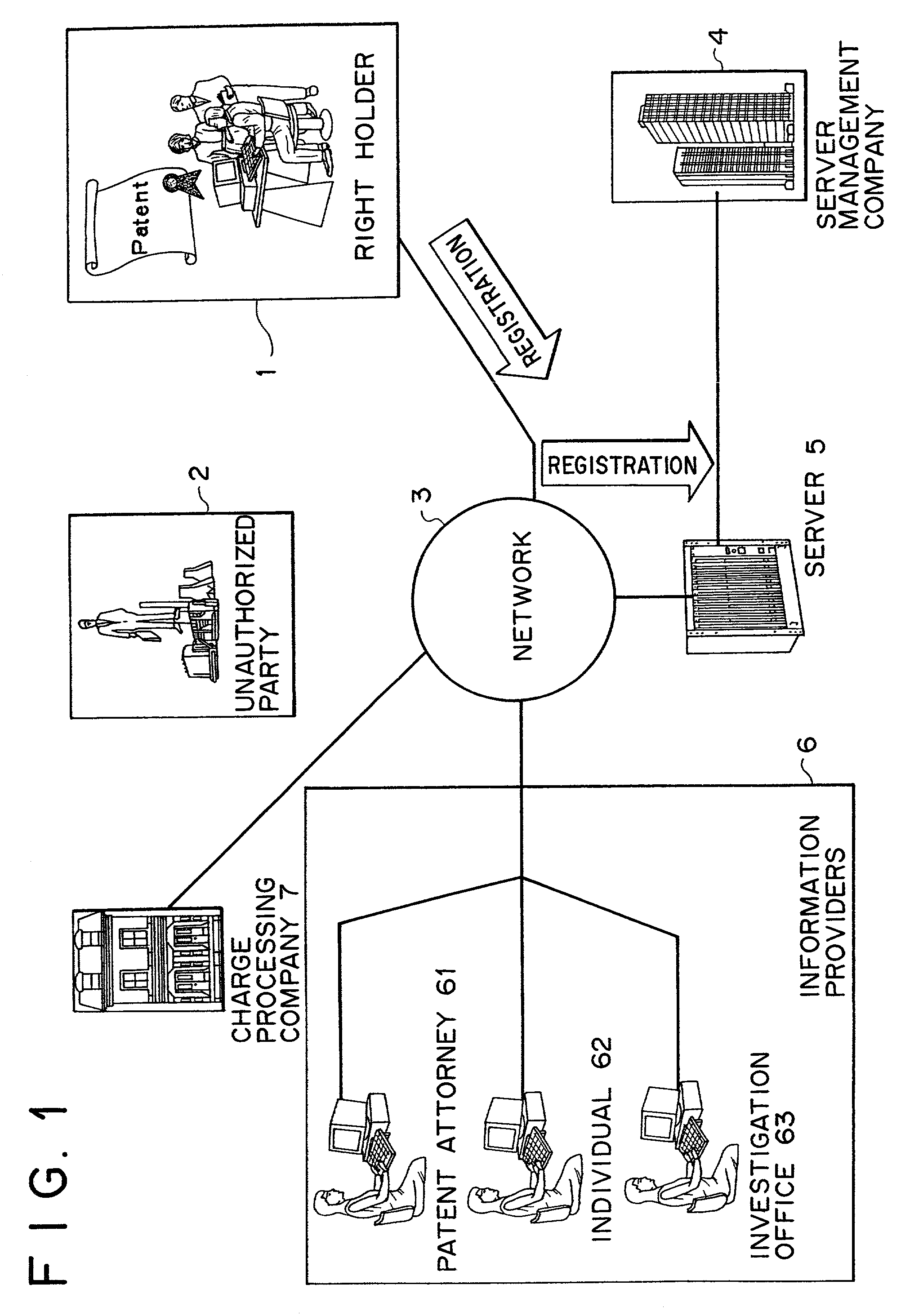

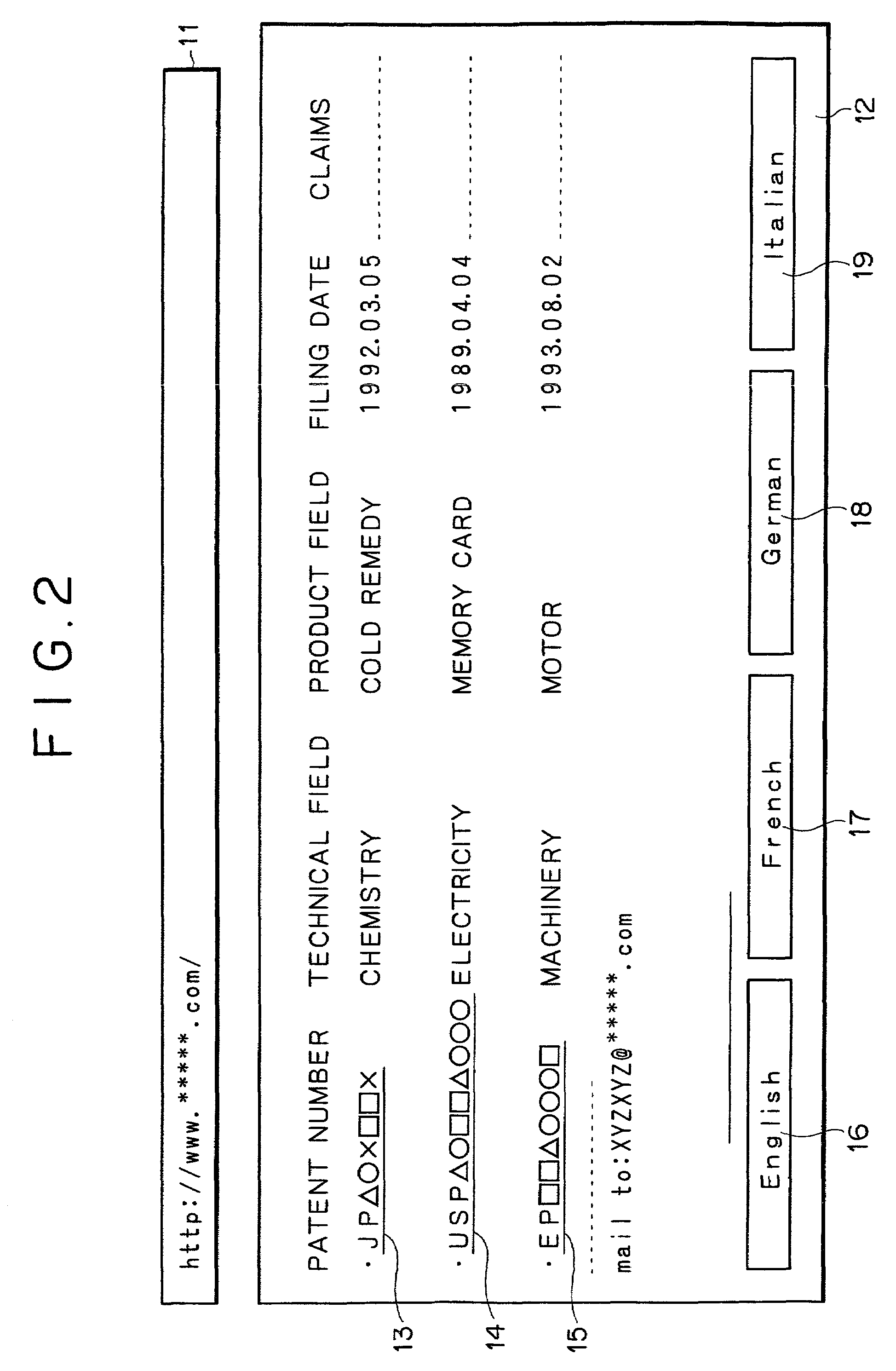

Information providing apparatus, server apparatus and information processing method

InactiveUS7082399B2Increase exerciseEfficient use ofComputer security arrangementsPayment architectureThird partyInformation processing

A charging system is provided which solicits from third parties information about products supposedly infringing on a right holder's lawful right and which, upon exposure of the infringement, acquires royalty revenues from the trespassing party for a reimbursement to any third party having contributed the information on the infringement, whereby right-related information is collected more efficiently and a market on which such information circulates is actively promoted.

Owner:SONY CORP

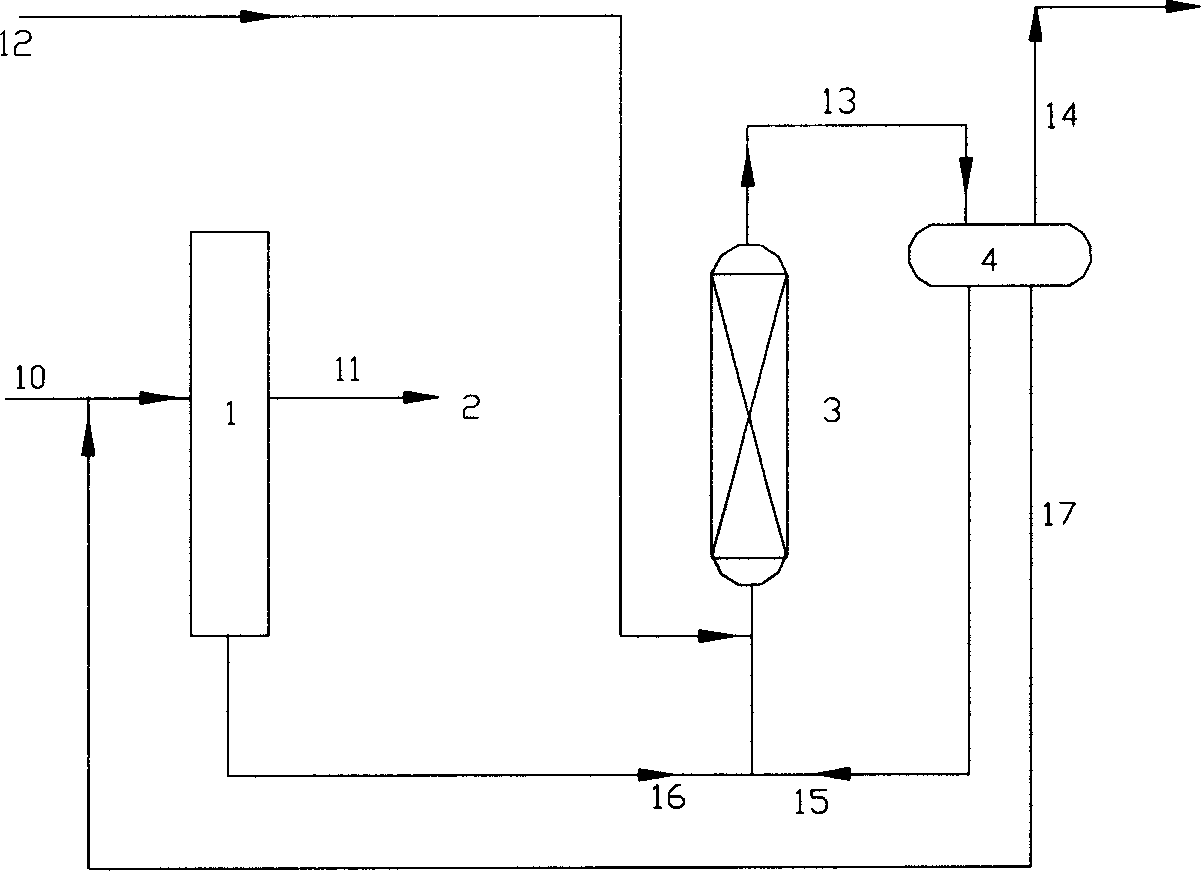

Selective hydrogenation technology of hydrocarbon material flow rich acetylene in hydrocarbon

InactiveCN1590513AReduce lossesImprove performanceRefining by selective hydrogenationFixed bedAlkyne

A process for selectively hydrogenating the hydrocarbon material rich in acetylene hydrocarbon, which is the residue in butadiene extractor, features that said hydrocarbon material flows through a fixed-bed hydrogenating reactor with circulator, where acetylene hydrocarbon reacts on H2 to remove the acetylene hydrocarbon, and then back to said butadiene extractor.

Owner:CHINA PETROLEUM & CHEM CORP

Rotary-vane multifunctional multi-purpose valve

Owner:中山市九虹机器人科技有限公司

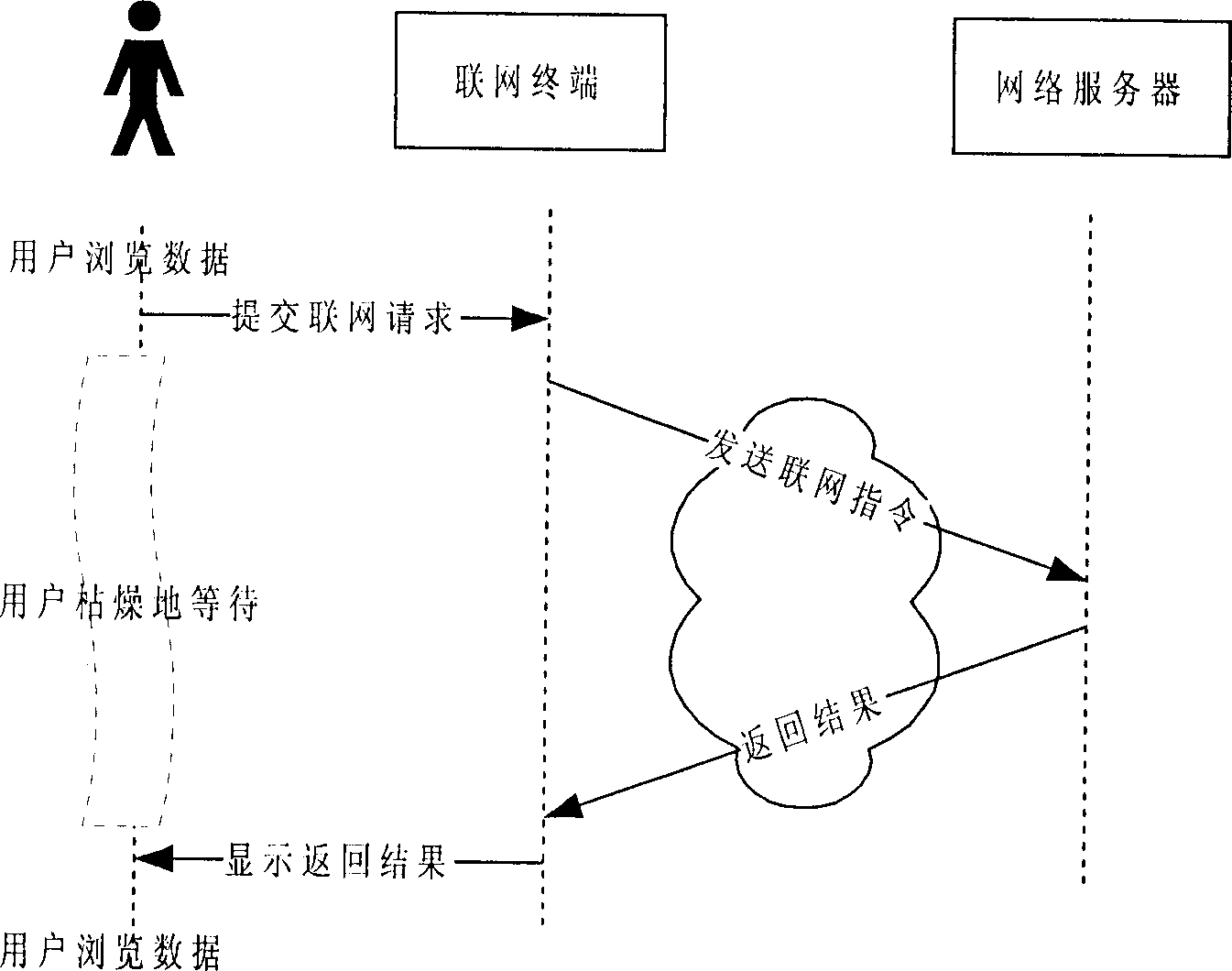

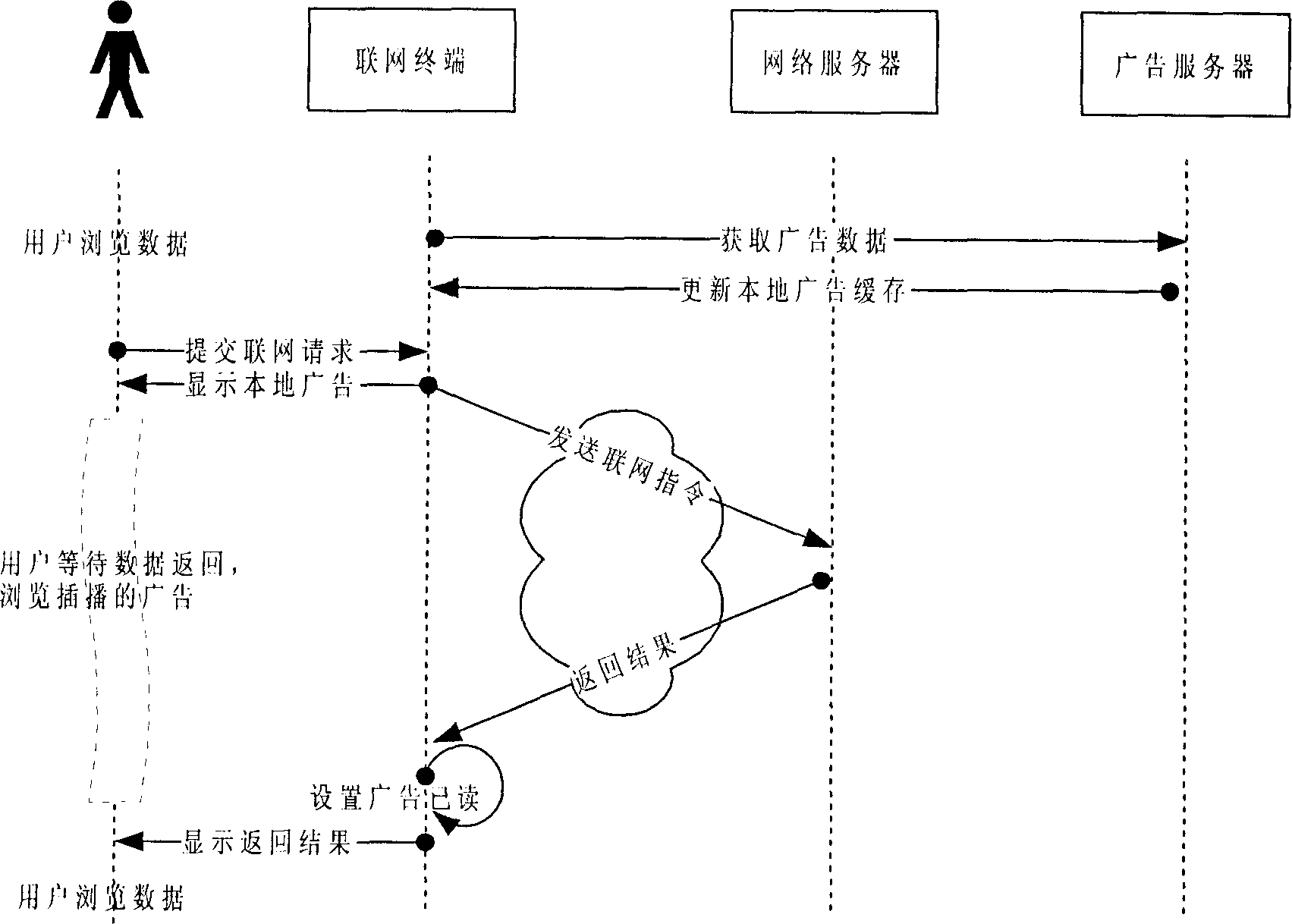

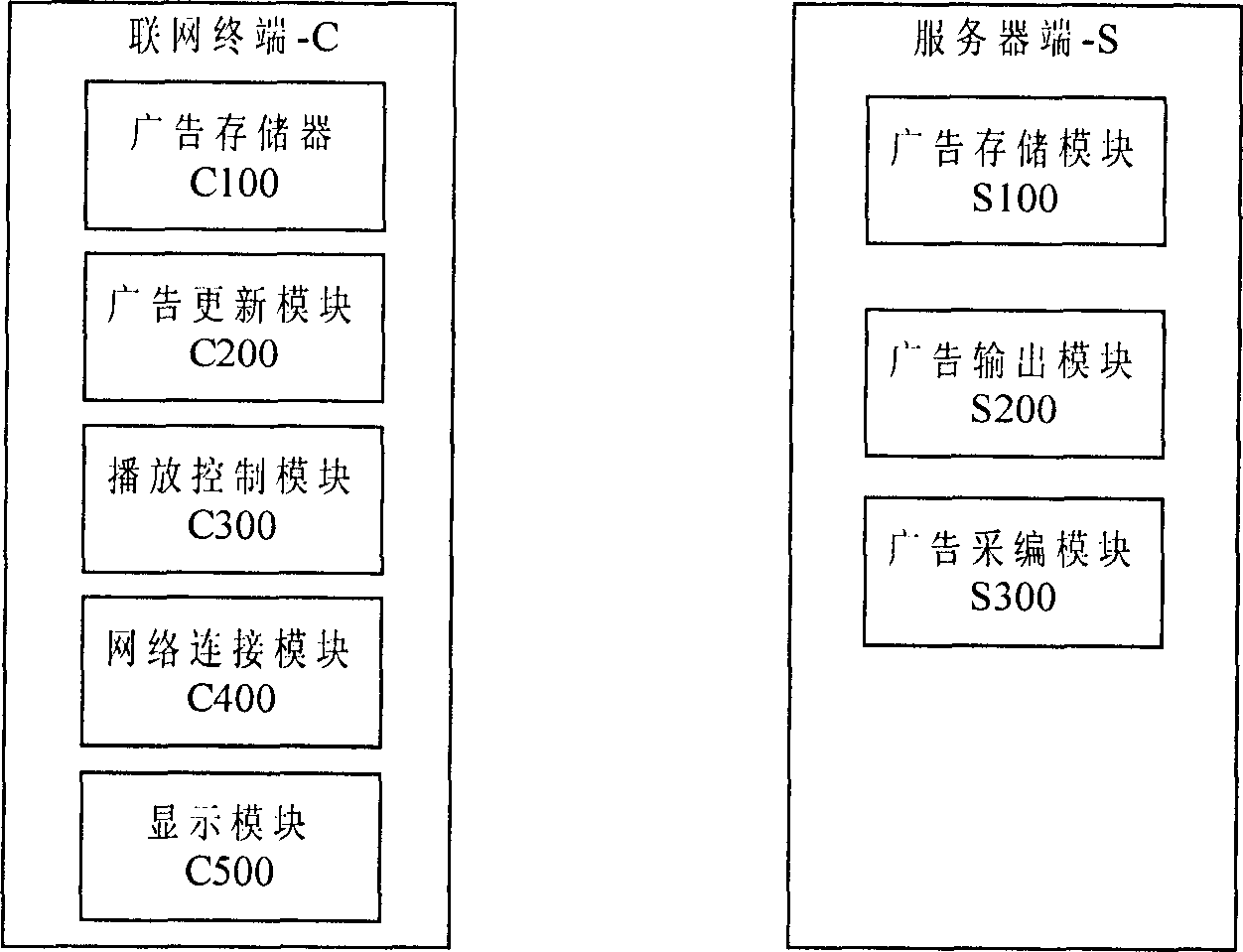

System and method for insert broadcasting advertisement in connecting net waiting process

InactiveCN1901461AImprove user experienceIncrease profitSpecial service provision for substationData switching by path configurationNetwork connectionUser input

This invention relates to a system and a method for broadcasting advertisements in the process of waiting for on-line, in which, the system includes an on-line terminal including a network connection module, an ad storage and a play control module, also an ad server and a network server, in which, the play control module reads ad files from the internal ad storage of the on-line terminal to play it and switches the display screen to the current played ad content when the terminal sends connection to the being accessed server based on the input instruction of the user and waits for returning related data, once it receives data returned back from the network server, it stops playing the ad files and switches the screen to the interface of connecting to the internet.

Owner:马堃 +1

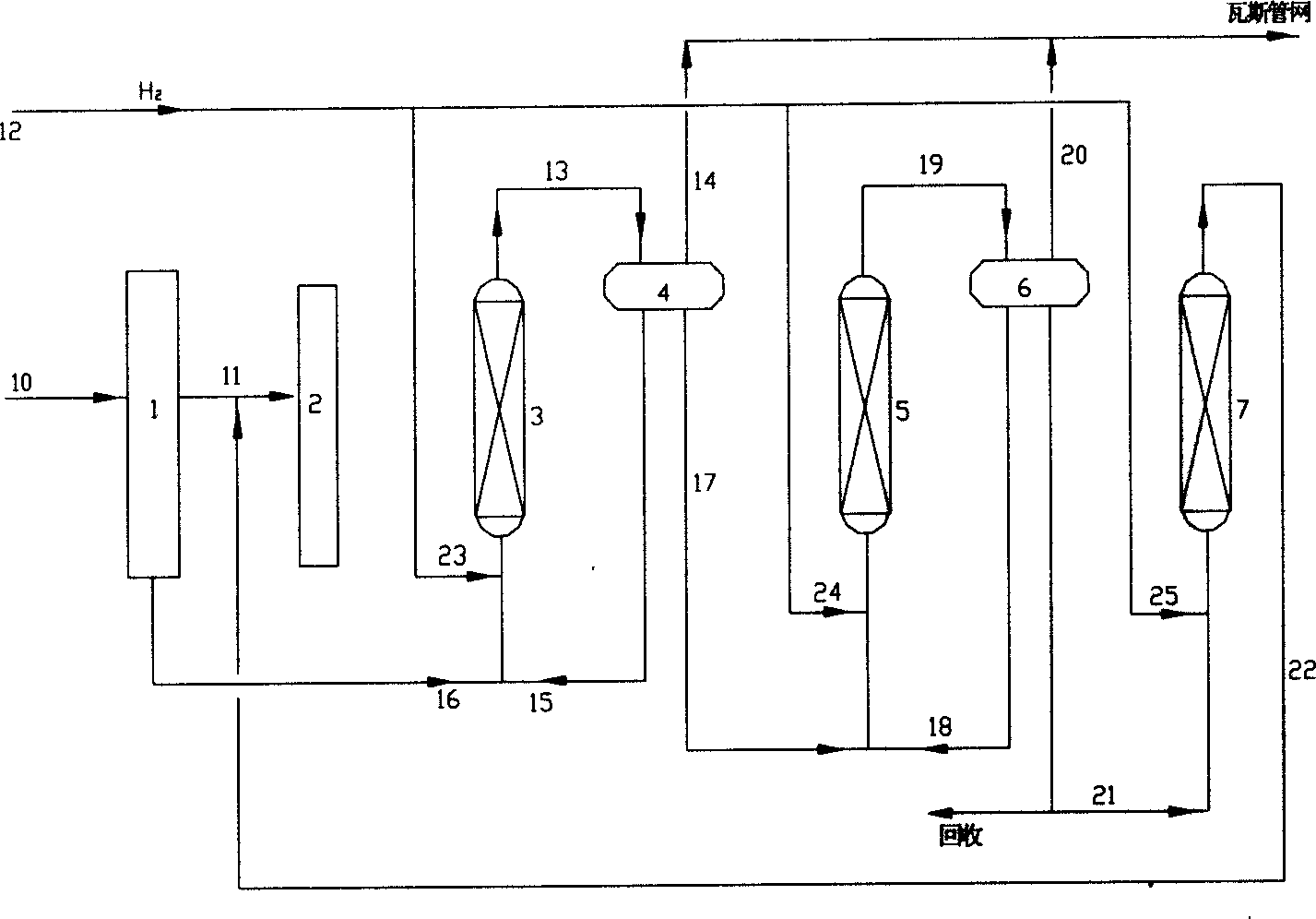

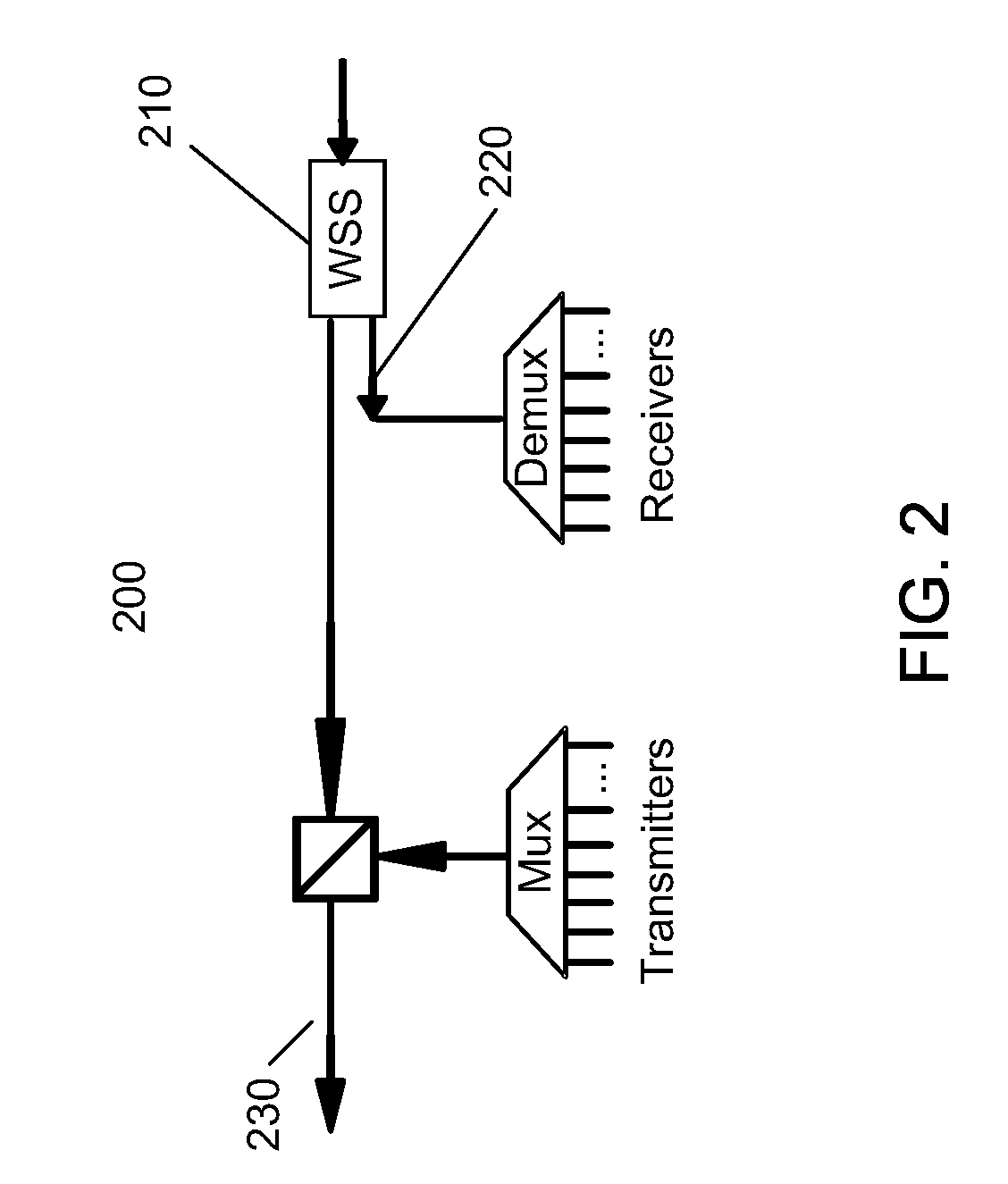

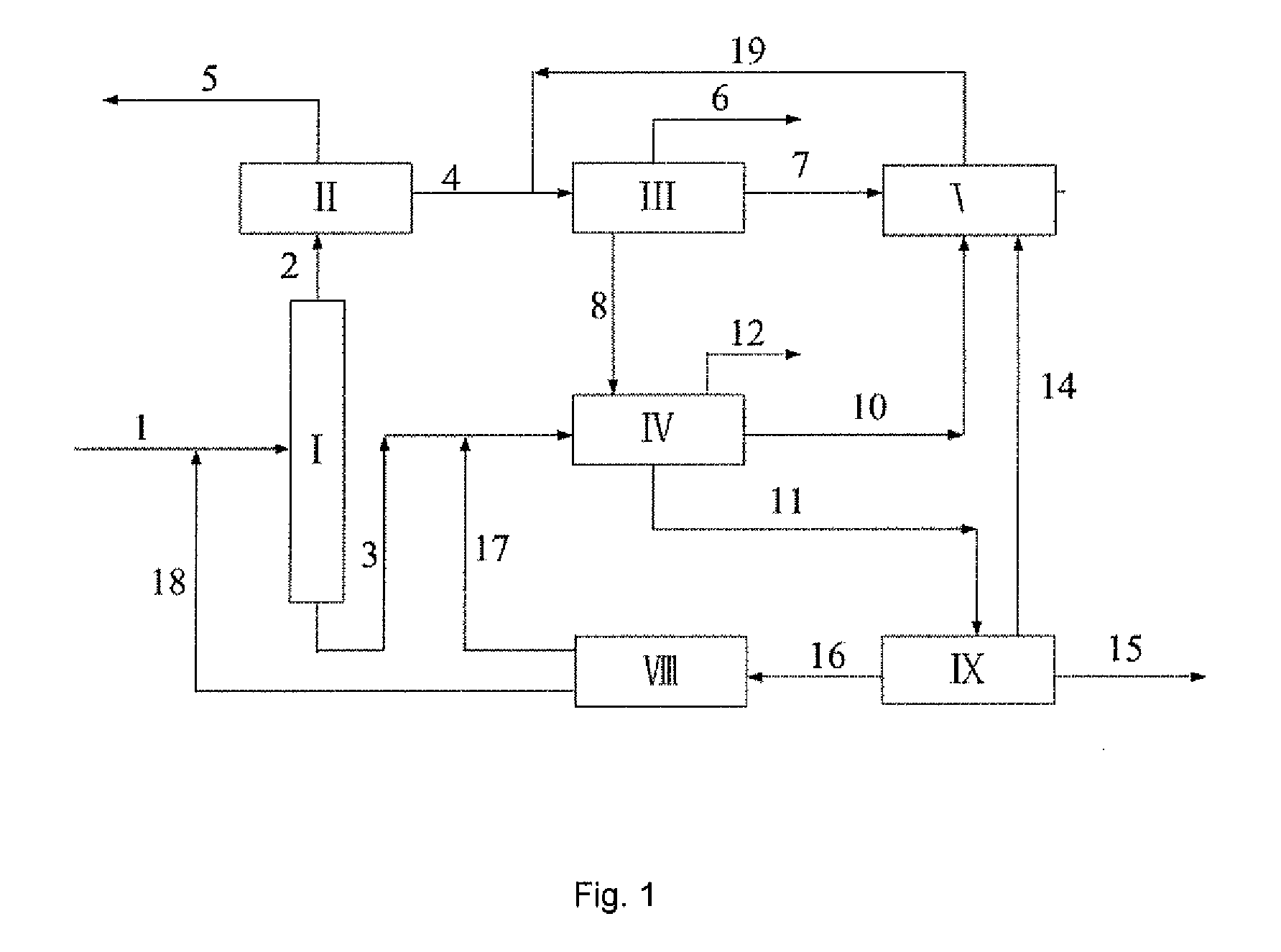

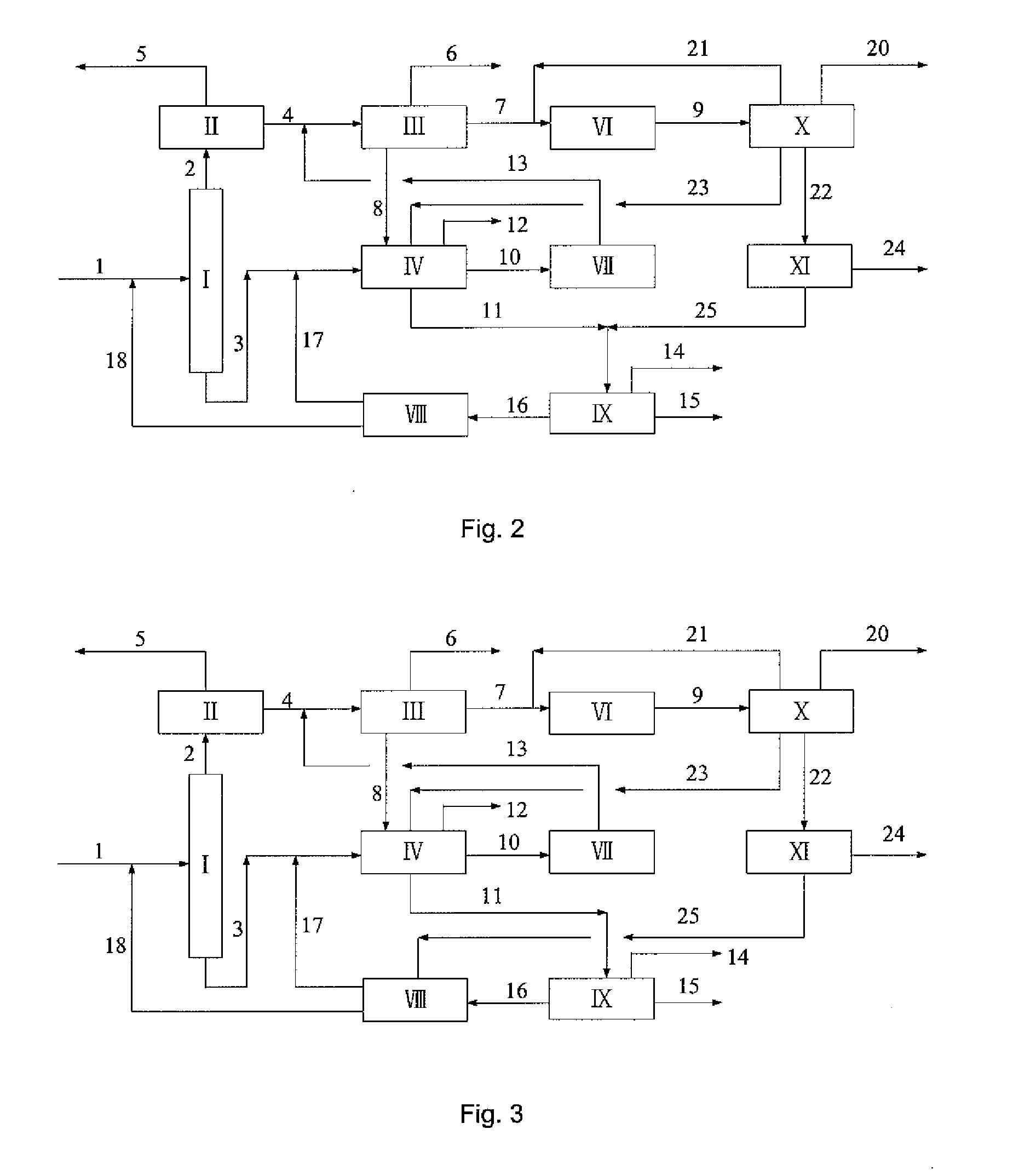

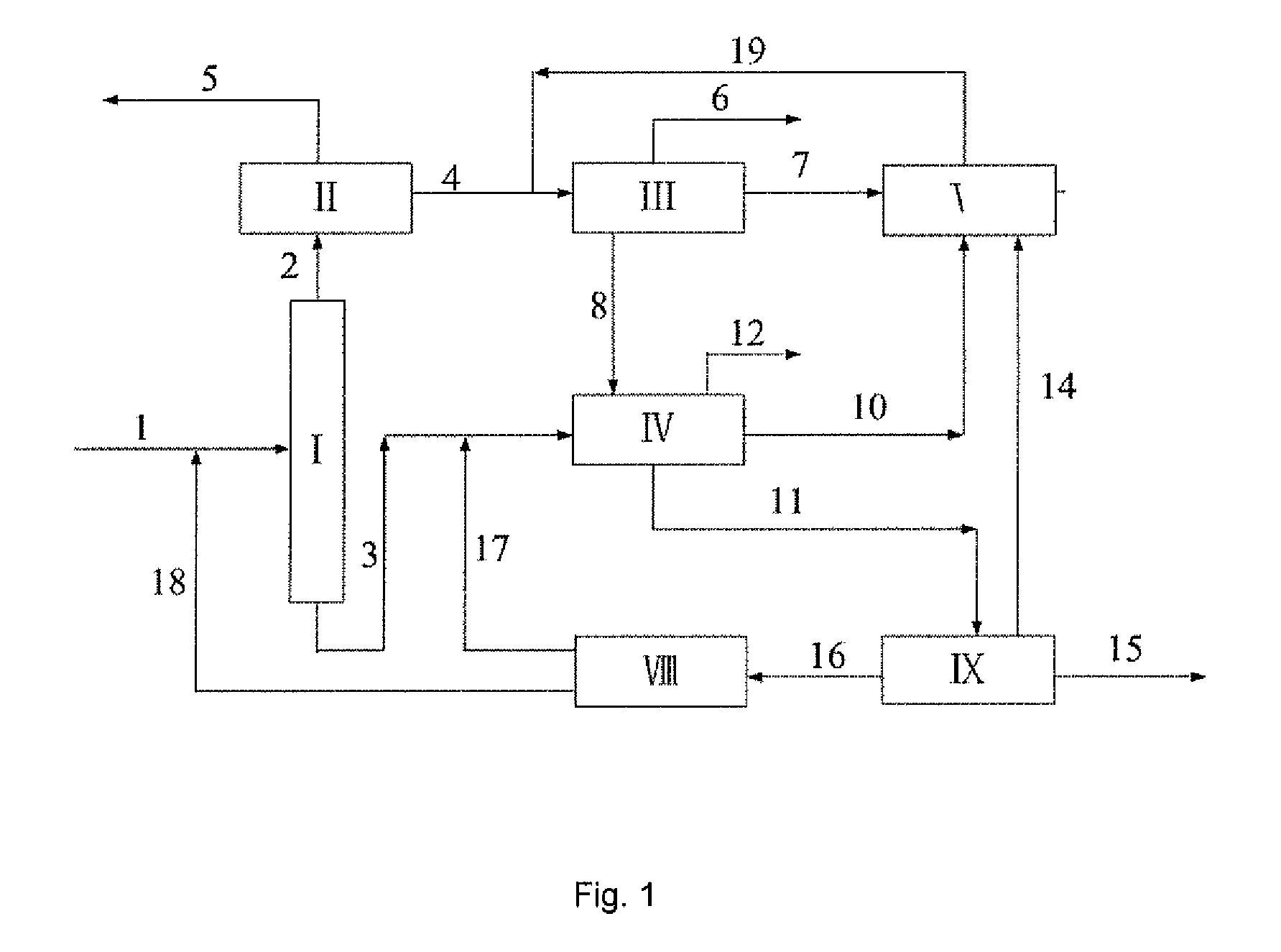

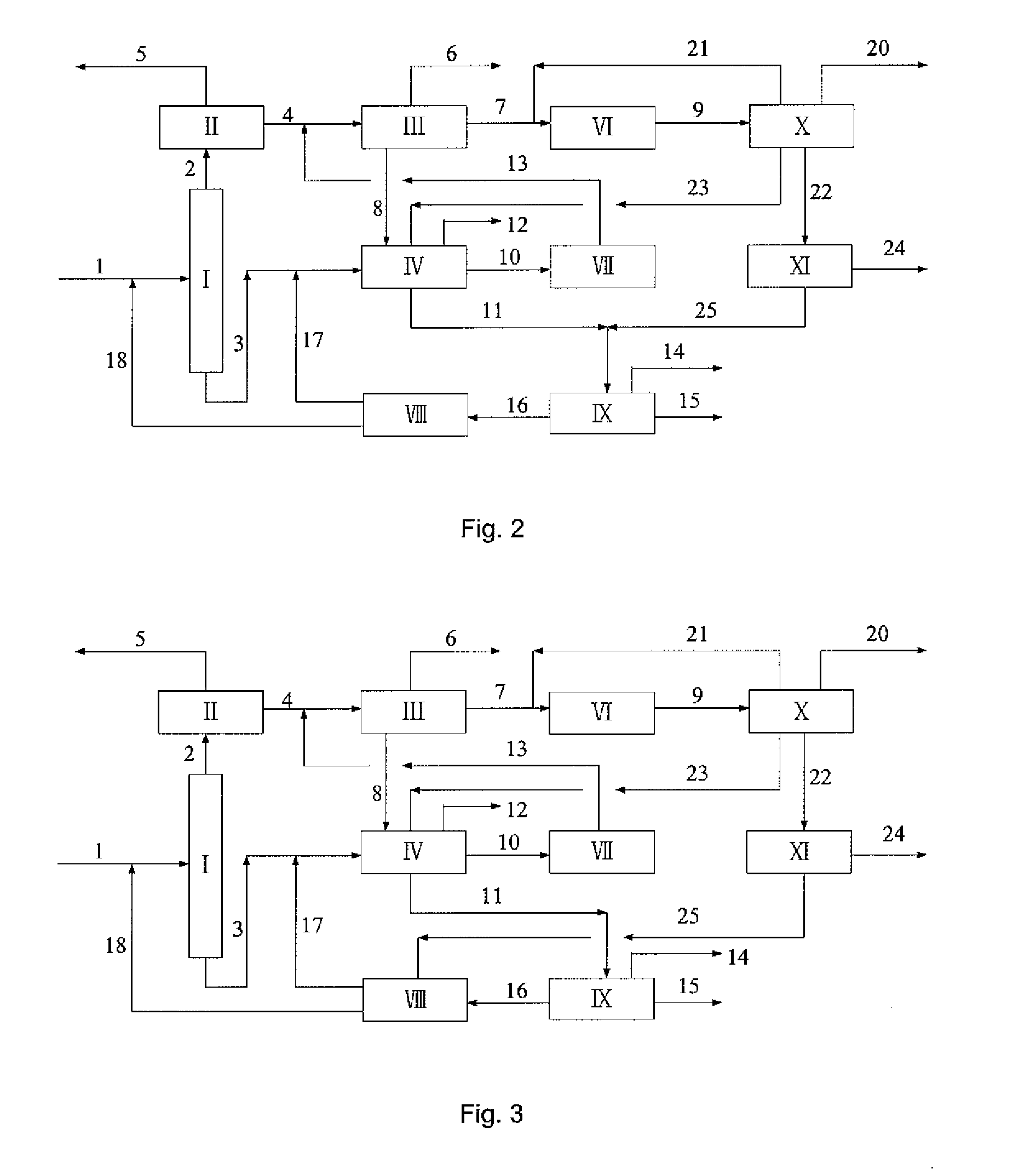

Integrated Process for the Production of P-Xylene

ActiveUS20100228066A1High energy consumptionImprove concentrationHydrocarbon by isomerisationMolecular sieve catalystsIsomerizationHydrogen

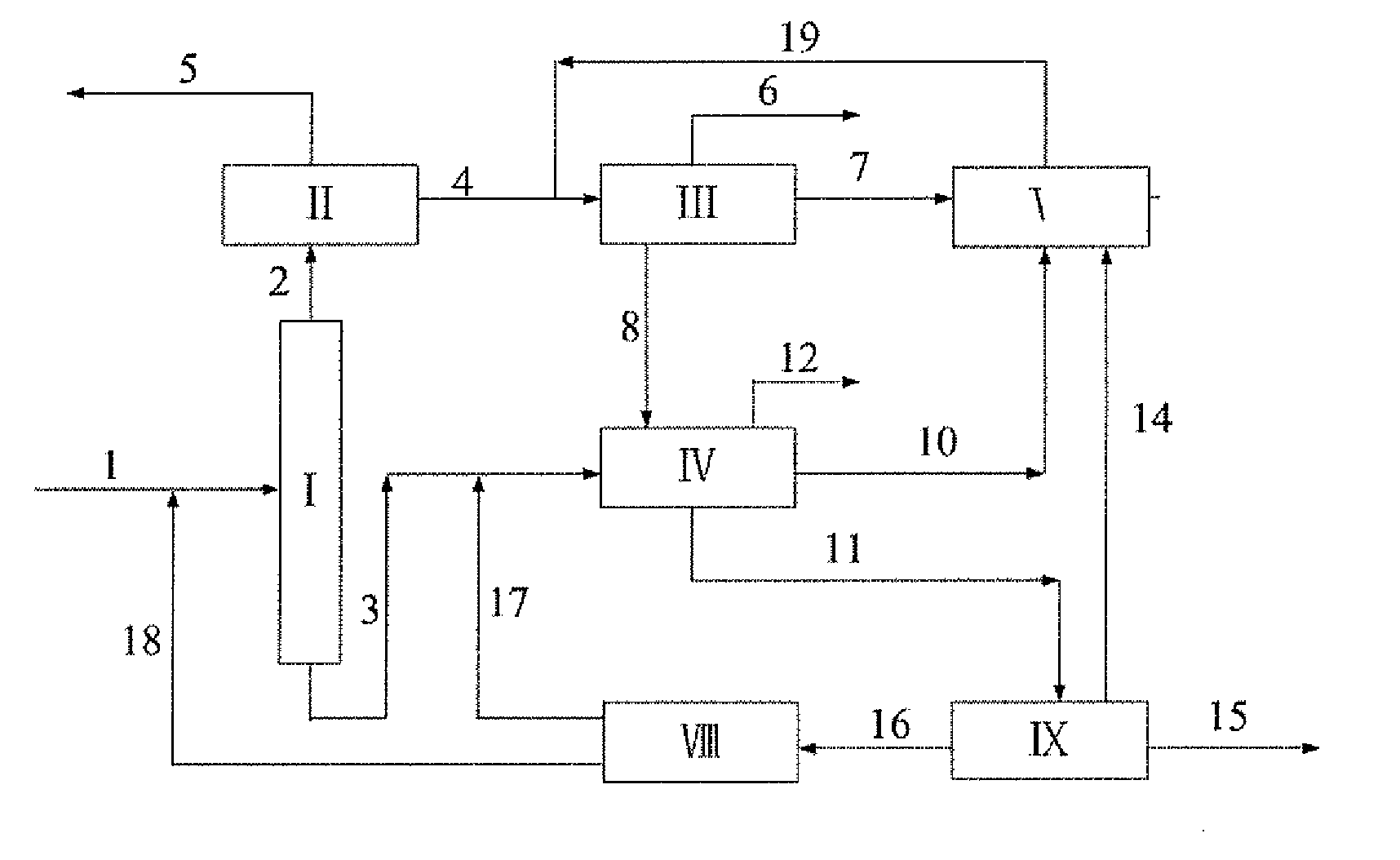

The present invention provides an integrated process for the production of p-xylene, comprising the steps of A) separating a mixed feedstock containing benzene, toluene, C8 aromatic hydrocarbons, C9 and higher aromatic hydrocarbons, and non-aromatic hydrocarbons from a reforming unit, to obtain a first benzene stream, a first toluene stream, a first C8 aromatic hydrocarbon stream, a stream of C9 and higher aromatic hydrocarbons, and a stream of non-aromatic hydrocarbons; B) feeding the stream of C9 and higher aromatic hydrocarbons from step A) to a C9 and higher aromatic hydrocarbon dealkylation unit, where dealkylation reaction occurs in the presence of hydrogen, and separating the reaction effluent to obtain a second benzene stream, a second toluene stream, and a second C8 aromatic hydrocarbon stream; C) feeding both the first toluene stream and the second toluene stream to a toluene selective disproportionation unit, where toluene selective disproportionation reaction occurs in the presence of hydrogen to produce a stream containing C8 aromatic hydrocarbons including p-xylene and benzene, which stream is separated to obtain a third C8 aromatic hydrocarbon stream, a third toluene stream, and a third benzene stream, with the third toluene stream being returned to an inlet of this unit; D) feeding both the first C8 aromatic hydrocarbon stream and the second C8 aromatic hydrocarbon stream to an adsorption separation unit, to obtain a first p-xylene product stream and a fifth C8 aromatic hydrocarbon stream, with the fifth C8 aromatic hydrocarbon stream being passed to an isomerization unit; E) feeding the third C8 aromatic hydrocarbon stream to a crystallization separation unit, to obtain a fourth C8 aromatic hydrocarbon stream and a second p-xylene product stream, with the fourth C8 aromatic hydrocarbon stream being passed to the adsorption separation unit or the isomerization unit; and F) feeding an effluent of the isomerization unit to an inlet of the adsorption separation unit.

Owner:CHINA PETROCHEMICAL CORP +1

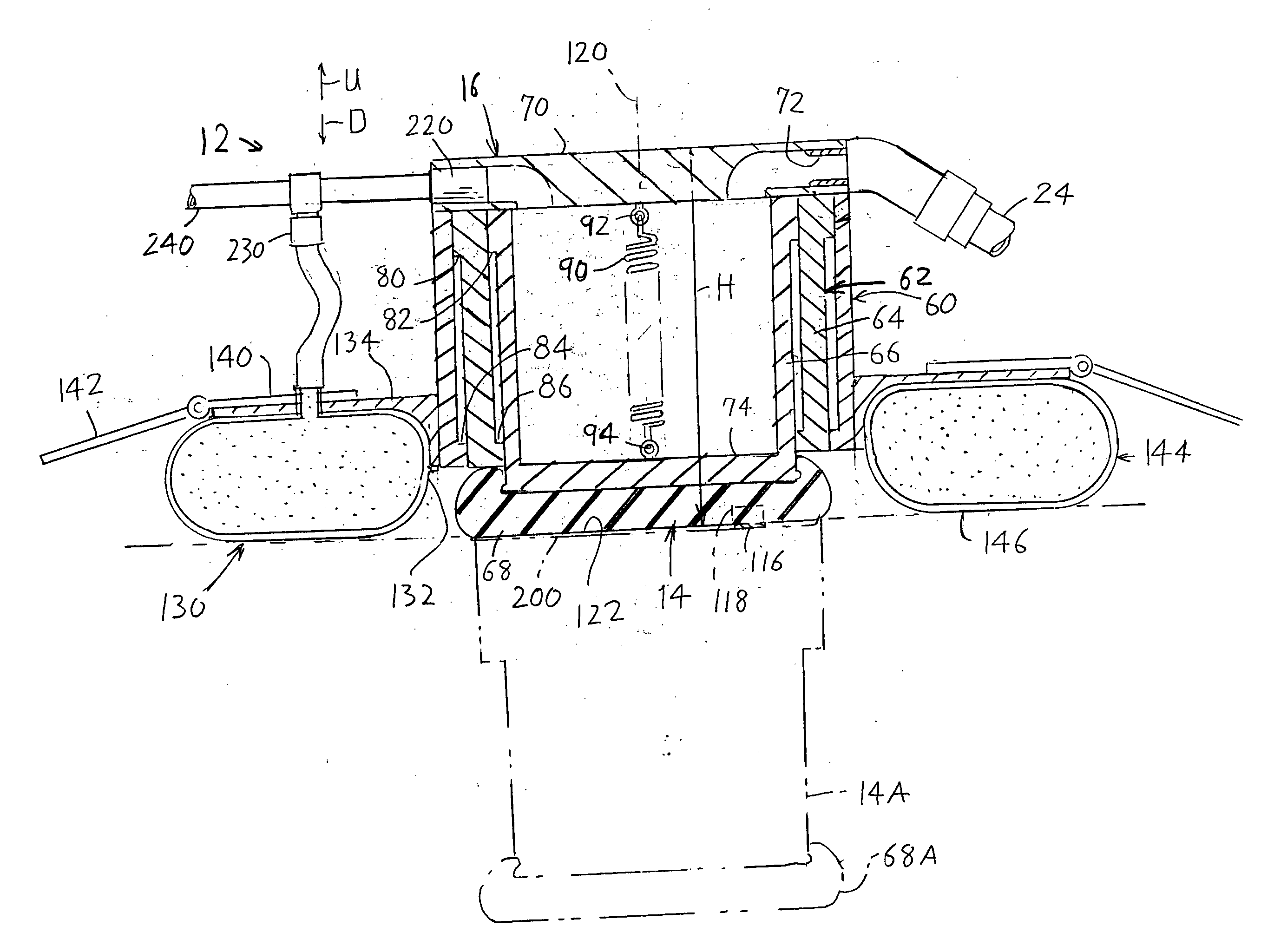

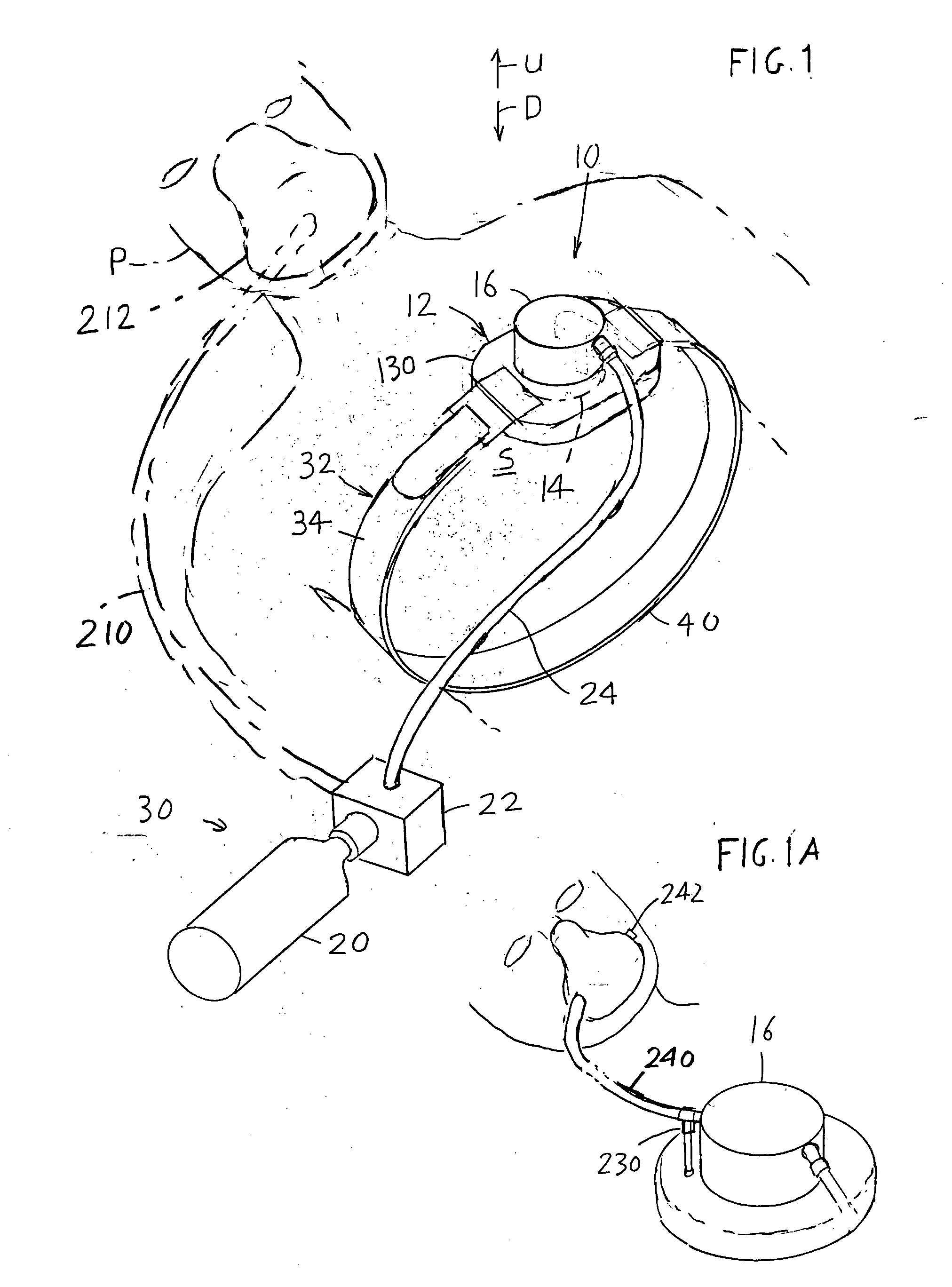

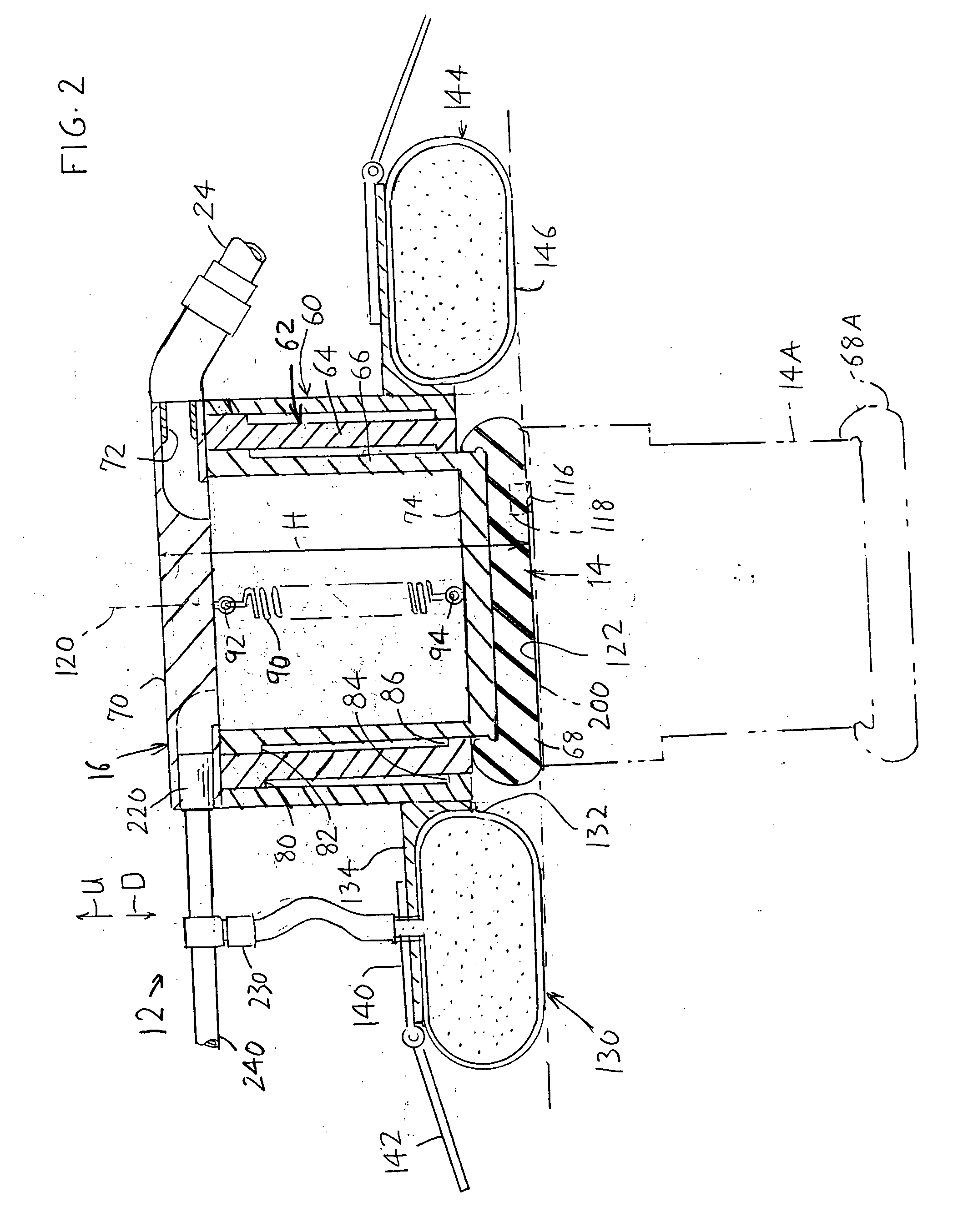

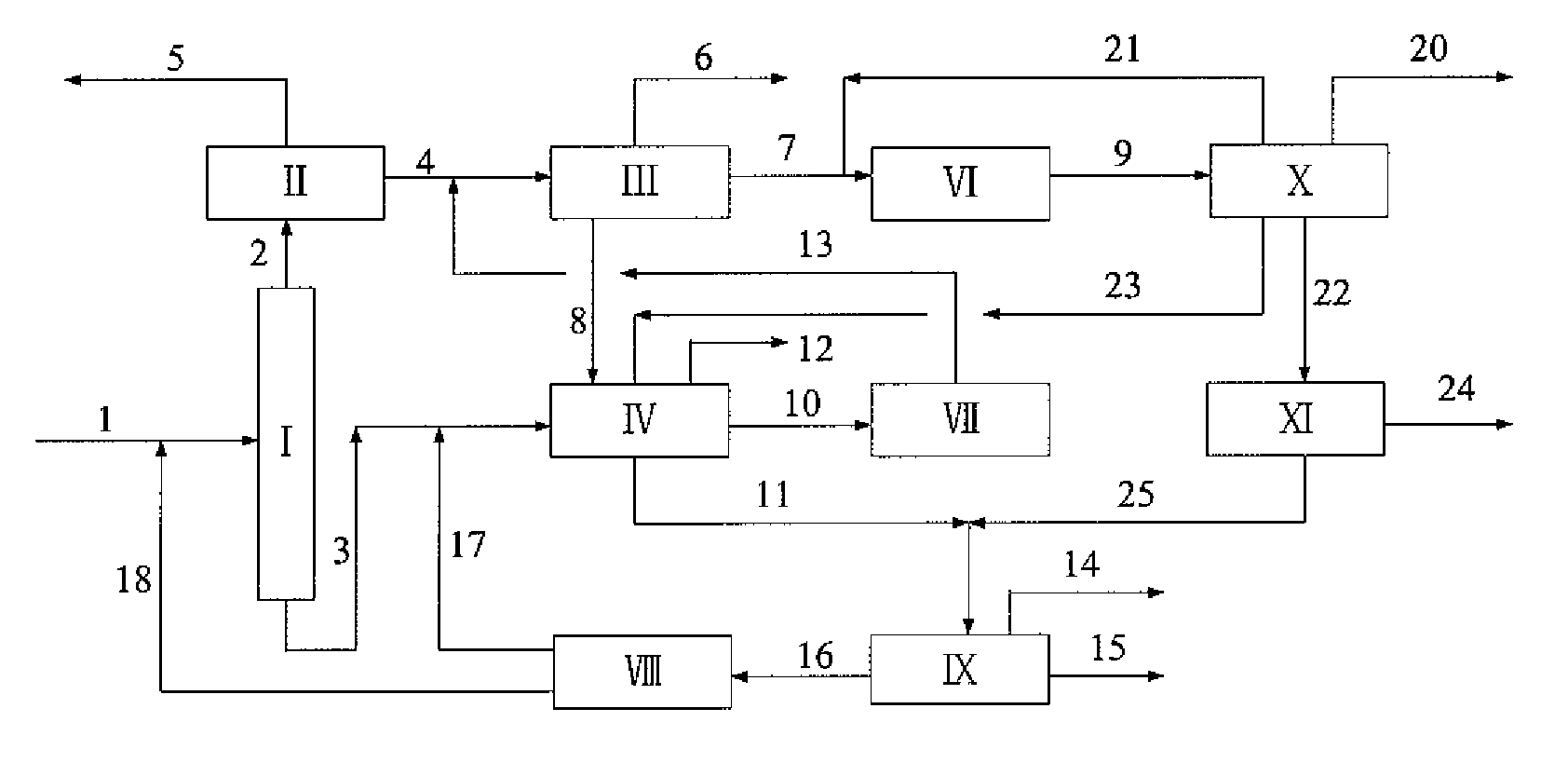

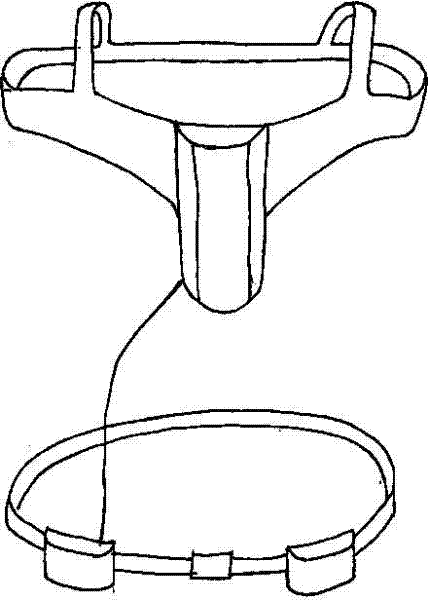

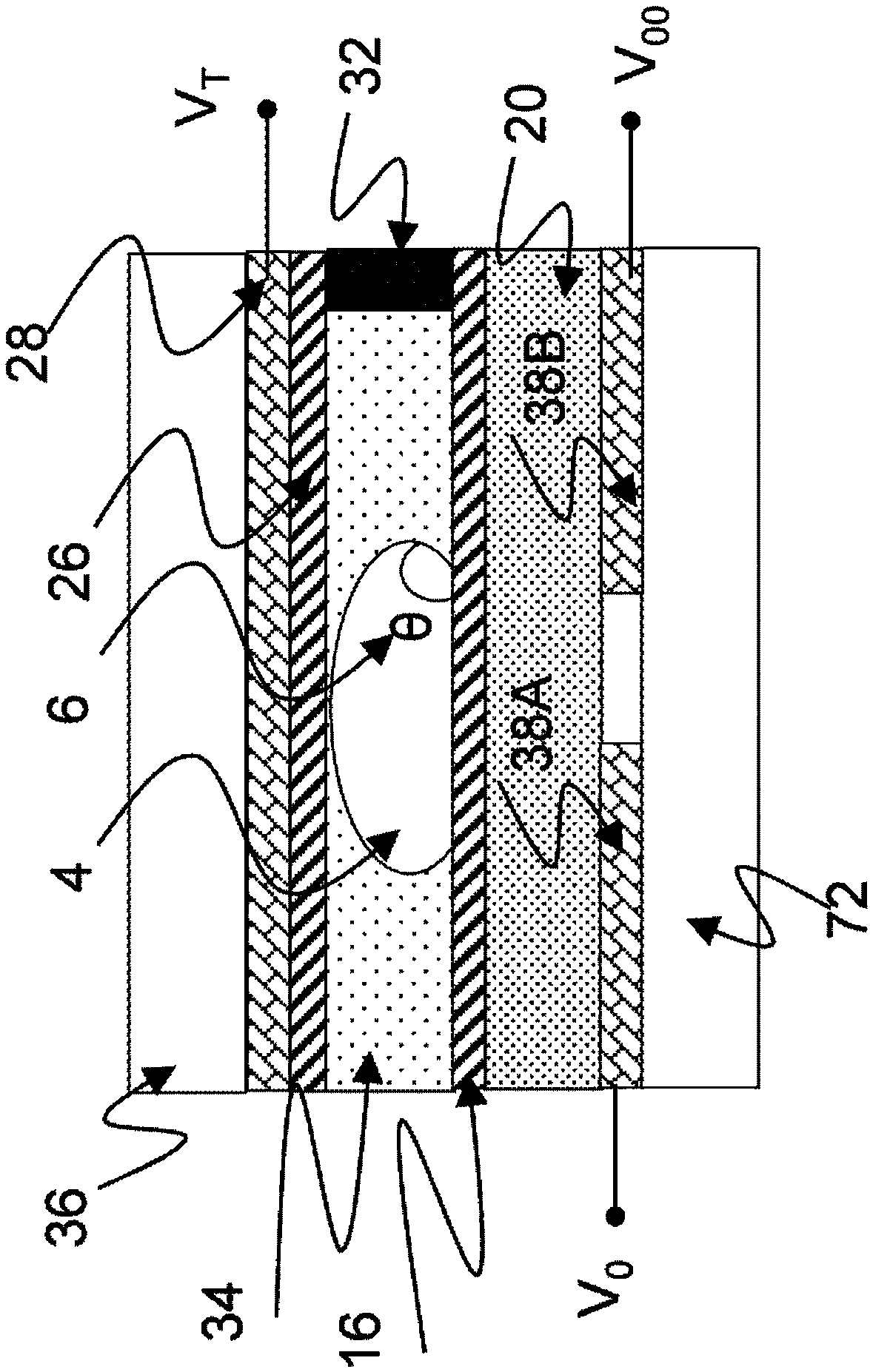

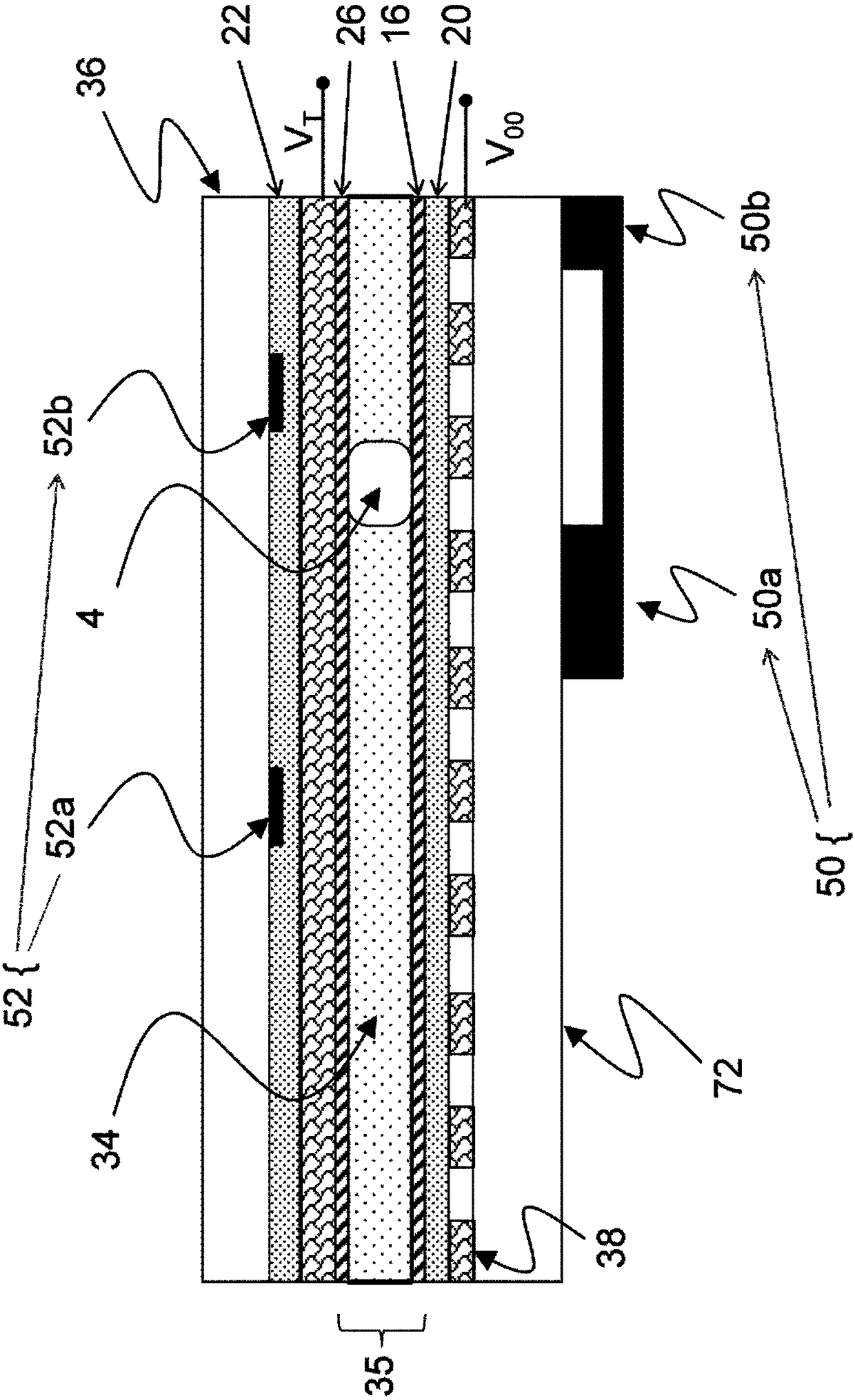

Controlled chest compressor

InactiveUS20050015026A1Large circulationEliminates and reduces loadingElectrotherapyPneumatic massageReciprocating motionBreathing gas

Apparatus for repeatedly compressing the chest of a patient to stimulate blood circulation and breathing, includes an energizable actuator (16) that repeatedly presses against the patient's chest, a torso wrap (32) that wraps to the back of the patient, and a stabilizer (130) that minimizes tilt of the actuator. The stabilizer is generally in the form of an inflatable toroid, or foam toroid, which extends substantially completely around the actuator to prevent tilting in any direction. The actuator includes a reciprocating member (14) that is not only moved down to compress the chest, but that is also pushed up to allow the chest to rise more rapidly. A pressing member (68) at the bottom of the reciprocating member, can tilt. The means for cycling includes compressed breathing gas for cyclically pushing down the reciprocating member, the actuator exhaust being delivered to the patient for breathing. Chest compression and chest recovery, respectively occupy under 30%, and over 70% of the duration of each cycle.

Owner:WEIL INST OF CRITICAL CARE MEDICINE

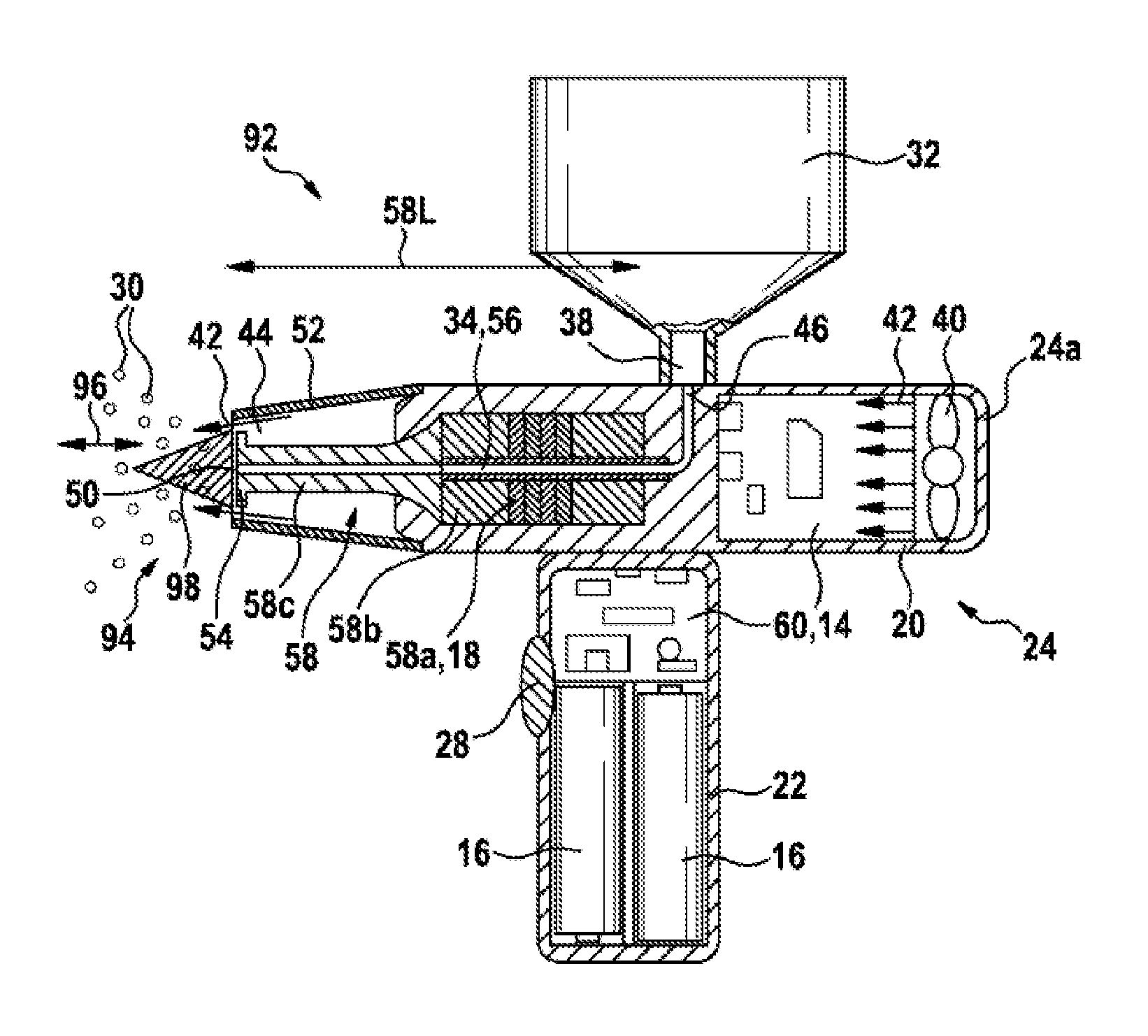

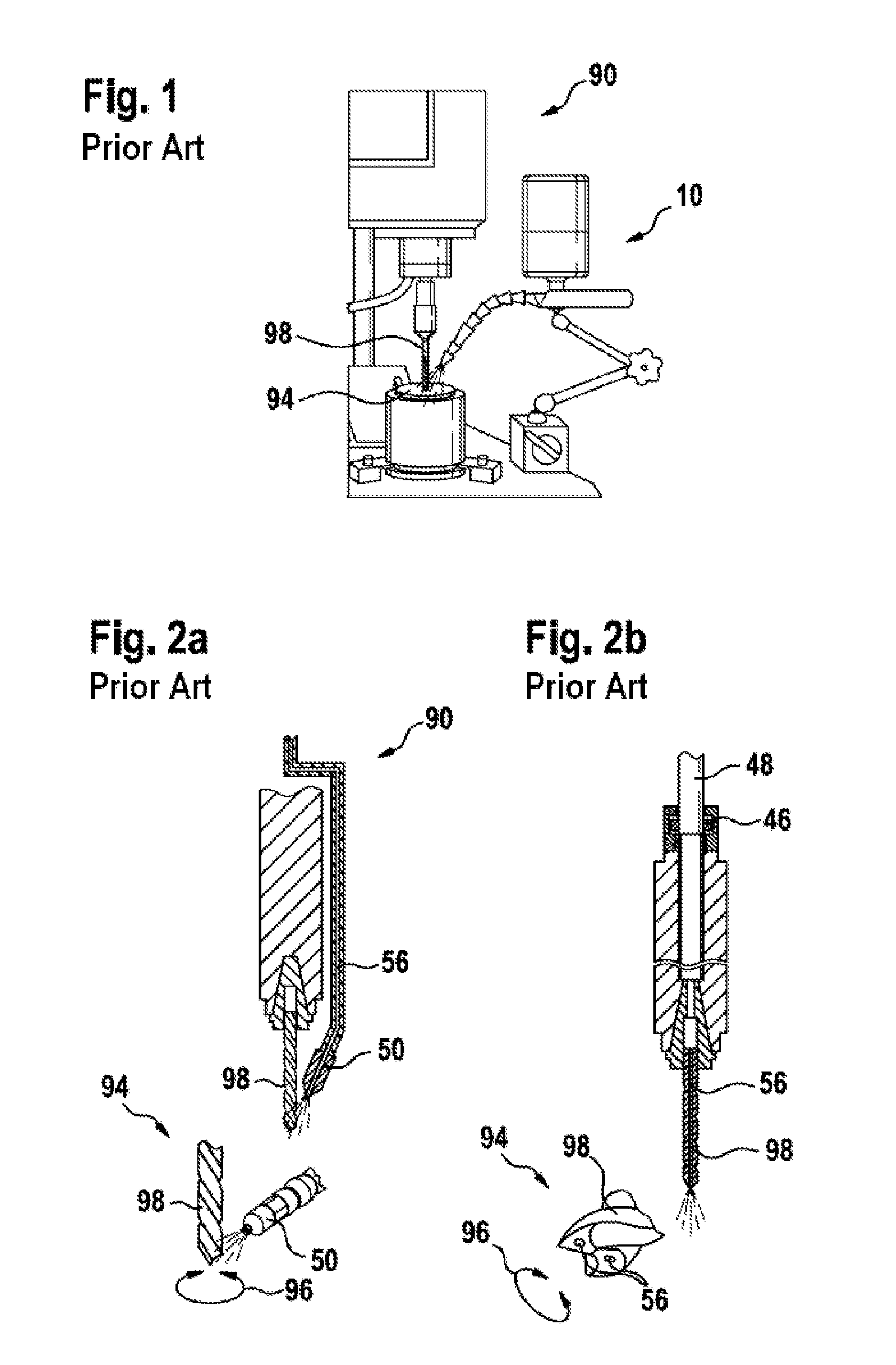

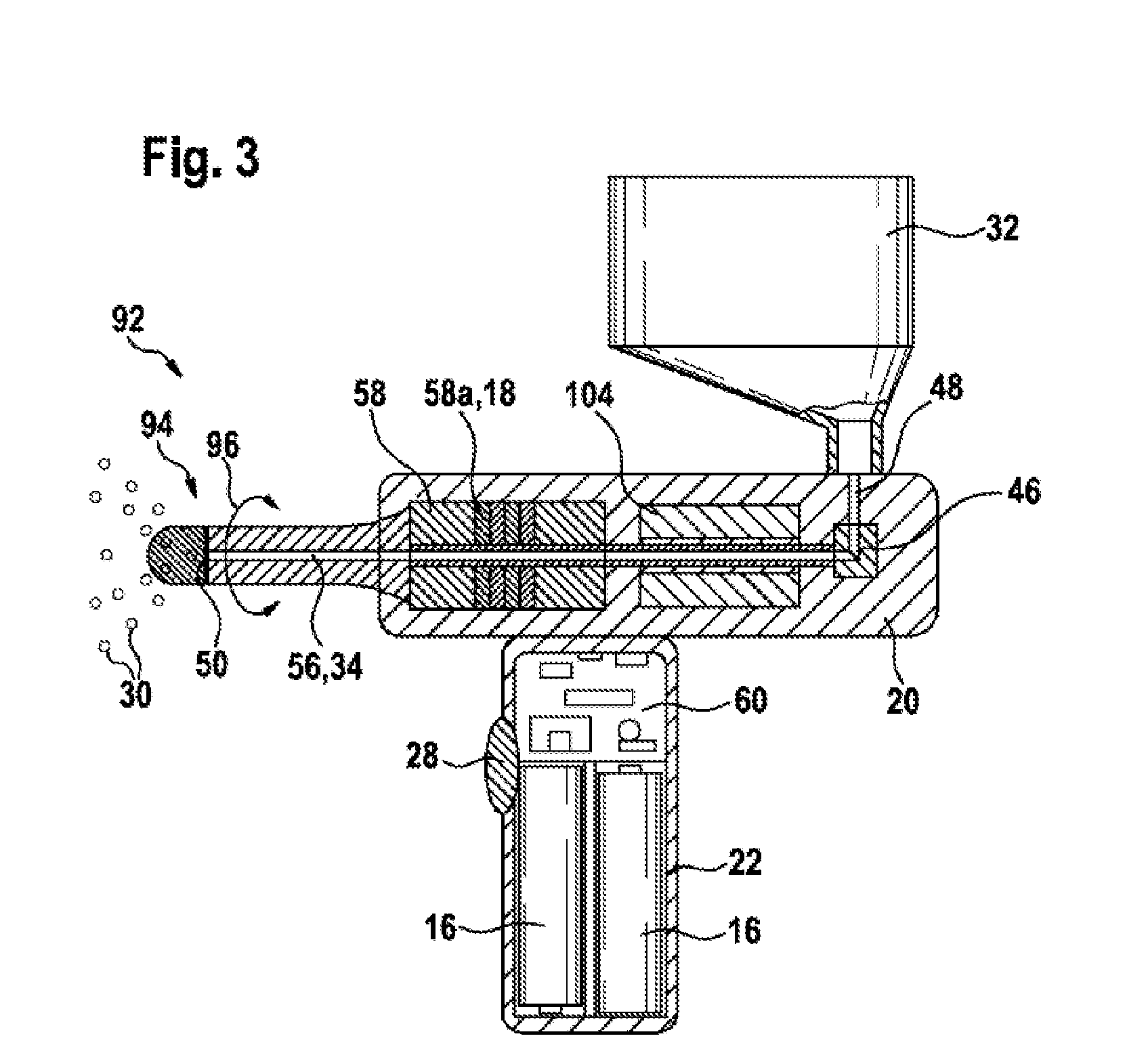

Minimal Quantity Lubricating System

InactiveUS20130206441A1Increase amplitudeEfficient droplet generationDrilling machinesPortable percussive toolsMachining processElectric power

A minimal quantity lubricating system for a handheld electric power tool is configured to output a lubricating fluid for cooling and / or lubricating a material machining process. The system comprises at least one oscillating unit, an electronic unit for applying at least control and / or feedback signals to the at least one oscillating unit, an operating power unit for providing electric power to the electronic unit, a storage tank for the lubricating fluid, and at least one nozzle associated with the at least one oscillating unit for feeding and atomizing the lubricating fluid in a tool working area. A fluid feed line connects the storage tank to a capillary feed of the lubricating fluid to the oscillating unit, and at least one fluid channel at least partially runs through the oscillating unit to connect the oscillating unit to the nozzle for pulsing the lubricating fluid.

Owner:ROBERT BOSCH GMBH

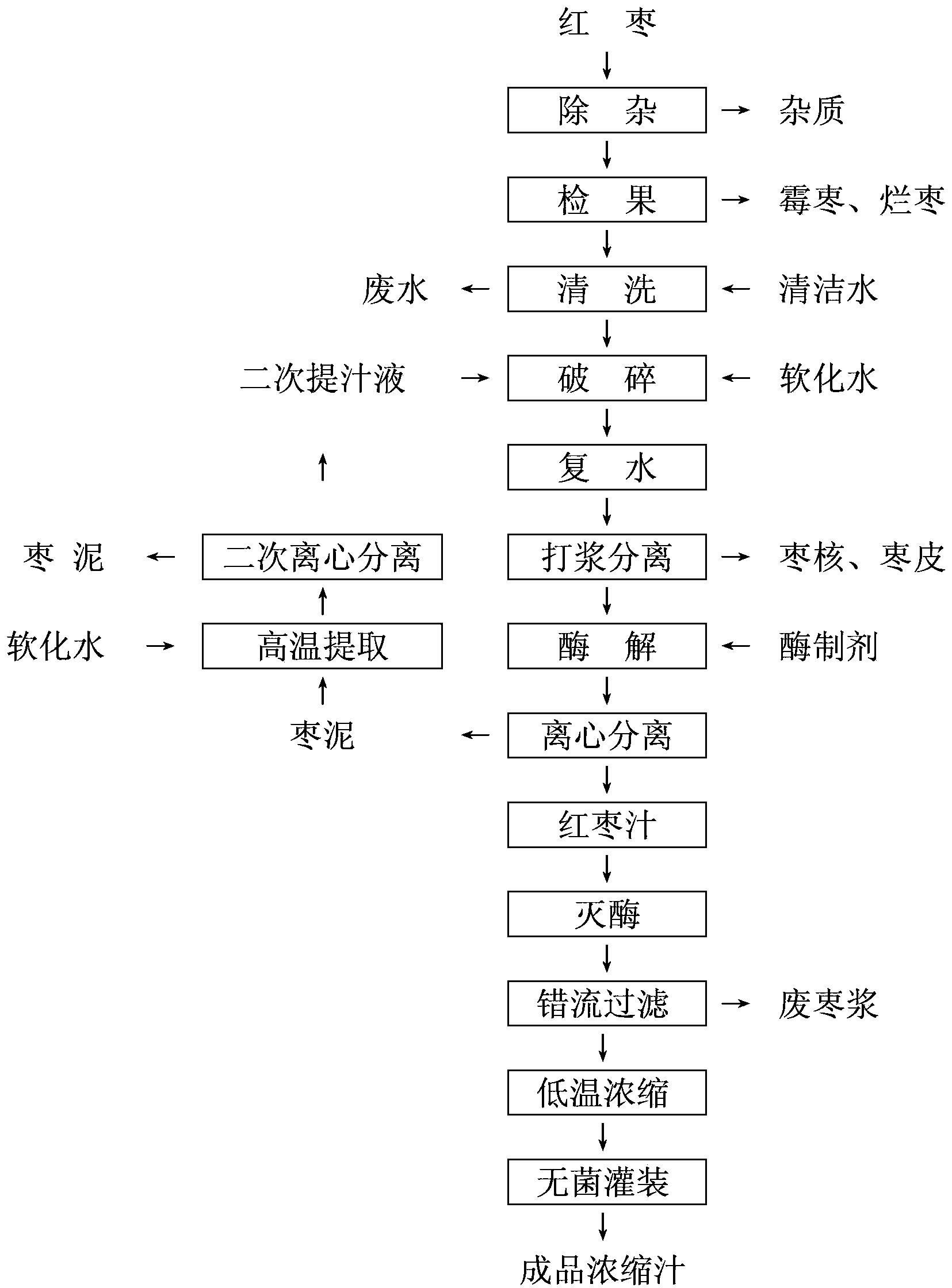

Production technology of red date concentrated clear juice

ActiveCN103519260AAdd flavorKeep the aromaFood thermal treatmentFood preparationAdditive ingredientCross-flow filtration

The invention relates to a production technology of red date concentrated clear juice, which comprises the following steps: impurity removal, fruit check and cleaning; breaking and rehydration; pulping and separation; enzymolysis; centrifugal separation; enzyme deactivation; high-temperature extraction; secondary centrifugal separation; cross flow filtration; vacuum low-temperature concentration; and sterile filling. The production technology provided by the invention has the advantages that with the red dates as the raw materials and by adopting a two-step breaking process, the breaking effect is improved, and the extraction rate of the raw materials is improved; by adopting the low-temperature rehydration process, the bright color, pure flavor and high content of nutritional ingredients of the date juice are guaranteed; by adopting the high-temperature extraction process, the physiologically-active substances in the red dates can be extracted to the greatest degree; since the high-temperature extracted juice returns to the rehydration section, the utilization rate of the raw materials is improved; and by adopting the cross flow filtration, the product has bright color and rich date aroma and is the best raw material for the deep processing of red dates. The production technology provided by the invention is reliable in the production technique of the domestic advanced level, fills up the blank of the key processing technology in domestic red date juice production, is a national initiative and meets the industrial production need.

Owner:CHINA LIGHT IND INT ENG CO LTD

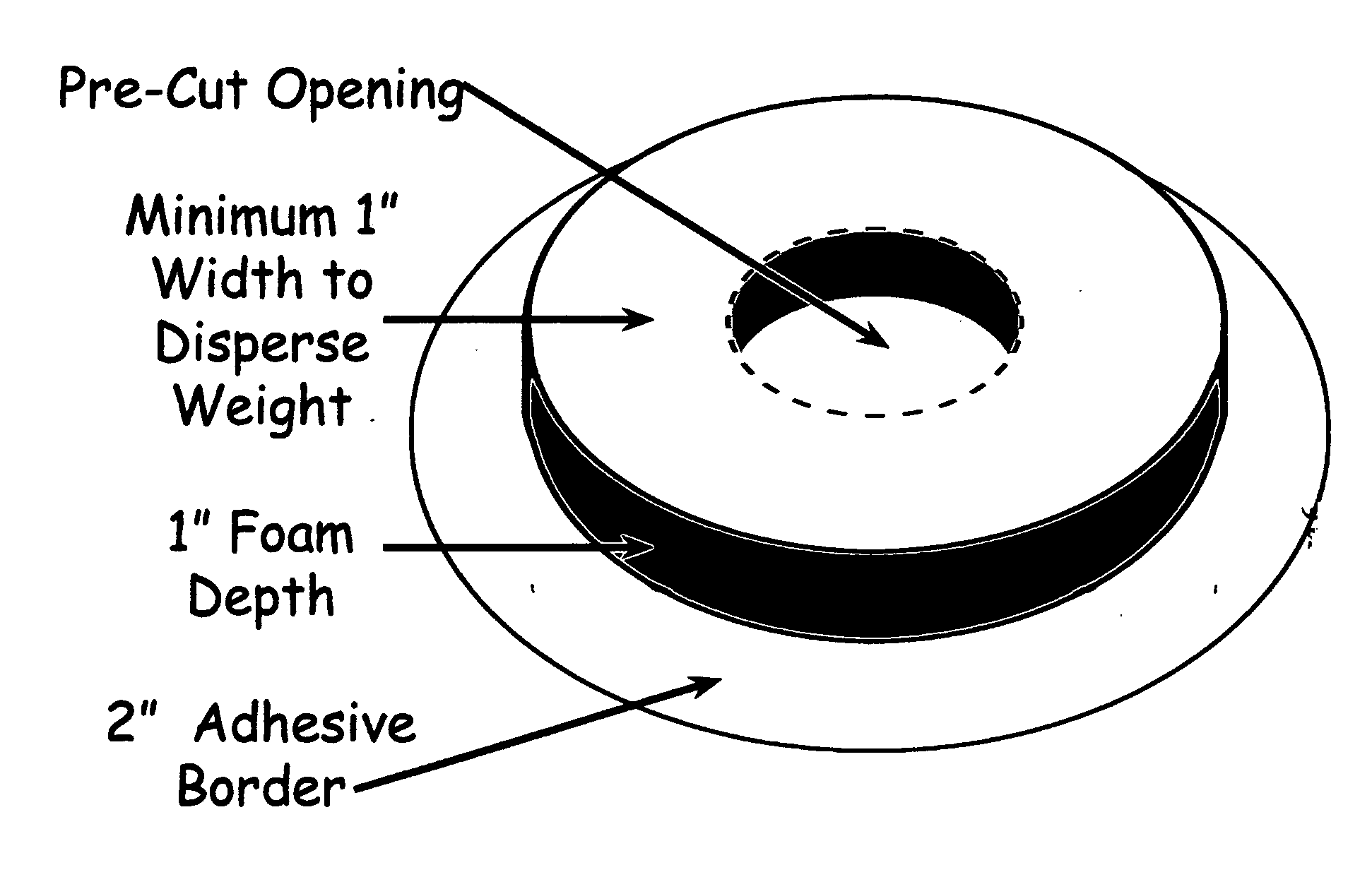

Pressure relief dressing

InactiveUS20090069737A1Large circulationEliminate contactAdhesive dressingsFeet bandagesMedicineAdhesive

The Pressure Ulcer Bandage is designed for application to the skin of an individual to treat pressure ulcers. The bandage will be constructed of flexible, round hydrocellular polyurethane foam, approximately one inch deep and will range in diameter with a precut opening to allow pressure relief from the ulcer itself and disperse weight away from the wound. The precut openings should be in various sizes to allow an opening at least 0.25 inches larger than the wound to be utilized The foam bandage will have at least 1.5 times the size of the precut opening of remaining foam outside the opening. Ring shaped bandages have been ineffective in the past because of the lack of flexibility of the material used and the limited amount of padding away from the opening. This bandage can be produced in an adhesive and in a non-adhesive format. Additionally, the packaged product will be sterile.

Owner:STAPLEY SCOTT +1

Integrated process for the production of P-xylene

ActiveUS8084657B2High energy consumptionLarge circulationHydrocarbon by isomerisationMolecular sieve catalystsIsomerizationAromatic hydrocarbon

Owner:CHINA PETROCHEMICAL CORP +1

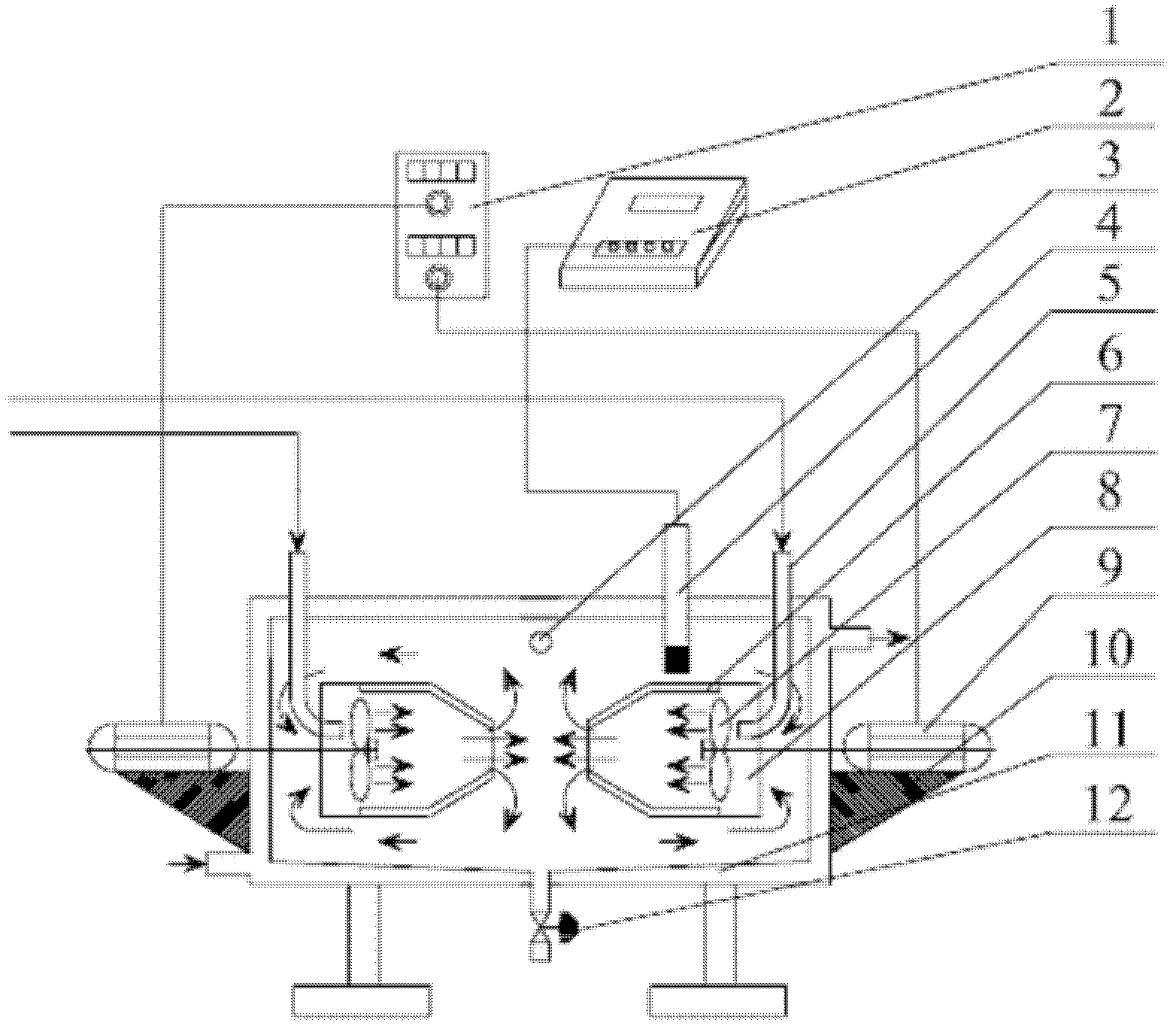

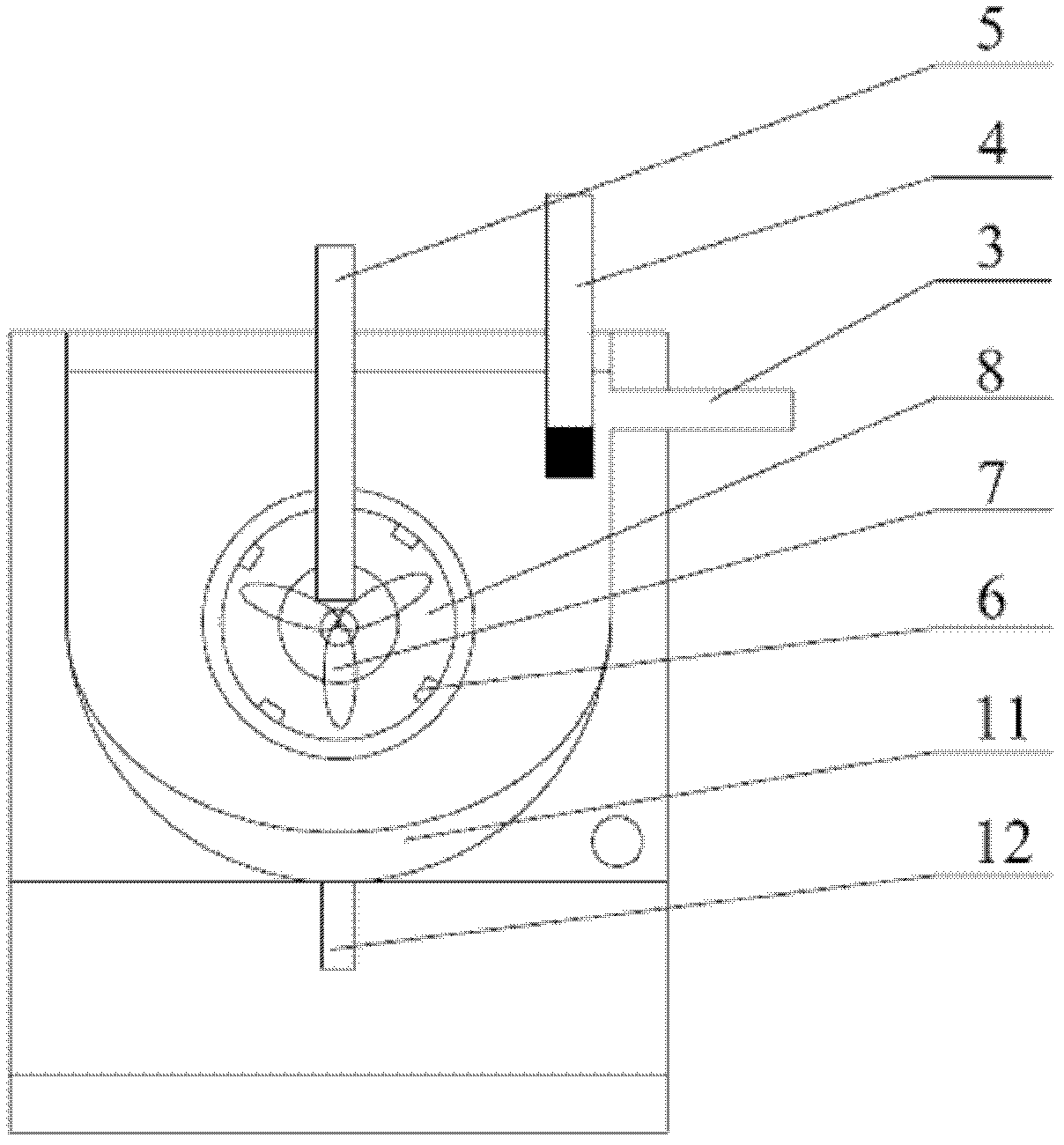

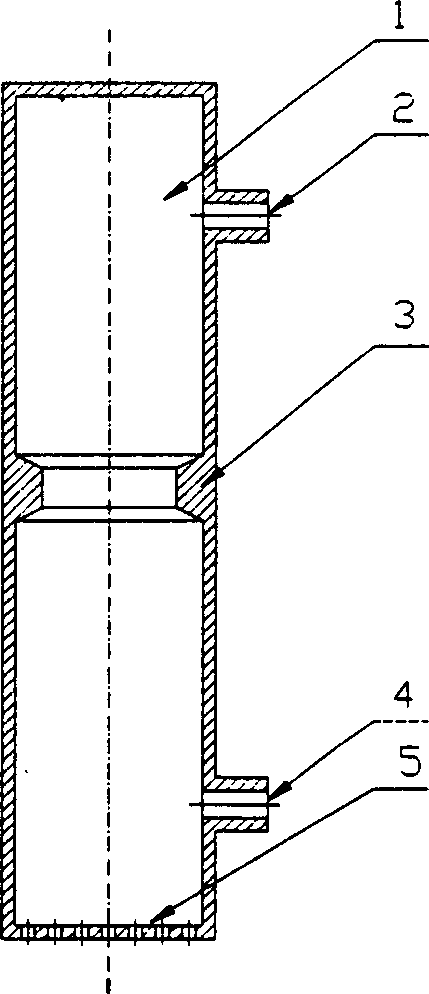

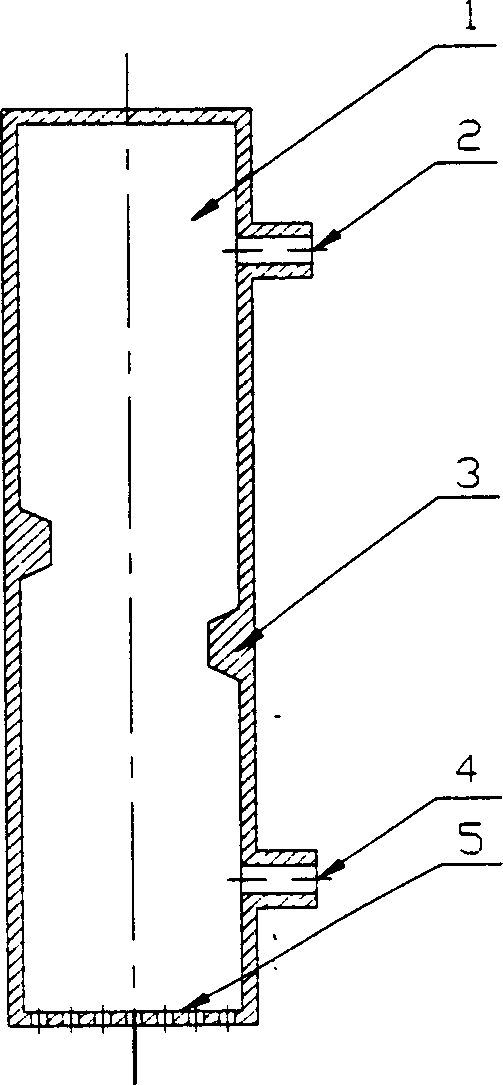

Liquid phase impinging stream reactor with controllable acidity

ActiveCN103203213AIncrease impact speedSuppress swirlChemical/physical/physico-chemical stationary reactorsChemical reactionEngineering

The invention discloses a liquid phase impinging stream reactor with controllable acidity, belonging to the field of chemical reaction technical equipment. In the reactor, 1-6 pairs of draft tubes with changeable diameters are horizontally arranged coaxially and oppositely; raw materials are introduced by feeding tubes with curved nozzles; fluid is accelerated by push-type three-blade stirrers at the entrance of the draft tubes; the rotation speed of the push-type three-blade stirrers is controlled by a controller; rotational flow is inhibited by deflection baffles; the inner diameters of the draft tubes become smaller gradually; cross-section area of a flow channel is decreased; flow speed is increased; the flow speed at the exits of the draft tubes is the maximum; two fluids impinge face to face at a high speed in the container and mixed efficiently and rapidly; the fluids flow to the entrance of the draft tubes from central impinging areas through the outer sides of the draft tubes, thus realizing circulation; motors are fixed and anti-vibrated by triangle support plates, the acidity of a reaction system is on-site monitored by a pH meter probe and displayed in real time by a pH meter display; constant acidity of the reaction system is realized by adjusting liquid inlet flow quantity; and materials in the contained are discharged from a material-discharging port after the reaction is finished. The liquid phase impinging stream reactor can be heated or cooled, and can be operated continuously, intermittently or semi-continuously.

Owner:TSINGHUA UNIV

Multi-level sliding sleeve

ActiveUS20140182838A1Large circulationPreventing sand blockingFluid removalWell/borehole valve arrangementsEngineeringMechanical engineering

A multi-level sliding sleeve including an outer cylinder, an inner sliding sleeve, a combined ball socket, a guider, an expander, an upper gland, a lower gland, and a ball. The outer cylinder includes internal threads in an upper end and external threads in a lower end, and the outer cylinder including an external wall including a plurality of drainage holes along the peripheral direction. The inner sliding sleeve is mounted to an inner wall of the outer cylinder through shear pins. The inner sliding sleeve includes a plurality of square holes in the middle along the peripheral direction, each of which is equipped with a ball socket inside. The ball sockets combine together to form a combined ball socket. The combined ball socket is equipped with the guider in the upper end and the expander in the lower end.

Owner:CNPC BOHAI DRILLING ENG

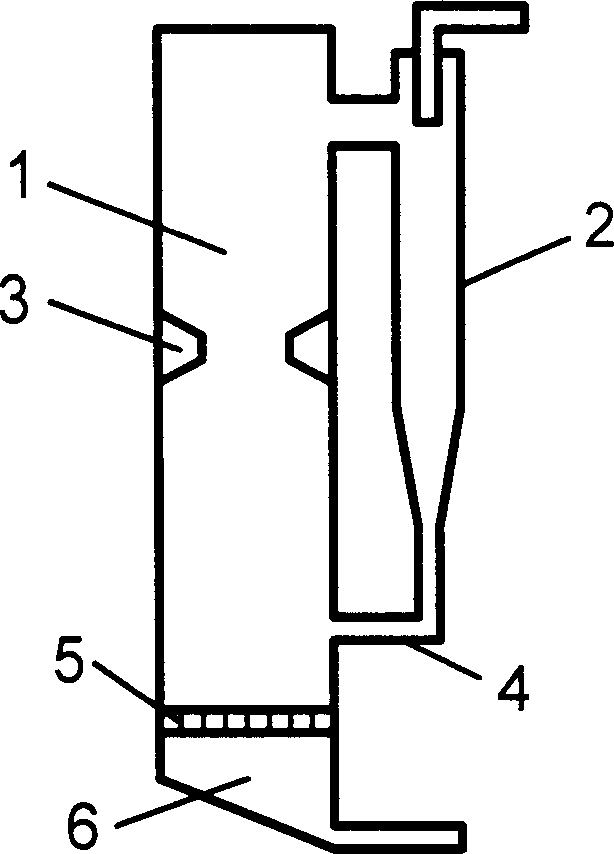

Combined circulating fluid bed boiler

InactiveCN1445477AImprove ascentReduce density differenceFluidized bed combustionApparatus for fluidised bed combustionCycloneCombustion chamber

A combined circulating fluidized-bed boiler is composed of combustion chamber, cyclone separator, throat, material return valve and air distributing plate, and features that said throat can divide the combustion chamber into several combustion chambers for intensifying the combustion of particles in combustion chamber.

Owner:SHANGHAI JIAO TONG UNIV

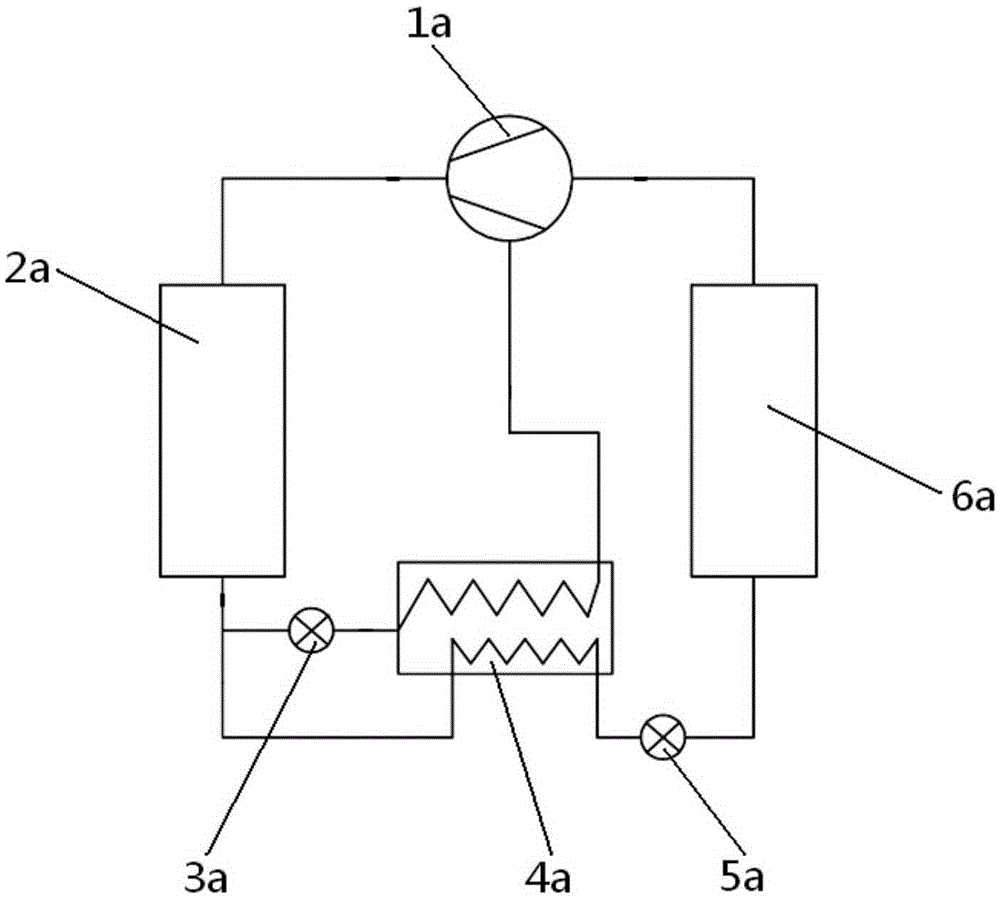

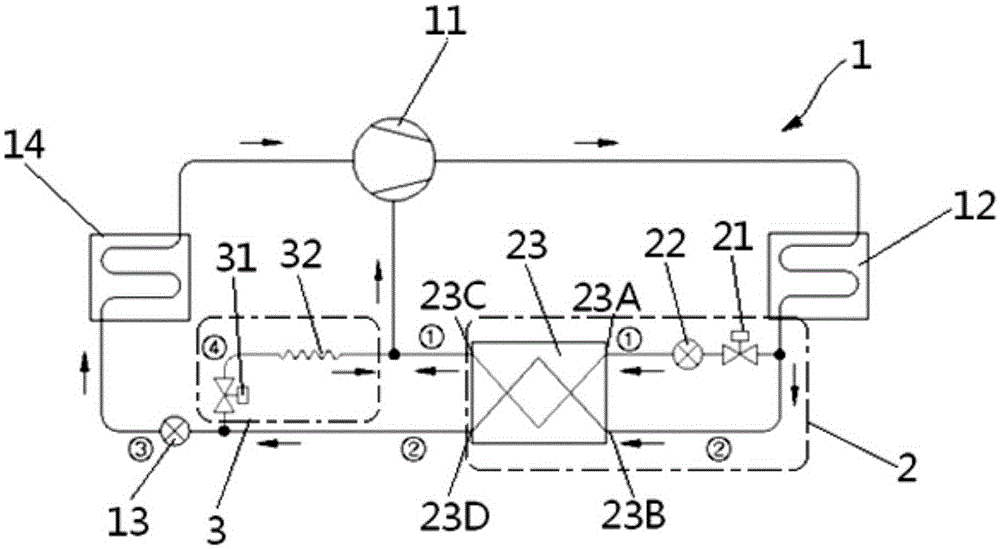

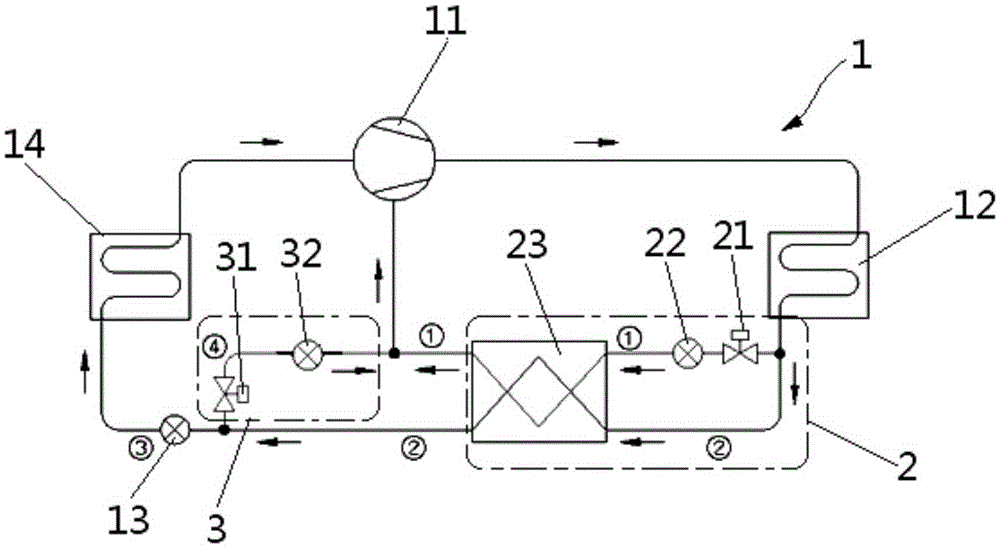

Heat pump heating system, control method and heat pump water heater

The invention relates to a heat pump heating system, a control method and a heat pump water heater. The heat pump heating system comprises a main loop (1), an air supplementing enthalpy increasing branch (2) and a liquid spraying branch (3). The main loop (1) comprises a compressor (11), a condenser (12), a first throttling component (13) and an evaporator (14) which are sequentially connected in the refrigerant flowing direction. One end of the air supplementing enthalpy increasing branch (2) and one end of the liquid spraying branch (3) are both connected to the part, between the condenser (12) and first throttling component (13), of the main loop (1). The other end of the air supplementing enthalpy increasing branch (2) and the other end of the liquid spraying branch (3) are both connected with an air supplementing port of the compressor (11) to supplement gas-phase and liquid-phase refrigerant to the compressor (11). According to the heat pump heating system, the reliability of the system during low-temperature running can be improved.

Owner:GREE ELECTRIC APPLIANCES INC

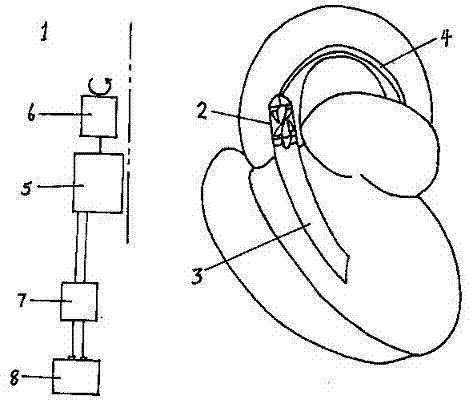

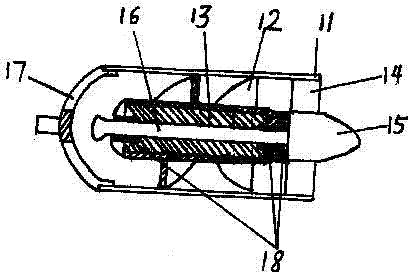

Novel intrusive assisted circulation device

InactiveCN102475923ANo biocompatibility concernsEasy maintenanceSuction devicesHuman bodyAxial-flow pump

The invention belongs to the field of biomedical engineering and particularly relates to an intrusive assisted circulation device used in the department of cardiac surgery. The device is characterized in that a magnetic drive mode is adopted for power transmission. The device is divided into two parts, namely an invitro driving device and an auxiliary device capable of being implanting into a human body through percutaneous coronary intervention, wherein an invitro driving device main body is a rotating magnetic field generation device capable of generating a rotating magnetic field which is strong enough; the auxiliary device implanted into the human body is internally provided with a minitype axial flow pump; a high-energy magnet is embedded in an impeller of the minitype axial flow pump, and is driven to rotate by the rotating magnetic field so as to push blood to flow; and the pump is implanted into the part, crossing over an aortic valve or pulmonic valve, of a heart, so as to play a role in assisting the heart to pump blood, thus effectively relieving the cardiac muscle load and assisting heart recovery.

Owner:DALIAN CHUANGDA TECH TRADE MARKET

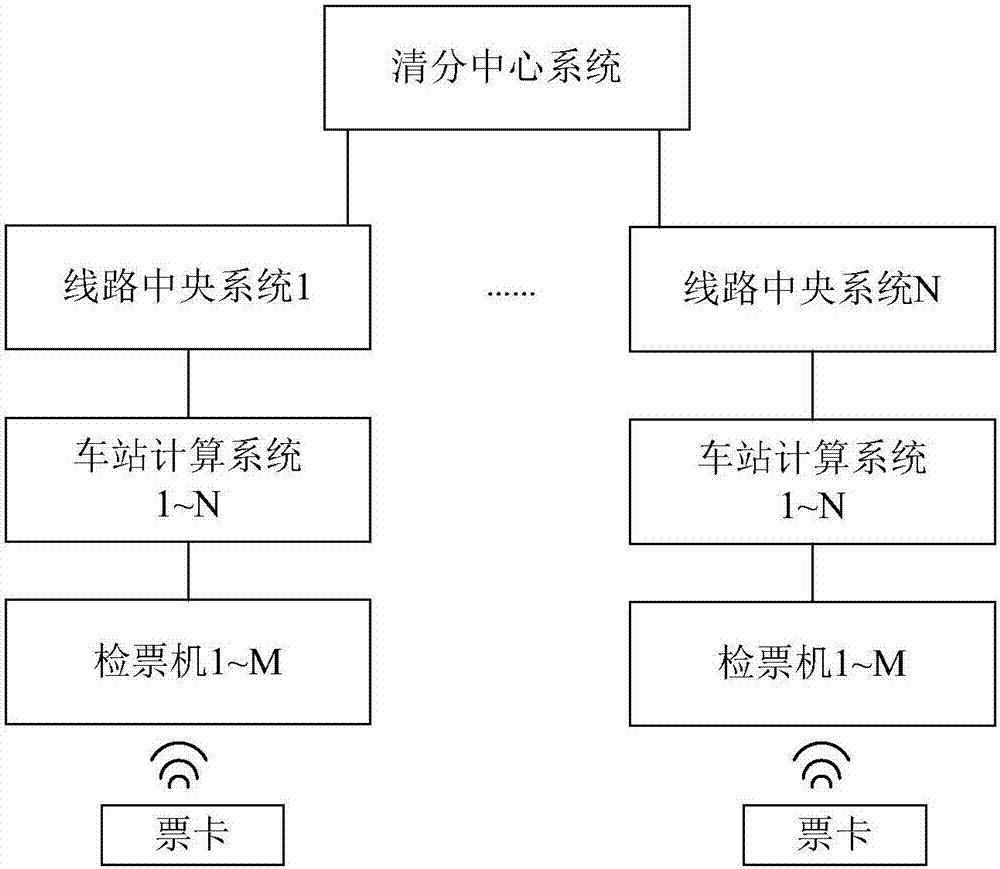

Ticket check and payment system and method for urban rail transit financial IC cards

PendingCN107093074ALarge circulationWide coverageTicket-issuing apparatusCredit schemesOperating systemReading card

The invention discloses a ticket check and payment system and a method for urban rail transit financial IC cards. The ticket check and payment system comprises ticket gates used for reading card information of financial IC cards and generating transaction data, clearing center systems used for calculating fees according to the transaction data and generating transaction records, and a financial preprocessing system used for sending payment requests and the transaction records to a CUPS (China Union Pay System) to enable the CUPS to make payment online according to the transaction records and a corresponding bank background system. Financial IC cards are applied to the field of urban rail transit. Based on the fact that financial IC cards have a large circulation and wide coverage, post-payment is adopted. Online real-time verification is avoided. The transaction speed is ensured. Financial IC cards can be used in urban rail transit throughout the country. The demand of the masses for taking the subway fast is well satisfied.

Owner:GUANGZHOU METRO DESIGN & RES INST

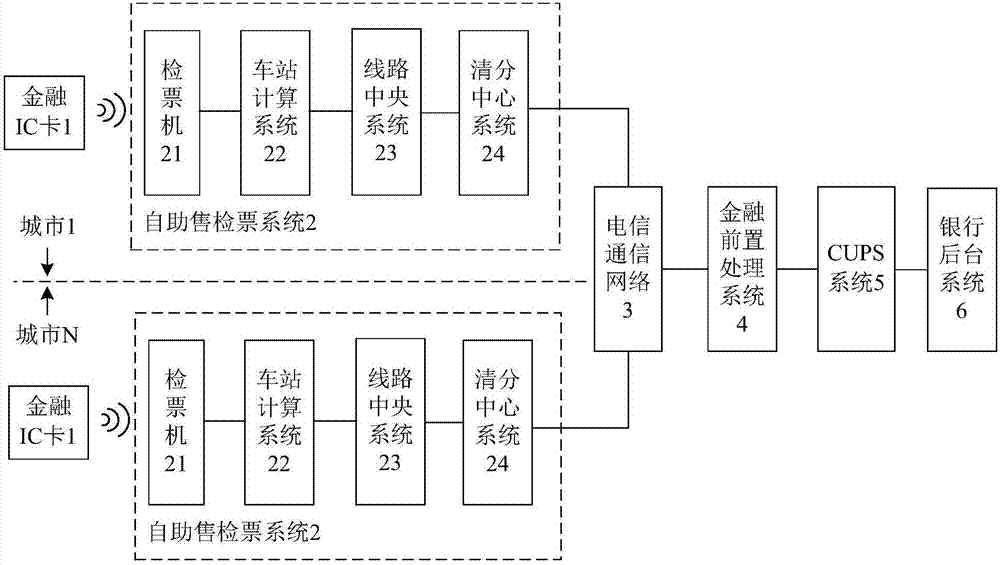

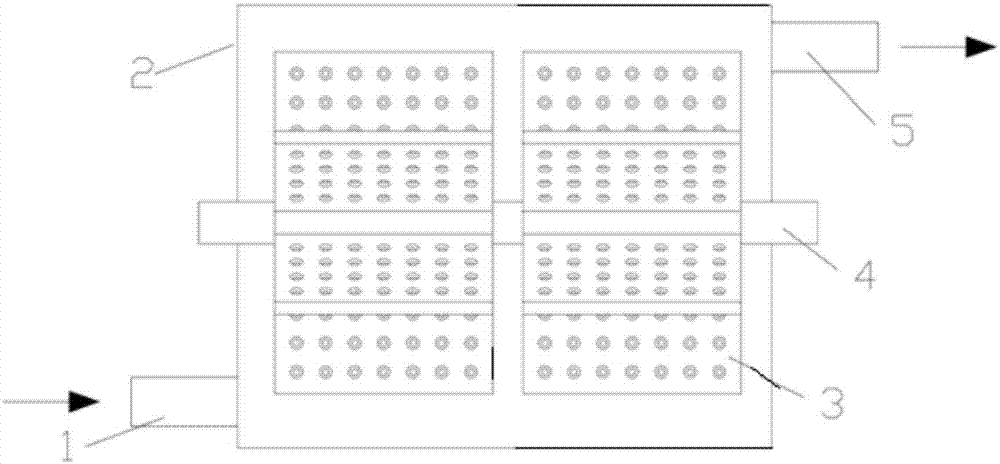

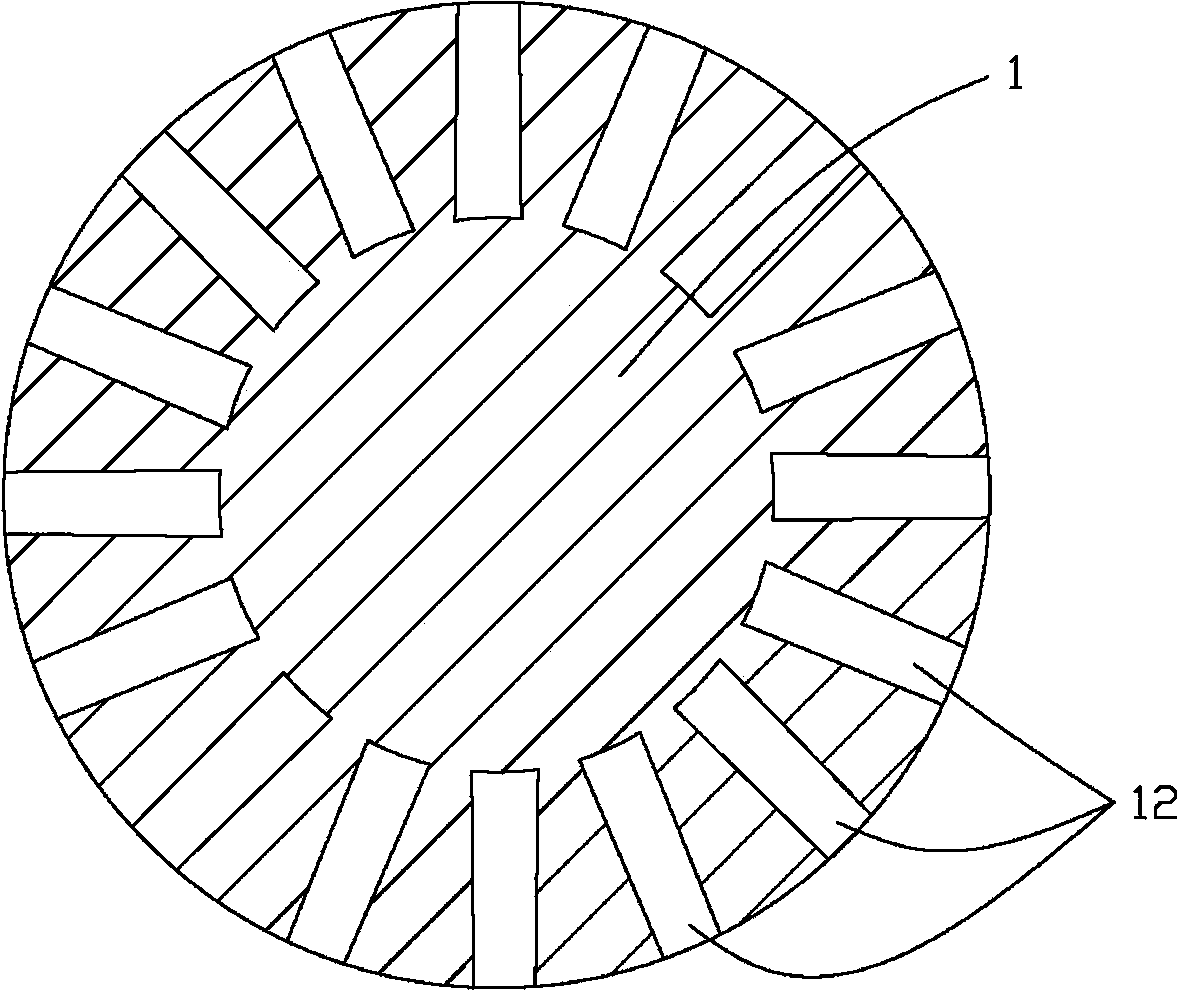

Multi-impellor rotary vane type hydrodynamic cavitation generator and hydrodynamic cavitation method

PendingCN107228090ASimple structureLarge processing throughputPump componentsWater/sewage treatment with mechanical oscillationsImpellerElectric machine

The invention discloses a multi-impellor rotary vane type hydrodynamic cavitation generator and a hydrodynamic cavitation method. The multi-impellor rotary vane type hydrodynamic cavitation generator comprises a box body and a cavitation mechanism. The box body is used for containing liquid, the bottom end of the front side of the box body is provided with a liquid inlet, and the top end of the back side of the box body is provided with a liquid outlet. The liquid inlet and the liquid outlet are correspondingly arranged at the two ends of the diagonal of the box body. The cavitation mechanism comprises a rotating shaft and a plurality of impellors. The rotating shaft is installed in the center of the interior of the box body and driven by an outer-arranged motor. The impellors are coaxially installed on the rotating shaft, and each impellor is composed of a plurality of vanes. The vanes are provided with penetrating through holes. The multi-impellor rotary vane type hydrodynamic cavitation generator has the advantages of being low in energy consumption, high in cavitation efficiency and the like.

Owner:RES INST OF PHYSICAL & CHEM ENG OF NUCLEAR IND

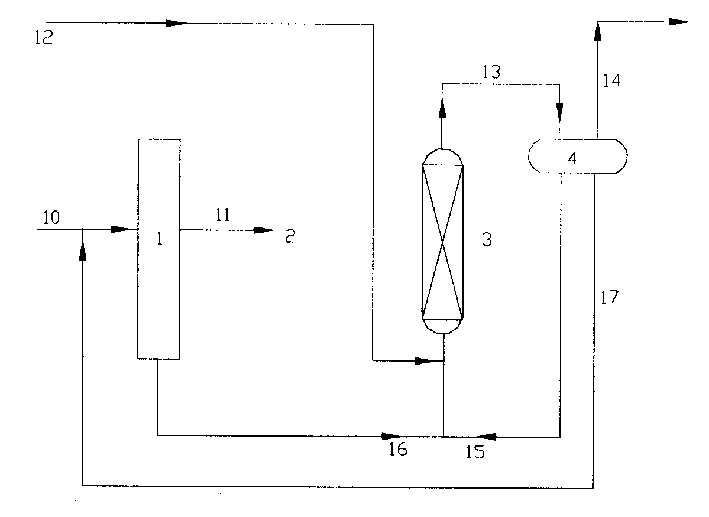

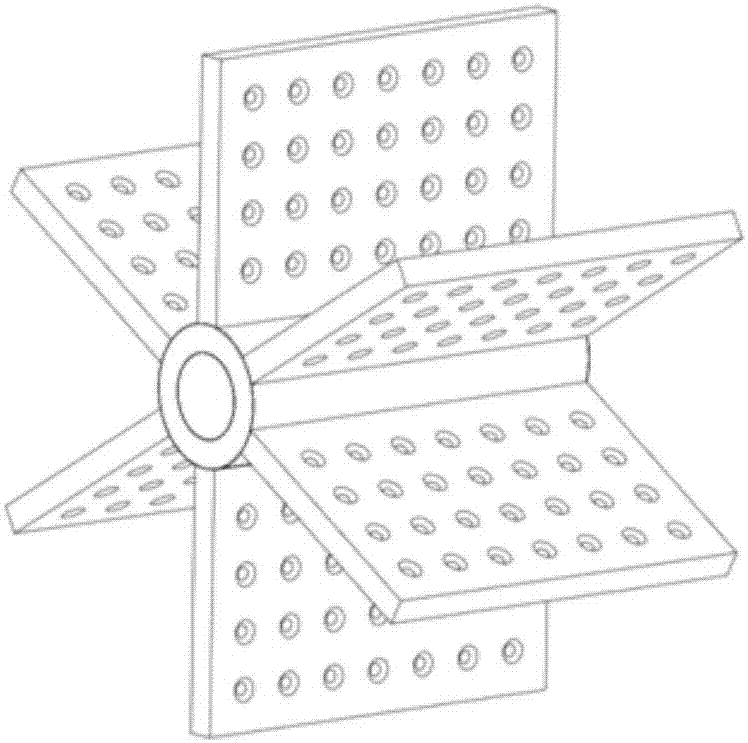

Device and process for recovering volatile organic gas

ActiveCN104801146AFacilitate desorptionImprove adsorption capacityDispersed particle separationSorbentDesorption

The invention provides a device and a process for recovering volatile organic gas. The device comprises an adsorption tower A, an adsorption tower B, a vacuum pump, a condensing unit, a recovery tank, a recycling and regeneration tank, an automatic nitrogen pressurizer, an oxygen content analyzer and a heat exchanger. When the device is adopted to recover the volatile organic gas, the adsorption tower A and the adsorption tower B are switched in turn for adsorption and desorption, and circular washing gas is provided by the recycling and regeneration tank in the desorption and regeneration process. Thorough desorption and regeneration of an adsorbent is facilitated by the aid of the device, the adsorption capability of the adsorbent and the device efficiency are improved, and the nitrogen use amount is reduced.

Owner:李振华

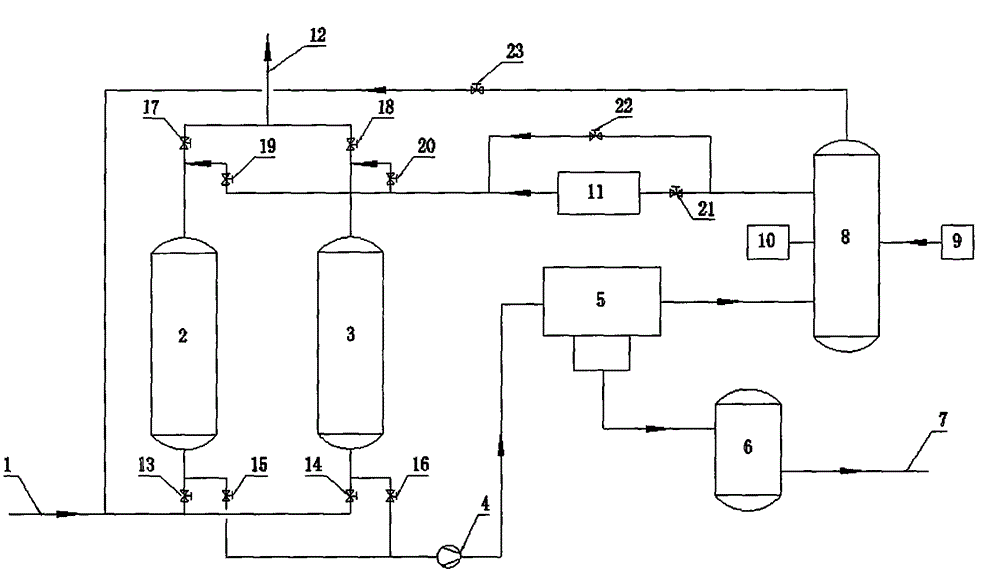

Hydrodynamic cavitation generating device

InactiveCN104043382ASimple structureLow costLighting and heating apparatusChemical/physical/physico-chemical processesCavitationCurrent limiting

The invention relates to a hydrodynamic cavitation generating device which comprises a support unit, a driving unit and a cavitation generating unit, wherein the driving unit is arranged on the support unit; the cavitation generating unit is arranged on the support unit and driven by the driving unit; the cavitation generating unit comprises a container and a rotor, wherein a cavity is formed in the container, the rotor is a current limiting device and is arranged in the cavity, and the rotor can be driven to rotate by the driving unit.

Owner:TSINGHUA UNIV

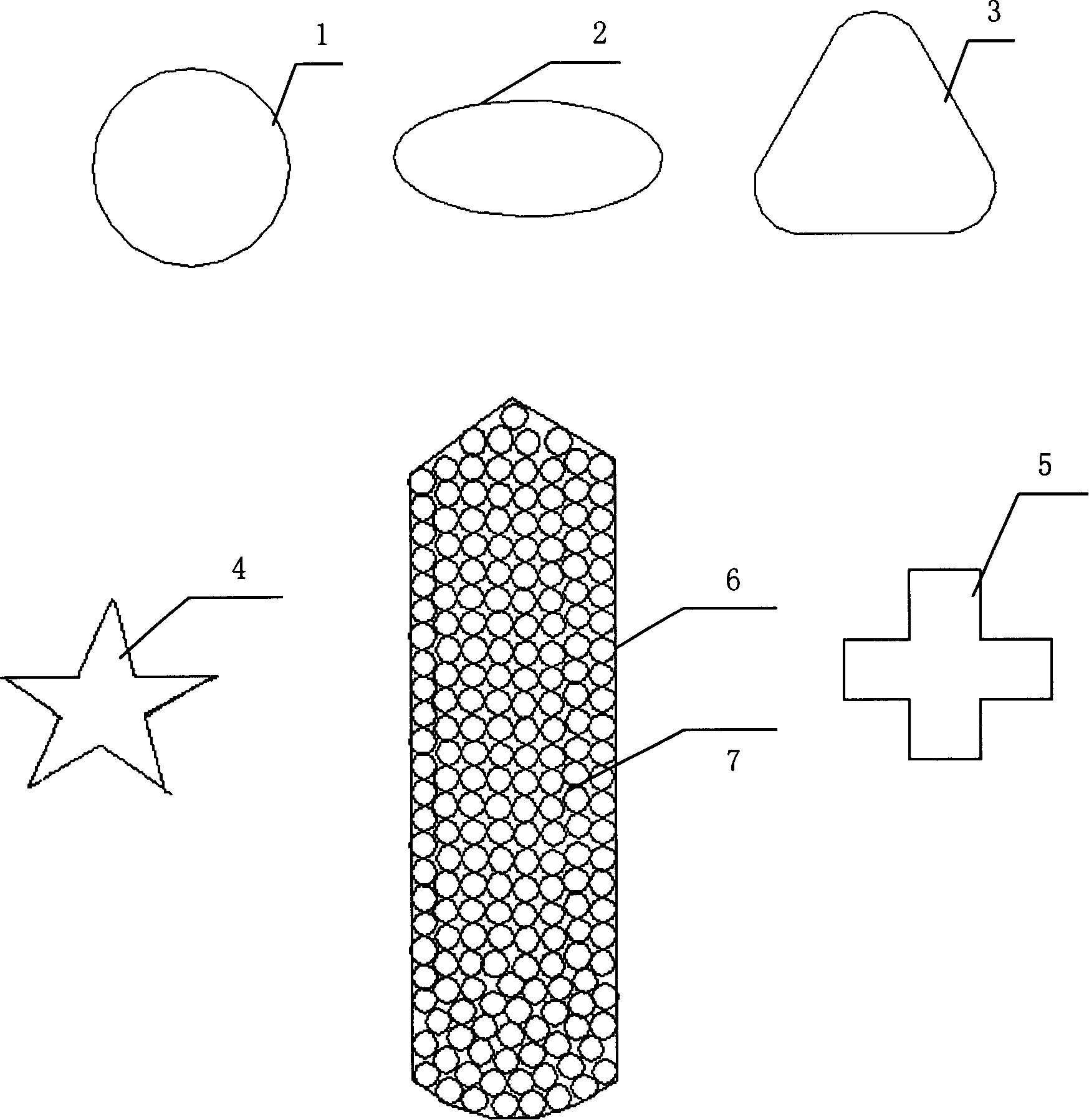

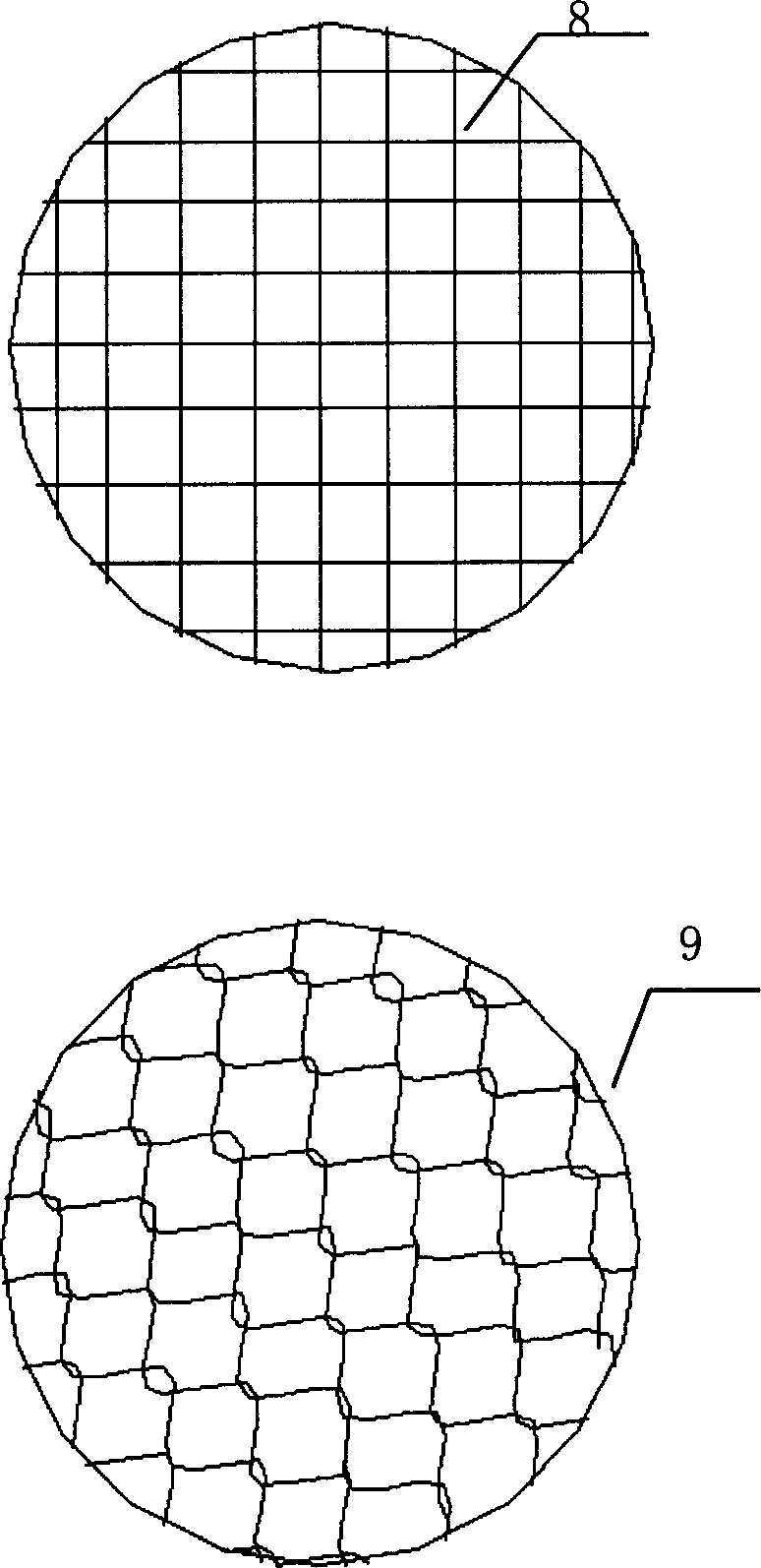

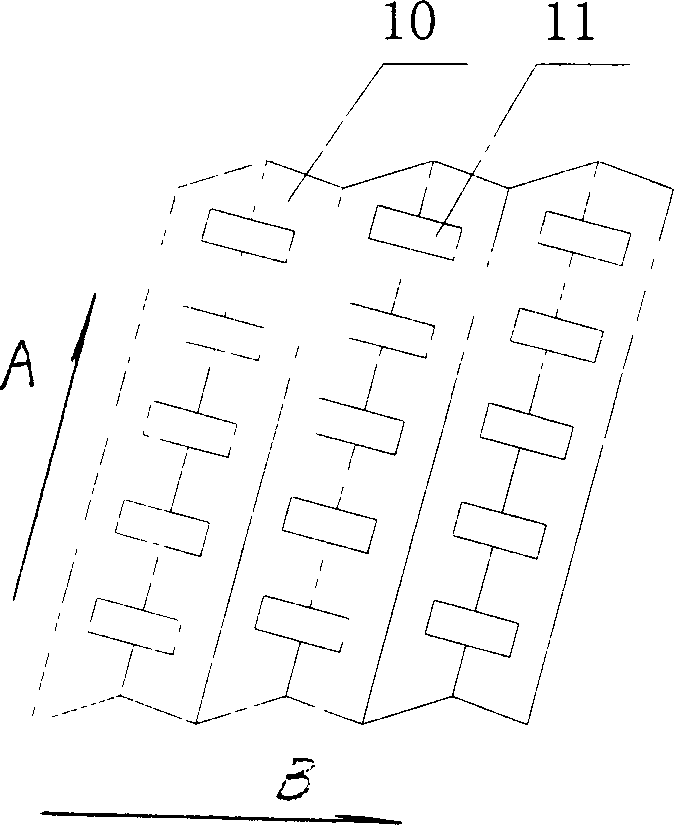

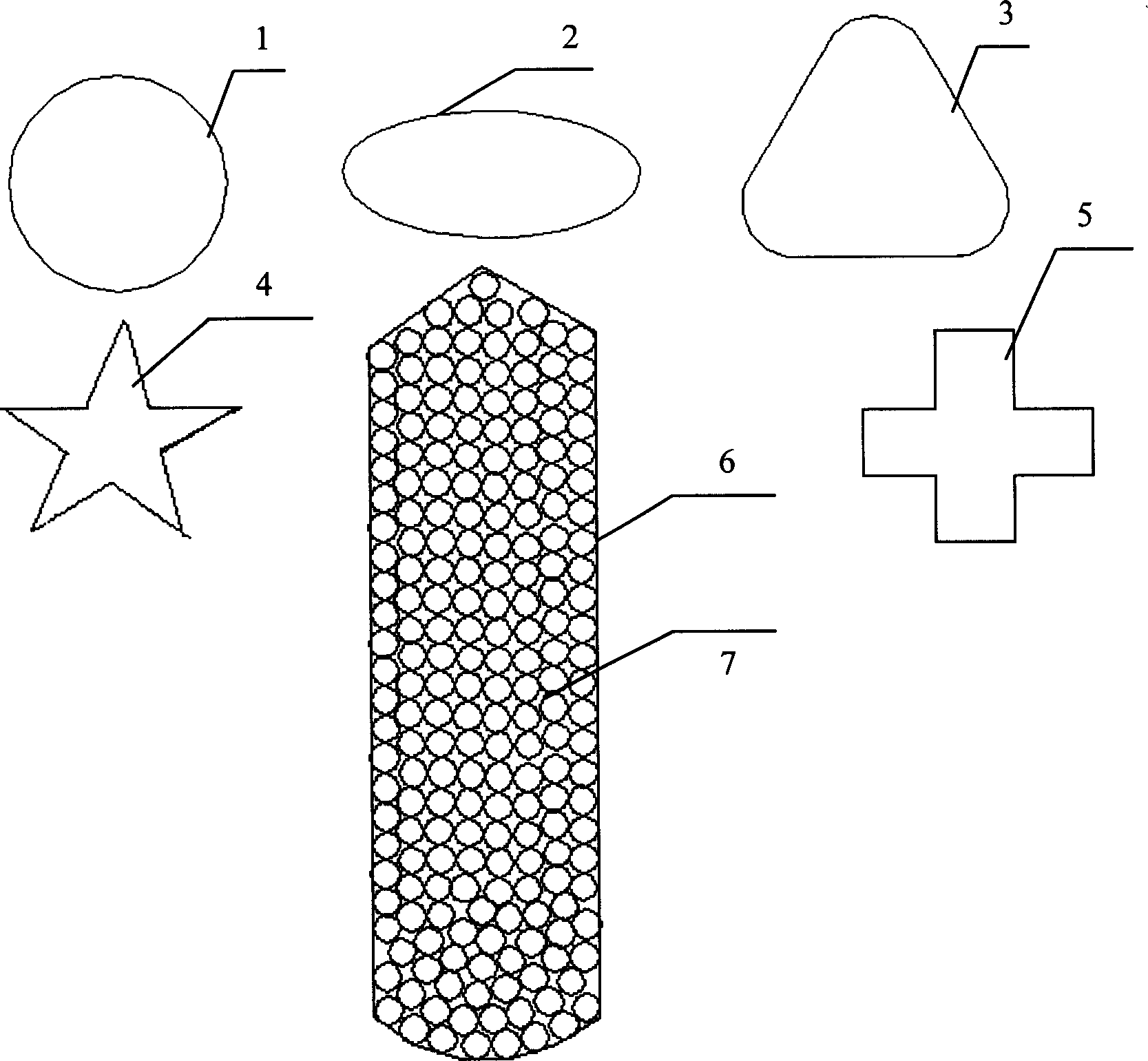

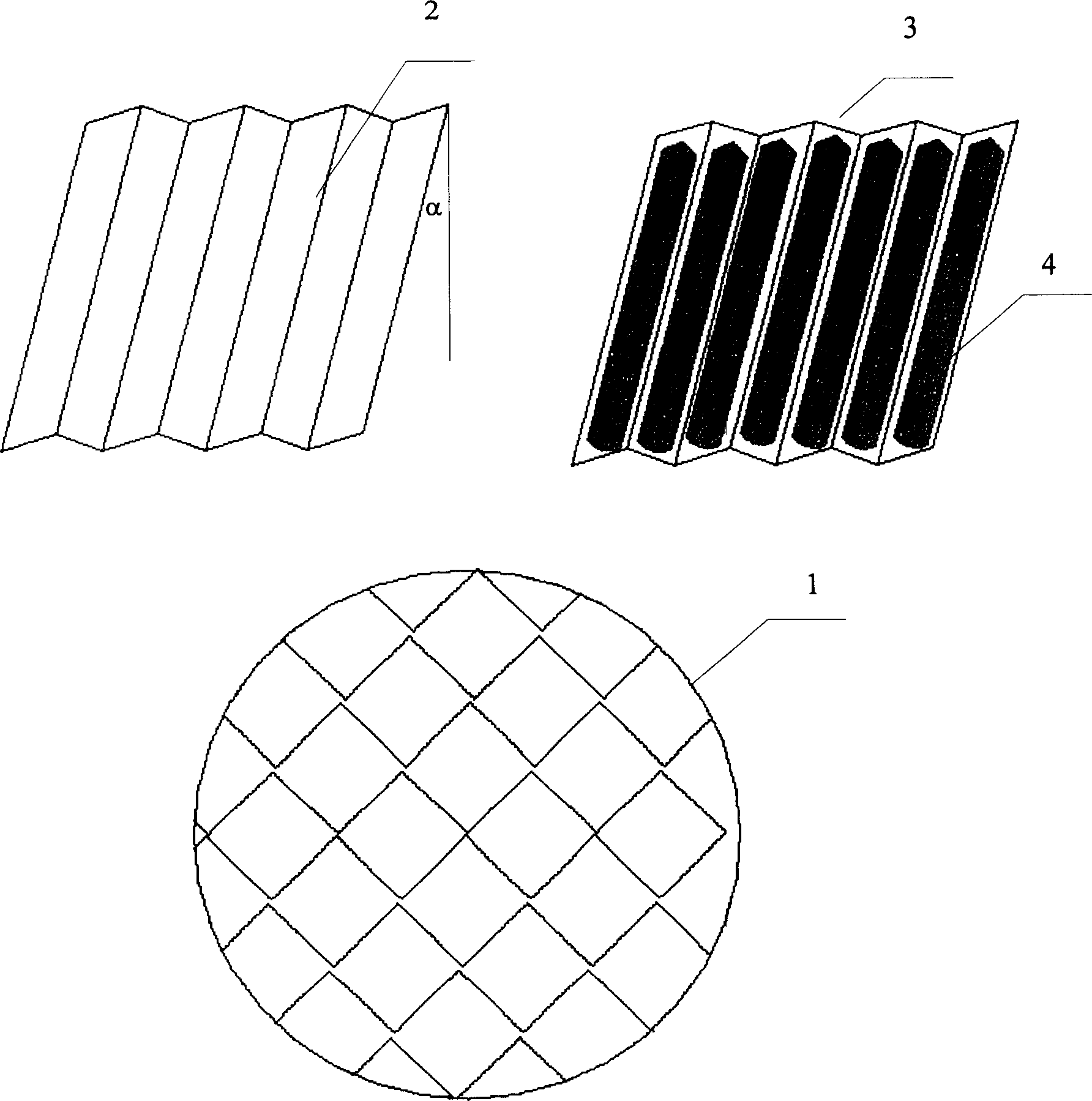

Catalyst distillation component and catalyst distillation method used said component

InactiveCN1602988AGood liquid redistribution abilityOvercome the defect of mass transfer effect declineChemical/physical processesFractional distillationCatalytic distillationReaction zone

The invention discloses a kind of catalyst distillation module and uses this module the catalyst distillation method.The invention catalyst distillation module includes the granules of catalyst, the silk screen vessel and the filler plate, its characteristic lies in, in the stated silk screen vessel which is used to load and fill granules of catalyst one by one or interval lays to the stated free channel which is formed by fold put the filler plate;Among them the stated filler plate is the corrugated sheet padding,open arbitrary shape holes on the corrugated sheet trough,remove the open hole part on the stated corrugated sheet, or divides the hole opened part into two parts along the ripple direction, then move upward or downward the formed two teeth pieces.The invention module has the force fluid redistribute ability, overcame the flaw that channel and so on cause the mass transfer effect droppes ; Lengthenes the fluid mobile way, increases the hold liquid volume of the reaction zone liquid.

Owner:CHINA PETROLEUM & CHEM CORP +1

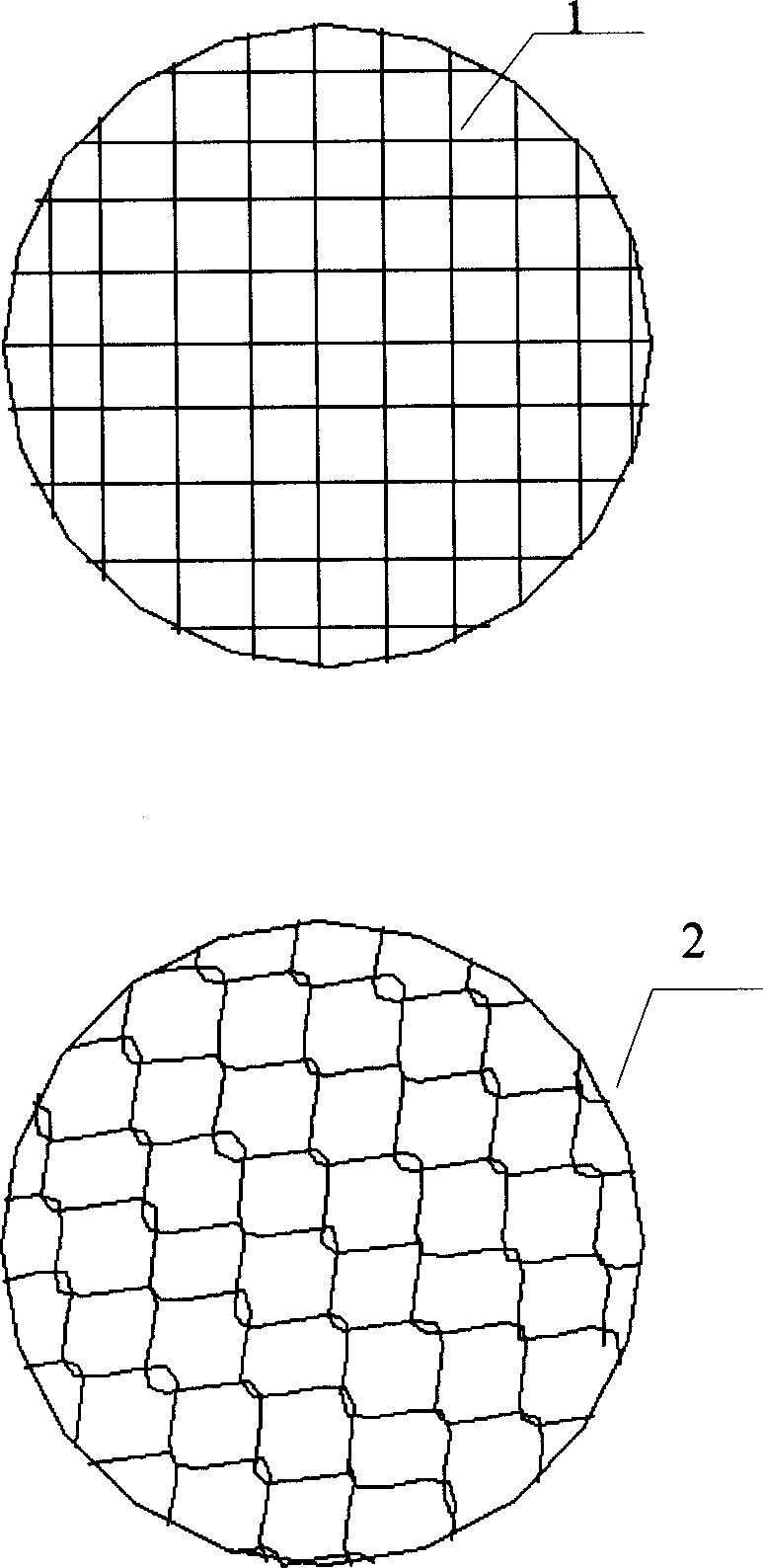

Catalytic distillation assembly and catalytic distillation method using the same

InactiveCN1569301AImproved hydrodynamic propertiesSmall pressure dropChemical/physical processesFractional distillationVoid ratioGas phase

The invention relates to a catalyzing distillation component and a method. The component includes catalyst particles, silk network container and regulated fillers, its character lies in: the catalyst particles and other inertial particles are blended together and filled into the container, and the mentioned silk network containers are arranged in the regulated fillers one by one. The invention favors the transition of media to liquid phase in the gas phase reaction. It can make the reacting bed with large gap rate, and the catalyst is distributed in the whole reaction segment evenly.

Owner:CHINA PETROLEUM & CHEM CORP +1

Fuel oil filter paper and producing technique thereof

ActiveCN101210404AIncrease filter gapImprove breathabilityInorganic fibres/flakesNon-fibrous pulp additionFiberExhaust gas emissions

The invention relates to oil filter paper and a production process thereof. The production process of the oil filter paper comprises the steps of pulping, pressing, corrugating and drying. The final paper comprises a resin with a weight ratio larger than 0 but equal to or smaller than 8%, a ceramic fiber a weight ratio larger than 0 but equal to or smaller than 5%, and wood pulp fiber with a weight ratio equal to or larger than 87% but smaller than 100%. The oil filter paper is corrugated paper with a longitudinal elongation rate equal to or larger than 12% but equal to or smaller than 17%. Accordingly, the oil filter paper has the advantages of good air penetrability, large filter space, small maximal aperture and high filter accuracy, and can effectively remove impurities in oil, thus improving the quality and the utilization rate of the oil product. The oil filter paper can be used for the oil supply system of an electro-spray device to reduce spray particle and effectively reduce exhaust emission of vehicles and air pollution.

Owner:王金夫

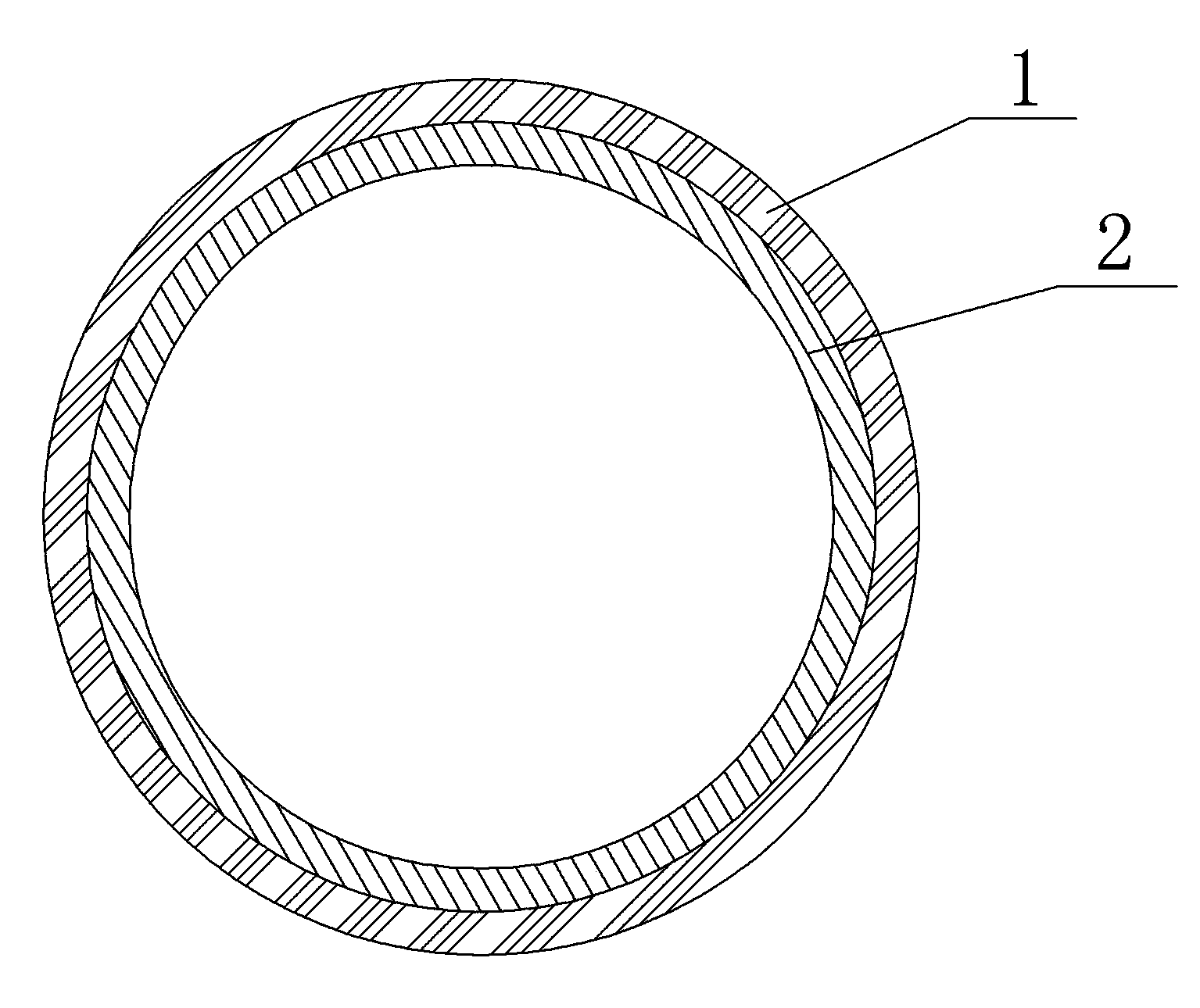

Double-layer composite tube and manufacturing method thereof

ActiveCN104019298AImprove stress resistanceFlow fastFlexible pipesLow-density polyethyleneWater quality

The invention discloses a double-layer composite tube and a manufacturing method thereof. The double-layer composite tube and the manufacturing method aim to solve the technical problems that black pigment is added into traditional HDPE tubes, accordingly inner walls are not smooth, water scale is prone to being generated, bacteria grow, and secondary pollution of water is caused. The double-layer composite tube comprises an inner layer and an outer layer, the inner layer is made of ultrahigh molecular weight polyethylene and ethylene-vinyl alcohol copolymers or low-density polyethylene, and the outer layer is made of high-density polyethylene, ethylene-vinyl alcohol copolymers and special melanin particles C of PE. The method includes the following steps of material proportioning and dehumidifying, material plastifying, material forming, vacuum sizing and spraying and cooling. The double-layer composite tube has the advantages of being good in toughness and flexibility, high in chemical stability, good in corrosion resistance, good in sealing performance, large in distribution power, long in service life, high in low temperature resistance, hygienic, free of toxin and the like. The manufacturing method is simple, easy to operate and capable of achieving integral production of the double-layer composite tube.

Owner:菏泽三垒塑业股份有限公司

Intelligent indoor air replacement and purifying device and method

InactiveCN106152288AAvoid cloggingSolution to short lifeMechanical apparatusSpace heating and ventilation safety systemsGas detectorCarbonization

The invention discloses an intelligent indoor air replacement and purifying device and method and belongs to the field of indoor and outdoor fresh air purifying devices. The indoor air replacement and purifying device is internally provided with a plurality of filters comprising the heating carbonization ceramic filter, the bilateral rotation draught fan and the conical ceramic filter; the heating carbonization ceramic filter and the conical ceramic filter are spongy micropore ceramic filters; the upper portion of the heating carbonization ceramic filter inclines towards the outer side; the periphery of the intelligent indoor air replacement and purifying device is provided with an automatic sample connection communicating with the interior of a room; the automatic sample connection is provided with a gas detector; the intelligent indoor air replacement and purifying device is internally provided with an electric current detector and further configured with an intelligent controller; the acquisition cost of an air purifying device, the consumable investment and the installation and maintenance cost can be reduced through the intelligent indoor air replacement and purifying device; the air purifying effect of the intelligent indoor air replacement and purifying device is improved; the device manufacturing cost is reduced; and intelligent operation of the air purifying device is achieved.

Owner:ANYANG HENGAN MOTOR

Minimizing bandwidth narrowing penalties in a wavelength selective switch optical network

ActiveUS8542999B2Reduce in quantityReduce probabilityMultiplex system selection arrangementsWavelength-division multiplex systemsEngineeringLength wave

This invention relates to provisioning wavelength-selective switches and reconfigurable optical add-drop multiplexers to minimize the bandwidth narrowing effect from the optical filters. Novel architectures and methods are disclosed that can significantly reduce bandwidth-narrowing on channels in a reconfigurable WDM network where a large number of optical filter elements are cascaded. Instead of blocking unused channels as in the prior art, unused channels are selectively provisioned depending on the state of their adjacent channels. Unused adjacent channels of an active channel are provisioned to follow the same path as the active channels. As each channels is deployed, the channel frequency is selected so as to minimize bandwidth narrowing.

Owner:SNELL HLDG LLC +1

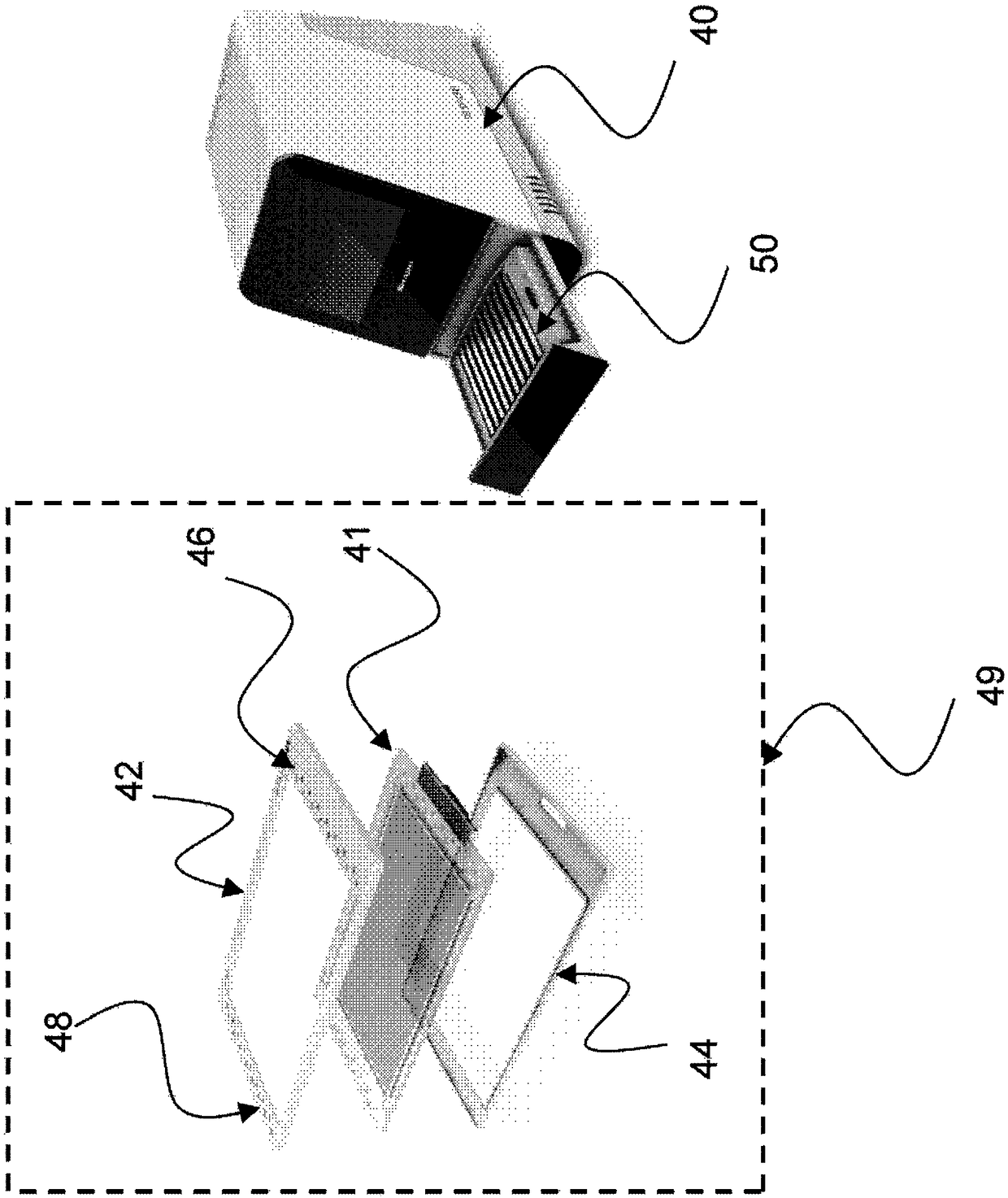

Microfluidic device with multiple temperature zones

ActiveCN108393101AHigh densityReduce spacingMaterial analysis by electric/magnetic meansLaboratory glasswaresTemperature controlHot zone

Disclosed is an EWOD device for processing multiple droplets through multiple temperature zones. The device is configured to achieve a high spatial density of temperature zones with a wide temperaturedifference between hot and cold zones. A first set of temperature control elements is arranged above (or below) a fluid gap in an EWOD device and a second set of temperature control elements is arranged below (or above) the fluid gap. A temperature control element of one set is offset from temperature control elements of the other set in the plane of the fluid gap. The temperature control elementof one set may be located at a different separation from the fluid gap to the temperature control element of the other set. The device has an optional temperature control element and / or arrangement which offsets the low temperature point from the inlet temperature. The two sets of temperature control elements are substantially interacting, in the sense that they cannot be considered to be thermally isolated from one another. This invention also describes methods to process multiple droplets within the multiple temperature zones.

Owner:SHARP LIFE SCI EU LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com