Rotary-vane multifunctional multi-purpose valve

A multi-functional and multi-purpose technology, applied in the field of invention, can solve problems such as single function, and achieve the effects of large circulation, high pressure resistance and increased cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

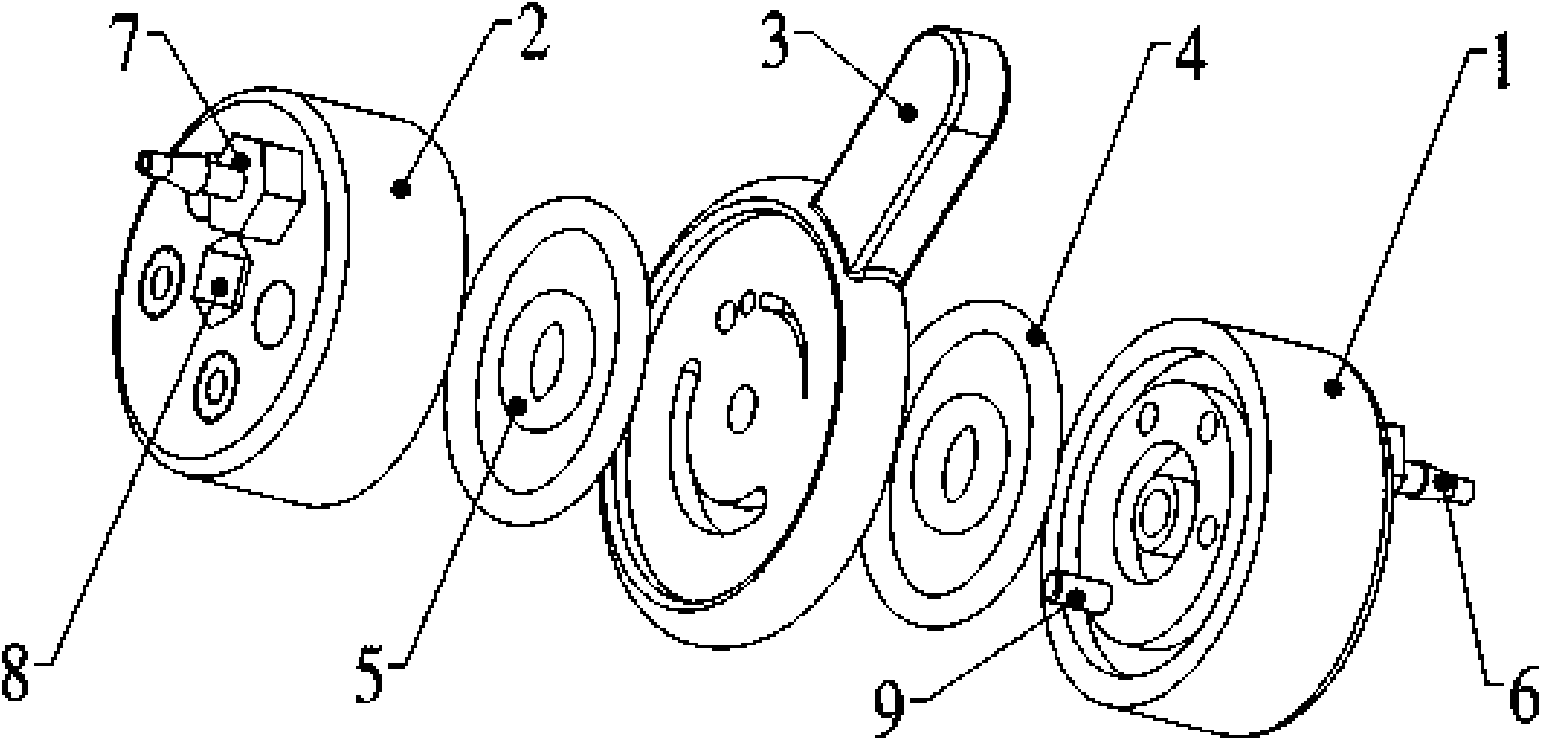

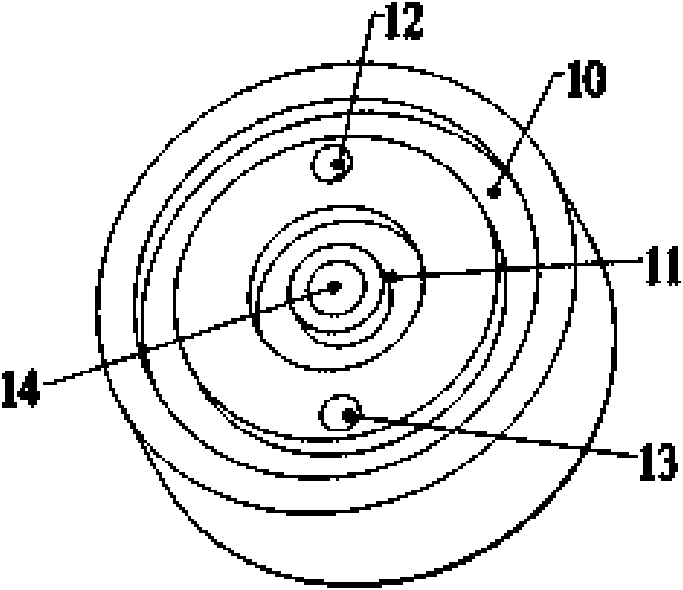

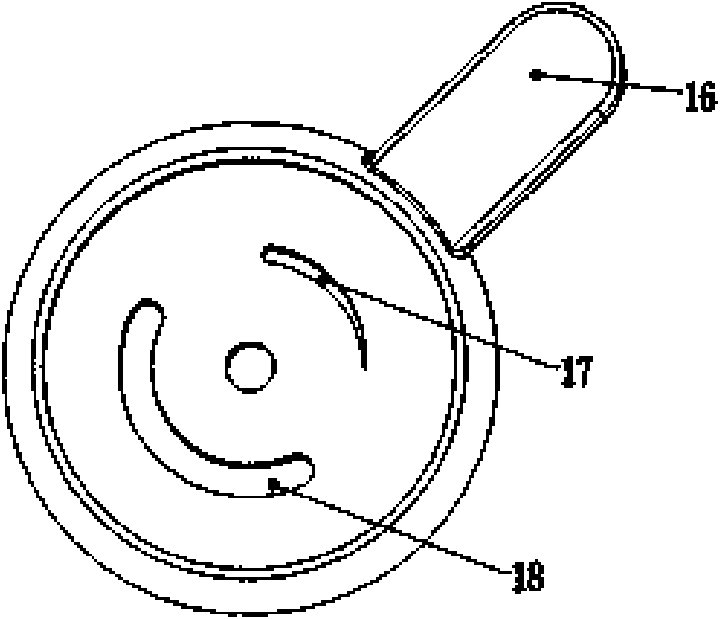

[0031] A rotary vane multifunctional multipurpose valve, such as figure 1 As shown, there are two circular valve bodies, that is, the first valve body 1 (inlet), the second valve body 2 (outlet), valve plate (rotary plate) 3, large circular sealing ring 4, small circular The sealing ring 5, the water inlet nozzle 6, the water outlet nozzle 7, the fastening screw 8 and the positioning pin 9 are assembled together. Wherein, on the opposite surfaces of the first valve body 1 and the second valve body 2, the center is a fastening hole 14, and two circles of different sizes for installing the large circular sealing ring 4 and the small circular sealing ring 5 are arranged concentrically. There is a liquid-inlet hole 12 and a positioning pin hole 13 at the position between the two circular sealing rings, and the valve plate 3 is provided with an arc-shaped groove 18 for passing the positioning pin 9, see figure 2 and image 3 .

[0032] On the other side of the first valve body ...

specific Embodiment 2

[0035] On the basis of Embodiment 1, the right liquid outlet hole on the second valve body 2 is connected, that is, two adjacent fluid passages are opened, see Figure 7 As shown, the distance between the openings of two adjacent fluid passages is less than the length of the flow regulating groove, and an adjustable bypass can be formed by rotating the valve plate 3 . When the valve plate 3 is rotated to the maximum open position, the valve can be used as a three-way.

Embodiment 3

[0037] On the basis of Embodiment 1, close the plug of the middle fluid passage on the second valve body 2, open the left and right fluid passages on the second valve body 2, that is, open two non-adjacent fluid passages, and the distance between the mutually spaced openings is greater than the length of the flow regulating groove, see Figure 8 As shown, when the valve plate 3 is in the Figure 6 When rotating between the positions shown, the switching between the fluid passage on the first valve body 1 and the two different passages on the second valve body 2 can be completed, from Figure 8 The connected state on the left becomes the connected state on the right.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com