Patents

Literature

518results about How to "Extend the mixing time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Haydite aerated concrete block and method for manufacturing same

InactiveCN101306934AImprove performanceIntegrity guaranteedSolid waste managementCeramic shaping plantsBrickSlag

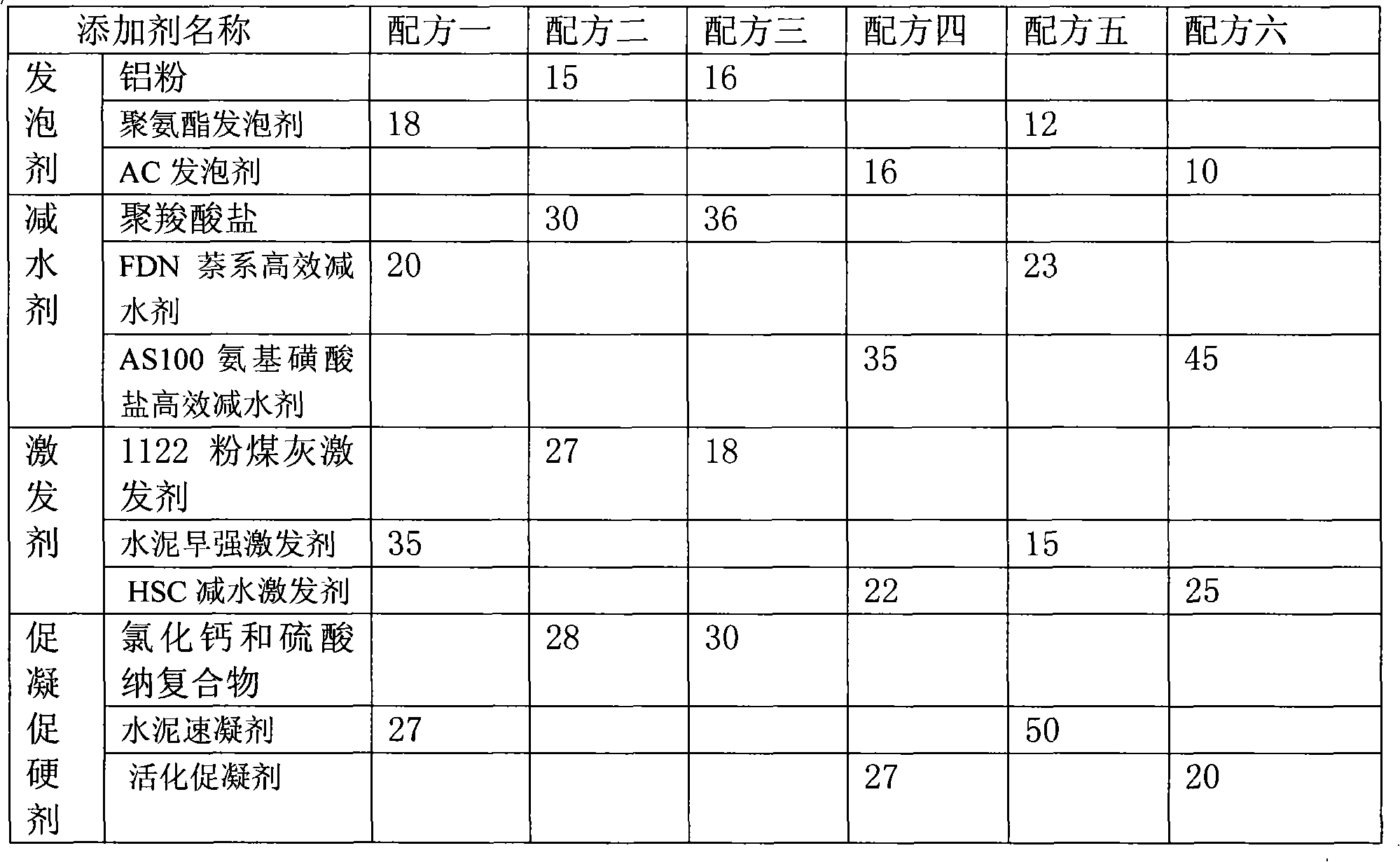

The invention discloses a formula of a ceramic aggregate aerated concrete brick and a method for making the concrete brick. The compositions in portion by weight of the concrete brick are: 12 to 26 portions of cement, 26 to 46 portions of fly ash, 16 to 28 portions of ceramic aggregate, 2 to 6 portions of slag, 2 to 6 portions of cinder, 16 to 26 portions of water and 2 portions of addition agent, wherein the concrete matters in percentage by weight of the addition agent are: 10 to 18 percent of aluminum powder (a foaming agent), 20 to 45 percent of polycarboxylate (a water reducing agent), 15 to 35 percent of 1122 fly ash excitant and 20 to 50 percent of coagulant hardening accelerator in which calcium chloride and sodium sulfate compounds respectively occupies 50 percent. The concrete steps for making the ceramic aggregate aerated concrete brick are as follows: raw materials are weighed; the weighed raw materials are placed in a stirring machine to carry out stirring and mixing in advance; an addition agent is added in the stirring machine to carry out full stirring; a brick die is prepared, and stirred raw materials are cast in the brick die; initial set and forming are carried out; stripping is carried out; a water-proofing agent is sprinkled on a stripped brick; and natural curing is carried out. Moreover, the obtained brick has light dead weight, low density, high strength, low water absorption rate and excellent sound insulation performance and heat-shielding performance.

Owner:胡宗芳 +1

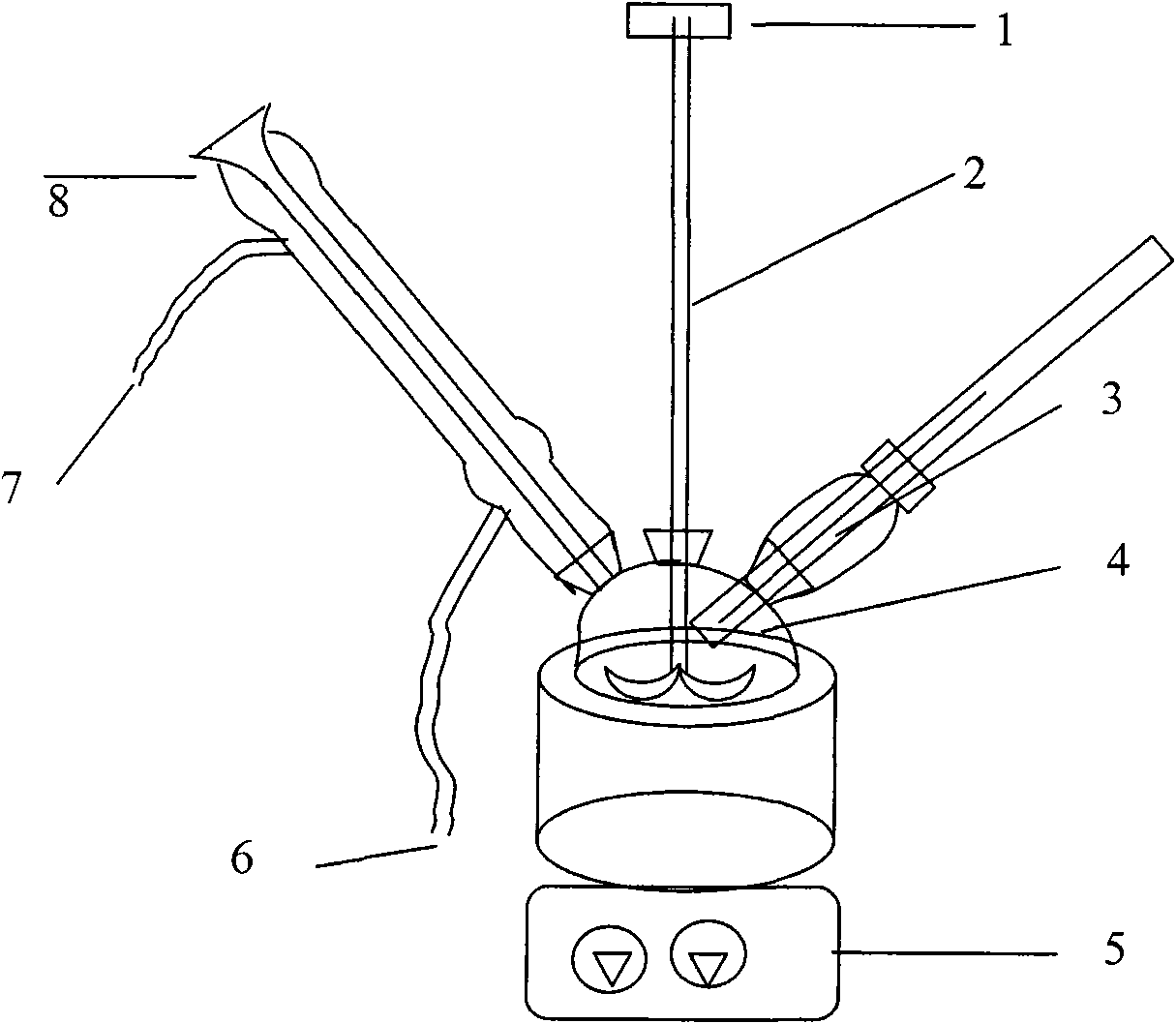

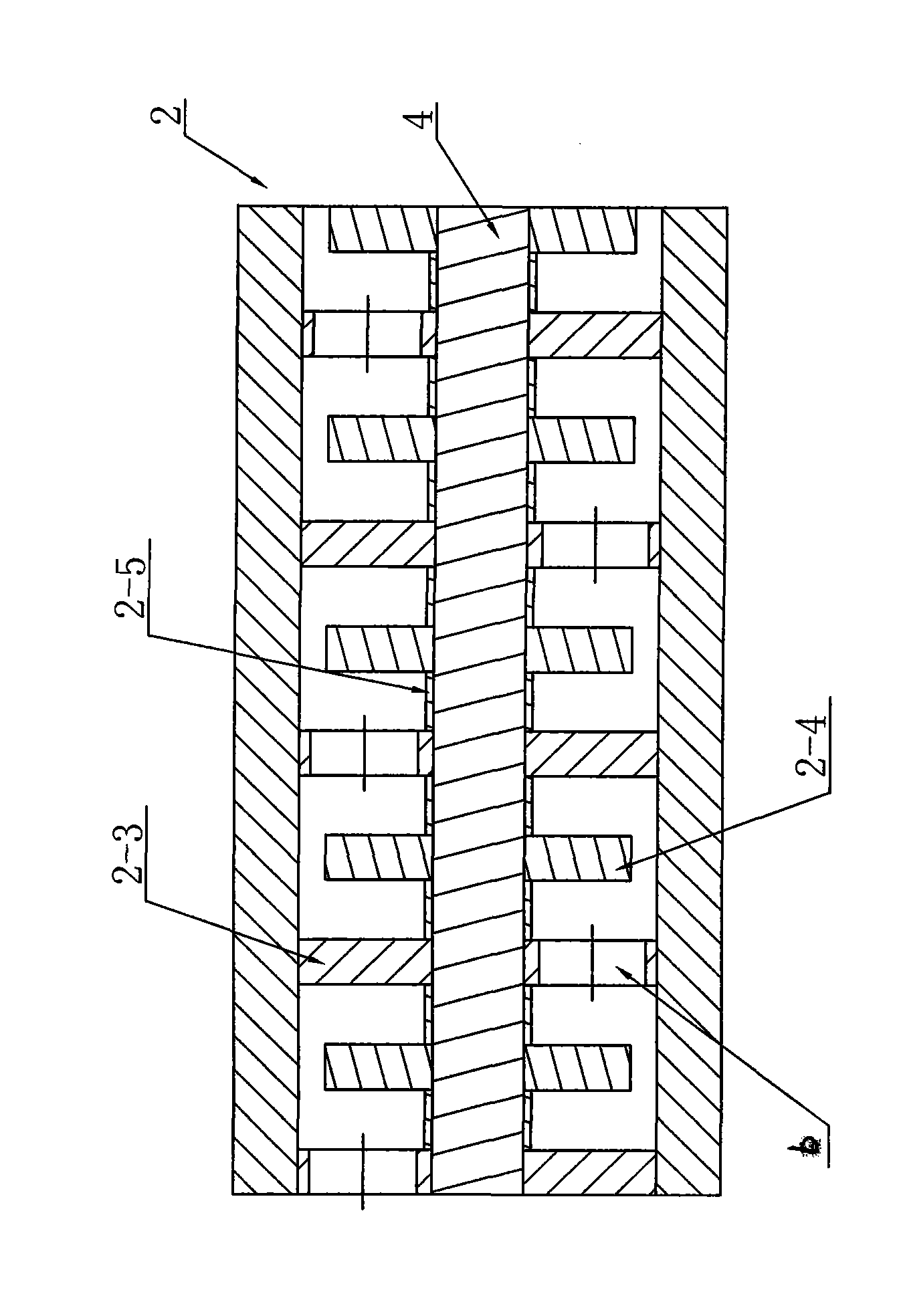

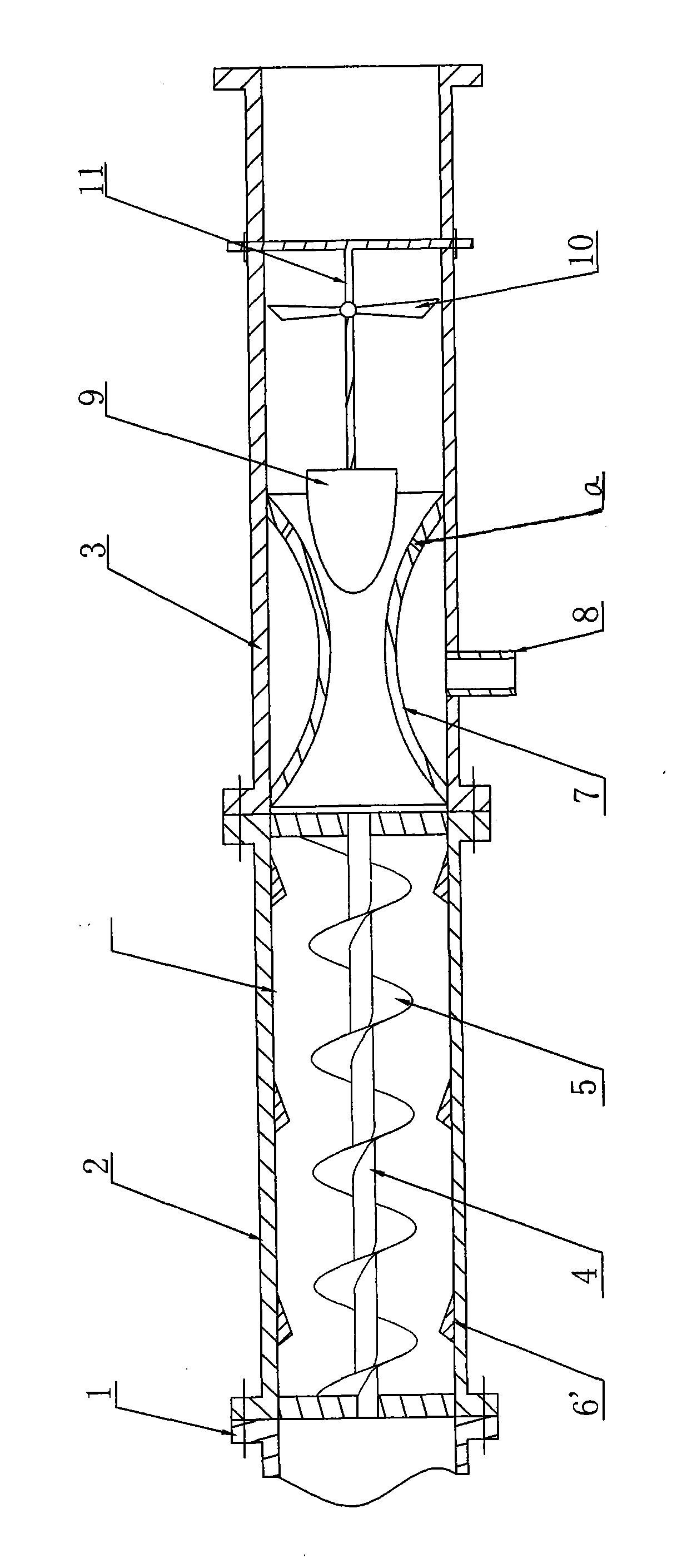

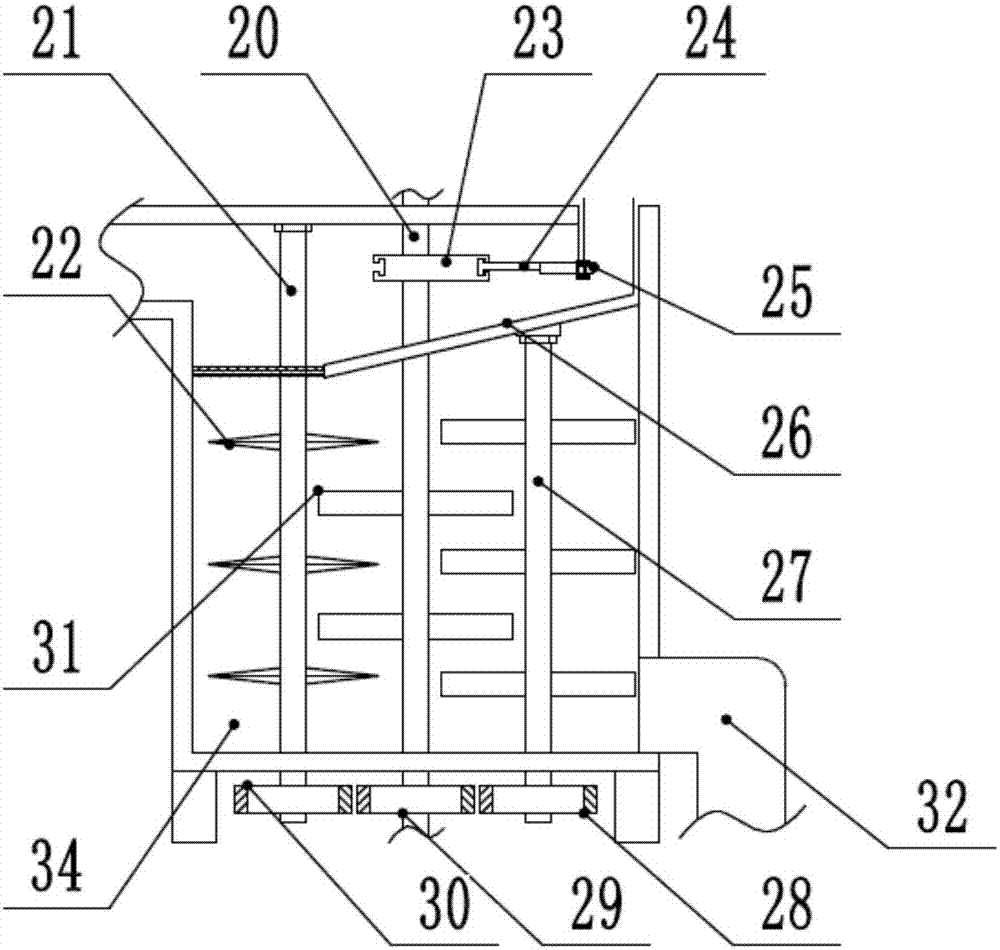

Stirred tank reactor

InactiveCN102358760ALarge circulationShort mixing timeRotary stirring mixersChemical/physical/physico-chemical stationary reactorsSizingProcess engineering

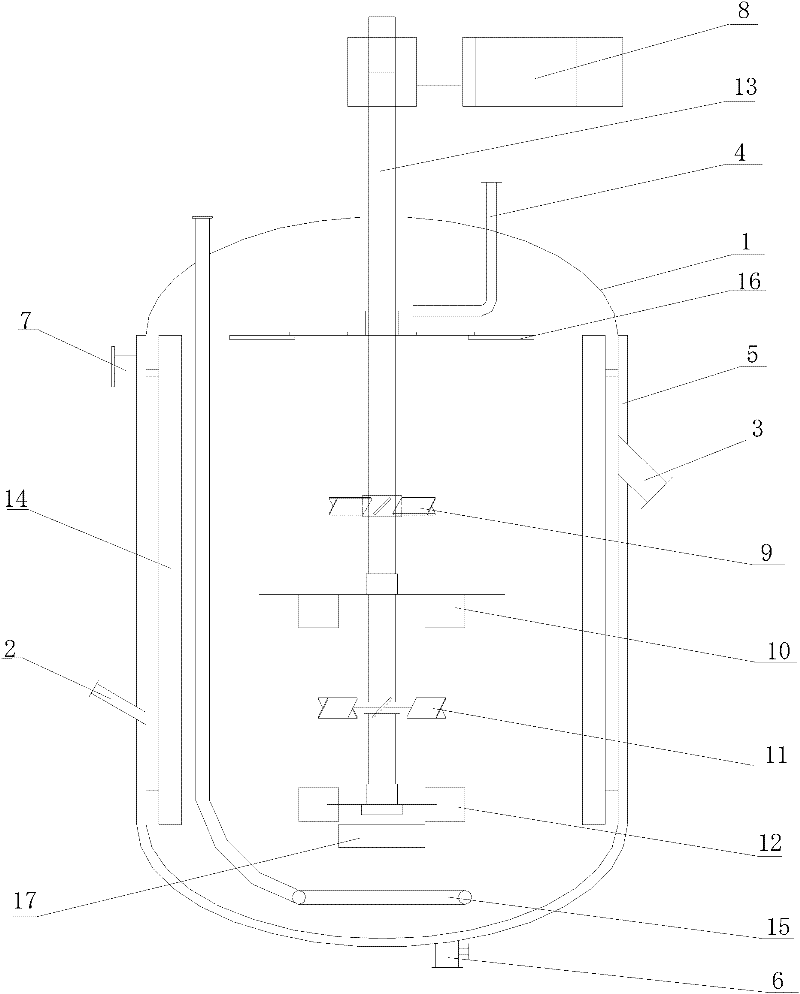

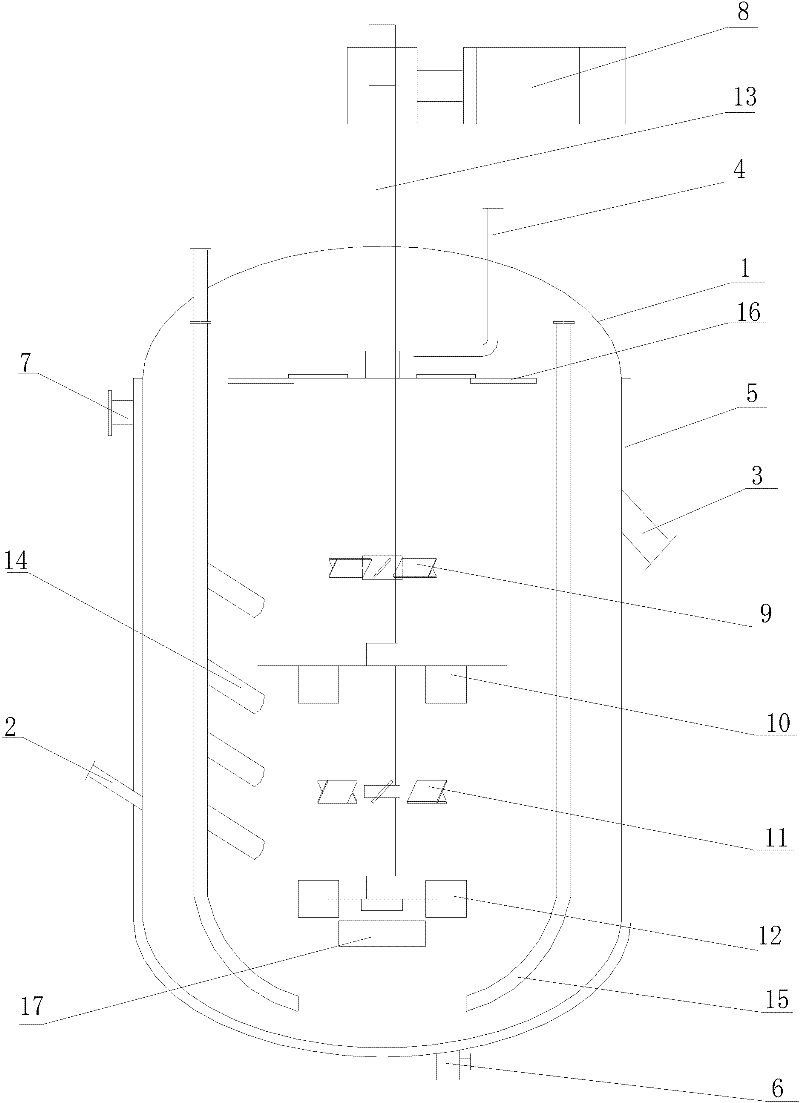

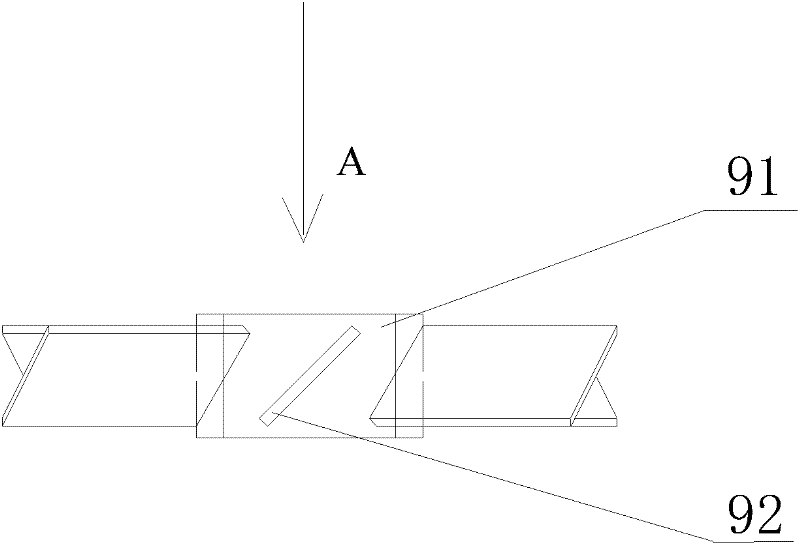

The invention discloses a stirred tank reactor and aims at improving a stirring turbine in the stirred tank reactor by using a four-layer combination stirring turbine. The stirring turbine comprises a first layer turbine, a second layer turbine, a third layer turbine and a fourth layer turbine which are arranged from the middle to the bottom of a stirring shaft sequentially. The first layer turbine is an upward axial flow turbine, the second layer turbine is a disk type turbine, the third layer turbine is an upward axial flow turbine, and the fourth layer turbine is a radial flow turbine. Radial circulation close to a liquid level, radial circulation close to a middle area of a stirred tank and radial circulation in a bottom area of the stirred tank are formed, so that circulation quantity inside the stirred tank is big and mixing time is short. Poor mixing area does not exist, and solid containing rate and gas containing rate are evenly distributed. A mass transfer condition of air and liquid is good, and single transfer efficiency is high. Entrainment quantity of sizing is greatly reduced, fouling of a heat exchanger is reduced, and service life is long. Operation cost is lowered, and production cost is saved.

Owner:ZHEJIANG UNIV

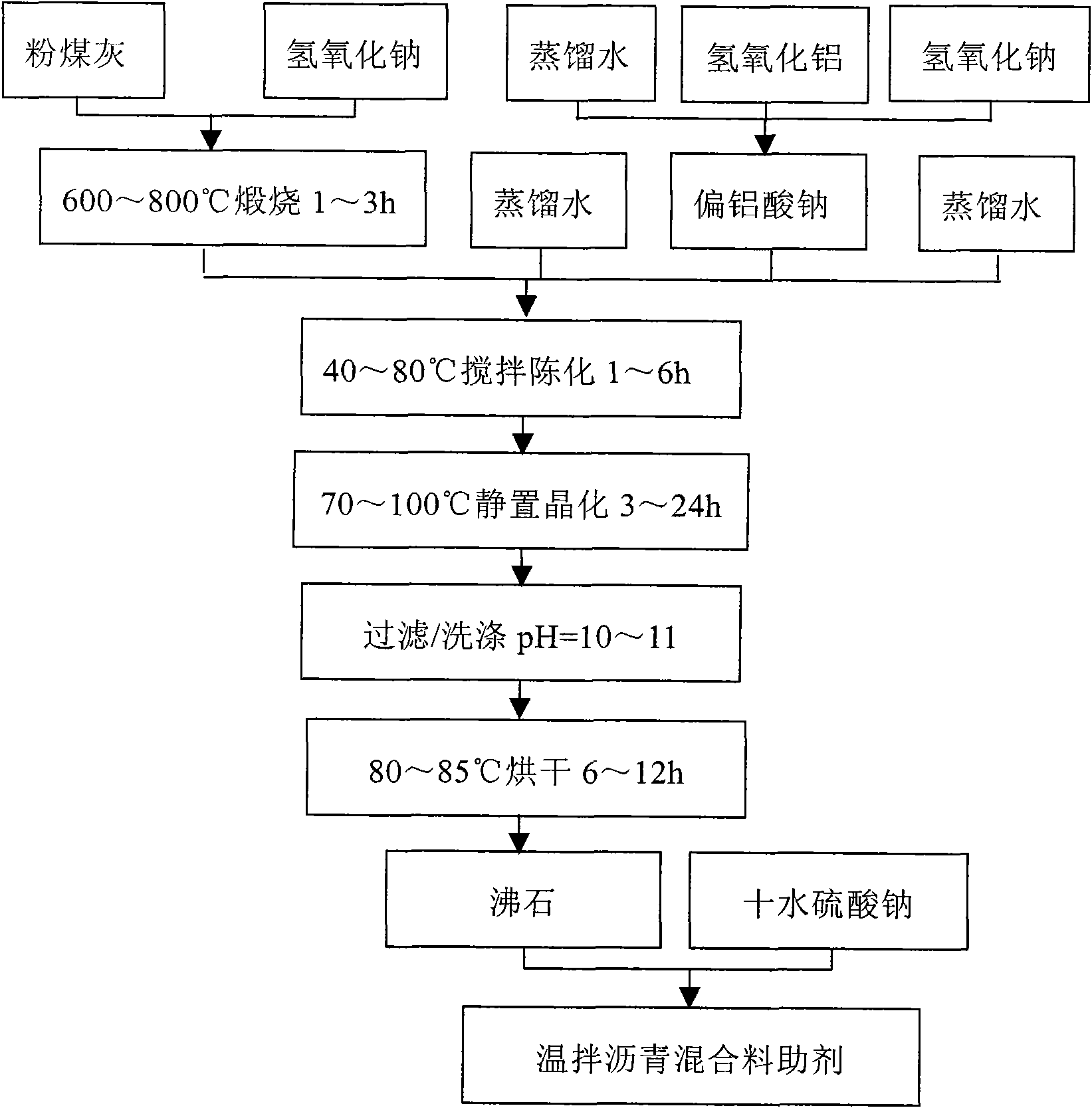

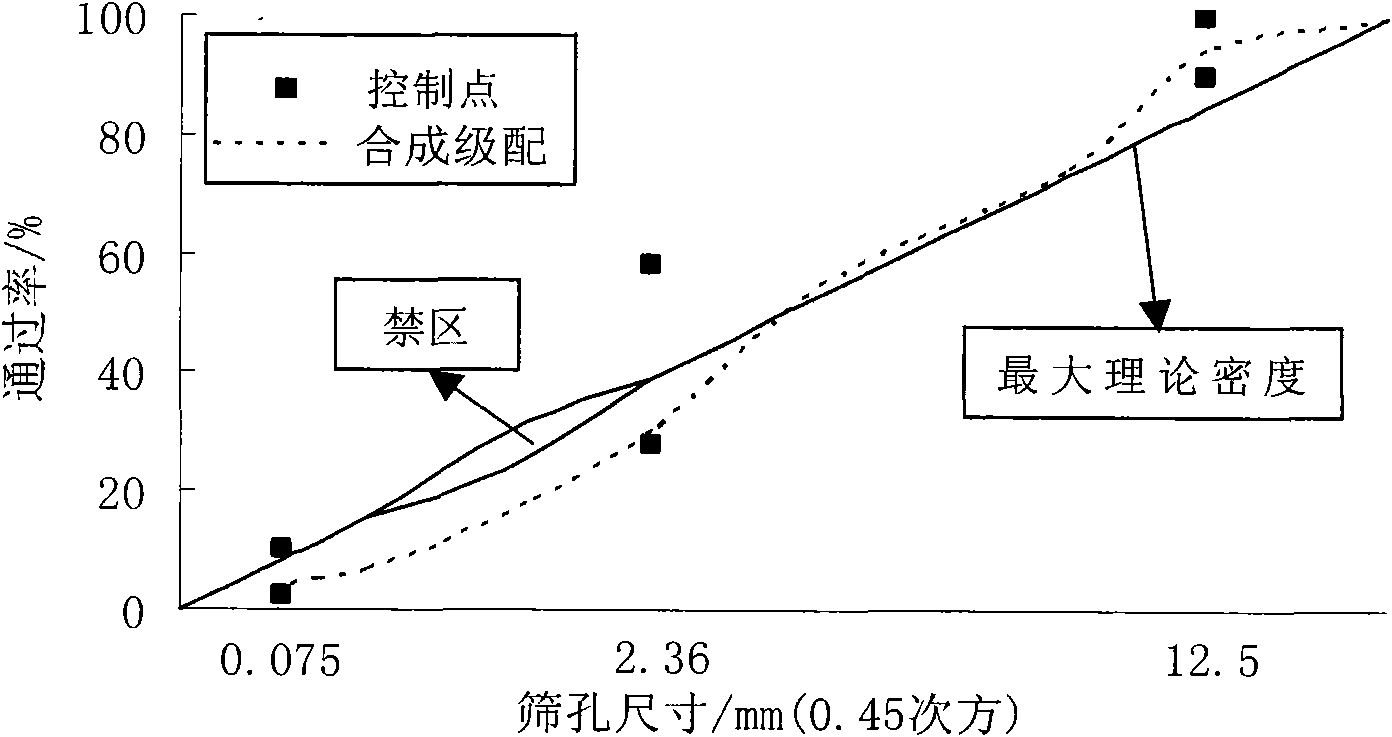

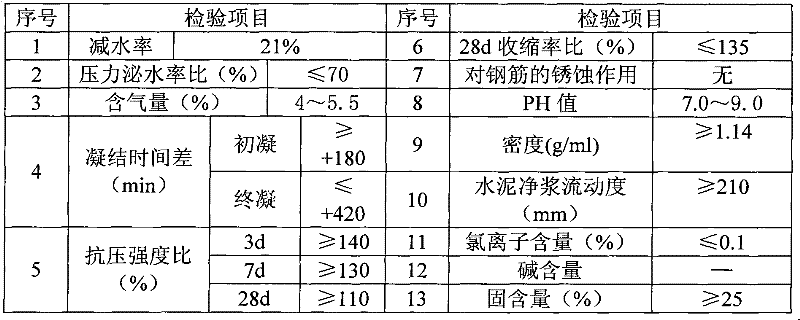

Warm-mixed auxiliary agent for asphalt mixture and preparation method thereof

ActiveCN101602583AEnergy savingReduce exhaust emissionsClimate change adaptationFilling materialsPitch blende

The invention relates to a warm-mixed auxiliary agent for asphalt mixture. The auxiliary agent is formed by uniformly mixing 93 to 97 percent of synthetic zeolite with 3 to 7 percent of granular sodium sulfate decahydrate by weight, wherein the synthetic zeolite includes 15 to 22 percent of crystal water, and the sodium sulfate decahydrate includes 55.9 percent of crystal water. Under normal temperature, the auxiliary agent is mixed with other raw materials according to the content of 0.3 to 0.5 percent of the total mass of the mixture, thereby preparing the product of the warm-mixed asphalt mixture; and other raw materials are 150 to 165 DEG C asphalt, 140 to 180 DEG C aggregate and mineral powder filling materials. During the blending of the mixture, the warm-mixed addition agent and the heated asphalt are added simultaneously, great amount of vapor generated by the moisture-containing auxiliary agent are released, which results in volumetric expansion of the asphalt, thereby forming foamed asphalt; meanwhile, the workability of the asphalt can be enhanced, the blending and mold temperature of the mixture can be reduced by 15 to 25 DEG C, exhaust emission can be effectively reduced, energy consumption is lowered, the aging of asphalt during blending is reduced, and the auxiliary agent has the advantages of simple preparation and low cost.

Owner:WUHAN UNIV OF TECH

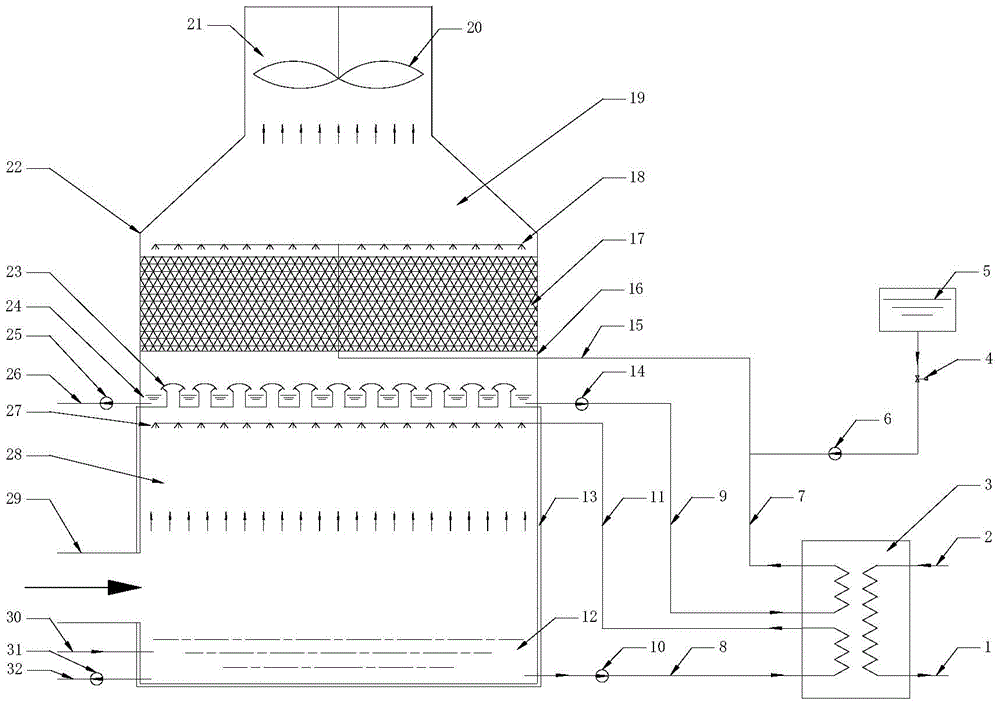

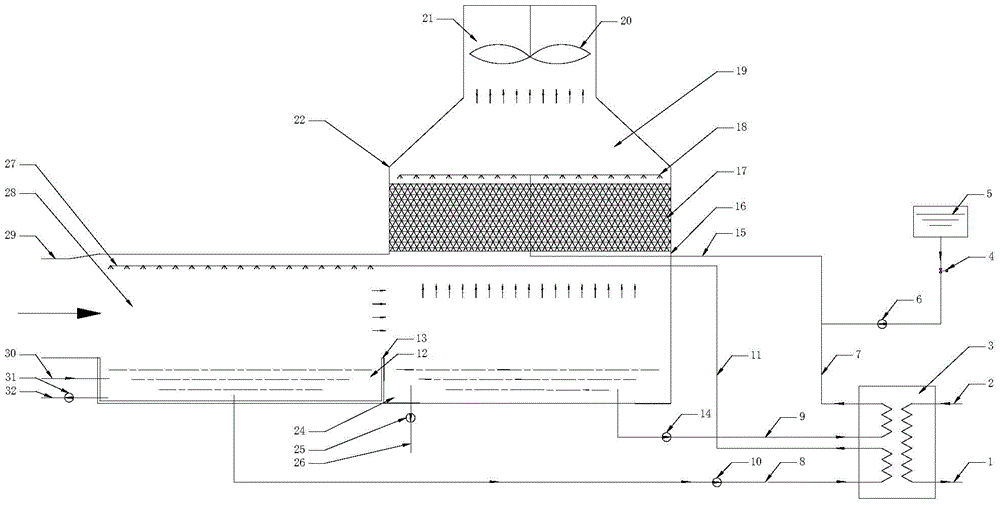

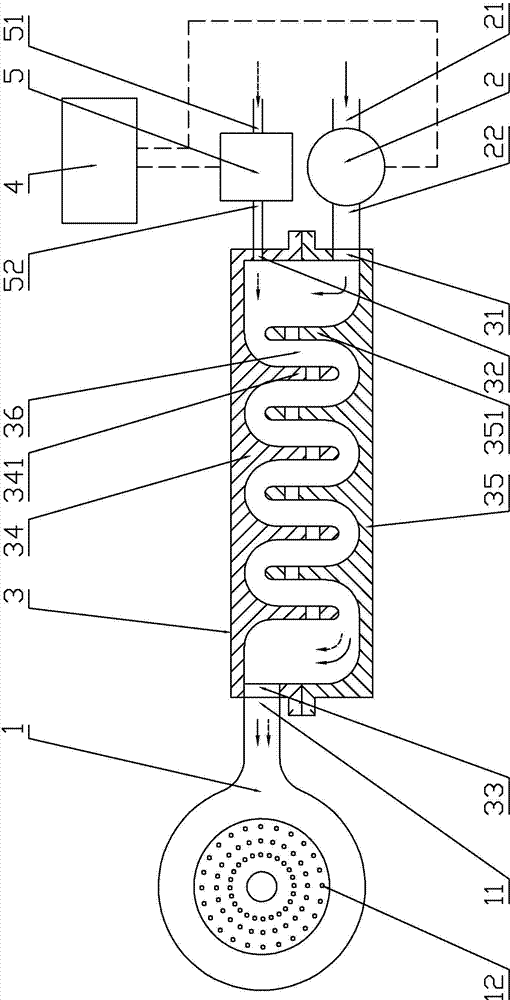

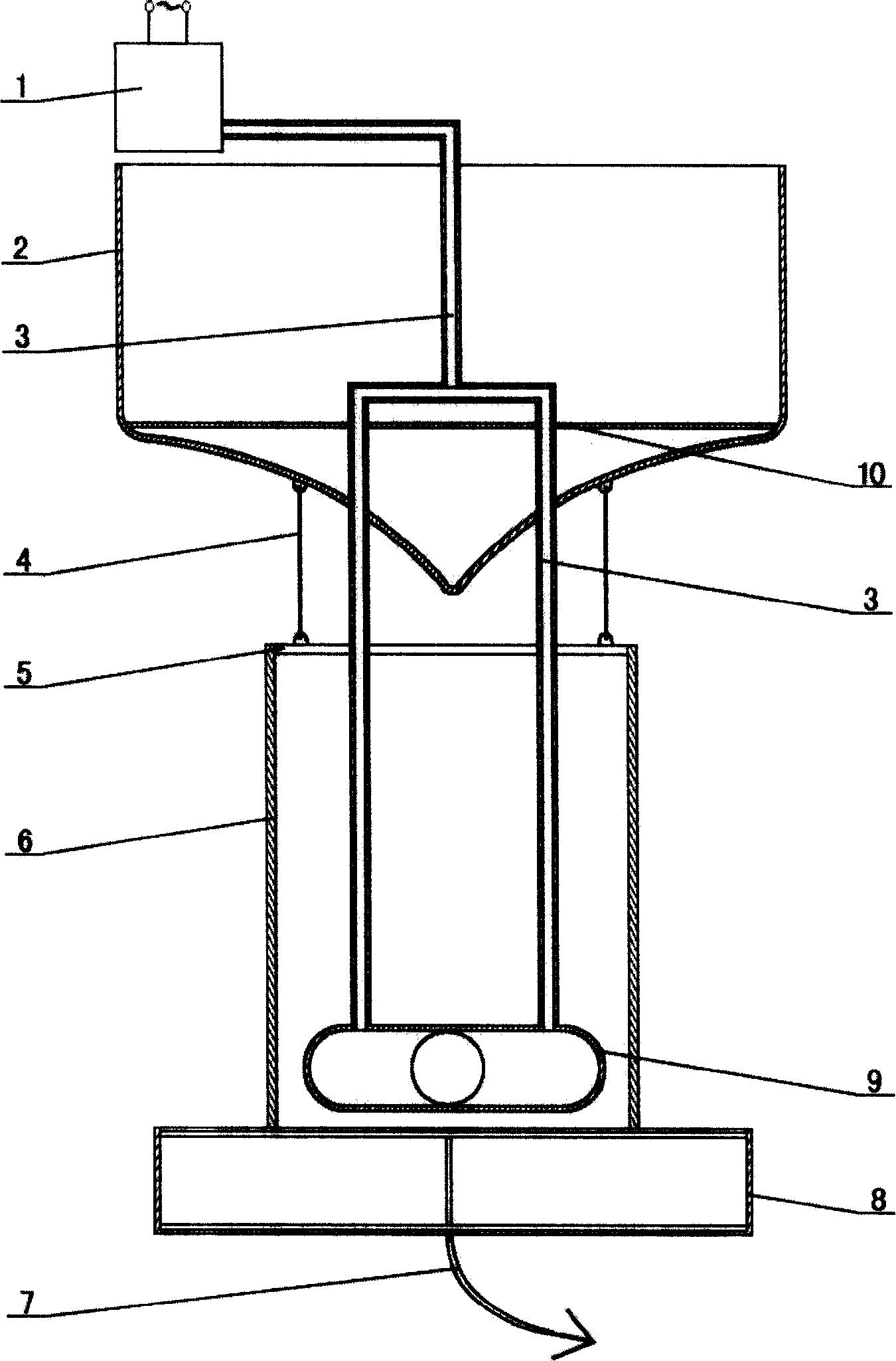

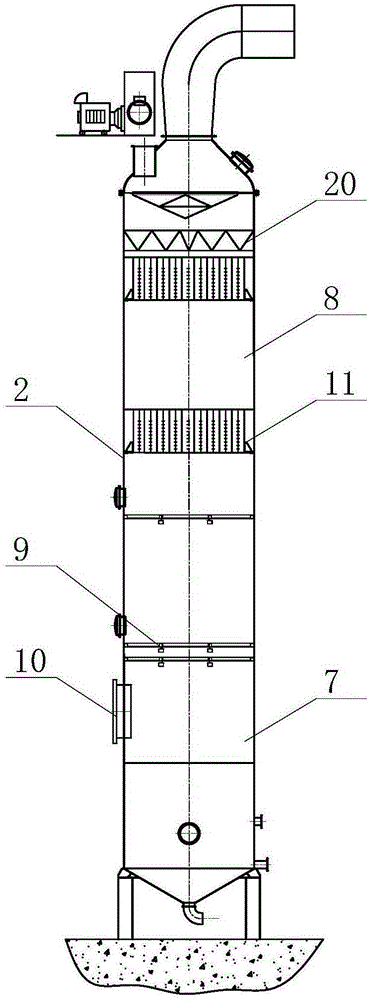

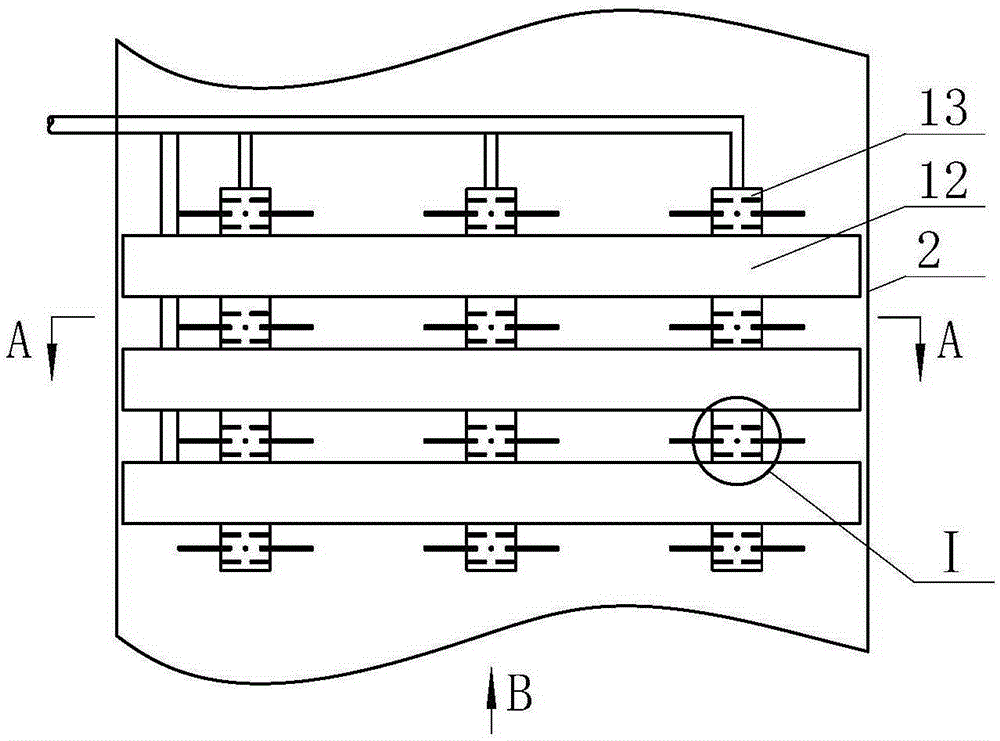

Smoke purifying and residual heat deep recycling integrated device

InactiveCN104014236ASimple structureImprove heat transfer effectUsing liquid separation agentTrickle coolersWater qualityRecuperator

The invention discloses a smoke purifying and residual heat deep recycling integrated device, which comprises a purification and heat exchange tower, a smoke system and a heat exchanger, wherein the inside of the purification and heat exchange tower is partitioned into a spraying chamber at the lower part and a filling chamber at the upper part by a wind cap layer; the spraying chamber comprises a spraying layer and a water pool; the water pool is connected with a water supply system, a water treatment pump, a water quality treatment system and a water circulation pump respectively; the outlet of the water circulation pump is connected with the heating hot water inlet of the heat exchanger; the outlet of the water pool is connected with the spraying layer; a smoke inlet is formed in the tower wall above the water pool; the filling chamber comprises a slurry distribution layer, a filling layer, a slurry pool and a slurry supply device; the slurry pool is connected with a slurry treatment pump, a slurry treatment system and a slurry circulation pump; the outlet of the slurry circulation pump is connected with the heating slurry inlet of the heat exchanger and the outlet of the slurry pool is connected with the slurry supply device. The smoke purifying and residual heat deep recycling integrated device is applicable to comprehensive treatment of tail smoke in gas heating, power and cooling triple combination distribution type systems, natural gas boilers, gas-steam combined circulation and fuel power stations.

Owner:NANJING KESEN KENEN ENVIRONMENT & ENERGY

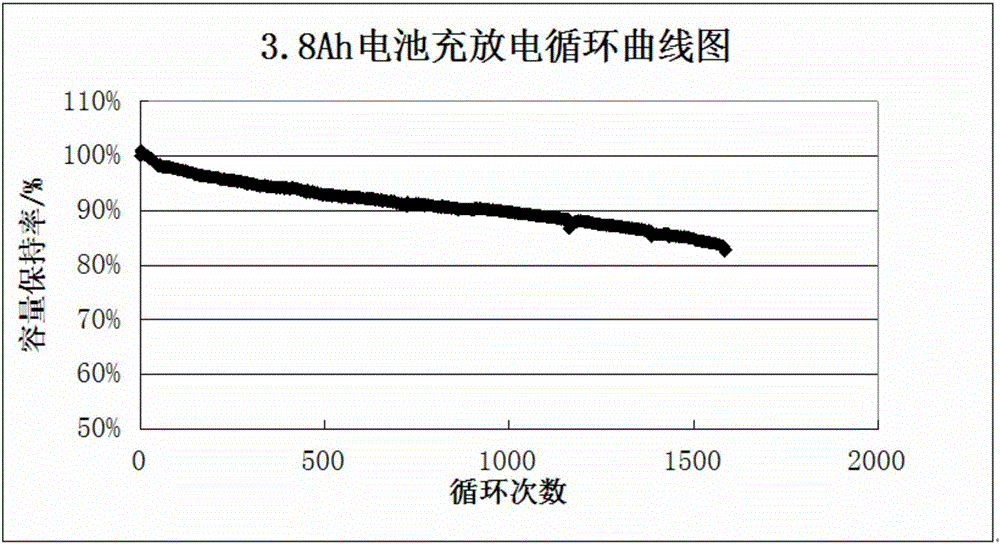

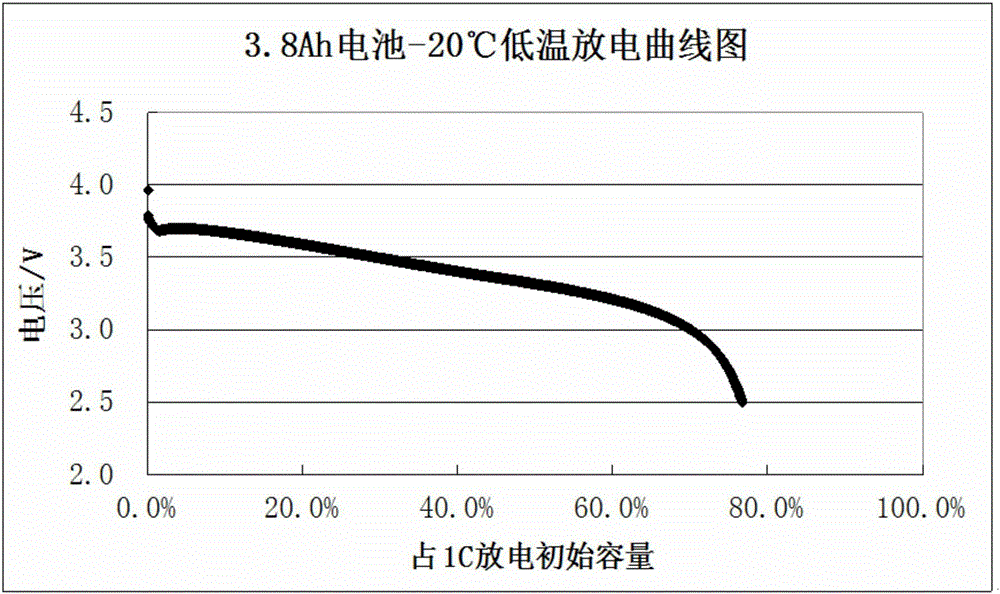

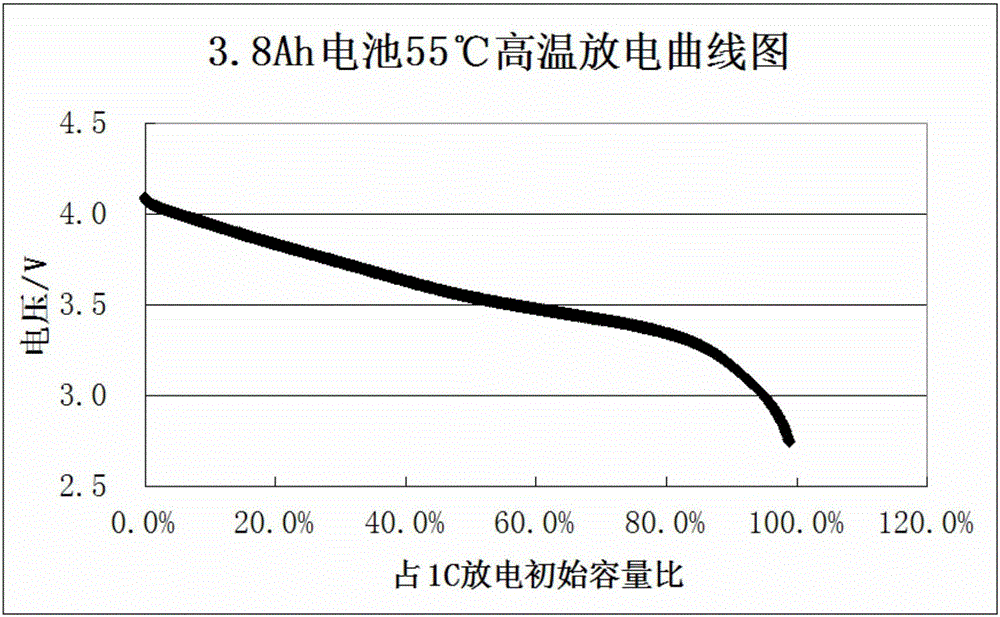

High specific energy lithium-ion power battery and preparation method thereof

InactiveCN106299485AShorten mixing timeIncrease productivityFinal product manufactureCell electrodesElectrical batteryPositive current

The invention discloses a high specific energy lithium-ion power battery and a preparation method thereof. The preparation method includes the steps: 1) coating the front and the back of a positive current collector with positive slurry, and performing drying, rolling, slitting and flaking to obtain a positive plate; 2) coating the front and the back of a negative current collector with negative slurry, and performing drying, rolling, slitting and flaking to obtain a negative plate; 3) forming a set by the positive plate, a diaphragm and the negative plate, placing the set into a steel shell and abutting the set to a rolling groove; 4) injecting electrolyte into the steel shell, and then performing capping, pressing and sealing to form a cell; 5) pre-forming the cell by grading current to prepare the high specific energy lithium-ion power battery. The high specific energy lithium-ion power battery prepared by the method has excellent specific energy, long cycle life and high high-low temperature initial capacity, and the preparation method is simple in process and easy to operate and industrialize.

Owner:江苏海四达电源有限公司 +1

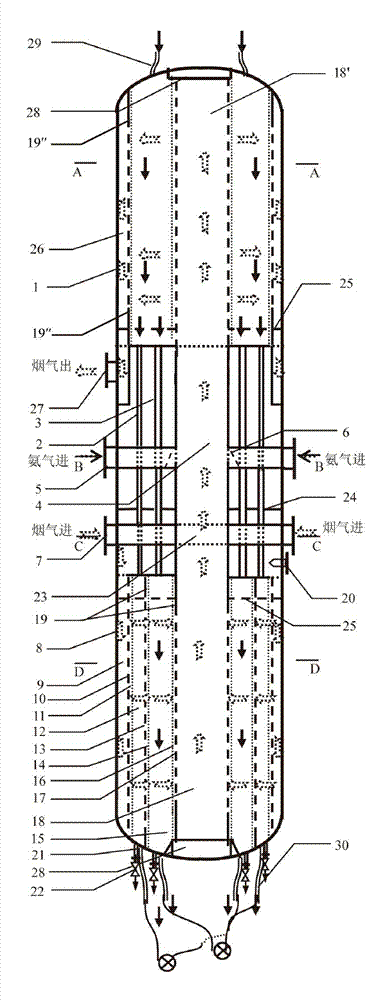

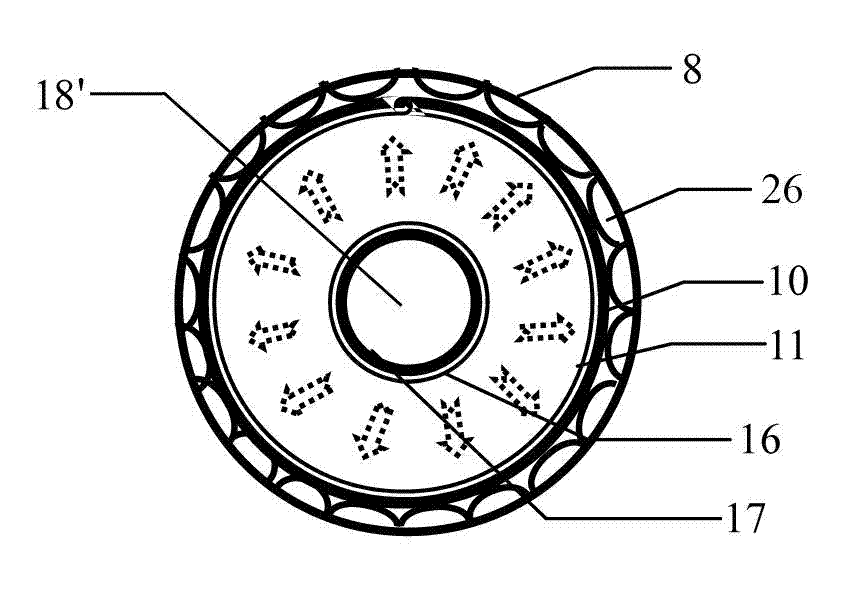

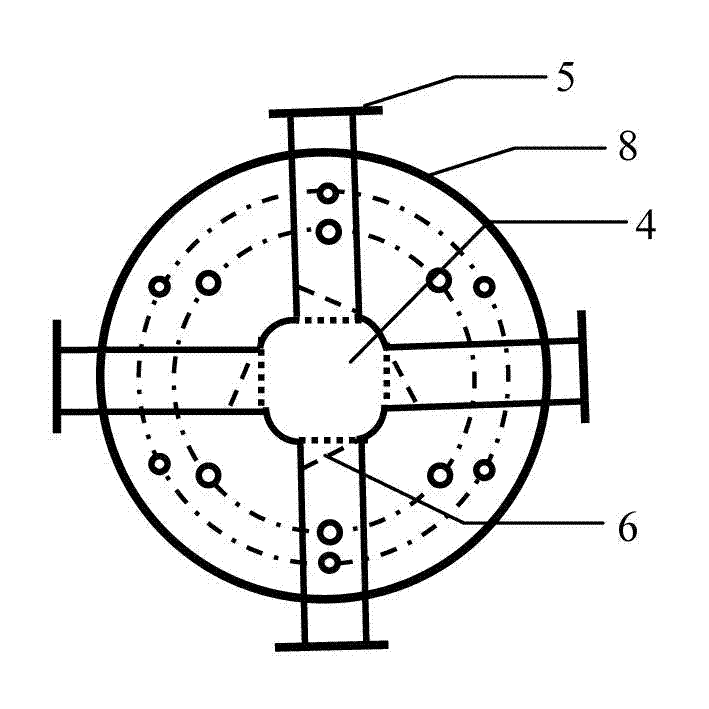

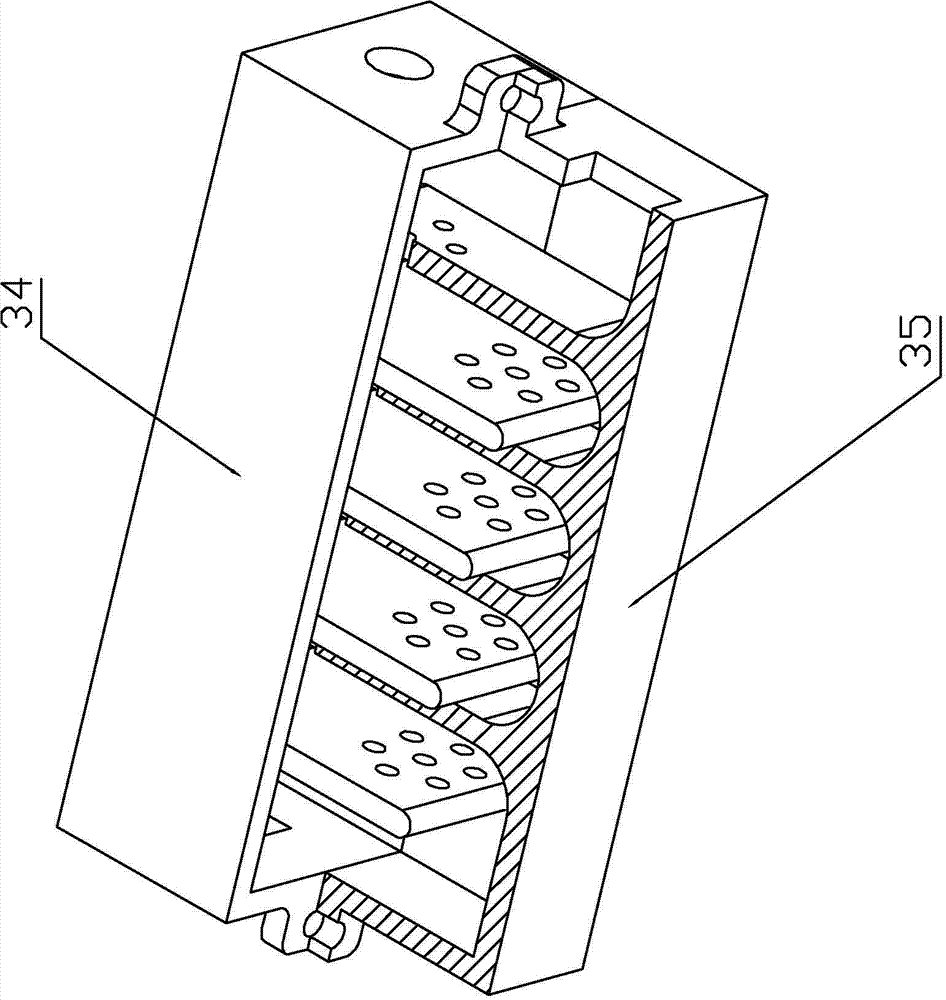

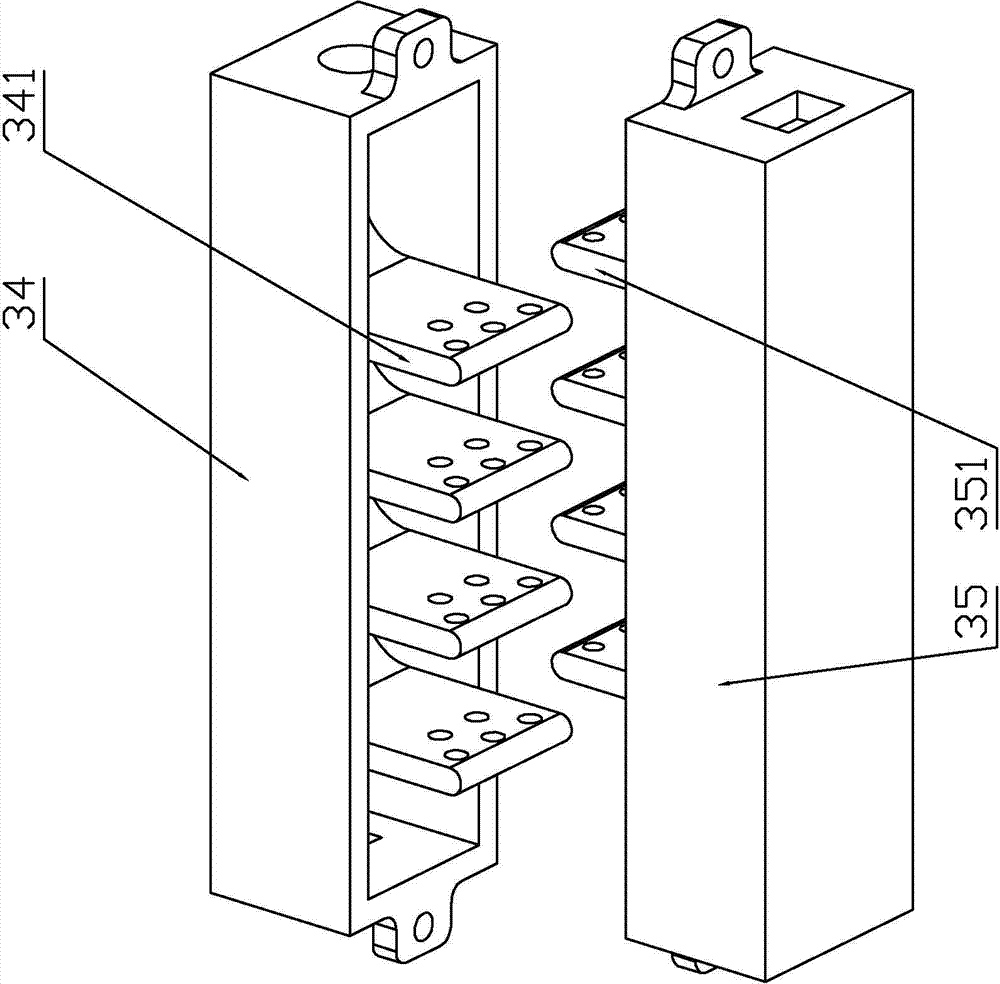

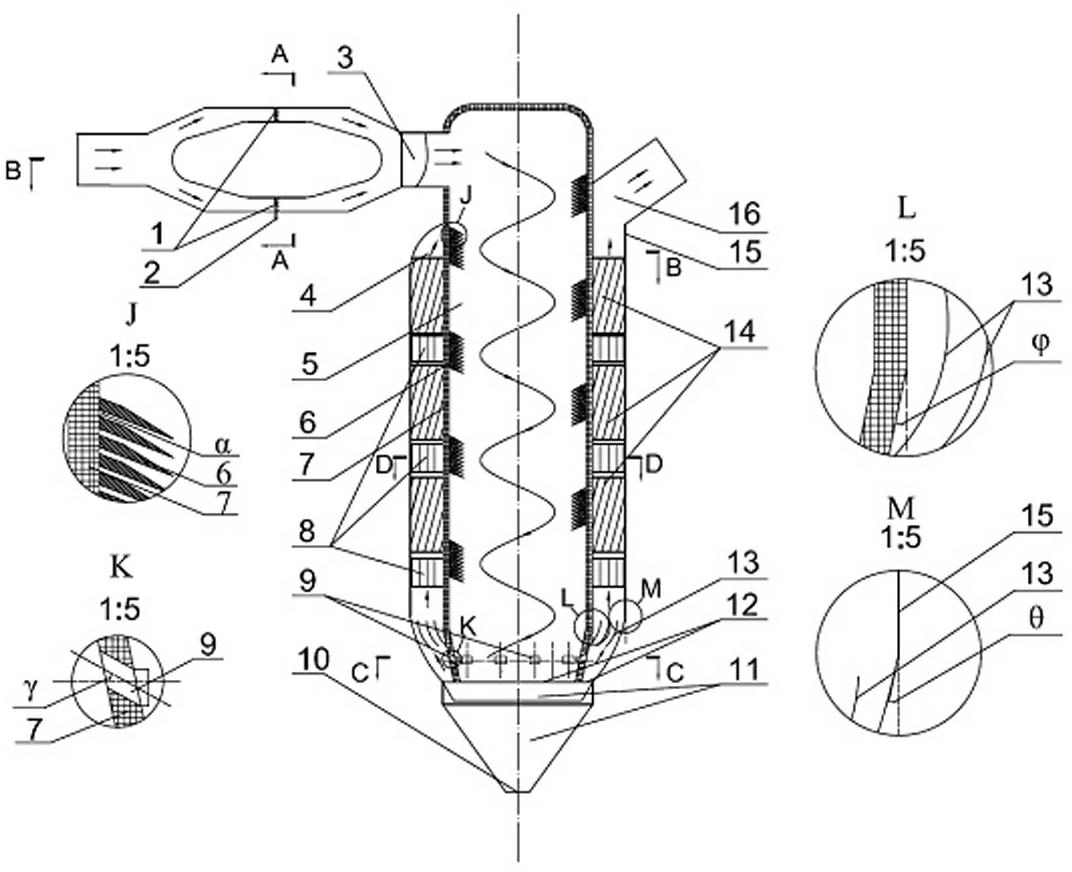

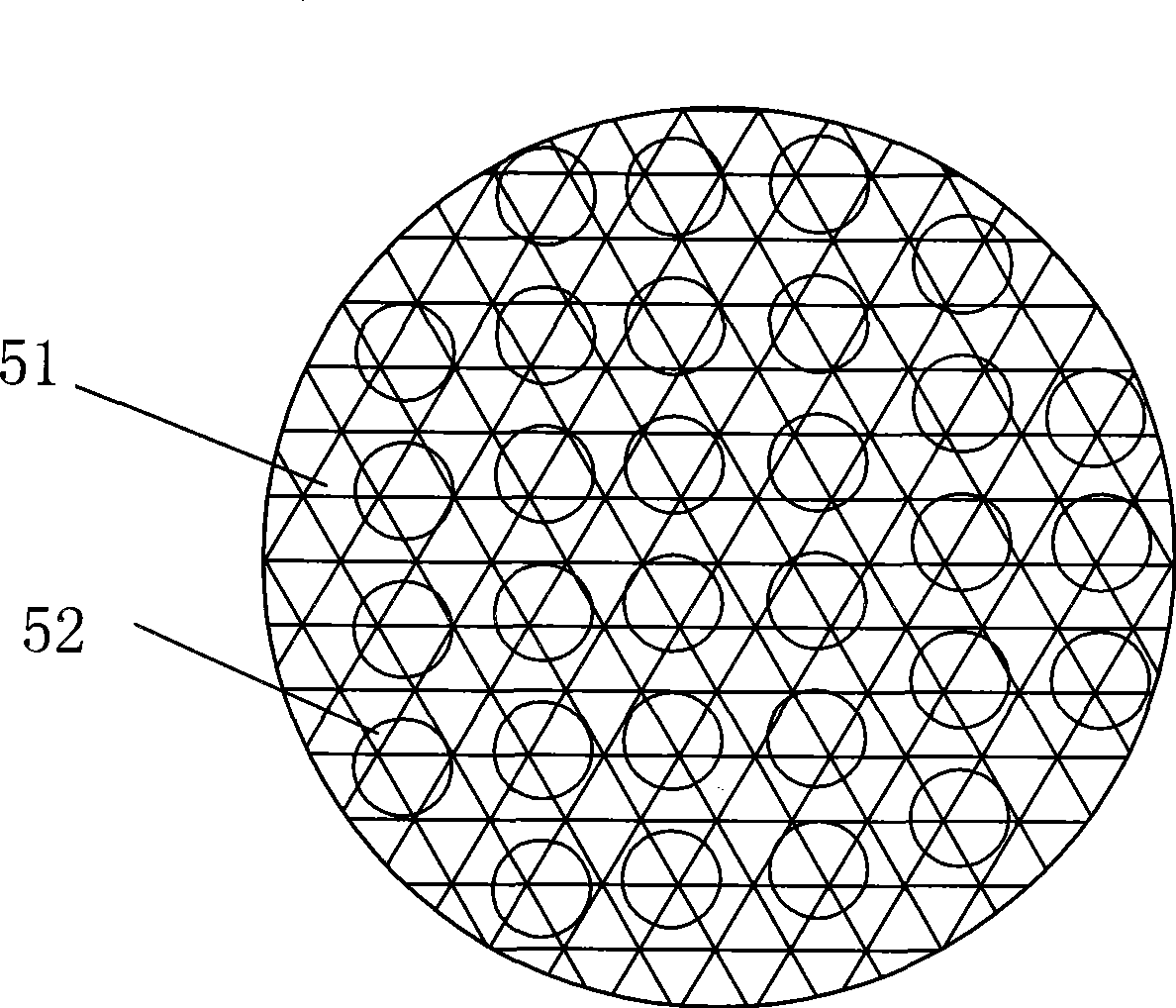

Axial and radial cross flow moving bed reactor and activated coke flue gas desulfurization and denitration technology thereof

ActiveCN102824846ACombined removalAchieve efficient utilizationDispersed particle separationAir quality improvementThermodynamicsFlue gas

An axial and radial cross flow moving bed adsorption reactor and an activated coke flue gas desulfurization and denitration technology thereof are used for realizing the purposes that SO2, NOx, mercury, dioxin and other pollutants in flue gas are unitedly removed and integrally purified in an adsorption reactor, and belong to the technical field of comprehensive waste flue gas treatment. The adsorption reactor is a combined type double-section double-inverse U-type axial and radial cross flow moving bed, awherein desulfurization area is arranged at a lower section of the axial and radial cross flow moving bed, an annular internal activated coke particle layer and an annular external activated coke particle layer are arranged, and the desulfurization area is divided into a coarse desulfurization area and a fine desulfurization area; a denitration area is arranged at an upper section of the axial and radial cross flow moving bed, and an activated coke particle layer is arranged; an ammonia spray pipe is arranged between the upper section and the lower section; and flue gas is filled along a double-port counter annular gas flow channel structure, the flue gas of the lower section centripetally flows to be desulfurized, and the flue gas of the upper section centrifugally flows to be denitrated. According to the reactor and the technology, desulfurization and denitration are realized in one adsorption reactor, so the adsorption reactor has the advantages of efficient utilization of activated coke, uniform flue gas mixing, sufficient gas-solid contact, stability and reliability in operation, operation cost saving and the like.

Owner:SHANGHAI LONGKING ENVIRONMENTAL PROTECTION

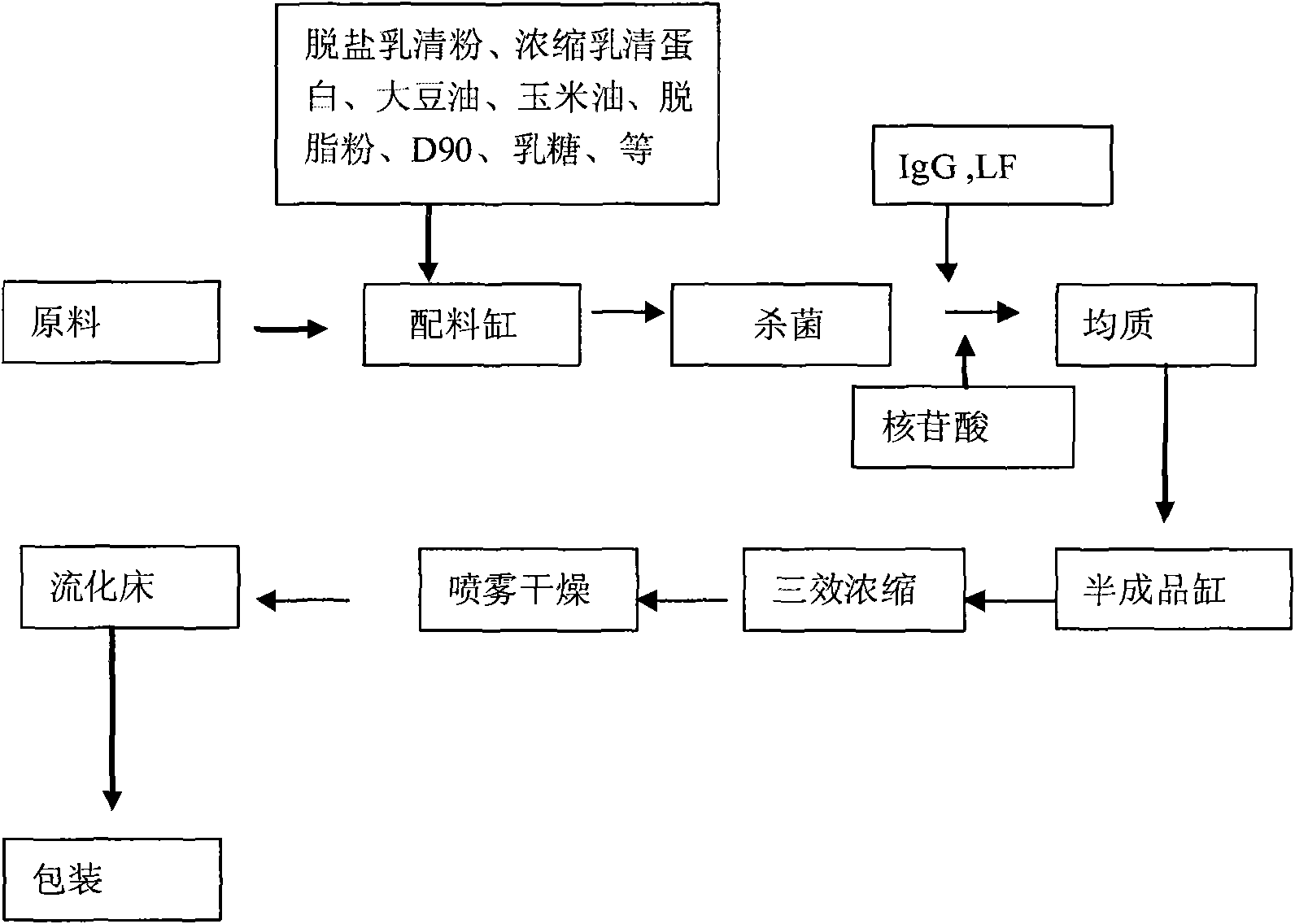

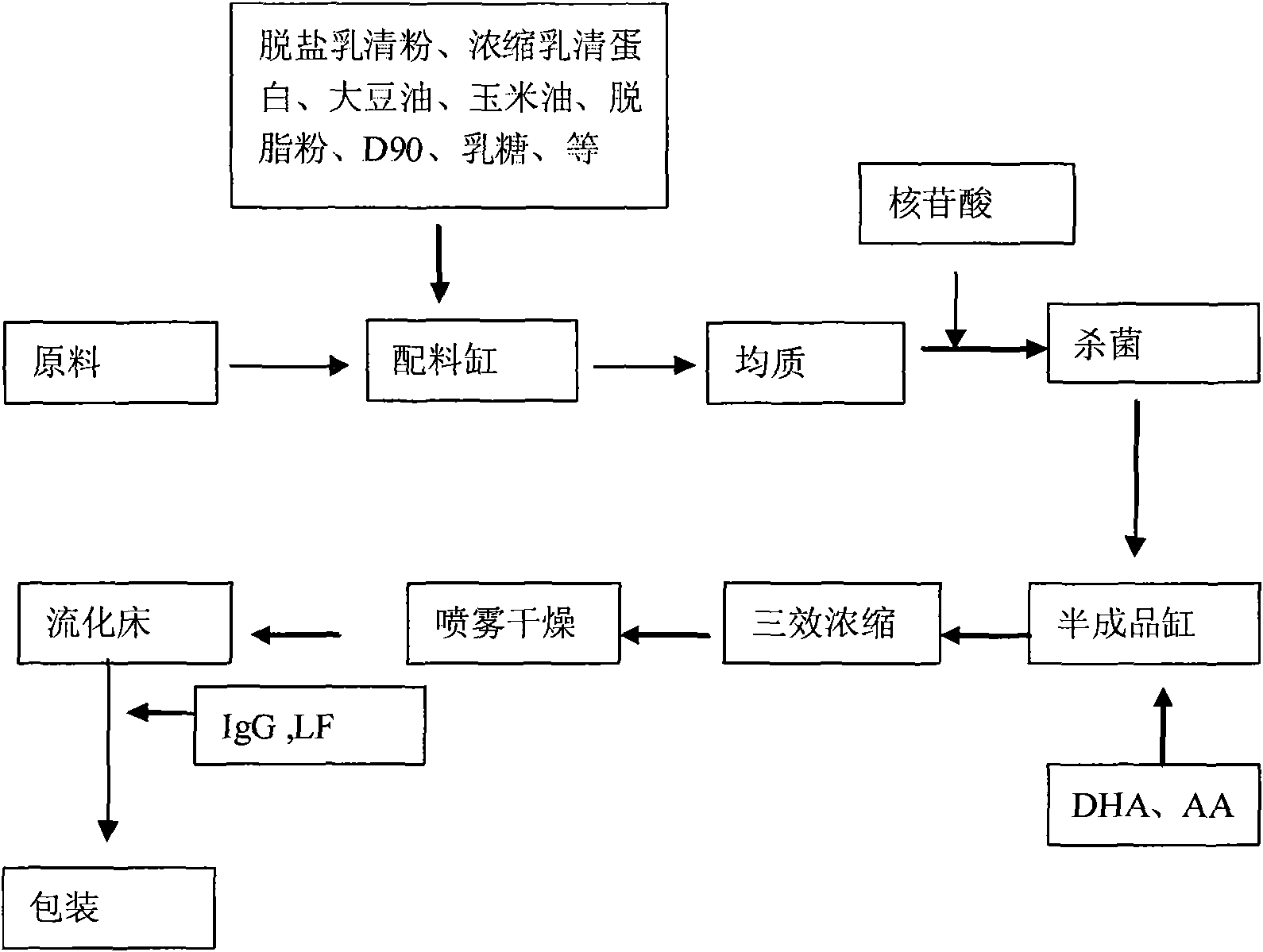

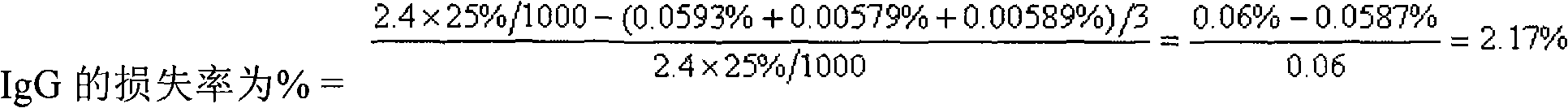

Process for producing powdered milk comprising multiple resistance nutrition immune optimization system

InactiveCN101869150AMaintain biological activityQuality assuranceWhey manufactureDocosahexaenoic acidFluidized bed drying

The invention discloses a process for producing powdered milk comprising a multiple resistance nutrition immune optimization system (MRN immune optimization system), which comprises the following steps: carrying out pretreatment on raw material milk and preparing a mixture of docosahexaenoic acid and arachidonic acid; preparing a mixture of an immune protein G and lactoferrin; and adding the mixed materials according to a certain proportion and respectively carrying out homogenizing, sterilization, concentration, spray drying, fluidized bed drying, cooling and packing inspection on the obtained product. The powdered milk produced by the method of the invention mainly comprises the following ingredients: the immune protein (IgG), the lactoferrin (LF), fructooligosaccharide (FOS), oligomate (GOS) and five nucleotides. The invention improves the conventional production process. The fructooligosaccharide (FOS) and the oligomate (GOS) improve intestinal flora. The five nucleotides can keep the immune system of the human body. The mixed material is prepared from the immune protein G and the lactoferrin in an amplified ratio so as to not only guarantee the bioactivity of the immune protein G and the lactoferrin, but also guarantee the quality of the product.

Owner:美国YOUTH-BASE制药国际有限公司

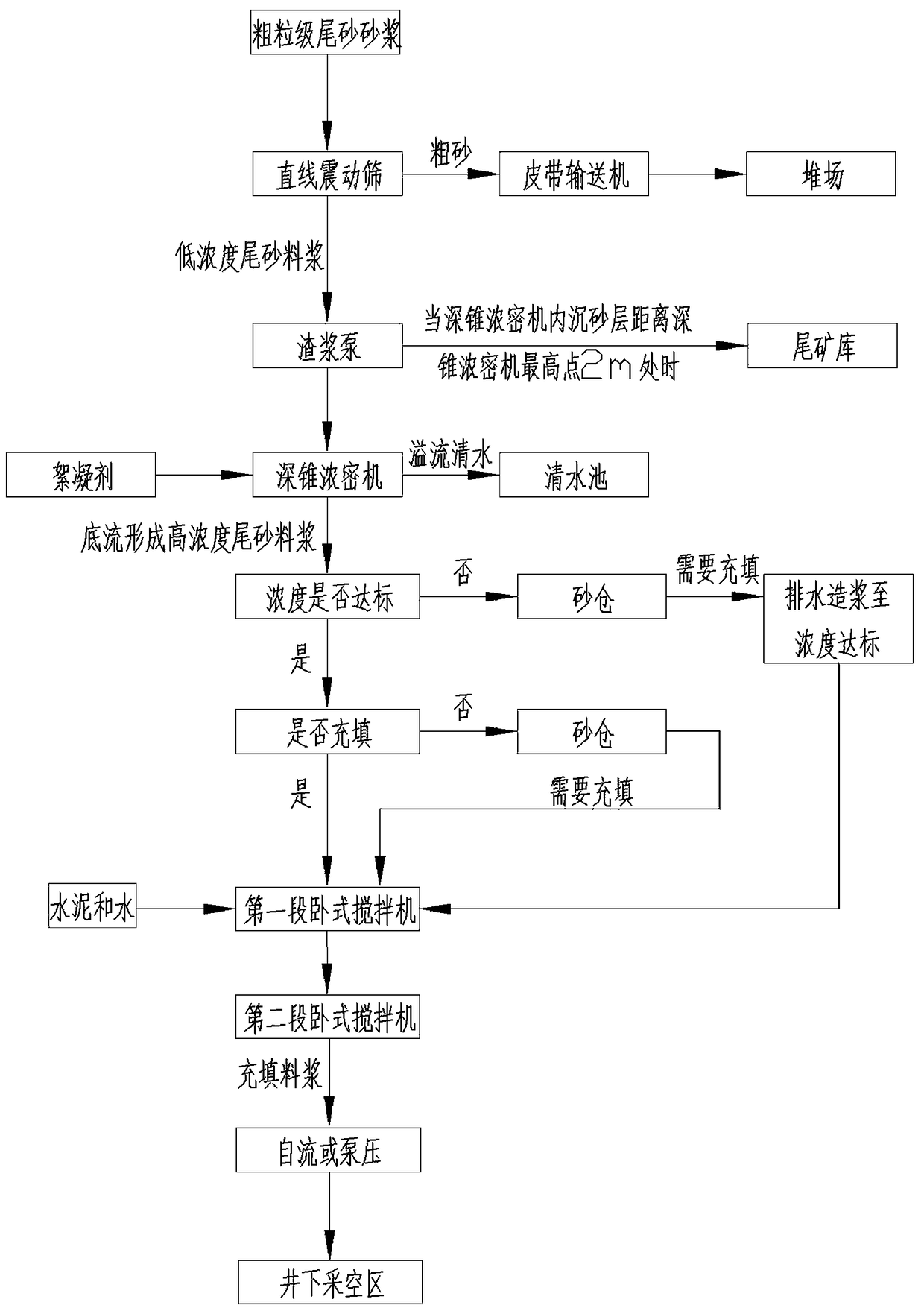

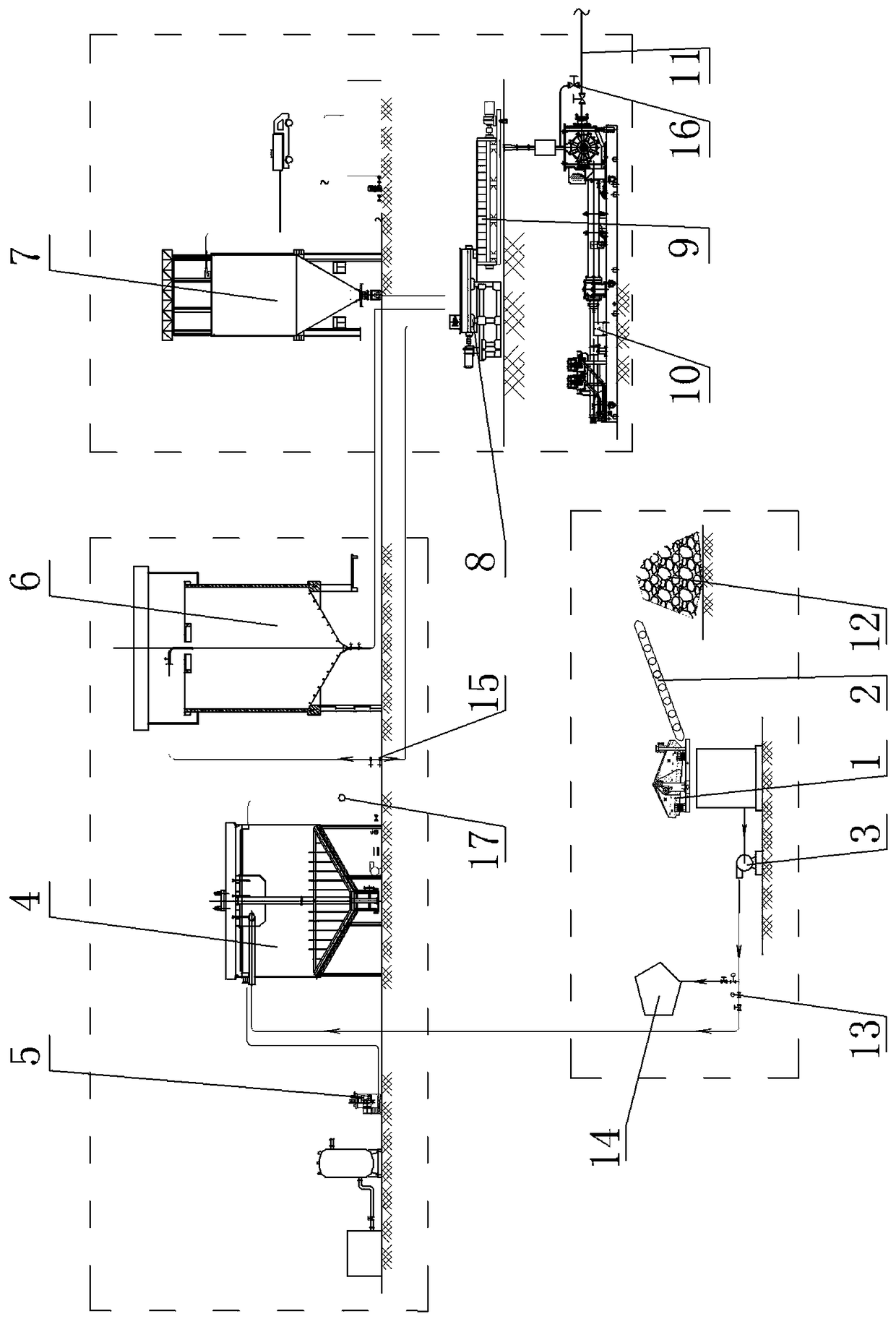

Coarse-fraction tailing paste filling method and system

InactiveCN108661703AImprove efficiencyImprove tailings utilizationMaterial fill-upHigh concentrationMaterials science

The invention discloses a coarse-fraction tailing paste filling method and system. The coarse-fraction tailing paste filling method comprises the following steps that (1) coarse-fraction tailing mortar is conveyed to a linear vibrating screen to be screened to obtain coarse sand and low-concentration tailing slurry; (2) the low-concentration tailing slurry is pumped into a deep-cone thickener, a flocculating agent is added, and high-concentration tailing slurry is formed in a base flow; (3) when a sand setting layer in the deep-cone thickener is away from the highest point of the deep-cone thickener by 2 m, the low-concentration tailing slurry is pumped into a tailing pond; (4) the high-concentration tailing slurry is pumped into a sand silo for buffer storage; (5) during filling, the high-concentration tailing slurry, with the concentration reaching the standard, in the step (2) and the high-concentration tailing slurry, with the concentration reaching the standard, in the sand silo in the step (3) are both pumped into a stirring system; cement and water are conveyed into a first-section horizontal-type stirring machine to be sufficiently stirred and mixed with the high-concentration tailing slurry, and filling slurry is obtained; and according to the magnitude of a stowing gradient, the filling slurry automatically flows or is pumped into a down-hole goaf to conducting filling. Operation is reliable, the cost is low, and abrasion is small.

Owner:CHINA MINMETALS CHANGSHA MINING RES INST

Household gas stove

ActiveCN103292325AWell mixedHomomixerDomestic stoves or rangesGaseous fuel burnerProcess engineeringGas cooking stove

A household gas stove comprises a combustor and a fan, wherein a gas inlet and a gas outlet are formed in the combustor, and an air inlet and an air outlet are formed on the fan. The household gas stove is mainly characterized by further comprising a mixer, a controller and a gas proportional valve, wherein a gas inlet and a gas outlet are formed in the gas proportional valve, a mixed gas outlet in the mixer is communicated with the gas inlet on the combustor, the gas outlet in the gas proportional valve and the air outlet in the fan are communicated with the mixer, the gas proportional valve, the fan and the controller are electrically connected, and the gas proportional valve and the fan enable proportion of gas and air in the mixed gas to be in a proportion for thorough burning under control of the controller. The household gas stove has the advantages of enabling the gas and the air to be mixed evenly and further enabling the gas to be fully burnt.

Owner:GUANGDONG VANWARD ELECTRIC

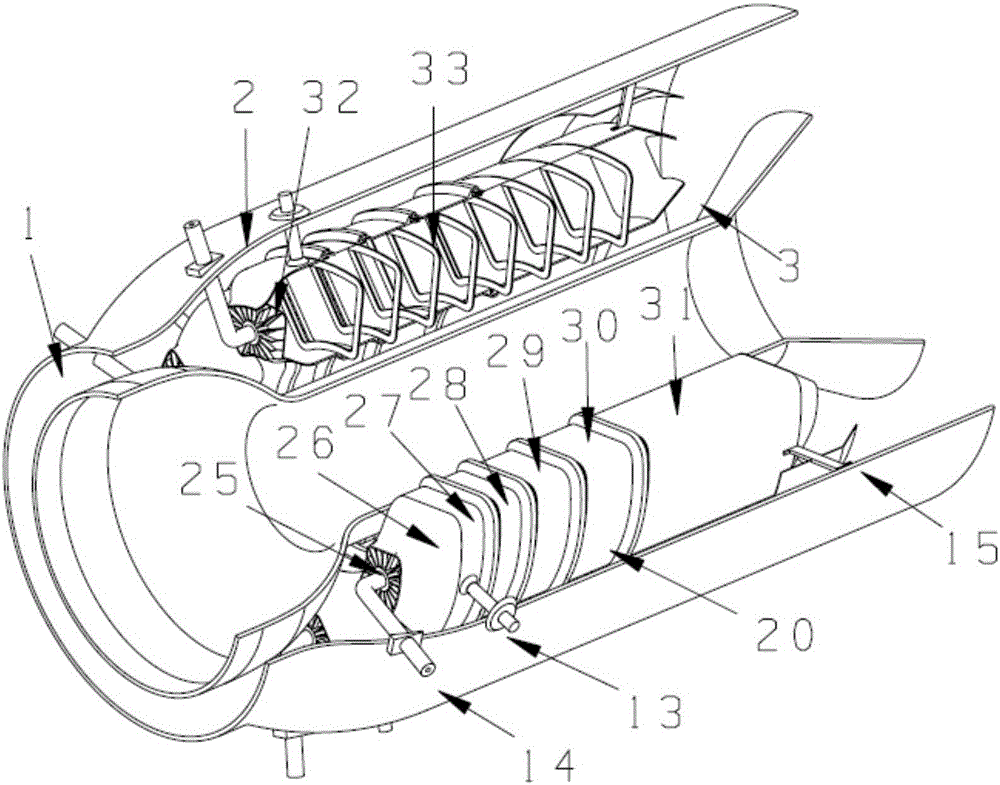

Shunting type multi-pipe pulse detonation combustion chamber

The invention provides a shunting type multi-pipe pulse detonation combustion chamber. After airflow passes through a front diffuser of the combustion chamber, part of the airflow flows into detonation pipes from the head portions of the detonation pipes, and the other part of the airflow flows through the outside of the detonation pipes; a valve block is arranged on the head portion of each detonation pipe, and four deflation rings are arranged on each detonation pipe; in a filling state, the valve blocks on the heat portions are opened so that air can enter the detonation pipes, the first two deflation rings on each detonation pipe are used for auxiliary air intake to increase the filling speed, and one-way valves are installed in the last two deflation rings on each detonation pipe; and the valves are closed in the filling stage. In the spreading and combustion product discharging stage formed by detonation waves, the gas pressure in the detonation pipes is higher than the pressure outside the detonation pipes, the air inlet valve blocks on the head portions are closed, the exhaust valves are opened, part of high-pressure high-temperature gas is exhausted from the deflation rings to be mixed with the airflow outside the detonation pipes, and the other part of the high-pressure high-temperature gas is exhausted from the tail portions of the detonation pipes and exhausted into a turbine after being mixed in a combustion chamber case. Through the two mixing processes, the effects of adjusting the exhaust temperature of the detonation chamber and reducing the impact of exhaust gas to the turbine are achieved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

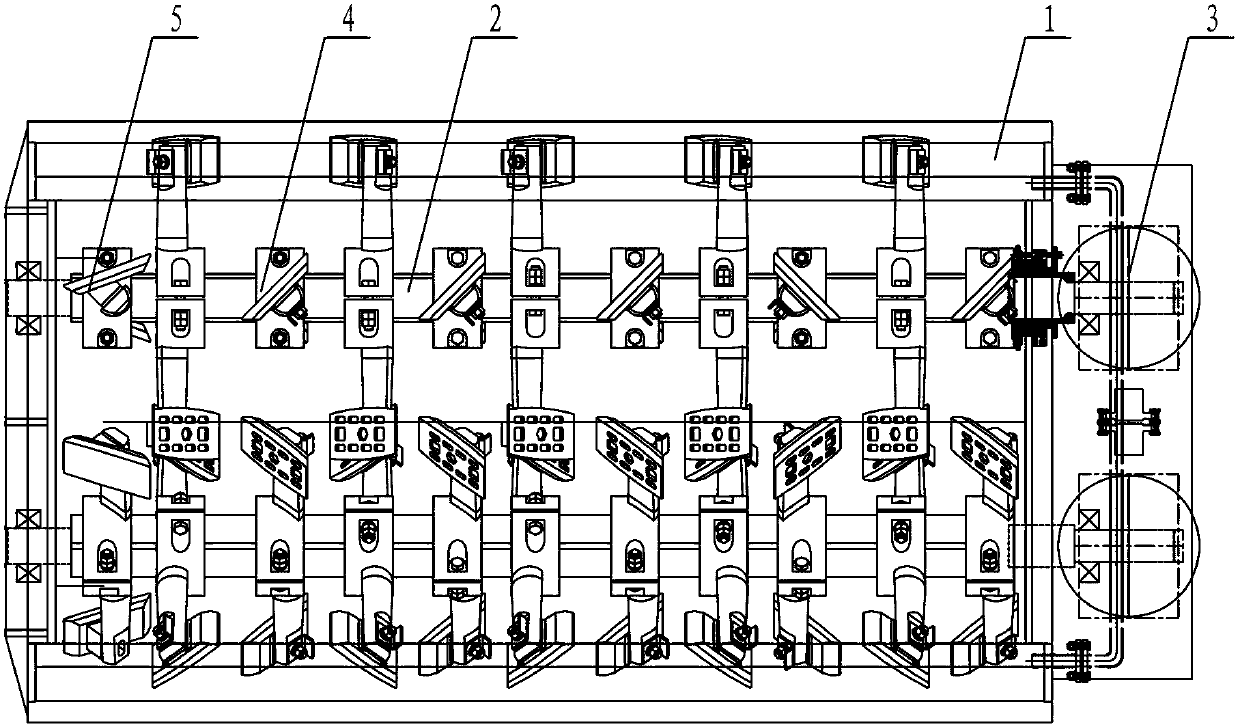

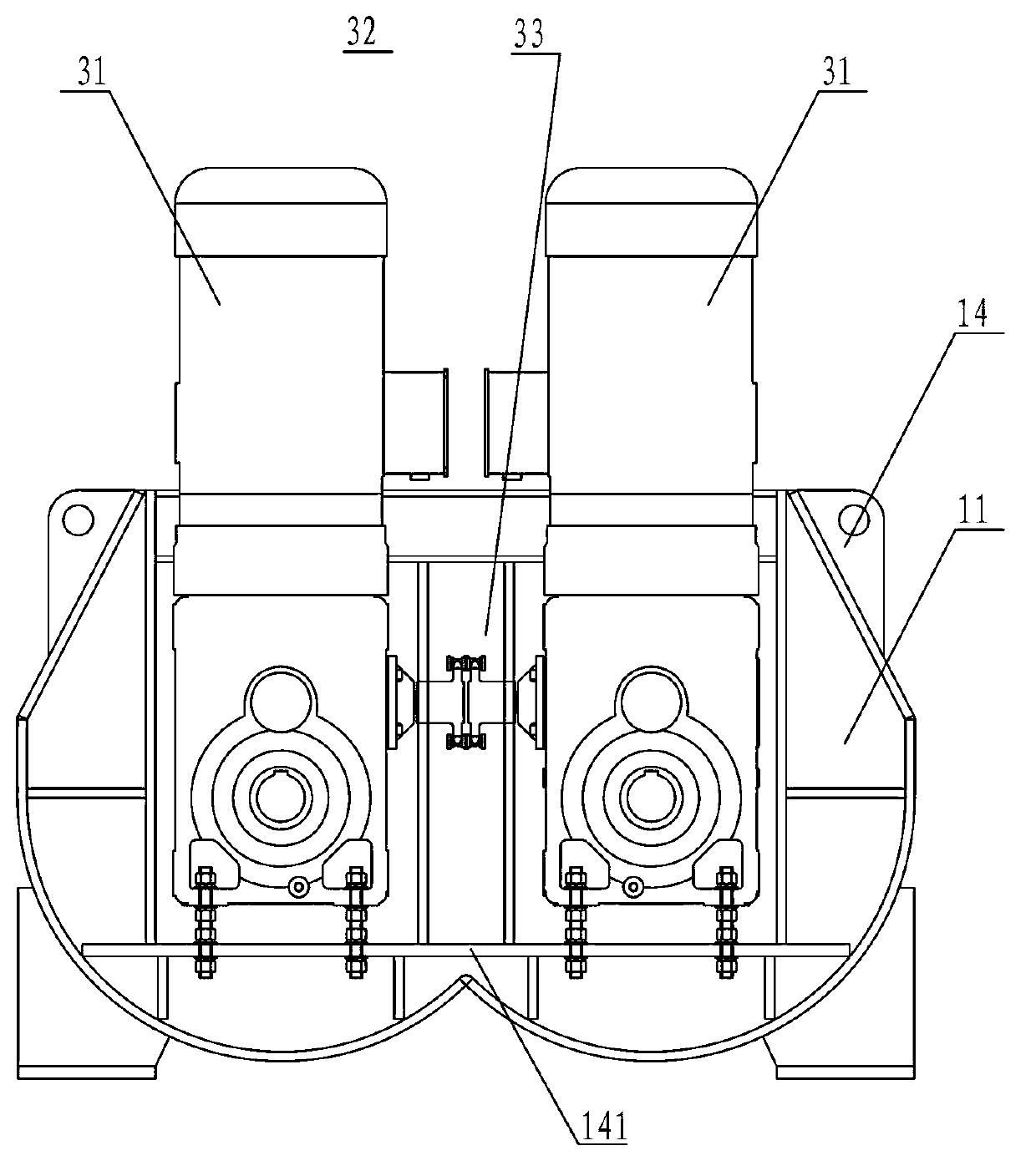

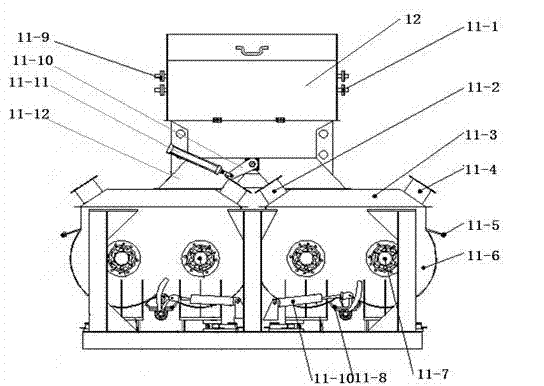

Continuous double-horizontal-shaft forced mixer for asphalt and concrete

ActiveCN103128854AYield easily achievedImprove transmission efficiencyDischarging apparatusMixing operation control apparatusContinuous mixingMechanical engineering

The invention belongs to the technical field of asphalt and concrete mixing, and particularly relates to a continuous double-horizontal-shaft forced mixer for asphalt and concrete. The continuous double-horizontal-shaft forced mixer for the asphalt and the concrete comprises a mixing tank provided with a feeding port and a discharging port, two mixing shafts which are arranged in the mixing tank in a parallel mode, a driving device which drives the mixing shafts to rotate synchronously and reversely, a plurality of groups of mixing units and a material scraping unit. Each mixing unit comprises mixing arms and blades, wherein the mixing arms are mounted on the mixing shafts in an opposite mode, the blades are mounted on the mixing arms and comprise a feeding blade and a returning blade, and the feeding blade and the returning blade are the same in structure and size and opposite in mounting direction. The material scraping unit comprises a group of mixing arms which are arranged in an opposite mode, and material scraping blades which are connected on the mixing arms, wherein an acute included angle is formed between each material scraping blade and a side plate of the mixing tank. According to the bituminous mixture mixer, namely the continuous double-horizontal-shaft forced mixer for the asphalt and the concrete, the methods of continuous grading feeding, continuous mixing and continuous discharging are used, and the output of the bituminous mixture mixer can reach 100-1,000 tons per hour.

Owner:FUJIAN SOUTHERN HIGHWAY MECHANICAL

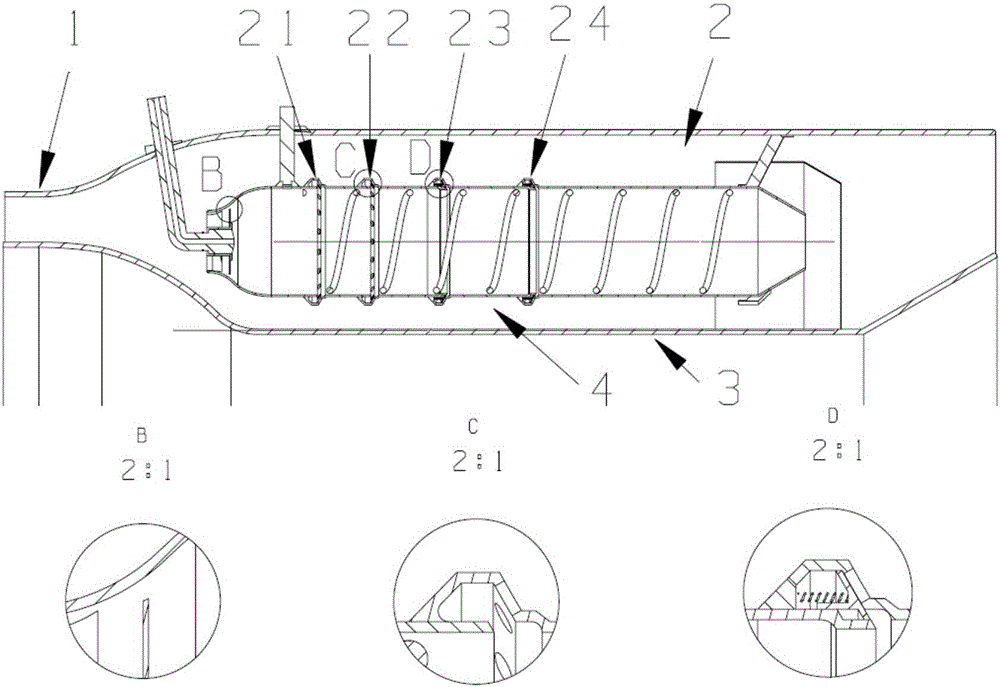

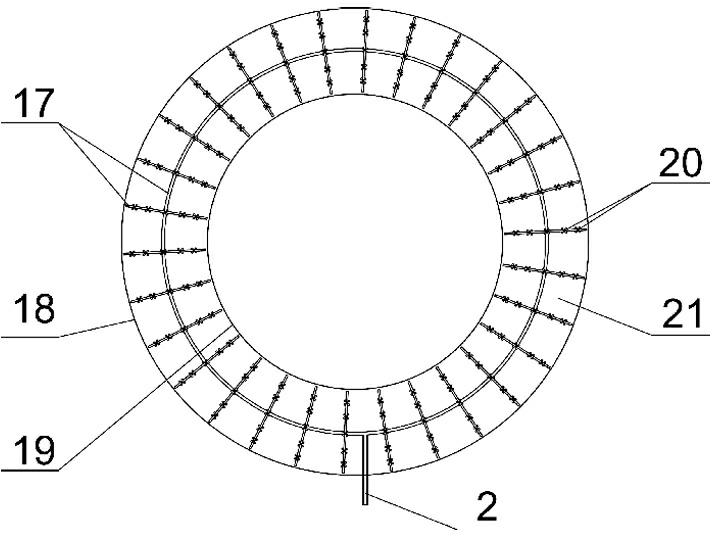

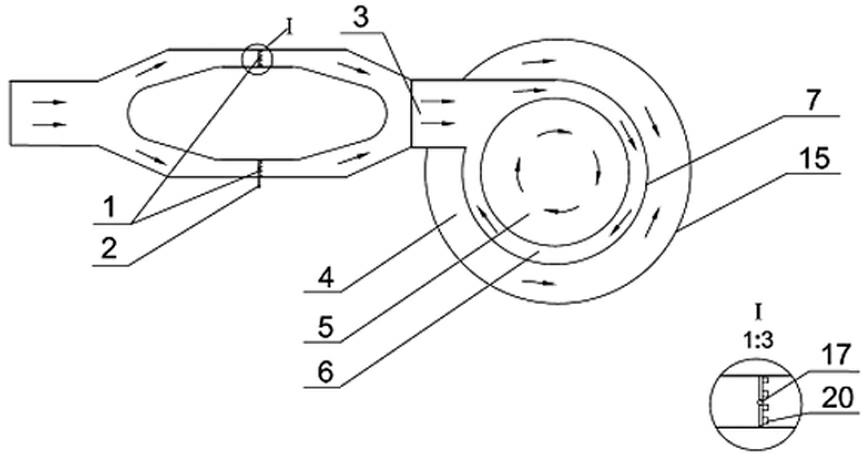

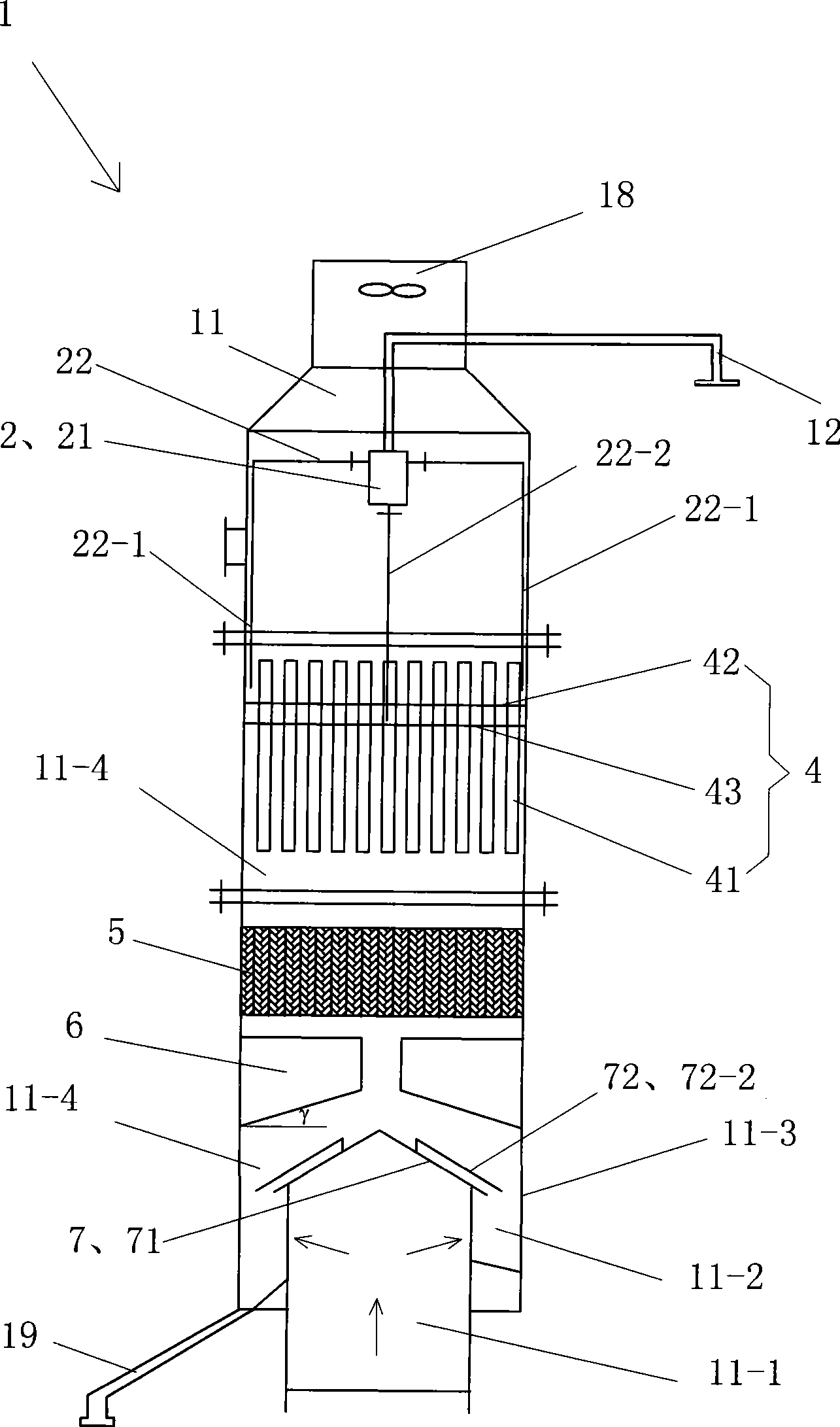

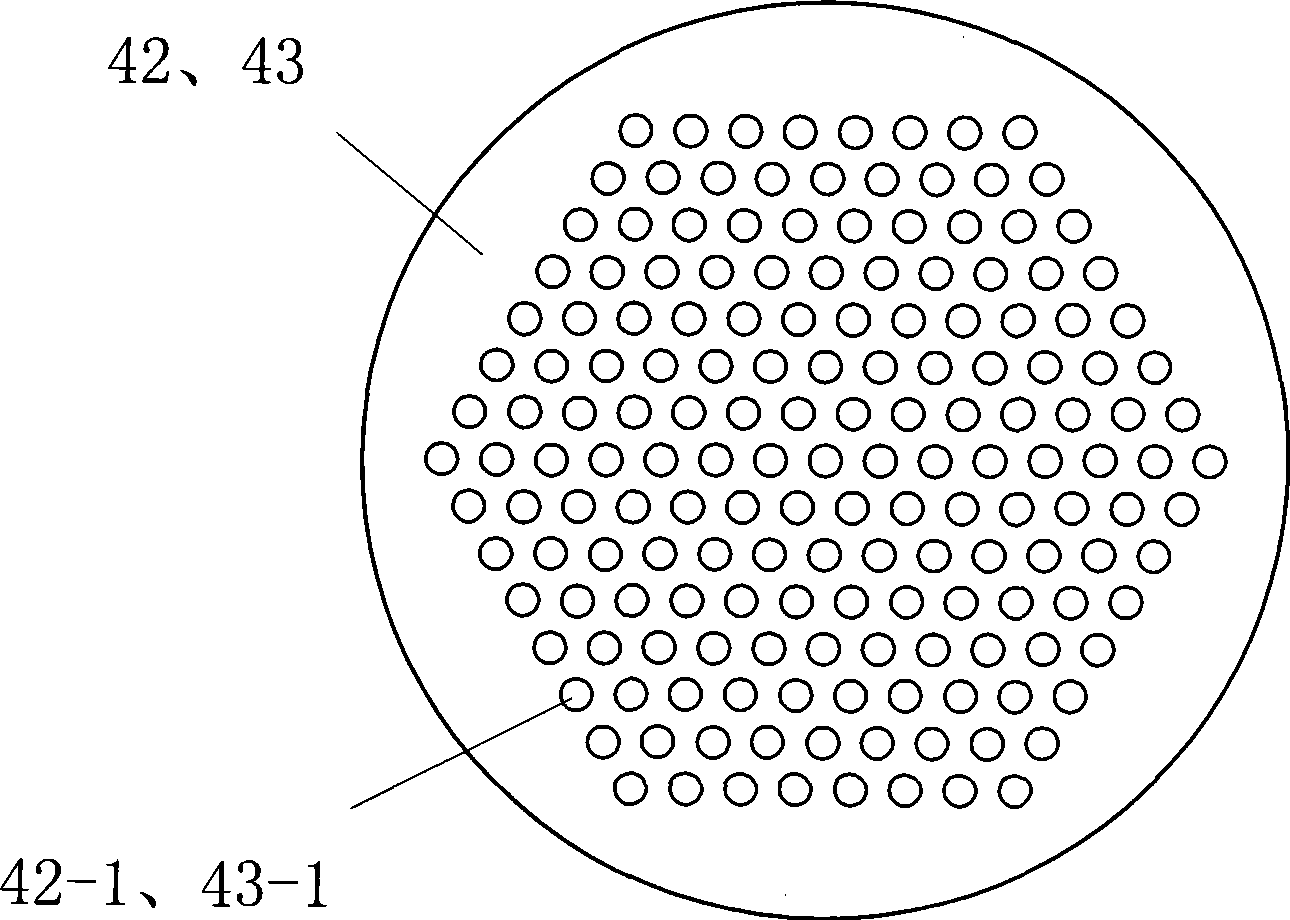

Dedusting-denitrating integrated device

ActiveCN102614779ASimple structureSimple control systemDispersed particle filtrationFlue gasProcess engineering

The invention discloses a dedusting-denitrating integrated device which comprises a flue gas channel, a mixed flue gas inlet and a shell consisting of an outer cylinder and an inner cylinder, and a ash hopper at the bottom of the shell, wherein the inner cylinder is mainly used for dedusting and ammonia mixing, the outer cylinder is mainly used for containing a denitrating catalyst bed, the crosssection of the flue gas channel is ring-shaped, and ammonia spray grilles are distributed in the flue gas channel in a radial manner so that the required NH3-to-NO ratio can be reached more easily. The device provided by the invention can be used for dedusting before carrying out denitrating, a catalyst can be effectively prevented from being worn, poisoned and blocked and the service life of thecatalyst can be prolonged. Under the condition that the length of the device is not increased, the ammonia mixing time is prolonged and ammonia mixing can be performed fully; heat absorbing spiral plates and cooling rectifier plates are arranged in both the inner cylinder and the outer cylinder to share heat of flue gas at the inlet, and therefore the heat loss of flue gas can be reduced, the denitrating efficiency can be improved and the catalyst is prevented from being sintered and inactivated under the action of superheated flue gas.

Owner:HUNAN UNIV

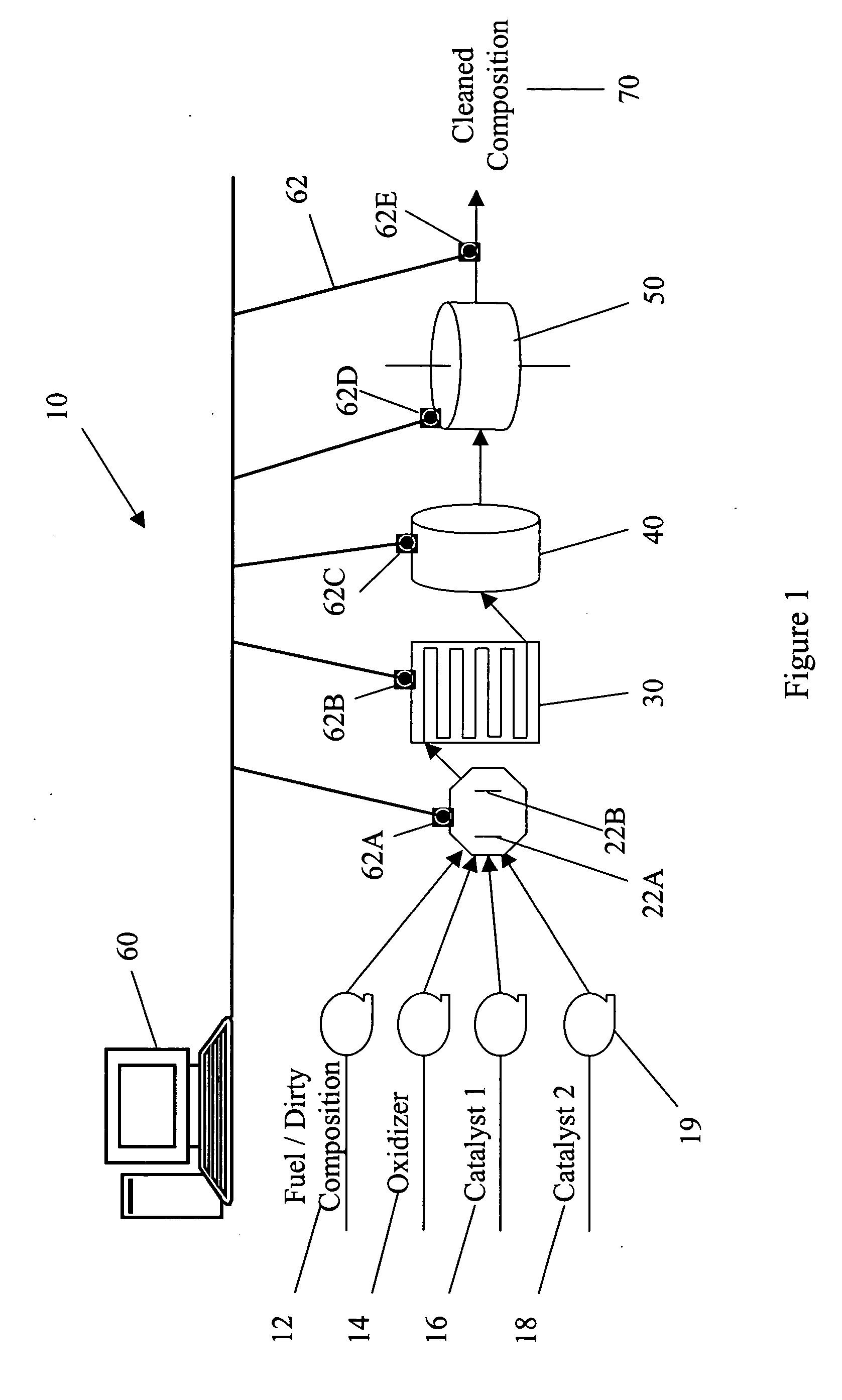

Methods and apparatus for processing fuels

InactiveUS20060111600A1Increase hydrogen peroxideExtend the mixing timeDewatering/demulsification with mechanical meansRefining with oxygen compoundsProcess engineeringEnvironmental engineering

A fuel or other process fluid is cleansed by a) combining the fluid with water and an oxidizer; b) mixing the combination in a mixer having a volume V; c) separating the mixed combination into hydrophobic and hydrophilic phases; d) filtering the hydrophobic phase through a filter; e) removing water from the filtered hydrophobic phase to produce the cleaned fluid; and accomplishing steps a-d in a continuous manner that produces an output of the cleaned fuel at an average rate of at least 10V / hour. A centrifuge can optionally reduce water content of the cleaned fluid to no more than 5 ppm, more preferably no more than 1 ppm, and most preferably no more than 0.5 ppm.

Owner:MECHAM LORRIE ELMER

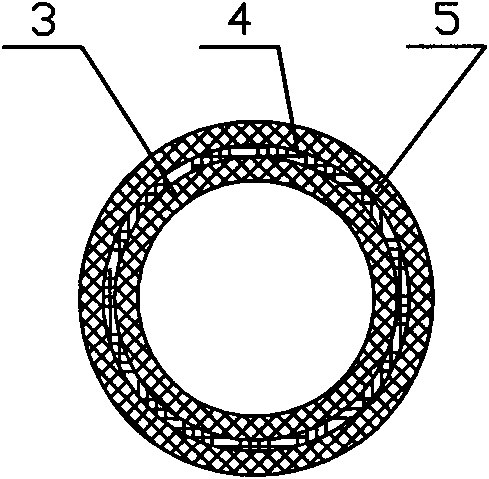

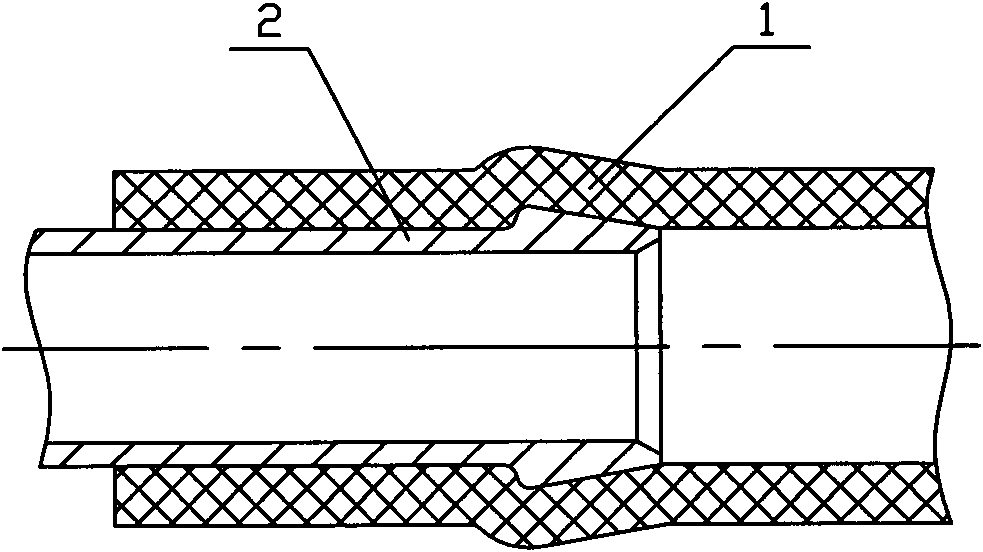

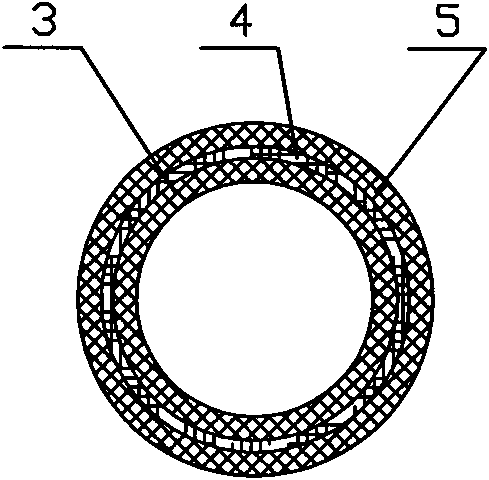

Cooling water pipe for electric vehicle and production technology thereof

InactiveCN101929586ATo achieve the effect of bondingSimple production processFlexible pipesFiberWork in process

The invention discloses a cooling water pipe for electric vehicle and production technology thereof, wherein a rubber pipe consists of an inner rubber layer, a fiber line reinforcement layer and an outer rubber layer from inside outwards. The cooling water pipe is prepared by the following steps of: (1) feeding rubber components of the inner and outer rubber layers into an internal mixer to mix the rubber components; (2) performing a fast testing on the semi-finished rubber after the rubber components are mixed; (3) putting the rubber into a 90 extruder with a straight machine head to extrude the inner rubber layer; (4) knitting a fiber line reinforcement layer on the extruded rubber layer of the inner pipe by using a knitter; (5) on the 90 extruder, extruding the semi-product in the step (4) out of the outer rubber layer by using a T-shaped machine head; (6) cutting the rubber pipe off and vulcanizing the pipe in a steam cylinder; (7) washing the rubber pipe and cutting the head of rubber pipe; and (8) performing injection molding and fast connecting the head to obtain the finished product. The production technology is simplified, the cost is saved and the operation is more convenient; meanwhile, the bonding is firm and the quality of product is good.

Owner:ZHEJIANG JUNHE RUBBER TECH

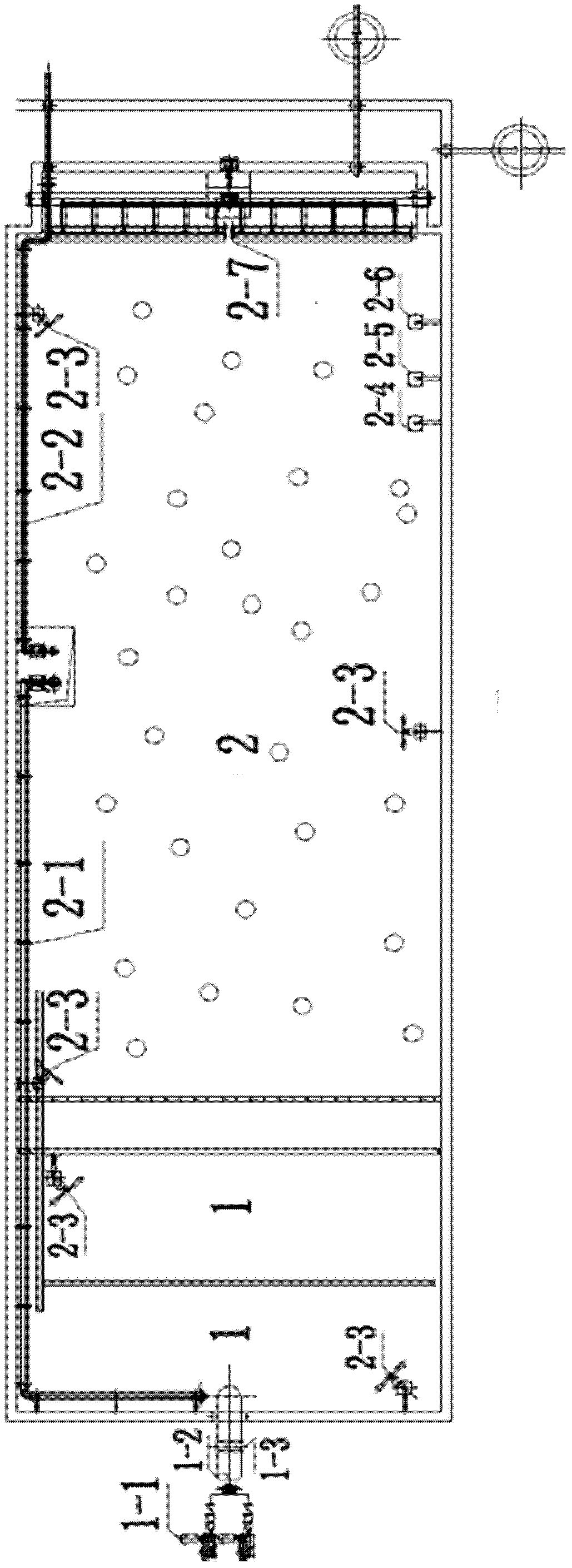

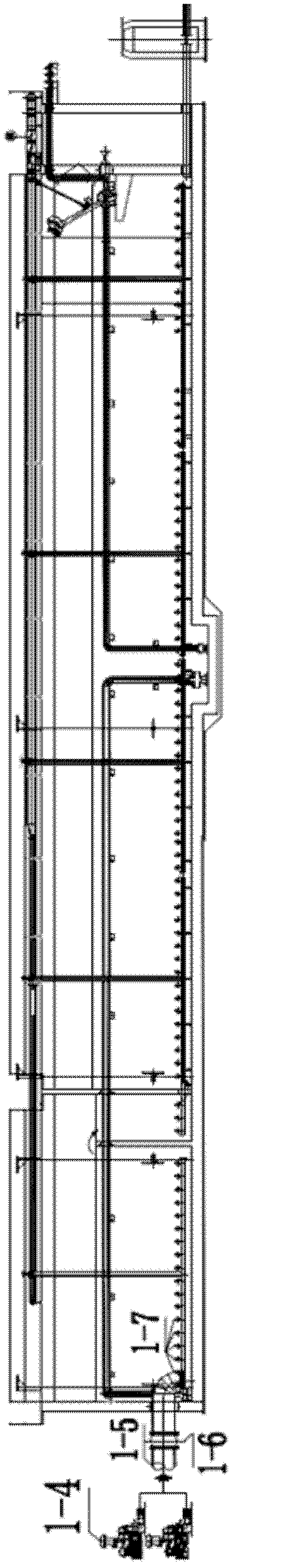

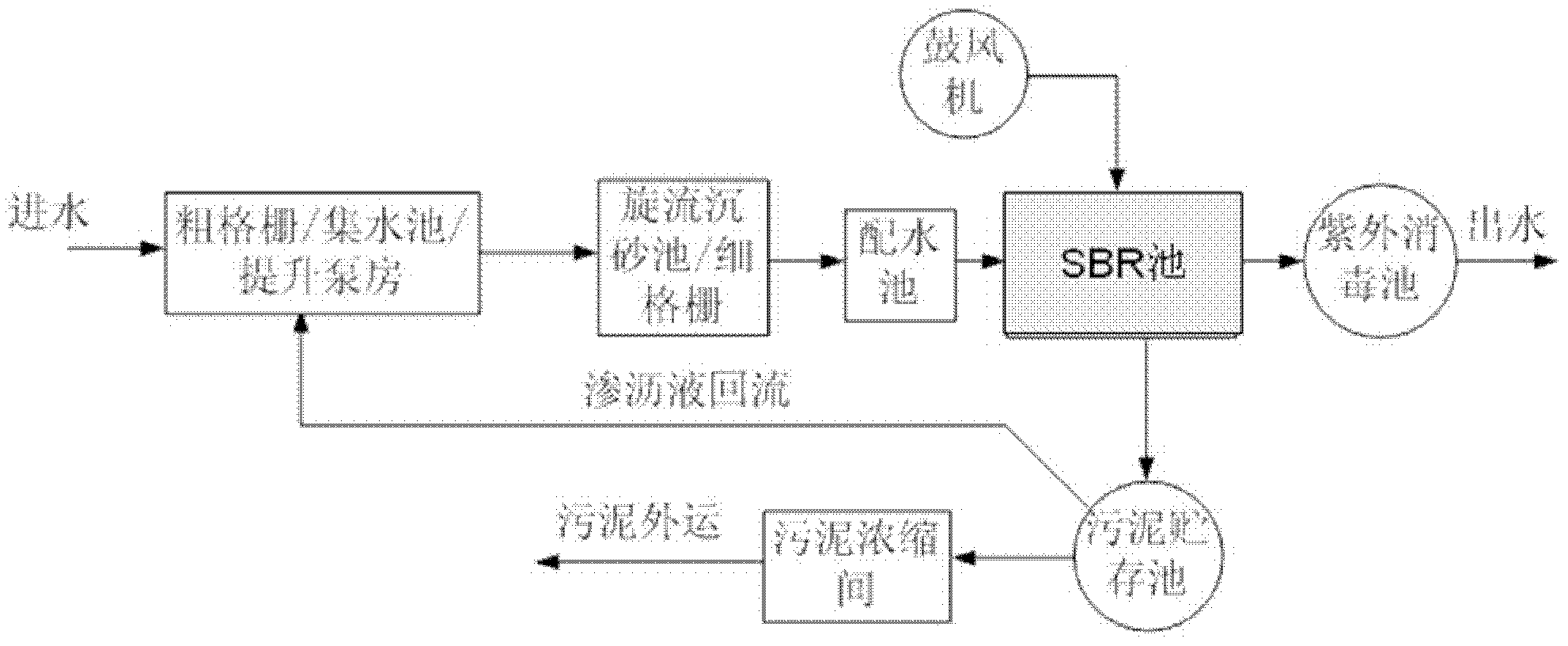

Reversed-order SBR (Sequencing Batch Reactor) water processing device and method for enhanced nitrogen removal

InactiveCN102674537AEfficient biological denitrificationBreak through the difficult problem of improving the denitrification efficiencySustainable biological treatmentBiological water/sewage treatmentActivated sludgeSequencing batch reactor

The invention discloses a reversed-order SBR (Sequencing Batch Reactor) water processing device and method for enhanced nitrogen removal and belongs of the field of activated sludge sewage processing. The device comprises a reversed-order SBR pool, a water inlet pipe, a water outlet pipe, an air inlet pipe and an aeration head, wherein the reversed-order SBR pool can carry out anoxia denitrification denitrification, anaerobic phosphorus release, aerobic denitrification and aerobic phosphorus uptake reaction; the water inlet pipe is connected with a water inlet pump; the inlet of the air inlet pipe is connected with an air blower; the outlet of the air inlet pipe is connected with the aeration head; a submerged stirrer, a dissolved oxygen (DO) sensor, an oxidation-reduction potential (ORP) sensor and a pH sensor are arranged in the reversed-order SBR pool are arranged in the SBR pool for monitoring on line; and the meters are respectively connected with a PLC (Programmable Logic Controller). On the basis of the traditional SBR reaction pool, the reversed-order SBR water processing device has the advantages that a water inlet mode is improved and a water inlet time sequence and water inlet duration of working procedures, such as stirring, aeration, precipitation, water cecantation and the like are adjusted, so that the denitrification efficiency of the reversed-order SBR technology is higher, the use ratio of the raw water carbon source is bigger, the processing effect is more stable, and the operation cost of a sewage treatment plant is directly lowered.

Owner:BEIJING HUALIJIA ENVIRONMENTAL ENG TECH CO LTD

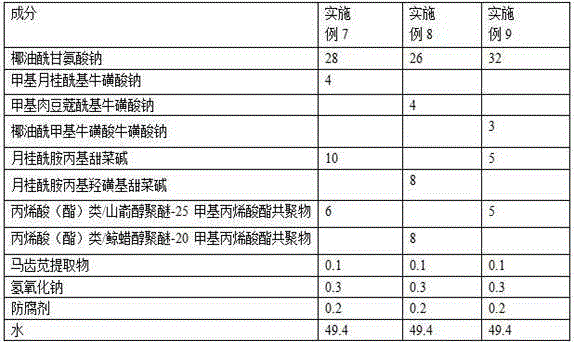

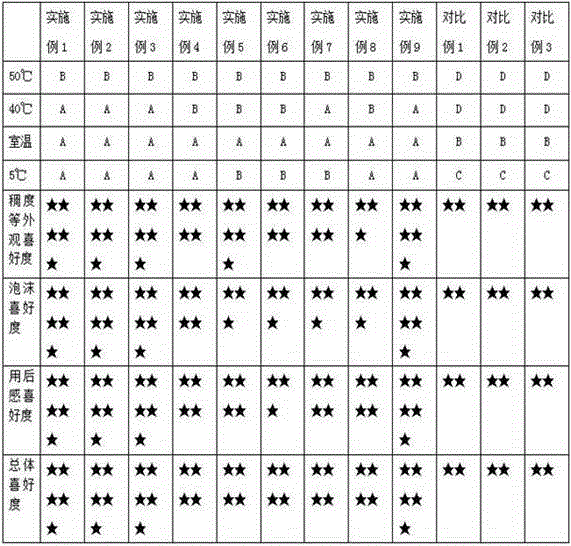

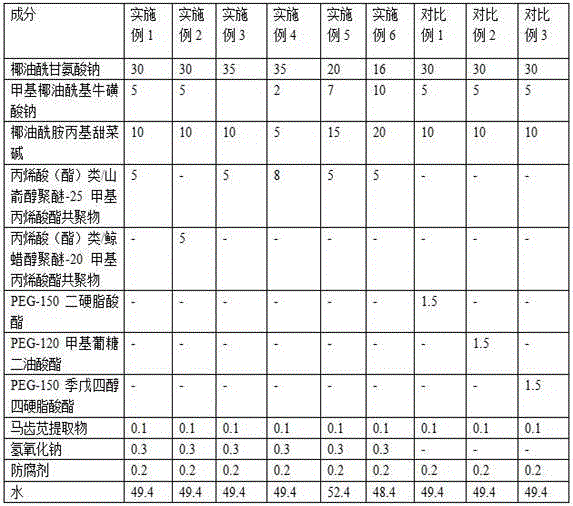

Cleansing gel and preparation method thereof

ActiveCN106667782AExtend the mixing timeEasy to handleCosmetic preparationsToilet preparationsSURFACTANT BLENDViscosity

The invention discloses cleansing gel and a preparation method thereof. The cleansing gel is prepared from the following components: 25-45 parts of an anionic surfactant selected from alkyl acyl glycinate, alkyl acyl taurate and a mixture of the alkyl acyl glycinate and the alkyl acyl taurate, 3-20 parts of a betaine-type amphoteric surfactant, 4-8 parts of acrylic acid (ester) polymers, 0.2-0.5 part of sodium hydroxide and the balance of water. The product prepared by the method has rich, fine and smooth foam; after using the cleansing gel, a person feels well and does not have obvious residual feeling; furthermore, the cleansing gel is stable in viscosity and is less affected by temperature; the preparation method is simple in technology and free of heating, so that more time is saved.

Owner:HUAANTANG BIOTECH GRP CO LTD

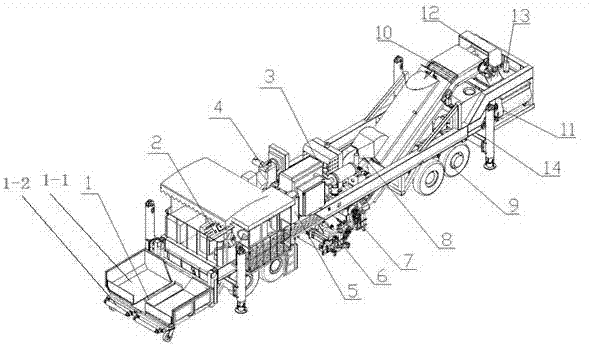

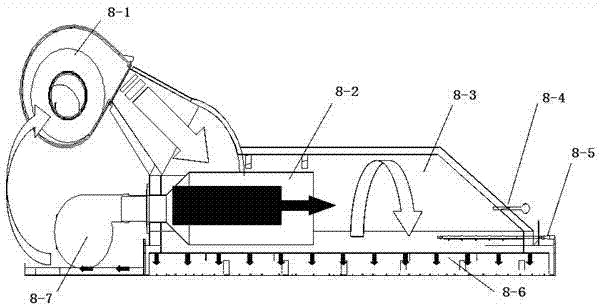

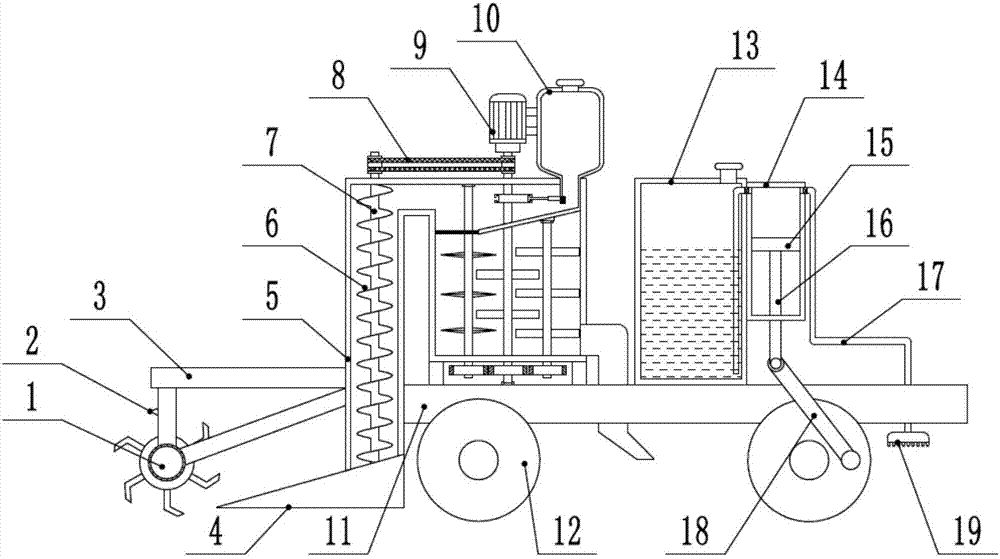

In-place heat regeneration integrated machine for bituminous pavements and control method

ActiveCN104727208AExtend heating timeExtend the mixing timeRoads maintainenceStopped workControl system

The invention provides an in-place heat regeneration integrated machine for bituminous pavements and a control method, wherein the in-place heat regeneration integrated machine for bituminous pavements integrates the functions of pavement milling-planing, bituminous mixture heating, remixing and the like. The regeneration integrated machine comprises a chassis, a milling-planing device, a conveyor, a conveyor heating device, an agitating pan, agitating pan heating devices, and a control system, wherein the conveyor is located behind the milling-planing device, the conveyor heating device is located above the conveyor, the agitating pan heating device is arranged at the top of the agitating pan, and the control system is used for controlling the travelling speed of the chassis, the heating temperature, the mixture metering and the agitating time of the agitating pan. The control method comprises the following steps: starting to accumulate travelling pulses, and if a required travelling distance reaches, switching a material distribution board to the other side; if the material distribution board is overturned, opening an agitating cylinder on the other side, discharging for a period of time, and waiting for the next switching of the material distribution board; and repeating the steps until the machine stops working.

Owner:SHANDONG LUQIAO GROUP

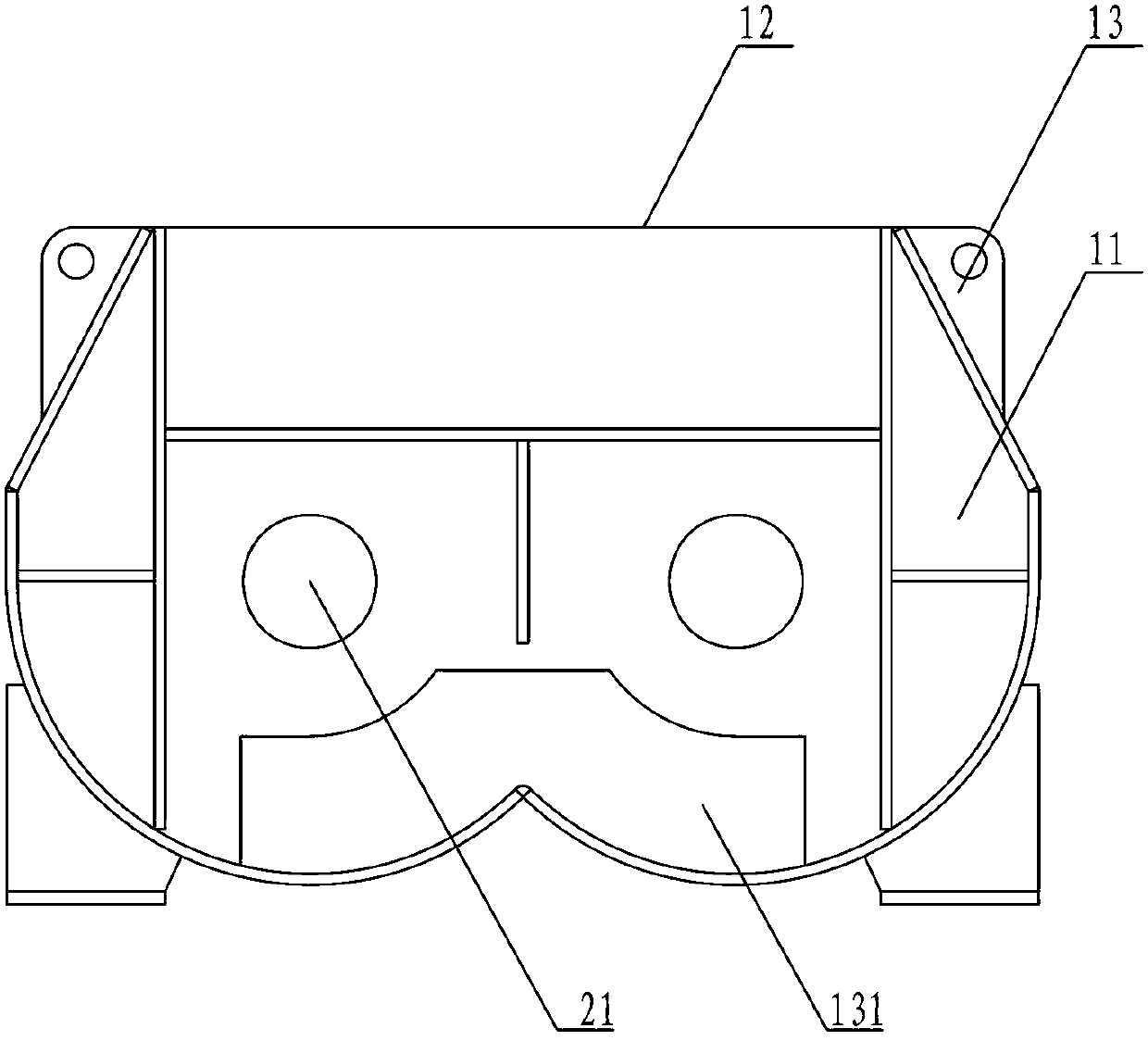

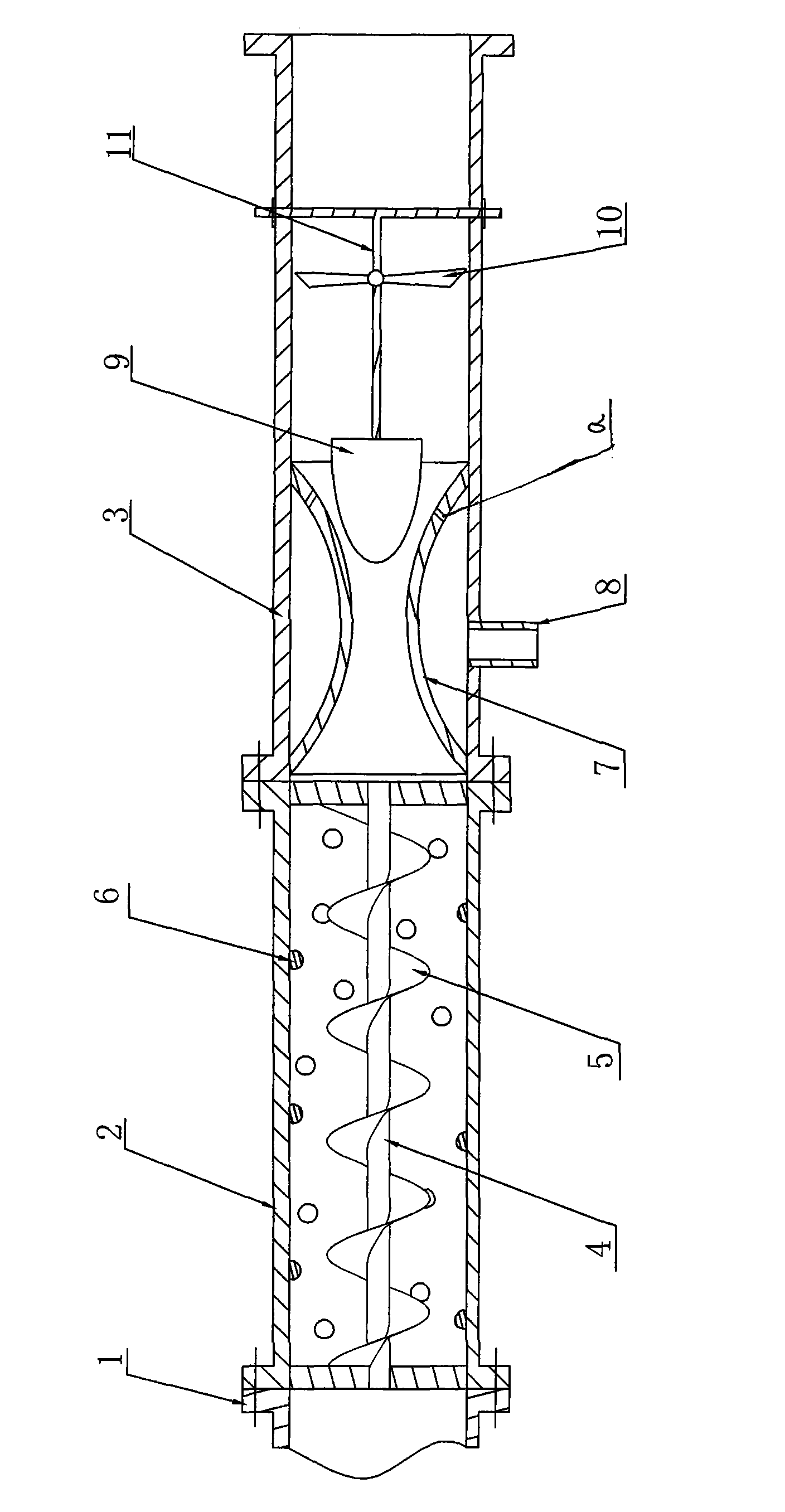

Foam generator for preventing and extinguishing fire in coal mine

ActiveCN102182496AExtend the mixing timeEasy to installDust removalFire preventionImpellerCurrent collector

The invention relates to a foam generator for preventing and extinguishing fire in a coal mine, which comprises a feed pipe, a mixer connected with the outlet end of the feed pipe, a foam generator barrel connected with the outlet end of the mixer, an air inlet pipe arranged on the front wall of the foam generator barrel, a Venturi tube arranged at the inner inlet end of the foam generator barrel, a current collector arranged at the outlet end of the Venturi tube in the foam generator barrel, a fixed rod arranged behind the current collector in the foam generator barrel, and an impeller arranged at the middle rear part of the fixed rod, wherein an air inlet hole is arranged in the rear wall of the Venturi tube, the current collector is arranged at the front end of the fixed rod, a mixer middle shaft arranged along the axis of the mixer is arranged in the mixer, and a stirring blade is arranged on the mixer middle shaft. The foam generator adopts a manner that the stirring blade is arranged in the mixer, so that mixed slurry can be mixed uniformly, material can not block the tube easily, the use is reliable, the fire can be effectively extinguished, the structure is compact and reasonable, and the maintenance is convenient; and the foam generator is applicable to quickly extinguishing the fire underground and efficiently preventing spontaneous combustion fire of coals.

Owner:XIAN XIKE COAL MINE SAFETY VENTILATION FIRE PREVENTION INST

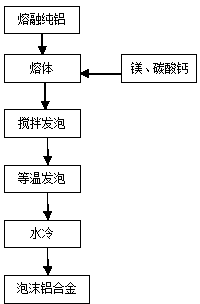

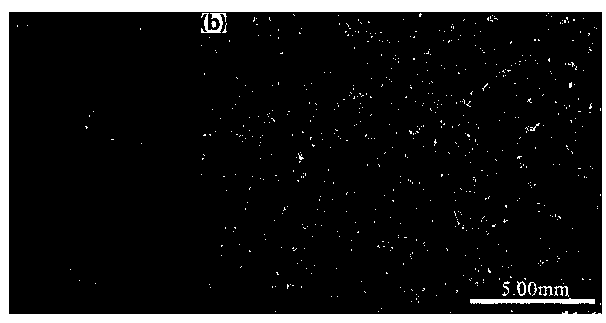

Technology for preparing small-aperture aluminum foam without viscous melt foaming method

The invention discloses a technology for preparing small-aperture aluminum foam without a viscous melt foaming method and belongs to the field of preparation of a porous metal material. The technology comprises the following steps: by taking calcium carbonate as a foaming agent, adding a pure magnesium block to melt, foaming the melt by a gas formed by reaction of Mg, Al and CaCO3. The viscosity of the melt can be improved by the oxide generated by reaction. The outgassing reaction is slow and stable, so that the problem of a thick aluminum foam structure is solved by the technology in comparison with titanium hydride as a foaming agent. The technology comprises the following concrete steps: adding the pure magnesium block to the aluminum melt; adding calcium carbonate after evenly agitating; agitating and foaming, carrying out water-cooling after keeping warm for a period of time, so as to obtain an aluminum foam sample of which the porosity is 50.0-85.0% and the mean pore size is about 1.0-2.0mm. The production technology is simplified, the production cost is reduced, and the technology is applicable to large-scale production under the condition of not needing tackifying.

Owner:HOHAI UNIV +1

Method for producing modified polyvinyl chloride and nitrile butadiene rubber composite cable material

InactiveCN101265350AExtend the mixing timeReduce investmentRubber insulatorsPlastic/resin/waxes insulatorsChemistryCalcium carbonate

The invention provides an improved production method for a polyvinyl chloride and chemigum compound cable material, which simplifies the production process, reduces the production cost and ensures the product quality. In the method, polyvinyl chloride, dicapryl phthalate, a stabilizer, a toner, calcium carbonate and chemigum are used as raw materials. The method comprises the following production steps: (1) premixing the polyvinyl chloride, the stabilizer, the toner, and the calcium carbonate in a homogenizer until the mixed temperature reaches 70 DEG C to 80 DEG C; (2) mixing the mixture at slow speed of revolution after the mixed temperature reaches 70 DEG C to 80 DEG C, and adding a liquid plasticizer (DOP); (3) mixing the mixture at slow speed of revolution so that DOP is completely absorbed when the temperature reaches 110 DEG C; (4) adding powdered chemigum, and mixing the mixture for 1 to 2 minutes at slow speed of revolution; and (5) discharging.

Owner:WUXI DONGTIAN CABLE

Antifreeze anticorrosion durable concrete and preparation method thereof

The invention discloses an antifreeze anticorrosion durable concrete. The concrete comprises the following components, by weight, 500 parts of a gelling material, 700-715 parts of medium sand, 1050 parts of broken stone, 164 parts of water and 10.56-18 parts of a water reducer, wherein the gelling material comprises 54-56wt% of cement and 44-46wt% of powder A; and the powder A comprises the following components: 30-35wt% of slag, 20-25wt% of zeolite, 35-40wt% of coal ash, 5-10wt% of long bluestone and 0-7wt% of quicklime. The invention also discloses a preparation method of the concrete. The preparation method comprises the following steps: 1, weighing raw materials of the components of the powder A according to above proportions, crushing by an ultrafine mill, and uniformly mixing; 2, weighing raw materials of the components of the concrete according to above proportions; 3, sequentially adding ordinary Portland cement, the powder A, the medium sand and the broken stone to a concrete stirring device, and stirring for 2-3min to fully and uniformly mix; and 4, slowly adding well weighed water and the well weighed water reducer to the obtained mixture while stirring, and continuously stirring for 1-2min to obtain the concrete. The concrete of the invention is high performance concrete which can resist strong sulfate corrosion, strong chloride corrosion, freeze-thaw cycles and drying and wetting cycles.

Owner:CHINA CONSTR THIRD ENG BUREAU GRP CO LTD

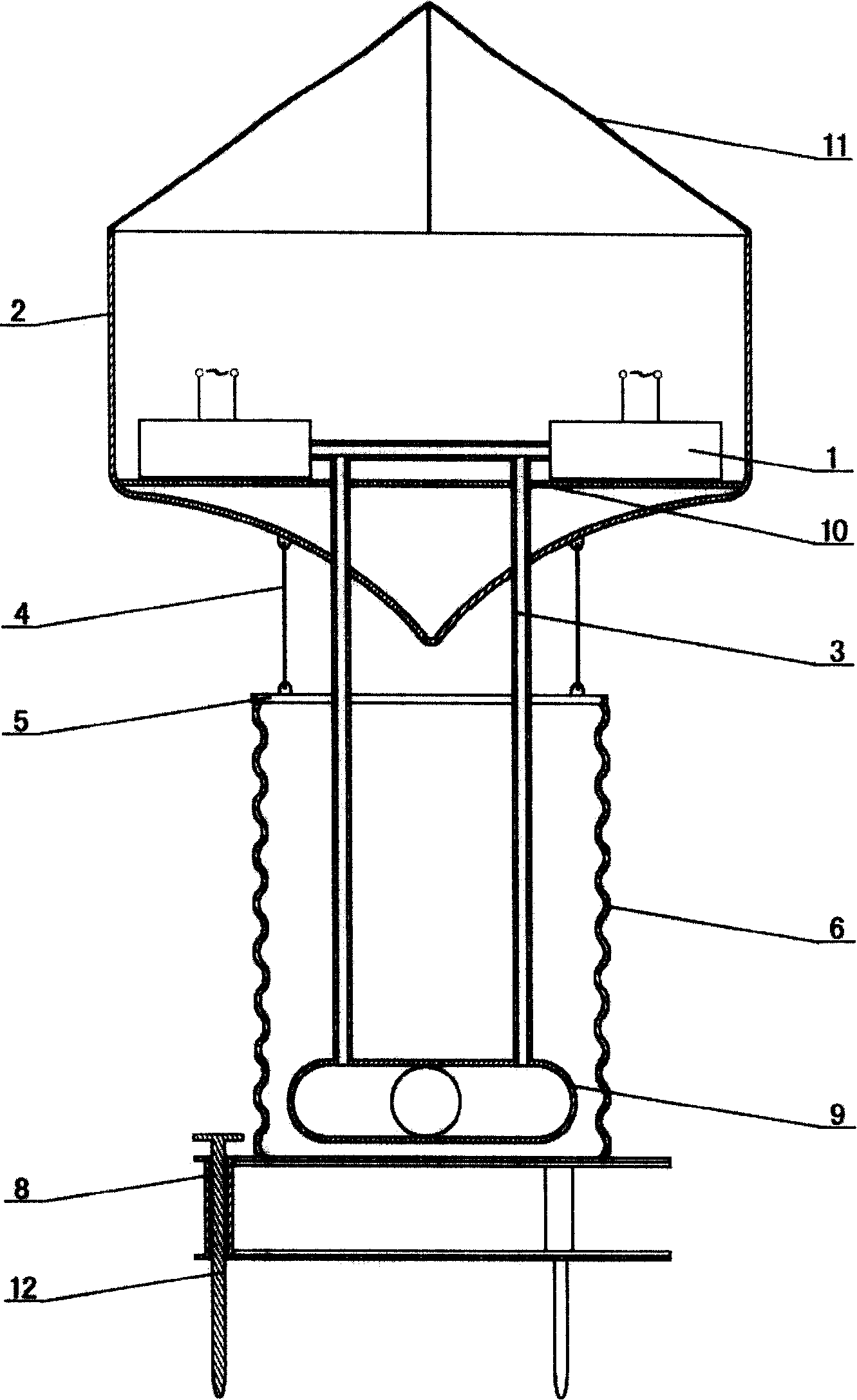

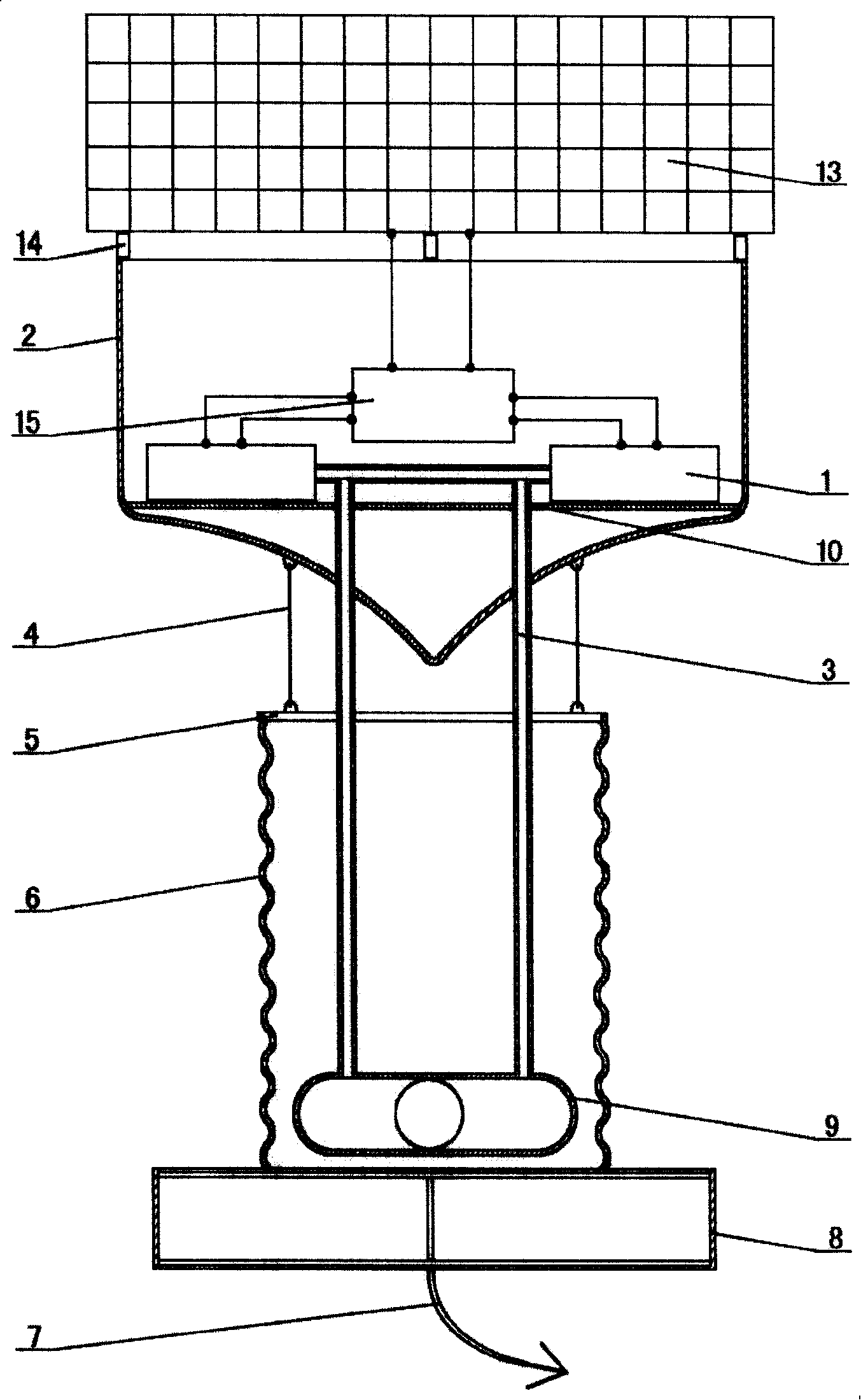

Aeration flow guiding water circulation treatment device

InactiveCN101168462AIncrease oxygenTackle eutrophicationWater aerationSustainable biological treatmentEutrophicationSludge

An aeration diversion water circulation treatment is composed of a diversion tube, an air pump, an air tube, a uniform distribution exhaust unit, a suspender, a sling, a weight diverter, and a power supply, which are connected, wherein the suspender via the sling is connected with the diversion tube of which the tail is connected with the weight diverter, one end of the air tube is connected withthe air pump while another end is connected with the uniform distribution exhaust unit suspended in the diversion tube, and the suspended depth of the exhaust unit in the diversion tube is relative to the exhaust pressure of the exhaust unit while the exhaust unit can exhaust normally, the air pump is mounted on the suspender and connected with the air tube, the space between the suspender and the diversion tube is a water outlet, the weight diverter at the bottom of the diversion tube is a water inlet. The invention can effectively improve water quality, resolve water eutrophication, degradeeutrophication sludge at water bottom, and resolve seasonal turnover problem of lake and large pool.

Owner:BEIJING HIKEEN TECH +1

Desulfurization dust removing method of industrial furnace

InactiveCN101362043AIncrease contact timeImprove dust removal efficiencyUsing liquid separation agentFlue gasLiquid water

The invention discloses a desulfurization and dust removal method for an industrial furnace, which comprises the followings steps: 1. a flue gas inlet of a desulfurization and dust removal device of the industrial furnace is communicated with a flue gas outlet of the industrial furnace; 2. cooling water is pumped into a water inlet pipe, enters a contact type cooling spraying device through a flow partitioning device, falls into a spraying area in spraying shape and then is discharged along a blowdown pipe; 3. flue gas generated from the industrial furnace enters the desulfurization and dust removal device of the industrial furnace from bottom to top from the flue gas inlet of a shell, is contacted with cooling water between a barrier cap and an annular bottom plate firstly and then with the cooling water in the spraying shape and falling down from the contact type cooling spraying device to carry out heat exchange; 4. after the heat exchange, phase change is carried out to steam so as to cause the steam to turn into liquid water drops, during the phase change, adjacent sulfur dioxide is absorbed by the water drops and adjacent minimal dust grains are adsorbed by the water drops effectively. The desulfurization and dust removal method for the industrial furnace has good dust removal effect, high desulfurization efficiency, as well as low energy consumption, low equipment investment and low operation cost.

Owner:姚立猛

Fe-Cu oxide and molecular sieve composite honeycomb-type denitration catalyst and preparation method thereof

InactiveCN107597177AEvenly dispersedSimple preparation processMolecular sieve catalystsDispersed particle separationIon exchangeHydrolysis

The invention belongs to the technical field of atmospheric pollution treatment technology and environment-friendly catalytic materials, and especially relates to a Fe-Cu oxide and molecular sieve composite honeycomb-type denitration catalyst and a preparation method thereof. In the invention, by means of the synergistic effect between Fe / Cu oxide-Fe / Cu supported molecular sieve / titanium-based supporter, the denitration activity and anti-water and -sulfur poisoning performance of the honeycomb-type denitration catalyst are improved. The catalyst is relatively low in usage amount of the high-cost molecular sieve supporter, so that the denitration catalyst is controllable in cost and is environment-friendly; because titanyl sulfate is easy to hydrolyze, during a mixing process, sulfuric acid, which is generated in hydrolysis, is reacted in situ with a Fe / Cu oxide precursor and the titanium-based supporter, so that not only is a metal ion source required in ionic exchange of the molecularsieve acquired, but also the supporter can be completely sulfated by means of the sulfuric acid generated during the hydrolysis and exchange, thereby further increasing the denitration activity of the final product of the catalyst.

Owner:VALIANT CO LTD

Concrete tube pile with fine milled slag micropowder and production me thod thereof

InactiveCN1598164AExtend the mixing timeReduce breakage rateSolid waste managementCeramic shaping apparatusCrack resistanceSlag

The invention relates to a concrete pipe pile mixed into size reduction slag miropowder, used in civil construction industry, and its production method. It includes cement, 1 (weight portion) yellow sand (1.5 to 2.9), broken stone (3.2 to 5.0), water (0.3 to 0.6), water reducing agent (0.025 to 0.045), size reduction slag miropowder (0.2 to 1). Its production method is premixing for thirty seconds, stirring with the water and the water reducing agent uniformly and poured continuously at one end of pipe pile mould, centrifugal forming, conserved. The advantages are improving its concrete intension, impermeability, crack resistance, and resistance to bending saving concrete and water and low cost.

Owner:CHINA MCC20 GRP CORP

Agricultural traveling soil turning and fertilizing integrated device

InactiveCN107969179AIncrease humidityExtend the mixing timeSpadesWatering devicesAgricultural engineeringUltimate tensile strength

The invention discloses an agricultural traveling soil turning and fertilizing integrated device which comprises a rotary blade, a lifting chamber, a bottom plate, wheels, a water tank, a cylinder body and a mixing chamber, wherein two ends of a rotating shaft of the rotary blade are rotationally connected with a supporting plate by virtue of a supporting rod; a bucket is arranged on the right side of the rotary blade and fixedly arranged at the lower end of the lifting chamber; the mixing chamber is formed in the right side of the lifting chamber; the water tank is arranged on the right sideof the mixing chamber; the right side of the water tank is fixedly connected with the cylinder body; a piston is connected into the cylinder body in a sliding manner; the lower end of the piston is fixedly connected with a push rod; the push rod penetrates through the lower end of the cylinder body and rotationally connected with a connecting rod; and the connecting rod is rotationally connected with an eccentric position of the wheels. The integrated device disclosed by the invention is novel in design, simple in structure and excellent in soil turning effect, and the fertilizer is fully mixed with soil in the soil turning process, so that the fertilization effect is improved, the labor intensity of labor personnel is lowered, and the land rearrangement efficiency is improved.

Owner:黄利伟

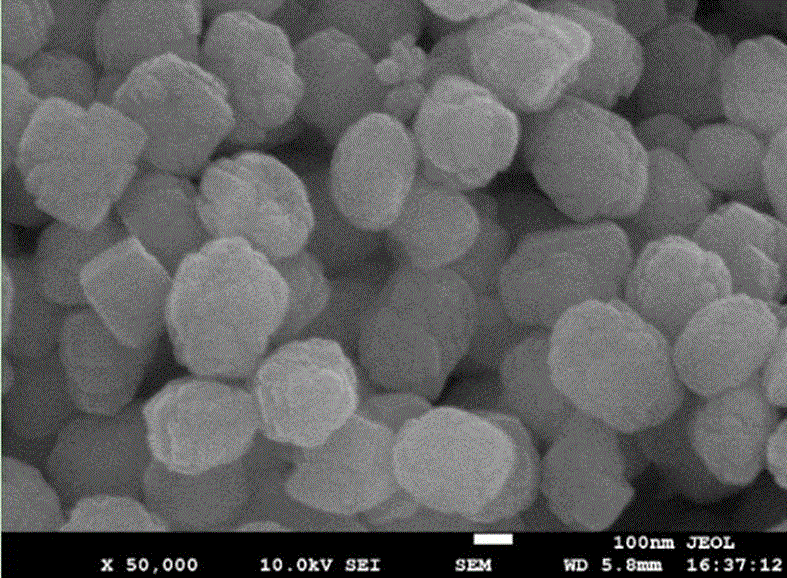

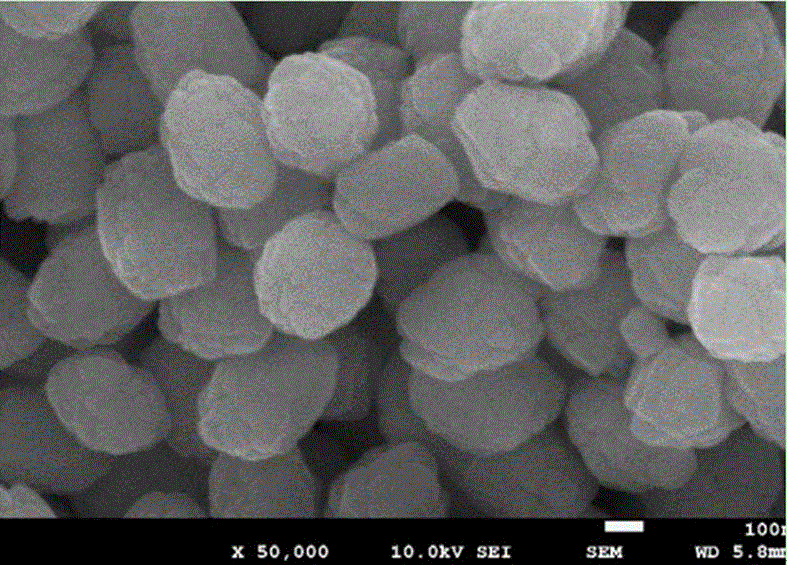

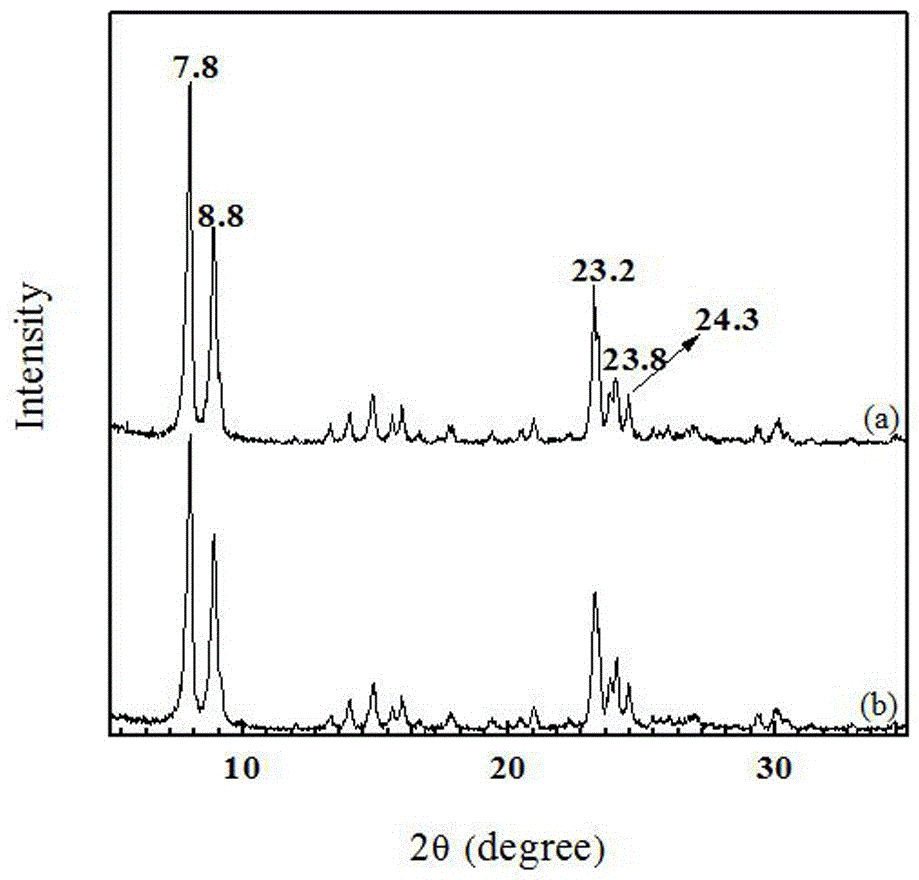

Synthetic method of TS-1 titanium silicate molecular sieve

ActiveCN106745025AThe system is well mixedShorten hydrothermal crystallization timeOrganic chemistryMolecular sieve catalystsMolecular sieveTitanium

The invention relates to a titanium silicate molecular sieve and a synthetic method thereof. The synthetic method comprises the following steps: mixing a silicon source, a titanium source, a template and water, stirring and hydrolyzing, putting the product into a hydro-thermal synthesis kettle and carrying out a pre-crystallization reaction; mixing the pre-crystallization product and a silicon source, uniformly stirring, carrying out hydro-thermal synthesis, washing and roasting to obtain the TS-1 molecular sieve. The synthesis process of the titanium silicate molecular sieve is easy to control and has good repeatability. Meanwhile, the catalyst has a higher catalytic activity, and use amount of the template is greatly reduced and synthesizing cost of the titanium silicate molecular sieve is decreased. The synthetic method of the invention is convenient for industrial production.

Owner:山西华阳集团新能股份有限公司

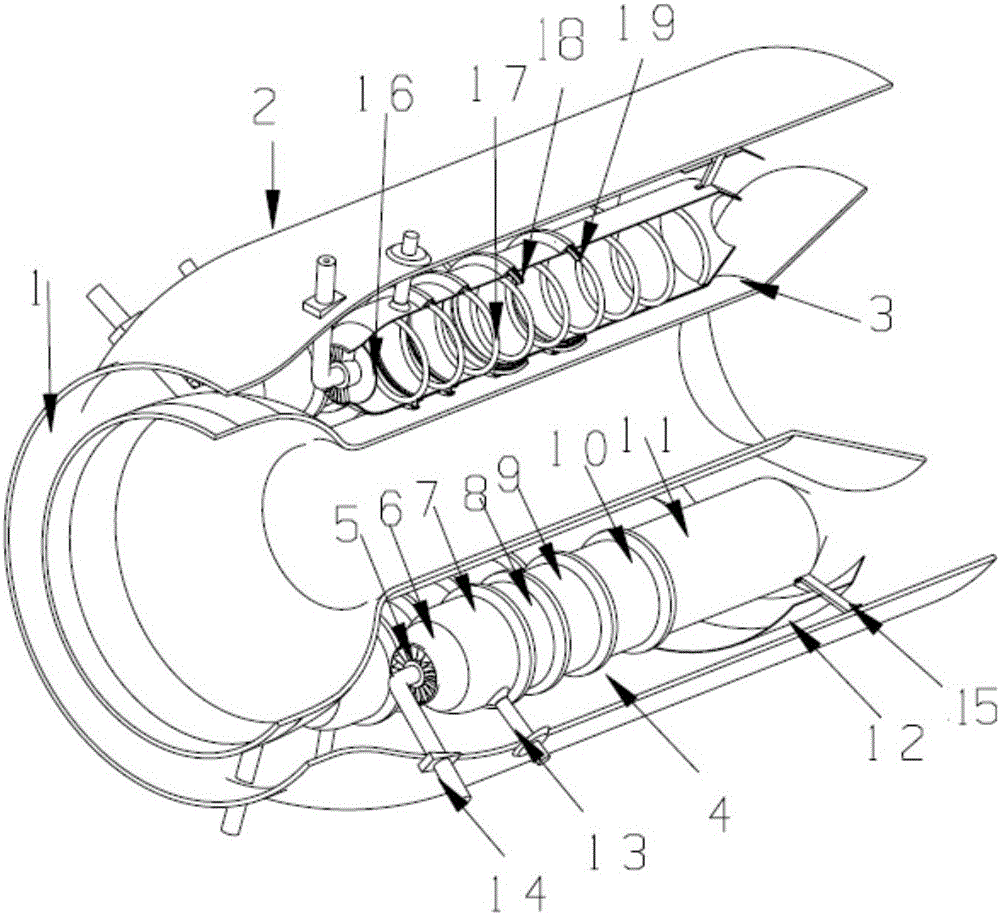

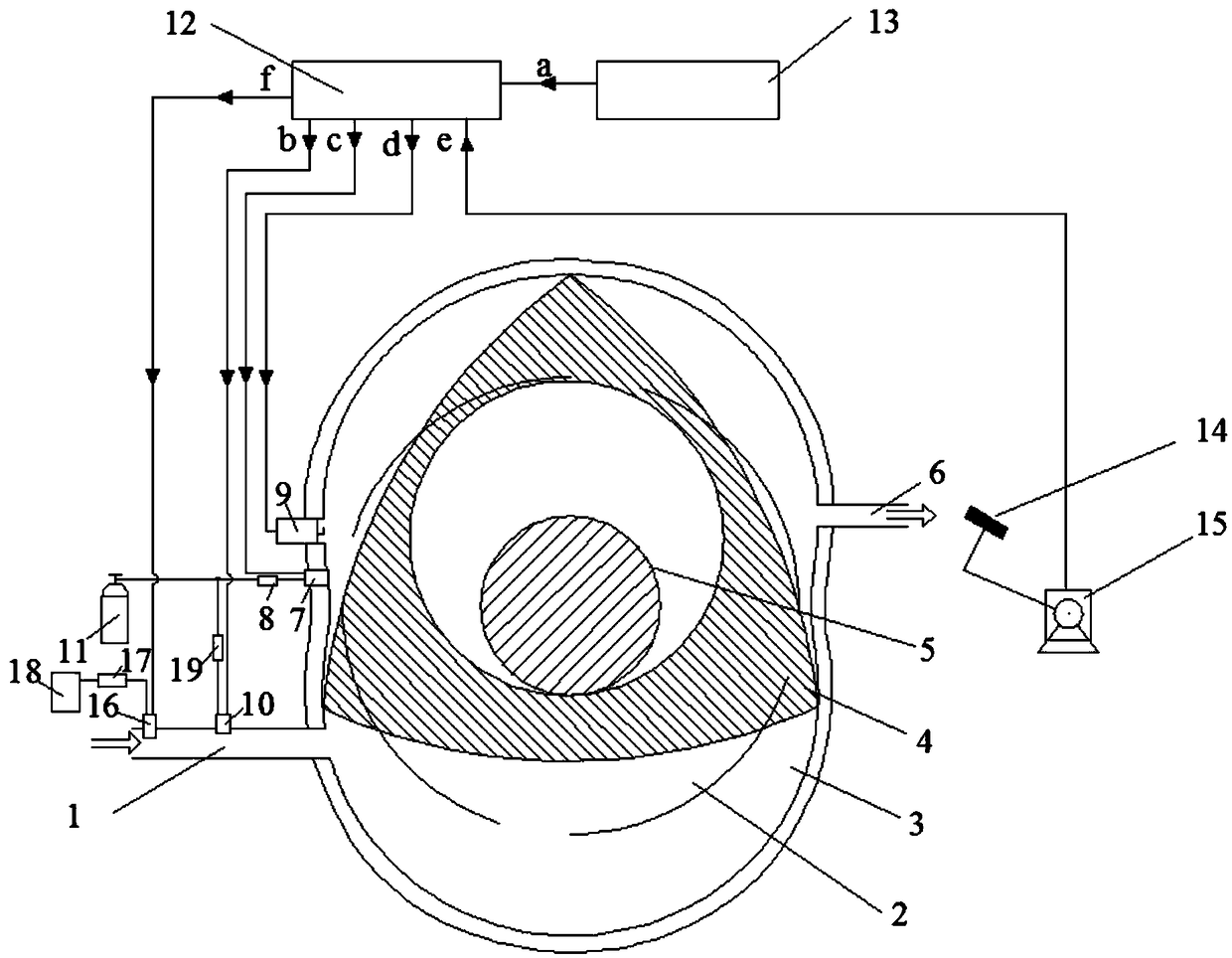

Spark ignition type oxyhydrogen gas rotor engine and control method

ActiveCN108825366AImprove efficiencyExtend the mixing timeElectrical controlInternal combustion piston enginesLubricationElectronic control unit

The invention provides a spark ignition type oxyhydrogen gas rotor engine and a control method, in particular to a pure oxyhydrogen gas spark ignition type rotor engine hydrogen and oxygen gas supplysystem and oxygen jetting and lubricating oil jetting control. According to the system, on the basis that original machine main parts are reserved, a burning electronic control unit (12), a lubricating oil spraying nozzle (16), a lubrication oil pump (17), a lubrication oil tank (18), a high pressure oxygen spraying nozzle (7) and a low pressure oxygen spraying nozzle (10) are additionally arranged. The burning electronic control unit (12) can judge the oxygen jetting manner according to needed power signals (e), an engine adopts an air passage for jetting oxygen to improve efficiency under the low power condition, and the engine adopts high pressure oxygen direct jetting to avoid fire return under the medium and high power condition. In order to solve the problem that a gas fuel rotor machine is difficult to lubricate, the burning electronic control unit can control the jetting pulse width of the lubricating oil spraying nozzle (16) according to the actual load of the engine, and efficient lubrication of the engine is guaranteed.

Owner:BEIJING UNIV OF TECH

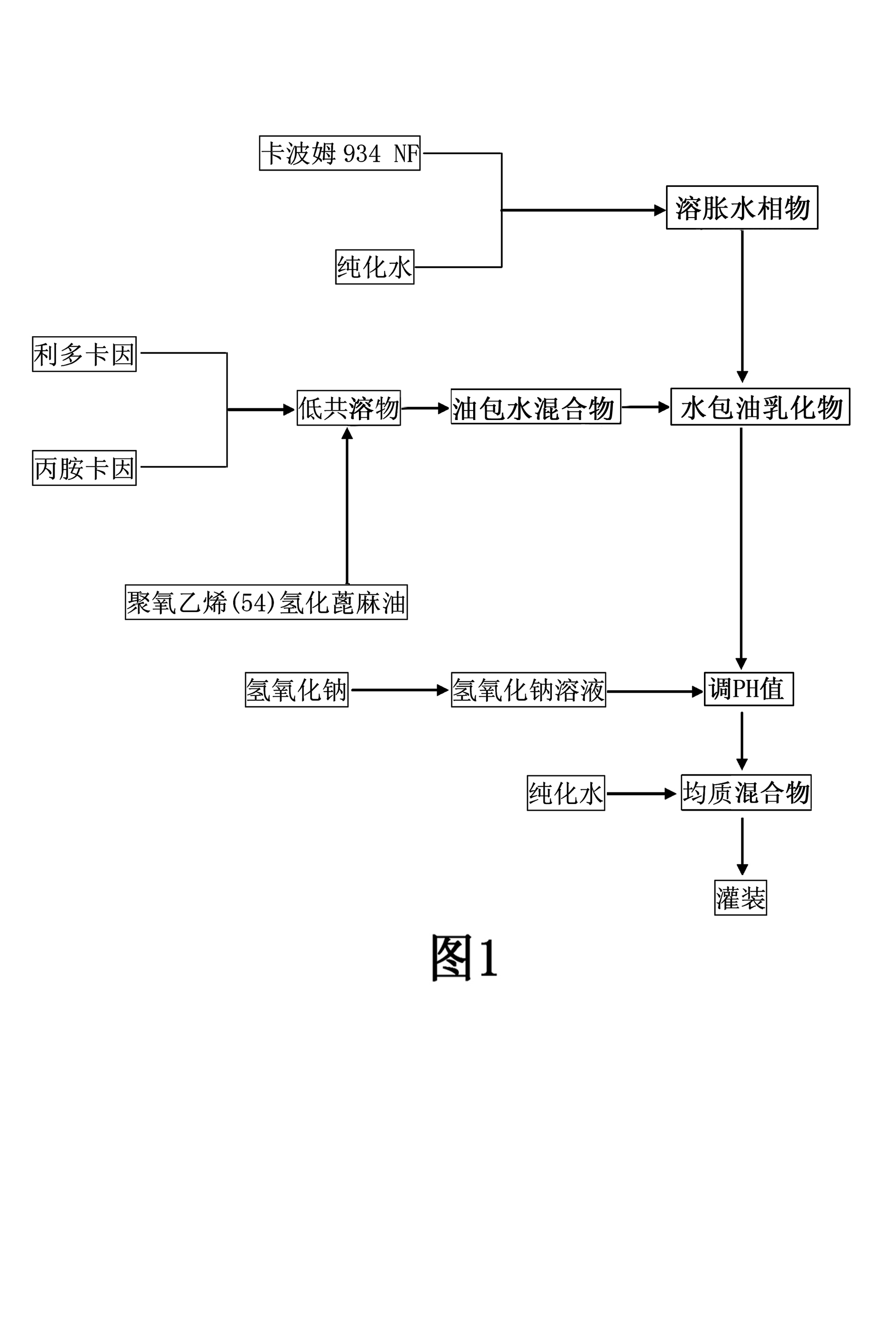

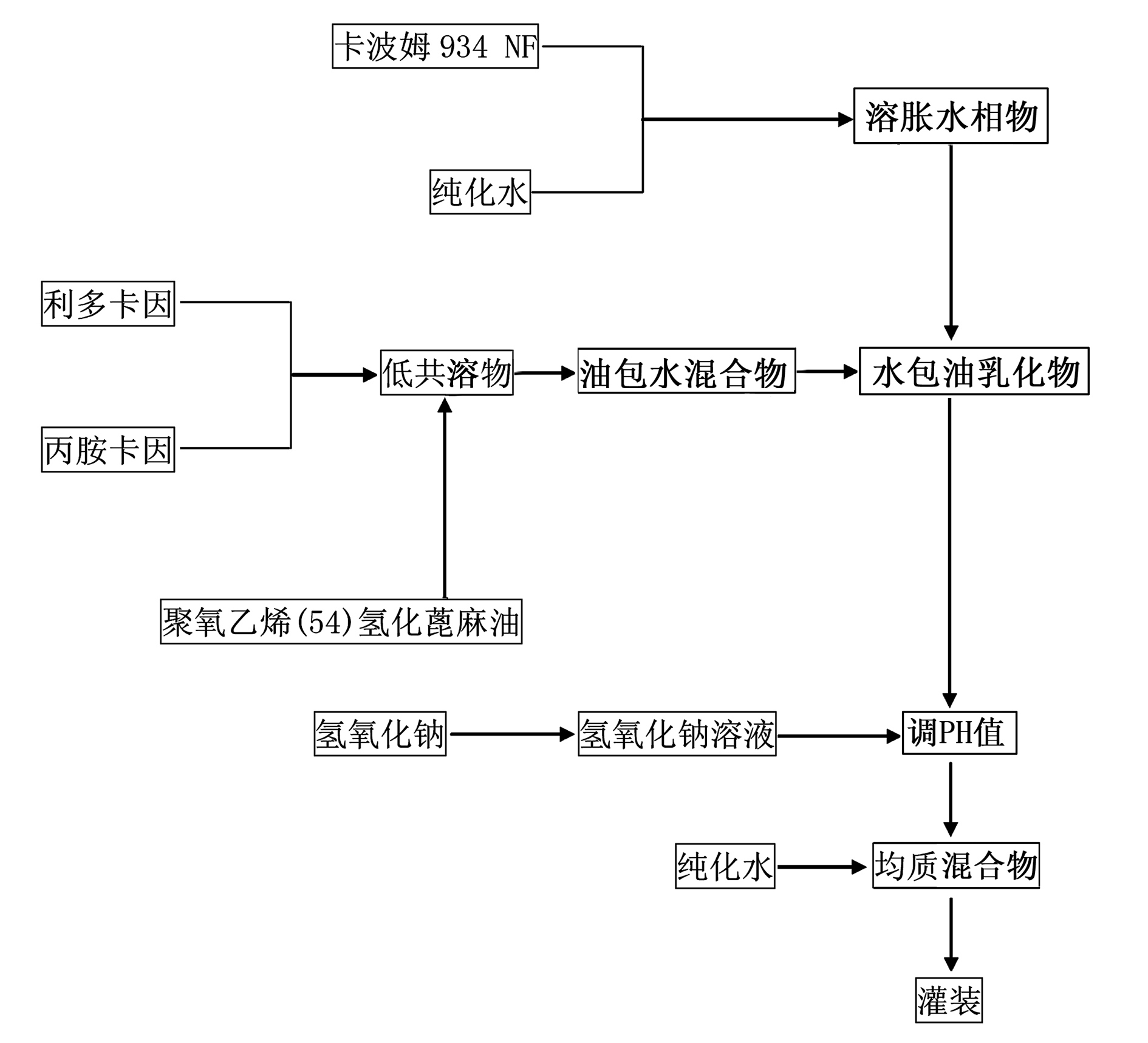

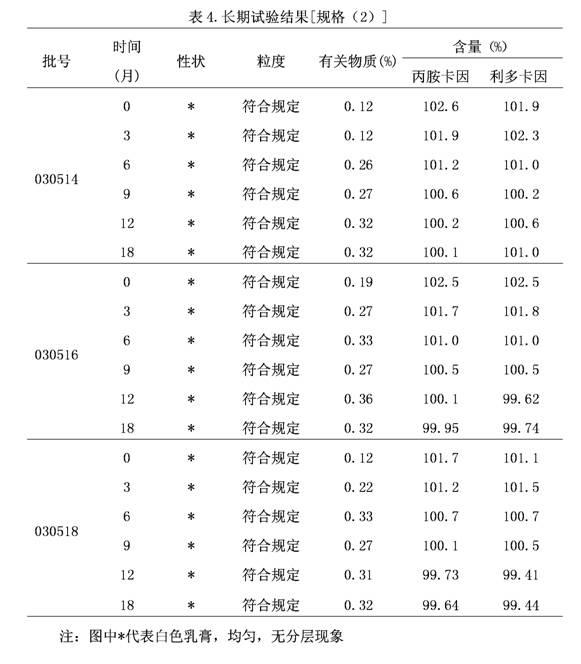

Compound lidocaine emulsifiable paste and preparation method thereof

ActiveCN101816642AAchieve anesthesiaNo corrosionAntibacterial agentsOrganic active ingredientsActive agentSurface-active agents

The invention discloses a compound lidocaine emulsifiable paste and a preparation method thereof. Each 10kg of the compound lidocaine emulsifiable paste comprises the following components according to the weight: 50-1000g of base lidocaine, 50-1000g of base prilocainum, 10-500g of polyoxyethylene hydrogenated castor oil, 10-300g of Carbomer, 40-200g of sodium hydroxide and the balance of pure water. The invention increases clinical use security through releasing lidocaine and prilocainum in base modes to the subcutaneous layer with the depth of 5mm without containing a penetrating agent or a surface active agent component, which is particularly suitable for children patients and patients for face beauty. Through improvement on production process steps, the invention enables the production operation to become easy and feasible, is easy to control the product quality and increases the product stability. The whole production cycle is only half day, and the production efficiency is improved by more than 3 times, thereby the raw materials are saved and the production cost is reduced.

Owner:北京中泰邦医药科技有限公司

Comprehensive utilization device for desulfurization and denitrification

ActiveCN105169905AIncrease concentrationImprove desulfurization efficiencyDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsHigh concentrationEngineering

The invention provides a comprehensive utilization device for desulfurization and denitrification. The device comprises an evaporator, a desulfurization and denitrification tower, an ammonia water tank, a concentration and separation tower, wherein a desulfurization chamber and a denitration chamber are arranged inside the desulfurization and denitration tower; the denitrification chamber is arranged above the desulfurization chamber; an ammonia-water atomization spray nozzle is arranged inside the desulfurization chamber; a flue gas inlet of the desulfurization and denitration tower is arranged below the ammonia-water atomization spray nozzle; an ozone and flue gas mixer is arranged inside the denitration chamber and communicates with an ozone source arranged outside of the desulfurization and denitration tower; the ozone and flue gas mixer is composed of a horizontal coil pipe and a vertical straight pipe; the horizontal coil pipe is arranged outside of the vertical straight pipe; the lower side of the horizontal coil pipe is provided with a plurality of first gas jet outlets; the inner side of the horizontal coil pipe is provided with a plurality of first cylindrical pins; the vertical straight pipe is provided with a plurality of second gas jet outlets; the outer side wall of the vertical straight pipe is provided with a plurality of second cylindrical pins; and the first gas jet outlets and the second jet outlets form a downward inclined angle a. The comprehensive utilization device provided by the invention has good desulfurization and denitrification rates, can obtain an ammonium sulfate solution with higher concentration at the same time, facilitates to production of a high-grade ammonia fertilizer, and achieves comprehensive utilization of desulfurization and denitrification of the flue gas.

Owner:SHANDONG HUANNENG DESIGN INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com