High specific energy lithium-ion power battery and preparation method thereof

A power battery and lithium-ion technology, which is applied in the field of high specific energy lithium-ion power battery and its preparation, can solve problems such as cycle life, rate, and low temperature effects, and achieve the effects of shortening mixing time, improving production efficiency, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The invention provides a preparation method of a high specific energy lithium ion power battery, comprising:

[0022] 1) Coating the positive electrode slurry on both sides of the positive electrode current collector, followed by drying, rolling, slitting, and sheeting to obtain positive electrode sheets;

[0023] 2) Coating the negative electrode slurry on both sides of the negative electrode current collector, followed by drying, rolling, slitting, and sheeting to obtain negative electrode sheets;

[0024] 3) Make the positive electrode sheet, diaphragm, and negative electrode sheet into an electrode group, then put the electrode assembly into the steel shell and roll the bottom;

[0025] 4) Inject the electrolyte into the steel case, and then cover, press and seal to make a cell;

[0026] 5) Using step current to preform the cells to produce high specific energy lithium-ion power batteries;

[0027] Wherein, the positive electrode slurry contains the positive elect...

Embodiment 1

[0054] 1) Carry out the preparation of positive plate according to the following steps:

[0055] a. Weigh the following solid raw materials according to the mass fraction ratio: modified NCM811 96.4%, SP 1.0%, graphene 0.6%, PVDF 5130 2.0%, and put each solid raw material in a vacuum oven at 120°C, and mix the materials for 240min. Vacuum degree≤-0.08MPa; then weigh the organic solvent N-methylpyrrolidone NMP whose mass fraction is 2 / 3 of the sum of the mass of the above four raw materials.

[0056] b, join modified NCM811, Super-P, graphene, PVDF 5130 in the vacuum mixer, the vacuum mixer rotates at 900RPM and stirs for 60min; then adds 60% by weight of organic solvent NMP, the vacuum mixer rotates at 1500RPM and stirs for 90min, and the stirring temperature is controlled at Below 50°C; then add 30% by weight of organic solvent NMP, the vacuum mixer rotates at 1500RPM and stir for 90min, and the stirring temperature is controlled below 50°C; finally add the remaining 10% by w...

Embodiment 2

[0077] Prepare a high specific energy lithium-ion power battery according to the method of Example 1, the difference is that the components and mass ratio of the positive electrode slurry material are: modified NCM811 96.0%, SP 1.0%, graphene 1.0%, PVDF 5130 2.0% , the components and mass ratio of the negative electrode slurry material are: modified silicon-carbon composite material 95.0%, SP 0.5%, KS 0.5%, PAA 2.0%, styrene-butadiene rubber 2.0%; the compacted density of the positive electrode plate is 3.37g / cm 3 , surface density is 240.6g / cm 2 ; The compacted density of the negative electrode sheet is 1.58g / cm 3 , surface density is 68.7g / cm 2 .

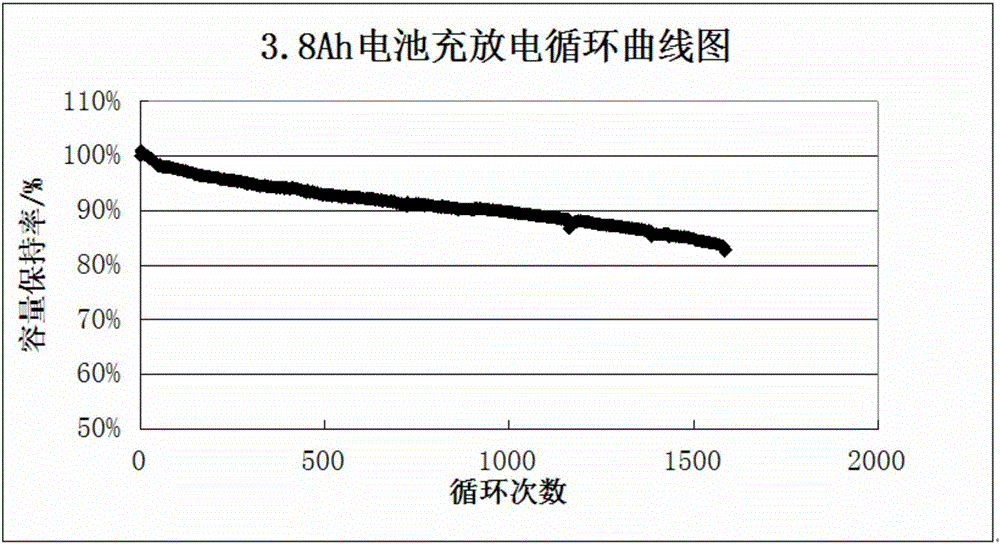

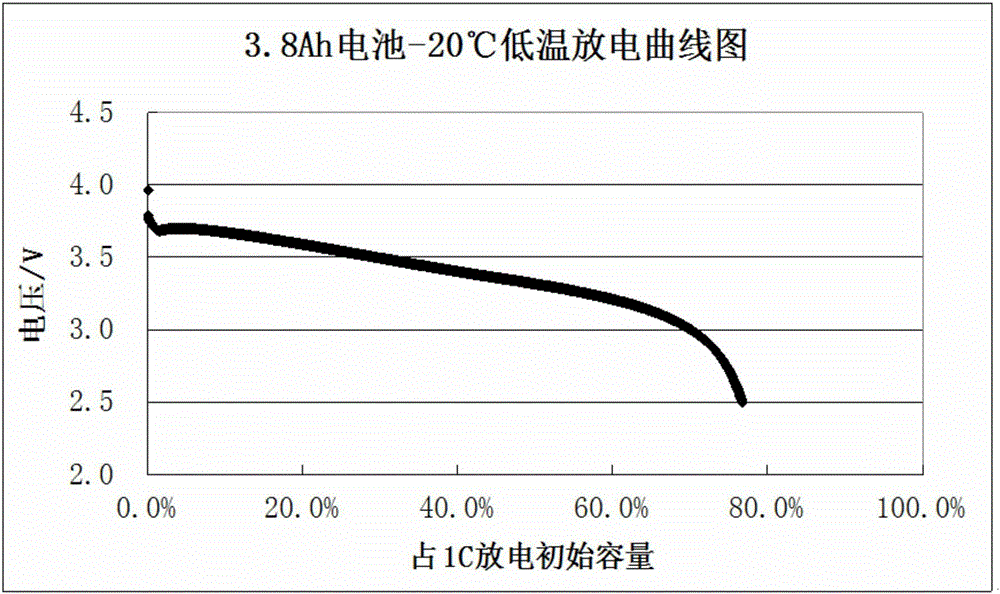

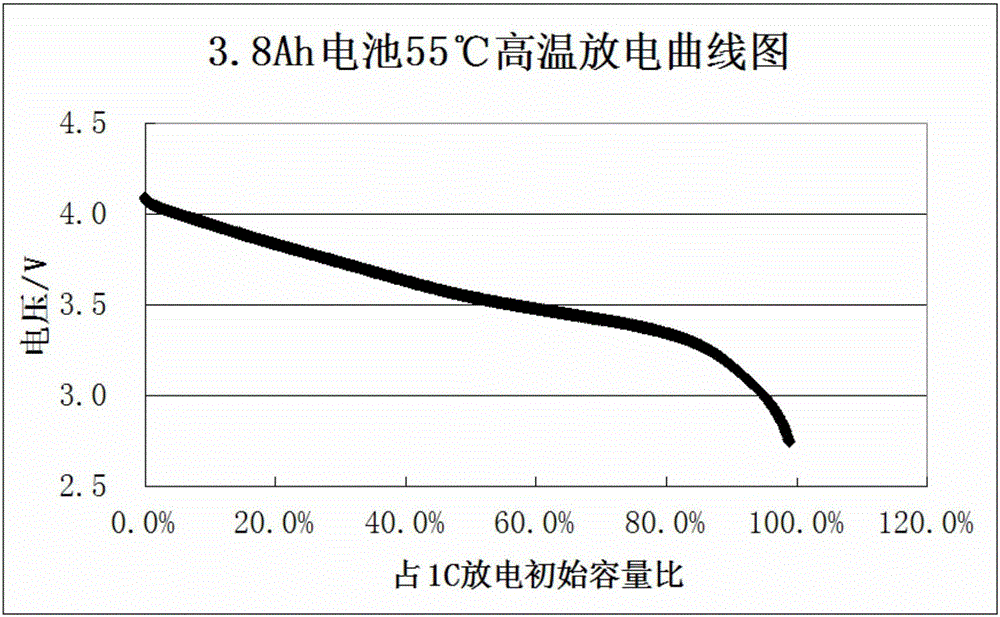

[0078] The test shows that the battery prepared in this case meets the following properties: the battery capacity is 3.8Ah, the weight is 46.70g, and the specific energy is 301.1Wh / kg. At the same time, the battery prepared in this case also has the following properties: cycle life ≥ 1500 times, -20°C low-temperature discharg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram capacity | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com