Preparation method of high-efficiency lithium-ion battery slurry

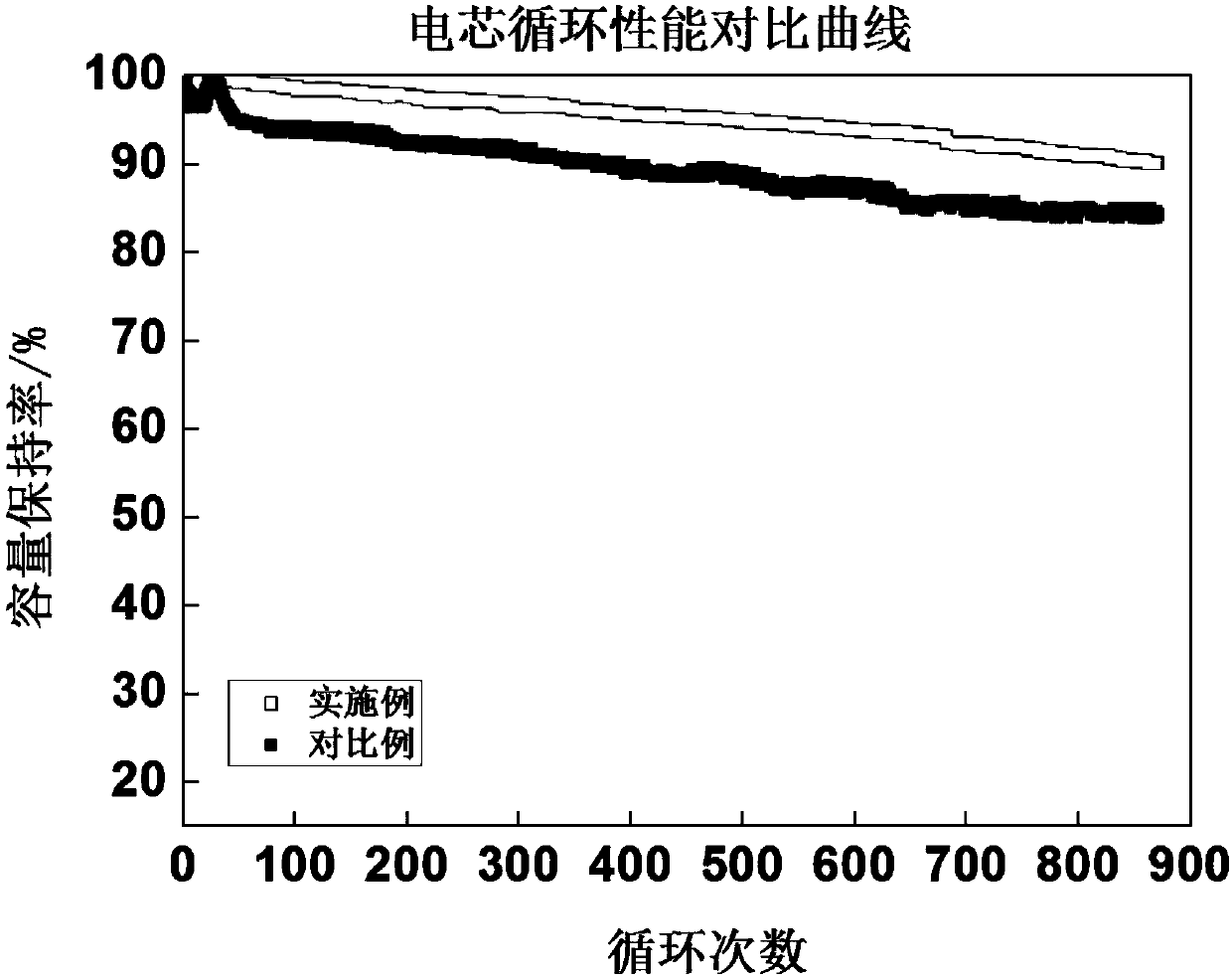

A lithium-ion battery and slurry technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of high comprehensive cost, many process steps, and low production efficiency, achieve good magnification and cycle performance, reduce process steps, The effect of shortening the mixing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

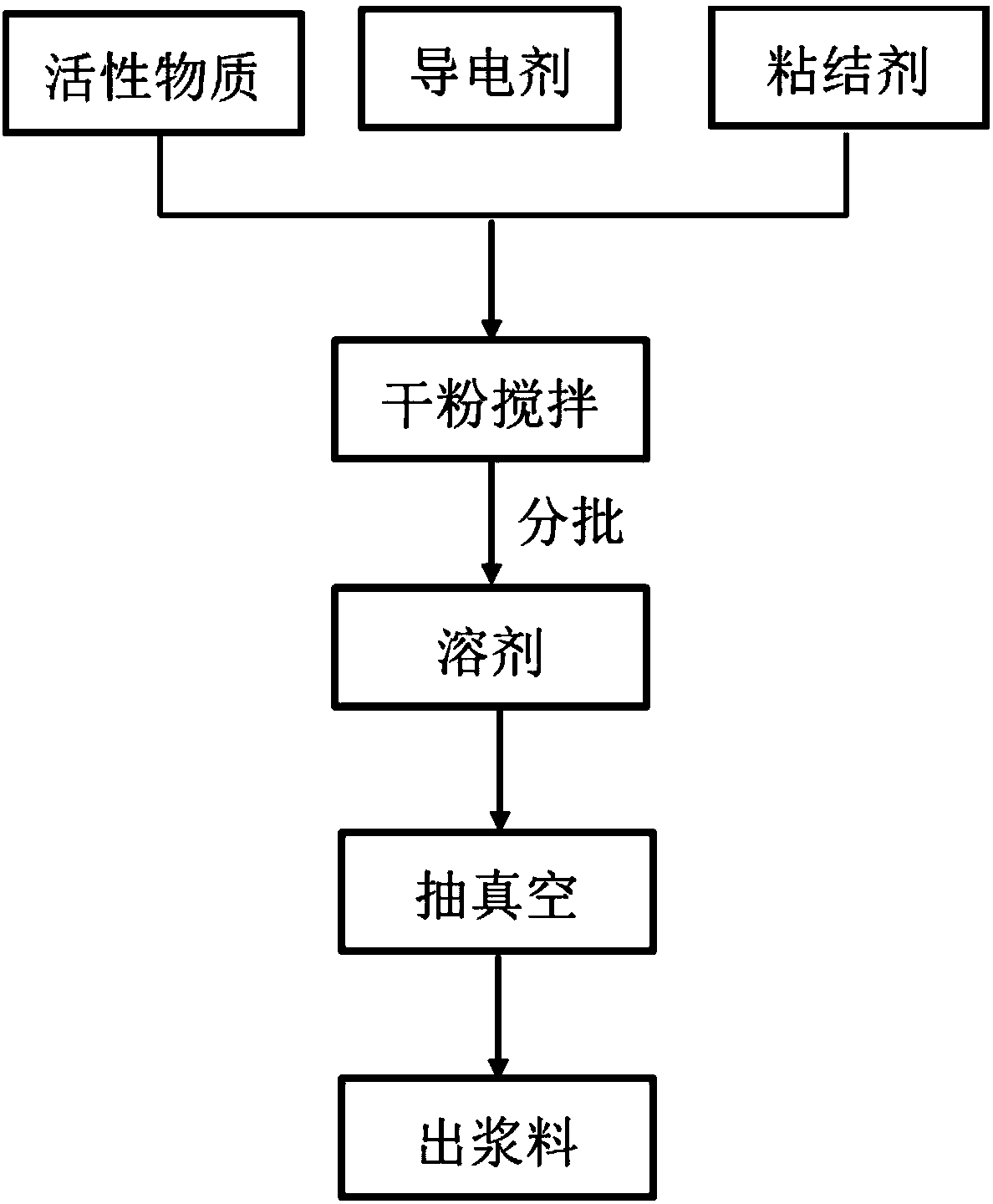

[0025] This embodiment provides a kind of preparation method of high-efficiency lithium-ion battery slurry, and its technological process is as follows figure 1 As shown, it specifically includes the following steps: add 950g of nickel-cobalt-manganese ternary material, 15g of conductive carbon black, 20g of conductive graphite and 15g of polyvinylidene fluoride into a 5L stirring tank, stir slowly for 30min without vacuum, and rotate at a speed of 10r / min , the rotation speed is 500r / min; then add 62.5g N-methylpyrrolidone and stir slowly for 10min, the revolution speed is 10r / min, the rotation speed is 500r / min, scrape the slurry on the stirring paddle into the stirring tank, and vacuumize to -90KPa, Adjust the revolution speed to 30r / min, the autorotation speed to 1500r / min, and stir for 30min; then add 200g of N-methylpyrrolidone and stir slowly for 10min, the revolution speed to 10r / min, the autorotation speed to 500r / min, and scrape the slurry on the stirring paddle Put ...

Embodiment 2

[0027] This embodiment provides a kind of preparation method of high-efficiency lithium-ion battery slurry, and its technological process is as follows figure 1 As shown, it specifically includes the following steps: add 950g of nickel-cobalt-manganese ternary material, 15g of conductive carbon black, 20g of conductive graphite and 15g of polyvinylidene fluoride into a 5L stirring tank, stir slowly for 30min without vacuum, and rotate at a speed of 10r / min , the rotation speed is 500r / min; then add 112.5g N-methylpyrrolidone and stir slowly for 10min, the revolution speed is 10r / min, the rotation speed is 500r / min, scrape the slurry on the stirring paddle into the stirring tank, and evacuate to -90KPa, Adjust the revolution speed to 30r / min, the autorotation speed to 1500r / min, and stir for 60min; then add 250g N-methylpyrrolidone and stir slowly for 10min, the revolution speed to 10r / min, the autorotation speed to 500r / min, and scrape the slurry on the stirring paddle Put it ...

Embodiment 3

[0029] This embodiment provides a kind of preparation method of high-efficiency lithium-ion battery slurry, and its technological process is as follows figure 1 As shown, it specifically includes the following steps: add 950g of nickel-cobalt-manganese ternary material, 15g of conductive carbon black, 20g of conductive graphite and 15g of polyvinylidene fluoride into a 5L stirring tank, stir slowly for 30min without vacuum, and rotate at a speed of 10r / min , the rotation speed is 500r / min; then add 162.5g N-methylpyrrolidone and stir slowly for 10min, the revolution speed is 10r / min, the rotation speed is 500r / min, scrape the slurry on the stirring paddle into the stirring tank, and evacuate to -90KPa, Adjust the revolution speed to 30r / min, the autorotation speed to 1500r / min, and stir for 90min; then add 300g of N-methylpyrrolidone and stir slowly for 10min, the revolution speed to 10r / min, the autorotation speed to 500r / min, and scrape the slurry on the stirring paddle Put ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com