Lithium iron phosphate-modified conductive carbon black composite electrode material preparation method

A technology of conductive carbon black and lithium iron phosphate, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as poor stability of lithium iron phosphate batches, large specific surface area of materials, and difficulty in controlling the distribution of carbon sources

Active Publication Date: 2013-10-02

HENGDIAN GRP DMEGC MAGNETICS CO LTD

View PDF5 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The use of organic pyrolysis products can obtain nanometer-level thickness and cover dense carbon sources, which can greatly improve the conductivity of the material, but the disadvantage is that the cracking products are not uniform, which easily leads to poor stability of the synthesized lithium iron phosphate batches; in addition The porous carbon produced by pyrolysis will lead to a large specific surface area of the material, which is not conducive to the preparation of battery slurry; using inorganic carbon sources such as carbon black, conductive graphite, graphene, etc., because the amount of carbon source added can reach 10wt% of the synthetic product, so It can greatly improve the rate performance of the material, but the disadvantage is that the inorganic carbon source has poor hydrophilicity, it is difficult to disperse in polar solvent water, the distribution of carbon source is difficult to control, and the addition of too much carbon source will lead to a decrease in the specific capacity of the synthesized product

For this reason, in order to obtain lithium iron phosphate materials with high capacity, good rate performance and good cycle stability, the inventors chemically modified the inorganic carbon source to make it easy to disperse in the water solvent, so that adding a small amount of carbon source can Greatly improve the conductivity of the material, and there is no related report in the industry about similar practices

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

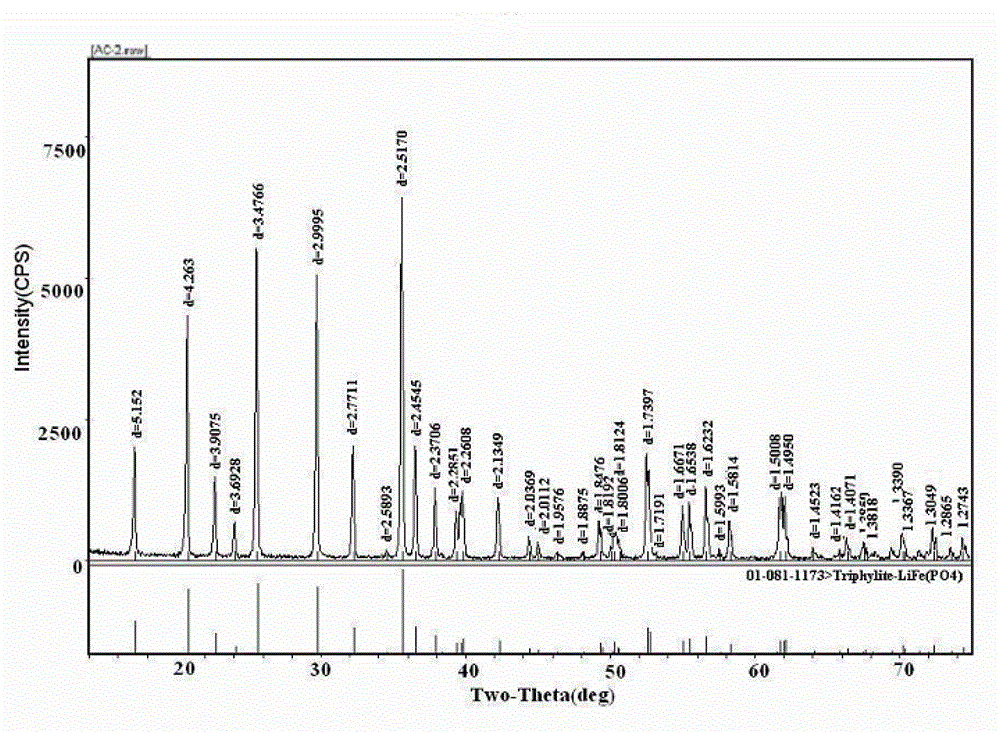

Embodiment 1

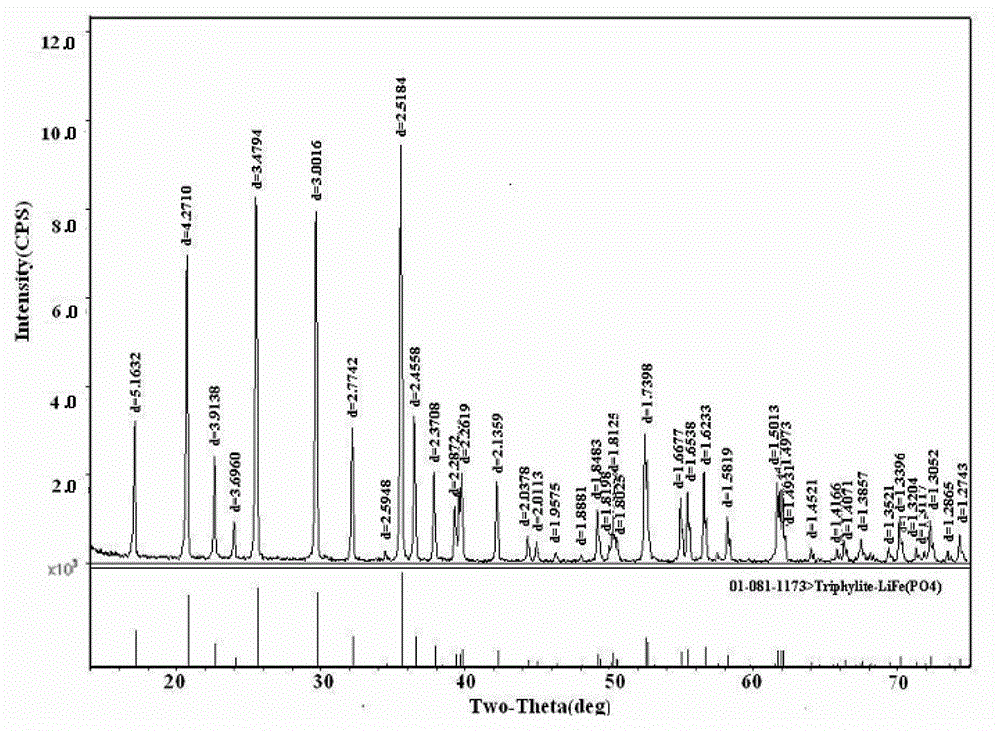

Embodiment 2

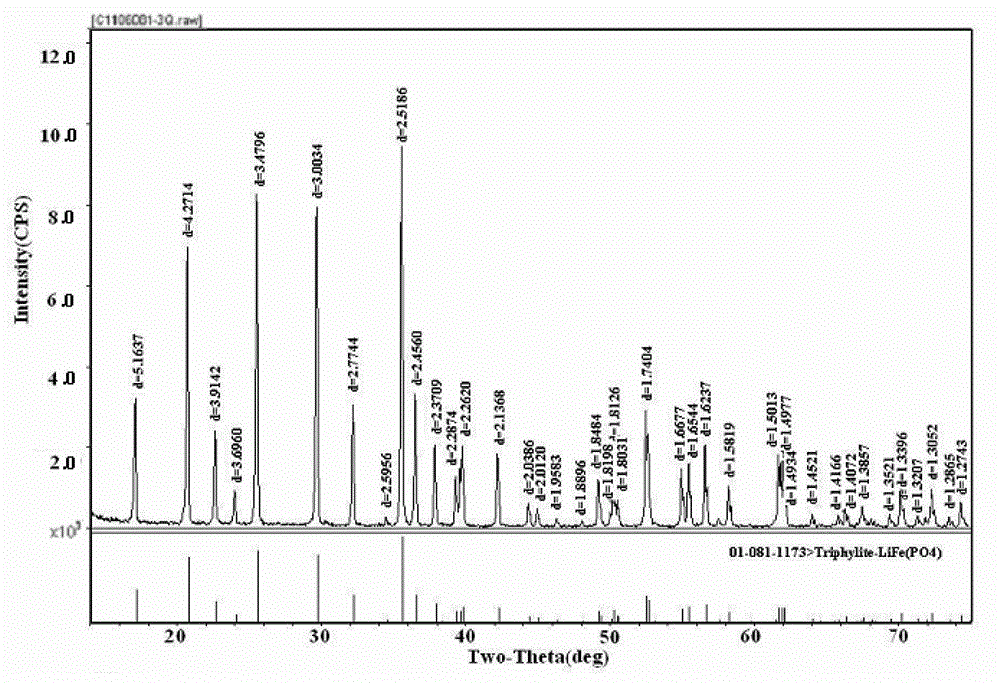

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to the fields of energy storage technology and power battery material technology, and specifically relates to a lithium iron phosphate-modified conductive carbon black composite electrode material preparation method. The preparation method comprises (1) a step of subjecting common conductive carbon black to annealing treatment, and then performing oxidation treatment in a strong oxidant to prepare the modified conductive carbon black; and (2) a step of preparing the lithium iron phosphate-modified conductive carbon black composite electrode material. According to the invention, by addition of modified SP which is easily dispersed, the composite electrode material prepared by the invention has small specific surface, thus facilitating battery preparation.

Description

technical field The invention relates to the technical field of energy storage and power battery materials, in particular to a preparation method of a novel lithium iron phosphate-modified conductive carbon black composite electrode material with high capacity, excellent rate performance and high cycle stability. Background technique Electrode materials with electrochemical activity can be used in the production and manufacture of batteries. Among them, the positive electrode materials of lithium ion batteries include lithium cobalt oxide, lithium nickel oxide, spinel lithium manganate, ternary nickel cobalt lithium manganate, etc. Among them, lithium cobaltate is commonly used in small lithium-ion batteries, but the use of cobalt is expensive and unstable under high current and overcharge conditions, which is very unsafe; the crystal structure of lithium nickelate is less stable and safe, and manganese The cycle performance of lithium oxide is poor, especially under high te...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01M4/58

CPCY02E60/10

Inventor 朱伟徐琛陈文洪程大洋周晓栋陆伟强包大新

Owner HENGDIAN GRP DMEGC MAGNETICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com