Patents

Literature

60results about How to "Smaller than surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation process for large pore volume and light bulk density activated alumina

InactiveCN102730724AChange the stacking methodFine grainAluminium oxides/hydroxidesWater vaporSodium aluminate

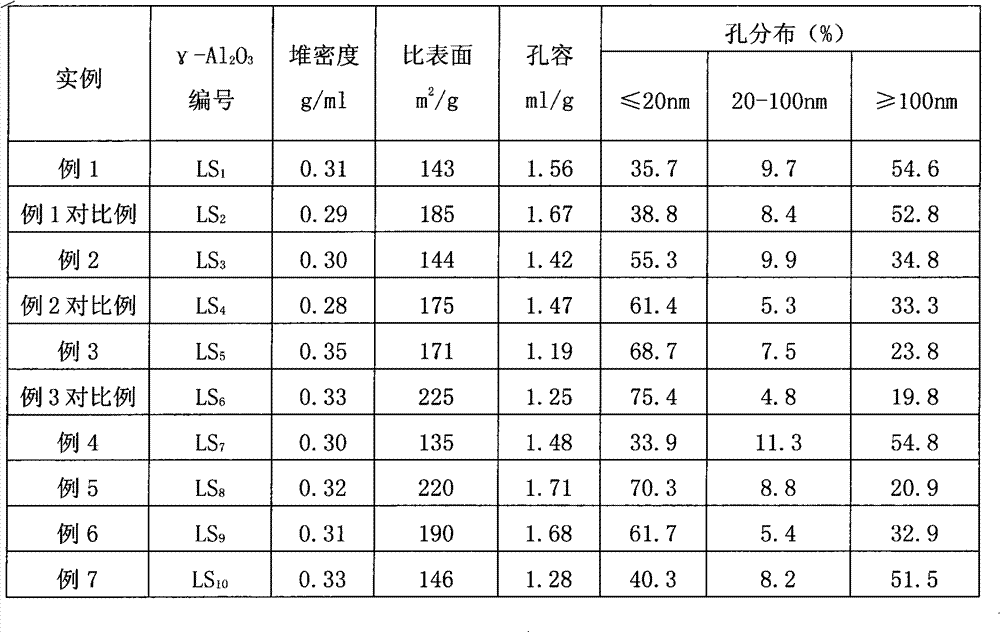

The invention relates to a preparation process for large pore volume and light bulk density activated alumina, and belongs to the technical field of activated alumina preparation. According to the process, an aluminum sulfate solution and a sodium aluminate solution form a glue in a stainless steel neutralization kettle through a continuous co-current flow method; then an aging treatment is performed for a certain time in a stainless steel aging washing tank; the resulting material is pressed to a plate and frame filter press with a material pressing pump to carry out continuous washing to prepare primary pseudo-boehmite particles with large grains; the removed filter cake is acidified, and proper amounts of a pore expanding agent and a surfactant are added during the acidification process to carry out forming; the formed wet balls are placed in a drying box to carry out drying; and the dried small balls are loaded into a calcination activation furnace to carry out high temperature calcination and pore expanding. The process of the present invention has characteristics of low cost and low equipment corrosion, can performs continuous washing cycle, and has advantages of low wastewater discharging, less pollution, and the like. With the process of the present invention, the production cycle can be reduced, the labor intensity can be reduced, and various performance indicators of the prepared gamma-Al2O3 can meet the international advanced level after pore expanding by water vapor.

Owner:JIANGSU JINGJING NEW MATERIALS

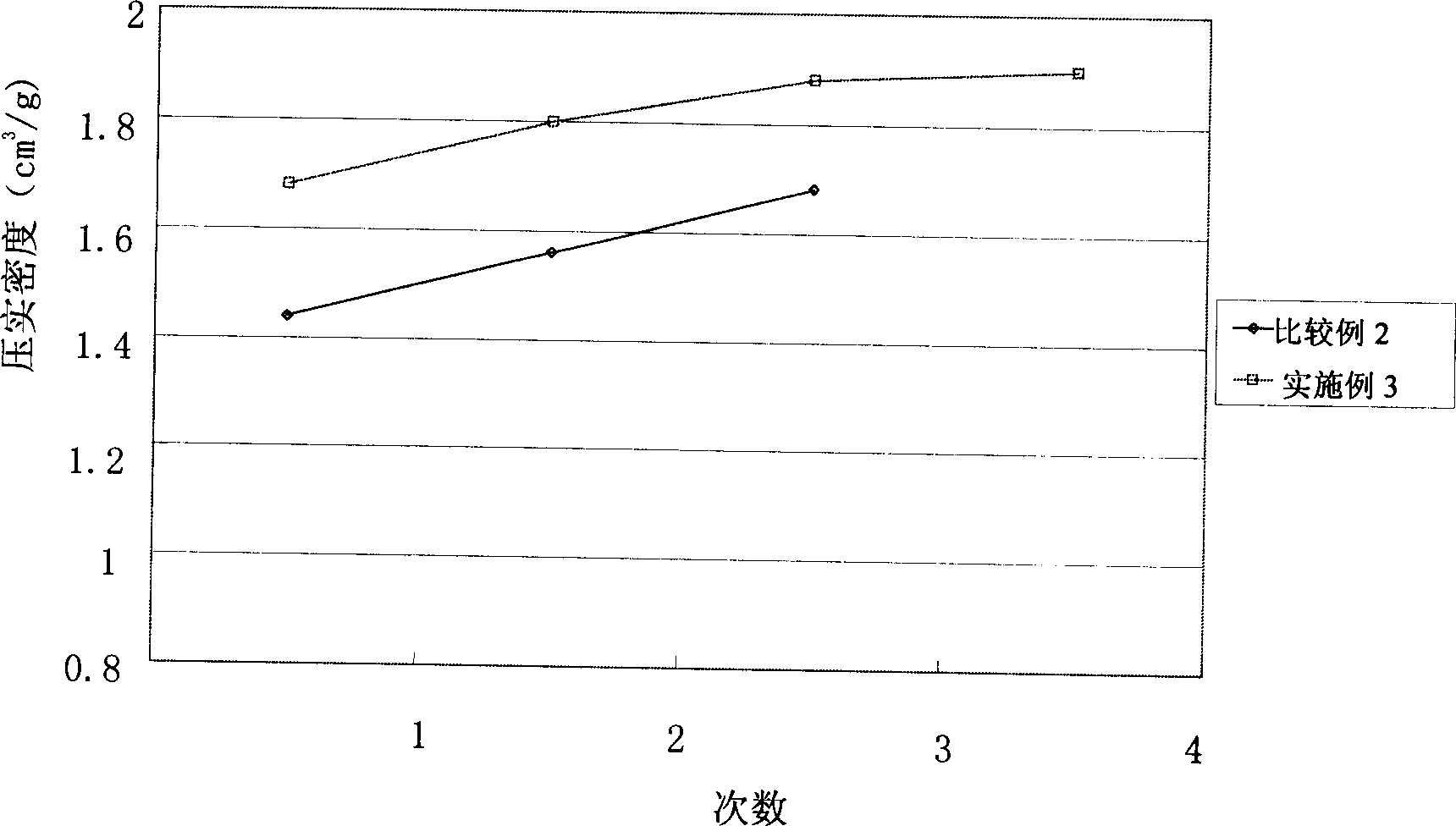

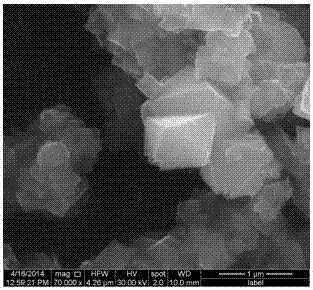

High-voltage and single-crystal ternary positive electrode material and preparation method thereof

InactiveCN107293744AEasy transferImprove cycle lifeCell electrodesHigh temperature storageChemical synthesis

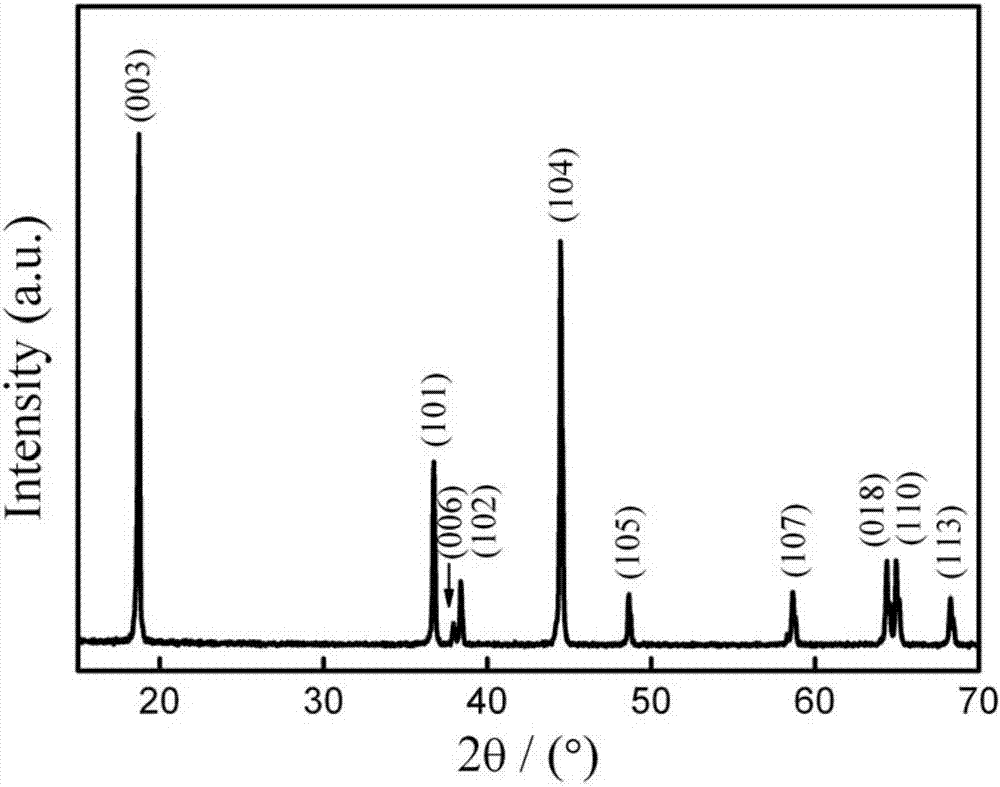

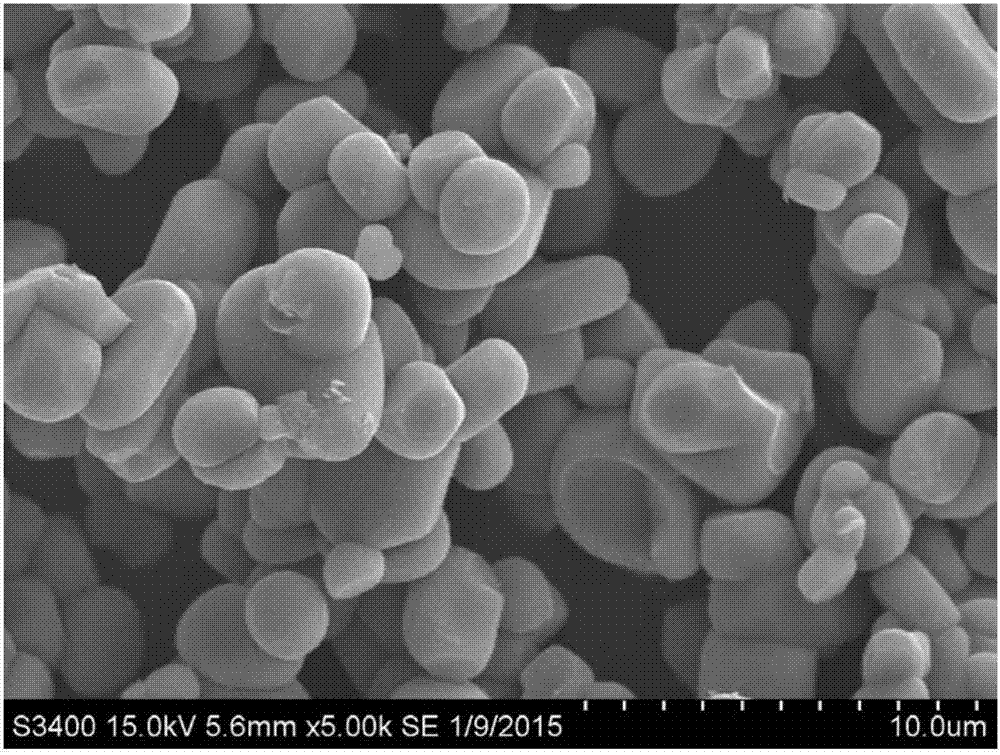

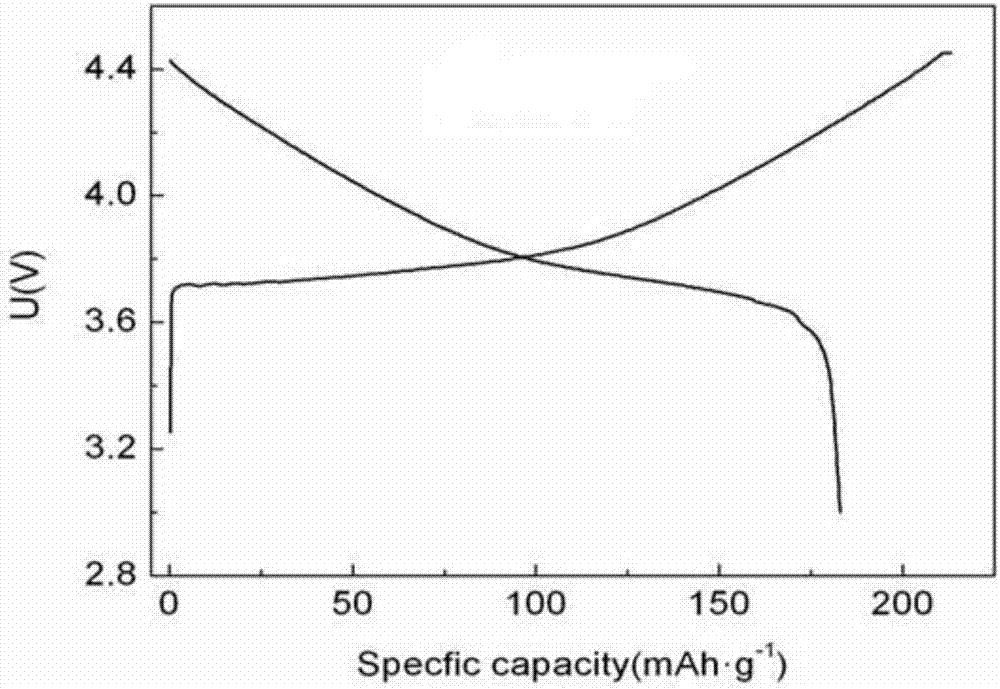

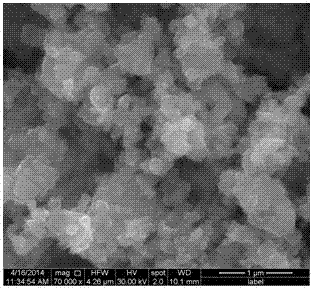

The invention discloses a high-voltage and single-crystal ternary positive electrode material and preparation method thereof. The general formula of the material can be expressed with Li<x>Ni<1-m-n>Co<m>Mn<n>O2, wherein x is more than 0.96 but less than 1.12, m is more than 0 but less than 1, n is more than 0 but less than 1, and (m+n) is less than 1. The preparation method comprises the steps of preparing a precursor by taking a nickel salt, a cobalt salt and a manganese salt as raw materials and by employing a co-precipitation method or a chemical synthesis method, mixing the precursor with a lithium source, adding a modifying agent into the mixture after pre-processing, and performing sintering, smashing and sieving after uniform mixing to obtain the high-voltage and single-crystal ternary positive electrode material. The grain size of the prepared high-voltage and single-crystal ternary positive electrode material is 2-15 micrometers, and the compaction density reaches 3.8-3.9g / cm<3>; meanwhile, the surface of the ternary positive electrode material is modified by a wet process to package Al, the material structure is stabilized, and side reaction of the material and an electrolyte is prevented; and according to actual detection, the cycle property, the high-temperature storage performance and the safety performance of the lithium ion battery under high voltages of 4.4V and 4.5V are effectively improved.

Owner:HENAN KELONG NEW ENERGY CO LTD

Nano-scale metal fluoride catalyst with domain-limited structure as well as preparation method and application thereof

ActiveCN109772379AHighly ordered and dispersedStrong resistance to sinteringPreparation by hydrogen halide split-offCatalyst activation/preparationSolventChemical industry

The invention discloses a nano-scale metal fluoride catalyst with a domain-limited structure as well as a preparation method and application thereof. The preparation process of the catalyst is as follows: under the presence of a mineralizer, carrying out crystallization reaction on a metal salt and an organic ligand in a solvent to prepare a MOF material, carrying out calcination carbonization treatment on the MOF material under an inert atmosphere to obtain a carbon-doped metal composite material, the , carrying out calcination and decarbonization on the carbon-doped metal composite materialin an oxidizing atmosphere to obtain a nano-scale carbon-doped metal composite material with a limited-domain structure, and carrying out gas-phase fluorination treatment on the composite material ina fluorination atmosphere for so as to obtain the nano-scale metal fluoride catalyst with the limited-domain structure. The metal active components in the catalyst are dispersed in an atomic level inthe carbon-based material, so that the catalyst has strong sintering resistance, and has the characteristics of strong anti-deposition carbon and the like; the unique structural characteristics of thecatalyst show good catalytic activity in the field of fluorine chemical industry.

Owner:ZHEJIANG UNIV OF TECH

Charcoal negative electrode material and its preparation method

ActiveCN1909269AImprove structural stabilitySmaller than surfaceCell electrodesGraphiteElectrode material

Owner:福建杉杉科技有限公司

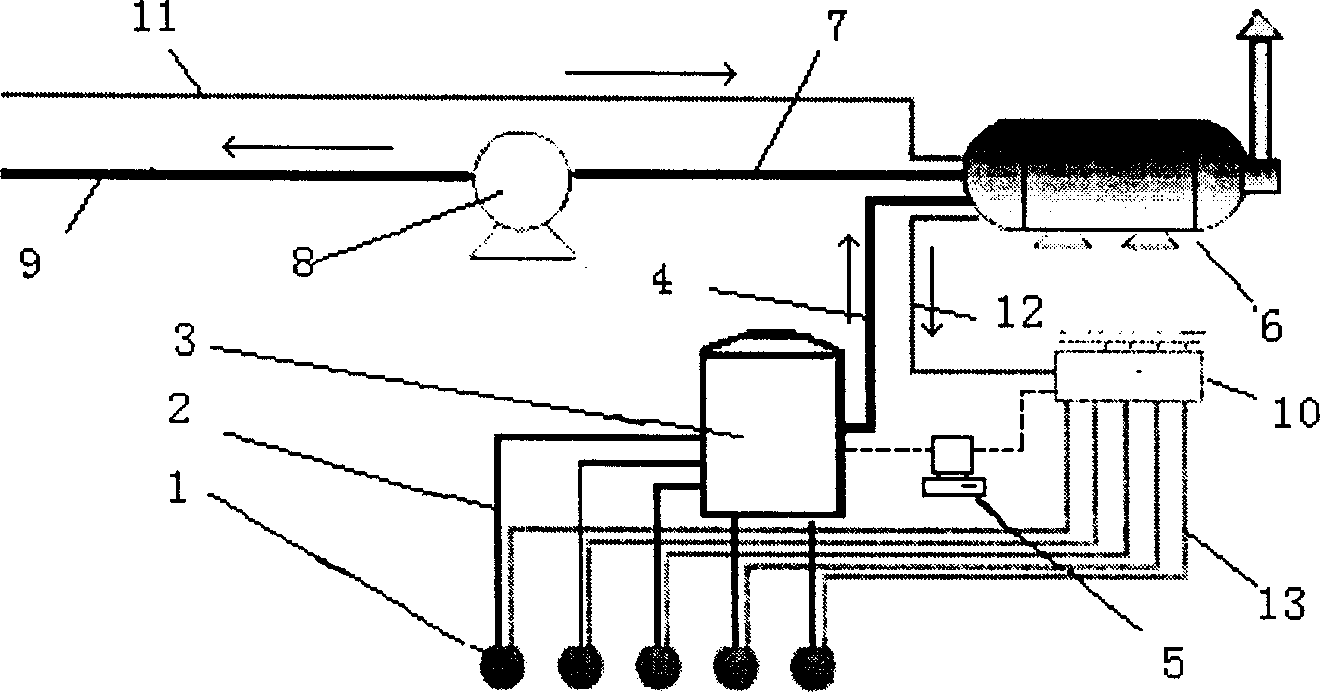

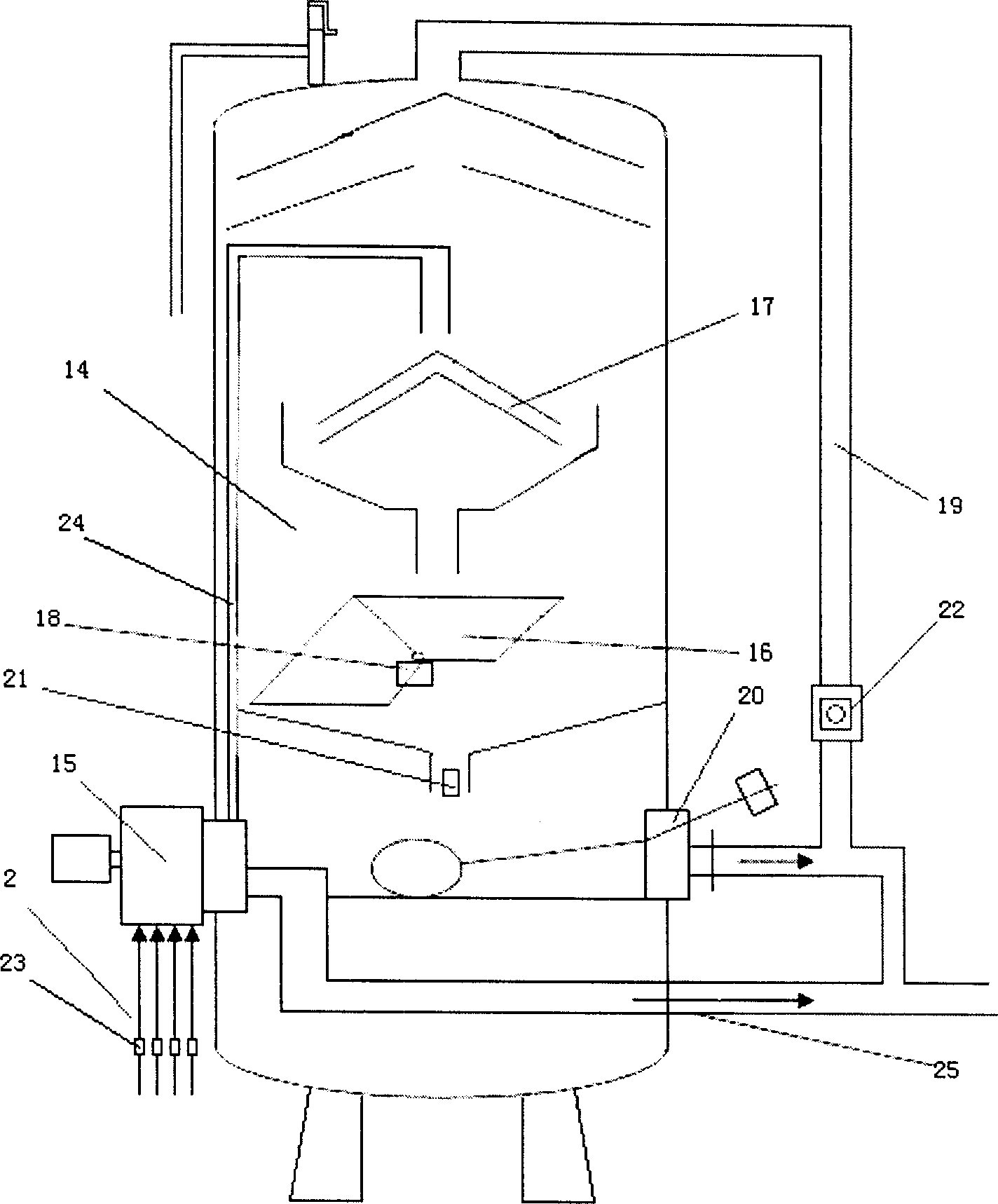

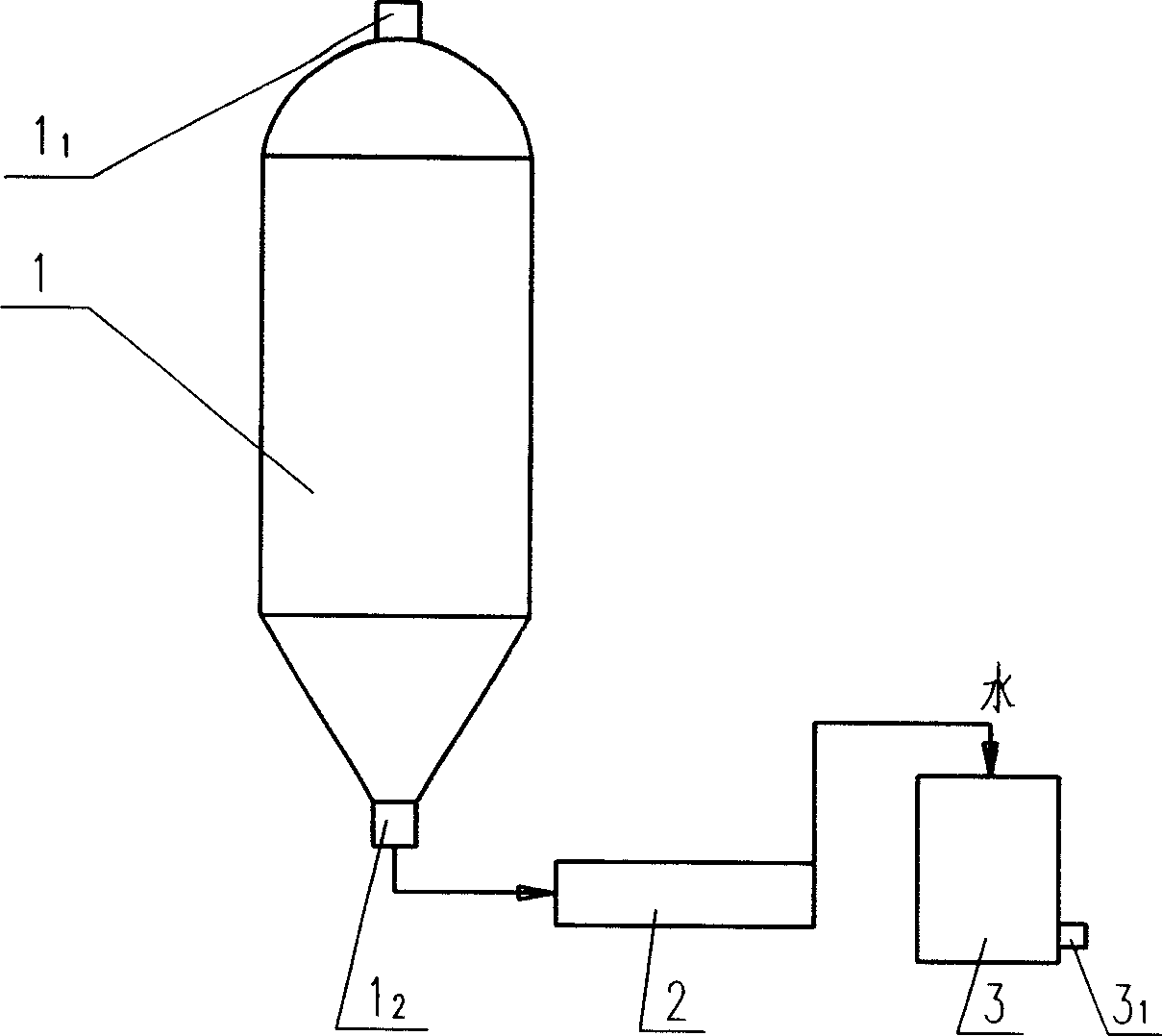

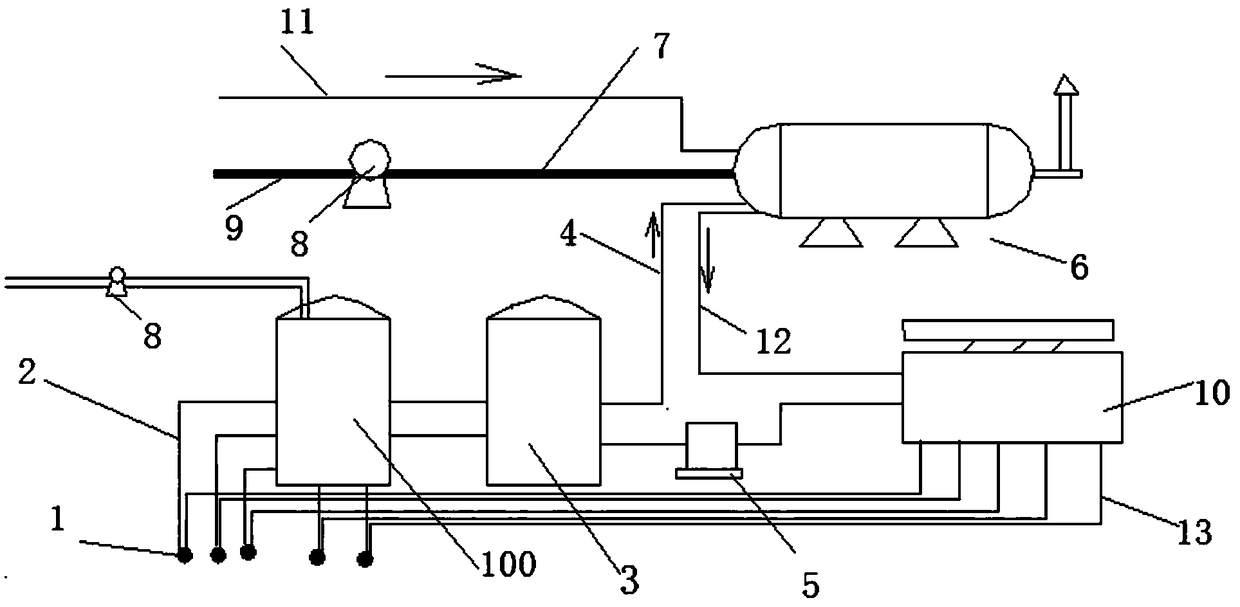

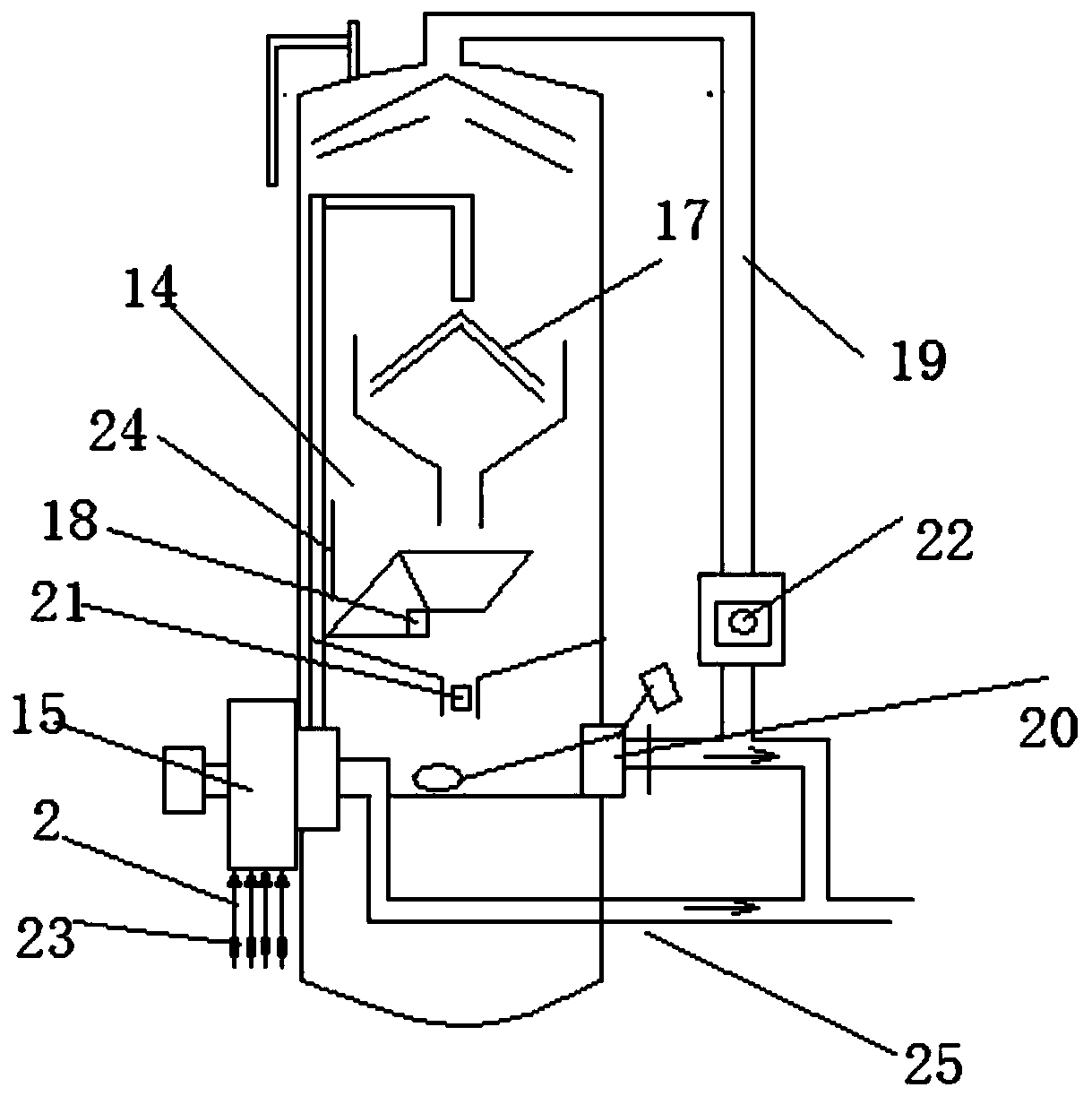

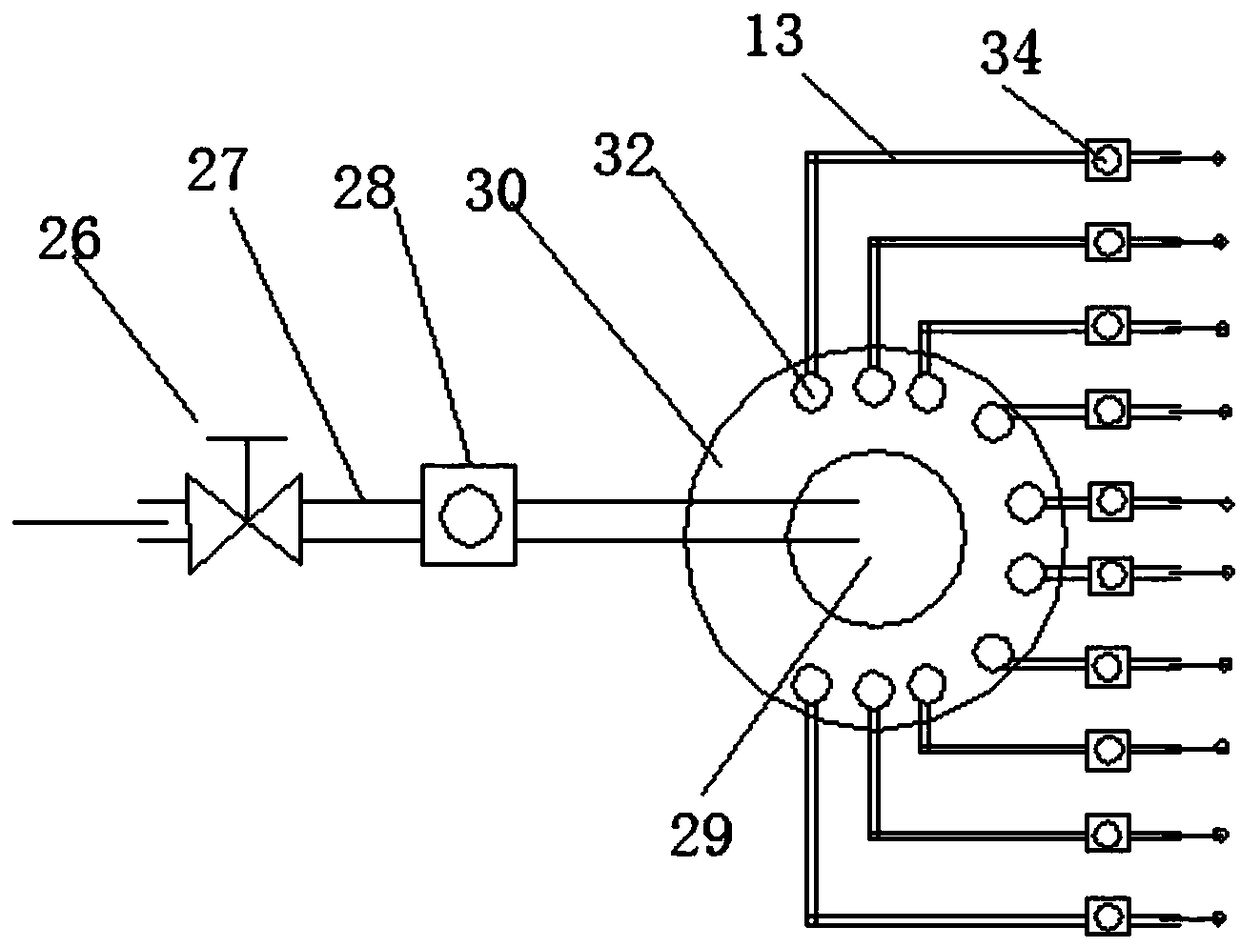

Overground gathering and transporting system for petroleum exploitation and method thereof

InactiveCN1828009ARealize automatic dosingImplement gas-liquid direct transmissionSurveyFluid removalPetroleumOil well

The invention relates to an oil exploitation ground transmission system and relative method, belonging to the oil exploitation technique. Said invention can measure the oil well, add liquid into oil well, heat the oil well and mixed transmit the oil gas. And said invention comprises four parts as aforementioned functions. Wherein, the oil well measuring part uses a liquid automatic measurer, which comprises a skip measurer, an automatic oil well switcher and a transmission tube. The invention uses industry computer to realize said functions, with high automatic degree, high practicability, and unmanned management.

Owner:岳玉全 +1

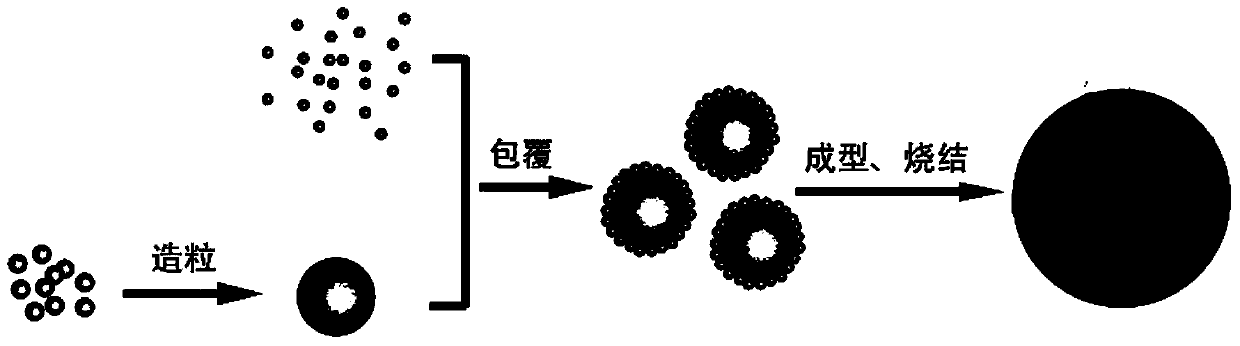

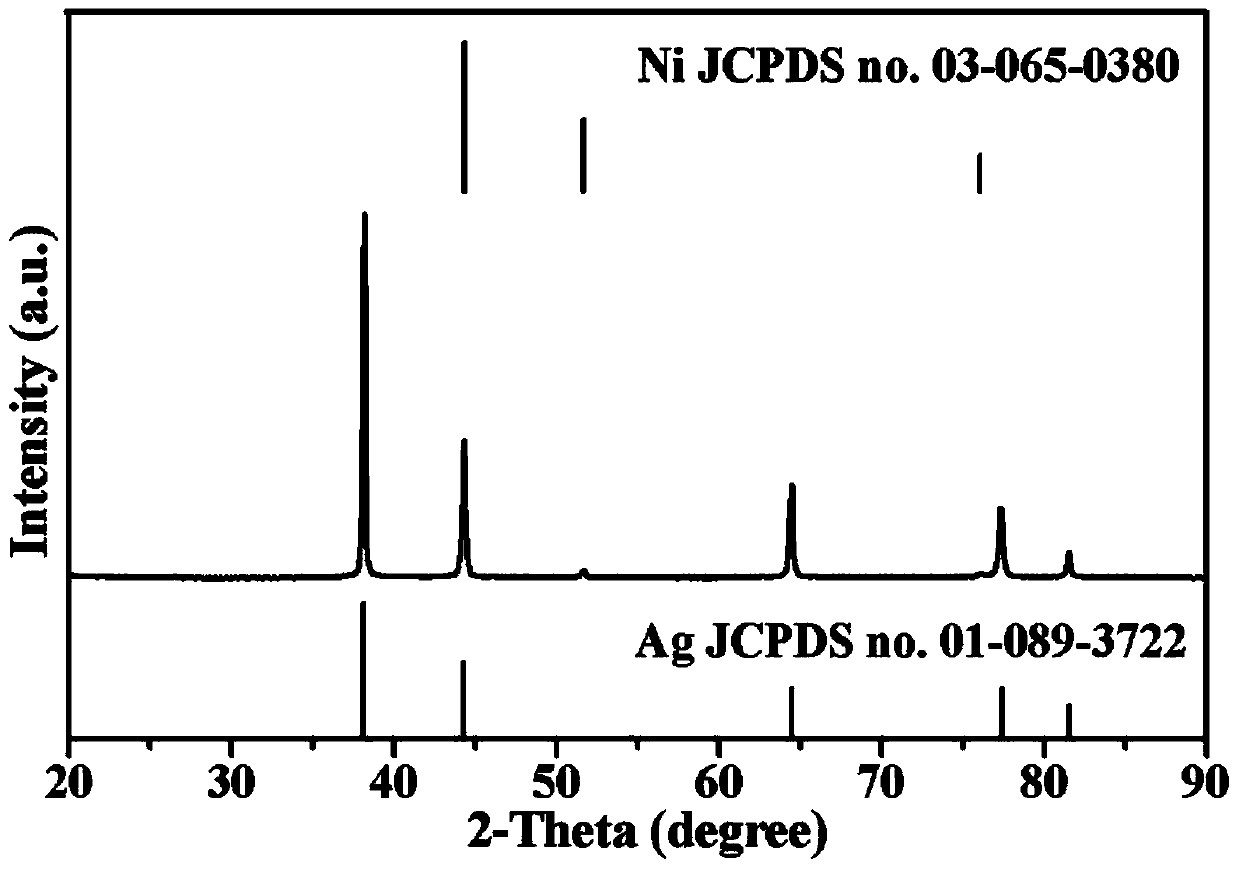

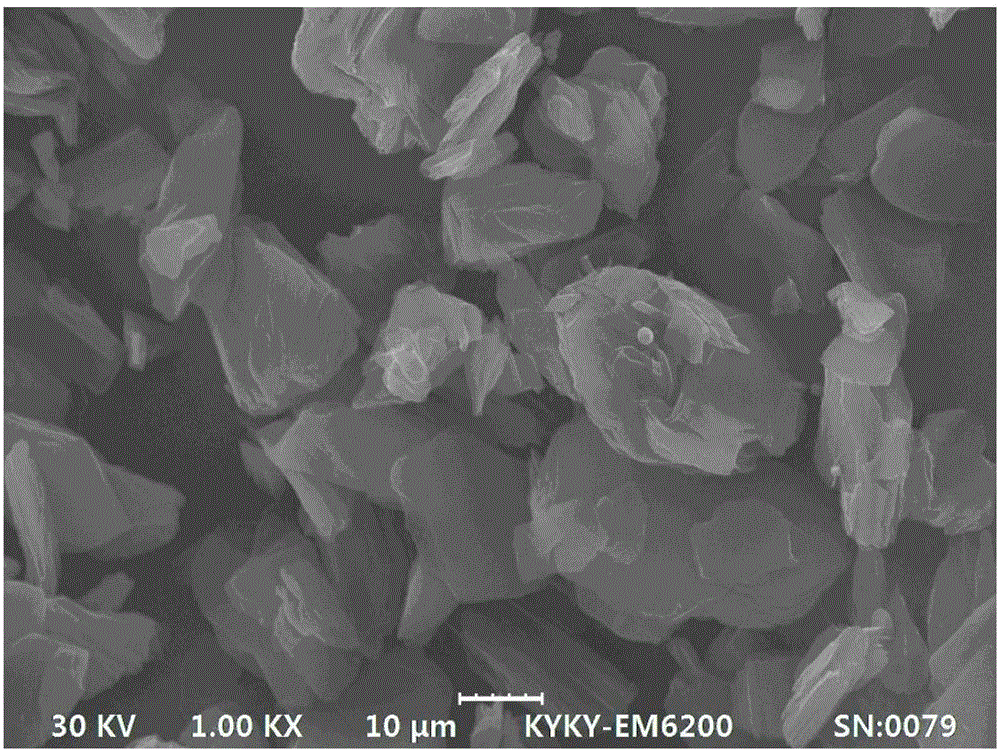

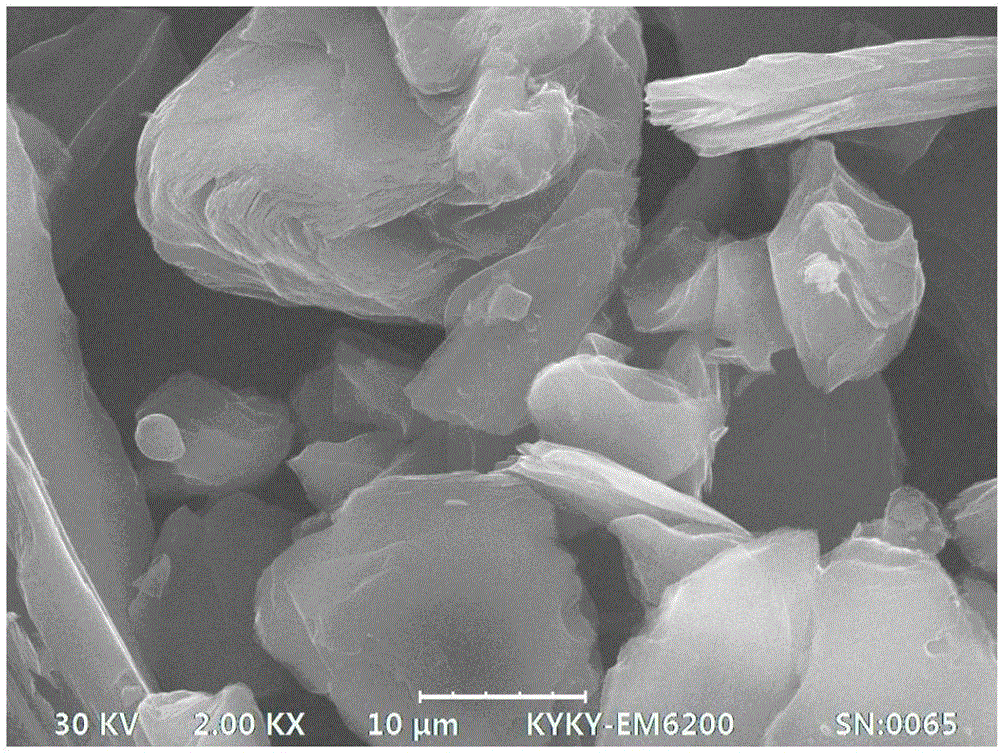

Silver-nickel composite electrical contact material with nickel distributed in net-shaped mode, and preparation method thereof

InactiveCN103996426ASmall sizeEasy to transformMetal/alloy conductorsCable/conductor manufactureElectricityAdhesive

The invention discloses a silver-nickel composite electrical contact material with nickel distributed in a net-shaped mode, and a preparation method of the silver-nickel composite electrical contact material, and belongs to the field of composite electrical contact materials. According to the silver-nickel composite electrical contact material with the nickel distributed in the net-shaped mode, the nickel is distributed in a silver base body in a continuous net-shaped mode. The silver-nickel composite electrical contact material is composed of, by mass, 50% to 98% of silver and 2% to 50% of nickel. The preparation method includes the steps of obtaining silver particles through a particle manufacturing method, annealing the silver particles, coating the surfaces of the silver particles with nickel powder through adhesives after weighing the material to obtain nickel-coated silver particle composite powder bodies, and obtaining the silver-nickel composite electrical contact material with the nickel distributed in the net-shaped mode through sintering and forming. In a silver-nickel composite material ingot blank, the pure silver areas are large and evenly distributed, the nickel is distributed in the continuous net-shaped mode, and the nickel is lengthened according to deformation of the silver base body after plastic working and distributed in the direction parallel to the pulling direction in a fibriform mode; the silver-nickel composite electrical contact material is high in conductivity, good in arc erosion resistance, easy to operate, short in technological procedure, low in energy consumption and suitable for industrial production, and raw materials can be easily obtained.

Owner:NORTHEASTERN UNIV +1

Production process of lithium battery negative electrode material

The invention provides a production process of a lithium battery negative electrode material. The production process comprises the following steps of 1, artificial graphite preparation: for impurity removal, preparing coal pitch, and performing catalytic modification on the coal pitch; for coke preparation, coking and calcining the modified coal pitch to obtain identical-nature coke; for shaping, performing shaping after the identical-nature coke is crushed and sieved, and obtaining pebble-shaped coke powder with the length-diameter ratio being 1 to 1.5; for graphitization, performing graphitization on the coke powder to prepare artificial graphite; 2, surface modification on the artificial graphite; 3, pre-oxidation: raising the temperature of the product obtained in the second step to be 300 to 330 DEG C, and then performing constant-temperature maintenance for 120 to 200min; 4, carbonization. The homemade low-impurity raw materials are used for preparing the negative electrode material; the peroxidation treatment is performed in a temperature programming mode before the carbonization; an amorphous carbon macromolecular chain of a coating layer is changed into a stable structure, so that the carbon macromolecular chain is in a thermodynamic stable state; the continuous carbonization yield is greatly improved; the performance of the negative electrode material is improved.

Owner:SHANXI SANYUAN CARBON CO LTD

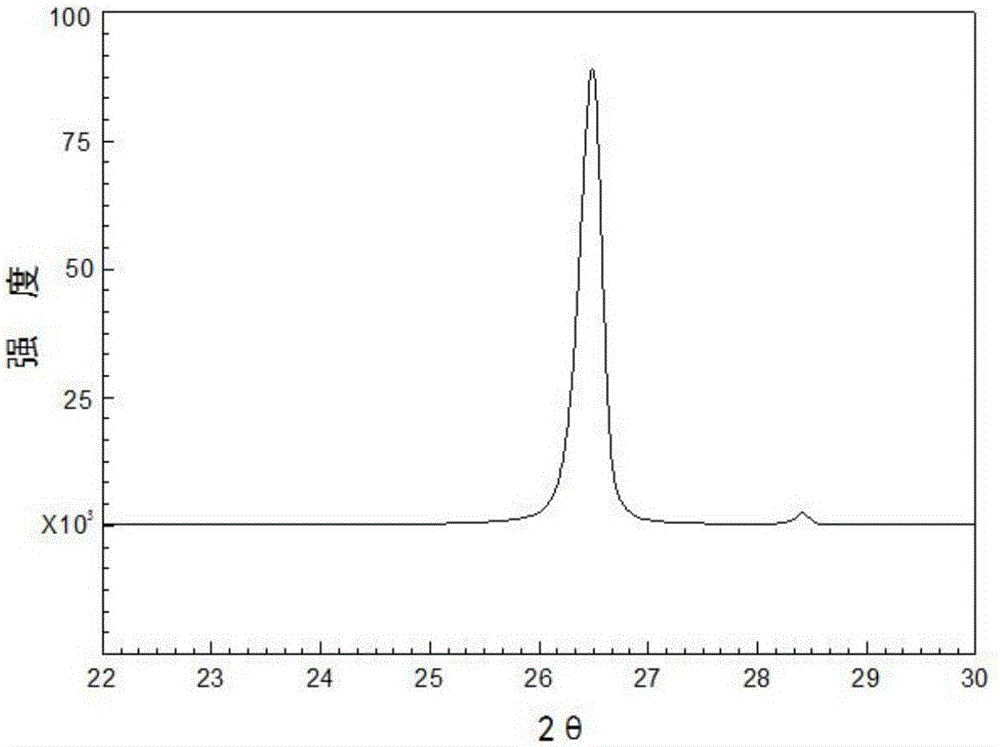

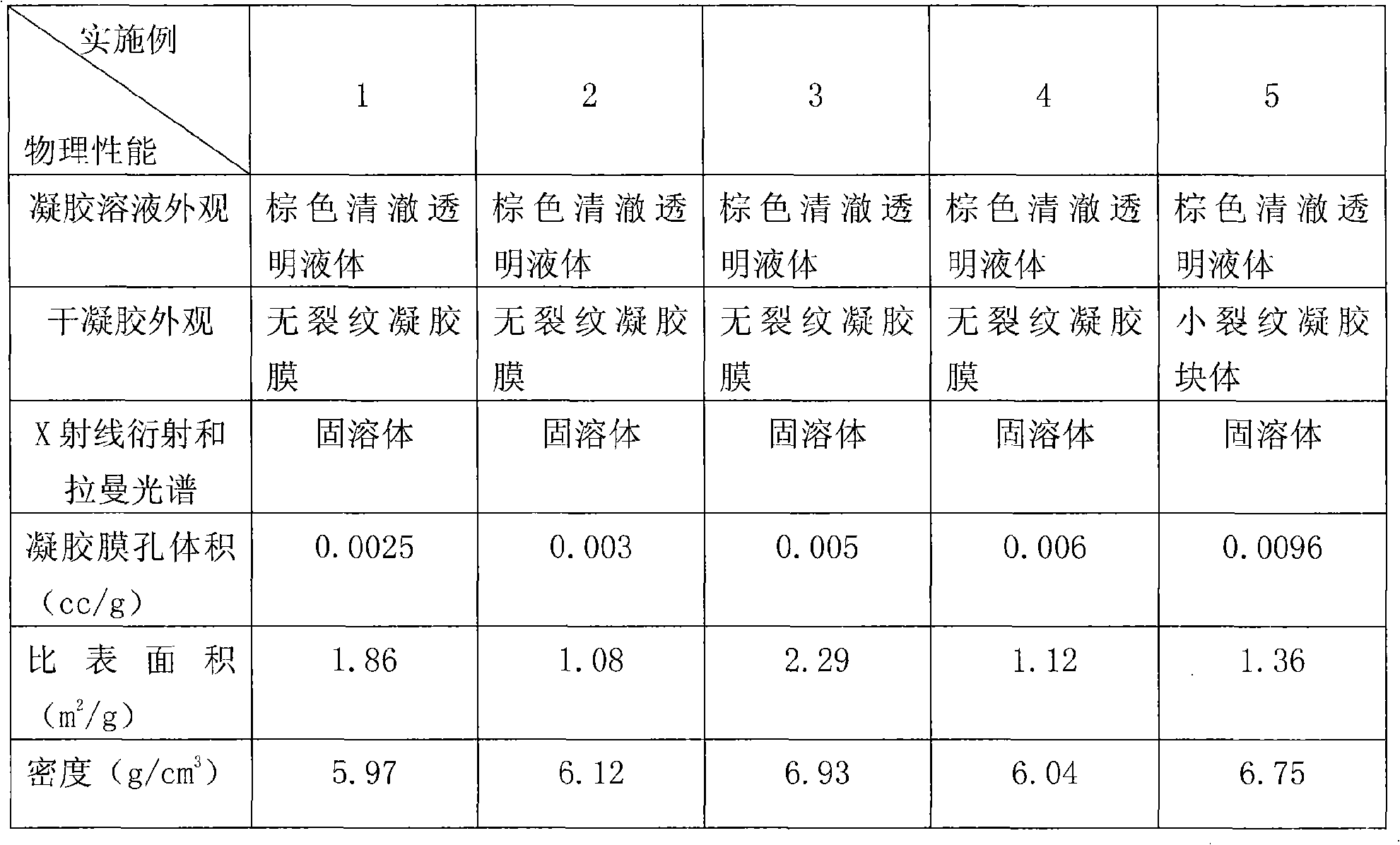

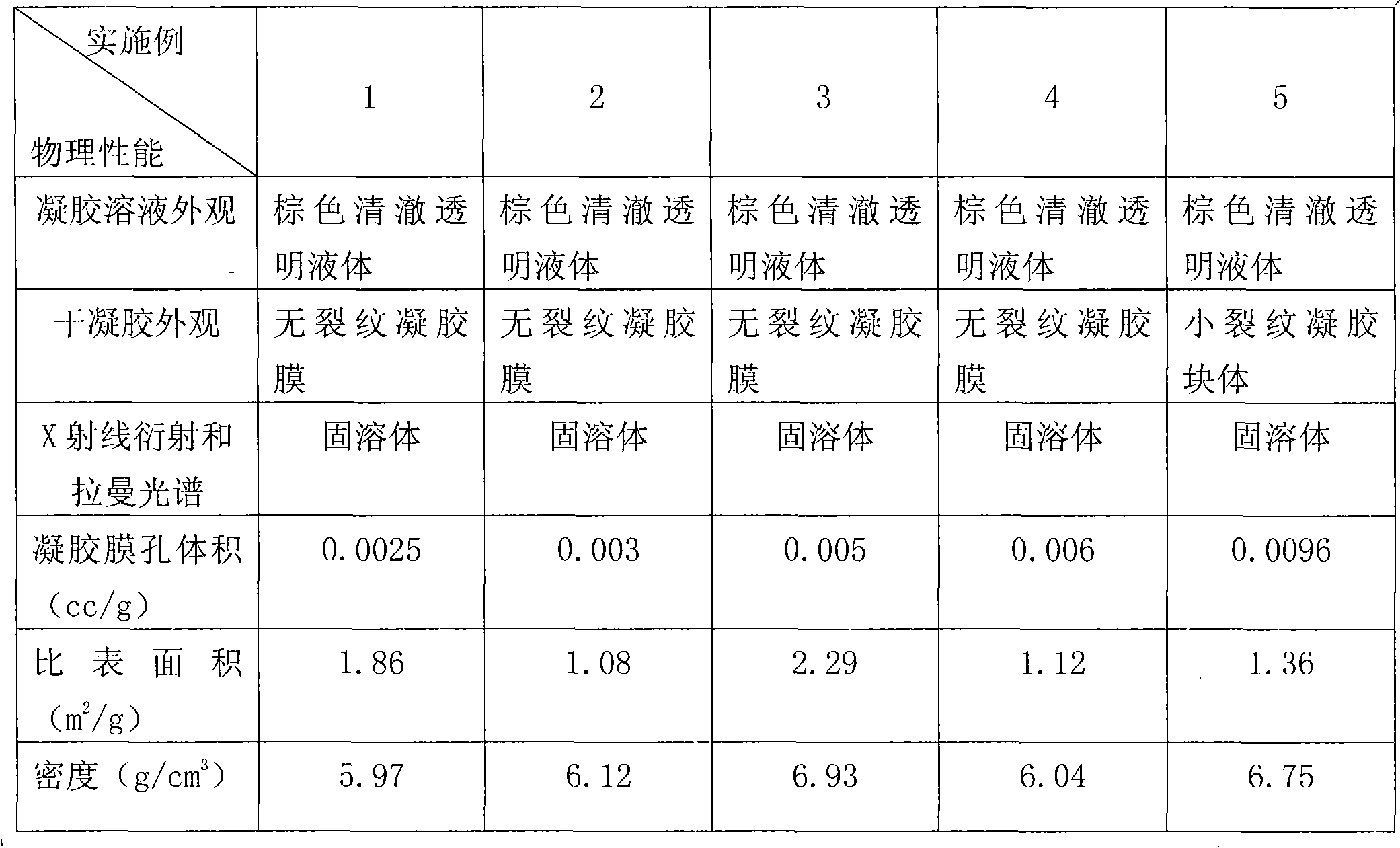

Method for preparing composite oxides mischcrystal jelly glue with gadolinium oxide adulterating cerium oxide

InactiveCN101552344AHigh sintering activityAvoid secondary film formationFinal product manufactureSolid electrolyte fuel cellsPorosityN dimethylformamide

The present invention relates to a method for preparing composite oxides mischcrystal jelly glue with gadolinium oxide adulterating cerium oxide. The method has characteristics of including steps as follows: (1) selecting raw material: weighing each raw material by weight part as follows: acetylacetone cerium aqua compound 1.5-2.5, acetylacetone gadolinium aqua compound 0.35-0.45, methanol 20-30, N, N-dimethylformamide 0.3-0.5; (2) mixing in room temperature and stirring 40-60 minutes, obtaining the colloidal solution; (3) gelating the colloidal solution in 45-70 DEG C and dehydrating dealcoholize 8-30 hours; (4) when the colloidal solution becomes viscous, the gelating reaction continues 40-60 minutes for obtaining jelly glue; (5) displacing the jelly glue to a vacuum drying case, vacuum drying 1-2 hours in 130 DEG C, and obtaining the composite oxides mischcrystal jelly glue with gadolinium oxide adulterating cerium oxide. The product has high denseness and low jelly glue porosity which is benefit for low temperature sintering into a gadolinium oxide adulterating cerium oxide electrolytes film with compact and high density.

Owner:WUHAN UNIV OF TECH

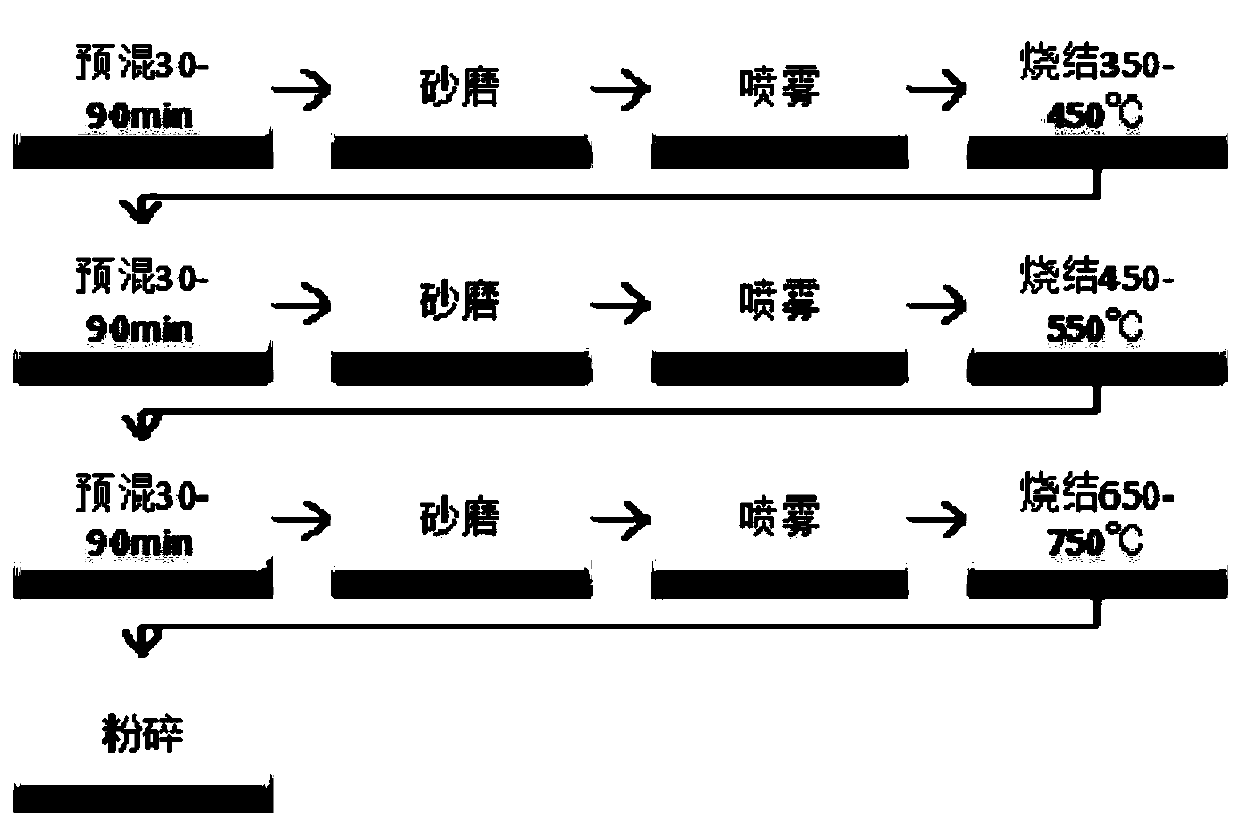

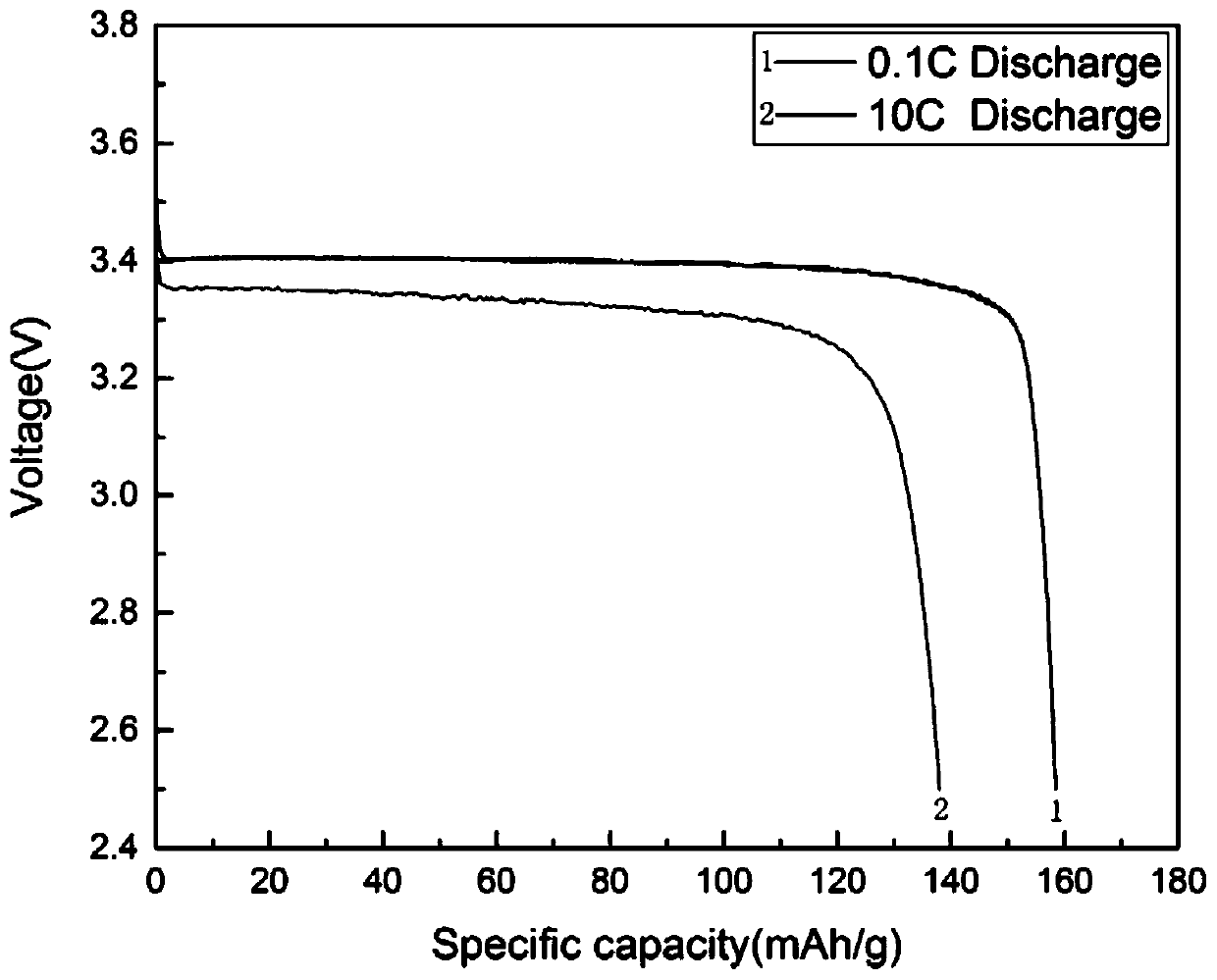

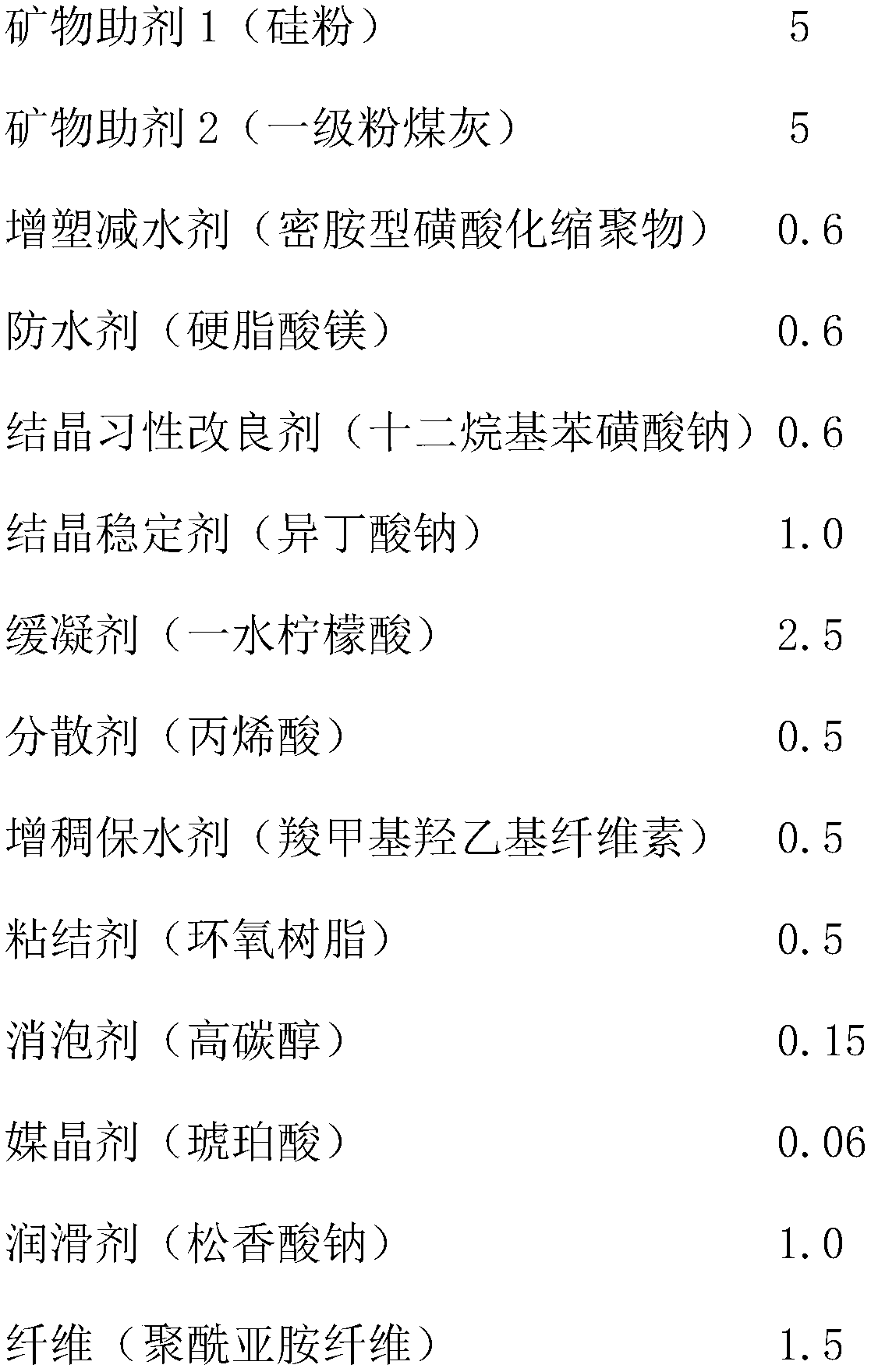

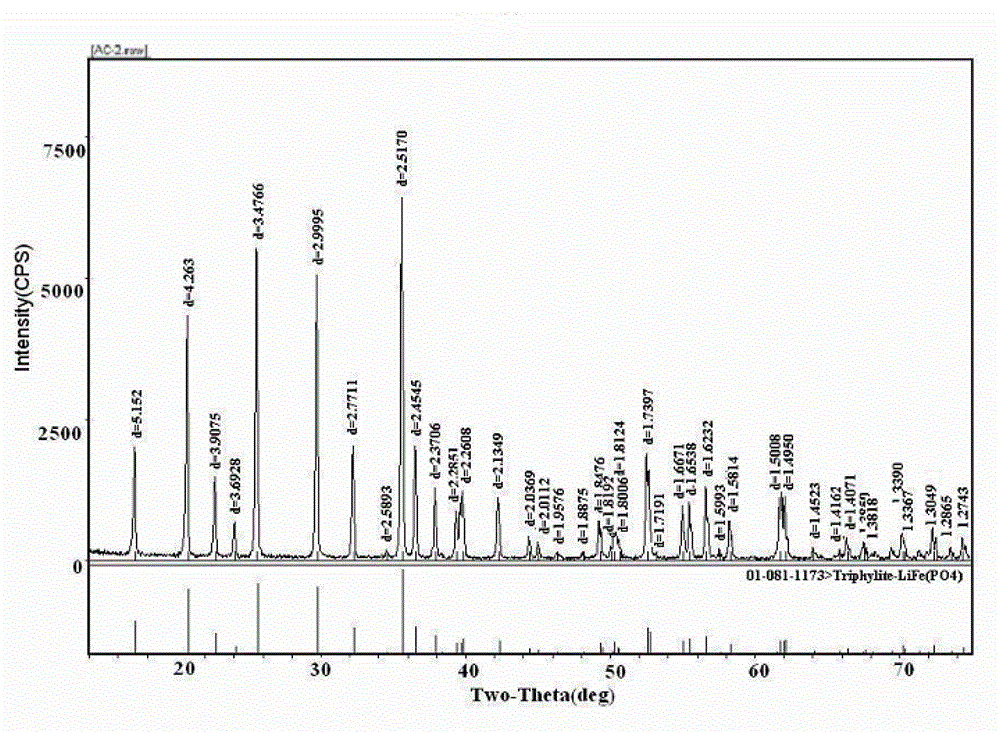

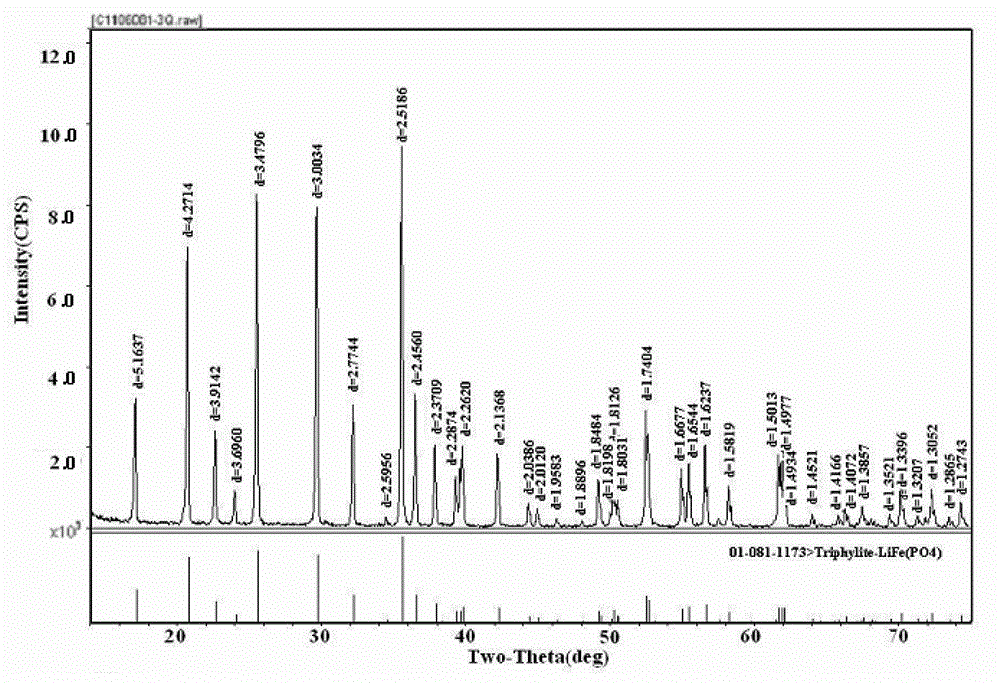

Preparation method of three-layer carbon-coated composite lithium iron phosphate cathode material

ActiveCN109920989AImprove conductivityCovering effect is uniform and denseCell electrodesSecondary cellsSanderPolyethylene glycol

The invention belongs to the technical field of the lithium ion battery cathode material, specifically a preparation method of a three-layer carbon-coated composite lithium iron phosphate cathode material. The method comprises the following steps: stirring and pre-dispersing ferro-phosphorous source, a lithium source, organic carbon source and dispersing agent in pure water, sanding through a sanding machine to obtain a precursor slurry; performing spray-drying pelleting to obtain spherical precursor powder; placing the precursor powder in a sintering furnace with protection atmosphere to perform low-temperature sintering, and cooling to room temperature; dispersing the sintered product, super-conducting carbon black, and dispersing agent in the pure water, and then performing sanding, spraying pelleting and sintering; and finally adding polyethylene glycol, the dispersing agent and the deionized water, firstly dispersing and sanding to prepare slurry, and then performing spraying pelleting, sintering and crushing to obtain the finished product. Three carbon sources are used for coating to prepare the lithium iron phosphate cathode material; compared with the single carbon source coating on the traditional lithium iron phosphate material, the coating of three carbon sources can greatly improve the own conducting performance of the material.

Owner:沈阳国科金能科技有限公司 +1

Method for preparing aluminium oxide-silicon oxide fibre

InactiveCN1434156ASmaller than surfaceHigh strengthInorganic material artificial filamentsFiberSilicon oxide

The preparation method of aluminia-silica fibre uses water soluble inorganic aluminium salt and metal aluminium as main raw material, uses distilled water as solvent, and adopts the following steps: under the reflux condition utilizing hydrolysis and polymerization to obtain uniform transparent alumina precursor sol, adding a certain quantity of silicide and water soluble polymer as spinning adjuvant into the sol, concentrating to obtain spinning dope with proper rheological property, using blast drawing method to make the spinning dope into precursor fibre, further heat treatment in nitrogengas atmospher to convert the alumina and silica precursor into alumina and silica so as to finally obtain the invented alumina-silica fibre.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

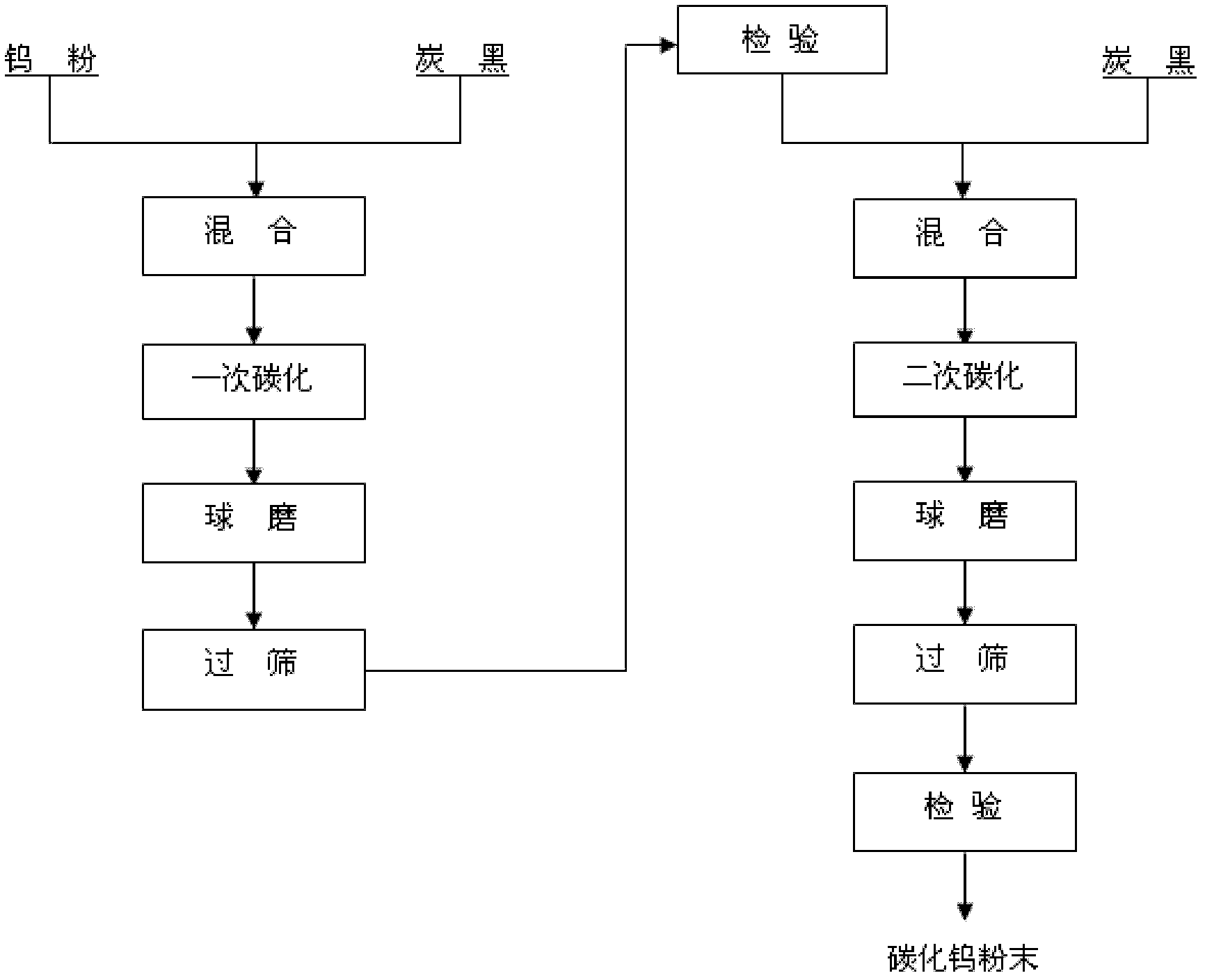

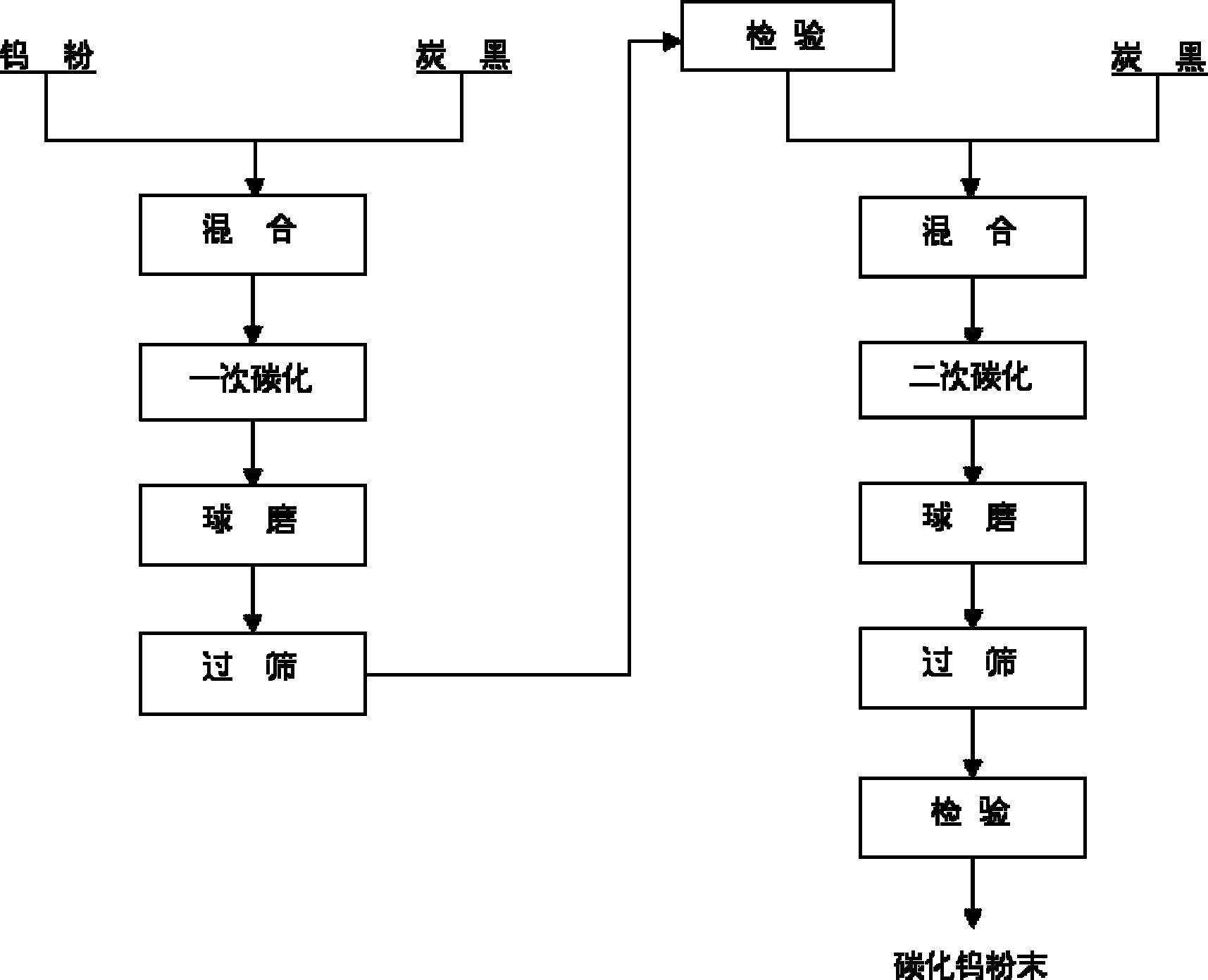

Method for preparing tungsten carbide by using regeneration tungsten powder

ActiveCN102583381AImprove chemical reactivityLarge granularityTungsten/molybdenum carbideGraphite carbonTube furnace

The invention discloses a method for preparing tungsten carbide by using regeneration tungsten powder. According to problems that the regeneration tungsten powder is big in particle size, small in specific surface area, poor in chemical activity and difficult to produce the tungsten carbide with high quality by using a traditional carbonization method directly, a two-step carbonization method is adopted to conduct carbonization on the regeneration tungsten powder. Firstly dosing is carried out according to the ratio of carbon black: tungsten powder=3.0-3.5:100 (weight), the carbon black and the tungsten powder are mixed in a ball mill, and primary carbonization is conducted under the conditions of 1800-2000 DEG C of the temperature and 50-80 minutes of carbonization time in a graphite carbon tube furnace; then carbon content in primary carbonization material is analyzed, carbon black amount is supplementally added and mixed in the ball mill, and secondary carbonization is conducted under the conditions of 1500-1700 DEG C of the temperature and 60-90 minutes of carbonization time in the graphite carbon tube furnace. Ball milling and screening are carried out on secondary carbonization products, and final tungsten carbide products are obtained. The method is simple in operation and easy to apply, and obtained tungsten carbide powder is stable in quality.

Owner:浏阳市鑫利粉末冶金有限公司

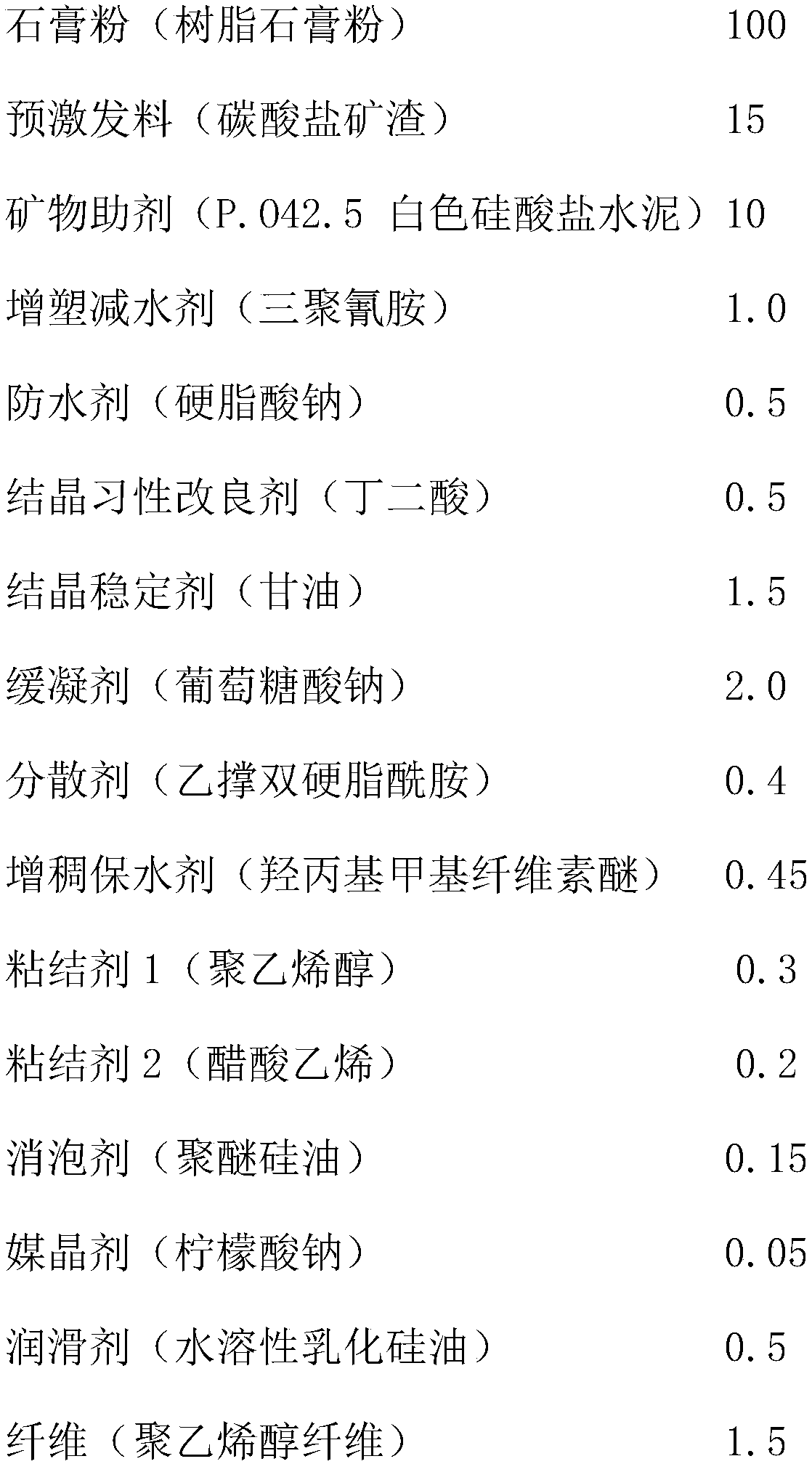

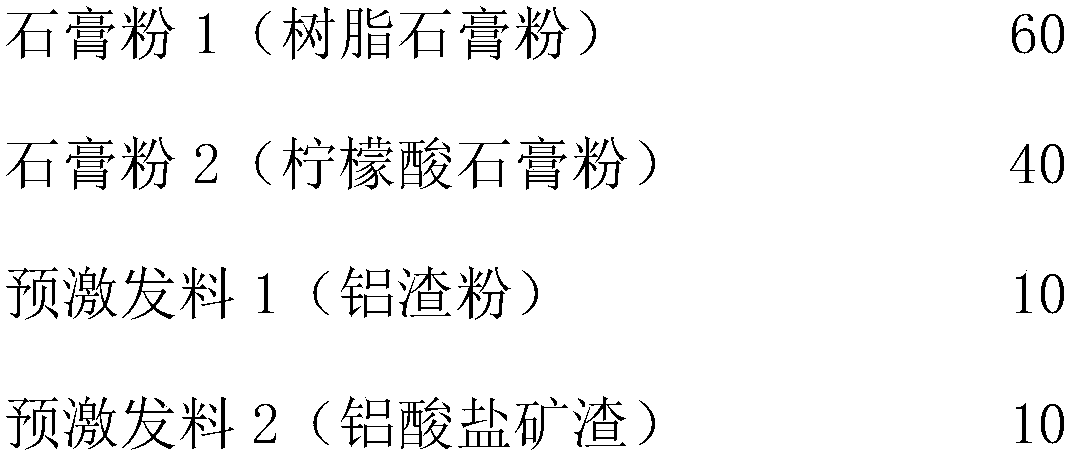

Gypsum-based composite binding material for extruded 3D printing and preparation method thereof

InactiveCN108383465AProlong clotting timeEasy to manufactureAdditive manufacturing apparatusCeramic shaping apparatusFiberCrack resistance

The invention discloses a gypsum-based composite binding material for extruded 3D printing and a preparation method thereof and relates to the field of civil engineering / 3D printing materials. Aimingat defects in the prior art, the invention provides the gypsum-based composite binding material for extruded 3D printing. The binding material is prepared from the following components: gypsum, pre-excited material, mineral additives, a plasticized water reducing agent, a waterproof agent, a crystal habit improver, a cystallizing stabilizer, a retarder, a dispersing agent, a water-retentive and thickening admixture, an adhesive, an antifoaming agent, a crystal modifier, a lubricating agent and fibers. The binding material disclosed by the invention has the beneficial effects that the preparedgypsum-based composite binding material for extruded 3D printing is wide in source, excellent in liquidity and environmentally friendly and has excellent extrusion continuity, constructability, mechanical property, water seepage resistance and cracking resistance.

Owner:深圳市明远建筑科技有限公司

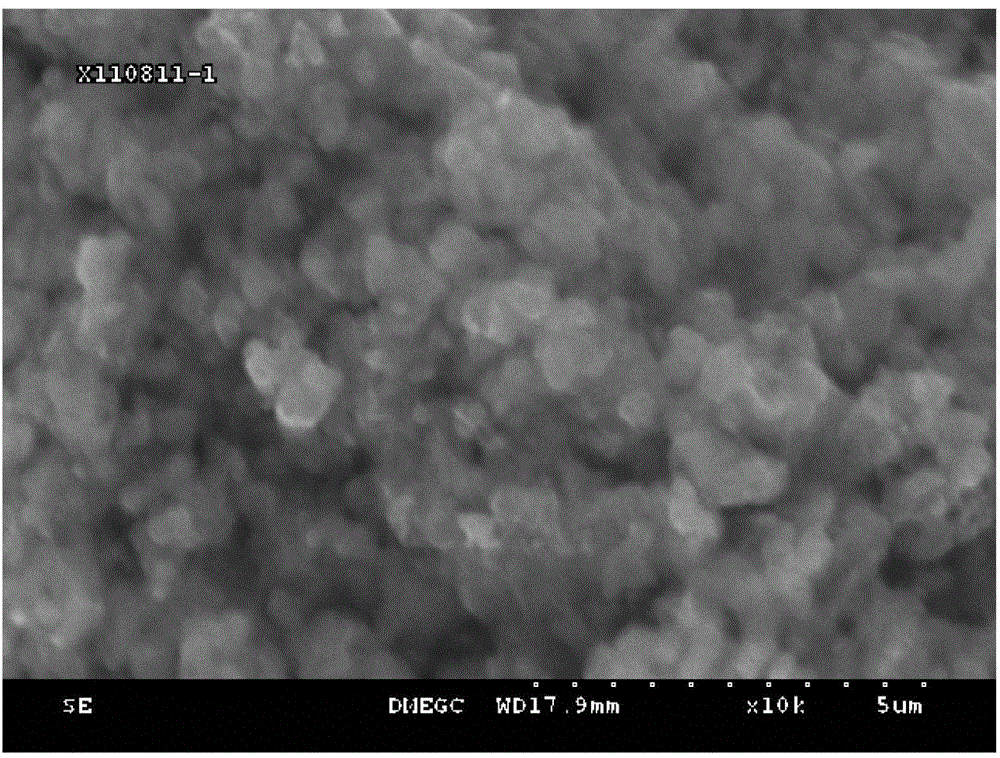

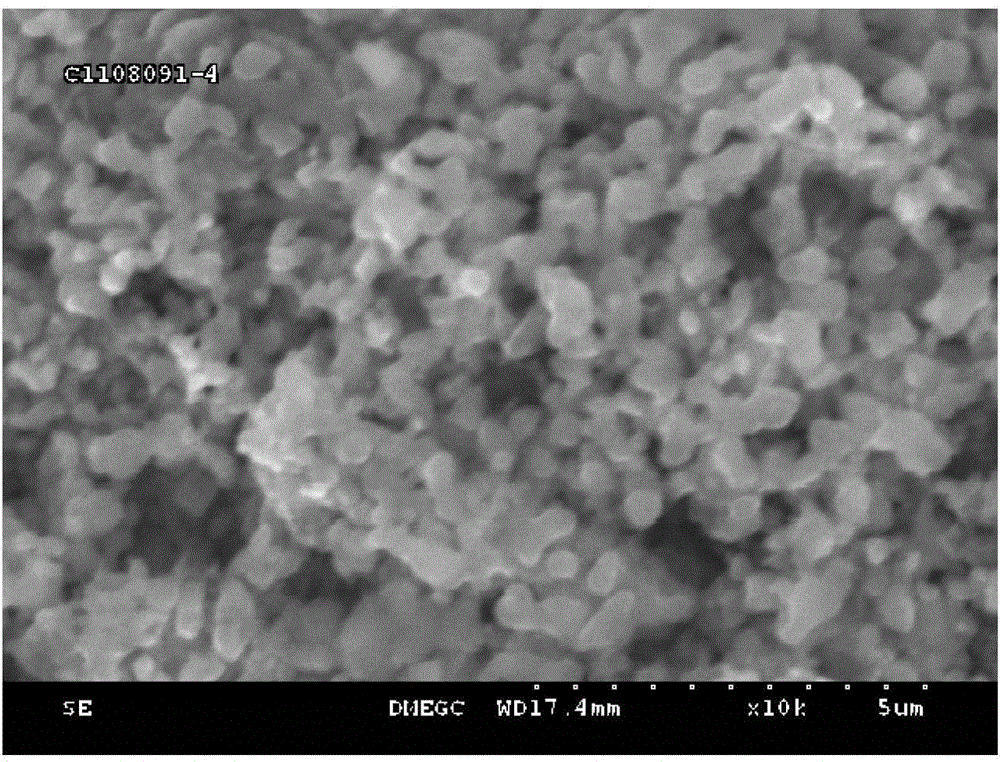

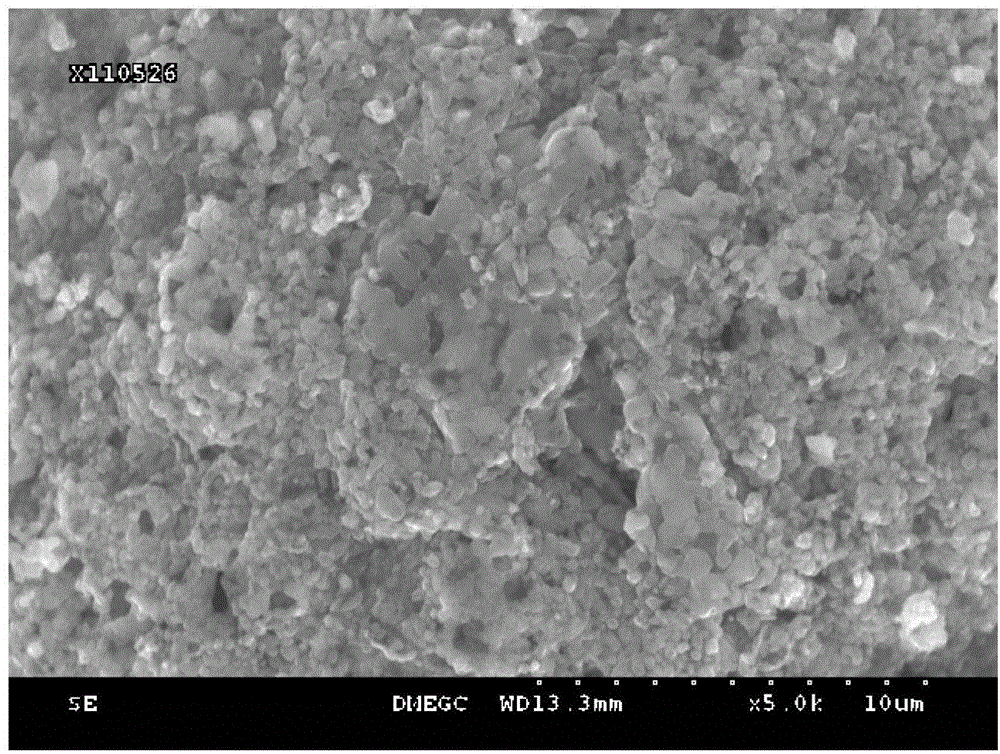

Lithium iron phosphate-modified conductive carbon black composite electrode material preparation method

ActiveCN103337625ASmaller than surfaceEasy to manufactureCell electrodesMaterials preparationPower battery

The invention relates to the fields of energy storage technology and power battery material technology, and specifically relates to a lithium iron phosphate-modified conductive carbon black composite electrode material preparation method. The preparation method comprises (1) a step of subjecting common conductive carbon black to annealing treatment, and then performing oxidation treatment in a strong oxidant to prepare the modified conductive carbon black; and (2) a step of preparing the lithium iron phosphate-modified conductive carbon black composite electrode material. According to the invention, by addition of modified SP which is easily dispersed, the composite electrode material prepared by the invention has small specific surface, thus facilitating battery preparation.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

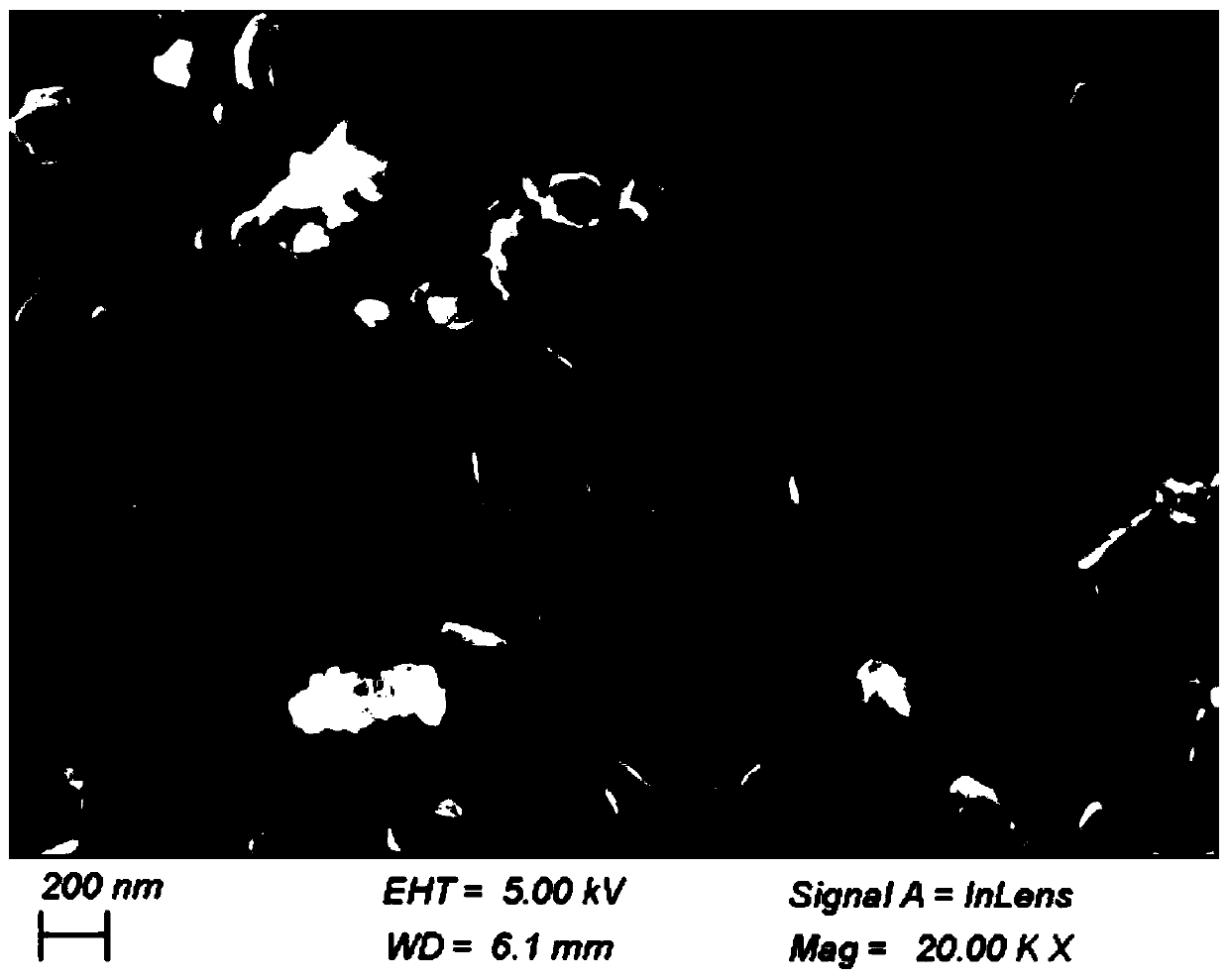

High-nickel nickel-cobalt-manganese ternary single crystal material as well as preparation method and application thereof

InactiveCN108221051AStable structureEasy to dopePolycrystalline material growthCell electrodesPh controlManganese

The invention discloses a high-nickel nickel-cobalt-manganese ternary single crystal material as well as a preparation method and application thereof. The general formula of the high-nickel nickel-cobalt-manganese ternary single crystal material is set to be LiNixCoyMnzRtO2, wherein x is more than or equal to 0.5 and less than or equal to 0.8, y is more than or equal to 0.1 and less than 0.3, z ismore than 0.1 and less than or equal to 0.2, and t is more than 0 and less than to 0.1. Sulfate ions are not introduced, so that washing water is not required. Thus, washing water does not need to beused, and pH control is not needed in a production process.

Owner:山东零壹肆先进材料有限公司

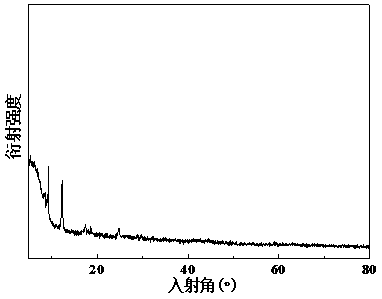

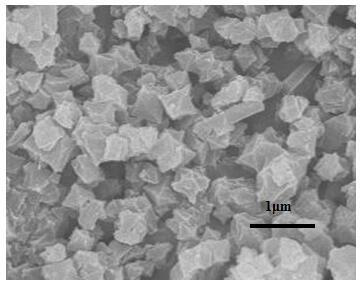

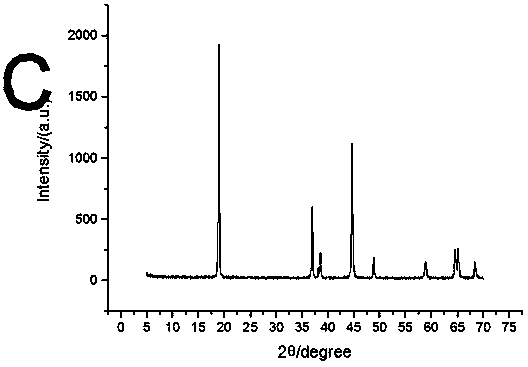

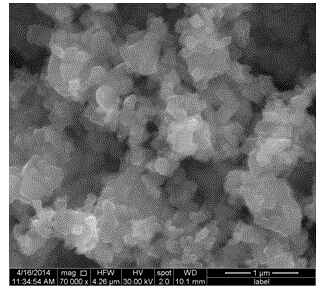

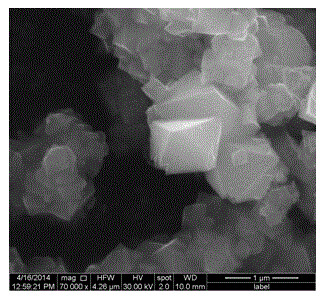

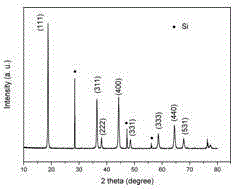

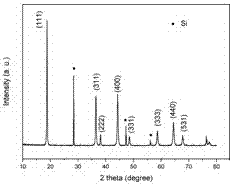

Preparation method of LiNi<x>Mn<2-x>O<4> cathode material

ActiveCN105185981APromote growthGood formabilityCell electrodesSecondary cellsCrystal planeLithium-ion battery

The invention relates to a preparation method of a LiNi<x>Mn<2-x>O<4> cathode material, and belongs to the technical field of lithium-ion battery cathode materials. The method comprises the following steps: firstly, carrying out ball-mill mixing on a lithium source, a nickel source, a manganese source and an assistant for 0.5-10 hours, and drying the mixture at 60-160 DEG C to prepare a precursor, wherein at least one of the lithium source, the nickel source, the manganese source and the assistant is chloride; and secondly, heating the obtained precursor in air or oxygen atmosphere to 500-800 DEG C at the rate of 1-20 DEG C / min, heating the precursor at constant temperature for 5-48 hours, and cooling the precursor to room temperature to obtain the product LiNi<x>Mn<2-x>O<4> cathode material, or washing and drying the precursor to obtain the LiNi<x>Mn<2-x>O<4> cathode material. According to the method, a raw material chlorination process is provided; and through introducing chloride ions, the LiNi<x>Mn<2-x>O<4> (x is less than or equal to 0.5 and greater than or equal to 0.4) material in the solid-solid reaction process is promoted to grow up and expose a {111} crystal plane at low temperature, so that preparation of the high-performance LiNi<x>Mn<2-x>O<4> (x is less than or equal to 0.5 and greater than or equal to 0.4) material can be simply and effectively achieved.

Owner:KUNMING UNIV OF SCI & TECH

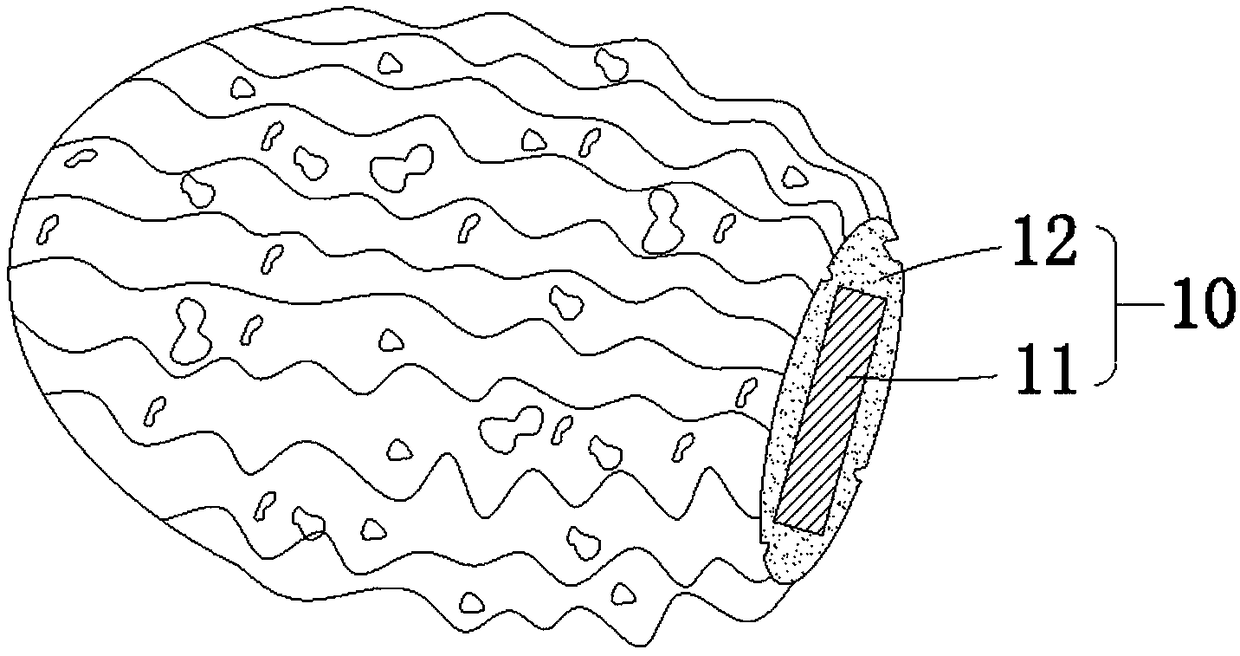

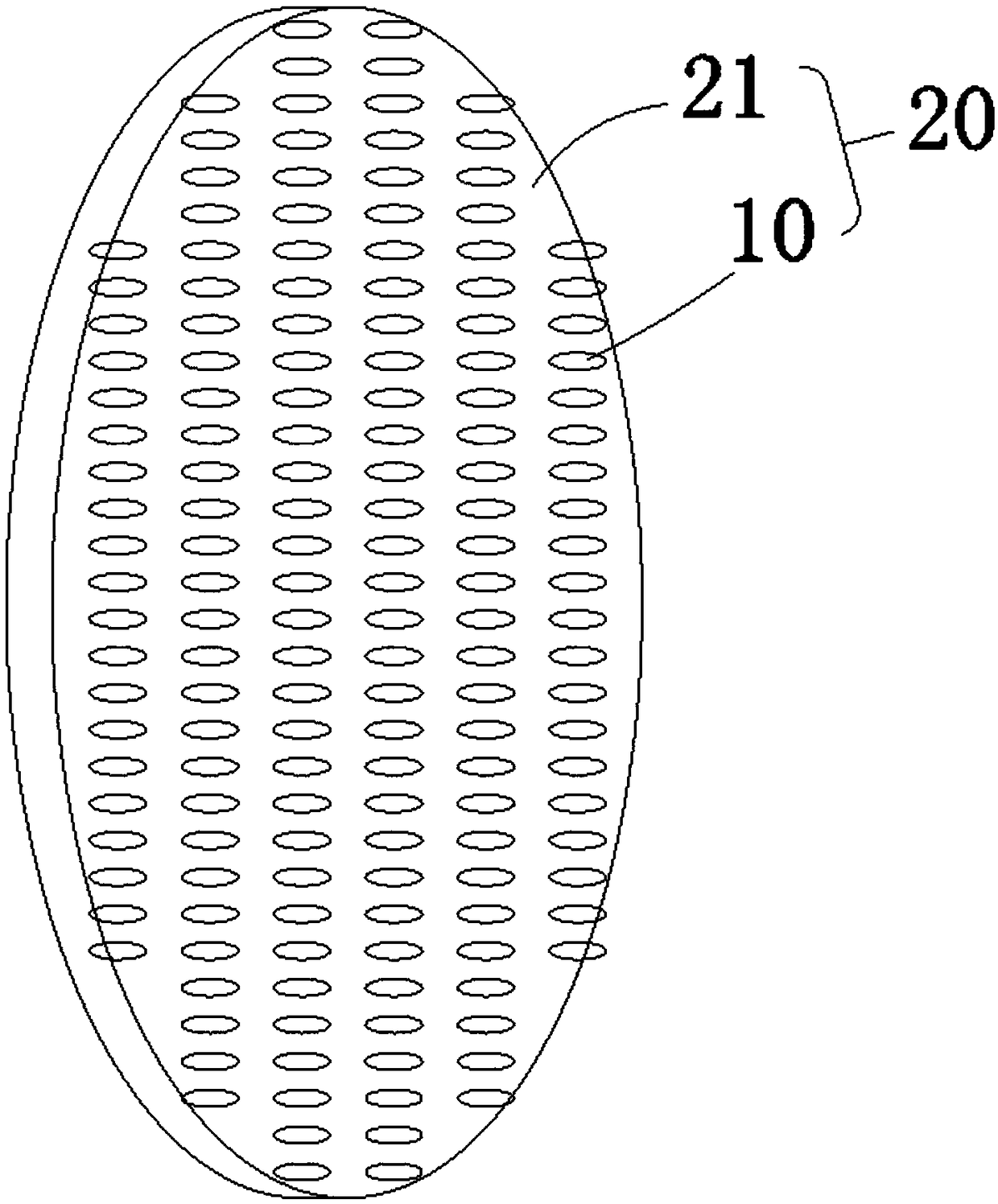

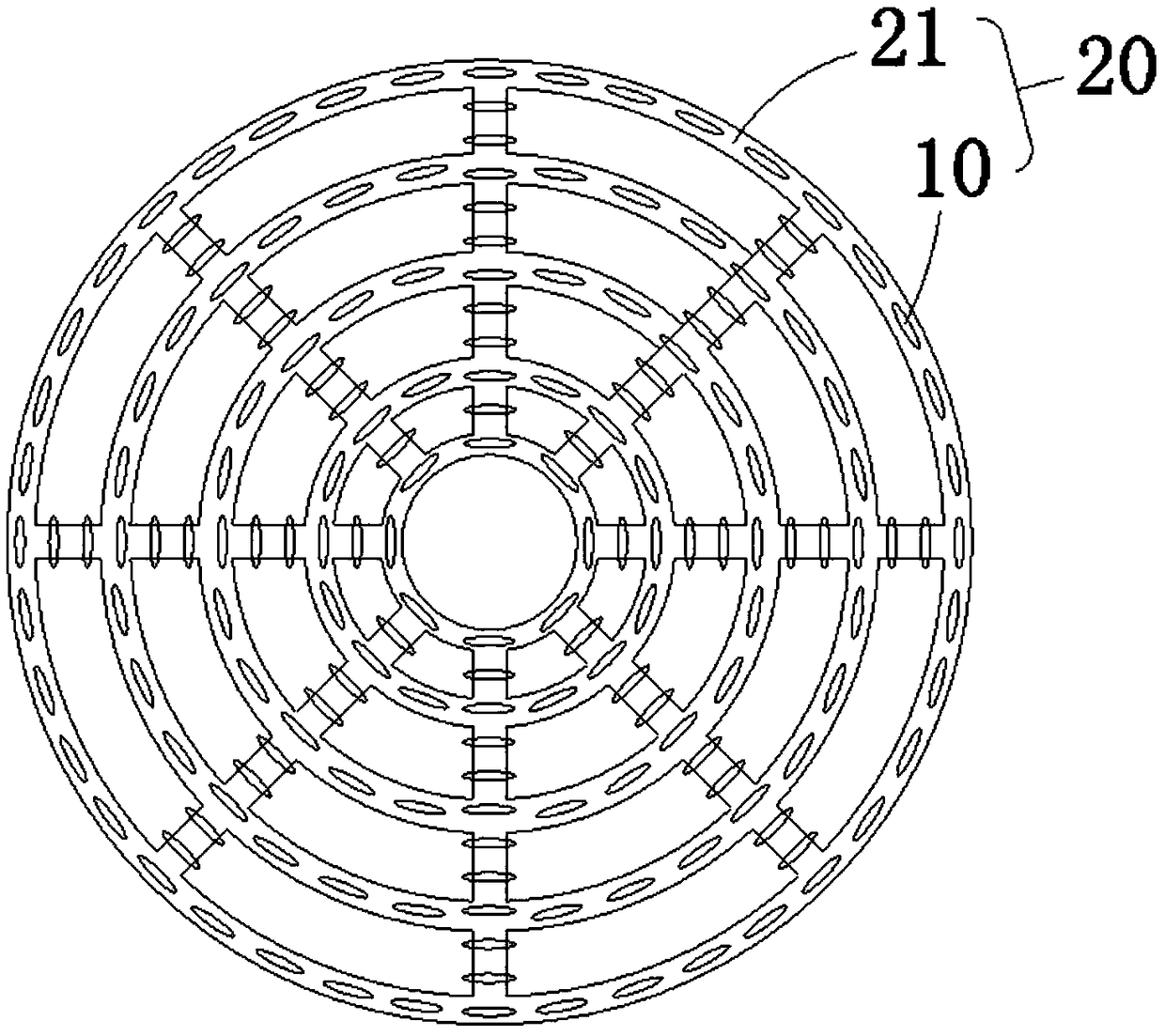

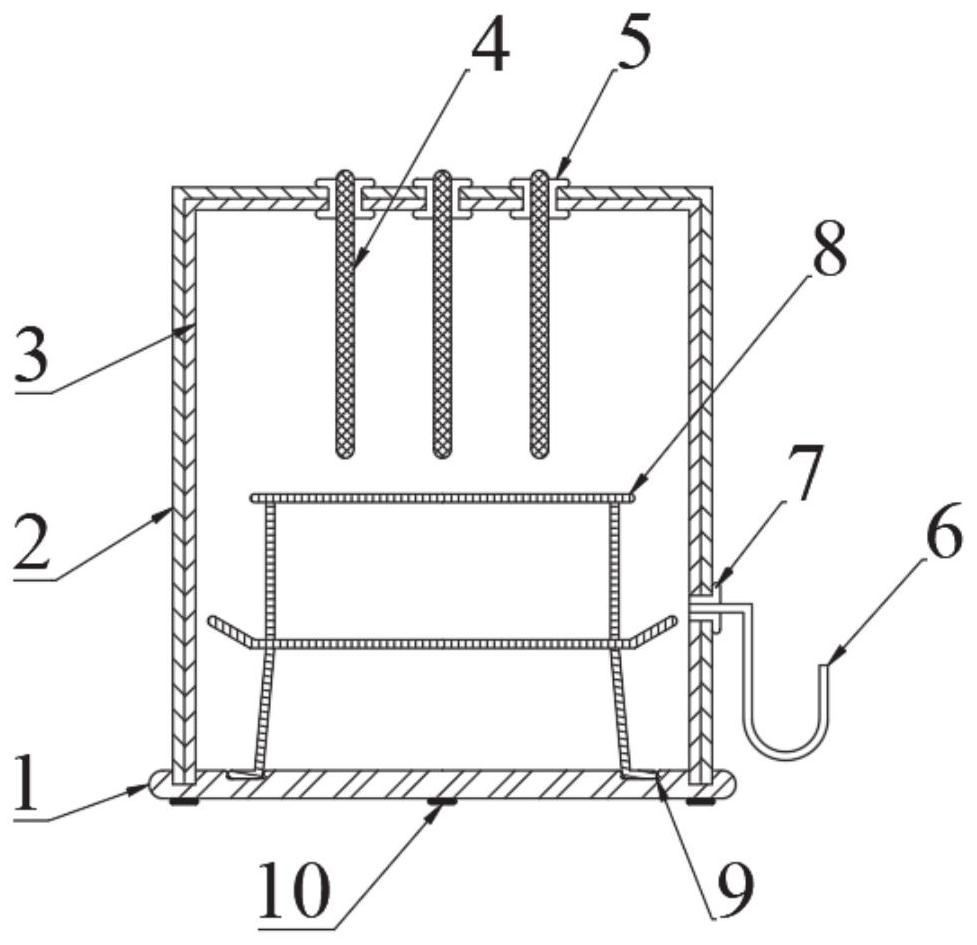

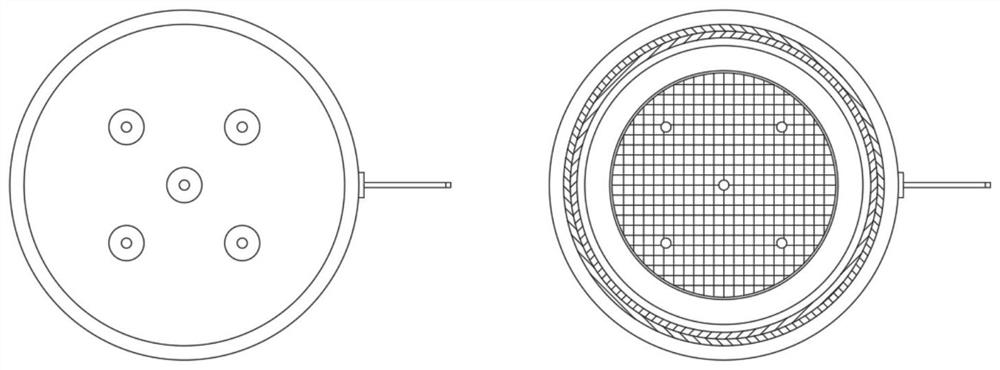

Biological membrane carrier, disk and biological rotary disk for sewage treatment

ActiveCN108203155AIncrease dissolved oxygenFully aerobic responseTreatment using aerobic processesWater/sewage treatment by magnetic/electric fieldsSolubilityHeavy metals

The invention provides a biological membrane carrier applied to sewage treatment. The biological membrane carrier comprises a magnetic carrier and a water membrane, wherein the magnetic carrier is prepared from a magnet and a magnet-conduction material; the water membrane is used for forming the biological membrane by microorganism adhesion, and is used for magnetizing a water membrane on the surface of the magnetic biological membrane; the magnetic carrier is arranged on the disk of the biological rotary disk, or is indirectly taken as the disk of the biological rotary disk. The biological membrane carrier is applied to the disk, the disk is applied to the biological rotary disk; during use, the biological membrane carrier rotating out of a contact reaction groove can be used for magnetizing the water membrane, dissolved oxygen in the magnetized water membrane is increased greatly, the microorganisms can be subjected to a full aerobic reaction, sewage treatment performance is improved, a part of organic matters can be mineralized, the absorption rate of water to light is increased, and the solubility of inorganic salt is improved through the magnetization of a water body, the growth of alga is facilitated, and removing performance is improved specific to element N and P, heavy metal elements and small particles.

Owner:SCIMEE TECH & SCI CO LTD

Magnetic fertilizer used for eucalyptus and production method thereof

InactiveCN104892091AAvoid churnImprove absorption efficiencyFertilizer mixturesBiotechnologyTrace element

The invention discloses a magnetic fertilizer used for eucalyptus, which is mixed by an inorganic fertilizer, an organic fermentation fertilizer and a magnetic powder base-material in proportion. The organic matter, a trace element, beneficial bacteria and a micro magnetic field are organically interlaced to a fertility supply net by the magnetic fertilizer, soluble substance loss is reduced, good environment for breeding microbe can be created, effectiveness is fast, and fertilizer efficiency is long. The invention also discloses a production method of the magnetic fertilizer, which comprises the following steps: respectively preparing an organic fermentation fertilizer, an inorganic fertilizer and a magnetic powder base-material, mixing the prepared organic fermentation fertilizer, the inorganic fertilizer and the magnetic powder base-material according to weight part, adding fungi mycelia in the mixing fertilizer and uniformly mixing to obtain the magnetic fertilizer used for eucalyptus, wherein, the addition of fungi mycelia accounts for 0.5-1% of weight of the magnetic fertilizer used for eucalyptus. The method has the advantages of scientific process and simple production technology, and is adapted to large scale production usage.

Owner:广西贵港市丰收肥业有限公司

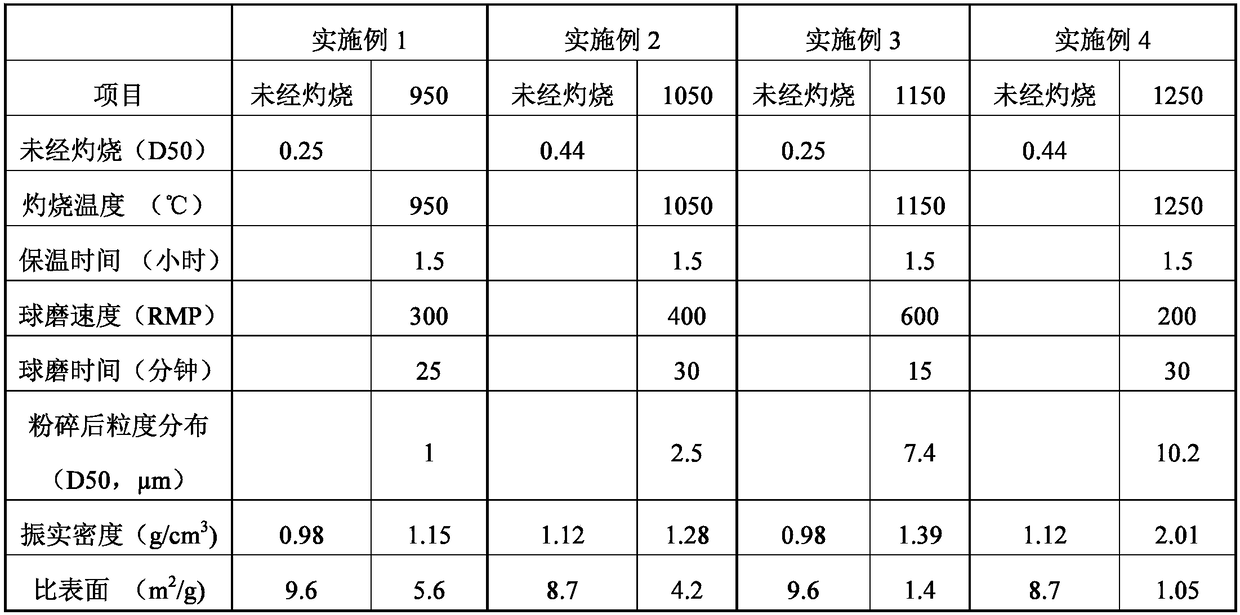

Preparation and surface modification method of stable titanium dioxide particle

The invention provides a preparation and surface modification method of a stable titanium dioxide particle. According to the method, commercial titanium dioxide powder is burned at a high temperatureto prepare a novel titanium dioxide particle, which has the advantages of high density, low specific surface area, micrometer level particle distribution, stable and high dielectric constant, and lowdielectric loss. After one step surface modification, the novel titanium dioxide particle can be used to prepare high performance high frequency copper-clad plates.

Owner:无锡睿龙新材料科技有限公司

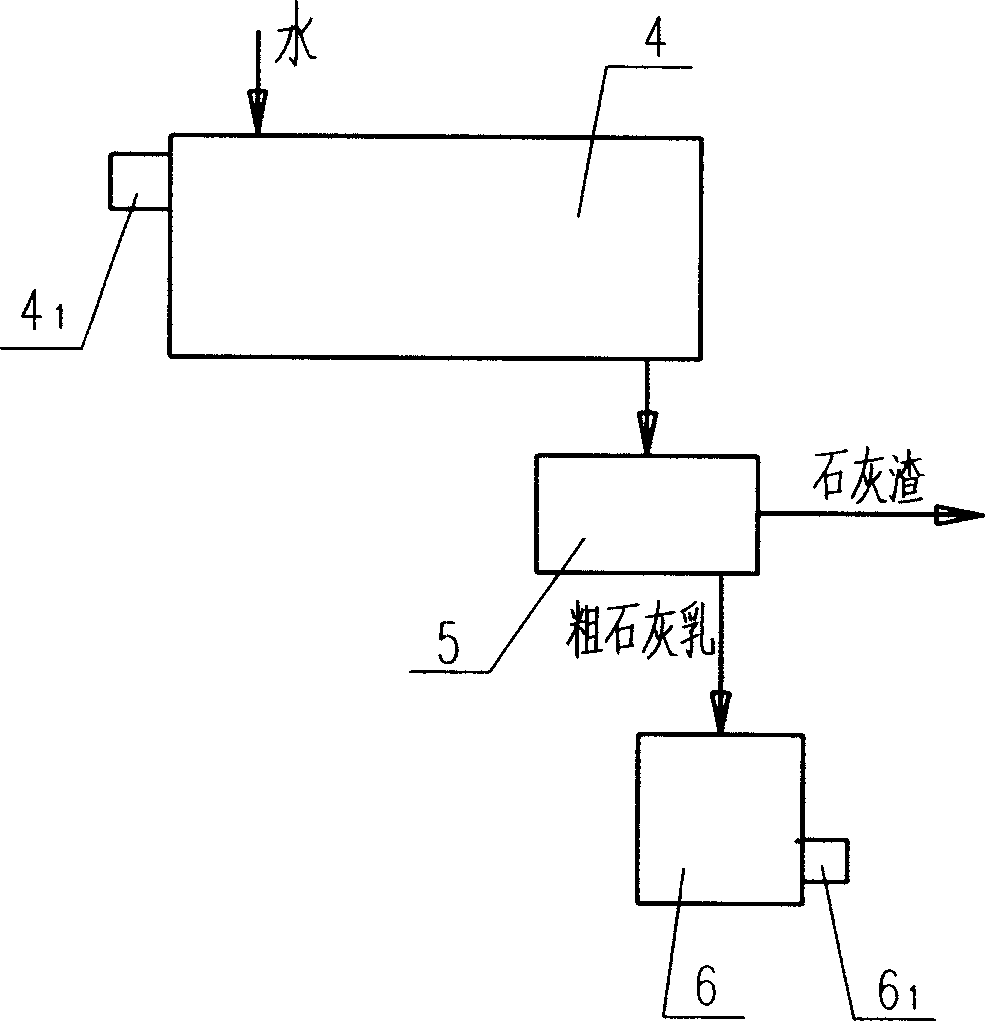

Method for clarifying sugar liquid using quick lime

ActiveCN1858259AImprove clarificationImprove juice qualityPurification using alkaline earth metal compoundsSlagReaction speed

The present invention relates to sugar refining technology, and the method of clarifying sugar liquid with quick lime includes the steps of slaking, adding lime cream and neutralizing. The present invention features the slaking step of mixing 50-300 mesh quick lime powder and water at 40-70 deg.c in the weight ratio of 1 to 2-10. The present invention has fast precipitating reaction speed, high lime cream quality, high lime utilization rate, no lime slag exhaust, raised sugar liquid clarifying effect and other advantages.

Owner:黄永春 +3

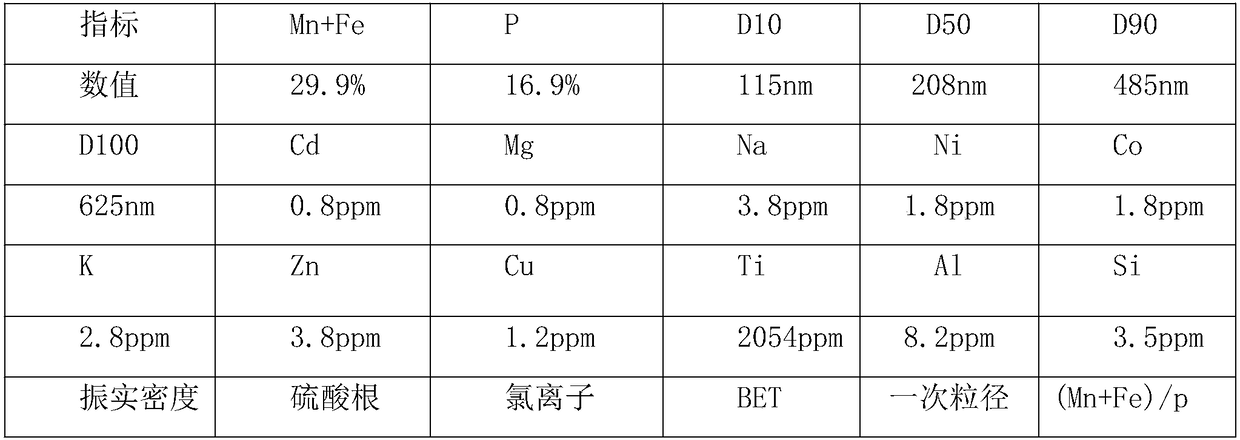

Preparation method of iron manganese phosphate

ActiveCN108306003AEvenly distributedUniform particle size distributionCell electrodesSecondary cellsPhosphoric acidSlurry

The invention discloses a preparation method of iron manganese phosphate. The preparation method comprises the steps of preparing a base solution, and adding a ferromanganese mixed solution and an ammonium hydrogen carbonate solution to the base solution in a stirring condition, and after adding is completed, continuously performing a stirring reaction to obtain carbonate paste; performing solid liquid separation on the carbonate paste, washing the filtering residue by hot pure water, and then adding the product into the pure water to be subjected to slurrying, and next, adding a phosphoric acid solution and hydrogen peroxide into the slurry material at the unfirm speed synchronously, and next, performing heating to obtain iron manganese phosphate paste; performing solid liquid separationon the iron manganese phosphate paste, washing the filtering residue by hot pure water, and then performing vacuum drying, screening and iron removing to obtain iron manganese phosphate; and adding iron manganese phosphate into a mixed solution of anhydrous alcohol and butyl titanate, performing grinding, and next carrying out spray drying on the paste to obtain titanium-coated iron manganese phosphate. The titanium-coated iron manganese phosphate material obtained in the invention has small grain diameter, high tap density, small specific surface, and uniform grain diameter distribution, without causing a ferromanganese segregation phenomenon.

Owner:蒋央芳

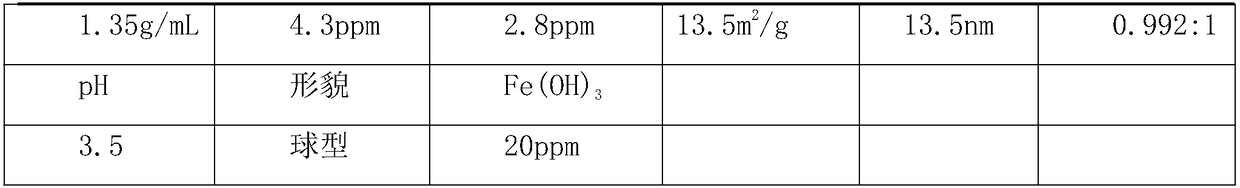

Preparation method of deodorant sanitary product

ActiveCN111249067AImprove photocatalytic effectGood catalyticAbsorbent padsBaby linensActivated carbonOrganic chemistry

The invention relates to the field of sanitary products, and provides a preparation method of a deodorant sanitary product. The preparation method of the deodorant sanitary product solves the defect of the sanitary products in the prior art that the sanitary products cannot eliminate odor after use, and comprises the following preparation steps: preparing a liquid-permeable surface layer; preparing an absorption core; preparing a non-permeable bottom layer; and then, compounding the liquid-permeable surface layer, the absorption core and the non-permeable bottom layer into a whole. The non-permeable bottom layer is specifically prepared by the following steps: preparing an activated carbon solution loaded with nano titanium dioxide; and then, coating the middle part of the non-permeable bottom layer with the activated carbon solution loaded with the nano titanium dioxide.

Owner:福建恒安家庭生活用品有限公司

Method for preparing composite oxides mischcrystal jelly glue with gadolinium oxide adulterating cerium oxide

InactiveCN101552344BHigh sintering activityAvoid secondary film formationFinal product manufactureSolid electrolyte fuel cellsPorosityN dimethylformamide

The present invention relates to a method for preparing composite oxides mischcrystal jelly glue with gadolinium oxide adulterating cerium oxide. The method has characteristics of including steps as follows: (1) selecting raw material: weighing each raw material by weight part as follows: acetylacetone cerium aqua compound 1.5-2.5, acetylacetone gadolinium aqua compound 0.35-0.45, methanol 20-30,N, N-dimethylformamide 0.3-0.5; (2) mixing in room temperature and stirring 40-60 minutes, obtaining the colloidal solution; (3) gelating the colloidal solution in 45-70 DEG C and dehydrating dealcoholize 8-30 hours; (4) when the colloidal solution becomes viscous, the gelating reaction continues 40-60 minutes for obtaining jelly glue; (5) displacing the jelly glue to a vacuum drying case, vacuumdrying 1-2 hours in 130 DEG C, and obtaining the composite oxides mischcrystal jelly glue with gadolinium oxide adulterating cerium oxide. The product has high denseness and low jelly glue porosity which is benefit for low temperature sintering into a gadolinium oxide adulterating cerium oxide electrolytes film with compact and high density.

Owner:WUHAN UNIV OF TECH

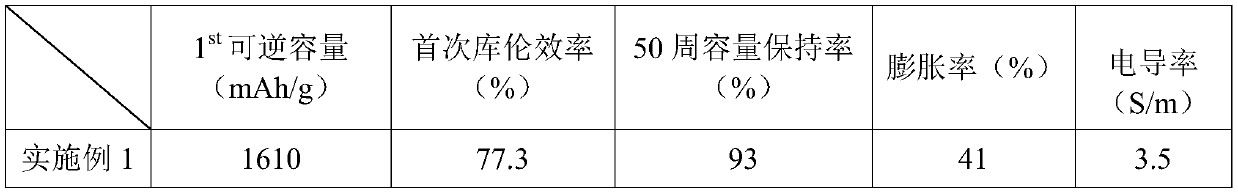

Nitrogen-containing silicon-oxygen-carbon compound composite negative electrode material of lithium ion secondary battery and preparation method

InactiveCN111403744AImprove conductivityImprove cycle performanceSecondary cellsNegative electrodesCarbon coatingSilicon oxygen

The invention discloses a preparation method of a nitrogen-containing silicon-oxygen-carbon compound composite negative electrode material of a lithium ion secondary battery, which comprises the following steps: stirring and mixing a silicon-oxygen precursor, a carbon source and a nitrogen source in an acidic aqueous solution to form slurry; drying the slurry, and carrying out high-temperature roasting, cooling, crushing and scattering under a protective gas to obtain a carbonized nitrogen-containing porous silicon-oxygen-carbon compound precursor; and blending the obtained nitrogen-containingporous silicon-oxygen carbide precursor with a carbon coating material, and carrying out high-temperature carbonization, cooling, crushing and scattering under a protective gas to prepare the nitrogen-containing silicon-oxygen-carbon compound composite negative electrode material with a uniform and stable coating structure for the lithium ion secondary battery. The lithium ion secondary battery nitrogen-containing silicon-oxygen-carbon compound composite negative electrode material prepared by the preparation method has good negative electrode material conductivity and cycle performance.

Owner:DONGGUAN KAIJIN NEW ENERGY TECH

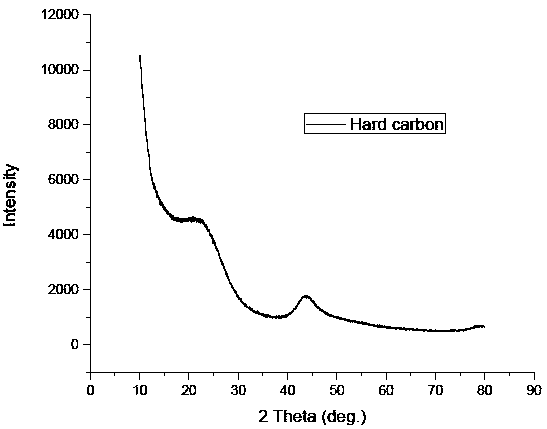

Method for preparing low-temperature lithium ion battery hard carbon negative electrode material

ActiveCN110600738AHigh tap densityIncrease energy densityCell electrodesSecondary cellsShort range orderHigh energy

The invention discloses a method for preparing a low-temperature lithium ion battery hard carbon negative electrode material, relates to the field of a lithium ion battery and particularly relates toa method for preparing a lithium ion battery hard carbon negative electrode material suitable for ultralow temperature. The method is characterized in that oxygen in the material can effectively reduced, the long-range structure of a crystal is broken, so the organization structure is short-range and ordered, the long range is disordered, and the interlayer spacing is increased. By adopting the method, a carbon material is consumed due to introduction of a trace amount of CO2, the long-range ordered structure is locally destroyed, and the obtained hard carbon negative electrode material has advantages of short-range order and long-range disorder of carbon lattices, low specific surface area, high jolt ramming density and excellent electrochemical performance. The method is advantaged in that the lithium ion battery hard carbon negative electrode material has high energy density and excellent rate capability and is suitable for the low-temperature environment, the process is simple, andcost is relatively low.

Owner:扬州华达新能源有限公司

Preparation method of porous electrode

InactiveCN108242547AImprove cycle stabilitySmaller than surfaceCell electrodesSecondary cellsElectrochemical responseSlag

The invention relates to a preparation method of a porous electrode. The method comprises the following steps: carbonizing tea leaf slag at a high temperature to be converted into nitrogen-doped hardcarbon; and compounding the hard carbon with graphene, wherein the specific surface of the graphene is reduced to a certain extent. The graphene surface treatment method provided by the invention canbe used for enhancing the chemical activity of the surface of graphite and enhancing the nucleation probability and the capacity of a material on the surface of the graphite in an electrochemical reaction. The porous electrode prepared by employing the method has relatively good conductivity and cycling stability, and has relatively high specific capacity and relatively long service life.

Owner:QINGDAO XIANGZHI ELECTRONICS TECH CO LTD

A kind of preparation method of linixmn2-xo4 cathode material

ActiveCN105185981BPromote growthGood formabilityCell electrodesSecondary cellsCrystal planeLithium-ion battery

The invention relates to a preparation method of a LiNi<x>Mn<2-x>O<4> cathode material, and belongs to the technical field of lithium-ion battery cathode materials. The method comprises the following steps: firstly, carrying out ball-mill mixing on a lithium source, a nickel source, a manganese source and an assistant for 0.5-10 hours, and drying the mixture at 60-160 DEG C to prepare a precursor, wherein at least one of the lithium source, the nickel source, the manganese source and the assistant is chloride; and secondly, heating the obtained precursor in air or oxygen atmosphere to 500-800 DEG C at the rate of 1-20 DEG C / min, heating the precursor at constant temperature for 5-48 hours, and cooling the precursor to room temperature to obtain the product LiNi<x>Mn<2-x>O<4> cathode material, or washing and drying the precursor to obtain the LiNi<x>Mn<2-x>O<4> cathode material. According to the method, a raw material chlorination process is provided; and through introducing chloride ions, the LiNi<x>Mn<2-x>O<4> (x is less than or equal to 0.5 and greater than or equal to 0.4) material in the solid-solid reaction process is promoted to grow up and expose a {111} crystal plane at low temperature, so that preparation of the high-performance LiNi<x>Mn<2-x>O<4> (x is less than or equal to 0.5 and greater than or equal to 0.4) material can be simply and effectively achieved.

Owner:KUNMING UNIV OF SCI & TECH

Light acrylic acid catalyst carrier and preparation method thereof

InactiveCN108273567ALarge specific surface areaImprove water absorptionCatalyst carriersCatalyst activation/preparationStone dustBall mill

The invention discloses a light acrylic acid catalyst carrier which is prepared from the following components: 10-20wt% of bauxite, 3-5wt% of Hunan Pukou sands, 3-5wt% of hemi-mountain mud, 30-40wt% of pseudo-boehmite, 10-20wt% of Jiangxi East Bridge sands, 10-30wt% of kaolin and 10-20wt% of wood flour. The preparation method comprises the following steps of performing ball milling and mixing on the bauxite, the Hunan Pukou sands, the hemi-mountain mud and half of the kaolin to obtain a uniform base material, and then lining the base material to prepare a green body; and then performing ball milling and mixing on the pseudo-boehmite, the Jiangxi East Bridge sands, the wood flour and half of the kaolin to obtain a uniform facing material, then adding the facing material in a ball milling machine for continuously lining to prepare pellets, adding non-metallic compound crystal particles in the ball milling machine, spraying the surface of each pellet with a layer of colloid, and then performing high-temperature firing on the pellets to prepare the light acrylic acid catalyst carrier. The light acrylic acid catalyst carrier is large in water absorption, small in specific gravity, largein specific surface area, strong in adsorption force, simple in technology and low in cost.

Owner:陈彦霖

Device for modifying hydrophobic property of MOFs through positive and negative micropressure conversion, and preparation method and application of hydrophobic MOFs

ActiveCN113101896AImprove water stabilityReduce adhesionOther chemical processesOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystHydrophobe

The invention provides a device for modifying the hydrophobic property of MOFs through positive and negative micropressure conversion, and a preparation method and application of the hydrophobic MOFs, and belongs to the technical field of adsorption catalyst preparation. Based on the device, positive and negative micro-pressure conversion is adopted, and positive pressure promotes a hydrophobic modifier to enter a microporous structure of the MOFs material, so that a hydrophobic layer is attached more uniformly; and after modification is finished, the residual hydrophobic modifier is promoted by negative pressure to rapidly escape from the MOFs material, so that the microporous structure of the MOFs is prevented from being blocked by the hydrophobic modifier, the specific surface area and porosity of the MOFs, which are similar to those of the MOFs before hydrophobic modification, are kept as far as possible, and the practical application value of the MOFs material is improved.

Owner:SHANDONG JIANZHU UNIV

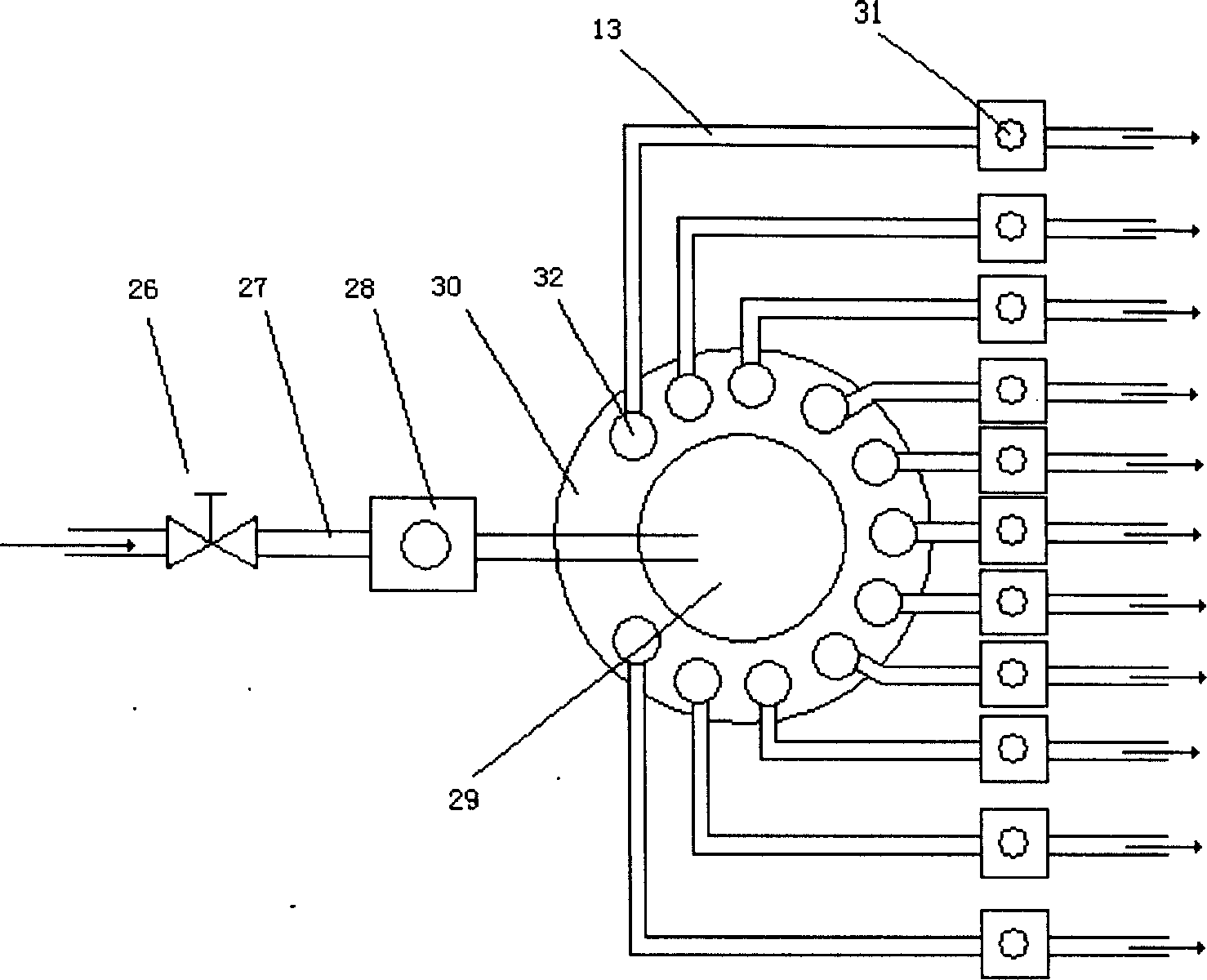

Fully automated oil exploitation system

InactiveCN109162679ALess investmentSmall footprintSurveyInsulationNetwork constructionSignal processing

The invention relates to a fully automated oil exploitation system. A liquid automatic metering device is employed by an oil well metering part. The device comprises a tipping bucket meter, an automatic oil well switcher and a gathering pipeline. The liquid automatic metering device cooperates with the tipping bucket meter through the automatic oil well switcher to achieve the automatic metering of an oil well. The gathering system further includes a signal processing unit, the signal processing unit transmits a yield signal of an oil well to be metered to the automatic oil well switcher, theautomatic oil well switcher switches an oil well pipeline and a gathering pipe, the yield of the oil well is metered through the tipping bucket meter, an upper end of a detection oil well is connectedto a polycarboxylate compound precipitation tank, the other end of the polycarboxylate compound precipitation tank is connected to the oil well metering part. According to the system, the floor spaceis occupied, the investment in constructing a transfer station is saved, the investment in pipe network construction is effectively reduced, the measurement accuracy is improved, the human resourcesare saved, the return pressure is reduced, the pump efficiency is improved, natural gas resources are saved, and the probability of accidents is reduced.

Owner:黄滢芝

A kind of preparation method of lithium iron phosphate-modified conductive carbon black composite electrode material

ActiveCN103337625BSmaller than surfaceEasy to manufactureCell electrodesCarbon compositesMaterials preparation

The invention relates to the fields of energy storage technology and power battery material technology, and specifically relates to a lithium iron phosphate-modified conductive carbon black composite electrode material preparation method. The preparation method comprises (1) a step of subjecting common conductive carbon black to annealing treatment, and then performing oxidation treatment in a strong oxidant to prepare the modified conductive carbon black; and (2) a step of preparing the lithium iron phosphate-modified conductive carbon black composite electrode material. According to the invention, by addition of modified SP which is easily dispersed, the composite electrode material prepared by the invention has small specific surface, thus facilitating battery preparation.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com